Patents

Literature

54results about How to "Injection implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

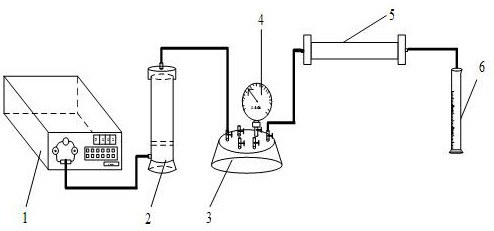

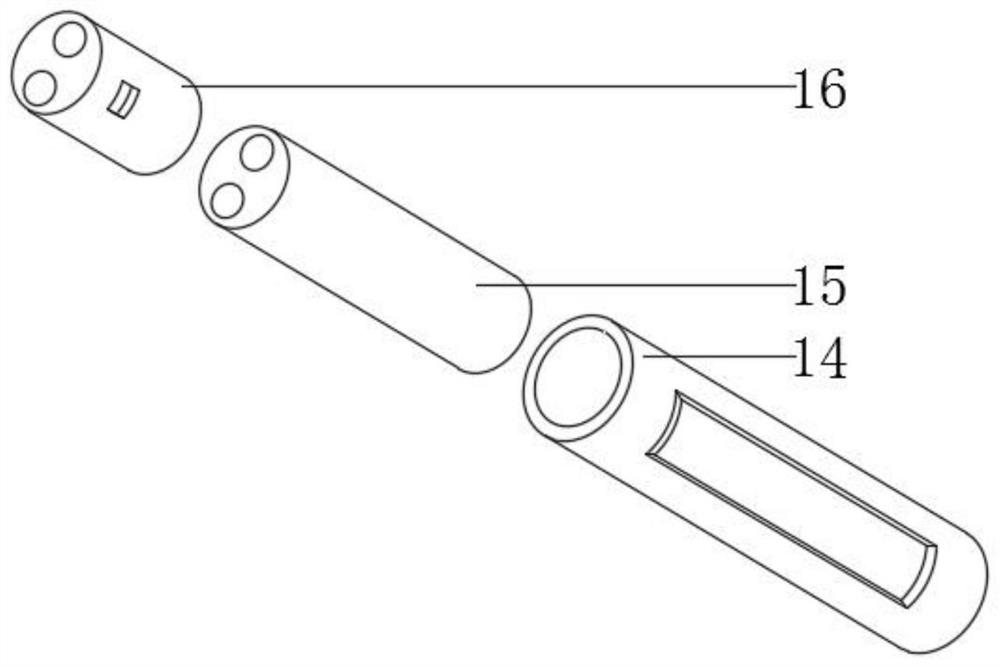

Novel fuel injection system for self-adaptive pulse detonation engine

InactiveCN109252980AJet adaptiveInjection implementationTurbine/propulsion fuel valvesIntermittent jet plantsInjection pressureCombustion chamber

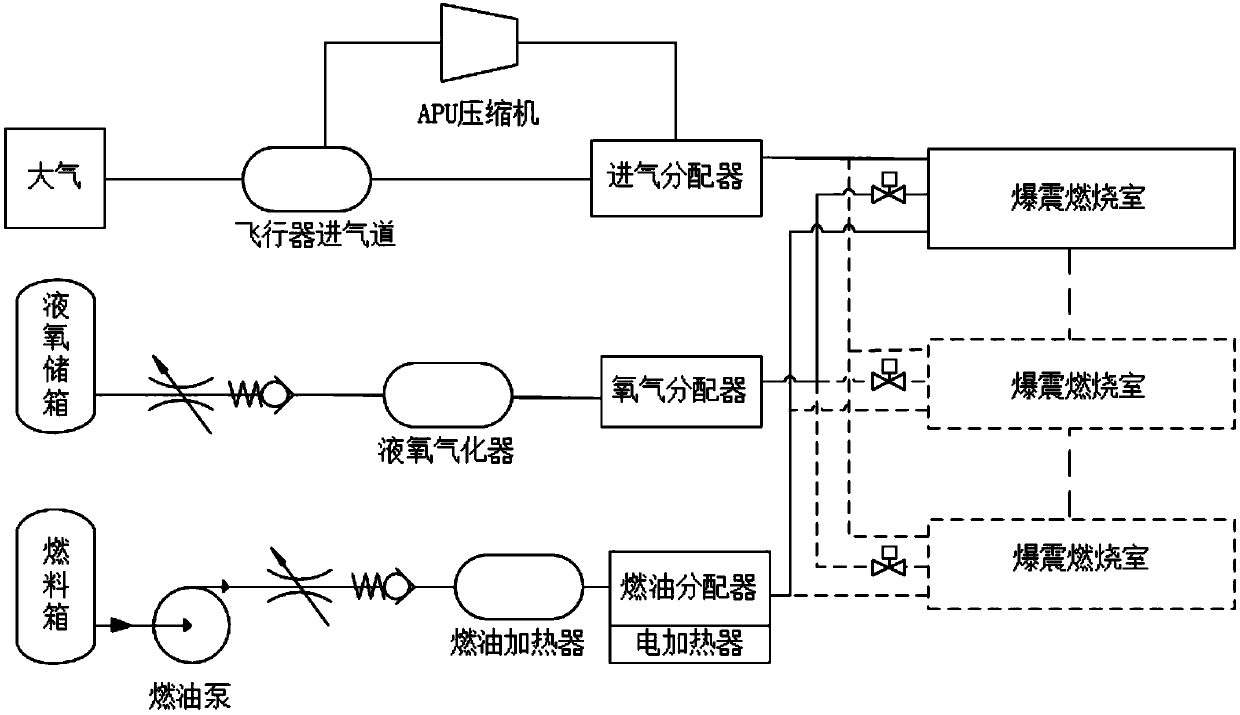

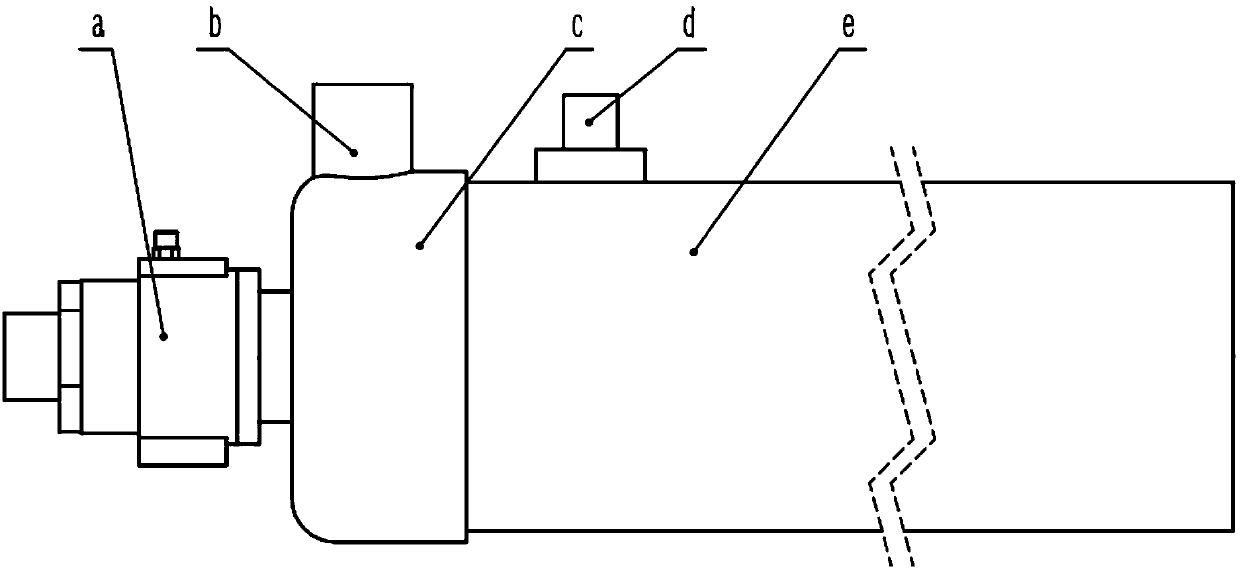

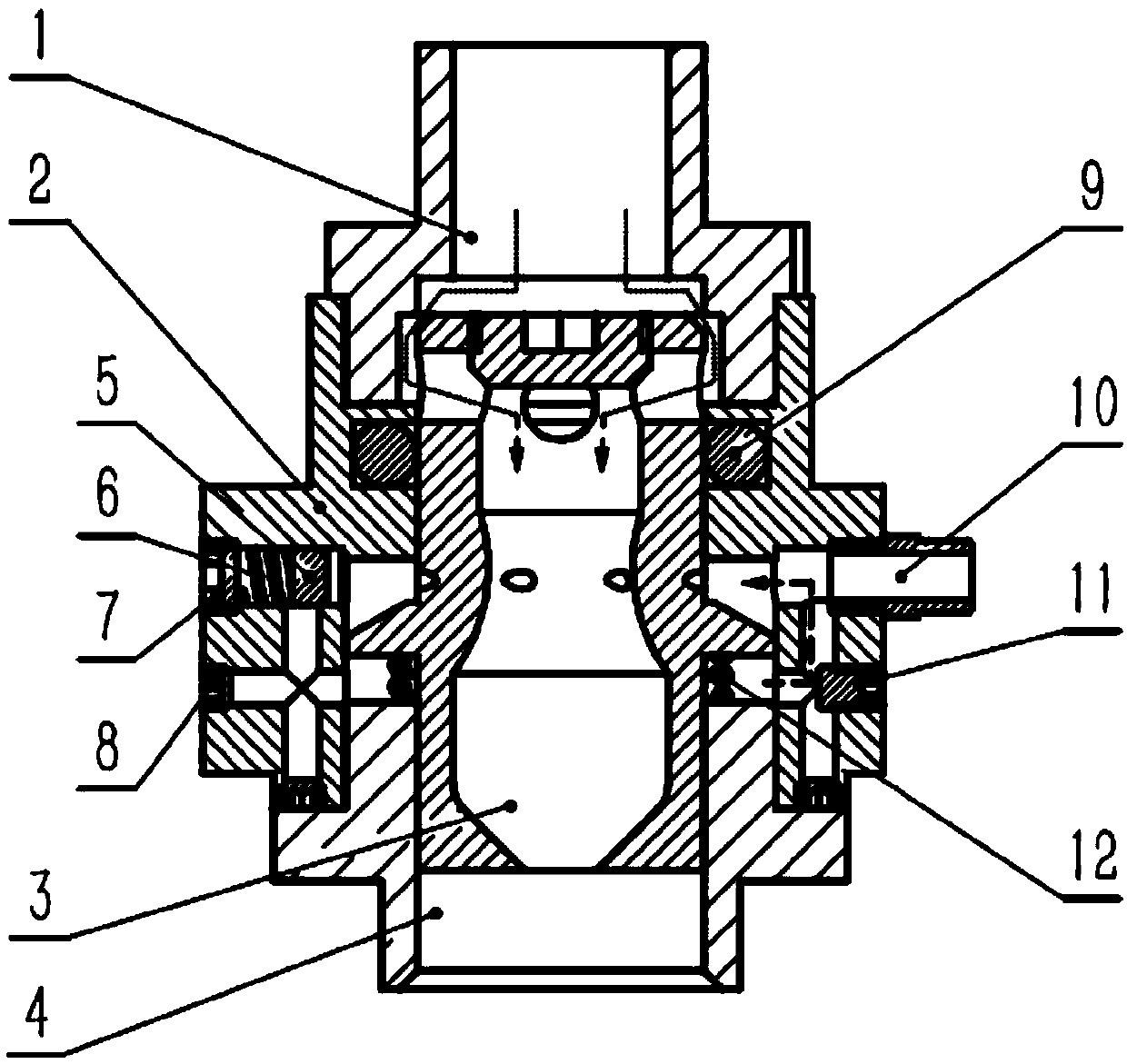

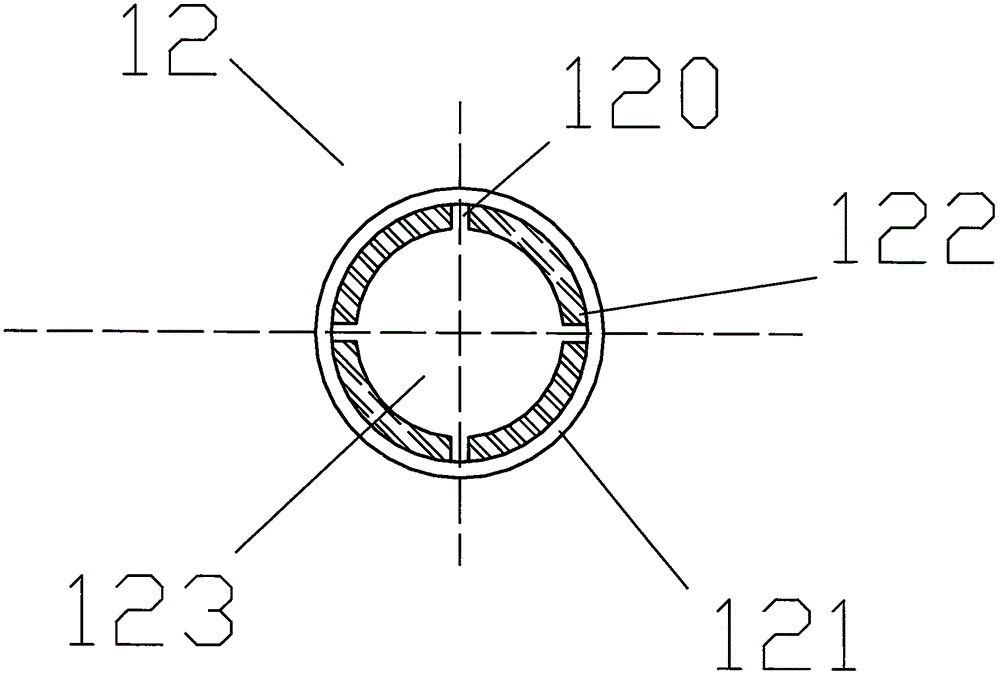

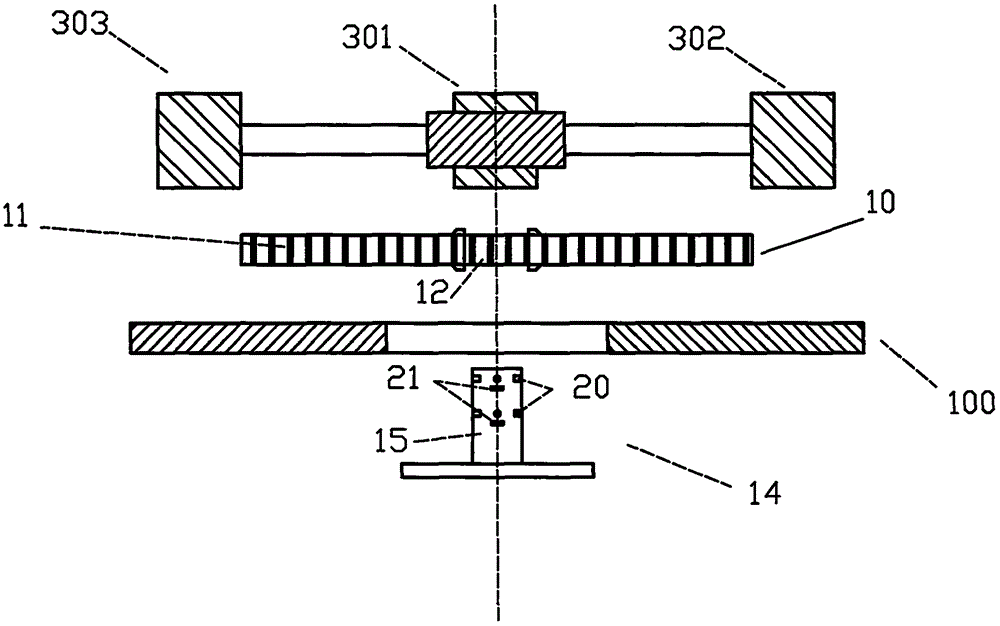

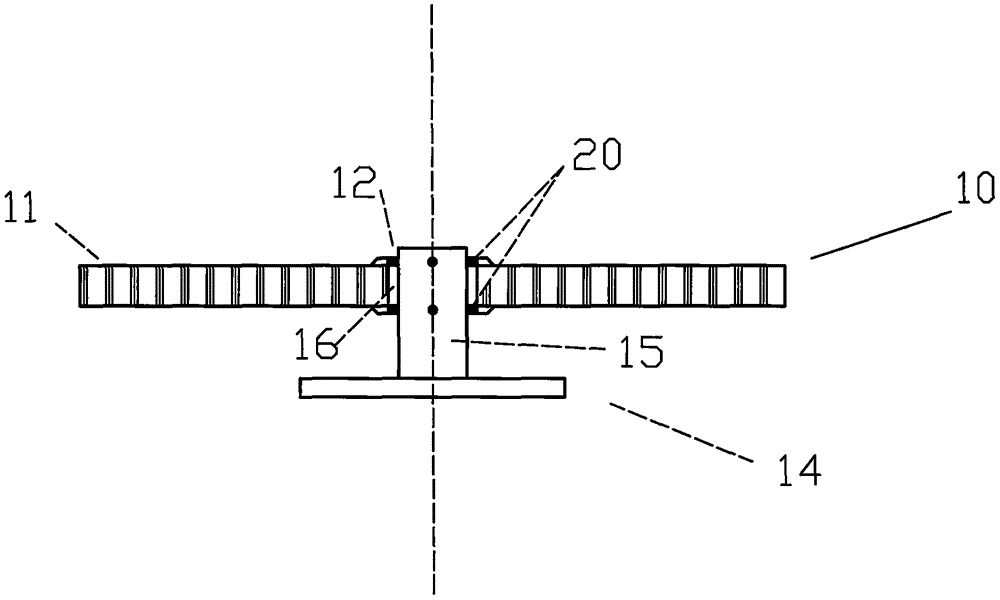

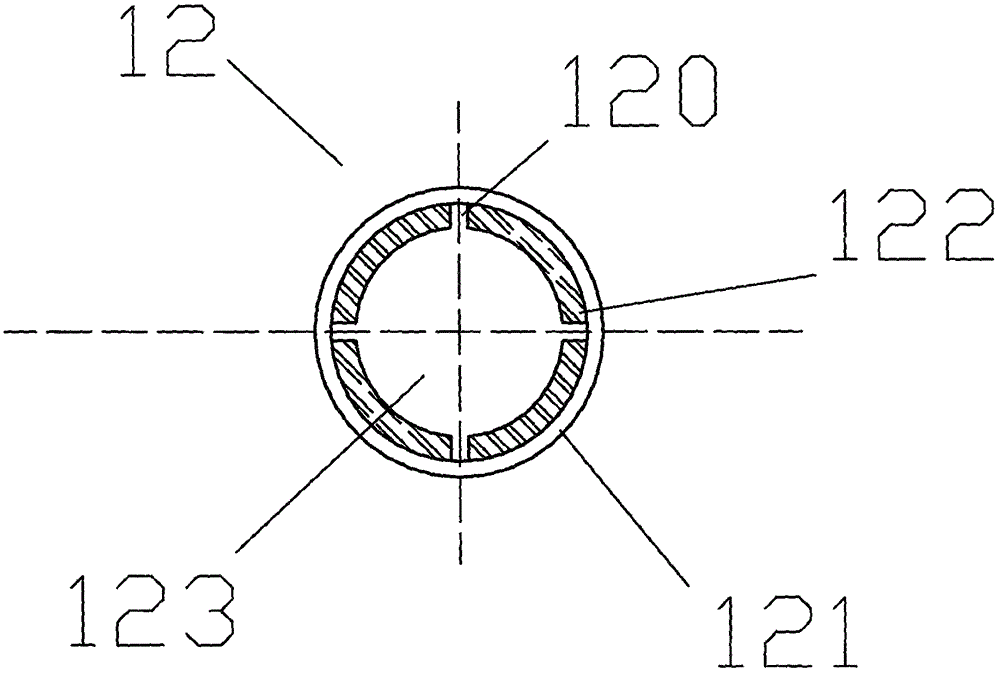

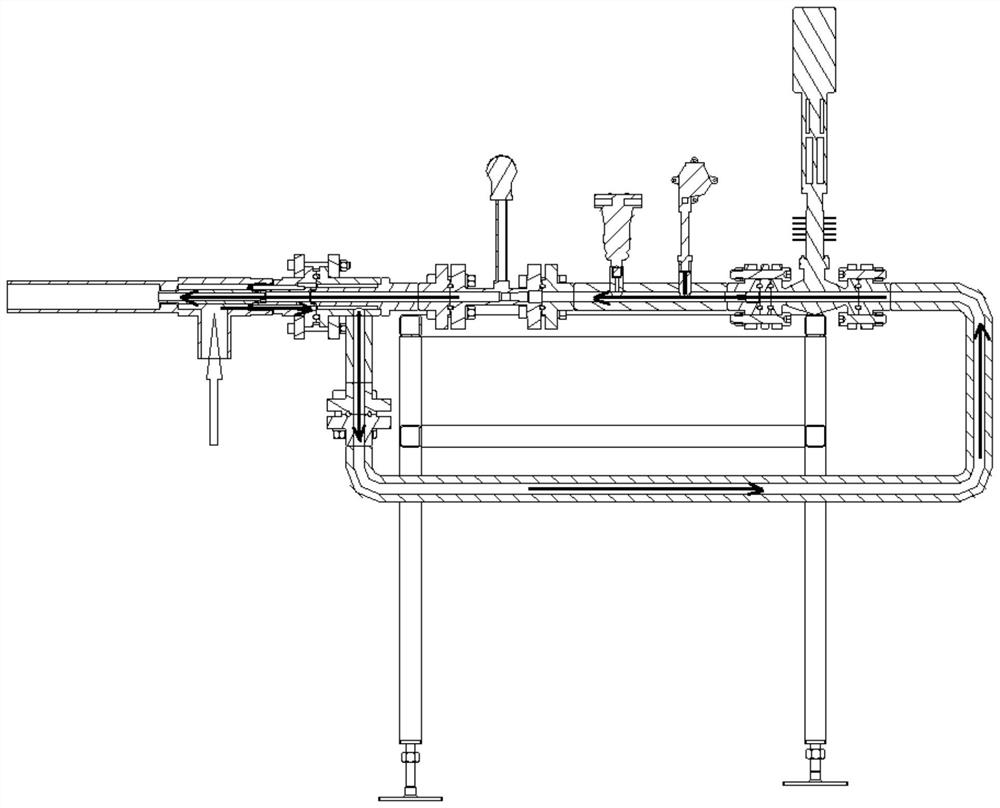

The invention discloses a device for self-adaptive fuel injection into a combustion chamber of a pulse detonation engine, and provides a fuel injection system applicable to the self-adaptive pulse detonation engine. The system mainly comprises an oxidant supply system, a fuel supply system and an injection valve. By periodic pressure fluctuation in a pulse detonation combustion chamber, self-adaptive periodic on and off of a fuel supply passage can be realized, and periodic detonation combustion in the pulse detonation combustion chamber can be realized. By adoption of the fuel injection device, high injection pressure can be adopted for acquiring great atomizing effects; by fuel liquid crushing and mixing action of oxygen, fuel atomization is enhanced. By fuel supply delaying, fuel chamber entering time of a fuel slightly lags behind that of air, air entering the fuel chamber easily serves as isolation air to realize isolation between a high-temperature combustion product and a newlyfilled explosive mixture, an isolation gas system required by a current self-adaptive pulse detonation engine is not needed, and a system structure is simplified.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

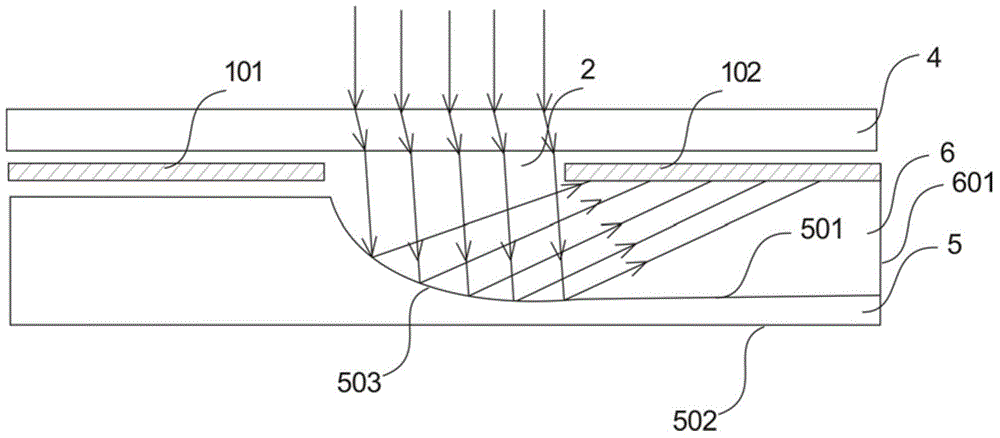

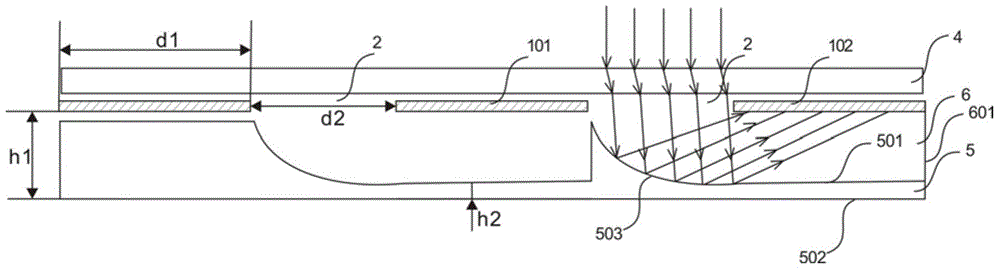

Double-face photovoltaic cell

InactiveCN104993002AReduce weightExpand the scope of applicationPhotovoltaic energy generationSemiconductor devicesPhysicsSunlight

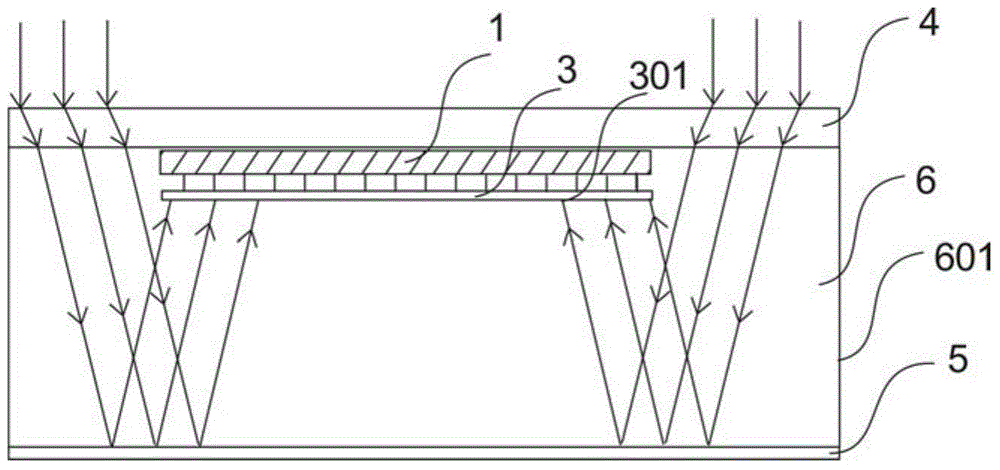

The invention provides a double-face photovoltaic cell. The double-face photovoltaic cell comprises a first protective layer, a photovoltaic cell and a reflecting member used for receiving and reflecting sun rays. There are multiple double-face photovoltaic cells. Gaps are present between adjacent double-face photovoltaic cells. The reflecting member is arranged under the gaps and makes received sun rays reflected to the lower surfaces of the double-face photovoltaic cells. The reflecting member is a second protective layer. The lower surface of the second protective layer is a planar surface while the upper surface is a curved surface. A reflecting coating layer is coated on the curved surface. The first protective layer and the second protective layer are connected in a sealing way to form a sealed chamber. A plurality of double-face photovoltaic cells are arranged inside the sealed chamber. By means of the reflecting members arranged under the gap located between adjacent double-face photovoltaic cells, sun rays emitted in the gap are reflected. The reflecting members are protective layers and achieve protection. Reflection is further achieved through the reflecting coating layer on the curved surface. The weight of the whole photovoltaic cell is reduced. Meanwhile, the double-face photovoltaic cell has a simple structure.

Owner:ARCTECH SOLAR HLDG CO LTD

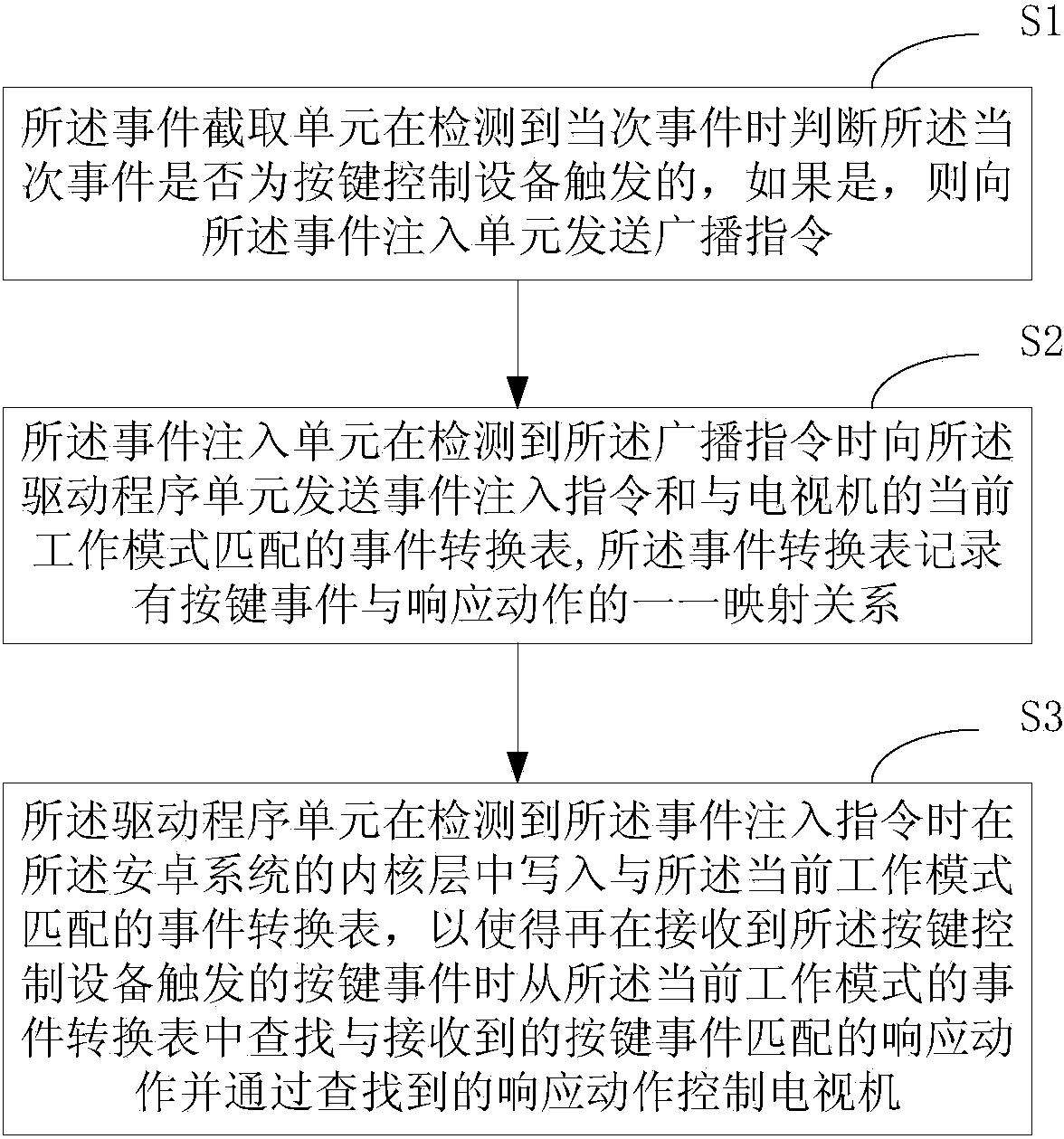

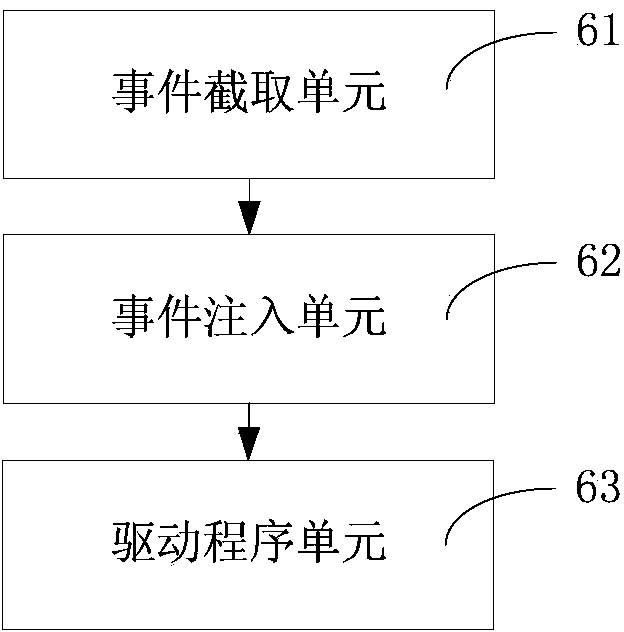

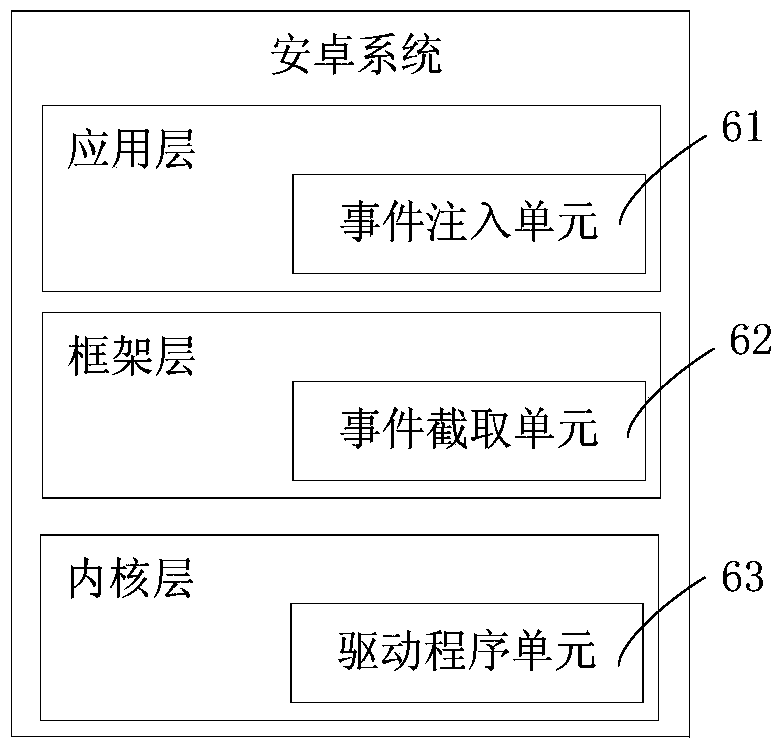

Control method and device based on television applying Android system

ActiveCN103929668AInject fast implementationInjection implementationSelective content distributionPattern matchingEvent triggered

The invention is applicable to the field of televisions and provides a control method and device based on the television applying an Android system. The control method comprises the steps that a broadcast instruction is transmitted to an event injection unit if a current event is triggered by the key control device when an event capture unit detects the current event; when detecting the broadcast instruction, the event injection unit transmits an event injection instruction and an event conversion table matched with the current work mode to a driving program unit; when detecting the event injection instruction, the driving program unit writes the event conversion table matched with the current work mode into a kernel layer of the Android system so as to search the event conversion table matched with the current work mode for a response action matched with a received key event when receiving the key event triggered by the key control device again and control the television through the found response action. By means of the control method and device, rapid event injection during switching of work modes can be achieved, and user experience is facilitated.

Owner:TCL CORPORATION

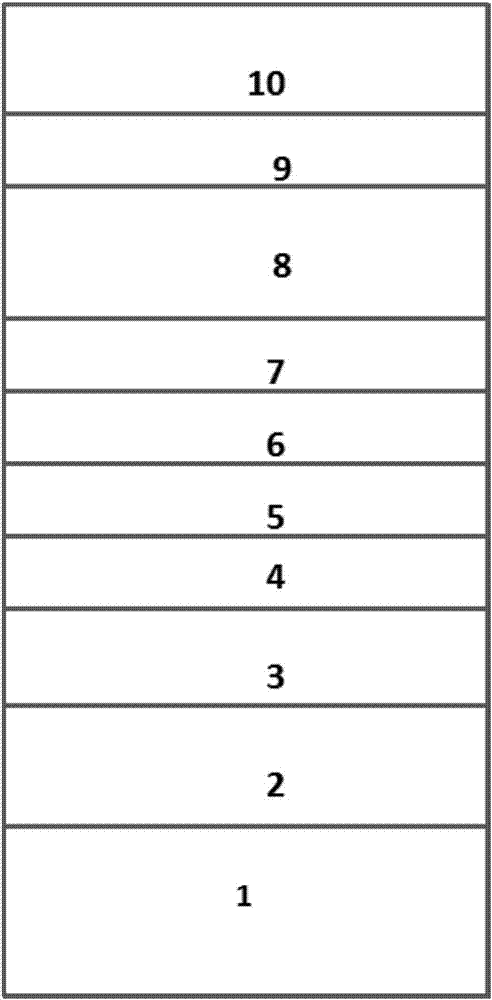

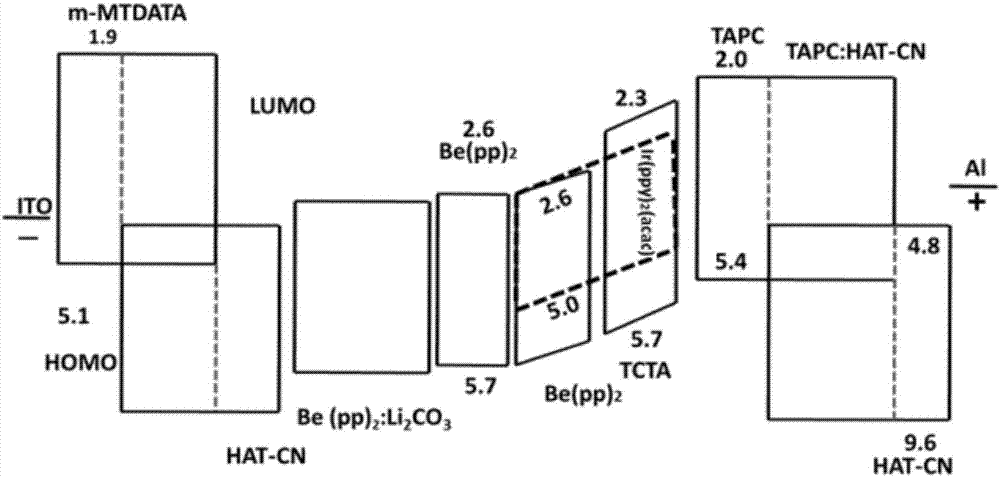

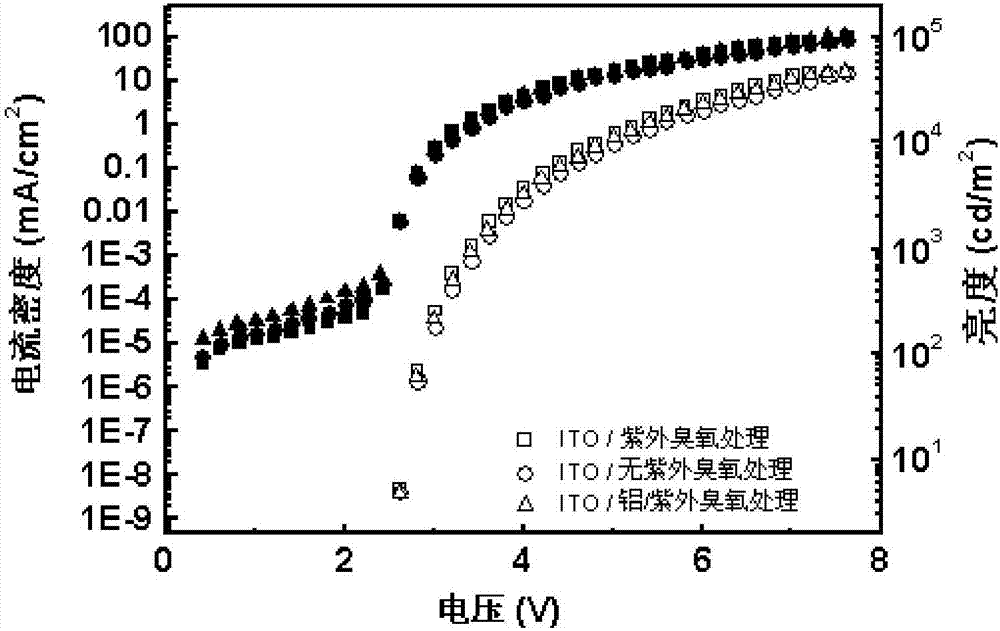

Inverted bottom-emitting organic light-emitting diode and preparation method thereof

ActiveCN107123742ASimplify device structure and processInjection implementationSolid-state devicesSemiconductor/solid-state device manufacturingChemistryOptoelectronic materials

The invention belonging to the technical field of the organic optoelectronic material discloses an inverted bottom-emitting organic light-emitting diode and a preparation method thereof. The inverted bottom-emitting organic light-emitting diode is composed of a substrate, a cathode, an organic heterojunction charge generation layer, an electron transport layer, a hole / exciton barrier layer, a phosphorescent dye doped light-emitting layer, an electron / exciton barrier layer, a hole transport layer, a hole injection layer and an anode that are connected in sequence. The organic heterojunction charge generation layer is a two-layer organic semiconductor heterojunction formed by a p type organic semiconductor and an n type organic semiconductor or a hybrid bulk heterojunction formed by mixing of two kinds of organic semiconductors. According to the invention, the organic semiconductor heterojunction is used as the electron injection layer to solve a problem of electron injection of the inverted bottom-emitting OLED, so that the prepared inverted bottom-emitting organic light-emitting diode has an advantage of high efficiency; and the device structure and the process are simplified.

Owner:SOUTH CHINA UNIV OF TECH

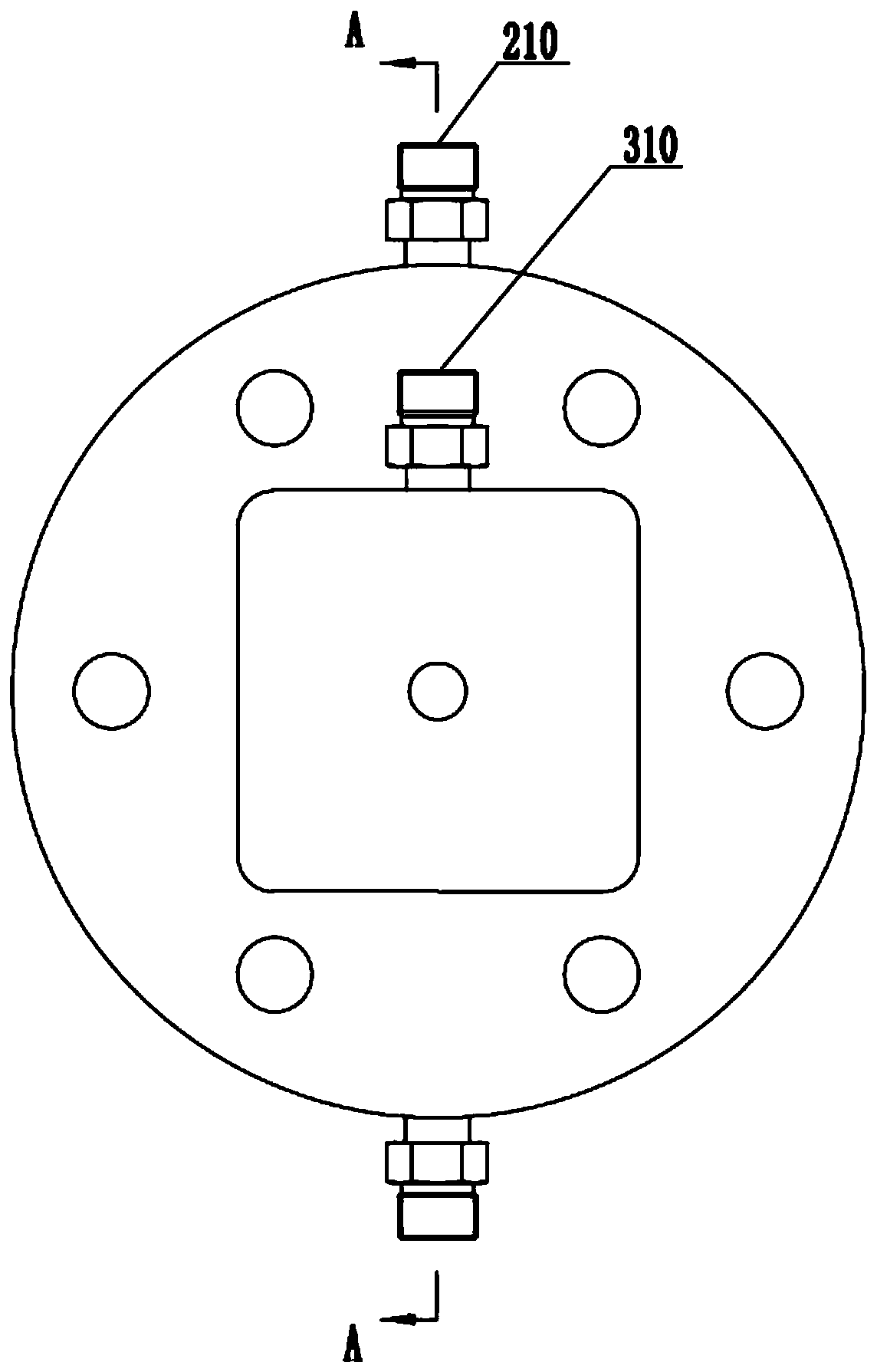

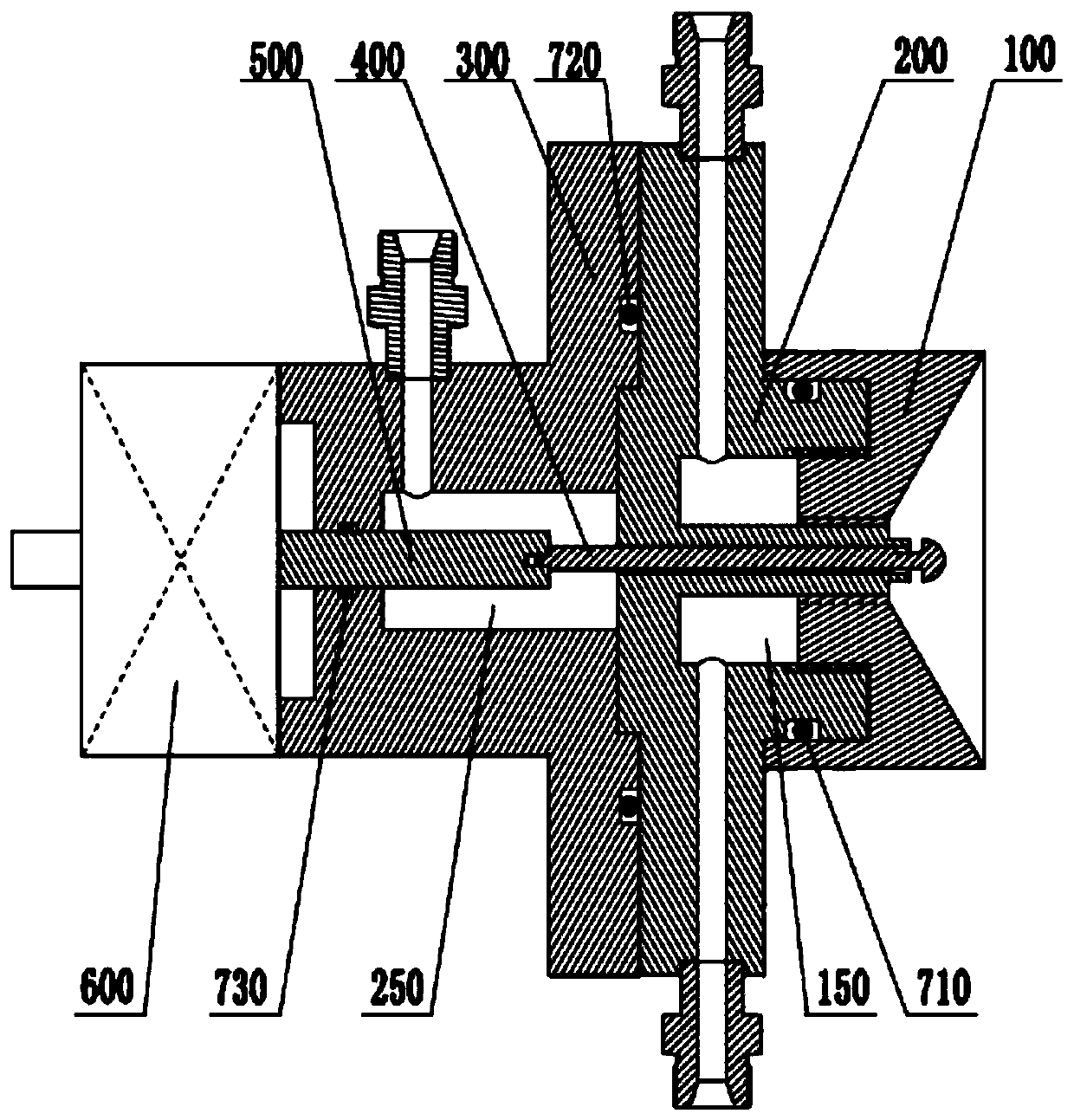

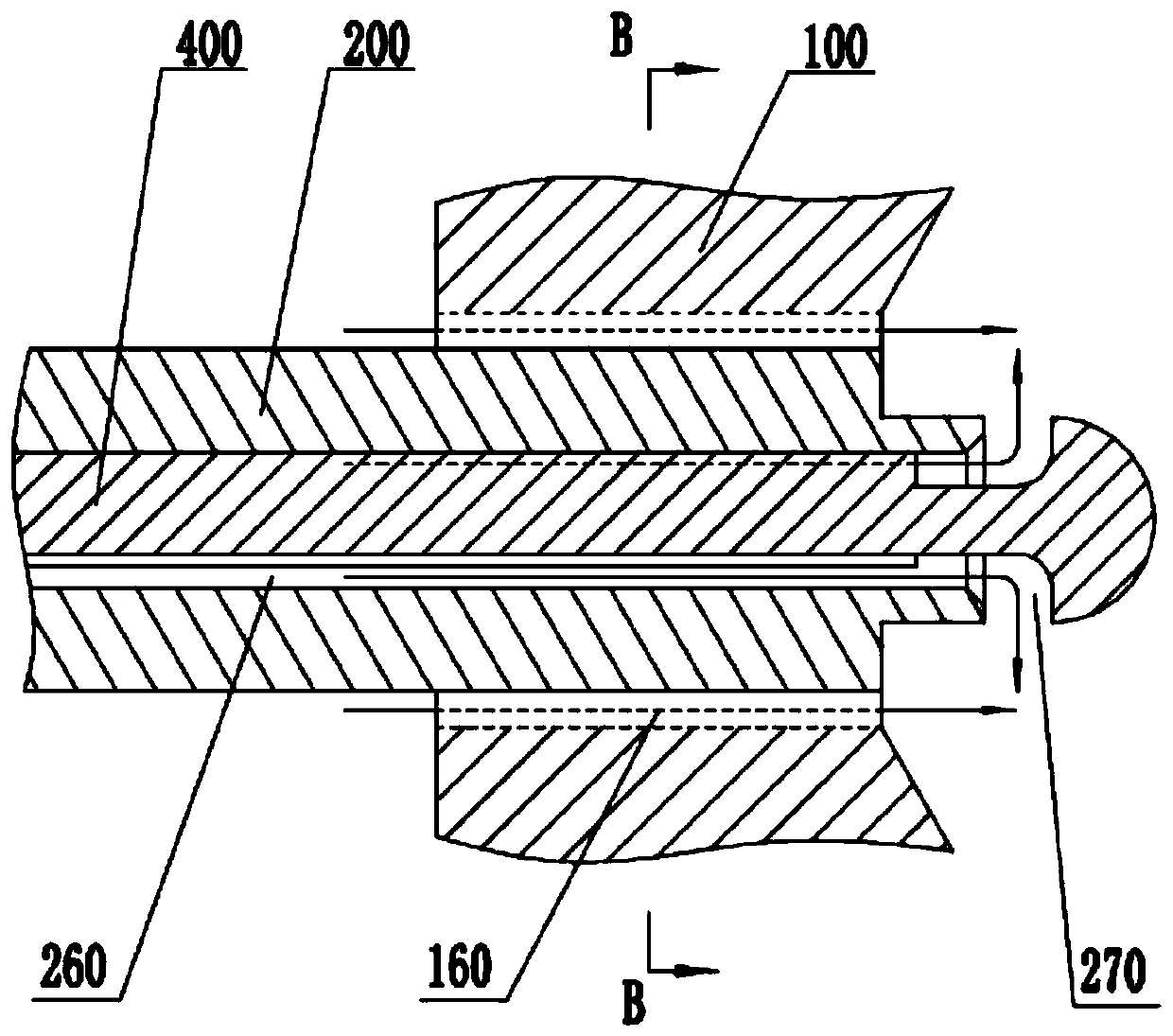

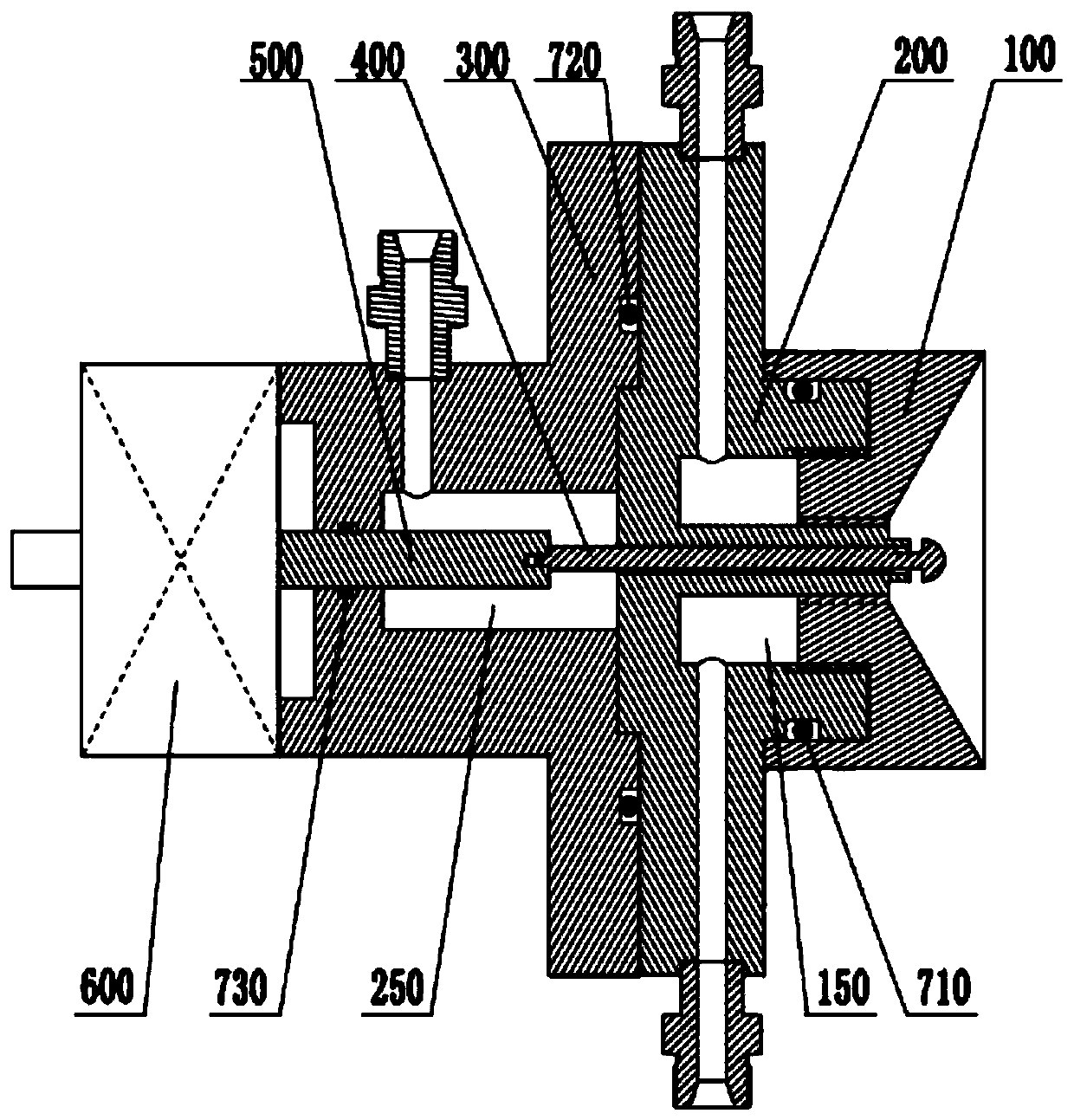

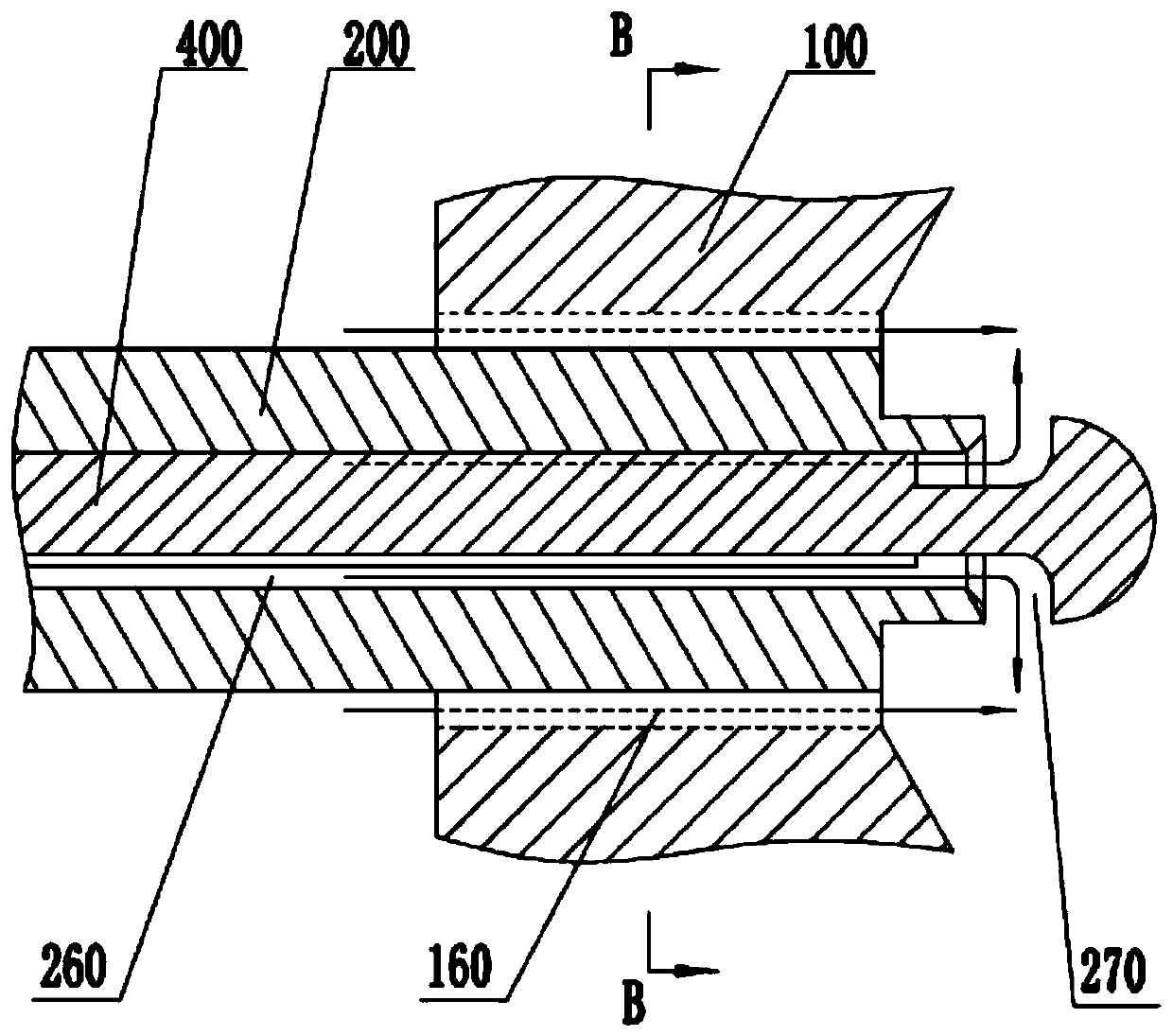

Injector, rocket engine and rocket

ActiveCN110714856AInjection implementationMitigate technical issuesRocket engine plantsCombustion chamberPhysics

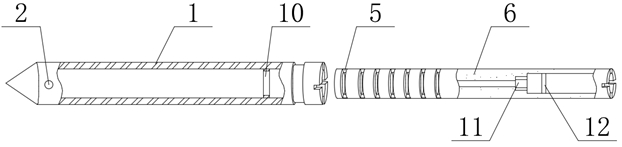

The invention provides an injector, a rocket engine and a rocket, and relates to the technical field of vehicles. The injector comprises an upper bottom, a middle bottom and a lower bottom, wherein one side of the middle bottom is connected with the upper bottom, a gas collecting cavity and a gas channel are arranged between the middle bottom and the upper bottom, the gas channel communicate the gas collecting cavity with a combustion chamber, and the gas collecting cavity is provided with a gas inlet; the other side of the middle bottom is connected with the lower bottom, a liquid collectingcavity is formed between the middle bottom and the lower bottom, and the liquid collecting cavity is provided with a liquid inlet; and the injector further comprises a pin bolt which penetrates through the lower bottom, the liquid collecting cavity and the middle bottom, the pin bolt is in sealing connection with the lower bottom, and a liquid channel used for communicating the liquid collecting cavity with the combustion chamber is arranged between the pin bolt and the middle bottom. In the injector, a gas propellant can enter the gas collecting cavity through the gas inlet and then enters the combustion chamber through the gas channel, and the liquid propellant can enter the liquid collection cavity through the liquid inlet and then enters the combustion chamber through the liquid channel, that is to say, the injector is capable of achieving a jet of a two-component propellant of a gas and a liquid.

Owner:BEIHANG UNIV

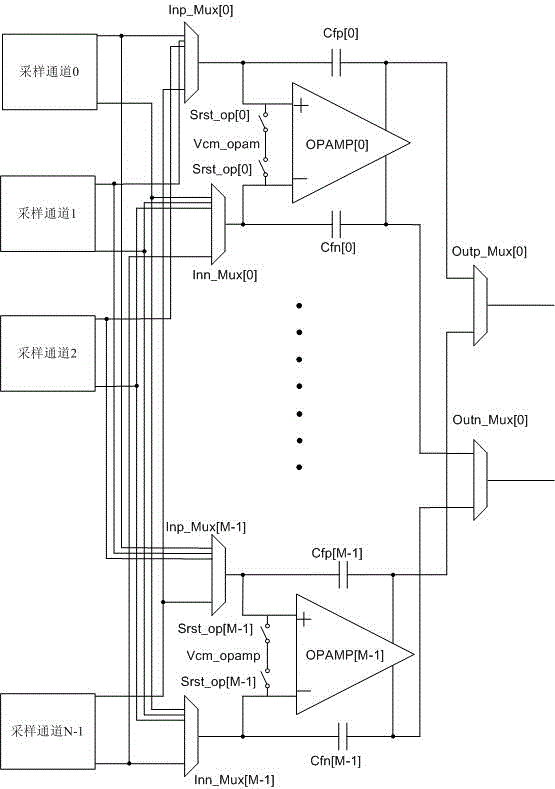

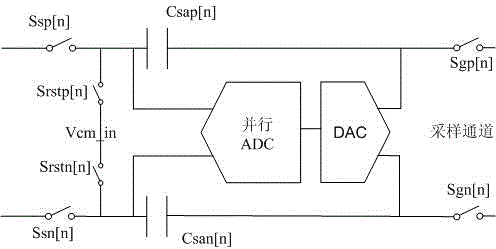

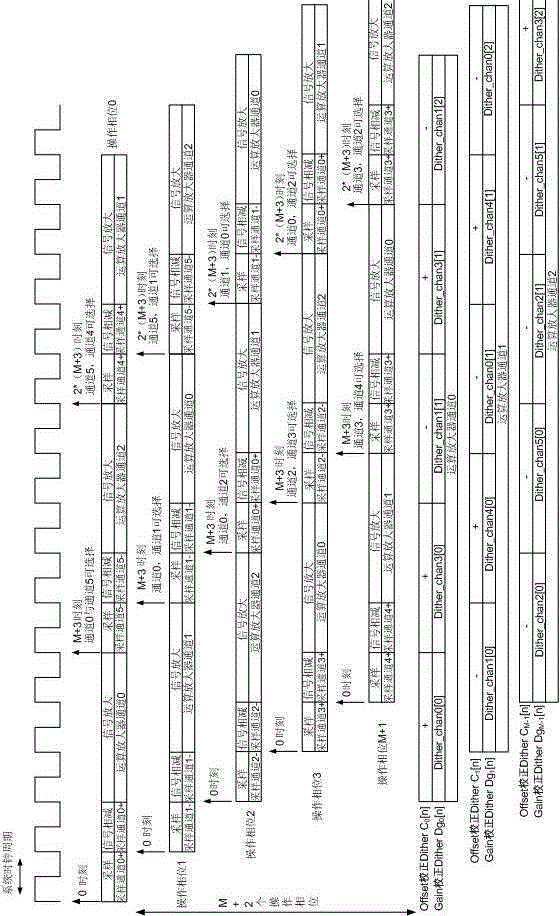

Time-interleaved assembly line ADC system and sequential operation method thereof

ActiveCN105406867ASave power and area overheadSave dynamic reverse circuitAnalogue-digital convertersVIT signalsCorrection method

The invention discloses a time-interleaved assembly line ADC system and a sequential operation method thereof. The time-interleaved assembly line ADC system comprises a digital-analogue converter structure, a disturbance calibrating signal injection structure and a self-adaptive algorithm principle; under the relatively low system overhead, the digital-analogue converter structure can realize injection of disturbance signals and normalized capacitance parameter correction of various channels; sampling randomization is realized by using a redundancy sampling channel, such that the channel delay deviation is reduced to the noise background; compared with the traditional delay correction method, a lot of power consumption and area overheads can be saved; in combination with randomized sampling channel section, a dynamic reverse circuit in the traditional operational amplifier offset correction circuit is saved by using a non-fixed positive and negative signal polarity channel, such that time sequence requests are reduced; injection of gain correction disturbance signals is separated by using multiple correctable channels; compared with the traditional scheme, a front high-speed sample hold circuit having high power consumption is saved; and the sampling speed of the time-interleaved assembly line ADC system is increased.

Owner:CHENGDU BOSIWEI TECH CO LTD

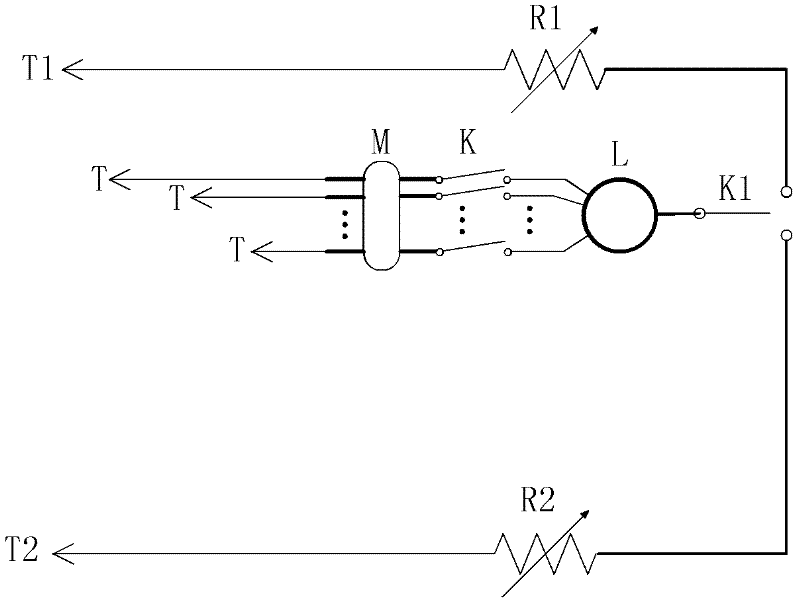

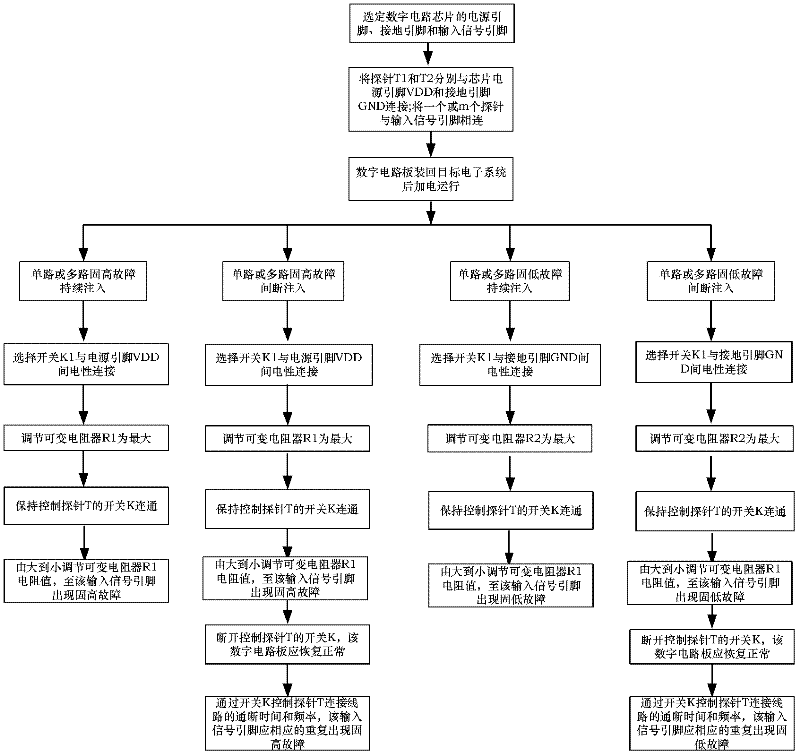

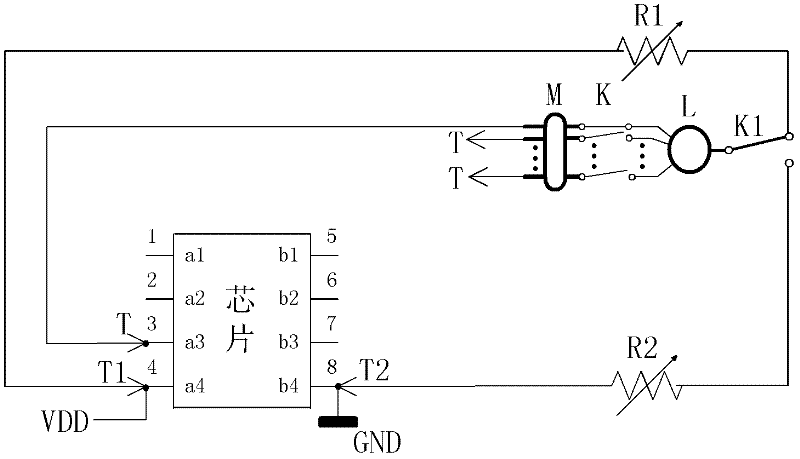

Fixed-high and fixed-low fault injecting circuit and method for online test of digital circuit board

ActiveCN102645628AInjection implementationWill not harmDigital circuit testingElectrical resistance and conductanceOnline test

The invention discloses a fixed-high and fixed-low fault injecting circuit and method for an online test of a digital circuit board. The circuit comprises variable resistors R1 and R2, a cable assembly M, a lead wire group L, a switch K, a selection switch K1 and probes T, T1 and T2, wherein the selection switch K1 selects the variable resistor R1 or R2 to be electrically connected with a power supply pin or a grounded pin of a digital circuit chip, is communicated with the probe T through the controlling of the switch K and then is connected with an input signal pin of the digital circuit chip, so that the variable resistor R1 or R2 is electrically connected with a line between the input signal pin of the digital circuit chip and the power supply pin or the grounded pin of the digital circuit chip; the resistance value of the variable resistor R1 or R2 is adjusted from big to small until the input signal pin has the fixed-high or fixed-low fault; and then, the adjustment of the resistors is stopped and the fault injection is successful. The fixed-high and fixed-low fault injecting circuit and method for the online test of the digital circuit board can realize single-path or multi-path continuous or discontinuous fixed-high or fixed-low fault injection of the input signal pin of the digital circuit chip and meet the technical requirements of testability experiments.

Owner:北京恒兴易康科技有限公司

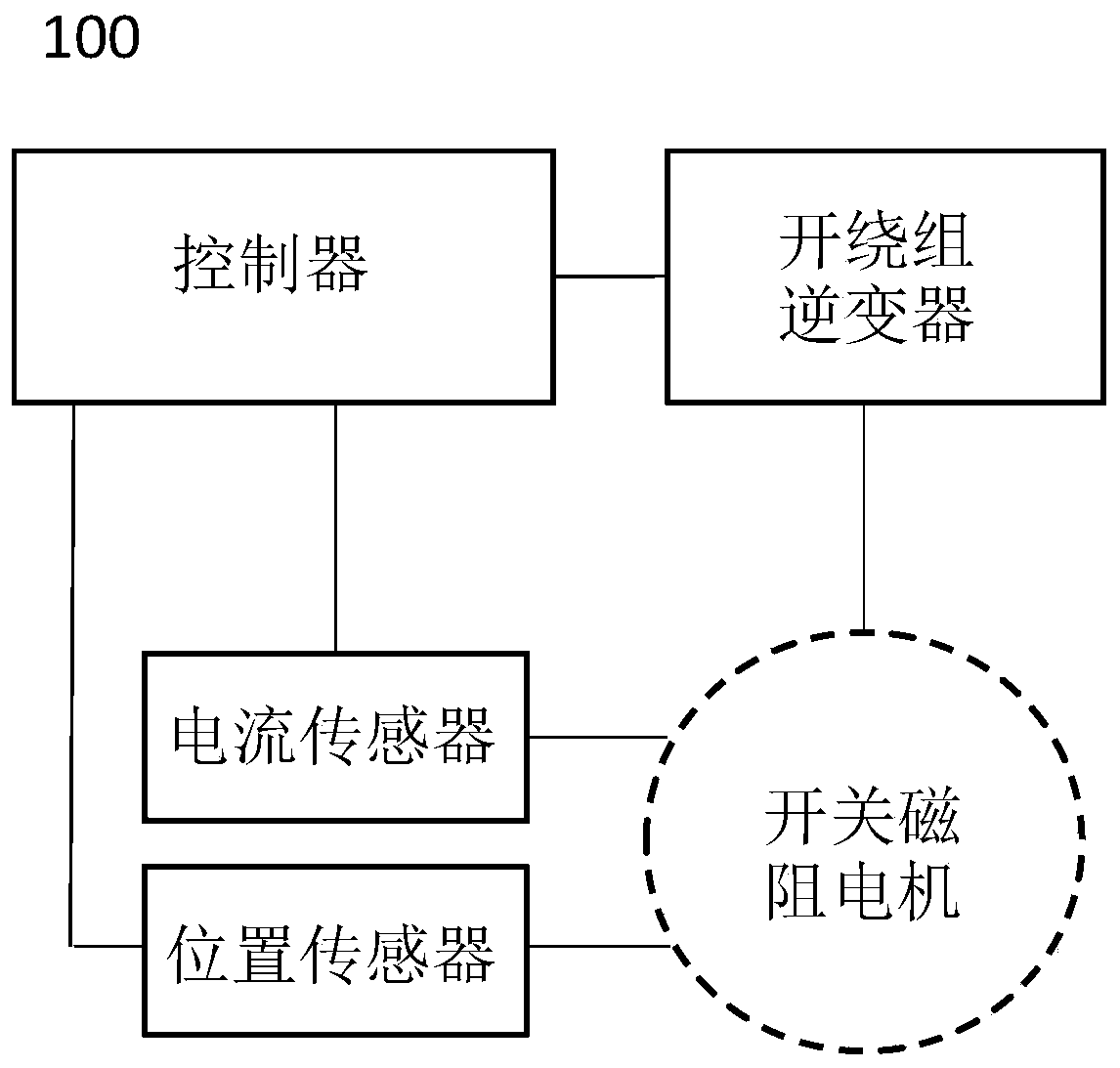

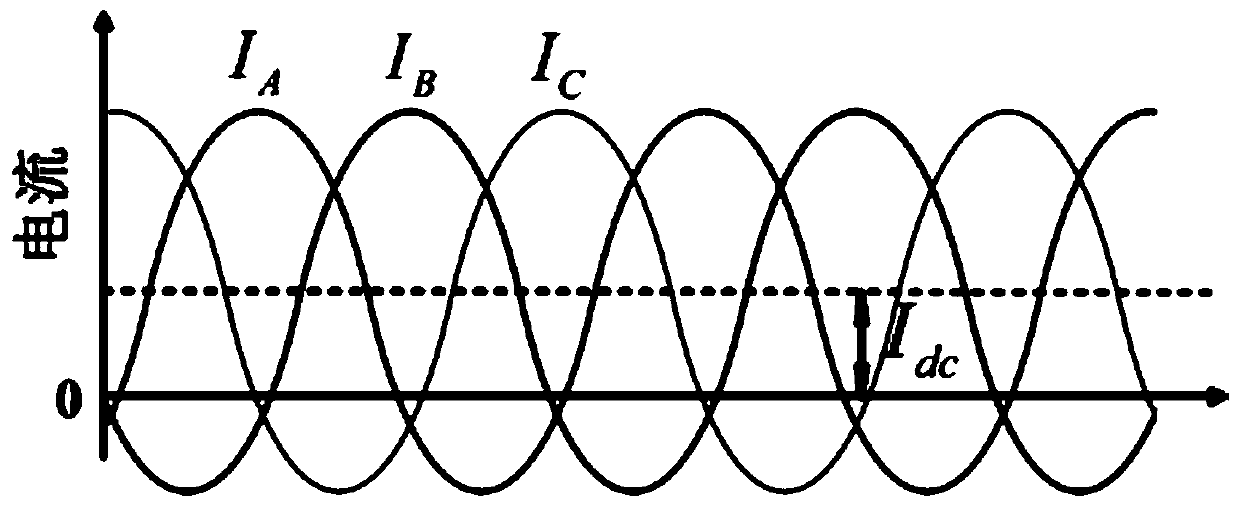

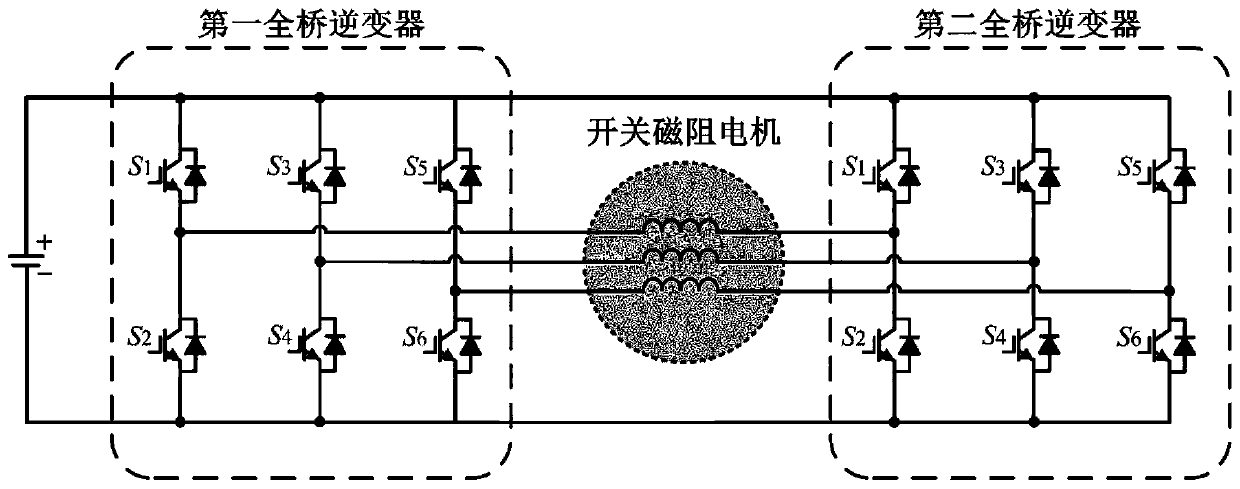

Switched reluctance motor open winding control system and control method

ActiveCN110247607AReduce torque rippleReduce vibration and noiseAC motor controlControl vectorThree-phase

The invention discloses a switched reluctance motor open winding control system and method. The system comprises a controller, a current sensor, a position sensor and an open winding inverter. The controller is used for receiving a three-phase current feedback value of the switched reluctance motor collected by the current sensor and a position and rotating speed feedback value of the switched reluctance motor collected by the position sensor and controlling the open winding inverter to generate bipolar sinusoidal current with DC bias and inject the bipolar sinusoidal current into the switched reluctance motor. based on a three-phase current feedback value of the switched reluctance motor collected by the current sensor and a position and rotating speed feedback value of the switched reluctance motor collected by the position sensor by adopting an AC motor rotating speed-current double closed-loop vector control method. The controller is introduced. The system is based on AC motor rotating speed-current double closed-loop vector control. By utilizing a three-phase open winding inverter, bipolar sine wave current injection with DC bias current is realized, the torque pulsation of the switched reluctance motor is effectively reduced, the flexible adjustment of an excitation magnetic field is realized. The system is suitable for a high-performance switched reluctance motor driving system with higher requirements on torque pulsation and torque output, and is wide in application range.

Owner:HUAZHONG UNIV OF SCI & TECH

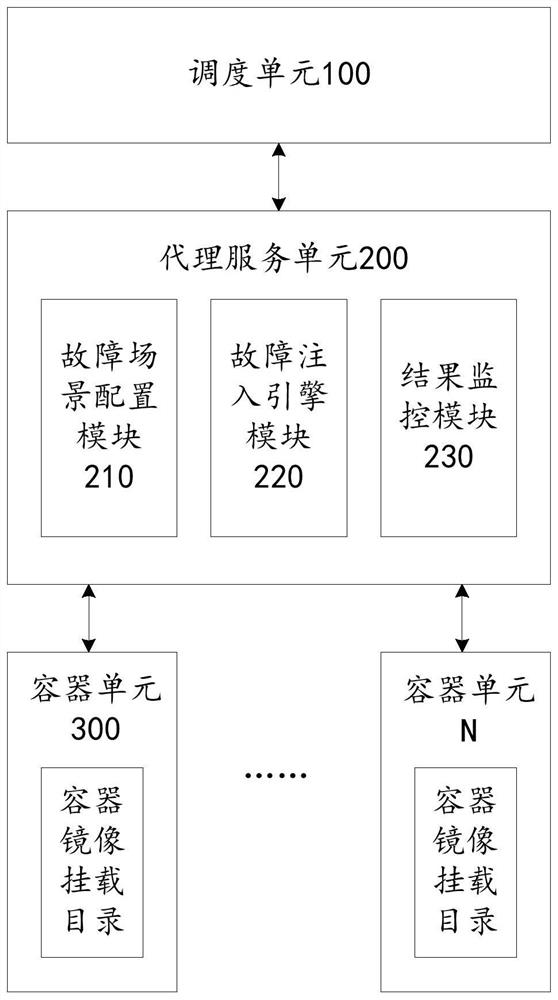

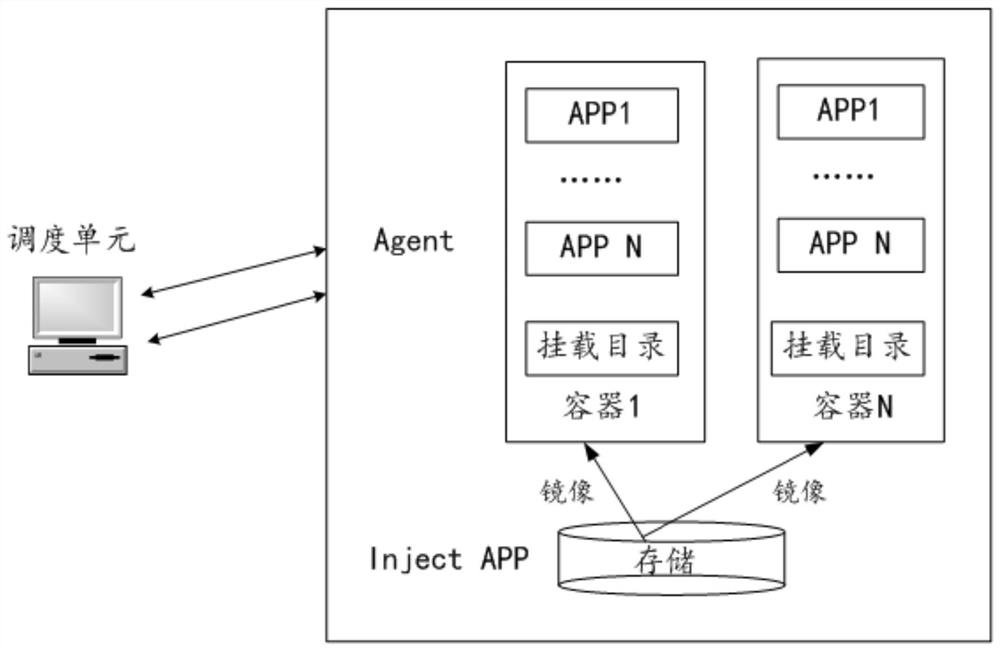

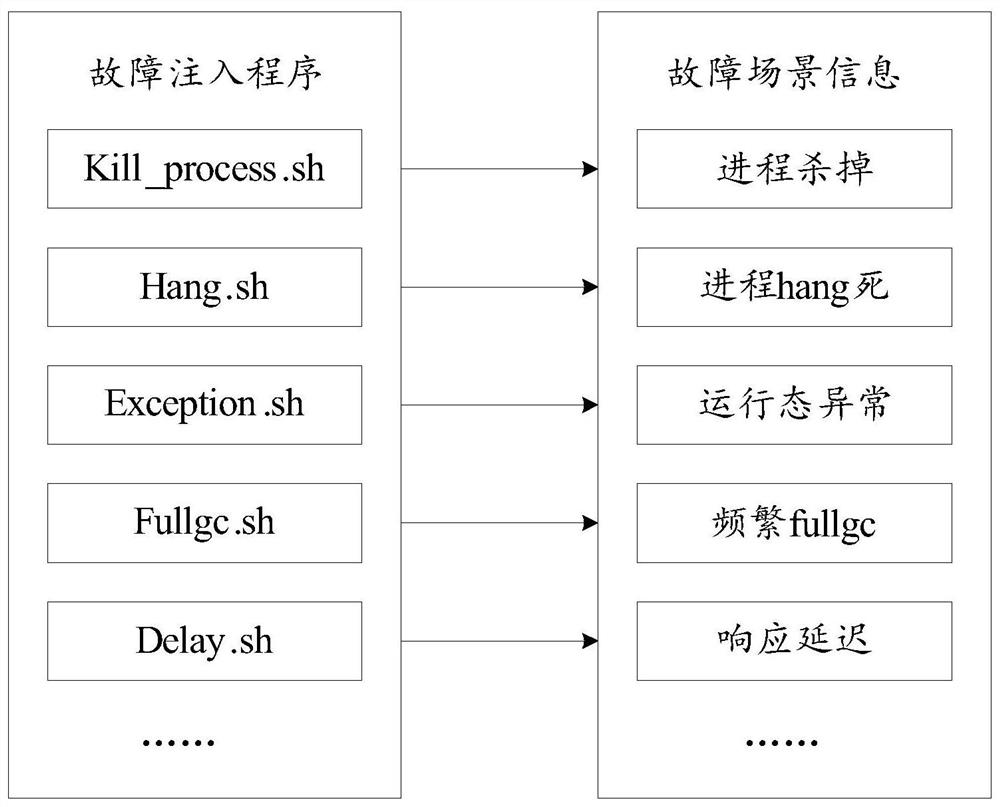

Fault injection system, method and device

PendingCN113535532AEasy injectionInject convenience implementationSoftware testing/debuggingDirectoryMirror image

The embodiment of the invention relates to the technical field of computers, and discloses a fault injection system, method and device, and the system comprises: a scheduling unit, which is used for transmitting a fault injection instruction to a proxy service unit; a container unit, which comprises a container mirror image mounting directory, wherein the container mirror image mounting directory is used for receiving a fault injection program sent by the proxy service unit; a proxy service unit, which comprises a fault scene configuration module, a fault injection engine module and a result monitoring module; a fault scene configuration module, which is used for configuring a corresponding fault injection program according to a preset fault injection scene; a fault injection engine module, which is used for receiving a fault injection instruction sent by the scheduling unit, acquiring a corresponding fault injection program from the fault scene configuration module according to the fault injection instruction, and injecting the fault injection program into a container mirror image mounting directory of the container unit; and a result monitoring module, which monitors the fault injection result. According to the embodiment of the invention, the fault injection efficiency is improved.

Owner:CHINA MOBILE GROUP ZHEJIANG +1

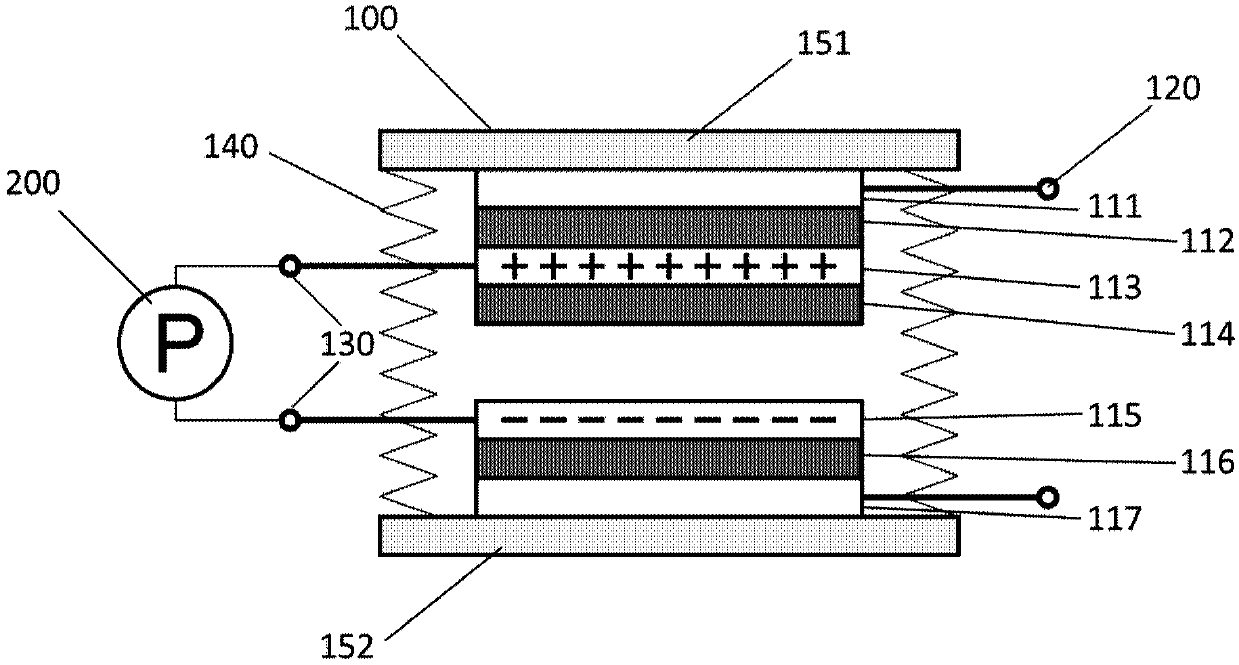

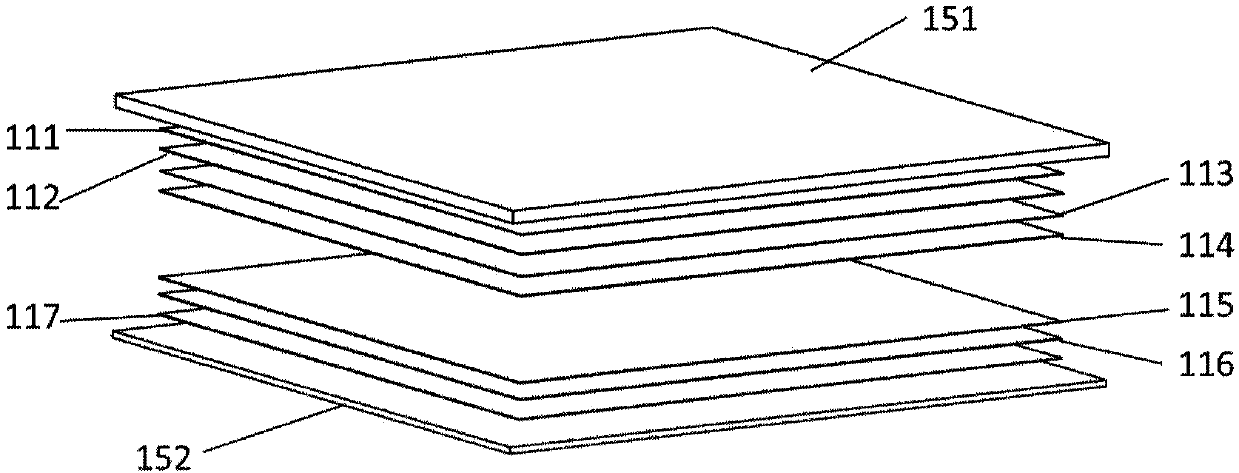

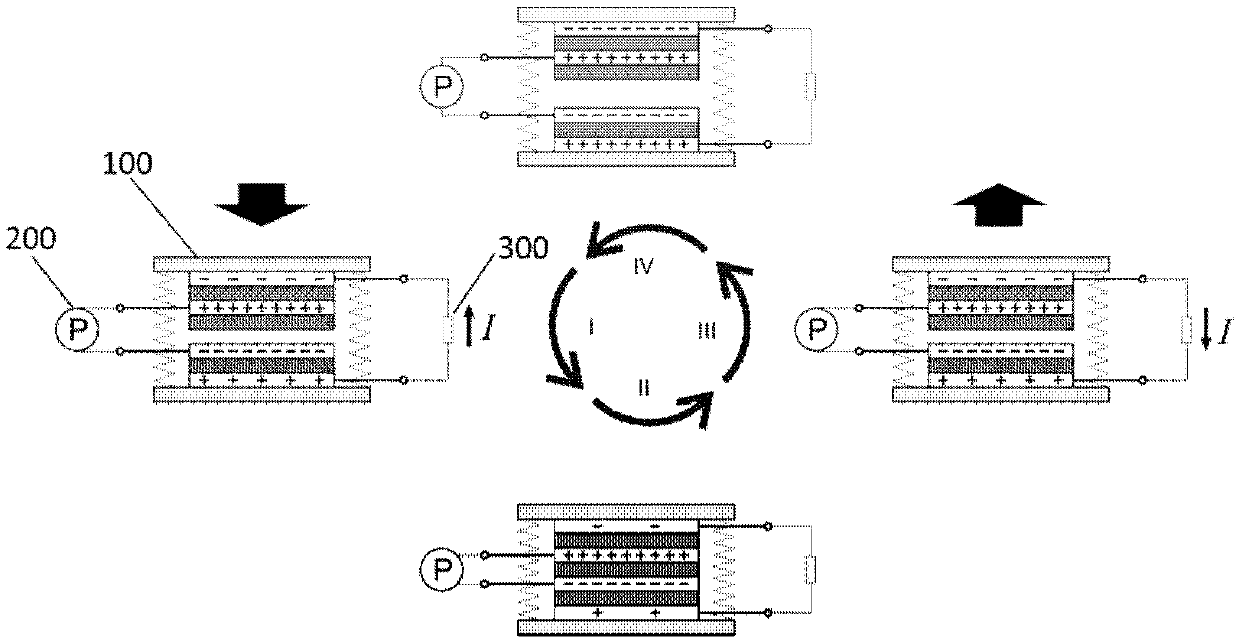

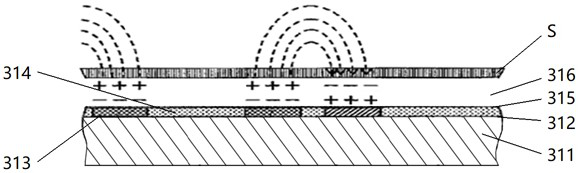

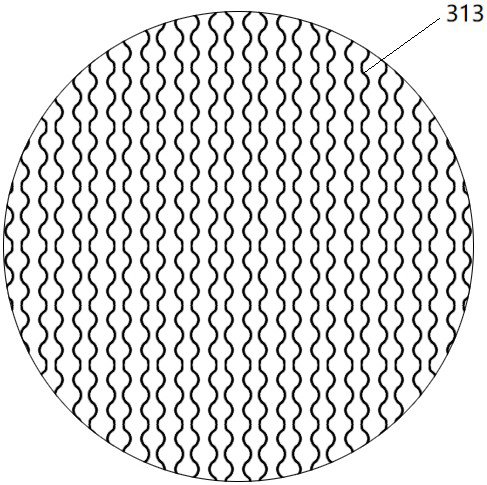

Nanometer generator system and power supply device

ActiveCN110176872AConstrained Dissipation VelocityFrom breakdownFriction generatorsNanogeneratorEngineering

The invention discloses a nanometer generator system and a power supply device. The nanometer generator system comprises an electrode layer, a floating layer, a dielectric layer arranged on the uppersurface and / or the lower surface of the floating layer, and a charge pump connected with the floating layer and used for injecting charge into the floating layer; and the generator system outputs an electric signal to an external circuit when the floating layer moves relative to the electrode layer. The floating layer and a combination of the floating layer and the dielectric layer are used as equivalence of at least one friction layer with friction electrification and electrostatic charge storage functions; and the charge can be controllably injected into the floating layer in real time through the charge pump. The charge density of the nanometer generator system is no longer generated by mainly depending on friction or contact and is not restricted by air breakdown and the like; and thenanometer generator system has high power output density.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

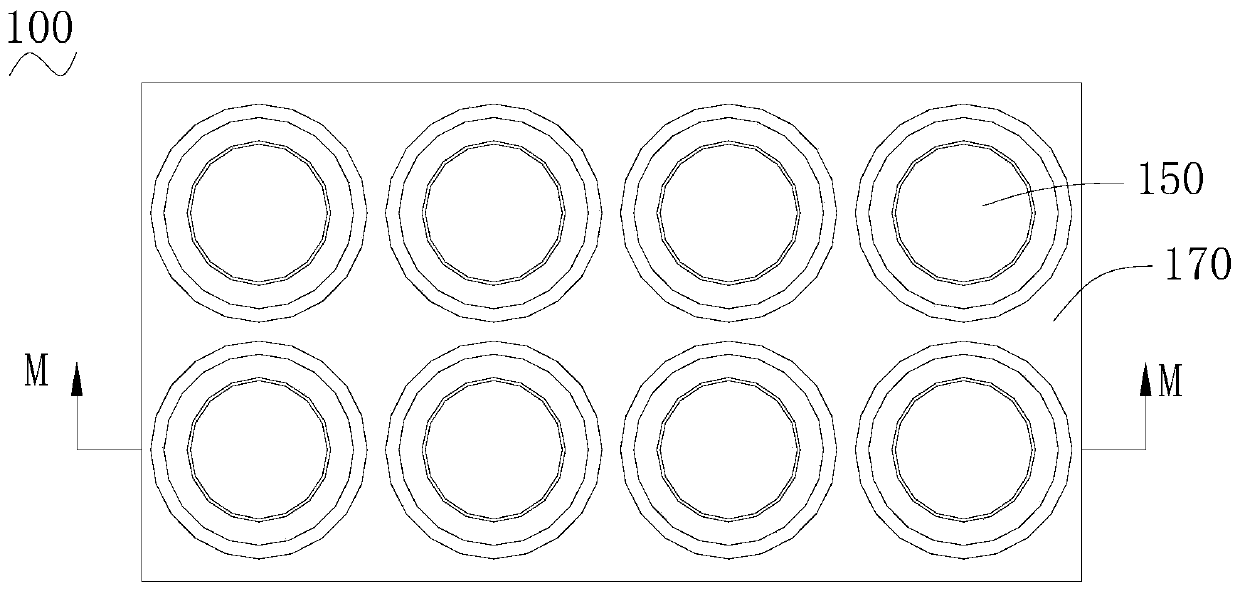

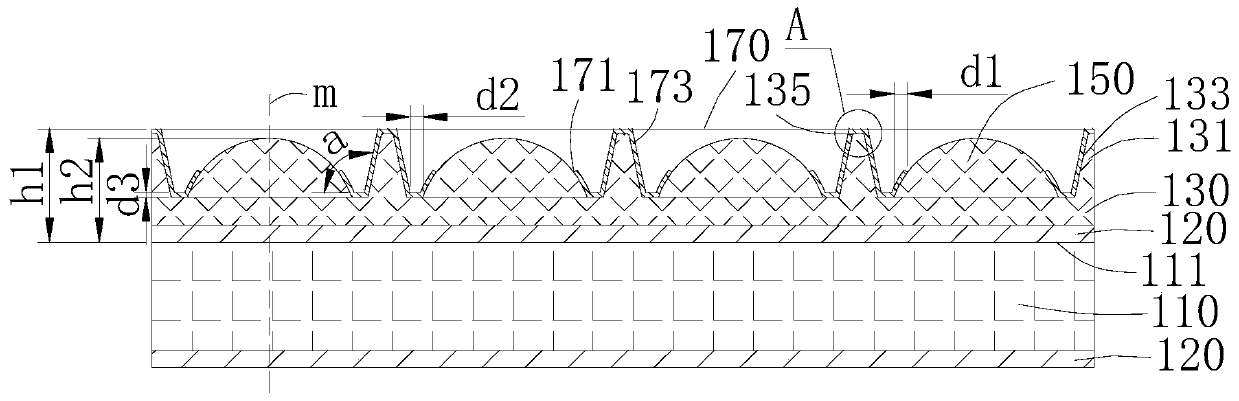

Microlens assembly, preparation method, optical fingerprint module and electronic device

InactiveCN111353479AEasy to coverReduce intensityCharacter and pattern recognitionLensEngineeringMicro lens array

The invention relates to a micro-lens assembly, a preparation method, an optical fingerprint module and an electronic device. The micro-lens assembly includes a transparent substrate; an imprinting base which is arranged on the transparent substrate, wherein bulges are arranged on the surface, far away from the transparent substrate, of the imprinting substrate, and a plurality of non-communicatedrecesses are defined by the bulges; a micro-lens array which comprises a plurality of micro-lenses which are arranged on the surface, far away from the transparent substrate, of the imprinting base and are arranged in an array, wherein the micro-lenses are in one-to-one correspondence with the recesses, and the micro-lenses are located in the recesses; a shading layer which completely covers thepart, which is not covered by the micro lenses, of the imprinting substrate and partially covers the micro-lenses; a shading layer which is provided with a plurality of hollow structures in one-to-onecorrespondence with the micro-lenses; in the direction perpendicular to the working surface, the central axis of the hollow structure is collinear with the central axis of the corresponding micro-lenses; in the direction perpendicular to the working face, the projection of the hollow structure on the micro-lenses completely falls on the micro-lenses, and a gap is formed between the projection ofthe hollow structure and the edge of the micro-lenses.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

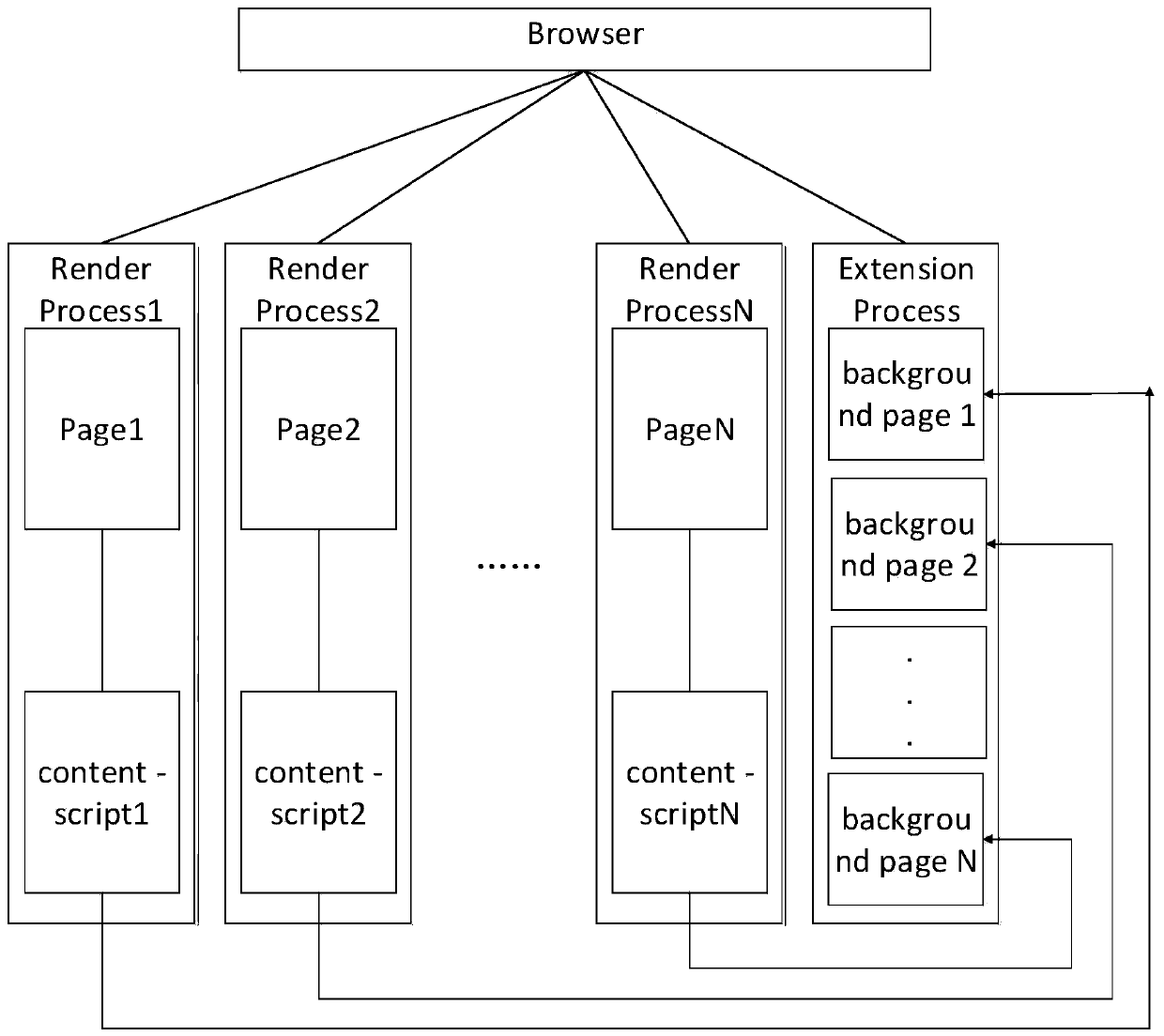

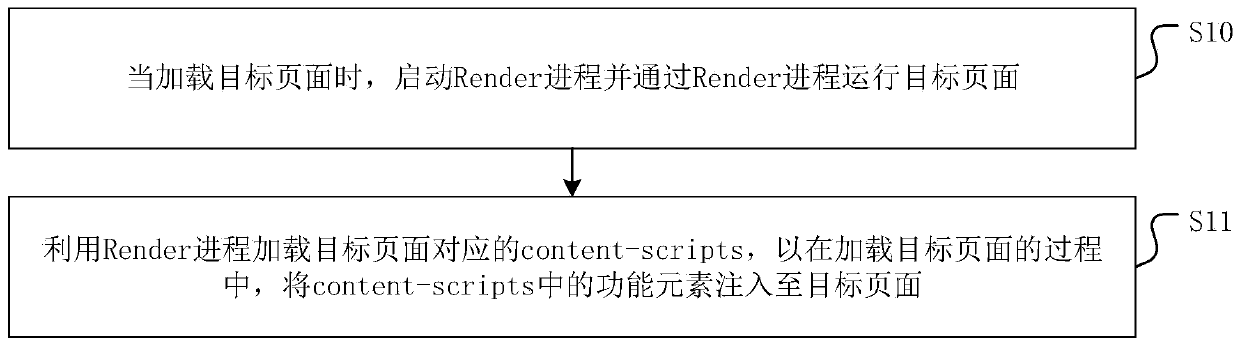

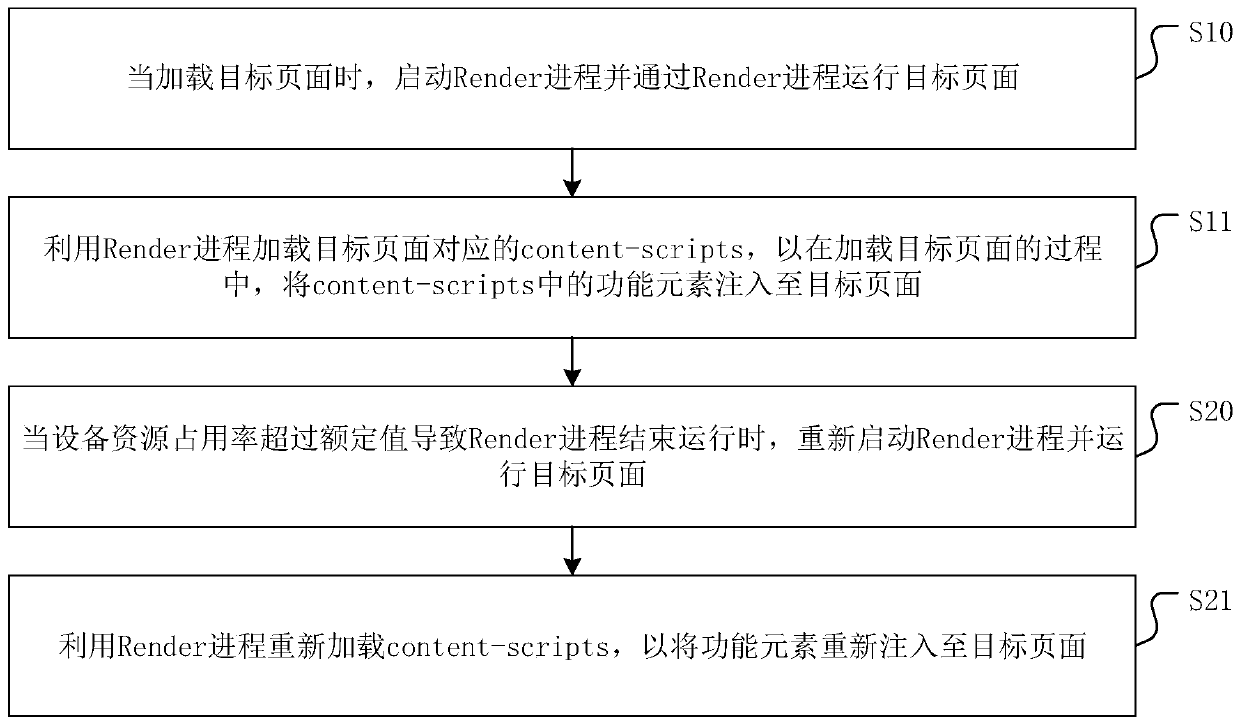

Page loading method, device and system and medium

ActiveCN109933385AInjection implementationAvoid continuous occupationWebsite content managementProgram loading/initiatingDatabaseFunction Code

The invention discloses a page loading method, device and system and a medium. The method comprises: when a target page is loaded, a Render process is started, and the target page is operated throughthe Render process; loading content-scripts corresponding to target page by utilizing Render process, so as to inject the functional elements in the content-scripts into the target page in the processof loading the target page, wherein, the functional elements in the content-scripts comprise the functional codes of the backhaul page injected into the target page. According to the method, normal injection of the function code in the original page is ensured, and then the overall reliability of the page loading process is ensured. In addition, the invention further provides a page loading device and system and a medium, and the beneficial effects are the same as those mentioned above.

Owner:SHENZHEN ONETHING TECH CO LTD

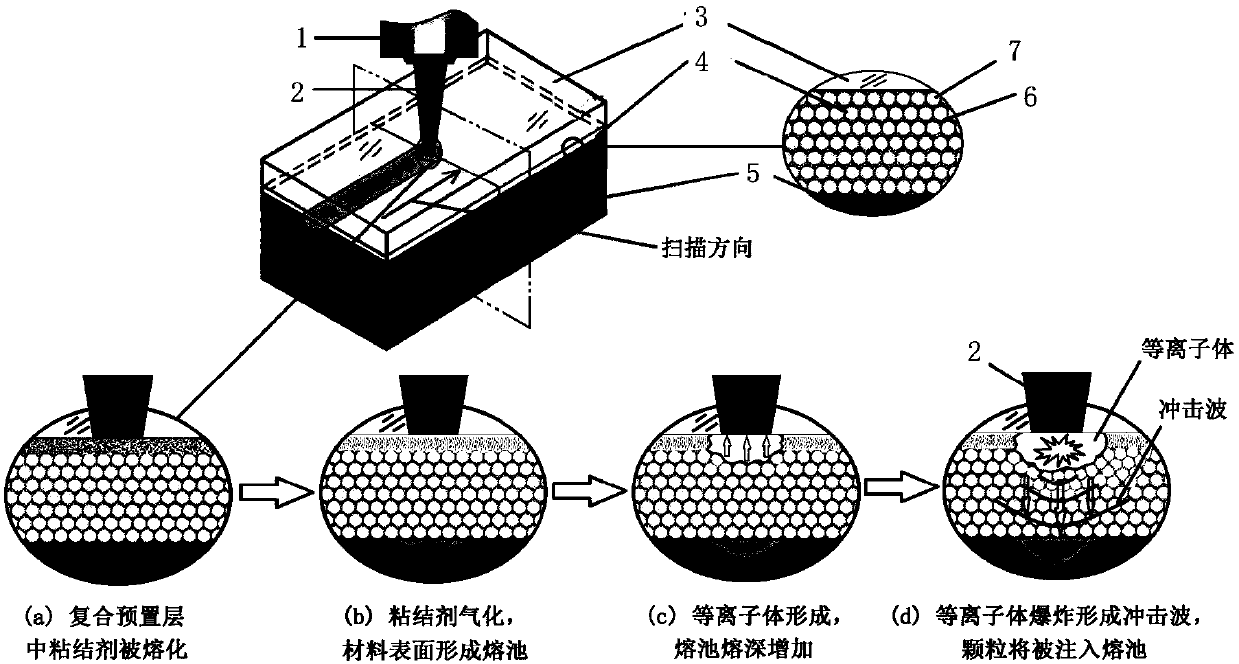

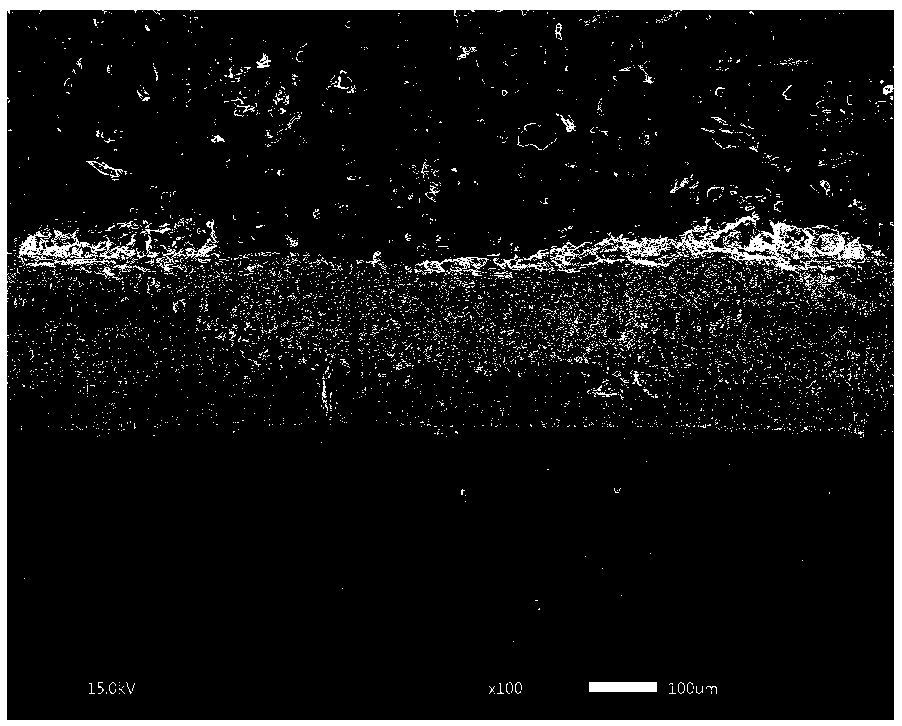

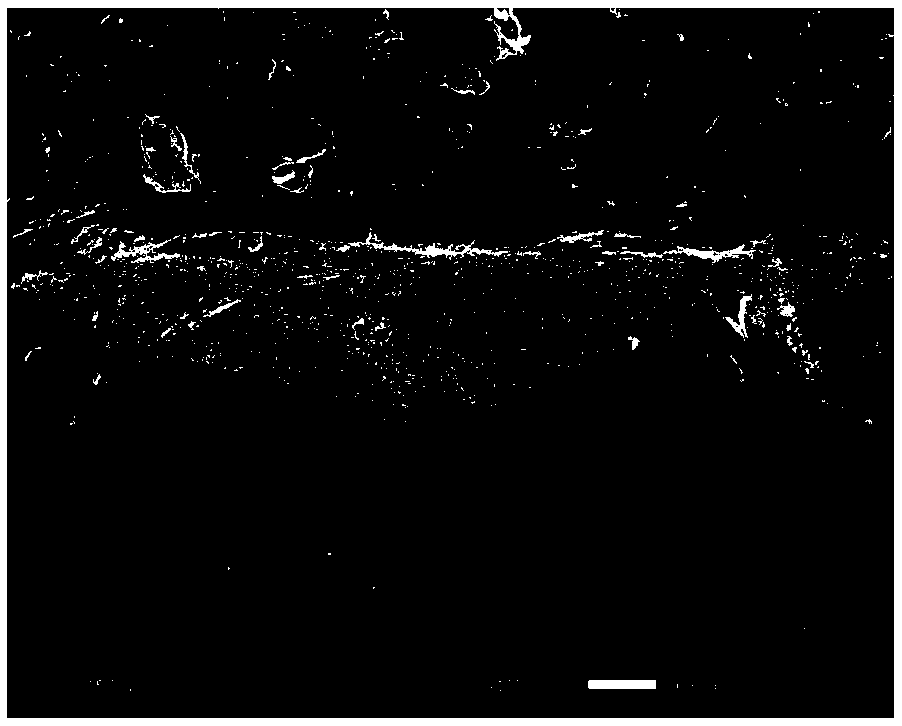

Method for continuous laser impacting micro particles to be melt-injected through injecting force formed by laser impacting work

ActiveCN107675166ABreaking down the technical barriers that are difficult to melt and inject fine particlesInjection implementationMetallic material coating processesBoiling pointLaser beams

The invention provides a method for continuous laser impacting micro particles to be melt-injected through injecting force formed by laser impacting work. The method is characterized in that a continuous laser beam is used to penetrate through a restraint layer for scanning a composite pre-arranged layer prearranged on the surface of a material to be modified, wherein the composite pre-arranged layer is formed by mixing a binder which inducing a laser impacting waves effectand the macro particles to be melt-injected; and through reasonable matching of parameters such as the melting point and the boiling point of the binder, the materials to be modified and the micro particles to be melt-injected, the binder is gasified to form the laser impacting waves under inducing of the continuous laser action, and the micro fine particles to be melt-injected are injected into a surface molten pool of the material to be modified, so that the micro particle reinforced composite layer is formed in situ. By means of the method, metallurgical bonding between the micro particles and the material to be modified is achieved in the composite material layer obtained from the surface of the material to be modified, the technical barrier that the micro particles are difficult to melt-inject in the prior art is broken, meanwhile, the injection depth of the micro particles is deep, the texture is fine,the enhanced particles are evenly distributed, and the micro particles are not restricted by plasticity of the material to be modified.

Owner:JIANGSU UNIV

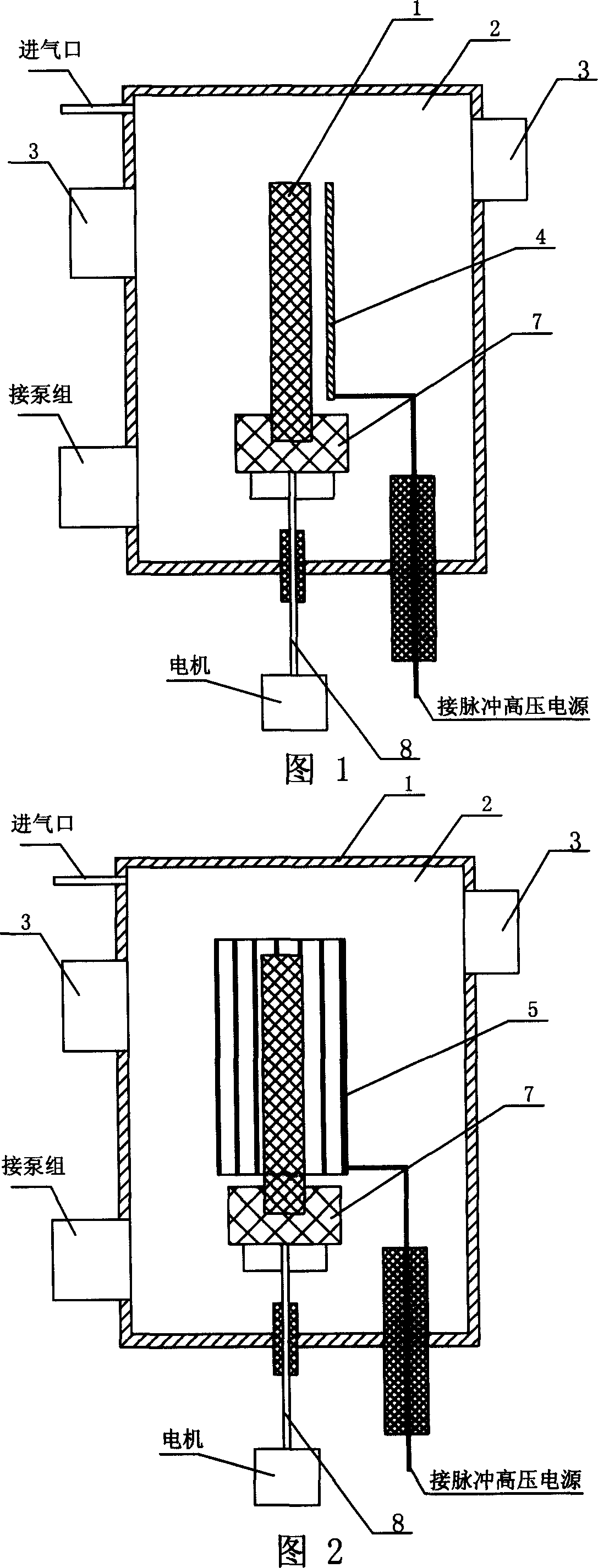

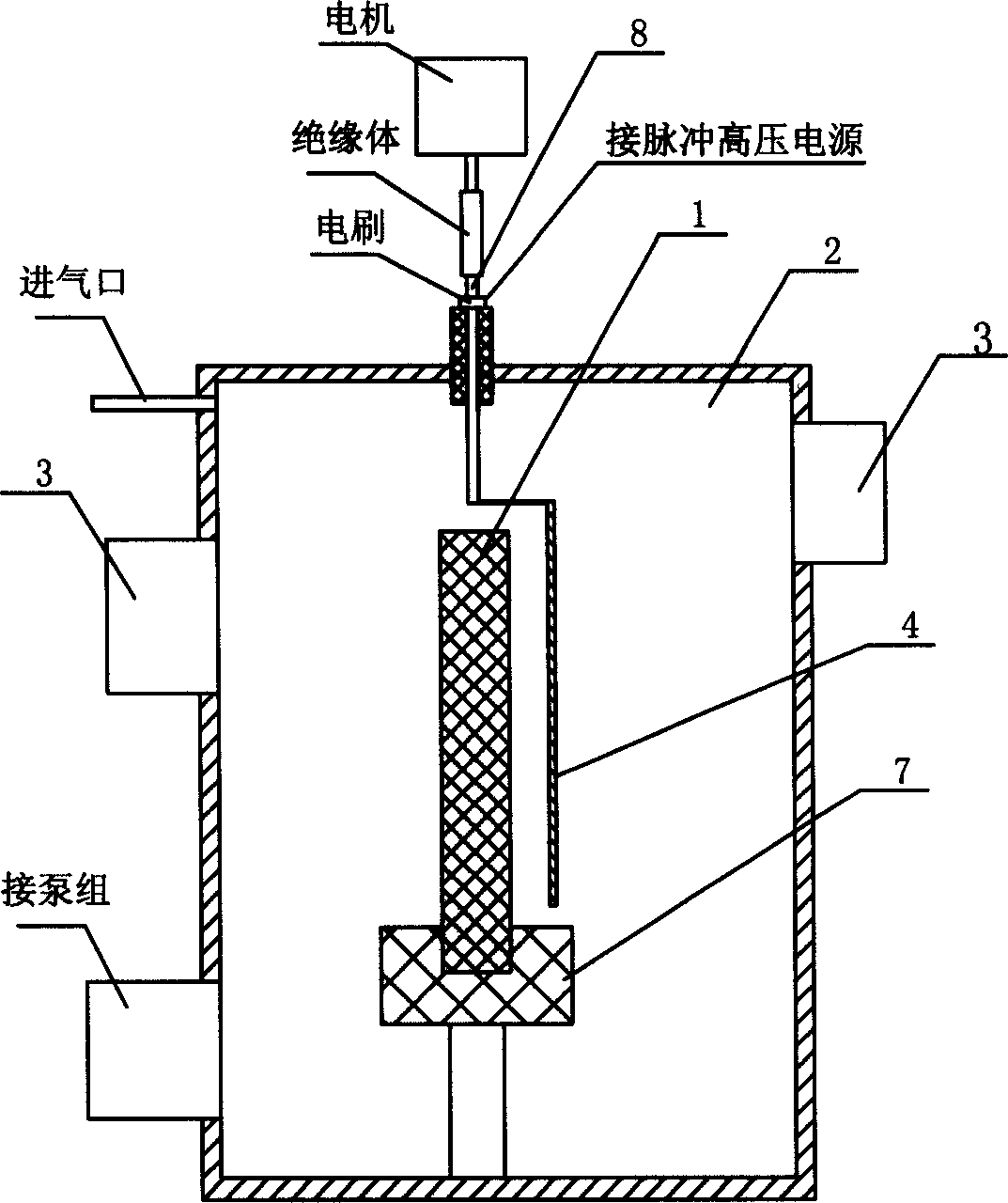

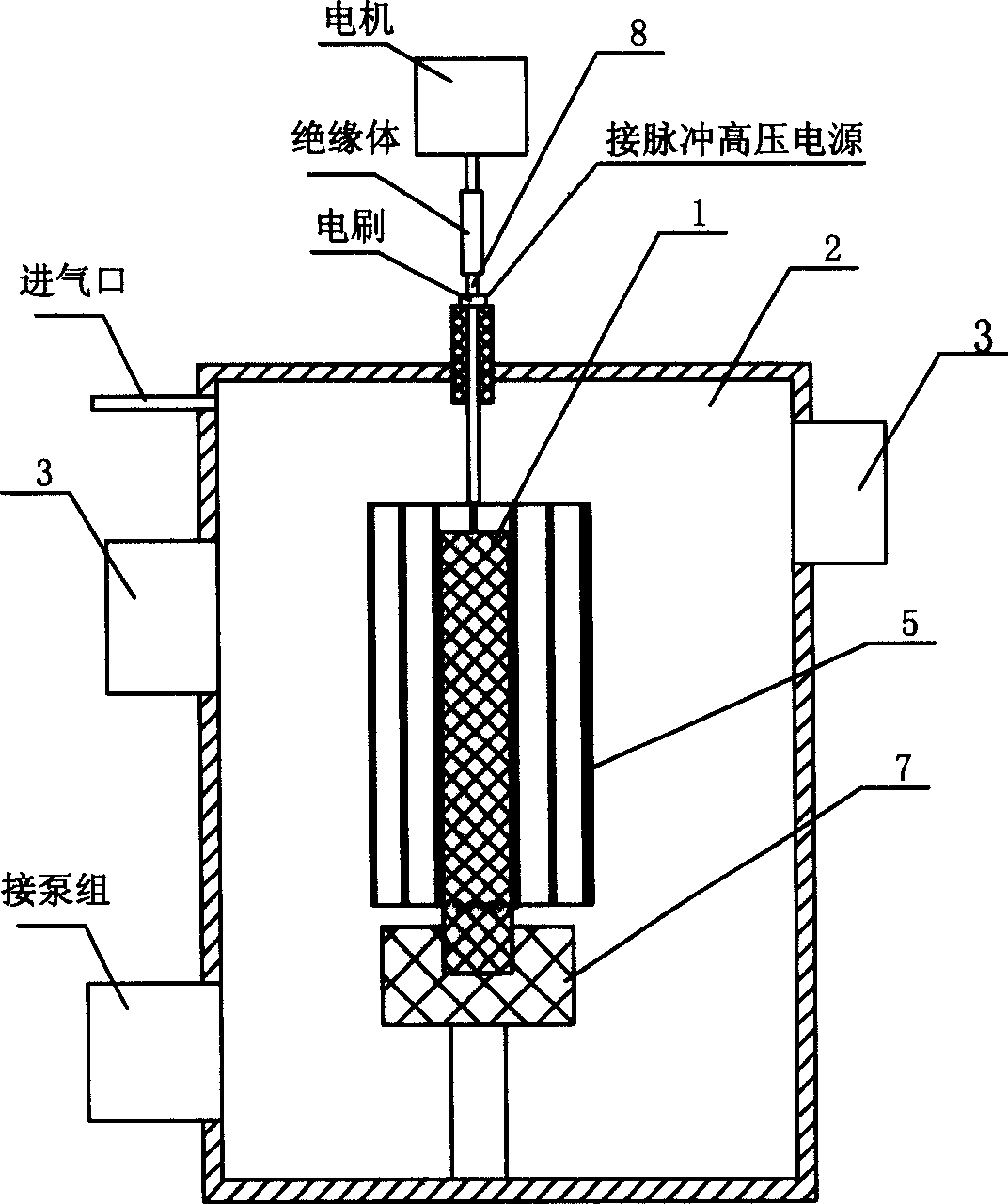

Plasma injection method and apparatus for insulation material spare parts

InactiveCN1603460AInjection implementationSimple structureVacuum evaporation coatingSputtering coatingElectricityEngineering

The insulation material spare part plasma pours into the method and its pours into the installment, involves a kind and pours into the installment to the insulation material spare part ion implantation method. The traditional plasma pours into the condition is the work piece can the electric conduction, is unable regarding the insulation material to pour into. The invention pours into the method, is in the insulation material spare part (1) exterior establishment meets the pulse high pressure power source cathode, may bonding jumper which relatively revolves with the insulation material spare part (4) or metal cylinder grid (5). The invention pours into the installment, the insulation material spare part (1) through moves the seal and the electricity engine shaft (8) is connected, in states the insulation material spare part (1) periphery fixedly has the bonding jumper (4) or the metal cylinder grid (5); Another kind of equipment, in insulation material spare part (1) periphery is equipped with with the electricity engine shaft (8) the connected bonding jumper (4) or the metal cylinder grid (5). The invention installment and the method may process a bigger area the insulation material spare part, this processing method efficiency high, the effect is good; The invention installment structure simple, the production cost is low, favor the promoted application.

Owner:HARBIN INST OF TECH

Gear subjected to surface treatment process

ActiveCN105927725AInjection implementationNo human intervention requiredPortable liftingGearing elementsWear resistantResin coating

The invention provides a gear subjected to a surface treatment process. The surface of gear is coated with a wear-resistant high-strength resin coating which is formed by pre-heating the gear and a mold, and then injecting a molten wear-resistant high-strength resin in a mold cavity between the mold and the gear face of the gear so that the wear-resistant high-strength resin is highly crystallized in the gradual cooling process. The gear has an intermediate hub portion. The intermediate hub portion has a first end face located outside the side of a body of the gear, and a second end face obliquely connecting the side and the first end face of the body of the gear. Grooves are disposed in the first end face and the face of a hub hole of the intermediate hub portion, so that the gear can be clamped and fixed to a predetermined axial fixed position.

Owner:重庆大合汽车配件有限公司

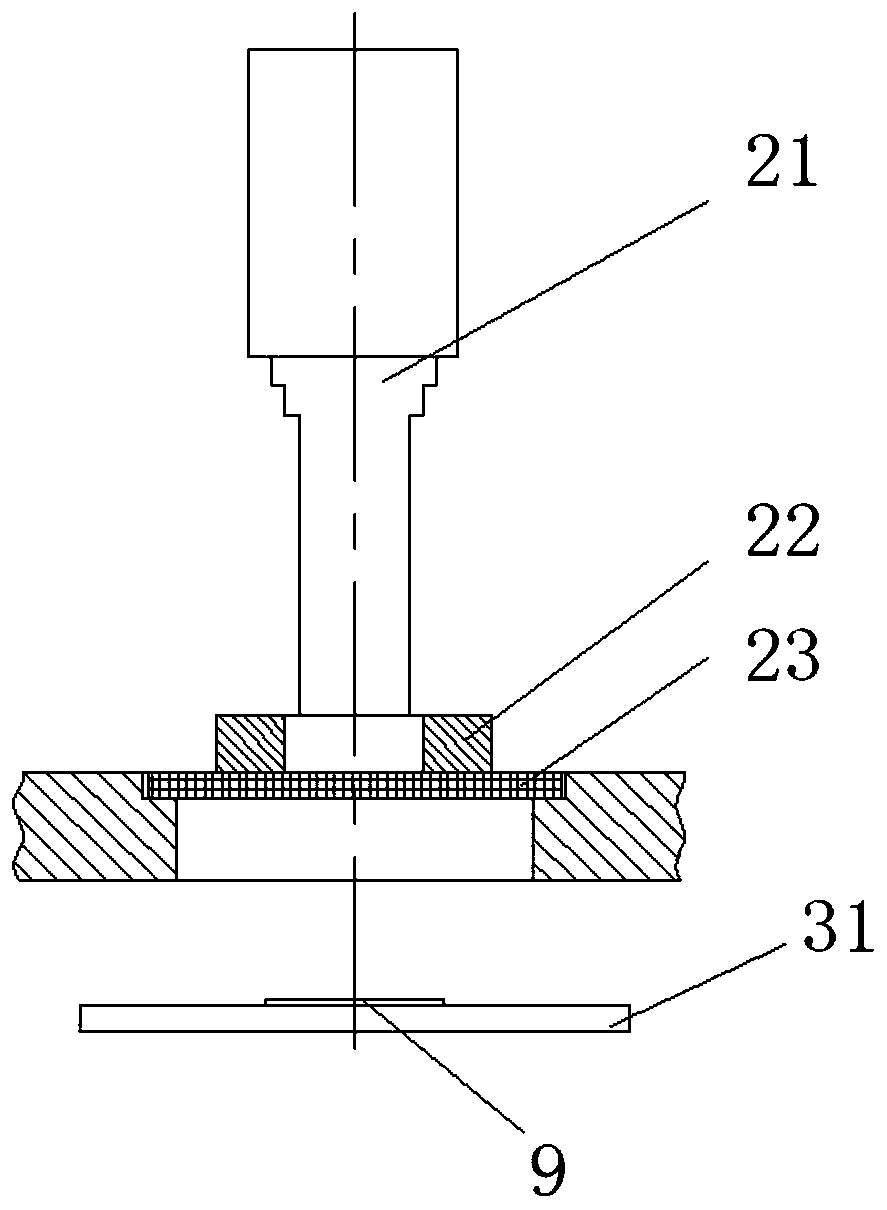

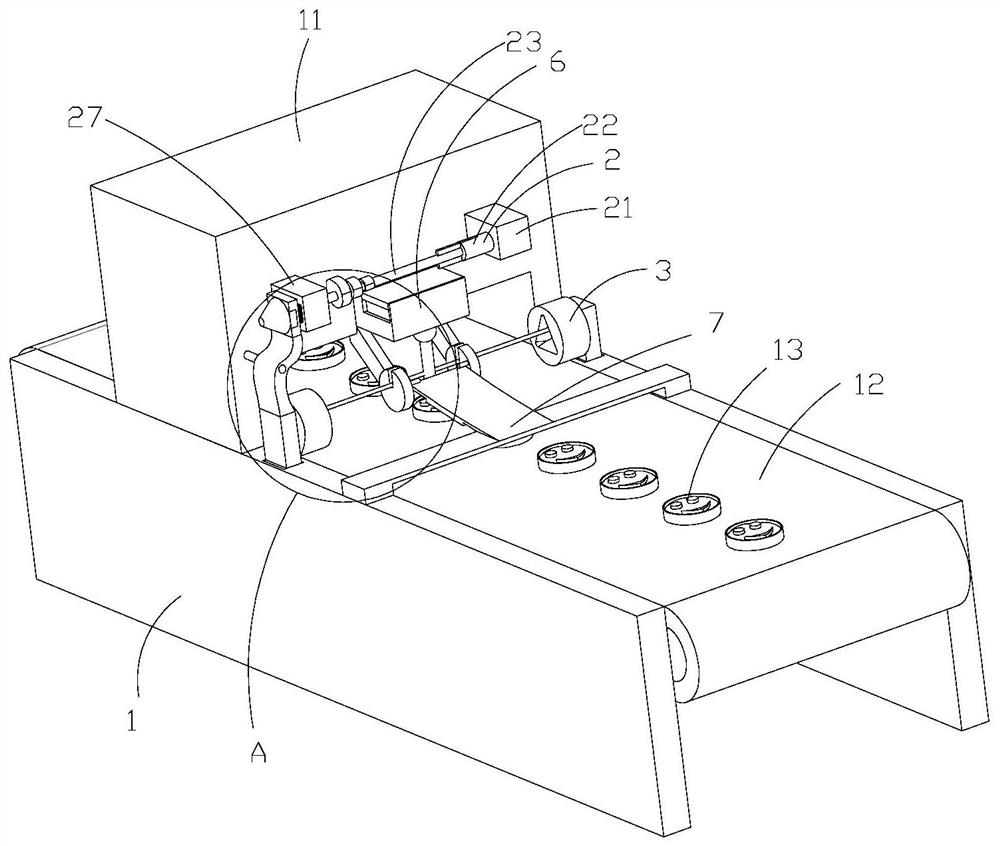

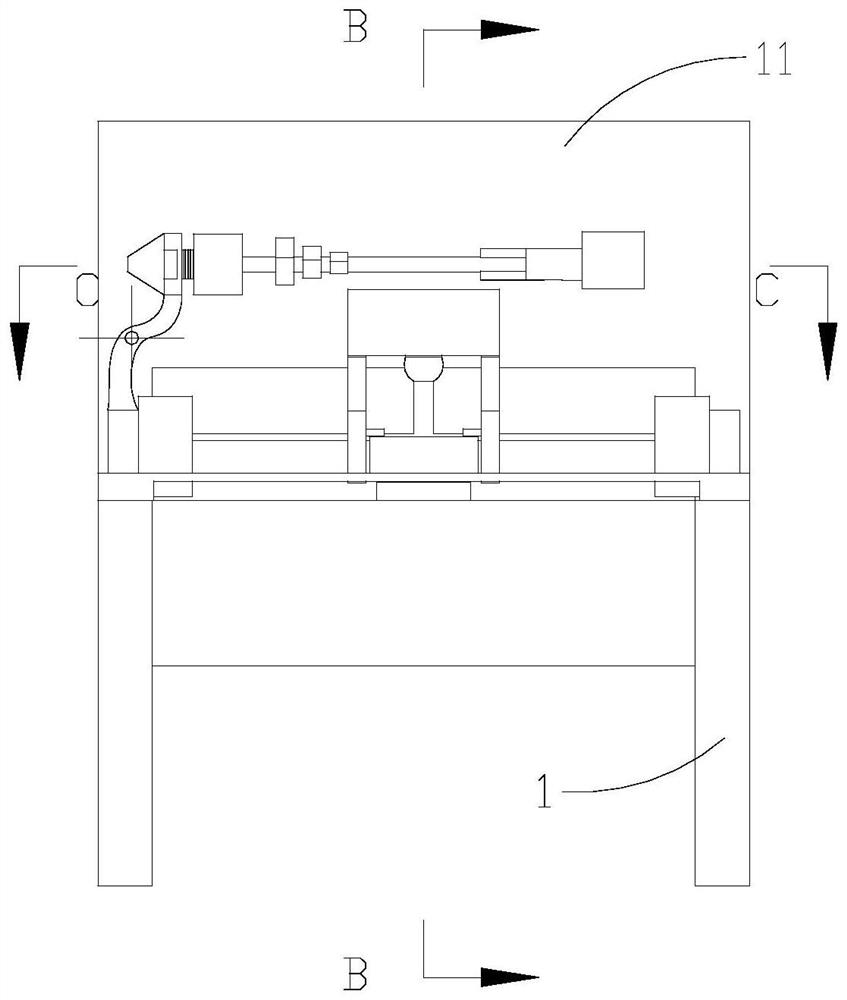

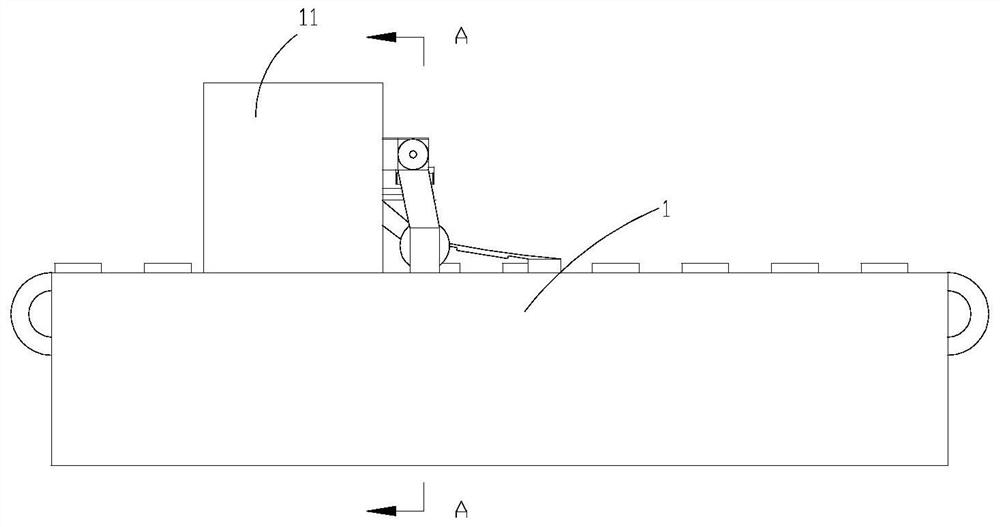

Device for conducting positioning and machining in gear surface treatment process

ActiveCN105690655AInjection implementationNo human intervention requiredCoatingsEngineeringFixed position

The invention provides a device for conducting positioning and machining in the gear surface treatment process. The device comprises a rack, and a positioning head arranged at the lower portion of an operation table of the rack. The positioning head can be axially rotatably coupled to the rack around a fixed vertical shaft and is located in an axial fixed position. The positioning head is provided with a top end and a middle hub part designed to be capable of axially sliding and connected to a gear. A gap is formed between the side wall of the top end and the side wall of the middle hub part. The top end comprises a moving pin which is used for positioning and maintaining the gear. The moving pin can move in the radial direction between a stretching position and a retracting position. The moving pin retracts into the top end in the retracting position so that the top end can move freely in the middle hub part, and the moving pin can be inserted into a corresponding groove in the middle hub part in the stretching position, and therefore the gear is clamped and fixed to the preset axial fixed position.

Owner:HUBEI SHENMA GEAR MFG

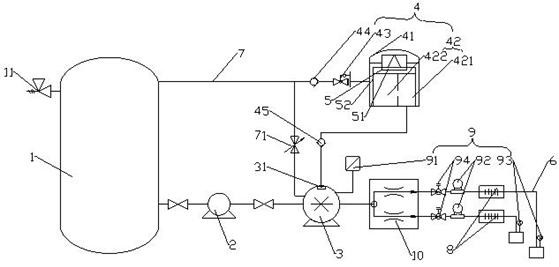

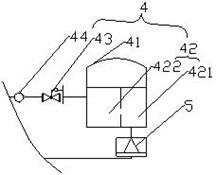

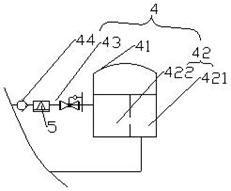

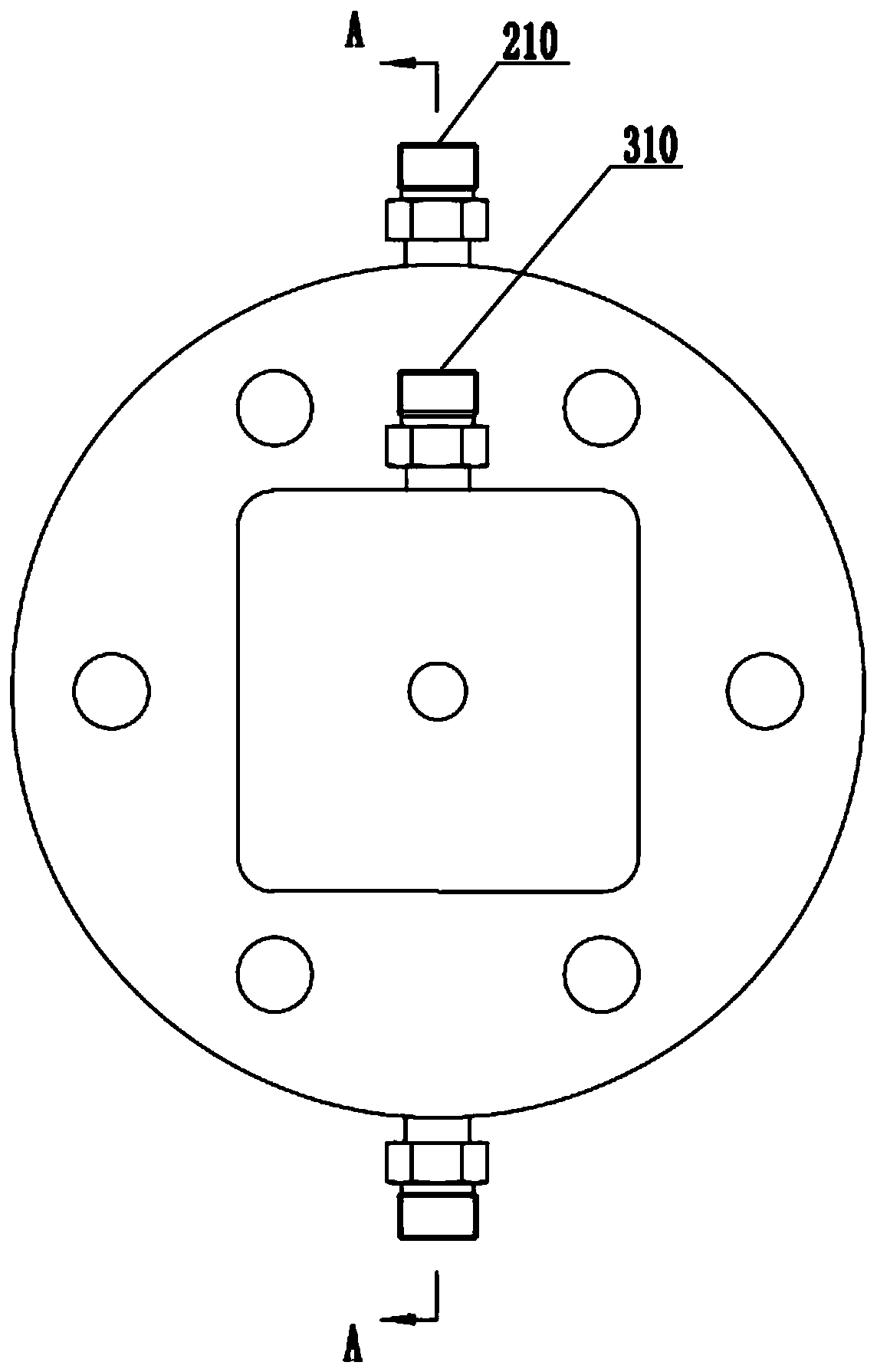

An injection device for carbon dioxide flooding

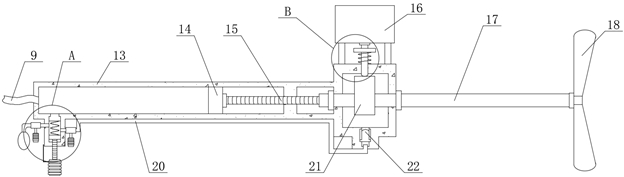

ActiveCN113638724BGuaranteed pressure stabilityAvoid drag lossOther gas emission reduction technologiesFluid removalExhaust valveLine tubing

The invention relates to the field of oilfield development, and discloses an injection device for carbon dioxide flooding, which includes a storage tank, a shielded pump, a high-pressure pump and an injection head arranged in sequence, an injection pipeline is arranged between the high-pressure pump and the injection head, and the storage tank and the injection head There is a return line between the high-pressure pumps, and a shut-off valve between the return line and the high-pressure pump. It also includes a gas collection device. The gas collection device includes a gas collection chamber and a pressure regulating device for the outlet of the gas collection chamber. valve, the inlet of the gas collection chamber is connected to the exhaust valve, and the outlet of the pressure regulating device is connected to the storage tank. The present invention for reflux CO 2 The pressure regulation treatment is beneficial to the stability of the storage tank pressure.

Owner:DESHI ENERGY TECH GRP CO LTD

Injectors, rocket engines and rockets

ActiveCN110714856BInjection implementationMitigate technical issuesRocket engine plantsCombustion chamberEngineering

The invention provides an injector, a rocket engine and a rocket, and relates to the technical field of vehicles. The injector comprises an upper bottom, a middle bottom and a lower bottom, wherein one side of the middle bottom is connected with the upper bottom, a gas collecting cavity and a gas channel are arranged between the middle bottom and the upper bottom, the gas channel communicate the gas collecting cavity with a combustion chamber, and the gas collecting cavity is provided with a gas inlet; the other side of the middle bottom is connected with the lower bottom, a liquid collectingcavity is formed between the middle bottom and the lower bottom, and the liquid collecting cavity is provided with a liquid inlet; and the injector further comprises a pin bolt which penetrates through the lower bottom, the liquid collecting cavity and the middle bottom, the pin bolt is in sealing connection with the lower bottom, and a liquid channel used for communicating the liquid collecting cavity with the combustion chamber is arranged between the pin bolt and the middle bottom. In the injector, a gas propellant can enter the gas collecting cavity through the gas inlet and then enters the combustion chamber through the gas channel, and the liquid propellant can enter the liquid collection cavity through the liquid inlet and then enters the combustion chamber through the liquid channel, that is to say, the injector is capable of achieving a jet of a two-component propellant of a gas and a liquid.

Owner:BEIHANG UNIV

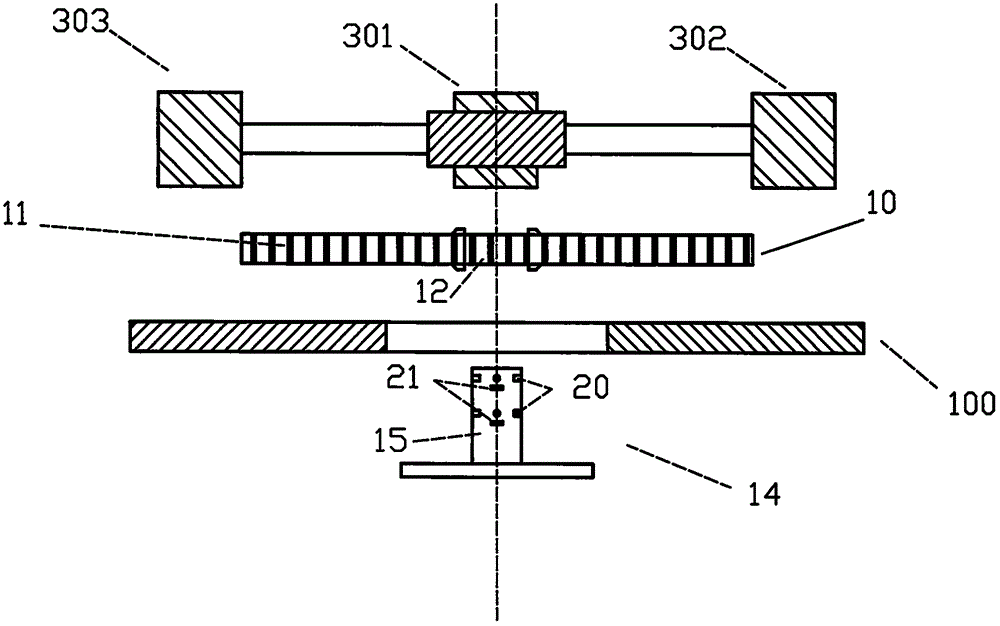

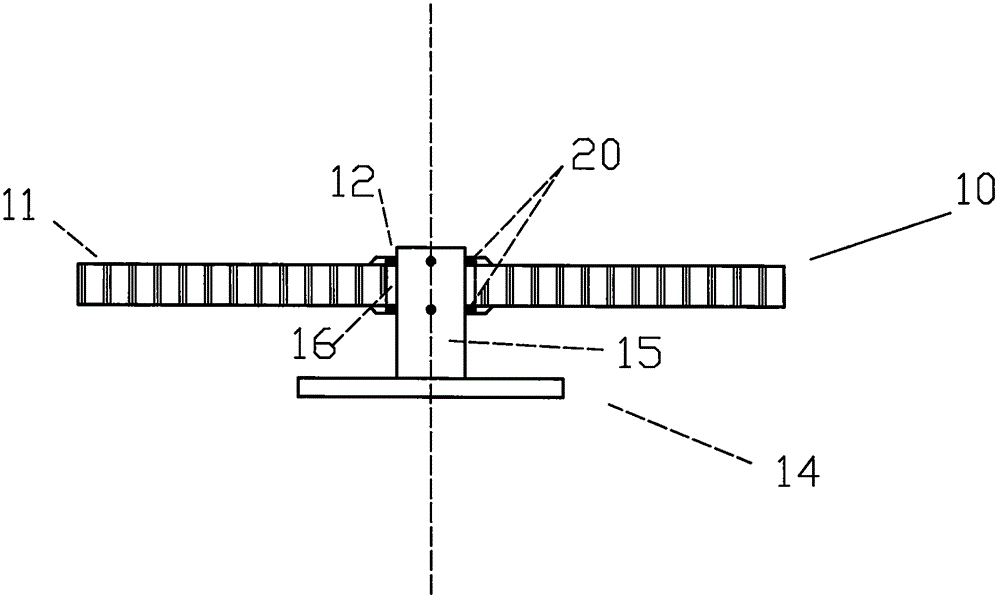

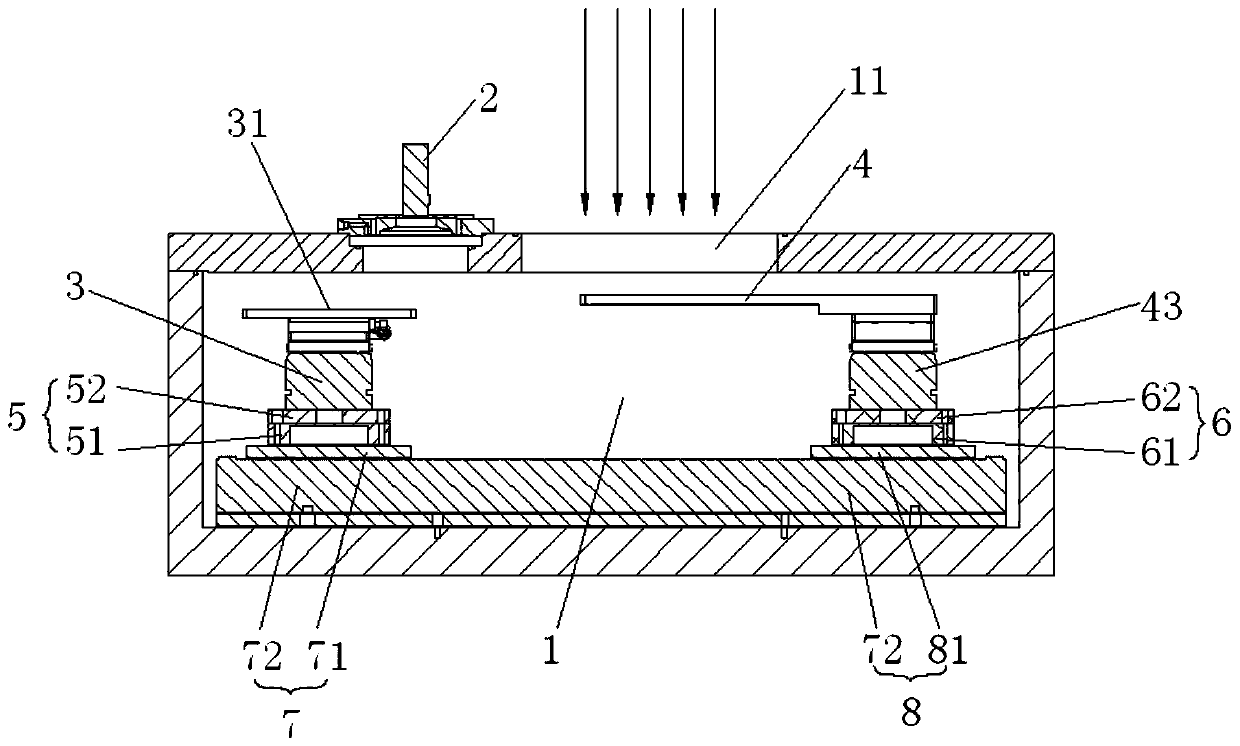

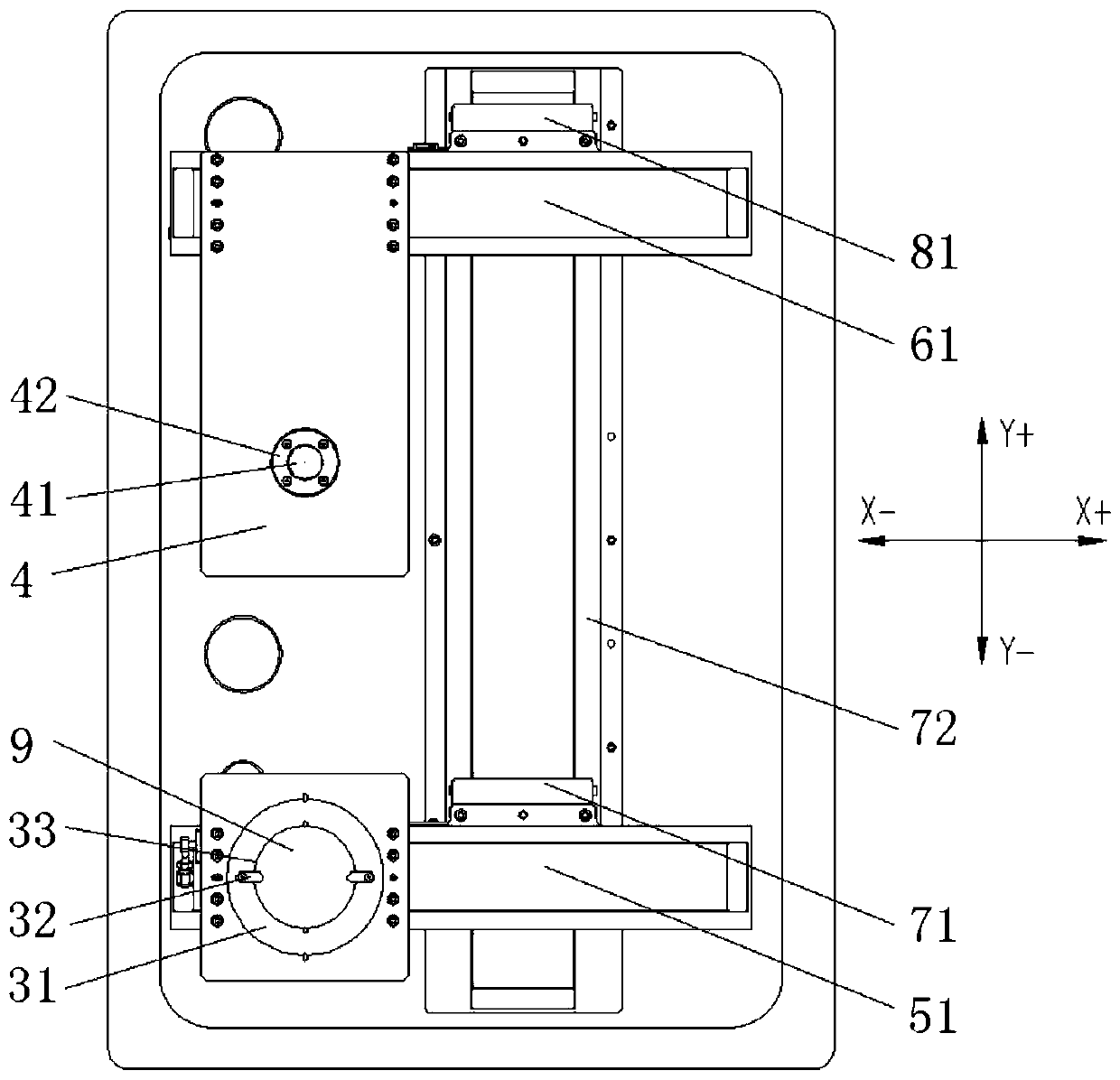

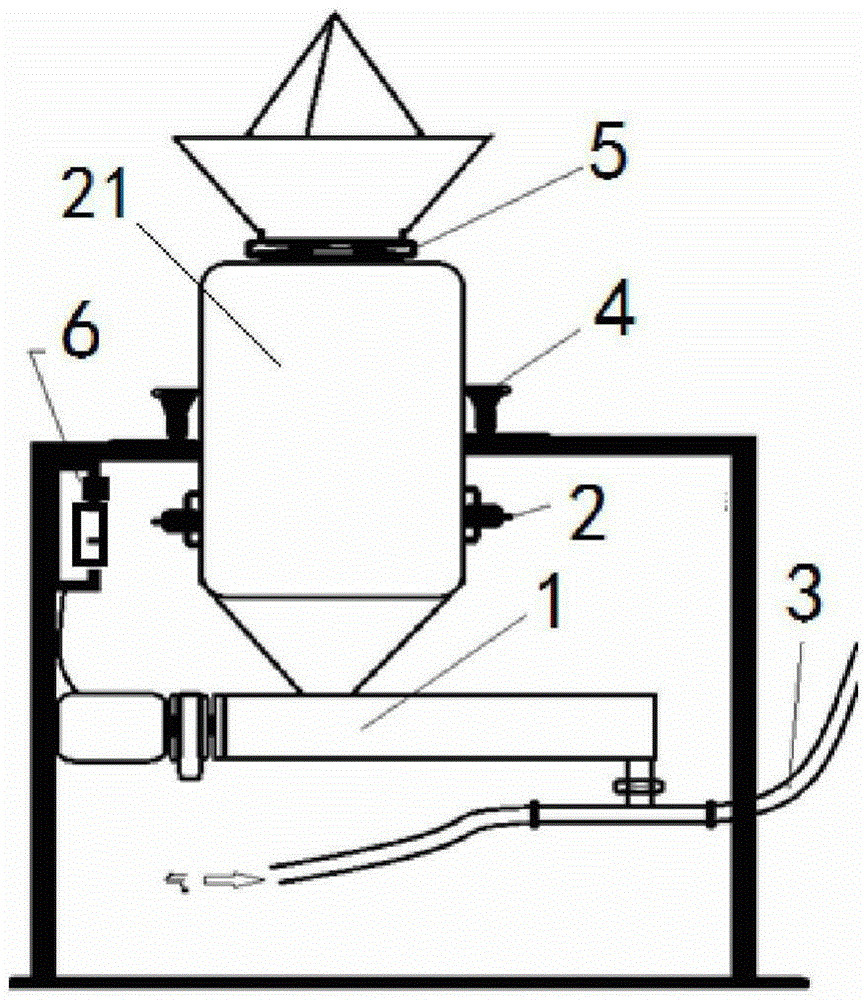

Fixed-point ion implantation device and implantation method for a substrate

ActiveCN109256314BFixed-point implementationAchieve precise positioningElectric discharge tubesIon beamControl cell

The invention discloses a fixed-point ion implantation device and an implantation method of a substrate, The apparatus comprises a control unit, a vacuum chamber, a substrate position device and a machine vision system, The substrate position device includes a substrate hold, a mask plate, a first X-axis moving mechanism, second X-axis moving mechanism, a first Y-axis moving mechanism and a secondY-axis moving mechanism, A substrate seat is arranged on the first X-axis moving mechanism, The mask plate is arranged on the second X-axis moving mechanism, a beam perforation is arranged on the mask plate, a machine vision system is used for detect the injection point position and the beam perforation center position on the substrate, and the mask plate is movable so as to align the central position of the beam perforation with the injection point position on the substrate. A method comprise vacuuming a vacuum chamber; measuring the position of the injection point on the substrate by movingthe substrate holder; moving the mask plate to measure the central position of the beam perforation, and moving the mask plate to align the central position of the beam perforation with the positionof the injection point; synchronously moving the substrate holder and the mask plate below the ion beam injection port; starting ion beams.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Facial mask processing method

InactiveCN111874289AInjection implementationAccurate pourSolid materialLiquid materialEngineeringRaw material

The invention discloses a facial mask processing method which comprises the following steps of (1) extruding raw materials for forming a facial mask in an extrusion form, and adjusting the up-and-downextrusion stroke so as to realize various discharge amounts; (2) pouring the raw materials of the facial mask into a mold in a swinging manner, and adjusting the swinging amplitude to realize pouringof molds of various specifications; and (3) extruding and striking off the facial mask raw materials on the molds to finally form the facial mask. Facial mask processing equipment comprises a supporting frame, a raw material box arranged on the supporting frame, a conveying belt arranged on the supporting frame, the mold arranged on the conveying belt, a first adjusting component arranged on theraw material box, a second adjusting component arranged on the supporting frame, a discharging box arranged on the supporting frame and an extruding component arranged on the supporting frame. According to the facial mask processing method, a hose swinging form is adopted, so that the raw materials can be accurately poured into the mold while the conveying belt continuously conveys the raw materials; and by adjusting the discharging amount and the swing amplitude, injection of the different molds is met.

Owner:赵龙

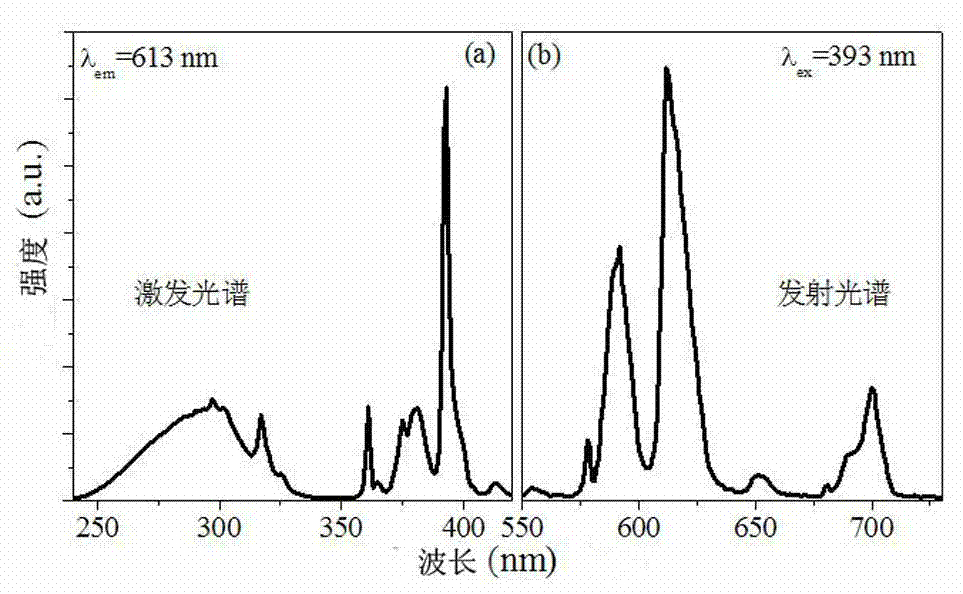

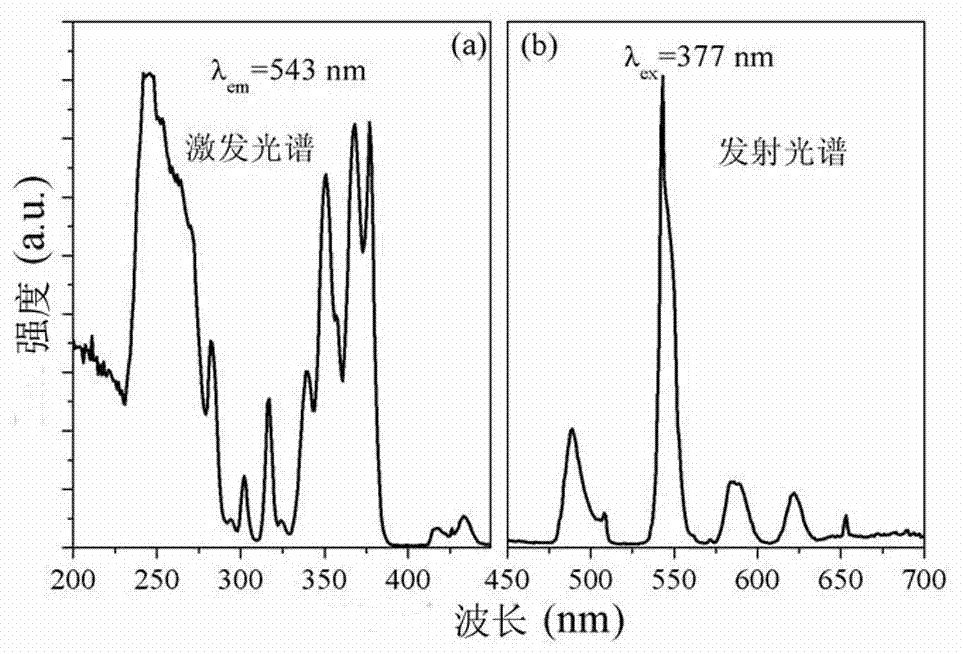

Method capable of improving conversion efficiency of crystalline silicon solar cell

ActiveCN103594548AInjection implementationEasy injectionFinal product manufacturePhotovoltaic energy generationBatch productionLight wave

The invention discloses a method capable of improving conversion efficiency of a crystalline silicon solar cell. The method comprises steps that: (1), texturing on a silicon wafer is carried out, a PN junction is prepared through expansion, etching and cleaning are carried out, PECVD plating on an anti-reflective film is carried out; (2), rare earth ion implantation into the anti-reflective film is carried out; (3), after rare earth ion implantation, the silicon wafer is annealed in a high temperature furnace in a nitrogen atmosphere and is taken out to cool to a room temperature; and (4), screen printing of the silicon wafer is carried out to form an electrode, and a finished product of the crystalline silicon solar cell having light wave conversion characteristics is formed through sintering. According to the method, rare earth ions are doped on the anti-reflective film by utilizing the ion implantation technology, so the anti-reflective film has the light conversion characteristics, a photon utilization rate of the crystalline silicon solar cell in a high-energy ultraviolet area is improved, and thereby conversion efficiency of the cell is improved; the technology utilized in the method is simple and easy and can be linked with a manufacturing process of a cell in the prior art, reconstruction for equipment in the prior art is not needed, cost is saved, batch production is easily realized through the ion implantation technology, and the method has good feasibility.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

A nozzle sleeve connector, gas injection wellhead fluid monitoring pipeline and system

ActiveCN110500075BEasy accessImprove access efficiencyFluid removalWell/borehole valve arrangementsInjection wellWellhead

The invention relates to an oil nozzle sleeve connector, a gas injection wellhead fluid monitoring pipeline and system. The oil nozzle sleeve connector includes an inner pipe part and an outer pipe part, wherein the inner pipe part penetrates into an inner hole of the outer pipe part, an inner diameter of the outer pipe part is larger than at least part of an outer diameter of the inner pipe part,one end of the inner pipe part extends into a step inner hole of the oil nozzle sleeve and is connected with the step inner hole in a sealed mode, the other end of the inner pipe part is used for connecting the gas injection wellhead fluid monitoring pipeline, one end of the outer pipe part extends into a step outer hole of the oil nozzle sleeve and is connected with an opening of the step outerhole in a sealed mode, an injection fluid accommodation space is formed between the inner wall of the outer pipe part and at least part of the outer wall of the inner pipe part and the inner walls ofthe step outer hole of the oil nozzle sleeve, the other end of the outer pipe part enables the injection fluid accommodation space to be closed, and a connection opening communicating with the fluid accommodation space is formed in the outer wall of the outer pipe part and used for connecting the loop wire part of the gas injection wellhead fluid monitoring pipeline. According to the oil nozzle sleeve connector, the gas injection wellhead fluid monitoring pipeline and system, the injection of limited flow is realized when injecting into the wellhead is carried out, precision is high, a response is fast, and the regulation efficiency is improved.

Owner:北京大业嘉成科技有限公司

Bone cement pedicle screw fixation and fusion system for spinal degeneration disease

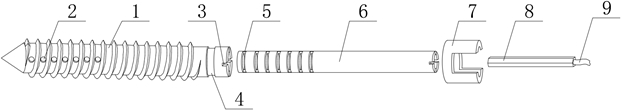

PendingCN114081602AEasy injectionReduce cloggingInternal osteosythesisSpinal columnPedicle screw fixation

The invention relates to a bone cement pedicle screw fixation and fusion system for the spinal degeneration disease, belonging to the technical field of bone cement pedicle screw fixation and fusion. The system comprises a hollow screw, a chute and a connector sleeving the chute, wherein an injection rod is slidably arranged on the inner side of the hollow screw, the injection rod is in sliding connection with the inner side of the hollow screw and can be used for overcoming the defect that the injection rod rotates along with rotation of the hollow screw, an injection ring corresponding to a side hole is formed in the front end of the injection rod and used for injecting bone cement, a friction ring is fixedly connected to the inner side of the hollow screw and used for friction, and the friction ring can maintain the relative stability of the position of the injection rod through the friction force. The fixation and fusion system further comprises an injection module, wherein the injection module is used for pressurizing the bone cement to enable the bone cement to enter and disperse, the injection module comprises an injection amount counting module and an injection pressure warning module, and the injection pressure warning module further comprises a pressure threshold value adjusting module.

Owner:LUOYANG ORTHOPEDIC TRAUMATOLOGICAL HOSPITAL

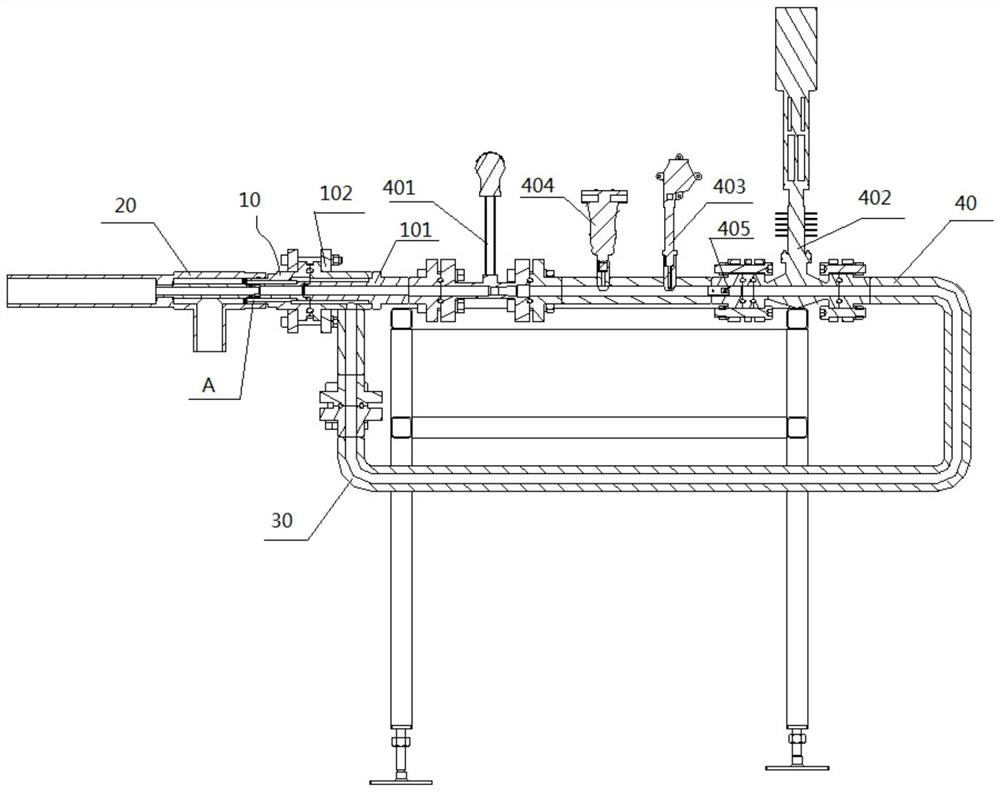

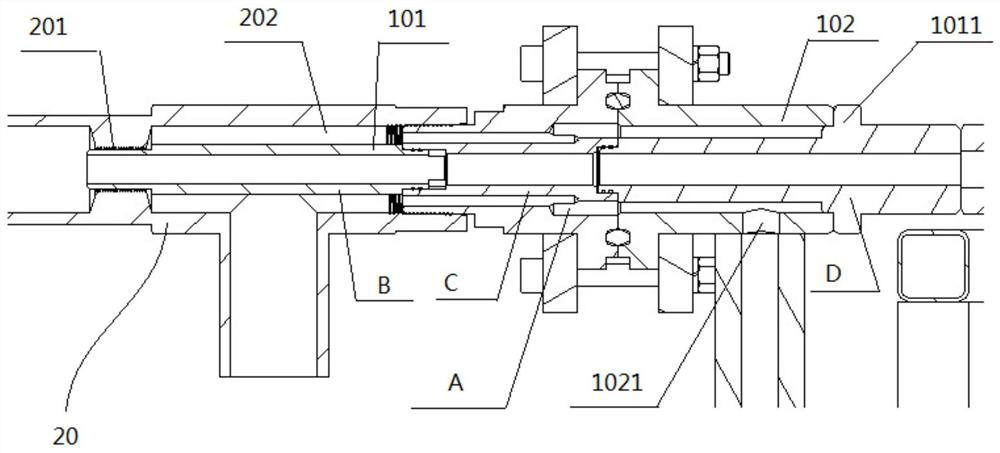

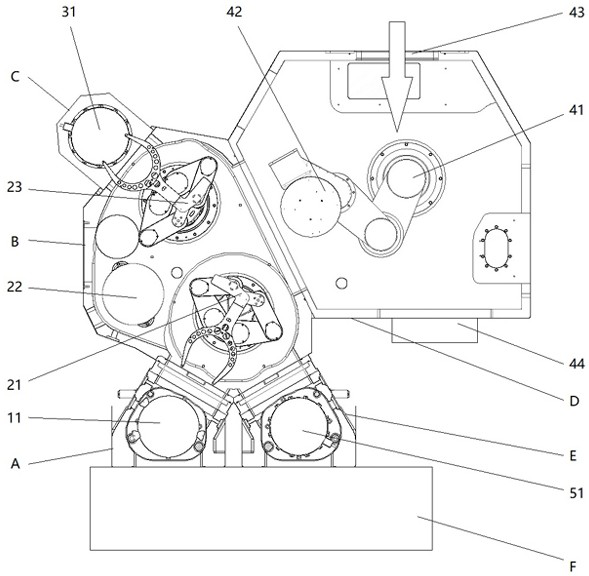

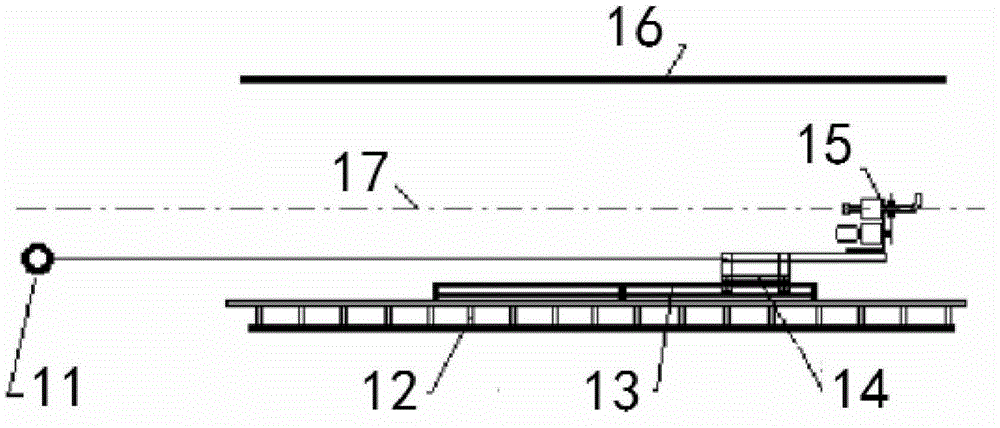

Ultralow-temperature wafer injection platform

ActiveCN113990727ASuppression of Transient Enhancement Diffusion EffectsSuppressed dynamic annealingElectric discharge tubesSemiconductor/solid-state device manufacturingPhysicsDynamic annealing

The invention provides an ultralow-temperature wafer injection platform. The platform at least comprises a front-end wafer conveying module, a loading module, a vacuum conveying module, a vacuum cooling module, a vacuum injection module and a vacuum heating module; the front-end wafer conveying module, the loading module, the vacuum conveying module, the vacuum cooling module, the vacuum injection module and the vacuum heating module are matched with one another to form an integrated body, and the integrated body realizes ultralow-temperature wafer ion implantation; in the vacuum cooling module, a wafer is rapidly cooled through a cooling platform for cooling the wafer and an electrostatic chuck for adsorbing the wafer, so that the wafer is in an ultralow temperature state, and the temperature in the ultralow temperature state is lower than minus 50 DEG C. According to the platform, dynamic annealing in the ion implantation process is effectively inhibited, so that atoms at gap positions cannot return to lattice replacement positions any more, the number of amorphous packages is increased, the range of the amorphous packages is gradually expanded, and finally, the boundaries of all the amorphous packages are connected together to form a complete amorphous layer. According to the platform of the invention, ultralow-temperature ion implantation is realized, and the complete amorphous layer is formed.

Owner:北京凯世通半导体有限公司

Deep plugging control system for heavy oil thermal production well and steam steering method

ActiveCN114075432AEasy injectionEnhanced overall recoveryGeothermal energy generationFluid removalThermodynamicsControl system

The invention relates to the field of heavy oil steam recovery, in particular to a deep plugging control system for a heavy oil thermal recovery well and a steam steering method. A plugging-controlling and channeling-sealing plugging agent comprises elastic particles and high-temperature molten particles, wherein the elastic particles are solid particles which are not decomposed or degraded at a temperature of 250 DEG C and can be elastically deformed; and the physical and chemical properties of the high-temperature molten particles are not changed under the condition that a temperature is lower than 150 DEG C, the high-temperature molten particles can be softened and deformed under the condition that the temperature is higher than 150 DEG C, and the high-temperature molten particles have an adhesion effect. The plugging-controlling and channeling-sealing plugging agent has good injectability in a stratum, and deep migration can be achieved; and the plugging-controlling and channeling-sealing plugging agent can realize effective deep steam steering, can better improve a crude oil recovery rate, and has good plugging strength and scouring resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

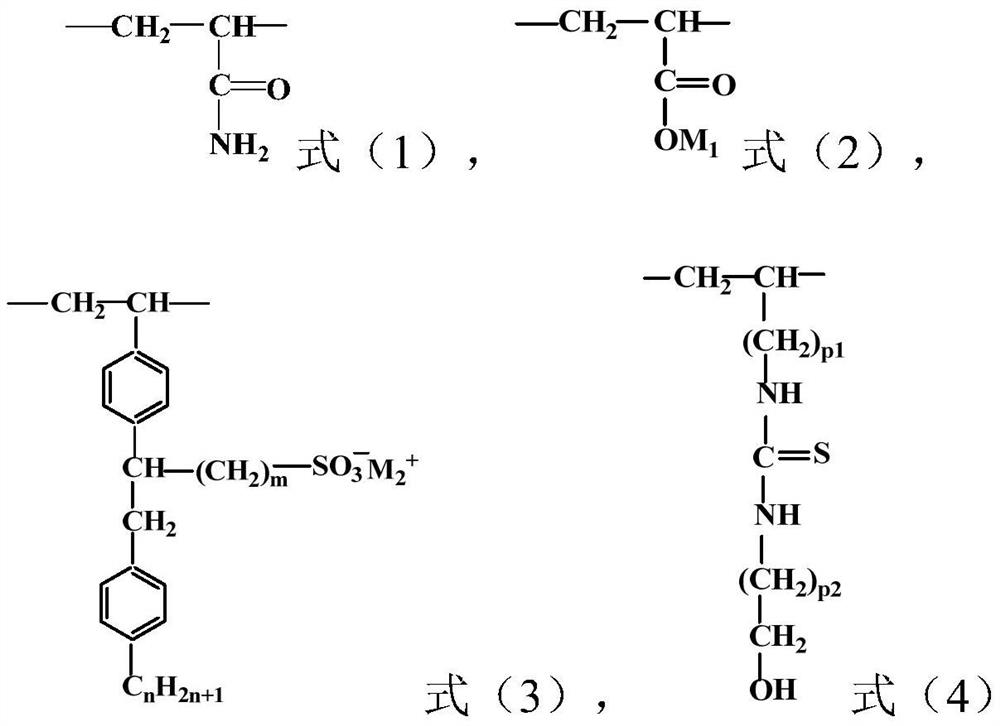

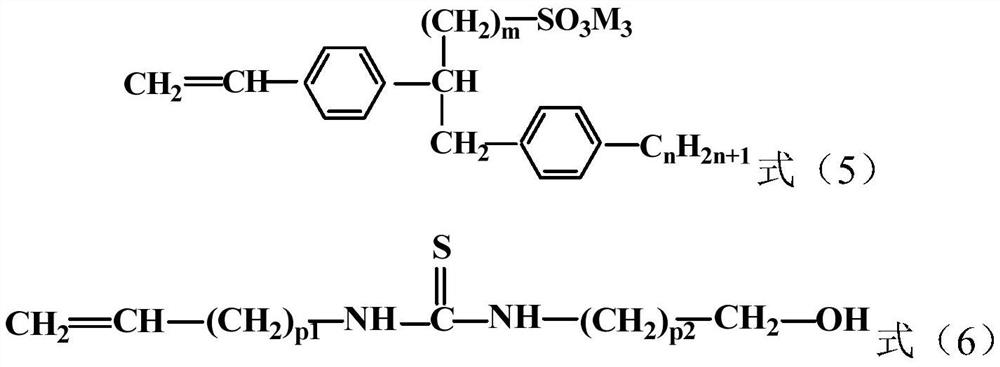

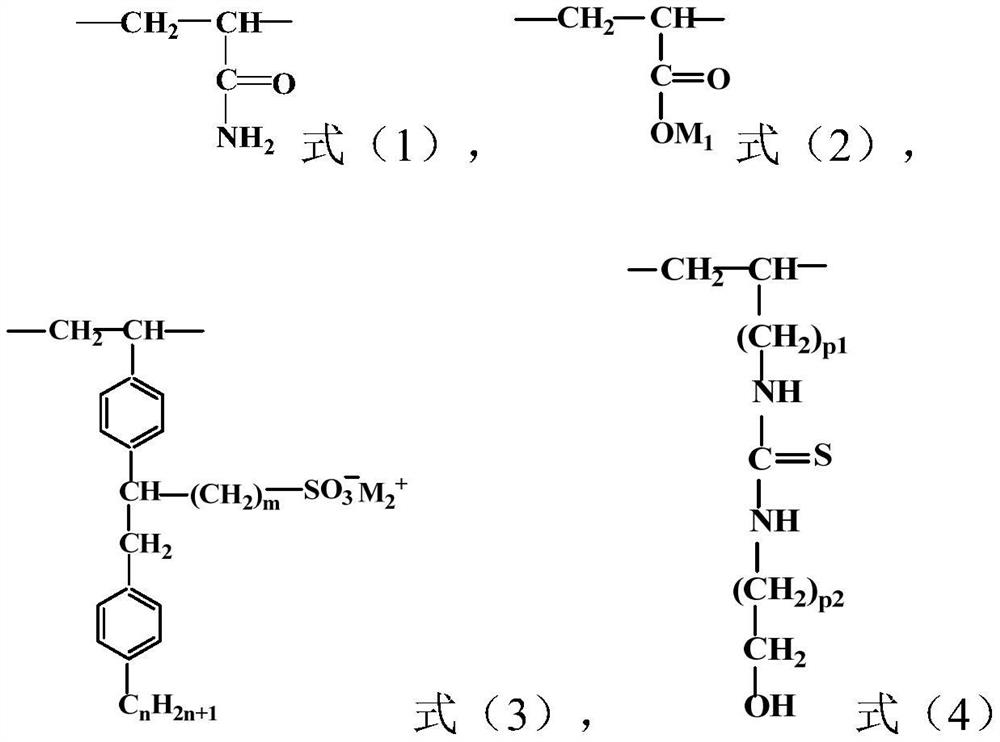

Surface active polymer, preparation method thereof and application of surface active polymer as polymer oil-displacing agent

ActiveCN114437294AGood viscosity increasing effectGood temperature and salt resistanceDrilling compositionActive polymerPolymer science

The invention relates to the field of petrochemical engineering, and particularly discloses a surface active polymer and a preparation method thereof and application of the surface active polymer as a polymer oil-displacing agent.The polymer contains a structural unit A, a structural unit B and a structural unit C. The structural unit A is a structural unit with a structure shown in a formula (1) and / or a formula (2), and the structural unit B is a structural unit with a structure shown in a formula (3). The structural unit B is a structural unit with a structure as shown in a formula (3), and the structural unit C is a structural unit with a structure as shown in a formula (4); wherein m is 1-8, n is 1-9, p1 and p2 are respectively and independently 1-6, and M1 and M2 are respectively and independently alkali metal. On the basis of excellent temperature resistance and salt tolerance, the polymer disclosed by the invention also has excellent tackifying property and emulsifying property, surface and interface tension is reduced, and the polymer has good oil displacement and oil washing capabilities.

Owner:CHINA PETROLEUM & CHEM CORP +1

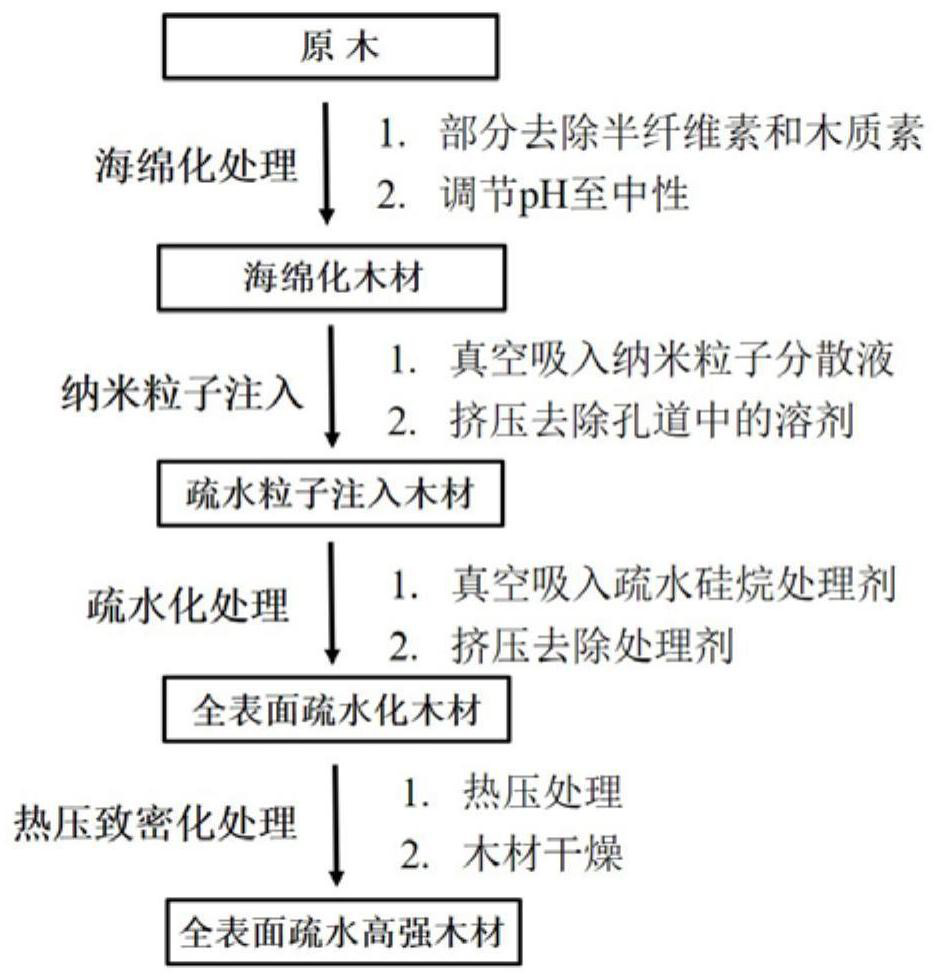

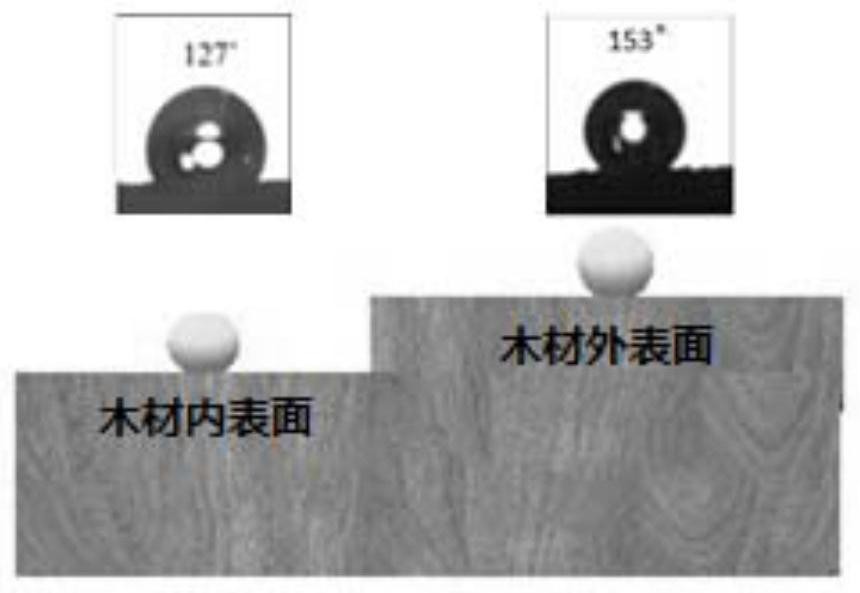

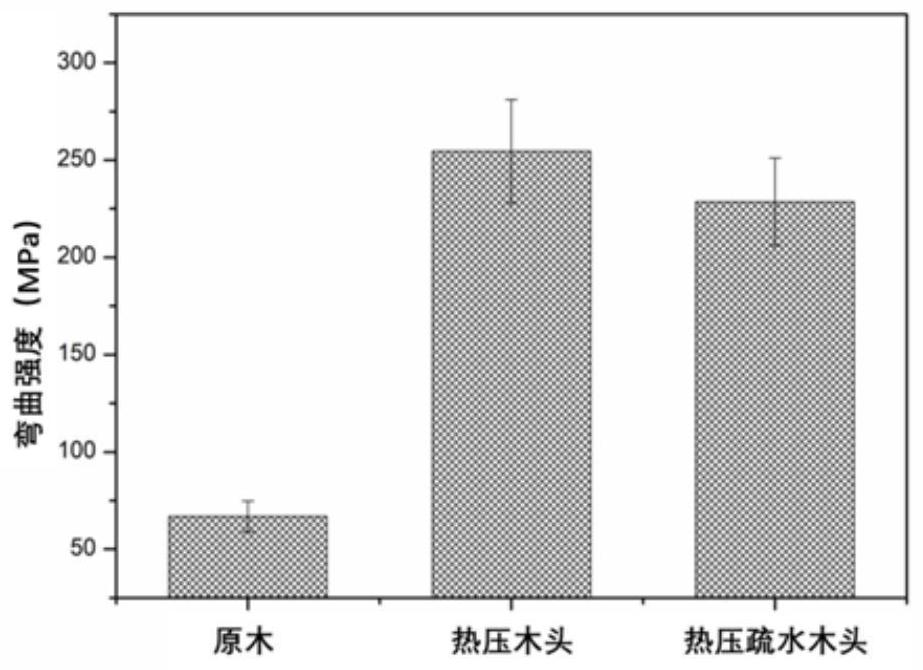

A full-surface super-hydrophobic antifreeze high-strength wood and its manufacturing method

ActiveCN111015857BImprove frost resistanceExcellent high strengthWood treatment detailsPretreatment apparatusPolymer scienceHemicellulose

Owner:DONGHUA UNIV

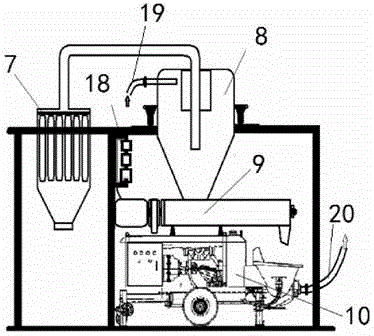

A blast furnace elevated pipeline wet injection system and method

ActiveCN104388614BInjection implementationReduce in quantityBlast furnace componentsBlast furnace detailsFar distanceCollection system

The invention discloses a blast furnace high-order pipeline wet-method ejection system and method, belonging to the technical field of blast furnace high-order pipeline ejection construction techniques and equipment. The blast furnace high-order pipeline wet-method ejection system comprises a set of high-order conveying equipment, a set of collecting equipment, a pumping device and a set of rotation ejection manipulator used in a pipeline, wherein the high-order conveying equipment comprises a material tank system with a feeding valve and a discharge spiral, a power conveying system, and a PLC electric control system for controlling the discharge speed of the spiral; a high-order collecting system comprises a cyclone collection cylinder and a belt type dust collection mechanism; a fire-resistant powder material collected through cyclone dust collection is directly fed into a continuous stirring machine; the rotation ejection manipulator used in the pipeline comprises a rotation ejection manipulator and a track system which ensures that the manipulator can move in the length direction of the pipeline inside the pipeline and can be detached and assembled. By adopting the blast furnace high-order pipeline wet-method ejection system and the blast furnace high-order pipeline wet-method ejection method, material conveying and wet method injection operation in ultra-high ultra-far distance (such as a blast furnace lifting tube or a descending tube) can be achieved, the manipulator can be externally and remotely controlled to eject, and thus the number of operators is reduced, and the working intensity of the operators is alleviated.

Owner:北京联合荣大工程材料股份有限公司

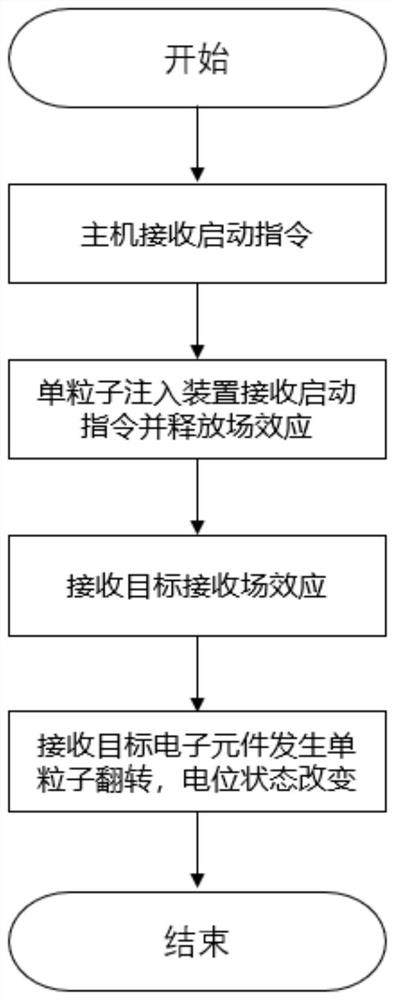

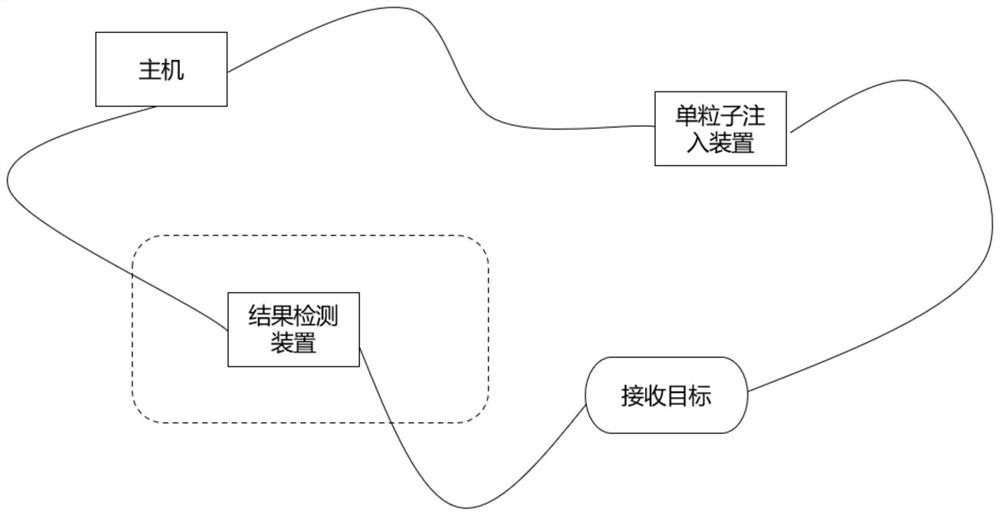

Single particle injection method and single particle injection equipment

PendingCN114509655AInjection implementationIndividual semiconductor device testingParticle injectionDevice material

The invention discloses a single-particle injection method and single-particle injection equipment, and relates to the field of storage, the single-particle injection method is suitable for the single-particle injection equipment, the single-particle injection equipment structurally comprises a host and at least one single-particle injection device, and the single-particle injection method comprises the steps that the host receives a starting instruction, the method comprises the following steps: starting a single particle injection device, transmitting a starting instruction to the single particle injection device, responding to the starting instruction, generating a field effect by at least one single particle injection device, transmitting the field effect to a receiving target, responding to the field effect, and converting a potential state of the receiving target. According to the single-particle injection method and the single-particle injection equipment provided by the embodiment of the invention, the field effect is released and transmitted to the receiving target through the single-particle injection device, and the conversion of the high and low states of the potential state of the semiconductor device of the receiving target is induced through the field effect. And field effect release, intensity and period can be controlled according to requirements so as to realize artificial single particle injection.

Owner:BEIHANG UNIV

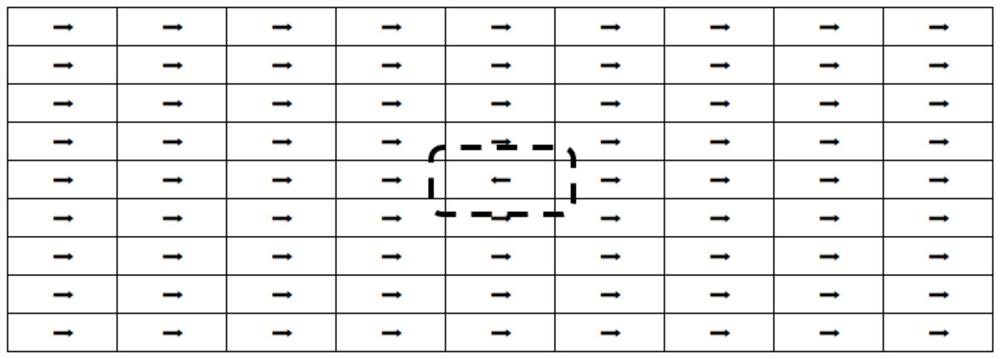

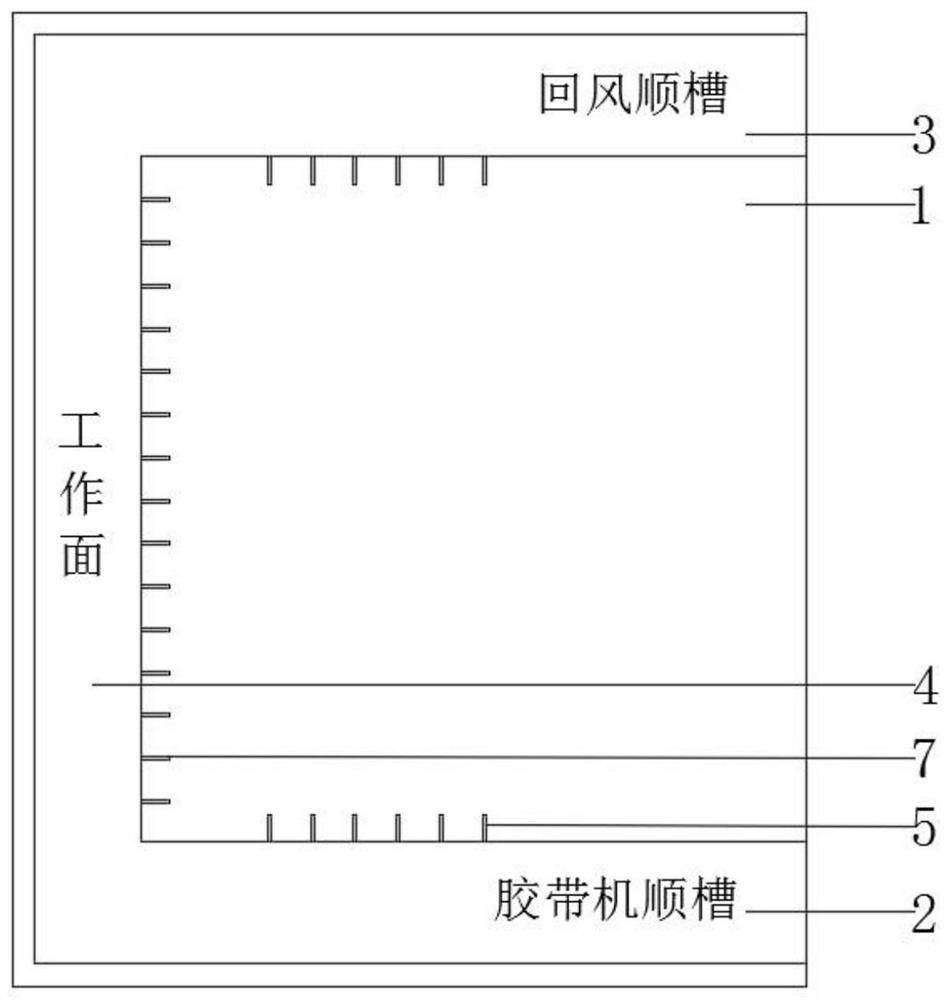

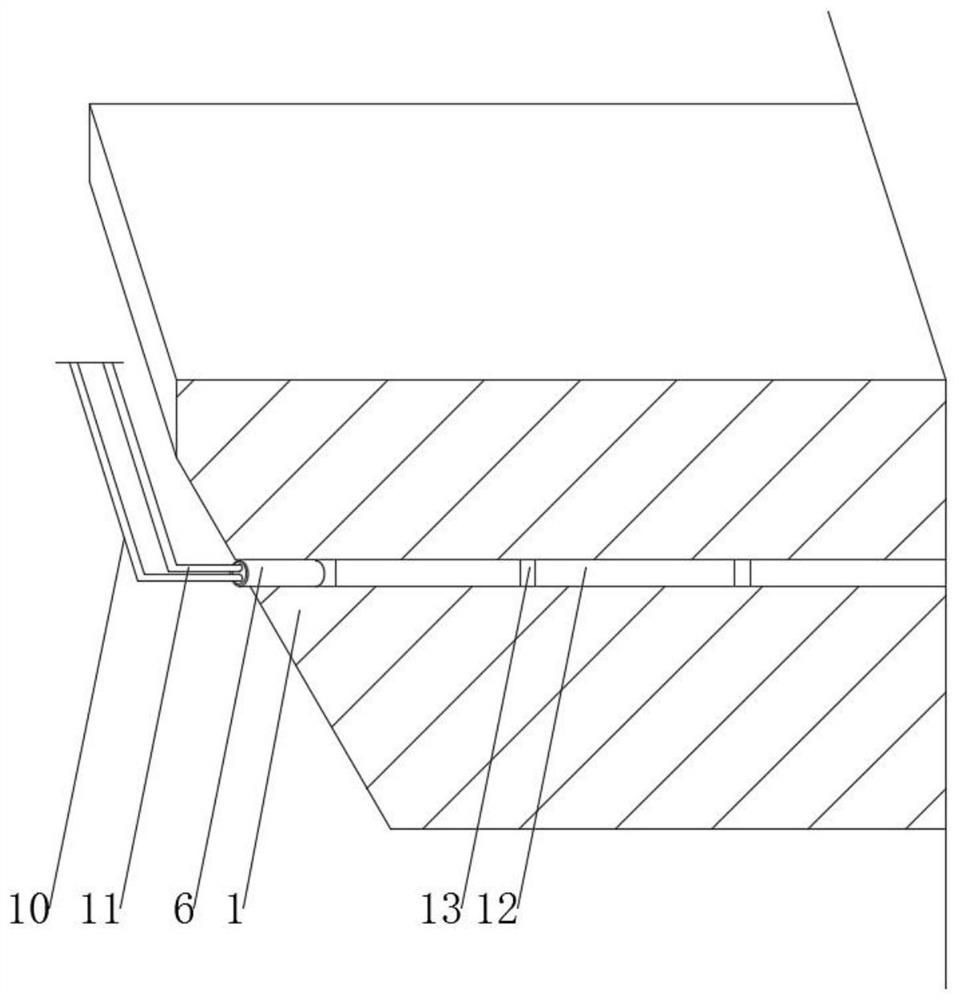

Dust-settling method of working face for layered and fully-mechanized coal mining of gently-declined thick coal seam by water injection under dynamic pressure

ActiveCN111794798AAvoid compaction effectReduce aggregation effectDust removalFire preventionMining engineeringMechanical engineering

The invention discloses a dust-settling method of a working face for layered and fully-mechanized coal mining of a gently-declined thick coal seam by water injection under dynamic pressure. The methodcomprises the following steps of drilling a sealing-tape machine crossheading and an air return crossheading in the two sides of the coal seam respectively, and getting through and connecting the tail ends of the sealing-tape machine crossheading and the air return crossheading to form the working face used for fully-mechanized coal mining; conducting drilling at intervals in the sealing-tape machine crossheading and the air return crossheading in the length direction of the sealing-tape machine crossheading and the air return crossheading to drill out spaced dynamic pressure holes I, and filling the dynamic pressure holes I with cut-off devices I used for sealing the radial direction of the dynamic pressure holes I; injecting safe gas in the dynamic pressure holes I through the cut-off devices I according to a predetermined exhaust rule, and then replacing hazardous gas in the dynamic pressure holes I with the safe gas through the cut-off devices I; using the safe gas to sufficientlyopen up the intervals according to the predetermined exhaust principle to avoid the situation that the hazardous gas drifts away, causing decompression and accompanying compaction effect; and meanwhile, the hazardous gas and safe gas are mixed to constantly and continuously dilute the concentration of the hazardous gas, and therefore, the aggregation effect of the hazardous gas is reduced to a great extent.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com