Preparation method of high-temperature-resistant oxidation-resistant nickel-based alloy spring wire

A nickel-based alloy and spring wire technology, applied in the field of alloys, can solve the problems of difficulty in drawing, large difference between wire surface hardness and central hardness, easy wire breakage, etc., and achieve the effect of reduced tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In one embodiment, a method for preparing a high-temperature-resistant and oxidation-resistant nickel-based alloy spring wire includes the following steps:

[0028] a. Carry out chemical descaling to the alloy blank, dry and apply a lubricating coating to obtain a pre-processed alloy blank;

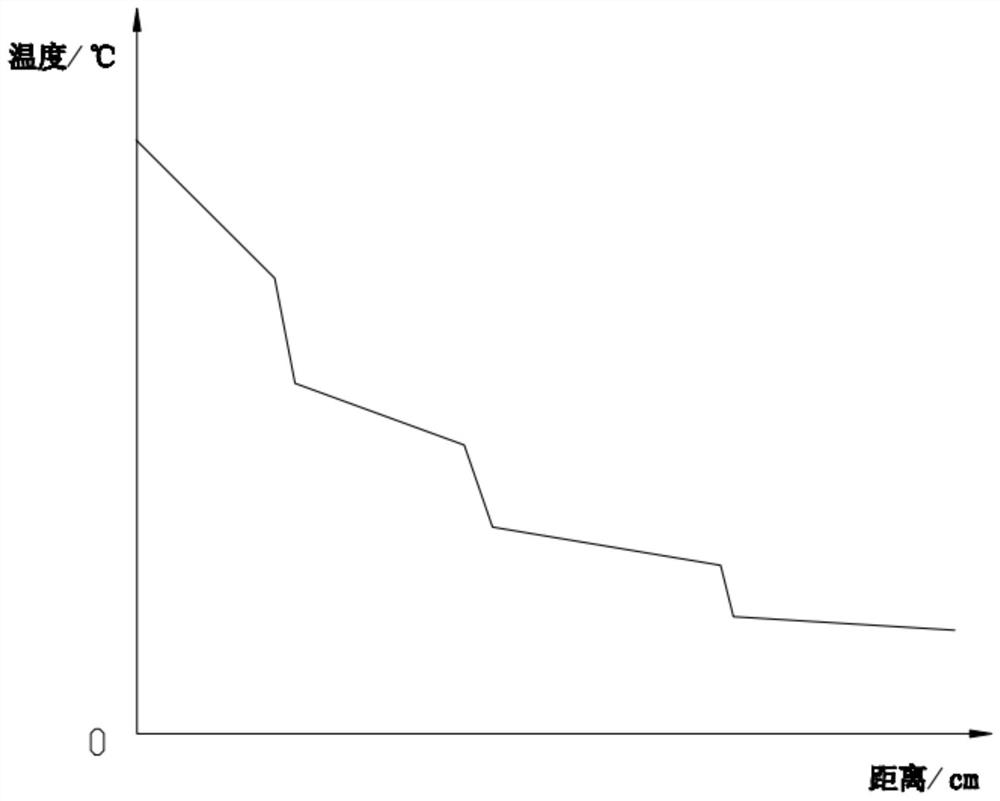

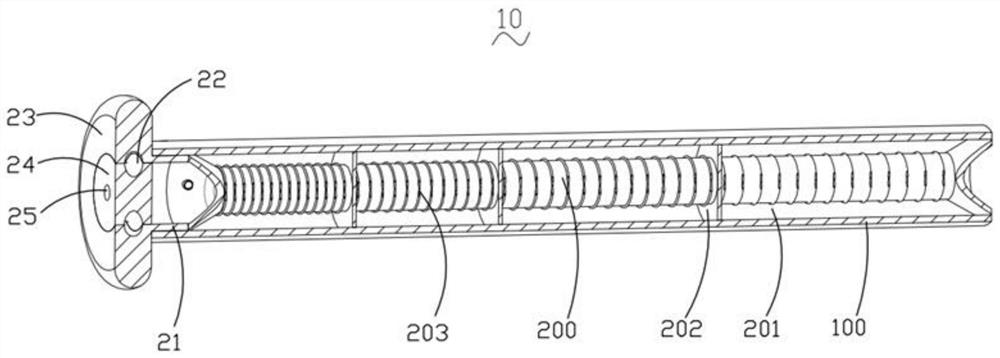

[0029] b. cold drawing the pre-processed alloy blanks through several fixed dies to obtain spring wire blanks, wherein, during the cold drawing process, keep the spring wire blanks passing through the fixed dies in an airtight or semi-closed space, and the surface temperature gradient decreases.

[0030] The above-mentioned method for preparing high-temperature-resistant and anti-oxidation nickel-based alloy spring wire keeps the spring wire blank in a closed or semi-closed space after passing through the fixed mold, and keeps the temperature in a gradient decline. On the one hand, it prevents the spring wire blank from After being directly exposed to the air after being fixed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com