Full carbon counter electrode dye-sensitized solar cell and preparing method

A technology for solar cells and dye sensitization, applied in the field of counter electrodes and their preparation, can solve problems such as electrode composition and production that are not involved, and achieve the effects of lightening, simplifying the preparation process, and reducing transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

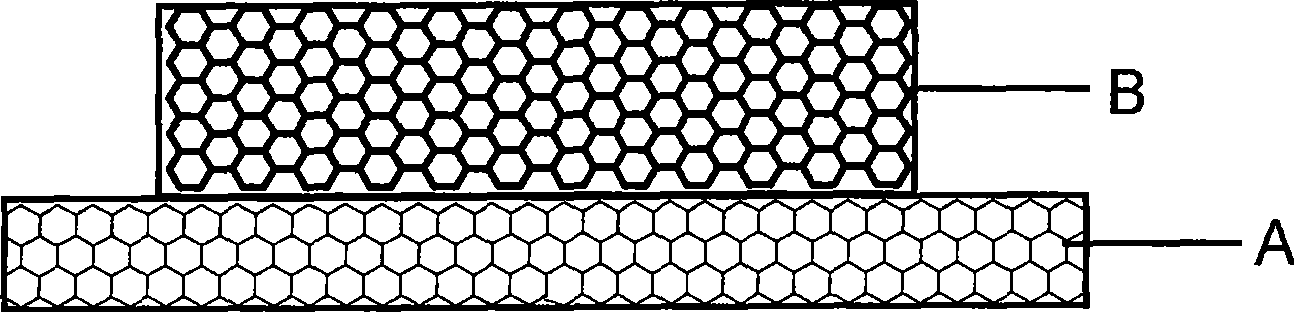

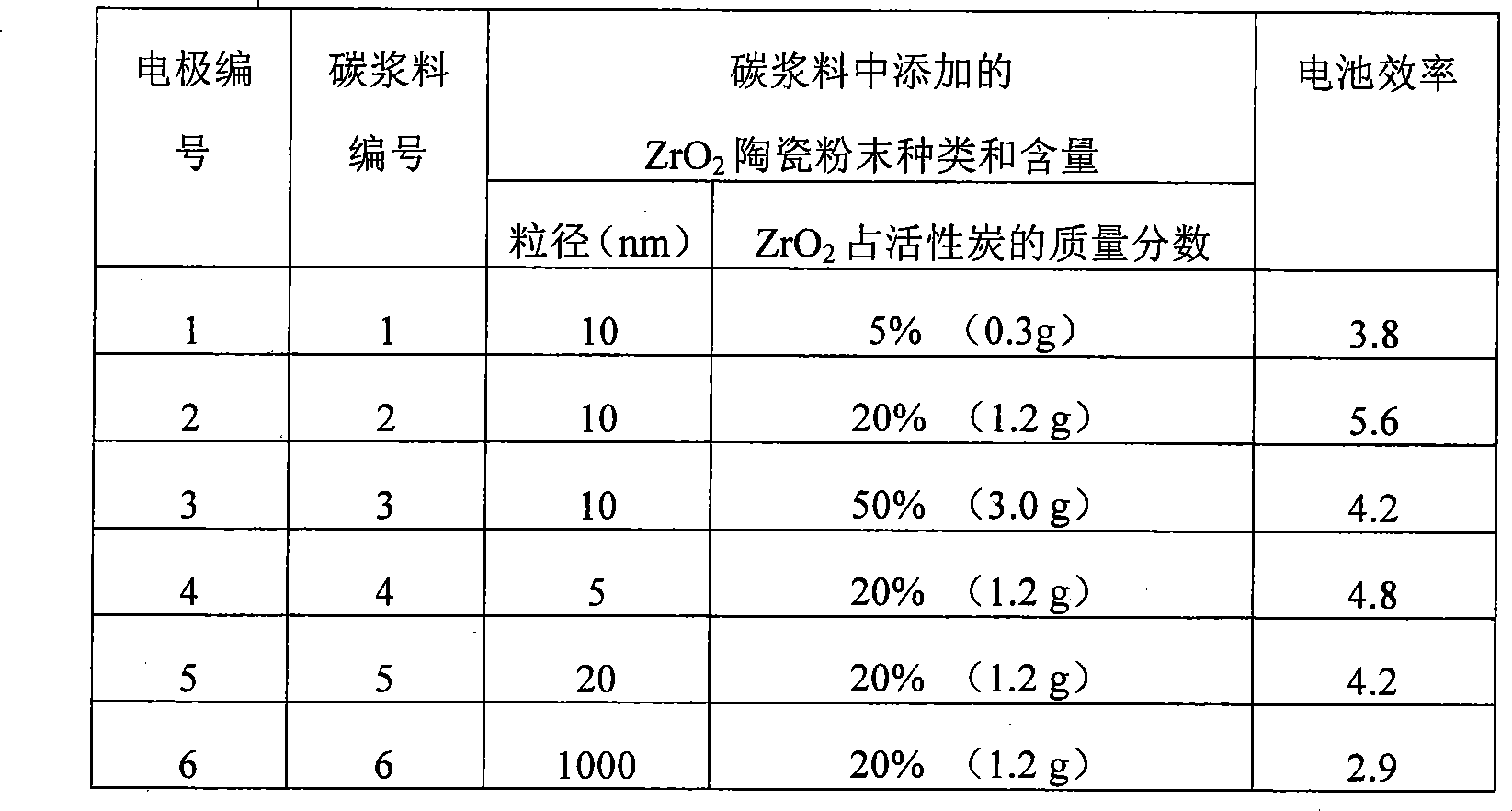

[0036] Select graphite paper with a thickness of 0.3mm and a surface resistance of 0.1Ω / □ as the conductive carbon substrate A, and select a specific surface area of 1958m 2 / g of activated carbon is a catalytically active material. According to the preparation method of the carbon slurry of the patent publication number CN101188257A, the carbon slurry is prepared, and ZrO is added in different proportions in the carbon slurry 2 Ceramic powder (the data of 6 kinds of embodiments is listed in Table 1), the prepared carbon slurry is coated on the carbon substrate A to form a catalytically active material layer B, wherein the thickness of the catalytically active material layer B is: 15 μm.

[0037] The concrete preparation process of the all-carbon counter electrode of 6 kinds of embodiments in table 1 is as follows:

[0038] 1) First prepare carbon slurry 1-6 according to the preparation method of carbon slurry in patent publication number CN101188257A, that is, change the s...

Embodiment 2

[0047] Graphite paper with a thickness of 0.5mm and a surface resistance of 0.07Ω / □ was selected as the conductive carbon substrate A, and the specific surface area was selected to be 830m 2 / g and 77m 2 / g of activated carbon and carbon black are catalytically active materials. Prepare carbon slurry according to the preparation method of the carbon slurry of patent publication number CN101188257A, add the ceramic powder of 1.2g in carbon slurry simultaneously, the type and size of ceramic powder are shown in Table 2 (the data of 6 kinds of embodiments are listed in Table 2 Middle), activated carbon and carbon black according to the mass ratio of 80:20, the carbon slurry is coated on the carbon substrate A to form a catalytic active material layer B, wherein the thickness of the catalytic active material layer B is: 10 μm. .

[0048] The concrete preparation process of the all-carbon counter electrode of 6 kinds of embodiments in table 2 is as follows:

[0049] 1) First pre...

Embodiment 3

[0058] A graphite plate with a thickness of 2mm and a surface resistance of 0.03Ω / □ was selected as the conductive carbon substrate A, and flake graphite with a specific surface area of 13m2 / g was used as the catalytic active material. Prepare carbon slurry according to the preparation method of the carbon slurry of patent publication number CN101188257A, add the ceramic powder of 1.2g in carbon slurry simultaneously, the type and size of ceramic powder are shown in Table 3 (the data of 6 kinds of embodiments are listed in Table 3 Middle), the carbon slurry is coated on the carbon substrate A to form a catalytically active material layer B, wherein the thickness of the catalytically active material layer B is: 20 μm.

[0059] The specific preparation process of the all-carbon counter electrode including 6 kinds of embodiments in Table 3 is as follows:

[0060] 1) Firstly, prepare carbon slurry 13-18 according to the preparation method of carbon slurry in the patent (publicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com