Patents

Literature

811results about How to "Good defoaming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Defoamer

To provide a defoaming agent causing less cissing. The defoaming agent contains an aluminum carboxylate (A) and hydrocarbon oil (B), but contains no alkaline earth metals, wherein (A) is an aluminum di-carboxylate (A2) or a mixture of an aluminum mono-carboxylate (A1) and an aluminum di-carboxylate (A2), the content, by weight, of (A) is 0.1-60% and the content of (B) is 40-99.9% based on the weight of (A) and (B), and the content of A(1) is <=40% based on the total weight of (A1) and (A2). In addition, the defoaming agent contains free fatty acid (FA) and the content of (FA) is preferably 1-30% based on the weight of (A1) and (A2). In addition, the defoaming agent contains hydrocarbon oil (B) containing aromatic carbon (BA), and the content of (BA) is preferably 1-30% by number based on the total number of carbons of (B).

Owner:日本诺普科助剂有限公司

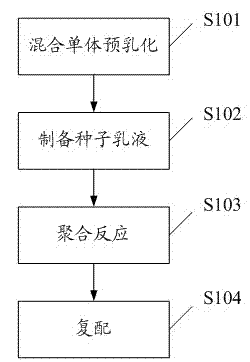

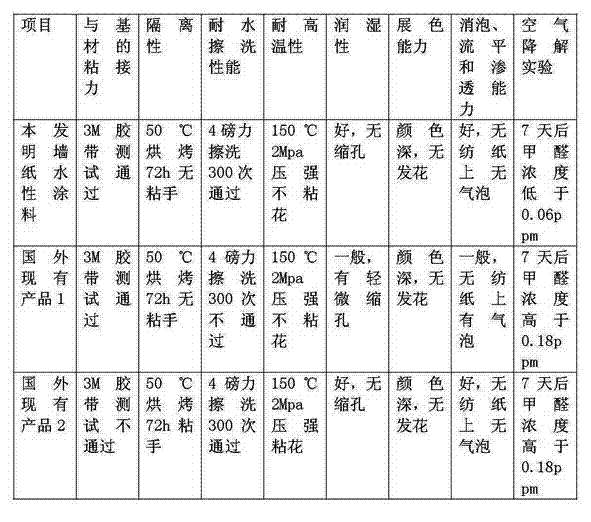

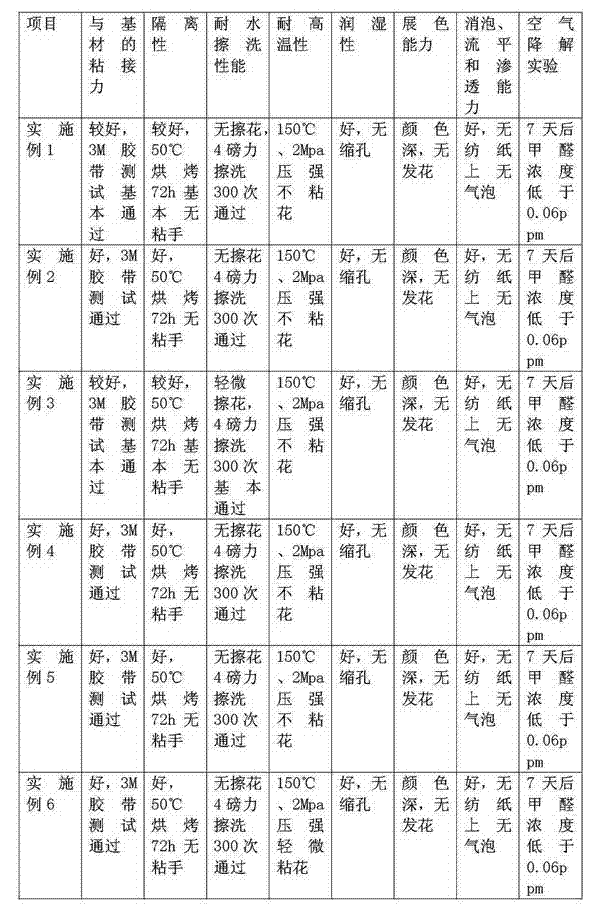

Wallpaper water-based paint, preparation method thereof and wallpaper

The invention discloses wallpaper water-based paint. The wallpaper water-based pain is water-based acrylate emulsion with solid content being 20-40% and the water-based acrylate emulsion is mainly made from a (methyl) acrylate monomer, a functional polymerizable monomer, an emulsifier, a photocatalyst, an initiator and deionized water through an emulsion polymerization method and a sol-gel method. Accordingly, the invention also discloses a method for preparing the wallpaper water-based paint and wallpaper made by adopting the wallpaper water-based paint. The wallpaper water-based paint is obviously improved in wallpaper substrate adaptability, the wallpaper water-based paint has good adhesive force, isolation, wettability and colour developing capability and is resistant to scrubbing and high temperature, defoaming is realized and the hole shrinkage phenomenon of a substrate is avoided; meanwhile, the wallpaper water-based paint also has light degradation property and can purify indoor air.

Owner:佛山市三水灏诚合成树脂有限公司

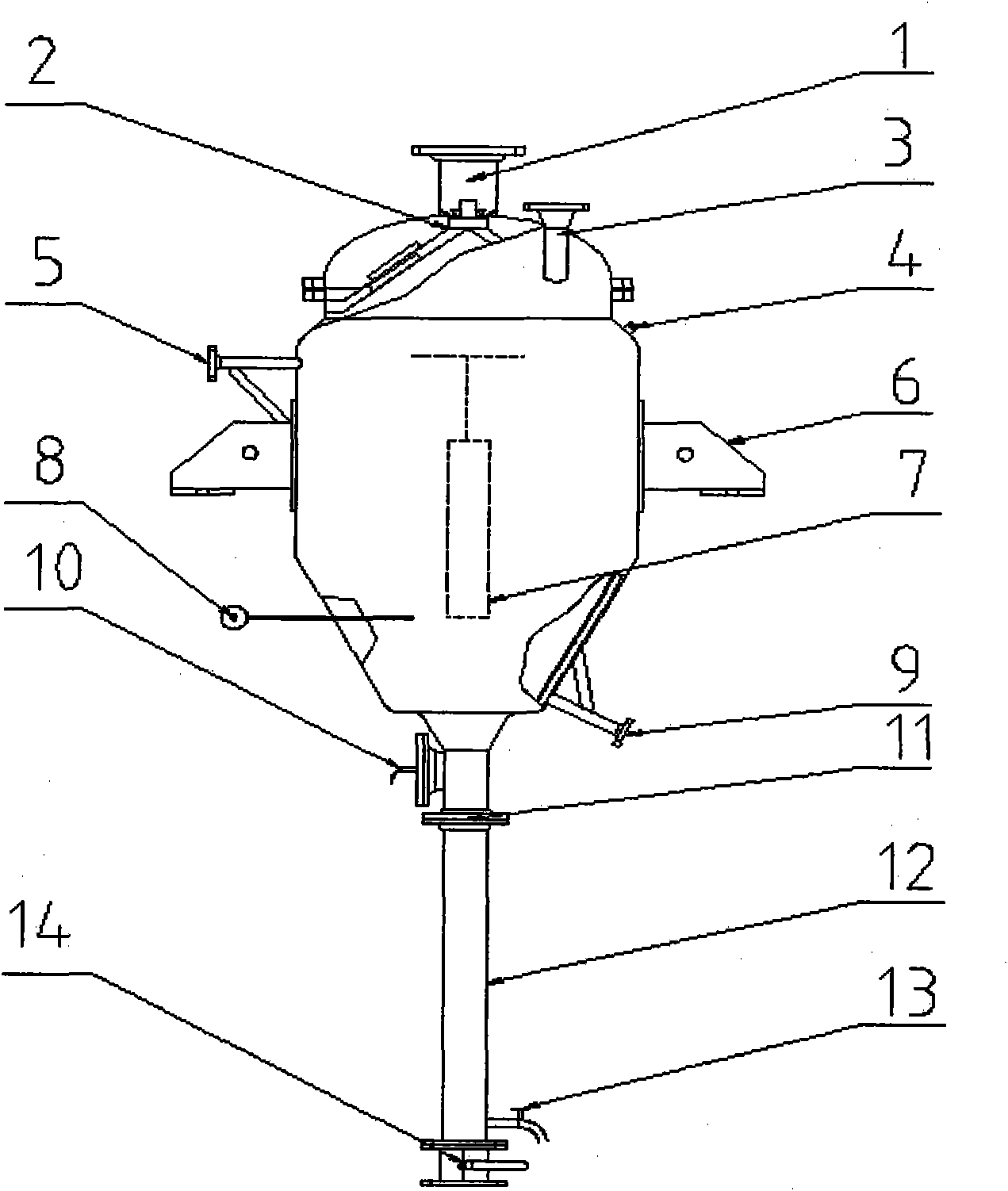

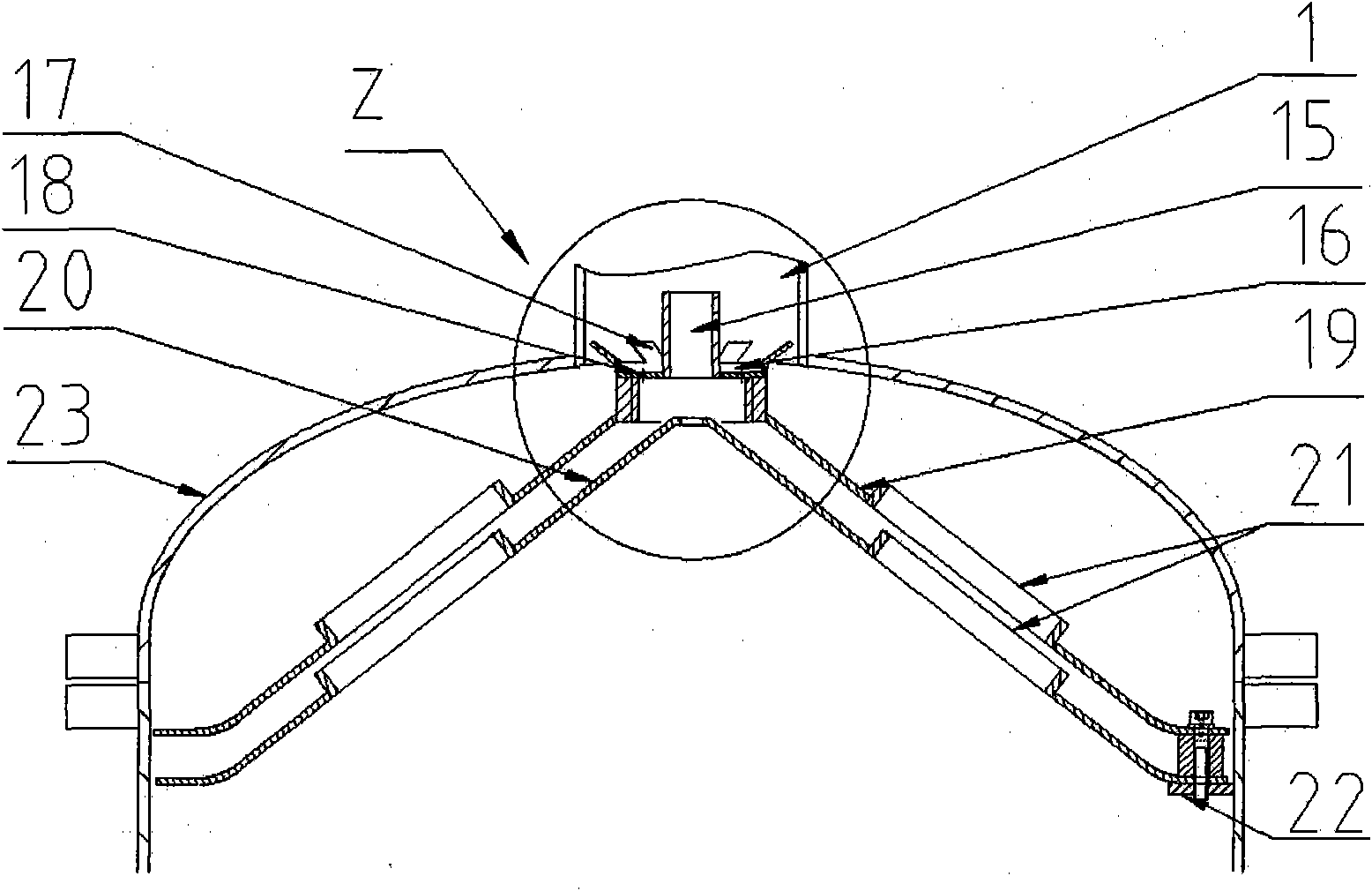

Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

ActiveCN101856570AContinuous quantitative feedingSingle and degassing continuous dynamicFoam dispersion/preventionCarbon fibersSolvent

The invention discloses a dynamic demonomerization and defoaming method and a dynamic demonomerization and defoaming device for carbon fiber spinning solution. An ultrasonic generator is arranged in the centre of a defoaming kettle; an air guide cylinder and a flow guide disk are arranged on a flow diversion and air guide cover; and the defoaming effect is improved to realize low-temperature high-vacuum demonomerization and defoaming of the spinning solution with different relative molecular masses and different charging rates by the processes of heating a demonomerization and defoaming device, continuous feeding, gravity demonomerization and defoaming, film stretch defoaming and ultrasound-assisted defoaming and controlling the defoaming temperature, the vacuum degree and the rotation speed of a demonomerization tower. The spinning solution obtained by the method has the residual monomer content of less than 0.1 percent, less than 5 small bubbles with diameter of less than 0.03mm and solvent loss of less than 5 percent during the demonomerization and defoaming. The method and the device can realize continuous dynamic demonomerization and defoaming at a low temperature under vacuum condition and has the characteristics of simple and practical process and good defoaming effect.

Owner:XIAN KANGBEN MATERIAL

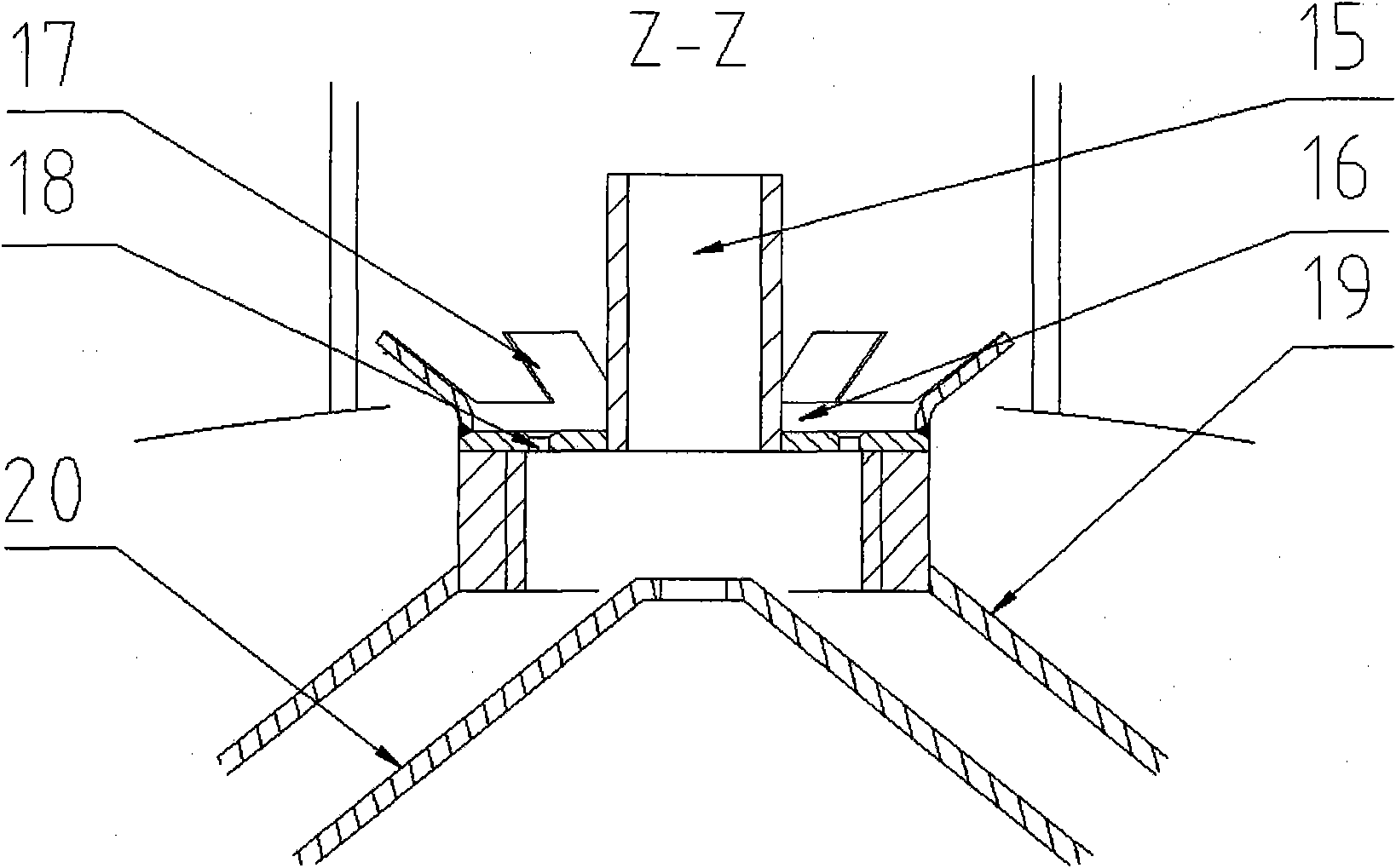

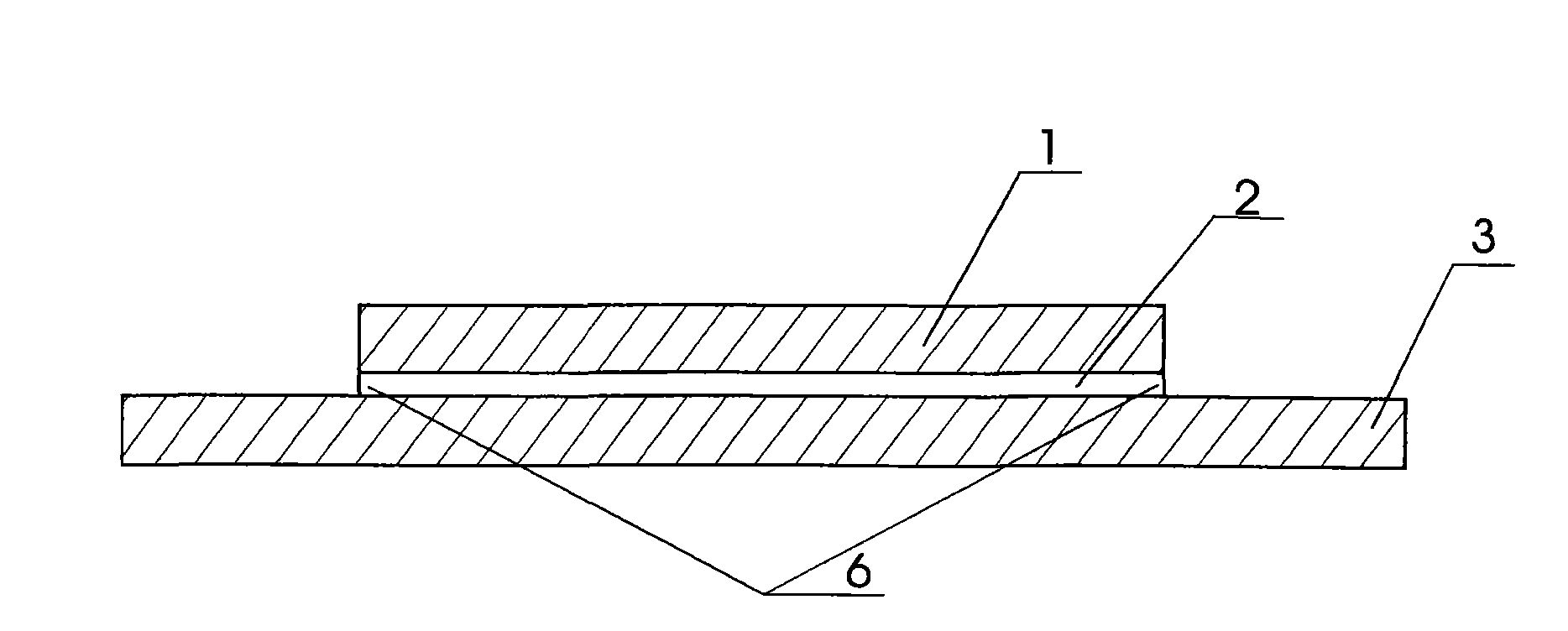

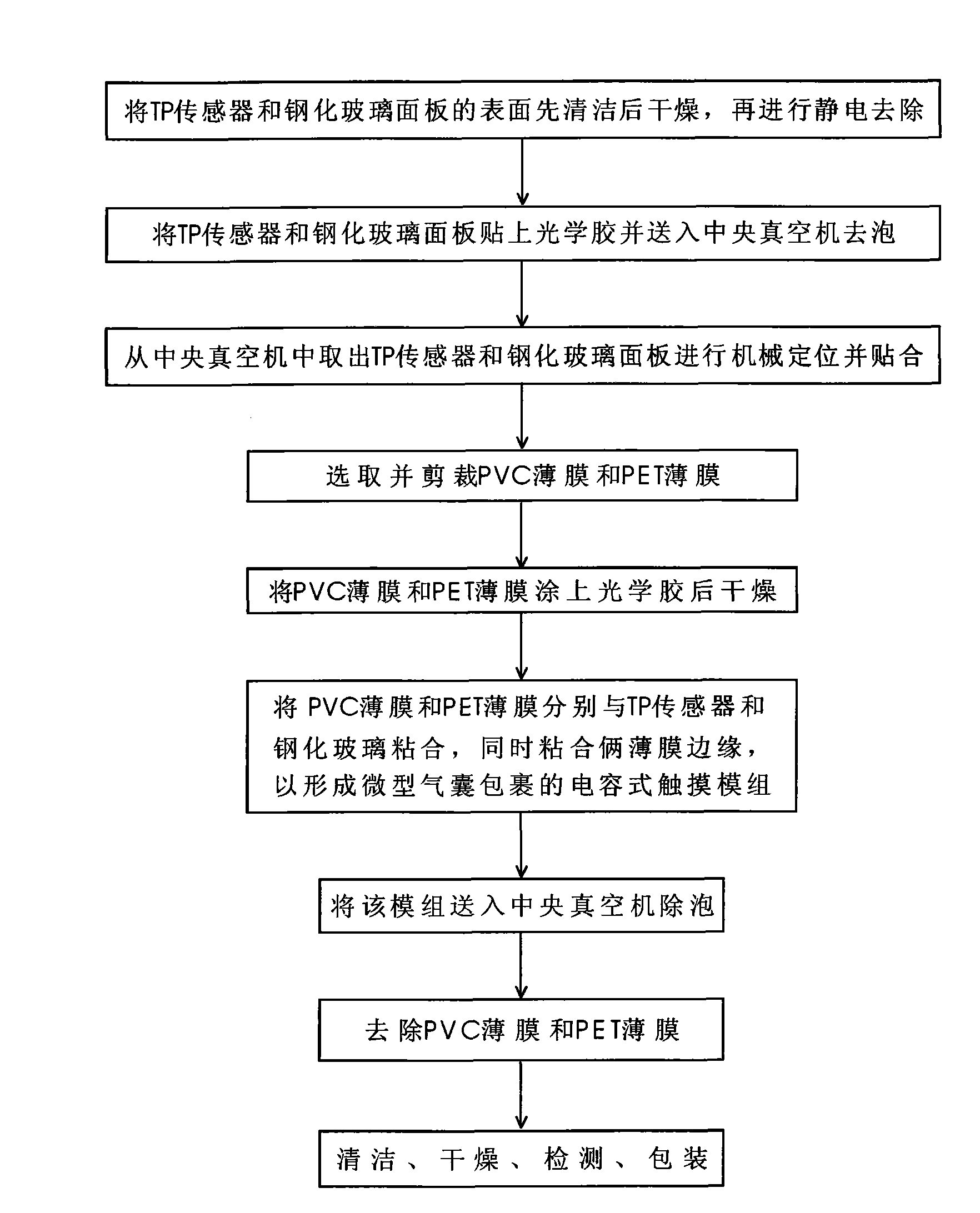

Technology for attaching capacitive touch screens

InactiveCN101650622AEliminate edge pressure effectsGood defoaming effectLaminationLamination apparatusEngineeringAdhesive

Technology for attaching capacitive touch screens relates to the technology for attaching touch screens and comprises the following steps: first cleaning and then drying the surfaces of a TP sensor and a toughened glass panel, and then carrying out electrostatic removing; attaching optical adhesives to the TP sensor and the toughened glass panel and sending the TP sensor and the toughened glass panel to a central vacuum machine for bubble removing; taking out the TP sensor and the toughened glass panel from the central vacuum machine for mechanical locating and attaching so as to form a capacitive touch screen module; selecting and clipping PVC films and PET films; coating adhesives on and drying the PVC films and PET films; adhering the PVC films and PET films respectively to the TP sensor and the toughened glass panel so as to form a capacitive touch screen module encapsulated by a miniature air bag; sending the module to the central vacuum machine for bubble removing and removing the PVC and PET films. The technology solves the problem of bubbles on the edge during attaching by adopting the method of removing bubbles with the miniature air bag and can be widely applied to attaching the capacitive touch screens.

Owner:城步新鼎盛电子科技有限公司

Defoaming agent composition

ActiveCN103768834ALarge specific surface areaStrong Hydrophilic PropertiesFoam dispersion/preventionSolventDefoaming Agents

The invention relates to a defoaming agent composition which is prepared by compounding 20-30 parts by mass of branched polyether, 10-20 parts by mass of modified nano silica, 20-30 parts by mass of polyorganosiloxane and 20-30 parts by mass of a solvent. The defoaming agent composition combines the hyperbranched polyether and the modified nano silica together, has an obvious synergistic effect, so that the hyperbranched polyether and the modified nano silica can be more compatible, defoaming properties of the hyperbranched polyether and the modified nano silica in high temperature environment can be increased, when the adding amount is about 30 mug / g, the defoaming rate can reach more than 90%, and the defoaming performance is strong.

Owner:CHINA PETROLEUM & CHEM CORP +1

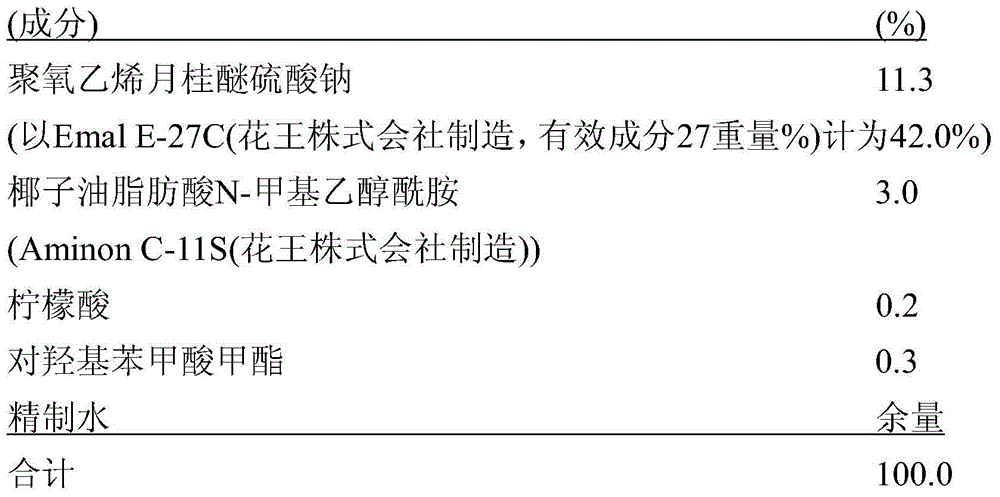

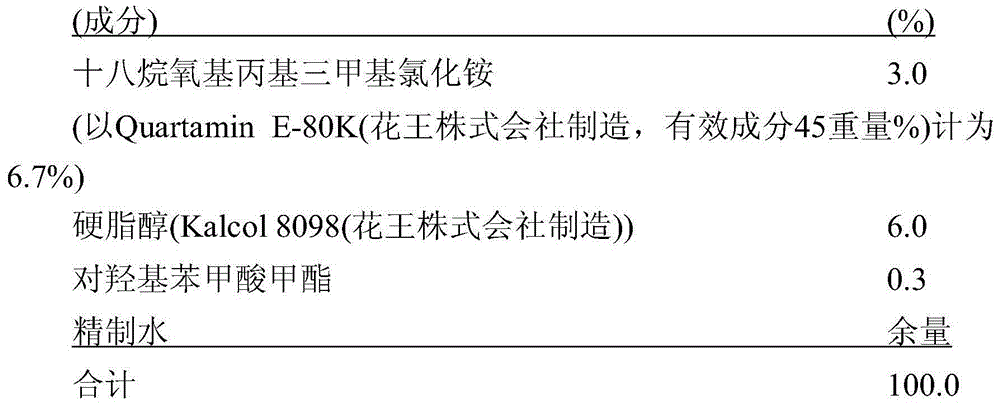

Internal olefin sulfonate composition and detergent composition containing same

ActiveCN104603251AImprove durabilityGood bubble qualityCosmetic preparationsHair cosmeticsSulfonateCarbon number

Provided is an internal olefin sulfonate composition that can achieve at high levels excellent foamability, foaming amount, rapid-foaming, foam disappearance, foam quality, foam persistence in the presence of sebum, and foam quantity in the presence of sebum; also provided is a detergent composition containing said internal olefin sulfonate composition. This internal olefin sulfonate composition contains (A) an internal olefin sulfonate having a carbon number of 16 and / or (B) an internal olefin sulfonate having a carbon number of 18. The total content of component (A) and component (B) is 50-100 mass%, the content ratio (A / B) of component (A) and component (B) is 0 / 100-70 / 30, and the content of internal olefin sulfonates having a sulfonic acid group in position 2 is 25 mass% or less. The mass ratio of the content of hydroxy bodies in the internal olefin sulfonates of component (A) and component (B) and the content of olefin bodies in the internal olefin sulfonates of component (A) and component (B) (hydroxy bodies / olefin bodies) is 75 / 25-100 / 0.

Owner:KAO CORP

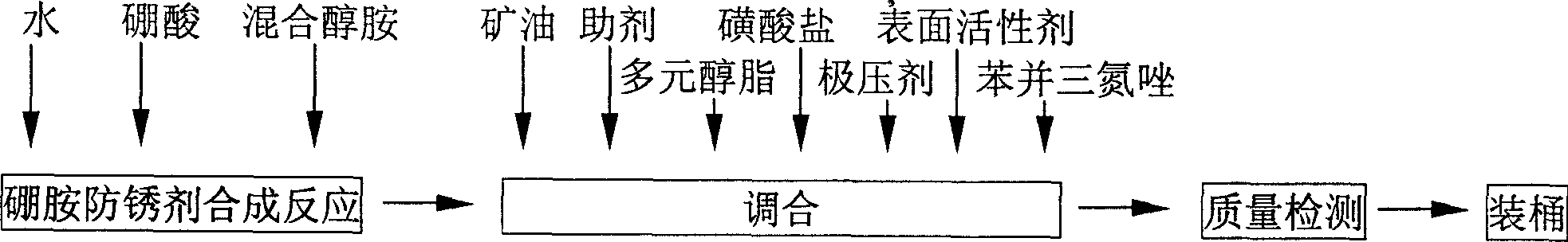

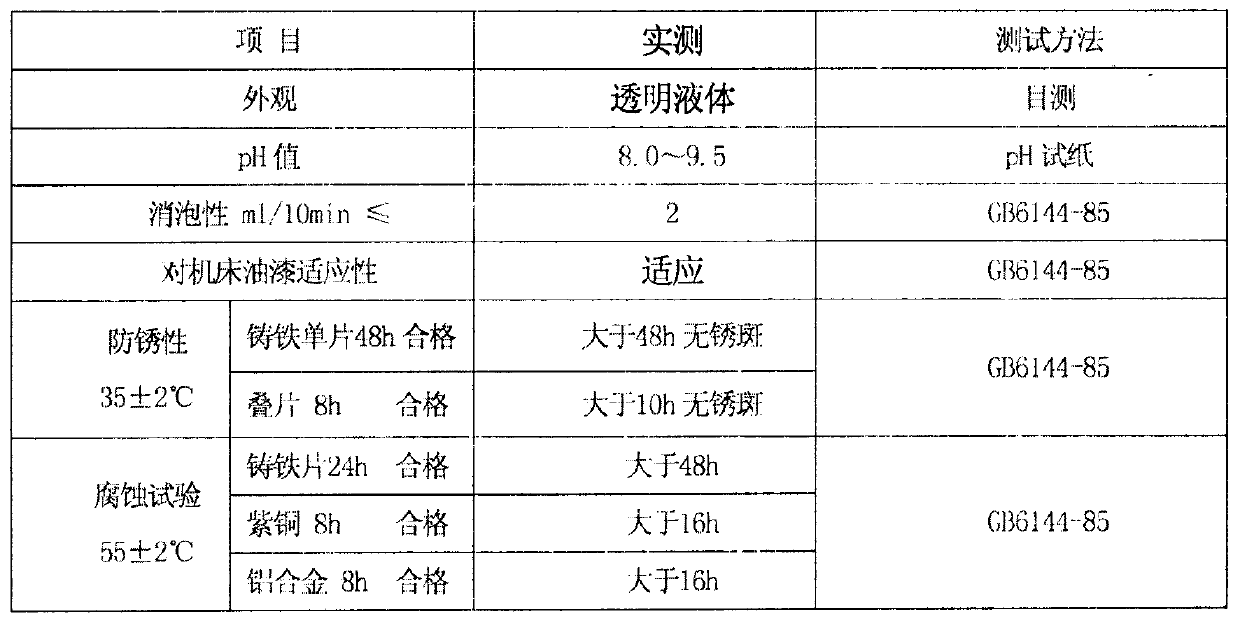

Extreme pressure cutting fuild microemulsion free of chlorine and its preparation method and uses

InactiveCN1730634AReduce emulsificationExtended service lifeLubricant compositionActive agentSurface-active agents

The invention provides a fluoro-free extreme-pressure microemulsion cutting liquid, whose constituents by weight percentage include water 20-40, mixed alkylolamide 6-12, boracic acid 2-6, sulfonates rust-preventing agent 8-12, auxiliary agent 1-5%, anionic surface active agent 8-12, polybasic alcohol 2-6, sulfurized grease 4-10, mineral oil 15-30, benzotrizaole 0.1-0.3. The invention also provides a process for preparing the liquid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

PVC (Polyvinyl Chloride) paste resin and preparation method thereof

The invention discloses PVC (Polyvinyl Chloride) paste resin and a preparation method thereof, belonging to the technical field of polymer chemical industry. Weighted in 100 parts by weight of vinyl chloride, the PVC paste resin with the average grain diameter of 0.5-2mum, the average degree of polymerization of 1600-1900 and the paste viscosity of 1500-3500mPa.s is prepared from the following components: 70-120 parts of deionized water, 0.5-5 parts of mixed emulsifier, 0.005-0.02 part of oil-soluble compound initiating agent, 0.05-0.5 part of pH value regulator and 0-0.1 part of chain extender through microsuspension polymerization. The paste resin prepared according to the invention has the advantages of high degree of polymerization, low paste viscosity, rapidness in plasticization, good transparency and favorable defoaming performance.

Owner:SHENYANG CHEM IND CO LTD

Optical glass, shapable glass material for press-shaping, optical element and process for producing optical element

InactiveUS20050049132A1Less coloringHigh light transmittanceGlass pressing apparatusGlass reforming apparatusTransmittanceLength wave

An optical glass that has high-refractivity and high-dispersion properties, that is less colored and that is suitable for a shapable glass material for press-shaping and various optical elements, the optical glass containing, as glass components and by mass %, 10 to 32% of P2O5, 27 to 65% of Nb2O5, 10 to 30% of BaO, 0 to 12% of B2O3, more than 0% but not more than 20% of TiO2, more than 0% but not more than 10% of total of Li2O, Na2O and K2O, and more than 0% but not more than 1%, based on the total content of the said glass components, of Sb2O3, and having a light transmittance that is 50% at a wavelength of 420 nm or shorter.

Owner:HOYA CORP

Environment-friendly highly efficient mighty defoamer prescription and production process

InactiveCN1765459AImprove surface activityReduce surface tensionFoam dispersion/preventionSolventDefoaming Agents

The invention relates to an emulsion defoaming agent and ití»s preparing method. The invention comprises (a) silicon oil; (b) olefin hydrocarbon; (c) auxiliary defoaming component; (d) emulsifier; (e) dispersant which is polyisobutene or polybutene or the assembly of them; (f) solvent. The inventive defoamting agent has high defoaming ability, long foam-restrain time, stable property, environment-friendly ability, innocuity, lower dosage and lower cost.'

Owner:SHANGHAI NORMAL UNIVERSITY

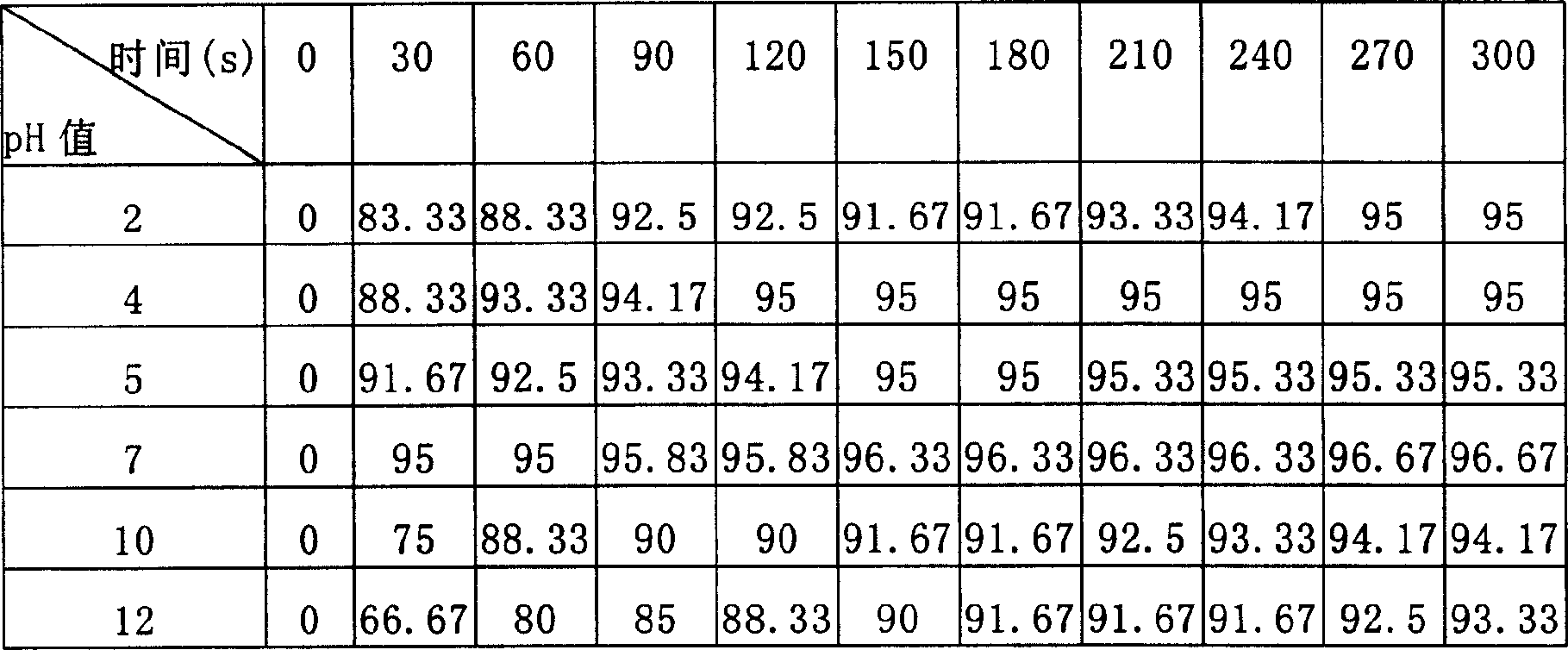

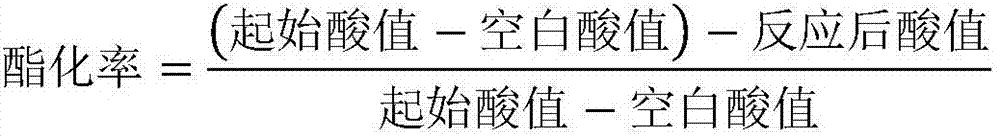

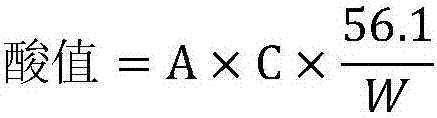

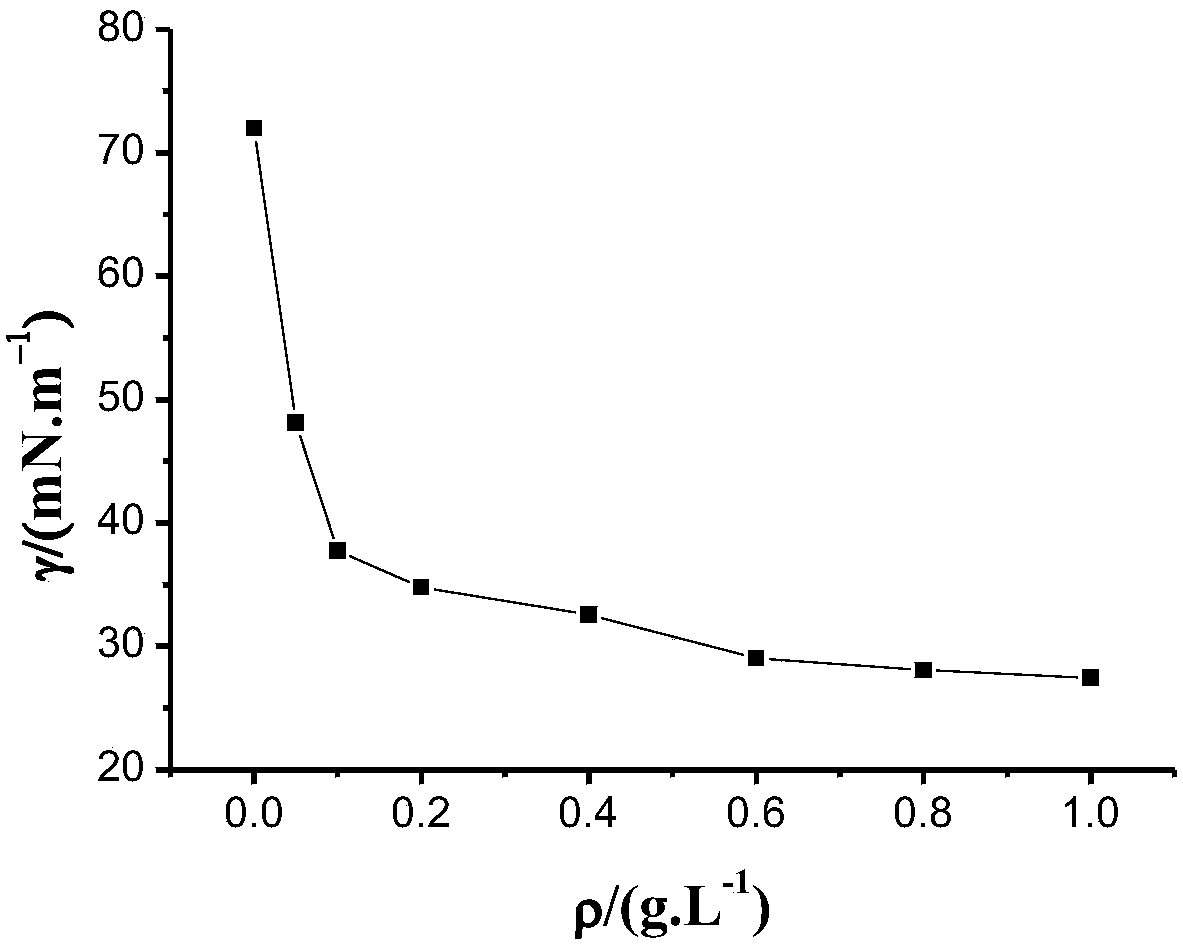

Novel polyether ester defoamer and preparation method thereof

InactiveCN106975247AReduce surface tensionGood defoaming effectFoam dispersion/preventionEtherCarbon chain

The invention provides a novel polyether ester defoamer prepared by using a higher aliphatic alcohol having carbon chain length of 18 as an initiator. A preparation method of the novel polyether ester defoamer comprises the steps of (1) subjecting a higher aliphatic alcohol as an initiator to polyether reaction with ethylene oxide and propylene oxide under the action of a first catalyst so as to prepare fatty alcohol polyoxyethylene polyoxypropylene ether; (2) subjecting the fatty alcohol polyoxyethylene polyoxypropylene ether to esterification reaction with fatty acid under the action of a second catalyst so as to prepare polyether ester. The novel polyether ester defoamer prepared herein is lower in surface tension and higher in defoaming capacity than traditional polyether ester defoamers; as the higher aliphatic alcohol is used as the initiator, the novel polyether ester defoamer is also better in degassing and foam-inhibiting effect than higher aliphatic alcohol defoamers.

Owner:济宁南天农科化工有限公司

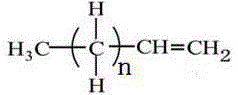

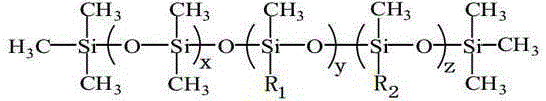

Preparation method of long-chain alkyl polyether co-modified silicone oil

The invention discloses a preparation method of long-chain alkyl polyether co-modified silicone oil. The method comprises the steps of adopting hydrogen-containing silicone oil, allyl polyoxyethylene polyoxypropylene ether and long-chain alkyl unsaturated olefin as raw materials, taking Pt as a catalyst, performing hydrosilylation reaction on the raw materials in a four-necked flask by heating to 80 to 130 DEG C, gradually heating up to 180 DEG C at -0.098MPa after reacting for 8 to 16 hours, performing devolatiligation for removing the unreacted raw materials, so as to obtain the long-chain alkyl polyether co-modified silicone oil. The product can be used for higher end application fields, and can be used as a defoamer, a release agent and the like.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Water-based cutting fluid for metal processing and preparation method of water-based cutting fluid

The invention discloses water-based cutting fluid for metal processing and a preparation method of the water-based cutting fluid. The cutting fluid mainly consists of a lubricating agent, a metal antirust agent, an anti-wear reagent at extreme pressure, a nonionic surfactant, a dispersing agent, an antifoaming agent and water, and the cutting fluid comprises the following components in percentage by weight: 8-12 percent of oleic acid, 1.8-2.5 percent of triethanolamine, 0.3-0.6 percent of boric acid, 0.2-0.5 percent of benzotriazole, 5-8 percent of sodium carbonate, 10-12 percent of polyethylene glycol, 0.2-0.5 percent of dodecylphenol polyoxyethylene ether (OP-10), 0.7-1 percent of glycine betaine, 0.5-0.8 percent of glycerin polyoxypropylene ether and the balance of water. According to the water-based cutting fluid disclosed by the invention, the problems that the conventional water-based cutting fluid is poor in antirust and lubricating performances, low in recycling period and harmful to the human and environment are solved, and the aims of improving the lubricating effect and the antirust performance, realizing harmlessness to the environment and a human body and reducing the production cost of metal processing are achieved by virtue of synthesis of polybasic esters.

Owner:中钢集团郑州金属制品研究院股份有限公司

Graphene oxide-modified organosilicone defoaming agent and preparation method thereof

ActiveCN107126729AHigh temperature resistantHas acid and alkali resistanceFoam dispersion/preventionPreservativePapermaking

The invention discloses a graphene oxide-modified organosilicone defoaming agent and a preparation method thereof. The graphene oxide-modified organosilicone defoaming agent is prepared from the following components in parts by mass: 30 to 60 parts of organosilicone oil, 3 to 6 parts of hydrophobic white carbon black, 5.05 to 10.1 parts of graphene oxide-modified organosilicone oil, 8 to 10 parts of composite emulsifier, 0.1 to 0.5 part of coupling agent, 0.2 to 0.5 part of thickener, 0.2 to 0.5 part of preservative, and 120 to 150 parts of deionized water. The prepared graphene oxide-modified organosilicone defoaming agent has the characteristics that the defoaming is quick and stable, the surface tension is low, and the like; the high temperature-resistant property, acid and alkaline-resistant property, hydrophilicity and the like of the graphene oxide are realized; the defoaming agent can be widely applied to the industries of dyeing and printing, ink, coating, papermaking and the like.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

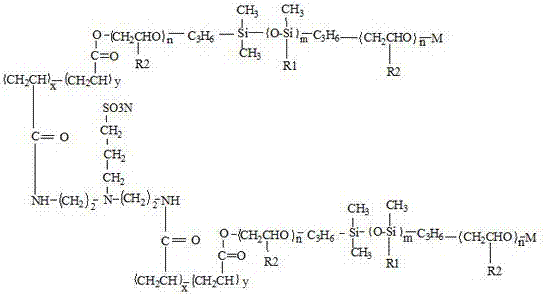

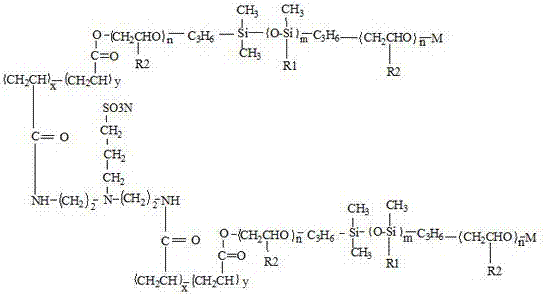

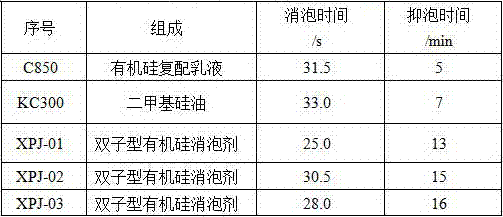

Gemini organic silicon defoamer

ActiveCN106977632AGood defoaming effectGood defoamingFoam dispersion/preventionDissolutionSilicone oil

The invention relates to a gemini organic silicon defoamer. The gemini organic silicon defoamer is of an improved polyether organosilicon diamide sulfonate structure; hydrophilic groups are ethylene oxide, an amido bond and sulfonate; hydrophobic groups are polysiloxane and epoxypropane; through a plurality of hydrophilic groups, the low-temperature defoaming affect is good; through a comb structure, polyether-modified silicone oil can quickly spread on a gas-liquid interface of a foaming system, and locally intrudes to break foam, and the gemini organic silicon defoamer has better defoaming activity; through a macromolecular comb structure, the dissolution rate in a system is reduced and a continuous foam inhibition effect is generated. The gemini organic silicon defoamer is a silicone-modified defoamer which is good in defoaming and foam inhibiting properties, especially good in low-temperature defoaming and foam inhibiting effects.

Owner:福建昆冈化学助剂科技有限公司

Optical glass

Optical glass containing bismuth oxide having good defoamability. The Optical glass contains, as % by mass, from 10 to less than 90% of a Bi2O3 component and at least 0.1% of a TeO2 and / or SeO2 component. The optical glass is on Grade 4 to Grade 1 in “JOGIS12-1994, Method for Measuring Bubbles in Optical Glass”. By controlling the amount of RO component (R is at least one selected from a group consisting of Zn, Ba, Sr, Ca, Mg) and Rn2O component (Rn=Li, Na, K, Cs), the clarifying time may be shortened.

Owner:OHARA

Antifoaming agent for flue gas desulphurization system and preparing method thereof

InactiveCN106334349AIncrease surface tensionLower free energyDispersed particle separationFoam dispersion/preventionEmulsionFlue gas

The invention discloses an antifoaming agent for a flue gas desulphurization system. The antifoaming agent is prepared from, by mass, 30%-60% of antifoaming components, 10%-20% of foam inhibition components, 5%-10% of an emulsion stabilizer, 5%-10% of a synergist and the balance deionized water. The antifoaming agent is suitable for a thermal-power-plant limestone-gypsum wet flue gas desulfurization system adapting to high chlorine, fluorion and solid-content slurry liquid and aeration, and has the advantages of being good in antifoaming effect and long in foam inhibition time; the foaming characteristic of desulfuration slurry liquid can be improved, the stability of a slurry-liquid oxidation zone is effectively controlled, the foam content of the slurry liquid is reduced, losses of the slurry liquid of a circulating pump are reduced, the circulation amount of the slurry liquid is increased, and it is avoided that foam overflows to a pipe zone, the slurry liquid is deposited in a pipe, and scale formation corrosion is caused.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

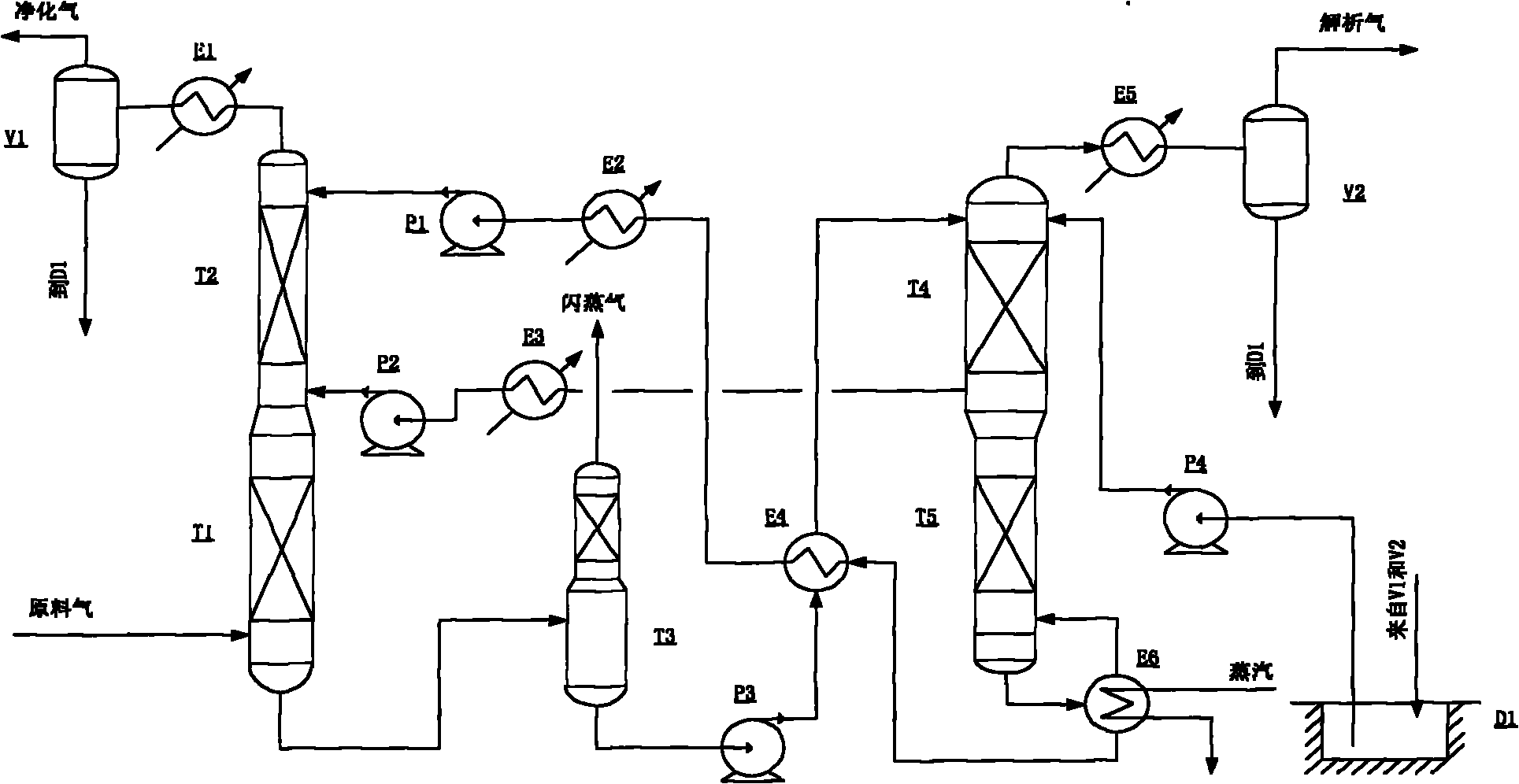

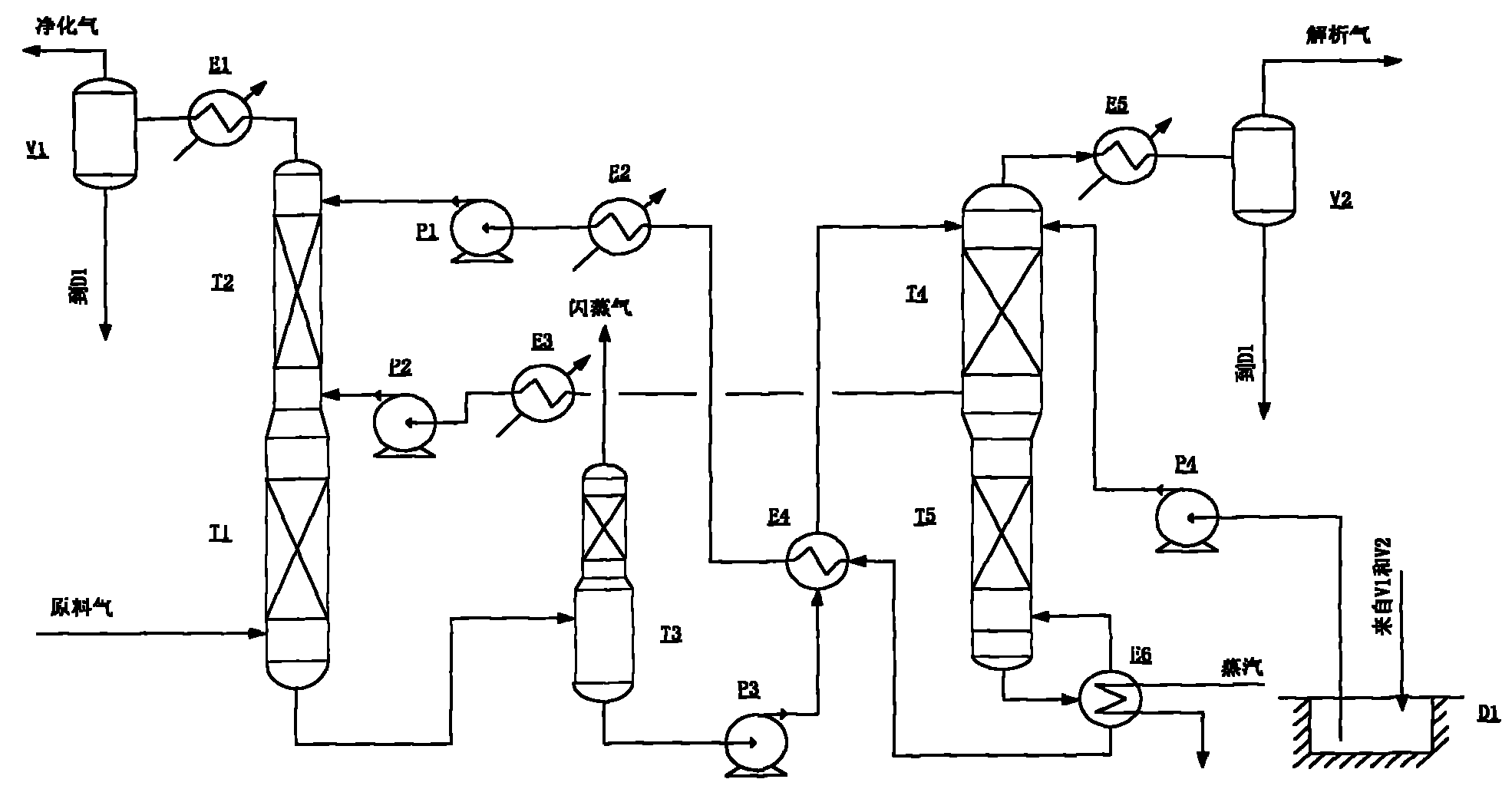

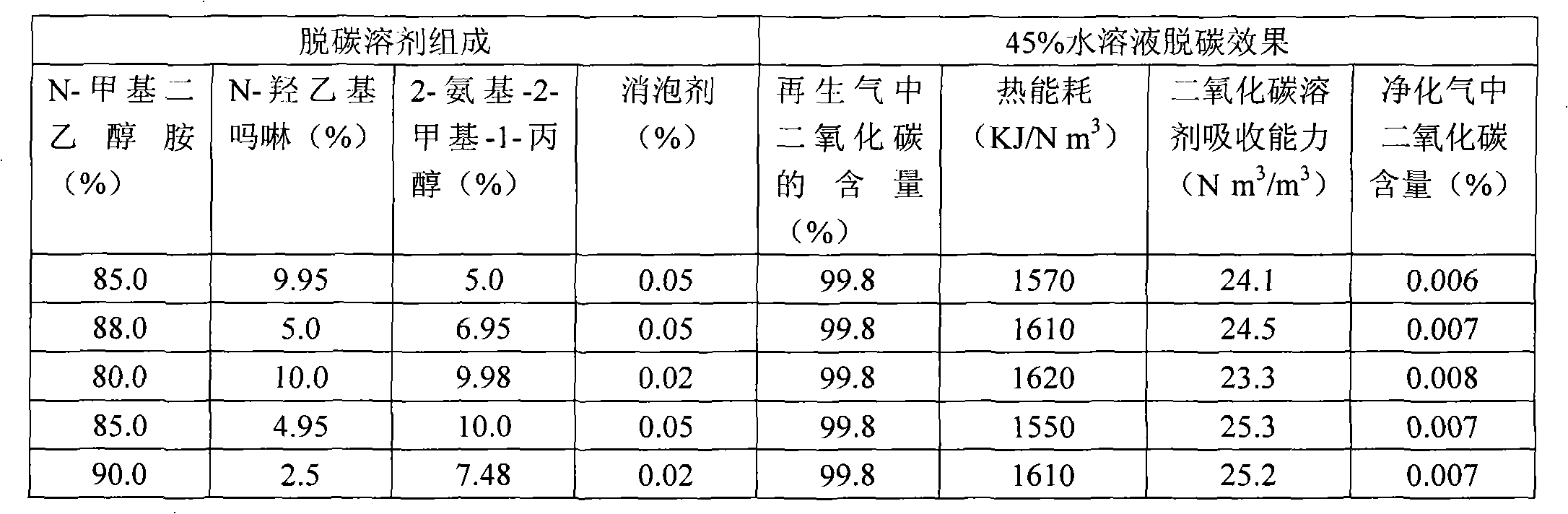

Novel high-efficient compound decarbonization solvent

ActiveCN101816878AHigh boiling pointReduce volatilityProductsCarbon compoundsAbsorption capacityCo2 absorption

The invention discloses a novel high-efficient compound decarbonization solvent which comprises N-methyldiethanolamine and an active agent. The active agent is a mixture which consists of at least two of N-hydroxyethyl morpholine, 2-amino-2-methyl-1-propanol and piperazine, wherein the weight ratio of the N-hydroxyethyl morpholine is 80 to 90 percent; the weight ratio of the active agent is 10 to 20 percent and a defoaming agent is also added into the compound decarbonization solvent. The novel high-efficient compound decarbonization solvent has the advantages of high carbon dioxide absorption capacity, high purification degree, low regeneration energy consumption, and no foams after long-term use of the decarbonization solvent.

Owner:四川精事达科技有限公司

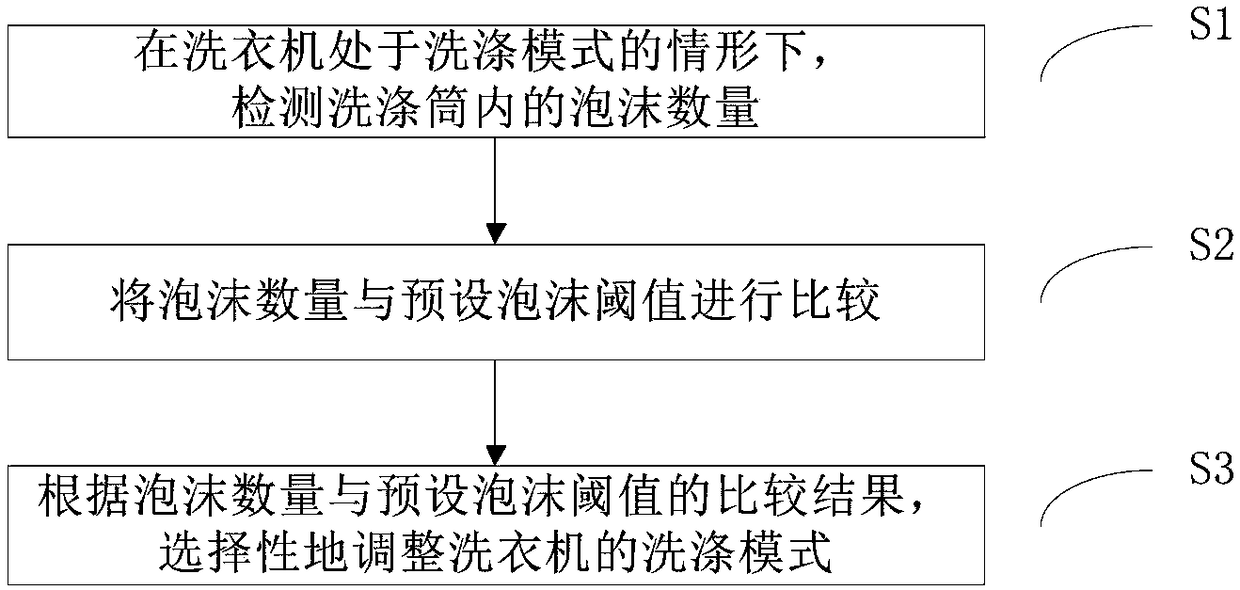

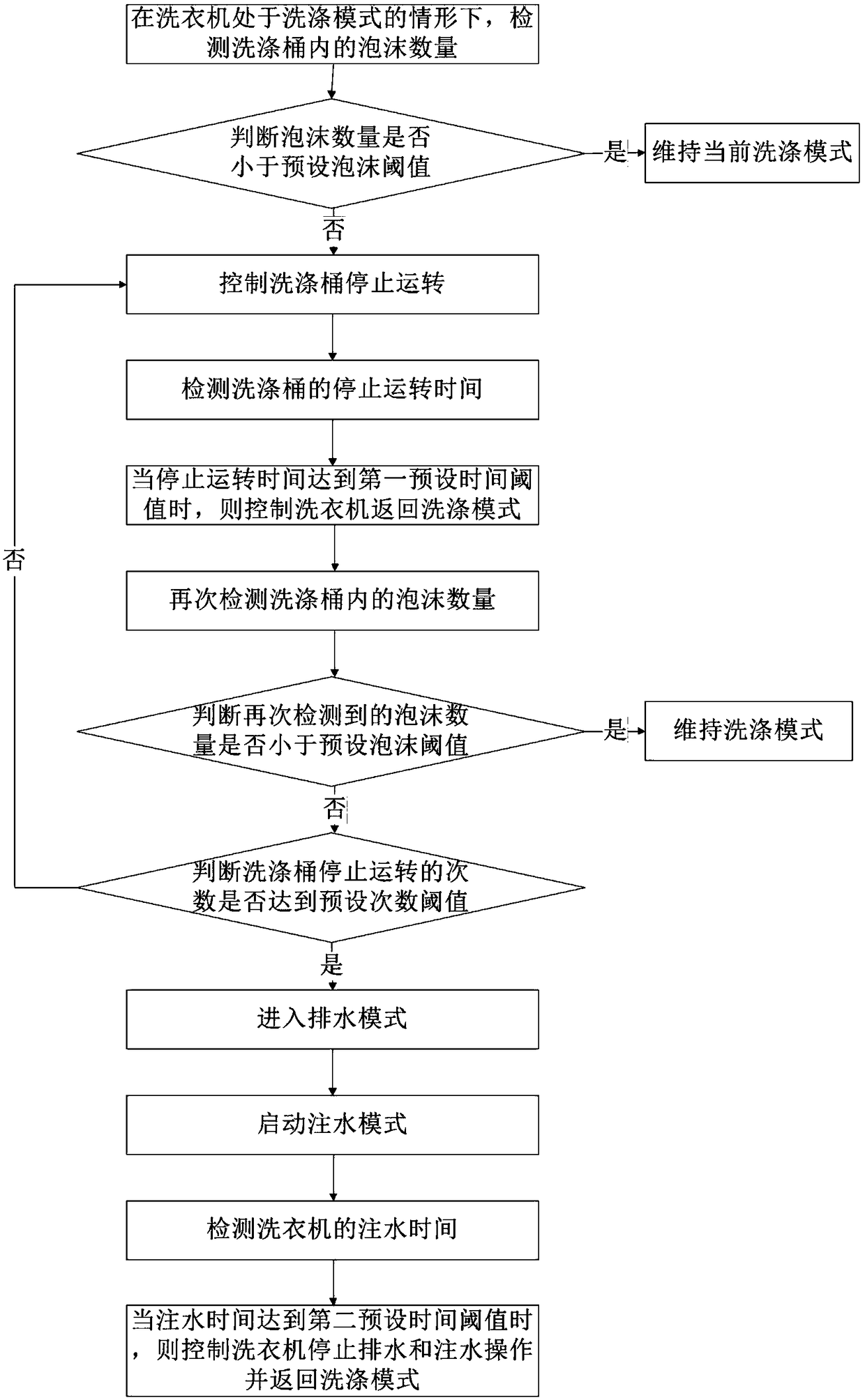

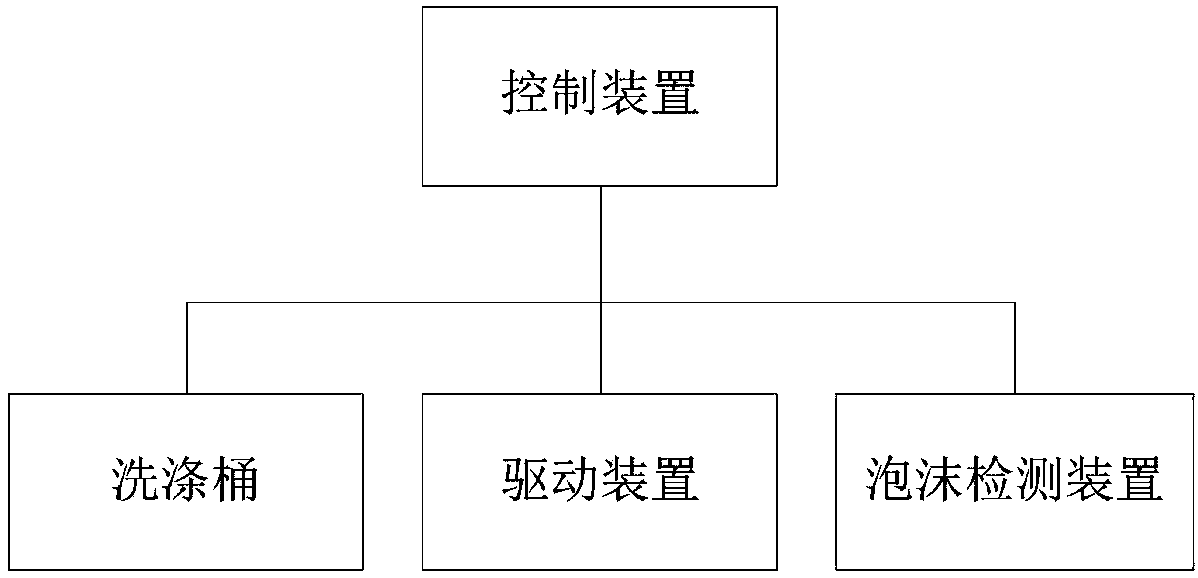

Defoaming method for garment treatment equipment and garment treatment equipment

InactiveCN109468798AAvoid it happening againWill not be impactedControl devices for washing apparatusTextiles and paperSpinsWaste management

The invention relates to the technical field of garment treatment equipment, particularly provides a defoaming method for the garment treatment equipment and the garment treatment equipment, and aimsat the solving the problem that existing garment treatment equipment cannot accurately judge when defoaming operation needs to be conducted. The garment treatment equipment comprises a washing bucket.The defoaming method comprises the following steps that when the garment treatment equipment is in a washing mode, the number of foams in the washing bucket is detected; the number of the foams is compared with a preset foam threshold value; according to the comparison result of the number of the foams and the preset foam threshold value, the washing mode of the garment treatment equipment is selectively adjusted. The garment treatment equipment comprises a control device, and the control device is used for executing the defoaming method. The garment treatment equipment selectively adjusts the spin-drying mode according to specific working conditions so that the foams in the washing bucket can be rapidly removed, the defoaming effect of the washing machine is improved, and the phenomenonof foam overflow is avoided.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

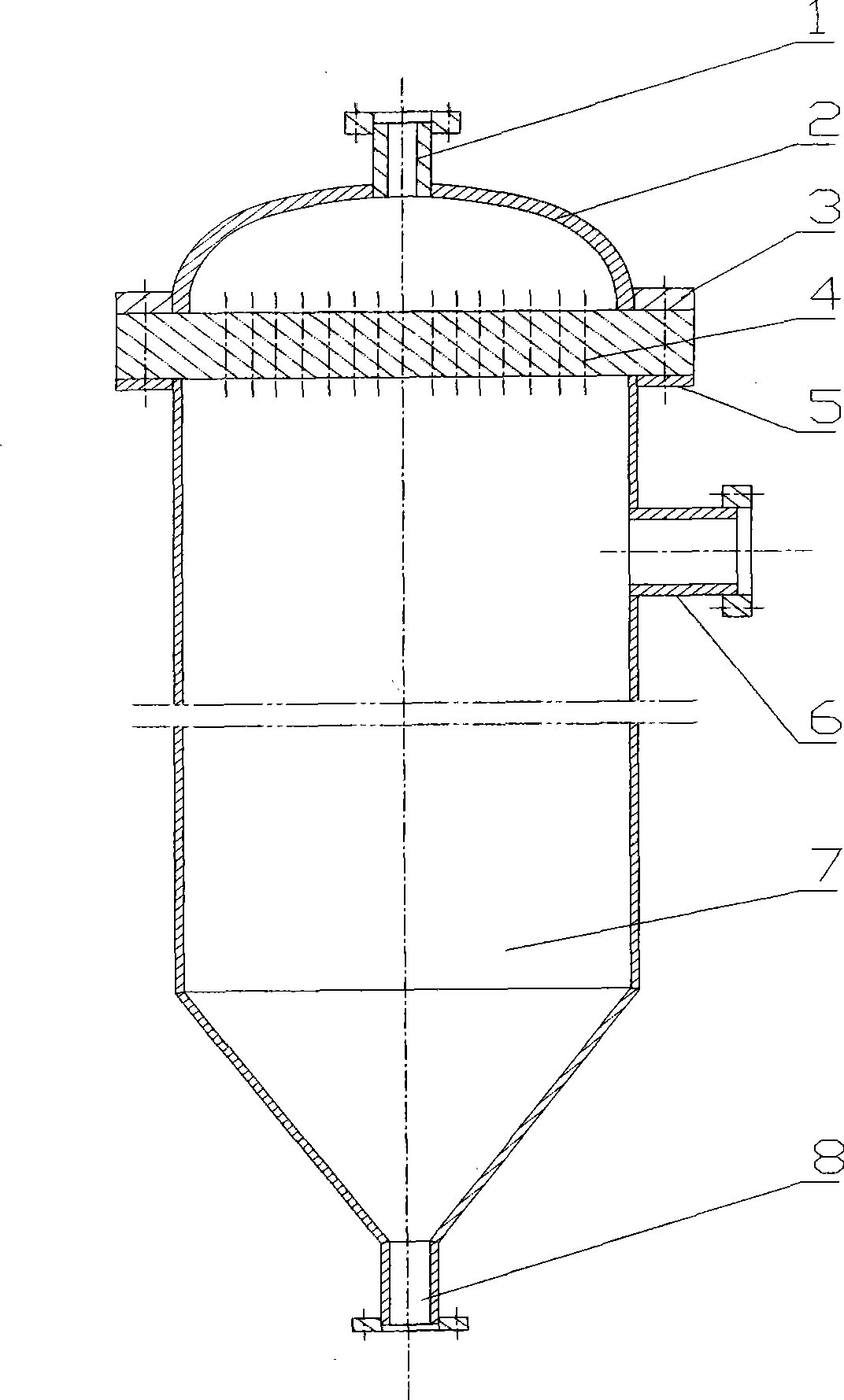

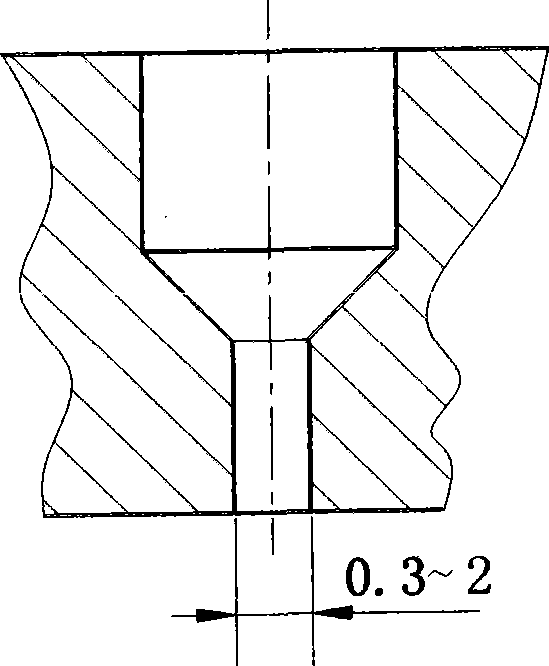

High-viscosity fluid defoaming method and device thereof

InactiveCN101519809AGood defoaming effectExtrusion speed is highLiquid degasificationFilament-forming treatmentThick plateBiochemical engineering

The invention relates to a high-viscosity fluid defoaming method and a device thereof. The upper part of the device is a round tank; the lower part is a cone; a feed inlet is arranged on the upper side of an end enclosure; the lower side of the end enclosure is connected with a film-extruding plate by a flange; and the end enclosure forms a containing cavity along with the film-extruding plate; normally, the film-extruding plate is a round or square thick plate, on which a large quantity of long-circular narrow holes are arranged; the upper part of each hole is wide and is a fluid-guiding area; the middle part of the hole is sloped and is a tapered transitional area; and the lower part of the hole is narrow and is a film-extruding area. A vacuum defoaming tower is located right below the film-extruding plate and connected with the film-extruding plate by a flange; a vacuumizing inlet is arranged on the side of the vacuum defoaming tower; and a discharge outlet is arranged on the lower side of the vacuum defoaming tower. The high-viscosity fluid rapid defoaming method and the device thereof have the advantages of good defoaming effect, short deforming time and high output.

Owner:SHAOYANG TEXTILE MACHINERY

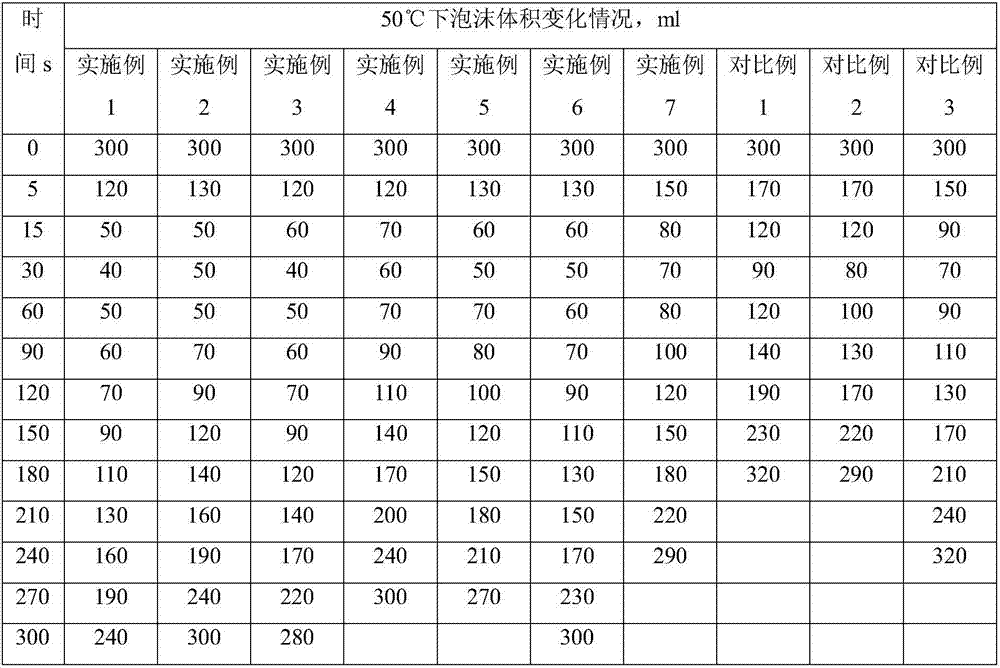

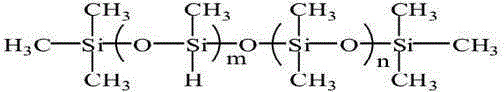

Diesel fuel and lubricating oil antifoams and methods of use

InactiveUS20020129542A1Good defoaming effectMaintain performance characteristicDewatering/demulsification with chemical meansLiquid carbonaceous fuelsDemulsifierOrganic group

The present invention relates to diesel fuel and lubrication oil defoaming agents, and crude oil demulsifiers, as well as methods for using same. In particular, the defoaming agents and demulsifiers are comprised of copolymers which have structures constituting a backbone of polysiloxane onto which is grafted an organic group. These structures comprise a polymer of the formula MD.sub.xD'.sub.yD".sub.zM, where M is O.sub.0.5Si(CH.sub.3).sub.3, D is a OSi(CH.sub.3).sub.2, D' is OSi(CH.sub.3)R, D" is OSi(CH.sub.3)R', R is a polyhydric C.sub.6-C.sub.28 organic group, R' is a phenol derivative or a long chain aliphatic group or polyethers, z is between 0 and 80, x+y+z is between 10-200, x / z is .gtoreq.1, and x / (y+z) is between about 1 and about 5, or formula M'D.sub.aM' where M' is O.sub.0.5Si(CH.sub.3).sub.2R, a is between 4-10, and R and D are the same as defined above.

Owner:GRABOWSKI WOJCIECH +1

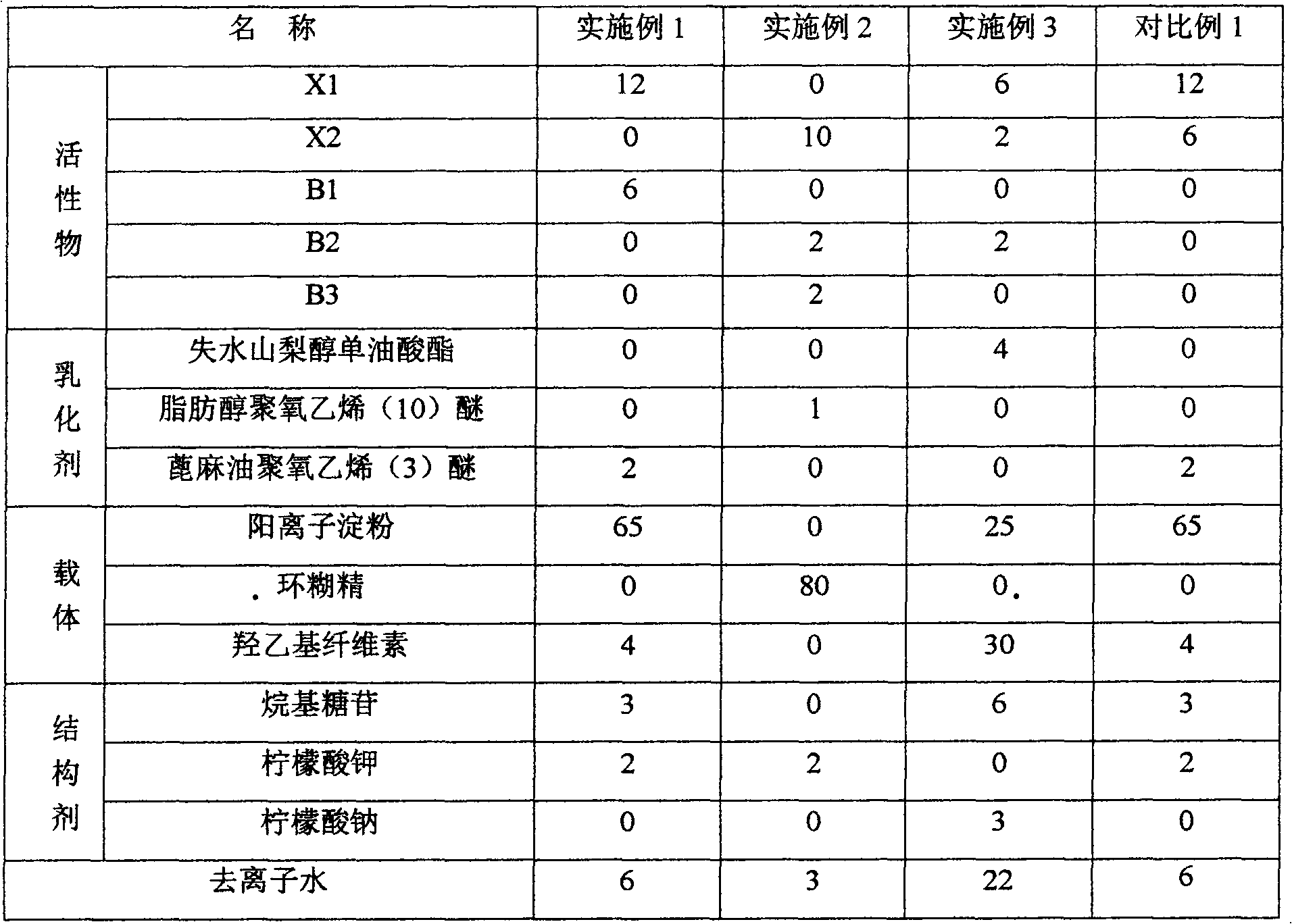

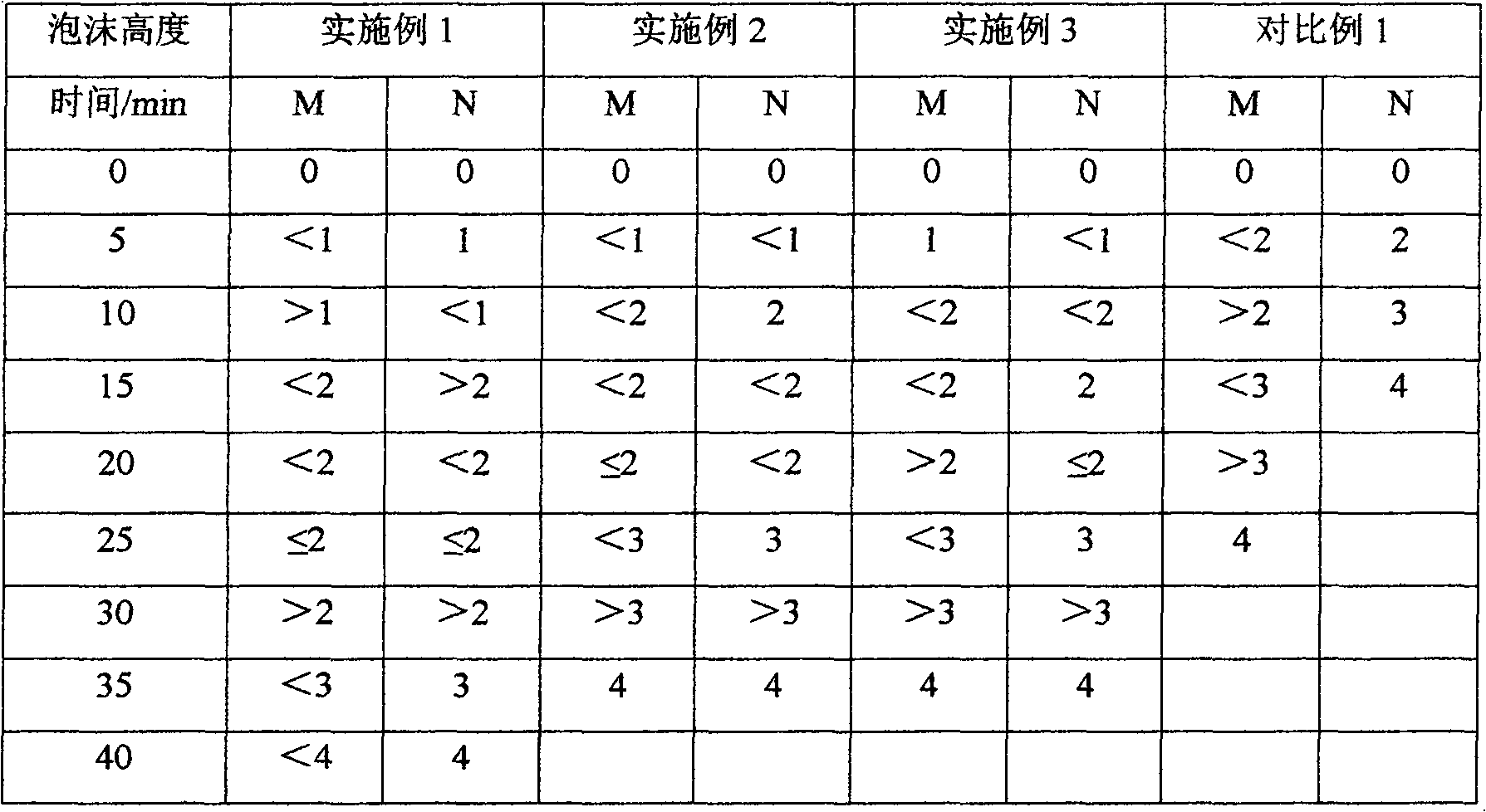

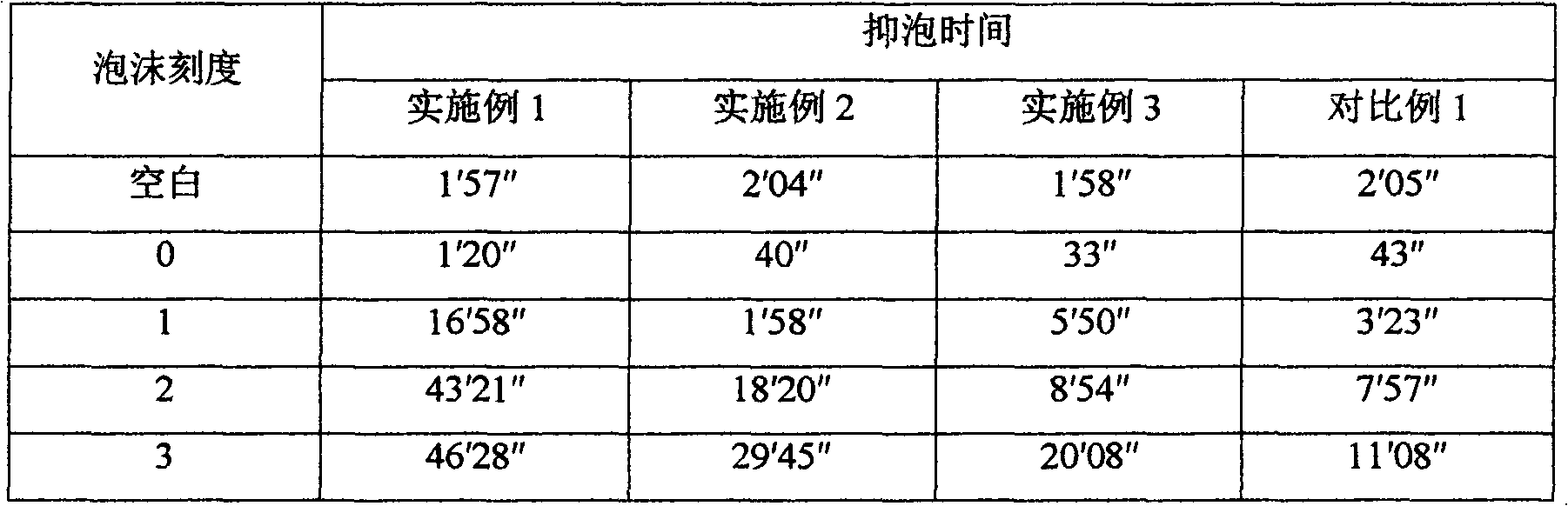

Solid particle foam inhibitor and method for preparing same

ActiveCN102302869AGood anti-foam performanceAdd lessFoam dispersion/preventionTextile printerAdditive ingredient

The invention relates to a solid particle foam inhibitor and a method for preparing the same. The ingredients of the foam inhibitor consist of 50-80% of organic carrier, 10-18% of main defoaming materials, 0.5-4% of emulsifying agent, 1-10% of structural agent and 3-25% of deionized water. The method for preparing the foam inhibitor comprises the following steps of: sufficiently mixing the main defoaming materials with the emulsifying agent; adsorbing the main defoaming materials and the emulsifying agent on the carrier; and adding the structural agent and forming particles with good liquidity through working procedures of granulating and drying. The prepared solid particle foam inhibitor has excellent applications in industrial processes, such as washing, sewage treatment and textile printing and dyeing.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

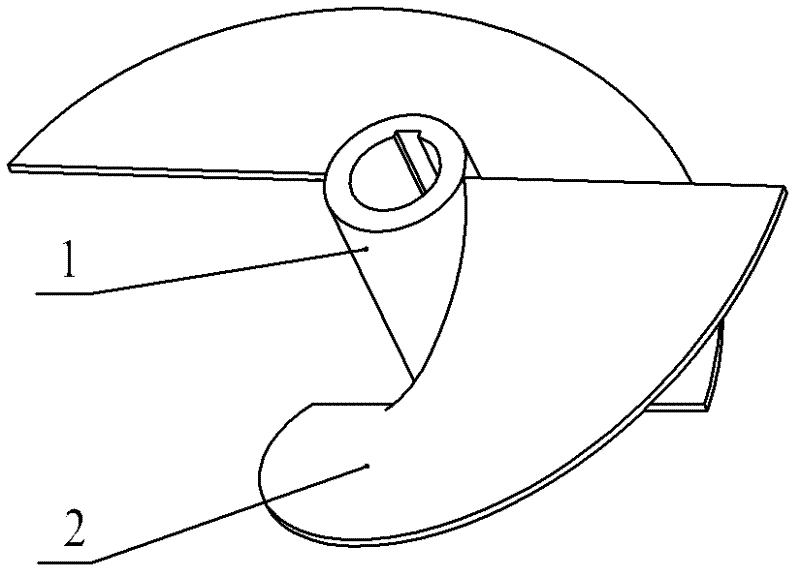

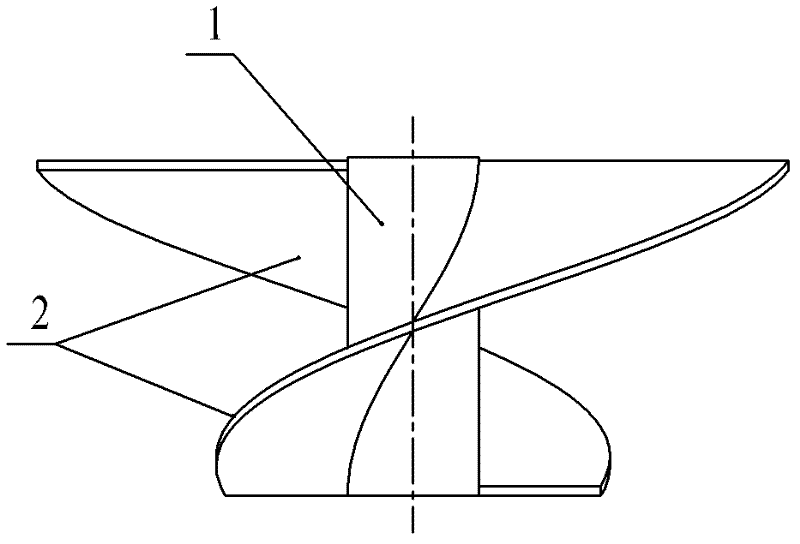

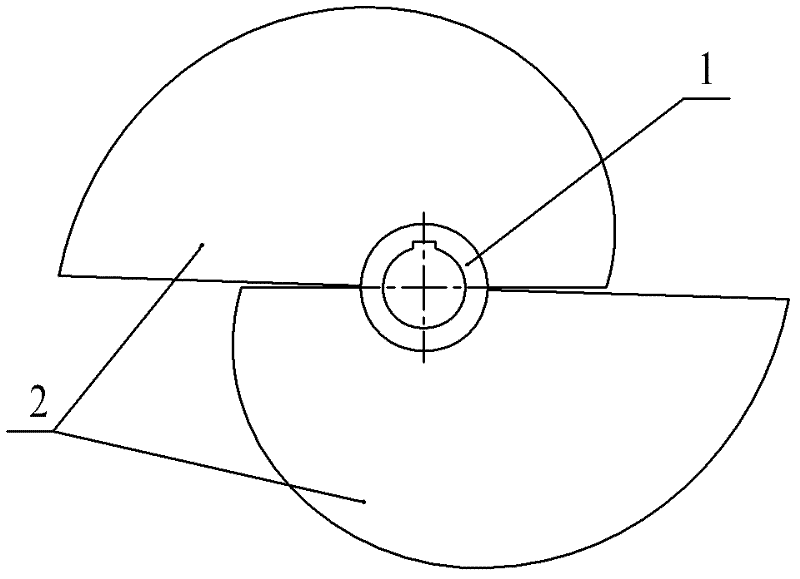

Spiral defoamer

InactiveCN102389649AGood defoaming effectSimple structureFoam dispersion/preventionDraw plateSpiral blade

The invention relates to a spiral defoamer which comprises a wheel hub and blades, and is characterized in that the wheel hub takes the shape of a long cylinder, the two spiral blades are symmetrically arranged, and the inner edges of the blades are spirally welded on the outer wall of the wheel hub along the length direction of the wheel hub. In the invention, the blades are symmetrically arranged to be spiral, when the defoamer rotates, central feed liquid is pushed to the outer edges of the blades under the actions of forced thrust of spiral surfaces of the blades and centrifugal force, and sprayed to a foaming layer on liquid surface through the edges of the blades, so as to play a role in breaking foam; planes of the blades are tapered spiral surfaces, linear speeds at the outer edges of the blades are different, and the feed liquid sprayed through the edges of the blades is covered on the foaming layer on the whole liquid surface, so as to achieve better defoaming effect; and the blades are simpler in structure, can be formed by drawing plates, does not need a mould for molding, can be manufactured to have different sizes and specifications according to needs, and is low in manufacturing cost.

Owner:JIANGSU HAOTELONG MIX EQUIP

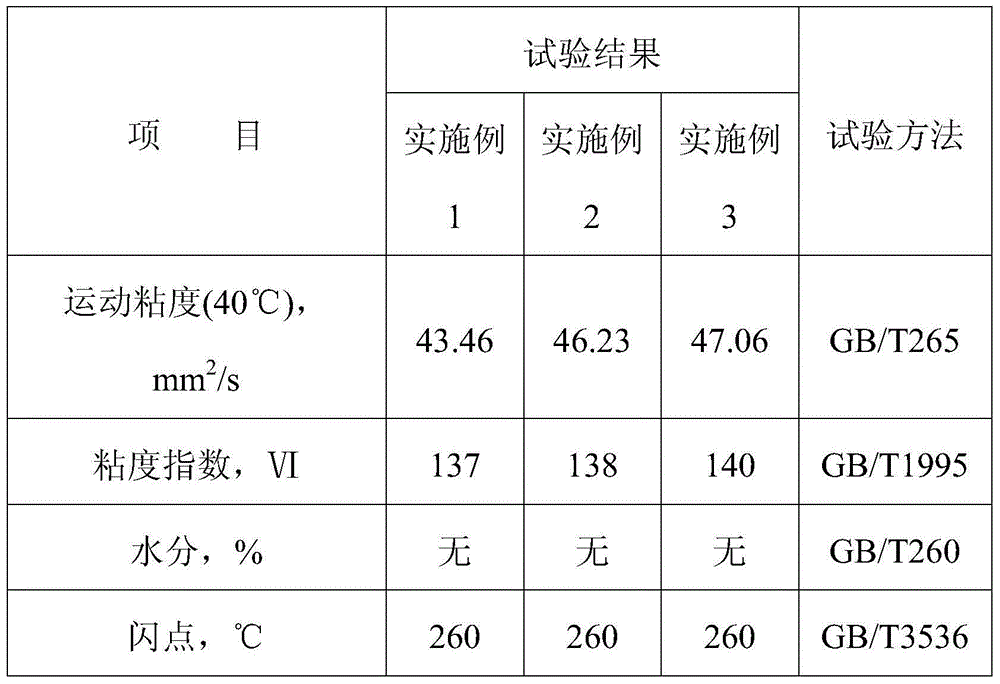

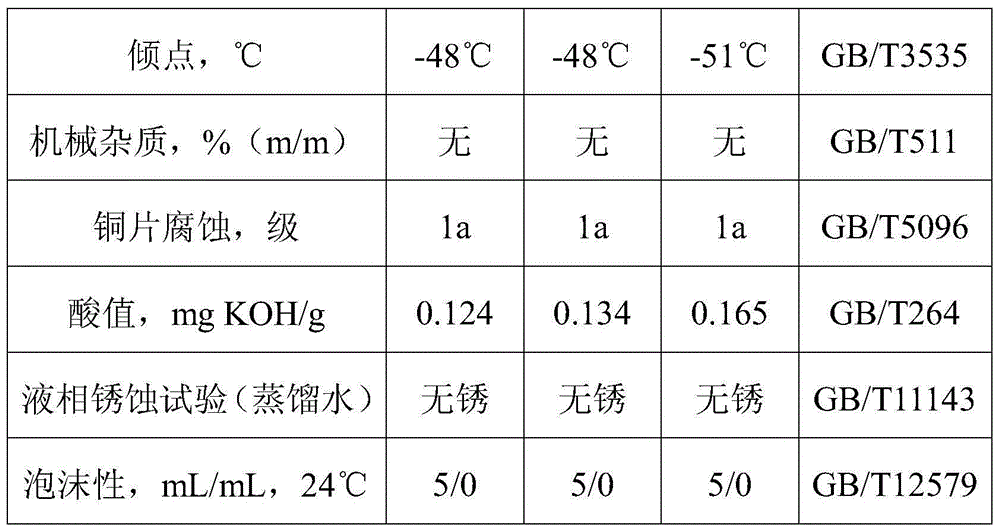

Oil-soluble polyether oil for screw-type air compressor

InactiveCN104130842AExcellent antioxidant stabilityGood demulsibilityLubricant compositionPerformance indexMechanical equipment

The invention discloses oil-soluble polyether oil for a screw-type air compressor. The oil-soluble polyether oil is prepared from 20-40 parts or 10-20 parts by mass of oil-soluble polyether base oil, 60-80 parts or 80-90 parts by mass of poly(alpha-olefin), 0.1-1.4 parts by mass of benzenamine, 0.8-2 parts by mass of a borate anti-oxidant, 1.2-2.2 parts by mass of a high-temperature ashless antiwear agent, 0.5-1.8 parts by mass of polyoxyethylene sorbitan fatty acid ester and 0.001-0.05 parts by mass of an acrylate-ether copolymer. The oil-soluble polyether oil for a screw-type air compressor is environmentally friendly, has the advantages of excellent antioxidation stability, emulsification resistance, corrosion and rusting resistance, very good defoaming performance and excellent viscosity-temperature performance, has performance indexes satisfying standards of air compressor oil 46 and can be used for mechanical equipment of an air compressor system.

Owner:张家港市胜宇石油化工制品有限公司

Foam eliminating dispersing agent for developer solution of photosensitive resists

InactiveCN1503057AGood defoaming effectPrevent adhesionTransportation and packagingMixingResistMixed fatty acid

Provided is a defoaming dispersant for a resist developer solution, the dispersant having excellent defoaming property for foams in a developer solution and excellent dispersibility of scum produced in the developer solution in a developing process of a photoresist using the developer solution. The defoaming dispersant for a photoresist developer solution contains a partial fatty acid ester obtained by allowing a mixture fatty acid having the proportion of 5 to 300 parts by mass of 6-14C middle fatty acid with respect to 100 parts by mass of >=15C higher fatty acid to react with an aliphatic trihydric alcohol.

Owner:ADEKA CORP

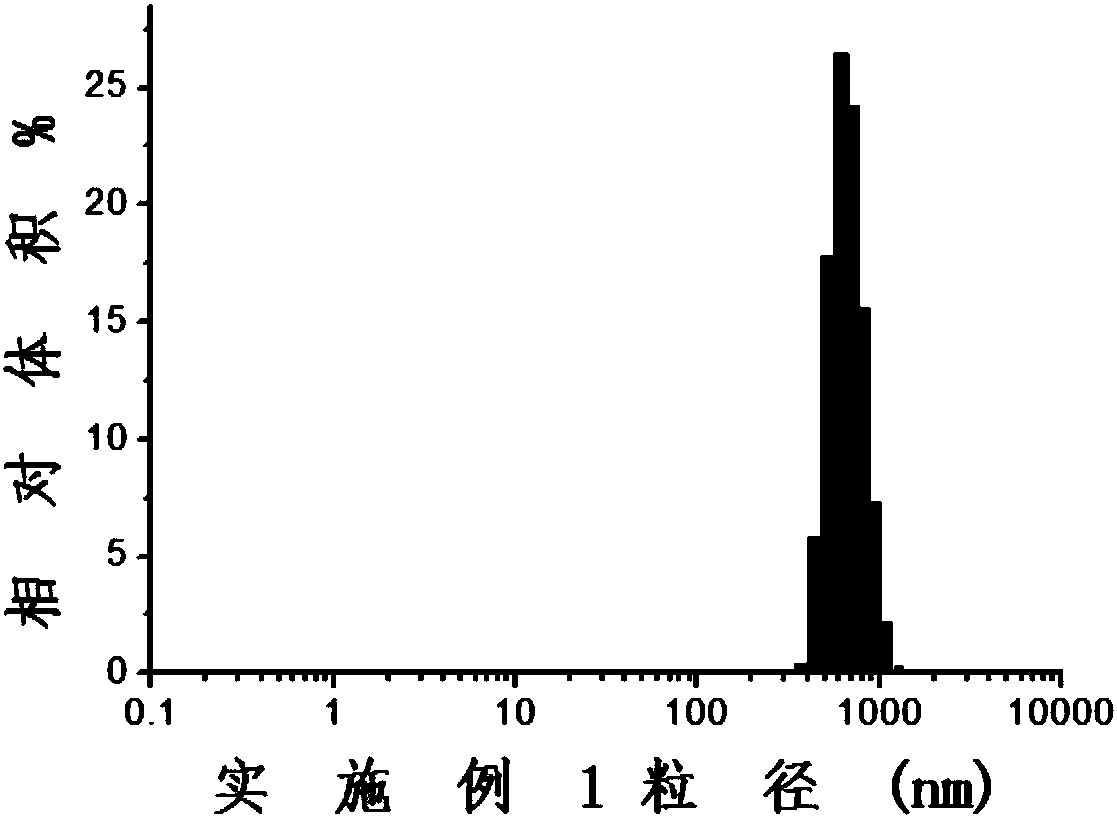

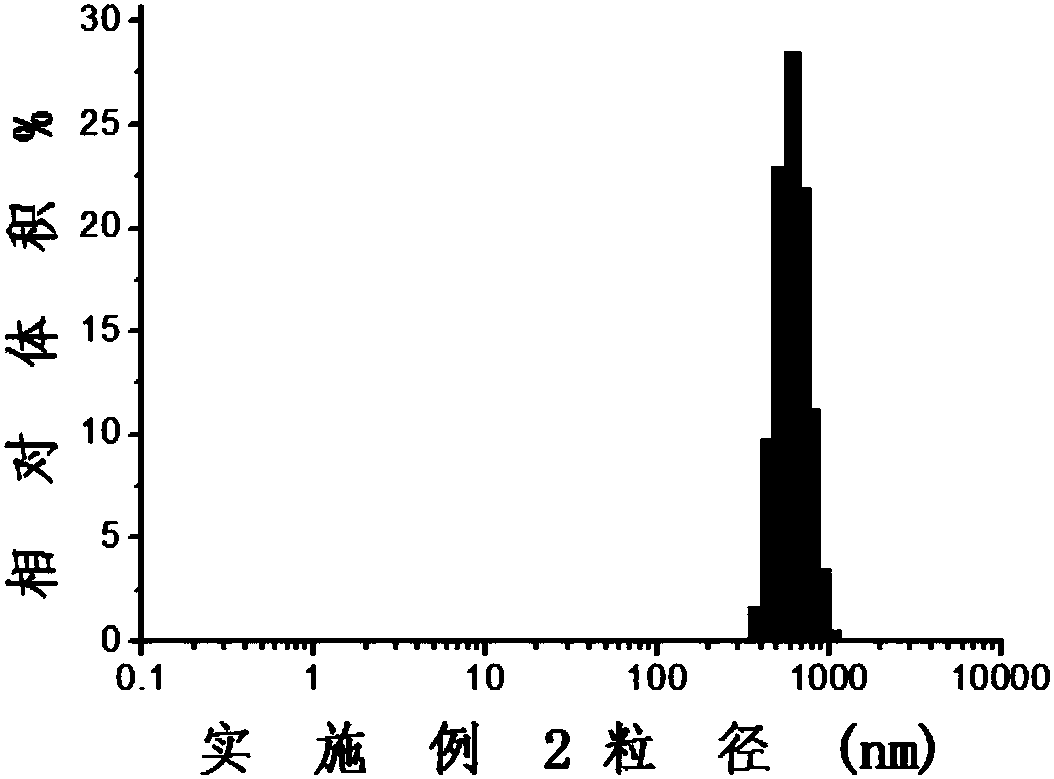

Seawater desalination de-foaming agent as well as preparation method and application thereof

PendingCN108499162ASmall particle sizeGood dispersionSeawater treatmentSpecific water treatment objectivesFoaming agentAqueous solution

The invention relates to a seawater desalination de-foaming agent as well as a preparation method and application thereof. The de-foaming agent is prepared from silicon paste, polyether modified organic silicon, an emulsifier, a thickening agent and water, wherein the mass percent of the silicon paste is 5 to 20 percent, the mass percent of the polyether modified organic silicon is 10 to 30 percent, the mass percent of the emulsifier is 2 to 10 percent and the mass percent of the thickening agent is 0.5 to 2 percent. The preparation method comprises the following steps: (1) weighing the silicon paste, the polyether modified organic silicon and the emulsifier according to the mass percent and mixing at 70 to 80 DEG C to obtain a mixture; (2) preparing the thickening agent into a water solution; (3) injecting 1 / 3 or less of the thickening agent water solution into the mixture of step (1); after uniformly mixing, adding the residual thickening agent water solution in batches to obtain thede-foaming agent. The de-foaming agent provided by the invention has the characteristics of high stability, rapid de-foaming speed, good foam inhibition performance, good compatibility with a scale inhibitor and the like and has good environment-friendly performance and a wide application prospect.

Owner:自然资源部天津海水淡化与综合利用研究所 +1

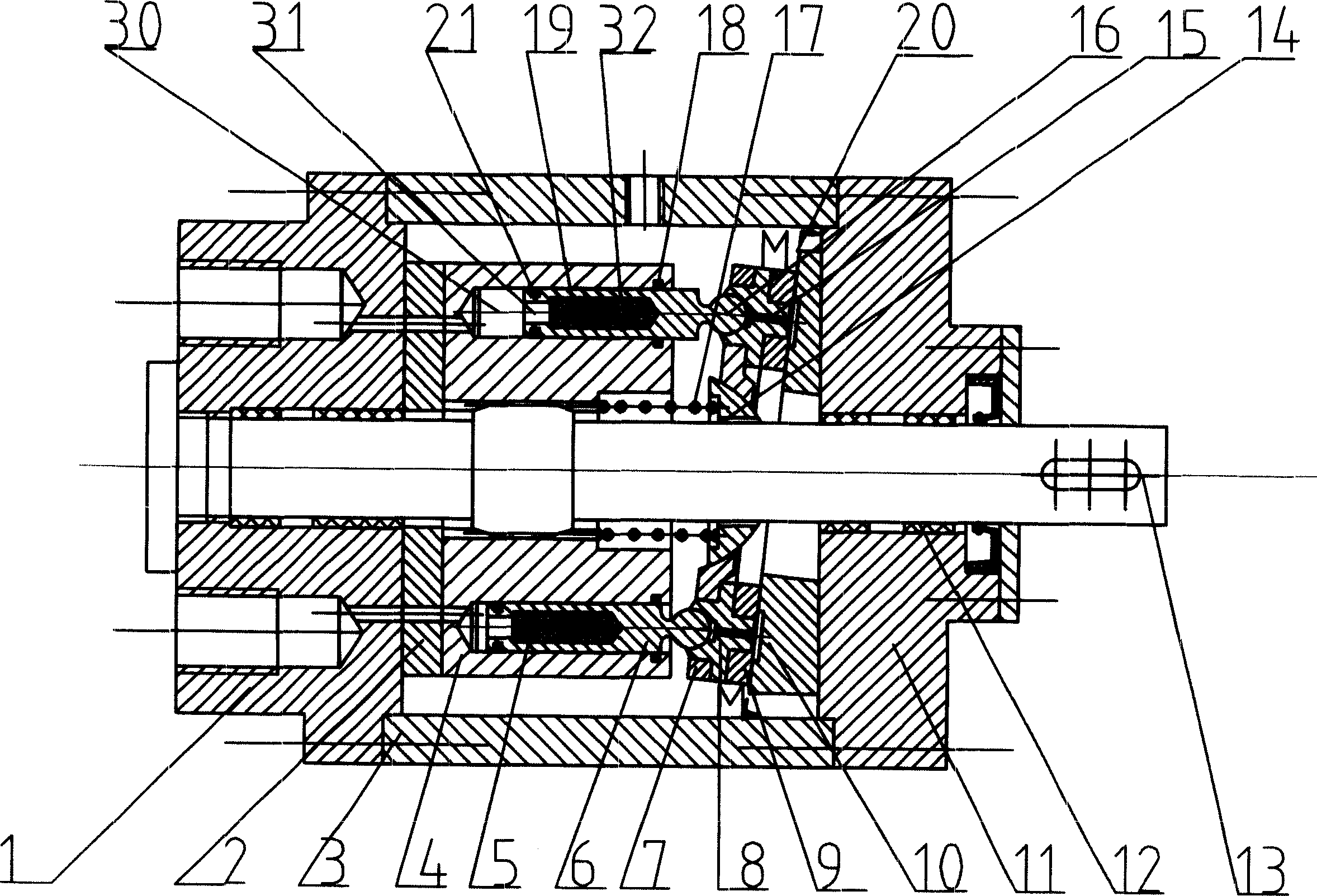

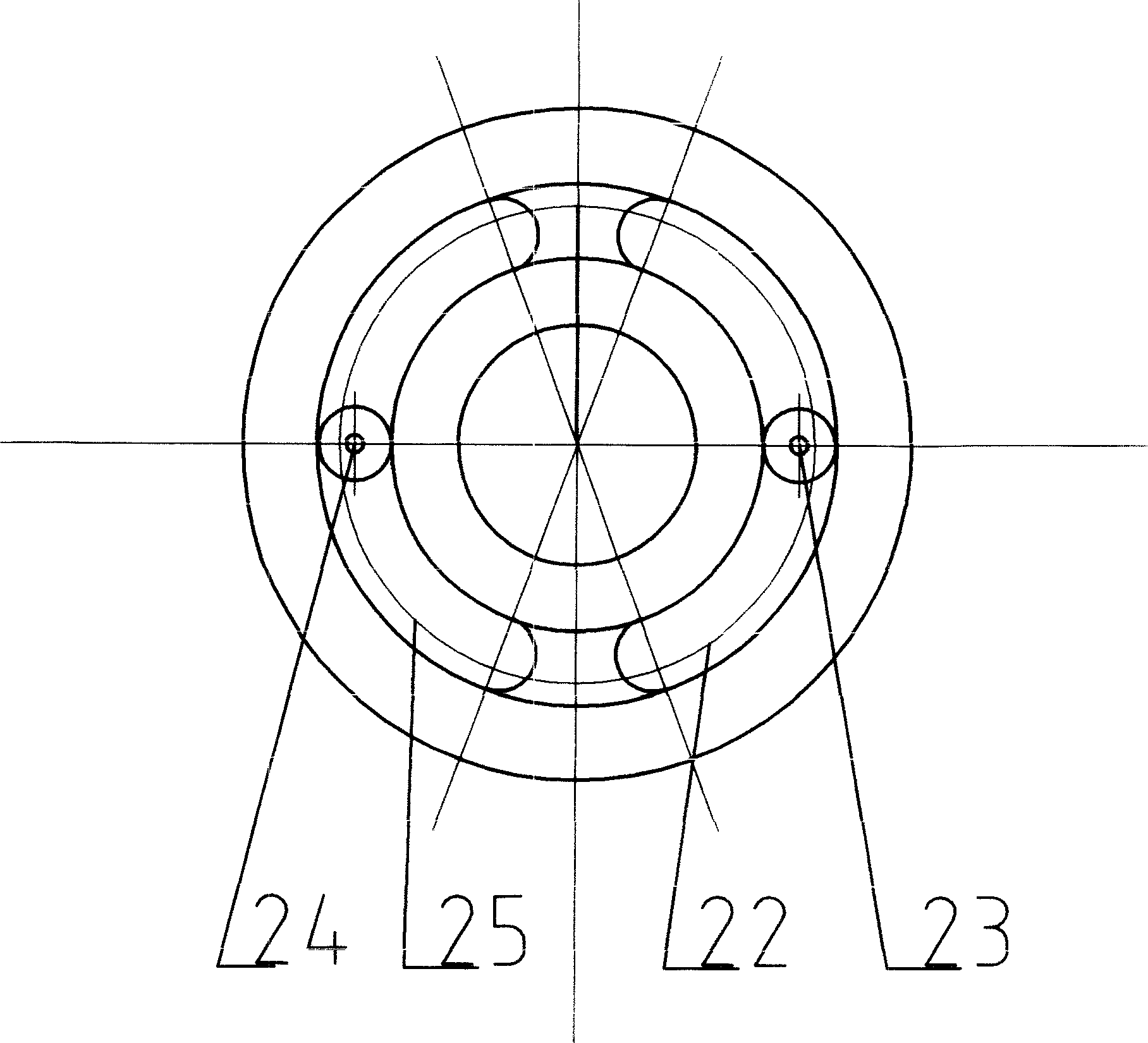

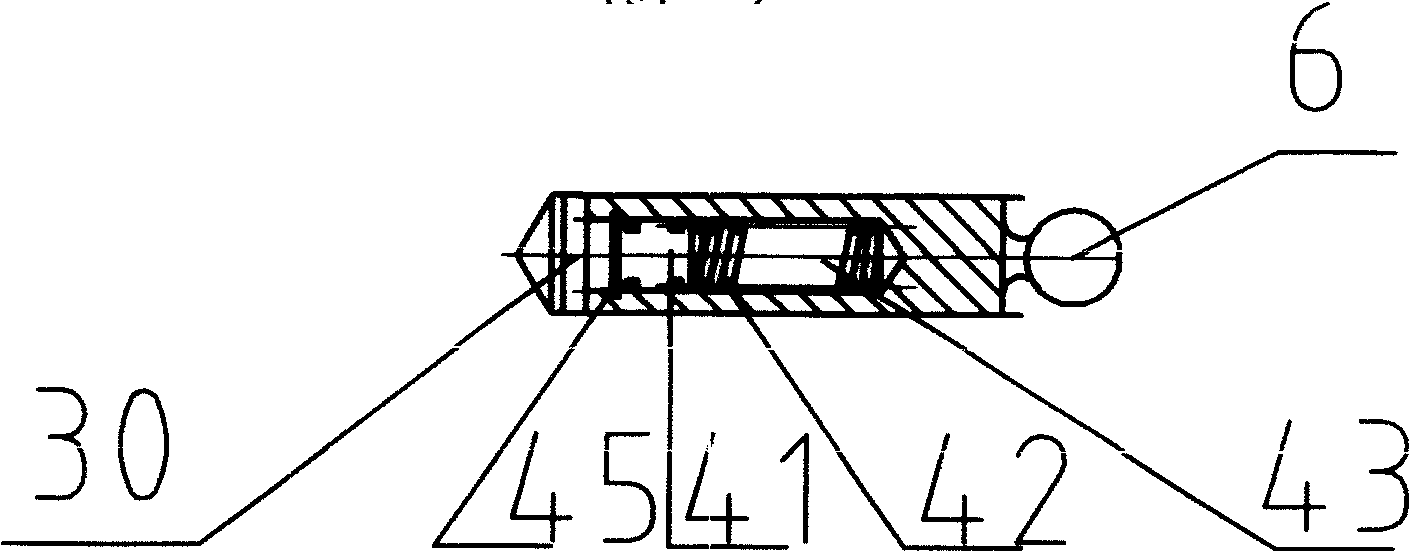

Slanting axial piston pump

InactiveCN1704591AUniform wearExtended service lifePump controlPositive-displacement liquid enginesWorking pressureDrive shaft

This invention comprises front pump cover 11, rear pump cover 1, pump 3, cylinder 4, porting device 2, plunger 6 whose one end hinges the sliding boot 8, the other end is in the plunger cavity 30, swash plate 10 whose incidence can be or not be adjusted, static supporting 20 between the swash plate 10 and the sliding boot 8, hold-down spring 15, drive axle bearing and seal assembly 12, and drive axle 13; wherein the plunger 6 has inner cavity 19, a blind hole cavity with accumulator 5; between the sliding boot 8 and the swash plate 10 is a supporting plate 9 which can be rotated. Said invention can absorb the pulsing flow and hydrodynamic shock effectively, and it is especially fit for hydraulic driving pump and motor.

Owner:袁训中

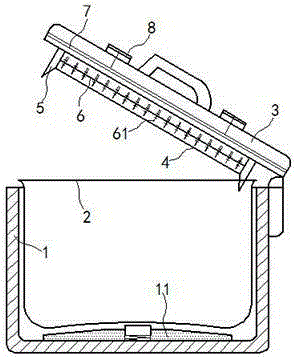

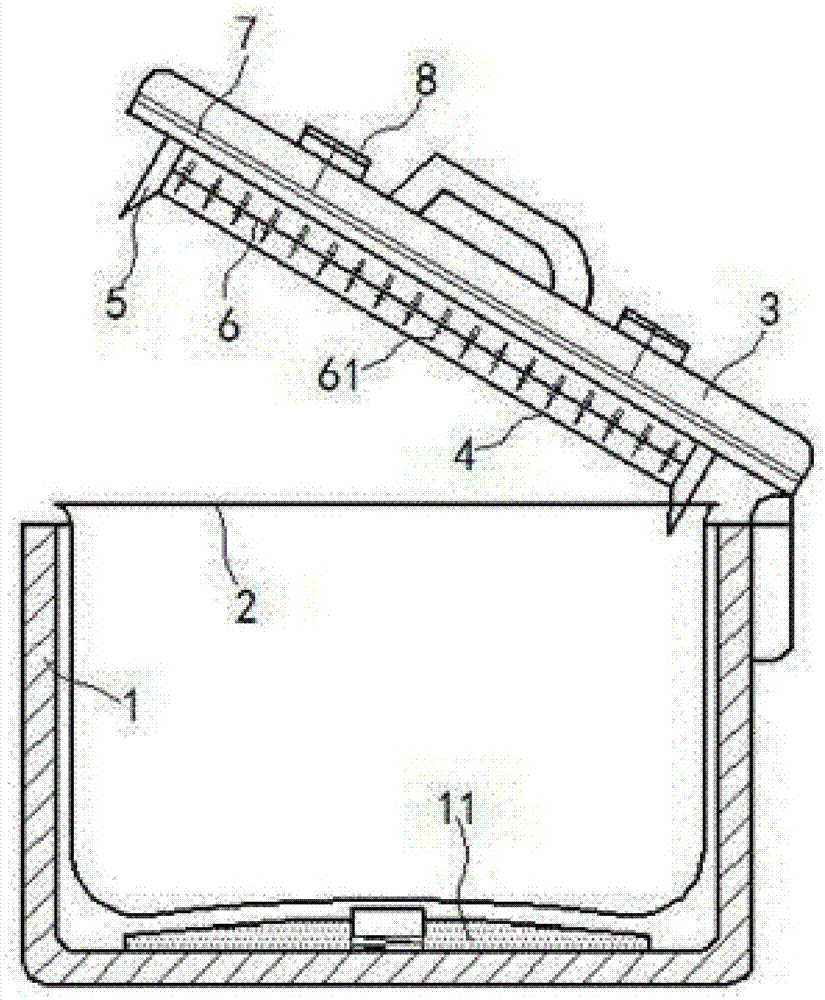

Anti-overflow rice cooker

ActiveCN105559512AWon't take up spaceGuaranteed usable volumeBoiling over preventionEngineeringMagnet

The invention relates to an anti-overflow rice cooker. The anti-overflow rice cooker comprises a cooker body, an inner container and a cover body, wherein a hard pore plate is fixedly mounted on the lower surface of the cover body, a defoaming plate is mounted between the hard pore plate and the cover body, and defoaming meters are arrayed on the defoaming plate at equal intervals, are made of a ferro magnetic material, and are capable of vibrating vertically in the vertical direction; a drive screen plate is further mounted in the cover body, and is made of a permanent magnet material; the drive screen plate is parallel to the defoaming plate, and is capable of sliding vertically along the inner side wall of the cover body; air exhaust holes are further formed in the upper surface of the cover body, and air exhaust baffle plates are mounted on the air exhaust holes, and are capable of moving vertically along the axes of the air exhaust holes; and the air exhaust baffle plates are connected with the drive screen plate through connecting rods. The anti-overflow rice cooker is ingenious in structure and convenient to clean, bubbles can be effectively broken, and the overflow of rice and soup is prevented.

Owner:广东省中山食品水产进出口集团有限公司

Method for preventing spillover of electric cooker

InactiveCN107174121AHigh efficiency defoamingWon't take up spaceBoiling over preventionVena contracta diameterEngineering

The invention relates to a method for preventing spillover of an electric cooker. The electric cooker comprises a pan body, a liner and a cover body, wherein a hard orifice plate is fixedly mounted on the lower surface of the cover body, a defoaming plate is mounted between the hard orifice plate and the cover plate, defoaming needles made of a ferro-magnetic material are arranged on the defoaming plate in an array at an equal interval, and the defoaming needles can vibrate in a vertical direction; a driving reticular plate made of a permanent magnetic material is installed inside the cover body; the driving reticular plate is parallel to the defoaming plate and can slide up and down along the inner side wall of the cover body; a vent hole is formed in the upper surface of the cover body, an exhaust baffle plate is mounted on the vent hole and can move up and down along the axial line of the vent hole; and the exhaust baffle plate and the driving reticular plate are connected via a connecting rod. The electric cooker disclosed by the invention has an elaborate structure, is convenient for cleaning, and can effectively deform to prevent spillover of rice and soup.

Owner:JIANGSU CHANGRUI AGRI CO LTD

Anti-flame hydraulic fluid

The invention provides anti-burning hydraulic fluid, which is characterized by the composition of diethylene glycol, polyether, lubricant, corrosion inhibitor, foam inhibitor, defoamer and water; wherein, the invention comprises 35 portions to 55 portions of diethylene glycol, 10 portions to 19 portions of polyether, 0.9 portions to 3.6 portions of lubricant, 3 portions to 4.5 portions of corrosion inhibitor, 0.4 portions to 0.8 portions of foam inhibitor, 0.02 portions to 0.04 portions of defoamer, and 35 portions to 55 portions of deionized water. The invention has excellent flammability resistance, lubrication, extreme-pressure abrasion resistance and defoaming performance. The invention can be widely used in such industries as metallurgy, coal, chemical, machinery, casting and other industries. The use of the foam inhibitor and defoamer can make the height of foam below 25cm and the defoaming time less than 15 seconds. The invention eliminates the influence of foam on the whole hydraulic system; the measurement according to the NAS 1638 standard has proven that the cleanliness standard has achieved the sixth grade.

Owner:沈阳晟豪化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com