Patents

Literature

138results about How to "Achieve surface modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nano tube composite film and preparation method thereof

ActiveCN103435027AEvenly dispersedAvoid reunionMaterial nanotechnologyCarbon compoundsComposite filmCatecholamine

The invention discloses a preparation method for a carbon nano tube composite film. The method comprises the following steps: first, allowing a phenolic hydroxyl group, a quinonyl group and other functional groups to be introduced on the surface of a carbon nano tube through oxidation autopolymerization reaction of catecholamine under an alkalescence condition, so as to realize the modification for the surface of the carbon nano tube; then, using water-soluble polymers with amino groups or mercapto groups as raw materials to realize layer-by-layer self-assembly under the action of chemical bonds formed by Schiff base or Michael Addition reaction, thereby obtaining the carbon nano tube composite film. The method has the advantages of mild reaction condition, environmental protection, simplicity and feasibility, and is suitable for industrialized production. The carbon nano tube composite film prepared by the method has the advantages of excellent thermal and chemical stability, ductility, mechanical strength and transparency.

Owner:ZHEJIANG UNIV

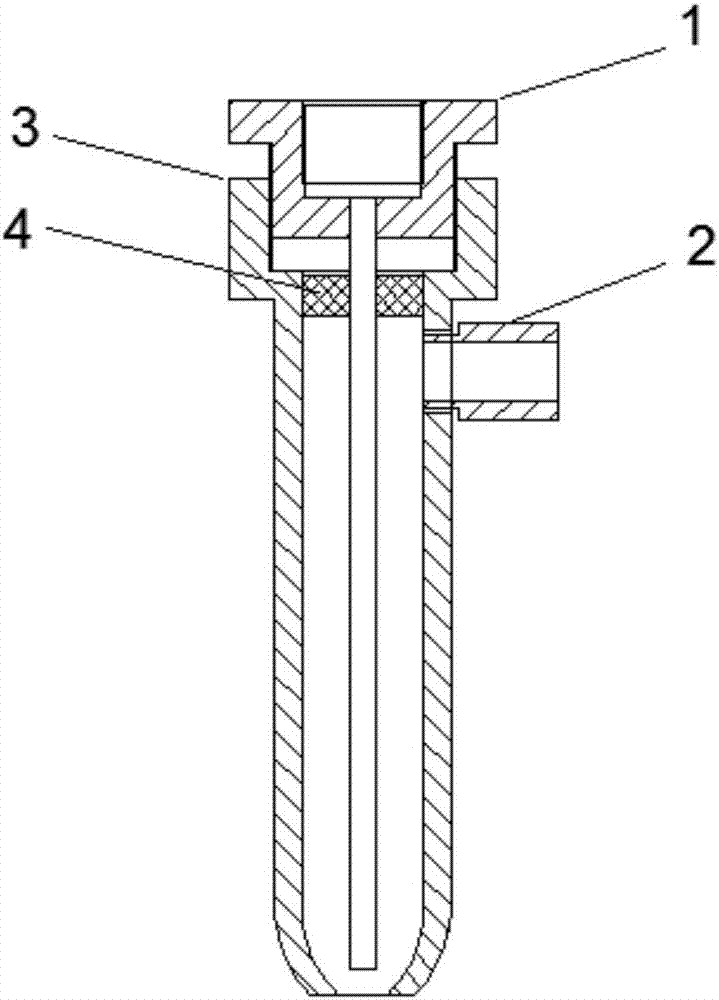

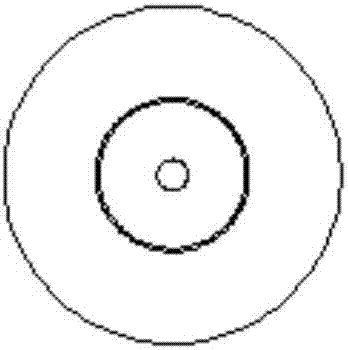

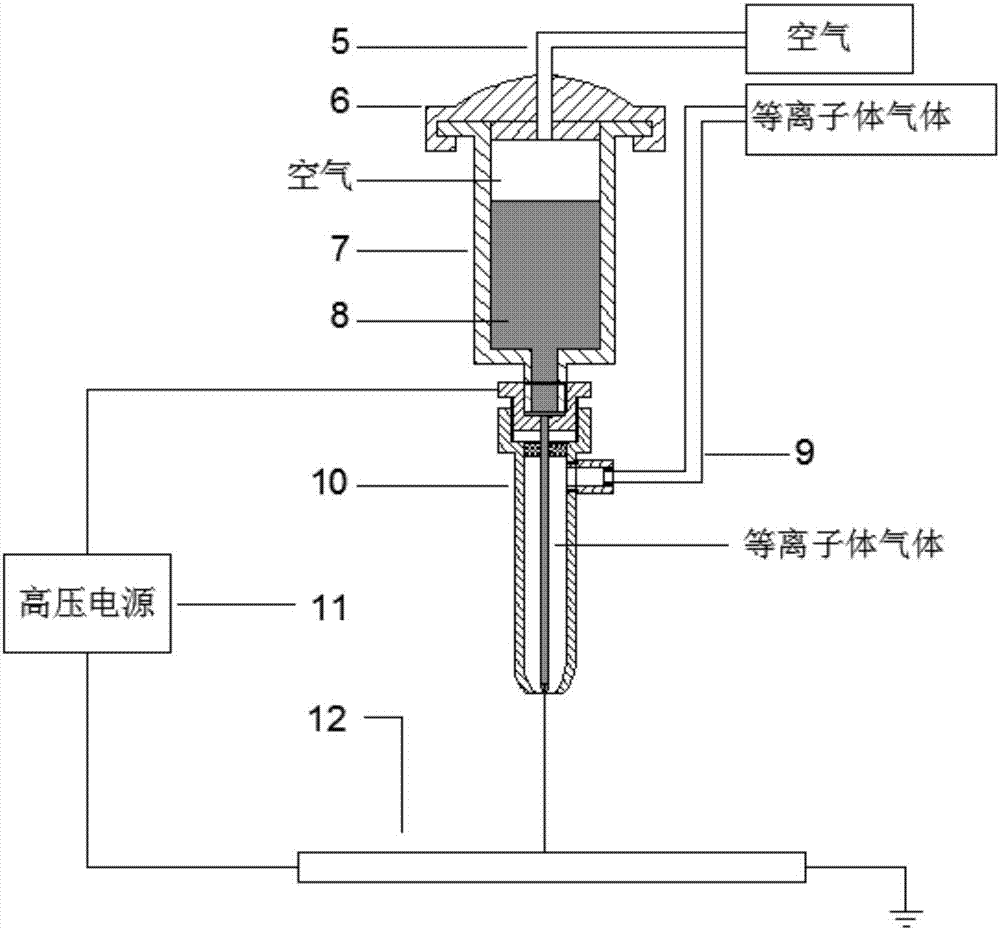

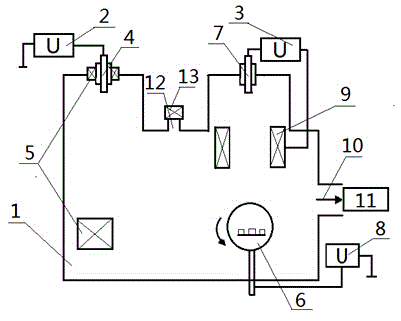

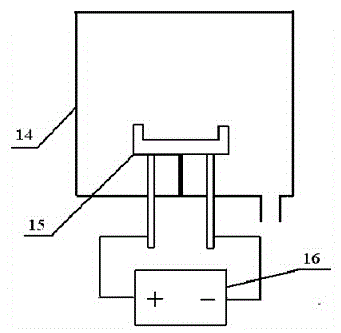

Integrated spray printing device used for additive and subtractive manufacturing

ActiveCN107199693ARealize electrojet printing processAchieve surface modificationManufacturing material handlingAdditive manufacturing processesPlasma jetProduct gas

The invention discloses a spray printing device integrating a plasma jet technology. The device comprises a spraying head, a high pressure power source, a collecting base plate and a liquid inlet barrel. According to the spray printing device, the high pressure power source is used for generating spray printing process electric field requirements and serving as a plasma jet excitation source, gas discharge is used for generating plasma jets, unified application of electric fluid spray printing machining (additive machining) and plasma etching machining (subtractive machining) is achieved on one device, and real-time surface modification of plasmas on electric spray printing materials in the machining process, sintering curing of electric spray printing deposition materials and additive and subtractive synchronization machining are included for achieving quick molding of complex patterns and multi-layer structures. By means of the spray printing device, application in a combination manner or an array manner can be achieved, and the spray printing device can be used for preparing large-area multi-layer complex structures. Through application of the spray printing device, the machining efficiency and the material performance are improved, and wide application prospects in the fields of MEMS machining and manufacturing and electric fluid jet printing are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Oleophilic modificatioon method for tiny inorganic Nano powder

ActiveCN1872918ARich surface chargeRealize surface lipophilic modificationPigment treatment with organosilicon compoundsSilicon oxideLead sulfate

This invention relates to a method for lipophilic modification of inorganic micro / nanopowder. The method comprises: (1) uniformly depositing a layer of inorganic oxide (zirconium oxide, magnesium oxide, aluminum oxide, silicon oxide, titanium oxide, zinc oxide or ferric oxide, 2-5 wt. % of the micro / nanopowder) or its hydrate onto the surface of the micro / nanopowder; (2) coating the composite micro / nanopowder with an organic compound (anionic surfactant, silane coupler, phthalate coupler or aluminum coupler, 3-7 wt. % of the composite micro / nanopowder). The micro / nanopowder is calcium carbonate, barium carbonate, magnesium carbonate, barium sulfate or lead sulfate, or their mixture. The sizes of the micro / nanopowder are in the range of 1-50000 nm. The obtained lipophilic micro / nanopowder can be used to manufacture paints, rubbers and plastics with improved properties.

Owner:SHANGHAI UNIV

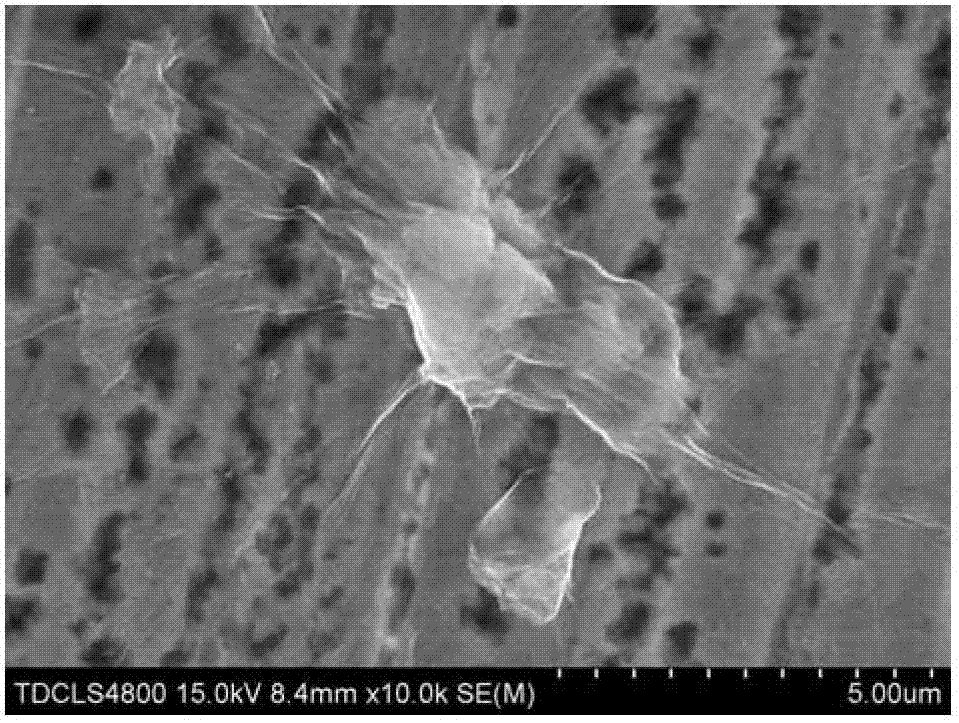

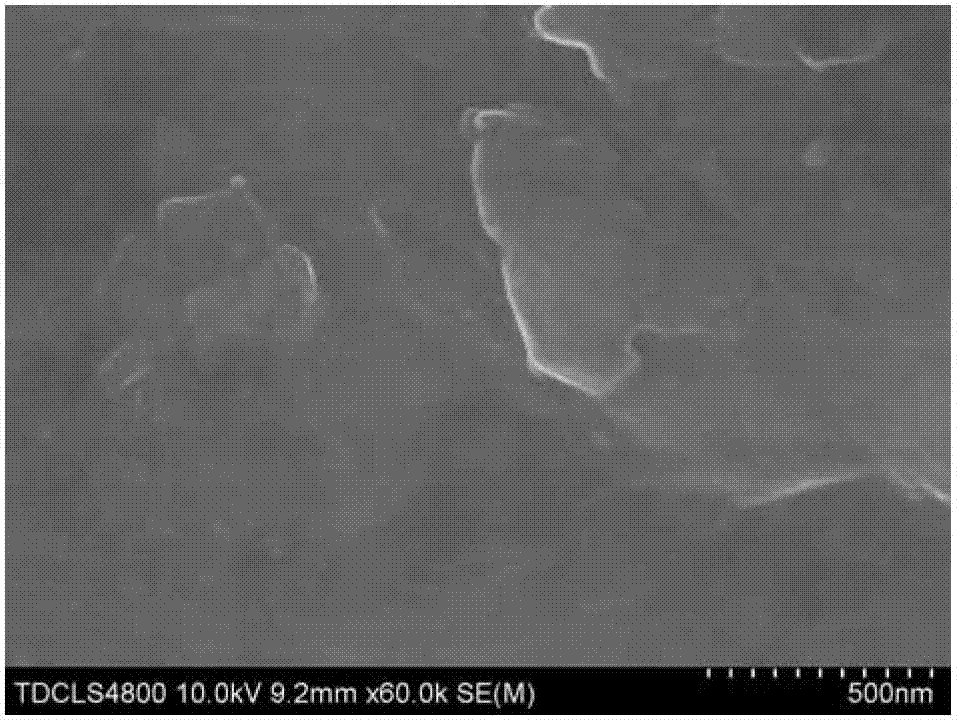

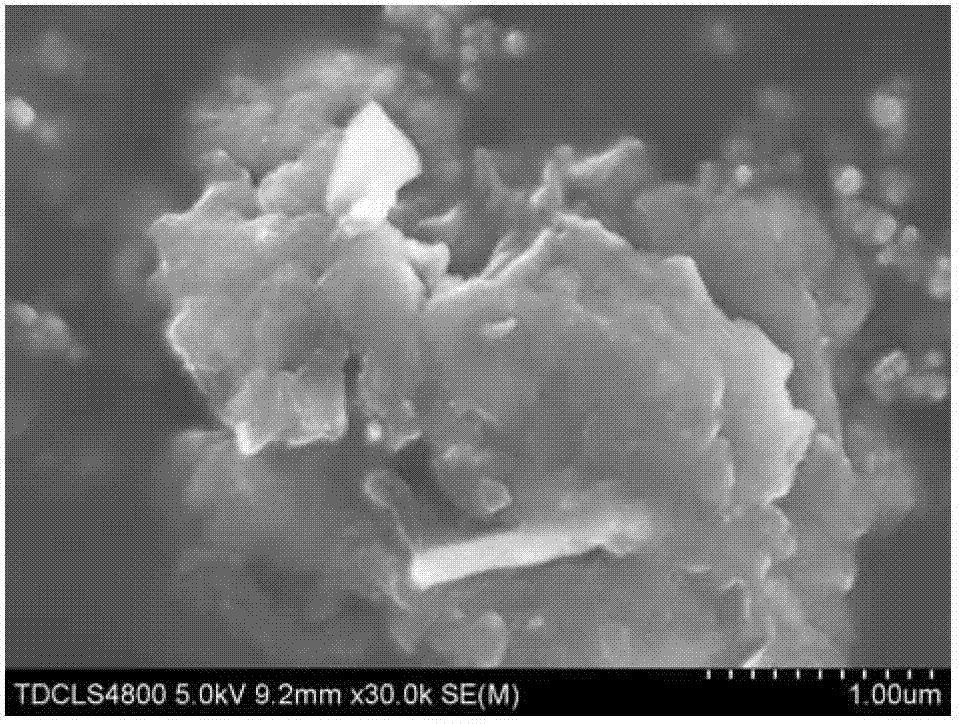

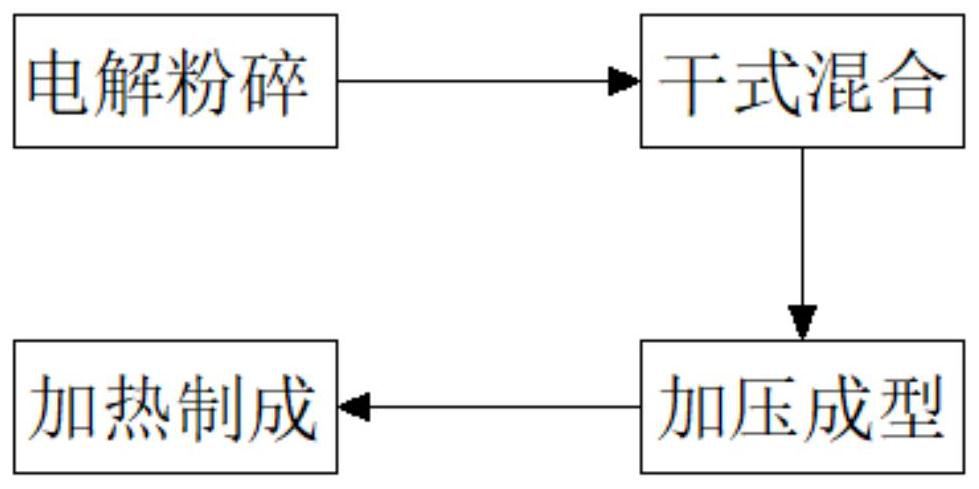

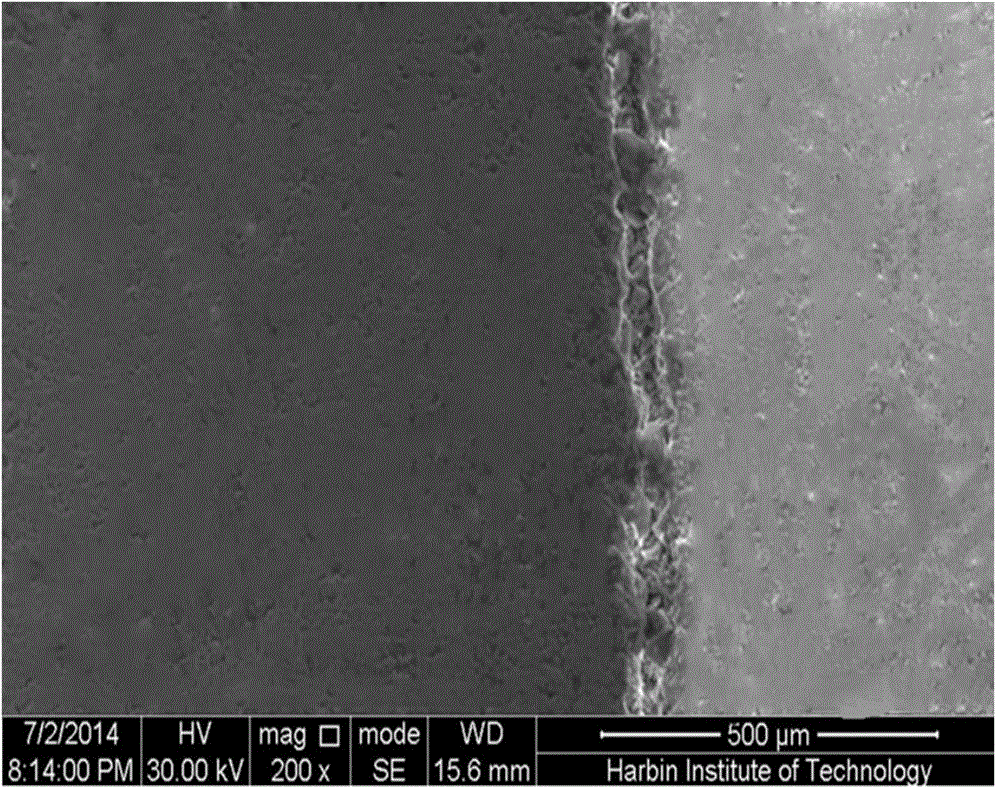

Copper-graphene composite material and method for preparation of graphene film on copper-based metal surface

The invention discloses a copper-graphene composite material and a method for preparation of a graphene film on a copper-based metal surface. The method comprises: first utilizing a strong oxidizing agent to fully oxidize graphite to prepare a graphene oxide solution; and then preparing a graphene oxide coating of certain thickness on a copper sheet surface by a Czochralski method, and finally making use of oxidation reduction to prepare the graphene film. The method of the invention combines the oxidation reduction method with the Czochralski coating method to prepare the graphene film on a copper surface, wherein the oxidation reduction method is characterized by simple principle, convenient operation, low cost, and ability to prepare a great amount of graphene, and the Czochralski coating method has the advantages of simple equipment, less investment, and is a good method for preparation of high performance films. The coated film has a high degree of uniformity, uniform particle size, and good activity. Being convenient to operate, the method provided in the invention has the ability to prepare films of complex shapes and large areas, and is easy to realize industrialization.

Owner:TIANJIN UNIV

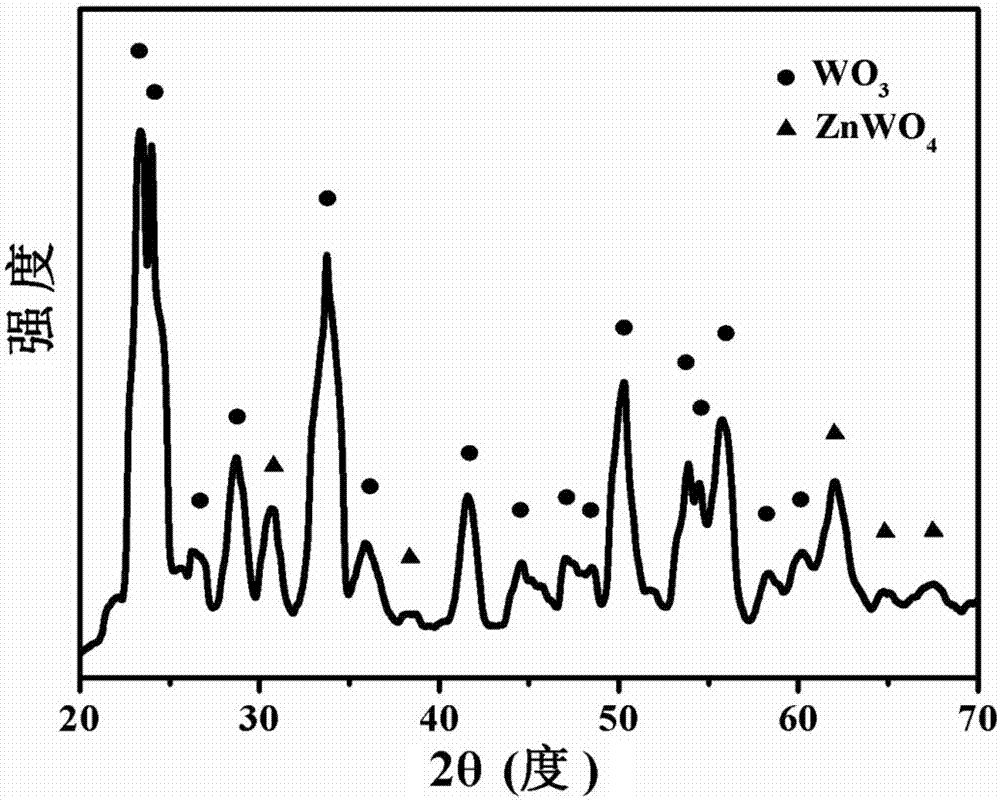

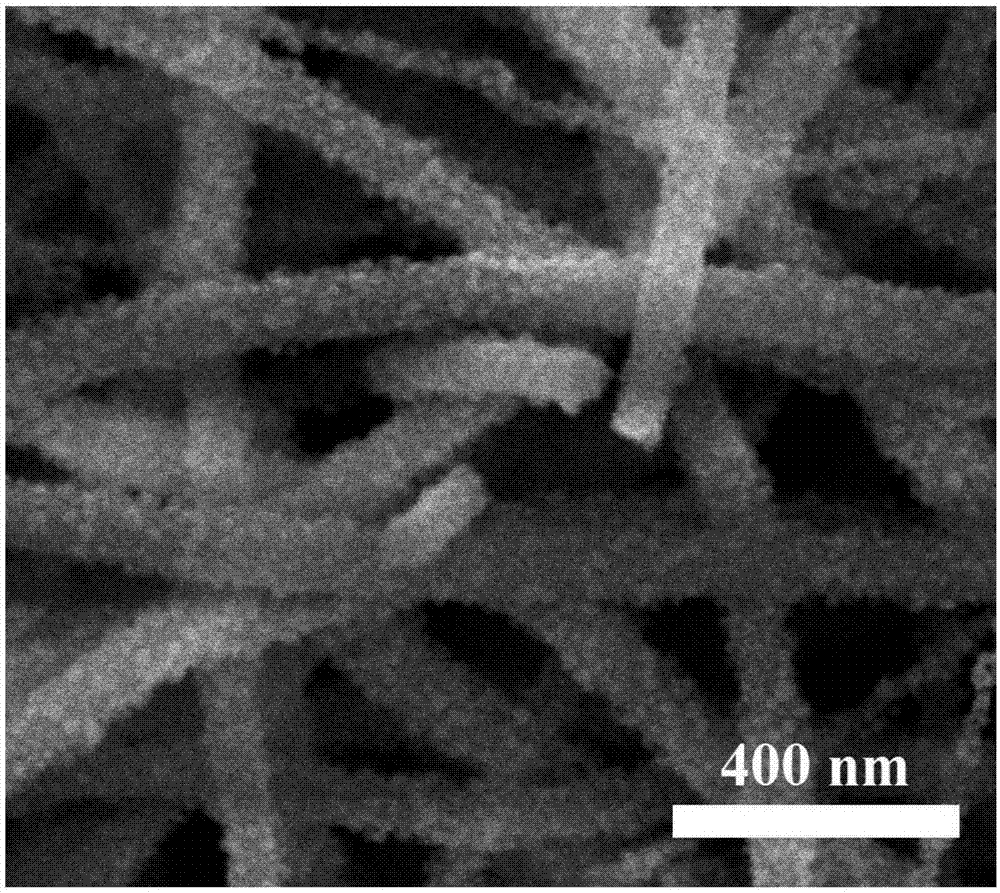

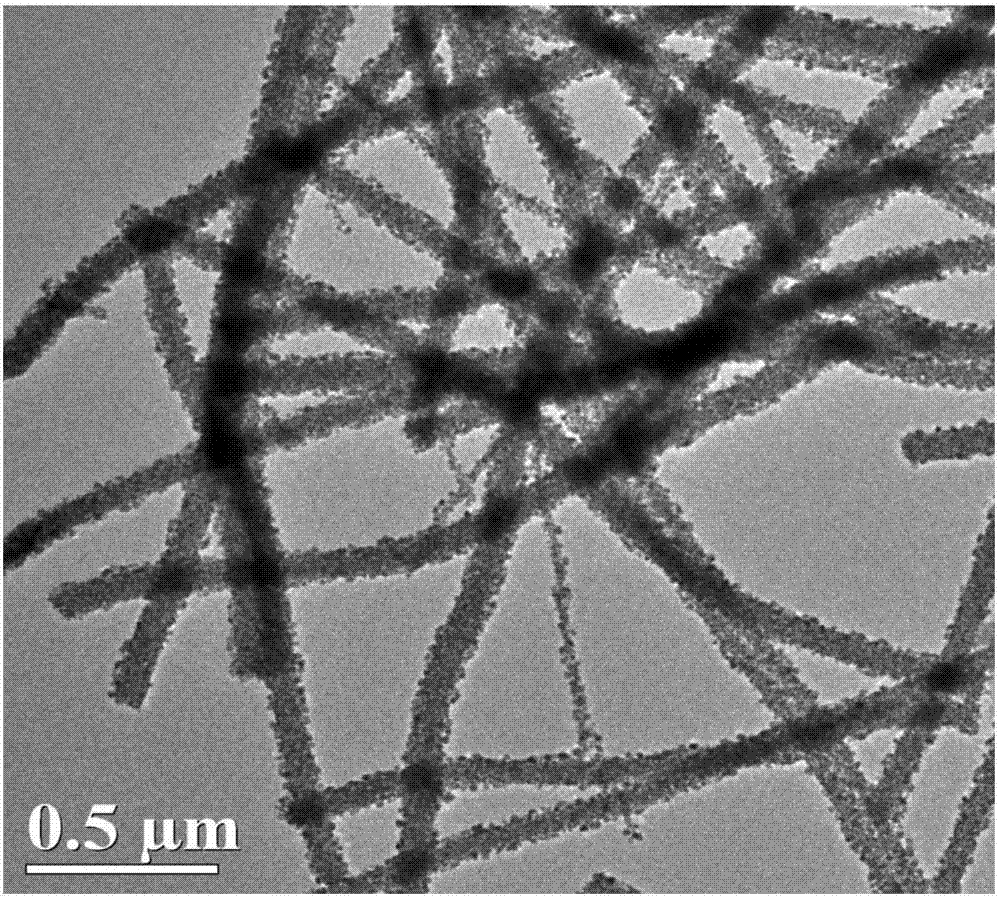

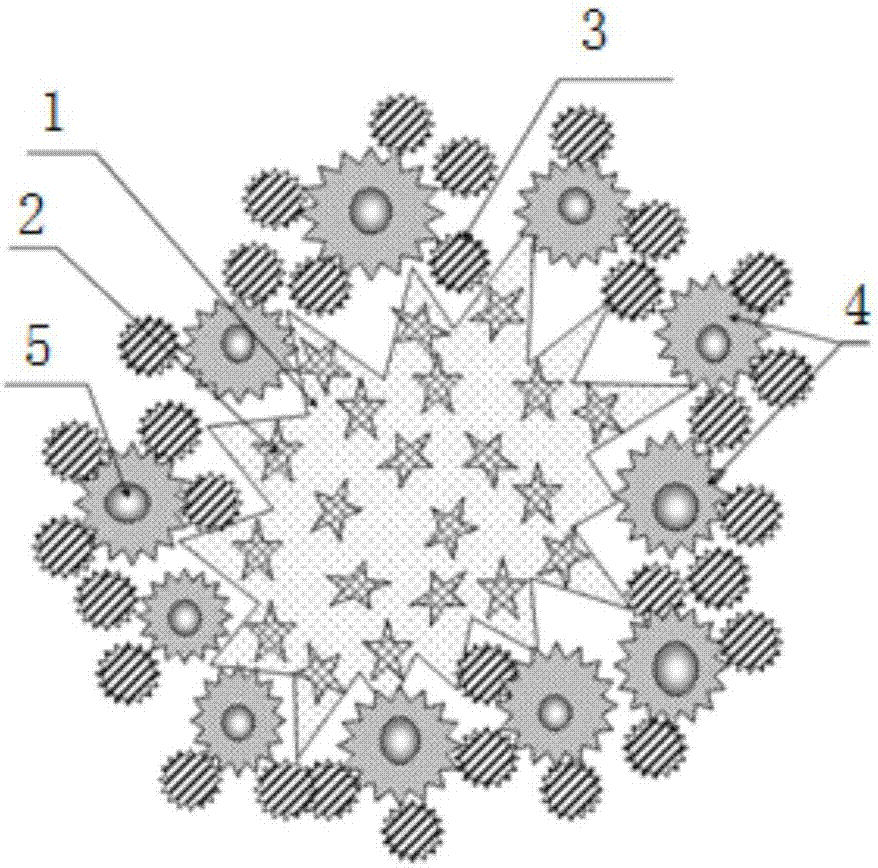

Preparation method of WO3/ZnWO4 composite micro-nano fiber and product of WO3/ZnWO4 composite micro-nano fiber

InactiveCN107299417AAchieve surface modificationImprove dispersion stabilityMaterial nanotechnologyInorganic material artificial filamentsMicro nanoFiber

The invention discloses a preparation method of WO3 / ZnWO4 composite micro-nano fiber. The preparation method comprises the following steps: firstly, preparing Zif-8 from zinc salt and dimethyl imidazole which serve as a raw material; then adding polyethylene glycol 200 and formamide to prepare a Tris-HCl solution of the Zif-8; dissolving tungstic acid in ammonia water, so as to obtain a solution; slowly dropwise adding the two solutions into a polyvinylpyrrolidone (PVP) solution, so as to obtain a precursor spinning solution, and performing electrostatic spinning and thermal treatment, so as to obtain a final product. According to the WO3 / ZnWO4 composite micro-nano fiber produced through the preparation method, a fiber main body is formed by compounding WO3 and ZnWO4 nano particles, and WO3 heterogeneous phase particles are generated on the surface. A metal organic framework material (Zif-8) is introduced into a synthesis process of the WO3 fiber, so that the preparation process is simple and convenient, high in reaction controllability and high in operability; a crystal phase structure and a microstructure of the product are adjustable, and the product has high repetitiveness. The WO3 / ZnWO4 composite micro-nano fiber obtained through the preparation method has an important market application prospect on the aspects of gas sensitivity, catalysis and the like.

Owner:UNIV OF JINAN

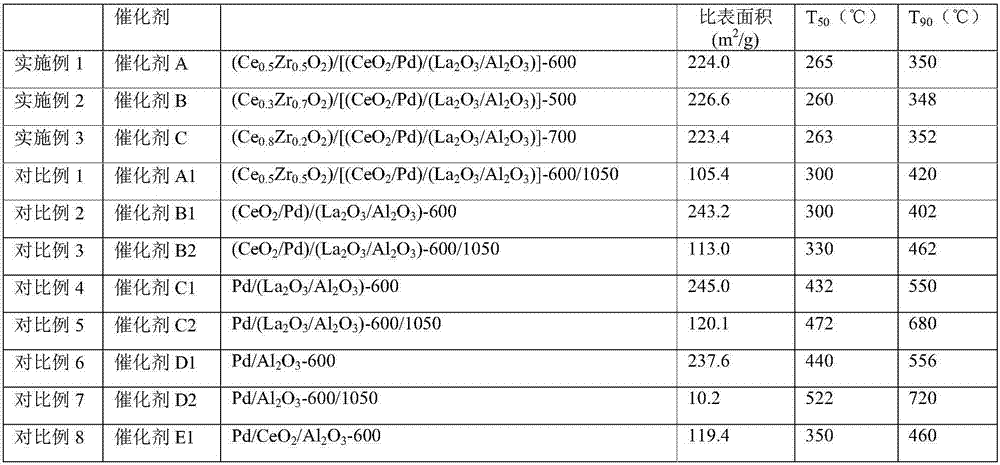

Catalyst for catalyzing methane combustion and preparation method thereof

ActiveCN107262093AGuaranteed high temperature stabilityImprove high temperature thermal stabilityHeterogenous catalyst chemical elementsDispersed particle separationActive componentOxygen vacancy

The invention provides a catalyst for catalyzing methane combustion and a preparation method thereof. The catalyst comprises a carrier, and an active component which is loaded on the carrier, wherein the active component is wrapped with a wrapping layer for providing oxygen vacancy. The catalyst further comprises a catalyst promotor which is a ceria-zirconia solid solution. According to the catalyst, the wrapping layer wraps the active component, so that oxygen molecule stored in the wrapping layer can be timely conveyed to the active component, so that the high-temperature stability of the active component of the catalyst is maintained; in addition, the catalyst further comprises the catalyst promotor which is the ceria-zirconia solid solution capable of generating more oxygen vacancies and timely effectively storing and discharging oxygen, so that the high-temperature stability of the active component of the catalyst is improved; in addition, the wrapping layer, the ceria-zirconia solid solution and the carrier are mutually dispersed and in contact, so that the mutual insulation effect is achieved, and the sintering of the carrier is inhibited, and as a result, the high-temperature thermal stability and the catalyzing activity of the catalyst can be improved.

Owner:FUZHOU UNIV +1

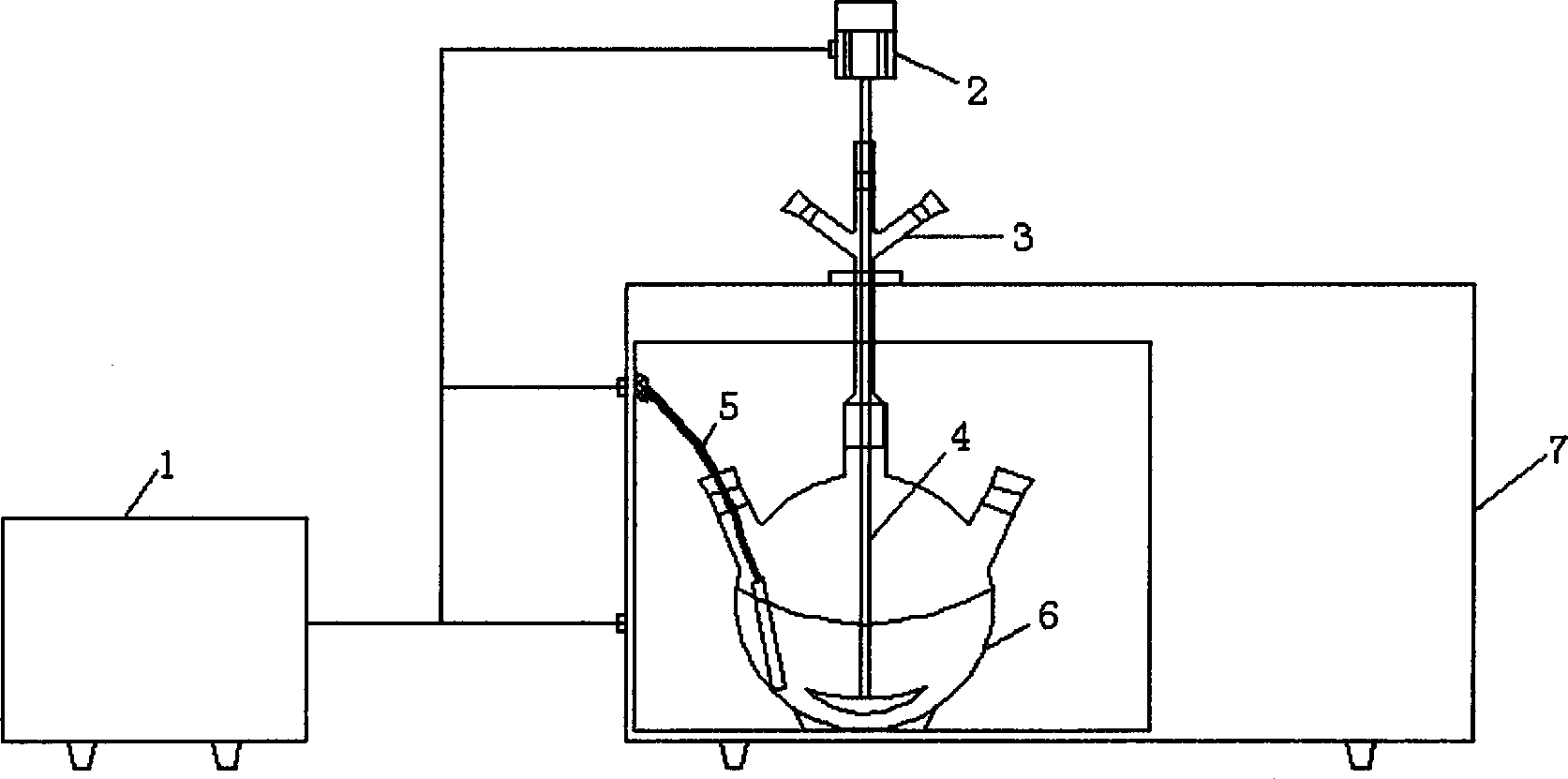

Wollastonite powder surface wet modification method assisted by microwave

InactiveCN101531835AGood modification effectImprove efficiencyChemical industryMicrowave heatingFiltrationHydrolysate

The invention relates to a wollastonite powder surface wet modification method assisted by microwave, which belongs to the technical field of powder surface modification. KH550 is used as coupling agent. The method comprises the processes of hydrolysate solution preparing, microwave-assisted coupled reaction, extraction and drying. The process of the microwave-assisted coupled reaction is as follows: wollastonite powder and ethanol are prepared into slurry to be put a constant-temperature microwave oven and stirred and heated to 50-80 DEG C; the hydrolysate solution is dripped into the slurry slowly and is stirred to react for 15 to 60 minutes; and a sample is dried in the constant-temperature microwave oven under the temperature of 90-130 DEG C after suction filtration. Compared with the prior wollastonite powder surface wet modification method, the invention uses the characteristic of heating by the microwave completely and realizes the goals of being assisted by microwave radiation and intensifying modification; the invention does not change the wollastonite crystal structure and the molecular structure of the coupling agent; and the invention can control the temperature exactly and ensures that the thermal efficiency and the heating speed during the modifying process are improved greatly.

Owner:JILIN UNIV

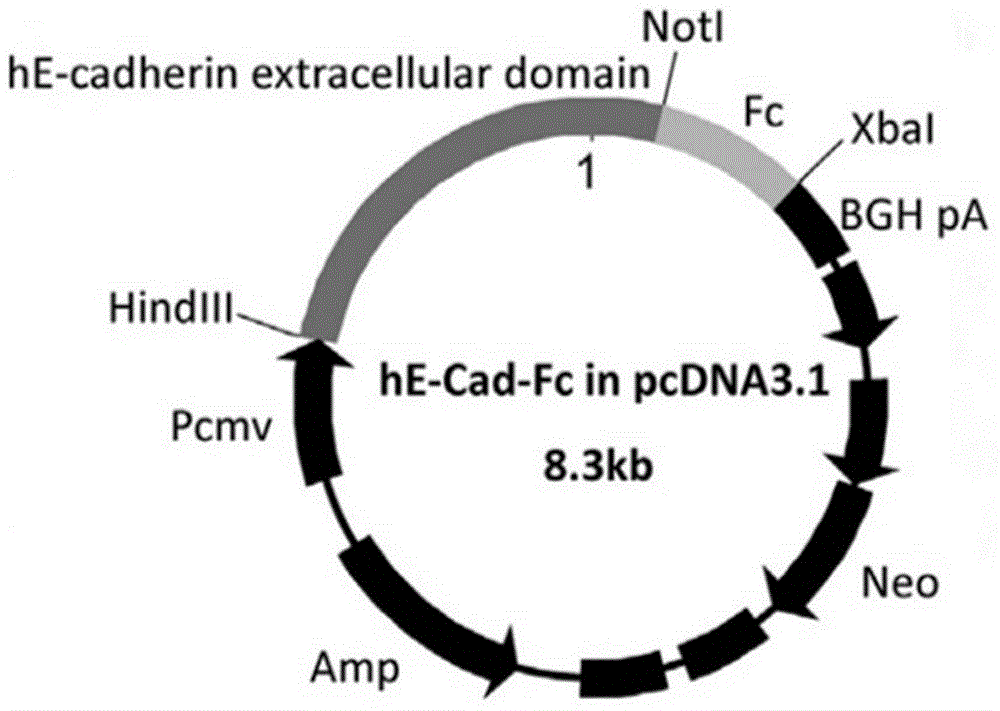

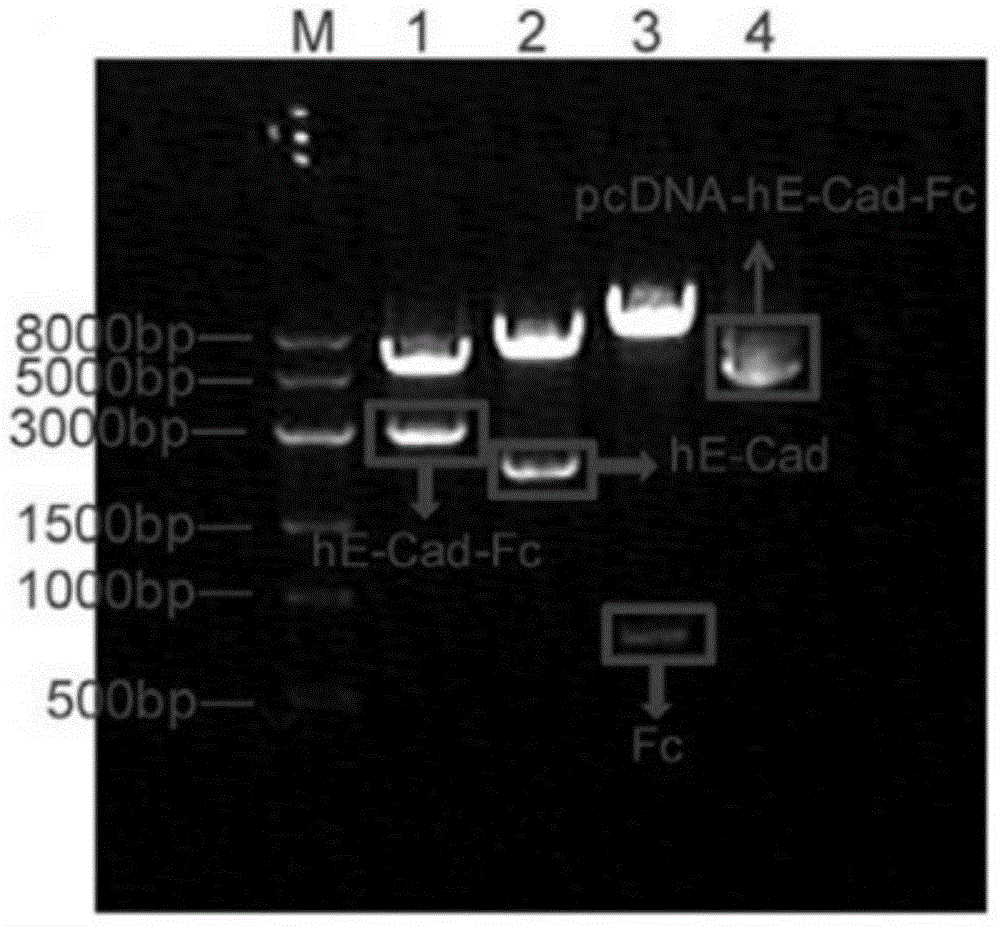

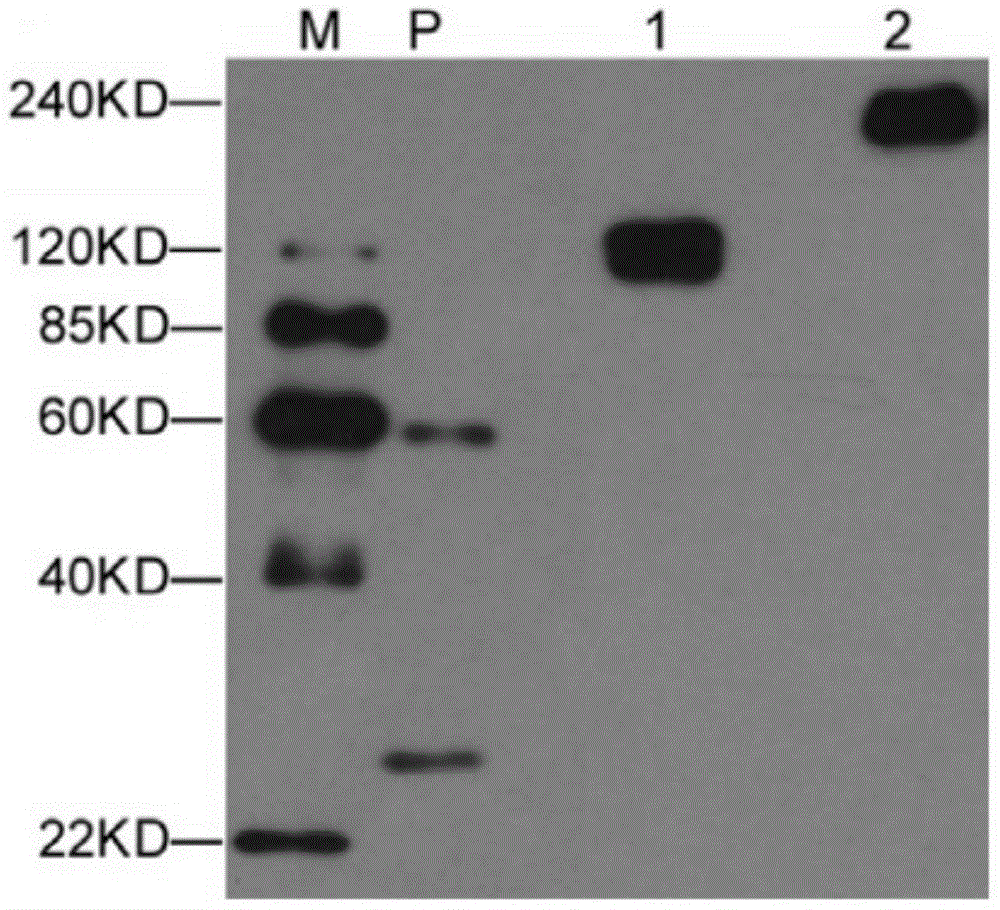

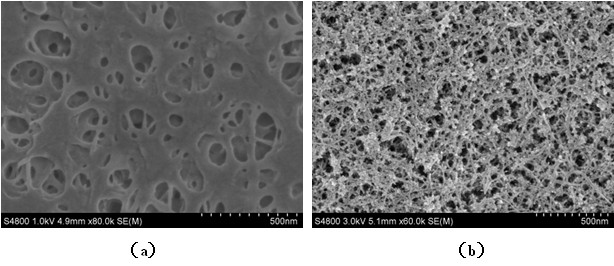

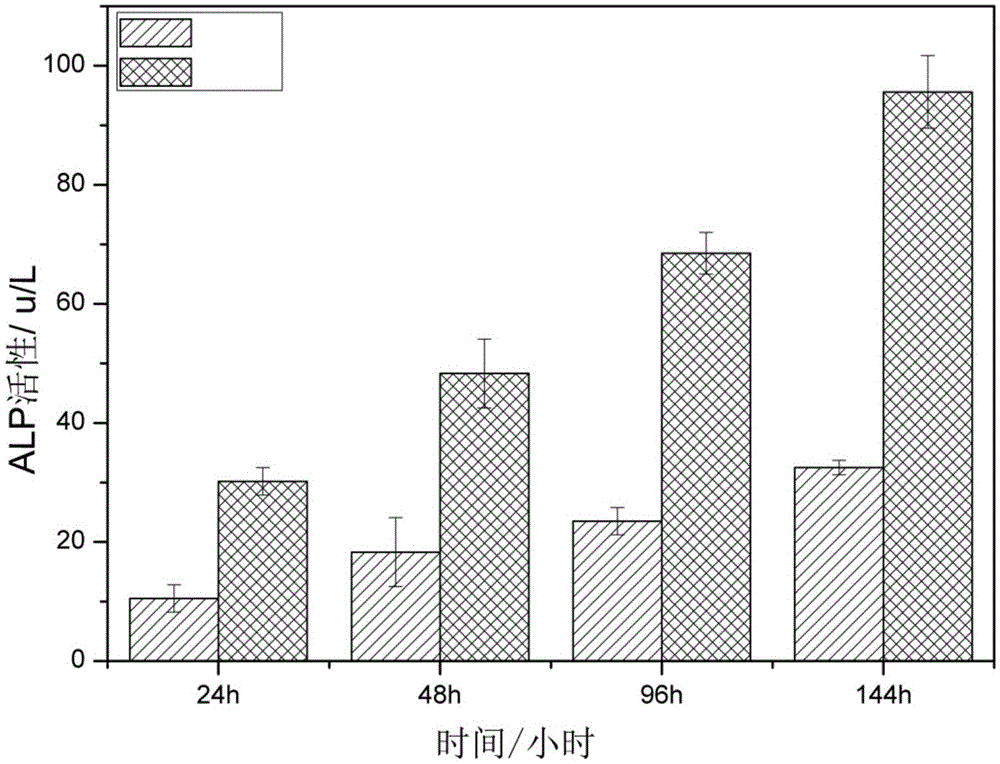

Three-dimensional complex cell aggregate model as well as preparation method and application thereof

ActiveCN104651300AOvercoming heterogeneous growthOvercome inhibitionSkeletal/connective tissue cellsEmbryonic cellsChemical synthesisCell-Extracellular Matrix

The invention provides a three-dimensional complex cell aggregate model as well as a preparation method and application thereof. According to the model, a natural or chemically synthesized polymer is used as a matrix material to prepare submicron-scale microspheres, and cell factors are embedded in or fixed on the surface of the submicron-scale microspheres and are co-cultured with cells to form a complex cell aggregate containing the microspheres, so that the biological activity of the cells in the aggregate can be regulated and controlled from inside to outside. The model can be used for researches of propagation and differentiation of stem cells in a three-dimensional state, overcomes the problems that the cell aggregate is heterogeneous in composition / structure, the cell proliferation efficiency is low and the directional induced differentiation efficiency is low due to non-uniform mass transfer and short acting time of liquid factors in a culture medium during the traditional three-dimensional culture of the stem cells, can be used for stimulating interaction between cells and cells, cells and an extracellular matrix as well as cells and soluble factors, thereby providing a theoretical and technical support for in vitro construction and optimization of a stem cell culture technology, and tissue engineering construction of various tissue and organ analogs or equivalents.

Owner:NANKAI UNIV

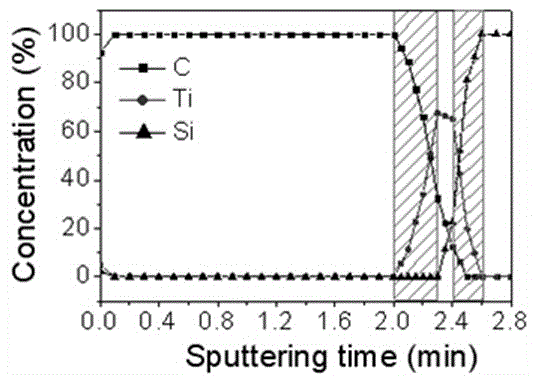

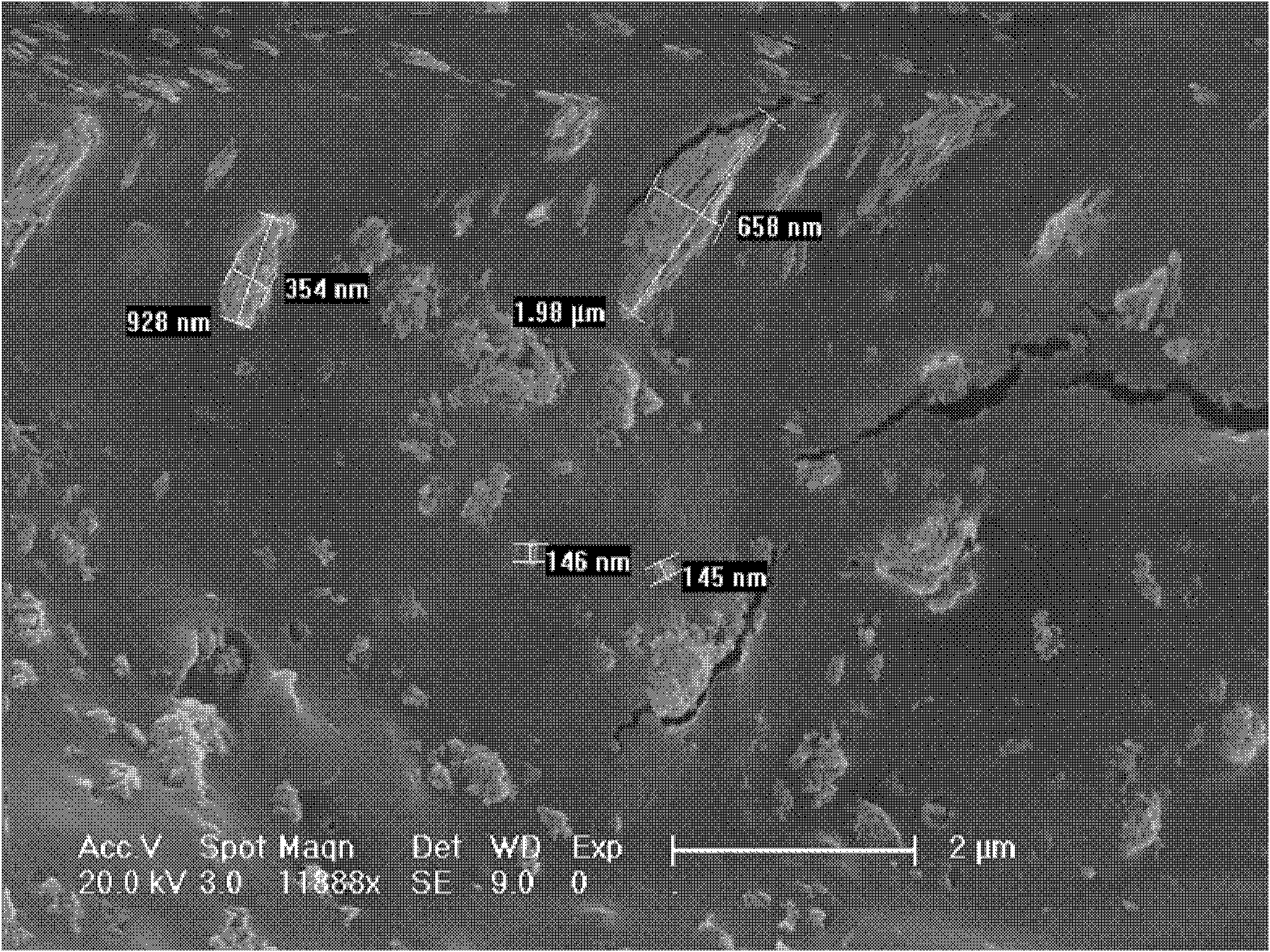

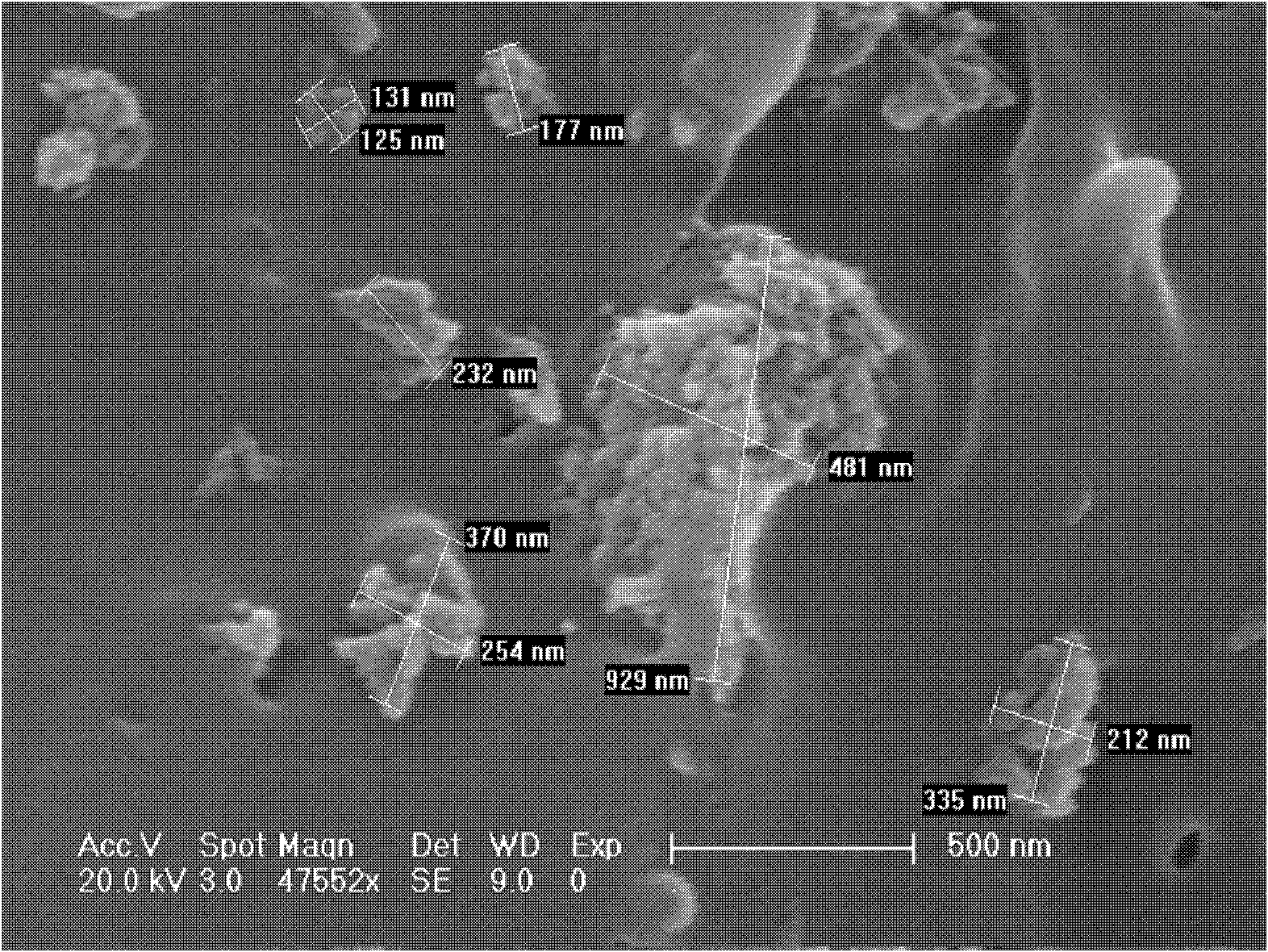

Method for preparing titanium/diamond-like nanometer multilayer film on silicon surface

InactiveCN105132878AHigh bonding strengthReduce interface stressVacuum evaporation coatingSputtering coatingComposite filmVacuum chamber

The invention discloses a method for preparing a titanium / diamond-like nanometer multilayer film on a silicon surface. The method concretely comprises the following steps of: drying a monocrystalline silicon substrate subjected to chemical cleaning in advance; putting the dried monocrystalline silicon substrate onto a rotating sample table of a cathode arcing device; performing vacuum pumping; introducing argon gas into a vacuum chamber; performing sputtering cleaning on the surface of the silicon substrate through an ion source; using high-purity metal titanium and graphite as targets, and using a direct current and pulse double-excitation-source cathode plasma discharge technology for respectively preparing a titanium nanometer function layer and a diamond-like film; and performing later-stage vacuum annealing treatment according to needs. The method has the advantages that the preparing process is simple; and the method can be used for preparing the diamond-like nanometer multilayer composite film with different surface structures. The titanium / diamond-like nanometer multilayer film prepared by the method provided by the invention has the advantages of high hardness, low stress and friction-reduction and abrasion-resistant performance.

Owner:TAIYUAN UNIV OF TECH

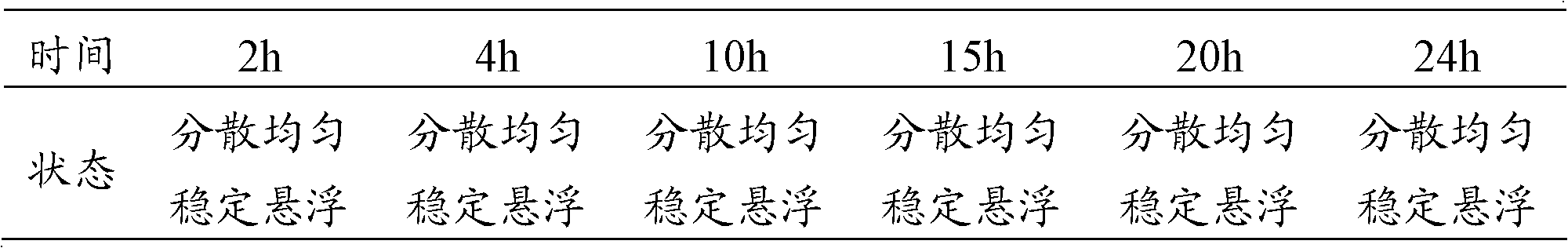

Method for modifying nano hydroxyapatite, nano hydroxyapatite/polylactic acid compound material and preparation method of nano hydroxyapatite/polylactic acid compound material

ActiveCN102153058AAchieve surface modificationGood dispersionNanotechnologyPhosphorus compoundsNano hydroxyapatiteChloroform

The invention provides a method for modifying nano hydroxyapatite. The method comprises the following steps of: a) providing an acetone solution with low polylactic acid, wherein the number-average molar mass of the low polylactic acid is 600 to 5,000; b) fully mixing the acetone solution with the low polylactic acid and nano hydroxyapatite sol so as to obtain a mixed solution, wherein the mass of water in the mixed solution is lower than 50 percent of the mass of acetone; and c) adding water into the mixed solution with stirring, and filtering and drying to obtain the nano hydroxyapatite with low polylactic acid surface modification. The invention also provides a nano hydroxyapatite / polylactic acid compound material and a preparation method thereof. By the method, the particle size of the modified nano hydroxyapatite with low polylactic acid surface modification is smaller and less than 2 microns; the dispersing performance of the modified nano hydroxyapatite is high; and the modified nano hydroxyapatite can still suspend in chloroform stably after being dispersed in the chloroform for 24 hours.

Owner:CHANGCHUN SINOBIOMATERIALS

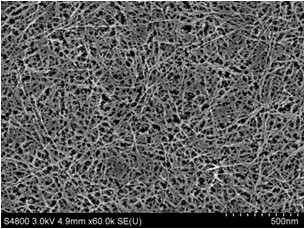

Method for preparing organic/inorganic composite nanowire filtering membrane

ActiveCN102585282ASmall apertureHigh hole densitySemi-permeable membranesPorous membraneAqueous solution

The invention discloses a method for preparing an organic / inorganic composite nanowire filtering membrane. The method comprises the following steps of: dissolving metal salt in an aqueous solution of ethanolamine to prepare a metal hydroxide nanowire; adding a heparin solution into a metal hydroxide nanowire solution to prepare a core-shell structured composite nanowire solution; fixing a polymerporous membrane in a filtering container, keeping a membrane surface upward, adding the core-shell structured composite nanowire solution into the filtering container, and filtering under reduced pressure; and drying. Negatively charged heparin is fixed on the surface of the positively charged metal hydroxide nanowire through electrostatic action to form the core-shell structured composite nanowire taking the nanowire as a core and the heparin as a shell, and the composite nanowire is deposited on the surface of the polymer porous membrane by a dynamic membrane preparation method to form the organic / inorganic composite nanowire filtering membrane with antibacterial property and blood compatibility. The nanowire has small diameter, small pore size when loaded, and high pore density, and the preparation process is simple and low in cost.

Owner:ZHEJIANG UNIV

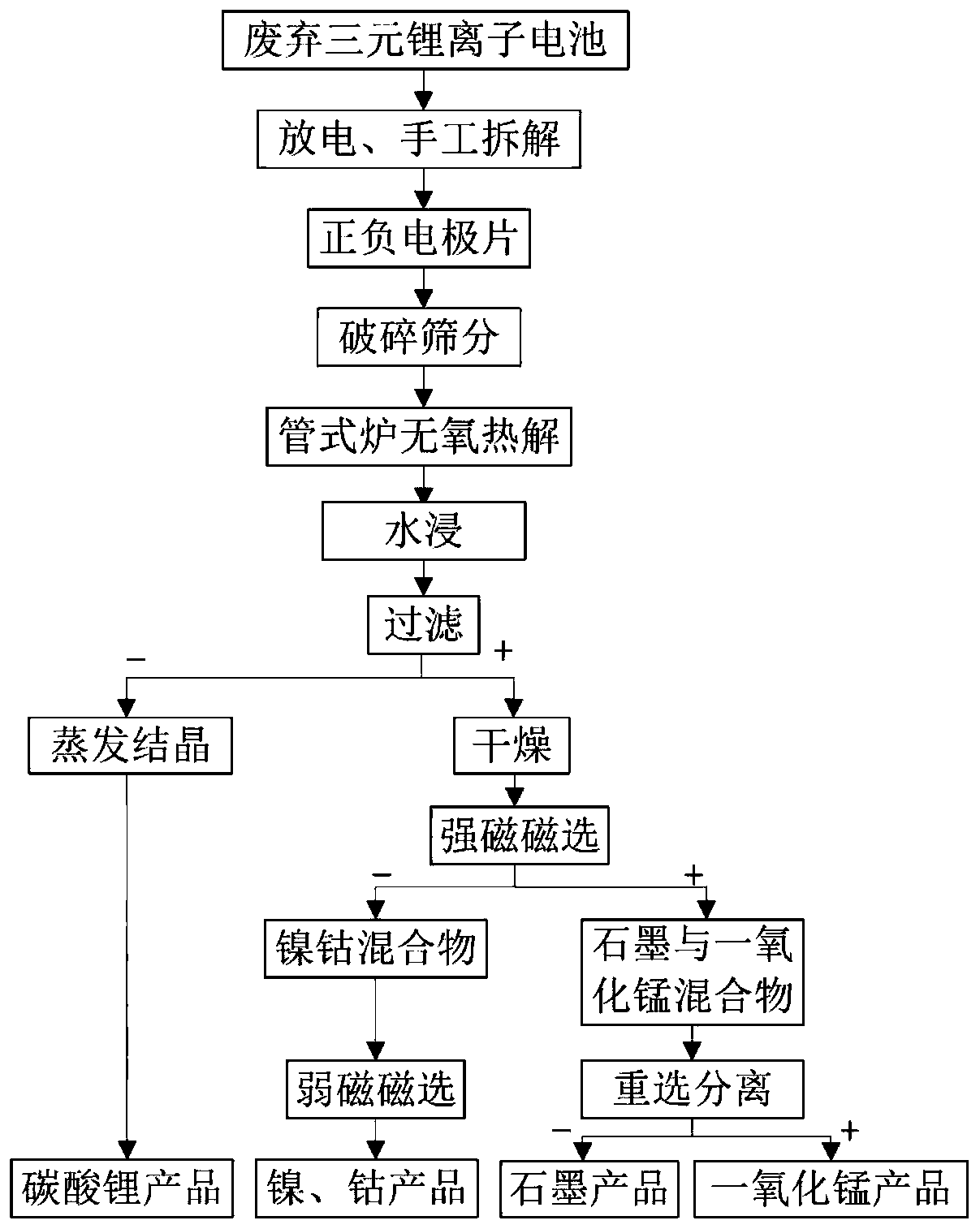

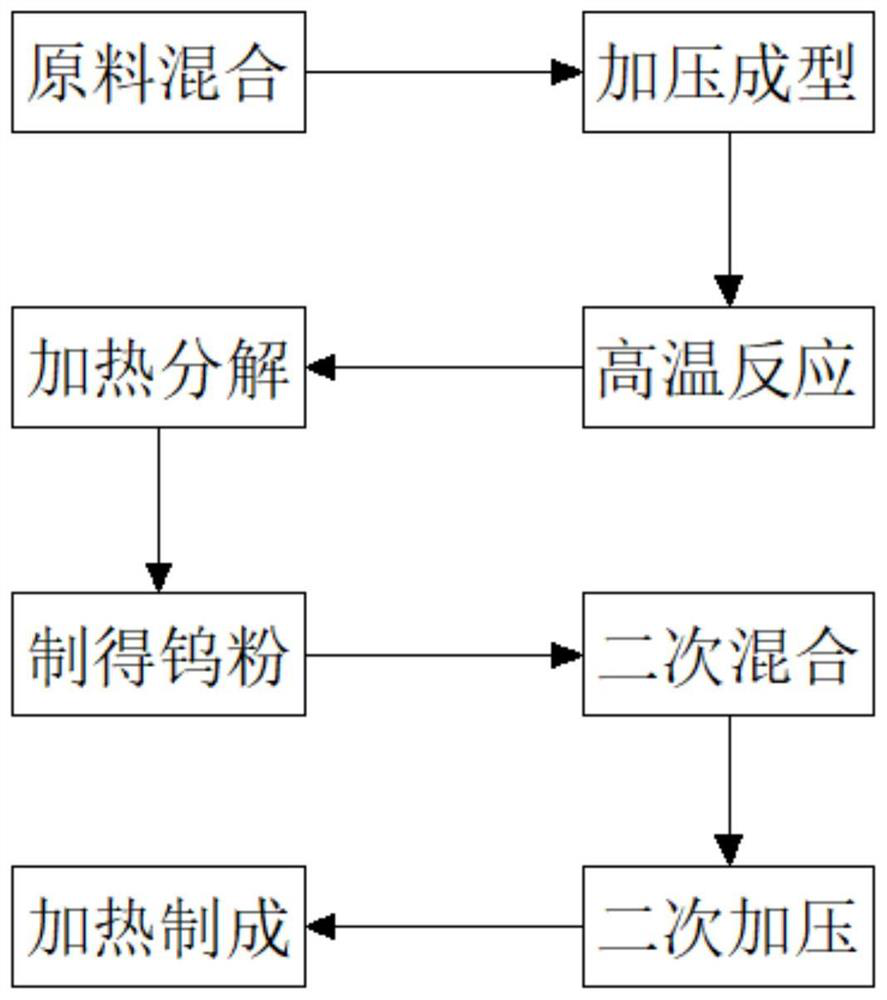

Method for recycling valuable components in waste ternary lithium ion battery through high-temperature in-situ heat treatment

ActiveCN111244566AReduce distractionsSimple recycling processWaste accumulators reclaimingBattery recyclingElectrolysisHydrometallurgy

The invention discloses a method for recycling valuable components in a waste ternary lithium ion battery through high-temperature in-situ heat treatment. The method comprises the steps of carrying out the in-situ thermal reduction on the nickel-cobalt-manganese high-valence elements in an electrode material by utilizing the organic substances, such as a positive and negative electrode material surface binder, carbon black, etc., reducing the nickel and cobalt to be in an elemental form, and reducing manganese to be low-valence oxide manganese monoxide; recycling the lithium element by adopting a water immersion method, and drying the residual materials, and then separating the ferromagnetic nickel-cobalt elementary substances, diamagnetic graphite and non-magnetic manganese monoxide through a magnetic separator with high magnetic flux; selecting a magnetic separator with low magnetic flux to separate and recover nickel and cobalt. Compared with a traditional ore pulp electrolysis process and other hydrometallurgy processes, a reducing agent does not need to be added, the interference of impurity elements in a recovery system is reduced, and finally the recovery rates of nickel, cobalt, manganese and negative electrode graphite are all larger than 98%. According to the process, the process of recycling the valuable components in the waste ternary lithium ion battery electrode material is simplified, the cost is reduced, and the method is a good choice for industrial application.

Owner:CHINA UNIV OF MINING & TECH

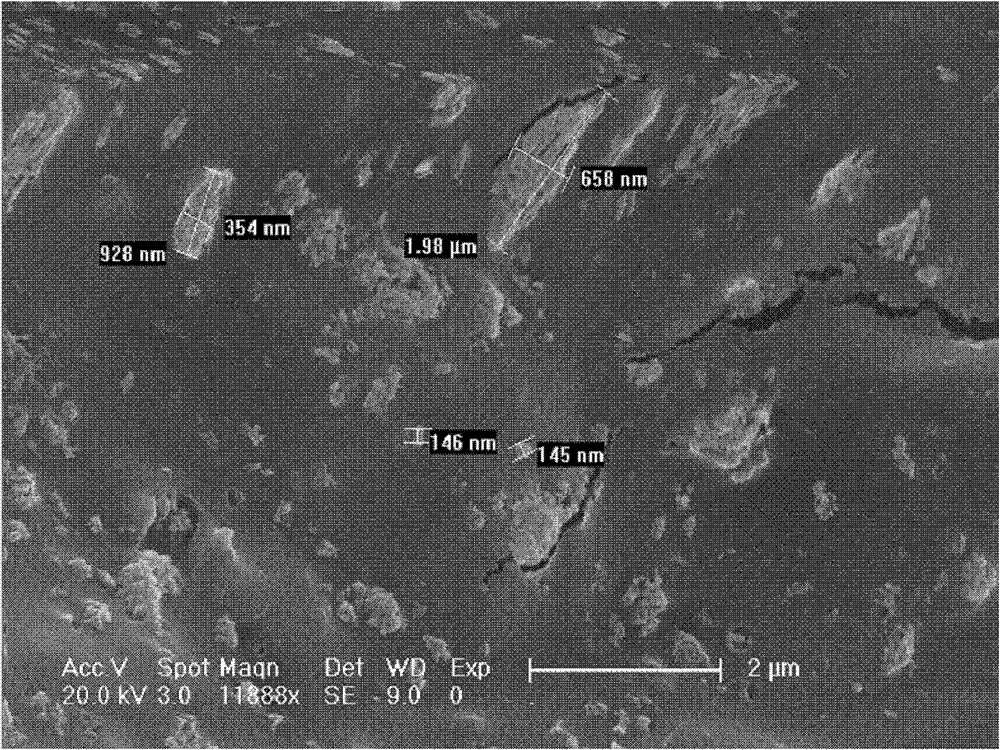

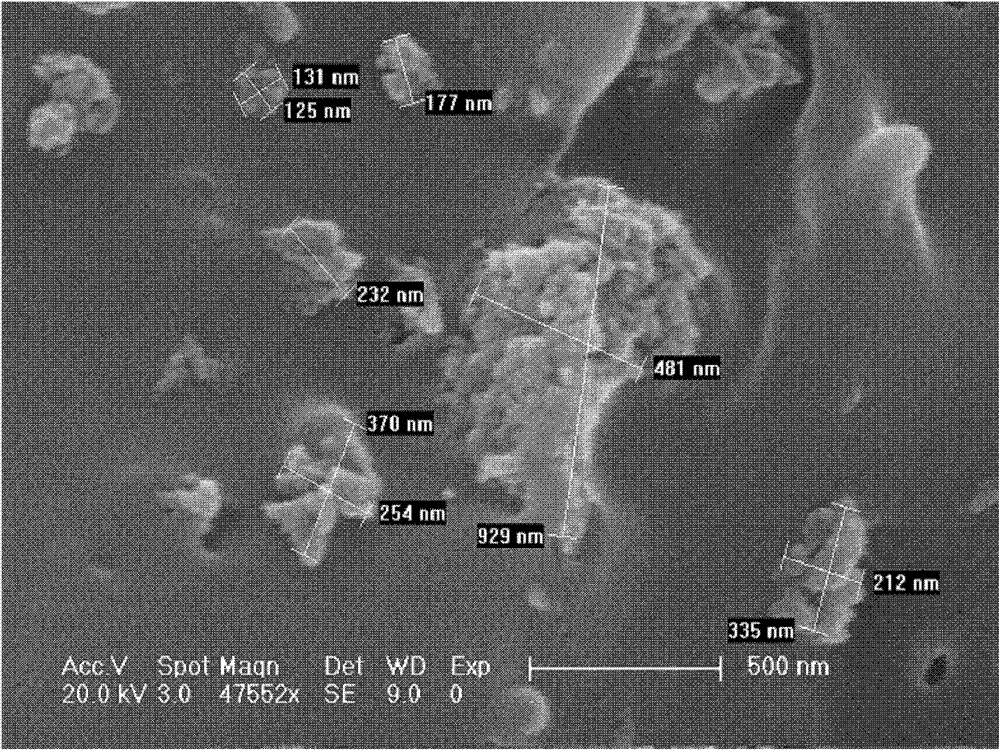

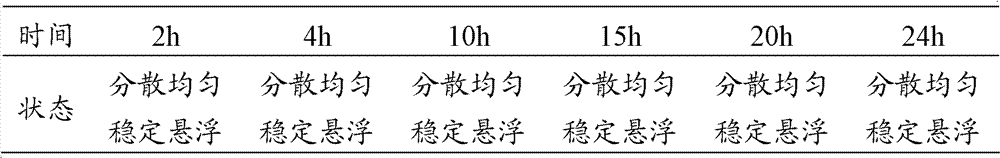

Method for modifying nano hydroxyapatite, nano hydroxyapatite/polylactic acid compound material and preparation method of nano hydroxyapatite/polylactic acid compound material

ActiveCN102153058BAchieve surface modificationGood dispersionNanotechnologyPhosphorus compoundsNano hydroxyapatiteChloroform

The invention provides a method for modifying nano hydroxyapatite. The method comprises the following steps of: a) providing an acetone solution with low polylactic acid, wherein the number-average molar mass of the low polylactic acid is 600 to 5,000; b) fully mixing the acetone solution with the low polylactic acid and nano hydroxyapatite sol so as to obtain a mixed solution, wherein the mass of water in the mixed solution is lower than 50 percent of the mass of acetone; and c) adding water into the mixed solution with stirring, and filtering and drying to obtain the nano hydroxyapatite with low polylactic acid surface modification. The invention also provides a nano hydroxyapatite / polylactic acid compound material and a preparation method thereof. By the method, the particle size of the modified nano hydroxyapatite with low polylactic acid surface modification is smaller and less than 2 microns; the dispersing performance of the modified nano hydroxyapatite is high; and the modified nano hydroxyapatite can still suspend in chloroform stably after being dispersed in the chloroform for 24 hours.

Owner:CHANGCHUN SINOBIOMATERIALS

Modified silica sol, fireproof liquid, composite fireproof glass as well as preparation method and application thereof

ActiveCN112320807AStrong adhesionHigh bonding strengthFireproof paintsSilicon compoundsOrageneOrganic polymer

The invention belongs to the technical field of inorganic nano materials, and particularly relates to modified silica sol, fireproof liquid, composite fireproof glass and a preparation method and application thereof. The preparation method of the modified silica sol comprises the following steps: 1) mixing silica sol to be modified with a silane coupling agent and reacting; and 2) mixing an organic polymer containing a reaction group with the material obtained in the step 1) and reacting to obtain the modified silica sol. The modified silica sol is prepared by the preparation method and is used for preparing the fireproof liquid, and the obtained fireproof liquid is high in crosslinking density and good in adhesive force.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +2

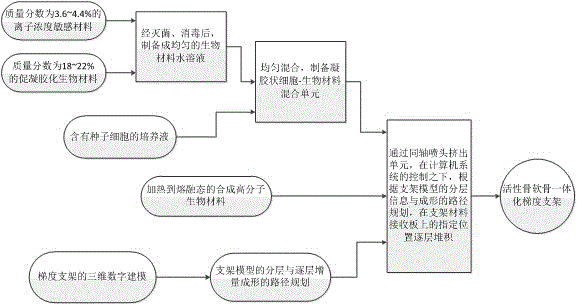

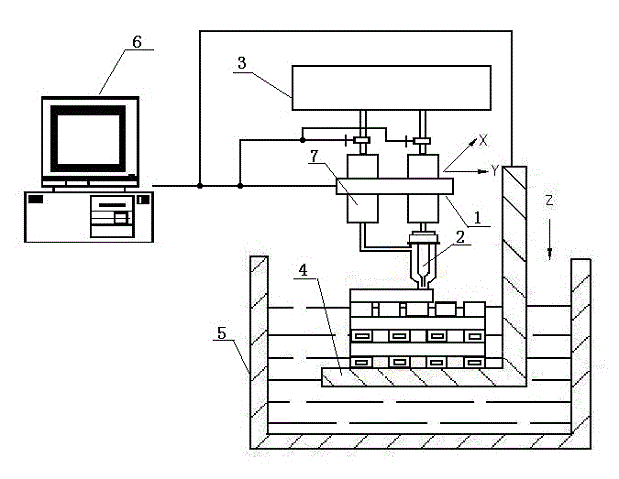

Three-dimensional controllable incremental forming method and forming system for active osteochondral integrated gradient scaffold

InactiveCN103143062AHighlight substantiveSignificant technological progressProsthesisSynthetic Polymeric MacromoleculesAdemetionine

The invention relates to a three-dimensional controllable incremental forming method and a three-dimensional controllable incremental forming system for an active osteochondral integrated gradient scaffold. According to the method, a natural biomaterial and seed cells are fully mixed to form cell-biomaterial active gel which is used as a main body material of a chondral layer and a surface modification material of a chondral lower bone layer in the integrated active scaffold, and a synthetic macromolecular biomaterial with good mechanical property and controllable degradability is used as a main body material of a chondral lower bone layer scaffold. The method comprises the following steps of: extruding the active bio-gel and the molten synthetic macromolecular biomaterial by coaxial nozzles according to the preset scaffold structure and forming path, controlling start and stop of feed power for the synthetic macromolecular biomaterial through a computer, performing layer-by-layer incremental forming, and thus obtaining the osteochondral integrated gradient scaffold with good mechanical property and bioactivity. The integrated gradient scaffold with the bioactivity can realize three-dimensional controllable forming of cells, meanwhile, good mechanical property of the scaffold can be ensured, and the scaffold with controllable pore structure and degradation rate is beneficial to three-dimensional culture of the cells and tissue regeneration.

Owner:SHANGHAI UNIV

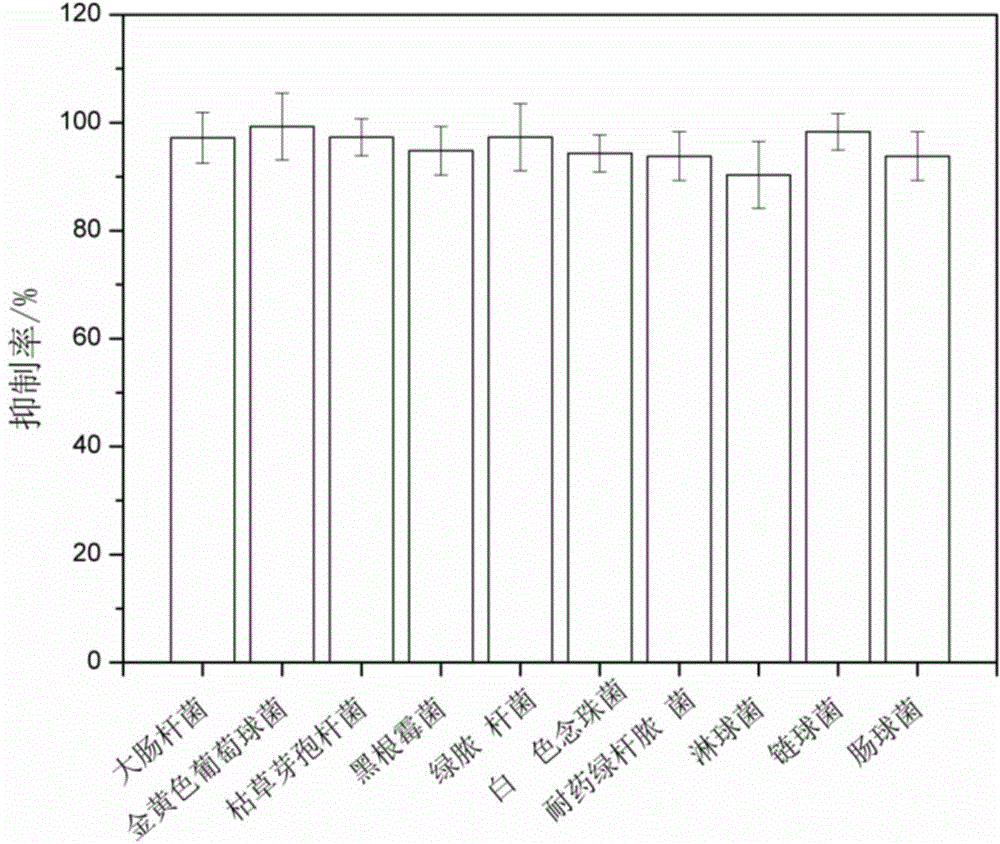

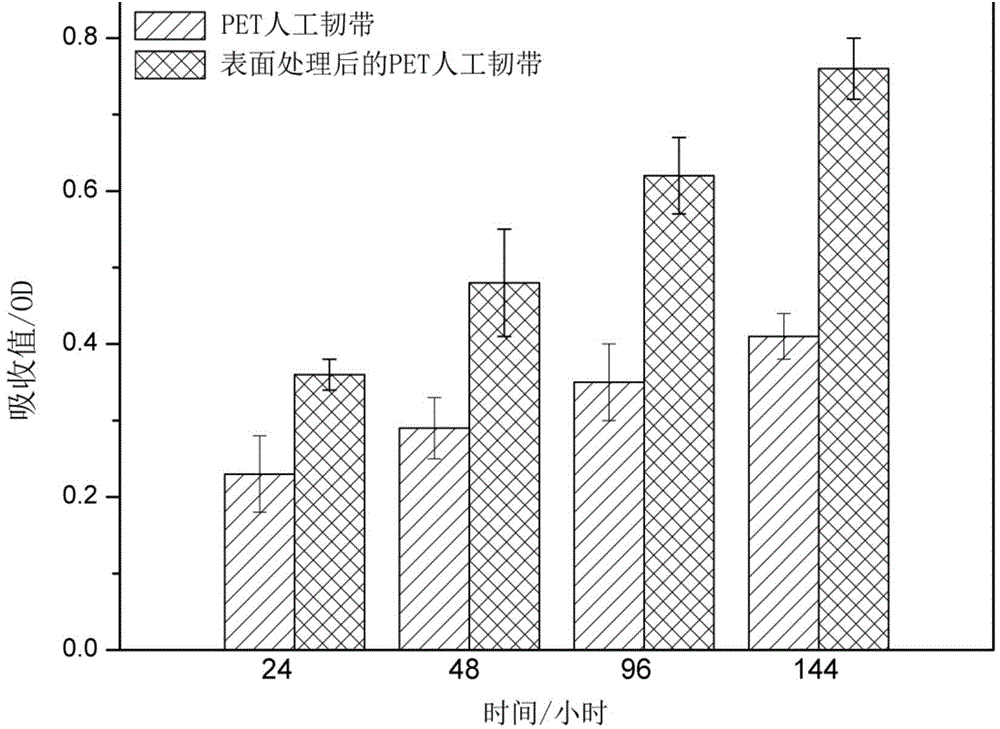

Preparation method of HAp blended silver and copper antibacterial composite coating

InactiveCN104127914AAchieve surface modificationHas antibacterial propertiesCoatingsProsthesisAnti-inflammatoryCruciate ligament

The invention provides a preparation method of a HAp blended silver and copper antibacterial composite coating. The method comprises the following steps: first, conducting ultrasonic cleaning treatment on the artificial ligament surface, conducting friction by using the steel grit, cleaning by distilled water, and conducting vacuum drying; second, mixing gelatin and a calcium source solution, adding silver and copper sources to form a mixed solution, regulating the pH value, stirring, soaking artificial ligament in the mixed solution, and stirring; and third, remove the taking out the artificial ligament, drying with filter paper, dipping in a Na2HPO4 solution, stirring, standing, drying with filter paper, and repeating cycles of mineralization. The invention uses a biomimetic mineralization method to form the HAp blended silver and copper antibacterial agent composite coating with uniform mineralized structure and stable performance on the artificial ligament surface by using gelatin as the mineralization template. The coating modifies the artificial ligament and further realizes surface modification on artificial ligament, so that the artificial ligament has antibacterial and anti-inflammatory properties to reduce postoperative synovitis and complications such as infection of cruciate ligament reconstruction of knee joint.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV

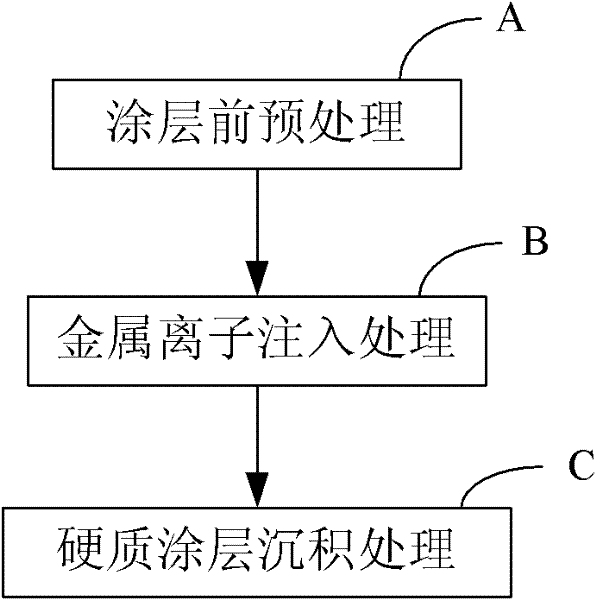

Method for preparing composite hard coating on min-cutter and min-cutter

InactiveCN102230156AEasy to processExtended service lifeVacuum evaporation coatingSputtering coatingIon beamPre treatment

The invention discloses a method for preparing a composite hard coating on a min-cutter and a min-cutter. The method for preparing a composite hard coating on a min-cutter comprises the steps of carrying out pretreatment before coating, implantation of metallic ions and deposition of hard coating on the surface of the min-cutter to be processed. According to the invention, metallic ions are implanted into the surface of the min-cutter through energy-loaded ion beams generated by an ion implanter before the hard coating is deposited on the surface of the min-cutter to be processed; therefore, physical and chemical properties of the surface of the min-cutter to be processed are changed, binding force between the hard coating and the min-cutter in the process of hard coating deposition is improved, and burns to the cutting edge of the mini-cutter are avoided, thereby enabling the min-cutter with the coating to have a more excellent processing property and a longer service life and successfully realizing surface modification of the min-cutter.

Owner:SHENZHEN JINZHOU PRECISION TECH

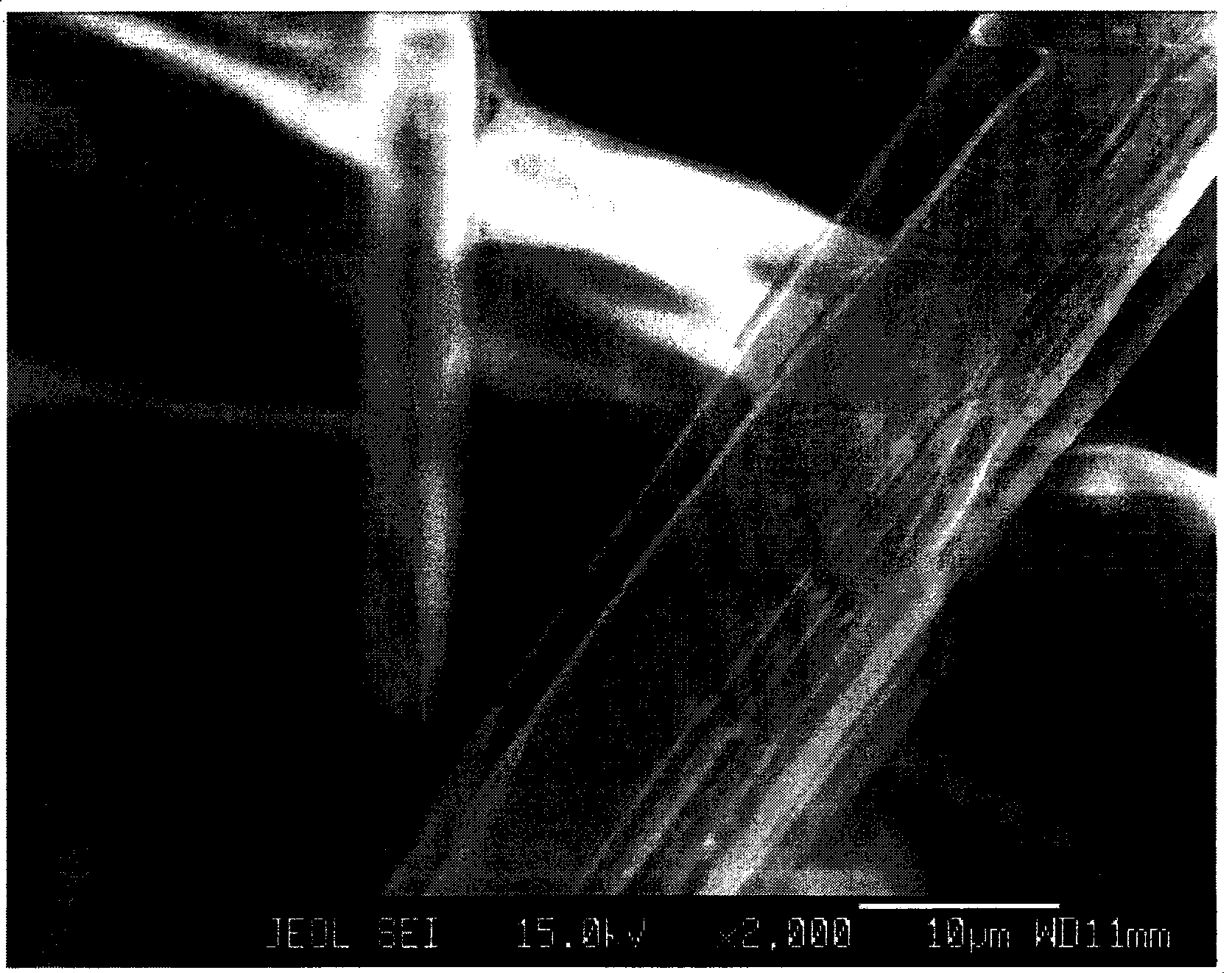

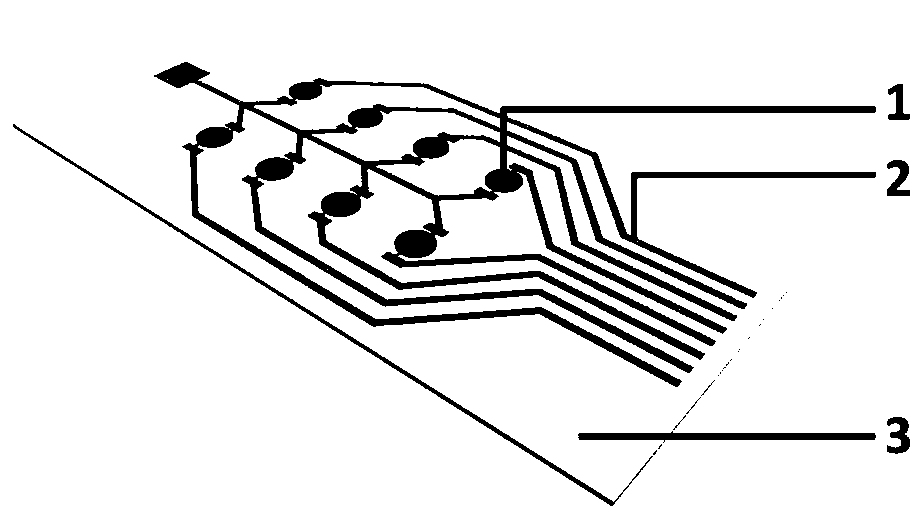

Preparation method of surface modified titanium dioxide nano-particle polyimide fiber membrane

ActiveCN108755104AThe process is simpleConditions are easy to meetFibre typesNon-woven fabricsElectrospinningNanometre

Provided is a preparation method of a surface modified titanium dioxide nano-particle polyimide fiber membrane. Firstly, a polyimide fiber membrane prepared through electrostatic spinning is put in apotassium hydroxide solution for etching, washing is performed to make the membrane neutral, then the polyimide fiber membrane is soaked in a titanium compound water solution for treatment, and finally the surface modified titanium dioxide nano-particle polyimide fiber membrane is prepared through washing, drying and temperature rise thermal imidization treatment. The method is simple to carry out, a basic structures is kept well, the cost is low, the thickness of titanium dioxide nano-particle layer can be controlled within 10 nm, and application prospect is good.

Owner:启鼎技术(北京)有限公司

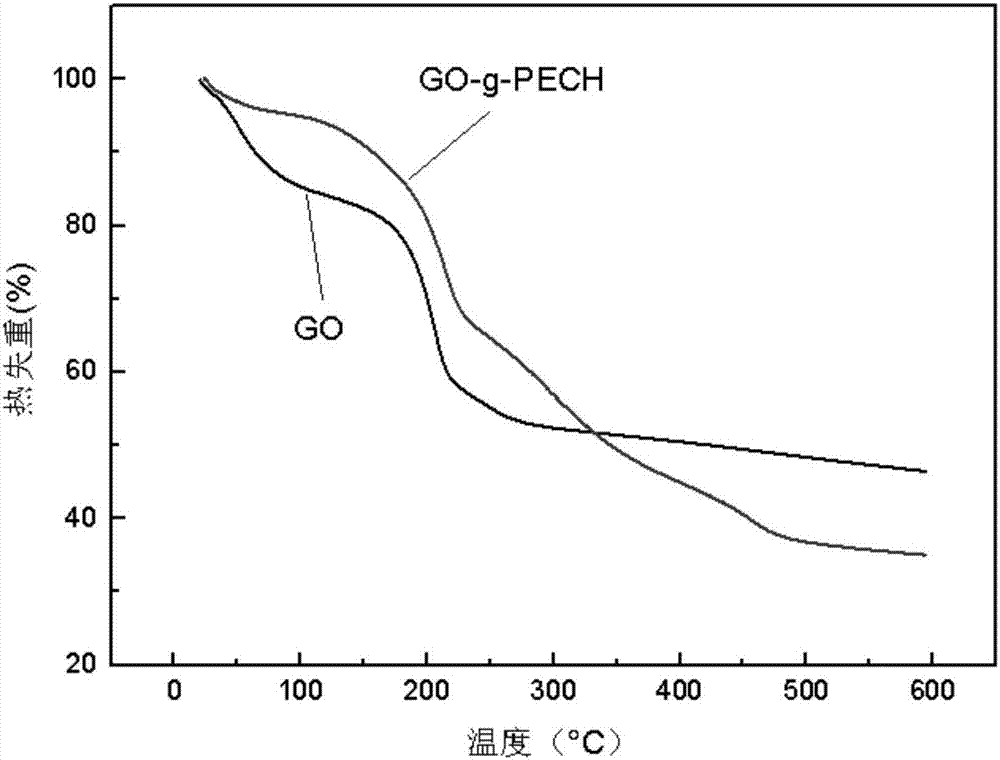

Method for initiating polymerization of epoxy monomer by using graphene oxide as initiator

ActiveCN107216461AAchieve surface modificationImprove interface performanceEpoxyCationic polymerization

The invention discloses a method for initiating polymerization of an epoxy monomer by using graphene oxide as an initiator. The method comprises the following steps: the epoxy monomer and the graphene oxide are added to a reaction system, wherein, the mass rate of the epoxy monomer to the graphene oxide is 300-5, the graphene oxide can prompt the epoxy monomer to undergo cationic ring-opening polymerization at the temperature of 0-100 DEG C, and the obtained epoxy polymer can be grafted in situ on the surface of a graphene oxide sheet layer, so that surface modification of the graphene oxide is realized, and cation-initiated polymerization and grafting amount are controlled by reaction time and reaction temperature.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

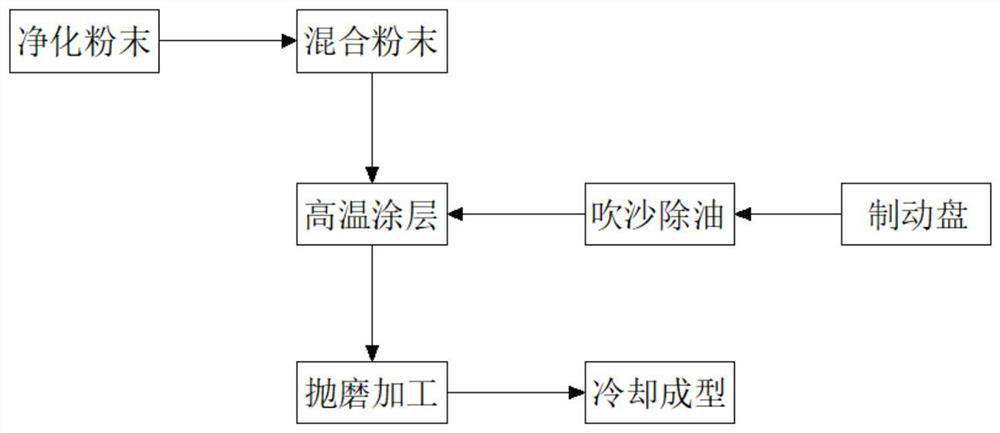

Manufacturing method of wear-resistant alloy coating of automobile brake disc

InactiveCN112593180AHigh bonding strengthQuality improvementMolten spray coatingMolten stateAlloy coating

The invention discloses a manufacturing method of a wear-resistant alloy coating of an automobile brake disc. The manufacturing method of the wear-resistant alloy coating of the automobile brake disccomprises the following raw materials: 25%-70% of tungsten carbide, 15%-70% of chromium carbide and a brake disc base material, and hypersonic flame is utilized. Through axially feeding powder to theflame, spraying particles can be heated to a molten or semi-molten state and accelerated to be up to 300-500 m / s, so that the compact high-quality coating with high bonding strength is obtained. The hypersonic flame speed is very high, but the temperature is relatively low and is about 3000 DEG C. For WC-Co series hard alloys, decomposition of WC in the spraying process can be effectively inhibited, and the coating is high in bonding strength and compact. The wear resistance is excellent, greatly exceeds that of a plasma spraying layer, is equivalent to that of an explosion spraying layer, andalso exceeds that of an electroplated hard chromium layer and a spray melting layer. The surface hardness is increased and can reach HV900-1200. The temperature resistance can reach 600-900 DEG C, the emission of brake dust is reduced by 90%, and the effect of no rusting can be achieved forever.

Owner:SUZHOU TONGMING MACHINERY

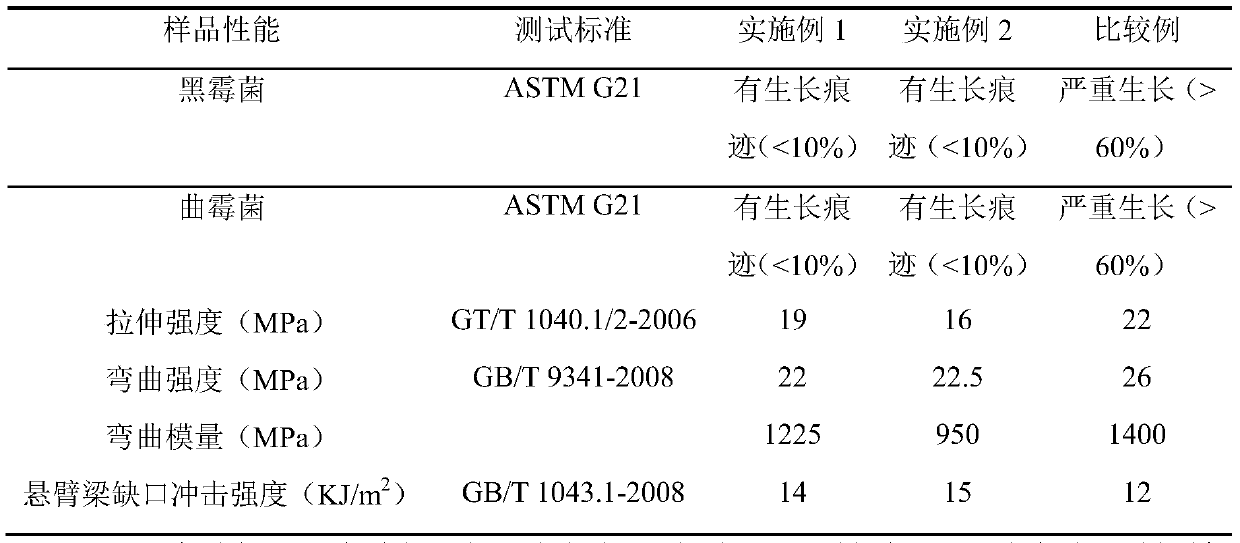

Antibacterial plant fiber reinforced composite material as well as preparation method and application thereof

The invention discloses an antibacterial plant fiber reinforced composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) soaking natural plant fibers in an alkaline solution; (2) mixing natural plant fibers, 3-mercaptopropyltrimethoxysilane and deionized water to obtain a plant fiber modified material; (3) adding the plant fiber modified material, an alkenyl quaternary ammonium salt monomer and an initiator into a mixed solution of ethanol and pure water, and carrying out a mercapto-alkene click reaction under the irradiation of an ultraviolet lamp to obtain antibacterial plant fibers; and (4) blending the antibacterial plant fiber with a matrix material to obtain the antibacterial plant fiber reinforced compositematerial. According to the invention, due to the advantages and characteristics of the thiol-ene click chemical reaction, the quaternary amine functional group-containing polymer molecular chain is applied to modification of natural plant fibers, wherein the plant fibers are endowed with good antibacterial performance, fiber surface modification by the polymer is realized through regulation and control of the conjugate molecular chain, so that the application range of the plant fibers is widened, and the application value of the plant fibers is improved.

Owner:贵州省材料技术创新基地

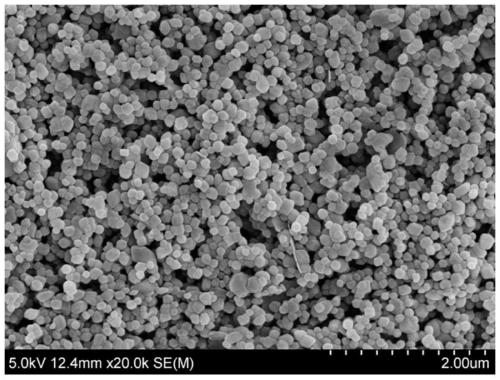

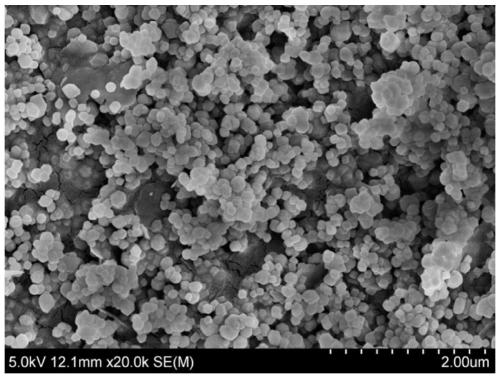

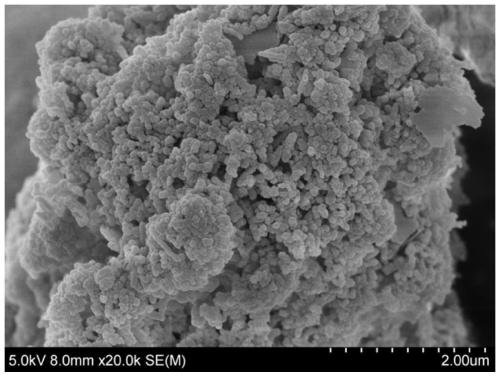

Preparation method of monodispersed nano-calcium carbonate with low surface energy

ActiveCN109850931ATo achieve the purpose of disaggregating secondary aggregatesLower surface energyCalcium/strontium/barium carbonatesMaterial nanotechnologyDepolymerizationFiltration

The invention provides a preparation method of monodispersed nano-calcium carbonate with low surface energy and relates to the technical fields of preparation and processing of nano-calcium carbonatepowder. The preparation method comprises the following steps: S1, preparing boiled nano-calcium carbonate pulp; S2, adding an aging agent into the boiled nano-calcium carbonate pulp prepared in S1, and carrying out aging treatment to obtain a nano-calcium carbonate aging suspension; and S3, adding a surface treating agent into the nano-calcium carbonate aging suspension prepared in S2 to carry outsurface treatment, and then, carrying out filtration pressing dehydrating, drying and smashing to obtain the monodispersed nano-calcium carbonate with low surface energy. According to the preparationmethod, due to the addition of the aging agent, secondary aggregate depolymerization is realized, meanwhile, the specific surface energy of a powder is greatly reduced, and a monodispersed nano-calcium carbonate product is achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

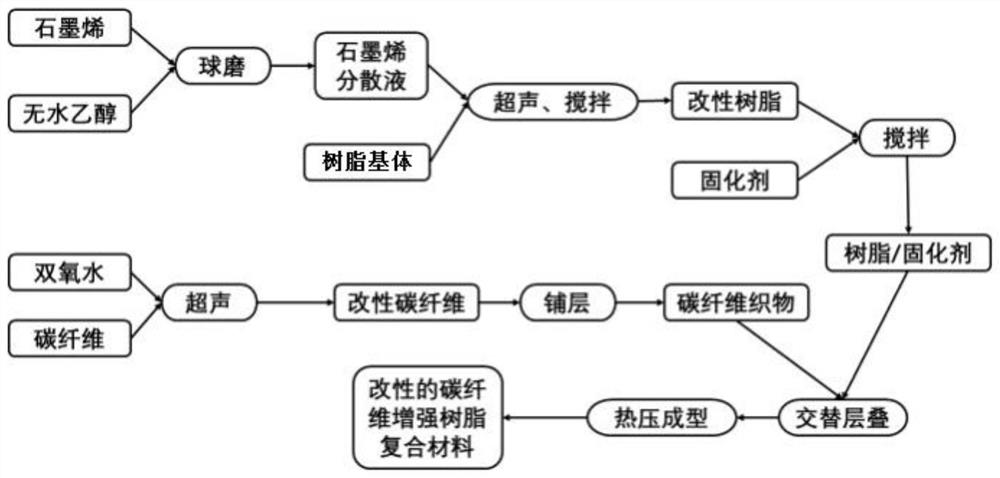

Modified carbon fiber reinforced resin-based composite material and preparation method thereof

The invention provides a modified carbon fiber reinforced resin-based composite material and a preparation method thereof, and belongs to the technical field of resin-based composite materials. According to the invention, graphene is used as a modifier of the resin matrix, and the graphene has a rough and wrinkled ripple structure, so that the carbon fiber and the resin matrix structure can be interlocked, the interface characteristics of the resin matrix and the carbon fiber are improved, and the strength of the carbon fiber reinforced resin matrix composite material is further improved; ultrasonic hydrogen peroxide combined oxidation is adopted to modify the carbon fiber, so that the activity of active oxygen-containing free radical groups such as hydroxyl and carbonyl on the surface of the carbon fiber can be improved, the purpose of surface modification is achieved, the carbon fiber and a resin matrix can be bonded more tightly, and the interlayer strength of the composite material is improved; and the obtained modified carbon fiber is used as a reinforcement skeleton to endow the composite material with the characteristics of excellent fatigue resistance, impact resistance, shock absorption, corrosion resistance, heat conduction, high temperature resistance, high strength, light weight, plasticity and the like.

Owner:LINGNAN NORMAL UNIV

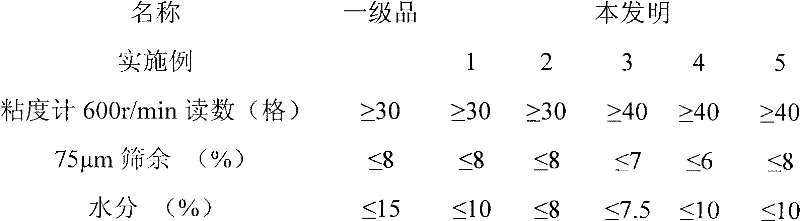

Preparation method of modified attapulgite clay for drilling fluid

InactiveCN102476804AEasy to operateGood modification effectAluminium silicatesClay mineralsWell drilling

The invention discloses a preparation method of modified attapulgite clay for drilling fluid. According to the invention, attapulgite clay is used as a raw material and a magnesium-containing substance is used as a modifier. By the adoption of a semi-dry production technology, the preparation method contains the following steps of: crushing clay mineral, adding the modifier for mixing, extruding, pulping, sieving, dehydrating, drying, crushing and packaging. The product provided by the invention can meet requirements of various geological drilling, geothermal drilling and petroleum drilling, and is especially applicable to inland saliferous strata drilling, offshore drilling and ultra-deep drilling.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for improving strength of waste paper fiber by constructing nano-polyelectrolyte multilayer films

InactiveCN102242524AAchieve surface modificationImprove physical strengthReinforcing agents additionPaper/cardboardFiberCationic polyelectrolytes

The invention discloses a method for improve strength of waste paper fiber by constructing nano-polyelectrolyte multilayer films. In the method, a nanoscale polyelectrolyte multilayer film structure is formed on the surface of regenerated fiber by means of electrostatic layer-by-layer self-assembly of anionic and cationic polyelectrolyte on the surface of the waste paper fiber. The method has thebeneficial effects that by changing consumption of the polyelectrolyte, regulating and controlling the electrolyte multilayer film structure and adjusting the pH value of an electrostatic layer-by-layer self-assembly environmental system, the polyelectrolyte multilayer films with different properties can be obtained on the surface of the regenerated fiber so as to increase fiber bonding quantity;electrostatic attraction between anions and cations is taken as a film-forming driving force to prepare the ordered lamellar self-assembled multilayer ultra-thin films by means of alternate deposition of monomolecular layers in opposite ionic systems, and the preparation process has the advantages of simple conditions and strong adaptability and can realize surface modification of the waste paperfiber reused for a plurality of times; and strength of the finished paper prepared from the waste paper fiber after electrostatic layer-by-layer self-assembly modification is obviously enhanced, and drainage property of paper pulp is obviously improved.

Owner:湛江市吉城纸业有限公司

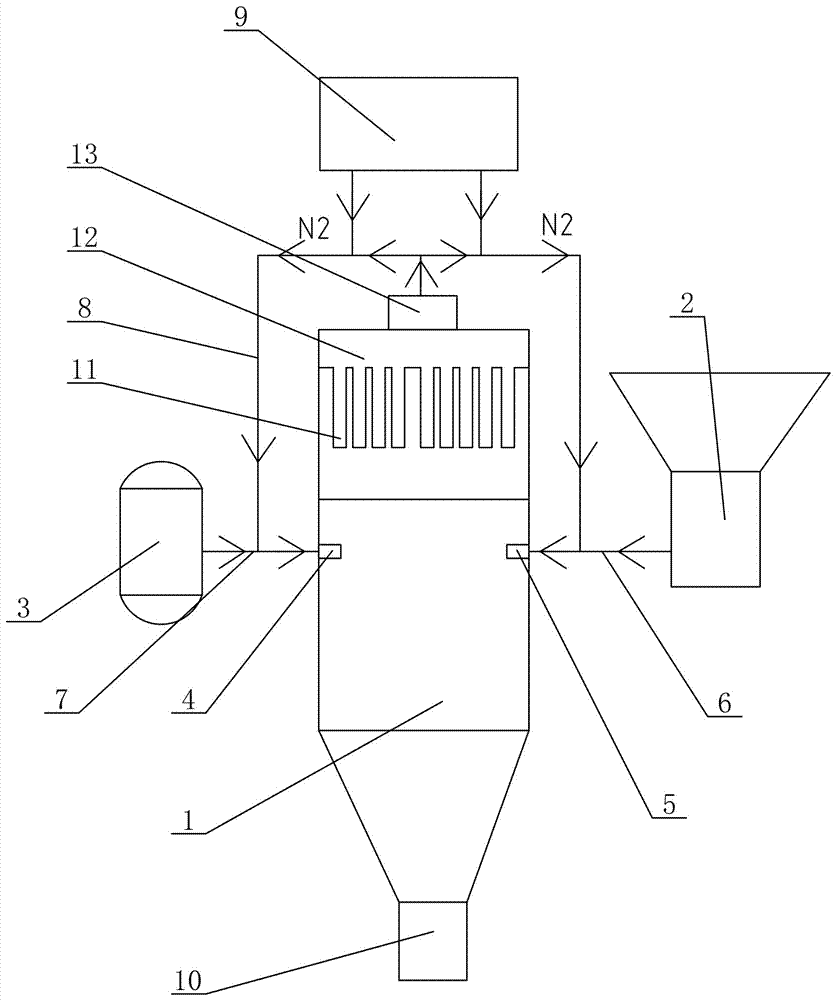

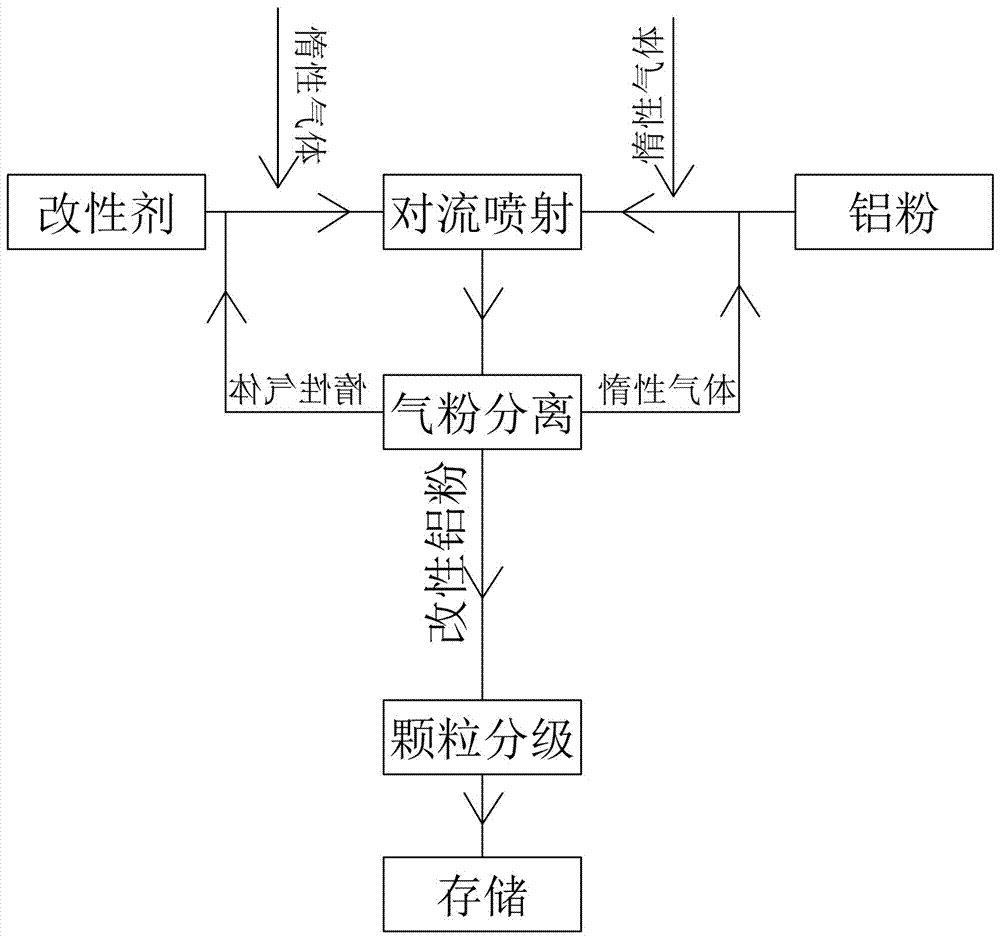

Surface modification method for spherical superfine aluminum powder and modification equipment for surface modification method

ActiveCN106862552AGuaranteed performanceFully contactedTransportation and packagingMetal-working apparatusAluminium powderTower

The invention provides a surface modification method for spherical superfine aluminum powder and modification equipment for the surface modification method. The modification equipment comprises an aluminum powder tank; the aluminum powder tank communicates with a mixing tower by an aluminum powder pipeline; a modifying agent storage tank communicates with the mixing tower by a modifying agent pipeline; the end, located inside the mixing tower, of the aluminum powder pipeline, is provided with an aluminum powder spray gun; the end, located in the mixing tower, of the modifying agent pipeline is provided with a modifying agent spray gun; the aluminum powder spray gun and the modifying agent spray gun are relatively arranged at two sides of the mixing tower; each of the aluminum powder pipeline and the modifying agent pipeline is connected with an inert gas connecting pipe; and each inert gas connecting pipe is connected with an inert gas source. A modifying agent and superfine aluminum powder are sprayed in a convection way under the protection of inert gases, the misty modifying agent and the misty superfine aluminum powder mutually impact and sufficiently contact, and superfine aluminum powder particles are wrapped by the modifying agent to form composite particles with core / shell structures, so that the aluminum powder particles are isolated from the air, the original performance of the aluminum powder is guaranteed, and risks are avoided.

Owner:HENAN YUANYANG POWDER TECH CO LTD

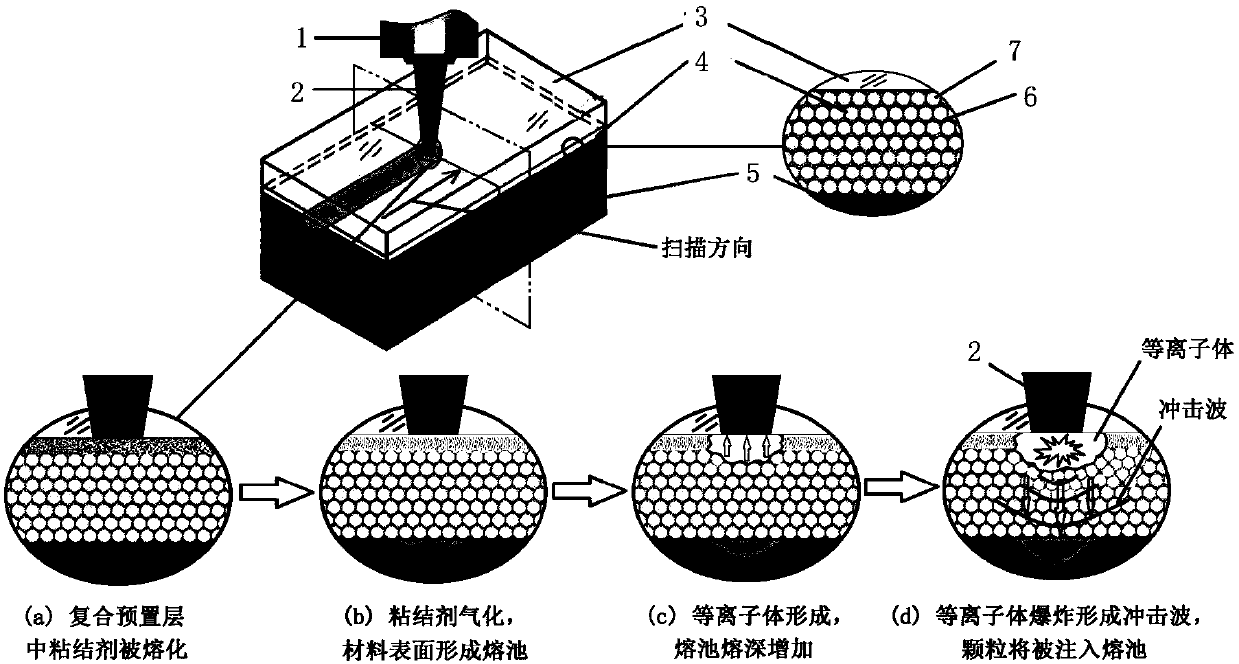

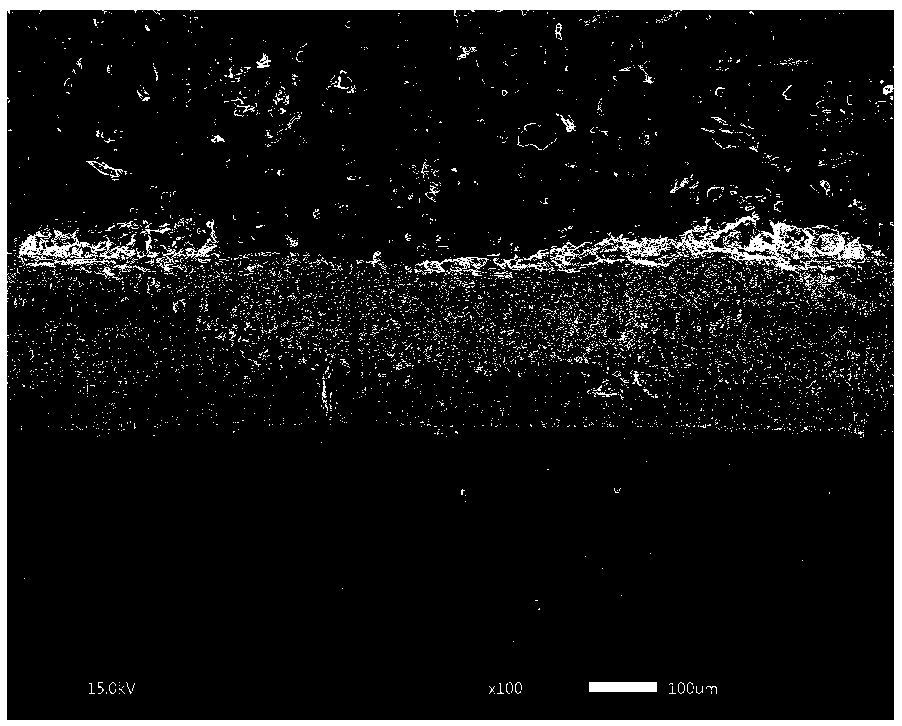

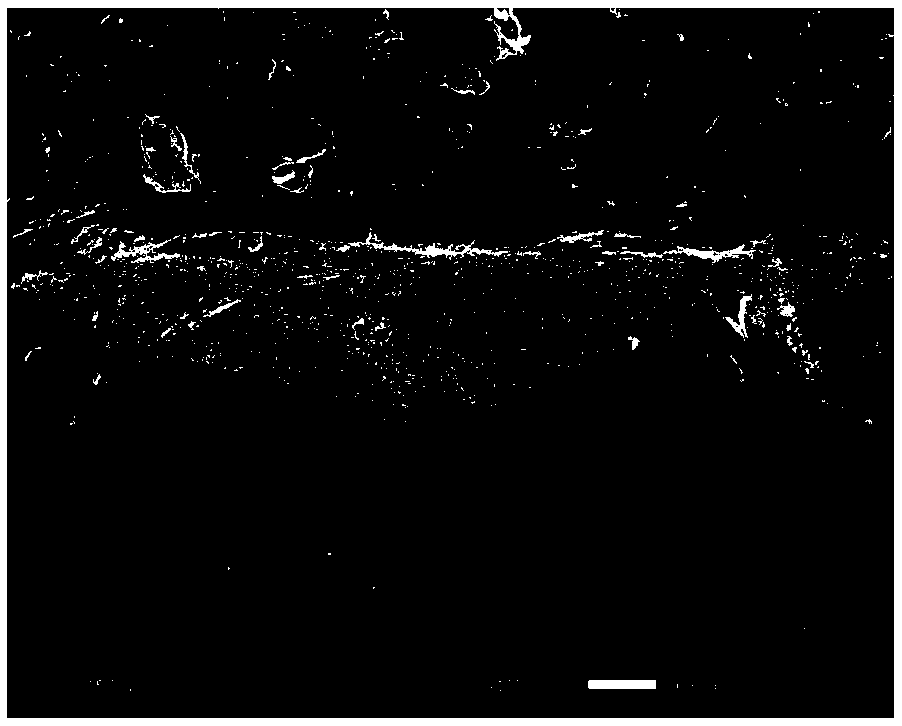

Method for continuous laser impacting micro particles to be melt-injected through injecting force formed by laser impacting work

ActiveCN107675166ABreaking down the technical barriers that are difficult to melt and inject fine particlesInjection implementationMetallic material coating processesBoiling pointLaser beams

The invention provides a method for continuous laser impacting micro particles to be melt-injected through injecting force formed by laser impacting work. The method is characterized in that a continuous laser beam is used to penetrate through a restraint layer for scanning a composite pre-arranged layer prearranged on the surface of a material to be modified, wherein the composite pre-arranged layer is formed by mixing a binder which inducing a laser impacting waves effectand the macro particles to be melt-injected; and through reasonable matching of parameters such as the melting point and the boiling point of the binder, the materials to be modified and the micro particles to be melt-injected, the binder is gasified to form the laser impacting waves under inducing of the continuous laser action, and the micro fine particles to be melt-injected are injected into a surface molten pool of the material to be modified, so that the micro particle reinforced composite layer is formed in situ. By means of the method, metallurgical bonding between the micro particles and the material to be modified is achieved in the composite material layer obtained from the surface of the material to be modified, the technical barrier that the micro particles are difficult to melt-inject in the prior art is broken, meanwhile, the injection depth of the micro particles is deep, the texture is fine,the enhanced particles are evenly distributed, and the micro particles are not restricted by plasticity of the material to be modified.

Owner:JIANGSU UNIV

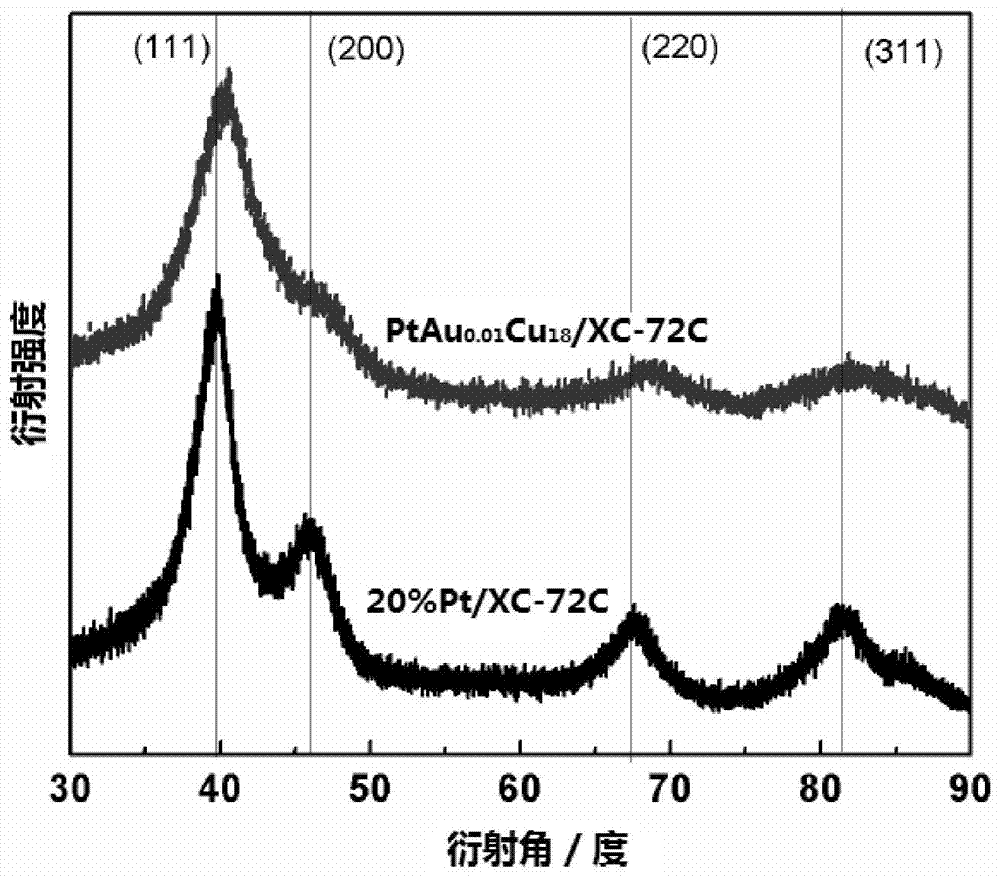

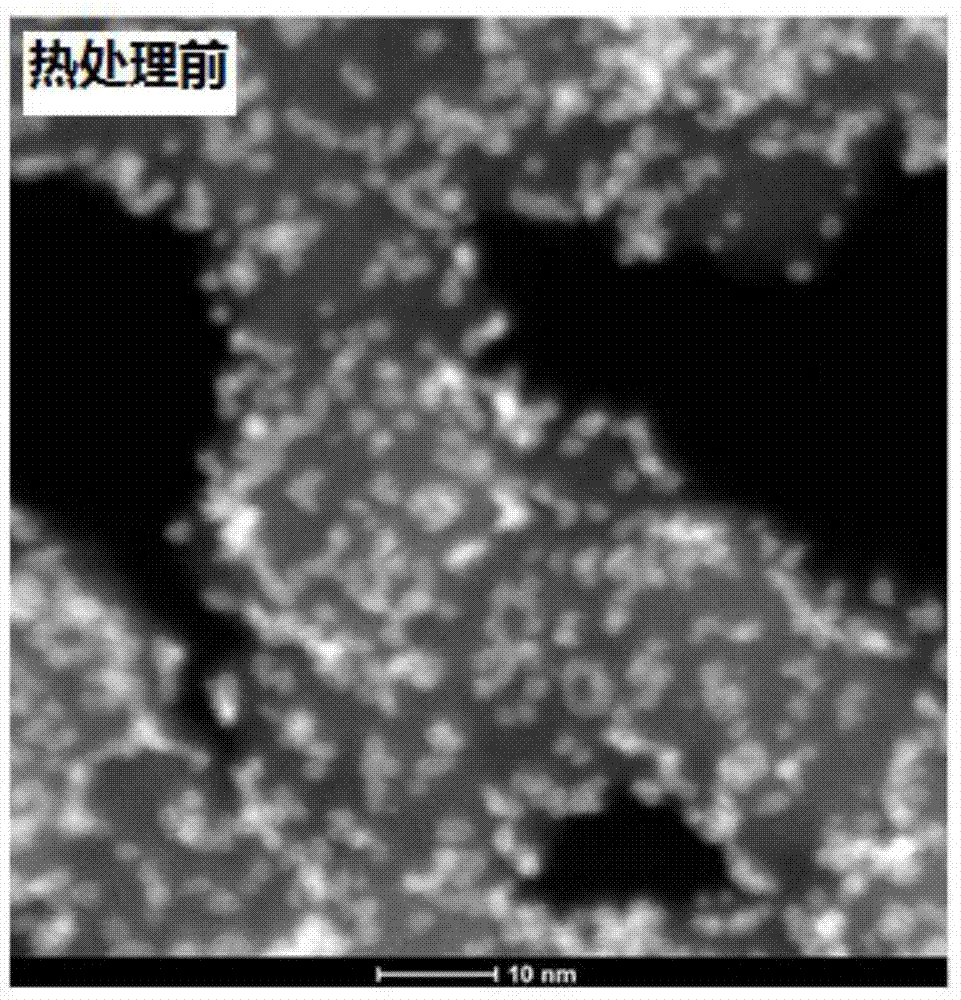

Preparation method of electrocatalyst of proton exchange membrane fuel cell

ActiveCN104707601AGood dispersionImprove electrochemical stabilityMaterial nanotechnologyCell electrodesMass ratioSurface modification

The invention relates to a preparation method of an electrocatalyst of a proton exchange membrane fuel cell, a core-shell-like structural PtxAuyMz nano seed colloid solution is prepared, PtxAuyMz is supported on the carbon carrier surface, and the catalyst is obtained by centrifugal filtration, washing and drying, distribution of x, y and z of PtxAuyMz nanoparticles is that: x:y:z =1:0.001-0.01:5-30, and the Pt loading amount is 10-40%; the catalyst surface atomic rearrangement is performed by the final heat treatment process; compared with the prior art, the catalyst nanoparticles prepared by the method are well dispersed, and have obvious Pt and Au enrichment characteristics, Pt surface enrichment helps to improve utilization ratio of Pt atoms so as to improve the precious metal mass ratio activity of the catalyst, and Au surface enrichment is conducive to the realization of surface modification and improvement of the electrochemical stability of the nanoparticles.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

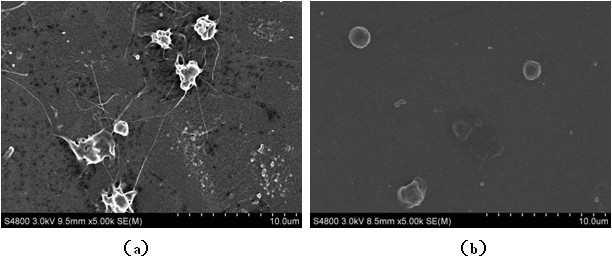

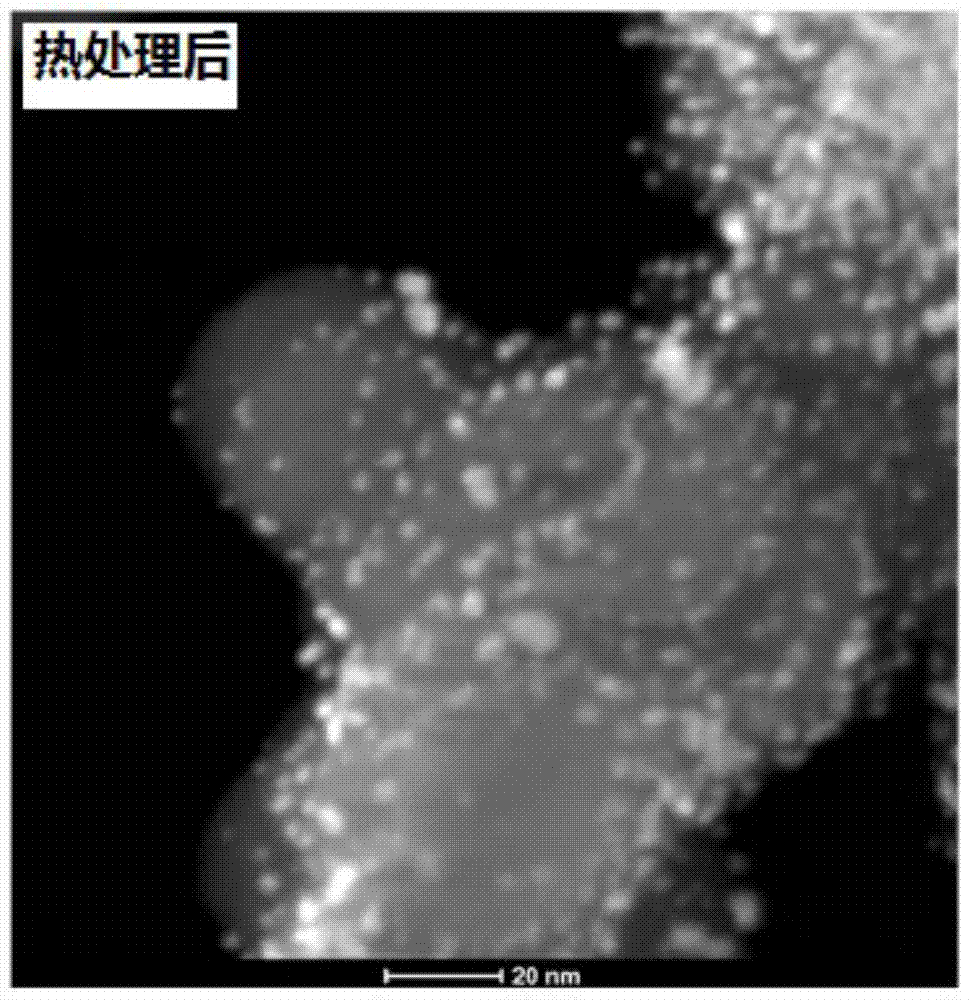

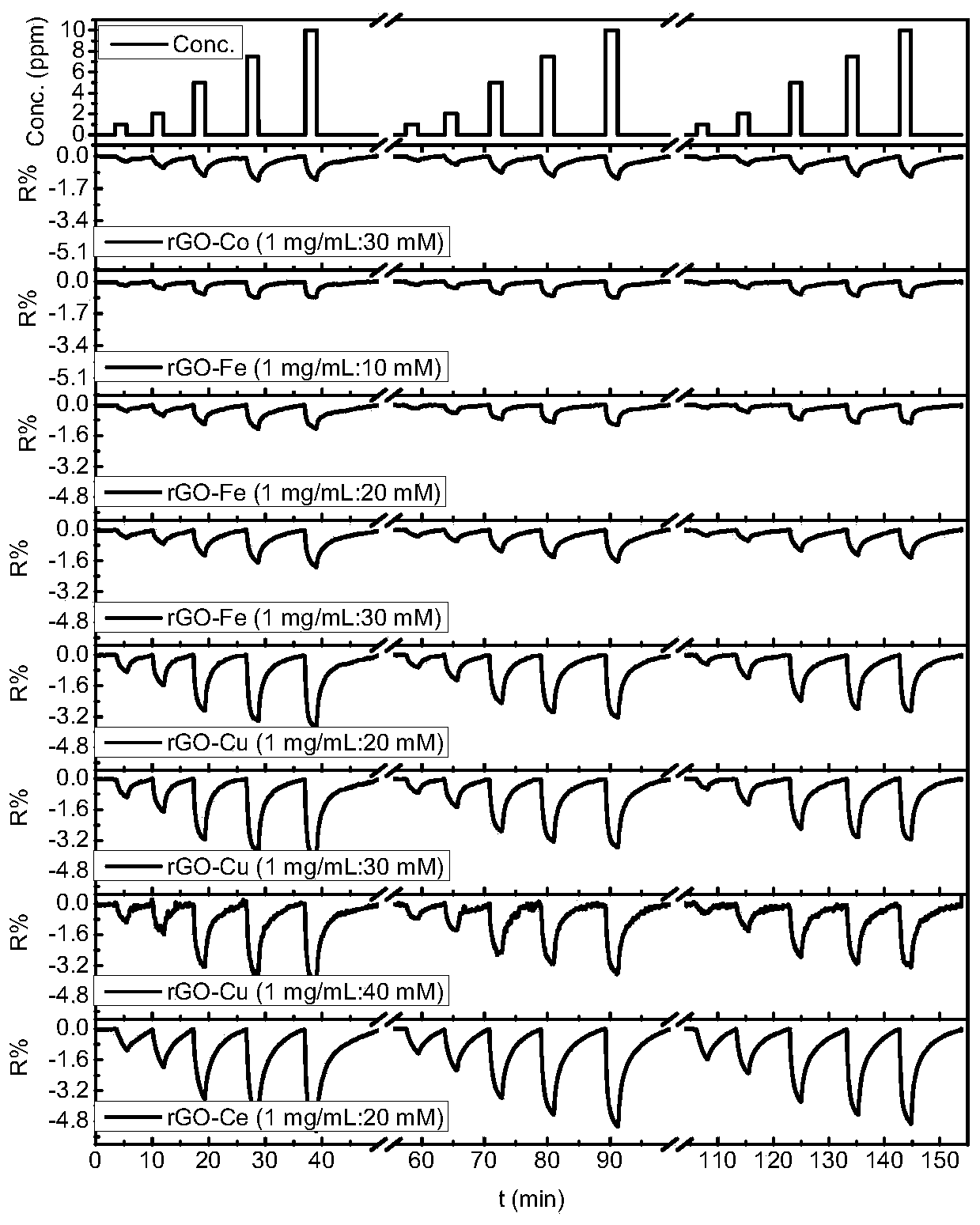

Preparation method of graphene material resistance type gas sensing array and application method thereof

The invention discloses a preparation method of a graphene material resistance type gas sensing array and an application method thereof. The preparation method comprises the following steps: adding ametal salt solution into a graphene oxide solution, adjusting a pH value of the mixed solution, carrying out ultrasonic dispersion, incubating the mixed solution on an oscillator for 4 to 12h, carrying out washing with deionized water and carrying out dispersion with deionized water to obtain a metal ion-induced graphene oxide self-assembled suspension, and changing configuration conditions to prepare a plurality of parts of metal ion-induced graphene oxide self-assembled suspensions; adding the plurality of parts of metal ion-induced graphene oxide self-assembled suspensions to interdigitalsof a multi-site fork-shaped electrode array respectively, carrying out natural drying, placing a product in reducing steam at a temperature of 60 to 120 DEG C for 3 to 30 minutes. With the disclosed preparation method, the uniform loading of the graphene material on the substrate is realized and the provided resistance type gas sensing array has the recognition capability on single gas and complexgas. The preparation method can be used for preliminary diagnosis of diseases, personal health monitoring and food and public safety monitoring.

Owner:HANGZHOU WELL HEALTHCARE TECH CO LTD

CIM (Computer Integrated Manufacturing)-process-based hot-work die steel material surface modification method

ActiveCN104550837AHigh strengthHigh wear resistance and high temperature resistanceComputer-integrated manufacturingBond strength

The invention discloses a CIM (Computer Integrated Manufacturing)-process-based hot-work die steel material surface modification method, relates to a hot-work die steel material surface modification method, and aims to solve the problem that a ceramic / hot-work die steel composite die prepared by a conventional hot-work die steel material surface modification method is low in bonding strength, maladaptive to the long-time continuous thermal shock and thermal corrosion of molten or semi-solid metal to the die in an extrusion casting process, short in service life and high in cost. The method comprises the following steps of 1, modifying Y2O3-stable zirconium oxide powder; 2, performing mixing; 3, performing injection molding; 4, performing degreasing and sintering to obtain a zirconium oxide ceramic / hot-work die steel composite die. The thickness of zirconium oxide ceramic in the obtained zirconium oxide ceramic / hot-work die steel composite die is 10 to 15mm, and the shear strength of the connection interface can reach 68 to 70MPa. The CIM-process-based hot-work die steel material surface modification method can be implemented.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com