Double-layer vacuum-type electric heating water boiling thermos bottle

A double-layer vacuum and thermos technology, which is applied to water-boiling utensils, non-pressure containers, lids of cooking utensils, etc., can solve the problems of large energy waste, inconvenient use, and high shell temperature, and achieve good thermal insulation effect and energy waste. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

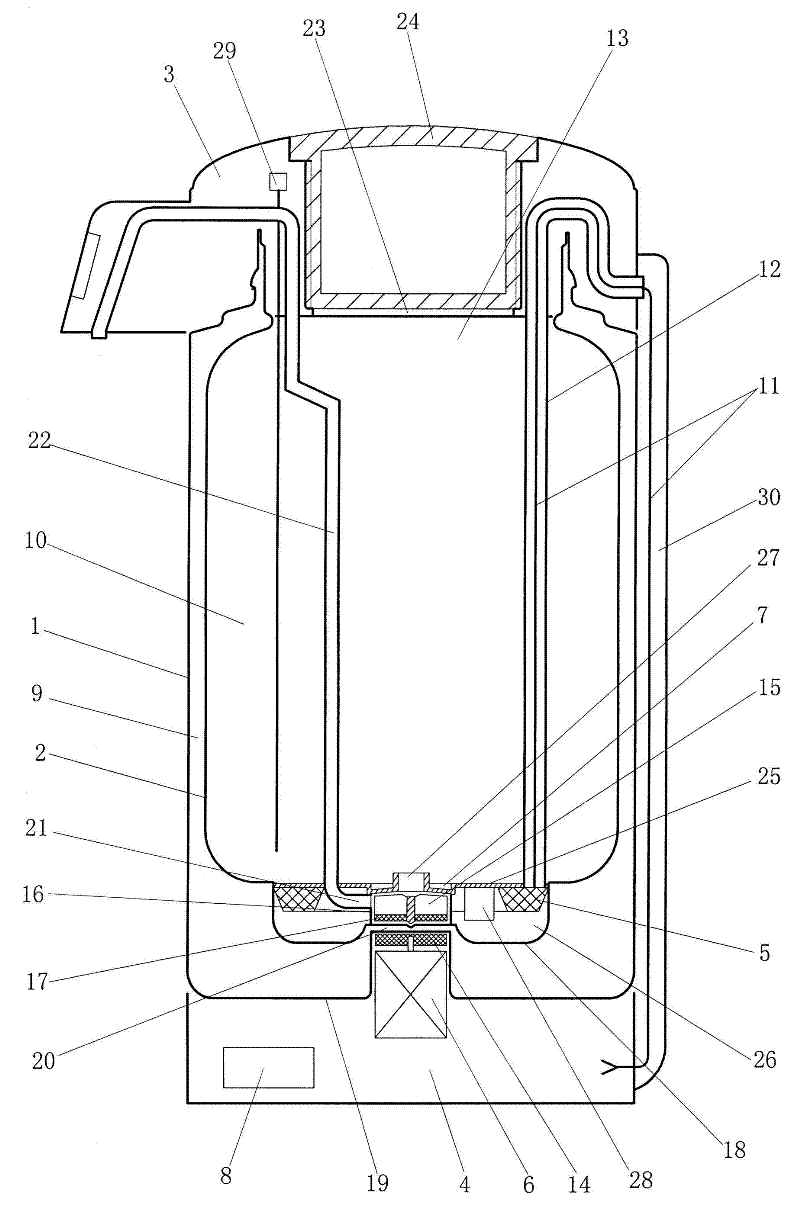

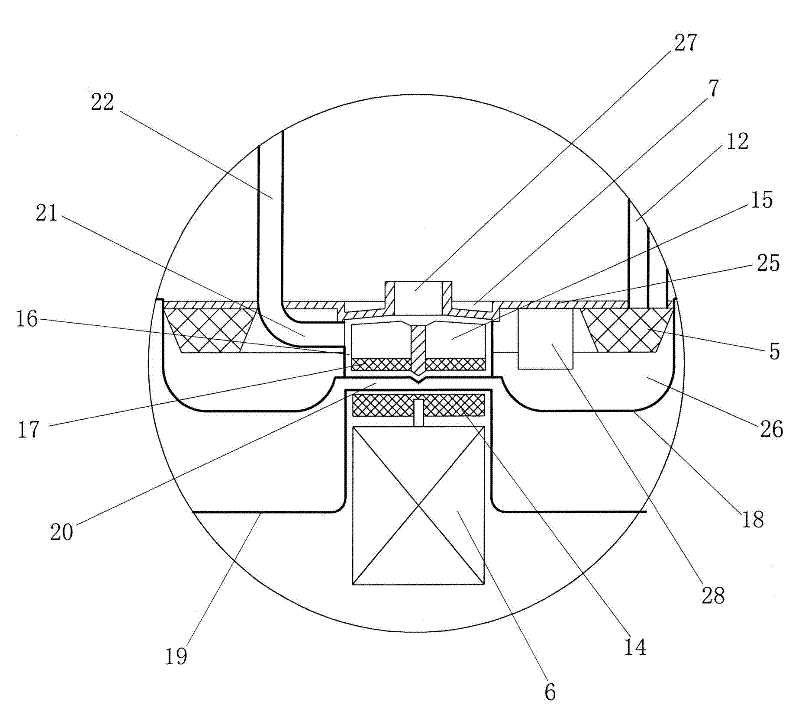

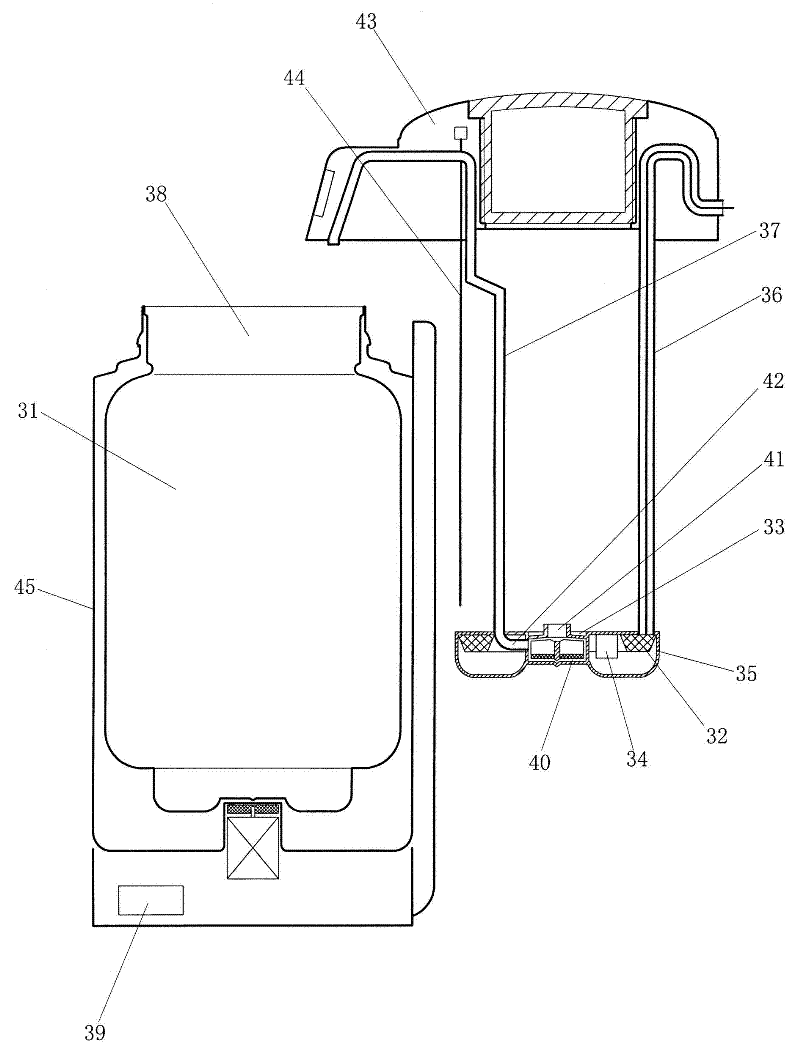

[0021] refer to Figure 1 ~ Figure 2 , the double-layer vacuum electric heating thermos bottle, including shell 1, liner 2, bottle top cover 3, bottle foot 4, electric heater 5, electric pump (including motor 6 and pump body 7), control circuit 8, wherein a vacuum insulation layer 9 is formed between the shell 1 and the liner 2, the electric heater 5 is arranged on the inner bottom of the liner cavity 10, the bottle top cover 4 is installed on the top of the shell 1 and the liner 2, the bottle The foot base 4 is installed at the bottom of the shell 1, and the control circuit 8 is installed in the bottle foot base 4. It is characterized in that: the power wire 11 of the electric heater 5 is drawn out from the upper mouth 13 of the inner tank by the wire tube 12 in the inner tank cavity 10, The electric pump is divided into two parts, the motor 6 and the pump body 7. The motor 6 is installed and fixed in the bottle base 4. A magnetic turntable 14 is installed and fixed on the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com