Boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof

A technology of microemulsion and cutting fluid, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as not being able to meet environmental protection regulations, and achieve the effects of reducing environmental and human hazards, reducing wear, and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

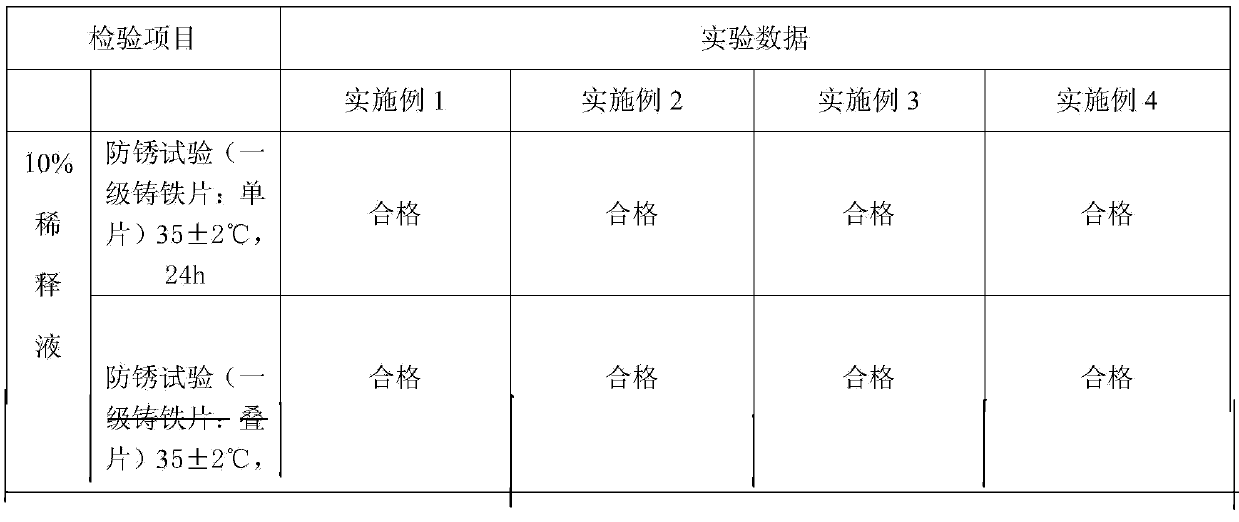

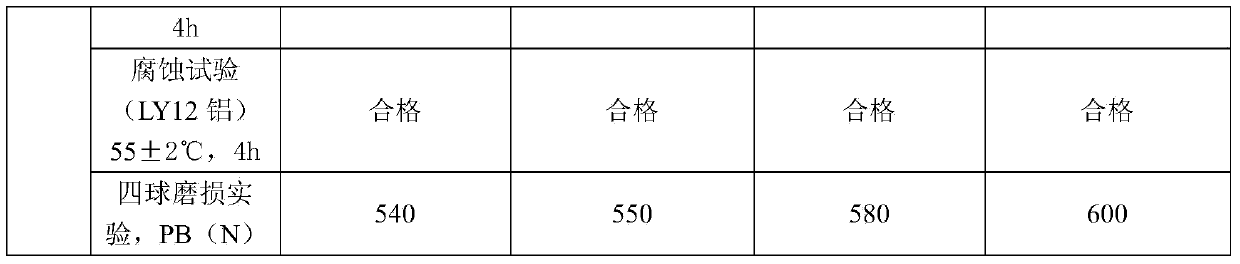

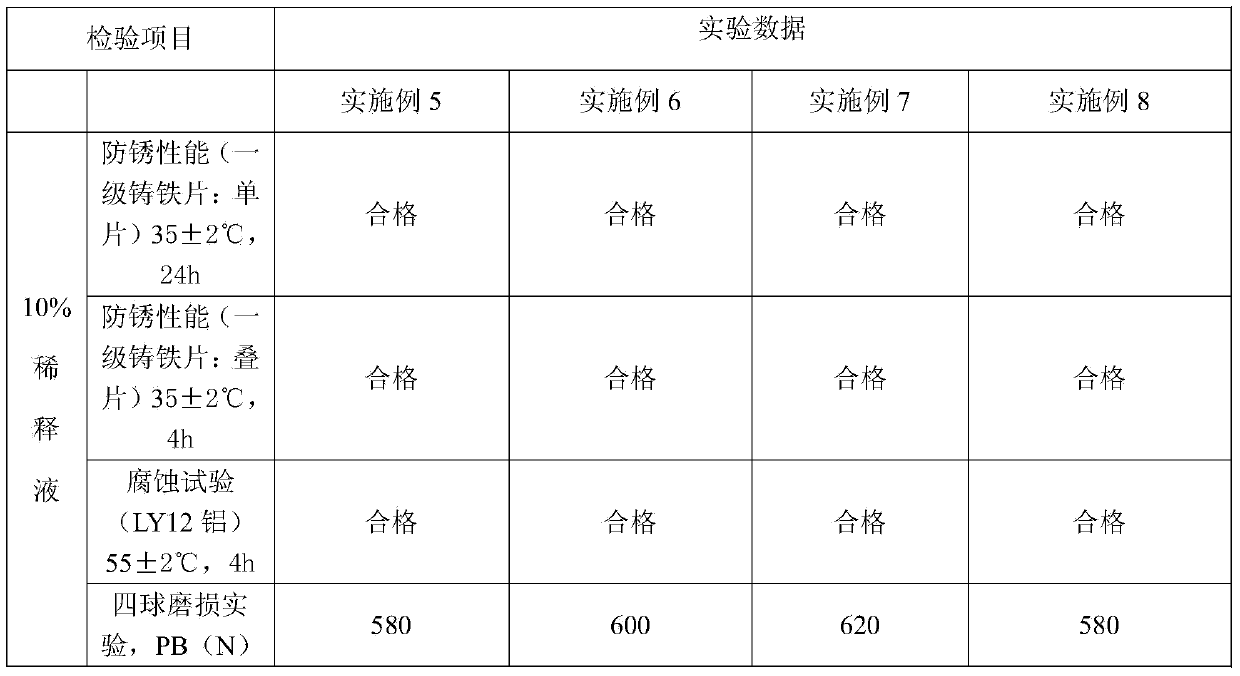

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0033] Implementation column 1

[0034] A boron-free, chlorine-free, formaldehyde-free microemulsion cutting fluid, including the following raw materials in weight percentage: 30% naphthenic mineral oil, 5% monoethanolamine, 10% triethanolamine, 20% pentaerythritol ester tetraoleate, fat Alcohol modified phosphate 5%, dodecenyl succinic acid 5%, diethylene glycol dimethyl ether 1%, fatty alcohol ether carboxylic acid 8%, phosphonate 3%, 1,2-benzoiso Thiazolin-3-one 1%, 2-butyl-1,2-benzisothiazolin-3-one 0.5%, tall oil 5%, synthetic sodium sulfonate 6%, fatty alcohol polyoxyethylene ether 3%, Sorbic Anhydride Monooleate 3%, balance Water.

[0035] Preparation method: first add naphthenic mineral oil, dodecenyl succinic acid derivatives and pentaerythritol ester tetraoleate into the kettle, then add monoeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com