A method for controllable growth of uniform nano nickel chain array induced by magnetic field

A growth method and nanowire array technology, applied in the field of controllable growth of uniform nano-nickel chain arrays induced by magnetic fields, can solve the problems that microscopic characteristics cannot be well reflected, and achieve effective controllable aspect ratio and uniform product morphology , large orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

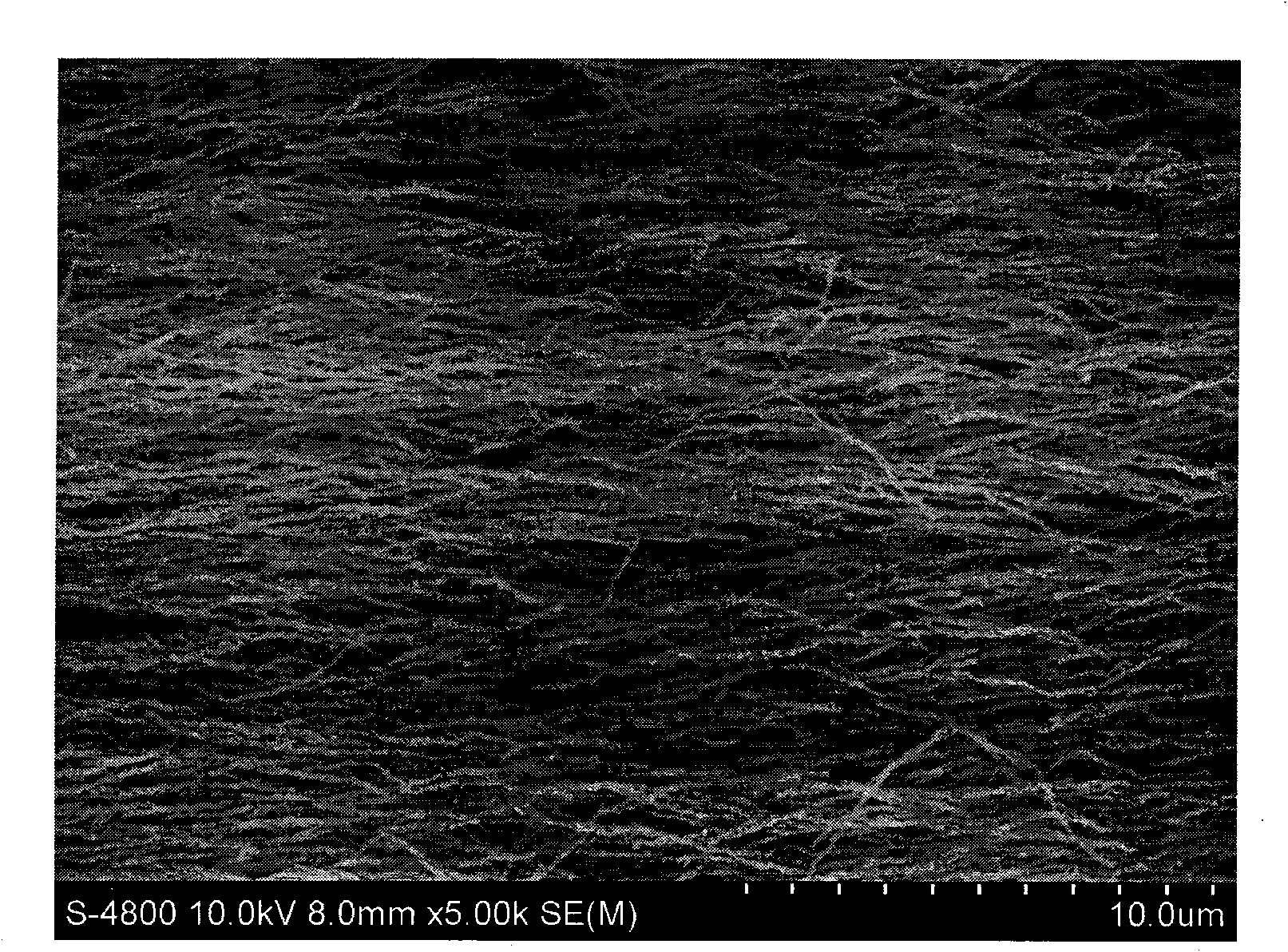

[0022] The length of the nano-nickel nanowire array obtained through the preparation method of the invention is 300nm-20μm, and the particle diameter is 20nm-2μm.

[0023] The controllable growth method suitable for nano-nickel chain arrays disclosed by the present invention can control the reaction temperature of the system, add sodium hydroxide, potassium hydroxide, etc. to adjust the pH value of the solution, and the strength of the magnetic field, etc. for the obtained nano-nickel chains. , to control particle size, aspect ratio and orientation. Its reaction mechanism is:

[0024] First, under the action of ethylene glycol molecules, hydrazine hydrate in the solution cooperates with nickel chloride to form a nickel-hydrazine complex.

[0025] NiCl 2 +3N 2 h 4 →[Ni(N 2 h 4 ) 3 ] Cl 2

[0026] Then, under the action of excess hydrazine hydrate, the nickel-hydrazine complex decomposes to generate nickel.

[0027] [Ni(N 2 h 4 ) 3 ] Cl 2 +N 2 h 4 →Ni↓+4NH 3 ↑+2...

Embodiment 1

[0030] Step 1: Under the condition of a magnetic field of 0.5T, heat the ethylene glycol solution to 150°C, drop in hydrazine hydrate with a concentration of 50% by volume, stir and mix thoroughly, and drop in a concentration of 1×10 -4 The nickel chloride hexahydrate of mol / L makes the first reaction solution after reacting for 60min;

[0031] Dosage: Add 20ml nickel chloride hexahydrate and 0.1ml hydrazine hydrate to 40ml ethylene glycol;

[0032] In this step, the entire reaction process is under a magnetic field environment, so the raw materials (nickel chloride hexahydrate, ethylene glycol, and hydrazine hydrate are selected as raw materials) complete the directional growth of nickel nanochains in a magnetic field, and then regenerated by a magnetic field. arrays to obtain regular arrays of Ni nanowire arrays.

[0033] Step 2: after the first reaction solution prepared in step 1 was left to stand for 30 minutes, the black deposit in the lower layer was removed, which was...

Embodiment 2

[0039] Step 1: Under the condition of a magnetic field of 0.25T, after heating the ethylene glycol solution to 120°C, drop in hydrazine hydrate with a concentration of 50% by volume, stir and mix thoroughly, and drop in a concentration of 5×10 -3 mol / L nickel chloride hexahydrate, react for 30min to prepare the first reaction solution; dosage: add 20ml nickel chloride hexahydrate and 0.4ml hydrazine hydrate to 40ml ethylene glycol;

[0040] Step 2: After the first reaction solution prepared in step 1 was left to stand for 10 minutes, the black deposit in the lower layer was removed, which was the first product;

[0041] Step 3: centrifuge the first product obtained in step 2 at a centrifugal speed of 12000 rpm for 5 minutes to obtain the second product

[0042] Step 4: The second product obtained in step 3 is ultrasonically cleaned with deionized water for 10 minutes in an ultrasonic wave of 100 MHz to obtain a third product;

[0043] Step 5: The third product prepared in Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com