Patents

Literature

3081 results about "Urea-formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

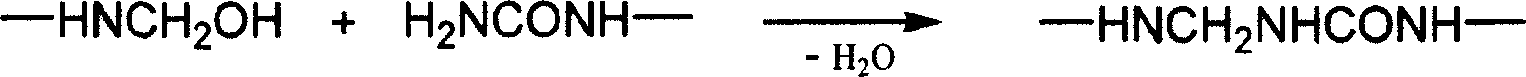

Urea-formaldehyde (UF), also known as urea-methanal, so named for its common synthesis pathway and overall structure, is a non-transparent thermosetting resin or polymer. It is produced from urea and formaldehyde. These resins are used in adhesives, finishes, particle board, medium-density fibreboard (MDF), and molded objects.

Perfume encapsulates

InactiveUS20040087477A1Improve stabilityImprove retentionGaseous substancesCapsule deliveryFlavorMelamine formaldehyde

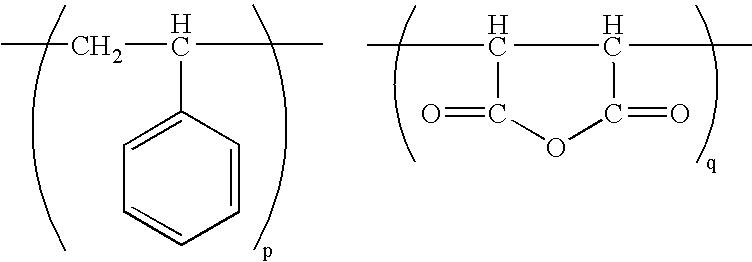

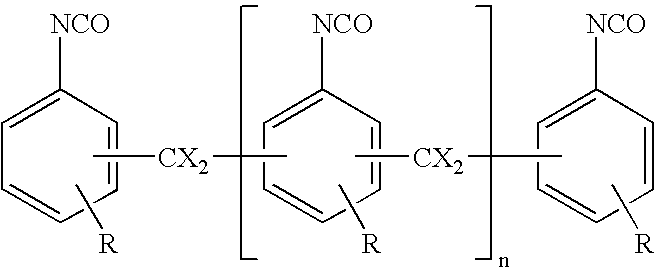

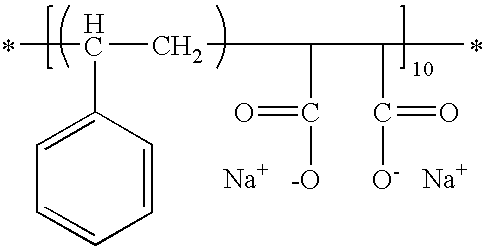

A perfume encapsulate comprises an aminoplast capsule, the capsule shell comprising urea-formaldehyde or melamine-formaldehyde polymer and a second polymer comprising a polymer or copolymer of one or more anhydrides, preferably ethylene / maleic anhydride copolymer. The second polymer improves the stability of the capsules with respect to surfactant, thus improving perfume retention properties and enabling use of the capsules in aqueous surfactant-containing products in a way that has not hitherto been possible.

Owner:QUEST INTERNATIONAL

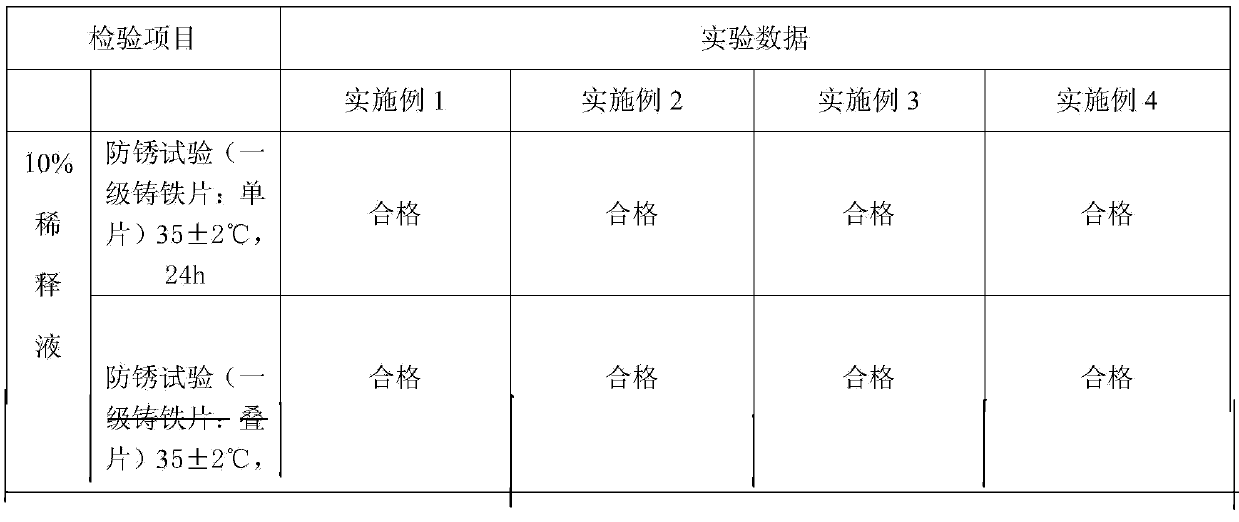

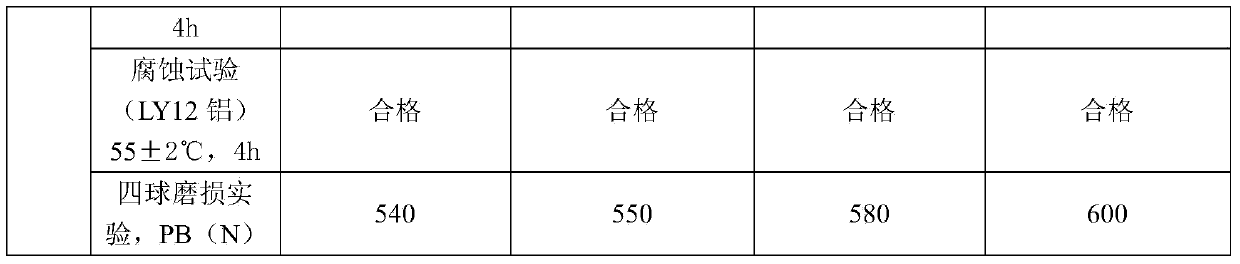

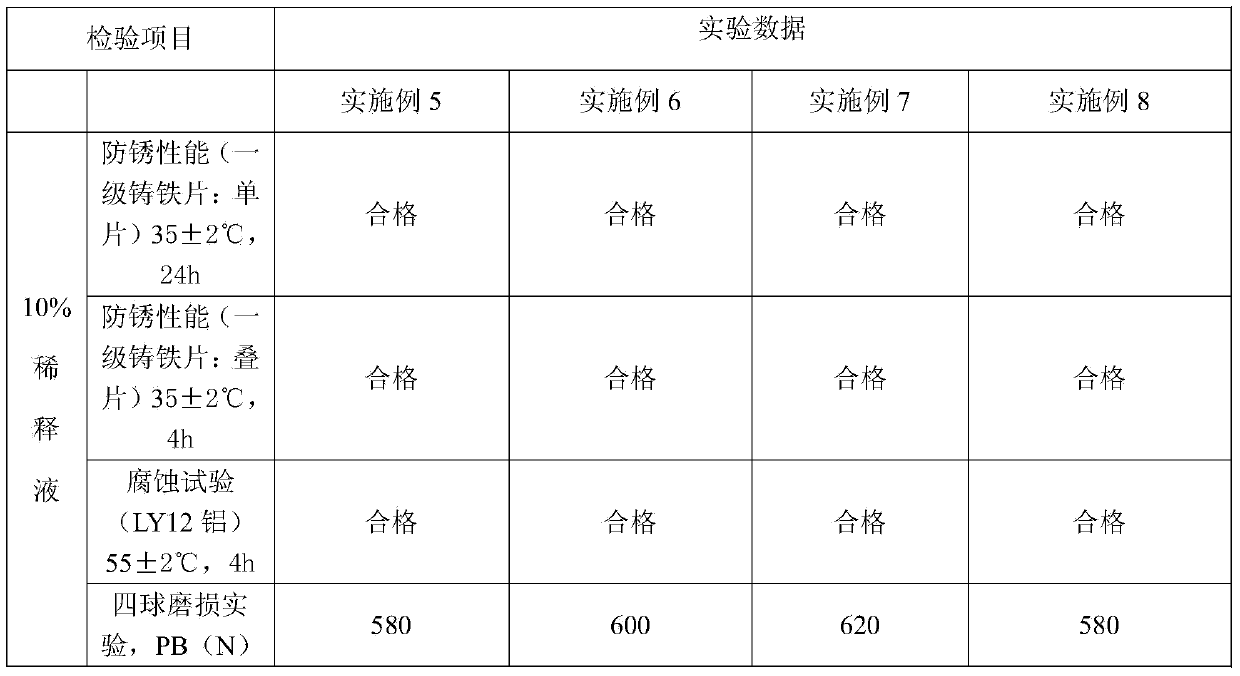

Boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof

The invention discloses a boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof. The microemulsified cutting fluid is prepared from the following raw materials in percentage by mass: 30-60% of base oil, 1-5% of rust inhibitor, 0-5% of extreme pressure agent, 1.5-8% of bactericide, 3-15% of mixed base, 0-5% of coupling agent, 1-8% of anti-hard water agent, 1.2-5% of corrosion inhibitor, 5-20% of lubricant, 3-15% of anionic surfactant, 3-20% of emulsifier and the balance of water. The microemulsified cutting fluid disclosed by the invention has excellent lubricating properties, and can simultaneously satisfy multiple processing modes, including fraising, boring, tapping, threading, high-speed milling, hole drilling and the like. The microemulsified cutting fluid is especially suitable for processing electronic aluminum alloys. In addition, the microemulsified cutting fluid has the advantages of excellent defoaming property, excellent wettability, high raw liquor stability, high emulsifying stability, high biological stability, longer service life, lower consumption and lower cost.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Method of manufacturing composite board

InactiveUS7022756B2Improve flow characteristicsIncreased flexural modulusSynthetic resin layered productsWood working apparatusThermoplasticFiber

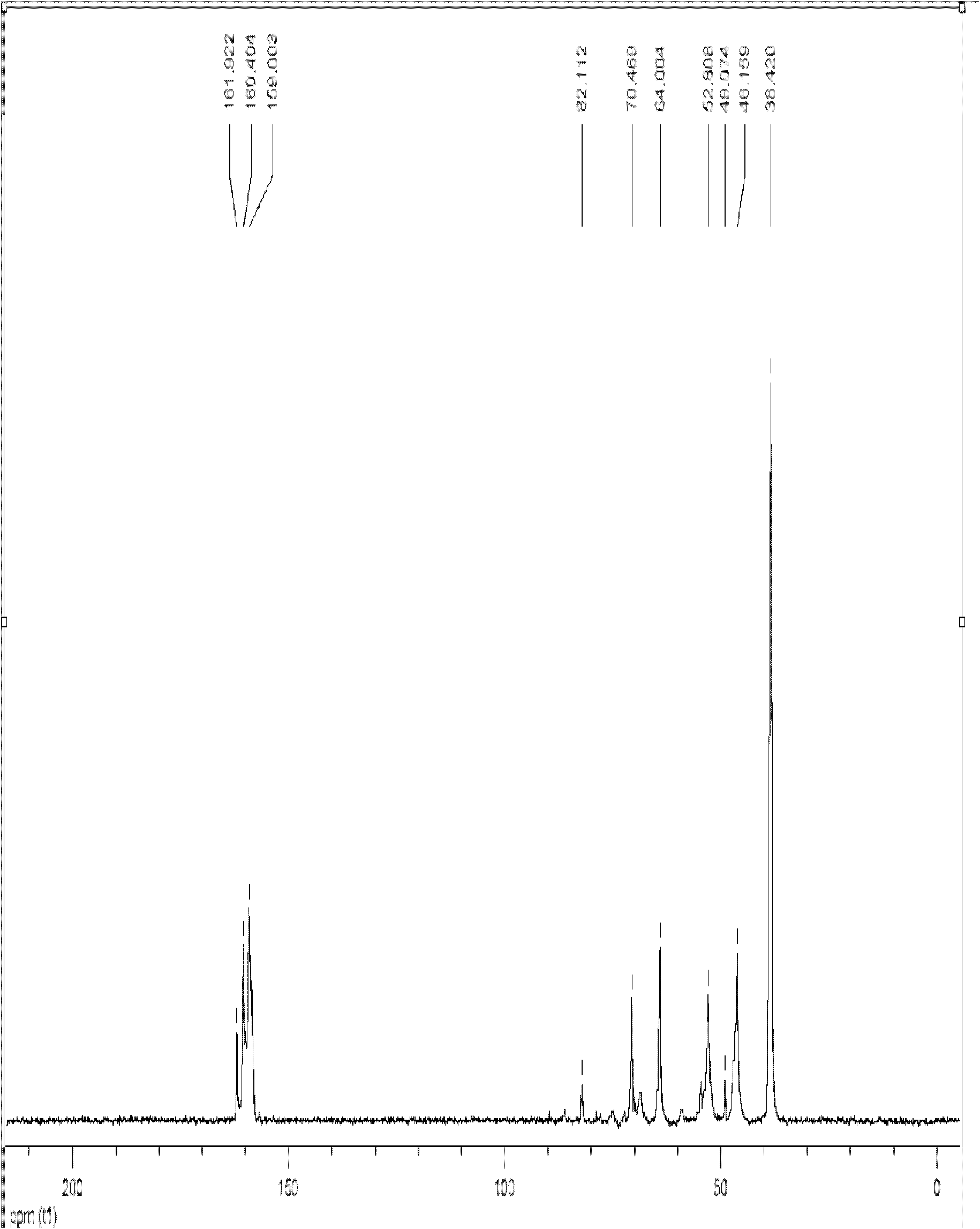

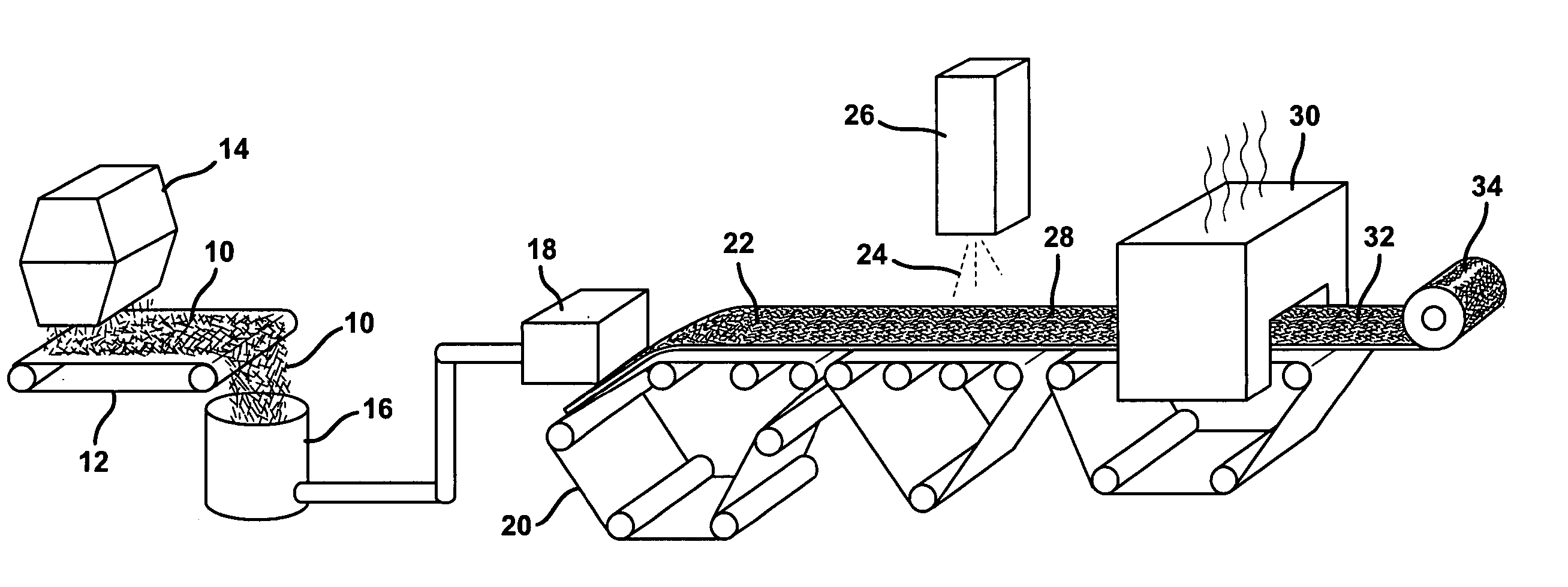

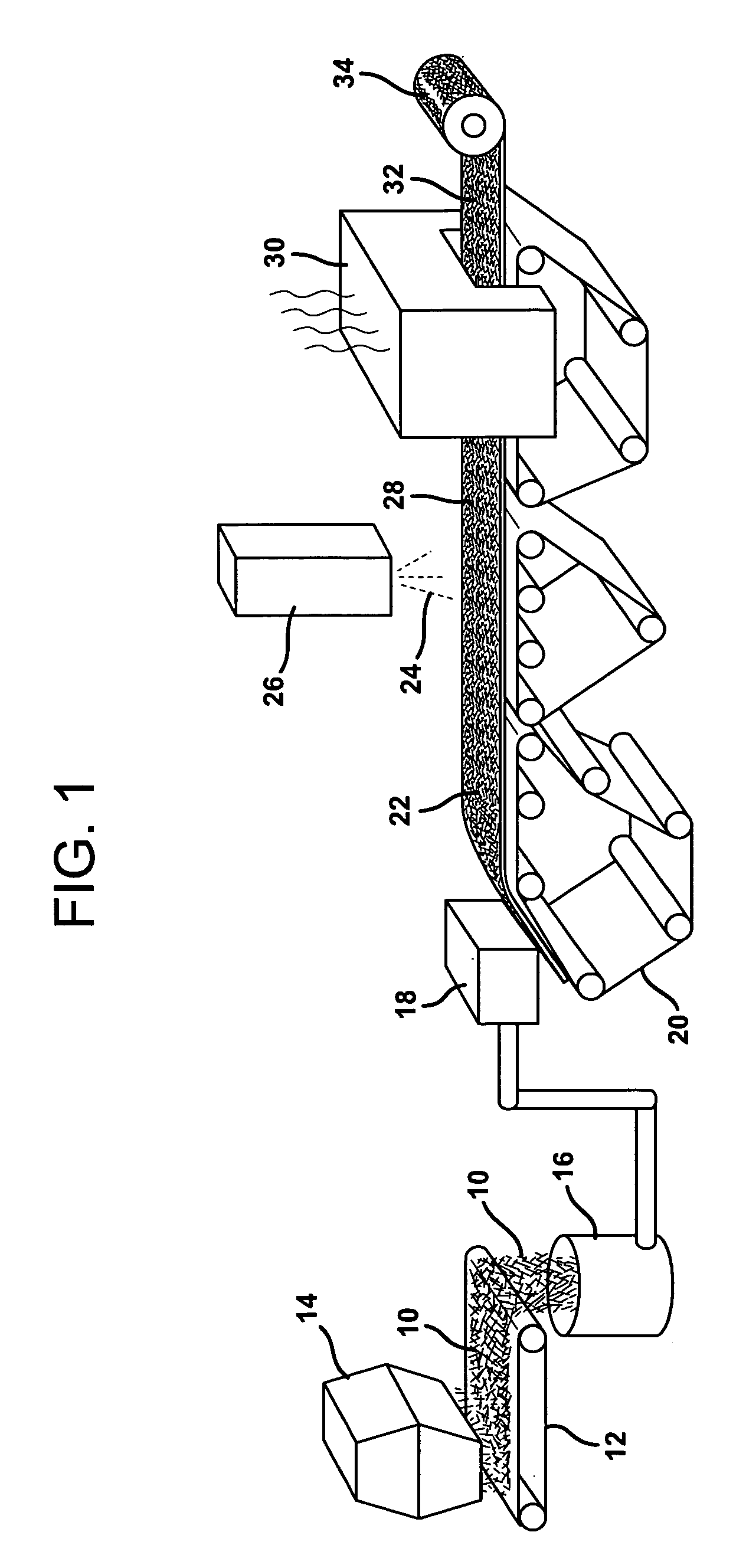

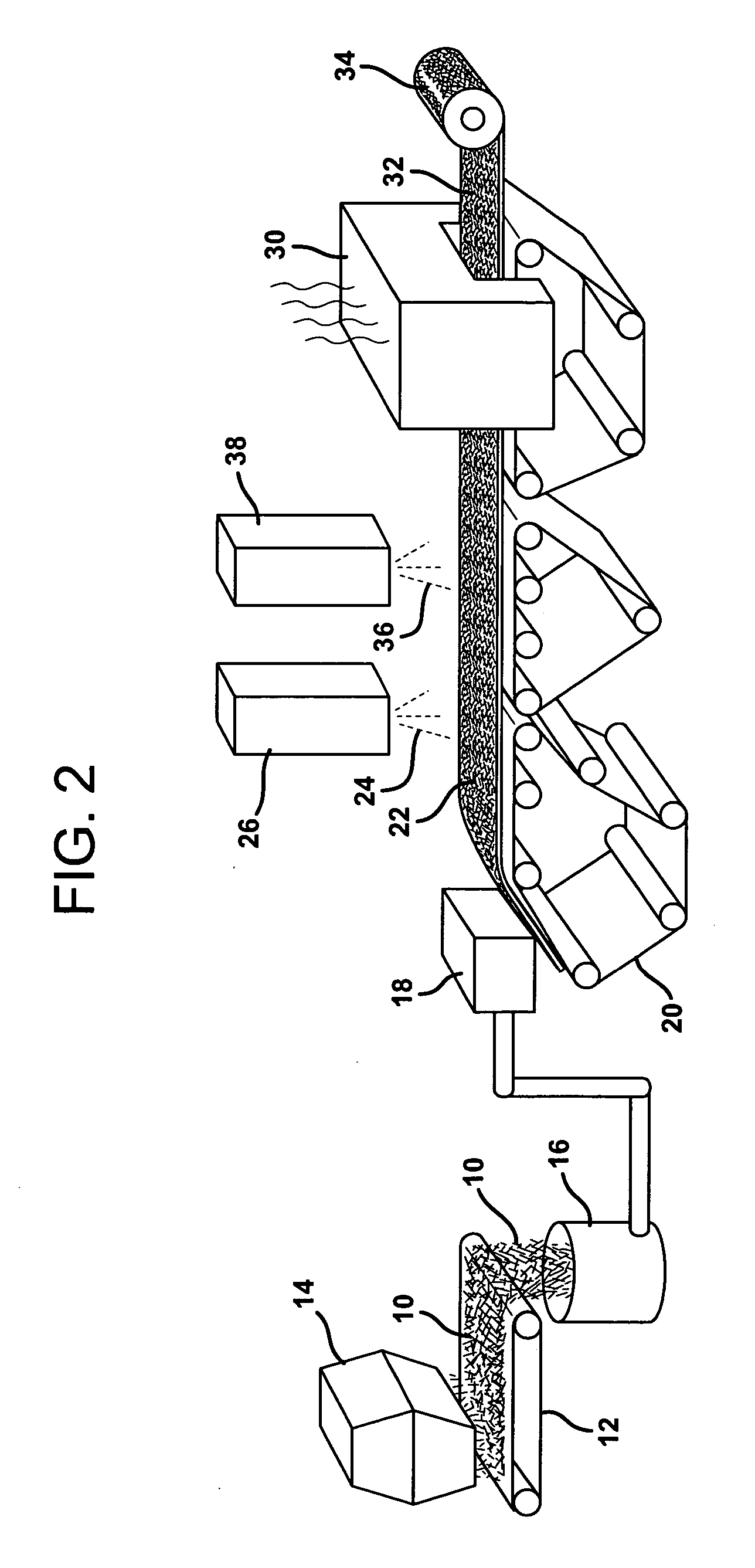

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO RETAIL CABINET GROUP

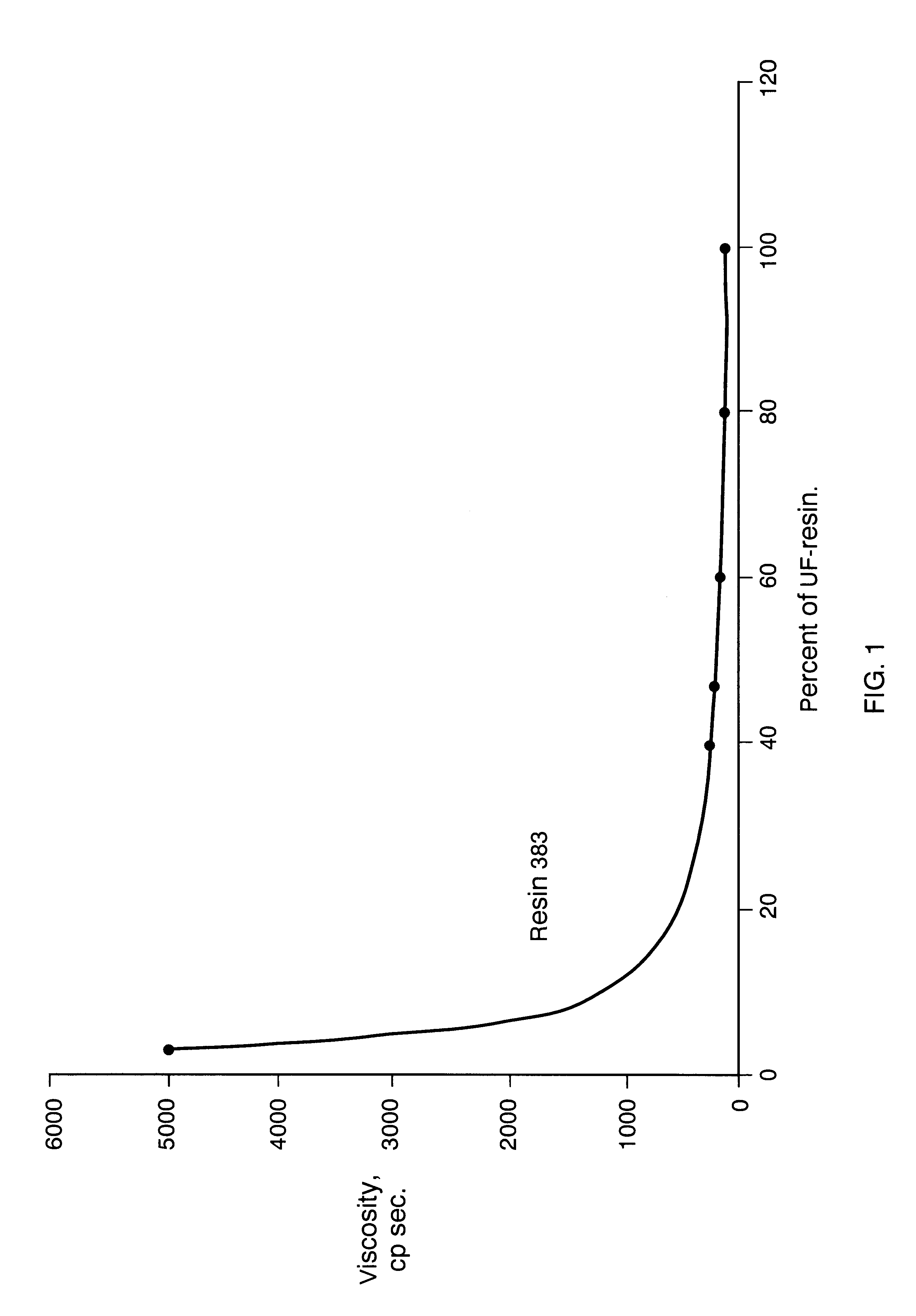

Urea-formaldehyde binder composition and process

An aqueous binder composition containing a urea-formaldehyde resin modified with a protein, preferably with a source of soy protein and the use of the binder for preparing fiber mats, especially glass fiber mats.

Owner:GEORGIA PACIFIC CHEM LLC

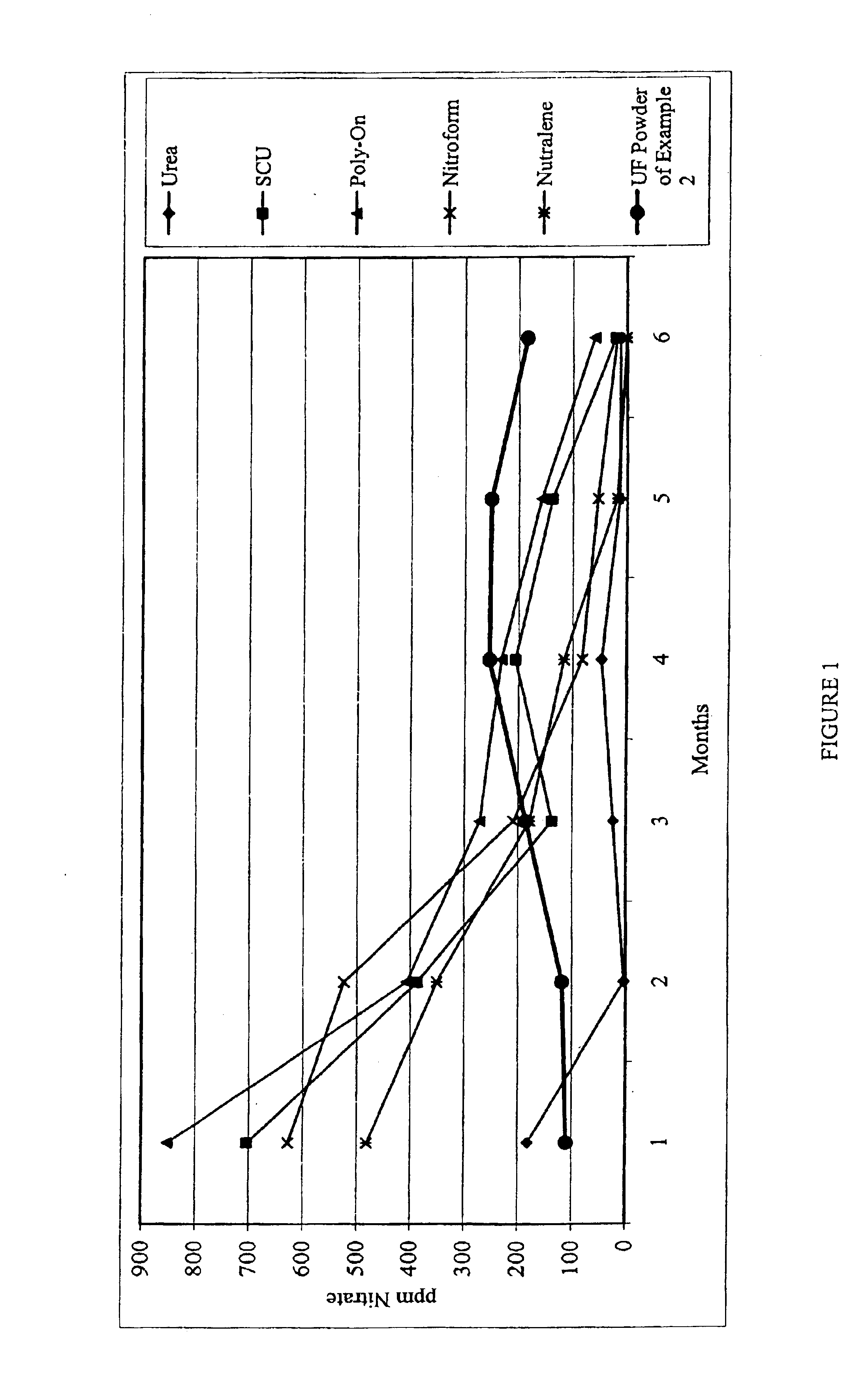

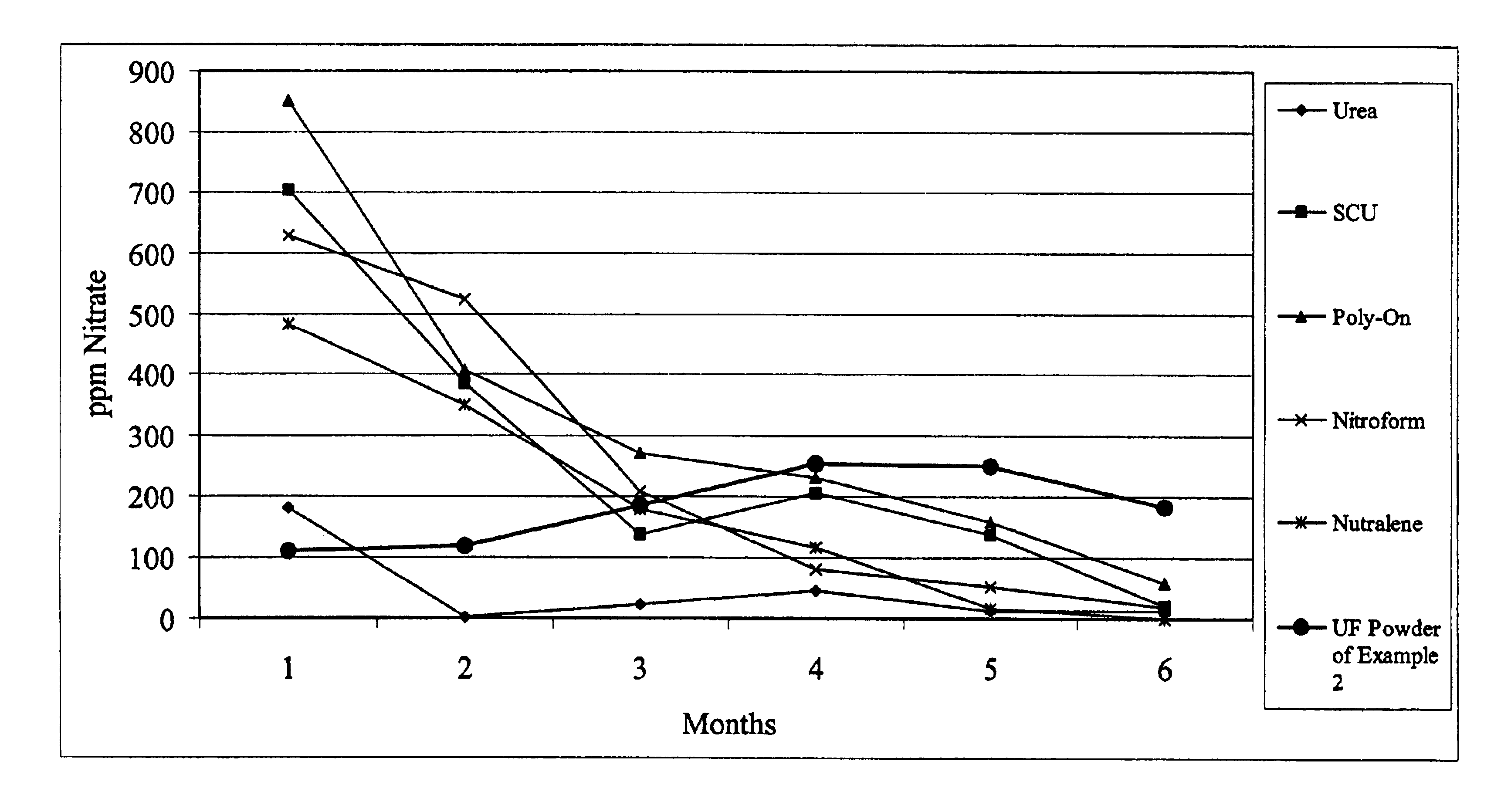

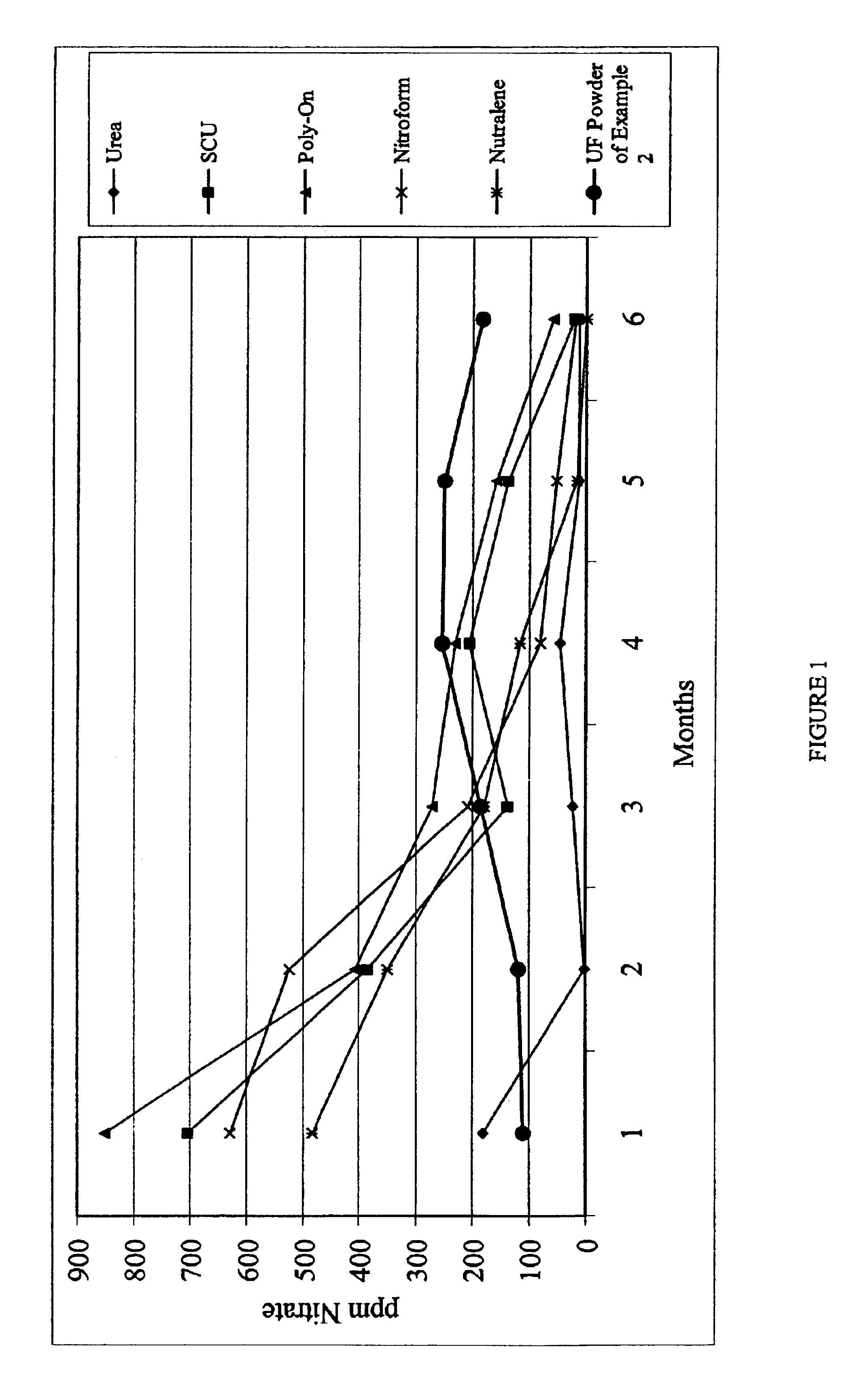

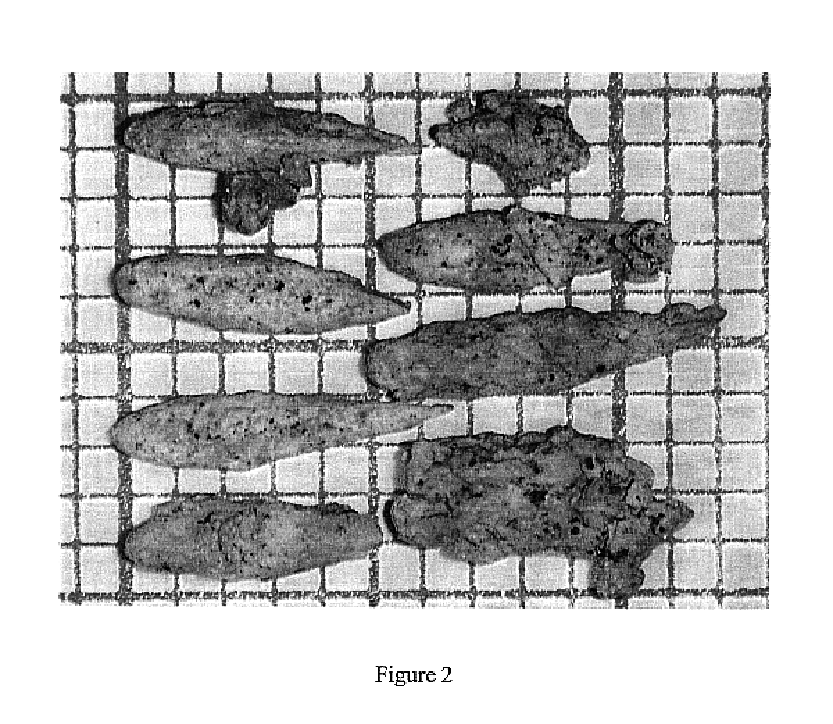

Slow release nitrogen root treatment

A method for treating a seedling by dipping the roots of the seedling into a composition containing a slow release, particulate urea-formaldehyde polymer, which is useful as a fertilizer for enhancing the extended delivery of nitrogen needed for plant development and growth and to the composition useful as the root dip, or as a soil drench.

Owner:KOCH AGRONOMIC SERVICES LLC

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

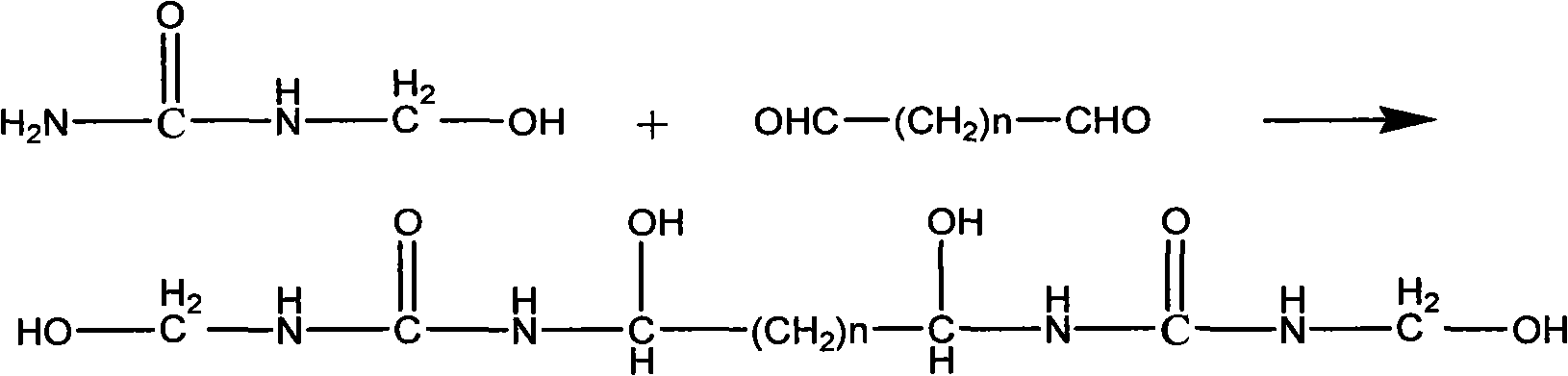

Slow release nitrogen fertilizer

InactiveUS6936681B1Easy to produceGood physical propertiesBiocideAgriculture gas emission reductionParticulatesPolymer

A slow release, particulate urea-formaldehyde polymer useful as a fertilizer for enhancing the extended delivery of nitrogen needed for plant development and growth and a granular fertilizer made with the particulate urea-formaldehyde polymer.

Owner:KOCH AGRONOMIC SERVICES LLC

Process for the manufacturing of an improved core for decorative laminates and a decorative laminate obtained by the process

InactiveUS6841023B2Improve brittlenessImprove the overall coefficientOrganic chemistryLamination ancillary operationsPolyesterFiber

A process for the manufacturing of a core forming a carrying structure for decorative laminates. The core comprises particles of cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin. The particles are bonded to each other in a pressing procedure with a bonding agent comprising an adhesive such as a polymerizing monomer.i) The particles are achieved by grinding cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin so that it passes through a 2 mm screen, preferably a 1 mm screen,ii) 100 parts per weight of particles is mixed with 1-100 parts per weight of fiber, the fiber additive having an average length in the range 1-15 mm.iii) The particle-fiber mixture is allowed to absorb a selected amount of water, the amount of water being in the range 1-15% by weight, The water is either added at any stage before the adding of bonding agent, and / or being used as a solvent in the bonding agent, and that,iv) 85 parts per weight of the particle mixture is mixed with 2-15 parts per weight of a bonding agent, the bonding agent selected from the group consisting of,a) A mixture of polyols, such as polyester or polyether, crude methylene diphenyl diisocyanate and possibly a small amount of blowing agent in a ratio forming a polymeric resin with a density in the range 600-1400 kg / m3.b) A formaldehyde based resin such as phenol-formaldehyde resin, urea-formaldehyde resin, melamine-urea-formaldehyde resin, melamine-urea-phenol-formaldehyde resin or phenol-resorcinol-formaldehyde resin, orc) Polyvinyl acetate resin.v)The mixture is applied between the belts of the continuos belt press or the press plates of a static press, optionally with at least one intermediate carrier web, the belts or press plates allowing a mainly uniform and specified material thickness to form. A slightly porous and preconditioned core with a selected water content in the range 0.8-12% is hereby achieved. The invention also relates to a decorative laminate achieved through the process.

Owner:PERGO

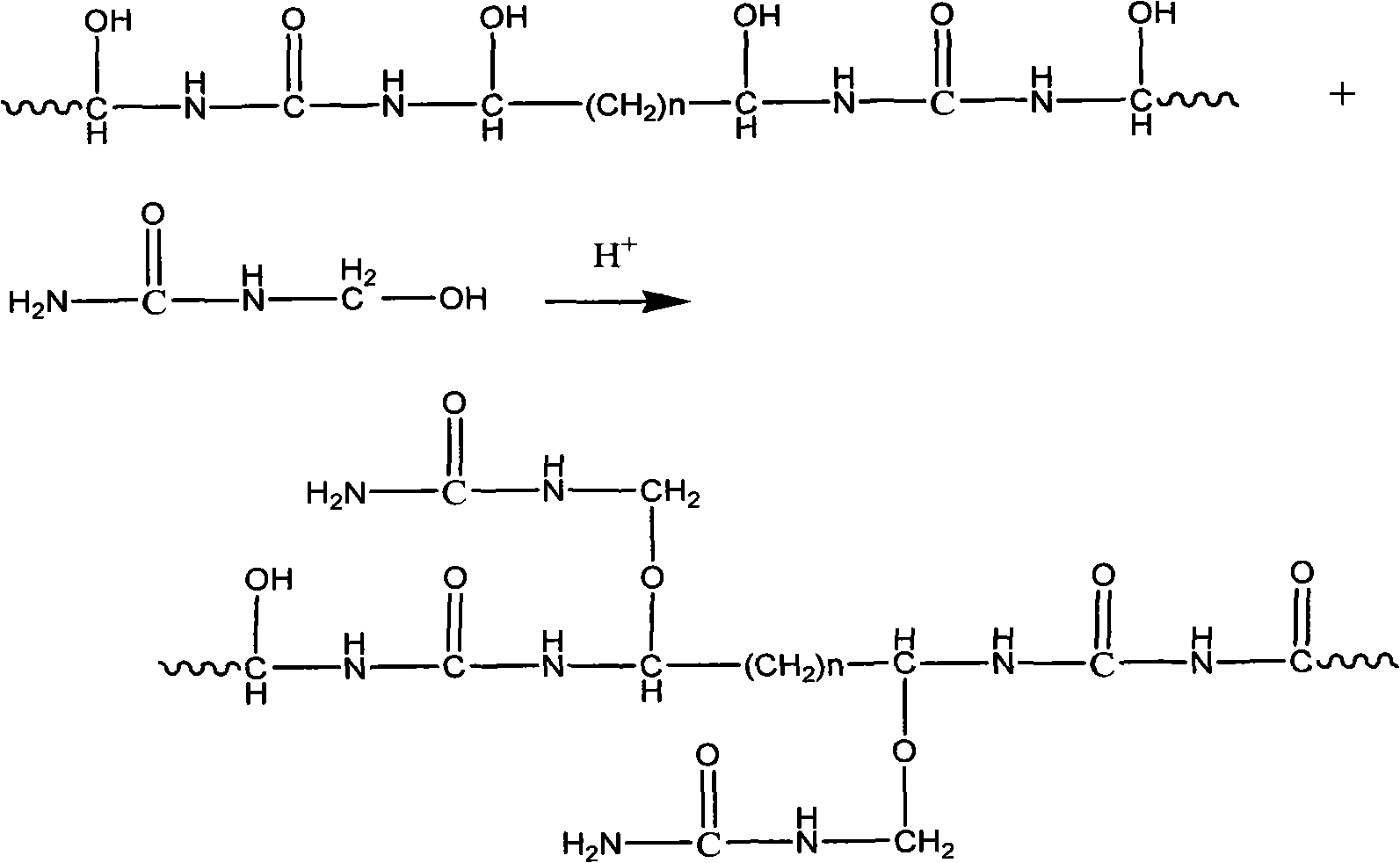

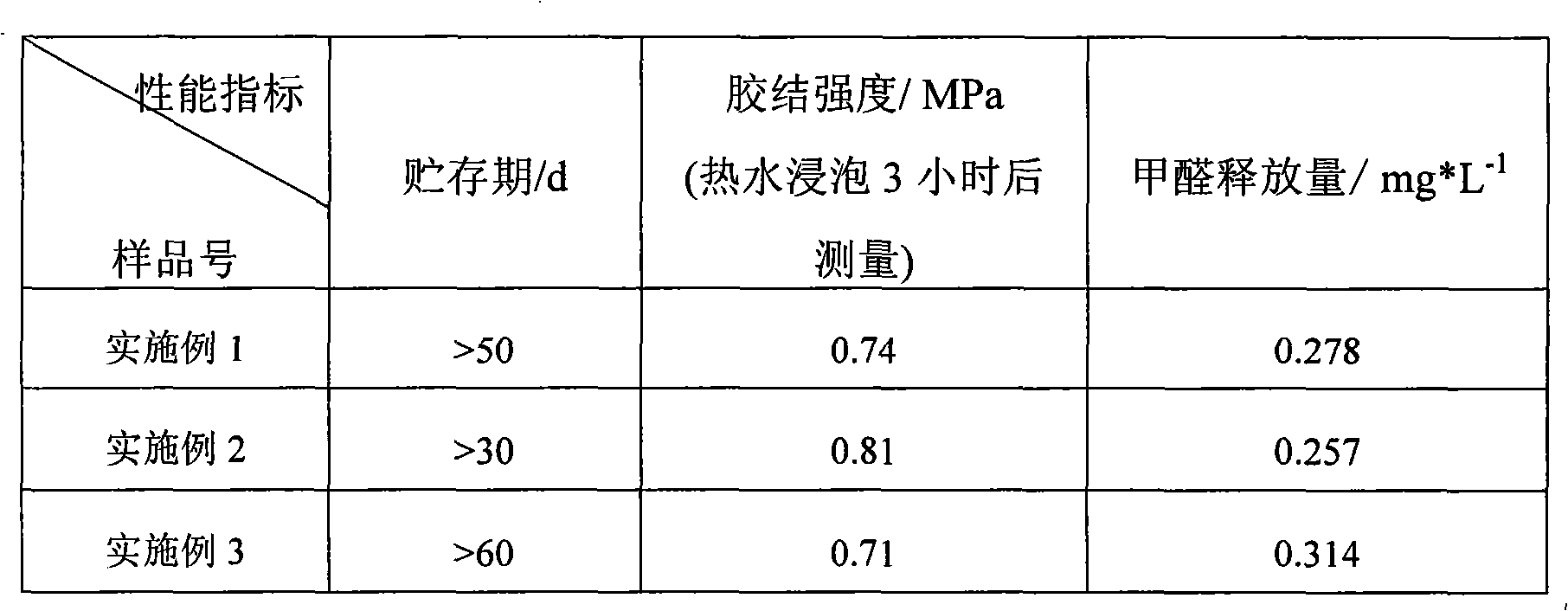

Environmental protection urea-formaldehyde resin and preparation method thereof

InactiveCN101265314ALow free formaldehyde contentExtended shelf lifeAldehyde/ketone condensation polymer adhesivesThermal waterWeak base

A novel environmental protective urea-formaldehyde resin and a preparation method belong to the field of wood processing adhesives. The urea-formaldehyde resin is formed by the reaction of urea, formaldehyde, aldehyde, one or more stabilizers and modifier according to the route of weak base-weak acid-weak base. The method firstly controls the F / U feed ratio, the pH value and the temperature during the reaction process to reduce the content of free formaldehyde in the resin; then the aldehyde is introduced to allow the resin to generate the stable alkyl ether (-(CH2)n-O-(CH2)n-) structure, thus reducing the content of methylene-ether bond (-CH2-O-CH2-) in the resin structure, simultaneously reducing the using amount of the formaldehyde and further greatly reducing the release amount of the formaldehyde during the using process of a plate from the two aspects; in addition, the introduction of a long chain and polyaldehyde can ensure the resin to have great bonding strength and water resistance. The urea-formaldehyde resin which is prepared by the invention has the advantages of low content of free formaldehyde, simple process, low cost, etc., the release amount of the formaldehyde of the plate which is prepared by using the adhesive achieves the E0 level standard, and the high bonding strength can be maintained after being boiled in hot water.

Owner:BEIJING UNIV OF CHEM TECH

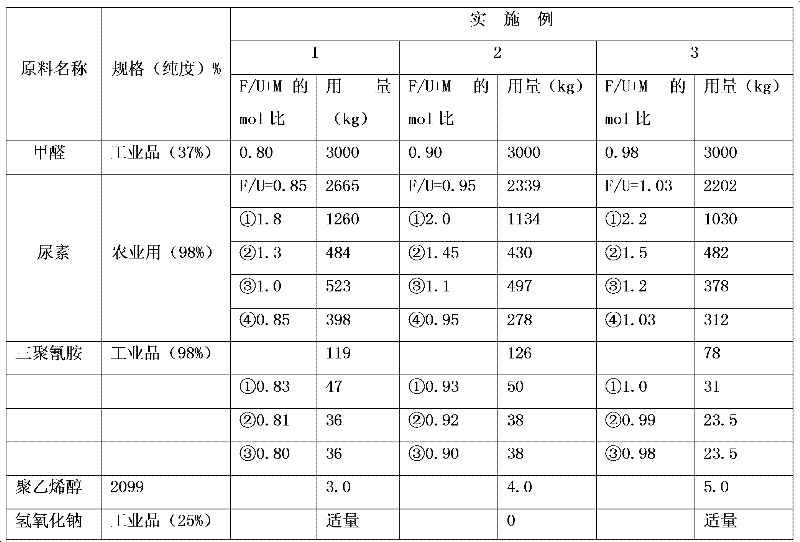

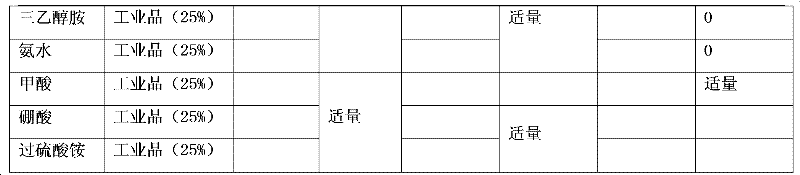

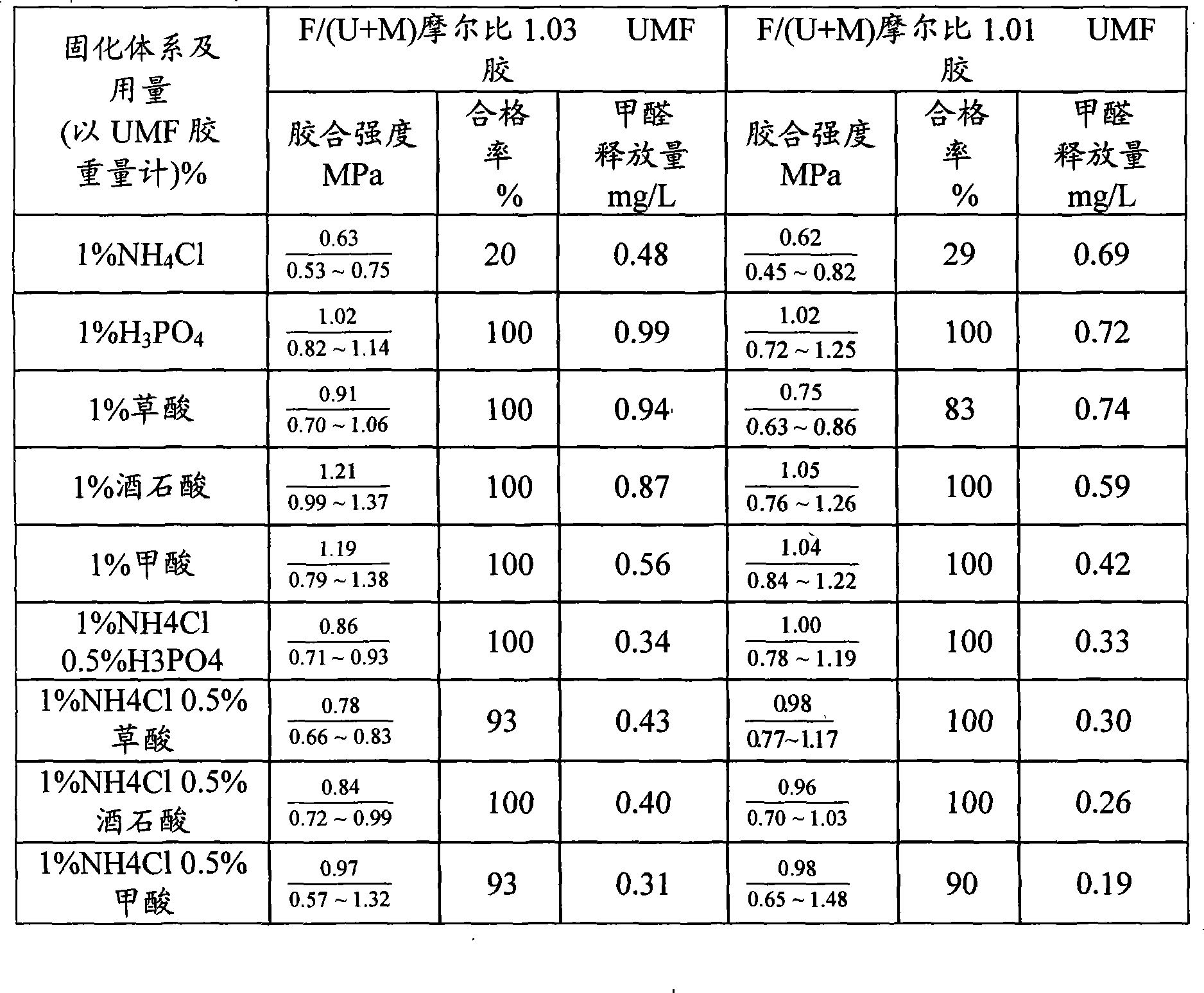

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

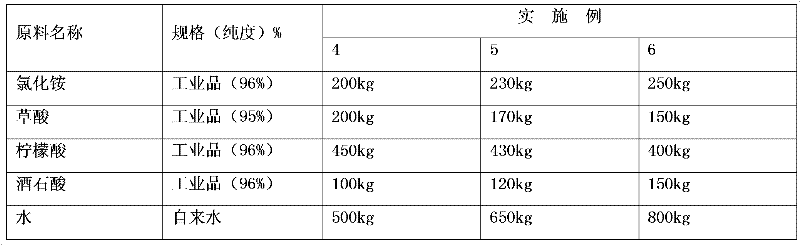

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

Microcapsules adapted to rupture in a magnetic field to enable easy removal of one substrate from another for enhanced reworkability

ActiveUS20130034739A1Excellent reworkabilityReduce bond strengthLamination ancillary operationsMagnetic paintsIn situ polymerizationMagnetite Nanoparticles

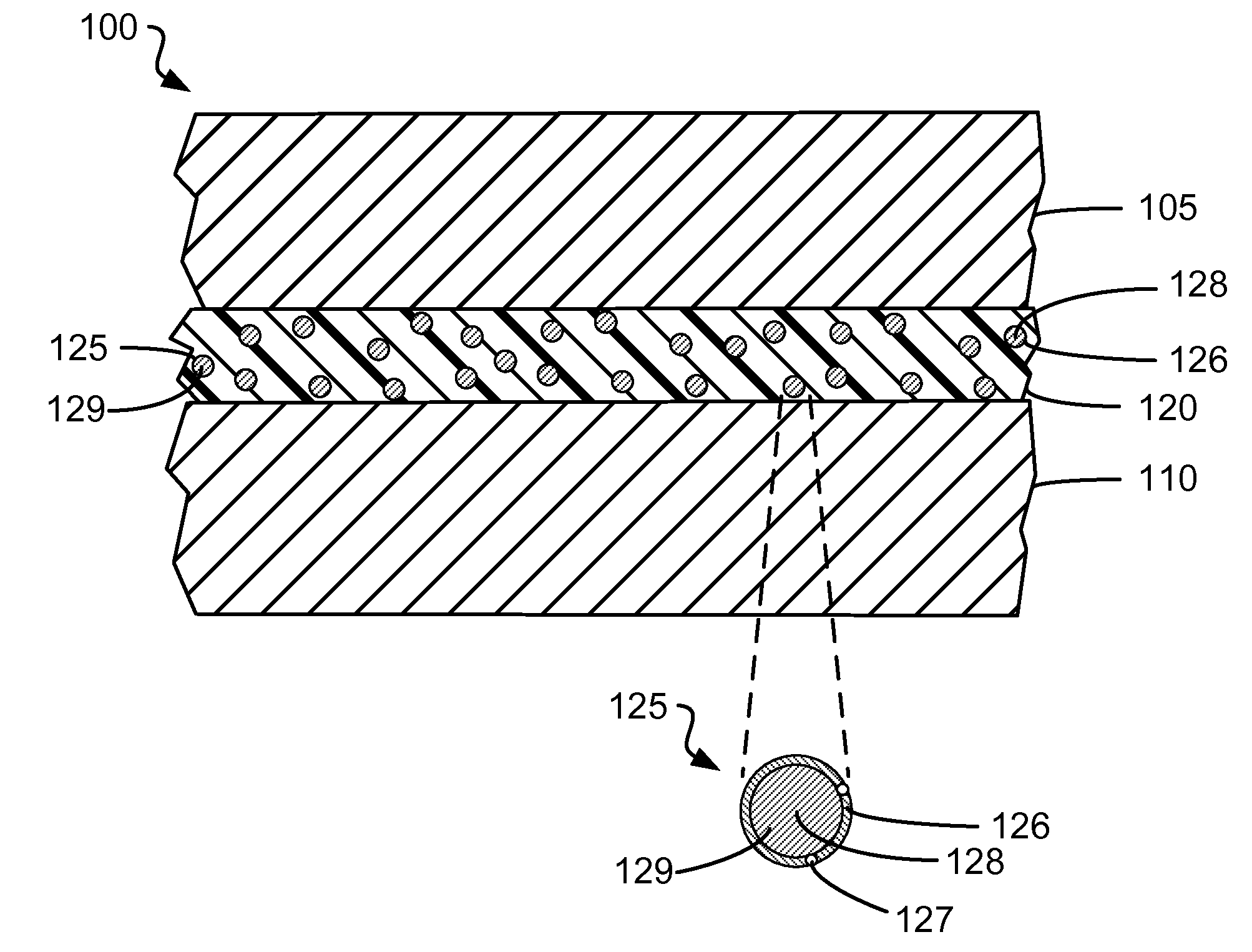

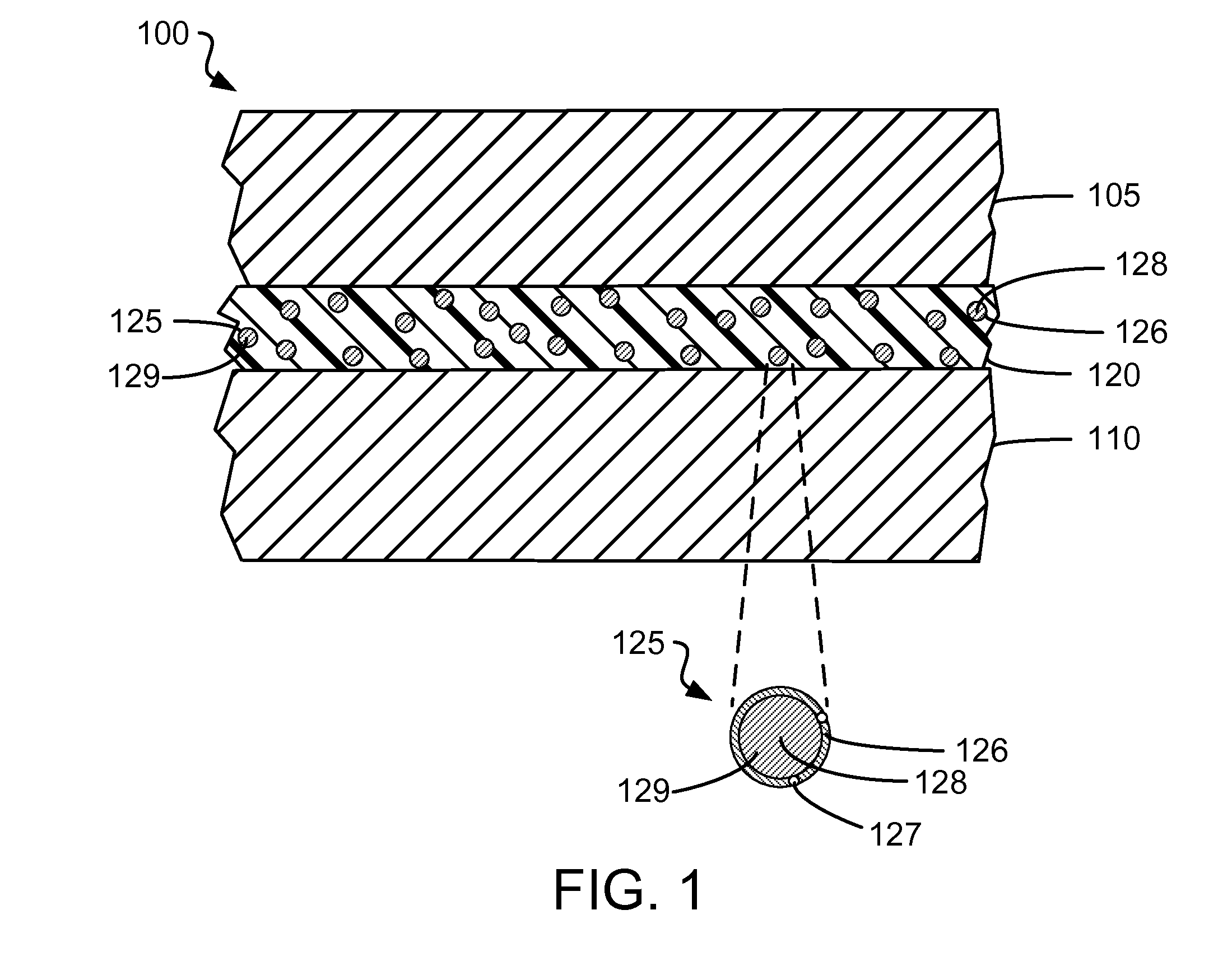

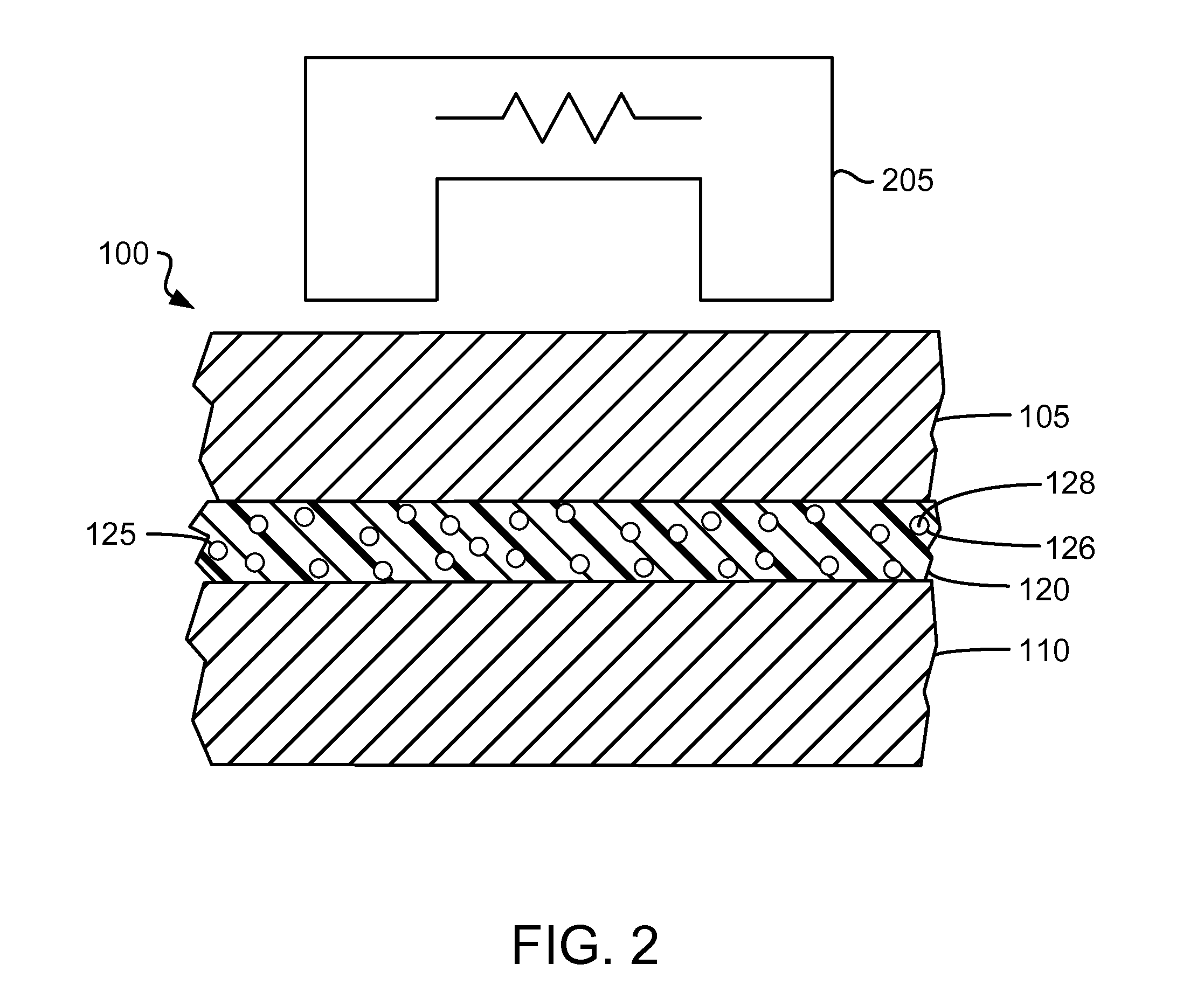

An enhanced thermal interface material (TIM) gap filler for filling a gap between two substrates (e.g., between a coldplate and an electronics module) includes microcapsules adapted to rupture in a magnetic field. The microcapsules, which are distributed in a TIM gap filler, each have a shell that encapsulates a solvent. One or more organosilane-coated magnetic nanoparticles is / are covalently bound into the shell of each microcapsule. In one embodiment, (3-aminopropyl) trimethylsilane-coated magnetite nanoparticles are incorporated into the shell of a urea-formaldehyde (UF) microcapsule during in situ polymerization. To enable easy removal of one substrate affixed to another substrate by the enhanced TIM gap filler, the substrates are positioned within a magnetic field sufficient to rupture the microcapsule shells through magnetic stimulation of the organosilane-coated magnetic nanoparticles. The ruptured microcapsule shells release the solvent, which dissolves and / or swells the TIM gap filler, thereby reducing the bond strength between the substrates.

Owner:IBM CORP

Microcapsule automatic fire extinguishing agent

InactiveCN109420281AImprove fire extinguishing efficiencyHigh strengthFire extinguisherEngineeringMelamine

Owner:XIAN WESTPEACE FIRE TECHNOLOGY CO LTD

Solid urea fertilizer

InactiveUS20070295047A1Agriculture gas emission reductionUrea compound fertilisersUrease InhibitorsNitrification inhibitors

A solid urea fertilizer prepared by mixing a solid, flowable, urea formaldehyde polymer with a urea source, such as molten or solid urea to form a fertilizer that has favorable crush strength characteristics, low biuret content, and / or desirable storage and handling properties. The urea fertilizer may contain additionally, an aqueous urea formaldehyde solution or mixture. Optionally, the fertilizer may contain a urease inhibitor and / or a nitrification inhibitor.

Owner:KOCH AGRONOMIC SERVICES LLC

Cyanurotriamide modified urea resin and prepn. process

InactiveCN1834186AImprove boiling water resistanceHigh activityAldehyde/ketone condensation polymer adhesivesCyanurotriamideAmmonium hydroxide

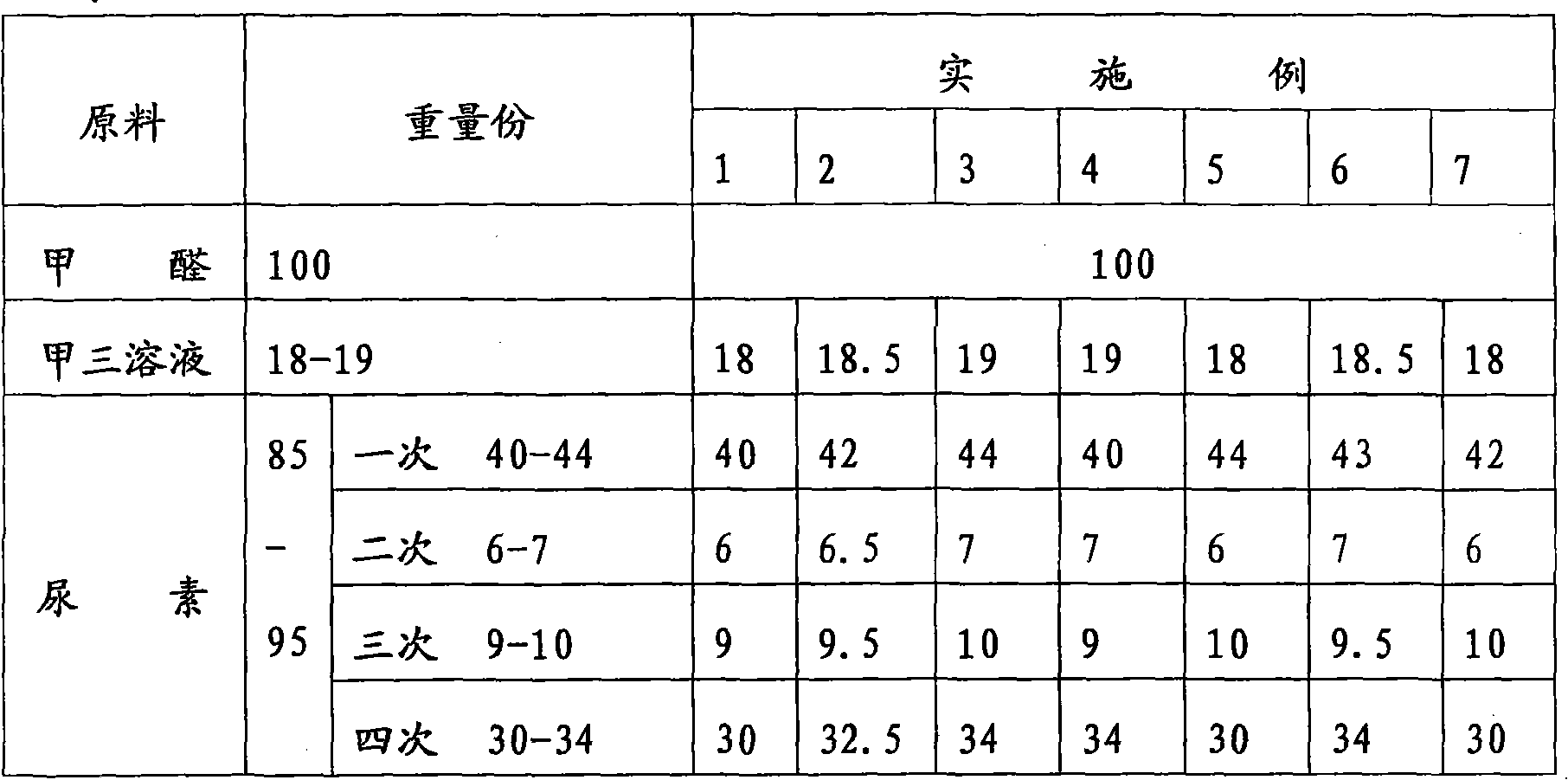

This invention provides a method for manufacturing melamine-modified urea-formaldehyde resin adhesive used on wood cement templates. The method adopts formaldehyde and urea at a molar ratio of 1.2-1.4 as the raw materials, and urea is added into formaldehyde in four times. Before the first time of urea addition, formaldehyde is activated at 50 minus or plus 5 deg.C for 15-25 min. in the third time of urea addition, melamine 3-20 wt. % of total urea is also added. After the fourth time of urea addition, ammonia solution is added for post treatment so that the content of free formaldehyde in the modified urea-formaldehyde resin adhesive is below 0.2 wt. %. at the same time the boiling water-resistance of the urea-formaldehyde resin adhesive can be improved. This invention can be used as a substitute for expensive phenol-formaldehyde resin adhesive; therefore the cost is reduced while the performance of wood cement templates can be guaranteed.

Owner:EVERFIRST WISEFUND TECH BEIJING +1

Method for manufacturing E0 level wood veneer

InactiveCN101244571AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesWood veneer joiningWood veneerEther

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

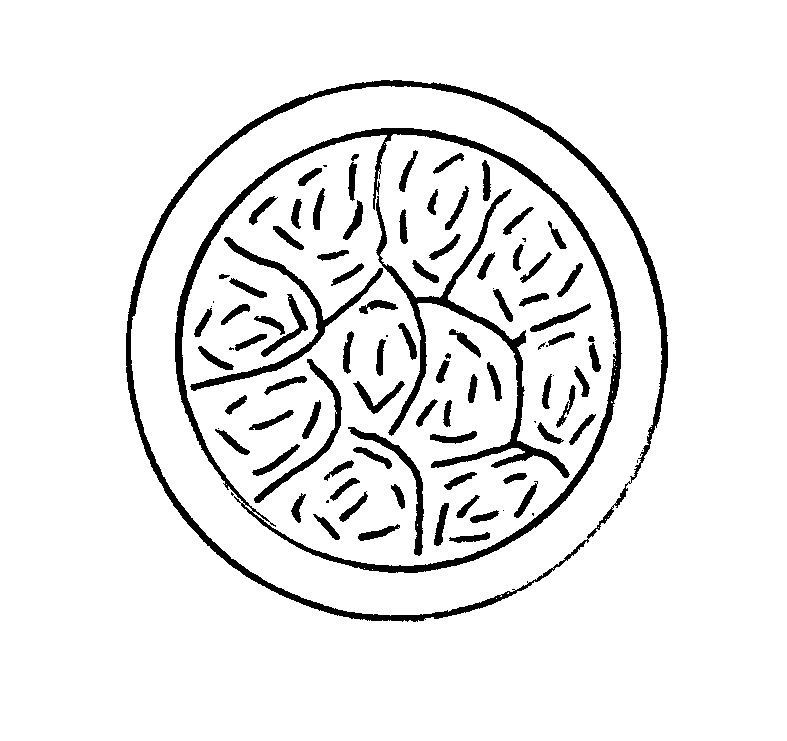

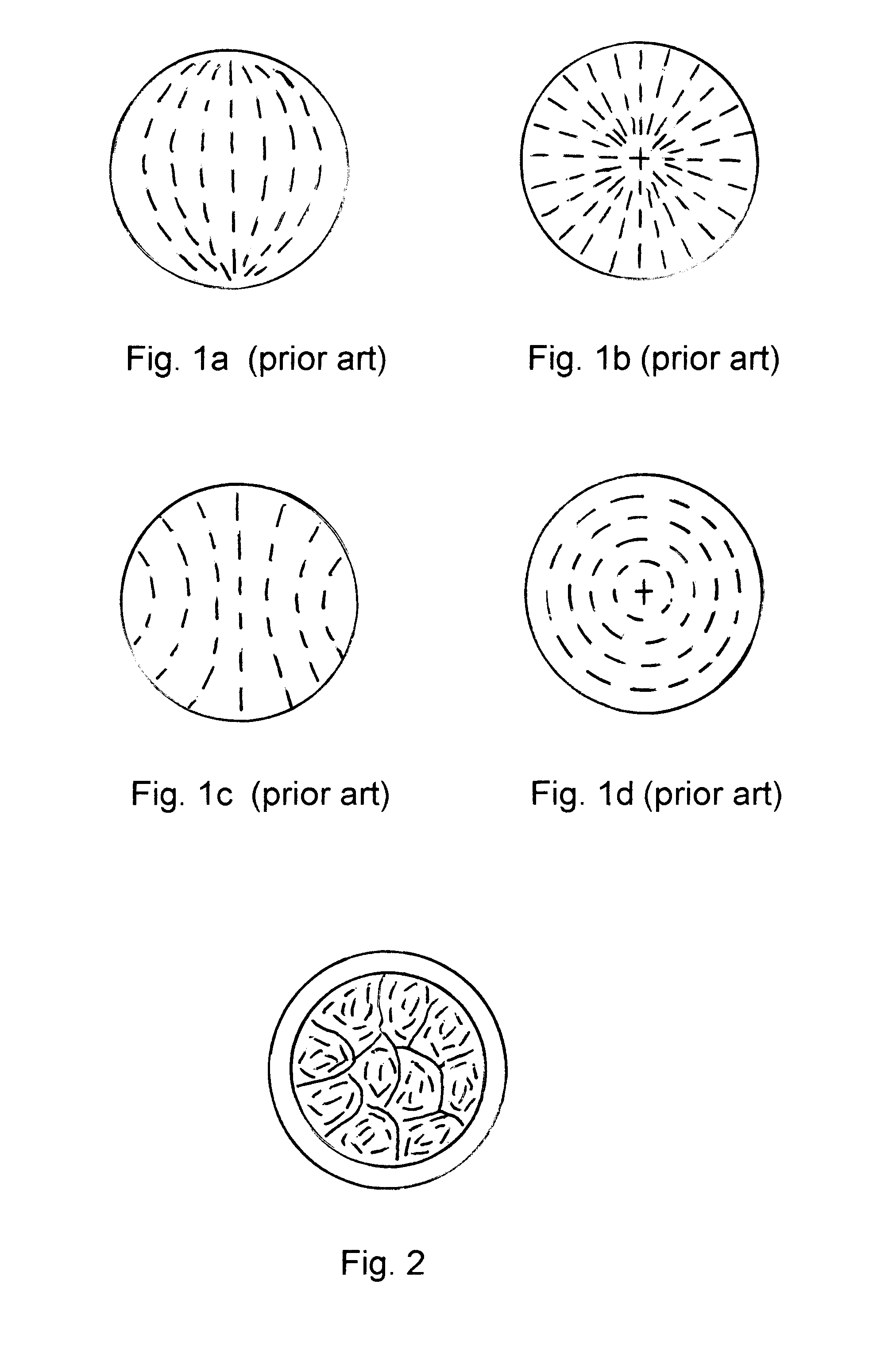

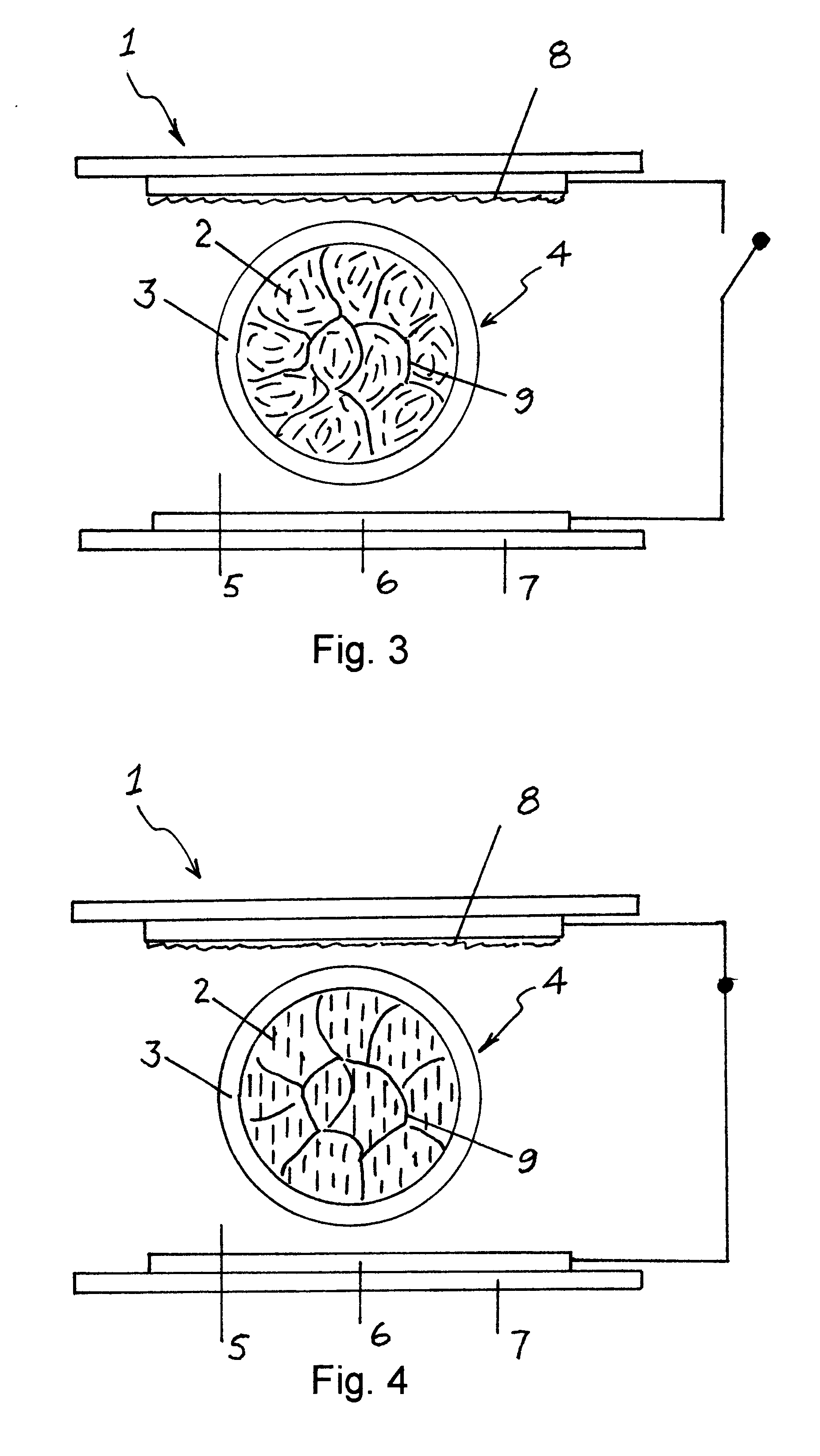

Microencapsulated liquid crystal having multidomains induced by the polymer network and method

A liquid crystal material containing polymer network forming material is microencapsulated by a method utilizing an interfacial polymerization which creates a combination of polyurethane and polyurea polymers or melamine fromaldehyde or urea formaldehyde polymer which form the capsule walls surrounding the discrete liquid crystal droplets. The prepolymer of urethane acrylate and acrylate within the liquid crystal capsules is cured under UV light irradiation to form a web-like structure and induce the formation of polydomain configuration of nematic director. This allows to produce the display having faster switching property and showing significant lower threshold voltage.

Owner:HSU YING YEN

Method for preparing modified urea-formaldehyde resin

InactiveCN101134835ALow free formaldehyde contentReduce formaldehyde emissionPolymer chemistryContact reaction

The process of preparing modified urea-formaldehyde resin includes the contact reaction of formaldehyde and urea, and the mixing of the resultant and the modifier added into urea-formaldehyde resin in at least two times. The modified urea-formaldehyde resin has very low content of free formaldehyde, say, below 0.20 %. When it is used in making artificial board, the artificial board will have very low formaldehyde releasing amount. In addition, the modified urea-formaldehyde resin may be in liquid and powder form, and may be applied in different conditions, including moist condition and outdoor condition.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Wood composites bonded with protein-modified urea-formaldehyde resin adhesive

InactiveUS20050070635A1Aldehyde/ketone condensation polymer adhesivesResin adhesiveUrea-formaldehyde

An adhesive binder composition containing a urea-formaldehyde resin modified with a protein, preferably with a source of soy protein and the use of the binder for preparing wood composites, especially particleboard.

Owner:GEORGIA PACIFIC RESINS INC

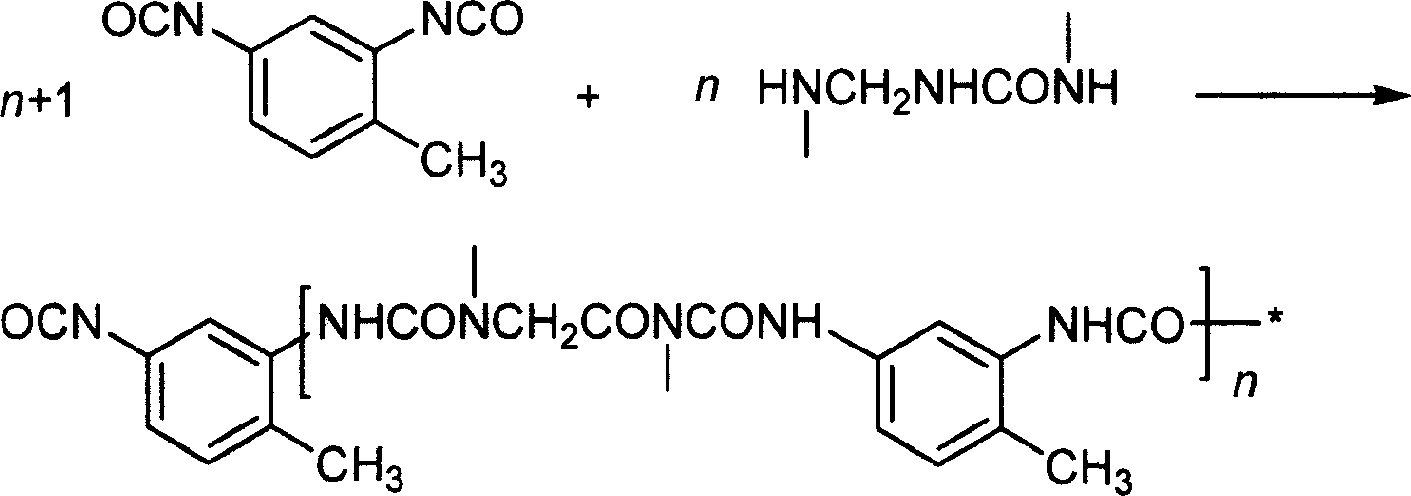

Preparation method of phase transformation material microcupsule

InactiveCN101045857AHigh mechanical strengthRaw materials are easy to getHeat-exchange elementsMicroballoon preparationParaffin waxToluene diisocyanate

This invention relates to preparation method of a facies change stuff microcapsule. It takes paraffin as phase-change material, takes toluene diisocyanate and urea-formaldehyde resin as cyst wall stuff, by interfacial polymerization and in situ polymeric method to carry out microencapsulate, to prepare double deck, microcapsule packed paraffin phase-change material. This method could prepare microcapsule phase-change material that contain any specification paraffin from 1% to 70%. Transformation temperature of this phase-change material is adjustable from 0 to 70 deg.C. This compound phase-change material can directly apply to construction region, textile region, and martial region and so on.

Owner:HUILIN SHENGDA ENERGY MATERIAL SCI & TECH DEV BEIJING

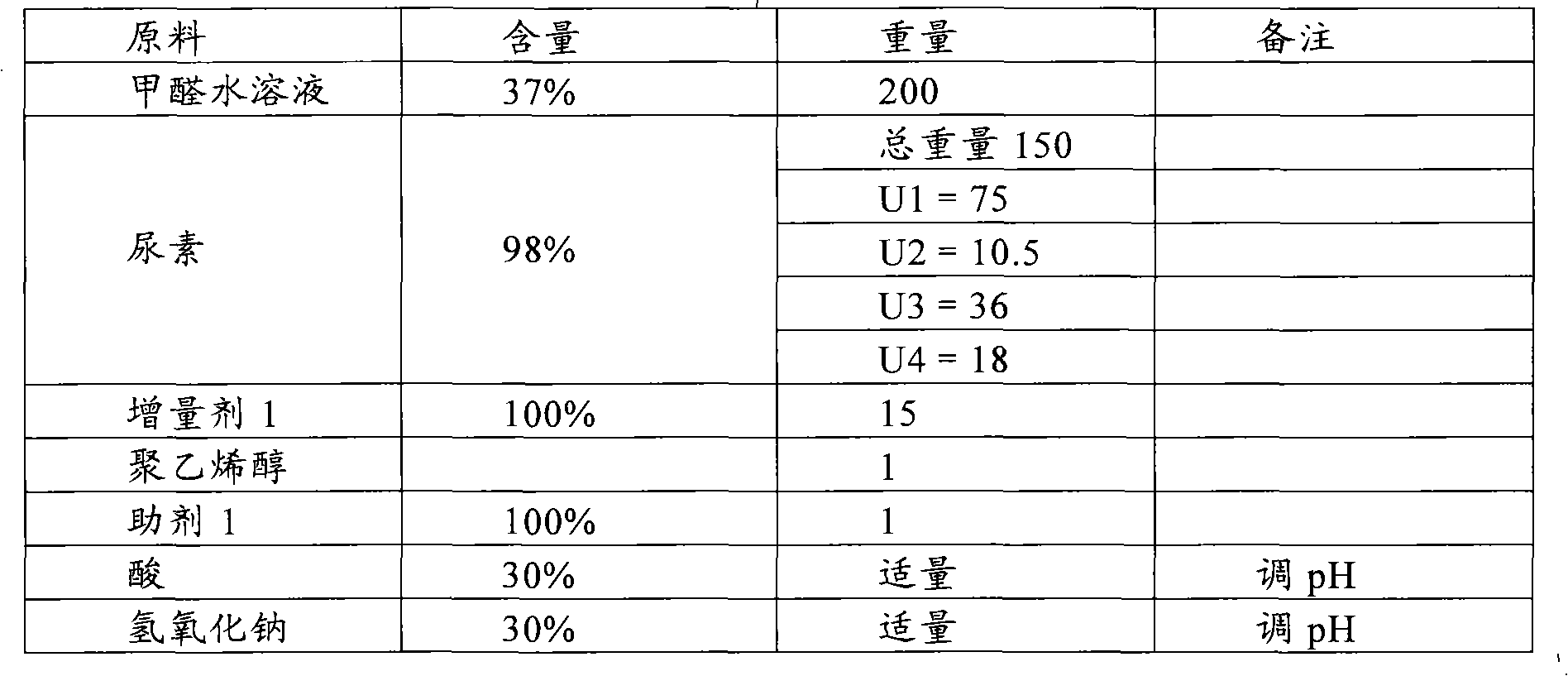

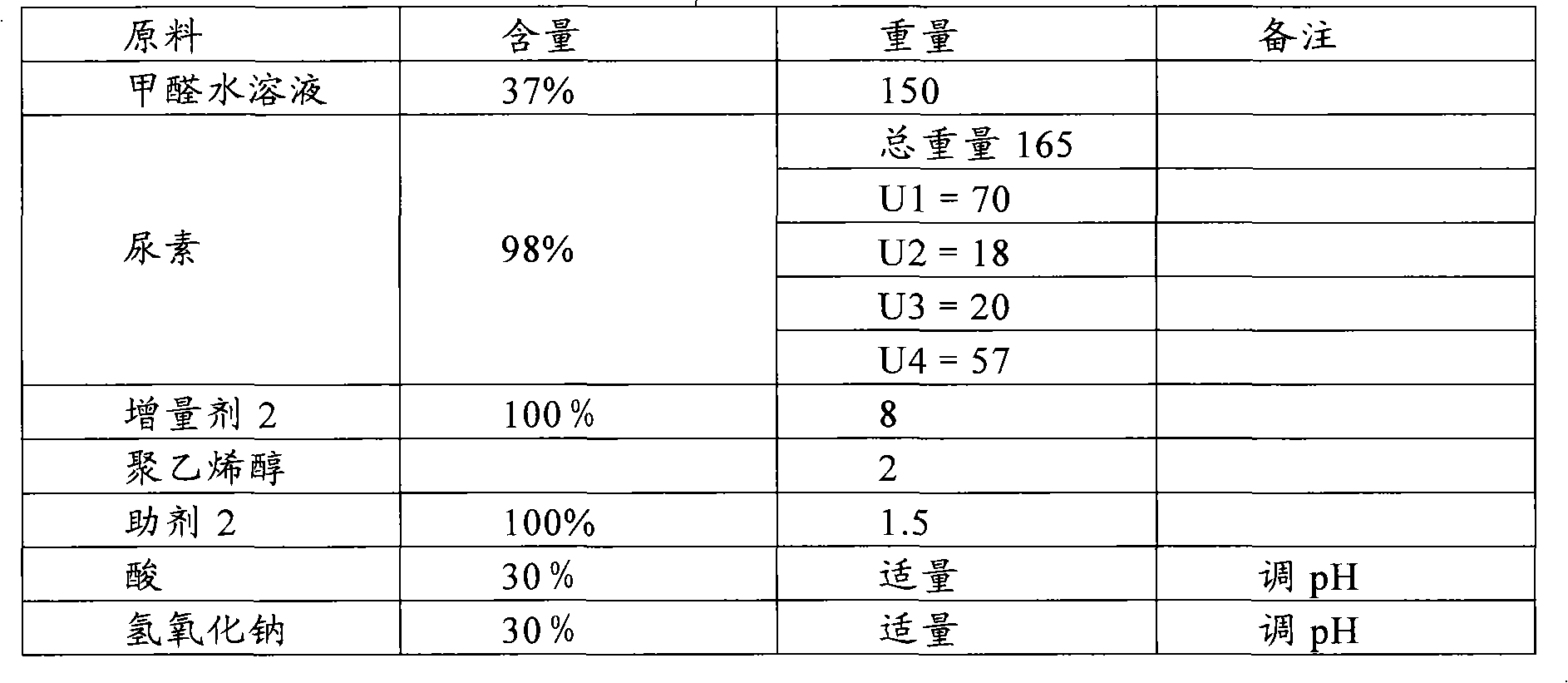

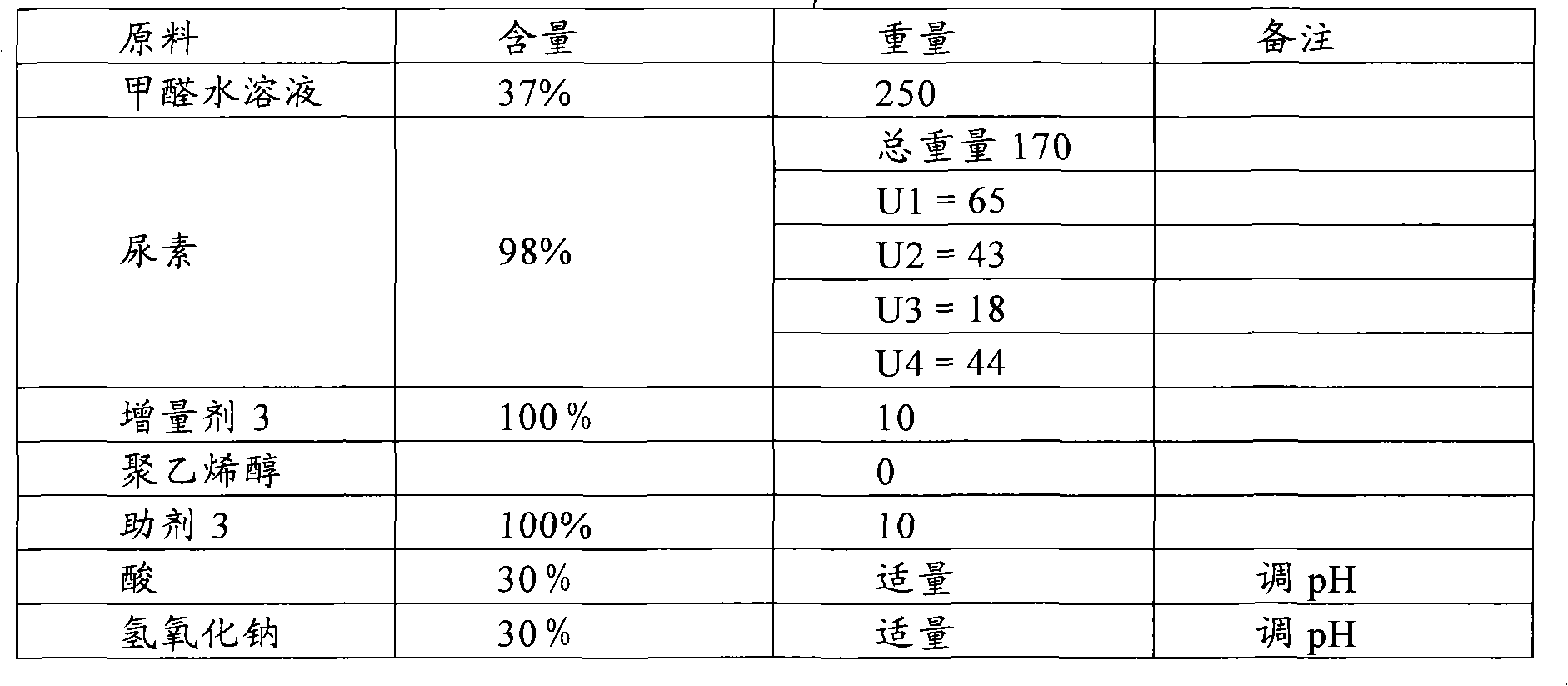

Urea-formaldehyde resin for non-dewatering particleboard and preparation method thereof

ActiveCN102086295AShorten the production cycleLower unit production costAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholWastewater

The invention relates to urea-formaldehyde resin and a preparation method thereof. The urea-formaldehyde resin comprises the following components in parts by weight: 200 parts of formaldehyde solution, 120-170 parts of urea, 0-2 parts of polyvinyl alcohol, 1-10 parts of additive and 3-20 parts of extender, wherein the concentration of formaldehyde solution is 37%; in the preparation process, ureais added three or four times and the reaction is performed in weakly alkaline medium, weakly acidic medium and neutral medium in turn; and additive and extender are added in the synthesis of urea-formaldehyde resin. The urea-formaldehyde resin can be used in the production of the particleboard without being dewatered, thus the problems of wastewater discharge and environmental pollution can be solved and the production cost of the particleboard can be greatly reduced; and the urea-formaldehyde resin is suitable for various large, medium and small particieboard enterprises.

Owner:江苏露水河人造板有限公司

Homogeneous granules of slow-release fertilizer and method of making the same

A process for making homogeneous granules of slow-release fertilizer to deliver high doses of slow-release nitrogen in pellets that disperse or fall apart when contacted by moisture. The method includes mixing particles of slow-release nitrogen with particles of a potassium source and particles of a phosphorus source, to make a homogeneous blend of the particles. Then, the blended particles are moistened with water or an aqueous solution of urea to moisten the homogeneous blend. After moistening, the blended particles are contacted with an aqueous suspension of urea-formaldehyde resin to bind the particles into homogeneous granules. The aqueous suspension of urea formaldehyde resin preferably has a urea:formaldehyde ratio of about 1:1.

Owner:LEBANON SEABOARD CORP

Production method of environmental-friendly type low-cost middle and high density fiber board

ActiveCN101791817AReduce formaldehyde contentReduce releaseNon-macromolecular adhesive additivesWood working apparatusOXALIC ACID DIHYDRATEFiber

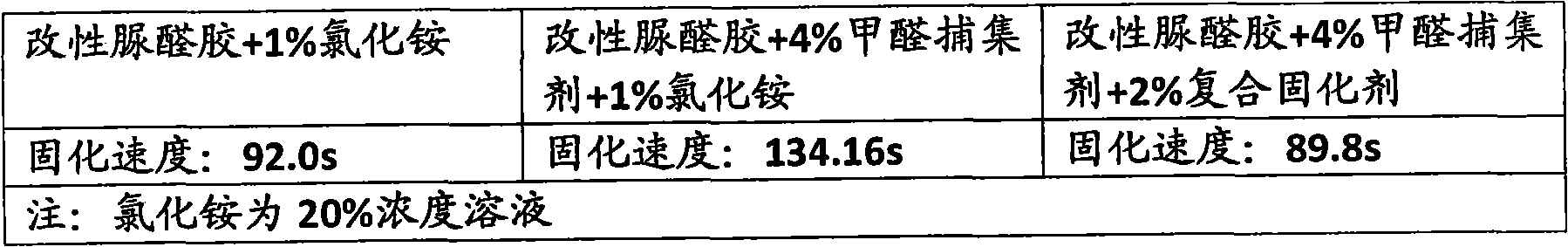

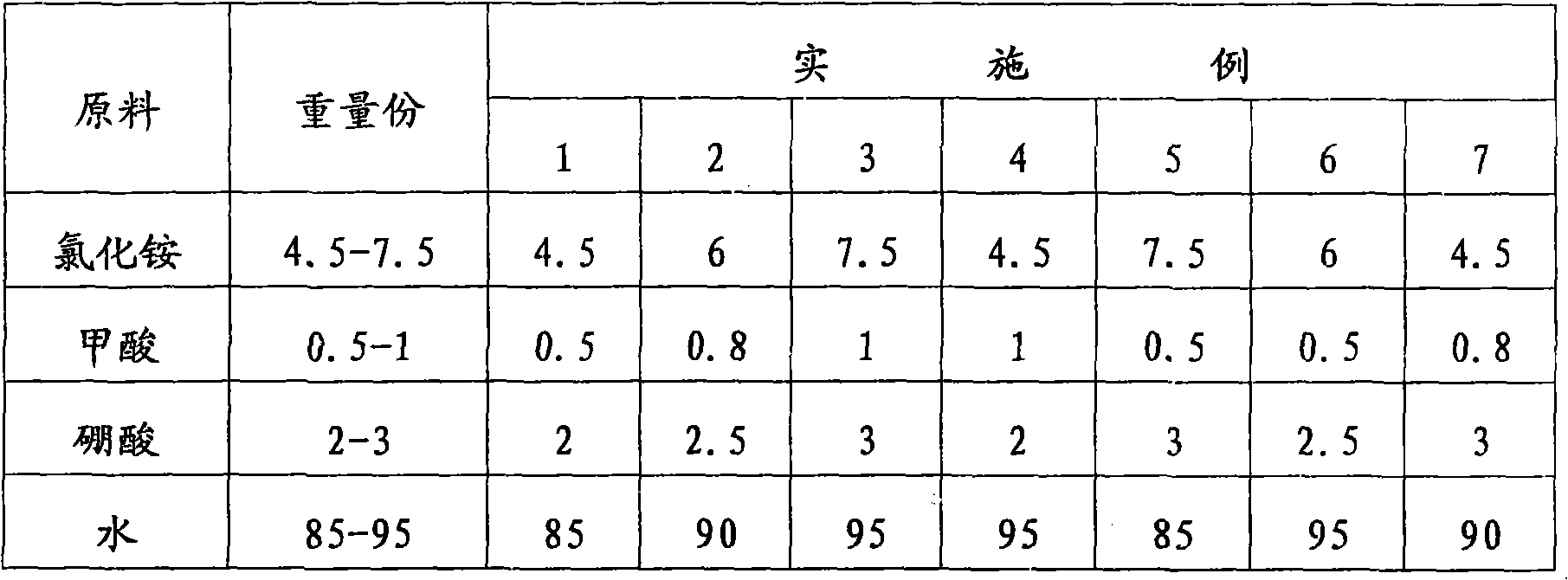

The invention relates to a production method of an environmental-friendly type low-cost middle and high density fiber board. Self-made modified urea-formaldehyde glue, a composite curing agent and a formaldehyde trapping agent are used in a glue blending procedure, wherein the modified urea-formaldehyde glue is prepared by heating formaldehyde, melamine and urea in a reaction kettle through a chemical reaction; the composite curing agent is prepared by mixing ammonium chloride, boric acid, oxalic acid and water; and the formaldehyde trapping agent is prepared from phosphoric acid, urea, a catalyst and water under a certain temperature condition. When the middle and high density fiber is produced, the application amount of the formaldehyde trapping agent is 3 percent or 4 percent of the weight of modified urea-formaldehyde glue solid, the application amount of the modified urea-formaldehyde glue solution is 12.5 percent of the weight of absolute dried fiber, and the application amount of the composite curing agent is 3 percent or 2 percent of the weight of the modified urea-formaldehyde glue solution. The middle and high density fiber board produced using the three ingredients can completely meet Eo level environmental-friendly requirements, has good compatibility and high bonding strength and greatly reduces production cost of the fiber board.

Owner:ZHEJIANG FORESTRY ACAD +1

Resin-polyester blend binder compositions, method of making same and articles made therefrom

ActiveUS20080207833A1High tensile strengthMaintaining (or improving) asphalt coating characteristicsAbrasion apparatusPolyester coatingsFiberWater dispersible

An aqueous binder system including a mixture of urea-formaldehyde resin and water-dispersible polyester resin. A combination of the binder system applied to fiber insulation, a composite glass mat, glass / polyester mat, polyester mat, or substrate of a coated abrasive product. Fiber insulation, a composite glass mat, glass / polyester mat, polyester mat, or coated abrasive product with the binder system including urea-formaldehyde resin and water-dispersible polyester.

Owner:BAKELITE UK HLDG LTD

Aldehyde-free adhesives for artificial board

The invention relates to an artificial board aldehyde-free adhesive, providing a method of preparing the adhesive. And its characteristic: in substance, it uses cross-linking and curing high-molecular compound, cross-linking agent, mildewproof agent, fillings and deionized water to prepare the adhesive to replace the urea formaldehyde for producing artificial boards, and it can radically eliminate dissociative formaldehyde pollution and harm in the industry.

Owner:NANJING FORESTRY UNIV

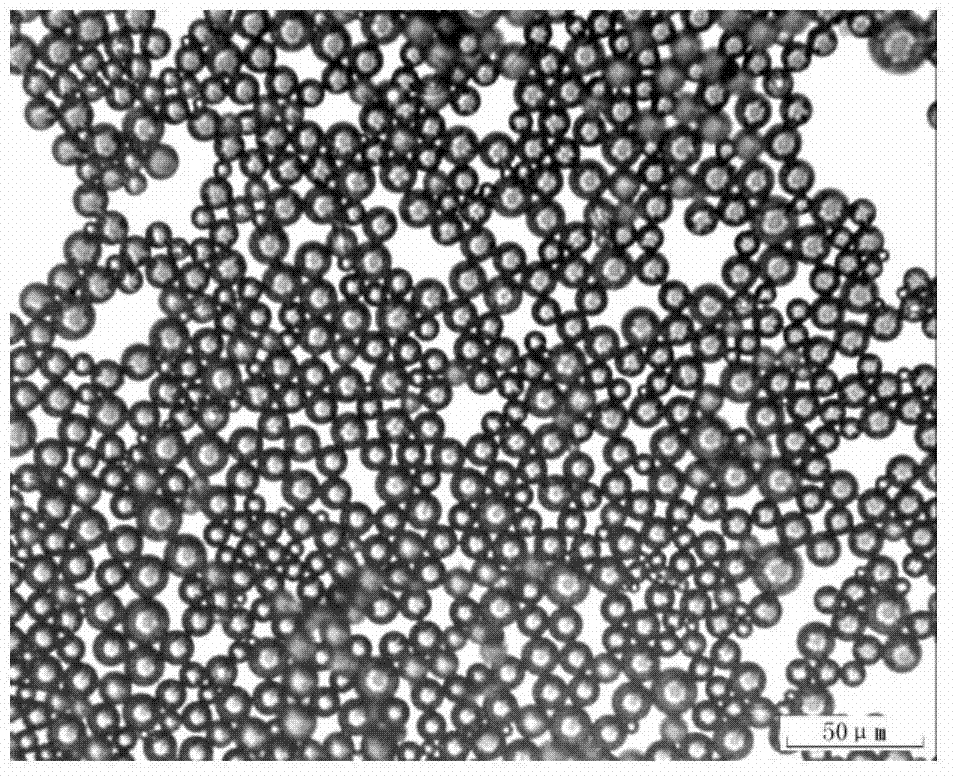

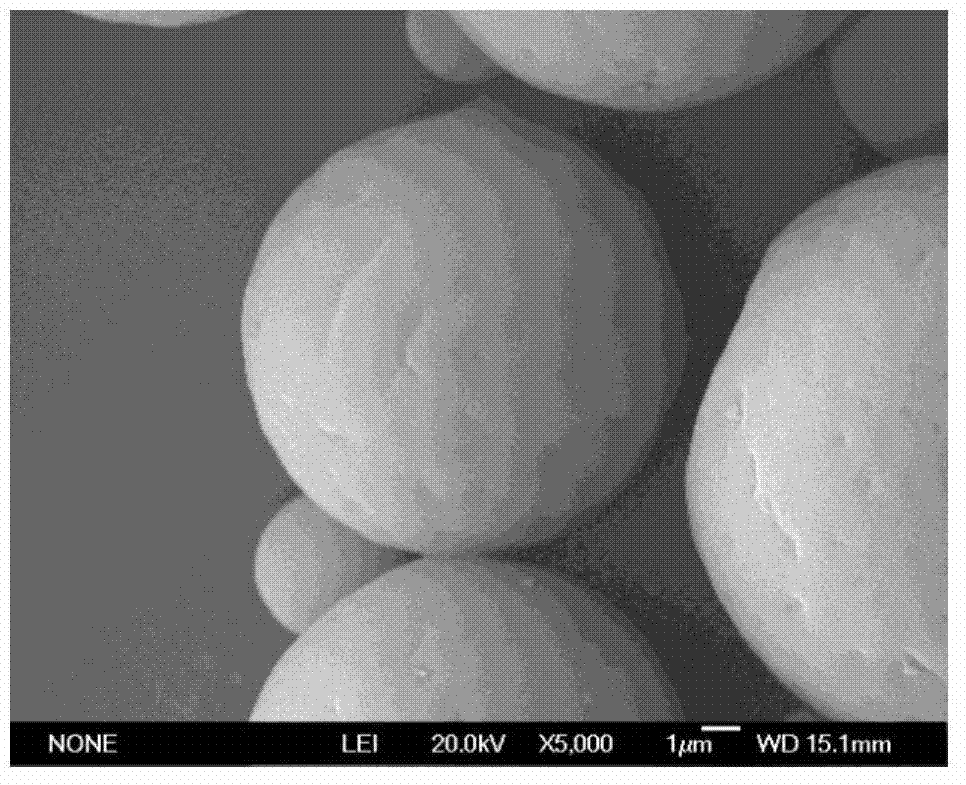

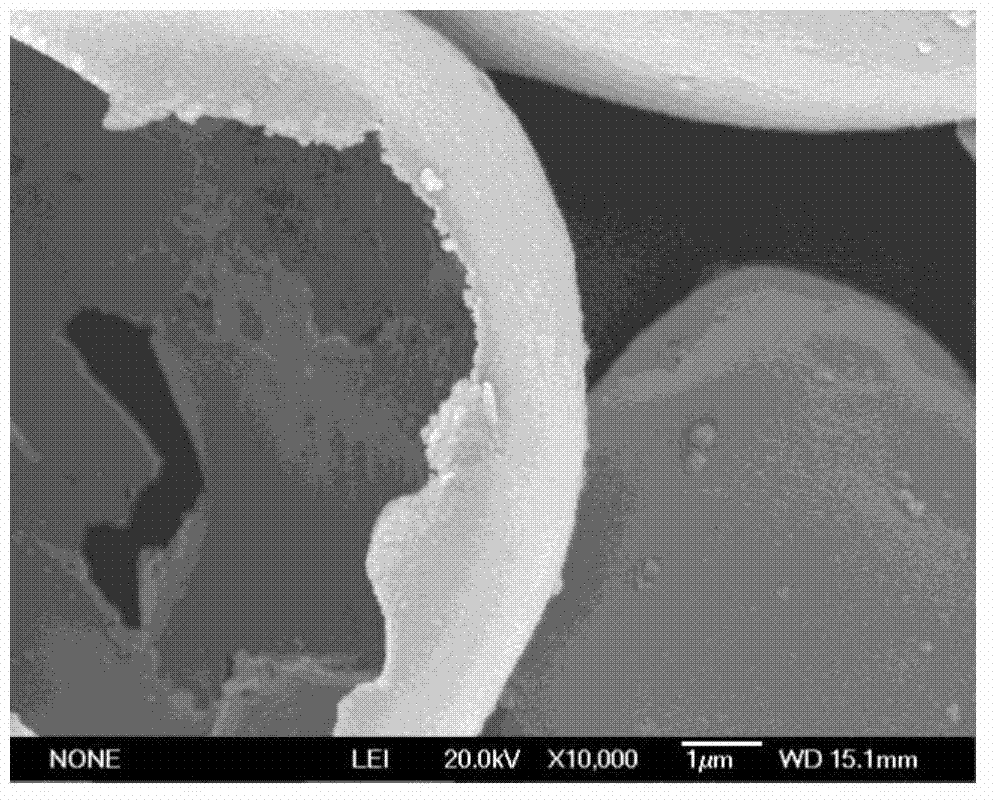

Urea-formaldehyde resin coated epoxy acrylic resin microcapsule for resin-base self-repair coating and preparation method thereof

ActiveCN102773053AHigh speedSphericity RulesMicroballoon preparationMicrocapsule preparationAcrylic resinResin coating

The invention relates to a urea-formaldehyde resin coated epoxy acrylic resin microcapsule for a resin-base self-repair coating and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding capsule core raw materials epoxy acrylic resin and acrylate reactive diluent into a water solution containing an emulsifier and a defoaming agent, dispersing the capsule core with a homogenizer or emulsifying machine to form a stable emulsion; regulating the pH value of the stable emulsion system to 2-3, adding capsule wall raw materials urea, formaldehyde and crosslinking agent, stirring until the capsule is formed, and after the reaction finishes, regulating the pH value of the system to neutral; and repeatedly washing with hot water and acetone, centrifuging, and carrying out vacuum drying to obtain the epoxy acrylic resin microcapsule. The capsule provided by the invention has the advantages of favorable sealability, regular sphericity, controllable grain size and controllable capsule wall thickness, and can be widely used for self-repair of a UV-cured acrylic resin coating or epoxy resin coating at low temperature and room temperature, thereby prolonging the service life of the coating material and widening the application range of the resin-base coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

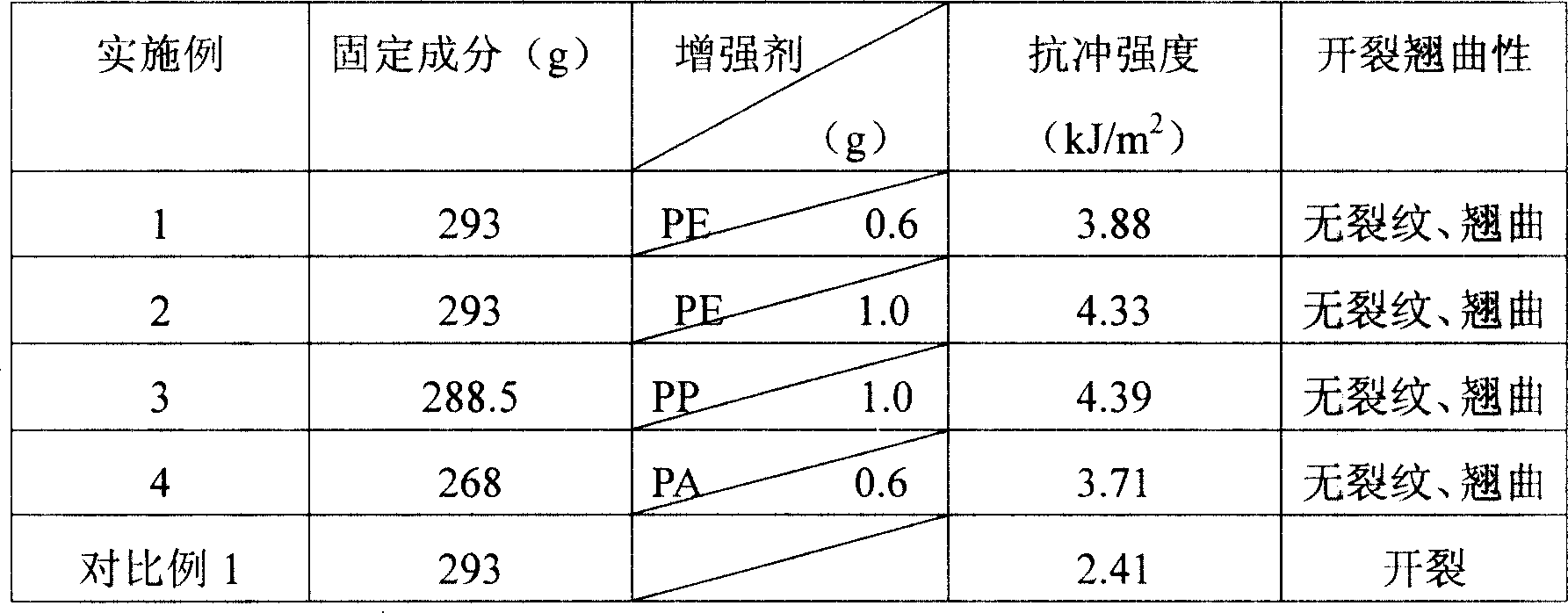

Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

InactiveCN101012360AHigh impact strengthImprove cracking performanceDecorative surface effectsOrnamental structuresAqueous solutionPoly methacrylate

The invention discloses a binder and making method of modified urea-formaldehyde resin, which comprises the following steps: adopting urea-formaldehyde resin, fill, reinforcer, deoxidation agent, formaldehyde catching agent, anti-aging agent, anti-shrinking agent, hardener and auxiliary reinforcer; adopting modified copolymer of acrylic acid, sodium acrylate, N, N-dimethylamino propyl methyl acrylamide as anti-shrinking agent; making polyacrylamide solution reacted by acrylamide and ammonium persulphate as formaldehyde catching agent; allocating each component according to proportion; blending evenly; casting; extracting into vacuum; stripping; stewing; drying naturally; coating a layer of polymethacrylate paint on the surface of product; proceeding colorful paint; obtaining the product.

Owner:XIAMEN UNIV

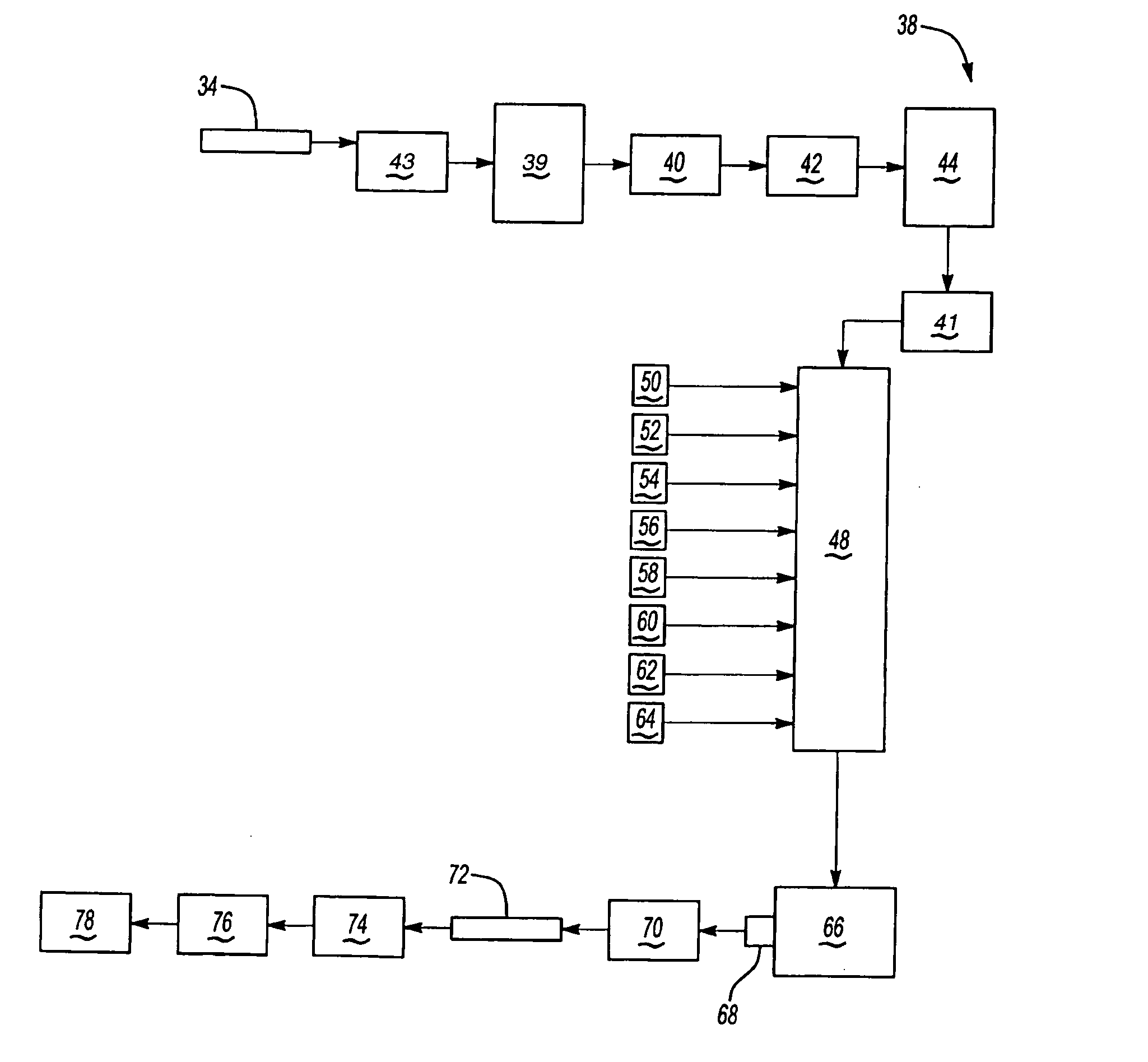

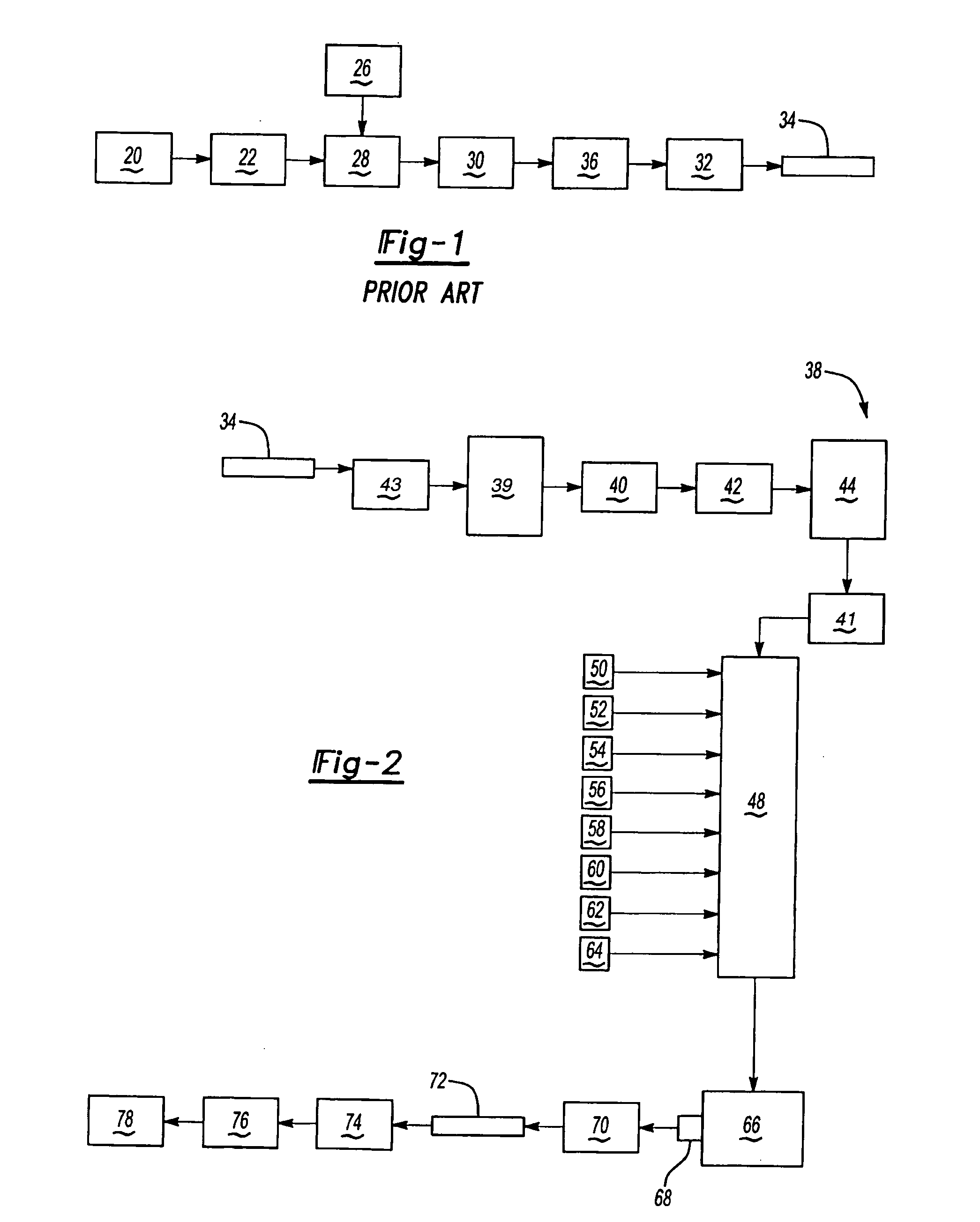

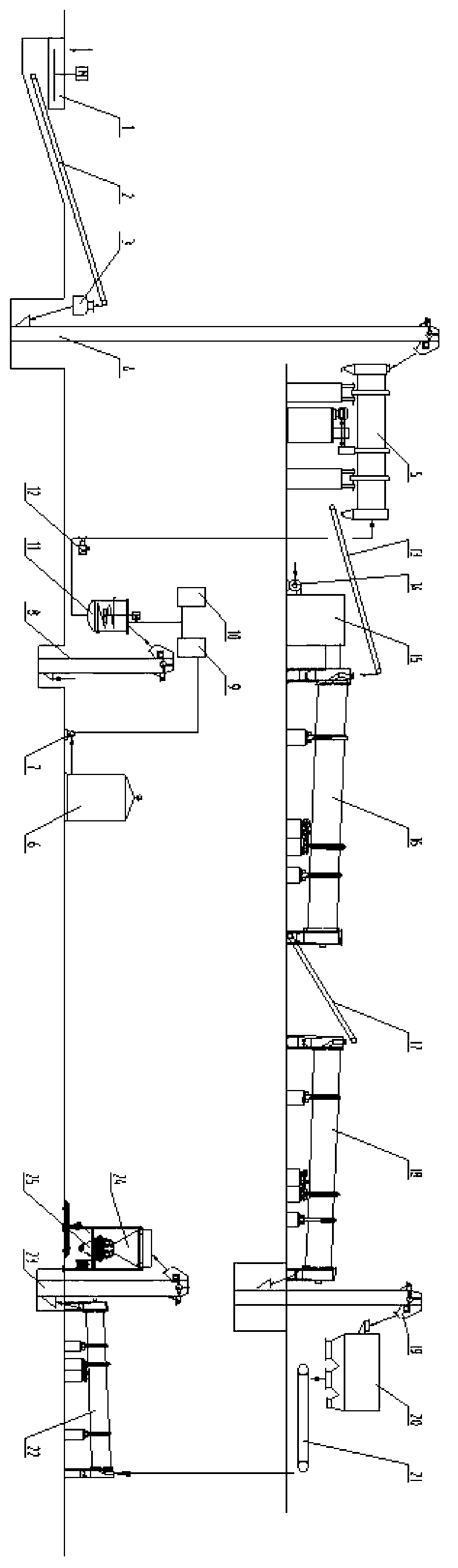

Industrial production method and device of urea-formaldehyde slow-release compound fertilizer

ActiveCN103011982ALow free formaldehyde contentMeet needsAgriculture gas emission reductionFertilizer mixturesPotassiumNitrogen

The invention relates to an industrial production method and device of a urea-formaldehyde slow-release compound fertilizer and a device thereof. The industrial production method comprises the steps of adding water and oxidized starch to a reaction still and then pasting, adding urea of which the nitrogen content is 46wt% and formalin, stirring, dissolving and then adjusting the pH value to 8.5-8.8 by an alkaline matter, reacting at constant temperature of 60 DEG C to obtain reaction liquid; adjusting the pH value to 5.4-5.1 by the reaction liquid; reacting for 45 minutes at the constant temperature of 65-68 DEG C, then adjusting the pH value to 6.8-7.2, and terminating reaction to obtain the urea formaldehyde condensation product solution; mixing the urea formaldehyde condensation product solution with nitrogen, phosphorus and potassium materials, pelletizing, drying and cooling to below 35 DEG C, and screening to obtain the urea-formaldehyde slow-release compound fertilizer. The industrial production device of the urea-formaldehyde slow-release compound fertilizer is also provided by the invention. Urea formaldehyde is taken as a skeleton; rapid disintegration phenomenon of fertilizer particles caused by water absorption expansion is effectively prevented; the urea-formaldehyde slow-release compound fertilizer has good nutrient slow-release performance, and is high in pelletizing rate in the production process and strong in granule hardness, and the total nutrient content is improved.

Owner:河南豫邮金大地科技服务有限公司

Composition board binding material

InactiveUS6291558B1Good dispersibilityImprove stabilityInksLignin derivativesLignosulfonatesReaction step

This invention features a graft copolymer of lignosulfonates reacted with an unsaturated carbonyl compound and an aldehyde, in two separate reaction steps. The resin can be used as a substitute for a majority of pure urea formaldehyde resin in the manufacture of composite board products. The resin can also be introduced directly into the urea formaldehyde resin production process.

Owner:CELLUTECH

Modified lignin and urea-formaldehyde resin synthesized from same and preparation methods of modified lignin and urea-formaldehyde resin

InactiveCN102241826AHigh bonding strengthReduce formaldehyde emissionAldehyde/ketone condensation polymer adhesivesSynthesis methodsEther

The invention discloses a modified lignin and a urea-formaldehyde resin synthesized from same and preparation methods of the modified lignin and the urea-formaldehyde resin, belonging to the field of bonding agents used in wood processing. A technological synthetic route with weak base-weak acid-weak base is adopted, the molar ratio of formaldehyde to urea is controlled during an addition stage to generate a reasonable structure, the modified lignin as well as residual hydroxymethyl and free formaldehyde are added at the later stage of reaction in order to accomplish reaction, thus the content of methylene ether link (-CH2-O-CH2-) and the content of hydroxymethyl in the resin are reduced to a certain extent, the formaldehyde emission of the resin is lowered, and simultaneously, higher bonding strength and water resistance are ensured. The urea-formaldehyde resin in the invention is simple and brief in process and low in cost, the formaldehyde emission of the plate prepared by adoptingthe bonding agent reaches the E0-level standard and the plate can maintain high bonding strength after being cooked in hot water. The modified lignin is simple in synthesis method and low in cost andis especially suitable for the modification of the urea-formaldehyde resin with low molar ratio.

Owner:BEIJING UNIV OF CHEM TECH

Wet formed mat having improved hot wet tensile strengths

InactiveUS20070039703A1Improves hot wet tensile strengthImprovement dry tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberEngineering

Wet-laid chopped strand glass mats for use in roofing applications that have improved hot wet tensile strengths are provided. The chopped strand mats are formed by the application or inclusion of at least one coupling agent to the chopped strand mat during a wet-laid mat forming process. The coupling agent may be added to the chopped strand mat as part of a two-part binder composition that includes a binder and at least one coupling agent. Alternatively, the coupling agent may be added directly to the chopped strand mat independent of the binder. As a further alternative, the coupling agent(s) may be added to the white water in the wet-laid mat forming process and incorporated into the formed glass mat via the glass fibers. The binder may be a modified urea-formaldehyde binder, a non-modified urea-formaldehyde binder, and / or a formaldehyde-free binder. The coupling agent(s) may be silane coupling agents and / or reactive siloxanes.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com