Downhole electronic instrument forced cooling insulation cabin

An electronic instrument and forced cooling technology, which is applied in the field of petroleum engineering, can solve the problems of increasing the volume of thermos flasks, etc., and achieve the effects of improving heat dissipation efficiency, improving work efficiency, and reducing reverse transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

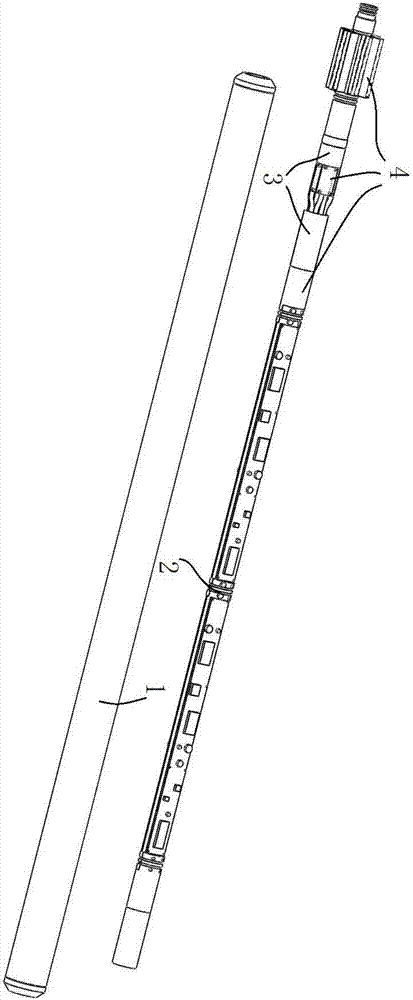

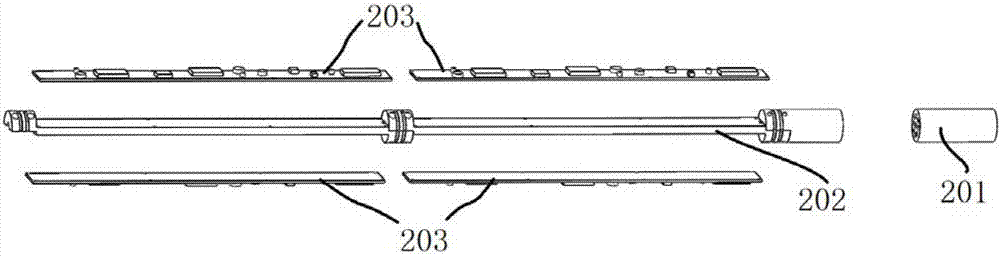

[0014] Such as Figure 1 to Figure 6 As shown, the downhole electronic instrument forced cooling insulation cabin includes: vacuum flask 1, electronic instrument nipple 2, bottle mouth heat insulator 3, semiconductor refrigeration device 4; among them: electronic instrument nipple 2, bottle mouth heat insulator 3 and The semiconductor refrigeration device 4 is sequentially installed in the thermos bottle 1 .

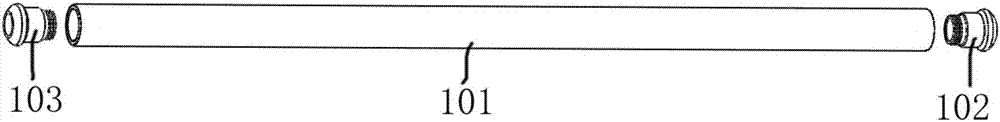

[0015] The thermos bottle 1 includes: a thermos bottle cover 101, a tail cap 102, and an end plug 103; As the heat insulation device of the short joint 2 of the electronic instrument, it can effectively reduce the thermal power entering the electronic instrument compartment, and correspondingly reduce the cooling power of the semiconductor refrigeration device 4 required; the tail cap 102 is screwed on the thermos bottle sleeve 101 tail, the end plug 103 is screwed on the end of the thermos bottle cover 101 by threads, and the tail protective cap 102 and the end plug 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com