Tensile synchronous experiment device

A technique for synchronous experiments and tensile samples, applied in the field of experimental devices, can solve problems such as inability to test the tensile properties of materials, and achieve the effect of overcoming local temperature rise and avoiding direct contact heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

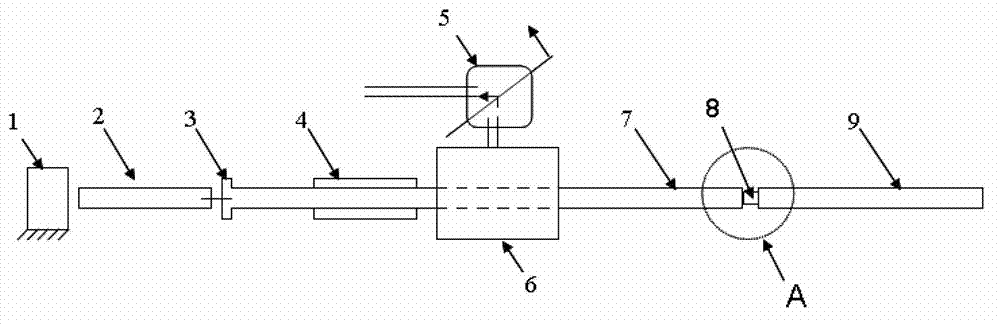

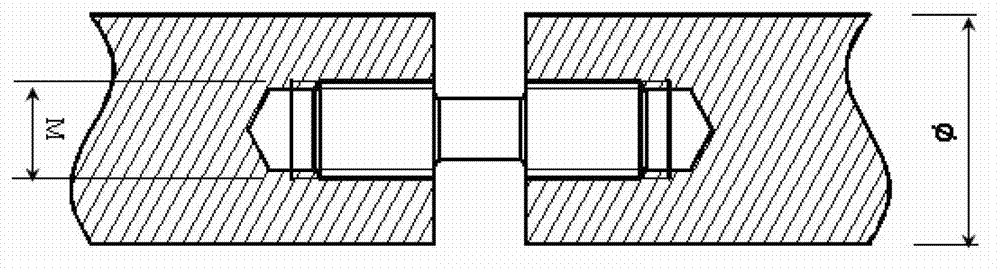

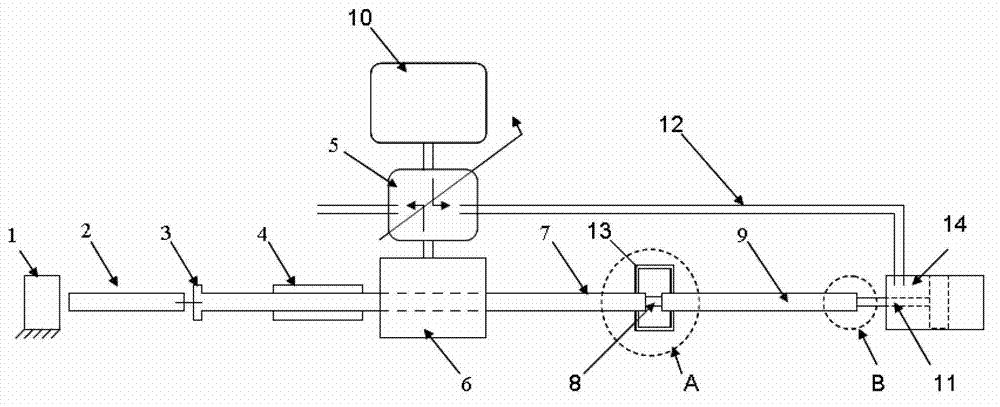

[0016] refer to Figure 3-6 , the stretching synchronous experiment device of the present invention comprises energy absorber 1, energy transmission rod 2, loading flange 3, impact tube 4, linkage launch valve group 5, impact gas chamber 6, incident rod 7, tensile sample 8, transmission Rod 9, synchronous air chamber 10, piston 11, gas pipe 12, high temperature furnace 13, stretching cylinder 14, thermocouple wire 15, heat insulating material 16. The energy absorber 1, the energy transmission rod 2, the impact gas chamber 6, the incident rod 7 and the transmission rod 9 are all placed on the platform. The energy transmission rod 2, the incident rod 7, and the transmission rod 9 are all cylindrical rods; the impact tube 4 is a tubular short rod, which is set on the incident rod 7 and can slide freely along the incident rod 7. The entire incident rod 7 penetrates the impact gas. Chamber 6; the collision position between the incident rod 7 and the impact tube 4 is designed as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com