Method for measuring mounting inclination angle of one-side-inclined structure

A measurement method and side tilt technology, which is applied in theodolite and other directions, can solve the problems of large deviation value, difficulty in controlling the tilt angle, and high requirements for structural installation accuracy, and achieve the effect of simple construction, convenient operation, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

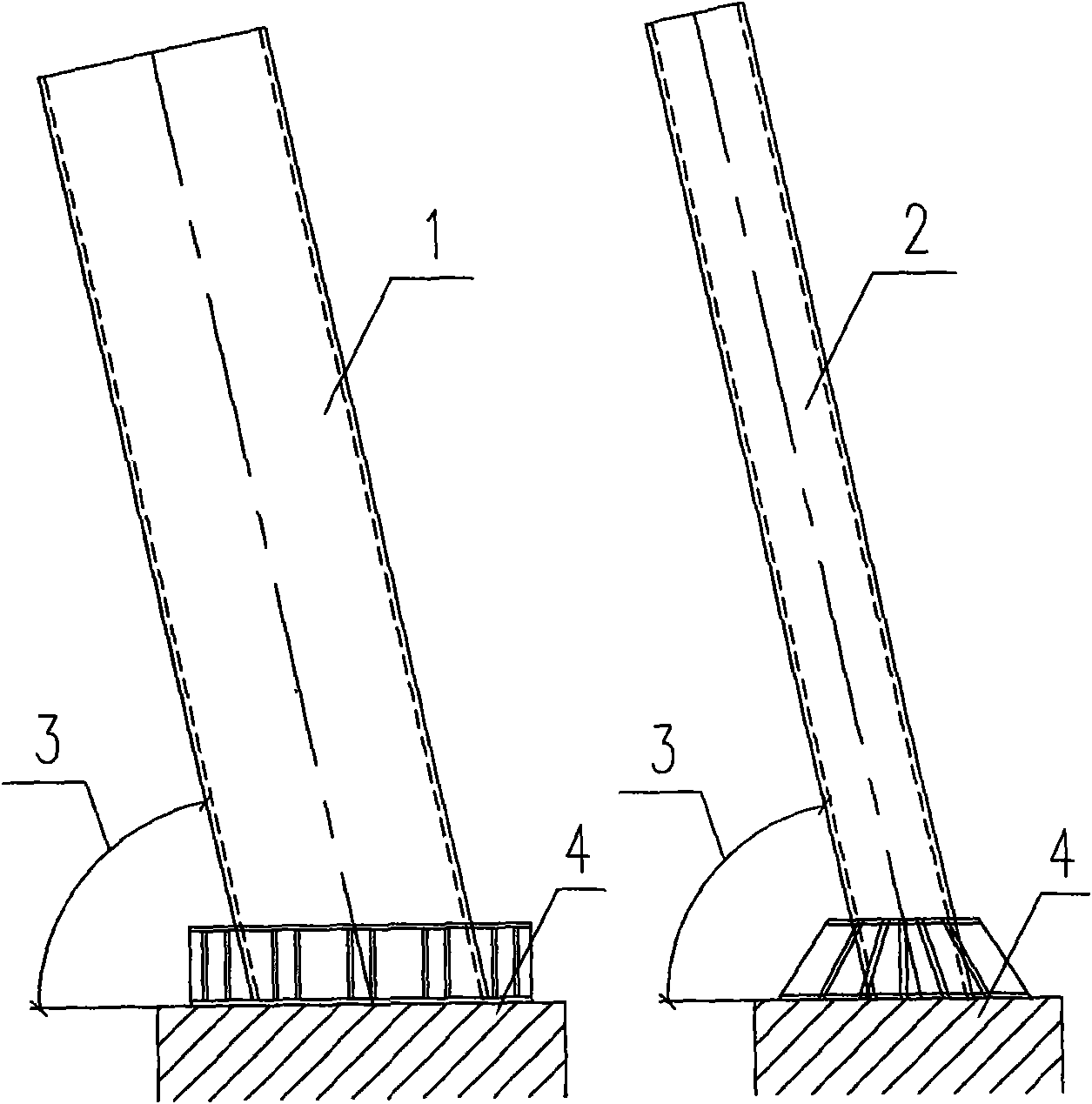

[0019] see figure 1 , in this embodiment, the structure is a steel structure, with a unilaterally inclined structure 1 with a wider inclined surface, a unilaterally inclined structure 2 with a slender structure and a smaller inclined surface, and the unilaterally inclined structure is supported on the concrete foundation 4, and The horizontal ground forms a unilaterally inclined elevation angle of 3.

[0020] The present embodiment carries out according to the following steps:

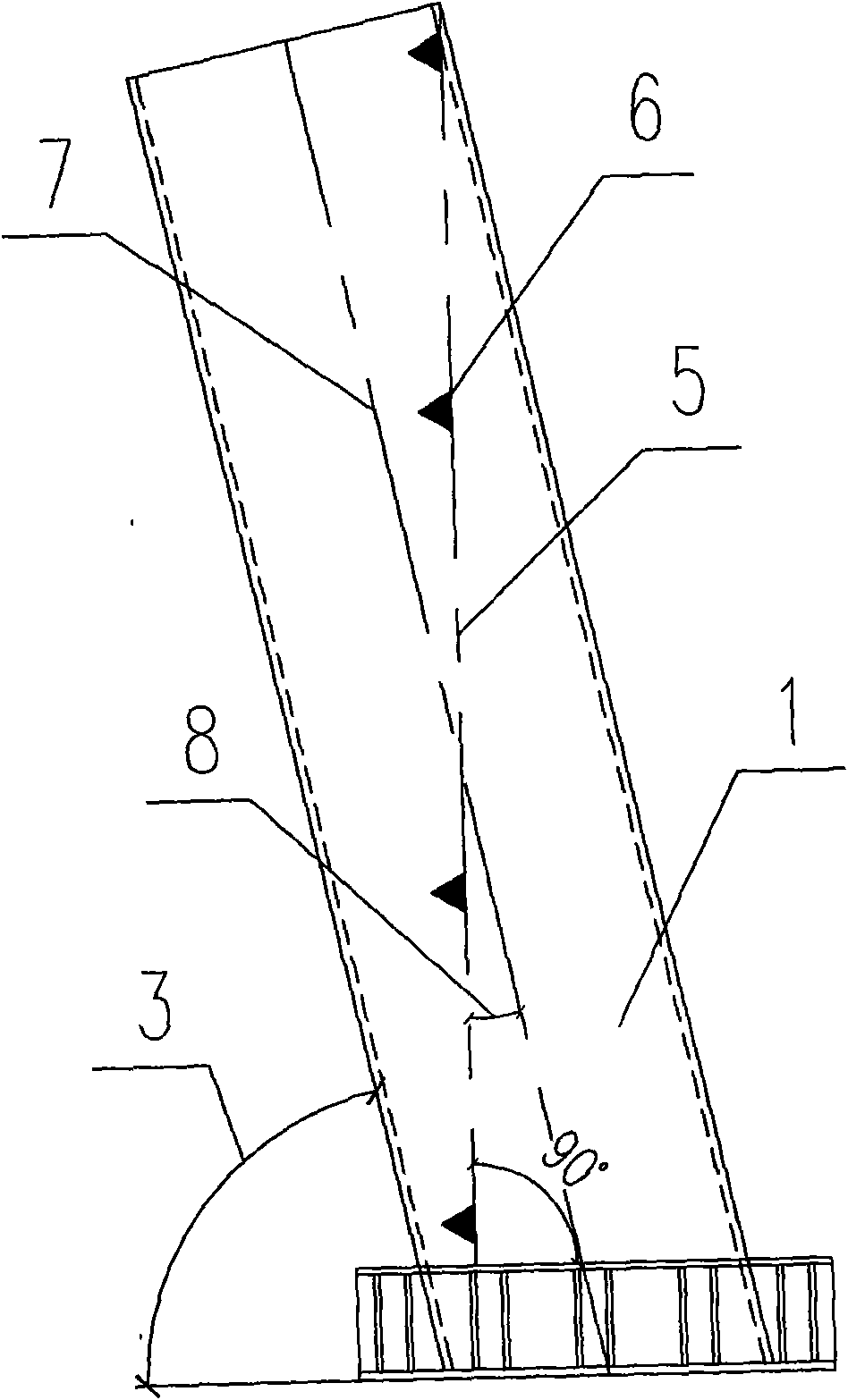

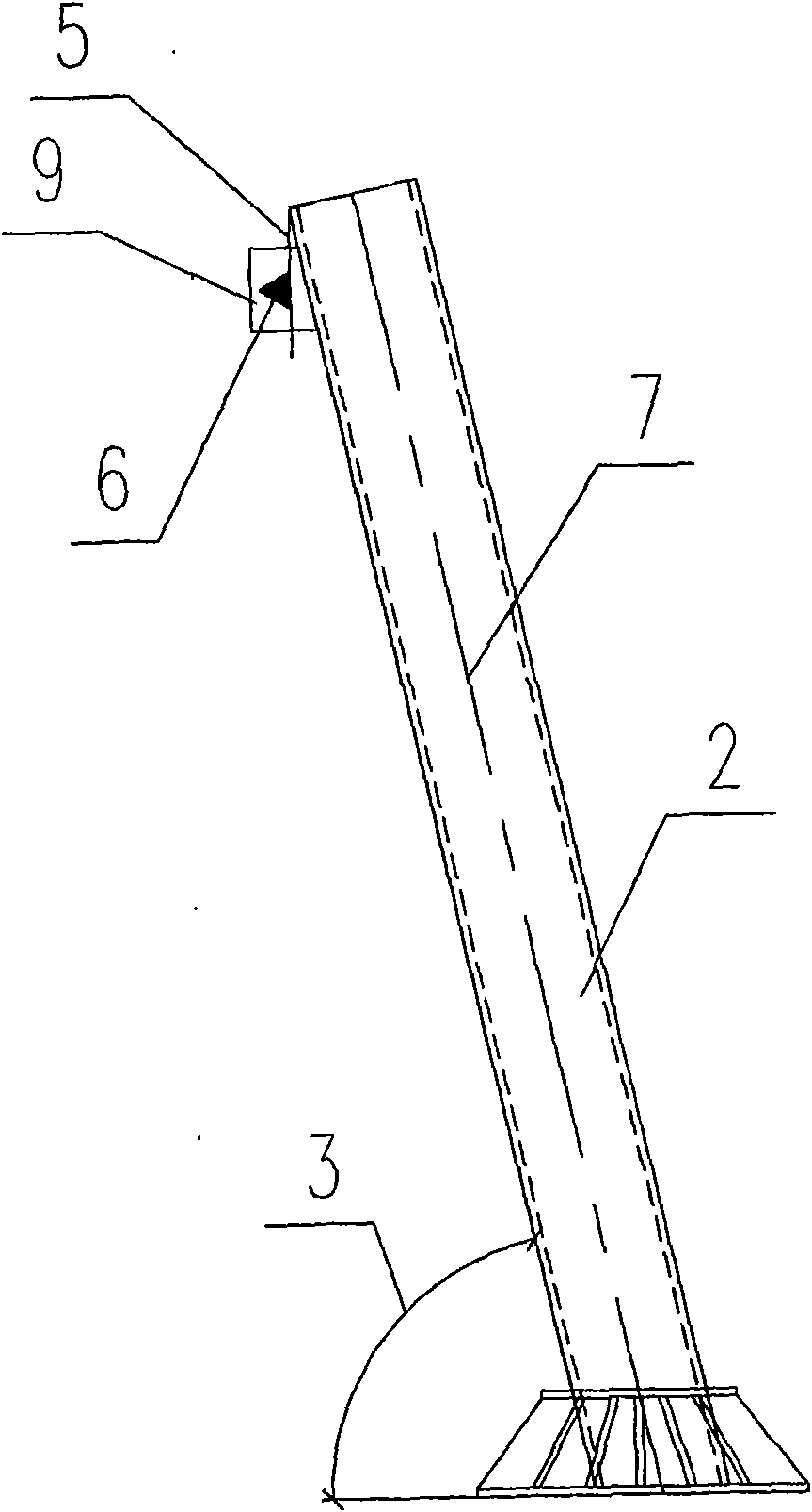

[0021] (1) For the unilateral inclined structure 1 with a wide inclined surface, before the structure is installed, draw the measurement auxiliary line 5 from the bottom to the top at the appropriate position on the structure surface according to the design angle 8 and the structure center line 7, and the measurement auxiliary line Line 5 is perpendicular to the horizontal g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com