Method for producing low-formaldehyde medium-density fiberboard

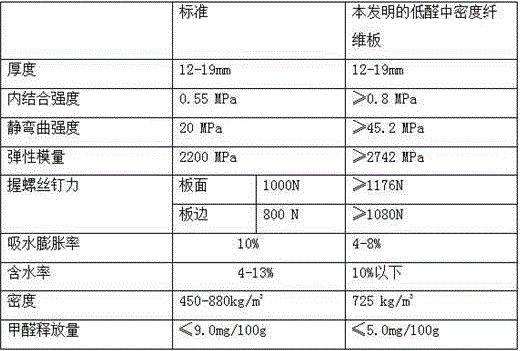

A production method and medium-density technology, which is applied in the field of wood resource utilization, can solve the problems of high formaldehyde residue, large expansion coefficient, and low environmental protection coefficient, and achieve low formaldehyde residue, reduced shrinkage rate, and reduced free formaldehyde content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0022] A kind of production method of low-aldehyde medium density fiberboard, concrete steps are as follows:

[0023] (1) Chipping of raw materials: Send the residues of wood processing including slats and waste veneers to the conveyor chain, and then enter the drum chipper to cut into pieces to obtain wood chips;

[0024] (2) Impurity removal and screening: Use a magnet device to remove metal objects mixed in the wood chips, screen the wood chips through a screening machine, remove debris, and separate the oversized wood chips to obtain uniform wood chips, and wash the wood chips with water washing equipment. Remove mud, sand and other impurities contained in wood chips;

[0025] (3) Cooking: Put the wood chips obtained in step (2) into a vertical cooking vat for cooking. In the vertical cooking vat, the wood chips are cooked and softened under saturated steam at a temperature of 130 ° C. The cooking time is 6 minutes;

Embodiment 2

[0033] A kind of production method of low-aldehyde medium density fiberboard, concrete steps are as follows:

[0034] (1) Chipping of raw materials: Send the residues of wood processing including slats and waste veneers to the conveyor chain, and then enter the drum chipper to cut into pieces to obtain wood chips;

[0035] (2) Impurity removal and screening: Use a magnet device to remove metal objects mixed in the wood chips, screen the wood chips through a screening machine, remove debris, and separate the oversized wood chips to obtain uniform wood chips, and wash the wood chips with water washing equipment. Remove mud, sand and other impurities contained in wood chips;

[0036] (3) Cooking: Put the wood chips obtained in step (2) into a vertical cooking vat for cooking. In the vertical cooking vat, the wood chips are cooked and softened under saturated steam at a temperature of 135 ° C. The cooking time is 5 minutes;

Embodiment 3

[0044] A production method of low-aldehyde medium density fiberboard, the steps are as follows:

[0045] (1) Chipping of raw materials: Send the residues of wood processing including slats and waste veneers to the conveyor chain, and then enter the drum chipper to cut into pieces to obtain wood chips;

[0046] (2) Impurity removal and screening: Use a magnet device to remove metal objects mixed in the wood chips, screen the wood chips through a screening machine, remove debris, and separate the oversized wood chips to obtain uniform wood chips, and wash the wood chips with water washing equipment. Remove mud, sand and other impurities contained in wood chips;

[0047] (3) Cooking: Put the wood chips obtained in step (2) into a vertical cooking vat for cooking. In the vertical cooking vat, the wood chips are cooked and softened under saturated steam at a temperature of 140 ° C. The cooking time is 4 minutes;

[0048] (4) wax application heat grinding: liquid wax is applied on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com