Patents

Literature

336results about How to "Uniform force distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

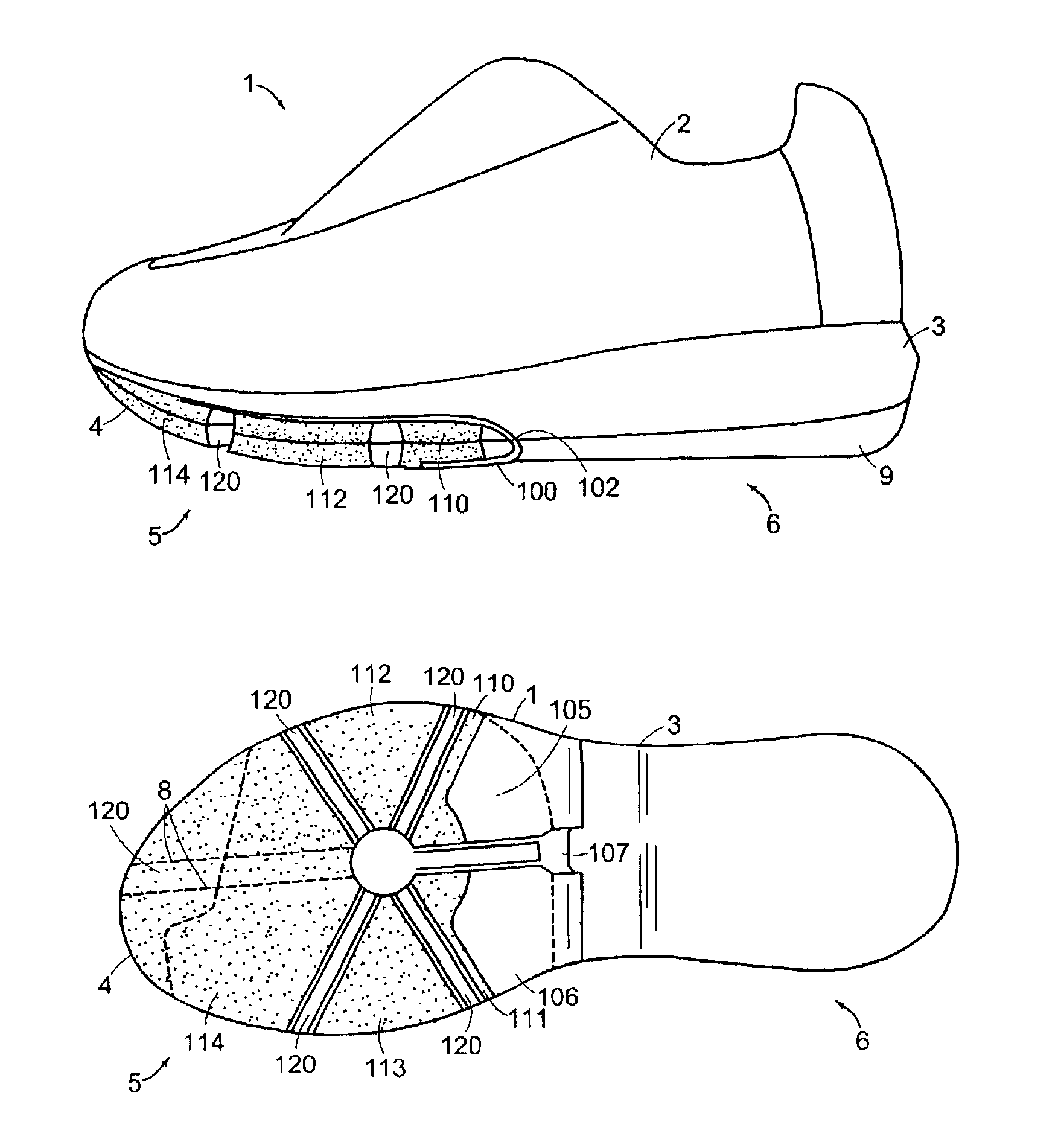

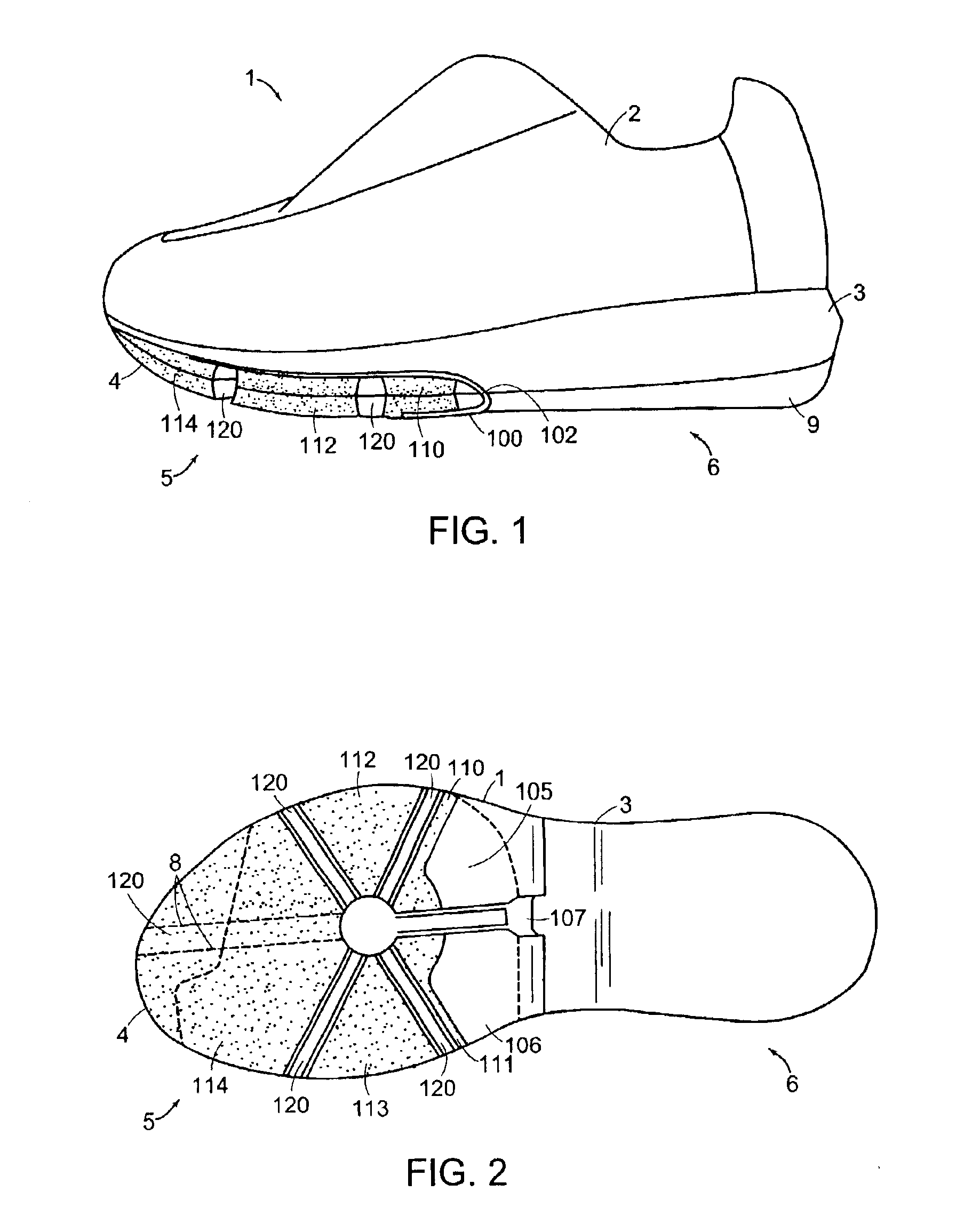

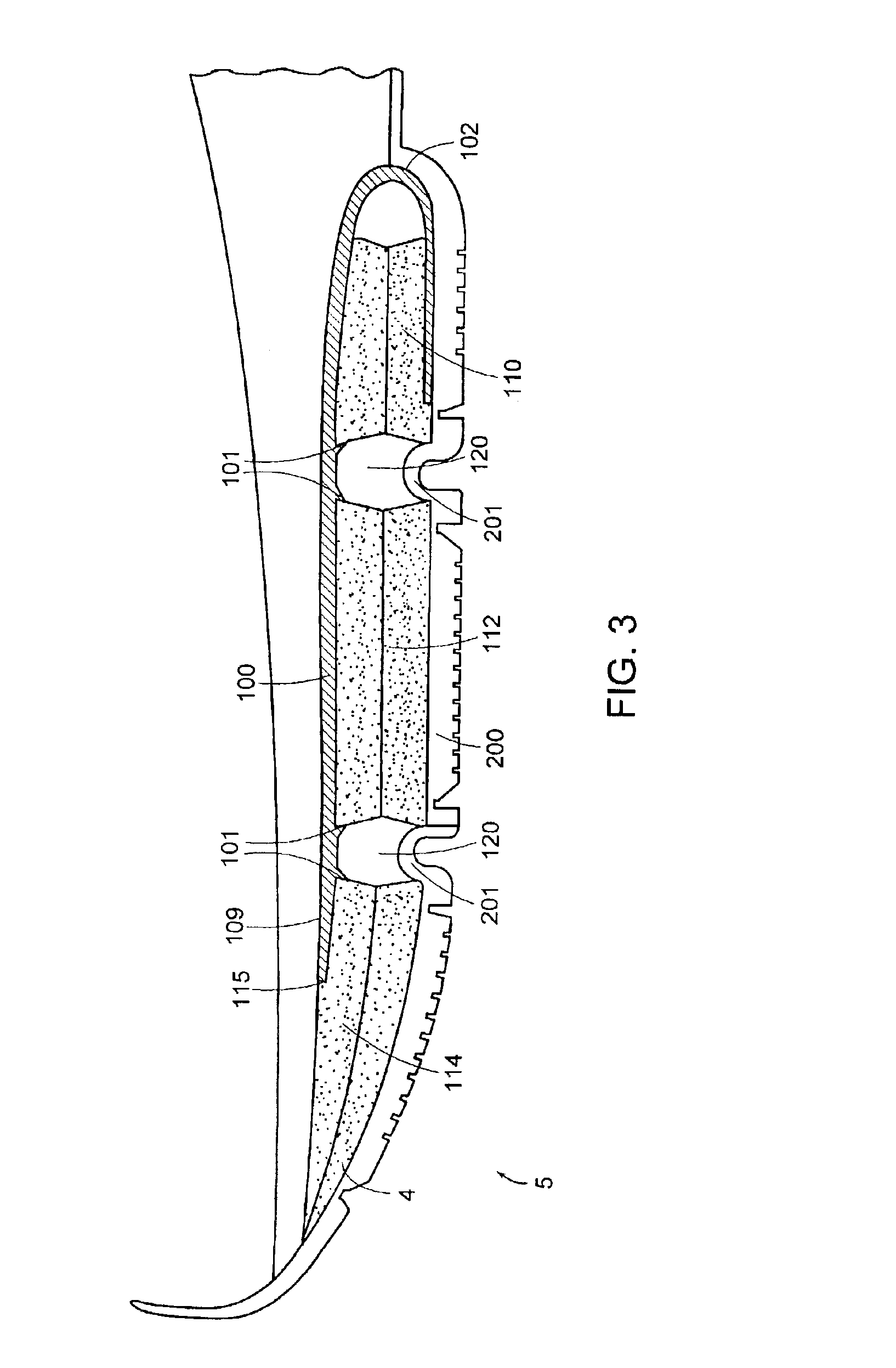

Shoe cartridge cushioning system

The present invention relates to a shoe sole, in particular for a sports shoe, where the sole includes a cartridge cushioning system that includes a load distribution plate and deformation elements disposed in a forefoot region of the sole to provide support and / or cushioning to the forefoot. The shoe sole may include a second cartridge cushioning system that includes a second load deformation plate and functional elements disposed in a heel region of the sole to guide the foot into a neutral position after the first ground contact.

Owner:ADIDAS

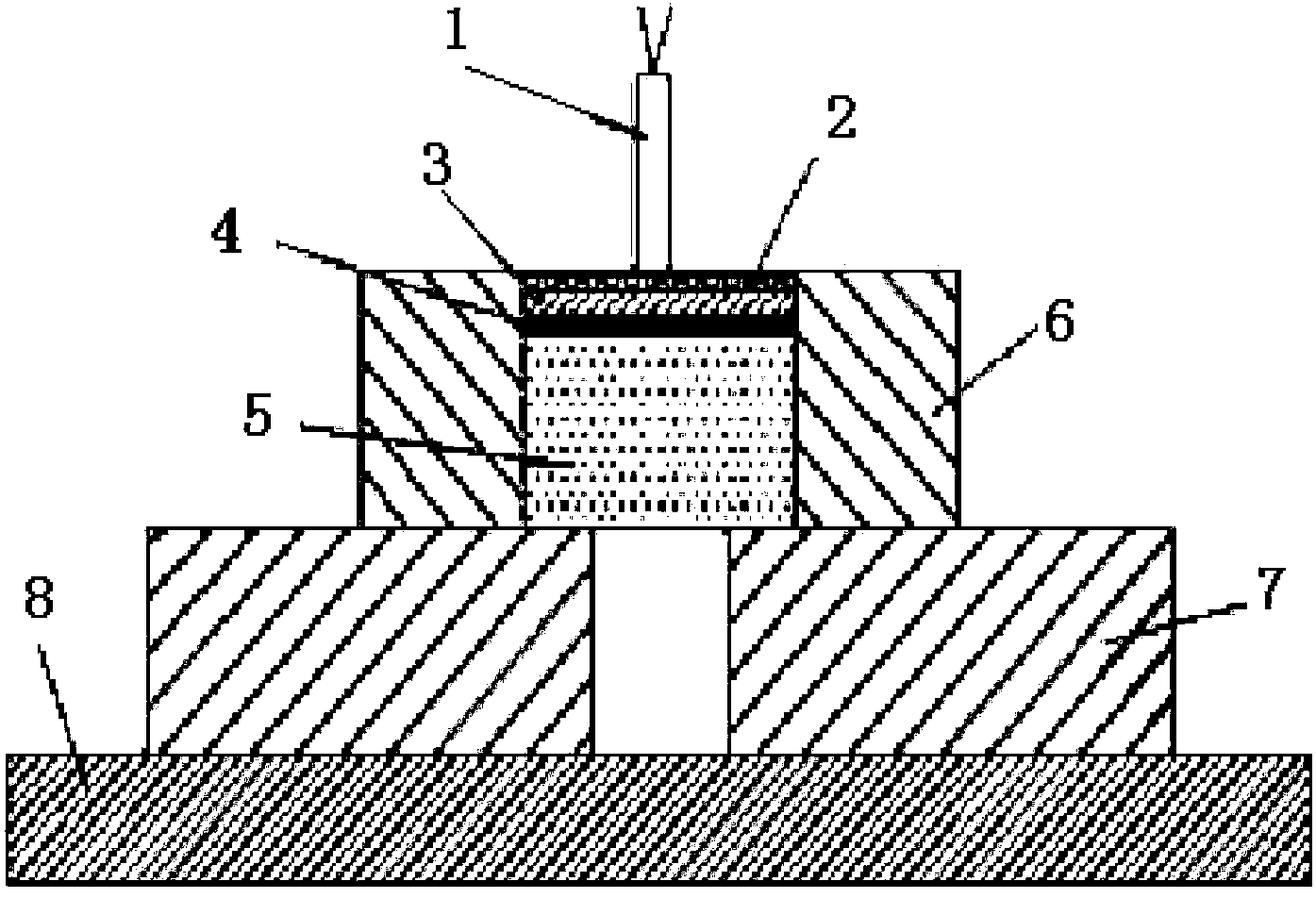

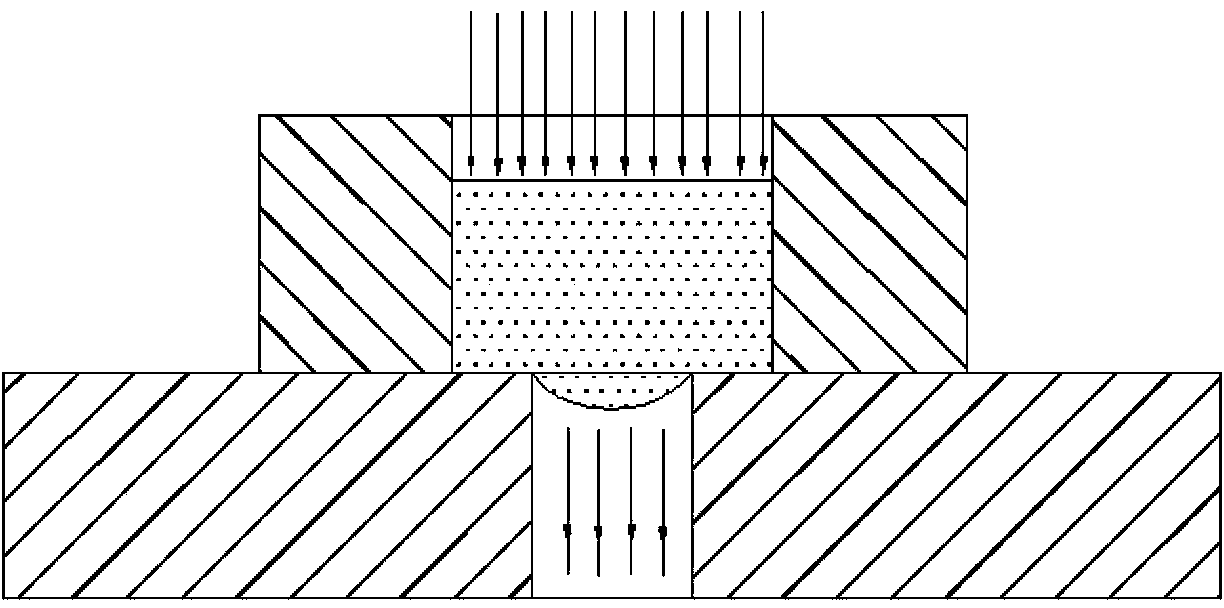

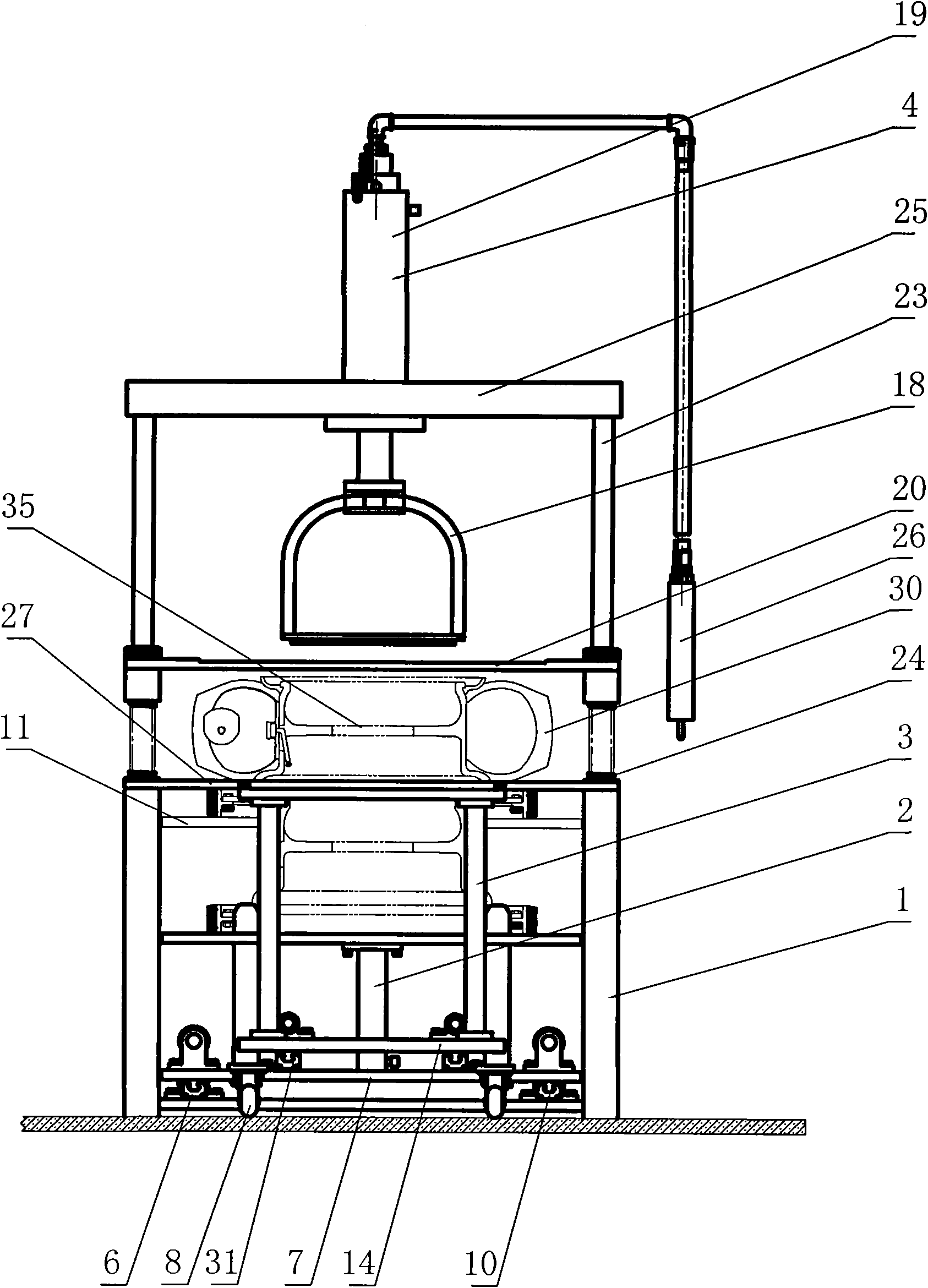

Composite loading test device for explosive blasting impact and shearing

InactiveCN103487337AThe test result is accurateHigh strain rateMaterial strength using steady shearing forcesMaterial strength using single impulsive forceDetonatorEngineering

The invention discloses a composite loading test device for explosive blasting impact and shearing. The composite loading test device comprises a loading source assembly, a shearing implementation assembly and a witness plate, wherein the loading source assembly comprises a detonator, a driving explosive, a buffer layer and a driving steel plate; the driving explosive, the buffer layer and the driving steel plate are circular sheets; the detonator is fixed on the circular driving explosive; the shearing implementation assembly comprises a main explosive, a limiting body and a base; the driving explosive, the buffer layer, the driving steel plate and the main explosive are sequentially arranged in the limiting body from top to bottom; the inner diameter of the base is smaller than the section diameter of the main explosive; the limiting body is arranged on the base; the witness plate is a cylinder; the base is fixed on the witness plate. The composite loading test device has an integrated impact and shearing action, has high strain rate, is used for performing an explosive blasting test caused by the impact and shearing action, and can meet requirements on research and investigation of influence of the integrated impact and shearing action on explosive loading and ignition.

Owner:XIAN MODERN CHEM RES INST

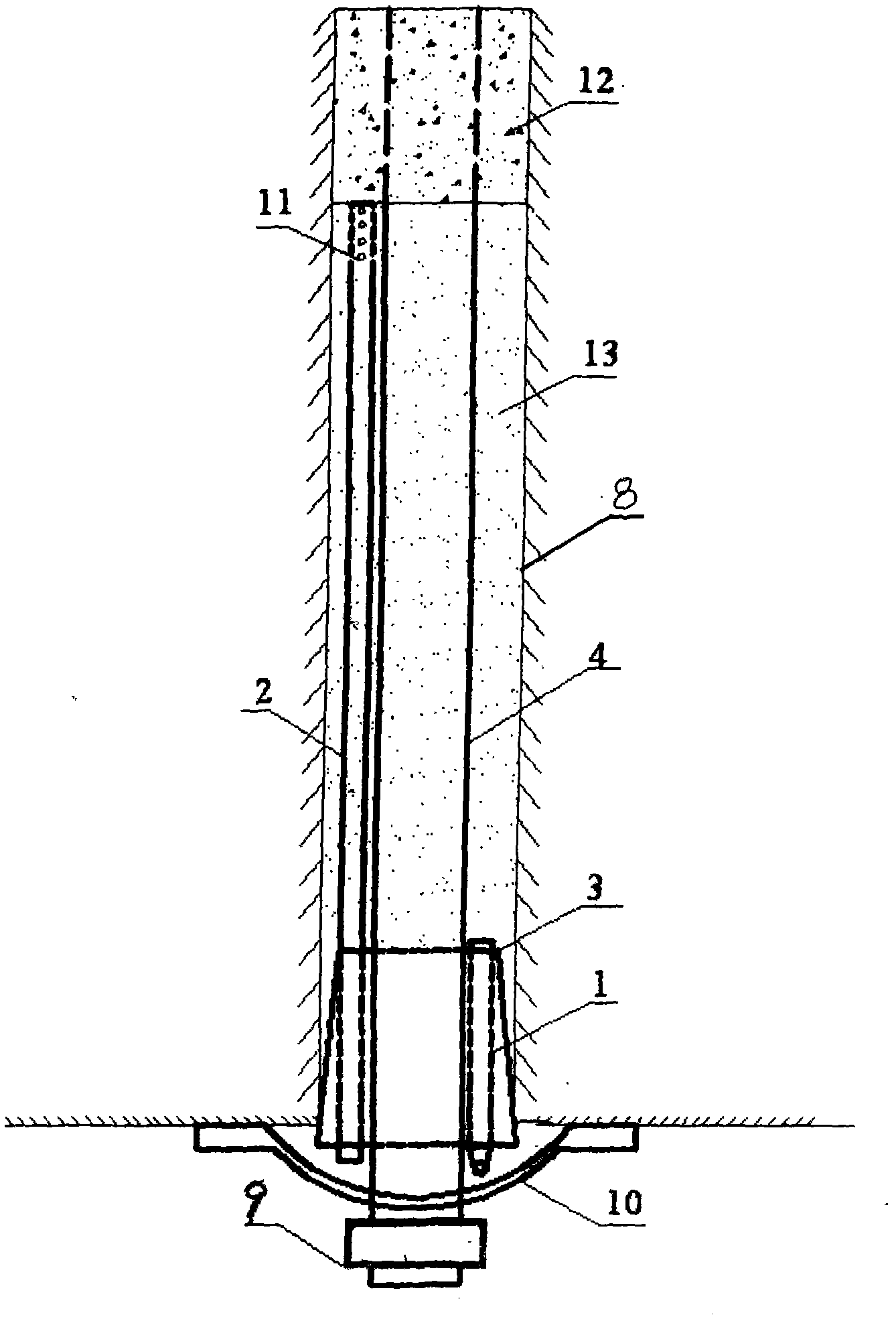

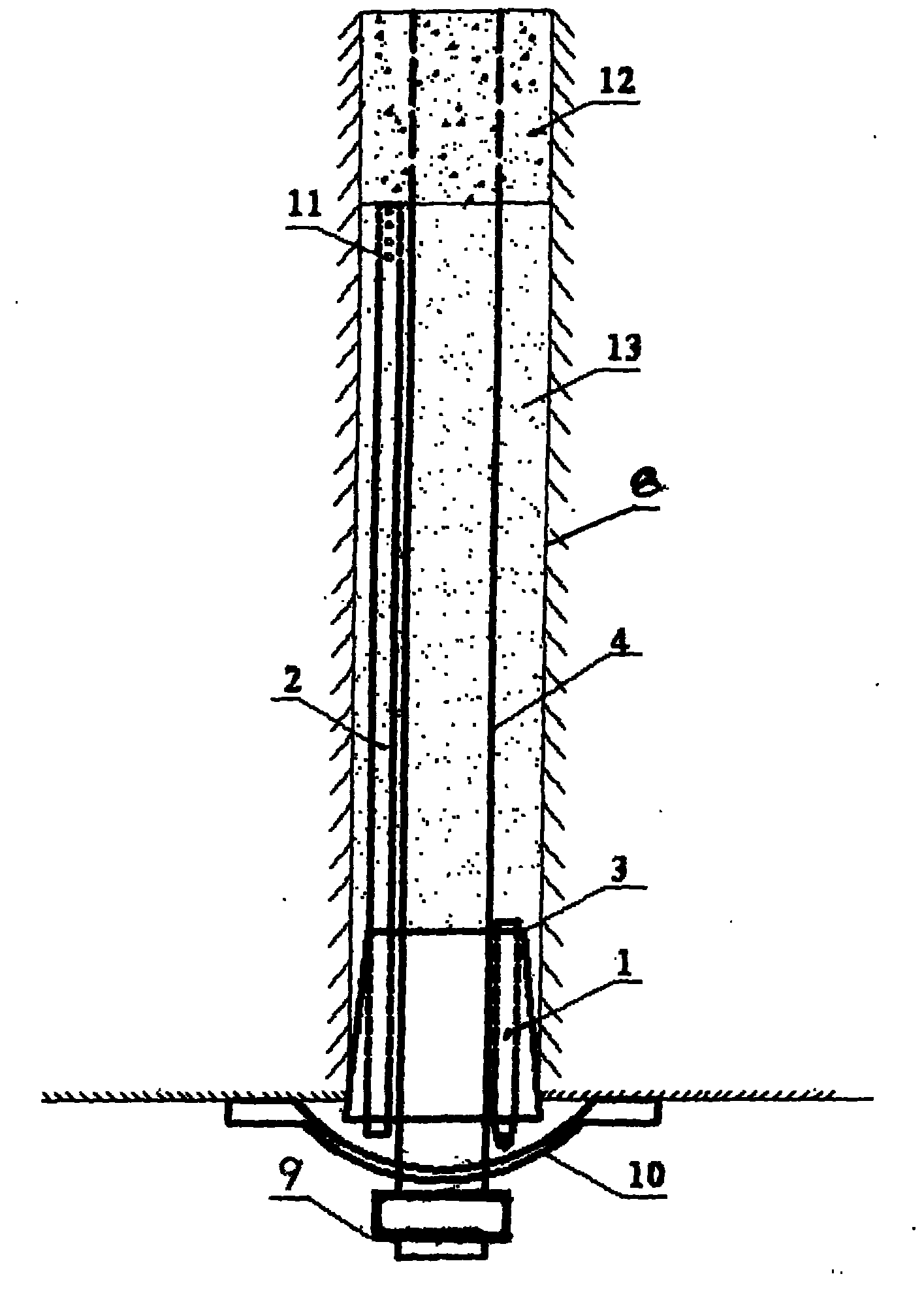

Anchoring structure for liquid-injection corrosion-resistant anchor rod or anchor cable and construction method thereof

InactiveCN102146673ASolve the sealing waterSolve corrosionAnchoring boltsBulkheads/pilesEngineeringSlurry

The invention discloses an anchoring structure for a liquid-injection corrosion-resistant anchor rod or anchor cable and a construction method thereof. The anchoring structure comprises a resin end-anchored anchor rod or anchor cable body arranged in an anchor hole, wherein a grouting-stop plug is also arranged at the opening of the anchor hole; an anchor rod head or an anchor cable head is exposed out of the anchor hole from the plug hole of the grouting-stop plug; the grouting-stop plug is also provided with two plug holes; a liquid injection nozzle is inserted into one plug hole and chemical grout is filled into the anchor hole through the liquid injection nozzle; an exhaust pipe with two open ends is inserted into the other plug hole; a check-valve ball and a return spring are arranged in the liquid injection nozzle; a locking slot connected with grouting equipment is reserved on the peripheral surface of the liquid injection nozzle; the length of the exhaust pipe is equivalent to that of the end-anchored anchor rod or anchor cable; and exhaust holes are reserved on the peripheral surface of the exhaust pipe close to the bottom of a drilled hole. The anchoring structure solves the problem of sealing water and preventing corrosion of anchor rod holes at the positions such as an arch part and the like, not only can serve as permanent support, but also can serve as temporary support.

Owner:SHANDONG UNIV OF SCI & TECH

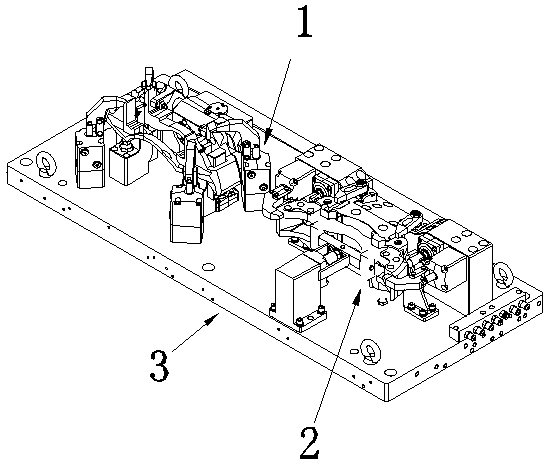

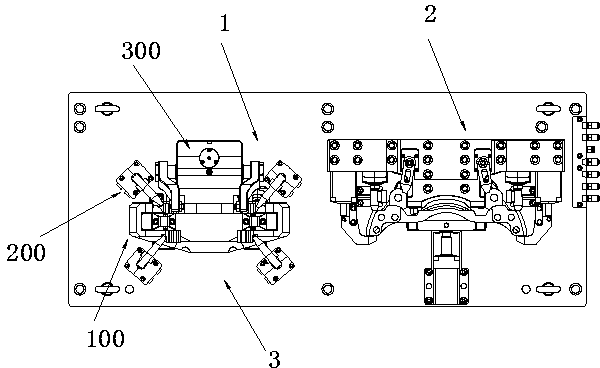

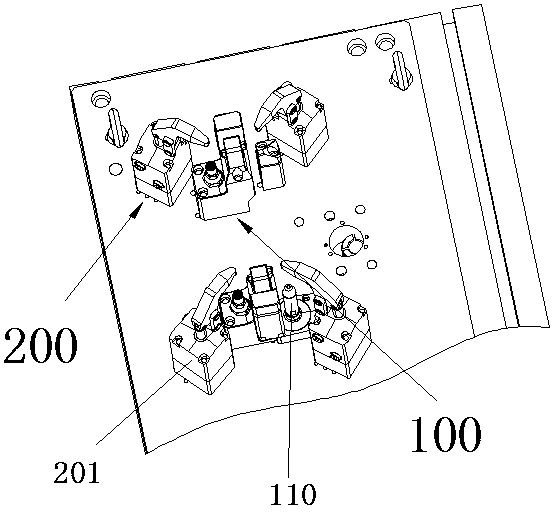

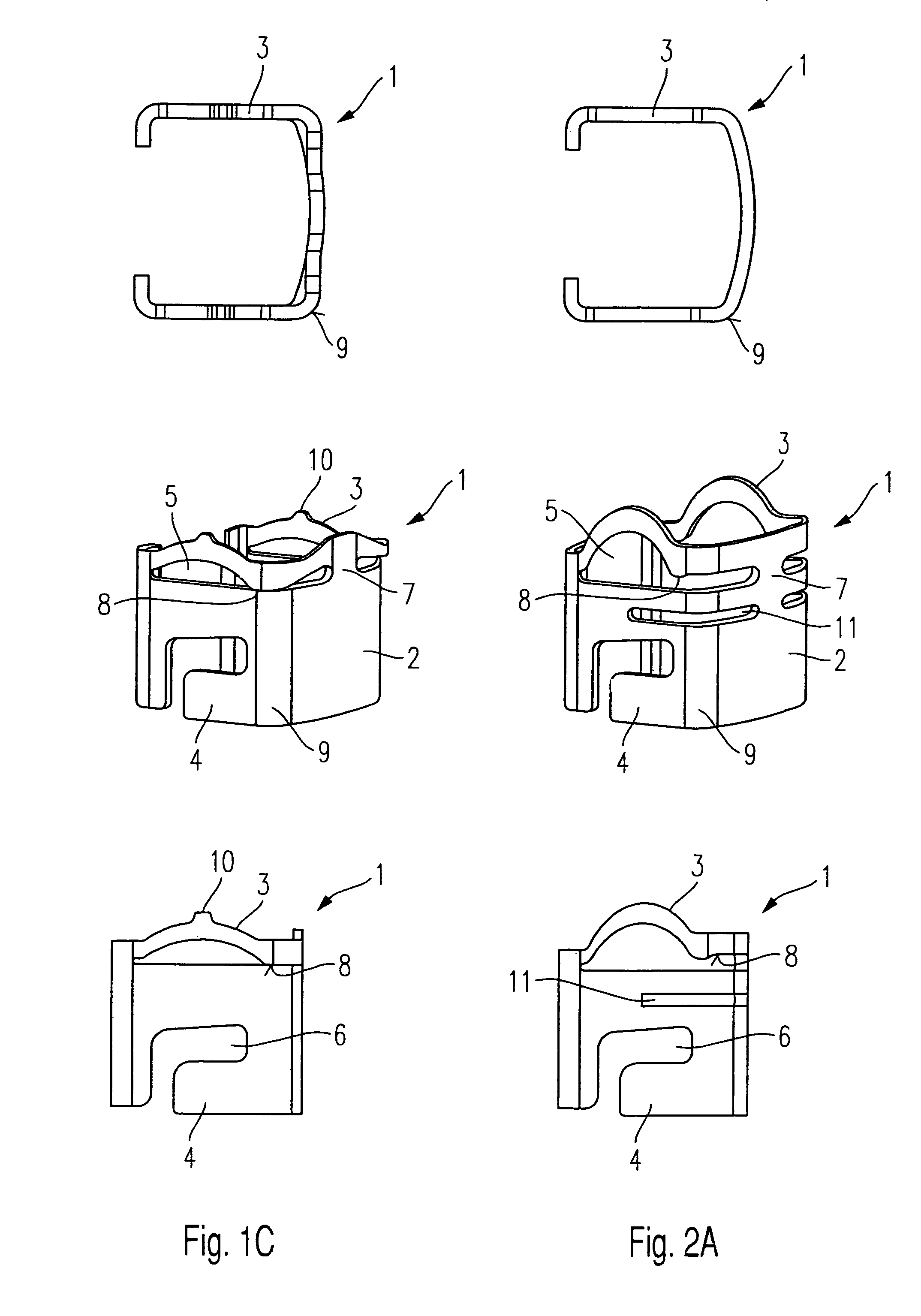

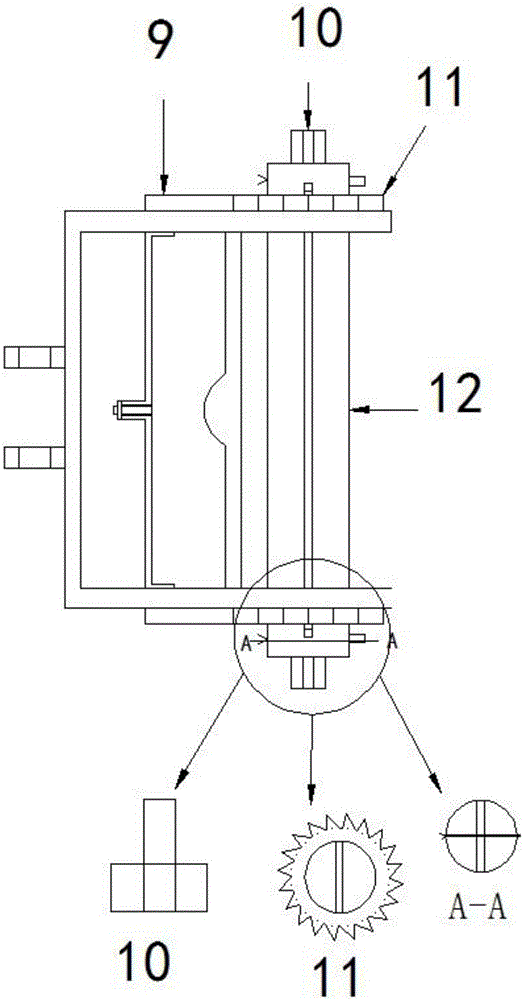

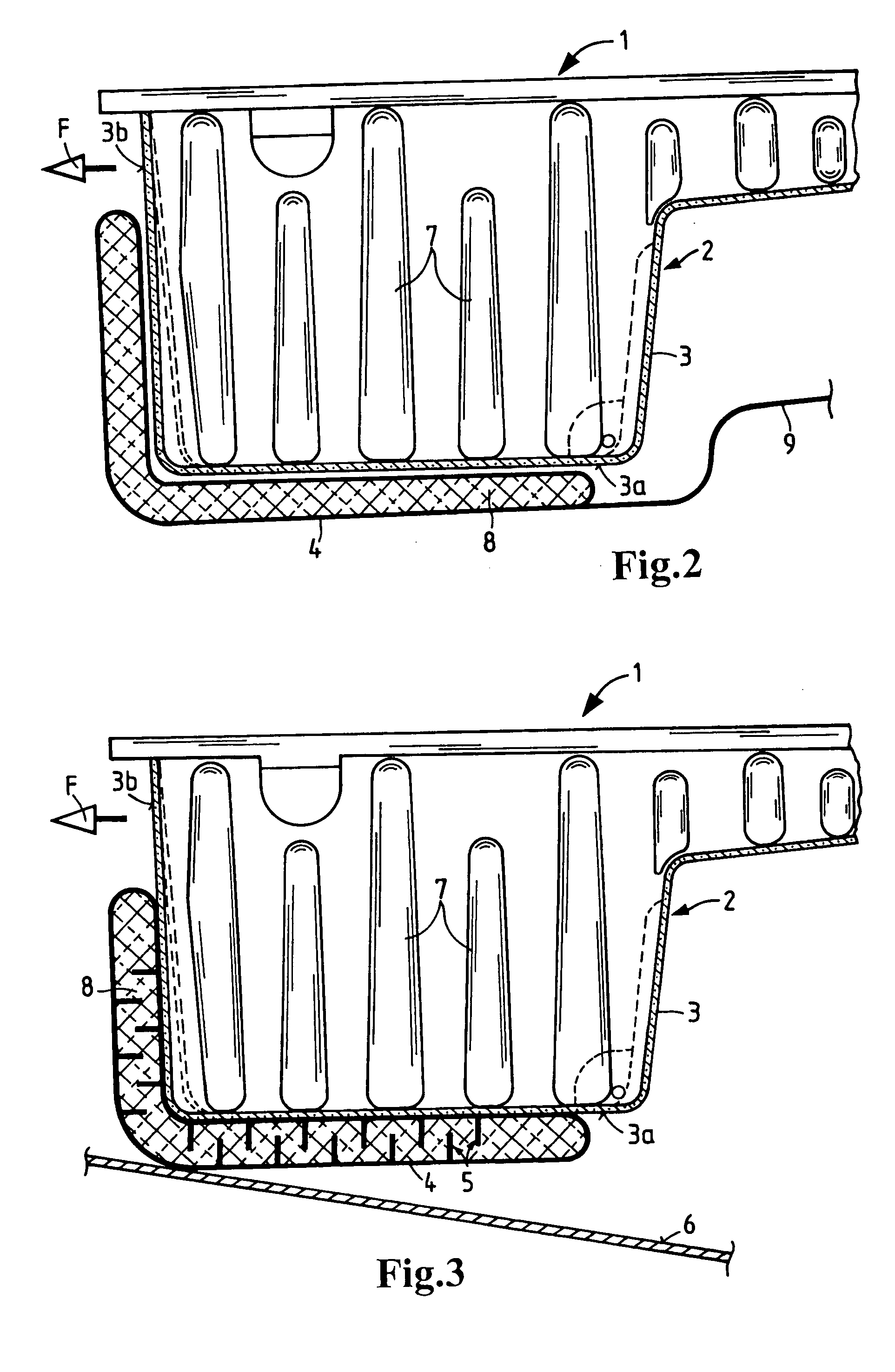

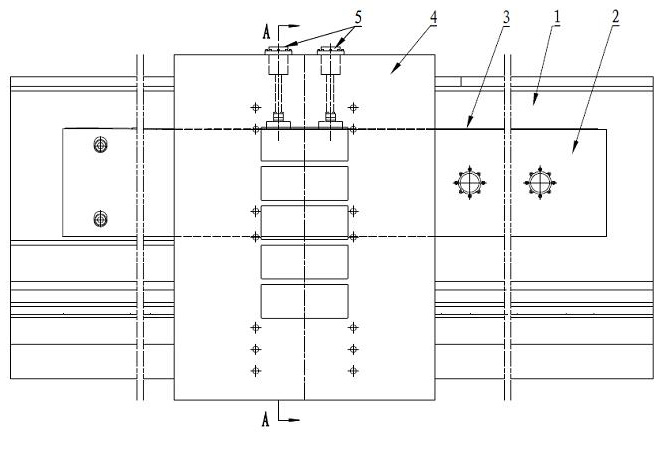

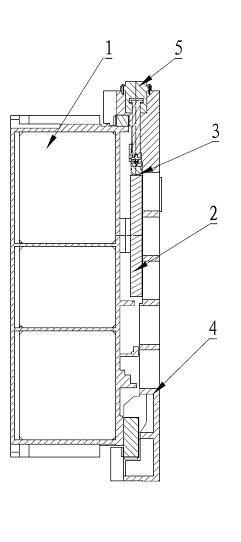

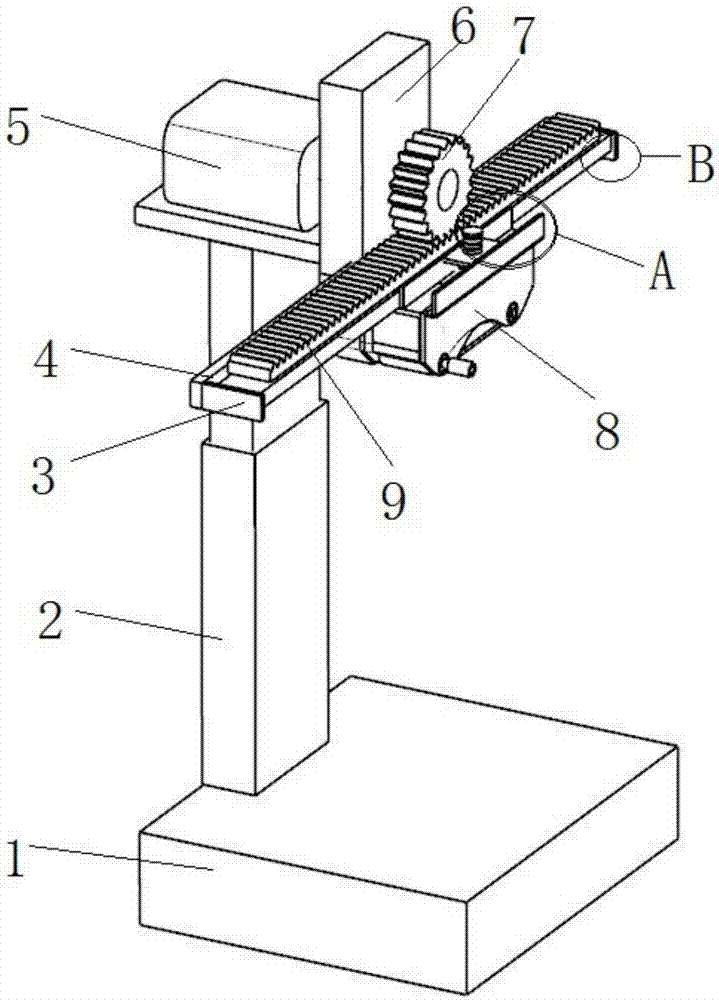

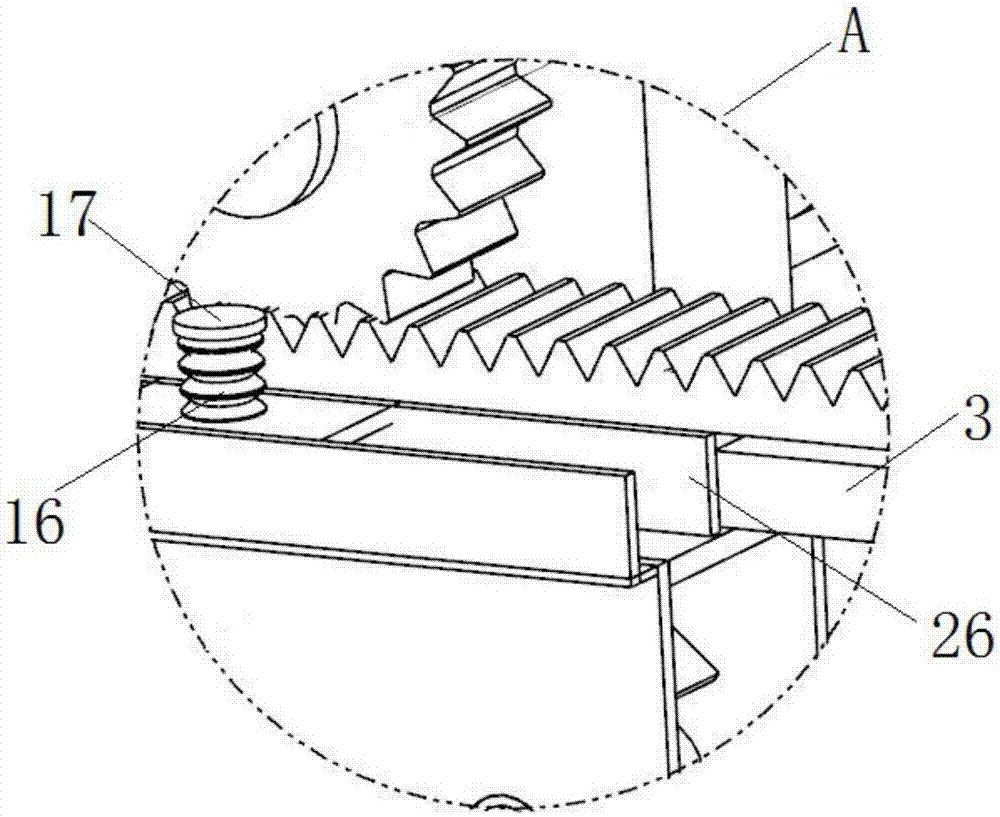

Fixture used for milling and boring support

ActiveCN103862309AHigh precisionUniform force distributionWork clamping meansPositioning apparatusWork supportDouble row

The invention discloses a fixture used for milling and boring a support. The fixture comprises a station I fixture body, a station II fixture body and a bottom plate, wherein the station I fixture body comprises a first positioning mechanism, a first clamping mechanism and a center positioning mechanism for strutting a workpiece outwards; the center positioning mechanism comprises a supporting seat, two pressing plates I, an angle pole, a guide screw and a driving device, wherein the two pressing plates I are symmetrically arranged at both ends of the supporting seat; the driving device comprises a gear mechanism and a driving oil cylinder; the gear mechanism comprises a double-row rack, gears II and a single-row rack, wherein the gears II are respectively meshed with the double-row rack, and the single-row rack is meshed with the gear II; one end of the angle pole is connected with the pressing plates I; the other end of the angle pole is connected with the single-row rack. According to the fixture disclosed by the invention, clamping can be performed rapidly, and is steady; the work support is not easy to deform, and therefore, the machining precision is improved; moreover, when the support of a symmetrical structure is milled, the center of the support can be rapidly and accurately positioned; moreover, the fixture can be suitable for volume production.

Owner:杭州钰友精密机械有限公司

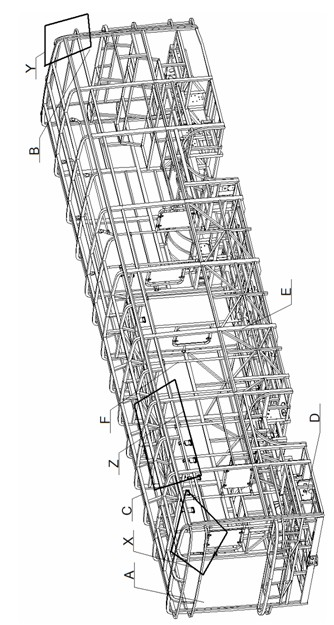

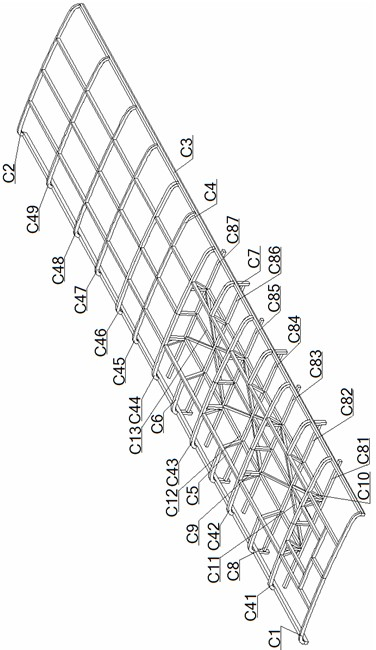

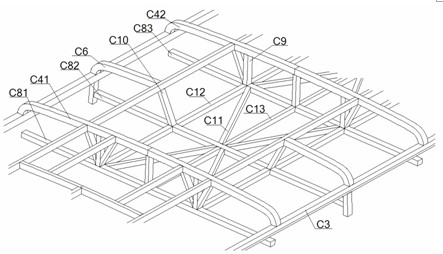

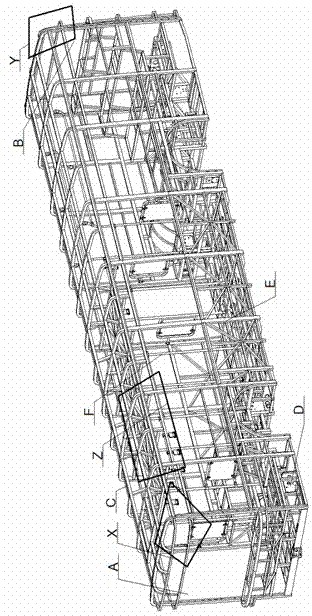

All-bearing car body structure of new-energy urban bus

ActiveCN102582689AImprove uniformityAvoid compressionMonocoque constructionsPassenger vehicle superstructuresNew energyEngineering

An all-bearing car body structure of a new-energy urban bus comprises a front wall assembly, a rear wall assembly, a top cover assembly, a bottom frame assembly, a support upright assembly and a closed stressed ring structure of a whole car body, wherein the closed stressed ring structure is formed by two side wall assemblies, the two ends of the support upright assembly are connected with the top cover assembly and the bottom frame assembly, so that the closed stressed ring structure is formed on the cross section of the car body conveniently, meanwhile, a two-layer frame cavity structure arranged in the top cover assembly not only facilitates the placement of energy storage equipment, but also optimizes the space in a car. According to the design, the passenger space in the urban bus is optimized, and the overall bearing uniformity of the car body structure is improved, moreover, the delivery effect of the local structure is stronger, and the closed stressed ring structure is arranged on the support upright assembly.

Owner:DONGFENG MOTOR CORP HUBEI

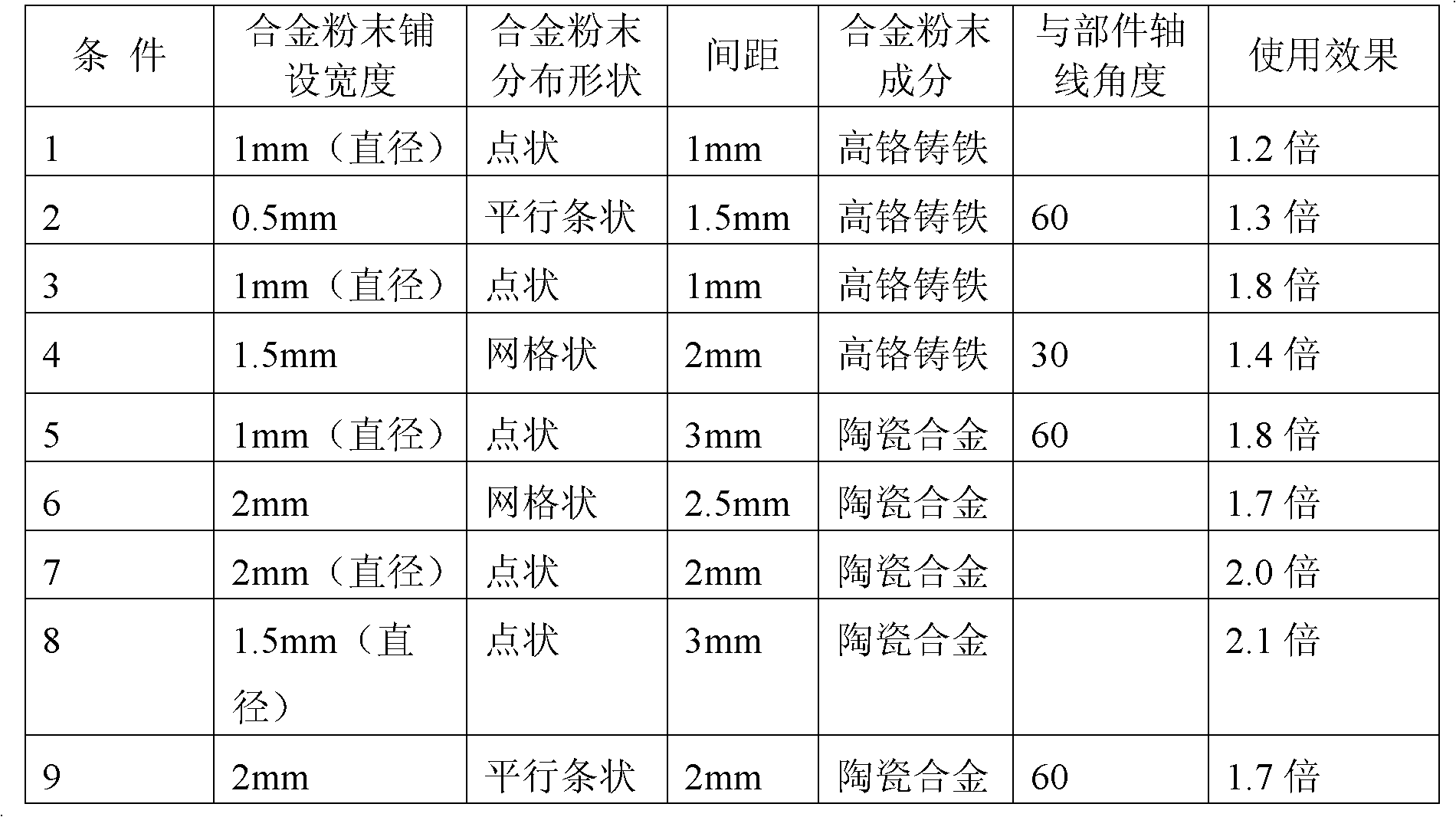

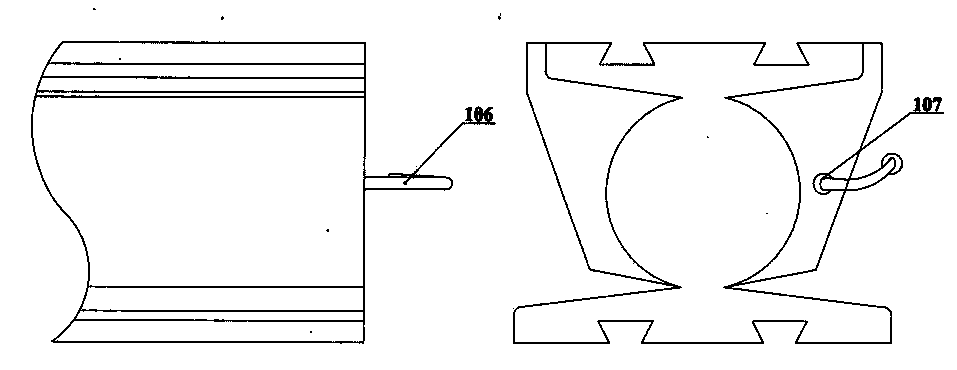

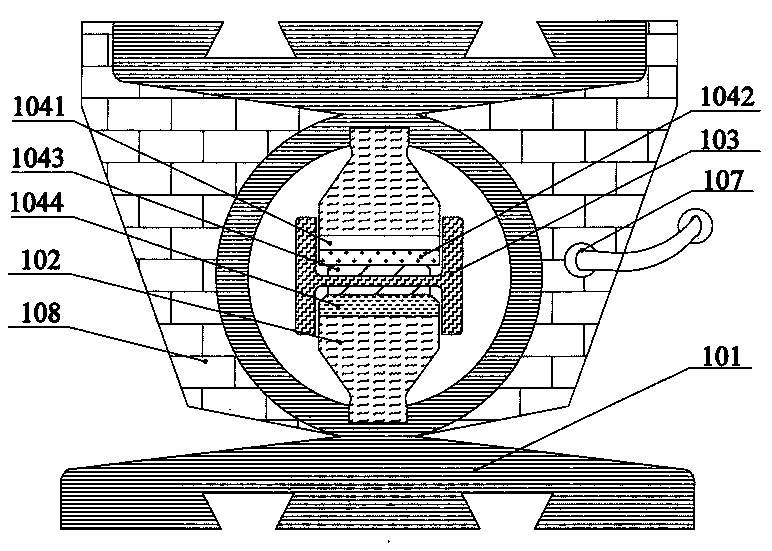

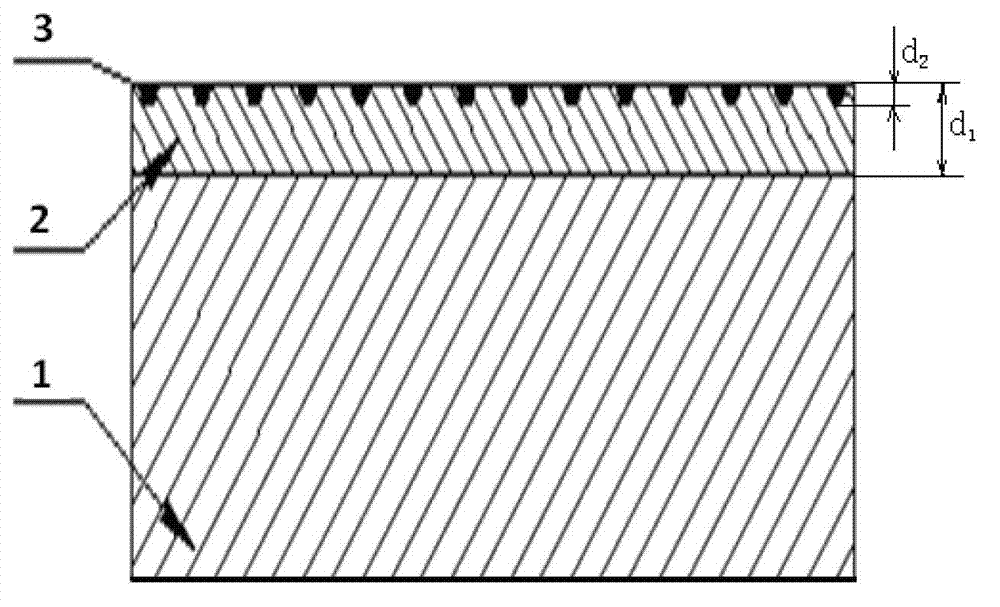

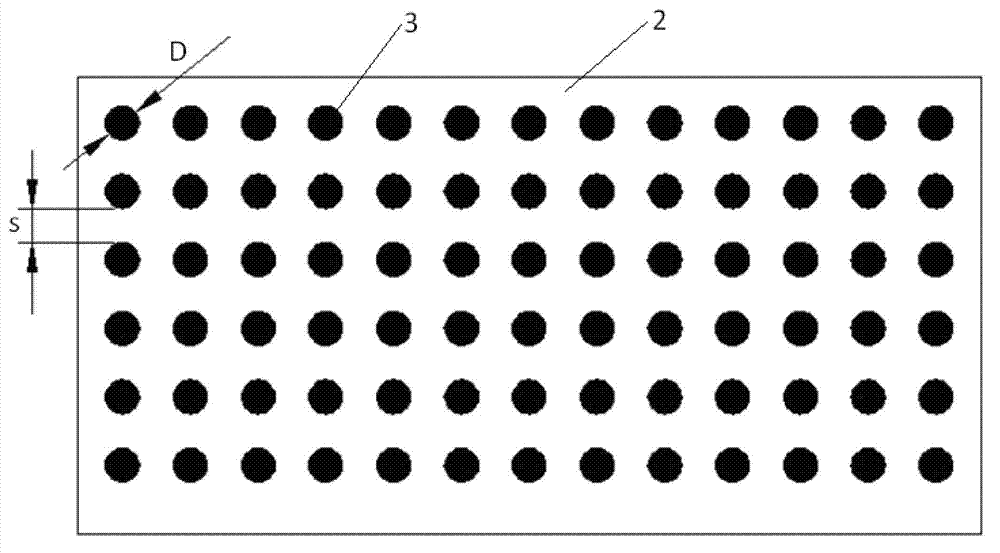

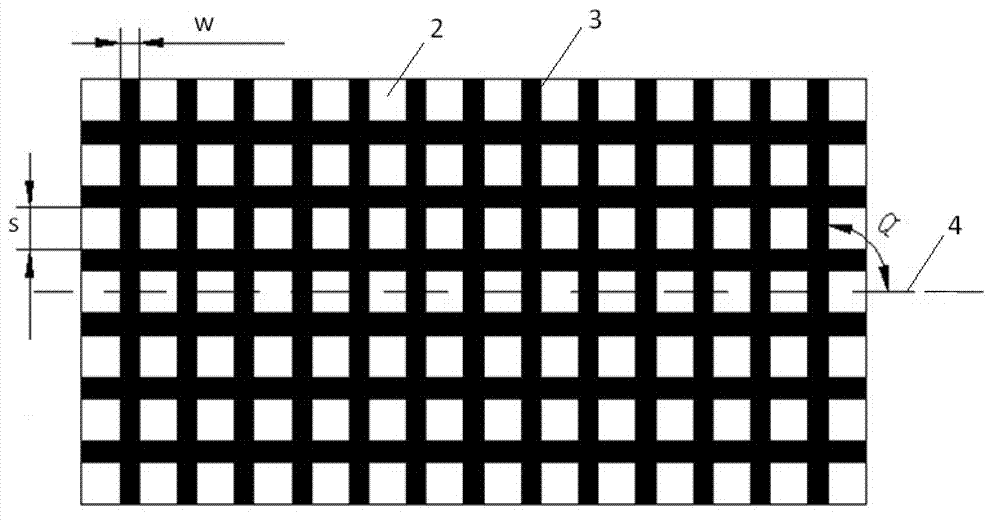

Bionic abrasion-resistant high-reliability guide rail of cast iron rolling machine tool and manufacturing method of bionic abrasion-resistant high-reliability guide rail

InactiveCN102501077AUniform force distributionHigh hardnessMetallic material coating processesLarge fixed membersCouplingCarbide

The invention relates to a bionic abrasion-resistant high-reliability guide rail of a cast iron rolling machine tool and a manufacturing method of the bionic abrasion-resistant high-reliability guide rail. A guide rail is integrated with a base of a cast iron machine tool, high-hardness cylindrical and grid-shaped units which are regularly distributed, have carbide textures and are combined with a guide rail base in a metallurgy manner are arranged on a rolling portion on the surface of the guide rail by the aid of a laser cladding method, and the units and the guide rail base of the machine tool jointly form a bionic coupling area which is provided with hard portions and soft portions at intervals and has a bionic structure. The laser cladding method includes steps of uniformly coating alloy powder on the units; directly irradiating and melting the alloy powder by the aid of laser, and quickly solidifying the melted alloy powder; and obtaining micron-sized carbide, martensite, alloy carbide, WC (wolfram carbide) or TiC which have textures different from those of the base and have hardness meeting HV (Vickers hardness) 630-1150. The bionic abrasion- resistant high-reliability guide rail and the manufacturing method have the advantages that limitation that a rail surface of a cast iron guide rail is low in hardness, cannot realize pressure resistance or abrasion resistance and cannot be used independently is broken through, and shortcomings that a steel guide rail is integrally or partially inlaid on a base of a machine tool in an original mode, production process is complicated, cost is high, and the steel guide rail falls off or is peeled off easily are overcome.

Owner:JILIN UNIV

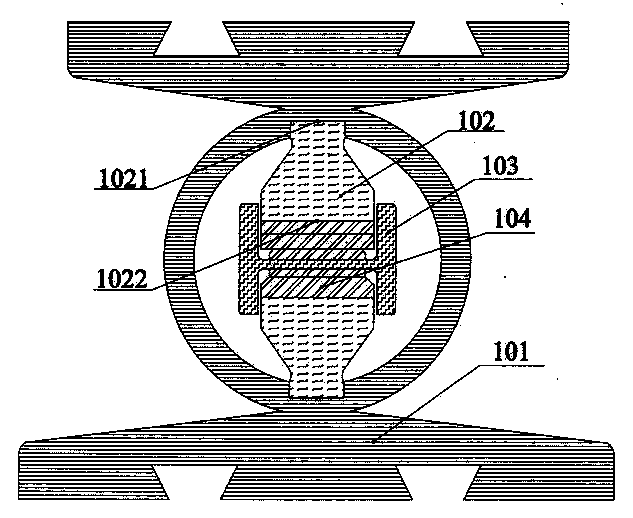

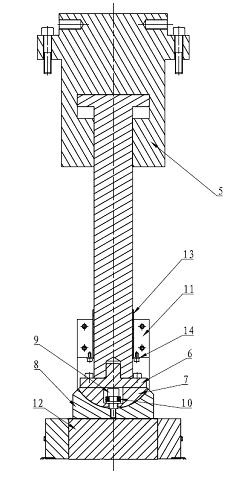

I-beam type vehicle dynamic weighing sensor

InactiveCN104374459AUniform force distributionAccurate weighing resultsWeighing apparatus using elastically-deformable membersOscillations damping for weighingInsulation resistanceVehicle dynamics

The invention relates to the technical field of sensors and provides an I-beam type vehicle dynamic weighing sensor. The I-beam type vehicle dynamic weighing sensor comprises an I-beam type elastic body, a measurement unit, power transmission blocks and an insulating protective sleeve, wherein a through cavity is formed in the I-beam type elastic body, the measurement unit and the power transmission blocks are arranged in the cavity, the measurement unit can be accommodated between the power transmission blocks in a pre-tightened mode, the measurement unit comprises an upper electrode, piezoelectric materials and a lower electrode from top to bottom in sequence, the horizontal surface of the insulating protective sleeve is arranged between the upper electrode and the lower electrode, through holes are formed in the horizontal surface of the insulating protective sleeve at equal intervals, the shape of each through hole is matched with that of each piezoelectric material, the insulating protective sleeve is made from an insulating material, and the piezoelectric materials are placed in the through holes. By the adoption of the I-beam type vehicle dynamic weighing sensor, insulation resistance is increased, a measurement result is more accurate, the pressure acting on the measurement unit is reduced, the piezoelectric materials are protected against damage caused by pressure, and service life is prolonged.

Owner:SICHUAN STONE EDGE POLYTRON TECH INC

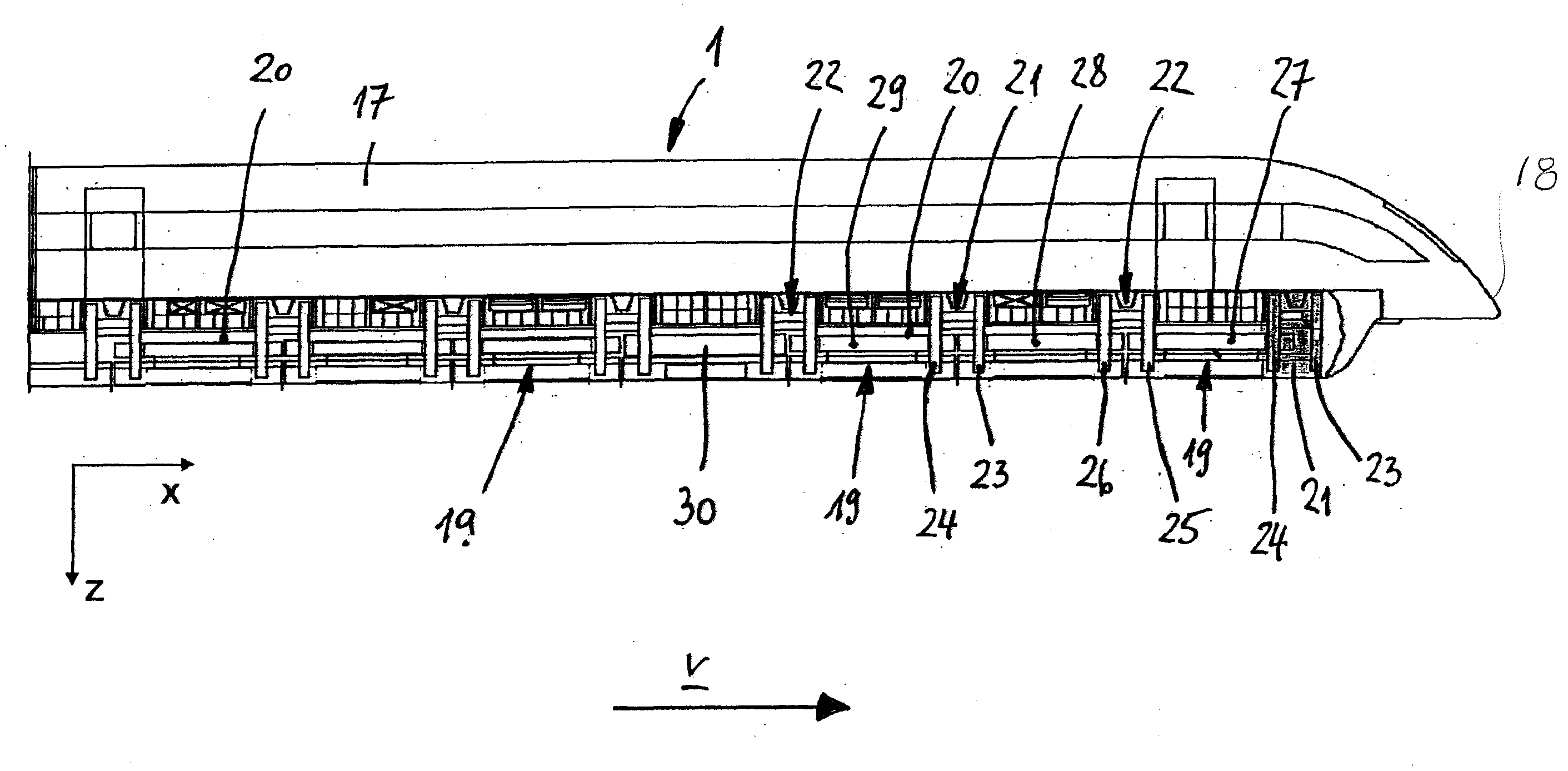

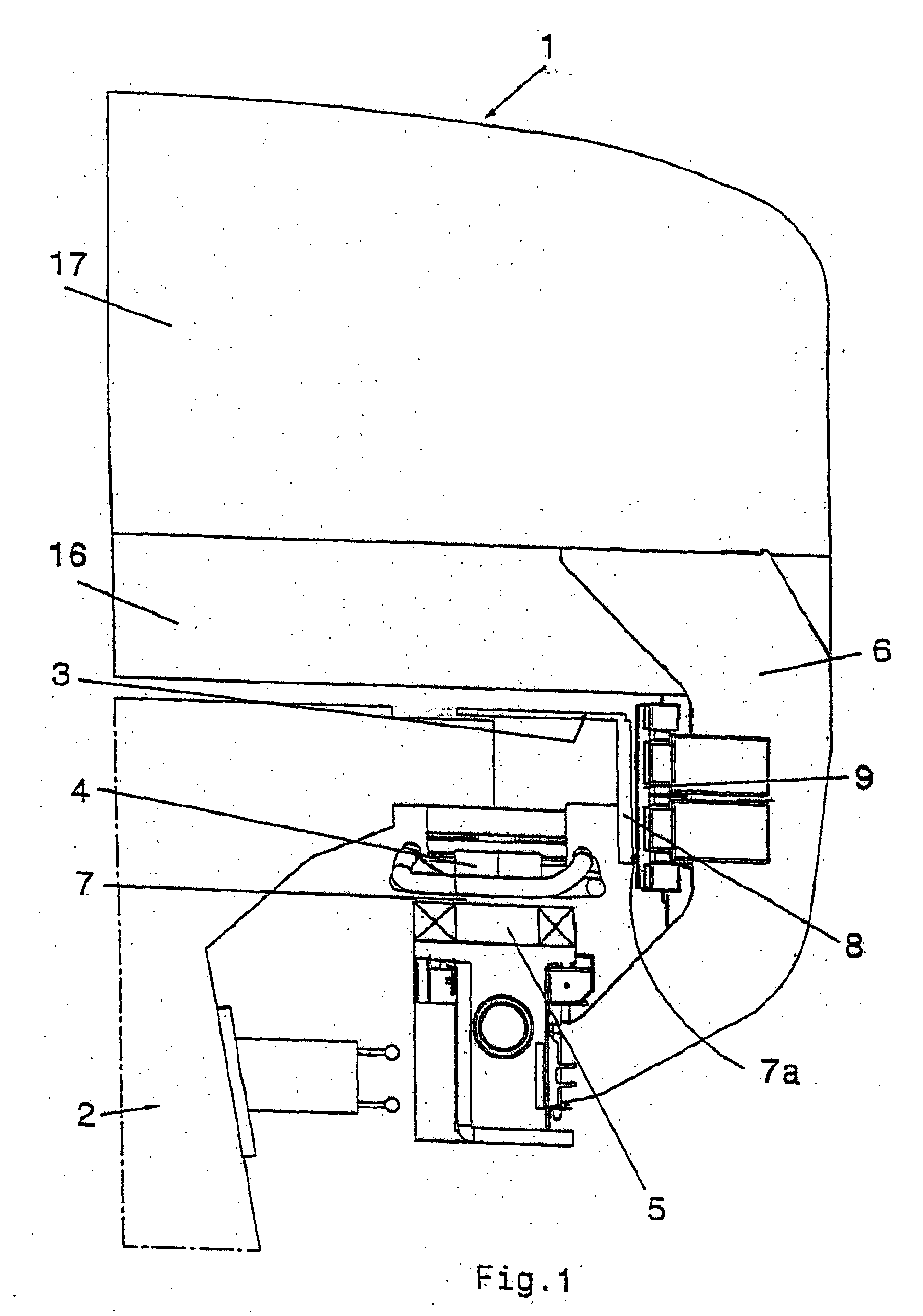

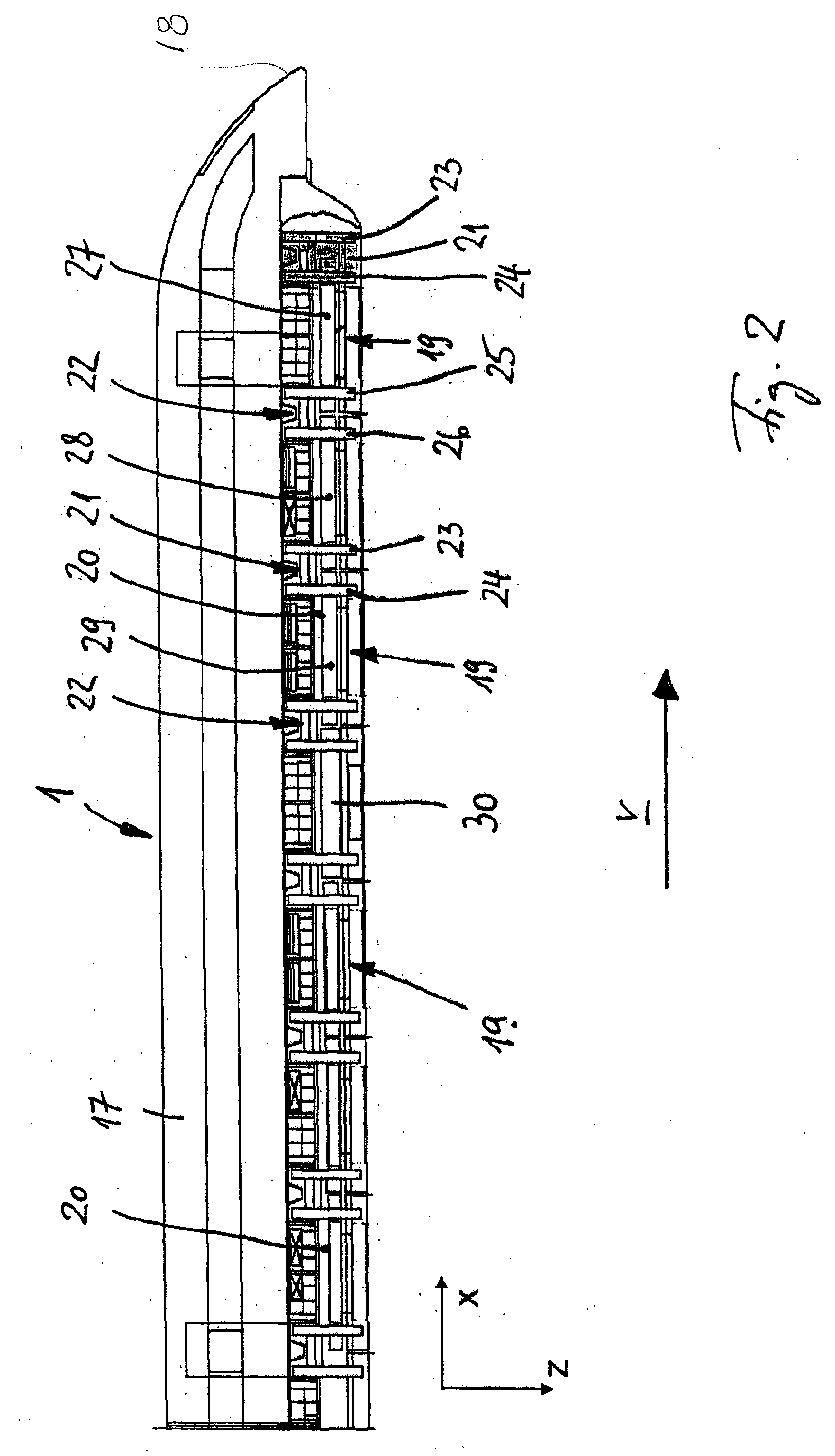

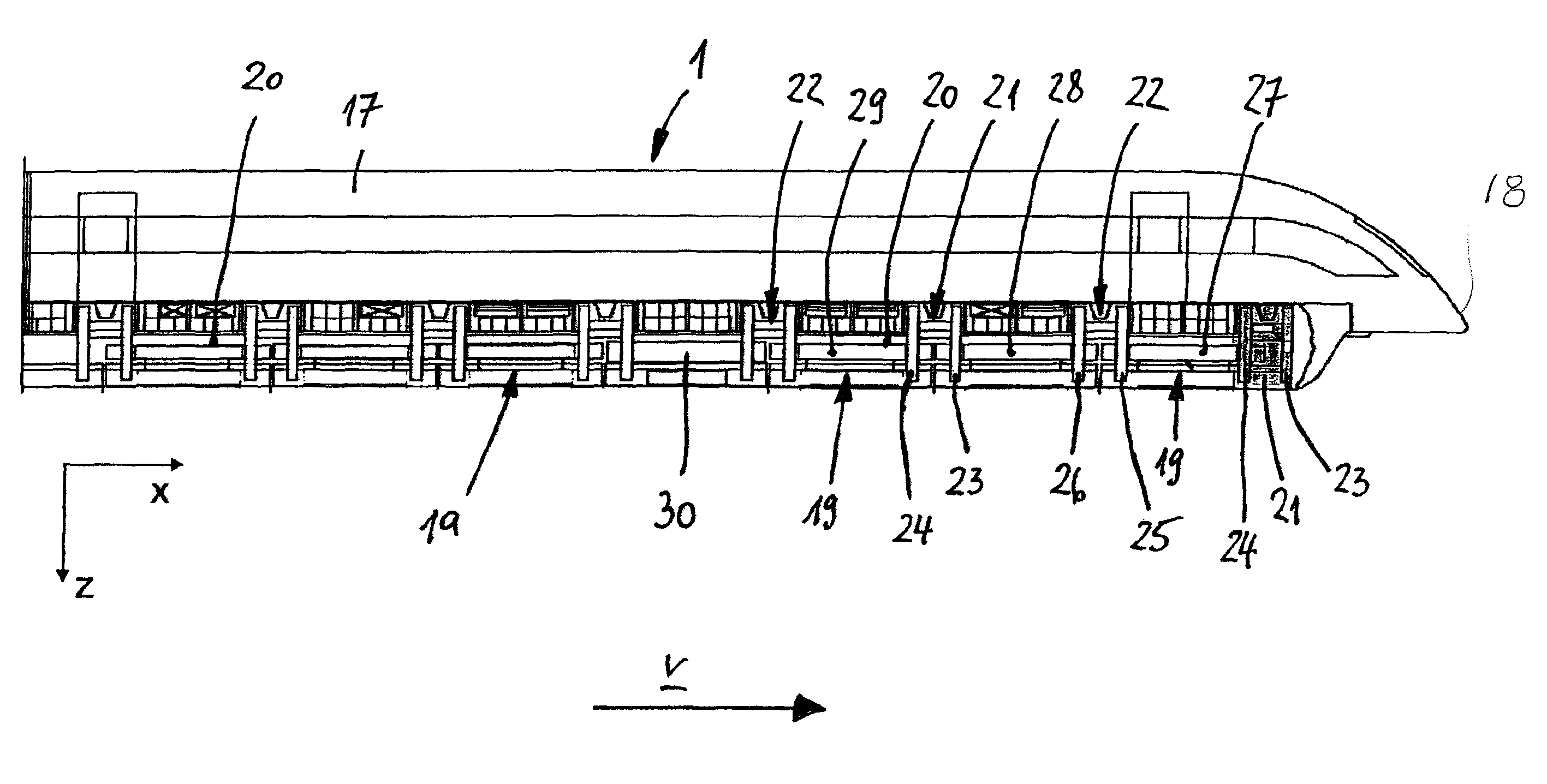

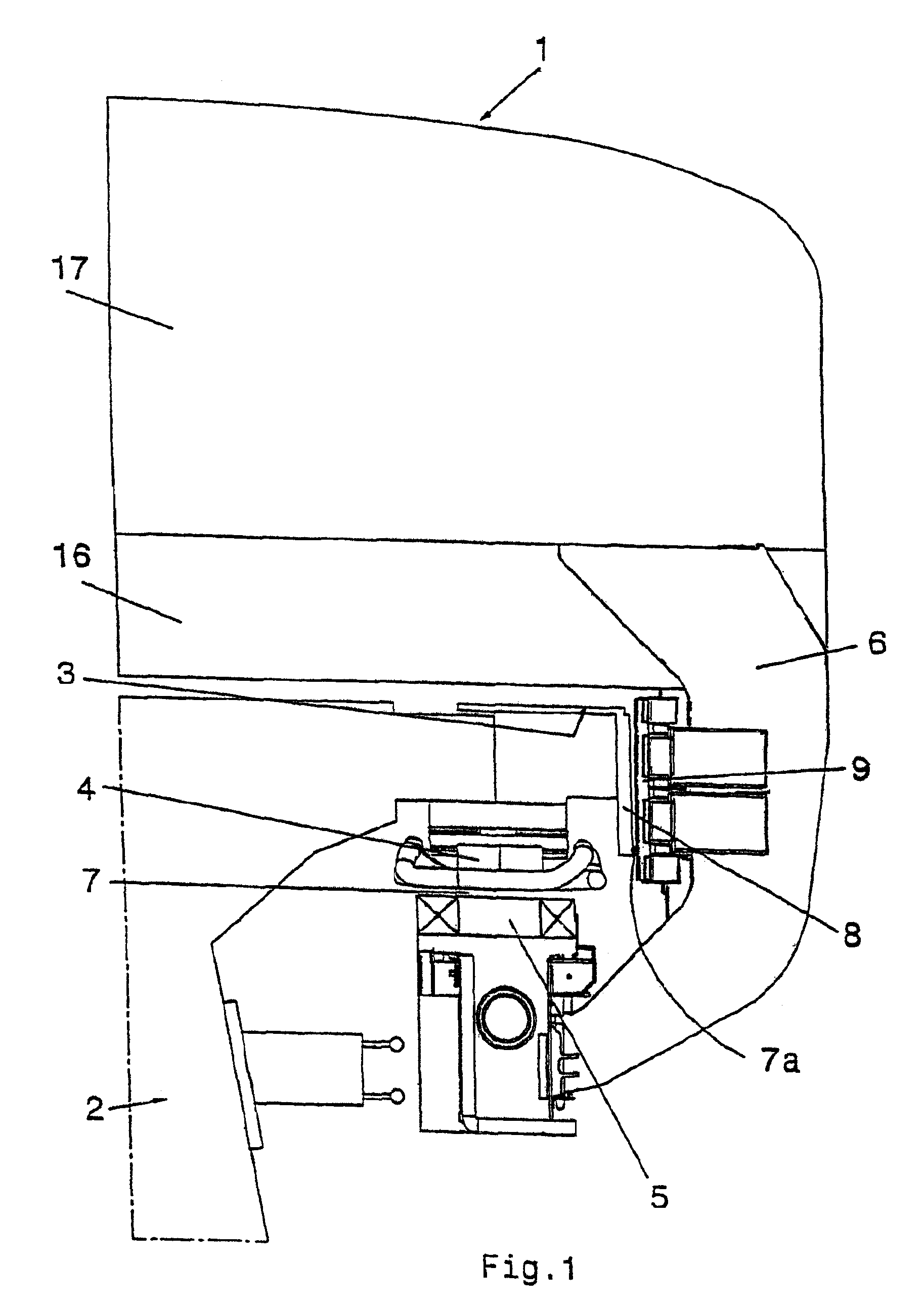

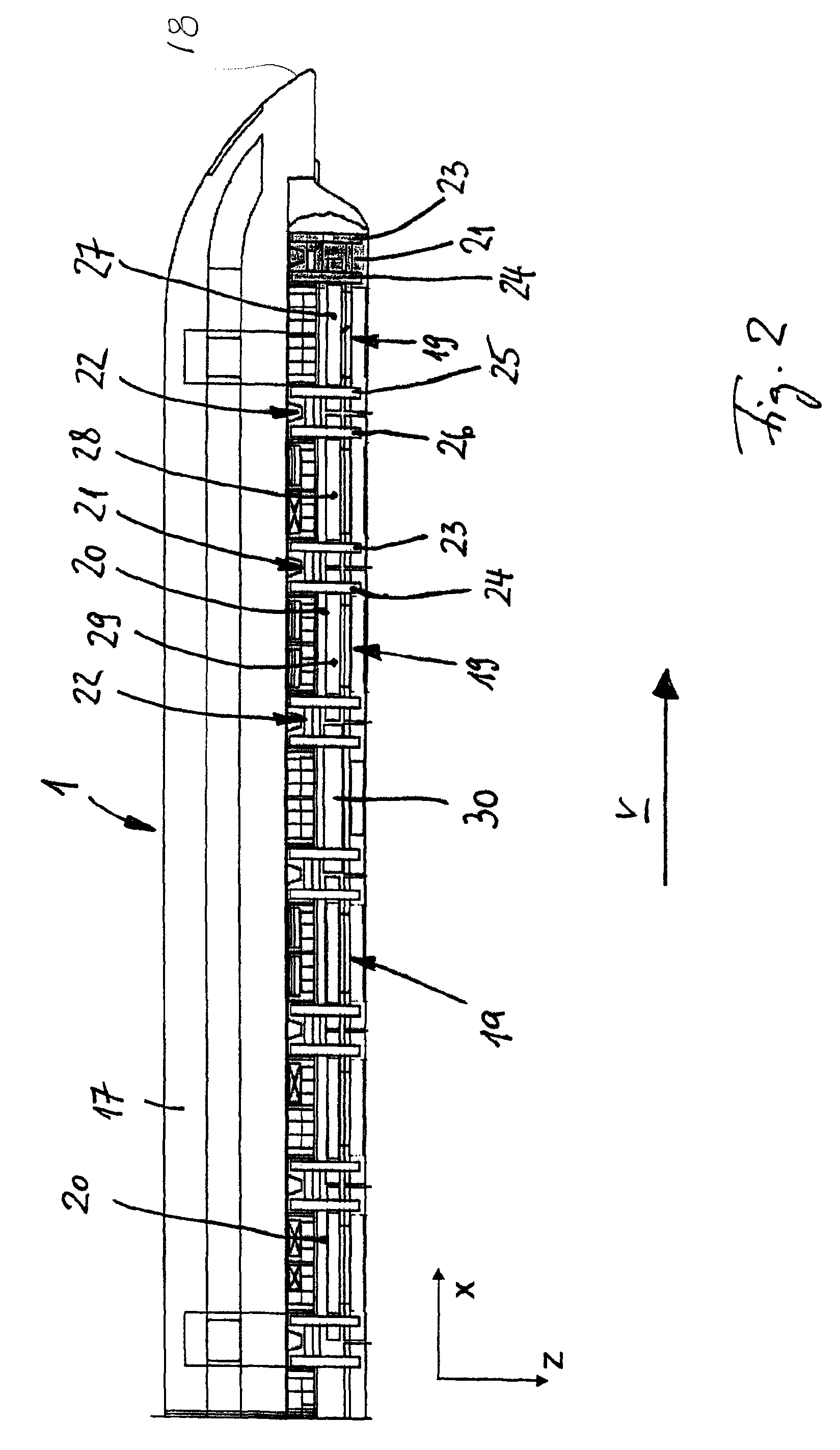

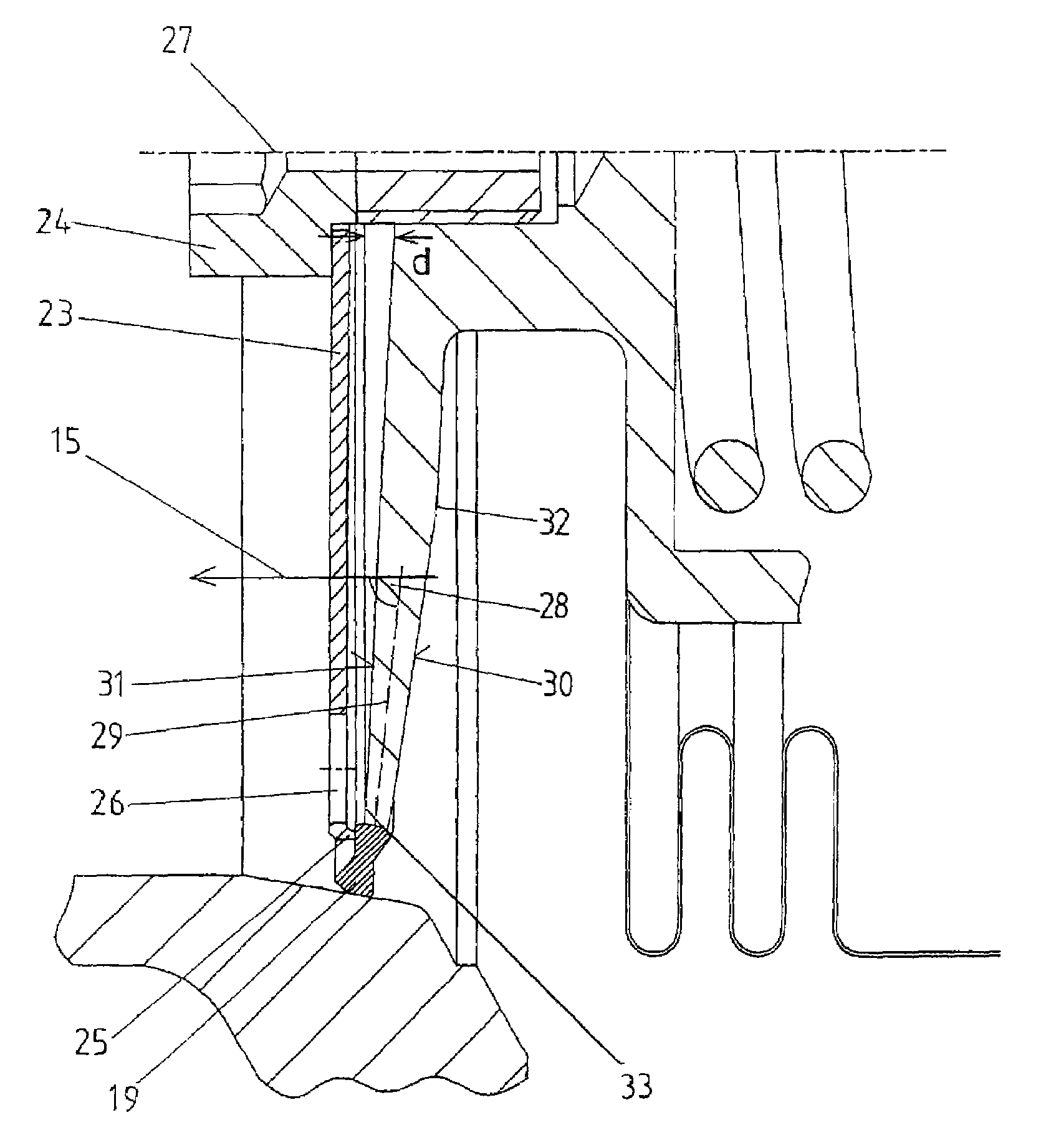

Magnetic levitation vehicle with at least one magnetic system

InactiveUS20100031846A1Uniform force introductionSimpler andRailway vehiclesElectric propulsionMagnetic polesEngineering

A magnetic levitation vehicle has at least one magnetic arrangement (27). The magnetic arrangement (27) contains a plurality of magnetic poles (27a . . . 27n) which are arranged one behind the other in the direction of travel and comprise windings (33) associated therewith. The magnetic levitation vehicle is also provided with a circuit for supplying the windings (33) with a direct current, said circuit containing switches for selectively switching the magnetic arrangement between a guiding function and / or a braking function.

Owner:THYSSENKRUPP TRANSRAPID

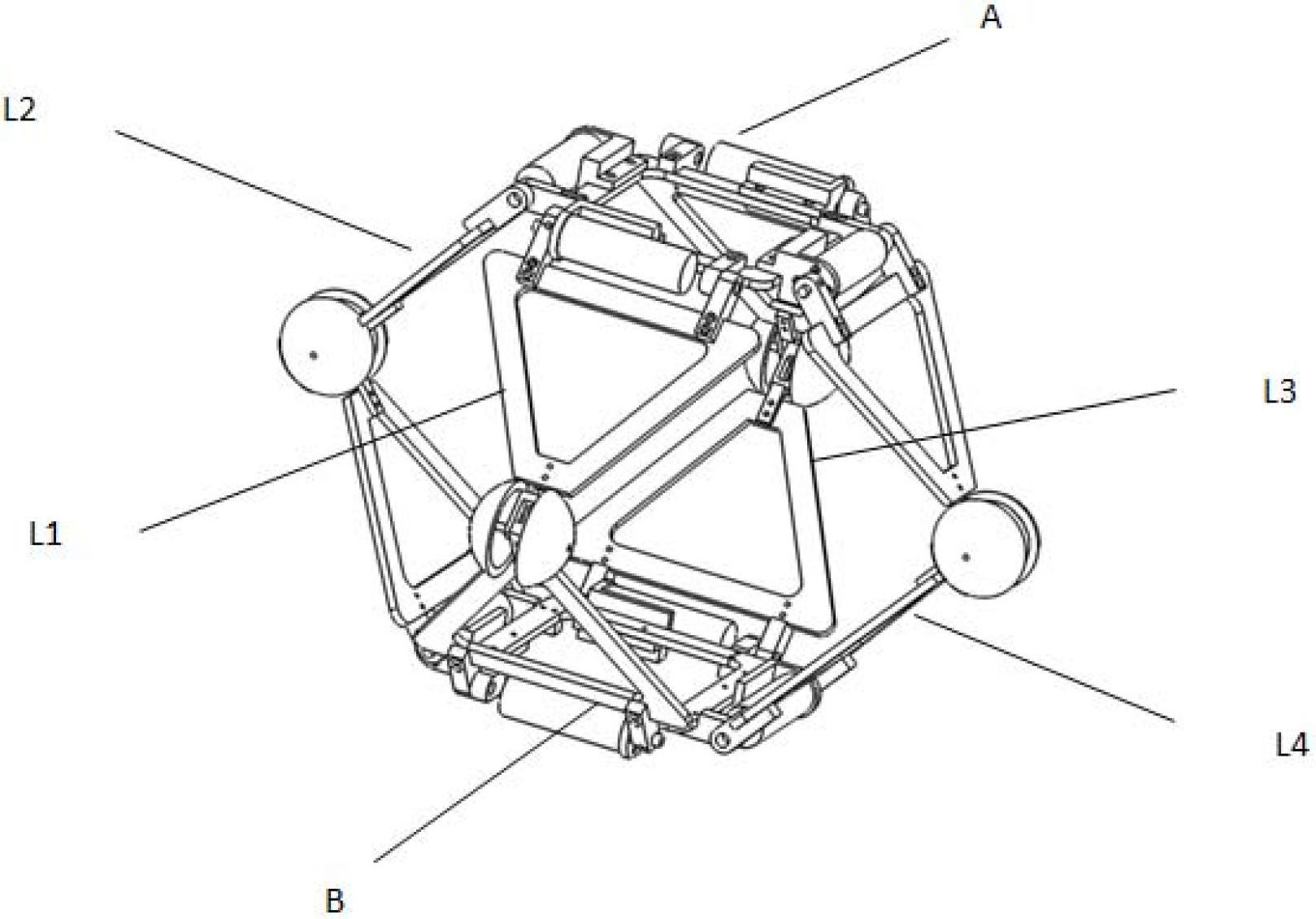

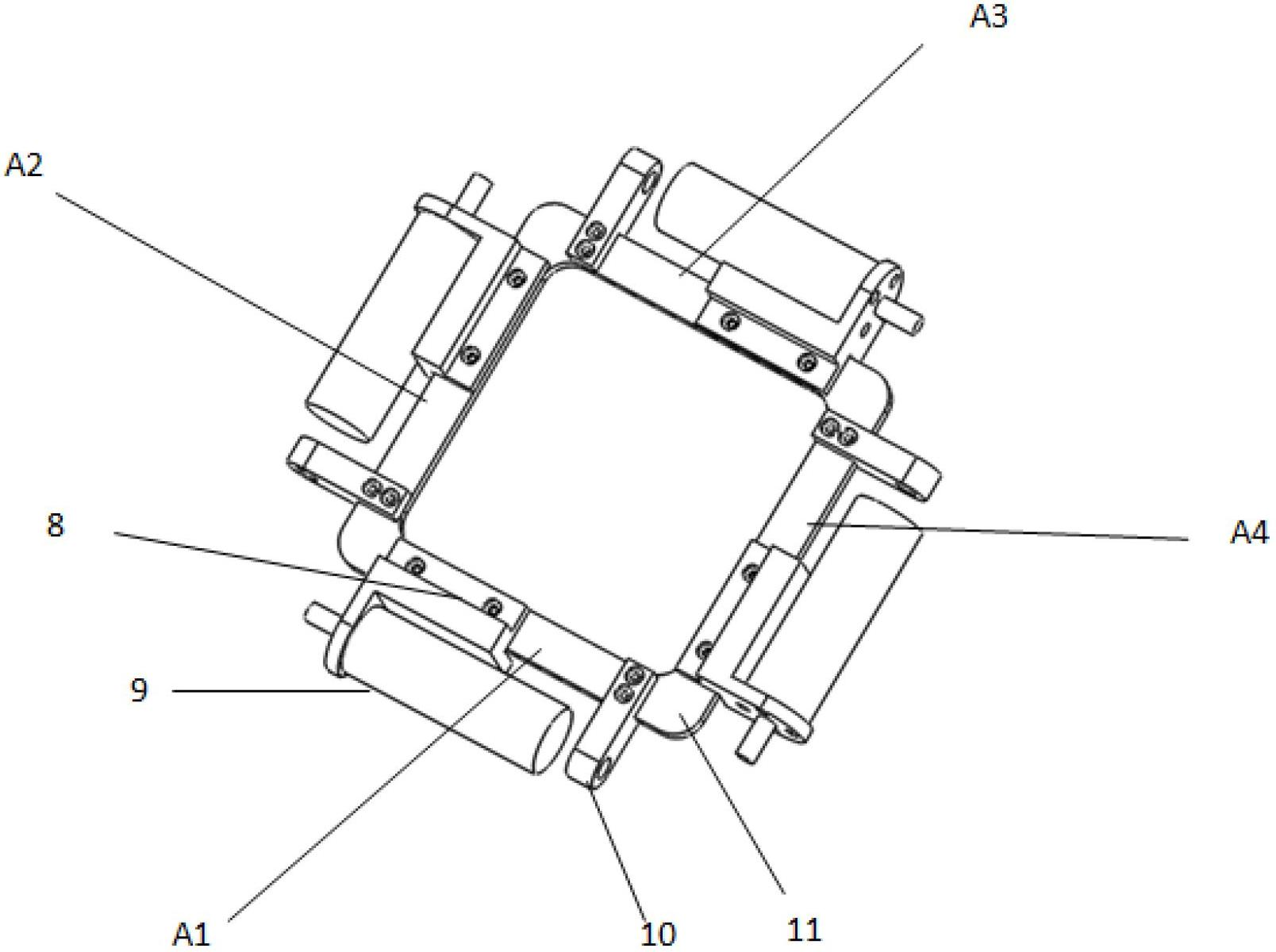

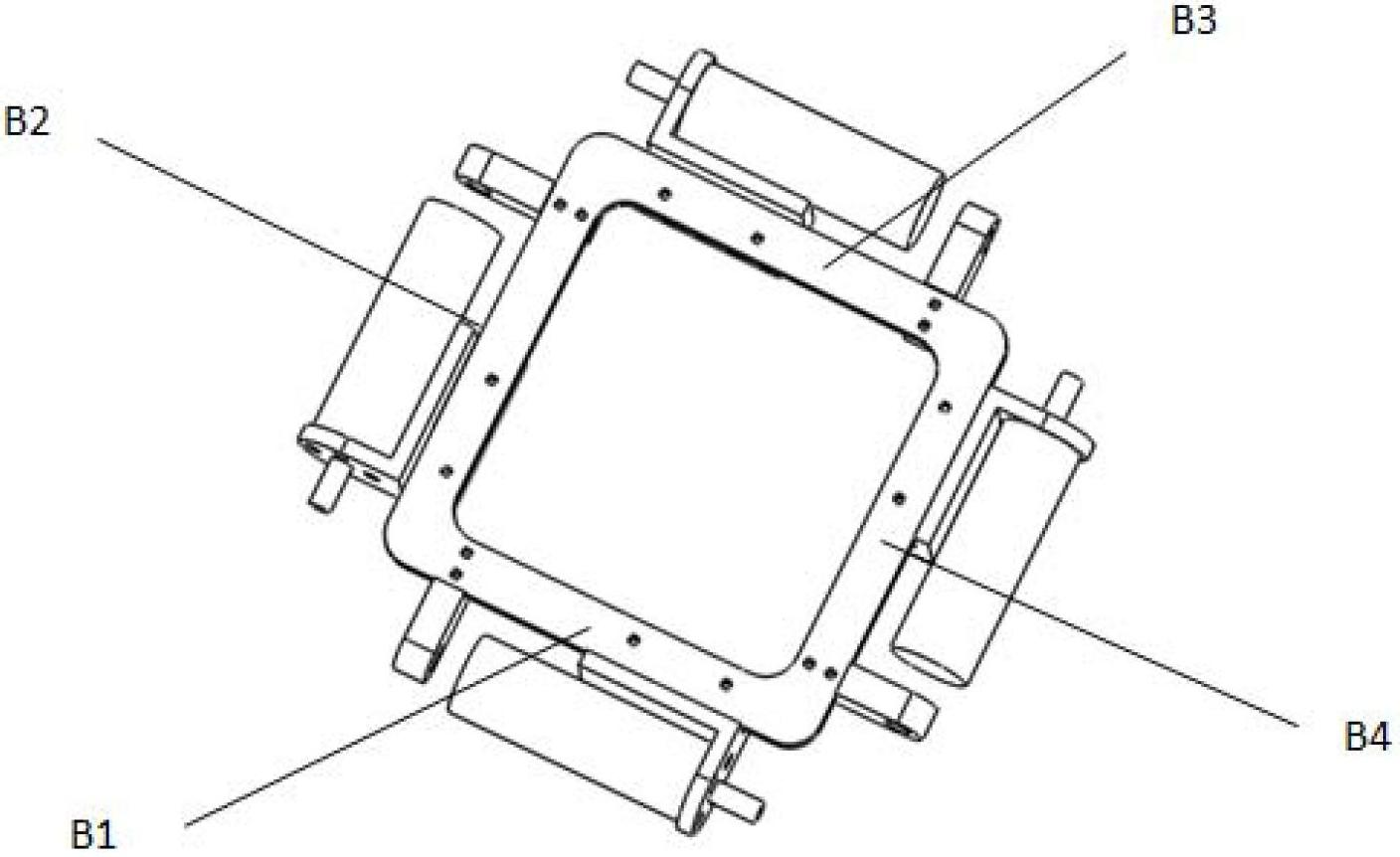

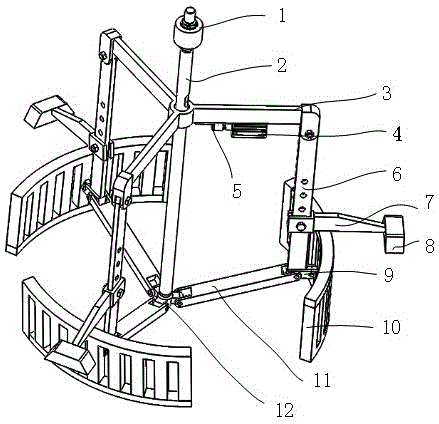

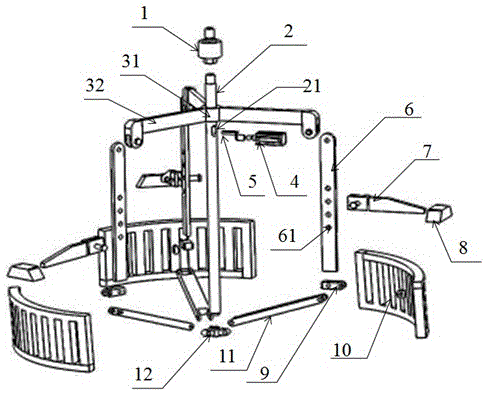

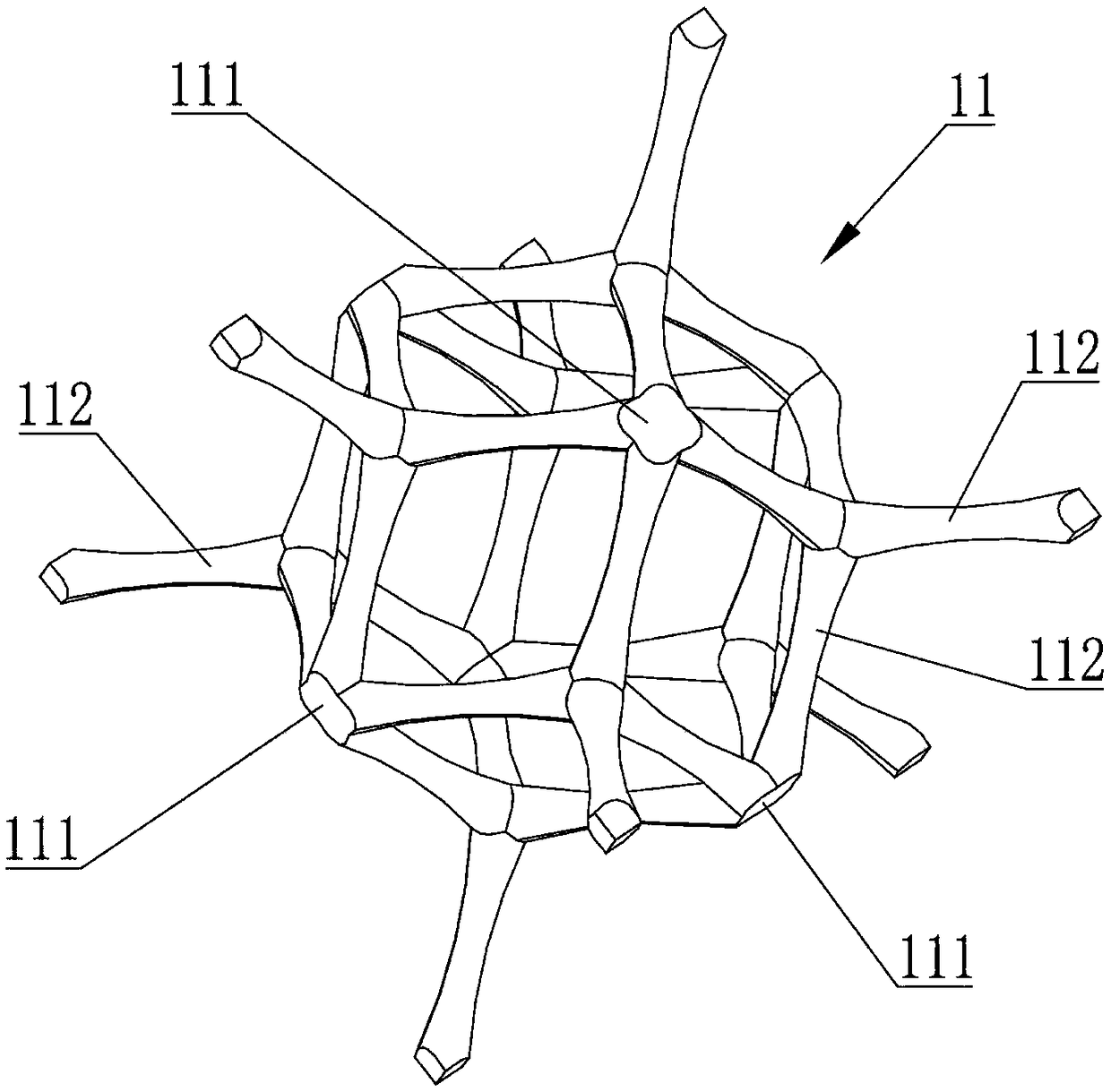

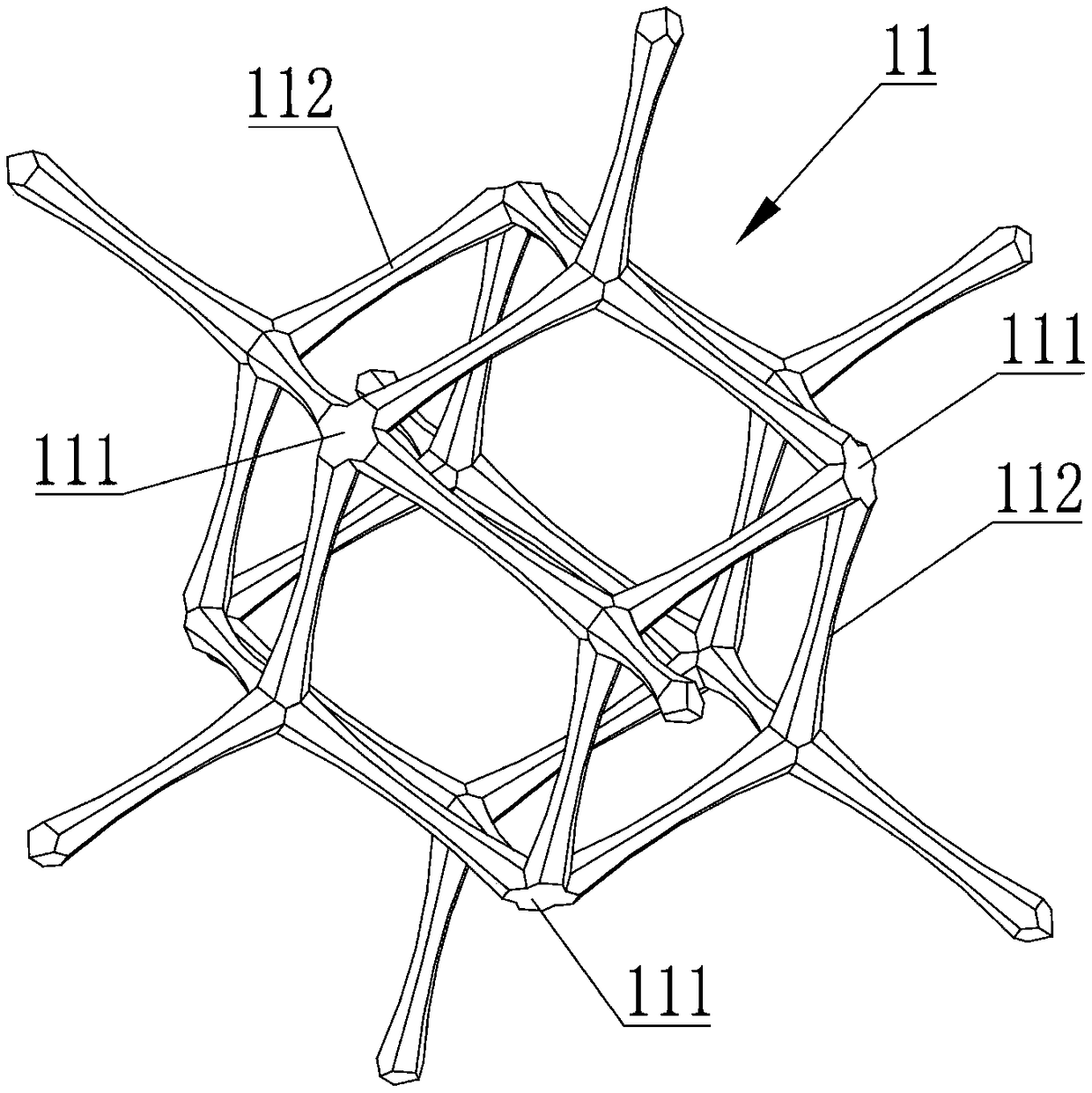

Polyhedral rolling mechanism

A polyhedral rolling mechanism is characterized by comprising an upper platform, a lower platform, a first branched chain, a second branched chain, a third branched chain and a fourth branched chain. Structures and sizes of the upper platform and the lower platform are identical, and structures and sizes of the first branched chain, the second branched chain, the third branched chain and the fourth branched chain are identical; the upper end of the first branched chain and an A1 side of the upper platform are fixed, the lower end of the first branched chain and a B1 side of the lower platform are fixed; the upper end of the second branched chain and an A2 side of the upper platform are fixed, and the lower end of the second branched chain and a B2 side of the lower platform are fixed; the upper end of the third branched chain and an A3 side of the upper platform are fixed, and the lower end of the third branched chain and a B3 side of the lower platform are fixed; the upper end of the fourth branched chain and an A4 side of the upper platform are fixed, and the lower end of the fourth branched chain and a B4 side of the lower platform are fixed; and the polyhedral rolling mechanism is formed through the connection. According to the polyhedral rolling mechanism, a closed chain structure is utilized, the robot rigidity is enhanced, loading capacity is improved, structure and control are simple and moving and veering in a plane can be achieved.

Owner:BEIJING JIAOTONG UNIV

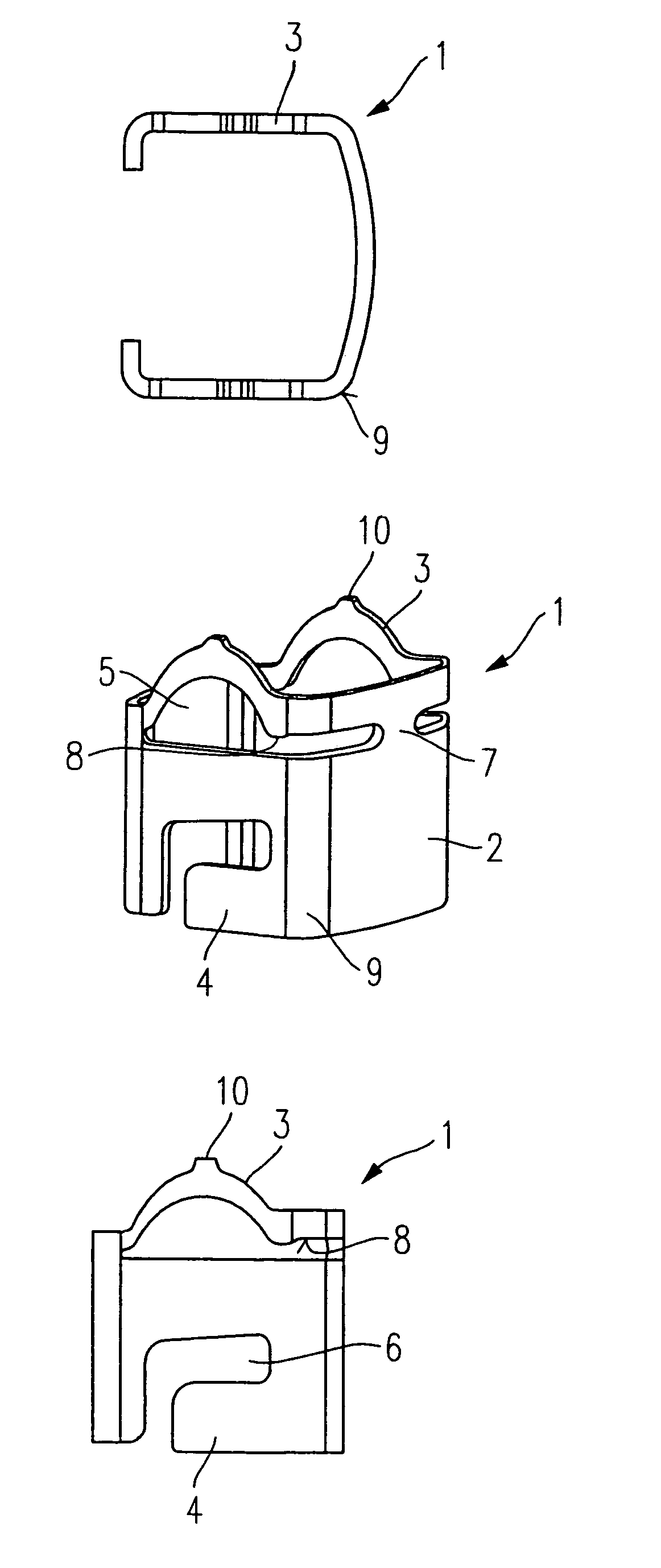

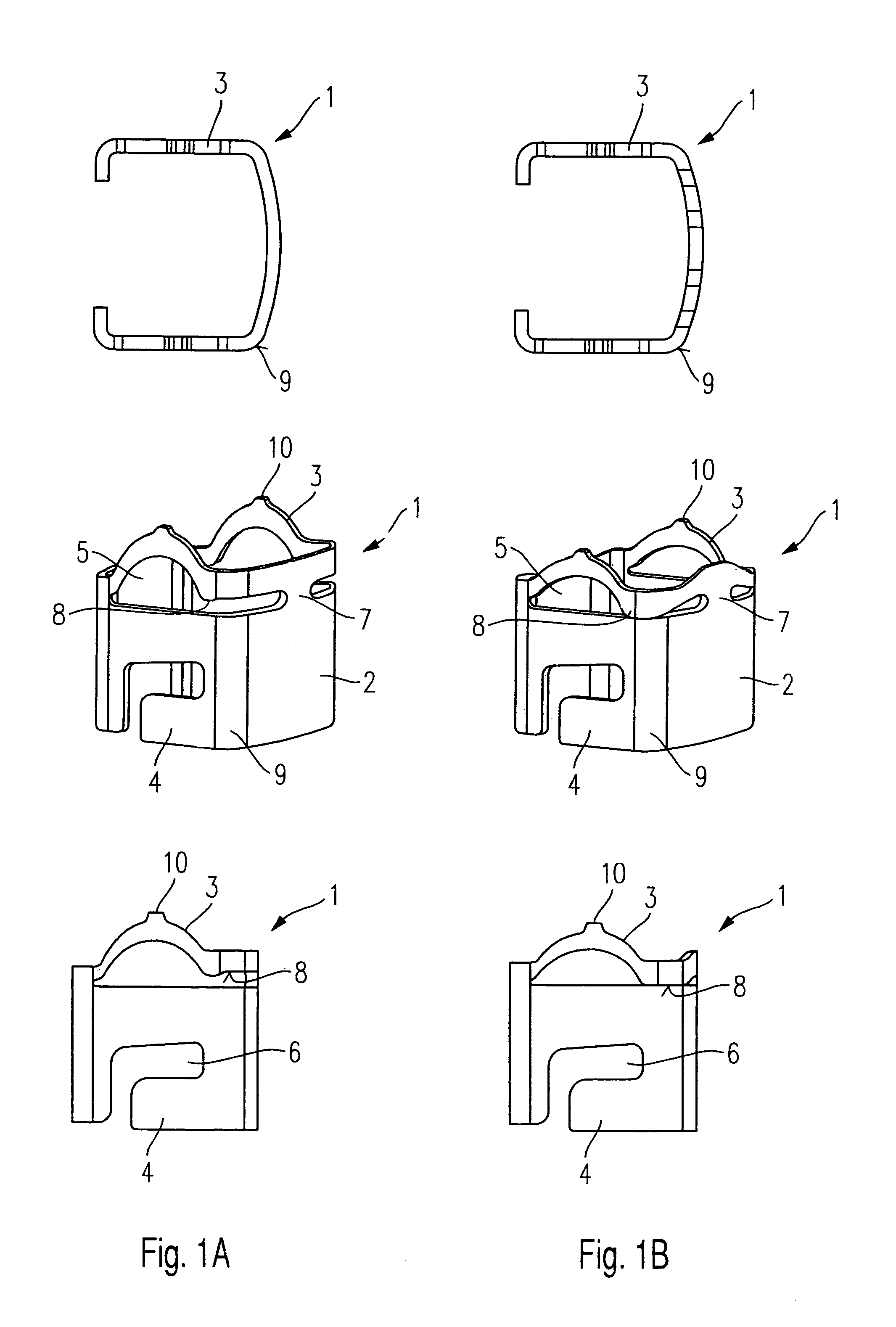

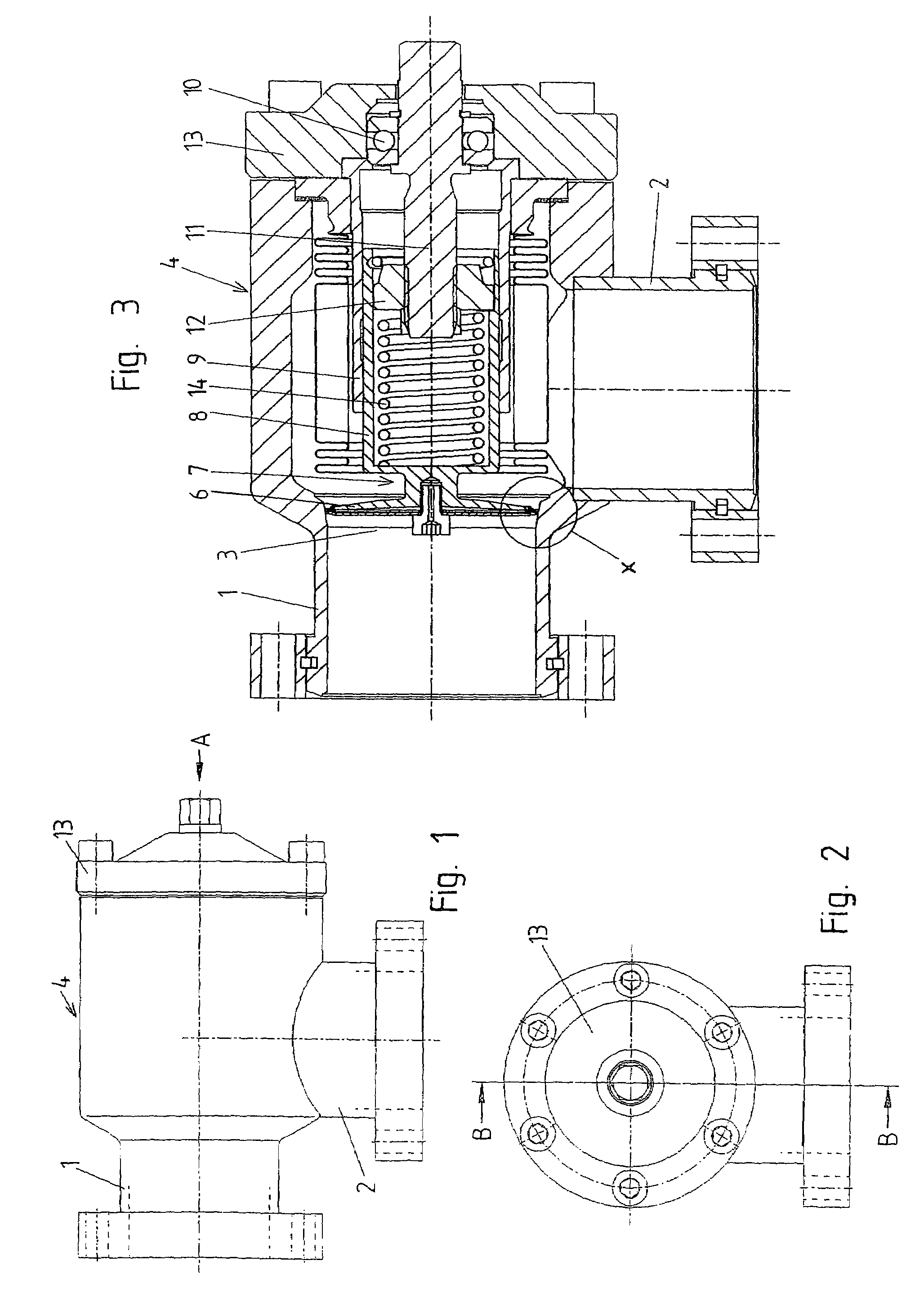

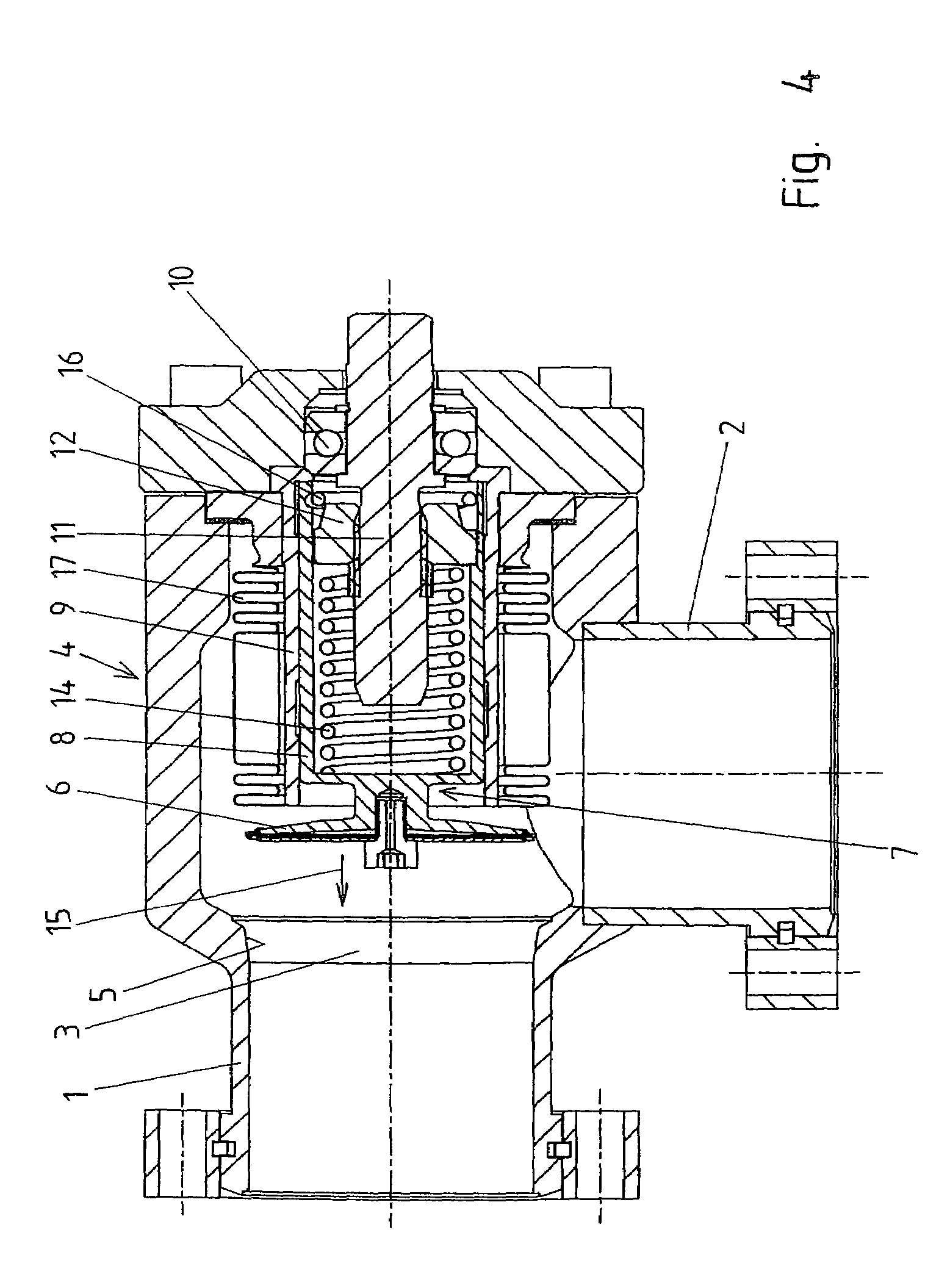

Support element

InactiveUS7210462B2Uniform force distributionImprove stabilityFuel injection apparatusMachines/enginesCylinder headExternal combustion engine

A support element for the mutual support of a fuel injector in a valve seat, in particular of the valve seat of a cylinder head of an internal combustion engine, and of the fuel injector at a fuel distribution line has a clasp and thereon developed radially and axially deformable clips.

Owner:ROBERT BOSCH GMBH

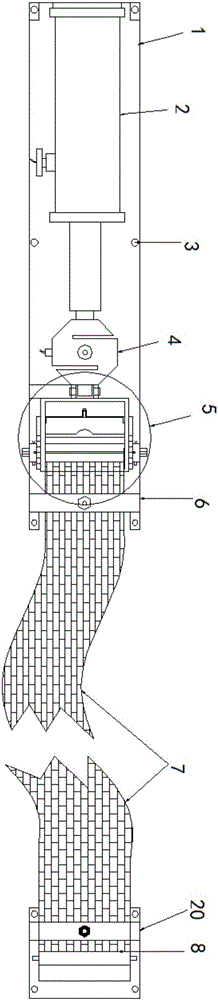

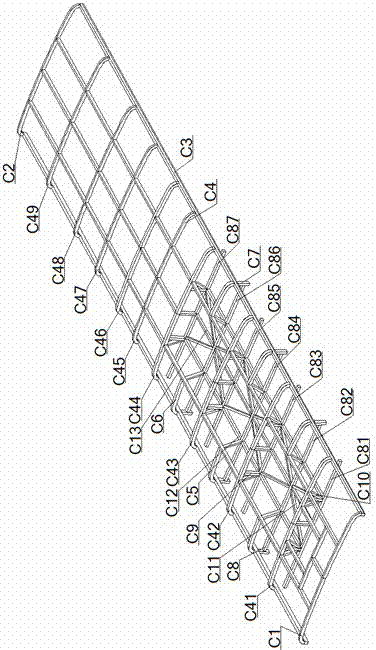

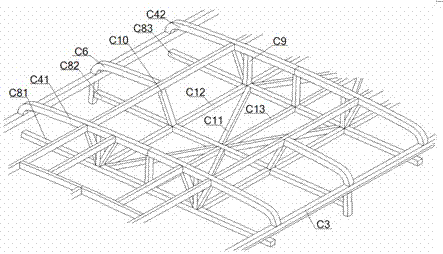

Device and method for tensioning and reinforcing double layers of pre-stress carbon fiber sheet at same time

InactiveCN105064224AUniform force distributionSolve the problem of distal anchoringBridge erection/assemblyBridge strengtheningFiberCarbon fibers

The invention discloses a device and method for tensioning and reinforcing double layers of a pre-stress carbon fiber sheet at the same time. The device comprises a tensioning device, an anchoring steel plate and a rolling device. The tensioning device comprises a jack, a tension sensor, a rotating locking device and a pressing device in a sequential connection mode, the bottom of the jack and the bottom of the pressing device are fixedly connected with a tensioning fixing support, and the tensioning device is detachably fixed to the reinforced component through the tensioning fixing support. The rolling device comprises a pressing device, a rolling shaft and a far-end fixing support, wherein the pressing device and the rolling shaft are detachably fixed to corresponding positions of the reinforced component through the far-end fixing support; at the near end of the tensioning device, one end of the carbon fiber sheet is fixed to the reinforced component through the anchoring steel plate, the other end of the carbon fiber sheet is fixedly tensioned to the rotating locking device after being wound around the rolling shaft, and the double layers of the carbon fiber sheet are tensioned at the same time through retracting and pulling of the jack.

Owner:SHANDONG UNIV

Bionic coupling cast iron guide rail and manufacturing method thereof and regeneration method of waste machine tool guide rail

InactiveCN103111850ASmall sizeImprove performanceLarge fixed membersLaser beam welding apparatusEngineeringLiving body

The invention relates to a bionic cast iron guide rail and a manufacturing method of the bionic cast iron guide rail and a regeneration method of a waste machine tool guide rail. The cast iron guide rail is composed of a guide rail main body and a surface structure refining layer of the guide rail main body. Nanoscale martensite units are distributed on the surface structure refining layer. The manufacturing method of the cast iron guide rail and the regeneration method of the waste machine tool guide rail mainly comprise the following steps of obtaining the surface structure refining layer by using high-frequency electric pulses to process the guide rail, and manufacturing the nanoscale martensite units on the surface structure refining layer by the adoption of laser fusing method. The units and a guide rail parent together form a bionic coupling area which is soft and hard and resembles a living body structure, the units function as firm pile screws or reinforcing ribs which are additionally arranged on the surface layer of the guide rail, and parent materials surround the units and enable the unit to be connected into a whole so as to enable local peak values of the surface of the guide rail to be dispersed and stress of the guide rail to be even. The bionic cast iron guide rail has superior mechanic property and fatigue and abrasion resistant performance.

Owner:JILIN UNIV

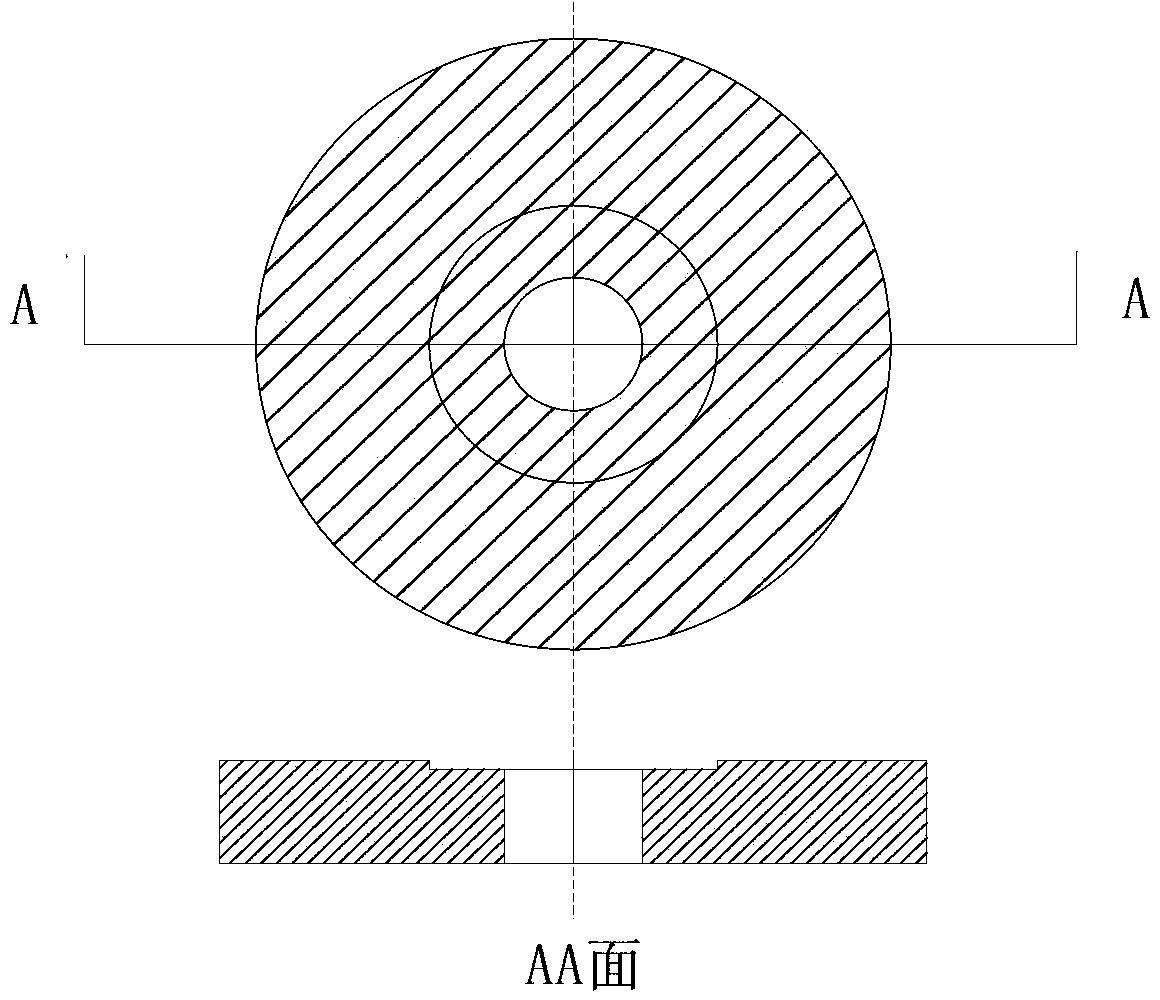

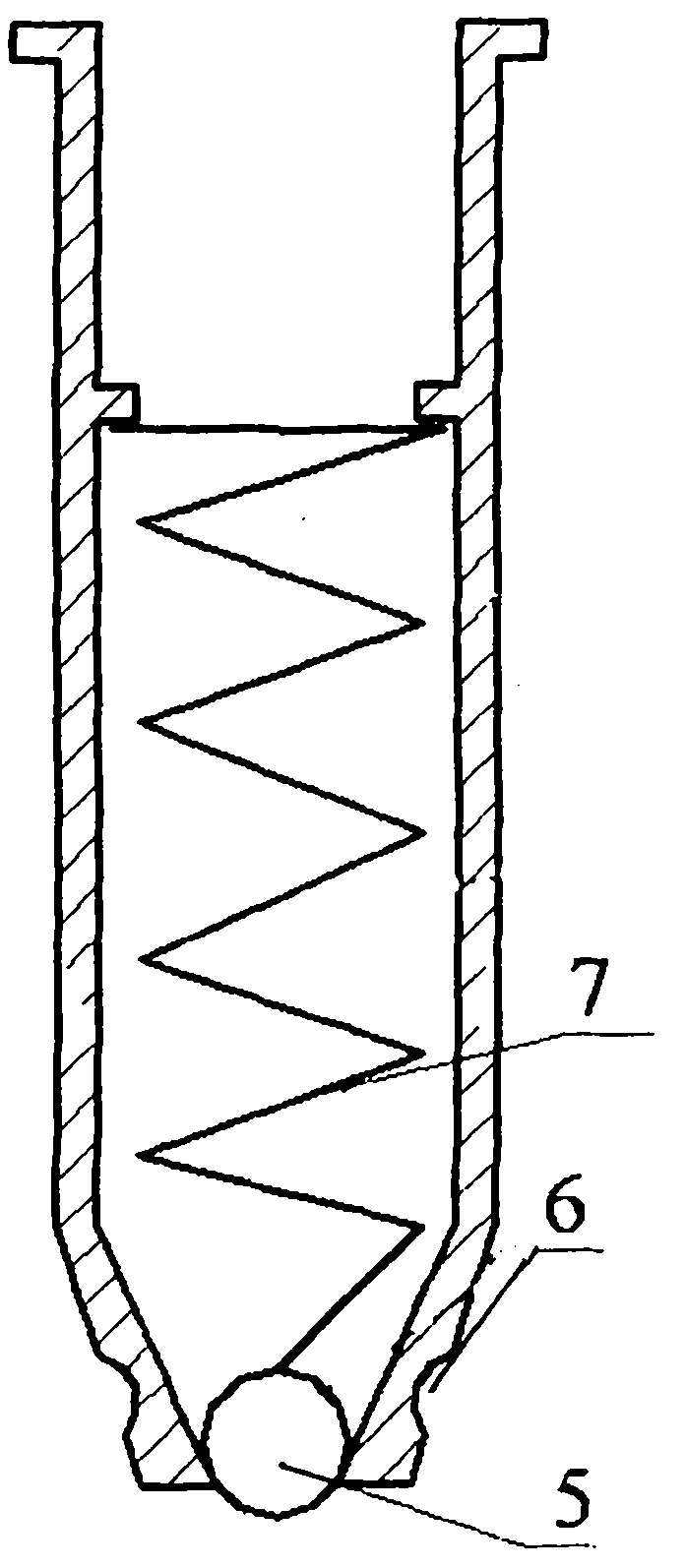

Segmented anchoring and grouting anchor rod device capable of achieving automatic clamping and anchoring method thereof

ActiveCN105257328AStrong controllabilityEnhance self-stable bearing capacityAnchoring boltsEngineeringRock bolt

The invention provides a segmented anchoring and grouting anchor rod device capable of achieving automatic clamping and an anchoring method thereof. According to the device, a grouting anchor rod, a first connecting piece, a cylinder, a second connecting piece and a resin anchor rod are sequentially connected into a rod body through threads; a piston and a piston rod are arranged in the cylinder and are fixedly connected; the end, connected with the second connecting piece, of the cylinder is provided with an annular groove, a plurality of supports are arranged at the end of the cylinder, one end of a movable connection rod is connected with the end of the piston rod, the other end of the movable connection rod penetrates through the annular groove of the cylinder and is hinged to a clamping wing, and the end of the clamping wing is hinged to the supports. According to the device and the method, resin cartridge anchoring and grouting anchoring are fully used, and the clamping wing is added and deeply embedded into the anchor hole wall, so that anchoring force is greatly enhanced. The device and method are suitable for unstable roadways with various mine soft rock crushing, can greatly improve anchoring capacity of a whole anchor rod, effectively improve self-stability of a roadway surrounding rock body, and have the advantages of being good in end anchoring effect, high in anchoring efficiency, convenient to install and the like.

Owner:HUNAN UNIV OF SCI & TECH

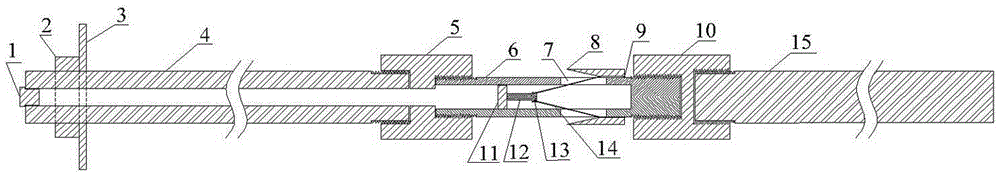

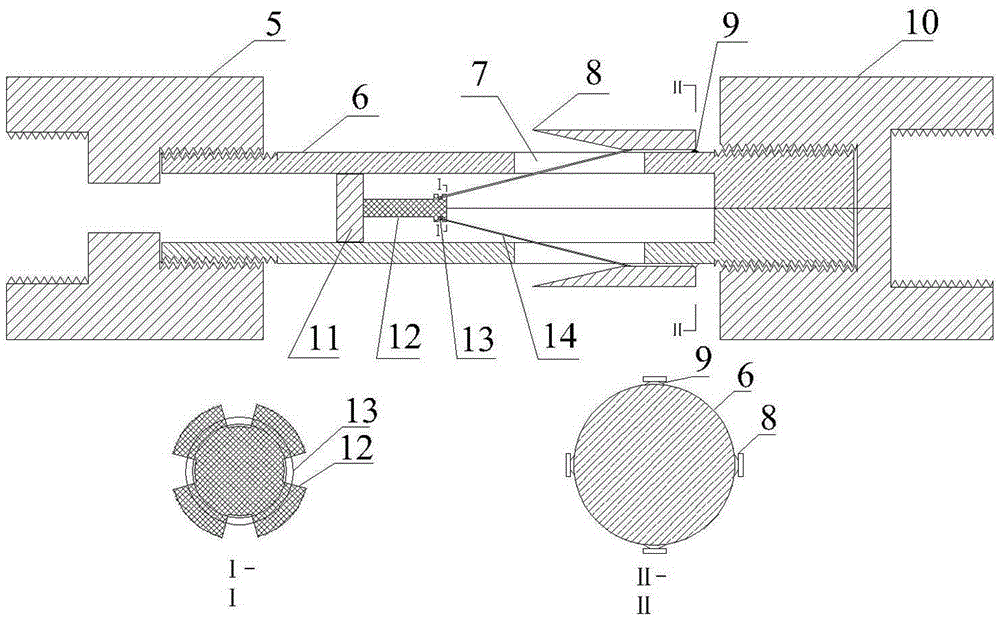

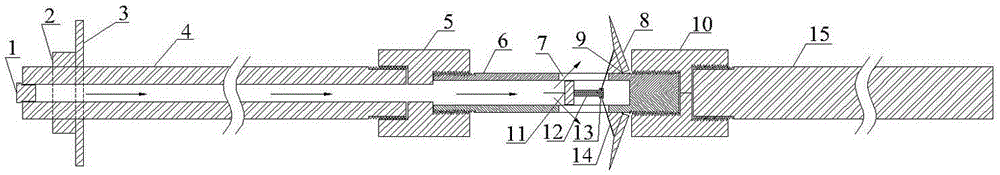

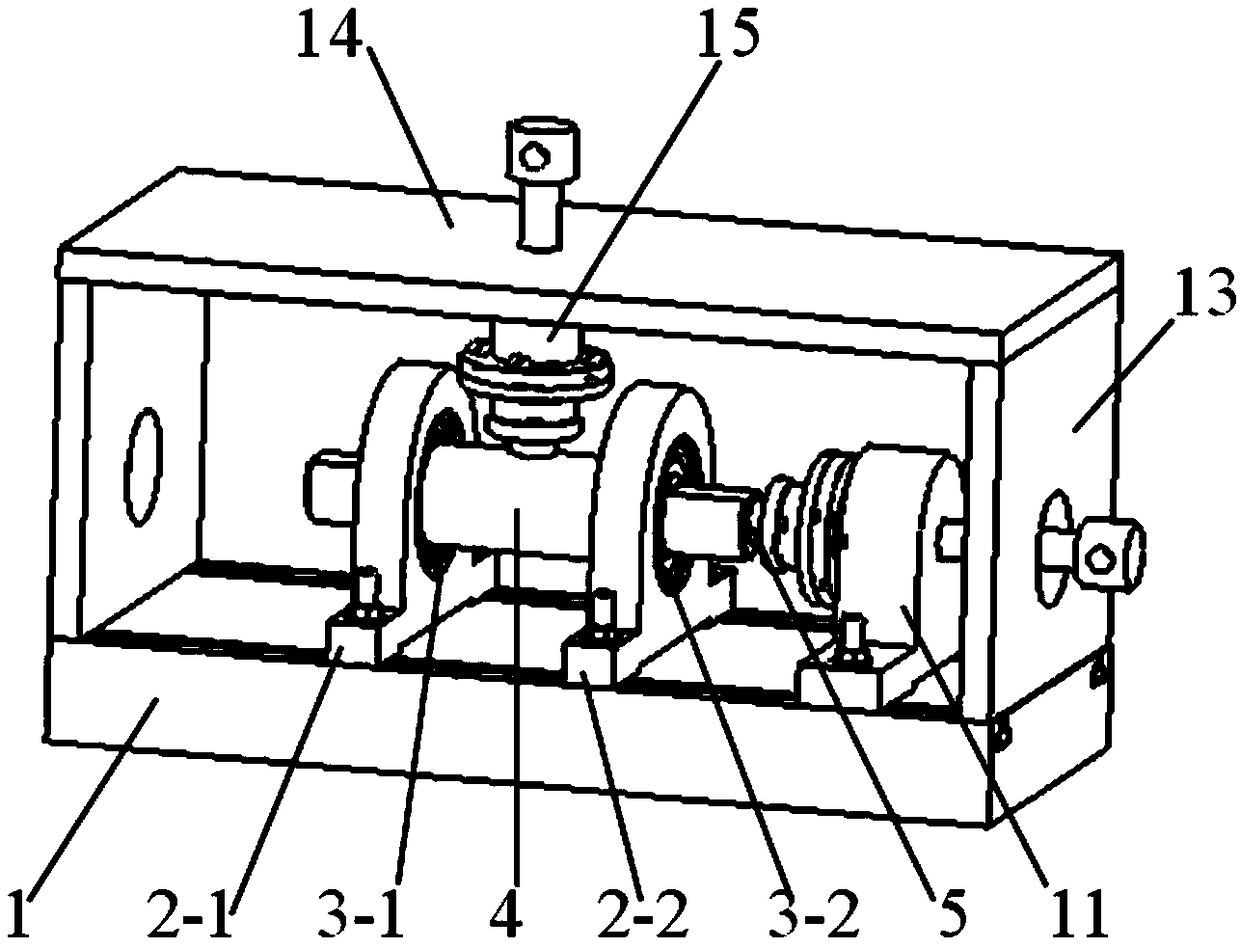

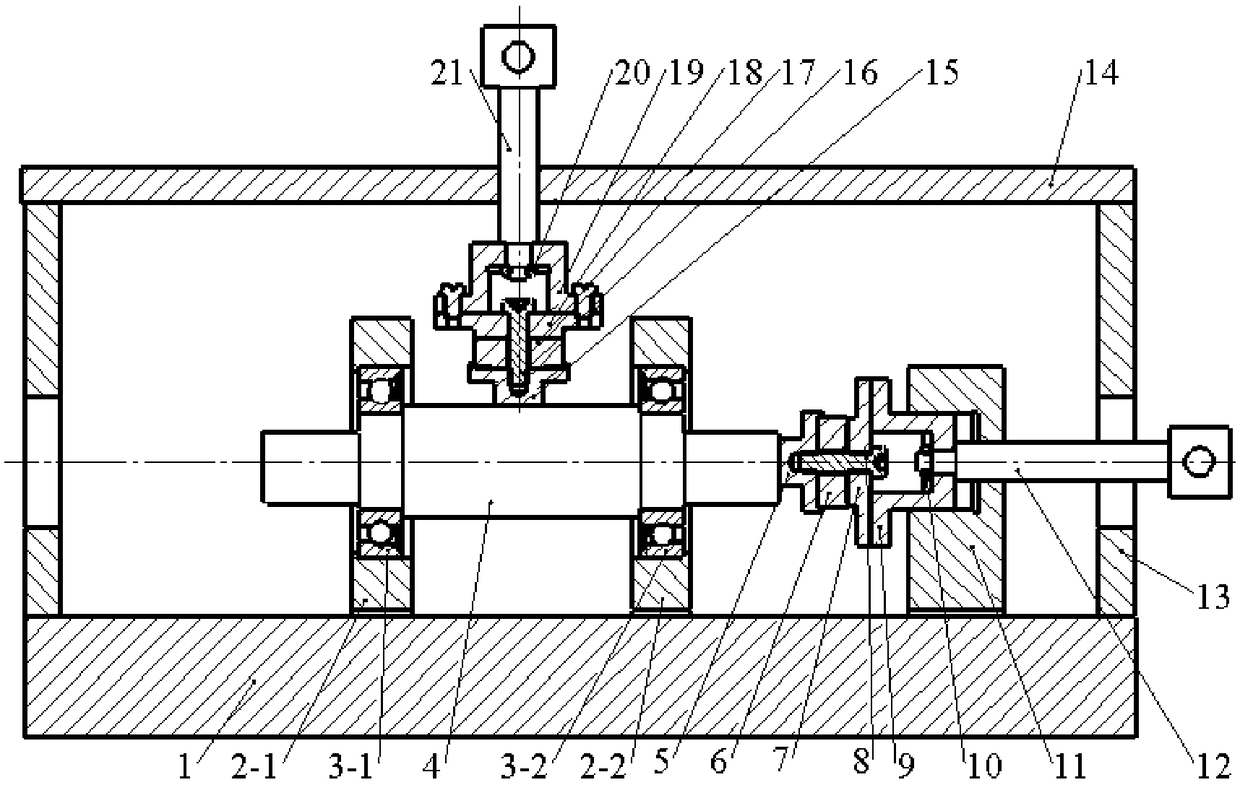

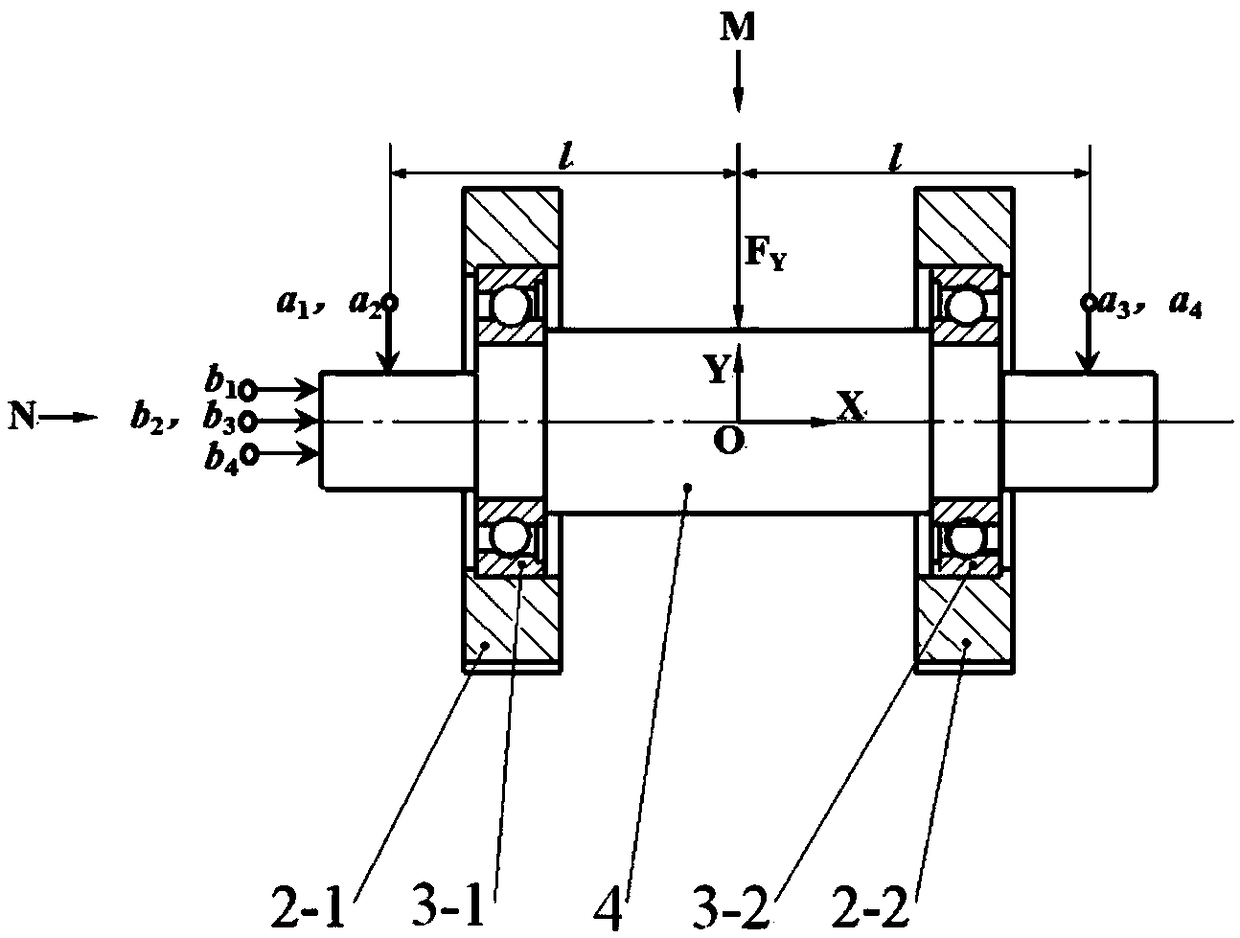

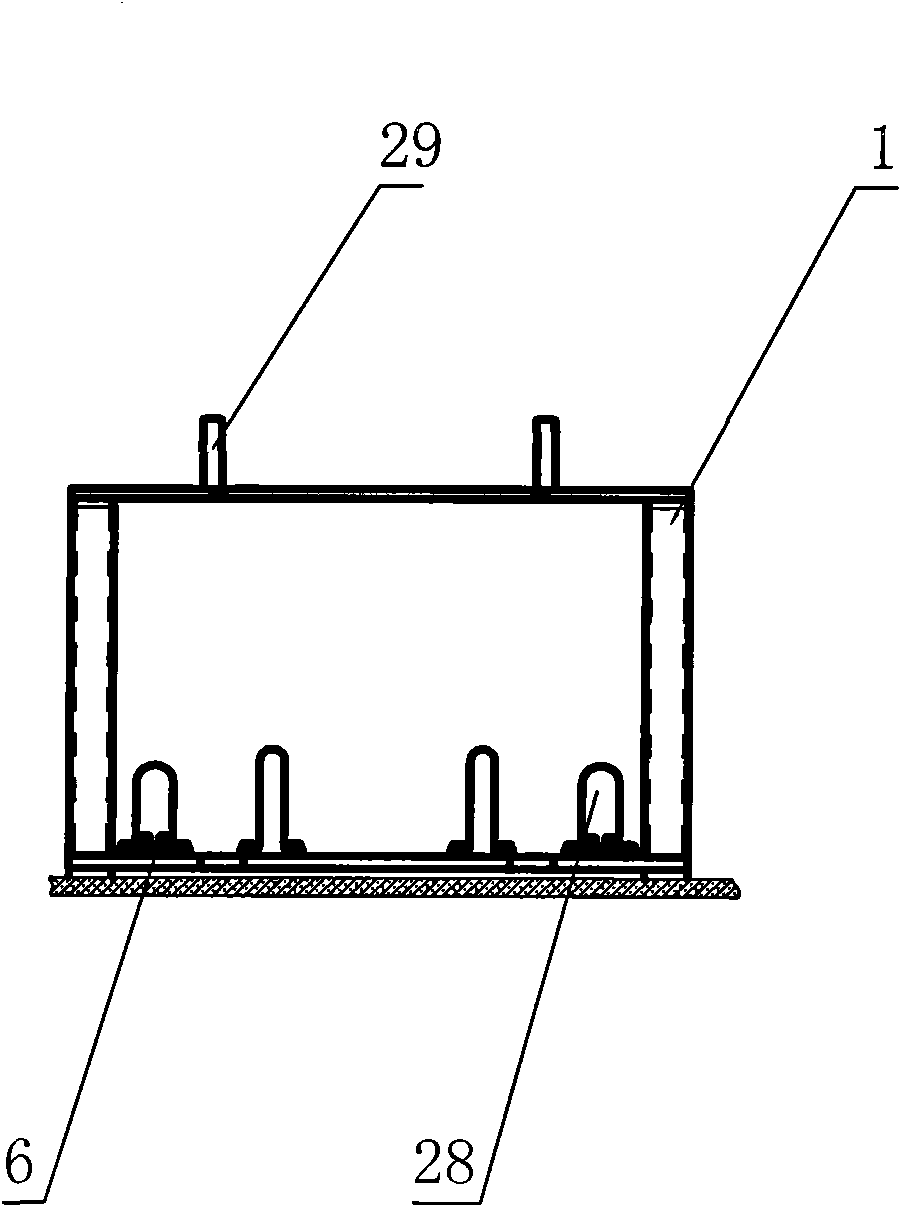

Device and method for measuring static characteristics of joint of rolling bearings

PendingCN108827635ARadial loads onlyUniform force distributionMachine bearings testingRolling-element bearingAxial force

Owner:SHAANXI UNIV OF SCI & TECH

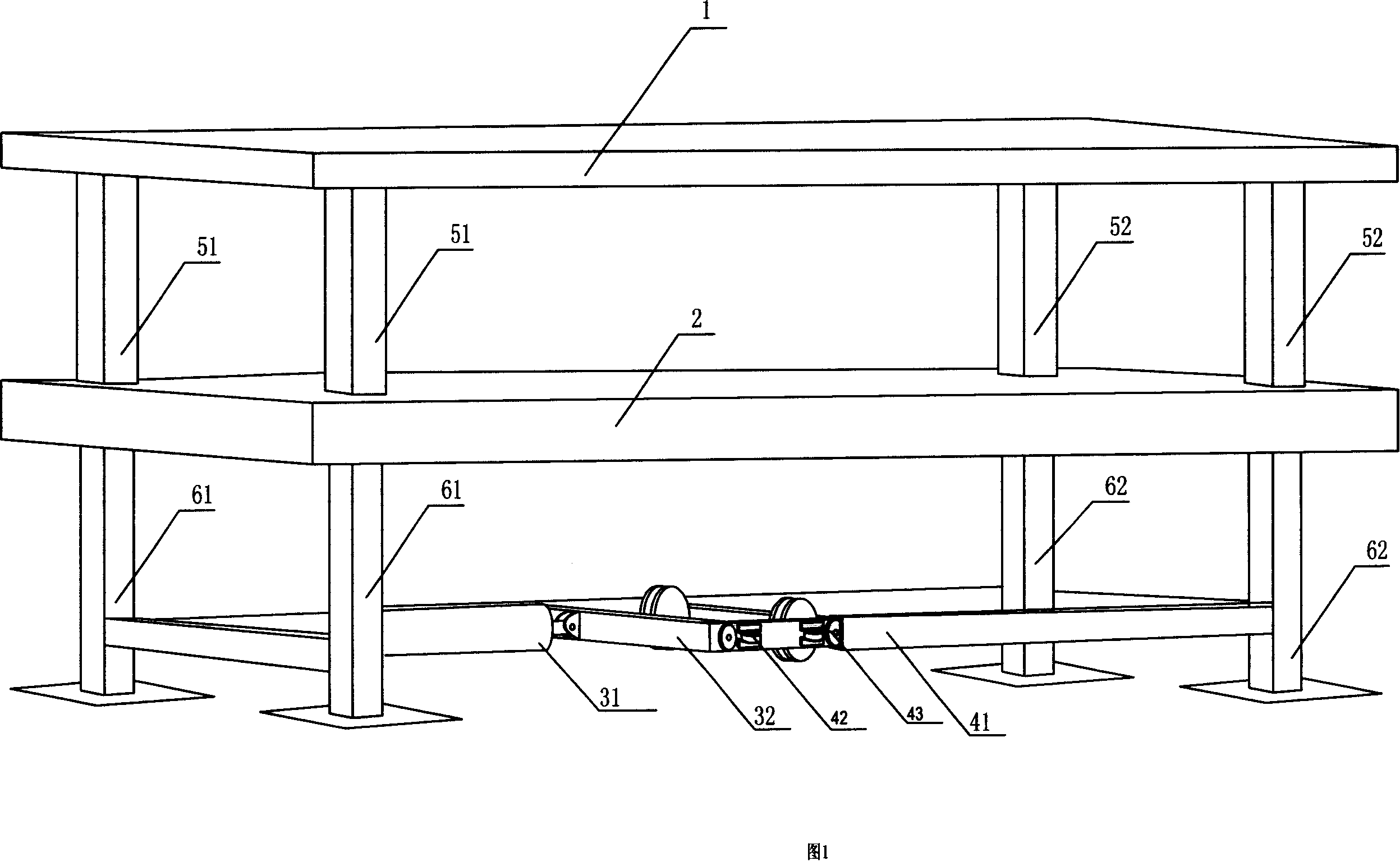

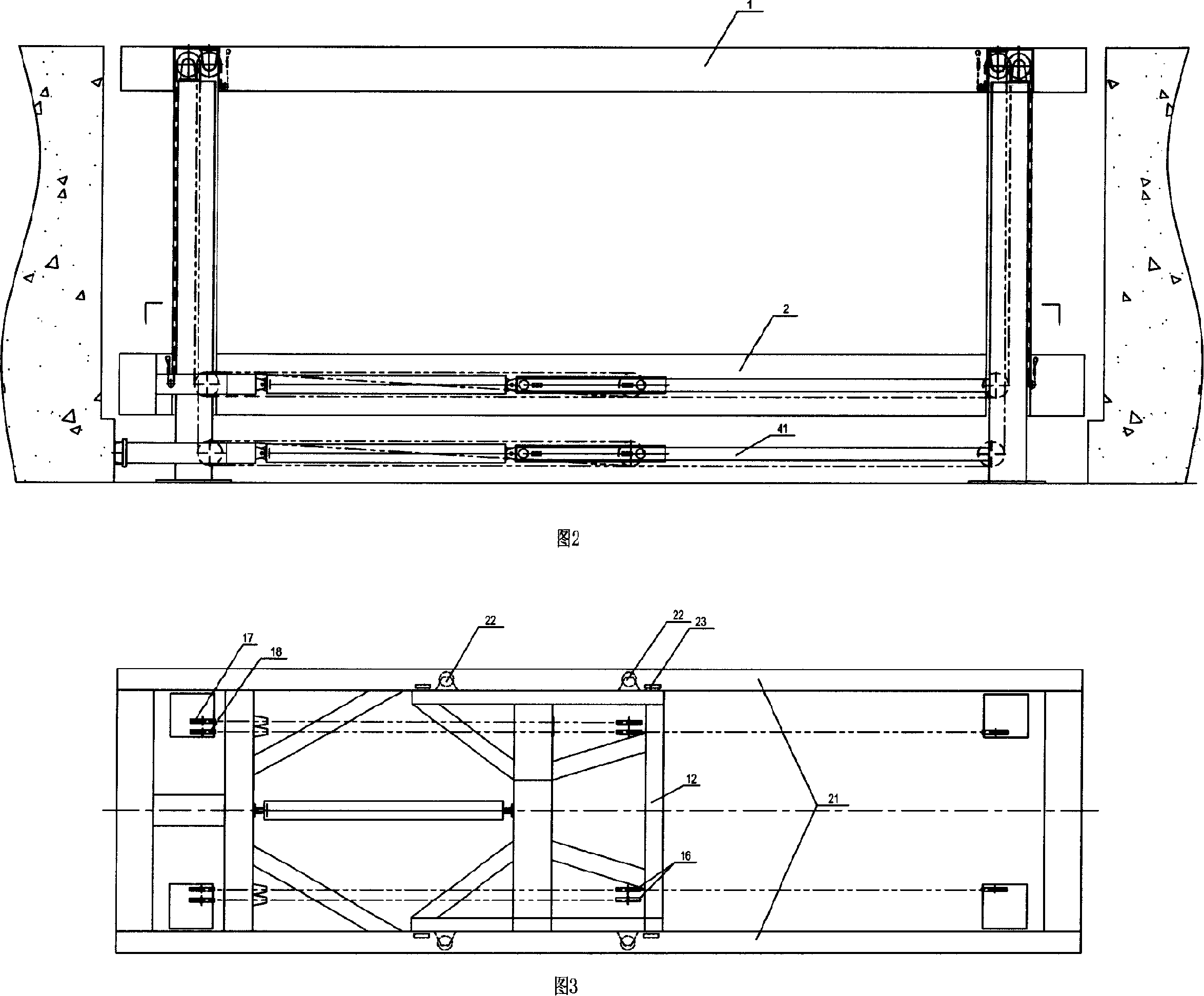

Double-deck liftable stage

A double layer up-down stage includes the upper table and the lower table which are installed up and down, the first up-down driving device which drives said upper table and the second up-down driving device which drives said lower table; the lower stable is sleeved on the lower pillar which is fixed on the ground foundation, the parts corresponding the lower pillar of the upper of said lower stable is equipped with hollow upper pillar, the inner diameter of said upper pillar is more than the outer diameter of lower pillar, the upper stable is sleeved on said upper pillar. The invention includes two layers of stages, lifting the upper stage through the first up-down driving device when needing one stage; lifting the lower stage continually through the second up-down driving device when using two stages together, so it meets the diversified requirements of tridimensional stage and the utilization effects are good; it uses four flexible alachlors (armored ropes) driving the hydraulic cylinder and achieves synchronization, the force is uniform, and the lift is smooth, safe and reliable.

Owner:倪湘凝

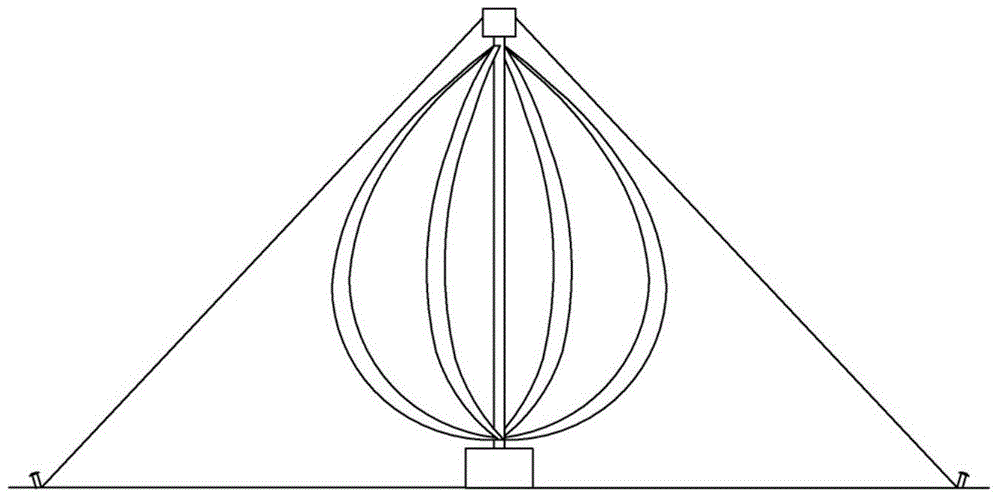

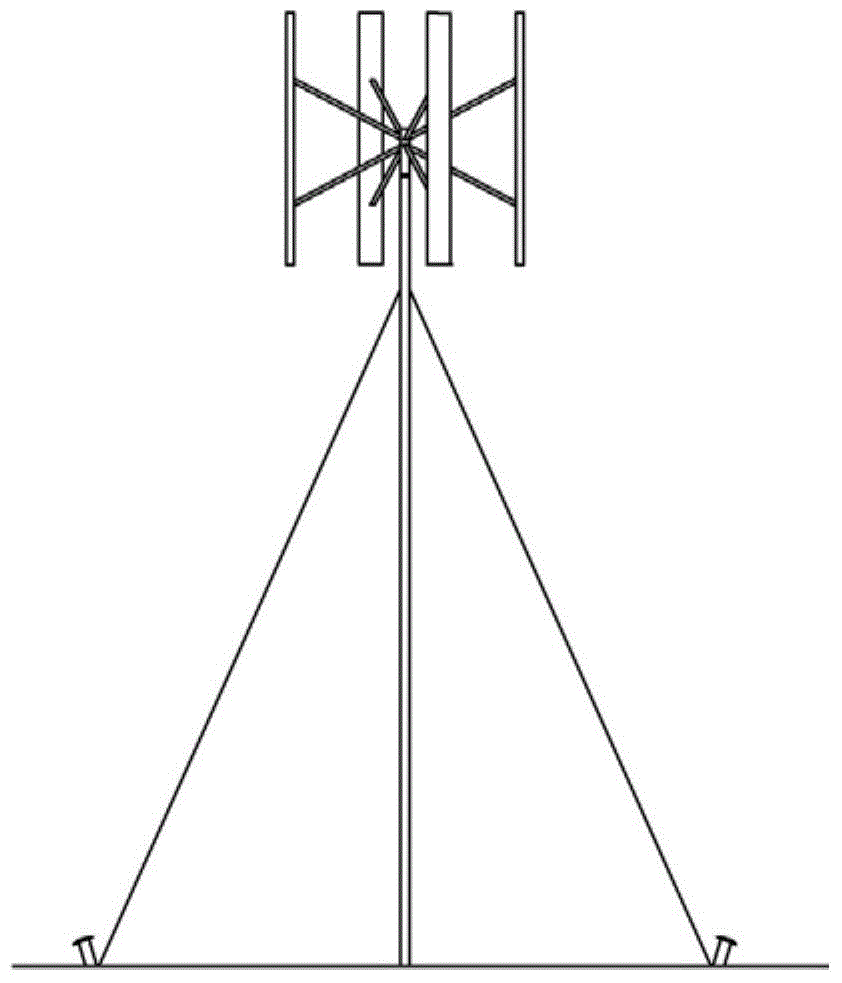

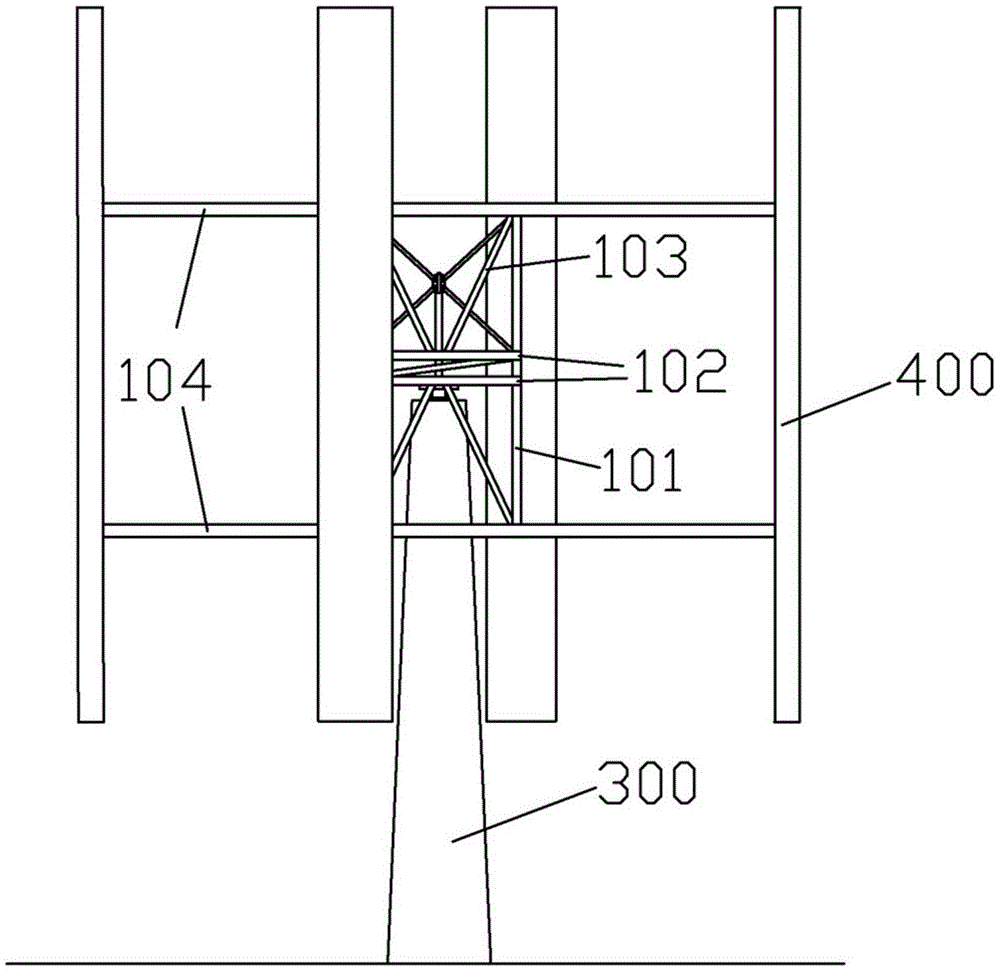

Vertical axis wind turbine and wind energy ship with same

ActiveCN104314751AExtended service lifeImprove structural strengthWind motor combinationsMachines/enginesVertical axis wind turbineTower

The invention discloses a vertical axis wind turbine and a wind energy ship with the same. The vertical axis wind turbine comprises a tower body (300), wherein a main shaft (108) which can rotate freely is arranged in the tower body (300); a cylindrical middle column body is arranged on the outer side of the main shaft (108); the middle column body is of a regular polyhedral frame structure which is formed by combining vertical columns (101) and cross beams (102), and is fixedly connected with the main shaft (108); the upper and lower groups of cross beams (102) or a plurality of upper and lower groups of cross beams (102) are provided with paddle arms (104) extending outwards; blades (400) are arranged on the paddle arms (104). The vertical axis wind turbine and the wind energy ship have the advantages of high structural strength and deformation resistance, more balanced and rational stress state, contribution to prolonging of service life of parts and high efficiency.

Owner:莫海路

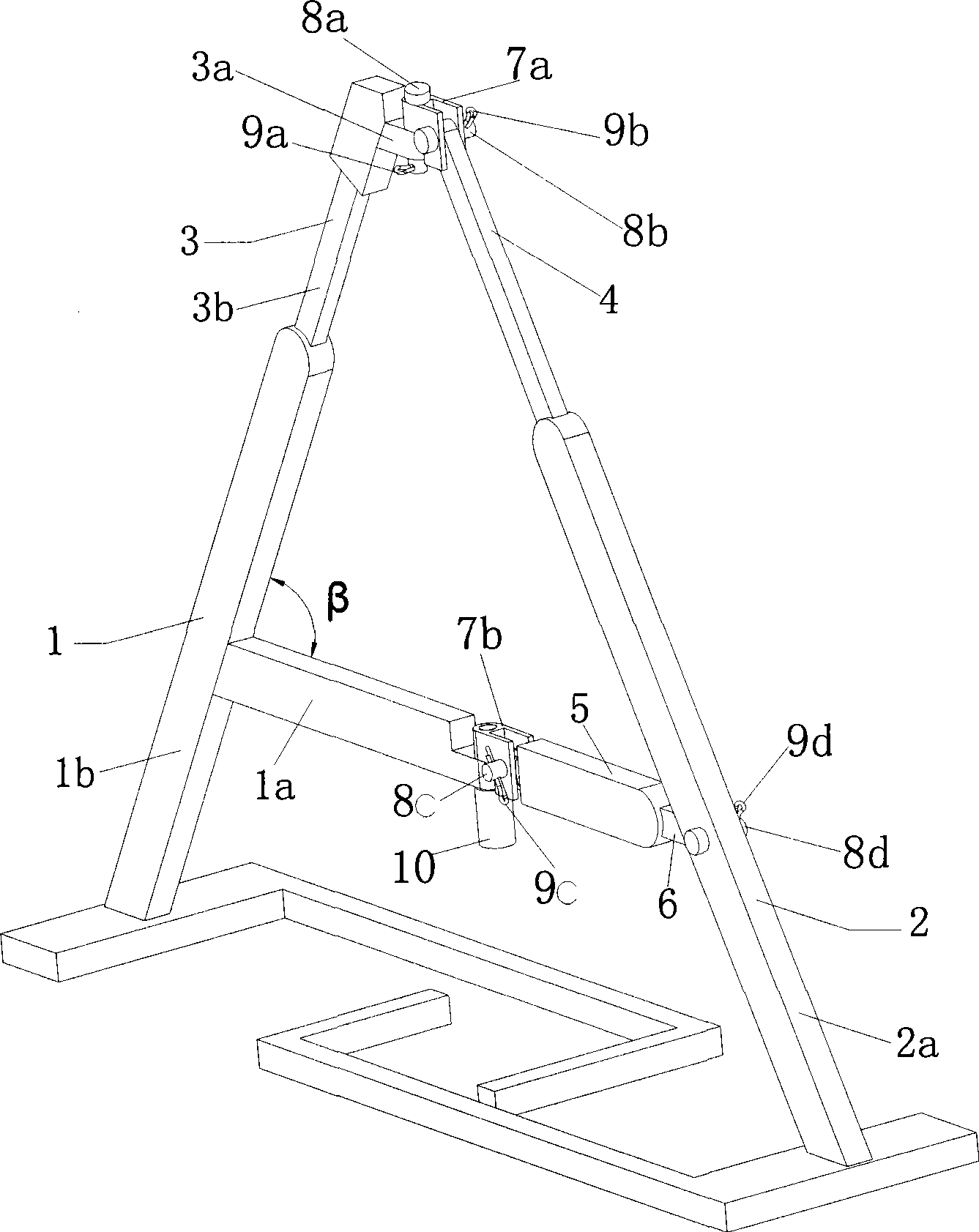

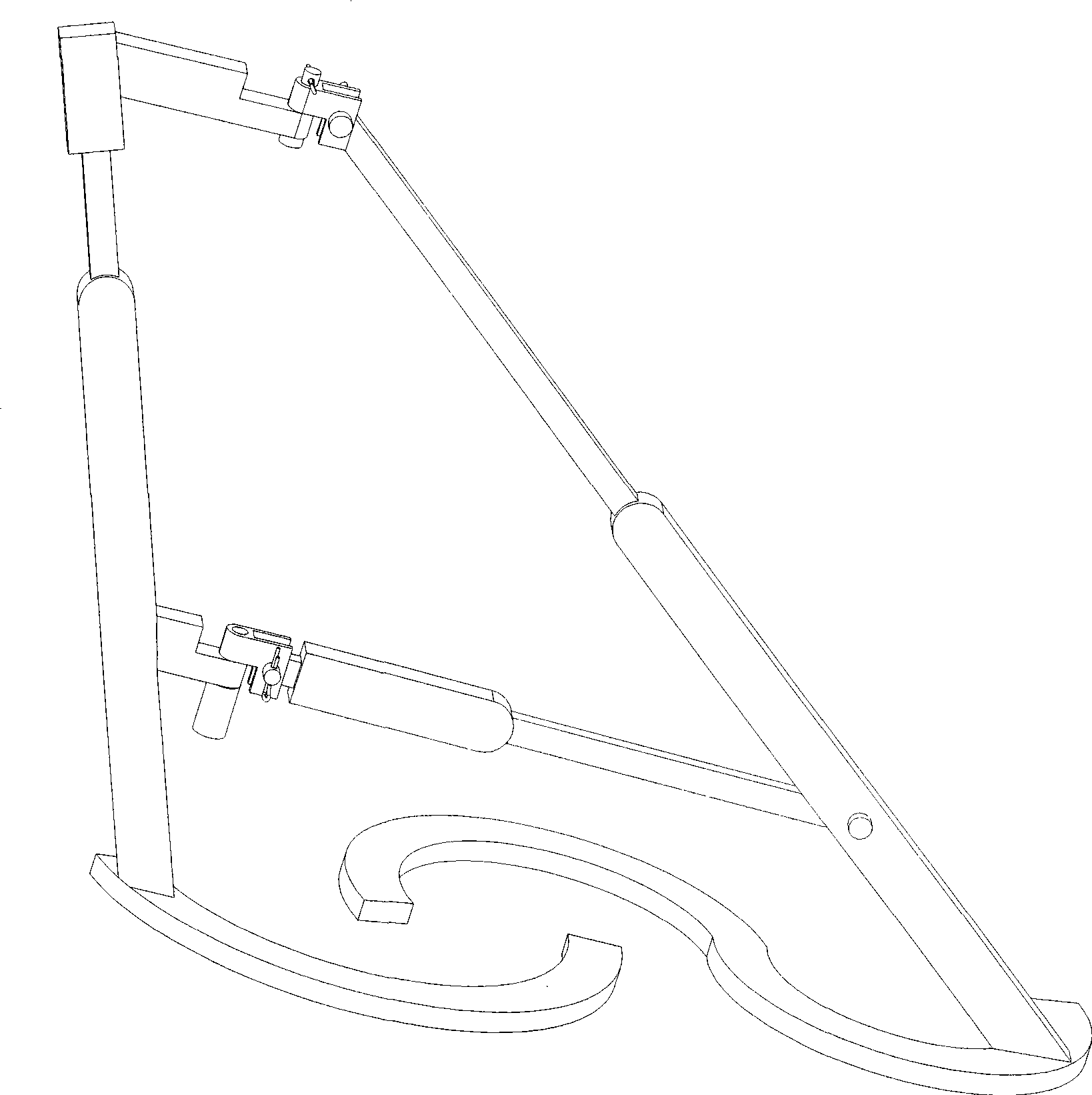

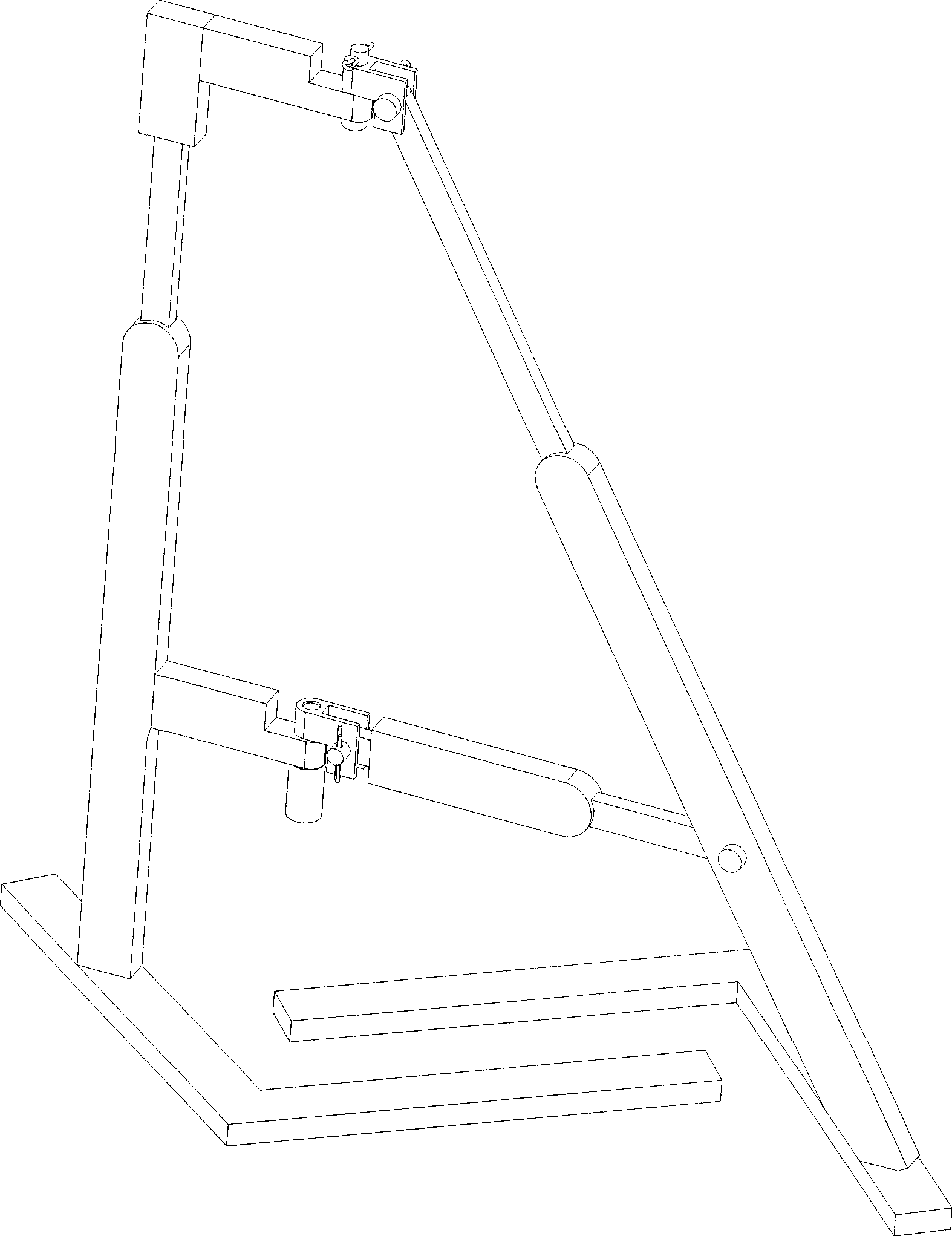

Two-foot walk triangle robot

A biped walking triangular robot comprises connections of the six member bars forming the three edges of the triangular robot, wherein, a moving pair which serves as one side edge of the triangular robot comprises a left foot outer rod (1) and a left foot inner rod (3); a moving pair which serves as the other side edge of the triangular robot comprises a right foot outer rod (2) and a tight foot inner rod (4); and a moving pair which serves as the bottom edge of the triangular robot comprises the rod (1a) of the left foot outer rod (1), cross rod outer rod (5) and cross rod inner rod (6). The triangular robot works as follows: regulating the lengths of the three edges to lift, protract or land the left foot outer rod (1) and the right foot outer rod (2) so as to realize the straight movement; stopping regulating the lengths of the three edges and starting the motor (10) when the vertical hole on the left foot outer rod (1) and the vertical hole on the left foot inner rod (3) are coaxial so as to realize the turning. The triangular robot has the advantages that the closed chain structure is adopted to increase the rigidity of the robot and improve the load capacity; the linear driving is adopted to avoid the amplification effect of the lengths of the member bars to the angle turning driving error; the elements are fewer; and the structure and the control are simple.

Owner:BEIJING JIAOTONG UNIV

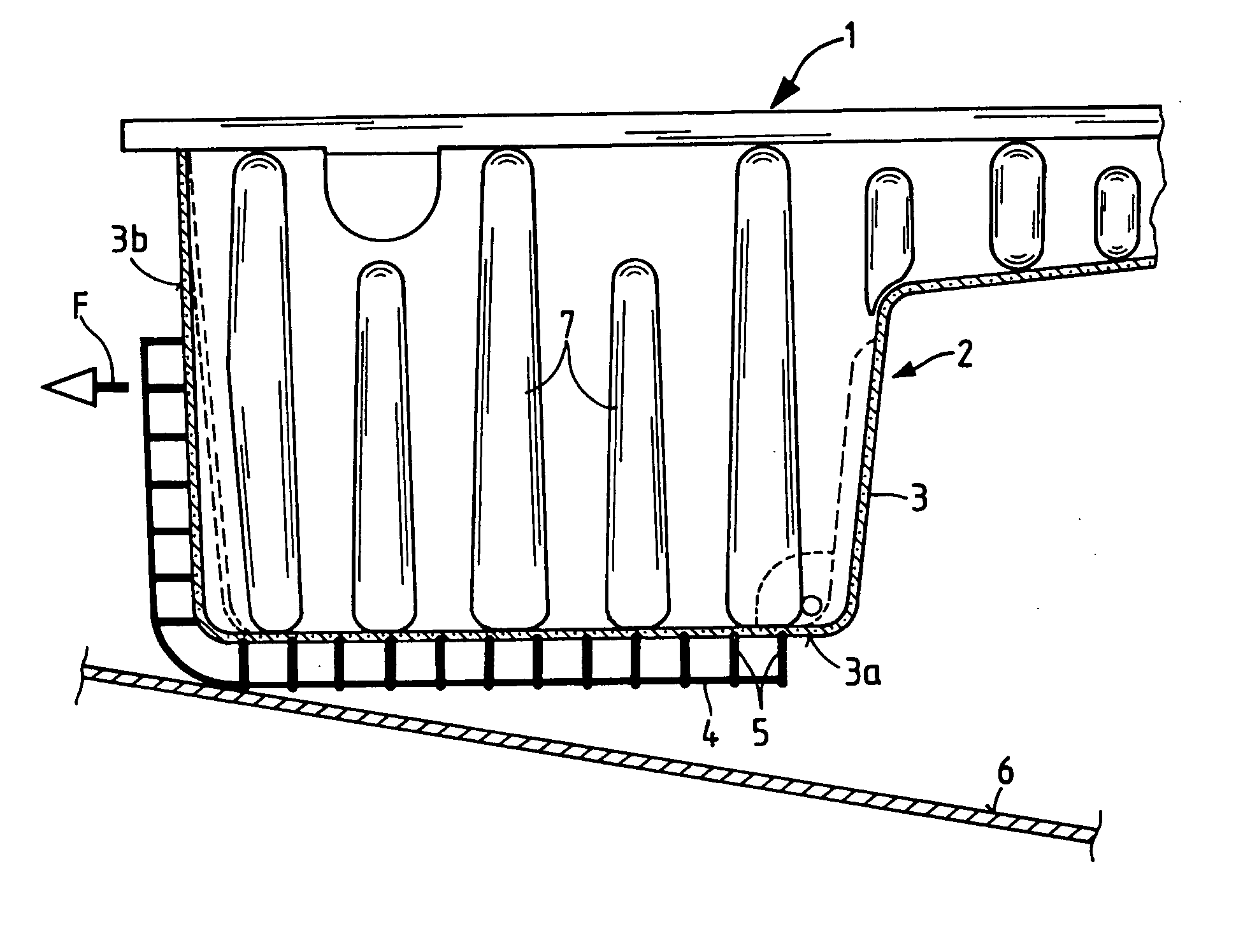

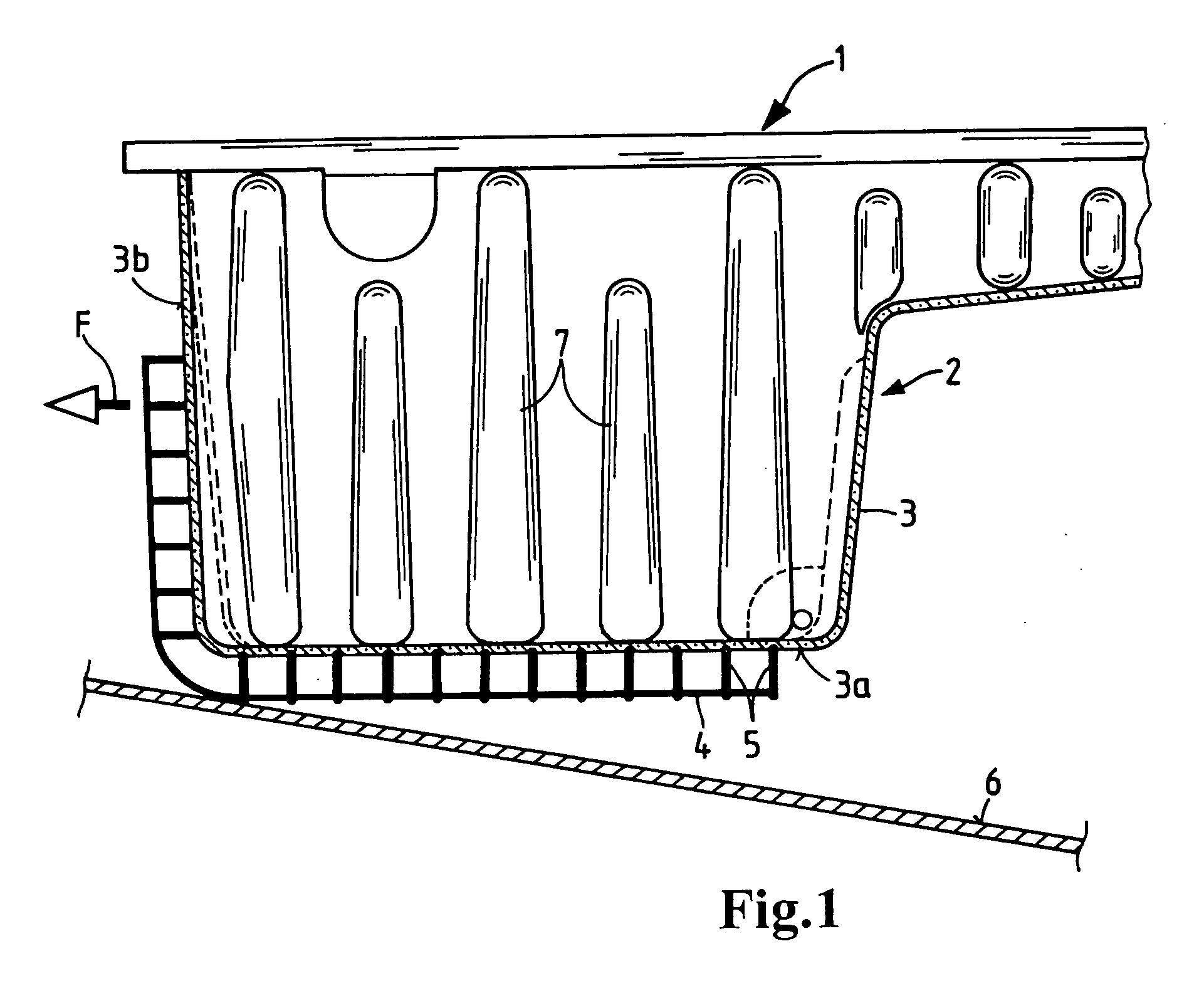

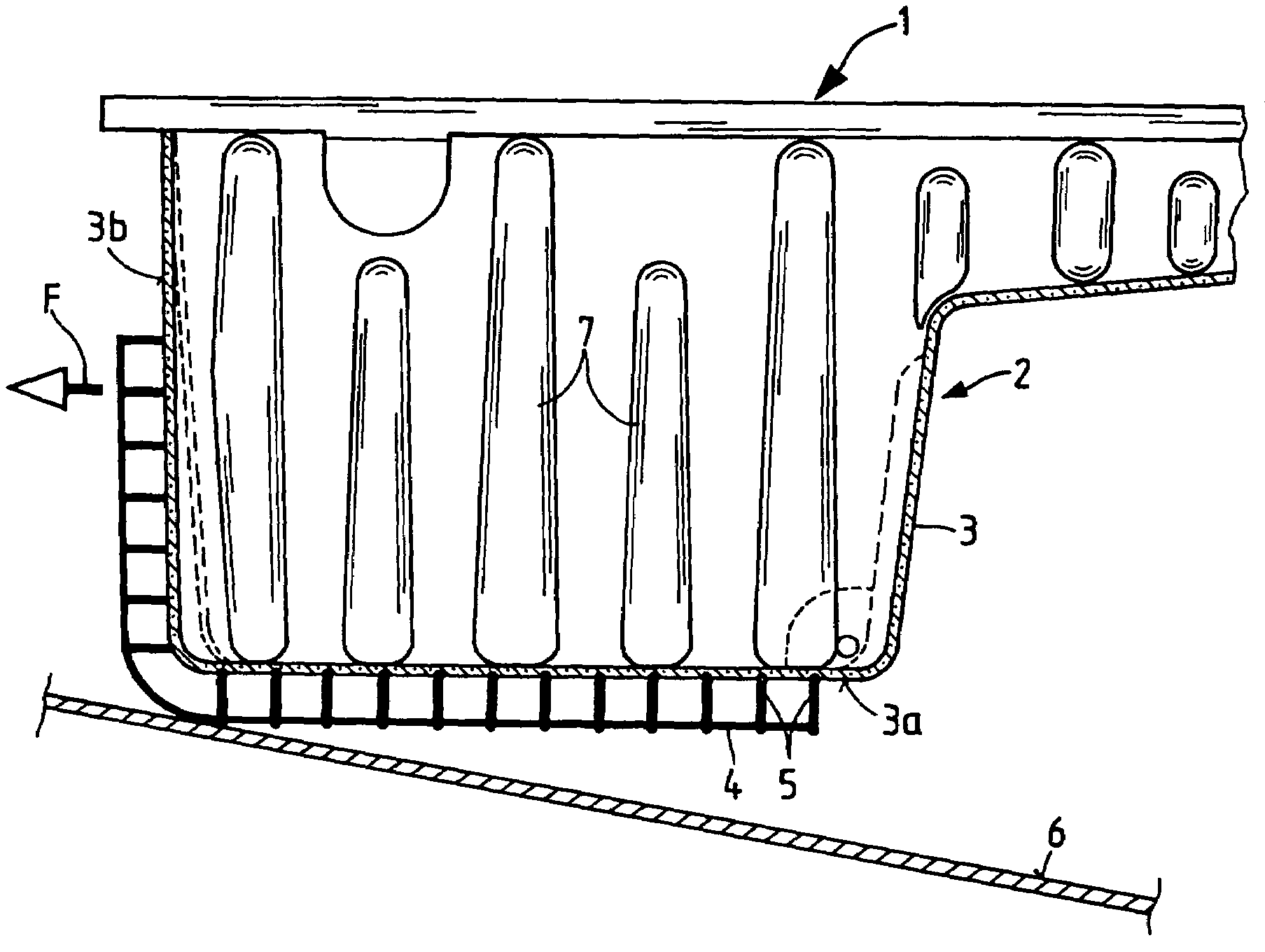

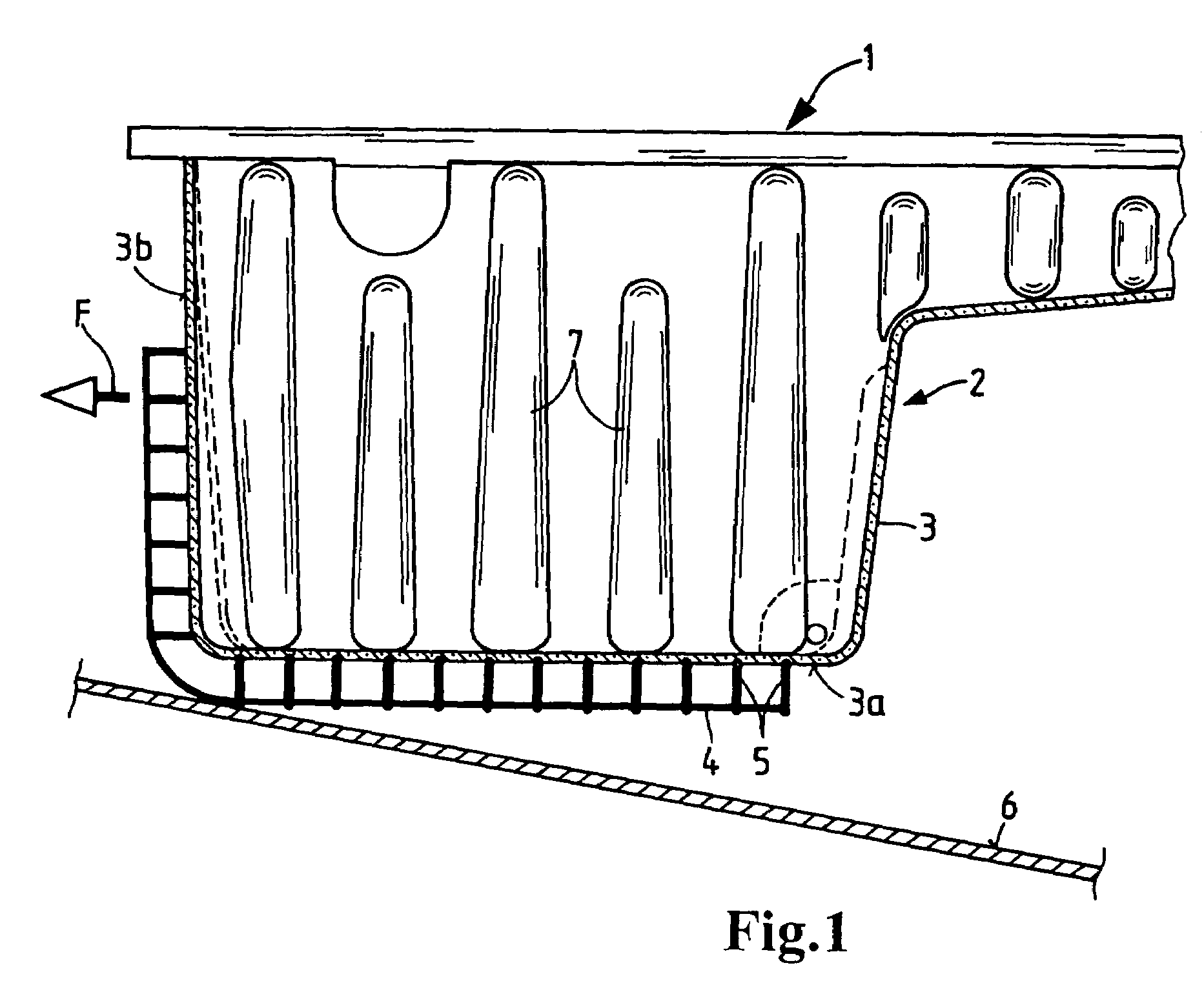

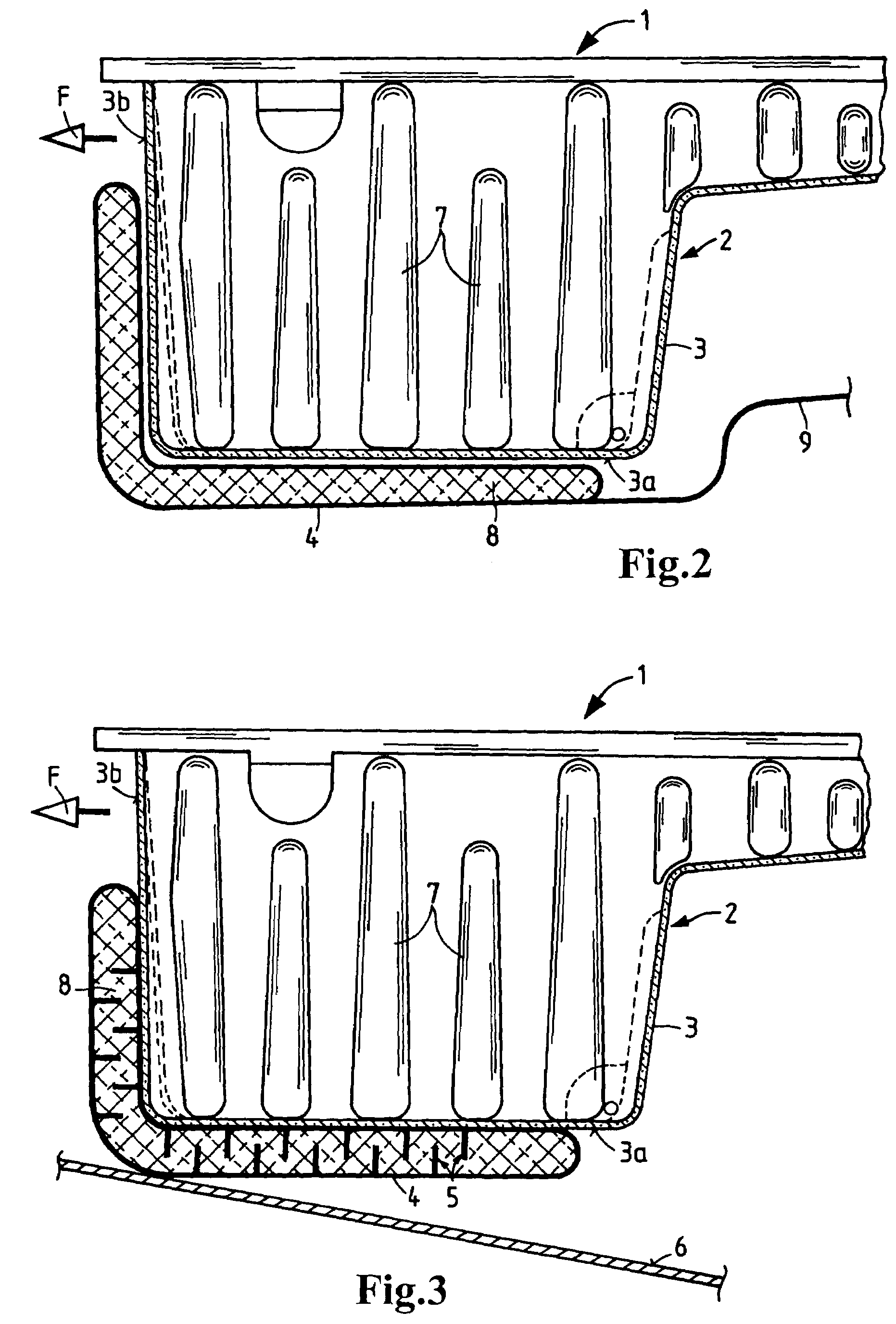

Oil pan useful for an internal combustion engine

InactiveUS20060278099A1Improve protectionProvide protectionCooking vesselsOilsumpsInternal combustion engineSynthetic resin

An oil pan, particularly for an internal combustion engine, having a protective contour member with a protective shell that is spaced apart from the outer wall of the oil pan. The protective shell at least partially encloses the outer wall of the oil pan and is held in a fixed position relative to the outer wall. The oil pan and the protective contour member are preferably made of a synthetic resin material. The protective contour member protects the oil pan against damage caused, for example, due to the impact of stones or if the oil pan comes into contact with an underlying uneven or sloped surface.

Owner:MANN HUMMEL GMBH

Copper tube inner ring gripper

ActiveCN105150236AUniform force distributionAdjustable structureGripping headsGrippersArchitectural engineering

The invention provides a copper tube inner ring gripper which comprises a floating connector, a pull rod, a hanging frame, a cylinder, an insertion pin, a vertical beam, a supporting rod, a rubber supporting handle, a fixed rod, a supporting plate and a connecting rod. The pull rod is installed at the lower end of the floating connector. The pull rod is sleeved with the hanging frame. The cylinder is installed below the hanging frame. One end of the cylinder is connected with the insertion pin. One end of the hanging frame is connected with the vertical beam which is provided with the supporting rod. One end of the supporting rod is provided with the rubber supporting handle. The lower end of the vertical beam is connected with the fixed rod and the connecting rod. One end of the fixed rod is connected with the supporting plate. One end of the connecting rod is connected to the lower end of the pull rod through a connecting piece. The copper tube inner ring gripper is simple in structure, high in adaptability, uniform in clamping strength distribution and not prone to causing copper tube deformation.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Magnetic levitation vehicle with at least one magnetic system

InactiveUS8171859B2Uniform force introductionSimpler andRailway vehiclesElectric propulsionMagnetic polesEngineering

A magnetic levitation vehicle has at least one magnetic arrangement (27). The magnetic arrangement (27) contains a plurality of magnetic poles (27a . . . 27n) which are arranged one behind the other in the direction of travel and comprise windings (33) associated therewith. The magnetic levitation vehicle is also provided with a circuit for supplying the windings (33) with a direct current, said circuit containing switches for selectively switching the magnetic arrangement between a guiding function and / or a braking function.

Owner:THYSSENKRUPP TRANSRAPID

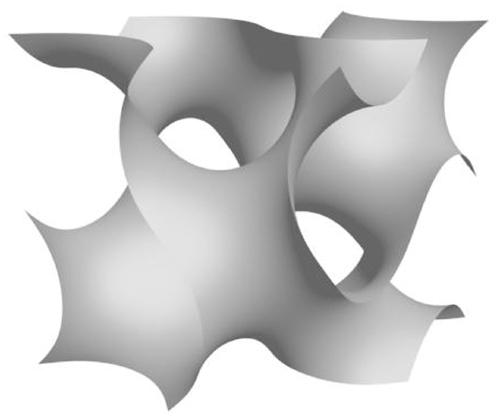

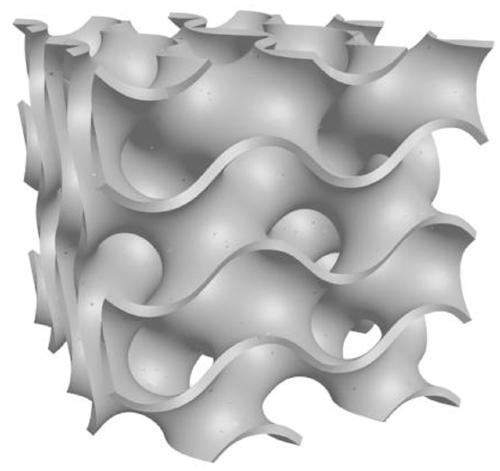

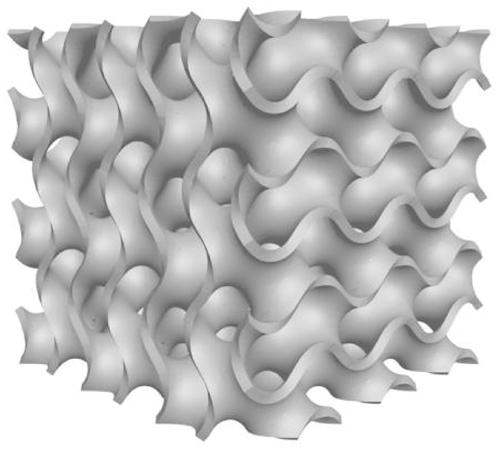

Preparation method of porous alumina ceramics based on Gyroid curved surface

The invention discloses a porous Al2O3 ceramic based on a Gyroid curved surface and a preparation method of the porous Al2O3 ceramic. The porous Al2O3 ceramic is formed based on a three-period minimalsurface Gyroid, and is excellent in mechanical property, smooth and continuous in pore structure and three-dimensional connective. The prepared porous Al2O3 ceramic based on the Gyroid curved surfacehas the characteristics of Al2O3 ceramics, such as high hardness, high-temperature insulating resistance and erosion resistance, can be combined with the functionality of the Gyroid curved surface structure, and has a wide application space in the industrial field. The preparation method mainly comprises the following steps: designing a Gyroid curved surface structure and performing 3D printing;preparing Al2O3 ceramic powder and slurry; and preparing the porous ceramic. By directly controlling the parametrization design of the Gyroid curved surface structure and accurately controlling the three-dimensional structure, pore size, porosity, pore shape distribution and the like, the prepared porous Al2O3 ceramic is suitable for industrial needs.

Owner:CHINA THREE GORGES UNIV

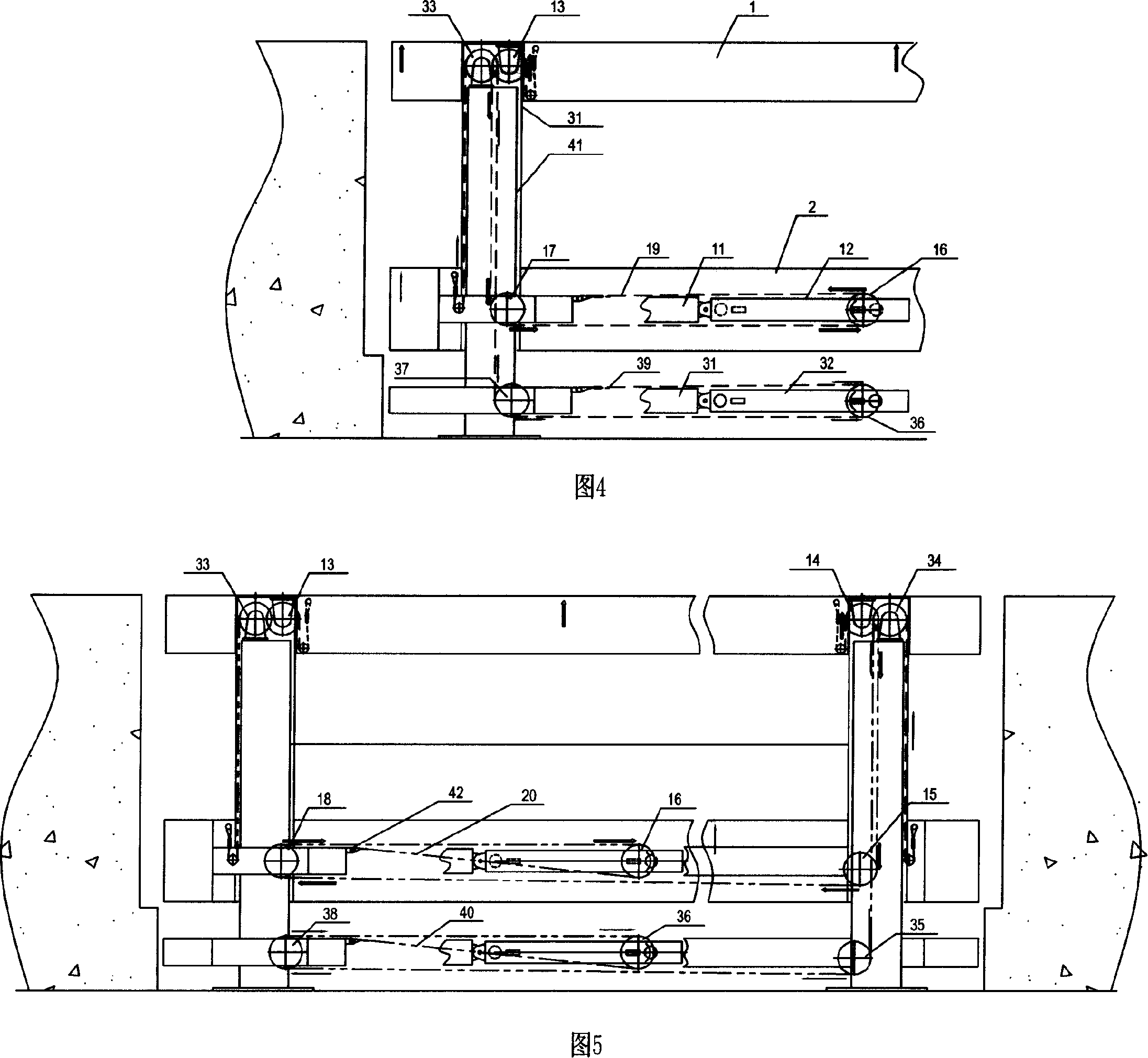

Guide track unloading device for crossbeam of large-sized machine tool and deflection compensation method

ActiveCN102581687AUniform force distributionReduce distortionOther manufacturing equipments/toolsMaintainance and safety accessoriesControl systemMachine

The invention relates to the technical field of large-sized machine tools, in particular to a deflection compensation and guide track unloading compensation method for a crossbeam of a large-sized machine tool and a guide track unloading device. The action of unloading oil cylinders is controlled by a convex surface of the upper surface of an unloading beam and electro-hydraulic proportional pressure valves, the unloading beam on the crossbeam moves on a transverse slide plate, the full stroke of the movement of the unloading beam is determined by means of theoretical computation and is divided into a plurality of compensation intervals, straightness compensation points and straightness variation of the compensation intervals are acquired by experiments and converted into pressure setting values of the left unloading oil cylinder and the right unloading oil cylinder, electric signal values corresponding to the pressure setting values of the left unloading oil cylinder and the right unloading oil cylinder are inputted into a numerical control system of the machine tool, straightness errors of the transverse slide plate is automatically compensated by means of acquiring the electric signals corresponding to the pressure setting values of the left unloading oil cylinder and the right unloading oil cylinder by the control system, pressure on a support surface of a reference guide track of the crossbeam is reduced, the reference guide track of the crossbeam is stressed uniformly, deformation of the crossbeam is reduced, and integral precision of running of the machine tool is enhanced.

Owner:ZHEJIANG YIFENG MACHINERY

All-bearing car body structure of new-energy urban bus

ActiveCN102582689BImprove uniformityAvoid compressionMonocoque constructionsPassenger vehicle superstructuresNew energyEngineering

Owner:DONGFENG MOTOR CORP HUBEI

Vacuum valve

ActiveUS7481417B2Little strengthReduce clamping forceSpindle sealingsMelt-holding vesselsEngineeringMechanical engineering

Owner:VAT HLDG AG

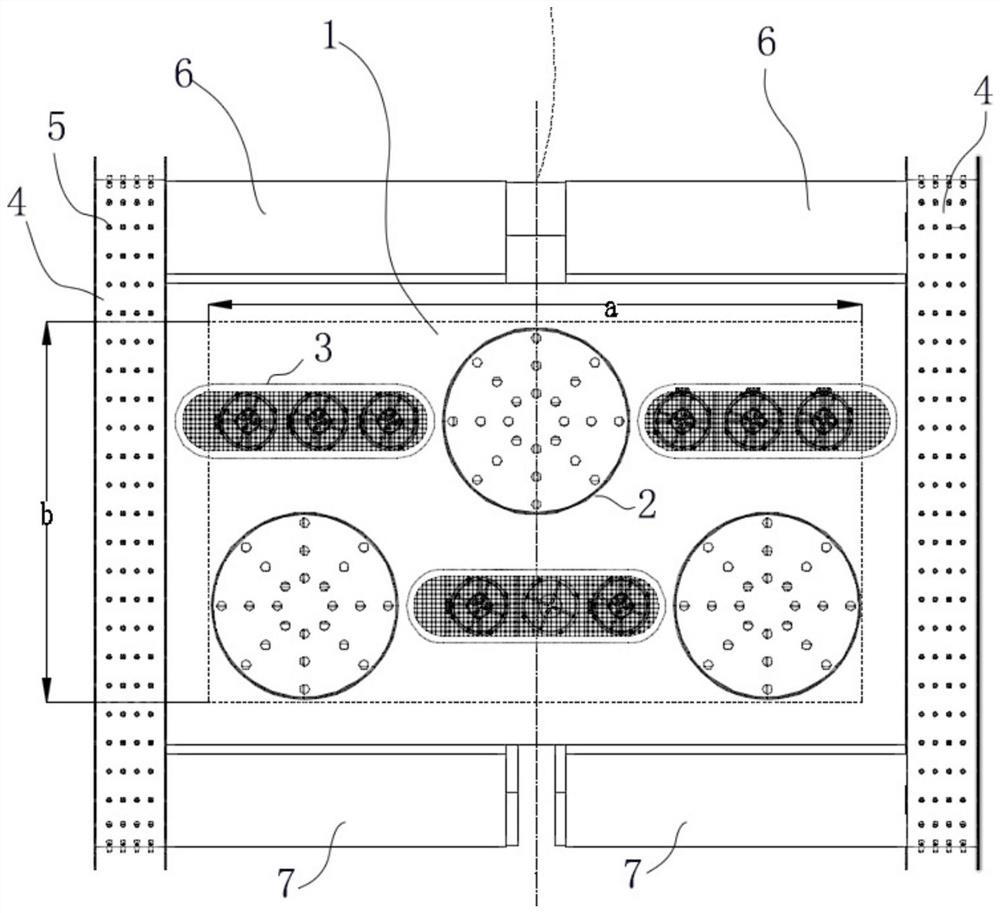

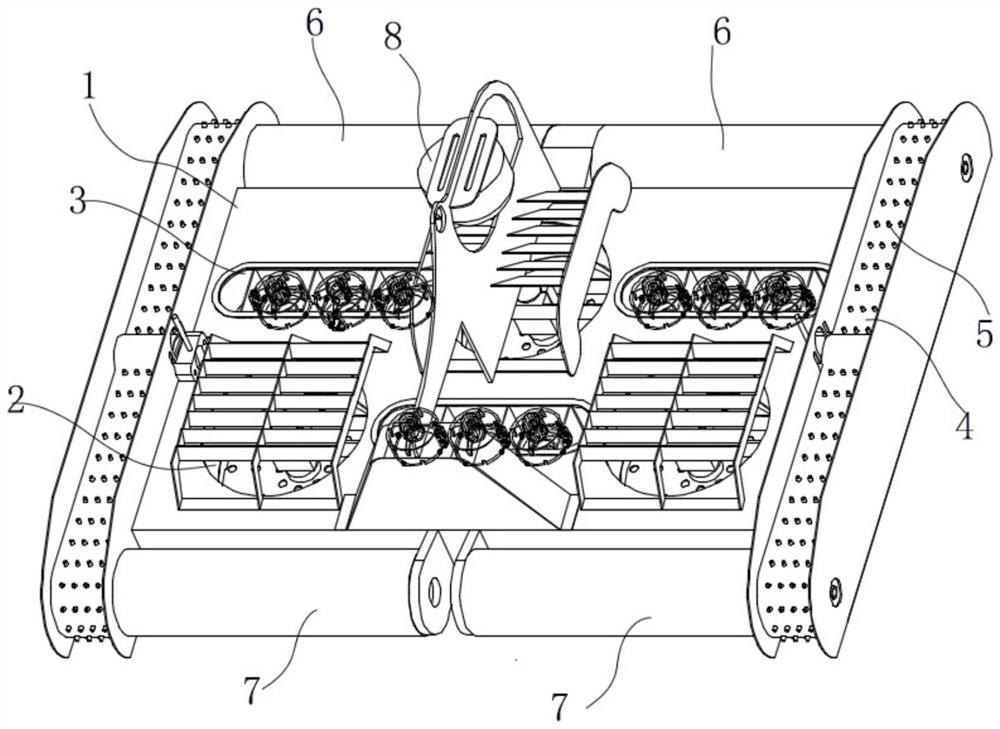

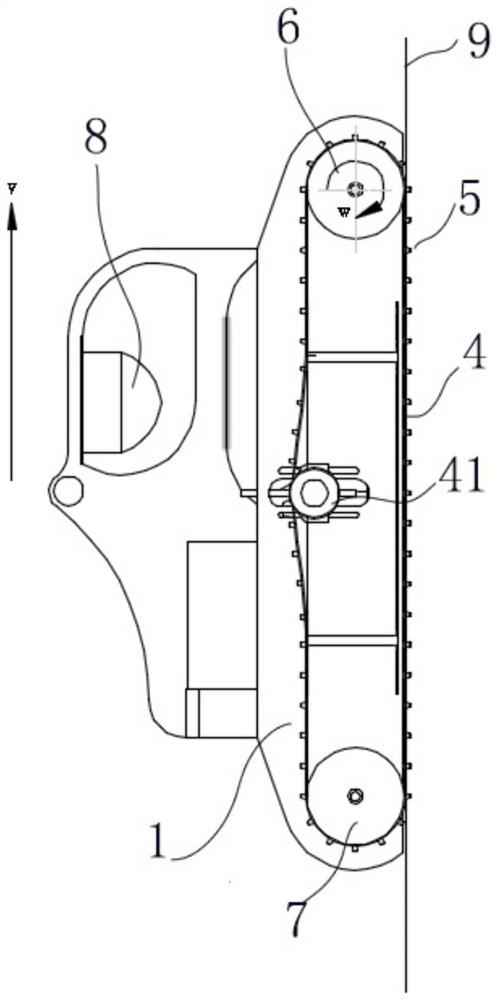

Crawler-type netting cleaning robot for seawater cage culture and netting cleaning method

ActiveCN113275295AFully automatic cleaningEasy to cleanCleaning using liquidsUnderwater vesselsSpray nozzleElectric machinery

The invention discloses a crawler-type netting cleaning robot for seawater cage culture and a netting cleaning method. The netting robot comprises a base frame, a cleaning rotary disc, a rotary disc driving motor and a propeller thruster are installed on the base frame, the rotary disc driving motor is used for driving the cleaning rotary disc to rotate, the propeller thruster is used for adjusting the distance between the cleaning rotary disc and a netting, the cleaning rotary disc is provided with a plurality of flow channels, the tail end of each flow channel is connected with a spraying nozzle for spraying water flow, and the robot is characterized in that the two sides of the base frame are further provided with mutually symmetrical walking crawler belts, the walking crawler belts are respectively connected with a driving motor, and gripping teeth matched with meshes of a to-be-cleaned netting are evenly distributed on the outer surfaces of the walking crawler belts, so that the gripping teeth correspondingly stretch into the meshes of the netting. According to the crawler-type netting cleaning robot for seawater cage culture and the netting cleaning method, the cleaning efficiency of the underwater netting is improved, and the manual labor intensity and the operation cost are reduced.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Oil pan useful for an internal combustion engine

InactiveUS7481196B2Improve protectionProvide protectionCasingsNon-fuel substance addition to fuelInternal combustion engineSynthetic resin

An oil pan, particularly for an internal combustion engine, having a protective contour member with a protective shell that is spaced apart from the outer wall of the oil pan. The protective shell at least partially encloses the outer wall of the oil pan and is held in a fixed position relative to the outer wall. The oil pan and the protective contour member are preferably made of a synthetic resin material. The protective contour member protects the oil pan against damage caused, for example, due to the impact of stones or if the oil pan comes into contact with an underlying uneven or sloped surface.

Owner:MANN HUMMEL GMBH

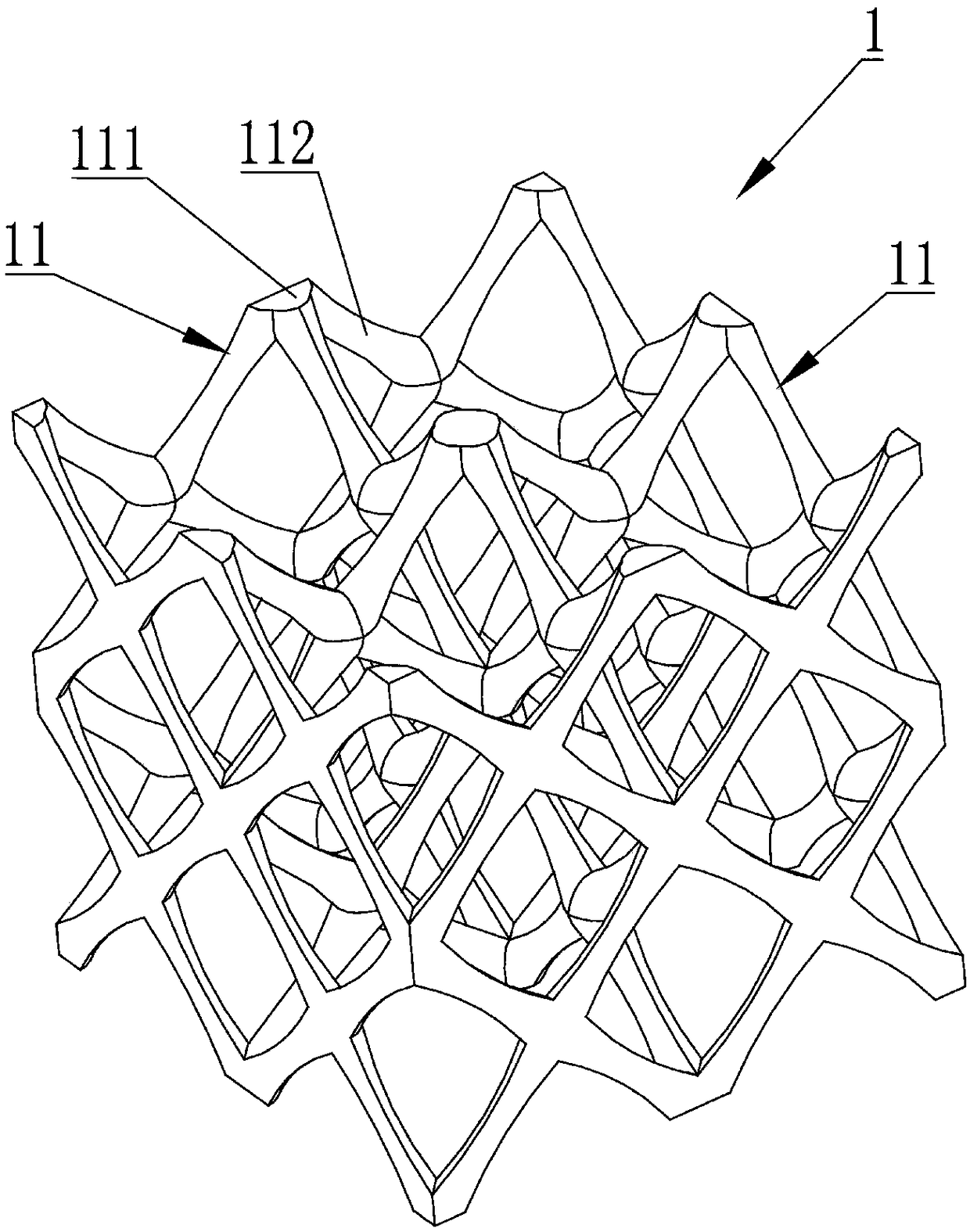

Lattice structure and lattice part

InactiveCN109084169AUniform force distributionReduce stress concentrationConstructions elementsStress concentrationEngineering

The invention relates to the technical field of material structures, in particular to a lattice structure. The lattice structure comprises a plurality of lattice cells, wherein the plurality of lattice cells are arranged in an array; each lattice cell comprises a plurality of variable-diameter connecting rods; the variable-diameter connecting rods are connected through nodes; the diameters of twoends of the variable-diameter connecting rods are larger than that of parts between the two ends; and the diameters of the variable-diameter connecting rods are in smooth transition change. The stressdistribution of the lattice structure can be more uniform to reduce the stress concentration of nodes, and the specific strength and specific rigidity are higher. The invention also relates to a lattice part comprising the lattice structure, and the reliability of the part is improved.

Owner:CENT SOUTH UNIV

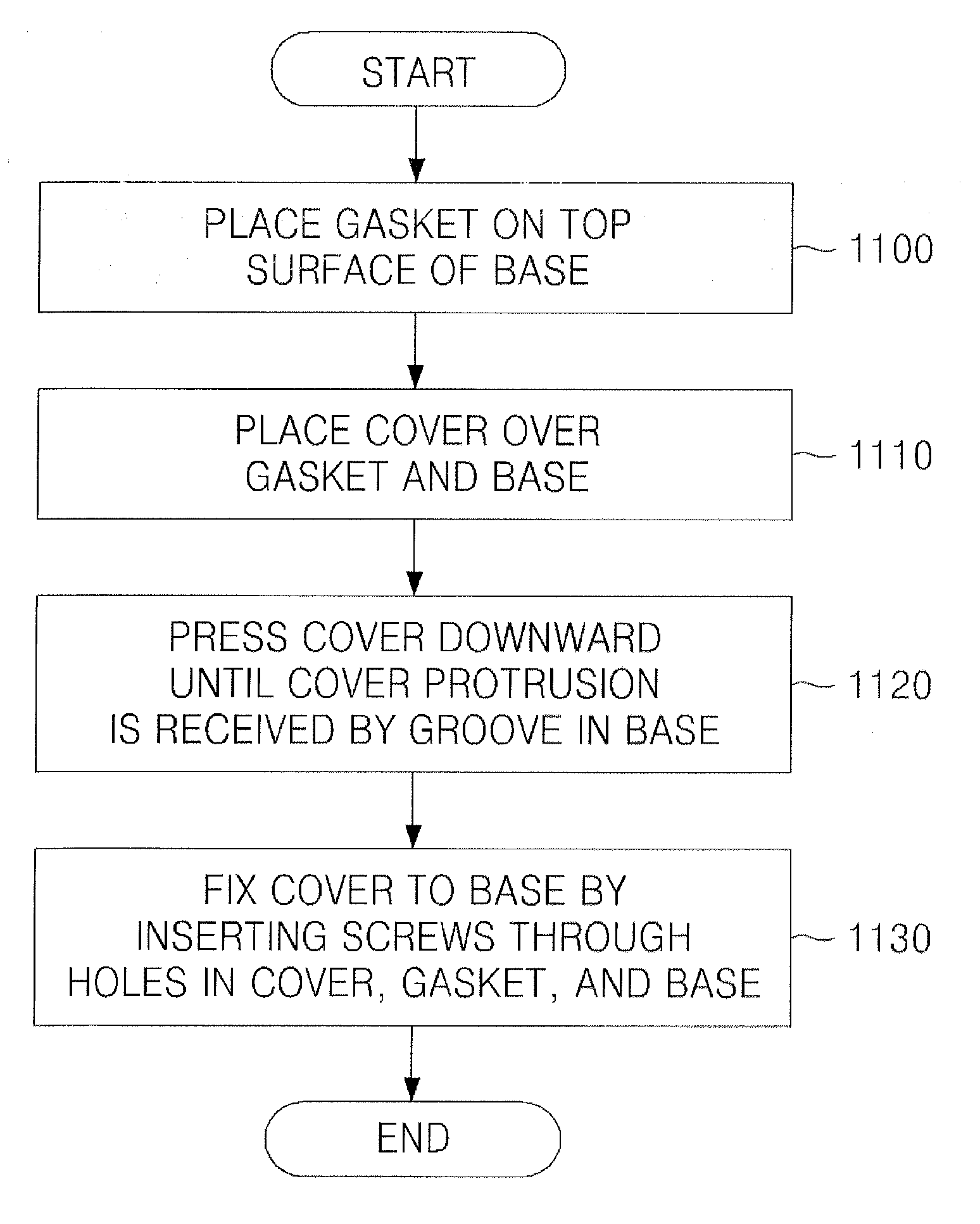

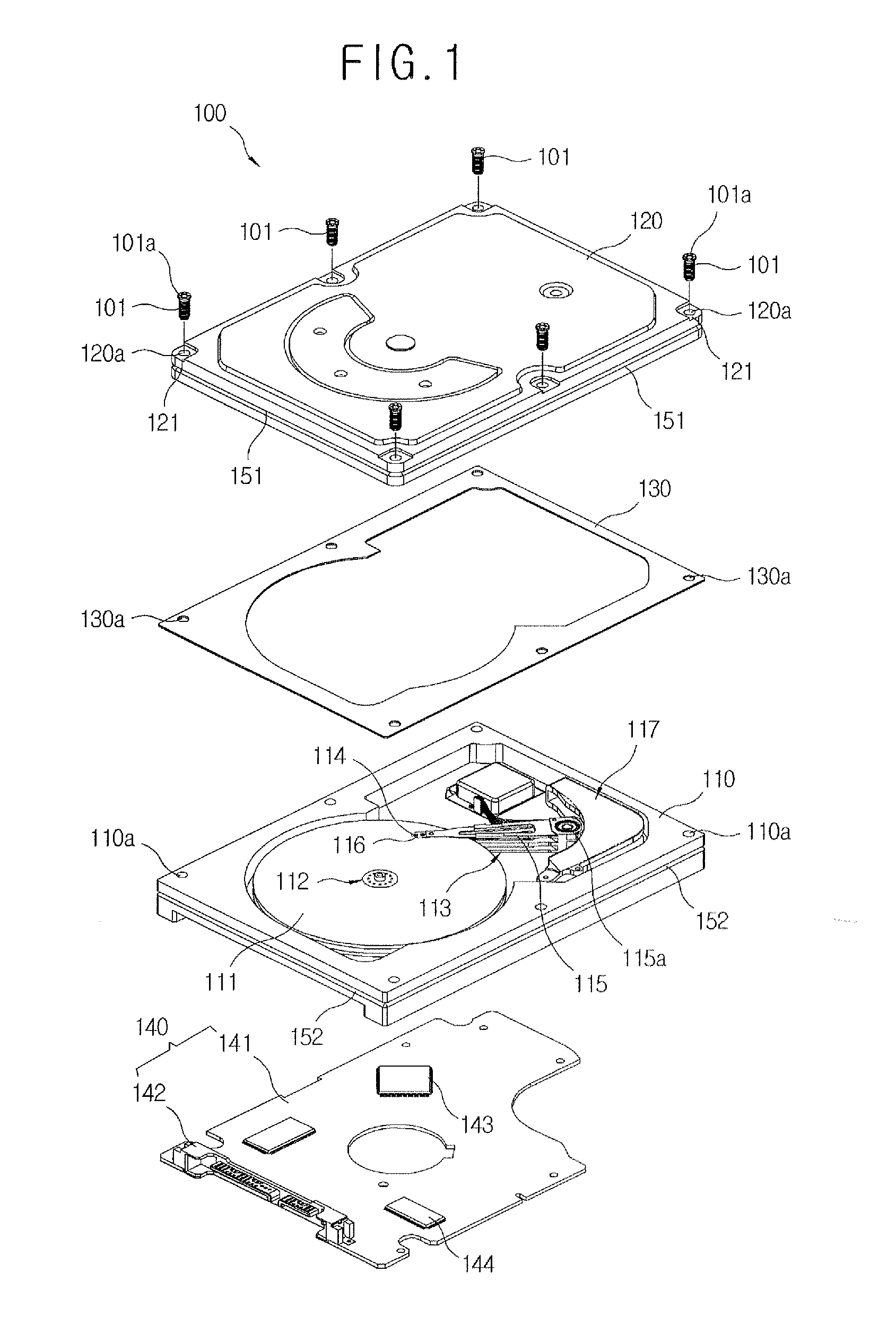

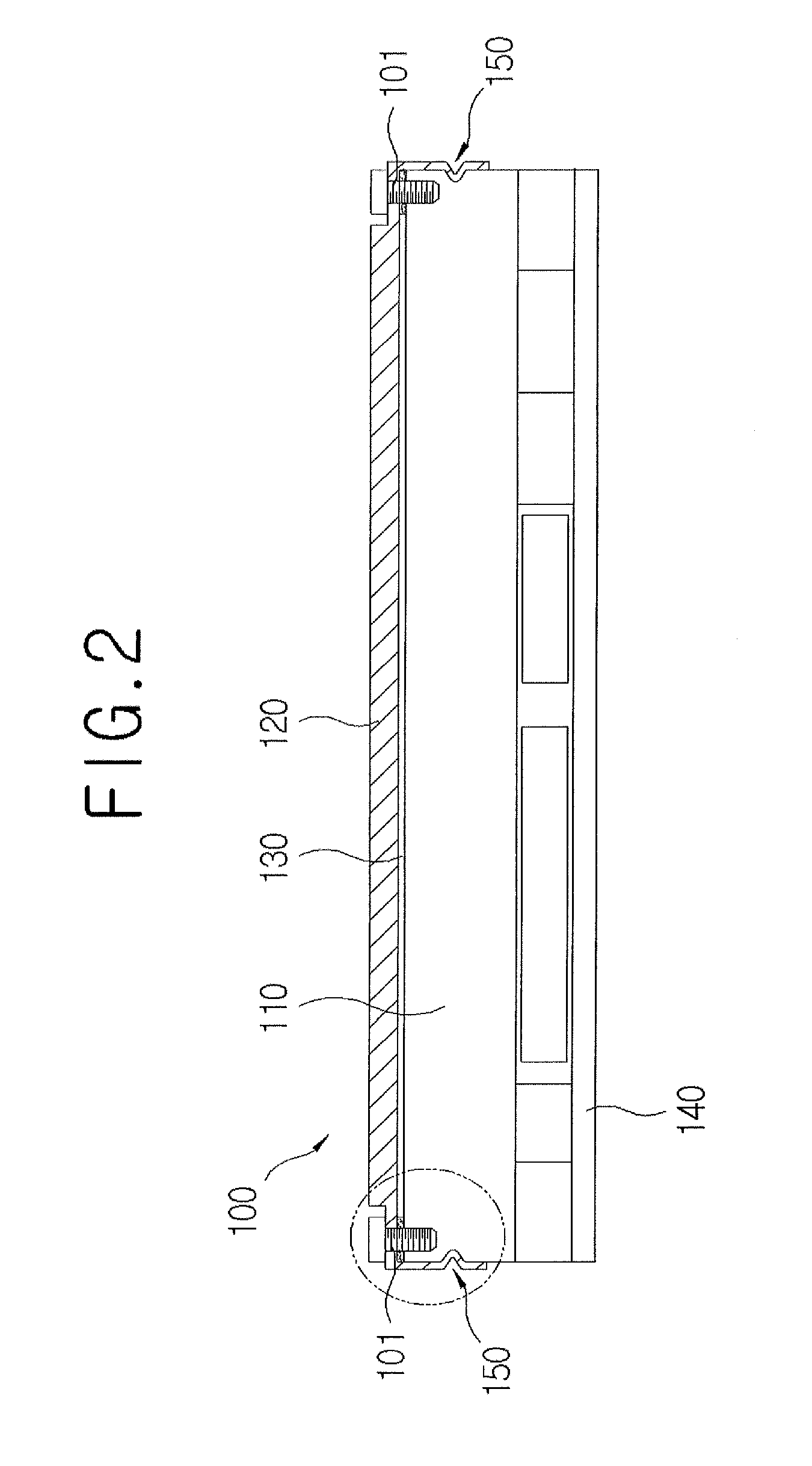

Hard disk drive

InactiveUS20100232059A1Increase pressureSimple and uncomplicated structureUndesired vibrations/sounds insulation/absorptionRecord information storageHard disc driveEngineering

A hard disk drive includes a base provided with a plurality of interior component parts related to reading and writing information; a cover placed on a top surface of the base with the interior component parts therebetween and assembled to the base by a plurality of screws; a gasket interposed between the cover and the base to provide a seal between the cover and the base; and a reinforcing coupling part provided in the cover and the base to reinforce pressurization of the cover to the gasket when the cover is assembled to the base.

Owner:SEAGATE TECH INT

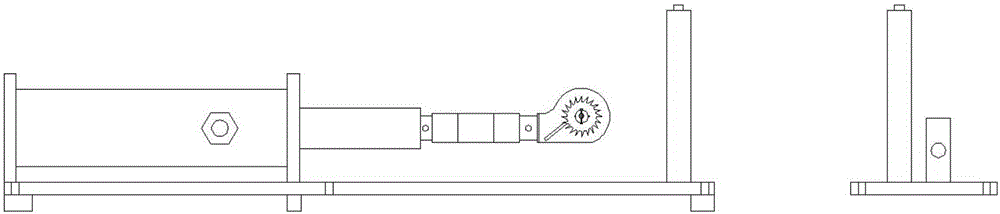

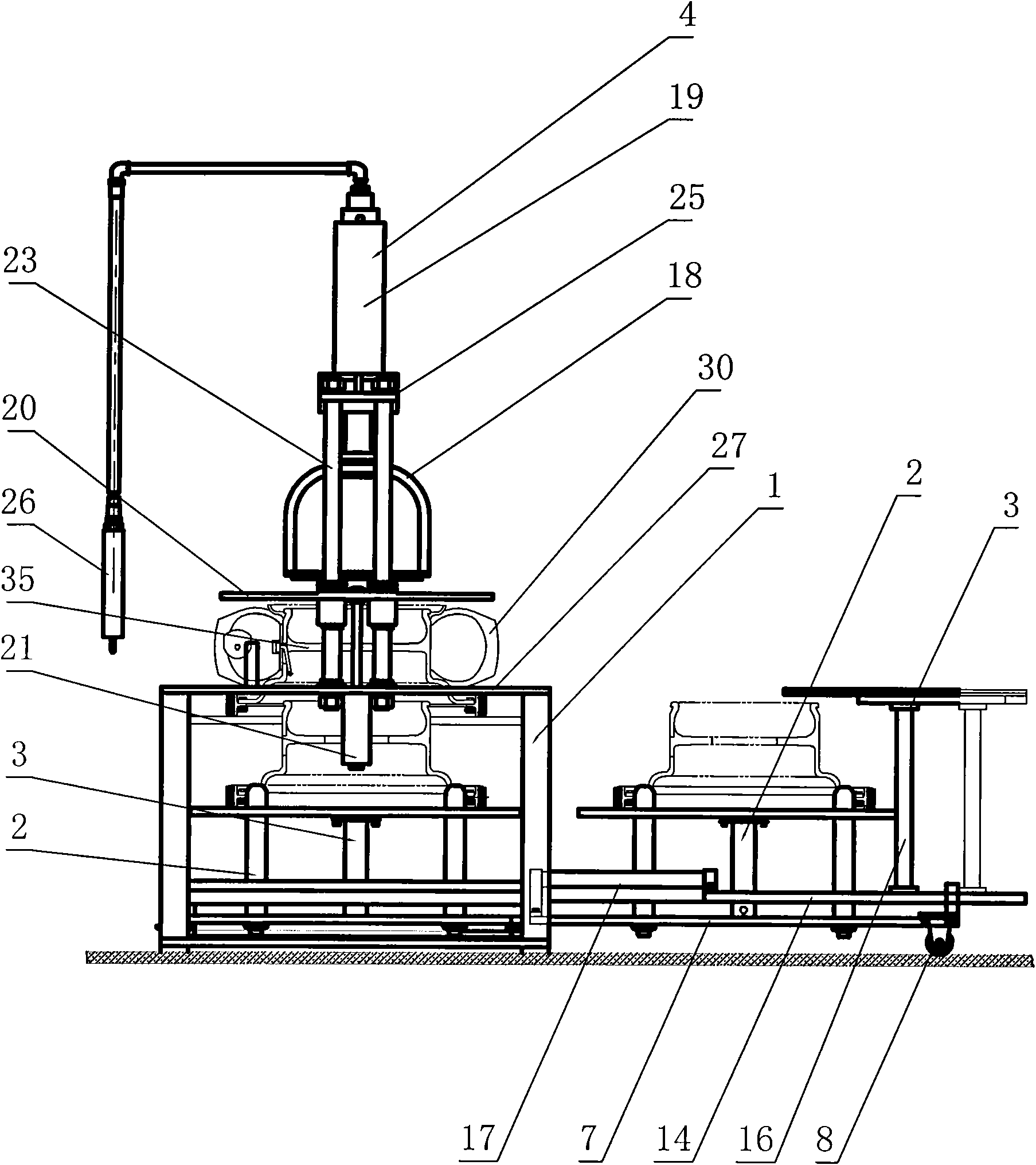

Tyre dismounting machine

InactiveCN101844493AImprove efficiencyPrecise positioningTyre repairingMechanical engineeringHydraulic pressure

The invention discloses a tyre dismounting machine, comprising a rack, a jacking device, a conveyer device used for conveying the jacking device in and out the bottom of the rack, a brake block device arranged on the conveyer device and a rimmer pressing device arranged at the top of the rack. The rimmer of the invention is positioned by the jacking device and is conveyed to the bottom of the rimmer pressing device by the conveyer device, rubber tyre is placed at the top of the rack and is positioned by the brake block device, the entire process is realized by cylinder, efficiency is high, and positioning is accurate; the rubber tyre is horizontally placed at the top of the rack, pressure is vertically applied to the rimmer by the rimmer pressing device, and the tyre is pressed out from the rubber tyre, the dismounting manner in the prior art is changed, the rimmer pressing device adopts hydraulic driving, pressure is large, and the rimmer can be rapidly pressed out from the rubber tyre; and the rubber tyre is pressed on the rack, the rimmer pressing device adopts a rimmer clamping ring to be touched with the rimmer, entire stress is realized when in pressure application, stress is uniformly distributed, and friction between the rimmer and the rubber tyre is reduced.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

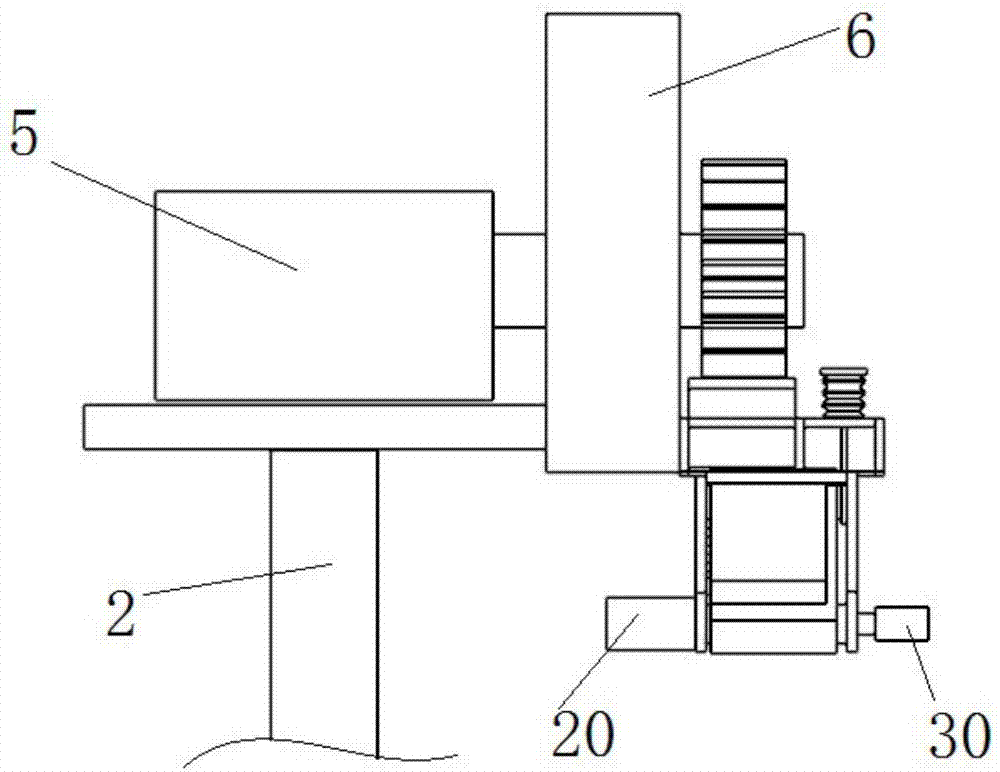

Automatically adjustable belt polishing machine and method

InactiveCN107363684AAvoid the phenomenon of surplus overthrowingImprove work efficiencyGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention discloses an automatically adjustable belt polishing machine and method, comprising a base, a support seat, a guide rail and a polishing device, the base is provided with a telescopic and adjustable column, and the top of the column is fixedly provided with a support seat, so A drive device is provided on the support base; the guide rail is fixedly arranged on the support base, and the guide rail is arranged parallel to the base, the polishing device is suspended on the guide rail, and the polishing device is driven by the drive device and runs along the guide rail. displacement. The invention provides an automatically adjustable belt polishing machine and method, which can automatically adjust the shape of the polishing surface of the polishing belt according to the shape of the polishing object, thereby improving the polishing effect.

Owner:SUZHOU SANTI INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com