Method for coal mine tunnel working surface to pass through abandoned roadway in forced caving pressure relief mode

A technology for coal mine tunnels and working faces, which is applied to surface mining, mining equipment, underground mining, etc., can solve the problems of shutdown of working faces, poor applicability, and influence on the progress of working faces, coal mine production, etc., so as to reduce roof pressure and reduce The effect of supporting strength and shortening the time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

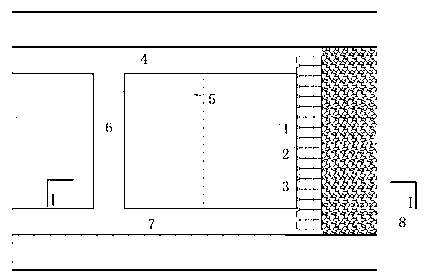

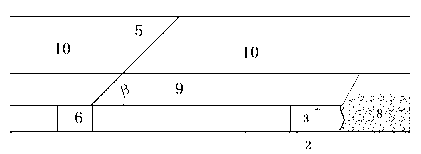

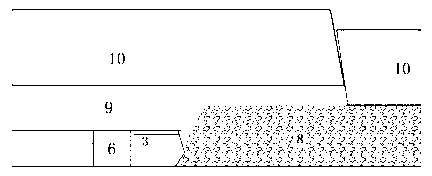

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The method for implementing a kind of working face of the present invention forcibly caving the top and unloading the pressure to go through the gob is to mine No. 3 coal seam at the fully mechanized mining face of Shanxi Coal Mine, and the mining height of the coal seam is 1.56m. The immediate roof is mudstone, with an average thickness of 4.8m; the basic roof is fine-grained sandstone, with an average thickness of 12.1m, and the sandstone is dense and hard, with a broken expansion coefficient =1.2.

[0022] The steps of the specific implementation method are as follows:

[0023] Step 1. During the excavation process of the coal mine underground roadway, when the working face is 10-20m away from the roadway in advance, press the spacing on the roof of the roadway Set up a number of blastholes, and arrange several blastholes in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com