Composite loading test device for explosive blasting impact and shearing

A technology of compound loading and explosive impact, which is applied in the direction of testing the strength of materials by using one-time impact force and applying stable shear force to test the strength of materials, etc. It can solve the problems of small loading rate, inability to reflect strong impact stress, and low strain rate. , to achieve the effect of avoiding detonation, avoiding accidental ignition response, and uniform force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

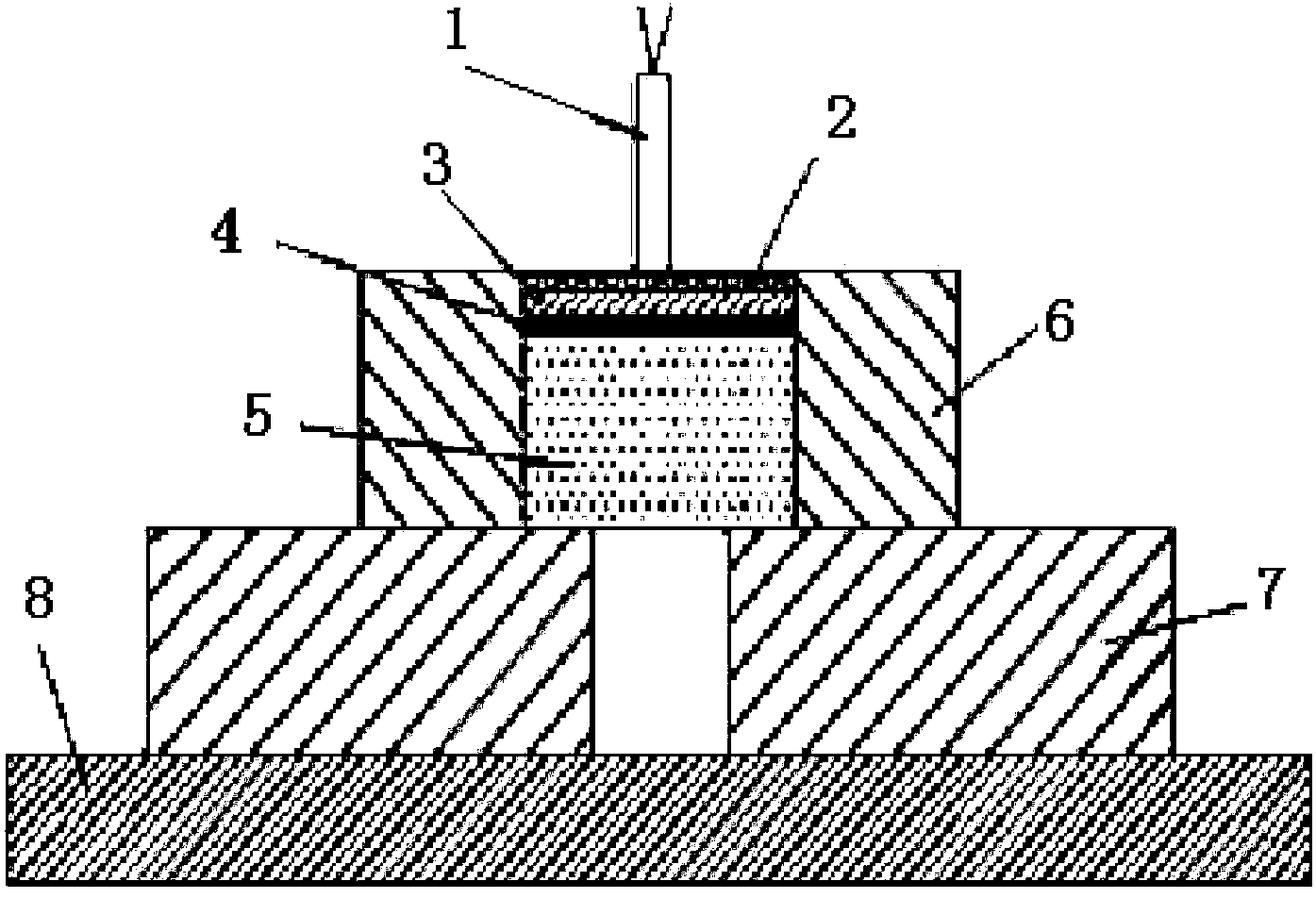

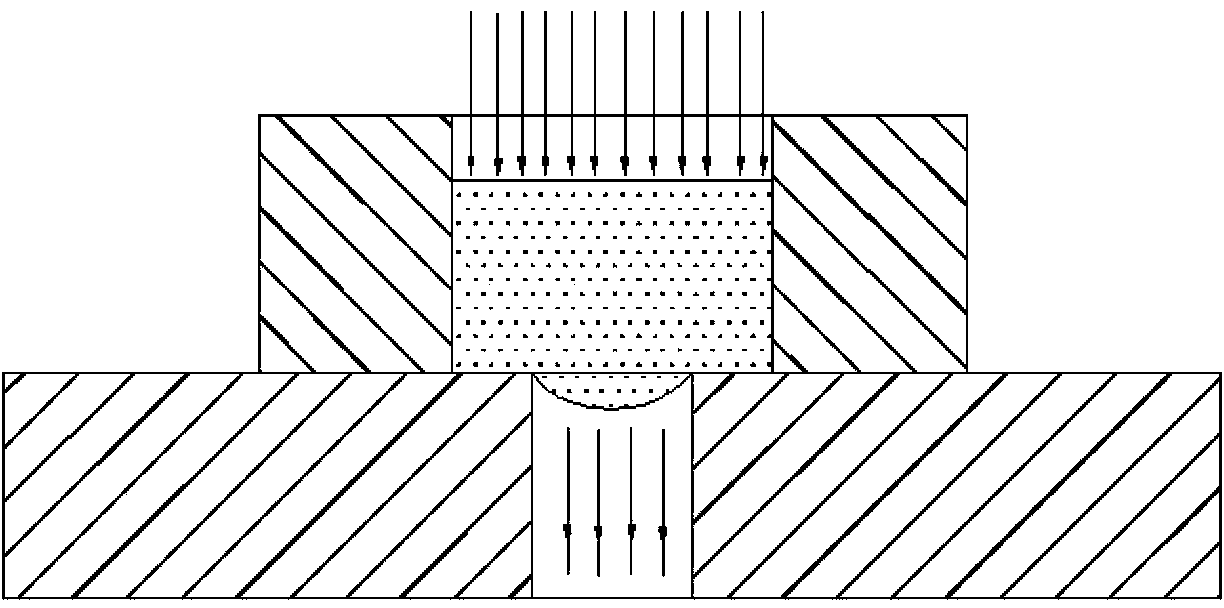

[0049] Embodiment: Following the above-mentioned technical scheme of the present invention, the processing and application process of the loading test device in this embodiment are as follows:

[0050] (1) Manufacturing

[0051] The metal parts of the present invention (including the driving steel plate 4, the limiting body 6, the base 7 and the witness plate 8) are all made of 45# stainless steel.

[0052] Detonator 1 chooses 8# copper detonator;

[0053] The driving explosive 2 is a flexible explosive made of 88% Taian (PETN) and 12% inert binder; the material of the buffer layer 3 is polytetrafluoroethylene, and the end surface is smooth and flat. The end face of the driving steel plate 4 is smooth and flat. All three have a thickness of 2mm and a diameter of 50mm.

[0054] The main explosive 5 is made of PBXN-109 explosive and compressed into a grain, and the size of the grain is Ф50mm×30mm.

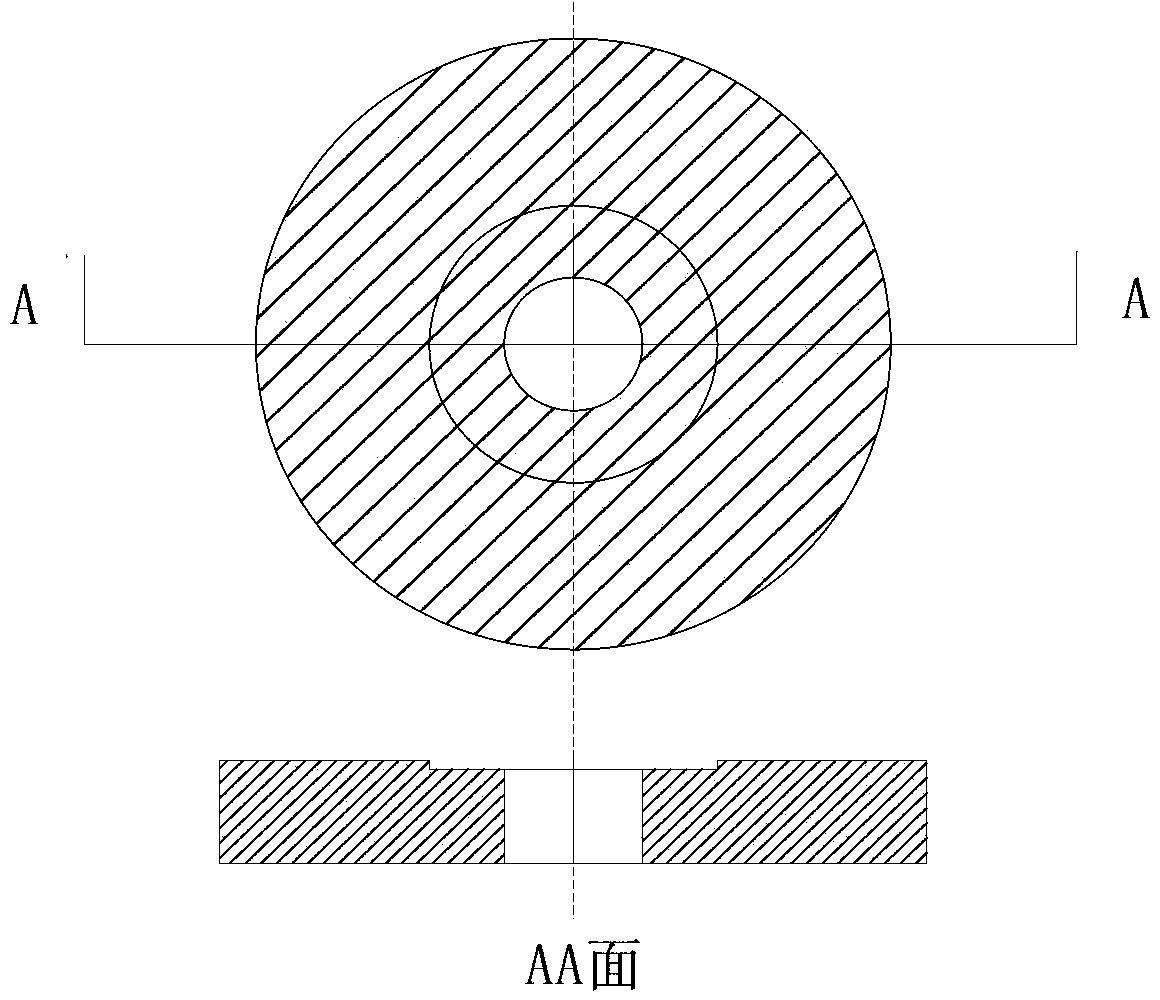

[0055] The limiting body 6 is a cylinder with an inner diameter of 50mm, a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com