Patents

Literature

244 results about "High strain rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

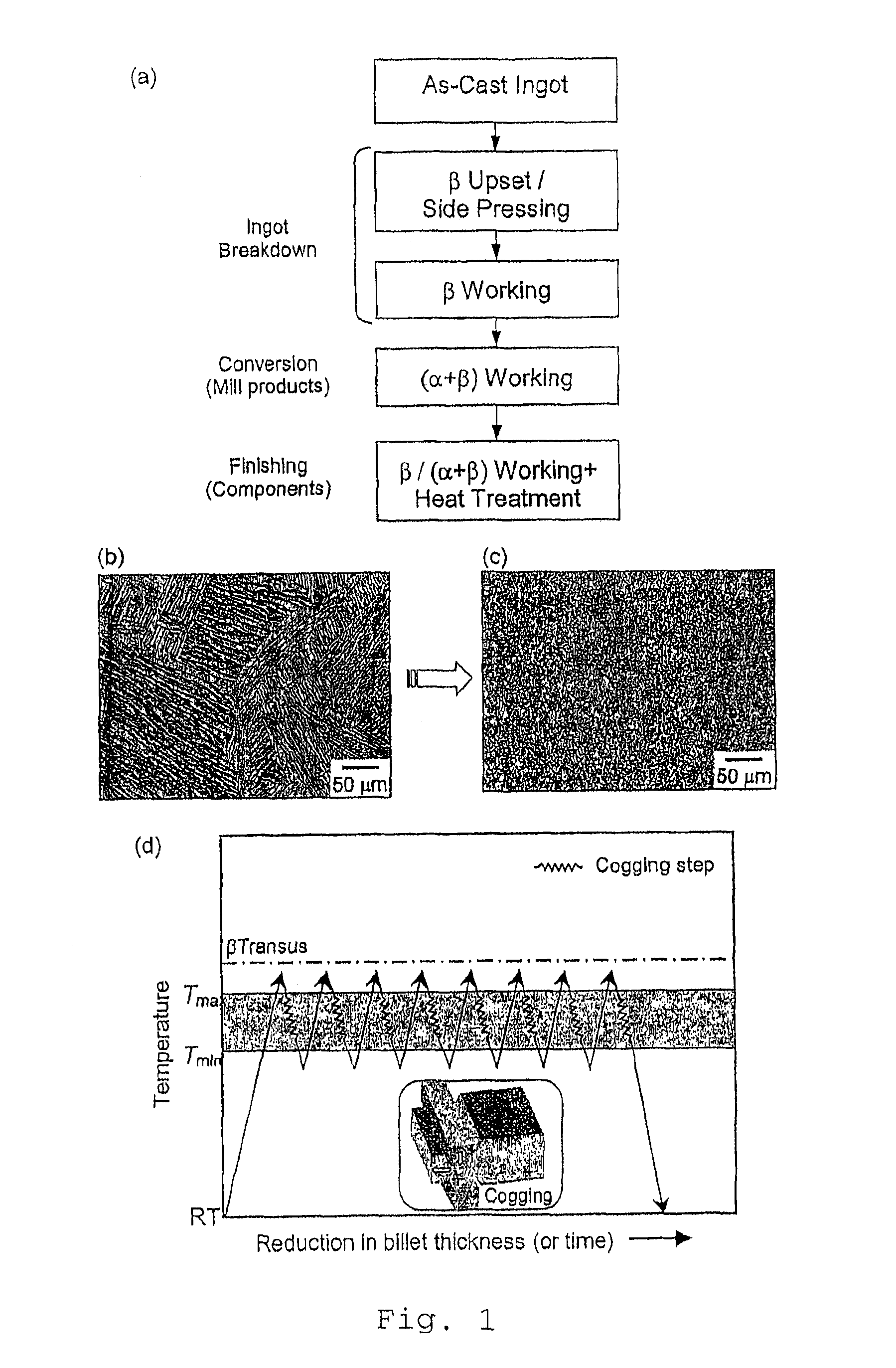

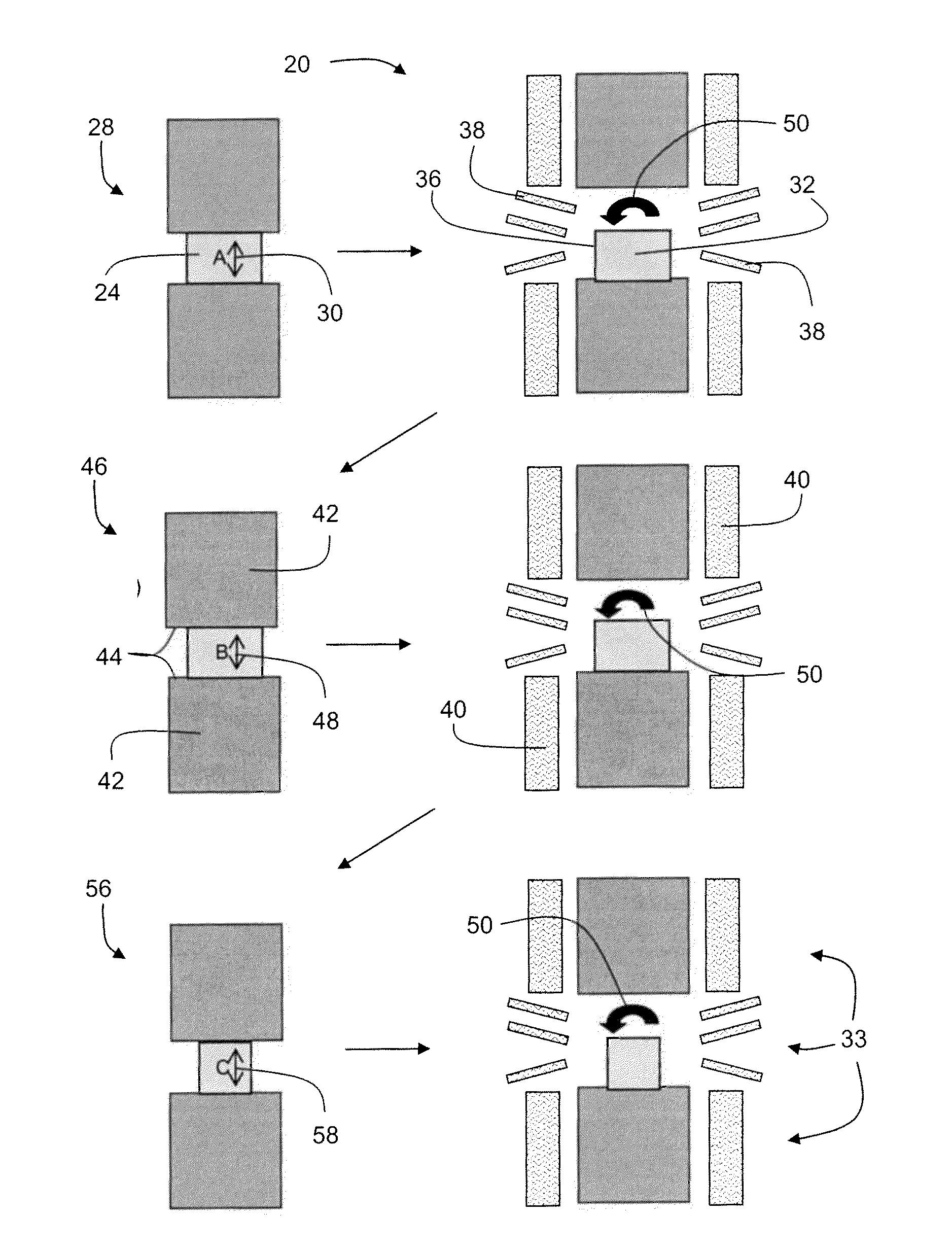

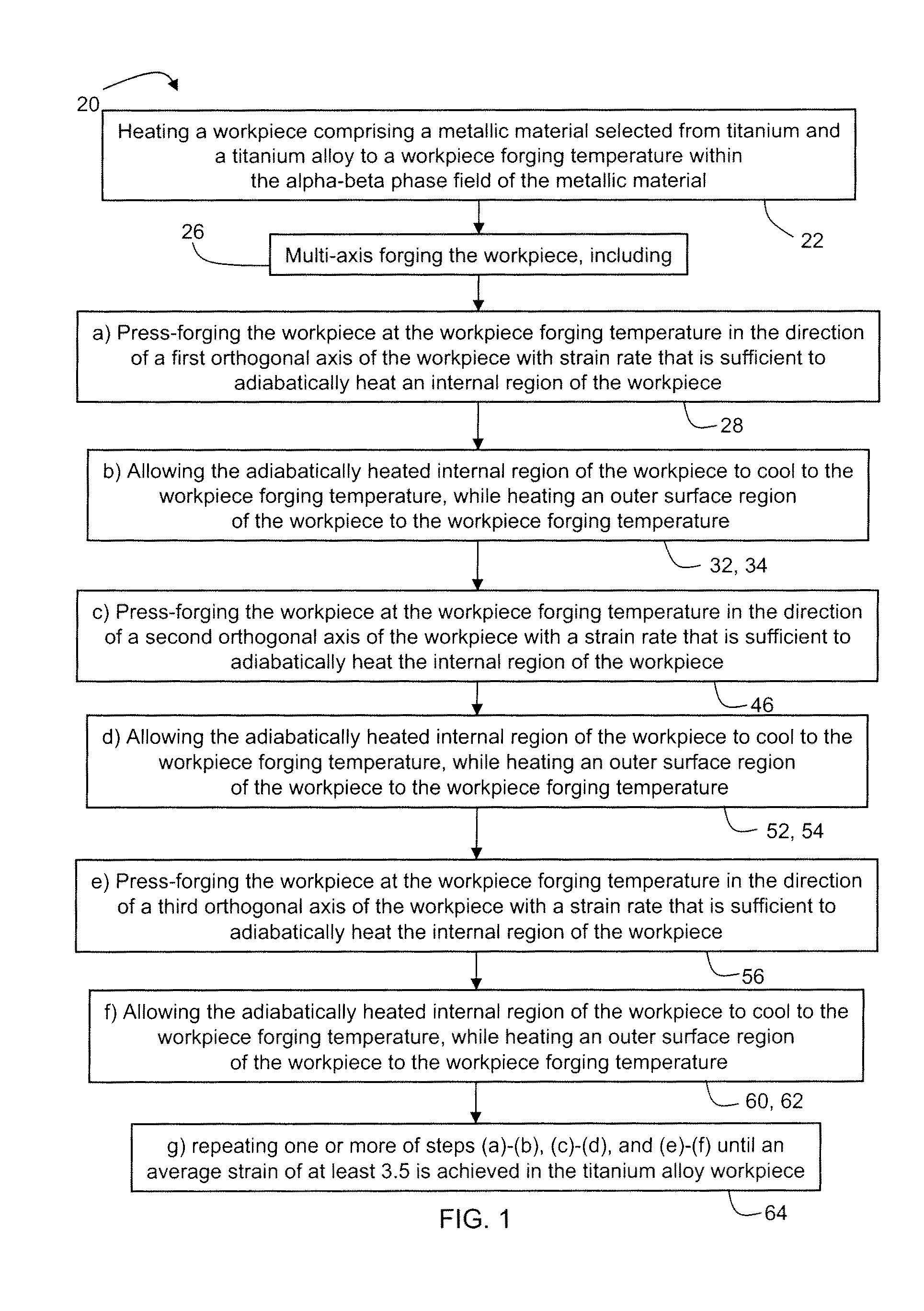

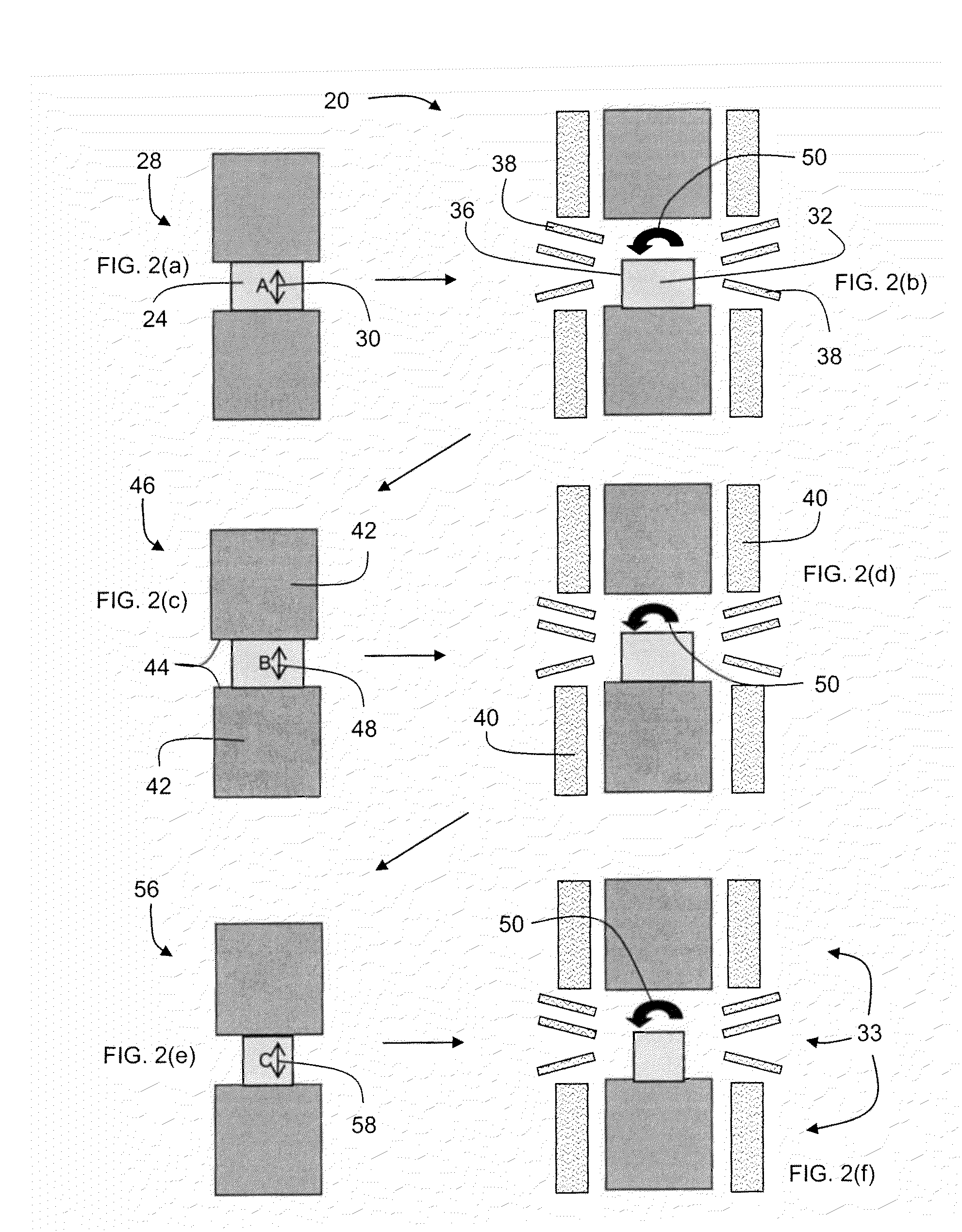

Processing Routes for Titanium and Titanium Alloys

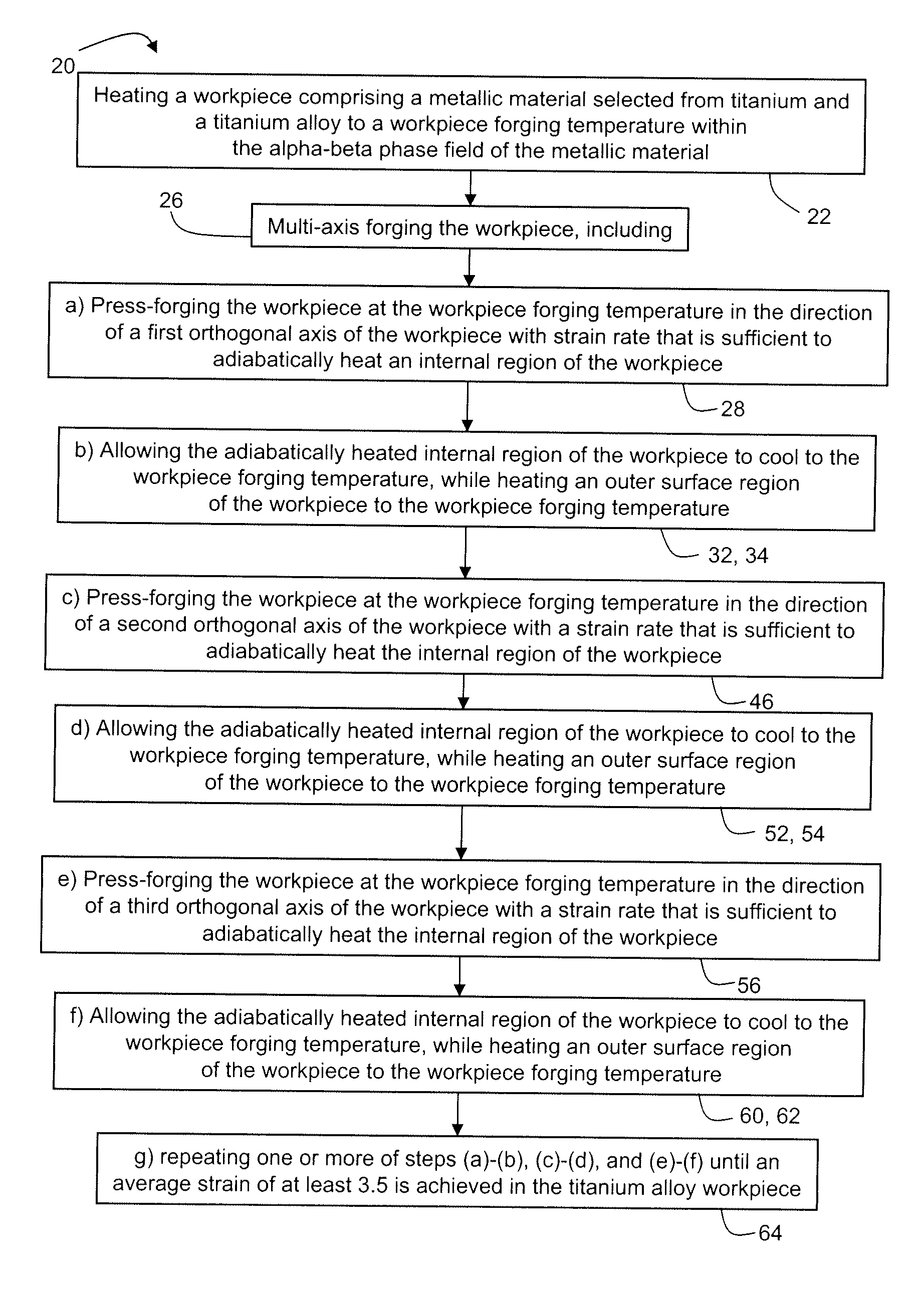

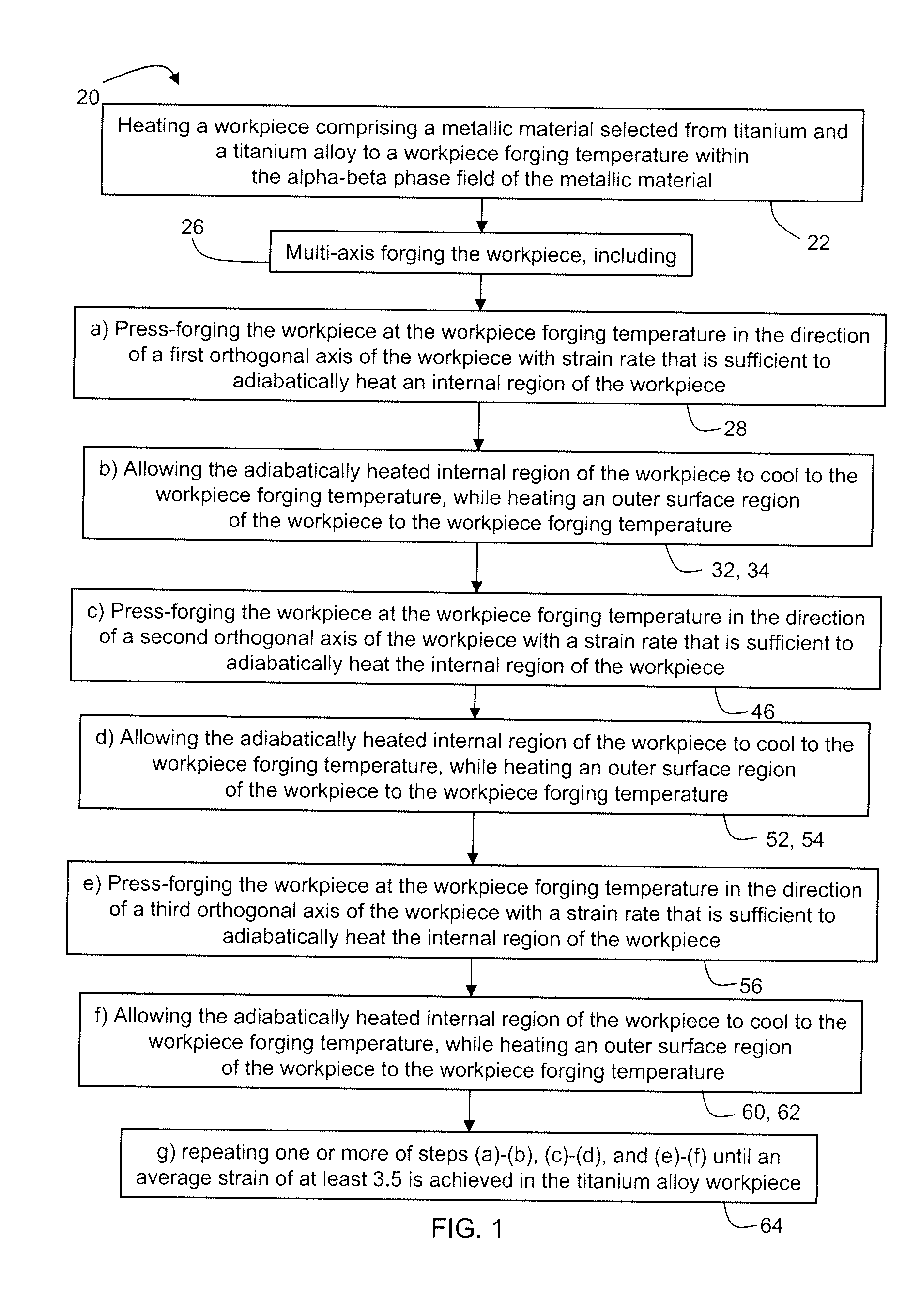

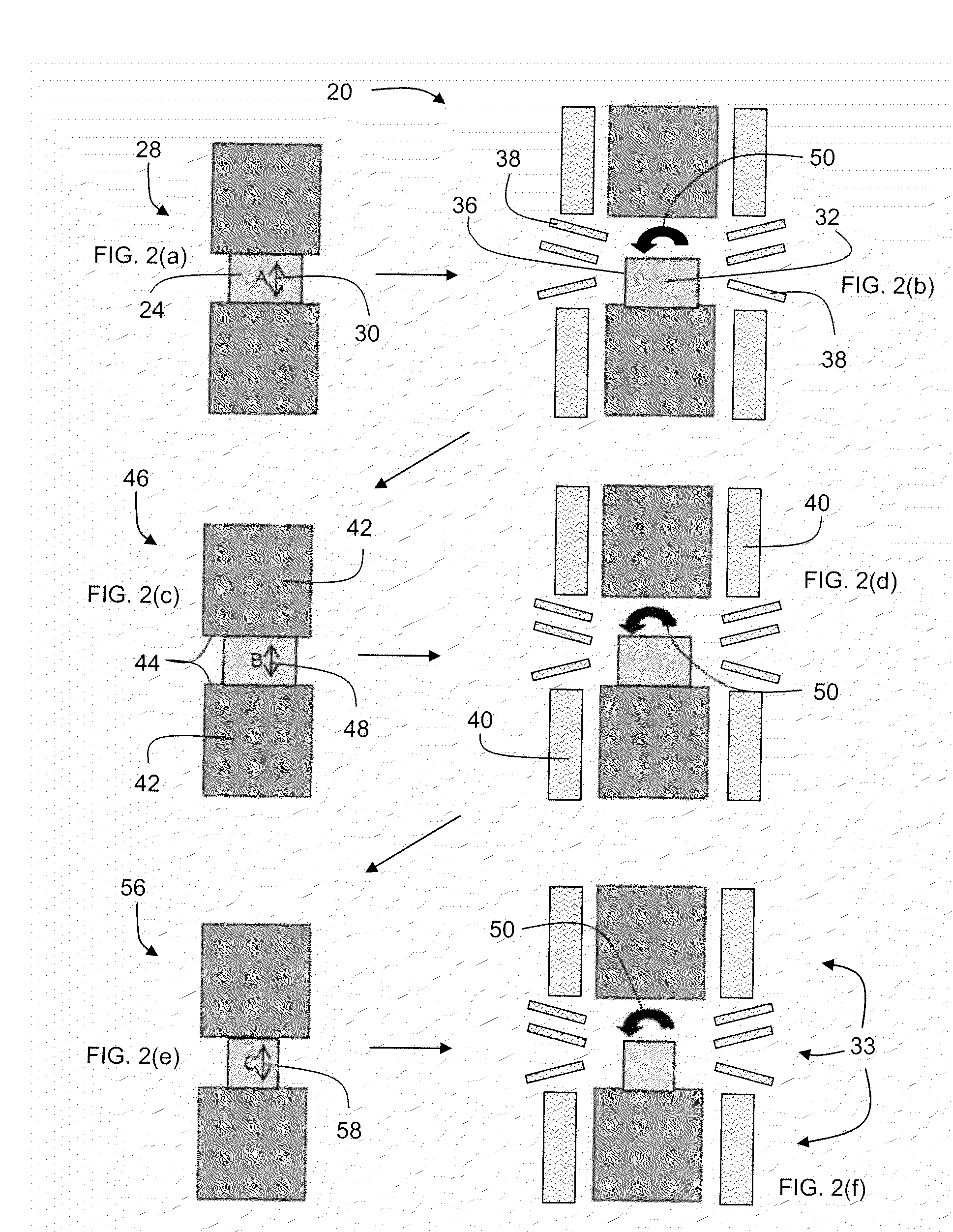

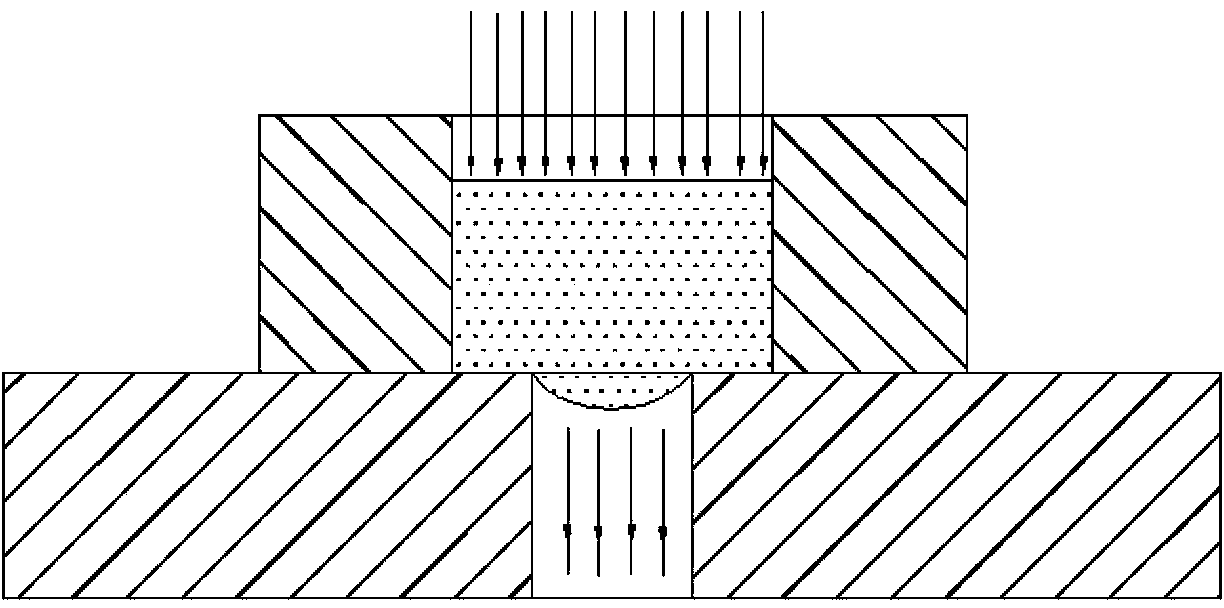

Methods of refining the grain size of titanium and titanium alloys include thermally managed high strain rate multi-axis forging. A high strain rate adiabatically heats an internal region of the workpiece during forging, and a thermal management system is used to heat an external surface region to the workpiece forging temperature, while the internal region is allowed to cool to the workpiece forging temperature. A further method includes multiple upset and draw forging titanium or a titanium alloy using a strain rate less than is used in conventional open die forging of titanium and titanium alloys. Incremental workpiece rotation and draw forging causes severe plastic deformation and grain refinement in the titanium or titanium alloy forging.

Owner:ATI PROPERTIES LLC

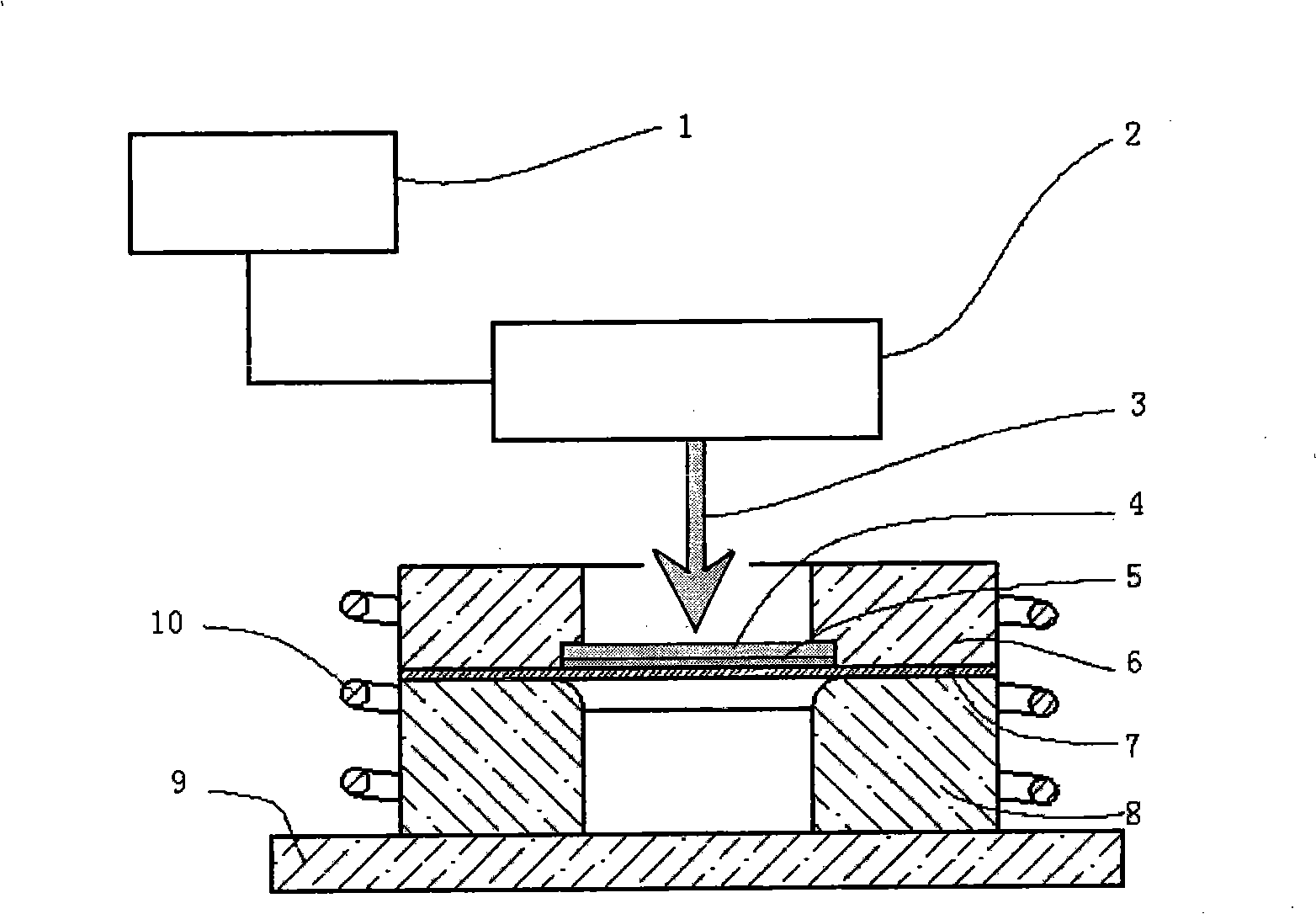

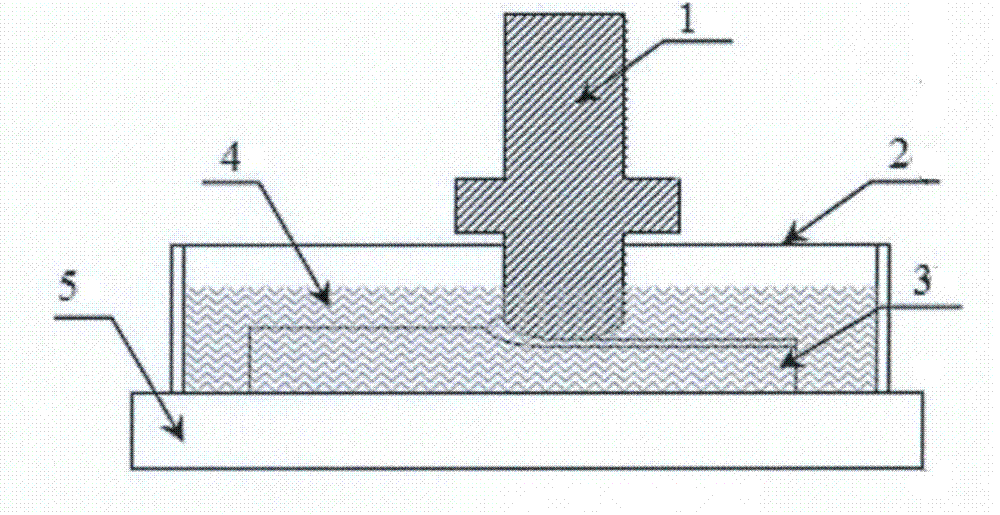

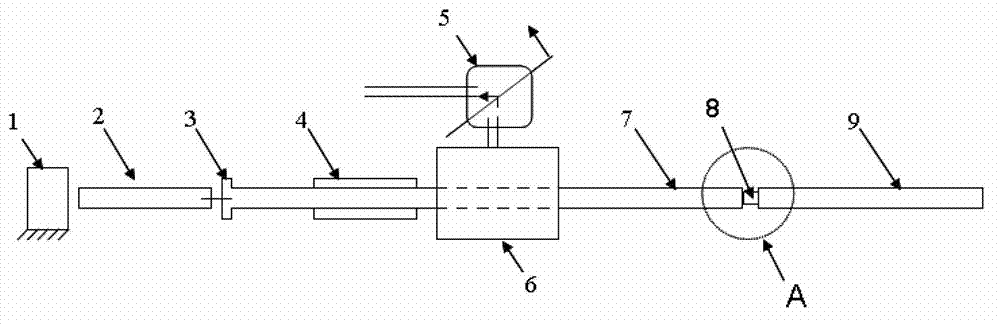

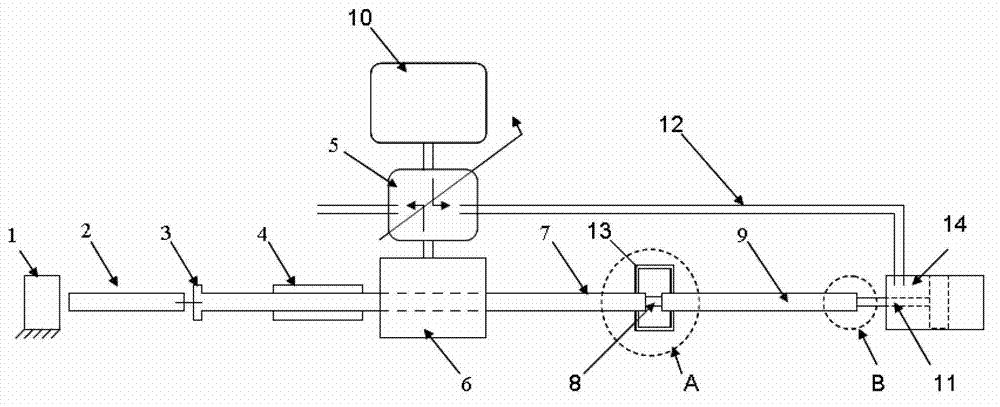

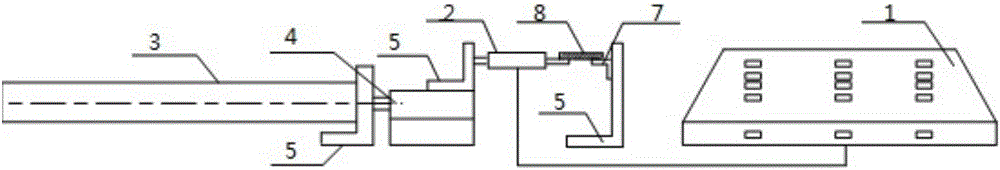

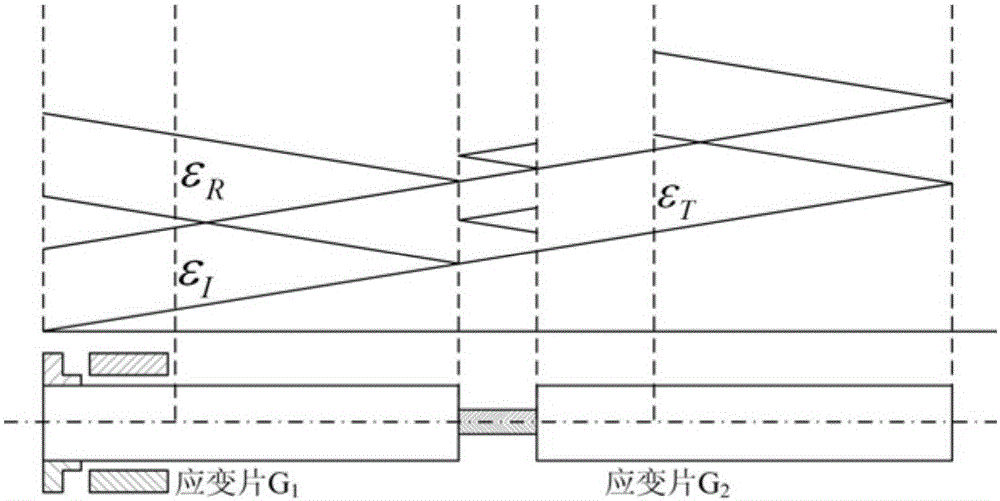

Experimental device of split hopkinson pressure bar based on electromagnetic force load

ActiveCN103913382AGood repeatabilityEasy to operateMaterial strength using tensile/compressive forcesElectromagnetic shieldingEngineering

The invention discloses an experimental device of a split hopkinson pressure bar based on electromagnetic force load. The experimental device comprises an electromagnetic riveting device and a split hopkinson pressure bar experiment device, wherein the electromagnetic riveting device is arranged at one end of an incident bar of the split hopkinson pressure bar experiment device; the end face of an electromagnetic riveting gun on the electromagnetic riveting device is in full contact with the end face of the end of the incident bar, so that the electromagnetic riveting device can generate stress pulse which is directly input into the incident bar and generated pulse signals can be accurately controlled. By adopting the experimental device, the split hopkinson pressure bar is not greatly improved; the electromagnetic riveting device is only used for replacing an air gun in a conventional split hopkinson pressure bar system; accurate control of stress wave is achieved in an electromagnetic way; meanwhile, the width of the stress wave generated by the electromagnetic load is not limited by the length of an impacting bar, so that the width of the stress wave generated by the experimental device is large enough at a high strain rate, thereby achieving the normalization of experimental technologies of the split hopkinson pressure bar.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

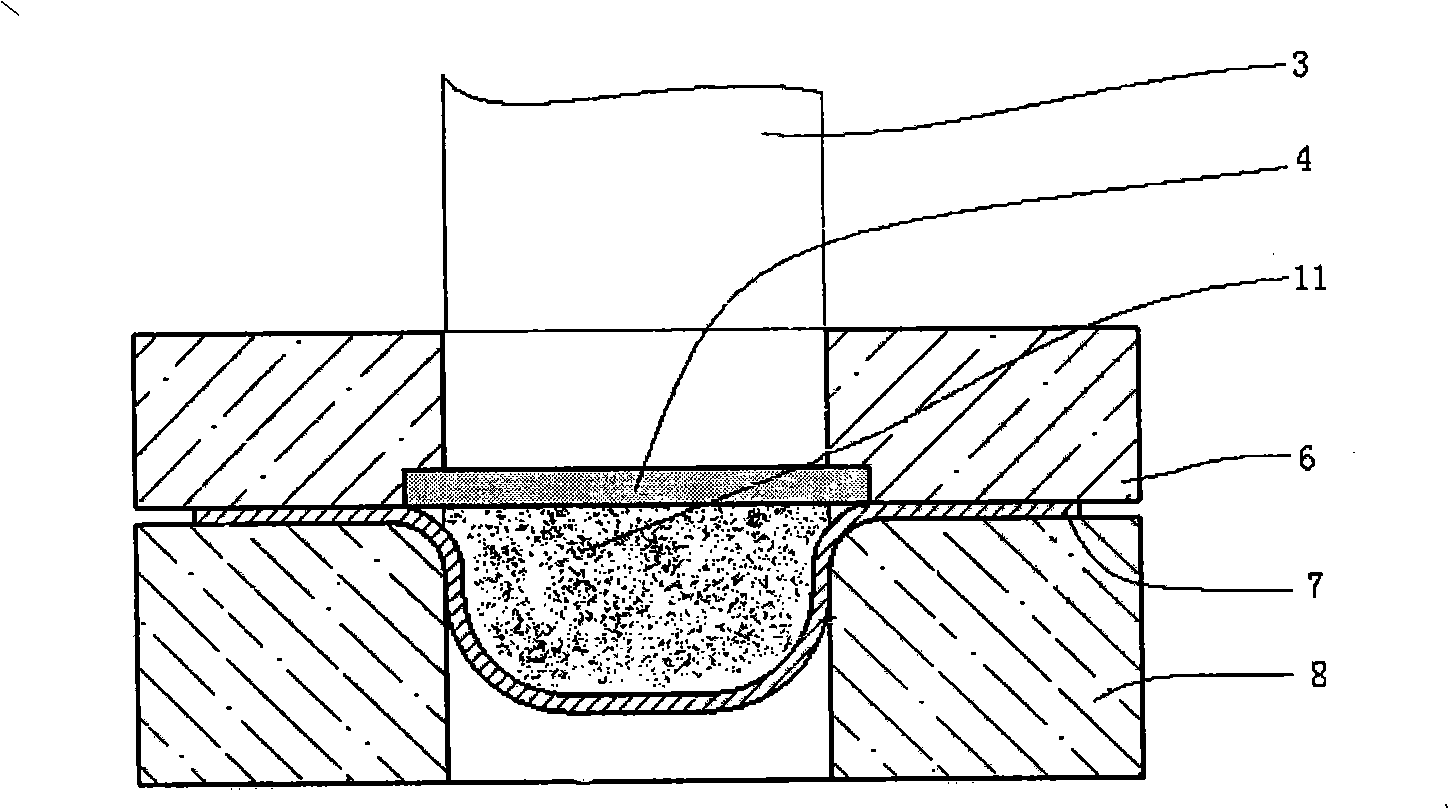

Composite loading test device for explosive blasting impact and shearing

InactiveCN103487337AThe test result is accurateHigh strain rateMaterial strength using steady shearing forcesMaterial strength using single impulsive forceDetonatorEngineering

The invention discloses a composite loading test device for explosive blasting impact and shearing. The composite loading test device comprises a loading source assembly, a shearing implementation assembly and a witness plate, wherein the loading source assembly comprises a detonator, a driving explosive, a buffer layer and a driving steel plate; the driving explosive, the buffer layer and the driving steel plate are circular sheets; the detonator is fixed on the circular driving explosive; the shearing implementation assembly comprises a main explosive, a limiting body and a base; the driving explosive, the buffer layer, the driving steel plate and the main explosive are sequentially arranged in the limiting body from top to bottom; the inner diameter of the base is smaller than the section diameter of the main explosive; the limiting body is arranged on the base; the witness plate is a cylinder; the base is fixed on the witness plate. The composite loading test device has an integrated impact and shearing action, has high strain rate, is used for performing an explosive blasting test caused by the impact and shearing action, and can meet requirements on research and investigation of influence of the integrated impact and shearing action on explosive loading and ignition.

Owner:XIAN MODERN CHEM RES INST

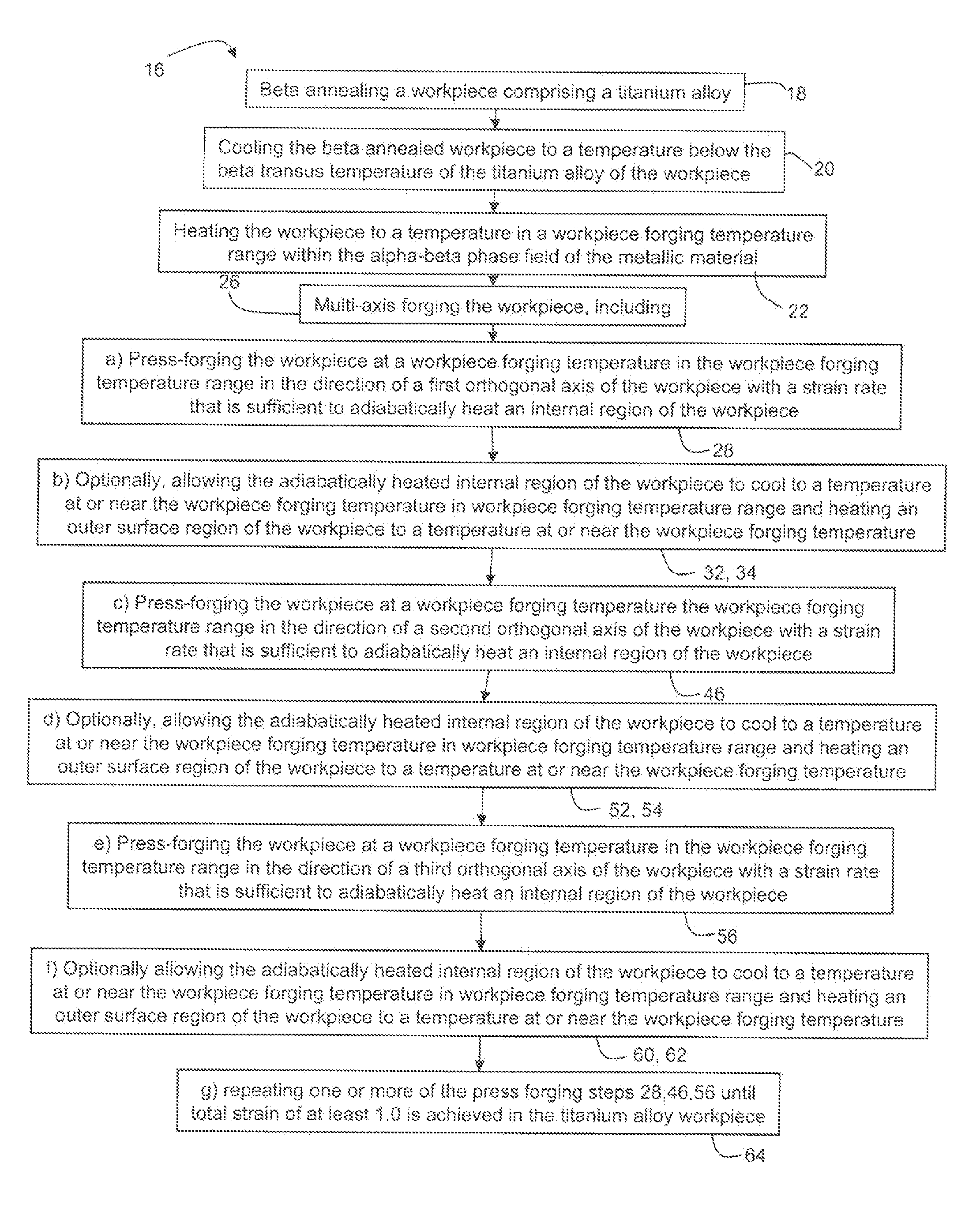

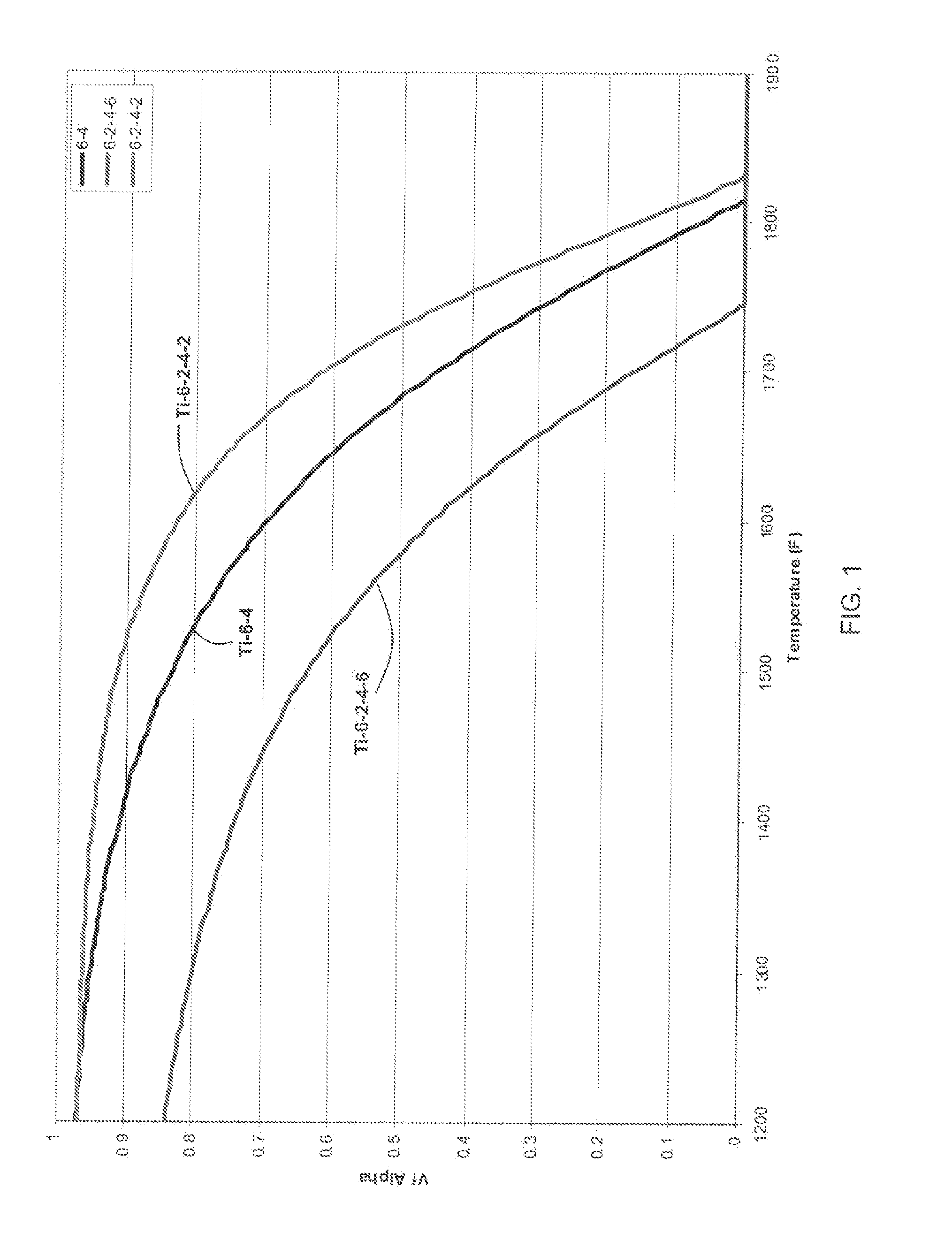

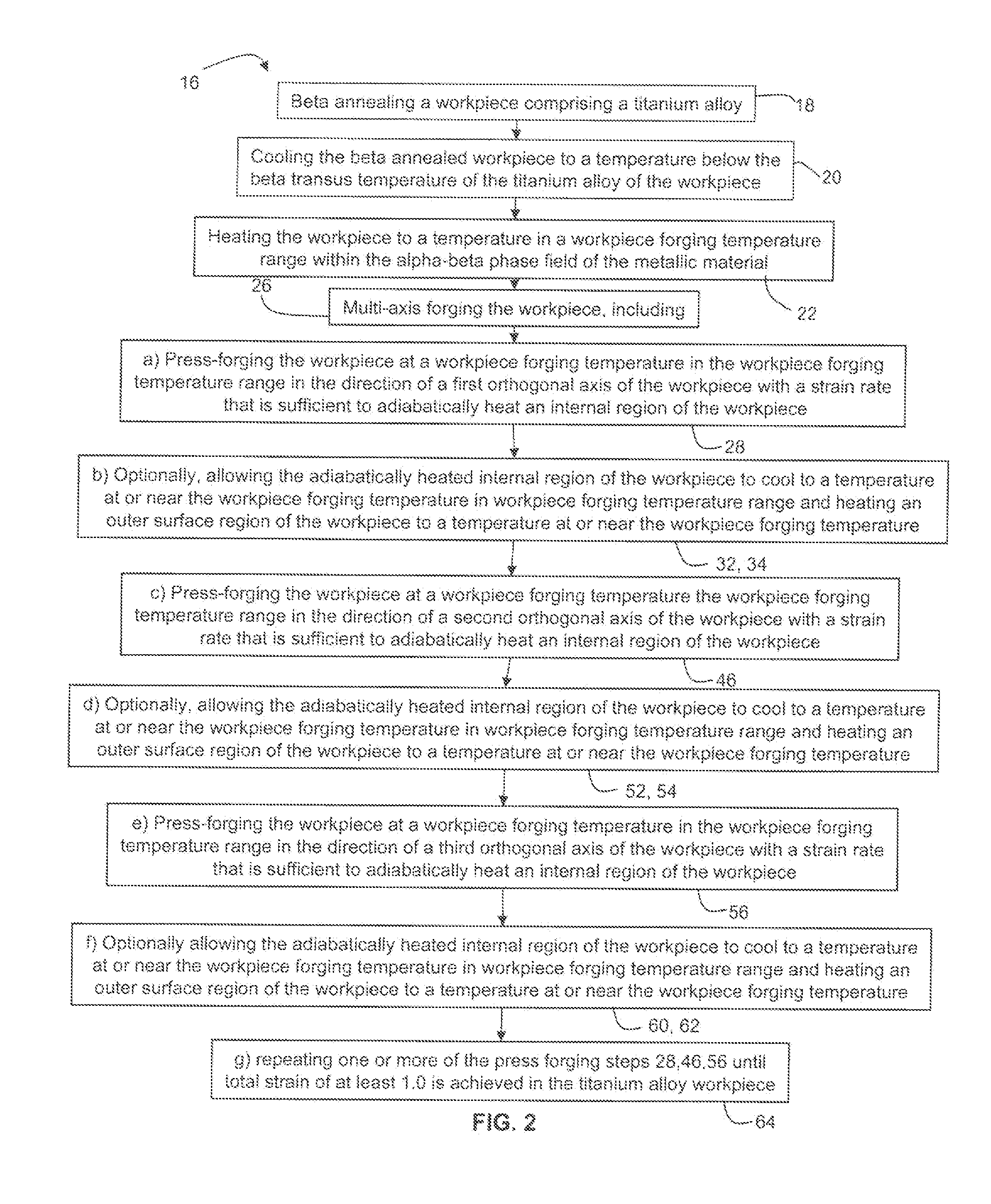

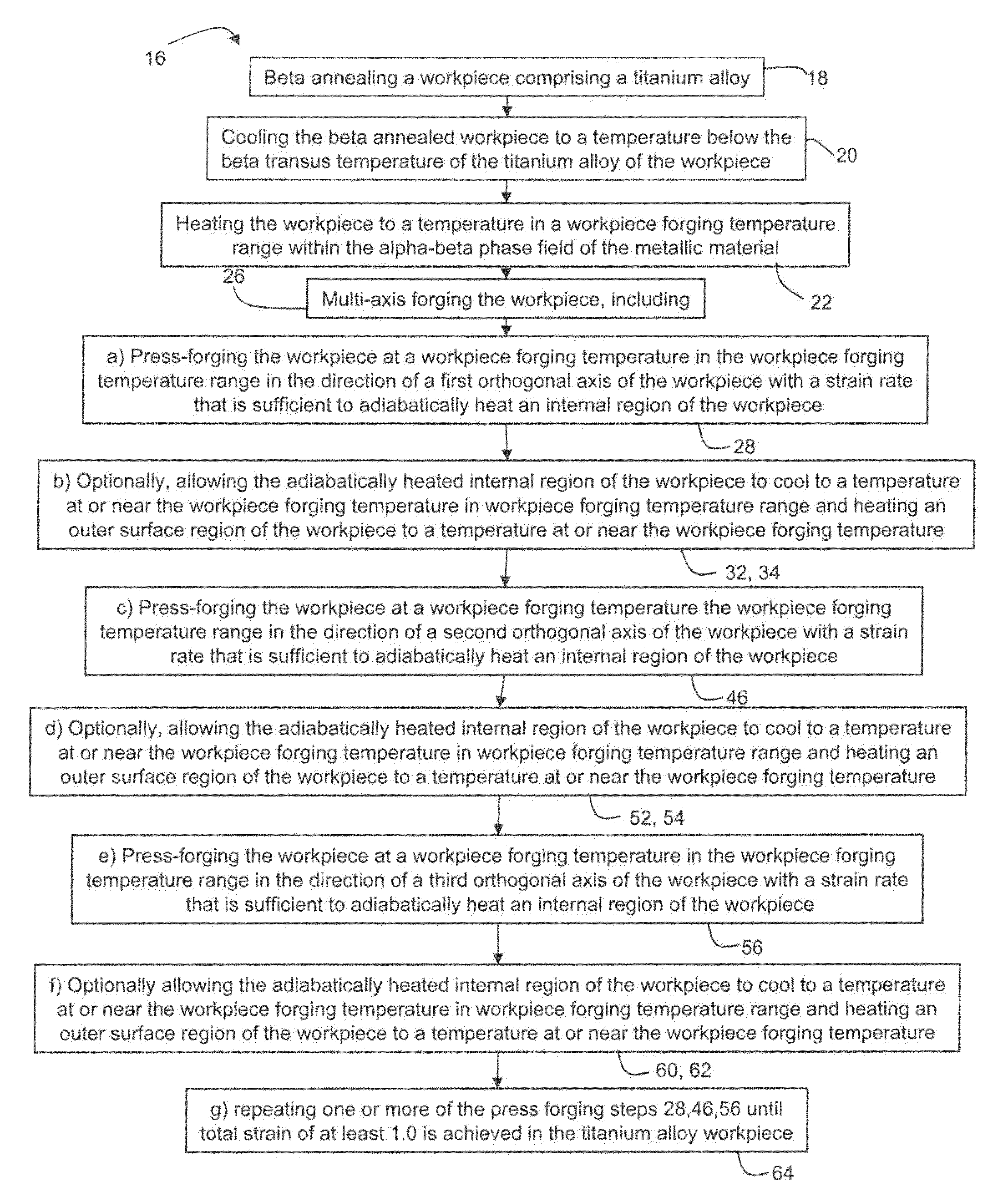

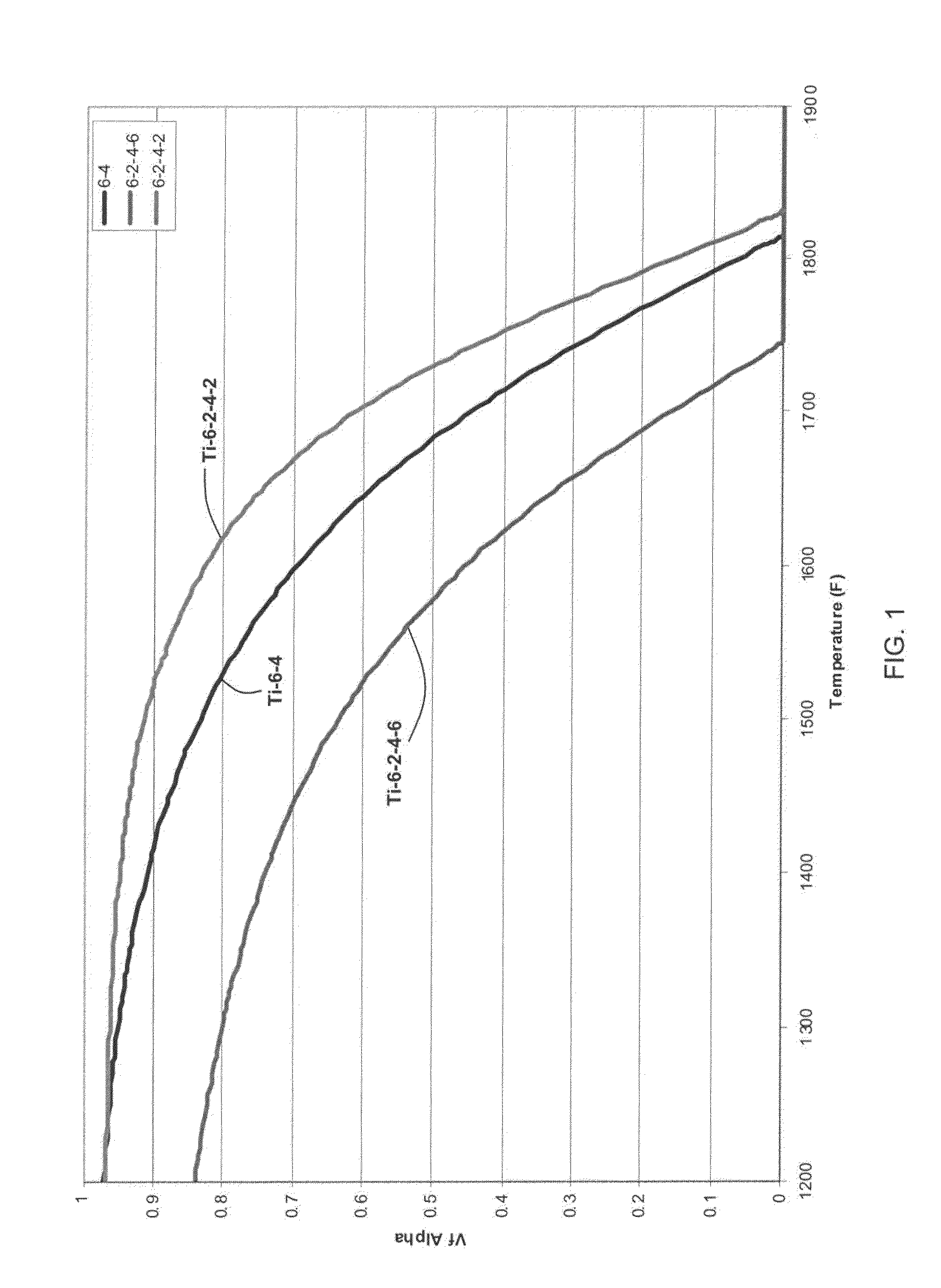

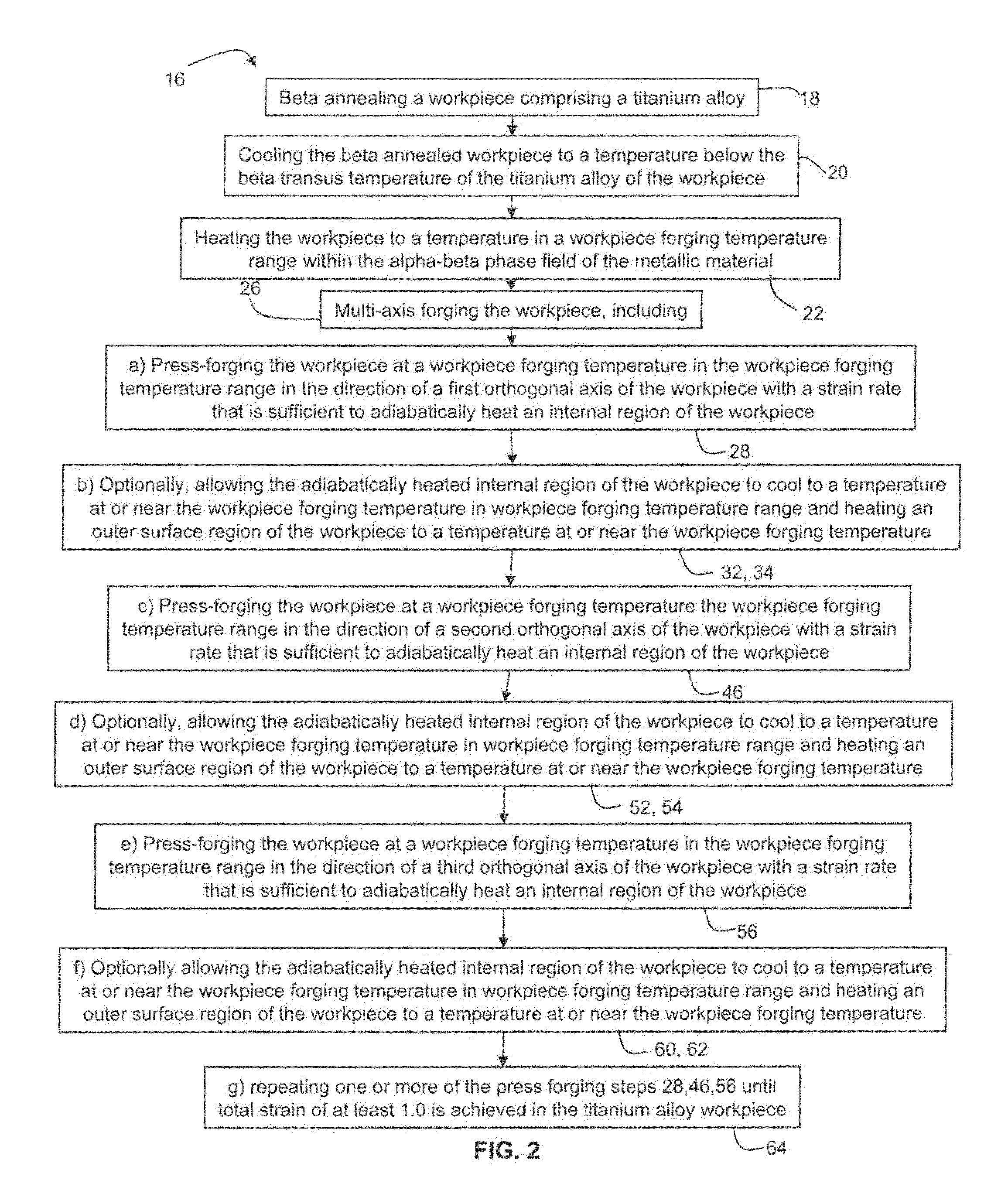

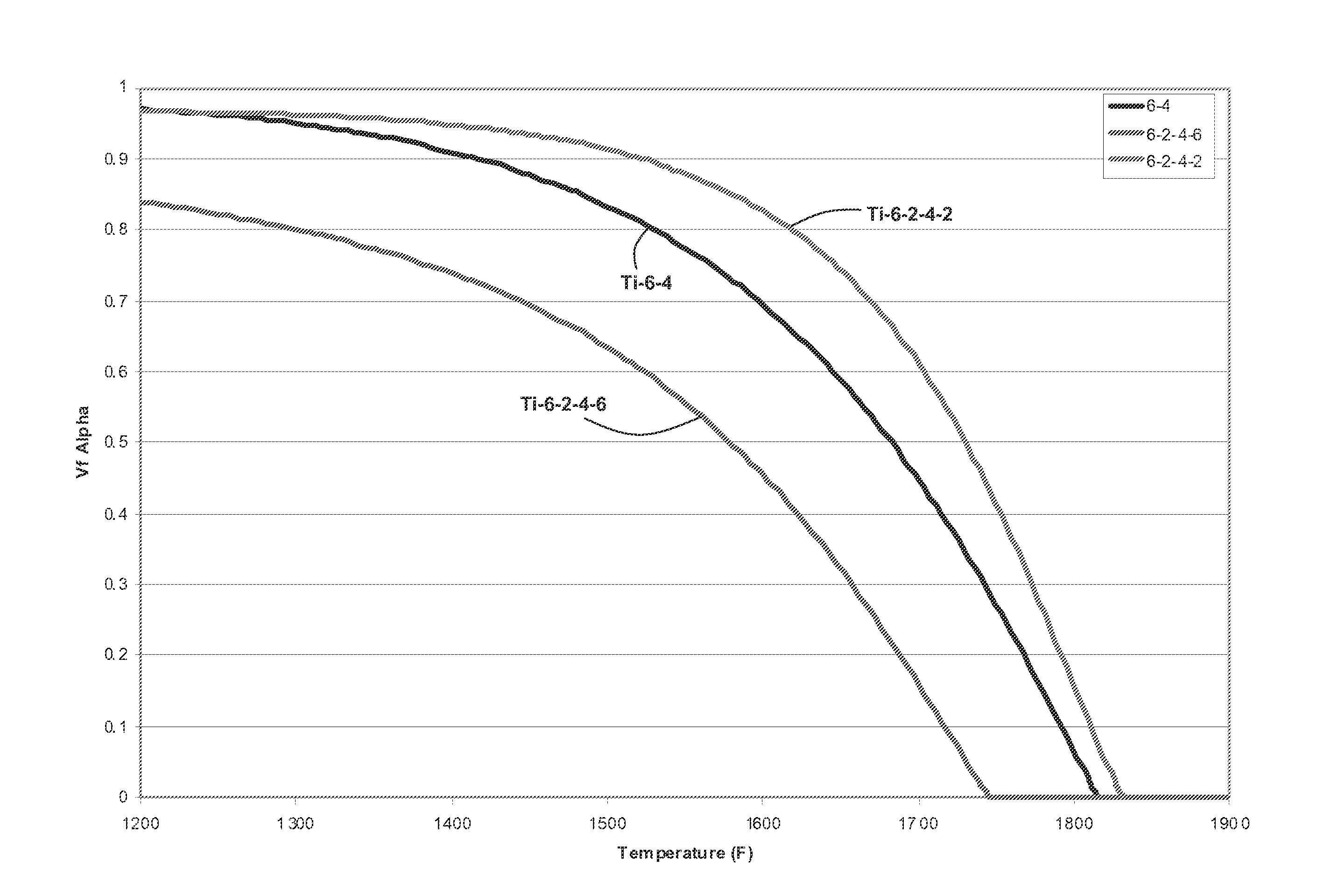

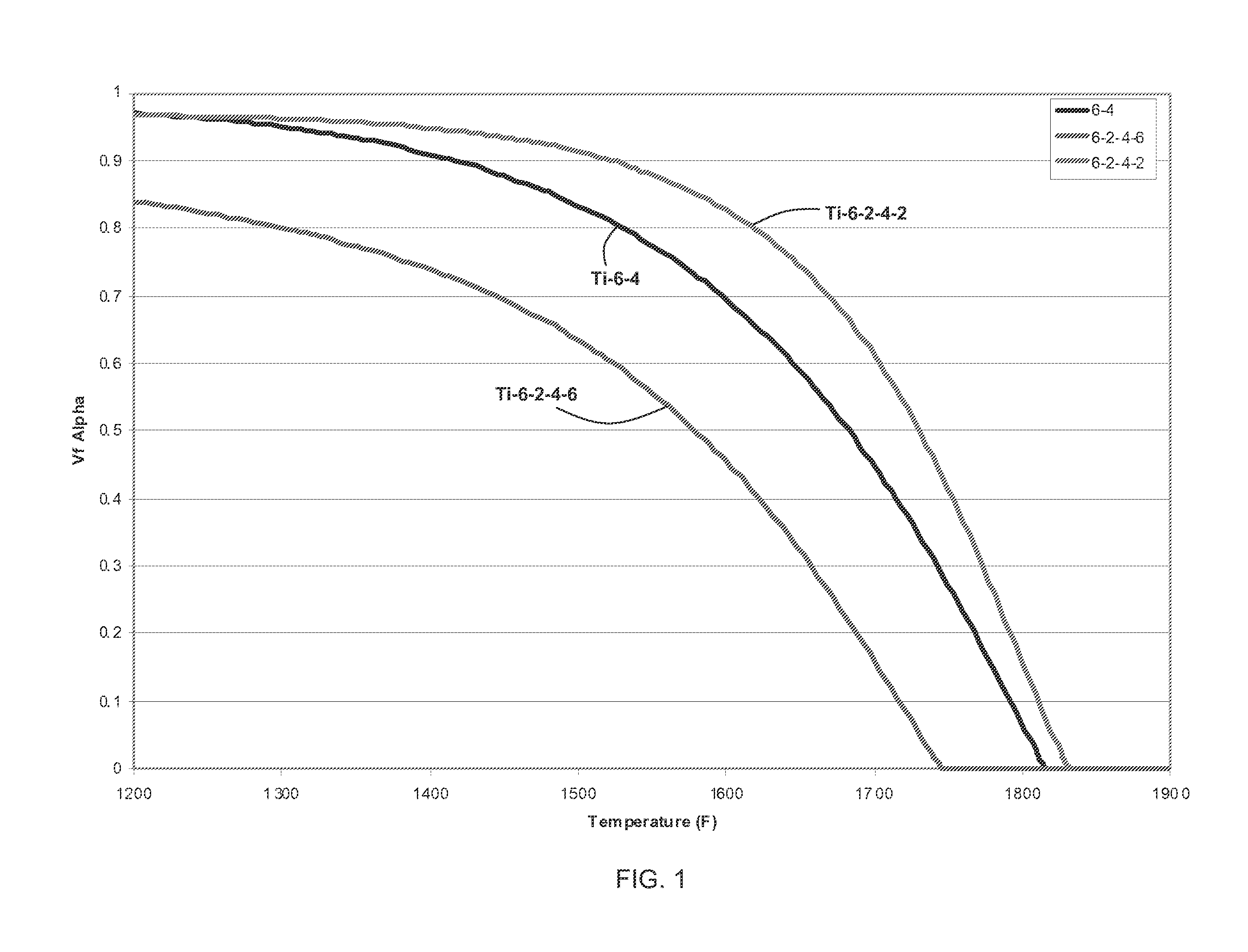

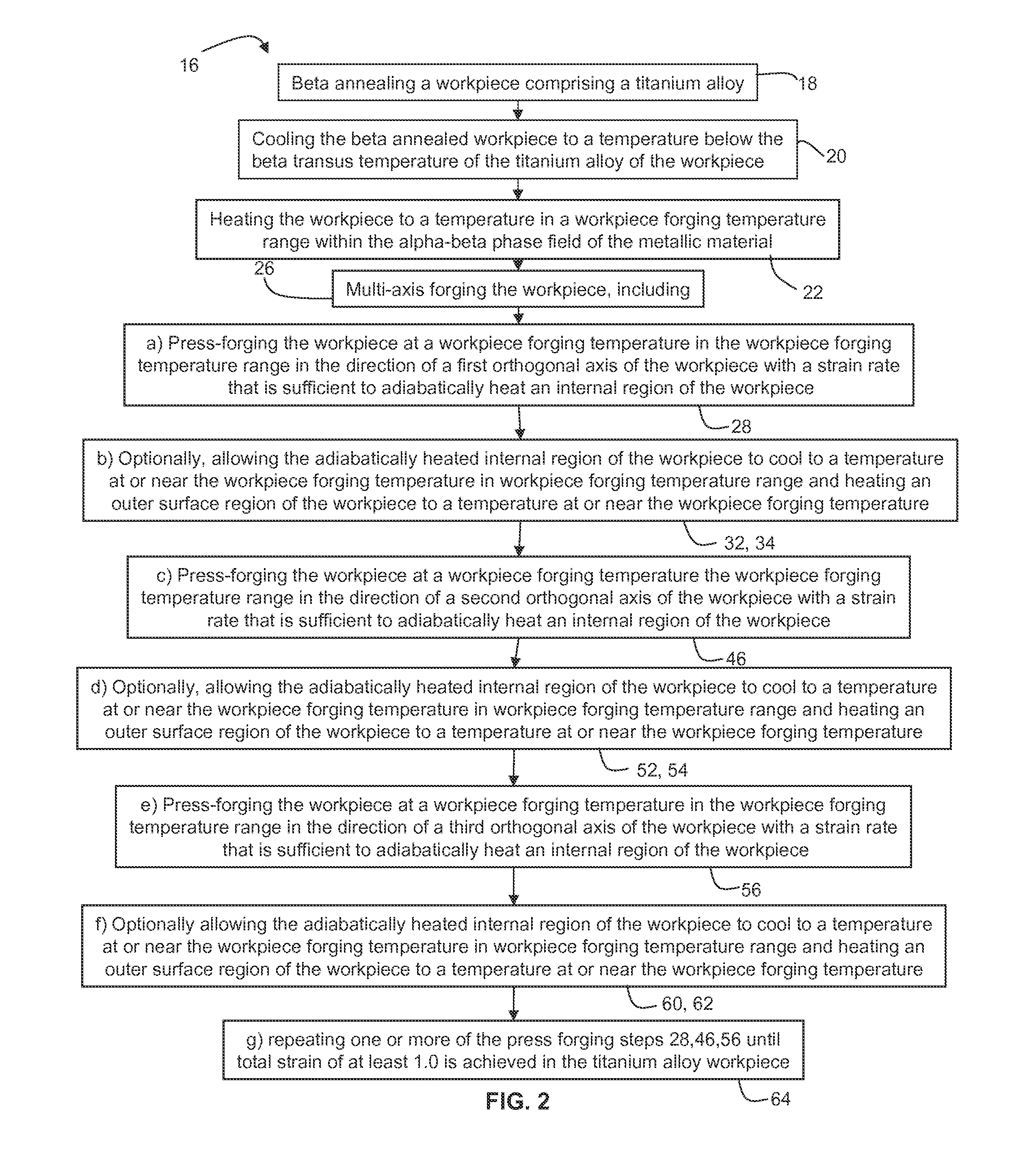

Methods for processing titanium alloys

Methods of refining the grain size of a titanium alloy workpiece include beta annealing the workpiece, cooling the beta annealed workpiece to a temperature below the beta transus temperature of the titanium alloy, and high strain rate multi-axis forging the workpiece. High strain rate multi-axis forging is employed until a total strain of at least 1 is achieved in the titanium alloy workpiece, or until a total strain of at least 1 and up to 3.5 is achieved in the titanium alloy workpiece. The titanium alloy of the workpiece may comprise at least one of grain pinning alloying additions and beta stabilizing content effective to decrease alpha phase precipitation and growth kinetics.

Owner:ATI PROPERTIES LLC

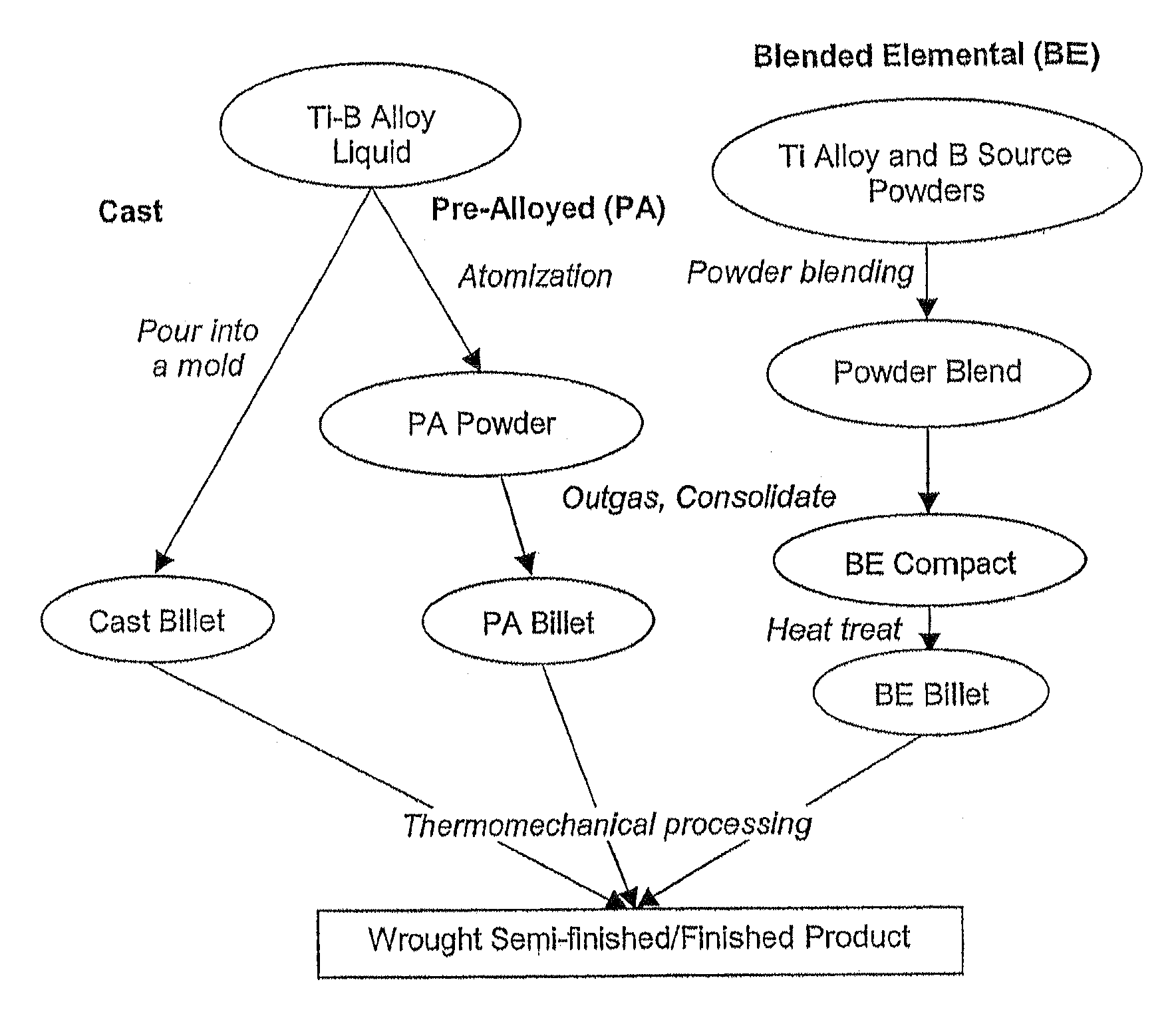

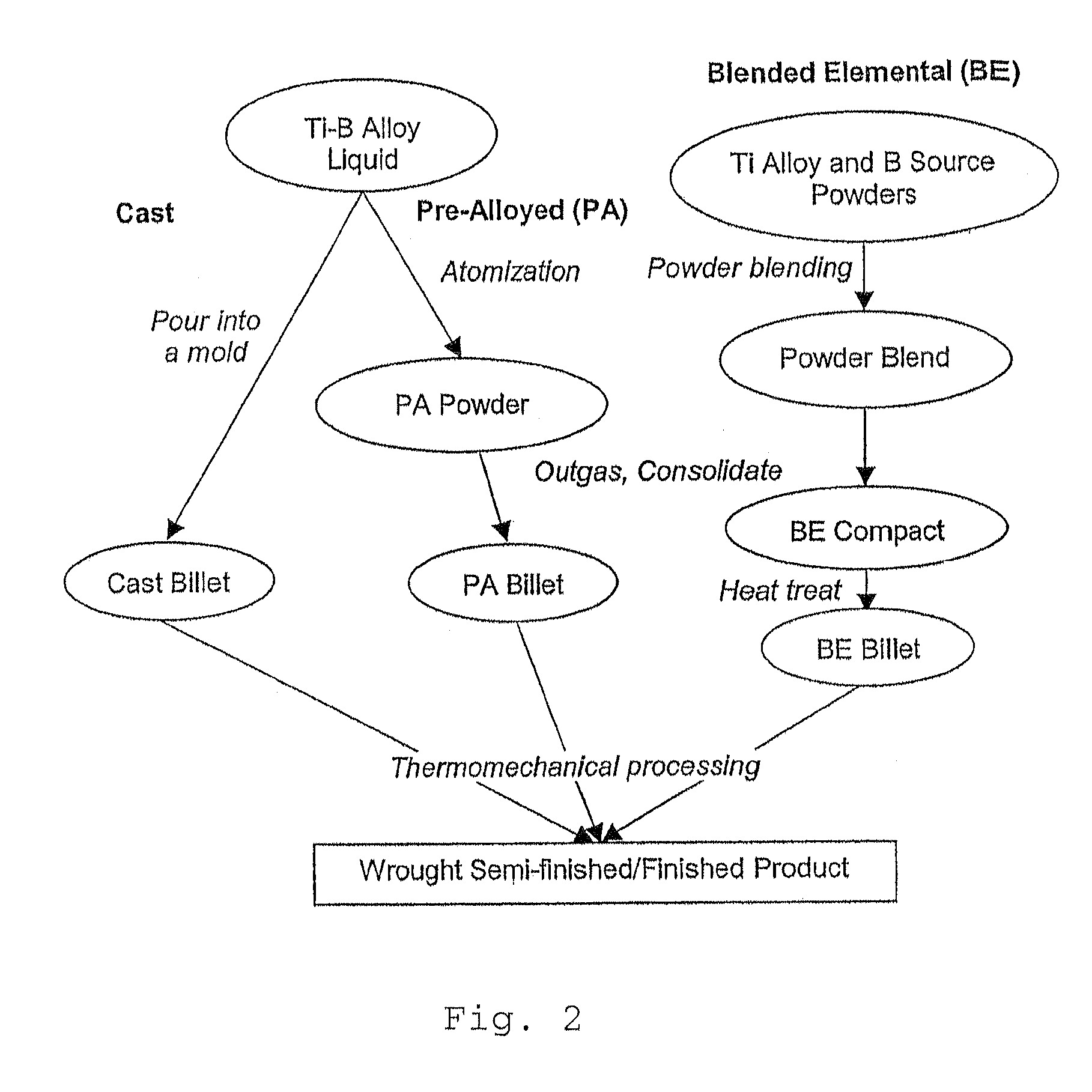

Titanium alloy microstructural refinement method and high temperature, high strain rate superplastic forming of titanium alloys

A method for refining the microstructure of titanium alloys in a single thermomechanical processing step, wherein the titanium alloy comprises boron. In some embodiments, the method comprises the steps of first adding boron to the titanium alloy then subjecting the boron-containing titanium alloy to a thermomechanical processing step. Also provided is a method for achieving superplasticity in titanium alloys comprising the steps of selecting a boron-containing titanium alloy, determining the temperature and strain rate necessary to achieve beta superplasticity, and applying sufficient temperature and strain rate to the boron-containing titanium alloy to deform the alloy to the desired shape. Also provided methods of forming titanium alloy parts and the parts prepared by these methods.

Owner:OHIO UNIV

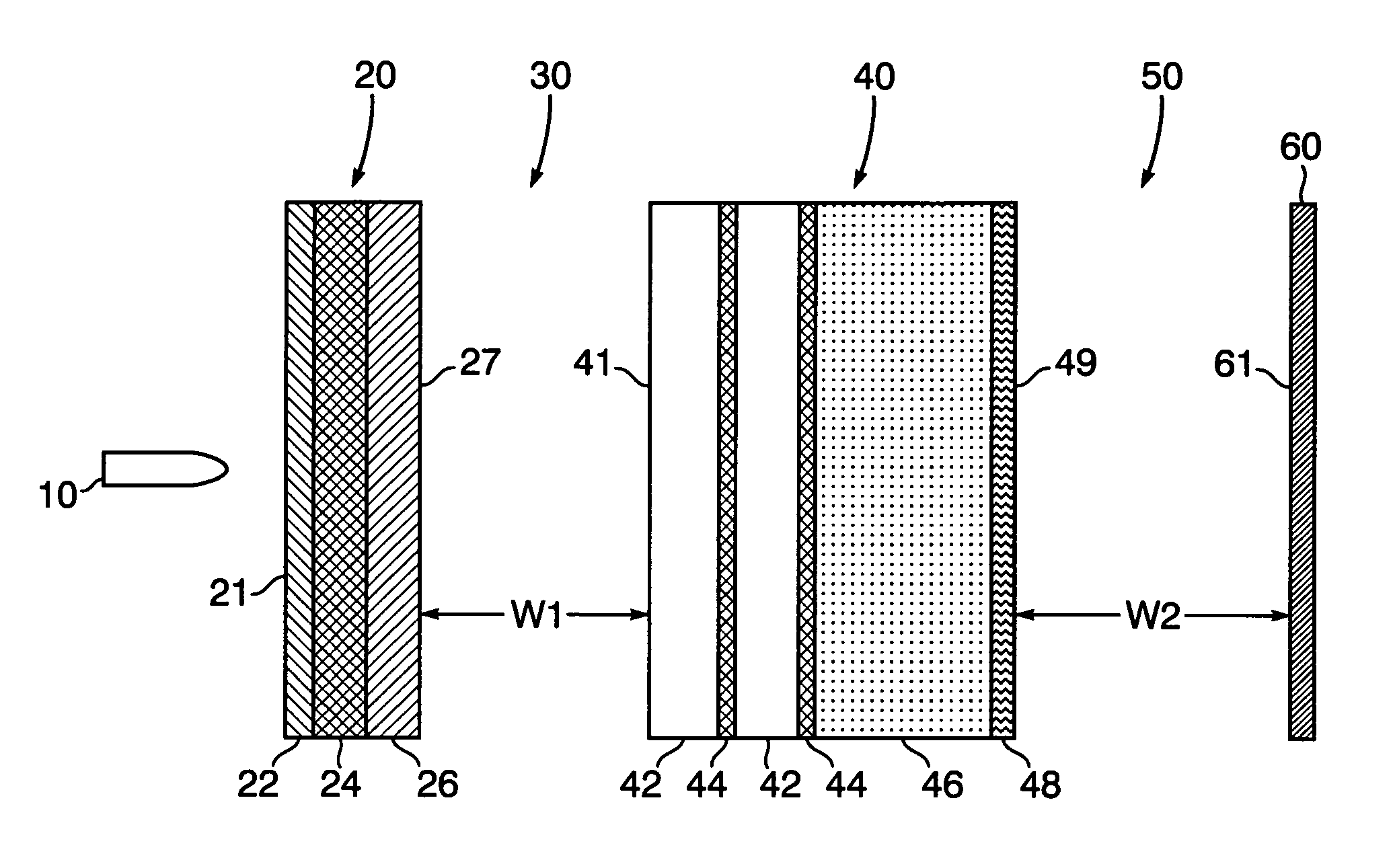

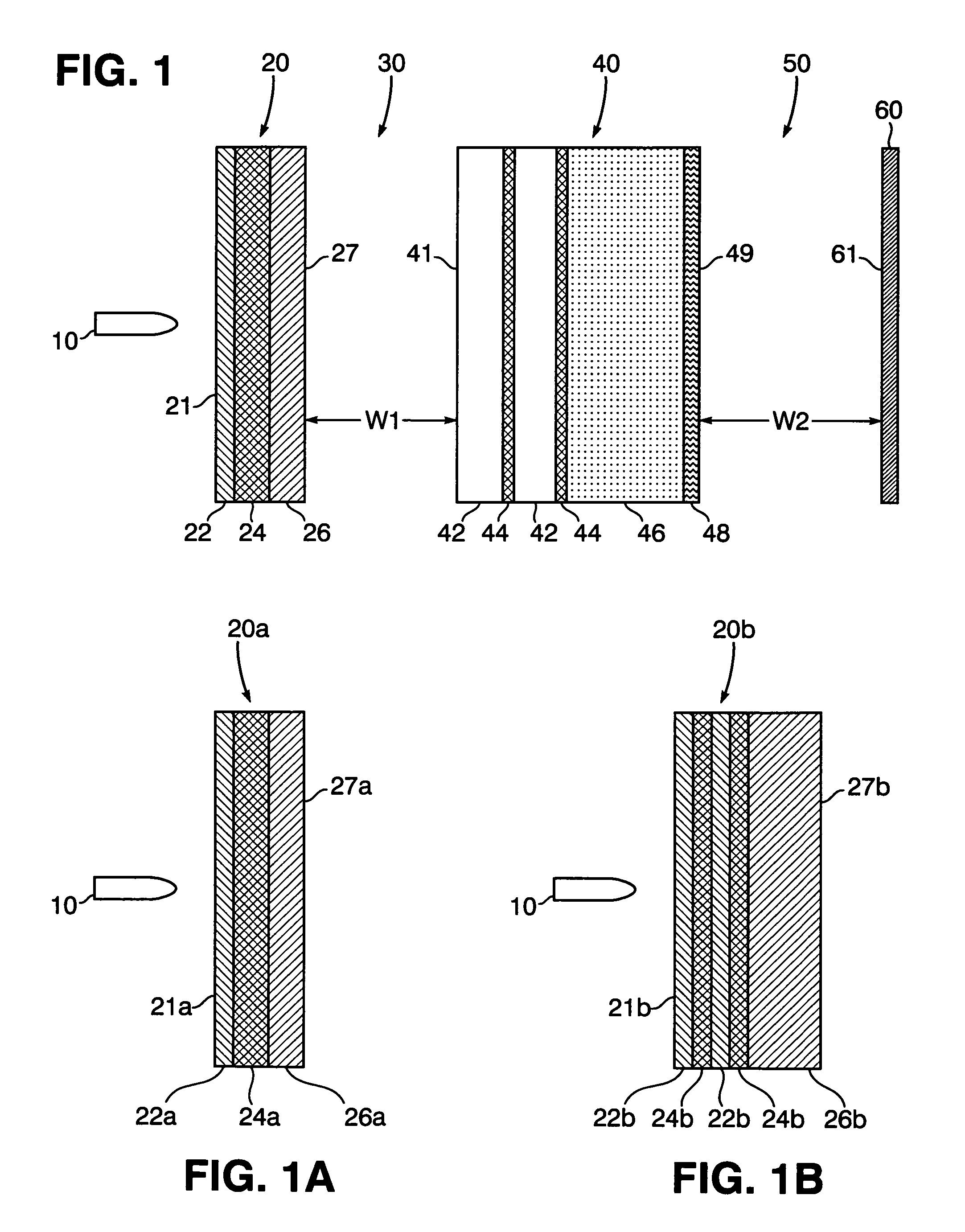

Armor

ActiveUS7938053B1Inexpensive and effectiveArmoured vehiclesGlass/slag layered productsSurface layerSilicon dioxide

A multi-layer armor comprises: an outer composite spaced from an inner composite. The outer composite comprises (a.) a high strength strike surface layer, (b.) a high strain rate sensitivity-hardening polymer and (c.) a second high strength layer. The inner composite comprises spaced silica glass layers, an acrylic glass layer and a spall liner. In one embodiment the armor is transparent and used to shield a vehicle windshield. In a second embodiment the armor is opaque and is attached to vehicle base armor. The armor may also be applied to a ship. The armor uses commercially available components, is relative inexpensive and is effective.

Owner:NAVY THE UNITED STATES OF AMERICA SEC OF THE

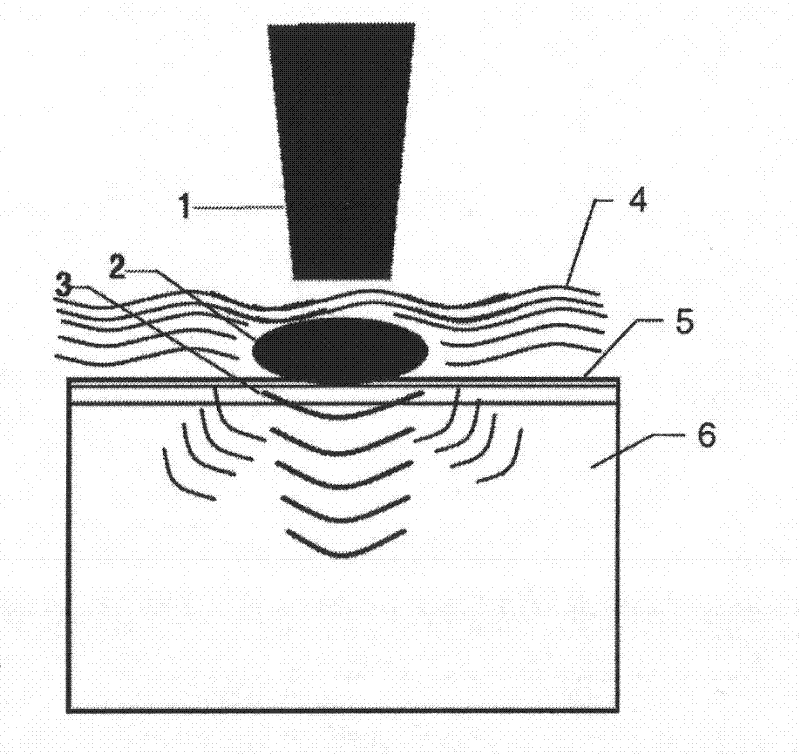

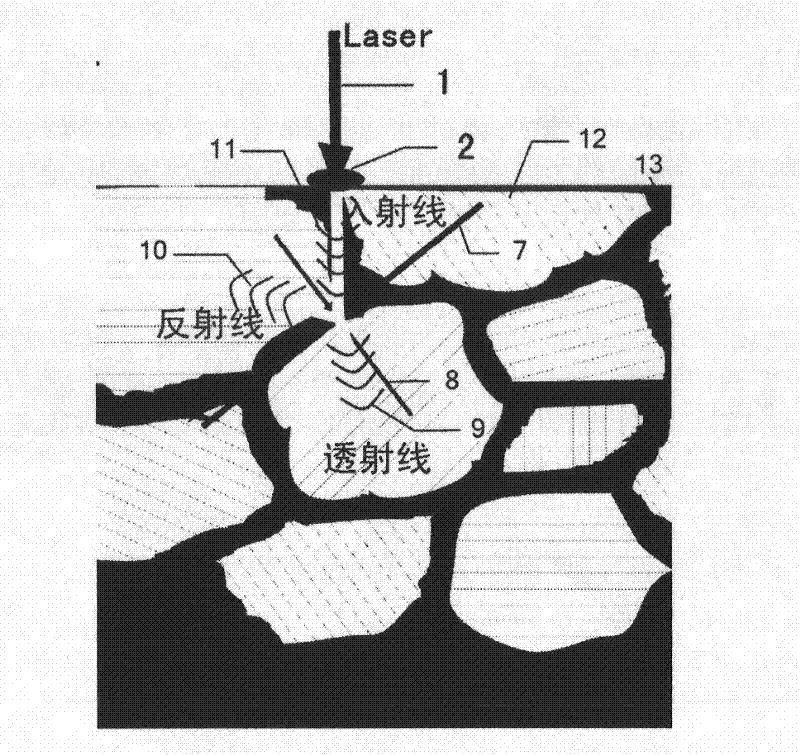

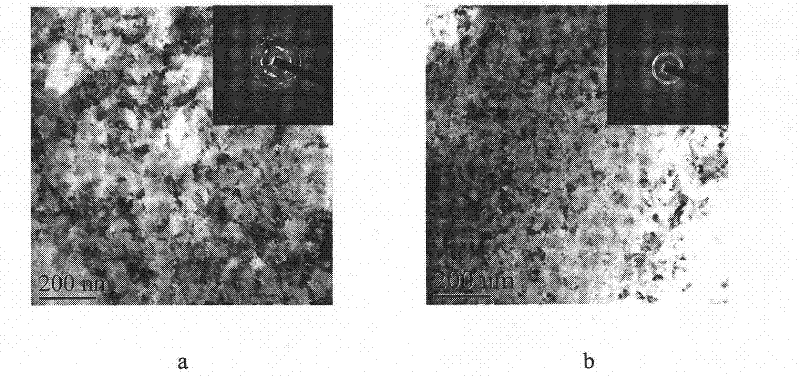

Laser plasma shock wave surface nanocrystallization method for polycrystal metal material

InactiveCN102199690AHigh strain rateAchieving surface self-nanometerizationMaterial nanotechnologyShock waveWear resistant

The invention relates to a laser plasma shock wave surface nanocrystallization method for a polycrystal metal material, which is characterized in that: a target is irradiated by a strong laser with high power density (> 1 GW / cm<2>) and short pulse (femtosecond, picosecond and nanosecond) to generate a high-pressure plasma shock wave, the high-pressure plasma shock wave acts on the surfaces of a component, a high-strain-rate dynamic deformation of a material is caused by the shock wave during the propagation process inside the material, and nanocrystals are formed on the surfaces of the component under the lapping and multiple actions of the shock wave with a pressure higher than a certain threshold value. The invention is applicable to any components of polycrystal metal, and the combination of laser plasma shock wave surface nanocrystallization and residual compressive stress intensifying mechanism can improve anti-fatigue, wear-resistant and other properties of the component, and overcomes the defects that the residual compressive stress is relaxed in a high-temperature environment and has low intensifying effect.

Owner:AIR FORCE UNIV PLA

Processing routes for titanium and titanium alloys

Methods of refining the grain size of titanium and titanium alloys include thermally managed high strain rate multi-axis forging. A high strain rate adiabatically heats an internal region of the workpiece during forging, and a thermal management system is used to heat an external surface region to the workpiece forging temperature, while the internal region is allowed to cool to the workpiece forging temperature. A further method includes multiple upset and draw forging titanium or a titanium alloy using a strain rate less than is used in conventional open die forging of titanium and titanium alloys. Incremental workpiece rotation and draw forging causes severe plastic deformation and grain refinement in the titanium or titanium alloy forging.

Owner:ATI PROPERTIES LLC

Bulk-heating sheet laser pressing method and device

InactiveCN101332540AGood formabilityFast formingLaser beam welding apparatusDeep drawingMaterials science

The invention relates to a plate laser stamping method with an integral heating function and a special device. In the method, ceramics is taken as a female die and a clamping ring; the female die, the clamping ring and the plate are arranged in an electrifying coil, the forming property of the plate is strengthened by heating, and then the plate is irradiated by short pulsed laser with energy density greater than the ignition threshold of the material and is shocked by the shock force of plasma produced by the interaction between the laser and the material to lead to the plastic deformation of the plate under the combined action of the rigid female die. The method belongs to a high-strain rate forming method of rapid forming speed, and can form materials which are hard to be deformed at a normal temperature; the method is especially suitable for deep drawing and bulging of small parts of thin plates and can be applied to the manufacturing field of the structural parts of micro electromechanical system.

Owner:SHANDONG UNIV

Method for preparing gradient nano-structure on surface of metal material

InactiveCN102816912AAdd Deformation DeformationImprove processing efficiencyNanotechnologyMetallic materialsEngineering

The invention relates to a method for preparing a gradient nano-structure on the surface of a metal material. According to the method, a processed plate workpiece is placed inside a cooling tank; a fixture is adopted to tightly press the workpiece; the lower end surface of a tool head is placed on the surface of the workpiece, and is pressed into the surface of the workpiece; a cooling medium is poured into the cooling tank, wherein the workpiece is submerged by the cooling medium; after a temperature of the workpiece reaches a temperature of the cooling medium, the tool head rotates at a certain speed while a work table horizontally moves at a certain speed to drive the workpiece to horizontally move at a certain speed so as to complete a shear deformation treatment by the high hardness end surface of the tool head during a high speed rotation process, wherein high strain rate and large strain are generated to the surface of the workpiece with the shear deformation treatment, and a plurality of deformation treatments are performed on the surface of the workpiece by using the high-speed shear deformation technology. Compared with the method in the prior art, the method of the present invention has advantages of high processing efficiency, low equipment loss, low manufacturing cost, simple process, strong applicability, and the like.

Owner:YANSHAN UNIV

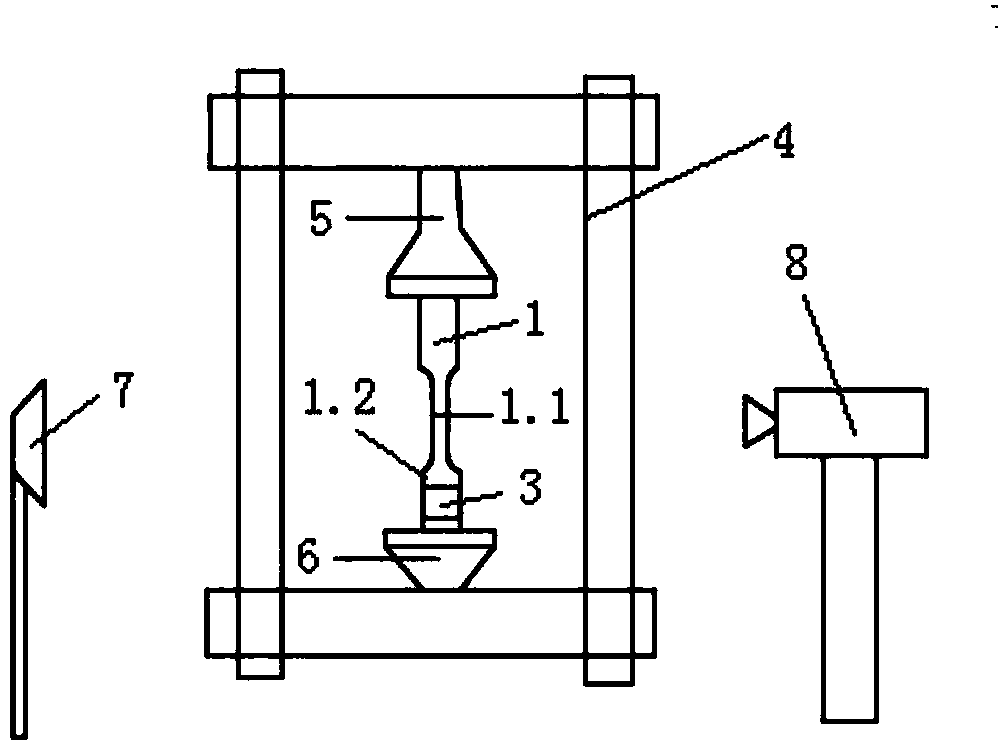

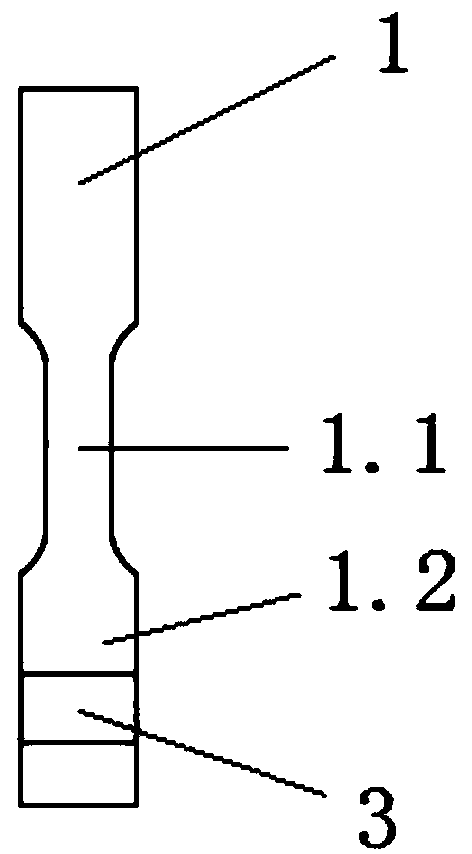

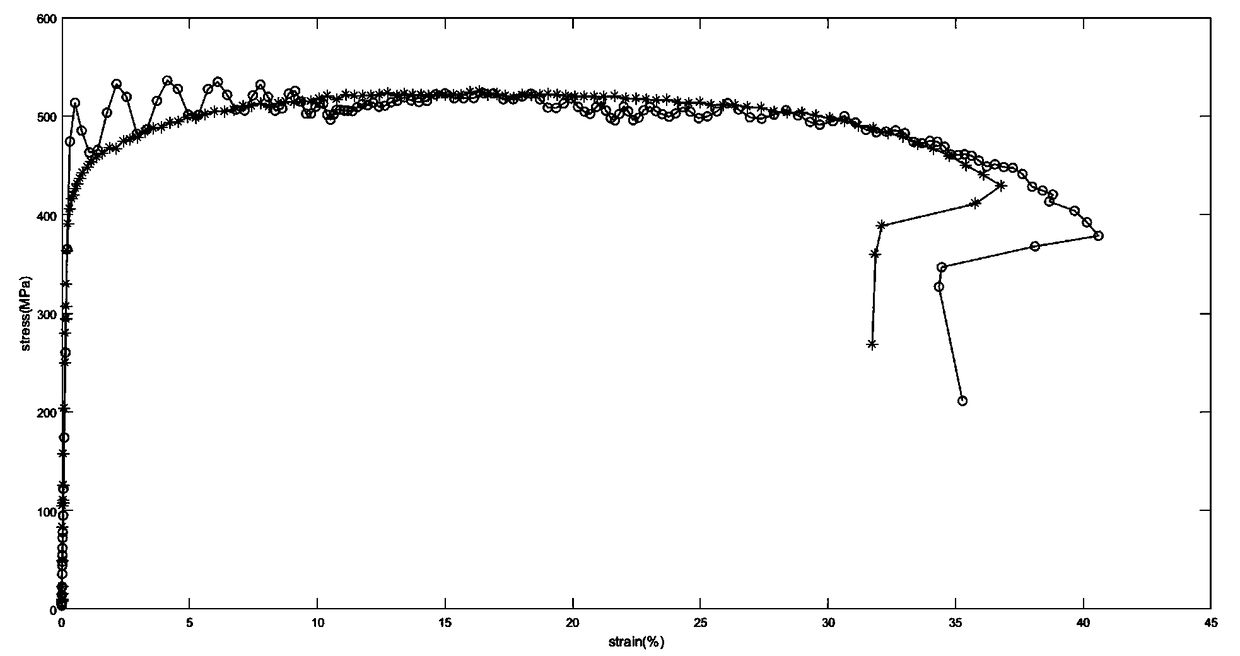

Equipment and method for testing high-speed tensile stress and strain of material

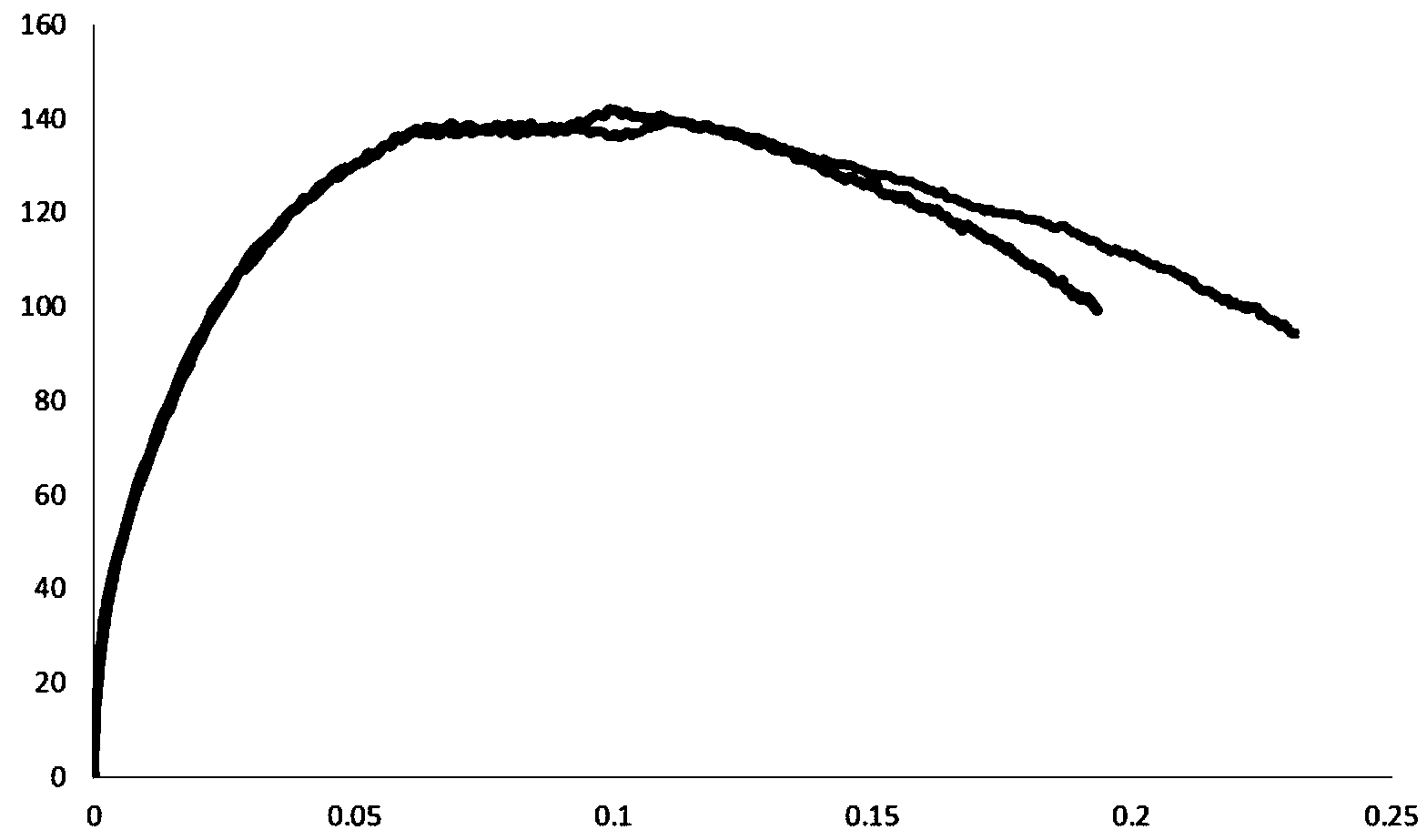

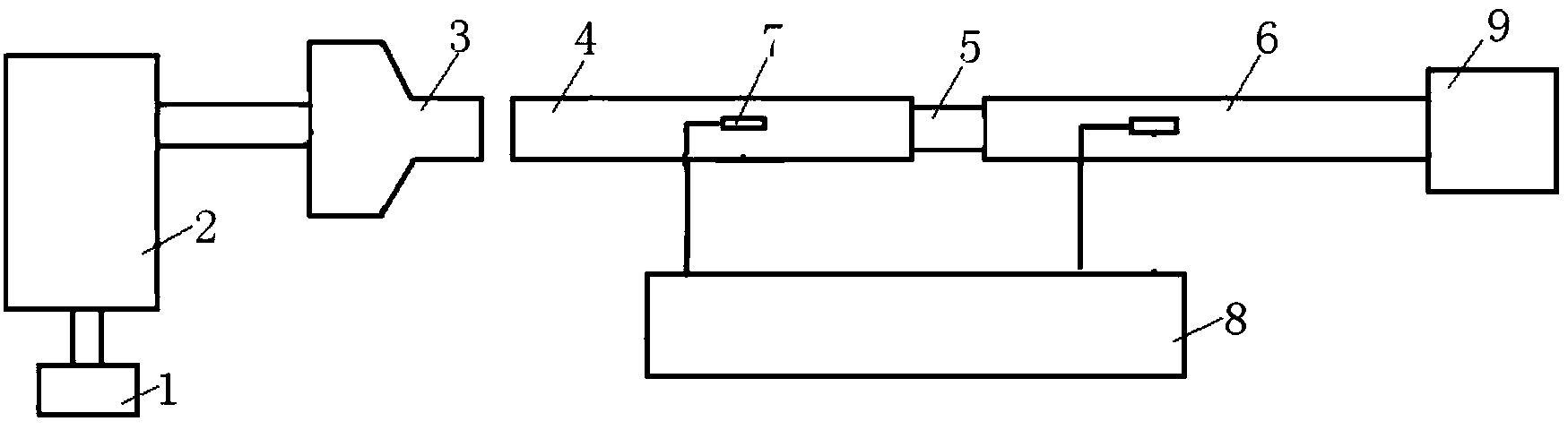

InactiveCN108593429ASolve the shockAccurate measurement dataMaterial strength using tensile/compressive forcesTest sampleStress–strain curve

The invention discloses equipment for testing high-speed tensile stress and strain of a material. The equipment comprises a test sample, a high-speed tensile testing machine, a strain gauge, a light source, a high-speed camera and a controller, wherein the test sample is shaped like a dumbbell, the middle part thereof is a parallel section, the lower part thereof is an elastic section, and the parallel section is sprayed with speckles; the high-speed tensile testing machine is used for stretching the test sample; the strain gauge is stuck on the elastic section of the test sample; a strain meter is used for receiving data transmitted from the strain gauge; the light source is used for aligning a test part of the test sample so as to make the speckles sprayed on the surface of the test sample clearly visible; the high-speed camera is used for aligning the parallel section of the test sample; the controller is used for receiving data transmitted from the high-speed tensile testing machine, the high-speed camera and the strain meter, and drawing a stress-strain curve of the test sample. The invention further provides a method for testing the high-speed tensile stress and strain of thematerial. Through the equipment and the method, the problem of oscillation of the stress-strain curve of the material under a high strain rate can be effectively solved, so that a test result becomesaccurate.

Owner:武汉钢铁有限公司

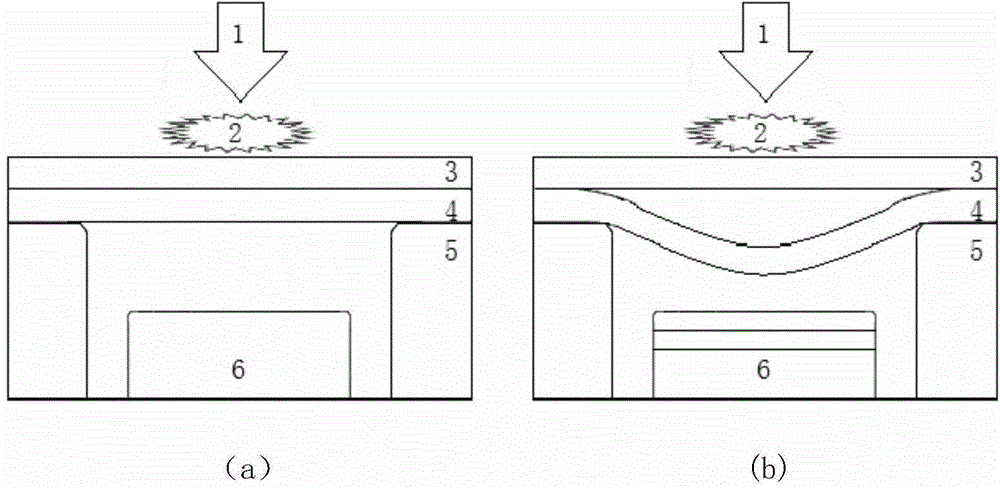

Pulse laser synchronous riveting and welding method and device of ultrathin plates

ActiveCN104816091ALow openness requirementsHigh strengthShaping toolsLaser beam welding apparatusEnergy absorptionShearing deformation

The invention relates to a pulse laser synchronous riveting and welding method and a device of ultrathin plates. An upper layer of plate and a lower layer of plate are stacked and positioned on a concave mold having mold holes; a bottom mold is arranged on the concave mold; a pulse laser beam is used for acting on the upper layer of plate or an energy absorbing layer coated on the surface of the upper layer of plate to form an explosive plasma; the lower layer of plate is collided by the upper layer of plate; the upper layer of plate and the lower layer of plate generate high-strain-rate plastic flow coupling; and under the restraint of the bottom mold, the upper layer of plate and the lower layer of plate are plasticized to form rivet button shapes so as to generate mechanical interlocking for riveting. In the plastic deformation process, the pressure stress exists on the contact interfaces of the upper layer of plate and the lower layer of plate, and the high-speed sliding and the shearing deformation are generated, so that the interfaces generate the melting and the atomic diffusion, and the upper layer of plate and the lower layer of plate are welded when colliding the bottom mold. The method and the device synchronously realize the riveting and the welding of the upper layer of plate and the lower layer of plate; and joints formed by the method and the device have higher connecting strength and fatigue resistance through the compounding effect characteristic of the mechanical bonding and the metallurgic bonding.

Owner:SHANDONG UNIV

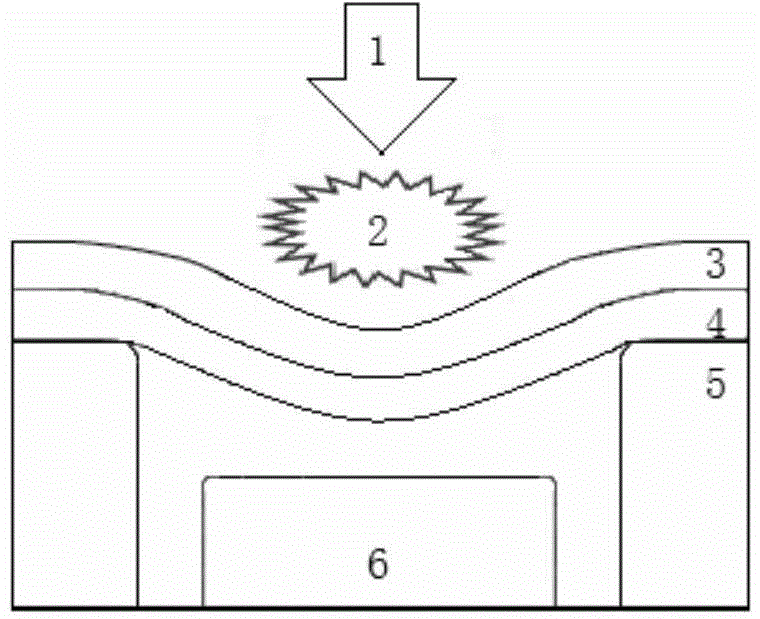

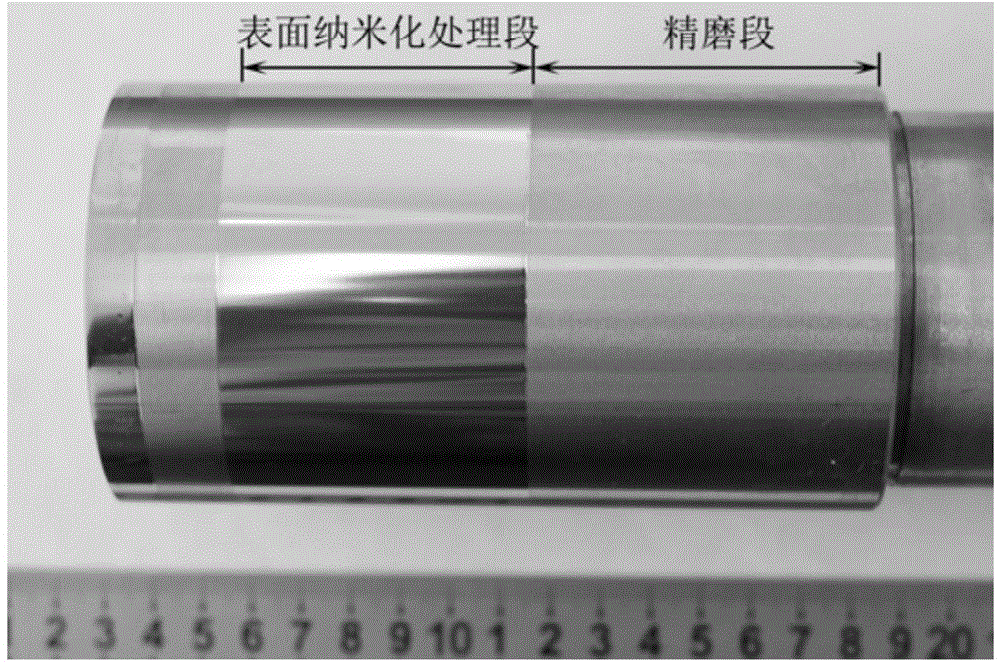

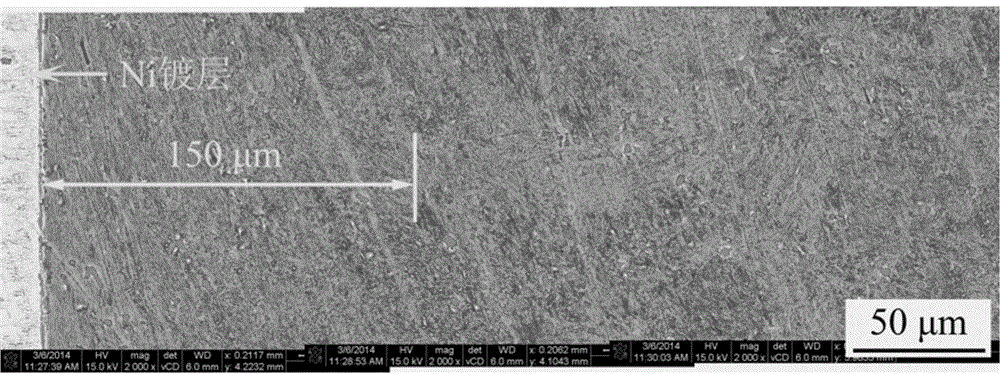

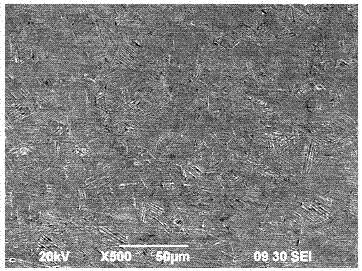

Method for producing gradient nanometer structure on martensitic steel surface

ActiveCN105369024AImprove surface propertiesEasy to scale production and applicationSurface layerSurface roughness

The present invention discloses a method for producing a gradient nanometer structure on the martensitic steel surface, and belongs to the technical field of metal material surface nanocrystallization. According to the method, a martensitic steel rotation member is treated by using a surface mechanical rolling processing technology (SMGT), the SMGT processing cutter hard ball capable of freely rolling performs high speed rolling and pressing on the martensitic steel rotation member surface, the martensitic steel surface to be treated is subjected to high speed plasticity deformation, and under the conditions of high strain, high strain rate and high strain gradient, the coarse grain structure on the surface layer is converted into the gradient structure sequentially comprising nano-grains, submicron grains and micro-scale grains. According to the present invention, the surface roughness Ra value of the martensitic steel being subjected to the SMGT surface nanocrystallization treatment is less than 0.30 [mu]m, and the surface property is significantly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

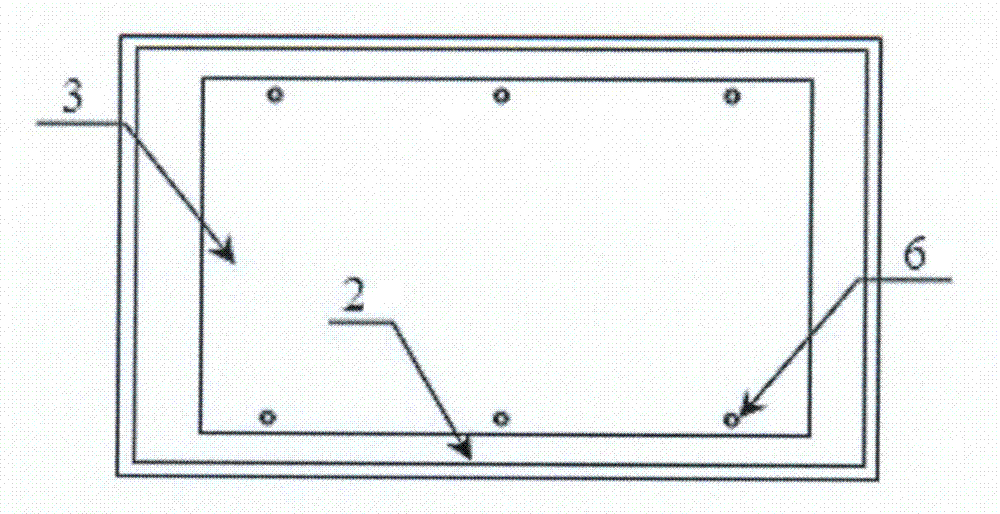

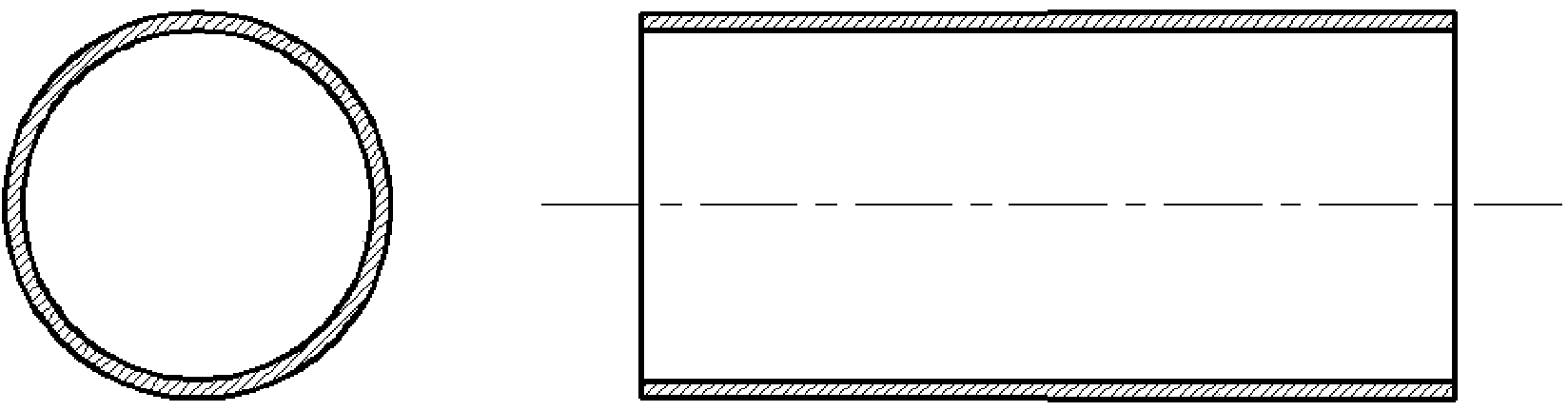

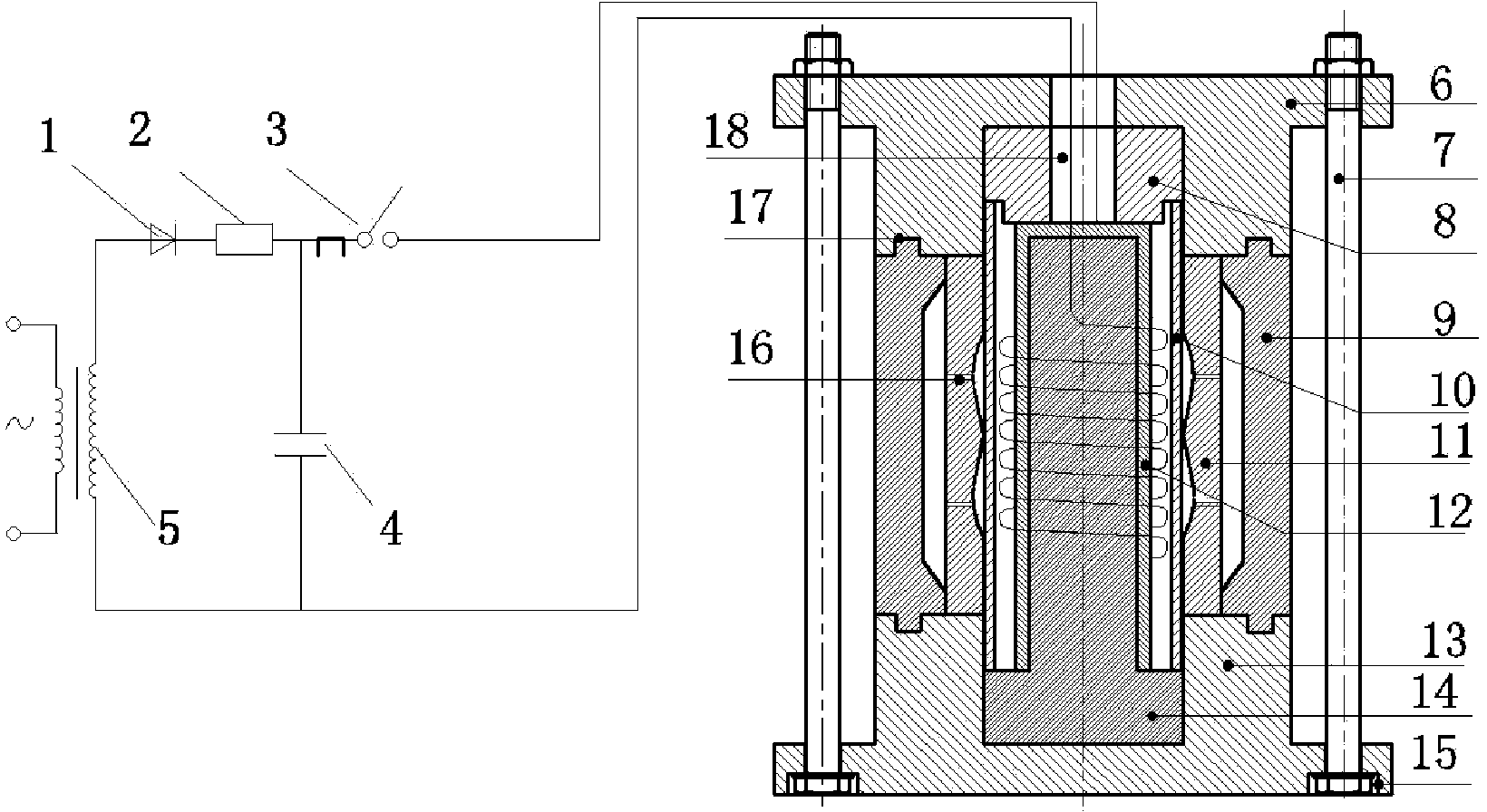

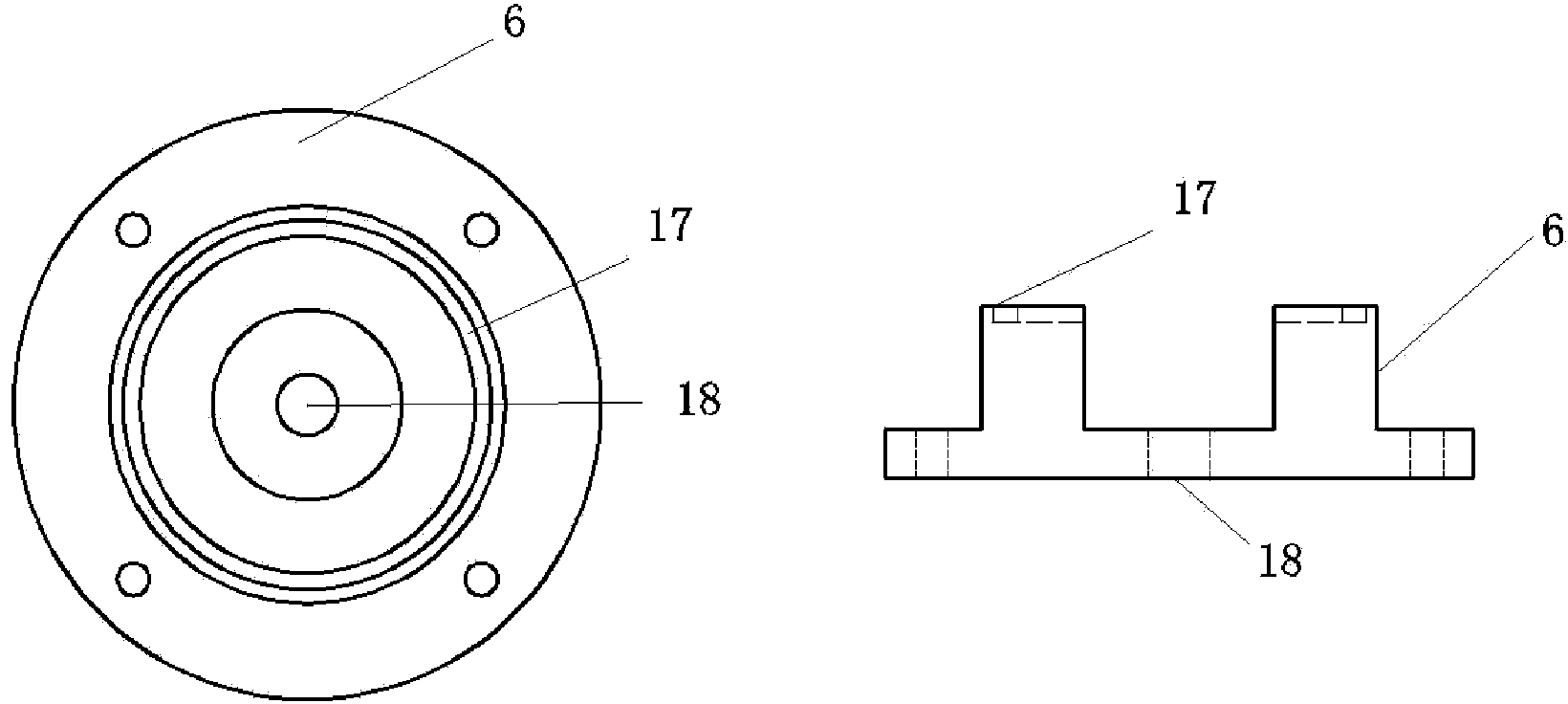

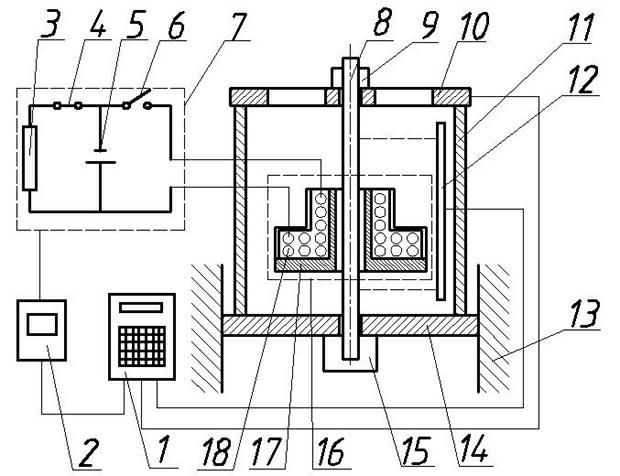

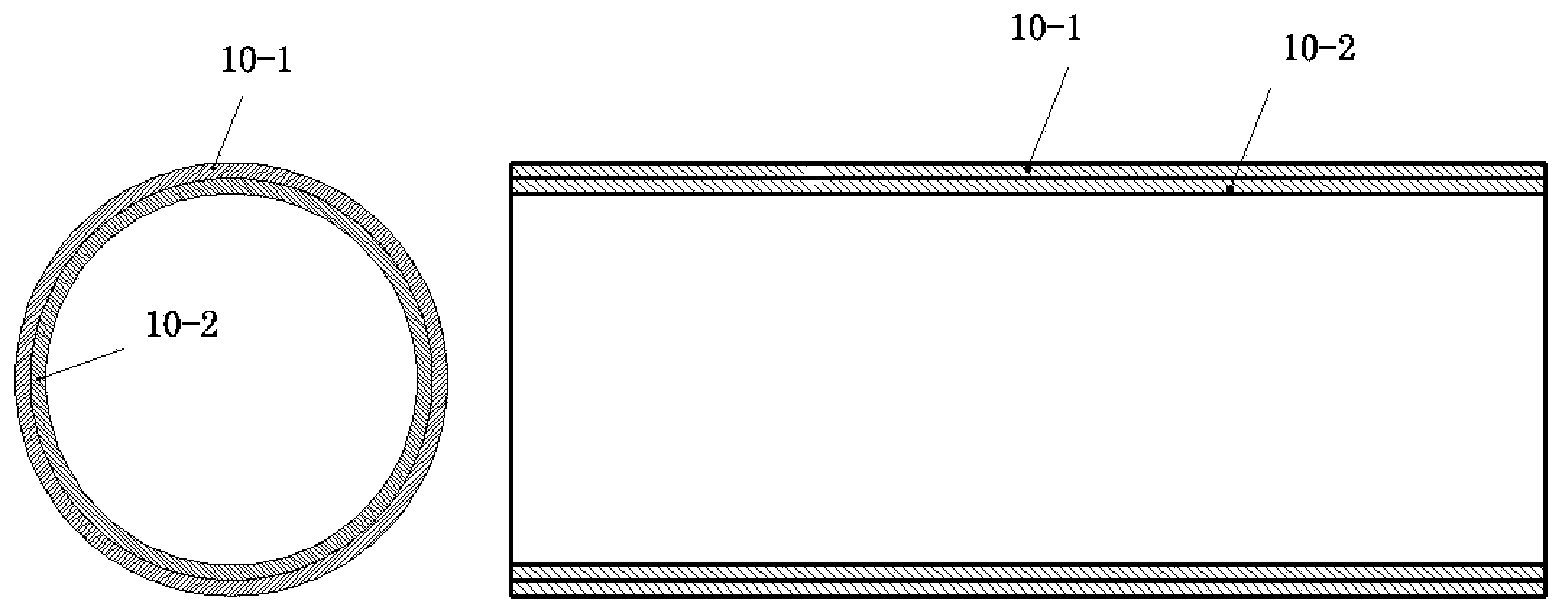

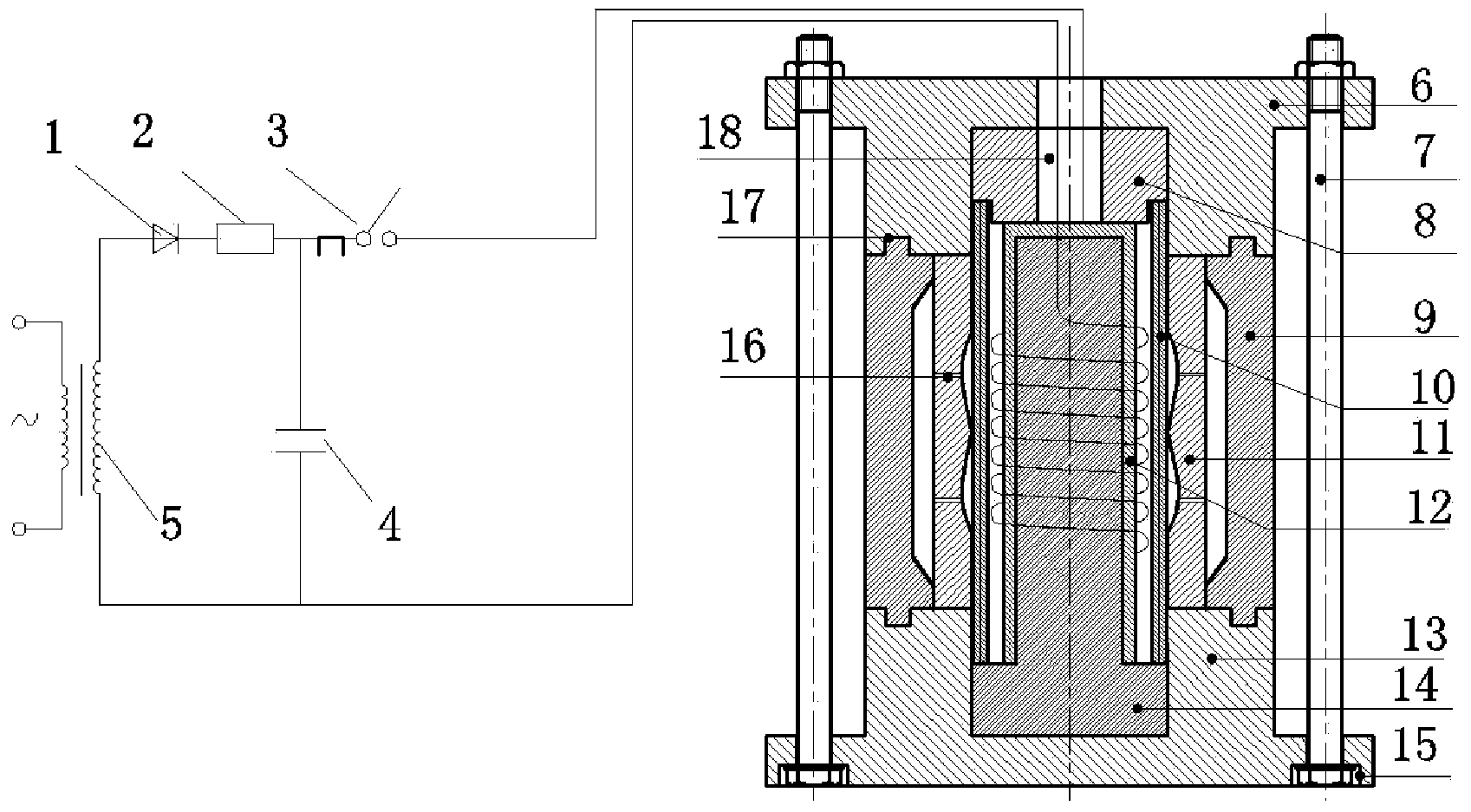

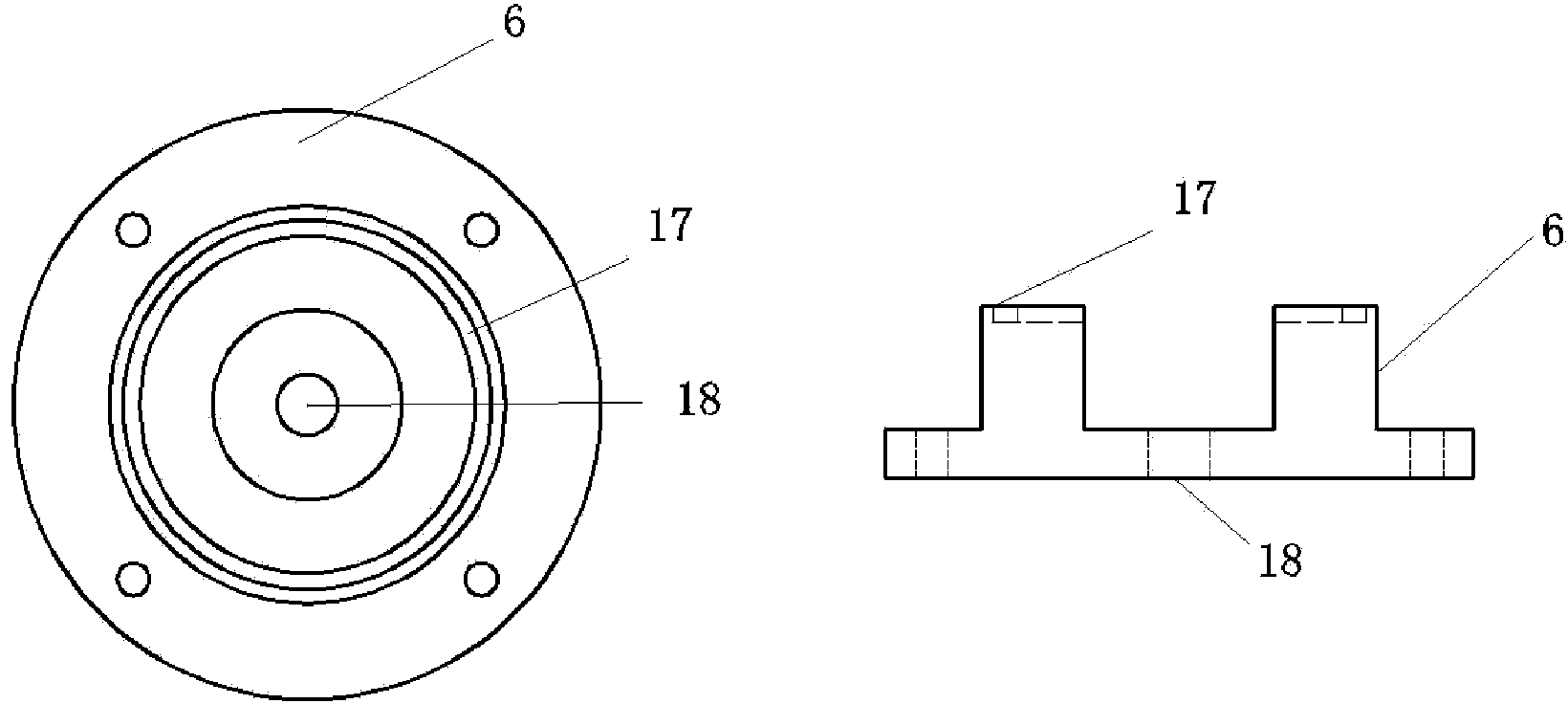

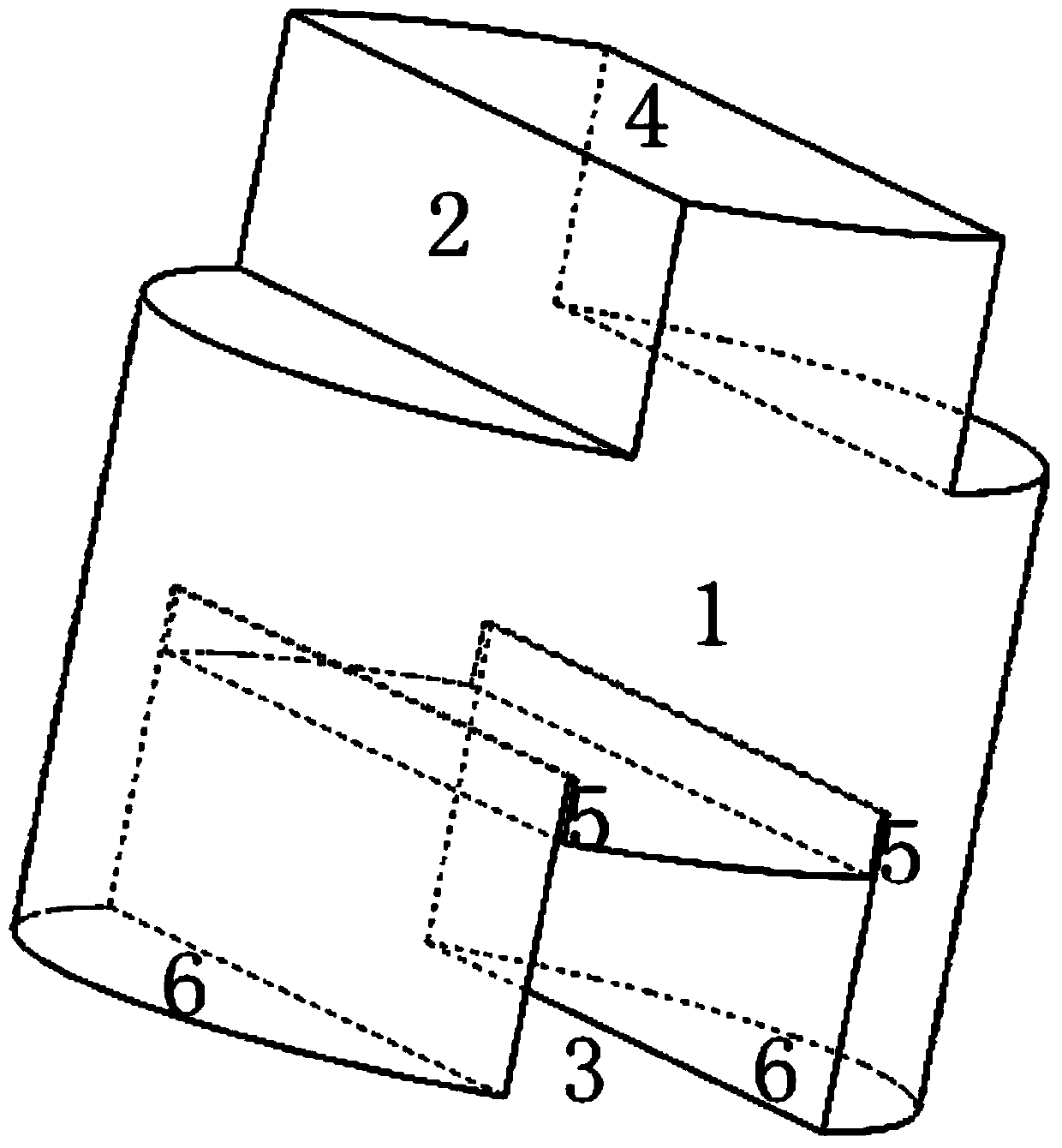

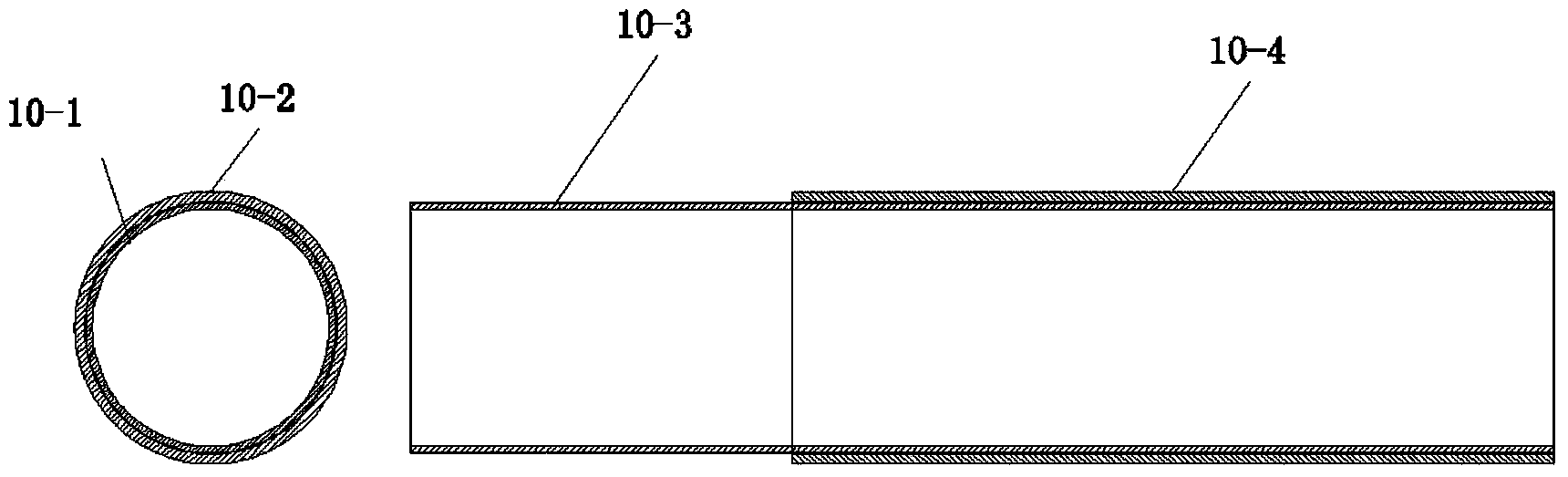

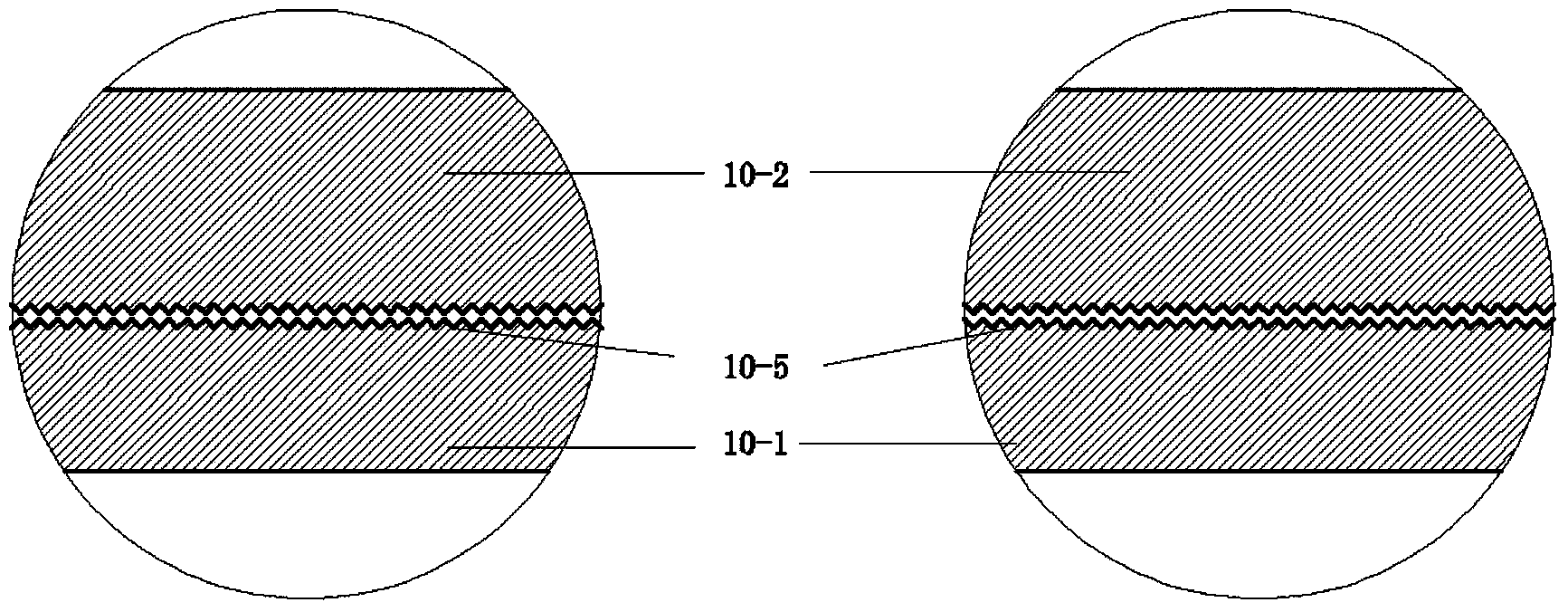

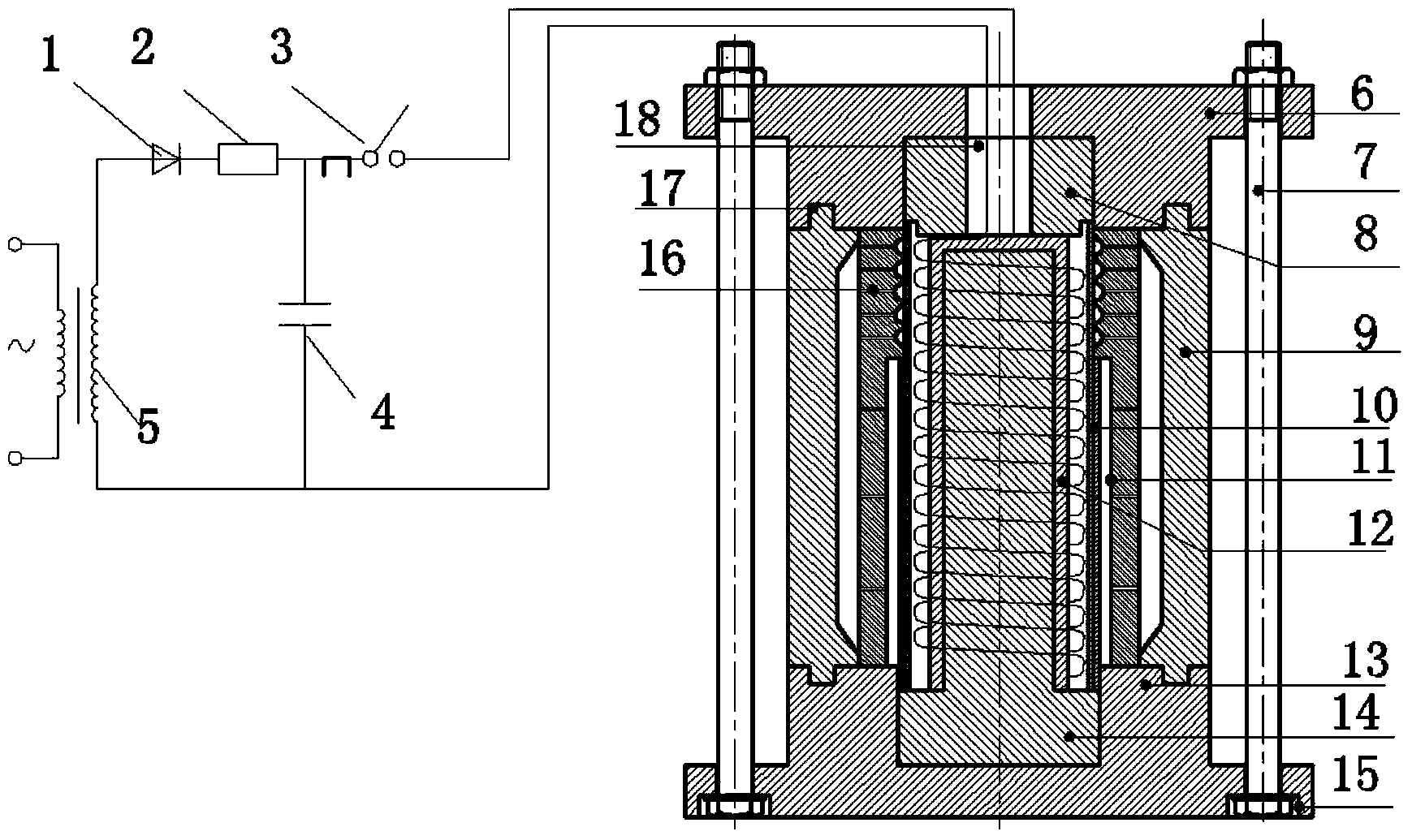

Corrugated pipe forming device and corrugated pipe machined through corrugated pipe forming device

The invention discloses a corrugated pipe forming device based on electromagnetic forming. The corrugated pipe forming device is characterized by comprising a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), fixing bolts (7), a pressing block (8), a mold base (9), a constraint mold (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), trapezoid holes (15), exhaust holes (16), fixing grooves (17) and a wire hole (18). In addition, a thin-wall energy-absorption corrugated pipe forming method based on the electromagnetic forming principle has the advantages that the number of machining processes is small, machining efficiency is high, forming accuracy is high, the pipe forming speed is high, a thin-wall metal pipe can be formed at a high strain rate, the plasticity of metal materials is improved greatly, and the yield strength of the materials is enhanced substantially. By changes of the shape of the constraint mold in the forming device, different wave shapes can be formed, and machining flexibility of the forming device is high.

Owner:HUNAN UNIV

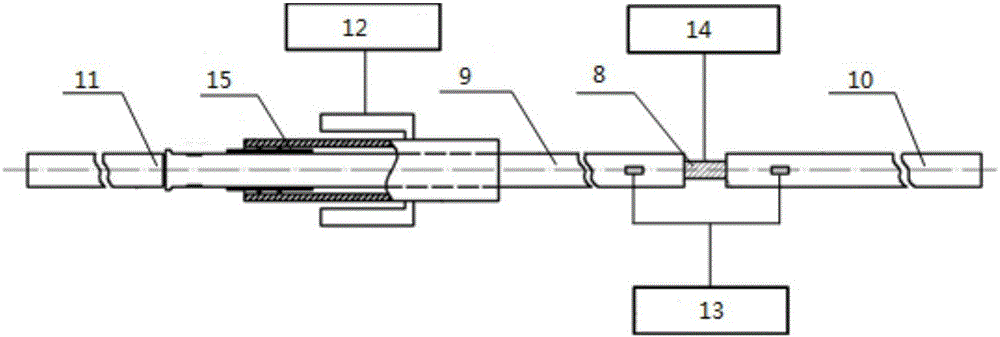

Electromagnetic impact dynamic tensile test method and device

ActiveCN102109436AAchieving Dynamic StretchEasy to controlMaterial strength using tensile/compressive forcesStrong pulseElectromagnetic pulse

The invention relates to an electromagnetic impact dynamic tensile test method and a device, and belongs to the technical field of dynamic tensile mechanical property test of materials. The device adopts an electromagnetic pulse to load; a tensile test piece (8) passes through a central hole of an electromagnetic pulse device (16); the electromagnetic pulse device (16) is used for arousing a strong-pulse magnetic field; the action of electromagnetic force is generated between a target (14) and an electromagnetic pulse coil (18), so that the tensile test piece (8) mounted between the target (14) and a bracket (10) obtains direct instantaneous tensile force to finish the dynamic tensile test of the tensile test piece (8). The method and the device are used for measuring the dynamic stress and strain relationship of the materials in a high strain state; and the device has simple structure and simple test process, can be used for carrying out direct dynamic tensile test as well as the dynamic tensile test of the materials under the conditions of different high strain rates and ultrahigh strain rates, and has low cost and good application prospect.

Owner:JIANGSU UNIV

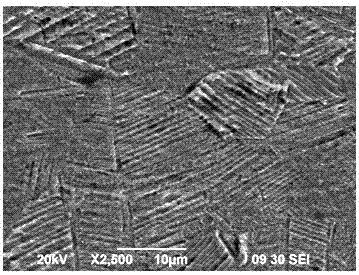

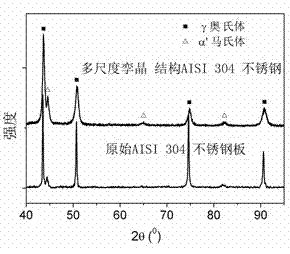

Steel with multi-scale twin-crystal structure and preparation method of steel

The invention discloses steel with a multi-scale twin-crystal structure and a preparation method of the steel. The steel with the multi-scale twin-crystal structure is of a complex microstructure, i.e., a multi-scale twin-crystal and complex phase structure, and the hardness of the steel is reduced in a gradient way from the surface to the center. The preparation method comprises the step of preparing the steel by taking austenitic stainless steel, TRIP (Transformation-Induced Plasticity) steel or TWIP (Twinning Induced Plasticity) steel as materials by using a high strain rate deformation method or high strain rate deformation and temperature deformation treatment combined method. The twin-crystal density of the multi-scale twin-crystal structure ranges from 10% to 90% and changes along with the change of depth, and the twin-crystal density of a surface layer of the multi-scale twin-crystal structure ranges from 30% to 85%, and the twin-crystal density of the center of the multi-scale twin-crystal structure ranges from 10% to 50%. The strength and the plasticity of the steel with the multi-scale twin-crystal structure, disclosed by the invention, are synchronously enhanced; and meanwhile, the favorable ductility is kept. The steel has the highest yield strength of 900-1800MPa, the tensile strength of 1000-2000MPa and the breaking elongation of 30-50%.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

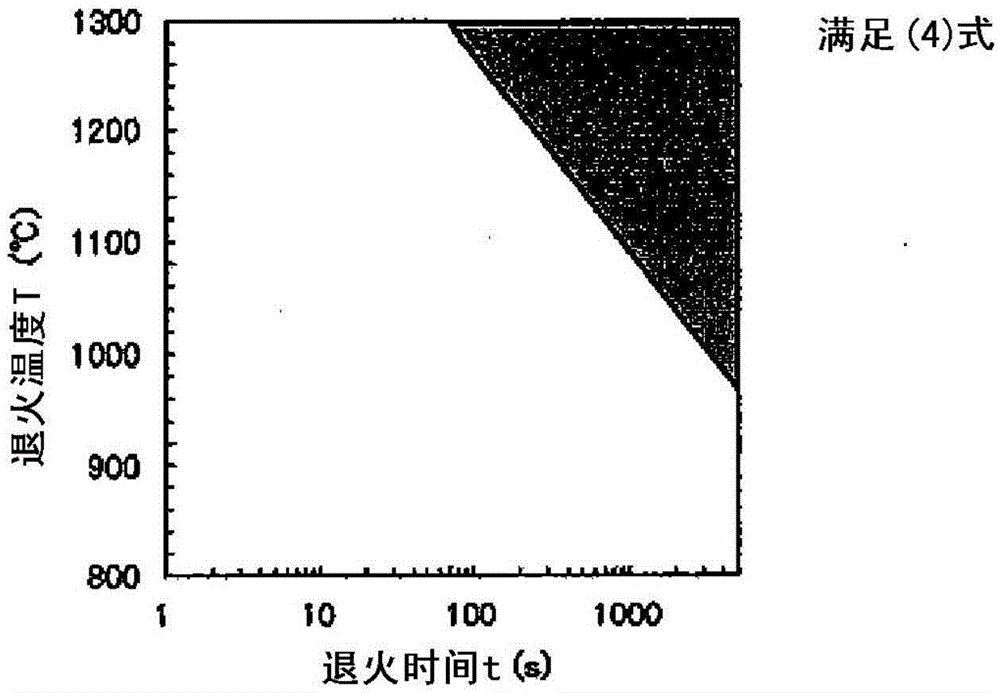

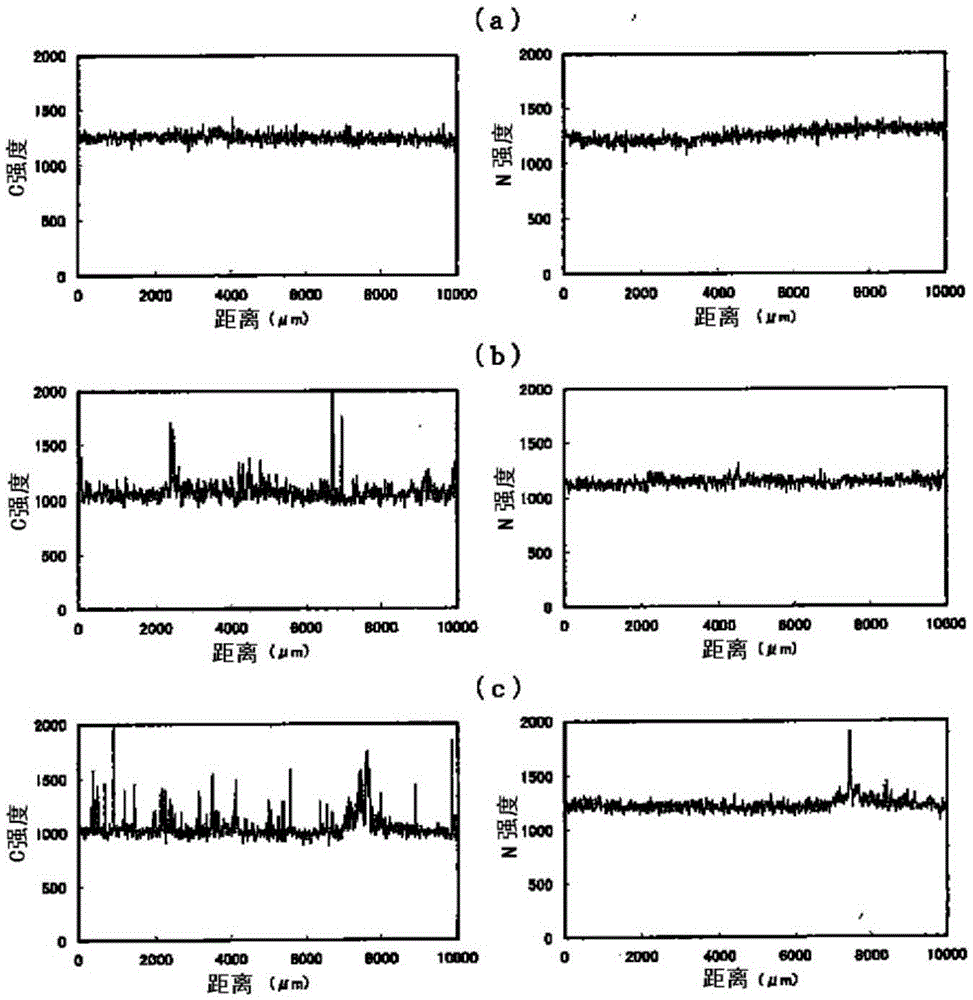

Austenitic stainless steel sheet and method for producing same

ActiveCN105452505AHigh intensityImprove toughnessFurnace typesHeat treatment furnacesFlow stressCarbide

Provided is an austenitic stainless steel sheet which has a product of the 10% flow stress at a strain rate of 1000 / s and the uniform elongation at a strain rate of 0.1 / s of 450 MPa or more and also has high strength at a high strain rate and improved ductility at a low strain rate. An austenitic stainless steel sheet containing, in % by mass, 0.02 to 0.30% of C, 10.0 to 25.0% of Cr, 3.5 to 10.0% of Ni, 0 to 3.0% of Si, 0.5% to 5.0% of Mn, 0.10 to 0.40% of N, 0 to 3.0% of Mo, 0 to 3.0% of Cu, 0 to 0.10% of Ti, 0 to 0.50% of Nb and 0 to 1.0% of V, wherein the value determined by the following formula: C + 3 * N is 0.4% or more, and the remainder is made up by Fe and impurities. In the austenitic stainless steel sheet, the Md30 value which is defined by formula (1) is 0 to 50 DEG C inclusive, the volume ratio of each of a Cr carbide and a Cr nitride is 1% or less, and the average crystal particle diameter of a parent phase is 10 [mu]m or less.

Owner:NIPPON STEEL CORP

Method of preparing TiAl alloy plate by virtue of spark plasma sintering and canning hot rolling

ActiveCN104588433AReduce oxygen contentHigh densityAdditive manufacturingIncreasing energy efficiencyChemical compositionAlloy

The invention discloses a method of preparing a TiAl alloy plate by virtue of spark plasma sintering and canning hot rolling, relates to a preparation method of an alloy plate and aims at solving the problems of uneven chemical components, inconsistency in tissues, poor performance of the plate and difficulty in preparation of the traditional preparation method of the TiAl alloy plate. The method comprises the following steps: carrying out spark plasma sintering on TiAl pre-alloyed powder firstly to prepare a pre-rolled plate slab, and then preparing the TiAl alloy plate by virtue of a canning hot rolling method. According to the method disclosed by the invention, the TiAl alloy plate slab prepared by spark plasma sintering is high in density, fine in tissue, uniform in components, excellent in performances, good in deformability, convenient in subsequent formation of the TiAl alloy plate, fine in grain size of the prepared plate and excellent in mechanical properties, is capable of carrying out high-temperature canning rolling on TiAl alloy at a relatively low temperature and high strain rate and is suitable for preparing the TiAl alloy plate.

Owner:HARBIN INST OF TECH

Methods for processing titanium alloys

Methods of refining the grain size of a titanium alloy workpiece include beta annealing the workpiece, cooling the beta annealed workpiece to a temperature below the beta transus temperature of the titanium alloy, and high strain rate multi-axis forging the workpiece. High strain rate multi-axis forging is employed until a total strain of at least 1 is achieved in the titanium alloy workpiece, or until a total strain of at least 1 and up to 3.5 is achieved in the titanium alloy workpiece. The titanium alloy of the workpiece may comprise at least one of grain pinning alloying additions and beta stabilizing content effective to decrease alpha phase precipitation and growth kinetics.

Owner:ATI PROPERTIES LLC

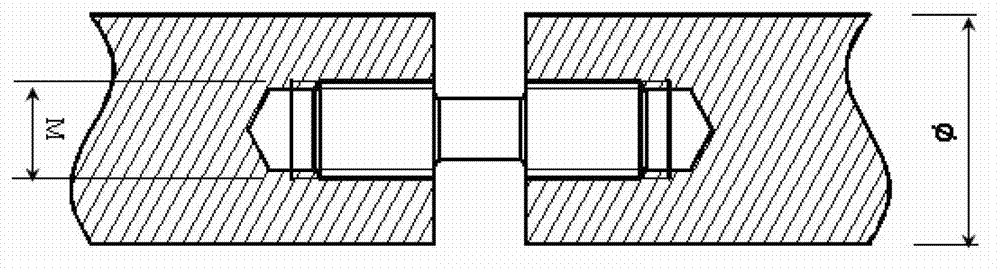

Tensile synchronous experiment device

InactiveCN102830019AAvoid direct contact with heat transferOvercoming the problem of local temperature riseMaterial strength using tensile/compressive forcesEngineeringTest material

The invention discloses a tensile synchronous experiment device for solving the technical problem that the conventional tensile experiment device cannot be used for testing tensile performance of a material at high temperature and high strain rate. The technical scheme is that an end head of tensile test piece is designed to be in the form of a convex edge, wherein an end head of a pull rod connected to the tensile test piece is designed to be in the form of a wedged groove; and high-temperature synchronization is realized under the control of a linkage emission valve block through matching of the two end heads. By designing a connection mode of the end head of the tensile test piece and the end head of the pull rod, a reserved gap is arranged; the tensile test piece and the pull rod are heat-insulated through a heat insulating material, so that direct contact heat transfer of the tensile test piece and the pull rod is avoided during heating of the test piece; and thus, an incidence bar and a transmission bar are kept in a normal temperature state in an experimental process all the time, and the problem of increase in local temperature of the incidence bar and the transmission bar in the background technology is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Composite corrugated pipe forming device based on electromagnetic forming

The invention discloses a composite corrugated pipe forming device based on electromagnetic forming. The composite corrugated pipe forming device is characterized by comprising a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), a fixing bolt (7), a pressing block (8), a die rack (9), a constraint die (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), a trapezoid hole (15), a vent hole (16), a fixing groove (17) and a wire hole (18). The composite corrugated pipe forming device has the advantages that the device is few in machining procedures, high in machining efficiency, high in forming precision, fast in pipe fitting forming, and capable of forming pipe fittings under high strain rate; due to high strain deformation, the device is applicable to forming of metal materials which are difficult to deform by conventional methods, plasticity of the metal materials is increased greatly, and yield strength of the materials is increased greatly; different corrugations can be formed by changing the shape of the constraint die, and high machining flexibility is achieved.

Owner:HUNAN UNIV

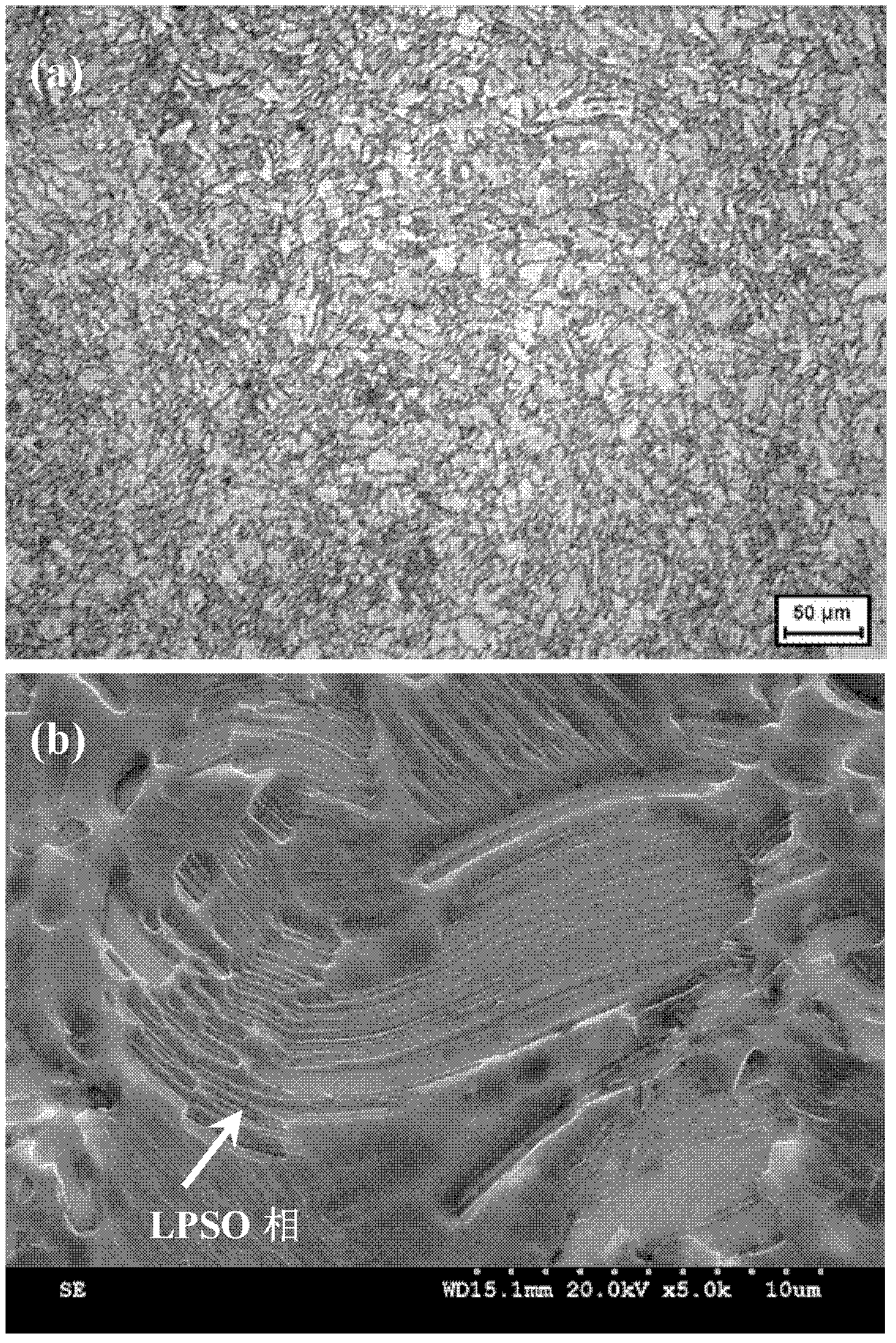

Magnesium-base rare-earth alloy material and preparation method thereof

InactiveCN102628135AImproved superplastic formabilityImproved deformation coordinationRare earthImpurity

The invention provides a magnesium-base rare-earth alloy material and a preparation method thereof. The magnesium-base rare-earth alloy material comprises the components by weight percent: 7.0-1.0% of Y, 1.0-2.5% of Er, 2.0-3.0% of Zn, less than 0.03% of inevitable impurities of Fe, Cu, Ni and Si, and the balance of Mg. The methods of conventional smelting, homogenizing treatment, hot extrusion treatment, and the like, are adopted by the invention, and meanwhile a superplastic magnesium rare-earth alloy material with high strain rate is obtained. Under lower temperature (300-380 DEG C), the alloy has high strain rate (0.8*10-2-1*10-2s-1) and superplasticity, the coefficient of elongation of the alloy after being broken is 350%-520%. The production cost is effectively lowered, the production efficiency is increased, the operation is easily performed and the magnesium-base rare-earth alloy material is beneficial to large-scale application and popularization.

Owner:HARBIN ENG UNIV

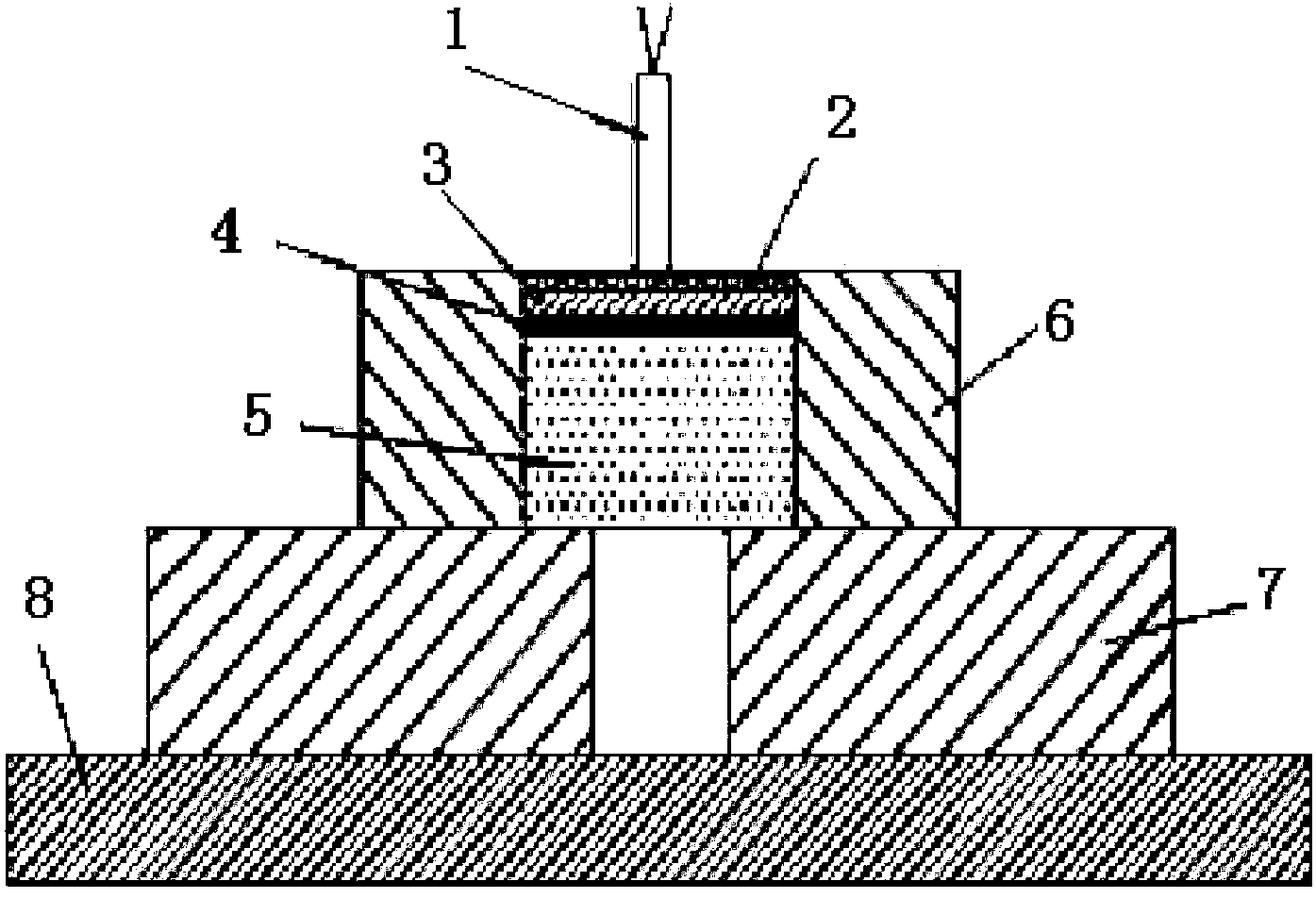

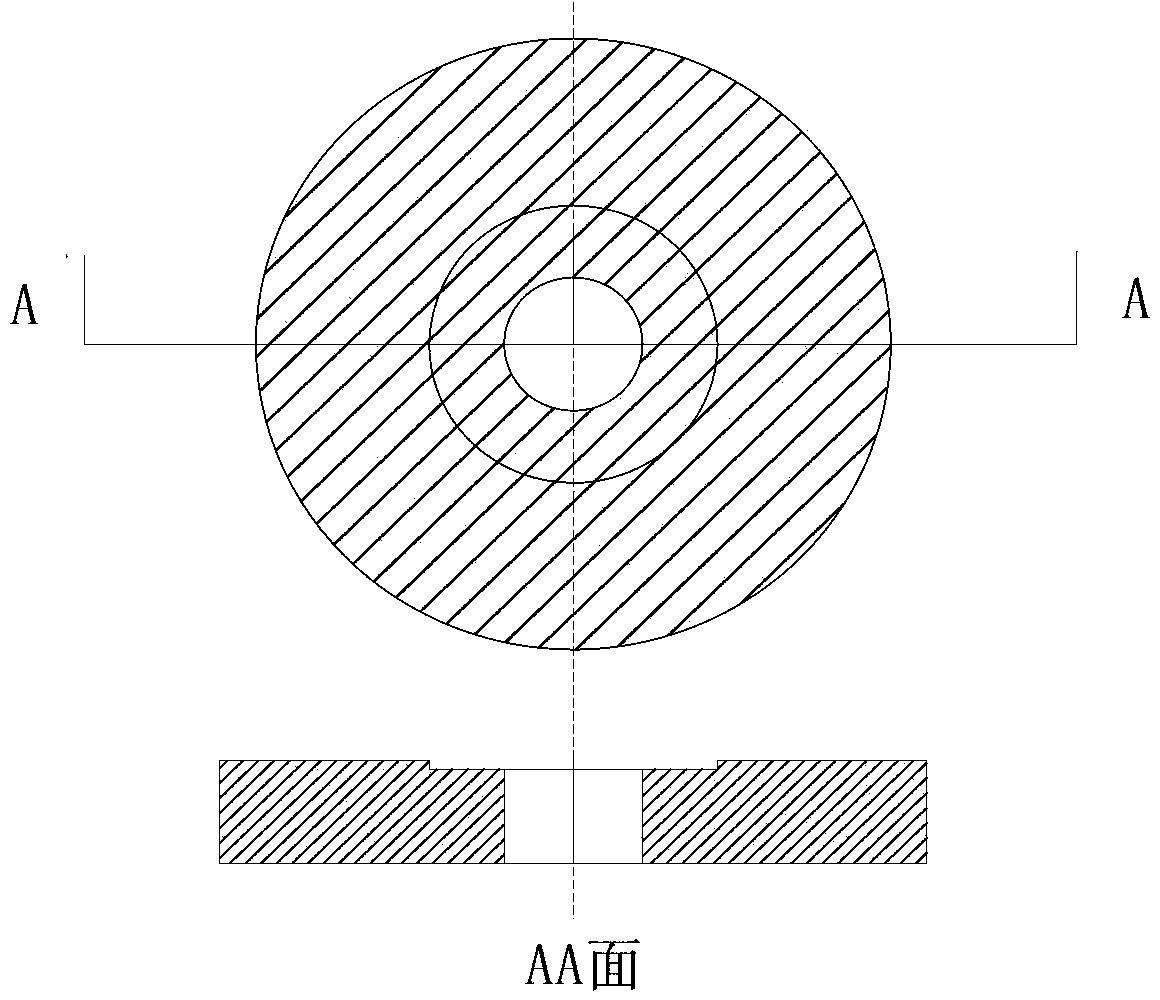

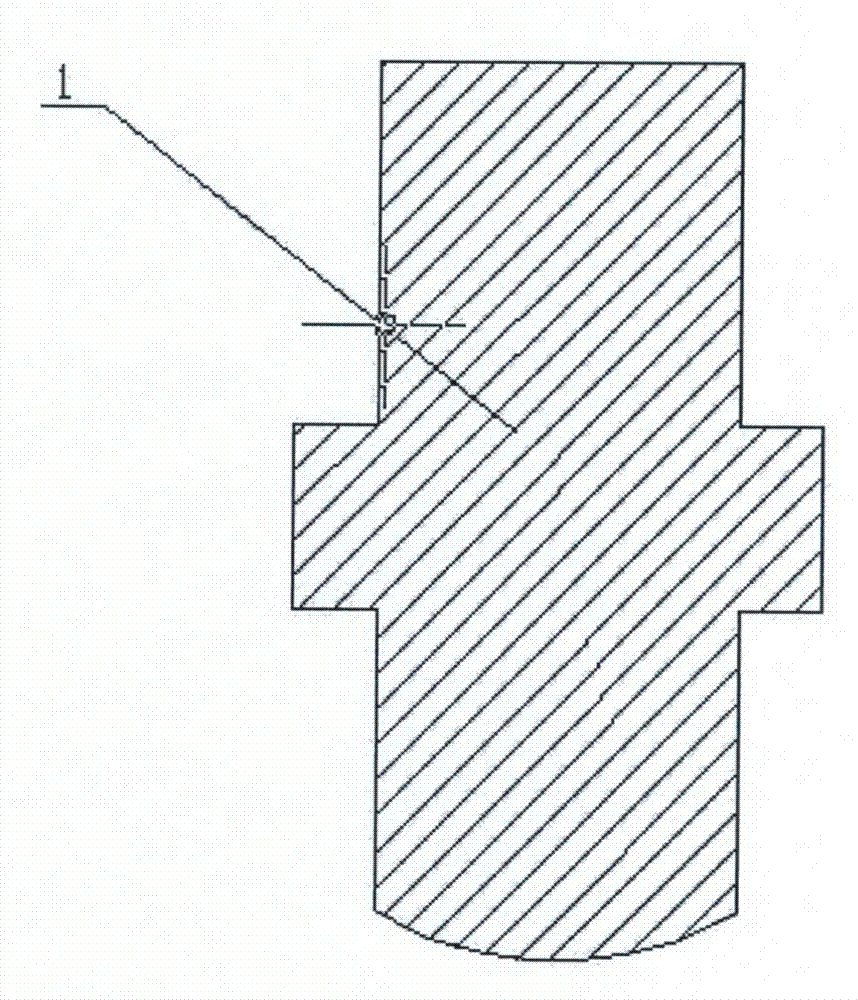

Shearing test piece for researching type II fracture of viscoelastic material under condition of high strain rate

InactiveCN103439197AMeet spreadFulfil requirementsPreparing sample for investigationMaterial strength using steady shearing forcesCylindromaEngineering

The invention discloses a shearing test piece for researching type II fracture of a viscoelastic material under the condition of high strain rate. A radial through groove is formed in one end of a cylinder, a radial through convex platform is arranged at the other end of the cylinder, the diameter and height of the cylinder are less than or equal to the diameter of an experimental Hopkinson bar, the radial through groove and the radial through convex platform are parallel to each other, the area of the end surface of the radial through convex platform is equal to the area of the bottom surface of the radial through groove and half of the sectional area of the cylinder, and two ends of the radial through groove are provided with prefabricated cracks along the direction of the side end surface of the radial through groove. The shearing test piece is relatively simple in structure, and meets the requirements on wave propagation in the test piece and a calculation method; the shearing test piece can be used for researching the mechanical properties of metal, brittle and the viscoelastic material in the Hopkinson bar and a quasi static experiment, so that experimental results have comparability.

Owner:NANJING UNIV OF SCI & TECH

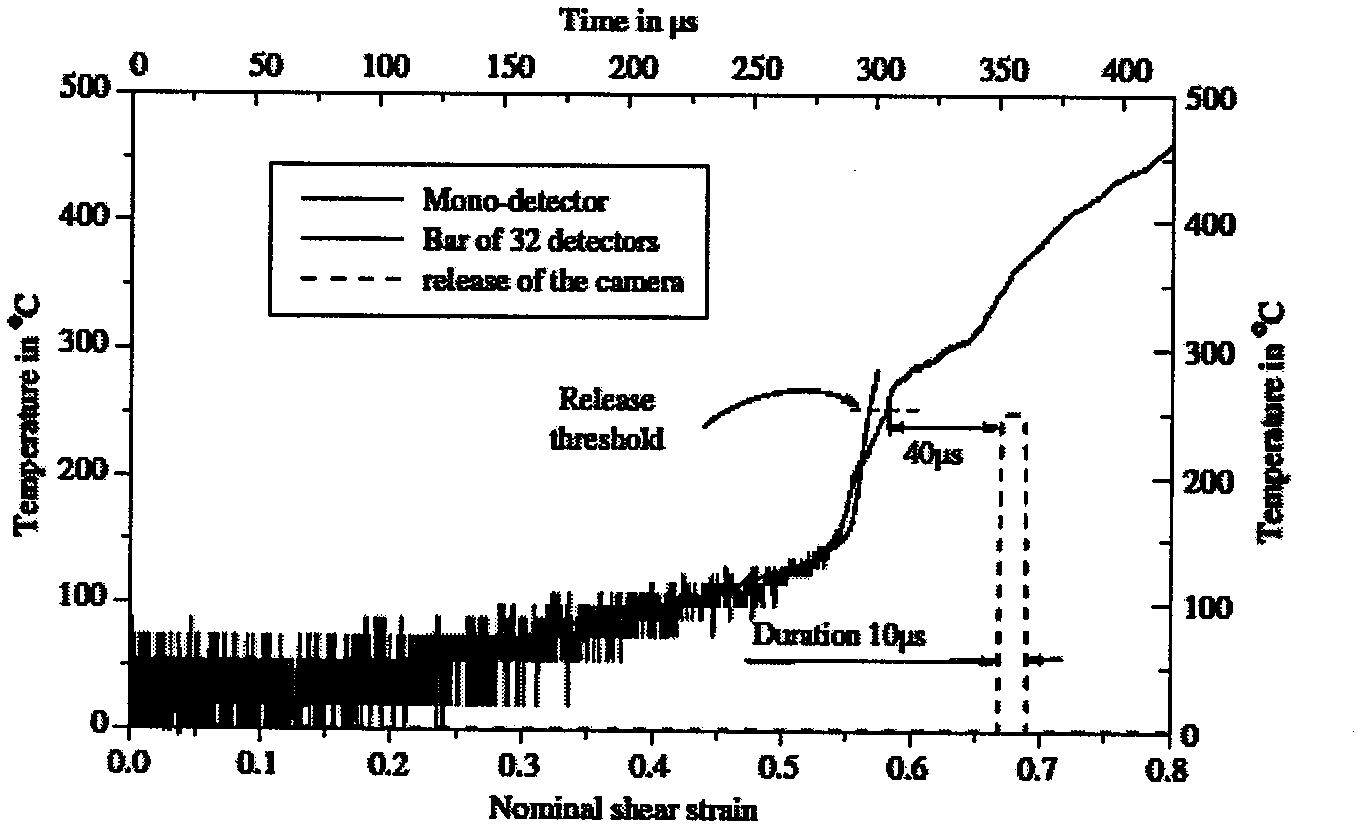

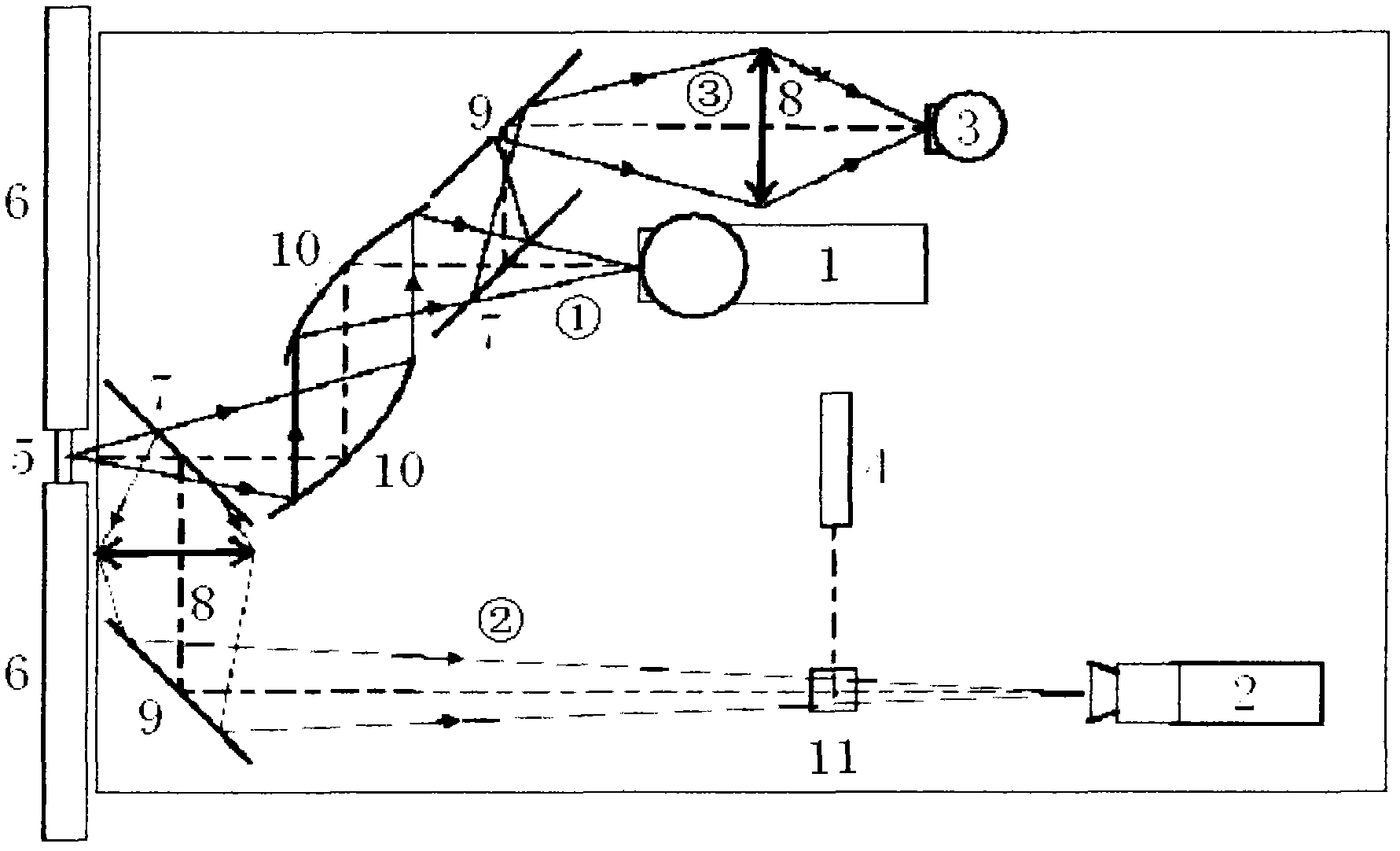

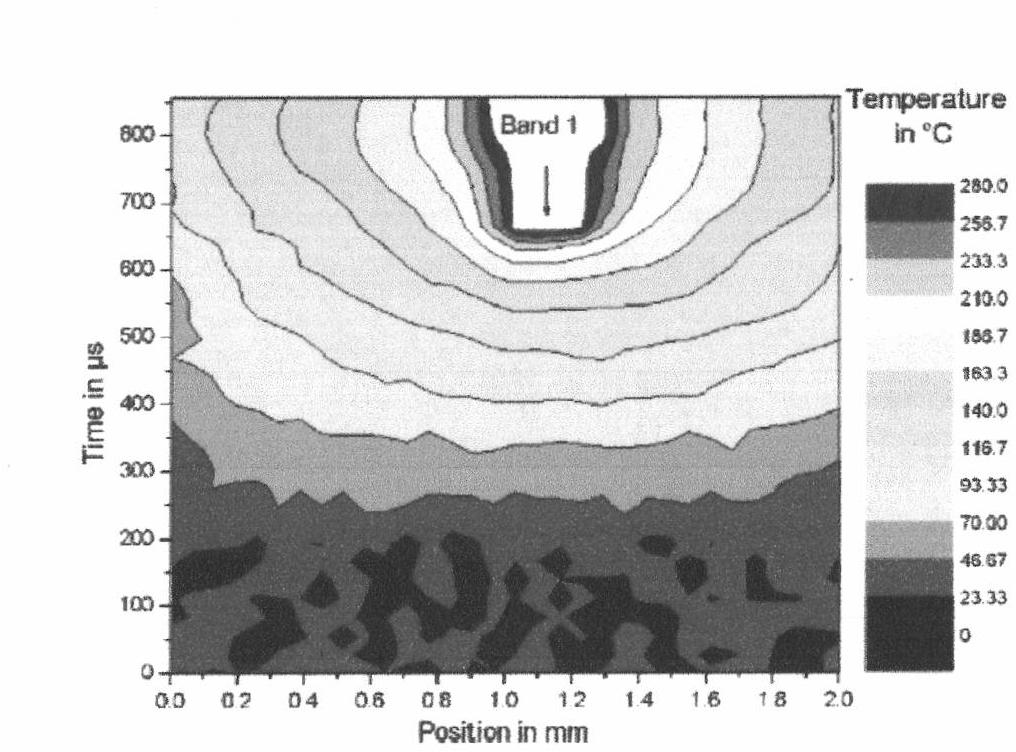

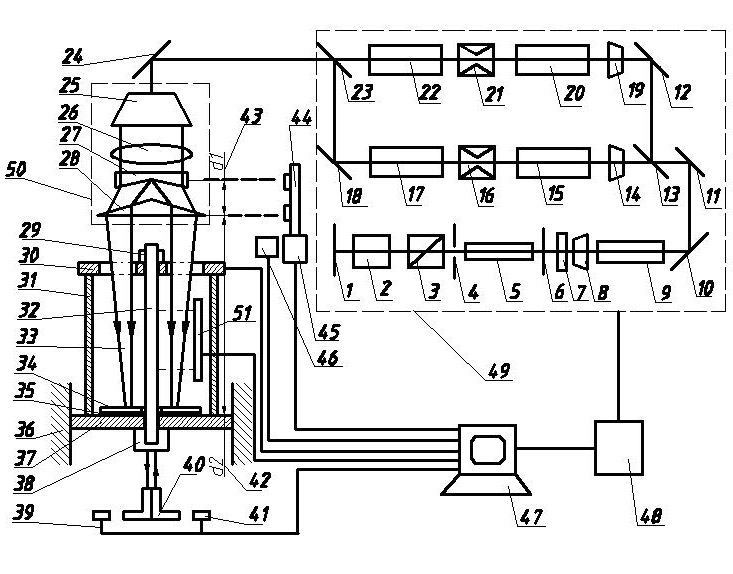

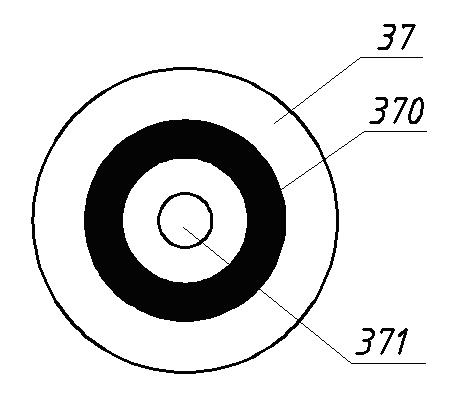

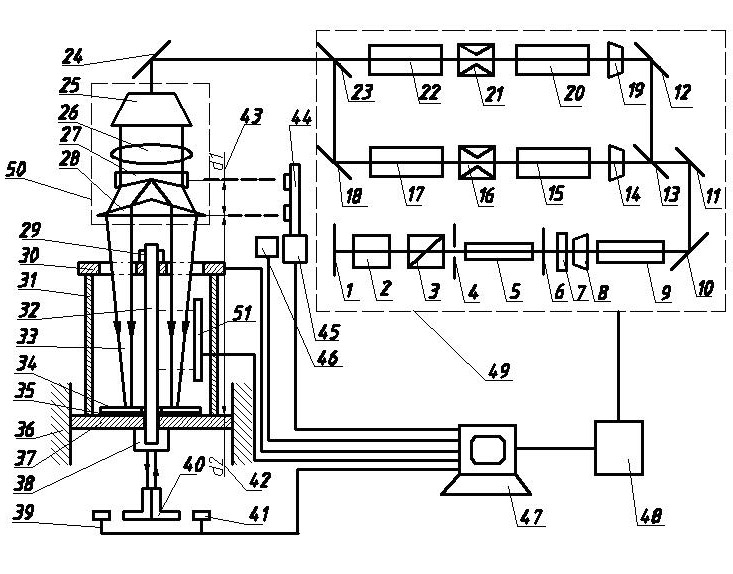

Adiabatic shearing failure temperature online detection method and system based on infrared thermal imaging

InactiveCN102645282AImprove spatial resolutionImprove time resolutionPyrometry using electric radation detectorsAdiabatic shear bandMetallic materials

The invention provides an online detection method and system based on infrared thermal imaging. The system comprises a sample loading device, an infrared optical imaging system, an infrared detection device, a multiplexing electric signal processing system and a data acquisition system, wherein the sample loading device is used for loading samples and subjecting to shock compression failure; the infrared optical imaging system is used for collecting the sample distorted radiation light and imaging in the infrared detection device; the infrared detection device converts a received optical signal into an electrical signal for detecting the temperature variation of the shock compression test; the multiplexing electric signal processing system processes the electrical signal which is converted by the infrared detection device, and outputs cushion and multipath transmission, and finally, an image is formed; and the data acquisition system acquires data. The system solves the problem of online testing the temperatures of the formation and development stages of an adiabatic shear band when a metal material or component is under the action of high strain rate, the spatial and time resolutions of the test system are improved through the infrared detection device and the high-speed data acquisition system which are arranged into an array, so the acquired data which is based on infrared imaging can satisfy the use requirements, and the research on the development process temperature characteristic of the adiabatic shear band is promoted.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Methods for processing titanium alloys

Methods of refining the grain size of a titanium alloy workpiece include beta annealing the workpiece, cooling the beta annealed workpiece to a temperature below the beta transus temperature of the titanium alloy, and high strain rate multi-axis forging the workpiece. High strain rate multi-axis forging is employed until a total strain of at least 1 is achieved in the titanium alloy workpiece, or until a total strain of at least 1 and up to 3.5 is achieved in the titanium alloy workpiece. The titanium alloy of the workpiece may comprise at least one of grain pinning alloying additions and beta stabilizing content effective to decrease alpha phase precipitation and growth kinetics.

Owner:ATI PROPERTIES LLC

Rubber material viscous and superelastic constitutive model building method considering correlation effect

InactiveCN106202683AWide range of predicted strainsFew parametersDesign optimisation/simulationSpecial data processing applicationsRubber materialPolymer science

The invention discloses a rubber material viscous and superelastic constitutive model building method considering a correlation effect. The method comprises the following steps of obtaining stress-strain of a rubber material through quasi-static uniaxial tension experiment; performing impact uniaxial tension experiment through an SHTB (split hopkinson tension bar) device to obtain the stress-strain of the rubber material at a high strain rate; obtaining corresponding response rules and deformation characteristics according to the stress-strain, obtained through the quasi-static uniaxial tension experiment and the impact uniaxial tension experiment, of the rubber material; building a viscous and superelastic constitutive model of the rubber material. The method has the advantages that by aiming at the study on the tensile mechanical property of the rubber material, the viscous and superelastic constitutive model of the rubber material is built; reference is provided for the study on the tensile mechanical property of the rubber material; the problem of mechanical characterization difficulty of the rubber material at different strain rates is solved.

Owner:NANJING UNIV OF SCI & TECH

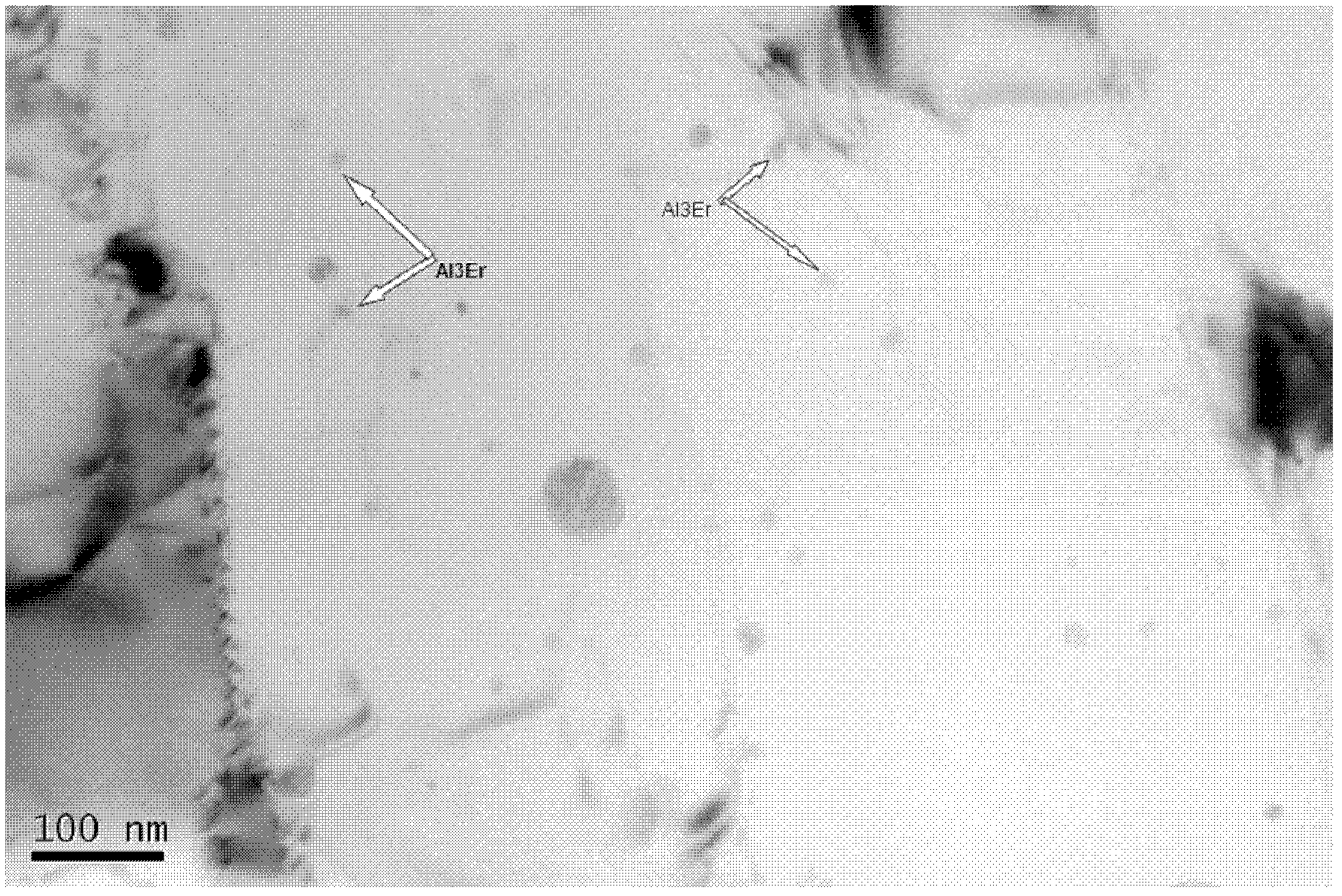

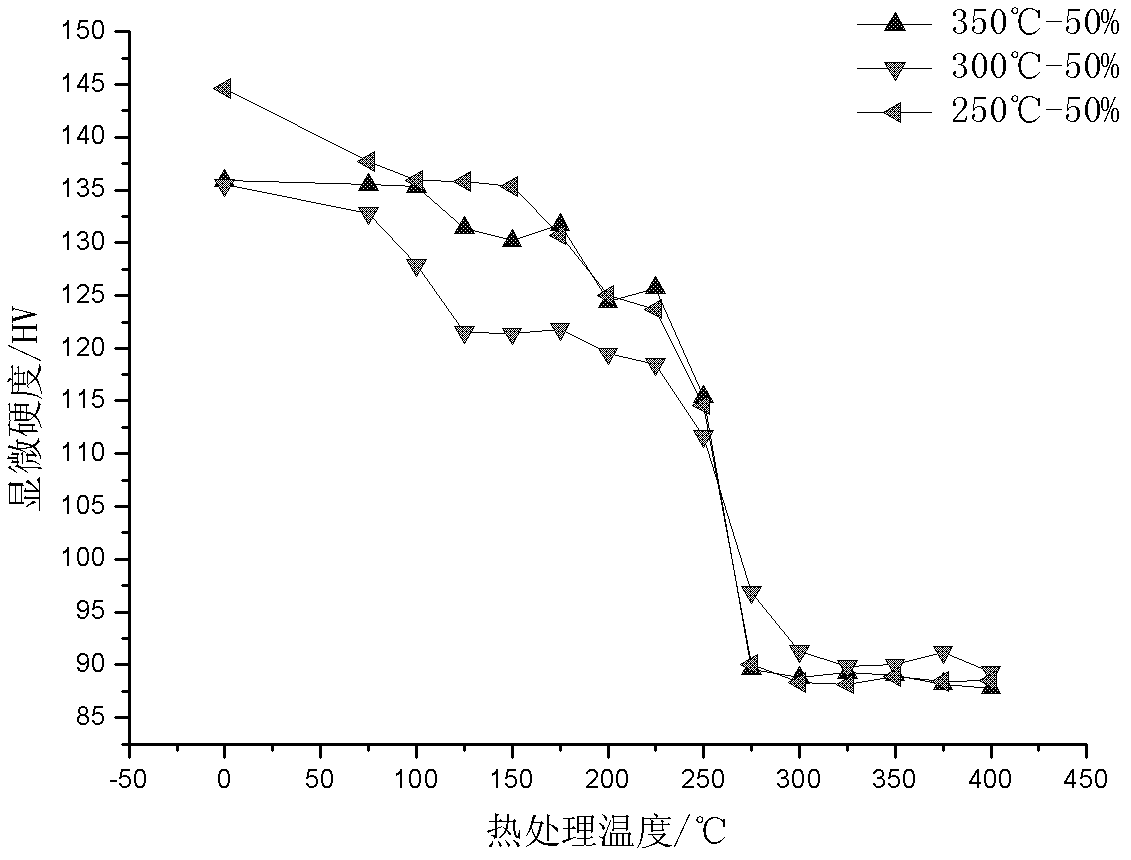

Process for strengthening temperature deformation of Er-containing aluminum-magnesium alloy sheet material

The invention relates to a process for strengthening the temperature deformation of an Er-containing aluminum-magnesium alloy sheet material, belonging to the technical field of non-ferrous metal. The process comprises the following steps of: carrying out heat insulation on the Er-containing aluminum-magnesium alloy sheet material at 400 DEG C for 2 hours, wherein the Er-containing aluminum-magnesium alloy sheet material contains 5.8-6.8% of Mg, 0.4-0.8% of Mn, 0.1-0.2% of Zr, 0.1-0.4% of Er, no more than 0.5% of inevitable impurities and the balance of Al; reserving the deformation quantity of 30-50% for a finished product sheet; hot rolling an aluminum sheet to a corresponding thickness at the temperature of 400 DEG C; carrying out heat insulation for 2 hours at the temperature of 250-350 DEG C, and carrying out single-pass deformation at the temperature for heat insulation, wherein the deformation quantity is 30-50%, and the rolling speed is 0.08-0.25 ms<-1>; and carrying out air cooling to room temperature. The process has the characteristics of high strain rate, large single-pass deformation quantity, low resistance to deformation and the like, and the Er-containing aluminum-magnesium alloy sheet material obtained through processing has the advantages of higher strength and excellent plasticity and corrosion resistance.

Owner:BEIJING UNIV OF TECH

Device and method for machining composite energy absorption tube

The invention discloses a composite energy absorption tube machining device which comprises a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), a fixing bolt (7), a pressing block (8), a mould frame (9), a constraint mould (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), an exhaust vent (16), a fixing groove (17) and a wire hole (18). Compared with a hydraulic forming method and a mechanical bulging method, a composite metal energy absorption forming method based on the electromagnetic forming principle and used in the composite energy absorption tube machining device is high in machining efficiency and high in the pipe fitting forming speed and enables composite metal tubes to be formed under the high strain rate; due to the fact that the high strain deformation process can be used for forming metal materials which are deformed difficultly through a conventional method, the plasticity of the metal materials is greatly improved, and the yield strength of the materials is greatly improved. Different wave forms and reinforcing ribs can be formed by changing the shape of the constraint mould in a mould body, and the machining flexibility is high.

Owner:HUNAN UNIV

Impact dynamic tension test method and device thereof of ring laser

InactiveCN102072841AEasy clampingThe testing process is simpleStrength propertiesRing laserEngineering

The invention relates to an impact dynamic tension test method and a device thereof of a ring laser, relating to the technical field of dynamic tension mechanics performance test of materials. In the invention, a high power ring pulse laser is adopted to contain a test-piece in a hollow part of a laser beam; and a ring pulse laser gets through the test-piece via the hollow part and impacts a target, so that the test-piece arranged between a bracket and the target acquires instant tension so as to complete the impact dynamic tension test of the test-piece. The method and the device of the invention are used for for measuring dynamic stress strain relation of the materials under ultrahigh strain state, the device has simple structure, simple and convenient test process, and can perform direct dynamic tension test; and the method and the device can perform the dynamic tension test of the materials under the conditions of different high strain rates and ultrahigh strain rates, thereby having low cost and good application prospect.

Owner:JIANGSU UNIV

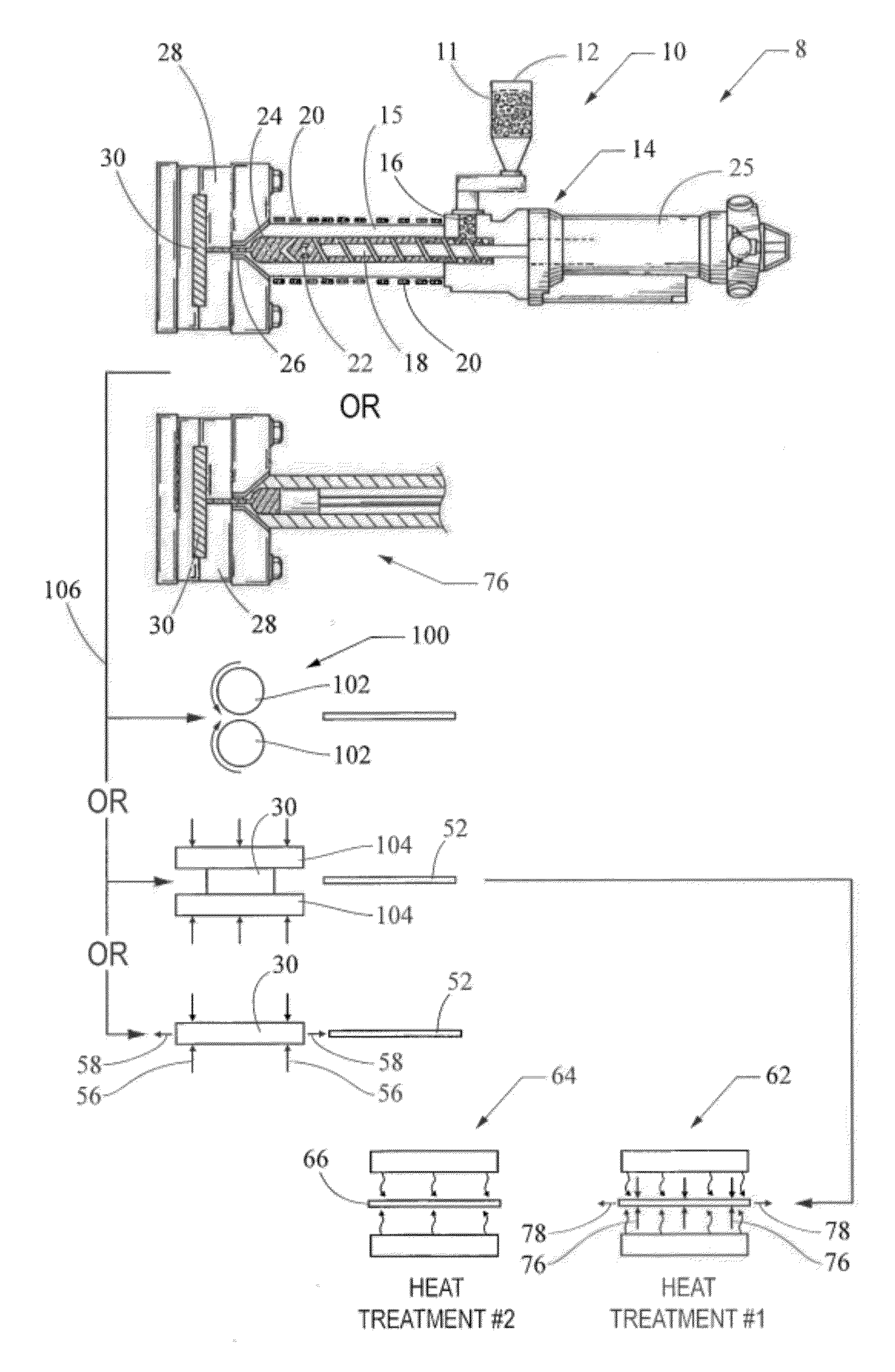

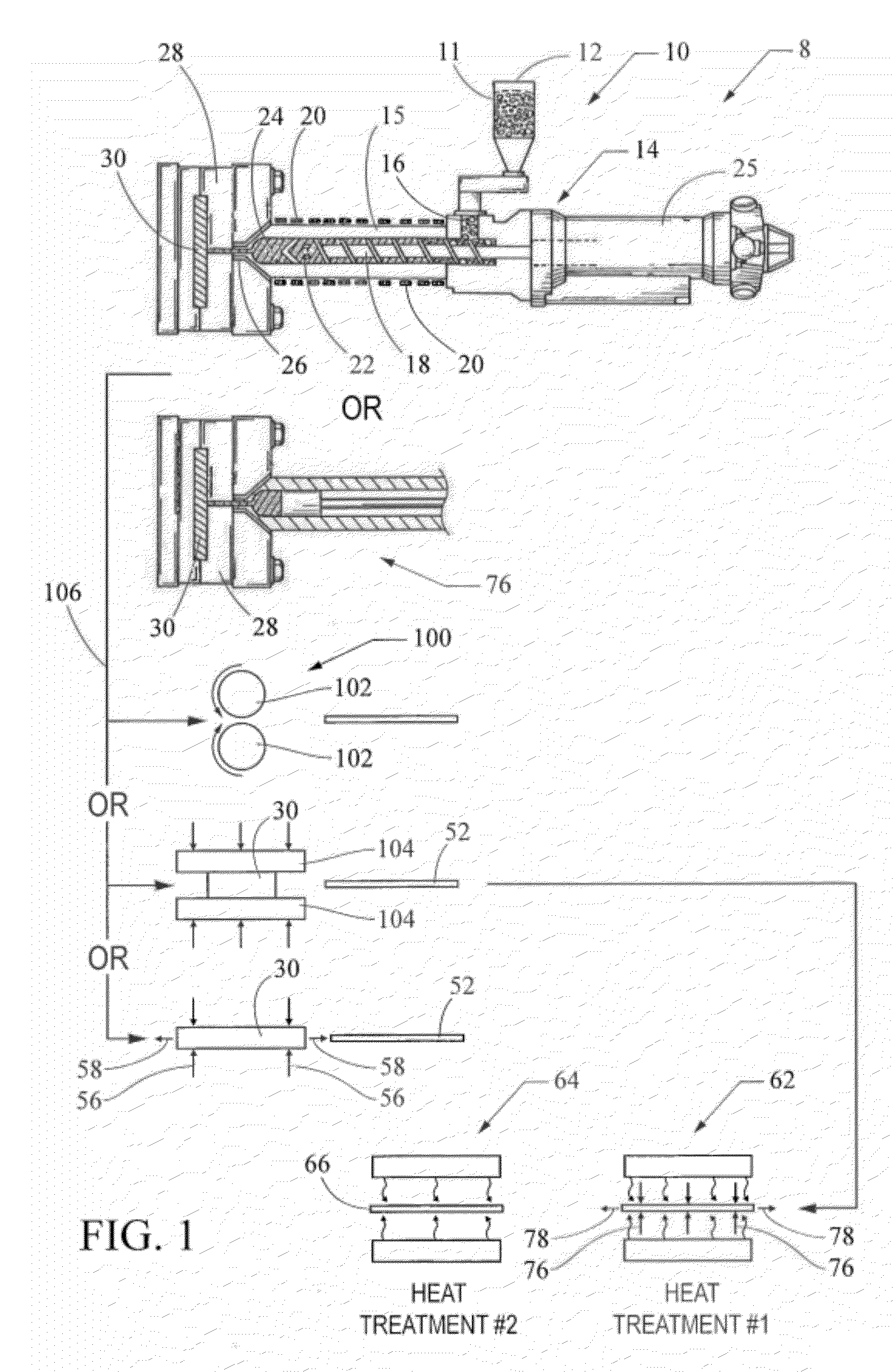

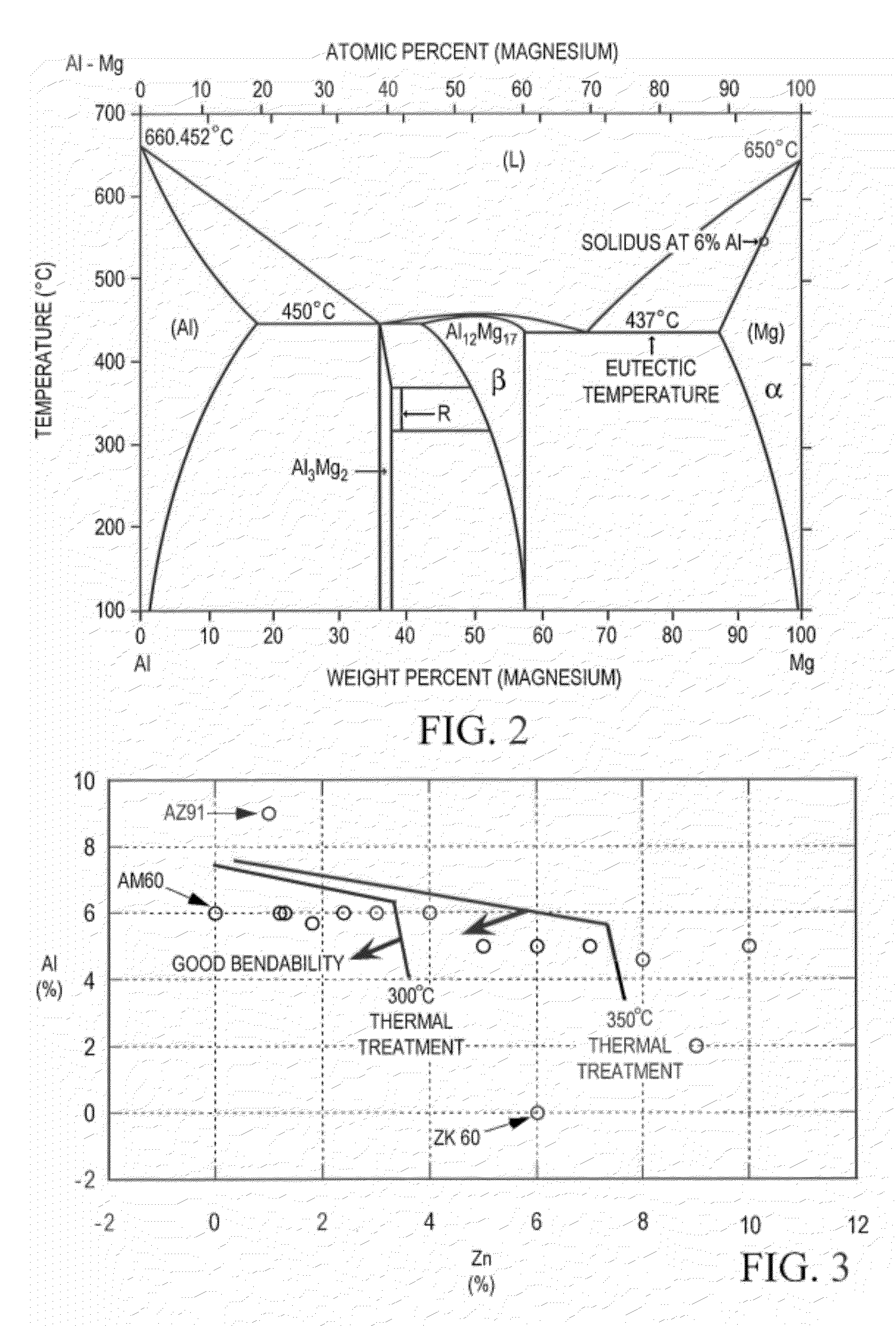

Method and apparatus of forming a wrought material having a refined grain structure

ActiveUS20120305145A1Provide formabilityProvide impact resistanceMould handling/dressing devicesMetal alloyShell molding

A method of forming a wrought material having a refined grain structure is provided. The method comprises providing a metal alloy material having a depressed solidus temperature and a low temperature eutectic phase transformation. The metal alloy material is molded and rapidly solidified to form a fine grain precursor that has fine grains surrounded by a eutectic phase with fine dendritic arm spacing. The fine grain precursor is plastic deformed at a high strain rate to cause recrystallization without substantial shear banding to form a fine grain structural wrought form. The wrought form is then thermally treated to precipitate the eutectic phase into nanometer sized dispersoids within the fine grains and grain boundaries and to define a thermally treated fine grain structure wrought form having grains finer than the fine grains and the fine dendritic arm spacing of the fine grain precursor.

Owner:THIXOMAT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com