Preparation method of phase transformation material microcupsule

A phase-change material and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., to achieve the effects of convenient operation, enhanced mechanical strength, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

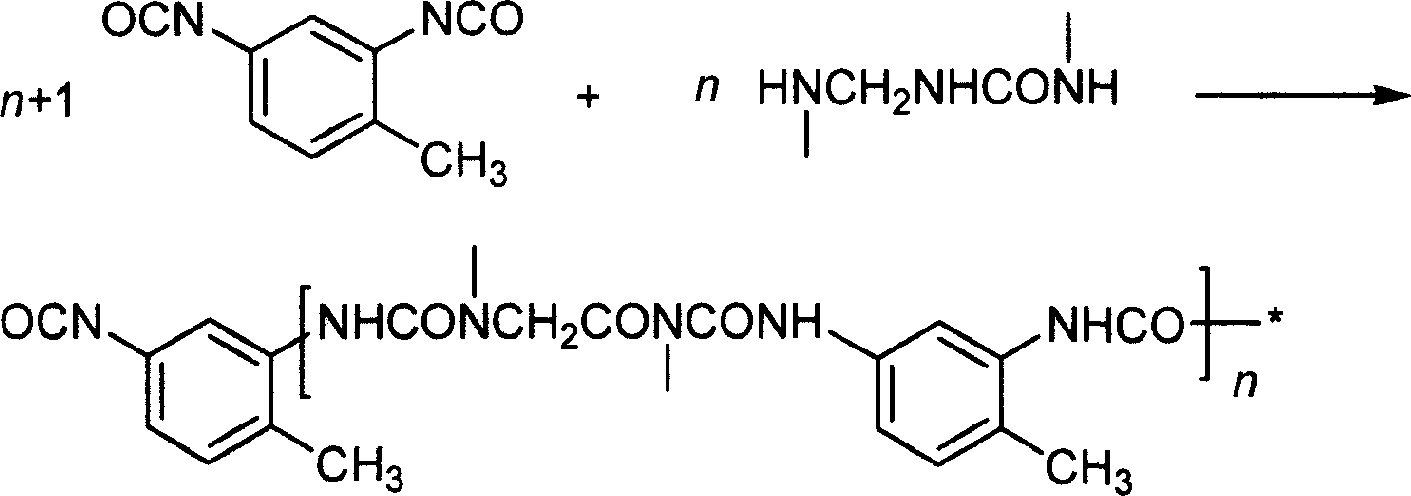

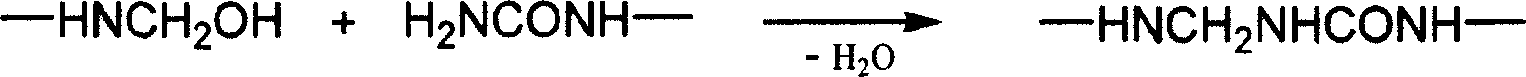

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of urea-formaldehyde resin prepolymer.

[0050] Prepare the component mass fraction of urea-formaldehyde resin prepolymer as follows:

[0051] Urea 100

[0052] 37% formaldehyde solution 200

[0053] Triethanolamine 0.6

[0054] The preparation method of urea-formaldehyde resin prepolymer is as follows

[0055] (1) Add urea, formaldehyde, and triethanolamine into the reaction kettle, and start stirring to completely dissolve the urea.

[0056] (2) Turn on reflux of condensed water, heat the reactor to 80° C., maintain the reaction for 1 hour, and cool down to room temperature. The product is a urea-formaldehyde resin prepolymer.

[0057] 2. Paraffin wax wrapped in double-layer microcapsules.

[0058] The composition mass fraction of double-layer microcapsule wrapped paraffin is as follows:

[0059] Paraffin (melting point 4°C) 100

[0060] Urea-formaldehyde resin prepolymer 200

[0061] OP emulsifier 0.2

[0062] Toluene diisocyanate 15

[0063]...

Embodiment 2

[0073] 1. Preparation of urea-formaldehyde resin prepolymer.

[0074] Prepare the component mass fraction of urea-formaldehyde resin prepolymer as follows:

[0075] Urea 120

[0076] 37% formaldehyde solution 220

[0077] Triethanolamine 0.2

[0078] The preparation method of urea-formaldehyde resin prepolymer is as follows

[0079] (1) Add urea, formaldehyde, and triethanolamine into the reaction kettle, and start stirring to completely dissolve the urea.

[0080] (2) Turn on reflux of condensed water, heat the reactor to 80° C., maintain the reaction for 1 hour, and cool down to room temperature. The product is a urea-formaldehyde resin prepolymer.

[0081] 2. Paraffin wax wrapped in double-layer microcapsules.

[0082] The composition mass fraction of double-layer microcapsule wrapped paraffin is as follows:

[0083] Paraffin (melting point 17°C) 100

[0084] Urea-formaldehyde resin prepolymer 200

[0085] Tween emulsifier 0.6

[0086] Toluene diisocyanate 30

[0...

Embodiment 3

[0097] 1. Preparation of urea-formaldehyde resin prepolymer.

[0098] Prepare the component mass fraction of urea-formaldehyde resin prepolymer as follows:

[0099] Urea 100

[0100] 37% formaldehyde solution 200

[0101] Triethanolamine 0.6

[0102] The preparation method of urea-formaldehyde resin prepolymer is as follows

[0103] (1) Add urea, formaldehyde, and triethanolamine into the reaction kettle, and start stirring to completely dissolve the urea.

[0104] (2) Turn on reflux of condensed water, heat the reactor to 80° C., maintain the reaction for 1 hour, and cool down to room temperature. The product is a urea-formaldehyde resin prepolymer.

[0105] 2. Paraffin wax wrapped in double-layer microcapsules.

[0106] The composition mass fraction of double-layer microcapsule wrapped paraffin is as follows:

[0107] Paraffin (melting point 17°C) 100

[0108] Urea-formaldehyde resin prepolymer 200

[0109] SP emulsifier 0.5

[0110] water 100

[0111] Toluene diis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com