Two-stage ultrasonic vibration atomizer

A technology of ultrasonic vibration and atomizer, applied in the direction of injection device, liquid injection device, etc., can solve the problems of large diameter of atomized particles, small atomization flow rate, low atomization efficiency, etc., and achieve large power capacity and adjustable power , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

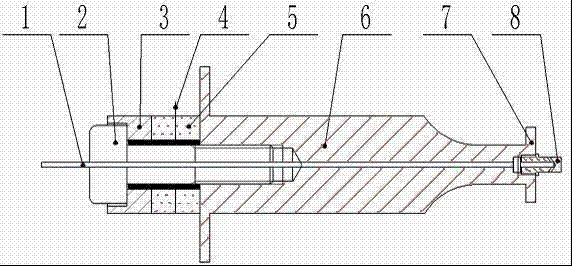

[0038] like figure 1 As shown, the two-stage ultrasonic vibration atomizer of the embodiment of the present invention adopts a piezoelectric ceramic sandwich structure, including a bolt 2 and a rear cover plate 3, a piezoelectric ceramic sheet 5, and an electrode sheet that are sequentially sleeved on the bolt. 4 and the horn 6, as well as the secondary atomizing radiation surface 7 arranged at the front end of the horn 6 and the primary atomizing nozzle 8 fixedly connected to the front end of the horn by threads. The rear cover 2, the piezoelectric ceramic sheet 3 and the electrode sheet 4 are clamped by the screw thread at the front end of the bolt 2 and the connection of the horn 6, and the rear cover 3, the piezoelectric ceramic sheet 5 and the The electrode sheet 4 is connected and compressed by the thread at the front end of the bolt 2 and the horn 6 to form a primary ultrasonic atomizing vibrator, and the secondary atomizing radiation surface 7 is located at the front ...

Embodiment 2

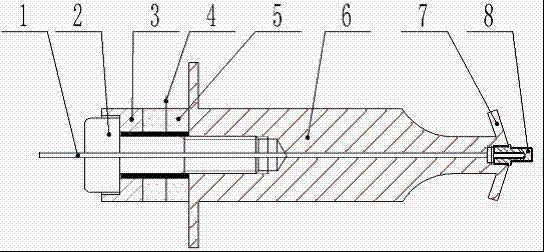

[0041] figure 2 Shown is another structural form of the two-stage ultrasonic vibrating atomizer, and figure 1 The difference is that the secondary atomization surface at the front end is a divergent radiation surface, which is suitable for occasions where the atomization area is required to be large. chemical spray nozzle 8 front ends.

Embodiment 3

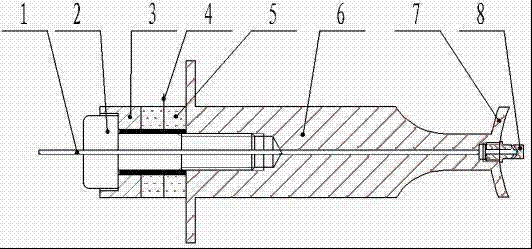

[0043] image 3 Shown is yet another structural form of the two-stage ultrasonic vibration atomizer, and figure 1 The difference is that the secondary atomization surface at the front end is a converging radiation surface, which is suitable for occasions where the atomization area is relatively concentrated. chemical spray nozzle 8 front ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com