Liquid heating device, electric vacuum flask and dry burning preventing control method thereof

The technology of a heating device and a control method is applied in the field of liquid heating device and anti-dry burning control, which can solve the problems of troublesome operation, inability to extract and drain water, and inability to automatically discharge water, and achieve the effect of preventing dry burning and preventing the phenomenon of dry burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

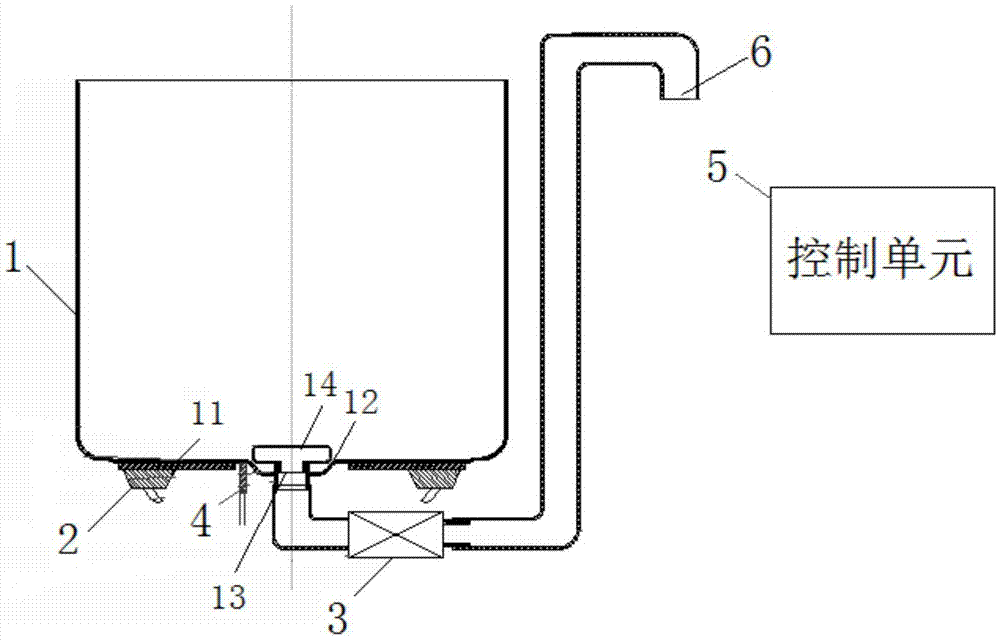

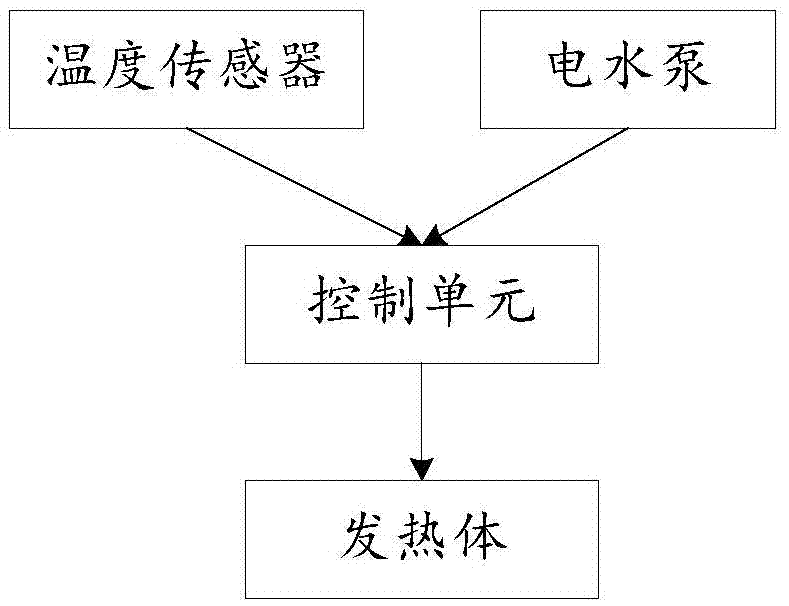

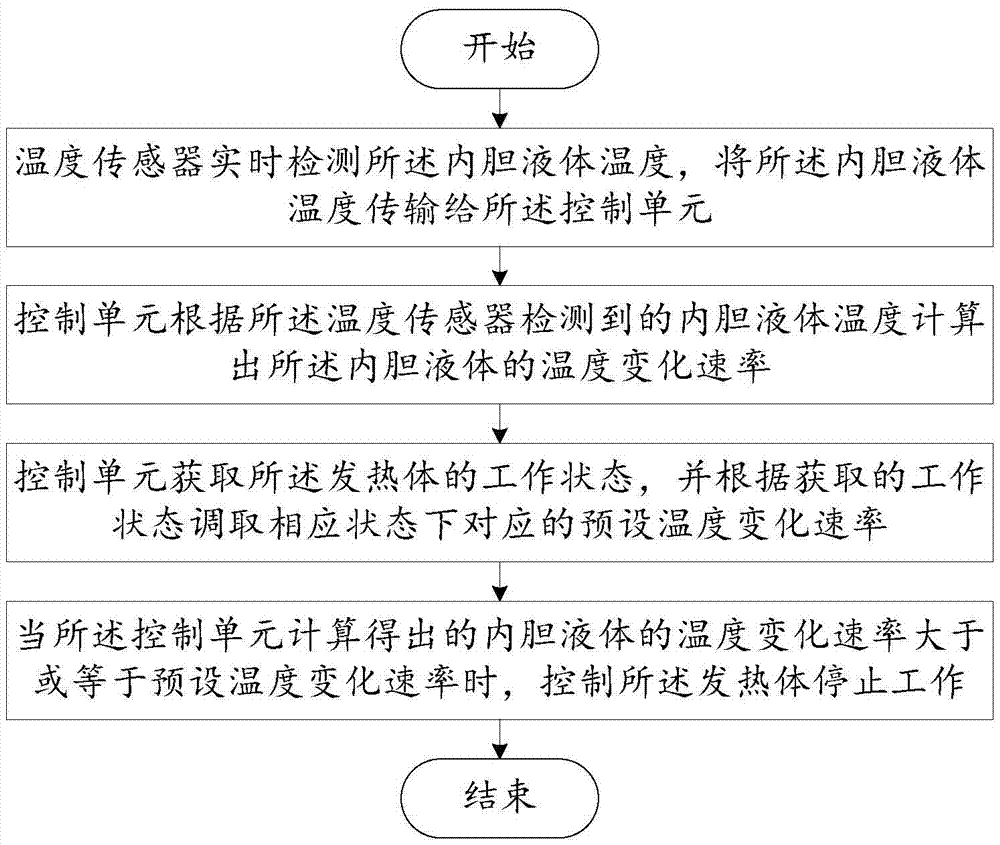

[0040] Example 1, such as figure 1 , 2 As shown, a liquid heating device includes an inner tank 1, a heating element 2, an electric water pump 3, a temperature sensor 4 and a control unit 5. The bottom of the inner tank 1 is a bottom surface 11 of the inner tank, and the bottom disc The surface 11 is provided with the lowest surface 12 of the inner container bottom plate whose height is lower than the surface 11 of the inner container bottom plate, the lowest surface 12 of the inner container bottom plate is excessively connected with the curved surface 11 of the inner container bottom plate surface, and the inner container The lowest surface 12 of the bottom plate is provided with an inner tank drain port 13, the inner tank drain port 13 is lower than the inner tank bottom surface, the inner tank drain port 13 is connected to the electric water pump 3 through a drain pipe, and the electric water pump 3 is drained The pipe is connected to the outlet 6 of the liquid heating de...

Embodiment 2

[0044] Embodiment 2, on the basis of Embodiment 1, the control unit is used to preferentially detect whether the electric water pump is started, if it is started, control the heating element to stop working, and if the electric water pump stops working, control the heating body Return to the state before the start of the electric water pump. Prioritize checking whether the electric water pump is working. If the electric water pump is working, control the heating element not to work. This effectively solves the problem that when the electric water pump is pumping water, the heating element heats up at the same time and generates air bubbles to block the electric water pump, resulting in poor water discharge or low water volume in the inner tank when pumping water. Dry burning occurs when the water level reaches a low level.

Embodiment 3

[0045] Embodiment 3. On the basis of Embodiment 2, the liquid heating device further includes a control panel, and the control panel includes a child lock key or a safety lock key. When the control unit detects that the electric water pump is started, it first detects the child lock key or safety lock key. The state of the lock key, when it is in the unlocked state, controls the heating element to stop working, controls the electric water pump to start, and the liquid heating device discharges water; when the child lock key or safety lock key is locked, the water output function is locked, the electric water pump stops working, and the heating element is controlled Return to the state before the start of the electric water pump. The control panel is equipped with a child lock key or a safety lock key, which can effectively ensure the safety of the product. Before using the electric water pump to pump water, you need to press the child lock key or safety lock key to unlock it. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com