Patents

Literature

823 results about "Mine tunnel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Woodsmith Mine Tunnel (also known as a Mineral Transport System [MTS]) is a 23-mile (37 km) long tunnel that will stretch between Woodsmith Mine at Sneatonthorpe near Whitby in North Yorkshire and the Wilton International complex on Teesside, England.The tunnel has been in development since 2016, but cutting of the tunnel bore did not start until April 2019, with an expected finish date of ...

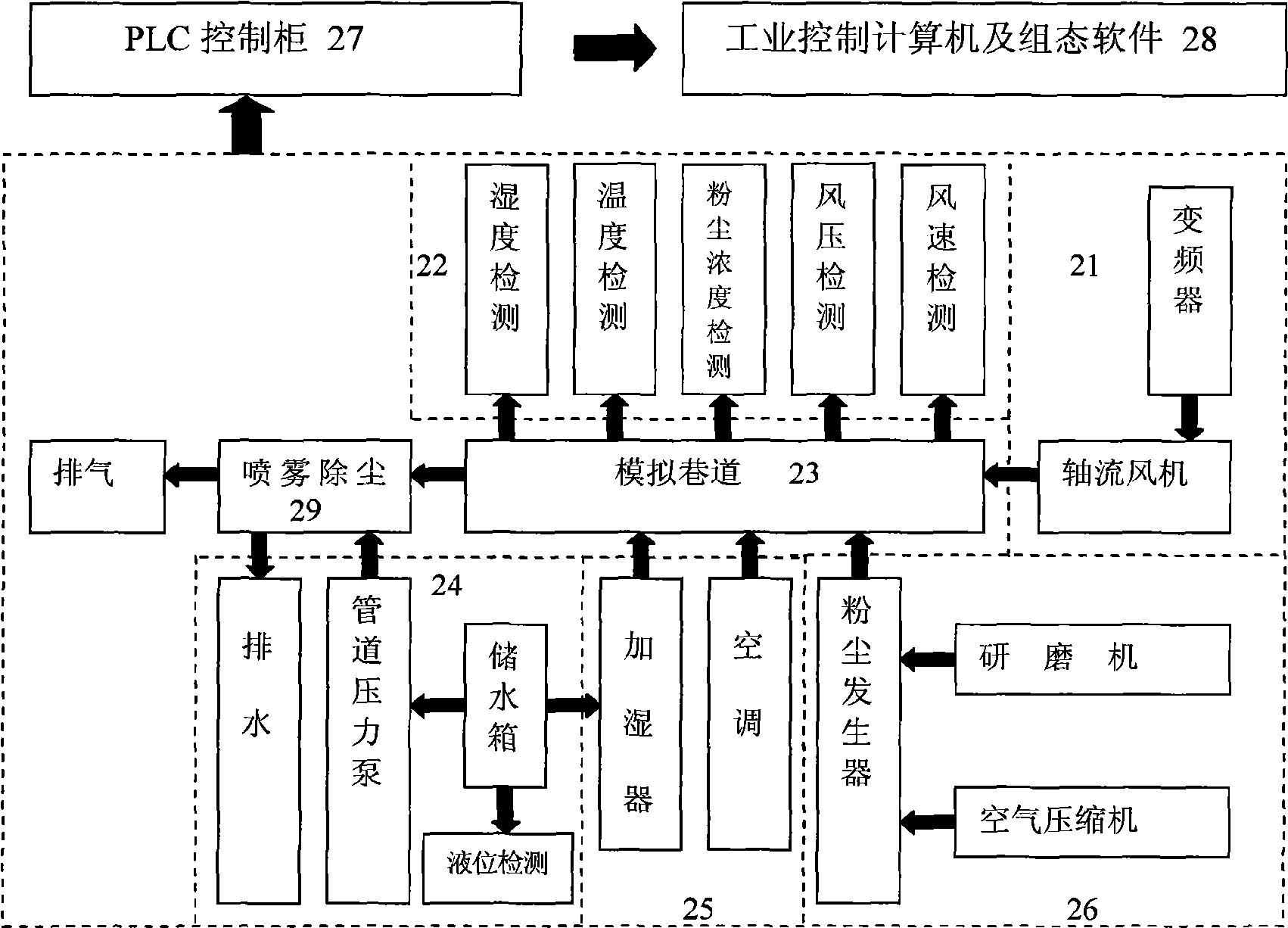

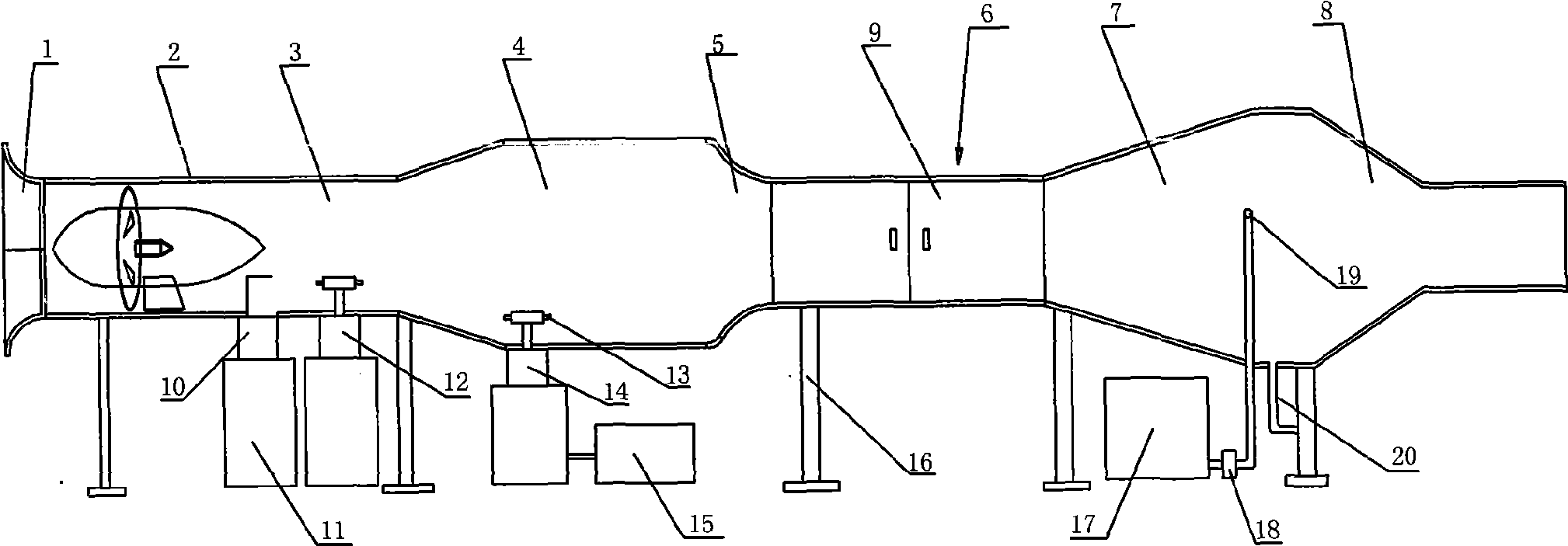

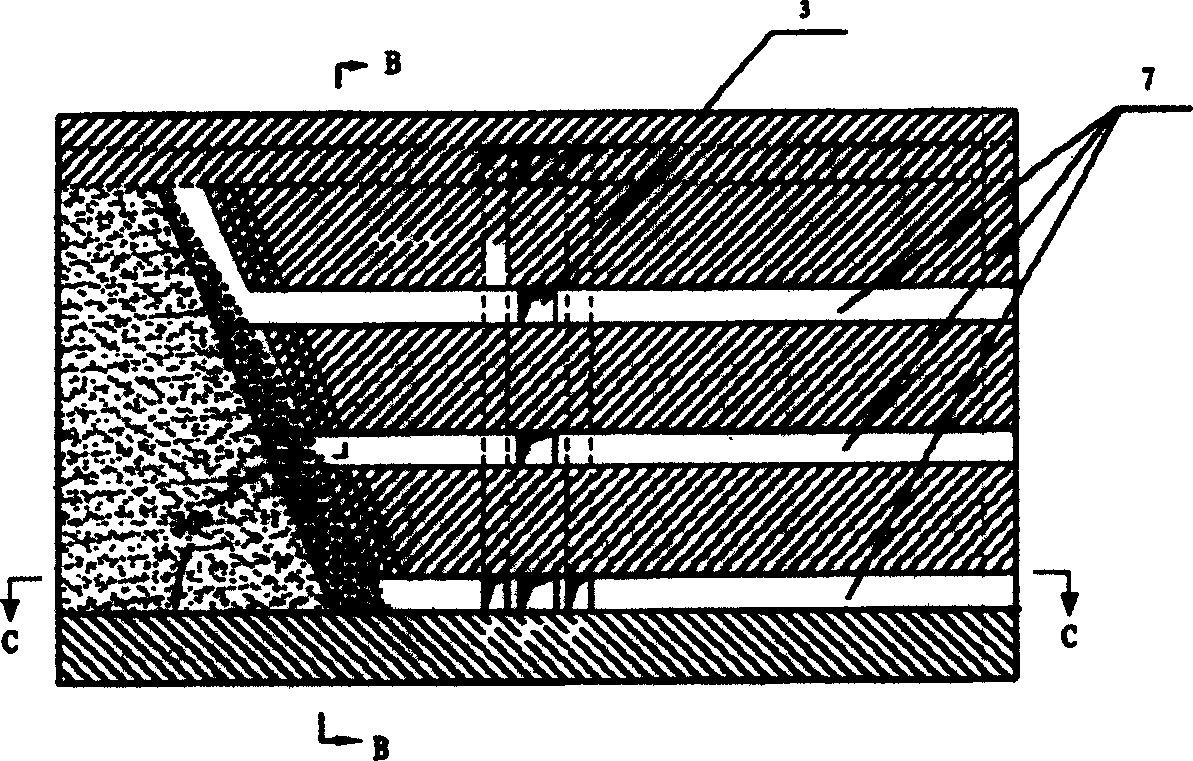

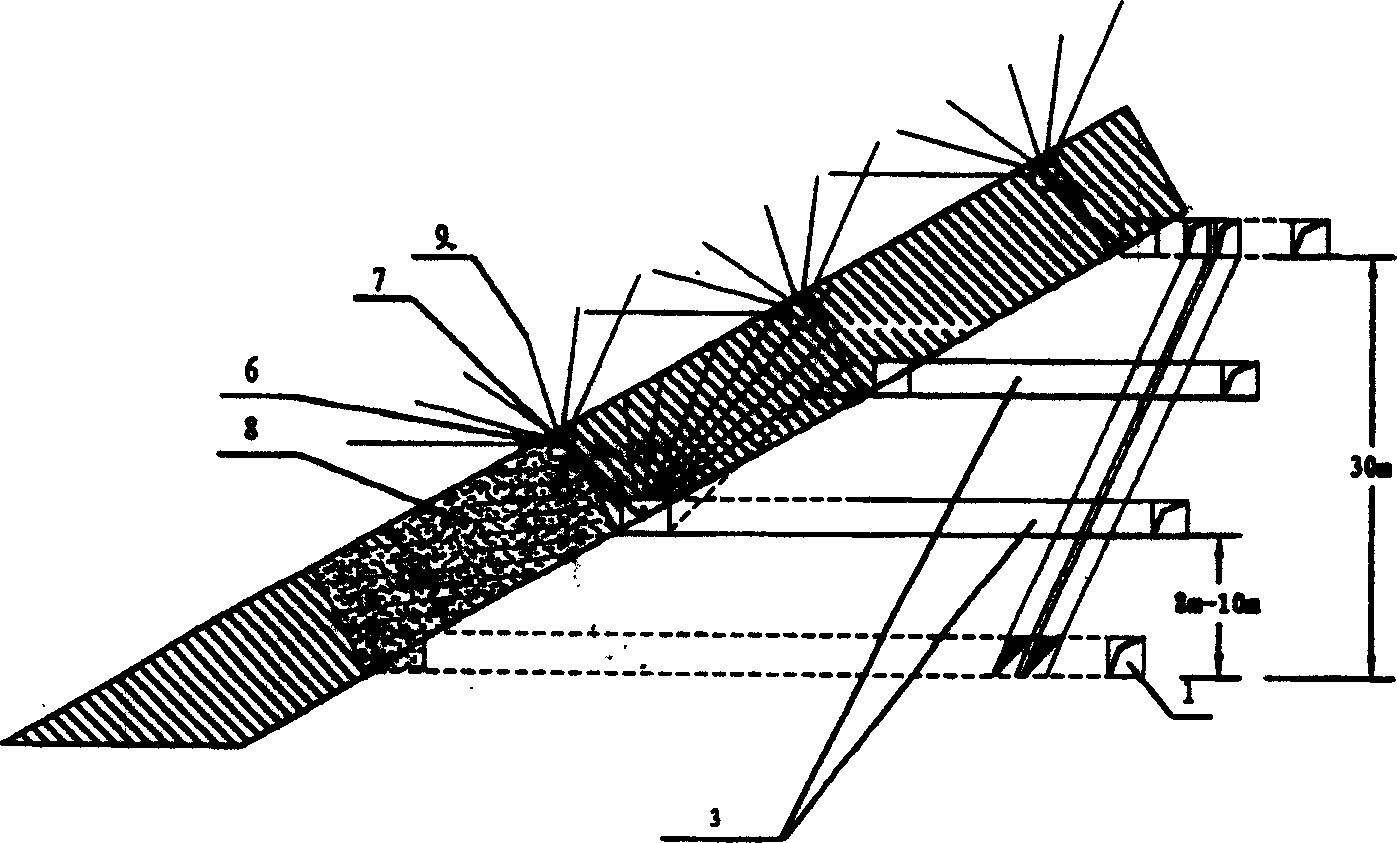

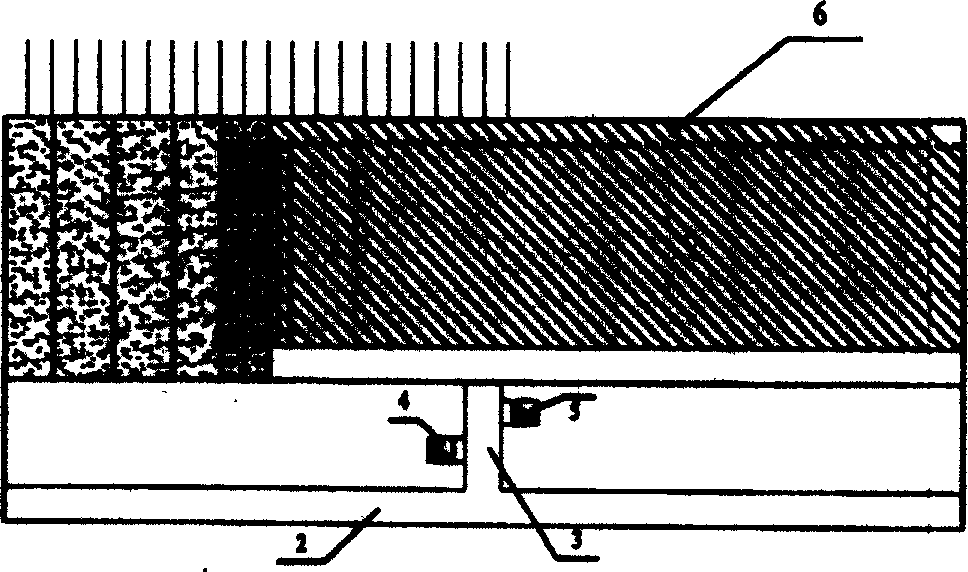

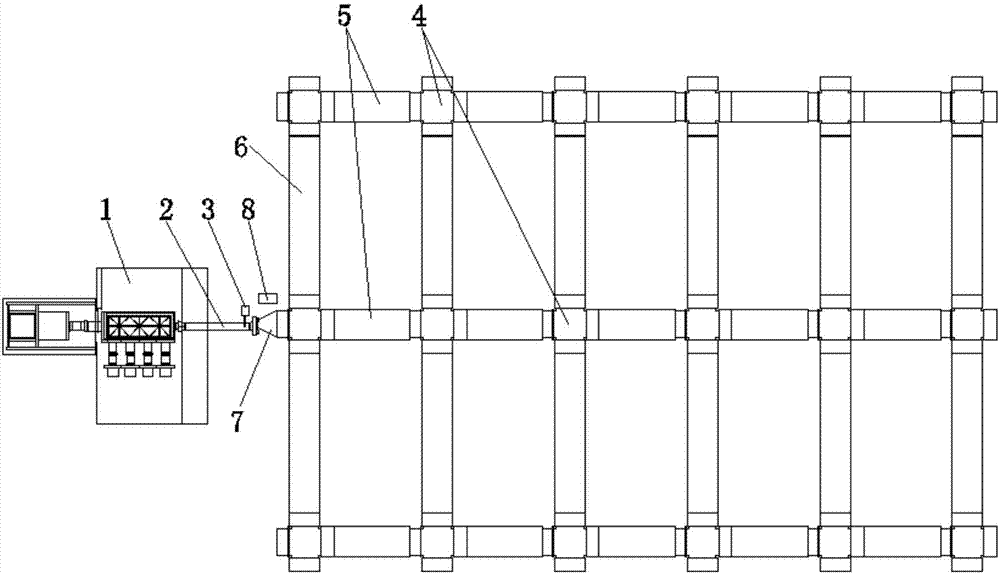

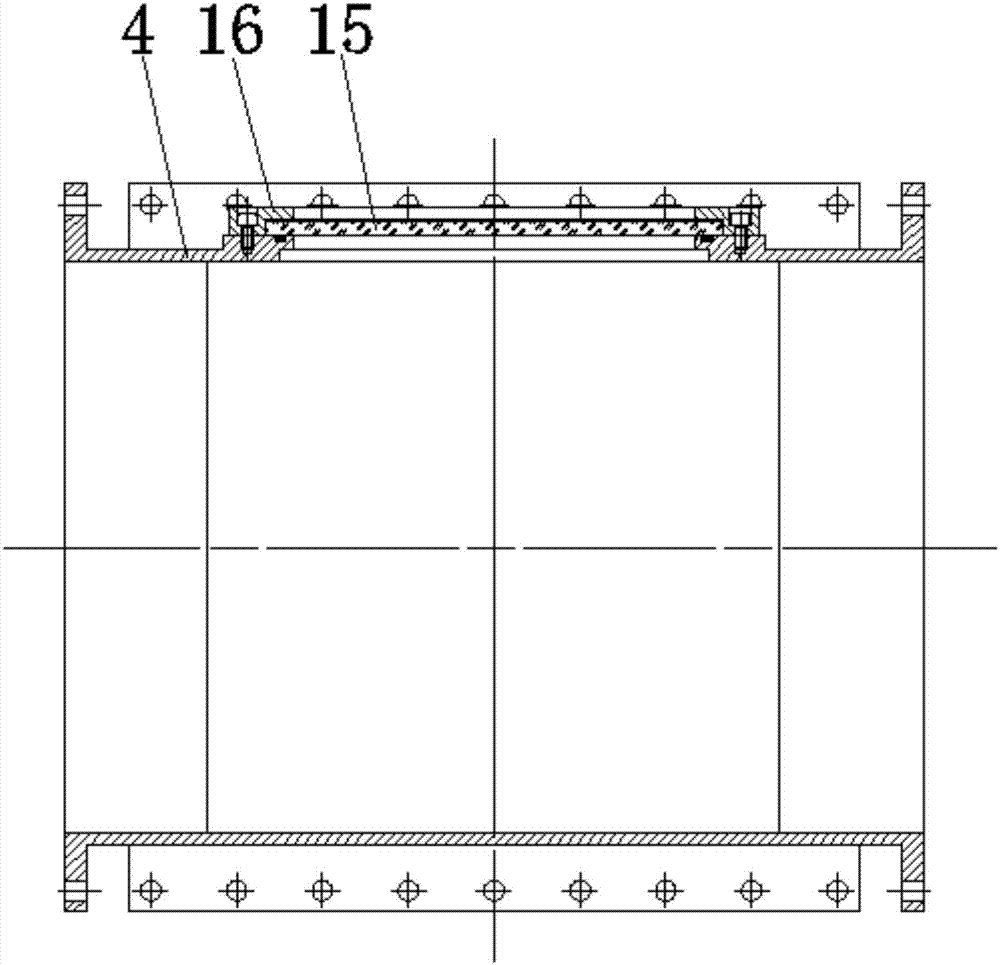

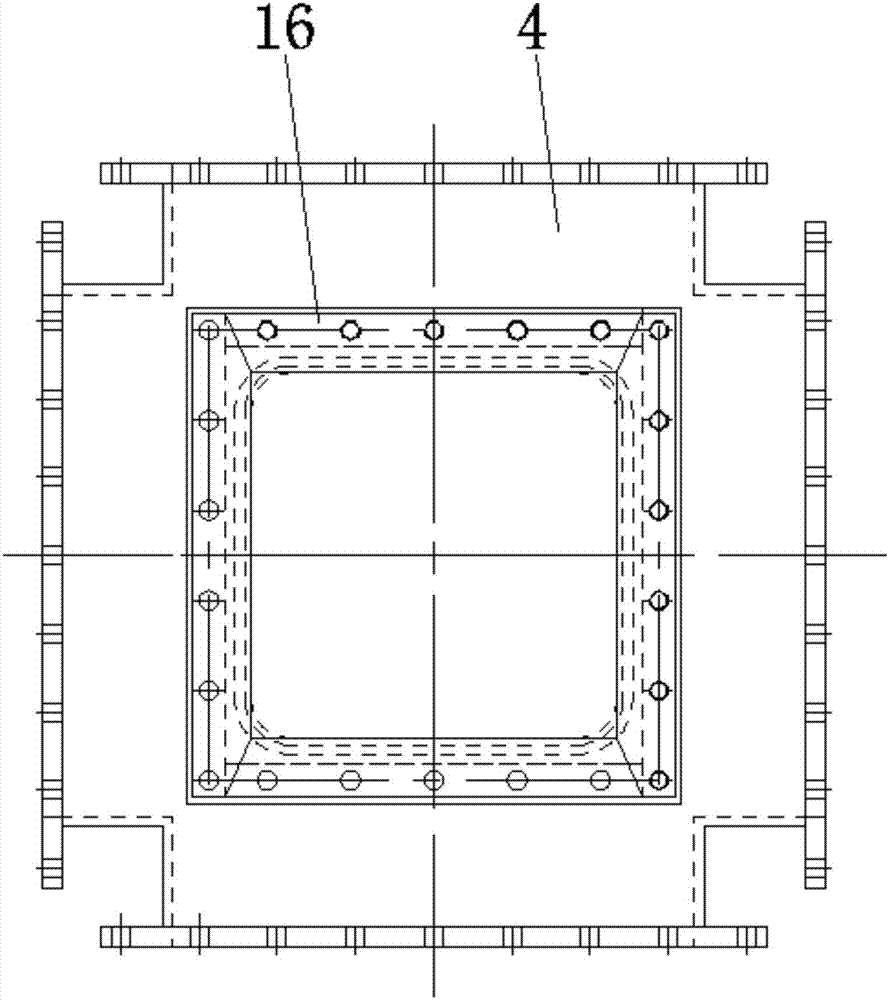

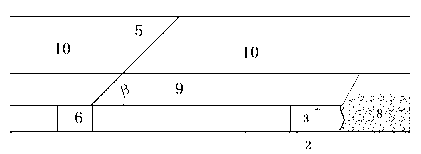

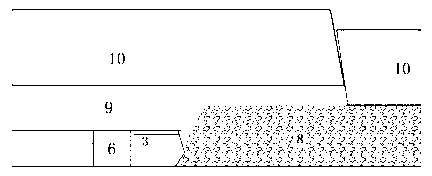

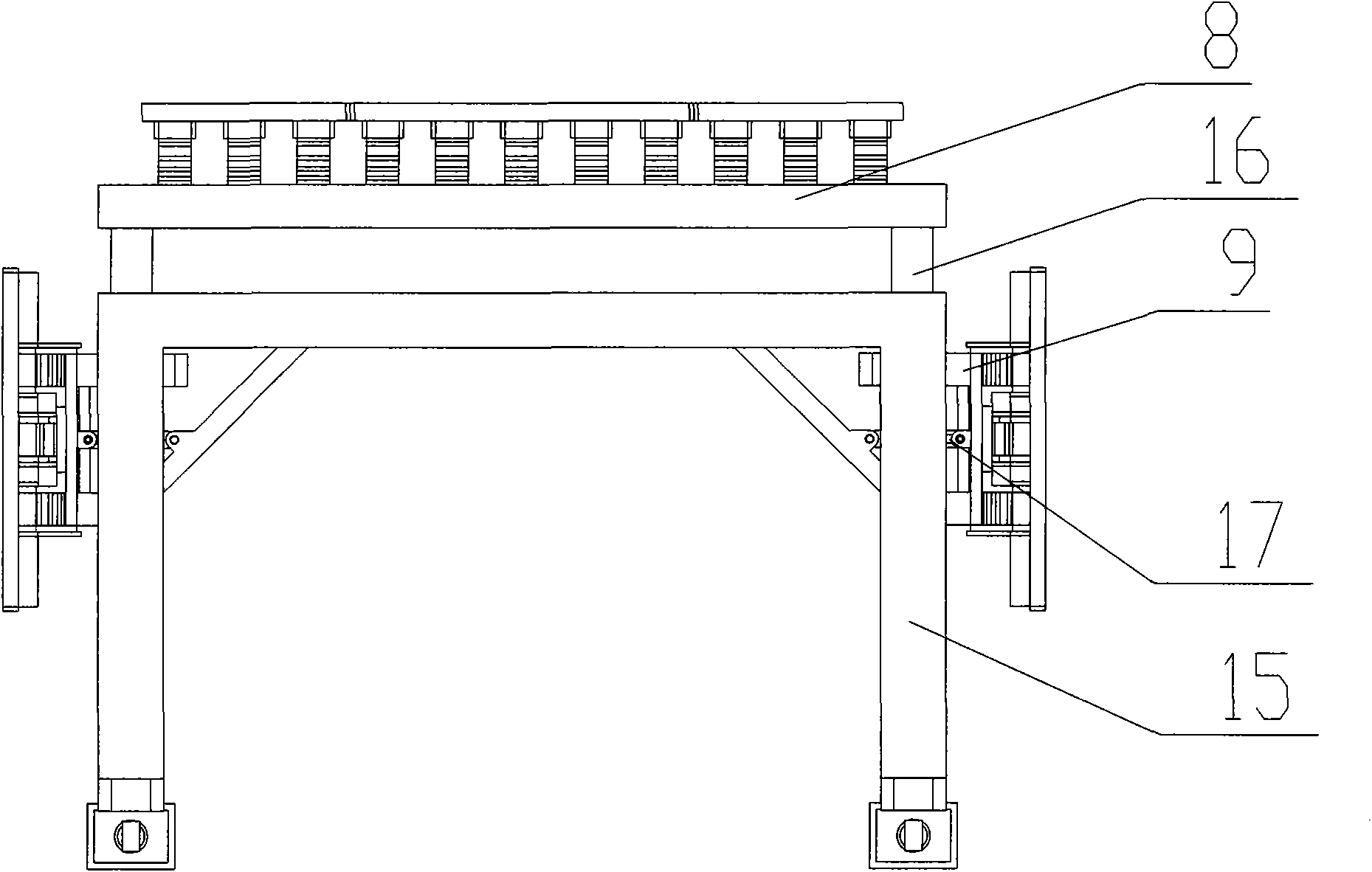

Simulation experimental system for controlling mine tunnel dust environment

InactiveCN101520365AOvercoming Hard-to-Simulate DefectsAerodynamic testingDust removalData informationDust detection

The invention discloses a simulation experimental system for controlling a mine tunnel dust environment, which comprises a simulation tunnel, a ventilation system, a dust generating system, a temperature and humidity controlling system, a water supplying and draining system, a dust removing system, a signal detecting system, and a computer controlling and data analyzing system, wherein the simulation tunnel is connected with the ventilation system, the dust generating system and the temperature and humidity controlling system in the tunnel to simulate the temperature, humidity, wind speed, air pressure and dust concentration parameters in the mine, and is connected with the water supplying and draining system and the dust removing system to spray and remove dust passing through the tunnel. The signal detecting system provides related data information for the computer controlling and data analyzing system. The simulation experimental system is similar to a DC-blowing-type wind channel in a small-scale mine environment. An area in which air flows uniformly is created in the tunnel. By using the demarcated flow field, various scientific research activities related to mine dust detection, dust prevention, and the like can be performed.

Owner:SHANDONG UNIV OF SCI & TECH

Continuous mining method of stepped sectional extruding and ore caving followed by filling

In the continuous mining method, ore body are divided into sections, subsections and mini-sections stepwisely along the ore vein; arranging mini-section drilling mine tunnels along the ore vein in the ore body bottom wall and connecting the mini-section tunnels with the main ramp way via linking tunnel; arranging support and filling tunnel along ore vein in the upper wall in the ore section; stoping from two ends to the central part of the bordroom via stepped continuous advance; drilling fanned holes with rock drill machine, breaking ore with rock explosive, charging with charging machine and combined elementary error detonation; filling finished stope via filling tunnel and filling dewatering device; and supporting crushed upper wall roof with deep anchor rod and steel fiber concrete. The present invention has high production capacity, high safety, less ore loss and low mining cost.

Owner:CENT SOUTH UNIV

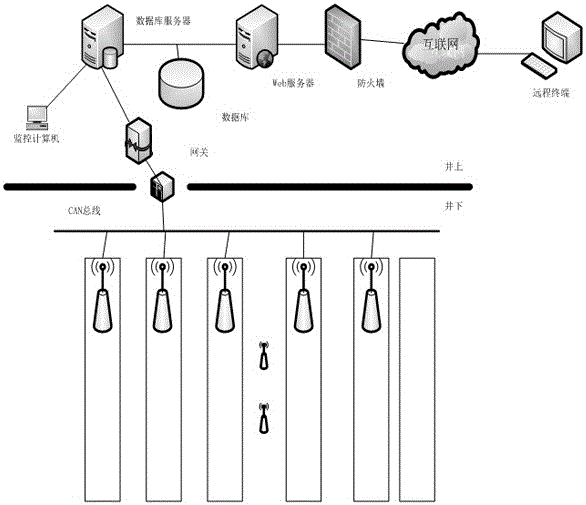

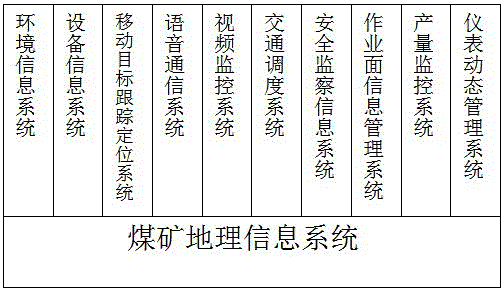

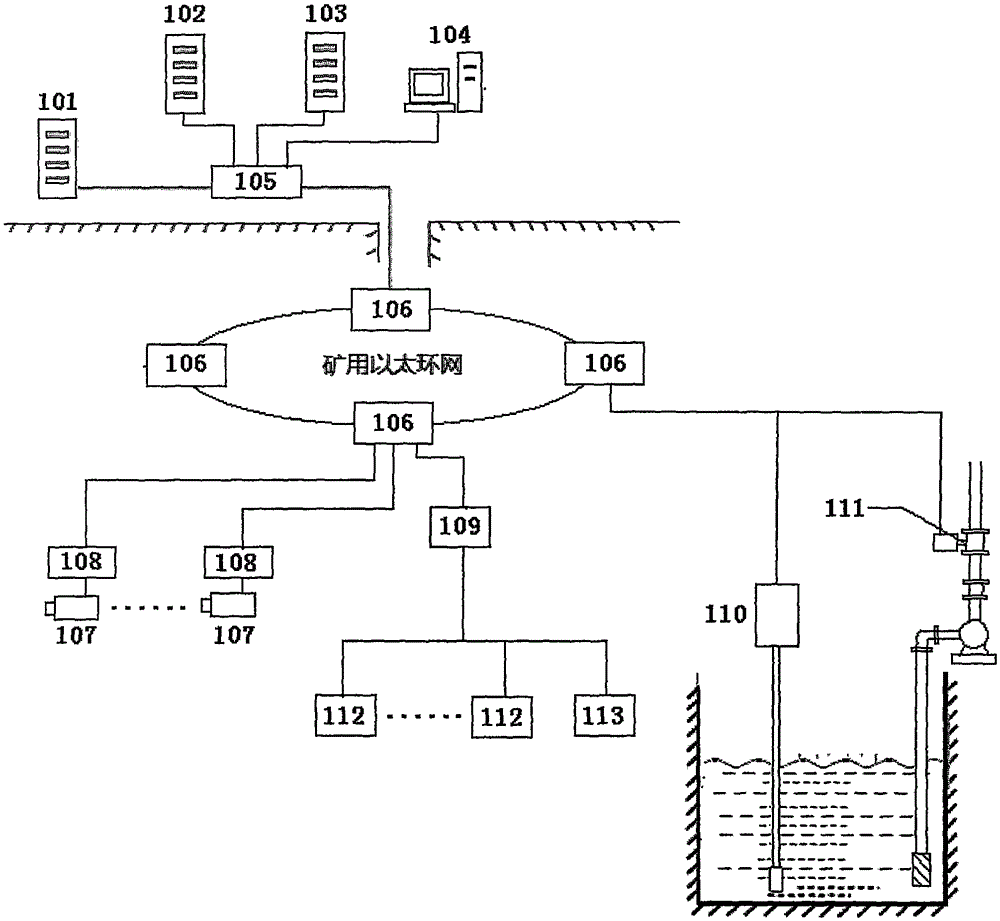

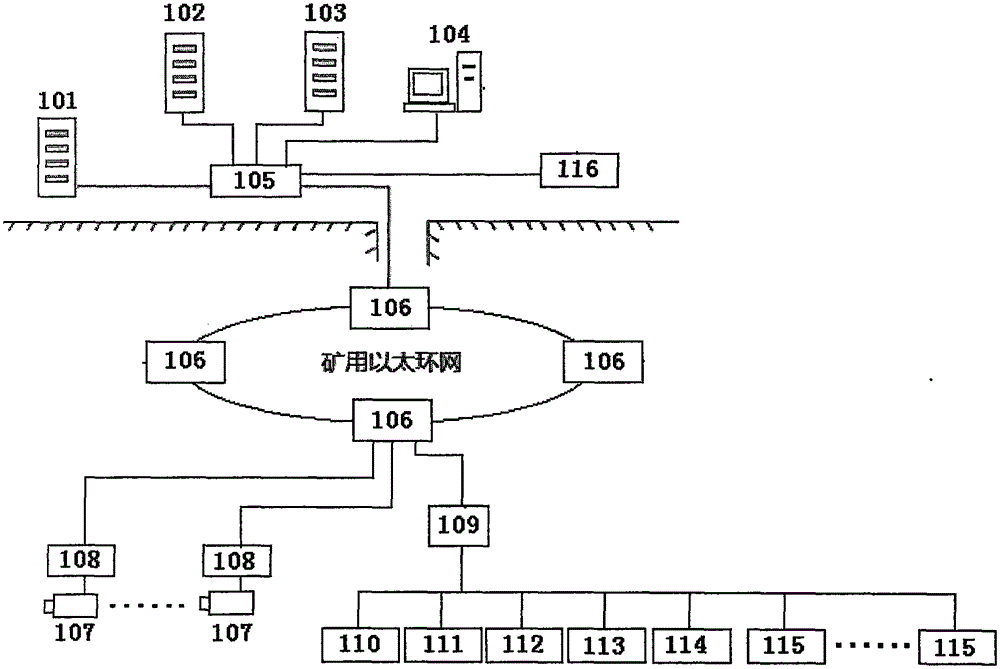

Coal mine safety integrated monitoring system based on Internet of Things

A coal mine safety integrated monitoring system based on the Internet of Things comprises an environment information system, an equipment information system, a mobile target tracking and positioning system, a voice communication system, a video monitoring system, a traffic dispatching system, a safety supervision information system, a working plane information management system, a yield monitoring system, a dynamic meter management system, a safety prewarning and decision supporting system and a rescue information assurance system. Nodes of the Internet of Things are installed to a coal mine tunnel, relevant equipment and workers, the nodes of the Internet of Things are connected with relevant sensors and actuating equipment, and objects, needing to be monitored, of an underground coal mine are connected with the Internet according to a unified agreement, so that the coal mine safety integrated monitoring system based on the Internet of Things is formed. The data information of the underground environment and equipment can be collected by every worker and underground equipment through the sensors carried with the workers and the underground equipment; besides, the state information of the workers and the underground equipment can be collected, so that intelligent recognition, positioning, tracking, monitoring and management are achieved.

Owner:HUAYANG COMM TECH CO LTD

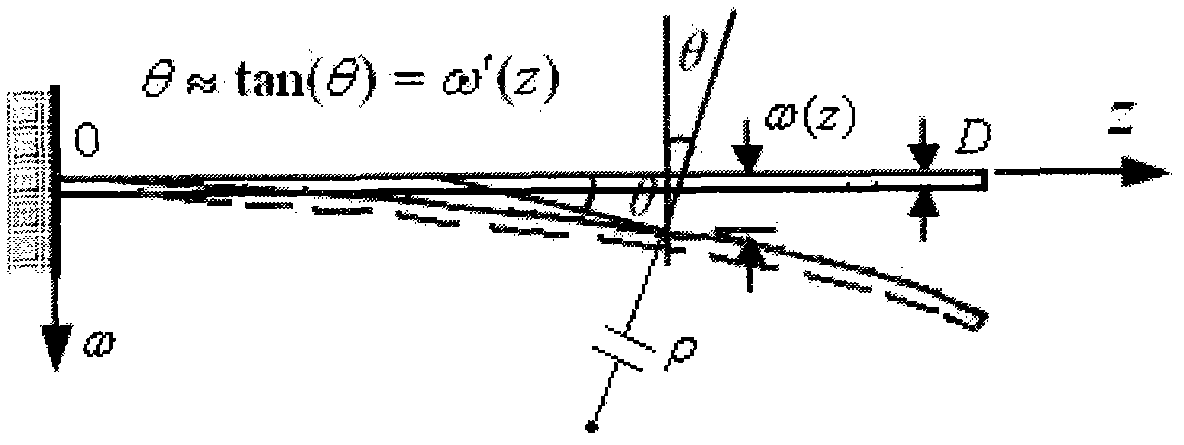

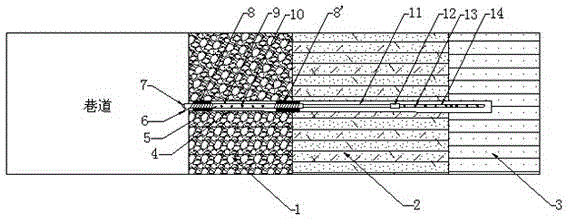

Method of using distributed optical fibers for advanced monitoring of tunnel surrounding rock deformation

ActiveCN102168950AOvercome the defect of discontinuous measuring pointsRealize advanced monitoringUsing optical meansData acquisitionOptical fiber cable

The present invention provides a method of using distributed optical fibers for an advanced monitoring of tunnel surrounding rock deformation. A monitoring device related to the method comprises a distributed optical fiber measuring pipe, an optical fiber sensing line, a Brillouin backscattering light data acquisition facility, and a data processing and analyzing software. The method comprises the steps of symmetrically laying sensing optical fibers on the external surface of a PP-R pipe to manufacture the distributed optical fiber measuring pipe, by which the displacement of soil along the measuring pipe can be obtained; embedding the distributed optical fiber measuring pipe in the drilling hole in the overlying surrounding rock of the tunnel, and injecting couplant to form a measuring pipe of a soil-pipe compatible deformation type, wherein the measuring pipe deforms with the synchronous displacement of the surrounding rock; and realizing monitoring of the deformation or displacement of the surrounding rock by measuring the deformation of the measuring pipe. The method provided in the invention has the characteristics of a distributed type, automatic data acquisition, real time and advanced monitoring, etc., and is suitable for monitoring surrounding rock two dimensional deformation or displacement in the geotechnical engineering field such as a tunnel cavern, a coal mine tunnel, etc.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

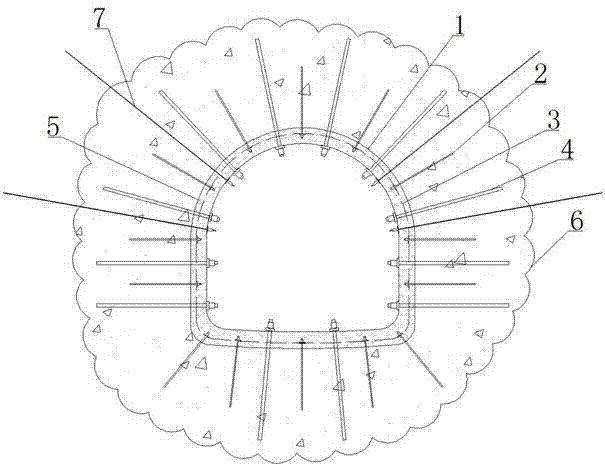

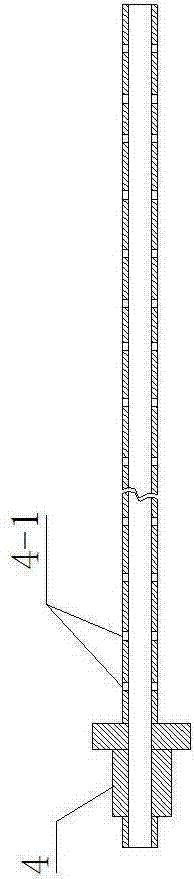

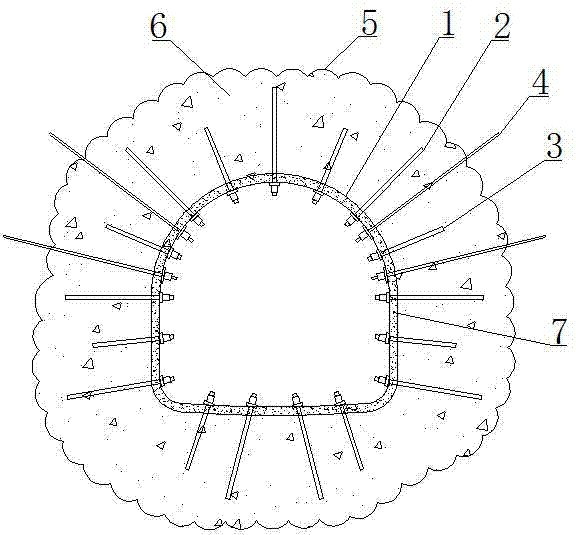

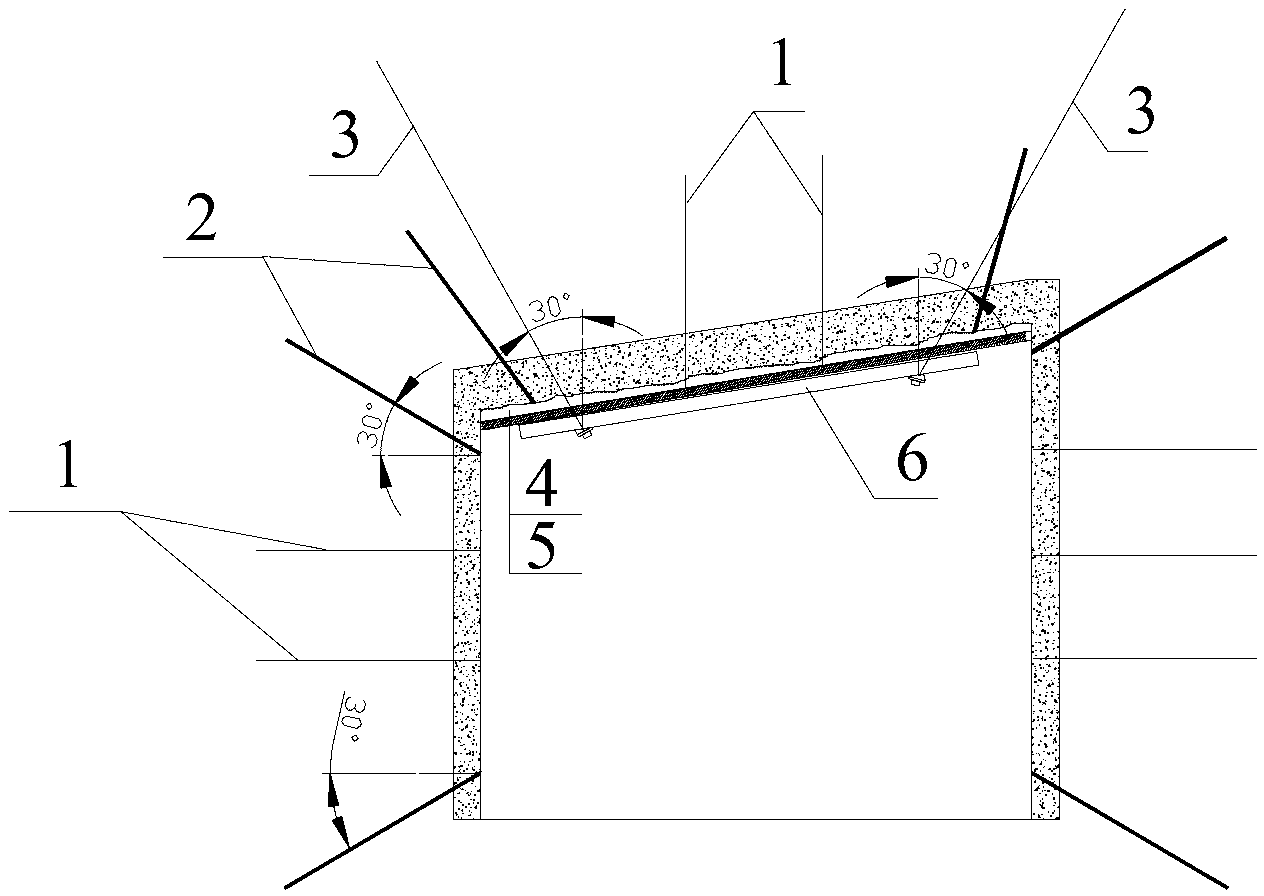

Supporting and reinforcing structure of coal mine tunnel and construction technology thereof

InactiveCN103195441AEven by forcePrevent weatheringUnderground chambersTunnel liningPre stressArchitectural engineering

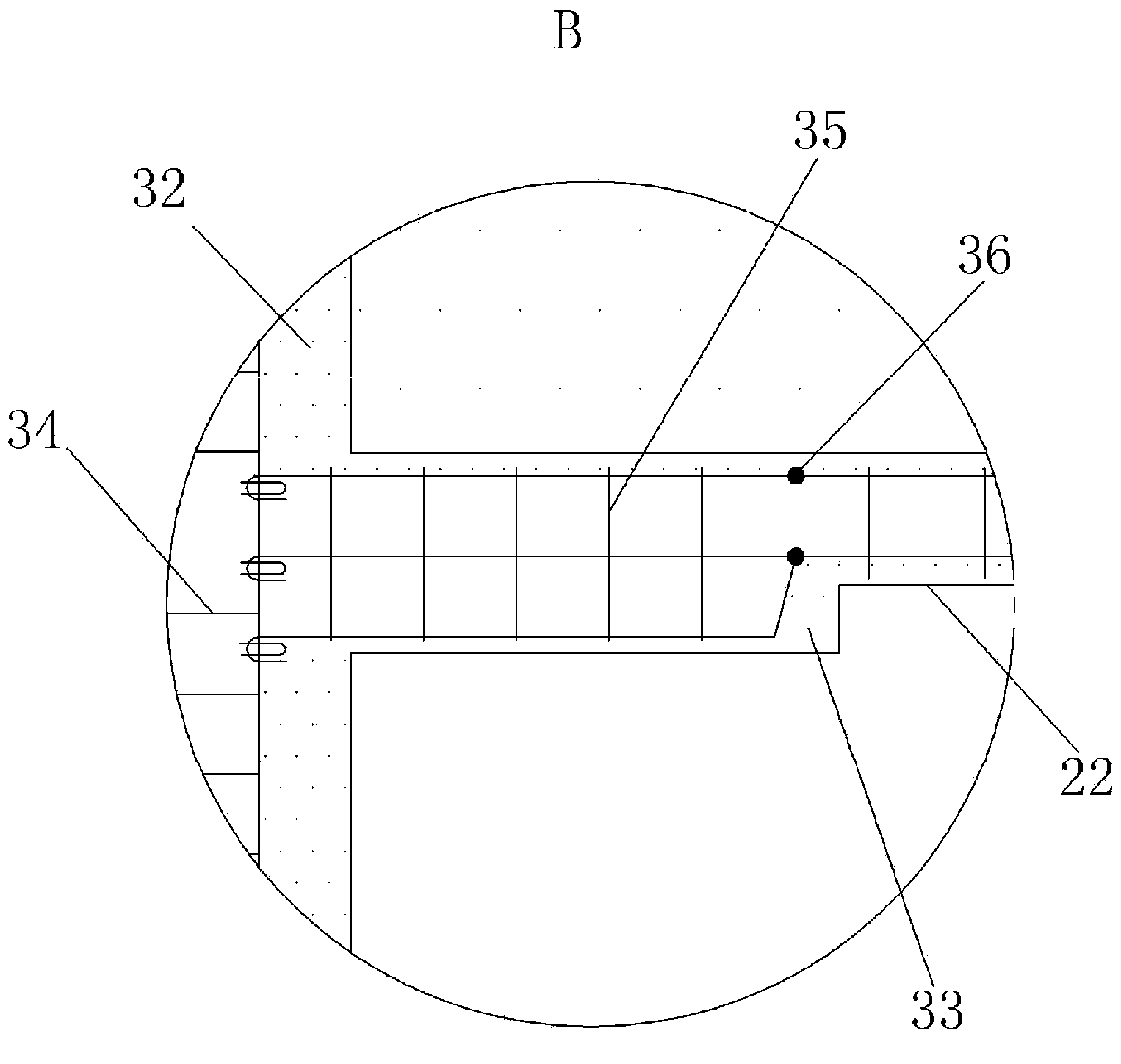

The invention discloses a supporting and reinforcing structure of a coal mine tunnel and a construction technology thereof. The supporting and reinforcing structure of the coal mine tunnel comprises a lane, wherein a grid-shaped reinforced layer is arranged on the inner wall of the lane, an anchor rod is arranged on the grid node portion of the reinforced layer, the inner end of the anchor rod is anchored in surrounding rock of the lane, and an anchor plate and a nut of the anchor reinforced layer are arranged at the outer end of the anchor rod. A concrete spraying layer covered on the reinforced layer and arranged at the outer end of the anchor rod is further arranged on the inner wall of the lane, a grouting anchor rod is arranged in the surrounding rock of the lane, an anchor cable is further arranged in the surrounding rock of the lane, the inner end of the anchor cable is anchored in the surrounding rock of the lane, and the outer end of the anchor cable is anchored on the outer side of the concrete spraying layer through a tray and a tensioning lock. The supporting and reinforcing structure of the coal mine tunnel integrates the surrounding rock of the lane in cementing mode with the initiative supporting theory as the guidance, prestress is reserved in the rock body, and stress is released and superimposed slowly, so that self integral strength and stability of soft rock and coal body are improved, the surrounding rock in a release ring of the lane can form a structure relatively homogenous and stable, and the aim of reinforcing and protecting the soft rock lane can be achieved within a long time.

Owner:PINGDINGSHAN TIANAN COAL MINING

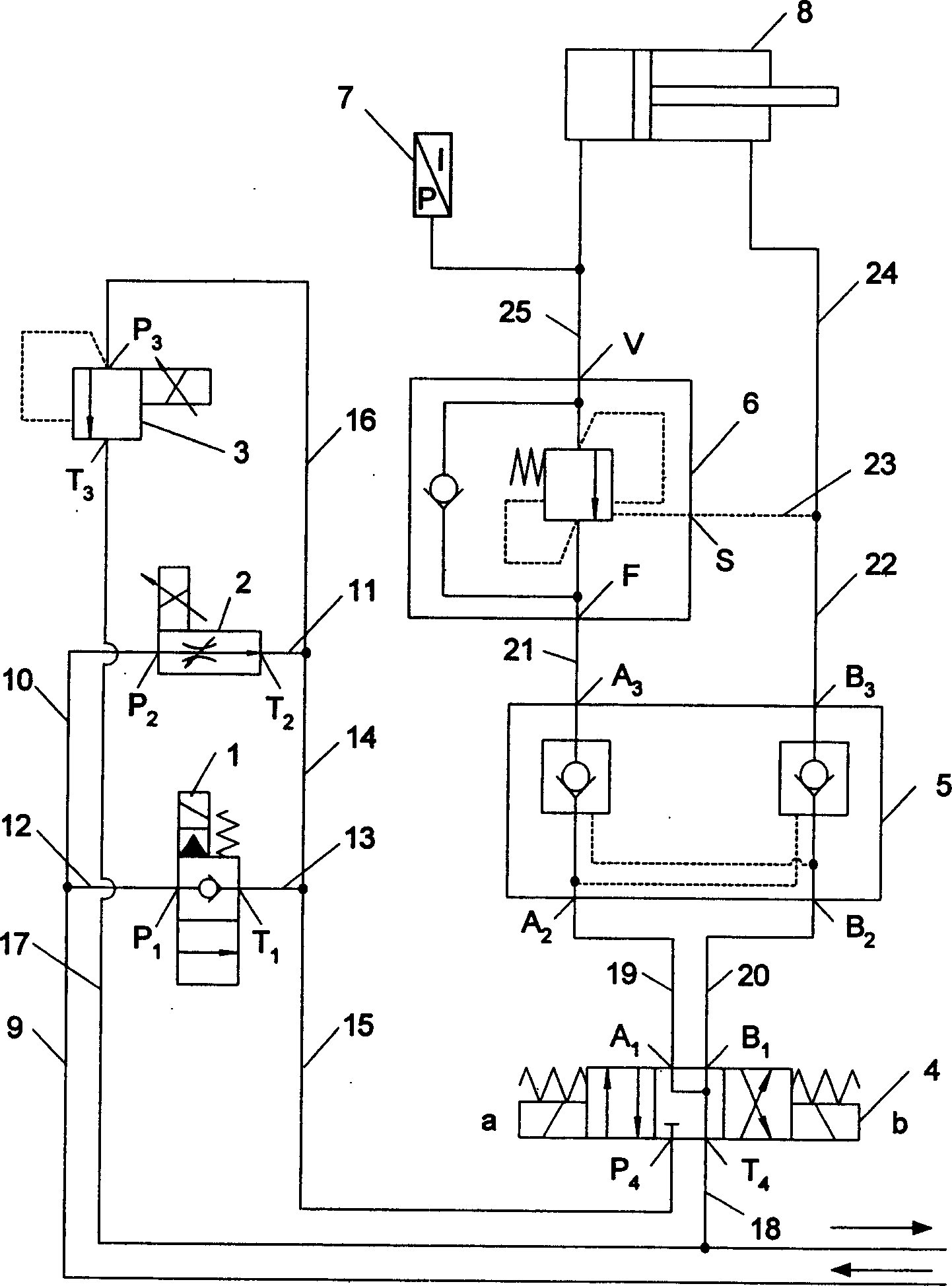

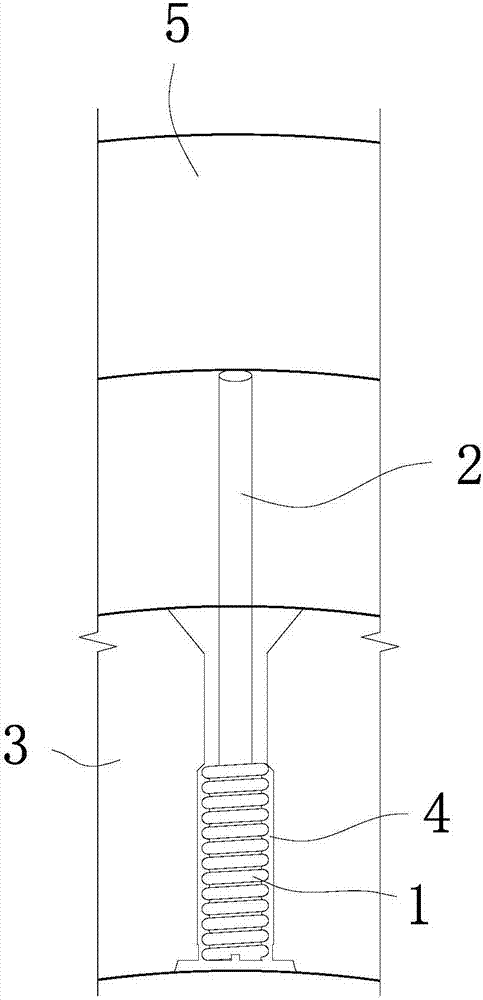

Hydraulic propelling system for mining tunnel driving machine controlled by ratio flow pressure

InactiveCN1560482AReal-time adjustment of propulsion speedAdjust pressure in real timeServomotor componentsTunnelsMachine controlEarth surface

The invention discloses a shield development machine hydraulic advancing system with proportion flow pressure compound control. It includes two bits two-way electromagnetic ball valve, proportion adjusting valve, proportion overflow valve, and three-bit four-way electromagnetic change valve, hydraulic lock, balancing valve, pressure sensor and hydraulic oil cylinder with inner shift sensor. The advancing system uses the proportion adjusting valve to control the advancing speed, uses proportion overflow valve to control the advancing pressure, it realizes the compound control of advancing speed and pressure with proper control tactics. Because the invention uses the compound control technology of the proportion flow pressure, it can realize the control to the advancing speed and advancing pressure in the advancing process of the shield development in real-time, thus realizes the control to the soil barn pressure, stratum stability and the ground sedimentation. The system in the invention can be adapted to each kind of stratums, realizes the control to the posture and direction precisely, the energy-saving effect of the system is good.

Owner:ZHEJIANG UNIV

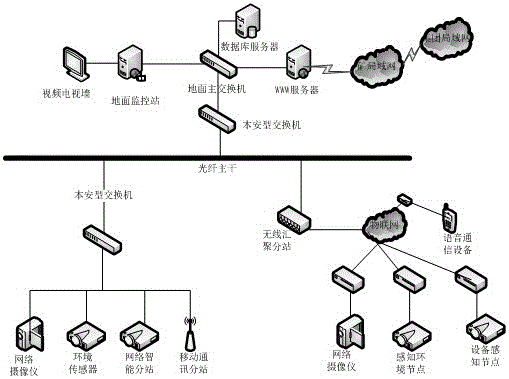

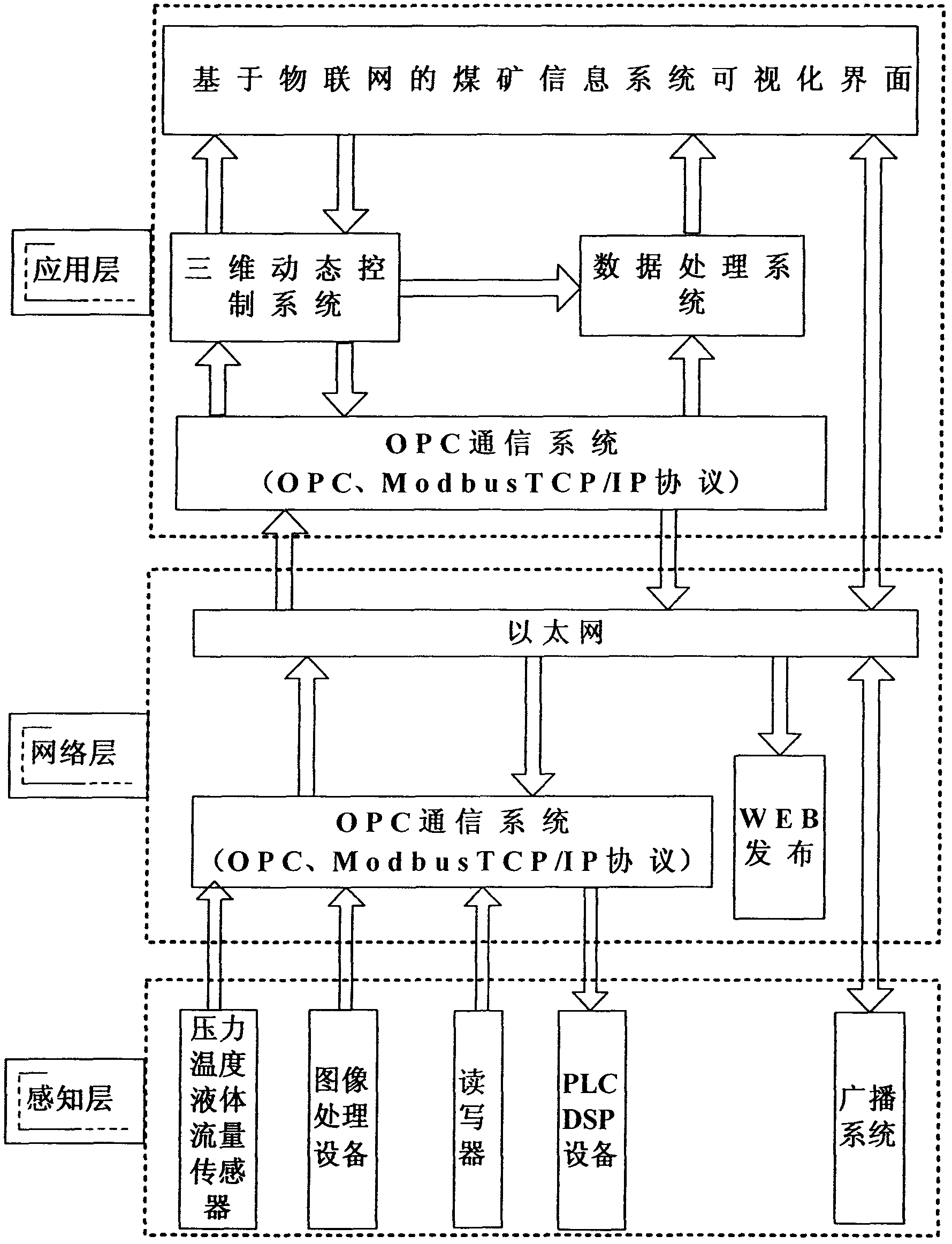

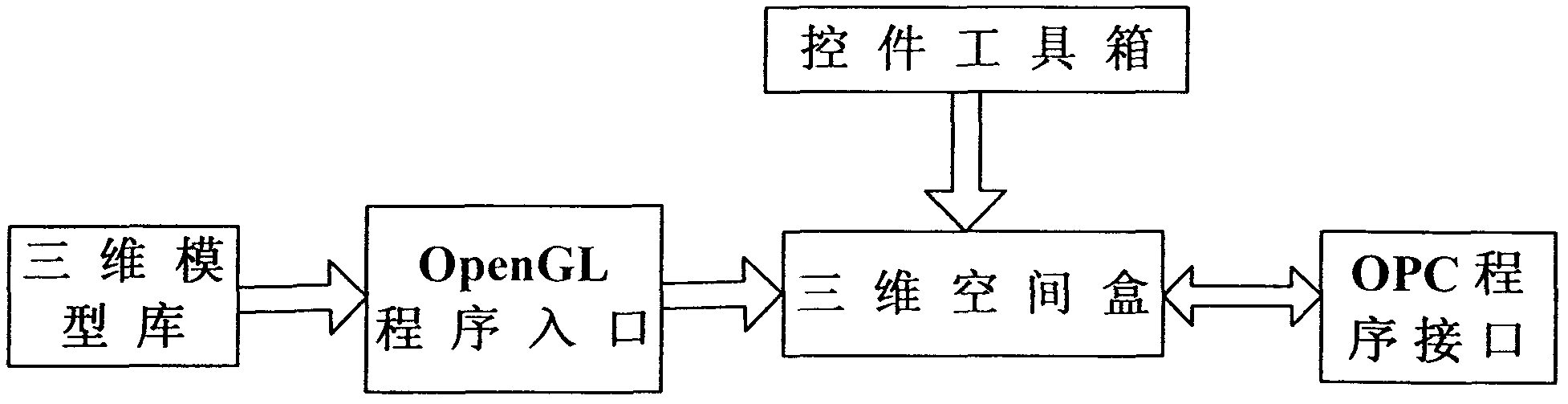

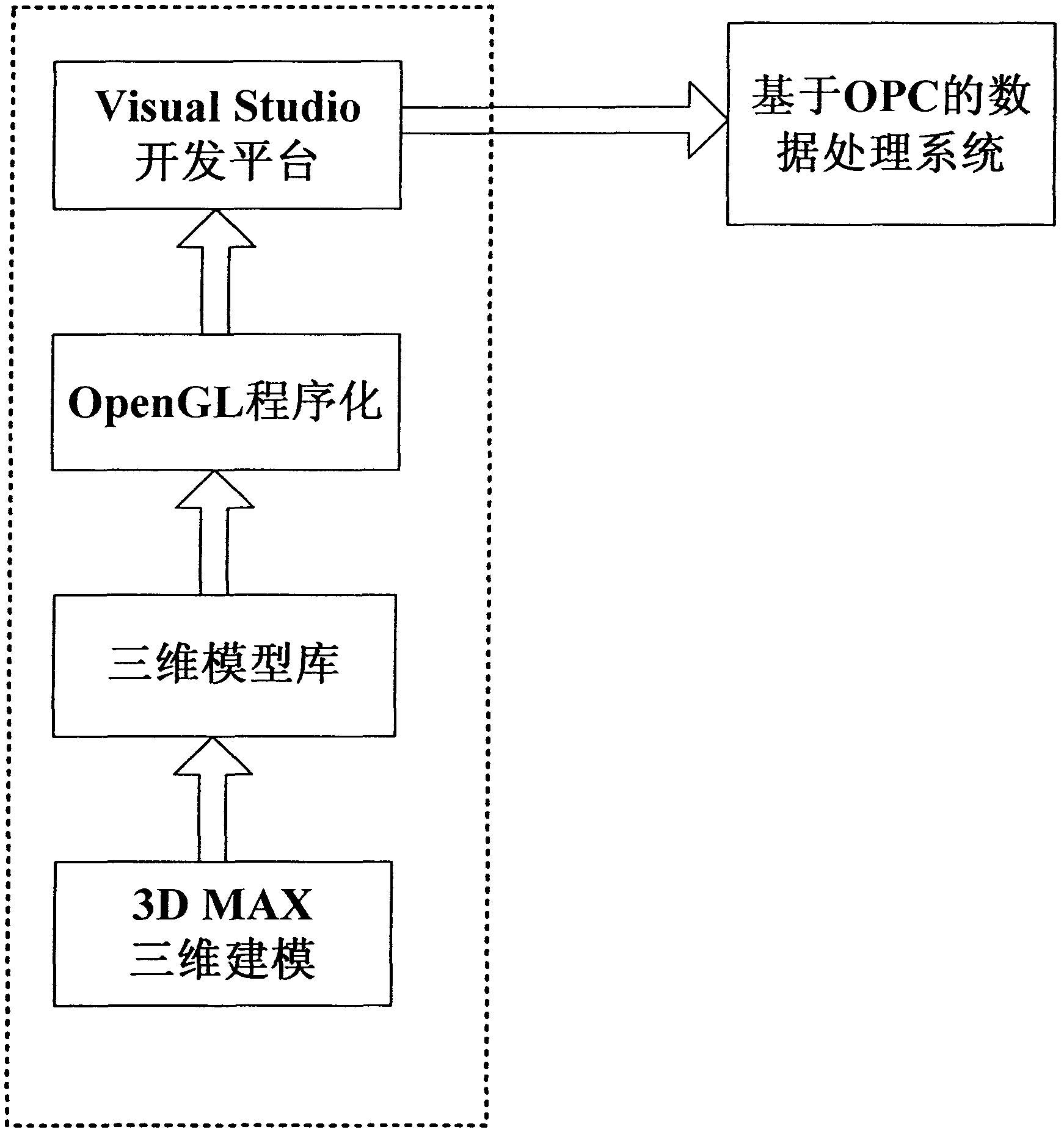

Coal mine production three-dimensional visualization information system based on Internet of things

InactiveCN102325177AChange transfer modeRealize one-stop managementData switching by path configurationThe InternetComputers technology

The invention provides a coal mine production three-dimensional visualization information system based on an Internet of things, belonging to the coal mine production safety integration information monitoring research field. According to the system, starting from an application layer of the Internet of things, through computer technology such as system integration, three-dimensional visualization and the like, the three-dimensional visualization information system is constructed. According to the coal mine production three-dimensional visualization information system based on the Internet of things, computer Internet and sensor technology are utilized to connect the real world with the Internet, integration of coal mine production safety and safety risk avoidance six systems and dynamic control of a three-dimensional image are realized, and one-stop management of a coal mine enterprise is realized. The system has the characteristics of clear structure, a friendly interface, and high easiness of operation. A coal mine tunnel, ground detection information, machine running, underground personnel activities can be subjected to three-dimensional displaying conveniently, data is subjected to situation analysis, accident early warning is provided for operation monitoring personnel, and personnel security and production efficiency of a coal mine are raised.

Owner:TAIYUAN UNIV OF TECH

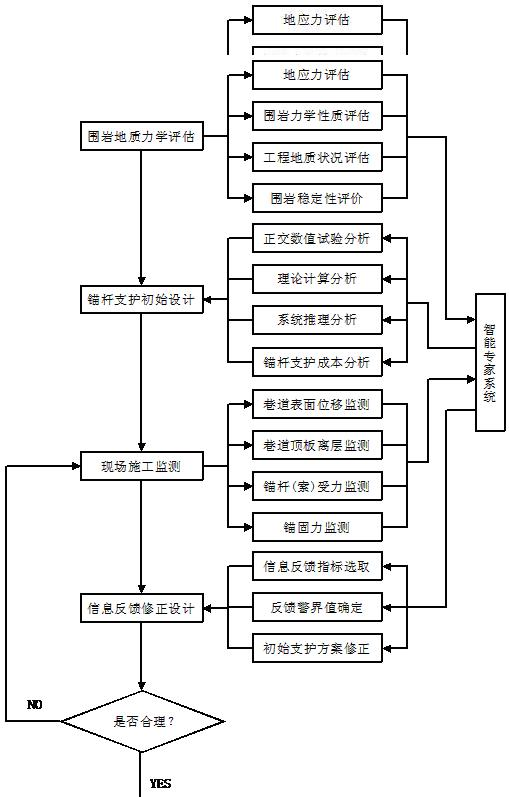

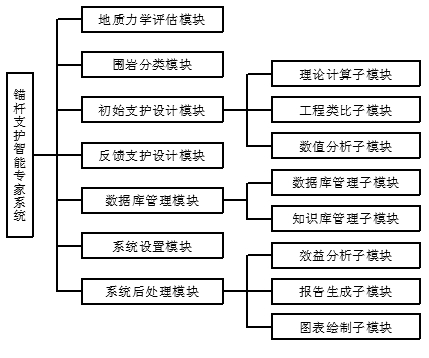

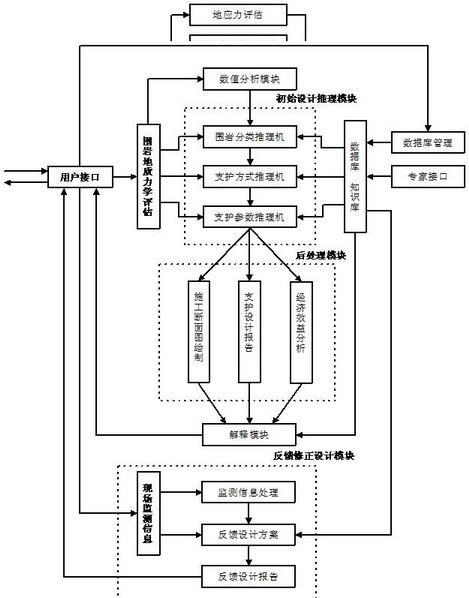

Method for intelligently designing bolting of coal mine tunnels

InactiveCN101968825ABenefit maximizationGuaranteed to be scientificSpecial data processing applicationsIntelligent designStress level

The invention discloses a method for intelligently designing the bolting of coal mine tunnels, which belongs to the method for designing the bolting of the coal mine tunnels. The design method comprises the following steps of: collecting the basic condition data of the tunnels, testing the physical and mechanical properties and ground stress level of surrounding rocks of the tunnels and establishing a bolting designing basic database; performing geomechanical estimation on the surrounding rocks by utilizing an intelligent expert system to obtain parameters required by the bolting design; establishing a bolting scheme and a parameter reasoning, computing and optimizing model by utilizing the intelligent expert system, and determining an initial design scheme; performing field construction and monitoring and feeding monitoring information back to the intelligent expert system; and judging the rationality of the initial design scheme by utilizing the intelligent expert system, performing necessary correction, and cyclically performing field construction, monitoring and verification on the corrected design until final design is formed. In the method, the problems of coal mine bolting material waste, poor tunnel safety and the like are solved, and orientation to the field engineering technical personnel can be achieved; and the method is widely practicable.

Owner:CHINA UNIV OF MINING & TECH

Even-grouting structure of coal mine tunnel and construction technology thereof

InactiveCN103195442AChange cohesionChanging the internal friction angleUnderground chambersTunnel liningSlurryRock bolt

The invention discloses an even-grouting structure of a coal mine tunnel and a construction technology thereof. The even-grouting structure of the coal mine tunnel comprises a lane, wherein a concrete spraying layer is arranged on the inner wall of the lane, a grouting anchor rod for filling reinforcing slurry into surrounding rock so as to form a reinforcing assembly arch on the outer side of the lane is arranged in the surrounding rock of the lane, the inner end of the grouting anchor rod is communicated with a crack in the surrounding rock of the lane, the outer end of the grouting anchor rod protrudes out of the concrete spraying layer, grouting anchor cables are further arranged at the top of the lane and in the surrounding rock on two sides of the lane, one end of each grouting anchor cable is anchored in the surrounding rock, and the other end of the grouting anchor cable is anchored on the outer side of the concrete spraying layer. Slurry is filled in cracks in the surrounding rock of the lane for reinforcing, the grouting is performed according to the softness and broken degree and the crack development degree of the rock, and repeated reinforcing and cementing are performed, so that cohesion and inner friction angles of the surrounding rock can be fundamentally changed, the surrounding rock in a broken rock zone of the lane can be in a relatively homogeneous and stable state, and the reinforcing assembly arch even in stress is formed on the outer side of the lane.

Owner:PINGDINGSHAN TIANAN COAL MINING

Sludge treatment method and sludge foaming lightweight concrete produced therefrom and use

InactiveCN101381191ASolve processing problemsNo pollutionSludge treatmentSolid waste managementFoaming agentFilling materials

The invention discloses a sludge treatment method, as well as sludge foamed lightweight concrete produced through the method and application thereof. In the method, sludge produced by sewage treatment first reacts with quicklime so as to form sludge hydrated lime; then the sludge hydrated lime is mixed with cement and water so as to form sludge concrete; foaming agent produces foam by utilizing a foaming system of a foaming machine; and the foam is mixed with the sludge concrete. The sludge treatment method can directly obtain the sludge foamed lightweight concrete. The sludge foamed lightweight concrete has a plurality of functions, which can be used as a filling material, a heat insulating material, a walling material, a sound insulation material, a mine tunnel filling material, an artificial landscape manufacturing material, a road recovery material, a pipe base filling material and the like. The sludge treatment method is low in cost and friendly to environment, can directly produce the sludge foamed lightweight concrete with a plurality of functions, and not only solves the sludge treatment problems in the sewage treatment industry, but also ensures the full utilization of the sludge.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

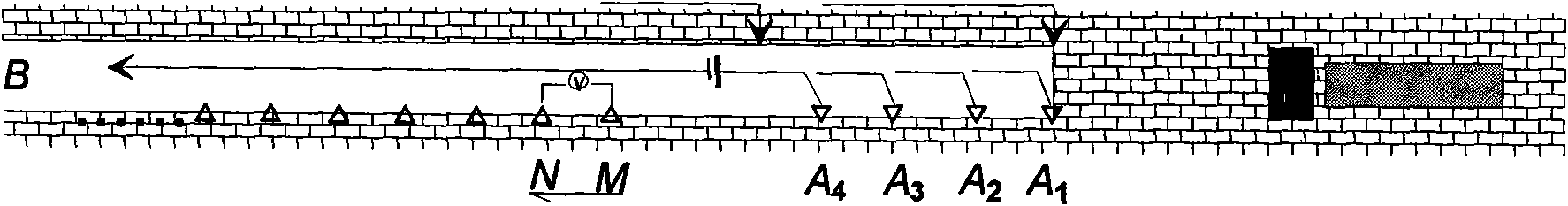

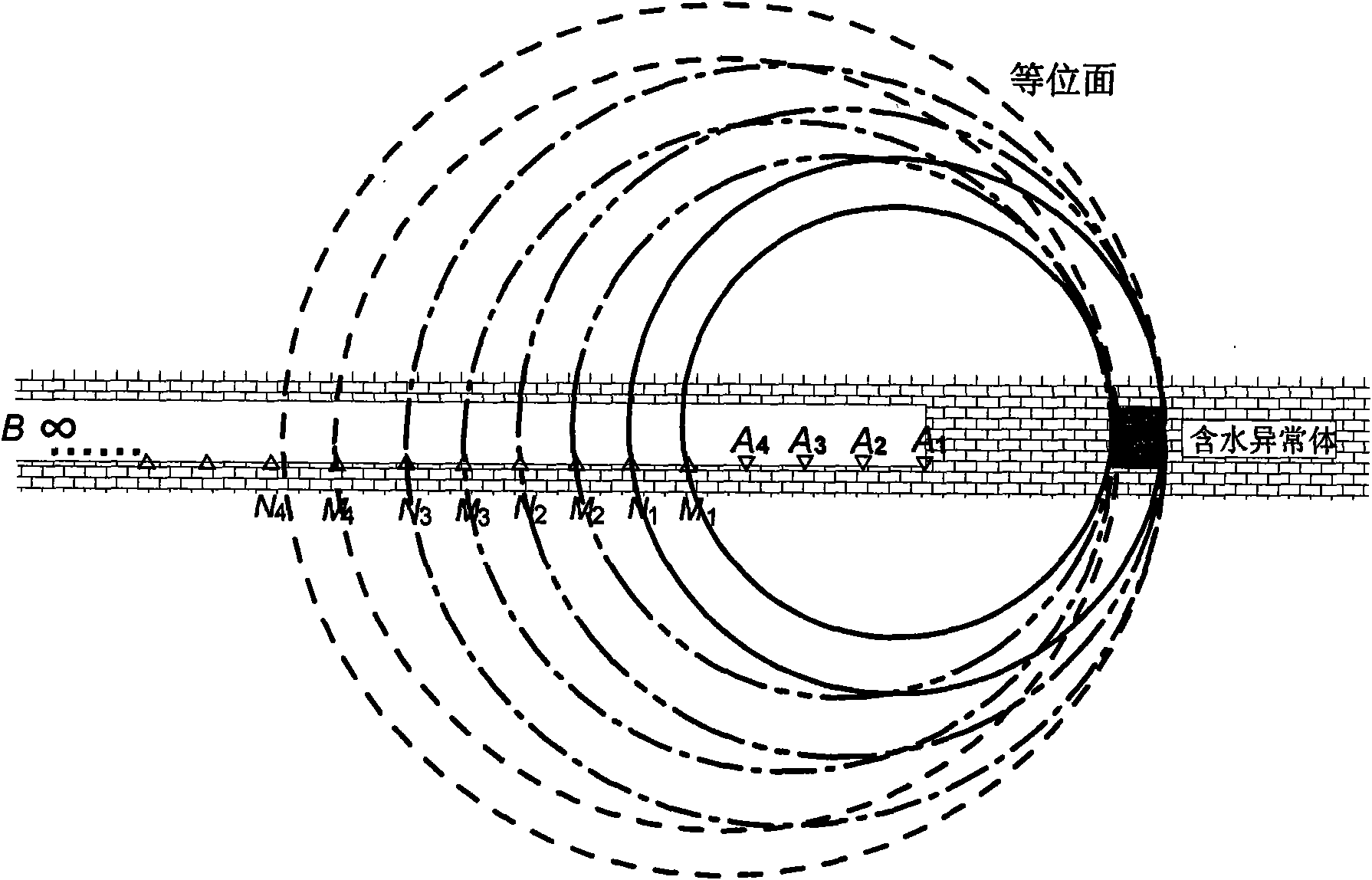

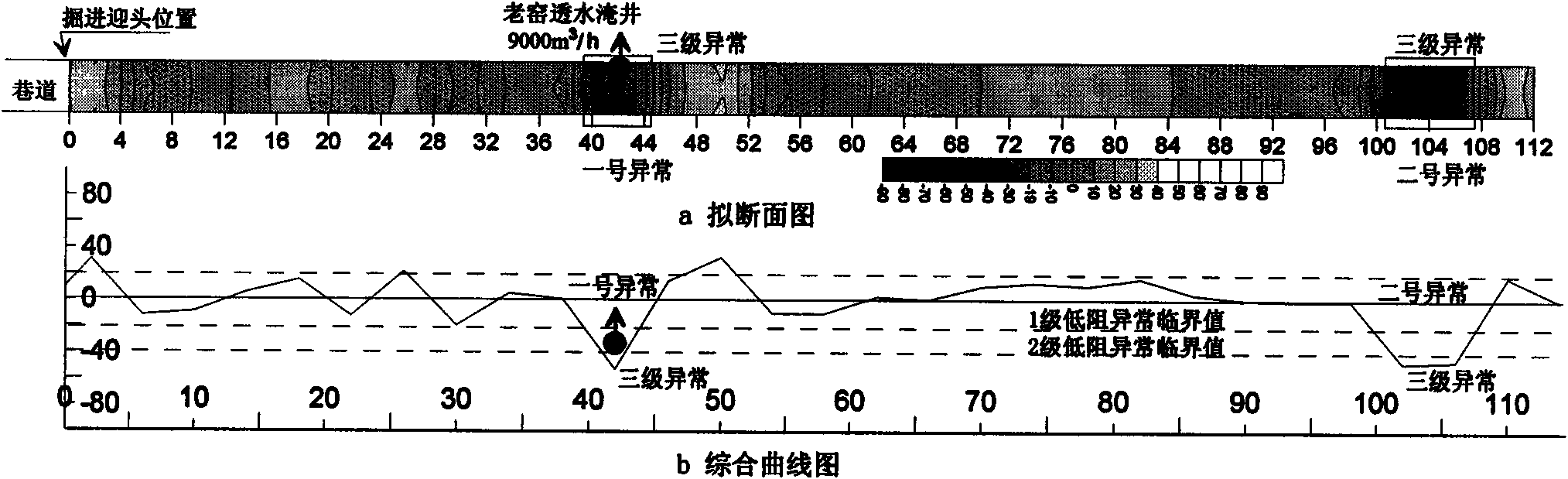

Direct current method for bed-parallel advanced detection of water bearing structure in mine tunnel

ActiveCN101603423AQuick detectionExplain quicklyElectric/magnetic detection for well-loggingWater resource assessmentProperty distributionElectric field

The invention discloses a direct current method for bed-parallel advanced detection of water bearing structure in mine tunnel. Common advanced detection technology comprises a seismic reflection wave method, a Rayleigh wave method and the like, but with the extensive application of a fully-mechanized roadheader, the above methods are harder to adapt to the present production task requirements. The method of the invention is as follows: a mine direct current method seven-electrode series detecting device is used to arrange four current-emitting electrodes of A1, A2, A3 and A4 which are arranged on one straight line near a mine tunnel heading end, and the four current-emitting electrodes respectively form a loop with another current-emitting electrode B arranged at infinity to supply direct current under the ground, so that a direct current field is built; meanwhile, two electrodes M and N with relatively fixed distance behind the tunnel are used for measuring the distribution rule of the electric field; after treatment with special mating interpreting technology, electrical property distribution information in a geologic body 0-140m ahead a drifting tunnel or a tunnel is obtained. The invention has the advantages of small workload, high speed, small possibility of influence by personal factors, high objectivity and high accuracy, and belongs to a non-destructive detection method.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Visual physical simulation test system for coal and gas outburst power caused disaster

ActiveCN107290343AOutstanding explosion venting functionClearly reflect the real migration formMaterial analysis by optical meansPilot systemData acquisition

The invention discloses a visual physical simulation test system for coal and gas outburst power caused disaster. A simulation tunnel pipeline is arranged on the rear side of a simulation test platform; three rows of crossing pipe joints are arranged on the simulation test platform; two adjacent crossing pipe joints in the same row are connected through a longitudinal square straight pipe; two adjacent crossing pipe joints in the same line are connected through a horizontal square straight pipe; a high definition camera is arranged at the top of each crossing pipe joint; axial measuring sections are arranged at the two ends of each square straight pipe; lateral pressure measuring sections are arranged on the middle parts of the square straight pipes; three pressure sensors, three temperature sensors and two concentration sensors are arranged on the axial measuring sections; three lateral pressure sensors are arranged on the lateral pressure measuring sections. The visual physical simulation test system can practically simulate the mine tunnel network, can comprehensively collect data and can utilize the collected data to deeply research a disaster-causing mechanism of coal-gas two-phase flows. The visualization degree is sufficient and the practical movement form of the coal-gas two-phase flows can be clearly reflected.

Owner:CHONGQING UNIV

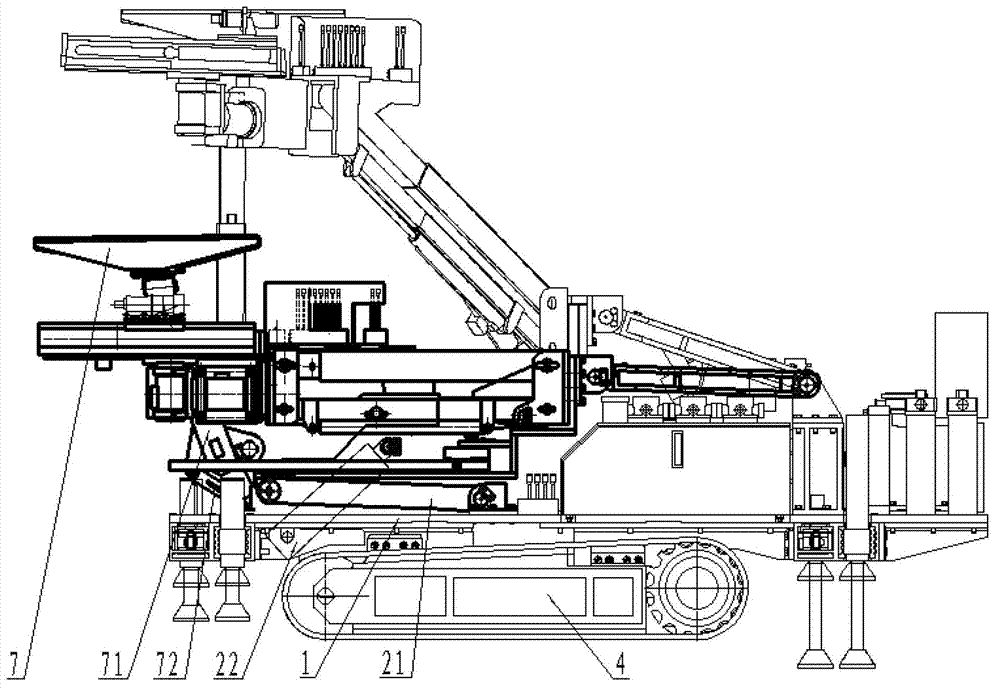

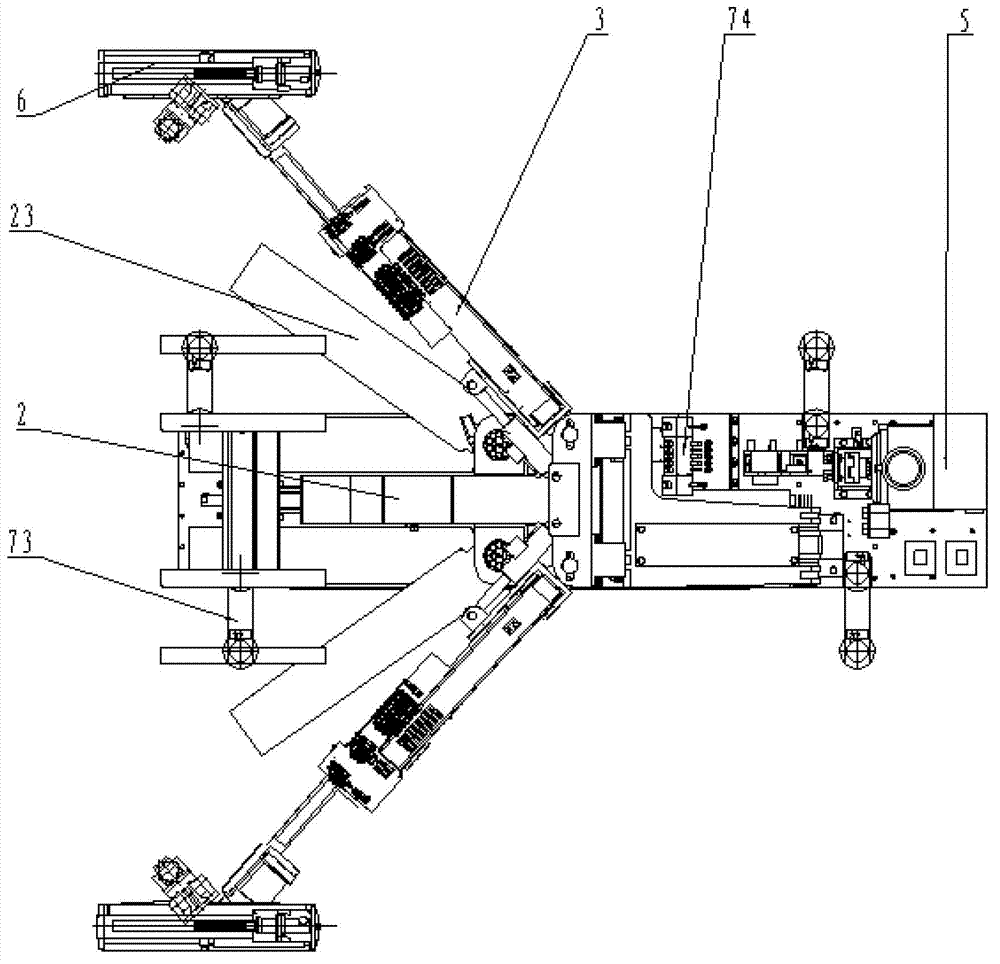

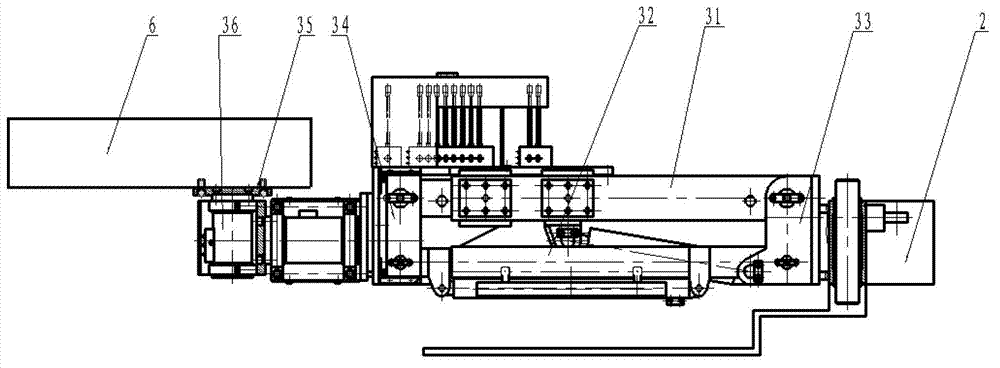

Narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for coal mine tunnel

InactiveCN102900362AMechanizationIncrease the level of mechanized supportAnchoring boltsCutting machinesEngineeringRock bolt

The invention relates to a narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for a coal mine tunnel. The narrow-machine-body full-hydraulic bolt and anchor cable drill carriage comprises a machine body part, a lifting platform, a drill boom mechanism, crawler-type walking mechanisms and an electric cabinet, wherein the lifting platform is arranged at the machine body part through a foldable connecting rod and a lifting oil cylinder; the drill boom mechanism is arranged on the lifting platform through a feeding mechanism; the crawler-type walking mechanisms are arranged on two sides of the machine body part; and the electric cabinet is used for controlling the lifting oil cylinder and the crawler-type walking mechanisms. According to the narrow-machine-body full-hydraulic bolt and anchor cable drill carriage disclosed by the invention, the support of an anchor rod is completely mechanized, the support efficiency and the support quality of the bolt and anchor cable are greatly improved, the standardization degree is improved, the better stabilizing action is realized and the reliable use of the drill carriage and the safe operation of operators are fully ensured.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

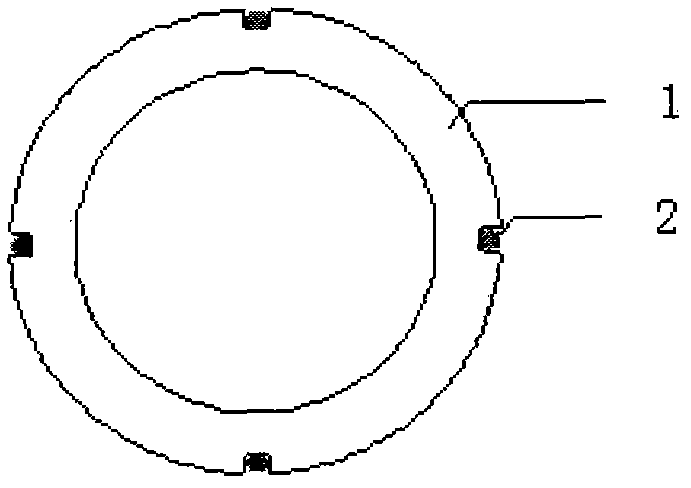

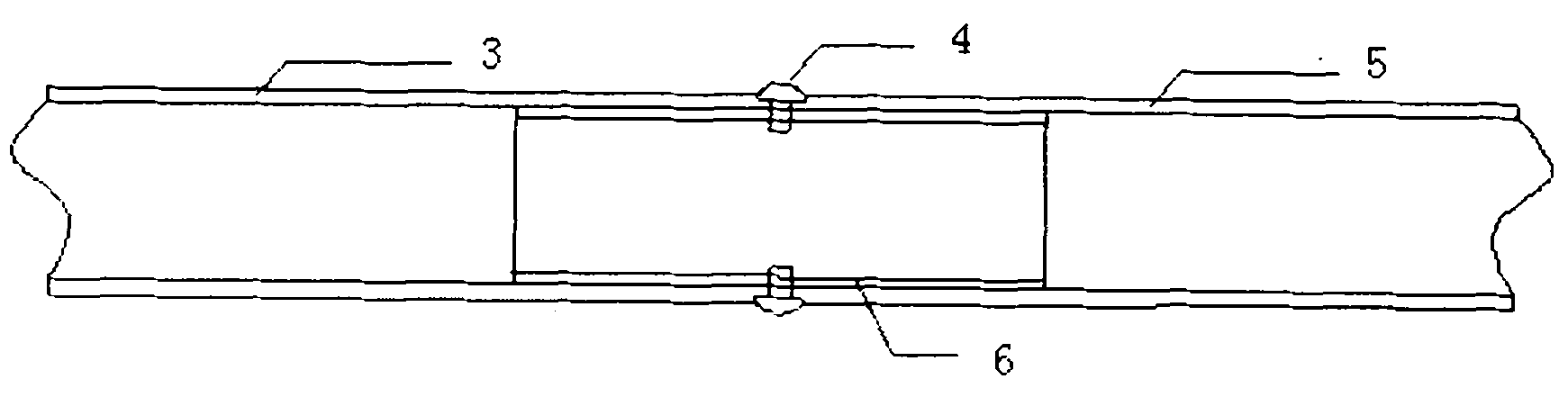

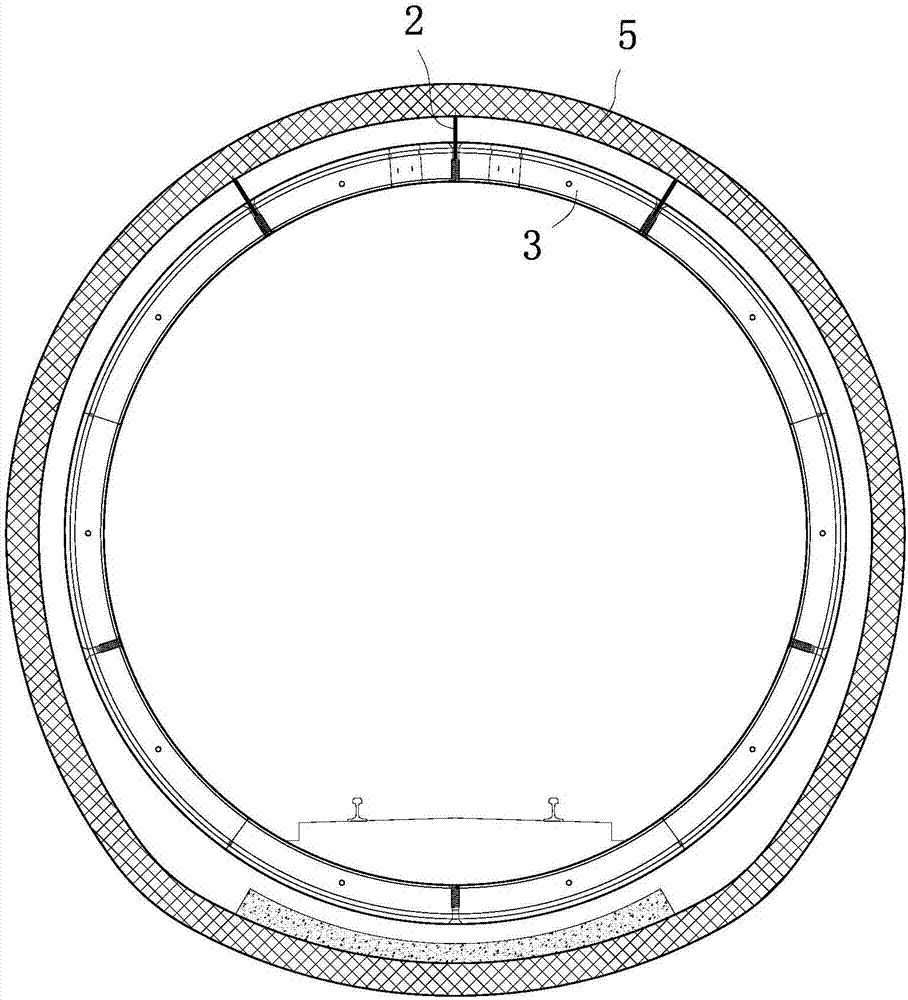

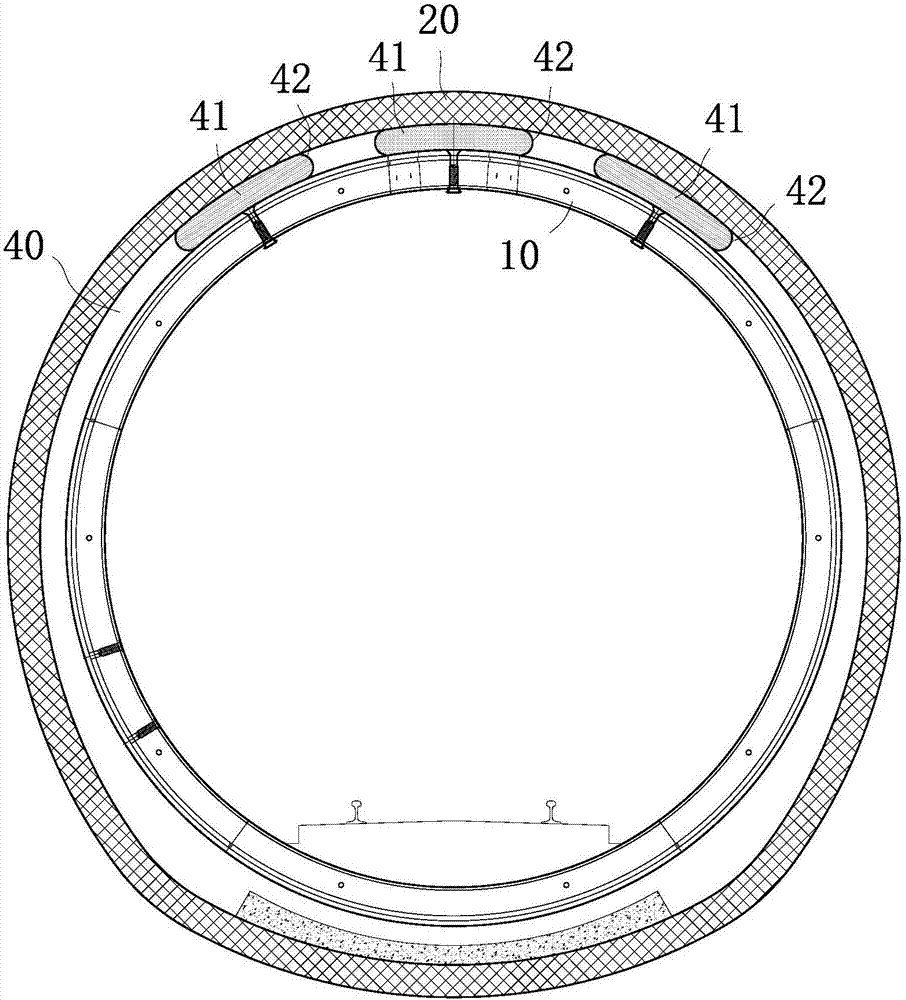

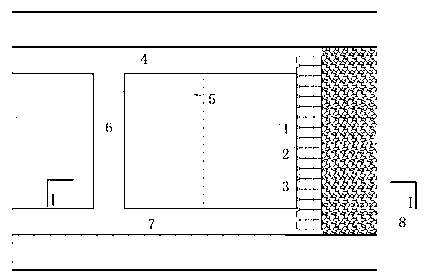

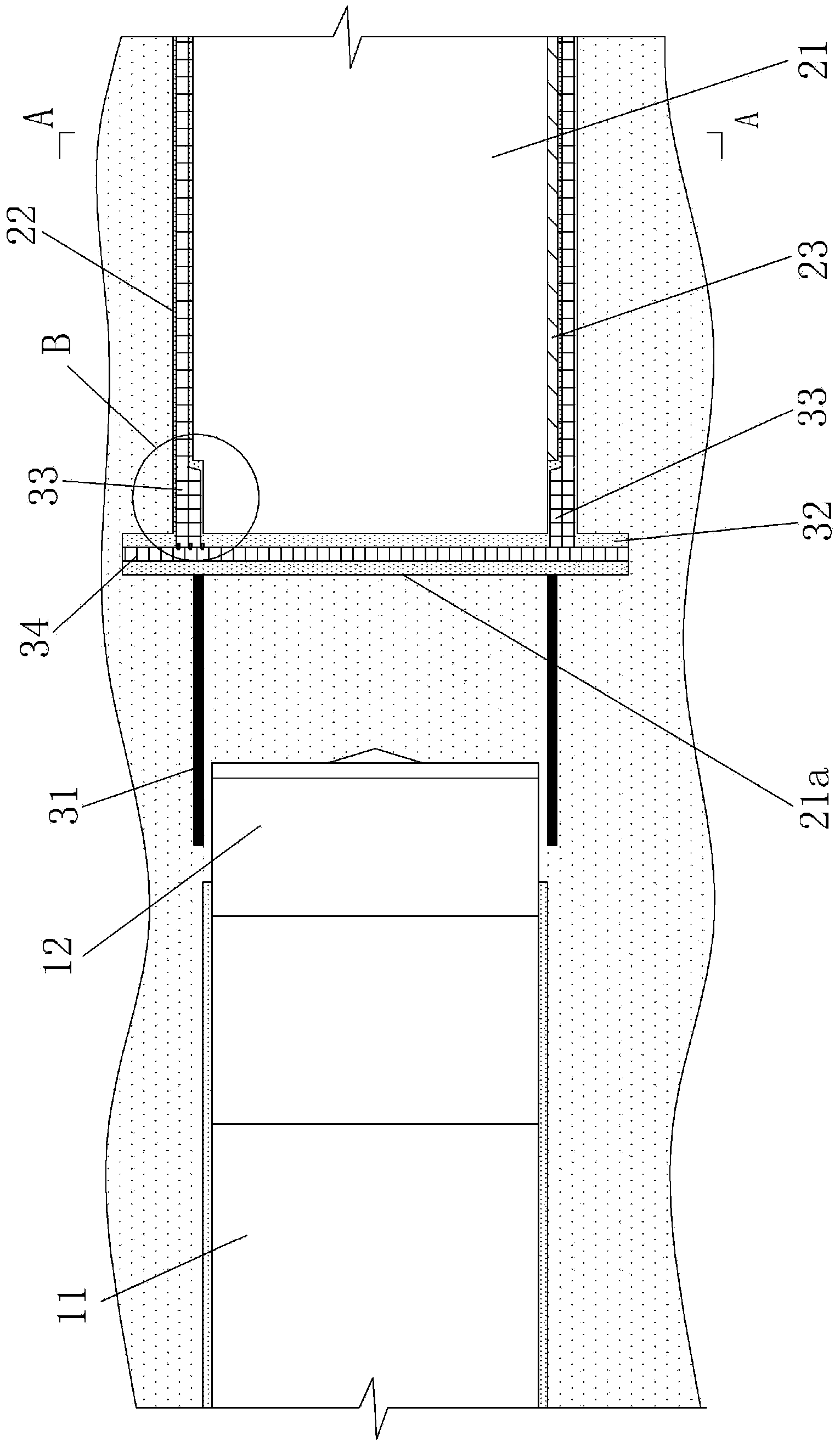

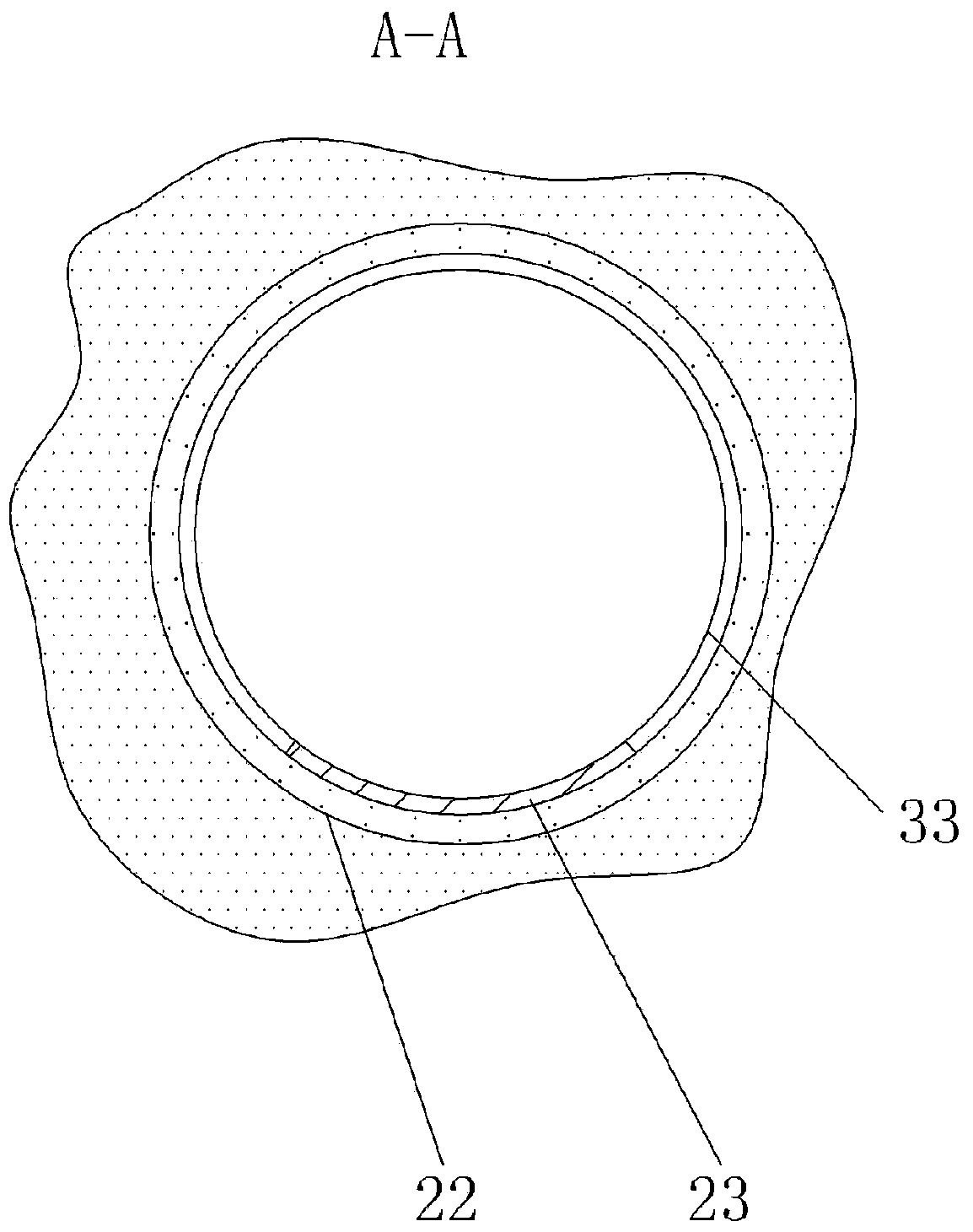

Duct piece floating resisting structure capable of passing through mine tunnel through shield empty pushing and construction method

PendingCN107130979AAvoid crackingAvoid deformationUnderground chambersTunnel liningStress concentrationCement slurry

The invention discloses a duct piece floating resisting structure capable of passing through a mine tunnel through shield empty pushing and a construction method. The duct piece floating resisting structure comprises a grouting bag body arranged between a mine tunnel primary lining and a shield duct piece, wherein the open end of the grouting bag body extends out of a grouting hole of the shield duct piece; a dual-liquid grouting duct member with threads can be screwed into the grouting hole of the shield duct piece; cement slurry and water glass are simultaneously injected into the grouting bag body through the dual-liquid grouting duct member; a cloth bag can restrain a range of formation of a floating resisting structural body, so that the block-shaped floating resisting structural body which has certain intensity and with which a gap between the mine tunnel primary lining and the shield duct piece is filled can be effectively formed; the gap between the mine tunnel primary lining and the shield duct piece is filled with the floating resisting structural body in a block-shaped surface contact manner, so that cracking and deformation of the duct piece due to local stress concentration can be effectively prevented; meanwhile, three floating resisting structural bodies which are arranged in a spacing manner at the upper part of the shield duct piece are relatively large in range, so that a tunnel can be well wrapped and tightened, and displacement and deformation of the shield duct piece are completely limited.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

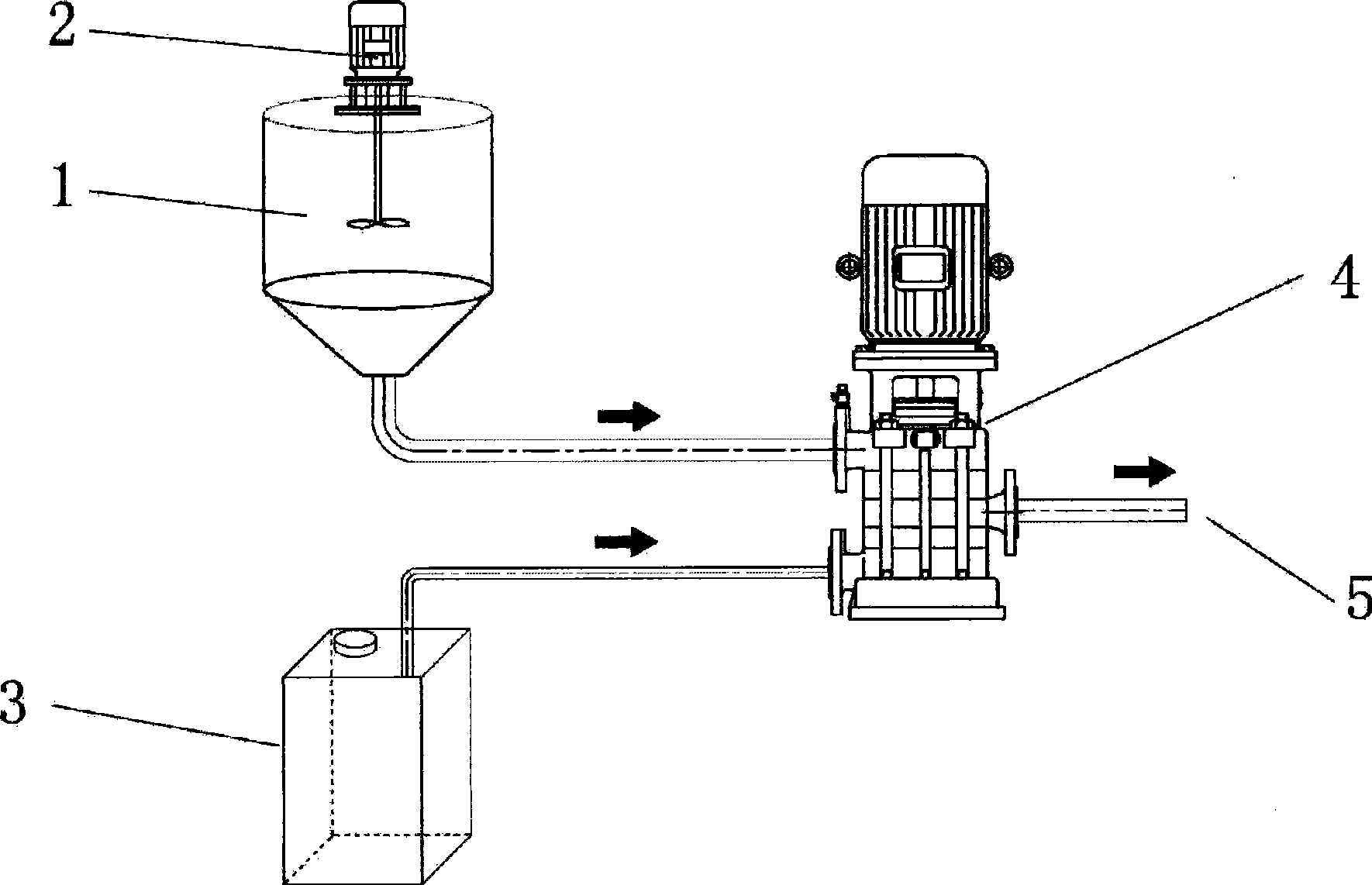

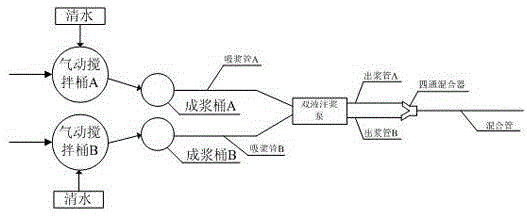

Coal mine tunnel broken surrounding rock layering grouting technology and method

InactiveCN104594914AReduce grouting costsGood grouting effectUnderground chambersTunnel liningViscosityCoal

The invention discloses a coal mine tunnel broken surrounding rock layering grouting technology and method. Novel double-fluid inorganic grouting materials are adopted, and the method is matched with a novel grouting hole sealing device to achieve drilling layering grouting. The method comprises the steps that grouting drilling is constructed at first, the dual-layer grouting hole sealing device is adopted for hole sealing, then, grouting materials with the low water cement ratio, high viscosity and high condensation speed are adopted to be used in cooperation with the low-pressure and low-flow grouting technology, an outer layer grouting pipe is utilized for conducting grouting on a surrounding rock shallow layer broken zone to form an effective grouting stopping layer, then, the water cement ratio of the grouting materials is improved gradually, the material permeability characteristics are improved, the material curing time is prolonged, the grouting pressure is gradually improved, and an inner layer grouting pipe is utilized for completing surrounding rock deep layer grouting. The method adapts to surrounding rock failure and permeability characteristic zoned characteristics, the grout leakage problem is effectively solved, and layering grouting in the same drilled hole is achieved.

Owner:HENAN POLYTECHNIC UNIV +1

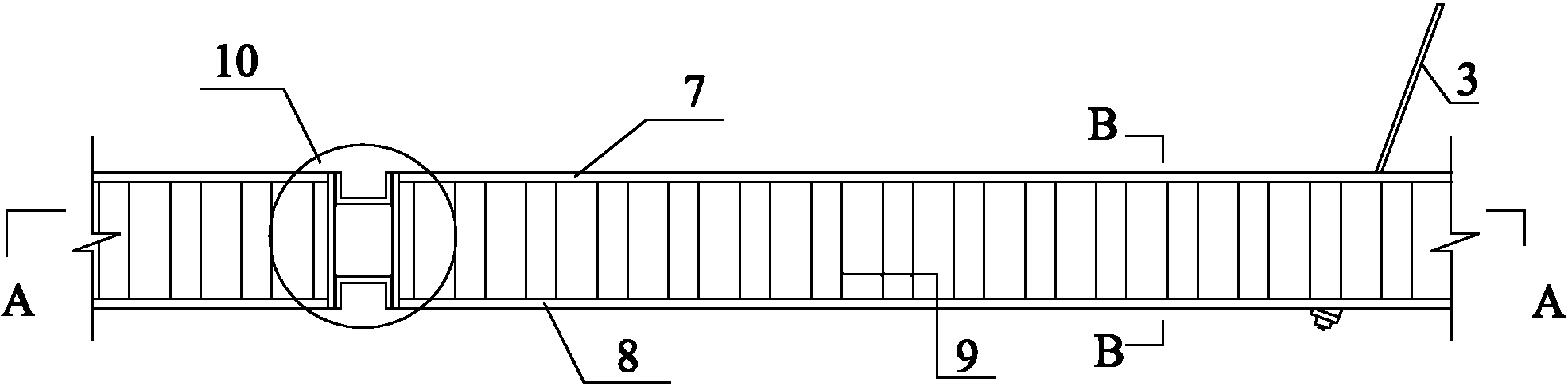

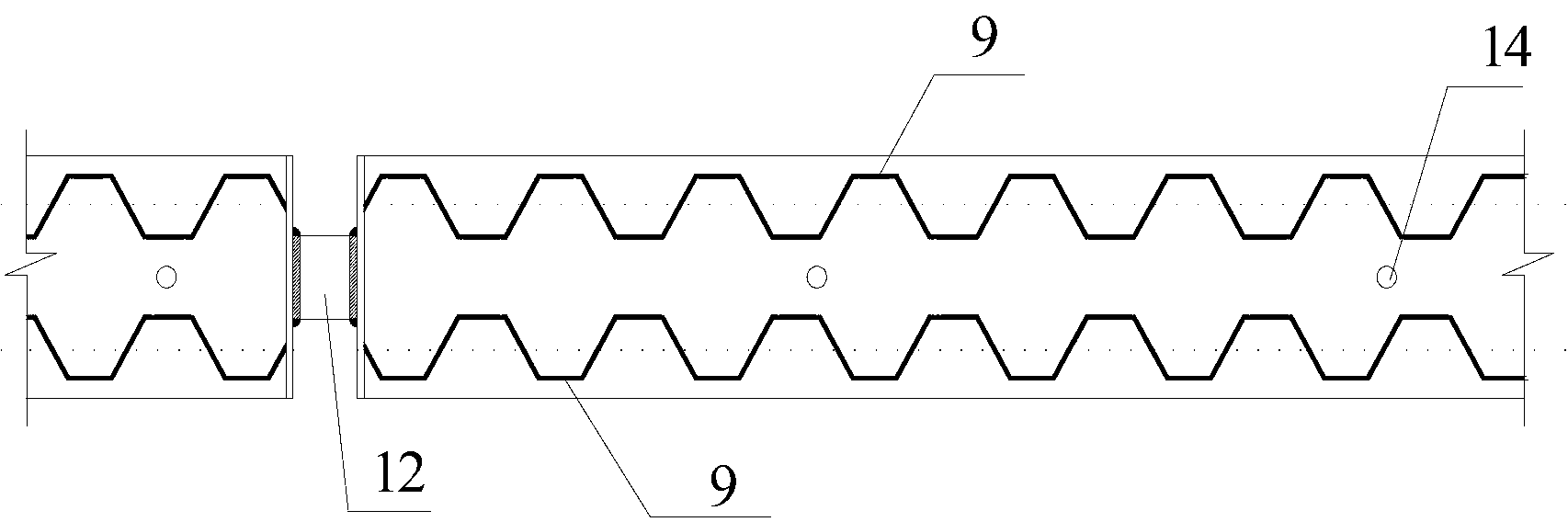

Loose broken tunnel top plate reinforcing and supporting method

InactiveCN103061788AImprove performancePrevent shear deformationUnderground chambersTunnel liningPre stressEconomic benefits

The invention discloses a loose broken tunnel top plate reinforcing and supporting method, and belongs to mine tunnel supporting methods. The method includes: spraying concrete on the surface of a loose broken tunnel top plate, adopting anchor bolt supporting and hollow anchor pipe grouting to support top plate surrounding rock, laying a steel fabric piece, and respraying concrete on a leveling layer; laying a flexible cushion layer appressed with the leveling layer, and reserving deformation amount between the flexible cushion layer and the leveling layer; and paving an anchor-tensioning support on the top plate. The anchor-tensioning support is composed of a pre-stressed anchor rope and multi-sections of corrugated steel web box-shaped beams, elastic connecting parts are adopted to connect adjacent sections, the anchor bolt / anchor rope penetrates through a reserved anchor hole anchoring rock layer on a pull rod, the whole anchor rope is pasted and applied with prestress, and the anchor-tensioning support is arranged parallelly along the direction of a tunnel. By the method, problems that the broken top plate is sunk greatly and supporting of conventional mining I-steel pull rods and flat steel box-shaped pull rods is quite prone to damages are solved, so that stability and safety of top plate supporting are effectively guaranteed, and economic benefit is evident.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

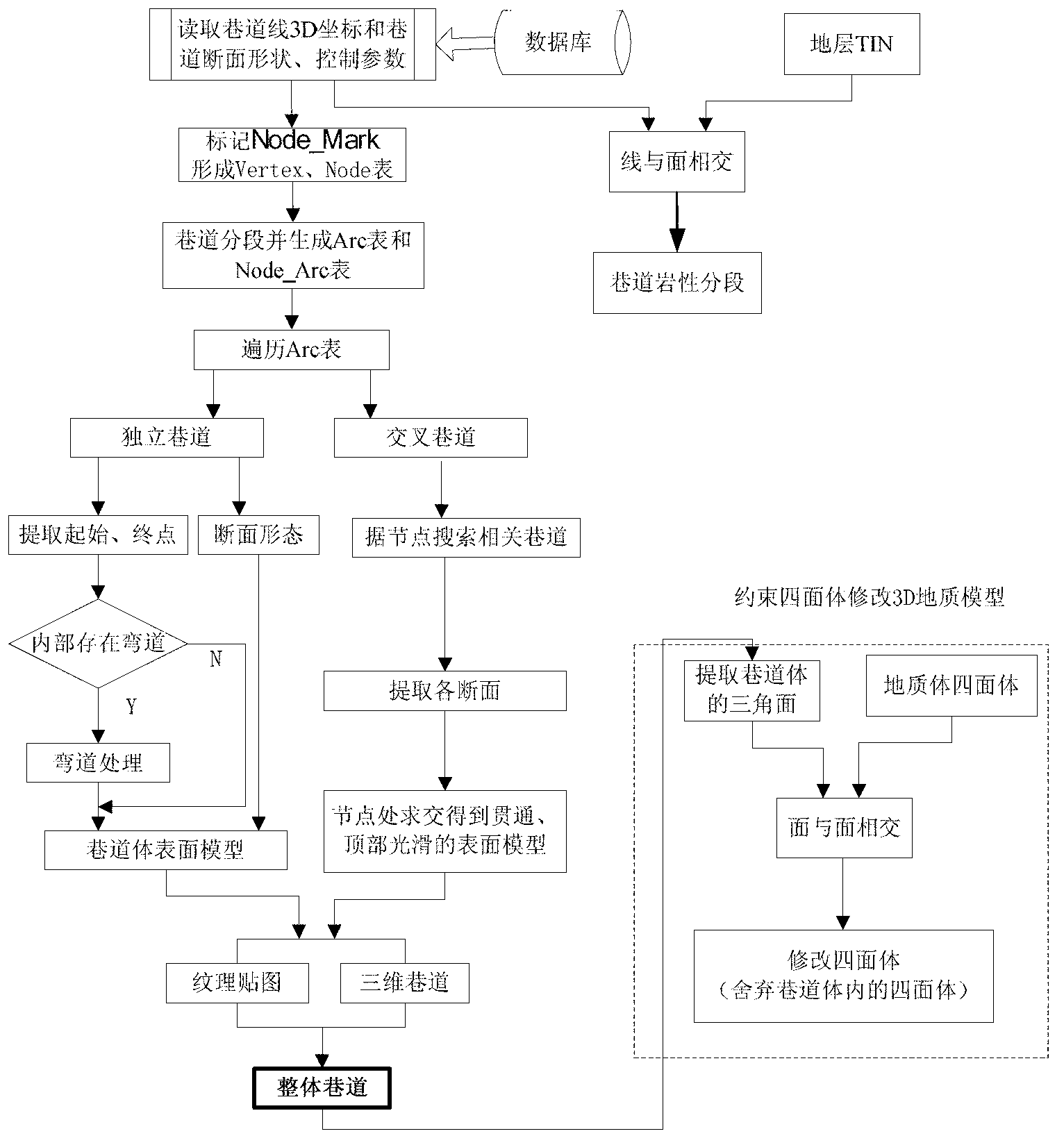

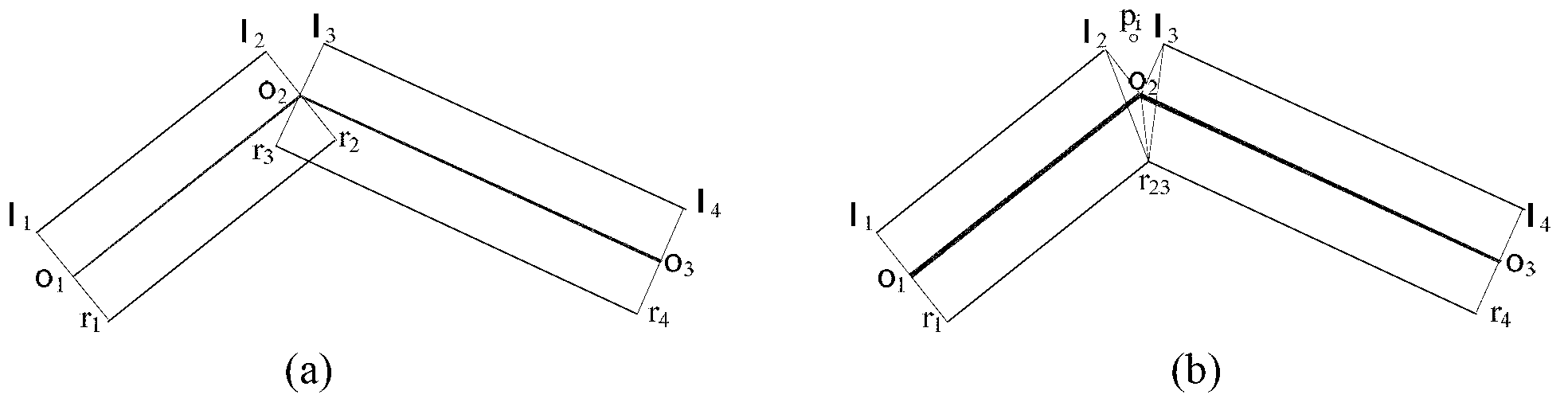

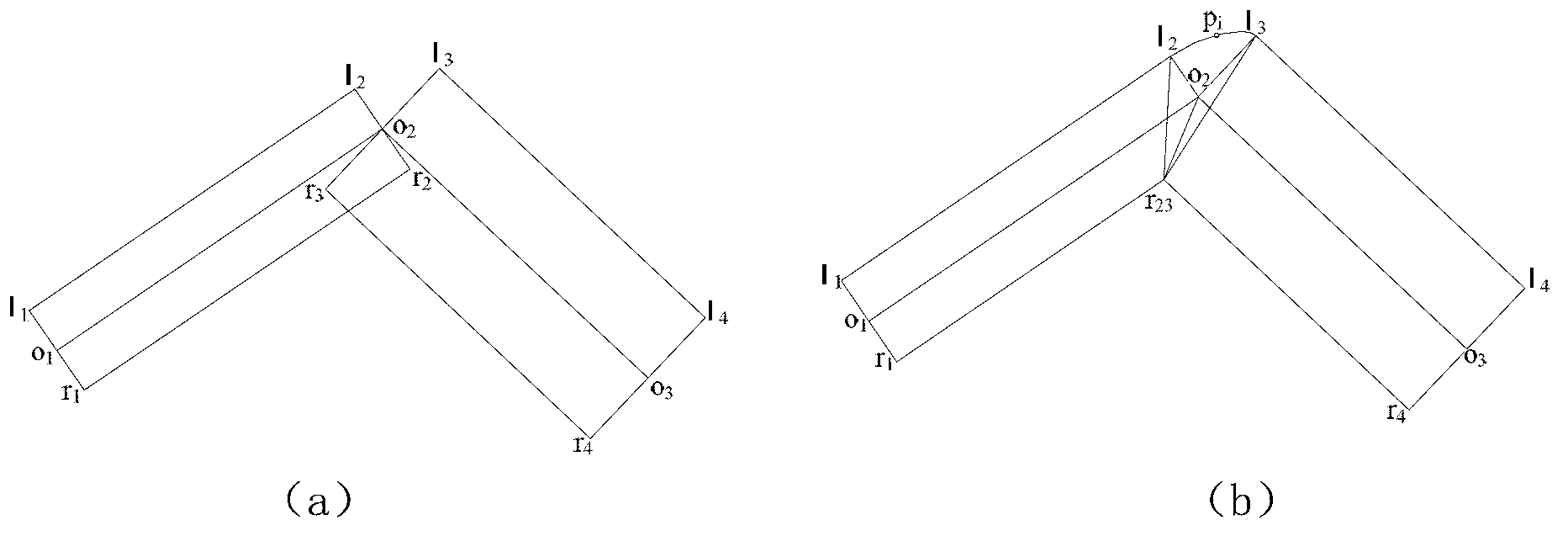

Three-dimensional geological tunnel modeling method based on spatial data structure system

InactiveCN103226844ASolve spatial form modeling problemsSolve the penetration problem3D modellingNODALSpatial structure

The invention discloses a three-dimensional geological tunnel modeling method based on a spatial data structure system. The method mainly comprises the following steps of: measuring the three-dimensional coordinate value of points on a top central line of the mine tunnel and the section shape parameter of the mine tunnel; reading the acquired three-dimensional coordinate values (namely vertex three-dimensional coordinate values) of points on the top central line of the tunnel from a database, to obtain the relation between the nodes and segmental arcs of the crossed tunnels according to the vertex three-dimensional coordinate values of multiple tunnels; calculating the feature point coordinate value of a three-dimensional surface model of a tunnel body according to the tunnel section shape parameter and the relation between the nodes and the segmental arcs and by using the top-bottom central line of the tunnel as a benchmark; and constructing the surface triangulation networks of the tunnel body according to the feature point coordinate value of the three-dimensional surface model of the tunnel body so as to establish the three-dimensional surface model of the whole tunnel body. By providing the 'section-node-segmental arc' spatial data structure, the effects that the curve of the tunnel is smooth and the crossed tunnels are through are achieved.

Owner:北京建筑工程学院

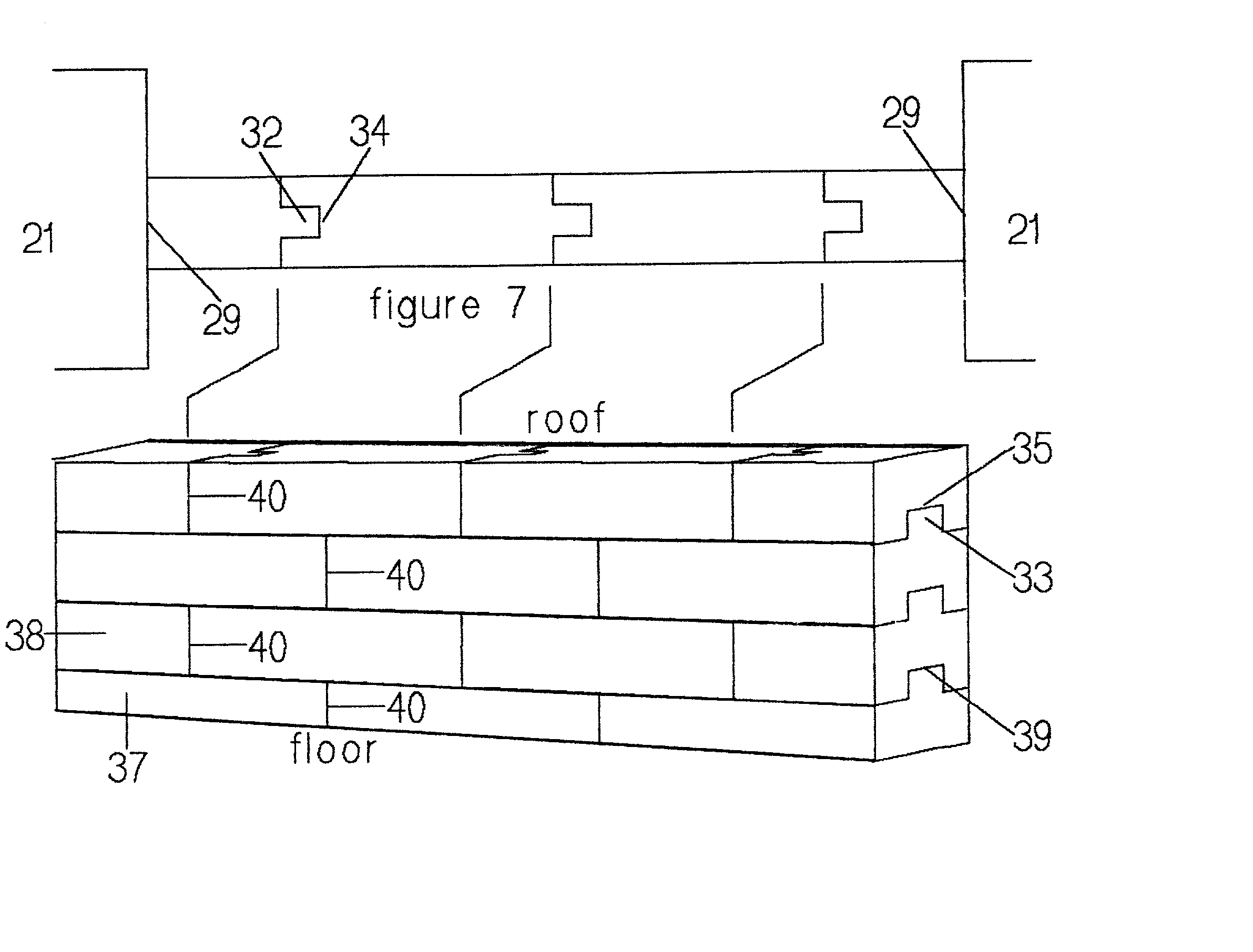

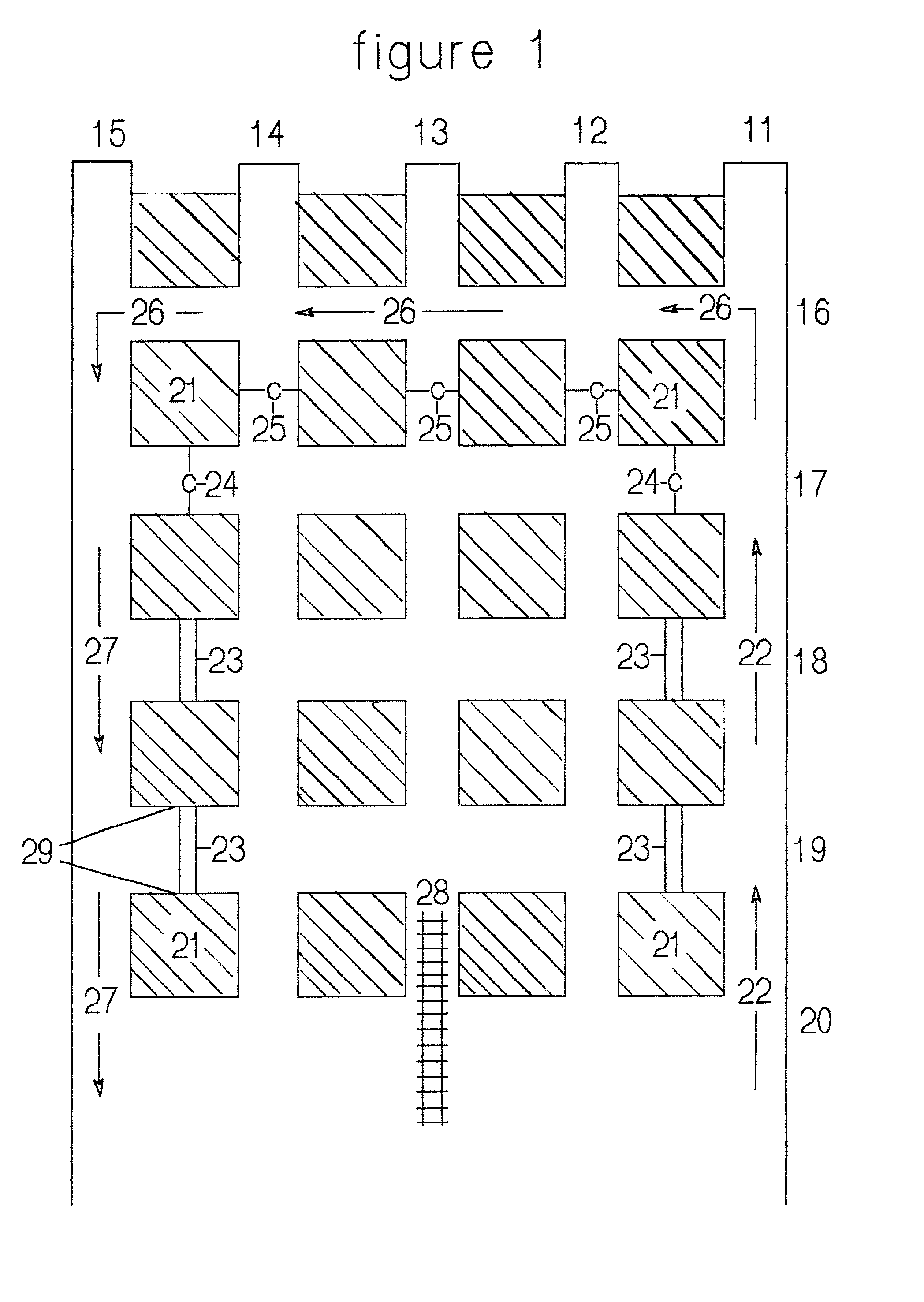

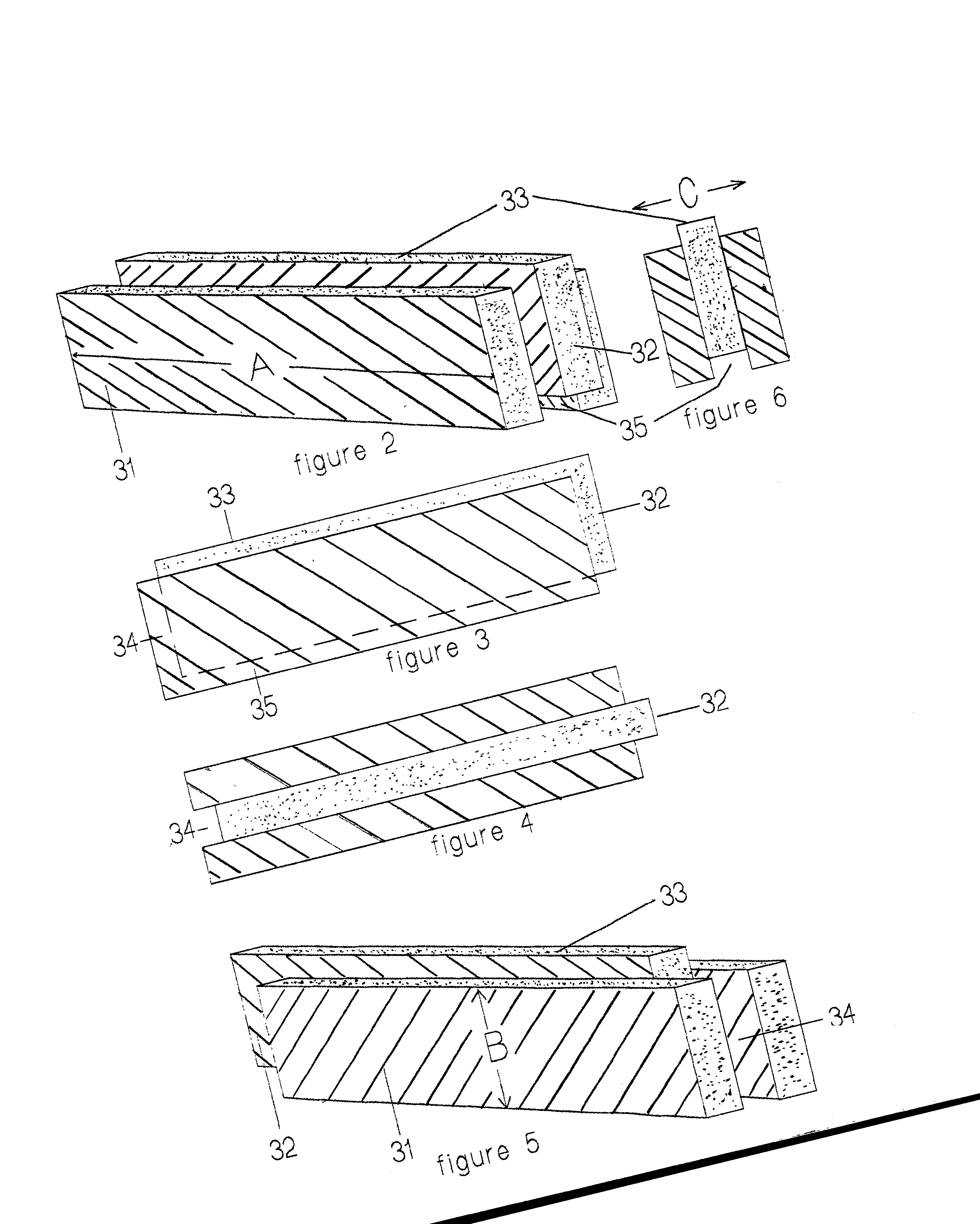

Foam blocks for construction of mine tunnel stoppings

InactiveUS20020021042A1Underground chambersUnderground miningArchitectural engineeringTongue and groove

A light weight foam block being substantially rectangular in shape, having horizontal and vertical pairs of tongues and grooves around its perimeter enabling it to interlock with horizontally and vertically adjacent blocks to construct a mine stopping wall.

Owner:DAMRON DANNY RAY

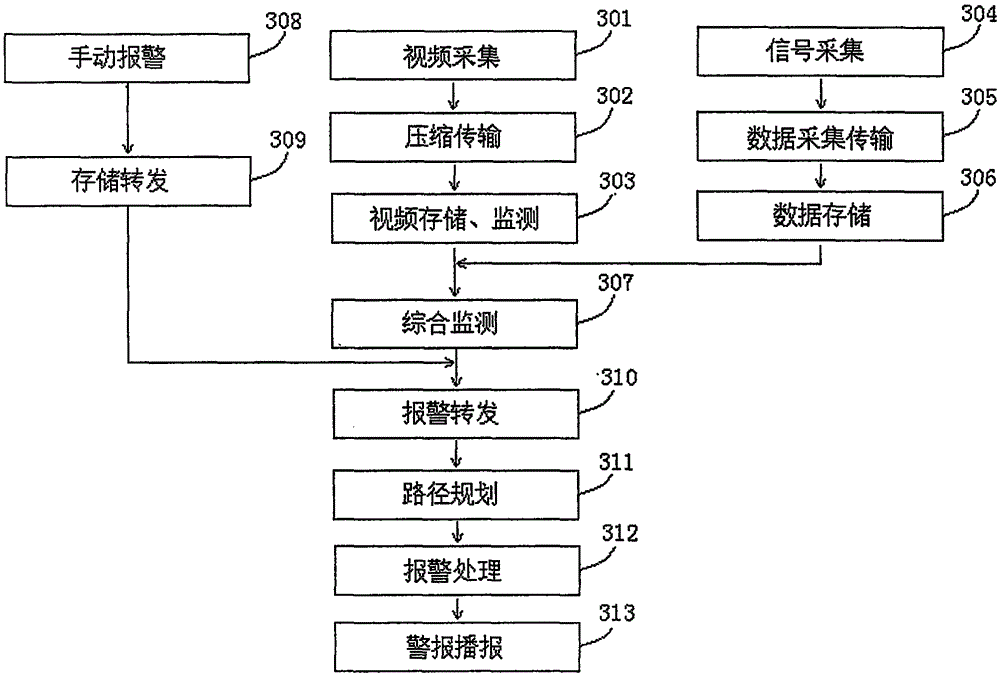

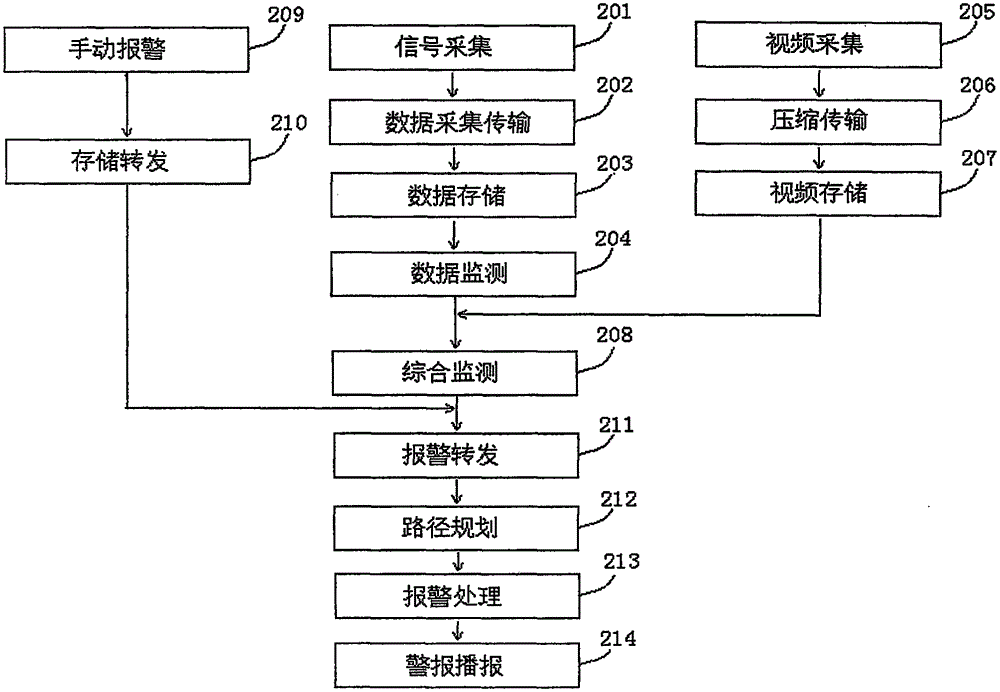

Underground flood alarm method based on image and water sump monitoring

The invention discloses an underground flood alarm method based on image and water sump monitoring. The alarm method includes the steps that cameras are placed on an underground coal mine tunneling working face, a coal working face or other operation faces possibly having a water inrush accident, and a water sump liquid level monitoring device and a water discharge monitoring device are placed in a downstream water sump of a drainage channel of a roadway monitored by each camera; when it is monitored that abnormal water flow appears in a set region in video images of the cameras, moreover, the duration time of the water flow exceeds a set time threshold value or water flow increasing speed exceeds a set threshold value, and meanwhile water intake quantity of the corresponding water sump is abnormal, a flood alarm signal is sent out. The alarm method fully considers the characteristic of a coal mine coal working face flood and is easy to implement, corresponding measures are taken automatically in time, an alarm can be given for water inrush of a coal mine accurately at first time, and valuable rescue and escape time is bought for underground staff, not at the flood site, in other regions.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

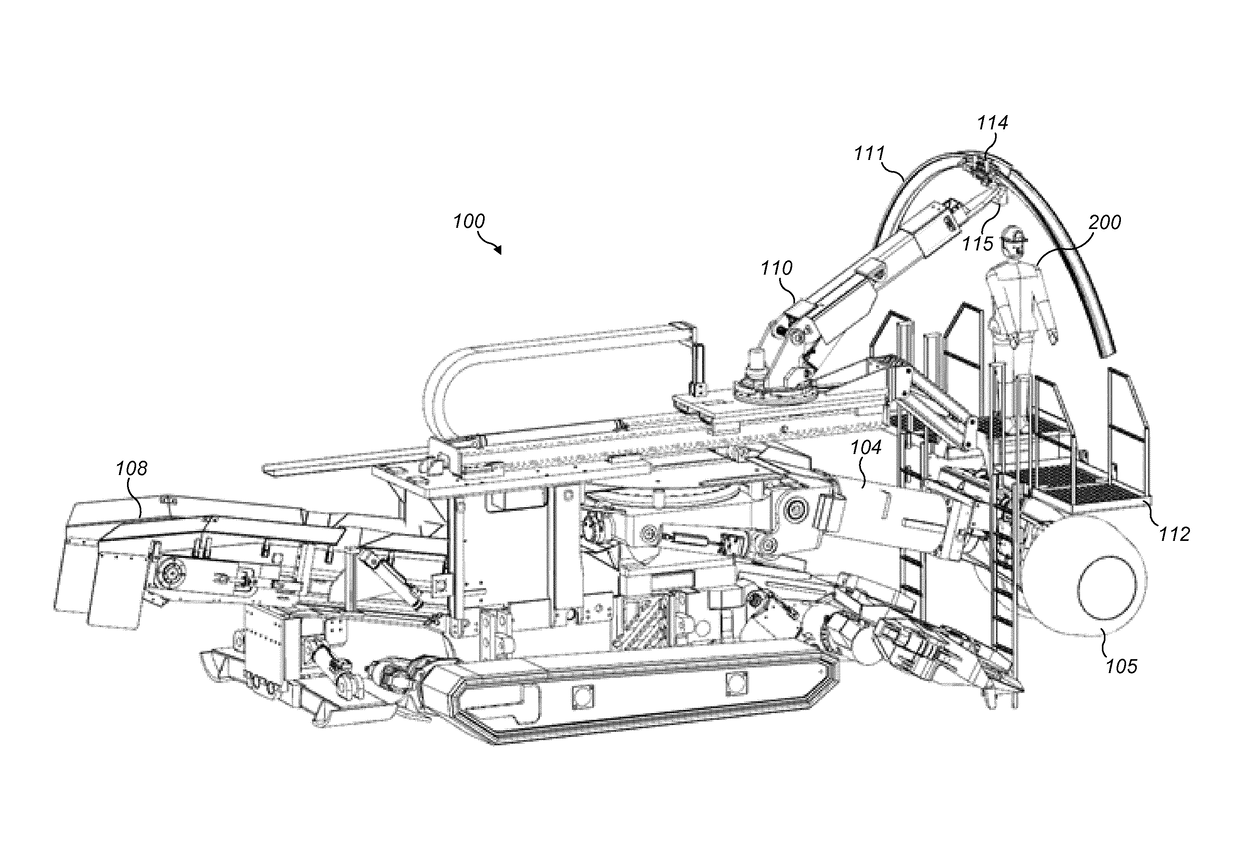

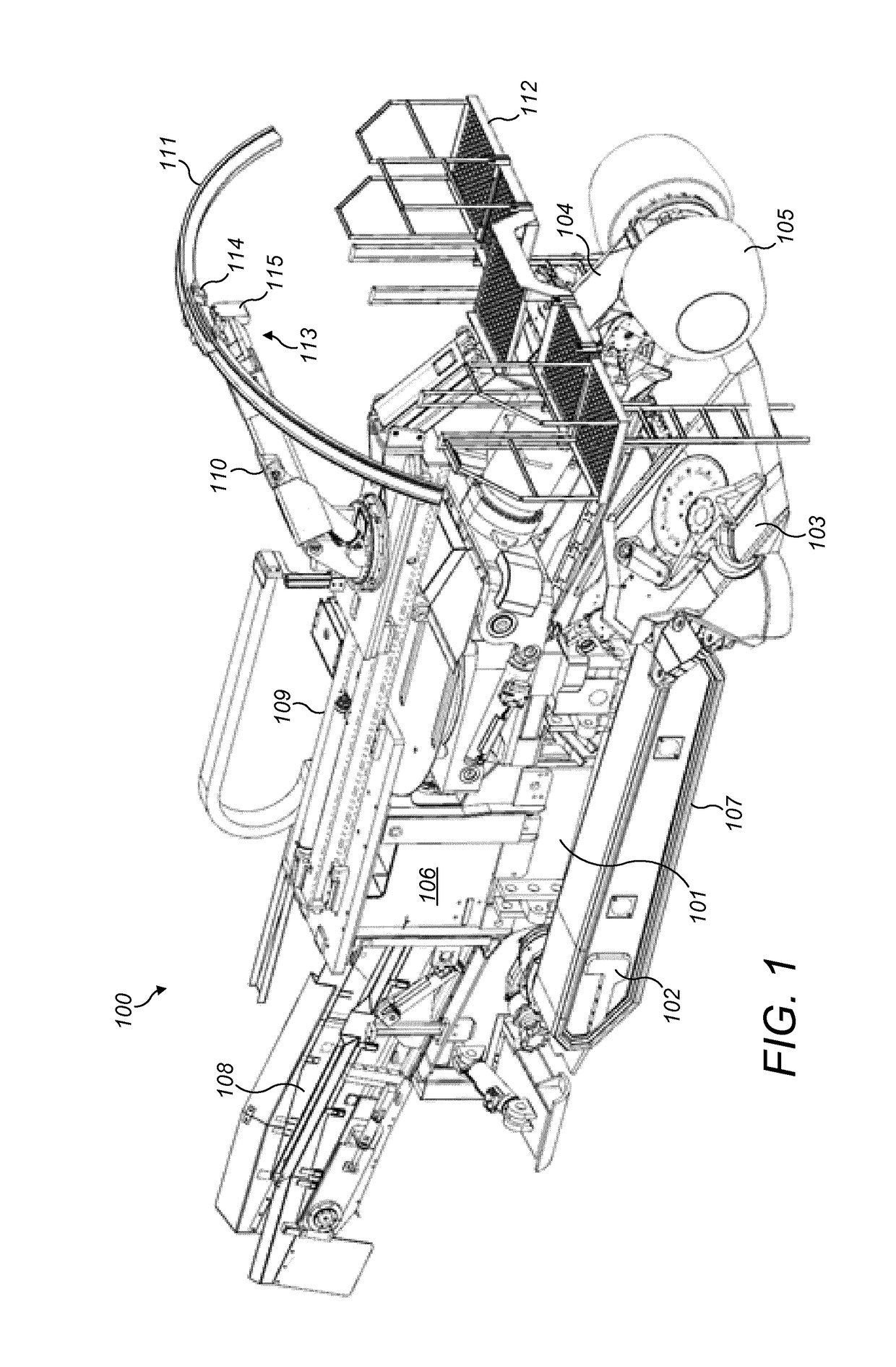

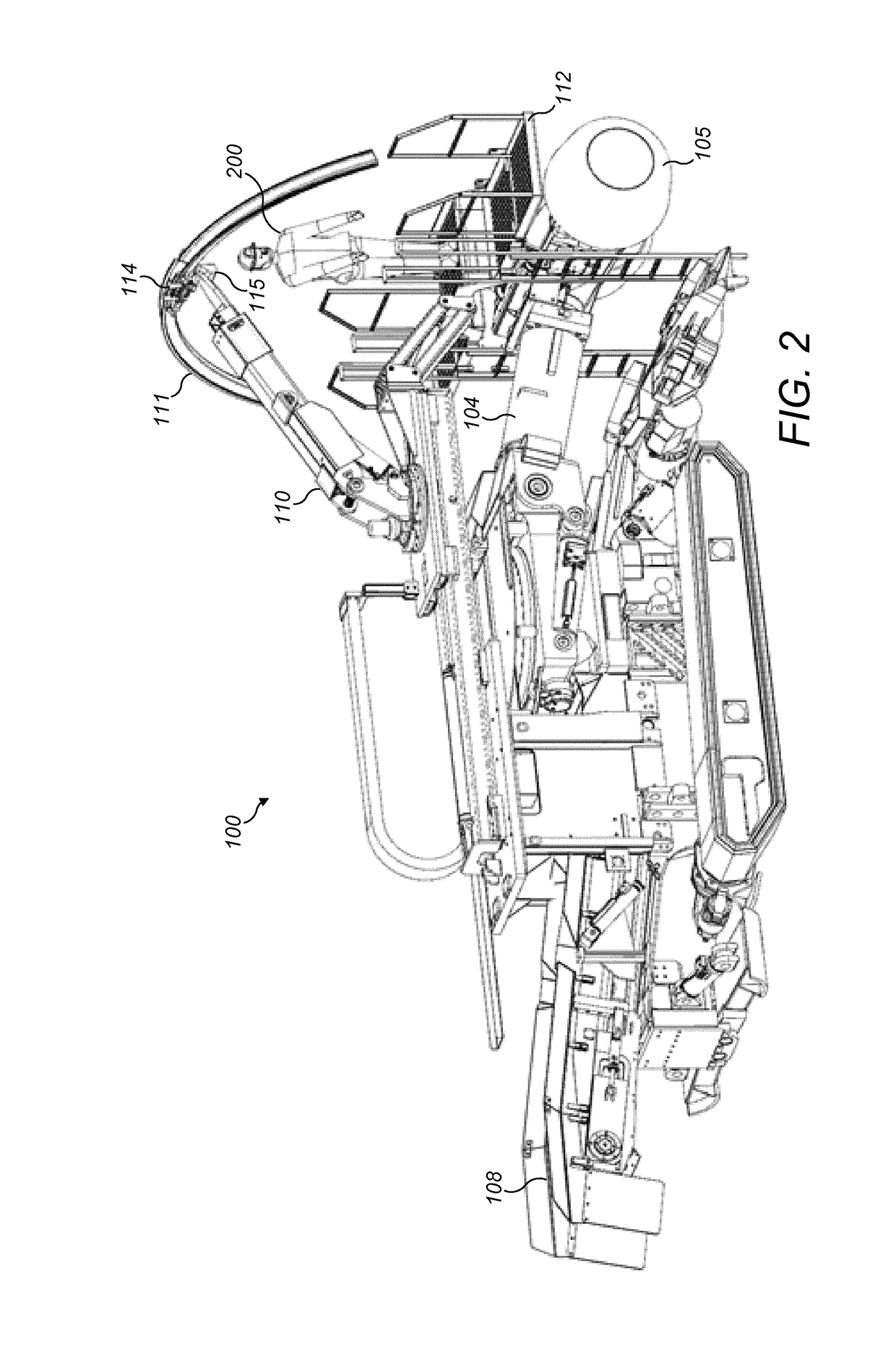

Tunnel support installation apparatus

InactiveUS20170152745A1Reduce weightExtended range of motionUnderground chambersSlitting machinesEngineeringManipulator

An apparatus to install structural supports in a mine tunnel is conveniently mountable on a mining machine having a cutting head mounted at one end of a boom. An extendable and slewing manipulator arm of the apparatus is mounted on a support platform that is slidable in the axial forward and rearward direction and includes a grasping device to hold the structural supports in a plurality of different positions.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

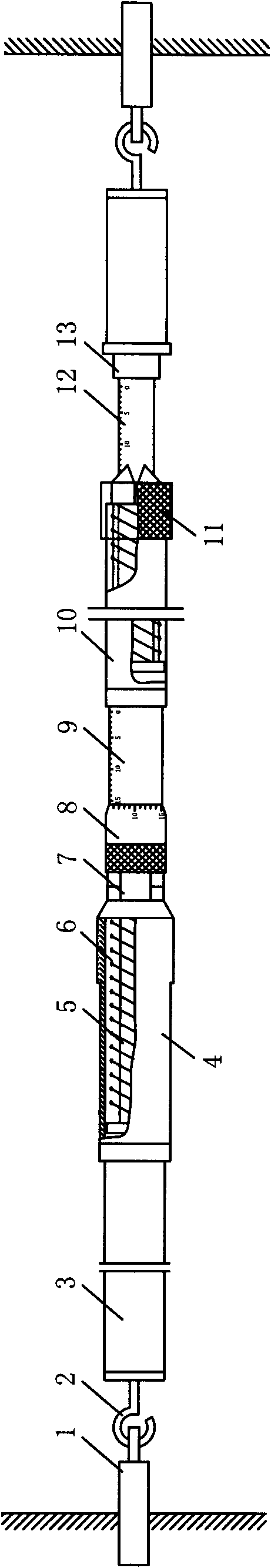

Precision rod type convergence gauge

InactiveCN101608897AEasy to testPrecise positioningMechanical solid deformation measurementsRailway tunnelMicrometer

A precision rod type convergence gauge comprises anchor heads which are respectively fixed at two ends of a measured distance, a universal hook and a tubular connecting rod; the precision rod type convergence gauge also comprises a micrometer caliper, wherein one end of the micrometer caliper is connected with an extracting-pulling type distance-measuring gauge and the other end is connected with a pull rod benchmark device which consists of a telescopic rod fixed with the micrometer caliper into a whole, a force-measuring spring guide sleeve matched with the telescopic rod and a limit spring. The connecting part of the force-measuring spring guide sleeve and the micrometer caliper is provided with a benchmark window marked with a benchmark line; the ends of the pull rod benchmark device and the extracting-pulling type distance-measuring gauge can be respectively connected with a plurality of sections of tubular connecting rods by threads; and an alignment line which can be aligned to the benchmark line of the benchmark window is arranged on the telescopic rod. The precision rod type convergence gauge is applicable to the stability monitoring of military caves, railway tunnels, bridges, underground hydraulic buildings and mine tunnel chambers, and the deformation observation of earth structures. The precision rod type convergence gauge has the advantages of the structure convenient for observation, high precision, combination of a plurality of sections of measurement rod and strong adaptability.

Owner:CHINA UNIV OF MINING & TECH

Advance support method for coal mine tunnel high-risk area

The invention discloses an advance support method for a coal mine tunnel high-risk area. The advance support method comprises the following steps of: taking a drill rod as a temporary support during roadway excavation; attaching the waste drill rod to the wall surface of a tunnel, and overlapping on the drill rod, and fixing tightly by using an iron wire to form a temporary support shed cover; under the temporary support of the shed cover, constructing an injection pipe, injecting cement and water glass or other solidified materials into the high-risk area by using a special grouting machine to make a top plate of the high-risk area solidified into a whole, and meanwhile, building a stone room by using dressed stones and taking the stone room as a permanent support; and performing 1 to 1.5m small cycle operation, and repeating the steps 2 to 4 to pass through the high-risk area smoothly. The high-risk area is difficult to pass through by a normal support technology; drilling shed and grouting support technologies are used as the advance support, so the high-risk area can be passed through safely and efficiently.

Owner:BIN COUNTY WATER CURTAIN CAVE COAL

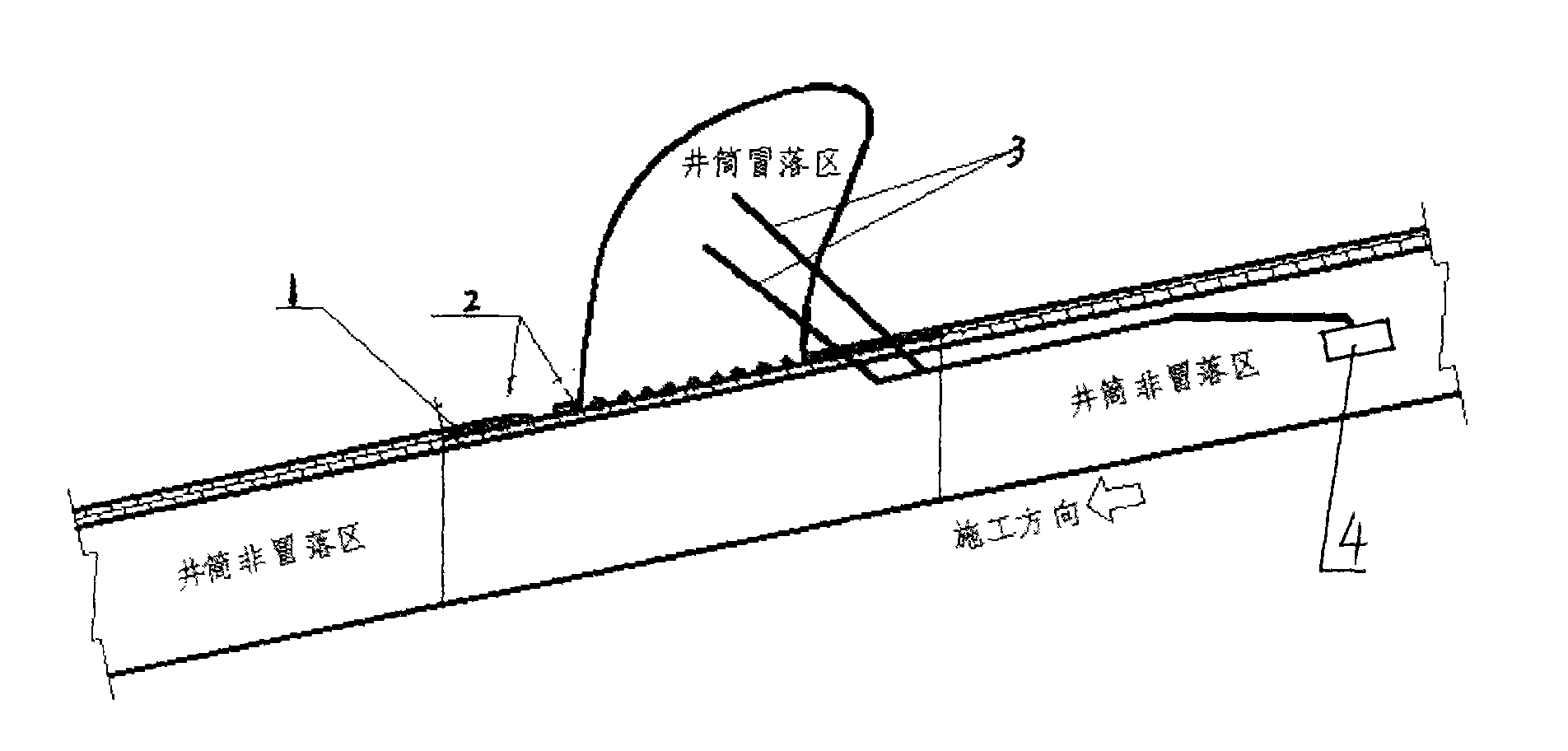

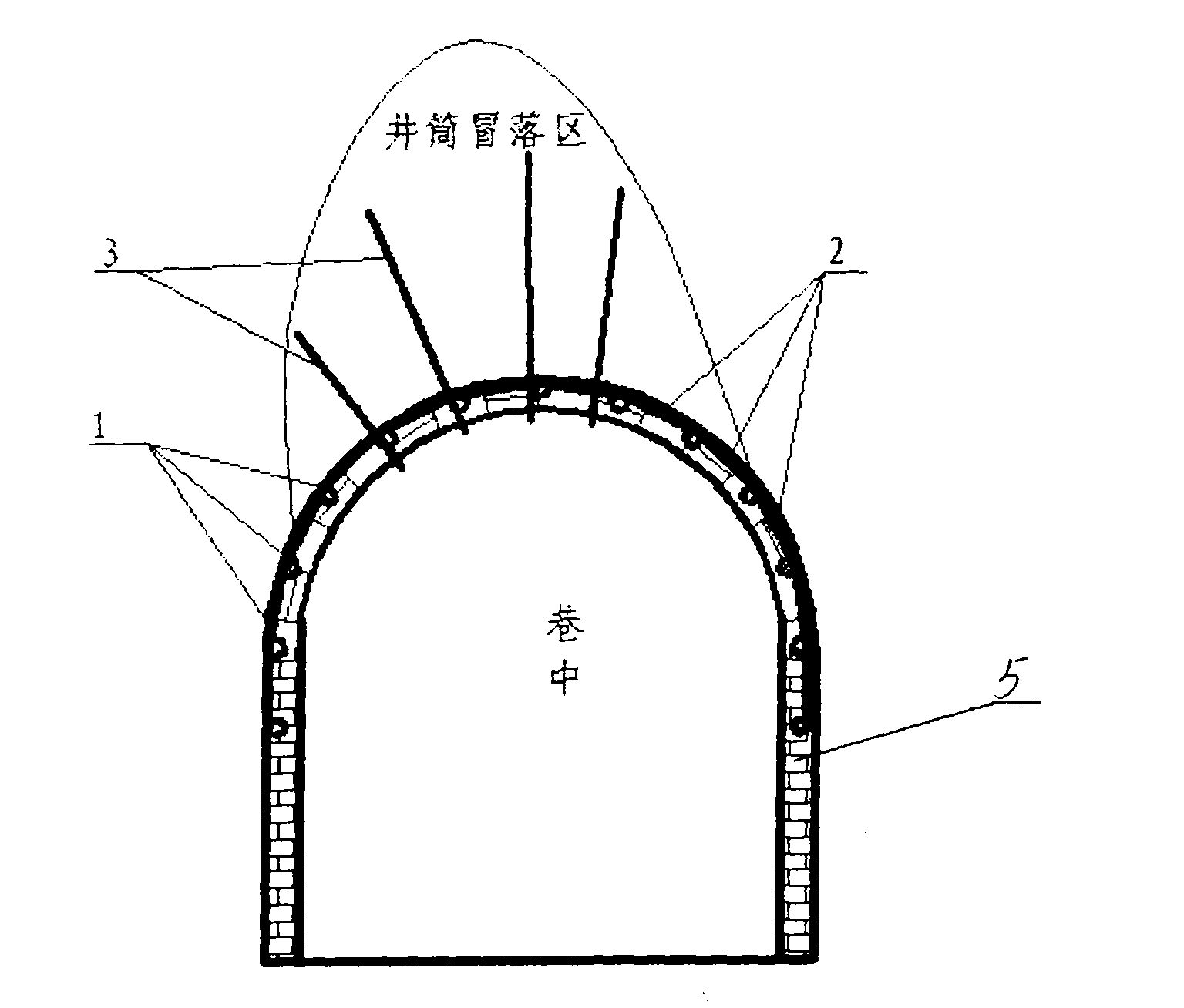

Method for coal mine tunnel working surface to pass through abandoned roadway in forced caving pressure relief mode

ActiveCN103244124ASpend less timeGuaranteed safety and reliabilityUnderground miningBlastingCoalDeep hole

The invention discloses a method for a coal mine tunnel working surface to pass through an abandoned roadway in a forced caving pressure relief mode. According to the method, in the process of advancing towards the abandoned roadway at the working surface, a row of blast holes with certain angles and depths are formed in the abandoned roadway ahead the working surface towards the coal wall direction of the working surface in advance, the completeness of a top board rock layer is damaged by adopting a deep hole presplitting method, and when the working surface passes through the abandoned roadway, a top board behind a bracket can collapse in time and fill a worked out section. By utilizing the method, the hidden danger that a large-area hanging arch occurs in back of the bracket when the working surface passes through the abandoned roadway is avoided, so that the purposes that the influence of the top board pressure to the working surface and the abandoned roadway ahead is reduced, and the working surface can safely and rapidly pass through the abandoned roadway are achieved. The method is simple and effective to operate and low in cost, and has great practical and popularization values.

Owner:旭辰矿业科技发展(徐州)有限公司

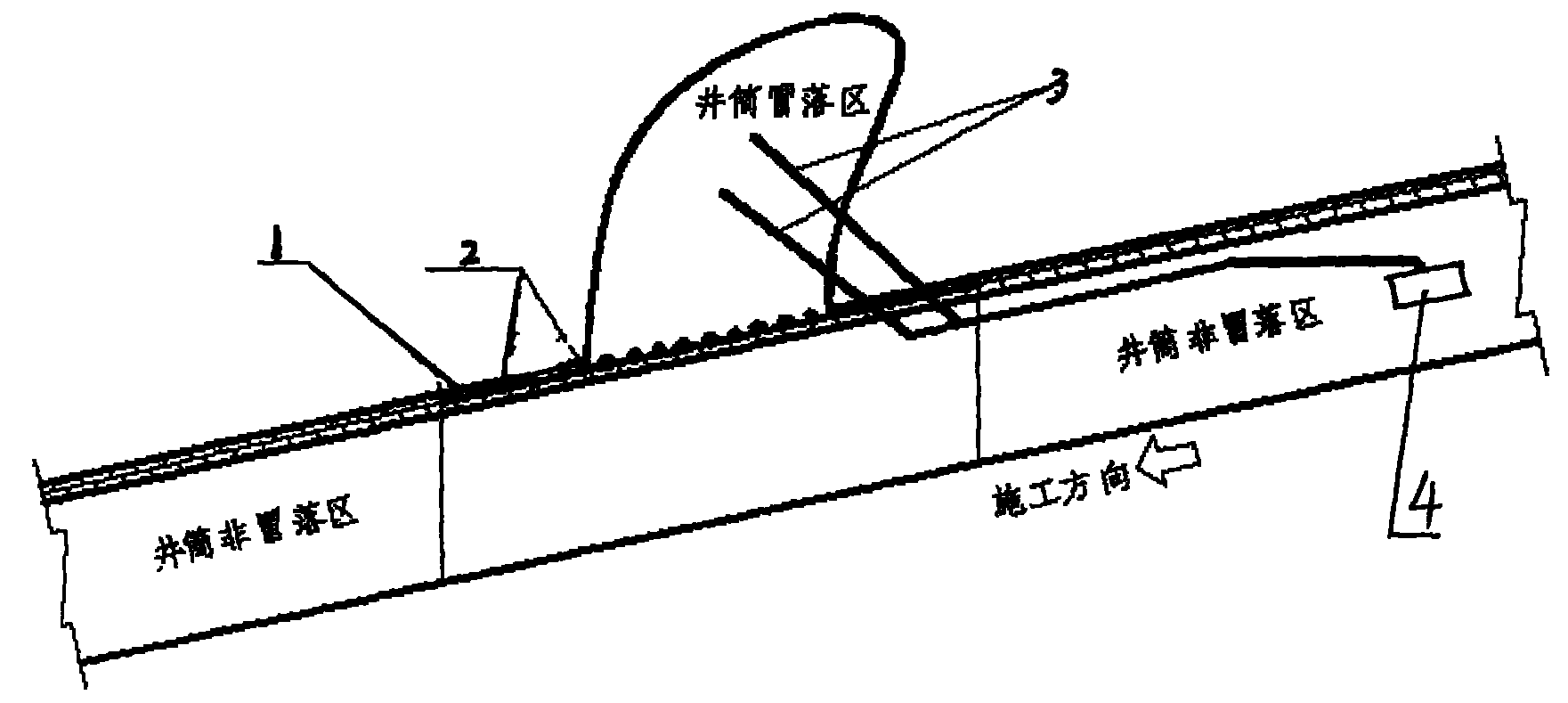

Propelling method for combined portion between shield tunnel segment and mine tunnel segment in subway tunnel

InactiveCN103711504ALow bond strengthLow elastic modulusUnderground chambersTunnel liningGlass fiberShotcrete

Provided is a propelling method for a combined portion between a shield tunnel segment and a mine tunnel segment in a subway tunnel. The propelling method includes the first step that a steel sleeve is horizontally struck into the surrounding rock in front of a tunnel face of the mine tunnel segment after construction of the mine tunnel segment is finished, and then a shotcrete support is applied on the tunnel face; the second step that glass fiber ribs of separation end walls are bound tightly close to the shotcrete support, the glass fiber ribs and steel bars for ring beams behind the glass fiber ribs are connected in a bound mode, next the steel bars for the ring beams are connected with reserved steel bar heads of a primary support of the mine tunnel segment in a welded mode, and then the separation end walls and the ring beams are poured; the third step that an arc-shaped concrete guiding platform is poured at the bottom of the mine tunnel segment; the fourth step that when a shield tunneling machine approaches to the mine tunnel segment, the propelling speed is lowered, the shield tunneling machine is accommodated in the steel sleeve, and then the shield tunneling machine is used for directly cutting and removing the surrounding rock in the steel sleeve, the shotcrete support of the tunnel face and the separation end walls and carrying out grouting and slag removing until the shield tunneling machine passes through the ring beams and is accommodated on the arc-shaped concrete guiding platform. According to the propelling method, construction risks are low, construction is easy, efficiency is high and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

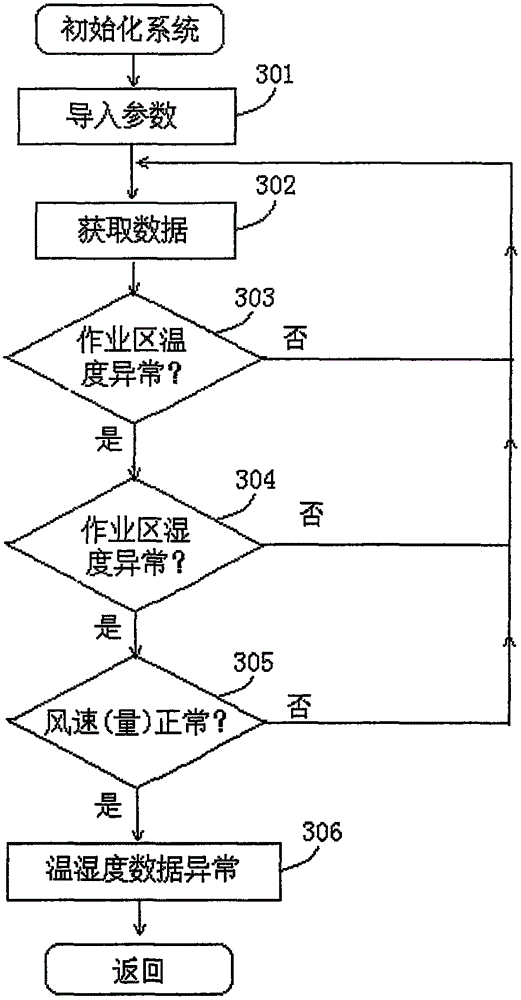

Underground flood alarm method based on temperature, humidity and image monitoring

The invention discloses an underground flood alarm method based on temperature, humidity and image monitoring. The alarm method includes the steps that cameras are placed on an underground coal mine tunneling working face, a coal working face or other operation faces possibly having a water inrush accident, a temperature and humidity sensor and a wind speed or volume sensor are installed on a roadway monitored by the cameras and used for collecting state data and the like of large equipment at the same time; when temperature and humidity data of the working face is abnormal, moreover it is monitored that abnormal water flow appears in a set region in video images of the cameras, and the duration time of the water flow exceeds a set time threshold value or water flow increasing speed exceeds a set threshold value, a flood alarm signal is sent out. The alarm method fully considers the characteristic of a coal mine coal working face flood and is easy to implement, corresponding measures are taken automatically in time, an alarm can be given for water inrush of a coal mine accurately at first time, and valuable rescue and escape time is bought for underground staff, not at the flood site, in other regions.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

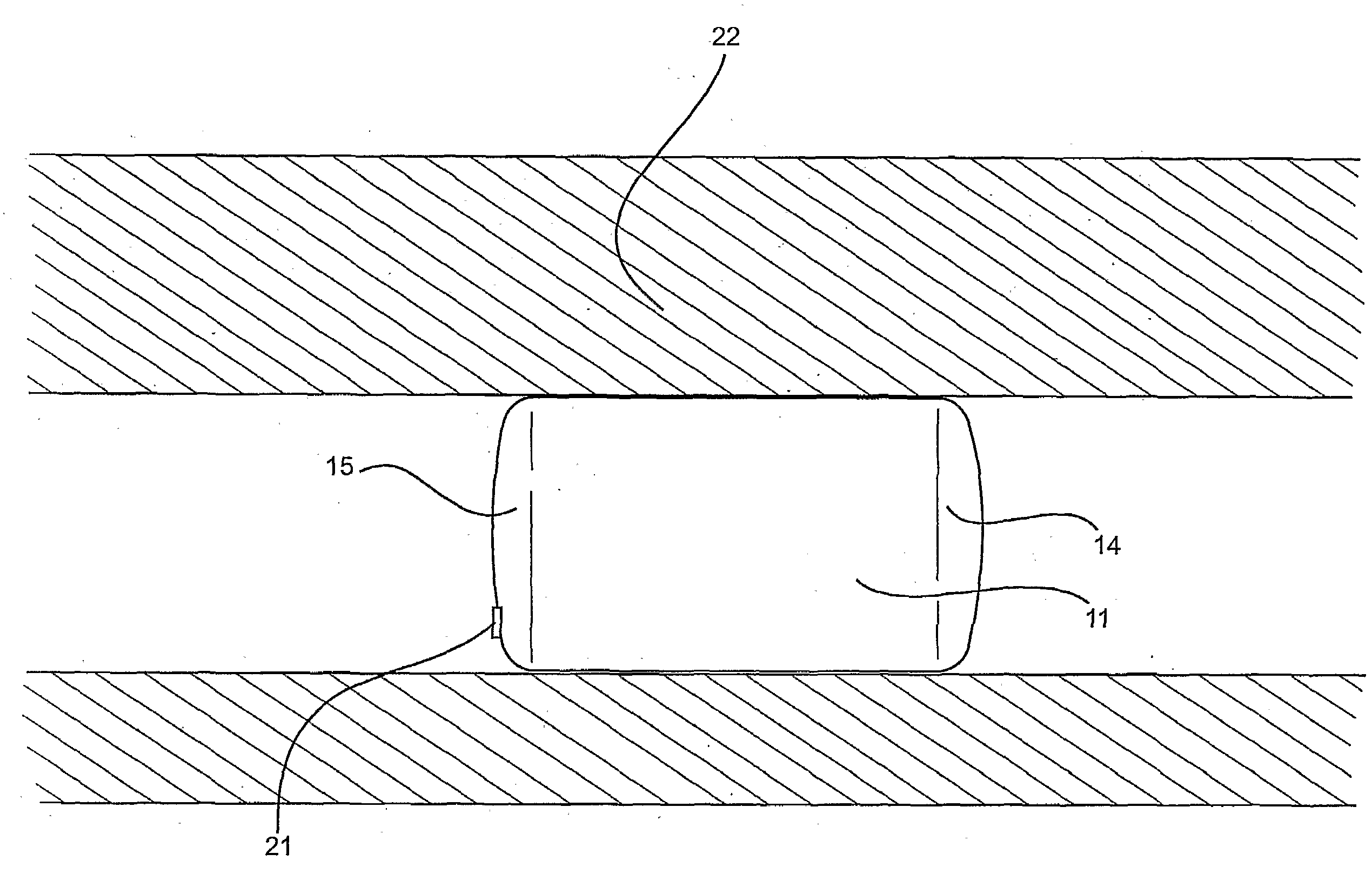

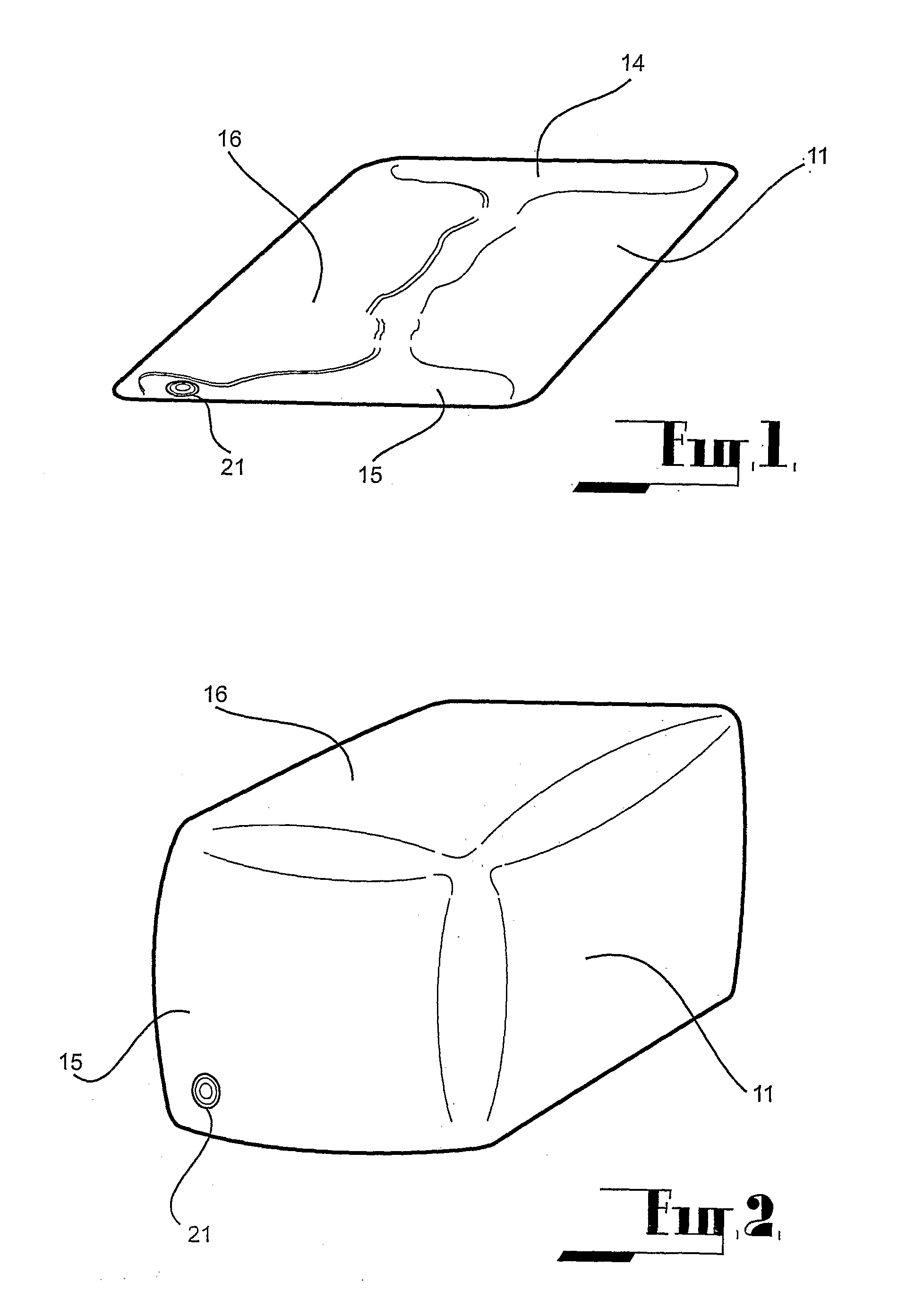

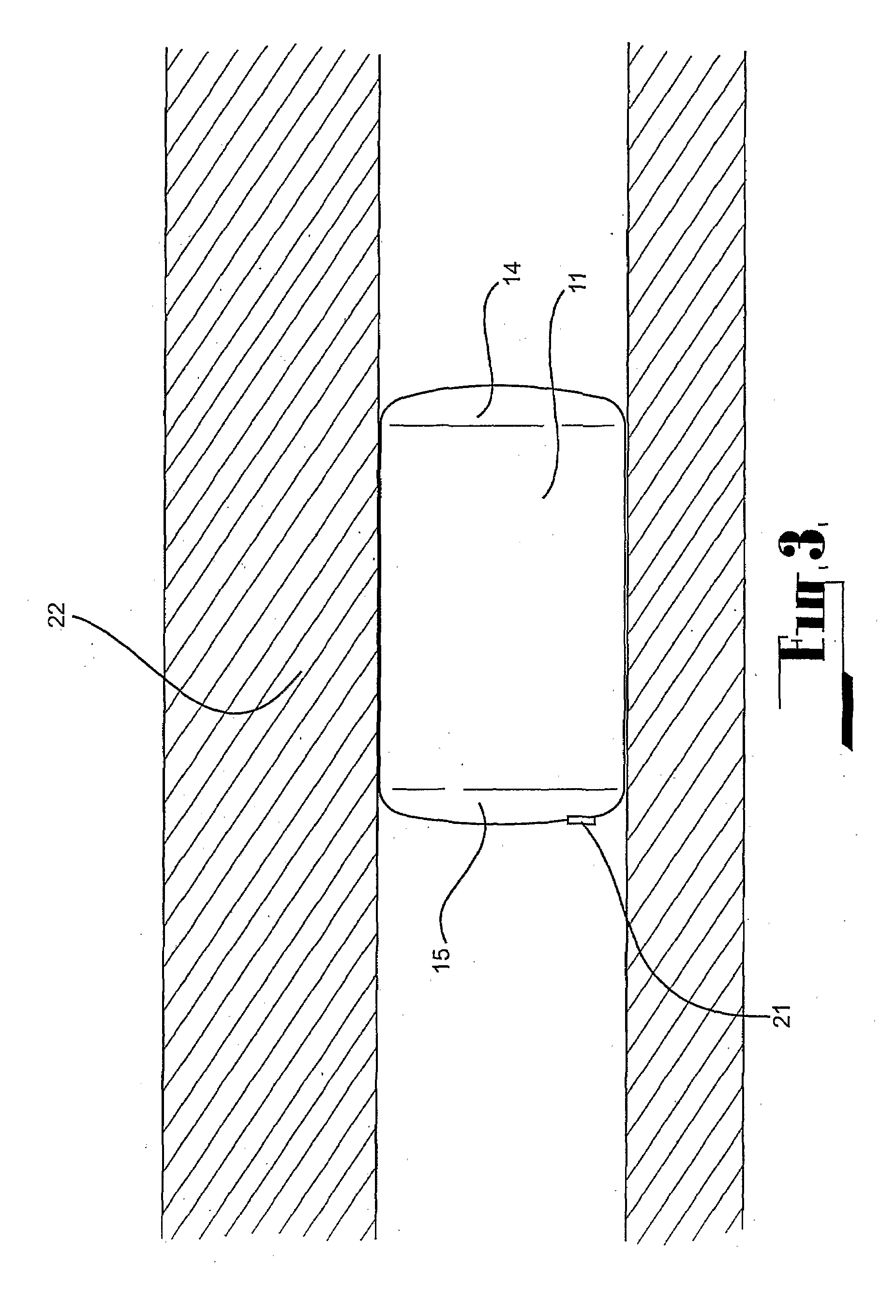

Tunnel Barrier

A tunnel barrier (11) adapted to seal a mine tunnel, the tunnel barrier (11) comprising an inflatable bladder having a front wall (14), a rear wall (15) and a side wall (16) and being adapted to be inflated by a suitable gas, wherein the side wall is adapted to contact the tunnel walls, including the roof and floor to thereby seal the tunnel.

Owner:ABC CANADA TECH GRP

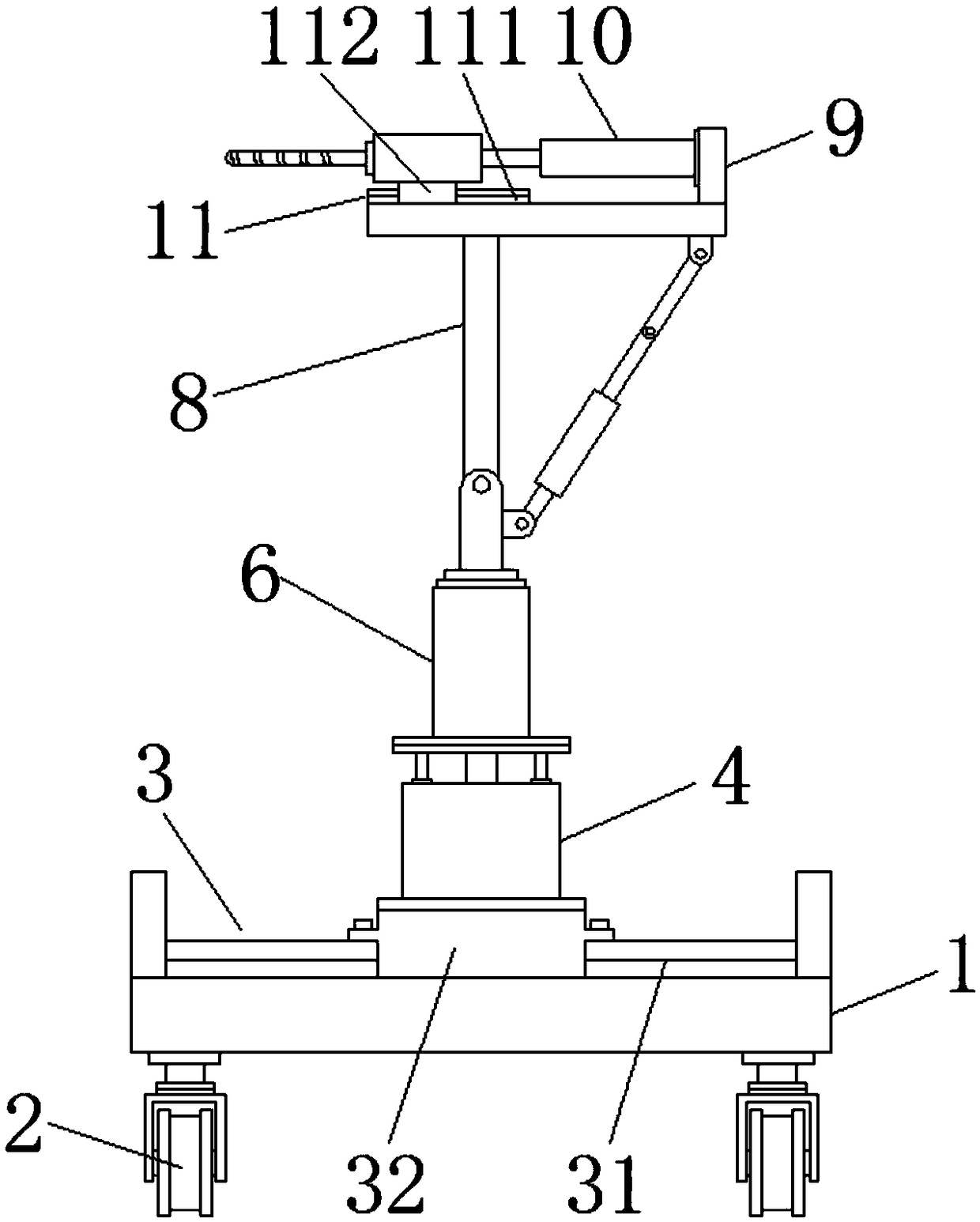

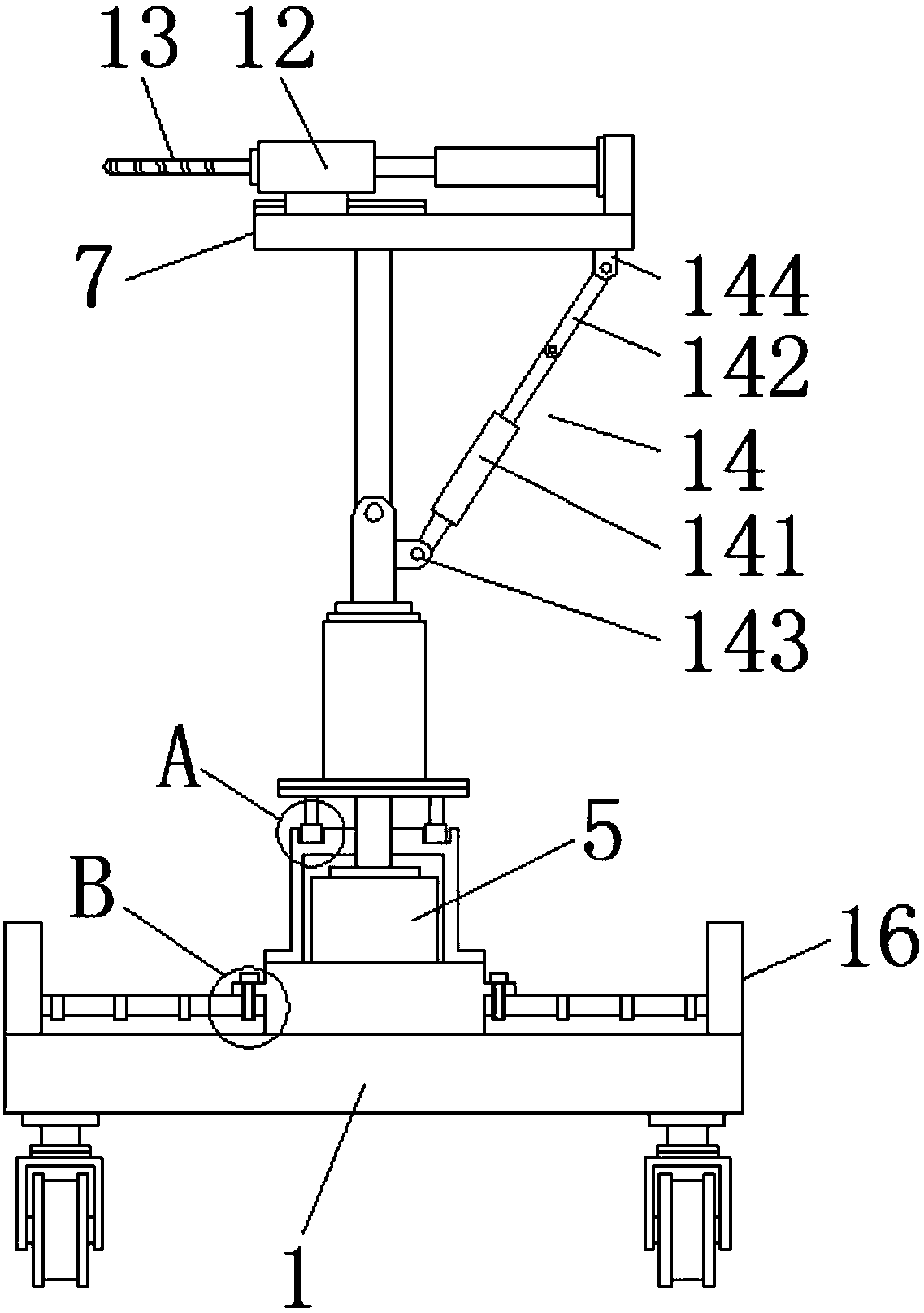

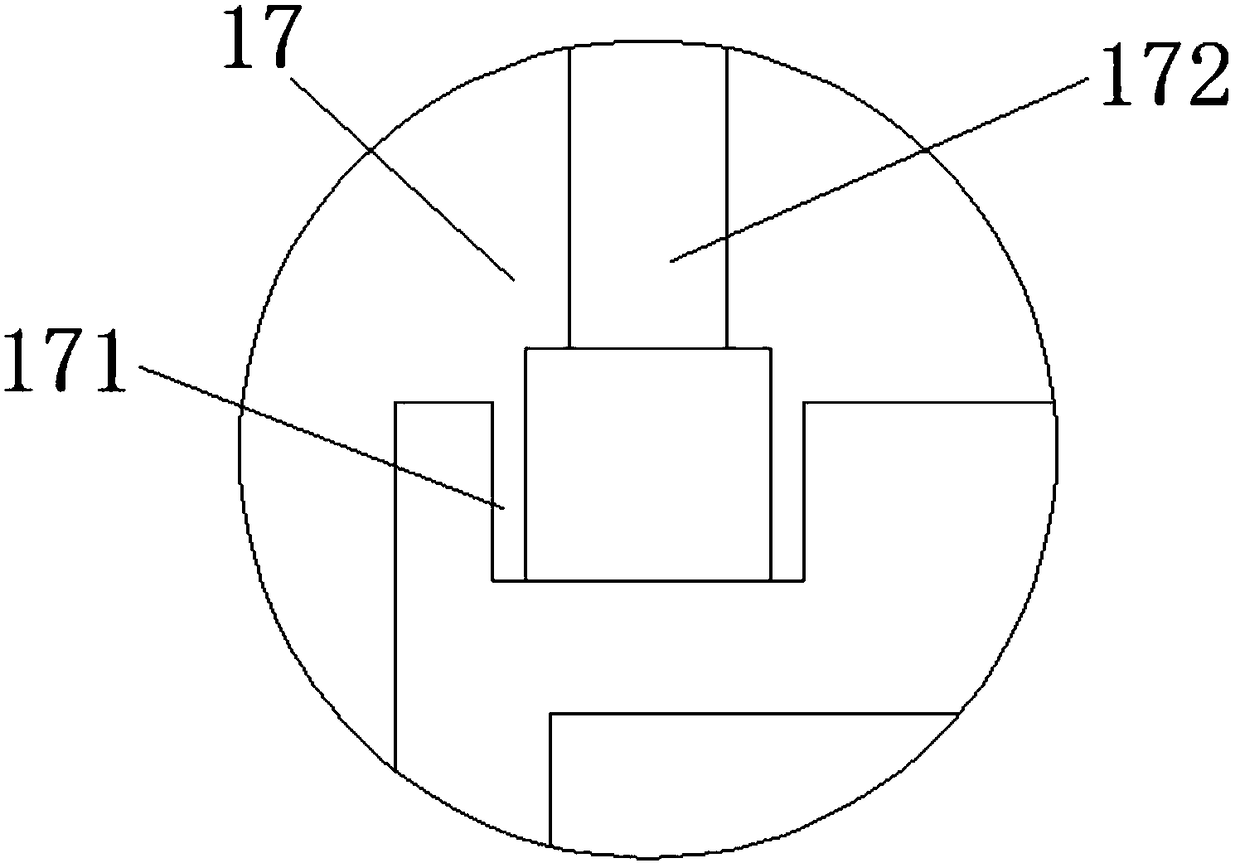

Drilling device for mine tunnel and with function of conveniently adjusting position and angle

InactiveCN108612478AEasy to adjust the position angleEasy to adjust the orientation angleDerricks/mastsDrilling machines and methodsHydraulic cylinderEngineering

The invention discloses a drilling device for a mine tunnel and with the function of conveniently adjusting the position and the angle. The drilling device comprises a base. Track wheels are fixedly mounted on the lower surface of the base through brackets. A first motor is fixedly mounted in an inner cavity of a motor box, an output shaft of the first motor penetrates through the motor box and then is fixedly connected with the cylinder bottom of a first hydraulic cylinder, and a supporting plate is arranged on the upper side of the first hydraulic cylinder. A supporting rod is fixedly weldedto the lower surface of the supporting plate, and a mounting plate is arranged at the right end of the upper surface of the supporting plate. A second motor is arranged on the upper surface of the supporting plate through a second sliding mechanism, and a drilling bit is fixedly mounted at the output end of the second motor. An angle adjusting mechanism comprises a servo electric cylinder, a connecting rod, a first hinging lug and a second hinging lug. According to the drilling device, the position and the orienting angle of a drilling bit are conveniently adjusted, drilling work of multipleposition and multiple stations can be rapidly conducted, the drilling device can move on a rail in the mine tunnel conveniently, and the labor intensity of workers is relieved.

Owner:程伟强

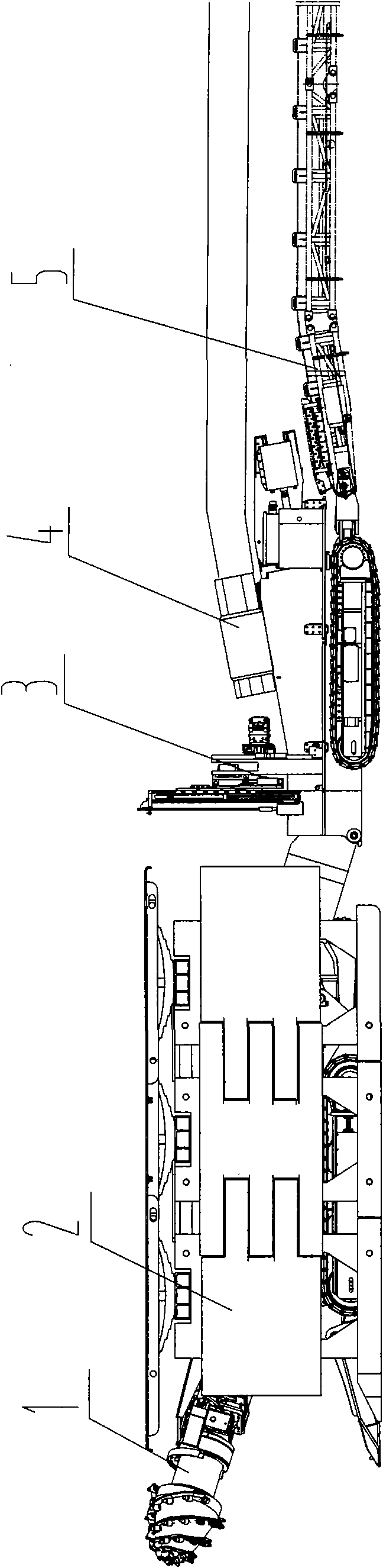

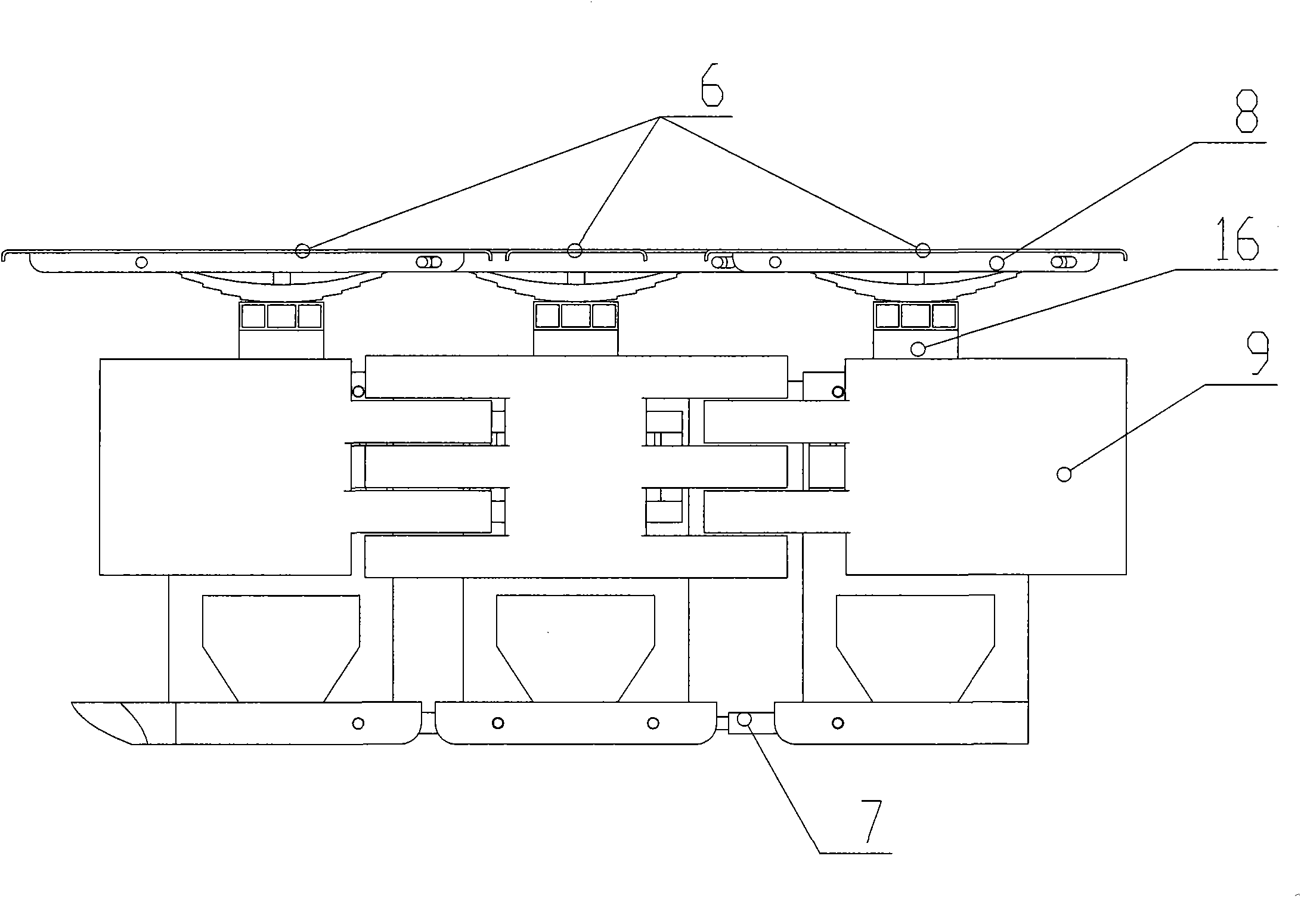

Excavating, supporting and bolting integrated self-contained machine

The invention relates to the field of coal mine tunnel mining, in particular to an excavating, supporting and bolting integrated self-contained machine, which can carry out excavation, temporary supporting, permanent supporting, coal output, dedusting and other operations in parallel in the process of excavating a coal mine tunnel in order to increase the overall working efficiency of the fully mechanized workface, thus solving the problems of the prior art, such as low coal mine tunnel excavation efficiency. The self-contained machine is provided with an excavator, a support, an anchor bolt jumbo, a dedusting fan and a second conveyer, the support is of a gantry type structure, and spans the excavator, the anchor bolt jumbo is positioned behind the excavator and the support, the dedusting fan is fixed on the anchor bolt jumbo, and the second conveyer is hinged with the rear of the anchor bolt jumbo. The excavator of the self-contained machine carries out cutting, collection and conveying at the coal head, the support spans the excavator, closely follows the excavator to automatically move forward, and temporarily supports the roof, the anchor bolt jumbo cooperates with the excavator to transfer coal, and carries out permanent supporting with anchor bolts and anchor cables, and the dedusting fan ventilates the tunnel and removes dust.

Owner:SANY HEAVY EQUIP

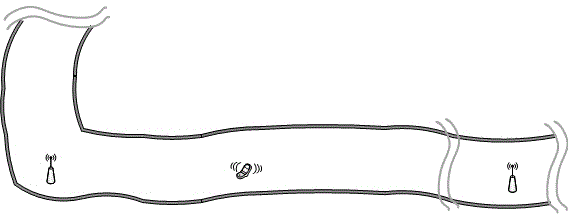

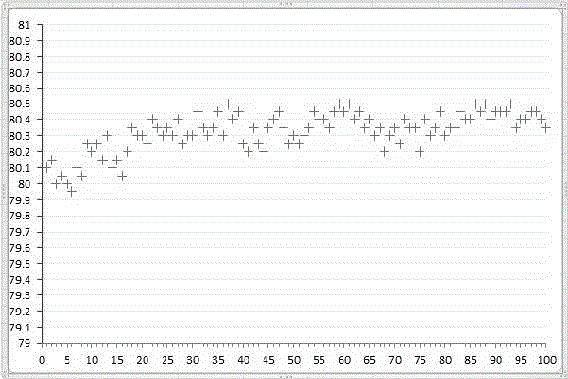

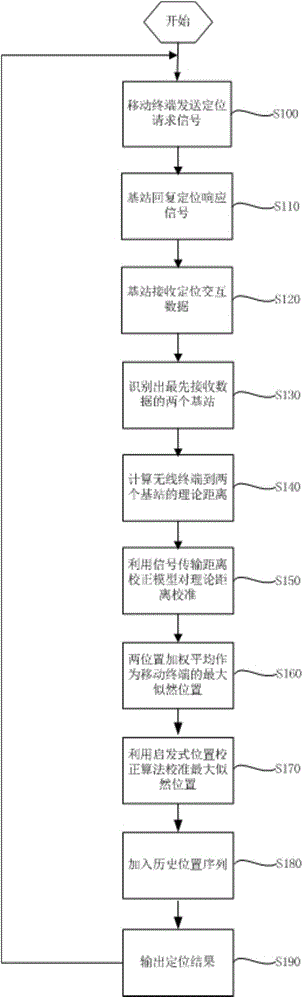

High-precision positioning method for wireless mobile terminal at mine tunnel

InactiveCN104316904ARealize high-precision positioningPosition fixationCorrection algorithmDistance correction

The invention being title as ''High-precision positioning method for a wireless mobile terminal at a mine tunnel'' provides a high-precision positioning method and system for a wireless mobile terminal in a mine tunnel environment, thereby solving a problem that high-precision positioning of a wireless mobile terminal at a mine tunnel can be not be realized by using the existing wireless positioning method and method. According to key points in the technical scheme, an on-site surveying is carried out to realize tunnel wireless signal sampling and a tunnel signal transmission distance correction model; a positioning base station receives a positioning request signal of a mobile terminal and a positioning response signal is returned; a mobile terminal transmits positioning interaction data to a positioning base station; the positioning base station calculates a theoretical distance of the mobile terminal; the theoretical distance is calculated by using the tunnel signal transmission distance correction model to obtain a maximum likehood position; and a final position of the mobile terminal is obtained by using a heuristic position correction algorithm in the method. The provided method can be widely applied to wireless high-precision positioning of the personnel and mobile equipment at the mine tunnel.

Owner:辽宁瑞华实业集团高新科技有限公司

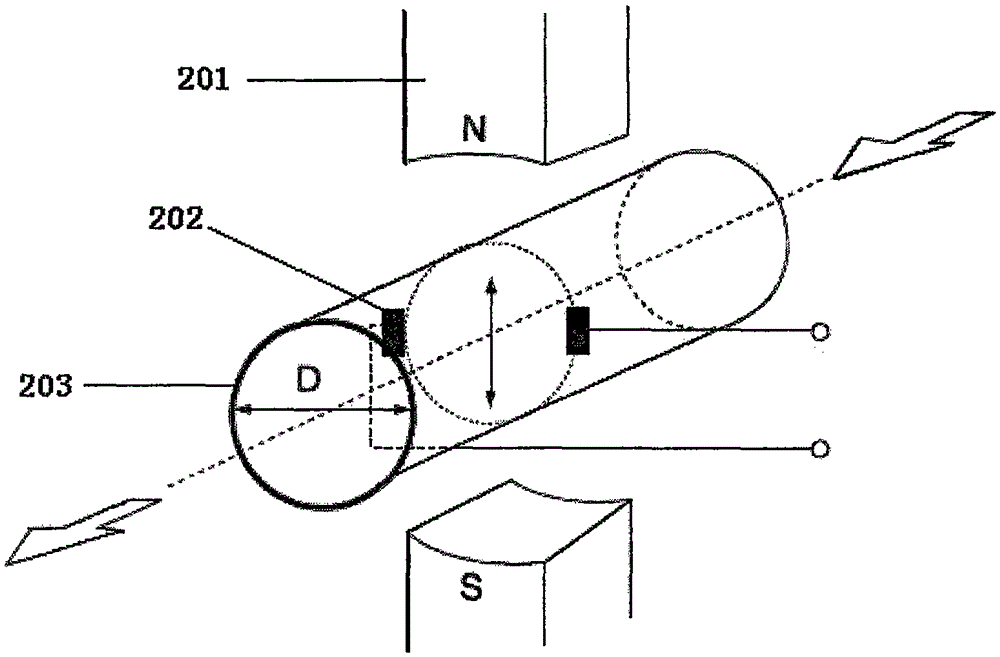

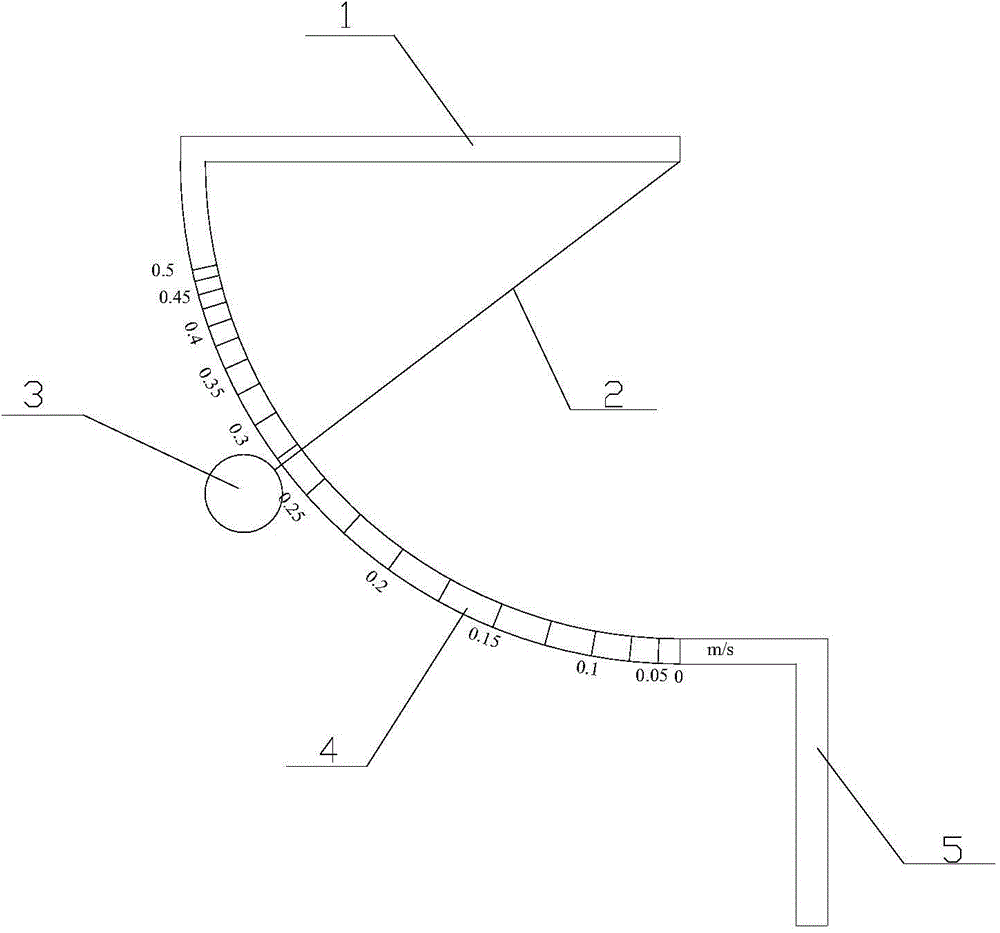

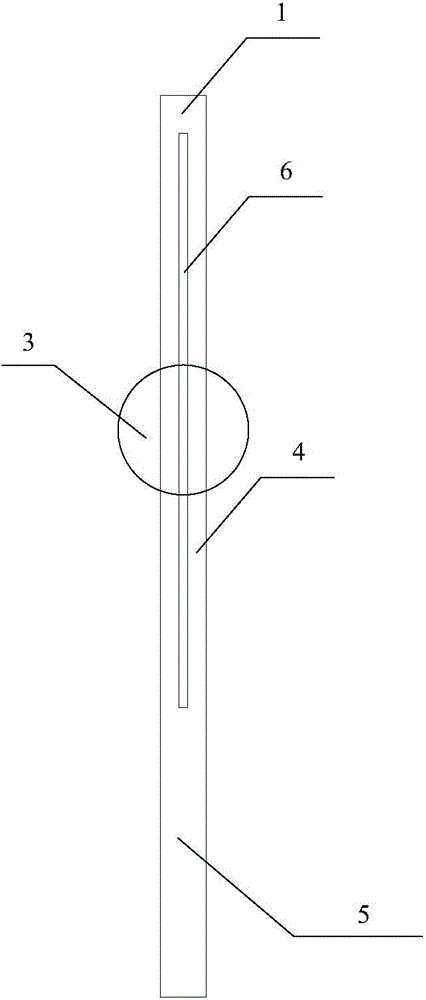

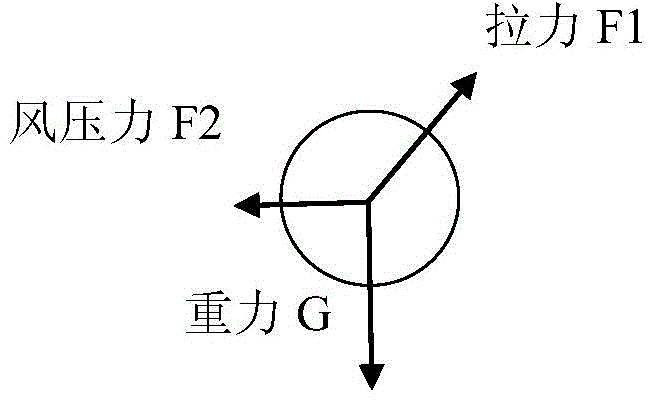

Gentle wind speed measurement device and method for coal mine tunnel

InactiveCN104865403AHigh measurement accuracyImprove measurement stabilityIndication/recording movementFluid speed measurementMeasurement deviceEngineering

The invention discloses a gentle wind speed measurement device and method for a coal mine tunnel, and the device mainly consists of an arc-shaped graduated scale, a light large-section ball, and a hauling rope. One end of the hauling rope is fixed at a top supporting point, and the other end of the hauling rope is used for hauling the light large-section ball. The light large-section ball can swing upwards through a certain angle under the action of gentle wind in the coal mine tunnel. The higher the wind speed is, the larger the swinging angle is. The arc-shaped graduated scale is used for measuring the swinging angle, and a corresponding wind size is marked on the graduated scale. The device is simple in structure, is low in cost, is portable, can measure the speed of gentle wind effectively and quickly, and facilitates the adjustment and management of a wind network of a coal mine.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com