Patents

Literature

218results about How to "Good anti-foam performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

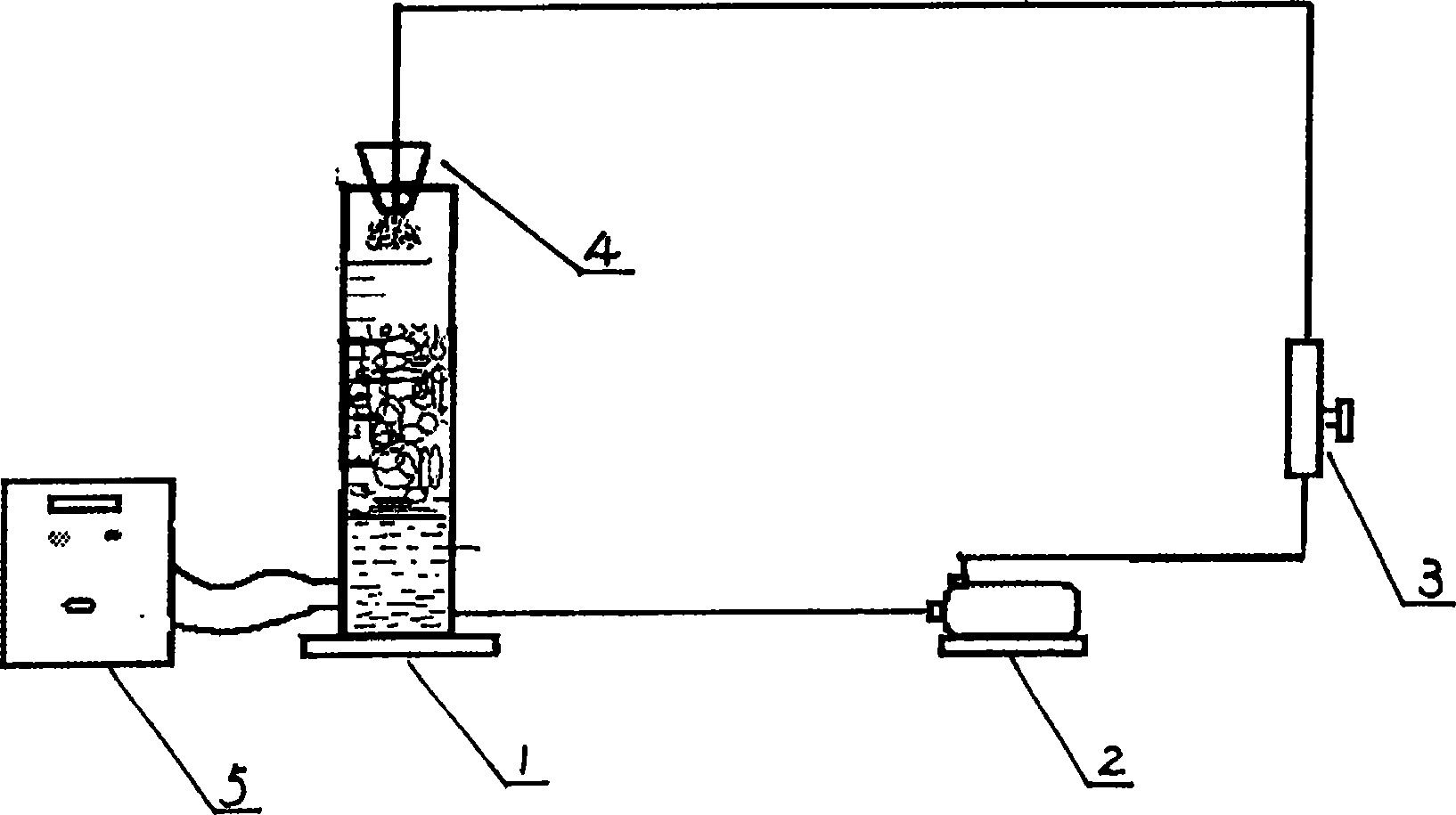

Preparation for general defoaming agent and its application

InactiveCN101053706AGood defoamingGood anti-foam performanceTransportation and packagingMixingDefoaming AgentsMetal

The invention discloses a general anorganosilicon antifoaming agent compound and preparation thereof, comprising 20-90% by weight of organic hydrocarbons material, 0.5-10% by weight of main antifoaming material, 1-15% by weight of antifoaming synergist and 1-10% by weight of emulsifying agent. The preparation method is: (1) mixing half of organic hydrocarbons material with main antifoaming material, rising the temperature to 80-120 degree C and keeping for 0.5-3h to make sure the main antifoaming material to be dispersed completely; (2) adding the rest of the organic hydrocarbons material and the antifoaming synergist to said mixture in turns, and keeping the temperature at 60-90 degree C for 0.5-2.0h to make sure to be mixed thoroughly; (3) dropping the temperature below 50 degree C, adding the emulsifying agent and mixing blend even. The anorganosilicon antifoaming agent compound substantially improves the defoaming properties of the antifoaming agent based on adding high molecular antifoaming synergist, has the advantage of good stability, little recruitment and good security, and is used in the process of papermaking and coating, circuit board developing and metal cleaning of the paper industry.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

High-efficiency antifoaming agent

InactiveCN102949867AGood anti-foam performanceStrong antifoam performanceFoam dispersion/preventionAdditive ingredientBULK ACTIVE INGREDIENT

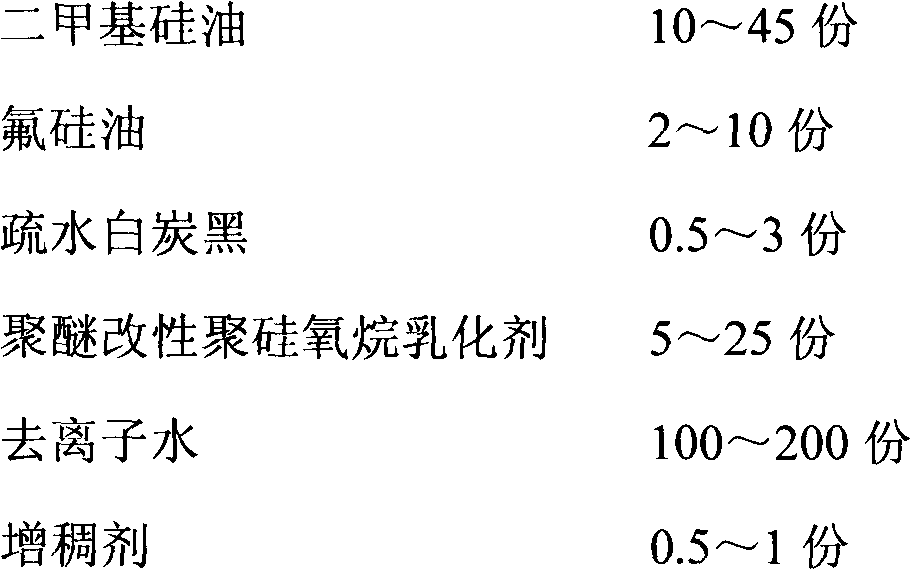

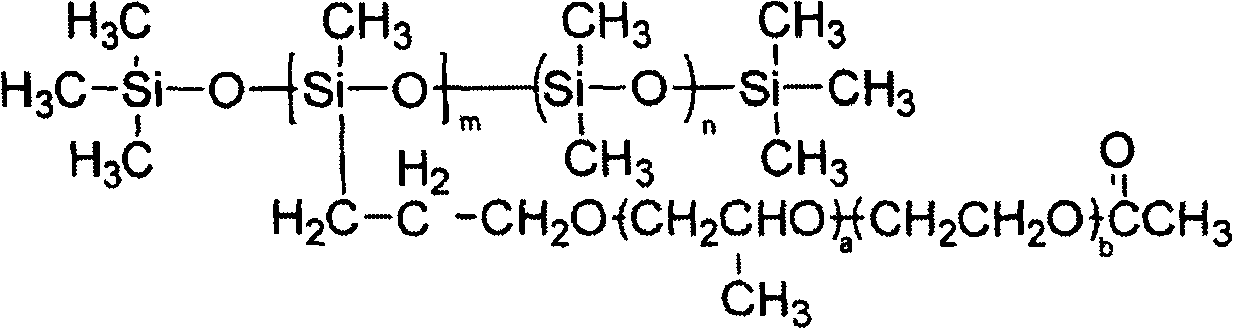

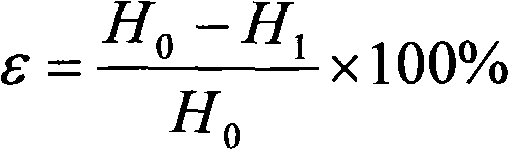

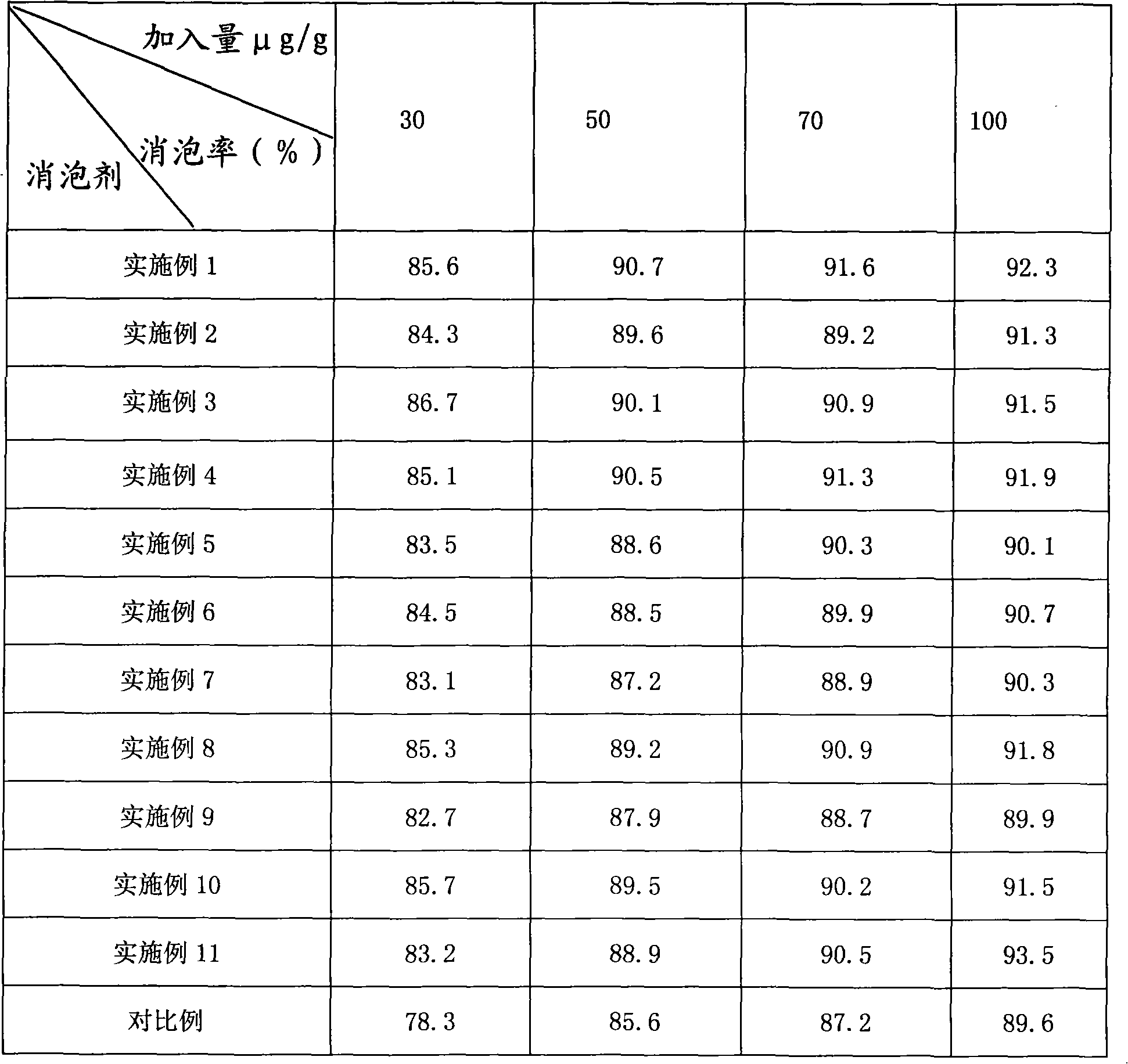

The invention relates to a high-efficiency antifoaming agent which comprises the following raw materials based on parts by weight: 10-45 parts of simethicone, 2-10 parts of fluorosilicone oil, 0.5-3 parts of hydrophobic white carbon black, 5-25 parts of polyether-modified polysiloxane emulgator, 100-200 parts of deionized water and 0.5-1 part of thickening agent. The antifoaming agent takes composition of the simethicone and the fluorosilicone oil as a main antifoaming active ingredient; and after the fluorosilicone oil is added, the surface tension of an antifoaming agent system can be reduced, and the antifoaming and foam-inhibiting performances can be improved. According to the polyether-modified polysiloxane emulgator, not only can the antifoaming active ingredients be emulsified, but also the effect enhancing action can be achieved due to the fact that the high-efficiency antifoaming agent further has good antifoaming ingredients. The antifoaming agent is high in antifoaming capacity, long in foam-inhibiting time, wide in application range, capable of being applied to various foam systems, and suitable for antifoaming and foam-inhibiting under severe conditions, i.e. high acid-base, high temperature and the like.

Owner:TIANJIN SCIPHARMACN

Delaying coking non-silicon defoaming agent with multiple active components and preparation method thereof

ActiveCN101780382ANo effectGood defoaming at high temperatureTransportation and packagingMixingAlcoholHigh carbon

The invention discloses a delaying coking non-silicon defoaming agent with multiple active components and a preparation method thereof, and the defoaming agent is formed by compounding 30-50 parts by weight of polyether or modified polyether polymer, 25-35 parts by weight of high-carbon alcohol mixture, 10-15 parts by weight of high-carbon alcohol fatty acid ester or fatty acyl amide and 15-20 parts by weight of alkymer. The preparation method of the defoaming agent comprises the following steps: adding the polyether or the modified polyether polymer, the high-carbon alcohol mixture, the high-carbon alcohol fatty acid ester or the fatty acyl amide and the alkymer into a reaction kettle according to the proportion, stirring, slowly increasing the temperature to 50-100 DEG C, carrying out reaction for 1-2h, finally stopping stirring, cooling, filtering for removing solid impurities and finally preparing the delaying coking non-silicon defoaming agent. The defoaming agent can effectively suppress and eliminate the formation of bubbles in a delayed coking reaction tower, improve the treatment capacity of the reaction tower, prolong the coking time of coke and prevent clogging phenomenon.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

Low-foam middle-cloud-point environment-friendly water base metal cleaner composition and preparing method thereof

The invention provides a low-foam middle-cloud-point environment-friendly water base metal cleaner composition and a preparing method thereof, and belongs to the field of metal cleaners. The low-foam middle-cloud-point environment-friendly water base metal cleaner composition is composed of low-foam low-cloud-point nonionic surface active agents, low-foam anion surface active agents, triethanolamine oleic soap, triethanolamine, styrene acrylic three azole nitrogen, ethylene diamine tetraacetic acid, sodium carbonate, polyether, organosilicone, sodium hydroxide and deionized water, wherein solid-phase raw material and liquid-phase raw material are sequentially added to a reaction container according to a formulation and metering, the organosilicone and the deionized water are finally added to the reaction container, stirring is conducted for 10min to 20min under the condition of indoor temperature, and clear products with a pH value ranging from 9 to 10 are obtained. The triethanolamine oleic soap is a cloud point improving agent, good water solubility is achieved after the triethanolamine oleic soap and the triethanolamine are re-compounded according to the ratio, solubilizing ability of the low-foam low-cloud-point nonionic surface active agents is enhanced, therefore the temperature of the solution cloud point of the cleaner is improved to 45 DEG C, cleaning efficiency of the cleaner is improved, and the low-foam middle-cloud-point environment-friendly water base metal cleaner particularly suitable for high-pressure spraying cleaning is obtained.

Owner:BOER TECH WUHAN

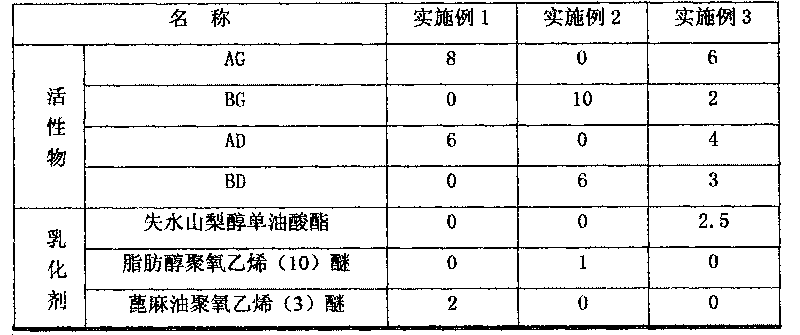

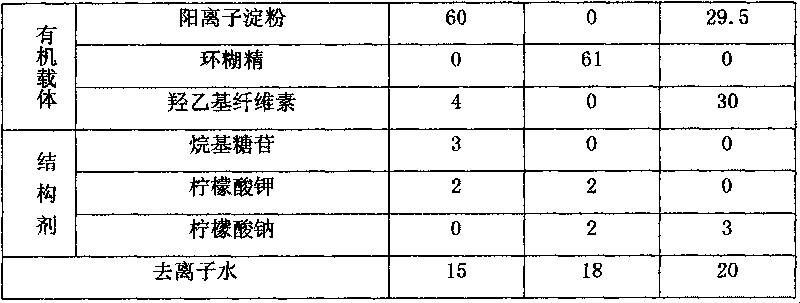

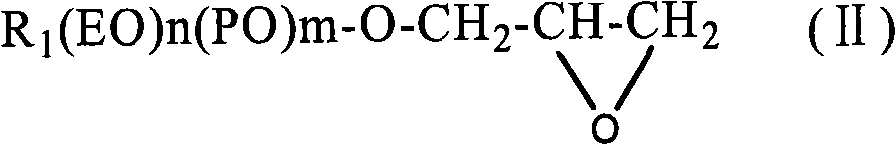

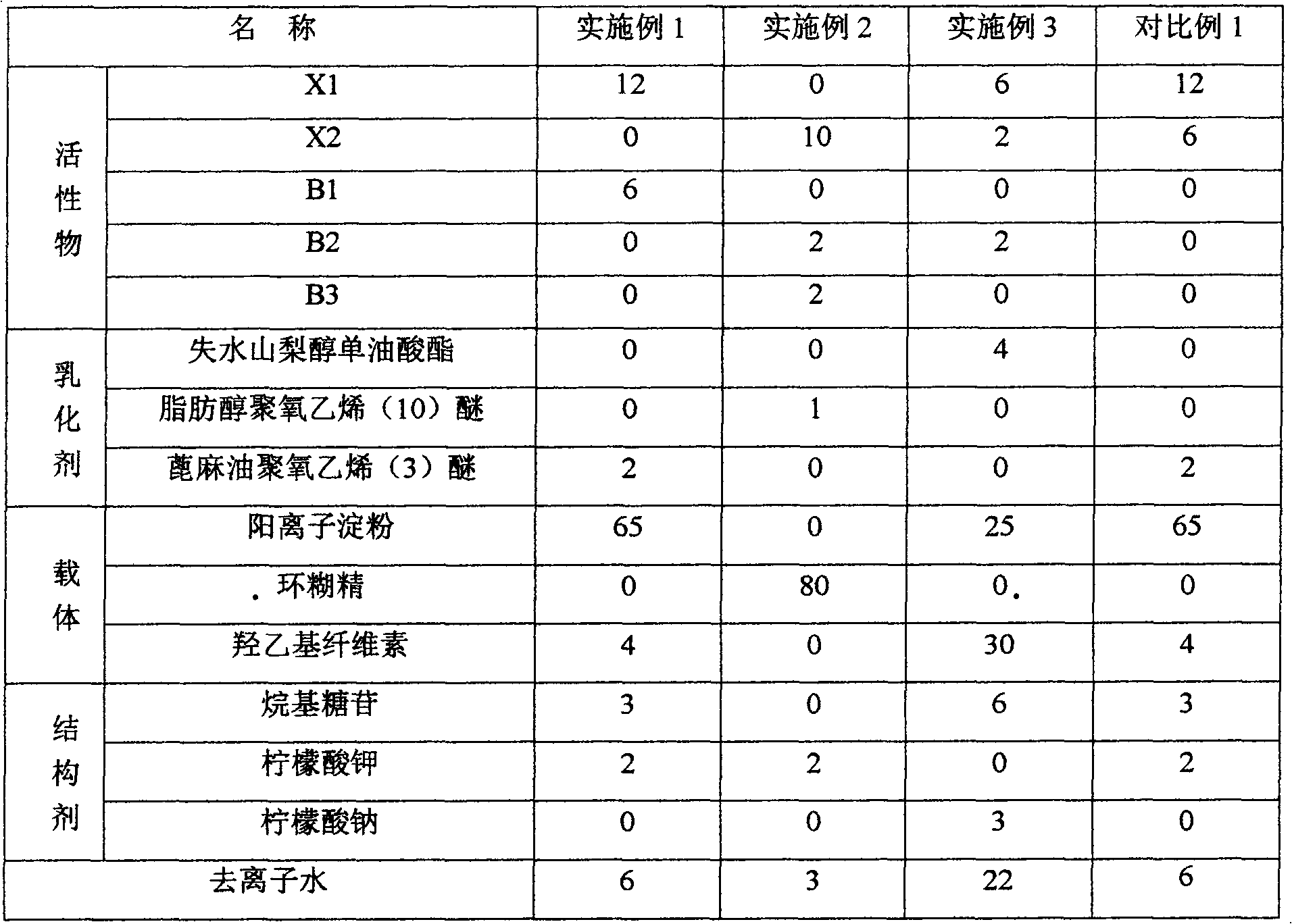

Solid particle foam inhibitor and preparation method thereof

InactiveCN101721843AGood anti-foam performanceAdd lessFoam dispersion/preventionTextile printerSolid particle

The invention relates to a solid particle foam inhibitor and a preparation method thereof. The foam inhibitor component comprises an organic carrier, a main defoaming substance, an emulsifying agent, a structural agent and deionized water, wherein the organic carrier can be dextrin, starch, and the like; the main defoaming substance is a complex of high-viscosity silicone and low-viscosity silicone; and the structural agent can be acrylic acid and maleic acid copolymer, sodium citrate, and the like. The preparation method of the foam inhibitor comprises the following steps of: fully mixing the main defoaming substance with the emulsifying agent; then adsorbing the mixture on a carrier; adding the structural agent and granulating and drying to form a particle with favorable mobility. The prepared solid particle foam inhibitor is quite applicable to the industrial processes of cleaning, sewage treatment and textile printing and dyeing.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

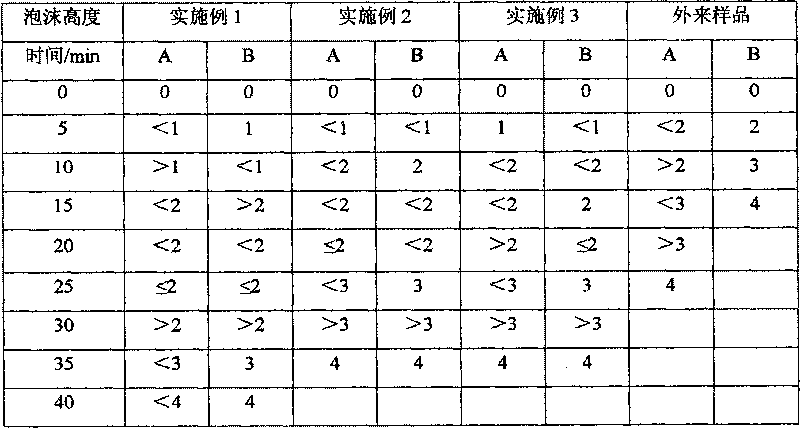

Preparation method of industrial defoaming agent

InactiveCN1721031AGood defoamingGood anti-foam performanceFoam dispersion/preventionGlycerolSugar refining

The preparation method for industrial defoaming agent belongs to organic chemical industry field. First polymerize the glycerin to polyglycerol with polymerization degree of 2-10 under activator, add glycerin fatty acid ester or fatty acid for determined mass rate to process ester interchange and obtain the product. It is simple in technique, has good defoaming and foam inhibiting effect, gets raw material easily and fits to many techniques, such as paper making, sugar refining and fermentation.

Owner:温木盛

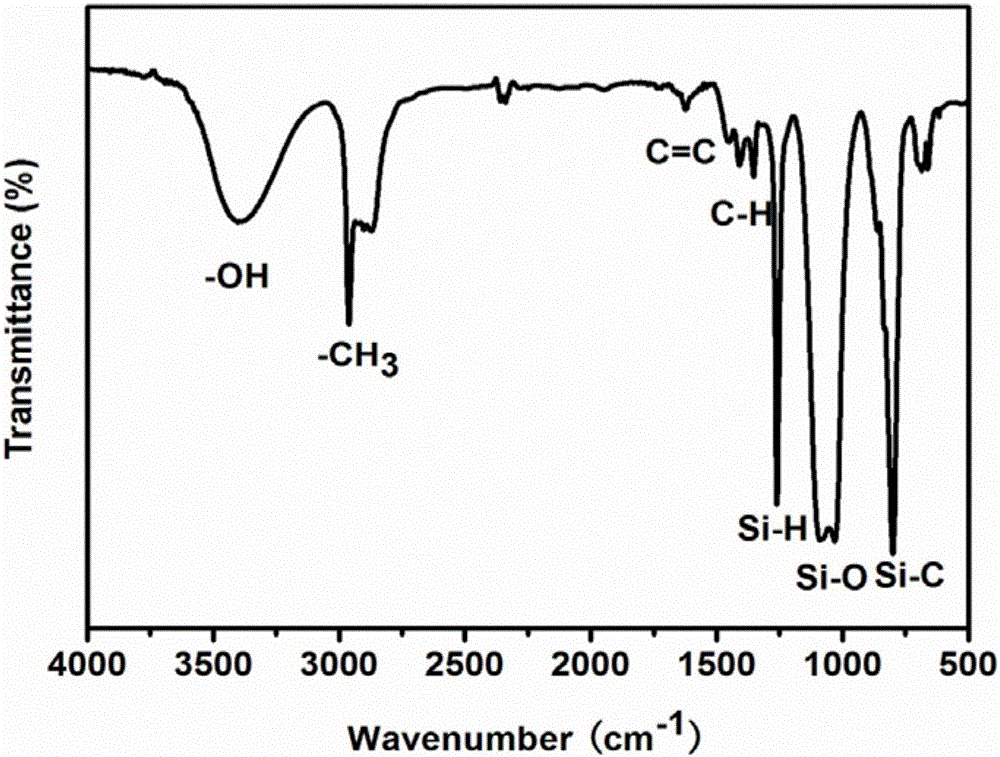

Organosilicone composition, preparation method and application thereof

ActiveCN104274998AGood defoamingGood anti-foam performanceFoam dispersion/preventionPolymer scienceUnsaturated hydrocarbon

The present invention relates to a crosslinked network polymer obtained on the basis of an addition reaction of a hydrogen-containing polyorganosiloxane, an organic silicon resin and an unsaturated hydrocarbon, followed by the process of adding a crosslinking agent containing an active group and silicon dioxide; the polymer has an improved defoaming performance, good anti-foaming effect, and is easy to handle and process, and the addition of an emulsifier does not reduce the anti-foaming effect. The polymer has a good anti-foaming performance with no decay, and the polymer formed therefrom can easily be processed.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Self-emulsifying molecular antifoaming agent and preparation method thereof

InactiveCN102160939AStrong anti-foaming abilityReduce surface tensionFoam dispersion/preventionPolymer scienceFatty alcohol

The invention discloses a self-emulsifying molecular antifoaming agent and a preparation method thereof. The antifoaming agent comprises the following components in percent by mass: 20 to 60 percent of antifoaming active substance and 40 to 80 percent of dispersion medium, wherein the antifoaming active substance consists of higher fatty alcohol, alkynol, polyether and silicone oil in a mass ratio of 1:(0.8-1.5):(2-3):(2-4); and the dispersion medium is grafted star polymer. The preparation method comprises the following steps of: adding 50 to 150 parts of trichloromethane and 1 to 2 parts ofp-methyl benzene sulfonic chloride into 20 to 60 mass parts of active substance and 40 to 80 mass parts of star polymer, raising the temperature to between 40 and 70 DEG C, and reacting for 3 to 6 hours; and after the reaction is finished, washing sodium carbonate until the ph is 7, drying by using anhydrous sodium sulfate, and evaporating the solvent under reduced pressure to obtain the antifoaming agent. The extended arm of the star polymer in the antifoaming agent is grafted with the active substance, so that various components are synergistic, and the obtained antifoaming agent is high instability, low in surface tension, high in surface activity, high in antifoaming capacity, long in foam inhibition time and small in dosage.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

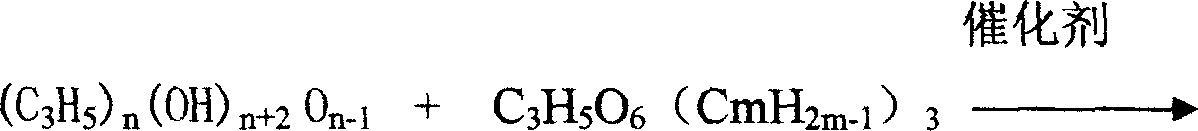

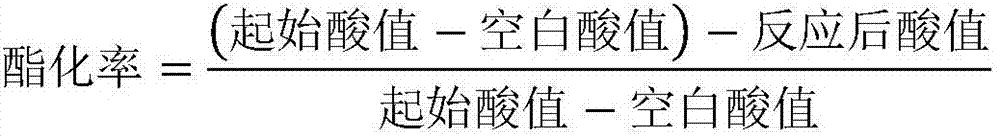

Novel polyether ester defoamer and preparation method thereof

InactiveCN106975247AReduce surface tensionGood defoaming effectFoam dispersion/preventionEtherCarbon chain

The invention provides a novel polyether ester defoamer prepared by using a higher aliphatic alcohol having carbon chain length of 18 as an initiator. A preparation method of the novel polyether ester defoamer comprises the steps of (1) subjecting a higher aliphatic alcohol as an initiator to polyether reaction with ethylene oxide and propylene oxide under the action of a first catalyst so as to prepare fatty alcohol polyoxyethylene polyoxypropylene ether; (2) subjecting the fatty alcohol polyoxyethylene polyoxypropylene ether to esterification reaction with fatty acid under the action of a second catalyst so as to prepare polyether ester. The novel polyether ester defoamer prepared herein is lower in surface tension and higher in defoaming capacity than traditional polyether ester defoamers; as the higher aliphatic alcohol is used as the initiator, the novel polyether ester defoamer is also better in degassing and foam-inhibiting effect than higher aliphatic alcohol defoamers.

Owner:济宁南天农科化工有限公司

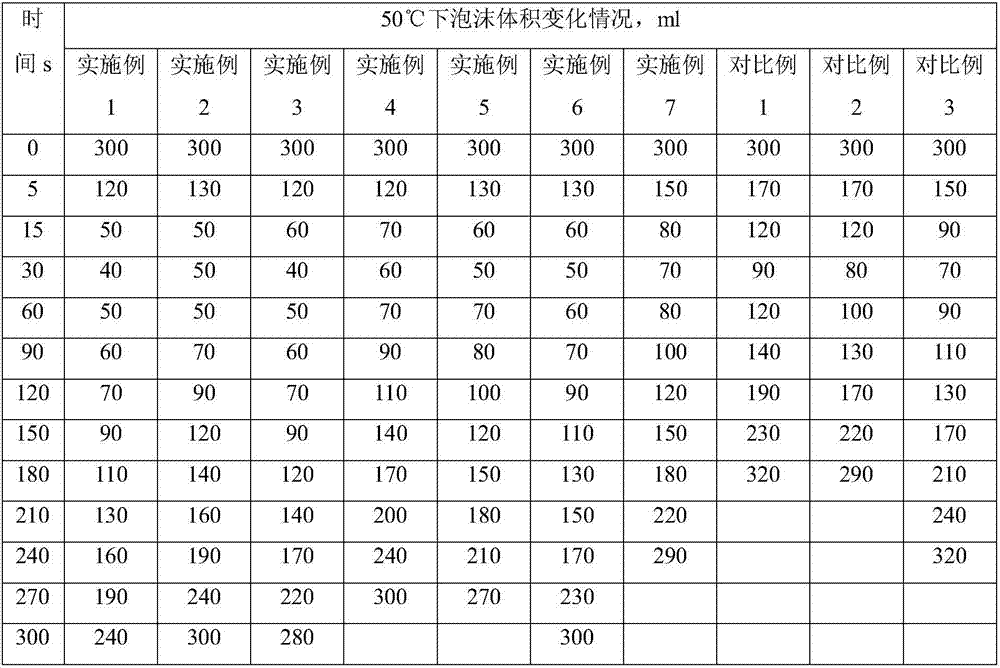

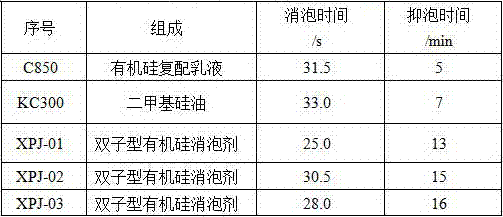

Gemini organic silicon defoamer

ActiveCN106977632AGood defoaming effectGood defoamingFoam dispersion/preventionDissolutionSilicone oil

The invention relates to a gemini organic silicon defoamer. The gemini organic silicon defoamer is of an improved polyether organosilicon diamide sulfonate structure; hydrophilic groups are ethylene oxide, an amido bond and sulfonate; hydrophobic groups are polysiloxane and epoxypropane; through a plurality of hydrophilic groups, the low-temperature defoaming affect is good; through a comb structure, polyether-modified silicone oil can quickly spread on a gas-liquid interface of a foaming system, and locally intrudes to break foam, and the gemini organic silicon defoamer has better defoaming activity; through a macromolecular comb structure, the dissolution rate in a system is reduced and a continuous foam inhibition effect is generated. The gemini organic silicon defoamer is a silicone-modified defoamer which is good in defoaming and foam inhibiting properties, especially good in low-temperature defoaming and foam inhibiting effects.

Owner:福建昆冈化学助剂科技有限公司

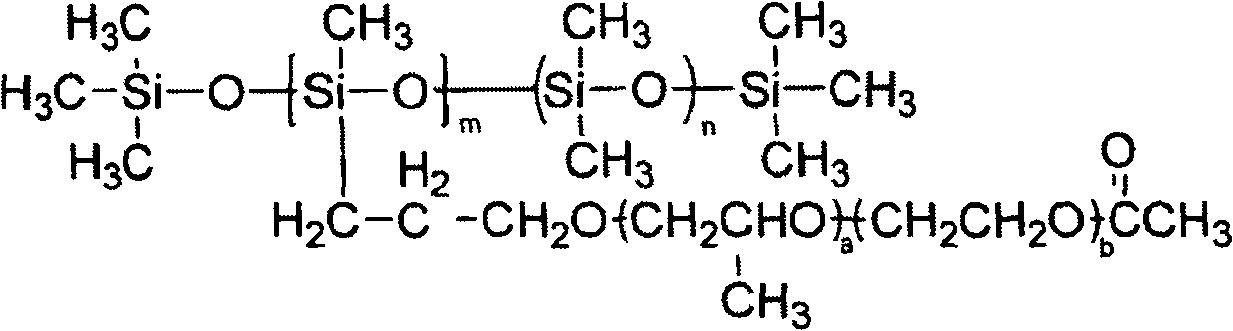

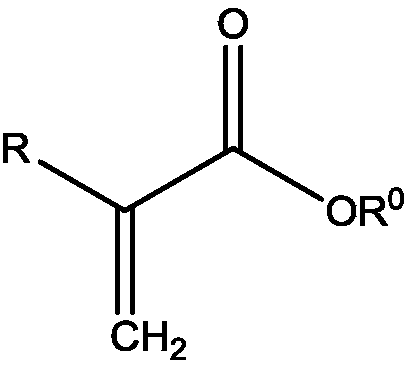

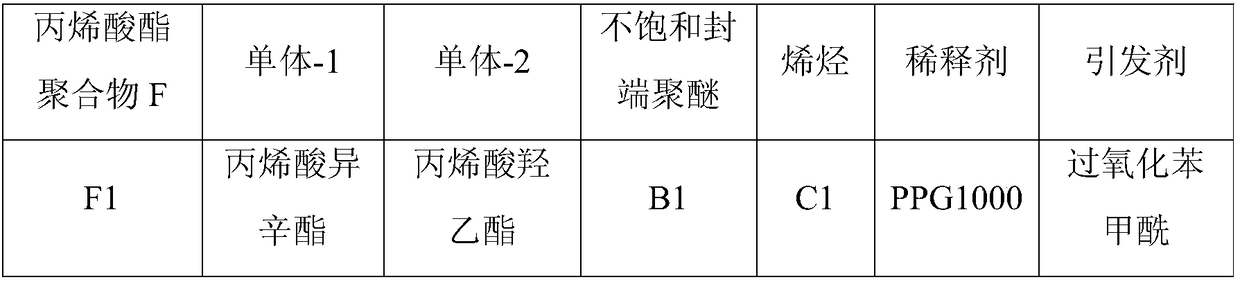

Non-silicon defoamer

ActiveCN108786188AGood defoaming performanceGood anti-foam performanceFoam dispersion/preventionPolyesterPolymer science

The invention belongs to the technical field of fine chemical industry and discloses a non-silicon defoamer which comprises acrylate polymer, organic solvent carrier, hydrophobic particle and defoaming aid. The acrylate polymer is prepared frommonomer-1, monomer-2, unsaturated terminated polyether, hydrocarbon, dilutent and initiator. The invention further discloses a preparation method of the non-silicon defoamer. The invention further discloses application of the non-silicon defoamer in defoaming and inhibiting foam in a system rich in an anionic surfactant. Acrylate polymer is taken as a main active matter, so that the defoamer has excellent foam eliminating and inhibiting performance. By dropwise adding monomer by steps, defoaming performance of the acrylate polymer is improved; unsaturated terminated polyester is utilized for modifying, so that hydrophilicity of the acrylate polymer is improved, and momentary defoaming ability of the acrylate polymer is further improved; foam inhibiting performance of the defoamer is improved by modifying through olefin with 6-22 carbon atoms.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Water-based metal cutting fluid suitable for soft water

InactiveCN103045335ASpeed up foam releaseImprove stabilityLubricant compositionWater basedSoft water

The invention discloses a water-based metal cutting fluid suitable for soft water. The water-based metal cutting fluid comprises the following components in percentage by weight: 20-45% of base oil, 5-15% of modified polymerized ricinoleic acid, 0.5-5% of non-ionic surfactant, 5-15% of anionic surfactant, 5-15% of synthetic ester, 1-6% of coupling agent, 1-5% of additive and water in balancing amount. According to the invention, as the special molecular structure of the modified polymerized ricinoleic acid is skillfully utilized in the formula of the cutting fluid, the bubble releasing speed of the cutting fluid in the soft water is effectively increased, and the stability and lubricating property of the cutting fluid are greatly improved.

Owner:QUAKER CHEM CHINA

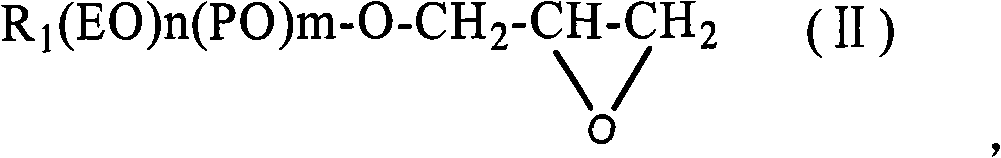

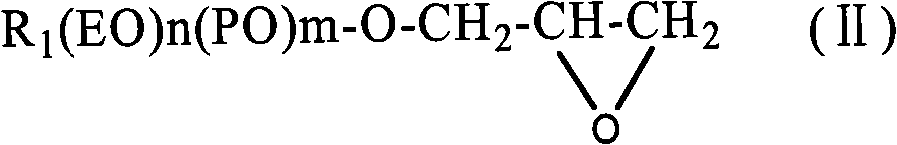

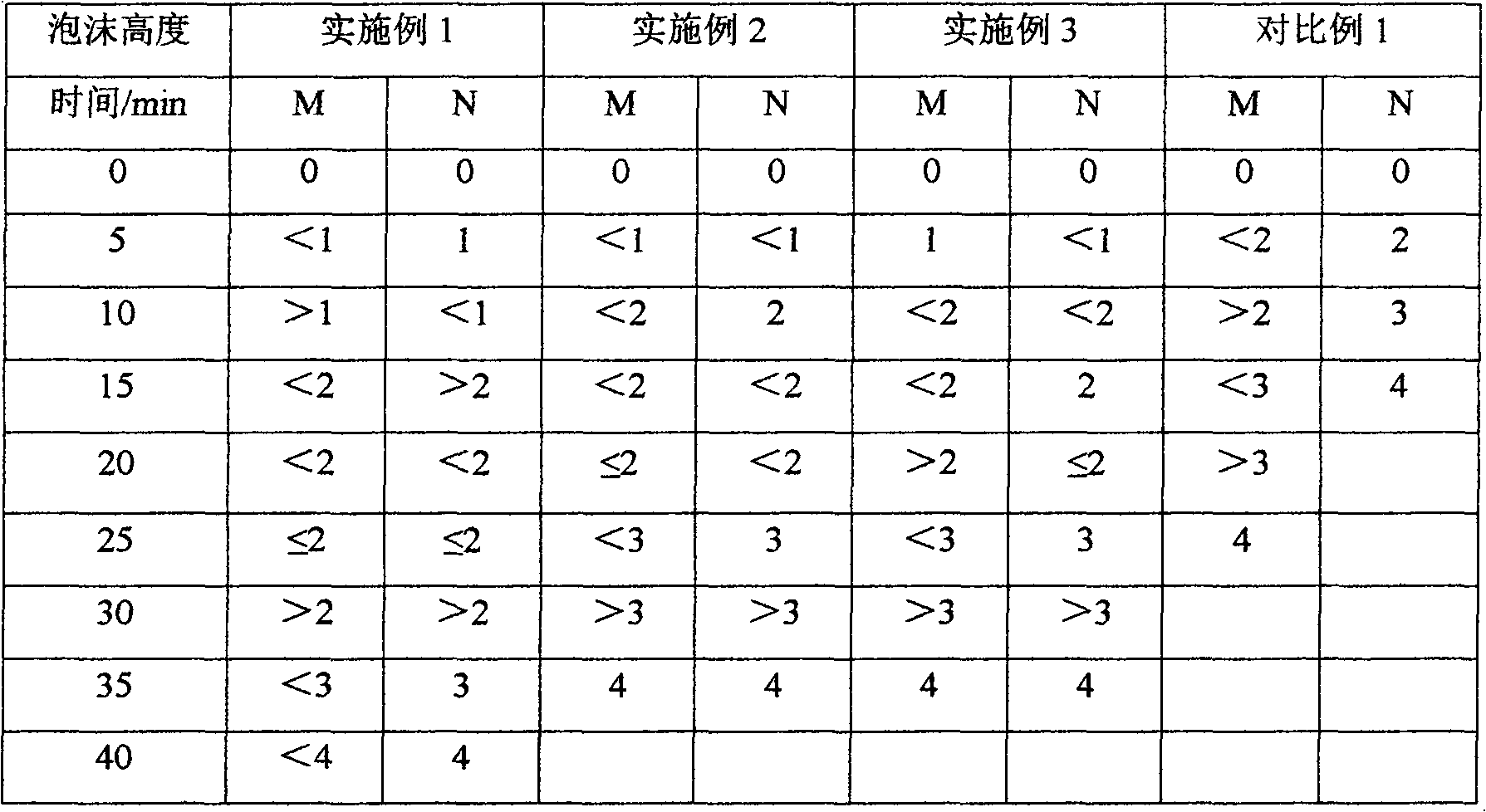

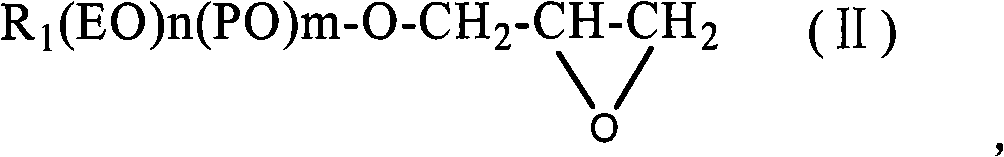

Glycidyl capped polyether, and synthesis method and applications thereof

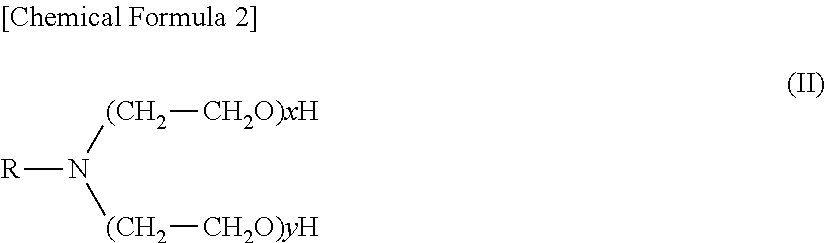

InactiveCN101805446AGood anti-foam performanceEnhanced defoaming and anti-foaming propertiesCoatingsSynthesis methodsPotassium hydroxide

The invention provides a glycidyl capped polyether, and a synthesis method and applications thereof. The synthesis method comprises the following steps: (1) adding alkali in polyether to react in a solvent system, wherein the alkali is taken from one or the mixture of the solids and water solution of sodium hydroxide and potassium hydroxide and the solids and alcoholic solution of sodium methoxide and potassium methoxide, and the reaction temperature is 80-120 DEG C, and the mol ratio of the polyether to the alkali is 1:1-2; (2) adding epichlorohydrin into the reaction system to continue the reaction, wherein the reaction temperature is 80-140 DEG C, and the mol ratio of the polyether to the epichlorohydrin is 1:0.9-2.1; and (3) and refining the reactants to obtain the glycidyl capped polyether which has the structure as disclosed in formula (II), wherein R1 is a C4-C18 alkyl group, n is equal to 0-25, and m is equal to 0-25. When being used in aqueous emulsion paint, the glycidyl capped polyether does not produce shrinkage cavities, has the functions of enhancing defoaming capability and inhibiting foams for a long time, and can be used for preparing defoamers of water paint.

Owner:广东省石油化工研究院

Solid particle foam inhibitor and method for preparing same

ActiveCN102302869AGood anti-foam performanceAdd lessFoam dispersion/preventionTextile printerAdditive ingredient

The invention relates to a solid particle foam inhibitor and a method for preparing the same. The ingredients of the foam inhibitor consist of 50-80% of organic carrier, 10-18% of main defoaming materials, 0.5-4% of emulsifying agent, 1-10% of structural agent and 3-25% of deionized water. The method for preparing the foam inhibitor comprises the following steps of: sufficiently mixing the main defoaming materials with the emulsifying agent; adsorbing the main defoaming materials and the emulsifying agent on the carrier; and adding the structural agent and forming particles with good liquidity through working procedures of granulating and drying. The prepared solid particle foam inhibitor has excellent applications in industrial processes, such as washing, sewage treatment and textile printing and dyeing.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Water and oil repellent aqueous composition

InactiveUS20060005317A1Improve processing stabilityGood storage stabilityOther chemical processesLiquid repellent fibresParaffin waxOrganic acid

To provide a water and oil repellent aqueous composition which is excellent in water and oil repellency, which is less likely to cause an ending phenomenon, which is excellent in stability of a processing bath, which is excellent in storage stability of the composition and which is excellent in foam suppression properties. A water and oil repellent aqueous composition comprising a fluorinated water and oil repellent (A), an emulsified product (B) comprising a paraffin wax (such as a paraffin wax having a melting point of from 50 to 70° C. and a penetration hardness at 25° C. of at most 20) and a carboxyl group-containing polyethylene (such as a carboxyl group-containing polyethylene having a melting point of from 90 to 135° C. and an acid value of from 10 to 30 mgKOH / g), and an organic acid (C).

Owner:ASAHI GLASS CO LTD

Aqueous emulsion non-silicon defoamer and preparation method thereof

ActiveCN101780383BImprove surface activityEnhanced defoamingTransportation and packagingMixingWater basedEmulsion

The invention discloses an aqueous emulsion non-silicon defoamer and a preparation method thereof. The defoamer consists of a material with defoaming activity, an emulsifying material and a dispersion medium, wherein the material with defoaming activity consist of alkynol, higher aliphatic alcohol and glyceryl polyether; the emulsifying material consists of anionic emulsifier and non-ionic emulsifier; and the dispersion medium consists of water and glycol. The defoamer of the invention has excellent defoaming and anti-foaming functions and high wettability and stability and is particular suitable for water-based paint, oil ink and other systems.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

Heat transfer medium special for solar heat pump and preparation method thereof

InactiveCN101787263AImprove protectionGood descaling effectHeat-exchange elementsEvaporationPhosphoric acid

The invention discloses a heat transfer medium special for a solar heat pump and a preparation method thereof, which belong to renewable energy source utilization technology. The heat transfer medium is prepared by mixing, heating and stirring ethylene glycol, ionized water, triethanolamine, sodium dihydrogen phosphate, sodium benzoate, phosphoric acid, tolyltriazole styrene, borax, a defoaming agent, an inhibitor and a color concentrate in different weight ratios. The transfer medium has the characteristics of low freezing point, freeze prevention, high low-temperature flowing property, high boiling point, low evaporation loss, high specific heat, high heat conductivity, less foam, high anti-foam performance, and good anti-rust protection and descaling functions for metal pipelines.

Owner:康树人

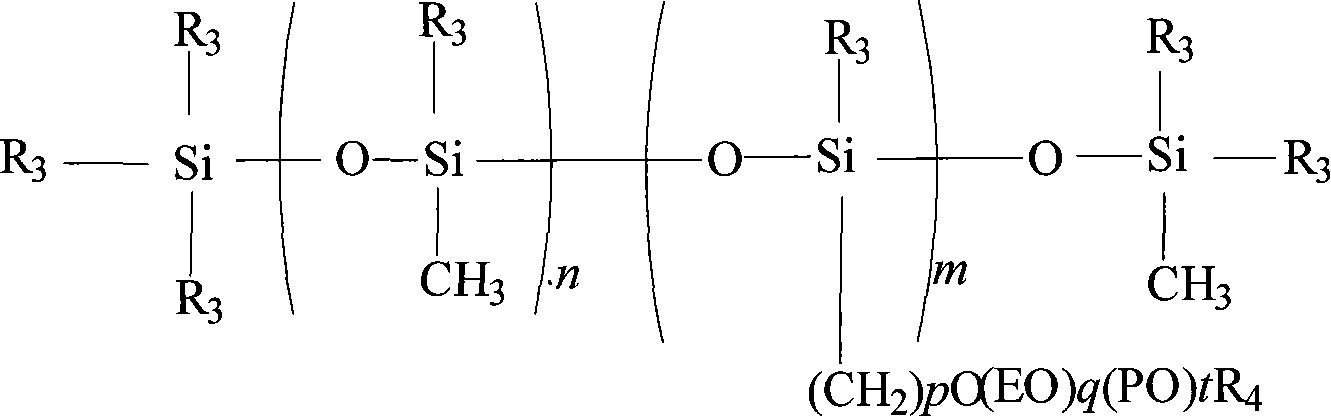

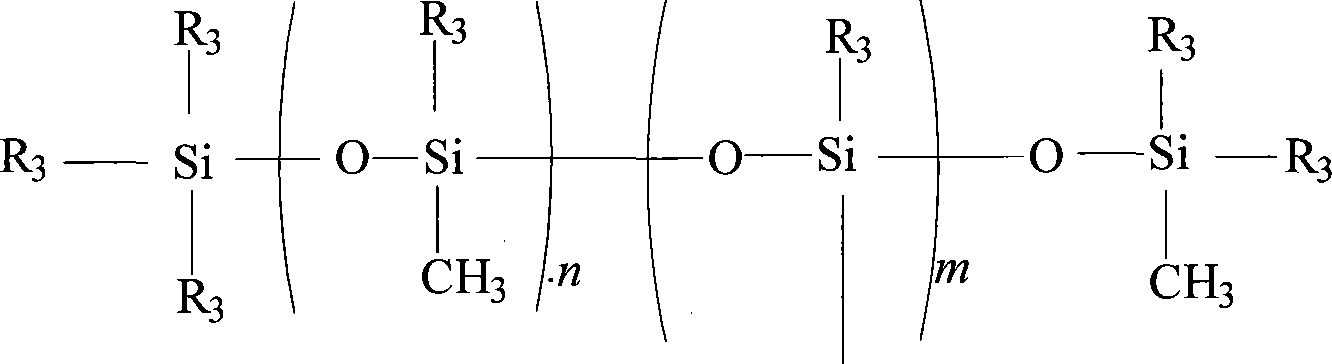

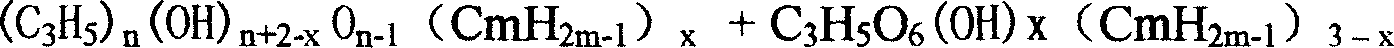

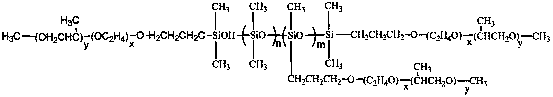

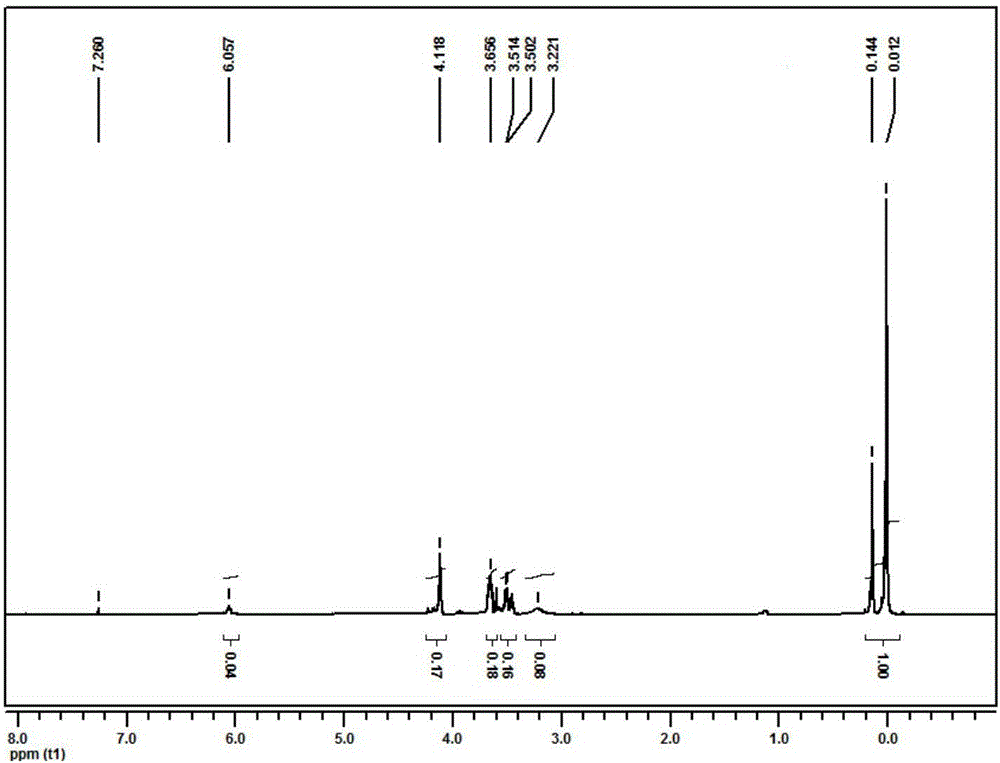

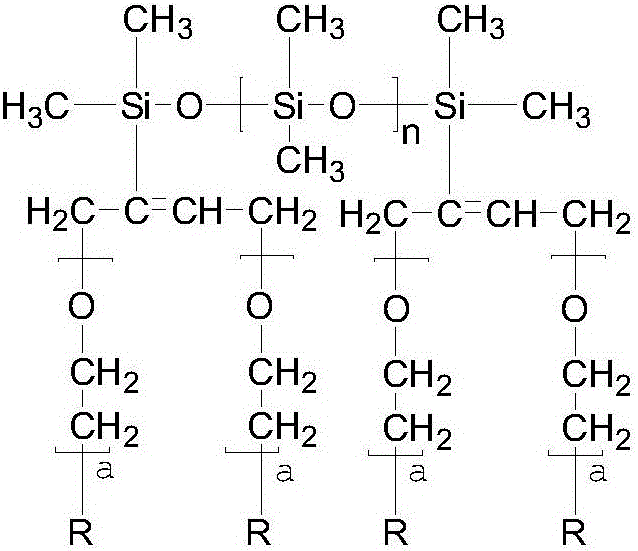

Preparation method of novel polyether modified organic silicon defoamer

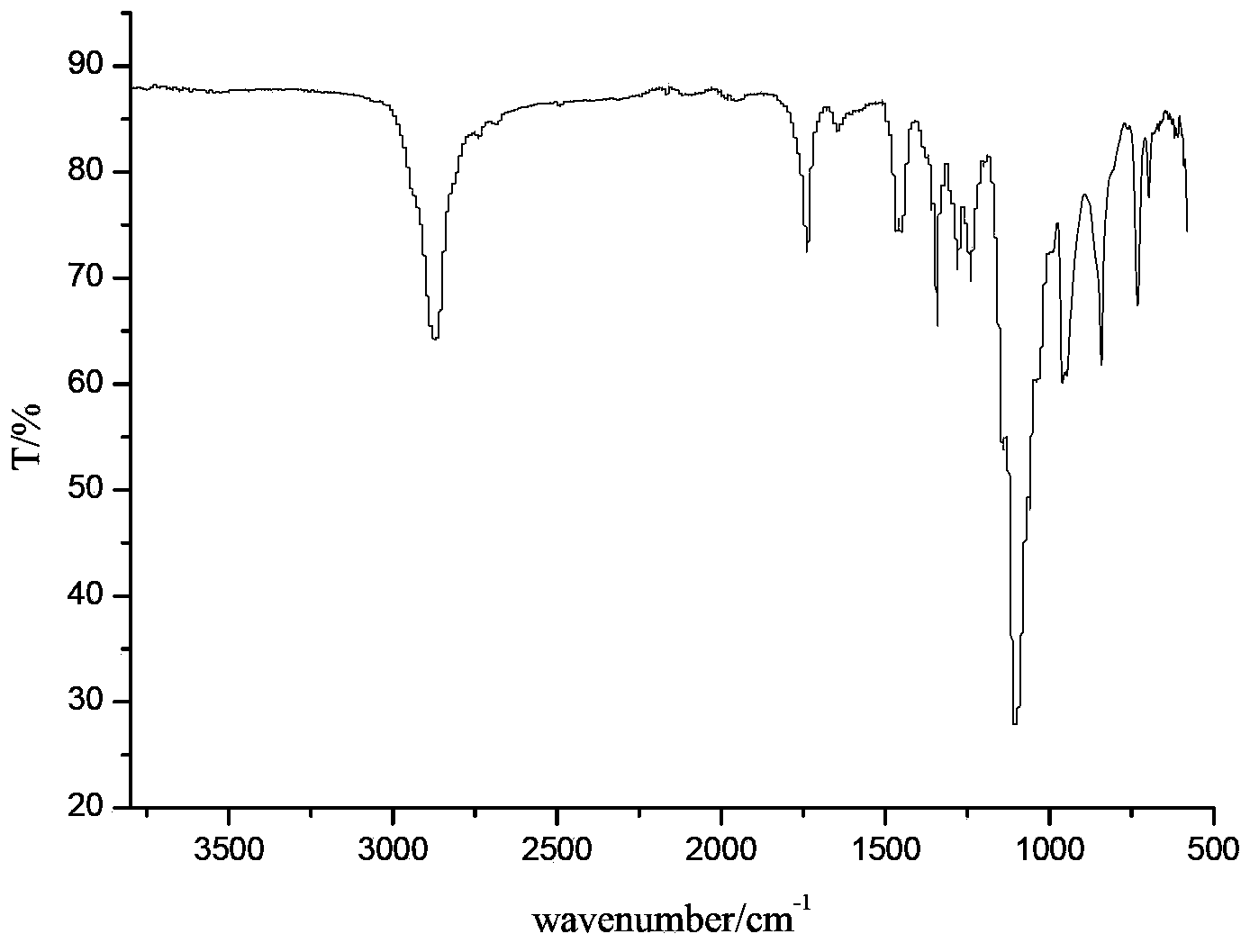

InactiveCN111151033AGood defoaming and anti-foaming propertiesGood dispersionFoam dispersion/preventionSide chainDisiloxane

The invention discloses a preparation method of a novel polyether modified organic silicon defoamer, wherein the method comprises the following steps: S1, preparing double-end and side-chain hydrogen-containing silicone oil by using tetramethyldihydrodisiloxane, octamethylcyclotetrasiloxane and tetramethylcyclotetrasiloxane as raw materials and concentrated sulfuric acid as a catalyst; S2, taking5 parts of the double-end and side-chain hydrogen-containing silicone oil and 1 part of allyl polyether as raw materials, and taking 0.15 part of chloroplatinic acid as a catalyst for grafting to obtain double-end and side-chain polyether modified silicone oil; and S3, mixing the double-end and side-chain polyether modified silicone oil, silicon paste and a compound emulsifier, emulsifying, homogenizing, then adding a thickener, stirring and diluting to obtain the novel polyether modified organic silicon defoamer which is high in foam breaking rate, strong in defoaming capacity, short in defoaming time, resistant to acid and alkali at high temperature, strong in stability and simple in process condition.

Owner:GUANGDONG IND TECHN COLLEGE

Seawater desalination de-foaming agent as well as preparation method and application thereof

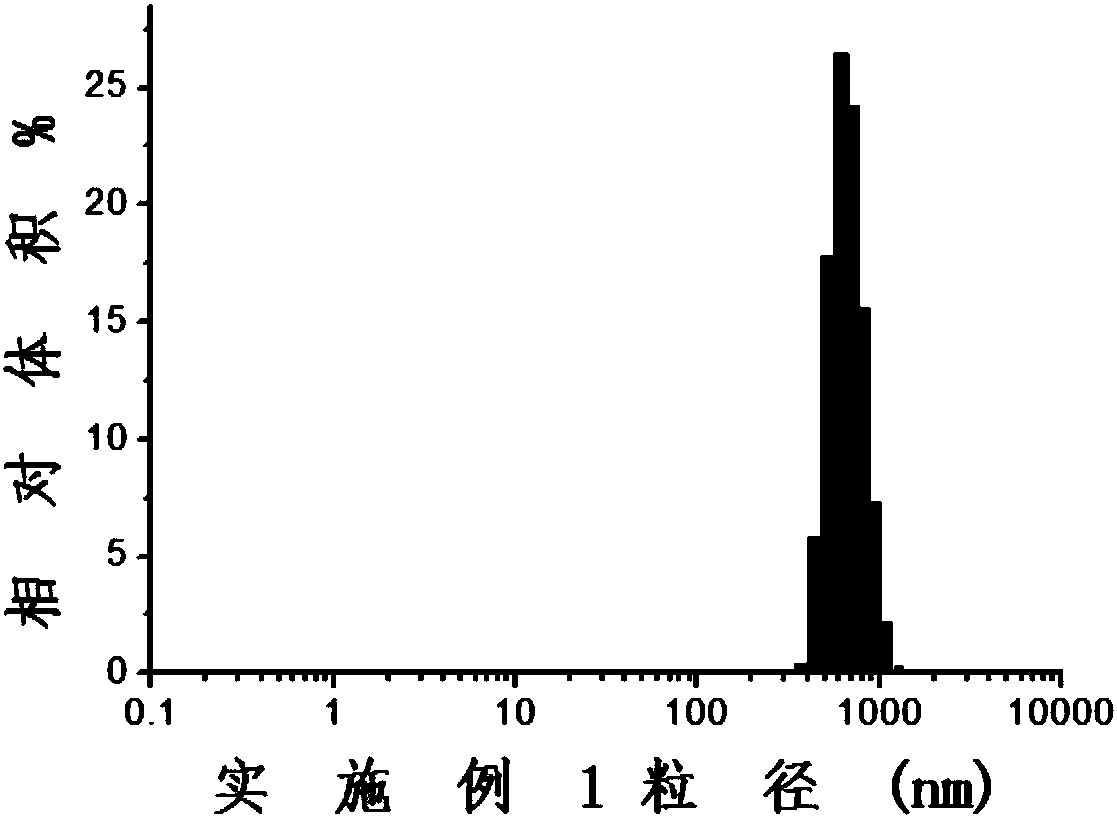

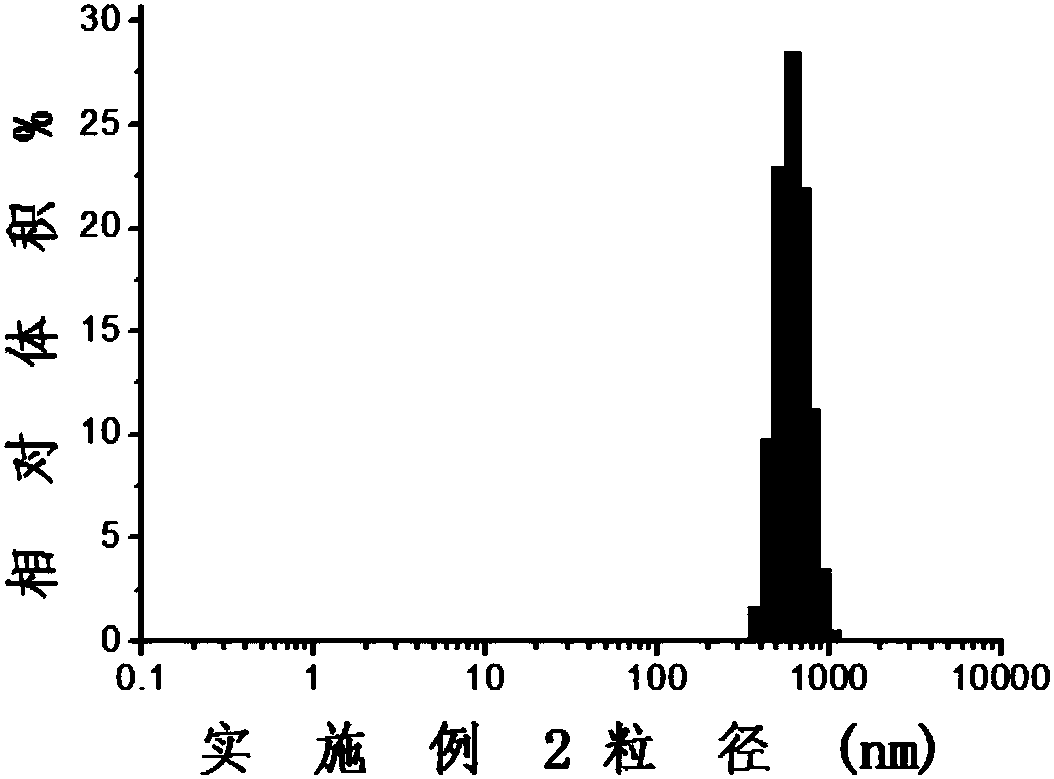

PendingCN108499162ASmall particle sizeGood dispersionSeawater treatmentSpecific water treatment objectivesFoaming agentAqueous solution

The invention relates to a seawater desalination de-foaming agent as well as a preparation method and application thereof. The de-foaming agent is prepared from silicon paste, polyether modified organic silicon, an emulsifier, a thickening agent and water, wherein the mass percent of the silicon paste is 5 to 20 percent, the mass percent of the polyether modified organic silicon is 10 to 30 percent, the mass percent of the emulsifier is 2 to 10 percent and the mass percent of the thickening agent is 0.5 to 2 percent. The preparation method comprises the following steps: (1) weighing the silicon paste, the polyether modified organic silicon and the emulsifier according to the mass percent and mixing at 70 to 80 DEG C to obtain a mixture; (2) preparing the thickening agent into a water solution; (3) injecting 1 / 3 or less of the thickening agent water solution into the mixture of step (1); after uniformly mixing, adding the residual thickening agent water solution in batches to obtain thede-foaming agent. The de-foaming agent provided by the invention has the characteristics of high stability, rapid de-foaming speed, good foam inhibition performance, good compatibility with a scale inhibitor and the like and has good environment-friendly performance and a wide application prospect.

Owner:自然资源部天津海水淡化与综合利用研究所 +1

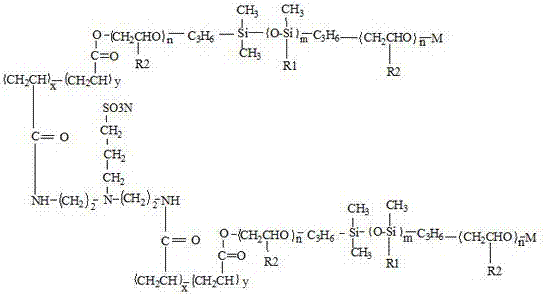

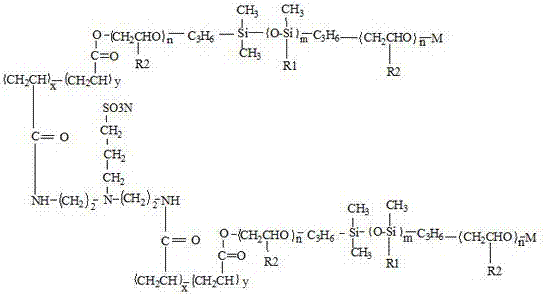

Rosinyl polyoxyethylene amine type gemini surfactant and preparation method thereof

ActiveCN103406066AEnvironmentally friendlyImprove surface activityTransportation and packagingMixingPolyoxyethyleneamineStructural formula

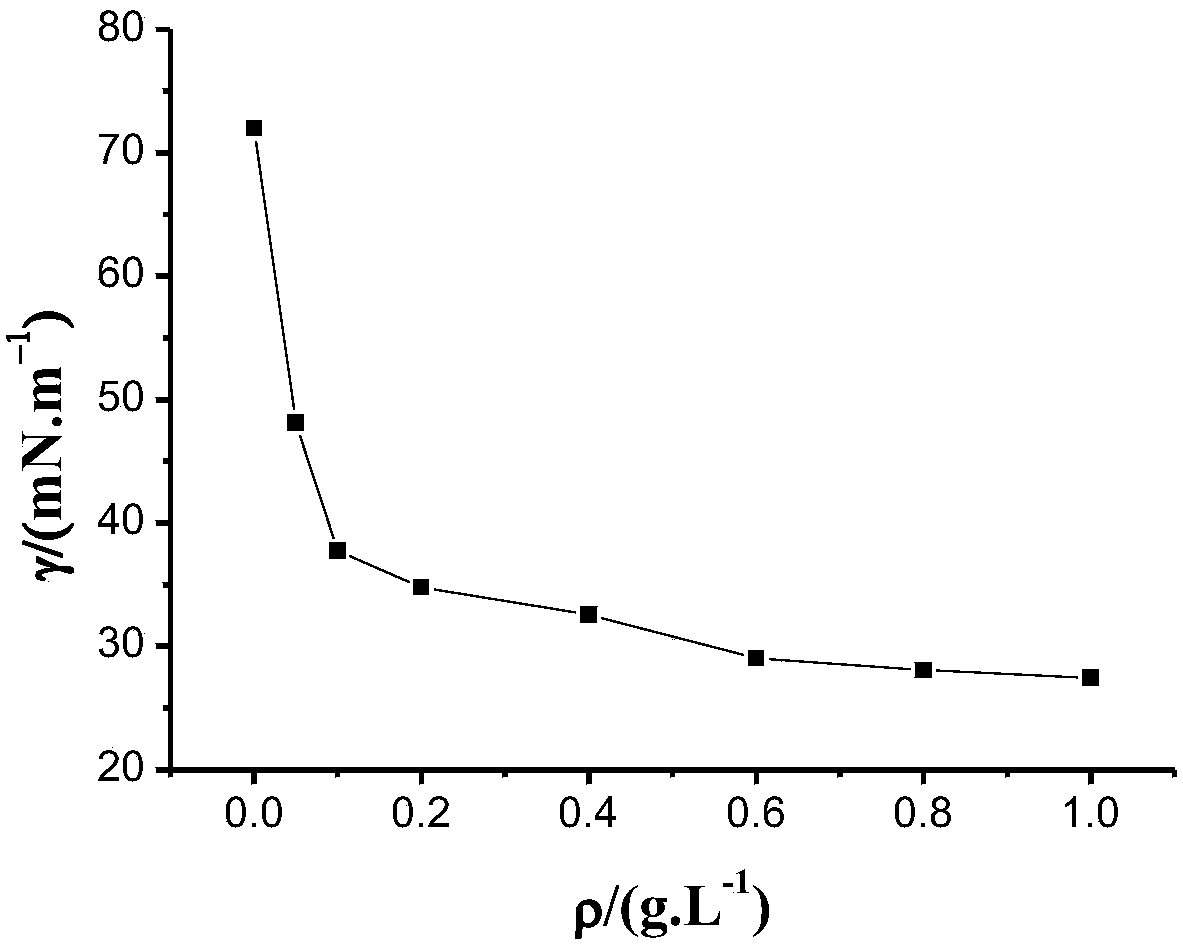

The invention discloses a rosinyl polyoxyethylene amine type gemini surfactant. The molecular structural formula of the gemini surfactant is shown in the specification, wherein the MPEG is ethylene glycol monomethyl ether. The gemini surfactant provided by the invention has the advantages that the surface activity, foam inhibition capacity and emulsibility are high, the critical micelle concentration (CMC) is 10<-3> to 10<-4> order of magnitudes, the surface tension (Gamma cmc) is 20-30 mN / m, and the foam inhibition capacity and emulsibility are both superior to those of nonylphenol ethoxylates TX-10 which is a commercial surfactant. According to a preparation method of the gemini surfactant, provided by the invention, rosin is taken as raw material, wherein the rosin is an abundant natural renewable resource, is environmental-friendly, and can meet the requirements of raw material greening in preparing the gemini surfactant. The preparation method is simple and easy to operate.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of organic silicon defoamer with high stability

InactiveCN106215466AImprove stabilityImprove durabilityFoam dispersion/preventionChemical industryEmulsion

The invention relates to a defoaming and foam inhibiting product for chemical industry, in particular to a preparation method of an organic silicon defoamer with high stability. The organic silicon defoamer is prepared from an organic silicon composition A, polyether-modified polysiloxane B, an emulsifier C, a coupling agent D, a thickener E and water, wherein the coupling agent D is selected from vinyl trimethoxy silane and vinyltriethoxysilane. The preparation method comprises the steps that the organic silicon composition A, polyether-modified polysiloxane B and the emulsifier C are mixed, and then heating stirring is conducted; the temperature keeps invariable, 30%-60% of water and 70%-90% of the thickener E are added while stirring is conducted, and the pH is regulated; the emulsion passes through a colloid mill, the coupling agent D is added, and stirring is conducted; dilution is conducted with the remaining thickener E and the remaining water, and the defoamer is obtained. According to the defoamer emusion product, the emulsion stability is significantly improved, so that the defoamer achieves the good stability under the extreme conditions such as strong acid and strong alkali, the durability of the defoamer is improved, and meanwhile the defoamer is not prone to be separated out.

Owner:合肥普庆新材料科技有限公司

Organosilicon antifoaming agent and preparation method thereof

InactiveCN108905306ALower surface energyGood defoamingFoam dispersion/preventionSolubilityAdditive ingredient

The invention provides an organosilicon antifoaming agent, which comprises the following ingredients (1000 parts by weight): 50-500 parts of poly[trifluoropropyl(methyl)siloxane], 0-100 parts of polydimethylsiloxane, 3-15 parts of white carbon black, 5-15 parts of an emulsifier, and the balance water. The organosilicon antifoaming agent is prepared by the following specific steps: mixing an organosilicon antifoaming component and white carbon black to obtain a silicon paste; and preparing an organosilicon antifoaming agent emulsion from the silicon paste, the emulsifier and water. The poly[trifluoropropyl(methyl)siloxane] has lower surface energy. Thus, in comparison with a regular antifoaming agent prepared from methylsilicone oil, the product has the following beneficial effects: with the addition of poly[trifluoropropyl(methyl)siloxane], surface tension of the antifoaming system is reduced, and defoaming and foam inhibition functions of the antifoaming agent are enhanced. As methylsilicone oil has certain dissolvability in an oil phase, the antifoaming agent is not easy to dissolve in the oil phase system with the addition of fluoroalkyl, and the use system range of the organosilicon antifoaming agent is broadened.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Polyether defoamer

The invention relates to a polyether defoamer suitable for papermaking processes such as pulping, papermaking, coating and the like. The polyether defoamer is prepared from the following compositions:polyglycol ether, epoxy ethane, butyl alcohol, lecithin and magnesium hydroxide of which the weight ratio is 80-160:60-120:20-50:30-65:40-70. The polyether defoamer has good defoaming capacity and foam inhibiting capacity, and strong emulsifying, dispersing and permeating capacities, can be self-emulsified in a water system, has lasting defoaming effect, no toxicity, cheap price, and no side effect on the cohesiveness, dispersity and printing adaptability of coatings, and can improve the glossiness, picking speed and lubricating performance of paper.

Owner:尹玉娟

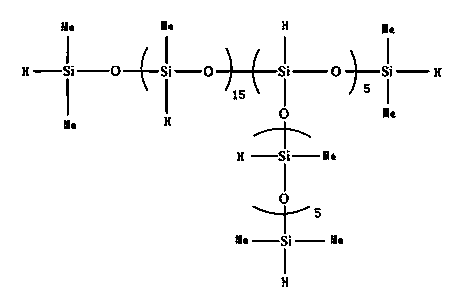

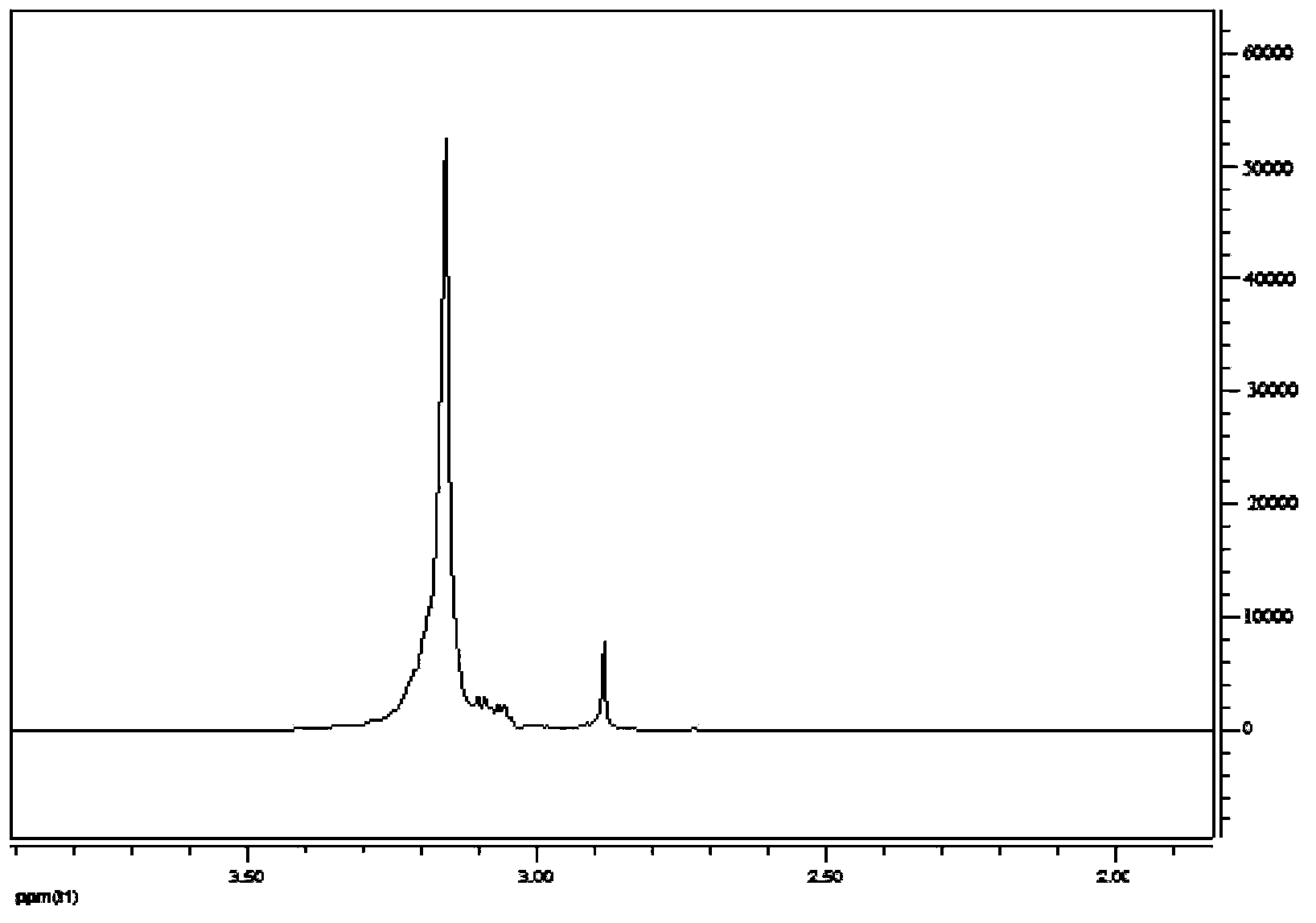

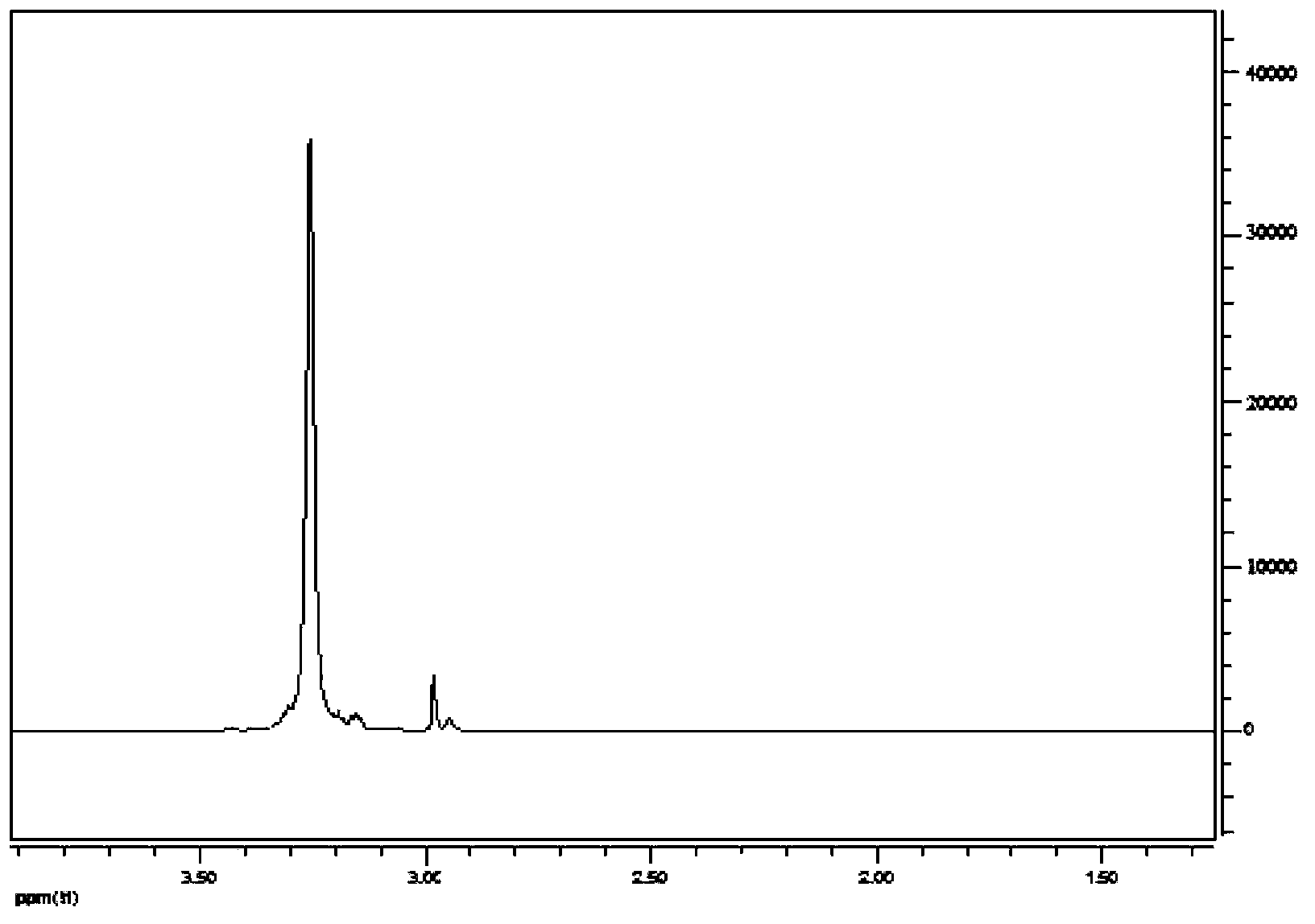

Butynediol ethoxylate modified bola type organosiloxane and preparation method thereof

The invention discloses butynediol ethoxylate modified bola type organosiloxane and a preparation method thereof. The preparation method includes: butynediol ethoxylate and tetramethyl dihydro disiloxane have reaction under the effects of a platinum catalyst and an amine composite catalyst to obtain butynediol ethoxylate modified tetramethyl disiloxane; balanced copolymerization is performed under the effect of a catalyst to obtain the butynediol ethoxylate modified bola type organosiloxane. The preparation method has the advantages that the method is large in grafted hydrophilic group proportion, high in grafting rate, free of solvent adding and suitable for large-scale industrial production; the prepared hydrophilic group butynediol ethoxylate modified bola type organosiloxane is good in water solubility, good in wetting and spreading ability, high in surface activity and high in defoaming / foam inhibiting performance.

Owner:CHINA RES INST OF DAILY CHEM IND

Method for improving foam suppression performance of organosilicone emulsion

ActiveCN102716600AGood anti-foam performanceImprove stabilityFoam dispersion/preventionPolyesterChemical reaction

The invention discloses a method for improving the foam suppression performance of organosilicone emulsion. The method is characterized by comprising the following steps: adding hydrophilic white carbon black into silicon polyester during preparation; and uniformly dispersing the hydrophilic white carbon black into the silicon polyester through chemical reaction, wherein the viscosity of the silicon polyester is increased, and the surface tension of the partial region of a bimolecular membrane layer of the silicon polyester is unstable because of solid particles, so that the bimolecular membrane layer is cracked; and therefore, the foaming capacity of the silicon polyester is reduced. The stability and foam suppression performance of an organosilicone emulsion defoamer prepared by the modified silicon polyester are remarkably improved.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Application of glycidyl terminated polyether in defoamer

InactiveCN101811007ALow foam heightGood anti-foam performanceTransportation and packagingMixingDefoamerPrinting ink

The invention provides application of glycidyl terminated polyether in a defoamer, and the defoamer is characterized by being prepared from the glycidyl terminated polyether shown as formula (II), wherein R1 in the formula (II) is C4-C11 alkyl, n is equal to 0-20 and m is equal to 0-20. The defoamer prepared from the glycidyl terminated polyether and used for water-based paint, water-based printing ink, polyacrylic acid size and the like has the property of producing no shrinkage cavity, strengthening dafoaming capability and lasting anti-foaming.

Owner:广东省石油化工研究院

Detergent for metal

InactiveUS20120316097A1Excellent corrosion inhibition propertyExcellent liquid stabilityOrganic detergent compounding agentsAnionic surface-active compoundsCorrosionNonionic surfactant

A detergent composition for metal according to the present invention contains a specific non-ionic surfactant, a specific nitrogen-containing organic compound, a specific carboxylic acid or salt thereof, and a specific alkanol amine, and has a pH of at least 9 that is measured at 25° C. when the detergent composition is diluted to 1% by mass of an aqueous solution. According to the present invention, the detergent composition for metal having excellent corrosion inhibition properties, excellent effluent treatment properties, excellent foaming suppressing properties and excellent liquid stability in addition to high detergent properties for metal, can be provided.

Owner:LION SPECIALTY CHEM

Hyperbranched polyether modified organosilicon defoaming agent with lasting foam inhibiting effect and preparation method thereof

InactiveCN106310727AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionCelluloseEpoxy

The invention discloses a hyperbranched polyether modified organosilicon defoaming agent with a lasting foam inhibiting effect, composed of the following raw materials in parts by weight: 28-45 partsof polysiloxane, 16-26partsof hyperbranched polyether, 20-28 partsof allyl glycidyl ether, 45-60 partsof epoxy propane, 0.3-0.7 partof bimetal cyanide complex, 50-70 partsof isopropanol, 0.3-0.7 partof chloro-platinic acid catalyst, 3-7 partsof superfine aluminum silicate, 1-2partsof sorbitol, 1-2 partsof tween 60, 2-4 partsof sodium cellulose glycolate, an appropriate amount of de-ionized water, 4-10 partsof white carbon black, 1-2 partsof methyl triethoxy silane, 0.5-1partof ammonium carbonate and 0.6-2 partsof potassium hydroxide. The hyperbranched polyether modified organosilicon defoaming agent takes the hyperbranched polyether containing a large quantity of hydroxyl groups at the terminals as a raw material to prepare allyl-terminated hyperbranched polyether, and a polyether terminal modified double bond structure is used to generate silicon hydrogen addition reaction with the polysiloxane to synthesize hyperbranched polyether modified polysiloxane, and the defoaming agent has excellent shear resistant performance.

Owner:合肥新万成环保科技有限公司

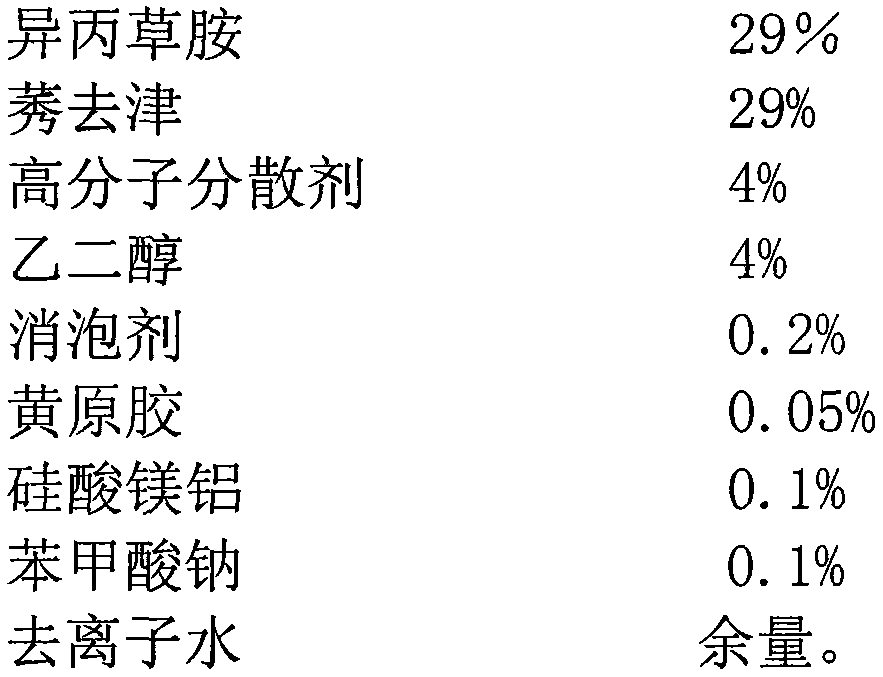

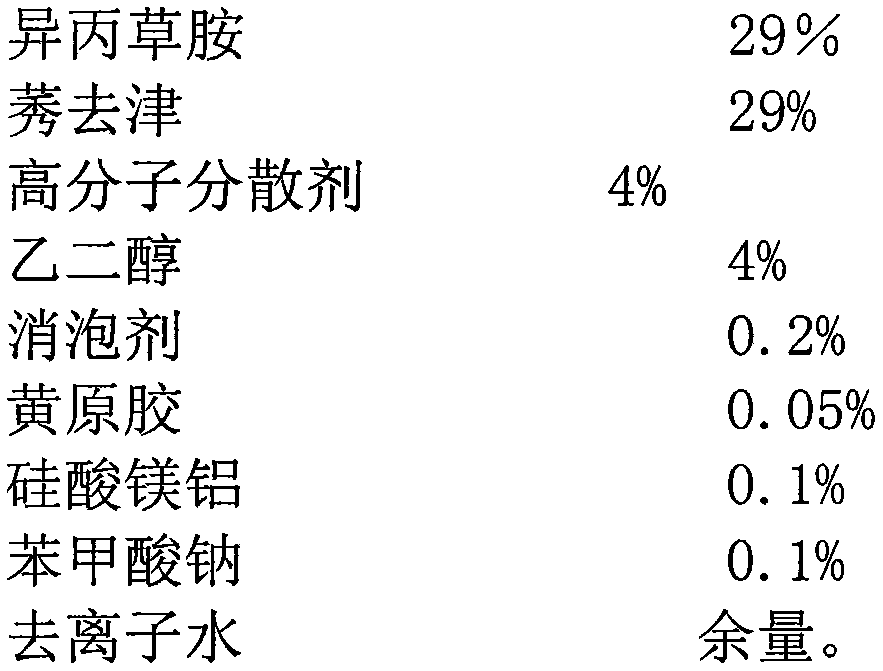

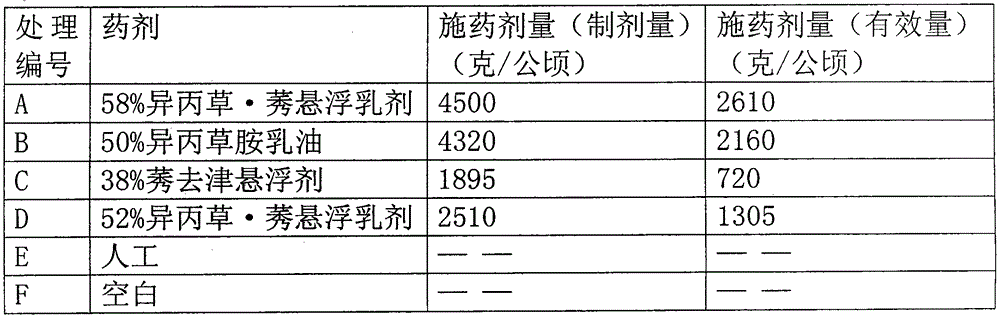

Herbicide composition containing propisochlor and atrazine and preparation method thereof

InactiveCN104982431AIncrease contentImprove weed control effectBiocideAnimal repellantsSodium benzoateXanthan gum

The invention provides a polymeric dispersant which comprises a block polymer of methyl methacrylate, butyl acrylate and acrylamide. A herbicide composition which is prepared from the polymeric dispersant and contains propisochlor and atrazine and a preparation method thereof are provided. The herbicide composition comprises, by weight, 29% of the propisochlor, 29% of the atrazine, 4% of the polymeric dispersant, 4% of ethanediol, 0.2% of defoamer, 0.05% of xanthan gum, 0.1% of aluminium-magnesium silicate, 0.1% of sodium benzoate and the balance deionized water. The herbicide composition containing the propisochlor and the atrazine and the preparation method thereof have the advantages of being high in content and good in weeding effect.

Owner:天津市华宇农药有限公司

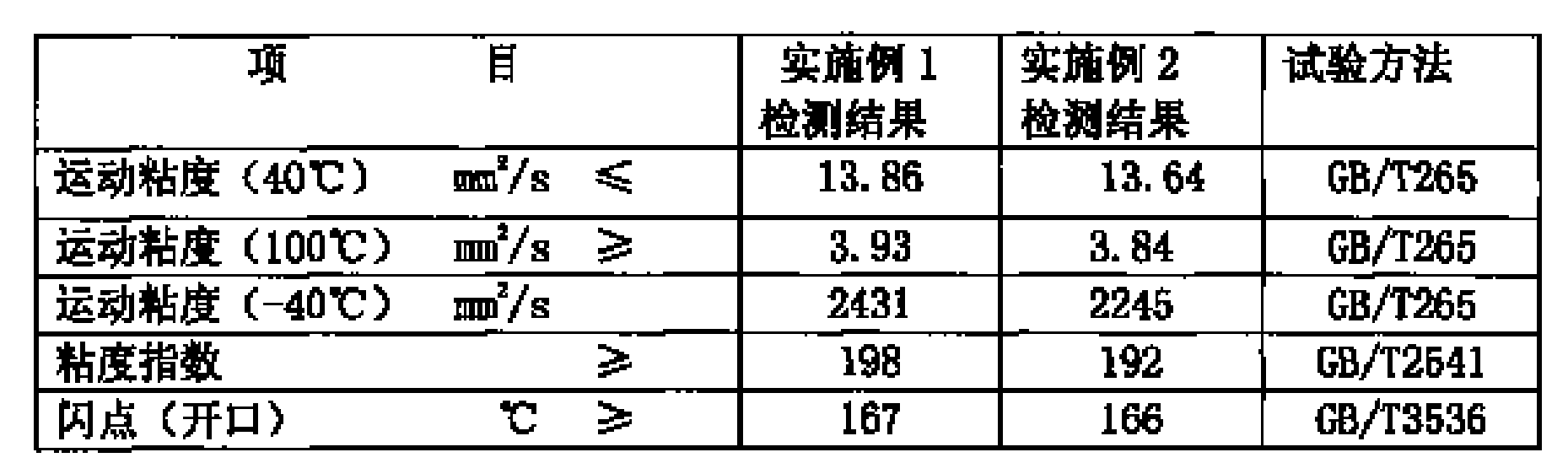

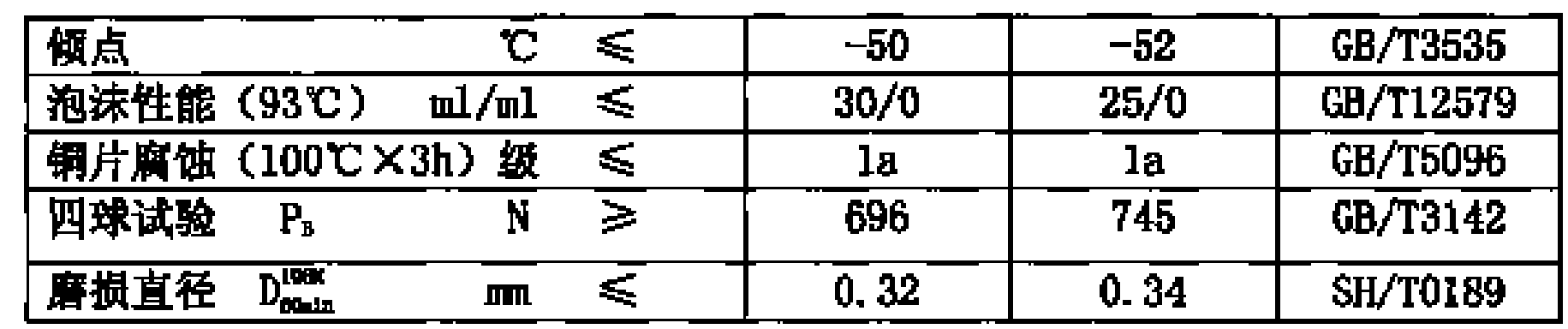

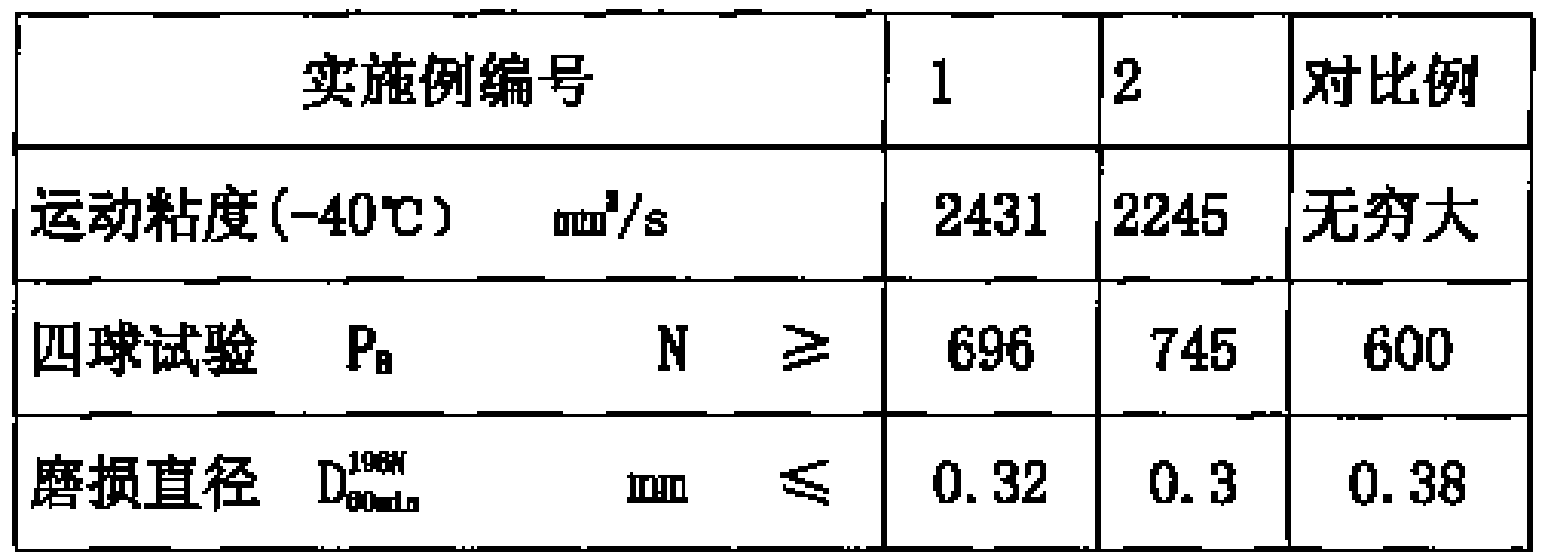

Shock absorber oil

ActiveCN101486944AImprove low temperature performanceImprove wear resistanceAdditivesSulfateTricresyl phosphate

The invention discloses oscillating damper oil; the components and contents include: 0.2 to 5.0 percent of antiwear agent, 2 to 25ppm of polymethylphenyl siloxane fluid, 0.1 to 1.0 percent of polymethyl methacrylate, 0.1 to 0.6 percent of N-octadecylamine oleyl sarcosinate, 0.5 to 4.0 percent of polyisobutylene (PB2400), and the balance of base oil; the antiwear agent consists of triphenyl phosphate sulfate and tricresyl phosphate. The oscillating damper oil has excellent properties and prominent low-temperature performance and wear-resistance performance.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com