Solid particle foam inhibitor and preparation method thereof

A technology of solid particles and anti-foaming agents, applied in the direction of foam dispersion/prevention, etc., can solve problems such as poor compatibility, affecting the performance of foaming systems, and environmental pollution of solid defoaming agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] 1. Preparation of main defoaming substances

[0022] Prepared according to the method of Example 1 and Example 2 of patent ZL200610040821.3, the obtained antifoaming active substances are high-viscosity silicone grease mixture AG and high-viscosity silicone grease mixture BG respectively.

[0023] Prepared according to the method of example 1 and example 2 in patent ZL200410066187.1, the obtained defoaming actives are low viscosity silicone grease mixture AD and low viscosity silicone grease mixture BD respectively.

[0024] 2, preparation embodiment solid particle antifoaming agent

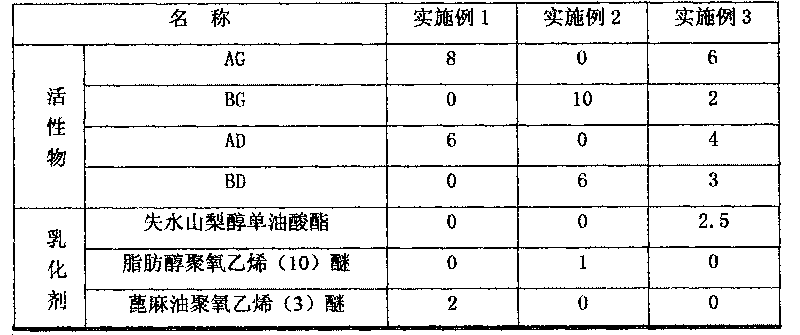

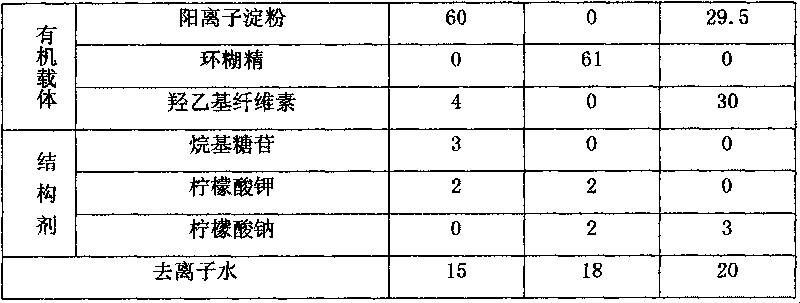

[0025] The ratio between each constituent material of specific embodiment sees the following table:

[0026] Table 1 The proportion of each component of the solid particle antifoaming agent (mass percentage, %)

[0027]

[0028]

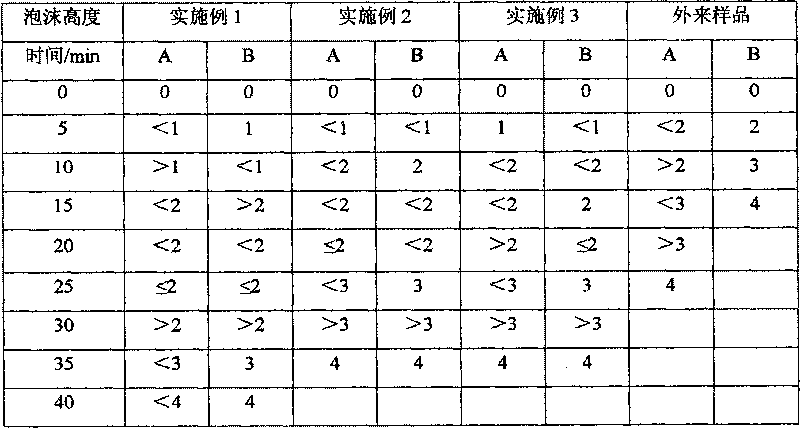

[0029] Each component in the above table was prepared respectively according to the aforementioned preparation method of the present invention as solid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com