Patents

Literature

62results about How to "Guaranteed pressure stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

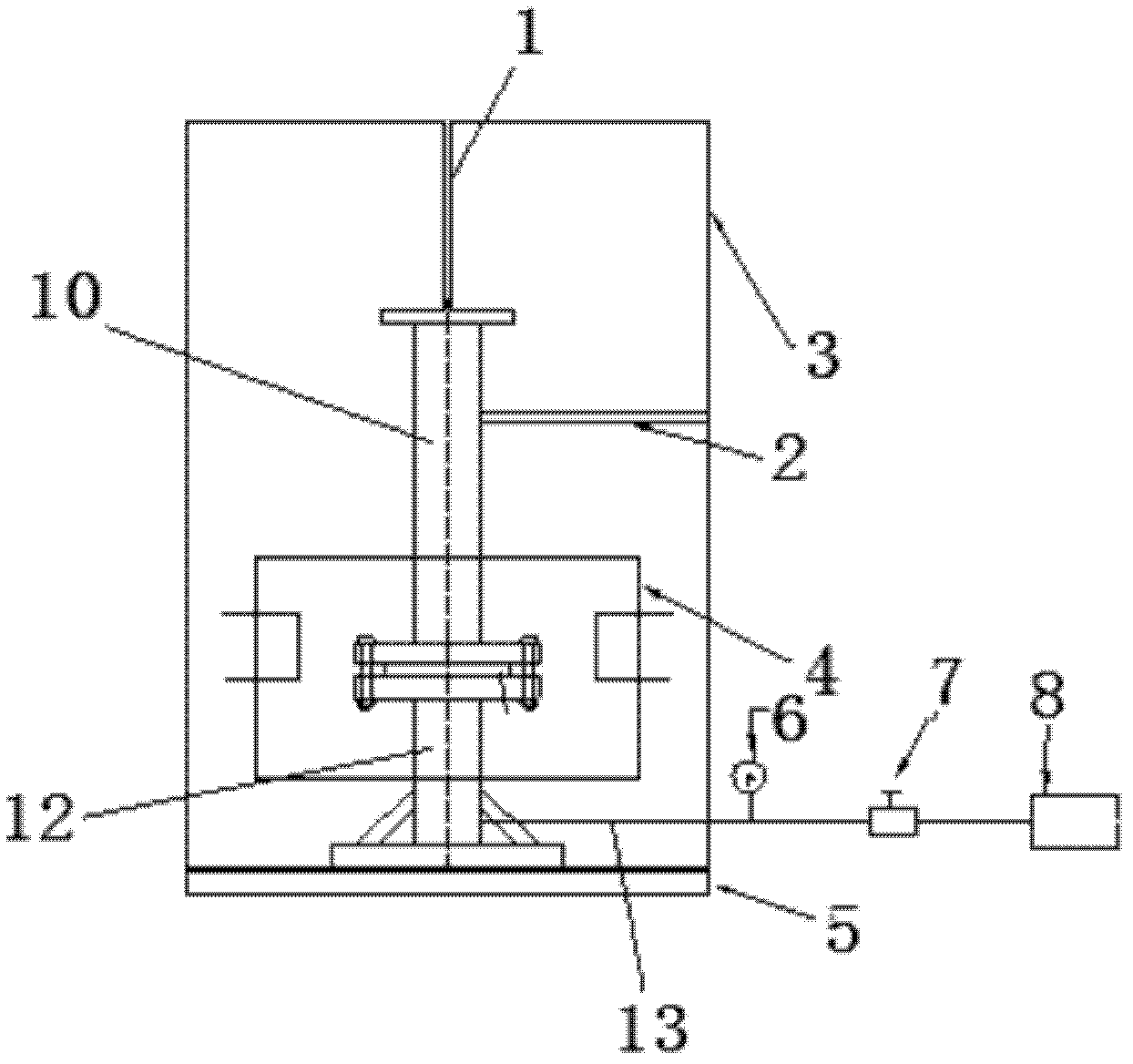

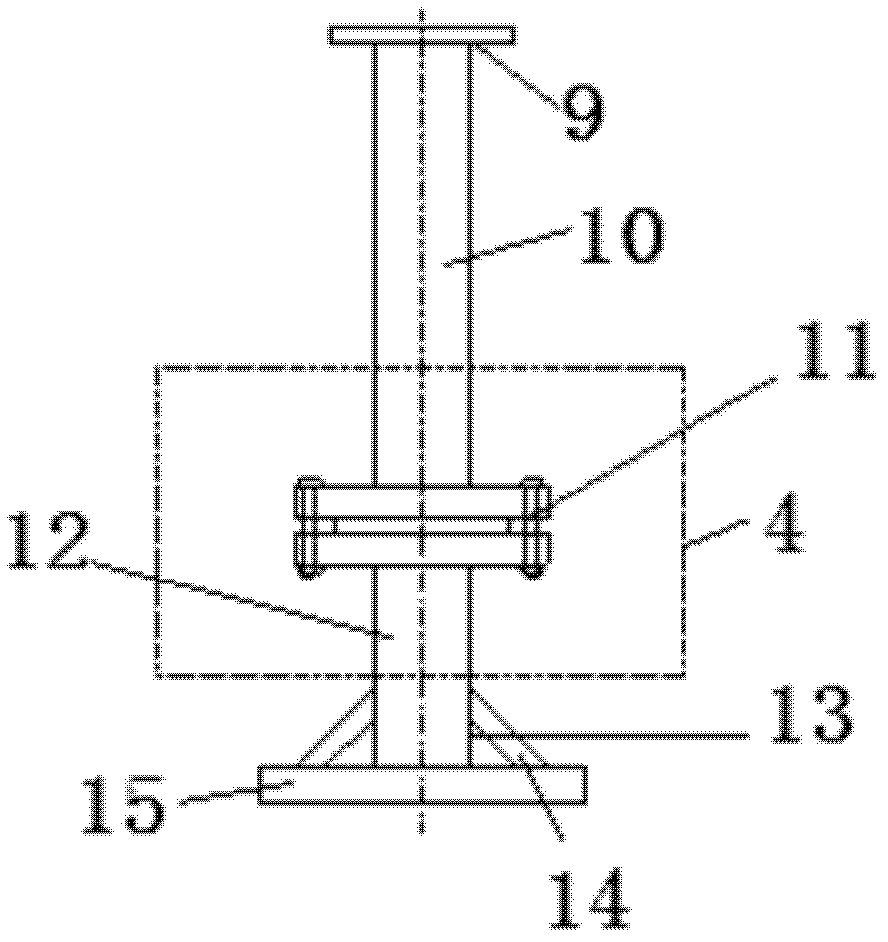

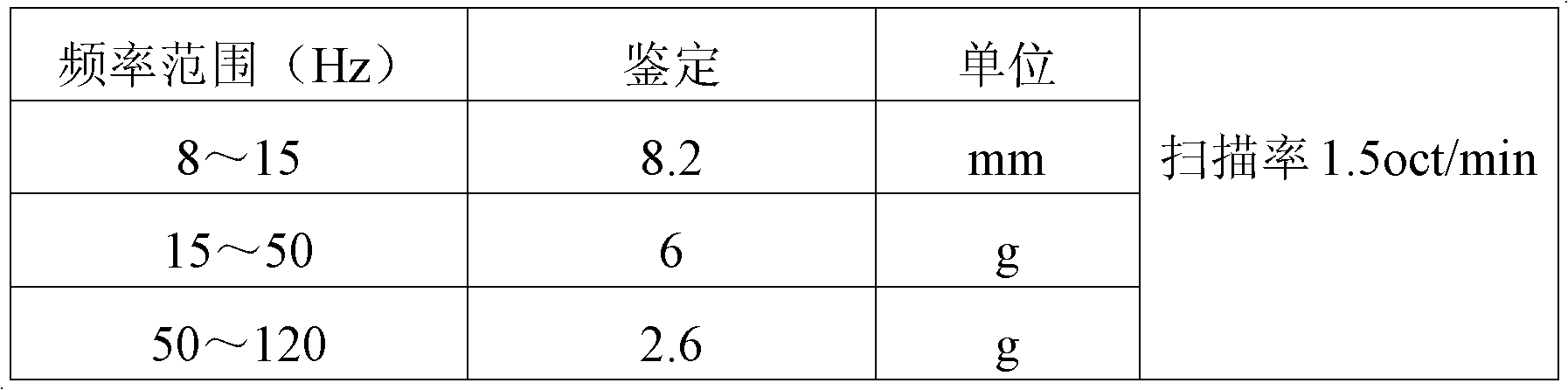

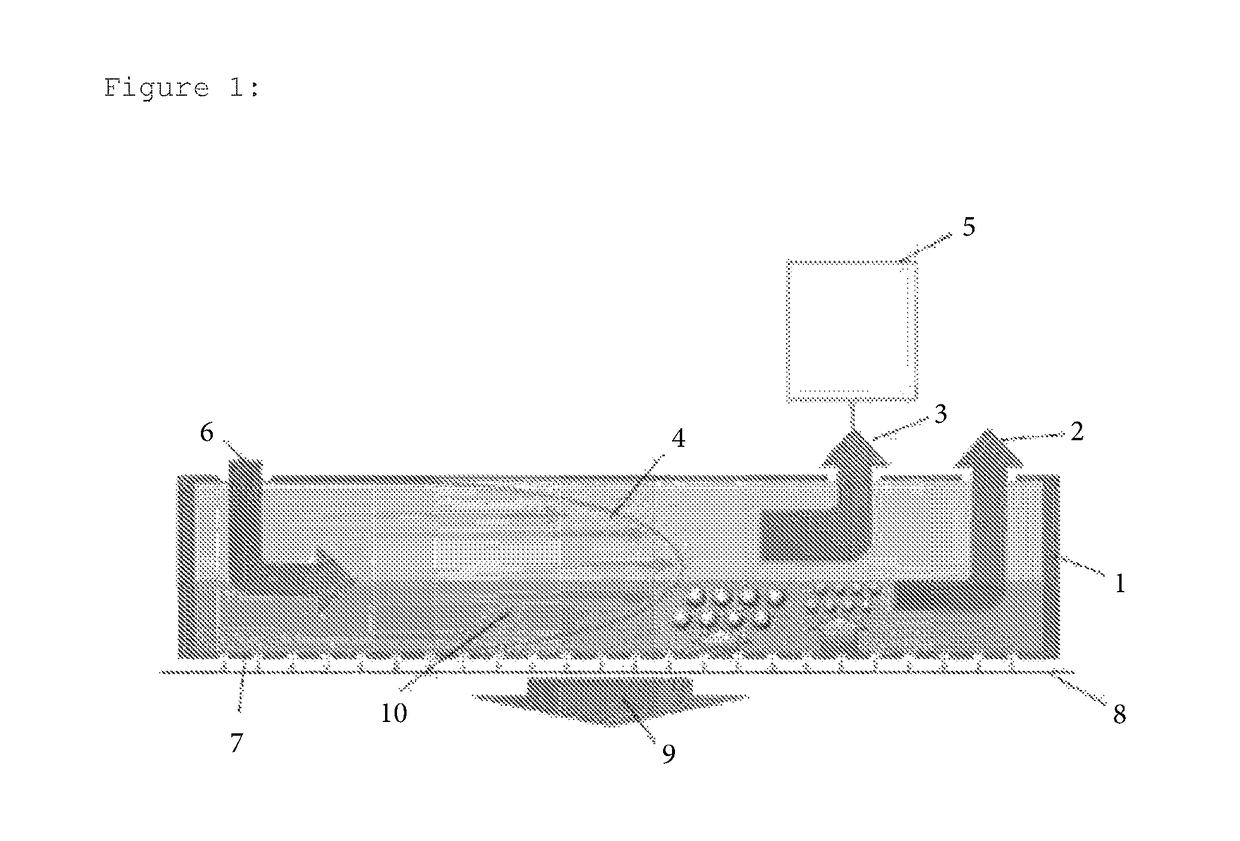

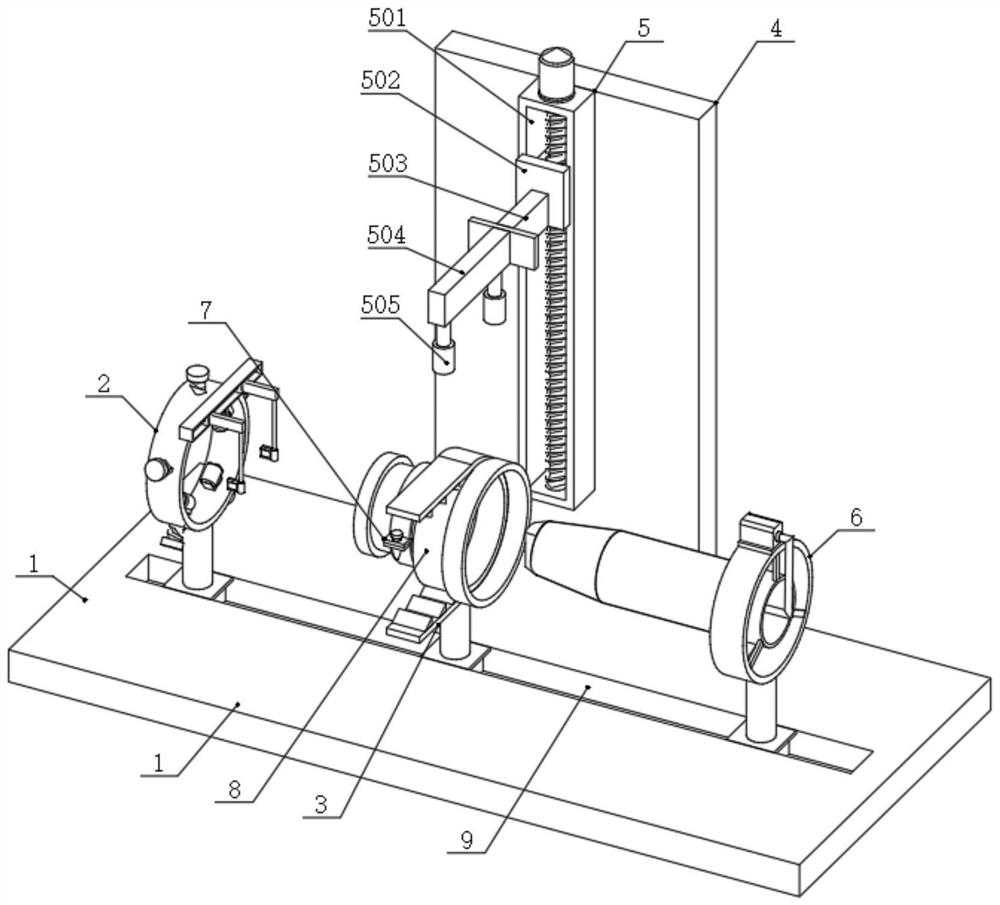

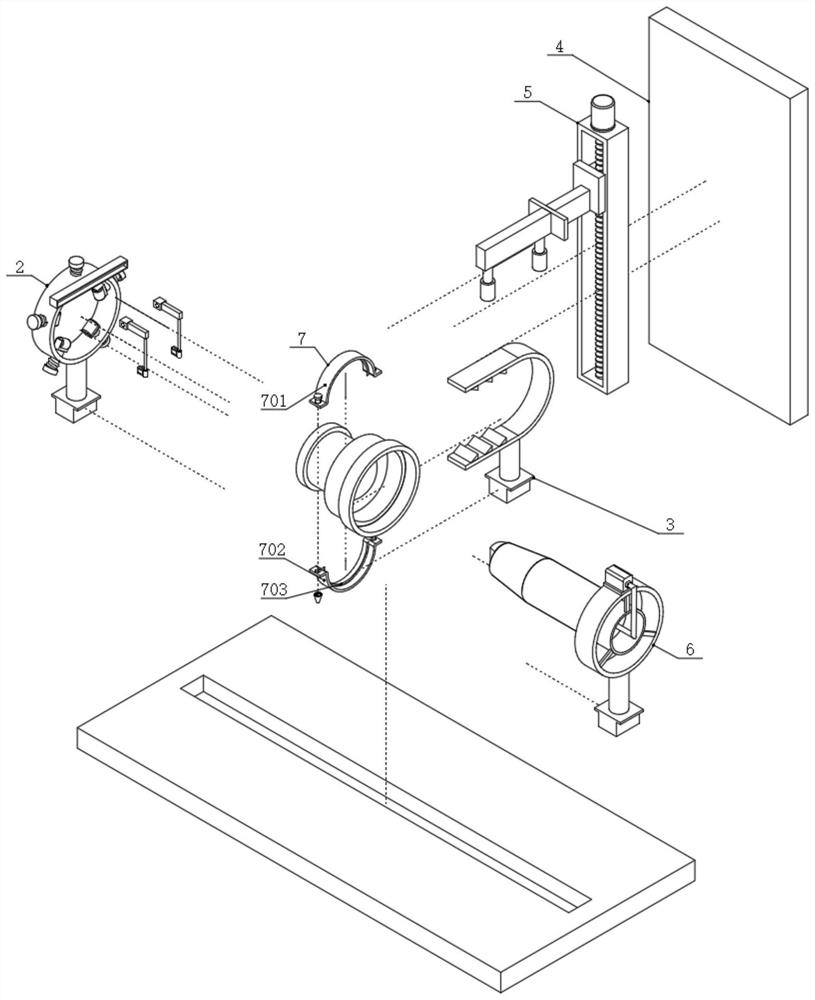

Thermal vibration joint test device and method of flange sealing structure under complicated loaded conditions

ActiveCN102435404AReal-time detection of tightnessGuaranteed pressure stabilityMeasurement of fluid loss/gain rateVibration testingEngineeringFlange

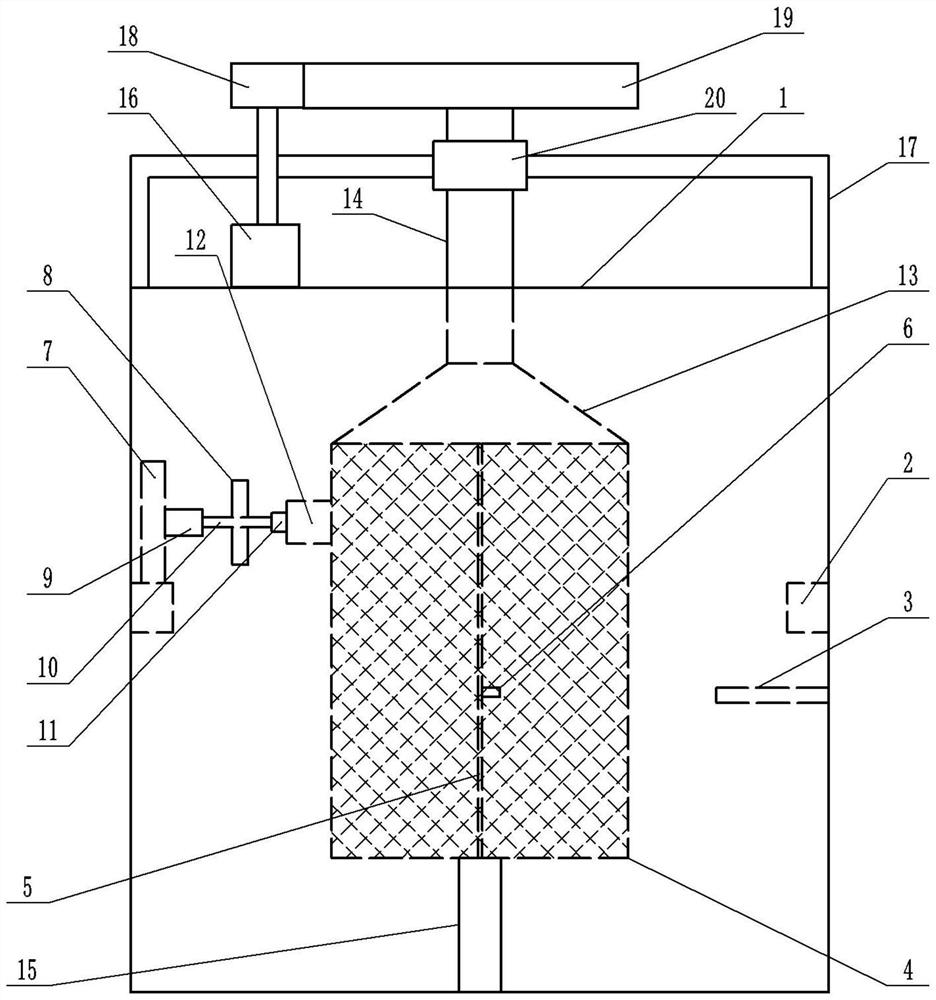

The invention aims to provide a thermal vibration joint test device and method of a flange sealing structure under complicated loaded conditions. A flange sealing structure to be tested is arranged between a flange of a force applying pipe section and a flange of a force bearing pipe section; then the force applying pipe section and the force bearing pipe section are fixed on a bottom plate in a test box body; the test box body is arranged on the surface of a vibration platform; heating devices are arranged around the force applying pipe section and the force bearing pipe section; a gas with a predetermined pressure value is charged into the force bearing pipe section through a pressurized gas input and monitoring pipeline; an adjusting pull rod applying axial force applies axial force to the force applying pipe section; and an adjusting pull rod applying lateral force applies lateral force to the force applying pipe section. Through the invention, the sealing performance of the flange sealing structure after high-temperature vibration under the flange loaded condition can be checked, and real-time detection of the sealing performance is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

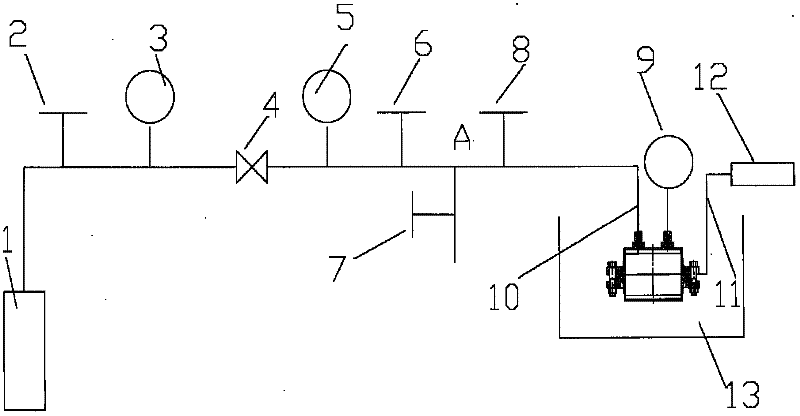

Simple high-temperature testing device and method for flange rubber sealing element

ActiveCN102445310AFast heat transferGuaranteed pressure stabilityDetection of fluid at leakage pointButt jointEngineering

The invention provides a simple high-temperature testing device and method for a flange rubber sealing element. A lower flange is in butt joint with an upper flange; the end face of the lower flange which is contacted with the upper flange is provided with a ring groove which serves a sealing groove for assembling the flange rubber sealing element to be tested; an upper cover is welded on the top of the upper flange; a bottom cover is welded at the bottom of the lower flange; the upper cover is connected to a gas medium charging pipeline; one end of a thermocouple is inserted into the upper flange through a gap, and the other end of the thermocouple is connected with a temperature indicator; and the upper flange and the lower flange which are connected one above the other are arranged in a high-temperature oil bath container. In the invention, a gas source is cut off by pressurizing under the normal-temperature condition, and a pressurizing way for reaching a preset pressure at the high temperature by using a gas expanding principle is adopted, so that the pressure constancy under the high-temperature condition is ensured; and an oil bath heating way is adopted, so that rapid heat transfer of a leakage test tool is realized. Due to the adoption of the device and the method, detection of the high-temperature sealing property of the rubber sealing element at the extreme usage temperature during short-time use is realized, and the development cost is greatly saved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

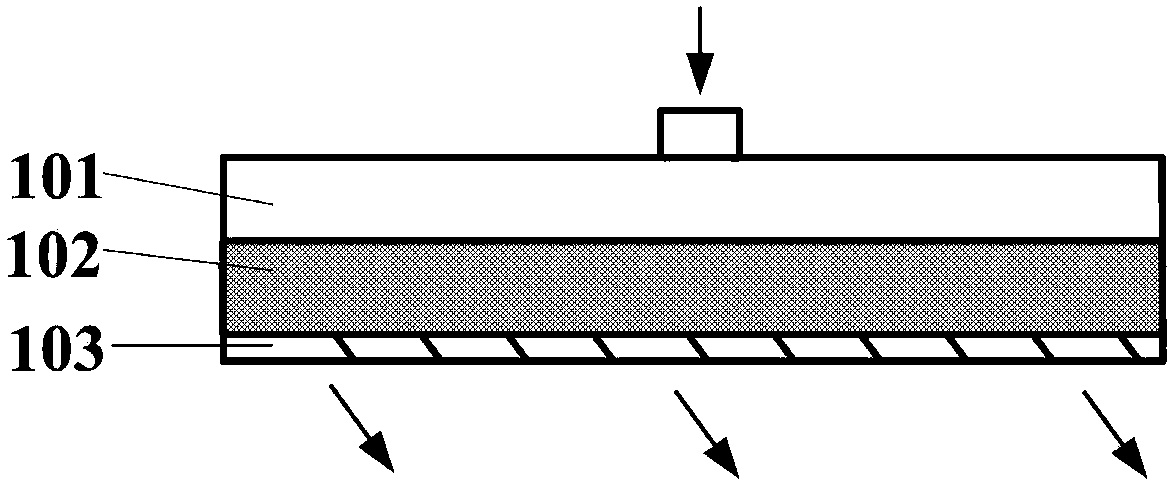

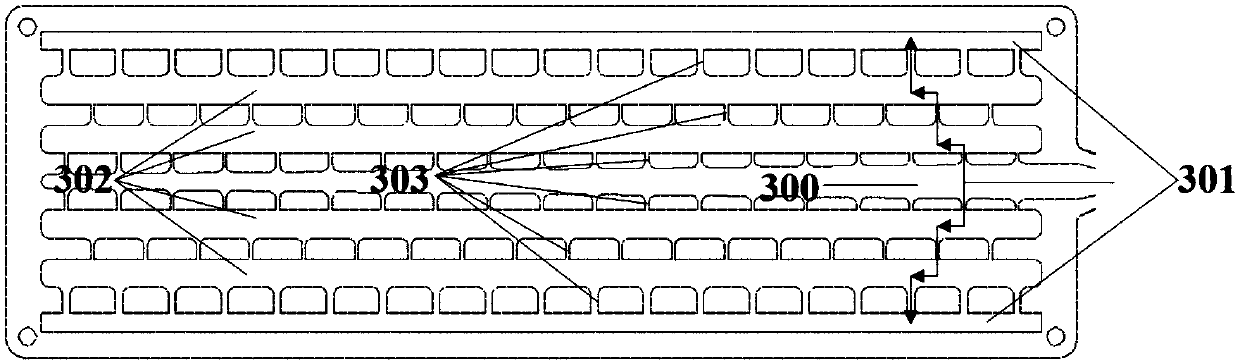

Apparatus for Field-Flow Fractionation

ActiveUS20160238571A1High measurement sensitivityReduce detection limitComponent separationPhase-affecting property measurementsEngineeringField flow fractionation

The present invention relates to an apparatus for field-flow fractionation and to a method for separating samples by means of field-flow fractionation using this apparatus. The apparatuses of the invention comprise a separation channel which, in addition to a first outlet for sample-containing solvent, comprises a second outlet for sample-free solvent, wherein the second outlet is arranged in a region of the separation channel from which sample-free solvent may be removed during elution and a flow volume control device is arranged downstream of the second outlet. They are characterized in that the flow volume control device is a mass flow controller.

Owner:POSTNOVA ANALYTICS

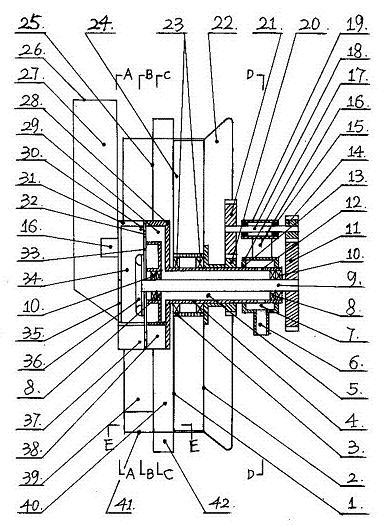

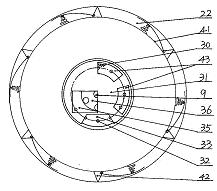

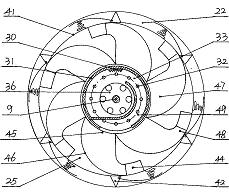

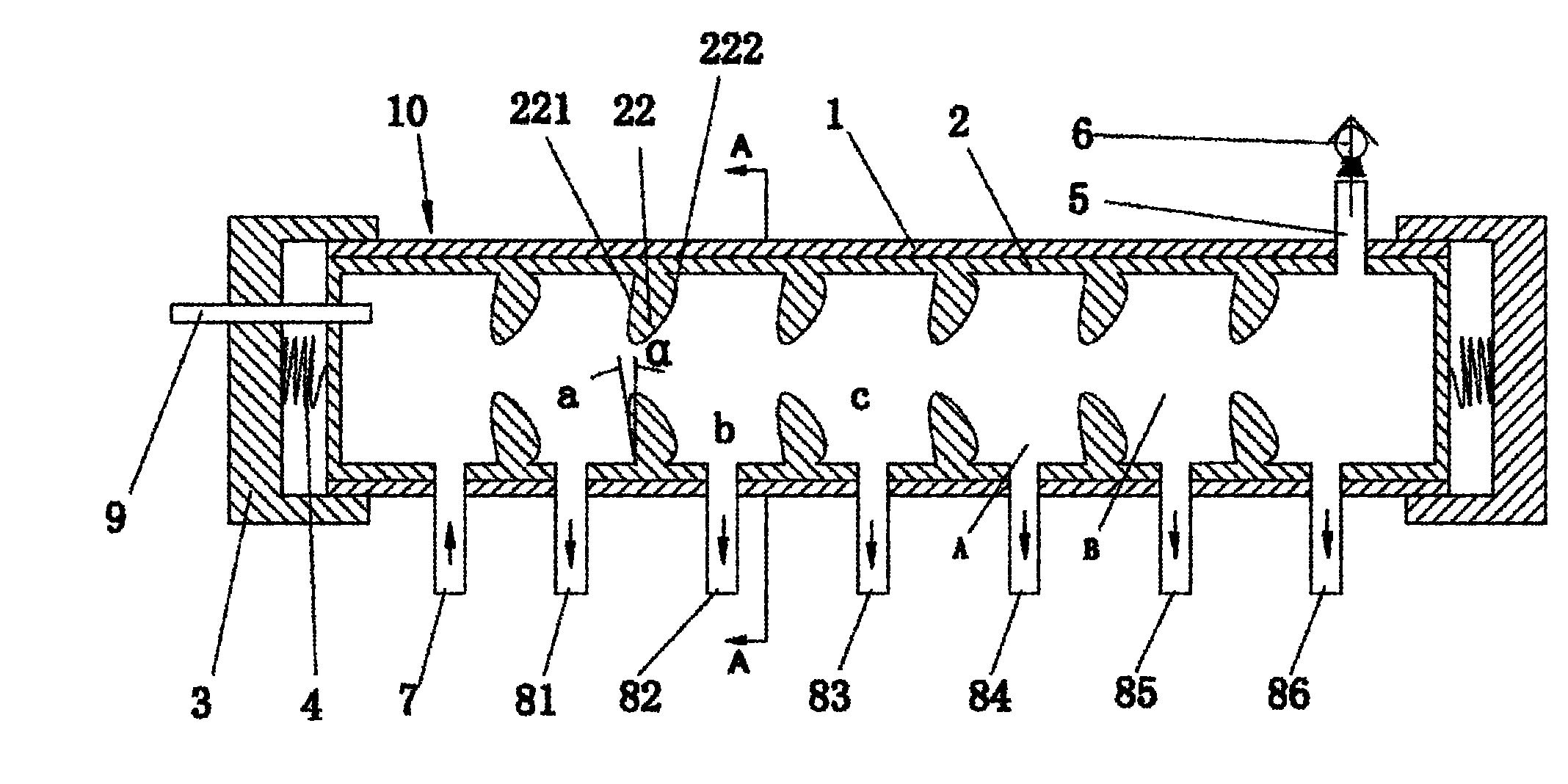

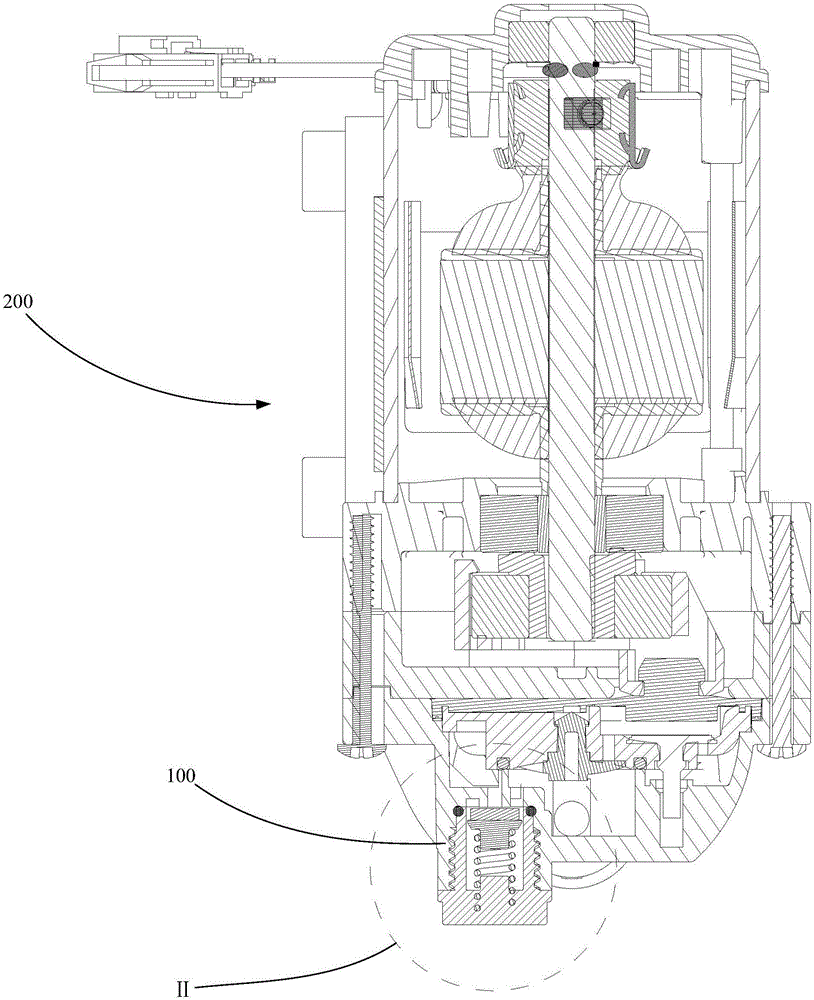

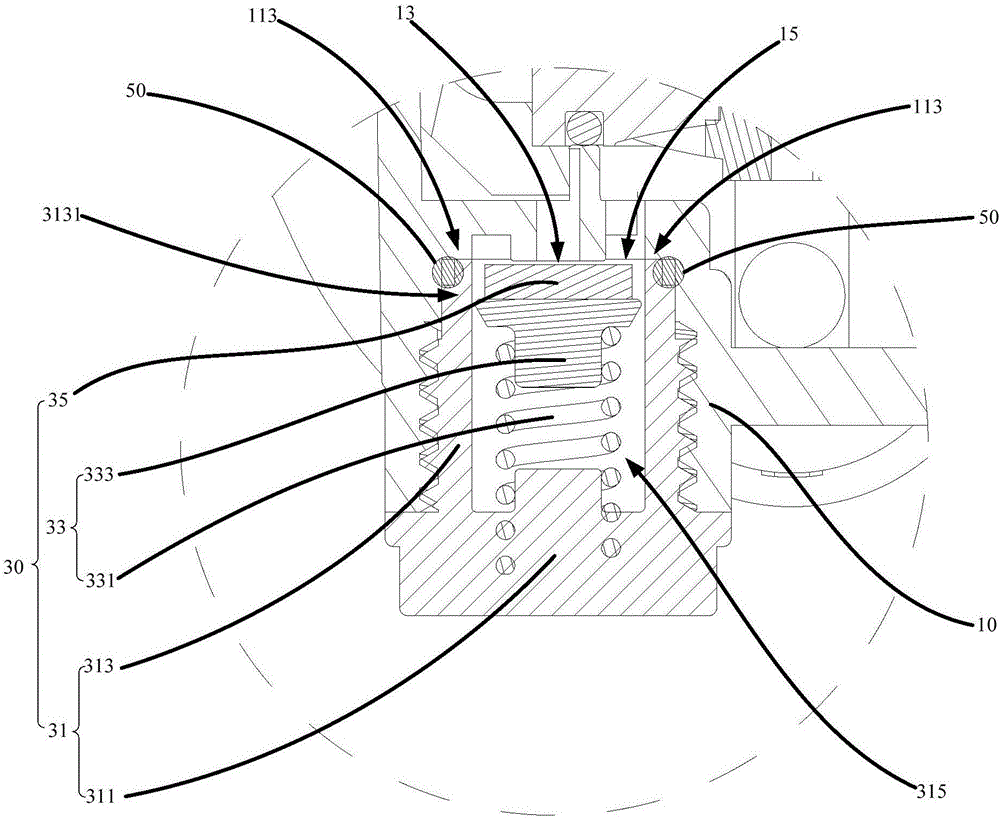

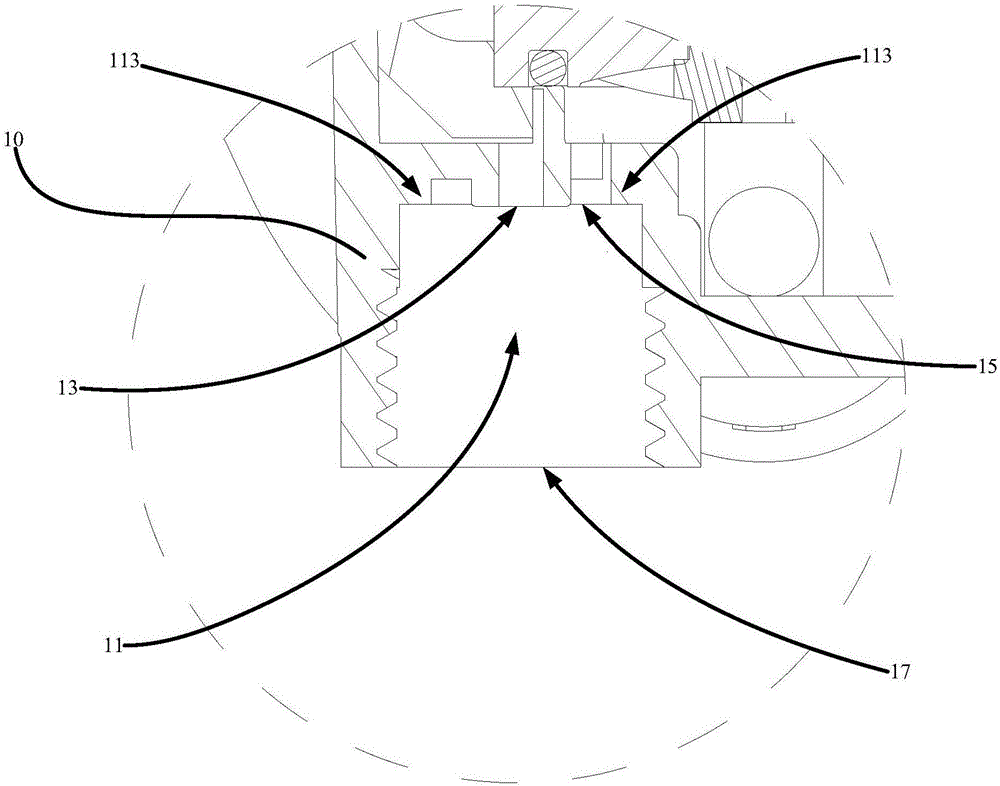

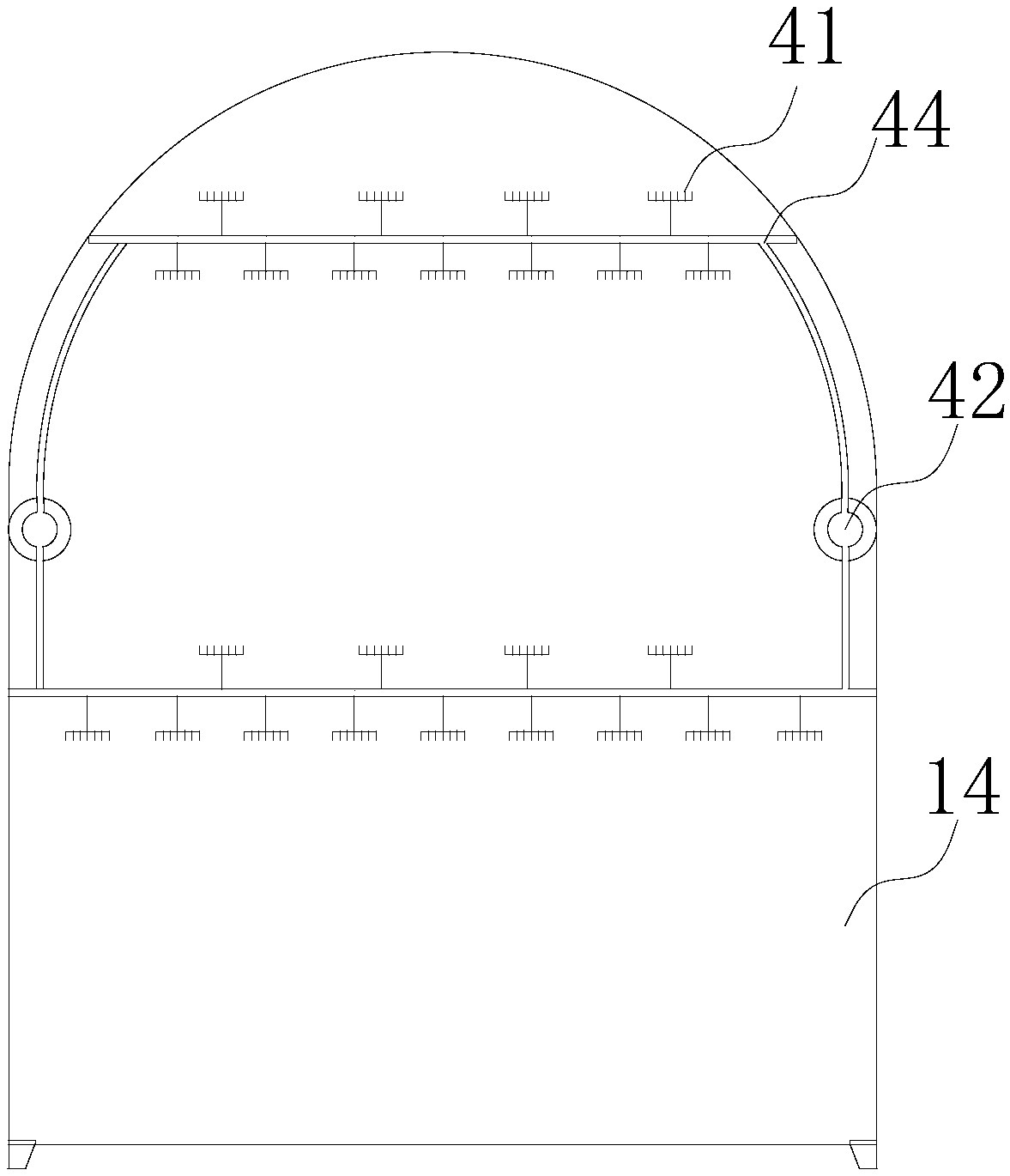

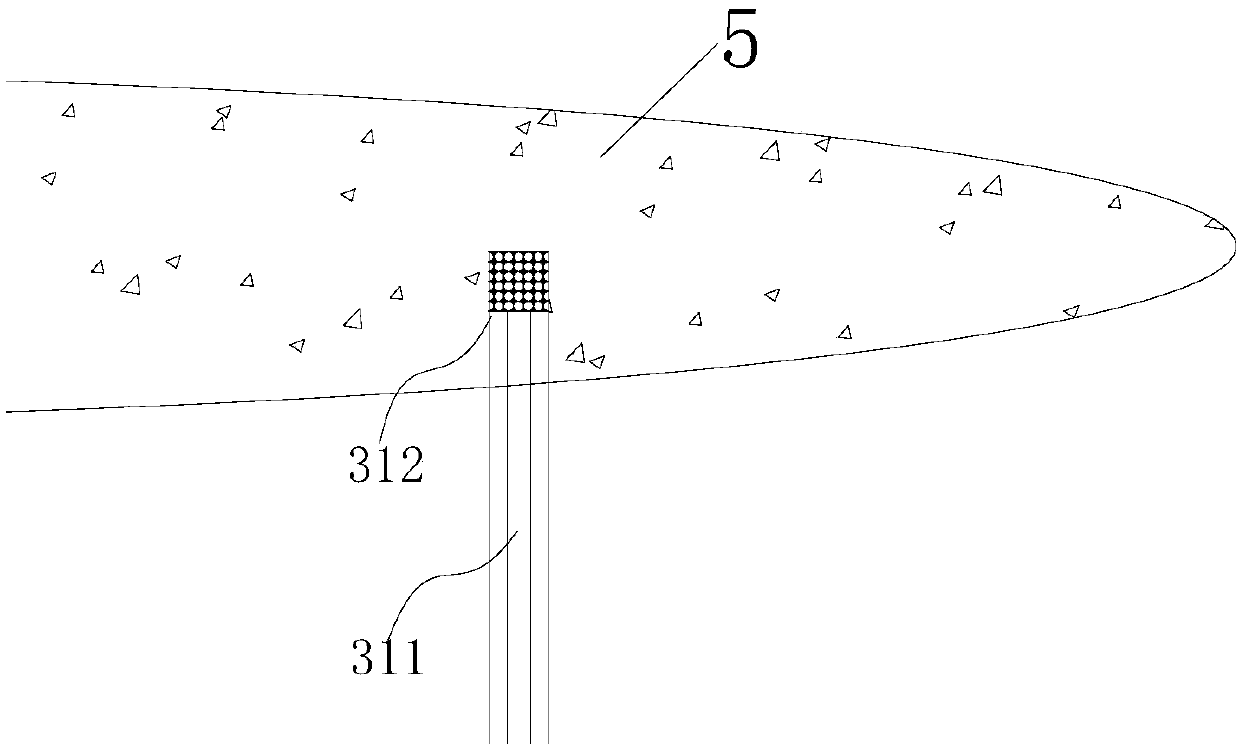

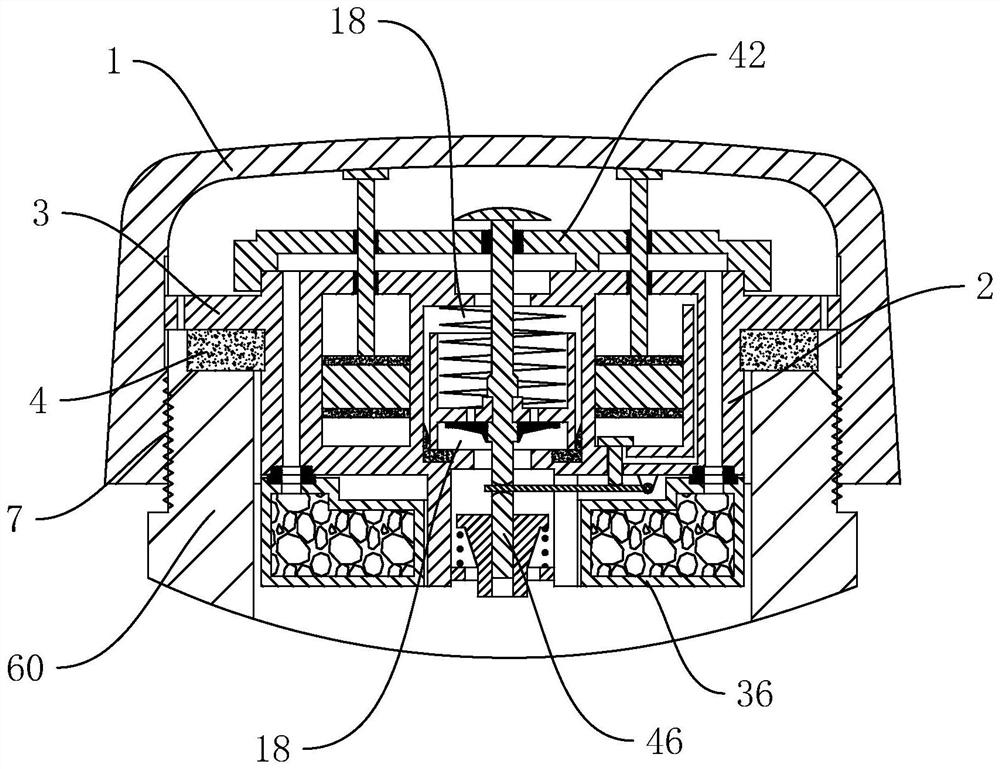

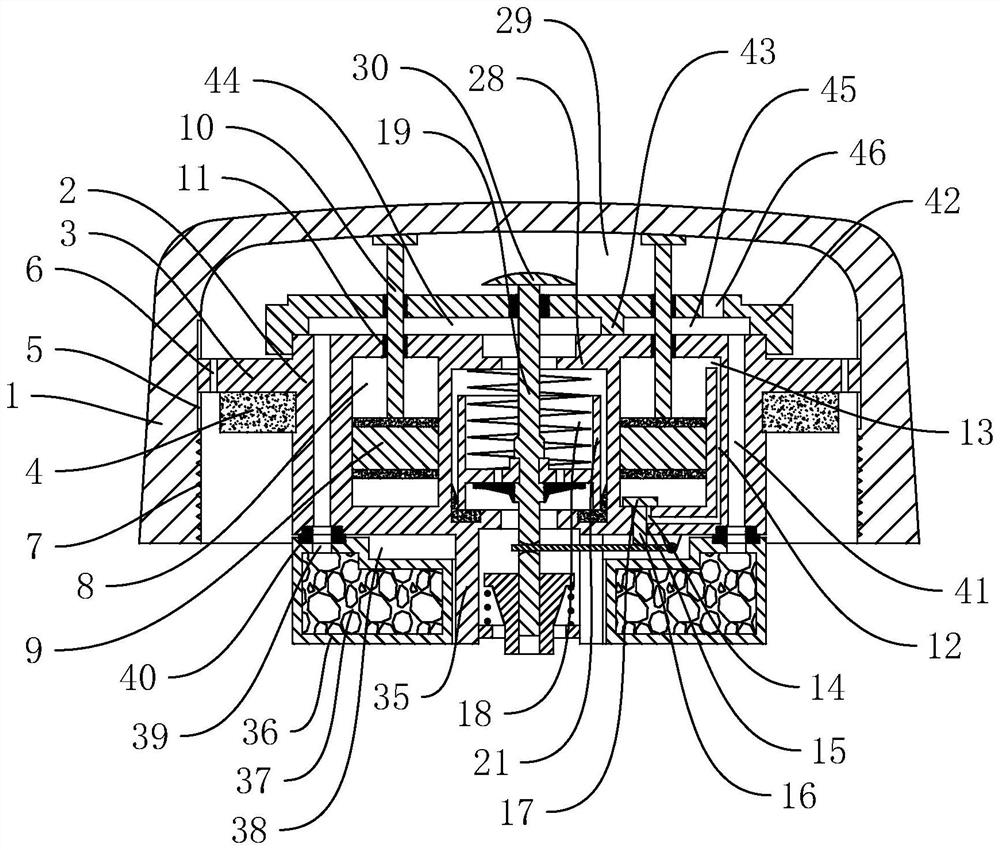

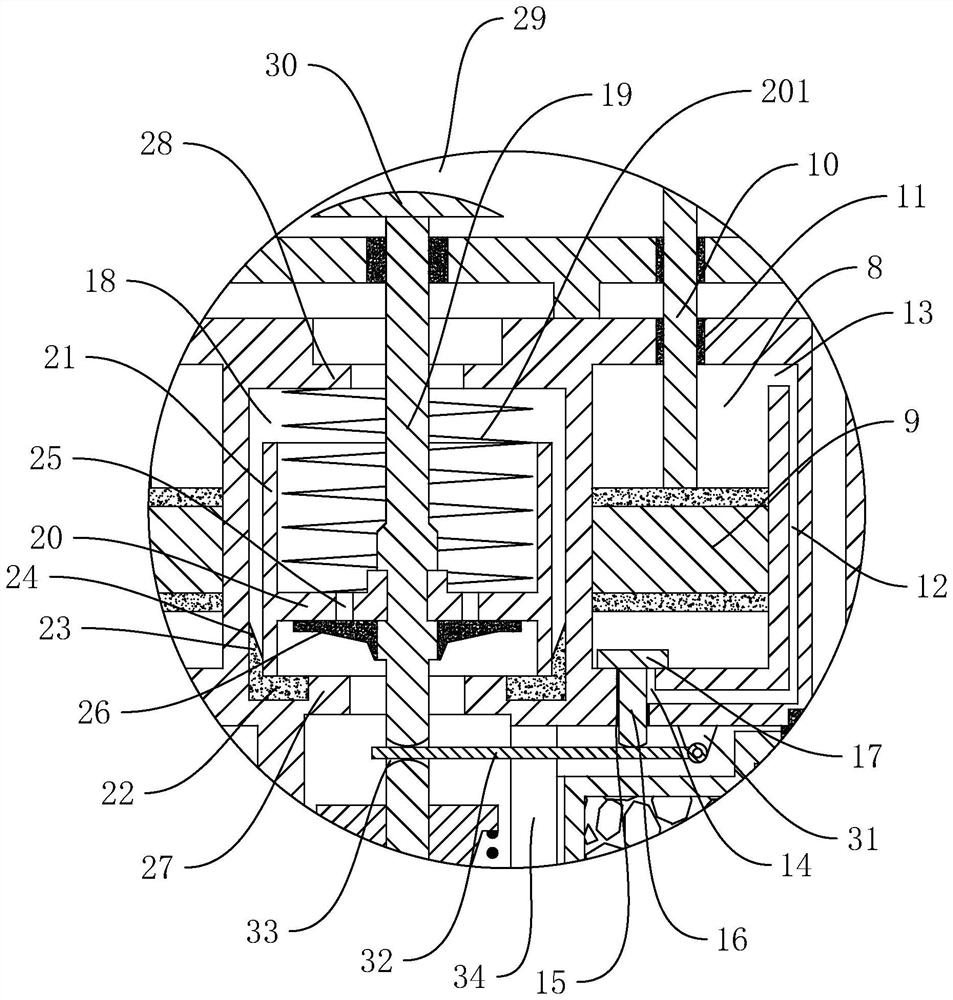

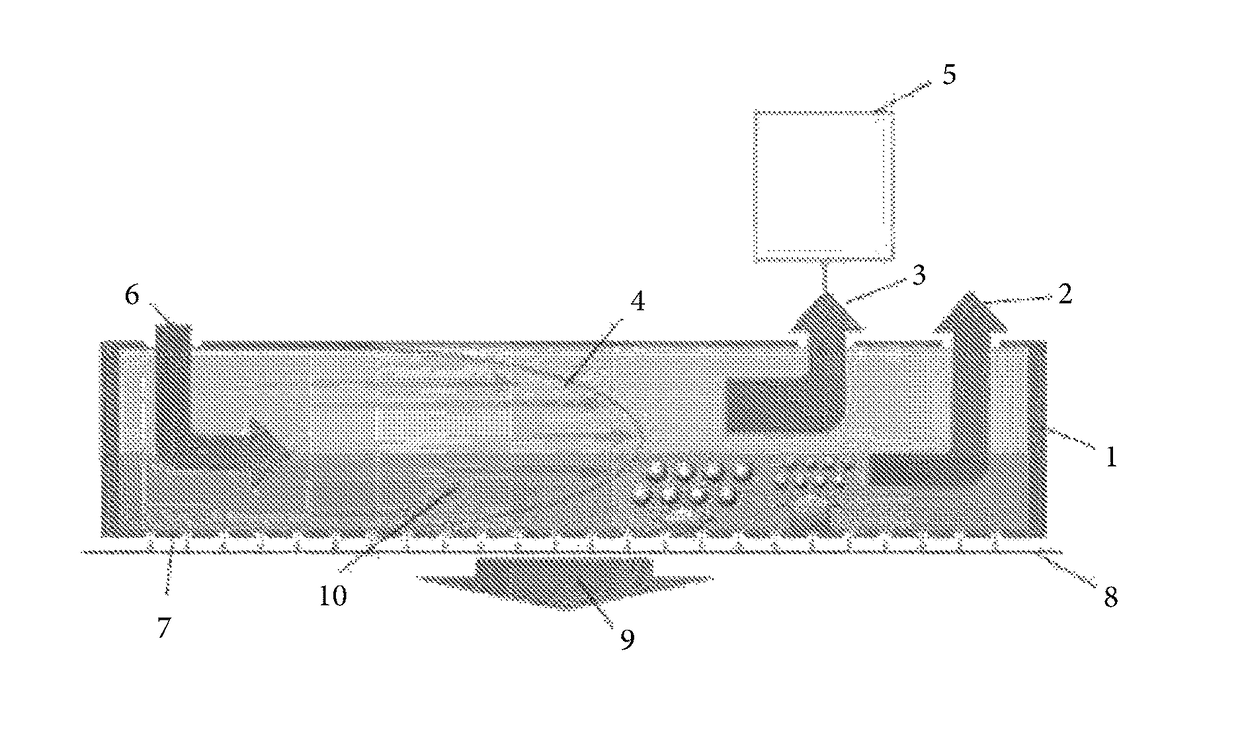

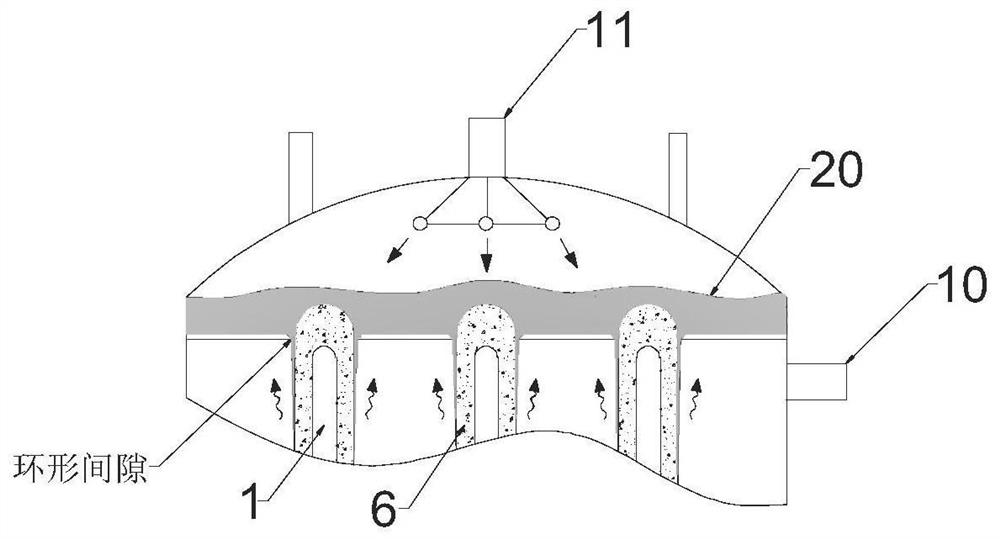

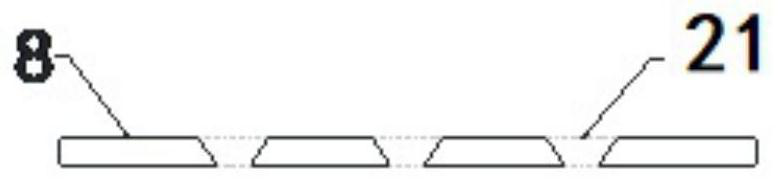

Suction type precision seed bunch planting device

InactiveCN101766078ALarge internal spaceIncrease heightSeed depositing seeder partsRegular seed deposition machinesAgricultural scienceAgricultural engineering

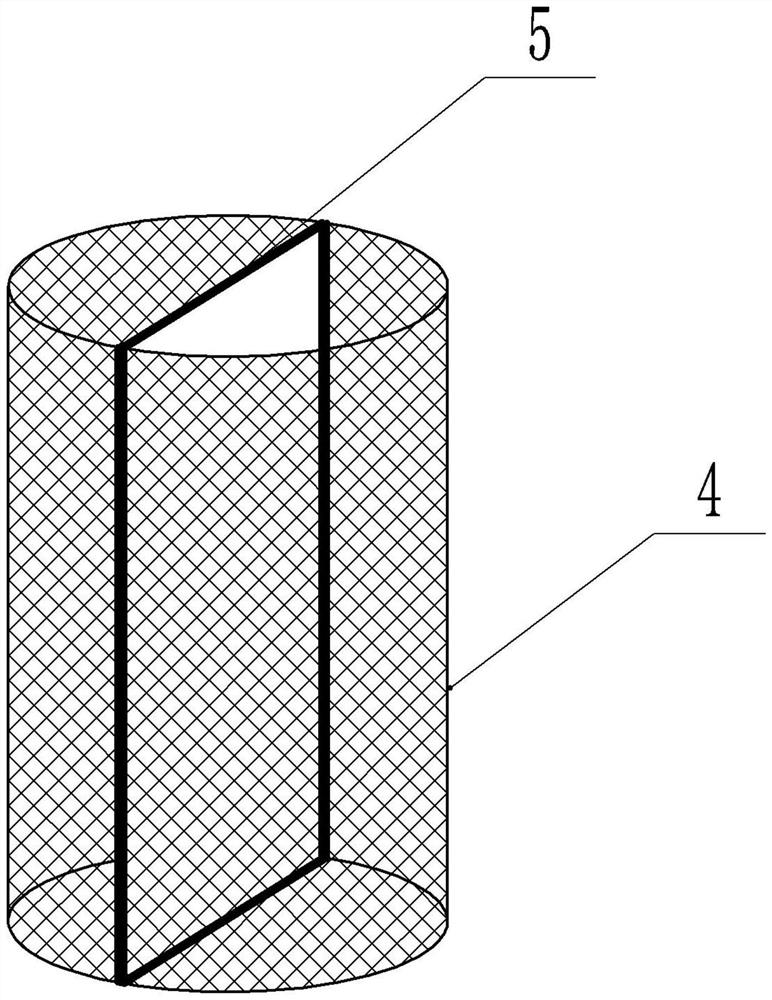

The invention relates to an agricultural seeding device, in particular to a suction type precision seed bunch planting device. The suction type precision seed bunch planting device mainly comprises a seed tank (26), a suction type seed sorter, a roller, a negative pressure air suction pipe (6), a speed shifting mechanism and a seed receiving and delivering device, wherein the suction type seed sorter is arranged in the roller and communicated with the negative pressure air suction pipe (6); a seed delivering box (47) is arranged between a seed outlet of the suction type seed sorter and a duck nozzle (42); a main shaft (4) of the roller is a hollow pipe; a main shaft (9) of the suction type seed sorter is arranged in the hollow pipe-shaped main shaft (4) of the roller; one end of the main shaft (9) of the suction type seed sorter is coupled to the suction type seed sorter through a bearing (8.1) and drives a seed suction disk (33), and the other end of the main shaft (9) of the suction type seed sorter passes through a sealing bearing (8) in the main shaft (4) of the roller; the main shaft (4) of the roller and the main shaft (9) of the suction type seed sorter are in speed-shifting connection through a gear or a chain or a notched belt. The suction type precision seed bunch planting device has the advantages of increasing the inner space of the roller as much as possible, increasing the height of the seed delivering box simultaneously, conveniently regulating the rotating speed ratio of the roller to the seed absorption box according to the agronomic requirements, and greatly improving the seeding speed while seeding accurately. Due to the unique transmission structure, the suction type precision seed bunch planting device is compact and steady, and the fault rate is reduced obviously under the environment of worse working condition.

Owner:陈恒

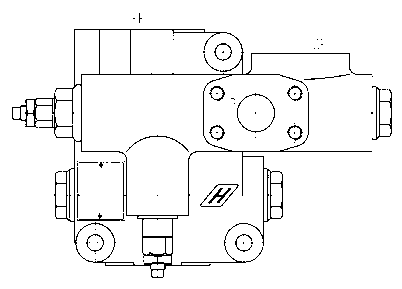

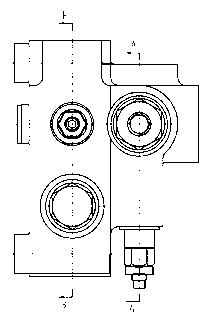

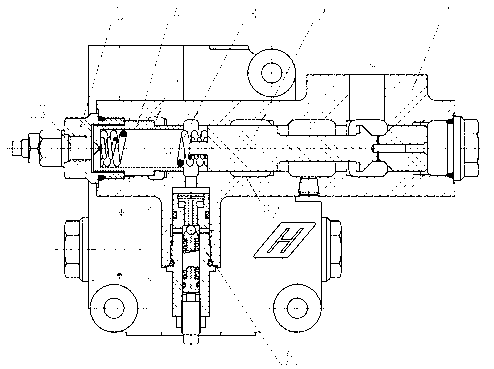

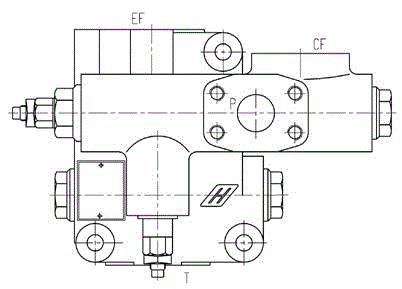

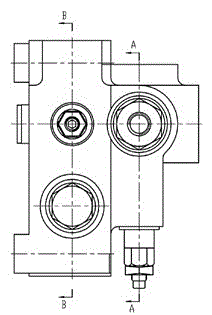

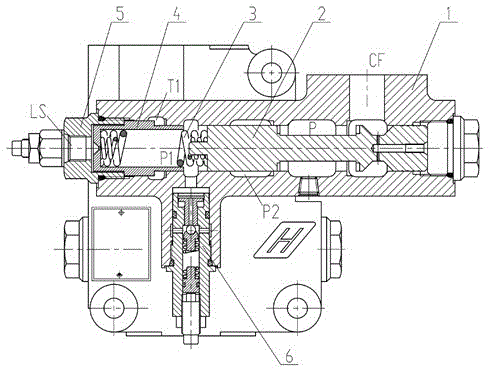

Energy-saving type prior unloading valve

The invention discloses an energy-saving type prior unloading valve which belongs to the technical field of hydraulic steering systems of engineering machinery. The energy-saving type prior unloading valve comprises a valve body, a prior valve core, a sliding valve, an unloading valve core and an LS control plug screw, wherein an oil channel CF, an oil channel P, an oil channel P2, an oil channel P1 and a return oil channel T1 are formed in a valve hole of the prior valve core; and the oil channel P2, a return oil channel T, an oil channel LS and an unloading safety valve guide return oil channel T2 are formed in a valve hole of the unloading valve core. A load sensing complete hydraulic steering hydraulic system is formed by the energy-saving type prior unloading valve together with a load sensing steering gear and a steering pump, the sliding valve is additionally arranged, and the movement of the sliding valve is controlled through the pressure of the steering gear LS, so that the divided and combined flow high / low pressure control is realized, and the steering prior is ensured; and when a loader is not steered, steering pump hydraulic oil is subjected to prior valve flow combination or load oil returning under the lower pressure, so that the pressure loss of the steering pump combination or the load oil returning in the working condition that the loader is not steered is reduced, the unnecessary energy loss of the system is reduced to the maximum extent, the oil temperature is lowered, and the energy saving effect is effectively achieved.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

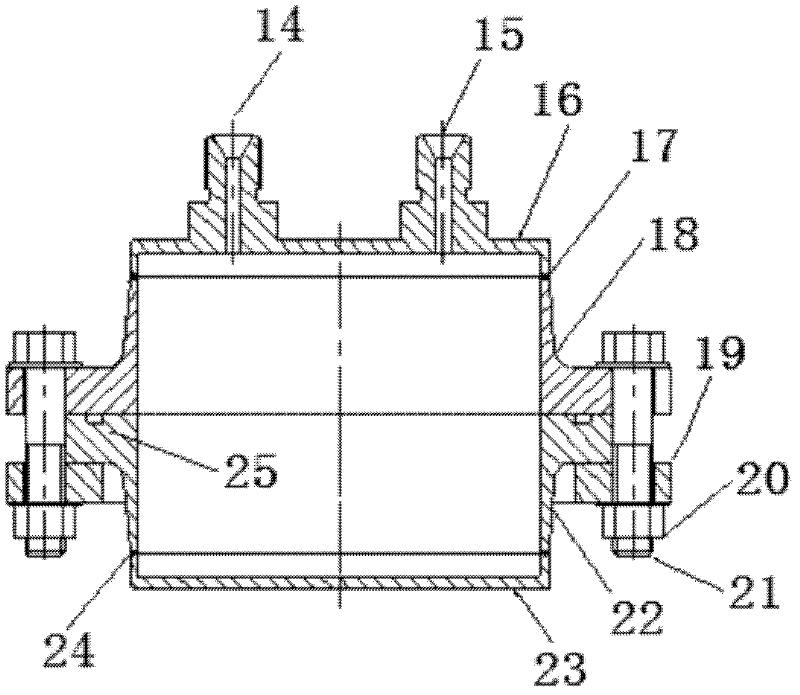

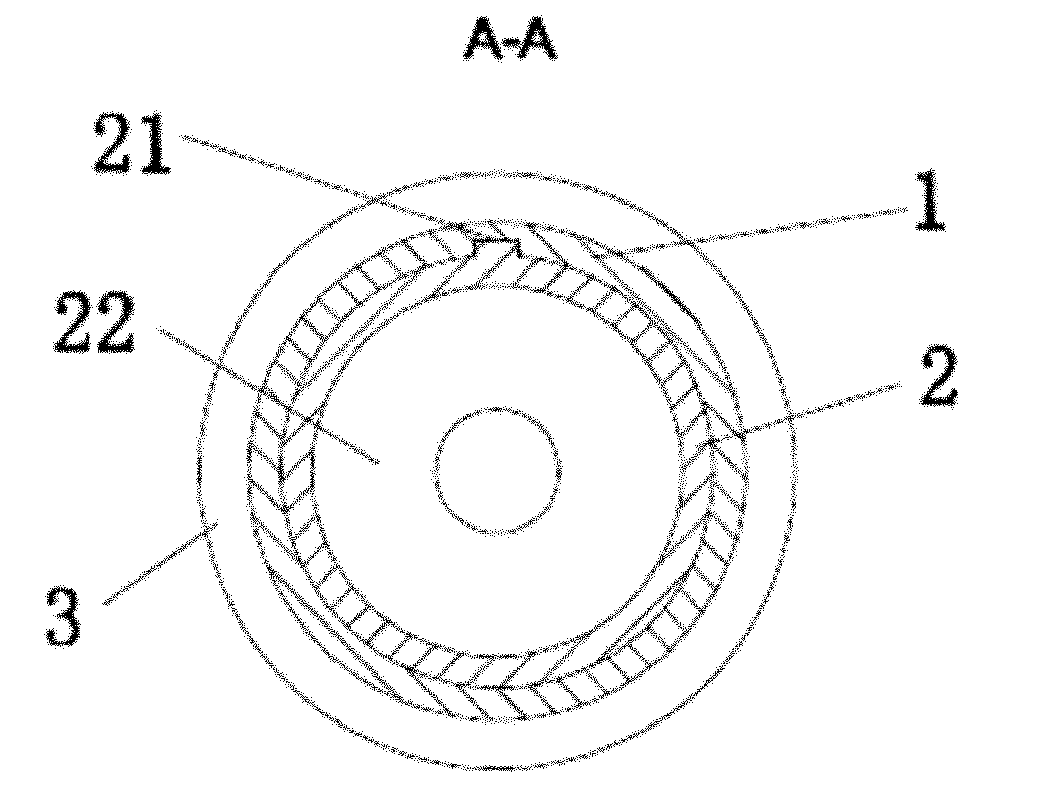

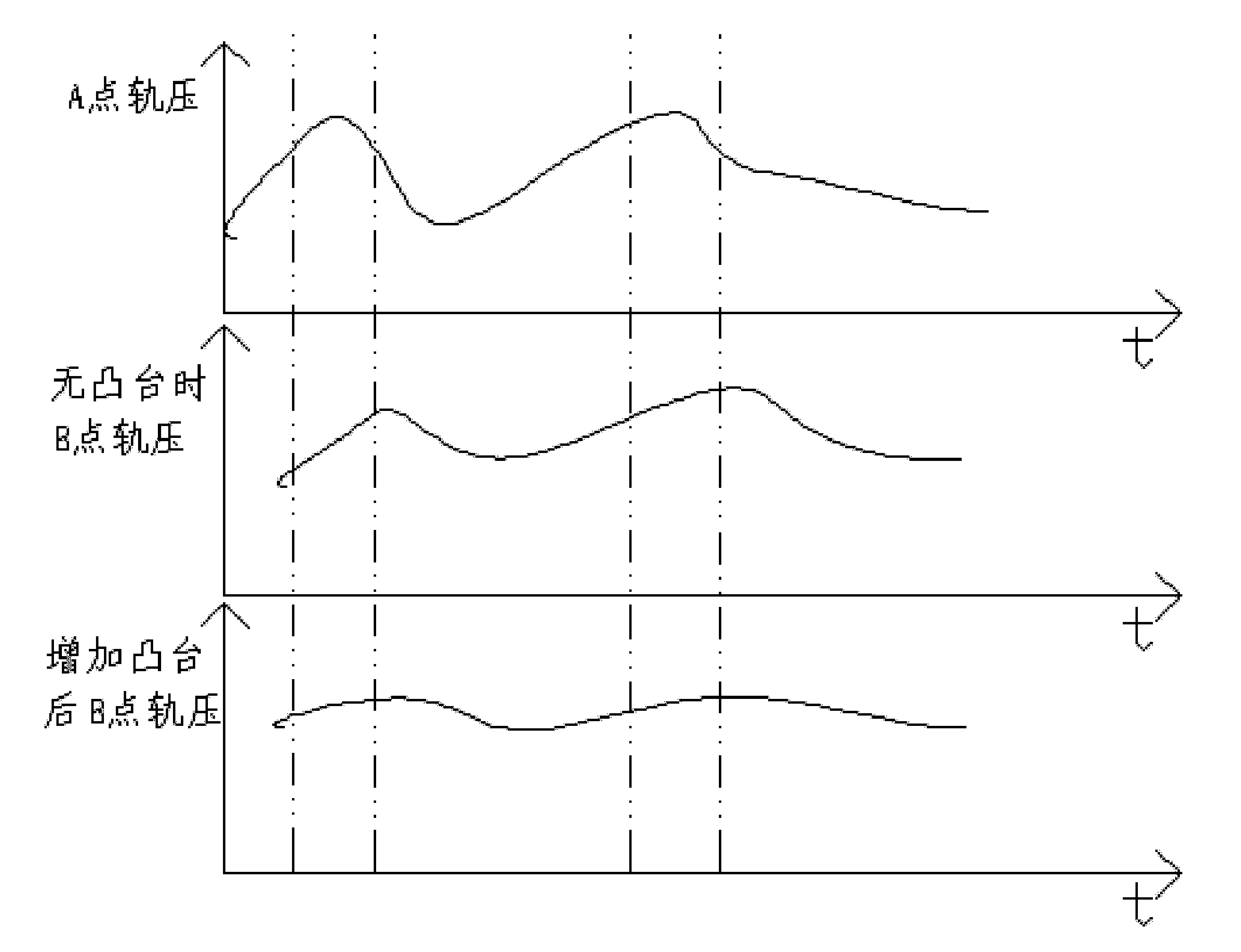

Component type high-pressure common rail device

InactiveCN102174918AReduces the effects of pressure fluctuationsSmall pressure fluctuationsFuel injection apparatusMachines/enginesCommon railComponent type

The invention discloses a component type high-pressure common rail device. A common rail pipe is provided with a pressure sensor and a pressure limiter. The common rail pipe comprises an inner pipe and an outer pipe; a circumferential limit device is arranged between the inner pipe and the outer pipe; the two ends of the outer pipe are fixedly sleeved with a seal cover and the seal covers are used for sealing the two ends of the outer pipe; the circumferential surface of the common rail pipe is provided with an oil inlet and multiple oil outlets; and on the inner circumferential surface of the inner pipe, an annular inward-convex table stretching along the circumferential direction of the inner pipe is respectively arranged between the oil inlet and an oil outlet adjacent to the oil inlet and between two adjacent oil outlets. The component type high-pressure common rail device disclosed by the invention can improve the pressure stability in the common rail pipe, reduce the fluctuation of pressure, and guarantee stability of fuel injection of the high-pressure common rail system.

Owner:北京建筑工程学院

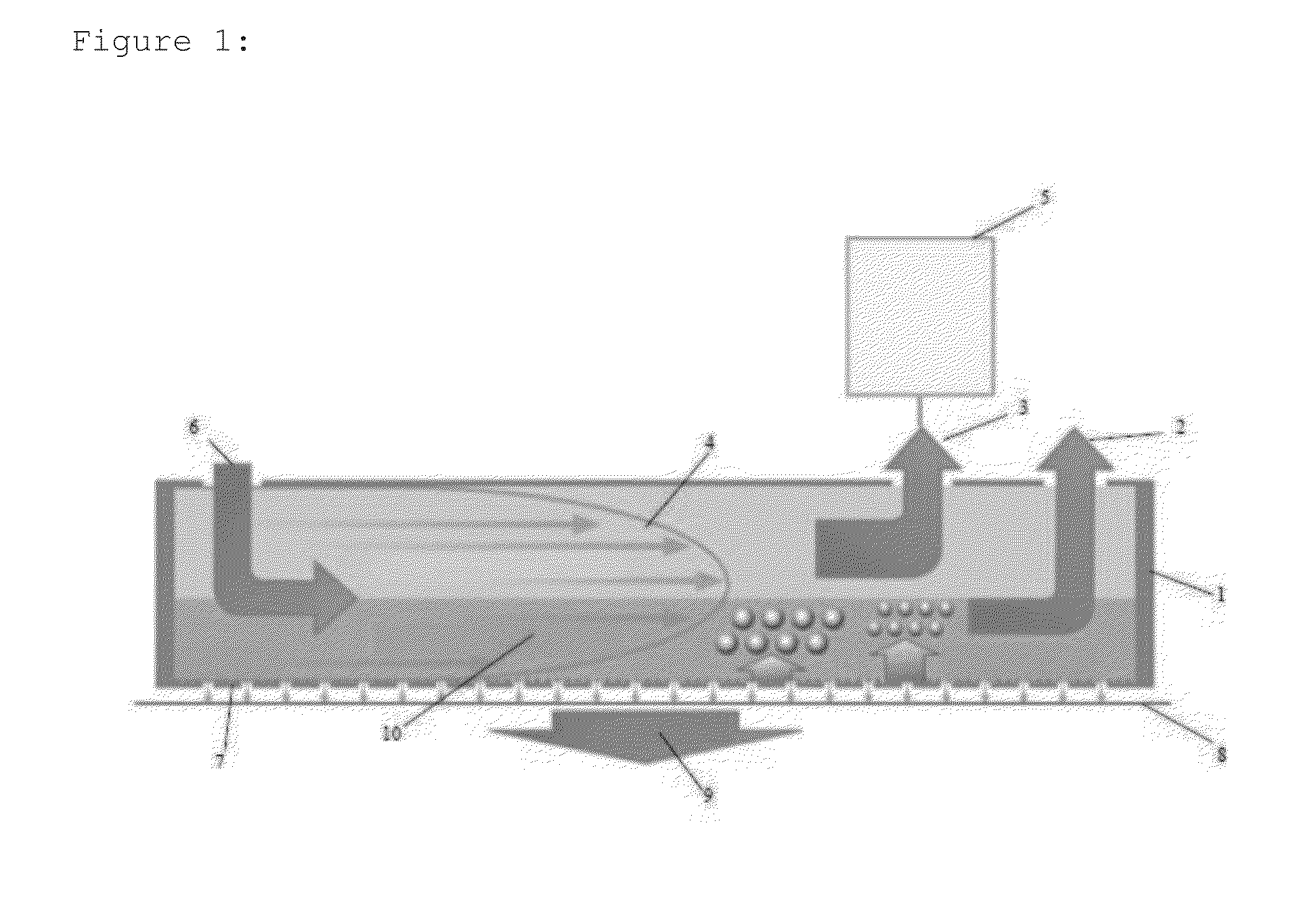

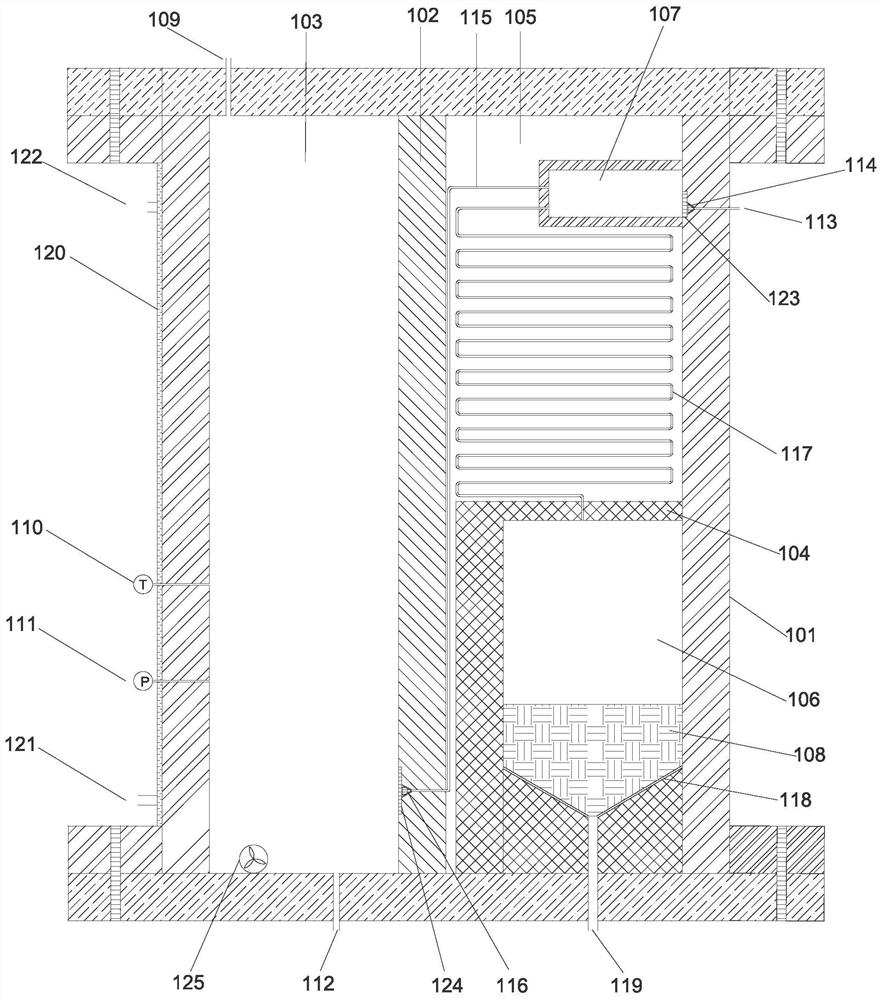

Reaction kettle, device and method for testing solubility of natural gas under high-temperature and high-pressure conditions

PendingCN112611675AGuaranteed tightnessGuaranteed stabilityComponent separationFuel testingSolubilityThermodynamics

The invention discloses a reaction kettle, device and method for testing the solubility of natural gas under high-temperature and high-pressure conditions. The reaction kettle comprises a kettle body and a heating device, wherein the kettle body is internally divided into a dissolution reaction cavity and a gas pressurization cavity, the gas pressurization cavity is internally divided into a pressurization cavity I and a pressurization cavity II, and a buffer cavity is formed in the pressurization cavity I; a high-pressure sealing piston is arranged in the pressurizing cavity II to divide the pressurizing cavity II into a first pressurizing cavity II and a second pressurizing cavity II; the dissolution reaction cavity is provided with a gas sampling port, a temperature sensor, a pressure sensor and a liquid inlet / outlet; the pressurizing cavity I is provided with an air source inlet, a one-way valve I is arranged in the air source inlet and connected with the buffer cavity, the buffer cavity is connected with the dissolution reaction cavity through an air outlet pipe I, and a one-way valve II is arranged on the air outlet pipe I; and the buffer cavity is connected with a first pressurizing cavity II through a gas outlet pipe II, spacer fluid is arranged in a second pressurizing cavity II, and a pressure-bearing liquid inlet is formed in the second pressurizing cavity II. The device can accurately measure solubility of natural gas under high temperature and high pressure.

Owner:中海石油(中国)有限公司海南分公司 +1

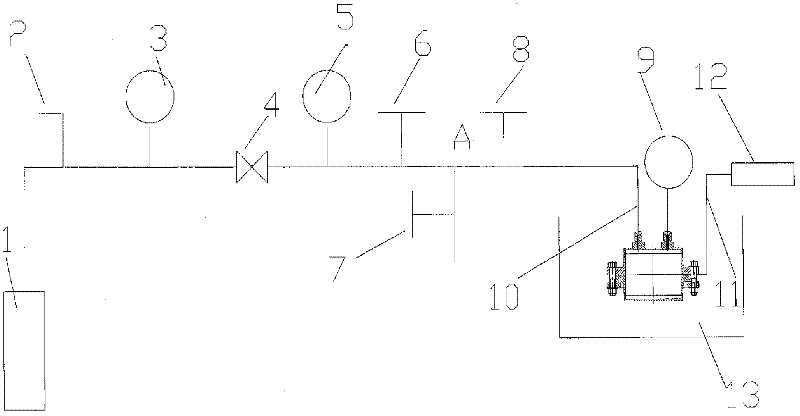

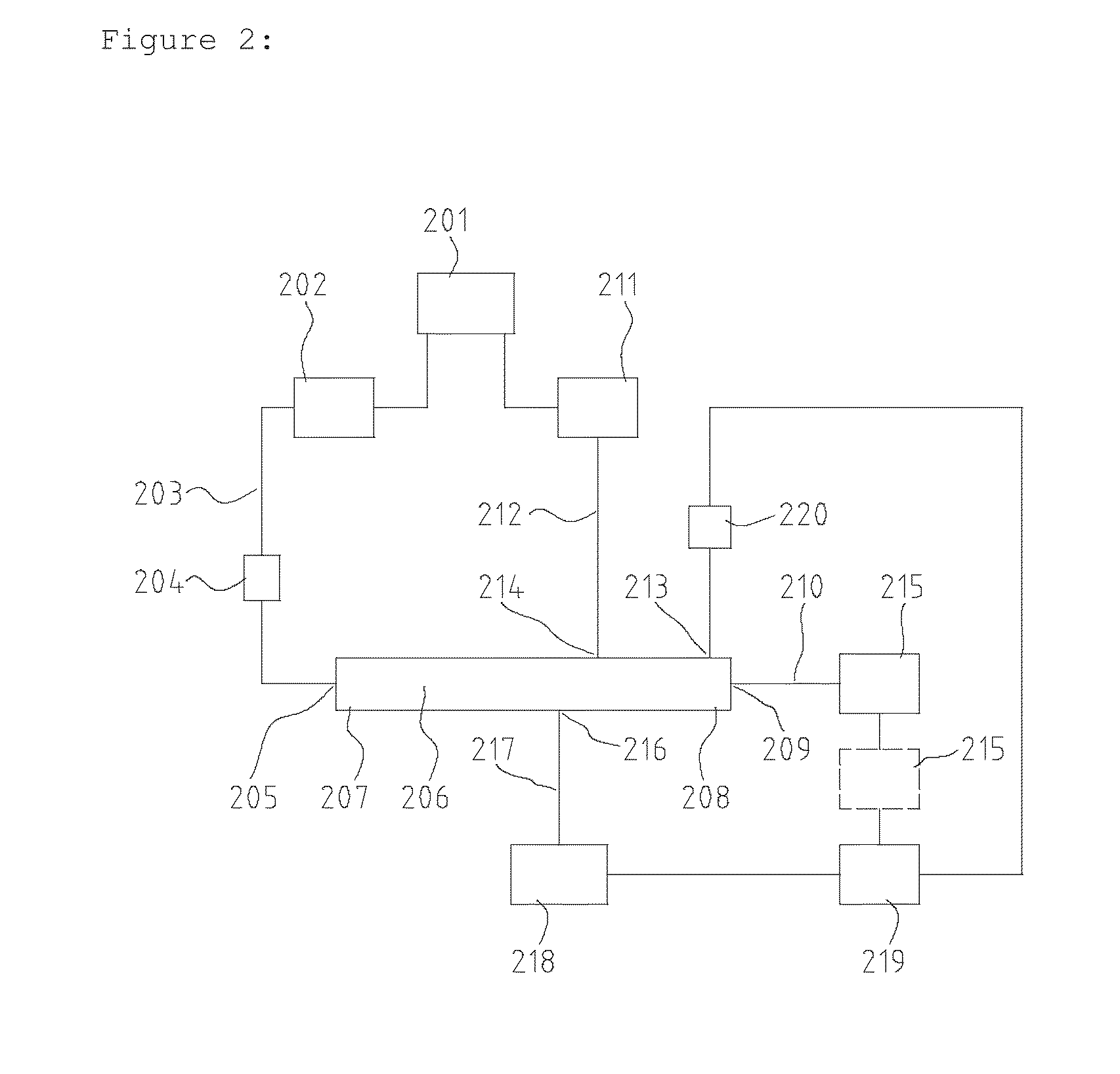

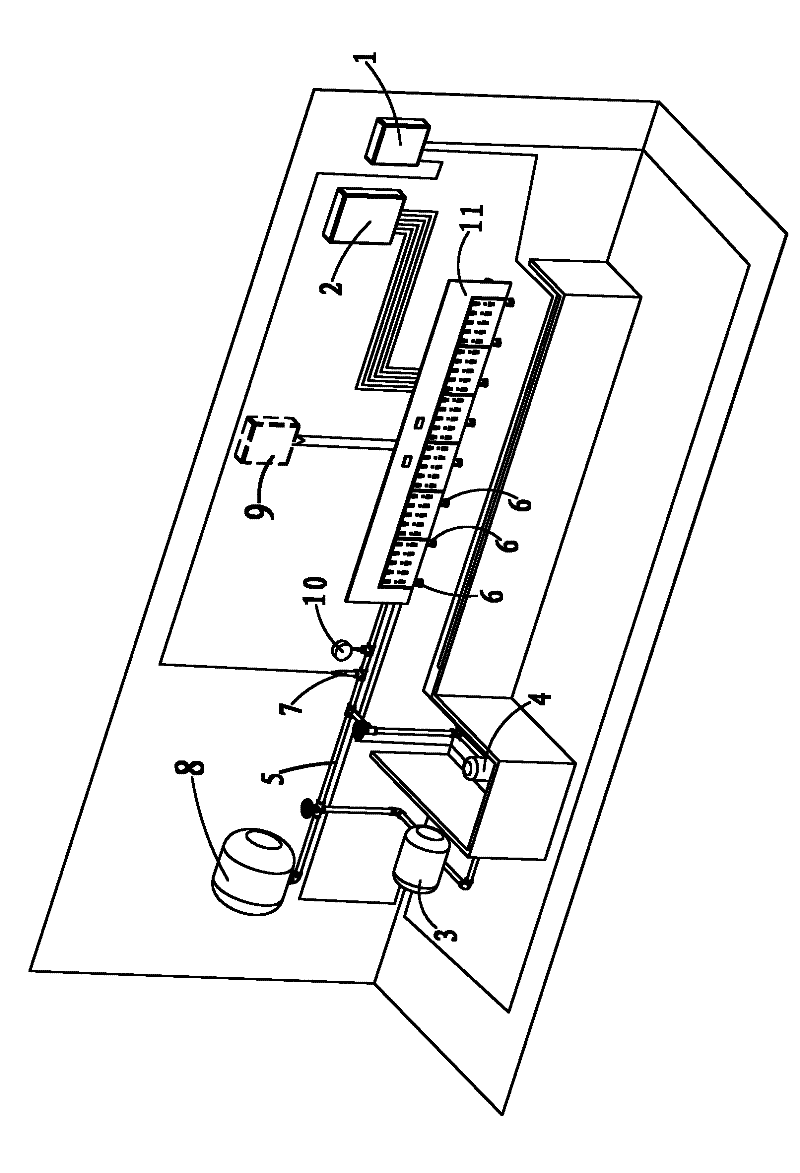

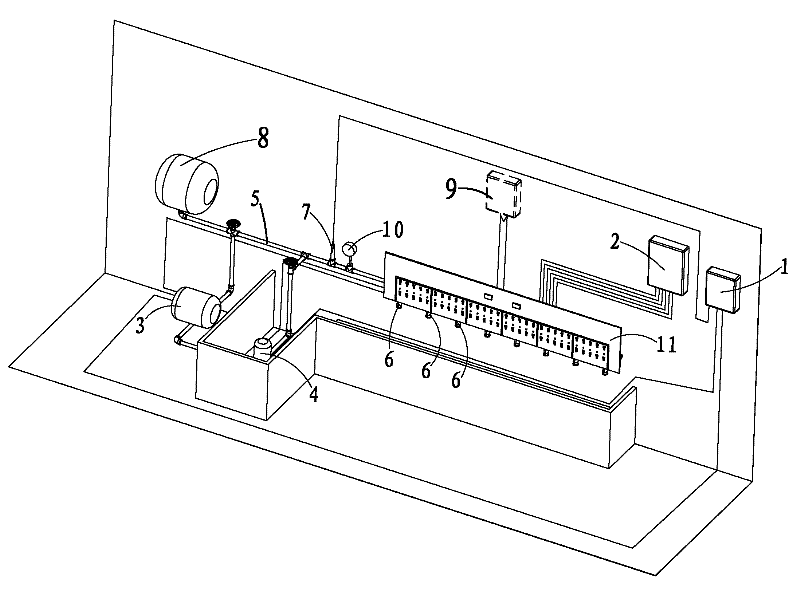

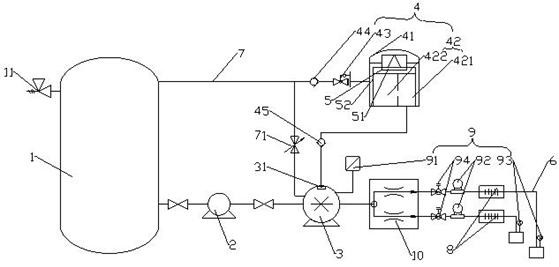

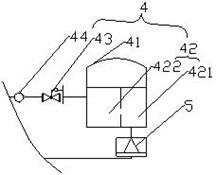

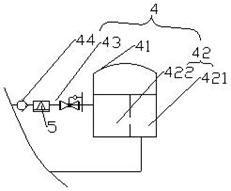

Automatic water-testing and pressure-testing control system of solenoid valve

ActiveCN102213640AImprove reliability and use costGuaranteed pressure stabilityMachine part testingAutomatic controlProgrammable logic controller

The invention provides an automatic water-testing and pressure-testing control system of a solenoid valve. The system provided by the invention comprises a constant-pressure controller, a PLC (programmable logic controller), a high pressure water pump, a low pressure water pump and a flow channel, wherein the high pressure water pump and the low pressure water pump are connected to the flow channel, a plurality of test ports for testing the solenoid valve are arranged on the flow channel, a station valve is arranged at each test port, and a pressure sensor is also arranged on the flow channel; the constant-pressure controller is respectively connected to the high pressure water pump, the low pressure water pump and the pressure sensor through lines; and the PLC is connected to the high pressure water pump, the low pressure water pump and each station valve. According to the invention, the automatic control on the water-testing and pressure-testing process of the solenoid valve can be realized, and the pressure stability of test water pressure of products can be ensured.

Owner:FUJIAN GIBO KITCHEN & BATH TECH CO LTD

Pressure relief structure, booster pump and water purification equipment

InactiveCN106704168APrevent spillageTo achieve voltage regulationPositive displacement pump componentsLiquid fuel engine componentsEngineeringCavity wall

The invention discloses a pressure relief structure, a booster pump and water purification equipment. The pressure relief structure comprises a pressure relief cavity shell and a pressure relief cover, wherein a pressure relief cavity is defined by the pressure relief cavity shell in an enclosed mode, and the pressure relief cavity shell is provided with a pressure relief opening communicating with the pressure relief cavity; and the pressure relief cavity shell is covered with the pressure relief cover, a sealing part is arranged between the pressure relief cover and the cavity wall of the pressure relief cavity, the sealing part surrounds the pressure relief opening, the pressure relief cover is further provided with a pressure relief gasket, and the pressure relief opening is blocked or opened by the pressure relief gasket. According to the technical scheme, the sealing capacity and pressure stabilizing capacity of the pressure relief structure of the booster pump can be improved.

Owner:FOSHAN WEILING WASHER MOTOR MFG

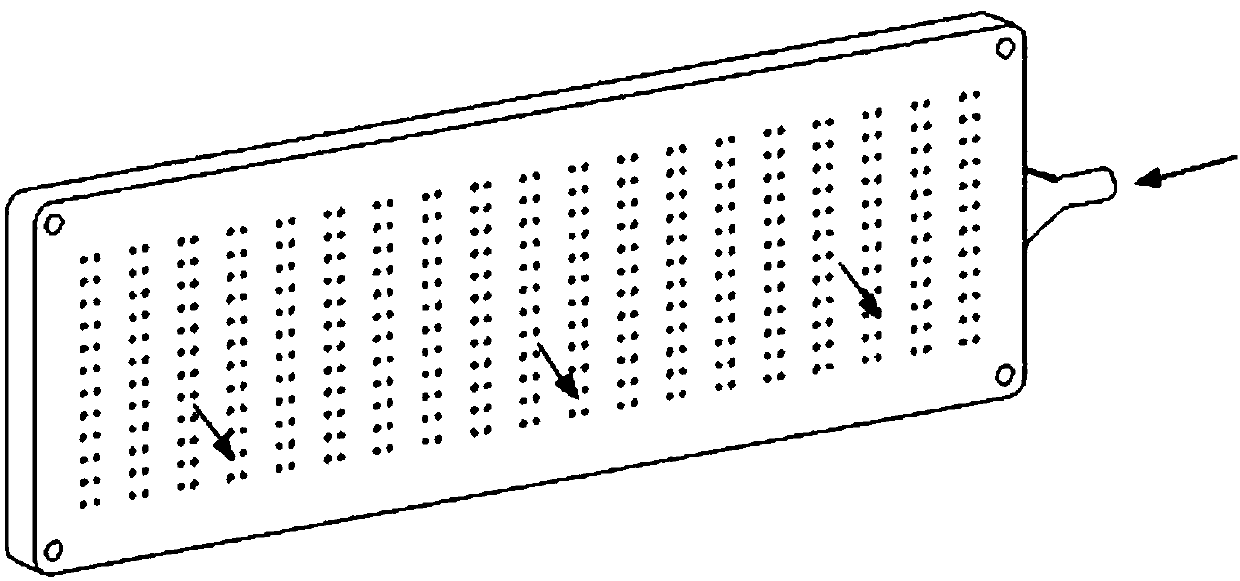

Air bath control device

ActiveCN107796299AThin structureGuaranteed pressure stabilityUsing optical meansEngineeringAtmospheric pressure

The invention provides an air bath control device which has a double-layer air bath structure that comprises an air pressure equalizing unit and an air releasing unit. The air pressure equalizing unitperforms pressure reduction on input air through a plurality of pipes for obtaining uniform-pressure air, and conveys the input gas to an edge through pipe. The air releasing unit comprises a plurality of air bath outlets, thereby releasing the uniform-pressure air through the air bath outlets, and forming thin-film air bath. The air bath control device provided by the invention has an ultrathinstructure and can be used in a compact space, thereby setting a problem of overlarge dimension of an existing air bath structure.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

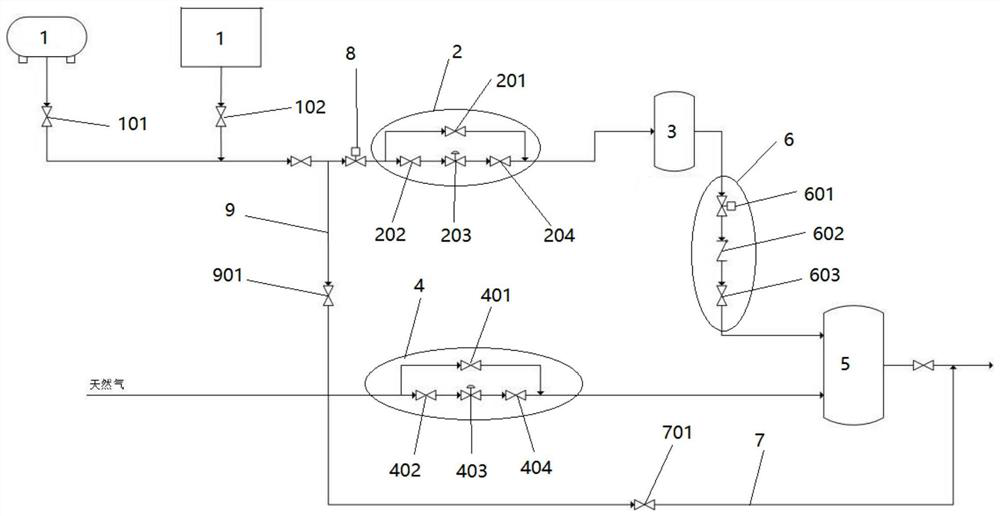

Hydrogen mixing system for natural gas

InactiveCN113390019AGuaranteed pressure stabilitySolve the problem of large-scale transportationPipeline systemsThermodynamicsPressure stabilization

The invention relates to a hydrogen mixing system for natural gas. The hydrogen mixing system for the natural gas comprises a hydrogen gas source, a hydrogen gas pressure regulating mechanism, a hydrogen gas buffer tank, a natural gas source, a natural gas pressure regulating mechanism and a mixing tank; the hydrogen gas source, the hydrogen gas pressure regulating mechanism and the hydrogen gas buffer tank are sequentially arranged on a hydrogen gas input pipeline, the hydrogen pressure regulating mechanism is used for regulating the gas supply pressure of hydrogen gas, the hydrogen gas buffer tank is used for storing hydrogen gas and buffering and stabilizing pressure; the natural gas source and the natural gas pressure regulating mechanism are sequentially arranged on a natural gas input pipeline, the natural gas pressure regulating mechanism is used for regulating the gas supply pressure of natural gas; and the mixing tank is connected with the tail ends of the hydrogen gas input pipeline and the natural gas input pipeline, is connected with a fuel gas main pipe network, and is used for uniformly mixing the input hydrogen gas and natural gas and outputting a mixture to the gas main pipe network for transmission and distribution. Pressure regulation is carried out on the input hydrogen gas and natural gas through the pressure regulating mechanisms, so that the gas supply pressure meets the mixing pressure, and it is guaranteed that hydrogen mixing of the natural gas in the mixing tank is smoothly carried out through pressure stabilization of the hydrogen gas buffer tank, the problem of large-scale hydrogen transportation can be solved without construction of a hydrogen transportation pipe network, and the hydrogen mixing system for the natural gas has a wide application prospect.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

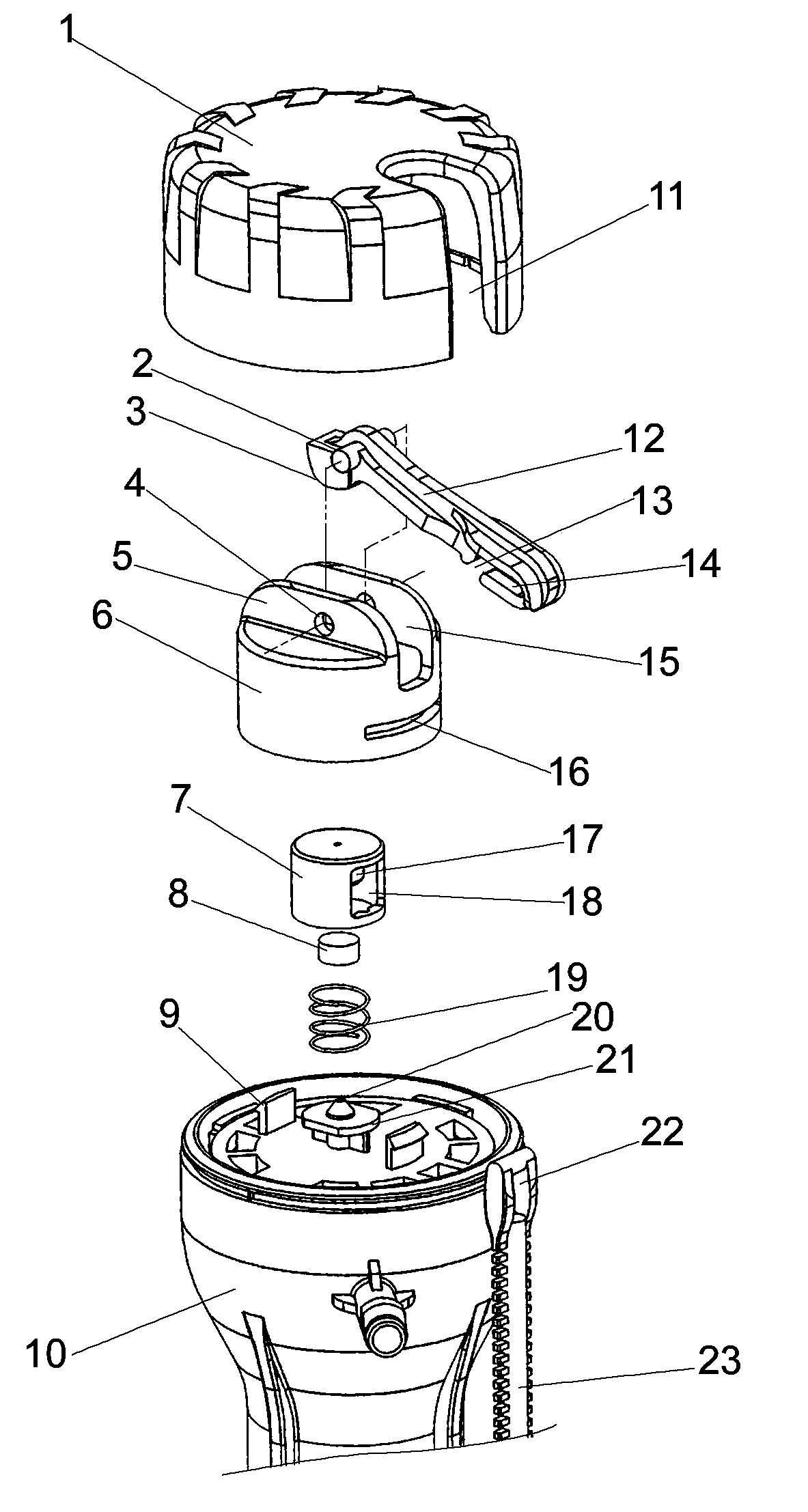

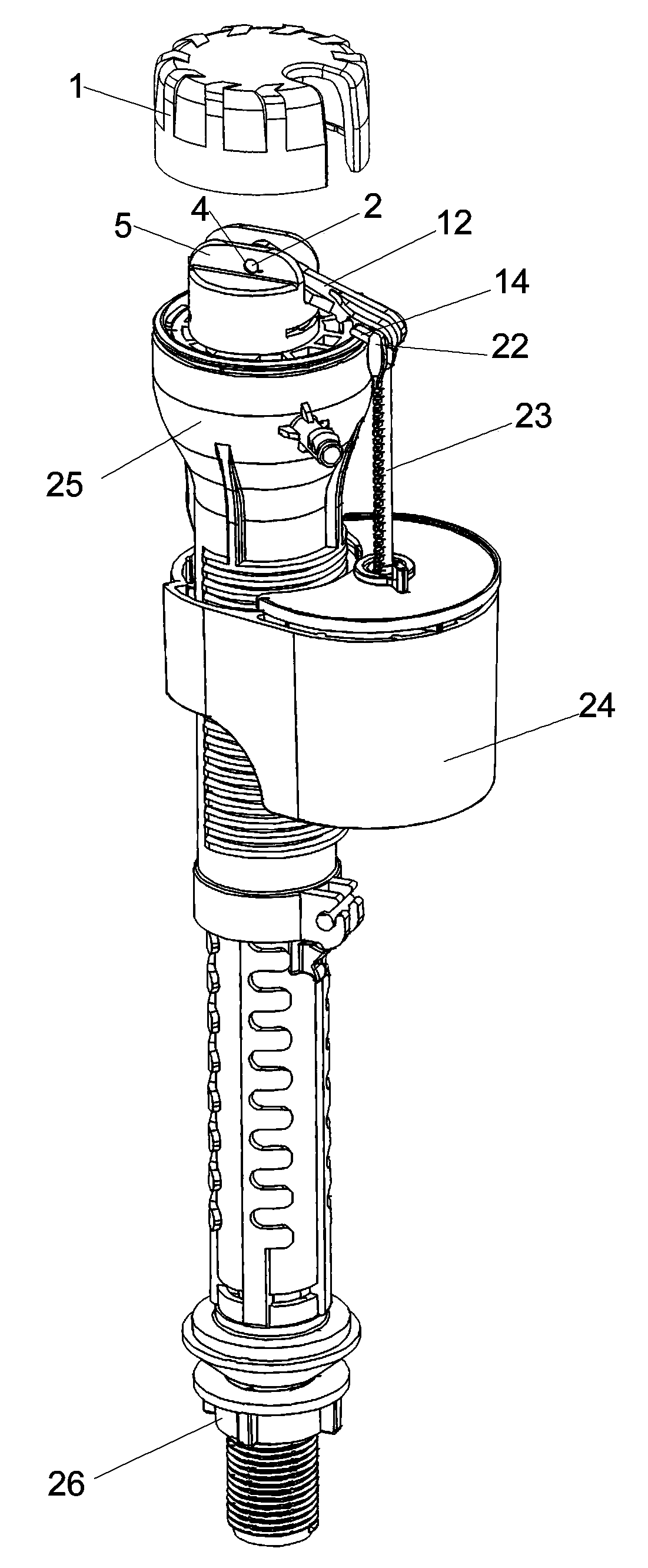

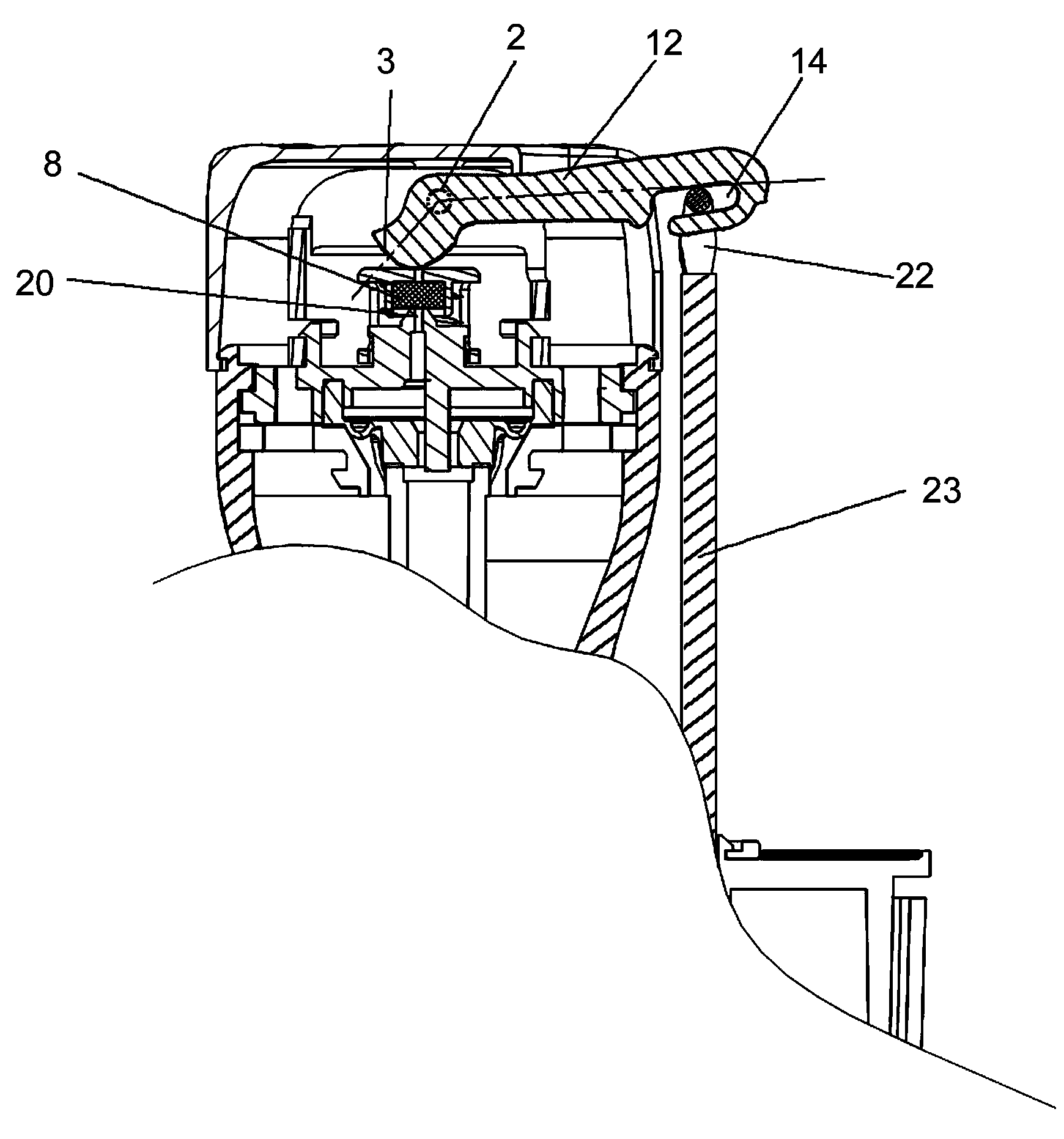

Water stop structure for water inlet device of toilet bowl

ActiveCN103981933AAchieving air-tight and water-stoppingRealize functionFlushing devicesInlet valveHigh pressure water

The invention relates to a water stop structure for a water inlet device of a toilet bowl. The structure comprises a water inlet valve and a lever support, wherein a ventilation seat stand is arranged at the center of the top surface of the water inlet valve, and a ventilation hole is formed in the surface of the ventilation seat stand. The structure is characterized in that convex edges are arranged on the two sides of the ventilation seat stand, the convex edges are connected with a pressing round cover in a clamped mode, a round groove is formed in the top of the interior of the pressing round cover, the round groove is filled with a sealing gasket, and a spring is connected to the outer side of the round groove in a sleeved mode; the lever support is clamped on the pressing round cover, a shaft hole is formed in the lever support, a lever swing arm is movably connected to the lever support through a rotary shaft and the shaft hole, a cam surface is arranged on one side of the lever swing arm and is in contact with the top surface of the pressing round cover in an abutting mode, and a slide-guiding groove is formed in the other side of the lever swing arm and is connected with a lifting rod connected to a float. The structure has the advantages of being small in structural member size, capable of achieving linkage transmission, high in lever ratio, suitable for high-pressure water supply and convenient to install and use.

Owner:广东恒通达科技有限公司

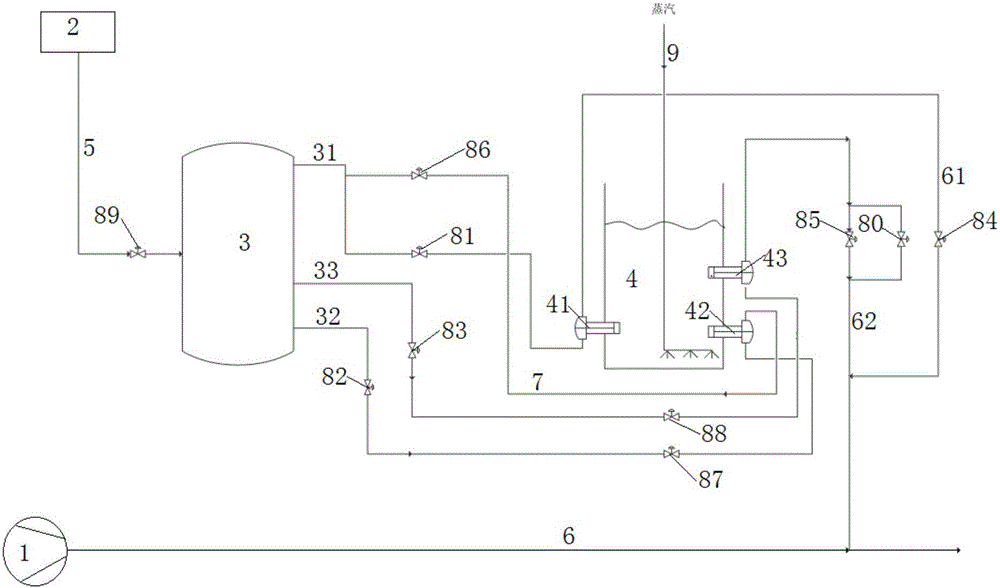

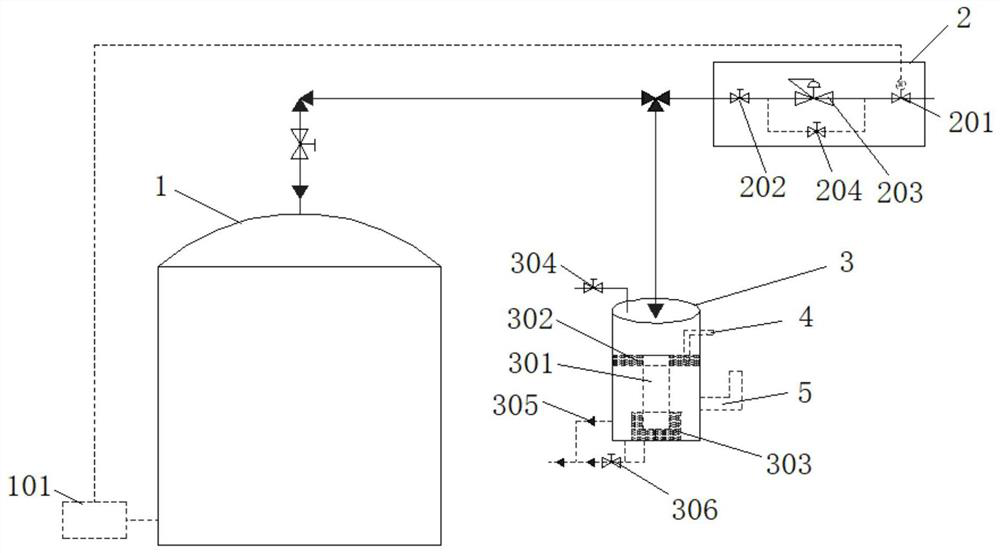

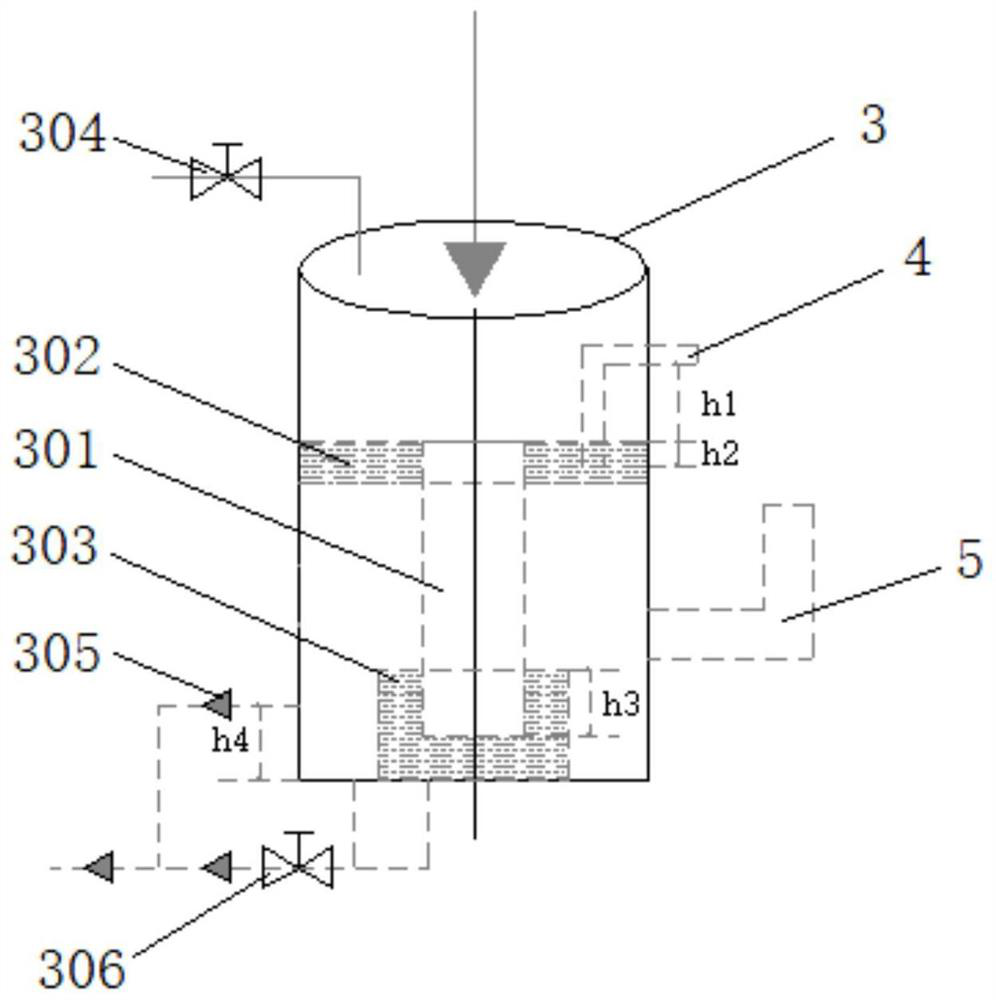

An injection device for carbon dioxide flooding

ActiveCN113638724BGuaranteed pressure stabilityAvoid drag lossOther gas emission reduction technologiesFluid removalExhaust valveLine tubing

The invention relates to the field of oilfield development, and discloses an injection device for carbon dioxide flooding, which includes a storage tank, a shielded pump, a high-pressure pump and an injection head arranged in sequence, an injection pipeline is arranged between the high-pressure pump and the injection head, and the storage tank and the injection head There is a return line between the high-pressure pumps, and a shut-off valve between the return line and the high-pressure pump. It also includes a gas collection device. The gas collection device includes a gas collection chamber and a pressure regulating device for the outlet of the gas collection chamber. valve, the inlet of the gas collection chamber is connected to the exhaust valve, and the outlet of the pressure regulating device is connected to the storage tank. The present invention for reflux CO 2 The pressure regulation treatment is beneficial to the stability of the storage tank pressure.

Owner:DESHI ENERGY TECH GRP CO LTD

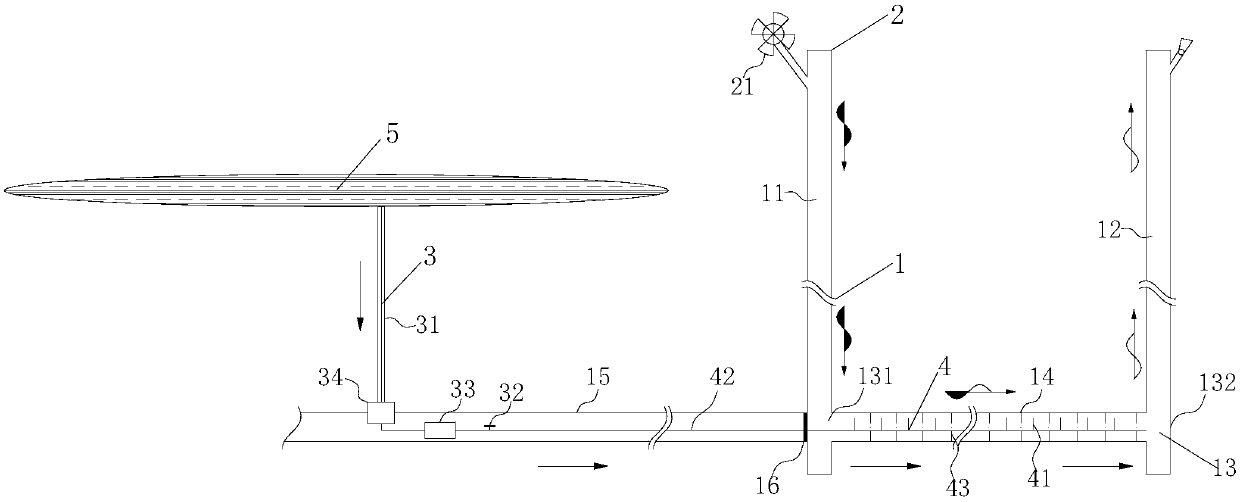

Self-pressure type temperature reduction dust removing system using coal mine water-bearing stratum

ActiveCN109538280ARealize automatic operationGuaranteed continuityDust removalFire preventionEnvironmental engineeringYard

The invention provides a self-pressure type temperature reduction dust removing system using a coal mine water-bearing stratum, relates to the technical field of air regulating, and solves the technical problem of the dust removing and temperature reducing performed by wasted coal mines by repeatedly using air. The system comprises a coal mine tunnel, a ventilation mechanism, a water taking mechanism and a temperature reducing and dust removing mechanism, wherein the ventilation mechanism is arranged in the coal mine channel, the water taking mechanism takes water from the water-bearing stratum on the upper part of the coal mine, the temperature reducing and dust removing mechanism is arranged in the channel to reduce temperature and remove dust using the water obtained by the water takingmechanism, the coal mine channel comprises a primary shaft, a secondary shaft, a shaft bottom yard and a large channel, and the temperature reducing and dust removing mechanism comprises atomizing nozzles, a water pipe and a dust removing net. The system has the advantages that water is constantly supplied for the temperature reducing and dust removing system by using the original channel and ventilation system of the coal mine and natural water pressure of the water-bearing stratum, so that the automatic operation of the temperature reducing and dust removing mechanism of the system is achieved, and the implementation cost is low.

Owner:SHANDONG UNIV OF SCI & TECH

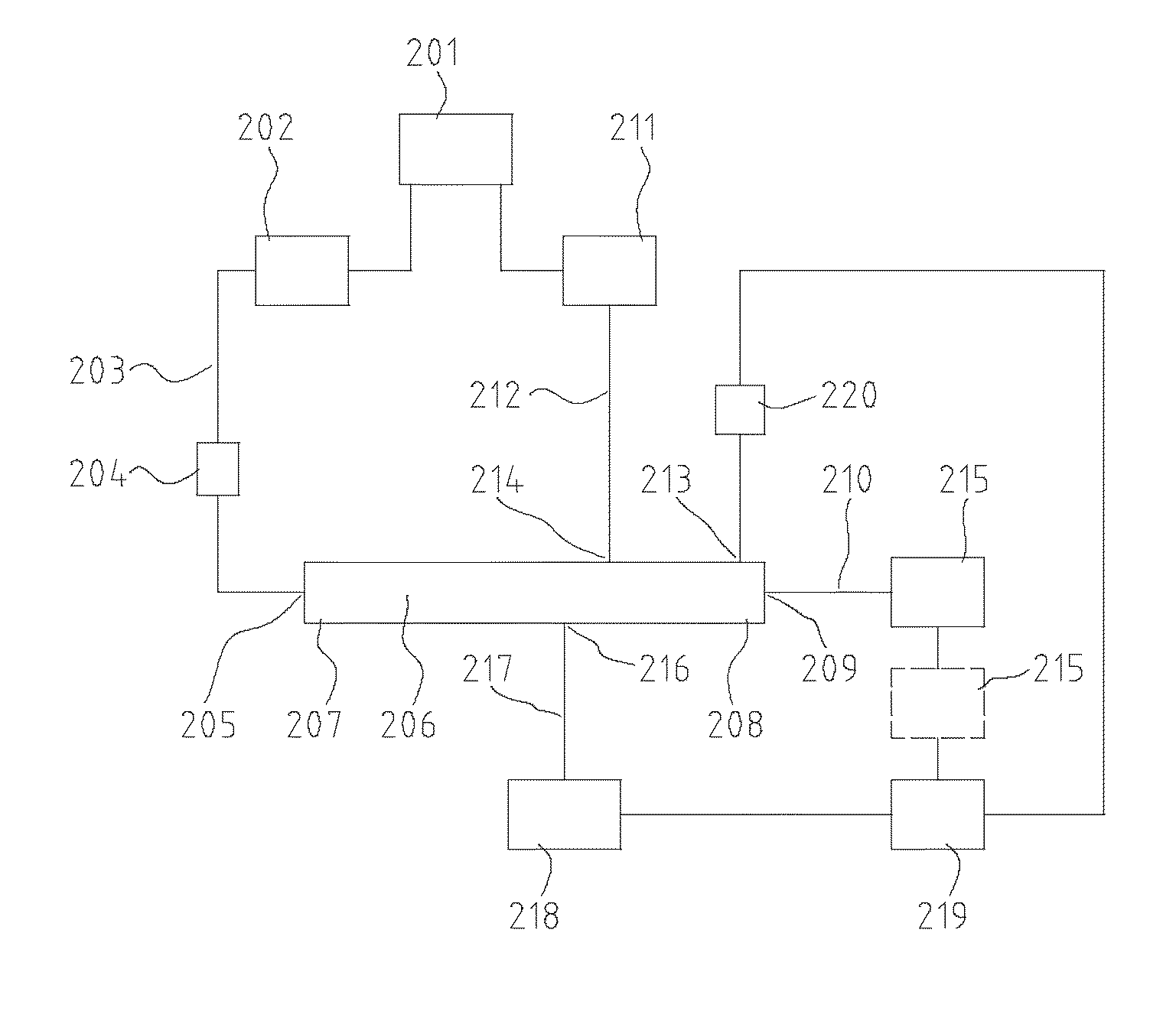

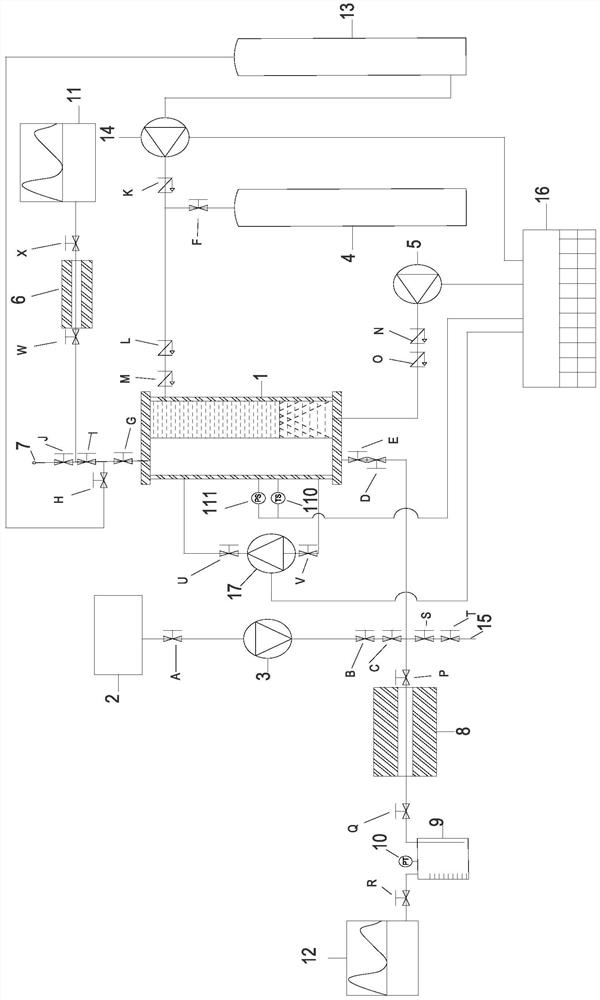

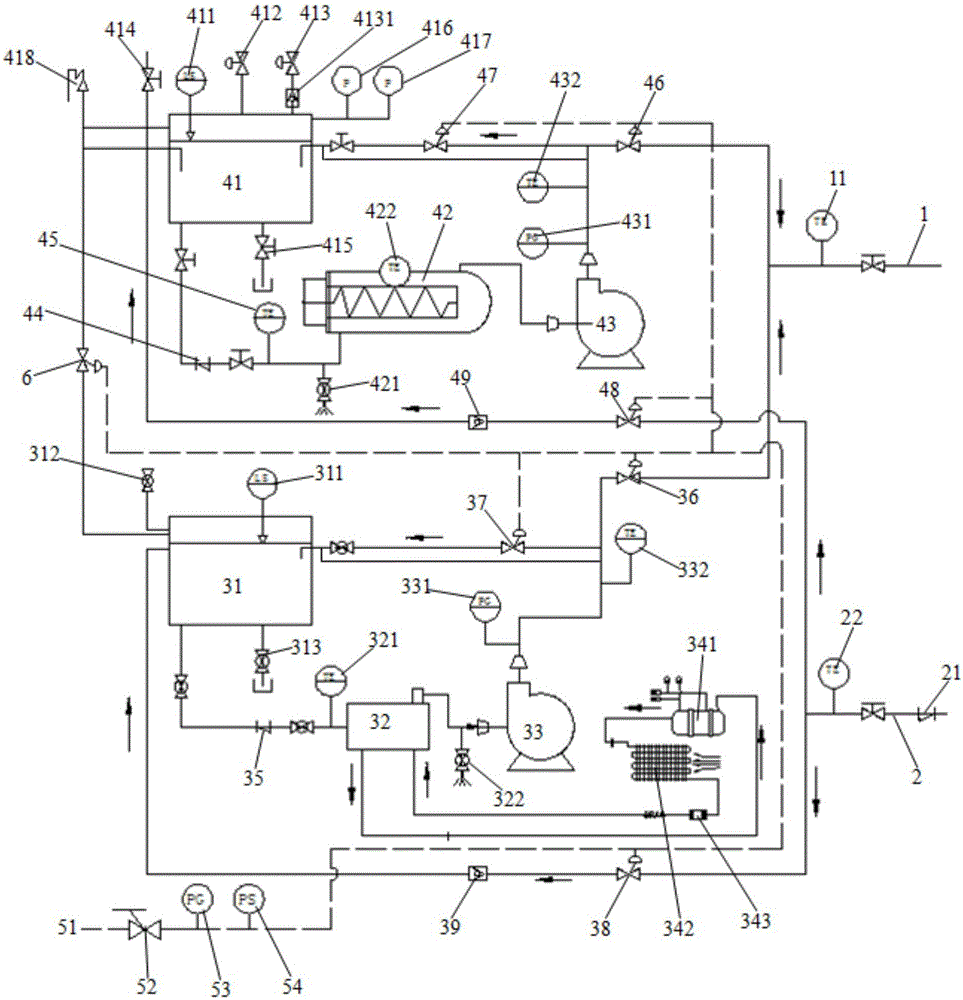

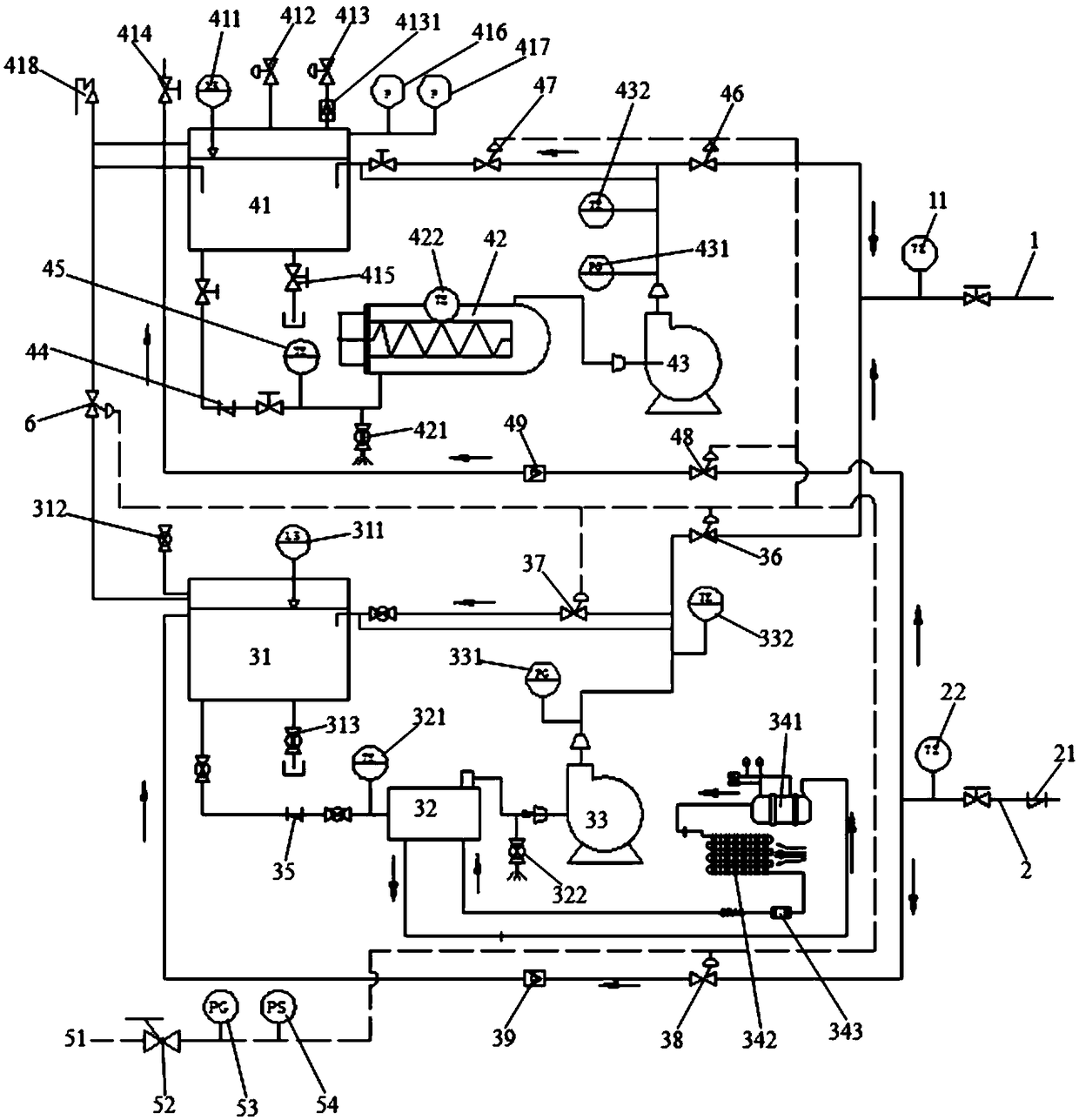

Quick-cooling quick-heating automatic switching temperature control system with characteristic of secure and precise control

ActiveCN106020268AAuto switchImprove securityTemperature control using electric meansTemperature controlFuel tank

The invention discloses a quick-cooling quick-heating automatic switching temperature control system with the characteristic of secure and precise control. The system comprises an oil outlet pipeline, an oil return pipeline, a cooling circulating system, and a heating circulating system, wherein the cooling circulating system and the heating circulating system are communicated with the oil outlet pipeline and the oil return pipeline by pipes. The cooling circulating system includes an oil cooling box and a first pumping unit; and the heating circulating system consists of an oil heating box and a second pumping unit. A first pneumatic valve and a second pneumatic valve are arranged on the communication pipelines between the cooling circulating system, the oil return pipeline and the oil outlet pipeline; a fourth pneumatic valve and a fifth pneumatic valve are arranged on the communication pipelines between the heating circulating system, the oil return pipeline and the oil outlet pipeline; a third pneumatic valve is arranged on the communication pipeline between the oil cooling box and the first pumping unit; a sixth pneumatic valve is arranged on the communication pipeline between the oil heating box and the second pumping unit; and the oil heating box and the oil cooling box are connected by a pipeline and a seventh pneumatic valve is arranged on the pipeline. According to the invention, opening or closing of the pipeline can be controlled precisely, thereby realizing automatic switching between heating and cooling; and the system security is high.

Owner:SUZHOU AODE MACHINERY

CO compensation supply system on CO conveying pipeline and application of CO compensation supply system

InactiveCN106764428AFulfil requirementsUninterrupted supplyPipeline systemsFluid transferredInternal pressureProcess engineering

The invention relates to a CO compensation supply system on a CO conveying pipeline and application of the CO compensation supply system. The CO compensation supply system comprises a CO liquid tank used for storing liquid CO and a vaporizer for vaporization of the liquid CO. The vaporizer is provided with a first heat exchanger, a second heat exchanger and a third heat exchanger used for vaporization of the liquid CO. A first pipeline, a second pipeline and a third pipeline are led out of the CO liquid tank. The first pipeline is connected with the first heat exchanger, the second pipeline is connected with the second heat exchanger, and the third pipeline is connected with the third heat exchanger. A first gas CO supply pipeline is led out of the first heat exchanger and connected to the CO conveying pipeline. A second gas CO supply pipeline is led out of the third heat exchanger and connected to the CO conveying pipeline. A backflow pipeline is led out of the second heat exchanger and connected to the first pipeline. Each pipeline is provided with a valve. The system is convenient to operate, and different compensation amounts can be controlled according to the situation of inner pressure of the CO conveying pipeline.

Owner:SHANGHAI HUALIN IND GASES

Exhaust gas treatment method and system in polysilicon production process

ActiveCN109678158AGuaranteed pressure stabilityMeet downstream process requirementsDispersed particle separationVapor condensationCooling towerHydrogen

The invention discloses an exhaust gas treatment method and system in the polysilicon production process. The exhaust gas treatment method comprises the following steps: (1) exhaust gas is subjected to cooling liquefaction separation through an exhaust gas cooling tower, tower bottom liquid of the exhaust gas cooling tower is obtained in a tower bottom of the exhaust gas cooling tower, and a primary mixture comprises the tower bottom liquid of the exhaust gas cooling tower; and (2) the primary mixture is introduced into a separation tower to be fed for distillation purification, overhead gas is collected at the tower top of the separation tower and comprises hydrogen and hydrogen chloride, beside collection liquid is collected on the lateral line or the upper part of the tower top of the separation tower and comprises trichlorosilane and dichlorosilane, and tower bottom liquid of the separation tower is collected and comprises silicon tetrachloride. Hydrogen, hydrogen chloride, dichlorosilane, trichlorosilane and silicon tetrachloride in the tower bottom liquid of the exhaust gas cooling tower are separated, the separated components are not homologous compounds, the obtained mixtures have different proportioning requirements, and the downstream process requirements can be met.

Owner:XINTE ENERGY

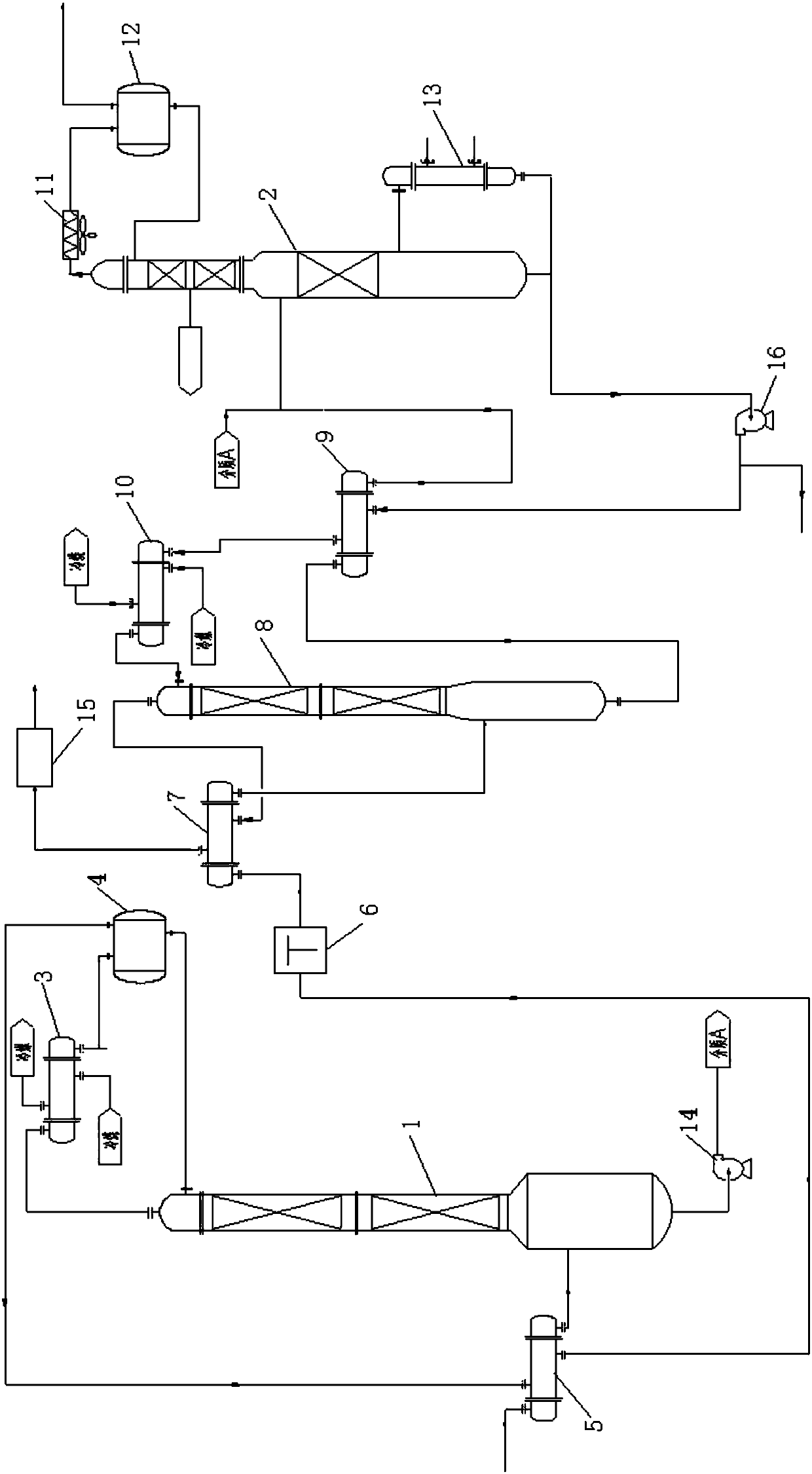

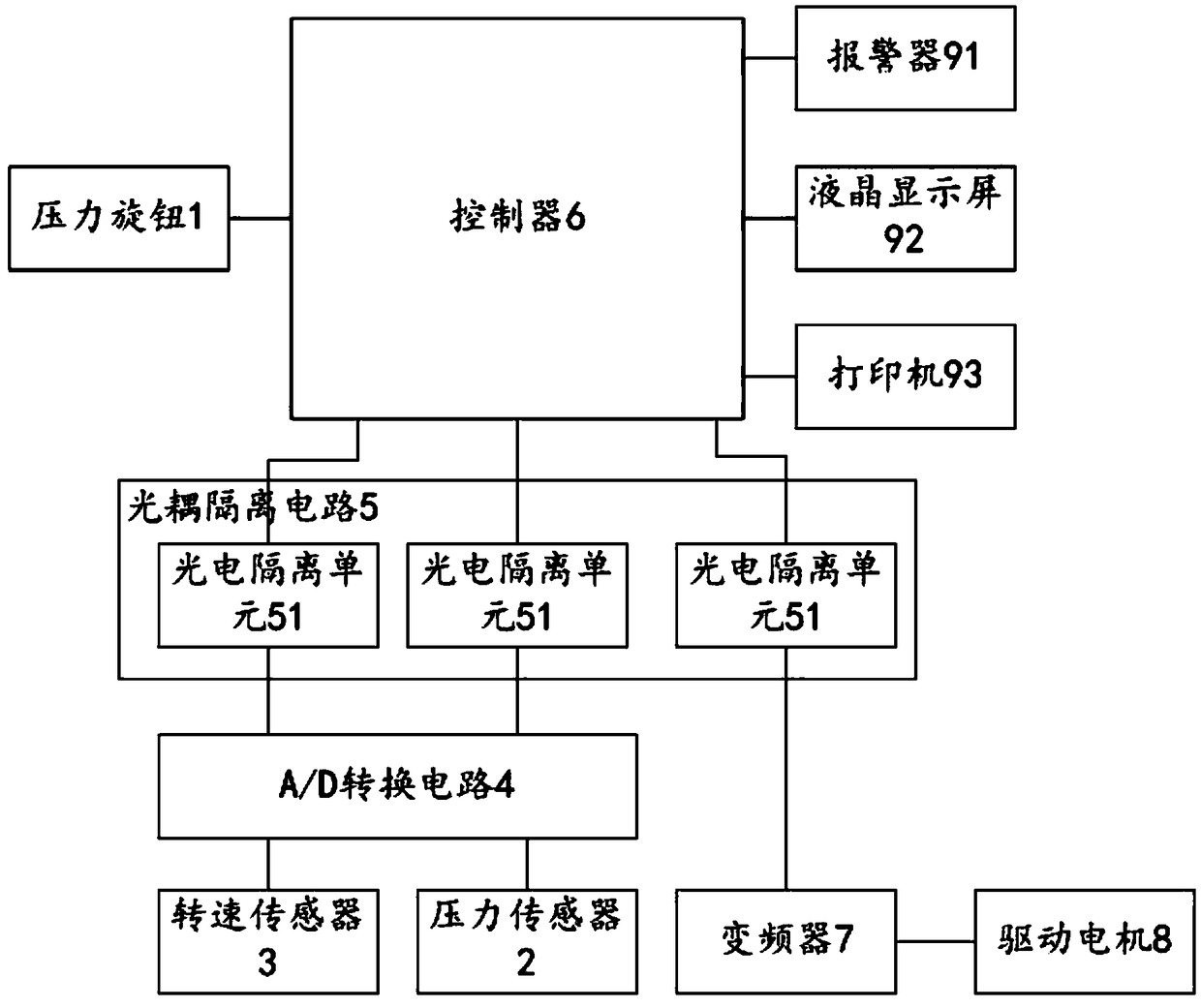

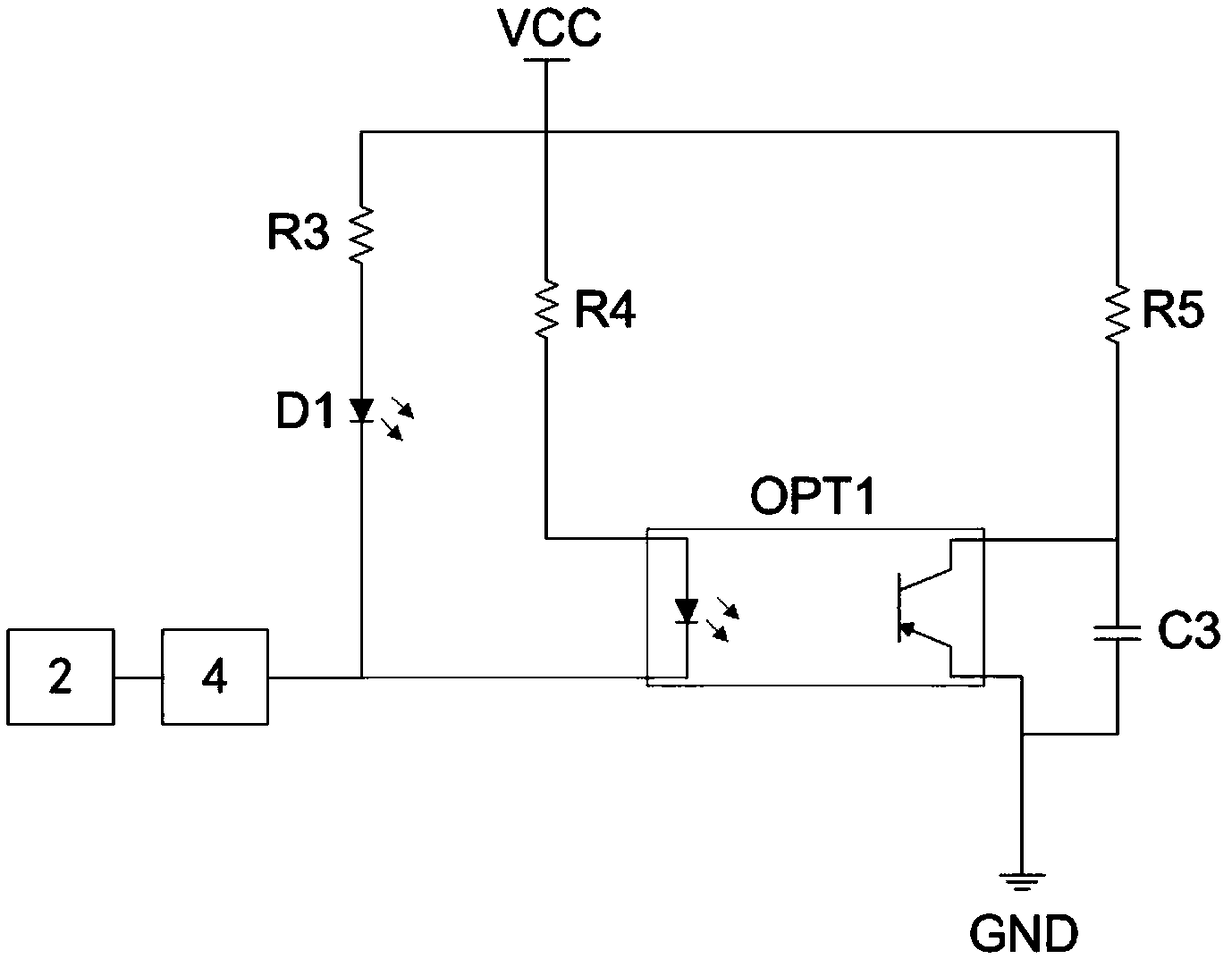

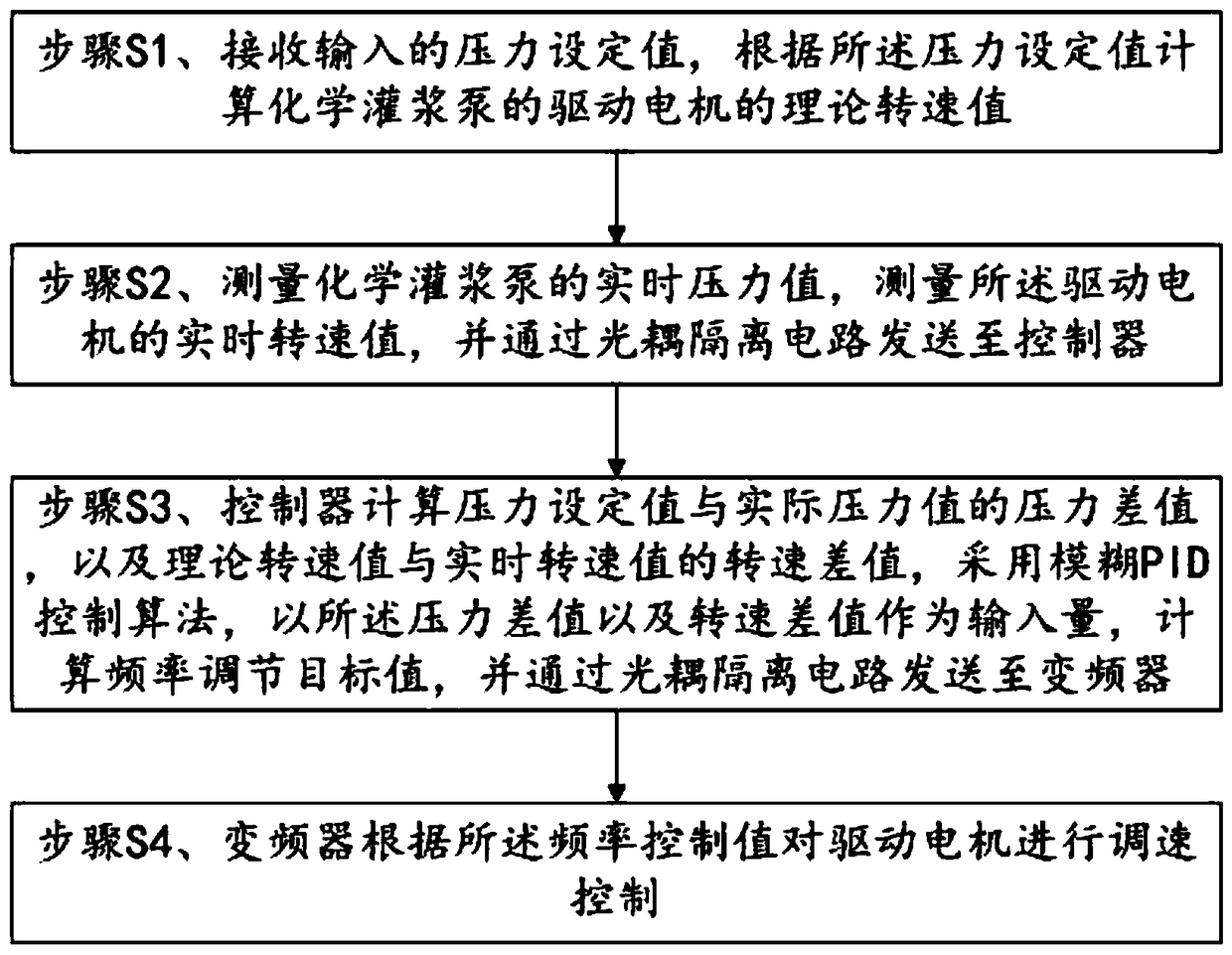

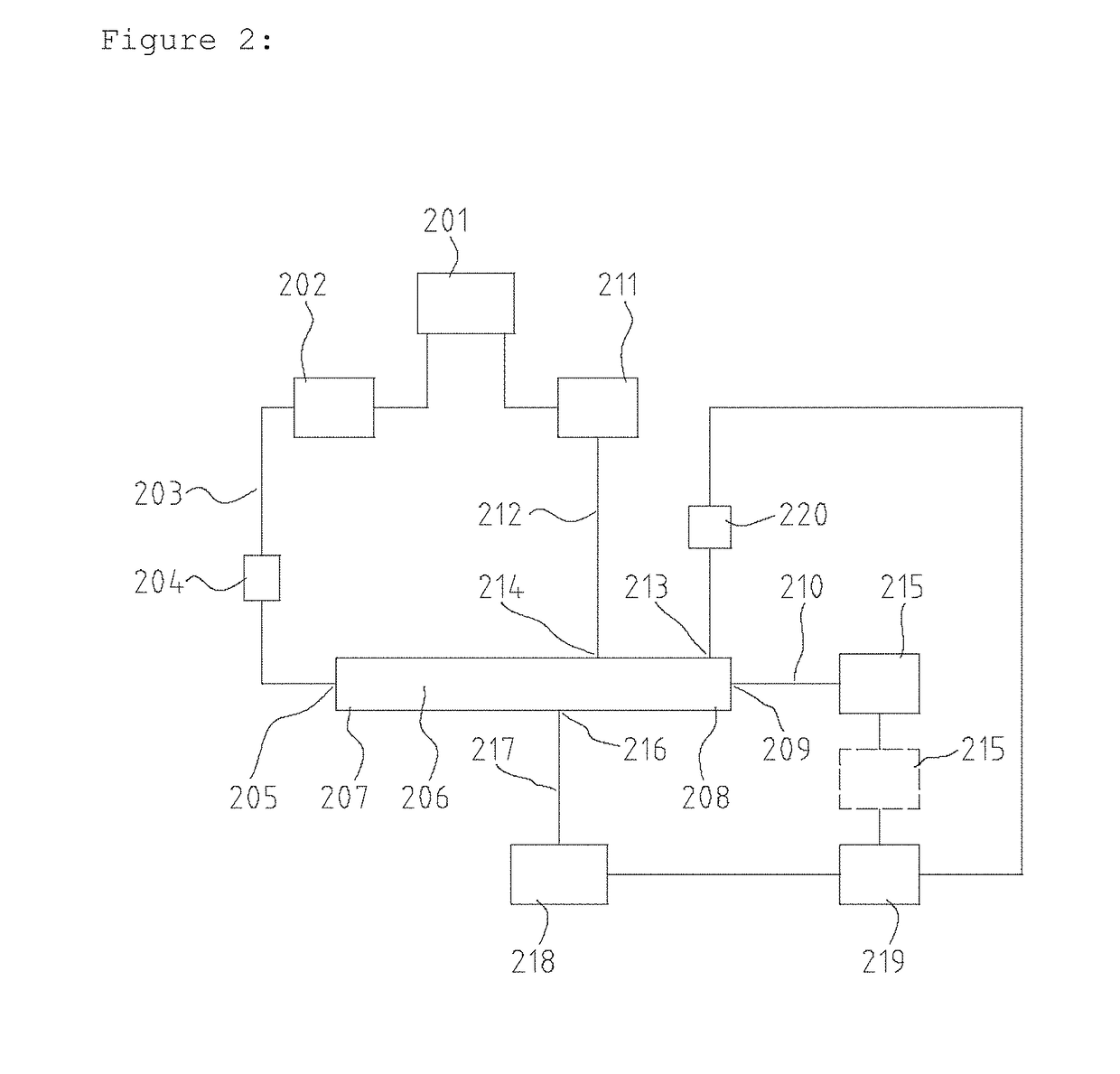

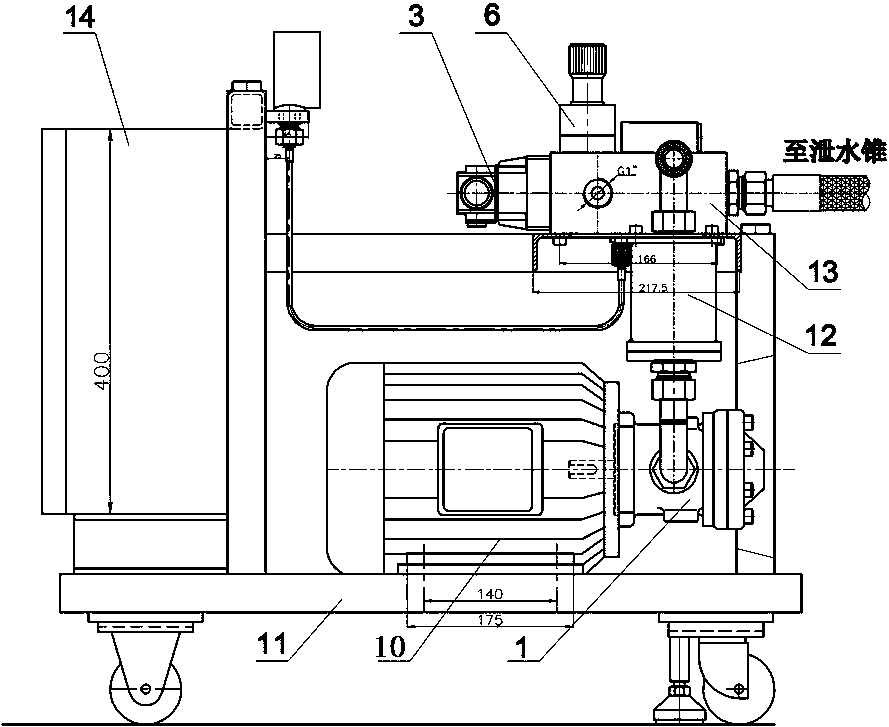

A constant pressure control system and method for chemical grouting pump

PendingCN108894966AAdaptableGuaranteed pressure stabilityPump testingPump controlFrequency changerElectricity

A constant pressure control system for chemical grouting pump Includes pressure knob, Pressure sensor, speed sensor, A / D conversion circuit, optocoupler isolation circuit, controller, frequency converter and drive motor, the pressure knob is electrically connected with the controller, the pressure sensor and the rotational speed sensor are electrically connected with the optocoupler isolation circuit through the A / D conversion circuit, the optocoupler isolation circuit is electrically connected with the controller, The controller is also electrically connected with the frequency converter through the optical coupling isolation circuit, the driving motor is electrically connected with an external power supply through the frequency converter, the pressure sensor is installed on the chemicalgrouting pump, the rotational speed sensor is installed on the driving motor, and the driving motor is drivingly connected with the chemical grouting pump. The invention has the technical effects of precise pressure control, high stability and good safety.

Owner:WUHAN CHANGJIANG KECHUANG TECH DEV +1

Oil tank cover and oil tank

ActiveCN114483395AImprove stabilityGuaranteed pressure stabilityMachines/enginesLiquid fuel feedersThermodynamicsPressure stabilization

Disclosed are a fuel tank cap and a fuel tank. According to the technical scheme, the fuel tank cap is characterized by comprising an outer cap body and an inner cap body, the outer cap body is used for being in threaded connection with a fuel tank opening, the inner cap body is arranged in the outer cap body and can be telescopically adjusted along the outer cap body, a baffle ring used for installing a first sealing ring is fixed to the periphery of the inner cap body, and an adjusting cavity is formed in the inner cap body; the adjusting cavity is sealed and filled with buffering media, an adjusting plug is connected in the adjusting cavity in a piston mode and can be adjusted in the telescopic direction of the inner cover in a piston mode, an adjusting rod is fixedly connected to one end of the adjusting plug, and the other end of the adjusting rod penetrates through a first through hole in the end of the inner cover and is fixedly connected with the outer cover. The adjusting rod and the first through hole are sealed. Pressure on the inner side and the outer side of the oil tank can be balanced, the pressure stability of the oil tank is kept, the tightness degree of the oil tank cover during covering can be improved, and the covering stability of the oil tank cover is improved.

Owner:浙江康思特动力机械有限公司

Apparatus for field-flow fractionation

ActiveUS10132782B2High measurement sensitivityReduce detectionComponent separationLiquid solutions solvent extractionElutionEngineering

The present invention relates to an apparatus for field-flow fractionation and to a method for separating samples by means of field-flow fractionation using this apparatus. The apparatuses of the invention comprise a separation channel which, in addition to a first outlet for sample-containing solvent, comprises a second outlet for sample-free solvent, wherein the second outlet is arranged in a region of the separation channel from which sample-free solvent may be removed during elution and a flow volume control device is arranged downstream of the second outlet. They are characterized in that the flow volume control device is a mass flow controller.

Owner:POSTNOVA ANALYTICS

A tank constant pressure control system

ActiveCN111522370BGuaranteed pressure stabilityImprove securityFluid pressure control using electric meansPressure stabilizationControl system

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Lithium ion pole piece rolling constant-pressure device

PendingCN112968145AGuaranteed pressure stabilityQuick responseElectrode manufacturing processesTension/compression control deviceButterfly valveVALVE PORT

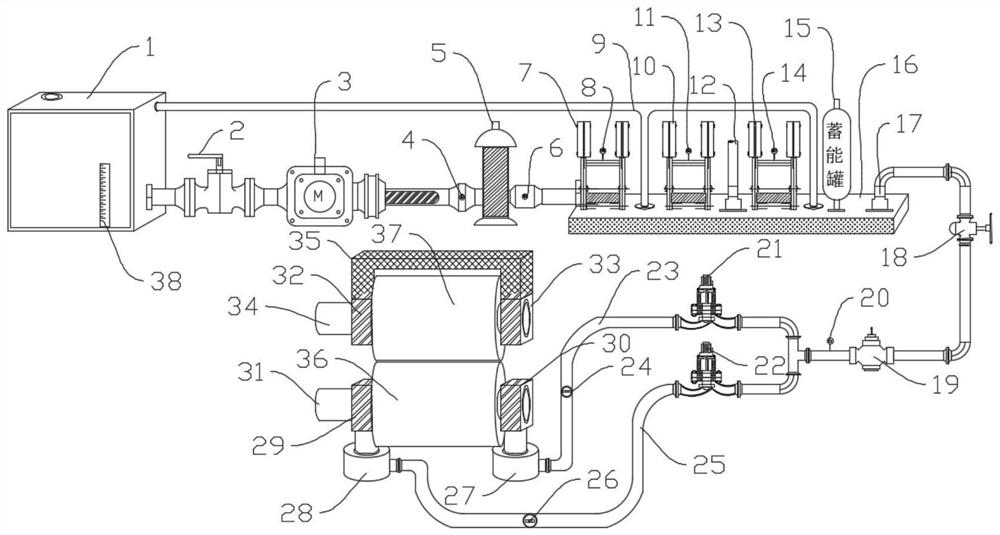

The invention discloses a lithium ion pole piece rolling constant-pressure device. The device comprises an oil tank, a pipeline switch, an electronic plunger valve, a filter, a hydraulic platform, a pipeline valve, an electronic butterfly valve, a regulating valve, a high-pressure pipeline, a rolling structure and a PID servo controller. The hydraulic platform is provided with an overflow valve, an anti-explosion valve, a return pipe, an external pipe, an energy storage tank and a hydraulic output pipe. The filter supplies filtered and purified hydraulic oil to the hydraulic platform, and the hydraulic platform is provided with pressure stabilizing devices such as the overflow valve, the anti-explosion valve and the energy storage tank; and the PID servo controller carries out PID valve adjustment according to the program logic controller to keep the pressure constant. A real-time monitoring and real-time adjusting mode is utilized to ensure the constancy of the pressure of the pipeline. The pressure supply speed and frequency are calculated through real-time calculation including a consumed pressure time curve, the magnitude of supply pressure and the magnitude of pressure received by the tail end (or the process loss amount). The device has the technical advantages that pressure control is accurate, the corresponding speed is high, and pressure changes are adjusted in real time.

Owner:佛山市天劲新能源科技有限公司

Magnetic lubricating oil and preparation method thereof

ActiveCN111778092AGood shear stabilityGood viscosity temperature performanceLubricant compositionSolventMagnetic field magnitude

The invention relates to the field of lubricating oil preparation. The invention particularly discloses magnetic lubricating oil and a preparation method thereof. The magnetic lubricating oil comprises the following components, 30 parts to 50 parts of synthetic base oil, 30 to 50 parts of hydrofining solvent oil, 5 to 15 parts of a viscosity index improver, 0.2 to 0.5 part of a pour point depressant, 0.2 to 1 part of a composite oxidation and corrosion inhibitor, 0.2 to 1 part of an antioxidant, 0.2 to 1 part of an antirust agent, 0.0005 to 0.002 part of an antifoaming agent and 1 to 5 parts of magnetic particles. The magnetic particles can be automatically gathered and diffused through the change of the surrounding magnetic field intensity, so that the viscosity of an oil product is changed, and the change of the viscosity of the oil product and the change of the oil film intensity are realized.

Owner:重庆合晶能源科技有限公司

Phase change heat storage type falling film evaporator

PendingCN112023427AStable outputSolve the \"dry pipe\"Evaporator accessoriesEvaporators with vertical tubesHeat flowEngineering

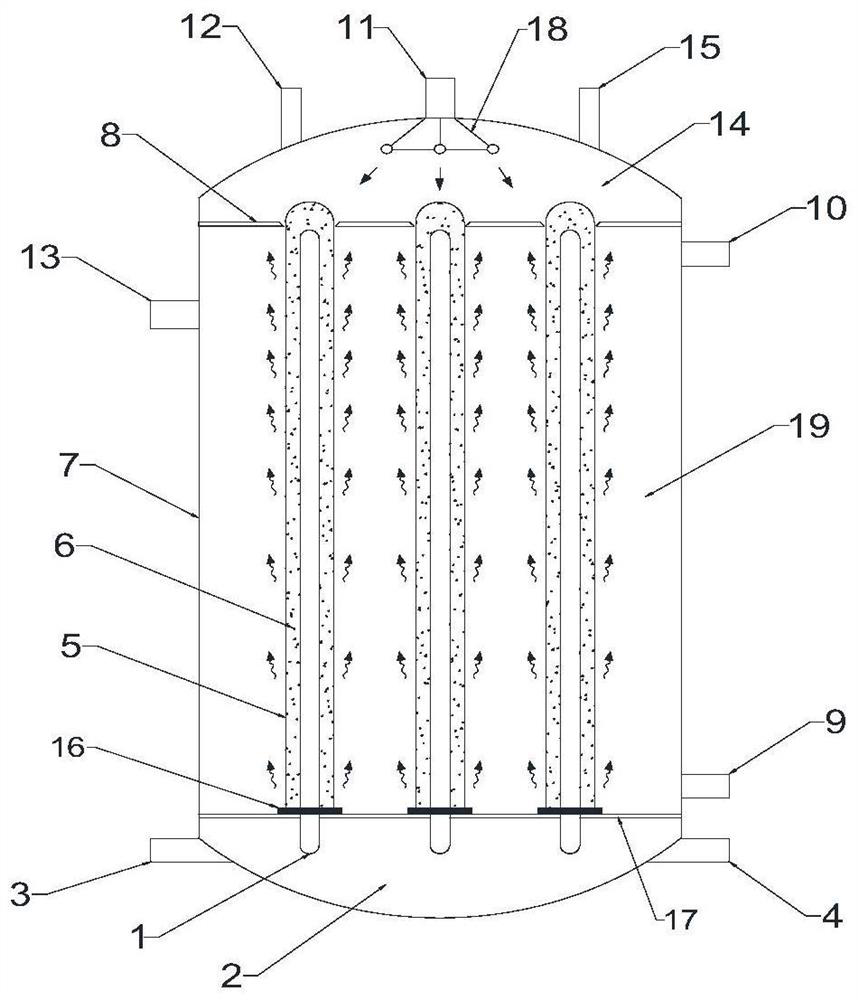

The invention discloses a phase change heat storage type falling film evaporator which comprises a cavity, a pipe assembly, and a liquid material distributor; the cavity comprises a liquid material chamber, an evaporation chamber and a heating chamber which are arranged in the cavity from top to bottom; the liquid material chamber and the evaporation chamber are separated by a falling film guide plate; the evaporation chamber and the heating chamber are separated by a sealing baffle plate; the pipe assembly comprises a falling film evaporation pipe, a metal heat pipe and a phase change heat storage material; and the liquid material distributor is arranged at the top of the liquid material chamber and is used for uniformly distributing liquid materials. According to the evaporation device,the temperature and heat flow stability in the evaporation process is achieved through the high heat storage density characteristic and the phase change constant temperature characteristic of the phase change material, meanwhile, medium-free flowing heat transfer in the evaporation pipe is achieved through the metal heat pipe, and therefore the problems existing in an existing falling-film evaporator are solved.

Owner:SHANGHAI MARITIME UNIVERSITY

Safe and precise control of fast cooling and fast heating automatic switching temperature control system

ActiveCN106020268BAuto switchImprove securityTemperature control using electric meansTemperature controlFuel tank

The invention discloses a quick-cooling quick-heating automatic switching temperature control system with the characteristic of secure and precise control. The system comprises an oil outlet pipeline, an oil return pipeline, a cooling circulating system, and a heating circulating system, wherein the cooling circulating system and the heating circulating system are communicated with the oil outlet pipeline and the oil return pipeline by pipes. The cooling circulating system includes an oil cooling box and a first pumping unit; and the heating circulating system consists of an oil heating box and a second pumping unit. A first pneumatic valve and a second pneumatic valve are arranged on the communication pipelines between the cooling circulating system, the oil return pipeline and the oil outlet pipeline; a fourth pneumatic valve and a fifth pneumatic valve are arranged on the communication pipelines between the heating circulating system, the oil return pipeline and the oil outlet pipeline; a third pneumatic valve is arranged on the communication pipeline between the oil cooling box and the first pumping unit; a sixth pneumatic valve is arranged on the communication pipeline between the oil heating box and the second pumping unit; and the oil heating box and the oil cooling box are connected by a pipeline and a seventh pneumatic valve is arranged on the pipeline. According to the invention, opening or closing of the pipeline can be controlled precisely, thereby realizing automatic switching between heating and cooling; and the system security is high.

Owner:SUZHOU AODE MACHINERY

An Energy Saving Priority Unloading Valve

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

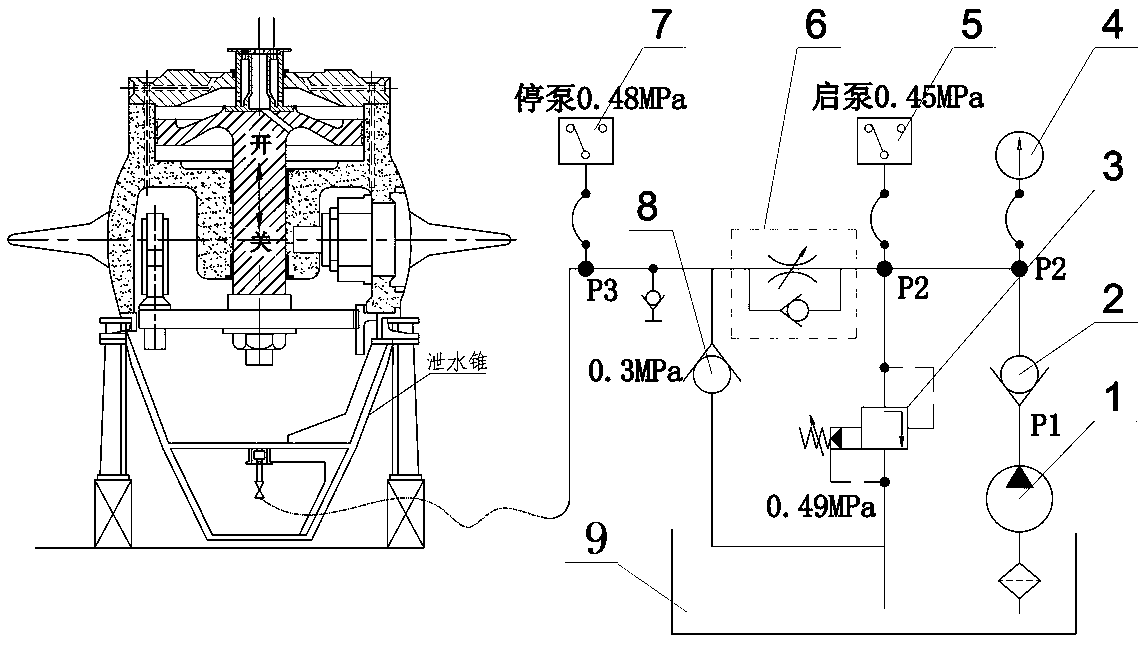

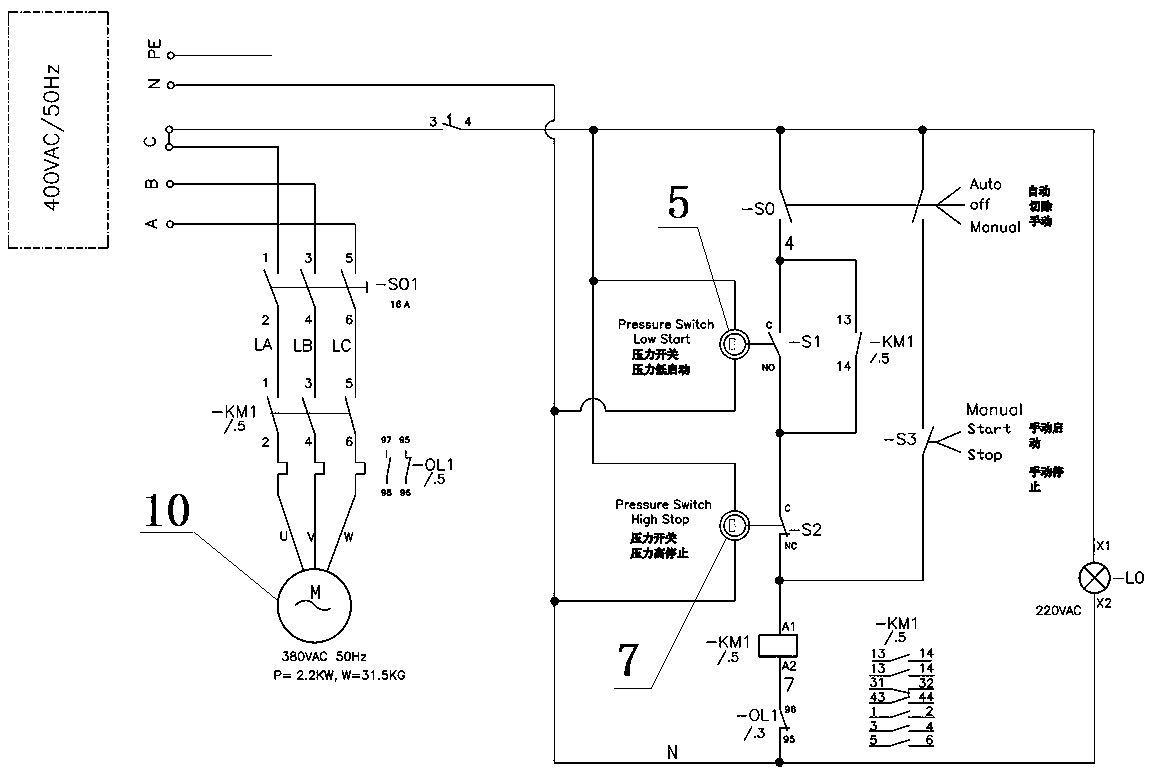

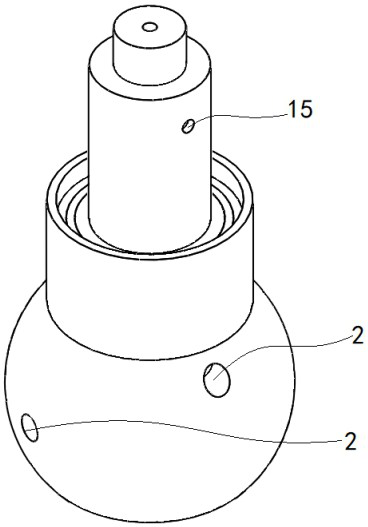

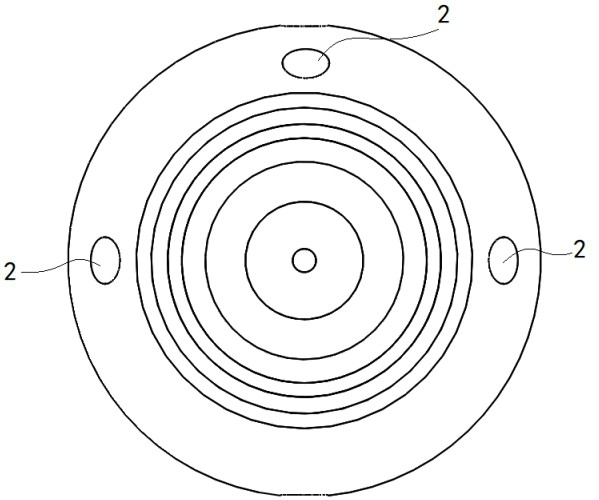

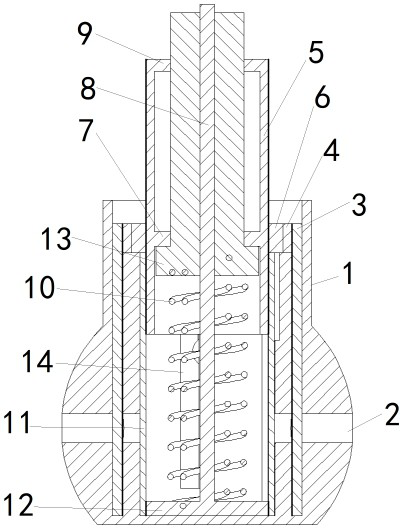

Runner cone pressure resistance test device of axial-flow Kaplan turbine and control method

ActiveCN110907097AGuaranteed pressure stabilityEasy to useFluid-tightness measurement using fluid/vacuumPressure stabilizationWater turbine

The invention provides a runner cone pressure resistance test device of an axial-flow Kaplan turbine and a control method. The runner cone pressure resistance test device is characterized in that a hydraulic system pipeline connected with a turbine runner hub runner cone is provided with an overflow valve, a first intelligent pressure switch and a second intelligent pressure switch; the overflow valve is used for controlling the highest working pressure of a system; the first intelligent pressure switch is used for starting an oil pump when the system pressure is lower than a preset low pressure value; and the second intelligent pressure switch is used for closing the oil pump when the system pressure is higher than the preset high pressure value. The runner cone pressure resistance test device can guarantee the pressure stability of the runner cone in the pressure-resistant test process effectively, is convenient to use, is high in automation degree, and enables the efficiency to be greatly improved.

Owner:FUJIAN SHUIKOU POWER GENERATION GROUP +1

A painting device and a painting multi-axis robot

ActiveCN113245112BGuaranteed pressure stabilityFlexible adjustment of the number of conductionsSpraying apparatusStructural engineeringSpray painting

Owner:广东科佩克机器人有限公司

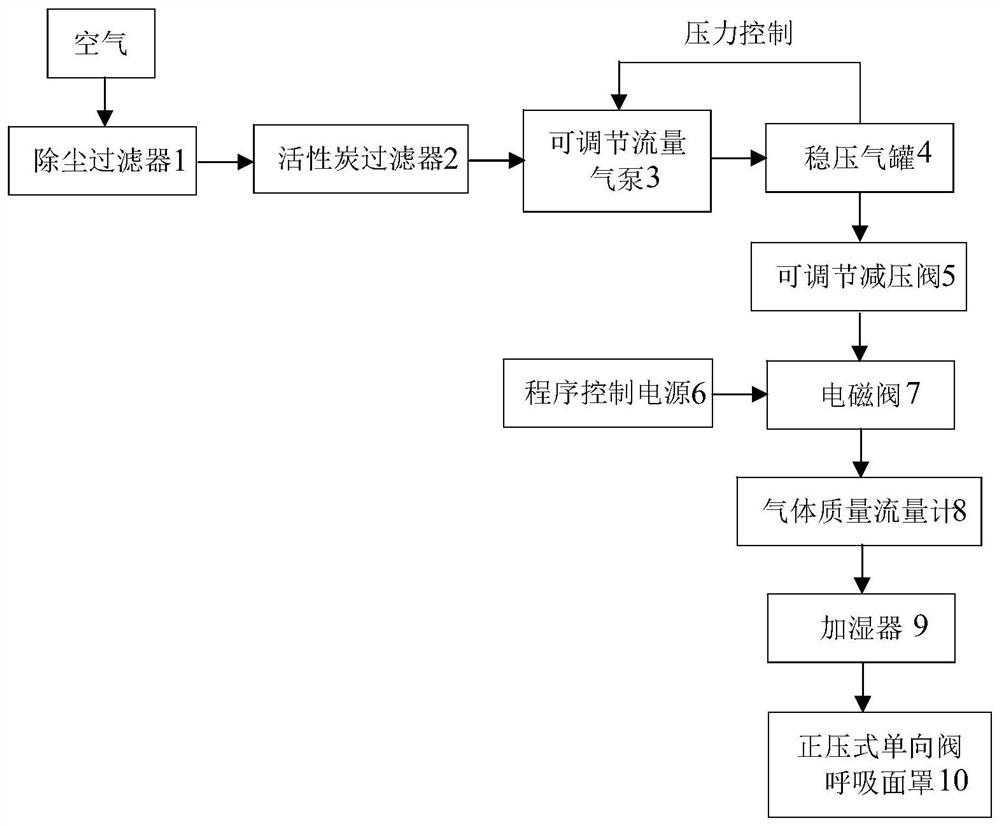

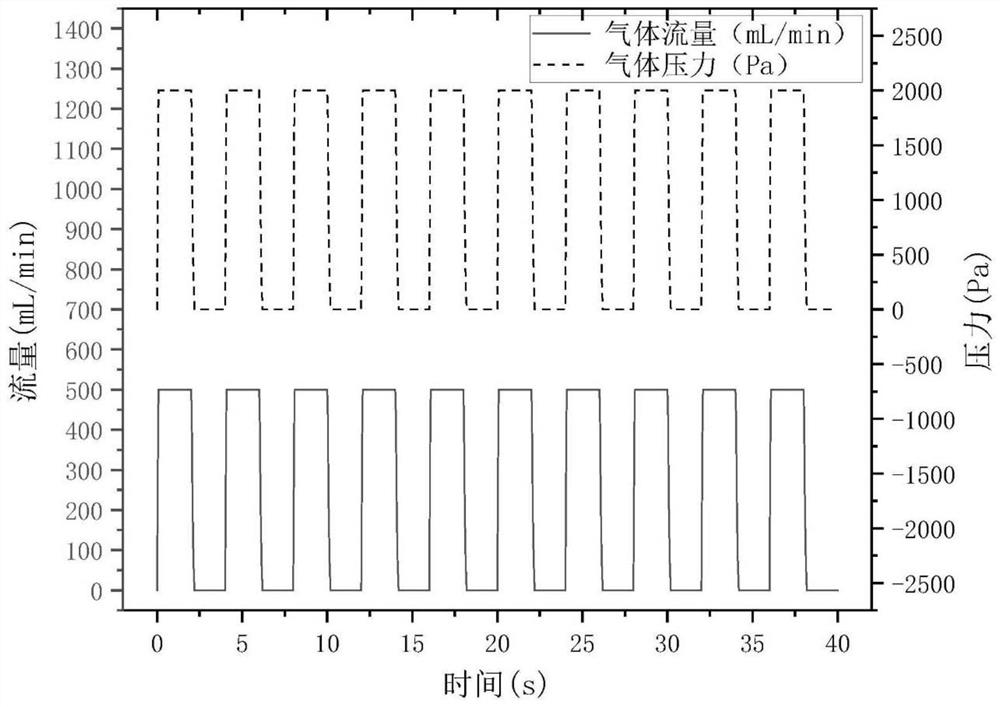

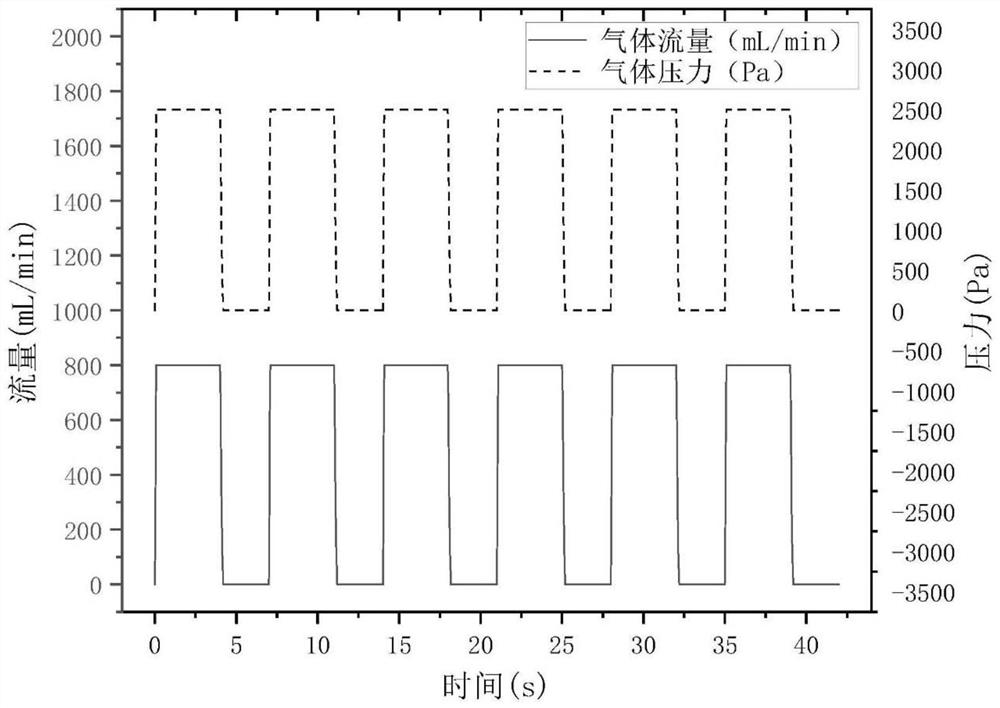

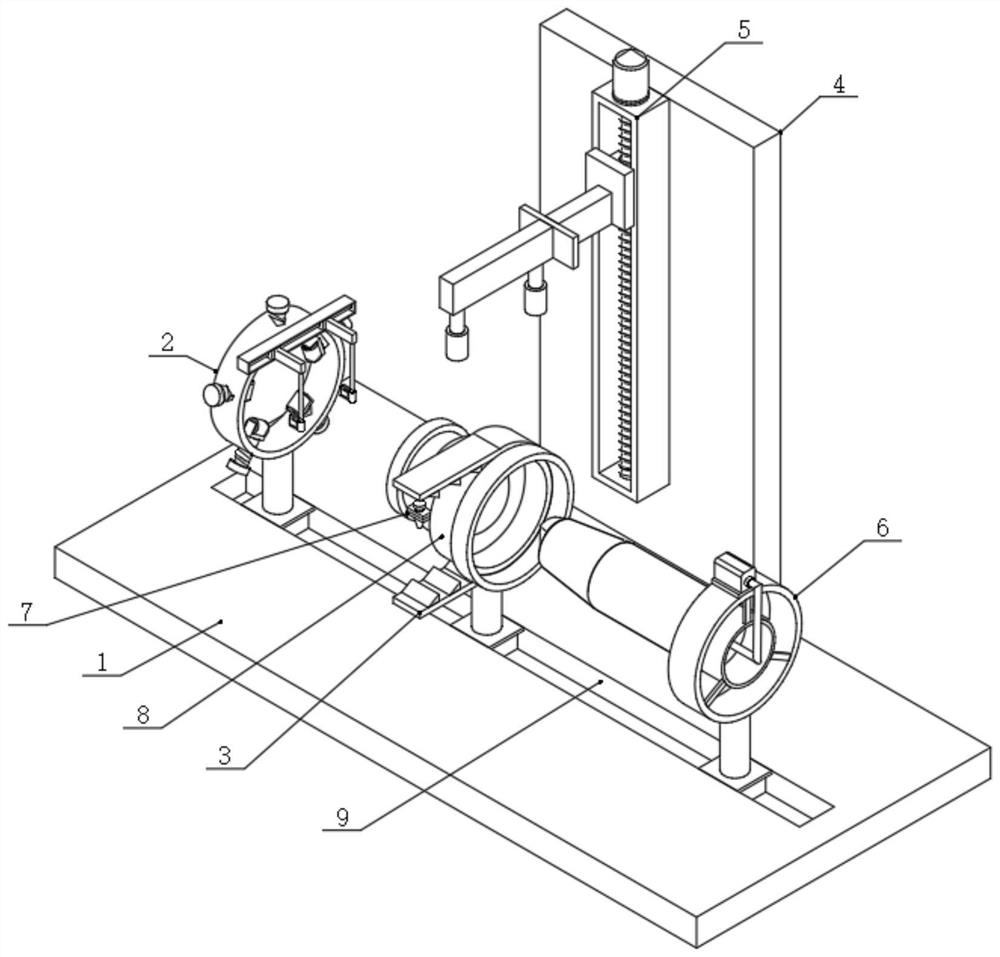

Quick response type automatic respiration controller

PendingCN113926041AFlexibleFlexible gas flowRespiratorsMedical devicesActivated carbon filtrationDust control

The invention discloses a quick response type automatic respiration controller, and belongs to artificial auxiliary respiration support equipment in the non-medical special field. The quick response type automatic respiration controller comprises a dust removal filter, an activated carbon filter, a flow-adjustable air pump, a pressure stabilizing air tank, an adjustable pressure reducing valve, an electromagnetic valve, a gas mass flow meter, a program control power supply, a humidifier and a positive pressure type one-way valve respiration mask. The dust removal filter, the activated carbon filter, the flow-adjustable air pump, the pressure stabilizing air tank, the adjustable pressure reducing valve, the electromagnetic valve, the gas mass flow meter, the humidifier and the positive pressure type one-way valve respiration mask are sequentially arranged, and the program control power supply is used for controlling the on-off of the electromagnetic valve. According to the quick response type automatic respiration controller provided by the invention, the parameter adjusting capacity is high, the gas flow / pressure stability is good, on-off of gas intermittent adopts a program control power supply to control on-off of the electromagnetic valve, the response is sensitive, the time lag is small, and the gas purifying capacity is high. The quick response type automatic respiration controller is simple, portable, high in universality and wide in market prospect.

Owner:广东省哥弟菩及公益基金会

Press-fitting equipment and press-fitting process for fire hose production

ActiveCN114147458ARealize self-feeding processingQuick release handleMetal working apparatusStructural engineeringMechanical engineering

The invention discloses press-fitting equipment and a press-fitting process for fire hose production in the technical field of fire-fighting appliance production, the press-fitting equipment comprises a press-fitting base, a supporting side plate is fixedly mounted on one side of the press-fitting base, and a press-fitting assembly is fixedly mounted on one side of the supporting side plate; a connector clamping assembly is fixedly installed at the position, corresponding to the press-fitting assembly, of the top of the press-fitting base. Through the designed water hose feeding assembly, a conical sleeve and a guide sleeve roller are sleeved with clamp bodies and a fire hose, after the clamp bodies on the two sides make contact with the inclined face of the conical sleeve, top clamp assembly rods on the two sides can be driven to move and unfold towards the two sides, and the unfolded clamp assembly rods can further unfold the fire hose; therefore, self-feeding treatment of the fire hose can be achieved, the situation that the sleeving and attaching efficiency between the material belt and the connector body is affected by manual feeding and sleeving is avoided, transverse feeding of the connector body is achieved through the clamping base with the lateral opening, and rapid separation treatment after the fire hose is assembled and connected is achieved.

Owner:泰州市神龙消防科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com