Vacuum flask

A vacuum bottle and bottle body technology, which is applied in vacuum/special atmosphere packaging, liquid distribution, packaging objects under special gas conditions, etc., can solve the problems of complex structure and high production cost, and achieve simple operation, low production cost, Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

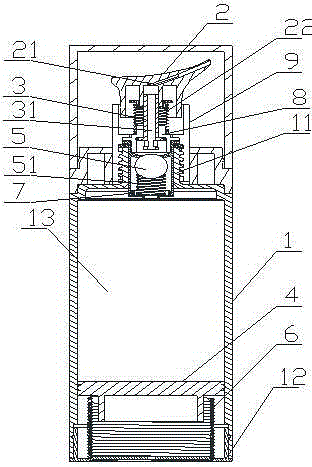

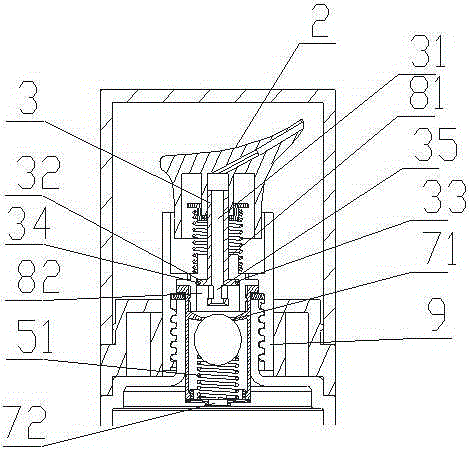

[0017] As shown in the figure, the vacuum bottle includes a bottle body 1 with a cavity 13, a spray head 2 with a first cavity 21 inside, a transmission rod 3 with a second cavity 31 inside, and a piston 4; the upper part of the bottle body is set There is an opening, and the opening is elastically provided with a valve block 5 to block the opening; the spray head can be connected to the upper end of the bottle body in a reciprocating manner along the axial direction of the bottle body, and the transmission rod 3 is connected to the lower end of the spray head. Specifically, the transmission rod 3 can be used to Plug in the end of the first cavity or connect the transmission rod to the lower end of the nozzle so that the second cavity communicates with the first cavity, and the lower end of the transmission rod is opposite to the valve block, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com