Patents

Literature

871 results about "Czochralski method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

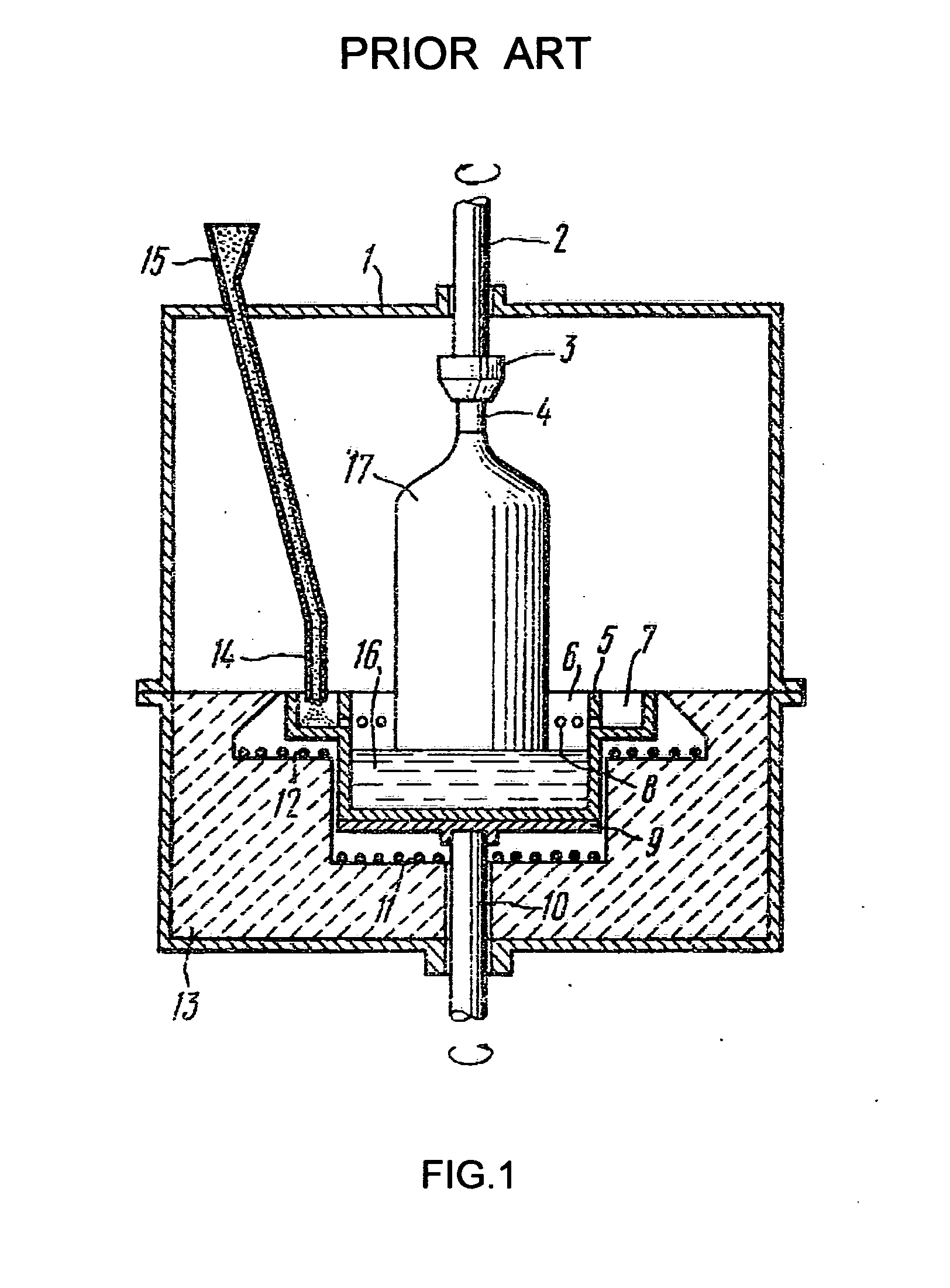

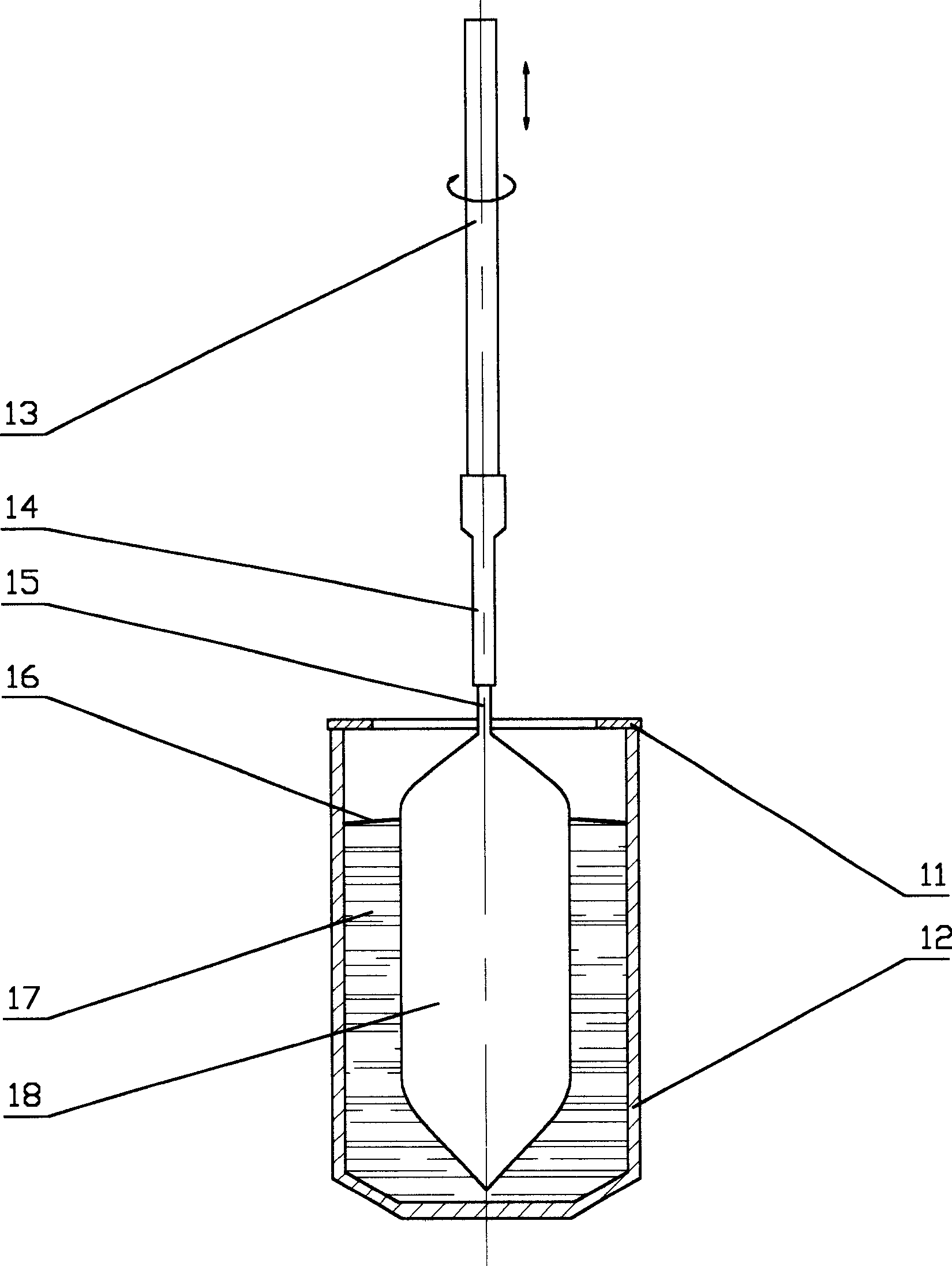

Thus, the Czochralski method was a method of producing large single crys tals by inserting a small seed crystal into a crucible filled with molten material, then slowly pulling the seed up from the melt with its simultaneous rotation. Later modifications of this method have also been reported.

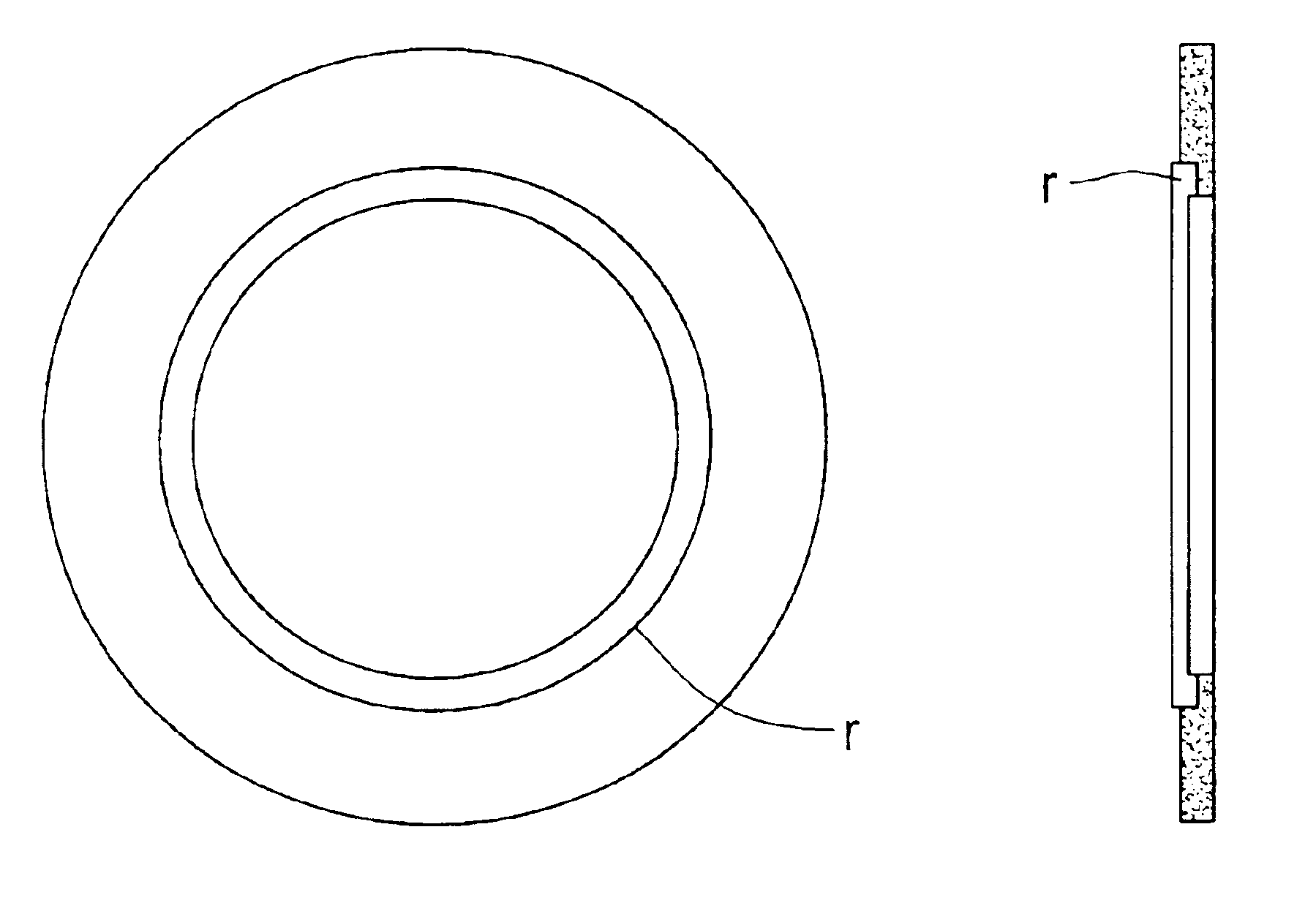

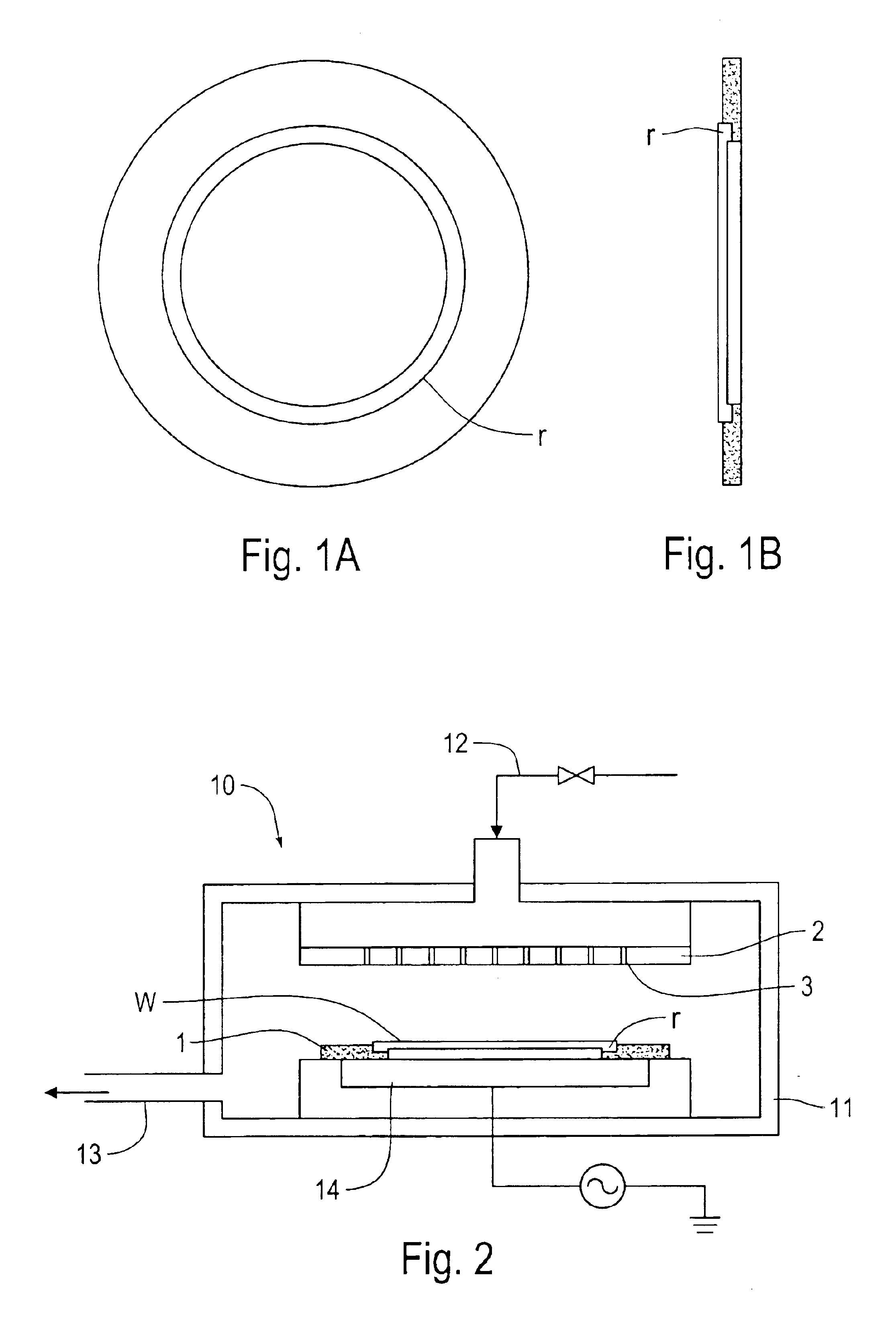

Silicon focus ring and method for producing the same

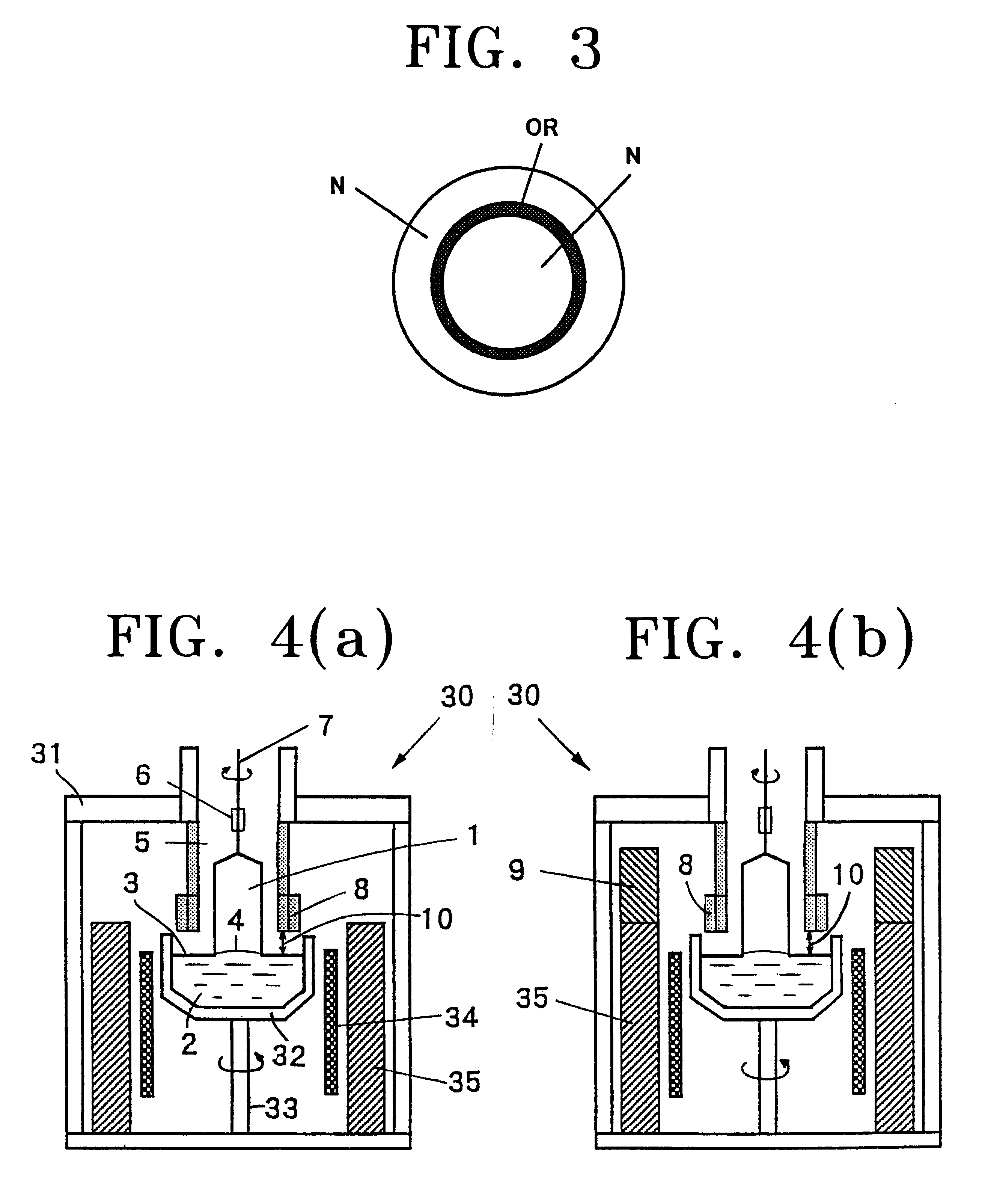

InactiveUS6815352B1Reduce Particle GenerationAvoid roughnessPolycrystalline material growthElectric discharge tubesCzochralski methodSingle crystal

There is disclosed a silicon focus ring consisting of silicon single crystal used as a silicon focus ring in a plasma apparatus, wherein concentration of interstitial oxygen contained in the silicon focus ring is not less than 5x10<17 >atoms / cm<3 >and not more than 1.5x10<18 >atoms / cm<3>, and a producing method for a silicon focus ring used for a plasma apparatus, wherein a single crystal silicon wherein concentration of interstitial oxygen contained in the silicon focus ring is not less than 5x10<17 >atoms / cm<3 >and not more than 1.5x10<18 >atoms / cm<3 >is grown by a Czochralski method, the single crystal silicon is processed in a circle, and a silicon focus ring is produced. There can be provided a silicon focus ring, which can prevent disadvantage due to impurities such as heavy metal.

Owner:SHIN ETSU CHEM IND CO LTD

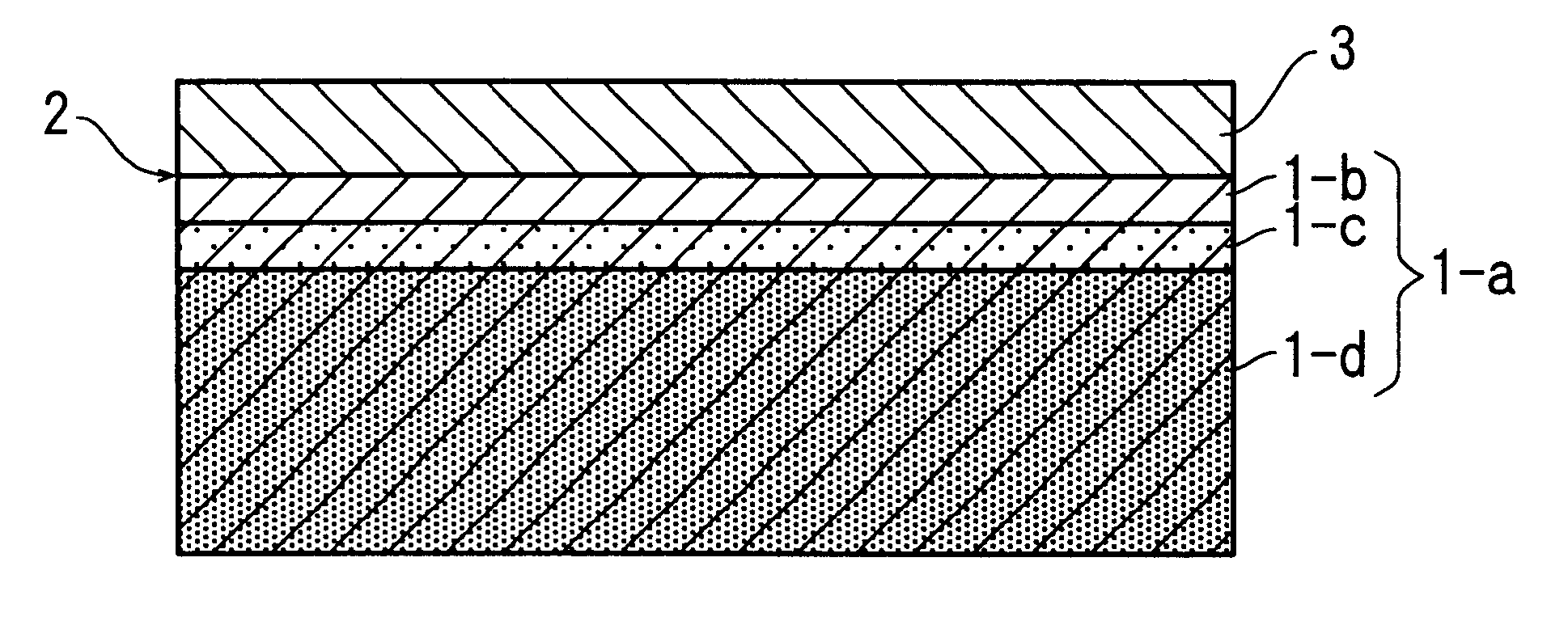

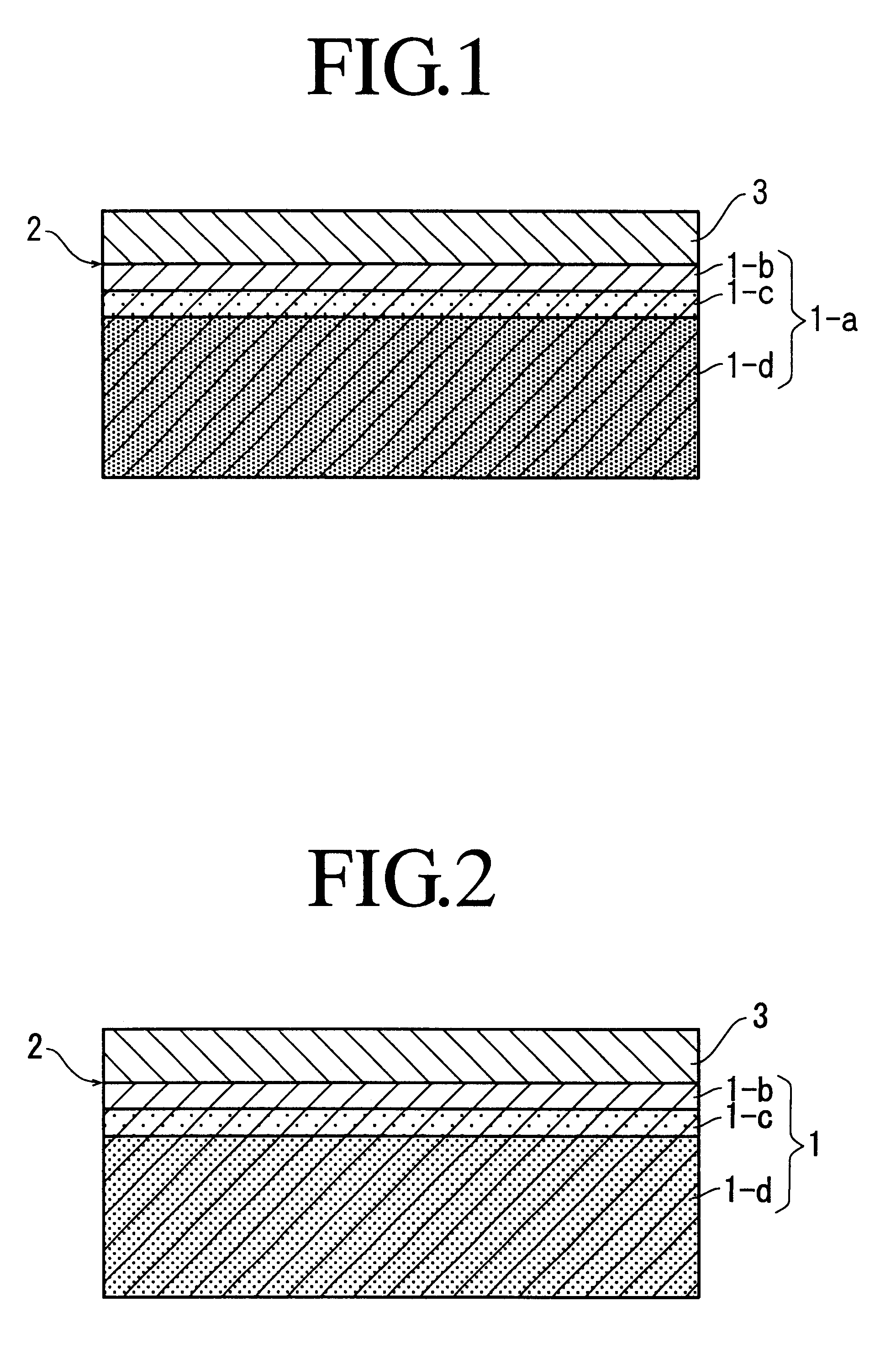

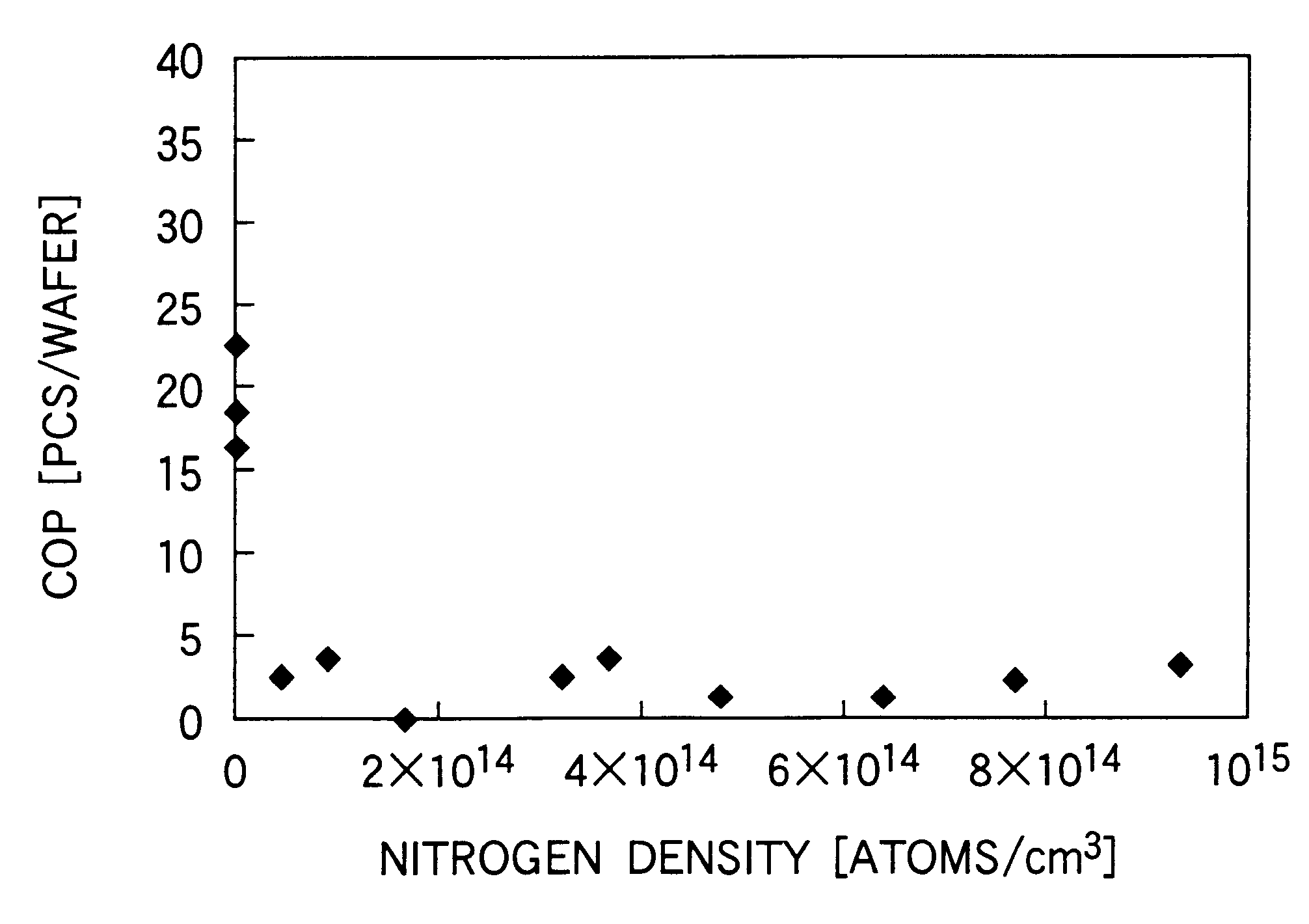

Silicon semiconductor wafer and method for producing the same

InactiveUS6548886B1Quality improvementLow costPolycrystalline material growthSemiconductor/solid-state device manufacturingCzochralski methodNitrogen

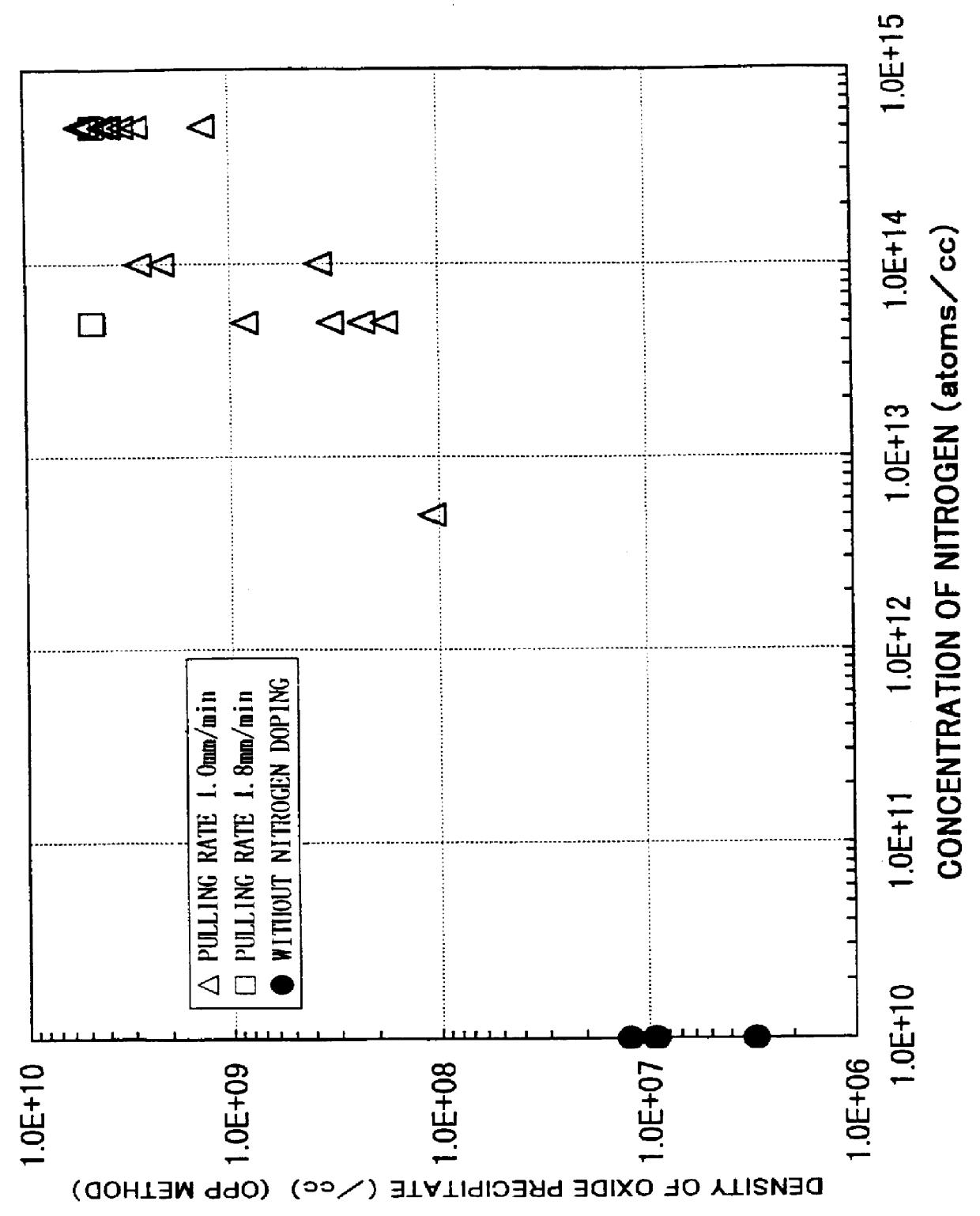

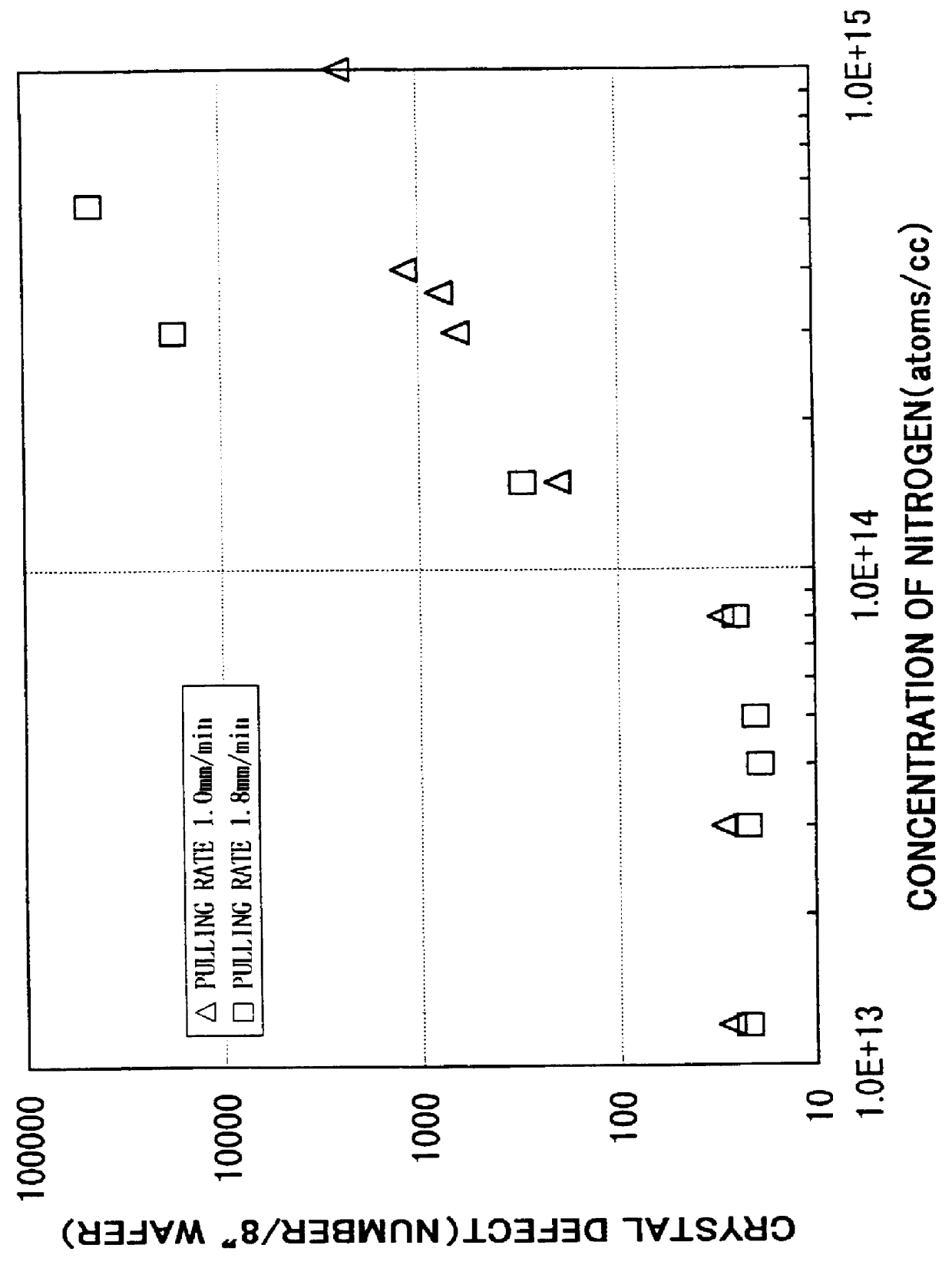

A silicon semiconductor substrate is obtained by deriving a silicon semiconductor substrate from a silicon single crystal grown by the Czochralski method from a molten silicon containing not less than 1x1016 atoms / cm3 and not more than 1.5x1019 atoms / cm3 of nitrogen and heat-treating the silicon semiconductor substrate at a temperature of not less than 1000° C. and not more than 1300° C. for not less than one hour and is characterized by the fact that the density of crystal defects measuring not less than 0.1 mum as reduced to diameter is not more than 104 pieces / cm3 at least in the region reaching a depth of 1 mum from the surface of the substrate and the nitrogen content at the center of thickness of the silicon semiconductor substrate is not less than 1x1013 atoms / cm3 and not more than 1x1016 atoms / cm3.

Owner:SILTRONIC AG

Method of producing high-quality silicon single crystals

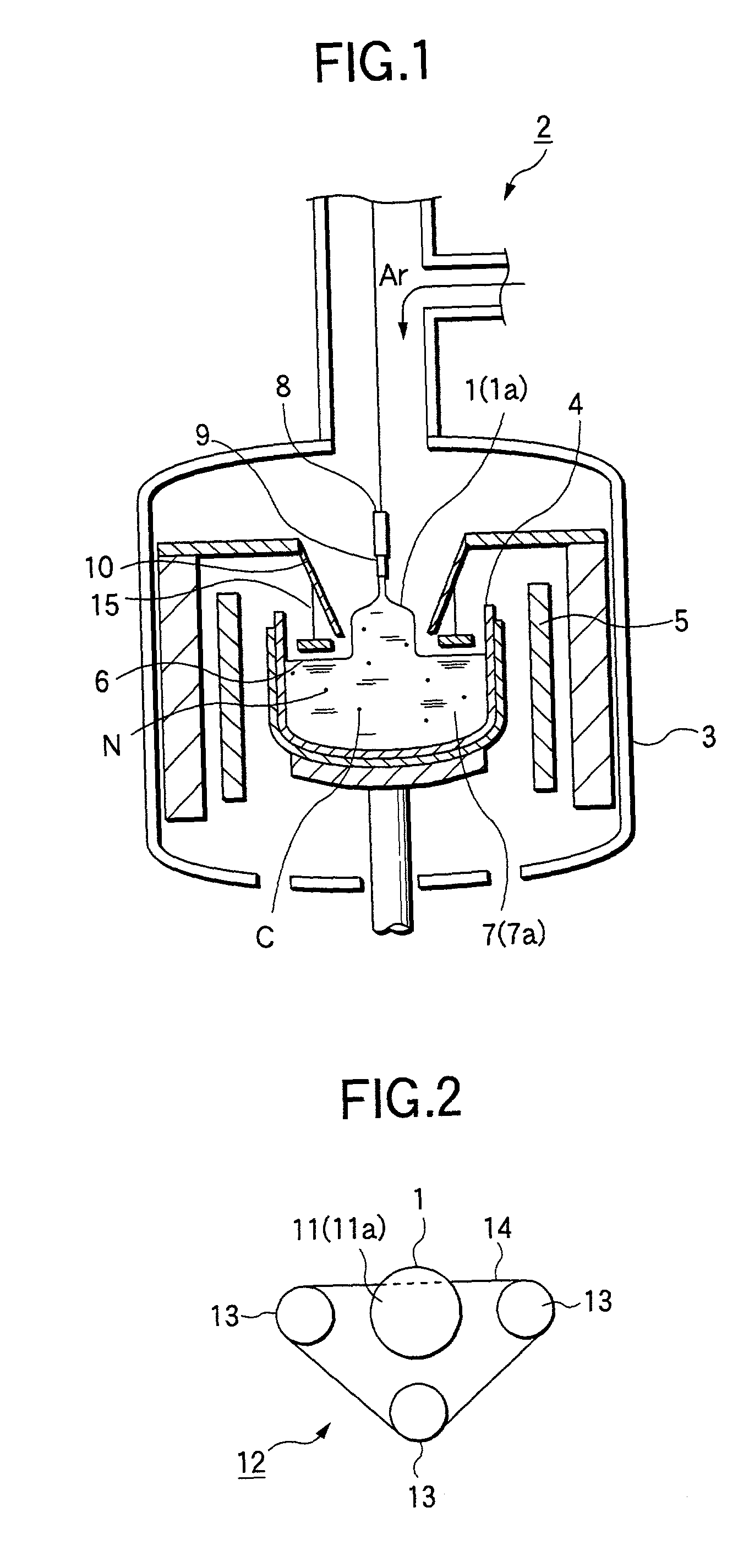

InactiveUS6458204B1Polycrystalline material growthSemiconductor/solid-state device manufacturingLaser scatteringSingle crystal

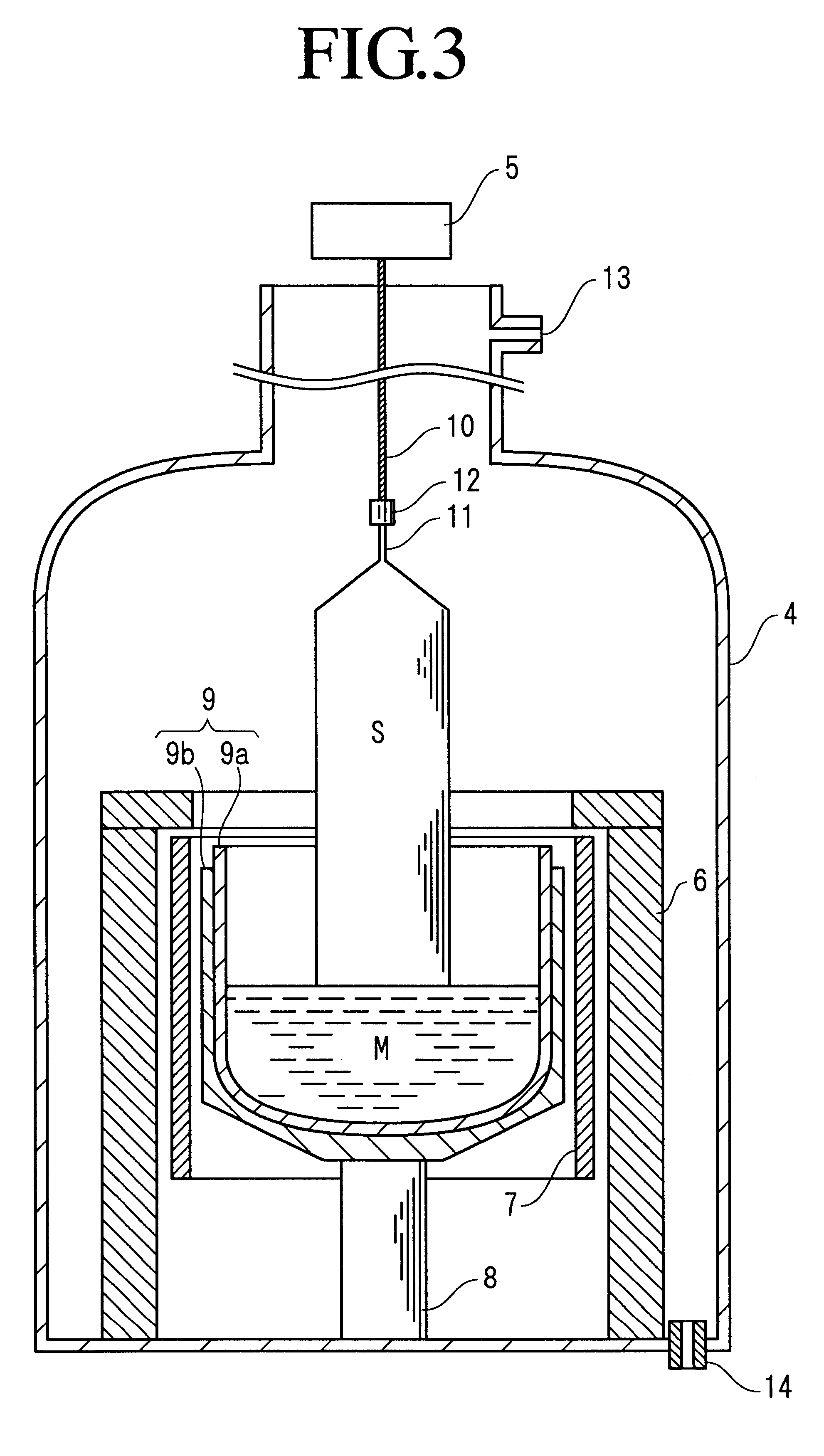

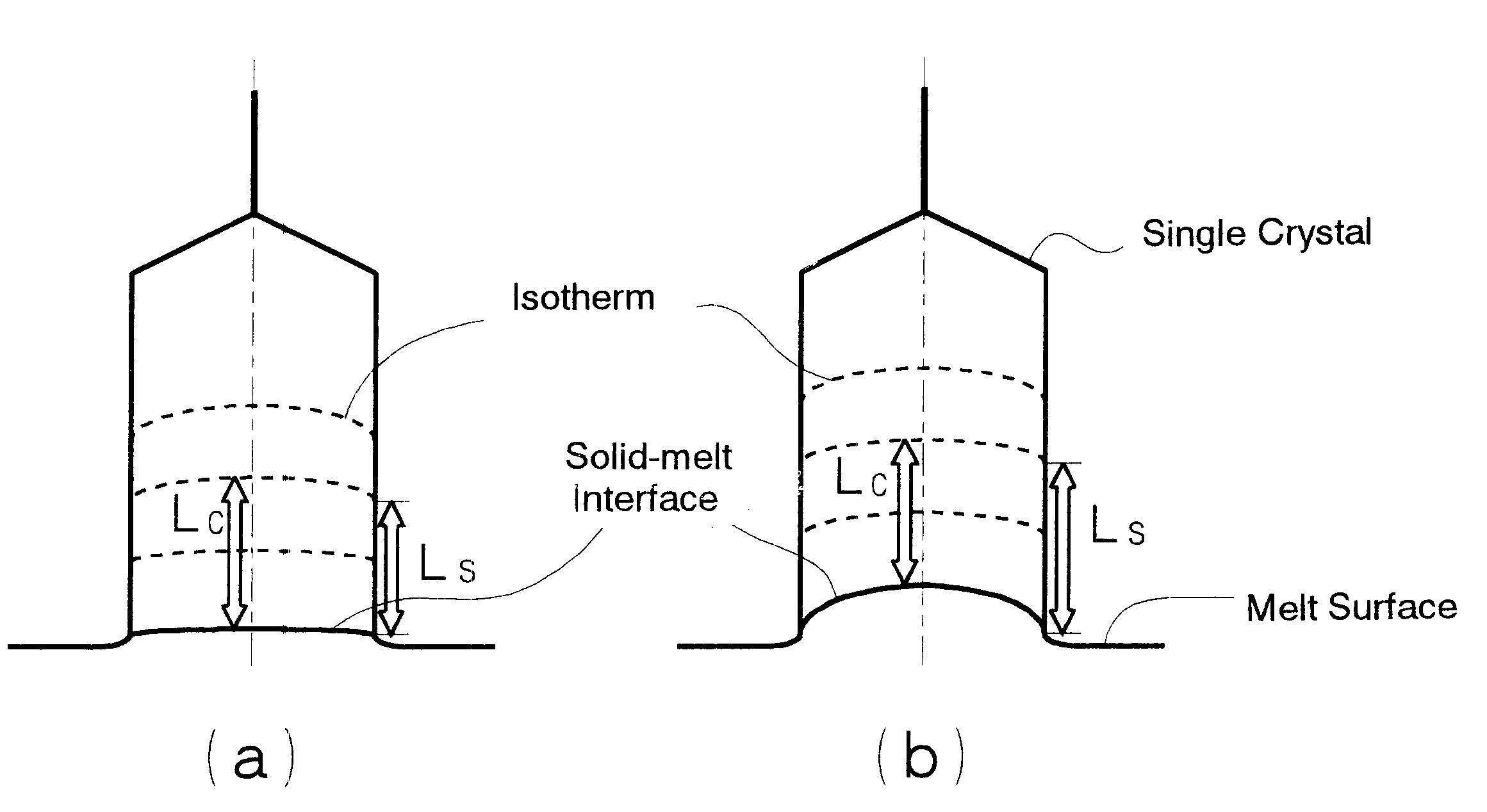

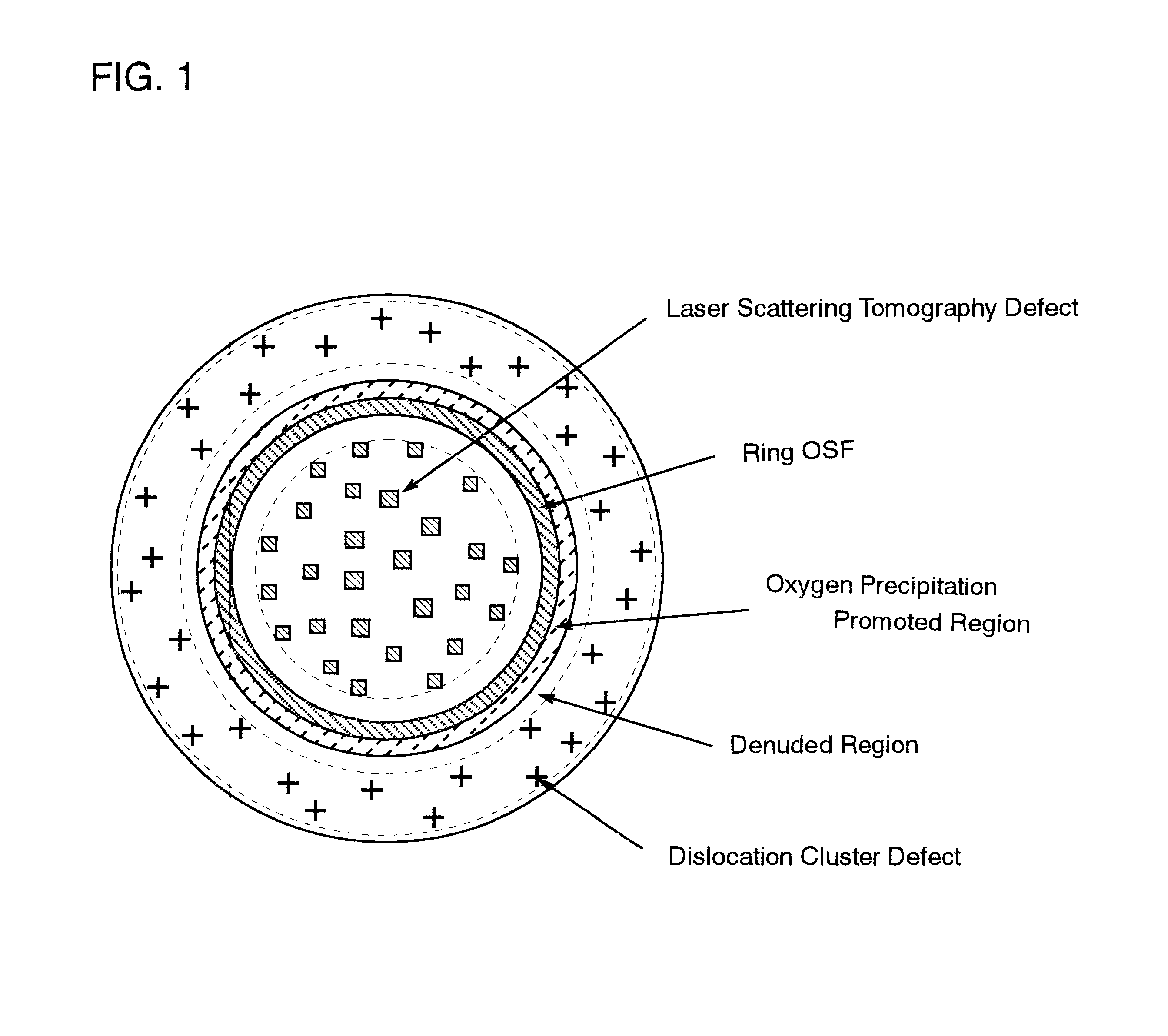

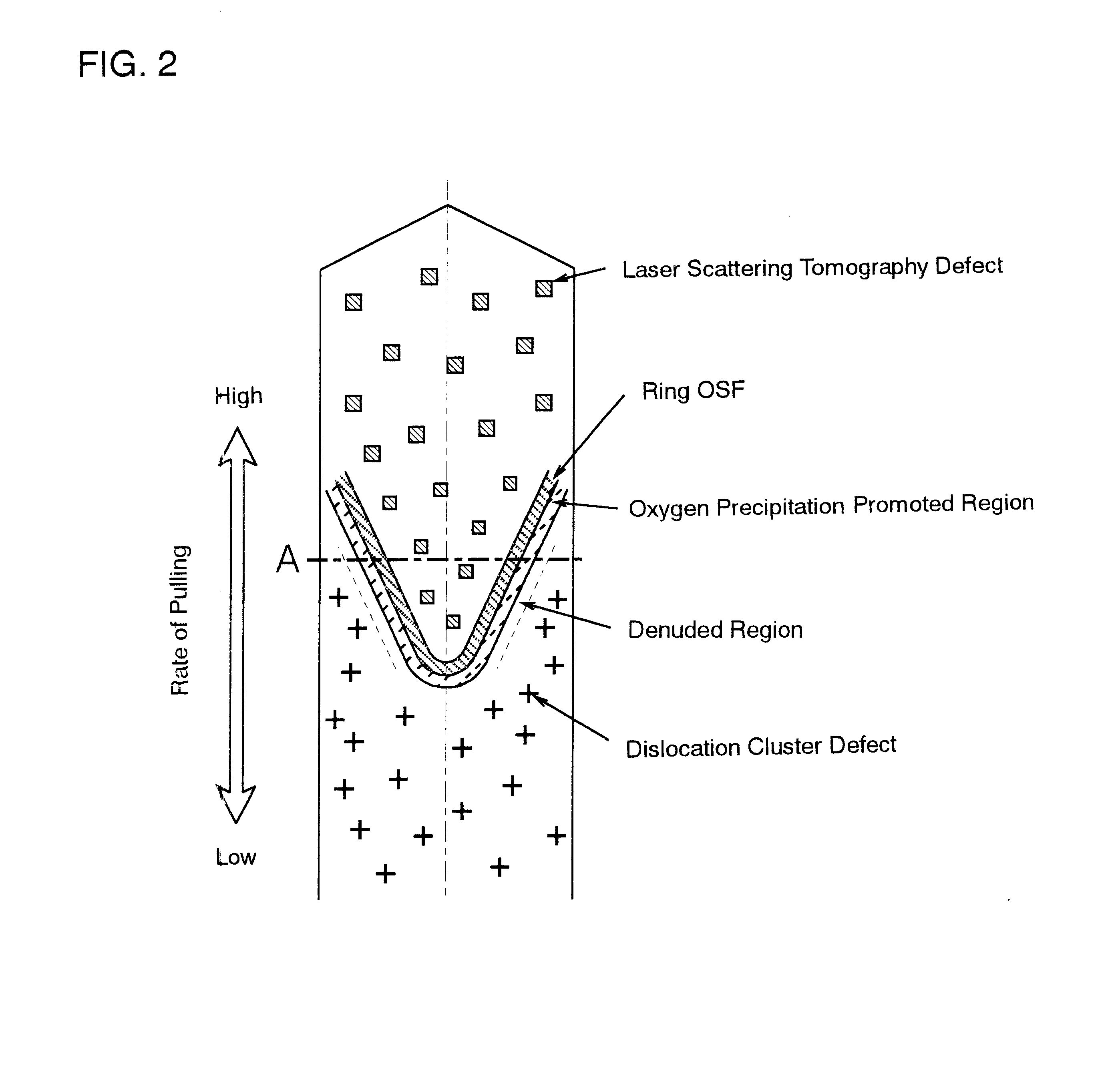

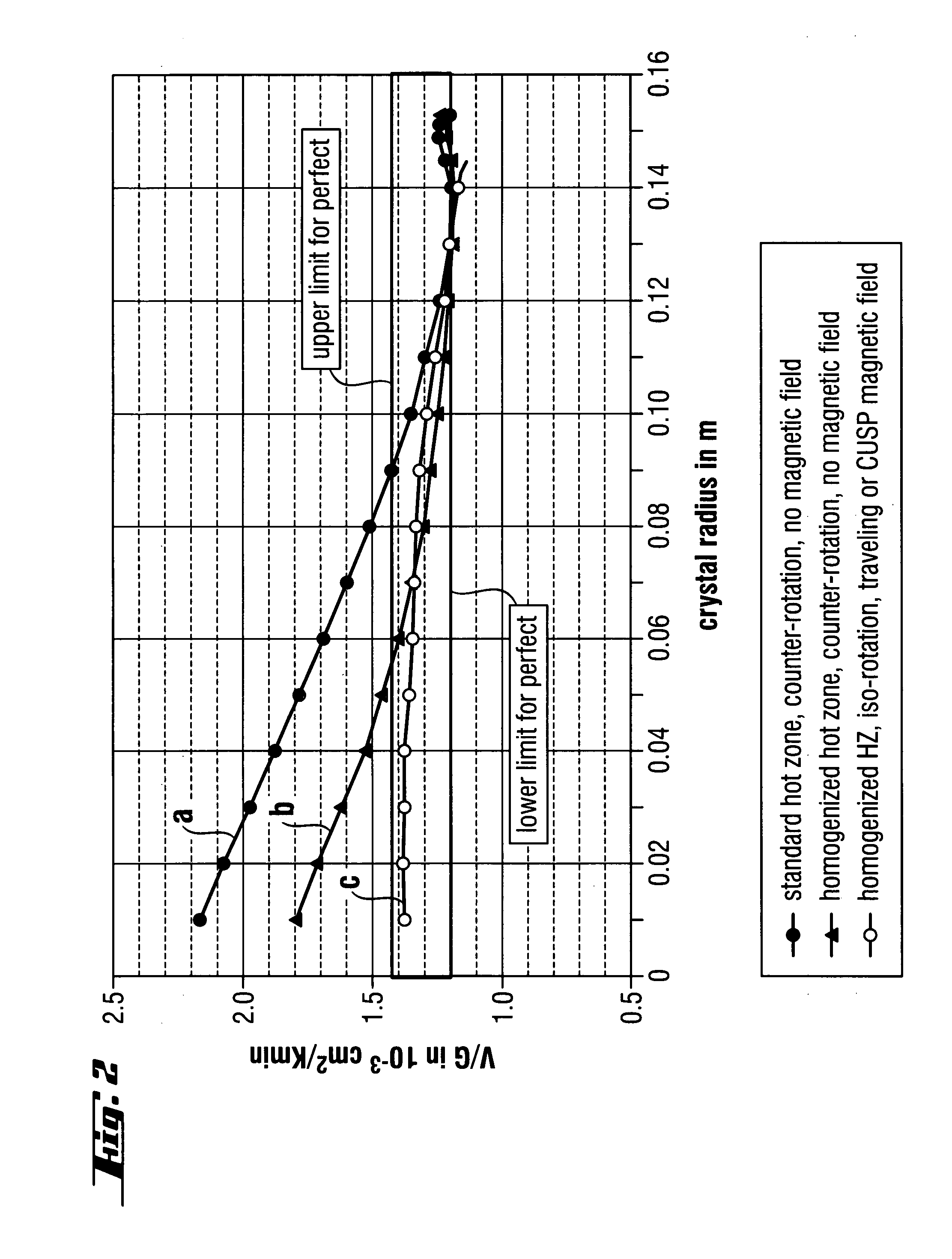

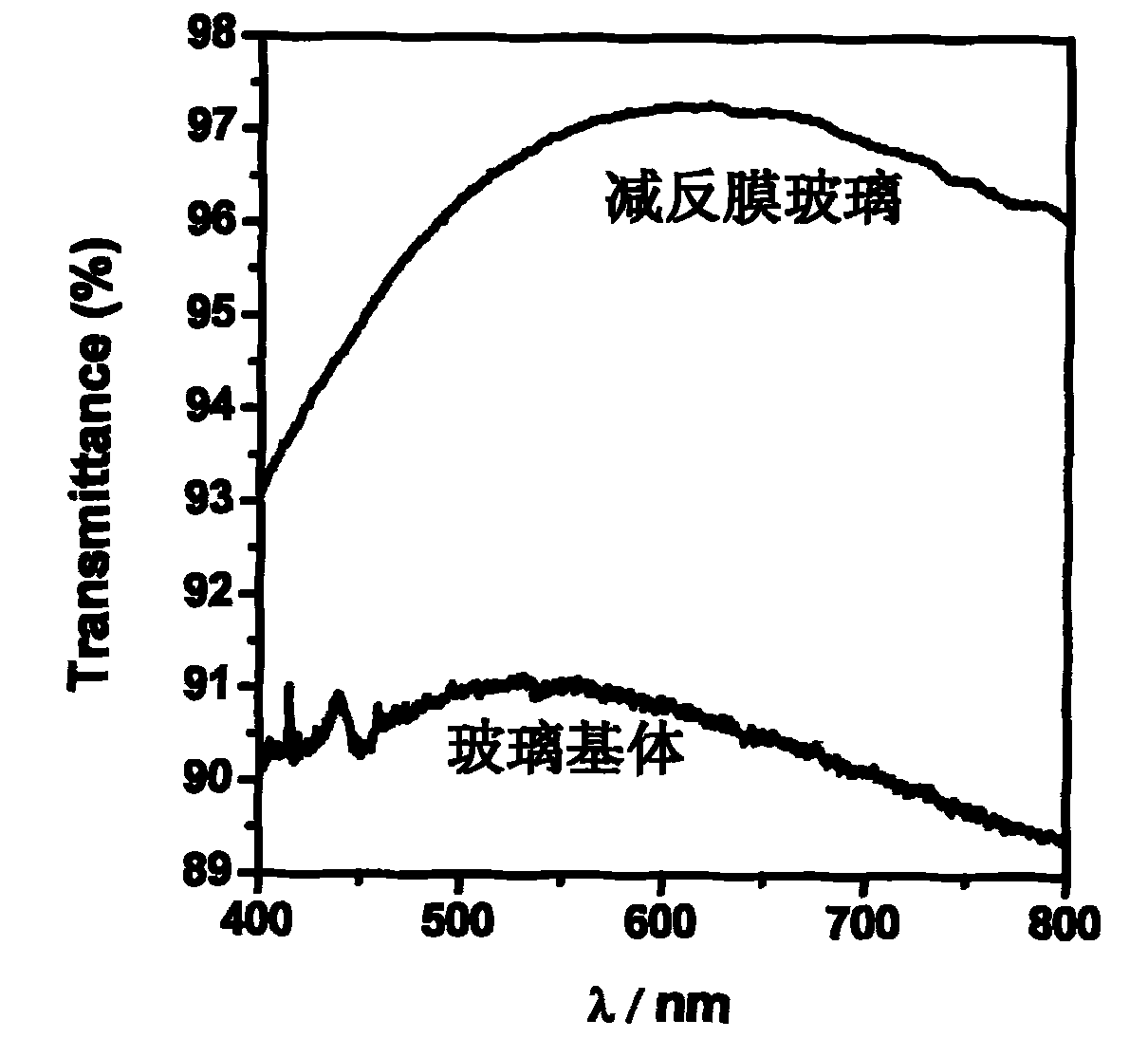

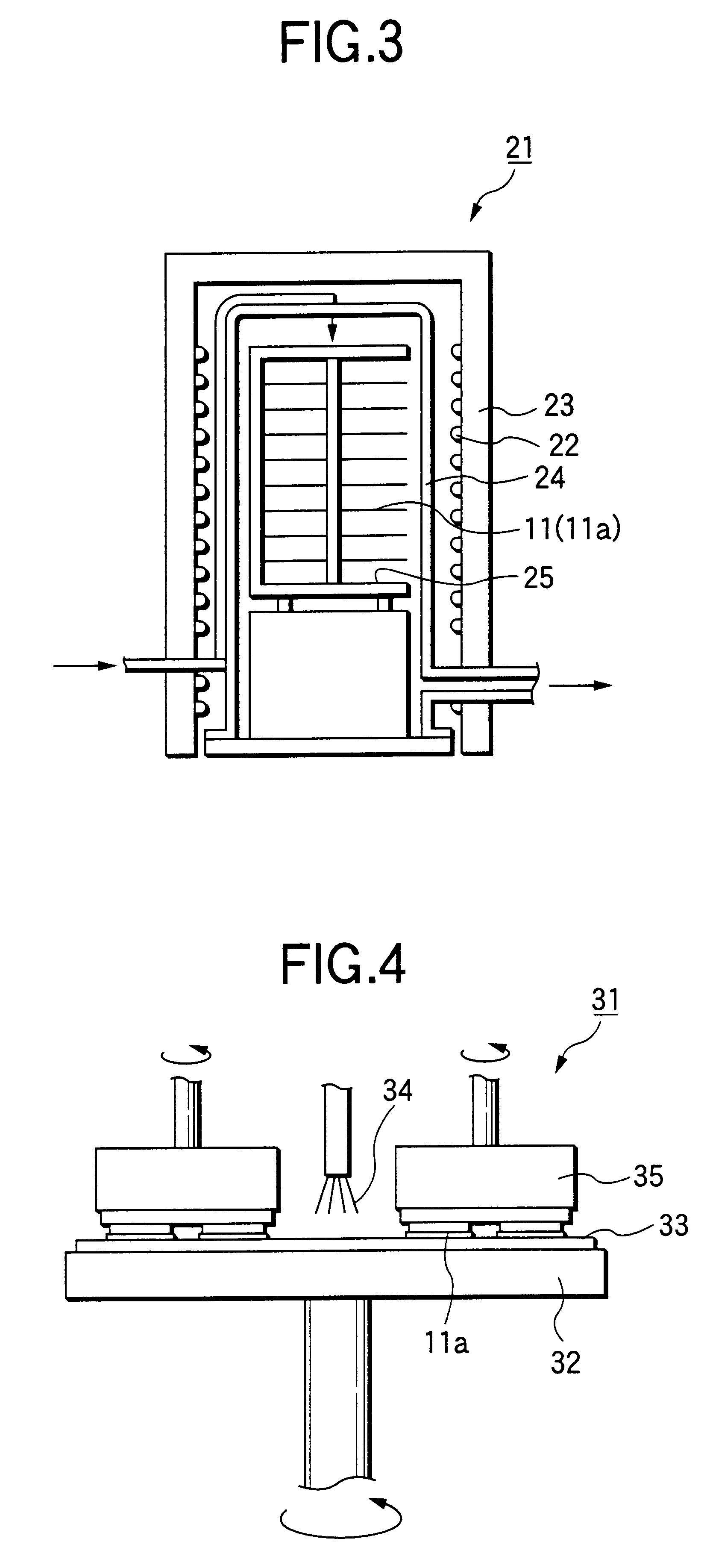

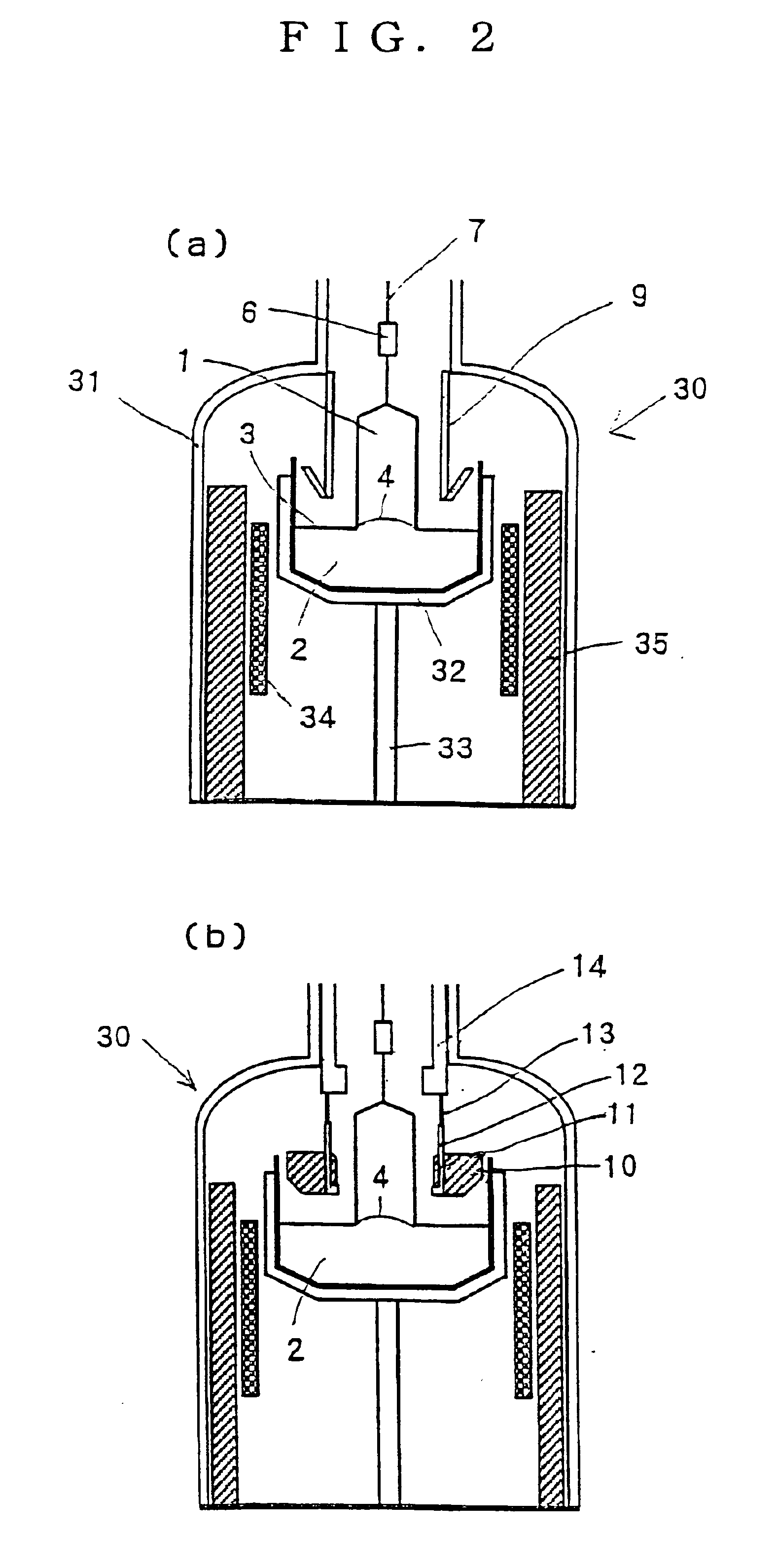

A method of producing high-quality and large-diameter single crystals by the Czochralski method is disclosed which can provide wafers with a minimized number of such grown-in defects as dislocation clusters and laser scattering tomography defects. Specifically, it is a method of producing silicon single crystals which comprises carrying out the crystal pulling while maintaining the solid-melt interface during pulling in the shape of an upward convex with the central portion of the interface being higher by at least 5 mm than the peripheral region thereof and while applying a magnetic field, and optionally in addition to the above, while maintaining the temperature gradient in the direction of axis of pulling in the peripheral region at a level lower than that in the central portion in the range of from the melting point to 1,200° C. In this case, it is desirable that the portion of the single crystal surface lying at least 50 mm above the melt surface be shielded from direct radiant heat from the heater and / or crucible wall, that a horizontal magnetic field of 0.08 to 0.3 T be applied in parallel with the melt surface or a cusped magnetic field showing an intensity of 0.02 to 0.07 T at a crucible wall site on the melt surface be applied and that the crucible be rotated at a speed of not more than 5 min-1 and the single crystal at a speed of not less than 13 min-1.

Owner:SUMITOMO MITSUBISHI SILICON CORP

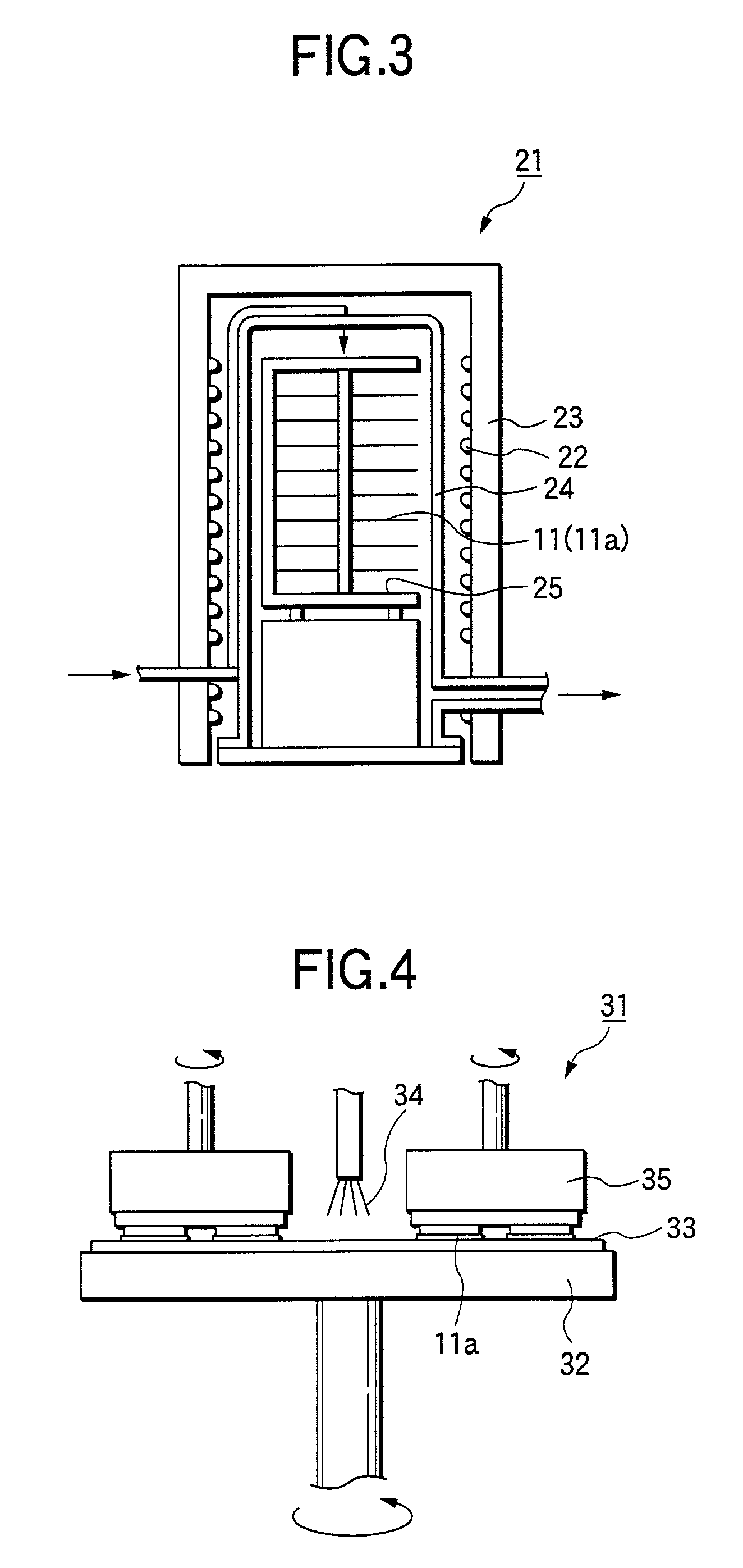

Method and device for the production of a silicon single crystal, silicon single crystal, and silicon semiconductor wafers with determined defect distributions

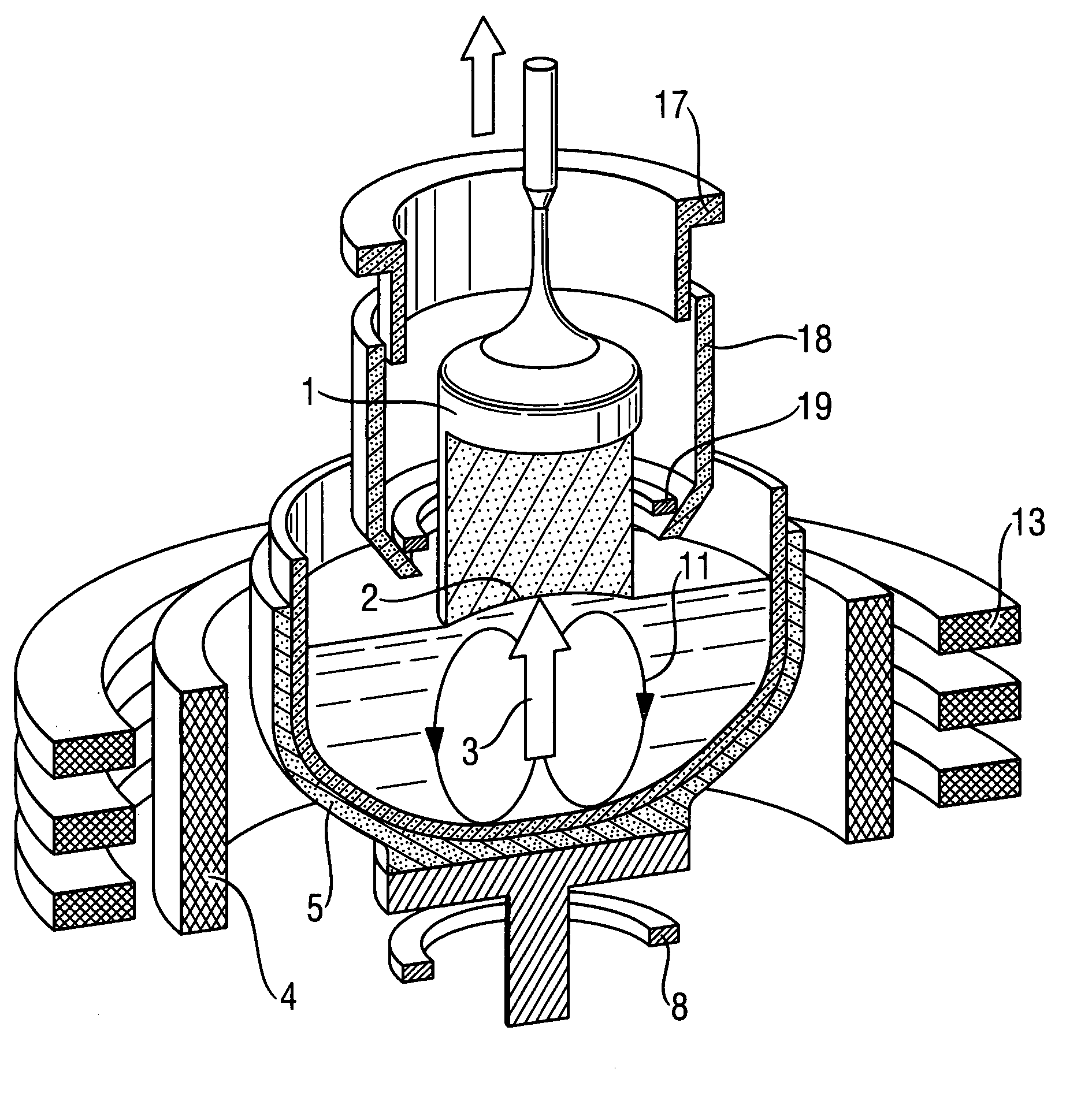

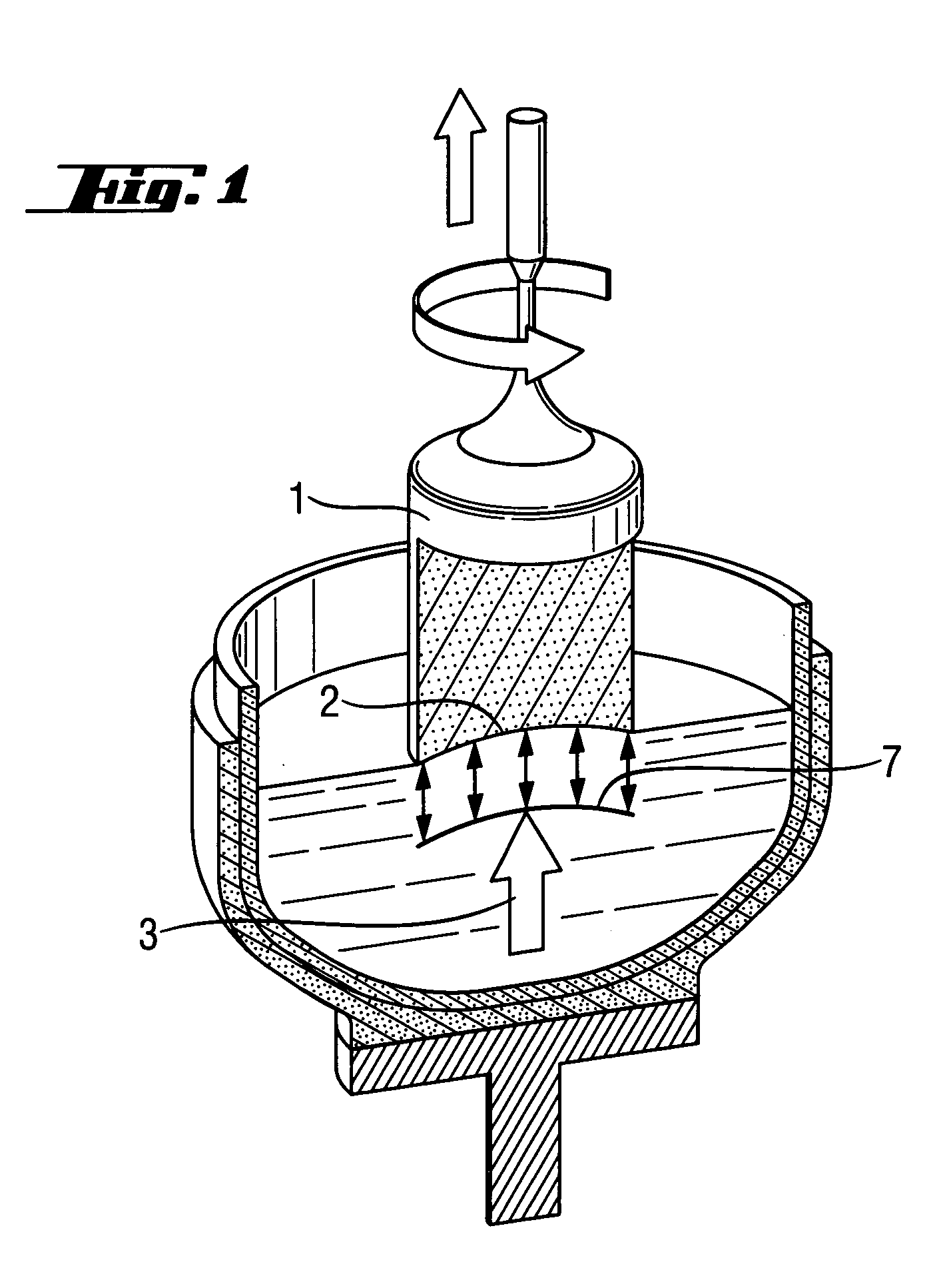

InactiveUS20040192015A1Increase productionMinimize thermal dissipationPolycrystalline material growthFrom solid stateVacancy defectHeat flux

A method for the production of a silicon single crystal by pulling the single crystal, according to the Czochralski method, from a melt which is held in a rotating crucible, the single crystal growing at a growth front, heat being deliberately supplied to the center of the growth front by a heat flux directed at the growth front. The method produces a silicon single crystal with an oxygen content of from 4*10<17 >cm<-3 >to 7.2*10<17 >cm<-3 >and a radial concentration change for boron or phosphorus of less than 5%, which has no agglomerated self-point defects. Semiconductor wafers are separated from the single crystal. These semiconductor wafers have may have agglomerated vacancy defects (COPs) as the only self-point defect type or may have certain other defect distributions.

Owner:SILTRONIC AG

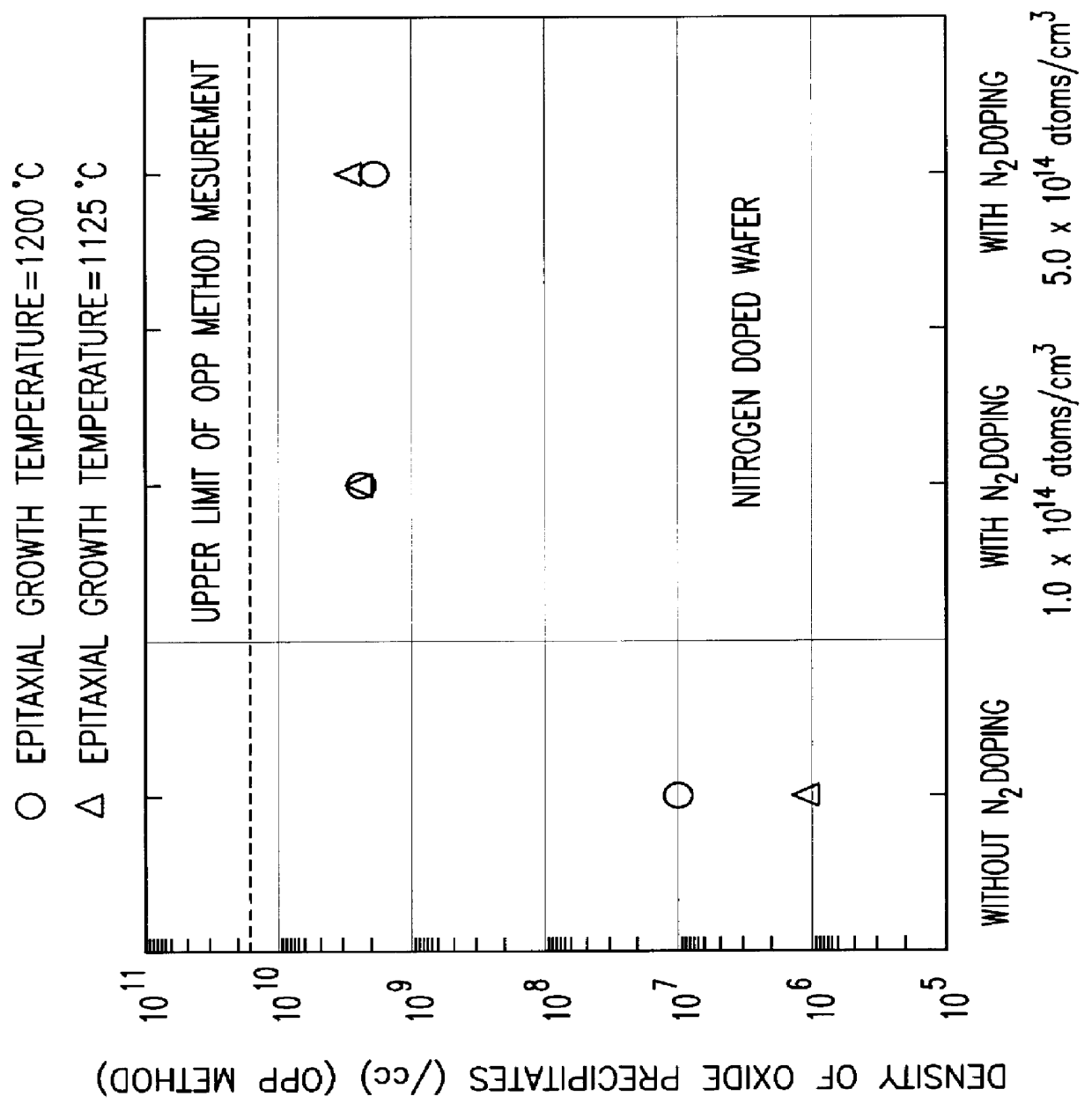

Method for producing an epitaxial silicon single crystal wafer and the epitaxial silicon single crystal wafer

InactiveUS6162708AReduce concentrationEasy to producePolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalCrystallinity

There is disclosed a method for producing an epitaxial silicon single crystal wafer comprising the steps of growing a silicon single crystal ingot wherein nitrogen is doped by Czochralski method, slicing the silicon single crystal ingot to provide a silicon single crystal wafer, and forming an epitaxial layer in the surface layer portion of the silicon single crystal wafer. There can be manufactured easily and in high productivity an epitaxial silicon monocrystal wafer which has high gettering capability when a substrate having a low boron concentration is used, a low concentration of heavy metal impurity, and an excellent crystallinity.

Owner:SHIN-ETSU HANDOTAI CO LTD

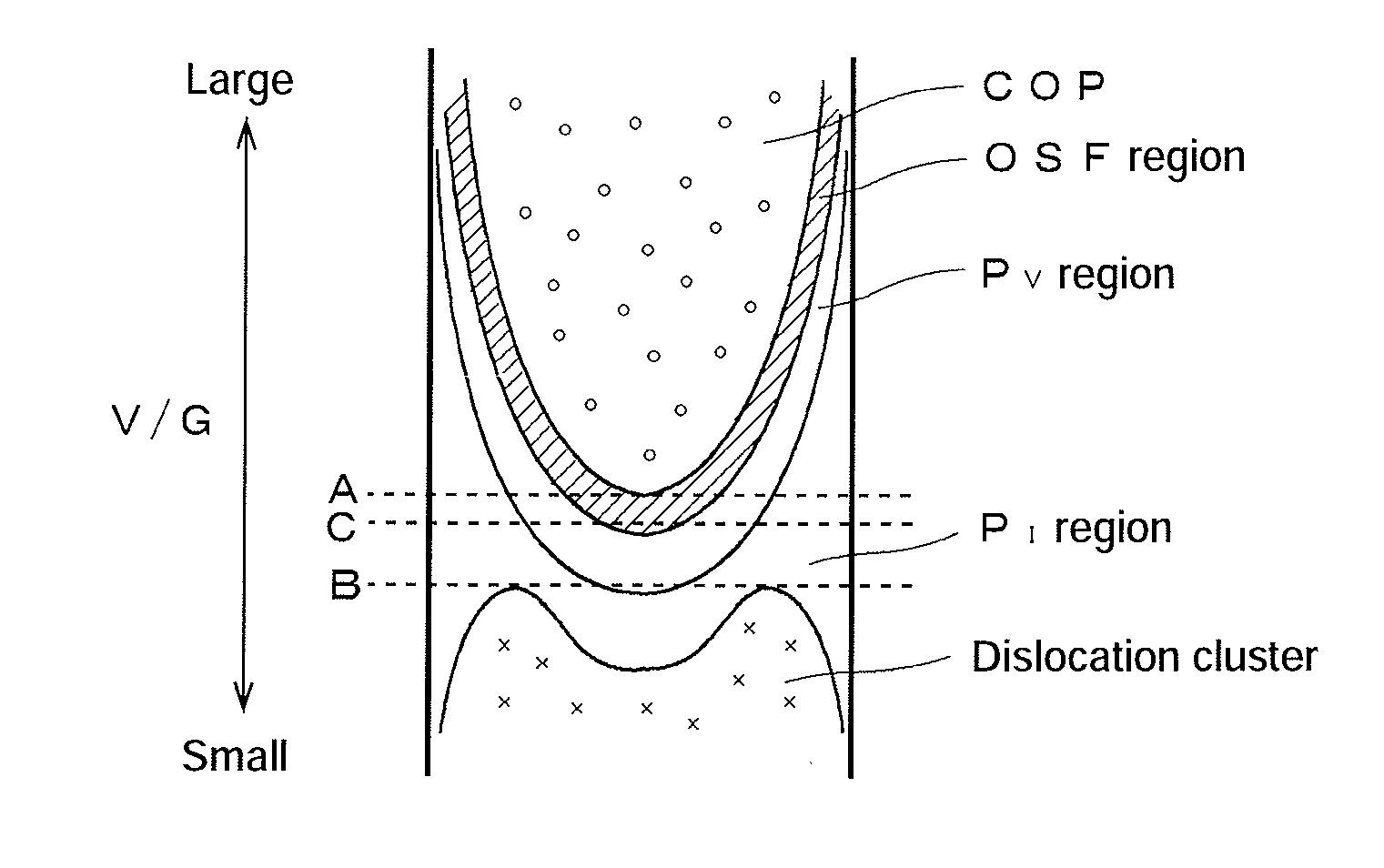

Silicon single crystal wafer and method for producing it

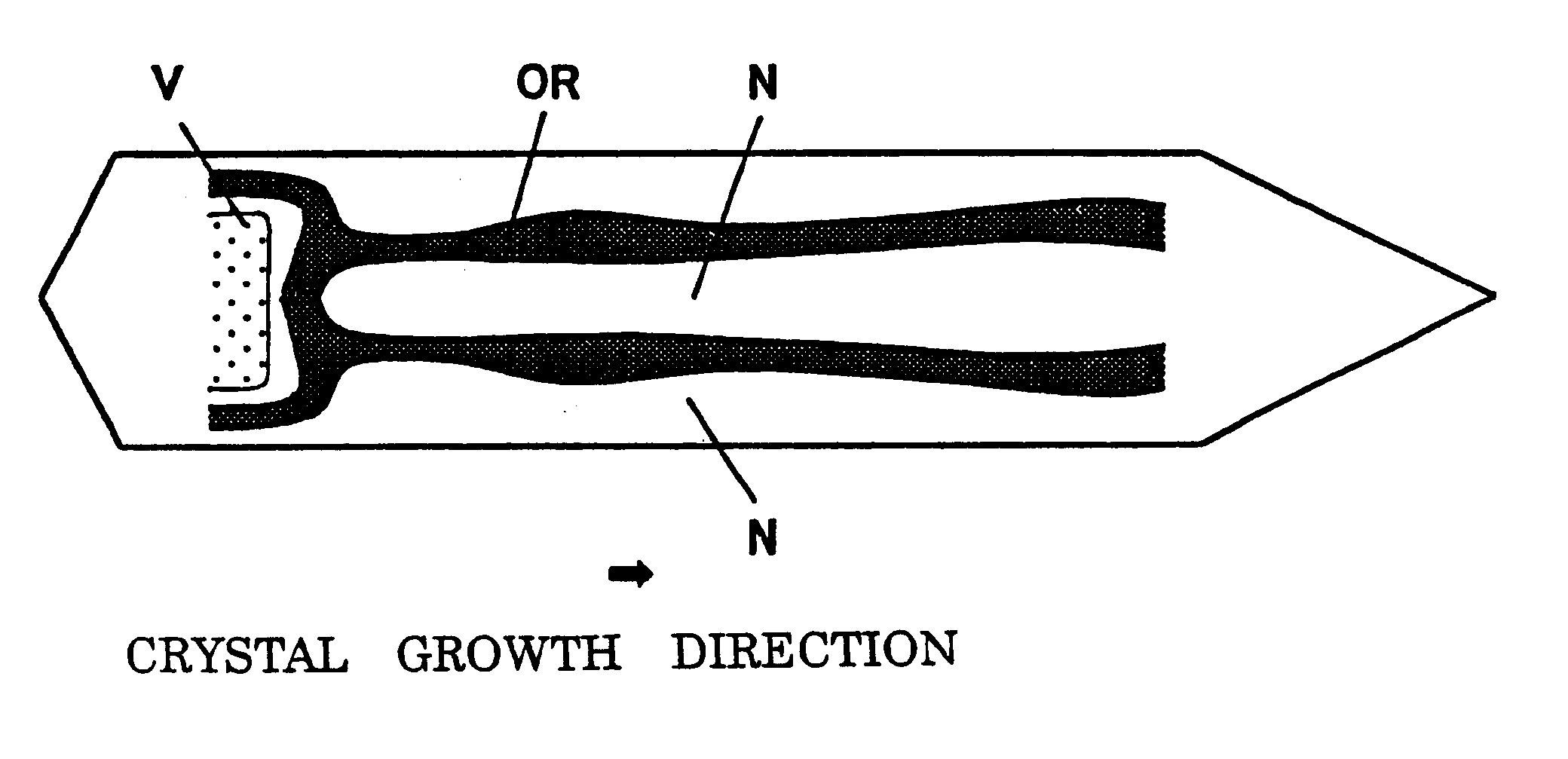

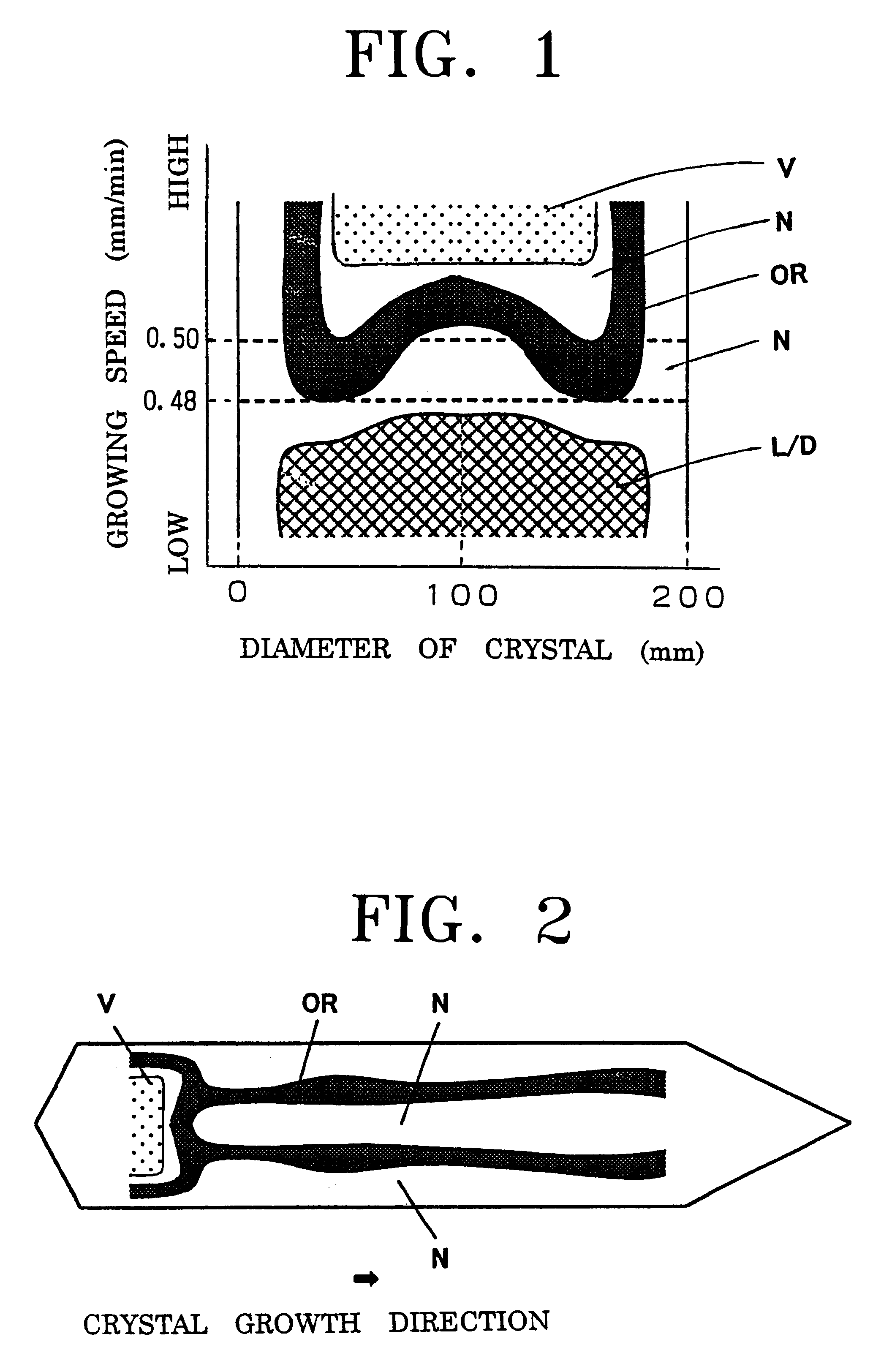

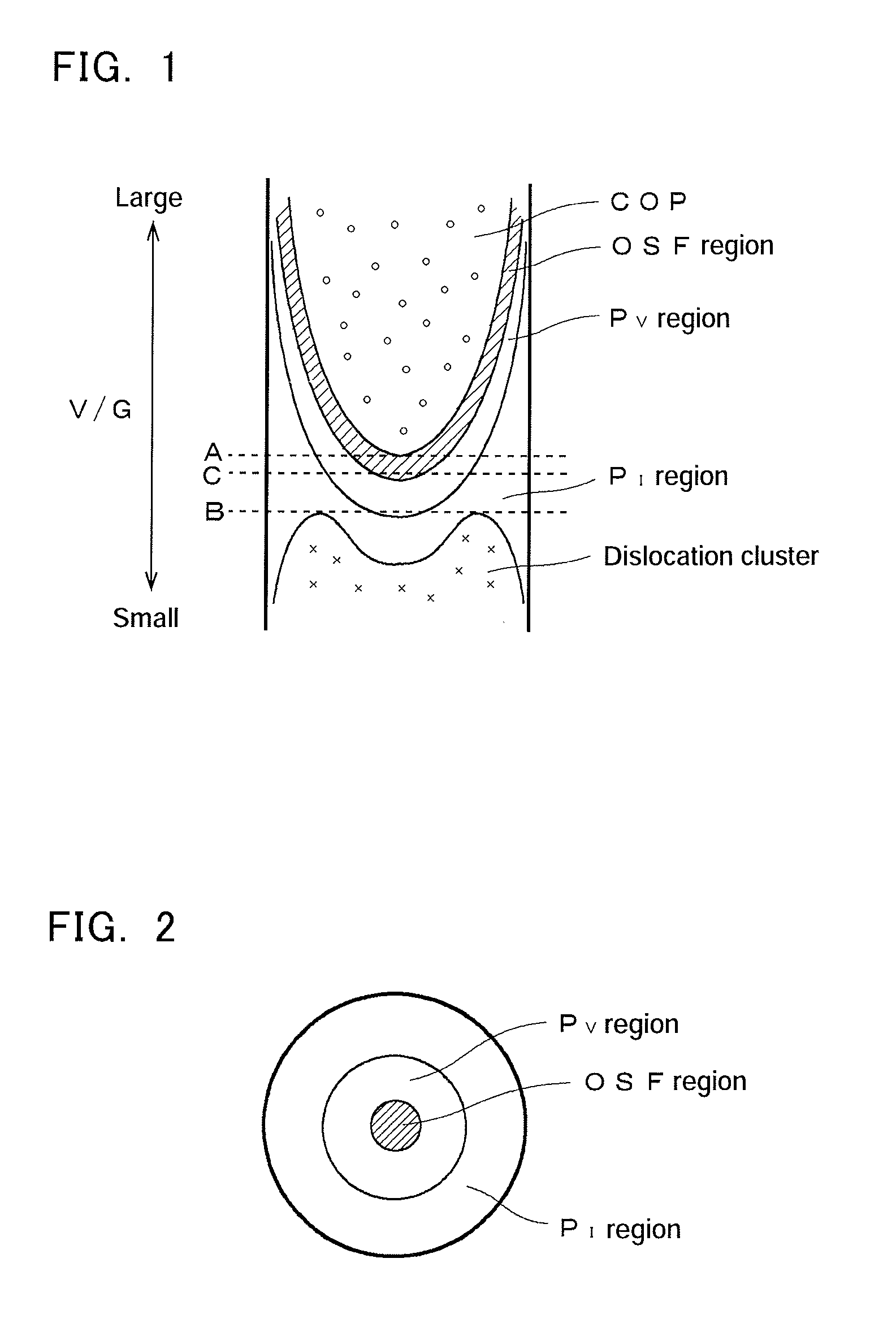

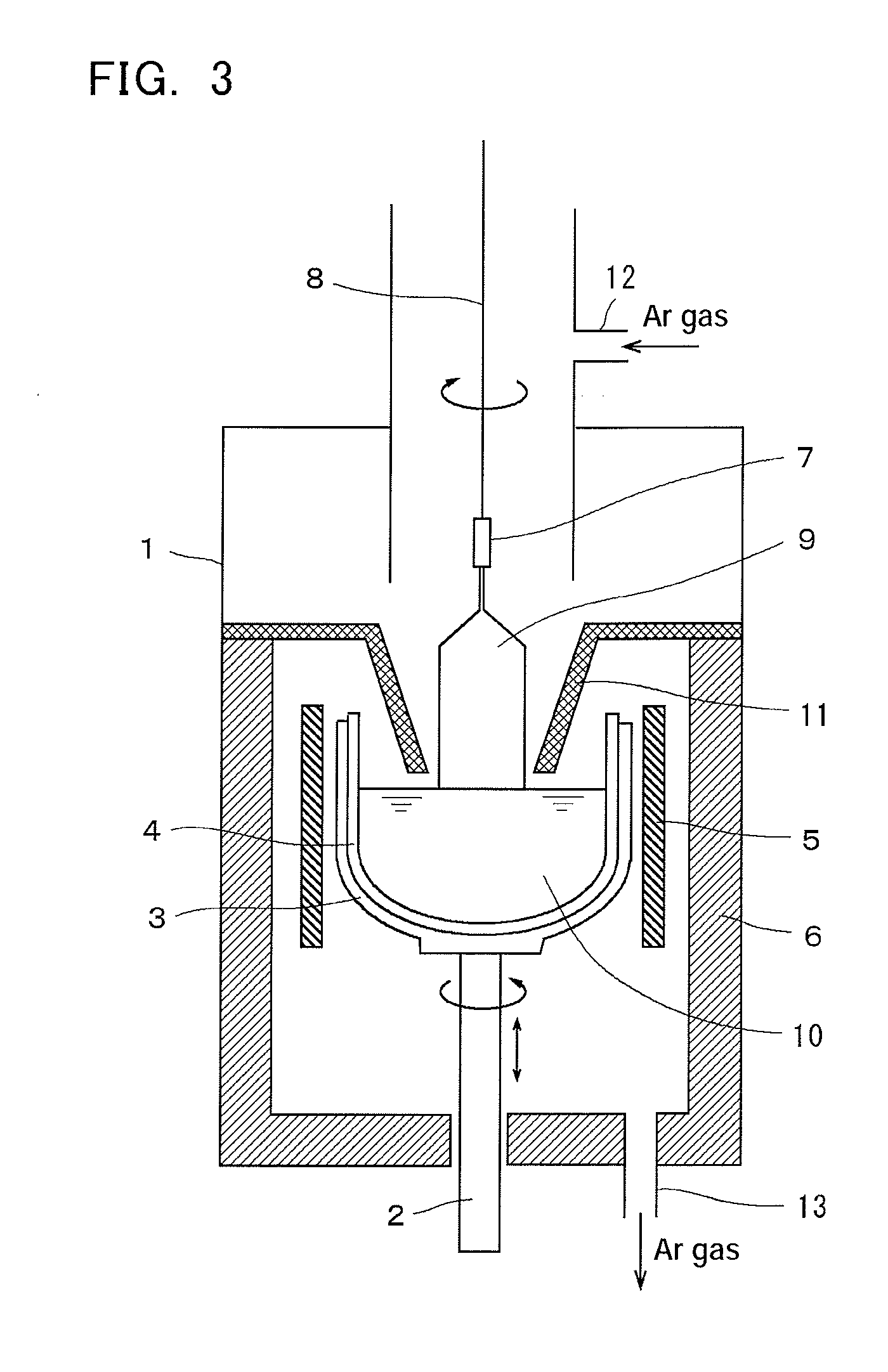

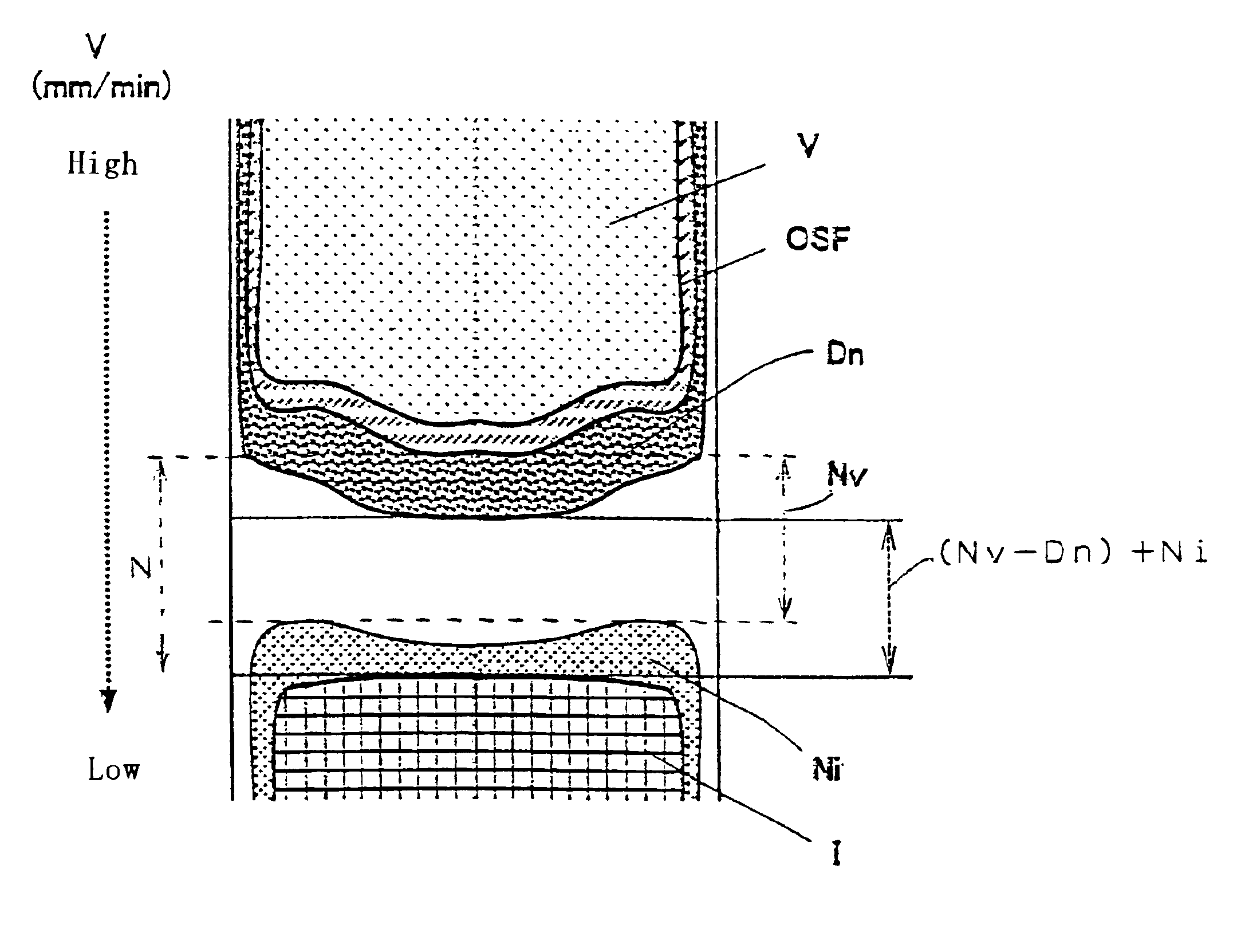

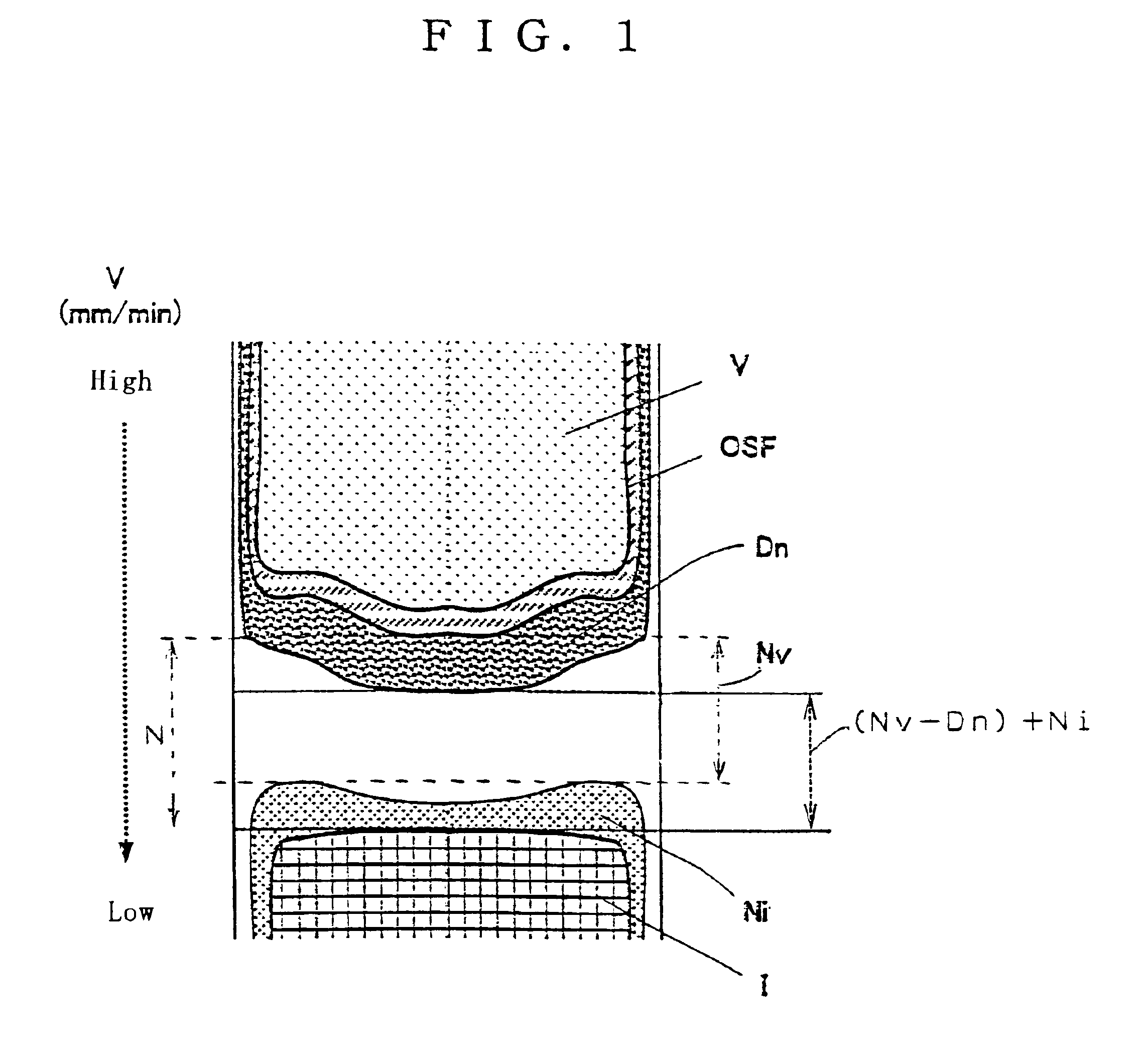

InactiveUS6190452B1Polycrystalline material growthSemiconductor/solid-state device testing/measurementCzochralski methodHorizontal axis

There is disclosed a method for producing a silicon single crystal in accordance with the Czochralski method wherein a crystal is pulled with controlling a temperature in a furnace so that DELTAG may be 0 or a negative value, where DELTAG is a difference between the temperature gradient Gc (° C. / mm) at the center of a crystal and the temperature gradient Ge (° C. / mm) at the circumferential portion of the crystal, namely DELTAG=(Ge-Gc), wherein G is a temperature gradient in the vicinity of a solid-liquid interface of a crystal from the melting point of silicon to 1400° C., and with controlling a pulling rate in a range between a pulling rate corresponding to a minimum value of the inner line of OSF region and a pulling rate corresponding to a minimum value of the outer line, when OSF region is generated in an inverted M belt shape in a defect distribution chart which shows a defect distribution in which the horizontal axis represents a diameter of the crystal and the vertical axis represent a pulling rate. There can be provided a method of producing a silicon single crystal wafer by CZ method wherein OSF in the ring shape distribution generated when being subjected to thermal oxidation or latent nuclei of OSF is present in a low density, and neither FPD, COP, L / D, LSTD nor defect detected by Cu decoration is present under a stable manufacture condition.

Owner:SHIN-ETSU HANDOTAI CO LTD

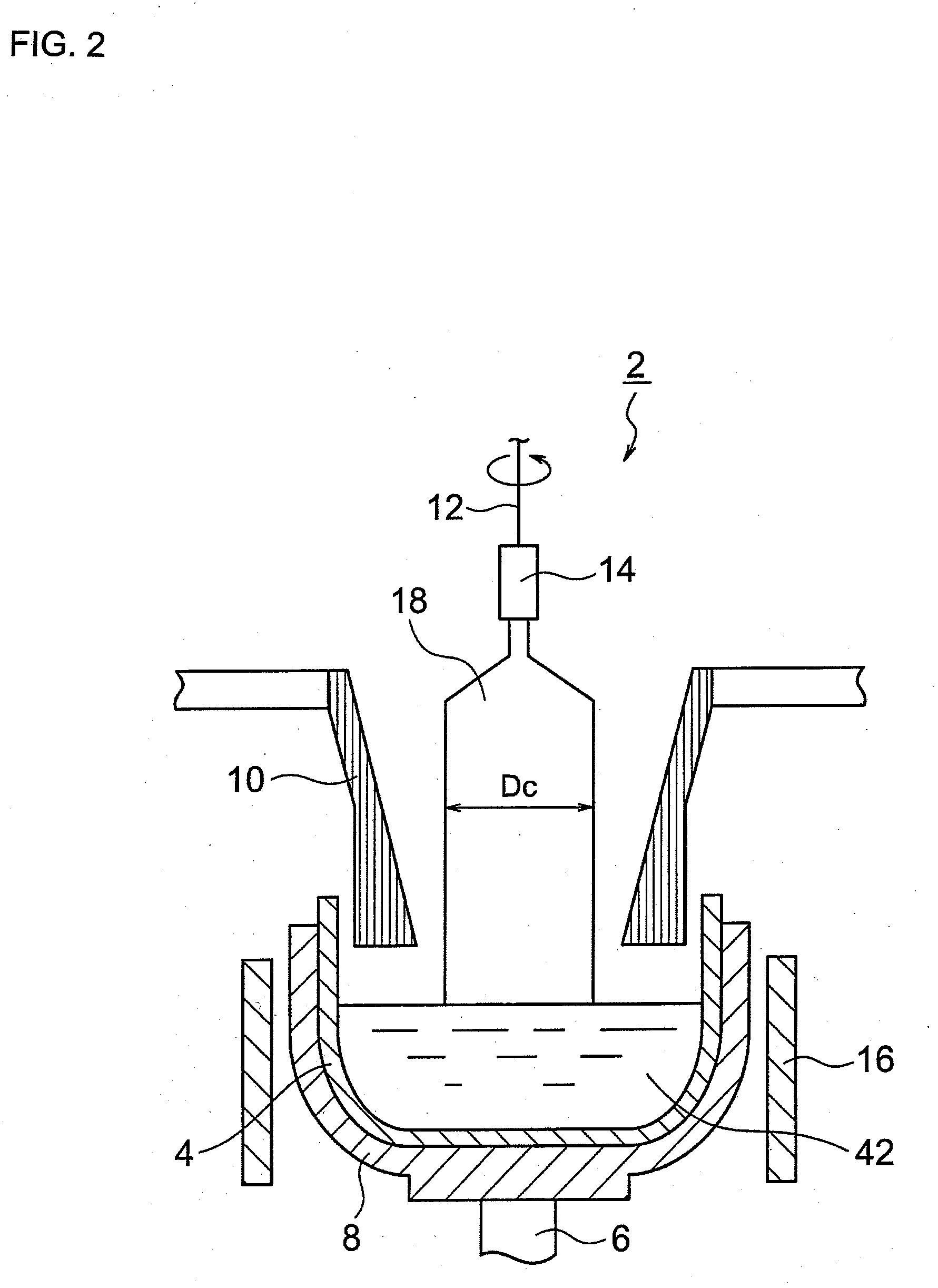

Method of fabricating a single crystal ingot and method of fabricating a silicon wafer

InactiveUS20010029883A1Polycrystalline material growthBy pulling from meltCzochralski methodNitrogen

A method of fabricating a silicon single crystal ingot and a method of fabricating a silicon wafer using the ingot, characterized in that: the method is structured in such a manner that the silicon single crystal ingot is pulled up from the silicon fused liquid 7 in which nitrogen N and carbon C are doped in polycrystalline silicon, by using the Czochralski method, and its nitrogen density is 1x1013-5x1015 atoms / cm3, and the carbon density is 5x1015-3x1016 atoms / cm3.

Owner:COVALENT MATERIALS CORP

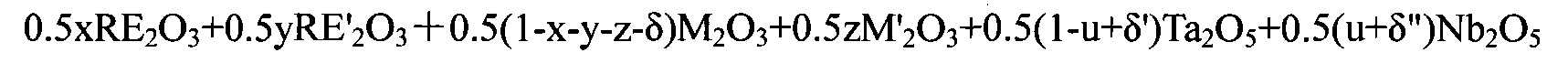

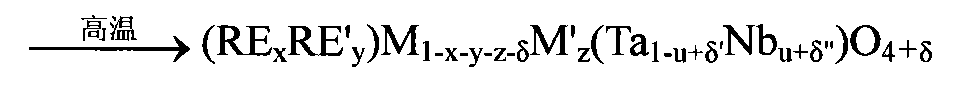

Luminescent material doped with niobate, tantalate and the mischcrystal thereof, and crystal growth method thereof for the melt process

InactiveCN101445727APolycrystalline material growthLuminescent compositionsCzochralski methodHigh energy

The invention discloses a luminescent material doped with niobate, tantalate and the mischcrystal thereof, and a crystal growth method thereof for the melt process. The molecular formula of the compound is (RExRE'y) M1-x-y-z-deltaM'z (Ta1-u+delta' Nbu+delta') O4+delta (x equals to 0 to 0.5, y equals to 0 to 0.5, 0 is smaller than x+y and x+y is smaller than and equal to 0.5, z equals to 0 to 0.5, delta equals to -0.4 to 0.4, and delta'+delta' equals to delta), wherein, the RE and the RE' are Yb, Nd, Er, Tm, Ho, Ce, Pr, Eu, Bi, Ti and Cr, and the M and the M' are Sc, Y, Gd and Lu. The well prepared raw material becomes the starting material of crystal growth after uniformly mixing, pressing molding and high temperature sintering; the starting material for crystal growth is put into a crucible and sufficiently heated and fused to form an initial melt for melt process growth, and then the melt methods can be used for crystal growth such as a Czochralski method, a Bridgman-Stockbarge method, a TGT method and other melt methods; and the (RExRE'y) M1-x-y-z-deltaM'z (Ta1-u+delta' Nbu+delta') O4+delta can be used as the detection material for the working laser material, the high-energy rays, the high-energy particle, and the like.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

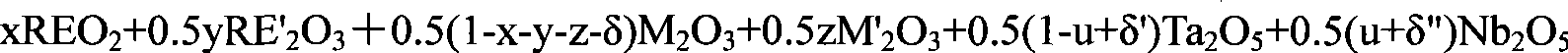

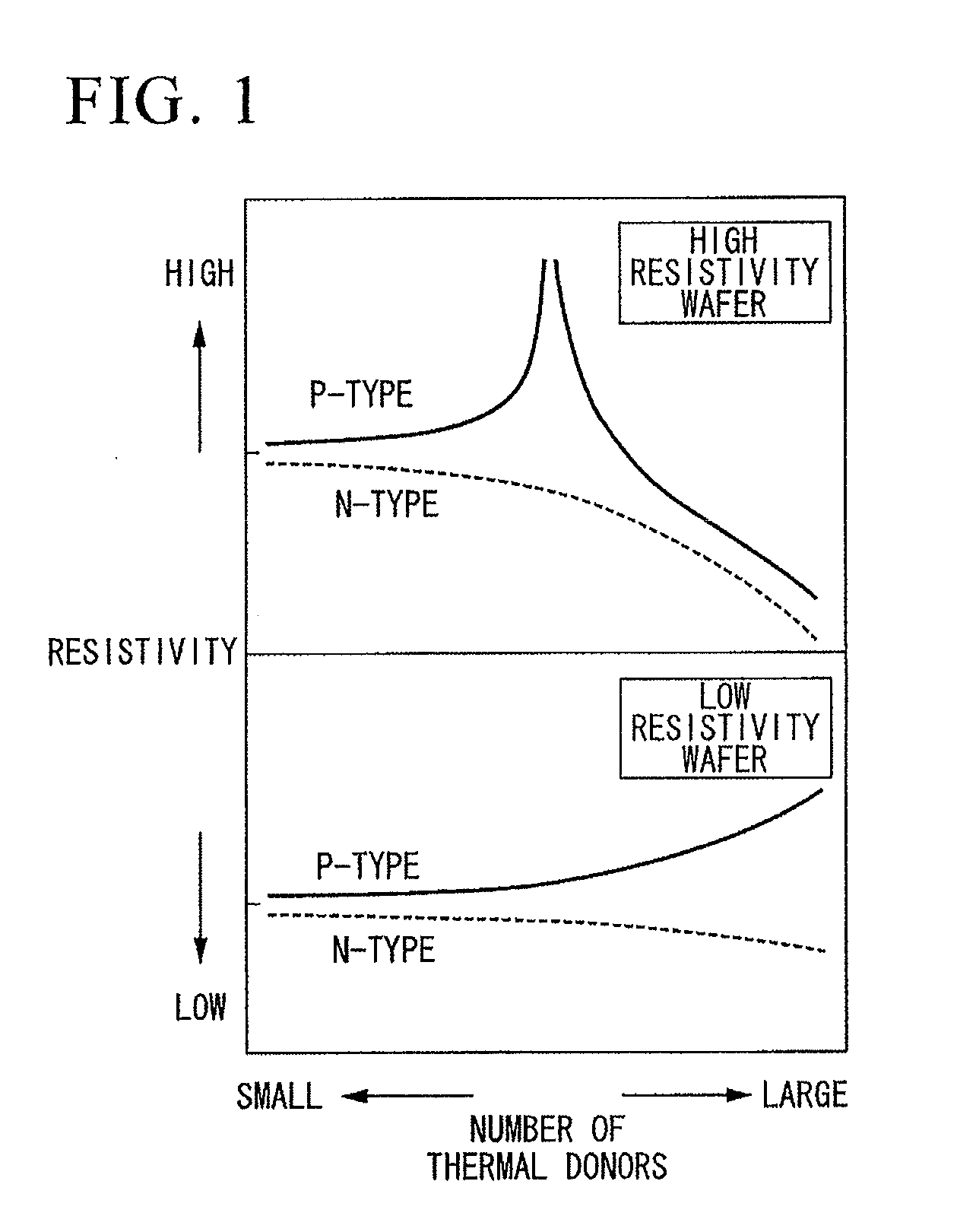

High resistivity silicon wafer and method for manufacturing the same

ActiveUS20100224968A1Avoid it happening againHigh mechanical strengthPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantCzochralski method

This method for manufacturing a high resistivity silicon wafer includes pulling a single crystal such that the single crystal has a p-type dopant concentration at which a wafer surface resistivity becomes in a range of 0.1 to 10 kΩcm, an oxygen concentration Oi of 5.0×1017 to 20×1017 atoms / cm3 (ASTM F-121, 1979), and either one of a nitrogen concentration of 1.0×1013 to 10×1013 atoms / cm3 (ASTM F-121, 1979) and a carbon concentration of 0.5×1016 to 10×1016 atoms / cm3 or 0.5×1016 to 50×1016 atoms / cm3 (ASTM F-123, 1981) by using a Czochralski method, processing the single crystal into wafers by slicing the single crystal, and subjecting the wafer to an oxygen out-diffusion heat treatment process in a non-oxidizing atmosphere. A peak position of a resistivity serving as a boundary between a p-type region of a wafer surface side and a p / n conversion region of an inner side of a thickness direction is adjusted by the nitrogen concentration or the carbon concentration such that the peak position is set to a boundary depth in a range of 10 to 70 μm from the wafer surface.

Owner:SUMCO CORP

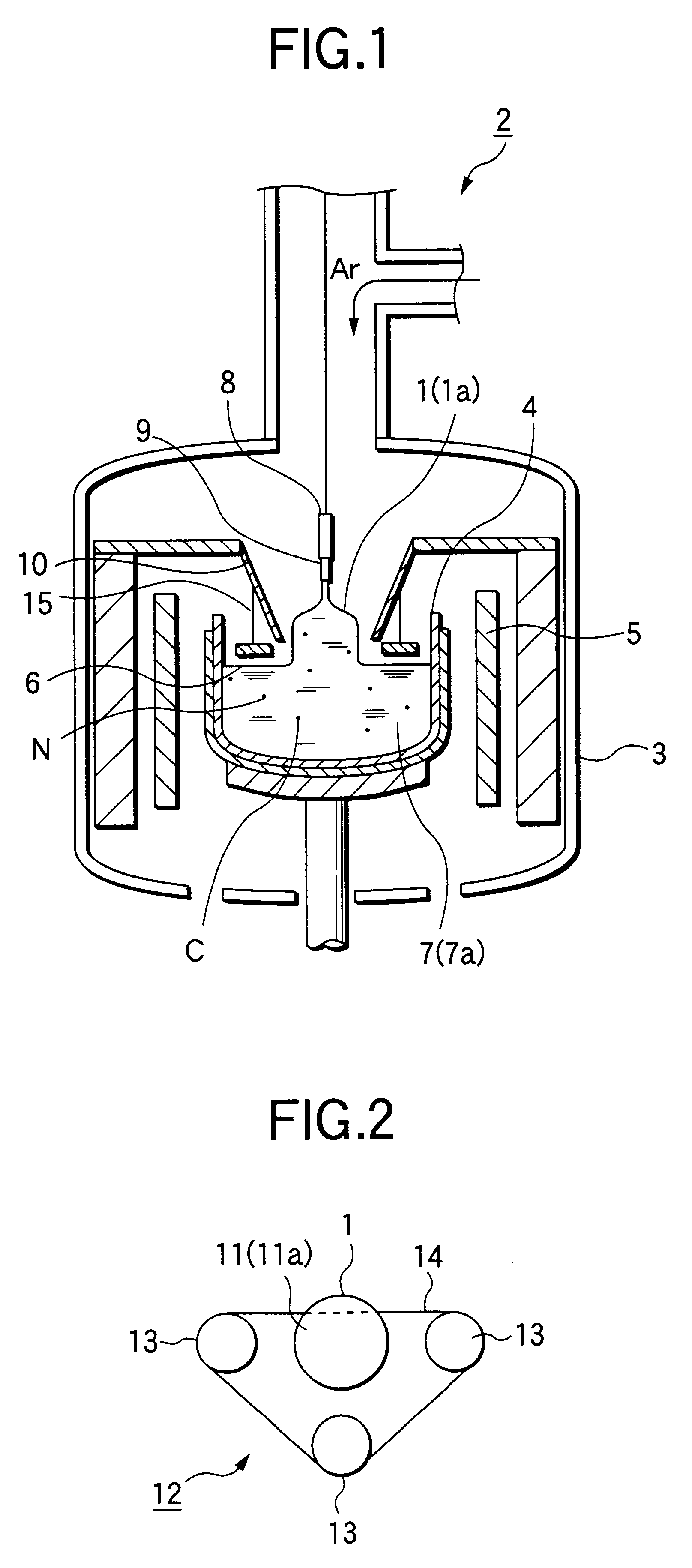

Method of effecting nitrogen doping in Czochralski grown silicon crystal

InactiveUS6059875APolycrystalline material growthBy pulling from meltSufficient timeCzochralski method

A method of introducing nitrogen into a melt for use in producing a nitrogen-doped silicon single crystal by the Czochralski method includes adding a silicon material to a vessel, such as a quartz crucible, adding a nitrogen-containing powder, preferably silicon nitride powder, to the vessel, and heating the vessel for a time sufficient to melt the silicon material and to dissolve the nitrogen-containing in the silicon material in order to form the melt. A nitrogen-doped silicon single crystal is then produced from the melt by the Czochralski method by pulling the silicon single crystal from the melt with a seed crystal.

Owner:SEH AMERICA

Filter plate of porous ceramic covered by Nano ceramic membrane filter, and fabricating method

InactiveCN101092307AAvoid easy cloggingExtended service lifeCeramicwareCzochralski methodNanoceramic

This invention discloses a porous ceramic filtration plate coated with nanoscale ceramic filtration film for liquid-solid separation. The nanoscale ceramic filtration film is prepared by: hydrolyzing aluminum isopropoxide, preparing a sol with HNO3, refluxing, aging to form aluminum sol, adding Al2O3 nanopowder, mixing, dispersing to form uniform nanoscale film gel, uniformly coating onto the surface of a substrate by Czochralski method, drying and sintering. The obtained porous ceramic filtration plate can effectively block the majority of fine particles in ore slurry, and has such advantages as no blockage, long service life and wide applications.

Owner:江苏省陶瓷研究所有限公司

Method for preparing porcelain insulator surface super-hydrophobic coating

The invention discloses a method for preparing a porcelain insulator surface super-hydrophobic coating, which takes ethyl orthosilicate as a presoma and absolute ethyl alcohol as flux, and comprises the following steps: preparing silicon dioxide sol through alkaline catalysis, and adding a silane coupling agent to perform the modification treatment; after the porcelain insulator surface is subjected to the cleaning treatment, dipping in the modified silicon dioxide sol for film coating through the czochralski method to form a primary coating and to obtain a micro-nanometer grade coarse structure which is similar to taro leaf; after drying, dipping in addition type liquid silicon rubber sol for secondary film coating through the czochralski method, and then placing into an oven for heat treatment at a temperature of 100-120 DEG C; and obtaining a transparent super-hydrophobic coating after subjecting the primary coating with the micro-nanometer coarse structure to the secondary film coating modification by the liquid silicon rubber with low surface energy.

Owner:XI AN JIAOTONG UNIV

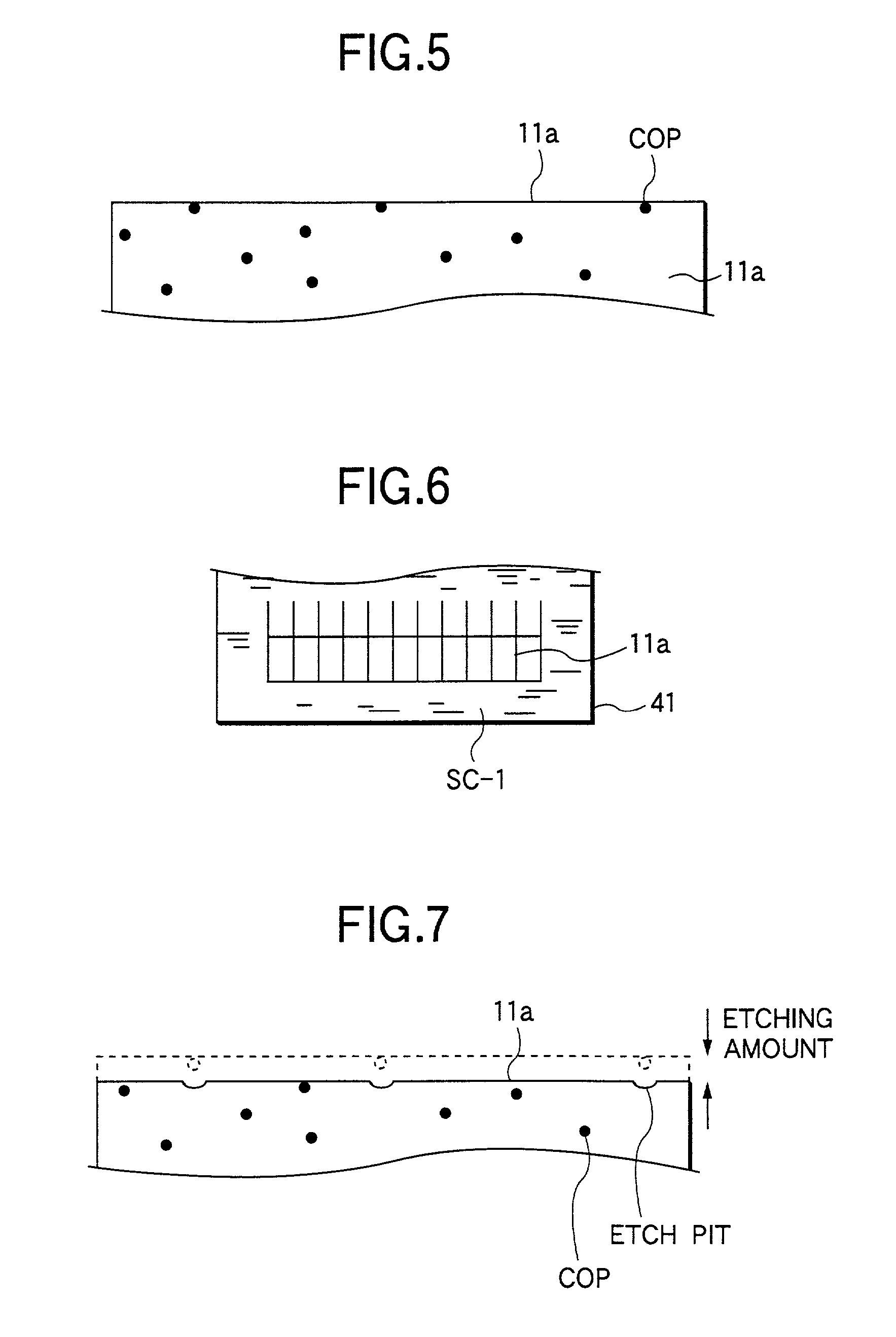

Silicon wafer and method for producing the same

ActiveUS20100290971A1Improve solubilityReduce heatPolycrystalline material growthAfter-treatment detailsWaferingSurface layer

It is possible to provide a silicon wafer that as well as being free of COPs and dislocation clusters, has defects (grown-in defects including silicon oxides), which are not overt in an as-grown state, such as OSF nuclei and oxygen precipitate nuclei existing in the PV region, to be vanished or reduced, by adopting a method for producing a silicon wafer, the method comprising the steps of: growing a single crystal silicon ingot by the Czochralski method; cutting a silicon wafer out of the ingot; subjecting the wafer to an RTP at 1,250° C. or more for 10 seconds or more in an oxidizing atmosphere; and removing a grown-in defect region including silicon oxides in the vicinity of wafer surface layer after the RTP.

Owner:SUMCO CORP

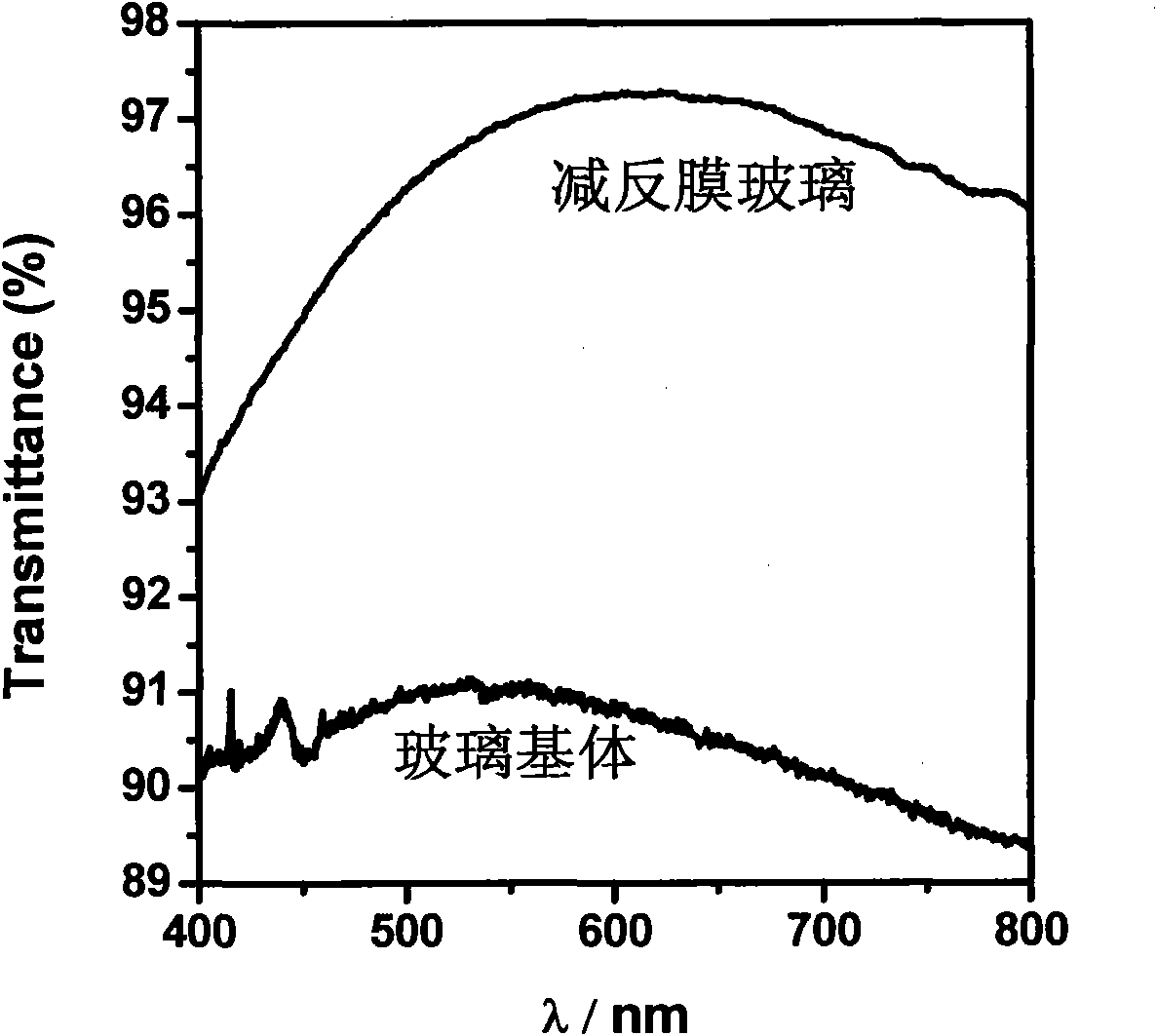

Preparation method of self-cleaning antireflection film with photocatalytic function on surface

The invention discloses a preparation method of a self-cleaning antireflection film with the photocatalytic function on the surface, relating to the field of solar photocatalysis. The method comprises the following steps of: proportionally mixing silica sol obtained through the acid catalysis and the base catalysis of acetate orthosilicate; firstly, coating an antireflection film on a clean glass surface by using a czochralski method; then, coating a layer of titania sol prepared through the hydrolysis of N-butyl titanate; and solidifying at 120 DEG C for 2 h and thermally treating at 500 DEG C for 2 h to obtain the self-cleaning antireflection film with the transmittance over 96 percent and the photocatalytic function on the surface. The antireflection film on the glass surface has higher transmittance while ensuring the firm combination with the glass; and the surface of the antireflection film has the photocatalytic function and the self-cleaning function.

Owner:常州龙腾光热科技股份有限公司

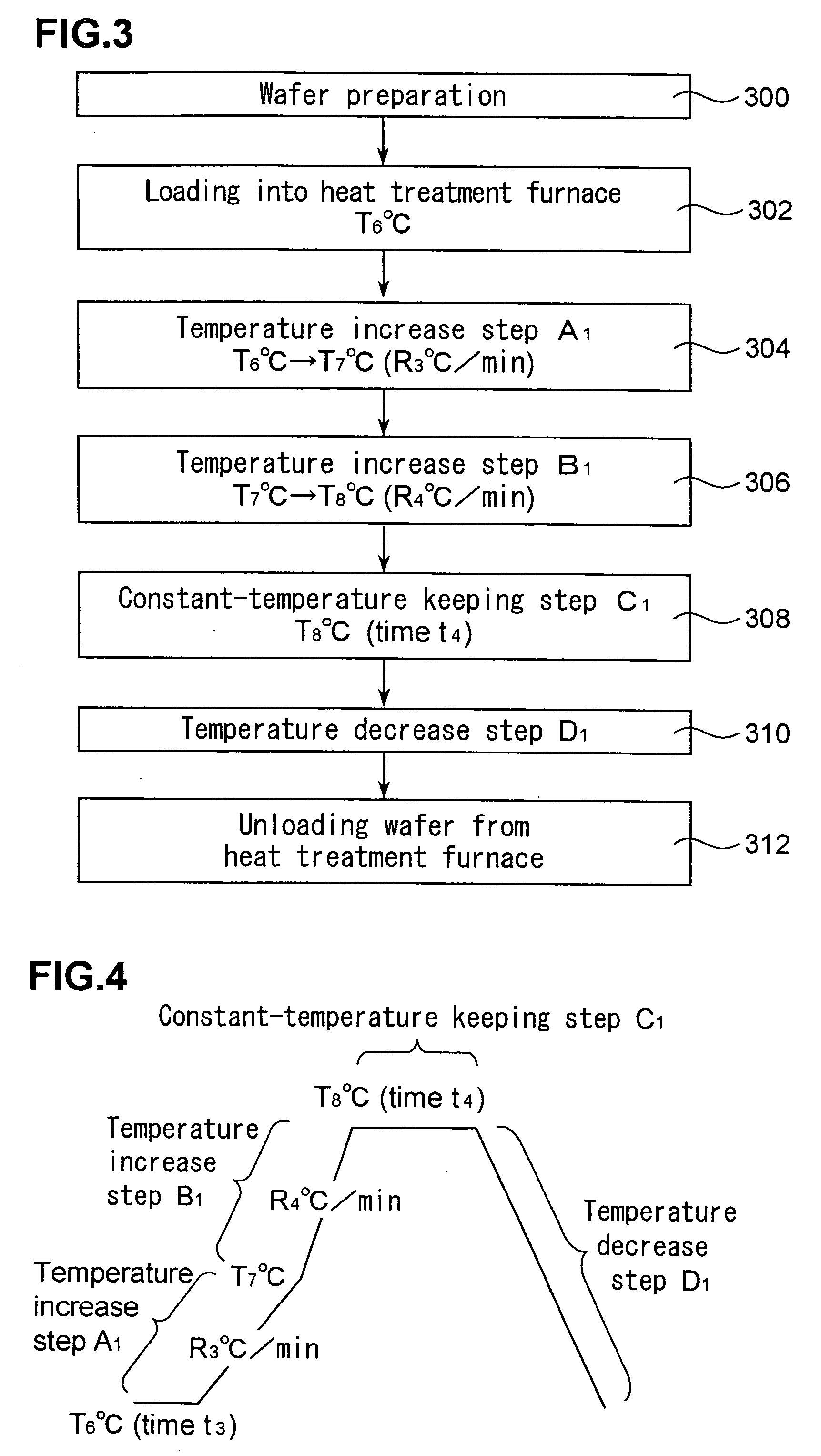

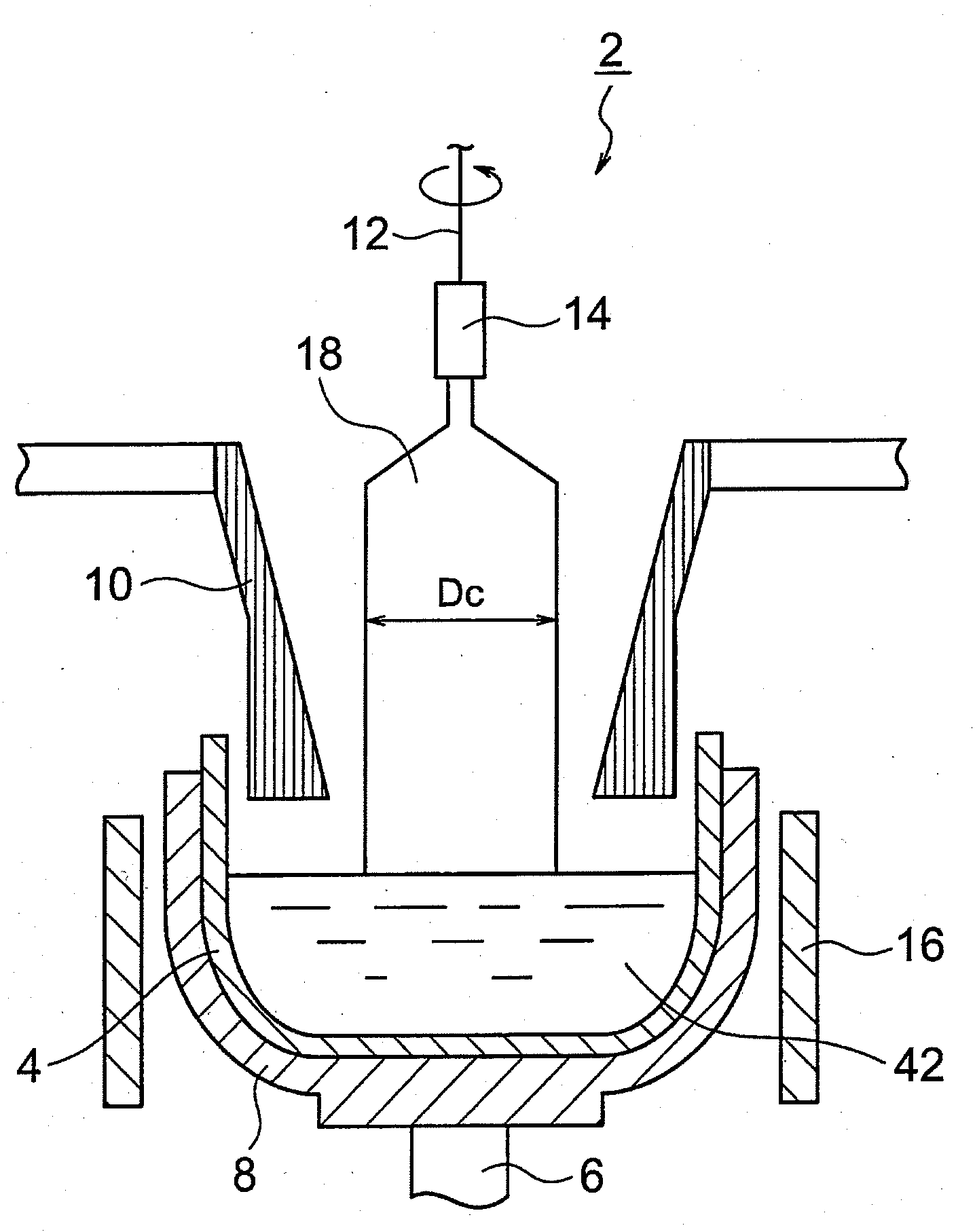

Annealed wafer, method for producing annealed wafer and method for fabricating device

InactiveUS20120001301A1Little changeGood TDDB characteristicPolycrystalline material growthAfter-treatment detailsWaferingCzochralski method

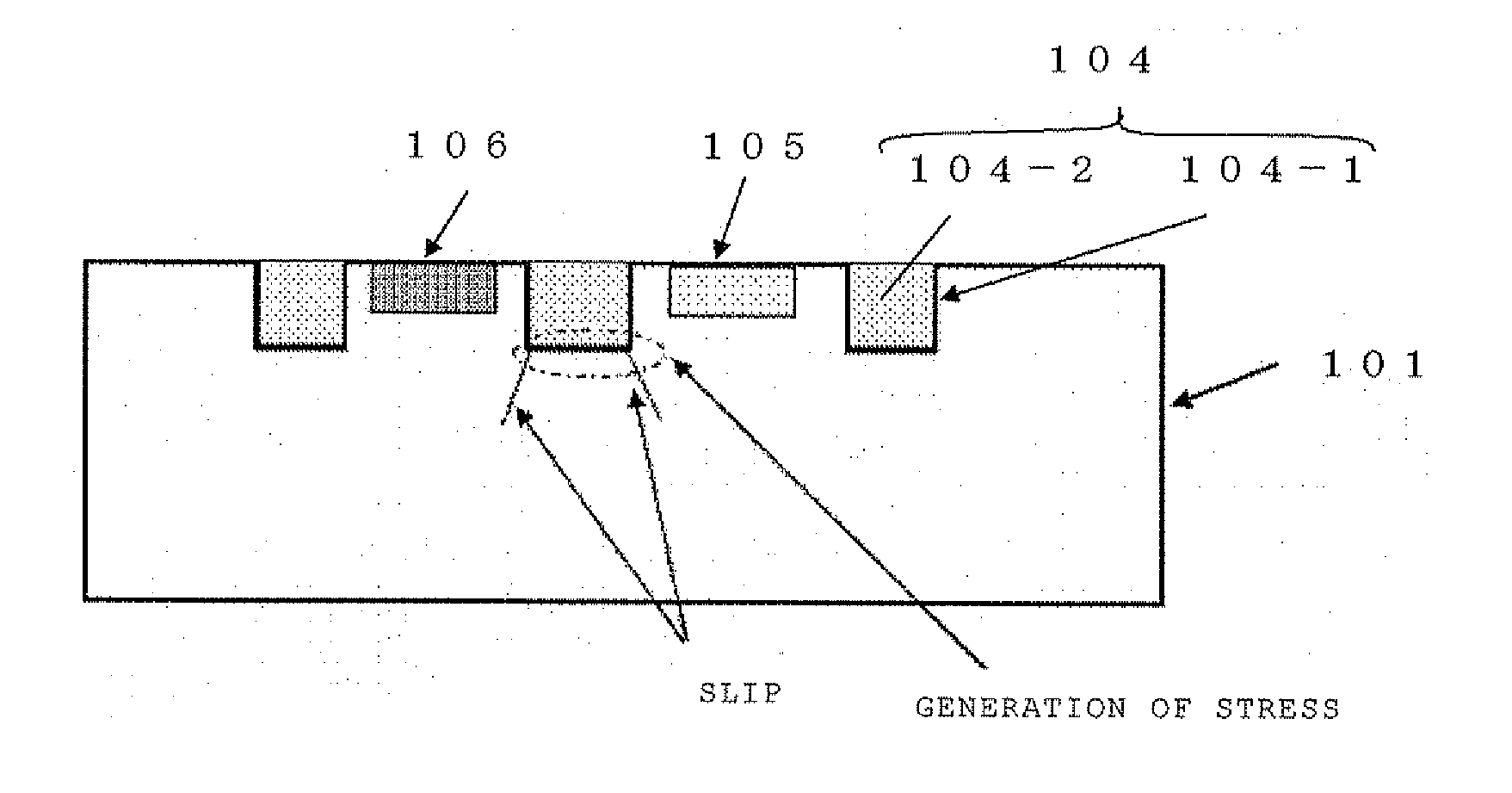

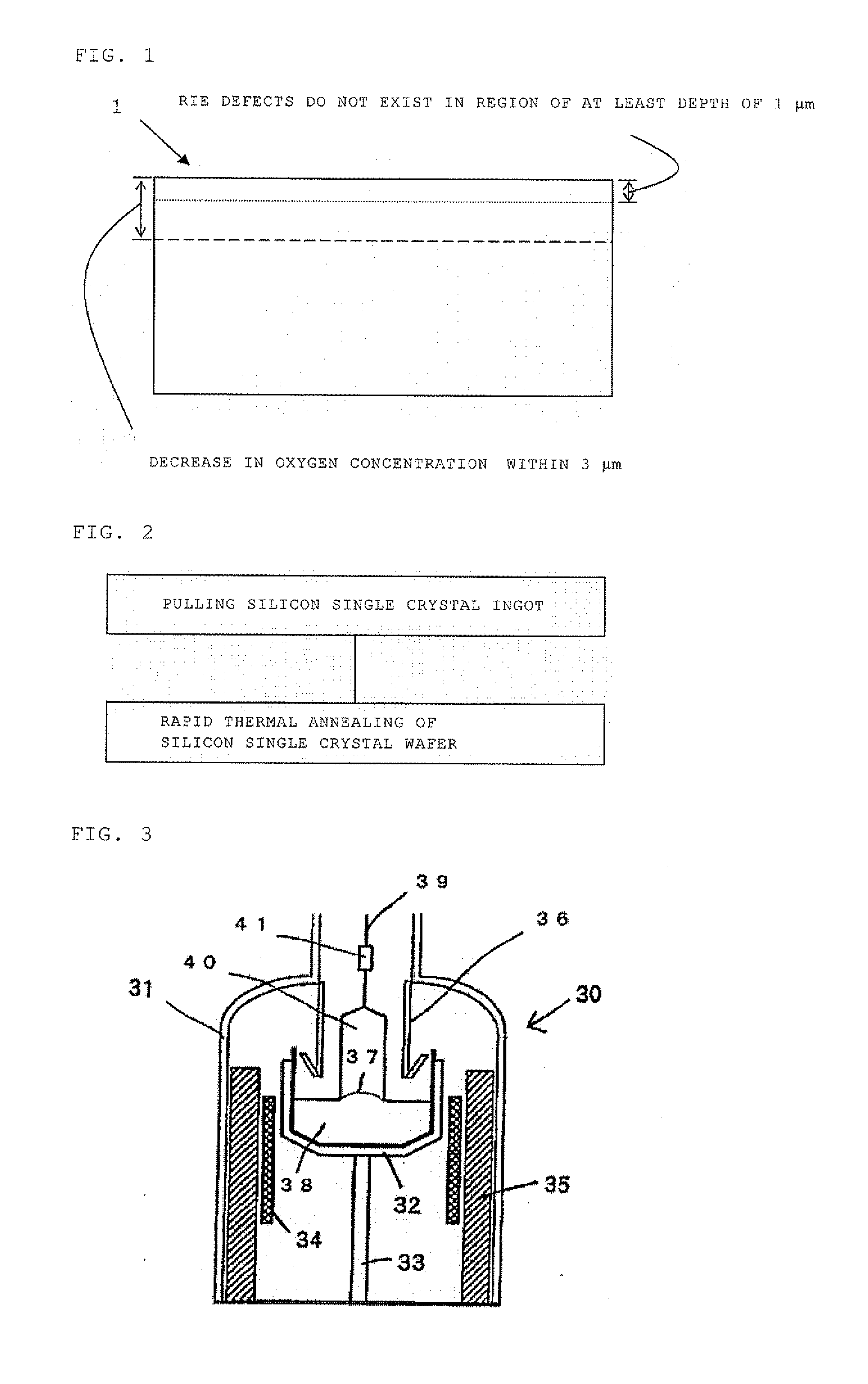

An annealed wafer obtained by performing rapid thermal annealing on a silicon single crystal wafer sliced from a silicon single crystal ingot in which an entire plane is an OSF region, an N region outside an OSF region, or a mixed region thereof, the silicon single crystal ingot being grown by the Czochralski method, in which RIE defects do not exist in a region having at least a depth of 1 μm from a surface, a good chip yield of a TDDB characteristic is 80% or more, and a depth of a region where an oxygen concentration is decreased due to outward diffusion is within 3 μm from the surface, and a method for producing an annealed wafer.

Owner:SHIN-ETSU HANDOTAI CO LTD

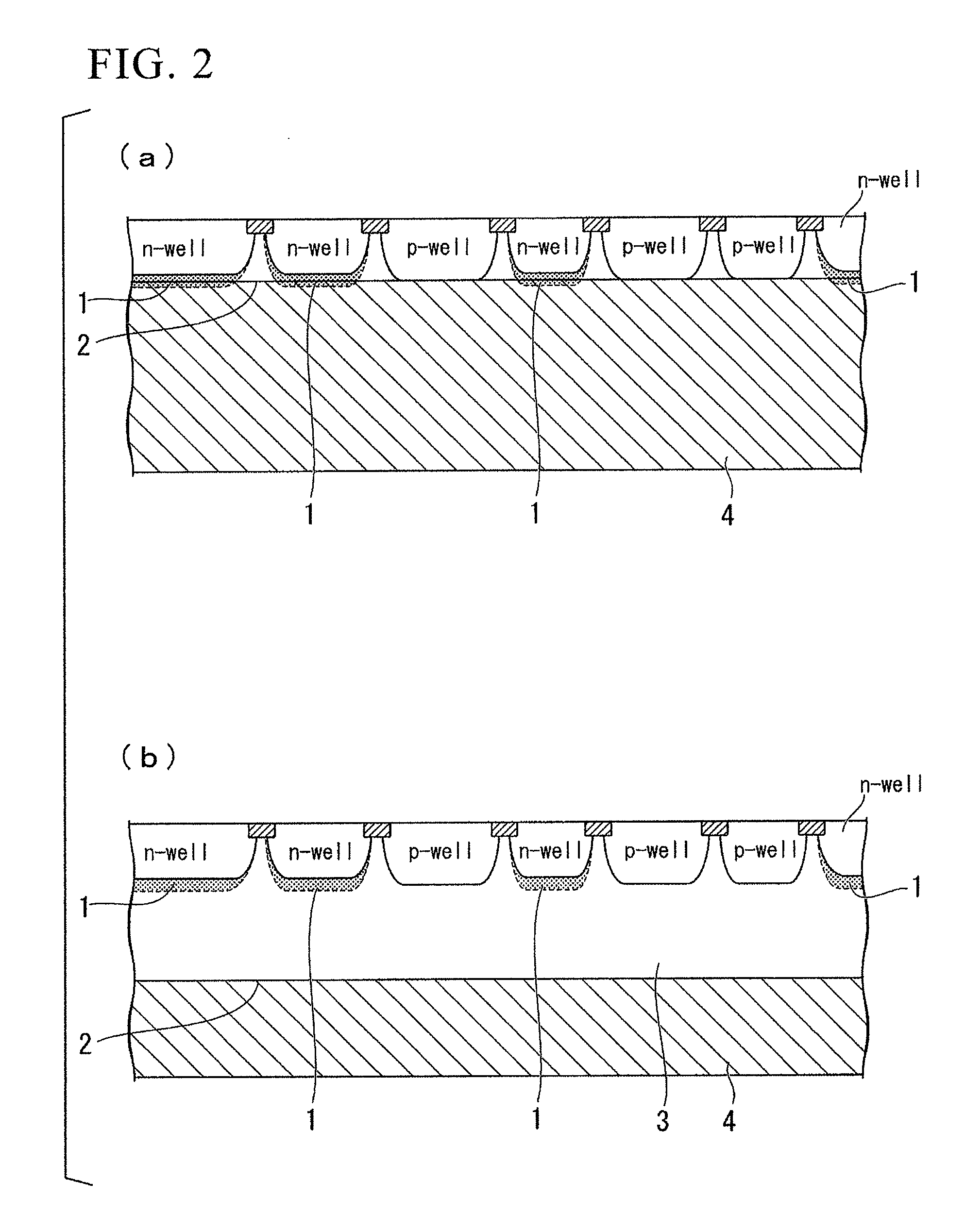

Silicon wafer for IGBT and method for producing same

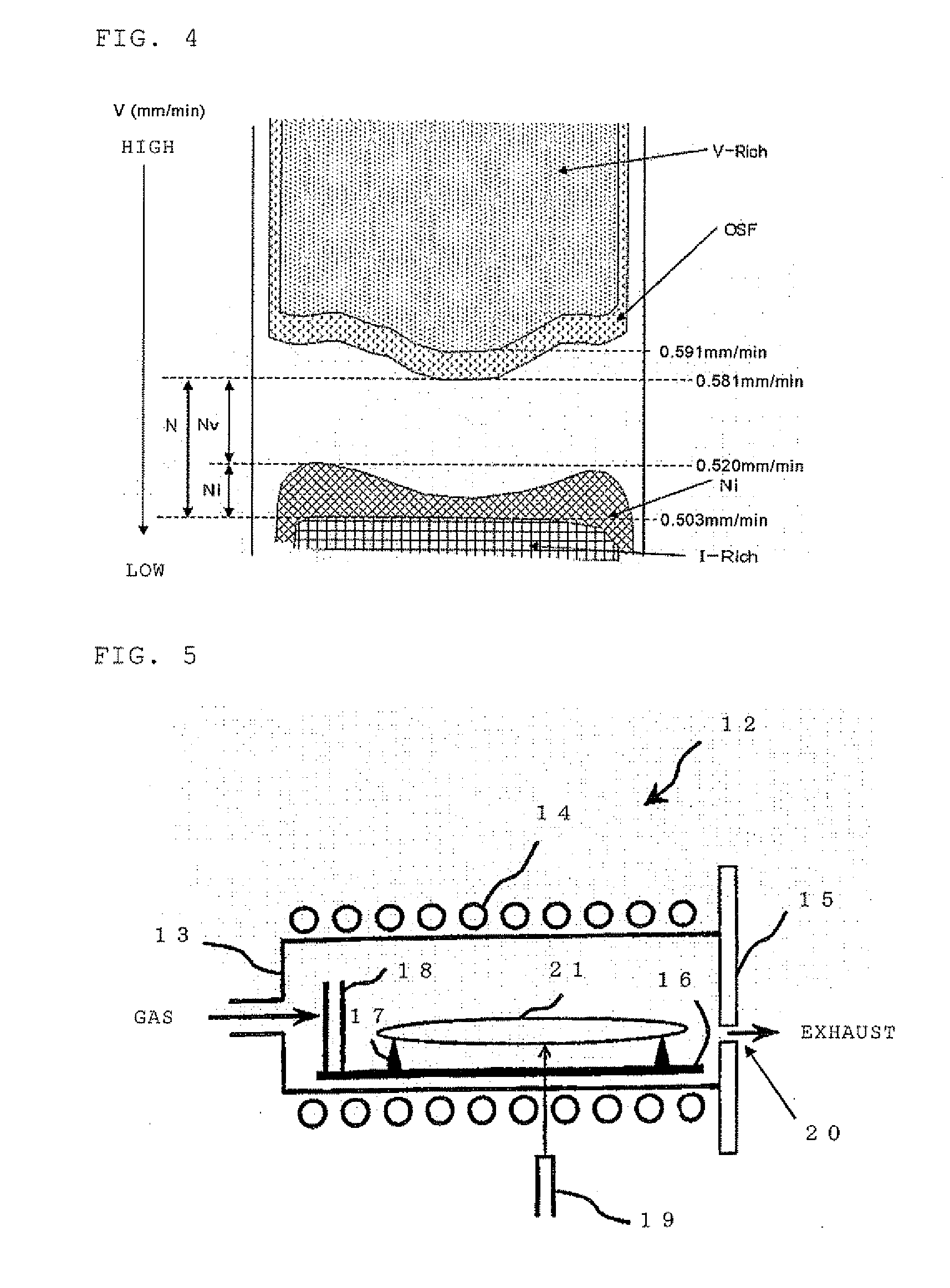

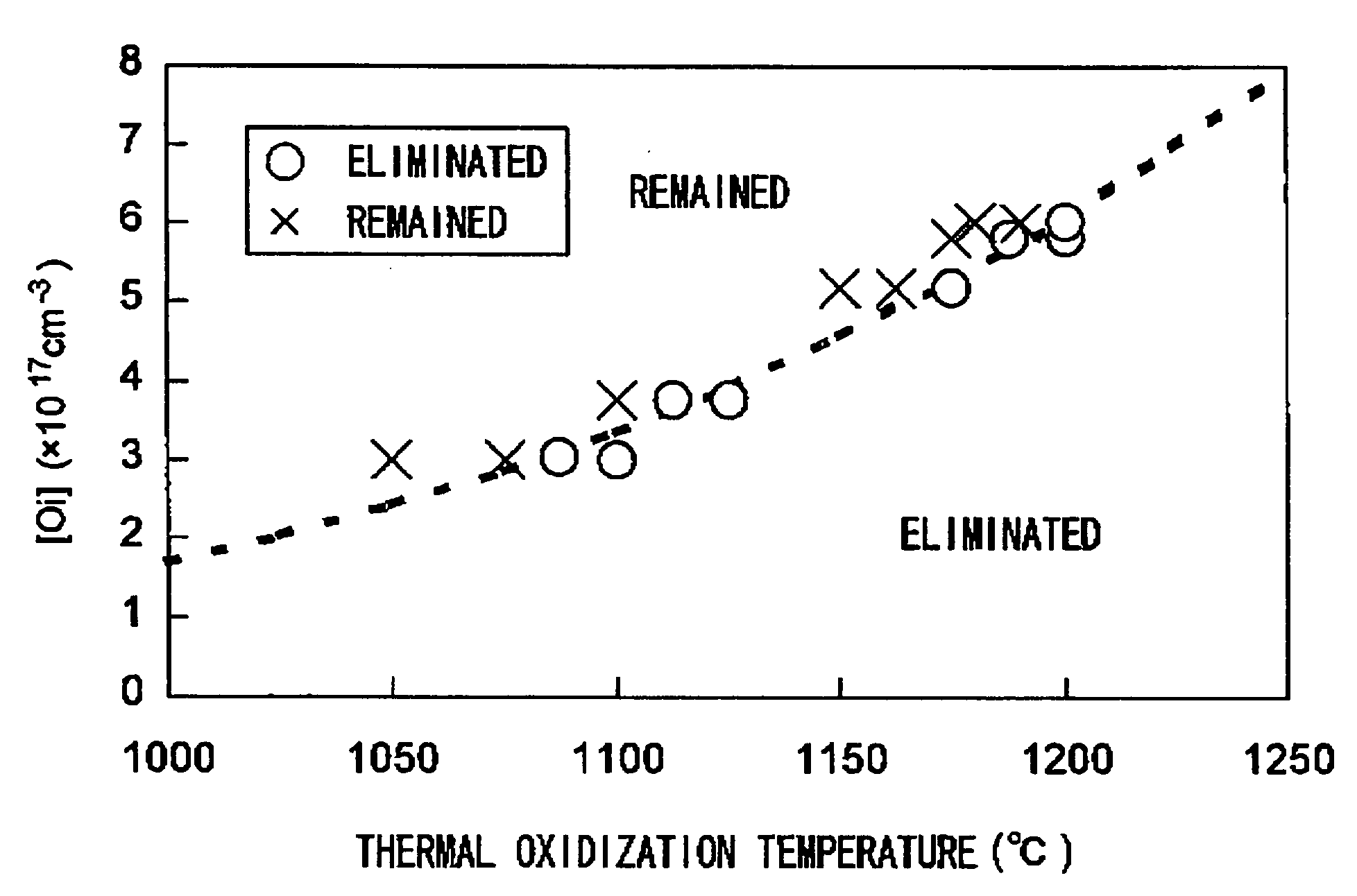

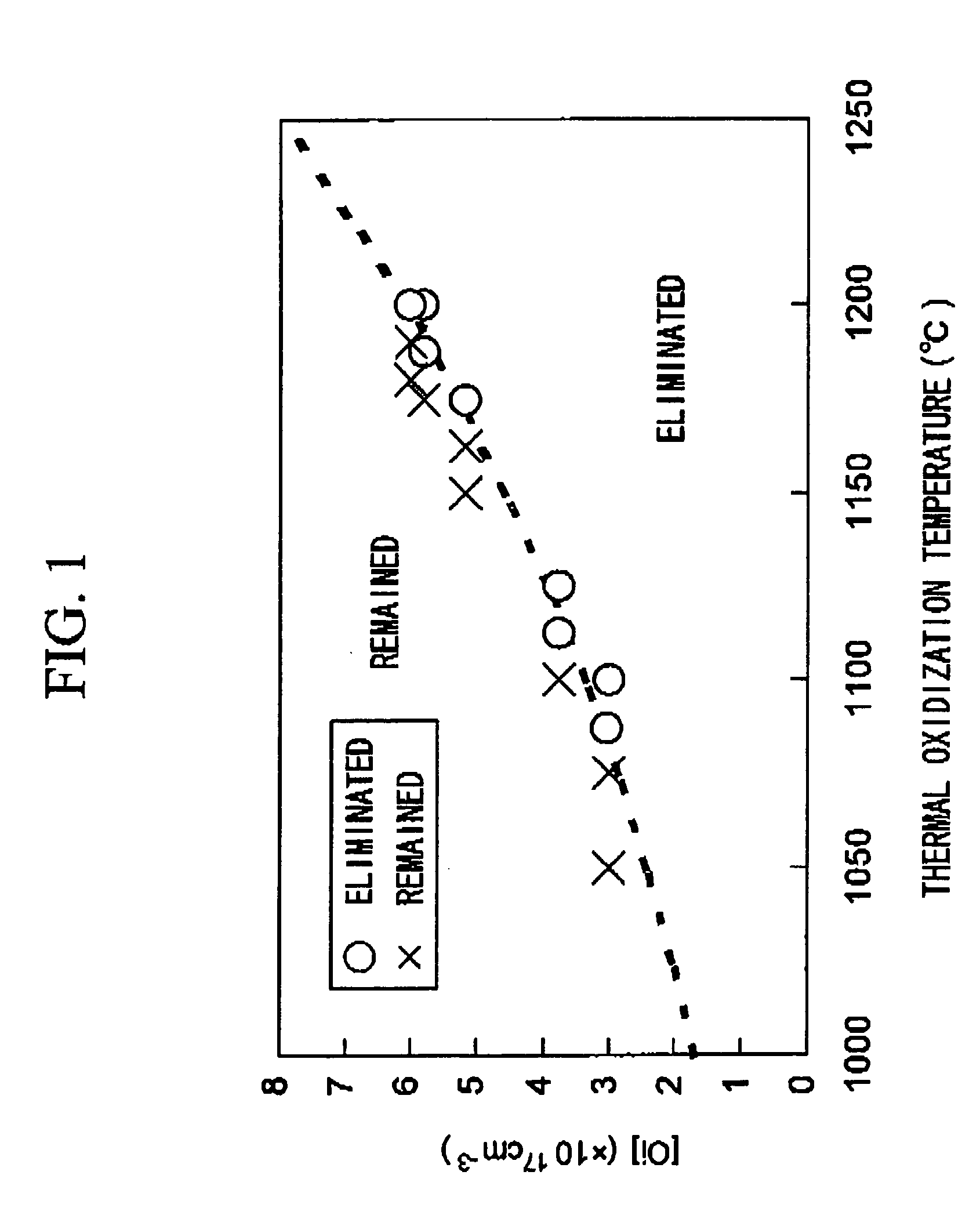

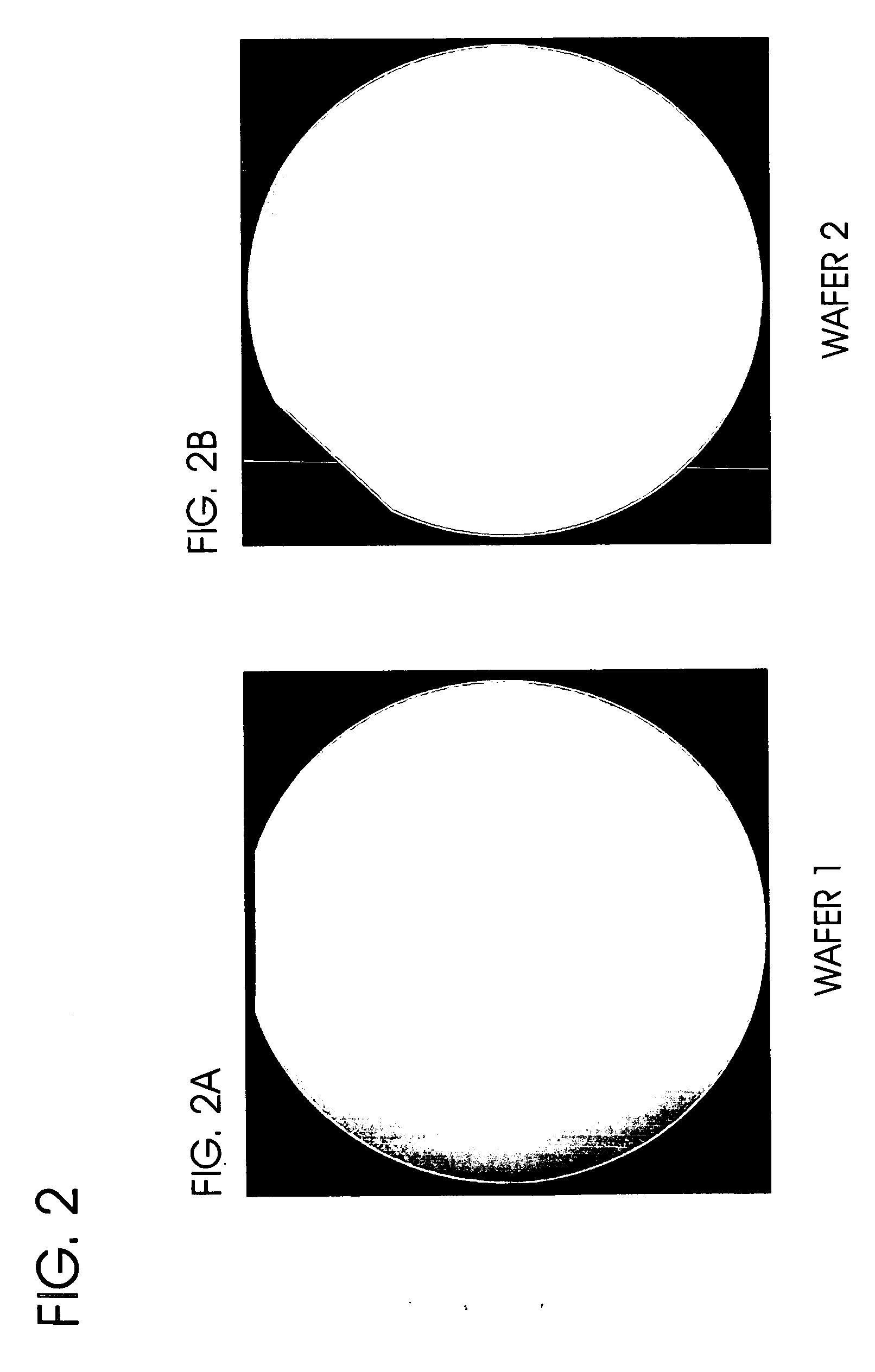

ActiveUS20070000427A1Eliminate COPsConstant resistivityPolycrystalline material growthAluminium silicatesWaferingCzochralski method

A silicon wafer for an IGBT is produced by forming an ingot having an interstitial oxygen concentration [Oi] of not more than 7.0×1017 atoms / cm3 by the Czochralski method; doping phosphorus in the ingot by neutron beam irradiation to the ingot; slicing a wafer from the ingot; performing annealing of the wafer in an oxidizing atmosphere containing at least oxygen at a temperature satisfying a predetermined formula; and forming a polysilicon layer or a strained layer on one side of the wafer.

Owner:SUMCO CORP

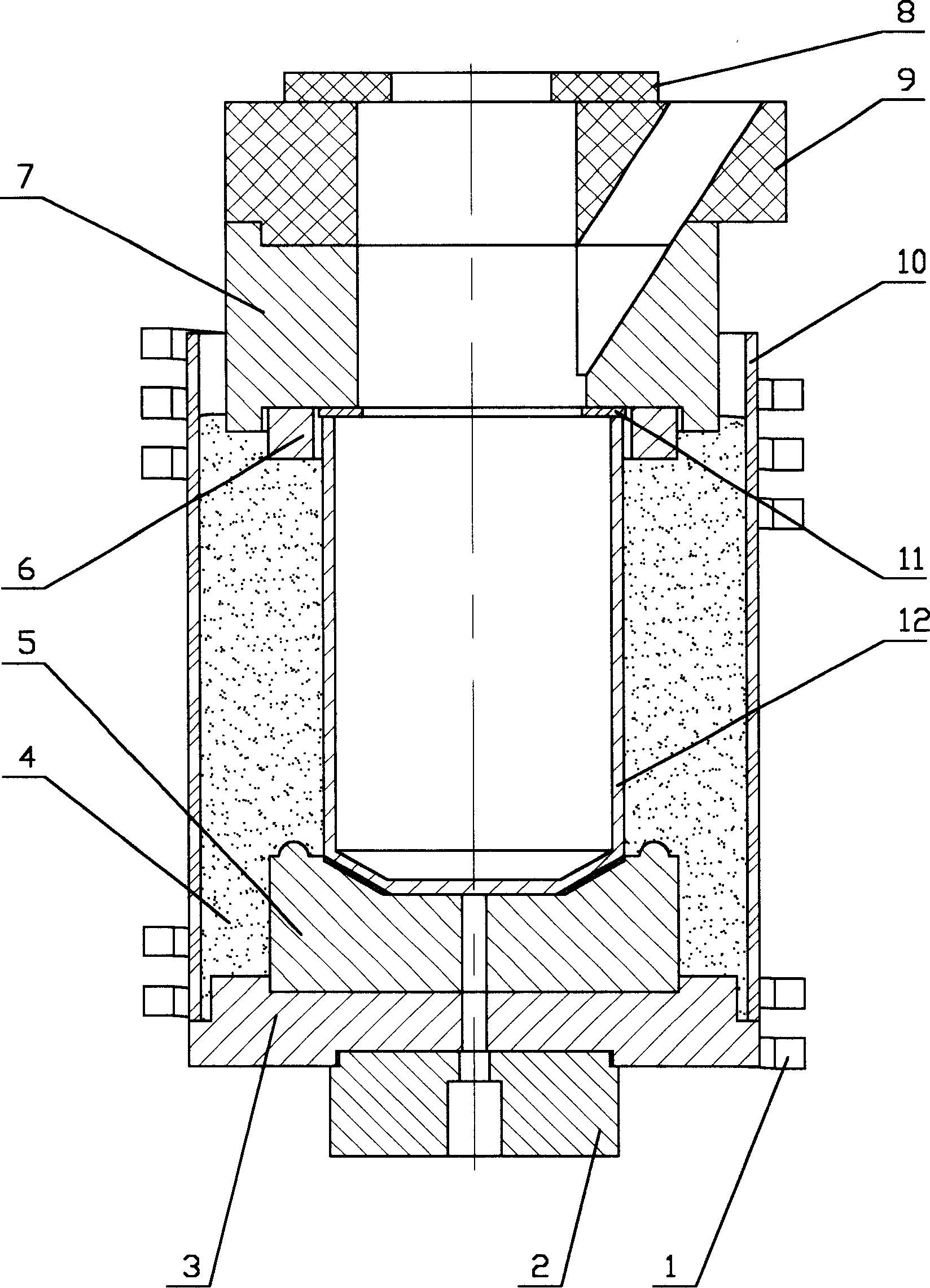

Method for preparing colorless corundum monocrystal

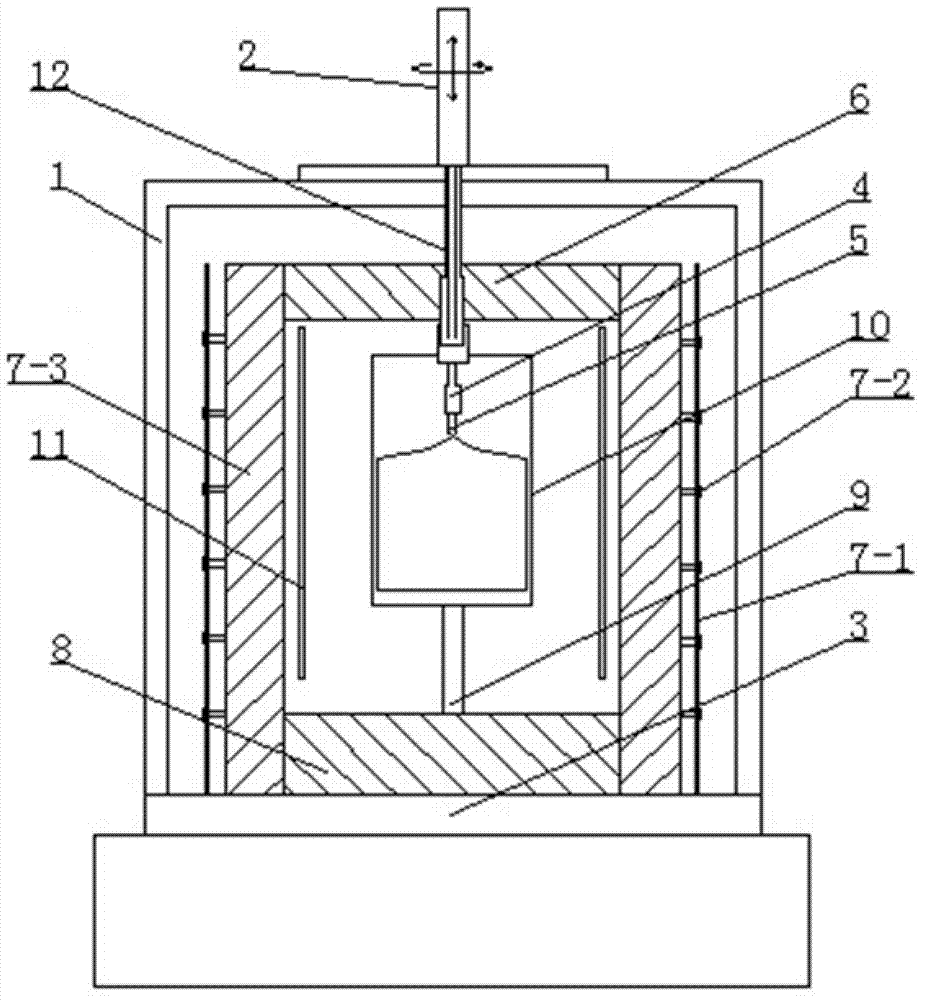

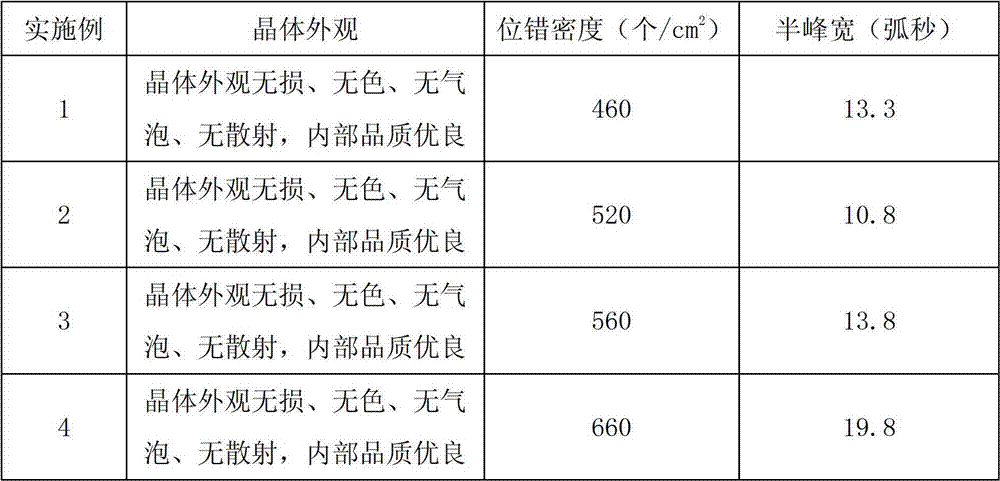

ActiveCN102758249AAvoid the effects of growthQuality assurancePolycrystalline material growthBy pulling from meltCzochralski methodSeed crystal

The invention discloses a method for preparing colorless corundum monocrystal and a special corundum crystal growth furnace structure. The preparation method comprises steps of preprocessing raw materials, cleaning, seeding crystal, enabling the crystal to grow through a Czochralski method, enabling the crystal to grow freely, performing in situ annealing and a cooling treatment and finally obtaining the colorless corundum monocrystal. By the aid of the method, the Czochralski method is combined with a Kyropoulos method in a creative way, a stable temperature gradient environment which meets crystal growth requirements is provided by a corundum crystal growth furnace, the quality of prepared crystal monocrystal is good, the success ratio of the crystal growth exceeds 90%, and the method is suitable to industrial production, convenient, energy-saving, safe and reliable.

Owner:登封市蓝天石化光伏电力装备有限公司

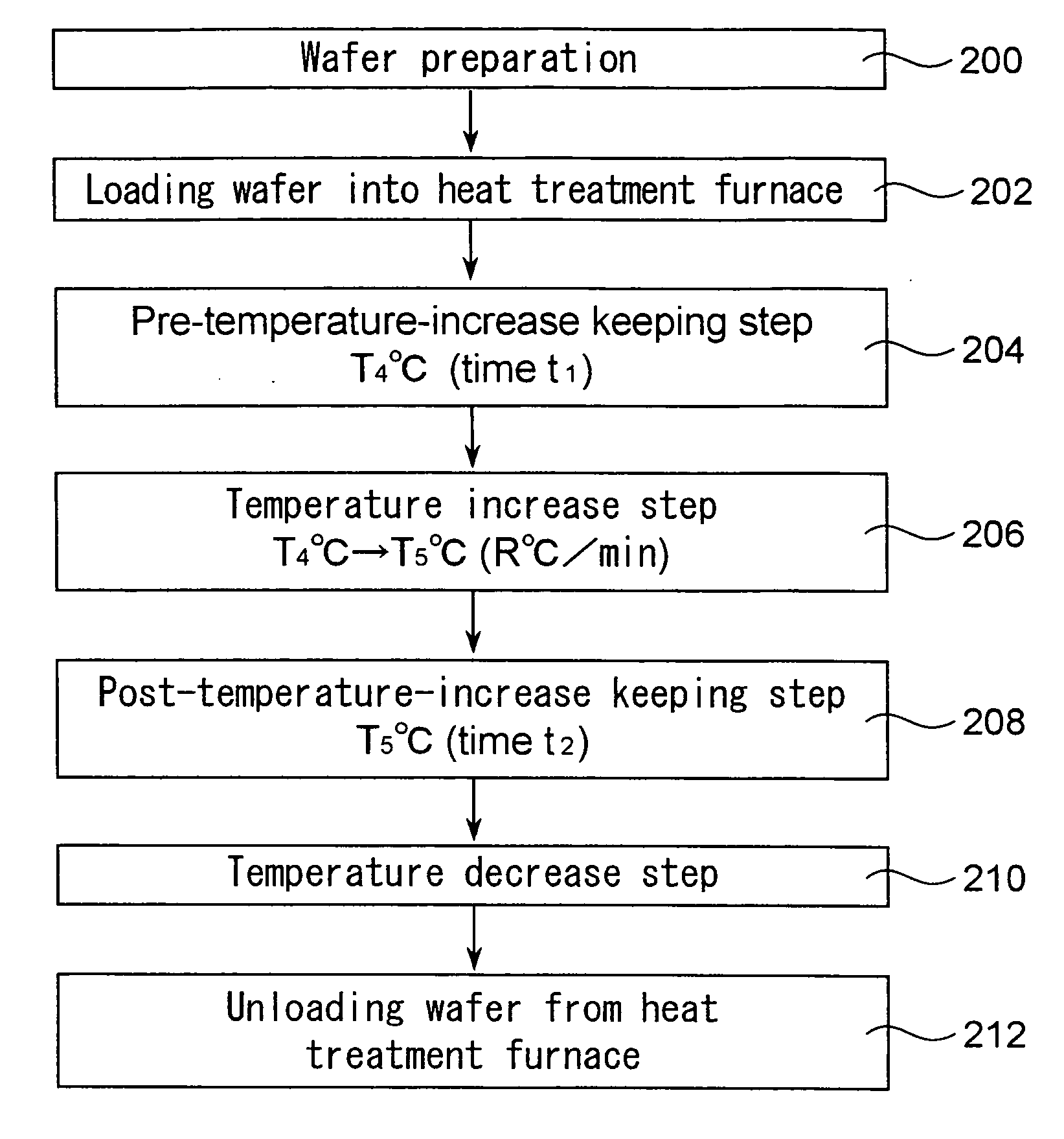

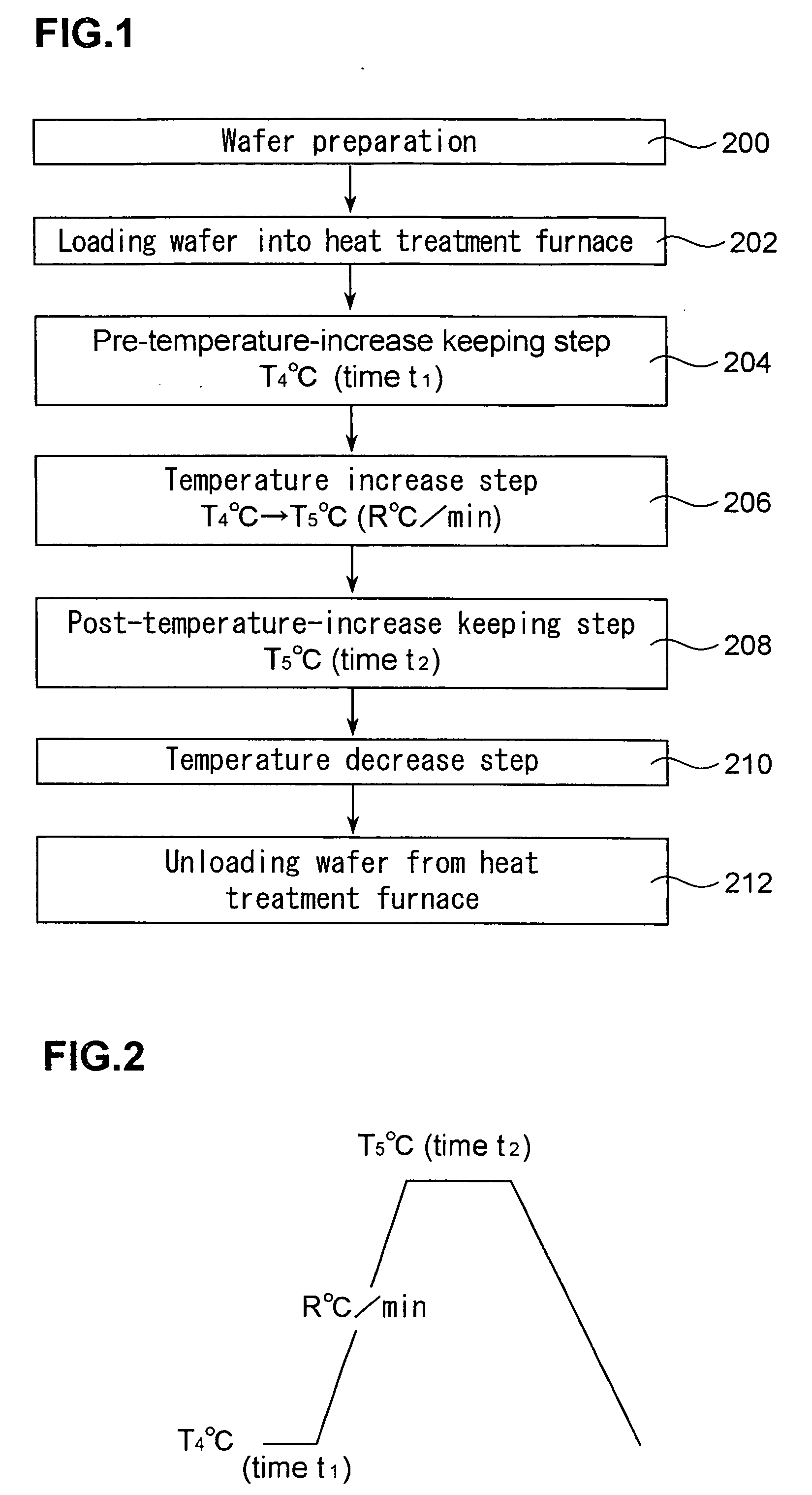

Annealed wafer and anneald wafer manufacturing method

ActiveUS20060075957A1Improve featuresImprove abilitiesPolycrystalline material growthAfter-treatment detailsDielectricSurface layer

The present invention provides an annealed wafer which has a wafer surface layer serving as a device fabricating region and having an excellent oxide film dielectric breakdown characteristic, and a wafer bulk layer in which oxide precipitates are present at a high density at the stage before the wafer is loaded into the device fabrication processes to give an excellent IG capability, and a method for manufacturing the annealed wafer. The present invention is directed to an annealed wafer obtained by performing heat treatment on a silicon wafer manufactured from a silicon single crystal grown by the Czochralski method, wherein a good chip yield of an oxide film dielectric breakdown characteristic in a region having at least a depth of up to 5 μm from a wafer surface is 95% or more, and a density of oxide precipitates detectable in the wafer bulk and each having a size not smaller than a size showing a gettering capability is not less than 1×109 / cm3.

Owner:SHIN-ETSU HANDOTAI CO LTD

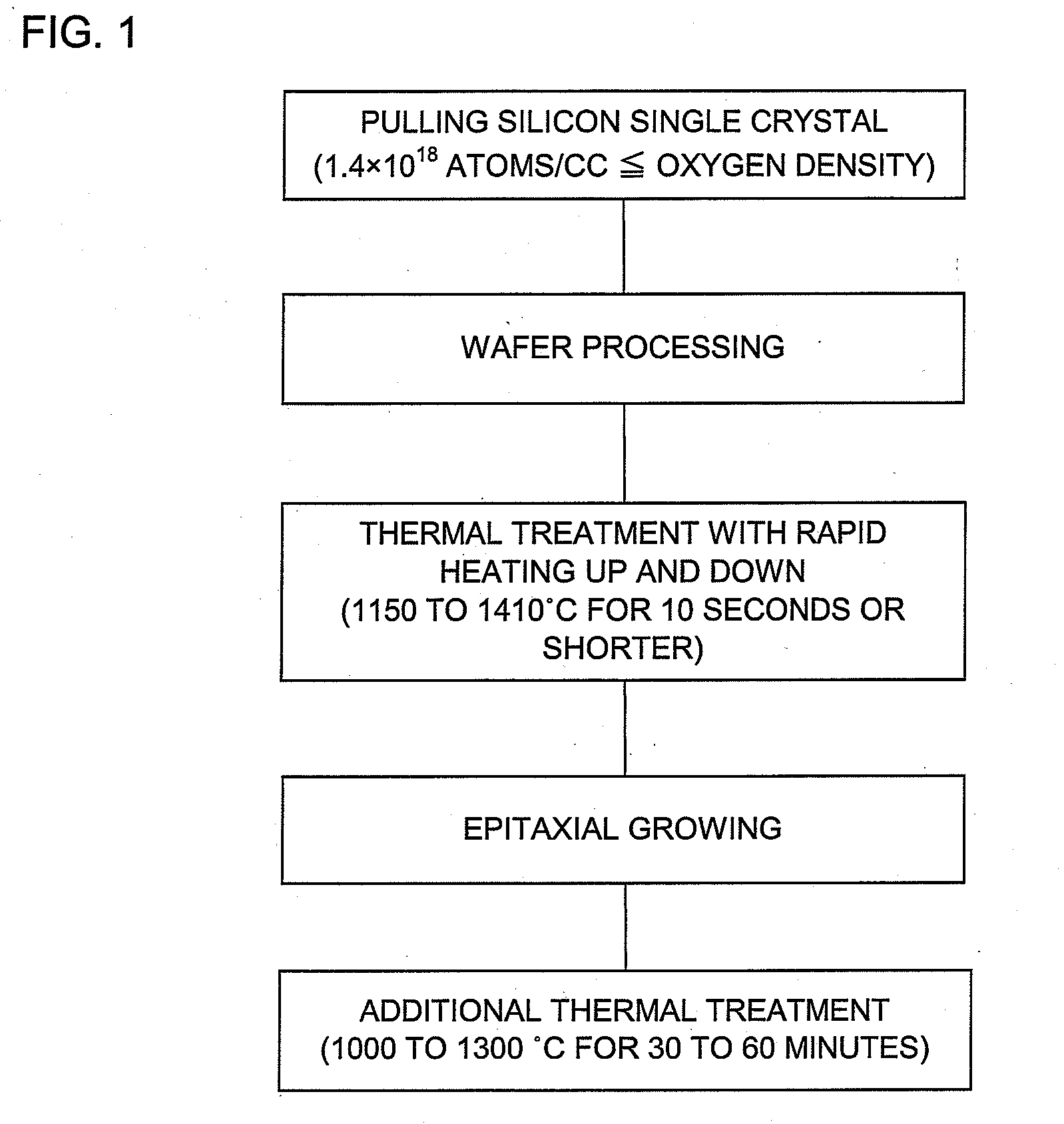

Silicon single crystal wafer and the production method

InactiveUS20080292523A1Good effectHeating up fastPolycrystalline material growthSiliconCzochralski methodSingle crystal

A production method of a silicon single crystal wafer capable of effectively bringing out a gettering effect also in a thin film device is provided: wherein a thermal treatment with rapid heating up and down is performed for 10 seconds or shorter on a silicon single crystal wafer obtained by processing a single crystal grown by the Czochralski method and having an initial interstitial oxygen density is 1.4×1018 atoms / cc (ASTM F-121, 1979).

Owner:SUMCO CORP

Method of fabricating a single crystal ingot and method of fabricating a silicon wafer

InactiveUS6517632B2Polycrystalline material growthBy pulling from meltCzochralski methodCarbon density

A method of fabricating a silicon single crystal ingot and a method of fabricating a silicon wafer using the ingot, characterized in that: the method is structured in such a manner that the silicon single crystal ingot is pulled up from the silicon fused liquid 7 in which nitrogen N and carbon C are doped in polycrystalline silicon, by using the Czochralski method, and its nitrogen density is 1x1013-5x1015 atoms / cm3, and the carbon density is 5x1015-3x1016 atoms / cm3.

Owner:COVALENT MATERIALS CORP

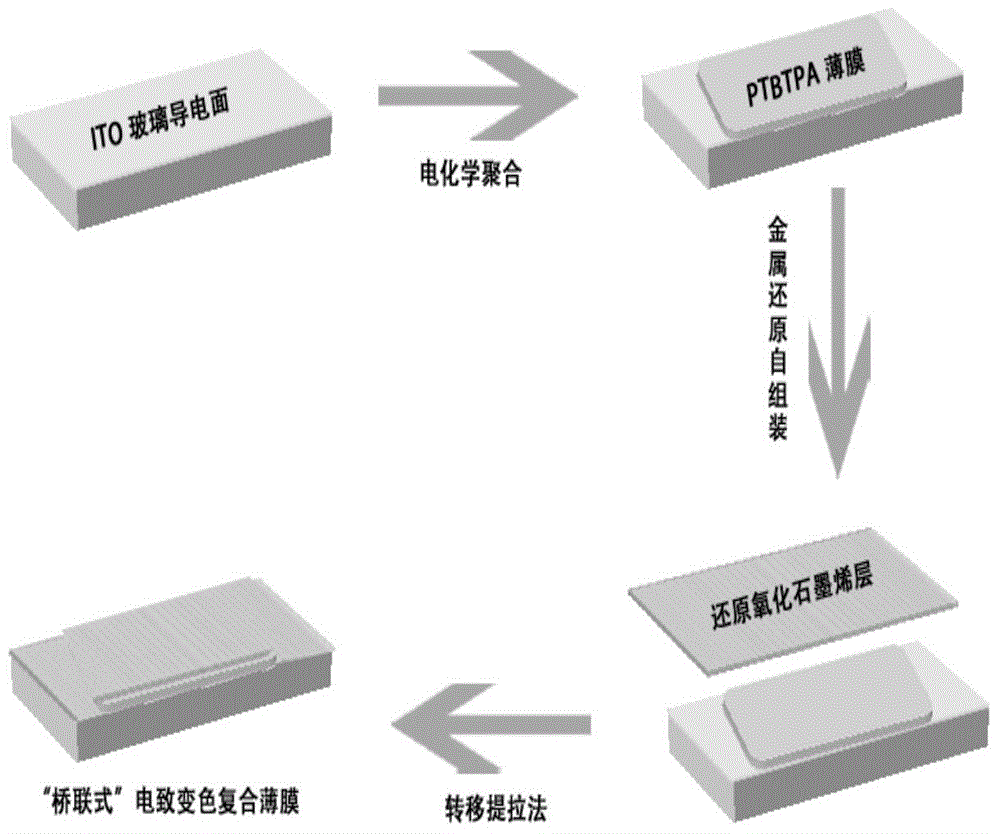

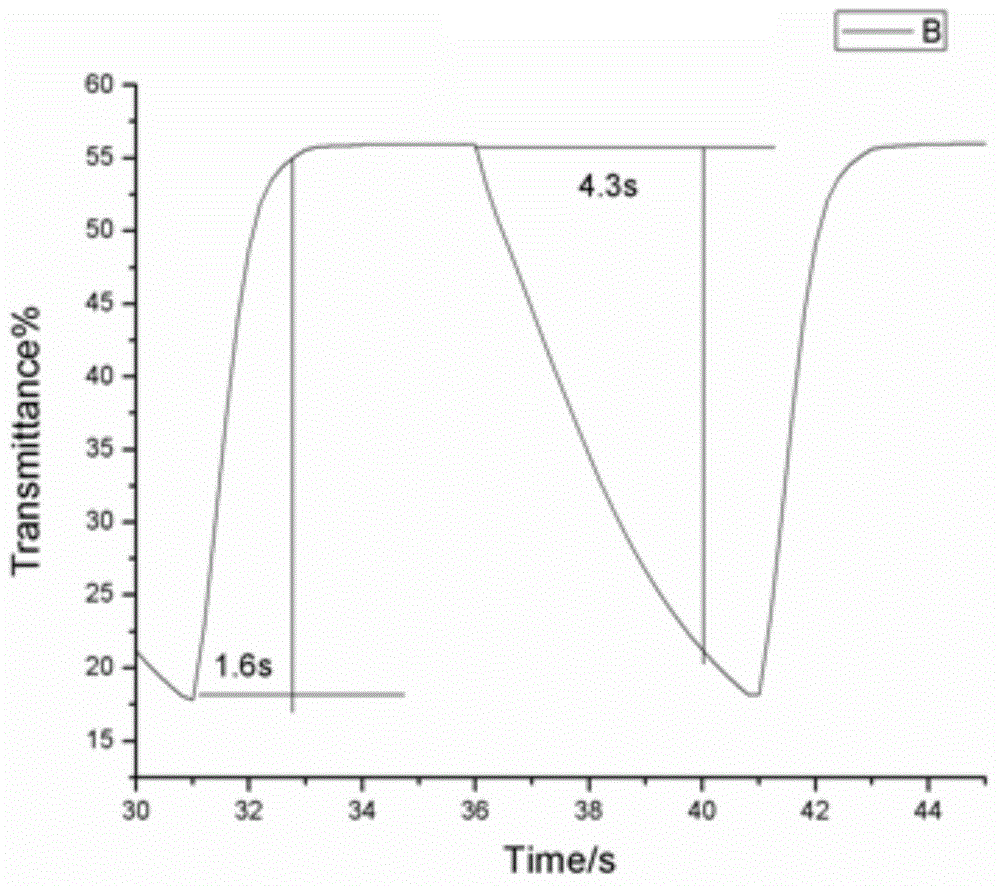

Electrically conductive polymer-graphene composite electrochromic film and preparation method thereof

The invention discloses an electrically conductive polymer-graphene composite electrochromic film. A preparation method of the film comprises the following steps: with an electrochemical polymerization method, a layer of electrically conductive polymer film is deposited on an electrically conductive substrate; a graphene oxide water solution is prepared with a modified Hummers method, and a graphene film is prepared with a metal base self-assembly synchronous reduction method; and the surface of the electrically conductive polymer film is covered by the graphene film with a Czochralski method, such that the composite electrochromic film is obtained. The composite electrochromic film provided by the invention has an innovative structure and excellent performances. The preparation method is simple.

Owner:ZHEJIANG UNIV OF TECH

Silicon single crystal wafer and method for producing silicon single crystal

InactiveUS6913646B2Stable supplyImprove electrical performancePolycrystalline material growthSemiconductor/solid-state device testing/measurementCzochralski methodSingle crystal

There can be provided a silicon single crystal wafer grown according to Czochralski method wherein the whole plane of the wafer is occupied by N region on the outside of OSF generated in a shape of a ring by thermal oxidation treatment and there exists no defect region detected by Cu deposition. Thereby, there can be produced a silicon single crystal wafer according to CZ method, which does not belong to any of V region rich in vacancies, OSF region and I region rich in interstitial silicons, and can surely improve electric characteristics such as oxide dielectric breakdown voltage characteristics or the like under stable manufacture conditions.

Owner:SHIN-ETSU HANDOTAI CO LTD

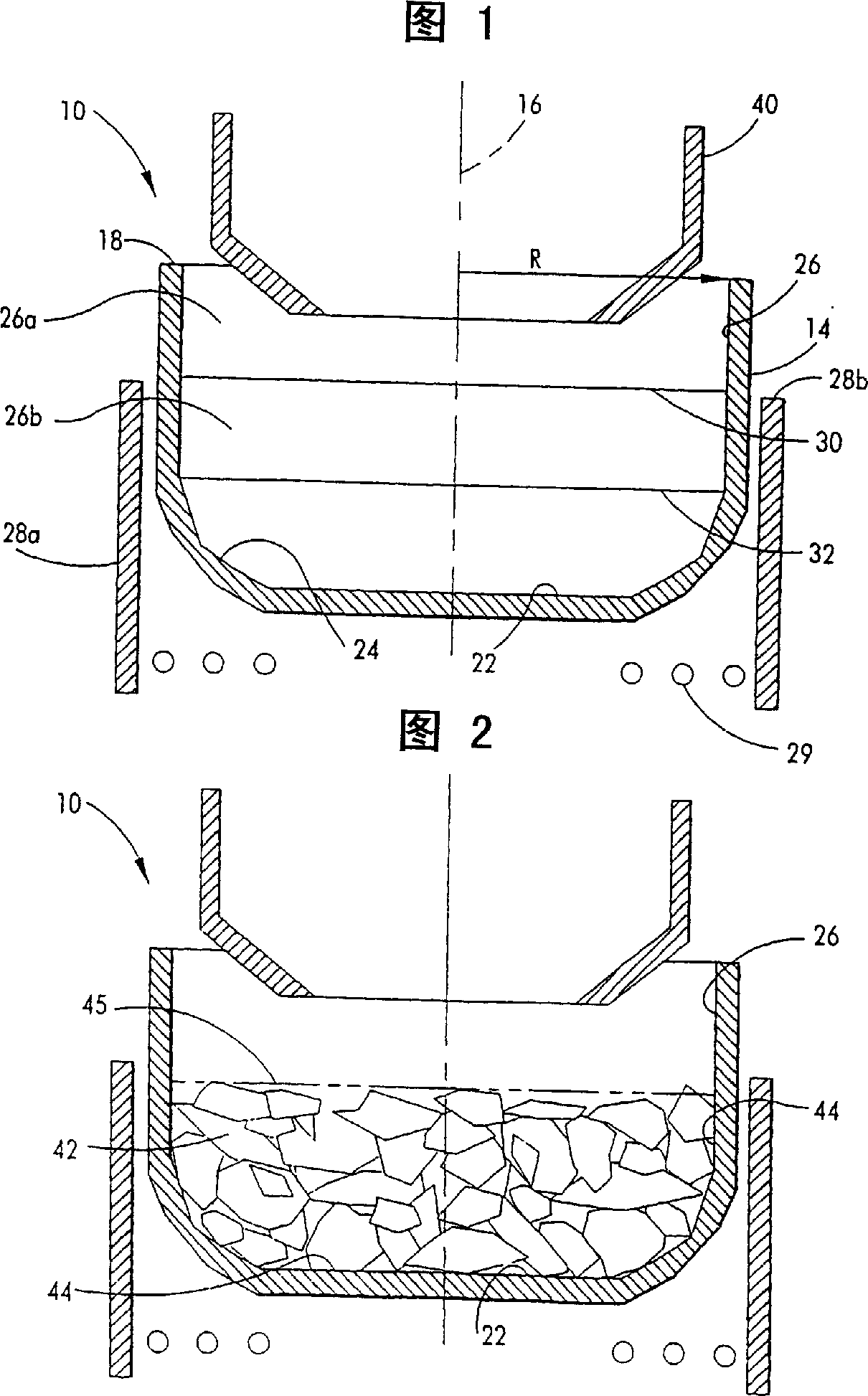

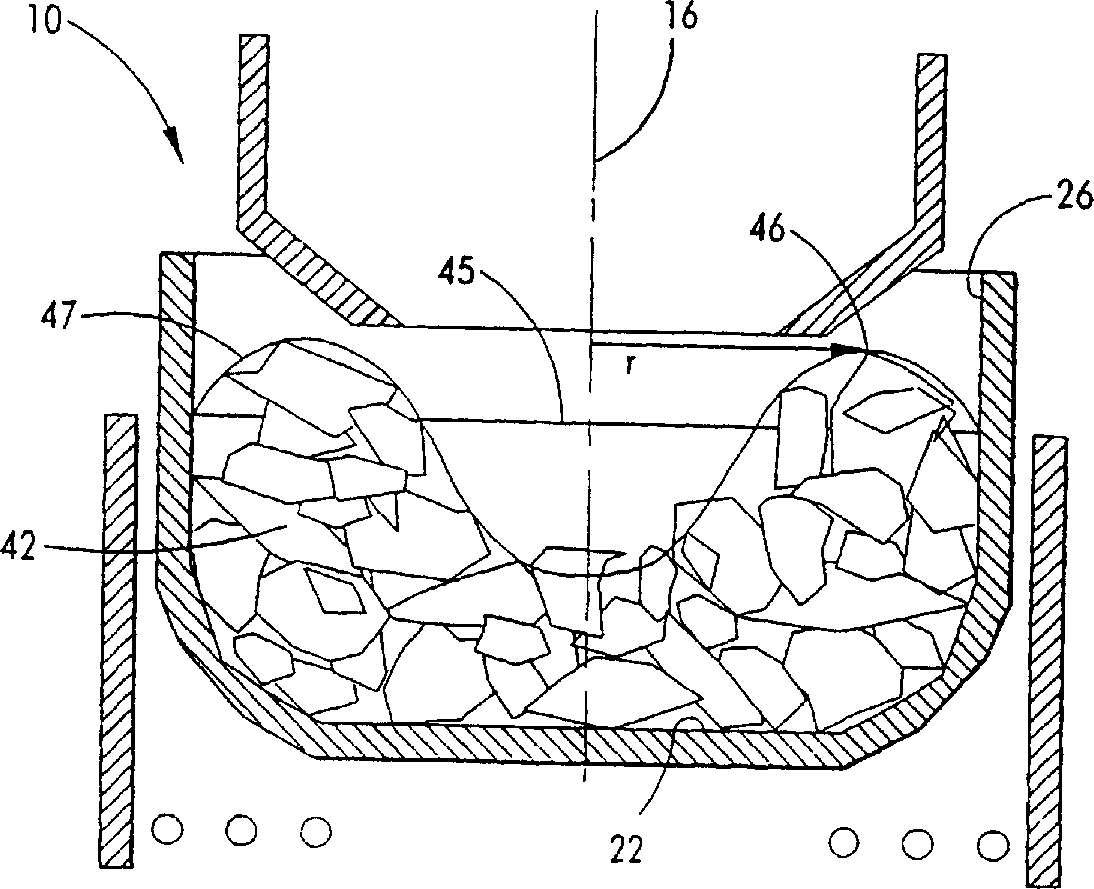

Process for preparing silicon melt from polysilicon charge

InactiveCN1276026AReduce hydrogen contentIncrease productionPolycrystalline material growthBy pulling from meltHydrogenCzochralski method

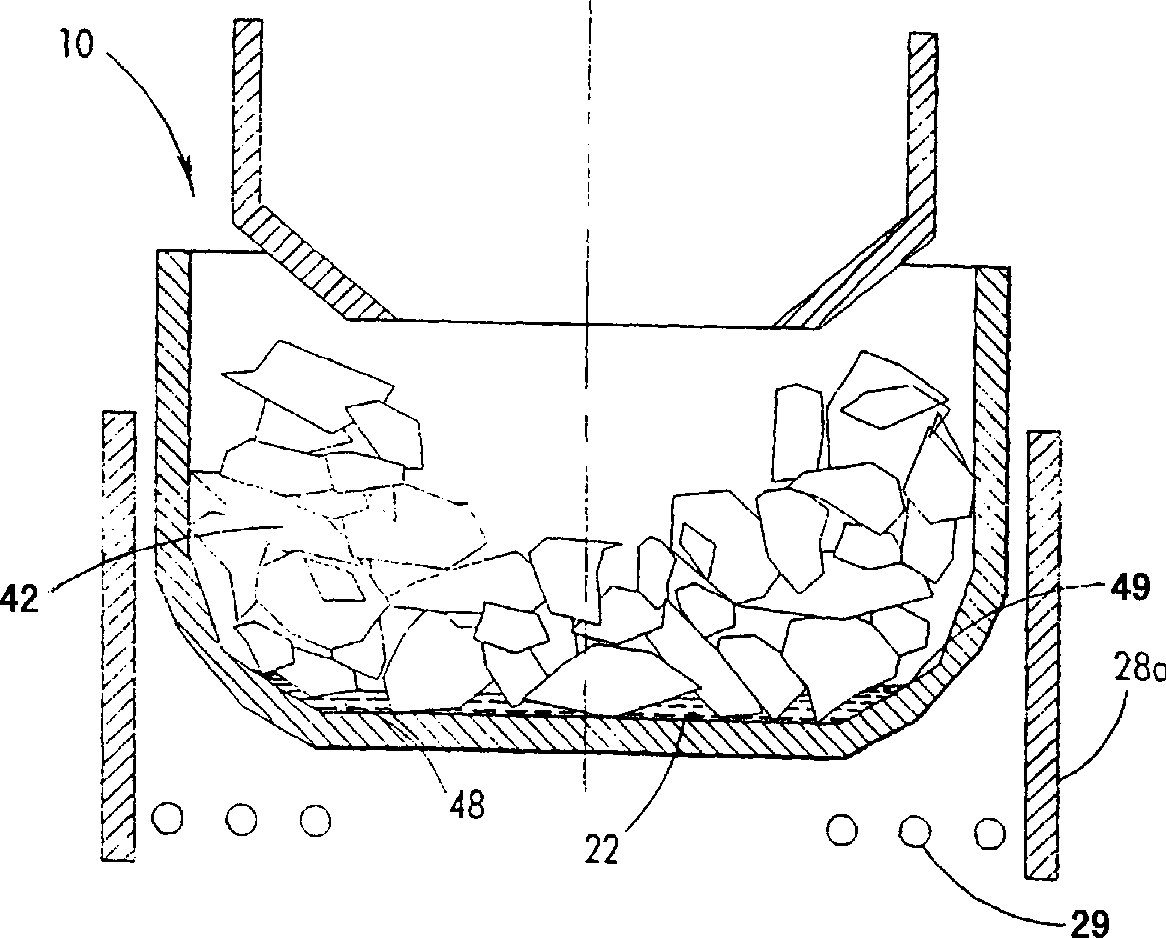

A process for preparing a silicon melt from a polysilicon charge, for use in the production of single crystal silicon ingots by the Czochralski method, in a crucible which has a bottom, a sidewall formation, a centerline which is substantially parallel to the sidewall formation and which intersects a geometric centerpoint of the bottom, and a radius extending from the centerline to the sidewall formation. In the process, the crucible is loaded with chunk polysilicon to form a charge having a bowl-like shape, wherein initially the load generally slopes radially upwardly and outwardly from the centerline toward the sidewall formation to an apex and then slopes generally downwardly and outwardly from the apex to the sidewall formation. The bowl-shaped chunk polysilicon charge is heated to form a partially melted charge, and granular polysilicon is fed onto the partially melted charge to form a mixed charge of chunk and granular polysilicon. As the mixed charge is further heated to form a silicon melt, the unmelted chunk polysilicon present above the melt surface acts to deflect any molten silicon that may be splattered as granular polysilicon rapidly melts and hydrogen is released.

Owner:MEMC ELECTONIC MATERIALS INC

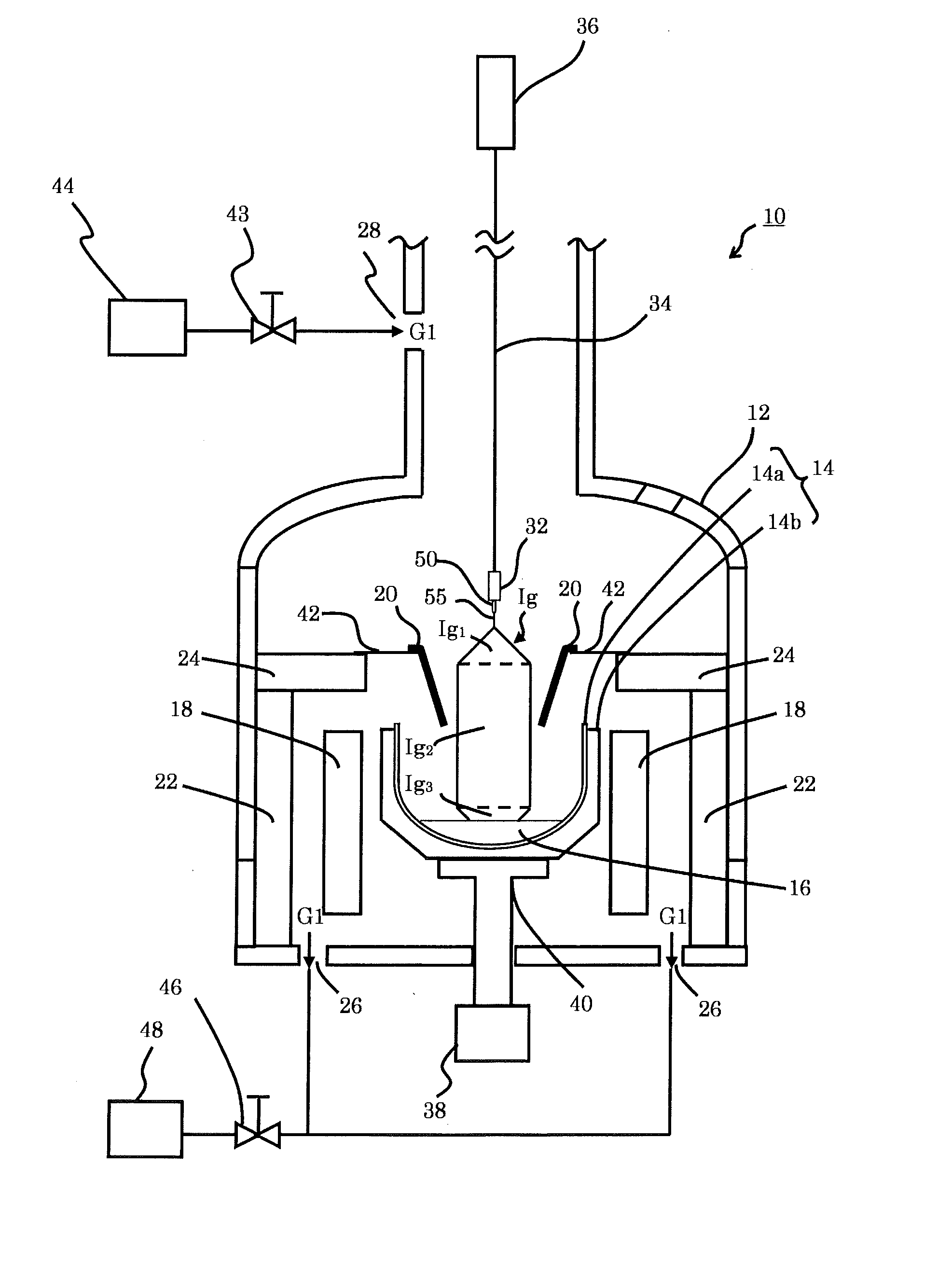

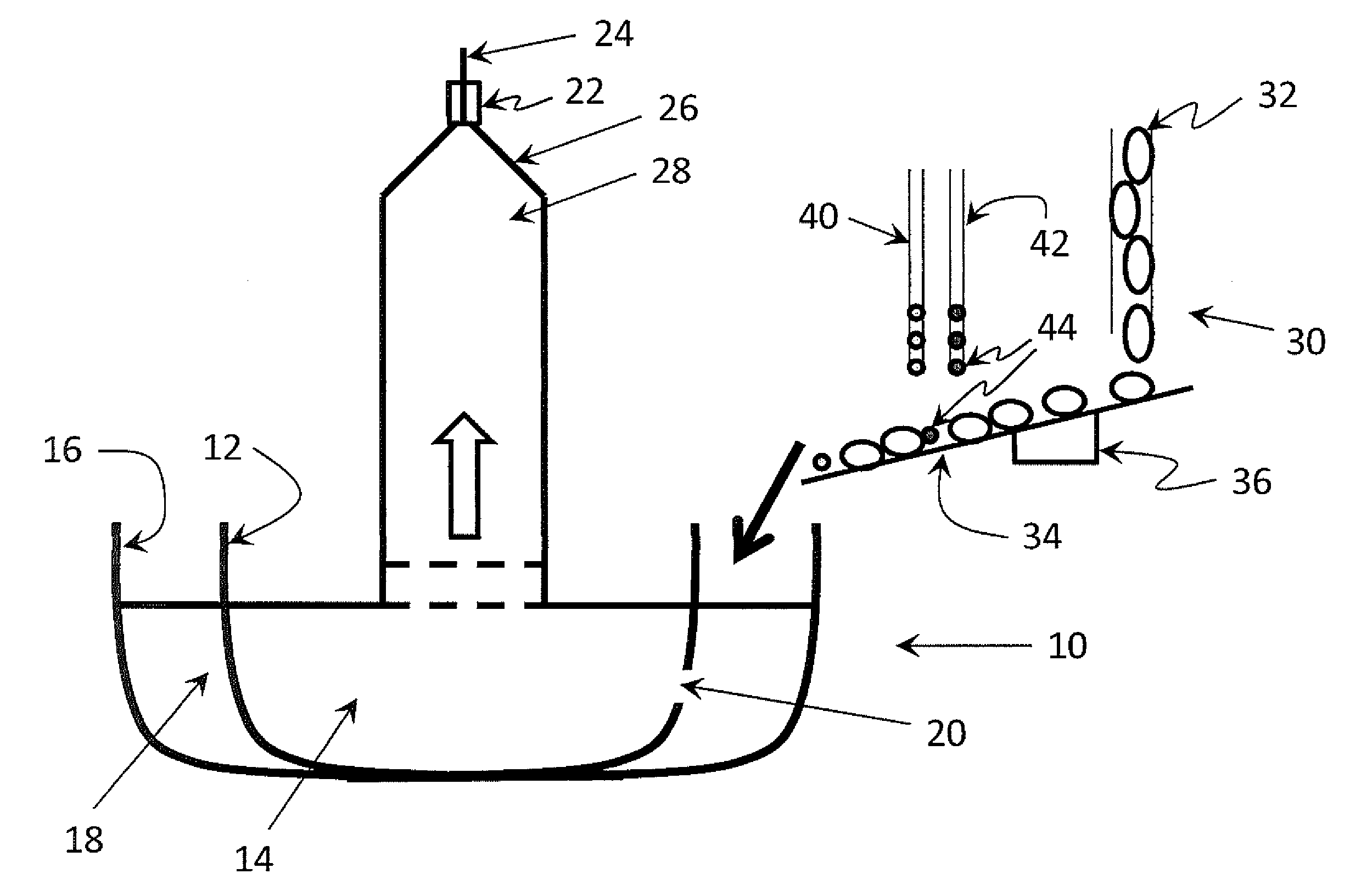

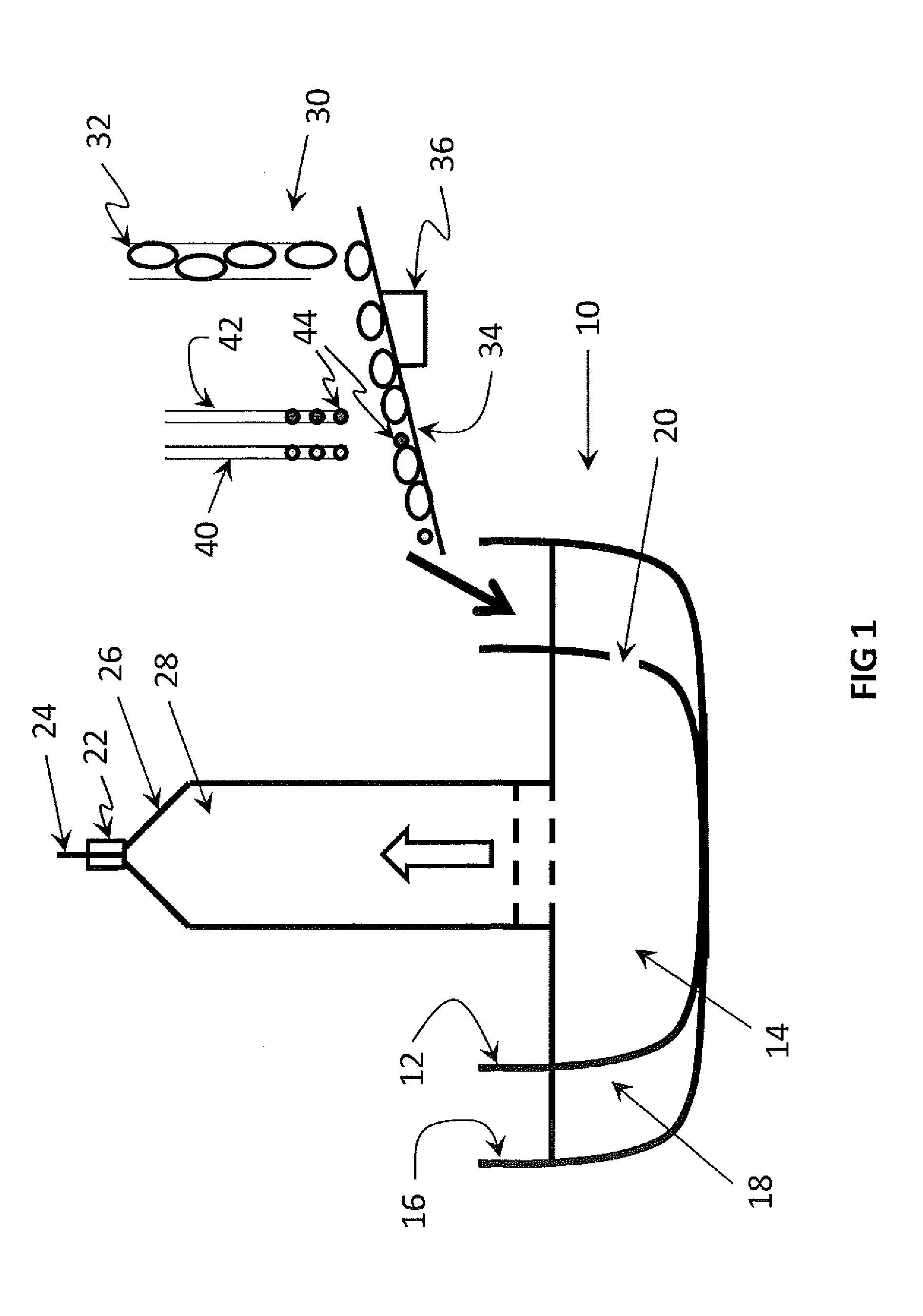

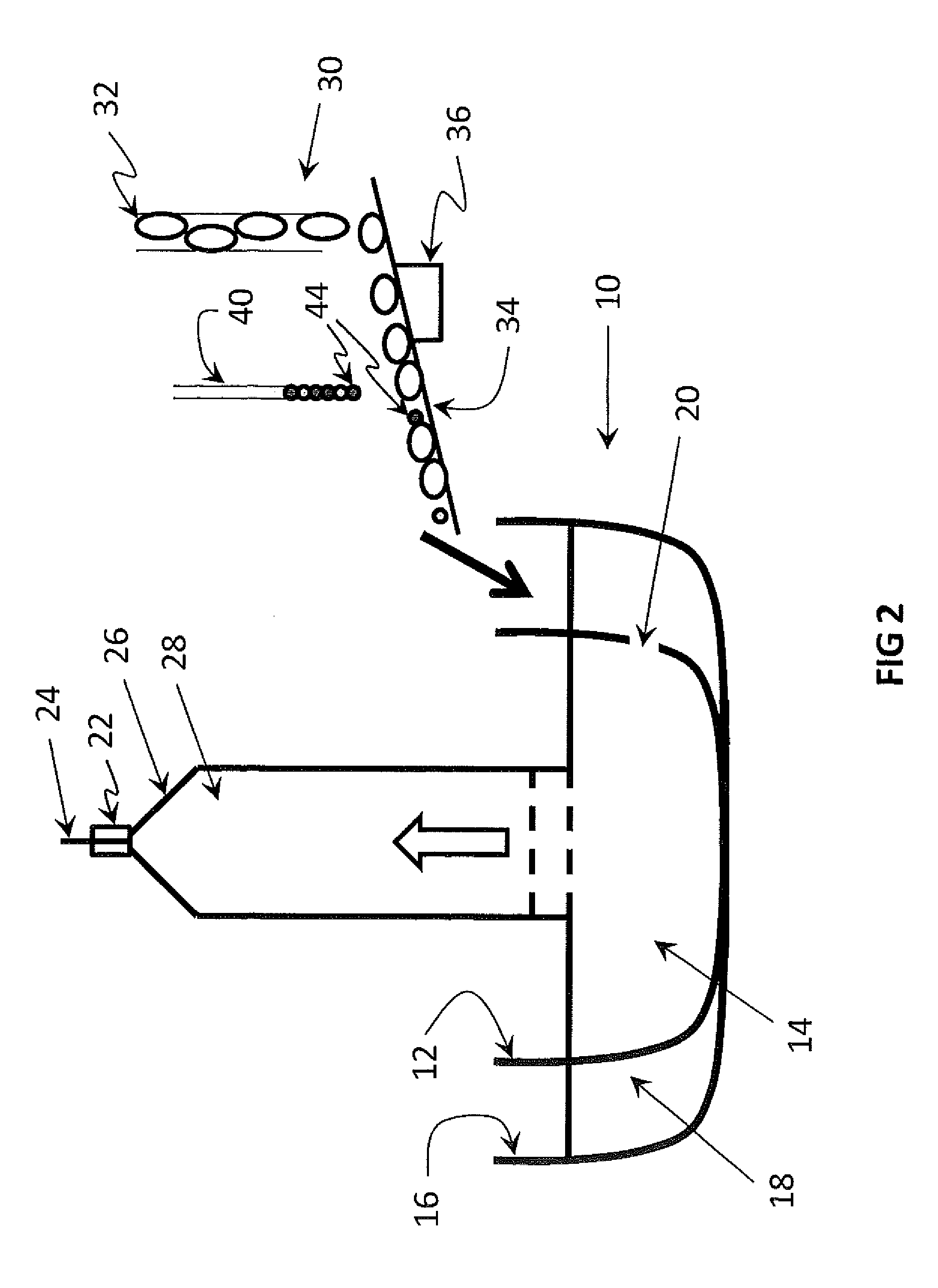

Controlled gravity feeding czochralski apparatus with on the way melting raw material

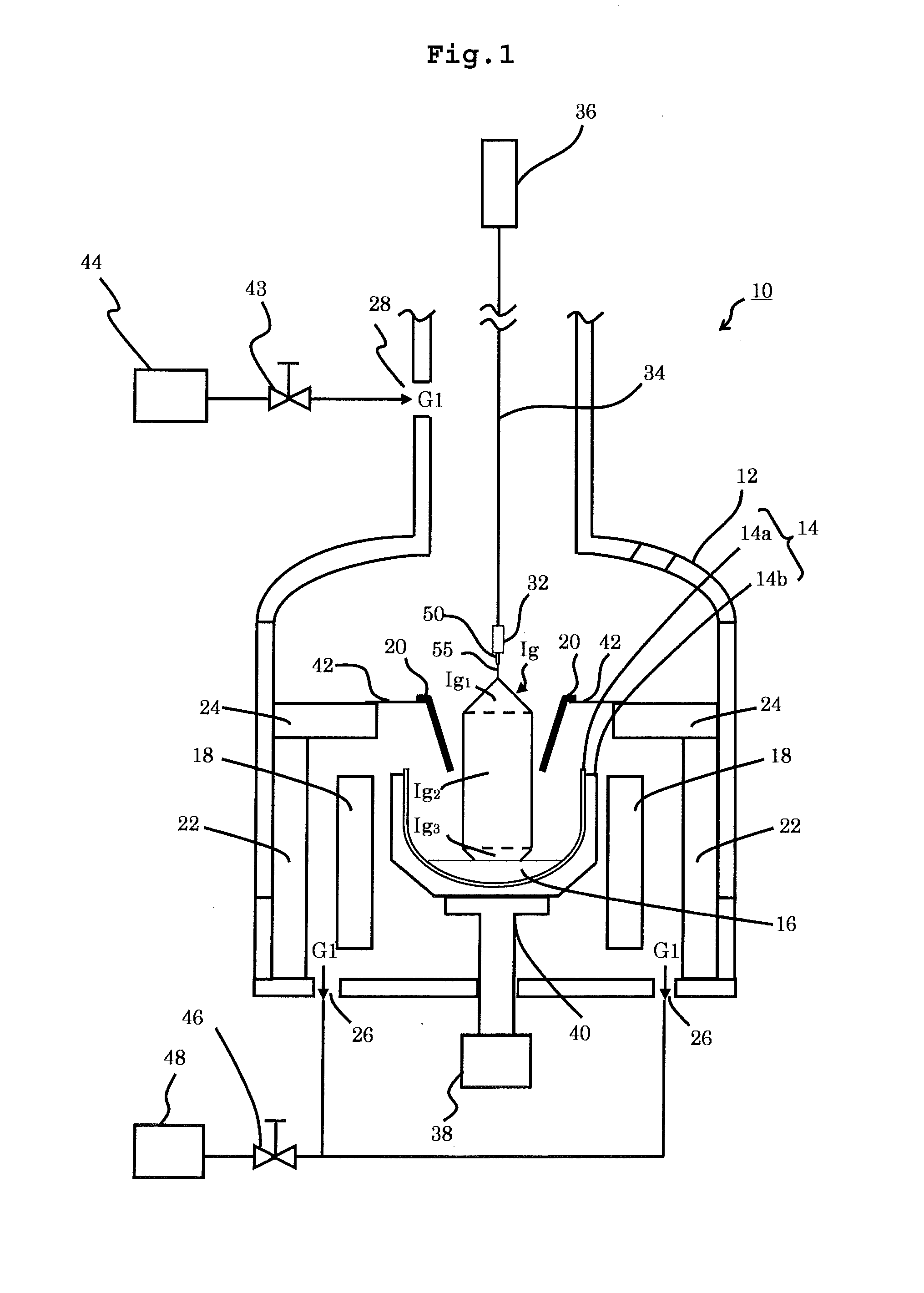

InactiveUS20130220215A1Independent controlPolycrystalline material growthBy pulling from meltLiquid stateCrucible

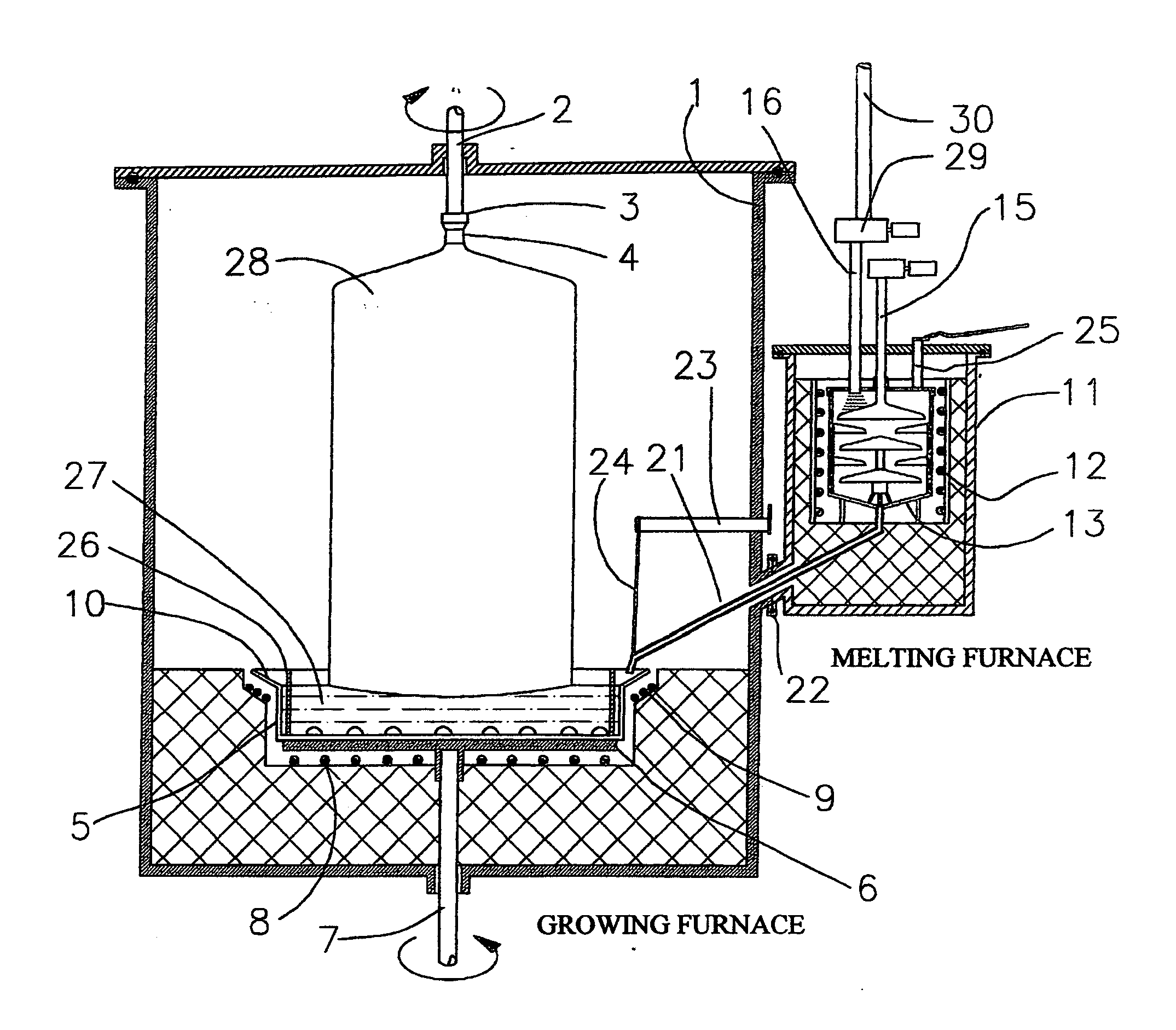

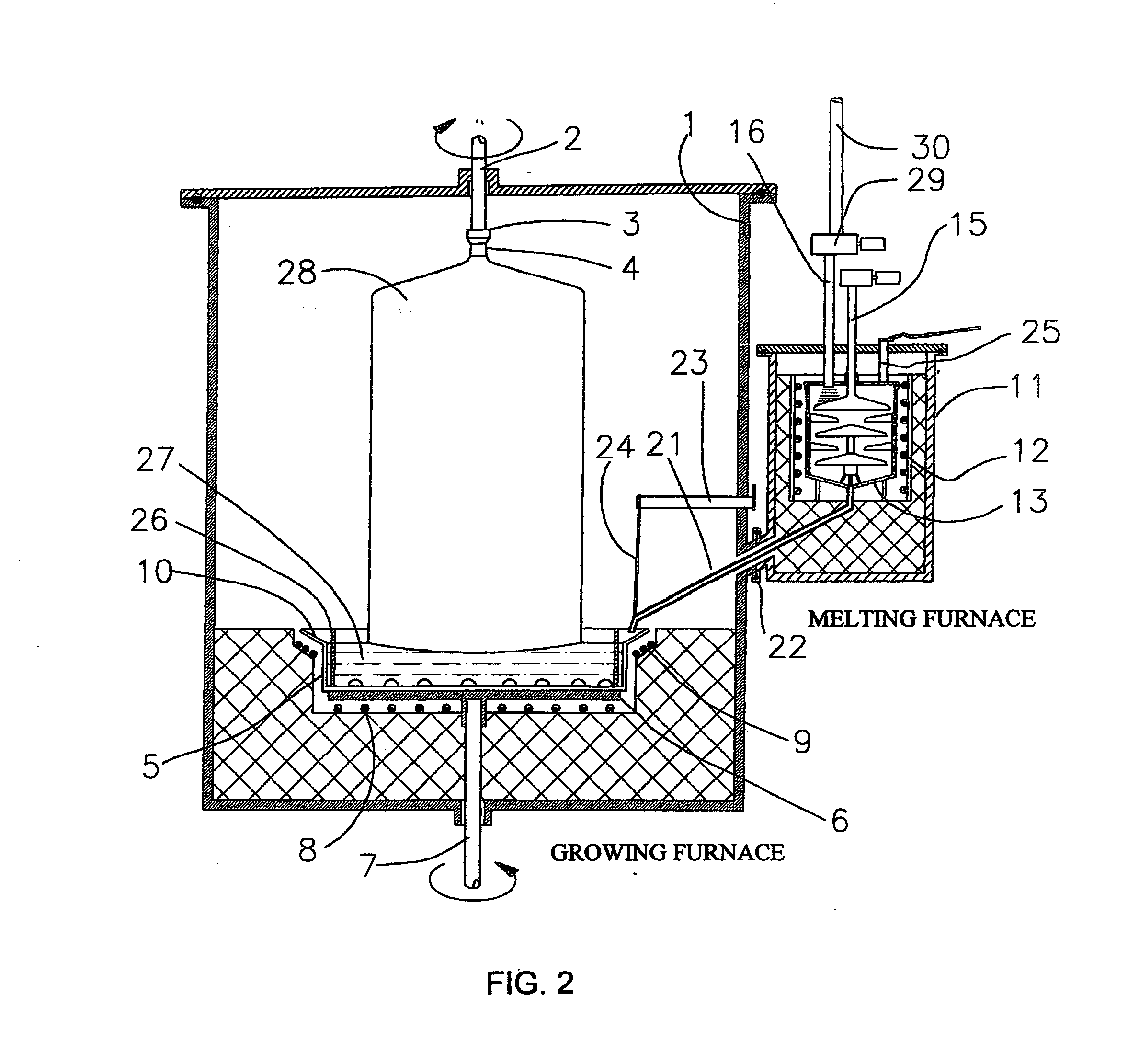

A melting furnace is mounted adjacent a growth furnace in which a single crystal ingot is pulled from the melt according to the Czochralski method. The melting furnace comprises a receiving container for melting therein raw material in a particle or powder form falling in it from a feeder. The receiving container accommodates a set of slope-wise plates providing a distributed sliding of partially melted raw material particles over the surface of these plates and their complete melting while moving downward; eventually the melted raw material flows into the crucible of the growth furnace through a heated conveying tube extending slantingly from the conical bottom of the receiving container to the crucible through coaxial openings in housings of both furnaces. The rate of feeding is defined solely by a feeder, and at continuous feeding the raw material flows continuously by gravity from the feeder to the crucible of the growth furnace, first in a solid state (powder, granules, pellets, etc.) and then in a liquid state.

Owner:LGS INNOVATIONS

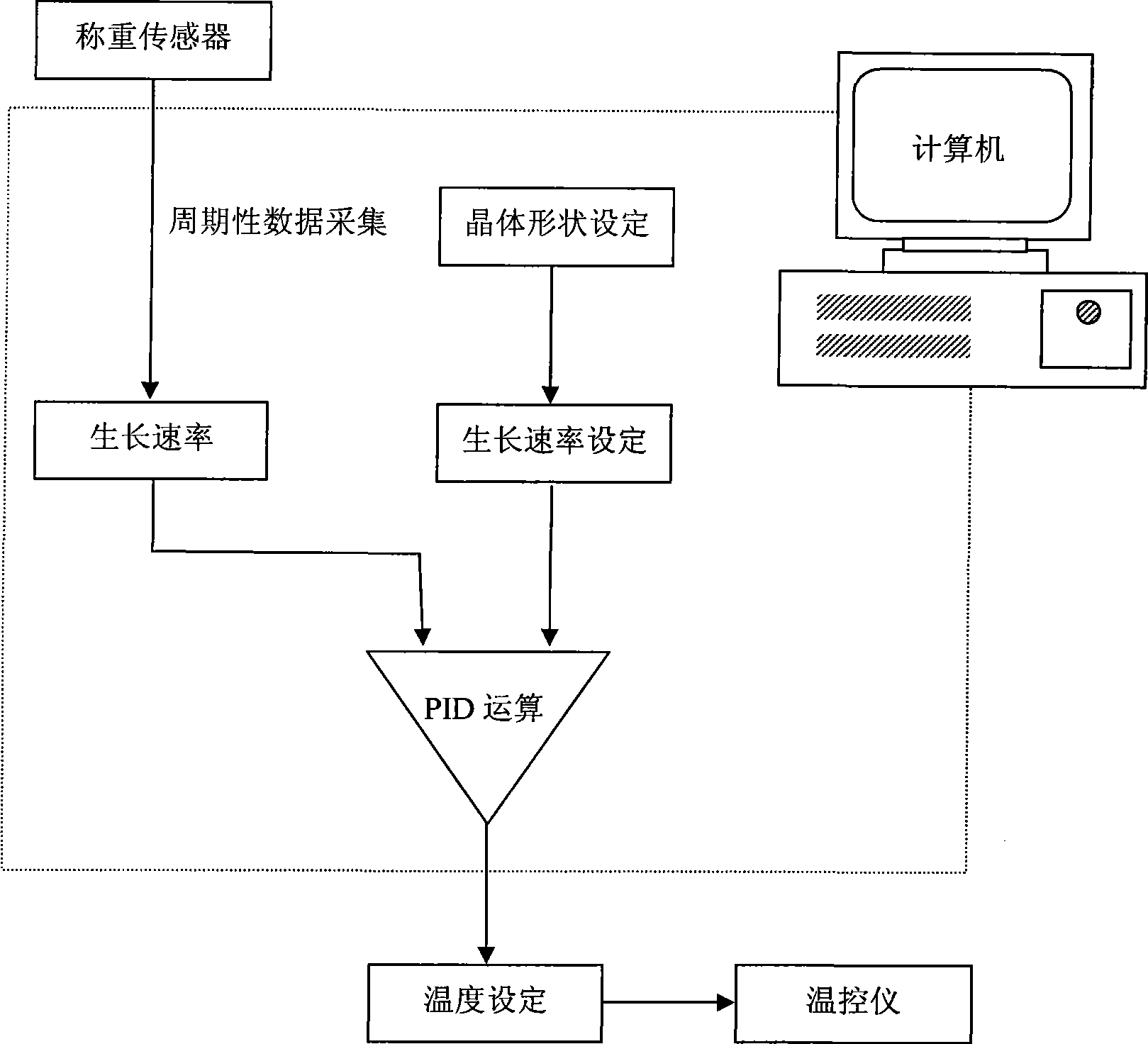

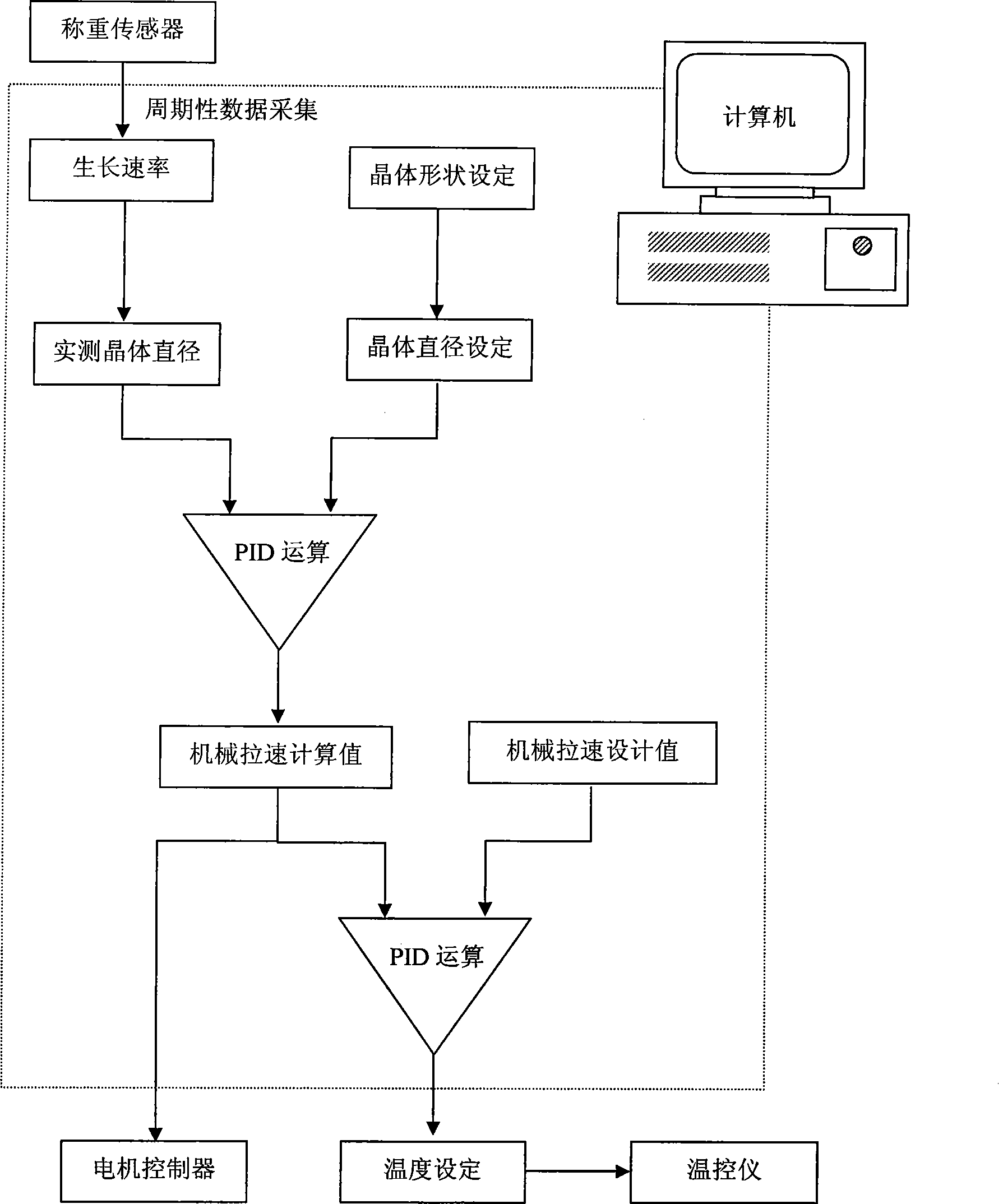

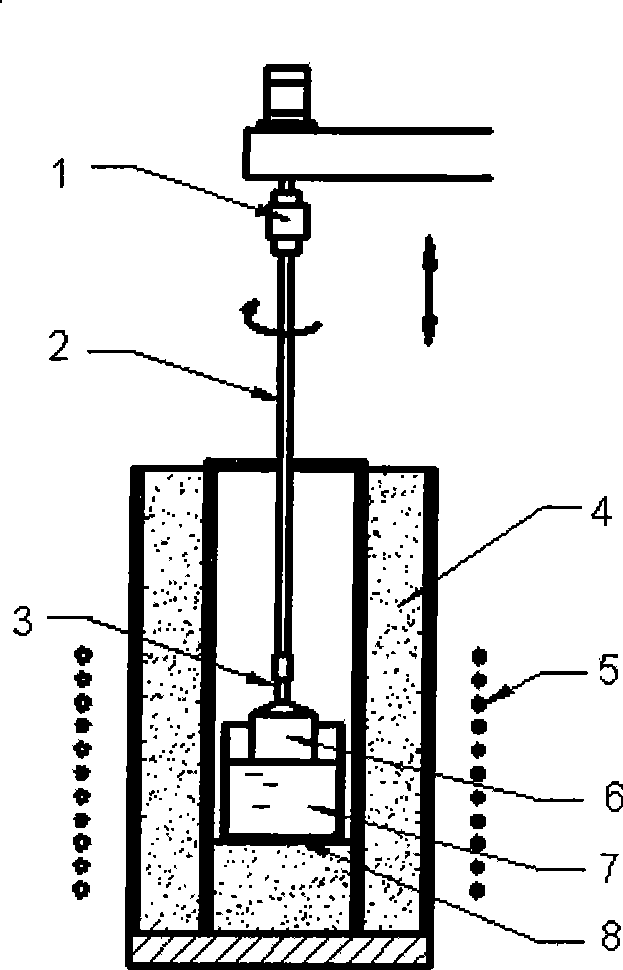

Control method of crystal growth by crystal pulling method

InactiveCN101392404AQuick responseGood isometric controlBy pulling from meltCzochralski methodEngineering

The invention relates to a control method for crystal growth by Czochralski method. A weight signal of a growing crystal is obtained by the sampling of a computer and is converted, according to a signal processing method, to a crystal diameter feedback signal independent of the growth rate; the crystal diameter feedback signal is compared with the preset crystal diameter value to acquire a signal error, and then the calculated value of a mechanical pulling speed for the control of a seed crystal is gained by the PID calculation of the signal error; the calculated value of the mechanical pulling speed is compared with the preset mechanical pulling speed value to get a new signal error, and the temperature (or power) is controlled through the PID calculation of the new signal error. The pulling speed is controlled by a primary control circuit while the temperature is controlled by a secondary control circuit; the constant diameter control of the growing crystal is realized by the synergism of the pulling speed circuit and the temperature circuit. The control method has the advantages of rapid response speed, good constant diameter control effect, smoother crystal surface, higher crystal growth rate and production efficiency, and the using of the control method is not affected by the material of the crystal and can be applied to most growing processes of Czochralski method.

Owner:惠梦君

Method of manufacturing silicon single crystal

InactiveUS20110214603A1Suppress pinhole formationPolycrystalline material growthBy pulling from meltCzochralski methodSingle crystal

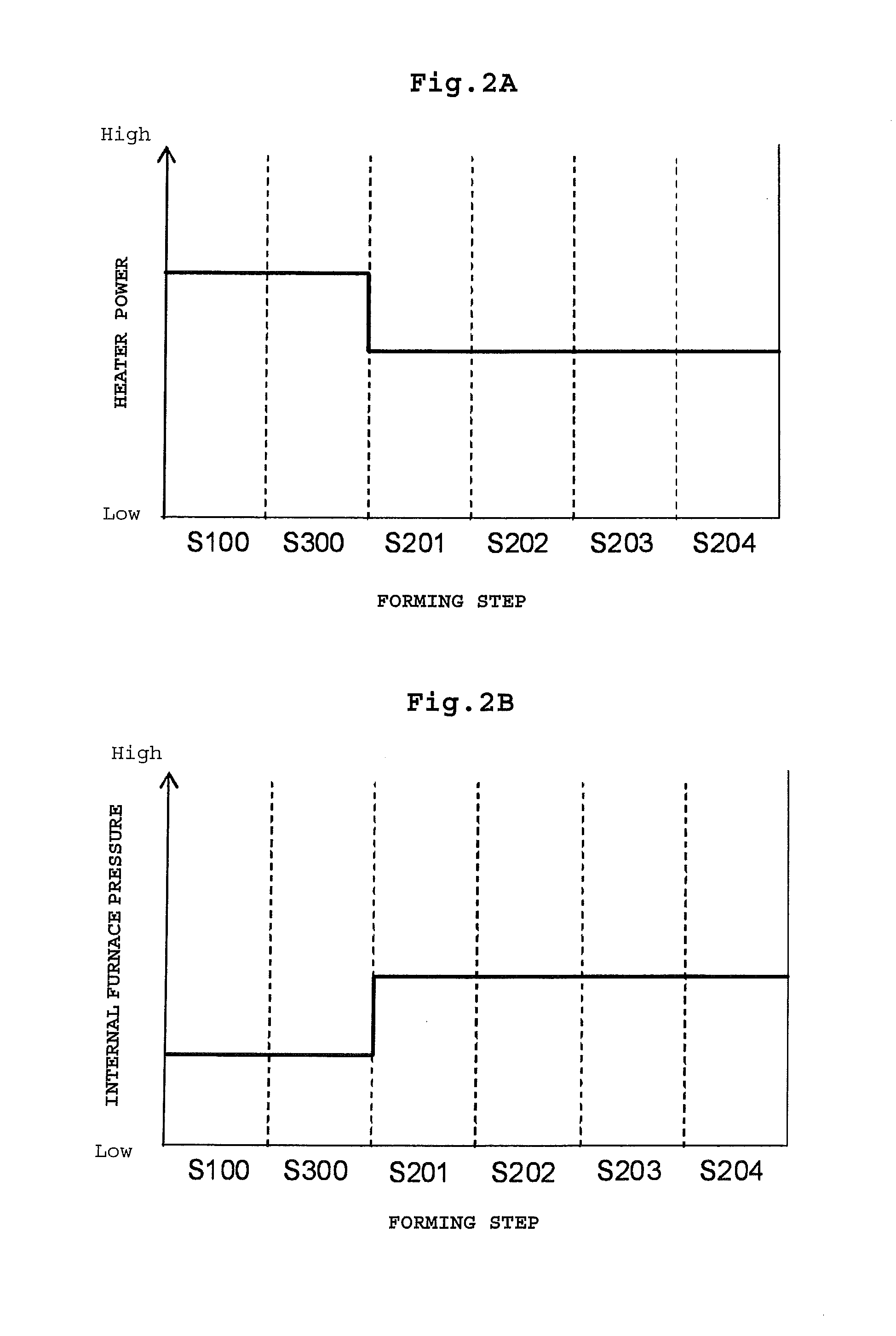

The present invention provides a method of manufacturing a silicon single crystal which can more greatly suppress a pinhole formation in the silicon single crystal, which is a method of manufacturing a silicon single crystal by the Czochralski method in which a silicon material to be silicon melt is melted in a furnace body and then a silicon single crystal is pulled up. After melting the silicon material and before the start of pulling up the silicon single crystal, a heater power is set to be higher than that during the step of pulling up the silicon single crystal, and an internal furnace pressure is set as 30 Torr or less, which is lower than that during the step of pulling up the silicon single crystal, the power and pressure being maintained for a predetermined time, and then the step of pulling up the silicon single crystal is carried out.

Owner:GLOBALWAFERS JAPAN

Copper-graphene composite material and method for preparation of graphene film on copper-based metal surface

The invention discloses a copper-graphene composite material and a method for preparation of a graphene film on a copper-based metal surface. The method comprises: first utilizing a strong oxidizing agent to fully oxidize graphite to prepare a graphene oxide solution; and then preparing a graphene oxide coating of certain thickness on a copper sheet surface by a Czochralski method, and finally making use of oxidation reduction to prepare the graphene film. The method of the invention combines the oxidation reduction method with the Czochralski coating method to prepare the graphene film on a copper surface, wherein the oxidation reduction method is characterized by simple principle, convenient operation, low cost, and ability to prepare a great amount of graphene, and the Czochralski coating method has the advantages of simple equipment, less investment, and is a good method for preparation of high performance films. The coated film has a high degree of uniformity, uniform particle size, and good activity. Being convenient to operate, the method provided in the invention has the ability to prepare films of complex shapes and large areas, and is easy to realize industrialization.

Owner:TIANJIN UNIV

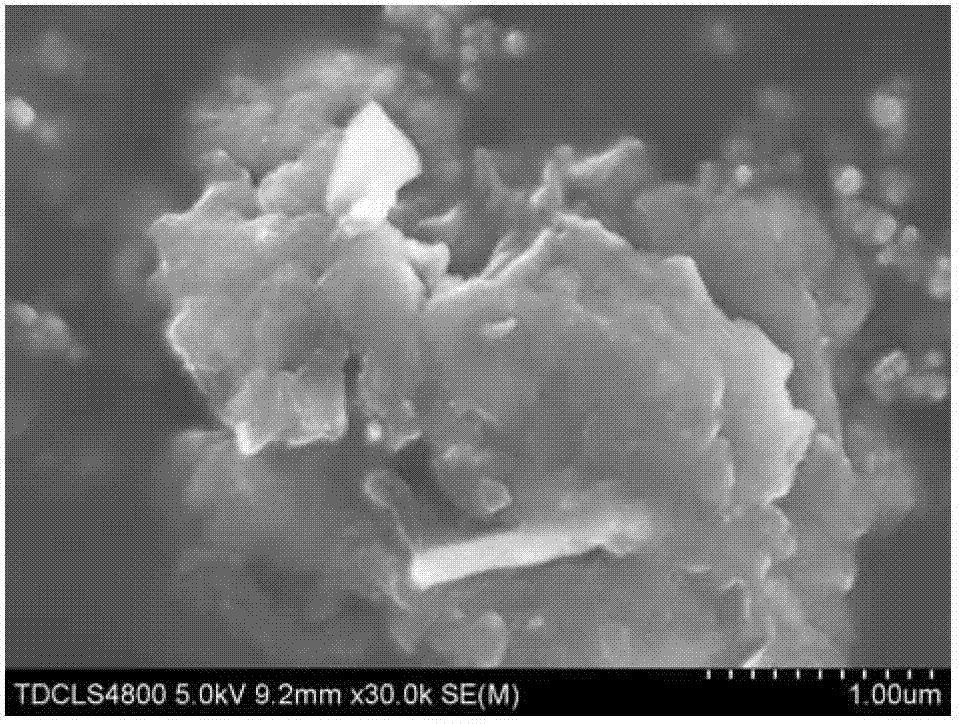

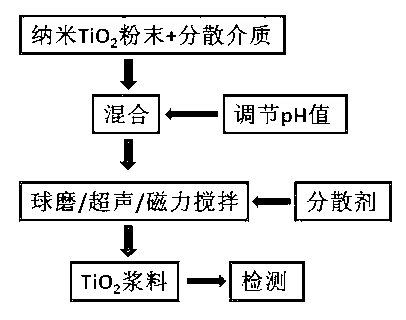

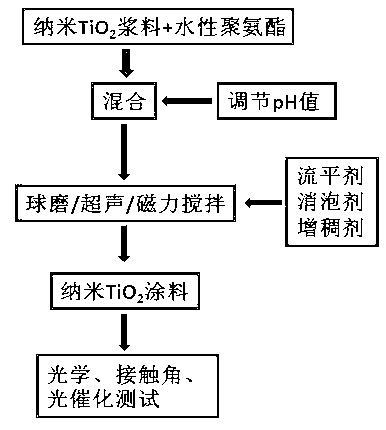

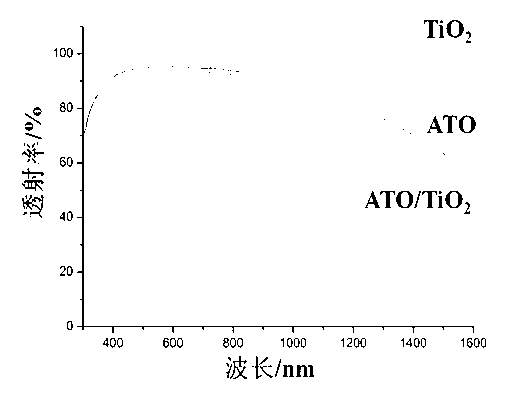

Preparation method of nano TiO2 self-cleaning transparent coating

ActiveCN103102791AHigh visible light transmittanceFunction increasePolyurea/polyurethane coatingsArchitectural glassCzochralski method

The invention discloses a preparation method of a nano TiO2 self-cleaning transparent coating. The method comprises the following steps: 1) preparation of a nano TiO2 slurry: mixing a nano TiO2 powder and a dispersant according to proportion and stirring thoroughly, and regulating a pH value to prepare the nano TiO2 slurry; 2) preparation of a nano TiO2 self-cleaning coating: mixing the nano TiO2 slurry and aqueous polyurethane, adjusting a pH value, adding a leveling agent, a defoaming agent and a thickener for dispersion, so as to prepare a nano self-cleaning coating; and 3) preparation of a nano TiO2 self-cleaning transparent coating: immersing a clean glass substrate in the prepared nano self-cleaning coating liquid, and preparing a transparent coating on the glass substrate by using a spin coating method / Czochralski method / bar coating method. The nano TiO2 transparent coating prepared by the method provided by the invention has high visible light transmittance and self-cleaning function, and is suitable for the field of building glass, such as antimicrobial coating and doors and window.

Owner:山东惠中新材料科技有限公司

Silicon ingot having uniform multiple dopants and method and apparatus for producing same

A Czochralski growth system is disclosed comprising a crucible, a silicon delivery system comprising a feeder having a delivery point overhanging the crucible and delivering a controllable amount of silicon into the crucible, and at least one doping mechanism controllably delivering at least one dopant material to the feeder. The system can comprise two or more doping mechanisms each loaded with a different dopant material and can therefore be used to prepare silicon ingots having multiple dopants. The resulting ingots have substantially constant dopant concentrations along their axes. Also disclosed is a method of Czochralski growth of at least one silicon ingot comprising at least one dopant material, which is preferably a continuous Czochralski method.

Owner:GTAT IP HLDG

Integrated melt method for crystal growth

The invention provides a synthetic melting body method of growing crystal, using pulling method to seed, shrink neck, and extend shoulder, as the growth at equal diameter, adopting soaking method and / or temperature gradient method. It can grow large-sized high-quality crystals, especially oxide crystals like sapphire substrate crystal, doped or undoped aluminum oxide crystal, aluminate crystal, etc. It has the advantages of adopting pulling, soaking and temperature gradient methods: able to grow large-sized crystals, a little pollution, and able to observe the liquid surface and the growing situation of crystal; able to use the original pulling devices; the crystal quality is good, and has low dislocation density and good integrity and optical uniformity, easy to industrialize.

Owner:长治虹源科技晶体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com