Preparation method of conductive organic matter/silicon nanowire solar cell and product thereof

A technology of conductive organic matter and solar cells, applied in the field of solar cells, can solve problems such as large surface area, affecting cell efficiency, and inability to effectively control the diameter of nanowires, so as to achieve high efficiency and improve cell efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

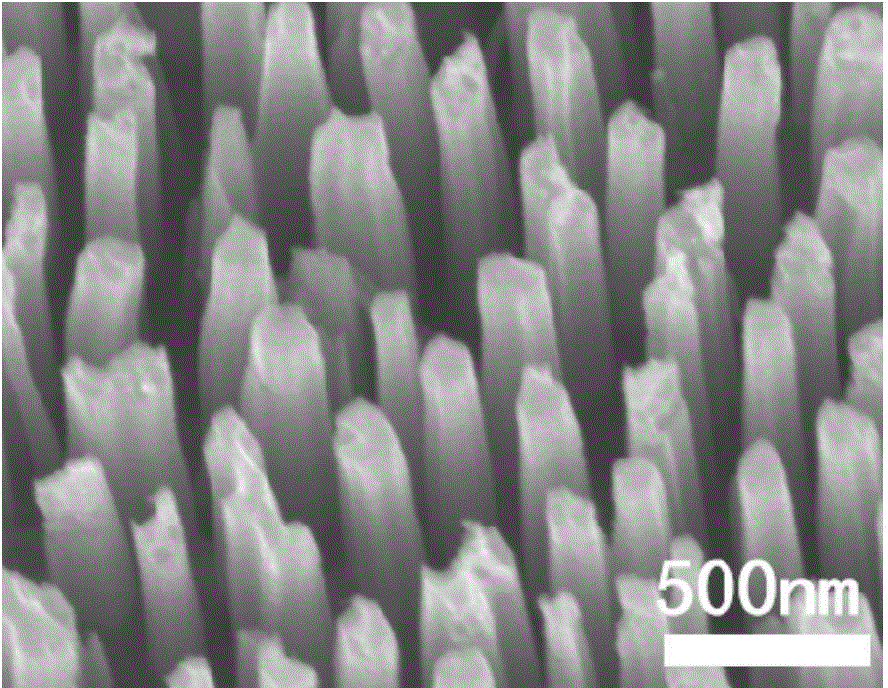

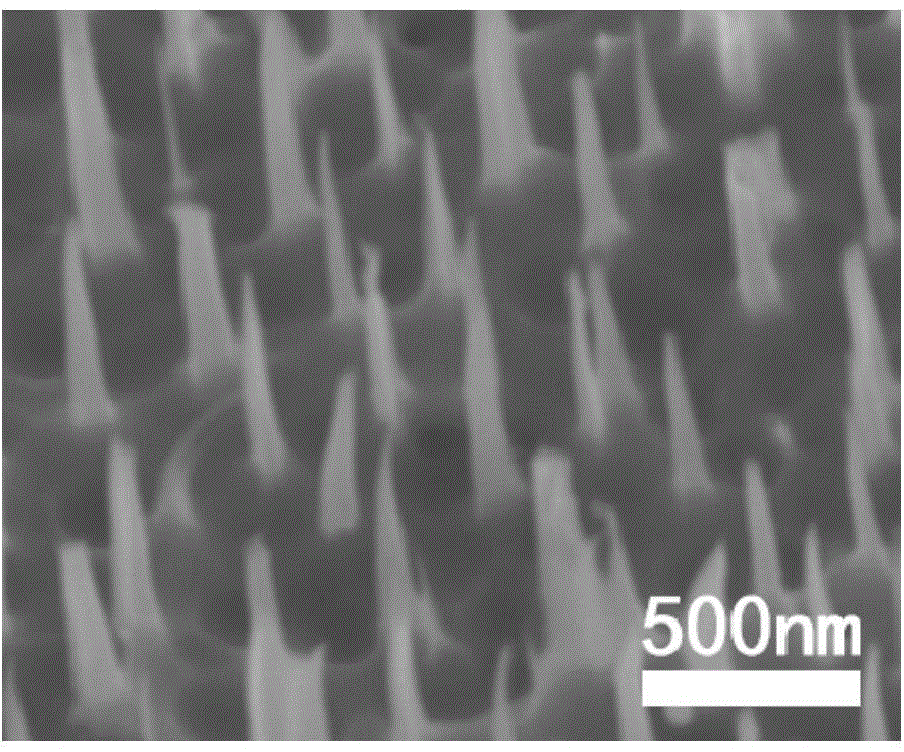

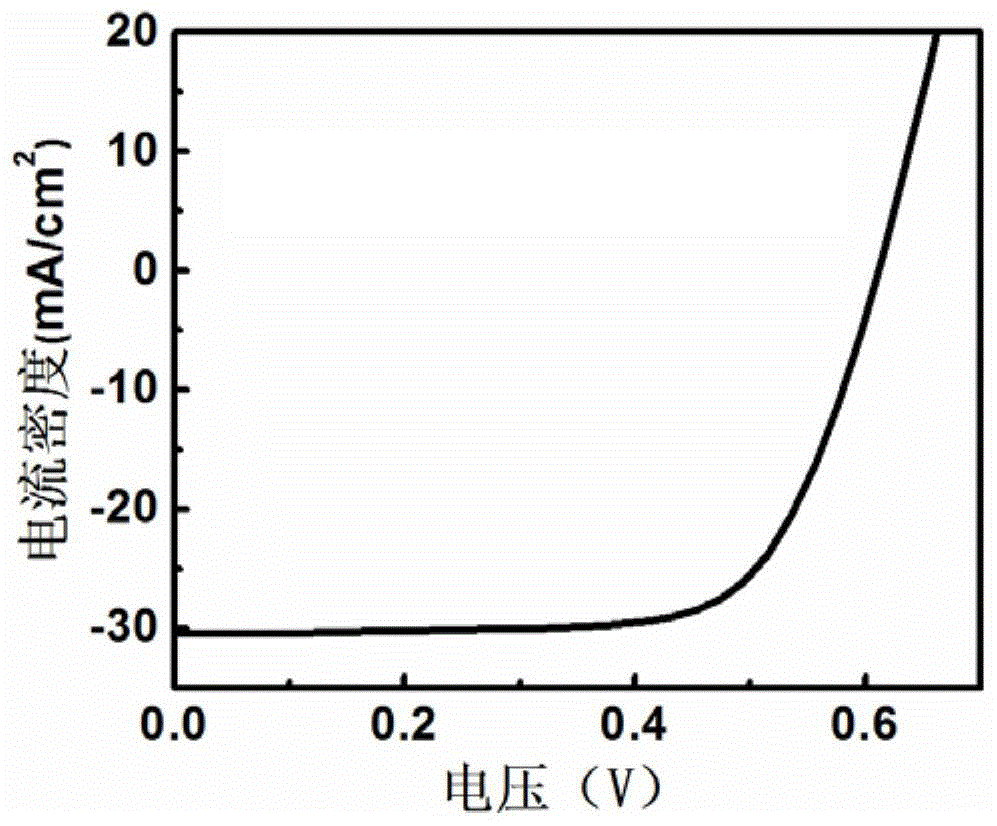

[0035] Sputter gold on the aluminum oxide template for 90s, then transfer the gold film to a silicon wafer, place it in a mixed solution of hydrofluoric acid (40% by mass) and hydrogen peroxide (30% by mass) and etch to obtain silicon Nanowires. Under an oxygen atmosphere, at 1000°C, after thermal oxidation for 360 minutes, silicon oxide is formed on the surface of the silicon nanowire, and then soaked in a hydrofluoric acid solution with a mass fraction of 30% until the silicon oxide is completely removed, and the treated silicon nanowire is obtained. The diameter is 90 ~ 100nm. Soak the treated silicon nanowires in an aqueous solution of 0.5% tetramethylammonium hydroxide for 60s; spin-coat PEDOT doped with dimethyl sulfoxide and polyethylene glycol octylphenyl ether on the surface :PSS, dimethyl sulfoxide, PEDOT: The mass ratio of PSS to polyethylene glycol octyl phenyl ether is 7:92:1, the spin coating speed is 2000r / min, heat treatment is carried out at 100 °C, and the h...

Embodiment 2

[0038]Sputter gold on the aluminum oxide template for 90s, then transfer the gold film to a silicon wafer, place it in a mixed solution of hydrofluoric acid (40% by mass) and hydrogen peroxide (30% by mass) and etch to obtain silicon Nanowires. In an oxygen atmosphere, at 900°C, after thermal oxidation treatment for 600 minutes, silicon oxide was generated on the surface of the silicon nanowires, and then soaked in a hydrofluoric acid solution with a mass fraction of 5% until the silicon oxide was completely removed, and the treated silicon nanowires were obtained. The diameter of the root is 65-75nm. Soak the treated silicon nanowires in an aqueous solution of 1% tetramethylammonium hydroxide for 90s; spin-coat silicon nanowires doped with dimethyl sulfoxide and polyethylene glycol octylphenyl The PEDOT:PSS of ether, the mass ratio of dimethyl sulfoxide, PEDOT:PSS and polyethylene glycol octyl phenyl ether is 5:94:1, spin-coating speed is 3000r / min, and carry out heat treatm...

Embodiment 3

[0041] Sputter gold on the aluminum oxide template for 90s, then transfer the gold film to a silicon wafer, place it in a mixed solution of hydrofluoric acid (40% by mass) and hydrogen peroxide (30% by mass) and etch to obtain silicon Nanowires. In an oxygen atmosphere, at 800°C, after thermal oxidation for 700 minutes, silicon oxide is formed on the surface of the silicon nanowire, and then soaked in a hydrofluoric acid solution with a mass fraction of 30% until the silicon oxide is completely removed, and the treated silicon nanowire is obtained. The diameter is 35 ~ 40nm. Soak the treated silicon nanowires in an aqueous solution with a mass fraction of 1.5% tetramethylammonium hydroxide for 120s; spin-coat silicon nanowires doped with dimethyl sulfoxide and polyethylene glycol octylphenyl The PEDOT:PSS of ether, the mass ratio of dimethylsulfoxide, PEDOT:PSS and polyethylene glycol octyl phenyl ether is 9:90:1, and spin-coating speed is 5000r / min, and heat treatment is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com