Assembling and welding tool for ceramic windows and application method for assembling and welding tool

A technology for assembling welding and ceramic windows, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the manufacturing cost of ceramic windows, difficult to ensure the structural accuracy of ceramic windows, etc., and achieve beautiful appearance and design accuracy. Guarantee and reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

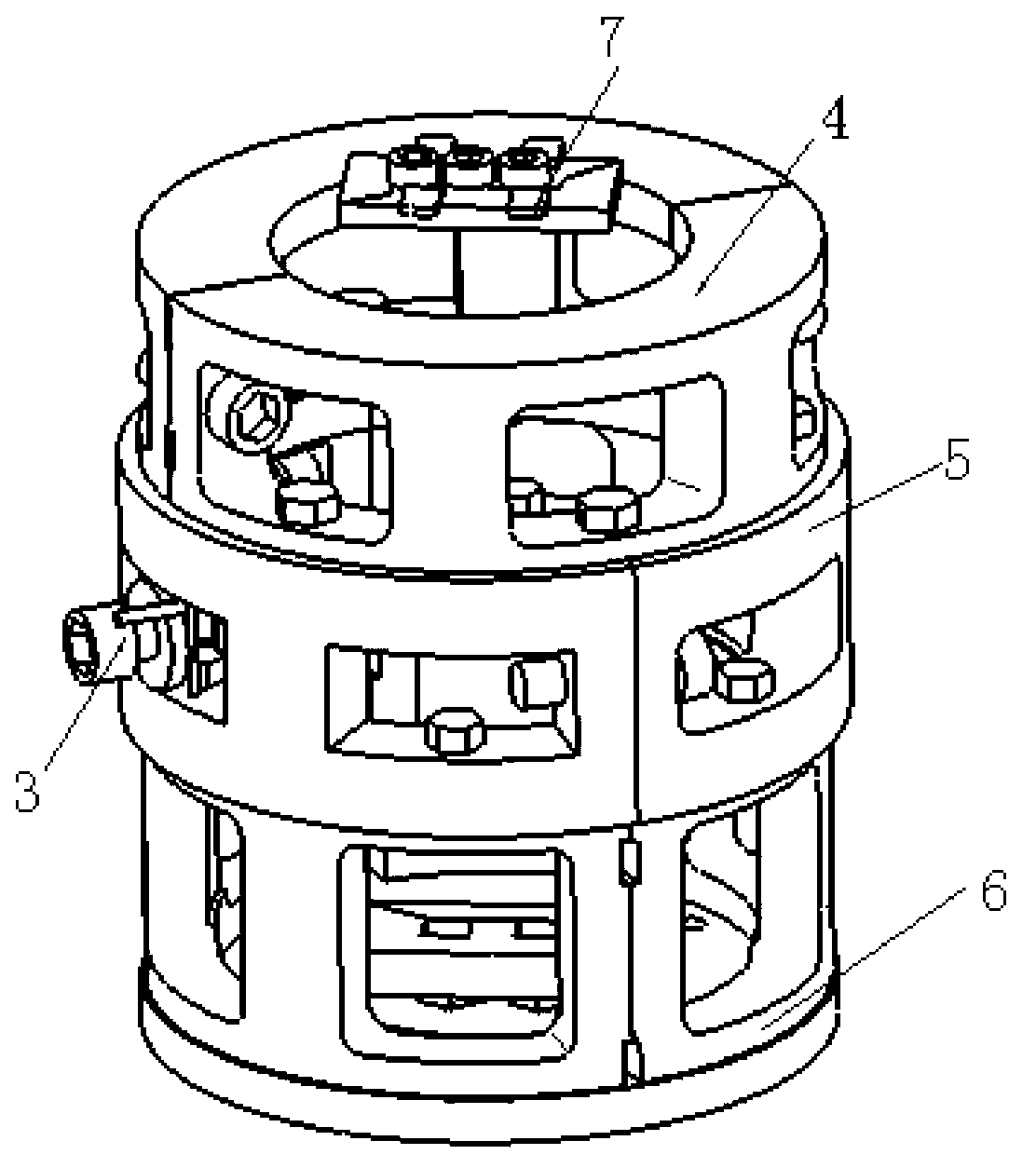

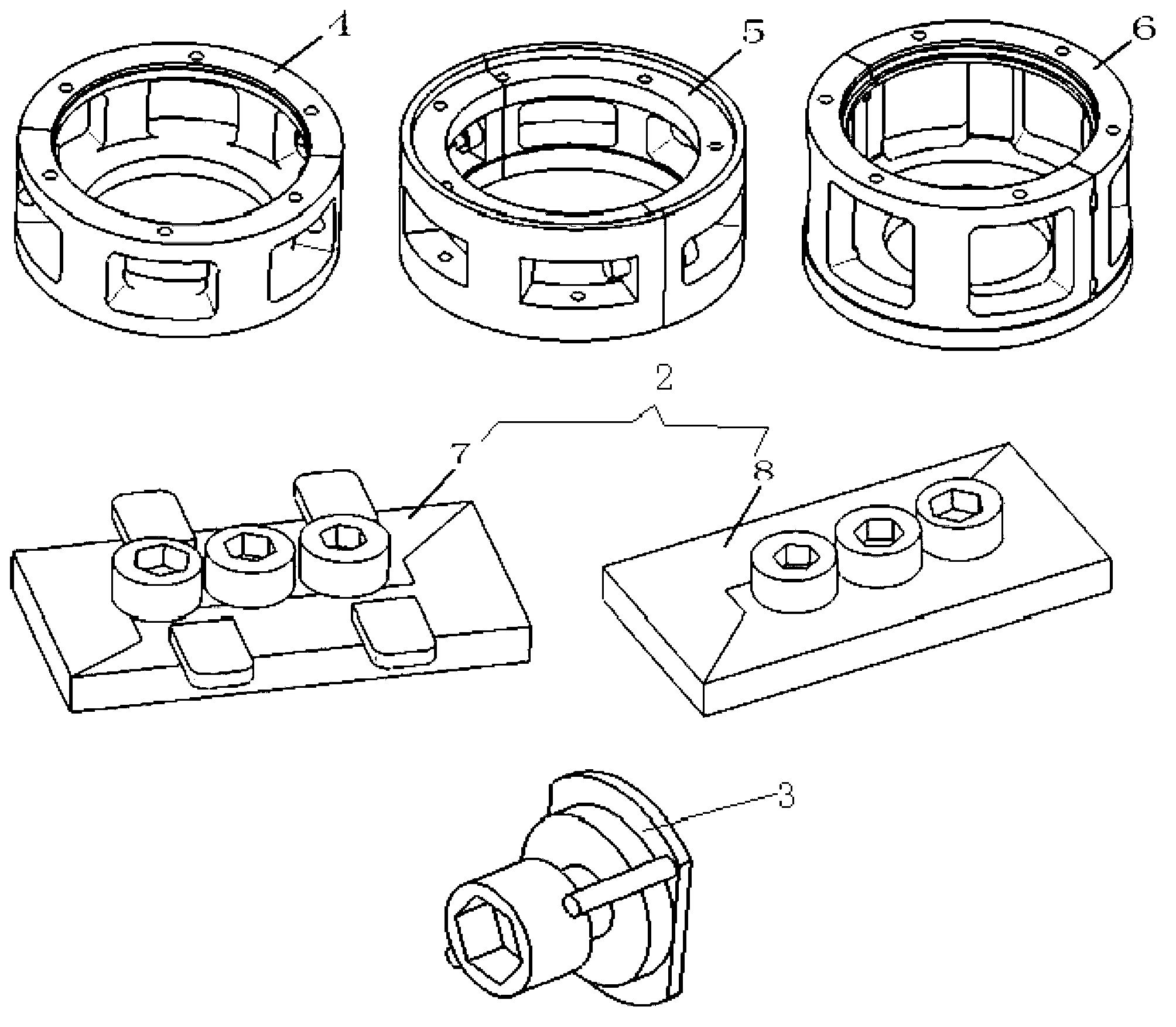

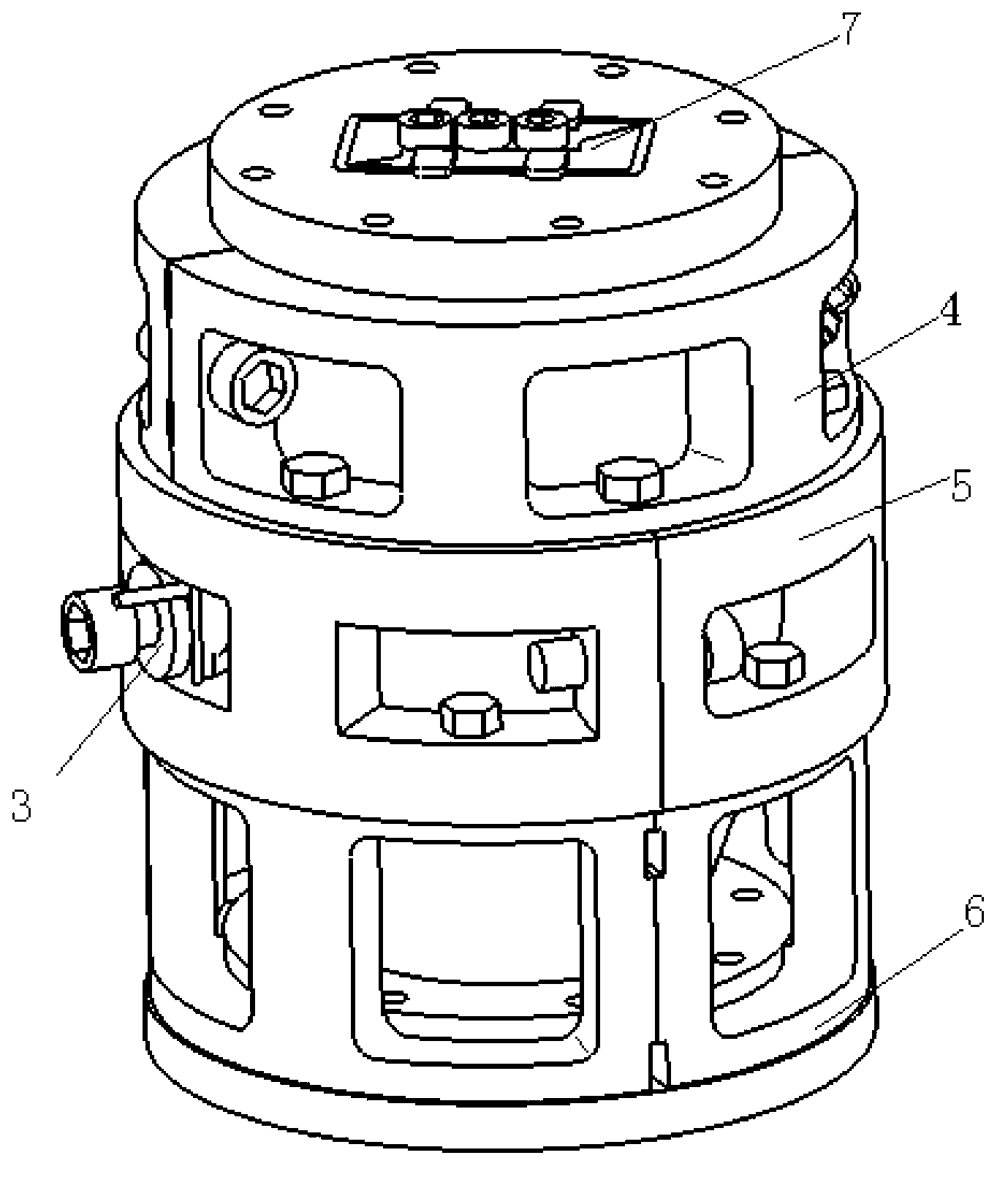

[0028] Referring to the accompanying drawings, a set of assembly and welding tooling for ceramic windows includes a main body tooling mold 1 for fixing the surroundings of the ceramic window form, an inner cavity support structure 2 for fixing the upper and lower ends of the ceramic window form, and a baffle plate 3 for fixing the cooling water joint. The main tooling mold 1 is composed of three tooling units, namely an upper tooling unit 4 , a middle tooling unit 5 and a lower tooling unit 6 . The upper tooling unit 4, the middle tooling unit 5 and the lower tooling unit 6 are all composed of two semicircular structures, which are fixed in pairs after pairing, and the inner holes after the pairing are all stepped holes, and the diameter of the stepped holes is the same as that of ceramic windows and windows. The circular waveguide section in the body fits. The inner cavity support structure 2 is composed of an upper waveguide inner cavity support structure 7 and a lower waveg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com