Tunnel support installation apparatus

a technology for installing equipment and tunnel supports, which is applied in the direction of shaft equipment, shaft lining, slitting machines, etc., can solve the problems of heavy existing structural support manipulators, difficult for personnel to work safely and comfortably for sustained periods, and disadvantages of conventional mining machine arrangements, etc., to achieve reliable transfer and extend the range of travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

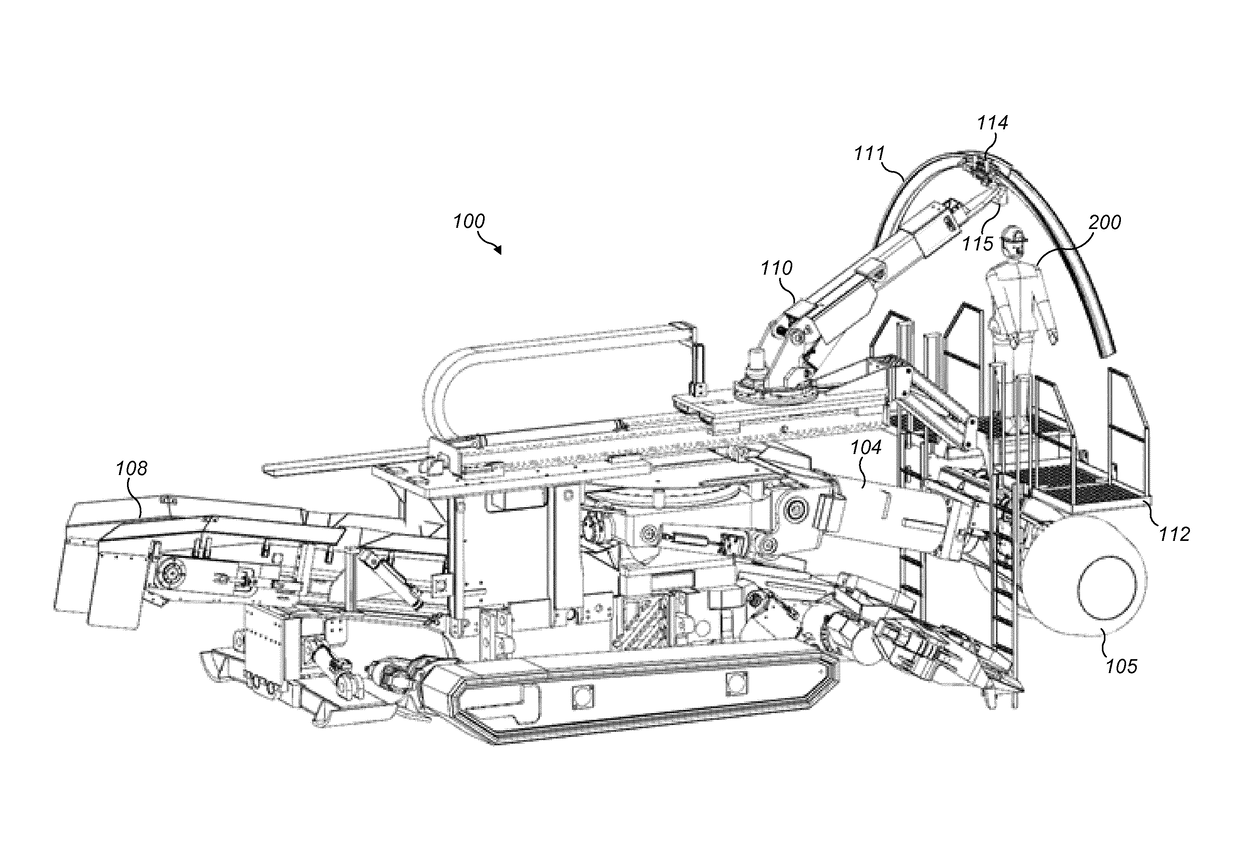

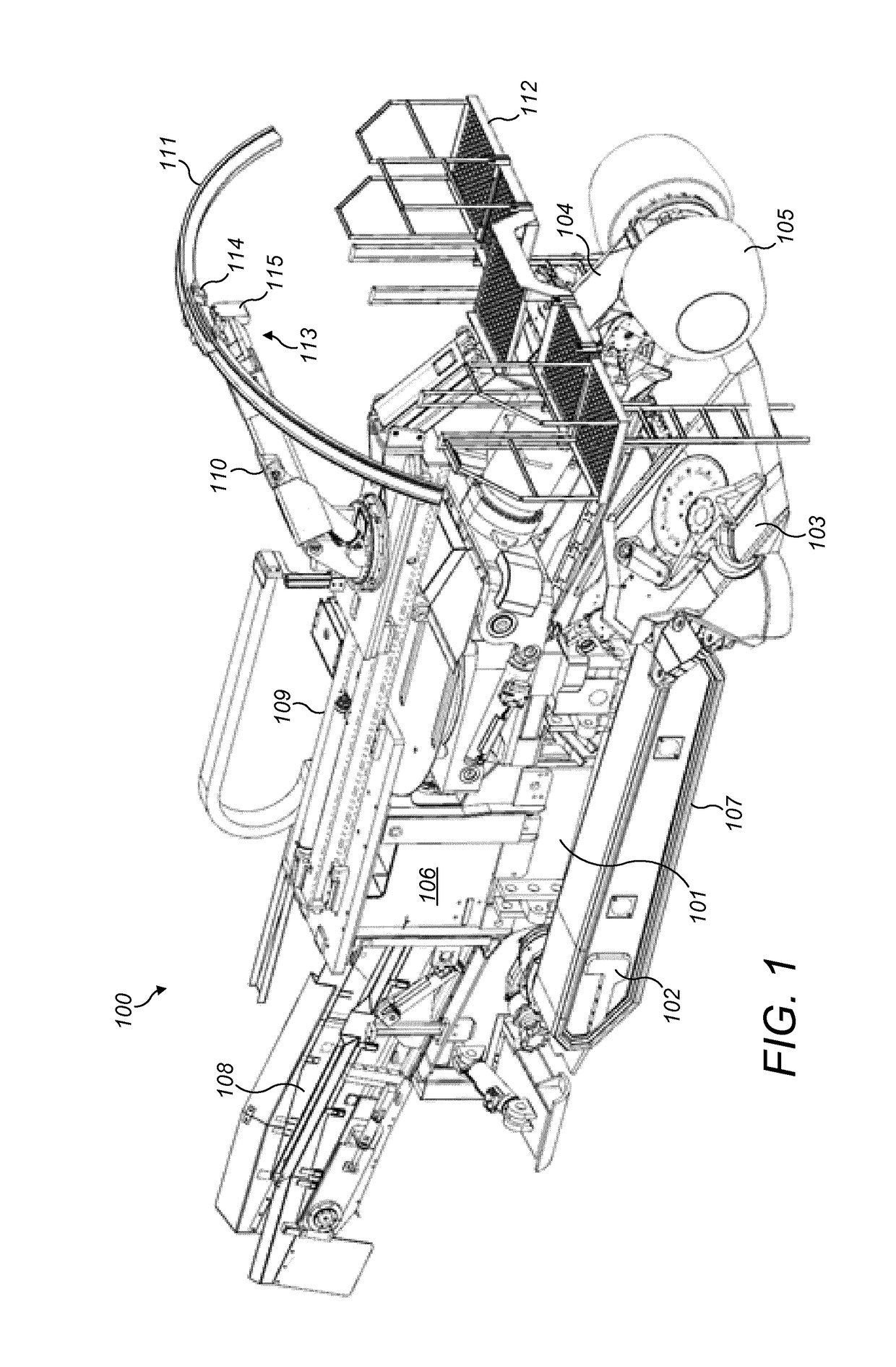

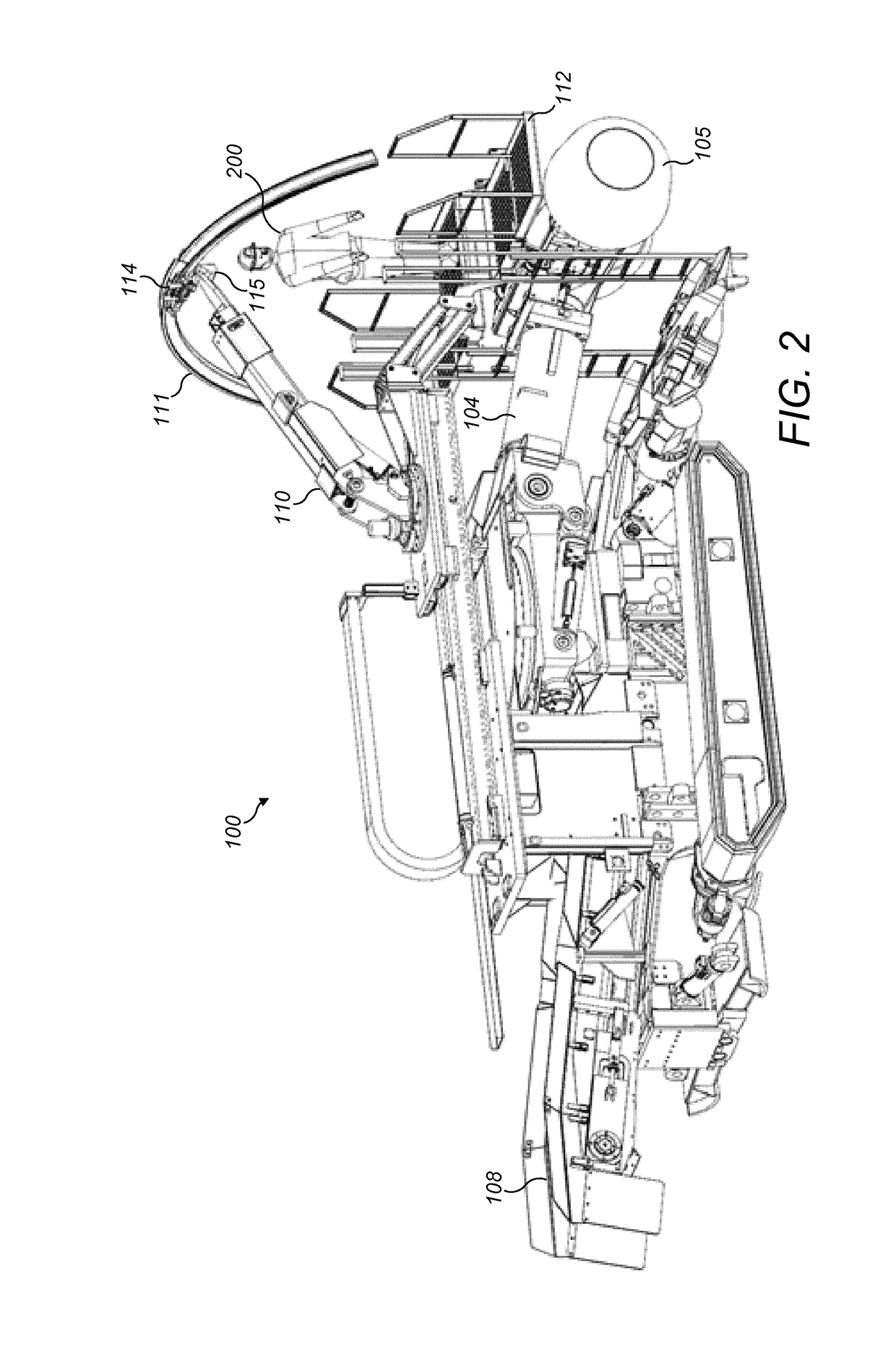

[0035]Referring to FIGS. 1 and 2, a mobile mining machine 100 comprises a mainframe 101 mounting a pair of endless tracks 107 via an undercarriage 102. A motor 106 is also carried by mainframe 101 and is positioned substantially centrally of the main body of machine 100. A rotatable cutting head indicated generally by reference 105 is positioned at a forward end of machine 100 and comprises a plurality of rotating drums that mount a plurality of cutting bits (not shown). Head 105 is mounted at mainframe 101 via an elongate boom 104 that is in turn pivotally mounted at its rearward end to mainframe 101. A gathering head 103 is also mounted at the machine forward end and is positioned below boom 104 so as to receive and gather material dislodged from the cutting face. Machine 100 further comprises a discharge conveyor 108 that extends rearwardly from gathering head 103 and projects rearwardly from the machine 100 behind motor 106.

[0036]Machine 100, typically referred to as a ‘Roadhead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com