Thermos flask welding machine

A technology for welding machines and thermos bottles, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy welding through workpieces, troublesome operation, easy loosening of the outer cylinder, etc., and achieve stable welding quality, Avoid loosening and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

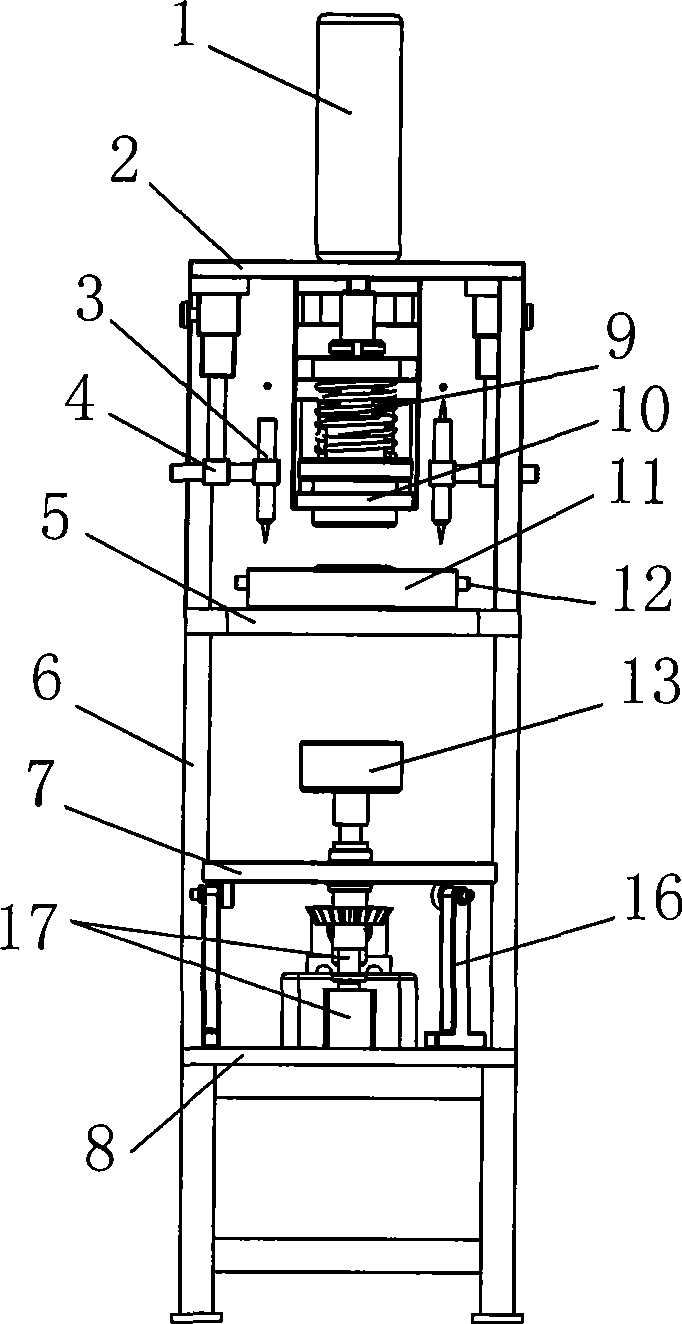

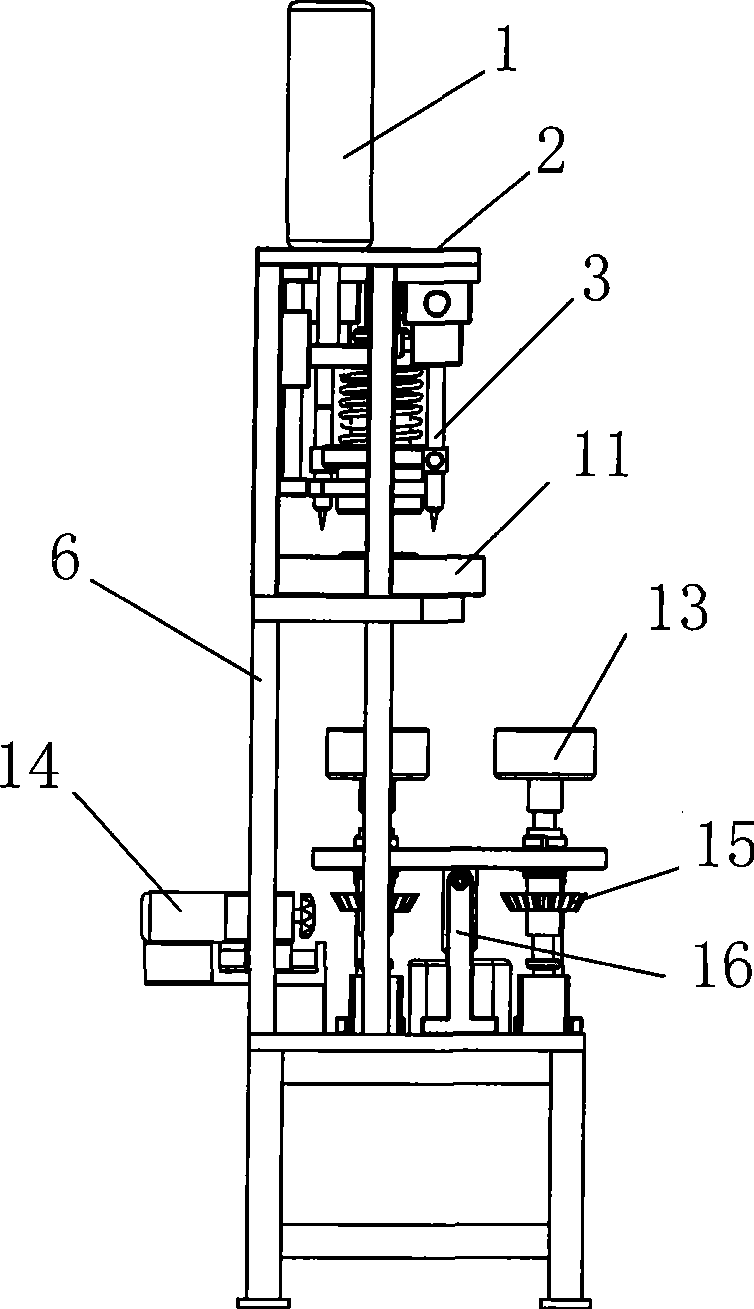

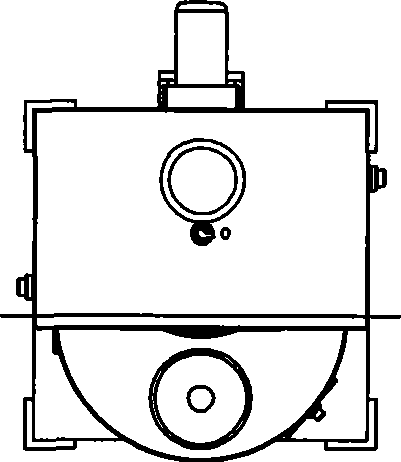

[0017] according to figure 1 , 2 , 3, the vacuum flask welding machine, the structure includes a frame 6, a driving mechanism, a workpiece rotation mechanism 15, a positioning bottom cover adsorption combination mechanism 10, a cooling water circulation system 12, and a double welding machine; the frame 6 is up, down, middle Each position is provided with upper, middle and lower panels 2, 5, 8, the driving mechanism on the lower panel 8 is connected to the workpiece positioning seat 13 through the workpiece rotating mechanism 15 and the workpiece positioning turntable 7, and the workpiece positioning seat 13 is connected under the workpiece rotating mechanism 15. Connect the workpiece top mechanism 17 with the adjustment cylinder; the middle panel 5 above the workpiece positioning seat 13 is provided with a rotating copper pole 11 and a cooling water circulation system 12; the upper panel 2 above the rotating copper pole 11 is provided with A positioning bottom cover adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com