Patents

Literature

144results about How to "Control verticality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

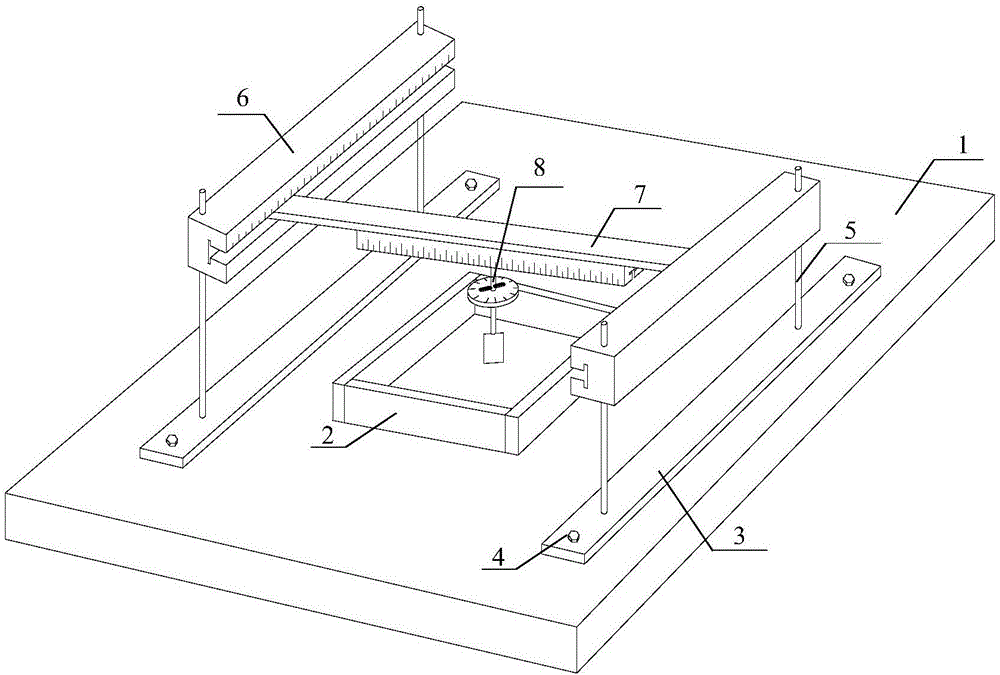

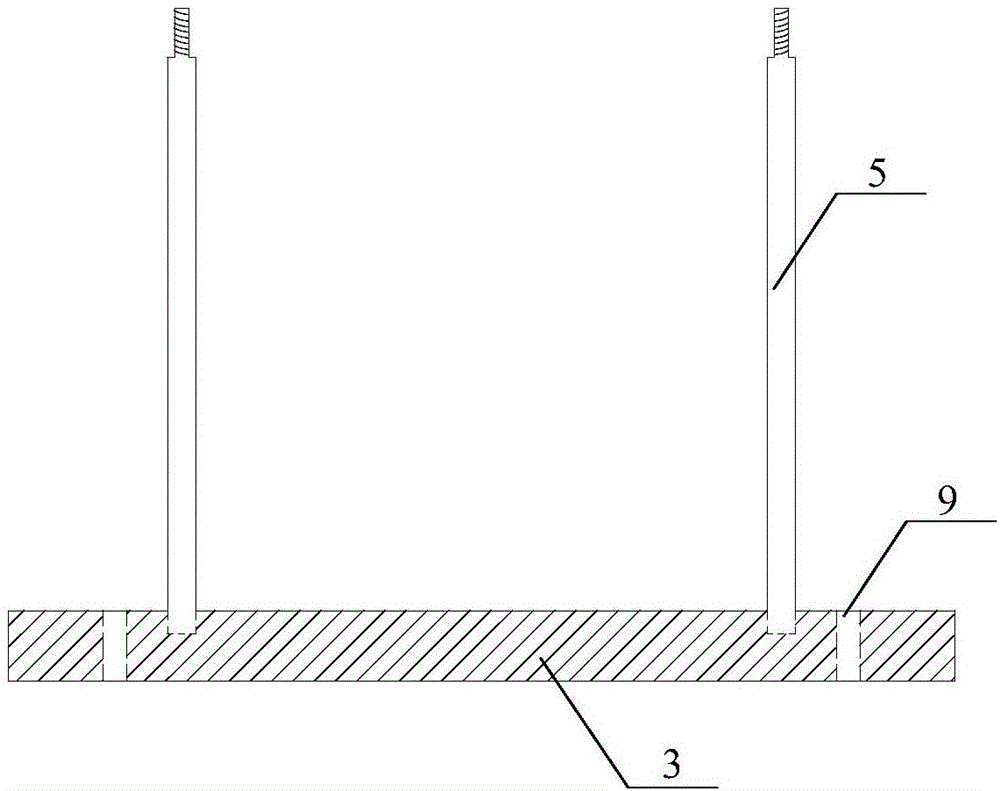

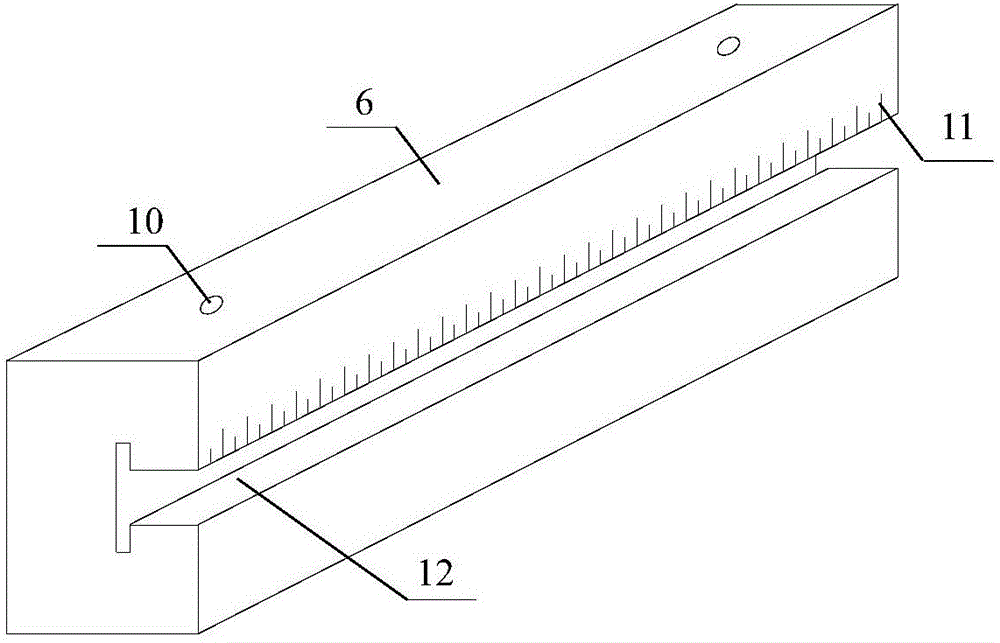

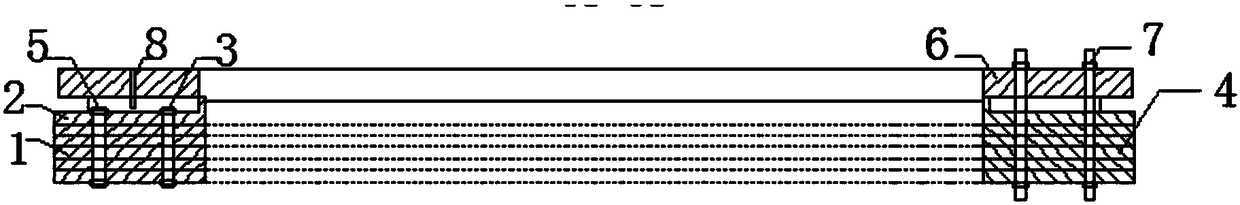

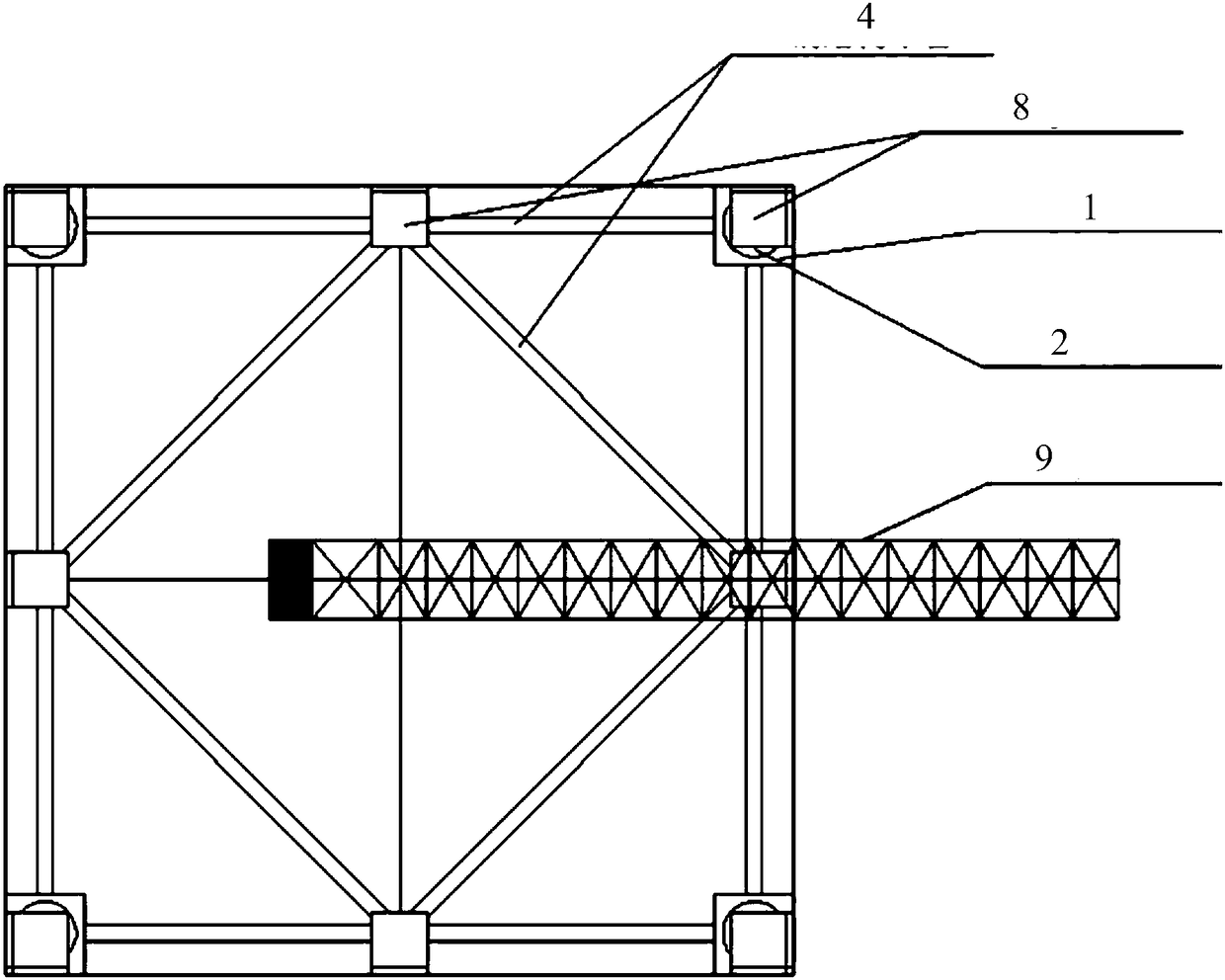

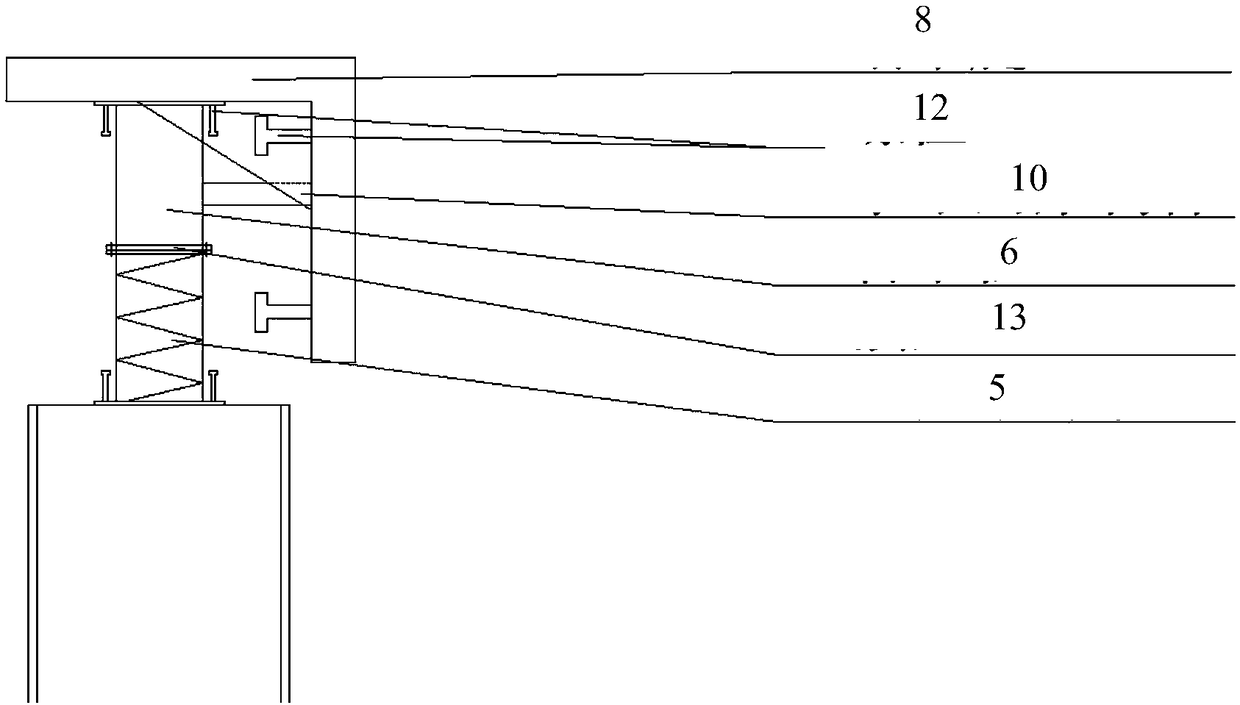

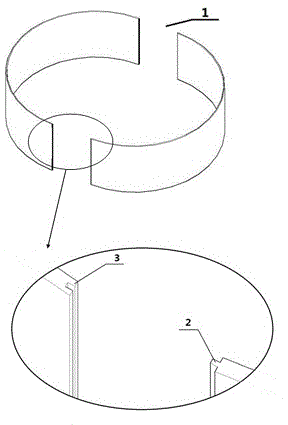

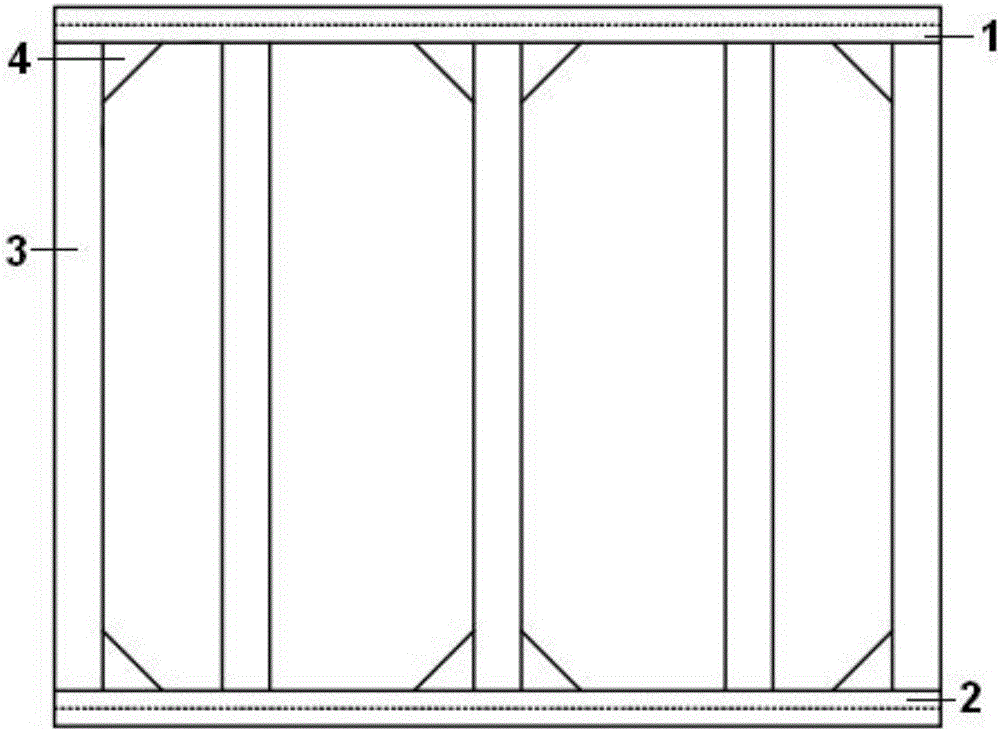

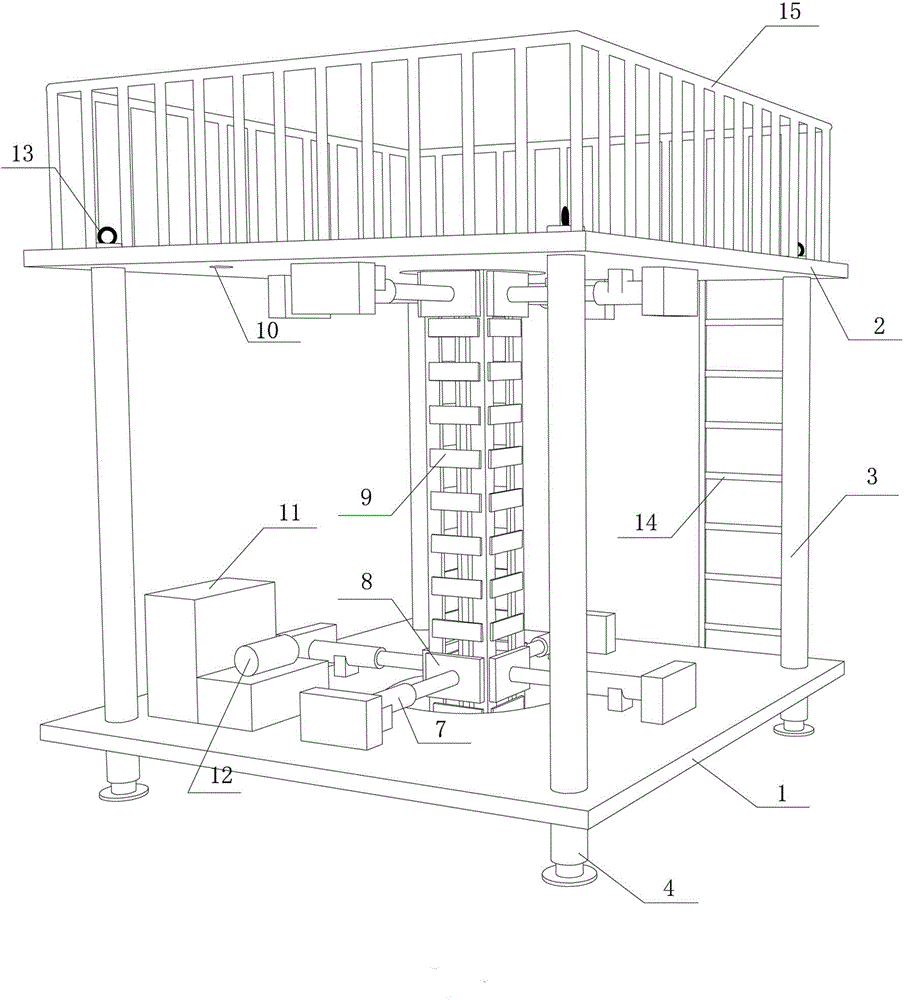

Accurate positioning and producing device for intermittent joints of similar-material rock mass samples

ActiveCN106124272AImprove stabilityMade in unisonPreparing sample for investigationTransverse fractureLongitudinal fracture

The invention discloses a device for accurately positioning intermittent joints of similar material rock mass samples. The bottom plate of the crack positioning bracket is arranged in parallel on both sides of the sample mold, and the anchor bolts of the crack positioning bracket are anchored on the sample preparation base plate. The crack positioning bracket It is connected with the bottom plate of the crack positioning bracket through threads, and the crack longitudinal positioning rods are respectively arranged parallel to the crack positioning bracket bottom plate and fixed on the four crack positioning brackets by screws. The slider of the horizontal positioning rod is stuck in the groove of the longitudinal positioning rod of the crack, and the angle positioning device is stuck in the groove at the lower end of the horizontal positioning rod of the crack through the square slider at the top, and the crack is made by the steel plate at the lower end of the angle positioning device. The structure is simple and the operation is convenient, which effectively guarantees the high-efficiency creation of fractures and the enrichment of fracture forms, which greatly facilitates the strength and deformation behavior tests of rock masses with different fractures, and quickly creates intermittent fractures with specified parameters.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

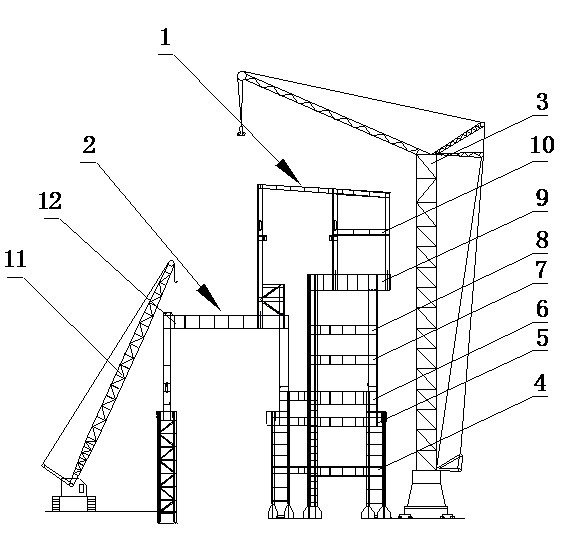

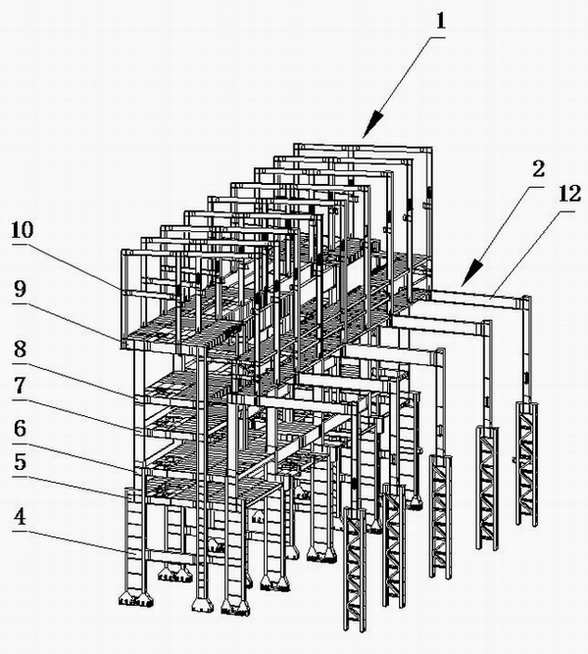

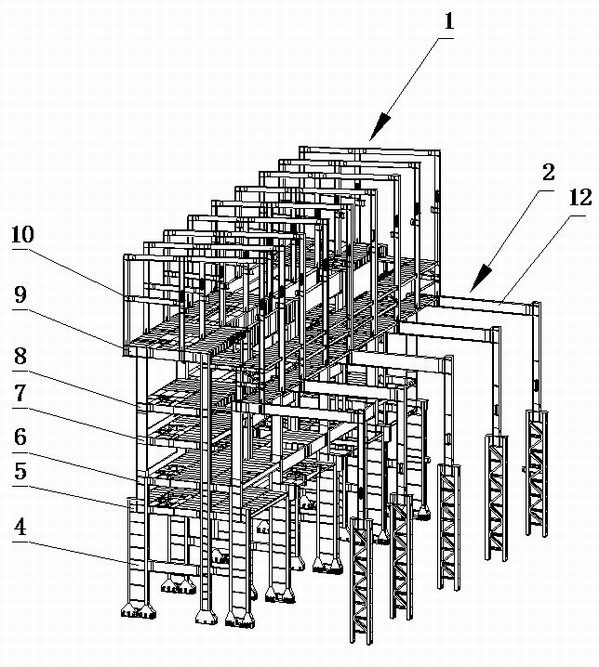

Method for two-way hoisting construction of converter tower steel structure

InactiveCN101899904AImprove efficiencyShorten the construction periodBuilding material handlingTower craneSteel columns

The invention discloses a method for the two-way hoisting construction of a converter tower steel structure, which comprises the following steps of: firstly, performing construction from a first layer to a fourth layer in a mode of hoisting steel columns by using a tower crane, hoisting a frame beam on the fourth layer by using a truck crane, and after the frame beam on the fourth layer is welded completely, paving a flat pallet immediately, so that an integral converter tower with seven layers is divided into an upper part and a lower part; secondly, for the upper part, performing layer-by-layer construction from bottom to top by adopting a forward hoisting method in a mode of hoisting the steel columns and the frame beam by using the tower crane; and finally, for the lower part, performing the layer-by-layer construction from top to bottom by adopting a backward hoisting method which is synchronous with the forward hoisting method in a mode of hoisting the frame beam by using the truck crane. In the method, starting from a platform of the fourth layer, platforms on the upper part of the converter tower are constructed by utilizing the tower crane, platforms on the lower part of the converter tower are hoisted by utilizing the truck crane to push towards the next layer, and the construction and installation are performed simultaneously by a method of combining forward hoisting and backward hoisting to form a dual working face, so that the efficiency is improved greatly, and the construction period is shortened.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

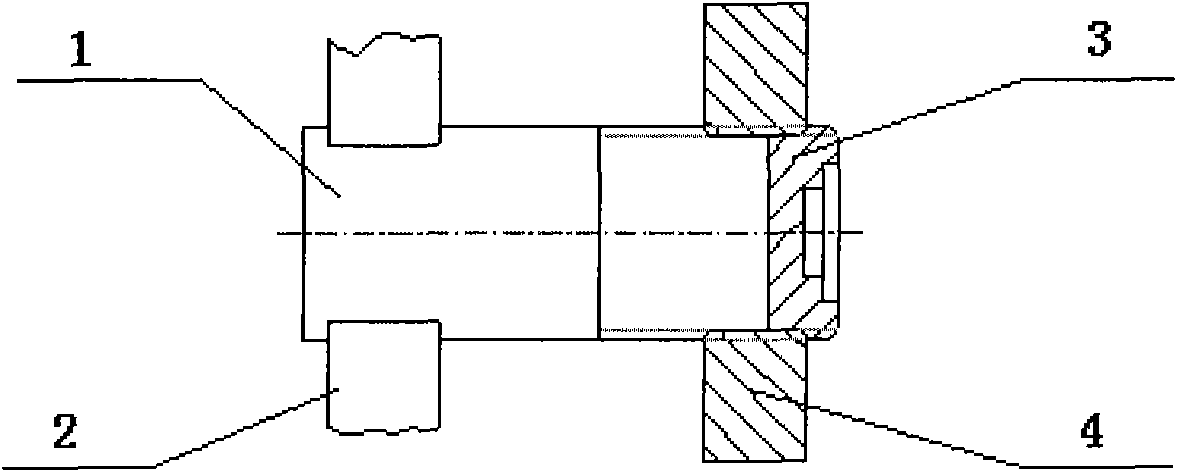

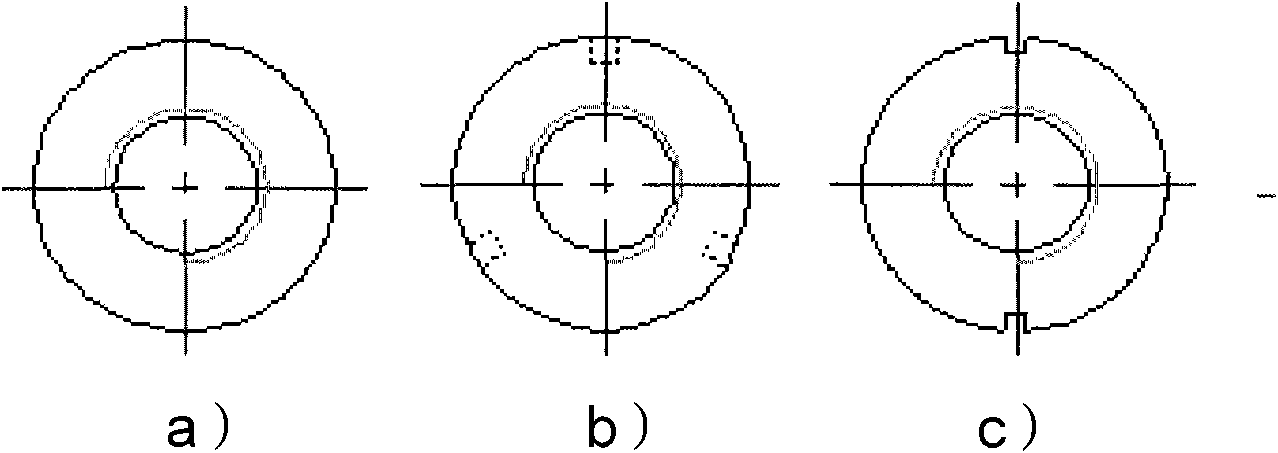

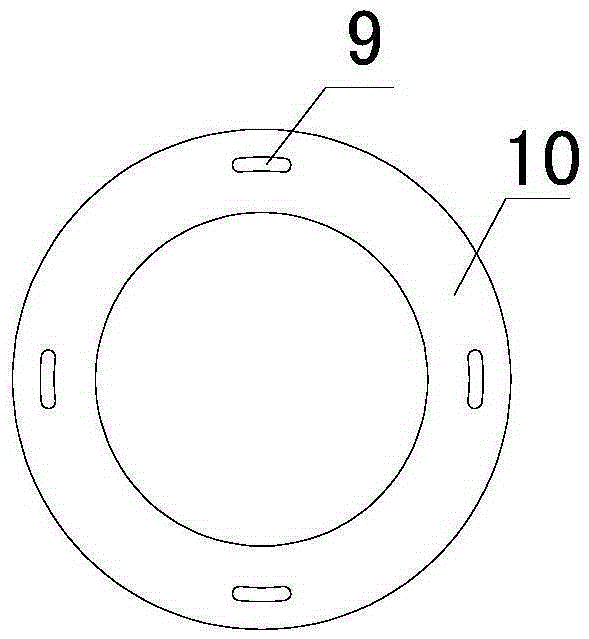

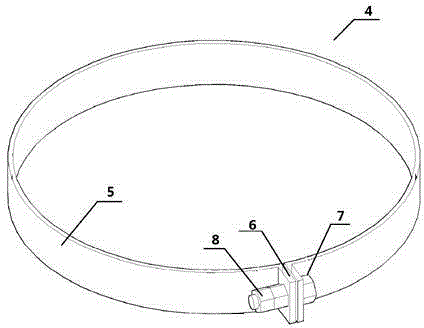

Turning positioning fixture for thin-wall rotational parts and clamping method

ActiveCN101972943AReduce distortionNot easy to damagePositioning apparatusMetal-working holdersEngineeringAxial force

The invention relates to a turning positioning fixture for thin-wall rotational parts and a clamping method. The fixture comprises a cylindrical positioning body and threaded rings, wherein an external thread is lathed on the external surface of the positioning end; the threaded rings are circular rings with internal diameter the same as the external diameter of the positioning body; the internal surfaces of the threaded rings are provided with internal threads matched with the external thread on the positioning body; and during positioning, one end of the positioning body is clamped on a machine tool and the positioning end is closely contacted with the part, and the positioning body is closely matched with the part through the external thread on the external surface and the internal threads on the threaded rings. In the embodiment, the clamp force on the part is mainly axial force, thus overcoming the negative effect that radial force leads to workpiece deformation during traditional machining; and the positioning body is clamped and lathed at the site, and during positioning and clamping, firstly the positioning body is ensured to be fit with the end face of the part and the end face runout of the part is ensured to be identical with that of the spindle of the machine tool, thus ensuring the flatness and the parallelism of the part. The fixture can carry out automatic alignment and positioning while screwing the threaded rings, is convenient to operate and reduces artificial operation errors.

Owner:BEIJING RES INST OF TELEMETRY

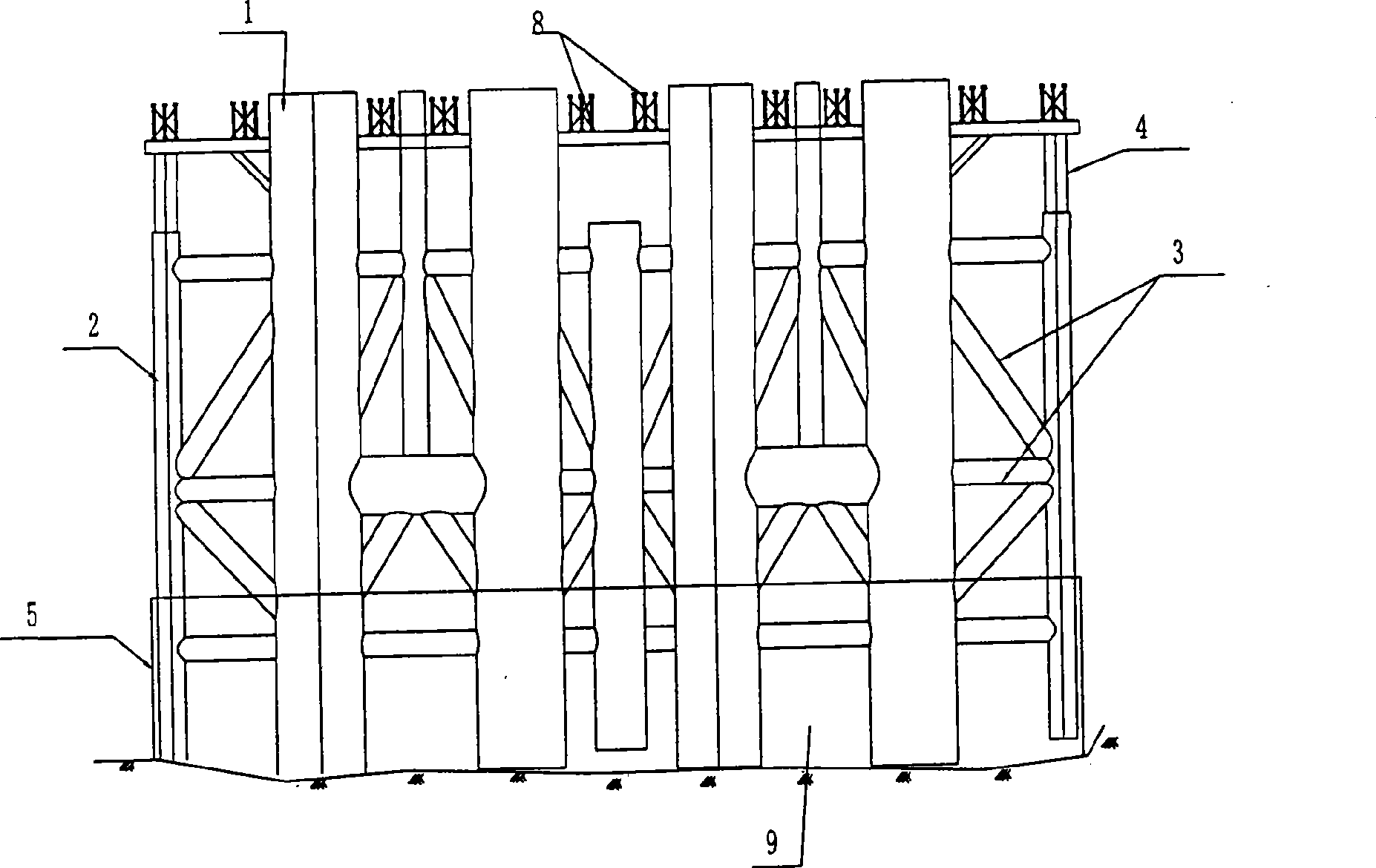

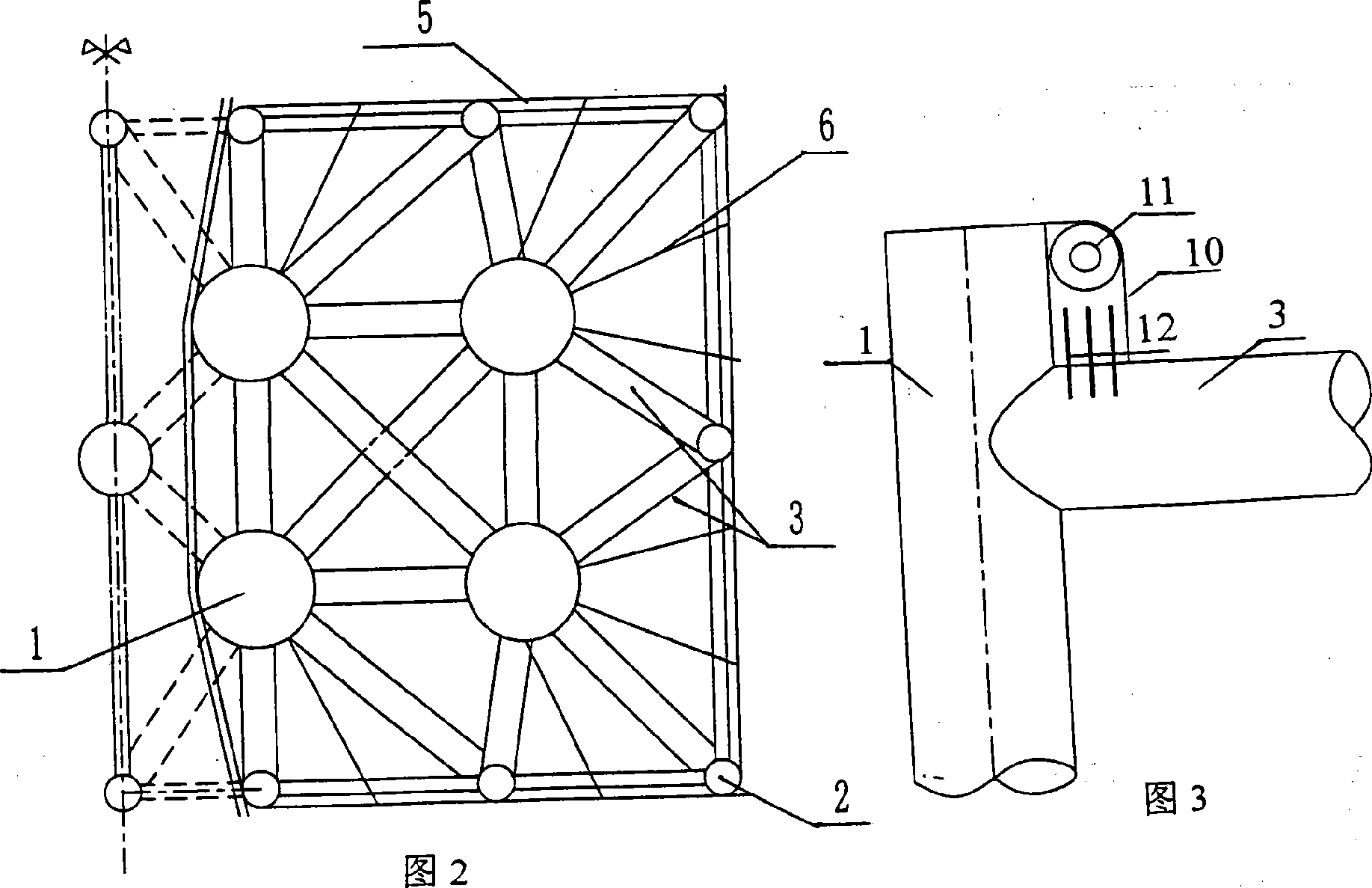

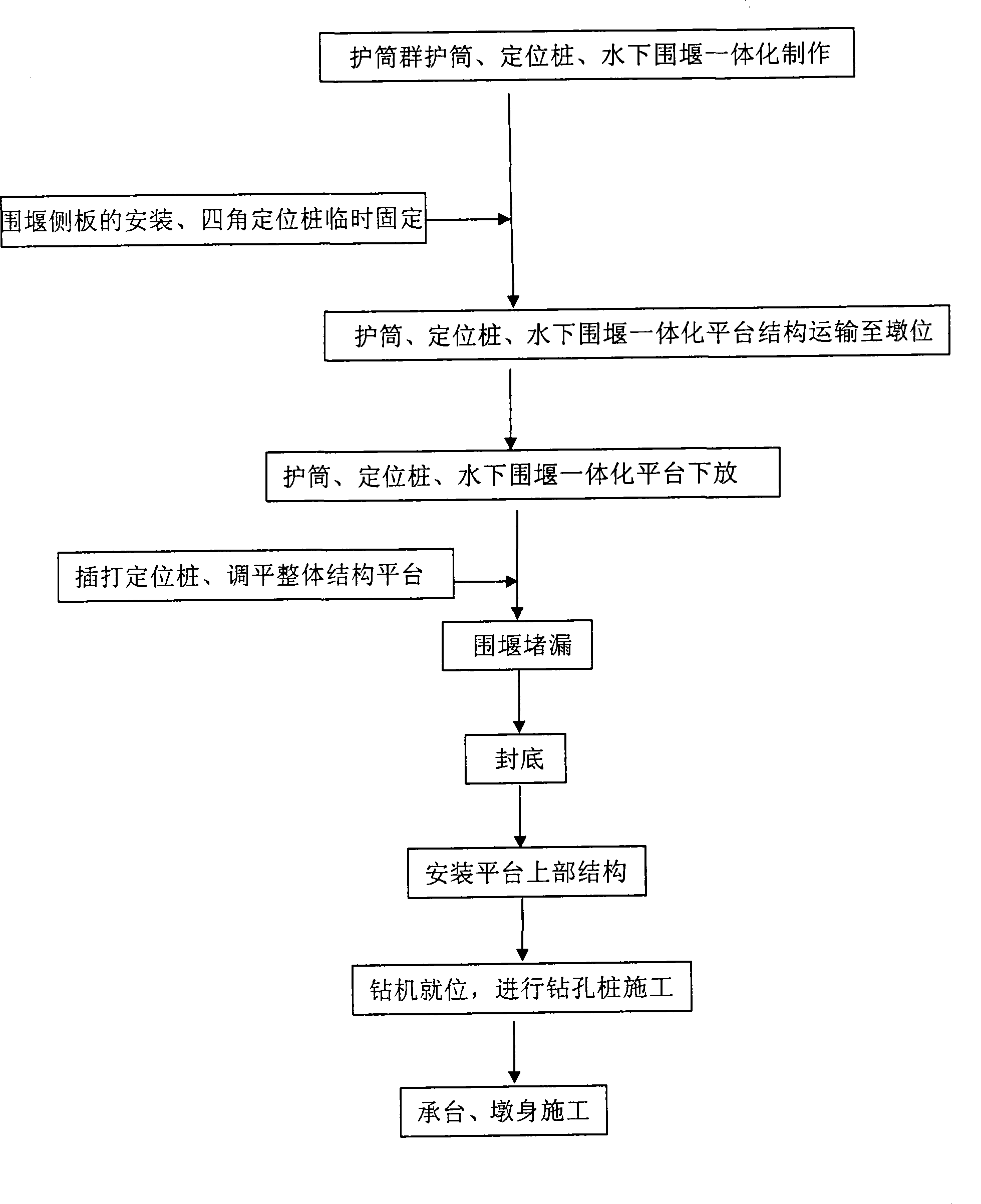

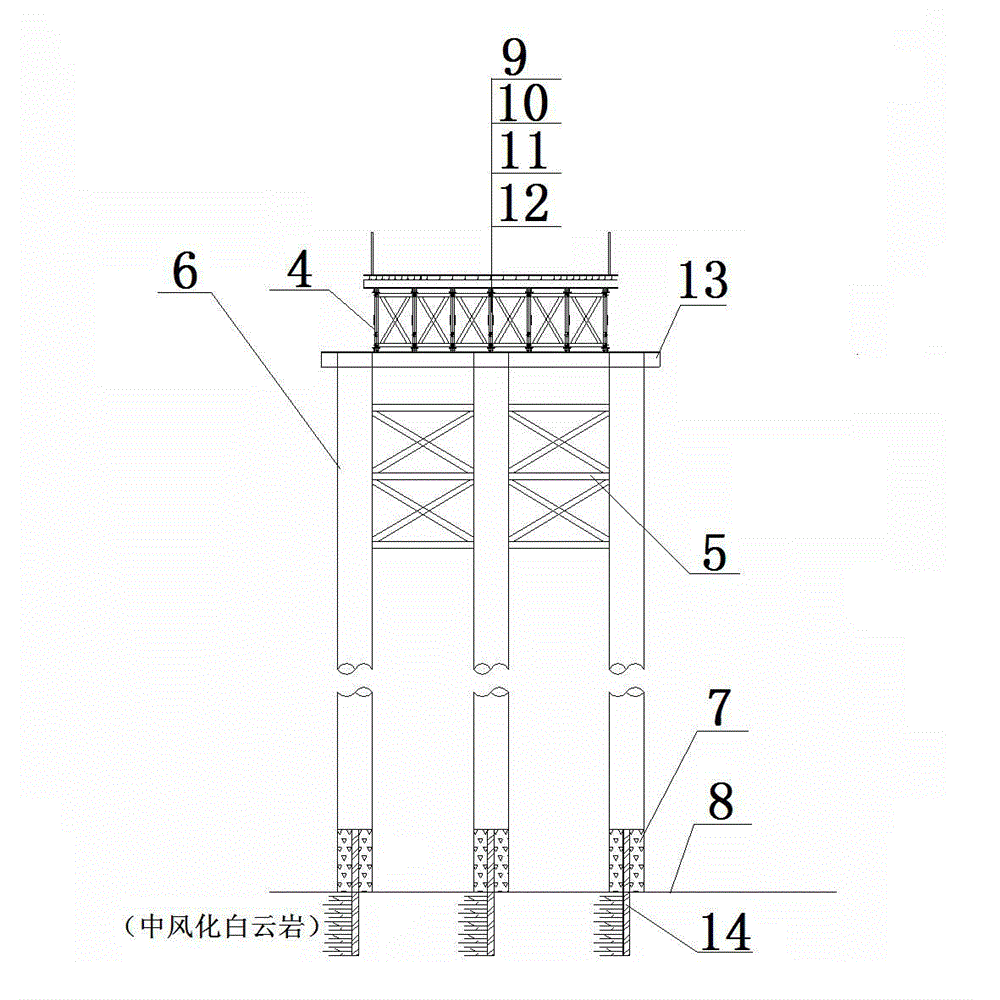

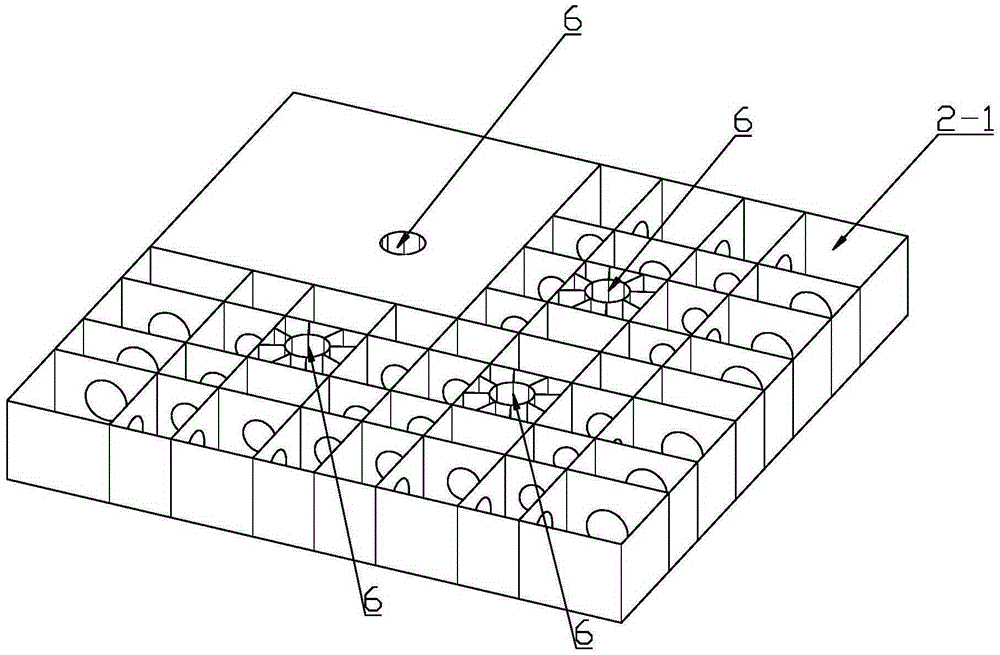

Deep sea bare rock pier protection barrel, positioning pile, underwater cofferdam integrated platform and construction method

InactiveCN101429761AImprove manufacturing precisionImprove horizontal displacementArtificial islandsUnderwater structuresRear quarterCofferdam

The invention relates to an integrated platform of a deep sea bare rock pier guard barrel, a guide pile and an underwater cofferdam and a construction method thereof. The structure of the integrated platform is as follows: the steel guard barrel and a steel sleeve are connected into a whole; the guard pile is inserted into the steel sleeve; side plates of the cofferdam are arranged along the outer ring at the bottom of the platform to form a closed bin body which is divided into a plurality of small bins; bottoming concrete is filled into each small bin; and bin baffle plates are supported on trusses of the side plates of the cofferdam. The construction method comprises the following working procedures of manufacture of the platform, lifting and conveying, descending, leak stoppage, pouring of bottoming concrete, tapped arrangement and so on. The construction method meets the requirements of construction of a bridge foundation of a bare rock pier of a bridge spanning the sea, and the requirement of the steel protective barrel and the guard pile on the pile stabilizing depth, is safe and stable to construct the prior guard pile platform, improves the construction efficiency due to overall assembly of the platform, controls the verticality and the horizontal deviation of the platform, has high construction precision, avoids overall stability of the platform and leakage stoppage of a bottom opening of the protective barrel, and provides convenient conditions and technological guarantee for bridge construction in sea areas with severe construction conditions.

Owner:THE 2ND ENG CO LTD MBEC

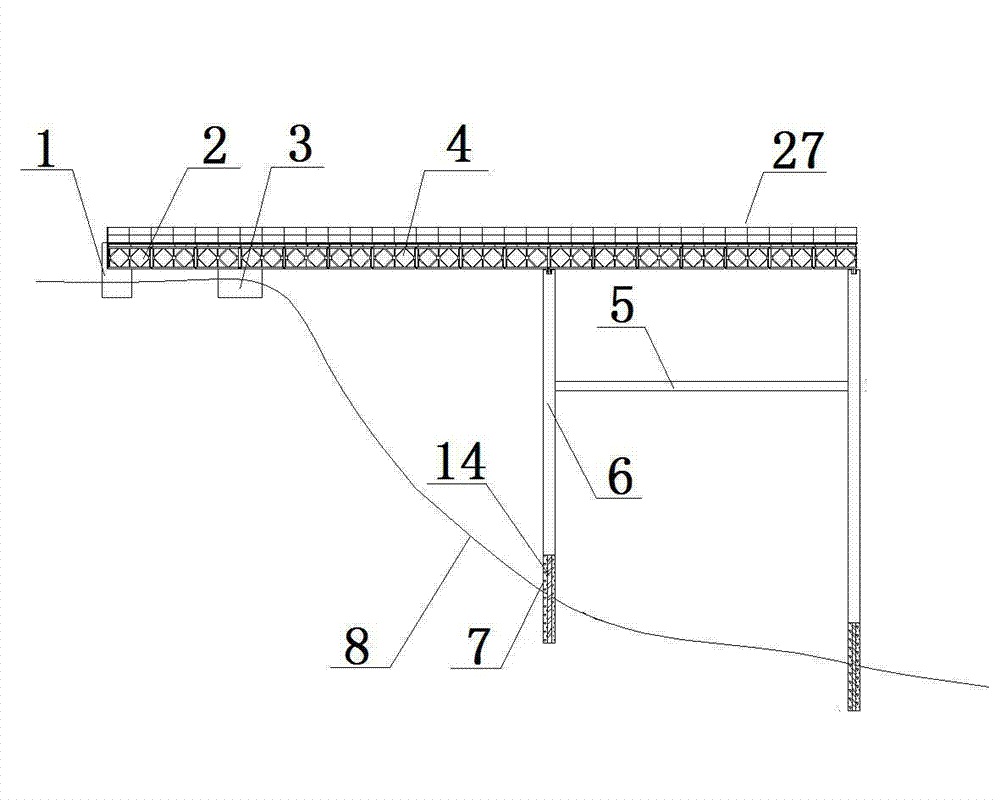

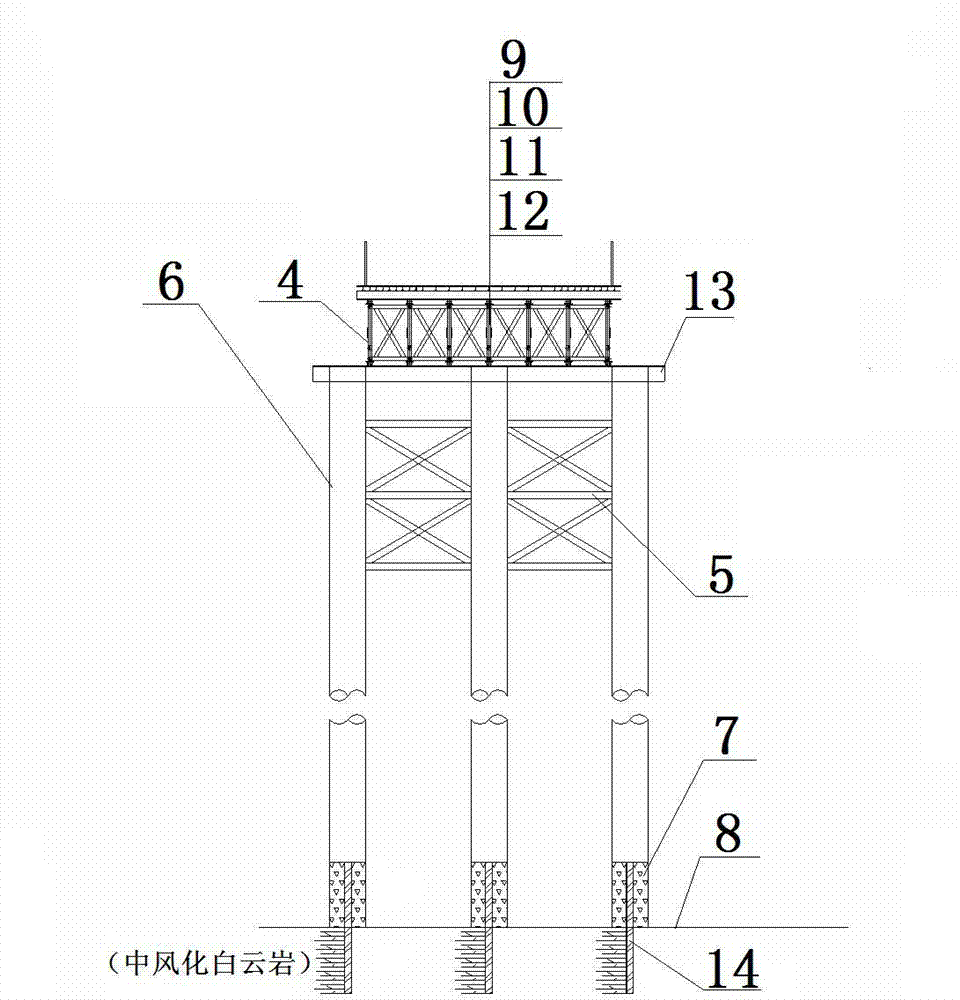

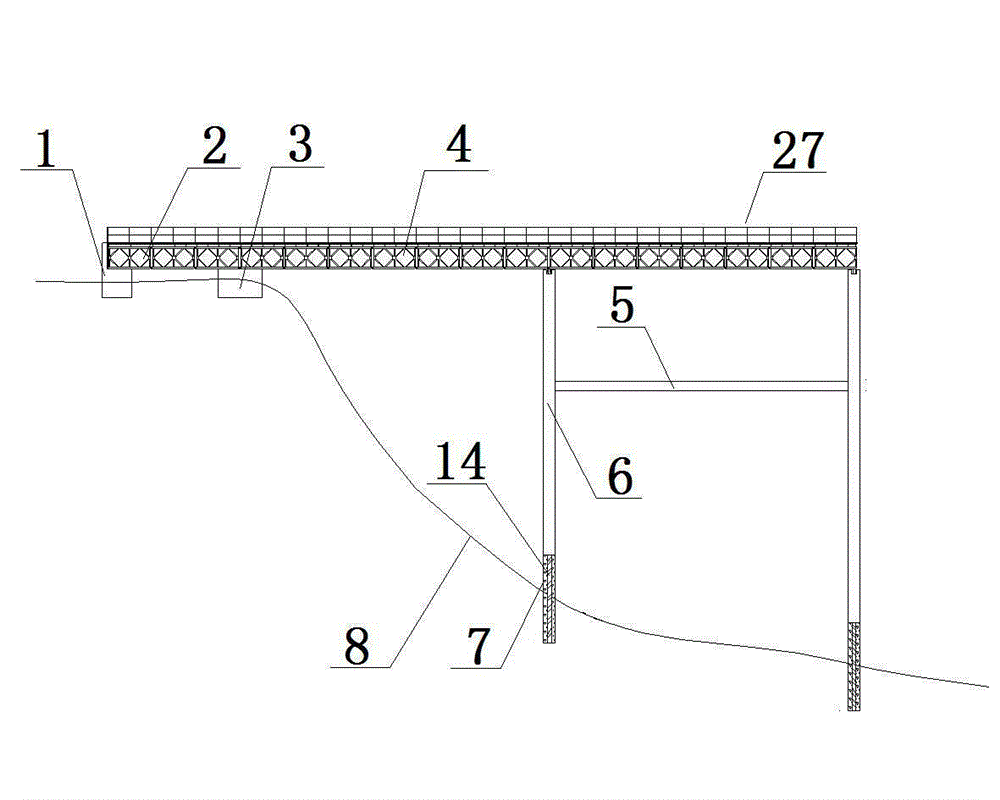

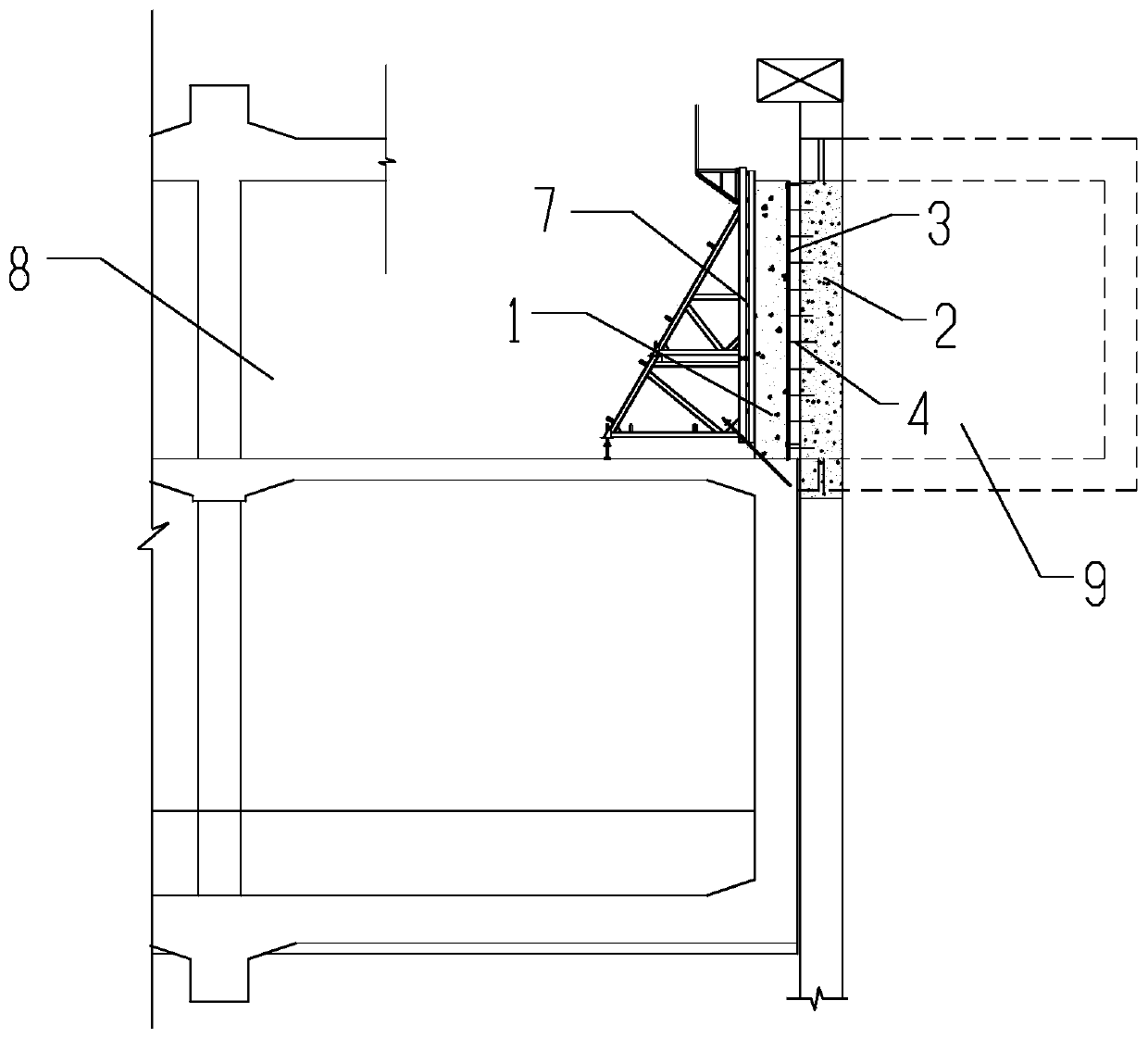

Overhead trestle structure built on non-covering steep bare rocks in deep rapids

ActiveCN102953341AControl verticalityAvoid welding qualityBridge erection/assemblyBulkheads/pilesBedrockEngineering

The invention belongs to the field of bridge construction and particularly relates to an overhead trestle structure built on non-covering steep bare rocks in deep rapids. The invention adopts the technical scheme that the overhead trestle specifically comprises a trestle body and steel pipe piles for supporting the trestle body, wherein the steel pipe piles are arranged on the surfaces of the steep bare rocks, bottom cavities of the steel pipe piles are connected and anchored with the steep bare rocks by anchor rods in a connected way, and the steel pipe piles, the steep bare rocks and the anchor rods are fixedly connected into an integral structure by a poured underwater concrete layer. The overhead trestle structure has the advantages that the steel pipe piles are connected with the surfaces of the steep bare rocks by a grouted and rock-socketed anchor rod structure, so that the steel pipe piles are firmly anchored to the surfaces of the steep bare rocks by the holding force of underwater concrete pulp andwith the holding force of the anchor rods, pile bottom concrete and river bed rocks; and the construction has a short period, is at a low cost and is safe and efficient.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

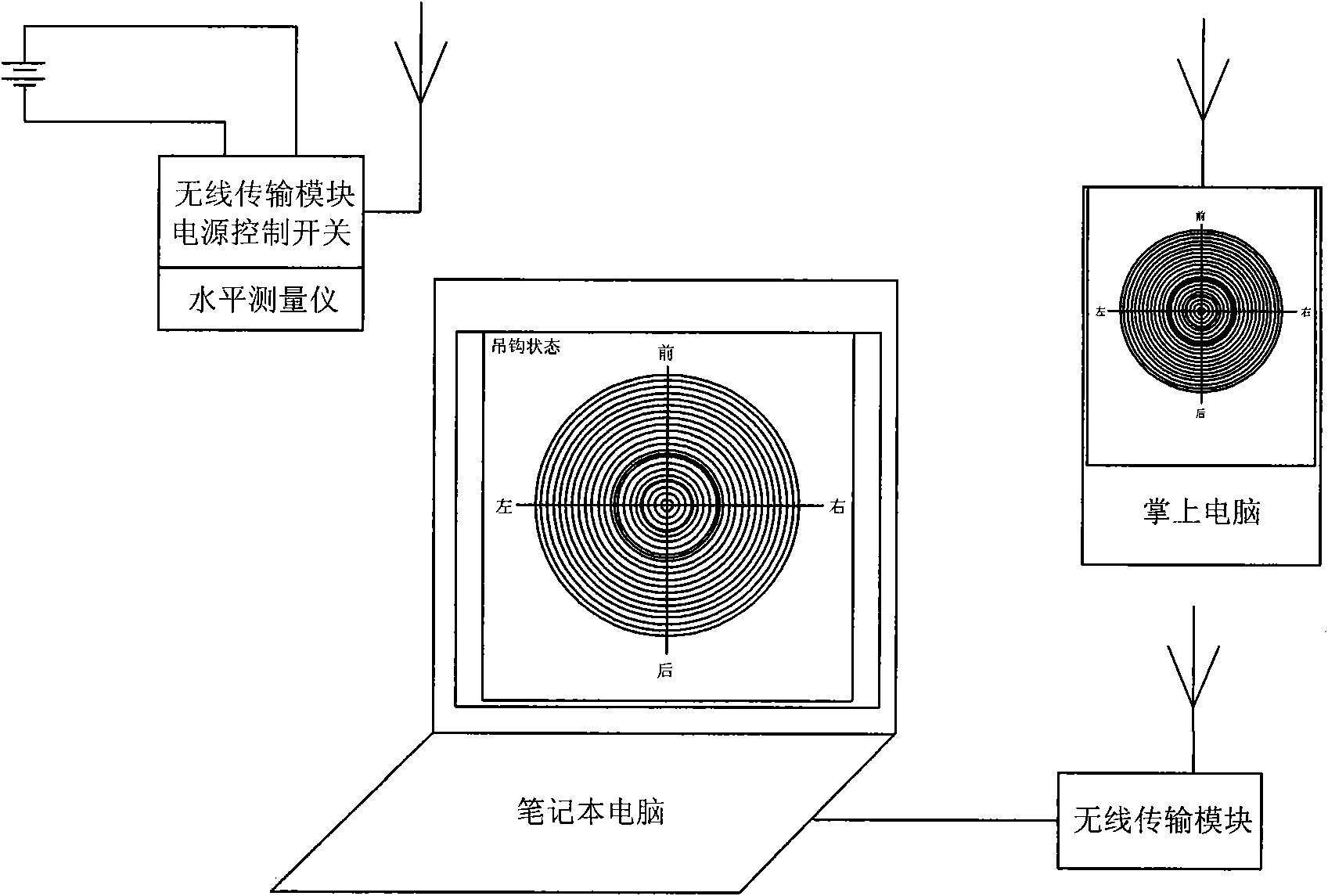

Dynamically measuring device and dynamically measuring method for measuring perpendicularity deviation of hoist lifting hook

InactiveCN101650174AControl verticalityImprove securityTransmission systemsIncline measurementData transmissionMechanical engineering

The invention relates to a dynamically measuring device and a dynamically measuring method for measuring the perpendicularity deviation of a hoist lifting hook, wherein the dynamically measuring device is characterized by comprising a horizontal measurement sensor, a signal receiving and transmitting mechanism, a center processing mechanism and a display mechanism, wherein the horizontal measurement sensor is installed on the plane perpendicular to the center line of a steel cable of a hoist lifting hook and used for measuring an angle of the steel cable of the hoist lifting hook deviating from the horizontal plane; the signal receiving and transmitting mechanism collects and transmits data measured by the horizontal measurement sensor; the signal receiving and transmitting mechanism transmits the collected data to the center processing mechanism, and the center processing mechanism acquires a calculation result by calculation; and the display mechanism displays the calculation resultcalculated by the center processing mechanism. The measuring method adopting the device is simple and convenient. Compared with the prior art, the invention can dynamically measure the perpendicularity of the lifting hook in real time, has high measuring precision, overcomes the adverse effect of measurement and improves the hoisting safety.

Owner:CHINA PETROCHEMICAL CORP +2

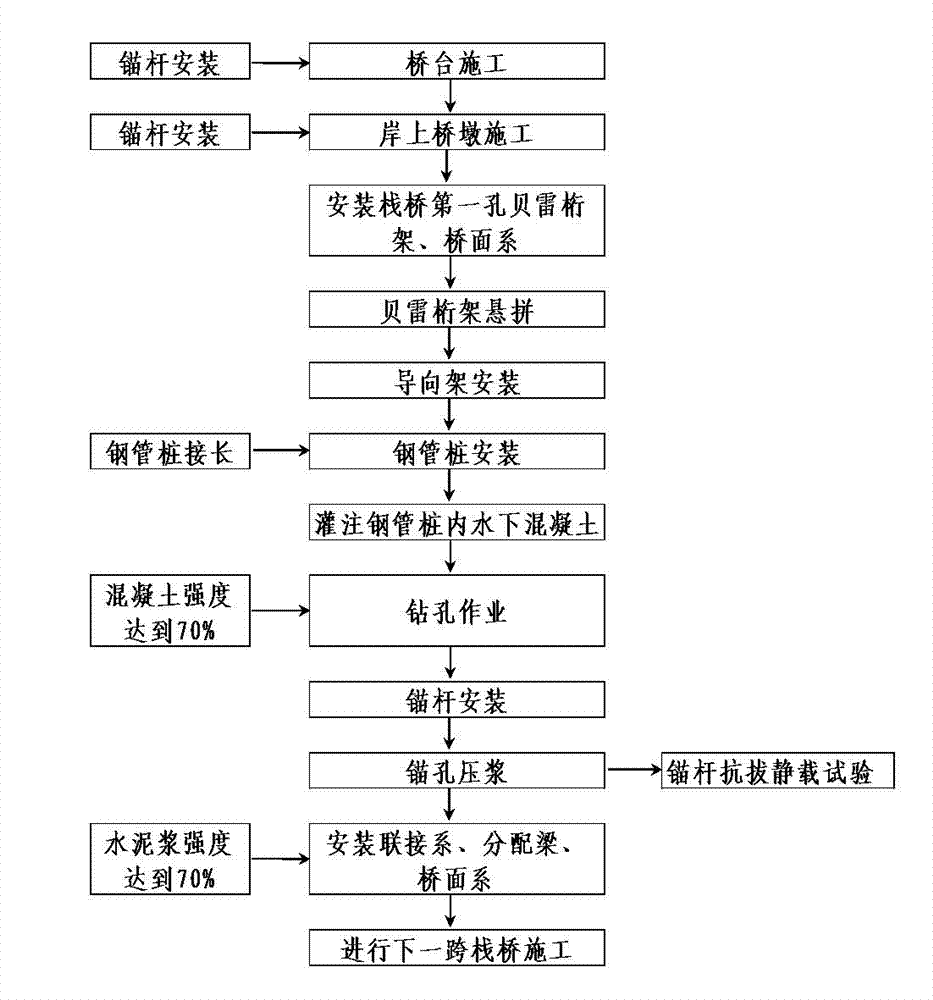

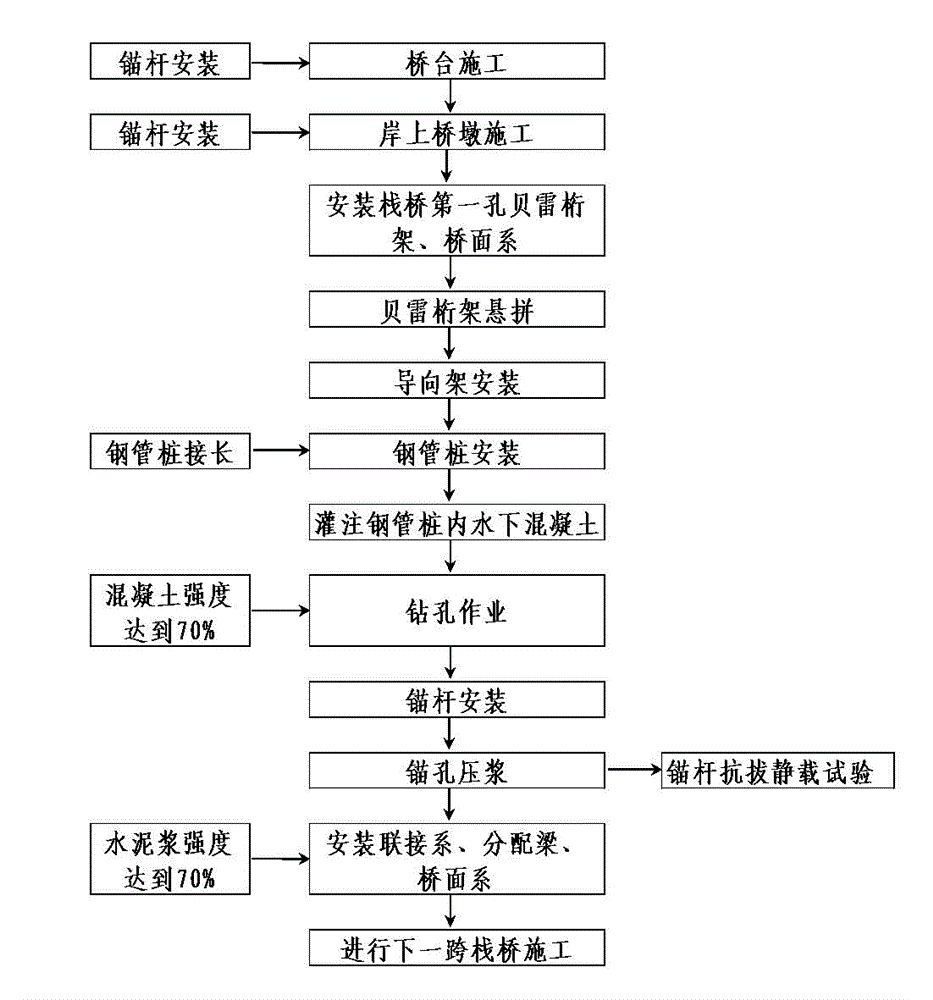

Elevated trestle bridge construction method on covering-free steep bare rock in deepwater and rapid stream

ActiveCN102979039AControl verticalityAvoid welding qualityBridge erection/assemblyBulkheads/pilesBasementBedrock

The invention specifically relates to an elevated trestle bridge construction method on covering-free steep bare rock in deepwater and rapid stream. A scheme of the invention is as follows: the elevated trestle bridge construction method comprises the following steps of: constructing a first porous trestle bridge on the bank, then constructing a second porous trestle bridge by adopting a cantilever method, and arranging guide frames on the tail end part of the second porous bridge; settling cut steel pipe piles in mounting sites, then casting an underwater concrete layer in the steel pipe piles, and drilling an anchor hole along the central axis direction of each steel pipe pile after the underwater concrete layer is cured, wherein each anchor hole penetrates through the underwater concrete layer and extends into basement rock of a river bed; and finally arranging an anchor bolt in each anchor hole, grouting and anchoring, then assembling a truss to form a third porous trestle bridge, and repeating the steps till finishing the construction of the whole trestle bridge. The elevated trestle bridge construction method disclosed by the invention has the advantages of reducing the deep diving operation load and the construction risk by adopting an underwater exploration technology in combination with precutting of a bottom opening of each steel pipe pile on the bank, enabling each steel pipe pile to be firmly anchored on the steep bare rock surface by adopting the anchor bolt grouting and rock-socketing technology between the steel pipe pile and the steep bare rock surface, shortening the construction peroiod and reducing the construction cost.

Owner:MUNICIPAL ENVIRONMENTAL PROTECTION ENG CO LTD OF CREC SHANGHAI GRP

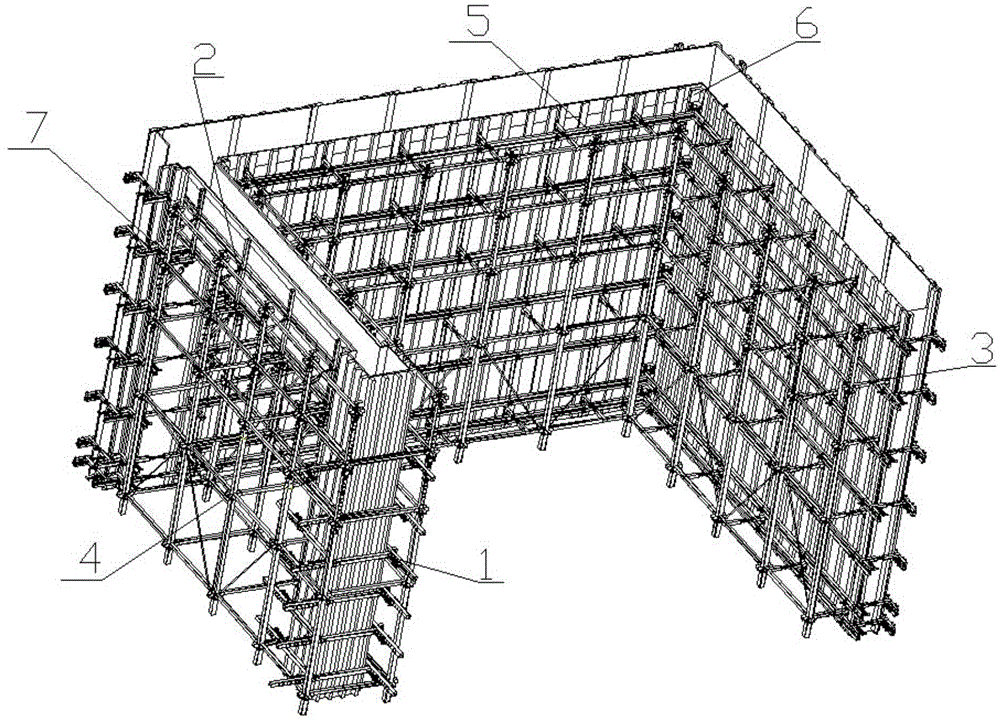

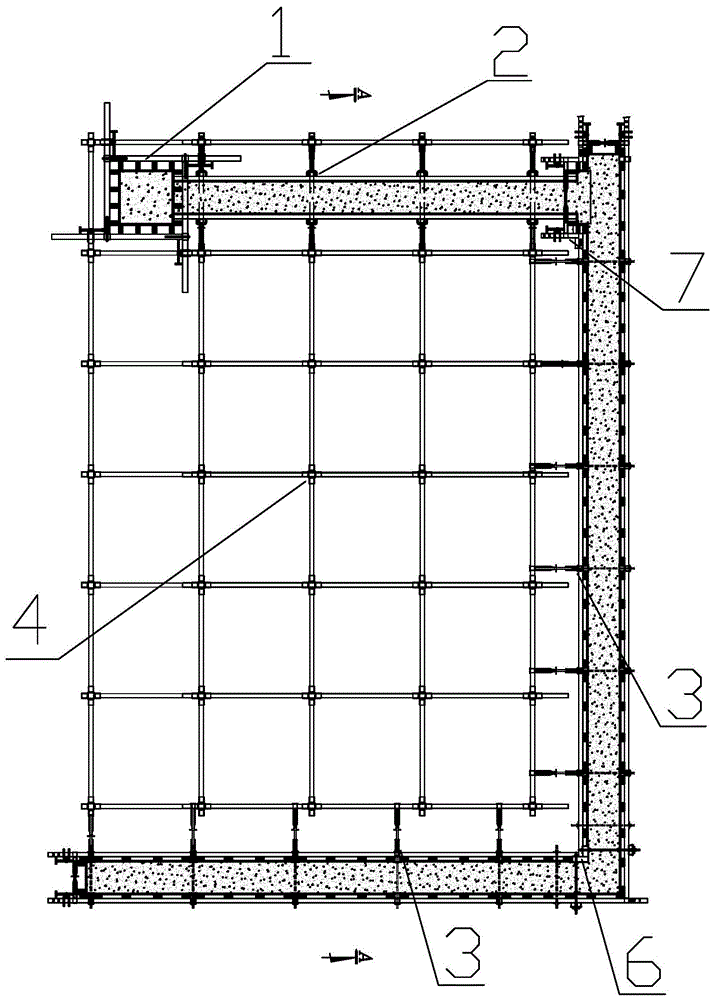

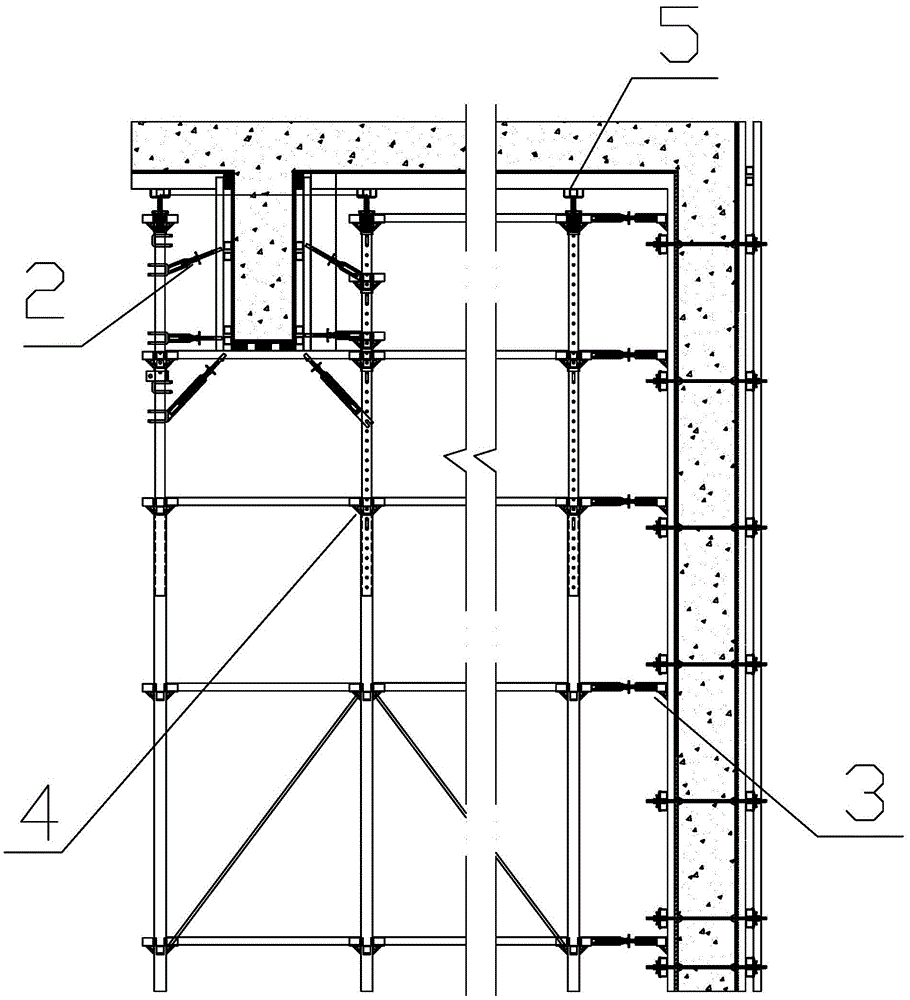

Concrete formwork support device

InactiveCN105625710AWon't tiltAvoid piercing operationsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksInterior spaceFloor slab

Owner:张海文

Manufacturing technique of rigid magnetic yoke of motor rotor of large pumped storage generator

ActiveCN108436394AEasy to operateImprove machining accuracyManufacturing stator/rotor bodiesMagnetic polesEngineering

The invention discloses a manufacturing technique of a rigid magnetic yoke of a motor rotor of a large pumped storage generator. According to the manufacturing technique, preassembling is conducted firstly through single disc bolt fixing holes, and rod fixing holes are drilled and reamed at the same time after a magnetic yoke section is fixed, so that the machining precision is improved; and an inner circular key groove is machined through a single section of a milling mold, and an outer circular T-shaped tail groove of the magnetic yoke section is machined integrally. By adoption of the manufacturing technique, the problems that scrap iron cannot be discharged through bolt holes which are reamed at the same time, and an inner circular key groove and an outer circular T-shaped tail grooveof a magnetic yoke section are staggered are solved, and successful hanging assembly of a magnetic pole in the subsequent stage is effectively ensured; and meanwhile, the manufacturing technique has the advantages of being easy and convenient to implement, high in machining precision, capable of shortening the machining cycle, and the like. The manufacturing technique is suitable for manufacturingrigid magnetic yokes of motors of all large pumped storage generators and has high application and popularization value.

Owner:HARBIN ELECTRIC MASCH CO LTD

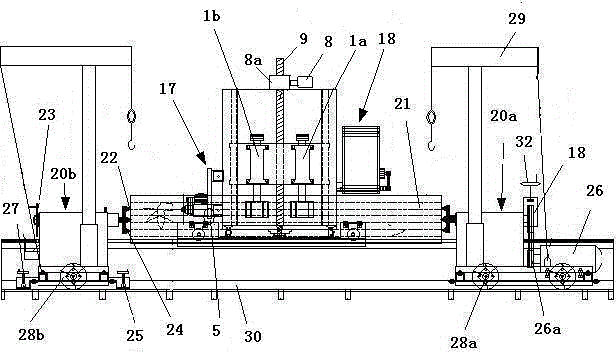

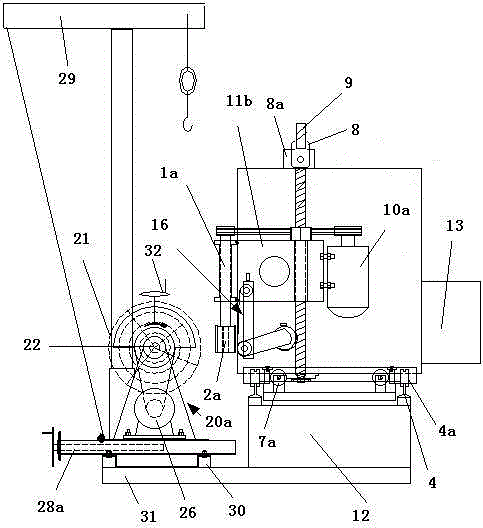

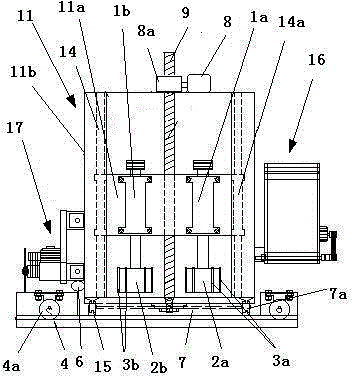

Multifunctional wood machining equipment

ActiveCN104890063AMove fastReduce resistance to movementMulti-purpose machinesBark-zones/chip/dust/waste removalWood machiningEngineering

The invention discloses multifunctional wood machining equipment and belongs to the field of wood machining equipment. A running vehicle comprises a movement and driving devices moving along X-axis direction, Y-axis direction and Z-axis direction, at least two rotating spindles taking vertical direction as axis are arranged at the front end of the movement, a knife is arranged at the lower end of each spindle, and multiple rows of blades are arranged around each knife, distances between the blades on different spindles and cut wood are difference, the spindles are rotatably connected with a motor respectively, multiple top discs different in diameter are arranged on a top tip seat and a top tip of a tail seat, a rolling device along the X-axis direction is arranged on the lower portion of the tail seat, and a control panel is arranged on the multifunctional wood machining equipment. By the multifunctional wood machining equipment, production efficiency can be improved, labor intensity of operating personnel can be lowered, machining diameter can be expanded, machining variety can be increased, and sales market can be expanded.

Owner:安阳市涵缘机械设备有限公司

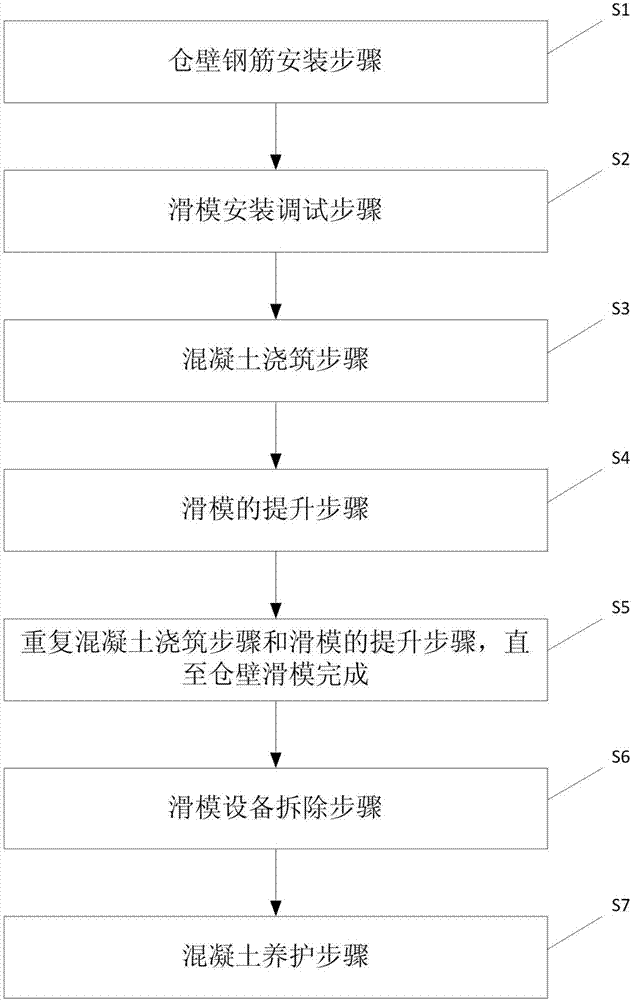

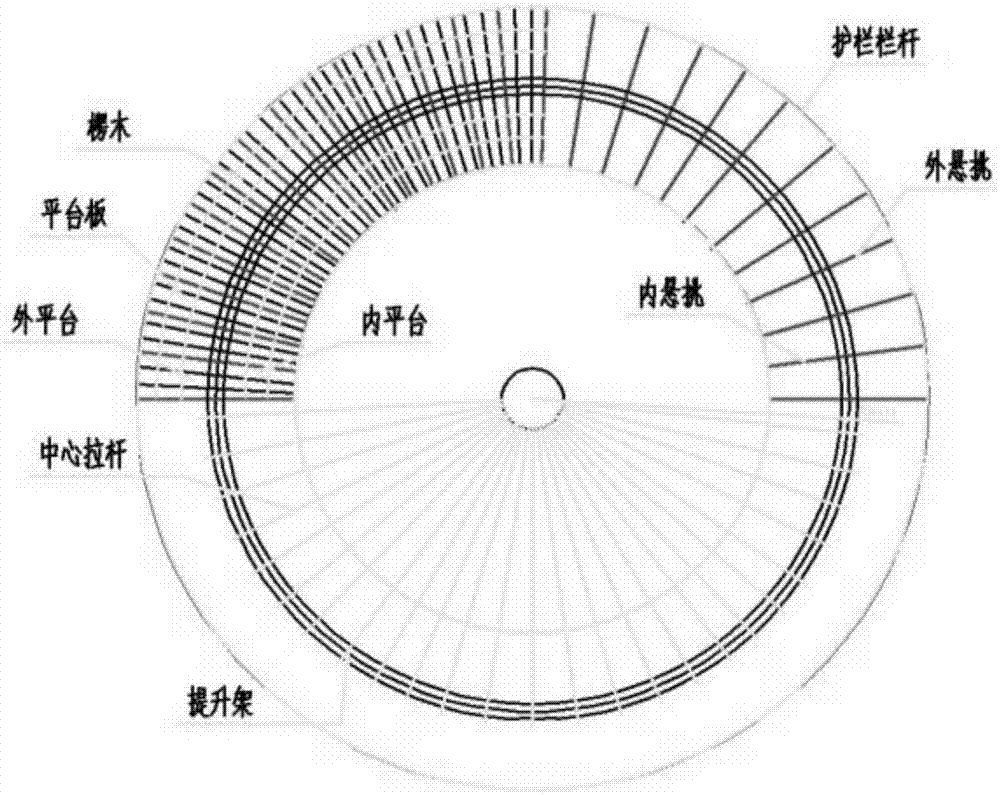

Construction method of sliding formwork for large-diameter silo

InactiveCN107882321ASave materialLabor savingForms/shuttering/falseworksBuilding material handlingFalseworkThree stage

The invention discloses a construction method of a sliding formwork for a large-diameter silo. The construction method comprises the steps that 1, silo wall steel bar mounting is conducted; 2, slidingformwork mounting and debugging are conducted; 3, concrete pouring is conducted; 4, sliding formwork lifting is conducted, wherein tank wall sliding formwork lifting is divided into three stages, namely primary sliding, normal sliding rising and tank wall top formwork sliding rising; 5, concrete pouring and sliding formwork lifting are repeated till the silo wall sliding formwork is completed; 6,sliding formwork device dismantling is conducted; and 7, concrete curing is conducted. According to the construction method, only one set of formworks is used, the formworks and an operating platformare lifted through a hydraulic jack, formwork supporting and scaffold setting up are not needed any longer, and thus the formworks, scaffold materials and manual work can be greatly saved; continuousoperation is kept during construction, various working procedures are simplified, the sections of the formworks do not need to be mounted and dismounted completely, and thus the construction speed ishigh; and concrete adopts continuous pouring, construction joints can be reduced, and integrality of a building can be ensured.

Owner:中铁建设集团南方工程有限公司

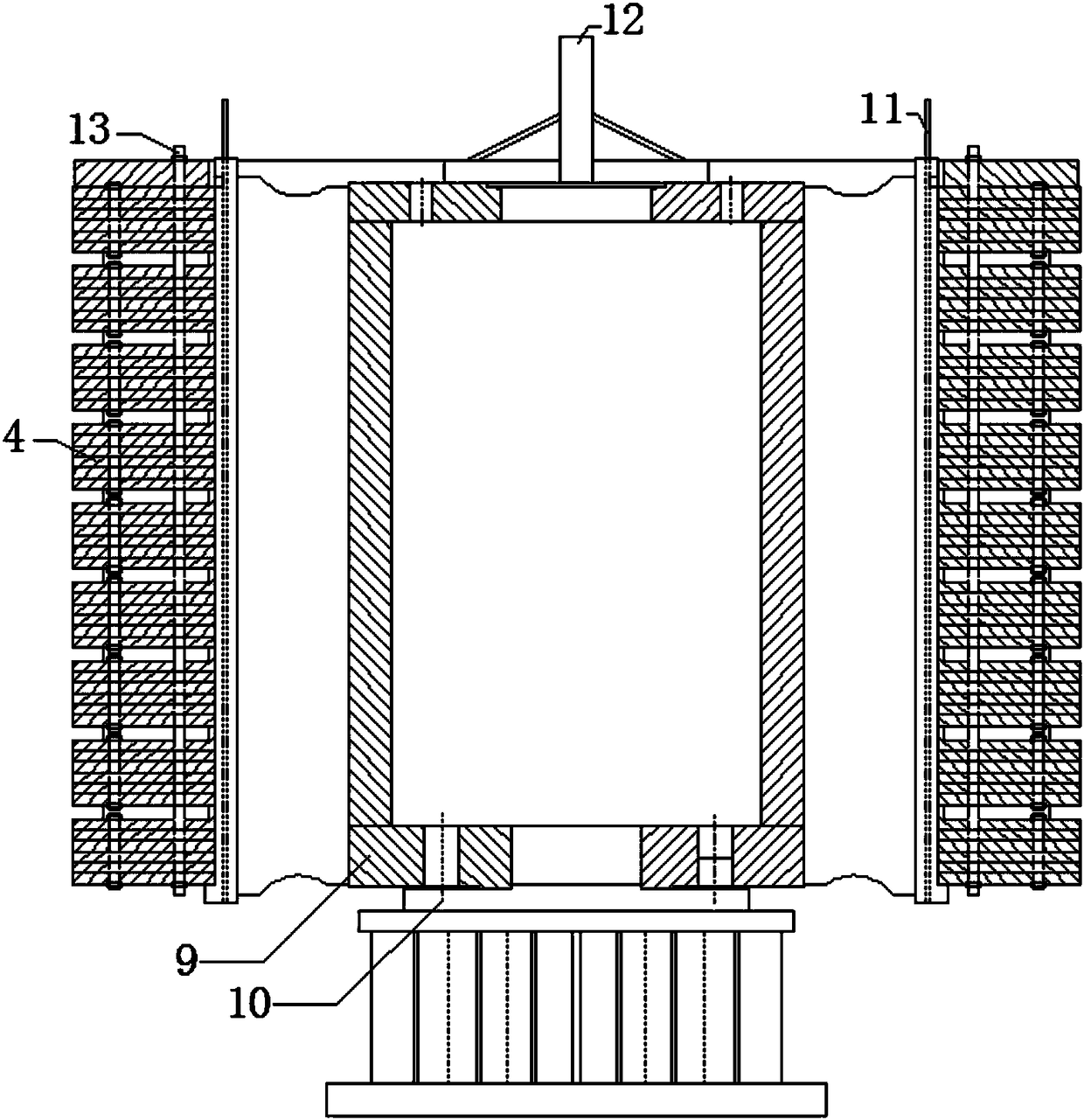

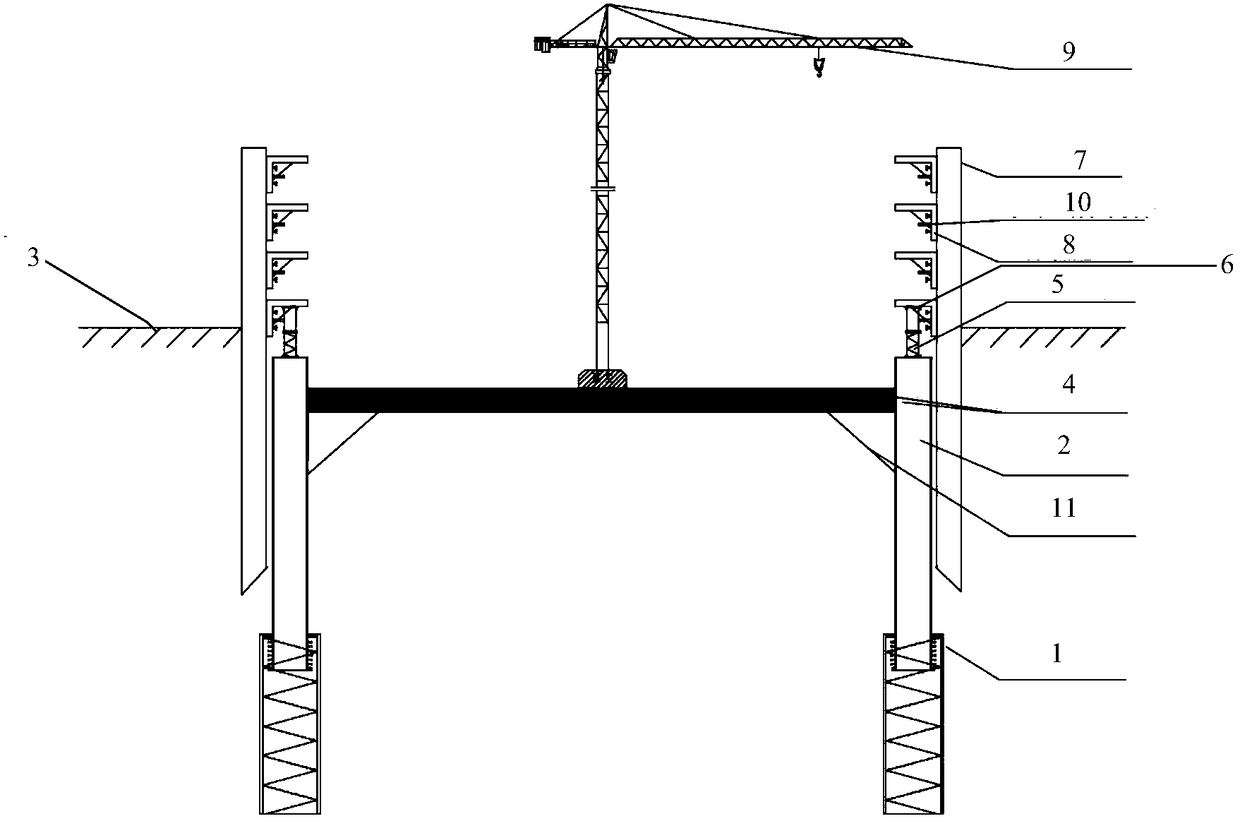

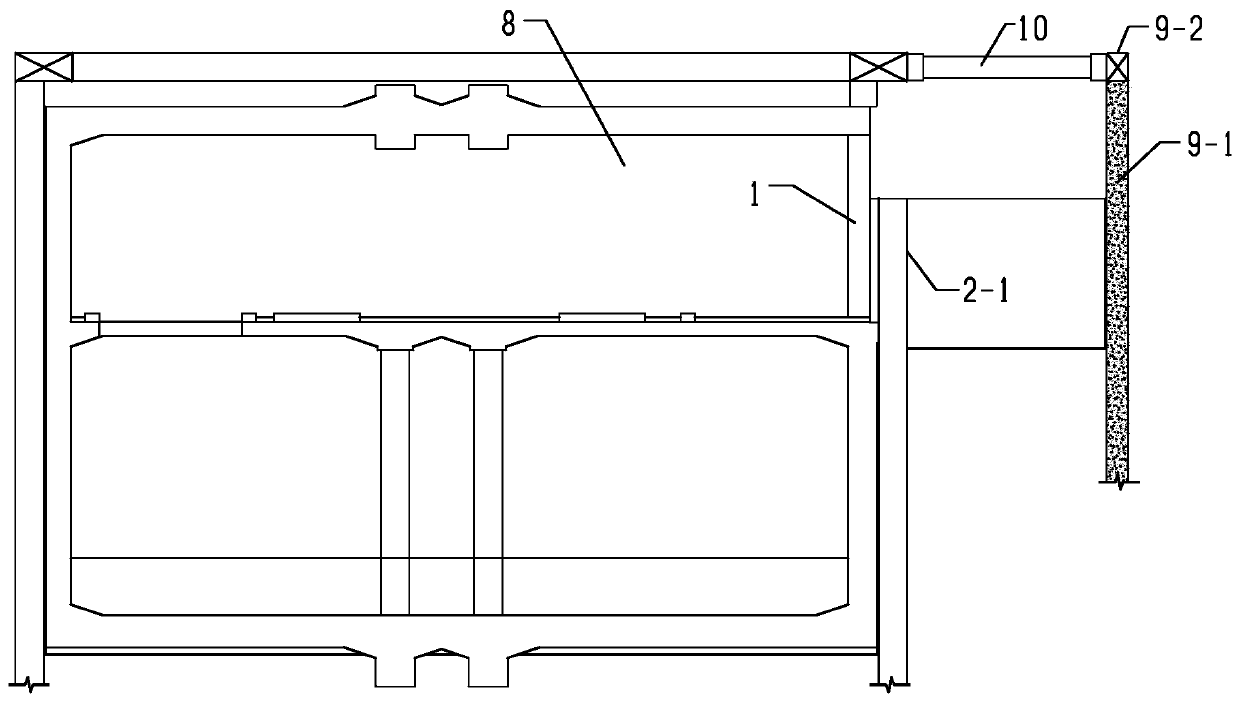

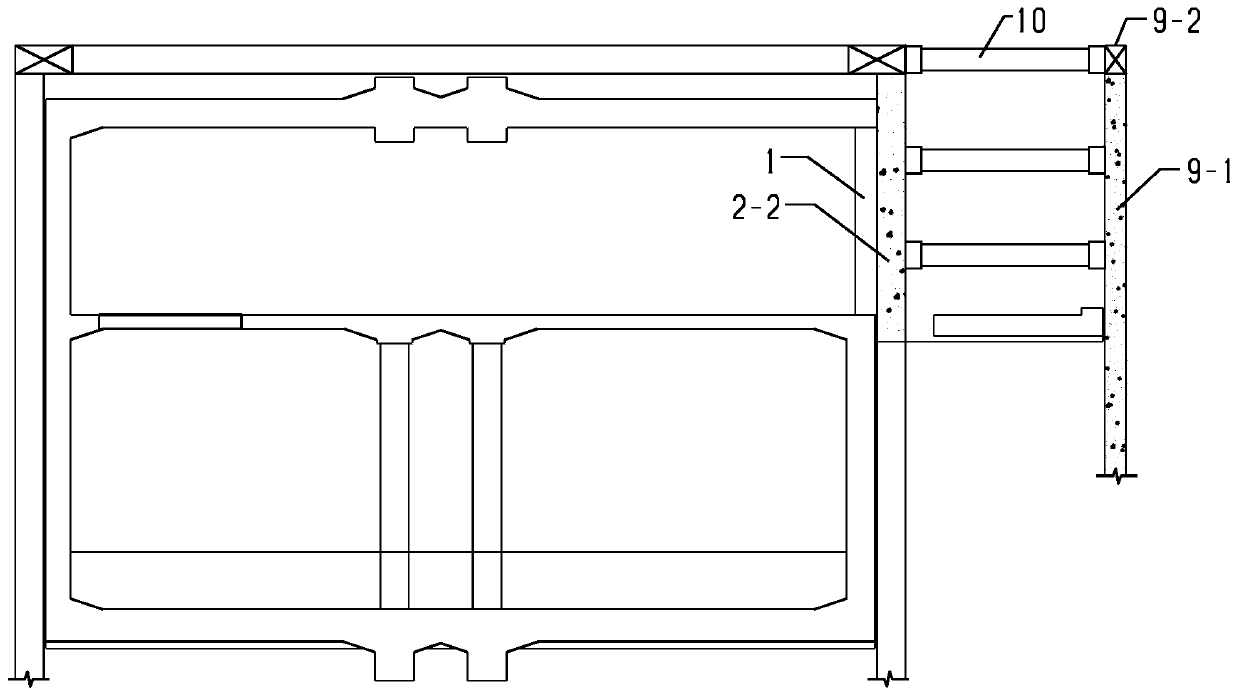

Construction structure and construction method for open caisson

ActiveCN108086340AGood for sinking stabilityControl verticalityExcavationsCaissonsBuilding constructionStructural engineering

The invention provides a construction structure and a construction method for an open caisson. According to the steel pipe column and cast-in-place pile guide type controllable construction structurefor the open caisson, the top part of each two-way jack is connected with a pipe joint column, steel brackets are erected on the pipe joint columns and serve as important guide components in the sinking process of the open caisson, when sinking of the open caisson is needed, soil in a foundation pit in space defined by steel pipe columns can be continuously excavated, meanwhile, the steel bracketsA erected at the bottommost parts on the pipe joint columns are disassembled, and then the open caisson can sink to the position where the steel brackets B on the upper parts of the steel brackets Aare erected on the pipe joint columns by virtue of the gravity of the open caisson; and in addition, in the sinking process of the open caisson, if inclination occurs, the height of the pipe joint columns can be adjusted through the jacks, so that the vertical state is always kept in the sinking process of the open caisson, and therefore the perpendicularity and the stability in the sinking process of the open caisson are effectively controlled, construction is facilitated, the construction risk is reduced, and cost is reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

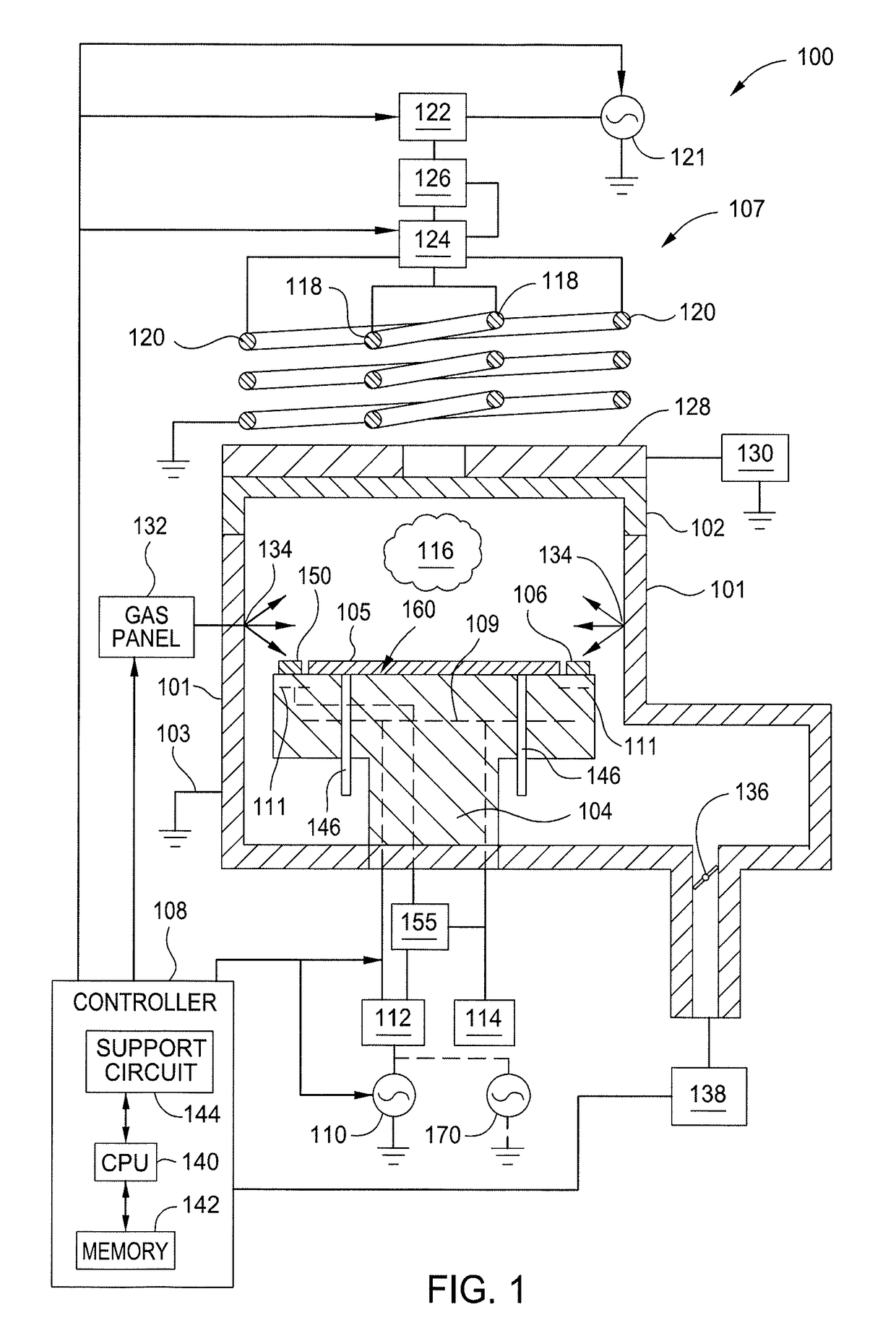

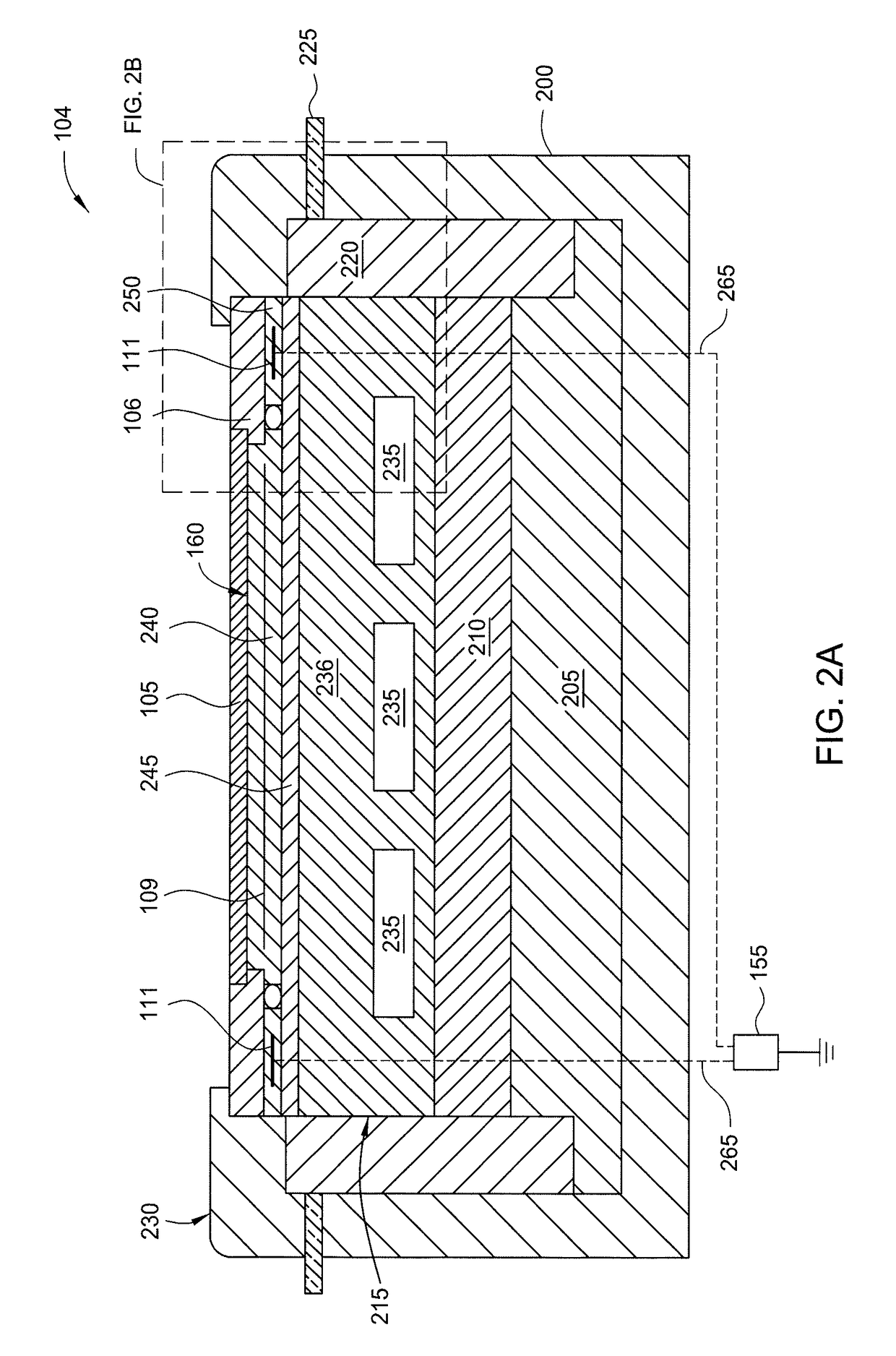

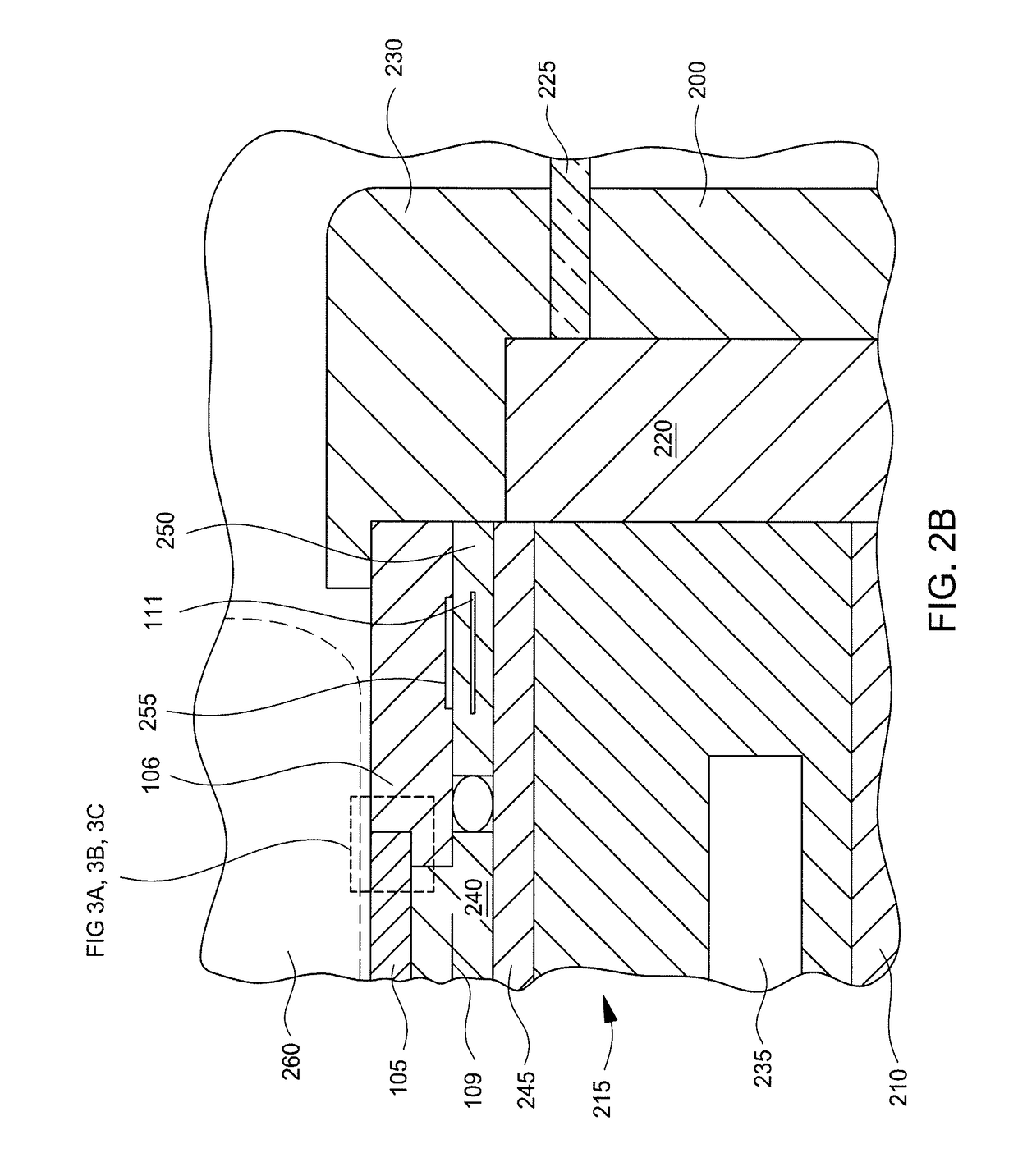

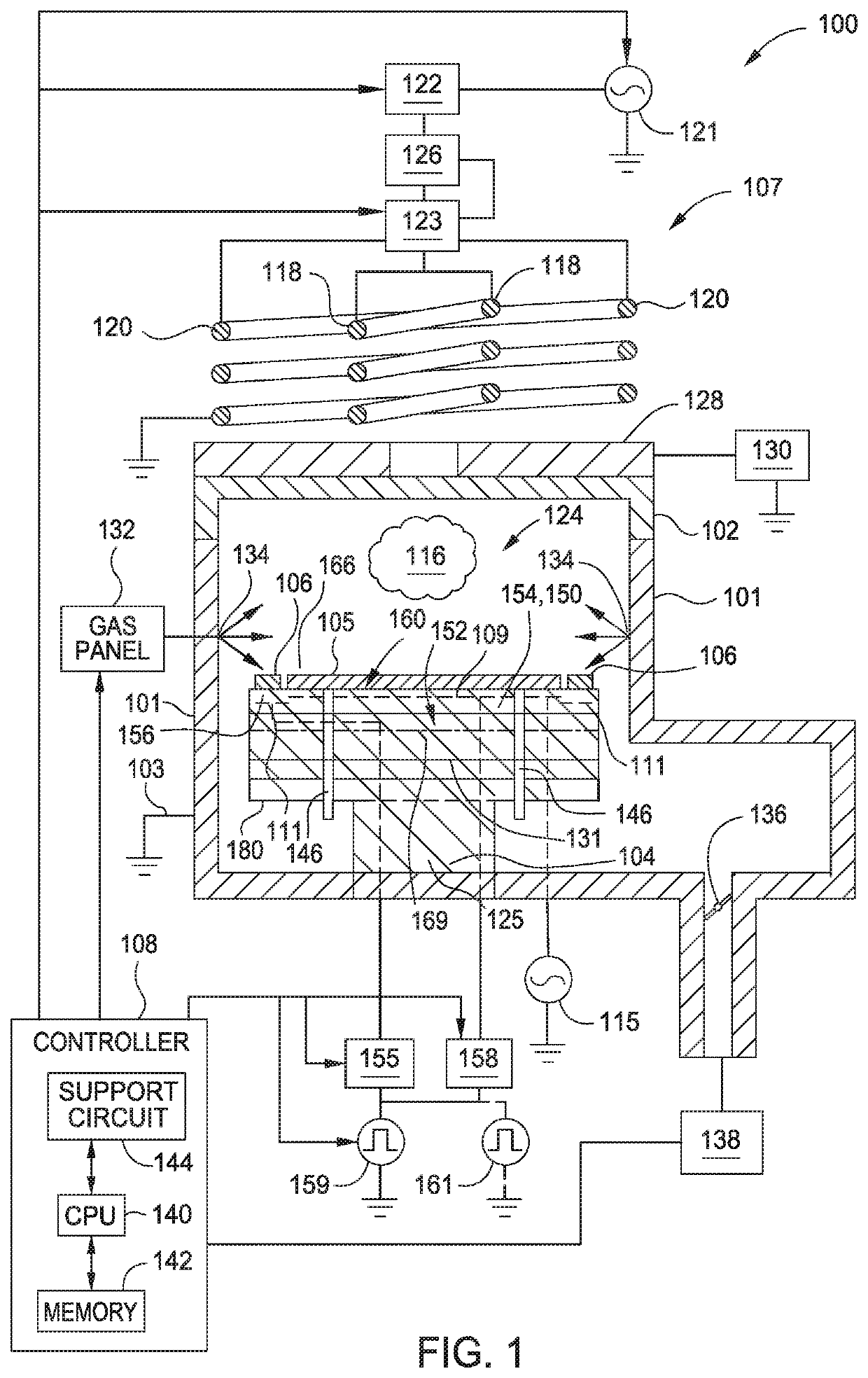

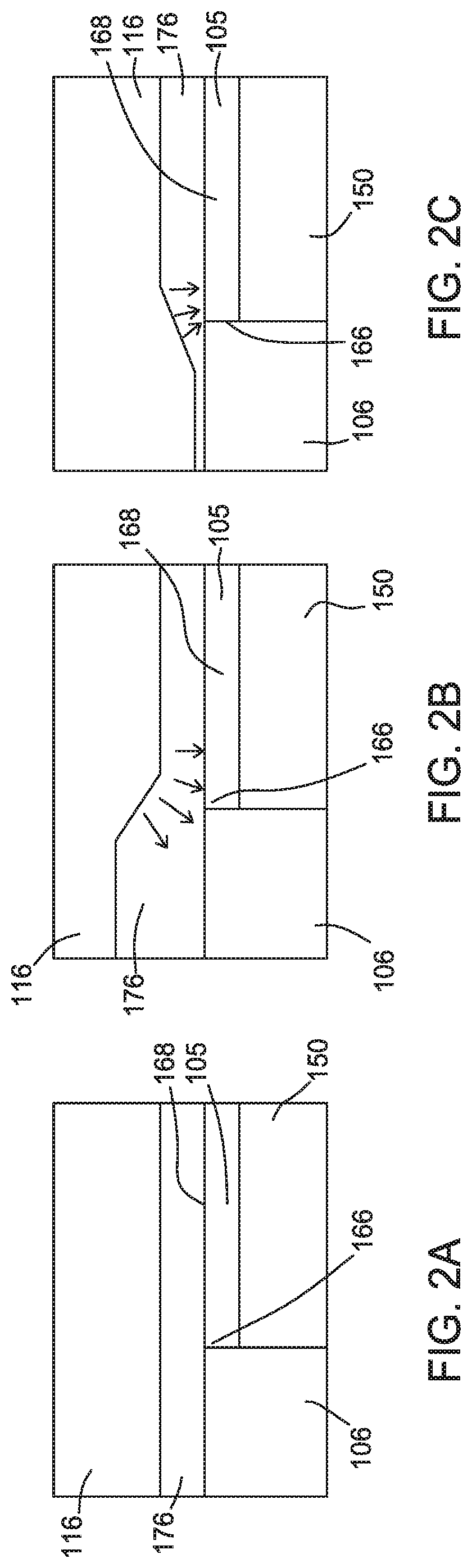

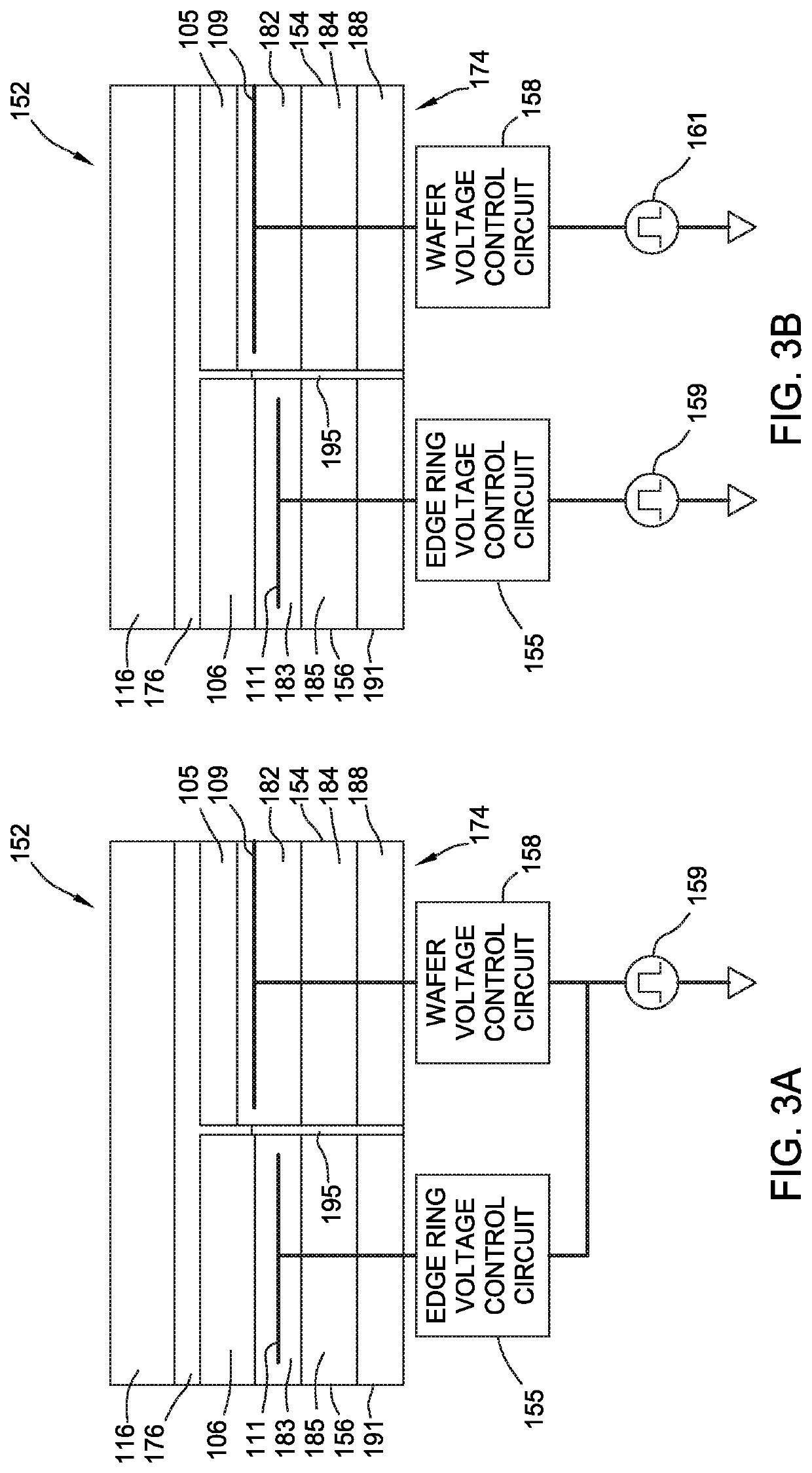

Apparatus and methods for manipulating radio frequency power at an edge ring in plasma process device

ActiveUS20190013184A1Improve uniformityControl verticalityElectric discharge tubesRadio frequencyVariable capacitor

The present disclosure relates to apparatus and methods that manipulate the amplitude and phase of the voltage or current of an edge ring. The apparatus includes an electrostatic chuck having a chucking electrode embedded therein for chucking a substrate to the electrostatic chuck. The apparatus further includes a baseplate underneath the substrate to feed RF power to the substrate. The apparatus further includes an edge ring disposed over the electrostatic chuck. The apparatus further includes an edge ring electrode located underneath the edge ring. The apparatus further includes a radio frequency (RF) circuit including a first variable capacitor coupled to the edge ring electrode.

Owner:APPLIED MATERIALS INC

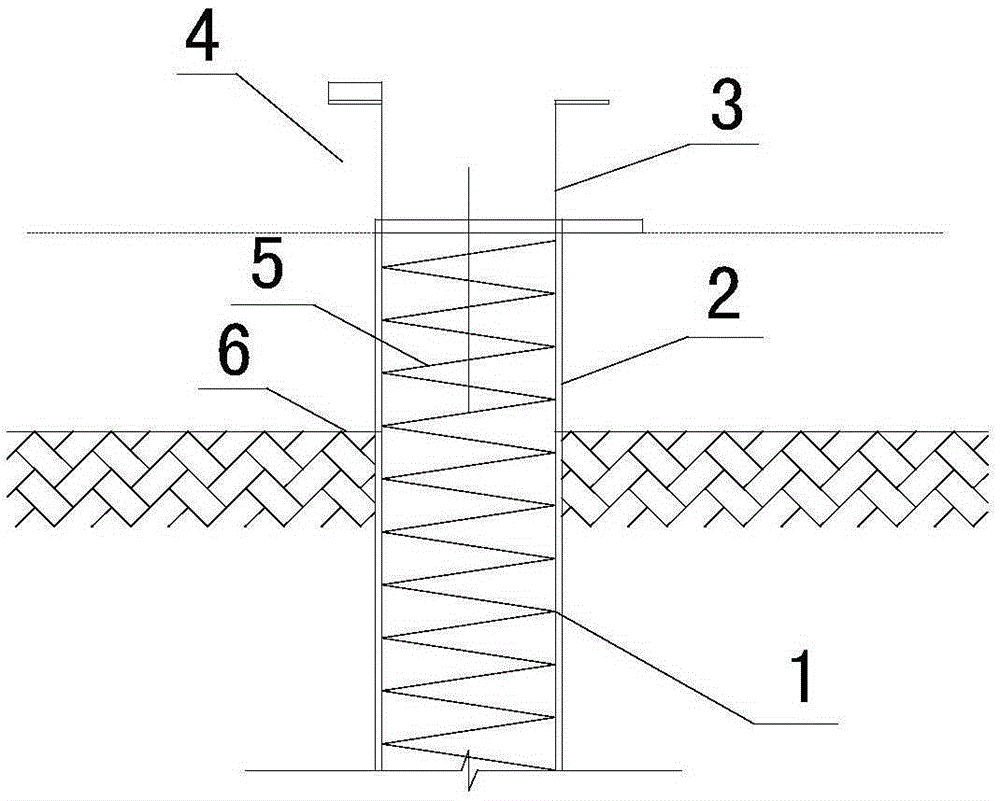

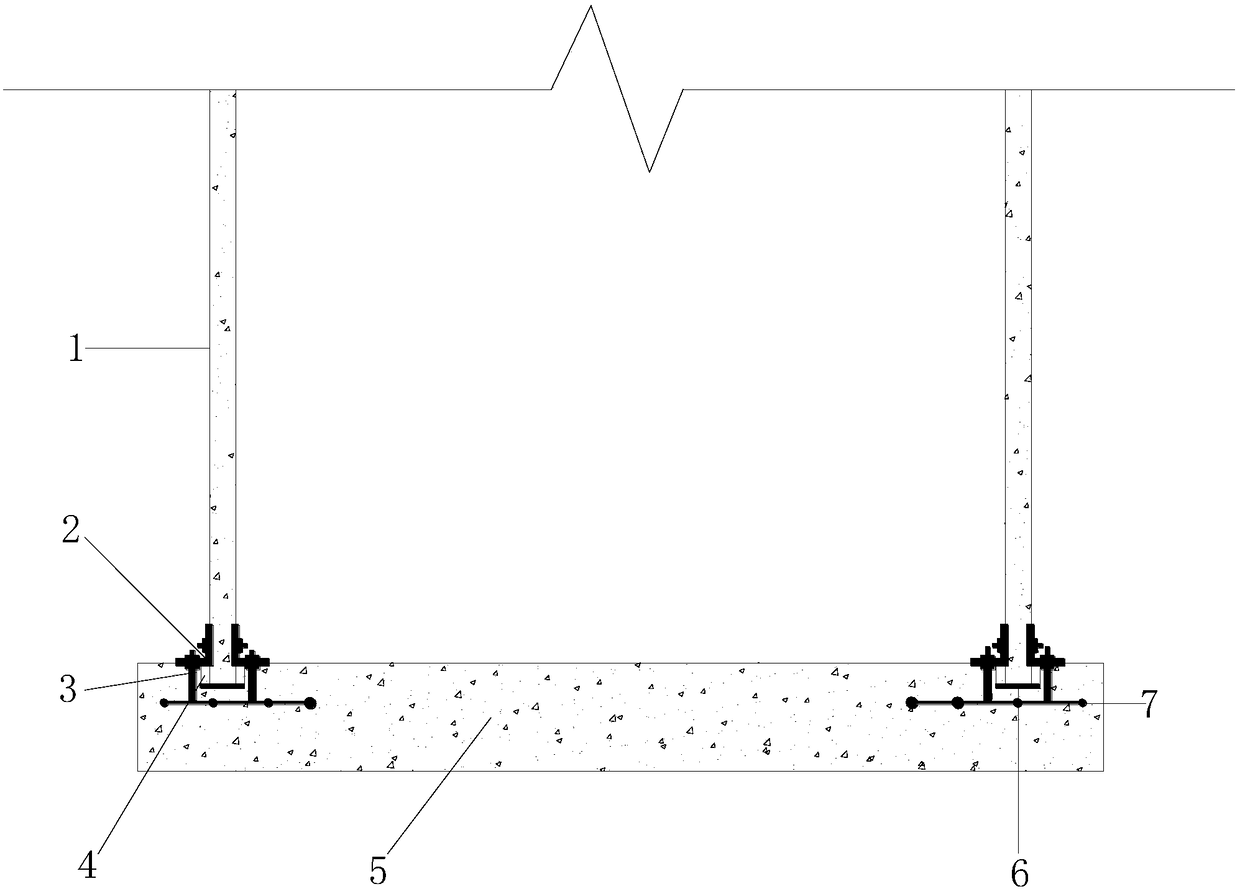

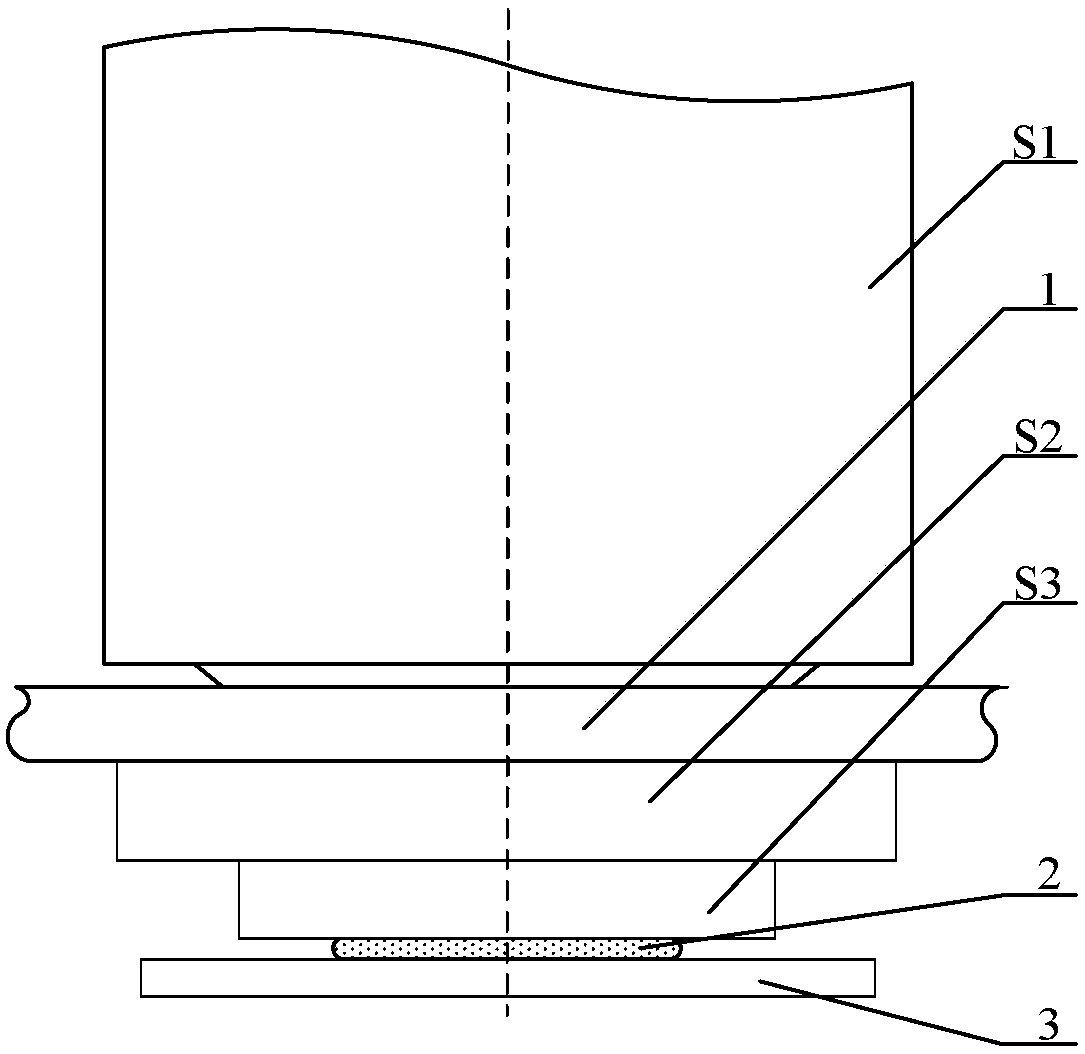

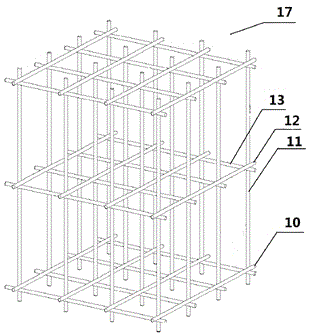

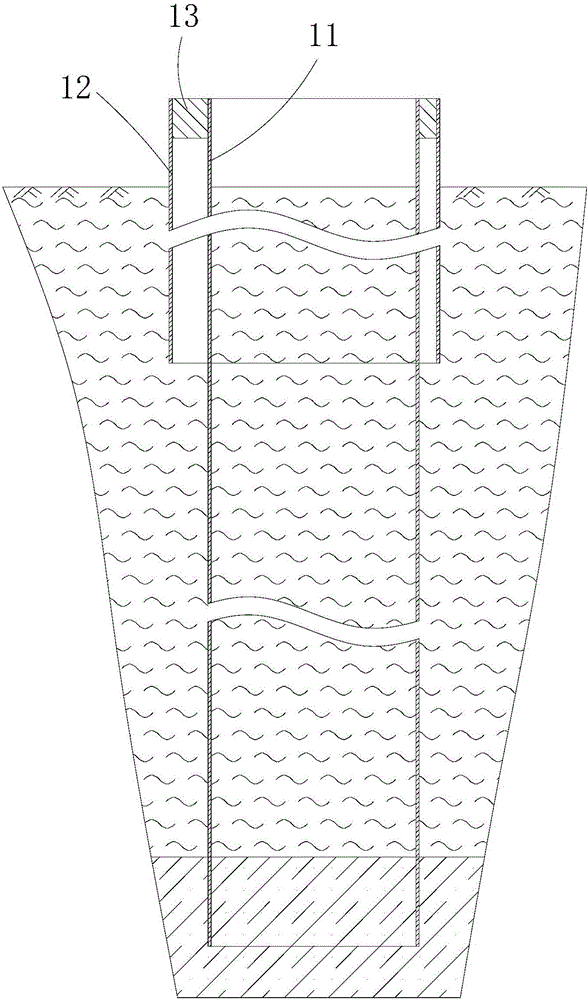

Integrative construction device and method for pile cap and pile body of pouring pile

The invention relates to an integrative construction device for a pile cap and a pile body of a pouring pile. The integrative construction device comprises a level gauge, a total station and a base plate with an annular cross section. The annular base plate is laid around an upper end opening of a pile hole and connected to an overall reinforcement cage in a sleeving manner. The overall reinforcement cage is arranged in the pile hole. The pile hole and the overall reinforcement cage coaxially coincide. The overall reinforcement cage is divided into a ground pile cap steel bar part and a pile foundation underground steel bar part. The overall reinforcement cage comprises a set of longitudinally-arranged main bars and a spiral stirrup surrounding the main bars. A set of groove holes is formed in the annular base plate, and bolts matched with the groove holes are arranged. The bolts are connected with bolt holes in a formwork in a matched manner. The formwork coincides with the base plate and the center of the overall reinforcement cage. The integrative construction device is low in construction difficulty and has high economic benefits and social environment benefits.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

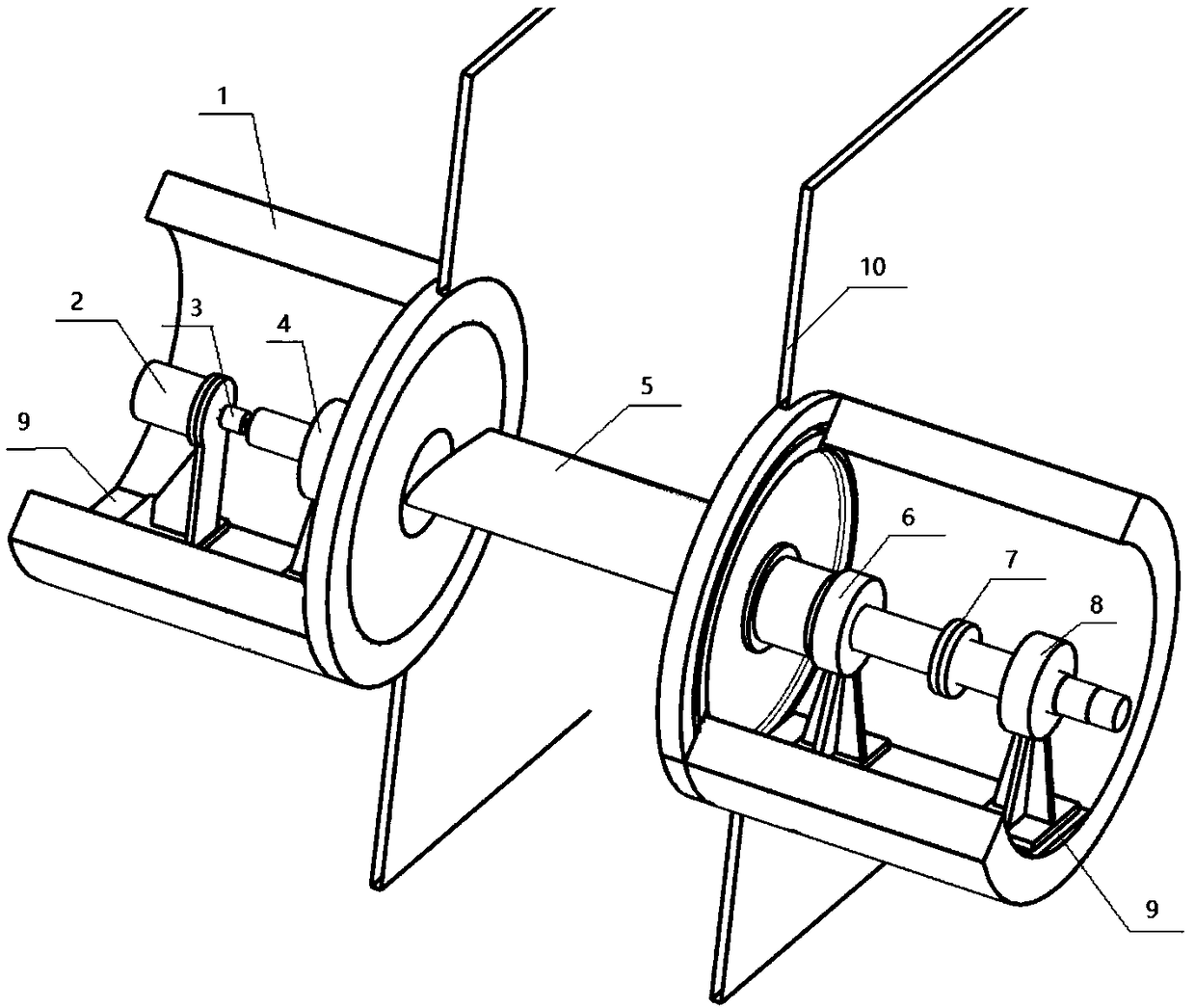

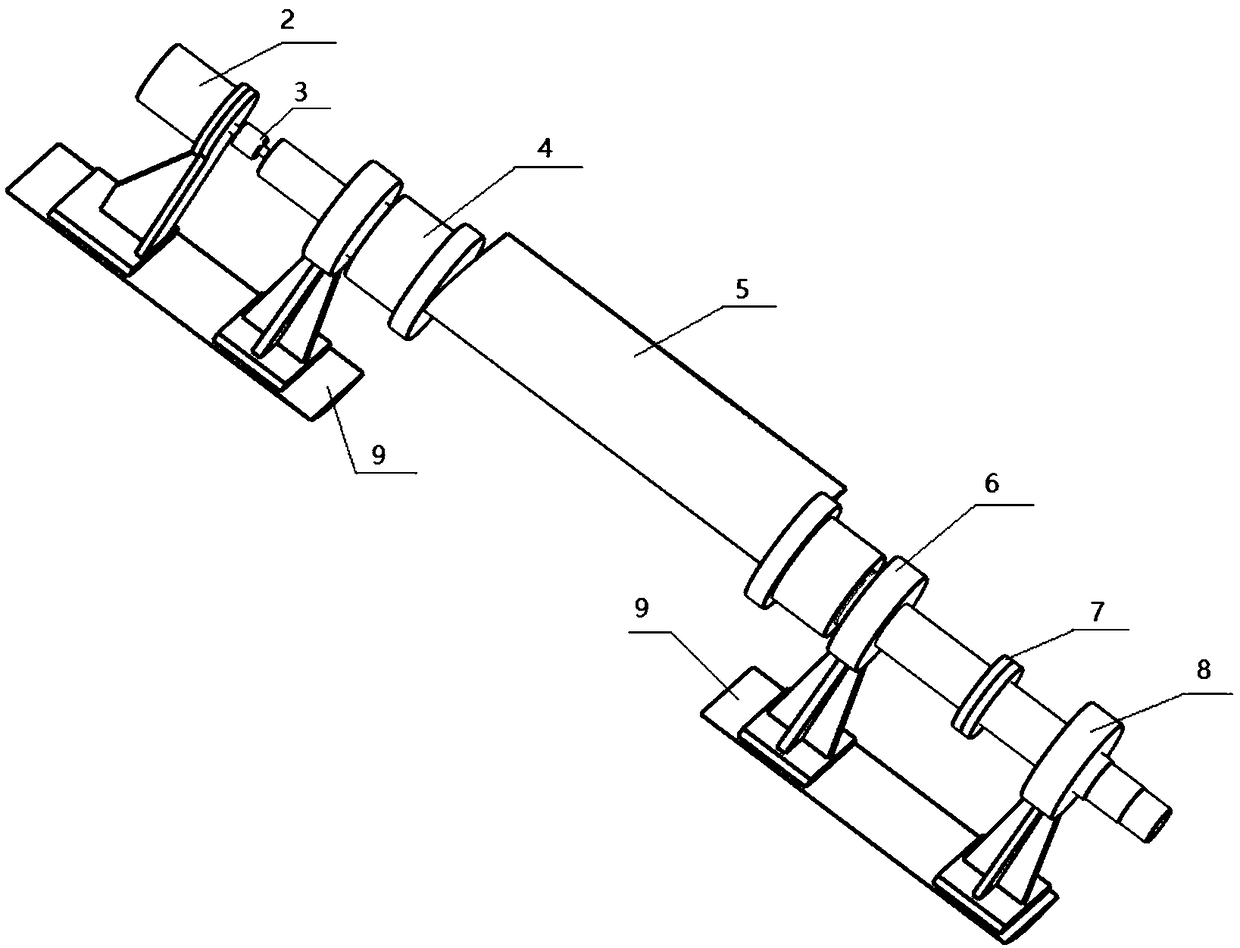

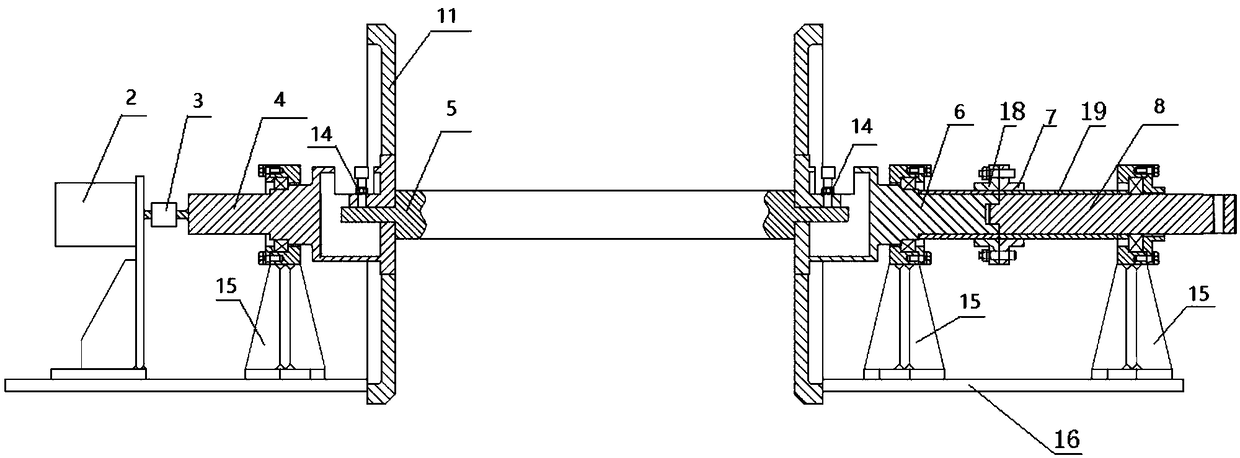

Average angle of attack adjustment mechanism of continuous transonic wind tunnel airfoil profile dynamic experiment

PendingCN109029903ALimited flight performanceLimit securityAerodynamic testingWind energy generationFriction lossAngular degrees

The invention provides an average angle of attack adjustment mechanism of a continuous transonic wind tunnel airfoil profile dynamic experiment. A first oscillating shaft is located at one end of a wind tunnel rotating window, and a second oscillating shaft and a third oscillating shaft are located at the other end of the wind tunnel rotating window. An average angle of attack adjustment disk is located on the second oscillating shaft, and an oscillating shaft adjustment disk is located on the third oscillating shaft. The average angle of attack adjustment mechanism provided by the invention overcomes the errors of an indirect adjustment mode of the traditional mechanism in machining and assembly processes, and the verticality of the axis of the oscillating shaft and a side wall of a windtunnel, a gap between the oscillating shaft and a rotating window through hole and the jump between an end face of a rotating shaft and the rotating window can be controlled more accurately in the installation of the oscillating shaft, thereby effectively reducing the friction loss of the oscillating shaft and improving the duality of the airfoil profile dynamic experiment; and the average angle of attack is adjusted by rotating the relative position of a flange plate of the average angle of attack, and the problems of small adjustment range of the traditional mechanism and few coverage angleswithin the adjustment range are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Circuits for edge ring control in shaped DC pulsed plasma process device

ActiveUS20200161098A1Improve uniformityControl verticalityElectric discharge tubesSemiconductor/solid-state device manufacturingPhysicsEngineering

The present disclosure relates to an apparatus and method that manipulate the voltage at an edge ring relative to a substrate located on a substrate support located within a processing chamber. The apparatus includes a substrate support assembly that has a body having a substrate support portion having a substrate electrode embedded therein for applying a substrate voltage to a substrate. The body of the substrate support assembly further has an edge ring portion disposed adjacent to the substrate support portion. The edge ring portion has an edge ring electrode embedded therein for applying an edge ring voltage to an edge ring. The apparatus further includes an edge ring voltage control circuit coupled to the edge ring electrode. A substrate voltage control circuit is coupled to the substrate electrode. The edge ring voltage control circuit and the substrate voltage control circuit are independently tunable to generate a difference in voltage between the edge ring voltage and the substrate voltage.

Owner:APPLIED MATERIALS INC

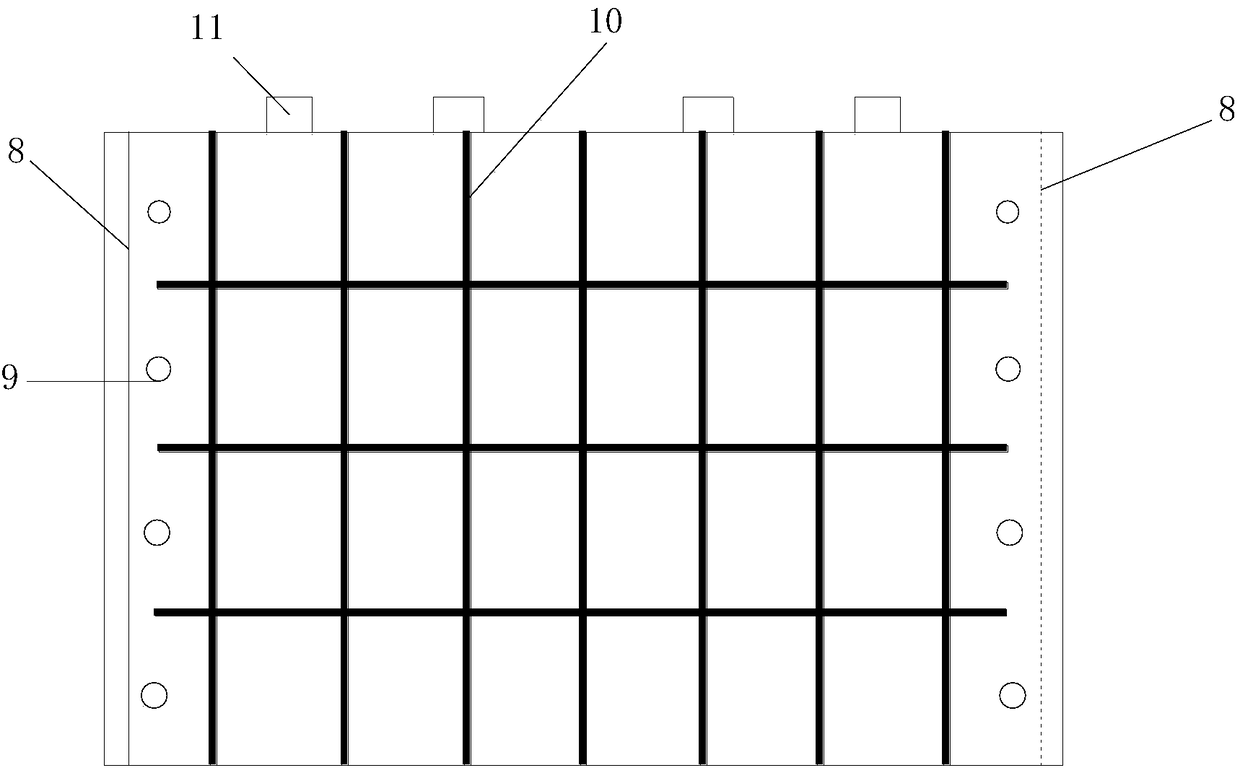

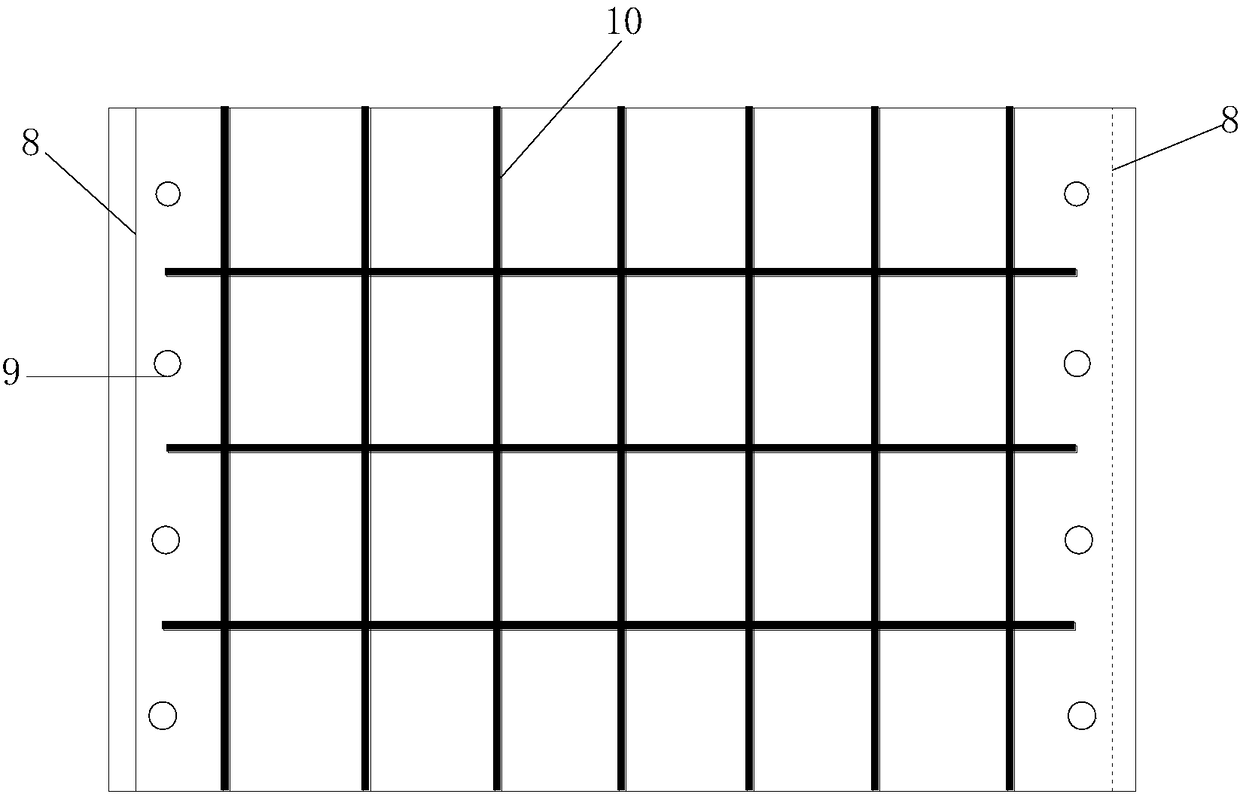

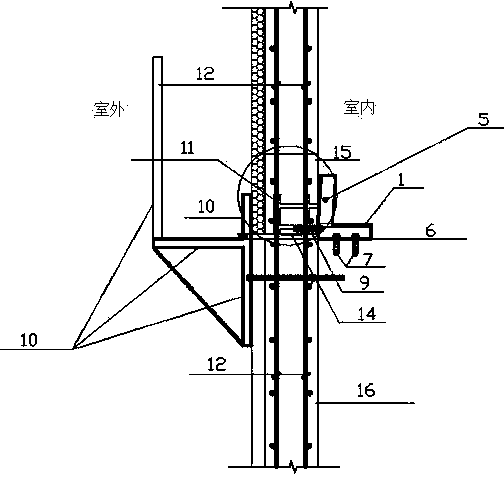

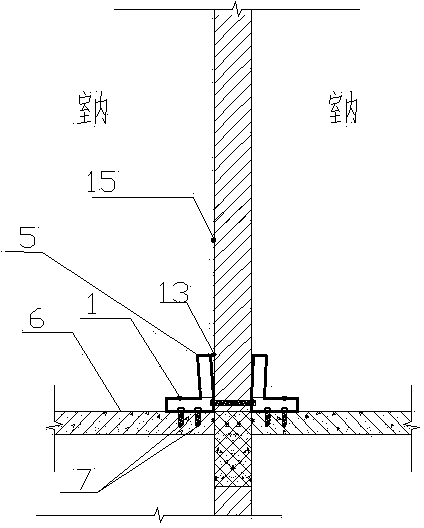

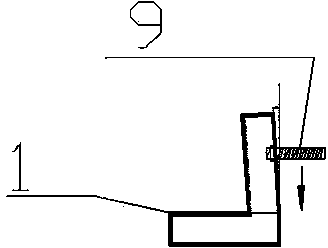

Prefabricated thin concrete slab formwork structure and construction method

InactiveCN108265738ABottom firmly fixedPrecise Positioning and PerpendicularityFoundation engineeringThin slabGrout

The invention relates to a prefabricated thin concrete slab formwork structure. The prefabricated thin concrete slab formwork structure comprises prefabricated thin concrete slabs, a cushion layer, grooves, integrally-embedded connecting screws, angle iron, leveling base grout layers and cast-in-situ bored piles. The prefabricated thin concrete slabs adopt rabbets for connection, are provided withscrew holes and connected through the evenly-distributed angle iron. The connecting angle iron on the inner side is of an embedded type. The angle iron is provided with lead screw through holes connected with the integrally-embedded connecting screws. Grid cloth anti-crack tapes are arranged in seams between the prefabricated thin concrete slabs. Connecting studs are evenly welded to the angle iron on the inner sides of the prefabricated thin concrete slabs. Lugs are evenly arranged at the tops of the prefabricated thin concrete slabs. The prefabricated thin concrete slab formwork structure has the beneficial effects that an inner formwork of a sliding formwork system is evenly divided into cavities at equal intervals, adjustable sand partition plates are arranged in the cavities to forma limiting balance weight frame, and bags between the partition plates are filled with sand to achieve regional ballasting; and a plate vibrator and a vibrating leveling beam are arranged on a lower panel of a sliding formwork, so that the slope concrete pouring quality is further improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

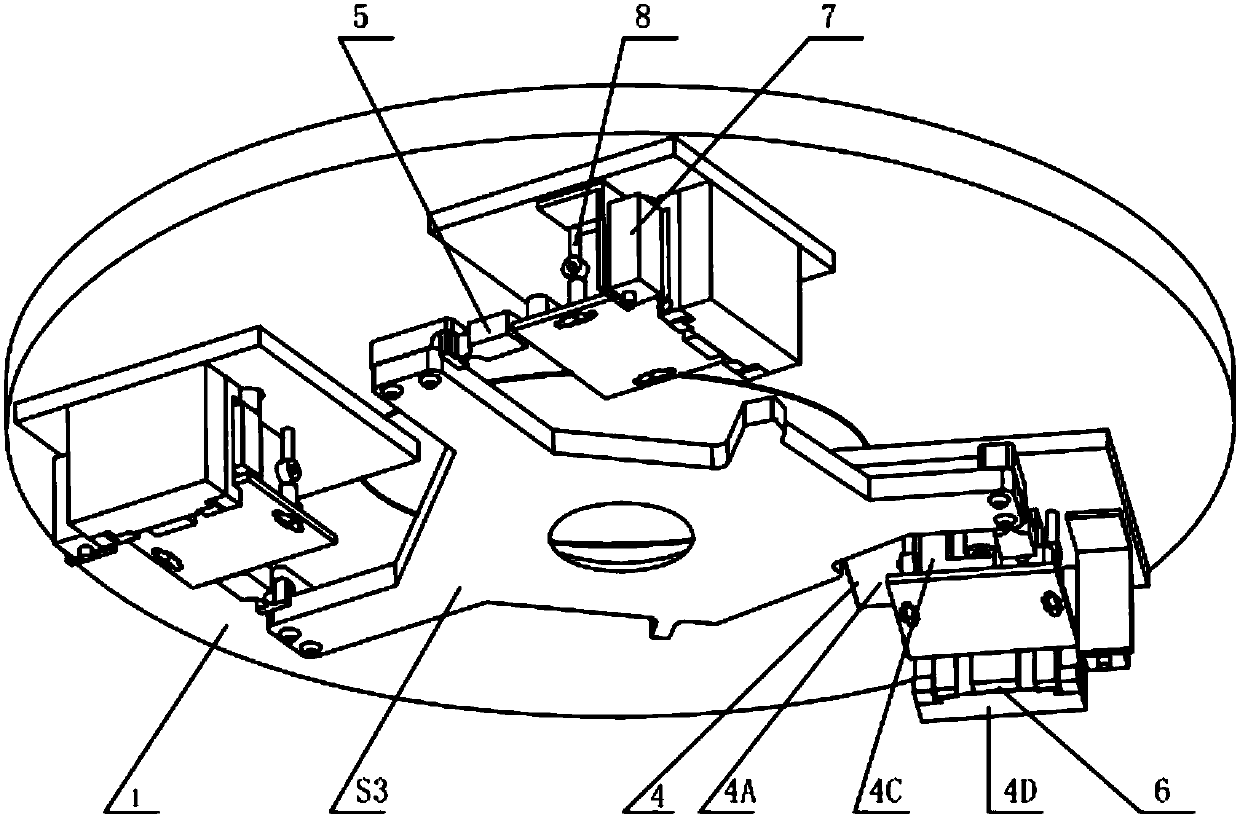

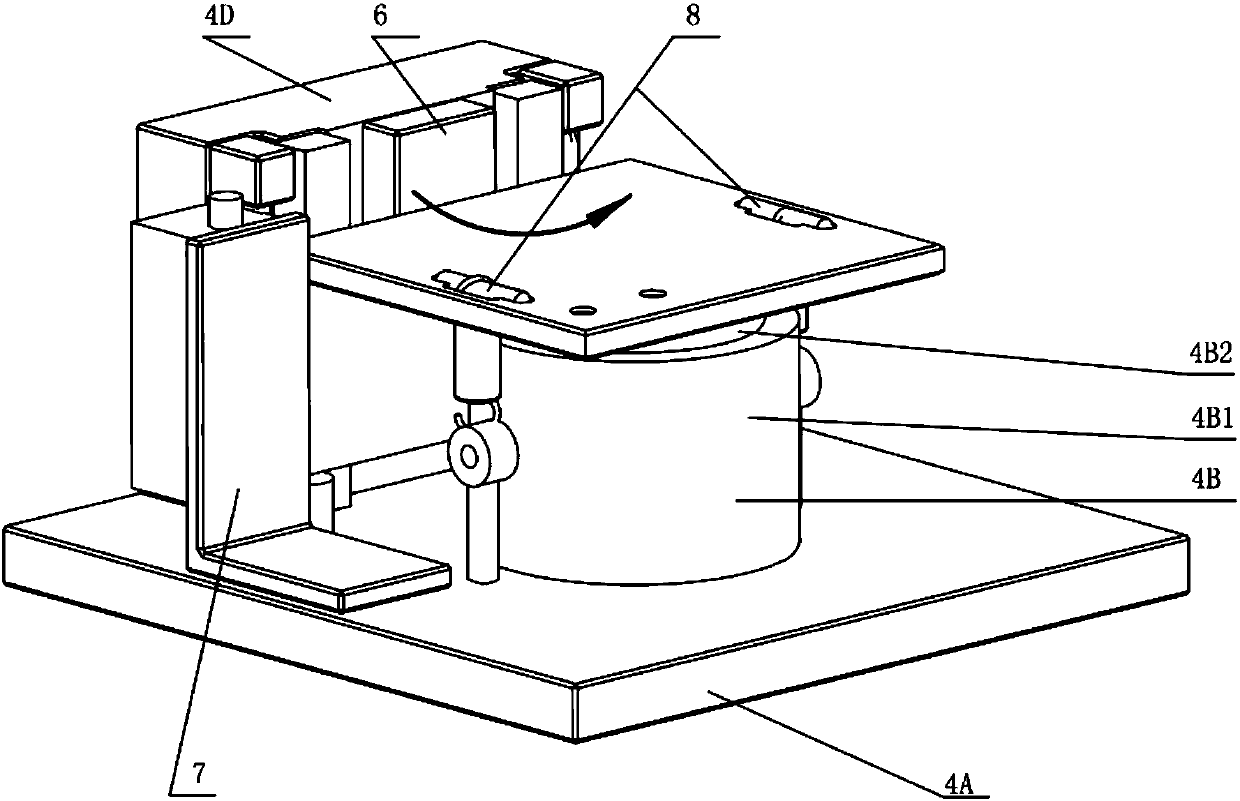

Double flexible pair-based three-degree-of-freedom precision adjustment parallel mechanism

ActiveCN107942622ANo pollution in the processNo pollutionPhotomechanical exposure apparatusMicrolithography exposure apparatusLinear motionModular design

The invention relates to a double flexible pair-based three-degree-of-freedom precision adjustment parallel mechanism, comprising three groups of motion branch chains which are connected in parallel and have the same structure, wherein the three groups of motion branch chains are in uneven circumference distribution at three extending ends of an immersion unit by taking a center hole of the immersion unit as a center; each group of motion branch chain comprises a linear motion assembly, a double flexible pair connecting rod assembly, a mechanical anti-collision assembly, a Z-direction displacement measuring assembly and a gravity compensation assembly. The double flexible pair-based three-degree-of-freedom precision adjustment parallel mechanism is used for realizing installation, fixationand space position adjustment of the immersion unit of an immersion type photoetching machine and realizing micron-level positioning of the immersion unit; double flexible pairs are adopted, the structure is simple and compact, and the advantages of no friction and no need of lubrication are achieved; the wholly mechanism adopts a parallel mechanism, the rigidity is high, the response is quick, the adjustment range is large, modular design and assembly are adopted, and the mechanism can be used for three-degree-of-freedom precision adjustment in other occasions except the immersion type photoetching machine.

Owner:ZHEJIANG CHEER TECH CO LTD

Construction structure of cylindrical die

InactiveCN104563496ASimple materialEasy constructionForms/shuttering/falseworksBuilding scaffoldsFalseworkEngineering

The invention discloses a construction structure of a cylindrical die, relates to the technical field of building construction and relates to design technology of an auxiliary tool for building construction, in particular to the construction structure of the cylindrical die. The construction structure is characterized in that the outer side of a hollow cylindrical template is fastened by muffling the template by steel strip post hoops at equal intervals; the hollow cylindrical template is vertically inserted into the middle of a dual-row scaffold; templates are overlapped to required height, and seams are connected by the steel strip post hoops; at the two thirds elevation of the cylindrical die, a throwing support structure used for guaranteeing the perpendicularity and the stability of a post is arranged. The construction structure has the positive effects that a post hoop material is simple, construction is convenient to perform, and a cylinder reinforcing effect is good; the safety of workers during construction can be guaranteed by the dual-row scaffold which encloses a cylinder; throwing support steel pipes and short steel pipes form a whole, so that the stability of the cylinder and the perpendicularity of concrete can be effectively controlled; the problem of poor reinforcing quality of a cylinder in a construction field is solved by the structure, and the construction process is improved.

Owner:ZHONGTIAN CONSTR GROUP

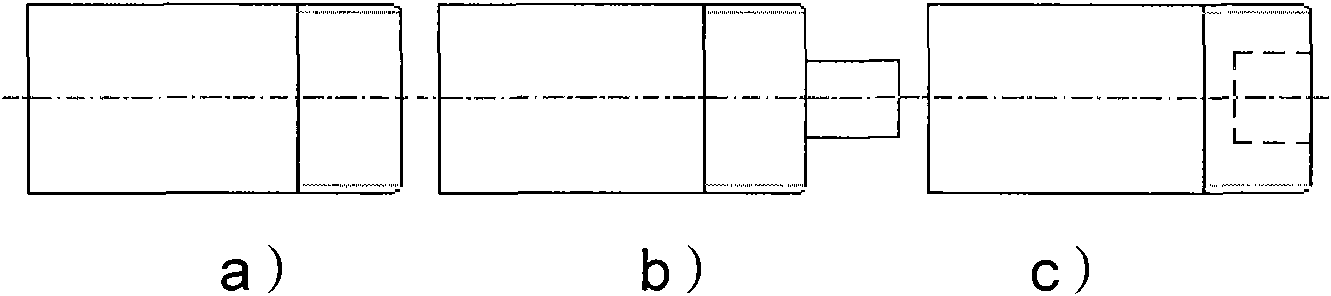

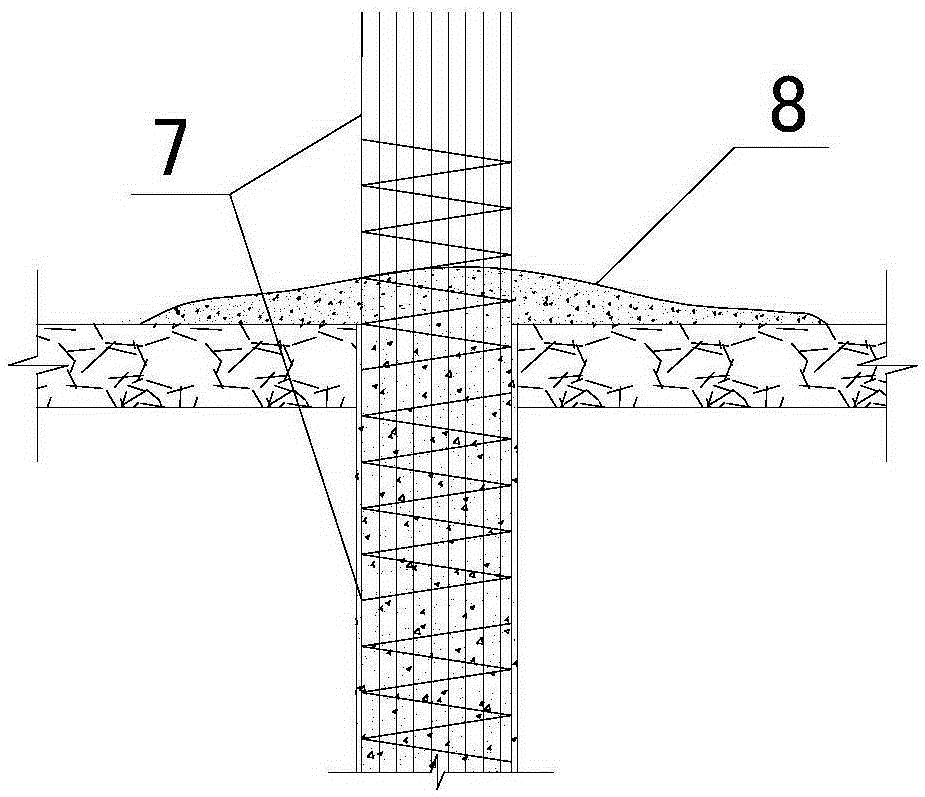

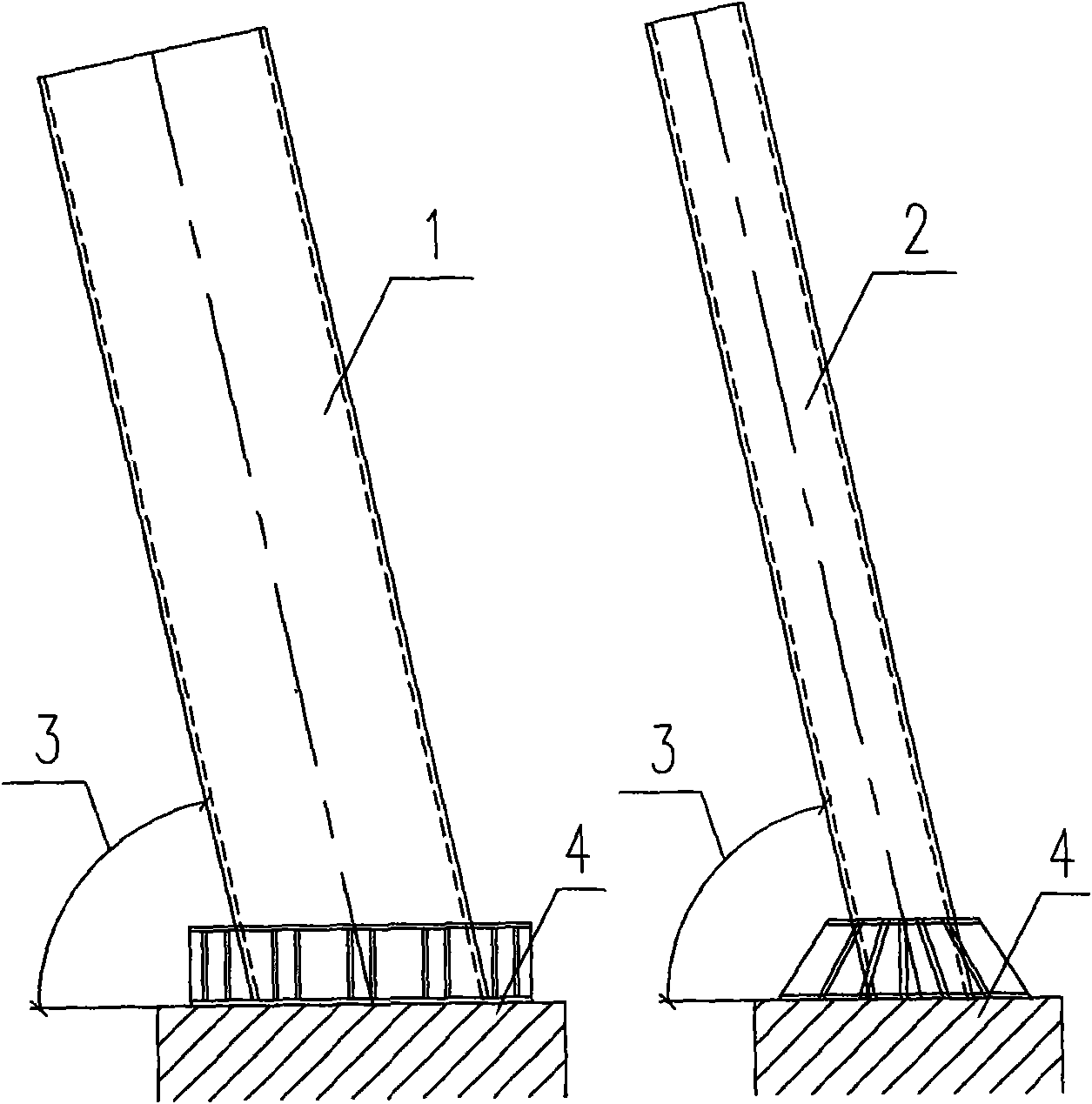

Double pile casing construction method for controlling perpendicularity

ActiveCN105672255AReduce frictionReduce construction costsBulkheads/pilesFrictional resistanceBuilding construction

The invention relates to the technical field of cast-in-place pile construction and discloses a double pile casing construction method for controlling the perpendicularity. The double pile casing construction method comprises the following construction steps of (1) measuring and locating a pile position on situ, and arranging four crossed locating points; (2) vertically submerging an outer pile casing within an encirclement ring formed by the four locating points; and (3) respectively convexly arranging a locating plate on a position, aligning to each locating point, on the inner wall of the outer pile casing; and vertically submerging an inner pile casing in the outer pile casing, and respectively enabling the outer ends of the four locating plates to support against the outer surface of the inner pile casing. The outer pile casing and the inner pile casing simultaneously act, so that the frictional resistances of the outer pile casing and the inner pile casing in the submerging and withdrawing processes are reduced; the inner pile casing and the outer pile casing can be utilized repeatedly, so that the construction cost is reduced; the inner pile casing is limited and located by using the four locating plates to ensure that the central point of the inner pile casing is coincided with the central point of a pile hole, so that the inner pile casing is accurately located, and the pile forming quality is effectively ensured.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

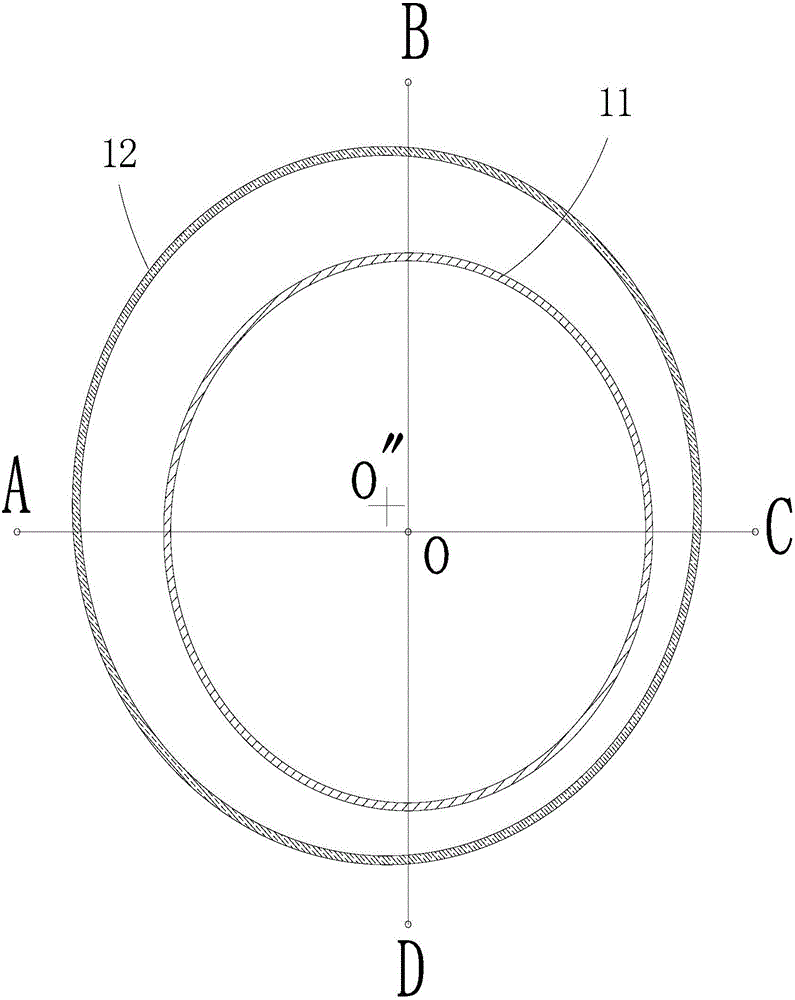

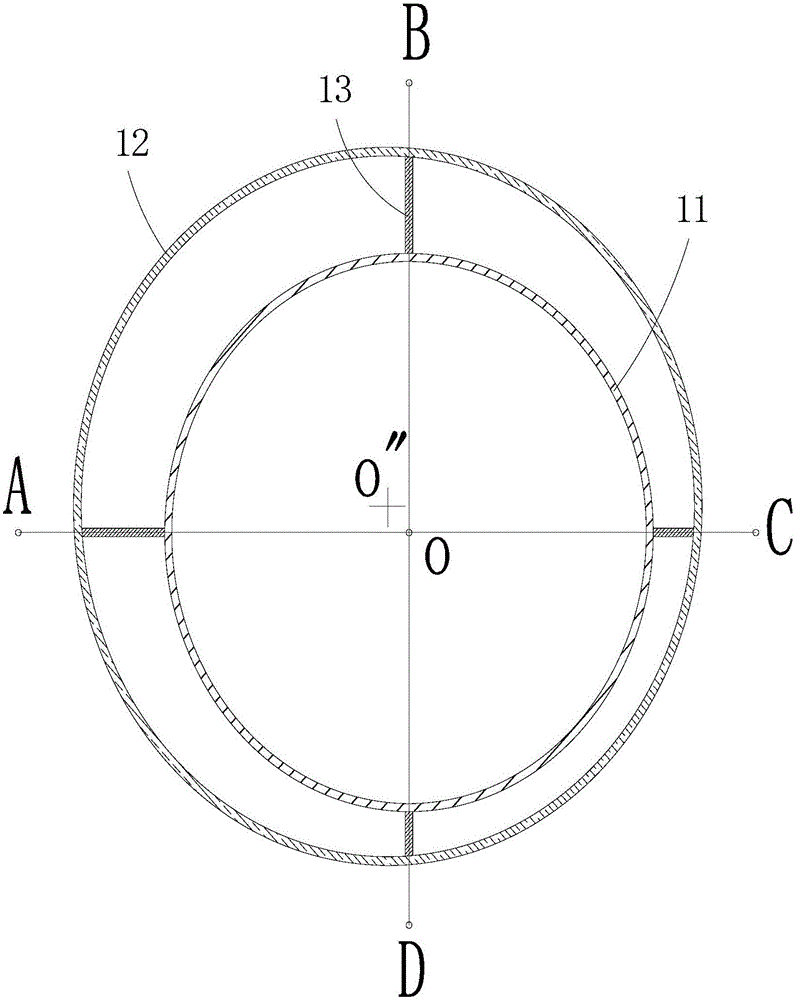

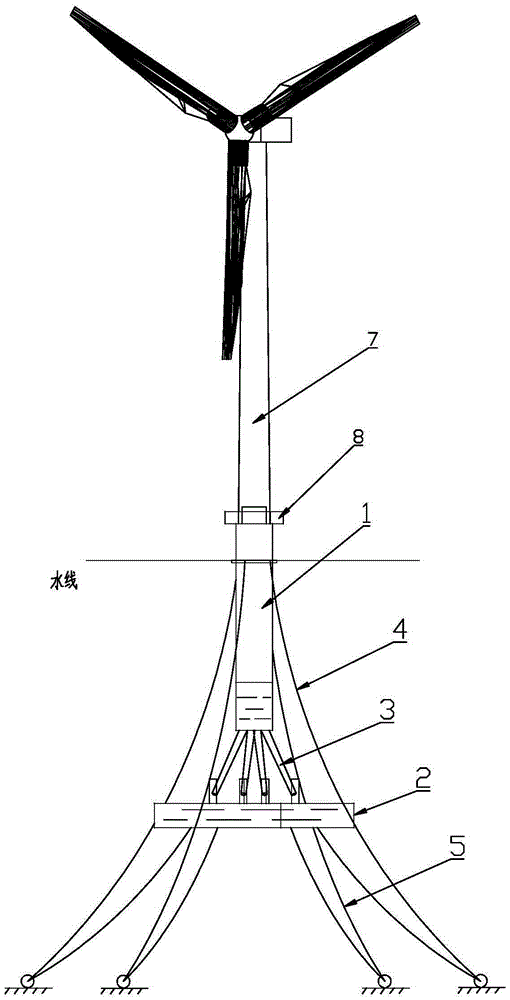

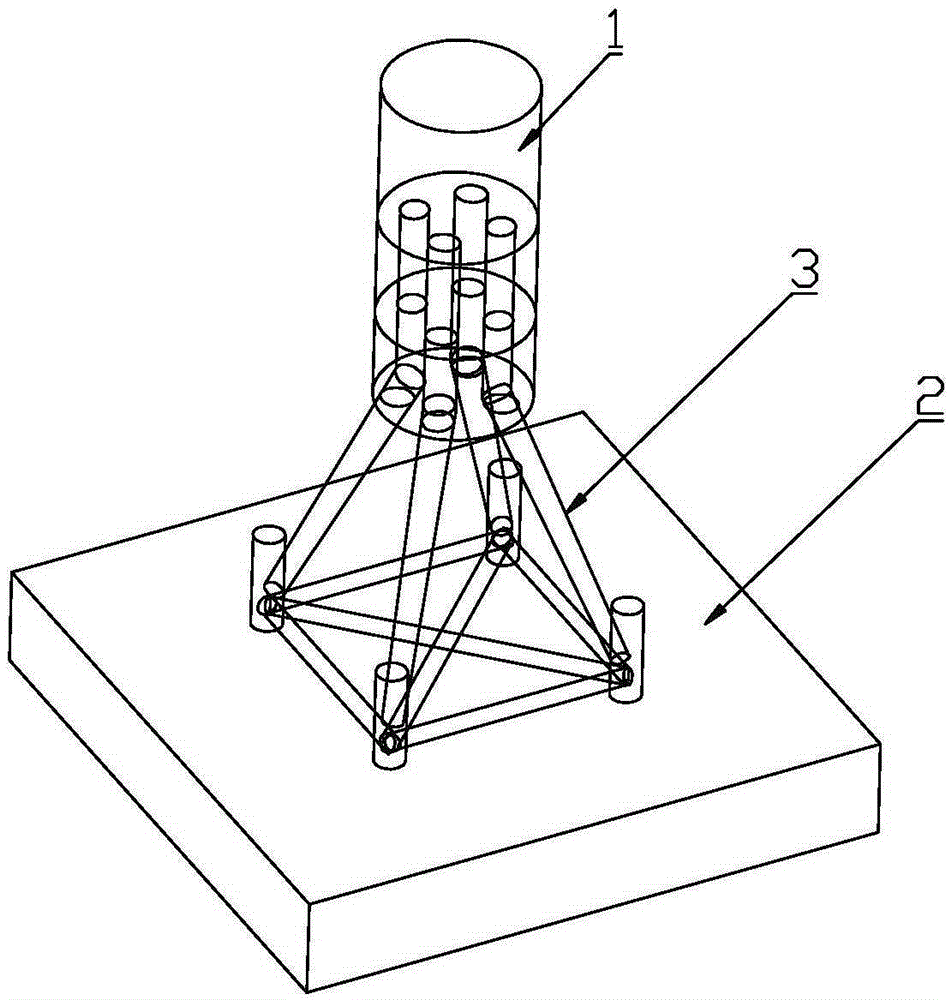

Offshore floating type draught fan and draught fan foundation thereof

InactiveCN105402091AOptimal balanceLimit horizontal movementWind motor supports/mountsWind energy generationOcean bottomEngineering

The invention relates to an offshore floating type draught fan and a draught fan foundation thereof. The draught fan foundation comprises a floating barrel structure, a support structure, a ballast tank, an upper-layer fixing device and a lower-layer fixing device. The ballast tank is located below the floating barrel structure. The floating barrel structure and the ballast tank are connected through the support structure. The ballast tank is of a flat box structure, and the outer contour of the ballast tank is larger than that of the floating barrel structure. The upper-layer fixing device comprises a plurality of upper-layer cables, the upper-layer cables are evenly distributed around the floating barrel structure, the upper ends of the upper-layer cables and the floating barrel structure are fixed, and the lower ends of the upper-layer cables and the seabed are fixed. The lower-layer fixing device comprises a plurality of lower-layer cables, the lower-layer cables are evenly distributed around the ballast tank, the upper ends of the lower-layer cables and the ballast tank are fixed, and the lower ends of the lower-layer cables and the seabed are fixed. The offshore floating type draught fan and the draught fan foundation thereof have the beneficial effects of being simple in structure, good in stability, not likely to be damaged, high in adaptability to water depth and especially suitable for sea areas with large water depth.

Owner:NEW UNITED GROUP

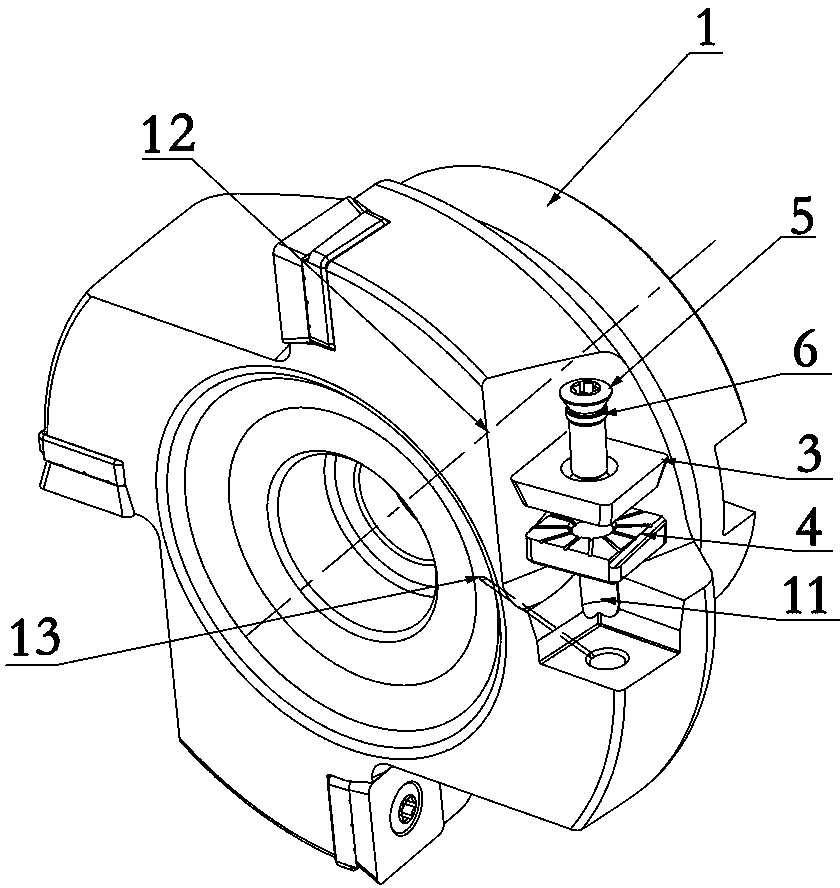

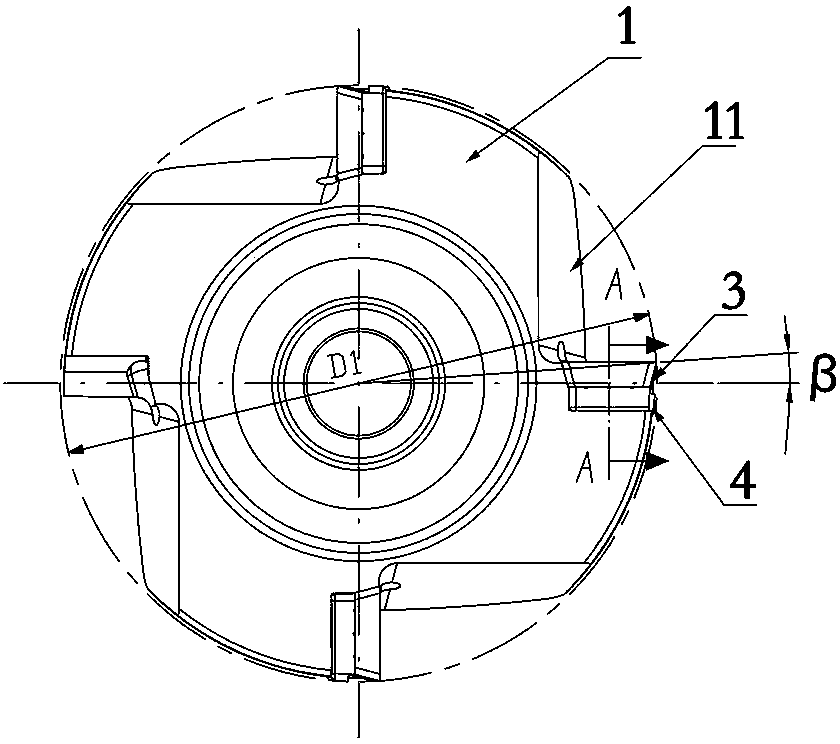

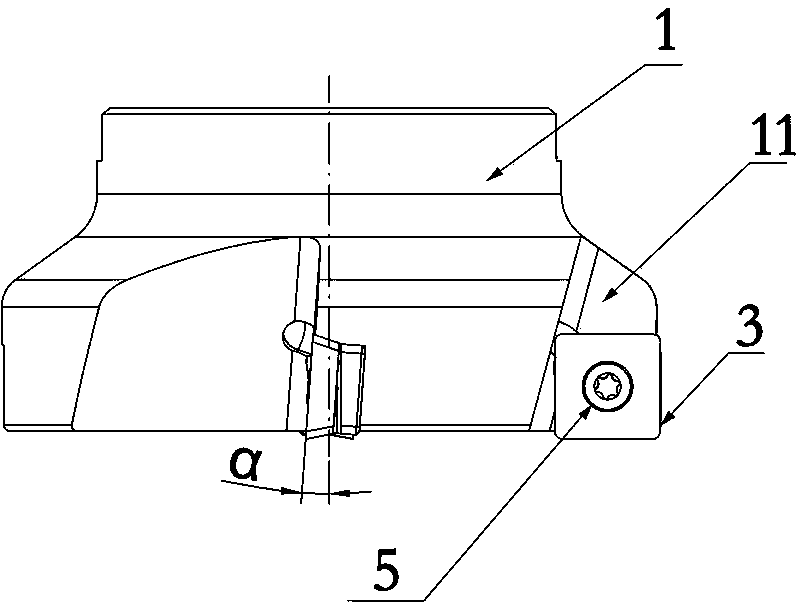

Finish machining rotating cutter

ActiveCN103737090AReduce vibrationImprove machined surface qualityMilling cuttersKnife bladesFastener

The invention discloses a finish machining rotating cutter. The finish machining rotating cutter comprises a cutter body, wherein the cutter body is provided with at least one group of cutter grooves; each cutter groove is internally provided with a first cutting blade and a second cutting blade which are fixed through a fastener, wherein the first cutting blade is tightly pressed on the second cutting blade, and the second cutting blade is tightly pressed on the cutter grooves; each first cutting blade is provided with a first side surface cutting edge; each second cutting blade is provided with a second side surface cutting edge which corresponds to the position of each first side surface cutting edge and is used for guiding shake resistance and dressing smoothness, and each second cutting blade and a rotating center shaft of the cutter body are parallel. The finish machining rotating cutter disclosed by the invention has the advantages that the structure is simple, the shake resistance and smoothness dressing effects are good, and the surface processing quality is high.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

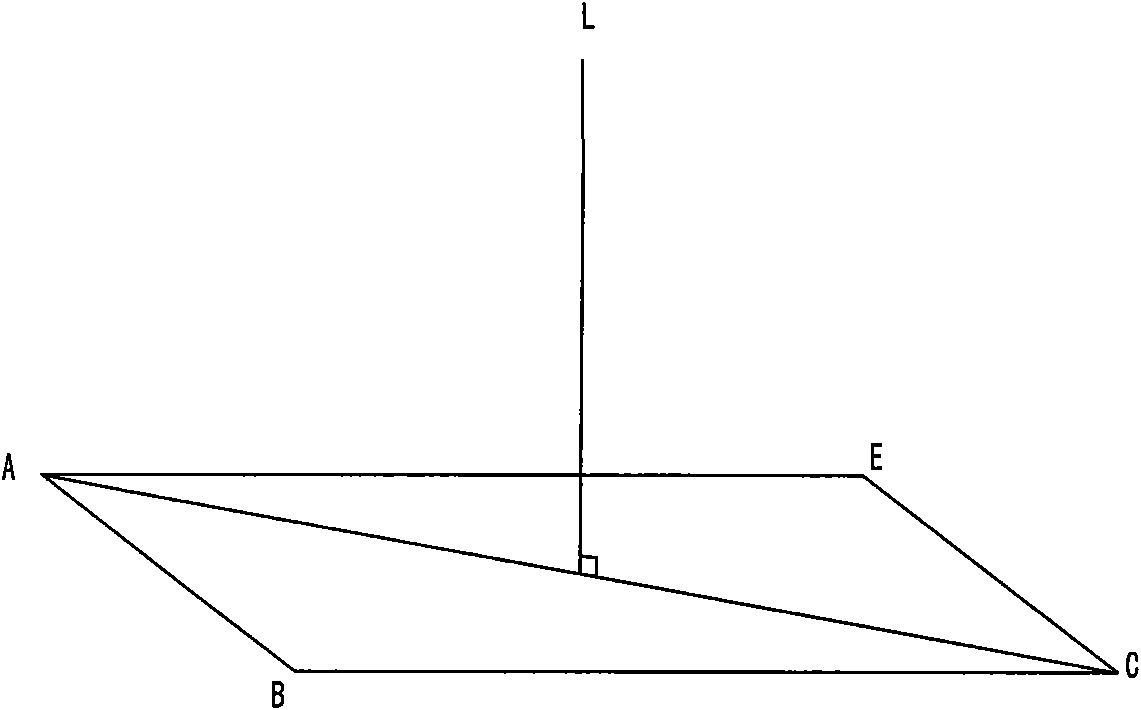

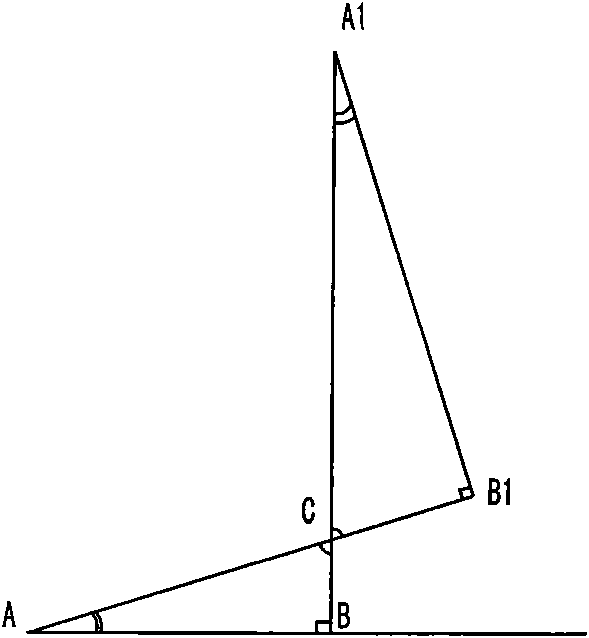

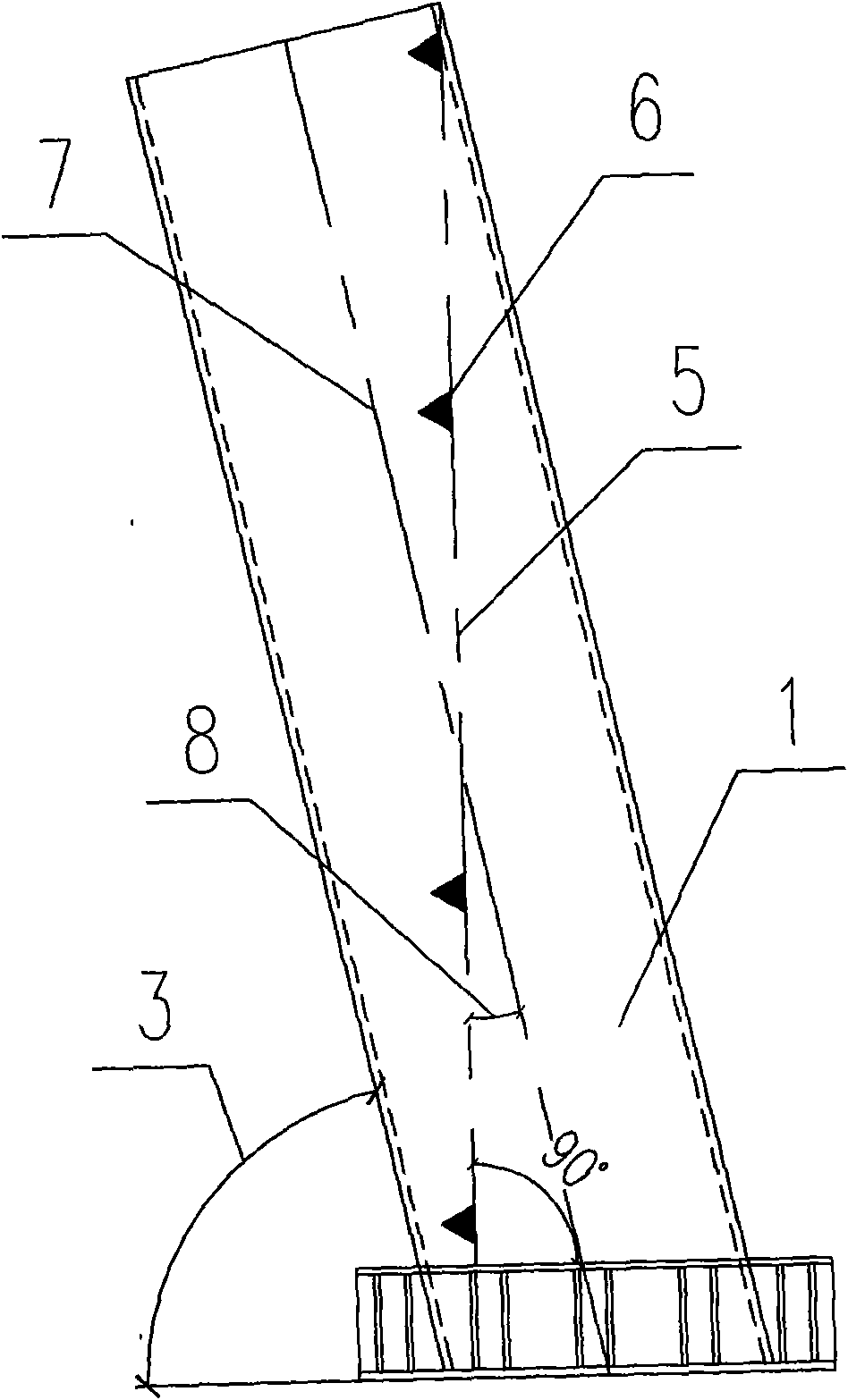

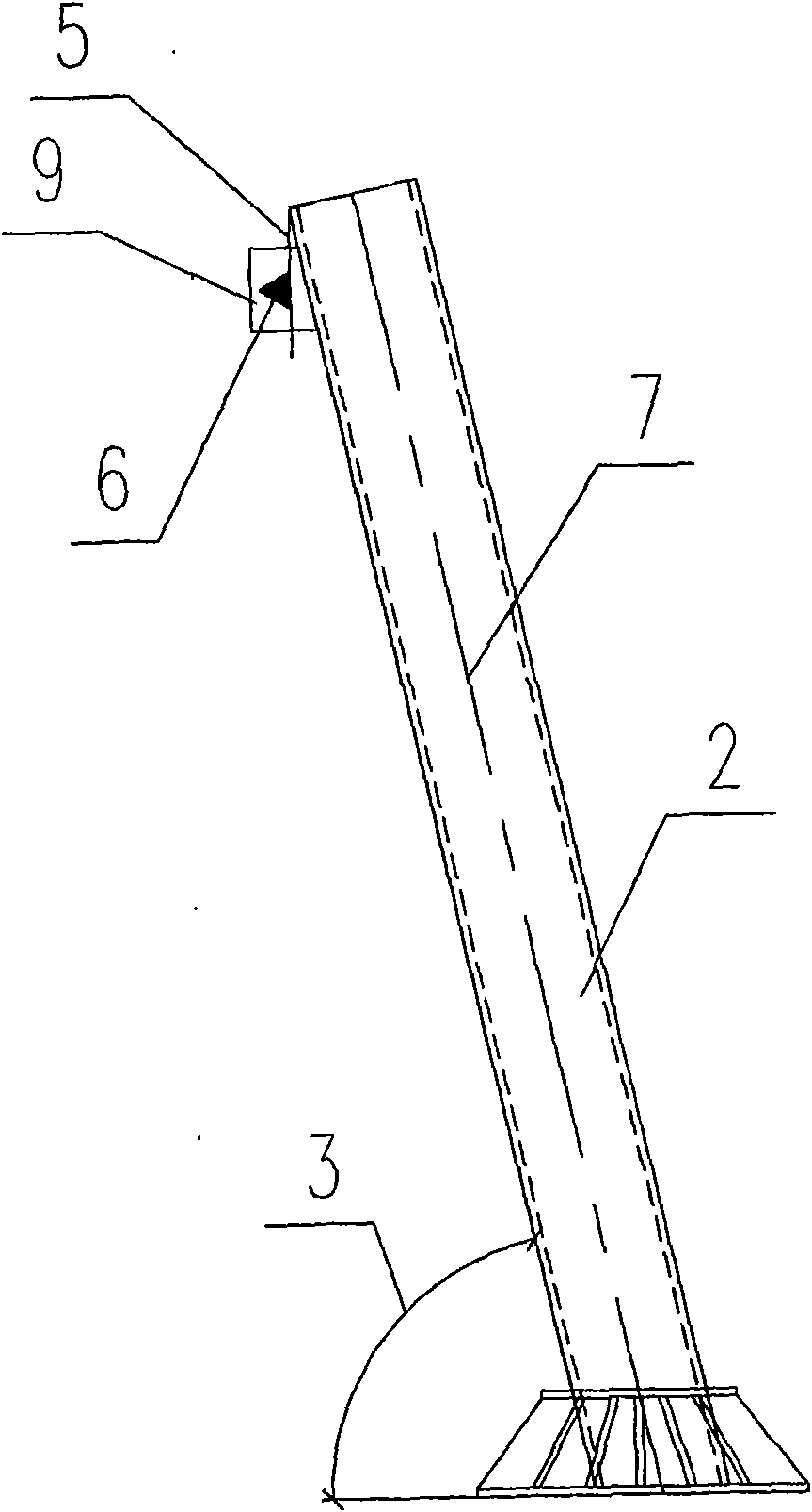

Method for measuring mounting inclination angle of one-side-inclined structure

The invention relates to a method for measuring the mounting inclination angle of a one-side-inclined structure, which comprises the following steps: on the one-side-inclined structure with a wider inclined plane, drawing a measurement auxiliary line by using the structural center line and designing an included angle according to plotting paper, and marking out the auxiliary line with a red triangle; on the one-side-inclined structure with a lathy structure and a smaller inclined plane, welding an auxiliary measuring steel plate close to the top of the structure or the interface part, drawing a measurement auxiliary line, and marking out the auxiliary line with a red triangle; according to the measurement auxiliary line drawn on the inclined plane of the structure, calculating the actual distance between the auxiliary line and a basic cross center line, and projecting a measuring point on the ground; projecting a measuring point of the central axial line in a structural perpendicularity direction on the ground by a measuring line in the structural perpendicularity direction according to the basic cross center line; and using two theodolites to perform bidirectional measurement and control, wherein the perpendicularity is measured and controlled on one side, while the inclination angle is measured and controlled on the other side, and the theodolites are erected on the ground projection points to adjust the structure so that the measurement auxiliary lines are superposed with the cross curves of the bidirectional theodolites. The method can effectively reduce the deviation and improve the accuracy of the inclination angle.

Owner:CHINA 22MCC GROUP CORP

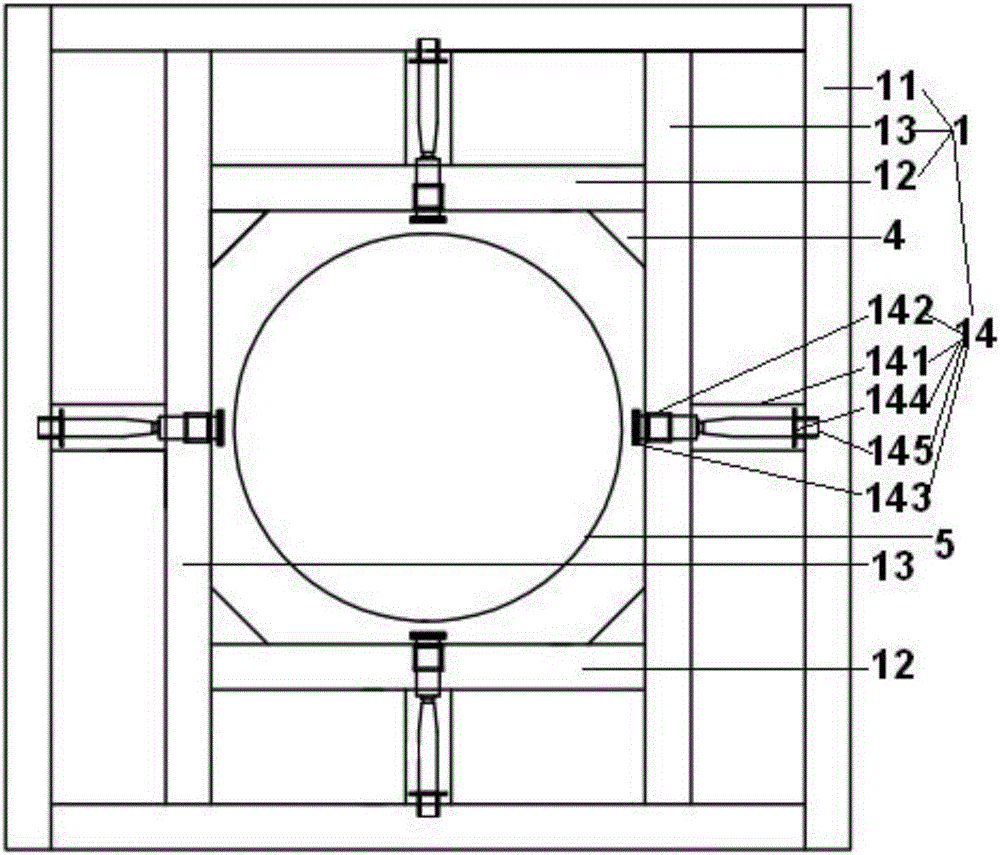

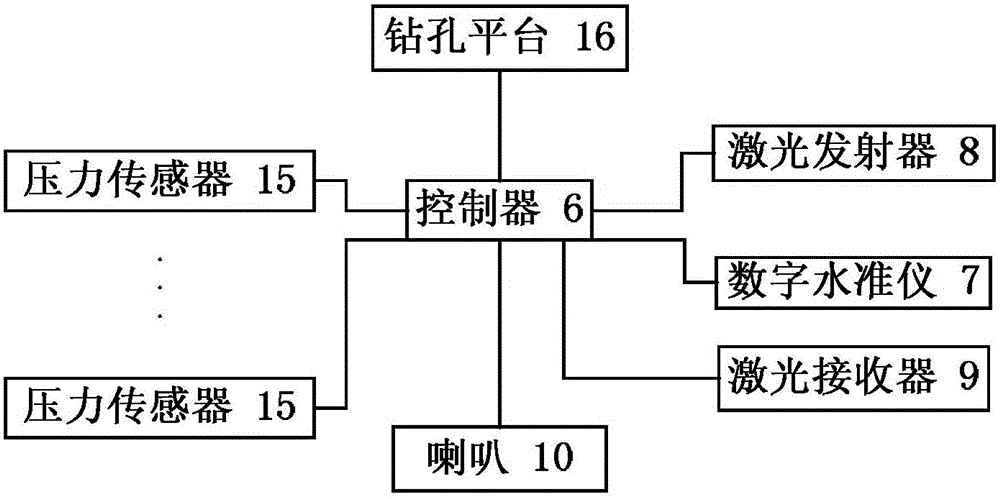

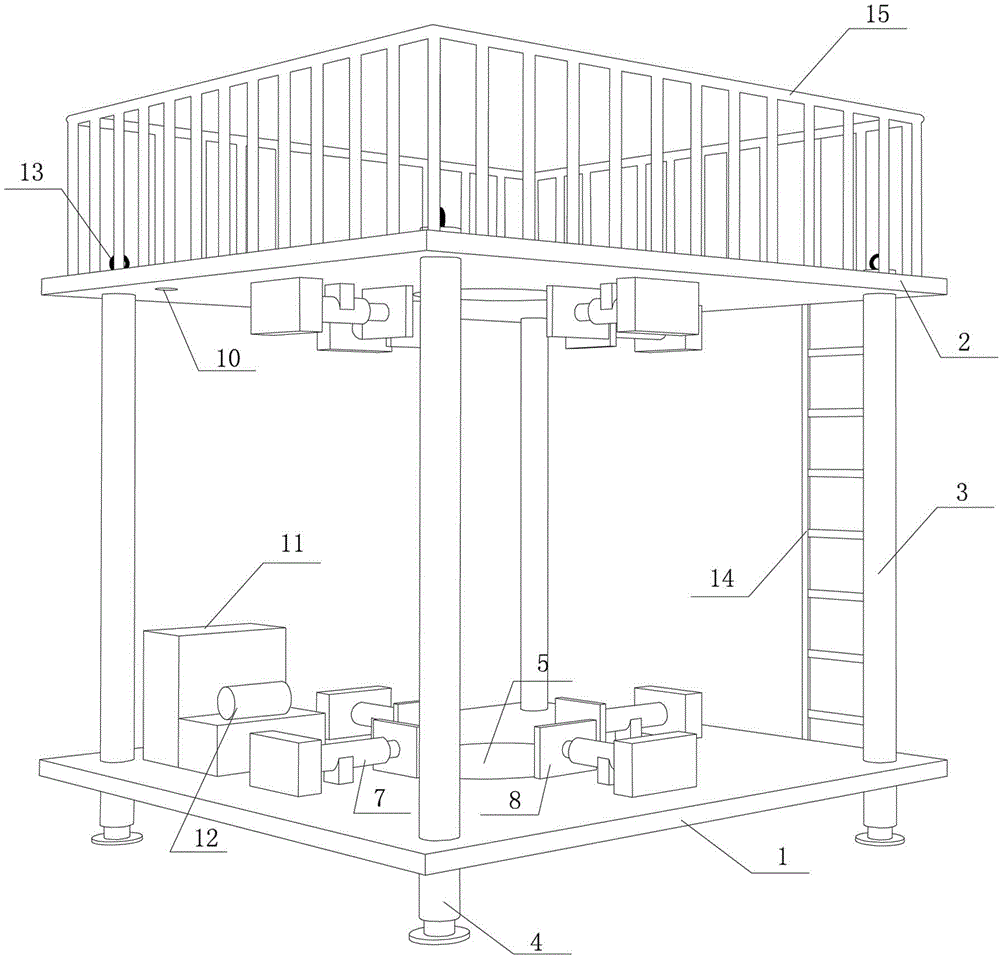

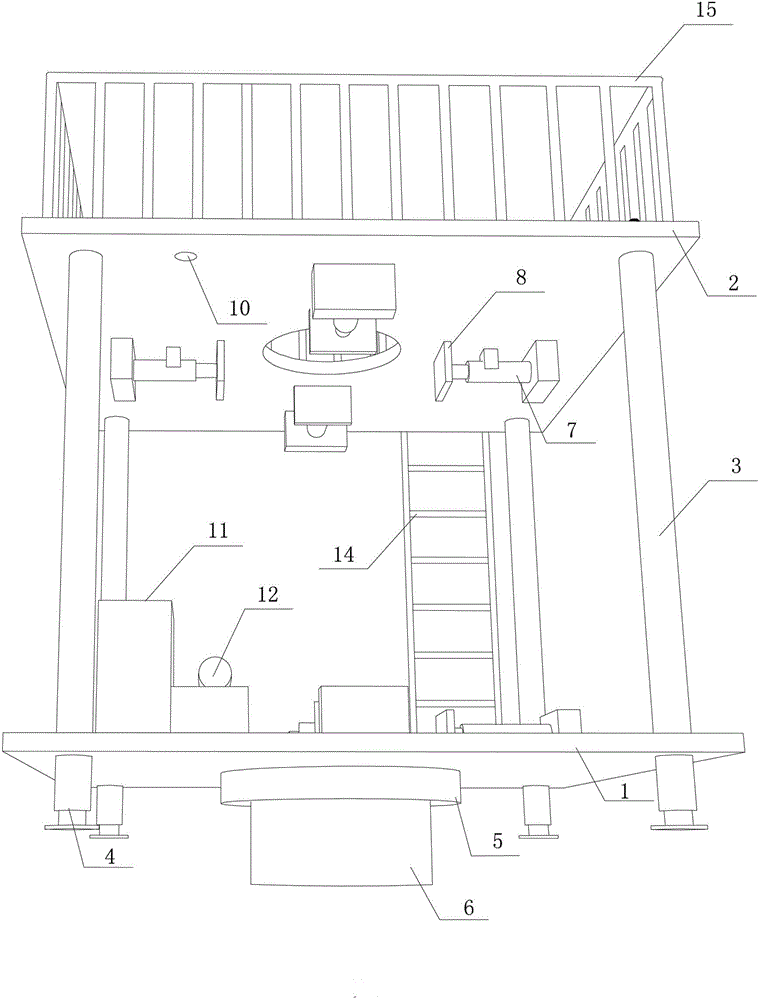

Drilling pile casing guide device provided with calibration mechanisms and control method

The invention discloses a drilling pile casing guide device provided with calibration mechanisms and a control method. The device comprises an upper support, a lower support, a plurality of supporting columns arranged between the upper support and the lower support, a controller, a digital level, a laser emitter, a laser receiver and a horn. The upper support comprises a rectangular frame, two transverse rods arranged in the rectangular frame, two longitudinal rods connected with the two ends of the two transverse rods correspondingly, the longitudinal calibration mechanisms and the transverse calibration mechanisms, wherein the longitudinal calibration mechanisms are arranged on the transverse rods and borders, corresponding to the transverse rods, of the rectangular frame, and the transverse calibration mechanisms are arranged on the longitudinal rods and borders, corresponding to the longitudinal rods, of the rectangular frame. The controller is electrically connected with the digital level, the laser emitter, the laser receiver and the horn. The lower support is identical with the upper support in structure. The device and the method have the characteristics of being capable of effectively controlling the perpendicularity of drilling pile casings and high in construction efficiency.

Owner:ZHEJIANG JINZHU TRANSPORTATION CONSTR

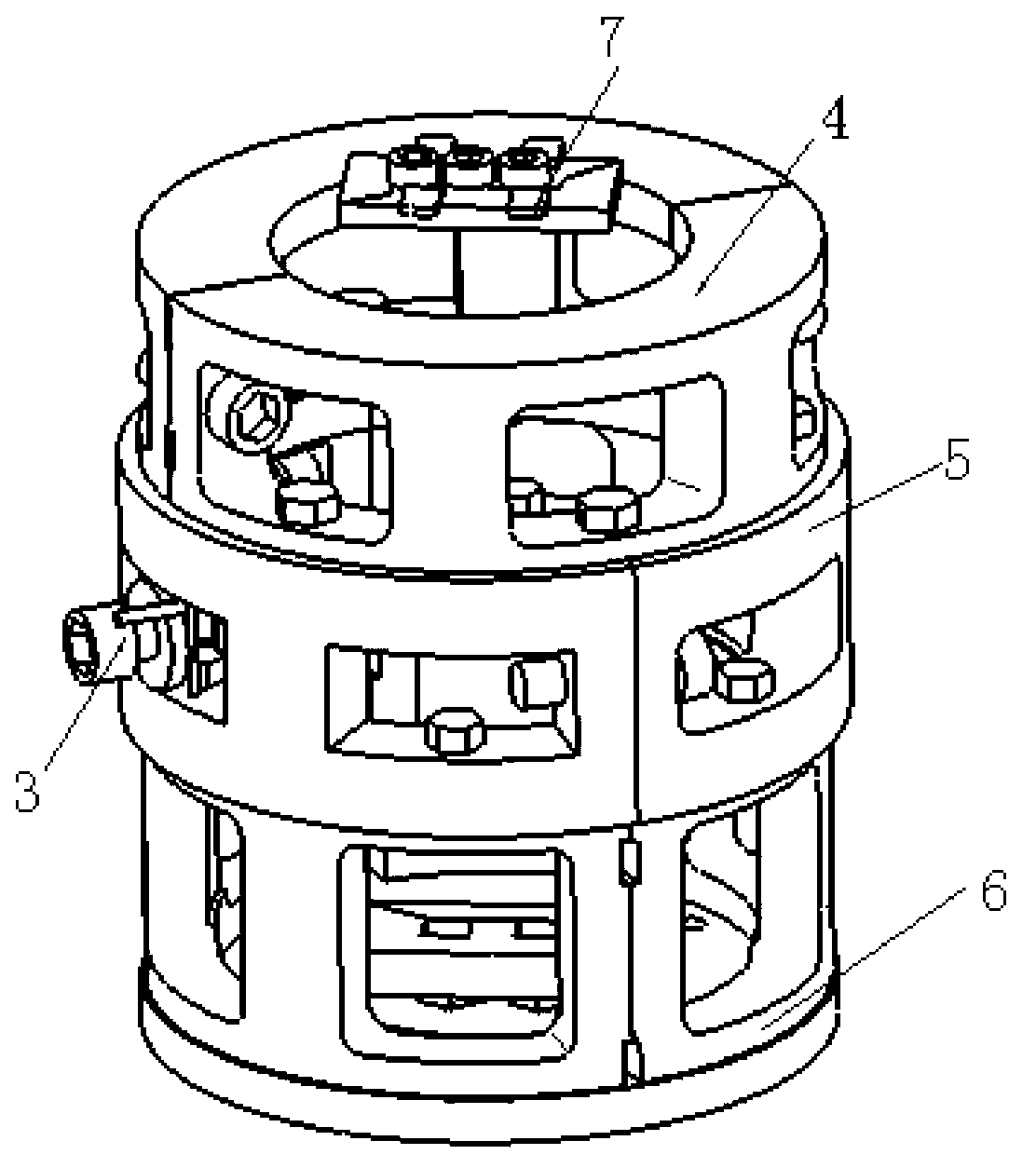

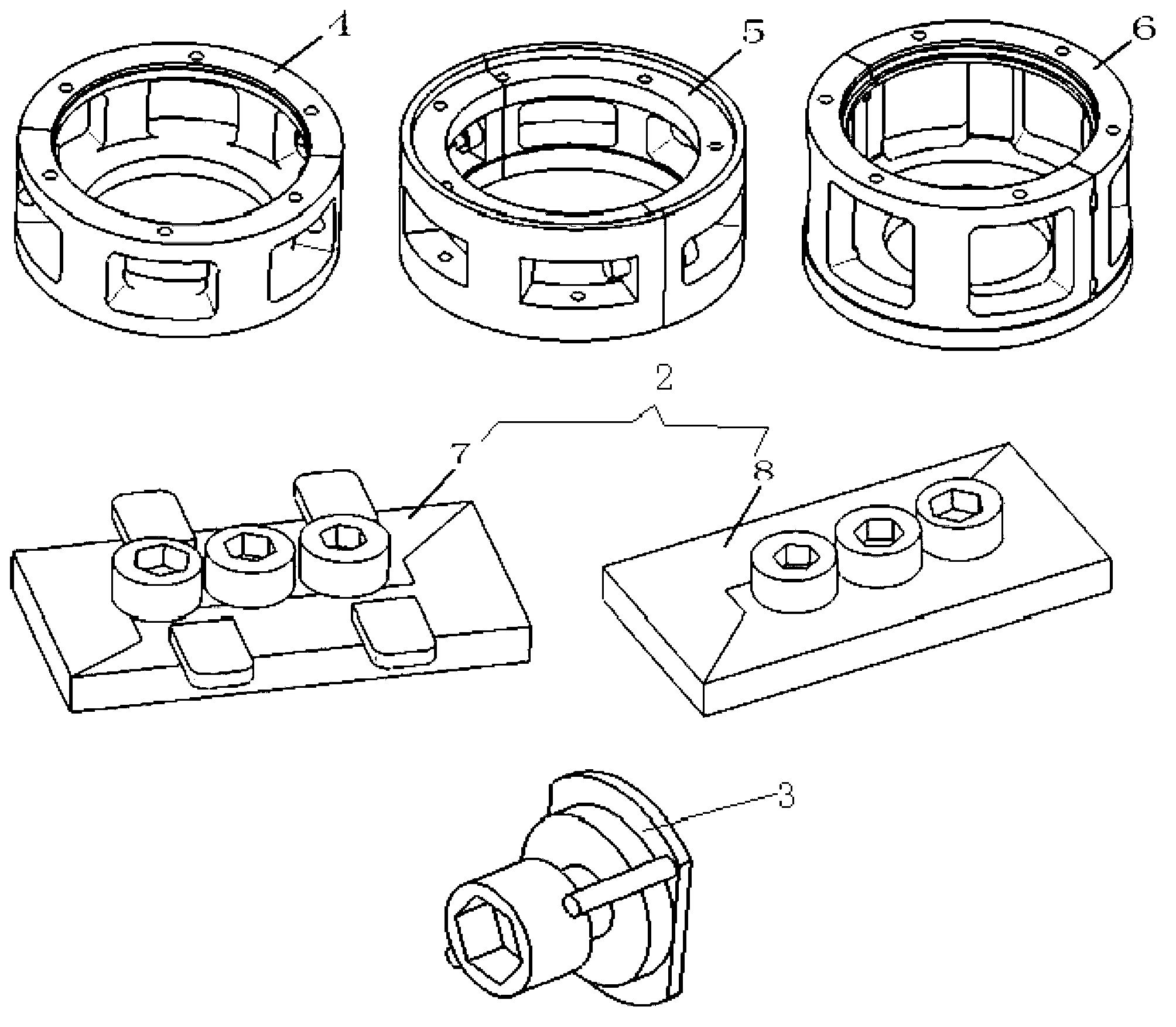

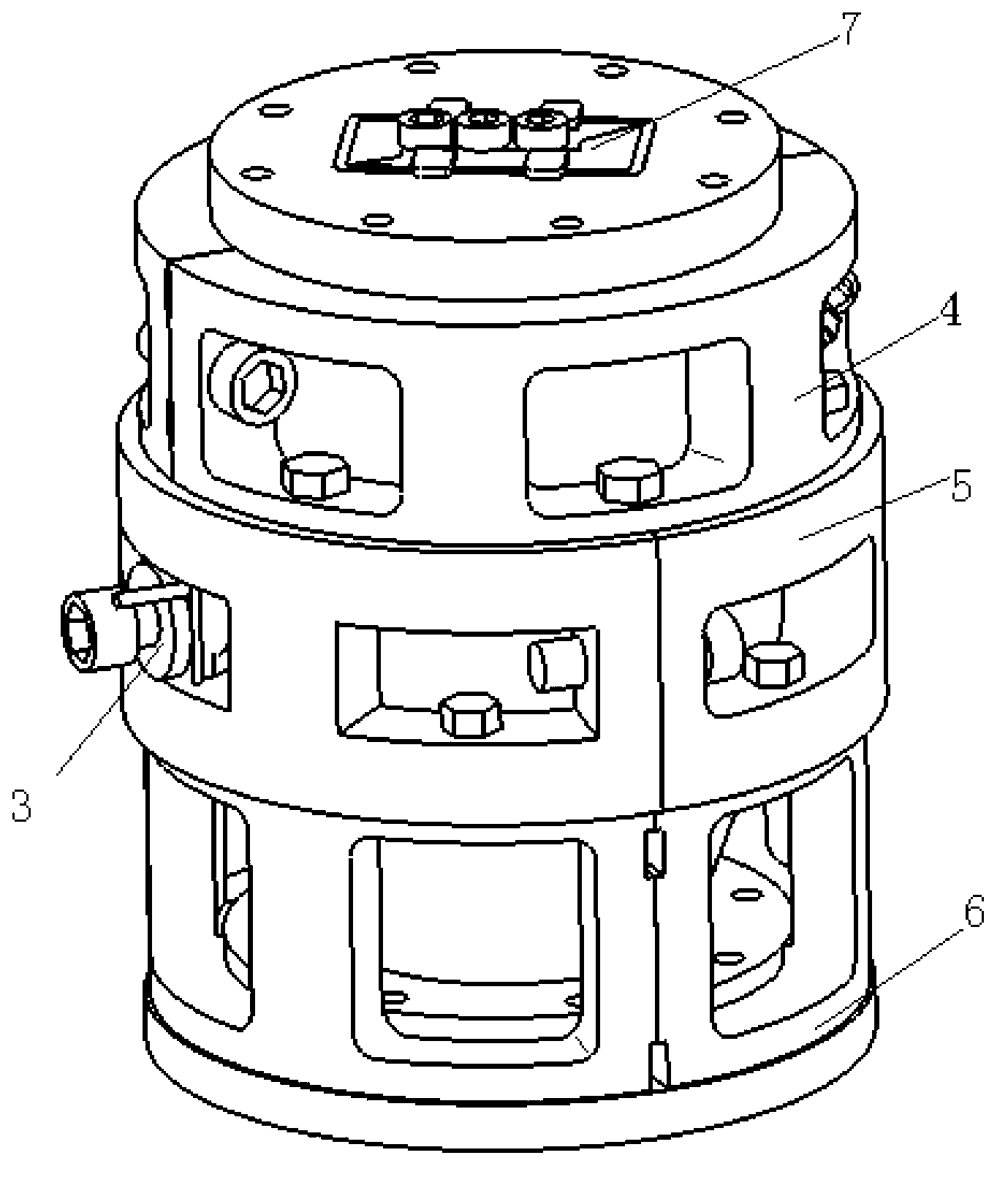

Inner-support and reverse-construction-technique column perpendicularity controller

ActiveCN103603506AImprove construction efficiencyReduce engineering timeBuilding material handlingHydraulic pumpHydraulic control

The invention discloses an inner-support and reverse-construction-technique column perpendicularity controller and belongs to the technical field of building construction equipment. According to the technical scheme, a bottom plate and a top plate are connected through four columns and are parallel, the parallel space is larger than 2000mm, a hydraulic support leg is arranged under each column, a round hole is formed in the center of the bottom plate and the top plate respectively, and the two round holes are identical in size. The lower round hole is connected with a sleeve, four hydraulic jacks are arranged uniformly on the circumferences of the round holes of the upper portion of the bottom plate and the lower portion of the top plate, clamping plates are arranged in the front of the hydraulic jacks, scales are arranged on the hydraulic jacks, a level bubble is arranged under the top plate, a hydraulic console and a hydraulic pump are arranged on the bottom plate, and a concrete casting platform is arranged on the top plate. The application proves that the scales which are accurate to 1mm are arranged on the hydraulic jacks, and the deviation of jacking of the upper and lower hydraulic jacks can be controlled within 1mm; the space between the bottom plate and the top plate is larger than 2000mm, so that the column perpendicularity can be controlled within 0.5%o, and the perpendicularity requirement of the columns can be effectively controlled.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

Construction electric switch box construction method once and for all

ActiveCN101392597AThe installation position is accurateReduce construction proceduresBuilding constructionsTape measureReinforced concrete

The invention discloses a one-time completed construction method for a building electrical distribution box. The method is to embed the box in place at a time before the concrete is cast during the construction process. The box on a wall takes the level control line on the layer as a reference, and the accurate position of the box is measured by a water level gauge, a steel measuring tape and a track level bar; lines are drawn on the surface of the box to determine the position for entering a pipeline and open an opening on the position by an opener; the box on a reinforced concrete wall is fixed on a steel mesh by a steel bar in a shape of a Chinese character 'jing'; the box on a brick wall or a light partition is connected and fixed with a matched pipeline before construction; the pipeline entering the box corresponds a hole, and the arrangement is orderly; and cut polystyrene foam plates are filled in the box and the periphery of the box is sealed by adhesive tapes. The aim of the method is to ensure the accuracy of the position of the box.

Owner:陕西建工第三建设集团有限公司

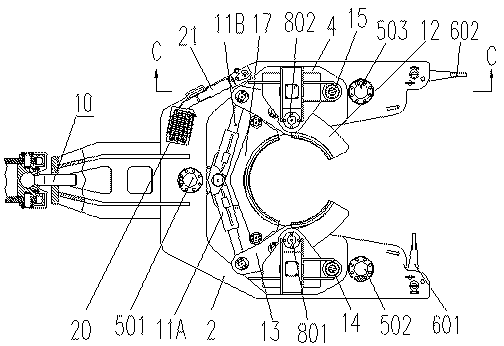

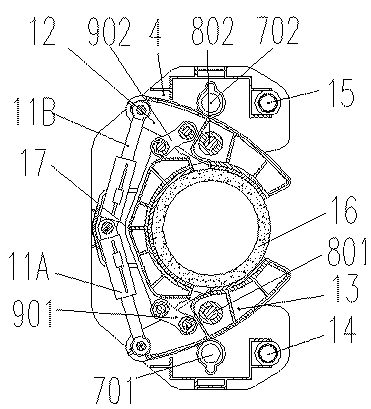

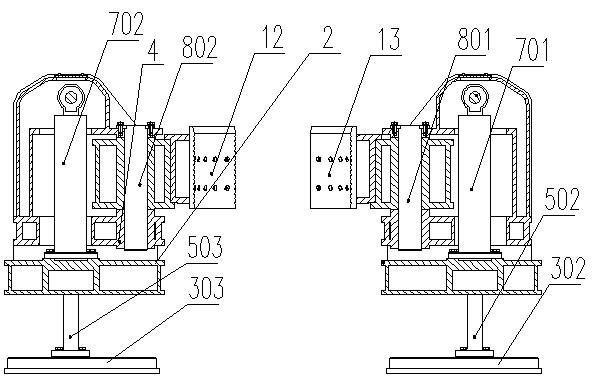

Open pile control device

InactiveCN102425169AControl verticalityDecentralized speed controlBulkheads/pilesThree levelMarine engineering

The invention relates to an open pile control device, which comprises a first platform, a pile clamp platform positioned above the first platform, pressing and pulling oil cylinders, a first pile clamp, a second pile clamp, a third pile clamp, pile clamping oil cylinders, pull rods, at least three leveling oil cylinders, leveling bottom plates, and a connecting mechanism, wherein the first pile clamp and the second pile clamp are hinged with the pile clamp platform and are respectively hinged with the third pile clamp through the pull rods, and the pile clamping oil cylinders are hinged with the first pile clamp and the second pile clamp; the first pile clamp and the second pile clamp are pushed by the oil cylinders to rotate around pin shafts of the first pile clamp and the second pile clamp, and drive the third pile clamp to move so as to clamp or loosen a pipe pile, and the leveling bottom plates with the same number of the leveling oil cylinders are positioned below the first platform; piston rods of the leveling oil cylinders are hinged with the leveling bottom plates, and the attitude of the first platform is controlled by adjusting the extension of the leveling oil cylinders; and the connecting mechanism is used for connecting the pile control device with a pile foundation construction host.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +2

High-precision positioning guide device and use method thereof

The invention relates to a high-precision positioning guide device and a use method thereof. The device comprises an outer side device and an inner side device which are combined, wherein the inner side device comprises first channel steel; the bottom of the first channel steel is provided with a fixing bolt hole; the side face of the first channel steel is provided with a Y-shaped guide groove. The problem of constraint on engineering progress and construction quality and safety can be solved, and meanwhile the problems such as poor environmental protection performance, complexness in disassembly and assembly, adverseness to recovery and recycling, poor stiffness performance, looseness in fixation, poor mechanical property and poor safety and reliability are solved; thus members such as prefabricated walls are quickly arranged in place and corrected, and the utilization rate and the hanging precision of a tower crane are improved.

Owner:SHANDONG SANJIAN CONSTR ENG +1

Construction method of air duct structure sharing side wall together with subway station

PendingCN110499779AReduce the amount of demolition worksVersatileArtificial islandsCellarsRebarInstability

The invention provides a construction method of an air duct structure sharing a side wall together with a subway station. The construction method of the air duct structure sharing the side wall together with the subway station specifically comprises the steps of firstly, adopting a mode of erecting templates on the two sides to construct the side wall shared by the air duct structure and the subway station; secondly, breaking station fender posts in a shared side wall area according to a mode of breaking one post every 2-4 posts; finishing excavation of earthwork and construction of an air duct bottom plate, wherein the air duct bottom plate is connected with a station middle plate through a fender post breaking area to form a temporary support; after a station main body structure is constructed, breaking the rest fender posts, and pouring micro-expansion concrete in the breaking area; and fixing the template on the air duct side of the shared side wall on a supporting net sheet by embedding a steel reinforcement anchor bolt in the station building envelope and welding the supporting net sheet on the exposed end of the steel reinforcement anchor bolt. The construction method of theair duct structure sharing the side wall together with the subway station can be widely used for construction of the air duct structure when the station and an air duct share the side wall; the apparent mass of concrete of a shared side wall cast-in-place structure is guaranteed; and the occurrence of foundation pit instability accidents is avoided.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

Assembling and welding tool for ceramic windows and application method for assembling and welding tool

InactiveCN103252602AGuaranteed design accuracyGood design precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses an assembling and welding tool for ceramic windows and an application method for the assembling and welding tool. The assembling and welding tool comprises a main tool mold, an inner cavity support structure and barriers. The periphery of a body of a ceramic window is fixed by the aid of the main tool mold, the upper end and the lower end of the body of the ceramic window are fixed by the aid of the inner cavity support structure, and a cooling water connector is fixed by the aid of the barriers. The application method includes steps of combining components of the main tool mold for assembling parts of the ceramic window with one another; assembling the inner cavity support structure and the barriers; integrally welding the ceramic window at one step; and disassembling the main tool mold, the inner cavity structure and the barriers to obtain a finished product. The assembling and welding tool and the application method have the advantages that three tool units with high concentricity and parallelism form the main tool mold to constrain the body of the ceramic window; the size of a waveguide inner cavity is fixed by the aid of the inner cavity support structure capable of moving in front, rear, left and right directions, and the waveguide inner cavity with the fixed size is prevented from deforming during welding; the cooling water connector is positioned by the barriers, and screws on the barriers are adjusted to be abutted to the water connector, so that the water connector cannot move; and owing to the method, all the parts are assembled at one step and are welded and molded at one step, so that the design precision of the ceramic window is effectively guaranteed, the production efficiency is greatly improved, and the ceramic window manufacturing cost is reduced.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com