Patents

Literature

255 results about "Vacuum flask" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum flask (also known as a Dewar flask, Dewar bottle or thermos) is an insulating storage vessel that greatly lengthens the time over which its contents remain hotter or cooler than the flask's surroundings. Invented by Sir James Dewar in 1892, the vacuum flask consists of two flasks, placed one within the other and joined at the neck. The gap between the two flasks is partially evacuated of air, creating a near-vacuum which significantly reduces heat transfer by conduction or convection.

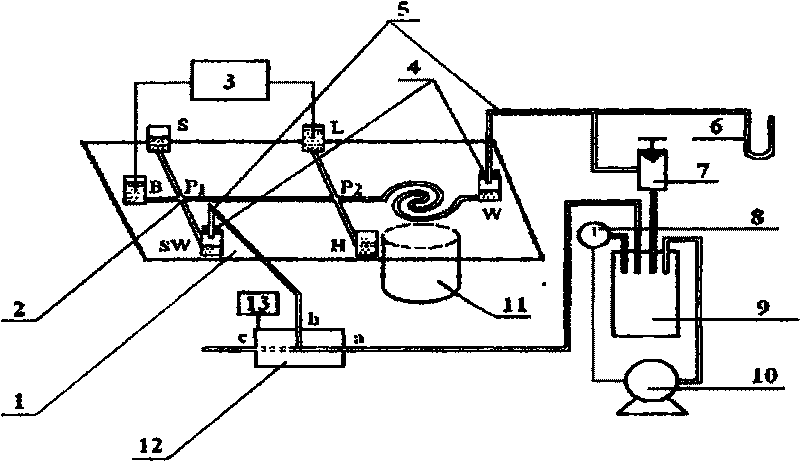

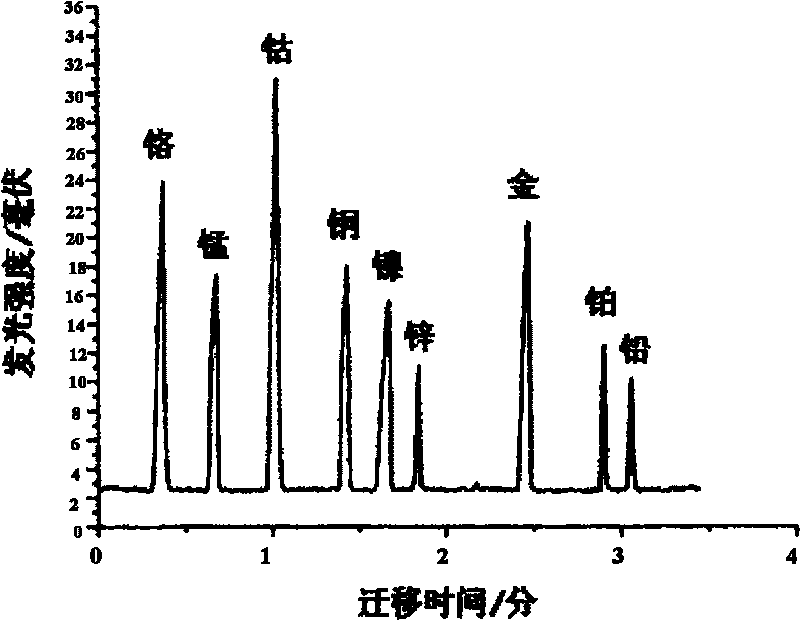

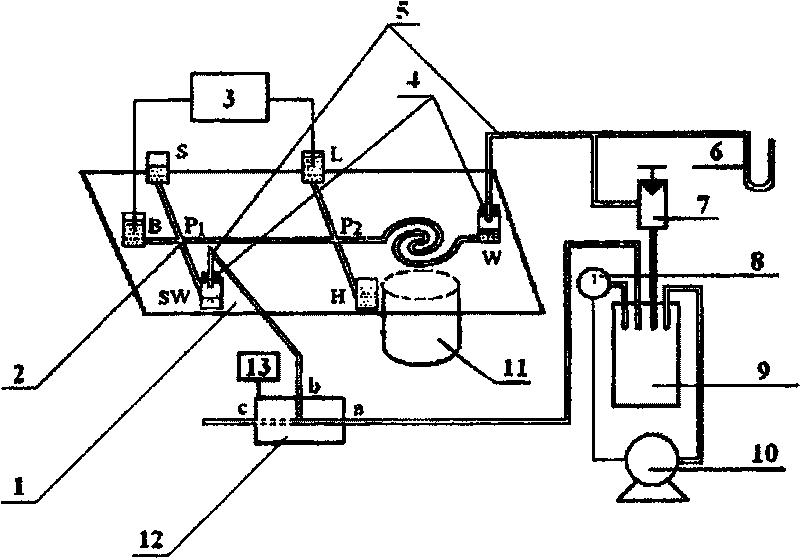

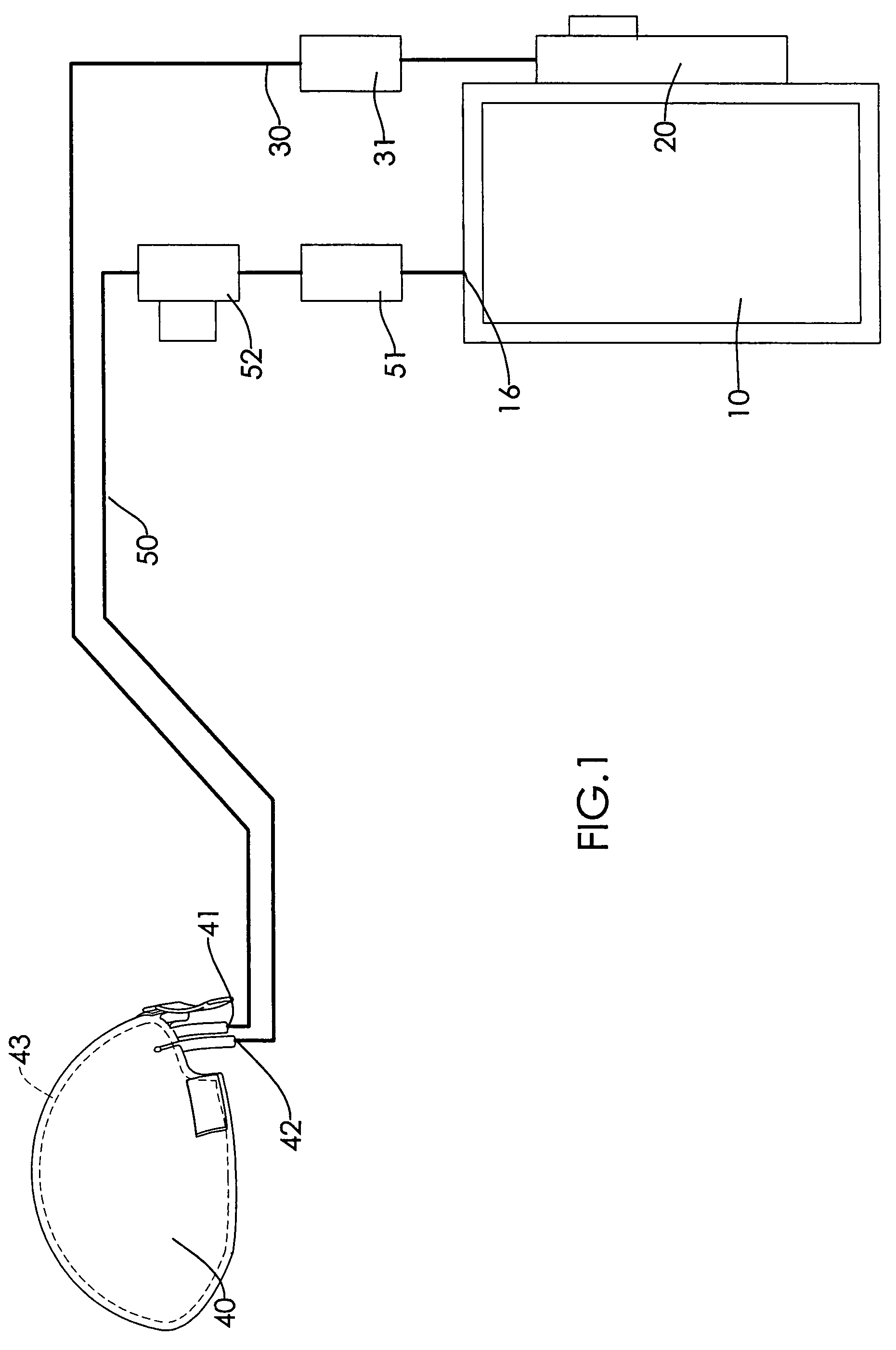

Microchip analysis system for capillary electrophoresis separation and chemiluminescence detection

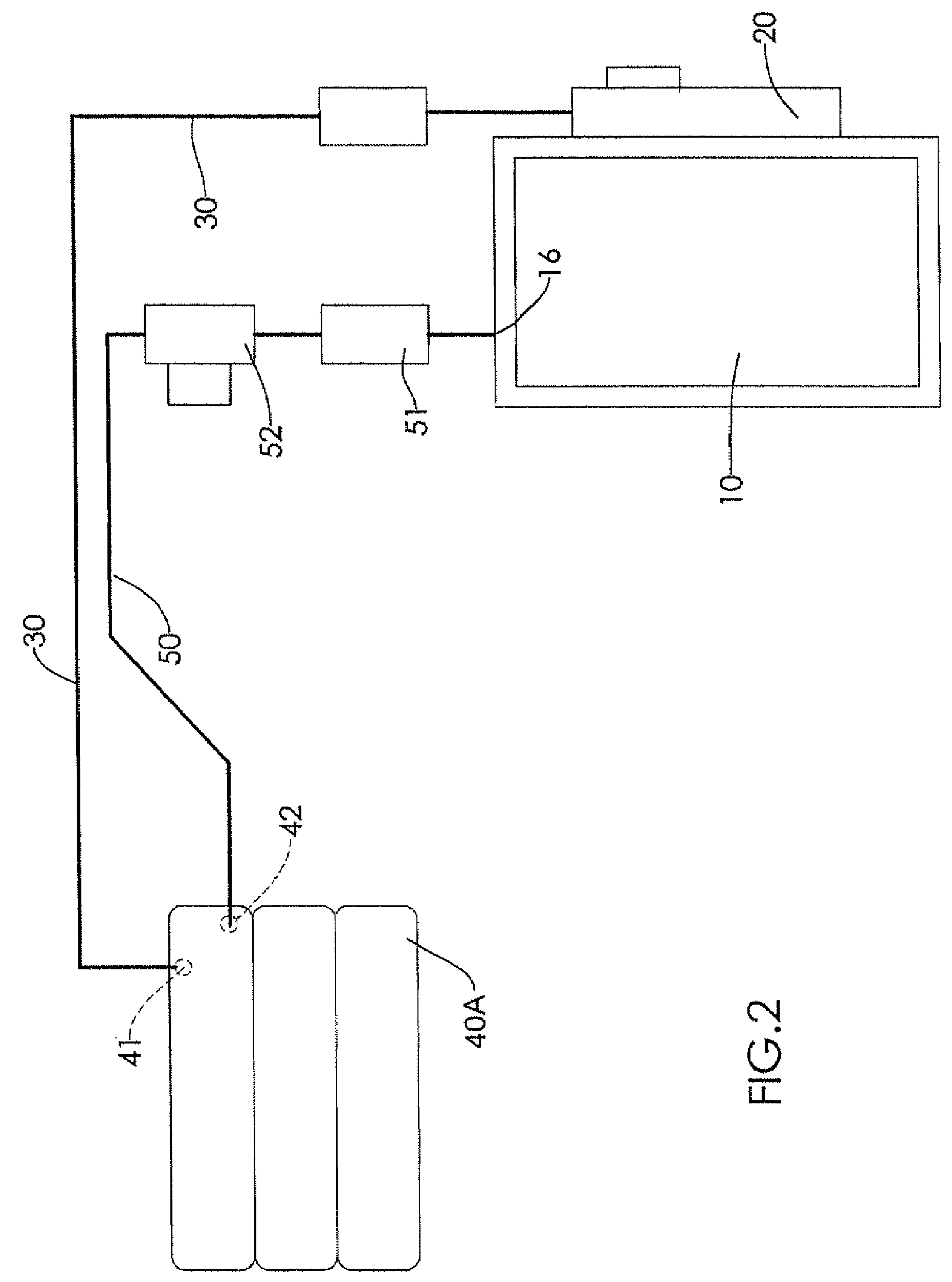

InactiveCN101692048AImprove separation efficiencyHigh sensitivityChemiluminescene/bioluminescencePreparing sample for investigationMicrochip AnalysisEngineering

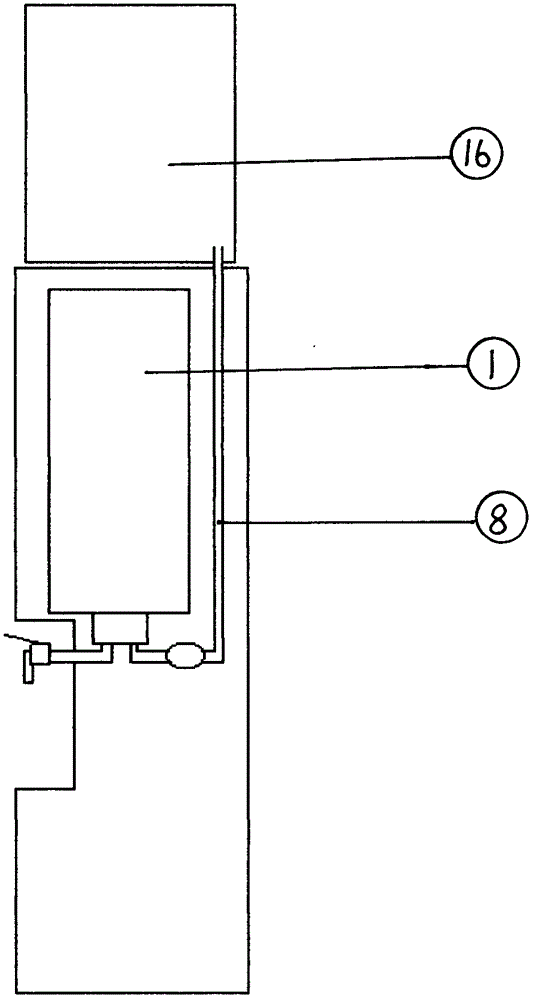

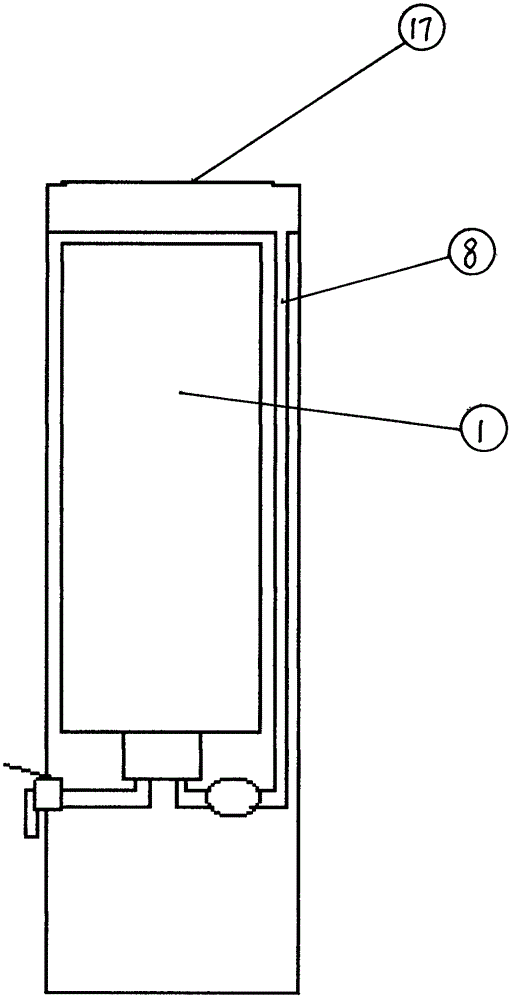

The invention provides a microchip analysis system integrated capillary electrophoresis separation with chemiluminescence detection, which consists of a microfluidic chip, a single-path high voltage power source, a minipump, a three-way valve, an interface, a needle adjusting valve, a U-tube type monometer, a photomultiplier, a vacuum flask, an electric contact vacuum gauge and a time relay. The microchip analysis system provided by the invention has simple structure, no mutual interference of the capillary electrophoresis separation and chemiluminescence detection, and high separation efficiency of the capillary electrophoresis and high sensitivity of the chemiluminescence, has the characteristics of high separation efficiency, high detection sensitivity, small volume, light weight, convenient operation, low cost and the like, and is an ideal portable microchip analysis system.

Owner:ZHEJIANG UNIV

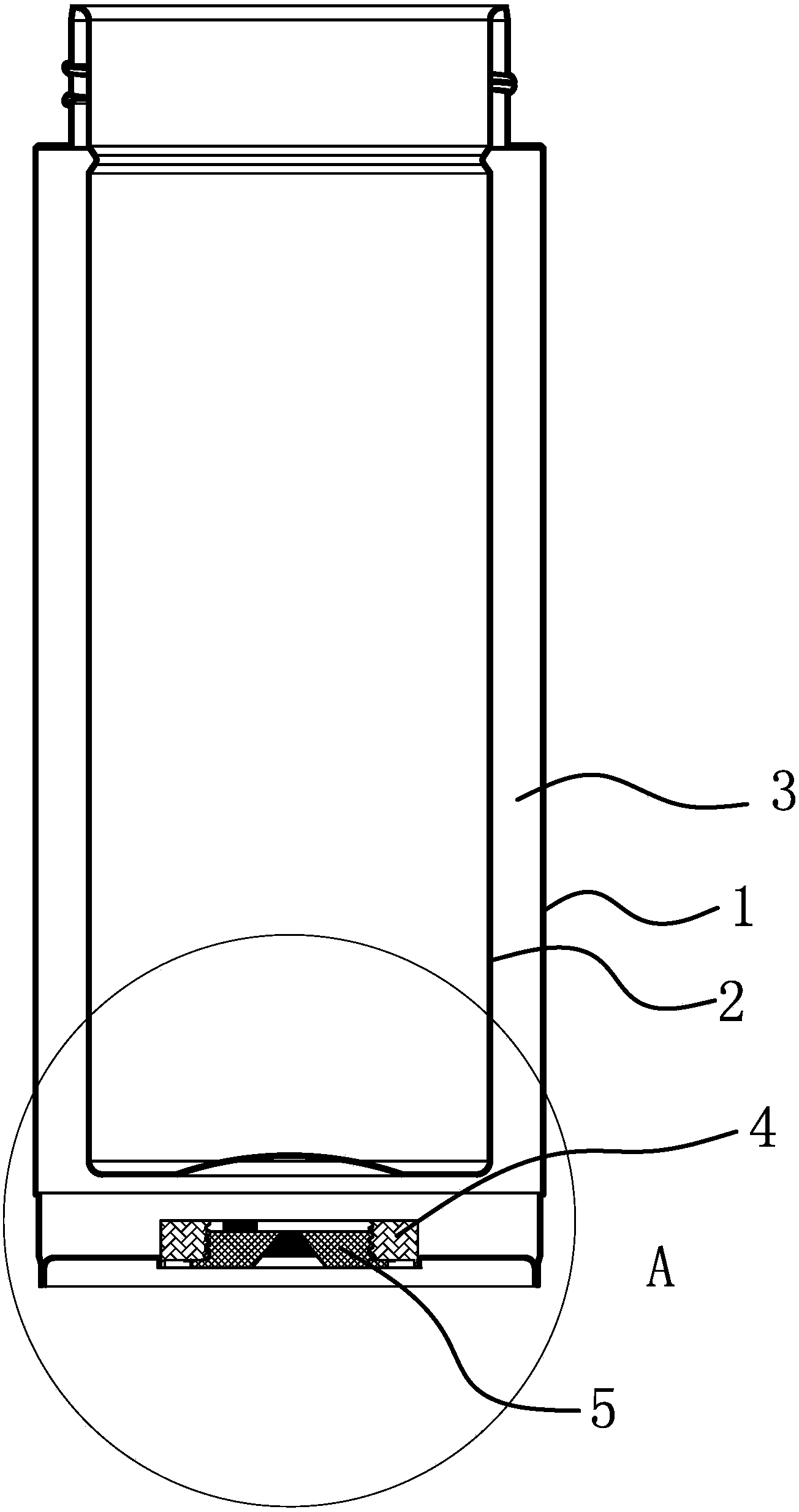

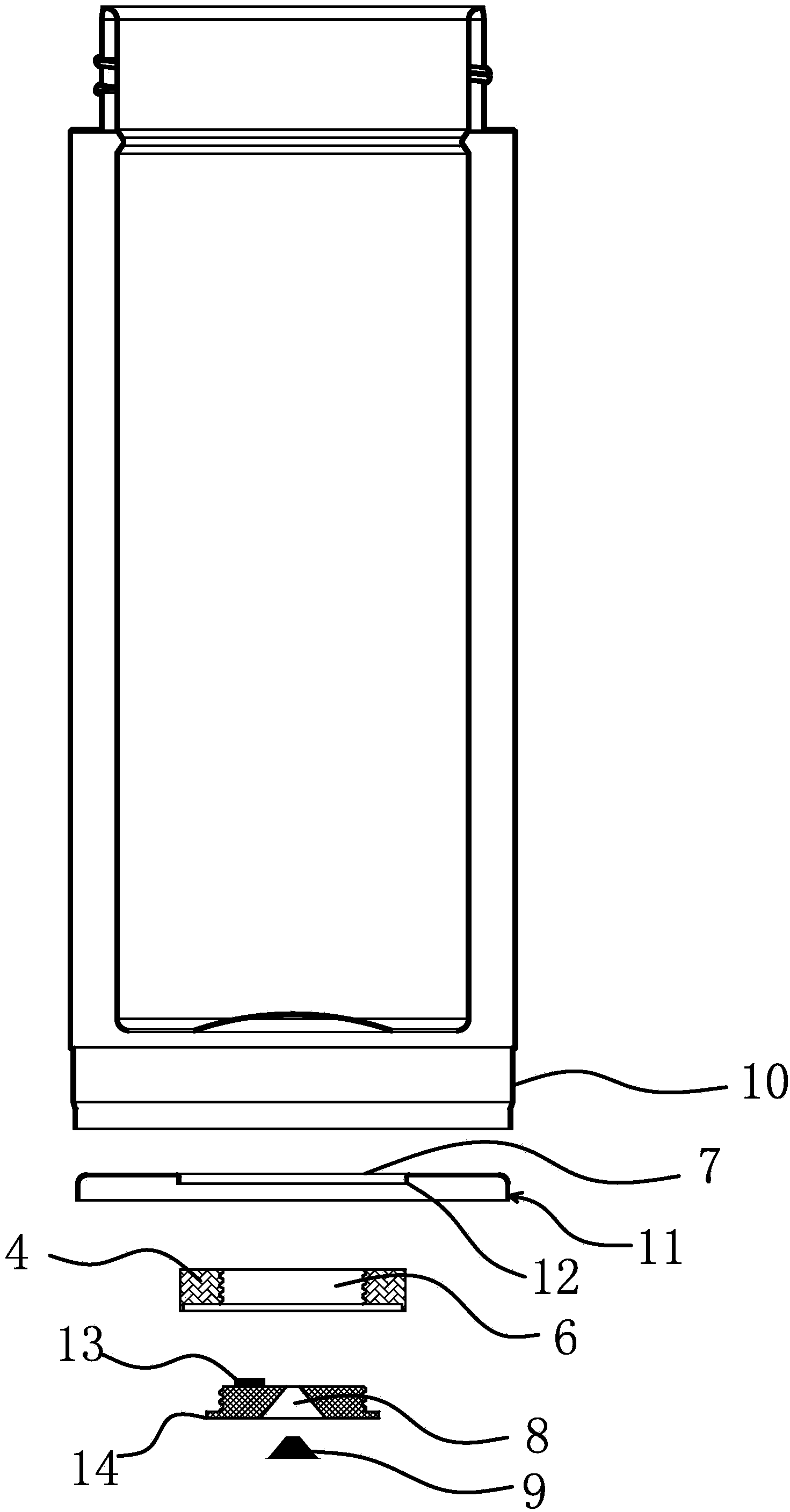

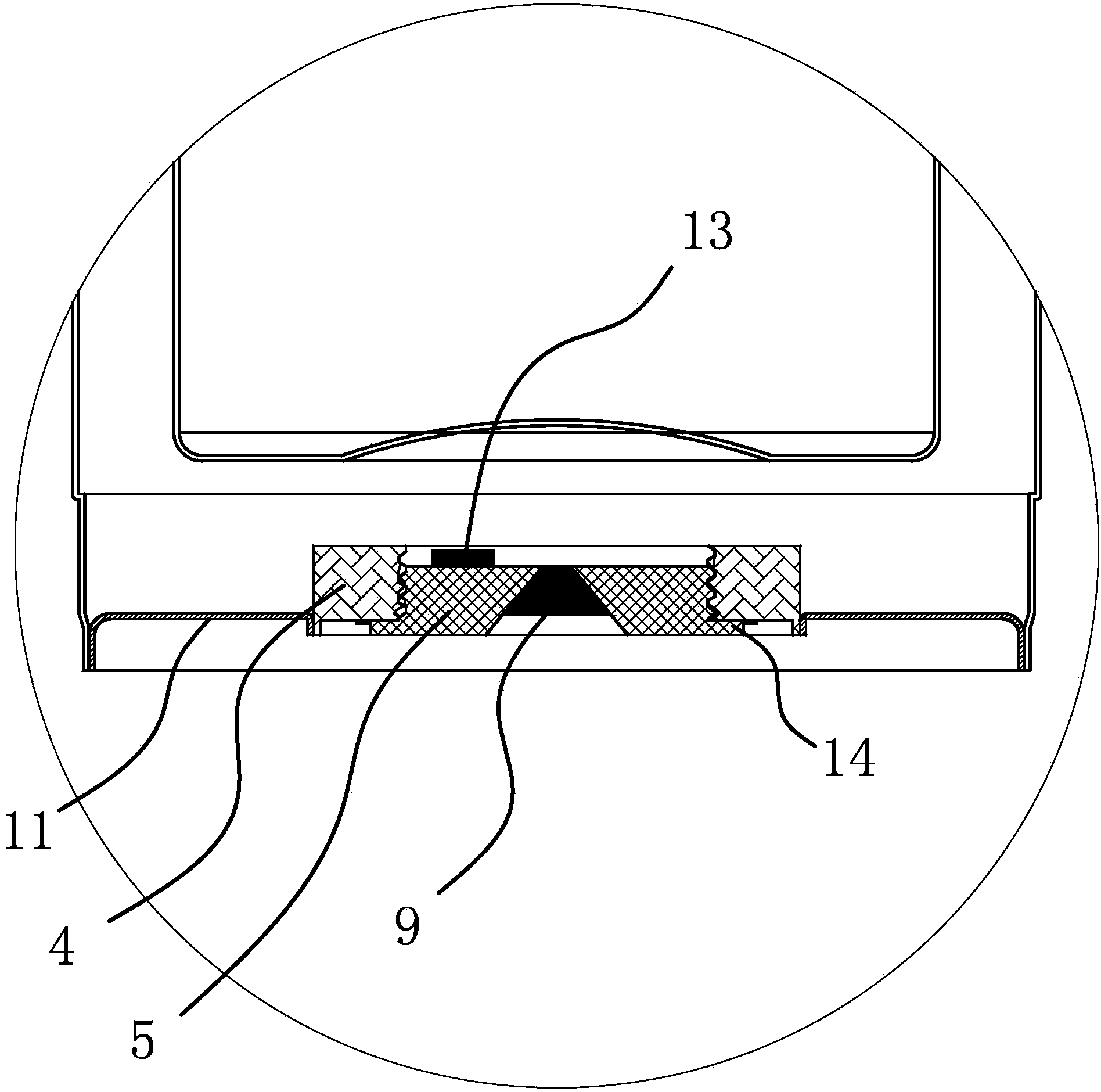

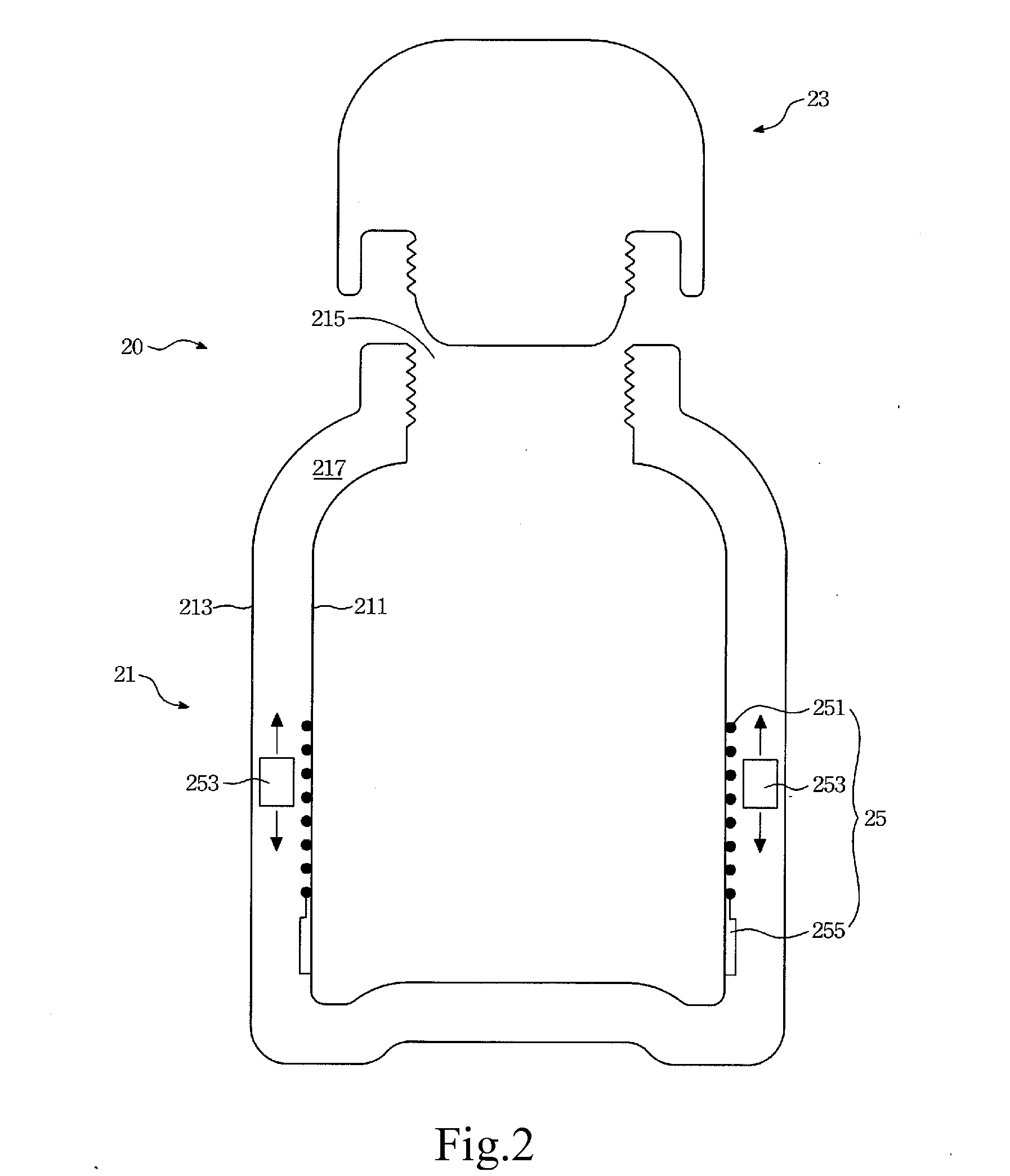

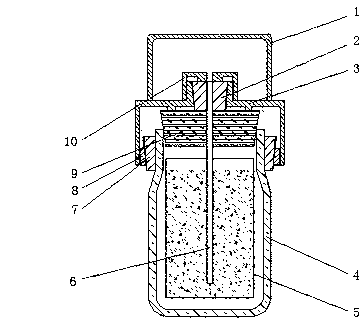

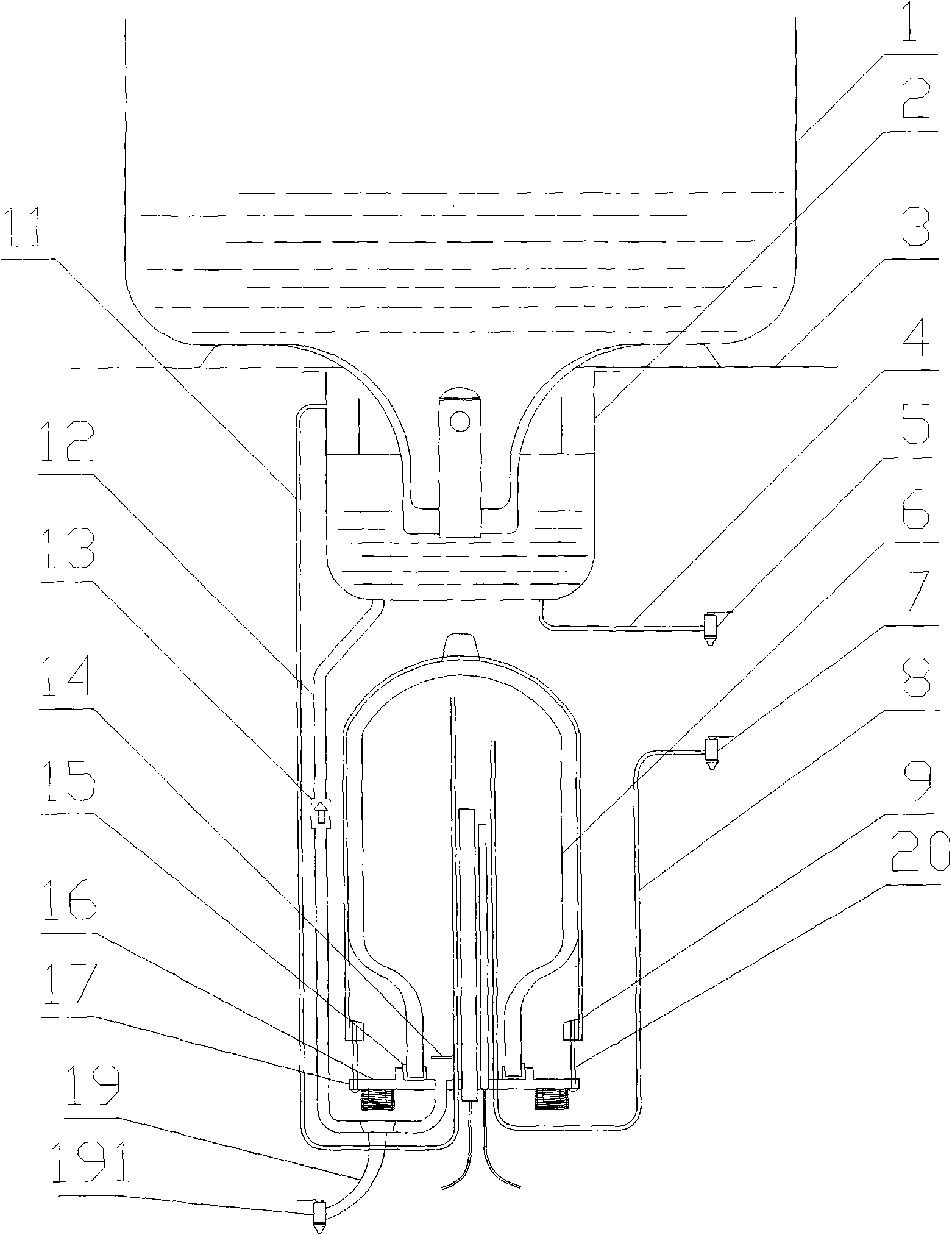

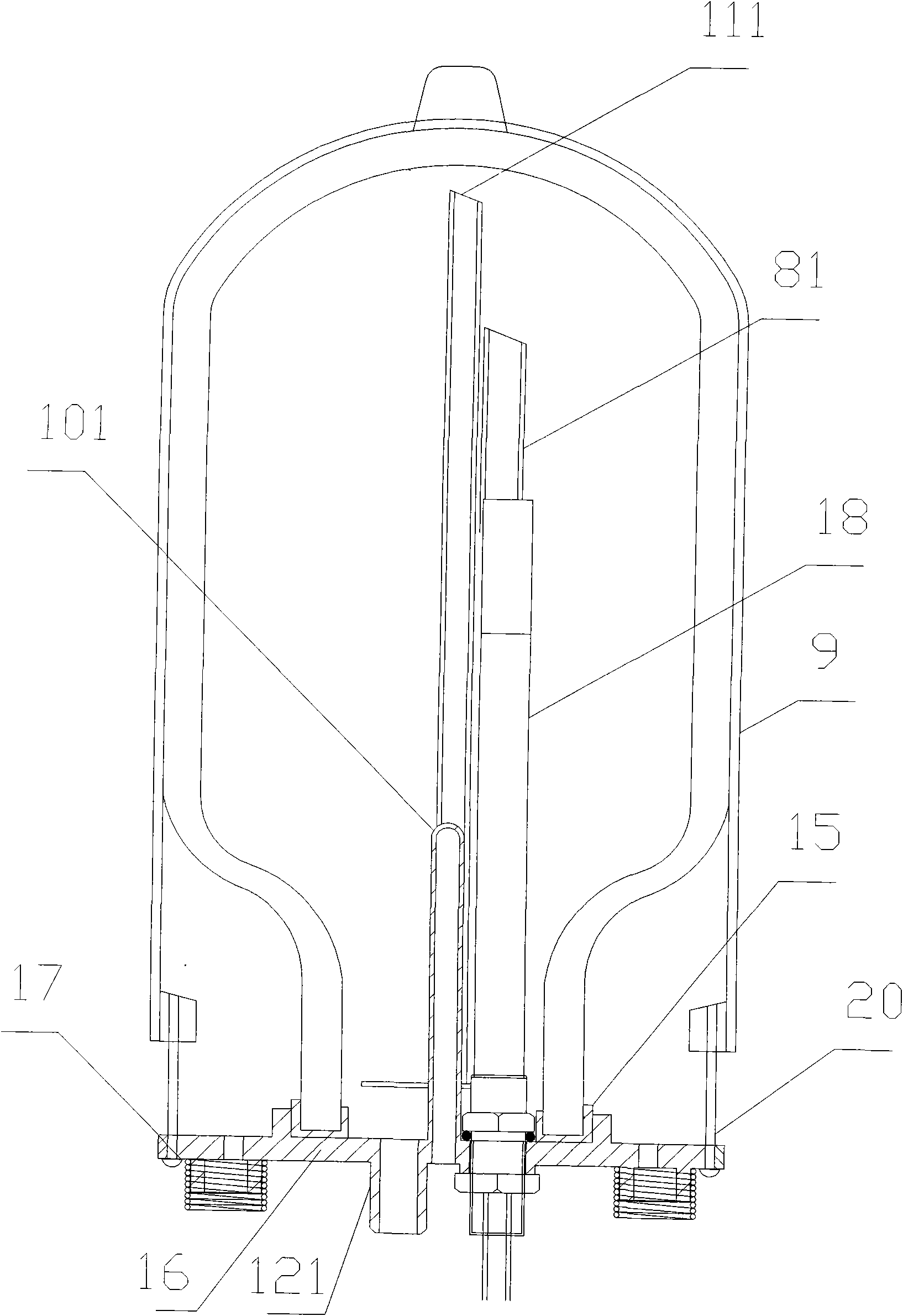

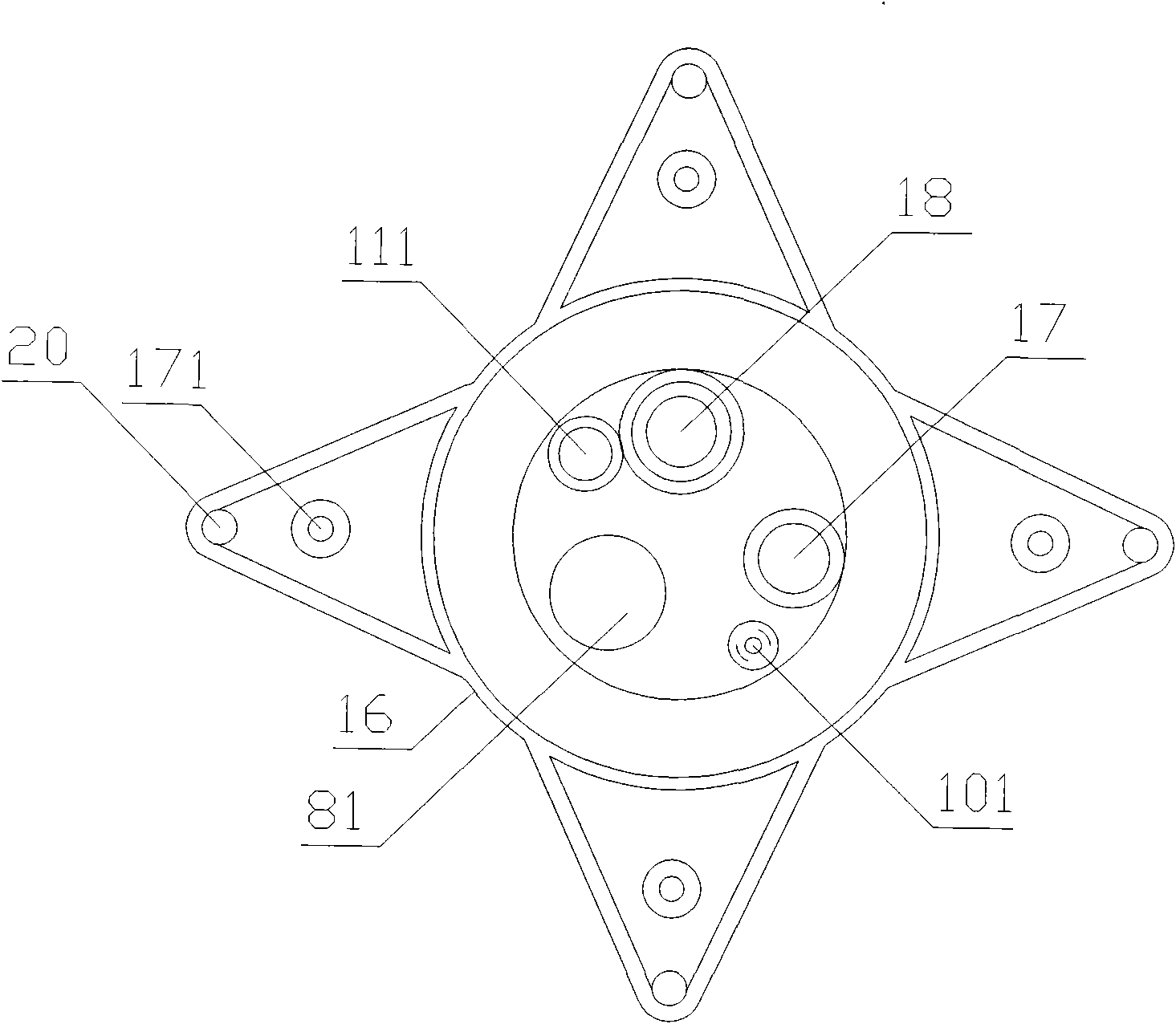

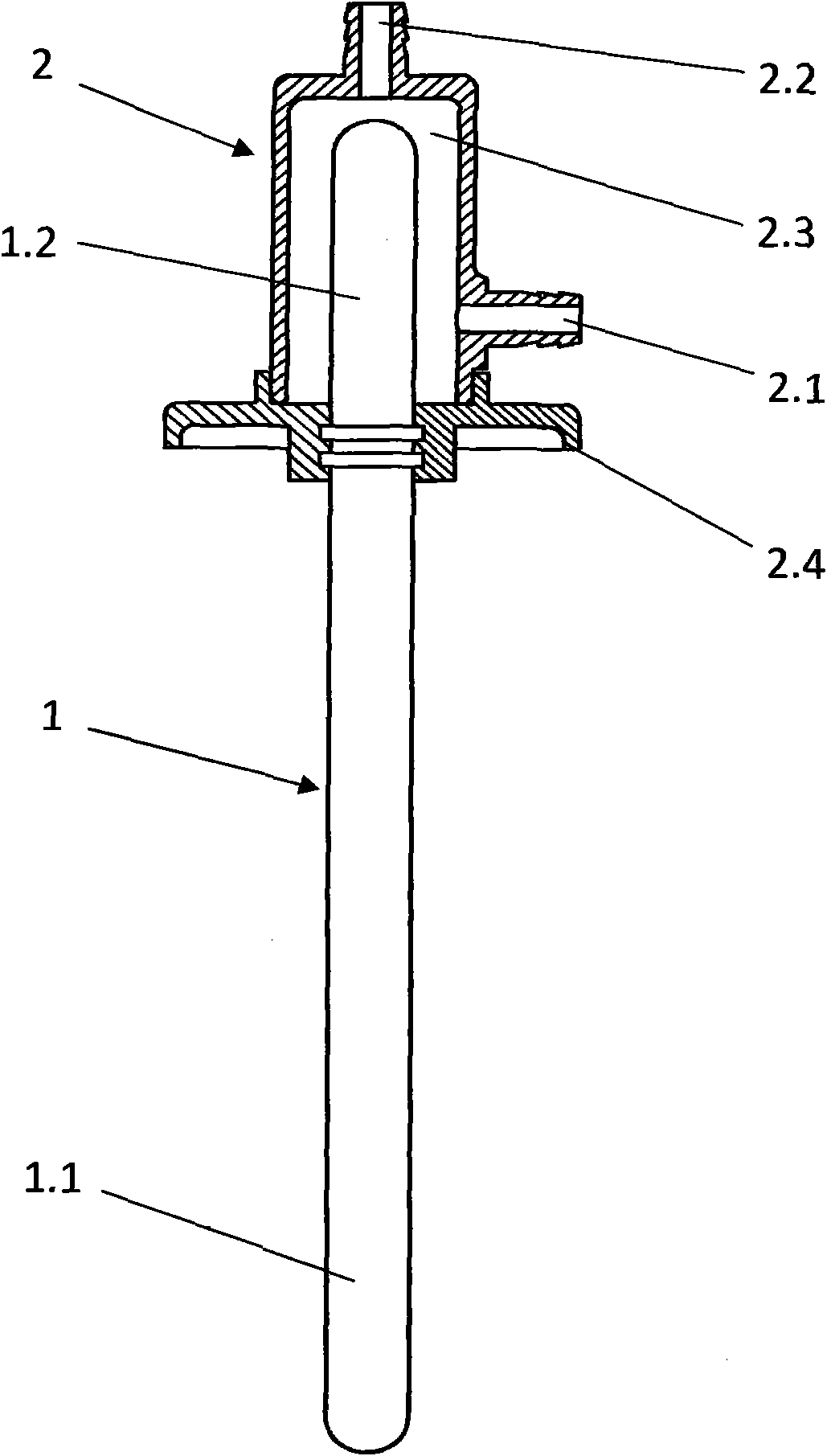

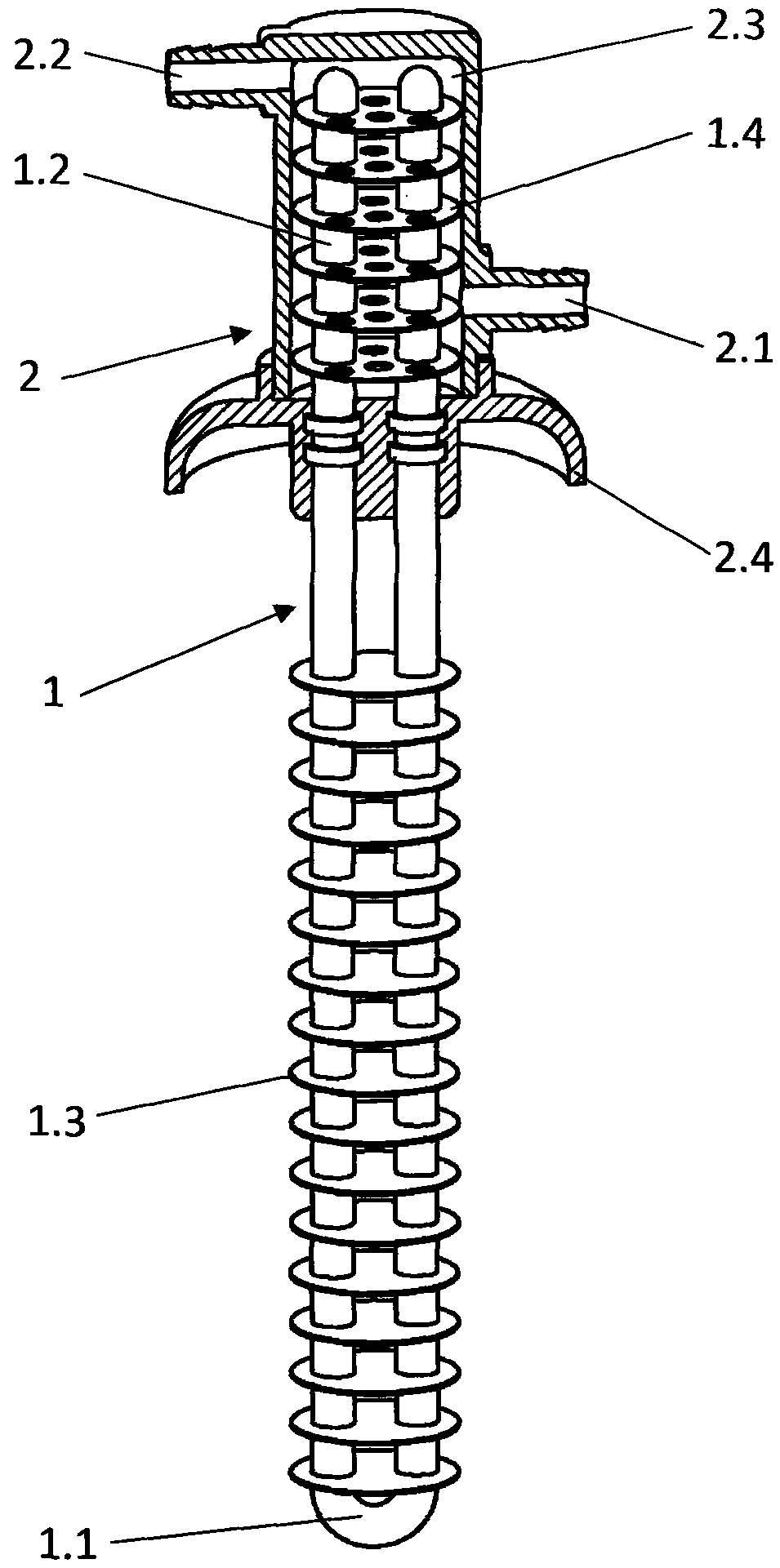

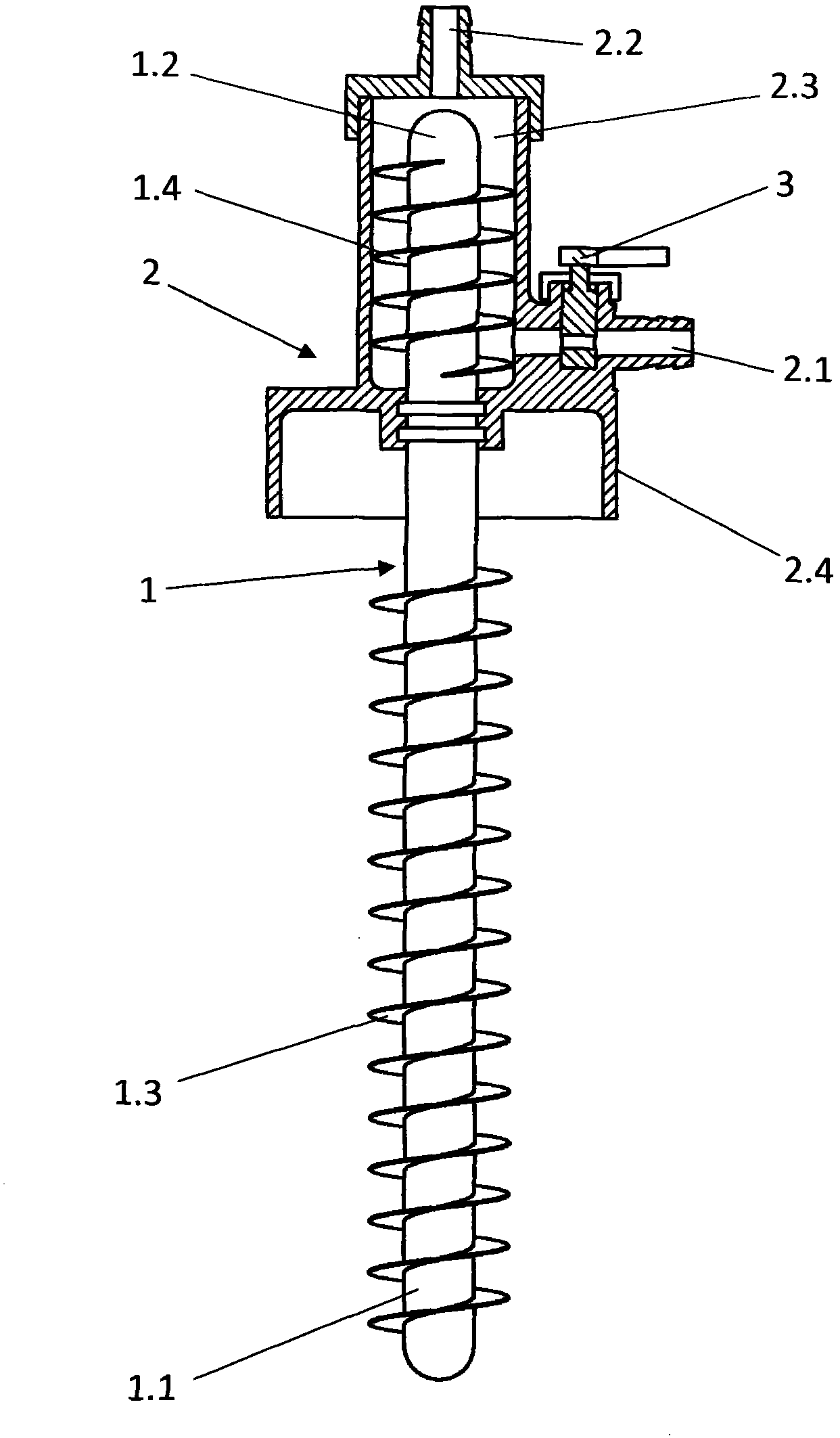

Vacuumizing structure for titanium vacuum flask

ActiveCN104161429AOvercome the defect of easy sheddingImprove firmnessDrinking vesselsTitaniumVacuum flask

The invention provides a vacuumizing structure for a titanium vacuum flask and belongs to the technical field of vacuum flasks. The vacuumizing structure solves the technical problem that due to the fact that the firmness of an existing solid glass cement seal is poor, the service life of the vacuum flask is influenced. The vacuum flask comprises an outer flask body and an inner container. The vacuumizing structure comprises a titanium metal nut and stainless steel screws. The nut is fixedly welded to the bottom of the outer flask body. The nut is provided with screw holes penetrating through the two end faces of the nut. The bottom face of the outer flask body is provided with through holes communicated with a vacuum cavity. The through holes are communicated with the screw holes. The screws are arranged in the screw holes in the outer flask body. The screws are provided with air outlet holes communicated with the screw holes. The air outlet holes of the screws are provided with solid glass cement seals in a fusion welding mode, wherein the solid glass cement seals can seal the air outlet holes. According to the vacuumizing structure, the titanium nut is welded and fixed to the titanium outer flask body, and then the stainless steel screws and the titanium nut are connected in a screwed mode so that the nut and the outer flask body can be connected firmly, and the service life is prolonged.

Owner:TAIZHOU TAI CHENG ELECTRONICS TECH

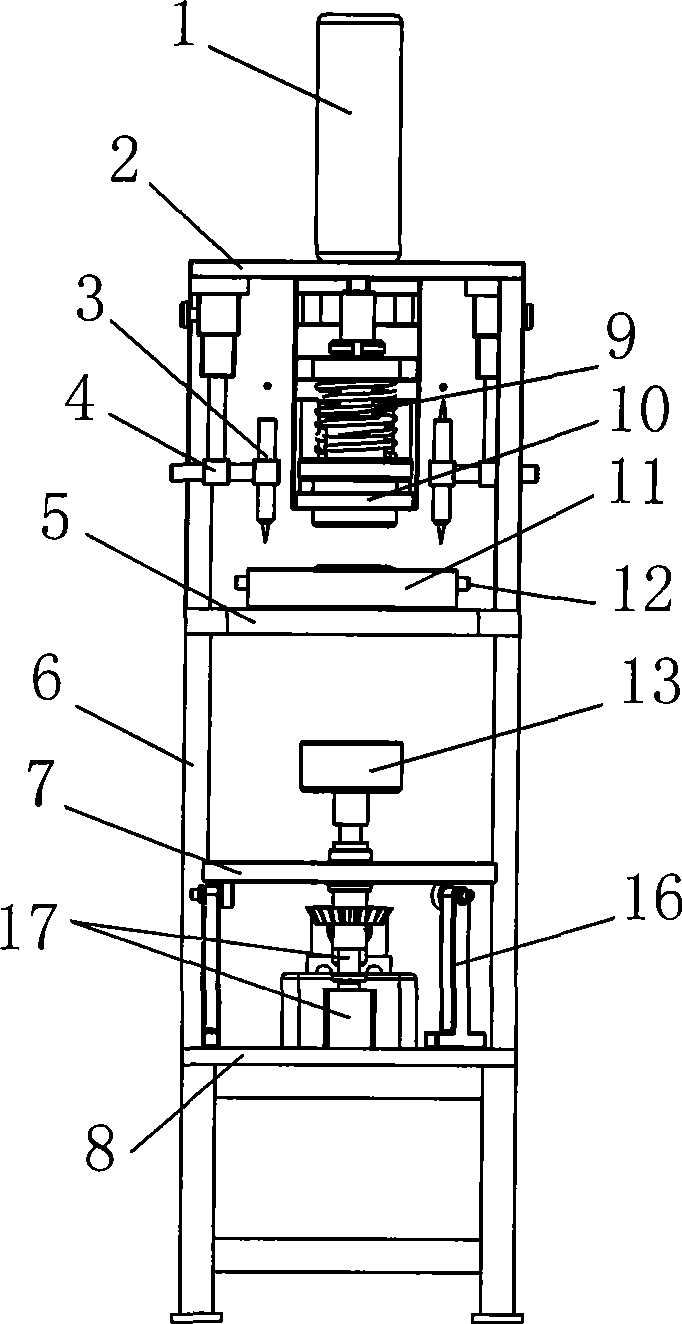

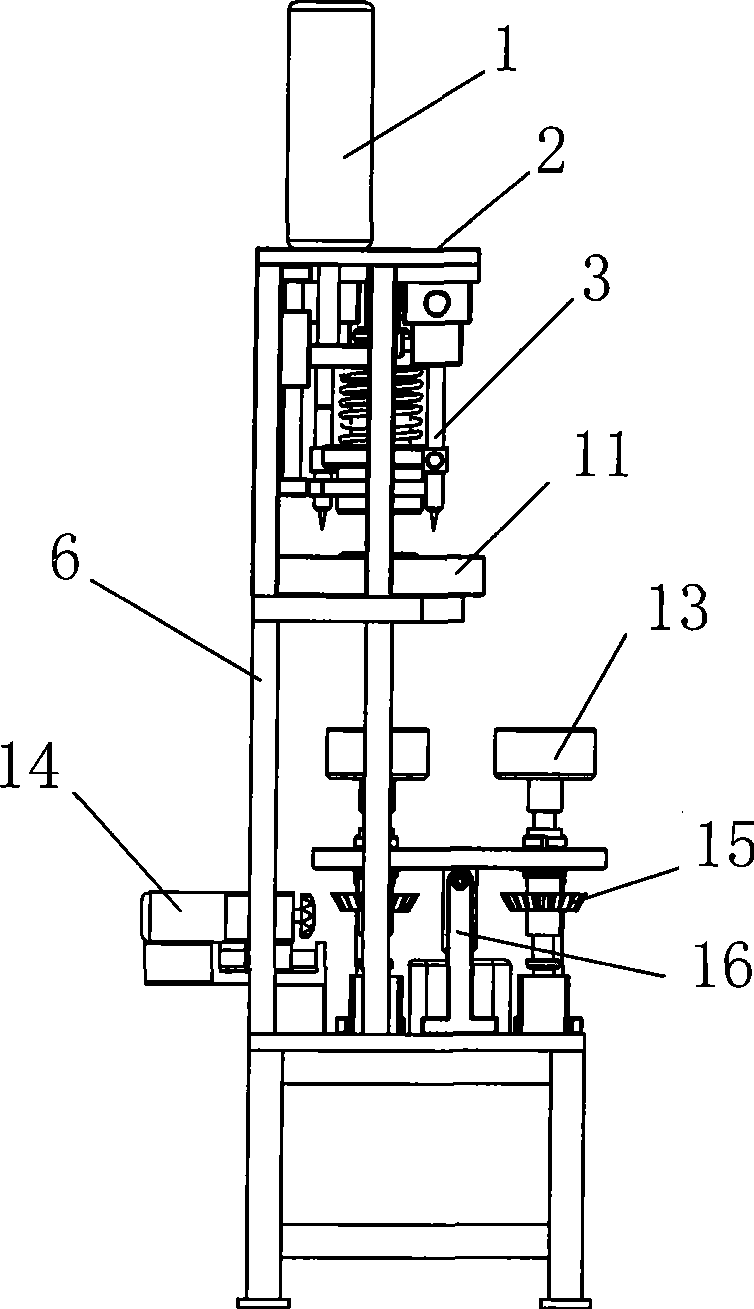

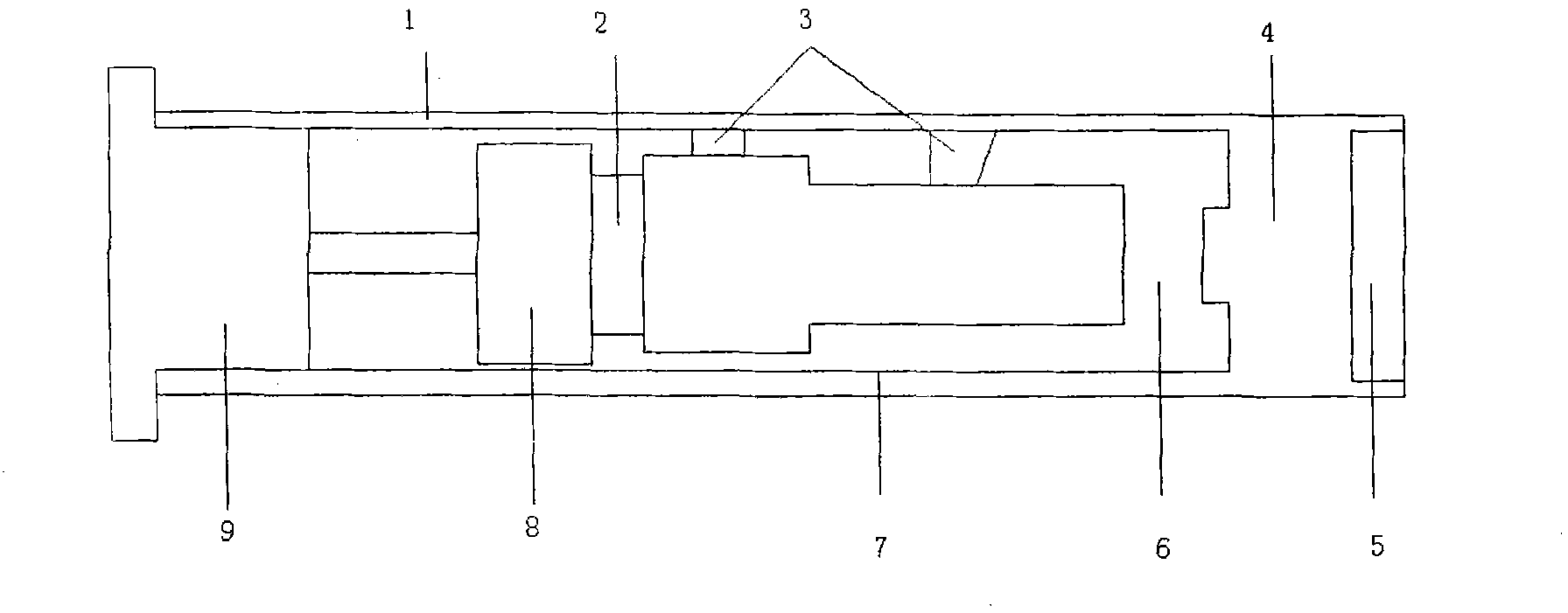

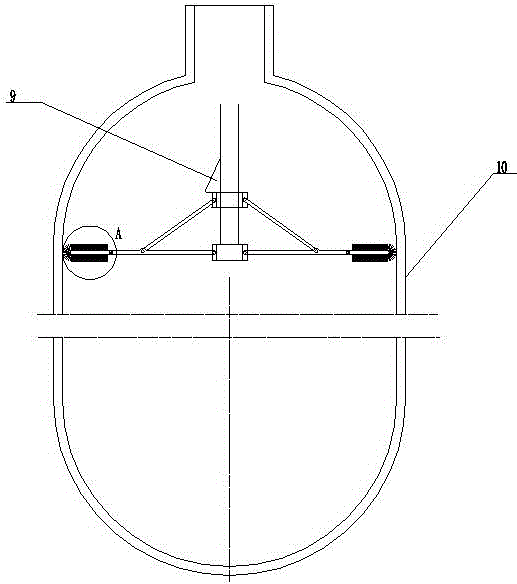

Thermos flask welding machine

InactiveCN101497158AEasy to operatePrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesWater circulationEngineering

The invention discloses a thermos flask welding machine. The upper part, the middle part and the lower part of a stander are provided with an upper panel, a middle panel and a lower panel respectively; an actuating mechanism on the lower panel is connected with a workpiece positioning seat through a workpiece rotating mechanism and a workpiece positioning turntable; the lower part of the workpiece rotating mechanism is connected with a workpiece shoring mechanism with an adjustable air cylinder; the middle panel above the workpiece positioning seat is provided with a rotating copper cathode and a cooling water circulation system; and the upper panel above the rotating copper cathode is provided with a positioning bottom cover adsorption and combination mechanism which is provided with a guidance axis core housing, an axle center and a spring, and a dual welding machine fixed with dual welding heads. The thermos flask welding machine has convenient operation and precise positioning, can simultaneously complete three multi-dimension and high-efficiency welding modes of welding work for a thermos flask only by replacing fixtures at a mouth part, the bottom of an inner cylinder and the bottom of an outer cylinder, achieves the aims of automatic and quick welding and stable welding quality, and avoids loosing between the bottom cover of the outer cylinder and the outer cylinder, saves materials of the bottom cover of the outer cylinder of the thermos flask and reduces working procedures by particularly using a stitch welding method.

Owner:上海兼助商贸有限公司

Battery operated self heating thermos container

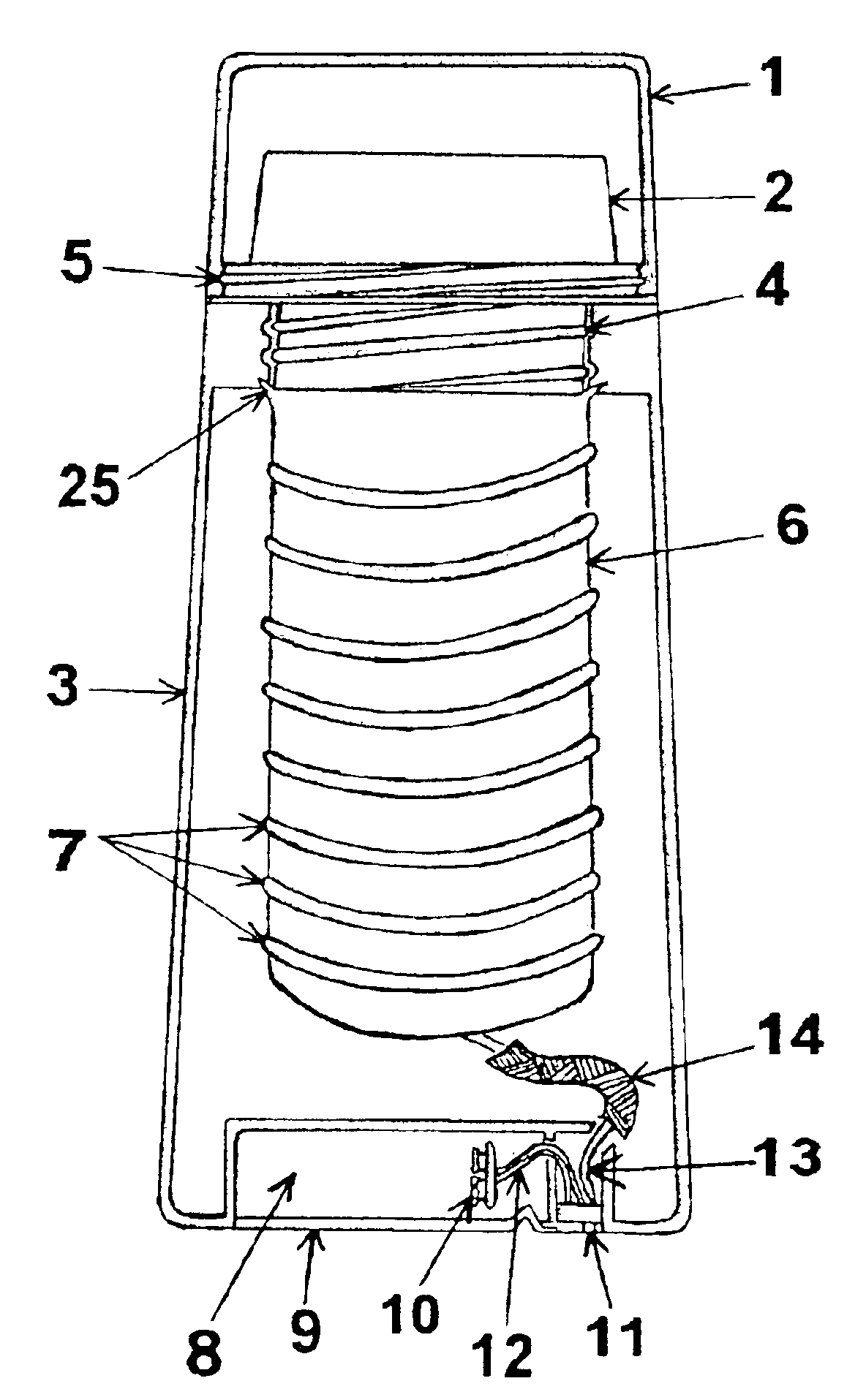

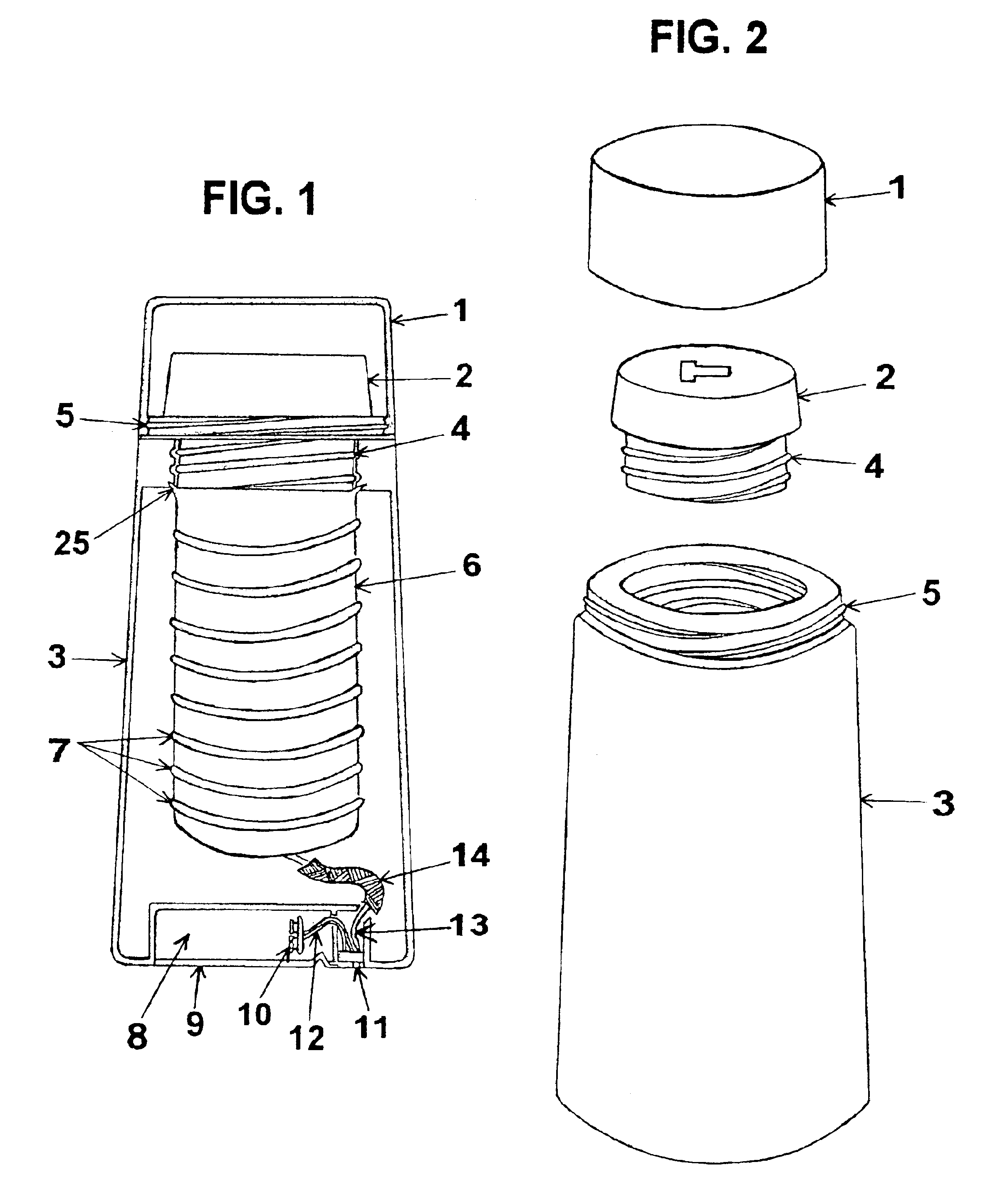

InactiveUS6943323B2The process is simple and effectiveEasy to operateHeater elementsBaking ovenVacuum flaskElectrical battery

A thermos container with inner sealing cap and outer cap used to contain solid or liquid foods. Integral heating coils contained within the innermost compartment of the receptacle receives energy from the main power cord connected to the On / Off sliding switch power conductor. When the sliding switch is moved to the On position it activates the battery power to heat the integral coils to a certain temperature to warm the contents of the thermos container. With such applications the invention is a battery operated self heating thermos thus allowing for storage and heat to foods contained within the inner receptacle.

Owner:IANNUCCI CLAUDINE

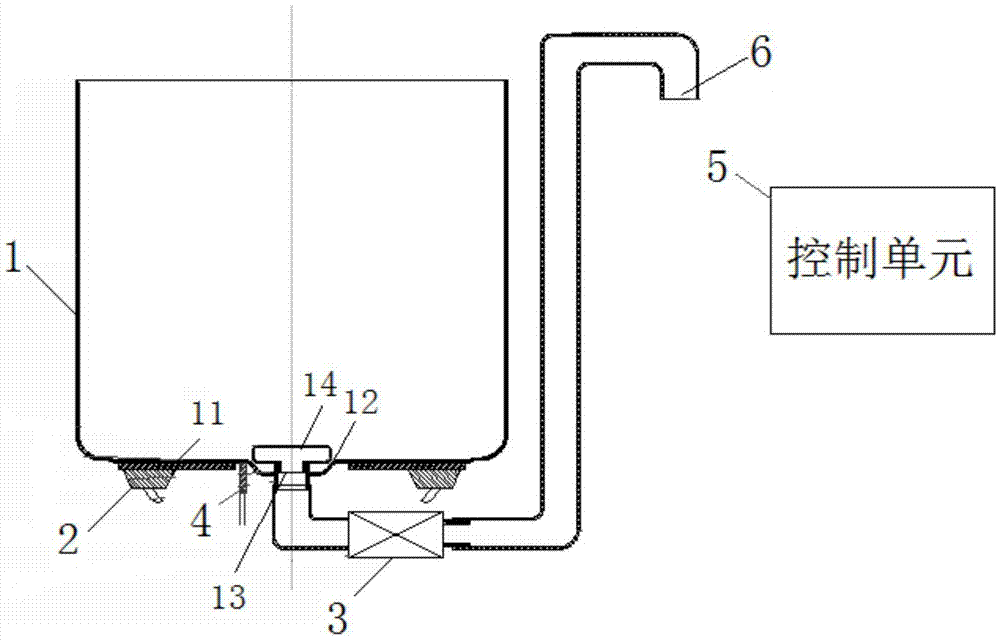

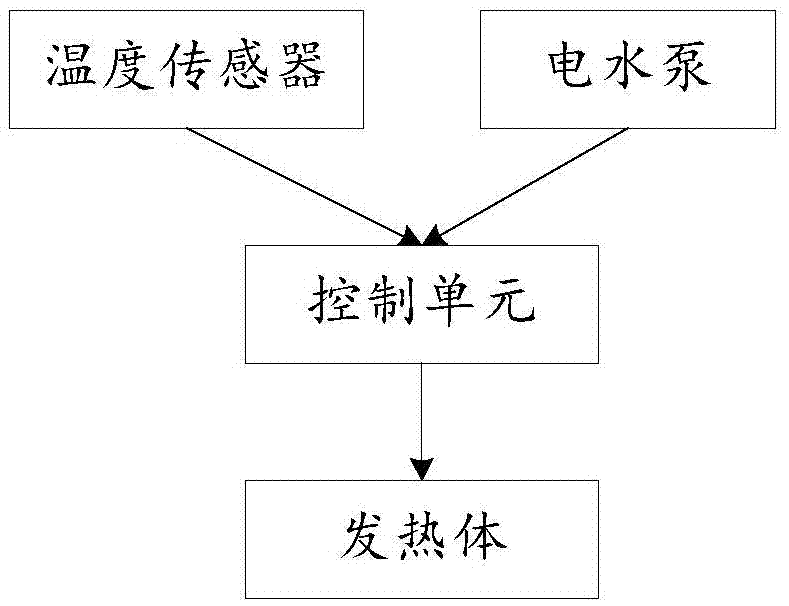

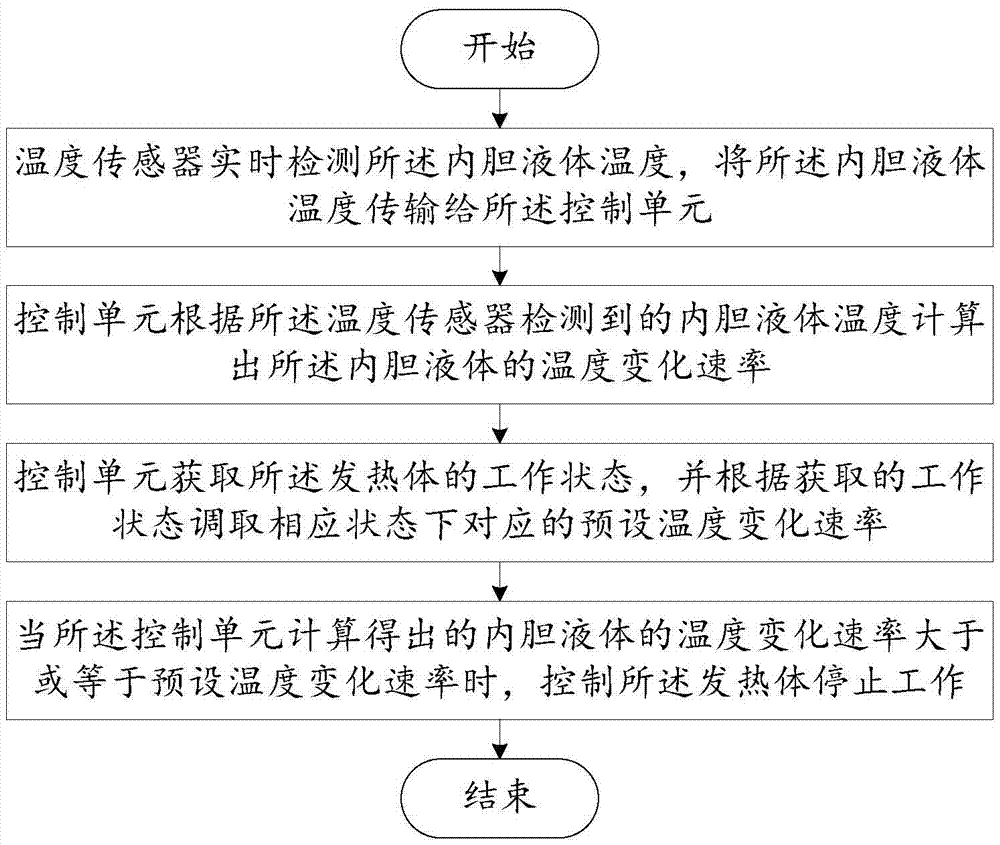

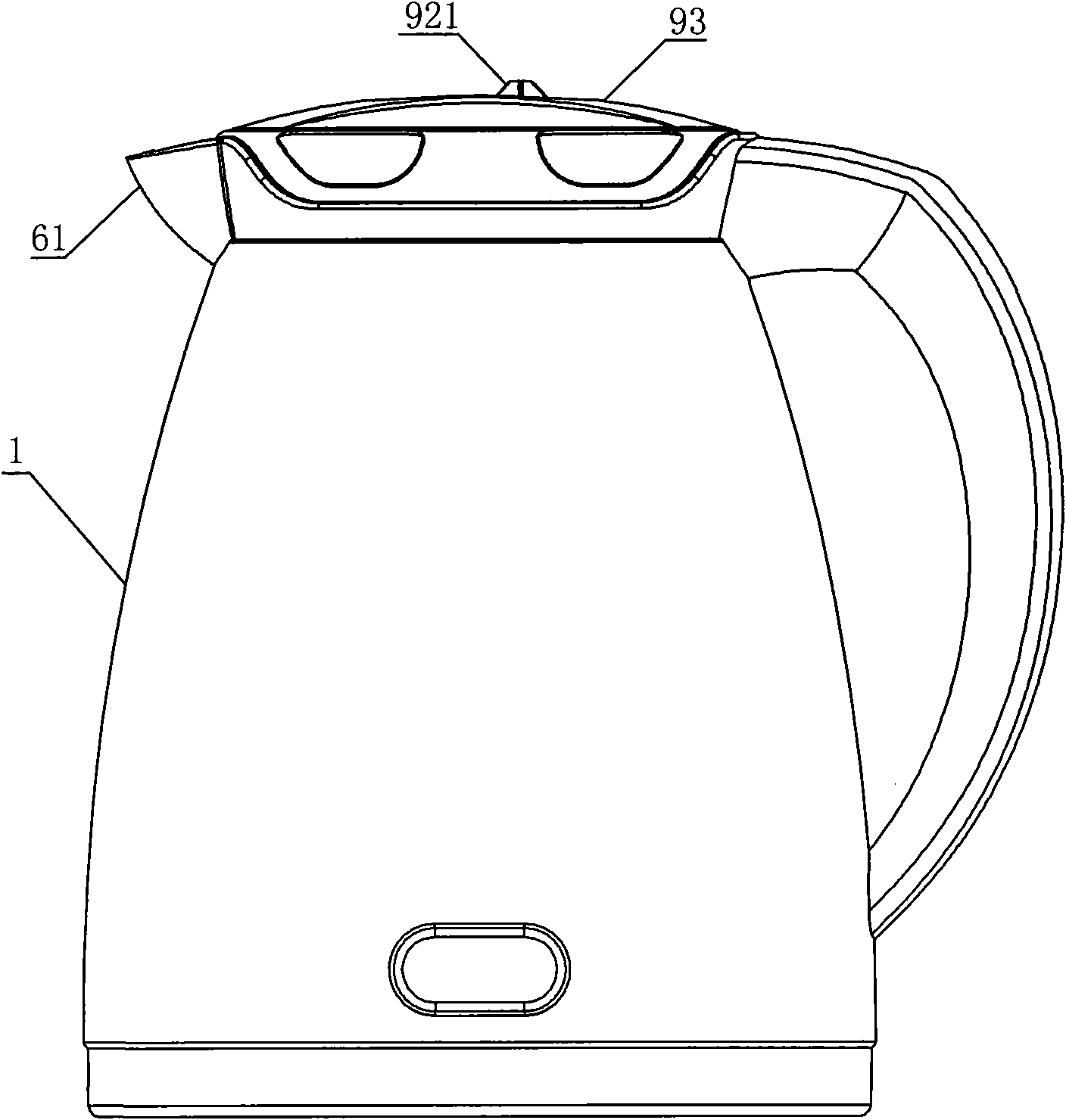

Liquid heating device, electric vacuum flask and dry burning preventing control method thereof

ActiveCN107157316APrevent dry burningGuarantee the safety of useWater-boiling vesselsElectricityStopped work

The invention relates to a dry burning preventing control method of a liquid heating device. The method comprises the following steps: detecting temperature of liquid in a liner in real time by virtue of a temperature sensor; then, transmitting the detected temperature of the liquid in the liner to a control unit; calculating a change rate of the temperature of the liquid in the liner by virtue of the control unit in accordance with the temperature, which is detected by the temperature sensor, of the liquid in the liner; acquiring a working condition of a heating body by virtue of the control unit, and calling a corresponding preset temperature change rate under a corresponding state in accordance with the acquired working condition; and controlling the heating body to stop working when the change rate, which is calculated by the control unit, of the temperature of the liquid in the liner is greater than or equal to the preset temperature change rate. With the application of the dry burning preventing control method provided by the invention, a dry burning phenomenon of the liquid heating device under various states can be effectively prevented. The invention also provides the liquid heating device and an electric vacuum flask.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

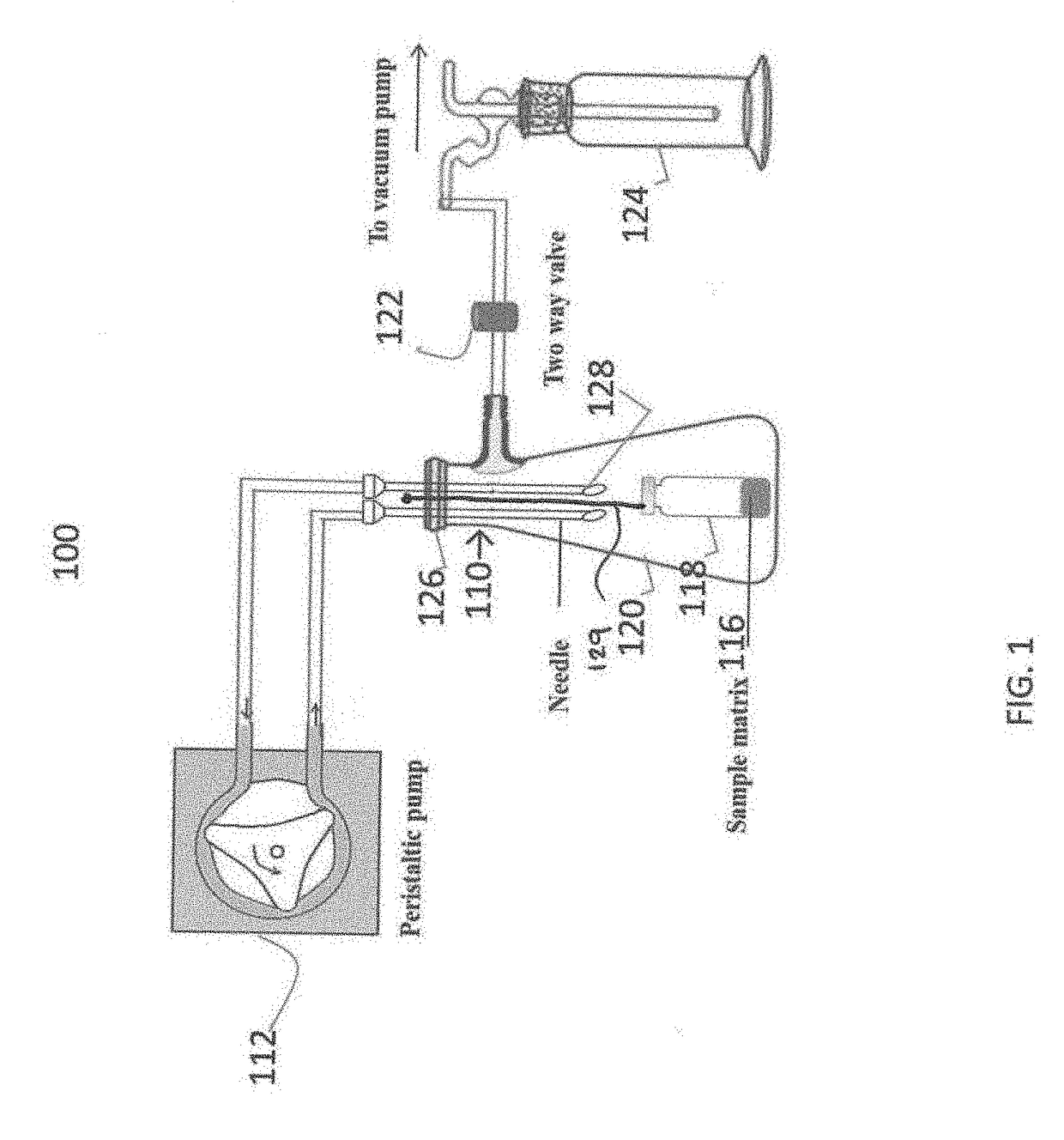

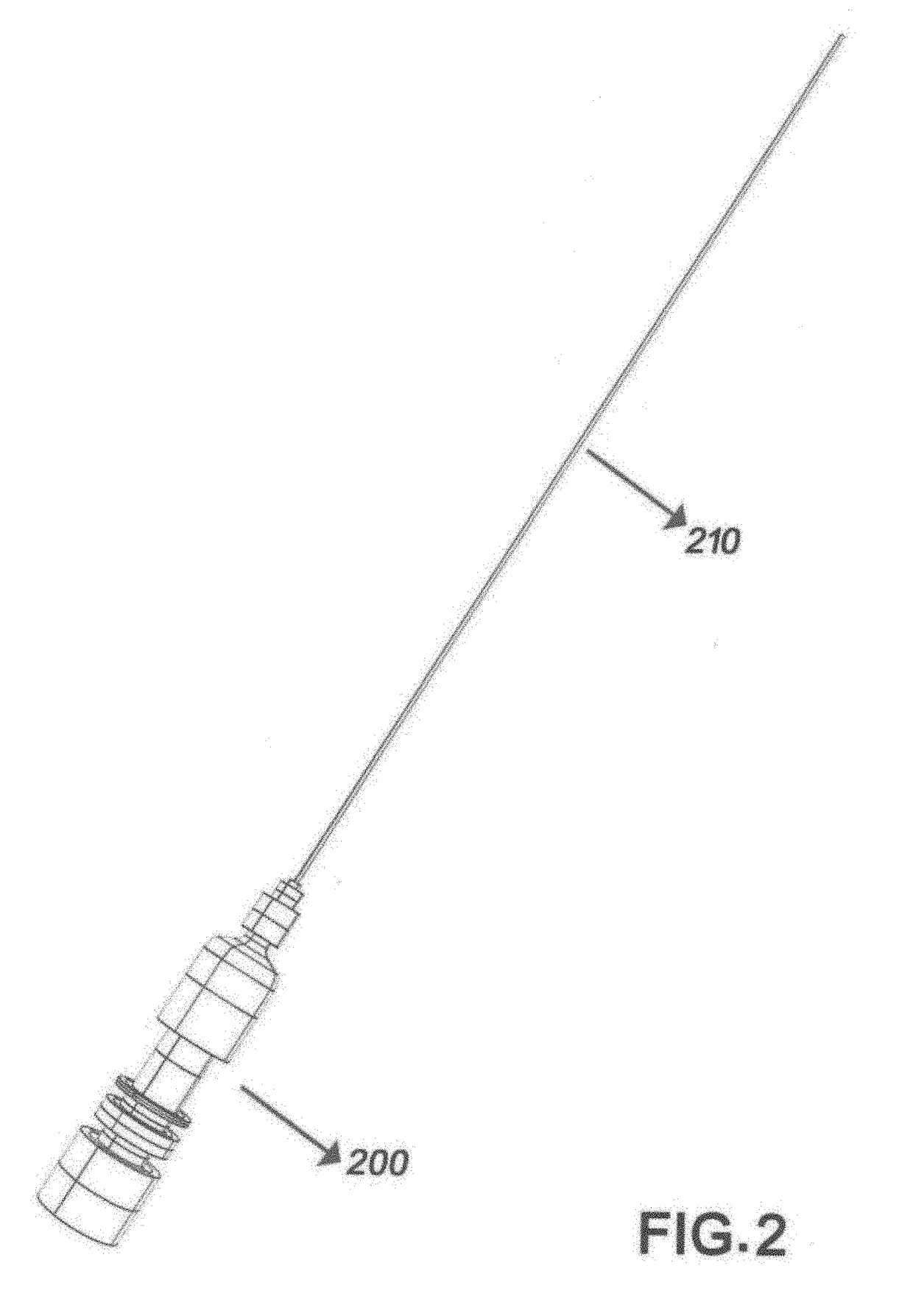

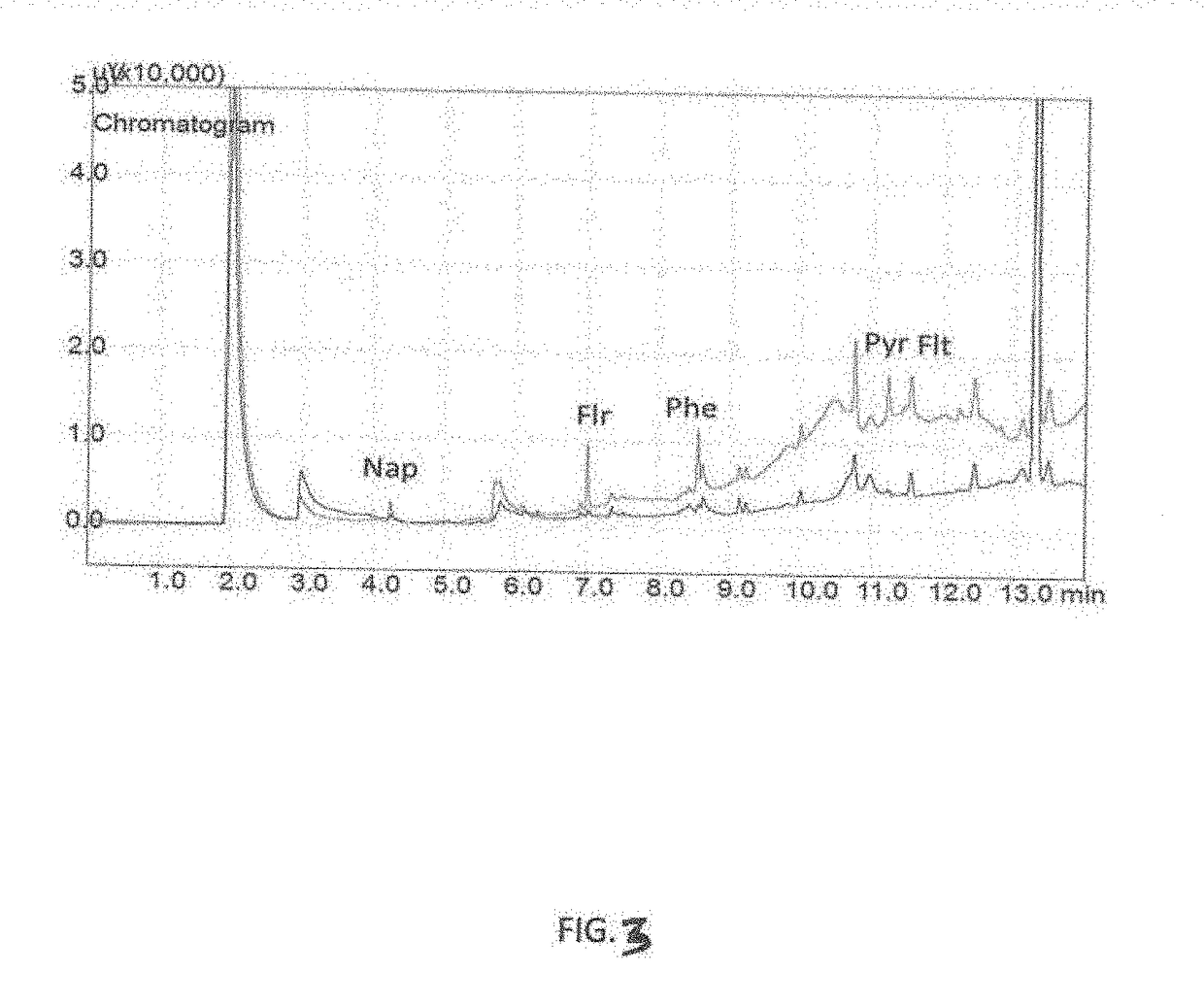

Vacuum-assisted in-needle capplicary adsorption trap with multiwalled polyaniline/carbon nanotube nanocomposite sorbent

InactiveUS20170184554A1Efficient evaporationComponent separationOther chemical processesInterior spaceAnalyte

A vacuum-assisted in-needle capillary adsorption trap (VA-INCAT) device for sampling and delivering materials to an analytical device is disclosed. A sorbent is multiwall carbon nanotube / polyaniline (PANI / MWCNT) nanocomposite and is coated within an interior space of the needle between the second end and the side aperture to entrap an analyte within a sample. The VA-INCAT device also includes a vacuum device configured to vacuum the vacuum flask to improve the extraction of the analytes vapors from the sample matrix to the sorbent bed.

Owner:GHIASVAND ALIREZA +2

Heat retaining bottle

InactiveUS20110132893A1Avoid dangerImprove efficiencyTravelling sacksDomestic cooling apparatusVacuum flaskBottle

A thermos consists of a body, a cap and a heating device. The body has an inner wall, an outer wall and a bottle opening, where an intermediate space is formed between the inner and outer walls. The cap is fitted to the bottle opening. The heating device contains an induction coil, a donut magnet and a resistance heater. The induction coil is wound in the inner wall. The donut magnet is placed in the intermediate space and it can move freely within the intermediate space. The resistance heater is electrically connected to the induction coil and touches the inner wall.

Owner:LIN CHIEN CHENG

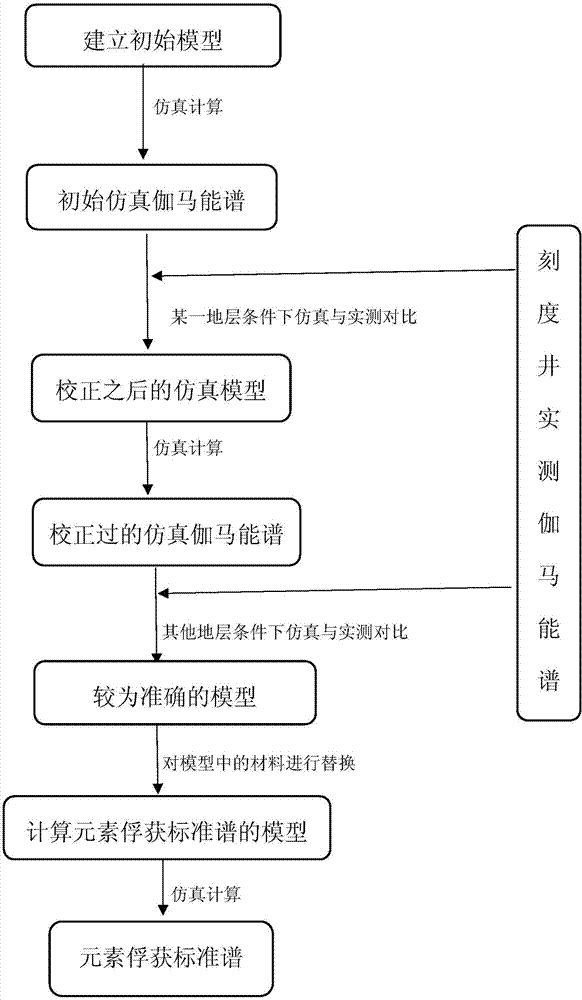

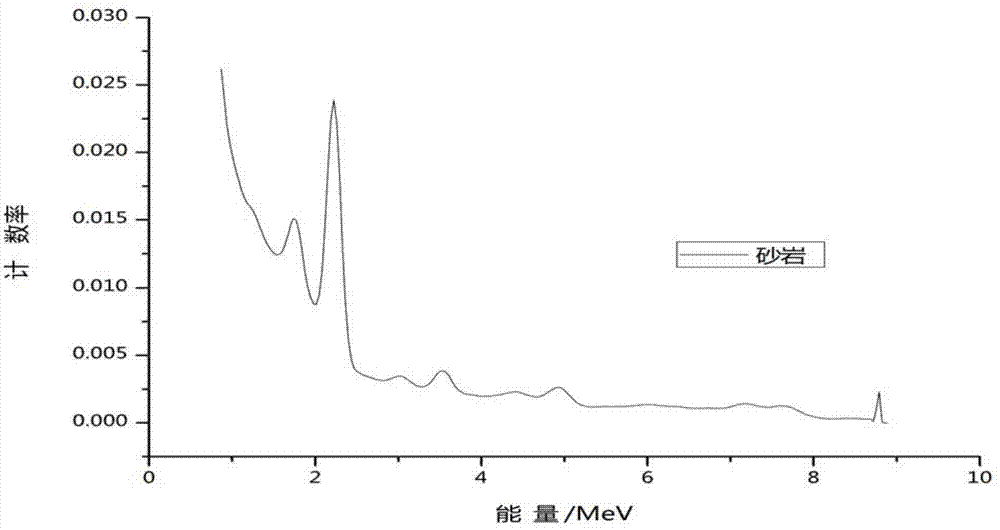

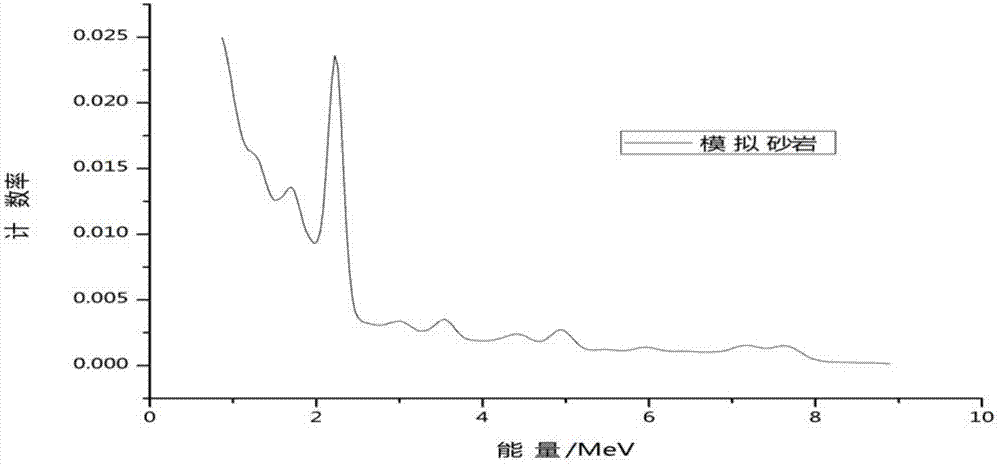

Obtaining method of element capture normal spectroscopy in elemental logging

ActiveCN104329075ALow costShorten acquisition cycleSurveyDesign optimisation/simulationSpectroscopyVacuum flask

The invention provides an obtaining method of an element capture normal spectroscopy in elemental logging. The method comprises steps of model establishment, model checking and the like, and the core of the method is to establish a simulation model according to conditions of carbon-oxygen saturability calibration wells, and then to perform computation through the established simulation model to obtain the element capture normal spectroscopy. The initial simulation model is established according to the calibration wells and the design size of a logging instrument, meanwhile certain structures of the logging instrument are reasonably optimized, and the modeling difficulty is reduced. The part between an inner casing and an outer casing of a vacuum flask is vacuum, the inner casing and the outer casing of the vacuum flask are combined, and vacuum parts of the instrument are combined. An MCNP input card required by modeling comprises a lattice cell card, a curved surface card, a material card and a counting card. The method has the advantages that a large quantity of calibration wells are not required, conventional calibration experiments are only required to be performed in a small quantity of calibration wells, and the cost is low.

Owner:XIAN AOHUA ELECTRONICS INSTR +1

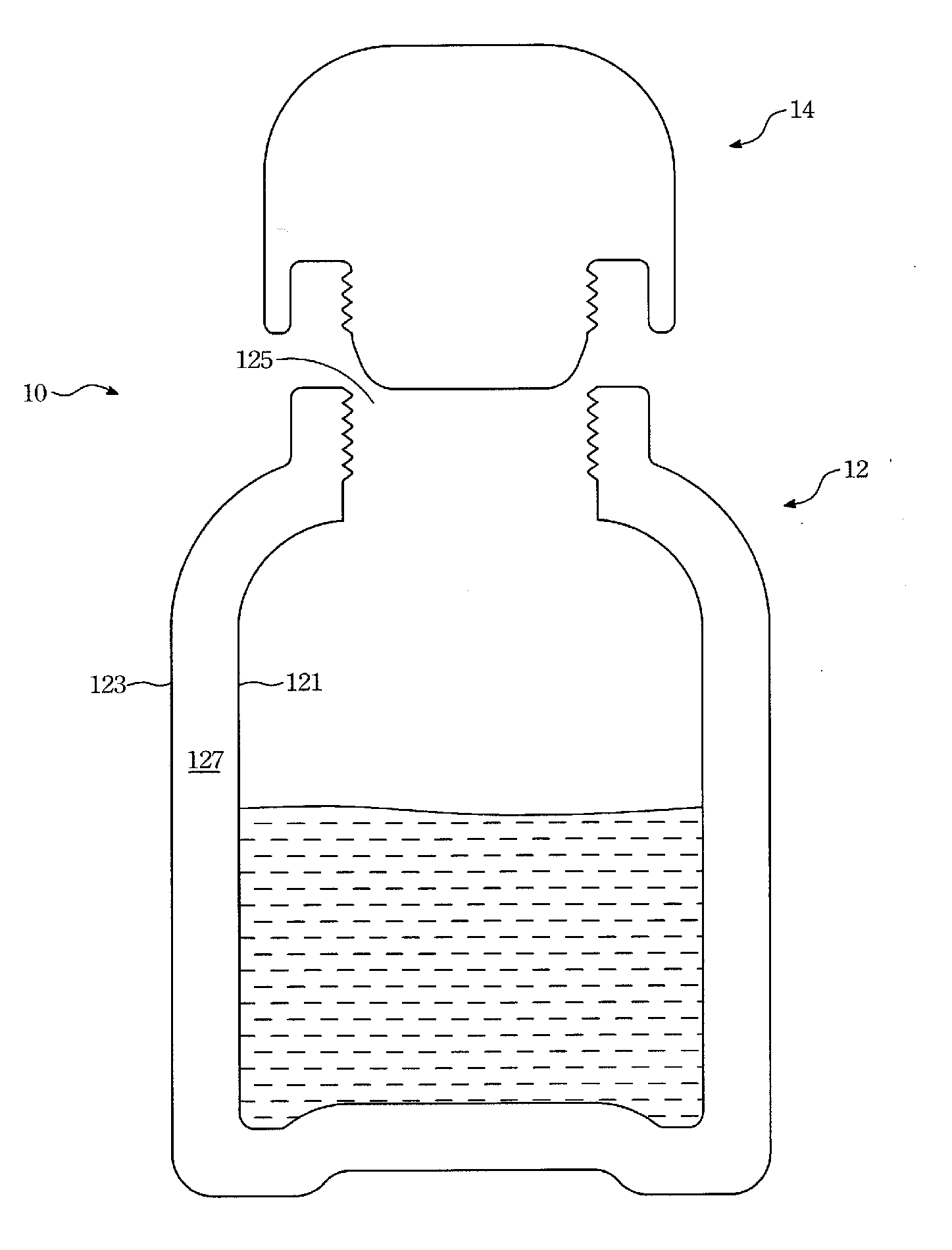

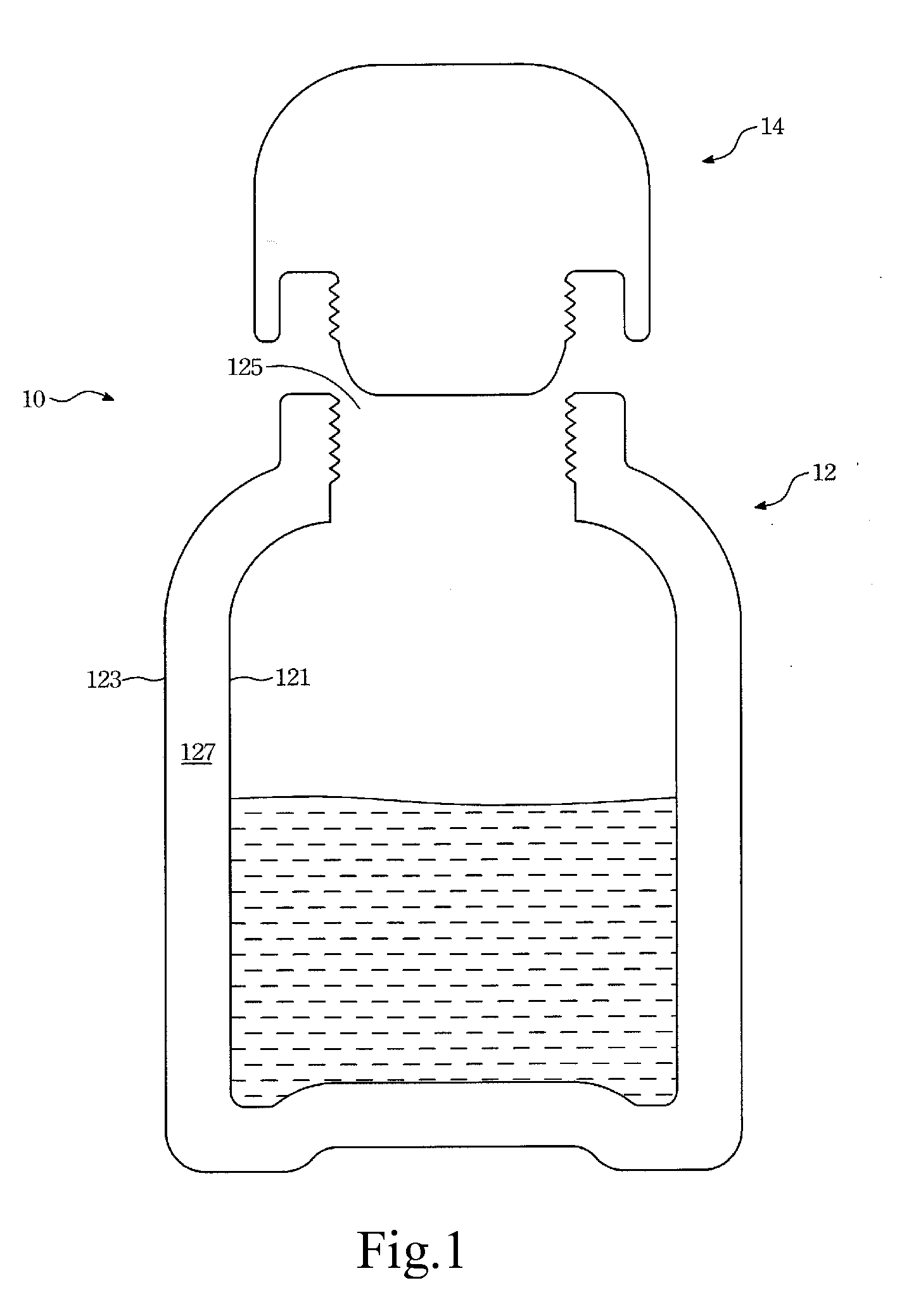

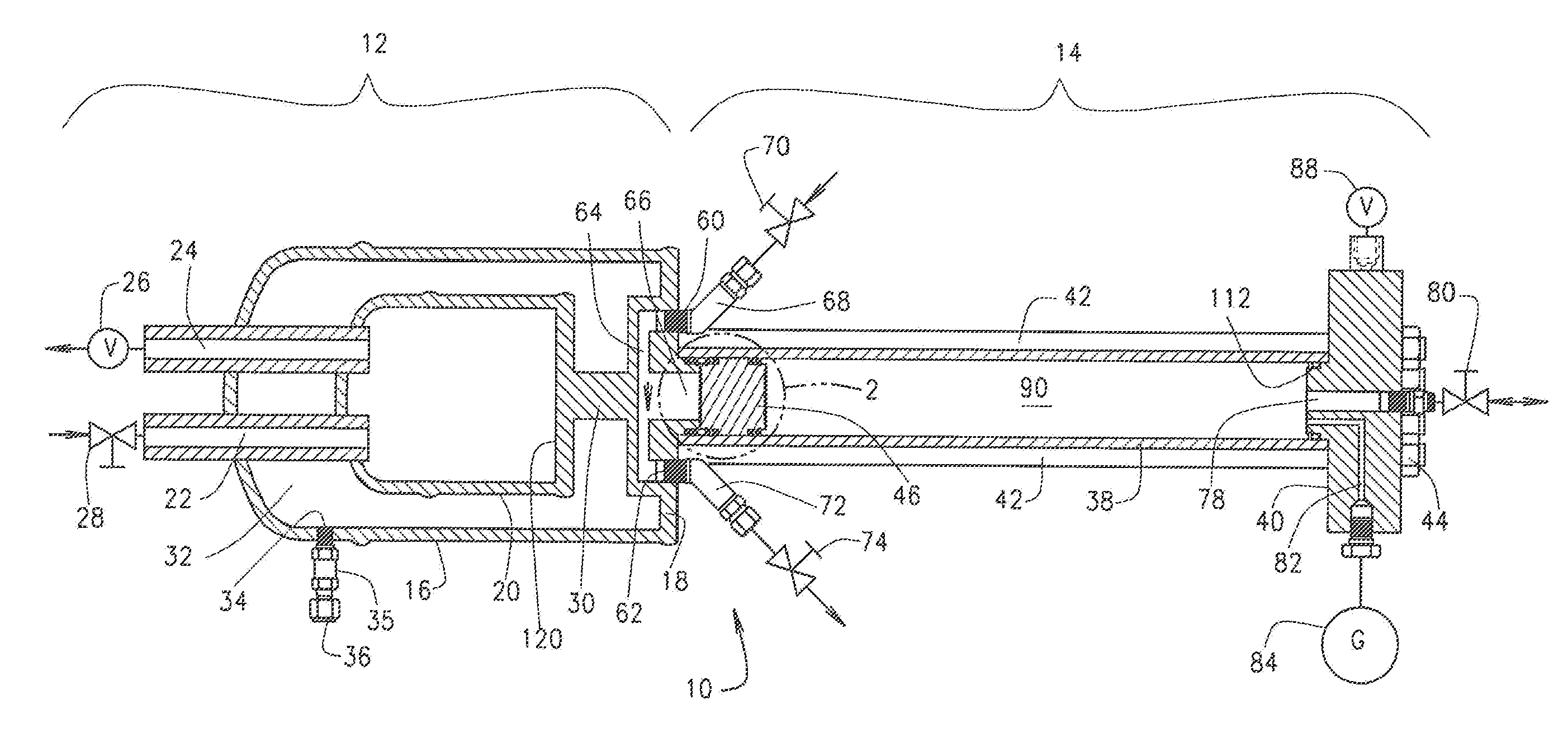

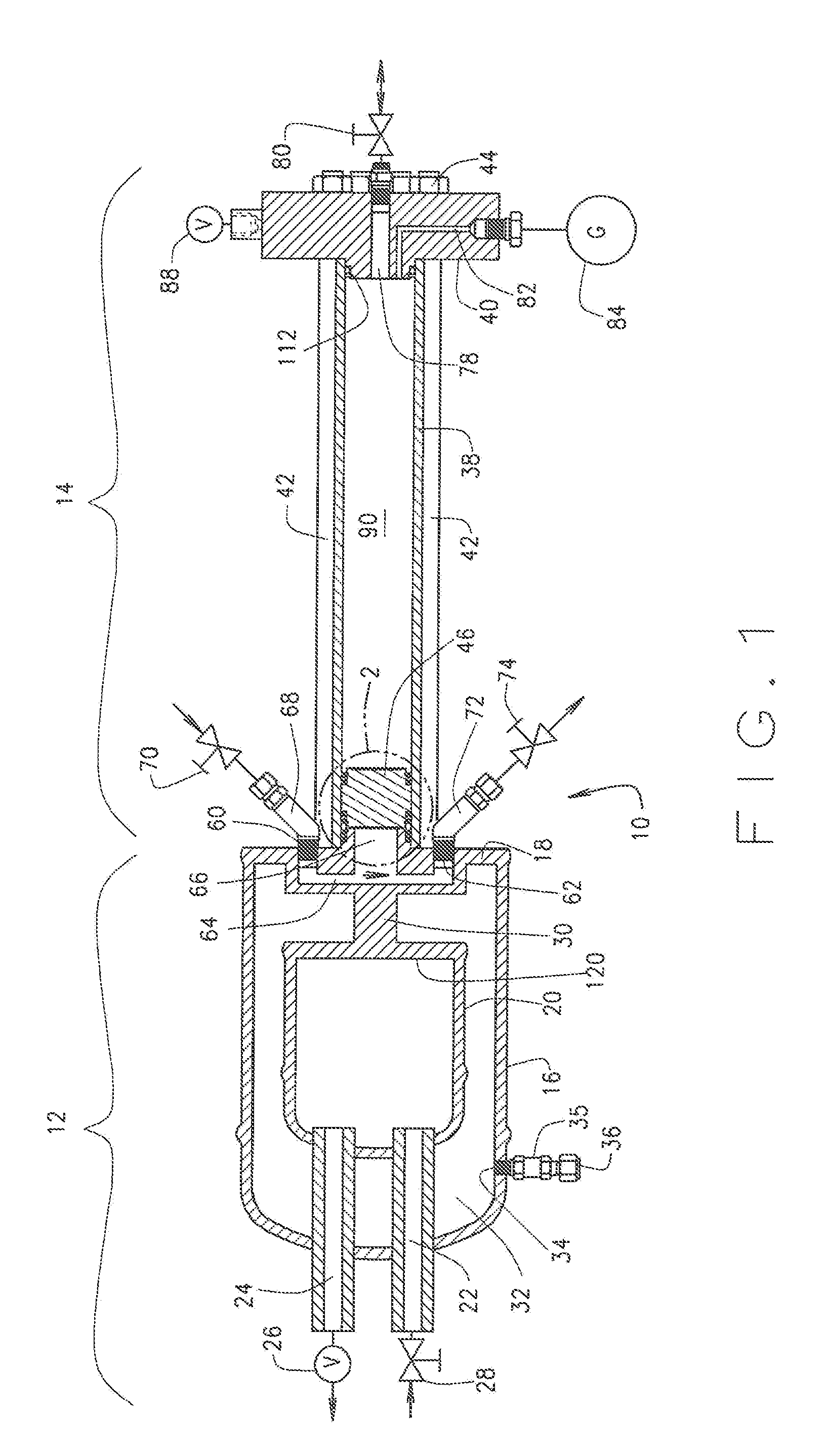

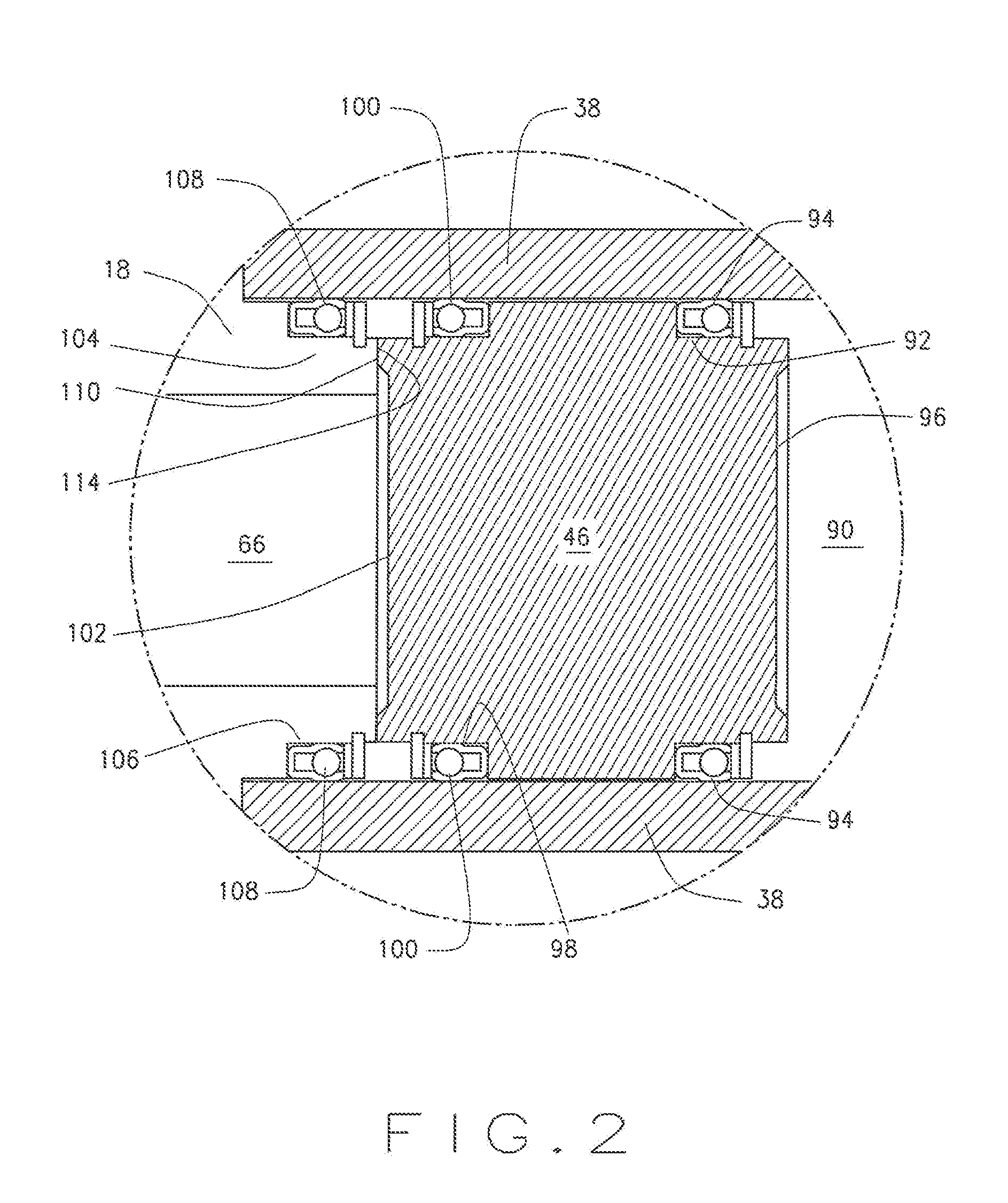

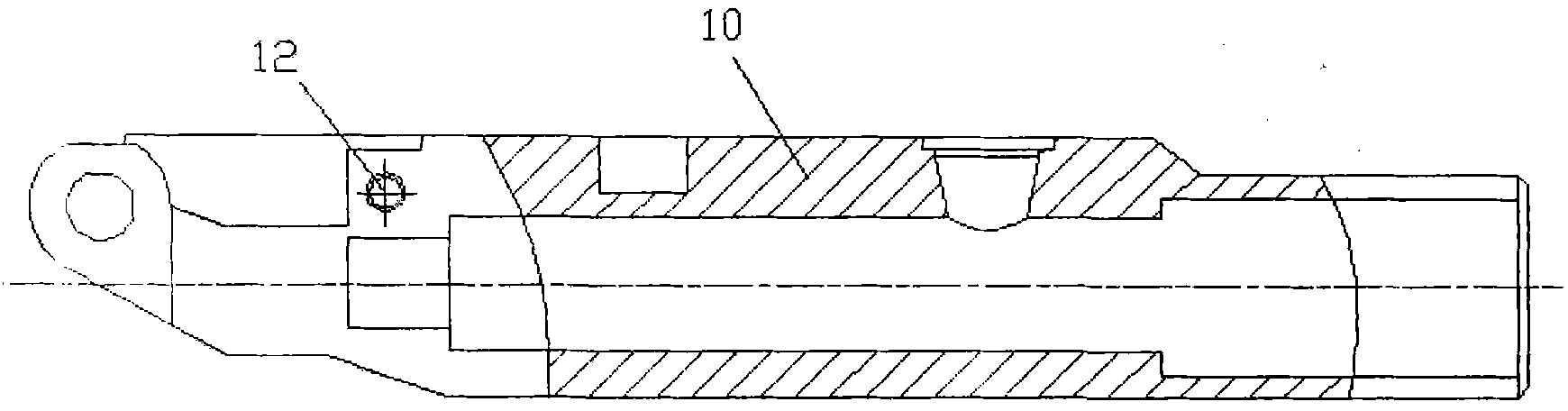

Transportable liquid phase LNG sample apparatus and method

ActiveUS20110192237A1Easy to transportEnough timeWithdrawing sample devicesPreparing sample for investigationGas phaseVaporization

A transportable Sample Apparatus includes a vacuum flask (Dewar flask) and integral sample container. The Sample Apparatus may be used to capture a liquid phase LNG sample at a custody transfer point and to transport the sample to a laboratory for analysis. Vaporization of the liquid phase sample may take place at a variety of different locations. For example, vaporization may begin and / or be completed during transport from the collection point to the laboratory. In another example, vaporization may begin and be completed in the laboratory. In yet another example vaporization may begin during transport and be completed at the laboratory. The gas phase sample is typically analyzed by a gas chromatograph for Btu content, among other things. Prior to capture of the sample, the Sample Apparatus goes through a pre-cool cycle to chill a sample end cap and other components to a temperature compatible with capture of a cryogenic liquid sample which is about −250° F.

Owner:WELKER ENG

Waterproof sealing device for cement hydration heat test

InactiveCN103072750AProtect liquid environmentWon't enterMaterial heat developmentSealingWater bathsEngineering

The invention relates to a waterproof sealing device for a cement hydration heat test. The waterproof sealing device comprises a wide-opening thermos bottle, a copper pipe and a cork stopper, wherein a silicon seal is sleeved at an adaptation position outside the opening of the wide-opening thermos bottle; the cork stopper is plugged in the opening; a fastening piece of which the outer ring is provided with threads is sleeved at the exterior of the silicon seal; the fastening piece is connected with a gland outside the fastening piece by virtue of the threads; a rubber stopper with the copper pipe is inserted in the upper port boss of the gland; and the rubber stopper props against the upper end of the cork stopper. The waterproof sealing device can be used for solving the problem that the cork stopper and the wide-opening thermos bottle are difficult to seal, and achieving a favorable waterproof sealing effect; and in addition, all the components of the waterproof sealing device can be subjected to cyclic utilization and are long in service life, so that while a water bath tank liquor environment is protected, resources are saved, and great convenience is brought to users.

Owner:SHENYANG JIANZHU UNIVERSITY

Water dispenser

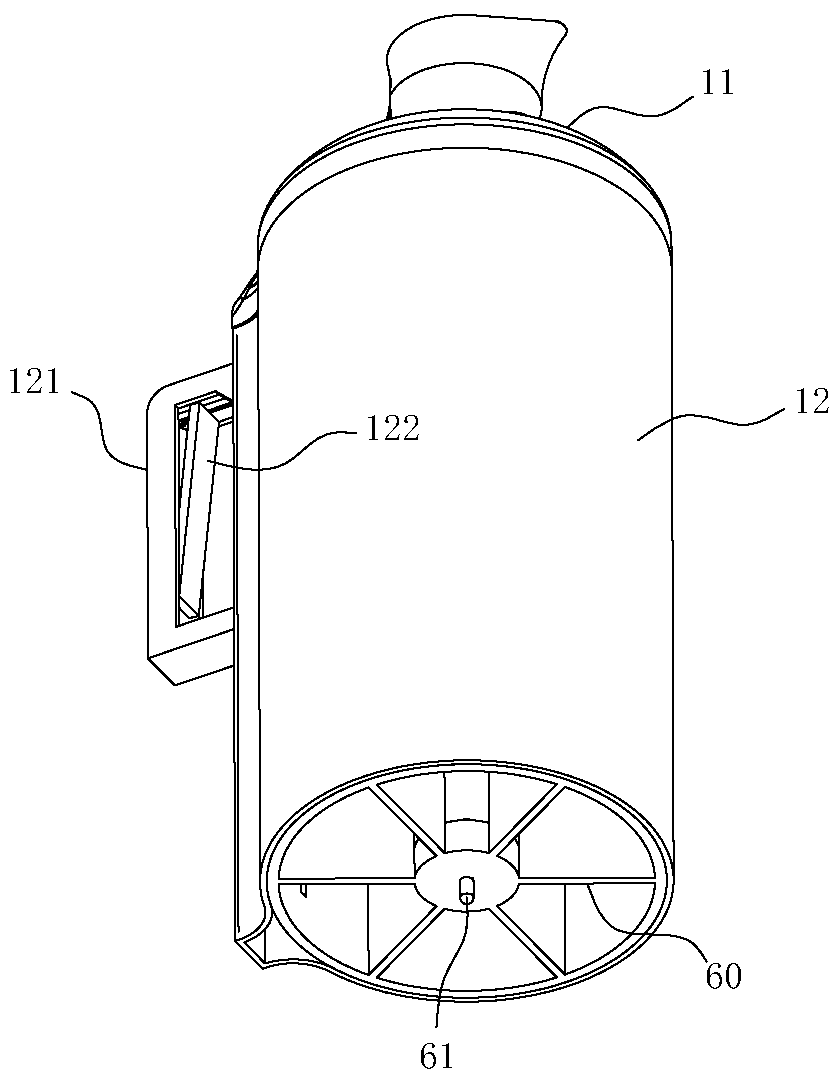

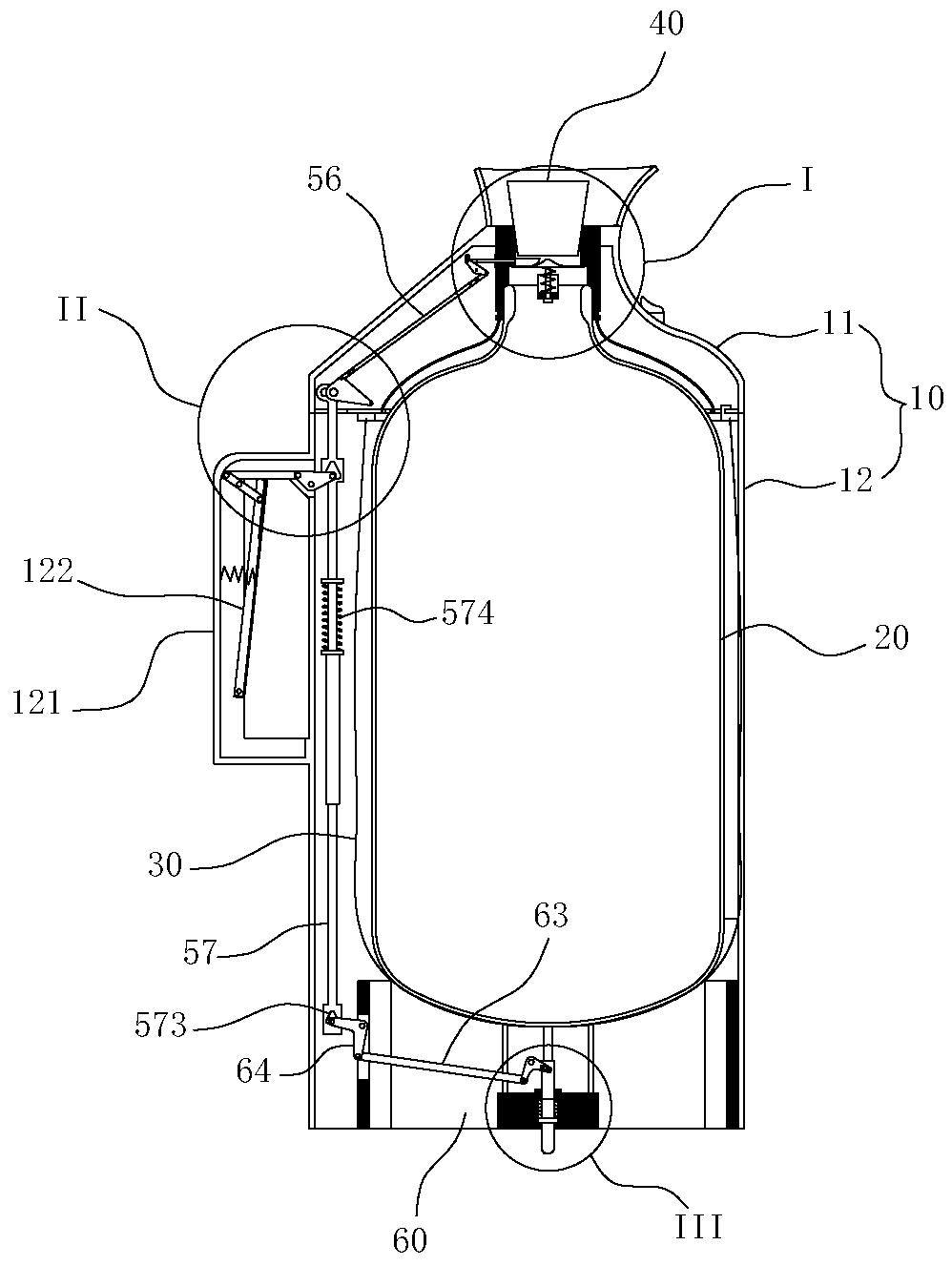

InactiveCN101569499AGuaranteed uptimeImprove insulation effectBeverage vesselsEngineeringVacuum flask

The invention relates to a water dispenser which is technically characterized in that a vacuum flask liner is reversely arranged in the water dispenser; the port of the vacuum flask liner is positioned at the bottom of the vacuum flask liner; a flask cover comprises an outer flask cover which is arranged on the inner wall of a base frame of the water dispenser and an inner sealing cover ring which is arranged in the outer flask cover; and the outer flask cover is sealed on the port of the vacuum flask liner through the inner sealing cover ring. The energy-saving rate of the vacuum flask liner of the water dispenser reaches more than 60 percent. When the vacuum flask liner of the water dispenser is used, the time that the temperature of water in the vacuum flask liner drops from 95 DEG C to 85 DEG C is 6 hours. Because the heat insulation effect is good, the water does not need to be repeatedly heated frequently. The water dispenser also solves the problem that residual water in a hot water liner of the prior water dispenser cannot be drained.

Owner:上海爱凯电器有限公司

Preparation method of cross-linked chitosan modified shaddock peel adsorption material for removing low-concentration heavy metals in waste water

InactiveCN105268418AImprove processing efficiencyNo secondary pollutionOther chemical processesWater contaminantsWater bathsIon content

The invention relates to a preparation method of a cross-linked chitosan modified shaddock peel adsorption material for removing low-concentration heavy metals in waste water and belongs to the field of waste water treatment. According to the preparation method, substances, such as chitosan, methanol water and the like, are filtered after being subjected to water circumfluence; filter residues are acid-pickled, alkaline-leached, washed and dried and are mixed with acetic acid and epichlorohydrin; after a pH value is regulated, the reaction is performed; by suction filtration, washing, drying and sieving, chitosan powder is obtained; then shaddock peel is obtained, is washed and dried and is ground into particles; the particles are added into sodium hydroxide solution and absolute ethyl alcohol for soaking; after centrifugation is carried out and the pH value is regulated, the obtained product is dried and is placed into a vacuum flask; in a negative pressure state, the obtained product is added into chitosan modification liquid for soaking; processing is carried out in a plasma form; filtration is carried out to obtain filter residues; and the filter residues are washed and dried to obtain the cross-linked chitosan modified shaddock peel adsorption material. In waste water treated by the cross-linked chitosan modified shaddock peel adsorption material prepared by the preparation method, mercury content is reduced to 0.5 to 1mg / L, nickel content is reduced to 0.5 to 0.7mg / L, and copper ion content is reduced to 0.04 to 0.05mg / L; treatment efficiency is high; secondary pollution cannot be generated.

Owner:雷春生

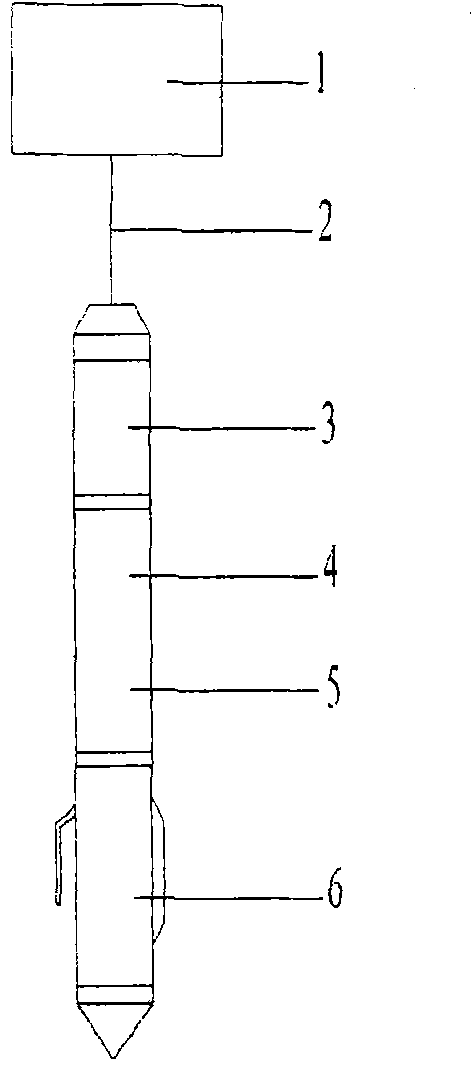

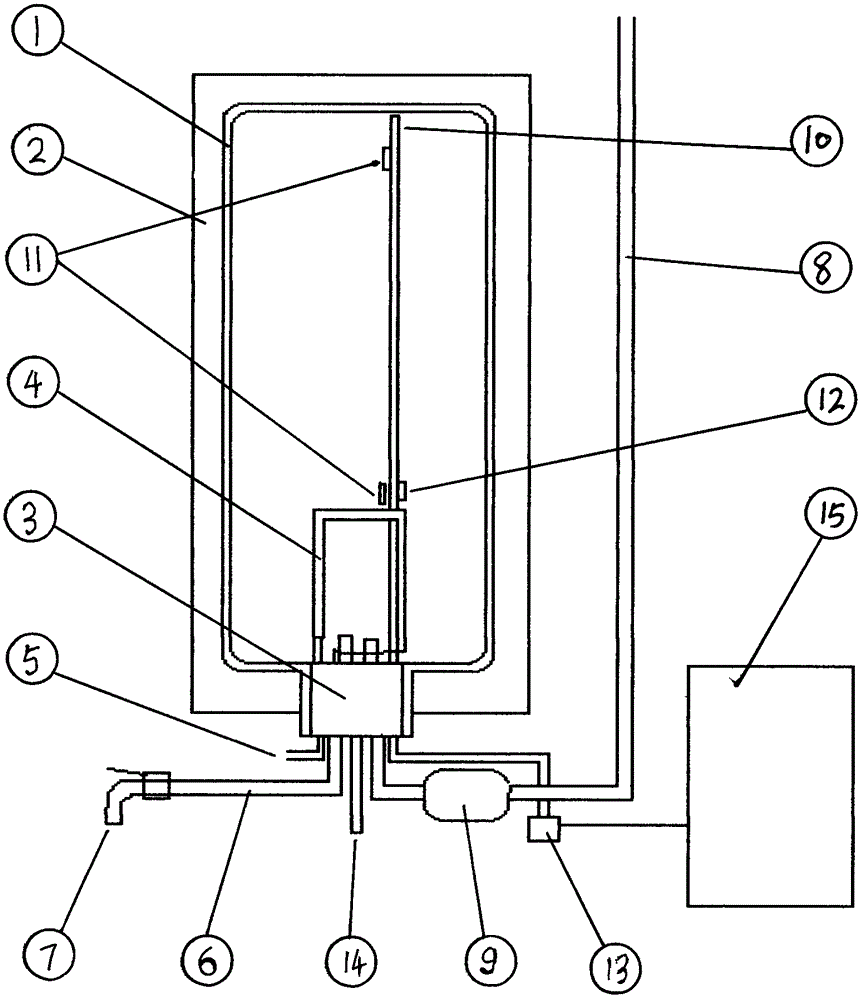

Lithology and density logging instrument

The invention provides a lithology and density logging instrument, which relates to an instrument for measuring formation lithology and the density. The invention is mainly used for the exploration and the development of petroleum and natural gas. Firstly, a heat insulation bottle base is fixed on a metal case of a probe through screws, then, all elements inside the probe are sequentially ranged and fixed in sequence to be encapsulated in a heat insulation bottle, a circuit inside the heat insulation bottle is connected with a circuit board through a multi-core cable, at the same time, an electric wire led out from the multi-core cable is led to the upper end of the probe through a groove arranged on the inner side of the probe case to be connected with an electronic signal processing circuit, and the communication of the whole control circuit is realized.

Owner:GI TECH (BEIJING) CO LTD

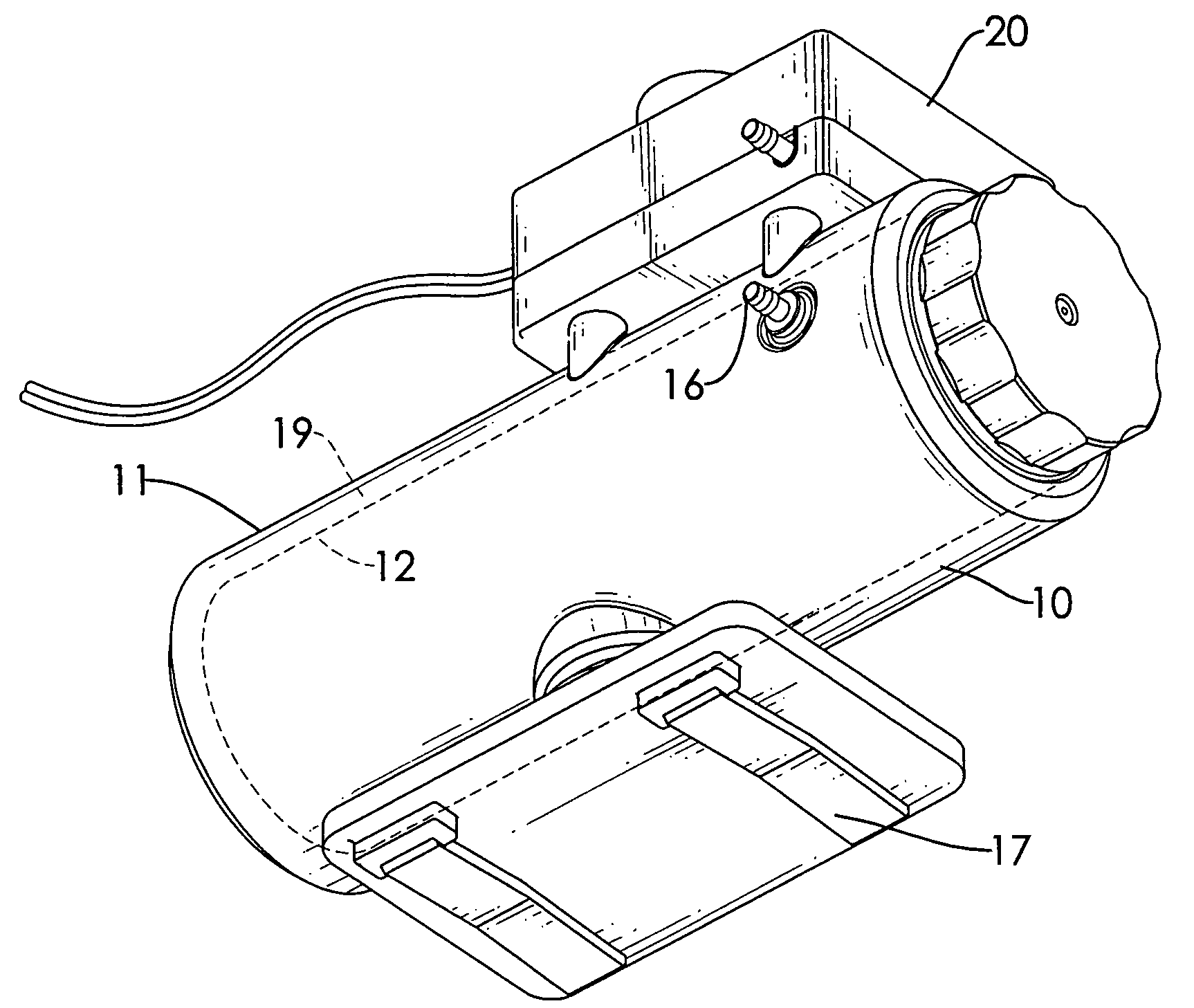

Portable cooling device

InactiveUS7640765B2Lower body temperatureCooling fluid circulationLaminated elementsEngineeringBottle

Owner:CHIU GARY +1

Superconductive energy-saving water heater

InactiveCN101876515ASolve the bathing problemSave energyOperating means/releasing devices for valvesIndirect heat exchangersEvaporationEngineering

The invention discloses a superconductive energy-saving water heater mainly comprising a heat pipe, a valve body and the like. The condensation end of the heat pipe is arranged in the inner cavity of the valve body, the internal diameter of the inner cavity of the valve body is larger than the external diameter of the heat pipe, the valve body is provided with a water inlet and a water outlet which are communicated with the inner cavity, running water can flow from the water inlet to the inner cavity of the valve body, flow through the outer surface of the condensation end of the heat pipe, and flow out of the water outlet. When the superconductive energy-saving water heater is used, the water inlet is connected to a running water tap through a flexible pipe, the water outlet is connected to a bath shower nozzle through a flexible pipe, the evaporation end of the heat pipe is inserted in a vacuum flask filled with hot water, and the hot water can flow out of the bath shower nozzle when the tap is opened, wherein running water is not mixed with the hot water in the vacuum flask, but only exchanges heat with the hot water. After the bath, the hot water in the vacuum flask becomes cold water, thereby obtaining drinkable cold water, realizing bath, and achieving the aim of energy saving.

Owner:王天然

Slim-hole natural gamma spectrometry logging device

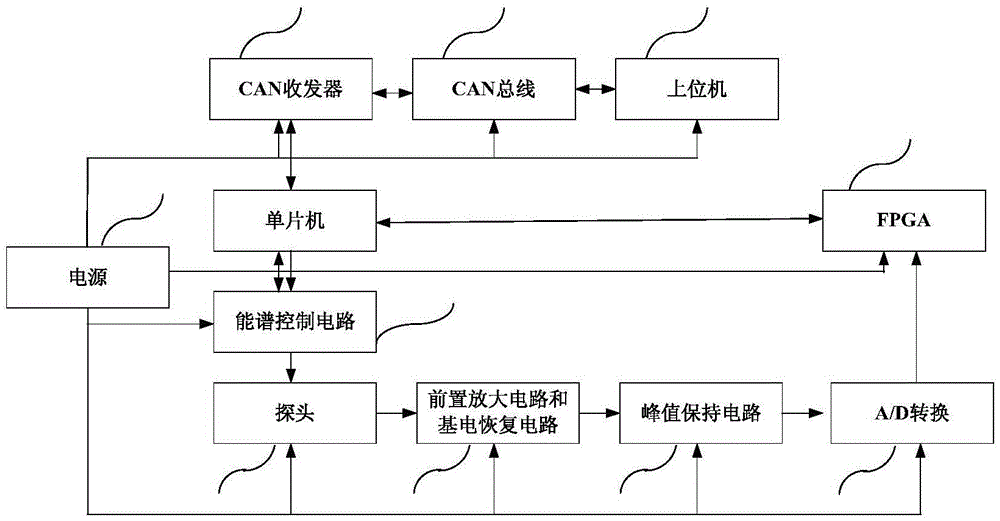

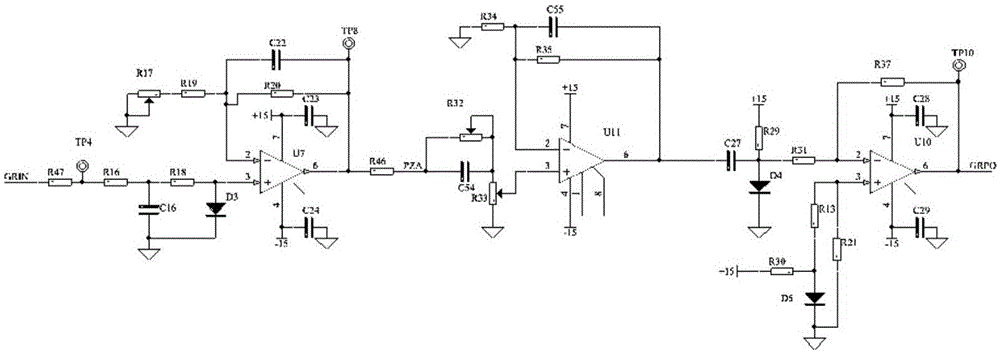

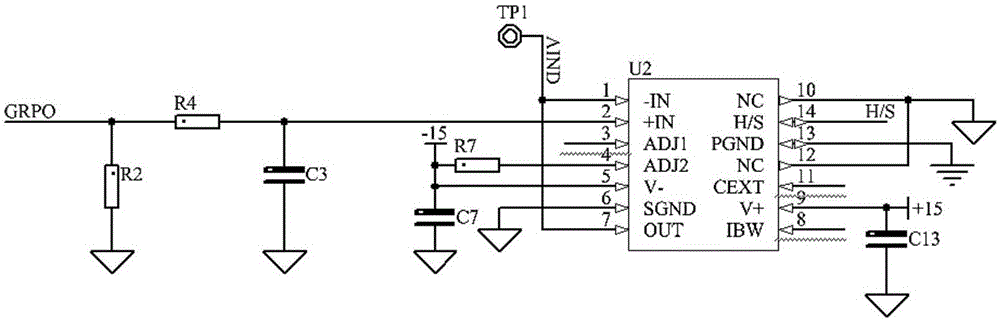

The invention relates to a slim-hole natural gamma spectrometry logging device. In one embodiment, the slim-hole natural gamma spectrometry logging device comprises a probe, an analog circuit and a digital circuit, wherein the probe comprises a photomuitplier and a sodium iodide crystal with the diameter Phi being 38*300mm; the analog circuit is used for magnifying voltage pulses converted by the probe and converting peak value signals into digital signals when voltage pulse peak value signals are stable; the digital circuit comprises an FPGA (Field Programmable Gate Array) and a single chip microcomputer; the FPGA is used for controlling voltage pulse signal conversion, accumulating the digital signals to form gamma spectrometry and transmitting the gamma spectrometry to the single chip microcomputer through UART (Universal Asynchronous Receiver / Transmitter) protocols; and the single chip microcomputer transmits the gamma spectrometry to an upper computer through a CAN (Controller Area Network) bus. The embodiment has the advantages that the FPGA technology is adopted for realizing high integration of a data collecting circuit; the instrument volume is reduced; and the 60mm slim-hole natural gamma spectrometry logging measurement under the condition without a vacuum flask is realized.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

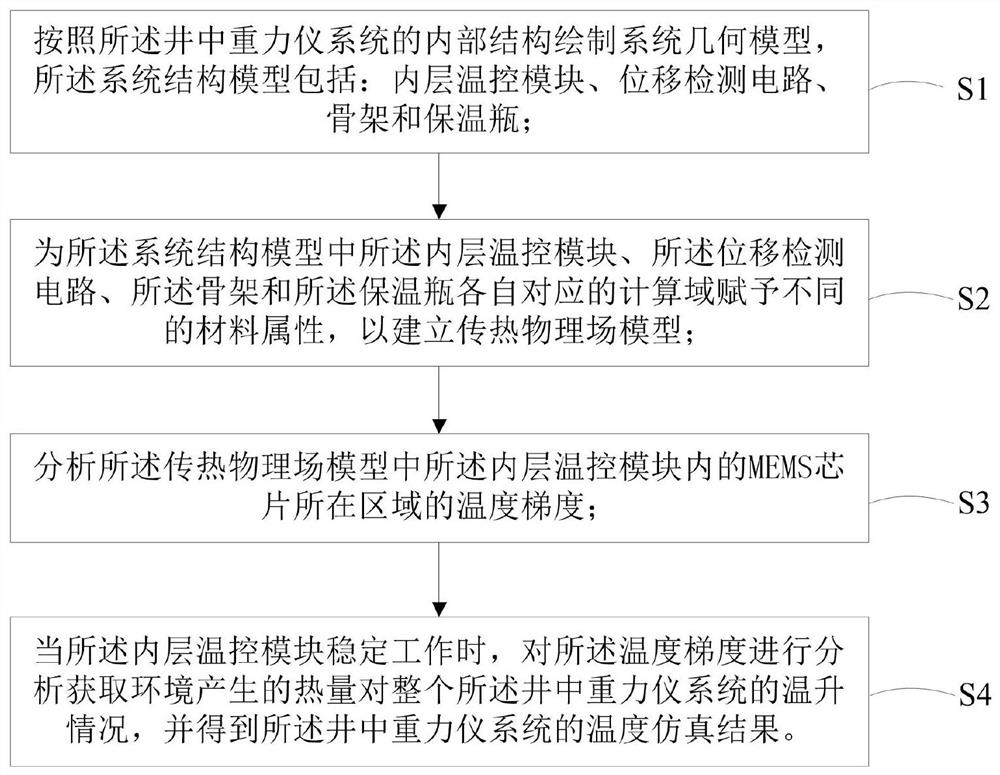

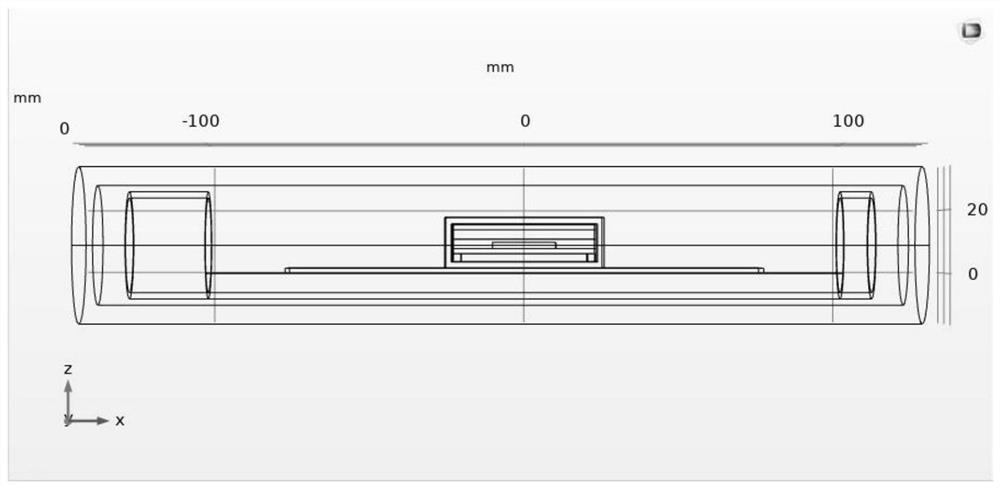

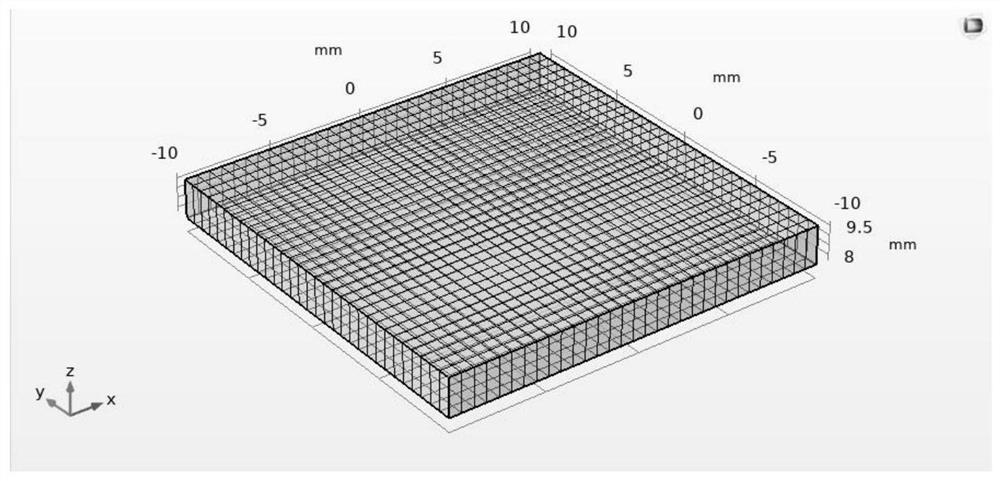

Internal temperature simulation method for borehole gravimeter system

PendingCN112784463AHigh measurement accuracyAccurate analysisGeometric CADDesign optimisation/simulationTemperature controlWell logging

The invention discloses an internal temperature simulation method for a borehole gravimeter system, and belongs to the field of logging instruments, and the method comprises the steps: S1, drawing a system geometric model according to the internal structure of the borehole gravimeter system, wherein the system geometric model comprises an inner layer temperature control module, a displacement detection circuit, a skeleton and a vacuum bottle; S2, endowing each computational domain in the system structure model with different material attributes so as to establish a heat transfer physical field model; S3, analyzing the temperature gradient of an area where the MEMS chip in the inner layer temperature control module in the heat transfer physical field model is located; and S4, when the inner layer temperature control module works stably, analyzing the temperature gradient to obtain the temperature rise condition of the heat generated by the environment on the borehole gravimeter system, and obtaining a temperature simulation result of the borehole gravimeter system. The problem that a constant-temperature environment cannot be guaranteed is avoided through modeling simulation, the temperature simulation result of the borehole gravimeter system can be accurately analyzed, and the temperature simulation result can provide reference for actual measurement, so that the measurement precision is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Traditional Chinese medicine for treating high blood pressure medicine and preparation method thereof

InactiveCN102100800AEasy to prepareWith antihypertensive laxativeCardiovascular disorderPlant ingredientsHigh blood pressure medicinesBurned fat

The invention discloses a traditional Chinese medicine for treating high blood pressure medicine and a preparation method thereof. The formula of the Chinese medicine comprises the following raw materials: chrysanthemum, Cassia occidentalis, hawthorn, barbary wolfberry fruit, uncaria and selfheal. The preparation method comprises the following steps: mixing the raw materials based on a certain weight ratio in a container; adding 1.5L of water; decocting for three times continuously; filtering out dregs of decoction; and putting liquid medicine into a vacuum flask or a vacuum cup. The traditional Chinese medicine can be taken for many times, and only needs to be heated to be warm before administration every time. The preparation method of the traditional Chinese medicine disclosed by the invention has the effects of reducing pressure, relaxing the bowel, burning fat, reducing cholesterol and the like, and simultaneously has good treatment effects and no side effect.

Owner:刘宗英

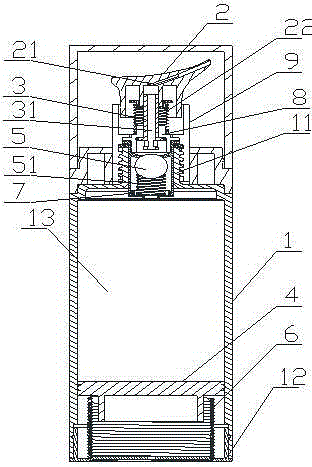

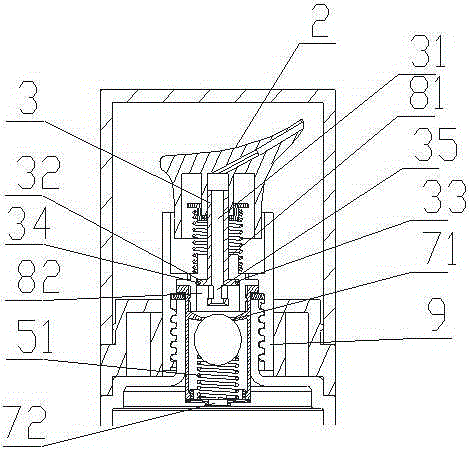

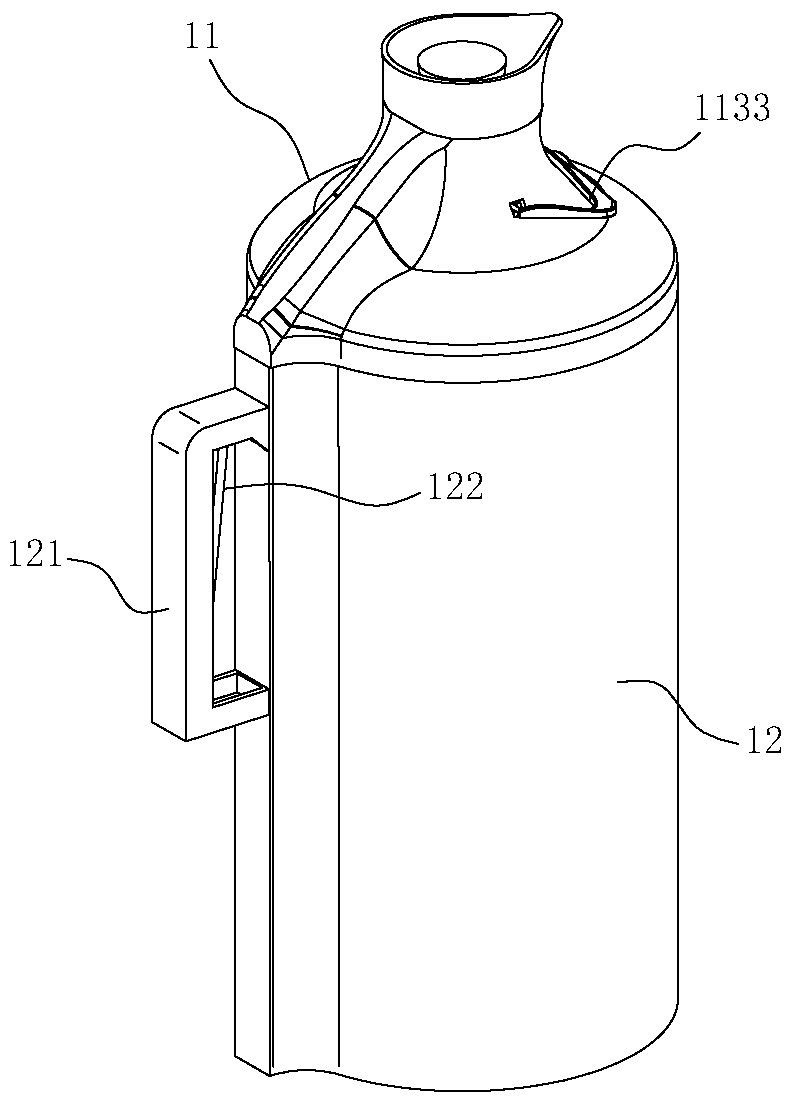

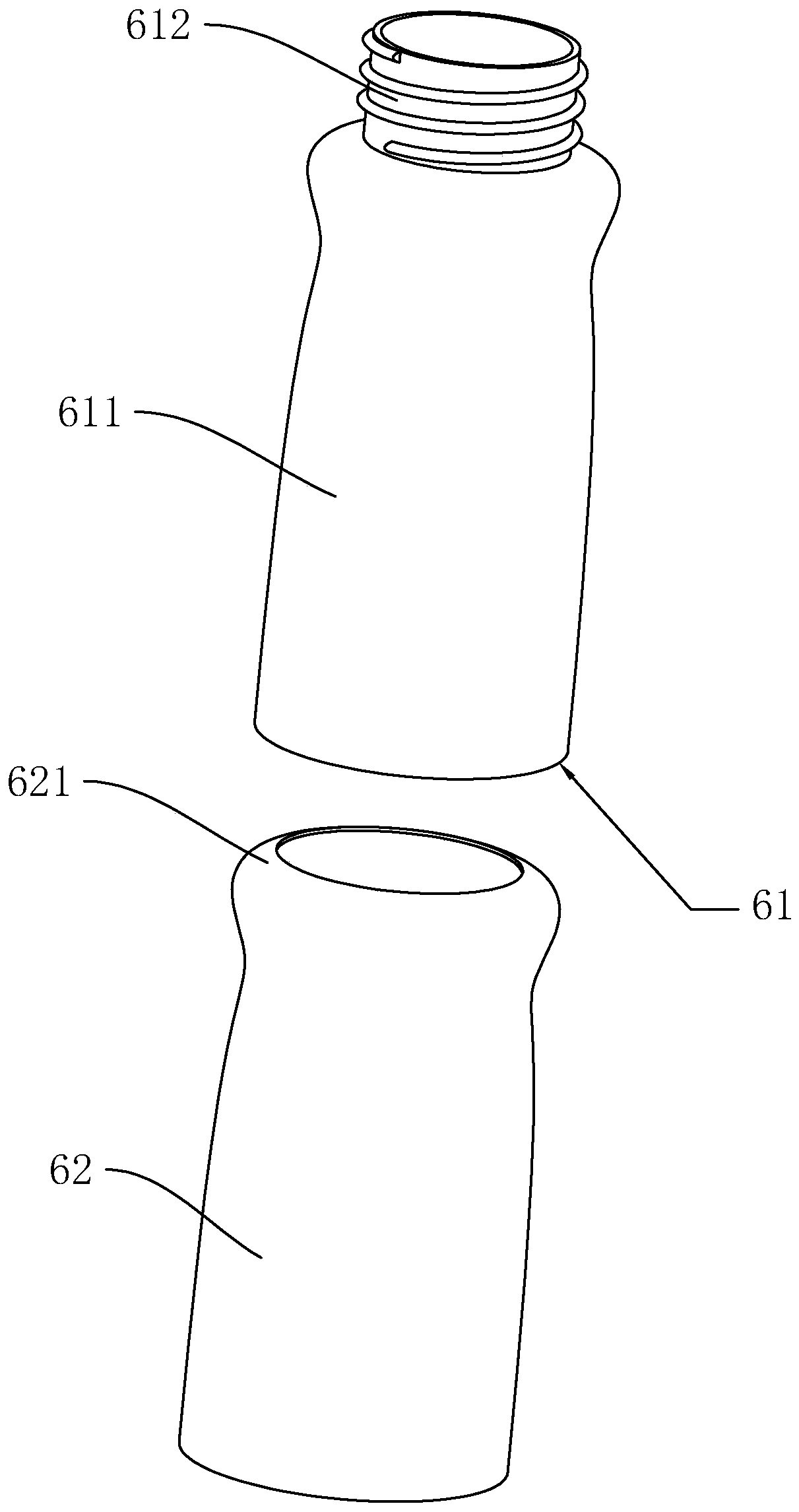

Vacuum flask

ActiveCN105217166AWon't leakEasy to operatePackaging under vacuum/special atmosphereLiquid dispensingSprayerReciprocating motion

The invention relates to a vacuum flask. The vacuum flask comprises a flask body with a containing cavity, a sprayer internally provided with a first cavity channel, a transmission rod internally provided with a second cavity channel and a piston. An opening is formed in the upper portion of the flask body. A valve block for sealing the opening is elastically arranged in the opening. The sprayer can be connected to the upper end of the flask body in a reciprocating mode in the axial direction of the flask body, the transmission rod is connected to the lower end of the sprayer, the second cavity channel and the first cavity channel are communicated, the lower end of the transmission rod is opposite to the valve block, and the diameter of the transmission rod is smaller than that of the valve block. The piston is arranged at the bottom of the flask body in a sliding mode. The diameter of the piston is the same as the internal diameter of the flask body. The bottom side of the piston is elastically connected with the flask bottom of the flask body through a compression spring. Power is supplied to liquid, emulsion and paste in the flask body through the piston via the compression spring, it is only needed to push the valve block to enable a channel to be formed between the containing cavity and the sprayer, the liquid, emulsion and paste can be sprayed out, and operation is simple.

Owner:JIANGYIN MINCHENG PLASTIC PRODS

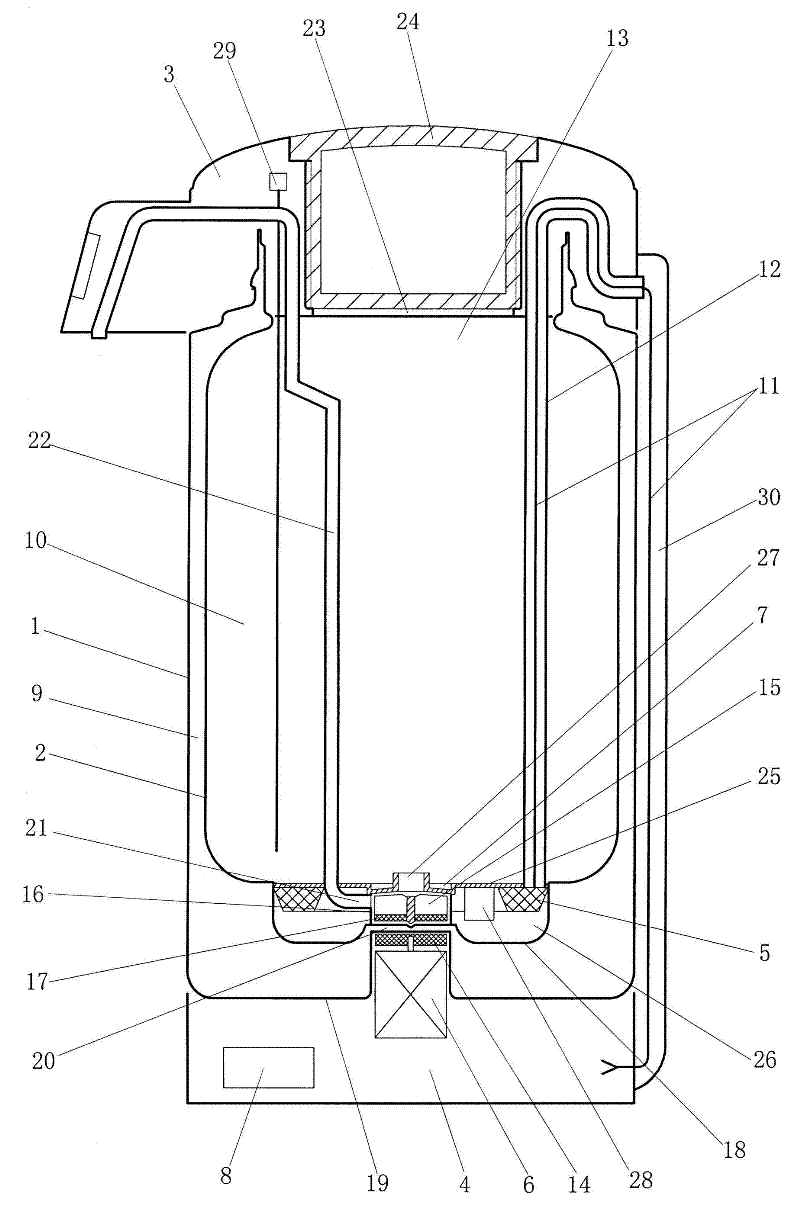

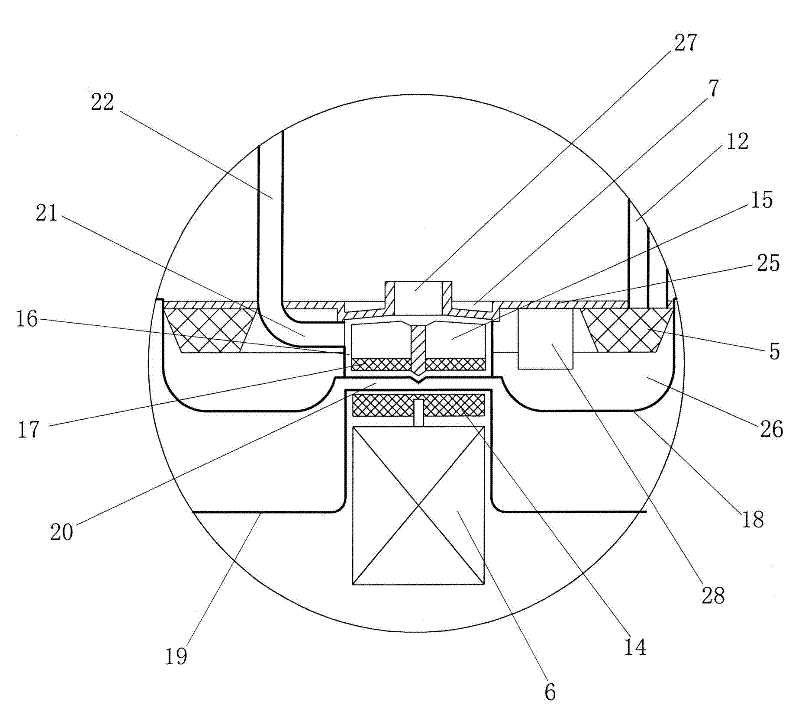

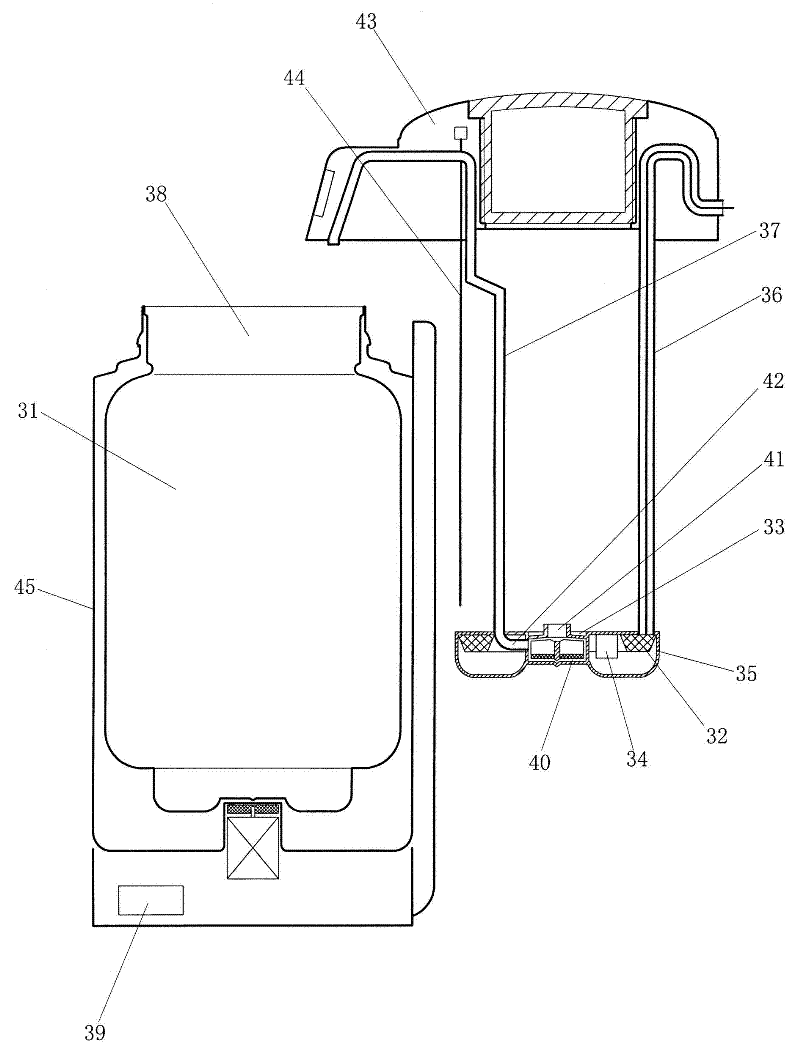

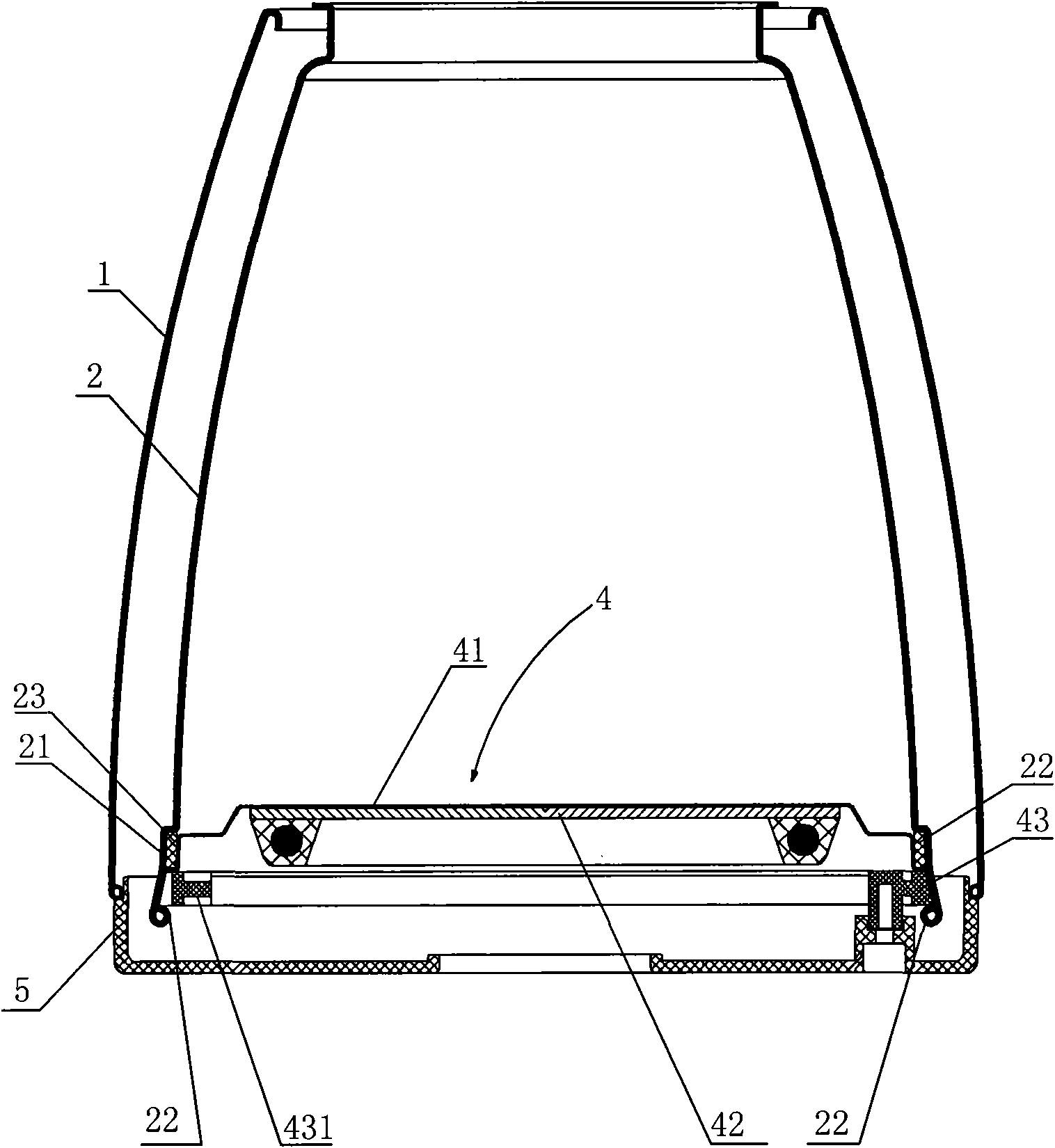

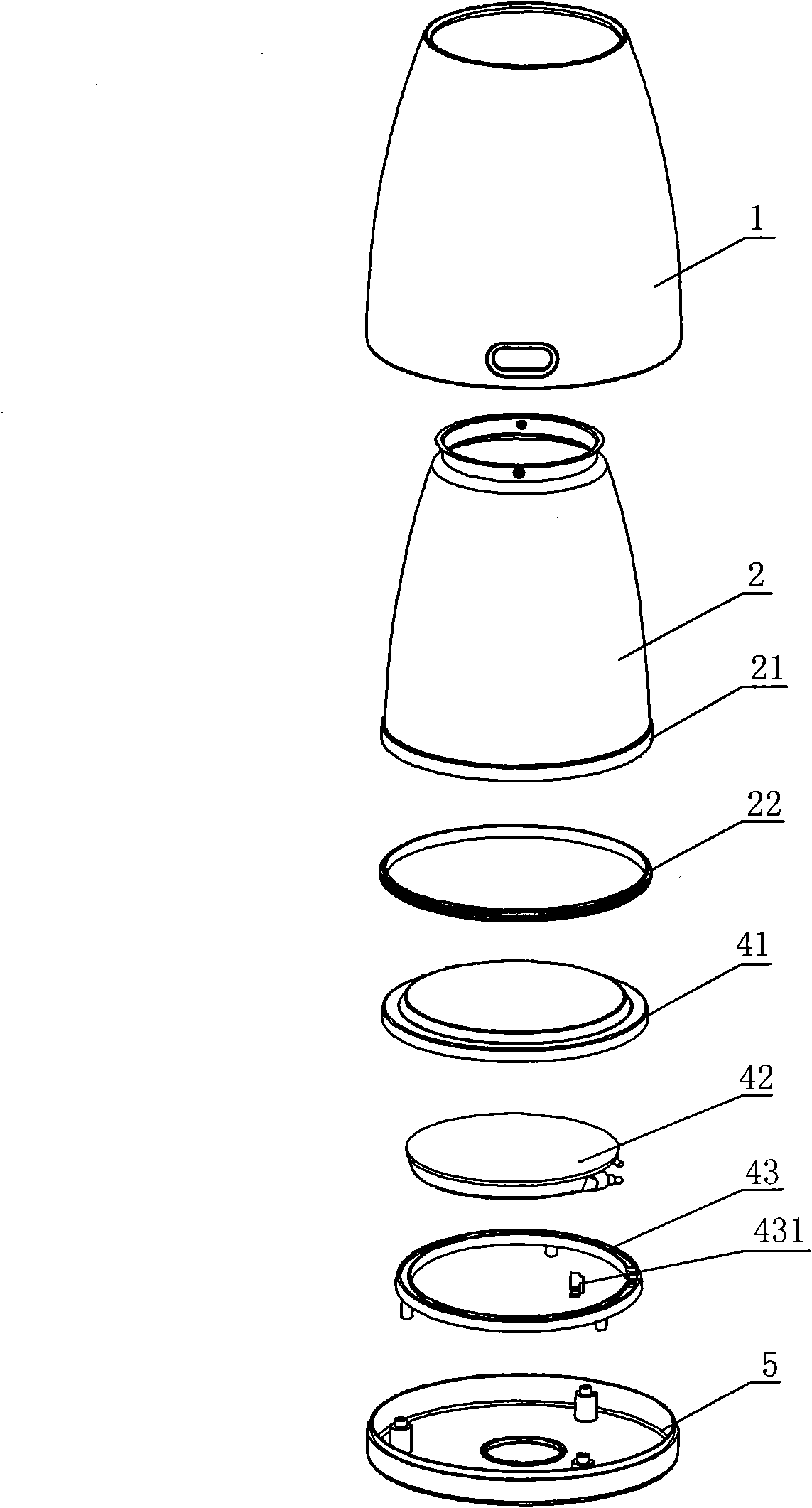

Double-layer vacuum-type electric heating water boiling thermos bottle

InactiveCN102240166AImprove insulation effectReduce wasteCooking-vessel lids/coversWater-boiling vesselsElectricityImpeller

The invention discloses a double-layer vacuum-type electric heating water boiling thermos bottle in order to overcome the defects of inferior thermal insulation effect, considerable energy waste and quite high housing temperature caused by the fact that a through opening cylinder is arranged between the base plates of an inner tank and a housing to form a channel for the base plate of the inner tank to transfer and dissipate heat outwards in the prior art. The technical scheme is as follows: the thermos bottle comprises a housing, an inner tank, a bottle top sealing cover, a bottle leg base, an electric heater, an electric pump and a control circuit, wherein a vacuum thermal insulation layer is formed between the housing and the inner tank and the electric heater is arranged at the bottom inside an inner tank cavity; the thermos bottle is characterized in that a power supply lead of the electric heater is led out through a conduit of the inner tank cavity from the upper opening of the inner tank, the electric pump is divided into two parts including a motor and a pump body, the motor is installed inside the bottle leg base, a magnetic rotating disc is installed on a motor shaft, the pump body is installed at the bottom inside the inner tank cavity, another magnetic rotating disc is arranged on the bottom surface of an impeller of the pump body, the magnetic rotating disc of the motor is in attraction fit with the magnetic rotating disc of the impeller in such a manner that the vacuum layer of the inner tank and the housing is arranged between the two magnetic rotating discs, and a water outlet channel of a pump body cavity is connected with a water outlet pipe which is arranged inside the inner tank cavity and is led out through the upper opening of the inner tank.

Owner:汕头市大堡礁水处理技术有限公司

Vacuum flask assembling method

ActiveCN110169720APrevent splashAvoid burnsNon-pressured vesselsThermally-insulated vesselsEngineeringVacuum flask

The invention belongs to the field of manufacturing of living supplies and particularly relates to a vacuum flask assembling method. A vacuum flask comprises a shell, a liner, a flask plug and an explosion-proof capsular bag. The vacuum flask assembling method comprises the steps that firstly, the explosion-proof capsular bag sleeves the liner, and then the liner and the explosion-proof capsular bag are mounted in the shell. Through ingenious assembling design, the explosion-proof capsular bag is placed in the vacuum flask, when the vacuum flask falls down accidentally, the explosion-proof capsular bag can effectively avoid splashing of boiled water, and scalding is avoided.

Owner:安徽字母表工业设计有限公司

Thermal shock-resistant glass for vacuum bottle liner and preparation method

The invention discloses thermal shock-resistant glass for a vacuum bottle liner and a preparation method thereof. The thermal shock-resistant glass is prepared from the following raw materials, by weight, 75-85 parts of sea sand, 15-25 parts of limestone, 10-15 parts of wollastonite, 10-15 parts of magnesite, 15-20 parts of flint clay, 5-10 parts of red mud, 20-30 parts of cullet, 8-12 parts of fluorite, 4-6 parts of borax, 3-5 parts of calcium phosphate, 2.5-4.5 parts of saltcake, 3.5-5.5 parts of mica powder and 3-6 parts of graphene. The thermal shock-resistant glass provided by the invention has low thermal expansion coefficient, good heat stability and excellent thermal shock resistance. By the use of the thermal shock-resistant glass, rupture caused by thermal shock is avoided, and service life of a vacuum bottle is prolonged.

Owner:FENGYANG JINXING IND

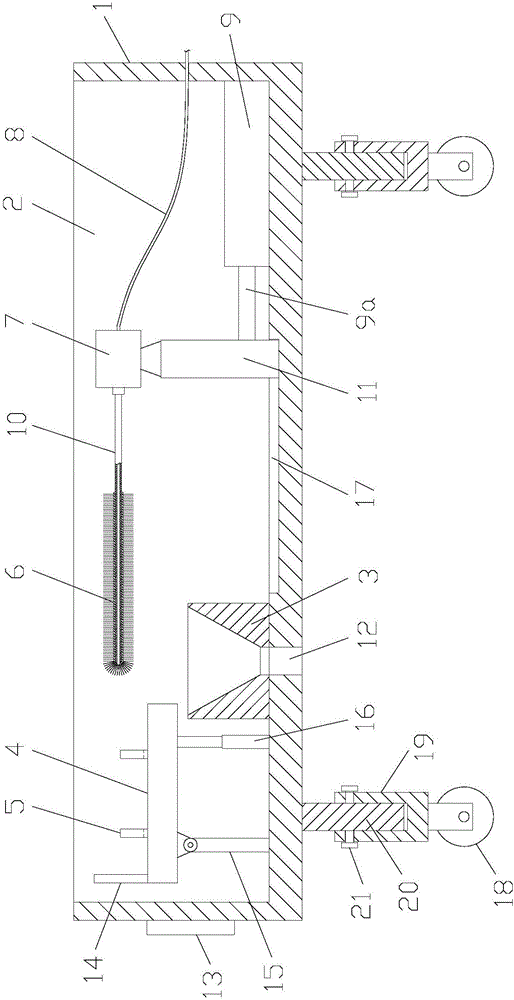

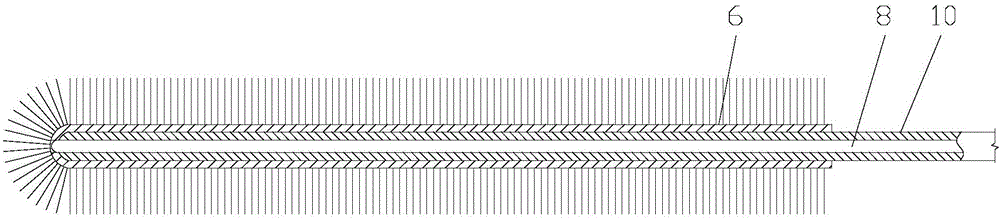

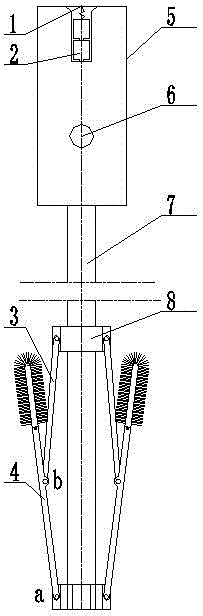

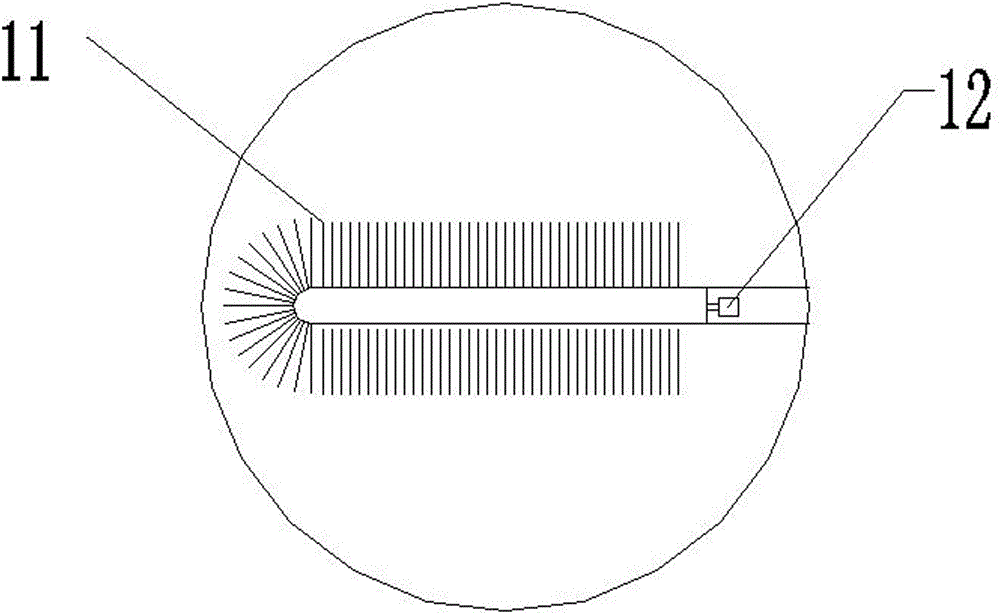

Movable cleaning device for inner container of vacuum bottle

InactiveCN106493134ARealize automatic cleaningConvenient heightHollow article cleaningDrive shaftBottle

The invention discloses a movable cleaning device for an inner container of a vacuum bottle. The movable cleaning device comprises a base provided with a cavity, a support mechanism, a cleaning mechanism and a drainage tank, wherein the support mechanism, the cleaning mechanism and the drainage tank are arranged in the cavity. The support mechanism comprises a support table, clamp pieces arranged at the top of the support table, and an adjustment post assembly. The support table is supported on the bottom wall of the cavity through the adjustment post assembly. The cleaning mechanism comprises a brush head, a motor, a water feed tube and an air cylinder. The brush head is detachably fixed to a drive shaft of the motor. A channel is formed in the drive shaft. A via hole communicating with the channel is formed in the end of the brush head. One end of the water feed tube penetrates through the channel of the drive shaft to be located in the via hole of the brush head, and the other end of the water feed tube penetrates through the side wall of the cavity to stretch out of the cavity. The motor is installed on a motor holder. The motor holder and the air cylinder are fixed to the bottom wall of the cavity. A piston rod of the air cylinder is connected with the motor holder. The drainage tank is fixed to the bottom wall of the cavity. Support foot assemblies are arranged at the bottom of the base. By adoption of the movable cleaning device for the inner container of the vacuum bottle, the inner container of the vacuum bottle can be cleaned automatically, the cleaning effect is good, moving and adjusting are convenient, and use is convenient.

Owner:CHONGQING TIANJIA COMMODITY IND

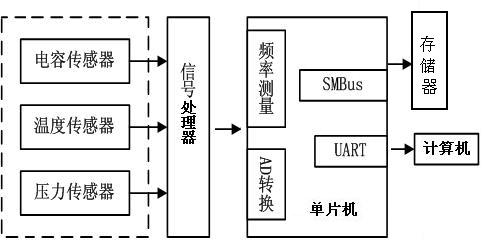

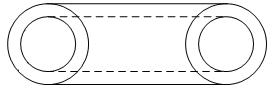

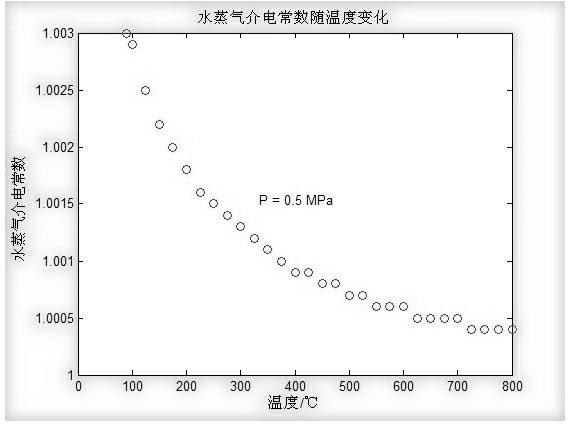

Device special for online measurement of dryness of steam injection well

InactiveCN102608175AStable static characteristicsSimple measurement systemMaterial capacitanceDielectricThermodynamics

The invention relates to a device special for online measurement of the dryness of a steam injection well, composed of a capacitance sensor, a temperature sensor, a pressure sensor, a signal processor, a singlechip, a memory and a computer, wherein the capacitance sensor, the temperature sensor and the pressure sensor are connected to the signal processor respectively; the signal processor is connected to the singlechip which is connected to the computer; the signal processor, the singlechip and the memory are mounted on a circuit board; the circuit board and a power supply battery are mounted in a vacuum flask; the capacitance sensor is tubular; one end of the capacitance sensor is fixedly connected to the vacuum flash; and the temperature sensor and the pressure sensor are fixed to the other end of the capacitance sensor. The device employs the cylindrical capacitance sensor for measuring the humidity of steam, and performs the measurement of the dryness of wet steam based on the difference between water and steam in dielectric constant; and the measurement system is simple without extracting steam for sampling, and low in requirements for the environment; the cost of equipment is low; and the operation process is simple and convenient.

Owner:NORTHEAST GASOLINEEUM UNIV

One-time heating heat-insulating water dispenser equipment

The invention relates to water storage modes of electric heating water dispensers and vacuum bottles. One-time heating heat-insulating water dispenser equipment is composed of an electric heating pipe, a sealing plug, a water inlet pipe, a water outlet pipe and the like. According to the equipment, water in a vacuum bottle is heated in one time by virtue of an electric heater, and then the water is preserved at a certain temperature; the vacuum bottle, which is made from an insulating material, has insulating performance of a conventional vacuum bottle, and boiling water, which is kept in the bottle, can be kept at a certain temperature for a long time; the equipment, during working, can automatically detect a water level in the bottle, an electromagnetic water valve is started to convey cold water in the water inlet pipe into the vacuum bottle when the water level is under a preset value, the electric heating pipe, after the water is conveyed, is started by the equipment so as to heat the cold water, and it stops heating as a preset temperature is reached, at which time, the boiling water can be kept under an insulating state; the electromagnetic water valve is opened by the equipment as the boiling water in the bottle is used to a certain position, so that the cold water can enter the bottle and can be heated once again; and with the adoption of a vacuum bottle type insulating mode, the temperature of boiling water can be kept for a long time, so that damage to water quality of water which is repeatedly heated by the equipment is avoided.

Owner:王明中

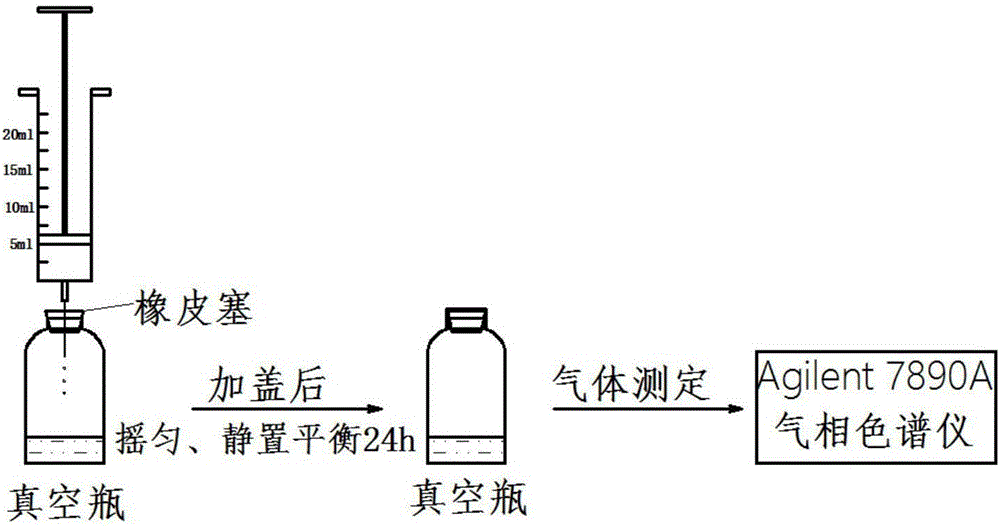

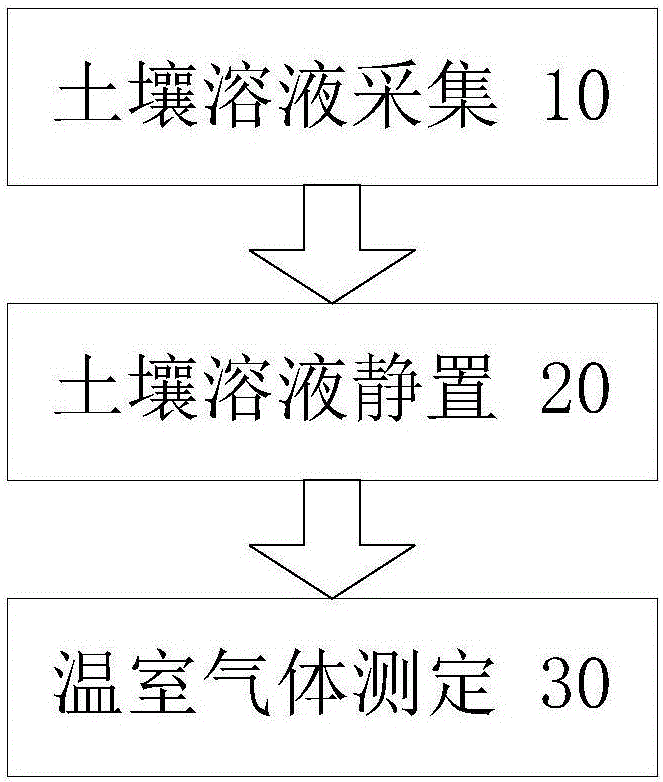

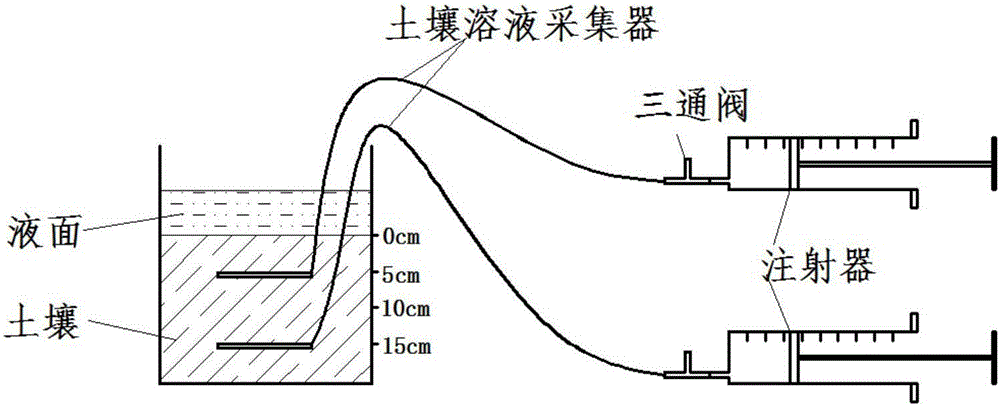

Method for measuring rice field greenhouse gases based on rice field soil solution

The invention discloses a method for measuring rice field greenhouse gases based on rice field soil solutions, and the method comprises the following steps: (10) soil solution collection, to be more specific, using soil solution collectors to collect soil solutions at different soil depths in a rice field; (20) soil solution standing, to be more specific, injecting the soil solutions into vacuum flasks, and standing for 24 hours; and (30) greenhouse gas determination, to be more specific, using a gas chromatograph for measurement of the concentration of greenhouse gases in the soil solutions. The method for measuring the rice field greenhouse gases has the advantages of simple operation and accurate measurement results.

Owner:YANGZHOU UNIV

Electric heating thermos flask

The invention discloses an electric heating thermos flask, which comprises a flask shell, a liner, a flask cover, an electric heating element and a base, wherein the lower end of the flask shell is fixed on the base; the lower end of the liner is provided with an open annular catching groove; the lowest end of the liner below the open annular catching groove is provided with a flange which rolls inwards; the flange and the open annular catching groove can play a role of fixing the heating element; and an elastic gasket is arranged between the electric heating element and the liner to prevent water from immersing the electric heating element. The electric heating thermos flask has the following advantages: 1) the electric heating element is buckled at the bottom of the flask liner for providing convenience for disassembling and cleaning to avoid the phenomenon of rust for the electric heating element after long-term use; 2) hot water cannot be splashed so as no to hurt people when the electric heating thermos flask is tilted accidentally; 3) the flask cover is provided with two symmetrical water outlets; and when the flask cover is rotated to either water outlet symmetrical with a water outlet nozzle, water flows out, so the electric heating thermos flask is quite convenient to use; and 4) a push-pull water locking valve switch is adopted and is not easy to damage after long-term use.

Owner:陆国郁

Processing and preserving technology of trichosanthes seeds

InactiveCN101611735AGuaranteed anti-corrosion performanceIsolation highSeed preservation by coatingWarm waterDissolution

The invention discloses a processing and preserving technology of trichosanthes seeds, comprising the following steps: 1) proportioning materials, wherein, the raw materials comprises flavoring, flour and potassium sorbate; and the flavoring consists of sodium cyclamate, fresh milk flavoured powder, vanillin, sugar, edible salt, salt and pepper seasoning; 2) dissolving all raw materials in warm water and then fully stirring for dissolution, putting the dissolved liquid into a vacuum flask for standby; 3) frying the trichosanthes seeds; 4) putting the well-fried trichosanthes seeds and the dissolved raw materials into a container to mix quickly and completely; 5) pouring out the well-mixed trichosanthes seeds to dry; and 6) utilizing airtight plastic bags to seal and encapsulate the dried trichosanthes seeds into small packets in different specifications and encapsulating deoxidant synchronously. Because a first line of defense comprising flour paste and potassium sorbate and a second line of defense formed by putting a certain proportion of deoxidant in a package of the trichosanthes seeds are adopted, the corrosion prevention and preservation of the trichosanthes seeds are effectively guaranteed.

Owner:长兴乐田栝楼开发有限公司

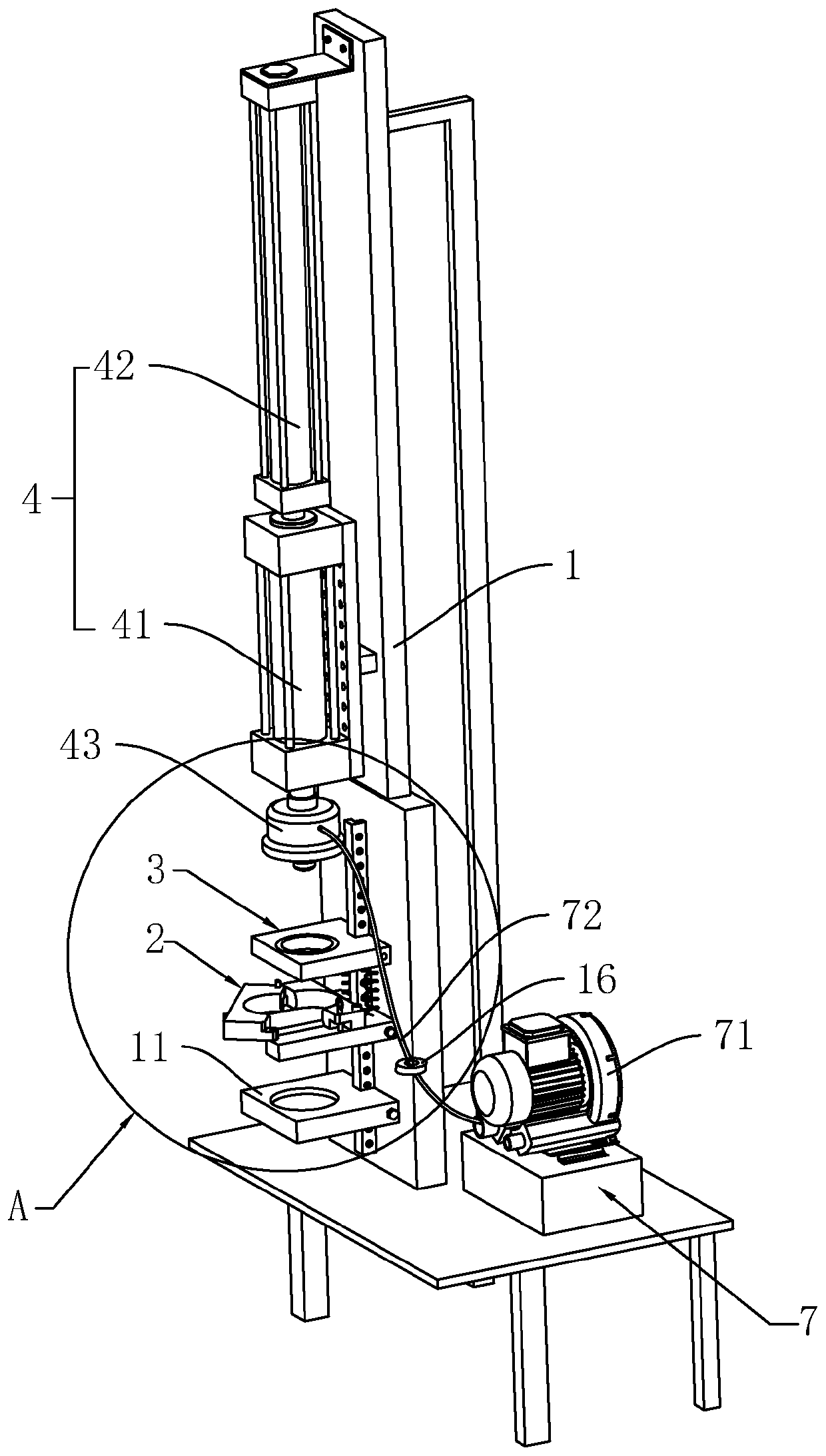

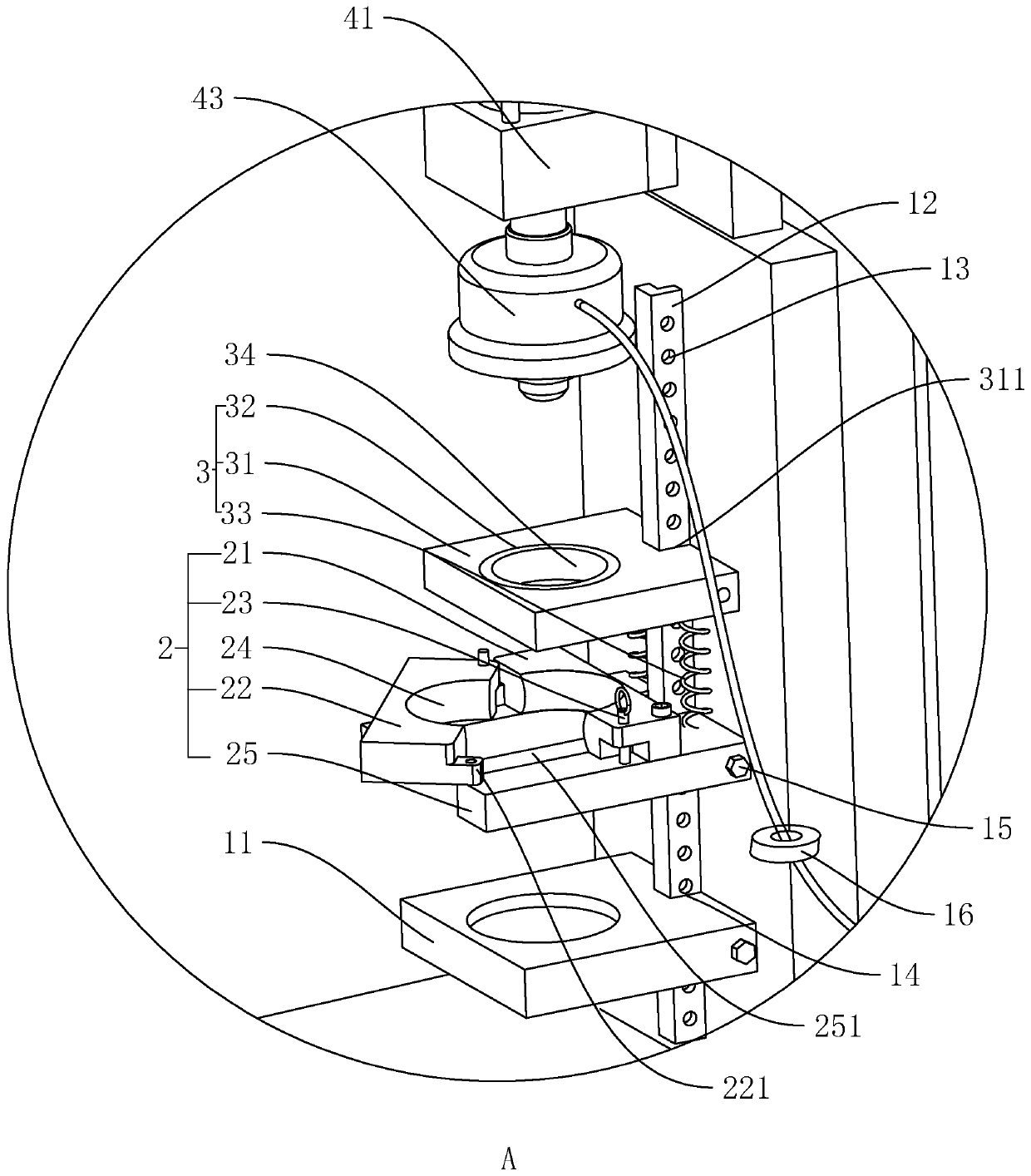

Convenient efficient thermos bottle assembling machine

The invention relates to a convenient efficient thermos bottle assembling machine. The thermos bottle assembling machine comprises a support, wherein the support is sequentially provided with a placing plate for placing an outer bottle, a fixing assembly for transversely fixing the side wall of the outer bottle, a positioning assembly for transversely fixing the side wall of an inner bottle, and apressing assembly for pressing the inner bottle body into the outer bottle from bottom to top; the positioning assembly comprises a horizontally arranged positioning plate and a positioning hole vertically formed in the positioning plate, and the inner bottle is vertically arranged in the positioning hole and abuts against the top of the outer bottle; and the positioning plate is vertically and slidably connected to the support, a spring is vertically fixed on the fixing assembly, and the top of the spring is fixedly connected to the lower side of the positioning plate. When the inner bottleand the outer bottle are assembled, a worker places the outer bottle vertically on the placing plate, and the outer bottle is vertically positioned at the corresponding position through the fixing assembly. At this time, the worker vertically penetrates the outer bottle into the positioning hole, and the bottom of the outer bottle abuts against the top of the outer bottle. At this time, the workerpresses the inner bottle downwards through the pressing assembly, so that the inner bottle is pressed downwards into the outer bottle.

Owner:欧科塑胶制品(深圳)有限公司

An automatic cleaner for vacuum flask inner container limescale

InactiveCN106606065AReduce quality problemsEfficient removalKitchenware cleanersBrush bodiesEngineeringMicro motor

The invention provides an automatic cleaner for vacuum flask inner container limescale. The automatic cleaner comprises a handle and a guide rod support connected with the handle. A sleeve is arranged on the outer side of the guide rod support in a sliding manner and the lower end of the guide rod support is provided with rocker supports; connecting rod supports are arranged on the two sides of the sleeve; a hair head brush is arranged at one end of each rocker support; micro-motors are installed in the rocker supports and close to the hair head brushes; the upper end of the guide rod support is provided with the handle; the tail of the handle is provided with a battery groove in which batteries is installed; a switch is arranged in the middle of the handle and a lead connects the battery and the micro-motors after penetrating the inside of the handle, the guide rod support and the rocker supports; the switch in the middle of the handle control on / off of the micro-motors. The mass of the automatic cleaner for vacuum flask inner container limescale is reduced; the automatic cleaner can enter and be taken out of a vacuum flask via an inner container opening conveniently; softened limescale on the wall of an inner container of a vacuum flask can be removed rapidly with high efficiency.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com