Patents

Literature

223results about How to "Controllable diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

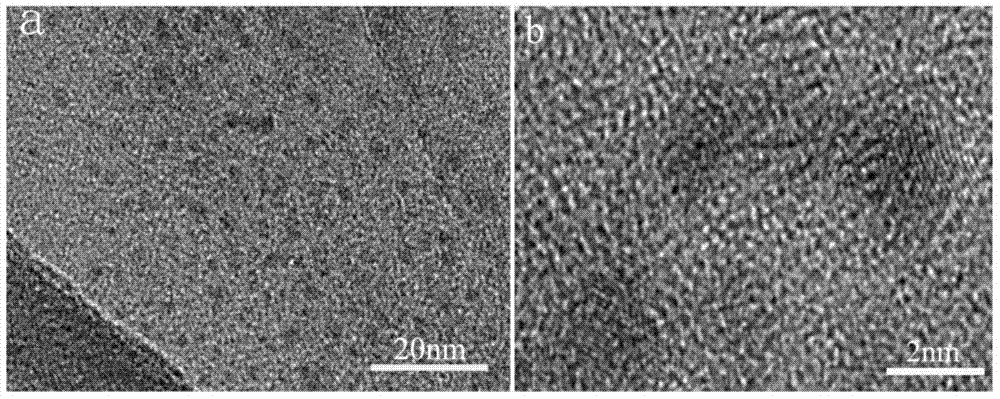

Method for preparing polyacrylonitrile-based porous hollow carbon fibers by coaxial electrospinning

InactiveCN102691136ALarge specific surface areaImprove efficiencyCatalyst carriersOther chemical processesPolymer scienceCarbon fibers

The invention discloses a method for preparing PAN (polyacrylonitrile)-based porous hollow carbon fibers by coaxial electrospinning. The method includes the steps: mixing polyacrylonitrile with additives to serve as outer solution; taking inner polymer to serve as inner solution; inputting the outer solution and the inner solution into outer layers and inner layers of coaxial needles respectively at the constant flow velocity and in the constant velocity ratio for electrospinning so that PAN-based sheath-core composite fibers are obtained; and subjecting the PAN-based sheath-core composite fibers to washing, pre-oxidation and carbonization so that the PAN-based porous hollow carbon fibers are obtained. The PAN-based porous hollow carbon fibers combine structural characteristics of original porous carbon fibers and original hollow carbon fibers, the specific surface area of the fibers can be greatly increased, and use efficiency of materials is improved. When the PAN-based porous hollow carbon fibers prepared by the method are applied to gas adsorption, gas can enter hollow portions of the fibers more easily, so that adsorbability is enhanced while time required by adsorption is shortened.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

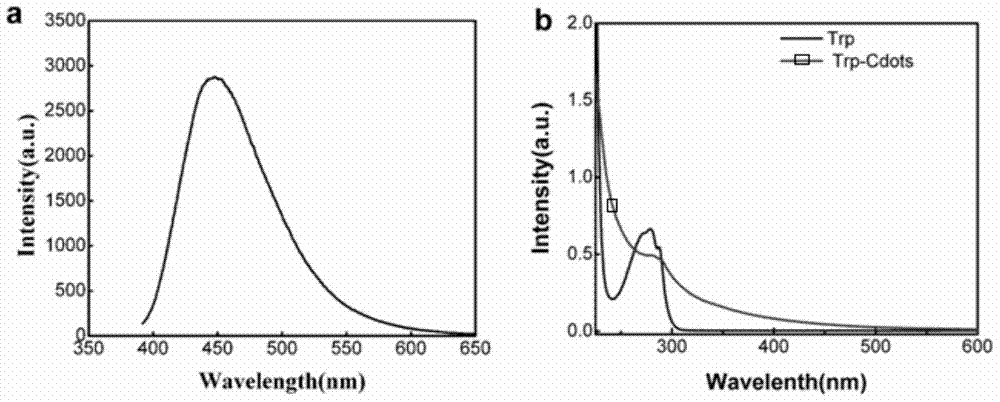

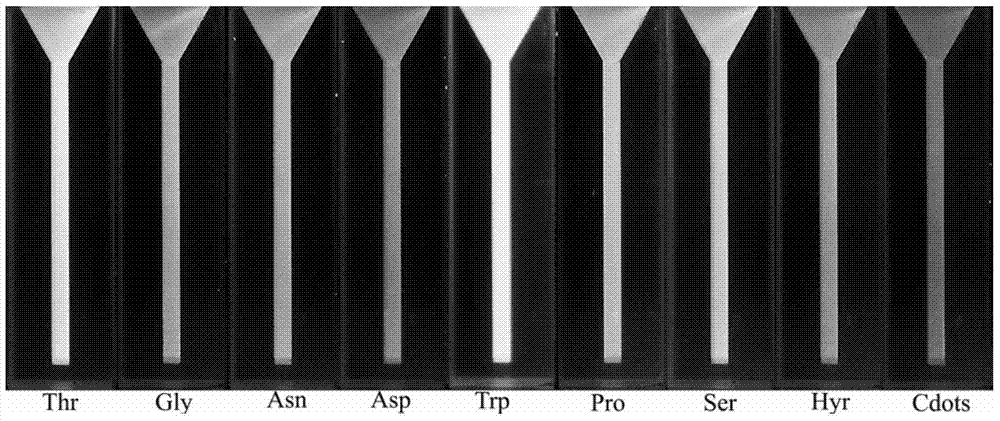

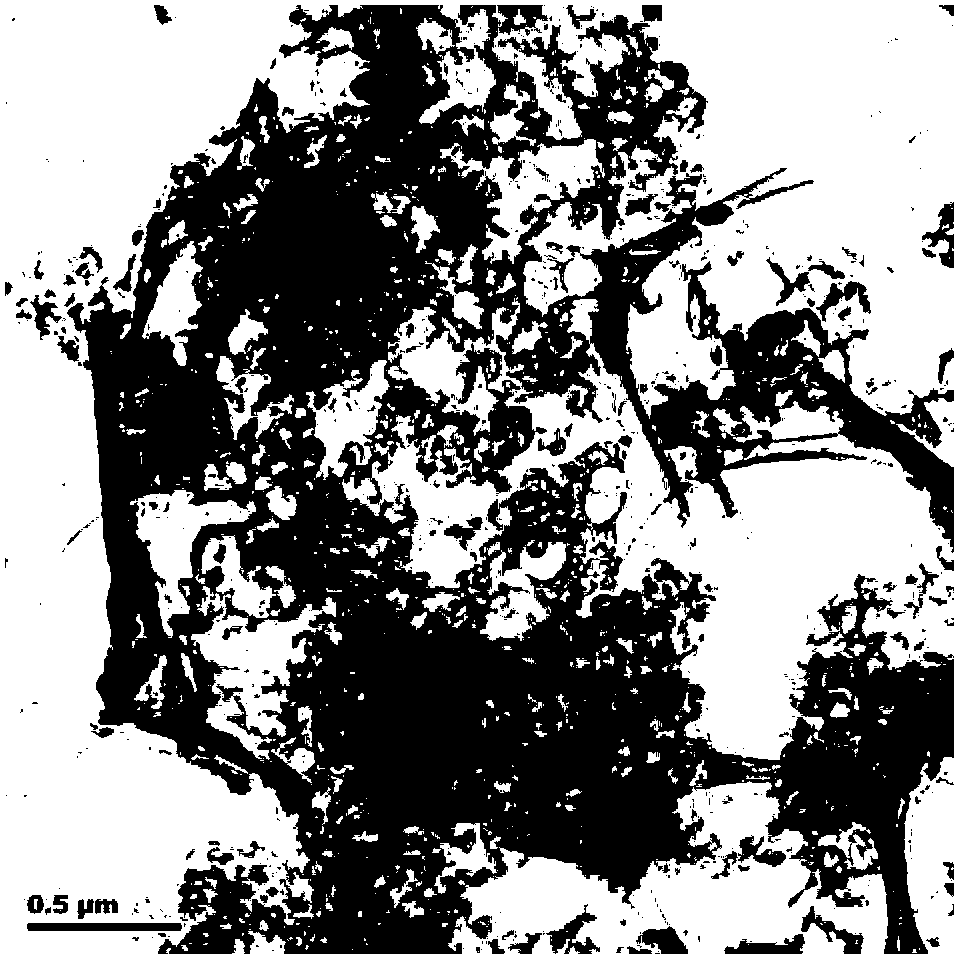

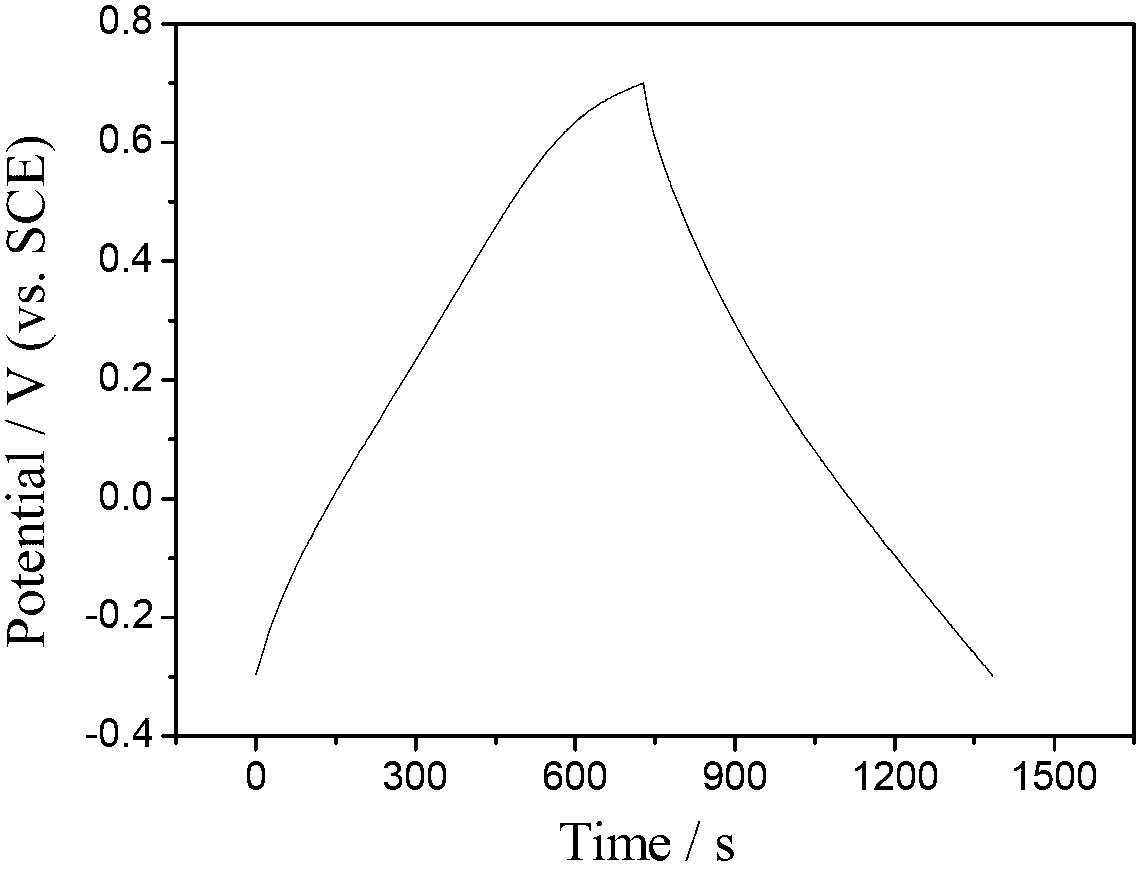

Method for green synthesis of fluorescent chiral carbon dots

InactiveCN103693633AHigh fluorescence quantum yieldHigh yieldNanoopticsNano-carbonQuantum yieldParticle-size distribution

The invention provides a method for green synthesis of fluorescent chiral carbon dots. The method comprises the steps of 1, ultrasonically dispersing a carbon precursor and amino acid in deionized water to prepare a transparent aqueous solution or latex, wherein the mass ratio of the carbon precursor to the amino acid is 200:1 to 5:1; 2, putting the mixed solution obtained in the step 1 into a microwave heating device for a microwave heating reaction so as to obtain yellow or brown-yellow liquid; 3, dialyzing the carbon quantum dot solution obtained through the reaction in the step 2 by a dialysis bag of which the molecular weight cut-off is 1,000-50,000 to remove unreacted carbon precursor and amino acid, thereby obtaining fluorescent carbon dots, of which the particle size distribution is narrow, without further purification. The method disclosed by the invention adopts a microwave synthetic method to obtain the chiral carbon dots with the relatively high fluorescent quantum yield through one step, the synthetic method is simple, the required equipment is simple, the repeatability is good, and the method is suitable for preparation of chiral carbon dots on a large scale.

Owner:SHANGHAI JIAO TONG UNIV

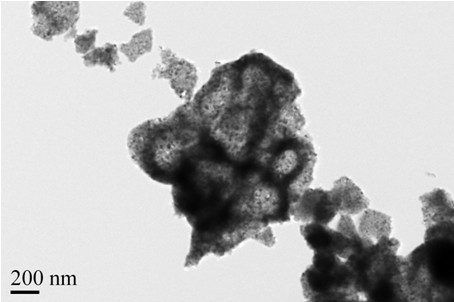

Method for preparing oxidized graphene/conductive polypyrrole nano wire composite material

InactiveCN102800432AIncrease the active siteLower internal resistanceElectrolytic capacitorsCable/conductor manufacturePolypyrroleFiltration

The invention relates to a method for preparing an oxidized graphene / conductive polypyrrole nano wire composite material. The method comprises the following steps of: preparing oxidized graphene by using natural graphite according to a chemical oxidization method, uniformly dispersing the oxidized graphene into deionized water by adopting an ultrasonic method to obtain a stable oxidized graphene suspension; adding hexadecyl trimethyl ammonium bromide with the mole concentration being 0.025 to 0.038 mol / L into the oxidized graphene suspension, uniformly stirring and mixing, adding pyrrole into the suspension, and uniformly mixing and stirring; polymerizing pyrrole monomers on an oxidized graphene nano sheet in situ by taking the hexadecyl trimethyl ammonium bromide as a surface active agent and ammonium persulfate as an oxidant, and performing frequent washing, suction filtration and vacuum drying on a product to finally obtain the oxidized graphene / conductive polypyrrole nano wire composite material. According to the preparation method, the process is simple, and the cost is low; and the product is high in specific capacity and high stability. The method can be applied to fields such as lithium ion batteries, sensors, electronic devices and fuel batteries.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

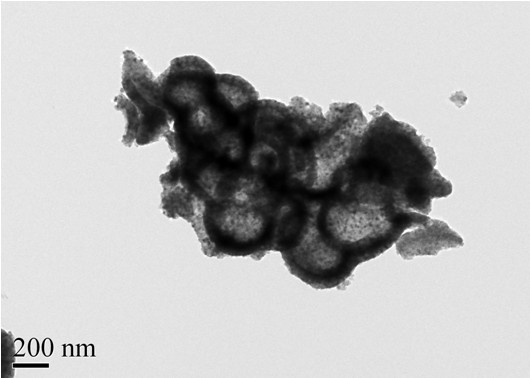

Polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst and preparation method thereof

InactiveCN102600907AEasy to makeLow costOrganic-compounds/hydrides/coordination-complexes catalystsSolar lightPolypyrrole

The invention discloses a polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst and a preparation method thereof. The preparation method comprises the following steps of: carrying out hydro-thermal synthesis to obtain nanometer carbon pellets by utilizing glucose; with the carbon pellets as a template agent, loading a titanium dioxide film layer on the surface through a sol-gel method to prepare carbon / titanium dioxide microspheres; sintering the microspheres to prepare hollow titanium dioxide nanometer microspheres; and loading a suitable amount of polypyrrole on the surface of the hollow titanium dioxide by utilizing a chemical in-situ polymerization method to obtain the polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst. The microspheres prepared by the method disclosed by the invention have adjustable diameters, and the thickness of the titanium dioxide layer can be also adjusted by changing the content of butyl titanate. The polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst disclosed by the invention has better photocatalytic activity, and especially, the response range of lights can be expanded to a visible light area, thus conditions are created for the application of the polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst to carry out photocatalytic degradation on pollutants by utilizing solar lights in the industry. The polypyrrole-sensitized hollow titanium dioxide nanometer photocatalyst and the preparation method thereof, disclosed by the invention, have the advantages of simplicity in preparation, environment friendliness, economy and suitability, and are favorable for circular economy and sustainable development.

Owner:NANJING UNIV

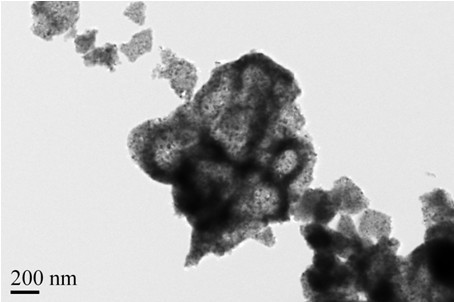

Method for manufacturing silver nanowires

The invention discloses a method for manufacturing silver nanowires. The method includes steps of (1), manufacturing mixed solution A from surfactants, halogen-containing inorganic salt, reducing sugar and water; (2), manufacturing mixed solution B from gelatin, water and silver salt precursors; (3), mixing the mixed solution A with the mixed solution B, uniformly stirring the mixed solution A and the mixed solution B, transferring the mixed solution A and the mixed solution B into a reaction kettle, sealing the reaction kettle, heating the reaction kettle, keeping the temperature of the reaction kettle unchanged and obtaining stock solution of the silver nanowires; (4), diluting the stock solution of the silver nanowires by mixed solvents comprising water and ethanol, and removing the surfactants and the salt of the diluted stock solution of the silver nanowires to obtain concentrated solution of the silver nanowires; and (5), drying the concentrated solution of the silver nanowires to obtain powdery products of the silver nanowires. The method has the advantages that organic solvents are omitted, and the method is environment-friendly; lengths and diameters of the silver nanowires manufactured by the method can be adjusted within large ranges; and a process is simple, operation is convenient, the repeatability is good, and large-scale production can be effectively implemented.

Owner:苏州冷石纳米材料科技有限公司

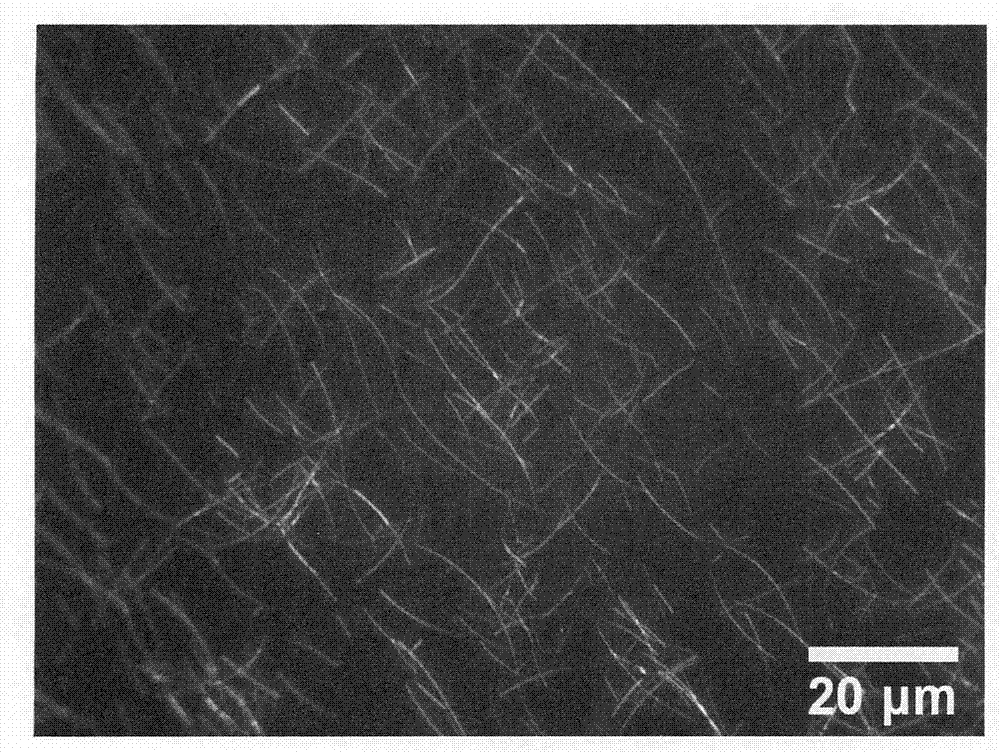

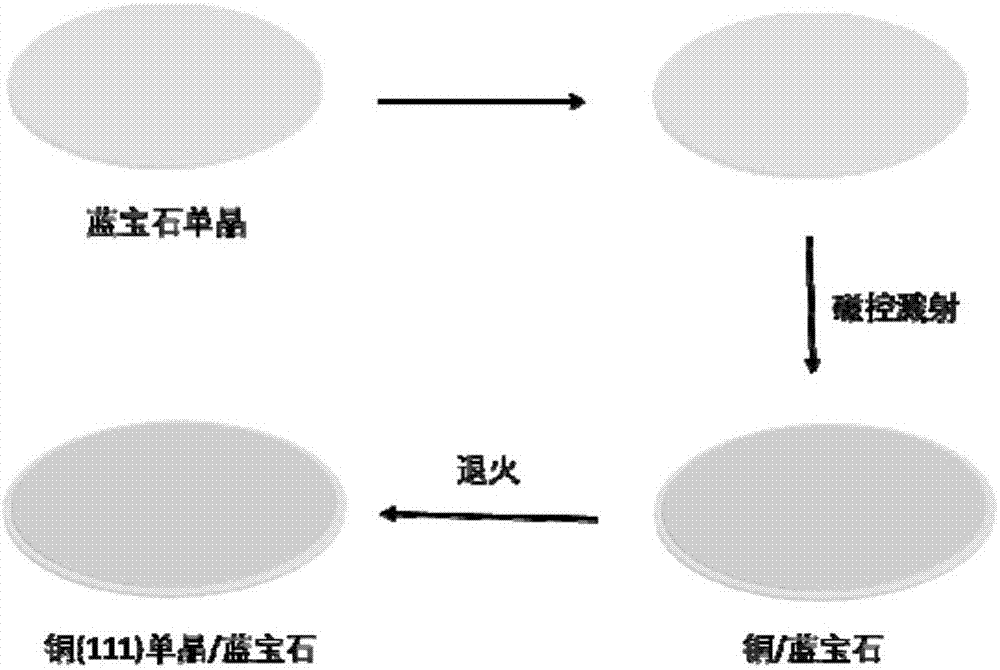

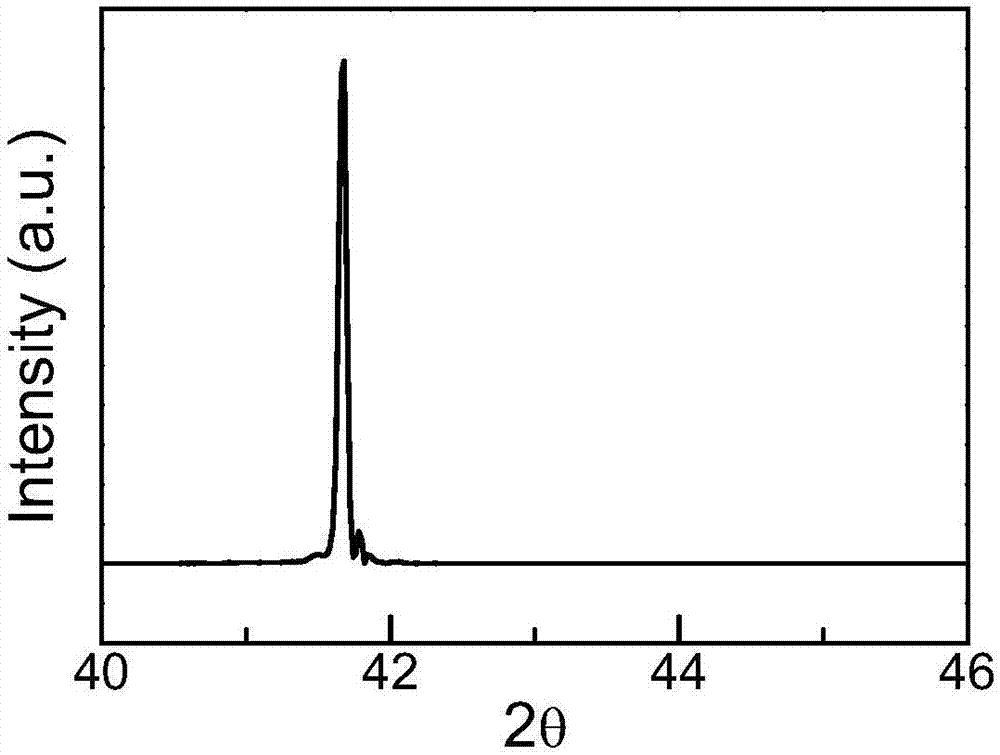

Method for preparing ultra-flat copper monocrystalline film

ActiveCN107354506AFlat surfaceControllable diameterPolycrystalline material growthVacuum evaporation coatingSputteringThin membrane

The invention discloses a method for preparing an ultra-flat copper monocrystalline film. The method for preparing the copper monocrystalline film, provided by the invention, comprises the following steps: taking a sapphire monocrystal as a growth substrate, carrying out copper target magnetron sputtering, and carrying out annealing, thereby obtaining the copper monocrystalline film. According to the method, sapphire is adopted as an epitaxial substrate of copper, a magnetron sputtering method is adopted, a copper film with consistent orientation is deposited on the surface of a c-face sapphire substrate, and copper with consistent orientation is aged and grows up during subsequent annealing so as to form a consistent-orientated monocrystalline copper (111) film without in-plane twin crystals. The monocrystalline copper (111) film prepared by the method is extremely flat in surface, controllable in diameter and high in repeatability and has a very extensive application prospect in the fields of communications, electronics, graphene preparation and the like.

Owner:PEKING UNIV

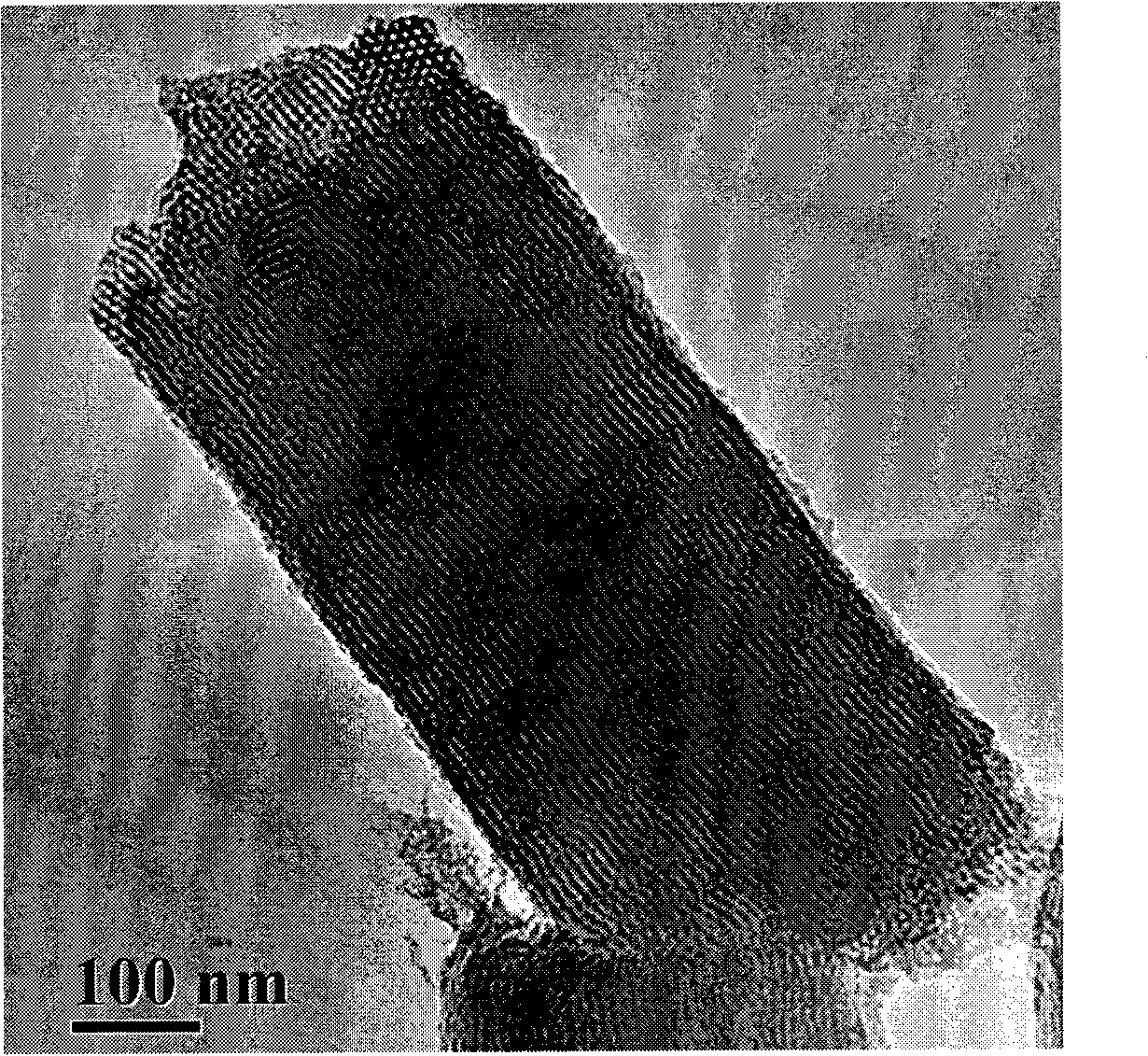

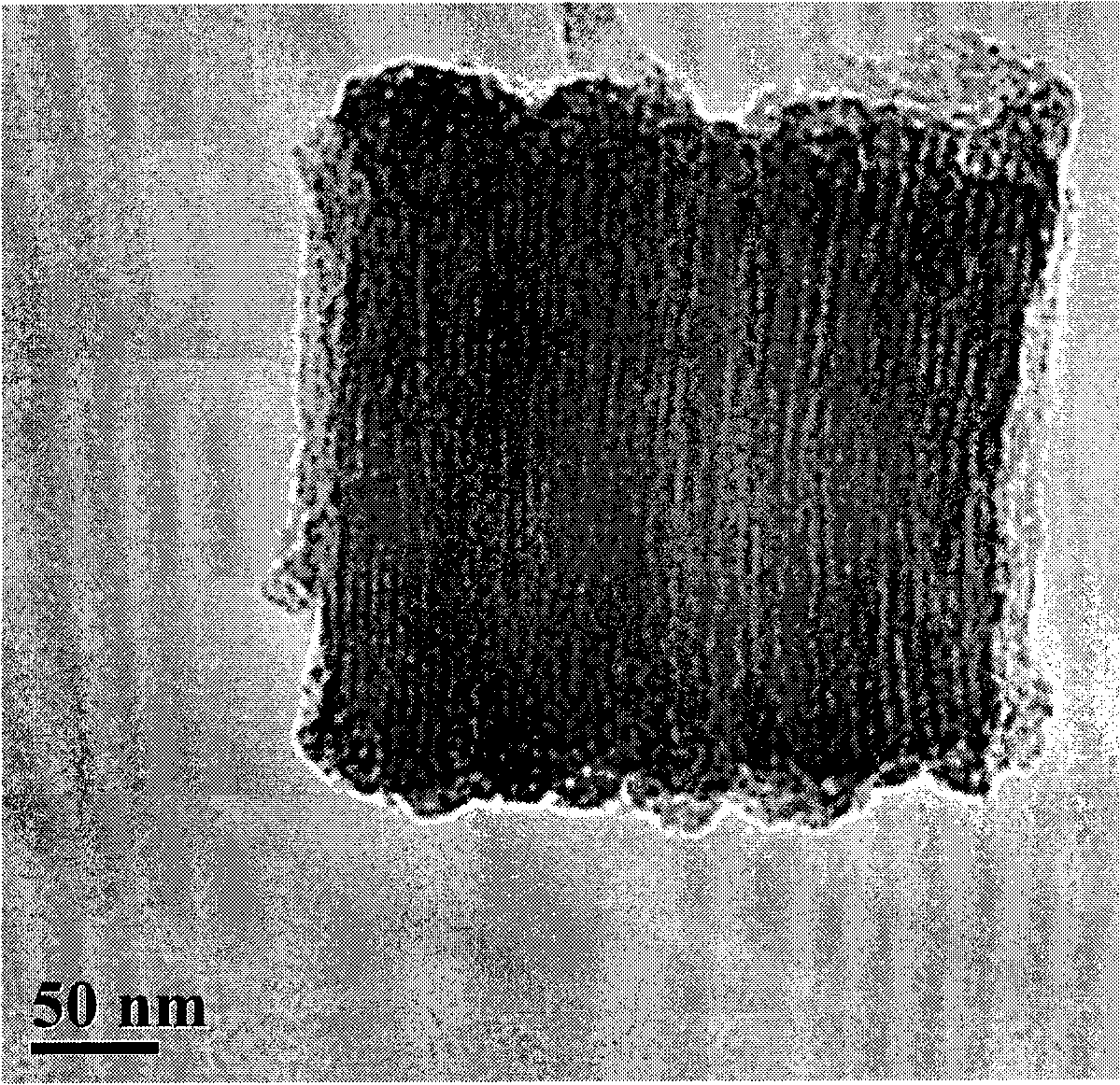

Bar-shaped ordered mesopore silicon dioxide nano material and preparation method thereof

InactiveCN101514001ASimple processSuitable for mass productionSilicaMolecular-sieve and base-exchange compoundsSurface-active agentsAnti-Tumor Drugs

The invention relates to a bar-shaped ordered mesopore silicon dioxide nano material and a preparation method thereof, belonging to the technical field of inorganic porous nano material. The bar-shaped ordered mesopore silicon dioxide nano material prepared by a method of chemical surface active agent has the bar length of 100-2000nm, the bar diameter of 60-800nm, the pore diameter of 3-30nm, the pore volume of being larger than 0.6cmg and the specific surface of being more than 600mg. The invention has large controllable pore diameter, controllable bar length and bar diameter with in nano scale and simple technique, so as to be suitable for mass production and used for carrying DNA molecule, antineoplastic molecule, biological enzyme molecule, organic fluorescence molecule, quantum dot, nano crystalloid, etc.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

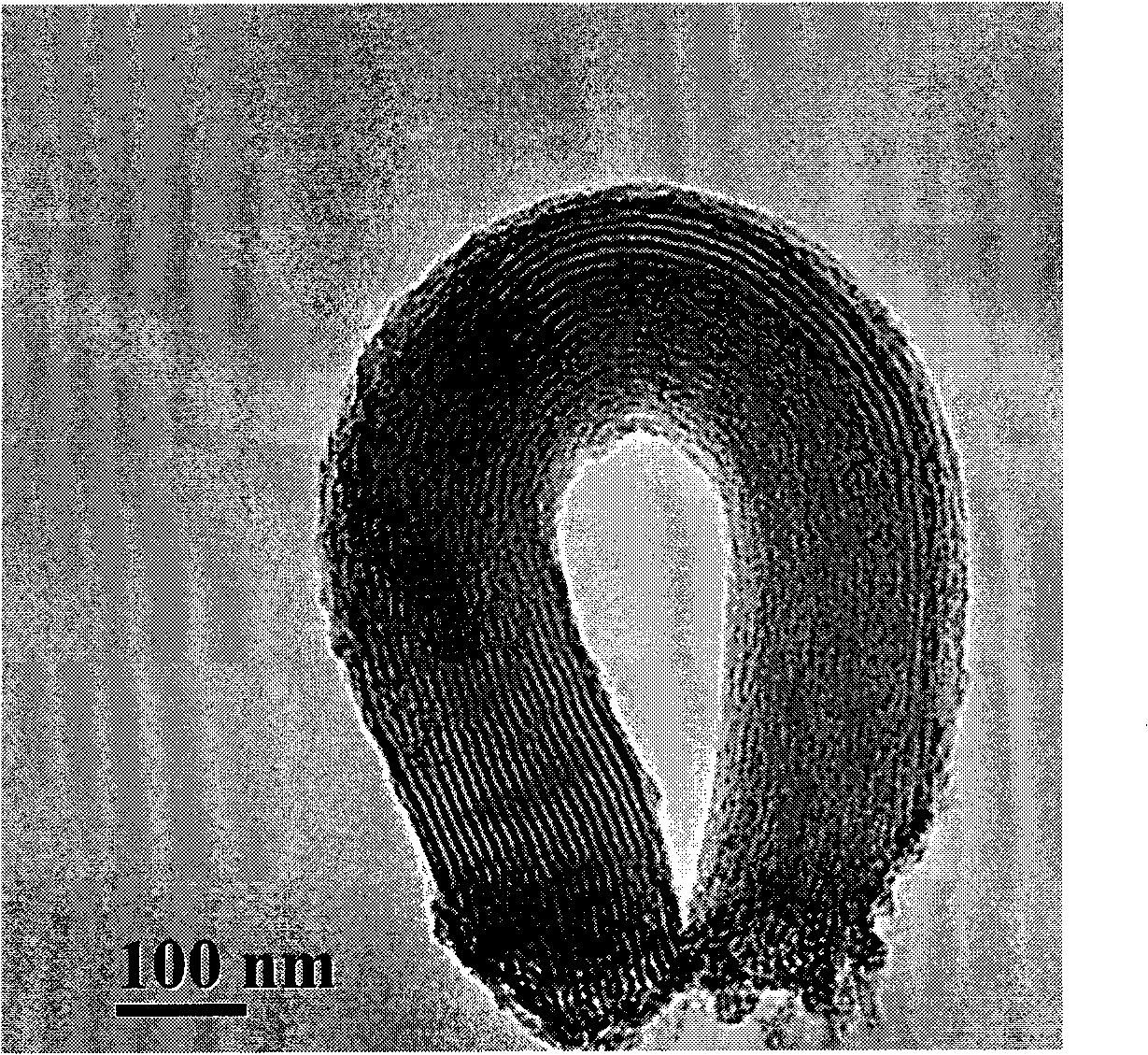

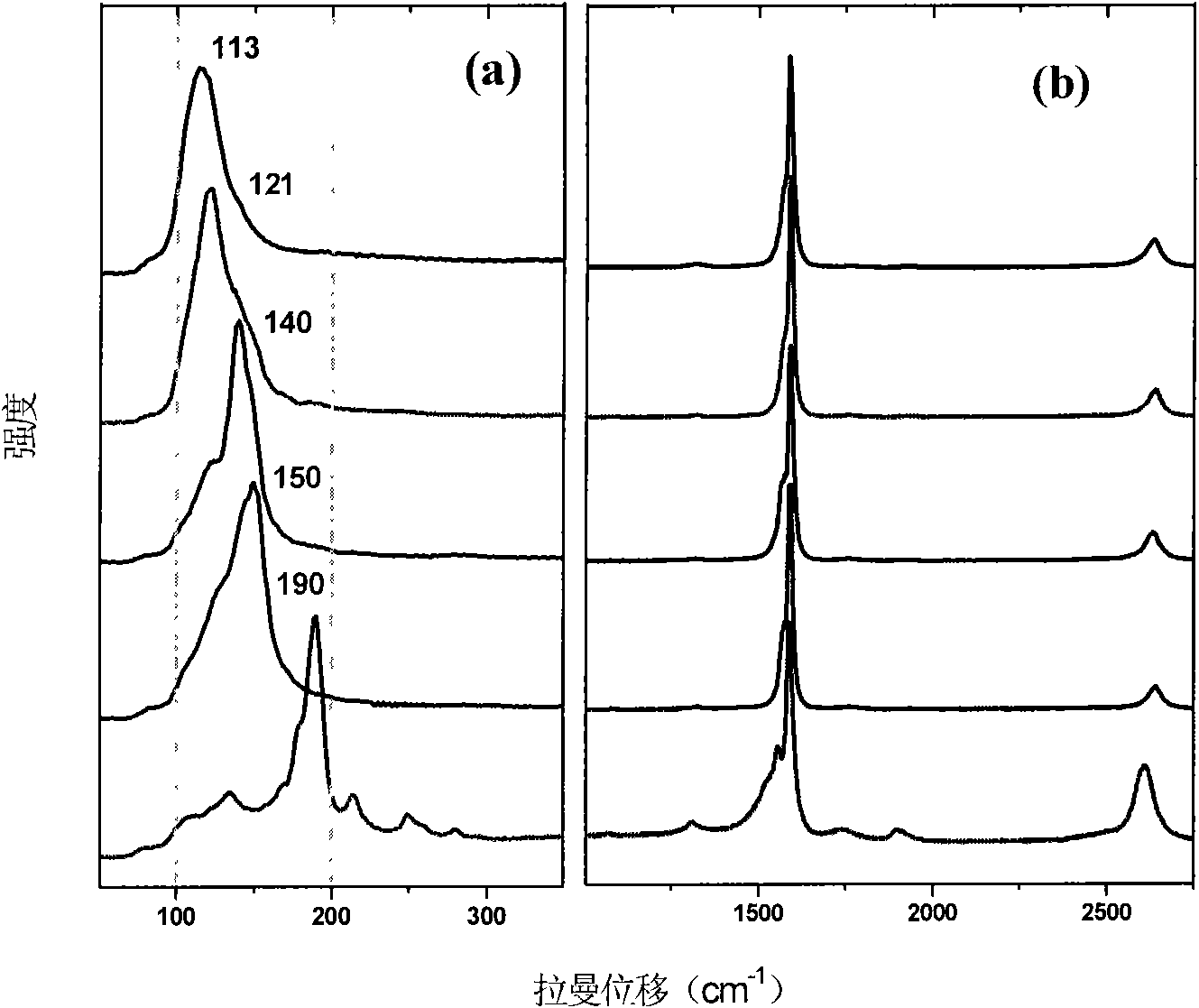

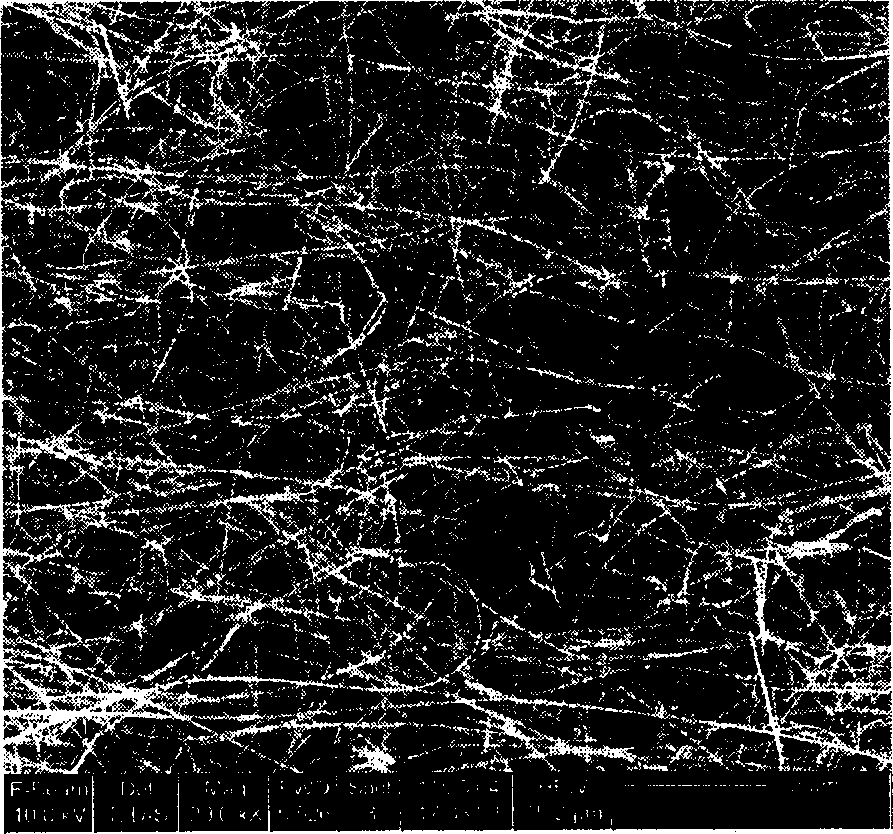

Preparation method of single-walled carbon nano-tube with adjustable diameter

InactiveCN101585525AInhibition of cleavage reactionsHigh purityNanostructure manufactureOrganic compoundCobalt

The invention relates to a preparation technique of carbon nano-tubes, in particular to a preparation method of a single-walled carbon nano-tube with adjustable diameter, which is suitable to prepare the single-walled carbon nano-tube with adjustable diameter. The single-walled carbon nano-tube with adjustable diameter can be produced by adopting organic compound catalyst containing iron, cobalt or nickel with ultra high hydrogen flow and ultra low carbon source flow, and sulfur-containing growth promoter after the organic compound catalyst and the sulfur-containing growth promoter are uniformly mixed in a gas state and are input into a reaction region, wherein the mol ratio of hydrogen and carbon source is more than 300, and the mol ratio of sulfur and iron, cobalt or nickel is 1 / 100-1 / 5. The invention inhibits the scission reaction of hydrocarbon with ultra high flow by adopting large-flow hydrogen as buffer gas, and large-flow hydrogen etches the generated agraphitic carbon and minor diameter single-walled carbon nano-tube, thereby improving the purity of the produced single-walled carbon nano-tube and narrowing the diameter.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

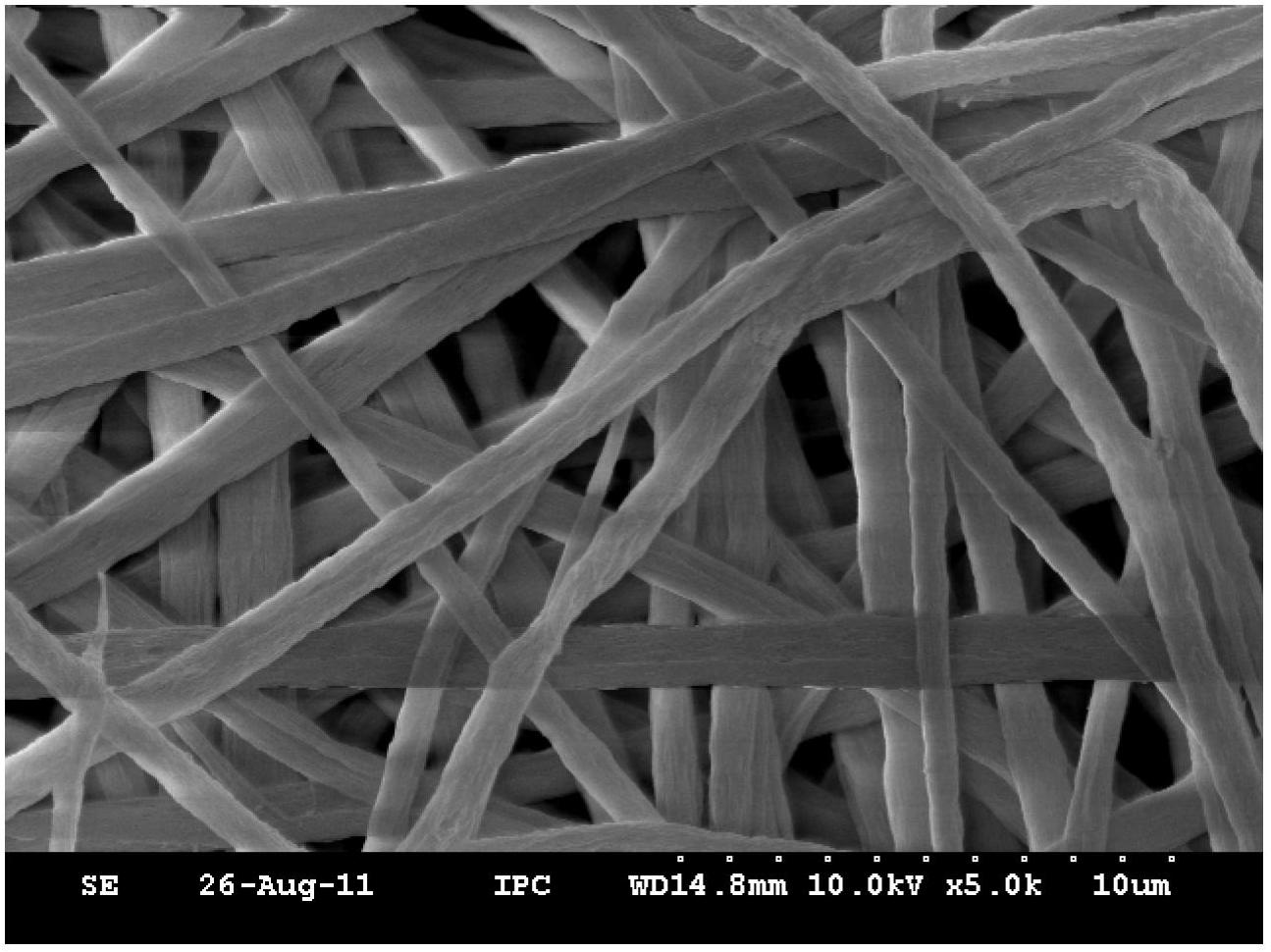

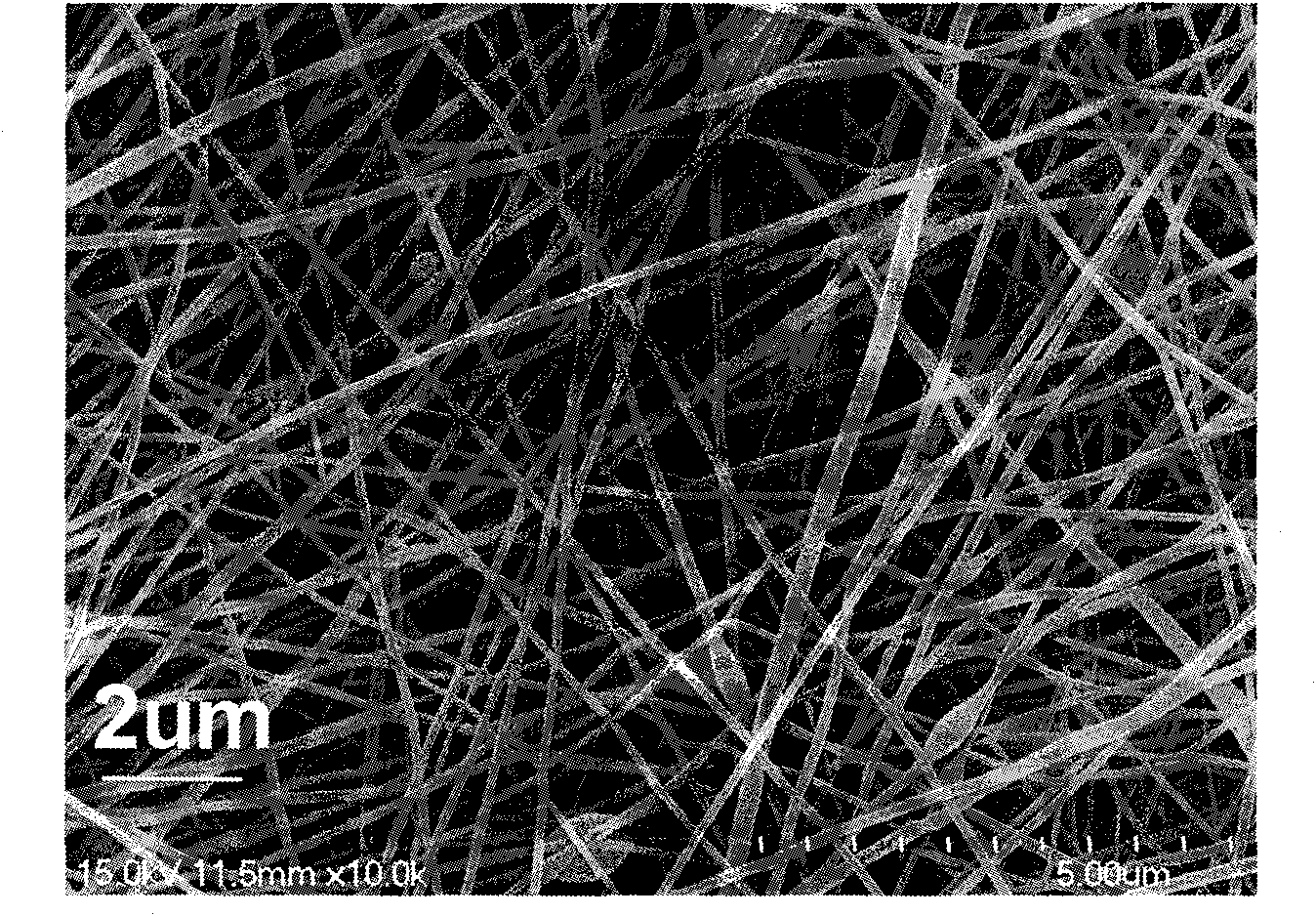

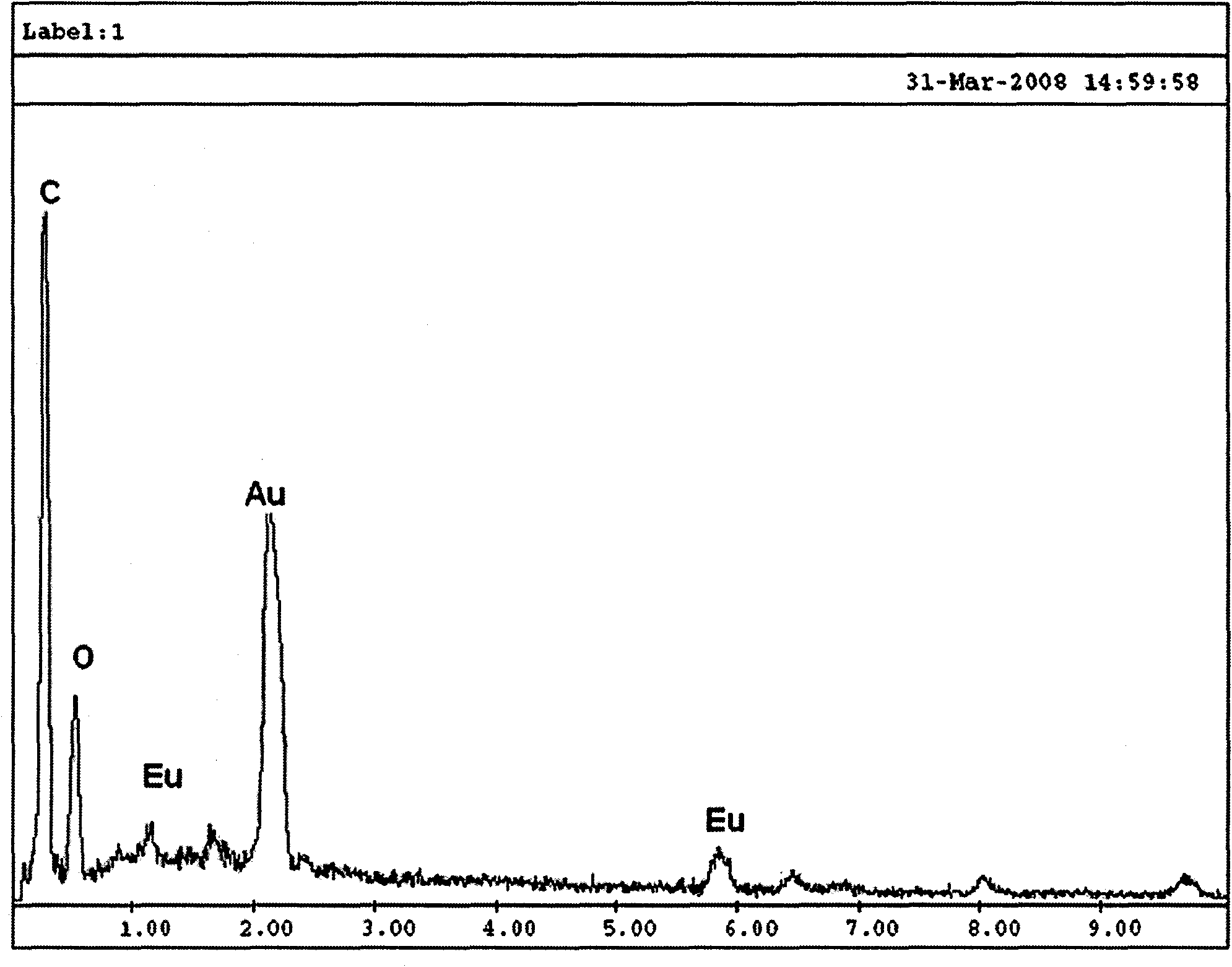

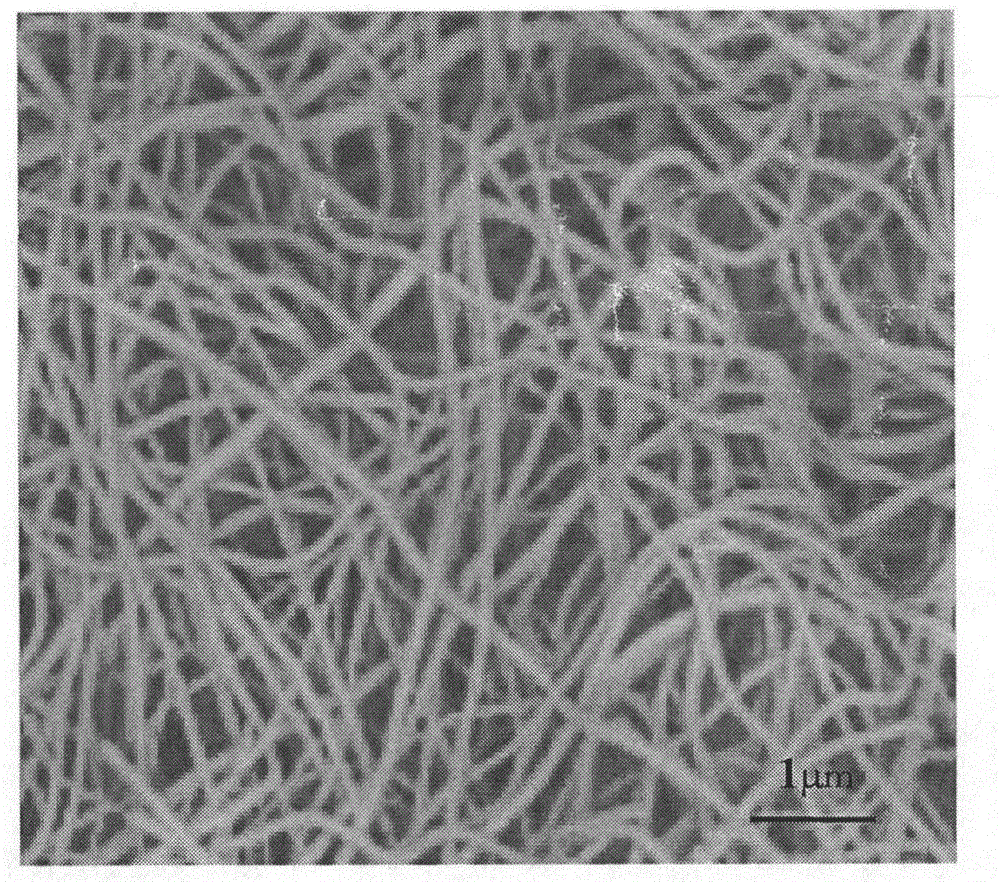

Polyimide nano-fiber and preparation method thereof

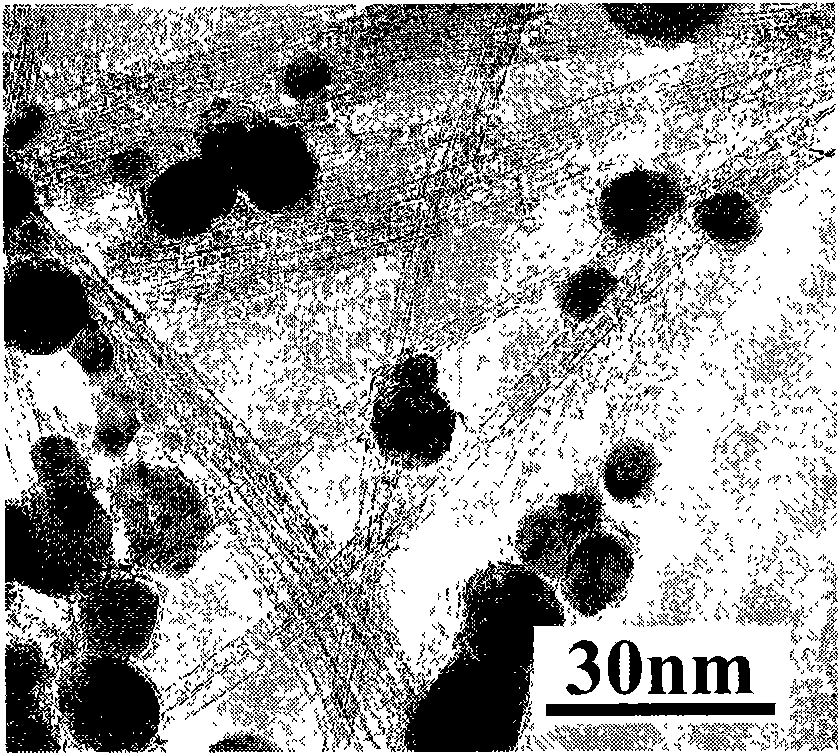

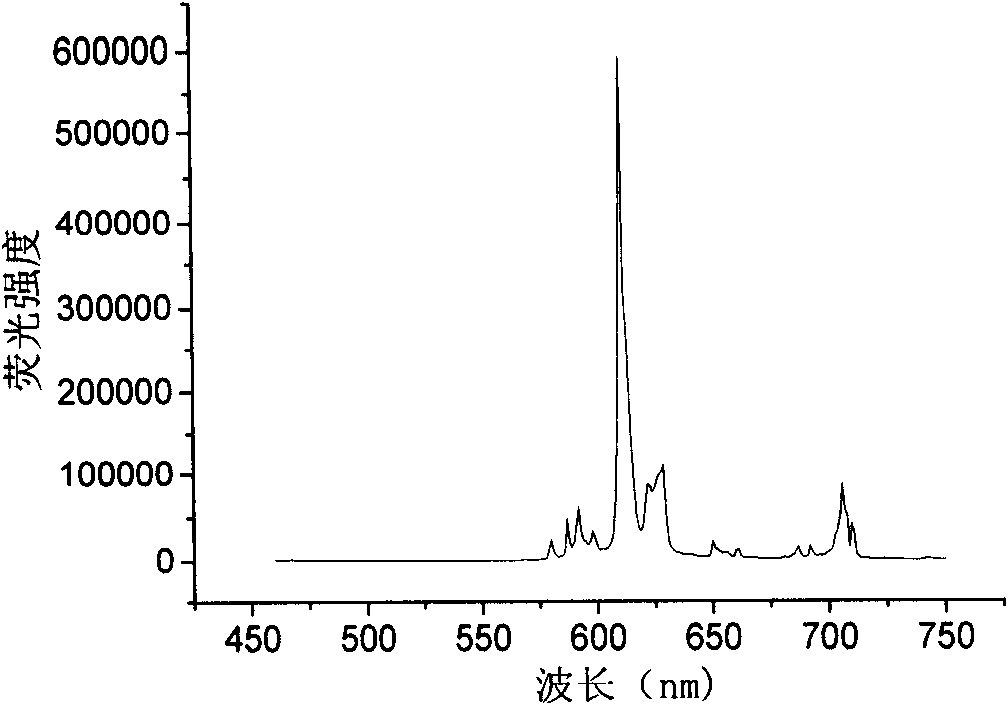

InactiveCN101603213AExcellent fluorescence effectImprove heat stabilityFilament/thread formingMonocomponent synthetic polymer artificial filamentDiaminodiphenyl etherFluorescence

The invention relates to a polyimide nano-fiber and a preparation method thereof. The invention adopts the technical scheme that 4,4'-oxydianiline (ODA) and pyromellitic dianhydride (PMDA) are used as polycondensation monomers to synthesize a polyamic acid (PAA) solution; in the reaction process, europium oxide which is processed by a coupling agent and has fluorescent effect is added, and then, the PAA / europium oxide nano-fiber is prepared by using the electrostatic spinning technology, wherein the fiber diameter can be controlled to be between 50 and 200nm; and then, the PAA / europium oxide nano-fiber is put in an oven to be heated gradually for imidization to enable the PPA / europium oxide to carry out polycondensation, thereby generating the polyimide nano-fiber with the fluorescent effect. The application of the polyimide in the high-technology fields, such as anti-falsification certificates, bills, aerospace, microelectronics and the like is extended.

Owner:SUZHOU UNIV

Method for preparing nanomaterial array system by porous alumina template nano mask method

InactiveCN1594068AUniform sizeControllable orientationNanostructure manufactureChemical reactionNanoparticle

Method for preparing nanomaterial array system by porous alumina template nano mask method is constituted by following steps: (1) adopting the porous pellumina as templet of the mask and covering it on the base material; (2) forming nano granule array system on the base material by coating technique; (3) removing porous pellumina template to get nano granule array system; (4) processing a chemical reaction conversion in situ by the nano granule array prepared from step (1)(2)(3), further obtaining nano granule array system of the other materials. The produced nano material has an good controllability in dimension, orientation and position and a wide adjustable property (5-200 nano) of the diameter of the nano material. The invention can produce multifunctional nano granule, nano wire, nano tube or nano column array system and assembles nano material on a plurality of nano materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for preparing Fe3O4 magnetotactic bacterial cellulose spheres

InactiveCN101979633AEvenly distributedControllable diameterMicroorganism based processesFermentationSuperparamagnetismCoprecipitation

The invention relates to a method for preparing Fe3O4 magnetotactic bacterial cellulose spheres. The method comprises the following steps of: preparing nanoscale Fe3O4 (with superparamagnetism) by a coprecipitation method; sterilizing the nanoscale Fe3O4 and a fermentation culture medium respectively and mixing; inoculating gluconacetobacter xylinum (CGMCC No. 2955); controlling the rotate speed of a shaker and culture time to obtain magnetotactic cellulose spheres with different diameters; immersing and washing the magnetotactic cellulose spheres in flowing water for one hour to remove the residual thalli and the culture medium; and washing by using deionized water for five times (the using amount of deionized water every time is 500 milliliters). Due to inconsistent diameters of the magnetotactic bacterial cellulose spheres formed by fermentation, the magnetotactic bacterial cellulose spheres with required diameters can be screened out by using a screen plate with a certain bore diameter, and Fe3O4 particles are distributed uniformly and wrapped in the bacterial cellulose spheres layer by layer along with the biosynthesis and secretion of bacterial cellulose (BC). The magnetotactic bacterial cellulose spheres can be used as a vector of immobilized enzyme or cells, and have the advantage that: after a reaction is finished, the magnetotactic bacterial cellulose spheres are separated by a magnetic field, and can be used repeatedly after the magnetic field is removed.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of tin oxide fiber precursor and tin oxide crystal fibers

ActiveCN103556303AUniform diameterGood whitenessInorganic material artificial filamentsTin oxidesElectrospinningPhotocatalysis

The invention relates to a preparation method of a tin oxide fiber precursor and tin oxide crystal fibers. The preparation method comprises the following steps: carrying out a replacement reaction on halides of tin and potassium (sodium) acetate to synthesize the tin oxide fiber precursor which takes acetic acid as a ligand; concentrating a precursor solution to obtain a spinning solution and carrying out centrifugal silk spinning to obtain tin oxide precursor fibers; and carrying out procedures of special atmosphere pre-treatment, high-temperature heat treatment and the like on the precursor fibers to obtain the tin oxide crystal fibers. According to the preparation method, the long-diameter ratio of the tin oxide crystal fibers is greater than 1000, the tensile strength of the fibers is 0.8GPa-1.1GPa, the whiteness of the fibers is good and the color and luster of the fibers are soft. The preparation method is simple in preparation process, moderate in condition and stable in quality of fibers in batches; spinning sol does not go bad after being placed for a long time. The tin oxide crystal fibers can be applied to the fields of photocatalysis, air sensitivity, humidity sensitivity and the like. The tin oxide fiber precursor can also be used for preparing oxide thin films, nano powder and nano wires or preparing tin-containing functional materials including nano tin oxide fibers and the like by an electrostatic spinning method.

Owner:SHANDONG UNIV

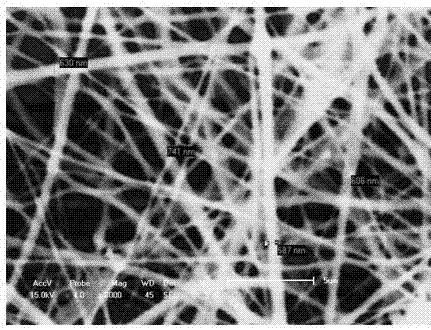

A method for controllable growth of uniform nano nickel chain array induced by magnetic field

The present invention discloses a method for controllable growth of uniform nano nickel chain array induced by magnetic field. NiCl2.6H2O, glycol and hydrazine hydrate are chosen as raw materials. The raw materials react in a stable magnetic field to get a black product. Through centrifugal separation and alcohol wash of the black product, a regularly arranged nickel nano linear array is obtained. Through controlling the reaction temperature of the system and magnetic-field intensity, the present invention may obtain a nickel nano linear array with controllable dimensions, high purity, high length-diameter ratio and high orientation. The preparation method of the present invention is characterized by simple process, easy operation, moderate reaction conditions, energy conservation and environmental friendliness.

Owner:BEIHANG UNIV

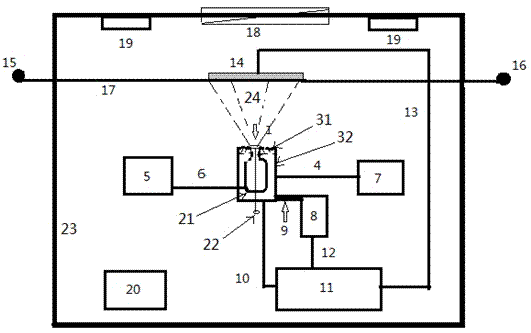

High voltage static power shuttle nano-spinning device

ActiveCN103898620AReduce intertwiningReduce generationFilament/thread formingSiphonLiquid storage tank

The invention relates to a high voltage static power shuttle nano-spinning device. The device is composed of a spinneret nozzle, a liquid storage cavity, a metal valve needle, an adjusting cap, a liquid supply tank, a multifunctional high voltage static generator, a cavitation machine, a cavitation machine deckle rod, a positive pressure power pump, a positive pressure power pipe, a siphon type feed pipe, a net structure electrode, a receiving substrate, an unwinding roller, a winding roller, nanofiber, a constant temperature system, a ventilating system, an illuminating system and an environment isolation box. A high voltage static power shuttle body is formed by the spinneret nozzle, the liquid storage cavity, the metal valve needle, the adjusting cap and a shell. A high voltage static power shuttle is jointly formed by the spinneret nozzle, the liquid storage cavity, the metal valve needle, the adjusting cap, the shell, the multifunctional high voltage static generator, a liquid storage tank, the siphon type feed pipe, the positive pressure power pipe, the cavitation machine, the cavitation machine deckle rod, an output line, the ventilating system, the illuminating system, a humidity and temperature regulator and the box. Through the establishment of the high voltage static power shuttle and the adjustment of the size of the spinneret nozzle, the static field intensity, the pressure and the frequency of the cavitation machine, the spinning speed and the diameter of the nanofiber can be adjusted, and the high voltage static power shuttle nano-spinning device has the advantages of being high in spinning efficiency, free of blocking, easy to clean, safe, reliable, easy and convenient to operate, environmentally friendly and the like.

Owner:盐城迈迪科技有限公司

Noble metal palladium deposited-polypyrrole sensitized hollow type titanium dioxide nanometer photocatalyst and preparation method thereof

InactiveCN102989514AEasy to makeLow costOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPolypyrrole

The invention discloses a noble metal palladium deposited-polypyrrole sensitized hollow type titanium dioxide nanometer photocatalyst and a preparation method thereof. The noble metal palladium deposited-polypyrrole sensitized hollow type titanium dioxide nanometer photocatalyst adopts hollow titania microspheres as a carrier for carrying polypyrrole and platinum. The preparation method comprises the following steps in sequence: carrying out glucose-based hydro-thermal synthesis to obtain carbon nanospheres; loading a titanium dioxide film coating onto the surface of the carbon nanospheres through a sol-gel method so as to obtain C / TiO2 microspheres, wherein the carbon nanospheres serve as the template agent; roasting the microspheres to prepare into hollow titanium dioxide nanospheres; loading platinum and polypyrrole on the surface of the hollow titanium dioxide through an in-situ chemical polymerizing method; and transferring to the ultraviolet rays to irradiate, thus obtaining the hollow type titanium dioxide nanometer photocatalyst. The grain size of the hollow type titanium dioxide nanometer photocatalyst can be adjusted, and the thickness of the titanium dioxide coating can be controlled. The noble metal palladium deposited-polypyrrole sensitized hollow type titanium dioxide nanometer photocatalyst is higher in photocatalytic activity; and as shown in UV-vis results, the photo response area is expanded to the visible region, so that the condition is provided for industrially degrading the pollutant through photochemical catalysis under the sunshine.

Owner:NANJING UNIV

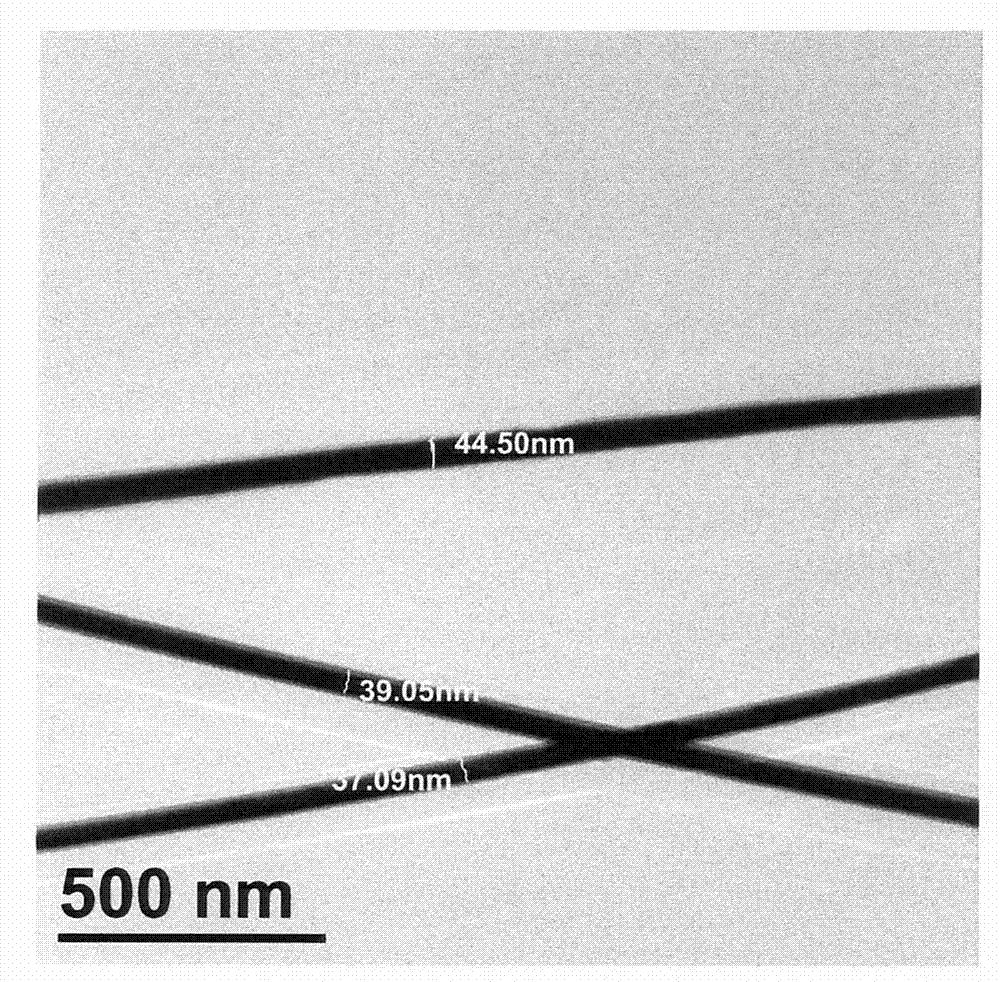

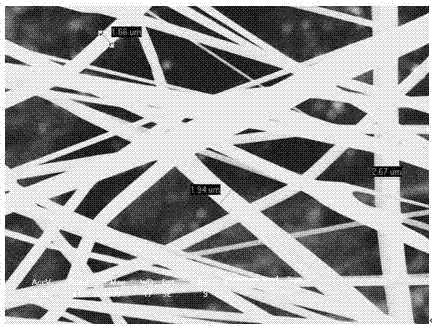

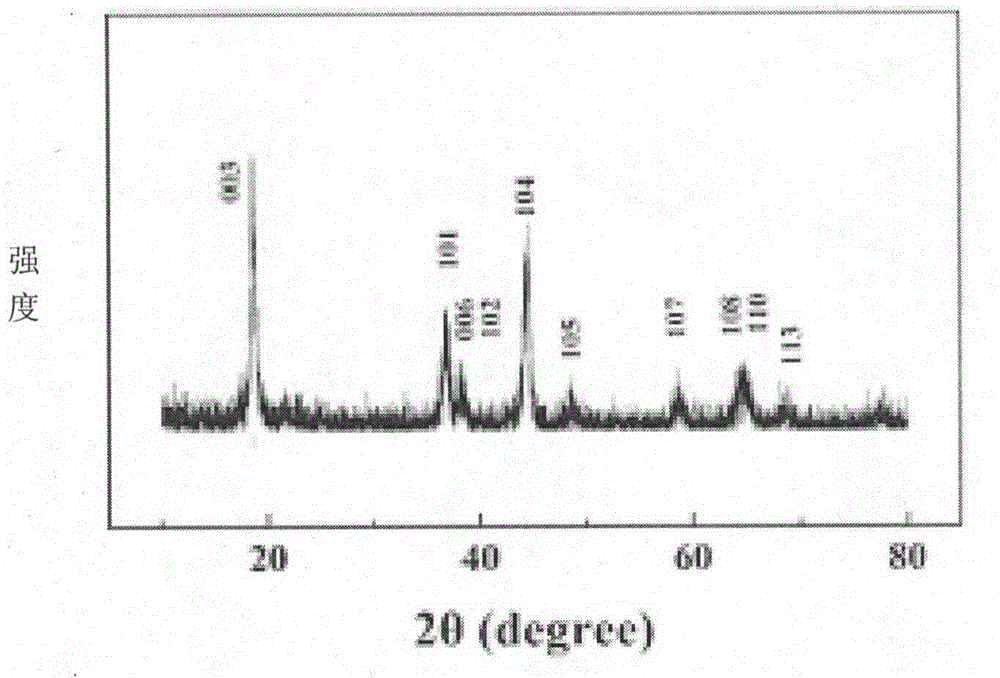

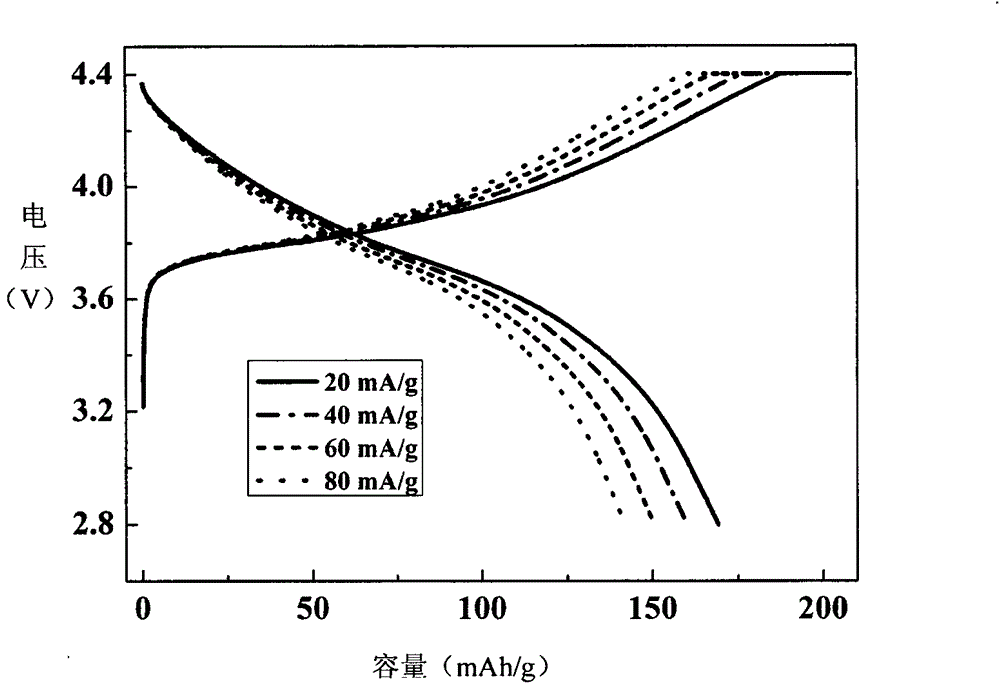

Preparation method for synthesizing LiNi1/3Co1/3Mn1/3O2 nanometer fiber by using electro-spinning technique

InactiveCN103560243ALarge specific surface areaControllable diameterCell electrodesSecondary cellsFiberMANGANESE ACETATE

The invention discloses a preparation method for synthesizing a LiNi1 / 3Co1 / 3Mn1 / 3O2 nanometer fiber by using an electro-spinning technique, and belongs to the technical field of lithium ion battery electrode materials and preparation of the materials. The preparation method comprises the steps: preparing a precursor solution by using raw materials of lithium nitrate, nickel nitrate, cobalt nitrate, manganese acetate, deionized water, polyacrylic acid and polyvinylpyrrolidone (PVP) as raw materials, preparing a PVP / LiNi1 / 3Co1 / 3Mn1 / 3O2 composite fiber through using an electro-spinning technique, insulating, sintering, and cooling to a room temperature to obtain the LiNi1 / 3Co1 / 3Mn1 / 3O2 nanometer fiber. The preparation method is simple in process, convenient to operate, low in cost and slight in pollution. An anode material of the LiNi1 / 3Co1 / 3Mn1 / 3O2 nanometer fiber prepared by using the preparation method provided by the invention has a good electrochemical performance.

Owner:TIANJIN POLYTECHNIC UNIV

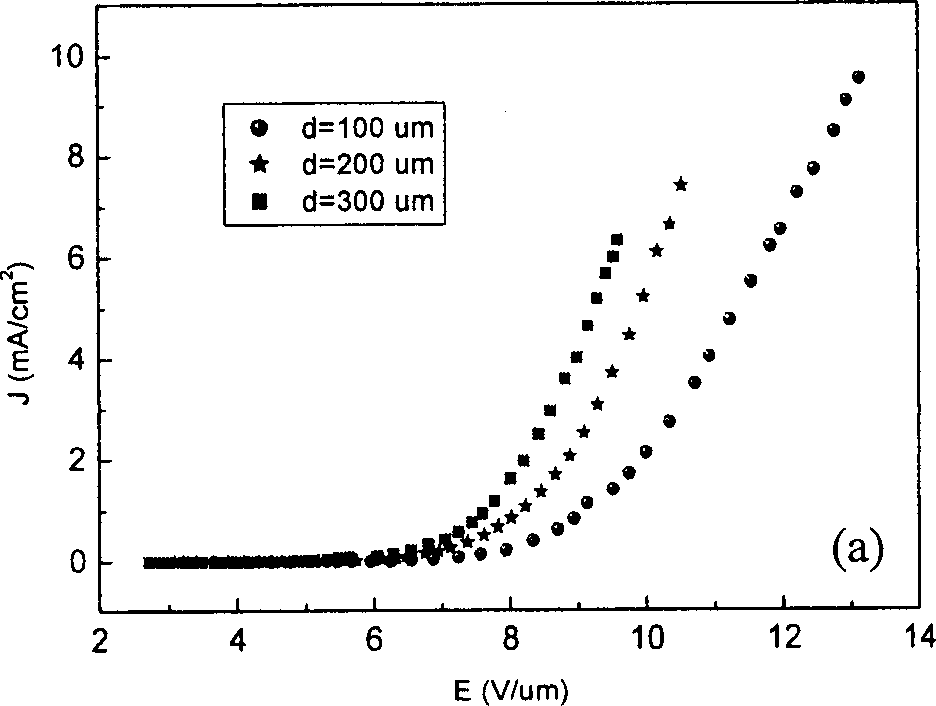

Ultra-fine zinc oxide nonometer line and its preparation method

InactiveCN1800029AHigh field emission currentSimple and easy operation processZinc oxides/hydroxidesZno nanowiresOxide

The invention discloses an ultra-fine unoriented zinc oxide nanometer wire and making method in the semiconductor nanometer material technique domain, which comprises the following steps: cleaning n-typed heavy silicon piece in the acetone and alcohol for 25-30 min by ultrasound; deposing a 0.5-2 nm thickness layer of gold plating catalyst film on the silicon piece through electronic beam evaporation method; taking the silicon piece with gold plating film as the receiving substrate and high-pure zinc powder as the evaporation source; putting the substrate and evaporation source on the glass; placing the glass in the pipe-typed furnace; charging high-pure Ar2 in the vacuumed pipe-typed furnace as the protecting atmosphere; heating the temperature at 460-540 deg.c at the speed of 10-20 deg.c per min; reacting for 100-150 min; reducing the reactant temperature to the room temperature protected by Ar2. The invention realizes the controllability and low cost synthesis of nanometer ZnO, which avoids the shielding effect due to array.

Owner:UNIV OF SCI & TECH BEIJING

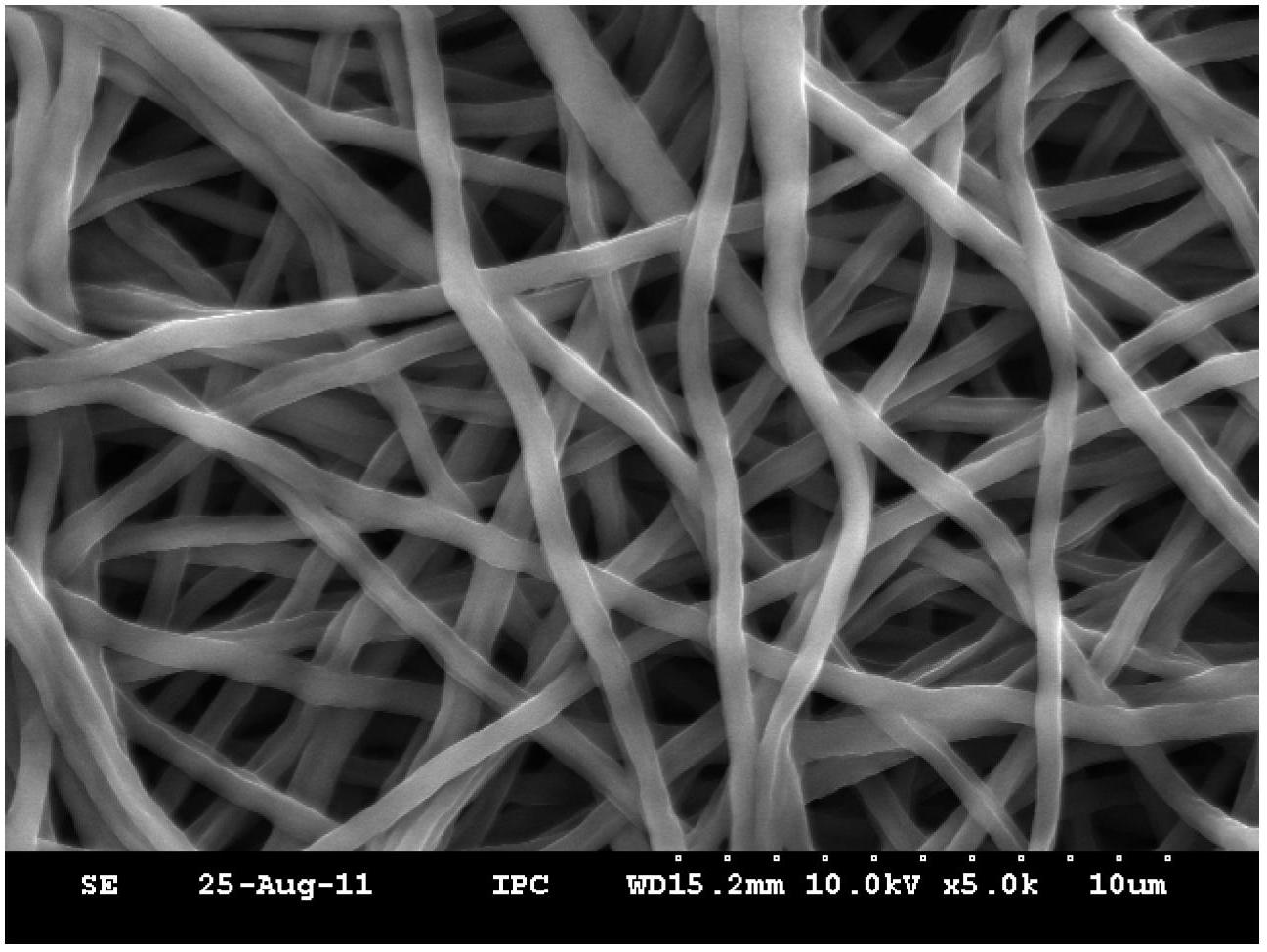

Method for enhancing thermal conductivity of phase-change energy-storage superfine composite polyamide fiber and method for producing phase-change energy-storage superfine composite polyamide fiber

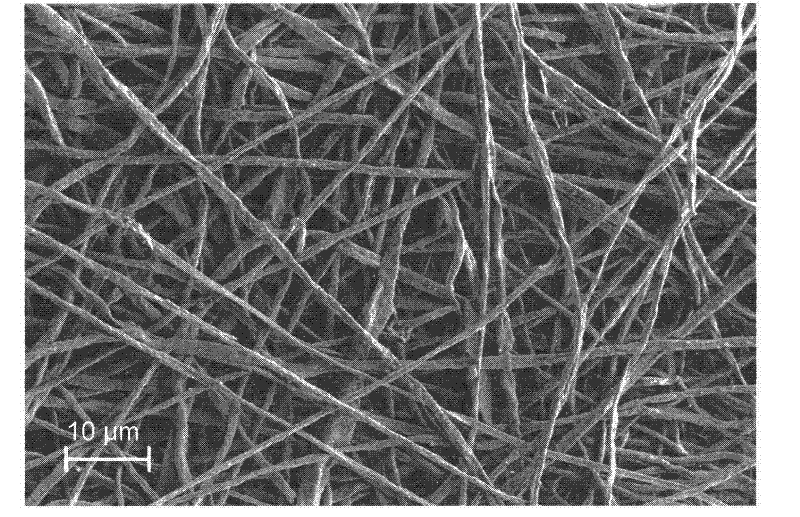

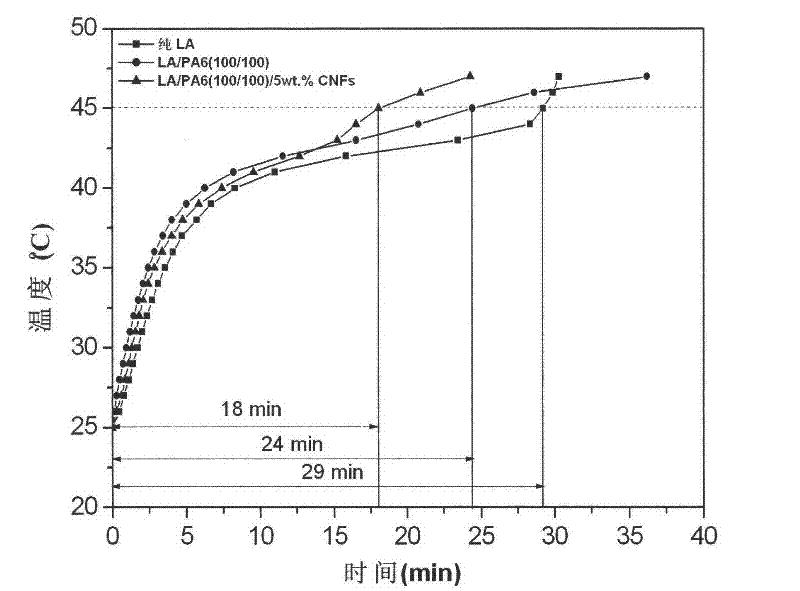

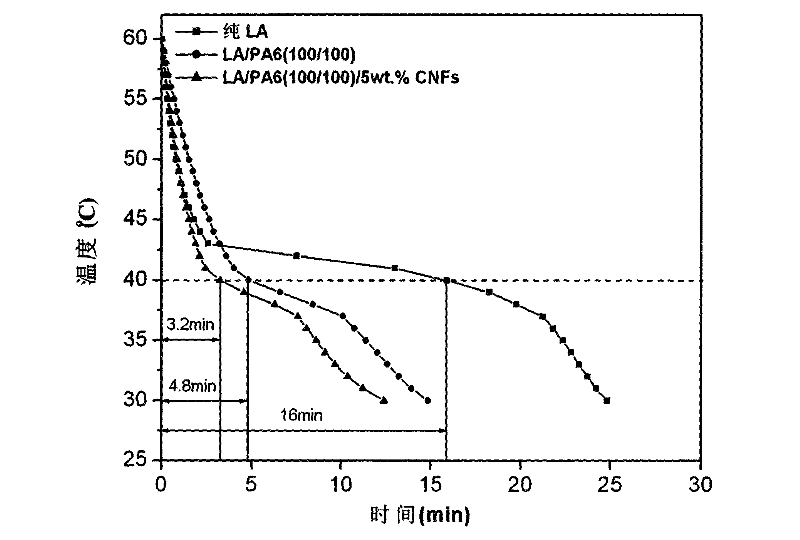

InactiveCN102517793APhase transition temperature is suitableHigh latent heat of phase changeFilament/thread formingNon-woven fabricsElectrospinningCarbon nanofiber

A production method for enhancing thermal conductivity of a fatty acid / polyamide-6 nano composite phase-change material belongs to the technical fields of nanocomposites, phase change materials, electrostatic spinning and the like, and particularly relates to a method of using an electrostatic spinning device to produce a nano composite fiber membrane of fatty acid / pollyamide-6 / carbon nano fibers. The production method is simple in process and easy in control. By effectively combining the production method with the electrostatic spinning technique, the produced fiber is small in diameter and uniform in distribution, the produced nano composite phase change material is uniform, stable and less prone to leakage, and has the thermal conductivity more evident than that of the conventional phase change material. Therefore, the material is more convenient in processing and application, and more widely applicable.

Owner:JIANGNAN UNIV

Preparation method for water-resistant nano microcrystalline cellulose/polyvinyl alcohol/polyacrylic acid/silicon dioxide composite nanofiber membrane

ActiveCN103882624AGuarantee structureUniform diameterNon-woven fabricsSpinning solutions preparationSpinningPolyvinyl alcohol

The invention relates to a preparation method for a water-resistant nano microcrystalline cellulose / polyvinyl alcohol / polyacrylic acid / silicon dioxide composite nanofiber membrane. The preparation method includes the steps that (1), a polymer solution is prepared by polyvinyl alcohol and polyacrylic acid by the mass ratio of 1:1-1:5; (2), nano microcrystalline cellulose different in weight is added into the polymer solution in the step1, and therefore a 1wt-8wt% nano microcrystalline cellulose / polyvinyl alcohol / polyacrylic acid solution is prepared; (3), 1 g-2 g of tetraethyl orthosilicate, 2 g of alcohol, 1g of water and 0.8 mol / L hydrochloric acid are mixed to prepare a tetraethyl orthosilicate solution to be subjected to prehydrolysis; (4), the tetraethyl orthosilicate solution after prehydrolysis and a solution in the step2 after ultrasonic processing for 2 minutes-5 minutes are mixed according to the mass ratio of 1:3 to prepare a spinning solution, and a nanfiber membrane is prepared through a static spinning technology; (5), the prepared nanofiber membrane is dried for 12 h in a vacuum drying box at the temperature of 40 DEG C and then placed in a high-temperature vacuum drying box to be heated for 1 h. The defect that a polyvinyl alcohol nanofiber membrane is poor in water-resistant performance is overcome, and the preparation method has the advantages of being simple in preparation process, little in environment pollution, excellent in mechanical performance and the like. Three kinds of functional groups on the surface of the nanofiber surface greatly enable the application space of material to be expanded.

Owner:TONGJI UNIV

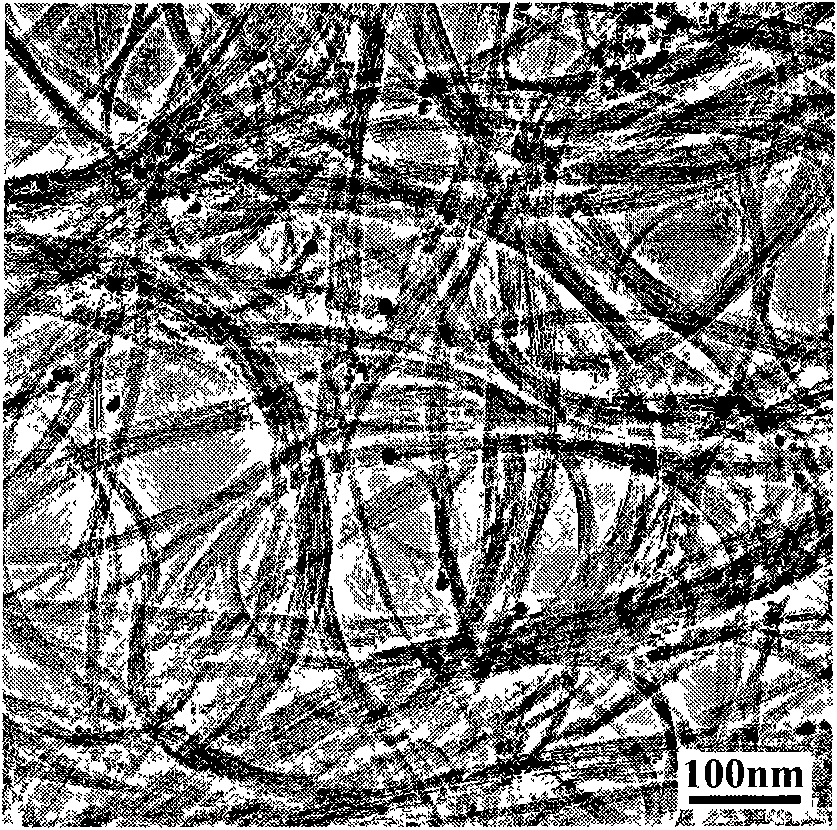

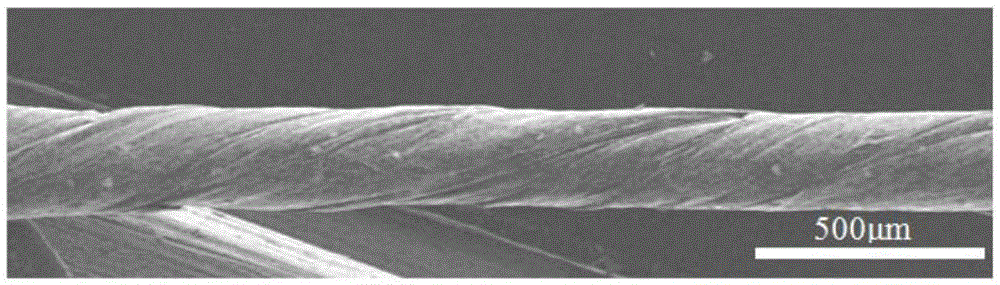

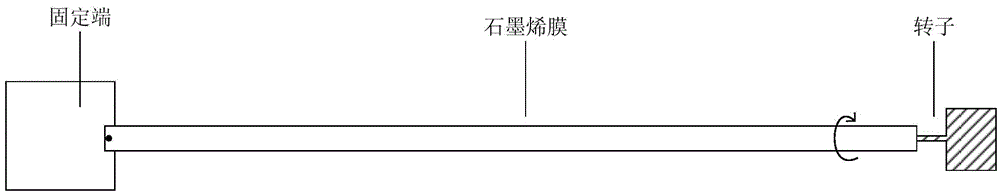

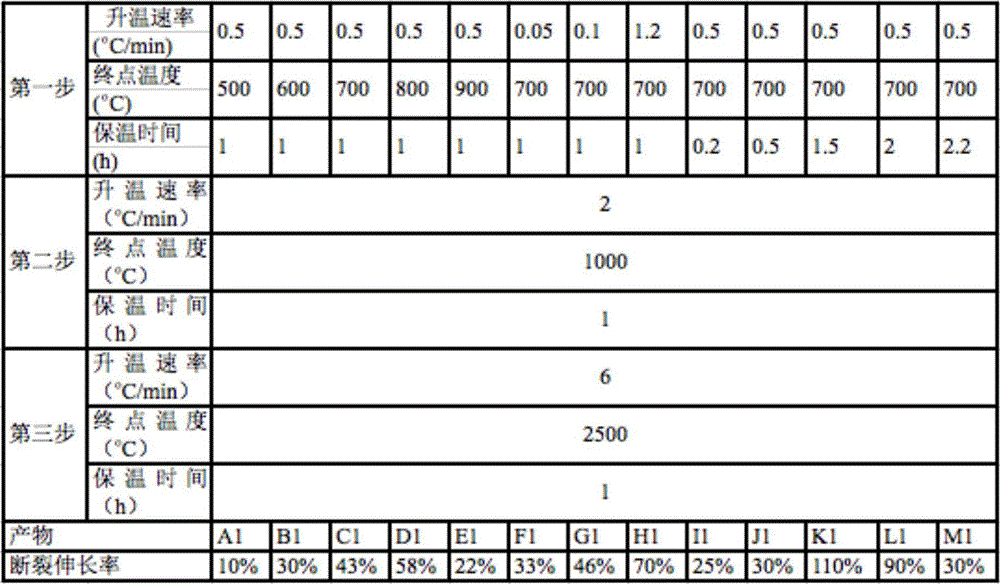

Super stretchable high-conductivity graphene fiber and preparation method thereof

The invention discloses a super stretchable high-conductivity graphene fiber and a preparation method thereof. The method comprises the steps that the temperature of a graphene oxide film is firstly raised to 500 DEG C to 800 DEG C at the rate of 0.1 DEG C / min to 1 DEG C / min, and heat preservation is carried out for 0.5 h to 2 h; then the temperature is raised to 1,000 DEG C to 1,300 DEG C at the rate of 1 DEG C / min to 3 DEG C / min, and heat preservation is carried out for 0.5 h to 3 h; the temperature is raised to 2,000 DEG C to 3,000 DEG C at the rate of 5 DEG C / min to 8 DEG C / min, and heat preservation is carried out for 0.5 h to 4 h; the graphene oxide film is wound, the super stretchable high-conductivity graphene fiber is obtained, the elongation at break ranges from 30% to 220%, and the conductivity is 1-2.36*106 S / m. The preparation method is simple in process, graphene fibers of different diameters and lengths can be obtained, the problem that a traditional graphene fiber is broken and is prone to be pulled to be broken is solved, the conductivity is excellent, and industrial prospects are achieved.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

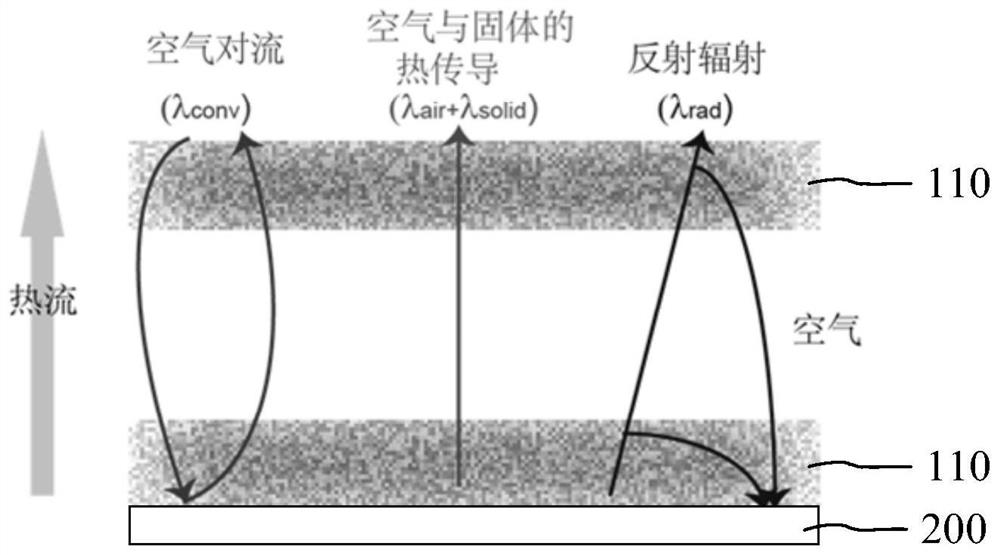

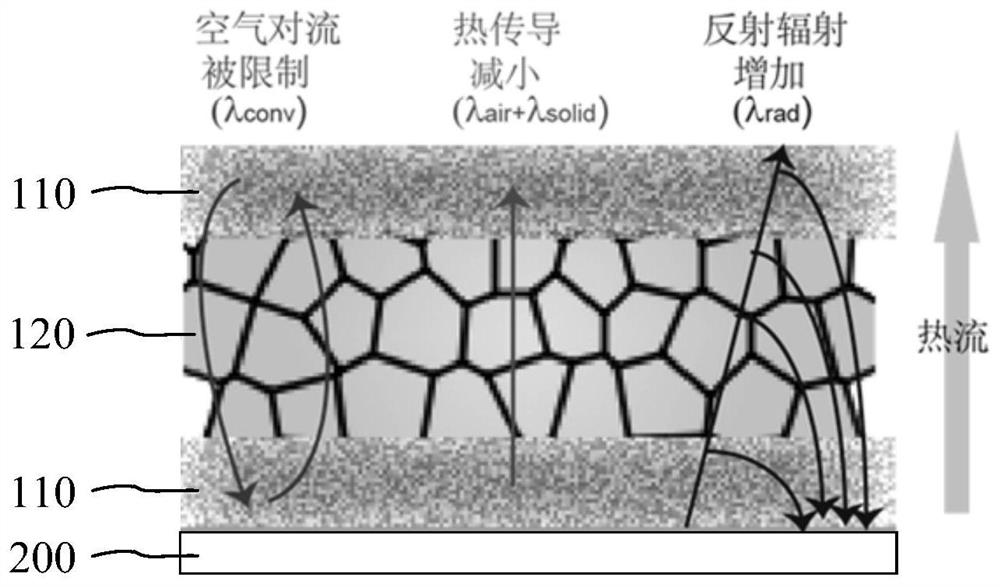

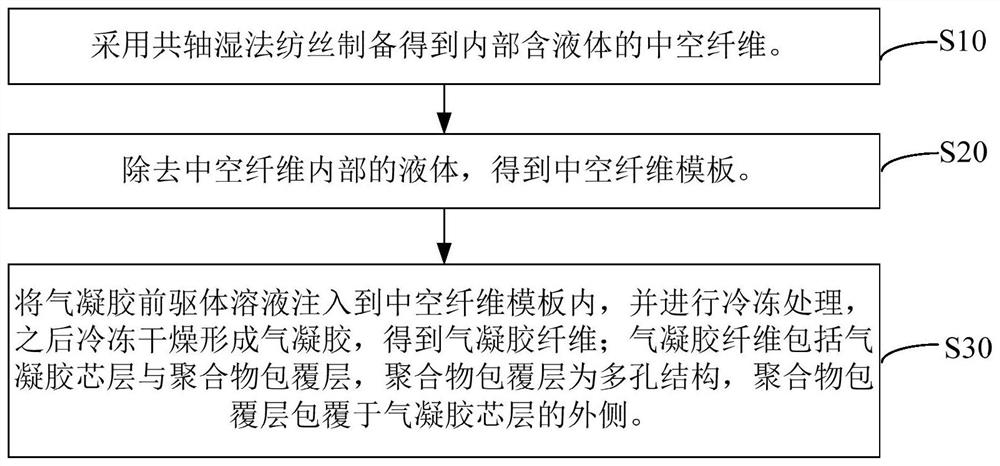

Aerogel fiber as well as preparation method and application thereof

The invention relates to an aerogel fiber as well as a preparation method and an application thereof. The aerogel fiber comprises an aerogel core layer and a polymer coating layer, the polymer coatinglayer is of a porous structure, and the outer side of the aerogel core layer is coated with the polymer coating layer. According to the aerogel fiber in the technical scheme, the polymer coating layer of the porous structure plays a role in protecting the aerogel core layer located on the inner side, so that the integrity of aerogel can be protected against damage of external force, and wide application is facilitated. In addition, the invention also relates to a preparation method of the aerogel fiber, and an application of the aerogel fiber in a building thermal insulation material, wearable equipment and a water-soluble coating.

Owner:FOSHAN GREEN INTELLIGENT MFG RES INST OF XIANGTAN UNIV +2

Noble metal silver deposition-polypyrrole sensitization hollow titanium dioxide nano photocatalyst and preparation method thereof

InactiveCN102614933AEasy to makeLow costOrganic-compounds/hydrides/coordination-complexes catalystsPolypyrroleIn situ polymerization

The invention discloses a preparation method of a noble metal silver deposition-polypyrrole sensitization hollow titanium dioxide nano photocatalyst, which comprises the following steps: hydrothermally synthesizing nano carbon spheres from glucose; by using the carbon spheres as a template, supporting a titanium dioxide film on the surface of the carbon spheres by a sol-gel method to prepare C-titanium dioxide microspheres; calcining the microspheres to prepare hollow titanium dioxide nano microspheres; and supporting metal silver and polypyrrole onto the surface of the hollow titanium dioxide by a chemical in-situ polymerization method to obtain the photocatalyst. The diameter of the prepared microspheres is adjustable, and the thickness of the titanium dioxide layer can be adjusted by changing the content of tetrabutyl titanate. The invention has favorable photocatalysis activity, and the optical response range can be extended to visible light area, thereby creating conditions for industrial photocatalytic degradation of pollutants with sunlight. The invention is simple to prepare, is environment-friendly, and is beneficial to circular economy and sustainable development.

Owner:NANJING UNIV

Hollow magnetic meso pore SiO2 nano-material and preparation method

InactiveCN103127886AEasy to makeLow costInorganic material magnetismMicroballoon preparationMicrosphereNano carbon

The invention discloses a hollow magnetic meso pore SiO2 nano-material and a preparation method, the material is in a hollow structure, a composition substance is magnetic particles and SiO2, the magnetic particles are coated by SiO2. The method comprises the following steps: using a hydro-thermal synthesis method to prepare cobalt ferrite nano particles, using glucose for hydro-thermal synthesis to obtain the nano carbon spheres; depositing SiO2 on the preparative magnetic particle surface through a silicon source reaction to prepare the magnetic meso pore SiO2 nano particles; taking carbon spheres as a template material, using an absorption for loading the magnetic meso pore SiO2 nano particles on the surface of the carbon spheres surface to prepare a SiO2-CoFe2O4-carbon spheres compound; and calcining the SiO2-CoFe2O4-carbon spheres compound to prepare the hollow magnetic meso pore SiO2 nano-material. The meso pore SiO2 nano-material has the advantages of adjustable aperture, controllable magnetic performance, uniform dimension and no physiology toxicity. The hollow structure enables the composite microspheres to have low density and high specific surface area.

Owner:NANJING UNIV

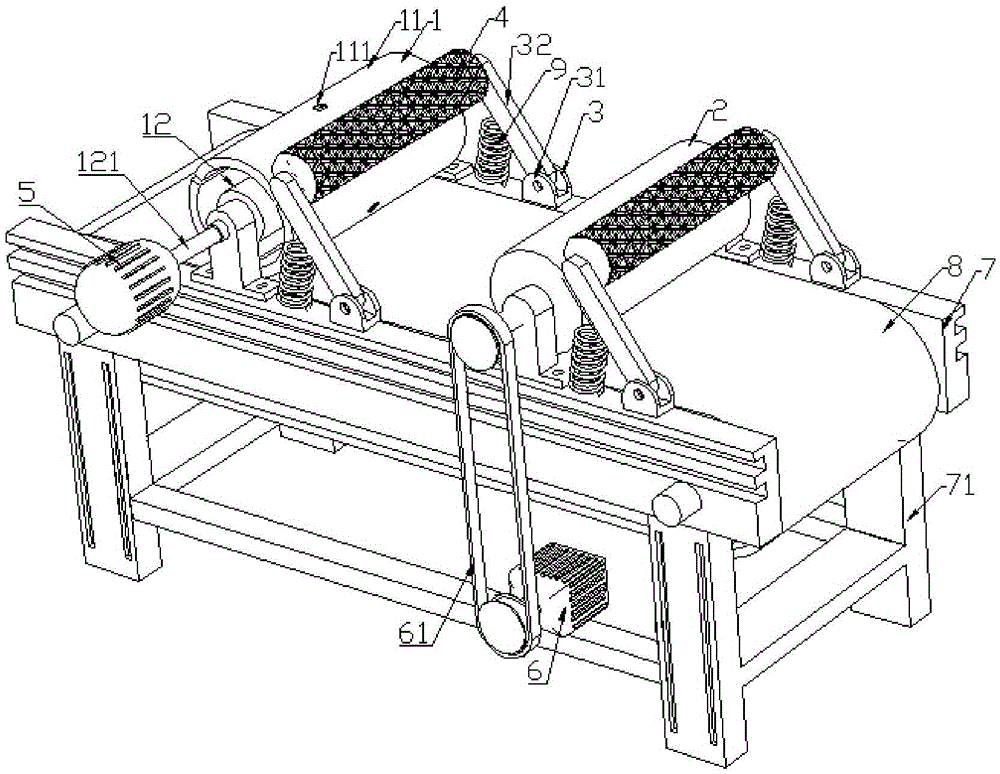

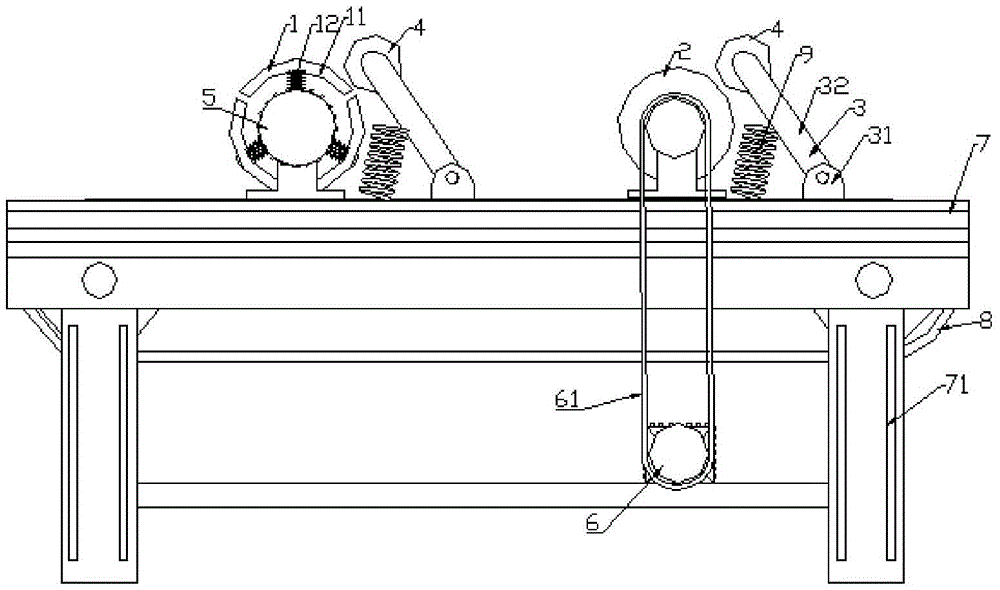

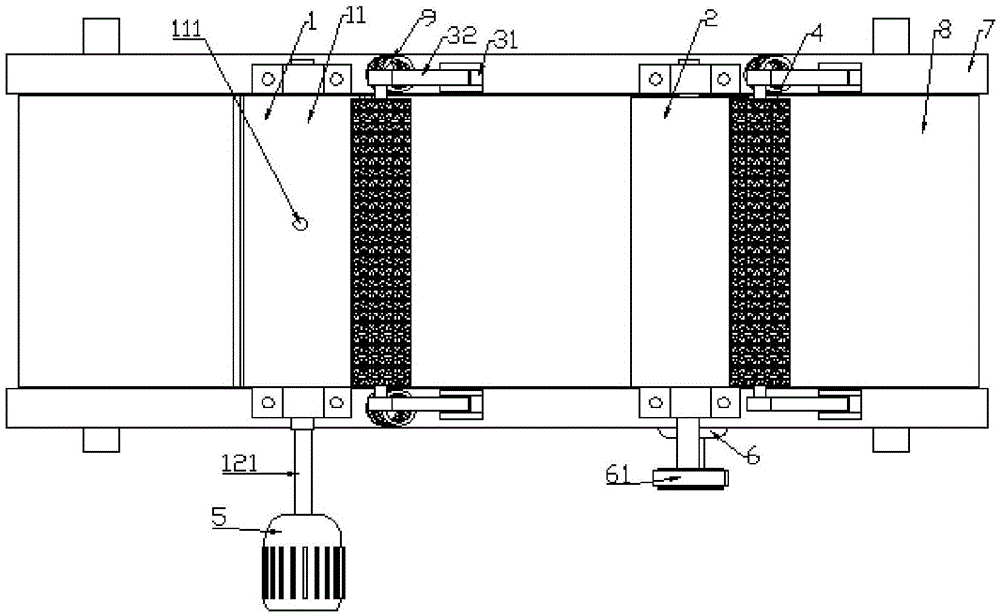

Flattening mechanism for textiles

InactiveCN105479791AClean up in timeImprove flattening effectCleaning using toolsRotary pressFiberAnnular array

The invention provides a flattening mechanism for textiles. The flattening mechanism comprises a conveying belt, and a pre-pressing roller and a flattening roller are sequentially arranged above the conveying belt; the pre-pressing roller comprises an inner roller and outer roller blades, the inner roller is cylindrical, the outer roller blades are arranged along the central axis of the inner roller in a ring array mode, the outer edge lines of the outer roller blades form an arc surface, a screw hole a is formed in the inner roller, screw holes b corresponding to the screw hole a are formed in the outer roller blades respectively, and the inner roller and the outer roller blades are fixedly connected through screws penetrating through the screw hole a and the screw holes b; a cleaning mechanism is arranged above the conveying belt and comprises a brush roller, and the brush roller makes contact with the pre-pressing roller and the flattening roller. According to the invention, the cleaning mechanism is arranged so that cotton fibers and the like can be cleared any time; the pre-pressing roller is adjustable in diameter so as to be capable of being used for flattening raw cotton material of different thicknesses; the raw cotton material is pressed twice, so that the flattening effect is good.

Owner:TIANJIN JIAXUAN TEXTILE

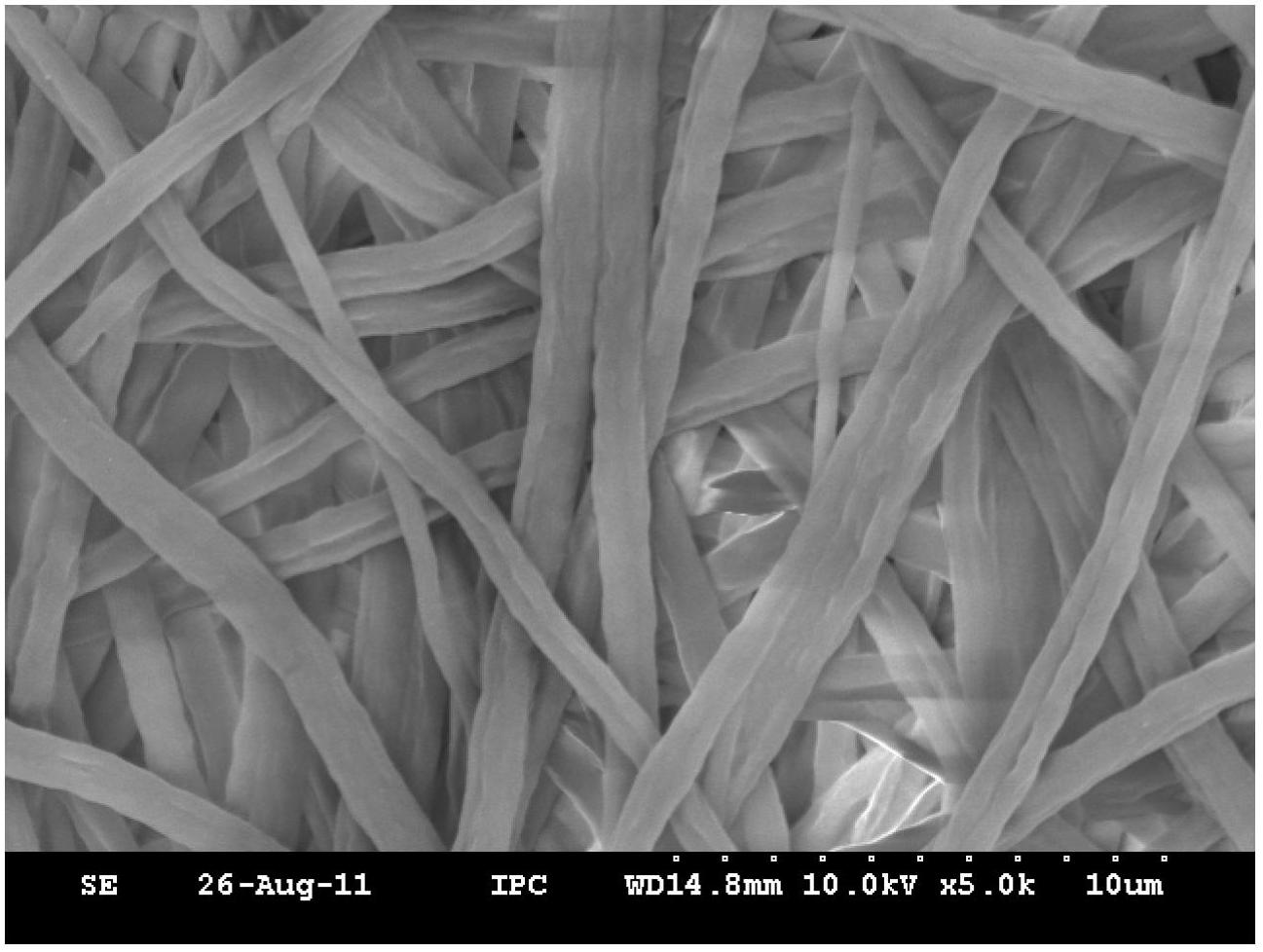

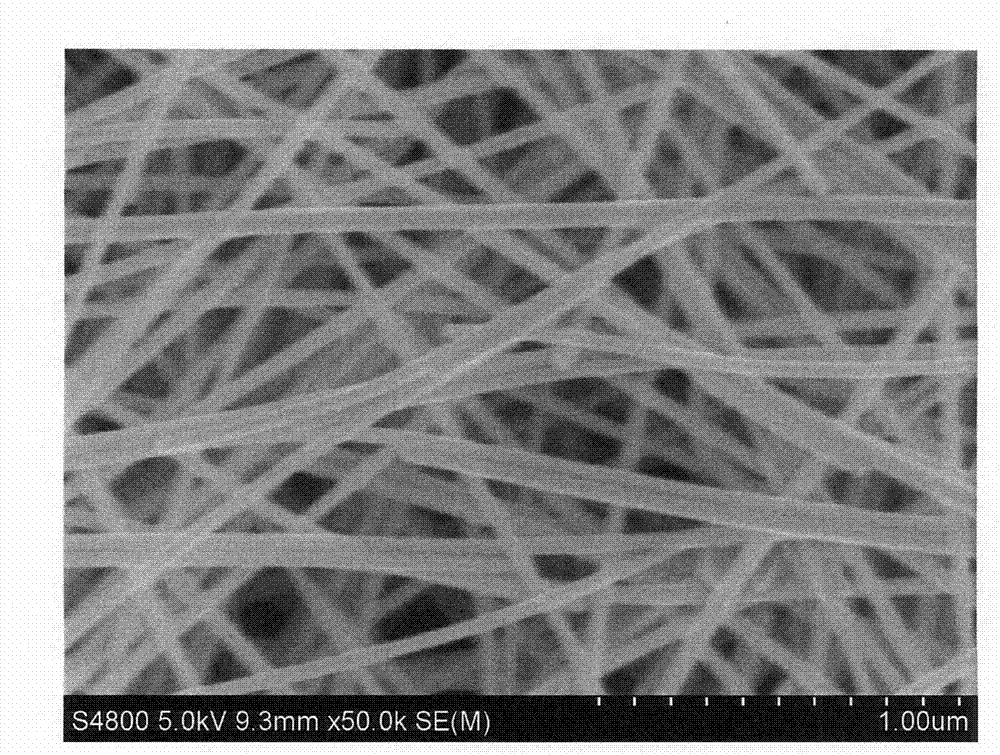

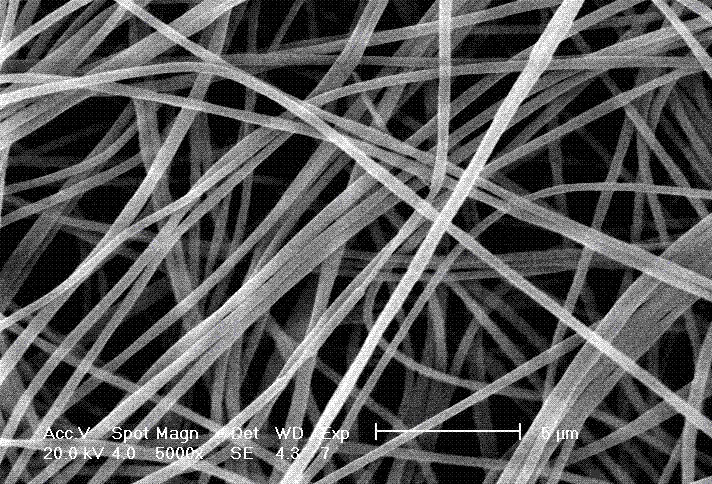

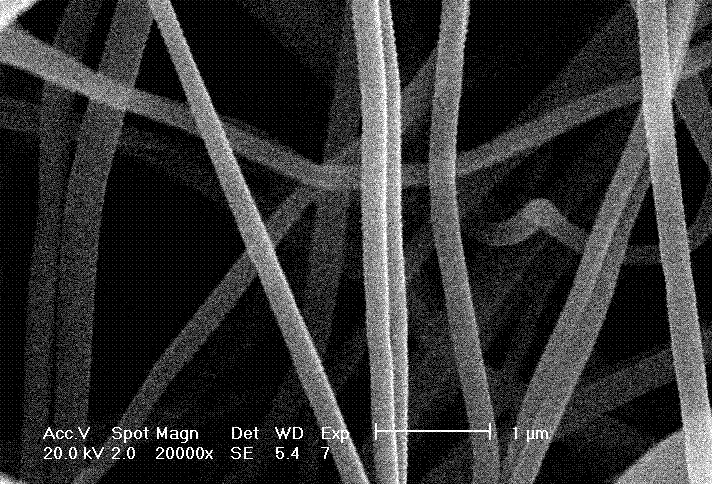

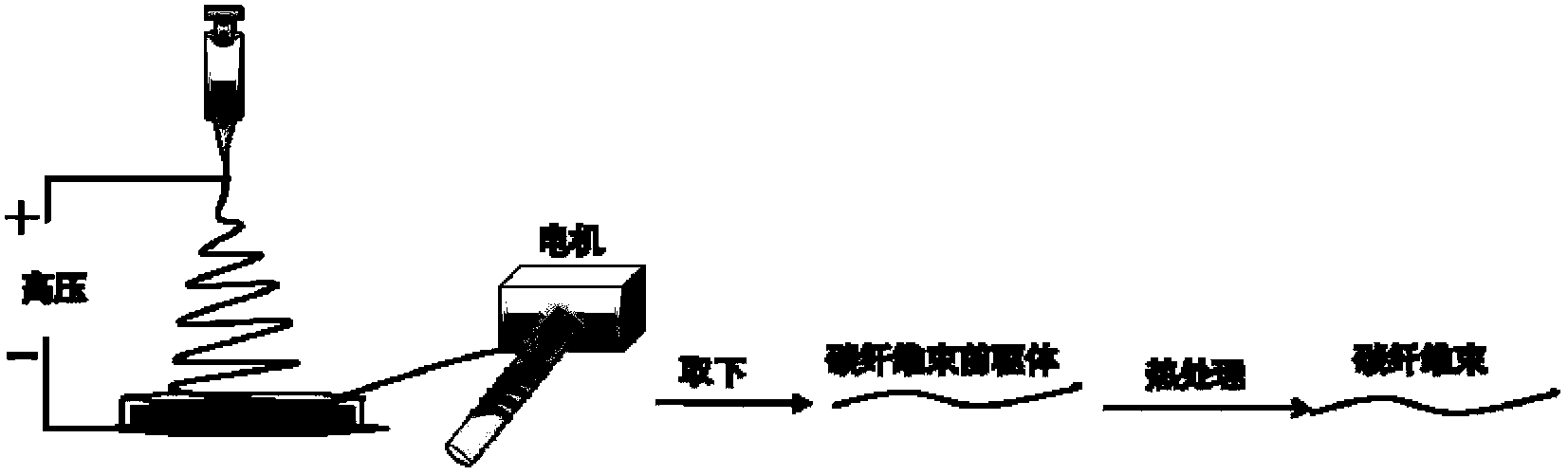

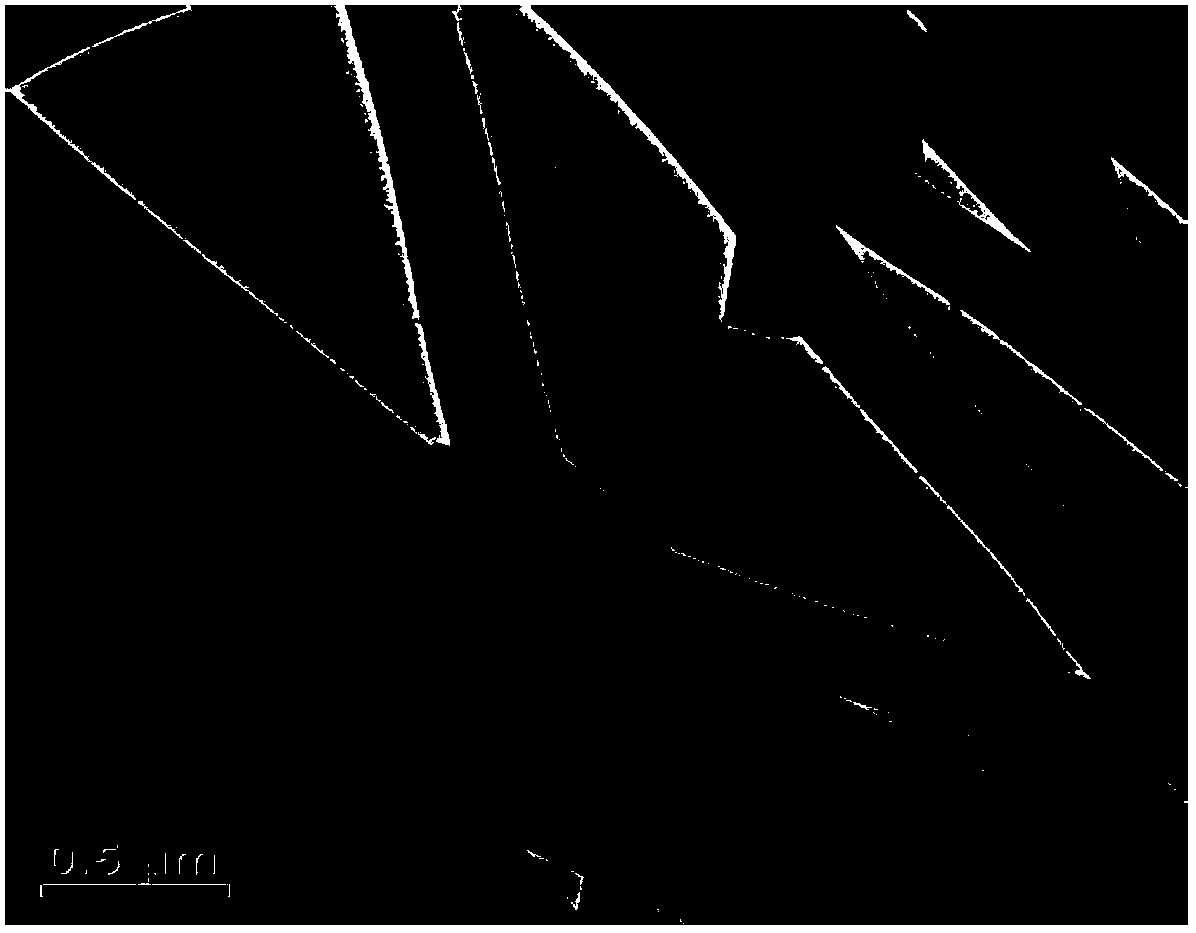

A nanometer or nanometer porous carbon fiber bundle, a preparing method thereof and applications of the bundle

InactiveCN104342783AControllable diameterMicrostructure is easy to controlHybrid capacitor electrodesFibre chemical featuresFiber bundlePorous carbon

A preparing method of a nanometer or nanometer porous carbon fiber bundle is disclosed. The method includes following steps of: (1) suspending precursor fiber prepared by a solution or a melt containing spinnable polymer through electrostatic spinning into a liquid carrying plate; (2) extracting the precursor fiber in the liquid carrying plate at a speed of 5-60 r / min and winding the precursor fiber onto a fiber taking shaft to obtain a continuous directionally arranged precursor fiber bundle; and (3) heating the precursor fiber bundle by sections and charing. The method integrates electrostatic spinning, continuous wiredrawing and heating and charing, and obtains the continuous nanometer or nanometer porous carbon fiber bundle. The diameter, the length and the microstructure of the obtained nanometer or nanometer porous carbon fiber bundle are controllable. The nanometer or nanometer porous carbon fiber bundle prepared by the method shows good electrochemical performance when being applied in the field of energy storage devices, especially as an electrode material of supercapacitors.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

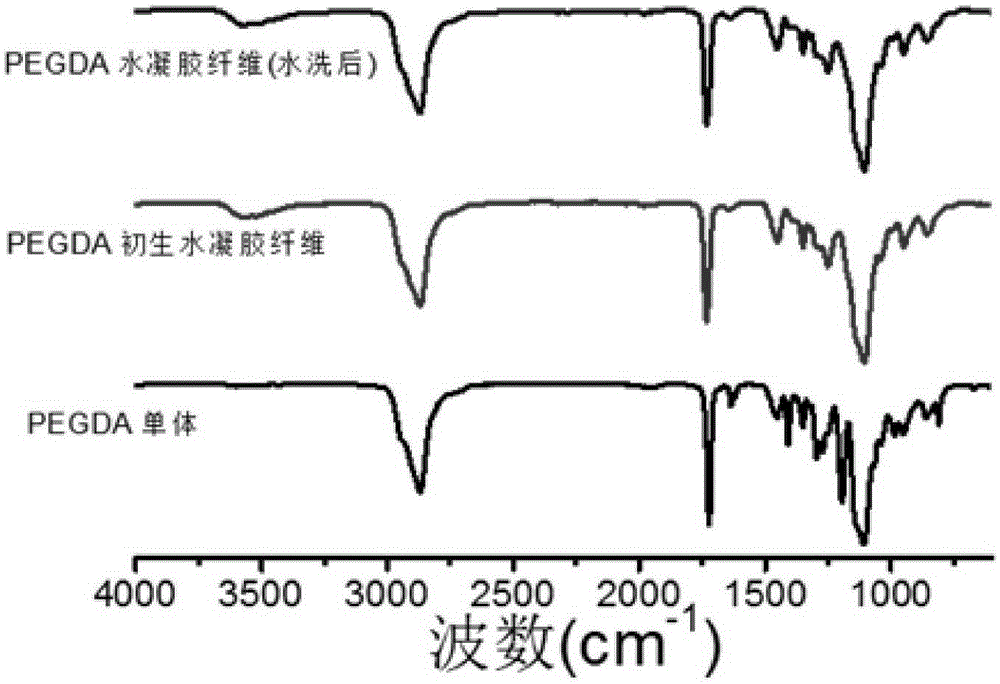

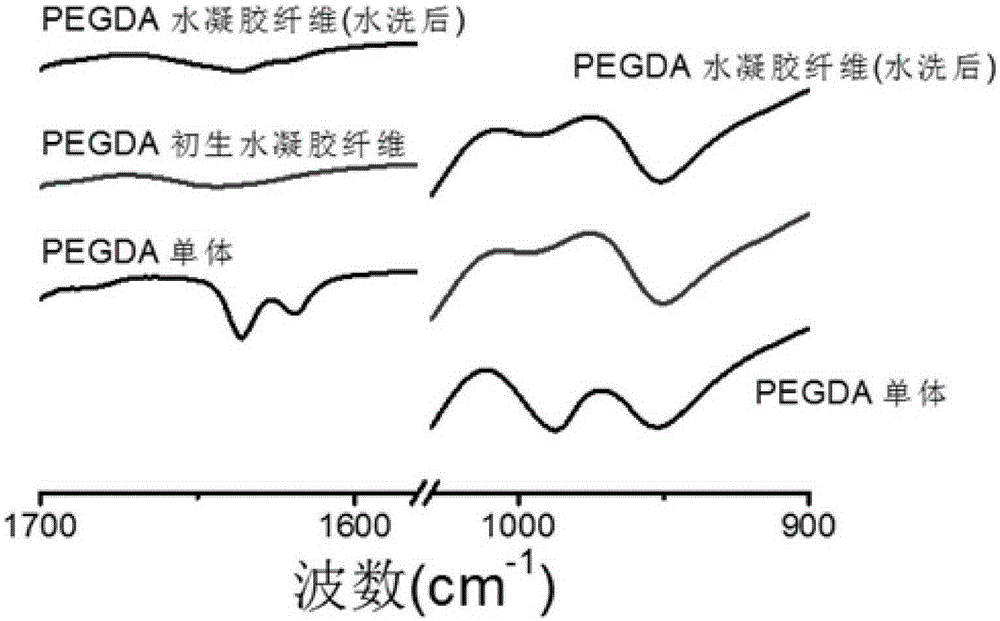

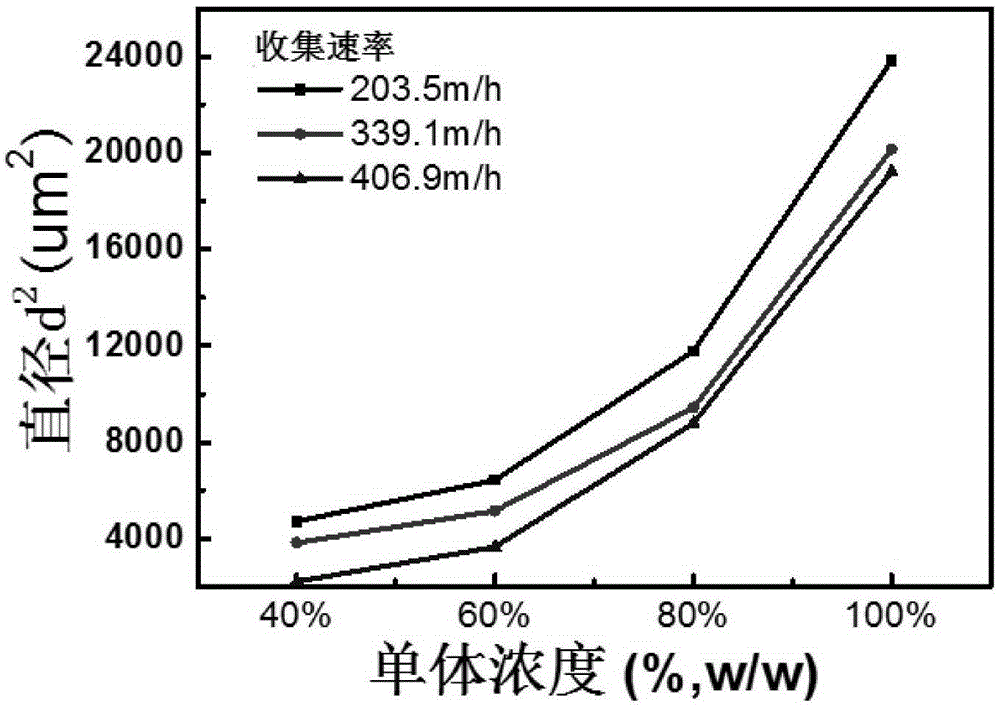

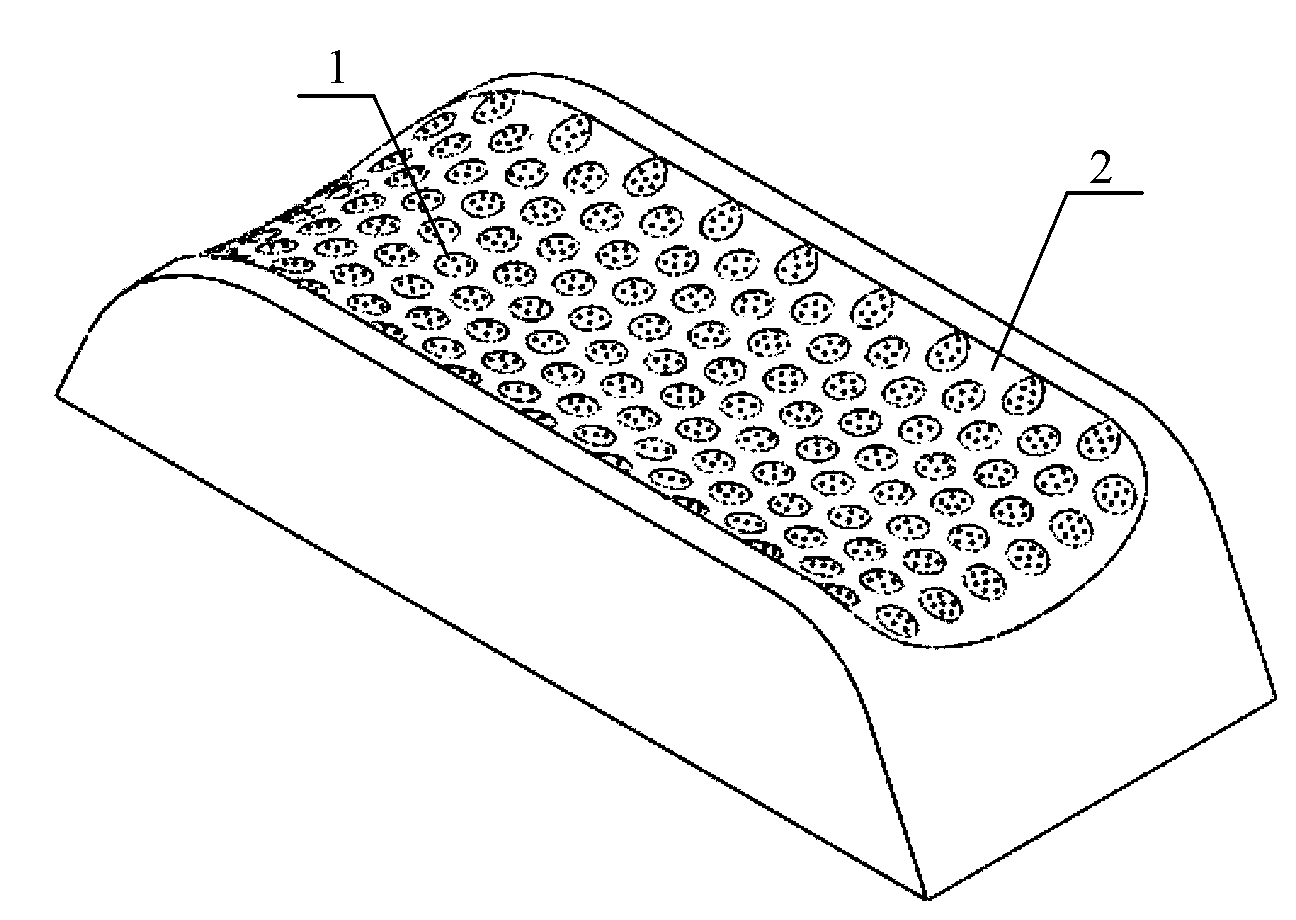

Preparation method for continuous micron-size polyethylene glycol diacrylate (PEGDA) hydrogel fiber

ActiveCN105155011AControllable diameterDiameter controlNew-spun product collectionWet spinning methodsFiberWater baths

The invention relates to a preparation method for a continuous micron-size PEGDA hydrogel fiber. The method comprises the following steps: adding a photoinitiator into an aqueous solution of PEGDA and carrying out stirring in a dark place until the photoinitiator is completely dissolved so as to obtain a PEGDA spinning liquid; introducing the prepared spinning liquid into a water bath, arranging an ultraviolet point light source, initiating free radical polymerization of PEGDA in the spinning liquid to obtain PEGDA nascent hydrogel fiber; and carrying out drafting on obtained nascent hydrogel so as to obtain the continuous micron-size PEGDA hydrogel fiber. The PEGDA hydrogel fiber prepared in the invention is a micron size and has the advantages of continuousness, uniformity, controllable diameter, etc. The diameter of the hydrogel fiber can be controlled by adjusting monomer concentration, an extrusion rate, a winding rate, etc.

Owner:DONGHUA UNIV

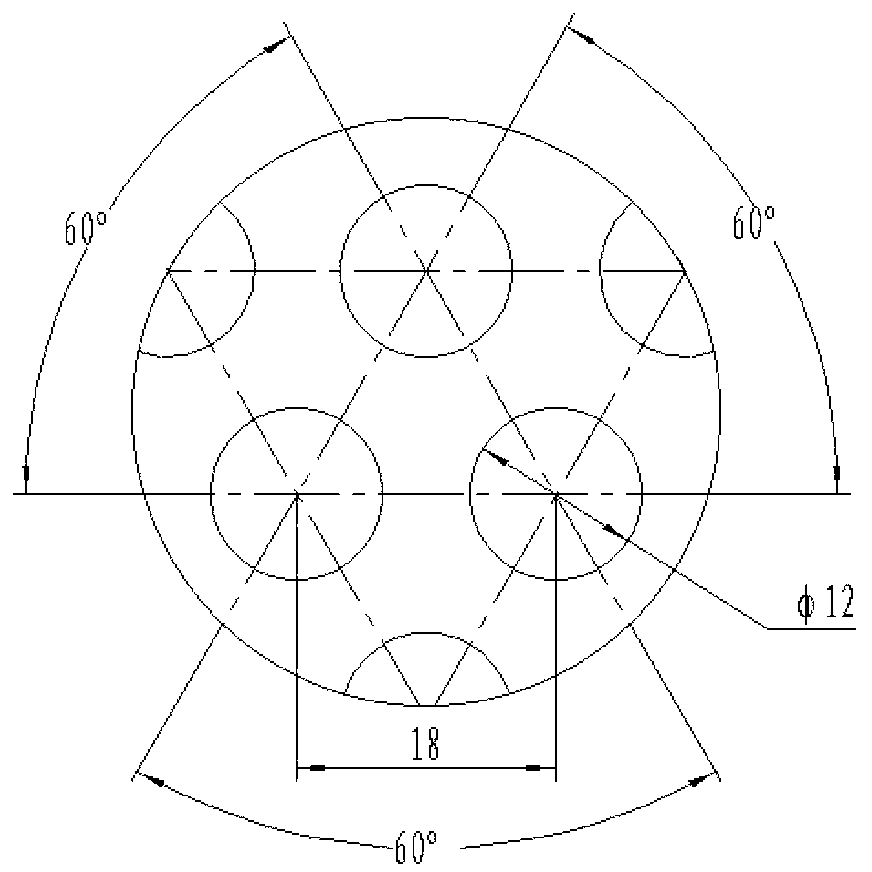

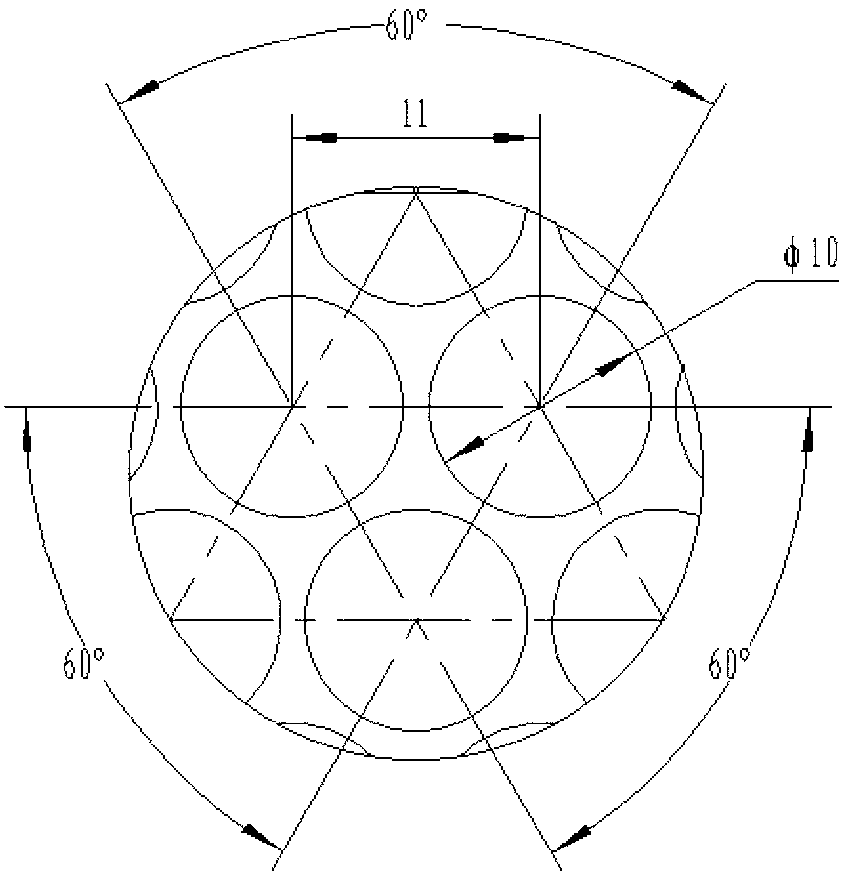

High temperature abrasion resistant guide plate and preparation method thereof

InactiveCN102912254ARealize "Hard Toughness Matching"Realize the "hardness and toughness matching"Guiding/positioning/aligning arrangementsBall millFiller metal

A high temperature abrasion resistant guide plate is formed by compounding WC particle rod-shaped strengthening phase and a high chrome-nickel substrate. A honeycomb-shaped structure is formed on a macroscopic view, and a preparation method comprises the following steps of: preparing a high chrome-nickel guide plate, then machining blind holes which are evenly arranged in a work surface layer of the high chrome-nickel guide plate at stagger, placing WC particles and Ni base brazing filler metal in a ball mill for ball milling and mixing, adding phenolic resin and absolute ethyl alcohol in mixture, evenly mixing to press blanks and pellet, then filling obtained powder in the blind holes in the work surface layer of the high chrome-nickel guide plate and pressing to be solid, placing the high chrome-nickel guide plate with pressed powder into a drying oven for drying, placing dried high chrome-nickel guide plate into a vacuum oven or a gas shield oven for burning and brazing, and then conducting furnace cooling to a room temperature. The high temperature abrasion resistant guide plate has the advantages of being high in hardness and good in abrasive resistance and inoxidizability. The preparation method is simple in process, low in cost and high in process stability.

Owner:XI AN JIAOTONG UNIV

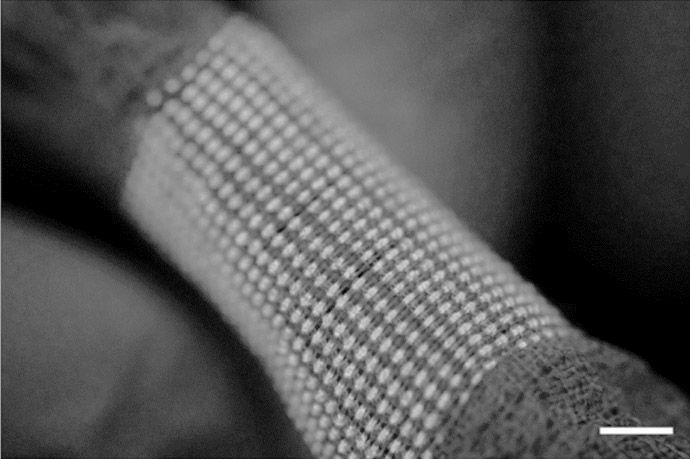

Electronic fabric with display function and preparation method thereof

InactiveCN112813558AExcellent electrodisplay performanceExtended service lifeWoven fabricsEngineeringControl circuit

The invention belongs to the technical field of textile chemical fibers, and particularly relates to electronic fabric with a display function and a preparation method thereof. The electronic fabric comprises warp-wise electroluminescent display fibers and weft-wise transparent conductive fibers, wherein the warp-wise electroluminescent display fiber sequentially comprises a flexible conductive fiber, an electroluminescent display active layer and a resin protective layer from inside to outside. The preparation method comprises the following steps: loading a display active material on the surface of the flexible conductive fiber to obtain an electroluminescent display fiber; dip-coating a transparent insulating packaging layer outside the electroluminescent display fiber; and weaving the electronic fabric with the display function by using the plurality of insulating electroluminescent display fibers as warp, and using the transparent conductive fibers as weft in a plain weaving mode. Through the design of a control circuit, matrix display of the fabric in a specific mode is realized. The brightness of pixel points can reach 200-500 cd / m<2>, and the service life is 1000-3000 h; and the fabric has excellent flexibility and air permeability, and still keeps stable after being bent for 1000 times.

Owner:FUDAN UNIV

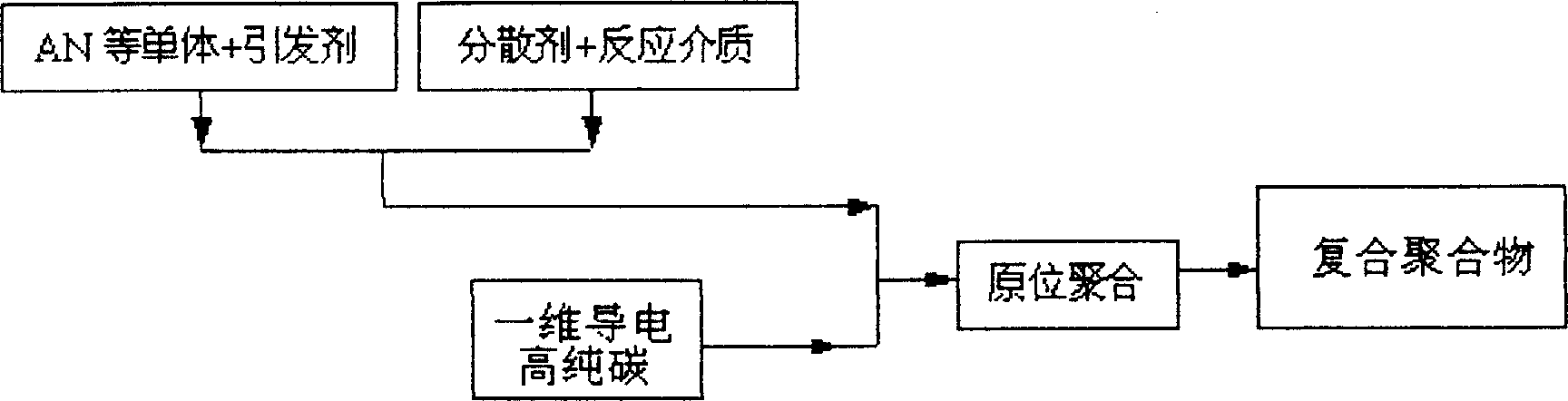

In situ polymerization one-dimensional electric high purity carbon/polyacrylonitrile composite polymer

the invention discloses a preparing method of composite priority through CVD method, which comprises the following parts: 100 wt% acrylon, 1-25 wt% one-dimension conductive high-purity carbon, 0-15 wt% comonomer, 1-3 wt% initiator, 0-1 wt% disperser, 0-3 wt% molecular weight modifier and 150-900 wt% reacting dielectric. One-dimension conductive high-purity carbon is dispersed in the acrylon to polymerize on the one-dimension conductive high-purity carbon, which removes non-reacted acrylon, comonomer and initiator.

Owner:XIAMEN UNIV

Preparation method of conductive organic matter/silicon nanowire solar cell and product thereof

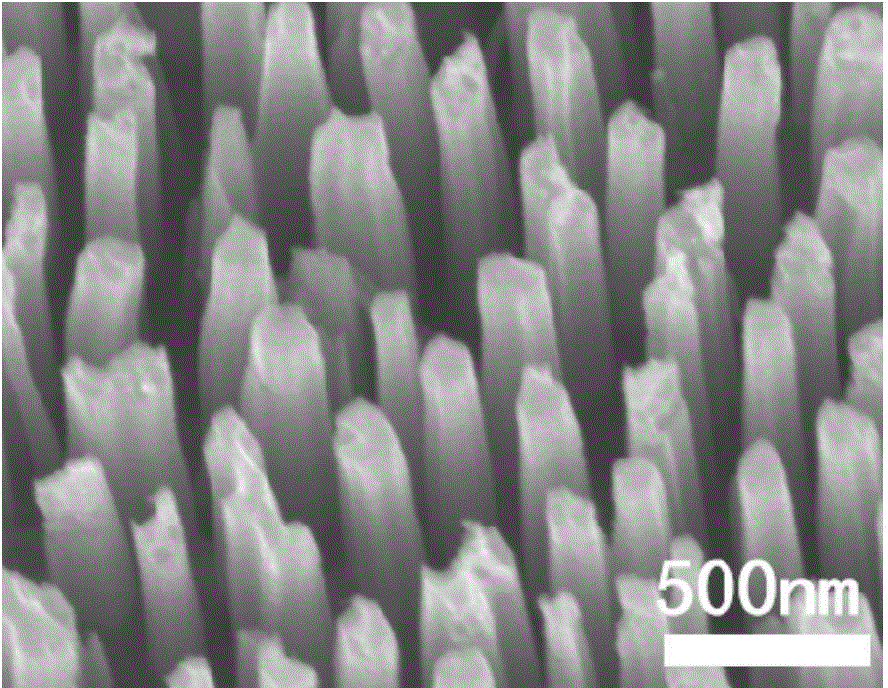

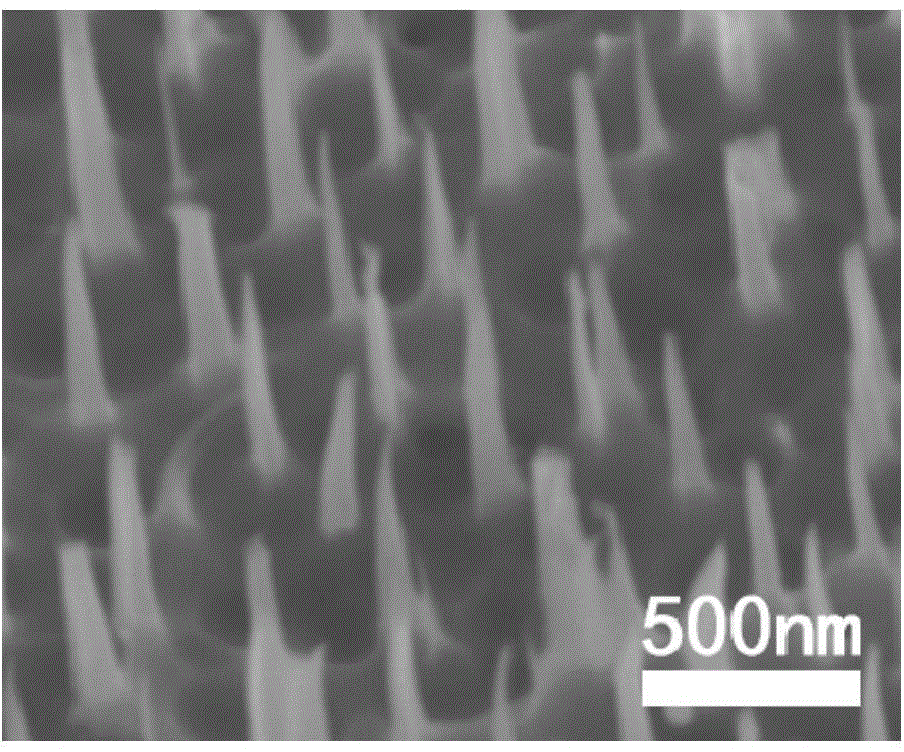

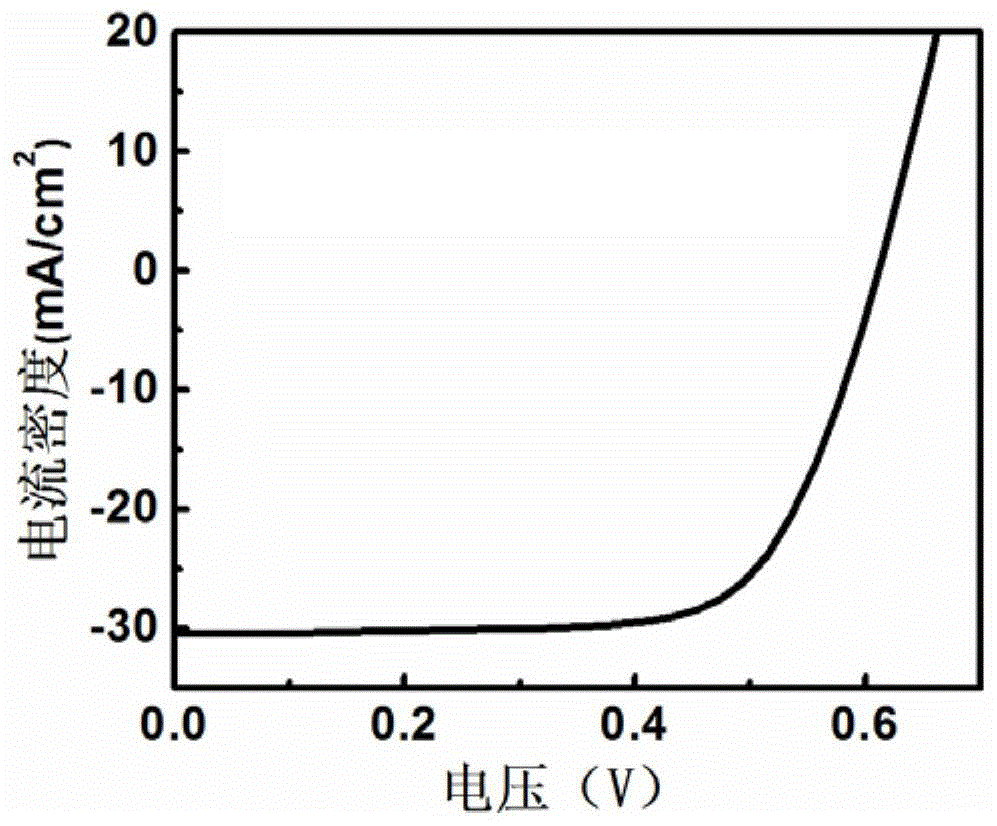

InactiveCN104600196AImprove battery efficiencyImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSilicon nanowiresAluminium

The invention discloses a preparation method of a conductive organic matter / silicon nanowire solar cell. The preparation method includes the steps of: taking aluminum oxide as a template, and combining with a metal-assisted chemical etching method to prepare silicon nanowires, thermally oxidizing for 60-800min at the temperature of 800-1000 DEG C to generate silicon oxide on the surfaces of the silicon nanowires, and steeping into hydrofluoric acid solution until the silicon oxide is completely removed; steeping the processed silicon nanowires into tetramethylammonium hydroxide solution, rotationally coating conductive organic matters on the surfaces after taking out of the solution, and further thermally processing to obtain knotted silicon nanowires; then respectively depositing silver and aluminum on the fronts and backs of the knotted silicon nanowires to serve as electrodes, and thereby obtaining the conductive organic matter / silicon nanowire solar cell. The invention provides a preparation method of the conductive organic matter / silicon nanowire solar cell; according to the preparation method, the silicon nanowires with ordered arrangement and controllable diameter can be prepared, and thereby the conductive organic matter / silicon nanowire solar cell with significantly improved cell efficiency can be prepared.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com