Patents

Literature

52results about How to "Reduce support strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

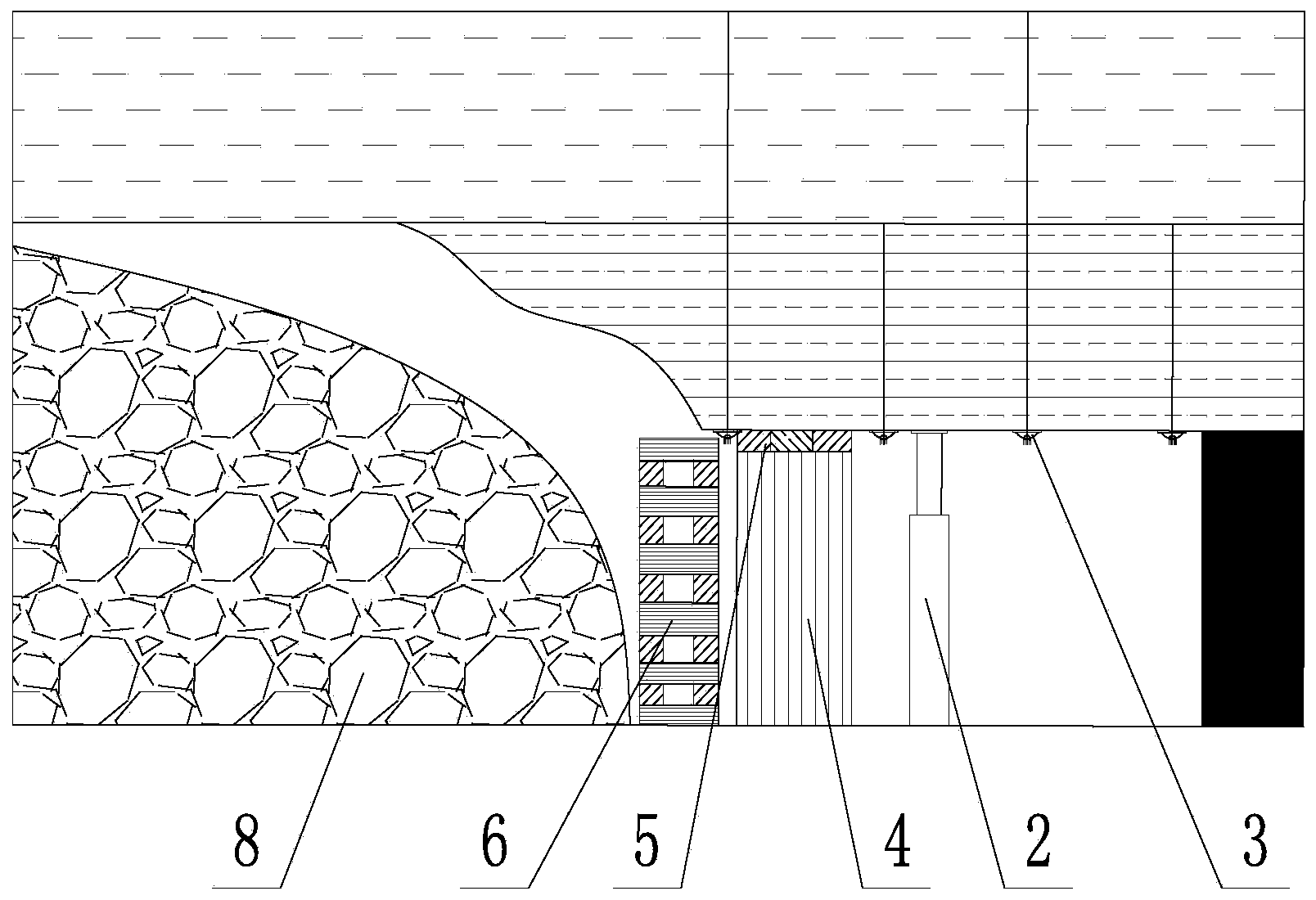

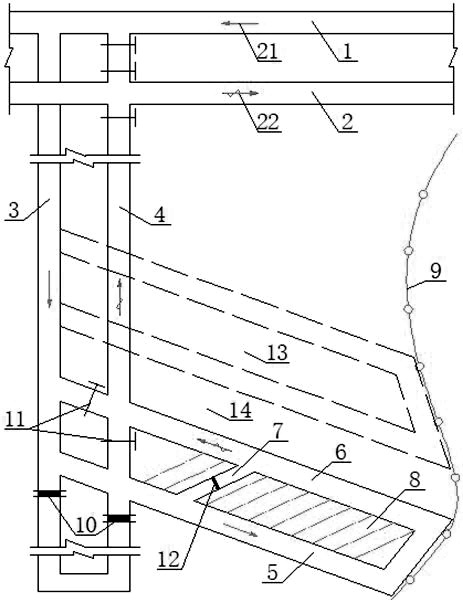

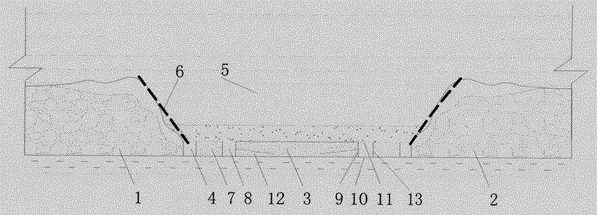

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930AReduce water pressure in tunnelReduce water and mud inrushUnderground chambersTunnel liningWorld classTunnel construction

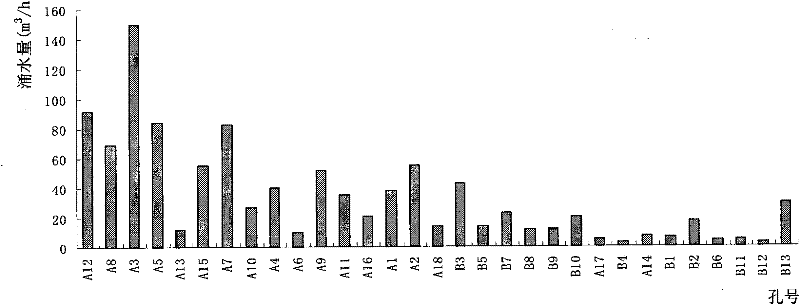

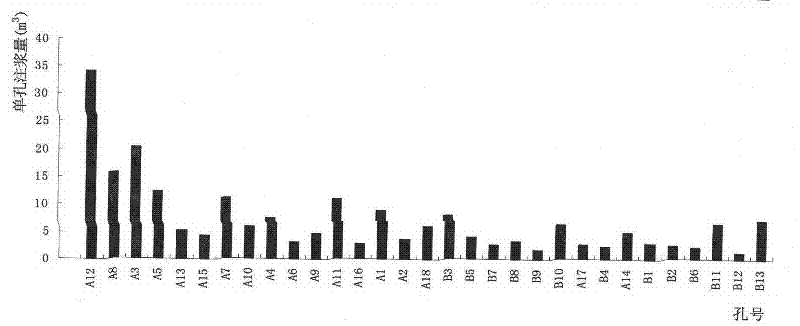

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

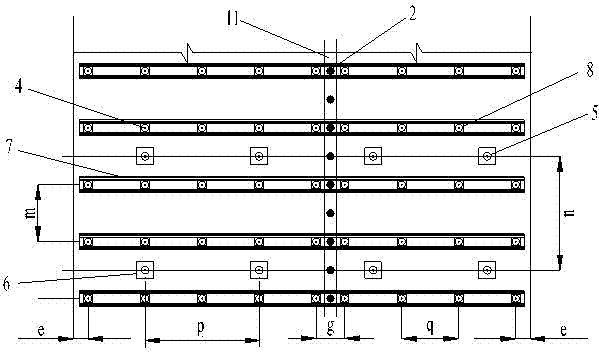

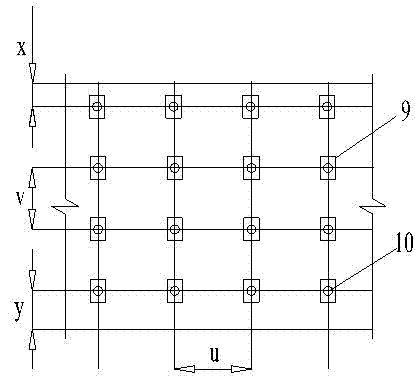

Support method for span reduction with double micro-arches in large-span cut-outs

InactiveCN102268998ASolve the problem of difficult to control the stability of the roofImprove top control effectTunnelsMine roof capsLong spanMonomer

The invention discloses a span-reducing support method with double micro-arches for large-span cutouts, which is suitable for span-reduction support in areas with complex structures and deep composite roofs with large-span cutouts. The secondary roadway is used instead of the first roadway, and the double micro-arch cutout is used to replace the traditional one-time long-span rectangular cutout, and the prestressed anchor / cable is used to strengthen the surrounding rock of the cutout. The distribution law of the plastic zone of the surrounding rock of the micro-arch cutout, select reasonable support parameters, give full play to the support function of the prestressed anchor rod / cable, add a row of single pillars and top beams to reduce the span support in the double micro-arch cutout protection, the top control effect is obvious. For large-span cutouts, the span reduction support method of secondary roadway formation + double micro-arch sections + anchor net cables + single pillars and hinged roof beams was adopted to solve the problem of difficult control of the roof of long-span rectangular cutouts and realize The large-span cutting eye is fast, safe and economical to construct, and its method is simple and easy to implement, with low support cost and good support effect.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

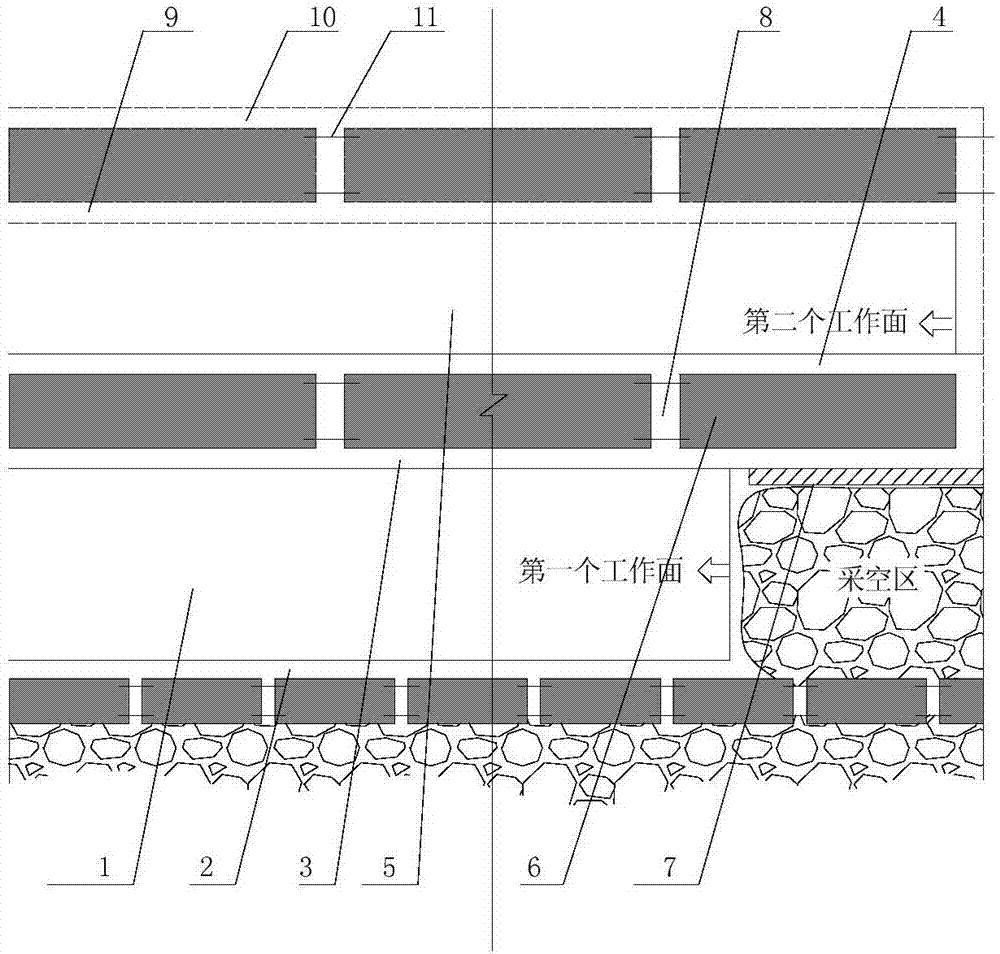

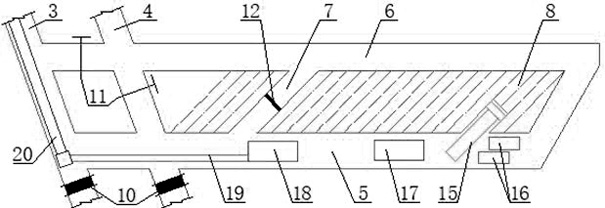

Double-roadway arrangement non-pillar mining method for high-gas-burst coal seam

InactiveCN108005655AReduce useless excavationLess gushUnderground miningSurface miningPeak valueUltimate tensile strength

The invention discloses a double-roadway arrangement non-pillar mining method for a high-gas-burst coal seam and belongs to the field of underground coal mine supporting and mining. The double-roadwayarrangement non-pillar mining method comprises the steps that an outer side roadway of a double-roadway tunneling working face is arranged outside a supporting pressure peak value area through a project analogy method or a stress monitoring method; during double-roadway tunneling, the length of a connection roadway between double roadways is 150-200 m, and thus the supporting cost is reduced; when the working face is stoped, gob-side entry retaining is conducted along the inner side roadway, air enters from two crossheading grooves of the working face, and the two crossheading grooves and theouter side roadway form a Y-shaped ventilation system; double-roadway tunneling of the next working face is also conducted through the method, and the air return roadway of the previous working faceis also turned into the air inlet roadway; and the steps are repeated, and high-gas-burst coal seam non-pillar mining of all the working faces is completed sequentially. By adopting the double-roadwayarrangement non-pillar mining method for the high-gas-burst coal seam, the roadway tunneling quantity can be decreased, the invalid roadway tunneling and outer side roadway supporting strength and cost are reduced, and non-pillar mining is achieved.

Owner:CHINA UNIV OF MINING & TECH

Gob-side entry retaining method of fully-mechanized mining/full-mechanized caving mining working face

InactiveCN104074534AEasy to installEasy to operateProps/chocksAnchoring boltsCoal miningStructural engineering

The invention provides a gob-side entry retaining method of a fully-mechanized mining / full-mechanized caving mining working face, belongs to the technical field of coal mine underground supporting, and is applicable to thick-coal-bed and high-gas-content coal mining working faces. By aiming at the problems generated when the existing gob-side entry retaining technology is adopted by the working face, the gob-side entry retaining method adopts the scheme that prefabricated cylindrical pier studs are arranged in a roadway arranged behind an end part hydraulic support frame of a stope working face, and in addition, square timbers are built above the pier studs, so that the pier studs can realize the in-time and firm contact with a top plate, and the effective supporting on the top plate is ensured; wood plates are used for sealing among the pier studs, the air leakage to a gob area can be effectively prevented, and the problem of spontaneous combustion of float coal in the gob area due to great air leakage quantity is solved; concrete foam is adopted for filling the steel pier studs; and the installation is convenient, the operation is simple, and the cost is low. Compared with the scheme requiring a single set of filling system for filling supporting, the method provided by the invention solves the problems of high supporting cost, system complexity and great operation difficulty, has wide practicability and belongs to the gob-side entry retaining method with the advantages that the cost is low; the construction is easy; the supporting intensity is high; and the stability is high.

Owner:LIAONING TECHNICAL UNIVERSITY

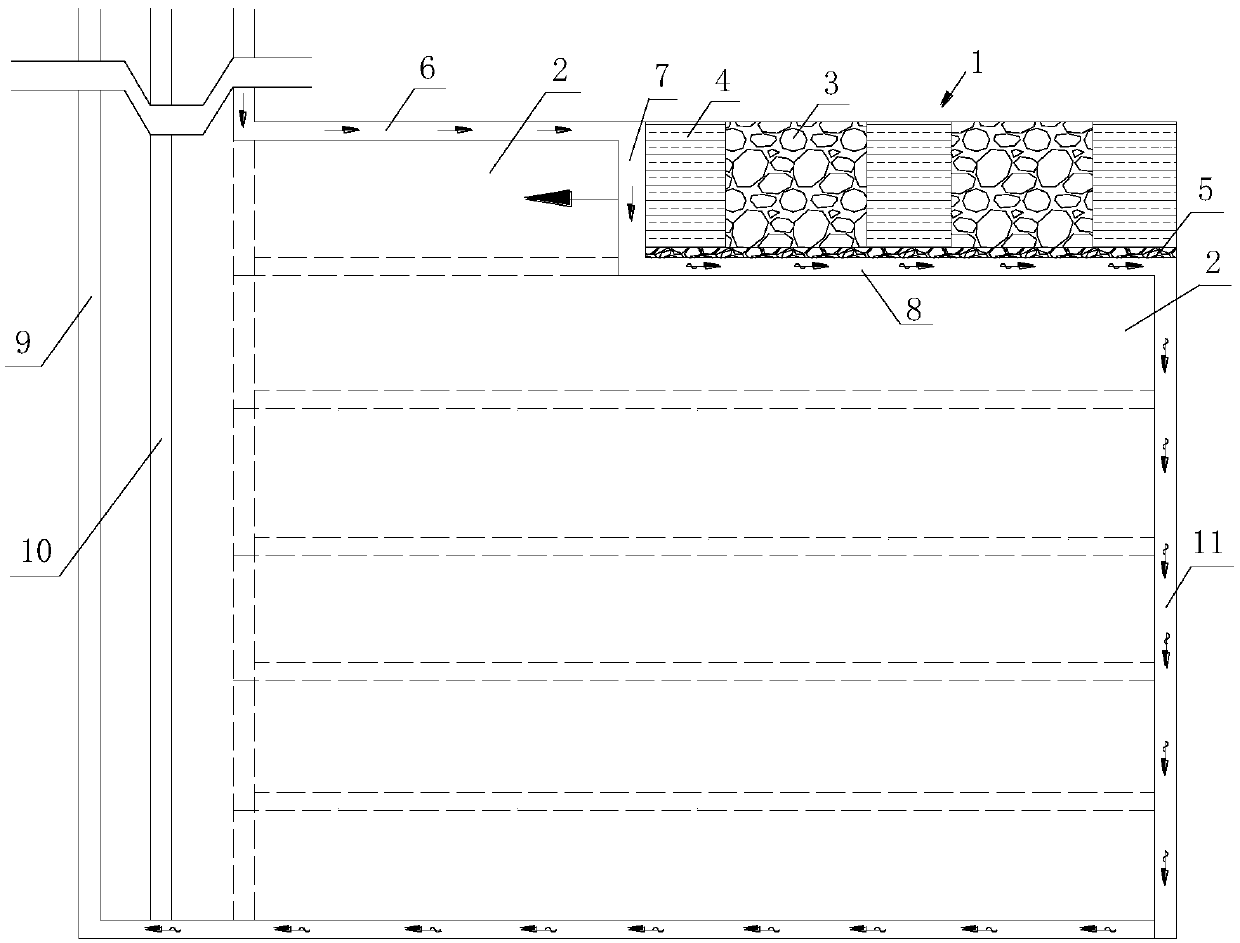

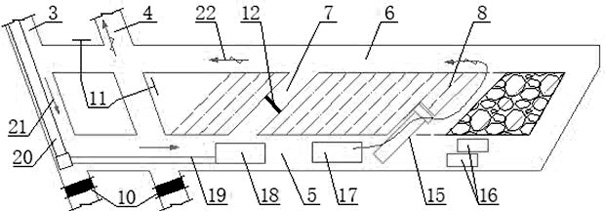

N00 mining method adopting mode of top cutting for filling

ActiveCN109630112AShorten the lengthGuaranteed stabilityUnderground miningSurface miningMining engineeringEarth surface

The invention relates to an N00 mining method adopting a mode of top cutting for filling. The problems in the prior art that the structure stability of a stope is poor, the earth surface sinks and isdeformed, and gangue is stacked on the earth surface are solved. The N00 mining method is characterized in that a plurality of mining work surfaces are arranged in a brand new panel, no-roadway tunneling is adopted, and in the mining process, gob-side entry retaining is achieved; after 10 m of the coal layer is mined completely, the immediate roof is mined, the width of the mined immediate roof is7 m, after one-time roof cutting, a roof cutting area is formed, and then roofs of the roof cutting area automatically fall for filling; mining continues forward by adopting the work surfaces, a newgoaf is filled with broken rock stored in a temporary storage chamber and gangue on the earth surface, the roofs of the roof cutting area fall for applying constraint to the two sides. The method improves the mining efficiency, resources are saved, subsidence is effectively controlled, transportation of gangue under a well is reduced, the gangue is directly utilized under the well, the problem ofaccumulating of the gangue on the ground is solved, and the method can be widely applied to the technical field of filling and mining for coal mines under wells.

Owner:SHANDONG UNIV OF SCI & TECH

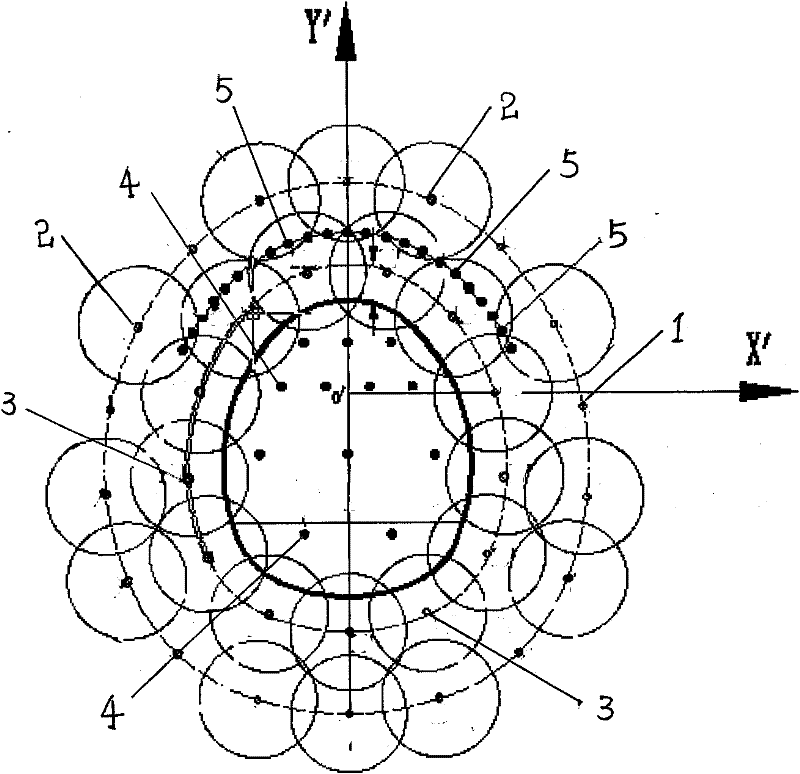

Gradient-type supporting method for selective laser melting forming of three-dimensional flow shrouded impeller

InactiveCN108374802AShorten the manufacturing cycleReduce support strengthPump componentsPumpsImpellerSelective laser melting

The invention provides a gradient-type supporting method for selective laser melting forming of a three-dimensional flow shrouded impeller. In the process of selective laser melting forming of the three-dimensional flow shrouded impeller, supporting structures of different strength are designed according to the distance from the forming part of the impeller to the opening part of the impeller andthe magnitude of an overhanging angle. Aiming at the structural characteristics of the three-dimensional flow shrouded impeller, a gradient-type supporting structure is designed according to the length from different parts of an inner cavity of the impeller to the opening part of the impeller and the overhanging angle. Under the condition that deformation in the process of selective laser meltingforming of the impeller is effectively controlled, the supporting strength is locally reduced, the supporting forming time is shortened, the difficulty of supporting removal is reduced, the workload is reduced, and the overall manufacturing cycle of the impeller is shortened.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

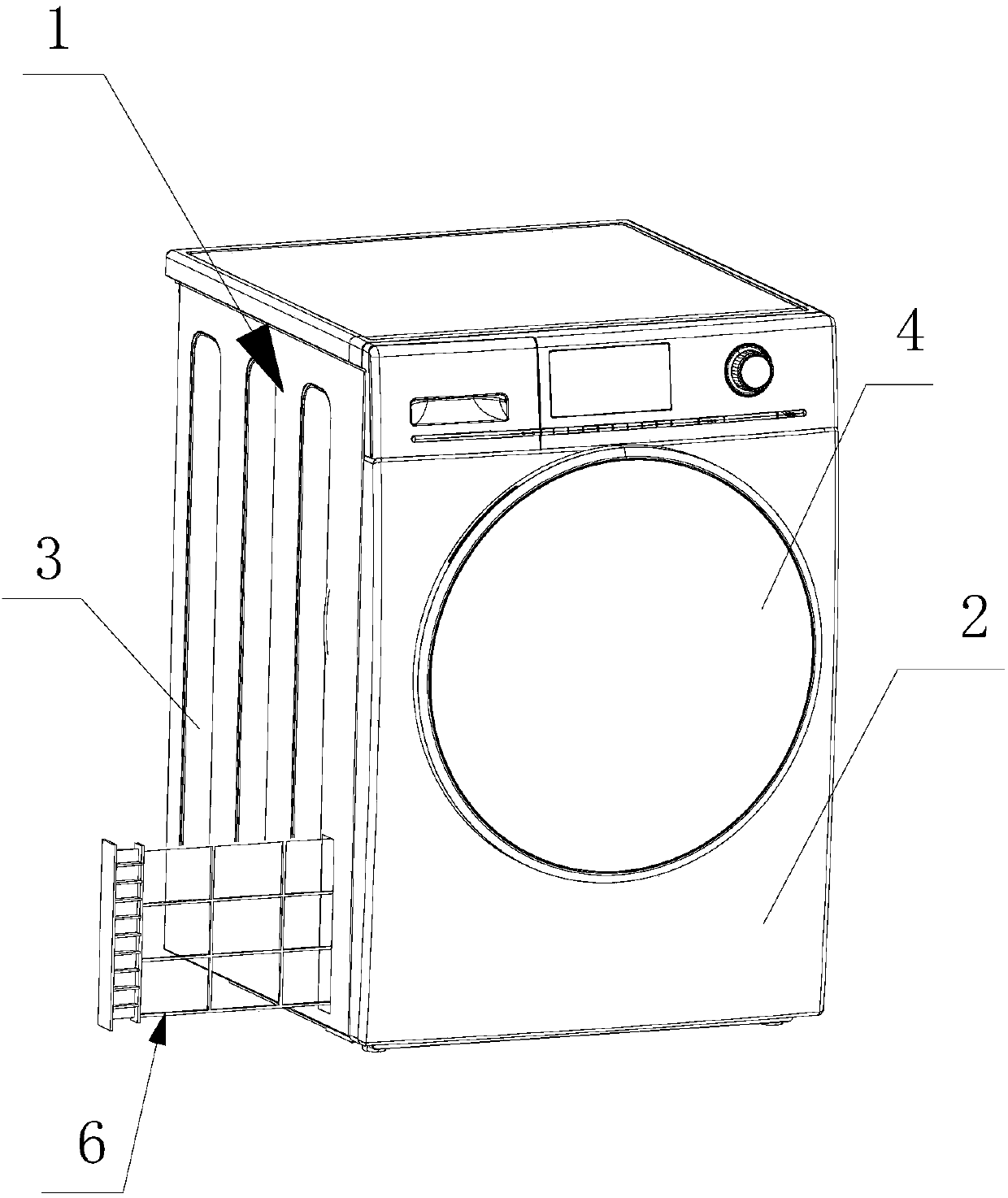

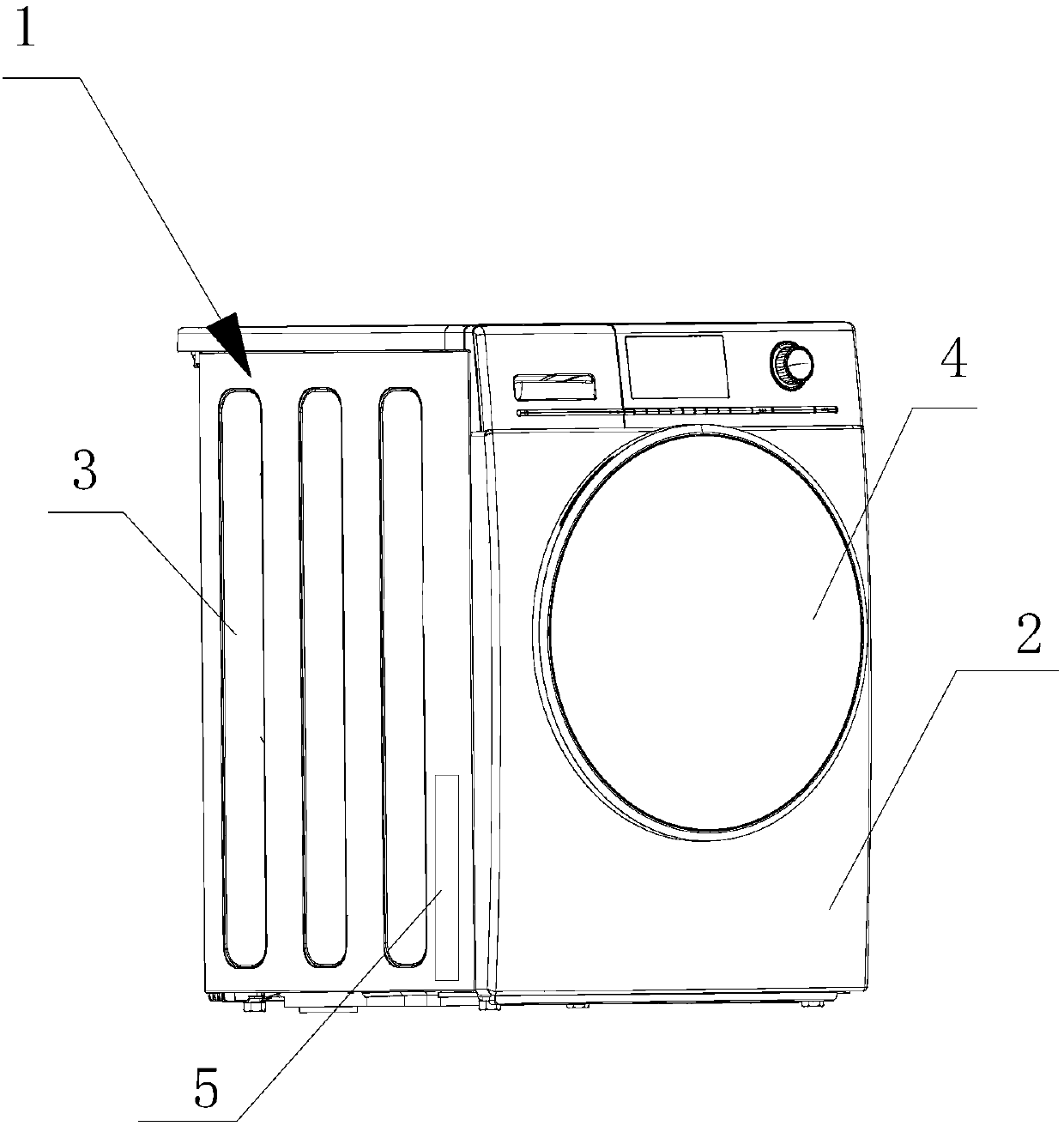

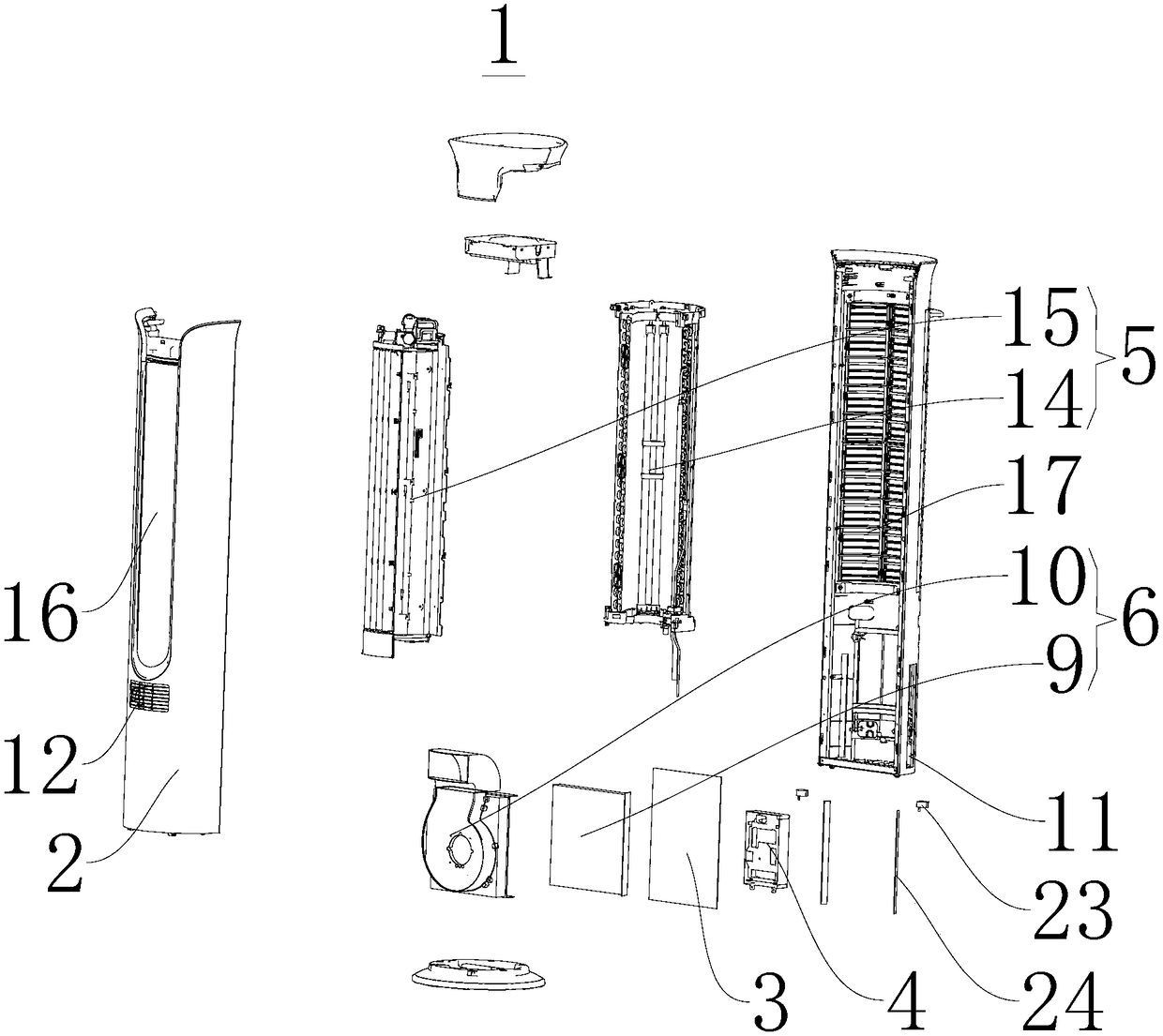

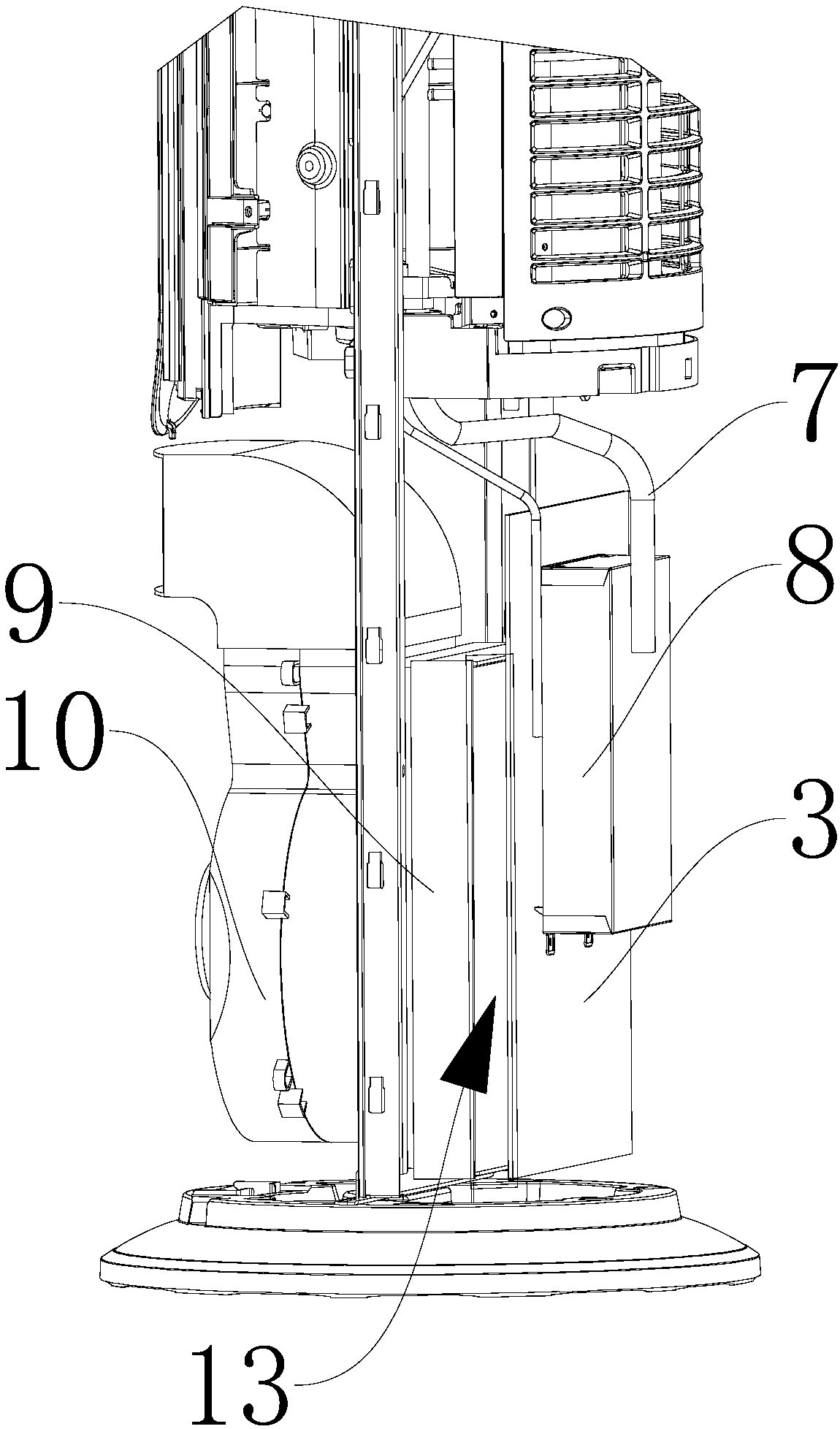

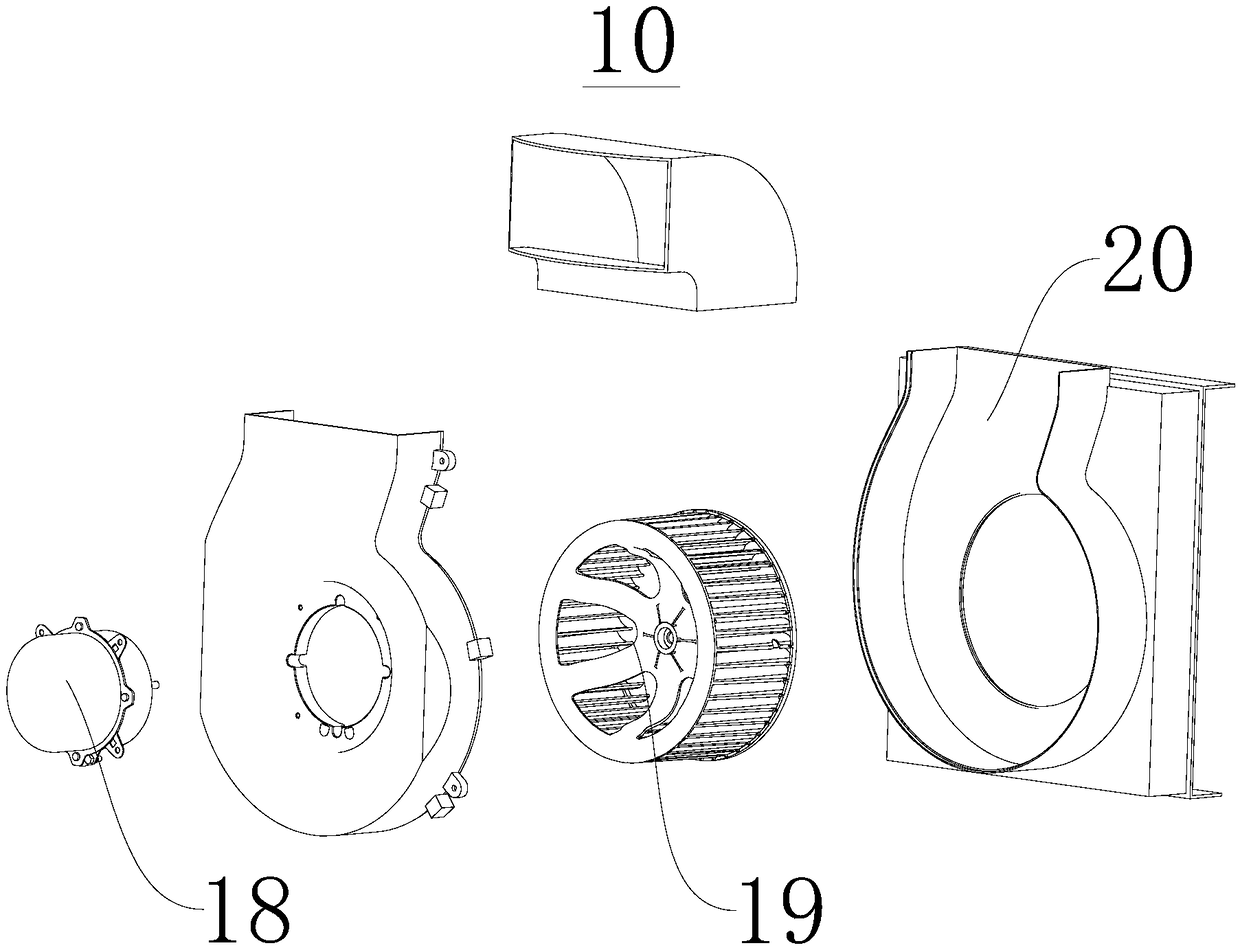

Clothes dryer

InactiveCN109898309AGuaranteed one-piece appearanceReduce support strengthTextiles and paperLaundry driersEngineeringStructural stability

The invention discloses a clothes dryer. The clothes dryer comprises a casing and a filtering device. A drying air duct is arranged in the casing; the casing comprises a front panel and side panels connected with the front panel, and the front panel is provided with a clothes feeding inlet; a mounting opening is formed in each side panel, and the filtering device is inserted and mounted in the drying air duct through the mounting openings. In the clothes dryer, the mounting openings for the filtering device are formed in the side panels of the casing, the filtering device can be inserted and mounted in the air duct through the side panels, and the mounting openings for the filtering device are prevented from being formed in the front panel, so that the integrated appearance of the front panel is ensured, and the problems that the supporting strength of a front support is reduced and the structural stability of the overall clothes dryer is not ensured when a large mounting opening for the filtering device is formed in one surface, facing the front panel, of the front support are avoided.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

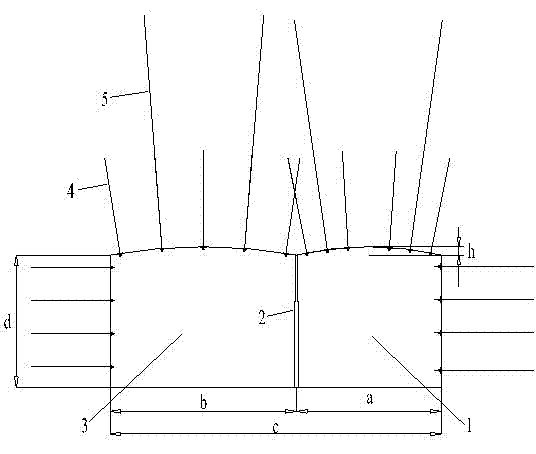

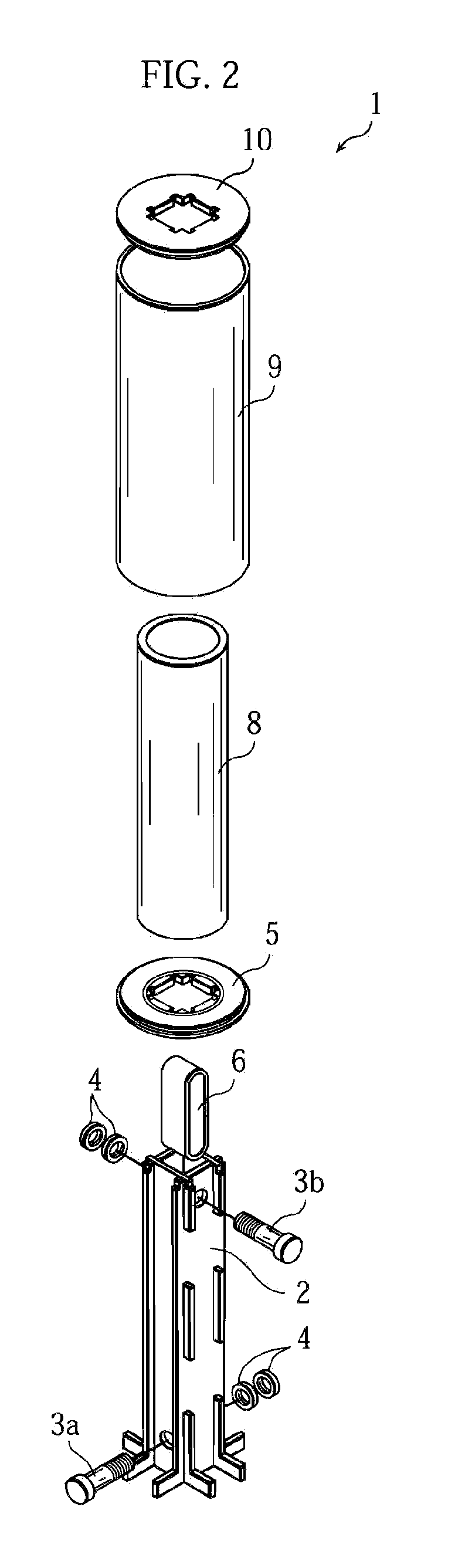

Temporary pier construction method adopting assembled heavy steel pipe supporting device

ActiveCN105568860AReduce the difficulty of assemblyEasy to installBridge erection/assemblyEngineeringPipe support

The invention relates to the technical field of bridge building construction, in particular to a temporary pier construction method. The method sequentially comprises the following steps: A: pouring a base used for supporting an assembled heavy steel pipe supporting device in a design position; B: according to a design requirement, making members of the assembled heavy steel pipe supporting device; and C: assembling the assembled heavy steel pipe supporting device on the base, wherein the height of the base ensures the assembled heavy steel pipe supporting device to have sufficient supporting strength, rigidity and stability vertically and horizontally. According to the scheme provided by the invention, the height of the base and the height of the assembled heavy steel pipe supporting device are coordinated, so that on the premise of ensuring the temporary pier to have reliable supporting strength, the construction difficulty of the temporary pier is lowered, the project time is shortened, and the construction cost and time are saved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

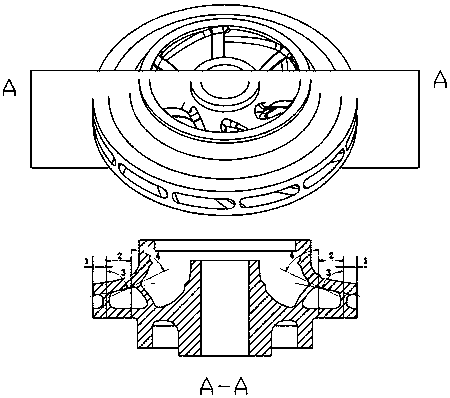

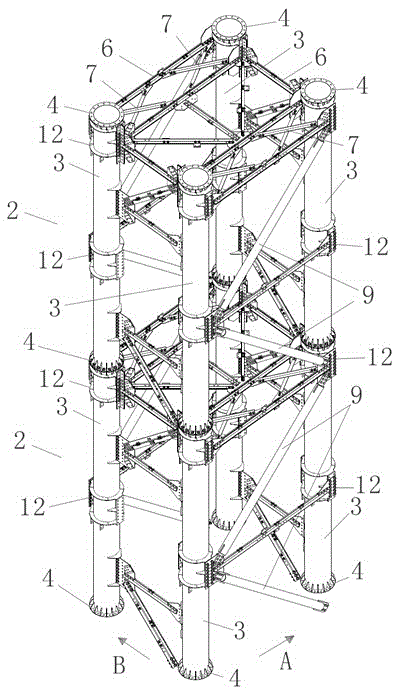

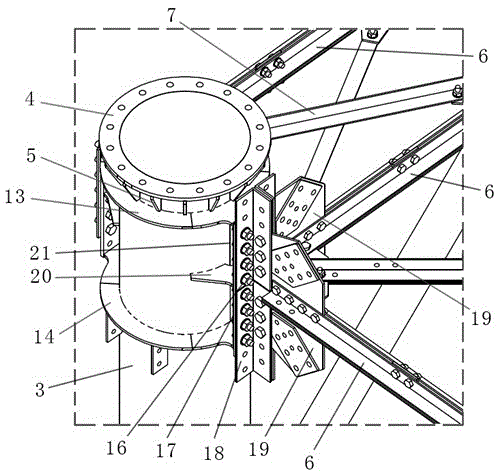

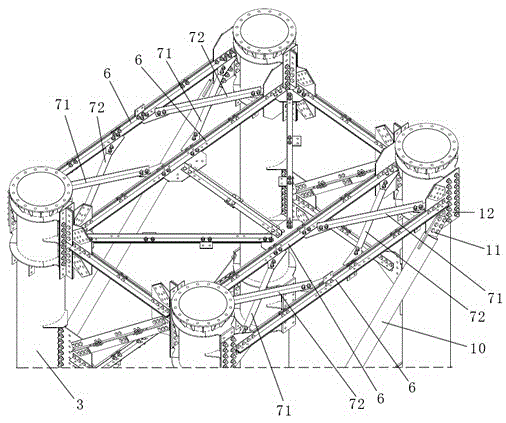

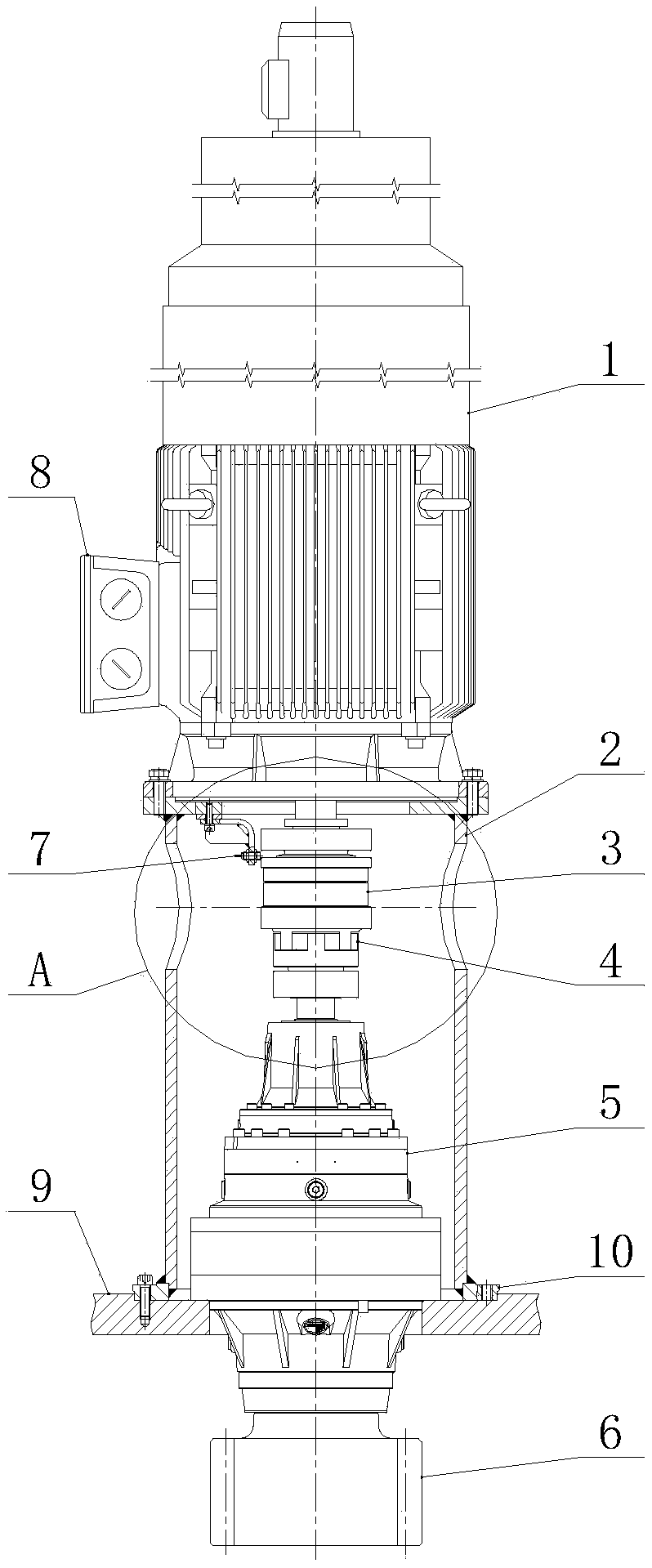

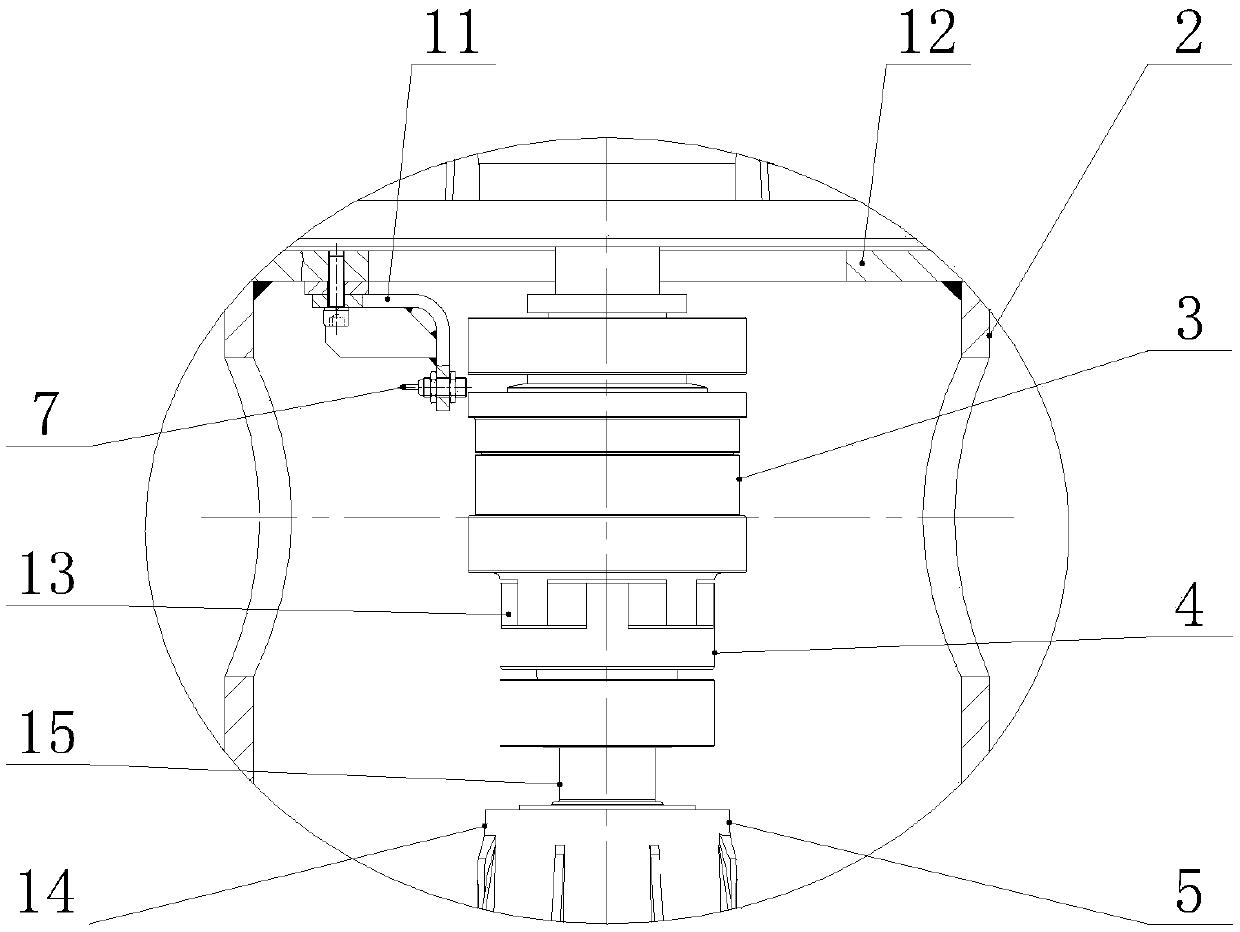

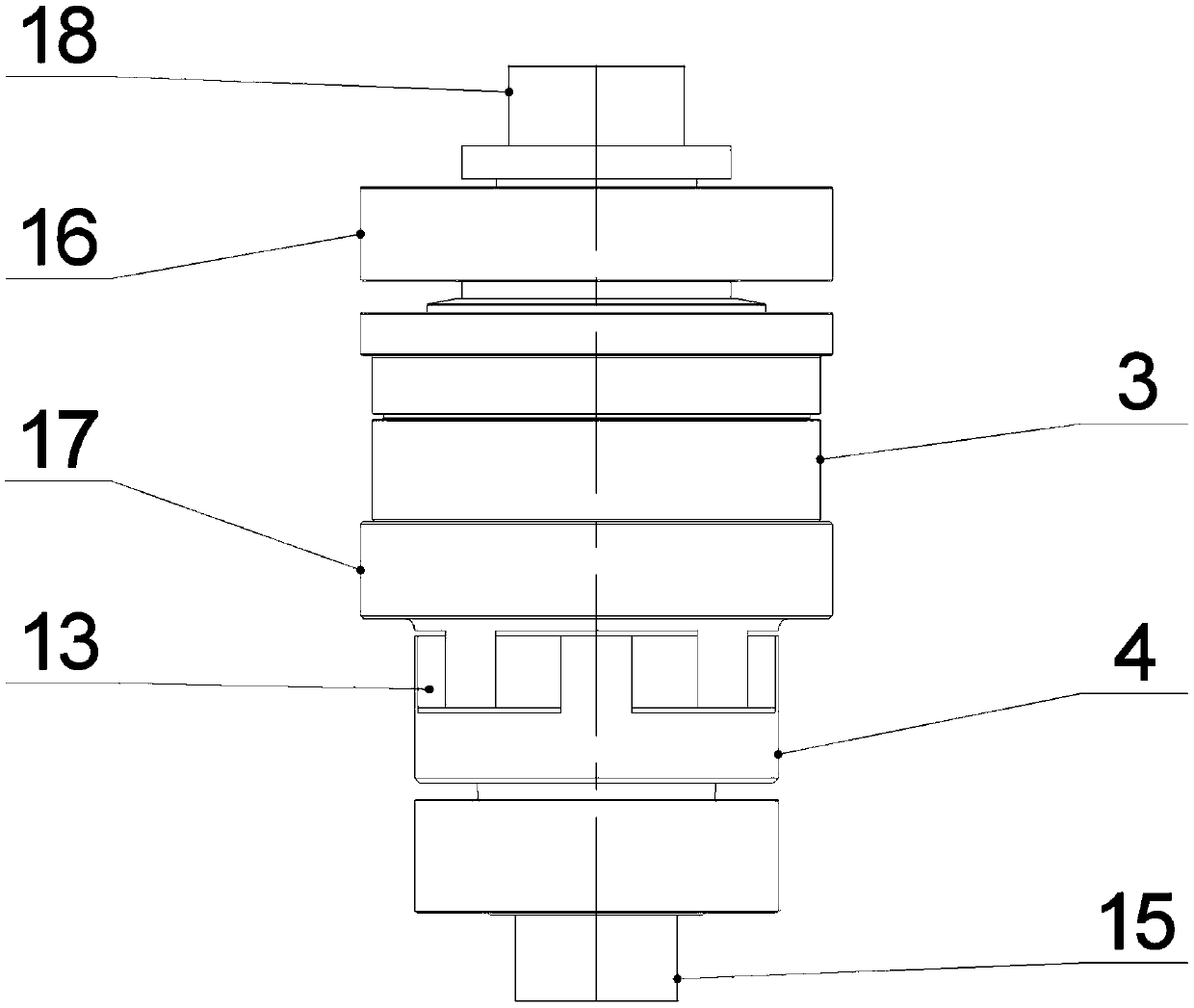

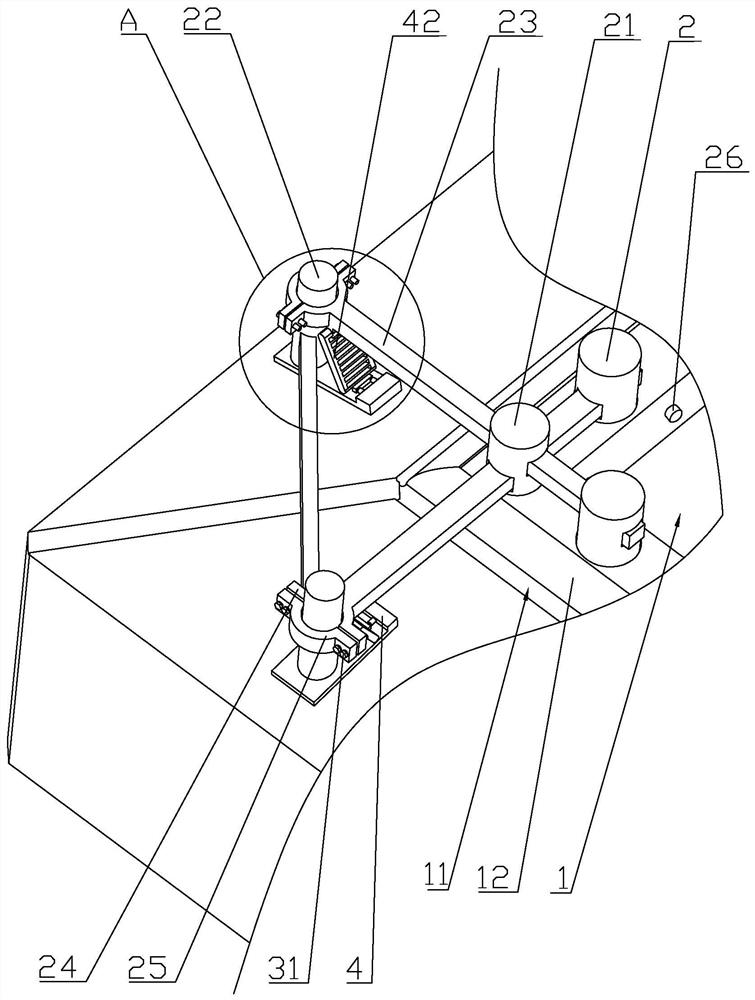

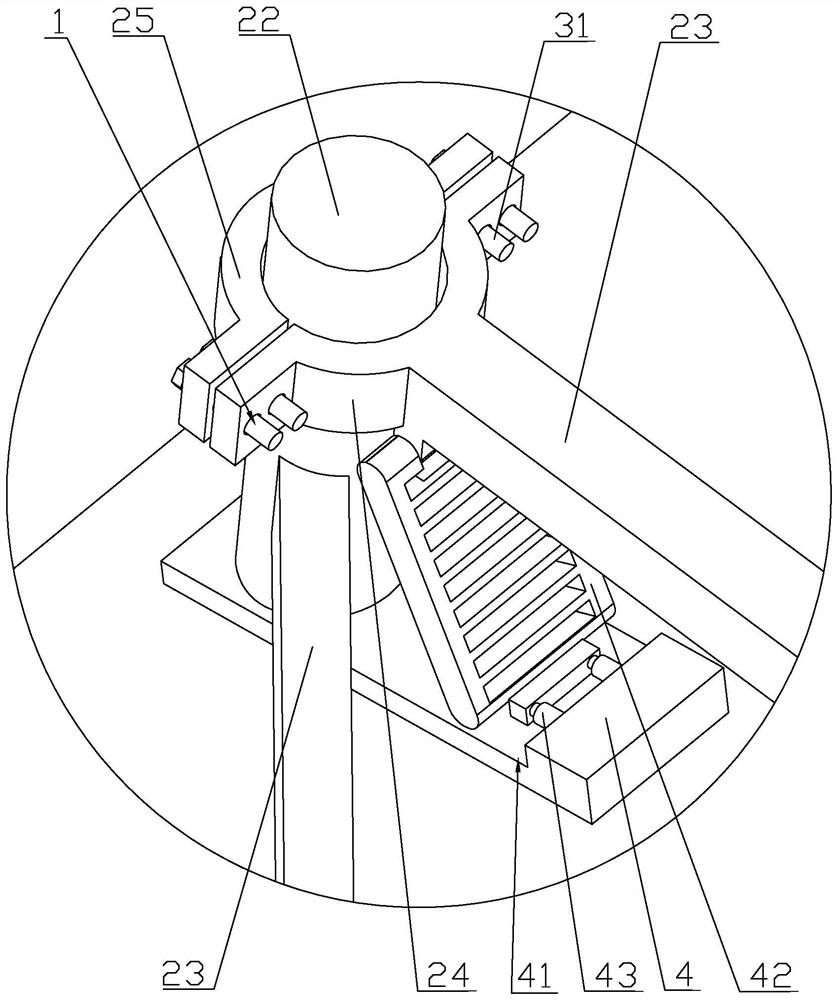

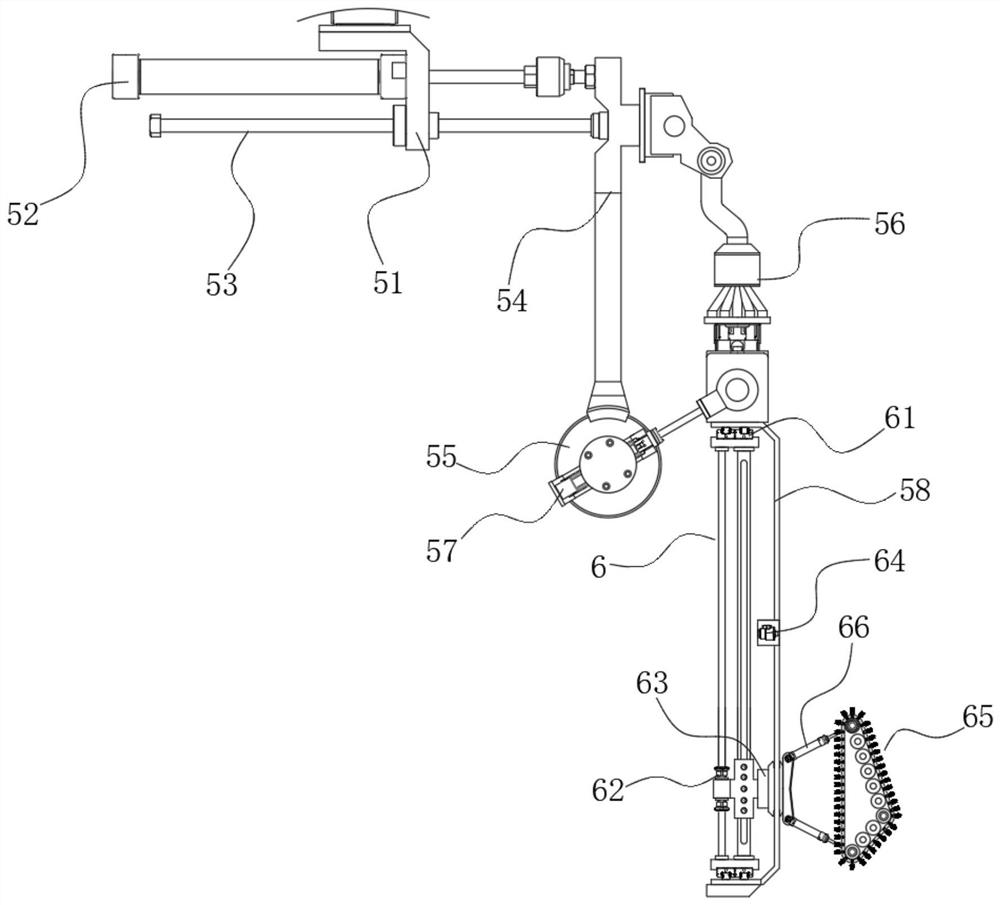

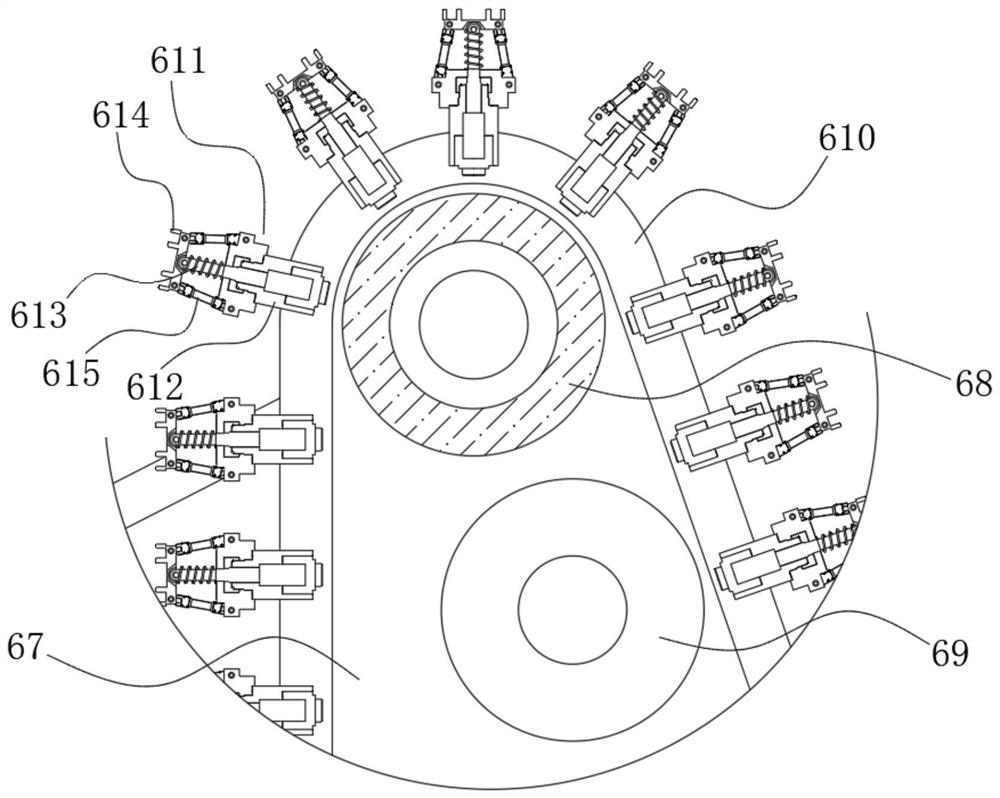

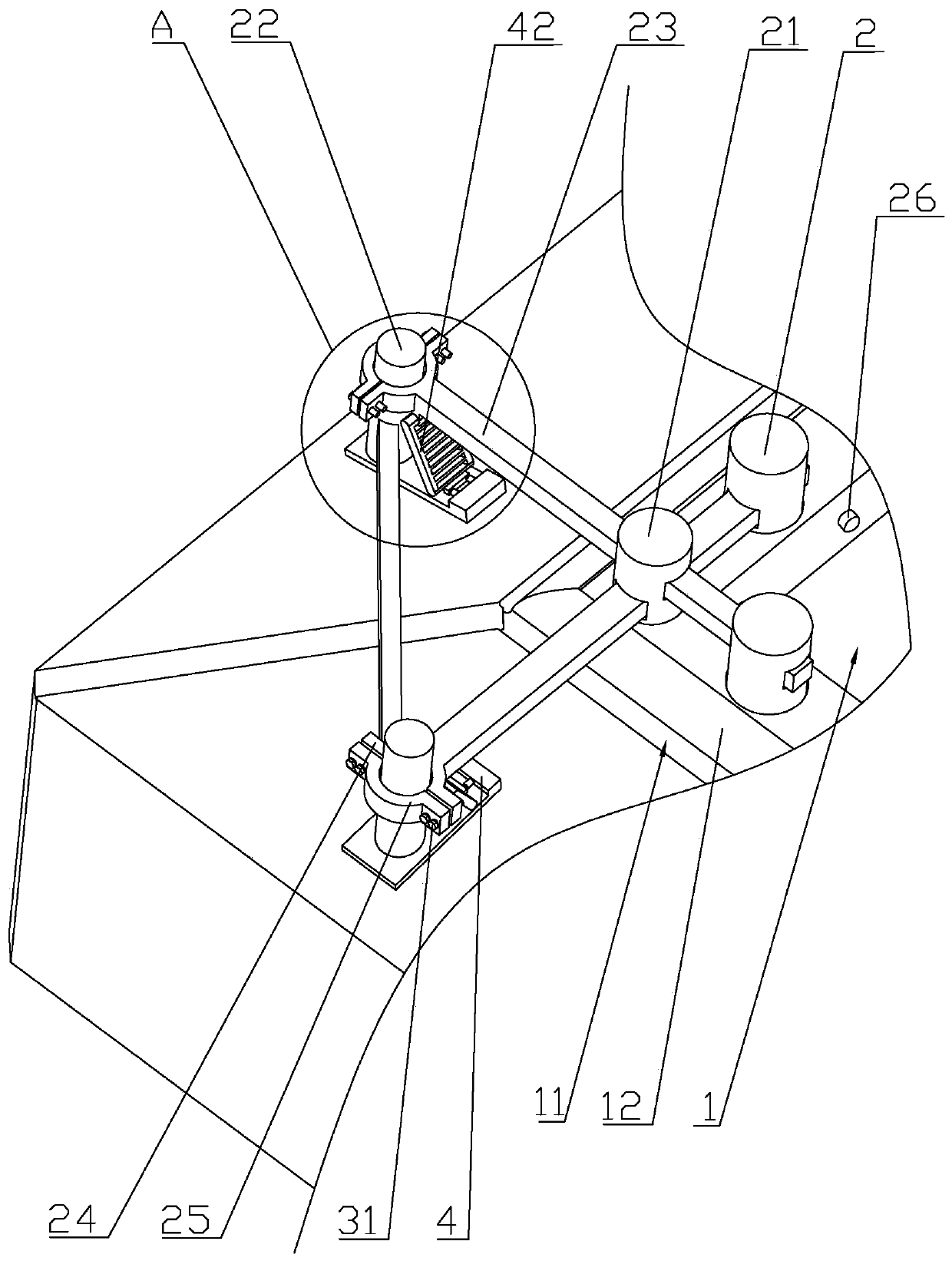

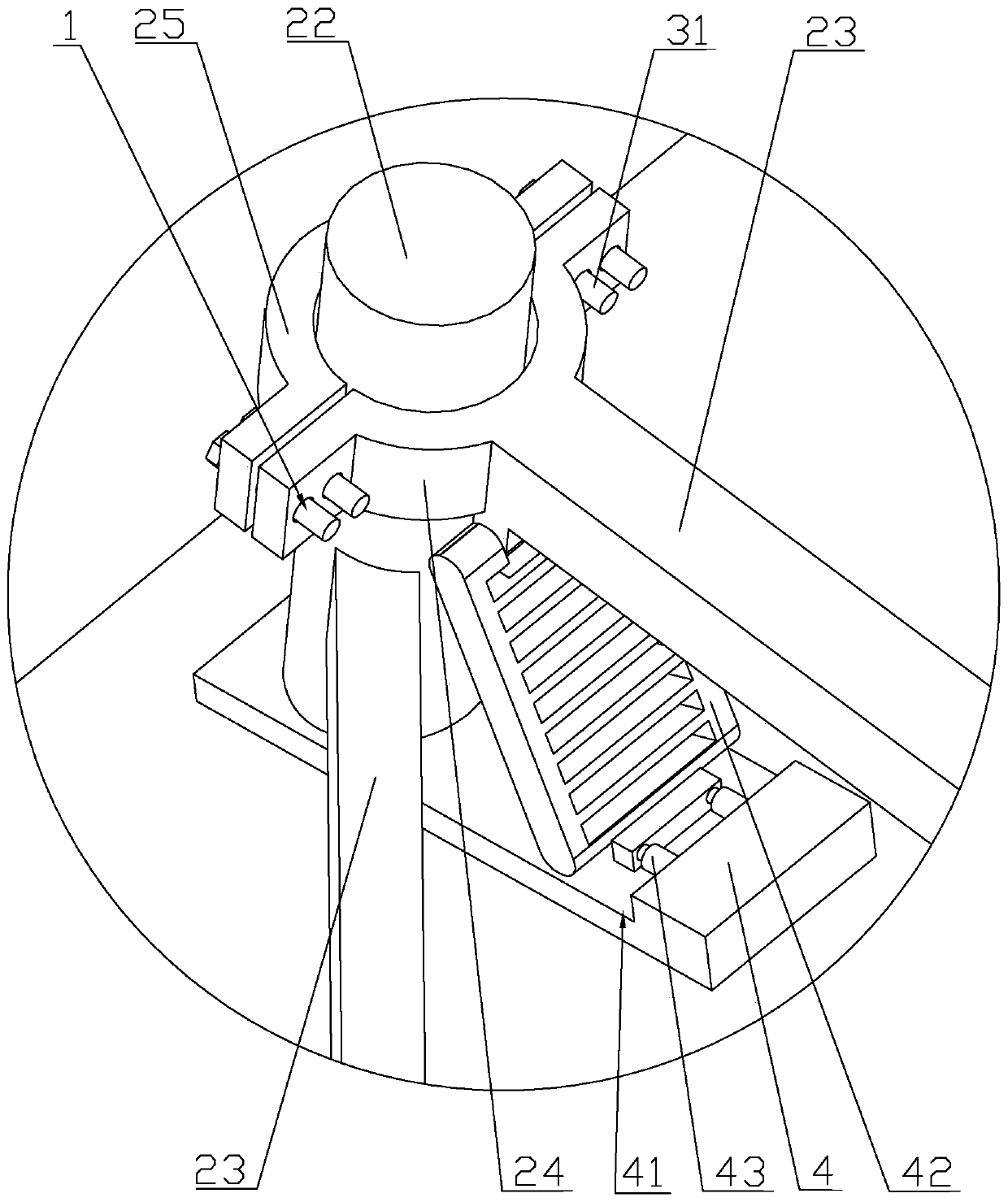

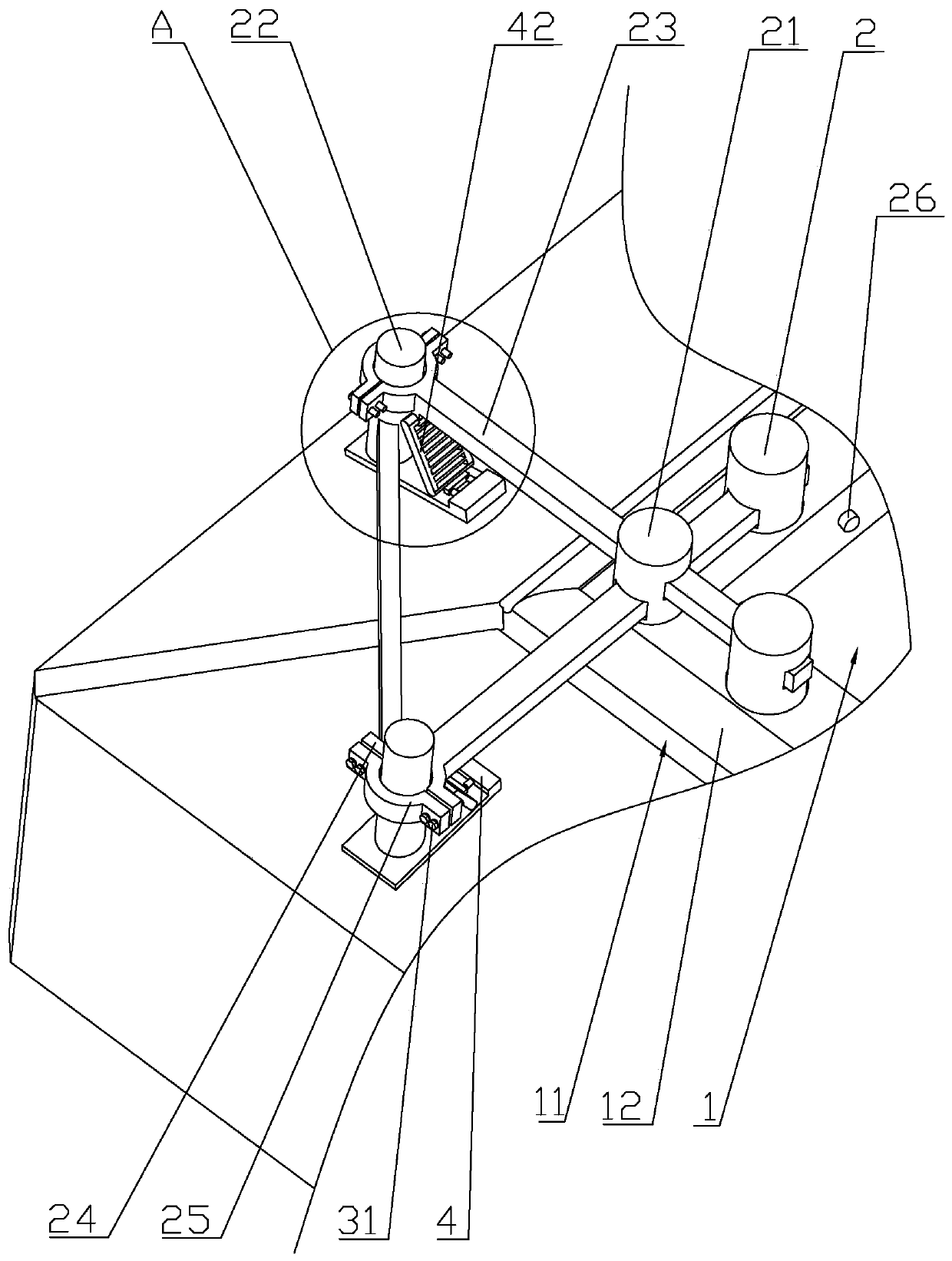

Motor steering transmission system for full-revolving propulsor

InactiveCN109533262AReduce support strengthReduced carrying capacitySteering ruddersSurface mountingControl theory

The invention discloses a motor steering transmission system for a full-revolving propulsor. The motor steering transmission system comprises a steering motor bracket, transverse plates and a mountingflange, wherein two ends of the steering motor bracket are fixedly installed through matching of two sets of parallel transverse plates and the mounting flanges, the upper end surface of the transverse plate at the upper end is fixedly mounted with a steering motor, and the bottom end surface of the mounting flange at the bottom end is provided with a rotary propeller. The steering motor of the motor steering transmission system for the full-revolving propulsor is supported by an independent steering motor bracket, so that the rigidity of the whole system is increased, and the support strength of a speed-reducing gear box is reduced. When the steering transmission system encounters a large external force, a safe clutch can be automatically disengaged to play a protecting effect, a position sensor can provide an alarm indication, the reset operation of the safe clutch is very simple, consumes short time and has little impact on the operation of a ship, the elastic coupler can bear larger end face runout and radial runout between the steering motor and the speed-reducing gear box.

Owner:合肥倍豪海洋装备技术有限公司

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930BSolve world-class problemsGood effect of water separation and pressure reductionUnderground chambersTunnel liningWater flowEngineering

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

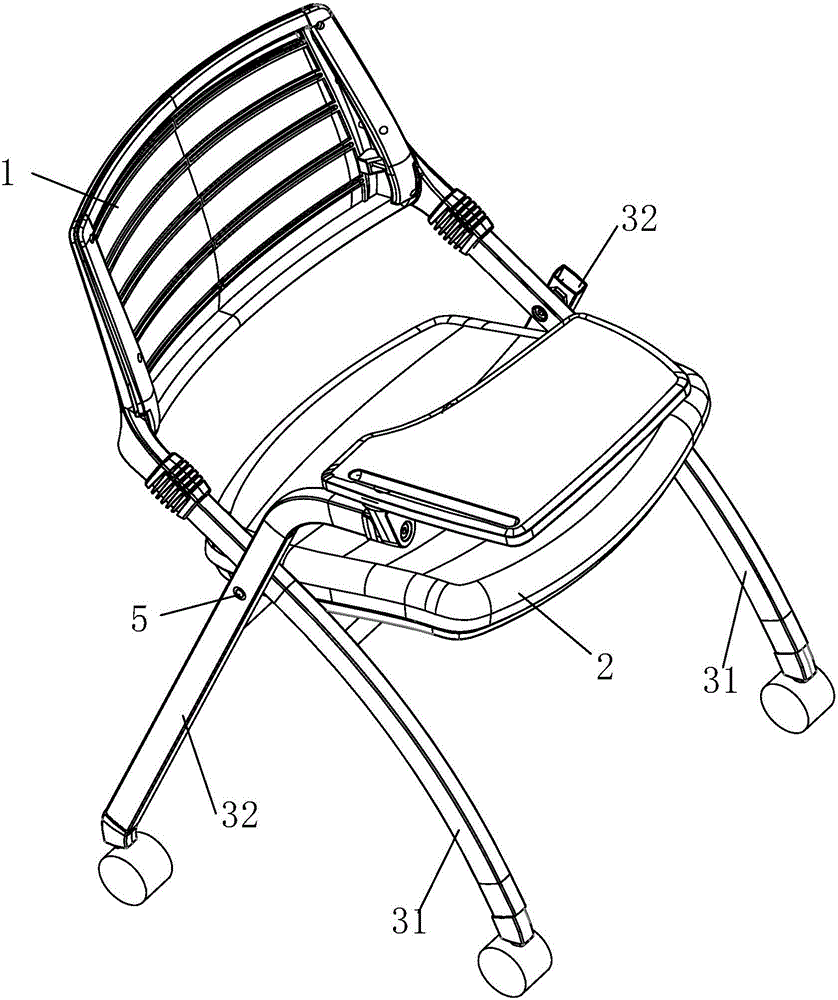

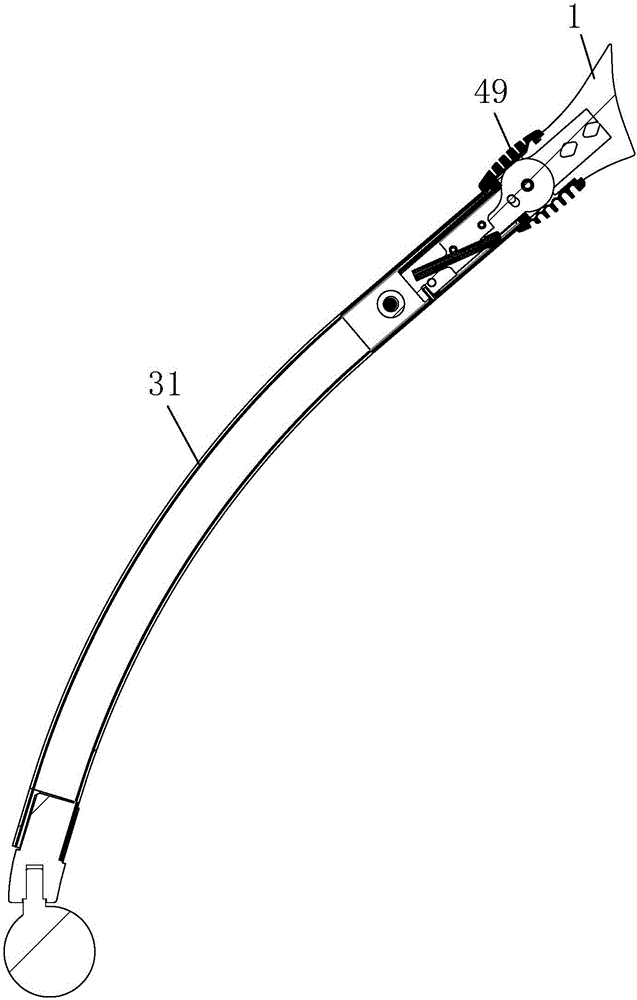

Conference chair

The invention relates to a conference chair. A rotary positioning mechanism is arranged at the joint of front chair legs and rear chair legs; due to the rotary positioning mechanism, the front chair legs and the rear chair legs can rotate opposite to each other to be folded or unfolded by a certain degree; a connecting rod A is fixed between the two rear chair legs; a connecting rod B is fixed between the two front chair legs; a seat is rotationally fixed on the connecting rod A; the chair is supported by the connecting rod A and the connecting rod B together; a chair back tilt adjusting assembly is arranged between the chair back and the front chair legs; and a writing board assembly is rotationally mounted on at least one rear chair leg. The conference chair has the beneficial effects that the structure is simple, the chair back can be slightly tilted, a user can conveniently perform conference records on the chair, and the chair can be folded and stored.

Owner:HENGLIN HOME FURNISHINGS CO LTD

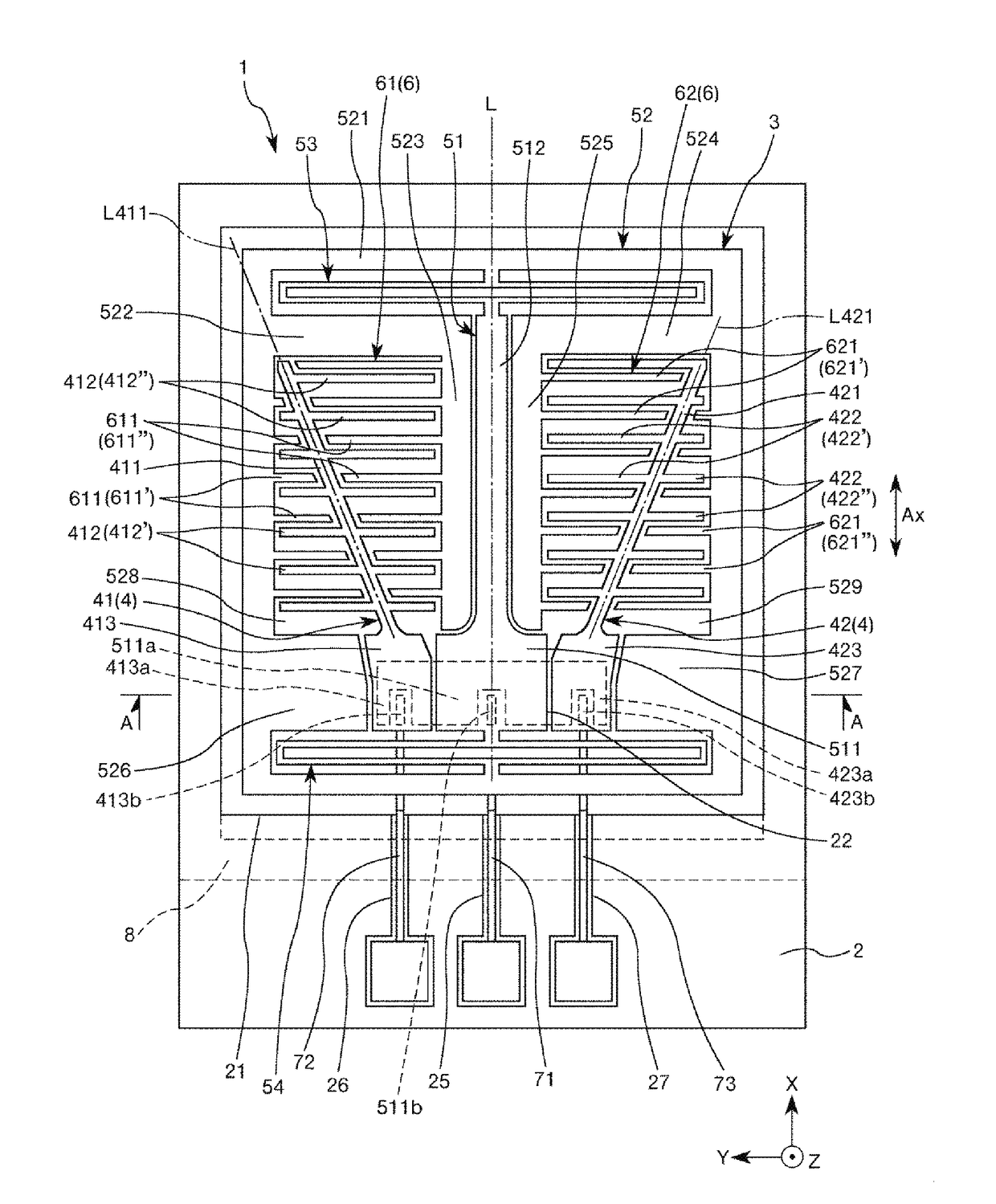

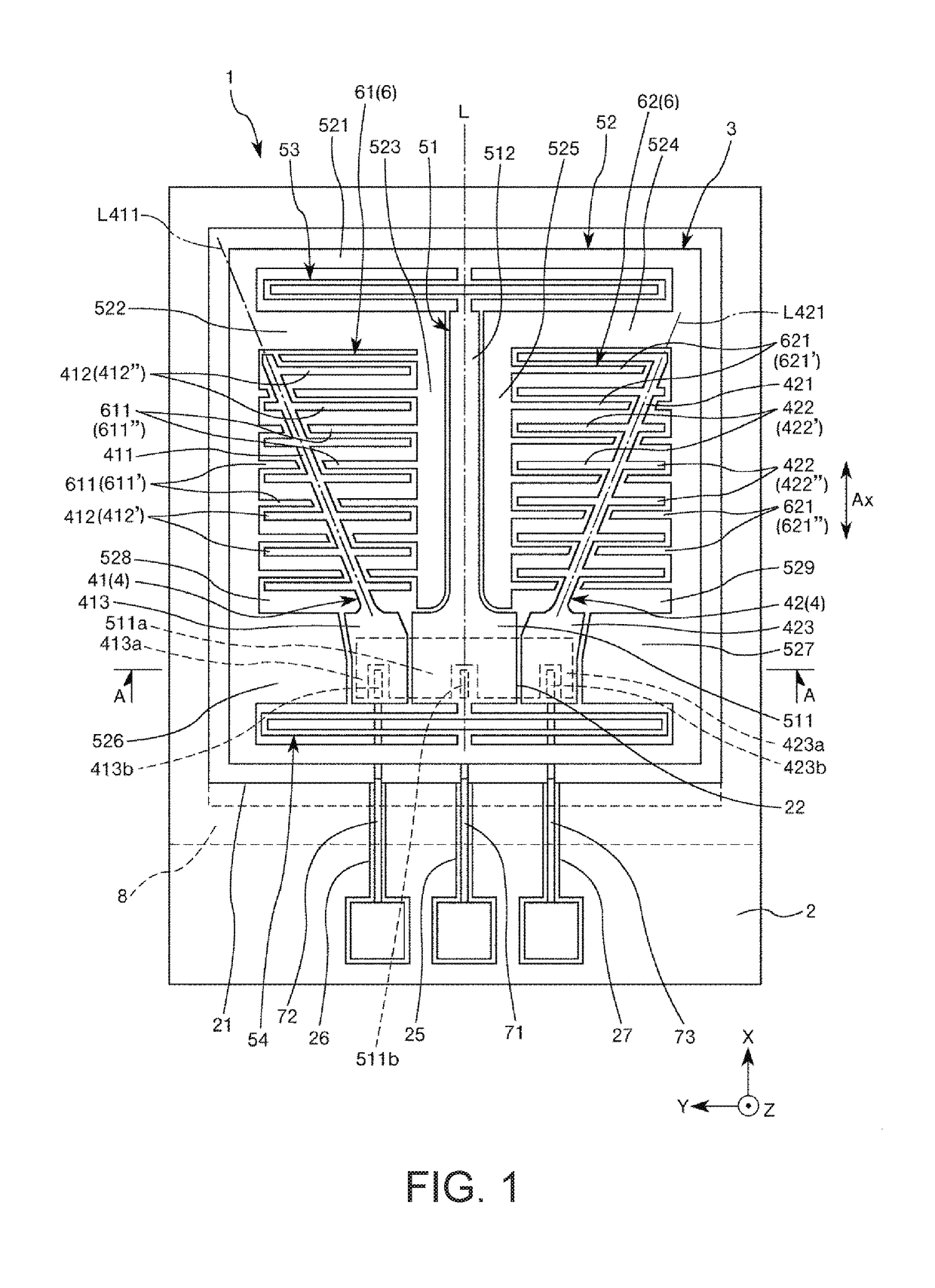

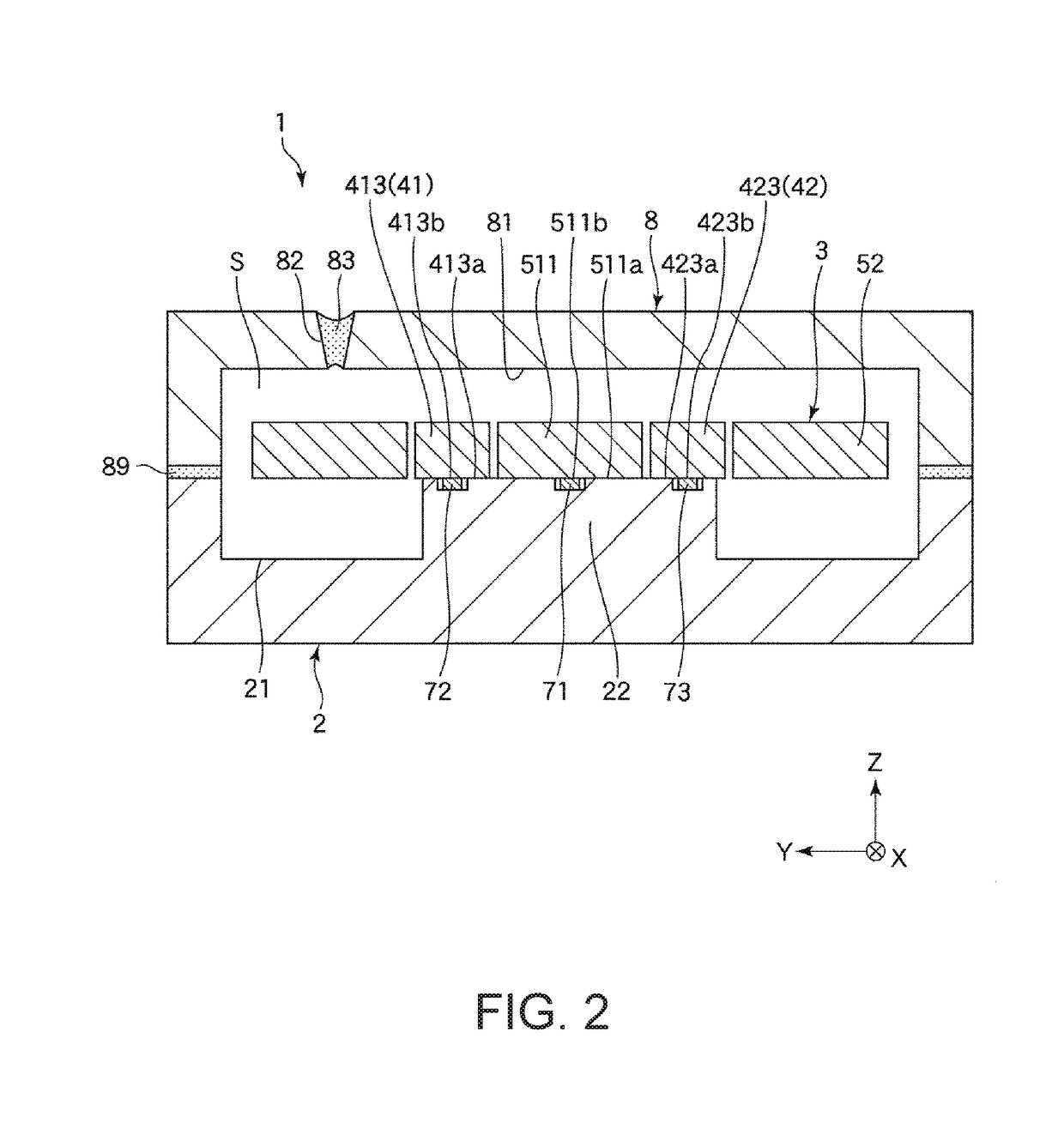

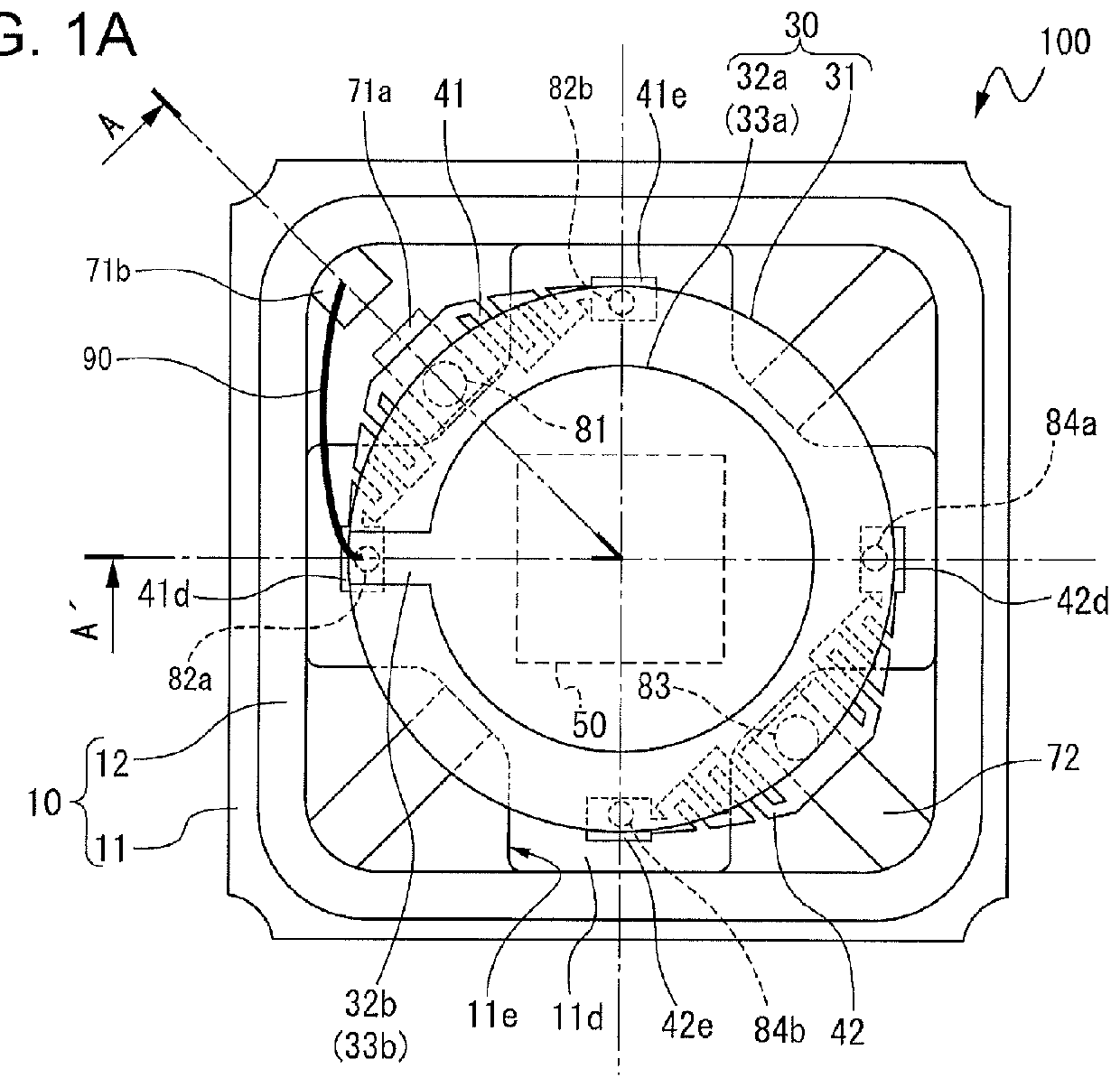

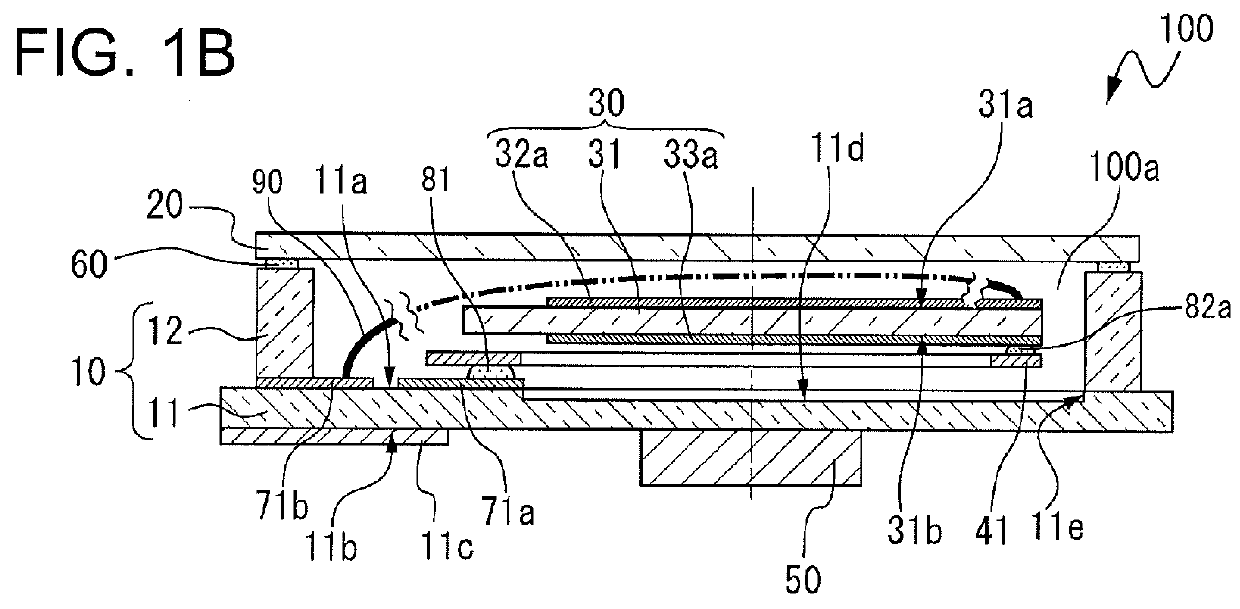

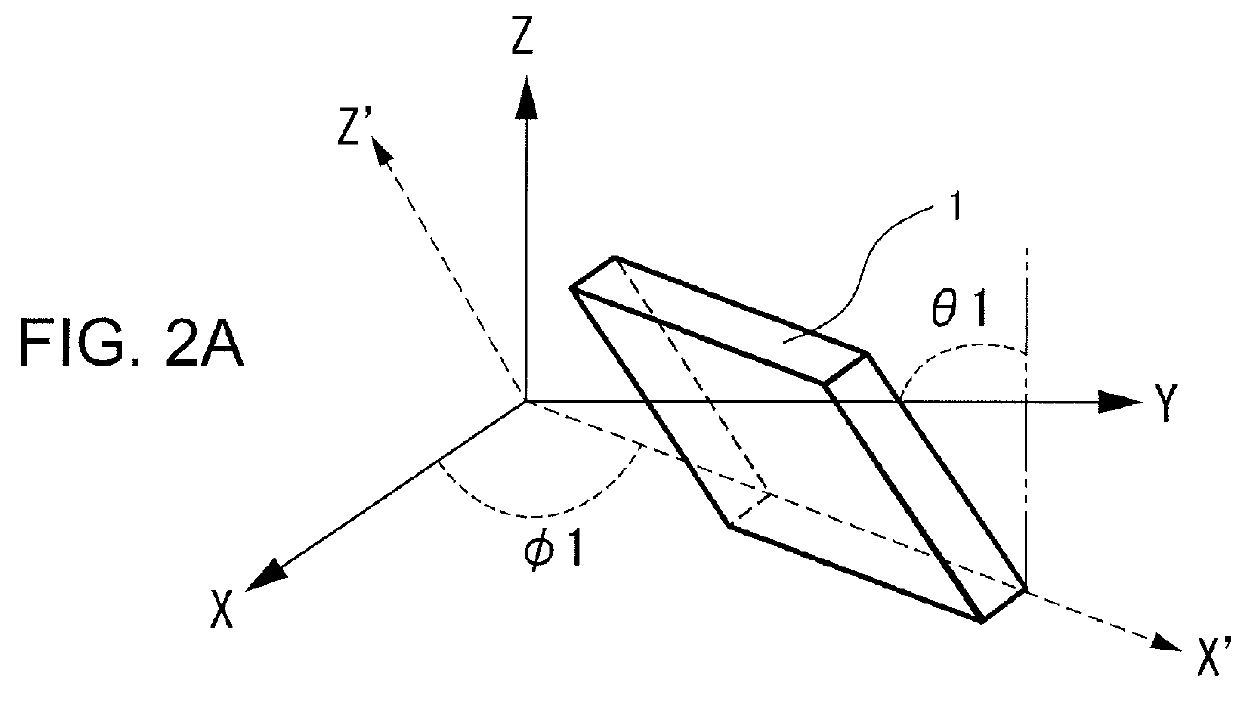

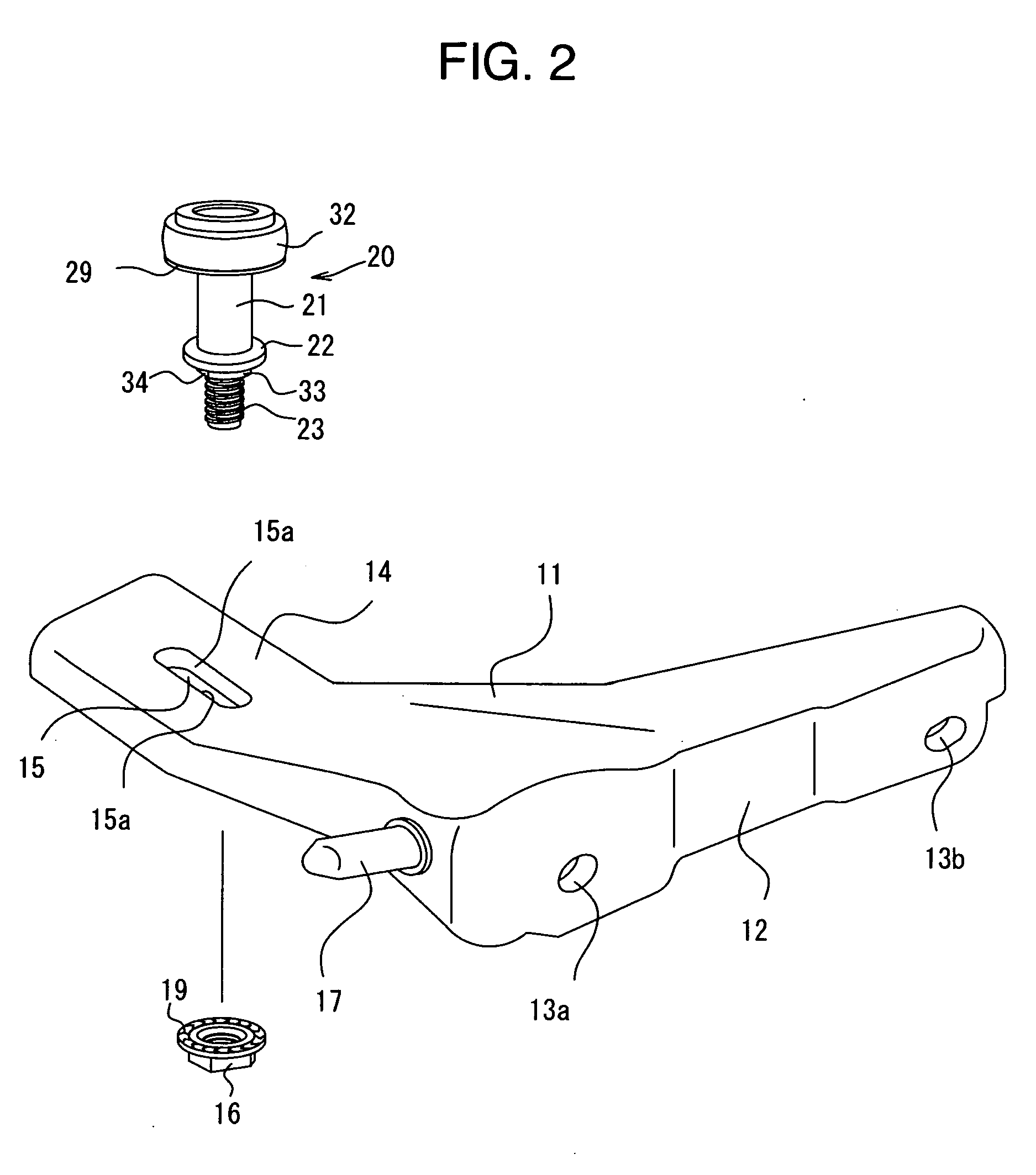

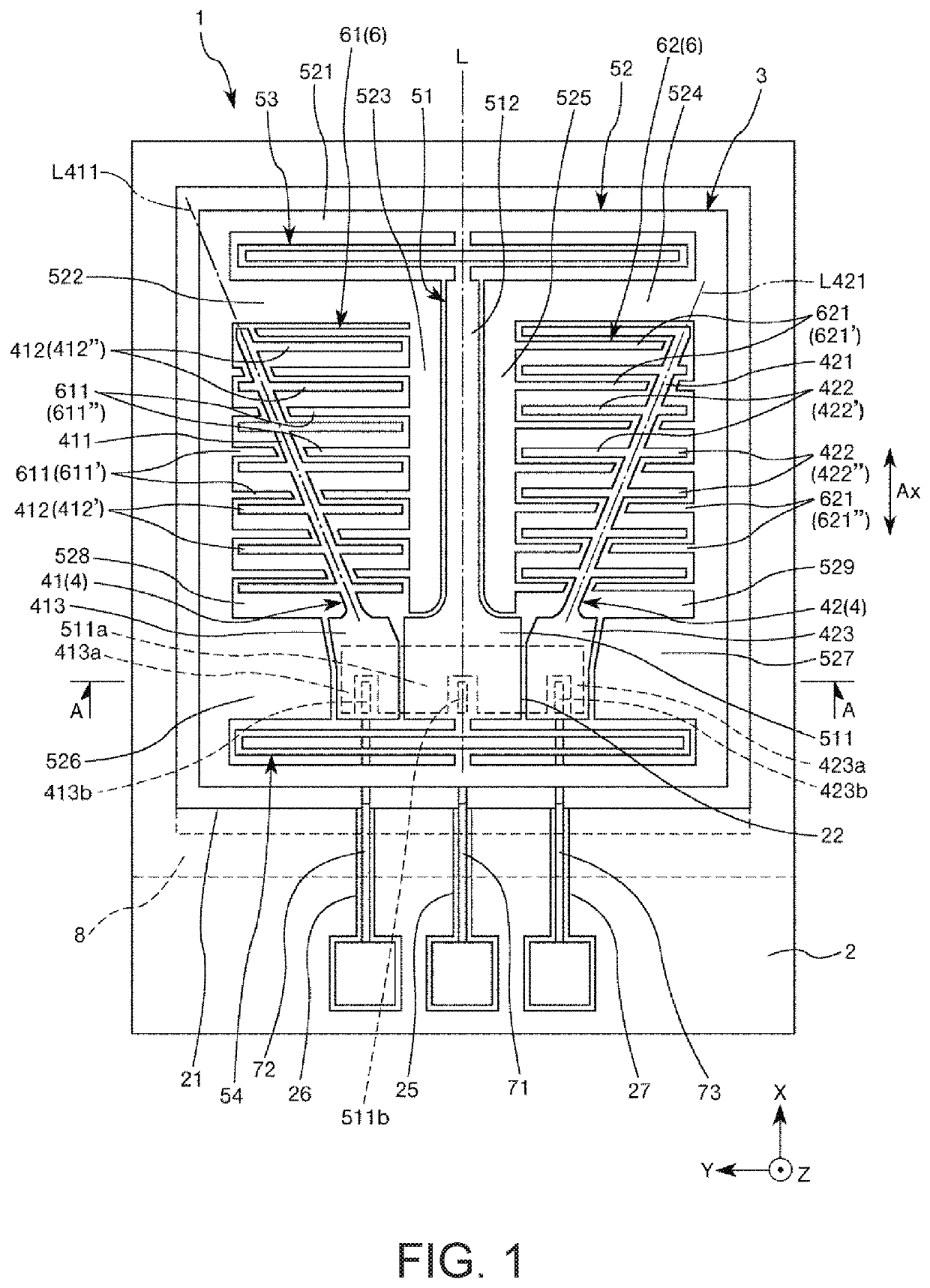

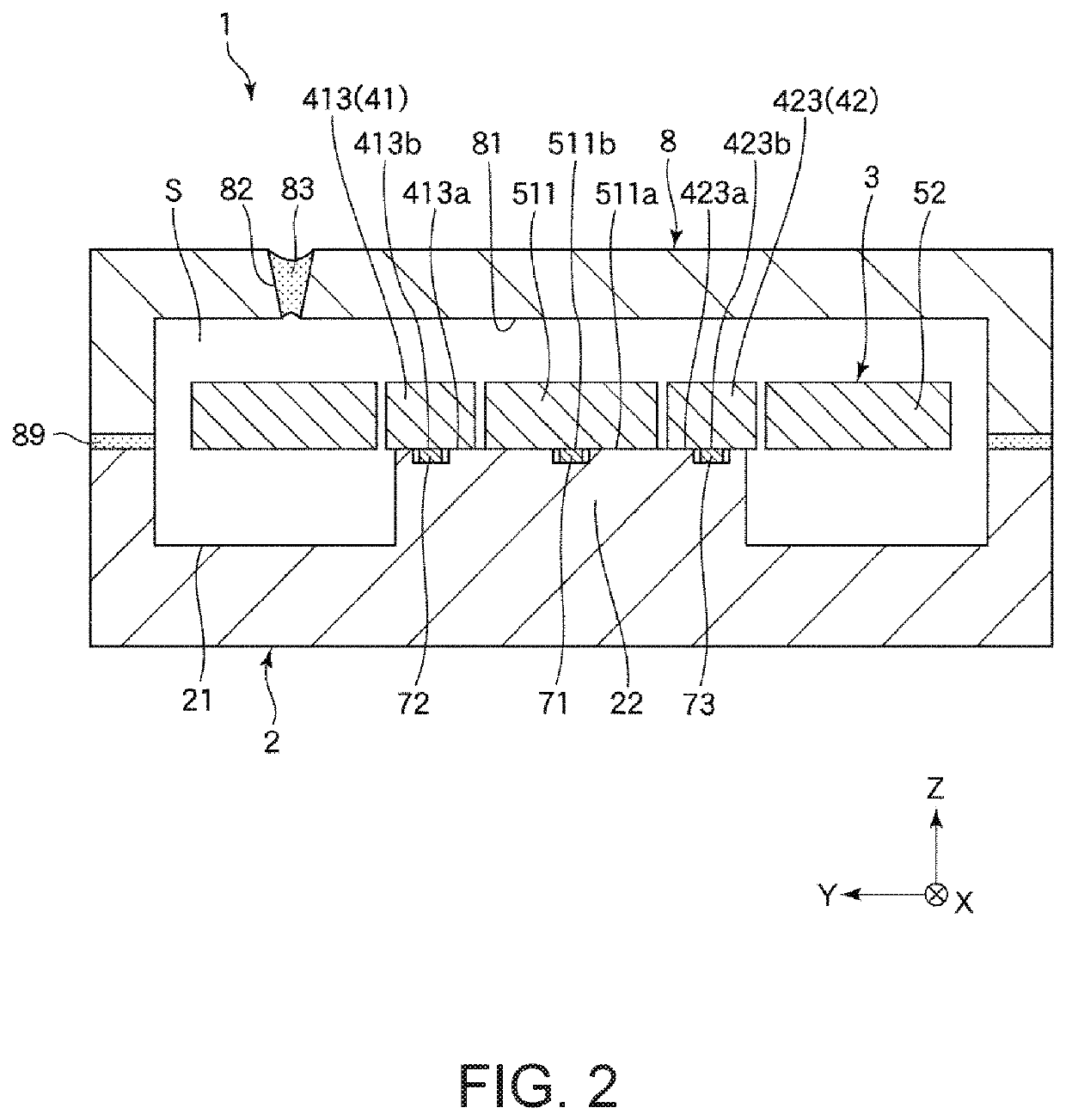

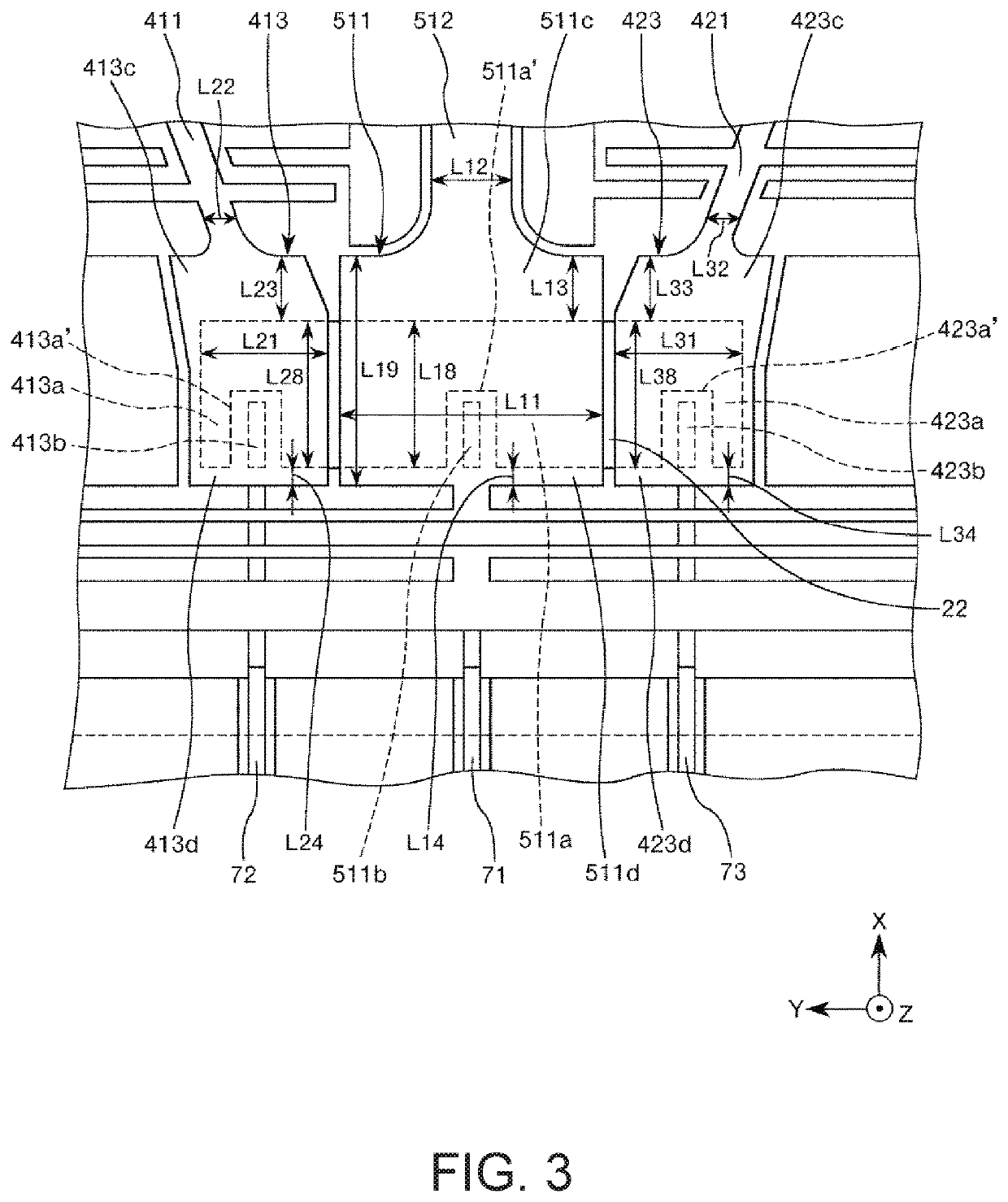

Physical quantity sensor, physical quantity sensor device, electronic apparatus, and vehicle

ActiveUS20180156840A1Reducing deterioration in temperature characteristicReduce support strengthAcceleration measurement using interia forcesResilient suspensionsEngineeringElectric devices

A physical quantity sensor includes: a base; wiring disposed in the base; a support that includes a first bonded surface bonded to the base and a second bonded surface bonded to the wiring; a suspension beam connected to the support; and an electrode finger supported by the suspension beam. The support is located between the first bonded surface and the suspension beam and includes a first overhang separated from the base.

Owner:SEIKO EPSON CORP

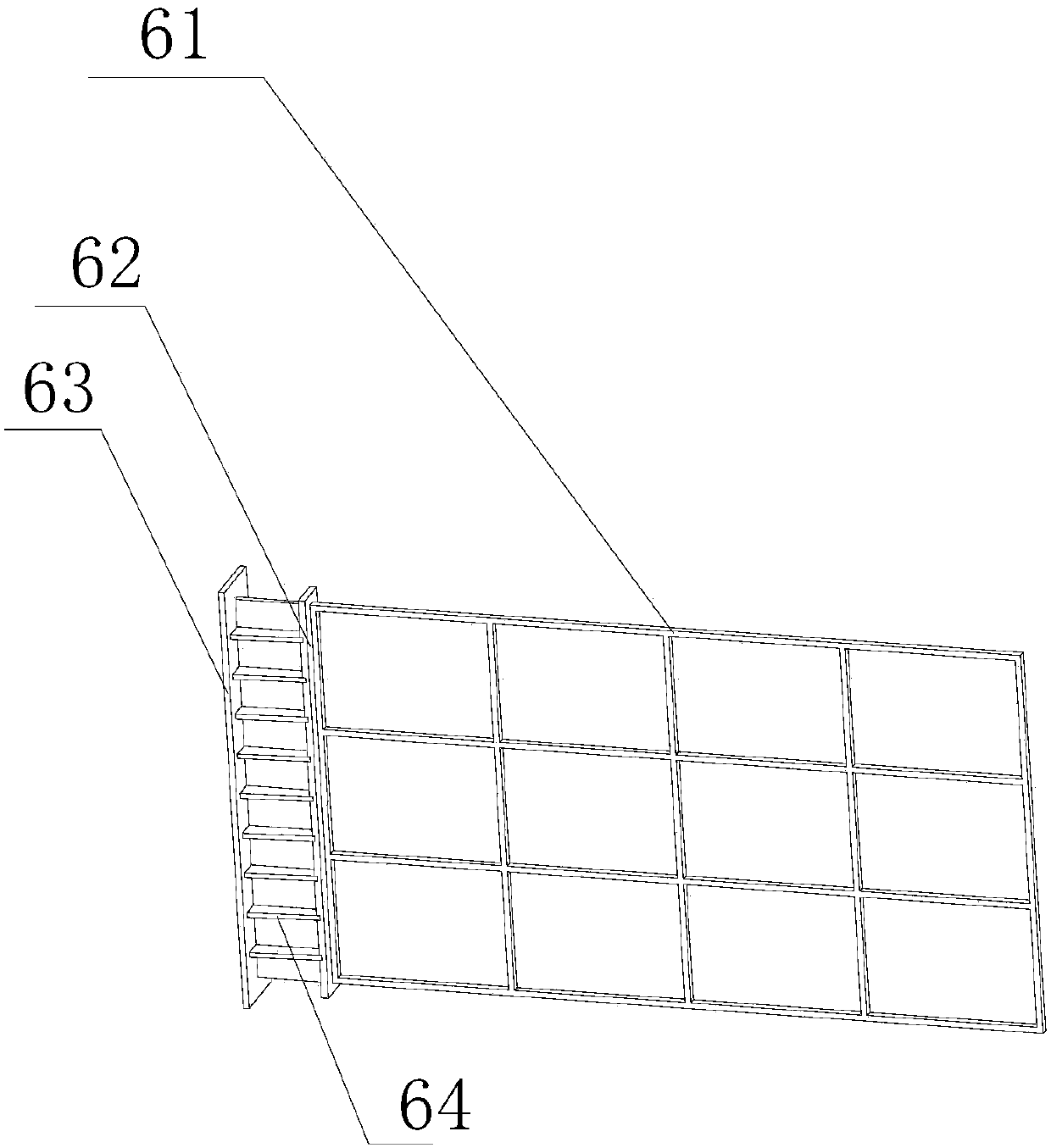

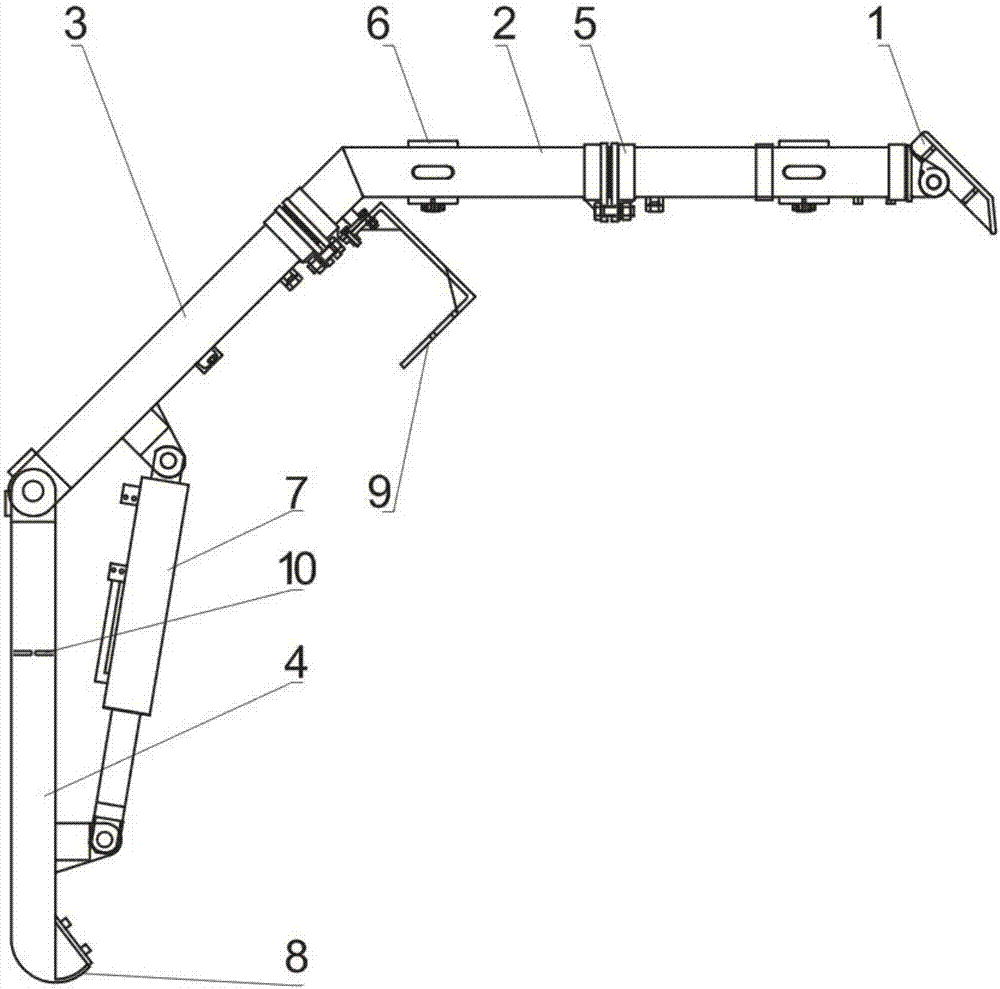

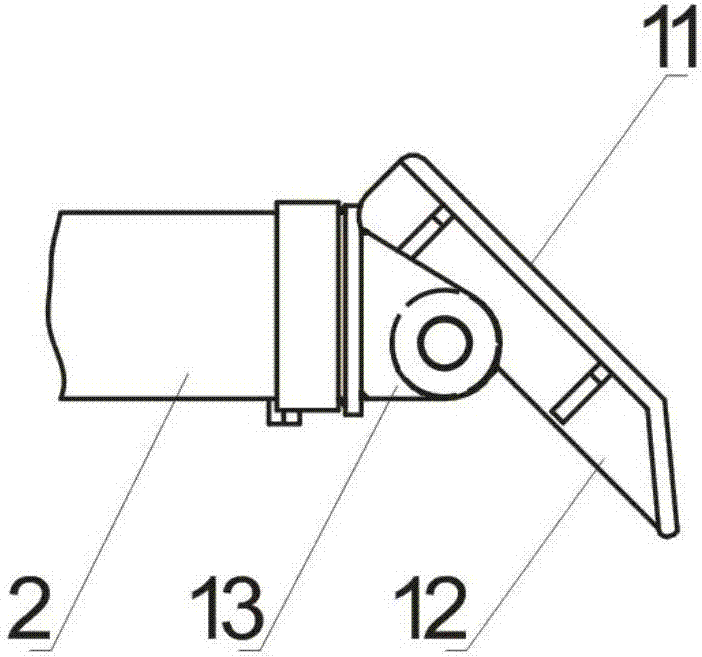

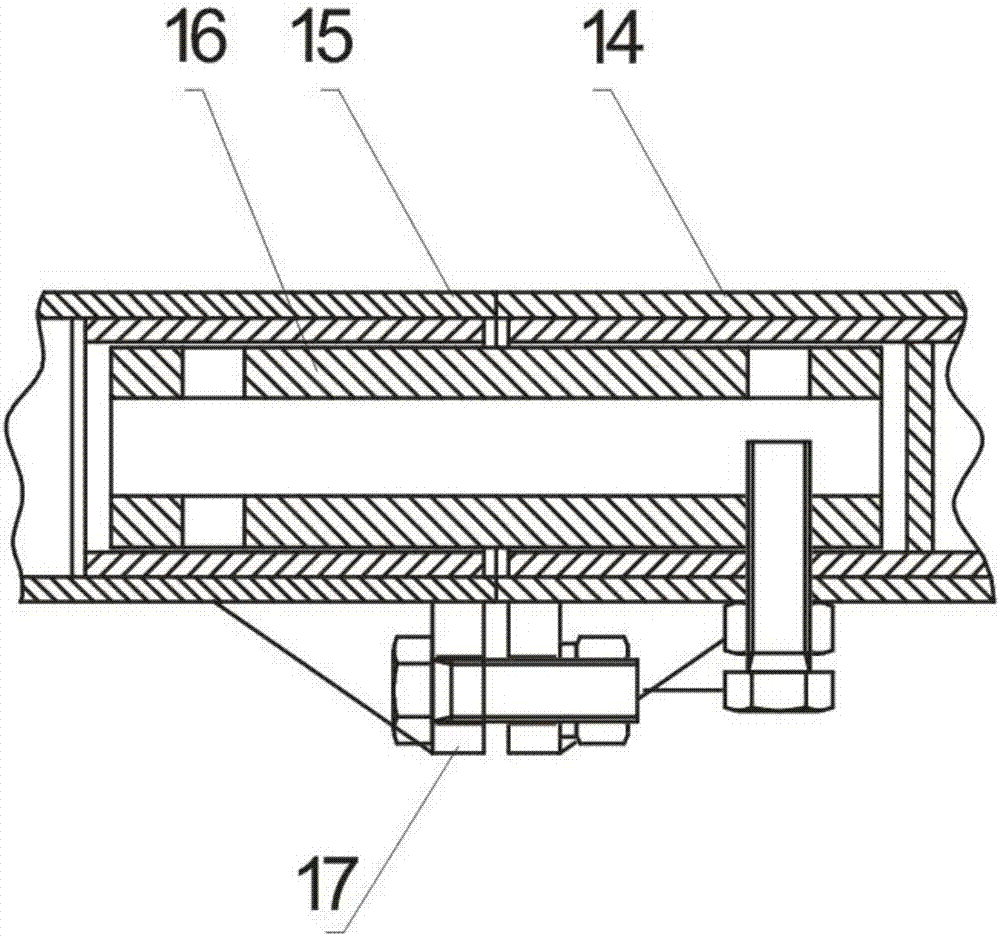

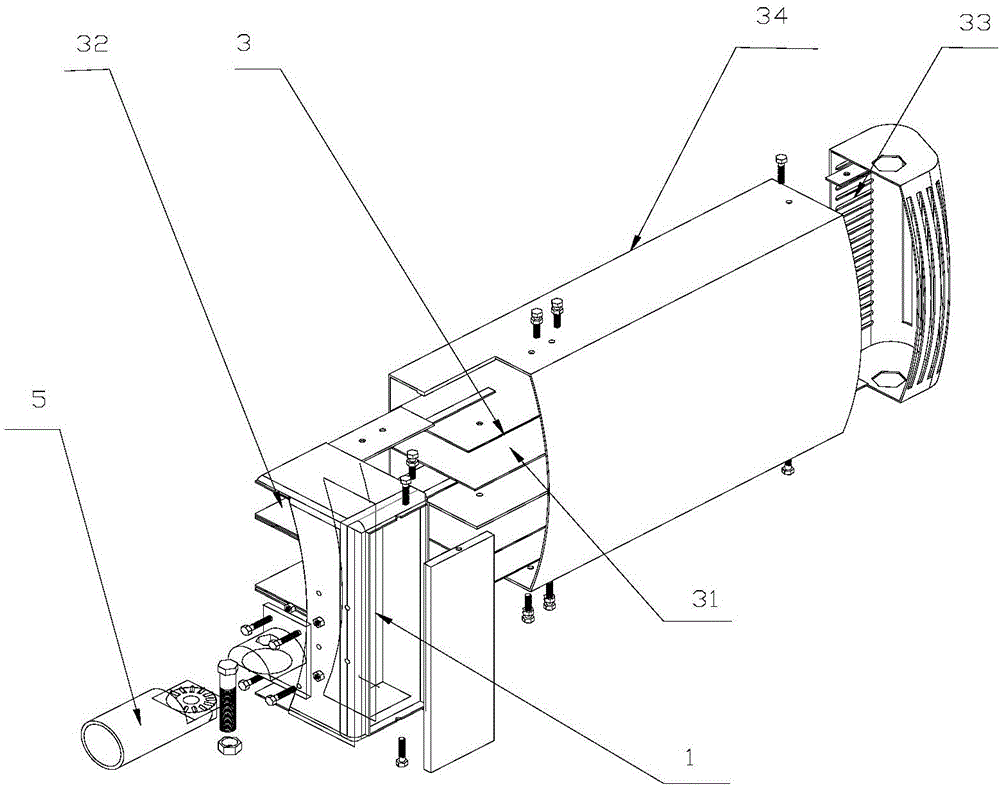

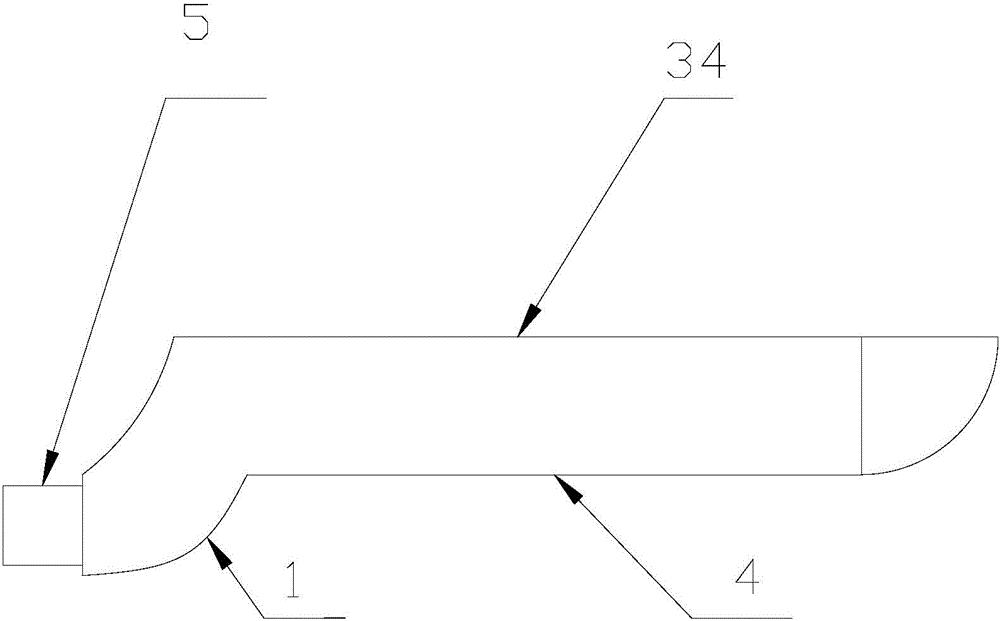

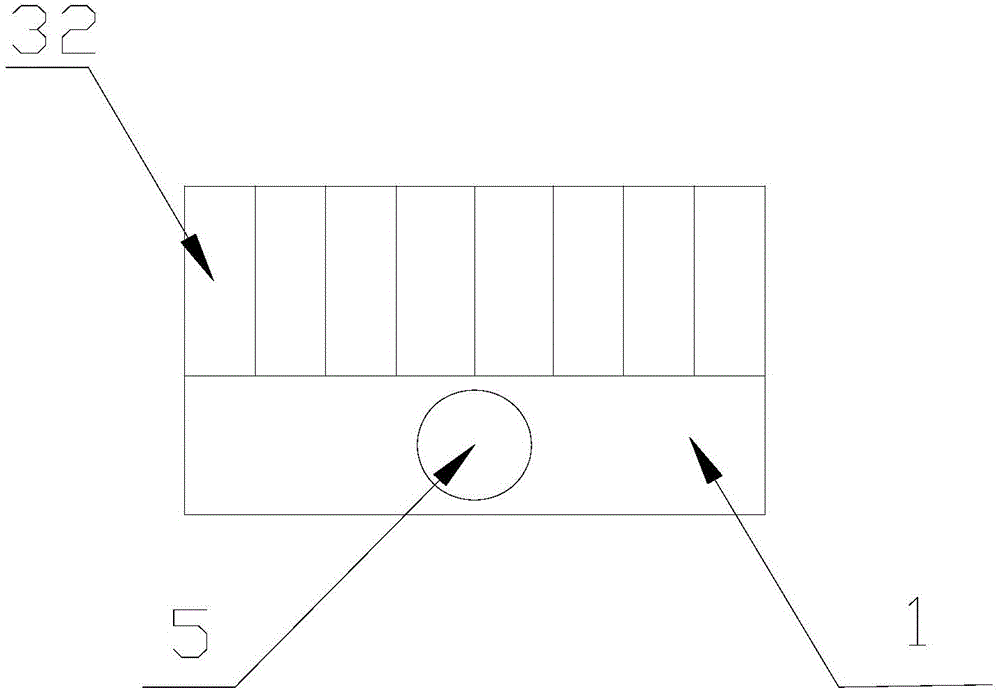

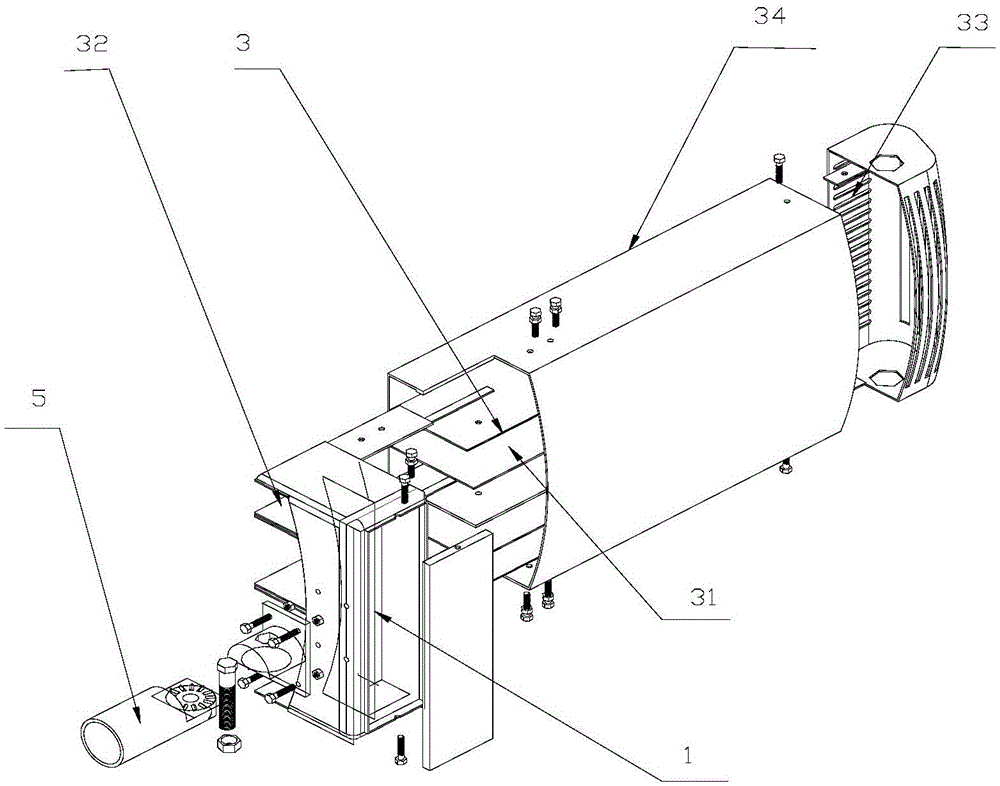

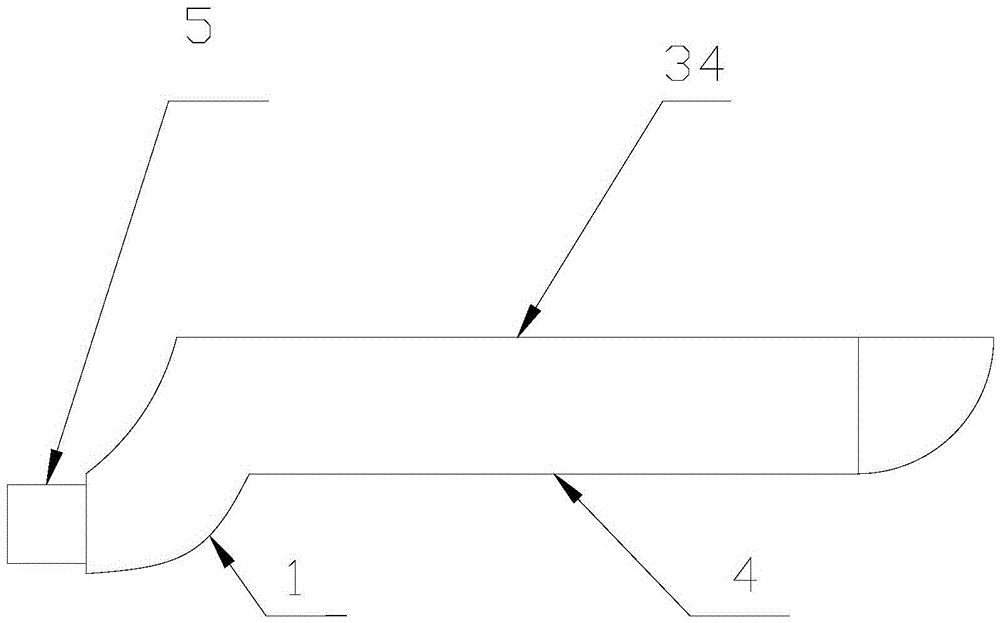

Light-weight telescopic flexible hydraulic shield support frame

InactiveCN107313795AReduce support strengthReduce your weightMine roof supportsMechanical engineeringUpper segment

The invention discloses a light-weight telescopic flexible hydraulic shield support frame, which is formed by sequentially connecting a top beam at the upper section, a shield beam at the middle section and a tail beam at the bottom end, wherein a guide beam is movably arranged at the front end of the top beam; the upper surface of the guide beam is a sliding surface; the sliding surface and the axial line of the top beam form an included angle; the shielding beam is hinged to the tail beam; a jack is used for supporting between the arm part of the shield beam and the arm part of the tail beam; and the tail end of the tail beam is provided with a slide boot used for sliding on a floor of a coal face. The light-weight telescopic flexible hydraulic shield support frame has the advantages that the support force is greater; the use is more flexible; the application range is wider; the installation and the use are convenient; and the automatic walking and moving can be reached. The light-weight telescopic flexible hydraulic shield support frame is mainly applicable to a false inclined and sharp inclined coal seam with the inclination angle being greater than 45 degrees or even a coal mining working face with the reverse condition, is applicable to a medium-thick coal seam or thicker coal seams, has certain applicability to the coal seam change, is applicable to a work face using inclined or false inclined wall type pitching inclined mining arrangement, and is applicable to a coal seam with a crushed roof.

Owner:四川广旺能源发展(集团)有限责任公司机械制造分公司

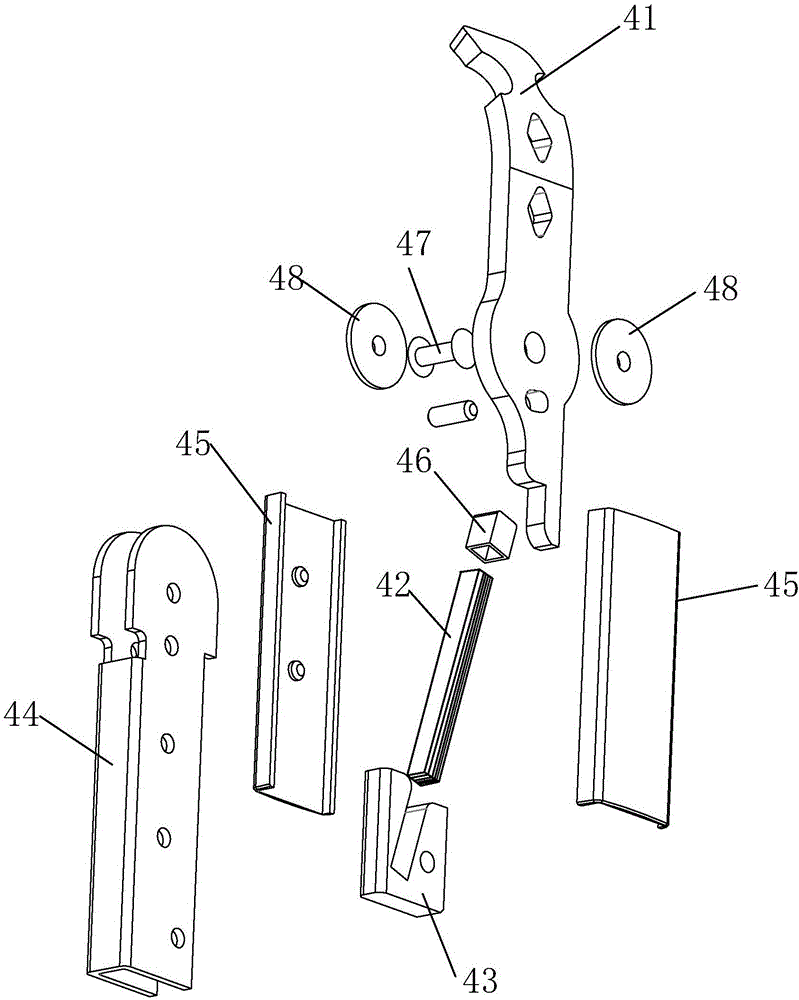

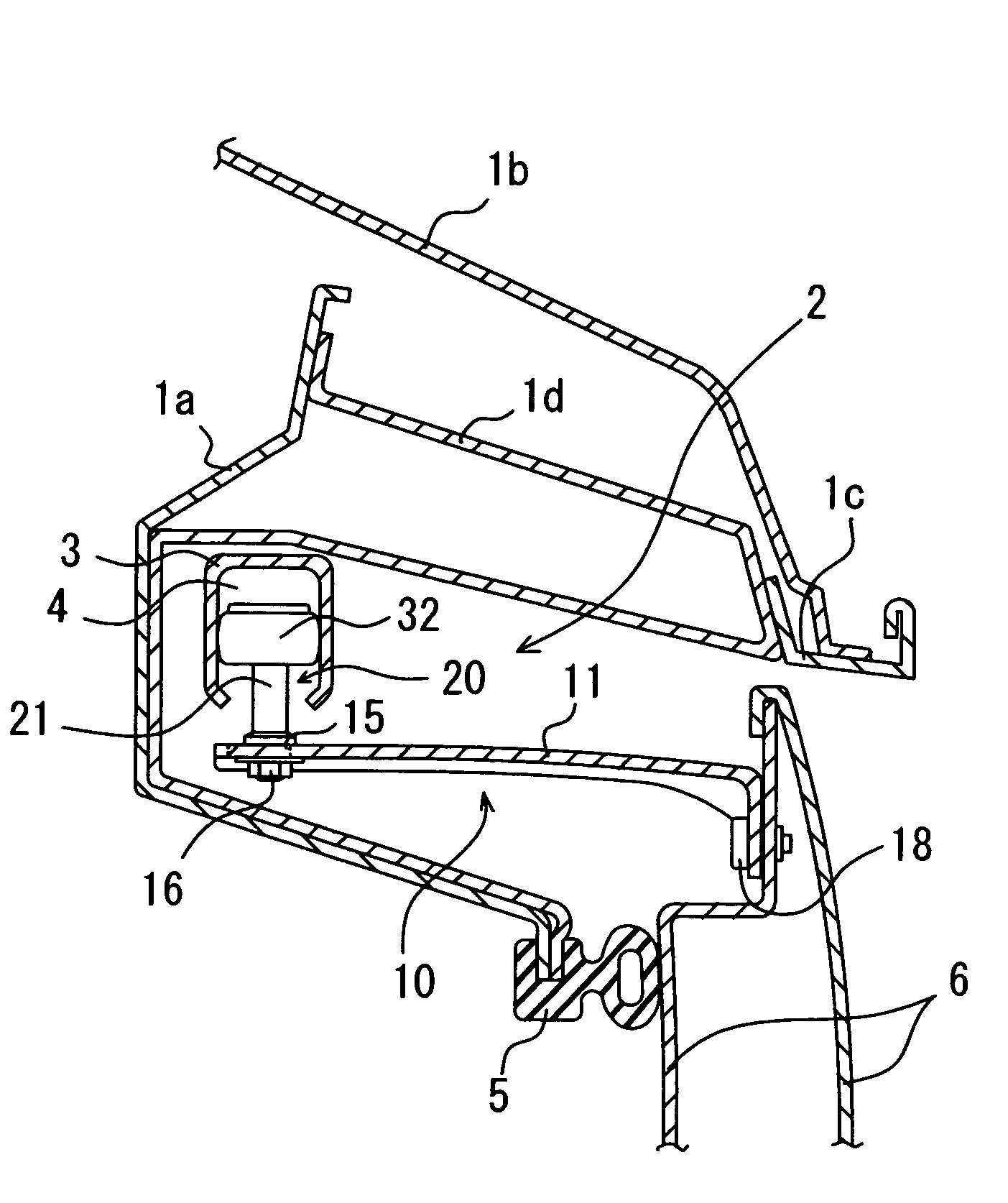

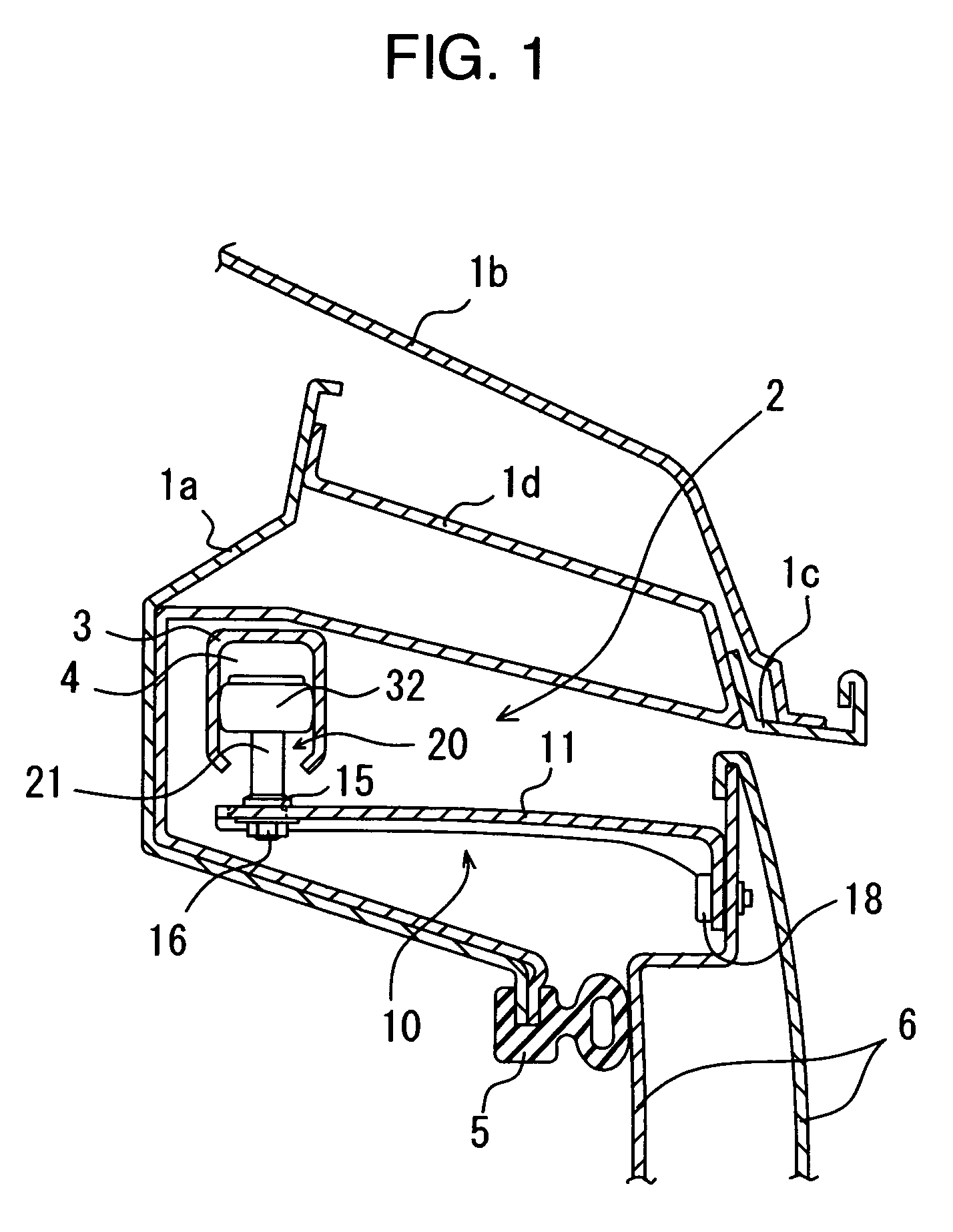

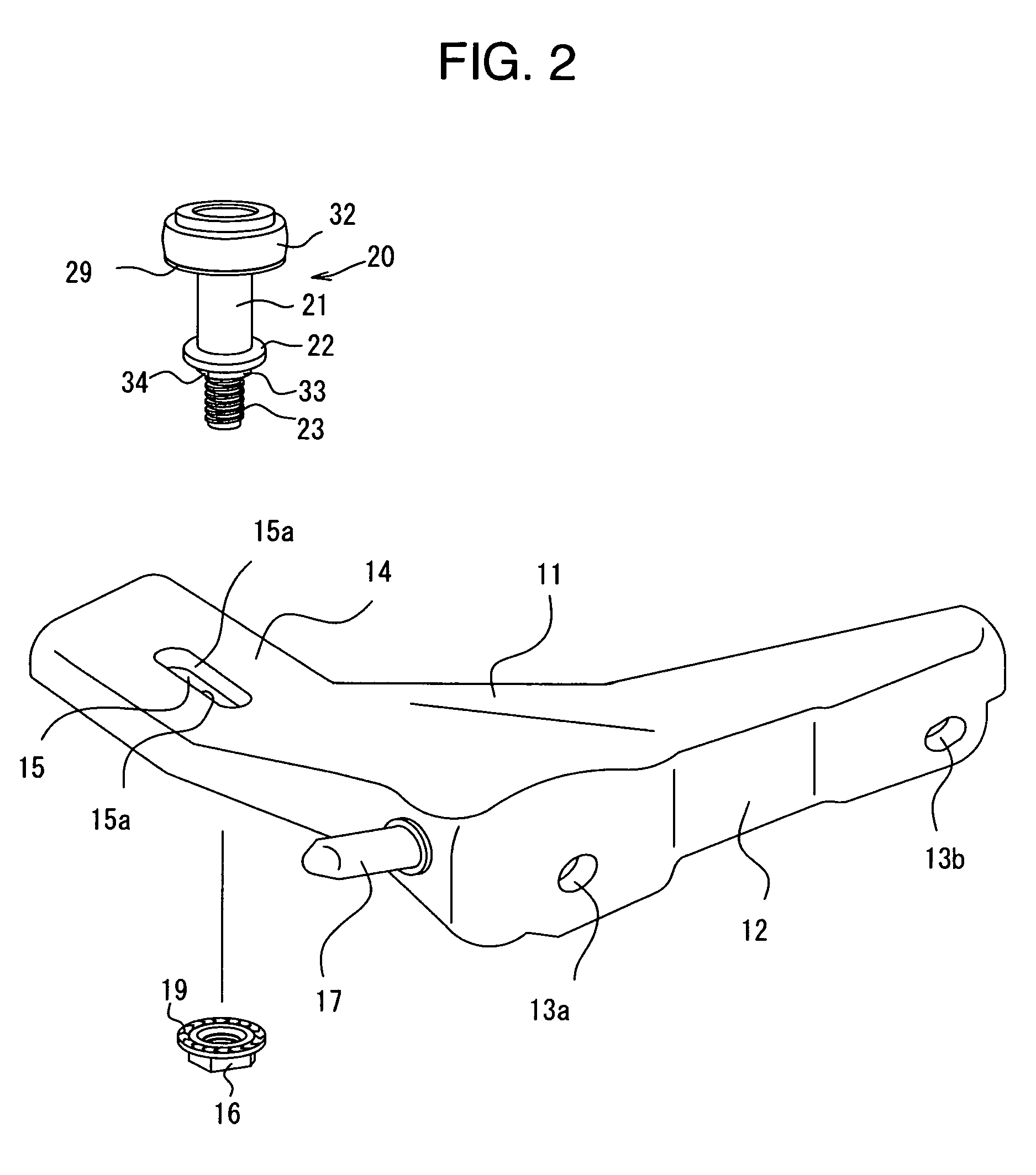

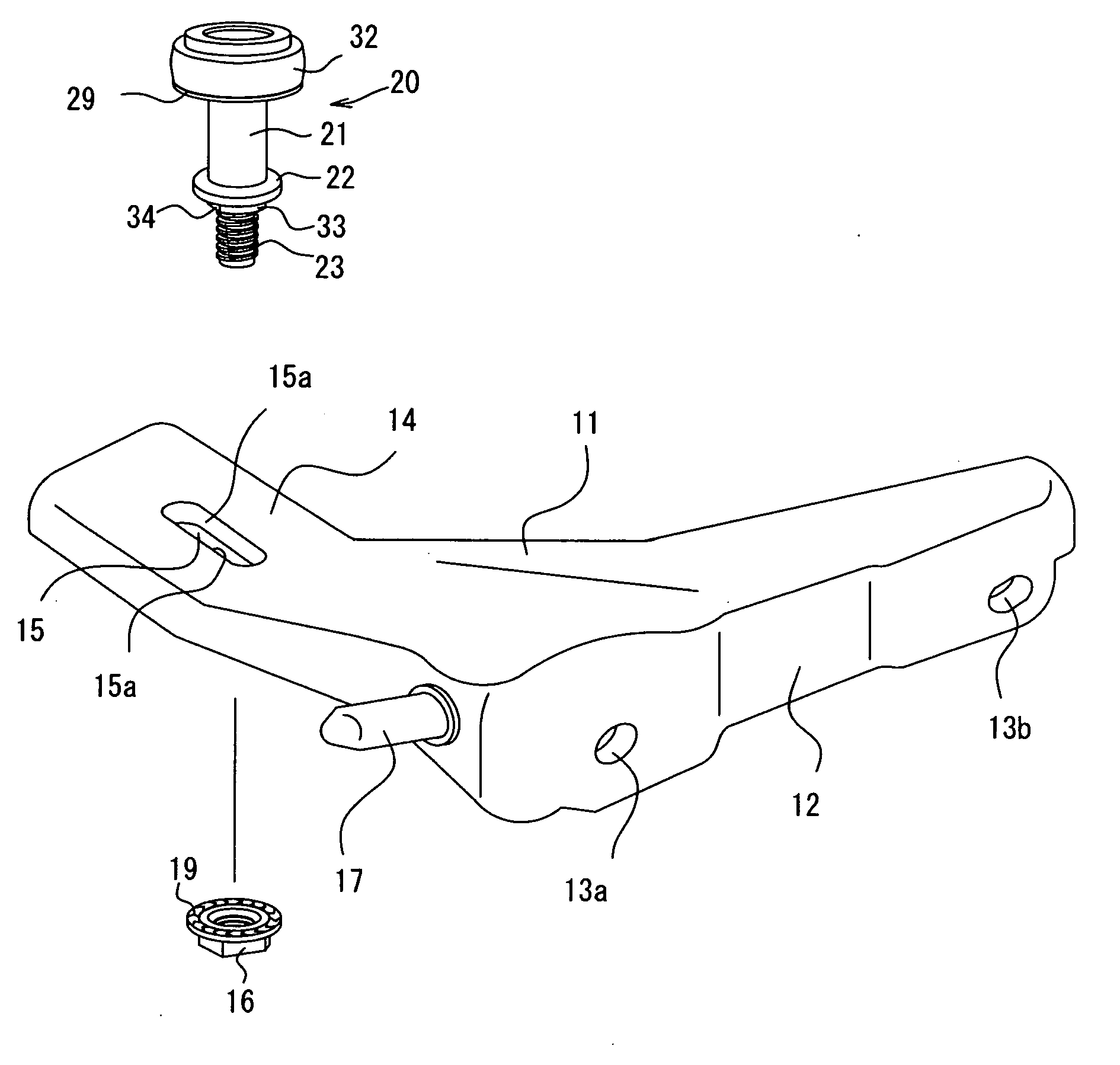

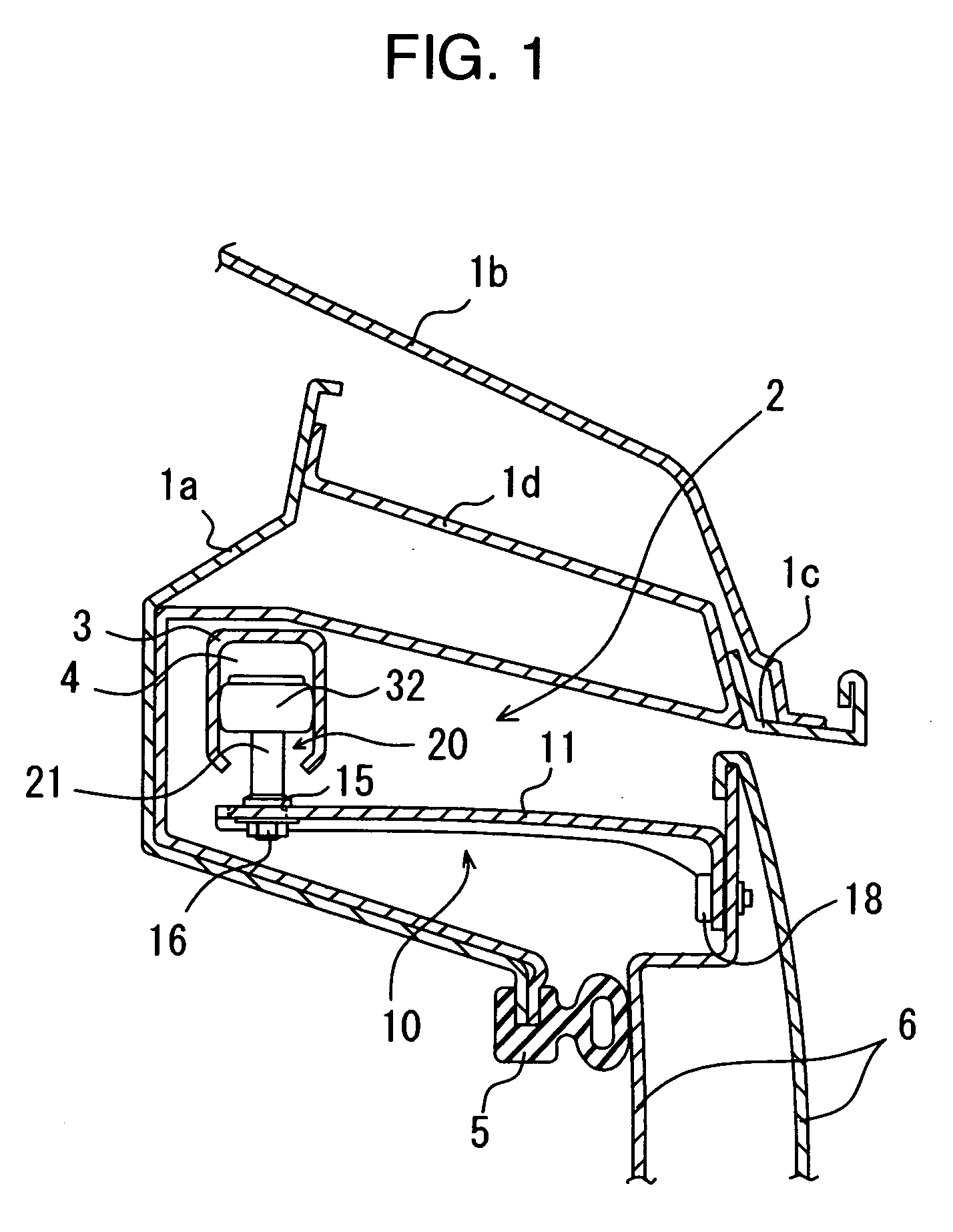

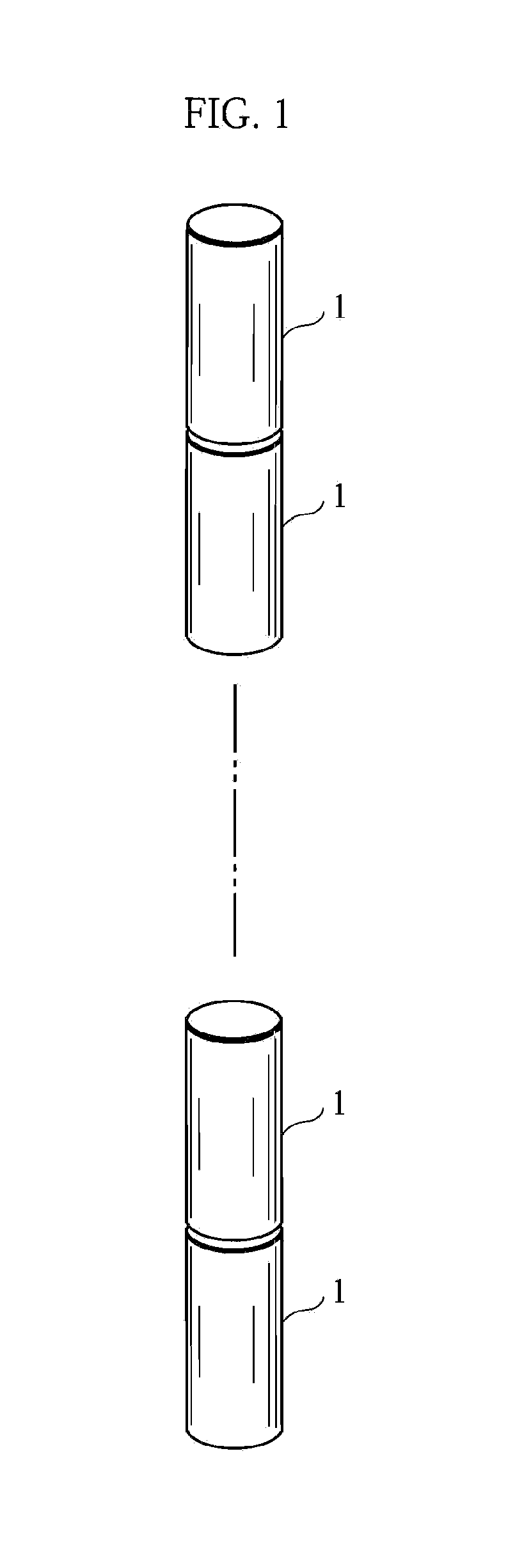

Guide roller of slide door for vehicle

In order to provide a guide roller which can be readily mounted on a support member and readily adjusted in position without reducing strength of a support shaft, according to the invention, when inserting a screw part of the shaft through a long hole of the support member and fixing the shaft by a nut on a back side, the screw part is inserted while contacting notched planes with contact parts, and an insertion position of the screw part is made adjustable in the long hole. It is possible, without necessity to form an engaging part for calking in the columnar shaped support shaft, to prevent reduction in strength of the guide roller, to position the guide roller with respect to a rail only by screwing the guide roller to the support member after previously fixing the support member to the slide door, and to make the operation efficient.

Owner:DAIDO METAL CO LTD

Vibration device, electronic apparatus, and mobile object

InactiveUS20160036411A1Reduce vibrationStable characteristicsMagnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringMobile object

Owner:SEIKO EPSON CORP

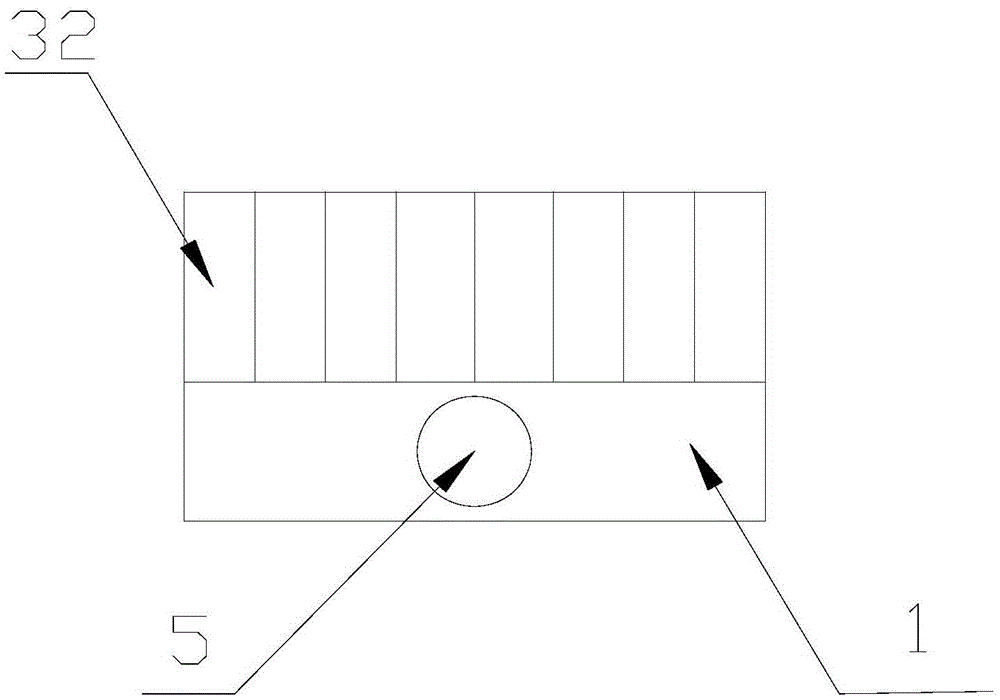

Light LED lamp efficient in heat dissipation

ActiveCN104089205AImprove cooling effectReduce weightPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses a light LED lamp efficient in heat dissipation. The light LED efficient in heat dissipation comprises a lamp holder, an LED lamp substrate and a heat sink. The lamp holder is connected with the heat sink, at least one LED lamp body is arranged on the LED lamp substrate, at least one heat dissipating channel is formed in the heat sink, at least one part of each heat dissipating channel is composed of part of the LED lamp substrate, and each heat dissipating channel is provided with an air inlet and an air outlet. The light LED lamp efficient in heat dissipation is fast in heat dissipation, simple in structure and light in weight.

Owner:梁蔚豪

Guide roller of slide door for vehicle

In order to provide a guide roller which can be readily mounted on a support member and readily adjusted in position without reducing strength of a support shaft, according to the invention, when inserting a screw part of the shaft through a long hole of the support member and fixing the shaft by a nut on a back side, the screw part is inserted while contacting notched planes with contact parts, and an insertion position of the screw part is made adjustable in the long hole. It is possible, without necessity to form an engaging part for calking in the columnar shaped support shaft, to prevent reduction in strength of the guide roller, to position the guide roller with respect to a rail only by screwing the guide roller to the support member after previously fixing the support member to the slide door, and to make the operation efficient.

Owner:DAIDO METAL CO LTD

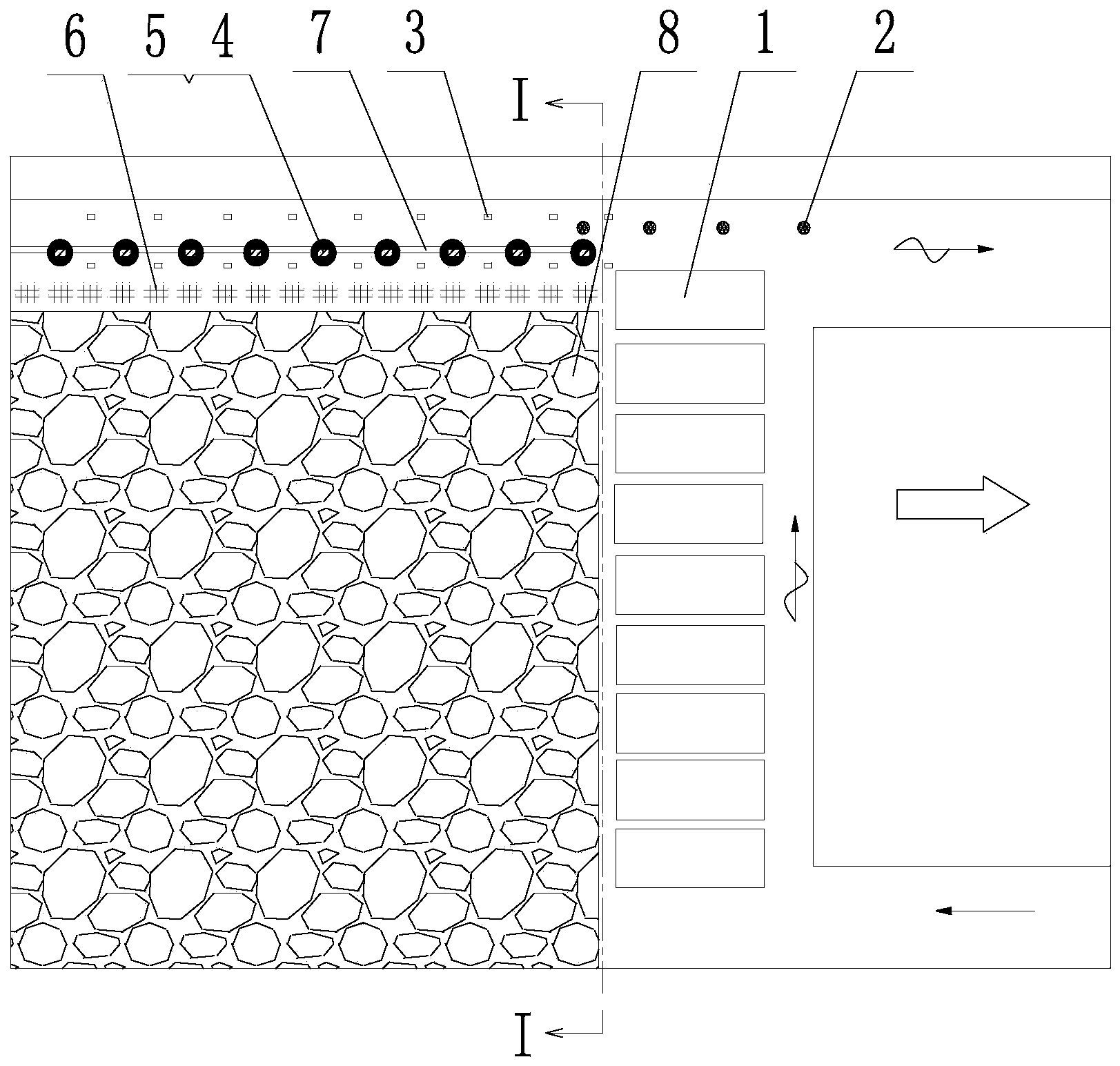

Coal mining method of full-negative-pressure continuous mining machine for leftover coal

ActiveCN113944464AReliable ventilation systemVentilation system safetyMining devicesUnderground miningMining engineeringResource recovery

The invention discloses a coal mining method of a full-negative-pressure continuous mining machine for leftover coal, and belongs to the technical field of coal mining. The problems that when a coal mining method of a continuous mining machine is adopted in leftover coal resources, full-negative-pressure ventilation cannot be achieved in a mining cave, and the yield is low are solved. The method comprises the four steps of crossheading roadway arrangement, stoping unit branch roadway arrangement, stoping unit mining and leftover coal section mining. According to the method, roadway arrangement is flexible, the resource recovery rate is high, local ventilator air supply is completely canceled during mining cave stoping, ventilation air methane air flow is prevented from returning to a stoping branch roadway, branch roadway through holes are additionally formed in a stoping unit, and ventilation management and safety are facilitated; and meanwhile, according to the coal mining method, one continuous mining machine and matched equipment are adopted for roadway tunneling and mining cave stoping, mining and tunneling are integrated, the number of newly-added personnel is small, the investment is relatively low, the coal yield is guaranteed, and good benefits can be obtained.

Owner:TAIYUAN DESIGN RES INST FOR COAL IND

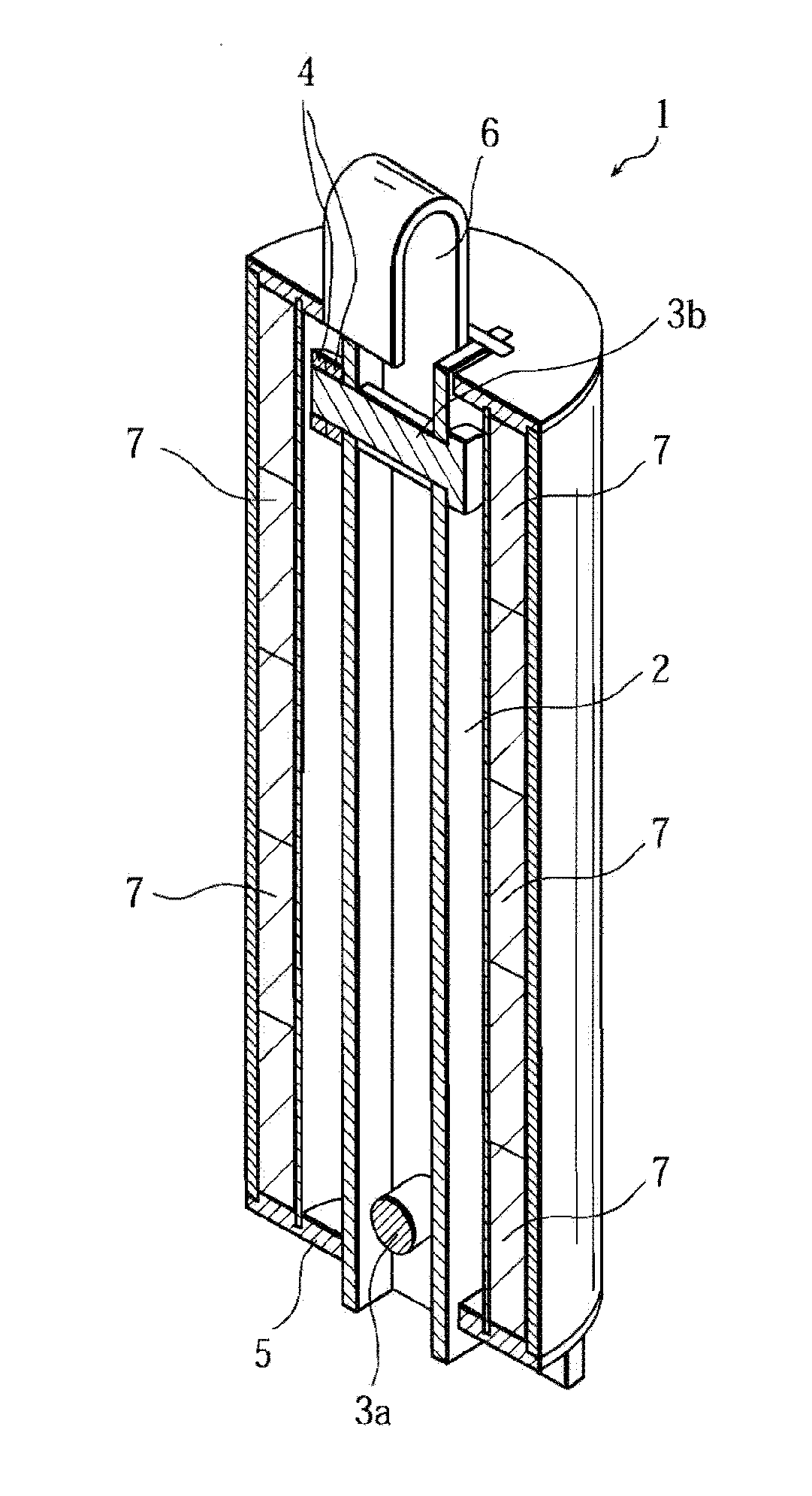

Control rod for high temperature gas reactor

ActiveUS20120207263A1Reduce support strengthReduce supportNuclear energy generationHeterogenous reactorsHeat resistanceNuclear engineering

A high-temperature gas reactor control rod is provided that does not degrade the joining state between the control rod elements even when stress is applied thereto, and that can improve the safety of the high temperature gas reactor remarkably by improving the heat resistance thereof.The high-temperature gas reactor control rod has a plurality of control rod elements (1) each having a neutron absorber (7) between an outer cylinder (9) and an inner cylinder (8) that form a double cylindrical tubular shape, the control rod elements (1) joined to each other in a vertical direction, characterized by: a columnar support member (2) for supporting at least the neutron absorber (7), disposed in the inner cylinder (8); and joining means for joining to another control rod element (1), provided at least one of upper and lower ends of the support member (2).

Owner:TOYO TANSO KK

Method for controlling stability of surrounding rock in gob-side entrydriving of working face of deep island

InactiveCN106761742AReduce resistanceReduce support resistanceUnderground chambersUnderground miningStress concentrationSupporting system

The invention discloses a method for controlling surrounding rock in gob-side entrydriving of a working face of a deep island. The method comprises the following steps of performing pre-cracking and top breaking before stoping of two adjacent working surfaces of the working face of the island, so as to avoid forming a hinge structure at the end surface of the working face, and avoid the hinged rock beam at the critical layer transferring the stoping stress of covering rock of the adjacent working faces to the working face; selecting a constant-drag large-deformation anchor bolt in a gob-side entrydriving support system, increasing the lengths of anchor bolts at the coal wall side and top plate side, deforming the anchor bolts to relieve pressure, and enabling anchor cables to transfer the concentrated stress of the surrounding rock to the farther physical coal wall; slantwise and downwards drilling pressure relief holes in the physical coal wall side with 3 to 4 cycle roof weighting paces in advance at the working face of the island; spraying slurry to the narrow coal column side. The method has the advantages that the stress concentration degree of the deep working face is effectively reduced, the drags of a bracket, a support column and support are reduced, the stoping efficiency of coal sources is improved, the safe and efficient stoping efficiency of the working face is also improved, and the major technical and economic benefits are realized.

Owner:XIAN UNIV OF SCI & TECH

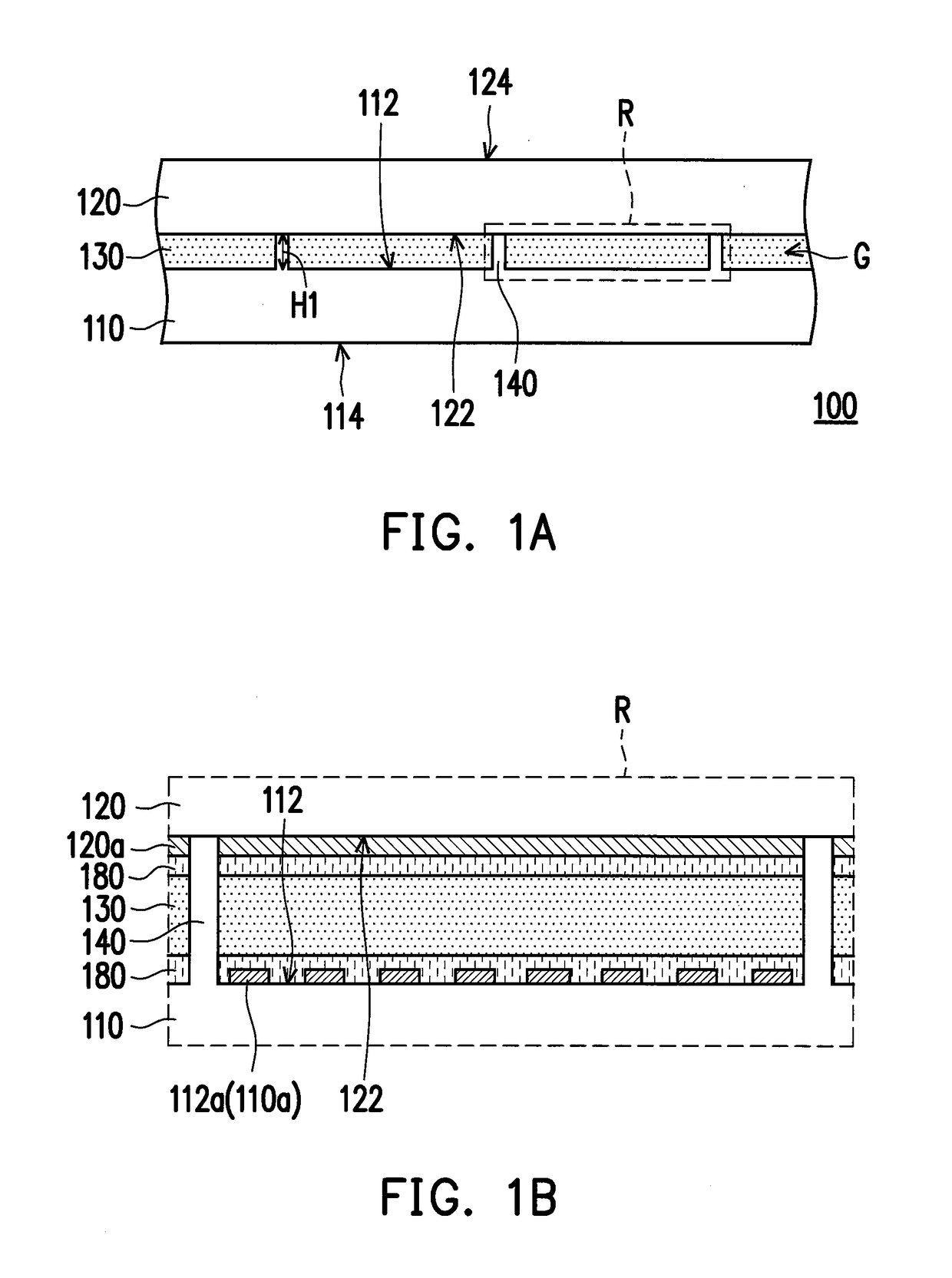

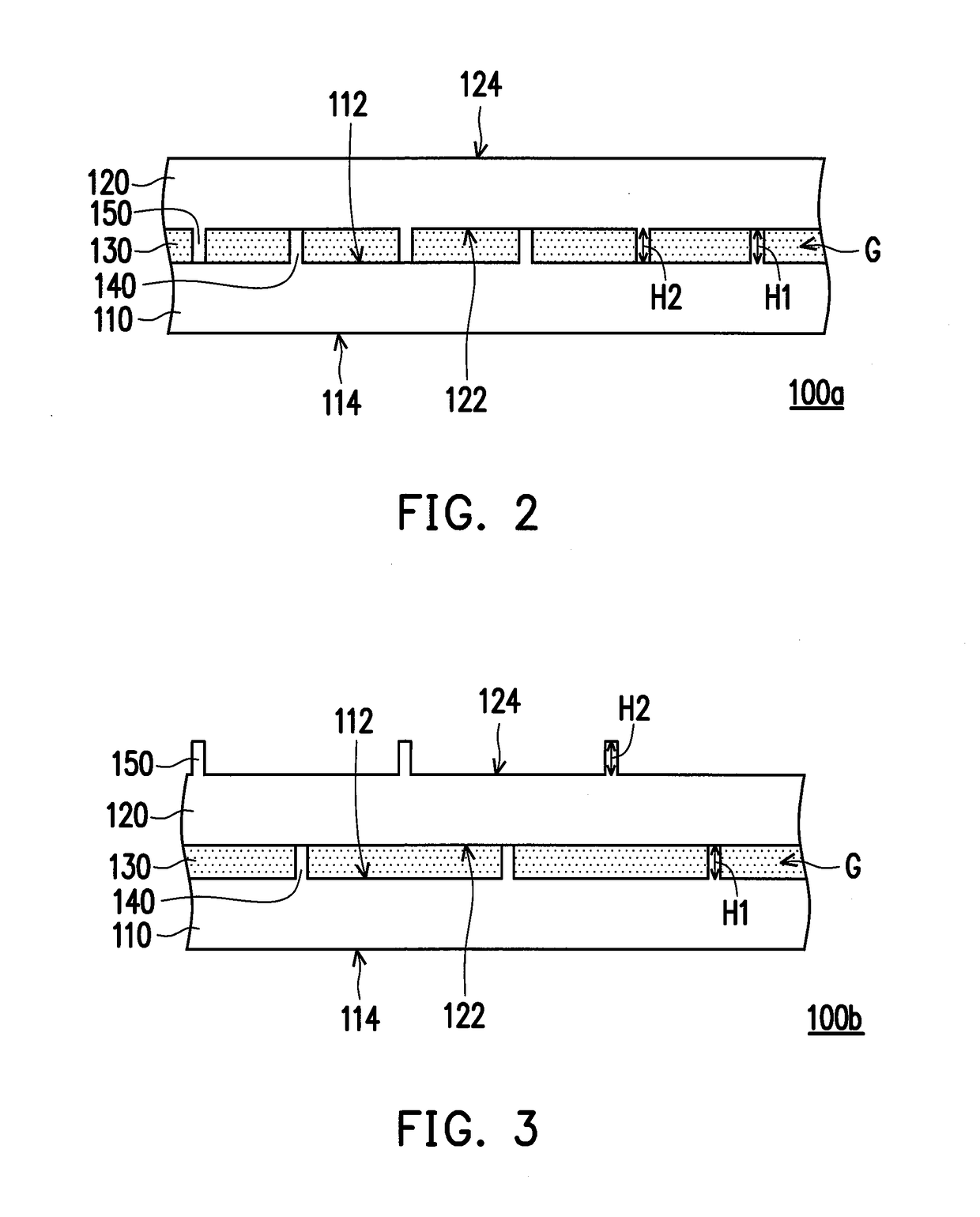

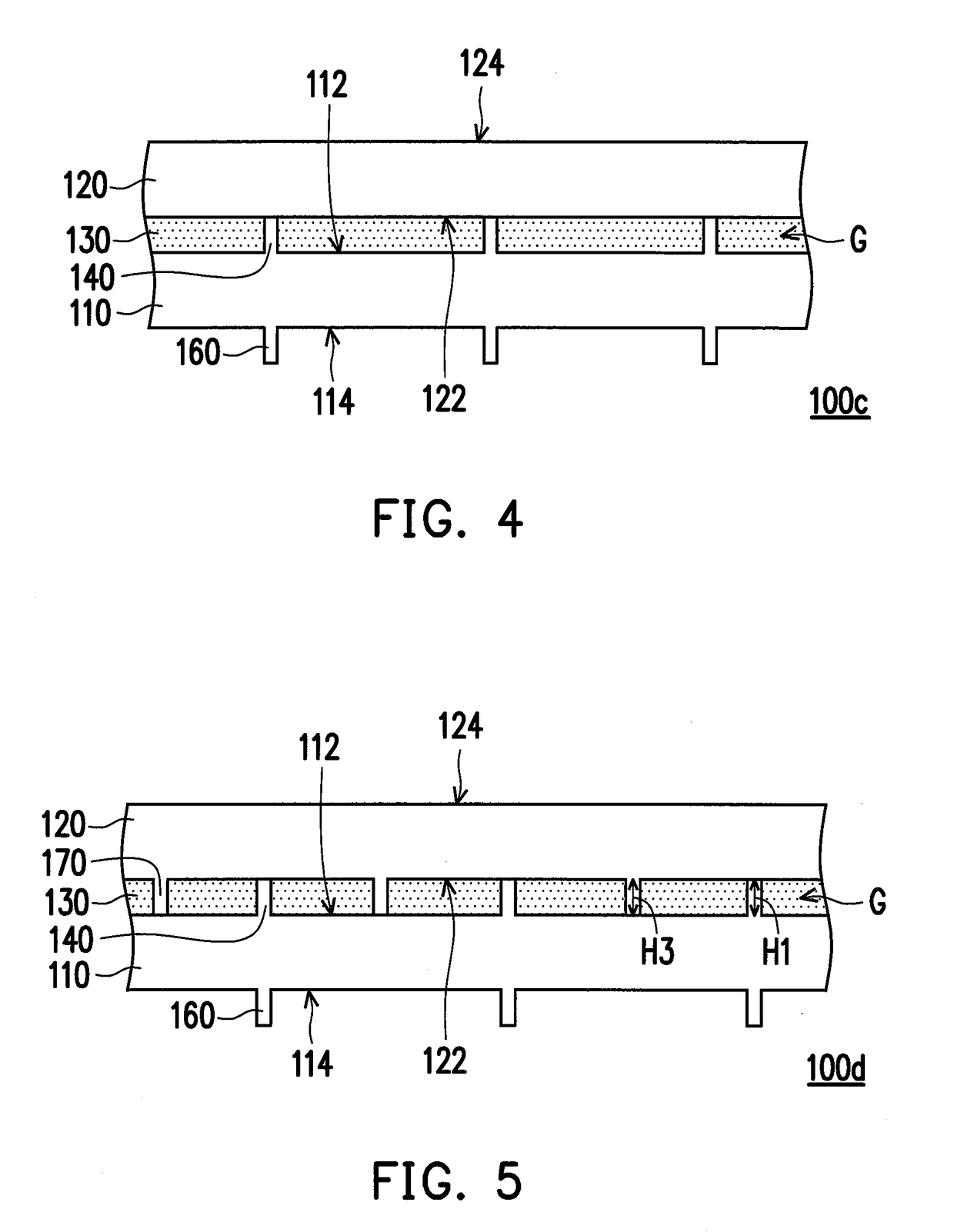

Liquid crystal cell and manufacturing method thereof

ActiveUS20180348564A1Insufficient adhesive strengthEasily formNon-linear opticsChemistryLiquid crystal cell

A liquid crystal cell including a first substrate, a second substrate, a liquid crystal layer and a plurality of first support pillars is provided. The first substrate has a first surface and a second surface opposite to the first surface. The second substrate is disposed beside the first substrate and has a third surface and a fourth surface opposite to the third surface. The first surface of the first substrate and the third surface of the second substrate face each other. The liquid crystal layer is disposed between the first substrate and the second substrate. The plurality of first support pillars are configured to form a cell gap of the liquid crystal cell and disposed on the first surface of the first substrate, wherein the first substrate and the plurality of first support pillars are integrally formed and made of a same material.

Owner:LIQXTAL TECH

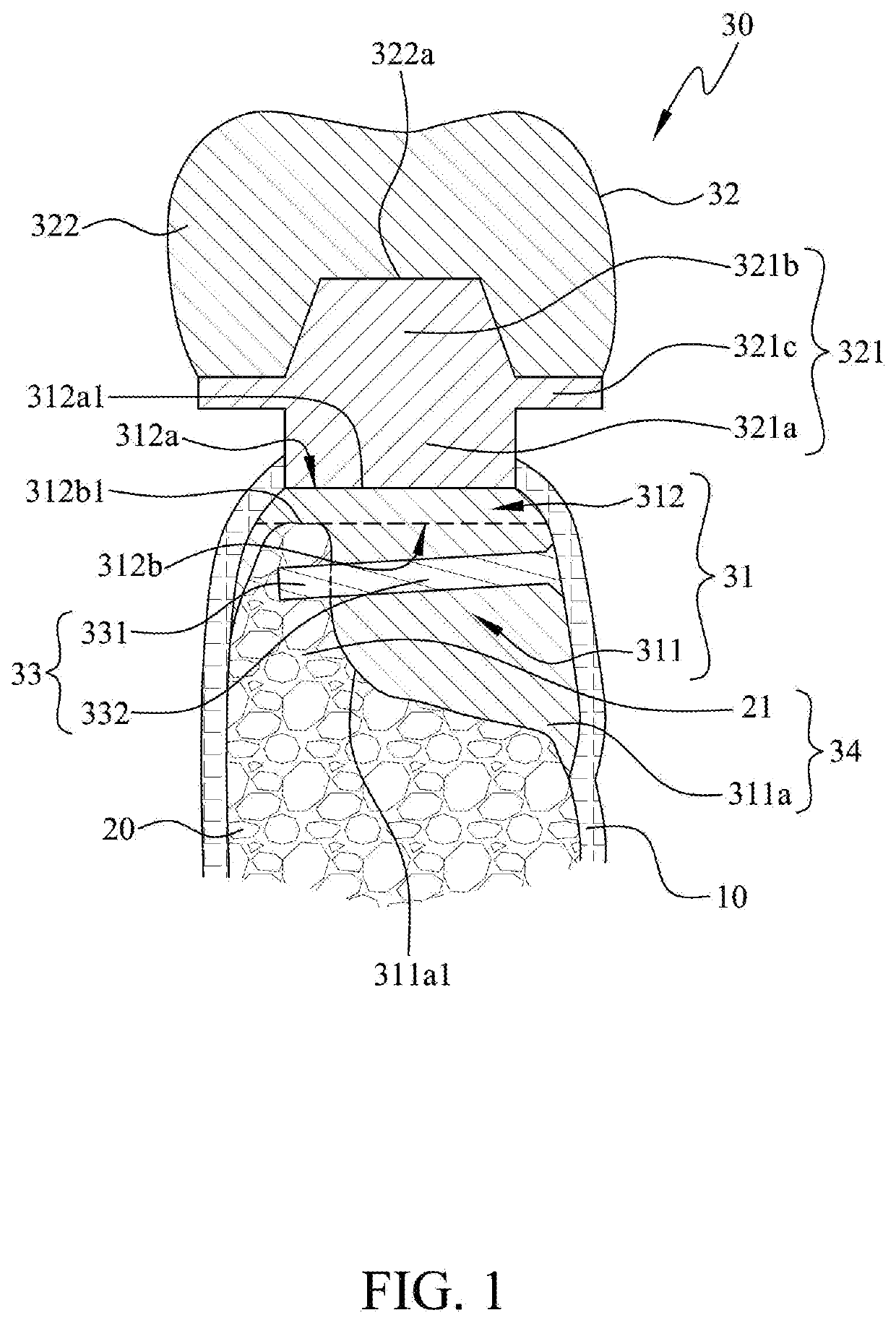

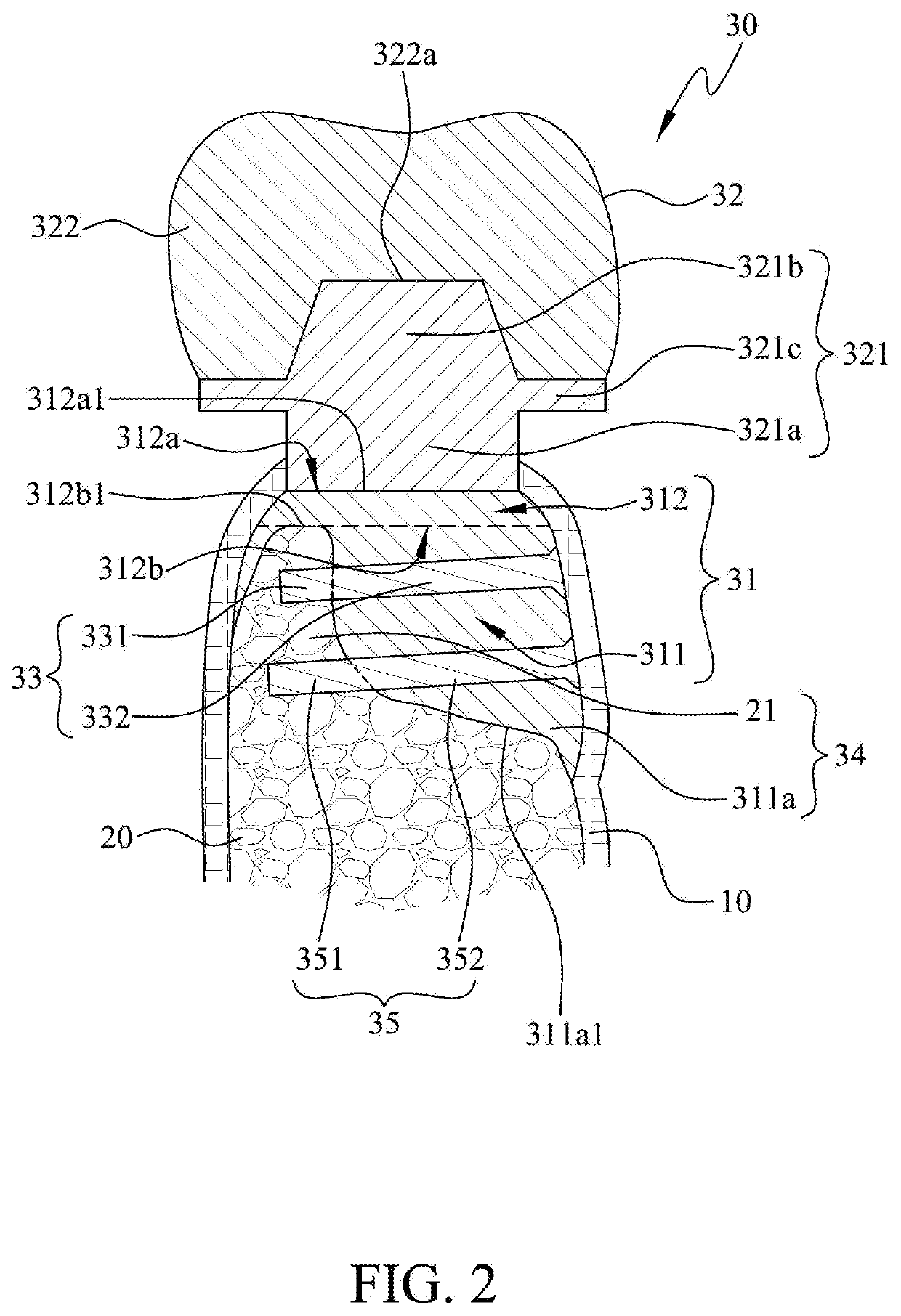

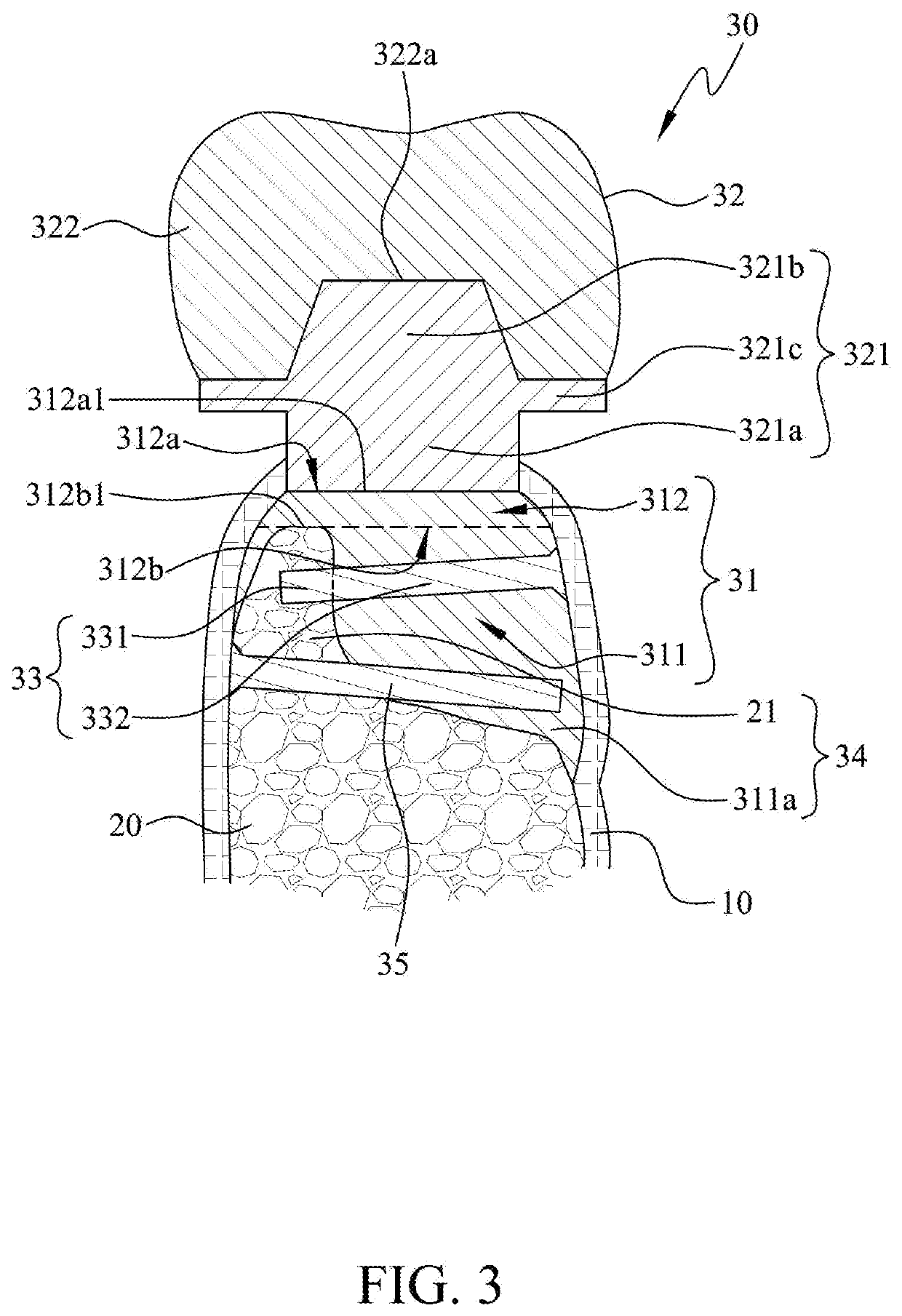

Bone-bonded artificial tooth structure

InactiveUS20210186664A1Stable supportLong time is neededDental implantsTooth crownsOsseointegrationDental Gingiva

A bone-bonded artificial tooth structure for fixing to a patient's partially atrophied and gum covered alveolar bone includes a base portion having opposed lower and upper connecting sections located below and above a peak of the atrophied alveolar bone, respectively, the lower connecting section being in contact with the atrophied alveolar bone, and one side of the upper connecting section opposed to the atrophied alveolar bone defining a connecting surface; a tooth portion fixed to the connecting surface; and a dental anchor having an anchoring section inserted into the atrophied alveolar bone and another anchoring section inserted in the base portion to restrict the base portion from displacing relative to the alveolar bone. The bone-bonded artificial tooth structure fixed to the alveolar bone can immediately provide good supporting strength for chewing food without needing to wait for a long time for the osseointegration of the bone with the base portion.

Owner:DENG YUN WEN

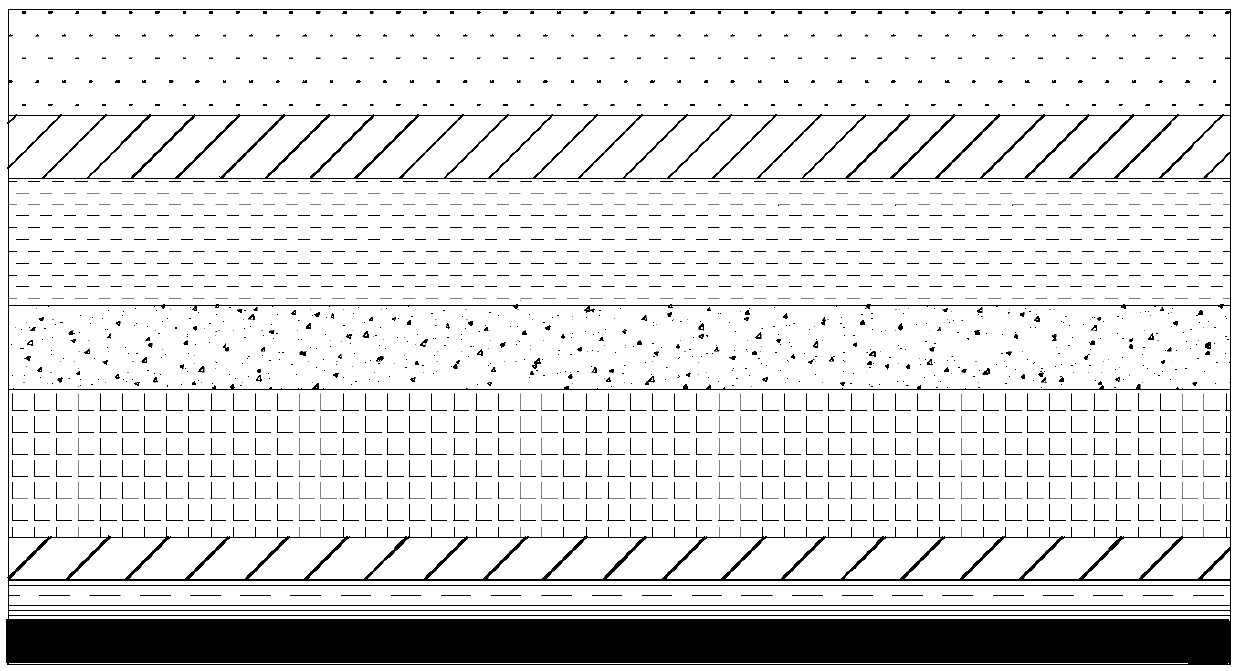

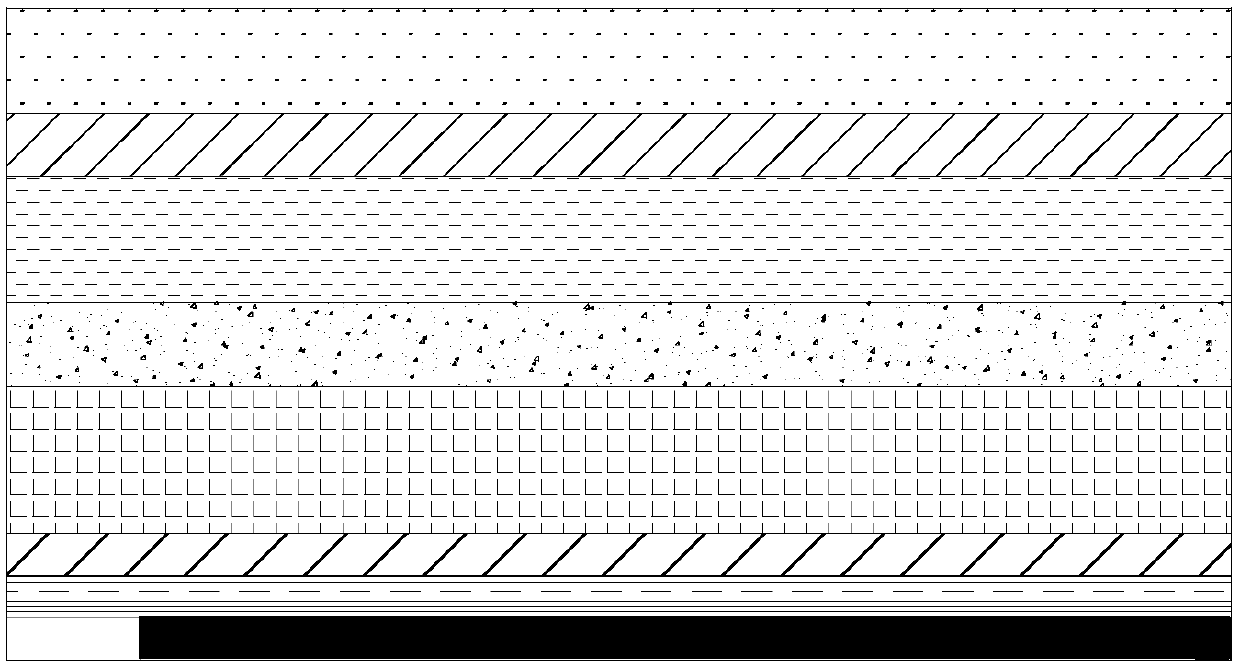

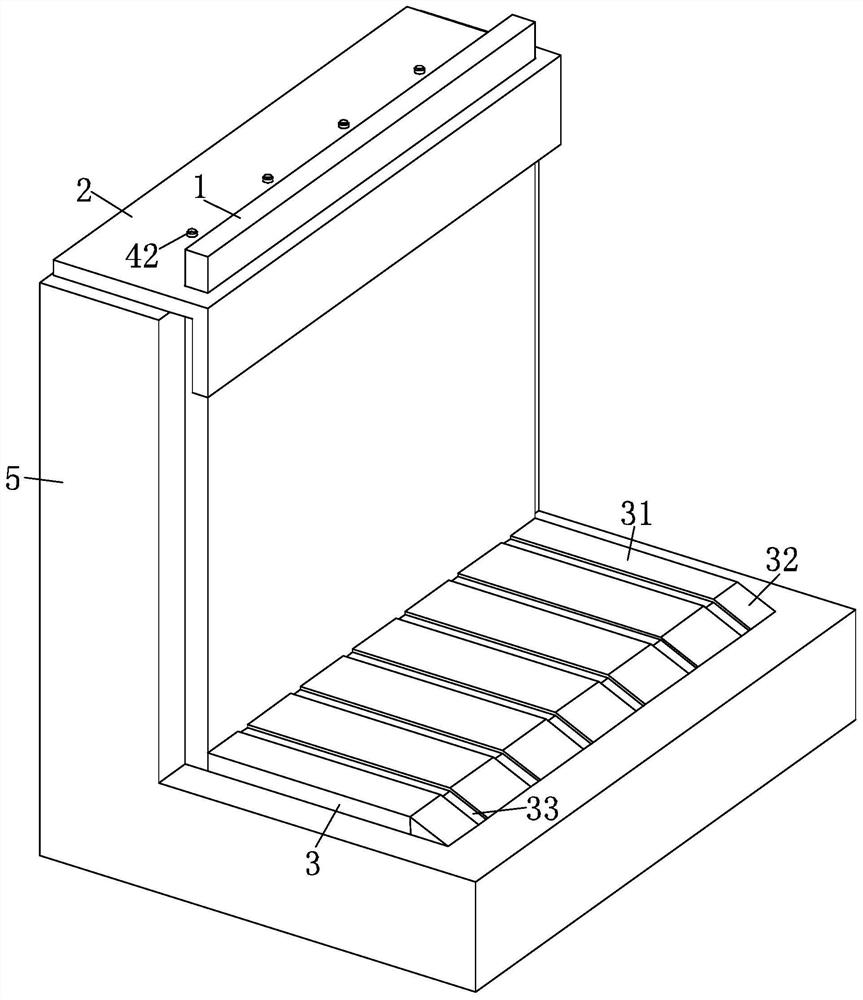

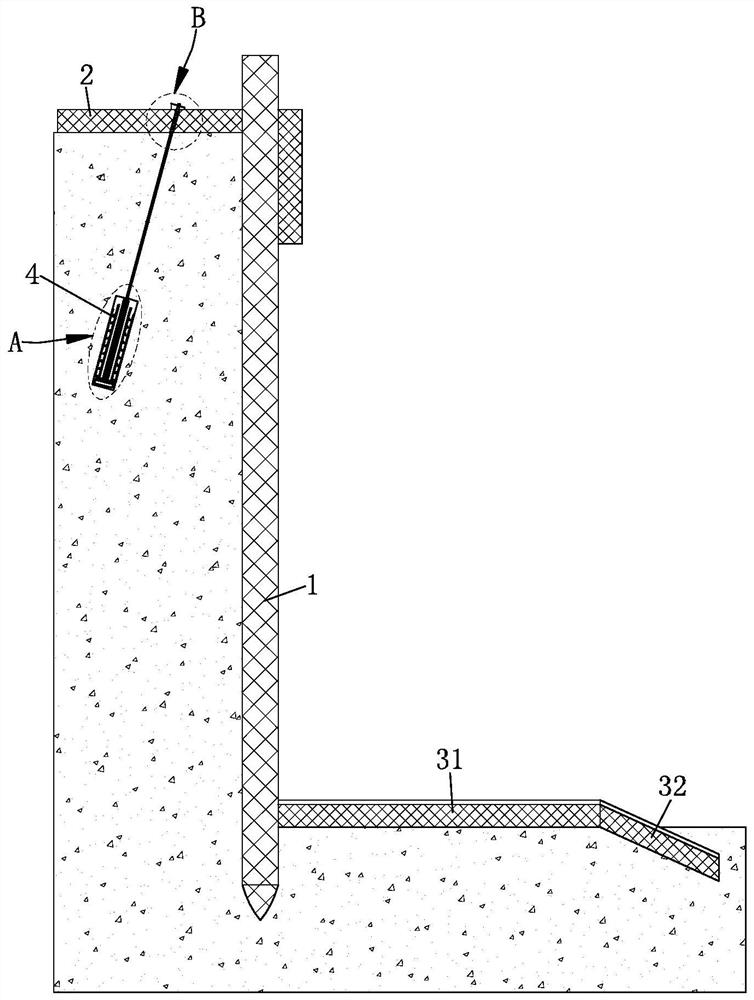

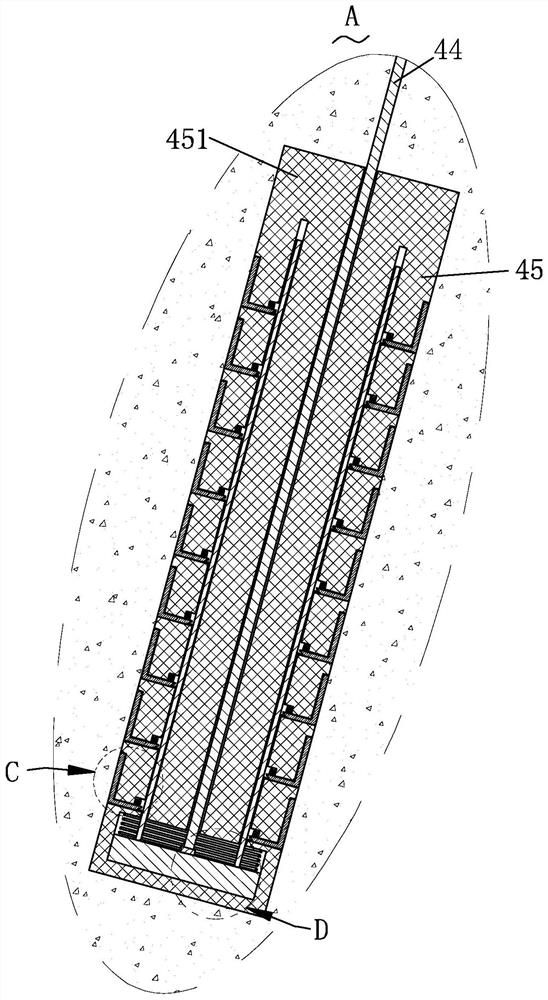

A construction technology for deep foundation pit support

ActiveCN110700281BControl verticalityImprove verticalityExcavationsBulkheads/pilesArchitectural engineeringSteel frame

The invention relates to a deep foundation pit support construction technology, and relates to the technical field of engineering facility construction. A single row of piles is arranged on the inside of the deep foundation pit, and the single row of piles is evenly distributed along the extension direction of the side wall of the deep foundation pit; At a position of 5 meters, the bottom of the fixed pile is lower than the preset lowest point of the deep foundation pit; S300: A horizontal steel frame is installed between the fixed pile and the single row of piles, and the two ends of the horizontal steel frame are connected to the fixed pile and the single row of piles respectively. The pile connection, the length direction of the horizontal steel frame is perpendicular to the side wall of the deep foundation pit. The invention has the effect of improving the verticality of the side wall of the deep foundation pit under the condition of reducing the occupation of the space in the deep foundation pit.

Owner:SHENZHEN DONGSHEN ENG CO LTD

Air-conditioning and air purification integral structure and air conditioner

PendingCN108571773ATake advantage ofSmall footprintMechanical apparatusLighting and heating apparatusAir conditioningElectric control

The invention provides an air-conditioning and air purification integral structure and an air conditioner, relating to the technical field of air conditioning. The air-conditioning and air purification integral structure comprises a shell, a partition plate, an electric control component, a heat exchange mechanism and an air purification mechanism, wherein the heat exchange mechanism and the air purification mechanism are independently arranged and are both mounted inside the shell; the partition plate is mounted inside the shell; the air purification mechanism is arranged on one side of the partition plate; the electric control component is arranged on the other side of the partition plate; and the partition plate is capable of supporting the shell. Due to adoption of the partition platemounted inside the shell and the air purification mechanism and the electric control component which are respectively arranged on both sides of the partition plate, compared with the prior art, the air-conditioning and air purification integral structure is capable of sufficiently utilizing a space inside the shell to mount components and elements, is small in floor space, in addition simple in structure, capable of ensuring support strength, high in heat exchange and air purification efficiency, and good in practicability.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

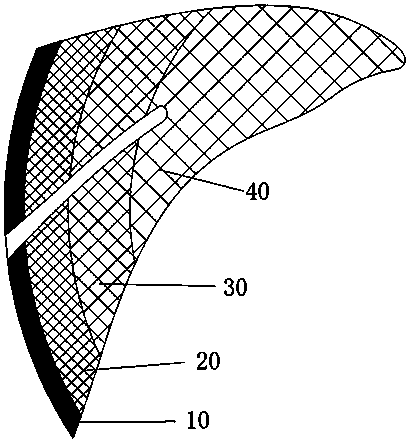

High-density and low-shrinkage rubber and plastic thermal insulation material and preparation method thereof

InactiveCN112940367AEvenly dispersedSmall shrinkageTubular articlesThermal insulationPlastic materials

The invention discloses a high-density and low-shrinkage rubber and plastic thermal insulation material and a preparation method thereof, and relates to the technical field of thermal insulation materials. The thermal insulation material includes 18 to 24 parts of rubber, 18 to 24 parts of a foaming agent, 68 to 82 parts of a smoke abatement flame retardant, 8 to 12 parts of carbon black, 13 to 17 parts of polyvinyl chloride resin, 1.3 to 1.7 parts of stearic acid, 1.3 to 1.7 parts of a dispersant, 1.3 to 1.7 parts of a calcium-zinc stabilizer, 28 to 32 parts of chlorinated paraffin oil, 5 to 8 parts of ointment, 14 to 17 parts of argil, 6 to 8 parts of silicon dioxide, 3.1 to 4.5 parts of an accelerant and 5 to 10 parts of glass fiber powder. By adding the glass fiber powder, the glass fibers can be arranged along the flowing direction in the processing process, so that the shrinkage of the rubber and plastic material is effectively reduced; besides, the argil, as a filler, can improve the mechanical properties of the rubber, improve the processability of the material, play a reinforcing role, reduce the supporting strength of the material to bubble walls, and reduce the problem of spouting or collapse.

Owner:亚罗斯建材(江苏)有限公司

Deep foundation pit supporting structure

The invention relates to the technical field of constructional engineering, in particular to a deep foundation pit supporting structure. The deep foundation pit supporting structure comprises a soil retaining plate, a limiting plate, a water guide plate and a fixing mechanism, during construction, the limiting plate is placed on the edge of the bottom of a foundation pit, an anchor rod penetrates through the limiting plate, the anchor rod is fixed through a gasket and a nut, the soil retaining plate penetrates through the limiting plate through a clamping groove and is attached to the side wall of the foundation pit, and the water guide plate is mounted at the bottom of the foundation pit. The deep foundation pit supporting structure is convenient to mount and dismount, adaptable to different topographic conditions, and high in stability; the construction cost is reduced and the economic benefit is increased; after installation is completed, when the side wall of the foundation pit generates rightward pressure on the soil retaining plate, the vertical part of the limiting plate generates a restraining effect on the soil retaining plate, the limiting plate tensions the anchor rod, a clamping block stretches out of a third cavity and is clamped into soil and stone, the contact area of a fixing block and the soil and stone is increased, then the stabilizing effect of the fixing mechanism is improved, therefore, the supporting effect of the soil retaining plate on the side wall of the foundation pit is improved.

Owner:浙江宝盛建设集团有限公司

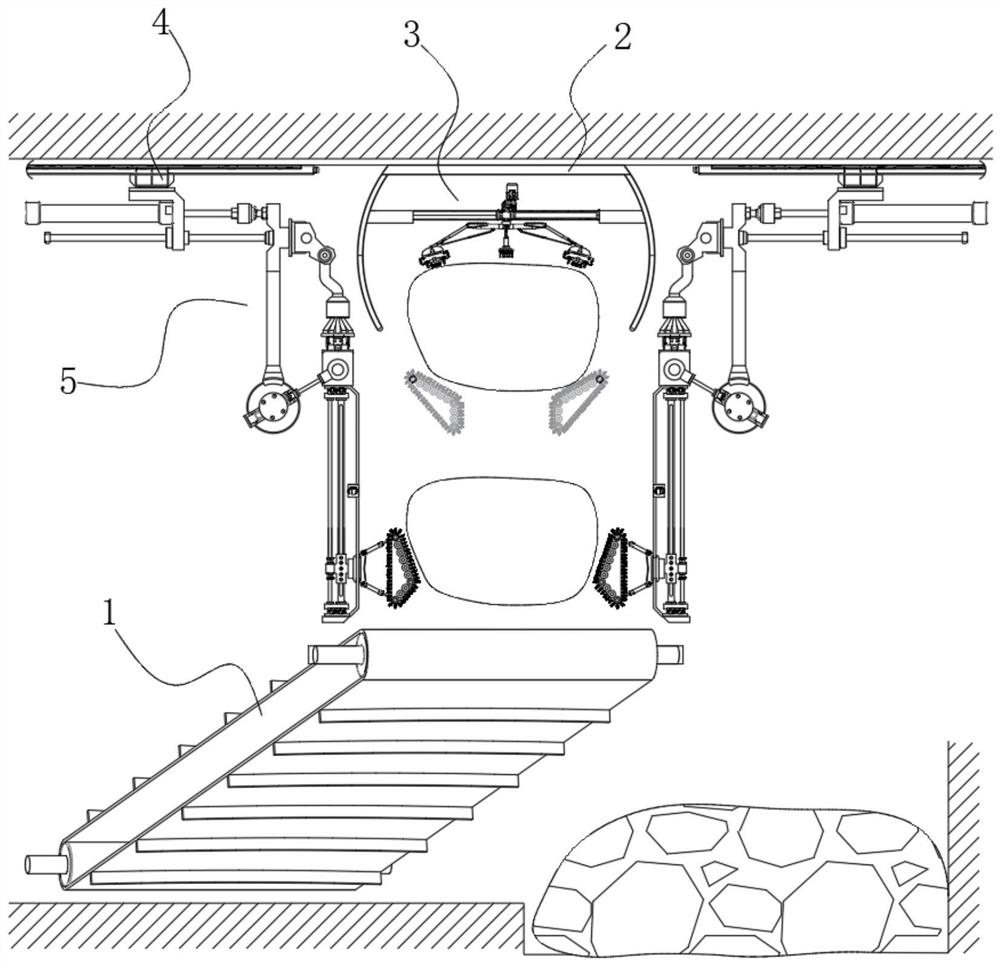

Waste rock throwing equipment suitable for fully mechanized coal mining face roadway

InactiveCN113482712AReduce sizeAvoid uneven gapsMaterial fill-upMining engineeringStructural engineering

The invention discloses waste rock throwing equipment suitable for a fully mechanized coal mining face roadway. The waste rock throwing equipment comprises a waste rock throwing belt inclining towards a filling area, a block cover frame arranged right above the waste rock throwing belt, crushing and angle grinding devices, first guide rails and a monitoring device; the multiple crushing and angle grinding devices are mounted in the block cover frame and are arranged in the conveying direction of the waste rock throwing belt, and the distances between the lower ends of the crushing and angle grinding devices and the upper surface of the waste rock throwing belt are equal; the first guide rails are symmetrically arranged at the left side and the right side of the blocking cover frame, the first guide rails and the crushing and angle grinding devices are longitudinally arranged in an alternative manner, and a set of first guide rail is installed between every two adjacent crushing and angle grinding devices; and the monitoring device is mounted on the first guide rails and clamped at the left side and the right side of the waste rock throwing belt.

Owner:PINGDINGSHAN COAL MINE MACHINERY EQUIP CO LTD

Physical quantity sensor, physical quantity sensor device, electronic apparatus, and vehicle

ActiveUS10830789B2Reducing deterioration in temperature characteristicReduce support strengthAcceleration measurement using interia forcesResilient suspensionsMechanical engineeringElectrical and Electronics engineering

A physical quantity sensor includes: a base; wiring disposed in the base; a support that includes a first bonded surface bonded to the base and a second bonded surface bonded to the wiring; a suspension beam connected to the support; and an electrode finger supported by the suspension beam. The support is located between the first bonded surface and the suspension beam and includes a first overhang separated from the base.

Owner:SEIKO EPSON CORP

Deep foundation pit support construction process

ActiveCN110700281AControl verticalityImprove verticalityExcavationsBulkheads/pilesArchitectural engineeringSteel frame

The invention relates to a deep foundation pit support construction process, and relates to the technical field of engineering facility construction. The deep foundation pit support construction process comprises the following steps that S100, a groove is pre-dug along the side line of a deep foundation pit on a construction site, an enclosure body is arranged, single-row piles are arranged on theinner side, close to the deep foundation pit, of the enclosure body, and the single-row piles are uniformly distributed in the extending direction of the side wall of the deep foundation pit; S200, fixing piles are arranged on the outer side, far away from the deep foundation pit, of the enclosure body, the fixing piles are arranged at the positions which are more than 5 meters away from the vertical distance of the enclosure body, and the bottom ends of the fixing piles are lower than the preset lowest position of the deep foundation pit; and S300, a horizontal steel frame is arranged between the fixing piles and the single-row piles, the two ends of the horizontal steel frame are connected with the fixing piles and the single-row piles respectively, and the length direction of the horizontal steel frame is perpendicular to the side wall of the deep foundation pit. The deep foundation pit support construction process has the effect that the perpendicularity of the side wall of the deep foundation pit can be improved under the condition that the space occupied in the deep foundation pit is reduced.

Owner:SHENZHEN DONGSHEN ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com