Patents

Literature

3419 results about "Textile dye" patented technology

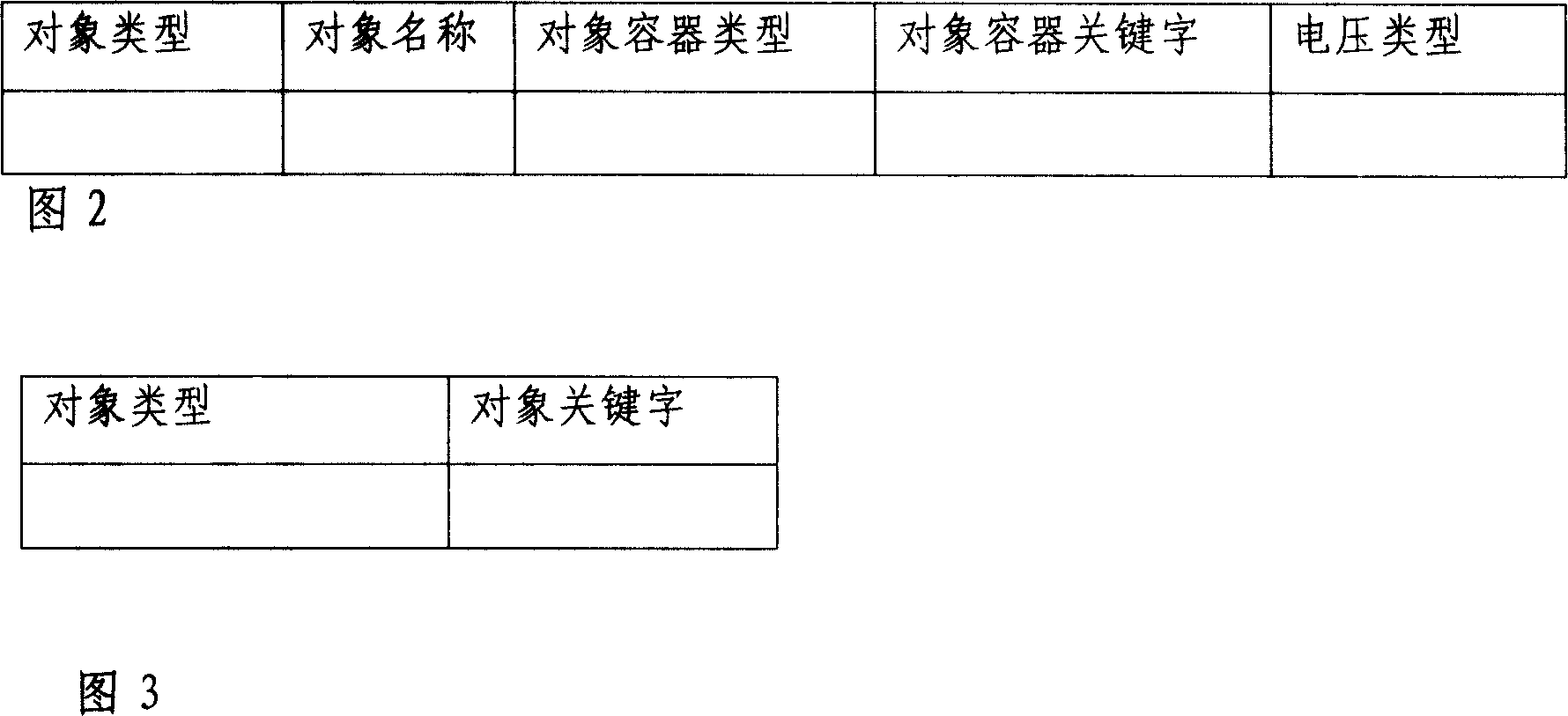

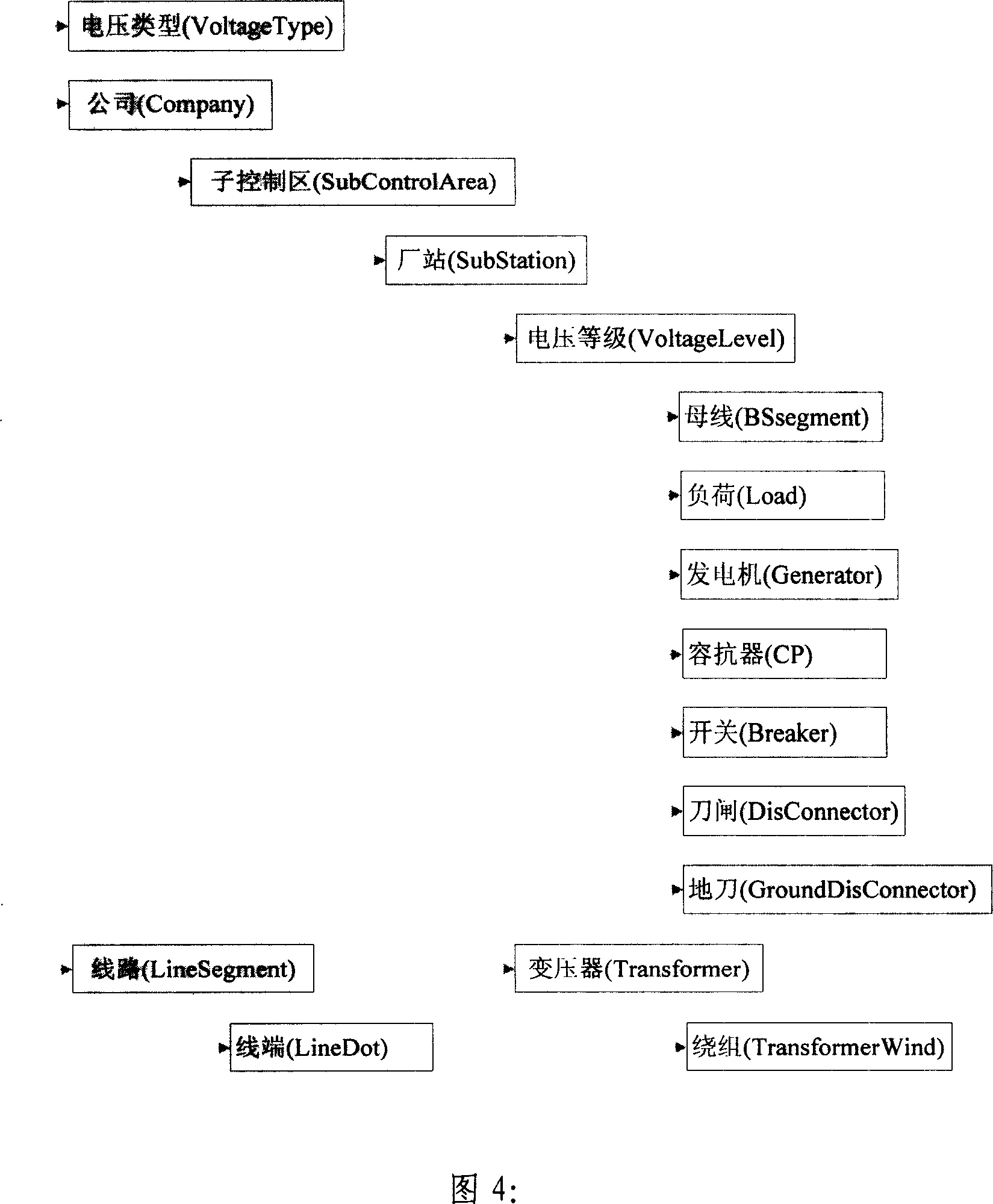

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing is the process of adding color to textile products like fibers, yarns, and fabrics. Dyeing is normally done in a special solution containing dyes and particular chemical material.

Microcapsules of essential oil from fragrant plants and preparation thereof

InactiveCN1680519AEasy to useEasy to storeEssential-oils/perfumesMicroballoon preparationOil phaseAromatic plants

The invention opened a process to produce the micro-capsule of aromatic plant essential oil. The micro-capsule is made up of aromatic plant essential oil and capsule material. The particle size is 10-30um; the process is: first to dissolve the capsule material, then to dissolve the surface activator in the water phase or the oil phase, next to stir to get the latex emulsion, last to get the product by the spray drier. The product can be used to food, medicine, cosmetic, printing and dyeing and coatings.

Owner:新疆芳香植物科技开发股份有限公司 +1

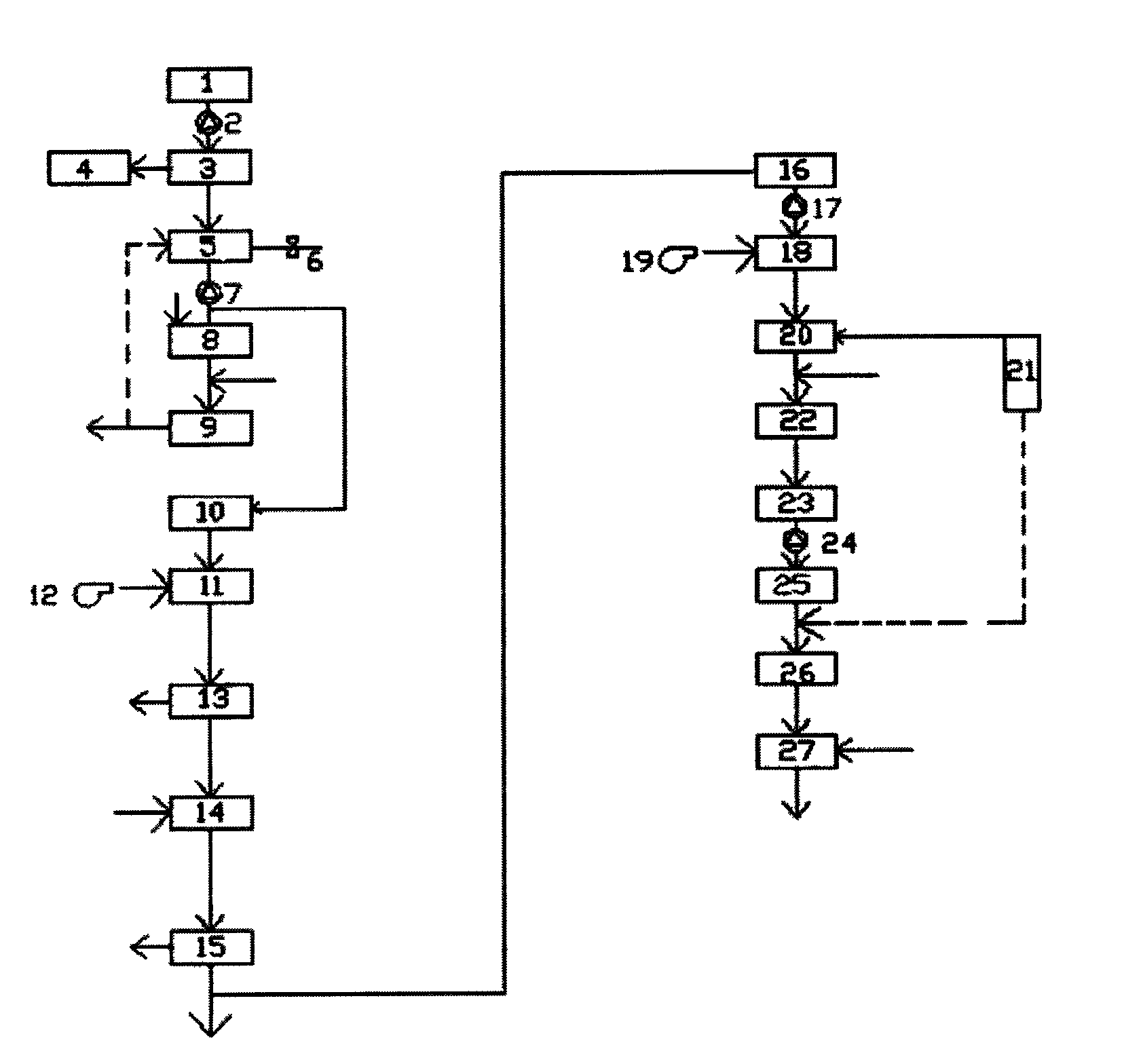

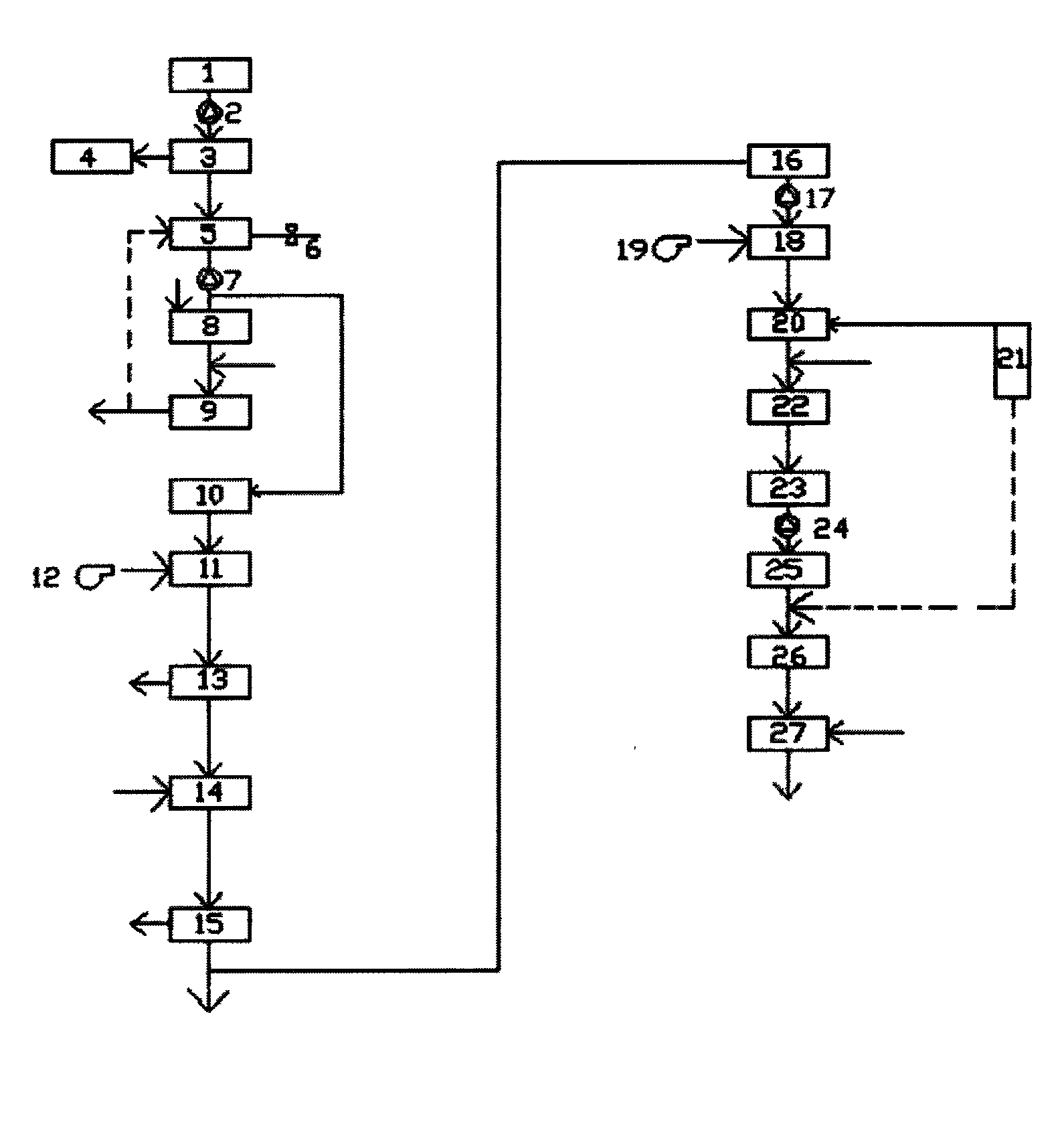

Textile dyeing wastewater advanced treatment recycling technology

InactiveCN102145965AReduce chromaImproved BioprocessingMultistage water/sewage treatmentWater/sewage treatment by neutralisationTextile fiberChemical treatment

The invention discloses a textile dyeing wastewater advanced treatment recycling technology. The technology comprises the following steps: filtering to remove textile fibers; cooling; neutralizing, degrading organic matters and decomposing, replacing or degrading (cracking) the chormophoric groups of the organic matters to reduce the chroma of the wastewater; performing biochemical treatment with the biomembrane; precipitating to ensure that the precipitated sludge enters a sludge treatment system and the supernatant enters a flocculation pool; performing chemical treatment, namely adding a medicament in the flocculation pool to remove the suspended matter (SS), CODcr (chemical oxygen demand), BOD (biochemical oxygen demand) and chroma of the water; performing secondary precipitation to ensure that the free SS is precipitated and the wastewater is decolored further; separating to remove and degrade the chloride ions of the reuse water; performing secondary biochemical treatment to further reduce the concentrations of the SS, CODcr and BOD in wastewater; performing ozone oxidation treatment, decoloring, degrading organic matters; performing chemical treatment to remove insoluble dye materials and SS and reduce the COD and chroma; and performing secondary filtration, and forming an ozone / activated carbon system to ensure that the hydroxyl radicals of activated carbon are used and the organic reaction in wastewater is adopted to decolor and degrade organic matters. The invention overcomes the defects of the existing physical method, chemical method and chemical method treatment technologies; and the technology has been used in many enterprises, and the good treatment effects are obtained.

Owner:李斌 +2

Ultraviolet light curing printing ink for digital printing and dyeing preparation thereof

UV solidified printing ink for digital code printing and dyeing is composed of polyurethane acrylate, prepolymer, activity monomer, dyestuff, light initiator, dispersant agent and other addition agents. The prepolymer has the character of low viscosity and good flexibility. The ink doesn't contain organic solvent and has wide material adaptation, storage stability and softness.

Owner:DONGHUA UNIV

Method of manufacturing color filters and liquid crystal display device using these color filters

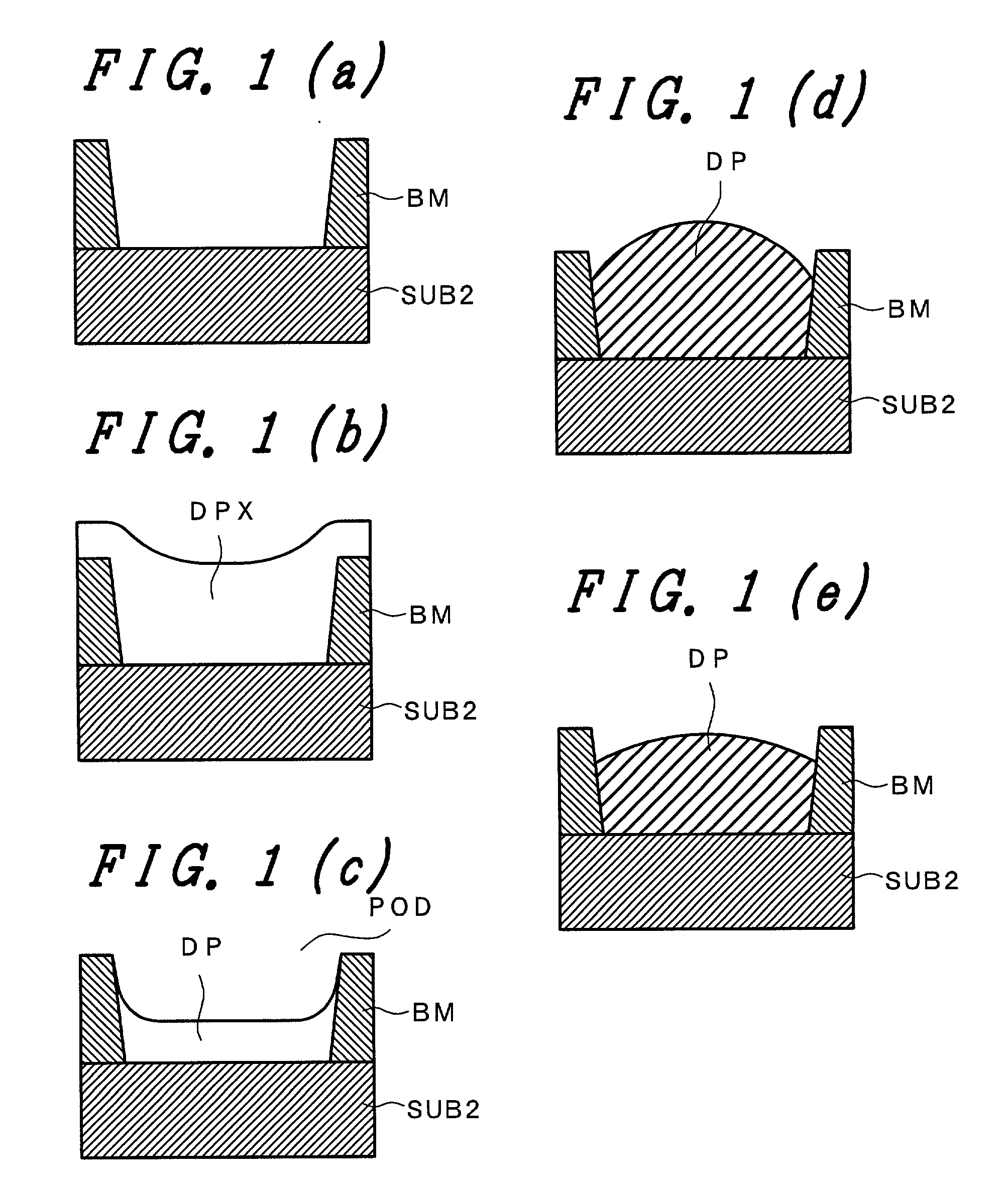

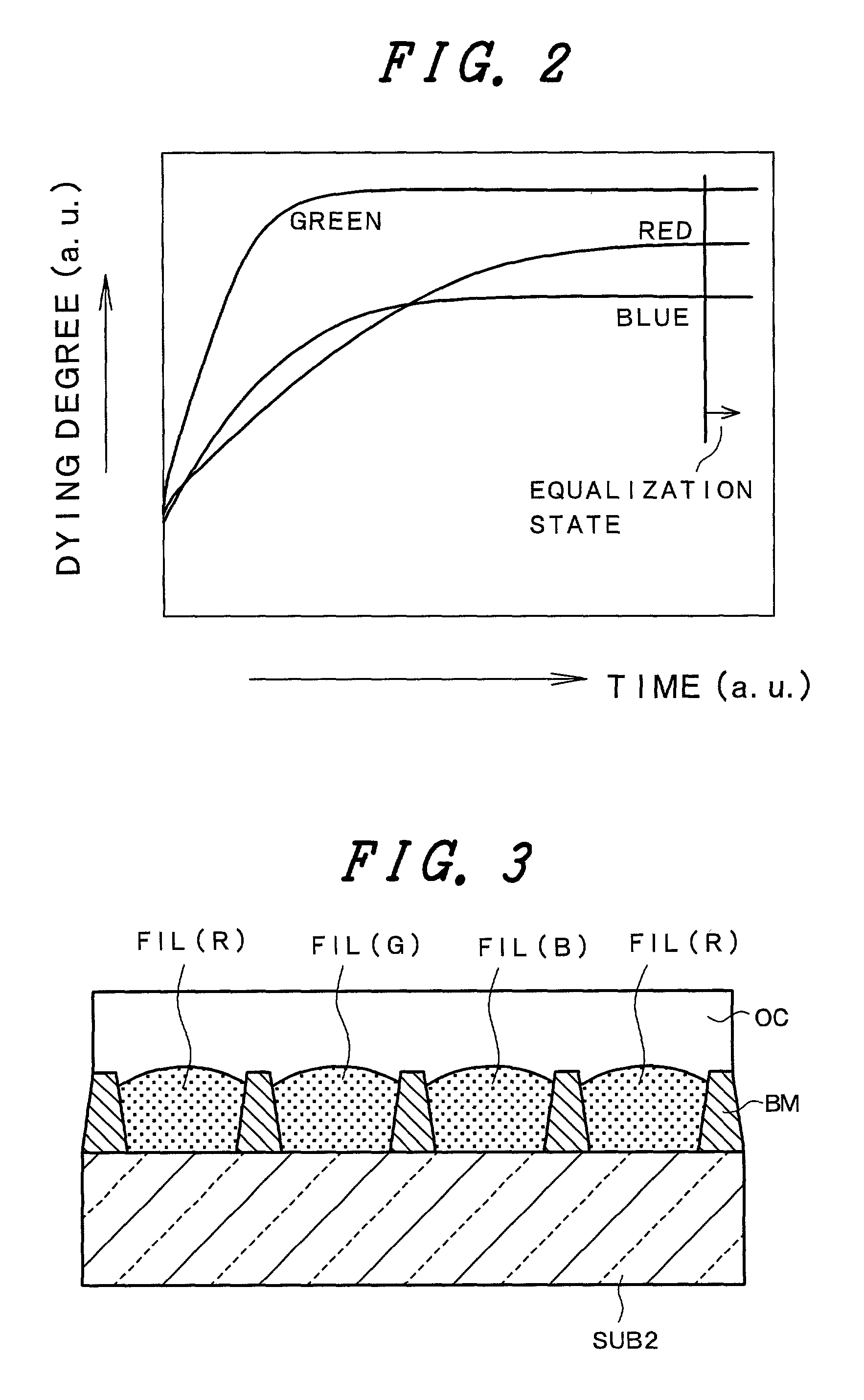

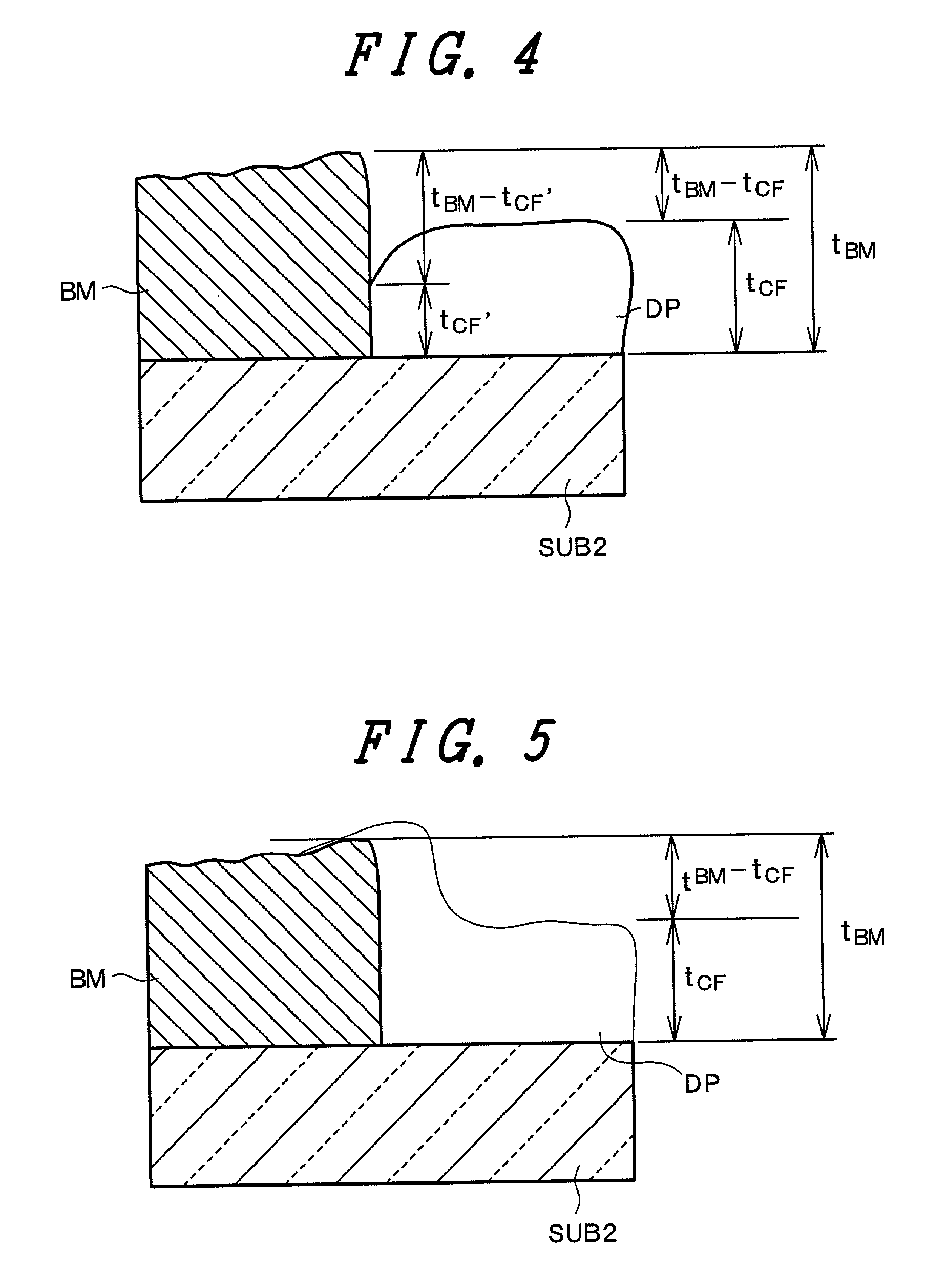

InactiveUS20010007733A1Improve flatnessImprove display qualityOptical filtersTypewritersUltravioletEngineering

After forming a black matrix which defines pixel regions on a substrate, dyed substrate layers of photo hardening property are formed. By irradiating ultraviolet rays to the dyed substrate layers from the back of the substrate and by developing, ink reservoirs which use the black matrix as partition walls are formed. The dyeing material such as the dye is supplied to these ink reservoirs by an ink jet system. Due to these partition walls, there is no possibility that the dyeing material scatters to the neighboring or adjacent pixel regions to cause the mixed color. Further, since the filters having a sufficient thickness can be formed in the ink reservoirs, the surface flatness of the color filters can be sufficiently ensured without coating the thick overcoat layer.

Owner:HITACHI LTD +1

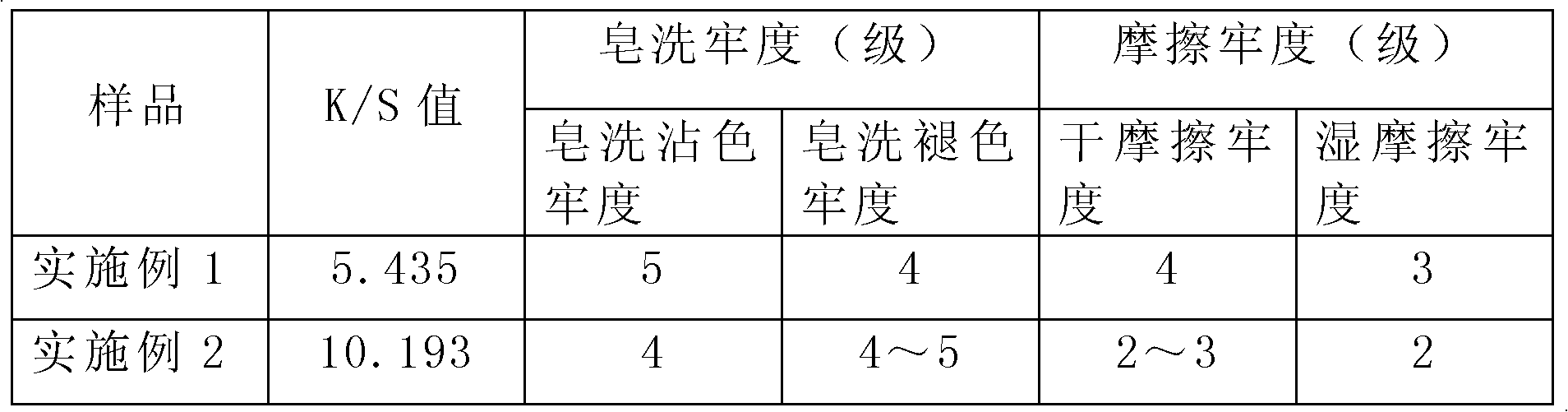

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

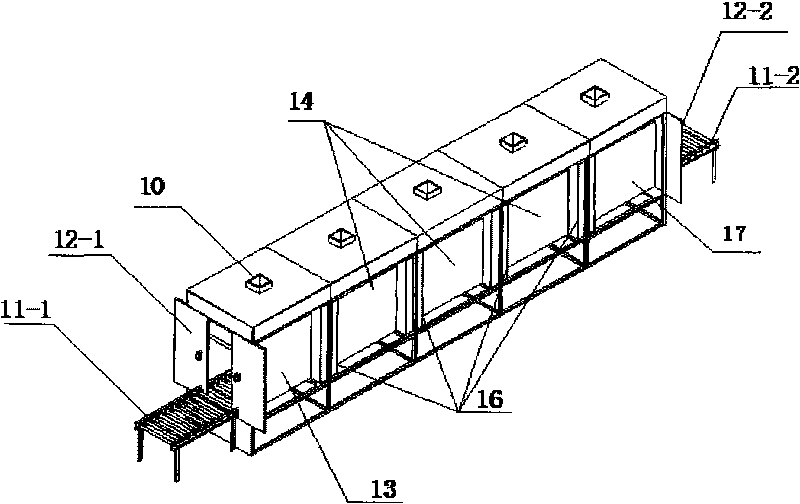

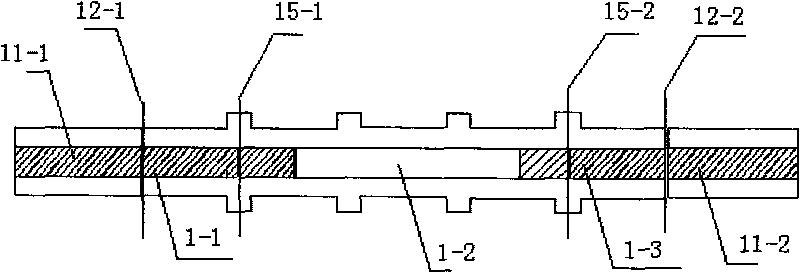

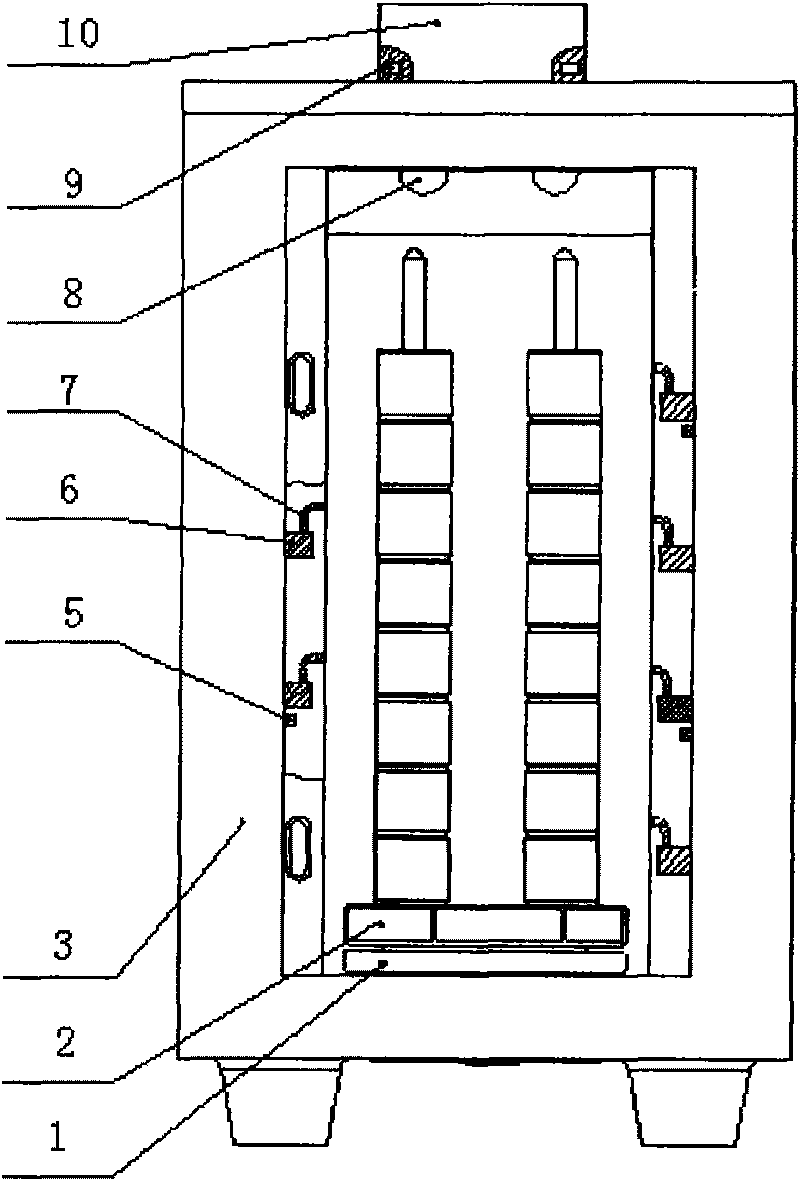

Device for drying fabric and method

ActiveCN101726165ADry evenlyControlled dryingDrying solid materials with heatDrying chambers/containersYarnProduction line

The invention discloses a device for drying fabric and a method, belonging to the field of drying the fabric. The device comprises a roller way, a drying support pan, a box body part, an on-line detection system and a PLC control system. The box body part comprises a plurality of heating boxes, the drying power of which are gradually reduced; the heating boxes are communicated with each other; and the inner walls of the heating boxes are provided with magnetic control pipes. The method comprises the steps of: leading the fabric to sequentially pass through the heating boxes with the function of microwave drying, and the drying power of the heating boxes are gradually reduced according to the pass sequence of the fabric. By adopting the technology of microwave drying, the device has high efficiency; is even, energy-saving and environment-friendly; can controllably dry the fabric; has high automation; can gradually and continuously dry the fabric by leading the fabric to sequentially pass through the heating boxes, the drying power of which are gradually reduced; leads the dried fabric to be evenly dried and have good quality; and is suitable for an unmanned automatic yarn dyeing and finishing production line.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

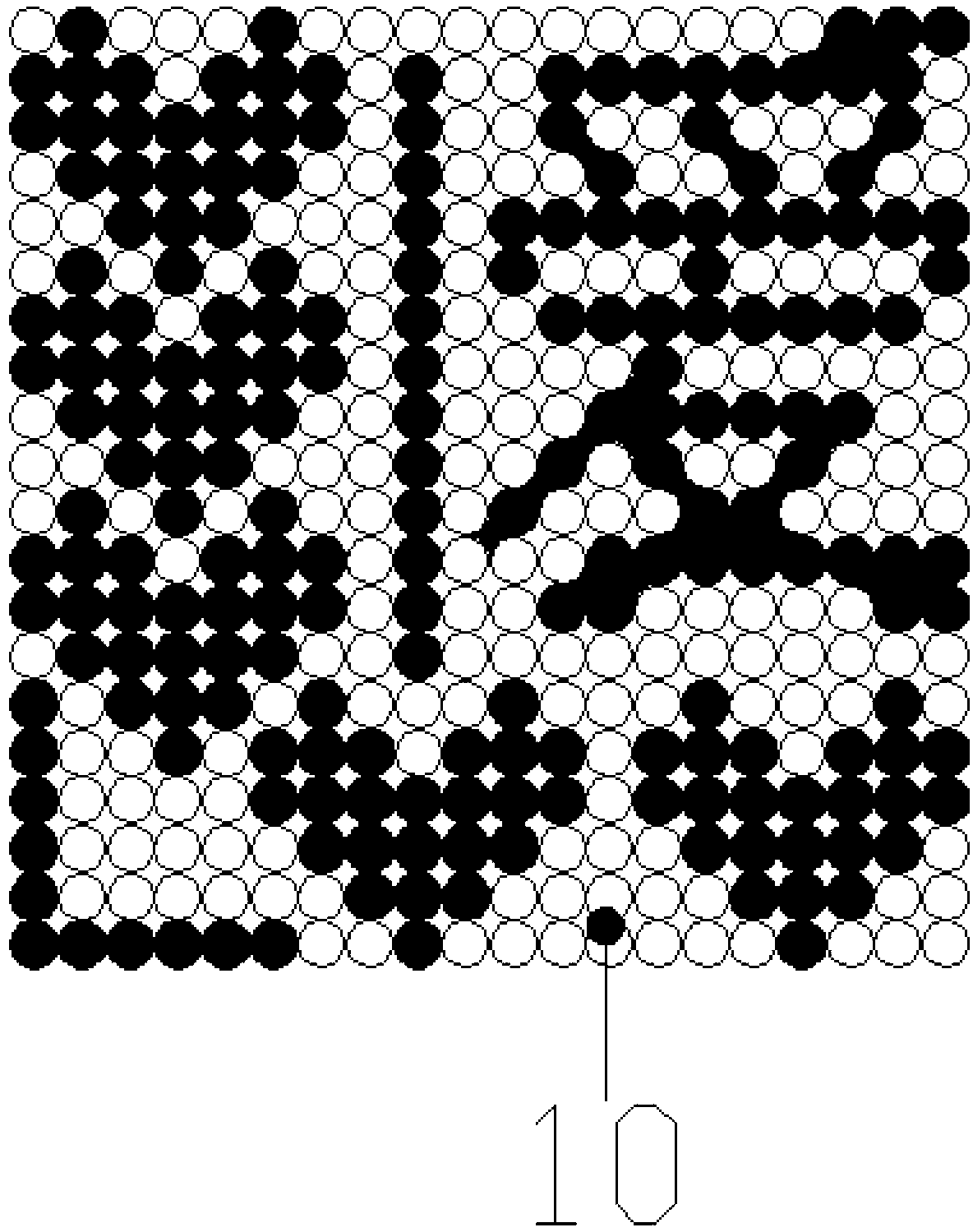

Production method of partitioned independent powder-charged post-dyed graphic fireworks

ActiveCN103234394AEasy to produceFlexible dyeing and moldingSpecial ornamental structuresFireworksFireworksEngineering

The invention discloses a production method of partitioned independent powder-charged post-dyed graphic fireworks. A graphic firework structure and a post-dyed graphic firework production method are included. The graphic firework structure comprises lattice structural bodies, the lattice structural bodies are filled with firework base color powder and connected with simultaneous launchers, the simultaneous launchers are connected with a simultaneous ignition bin, and the simultaneous ignition bin is filled with simultaneous ignition powder and connected with a lift-off rocket. The post-dyed graphic firework production method comprises a dyeing salt solution, a dyeing device and a dyeing method, wherein the dyeing method comprises designing graphic sample manuscripts, contacting the dyeing salt solution with the firework base color powder through the dyeing device, enabling the dyeing salt solution to permeate into the firework base color powder according to rule limitation, mixing, removing liquid components, performing full drying, and displaying desired colors after the original firework base color powder is lighted. The production method is simple in implementation and convenient to produce, inventory is not needed, and the graphic fireworks can be dyed before leaving factories and be dyed by users through free combination after being purchased.

Owner:SUZHOU ZZH INTPROP SERVICES

Modacrylic Shrinkable Fiber and Method for Manufacturing The Same

A modacrylic shrinkable fiber according to the present invention is containing a polymer composition obtained by mixing 50 to 99 parts by weight of a polymer (A) containing 40 wt % to 80 wt % of acrylonitrile, 20 wt % to 60 wt % of a halogen-ontaining monomer and 0 wt % to 5 wt % of a sulfonic-acid-containing monomer, and 1 to 50 parts by weight of a polymer (B) containing 5 wt % to 70 wt % of acrylonitrile, 20 wt % to 94 wt % of an acrylic ester and 1 wt % to 40 wt % of a sulfonic-acid-containing monomer containing a methallylsulfonic acid or metal salts thereof or amine salts thereof, in which a total amount of the polymer (A) and the polymer (B) is 100 parts by weight. In this way, a modacrylic shrinkable fiber that has a favorable color development property after dyeing and a high shrinkage ratio even after dyeing is obtained.

Owner:KANEKA CORP

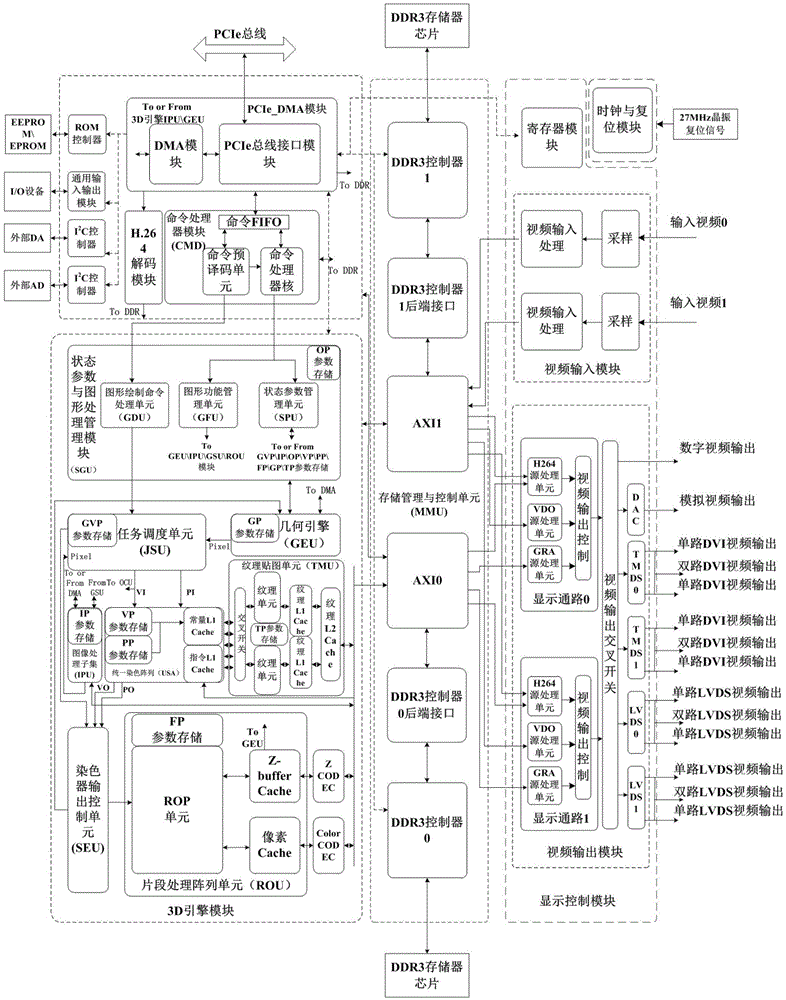

GPU (Graphics Processing Unit) system architecture based on uniform dyeing technology

ActiveCN105630441ARealize the effect of time division multiplexingIncrease profitProcessor architectures/configurationDigital output to display deviceGraphicsComputer module

The invention relates to a GPU (Graphics Processing Unit) system architecture based on a uniform dyeing technology. The architecture comprises a host interface module based on a PCIe (Peripheral Component Interface Express), a 3D (Three-Dimensional) engine module based on a uniform dyeing architecture, a storage control and management module based on AXI (Automatic X-ray Inspection) and two paths of independent display control modules, wherein the host interface module is connected with the 3D engine module, and, the host interface module, the 3D engine module and the display control module are all connected with the storage control and management module. The GPU system architecture can realize the hardware acceleration of an OpenGL API (Open Graphics Library) (Application Program Interface).

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

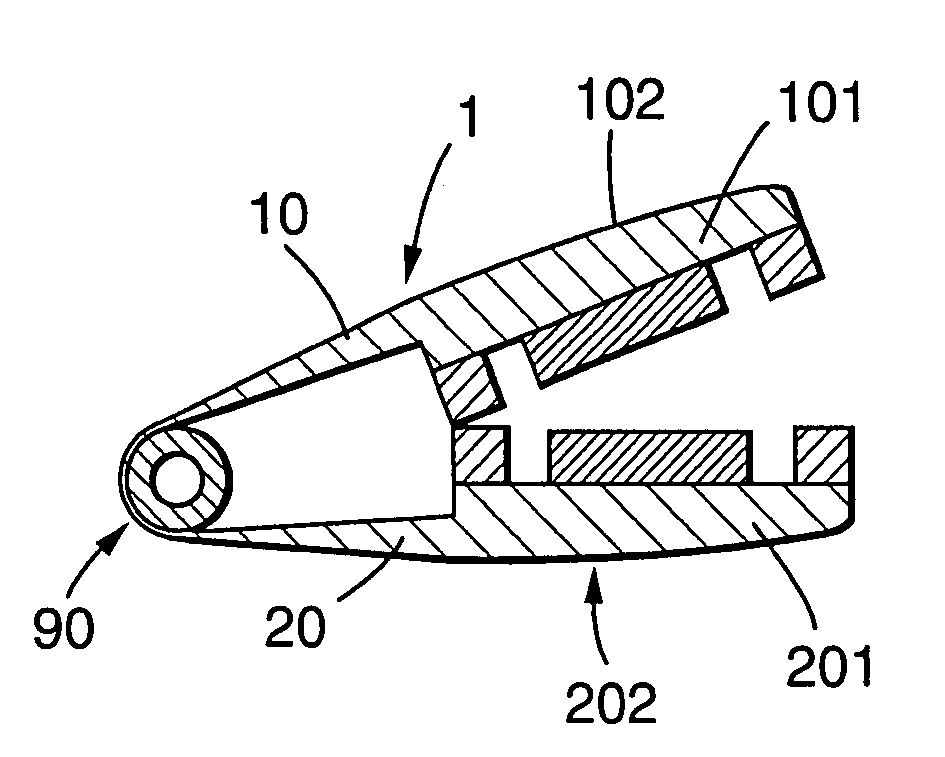

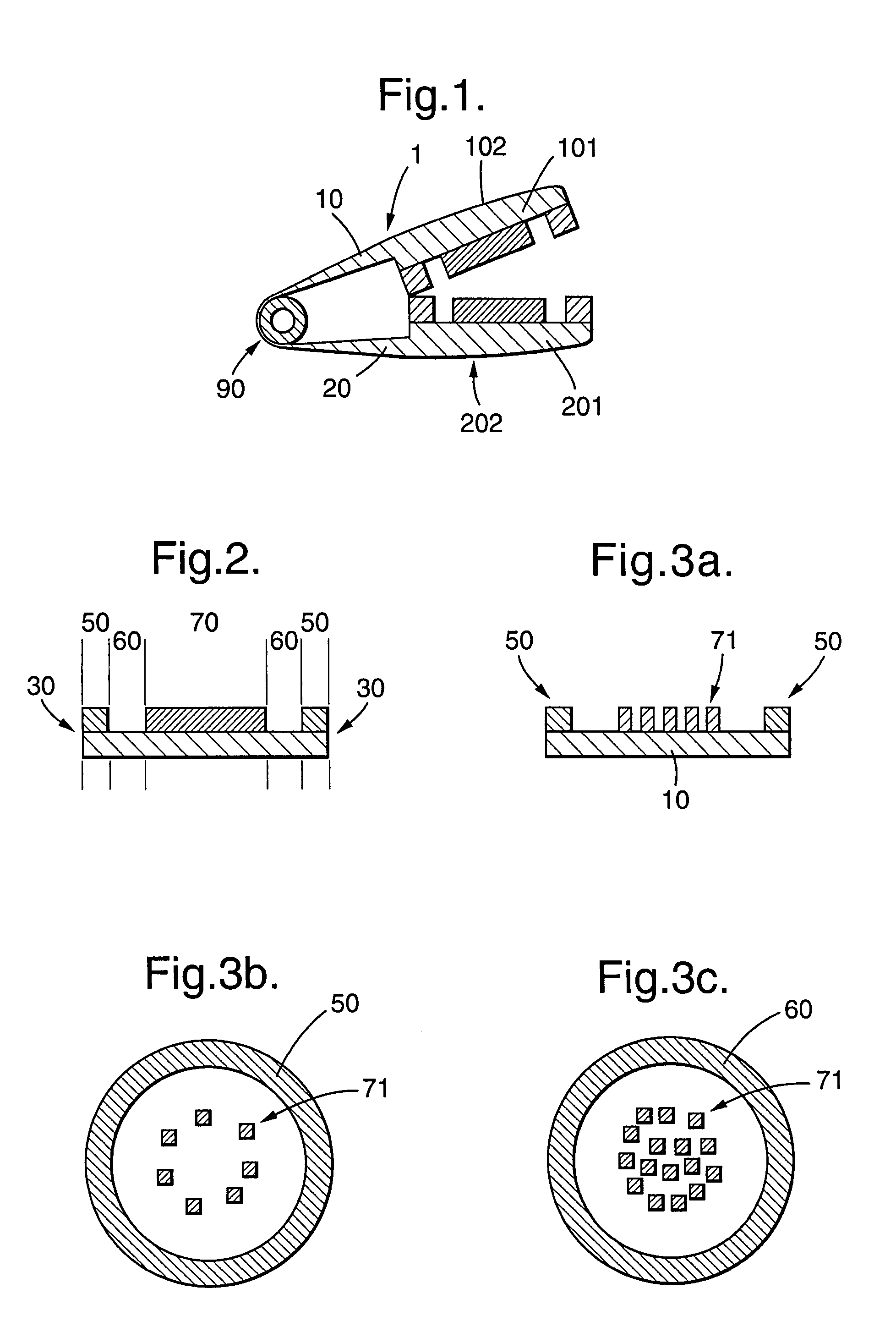

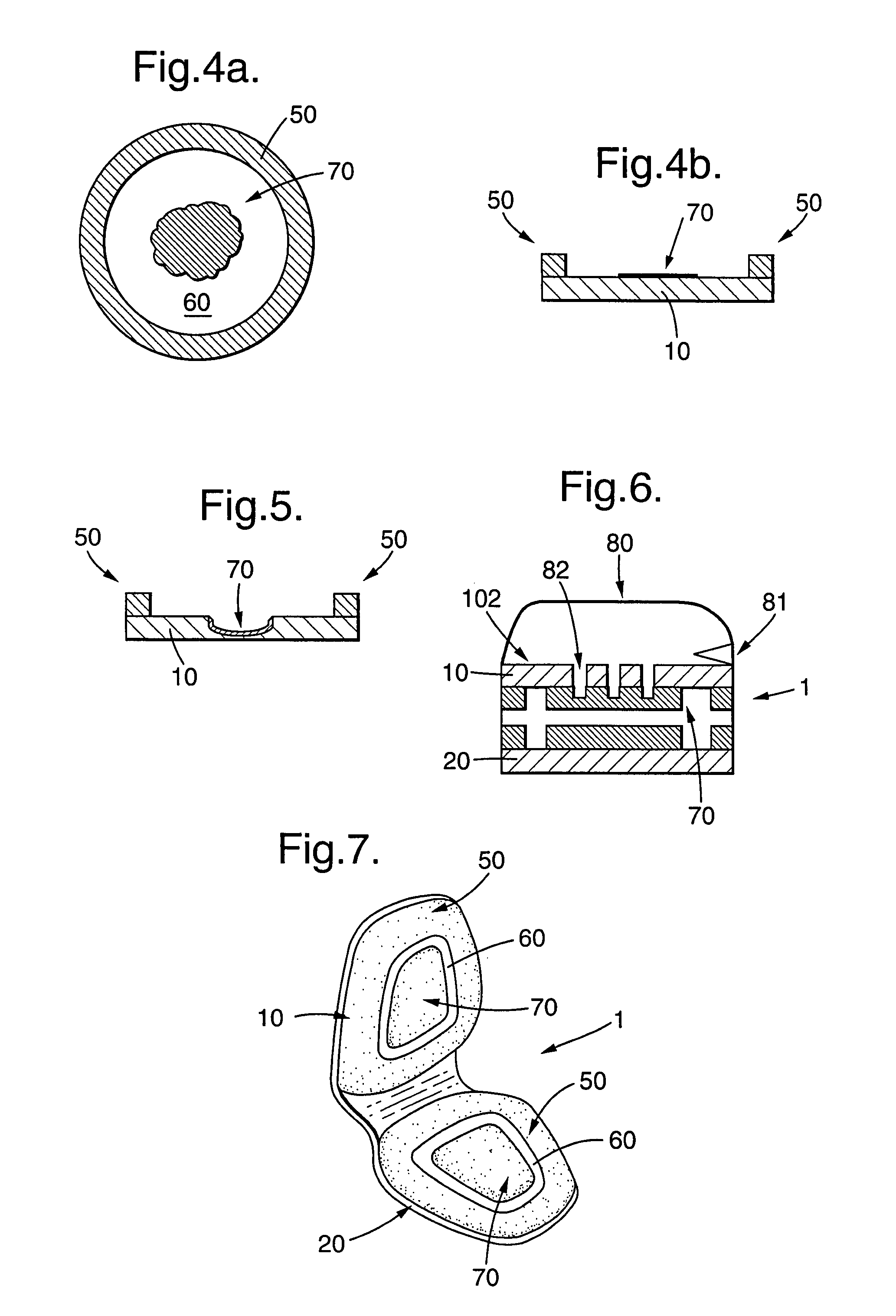

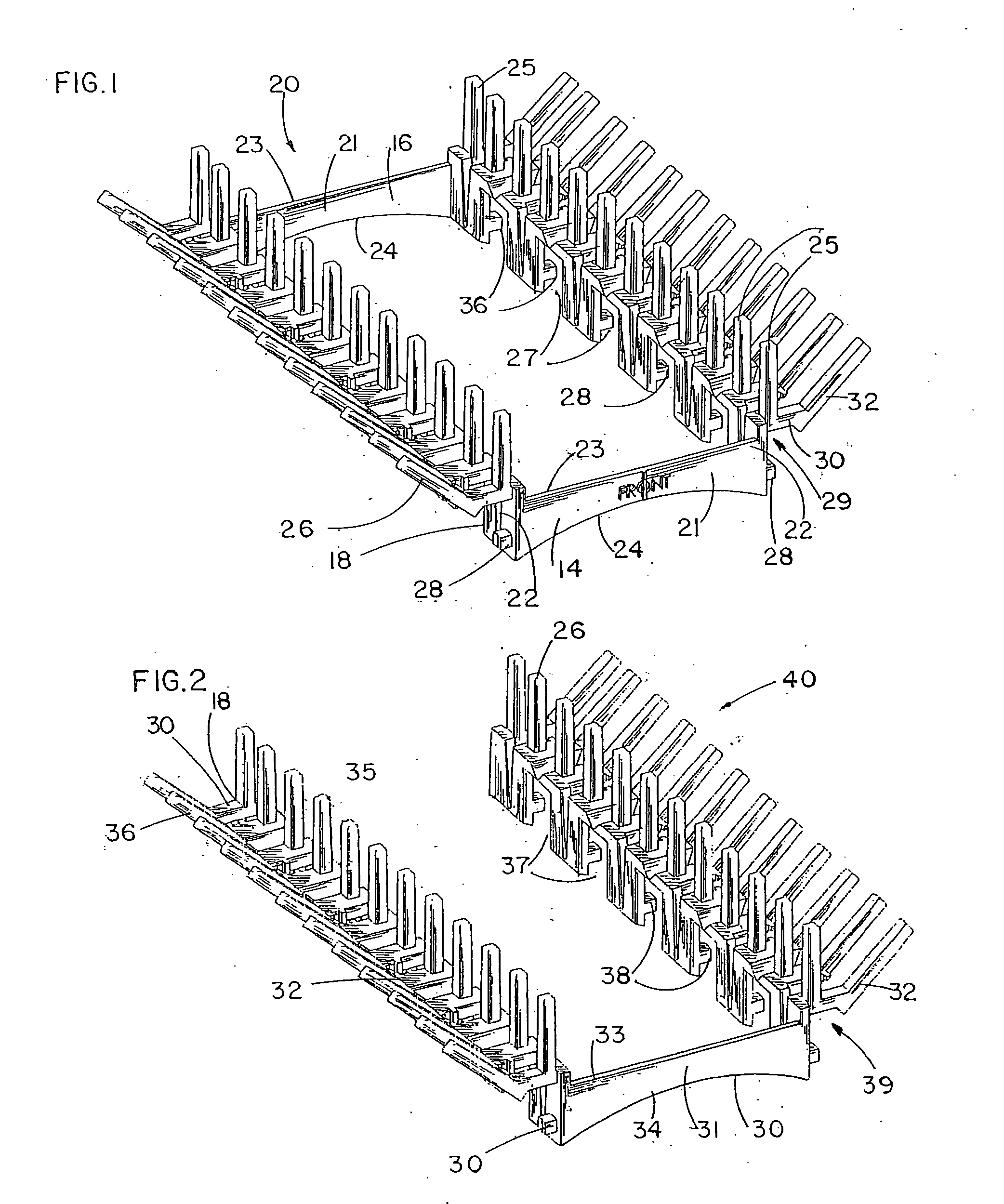

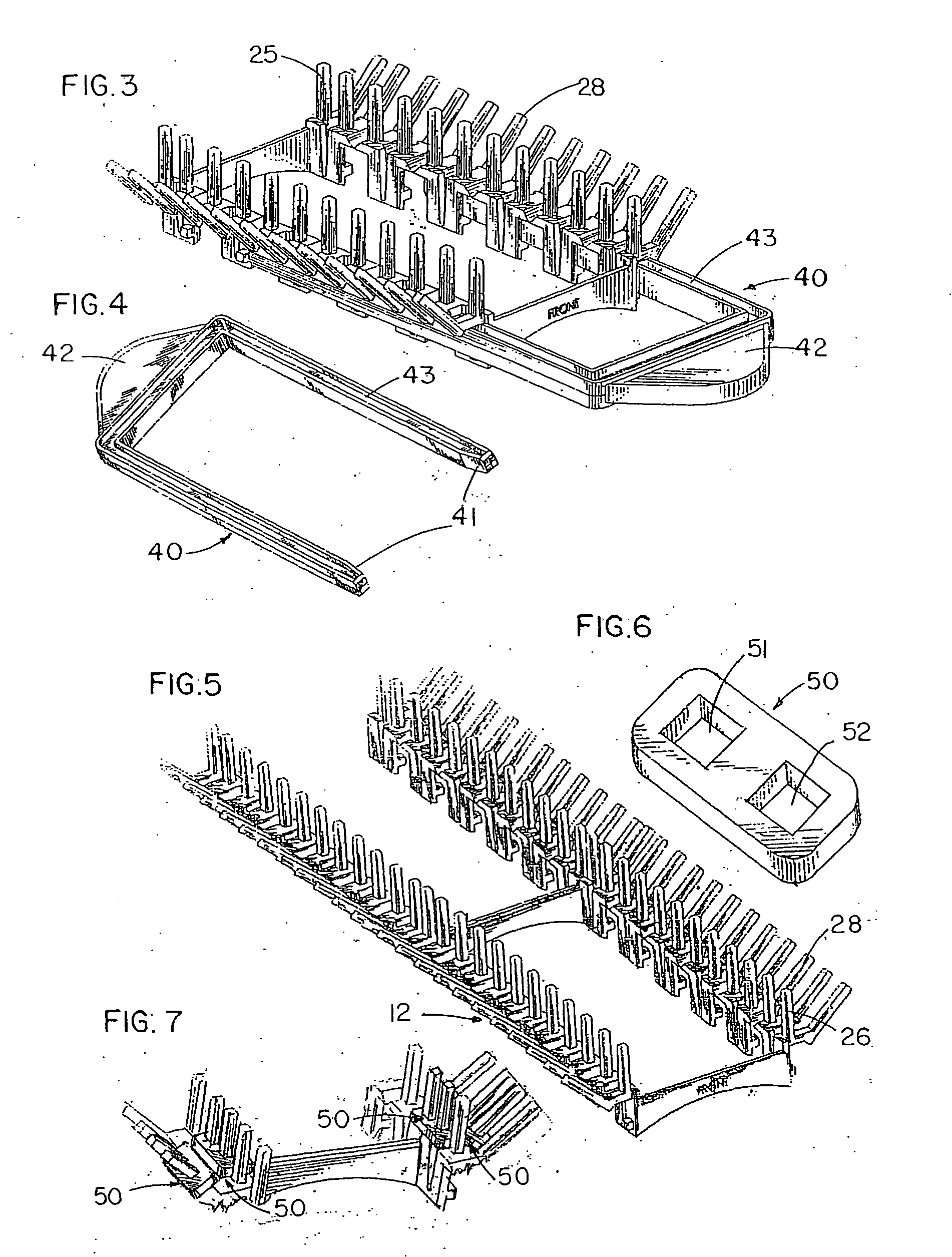

Hair highlighting application tool

Disclosed herein is an application tool (1) and methods to use the same. The application tool (1) comprises two plates (22), connected together. At least one of said two plates (22) comprises a fluid control zone (50), which run along the perimeter edge (30) of said at least one plate (22), a displacement zone (60), which at least partially separate said fluid control zone (50) from a containment zone (70). A hair treatment composition may be loaded onto the containment zone (70). Application of hair treatment compositions through the application tool (1) according to the invention allows for a precise, non-messy and clean targeting of the hair treatment composition on a hair strand and it is especially useful for highlighting and dyeing compositions.

Owner:NOXELL CORP

Polyester mutifilament yarn

InactiveUS20060014920A1Reduce thicknessExcellent toneMonocomponent polyesters artificial filamentPolyesterYarn

A polyester multifilament yarn having an individual filament thickness of 0.3 to 2.0 dtex, a total thickness of 90 dtex or less and a silk factor of 22 or more, can be obtained from a polyester polymer produced by polycondensing an aromatic dicarboxylate ester in the presence of a catalyst which comprises a mixture of a Ti compound component (A) comprising at least one member selected from titanium alkoxides and reaction products of the titanium alkoxides with carboxylic acids or anhydrides thereof, with a specific P compound component (B), and / or a reaction product of the Ti compound component (A) for the mixture with a specific P compound component (D), the resultant yarn having a good color tone (a low b* value) and an excellent weaving or knitting property and a good dyeing processability.

Owner:TEJIN FIBERS LTD

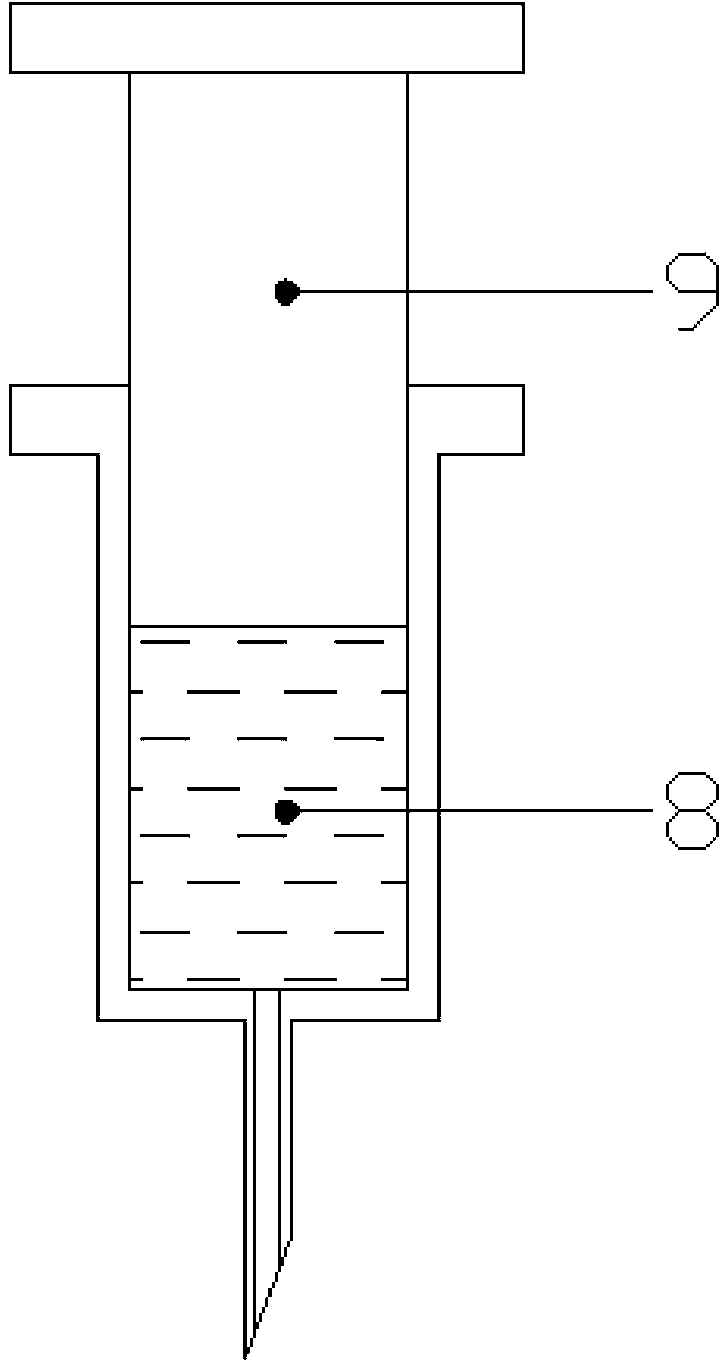

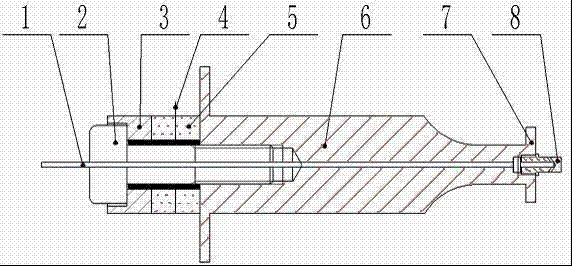

Two-stage ultrasonic vibration atomizer

InactiveCN102500502ALarge power capacitySimple structureLiquid spraying apparatusChemical industryTransformer

The invention discloses a two-stage ultrasonic vibration atomizer, which comprises a liquid conveying pipeline, a bolt, a rear cover plate, a piezoelectric ceramic plate, an electrode sheet, an amplitude transformer, a first-stage atomizing spray head and a second-stage atomizing radiation surface, wherein the rear cover plate, the piezoelectric ceramic plate and the electrode sheet are pressed by the connection between the amplitude transformer and the thread at the front end of the bolt, so as to form a second-stage ultrasonic atomizing vibrator; the first-stage atomizing spray head is connected with the front end of the amplitude transformer; and the second-stage atomizing radiation surface is clamped between the front end of the amplitude transformer and the rear end of the first-stage atomizing spray head. According to the invention, the vibrator part adopts a sandwich transducer structure, and has high power capability; the first-stage atomizing is realized by the micro-spraying holes on the first-stage atomizing spray head; the second-stage atomizing is realized by ultrasonic vibration; and through two-stage atomizing, the two-stage ultrasonic vibration atomizer has the advantages of small gas atomizing grains and the like, and can be applied to the fields of cooling of mechanical processing and cutting heat, air moistening, medical treatment, dedusting, deodorizing, weaving, printing and dyeing, tobacco, flowers, papermaking, electronics, spray-coating, chemical industry, granulating, fungus culturing, fruit storage and the like.

Owner:SUZHOU UNIV OF SCI & TECH

Preparation method for multicolor oxide film

InactiveCN101619477APerformance impactAccelerated corrosionAnodisationArtistic surface treatmentWear resistanceCarving

The invention relates to a preparation method for multicolor oxide film, comprising that an anode oxide film forming step is repeatedly carried out. The anode oxide film forming step comprises: oxidizing color anode, and forming a protective layer and laser carving on a color anode oxide film. The color anode oxidation comprises anode oxidation, dyeing and hole sealing are carried out in turn on the surface of a base material so as to obtain a color anode oxide film. The protective layer is used for separating electrolyte oxidized by a color anode and a color anode oxide film formed previously. The laser carving is used for removing at least one part of color anode oxide film formed previously so as to cause the surface of parts of base material to be exposed. The integral corrosion resistance and abrasion resistance of the oxide film on the surface of the base material, which is prepared according to the method of the invention, are high, and no other macromolecule materials need to be coated, so that the texture of the oxide film is kept.

Owner:BYD CO LTD

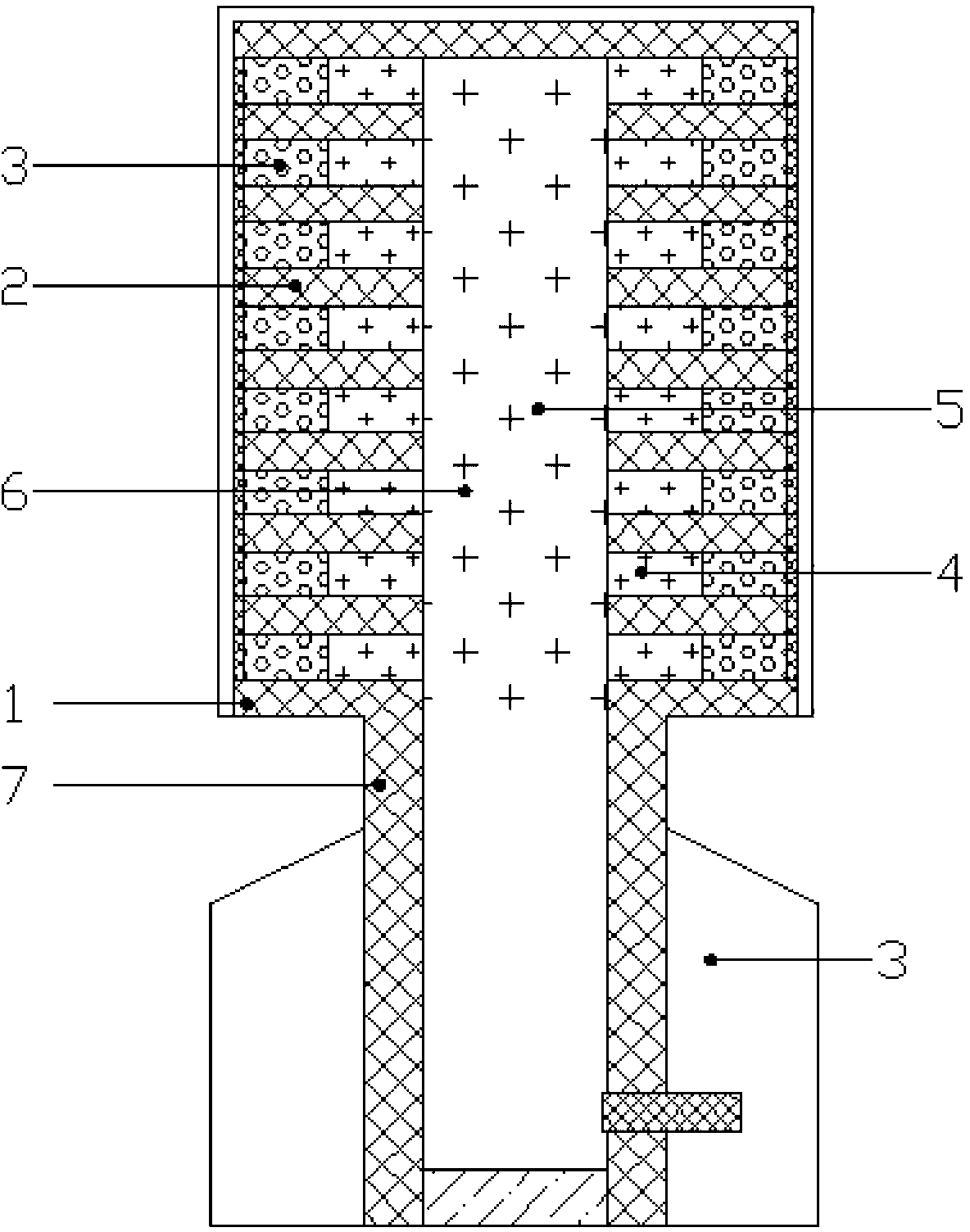

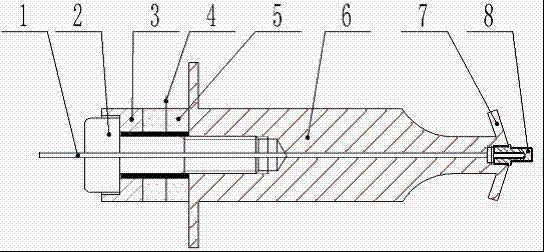

Cloth printing and dyeing device

ActiveCN105332189ADry evenlySimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

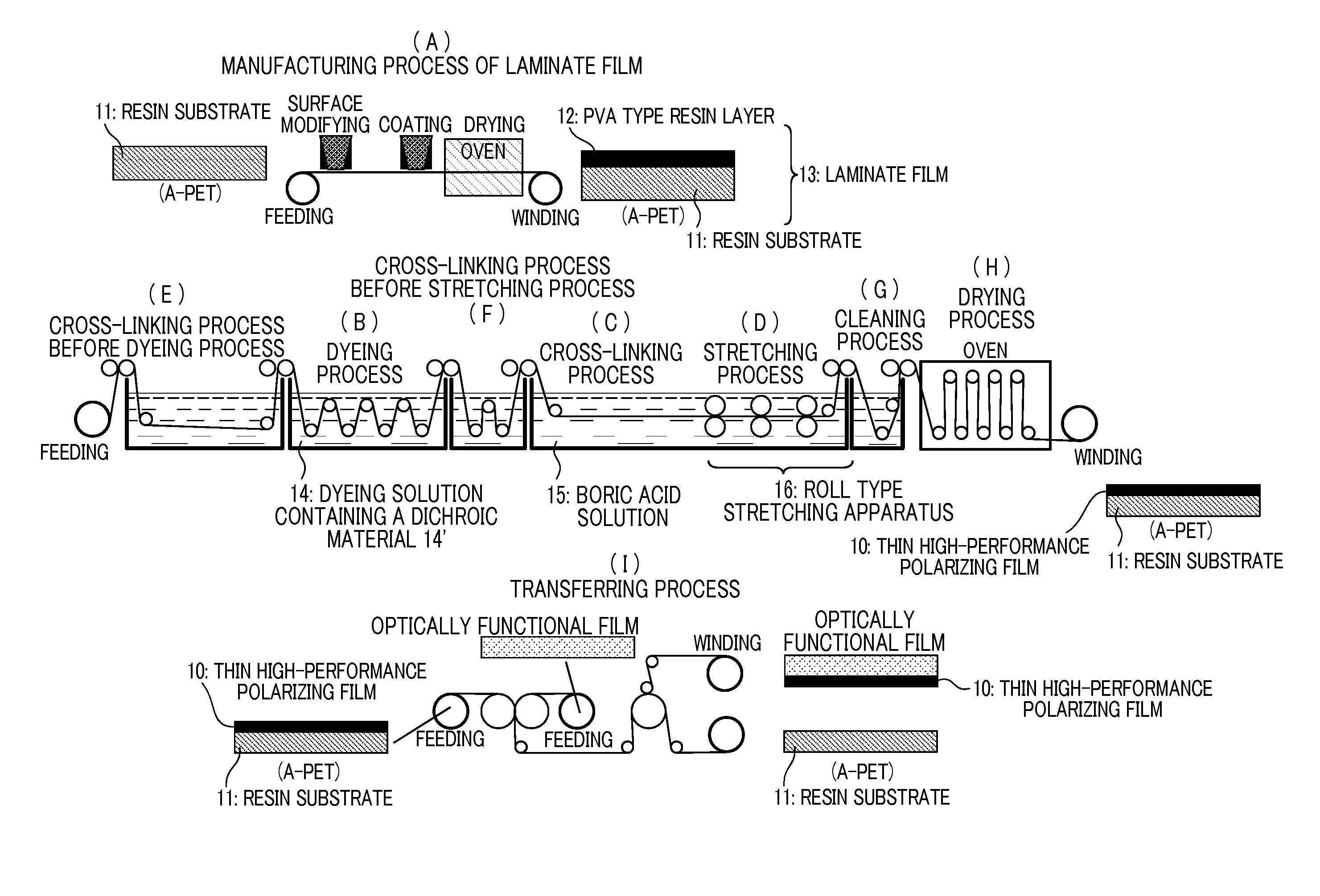

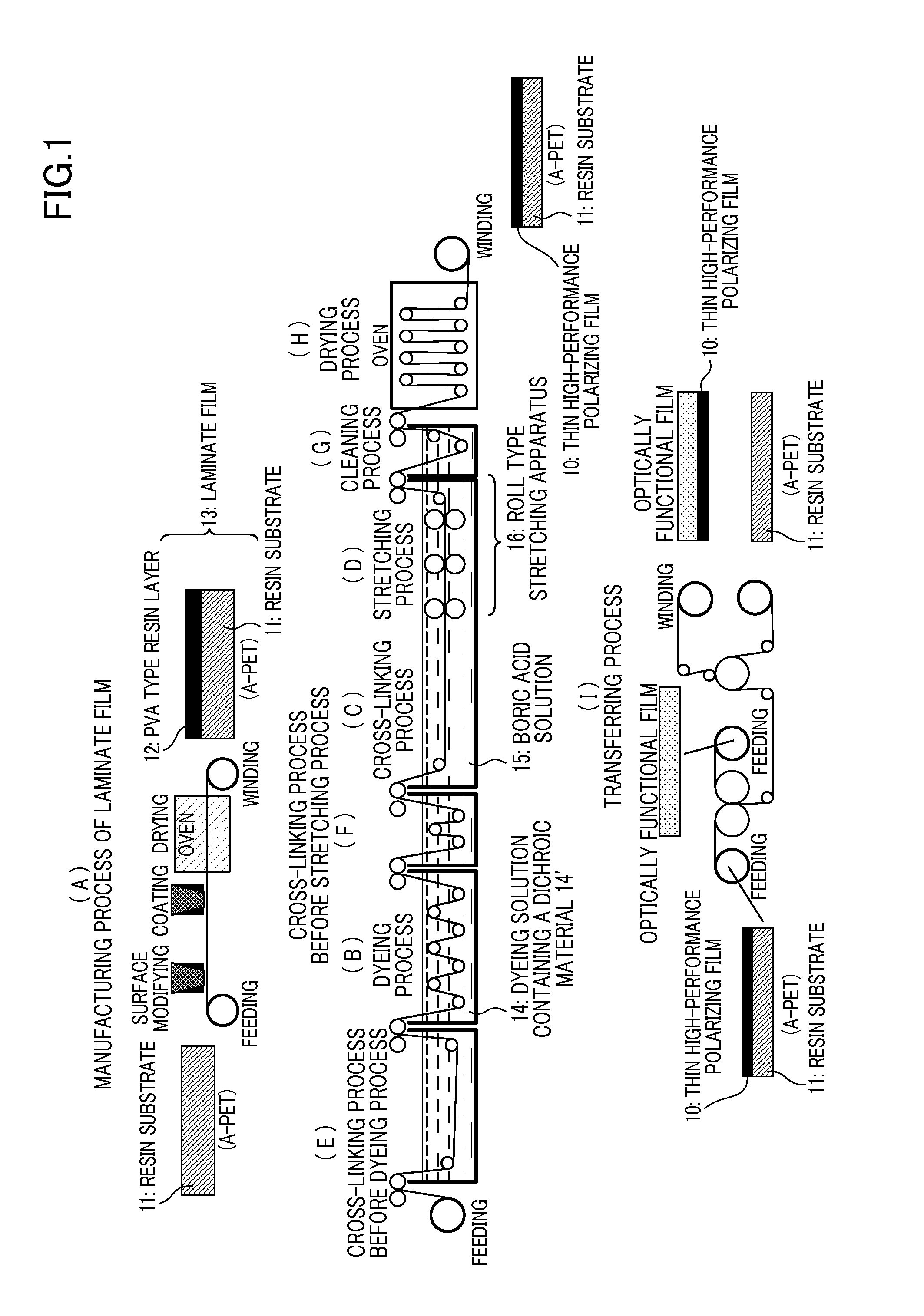

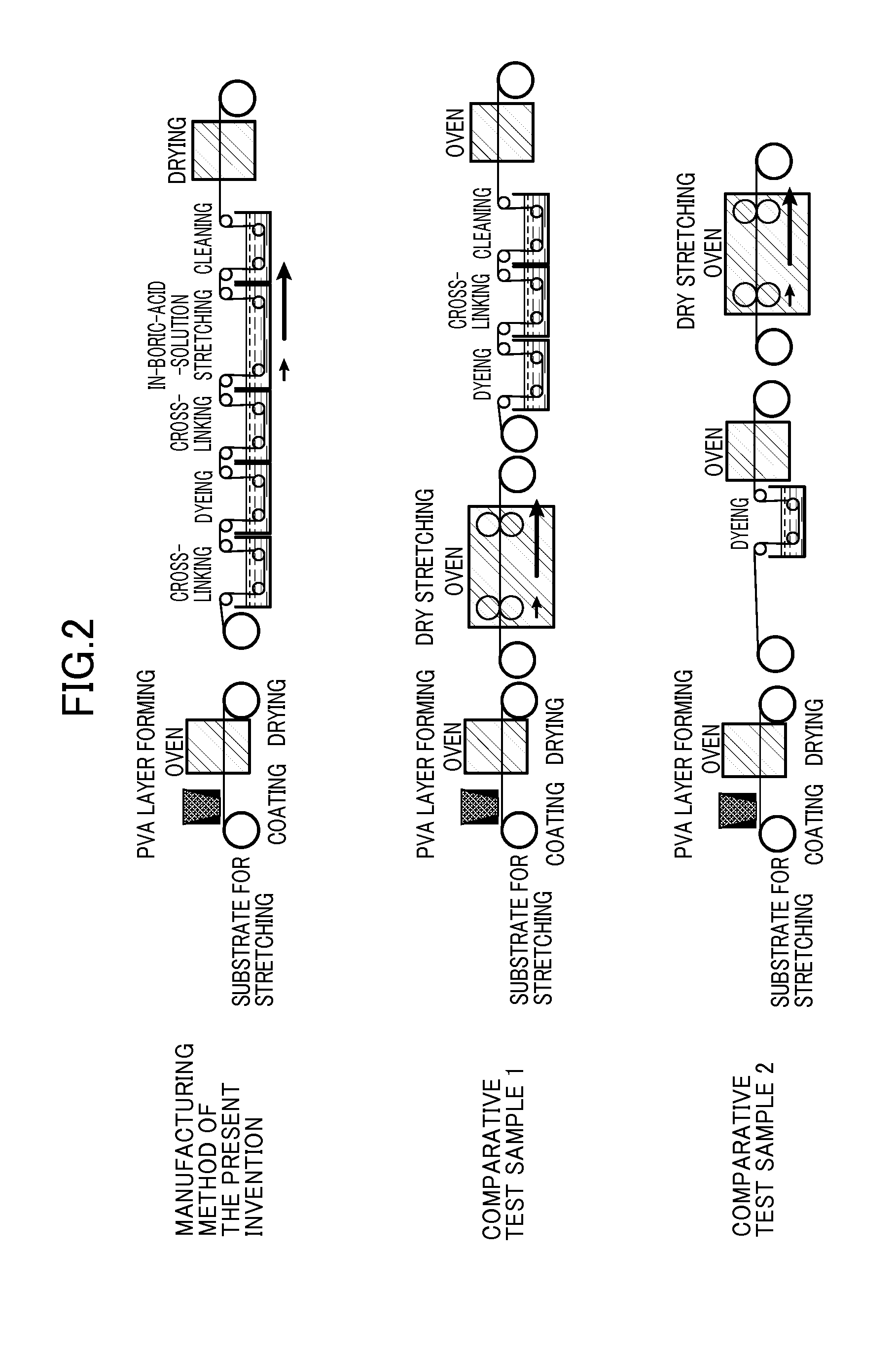

Thin high-performance polarizing film and method for manufacturing the same

ActiveUS20120327512A1Improve solubilityThin polarizingOptical articlesPolarising elementsBoric acidStretch ratio

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

Composite material and preparation method thereof

ActiveCN101768770ARich surface colorRetain glossAnodisationThin material handlingColor filmAnodic oxidation

The invention relates to a composite material and a preparation method thereof, which belong to the field of aluminum alloys. The invention provides the composite material against the defects of unevenness, no metal luster, easy scratch and easy abrasion of a gradient color film layer on the surface of the aluminum alloy, the composite material comprises a substrate, a porous anodic oxide film layer is arranged on the surface of the substrate, the substrate is aluminum or the aluminum alloy, at least one dye is filled in pores of the porous anodic oxide film layer, and the content of the same dye in part of the pores of the porous anodic oxide film layer is in gradient distribution. The preparation method of the composite material comprises the following steps: using the anodic oxidation method for forming the porous oxide film layer on the surface of the aluminum alloy; and dyeing the porous oxide film layer, wherein the dyeing method is to control the time of entering into the dye of different regions of the porous oxide film layer and further lead the content of the dye filled in the pores of the porous anodic oxide film layer to be in the gradient distribution. The composite material has the advantages of evenness, metal luster, difficult scratch and difficult abrasion of the film layer and is mainly applied on electronic products.

Owner:BYD CO LTD

Method of rapid hair dyeing

The present invention relates to a method of hair colouring and bleaching compositions providing a composition comprising i) at least one source of peroxymonocarbonate ions, ii) at least one alkalizing agent, preferably a source of ammonium ions, and iii) at least one radical scavenger, wherein said composition has a pH of up to 9.5, and applying the composition to the hair and retaining on the hair for a period of less than 20 minutes, which provide a high level of lift and lightening and the required dye deposition and grey coverage whilst reducing the concentration of peroxide, the ammonia odour and reducing the hair fibre damage.

Owner:WELLA OPERATIONS US LLC

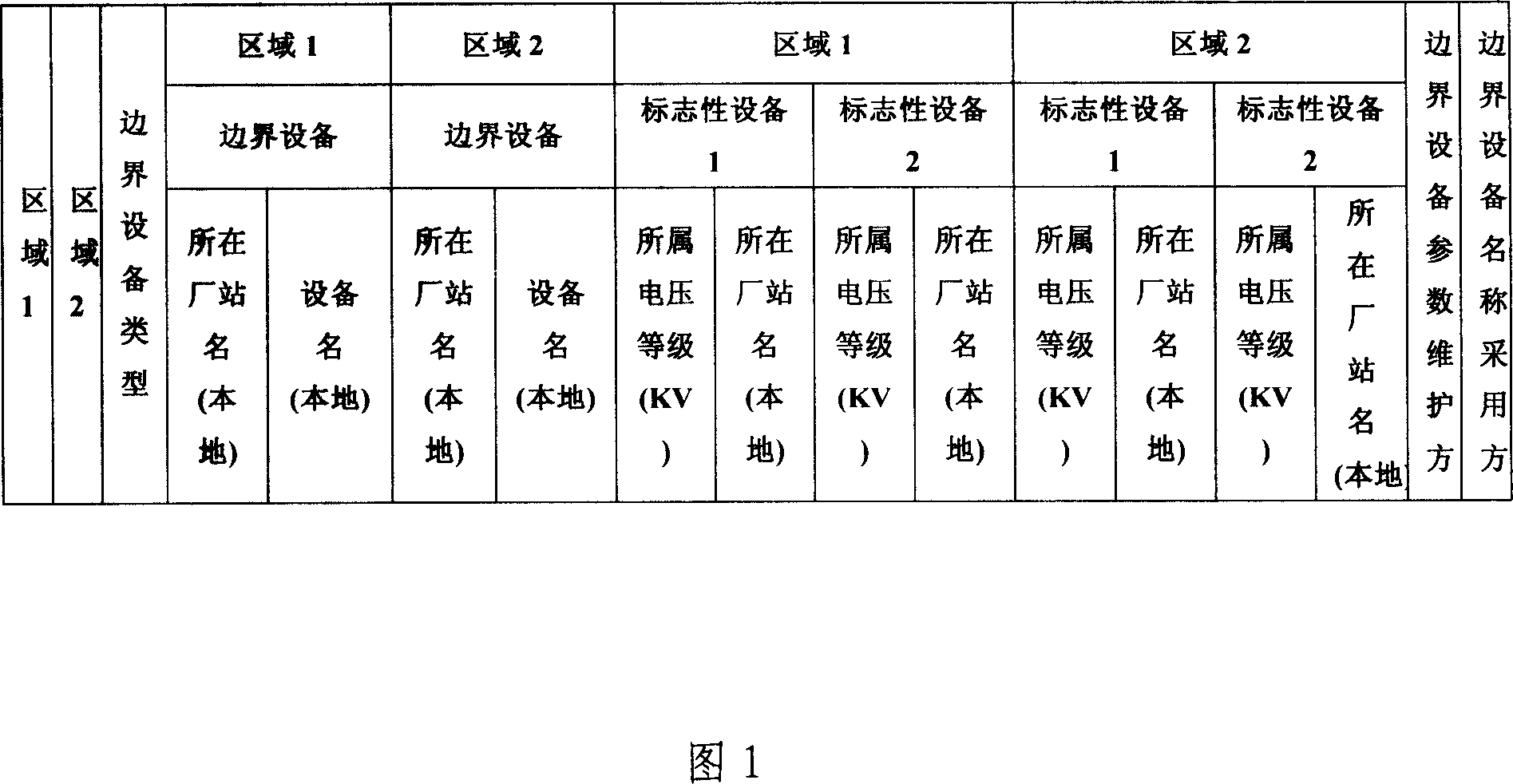

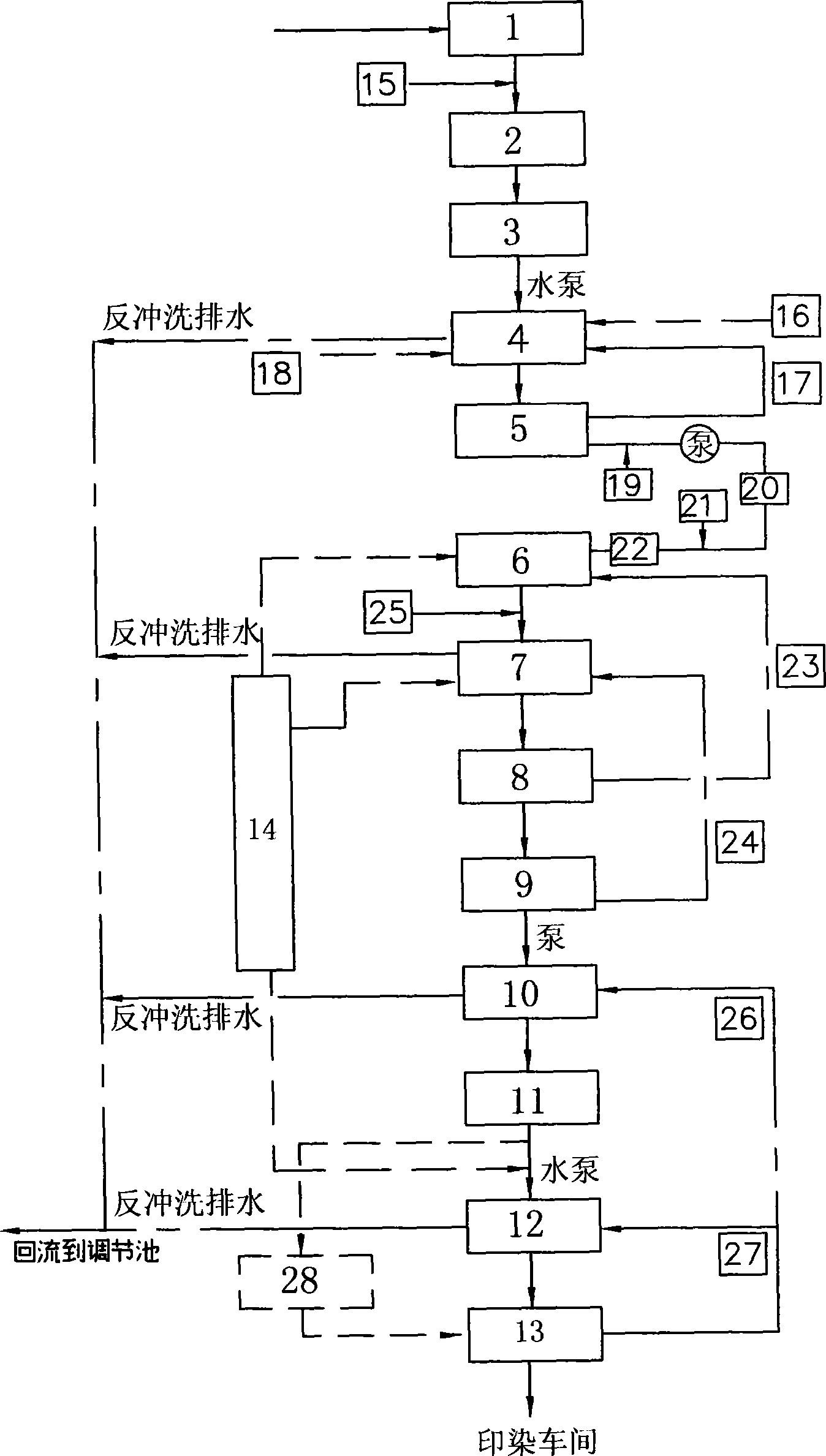

Method of jointing multiple regional net models of electric power system

ActiveCN101004752AReduce work intensityEase of workSpecial data processing applicationsElectric power systemNetwork model

A method for pasting-up multi-region network model of power system includes defining model boundary between relevant regions to be pasted-up, guiding file of region to be pasted-up into buffer area A and guiding pasted-up result of last model into buffer area B, using topological dyeing means based on physical node to cut model in buffer area A to be parts, matching objects in two said buffer areas from top to bottom of layer relation, calculating model variable increment, increasing or deleting model object in system databank as per increment result and guiding in the other region model for finalizing paste-up of complete model.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

Dyeing and printing waste clearing, synthetic wastewater advanced treatment circulation production and recycle technique

InactiveCN101172741AGood denitrification functionIncrease profitMultistage water/sewage treatmentWater/sewage treatment by oxidationComing outAir bearing

The invention discloses a deep treatment technique used for the printing and dyeing sewage recovery. The technique consists of a BAF pond, an air-bearing system, an ozone contact oxidation tower, a filter, an active carbon filter, an ozone generator and a medicine adding system. The technique is the improvement of the traditional BAF technique, removes the resolvable organism in the sewage through the biological degradation, outtakes the water into the air-bearing system and combines the flocculation medicine adding technique, so as to eliminate the non-solvent organism and colloidal substance in the sewage. The outtaken water enters into the ozone contact oxidation tower and gets mixed with ozone, so that the organism which is difficult to undergo the biological degradation in the printing and dyeing sewage is removed with the help of the strong oxidizing property of the ozone. The water flowing out of the ozone contact oxidation tower enters into the pond at the middle, and 30 percent of the water returns to a gas dissolving can under the action of a pressurizing pump, gets mixed with the pressurized air and then enters into the air-bearing system through utilizing the remaining pressure. The gas-water solution is dispersed into the small and equable drips through a dissolved gas releaser, and the drips drive the suspending substances and the colloidal substance to float up to the water surface so as to achieve the removal. The water coming out of the middle pond enters into the filter to remove the small suspending substances and enters into the ozone / active carbon filtering system so that the reaction of the ozone basic chain is caused under the action of the active carbon, thereby speeding up the decomposition of the ozone into OH and other free radicals, degrades a small amount of organism, eliminates the color and finally ensures that the outtaken water reaches the recovery standard of the printing and dyeing sewage.

Owner:王爱月 +1

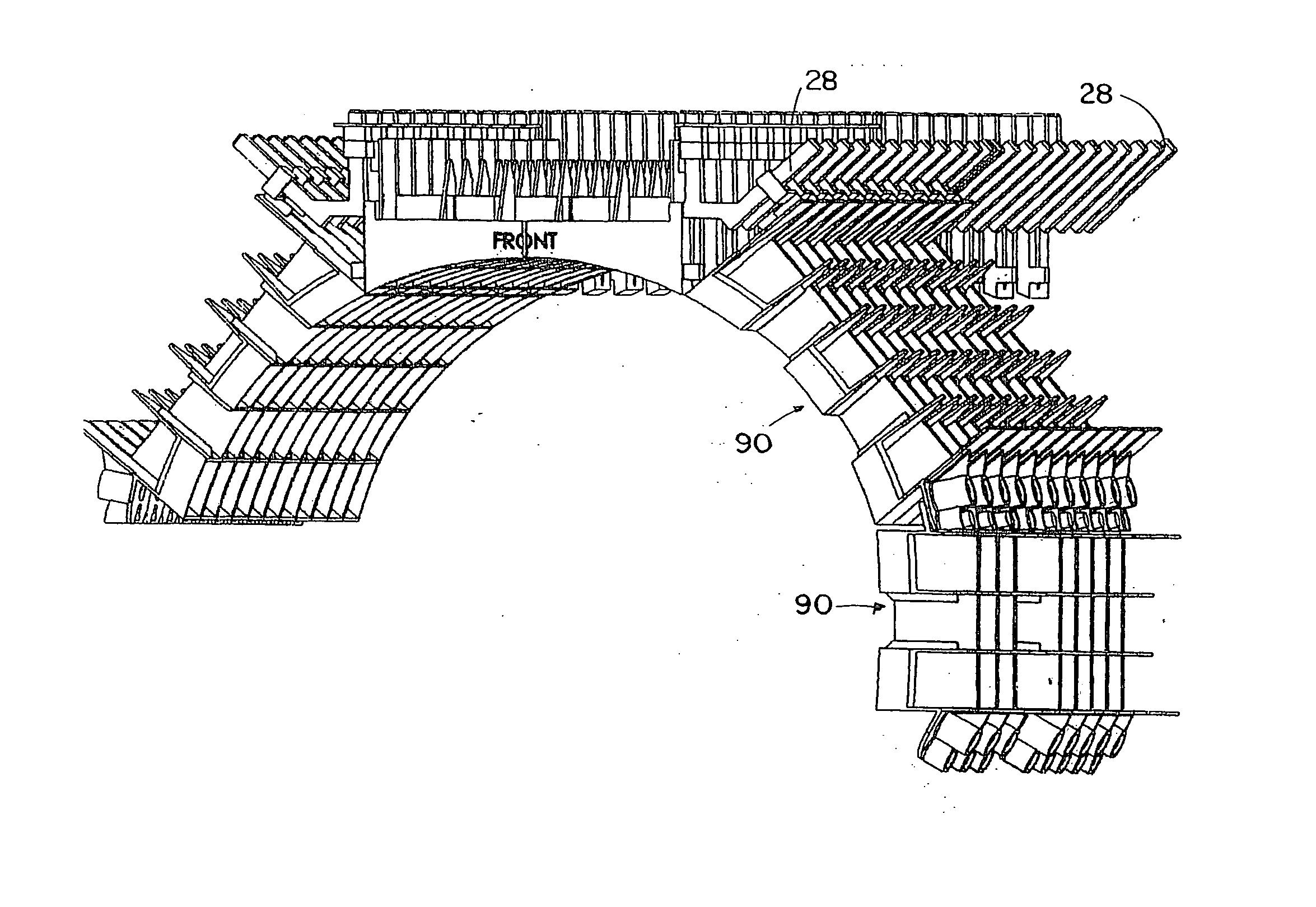

Hair coloring system

InactiveUS20060144415A1Easy and efficient to manufactureDurable and reliable constructionCurling devicesHair combsEngineeringScalp

A hair coloring system having a grid and associated quads. The quads are held against the scalp with a tie-down tool. Such placement allows the dyeing of hair up to the root structure. A hair manipulating tool enables a user to separate the hair into manageable quantities. The hair manipulating tool also enables the user to efficiently thread the hair strand through the quad structure.

Owner:MAGEE HARVEY

Dyeing and finishing process for wet absorptive quick drying polyester fiber fabric

InactiveCN1986951AImprove diffusion abilityKeep dryFibre treatmentHeating/cooling textile fabricsPolyesterFiber

Owner:金根苗

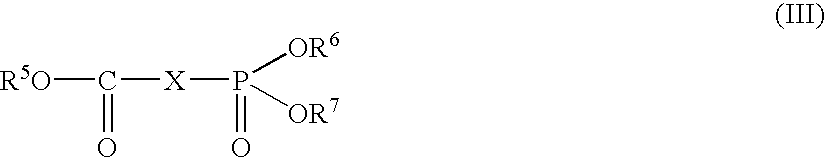

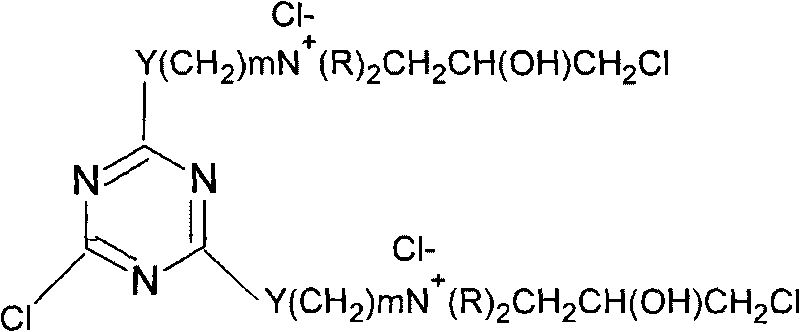

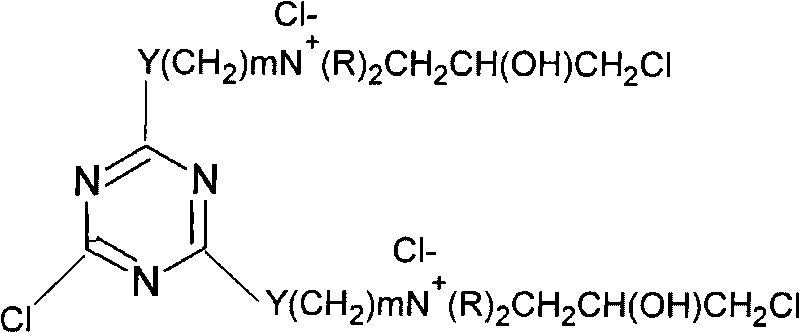

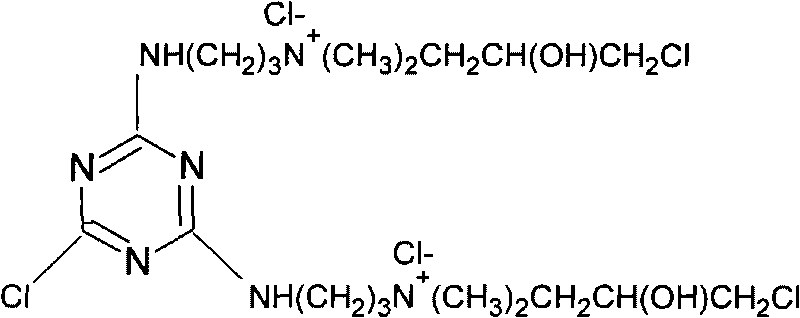

Method for preparing cationic grafting agent with multi-reactive groups

The invention relates to a method for preparing a cationic grafting agent with multi-reactive groups, which comprises the following steps: adding N,N-dimethyl diaminopropane or N,N-dimethylaminoethanol and hydrochloride solution of N,N-dimethylamino propanol into cyanuric chloride water suspension at the temperature of 0-10 DEG C, leading the molar ratio of cyanuric chloride to the N,N-dimethyl diaminopropane or the N,N-dimethylaminoethanol and the N,N-dimethylamino propanol to be 1: 0.34, using base for adjusting and controlling the pH to be 3-4, increasing the temperature to 35-45 DEG C after full reaction, and further adding the N,N-dimethyl diaminopropane or the N,N-dimethylaminoethanol, leading the molar ratio of the N,N-dimethyl diaminopropane or the N,N-dimethylaminoethanol to the cyanuric chloride to be 0.4:1, using hydrochloric acid for adjusting the pH to be 1-2 after full reaction, increasing the temperature to 70-85 DEG C, adding epichlorohydrin, leading the molar ratio of the epichlorohydrin to the cyanuric chloride to be 0.7:1, and obtaining a monochlorotriazine ammonium chloride derivative. The grafting agent is used for graft modification of fabric, thereby improving the dyeing effect.

Owner:JINQIU TEXTILE ARRANGEMENT +1

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

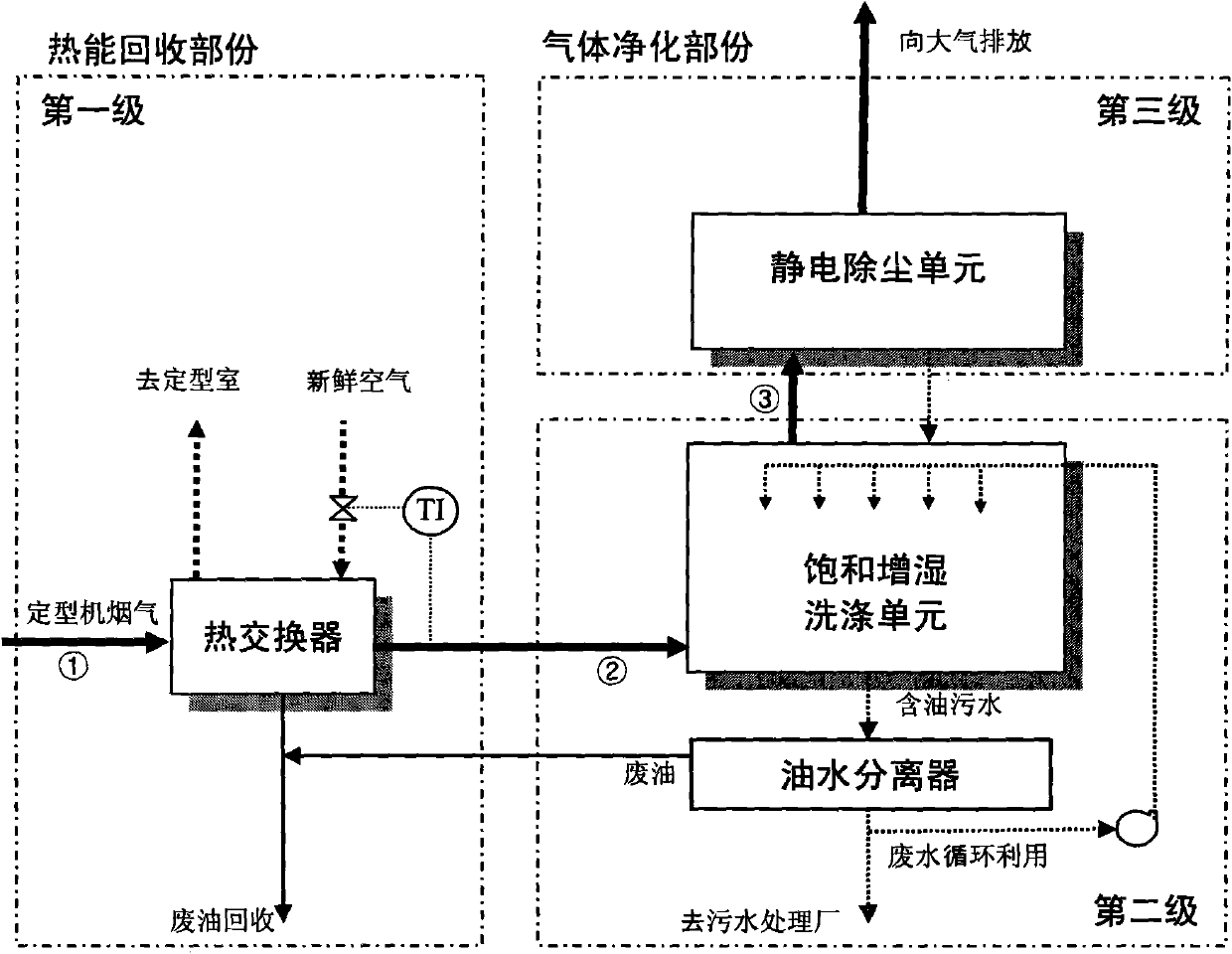

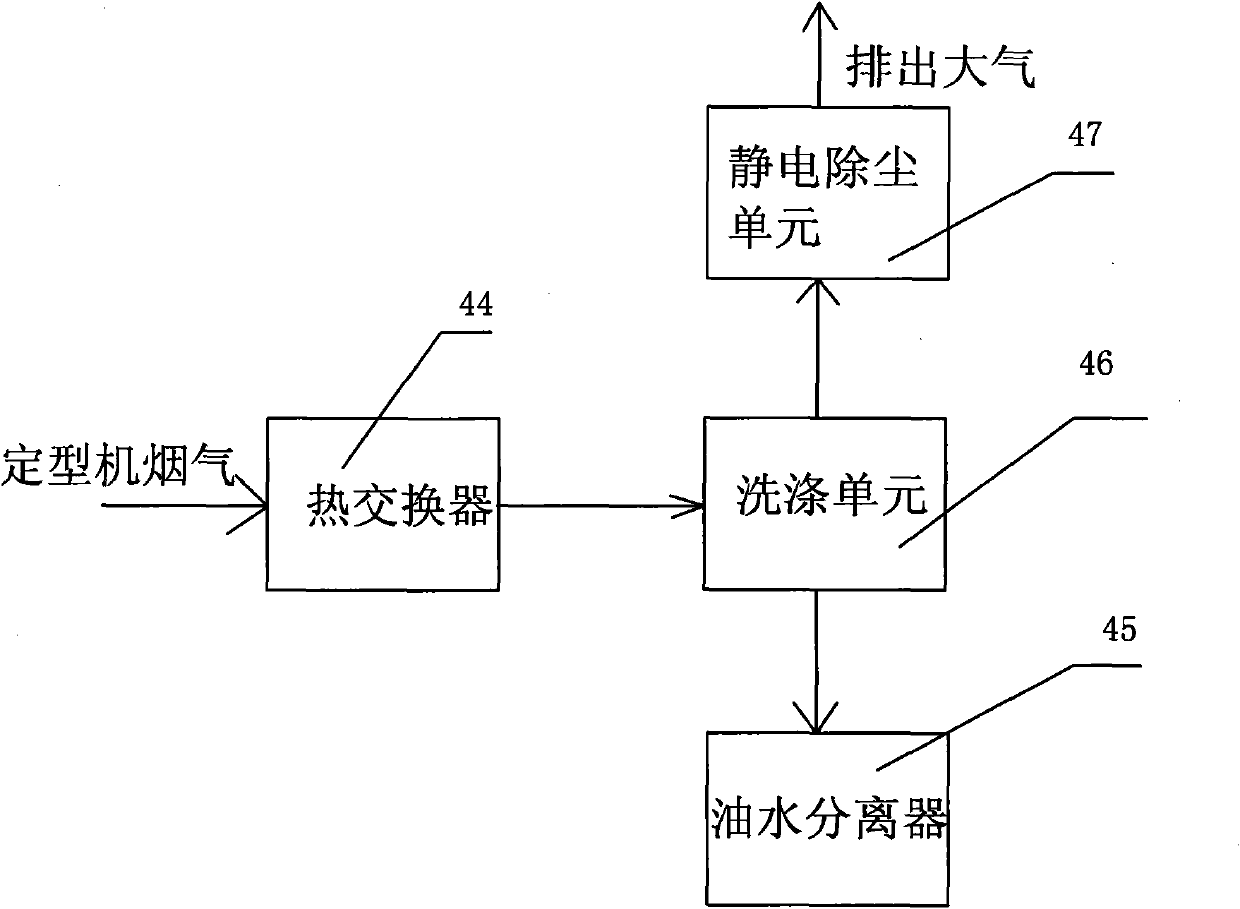

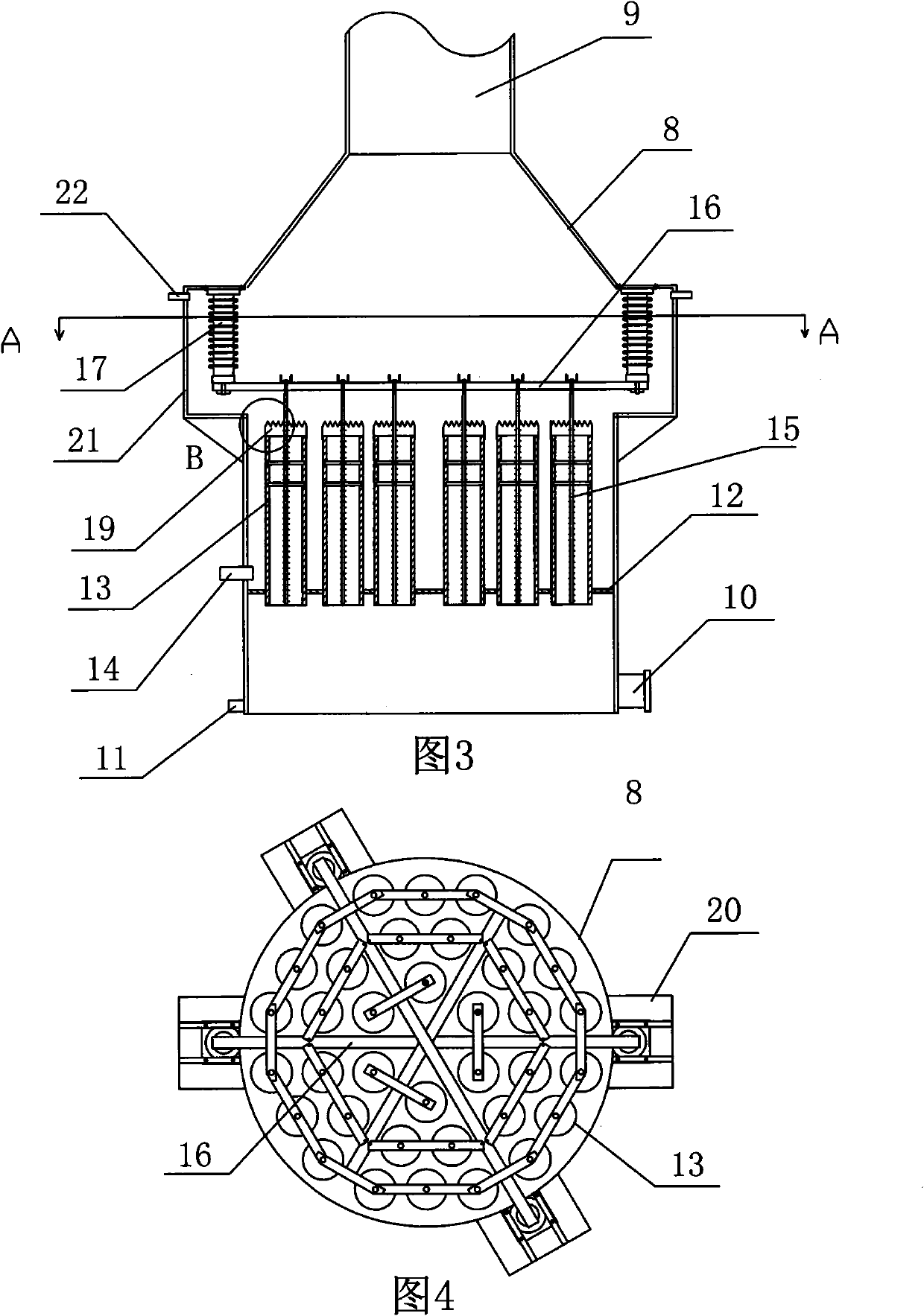

Method for treating flue gas of dyeing and finishing setter

InactiveCN101766943ASave energyReduce the amount of sewageCombination devicesParticulatesHigh density

The invention discloses a method for treating flue gas of a dyeing and finishing setter. The rear end of the setter is provided with a heat exchanger, a washing unit, an oil-water separator and an electrostatic dedusting unit. In the method, (1) the counterflow heat exchange is carried out between the flue gas of the setter and the air by the heat exchanger, the waste heat is recovered, and the energy is saved; (2) the flue gas treated by the heat exchanger enters from the bottom of the washing unit and is sprayed and washed by the spraying liquid in the washing unit, and the flue gas is in counterflow contact with the spraying liquid, so as to remove most soot grains with the grain diameter being more than 1mum; and (3) the flue gas treated by the washing unit is dedusted by the wet-type electrostatic dedusting unit, most soot grains with grain diameter being less than 1mum are attached by electrons with high density, the charged grains move to the wall of a condensation pipe directionally and are collected and captured by the wall of the pipe, and the liquid film on the inner wall of the condensation pipe is updated continuously, thereby achieving the self-cleaning function of the inner wall of the condensation pipe.

Owner:NINGBO UNIV

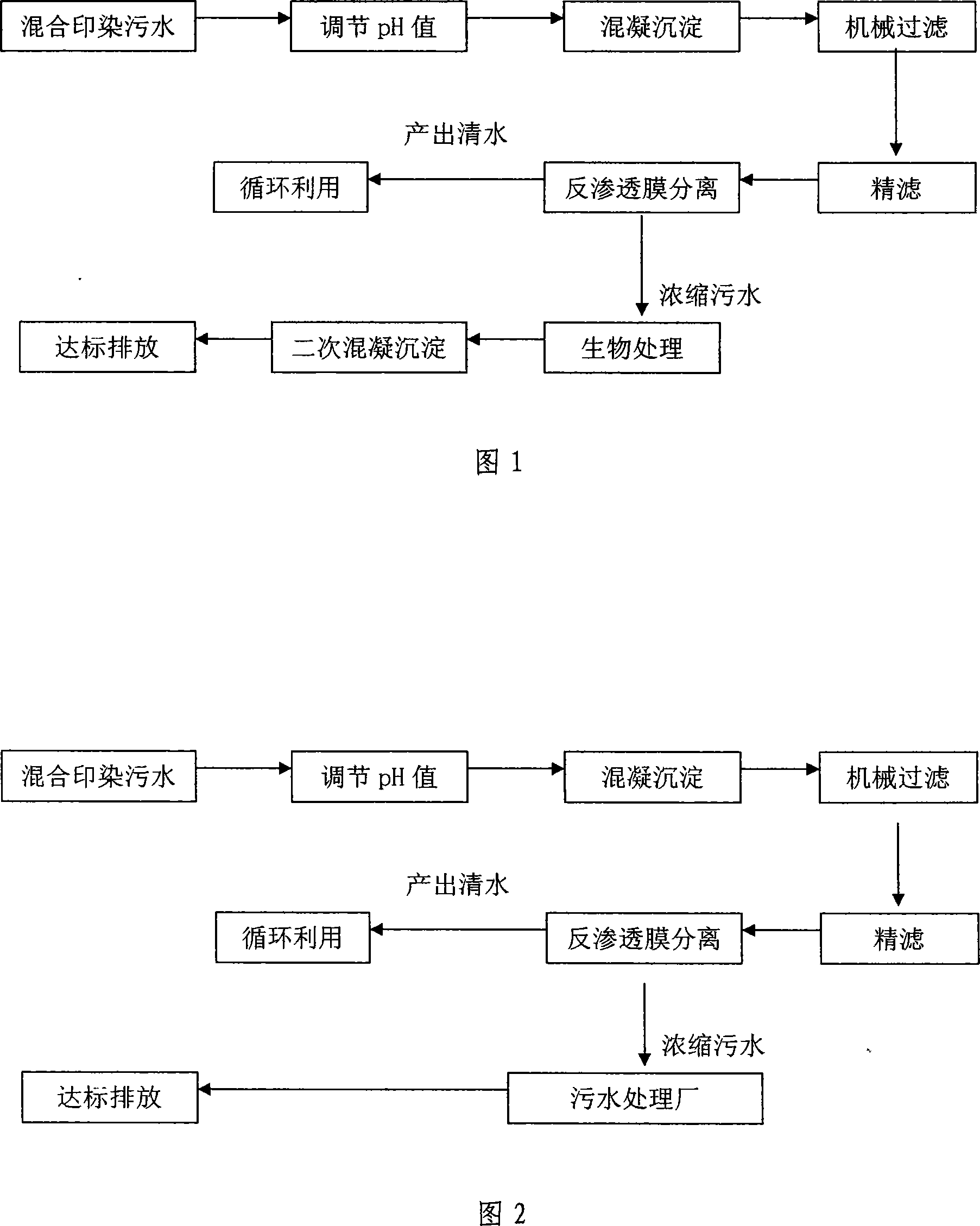

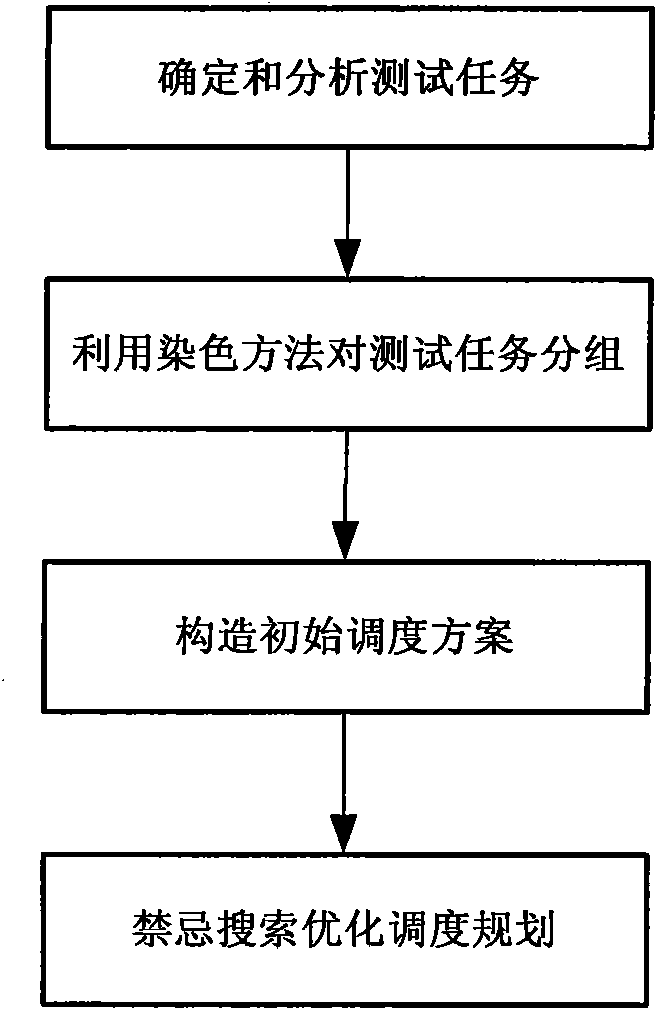

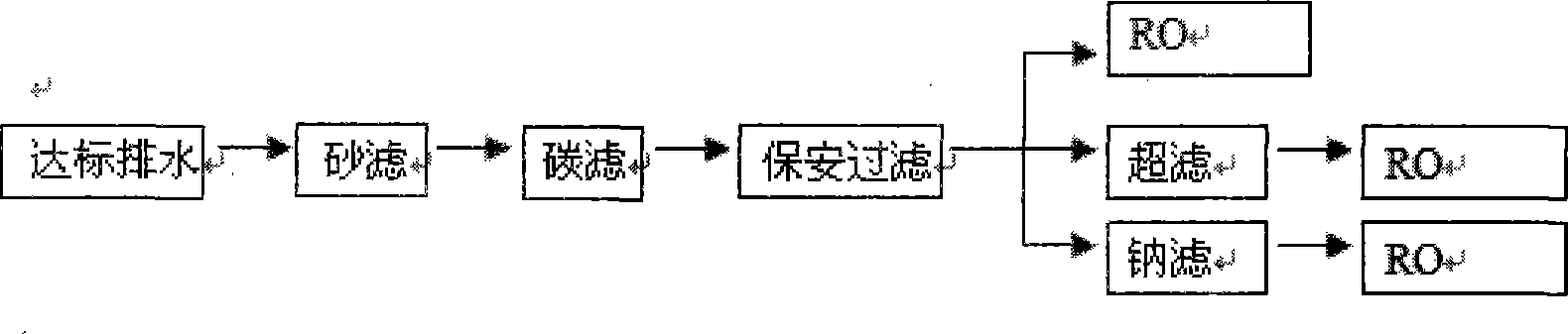

Regeneration treatment and cyclic utilization method of printing and dyeing wastewater

InactiveCN101205105AReduces problems with separation operating pressure increasesGood effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to a method for reproducing, treating, cycle using dyeing sewage, which is characterized in that the method comprises that: (1) adjustment of pH value: the pH value of the mixed dyeing sewage is on-line real-time detected and adjusted by automatically adding acid or alkali to a best pH value corresponding to adopted coagulant; (2) coagulation sedimentation: the coagulant is added to stirring reaction and gravity sedimentation; (3) mechanical filtration: supernatant is filtered by the mechanism to remove a little plurality of suspended particles in the water; (4) fine filtration: by adopting security filter, residual micro particles are caught; (5) reserve osmosis membrane separation: by using the reserve osmosis membrane to carry out membrane separation, output clear water is cycled for use; (6) biological treatment: by adopting the biological treatment to membrane separate concentrated sewage, organic pollutants in the sewage are removed; (7) secondary coagulation sedimentation: bio-chemical effluent adding with the coagulant is reacted and precipitated again, and discharged after reaching the national first class discharge standard.The biological treatment and the secondary coagulation sedimentation can be replaced by sewage treatment plant for centralized treatment.The method is characterized by small occupied area, little investment and low operating cost.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Method for processing and separate-recycling printing and dyeing wastewater

InactiveCN101293726AEasy to handleQuick reuseTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentUltrafiltrationAnaerobic reactor

The invention discloses a method for processing and separate recycling of printing and dyeing wastewater, which comprises the following steps: after the printing and dyeing wastewater is firstly processed by an anaerobic reactor, a hypoxia reactor and an aerobic reactor, the separate recycling of part of the water is used for a desizing process of printing and dyeing technology; then, after the rest wastewater is processed by an aerator biofilter, the separate recycling of the part of the water is used for a boiling-off process of the printing and dyeing technology; then, after the rest wastewater is processed by an ultrafiltration reactor, the separate recycling of the part of the water is used for bleaching process and mercerization process of the printing and dyeing technology; finally, the rest water is processed by an anti-permeability reactor and the separate recycling of the part of the water is used for dyeing process, printing process and ordering process. After being processed by the invention, the printing and dyeing wastewater can be carried out the separate recycling quickly and high-efficiently and the recycling rate of the wastewater reaches more than 70 percent; meanwhile, the fee of processing and recycling the wastewater can be saved; the service life of advanced treatment equipment can be prolonged, which is easy for a large-scale industrialized application.

Owner:NANJING UNIV

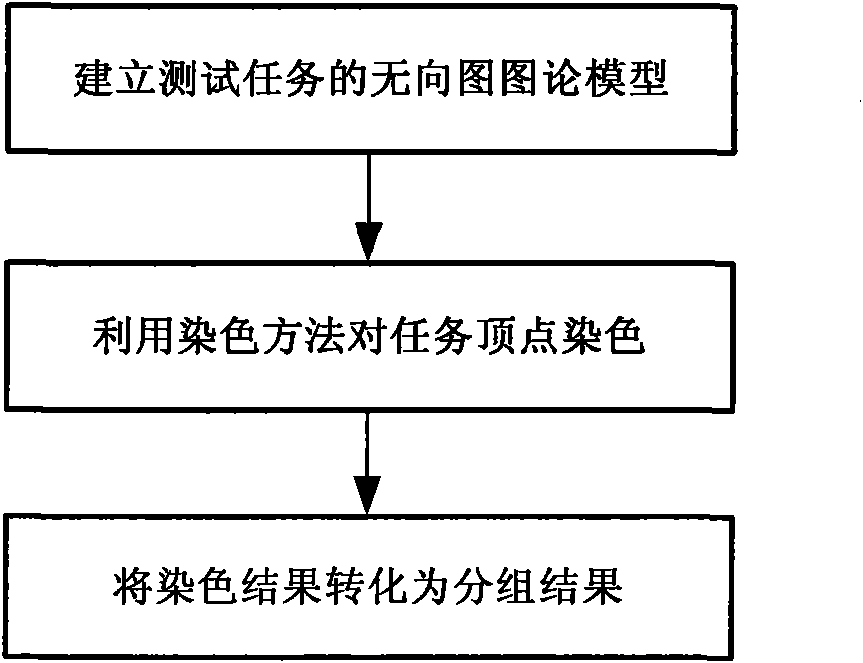

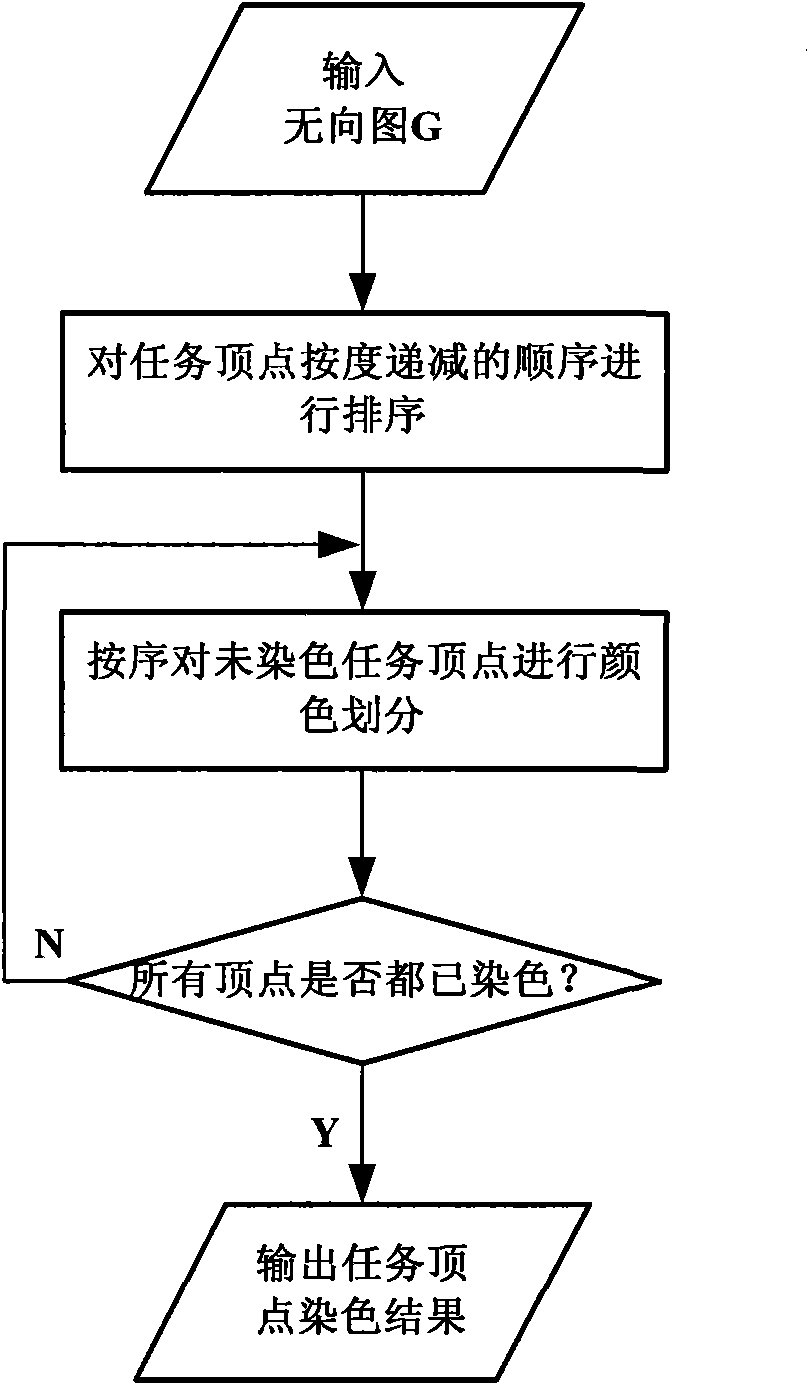

Method for scheduling parallel test tasks based on grouping and tabu search

InactiveCN101984412AHigh speedSolve the random choice problemResource allocationStart timeTheoretical computer science

Owner:BEIHANG UNIV

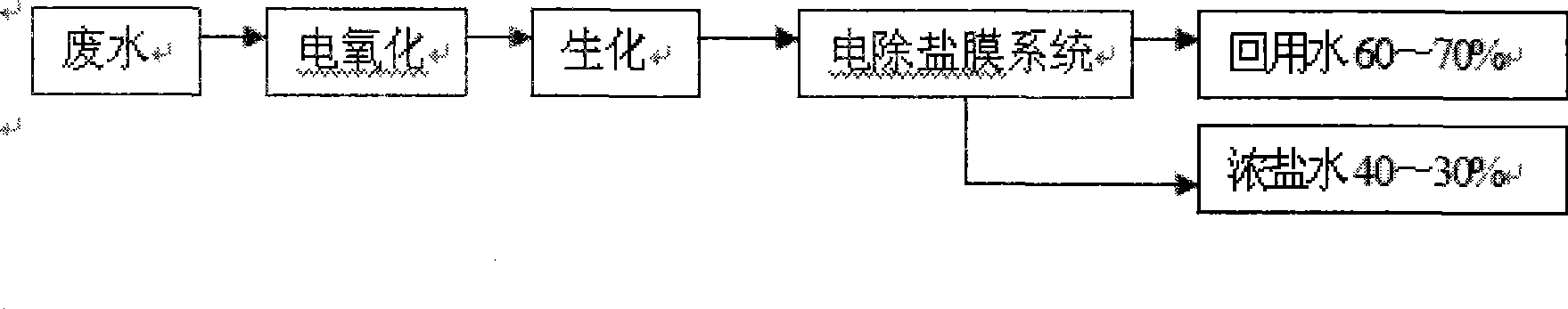

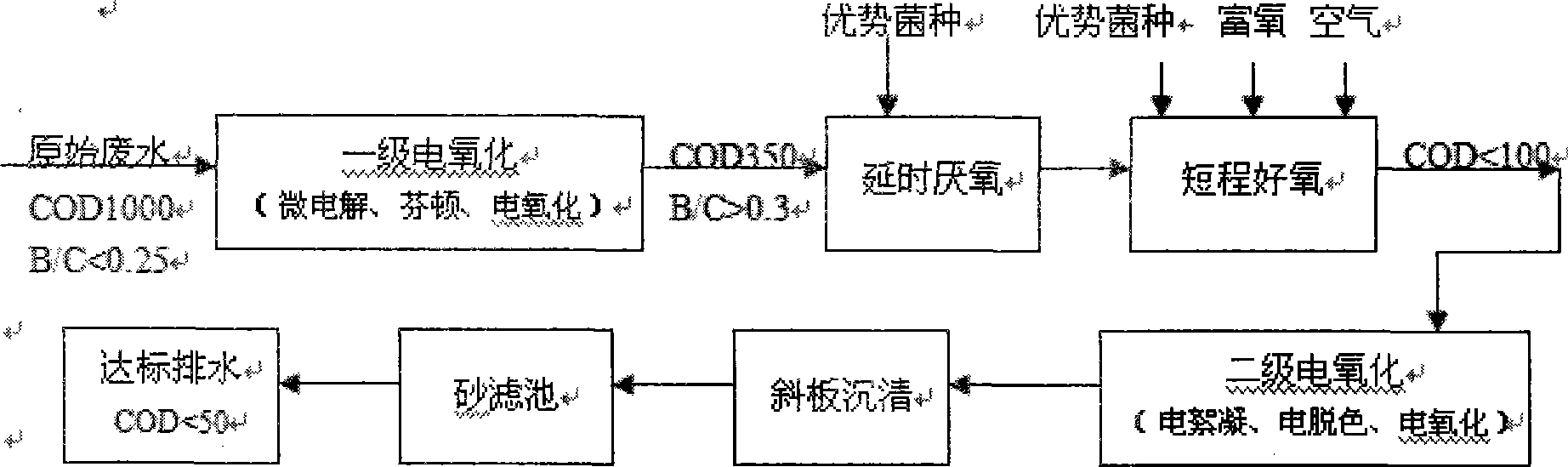

Zero discharge processing EBM method for dyeing waste water

InactiveCN101503268AReduce the load of purification and reuseSolve the blockageGeneral water supply conservationTreatment with aerobic and anaerobic processesFiberElectrolysis

The invention provides an EBM method for zero drainage treatment of dyeing wastewater. The method comprises that: step 1, a centrifuge dripping counter current washing process is carried out in a dyeing rinsing process; step 2, dyeing initial wastewater is subjected to standard-reaching treatment, step 2a, primary electro-oxidation is carried out, comprising micro-electrolysis, electro-oxidation, Fenton action and microwave, step 2b, biochemical treatment is carried out, comprising time delay anaerobism and short time aerobism, and superior bacteria is added in the same time, and step 2c, secondary electro-oxidation is carried out again after the biochemical treatment, comprising electrolytic flocculation, electric de-colorization and electro-oxidation; step 3, standard-reaching drainage water is subjected to deep purification treatment, which is to enter an electric desalination film system for treatment, plain water flows out after the standard-reaching drainage water is subjected to sand leach, fiber filtration, electric desalination and RO film in sequence, and can be recycled, and high concentrated water flows out from electric desalination. The treatment method saves water and energy, reduces COD drainage of the dyeing wastewater, and improves the de-colorization rate, the turbidity and the removal rate of ammonia nitrogen.

Owner:东莞市珠江海咸水淡化研究所

Fabric-like recombined decorated veneer and manufacture method thereof

ActiveCN101456197AClear linesBright colorOther plywood/veneer working apparatusWood treatment detailsEngineeringHigh contrast

The invention relates to a method for processing wood, in particular to a method for producing a recombined decorative veneer by using a dye with bright color to simulate cloth marks and the veneer manufactured by the method. In order to achieve the aim, the invention adopts a method for manufacturing the recombined decorative veneer simulating cloth marks, which comprises the processes of veneer bleaching, veneer dyeing, veneer drying, veneer digging and repairing, veneer combination, veneer sizing, veneer gluing, veneer maintenance, and veneer slicing. The method adopts the dye with the bright color to dye the veneer with the bright color, and adopts the veneer with high contrast grade to combine according to designed patterns; and the produced recombined decorative veneer has clear lines similar to wall cloth. Compared with other recombined decorative veneers, the color is brighter, the lines are clear, and the patterns mainly adopt a wall cloth series.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

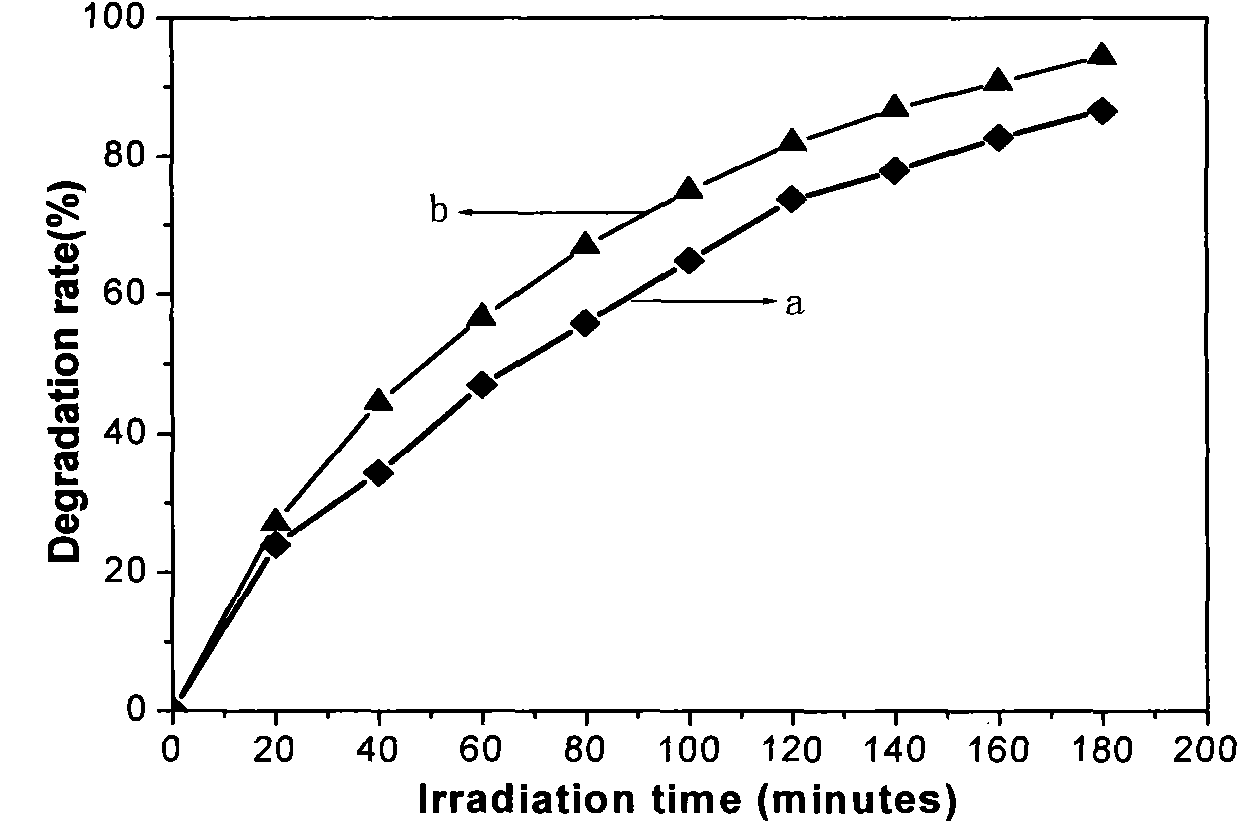

Method for treating industrial waste water by means of photoelectrocatalysis

InactiveCN101798126ANo physical transferHigh selectivityWater/sewage treatment by irradiationWater contaminantsOptical radiationTio2 nanotube

The invention provides a method for treating industrial waste water by means of chemical oxidation or chemical deoxidation in photoelectrocatalysis, belonging to the field of environmental protection. The method comprises the following steps of: taking a titanium positive electrode oxidation method-prepared high-ordered titanium-based TiO2 nanotube array thin film as an optical positive electrode or an optical negative electrode; taking high-purity black lead as an electrode; and degrading organic matter or heavy metal ion of the industrial waste water into H2O and CO2, low valent metal ion or metal simple substance under the conditions of the connection of an external circuit and the optical radiation. The invention has the advantages that: the adopted catalytic agent optical positive electrode is the high-ordered array thin film which is self assembled by anodic oxidation and is perpendicular to the bottom of the titanium base, thereby not only overcoming the defects of the existing powder body loading thin film optical positive electrode such as bad bond, easy falling and gradually-attenuated catalysis efficiency, but also being capable of directly using the sunlight by doping the modifying property to the array thin film, and being an advanced technology for treating single waste water (dye such as paper mill organic waste water, printing and dyeing mill organic waste water, or heavy metal ion such as electroplate factory chromium-containing waste water) or complex waste water with energy saving, high efficiency, high selectivity, cleaning and low cost.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com