Novel polyether ester defoamer and preparation method thereof

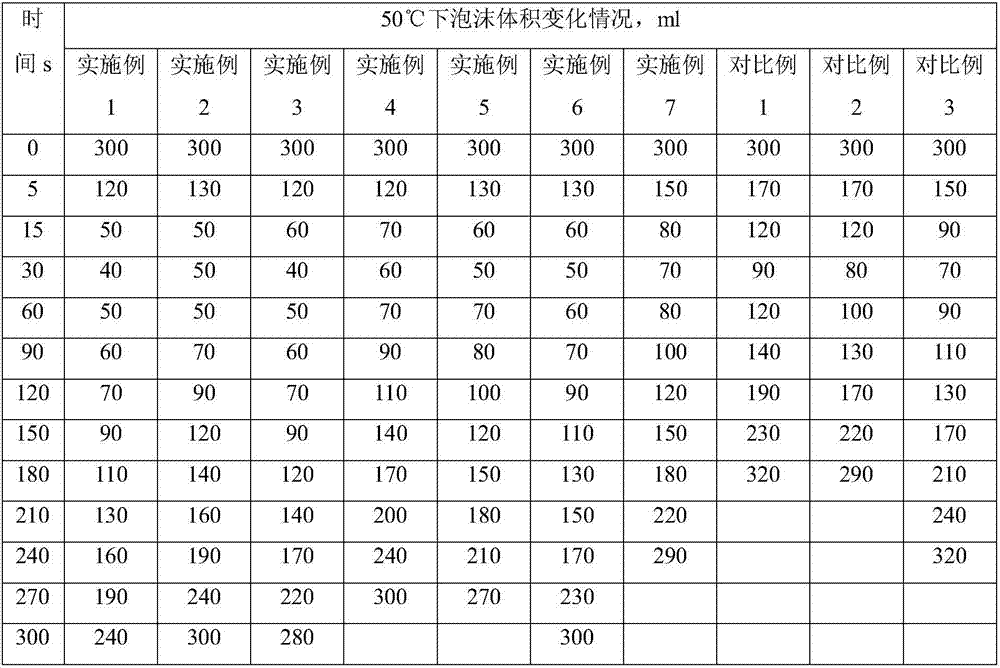

A technology of polyetherester and defoamer, which is applied in the field of new polyetherester defoamer to achieve the effects of good degassing and foam suppression, low surface tension and good defoaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention discloses a preparation method of a novel polyether ester defoamer. The novel polyether ester defoamer is prepared by using higher aliphatic alcohol with a carbon chain length greater than 18 as an initiator.

[0028] The preparation method of described novel polyether ester defoamer, comprises the steps:

[0029] (1) take higher fatty alcohol as initiator, carry out polyether reaction with ethylene oxide, propylene oxide under the effect of the first catalyst, prepare fatty alcohol polyoxyethylene polyoxypropylene ether;

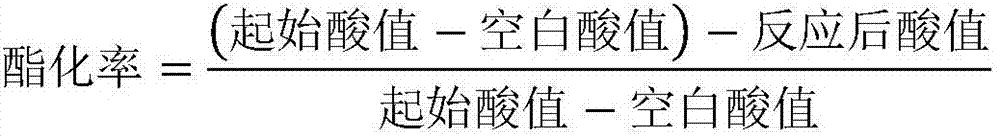

[0030] (2) The fatty alcohol polyoxyethylene polyoxypropylene ether prepared in step (1) is subjected to esterification reaction with fatty acid under the action of the second catalyst to prepare polyether ester.

[0031] Preferably, the synthetic fatty alcohols include but are not limited to Nafol 20+, Nafol1822, Nafol 2022 or Nafol 22+ synthesized by the Ziegler method; the natural fatty alcohols include but not limited to eicosanol, ...

Embodiment 1

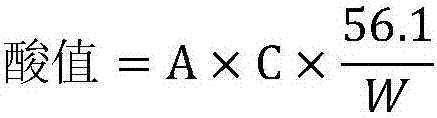

[0050] Using Nafol 20+ as the initiator, polyether reaction with ethylene oxide and propylene oxide under the action of DMC double metal cyanide catalyst, the molar ratio of ethylene oxide and propylene oxide is 1:2.7, the reaction The temperature is 110°C, the reaction time is 6-8 hours, and the hydroxyl value of the prepared fatty alcohol polyoxyethylene polyoxypropylene ether is 24.8mg KOH / g;

[0051] Under the action of p-toluenesulfonic acid, the above prepared fatty alcohol polyoxyethylene polyoxypropylene ether and lauric acid undergo esterification reaction at a molar ratio of 1.1:1, the reaction temperature is 150°C, and the reaction time is 2 to 4 hours. Polyether ester, the esterification rate is 72.4%.

Embodiment 2

[0053] Using Nafol 20+ as the initiator, polyether reaction with ethylene oxide and propylene oxide under the action of DMC double metal cyanide catalyst, the molar ratio of ethylene oxide and propylene oxide is 1:3.5, the reaction The temperature is 110°C, the reaction time is 6-8 hours, and the hydroxyl value of the prepared fatty alcohol polyoxyethylene polyoxypropylene ether is 26.4mg KOH / g;

[0054] In solid superacid (SO 4 2- / SnO 2 -TiO 2 -Al 2 o 3 ) under the action of the fatty alcohol polyoxyethylene polyoxypropylene ether prepared above and oleic acid in a molar ratio of 1:1 for esterification, the reaction temperature is 150 ° C, and the reaction time is 2 to 4 hours to obtain polyether ester. The esterification rate is 78.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com