Patents

Literature

63results about How to "Timely discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

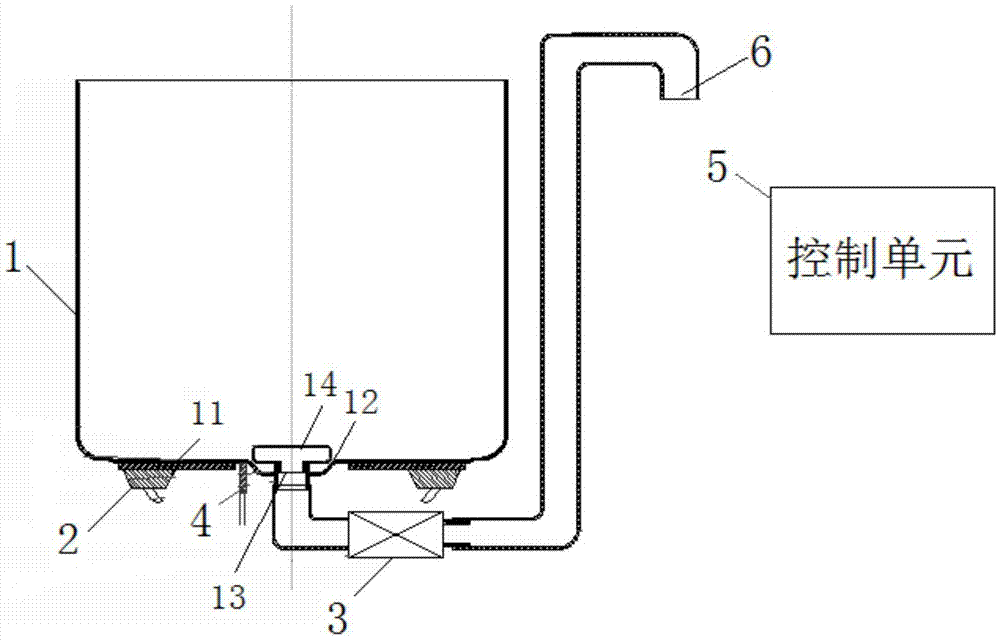

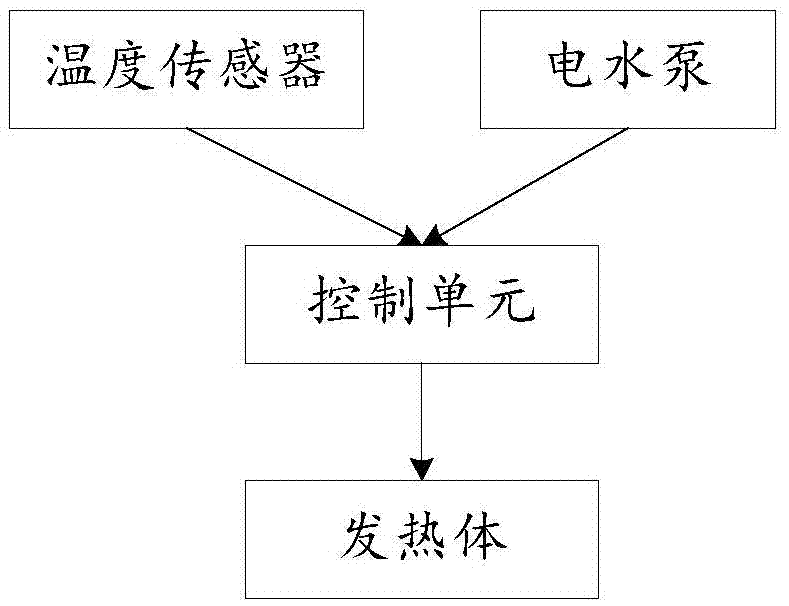

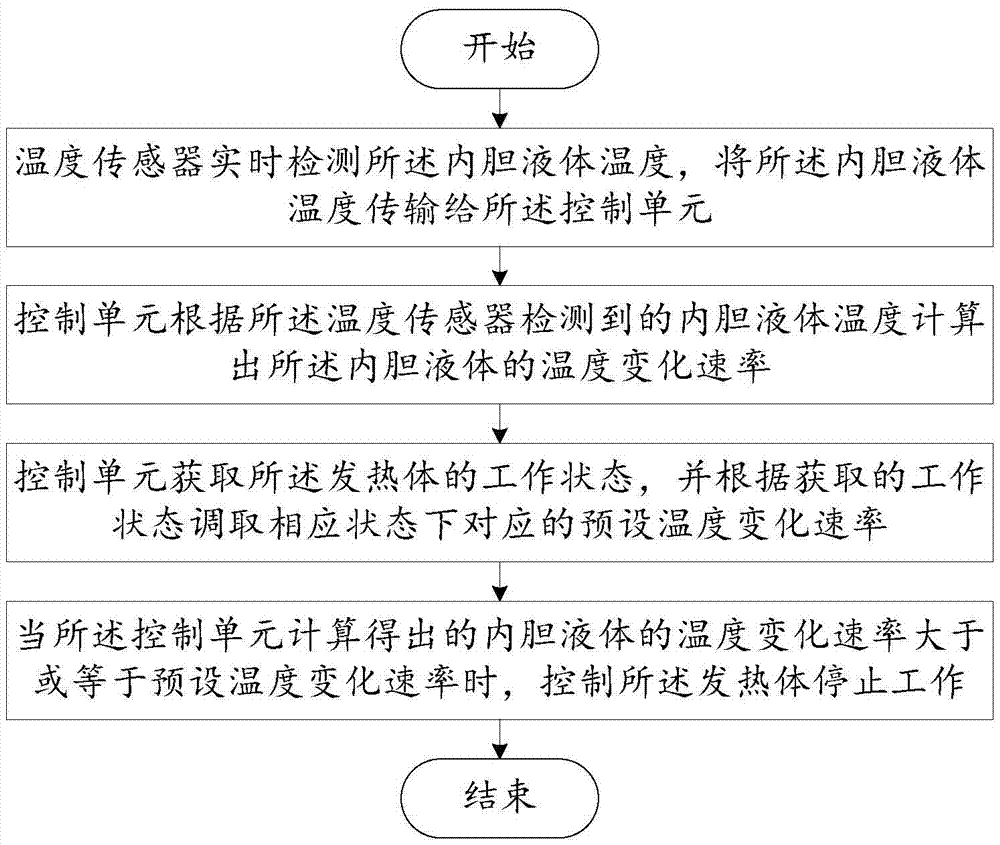

Liquid heating device, electric vacuum flask and dry burning preventing control method thereof

ActiveCN107157316APrevent dry burningGuarantee the safety of useWater-boiling vesselsElectricityStopped work

The invention relates to a dry burning preventing control method of a liquid heating device. The method comprises the following steps: detecting temperature of liquid in a liner in real time by virtue of a temperature sensor; then, transmitting the detected temperature of the liquid in the liner to a control unit; calculating a change rate of the temperature of the liquid in the liner by virtue of the control unit in accordance with the temperature, which is detected by the temperature sensor, of the liquid in the liner; acquiring a working condition of a heating body by virtue of the control unit, and calling a corresponding preset temperature change rate under a corresponding state in accordance with the acquired working condition; and controlling the heating body to stop working when the change rate, which is calculated by the control unit, of the temperature of the liquid in the liner is greater than or equal to the preset temperature change rate. With the application of the dry burning preventing control method provided by the invention, a dry burning phenomenon of the liquid heating device under various states can be effectively prevented. The invention also provides the liquid heating device and an electric vacuum flask.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

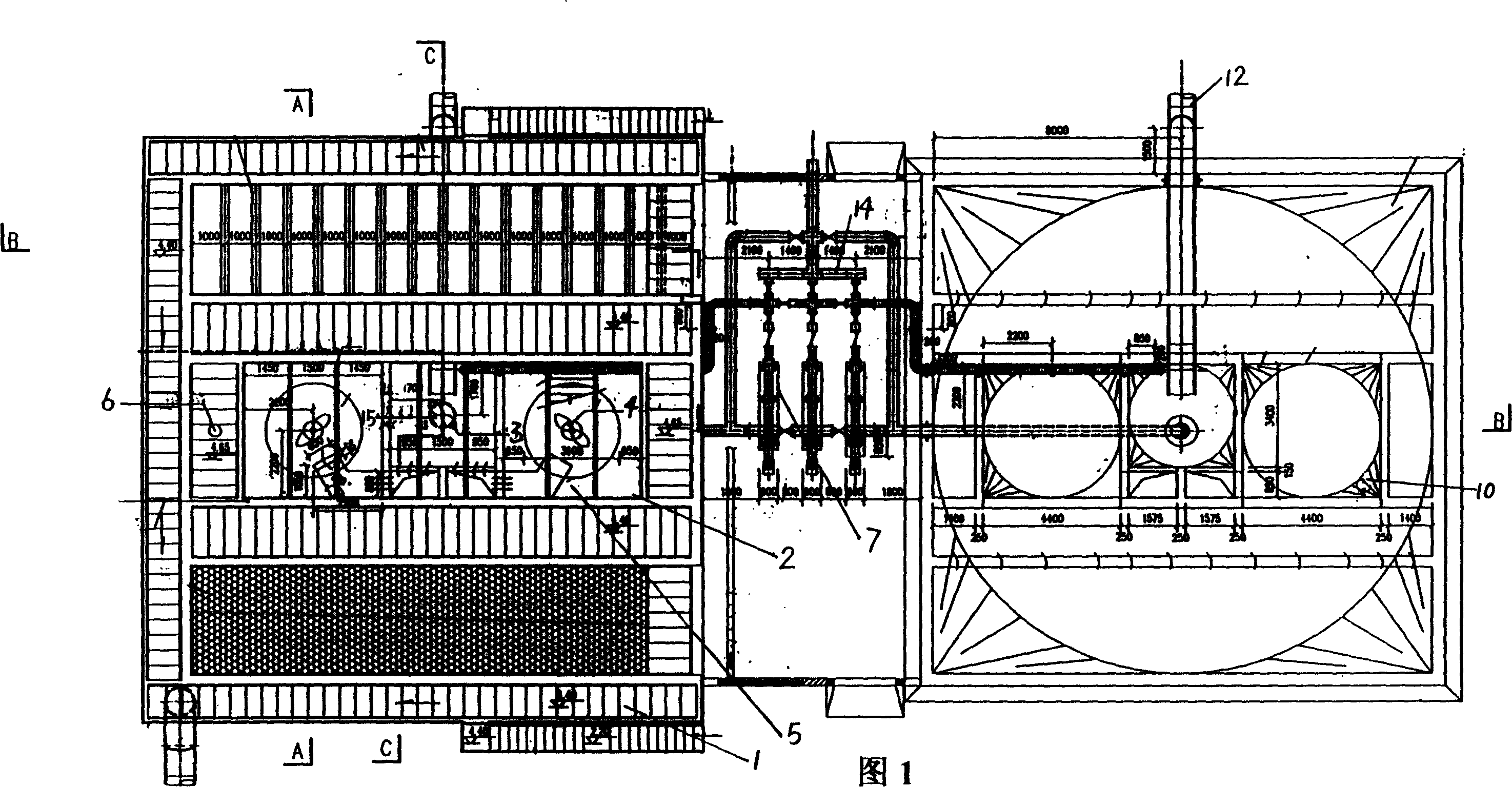

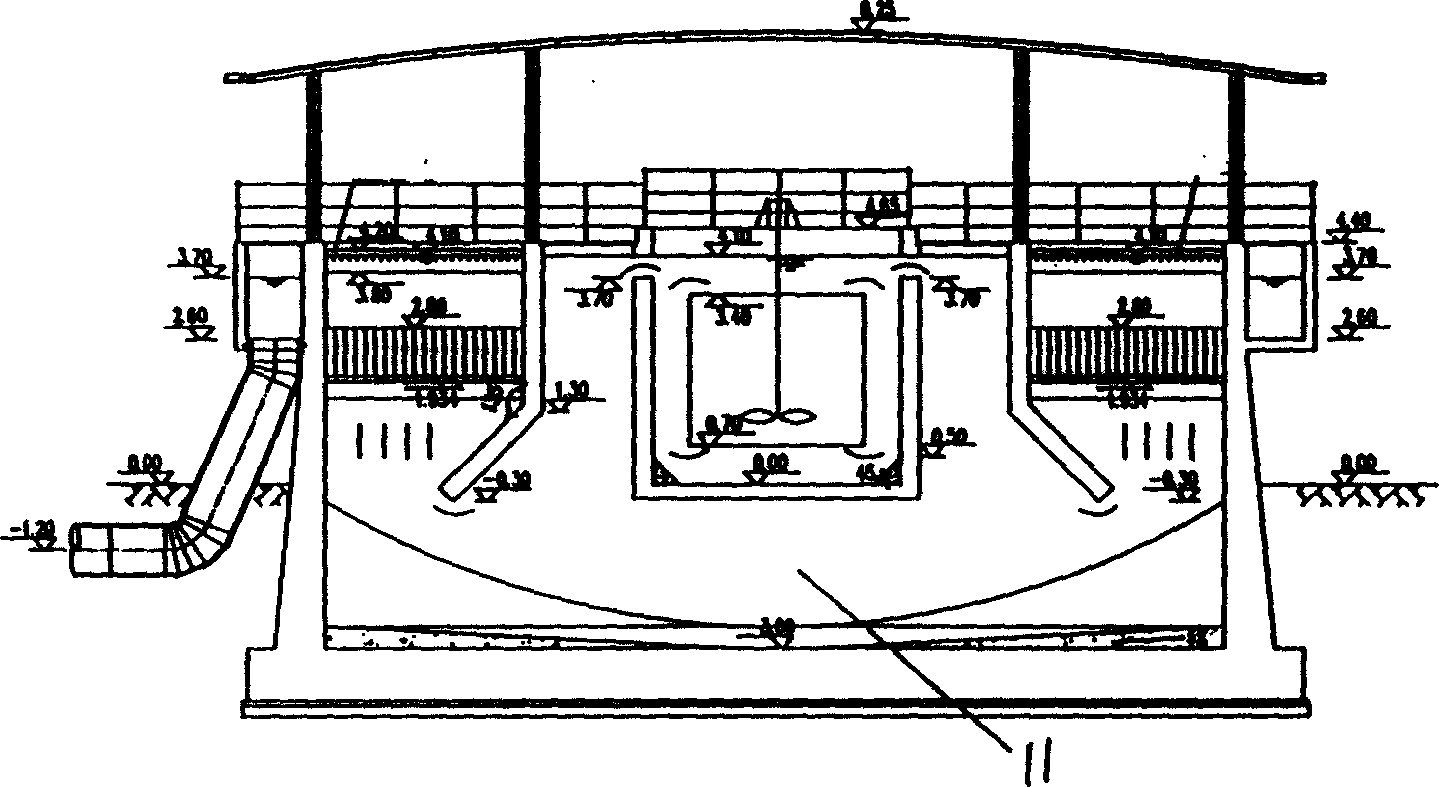

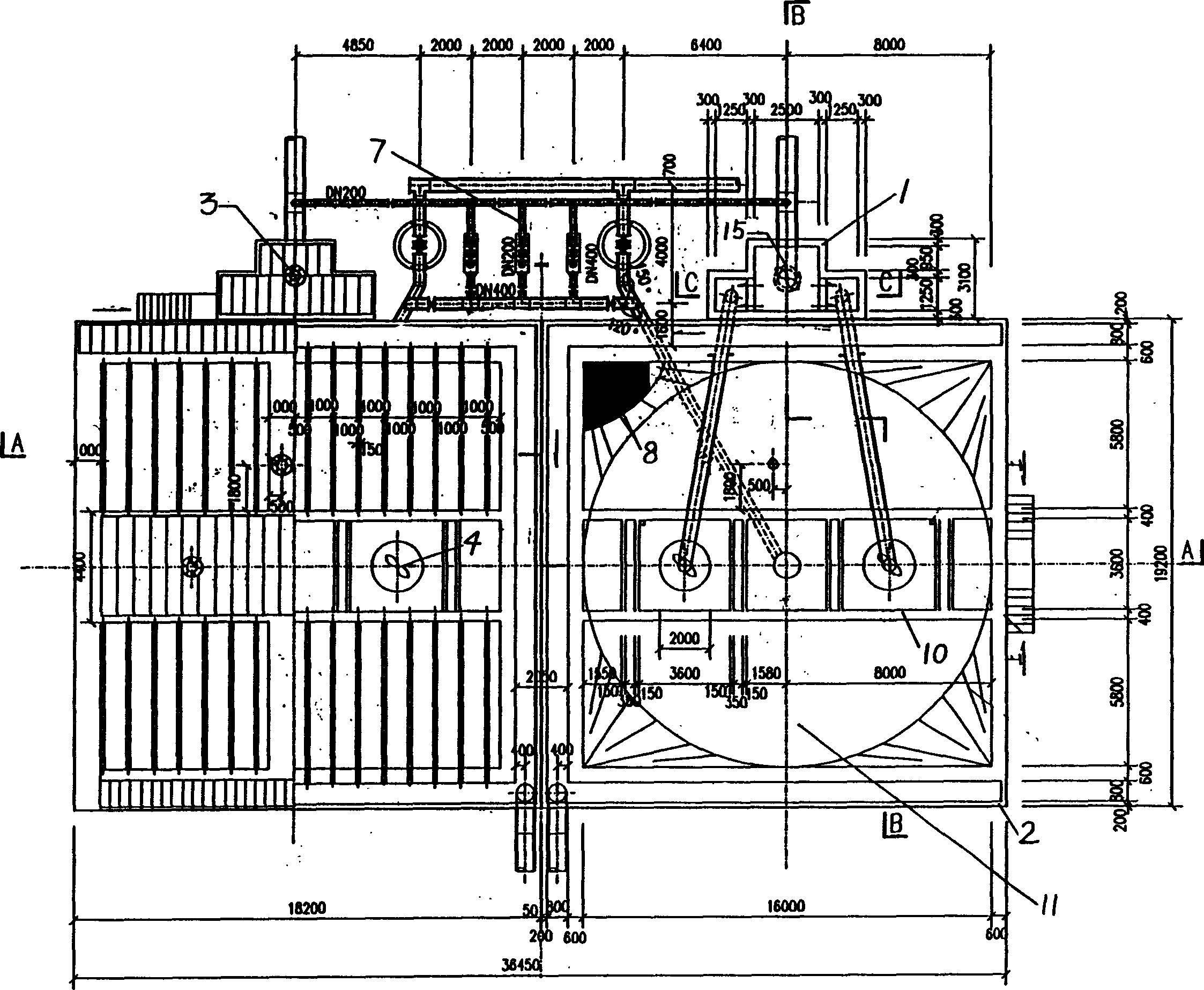

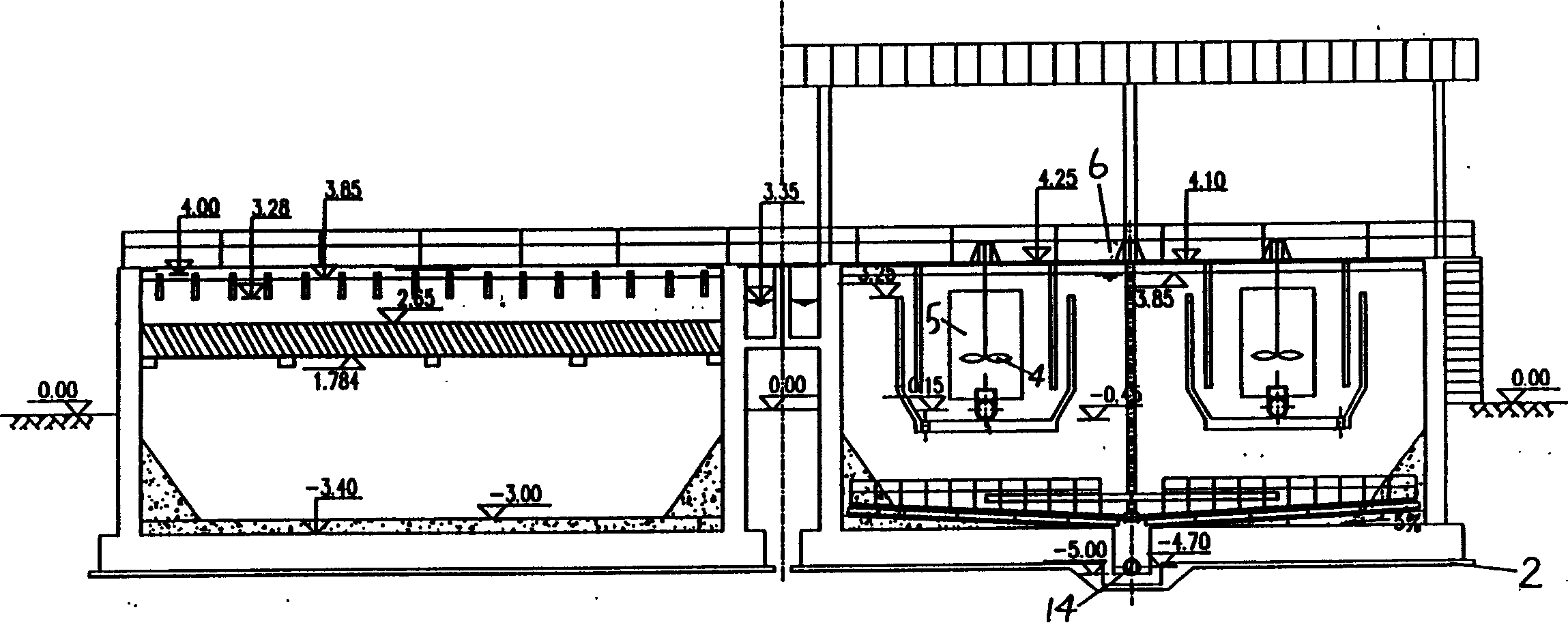

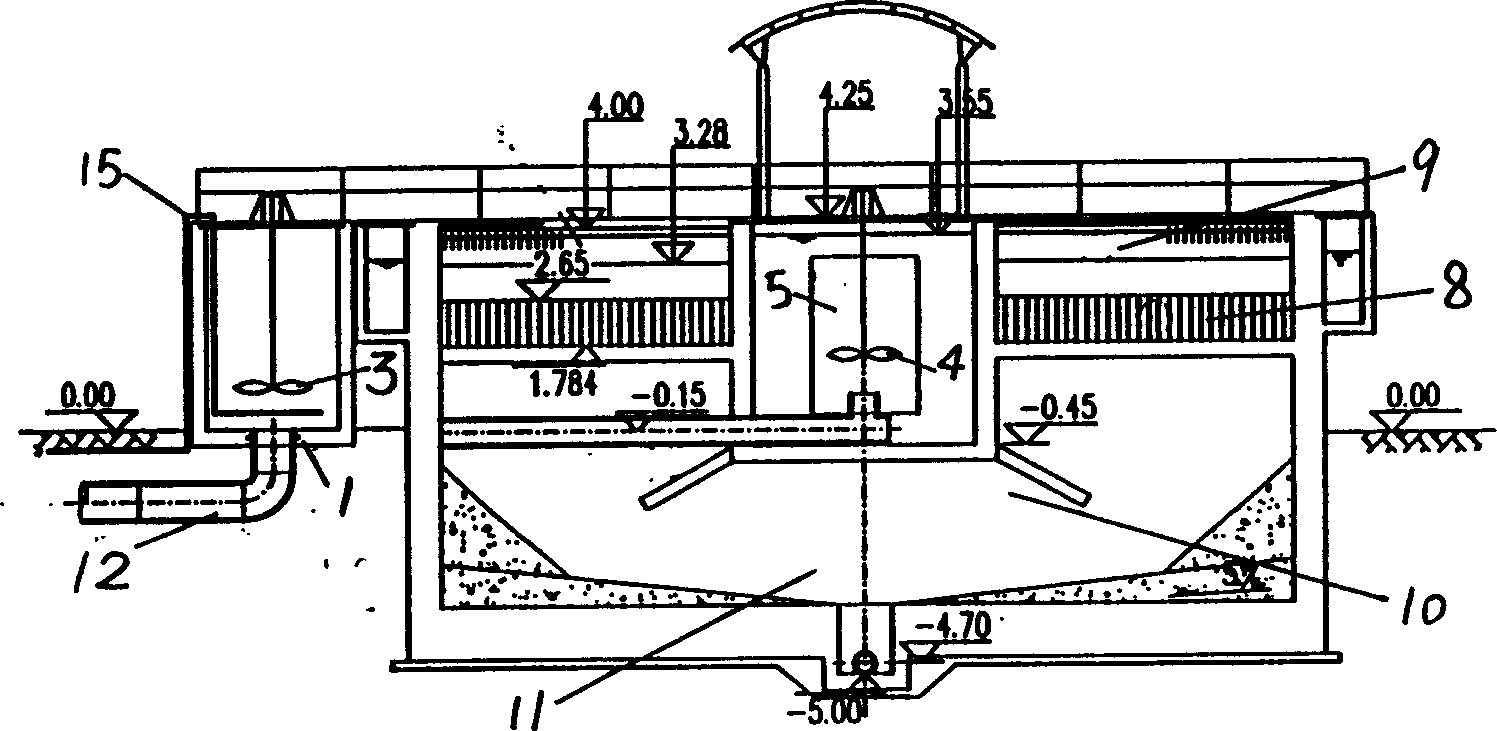

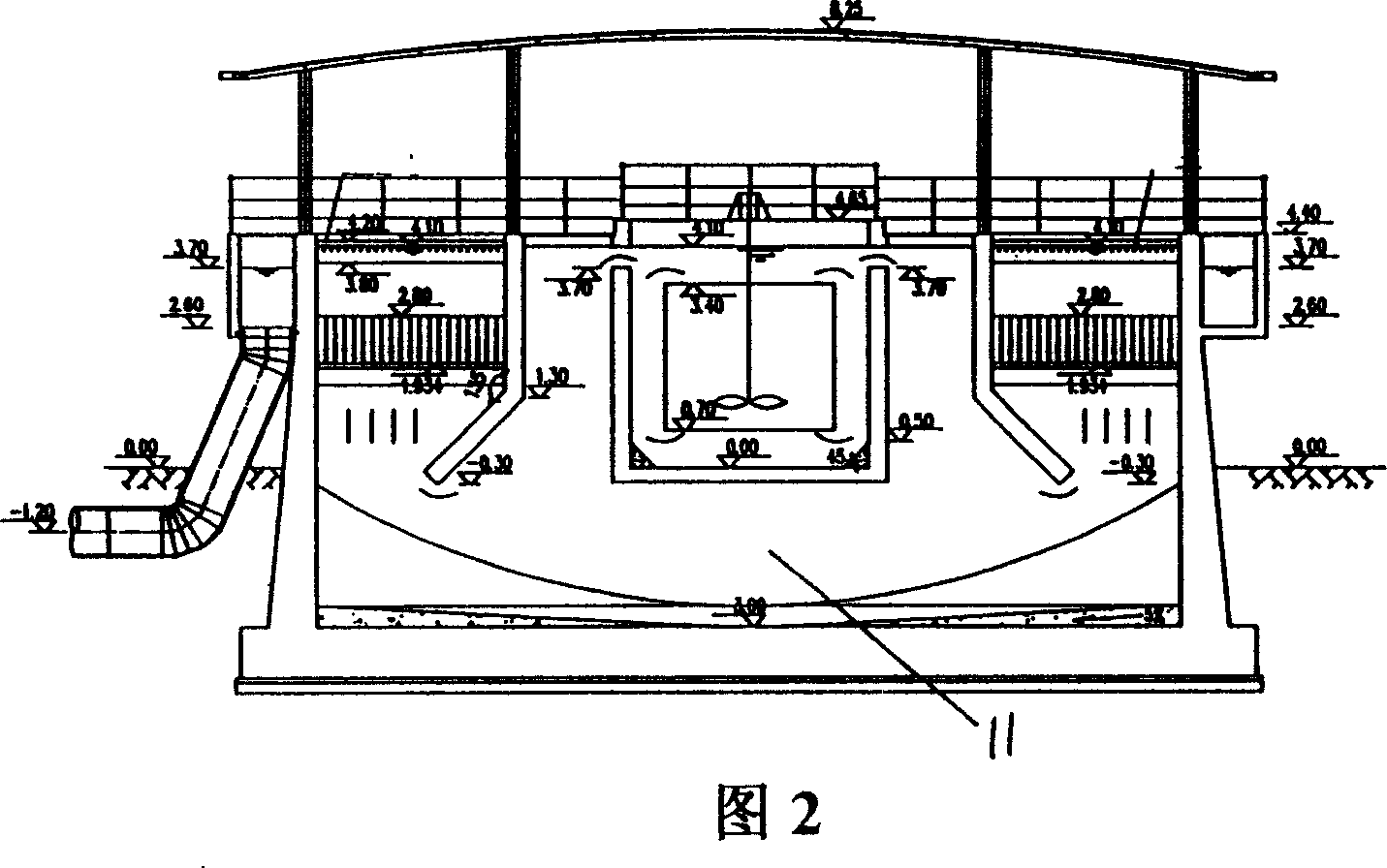

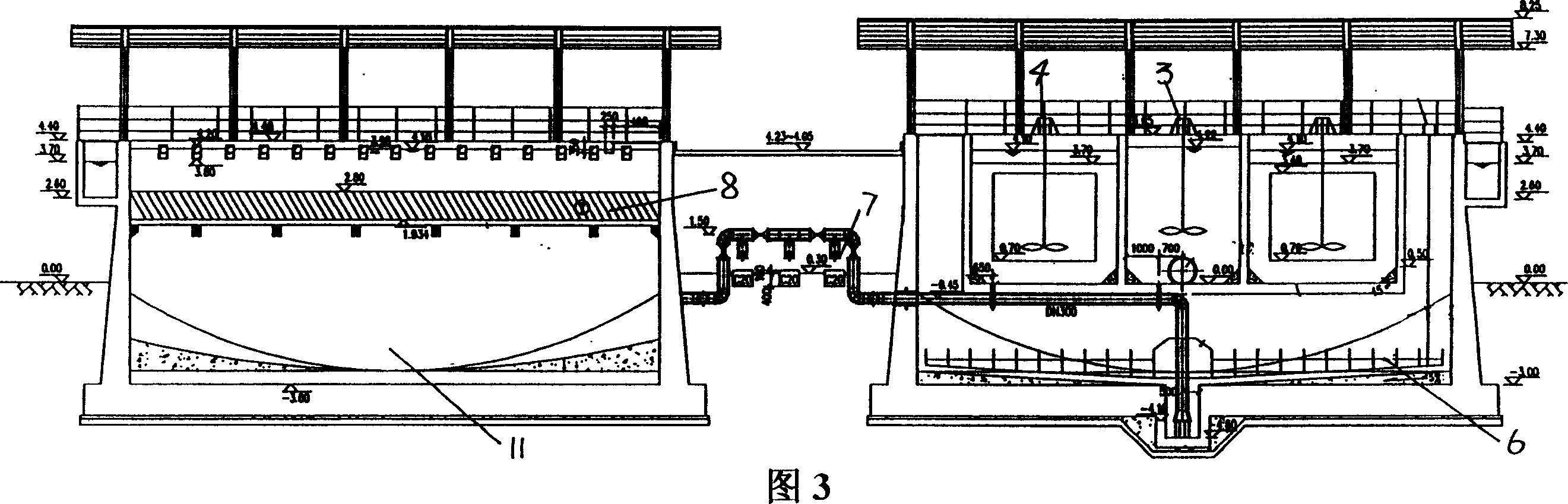

Full Chinese type settling pond

The settling pond features that all the mixing stirrer, the raising stirrer and its stainless steel barrel, the mud scraper, the inclined plastic pipe area and the rectangular water outlet stainless steel tank are located inside the main pond; the sludge pipe communicates the sludge screw pump, the water inlet pipe and the concentrating sludge draining area in the lower part of the main pond; and the chemical adding pipe is set below the mixing stirrer. The present invention has reasonable structure and homogeneous water distribution. The raising stirrer and the sludge screw pump are connected with the frequency varying motor for flexible regulation based on the practical condition to ensure the water effluent quality. The mud scraper can centralize and concentrate sludge. The present invention is suitable for use in water works and sewage yard.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

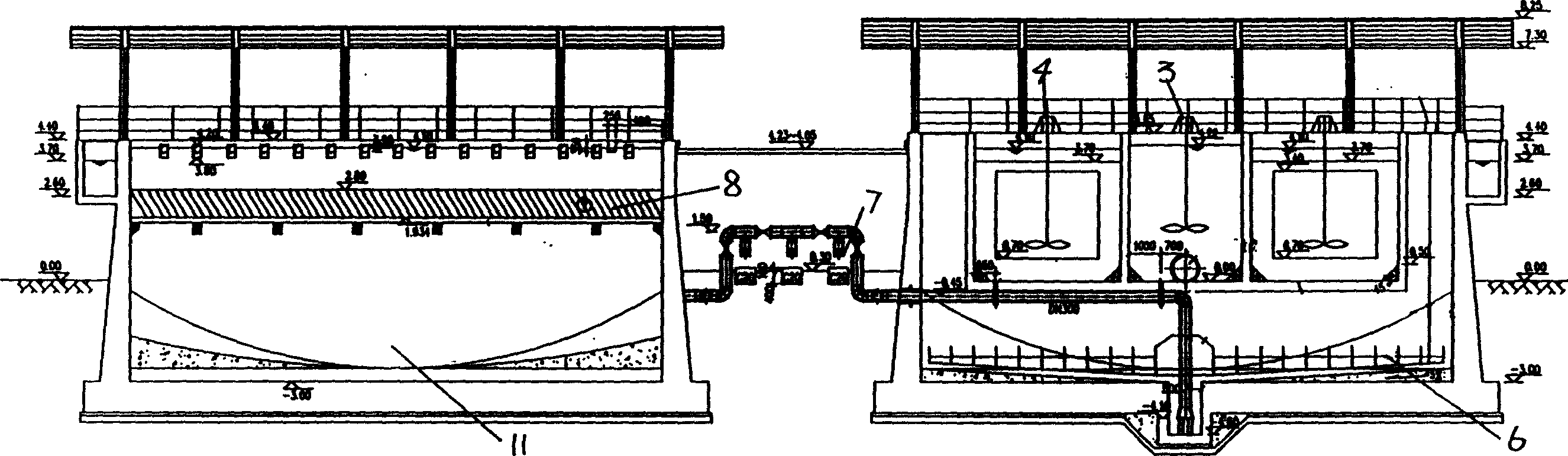

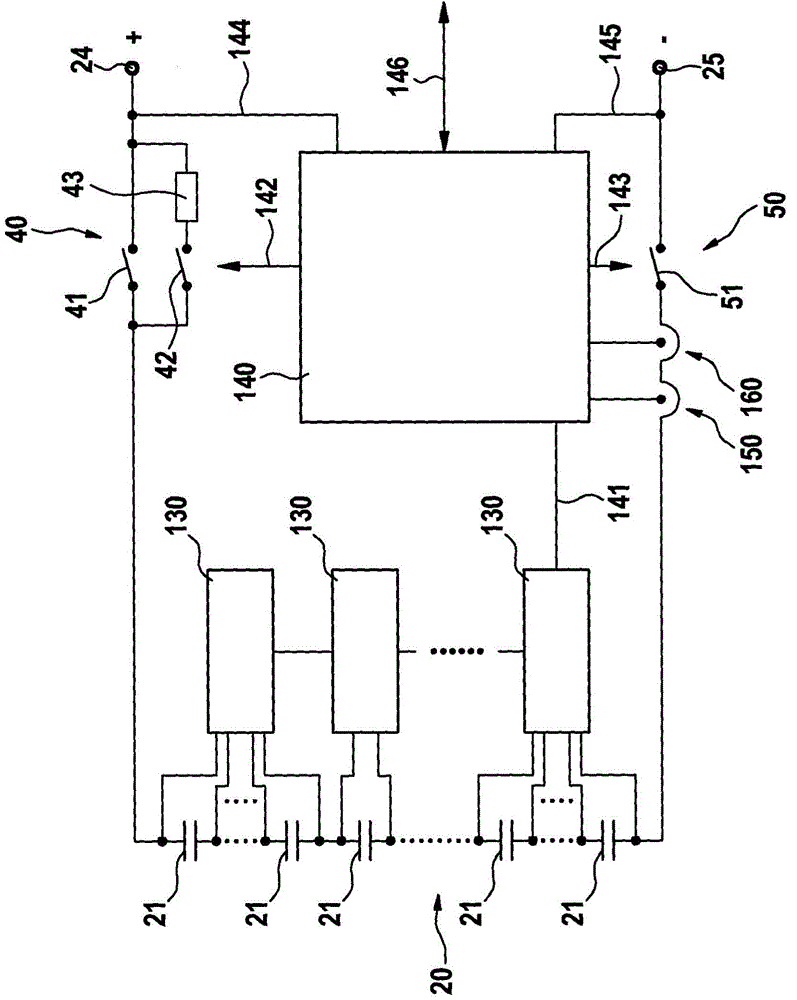

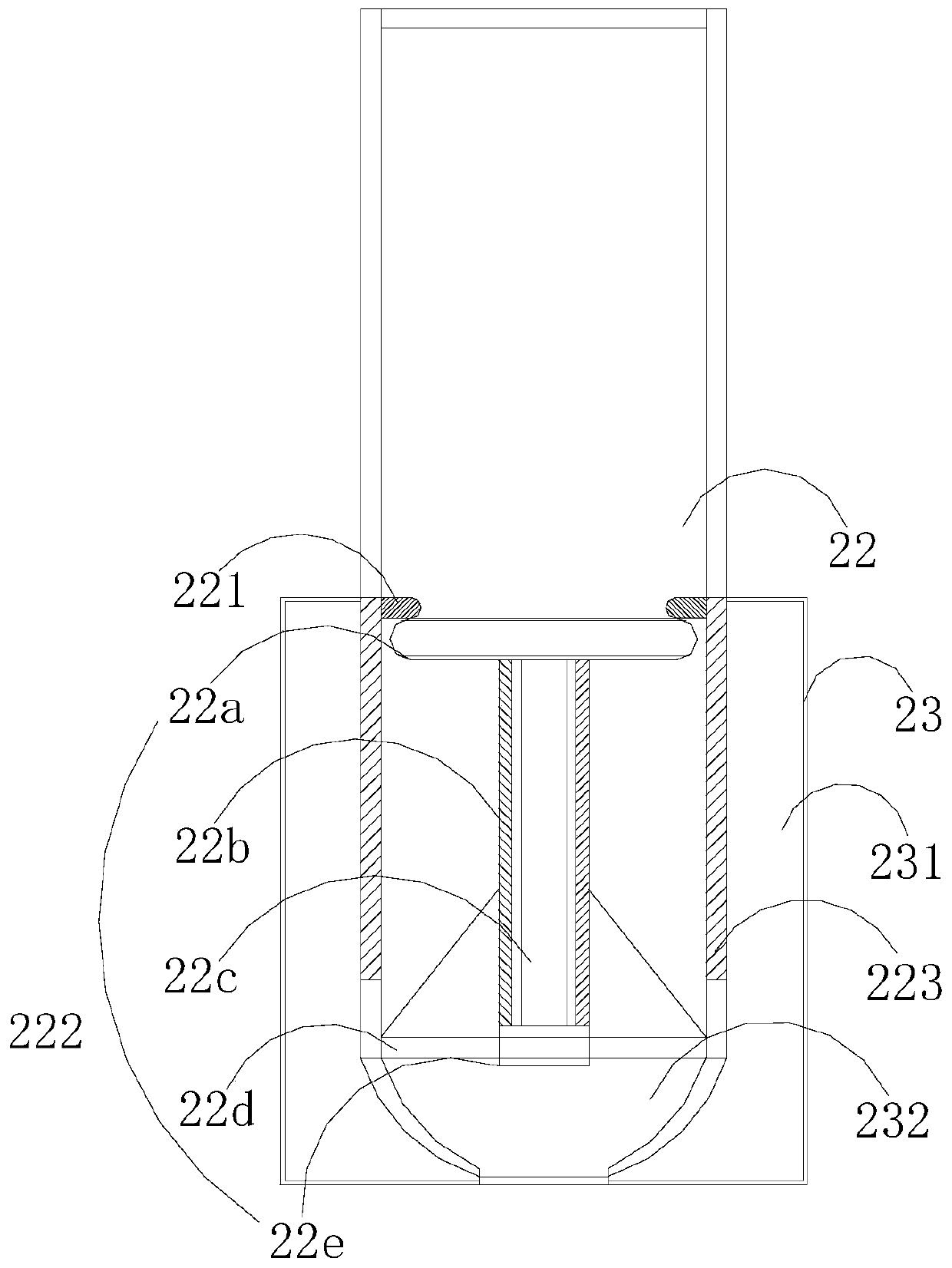

Battery module and method for monitoring battery module

InactiveCN104052102AAchieve dischargeTimely dischargeBatteries circuit arrangementsElectric devicesMonitoring and controlBattery cell

The invention discloses a battery module (221). The battery module (221) has a battery cell circuitry (226) that is provided with several battery cells (21), and a monitoring and control unit (230) which is used for monitoring the functional state of the battery module (221). The battery module (221) comprises a couple unit and a discharge circuit (270). The couple unit is connected with power semiconductors (241,242) in half bridge arrangement, for coupling the battery cell circuitry (226) to output terminals (224,225). The discharge circuit (270) is coupled with the battery cell circuitry, for enabling the fast discharge of the battery module. The couple unit and the discharge circuit are controlled by the monitoring and control unit (230).

Owner:ROBERT BOSCH GMBH +1

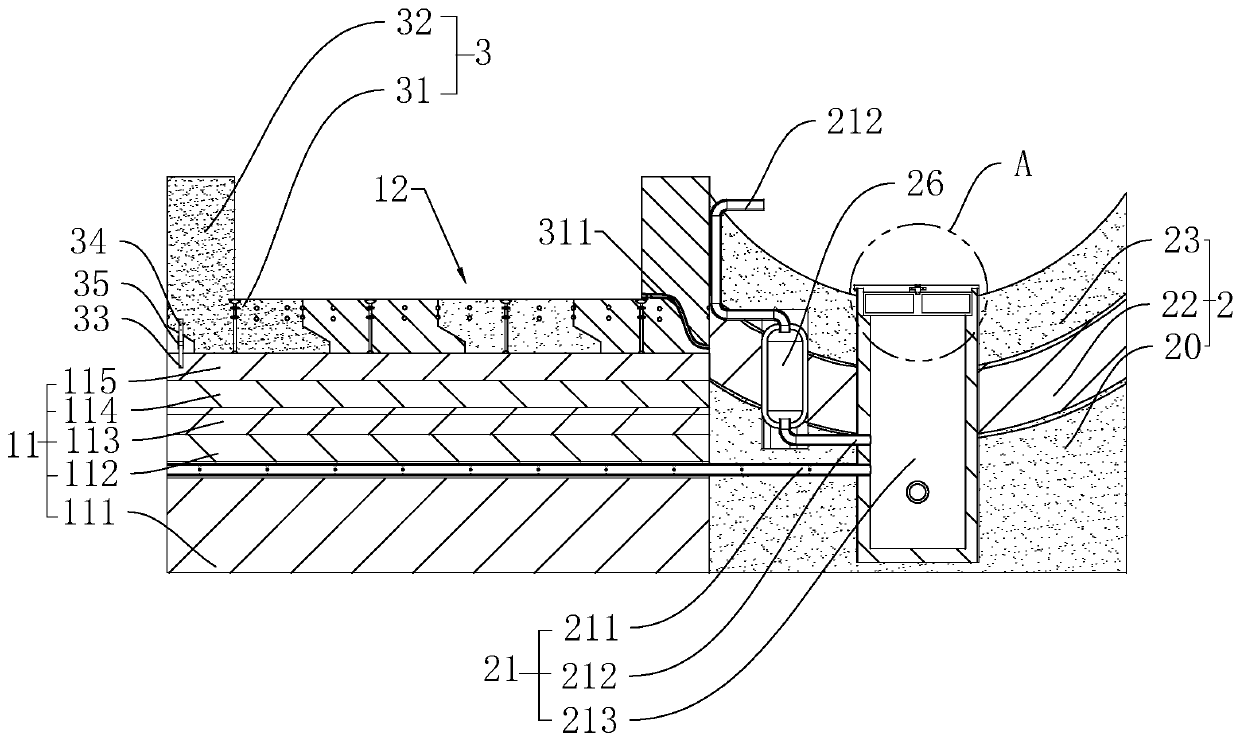

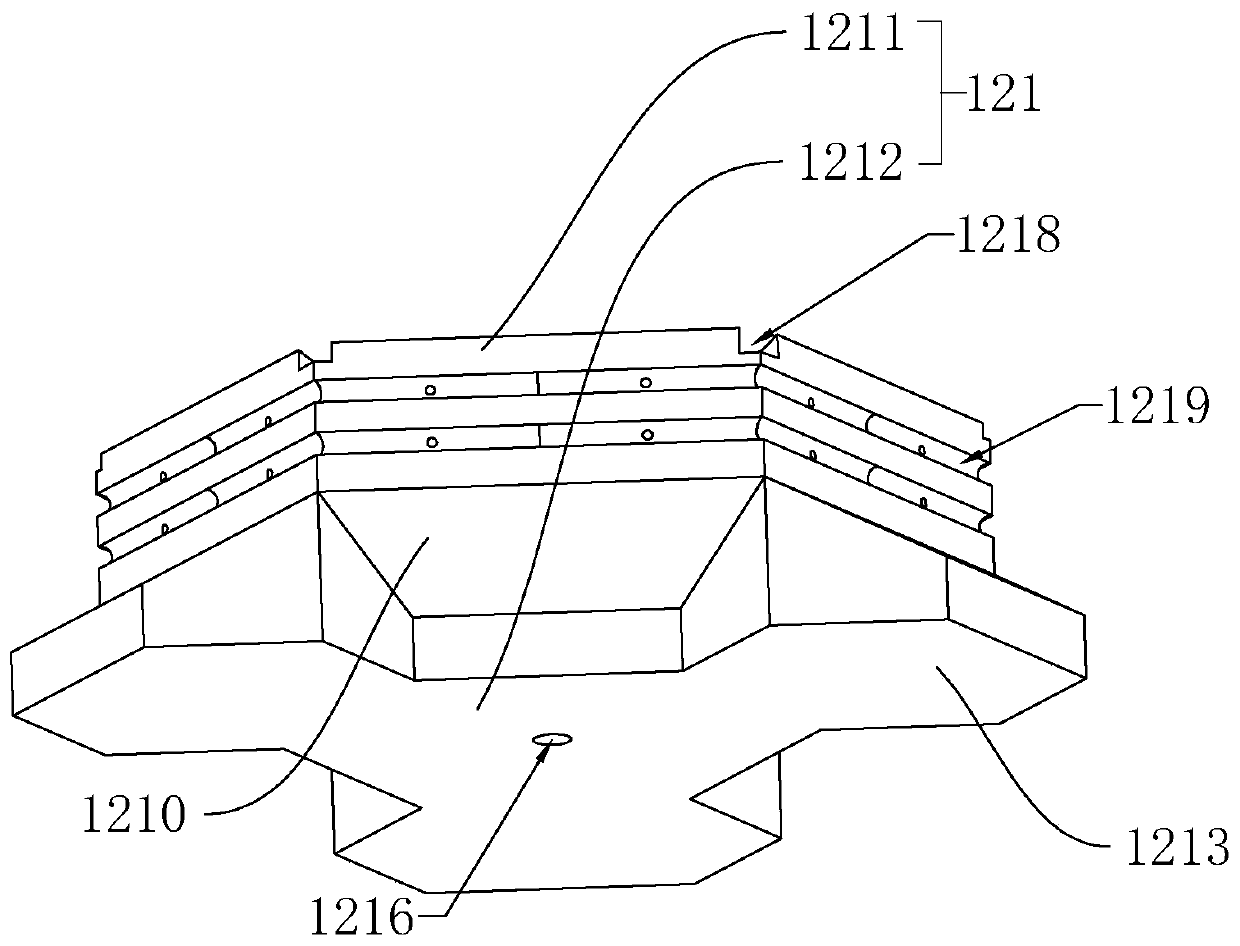

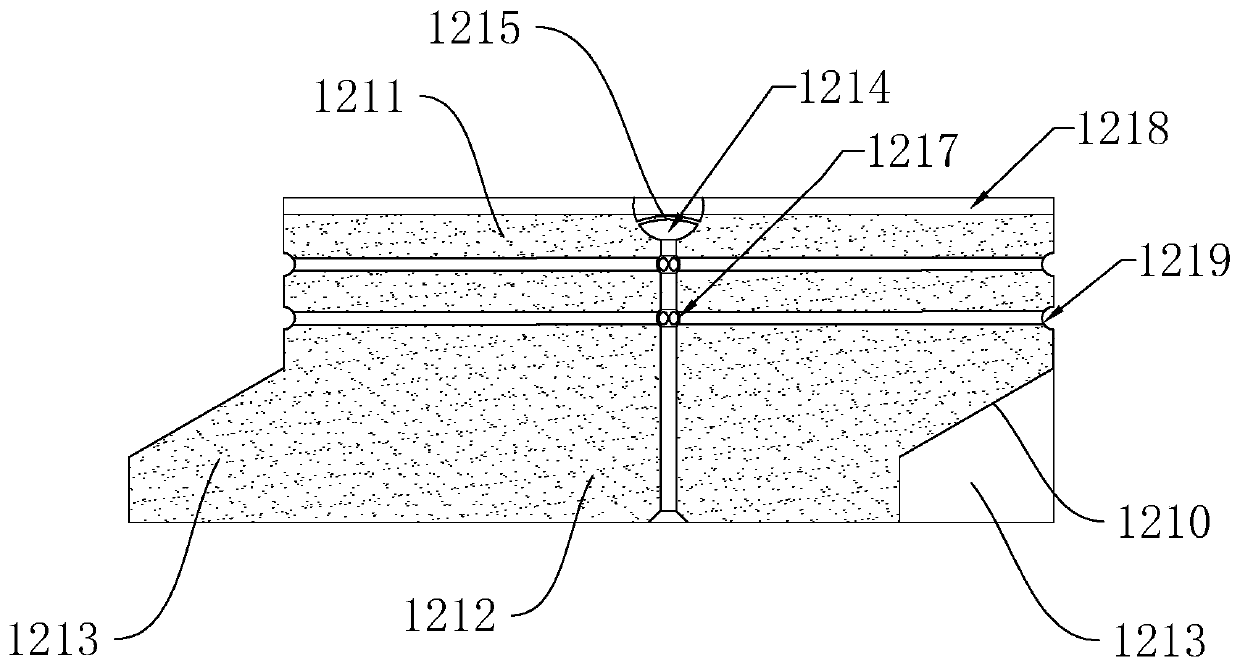

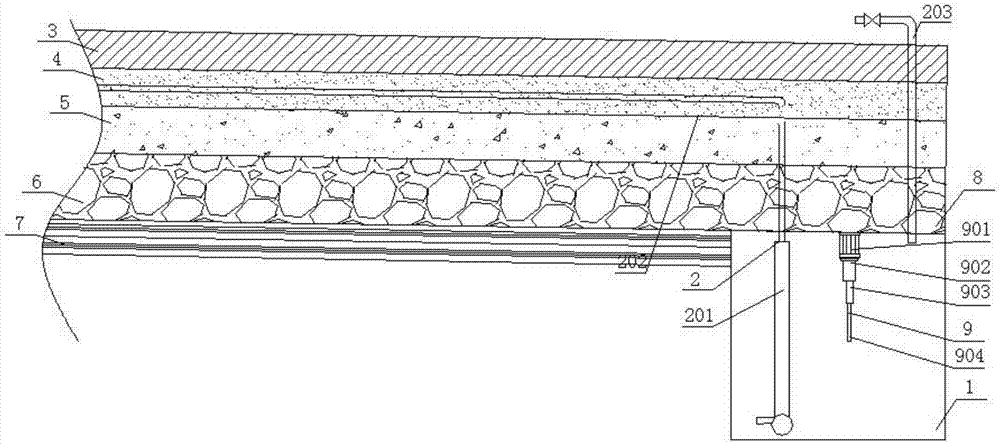

Sponge city permeable road and construction process thereof

ActiveCN111560812AFit tightlyImprove stabilitySewerage structuresSingle unit pavingsWater storageBrick

The invention relates to a sponge city permeable road comprising a road body and a grass planting ditch. Road shoulders are arranged on the two sides of the road body. A water storage structure is arranged in the grass planting ditch. The road body comprises a permeable roadbed and a pavement layer; the pavement layer comprises a plurality of road bricks; and each road brick comprises a cushion block I and a cushion block II which have hexagonal prism structures. The regular hexagonal prism structure of the cushion block I is larger than that of the cushion block II; three cushion blocks III with hexagonal prism structures are arranged around the cushion block II; two diagonal edges of each cushion block III are overlapped with two adjacent hexagonal edges of the cushion block I; the othertwo adjacent edges of the third cushion block coincide with the adjacent edges of the cushion block II, the cushion block III is away from the cushion block II and faces the edge of the cushion blockI in a chamfered mode, an inclined face is formed on the transition edge of the cushion block I and the transition edge of the cushion block II, and the inclined face is located between the two adjacent cushion blocks III and an annular groove I deviating from the opening of the central axis is formed in the cushion block I in an encircling mode. The drainage effect is relatively good; meanwhile,the possibility that water splashes to pedestrians can be effectively reduced.

Owner:重庆天地人建设集团有限公司

Middle arranged sedimentation tank

ActiveCN1669945AEven distribution of waterWell mixedWater/sewage treatment by flocculation/precipitationSedimentation settling tanksSiphonSludge

The invention discloses a built-in desilter, which is characterized in that lifting the agitator and its appendixes in the body tank such as a non-corrodible steel body, a sludge scraper, the plastic inclined tube area and a non-corrodible steel water outlet rectangular channel, arranging the mixing agitator in the mixture tank out of the body tank, connecting the sludge screw pump with incurrent siphon and concentrated sludge discharge area using a sludge pipe.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

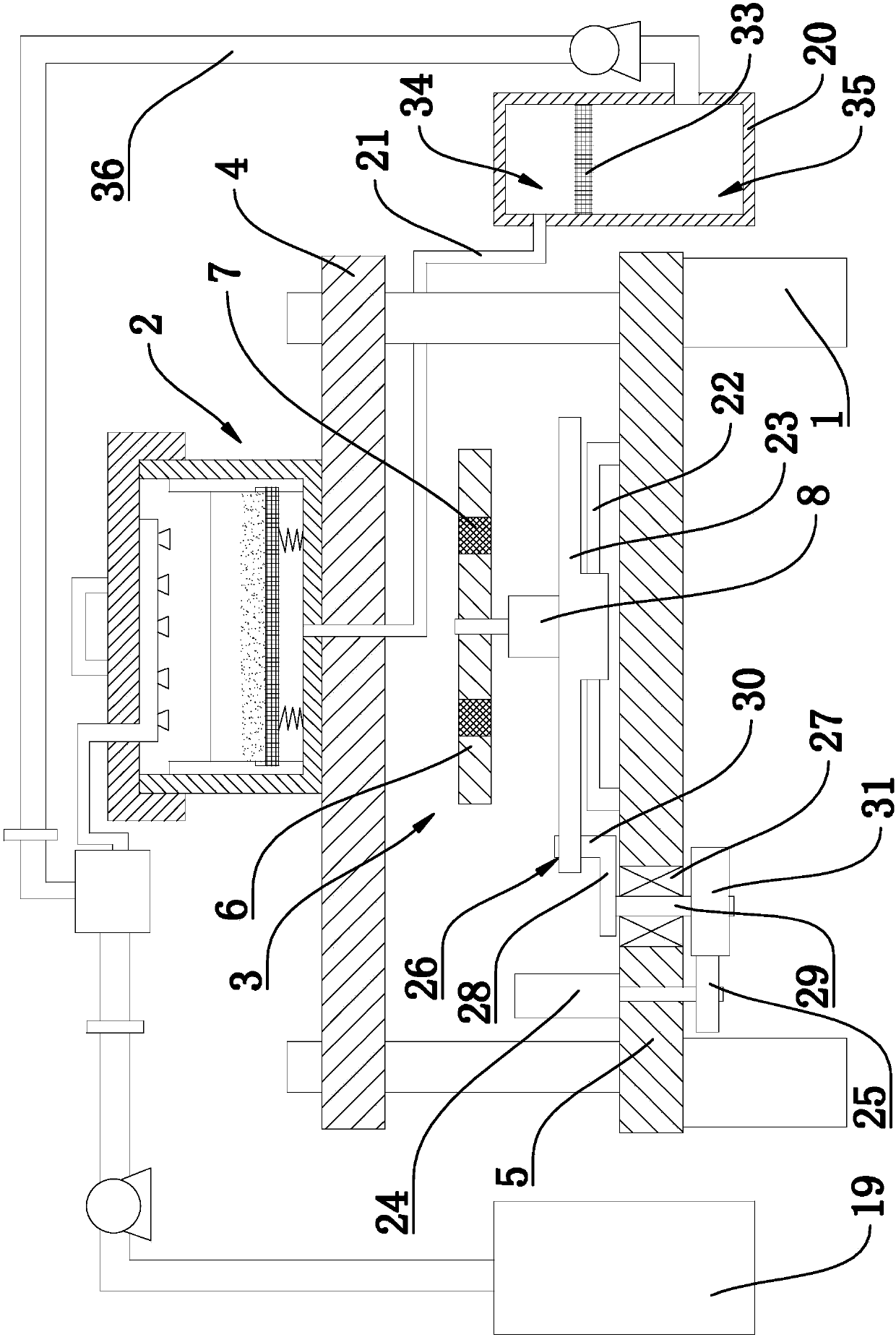

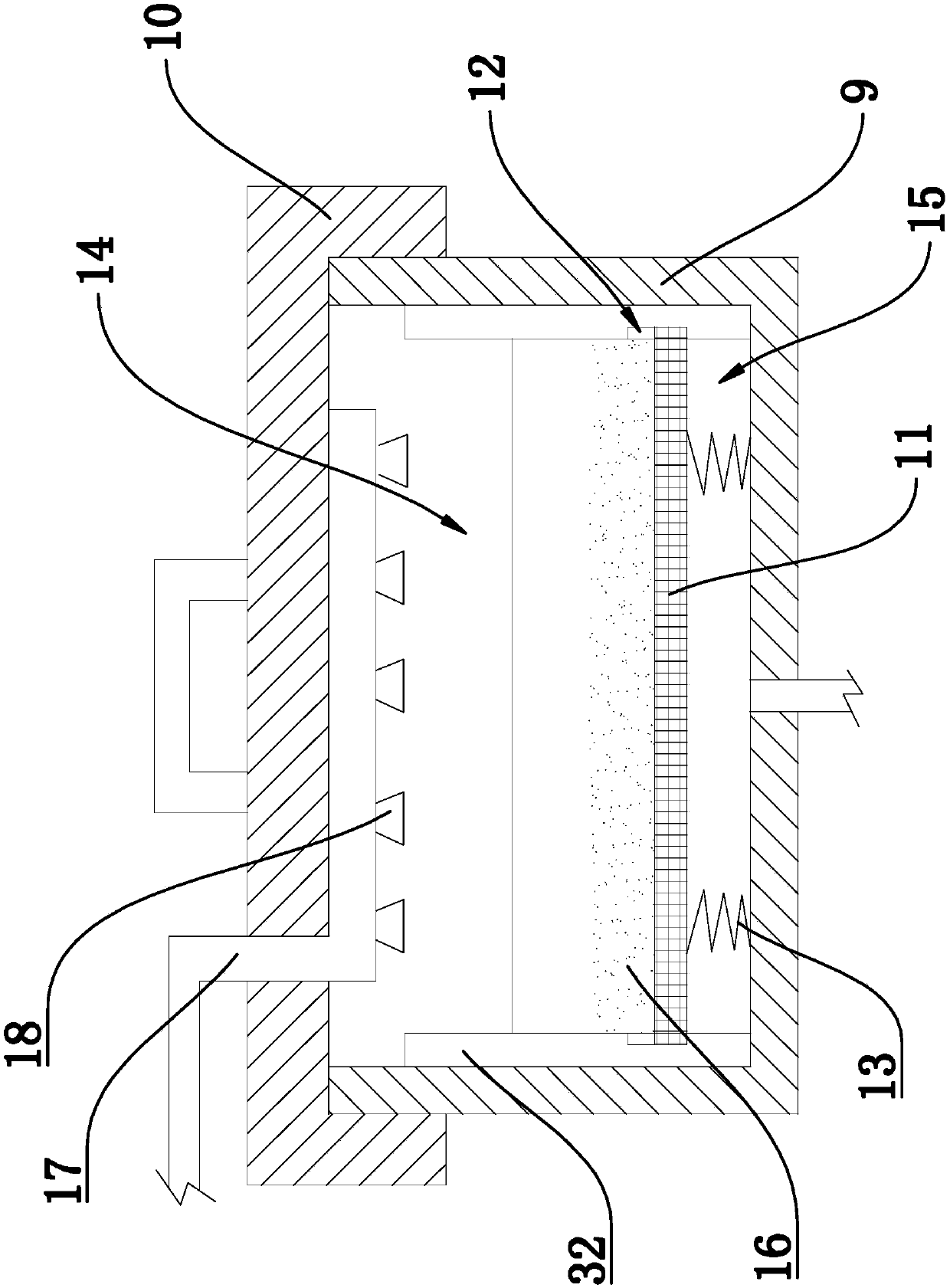

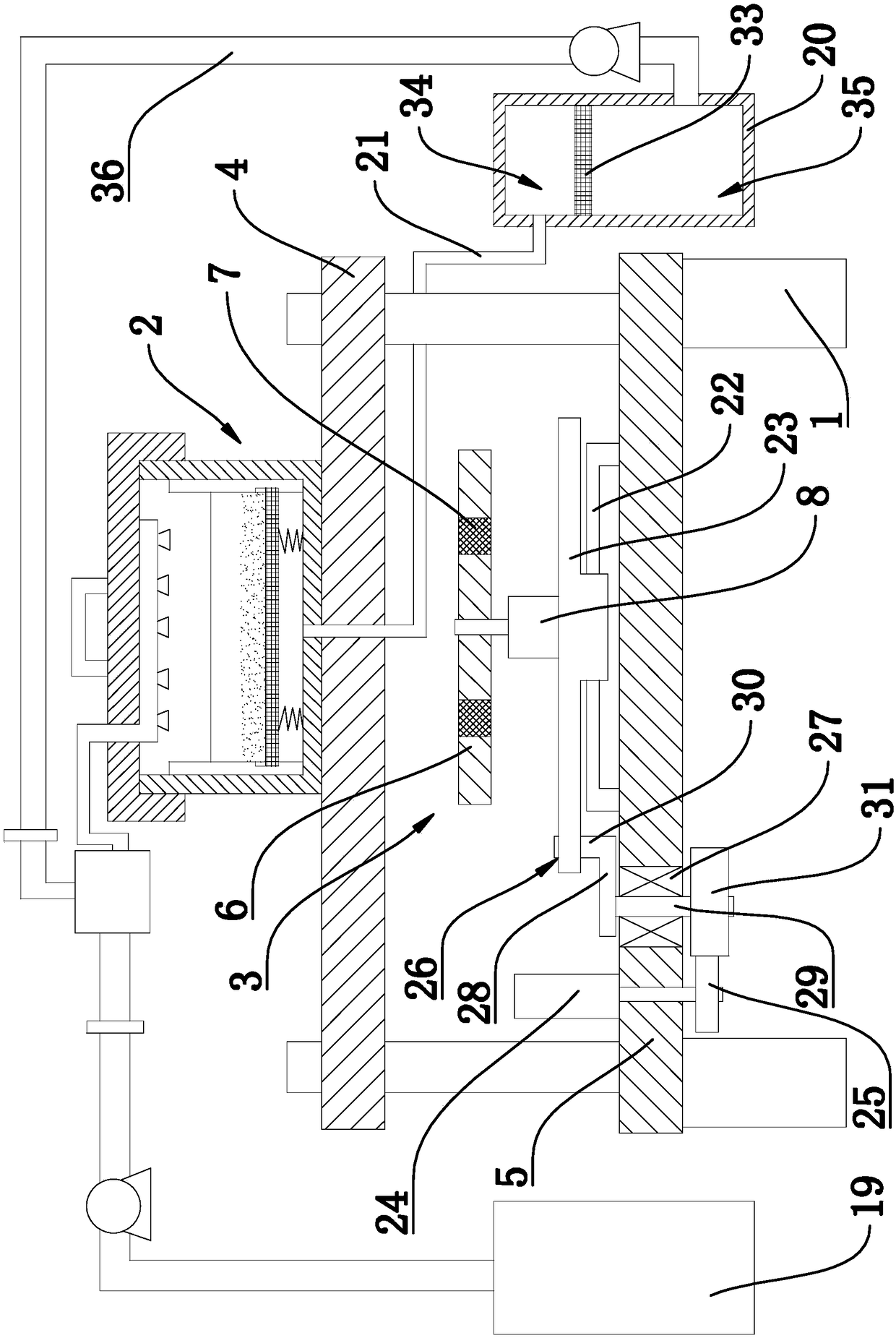

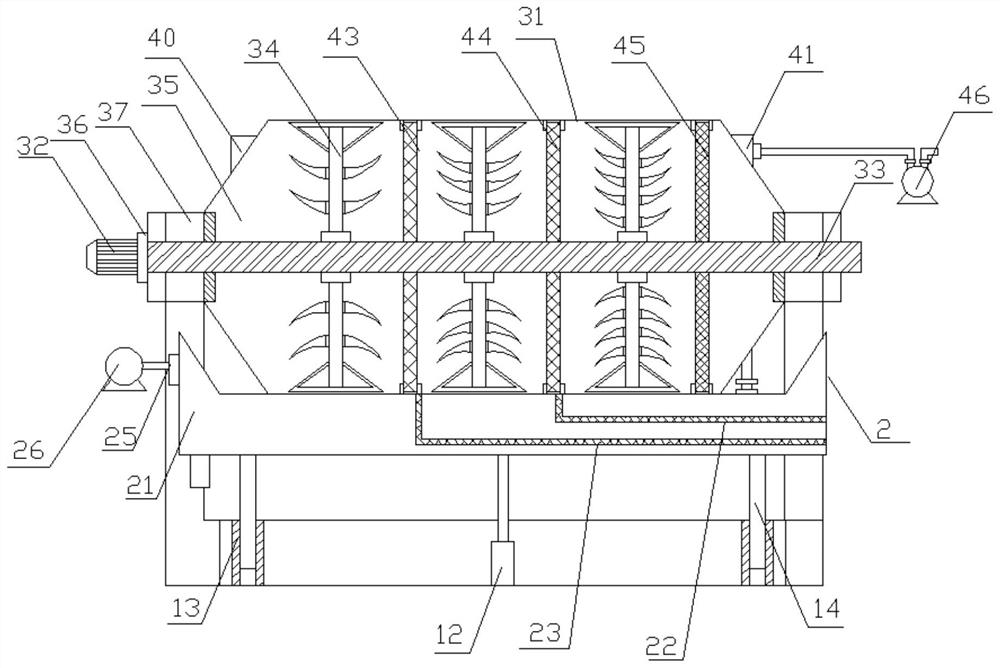

Magnetic abrasive finishing machine

InactiveCN107717637ATimely dischargeInto fastEdge grinding machinesGrinding carriagesEngineeringMachining

The invention discloses a magnetic abrasive finishing machine which comprises a machine base, a machining box and a rotating magnetic disk. The machine base consists of a first supporting table and asecond supporting table, and the machining box is placed on the first supporting table. The rotating disc consists of a rotating disc body and a magnet, the magnet is embedded and fixed on the rotating disc body, a first motor is installed on the second supporting table, and the rotating disc body is fixed to an output shaft of the first motor. The machining box comprises a box body and a cover body, a filter plate is arranged in the box body, and the filter plate is connected with the box body through a spring. The filter plate divides the box body into a machining cavity and a chip removal cavity, a plurality of magnetic grinding materials are placed in the machining cavity, and the size of the hole diameters of filtering holes is smaller than that of the magnetic grinding materials. Thetop of the inner wall of the cover body is fixedly provided with a liquid inlet pipe, a plurality of nozzles are installed on the liquid inlet pipe, a first liquid storage barrel and a second liquidstorage barrel are arranged beside the machine base, the first liquid storage barrel is connected with the liquid inlet pipe, and the first liquid storage barrel is used for supplying cooling liquid to the liquid inlet pipe. The second liquid storage barrel and the chip removal cavity are connected through a liquid discharge pipe, and the second liquid storage barrel is used for collecting coolingliquid and waste chips discharged by the machining box.

Owner:HAINING SHENGXIANG WIRE

Emission early-warning monitoring method for organic arsenic feed additive in water environment system

InactiveCN101482496ATimely dischargeQuick analysisPreparing sample for investigationColor/spectral properties measurementsFeed additiveStandard samples

The invention relates to an organic arsenic feed additive discharge pre-alarming monitoring method in a water environment system, belonging to the environmental monitoring technical field, comprising the following steps: preparing tetrahymena culture medium; preparing arsanilic acid standard sample solution / roxarsone standard sample solution; collecting the actual water sample and separating and extracting the organic arsenic feed additive compound; inoculating the tetrahymena into the prepared culture medium and then subpackaged the inoculated culture medium into the sample culture tubes; respectively adding the organic arsenic feed additive standard solution into the sample culture tubes and respectively measuring the corresponding tetrahymena cell density using absorptometry; making the actual water sample intervening the corresponding tetrahymena biological model and analyzing and determining the corresponding tetrahymena cell density; based on the comparison of the tetrahymena cell density and the contrast of the corresponding tetrahymena cell density after the actual water sample intervention, to obtain the concentration range of the pollutant presence, thereby pre-alarming the discharge condition of the organic arsenic feed additive in the corresponding actual water environment.

Owner:SHANGHAI JIAO TONG UNIV

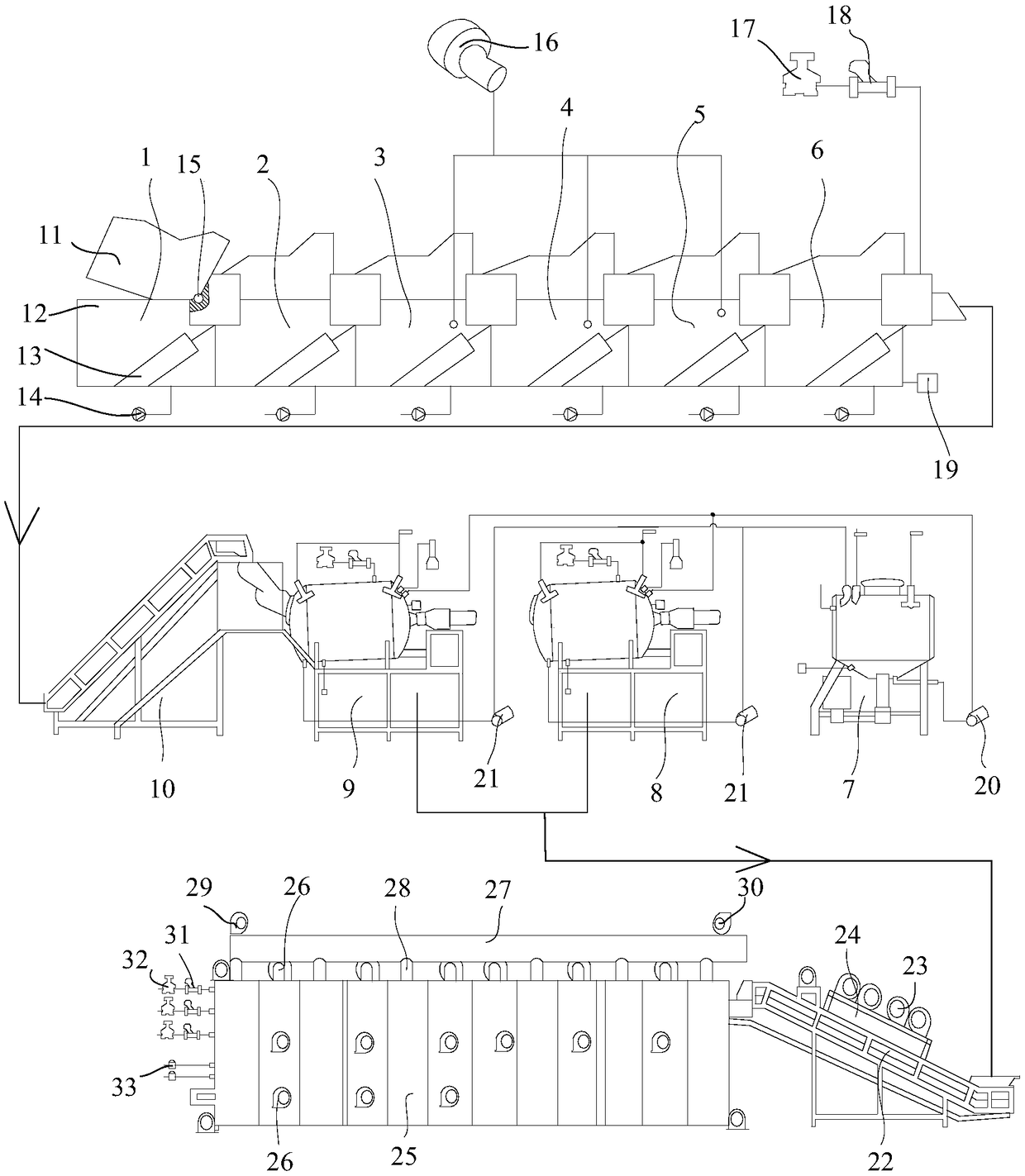

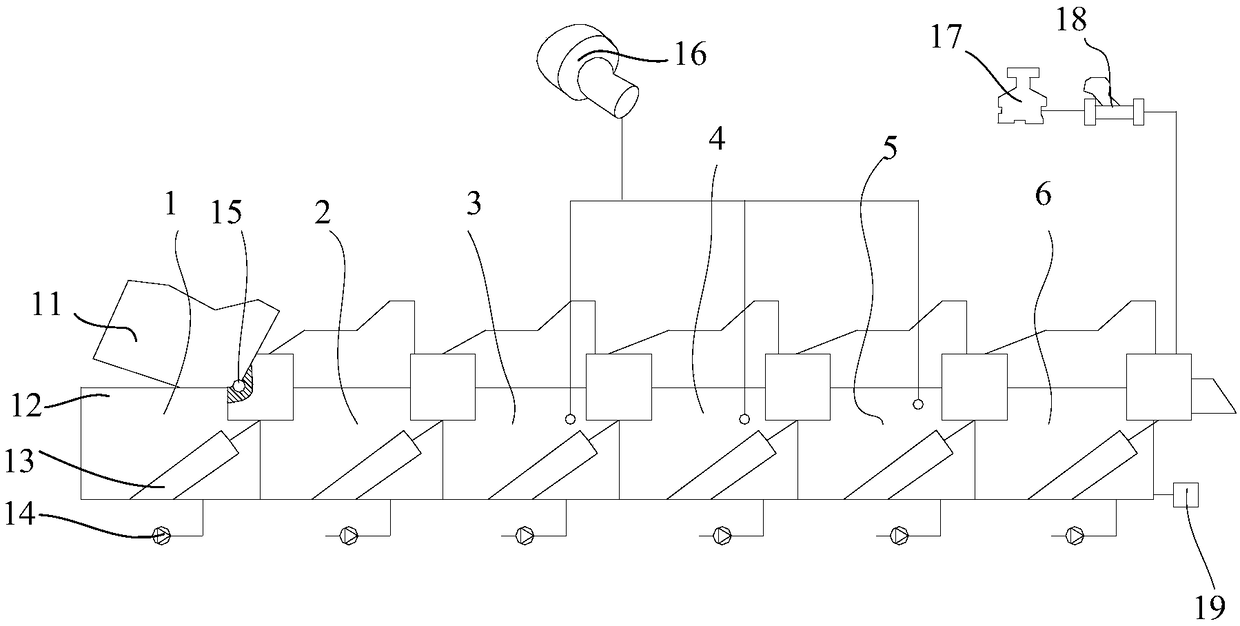

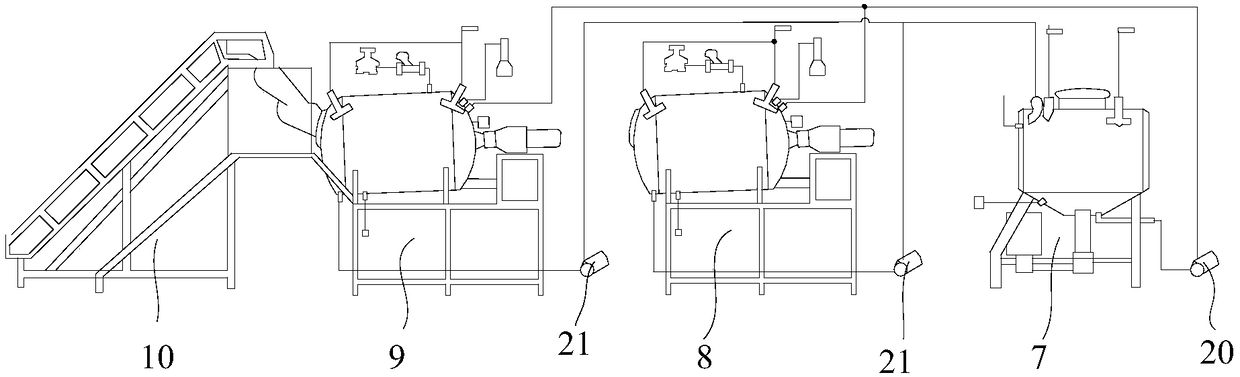

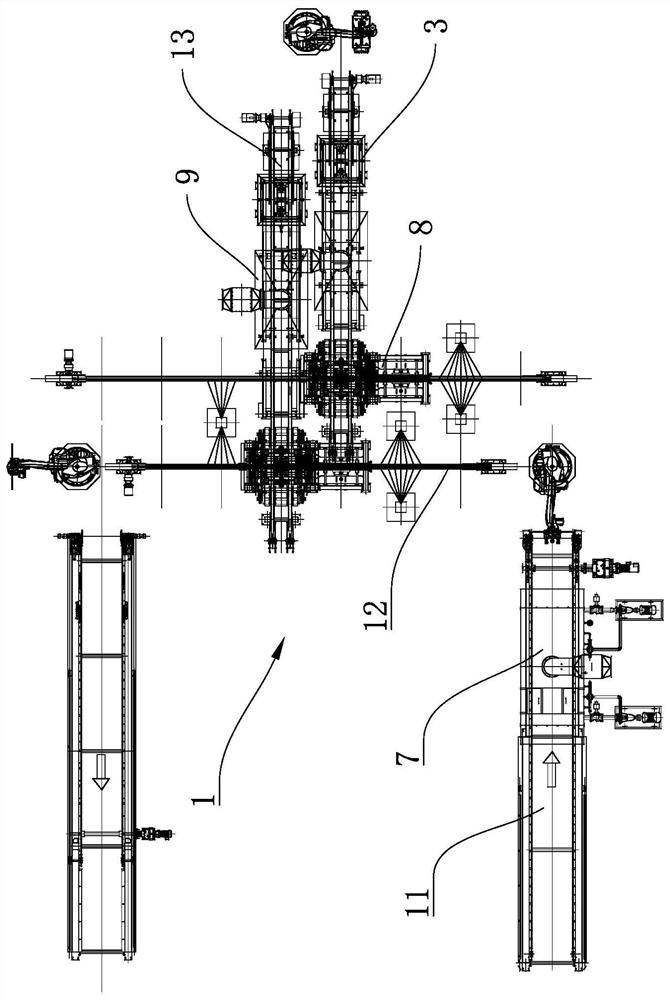

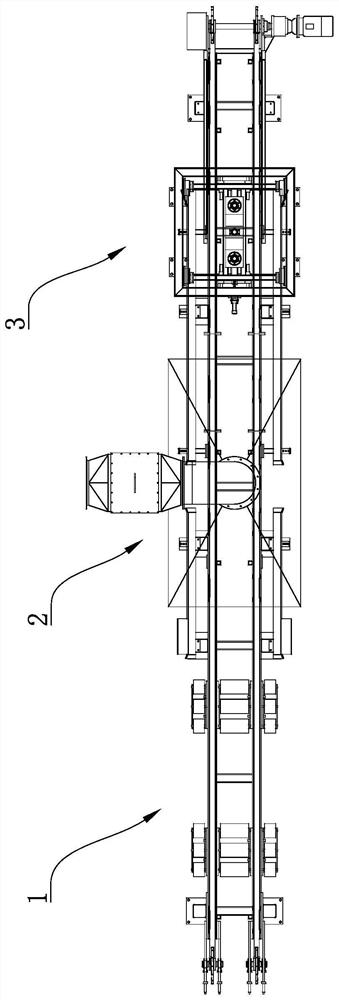

Production device of preserved roxburgh rose fruits

PendingCN108935880AQuick washReduce bad taste imaginationConfectionerySweetmeatsSteam condensationEngineering

The present invention relates to a production device of preserved roxburgh rose fruits. The device comprises a soaking and cleaning pool, a color protection pool, a first cleaning pool, a second cleaning pool, a third cleaning pool, a enzyme deactivation pool, a first elevator, a sugar soaking device, a second elevator and an oven drying machine which are sequentially connected, wherein the sugarsoaking device is connected to a high-speed sugar dissolving tank; the first cleaning pool, the second cleaning pool and the third cleaning pool all communicate with vortex air pumps; the enzyme deactivation pool is provided with a pipeline filled with steam, and a first stop valve and a first-angle seat valve are sequentially arranged on the pipeline, and a first trap valve used for discharging water obtained by steam condensation also is arranged on the enzyme deactivation pool; and the soaking and cleaning pool, the color protection pool, the first cleaning pool, the second cleaning pool, the third cleaning pool and the enzyme deactivation pool are all internally provided with turnover material pools which pour materials into adjacent devices by self over turning. The device realizes the automatic material over-turning in the processing pretreatment process of the preserved roxburgh rose fruits, has high sugar soaking efficiency and better oven drying efficiency, and greatly reducesthe labor cost consumption.

Owner:贵州宏财聚农投资有限责任公司

Secondary washing device for electrolytically refined metal plate

PendingCN111647912AGuarantee product qualityHigh degree of automationElectrolysis componentsPhotography auxillary processesElectrolytic agentMetallurgy

The invention belongs to the technical field of chemical engineering, and particularly relates to a secondary washing device for an electrolytically refined metal plate. The device comprises a conveying mechanism, wherein a first washing device, a stripping system and a second washing device are arranged along a conveying path of the conveying mechanism, the first washing device is used for washing a metal plate attached to a cathode plate, the stripping system is used for stripping the metal plate on the surface of the cathode plate, the second washing device is used for washing the strippedmetal plate, and the conveying mechanism sequentially passes through the first washing device, the stripping system and the second washing device. According to the secondary washing device, a cleaningdevice and a washing device are sequentially arranged in the conveying direction of the conveying mechanism, the cleaning device and the washing device respectively carry out preliminary washing on the metal plate and secondary washing on the stripped metal plate, residual electrolyte on the inner side surface of the metal plate can be completely removed, and the product quality is guaranteed; and in addition, an exhaust pipe is arranged in a washing chamber, acid mist generated during washing can be discharged into an exhaust system in time, and a good production environment is ensured.

Owner:SANMEN SANYOU TECH CO LTD

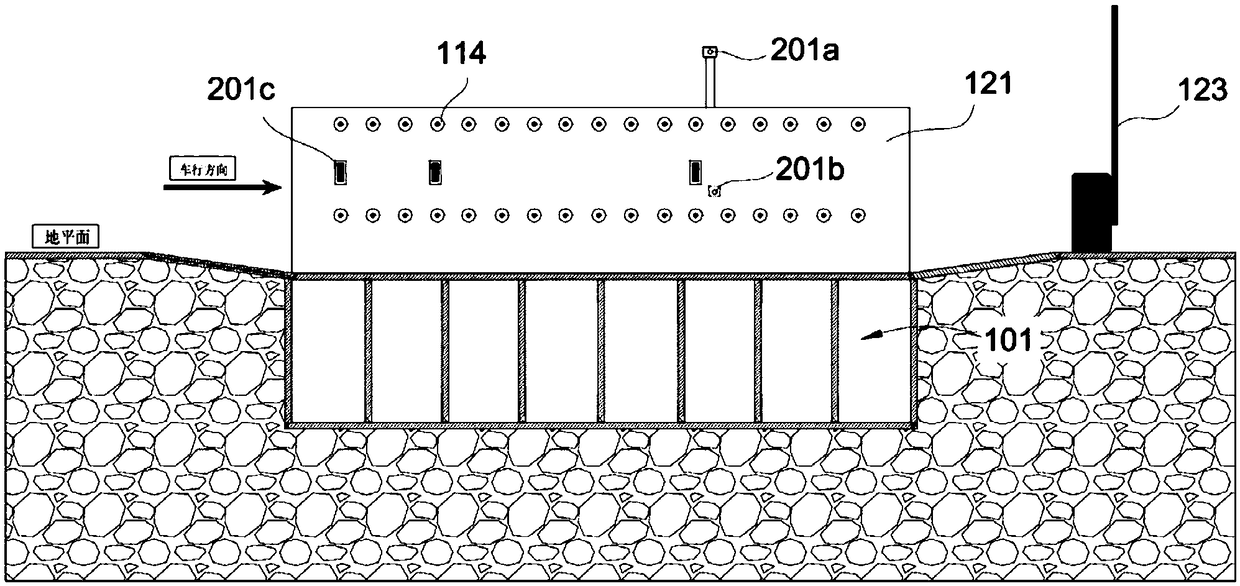

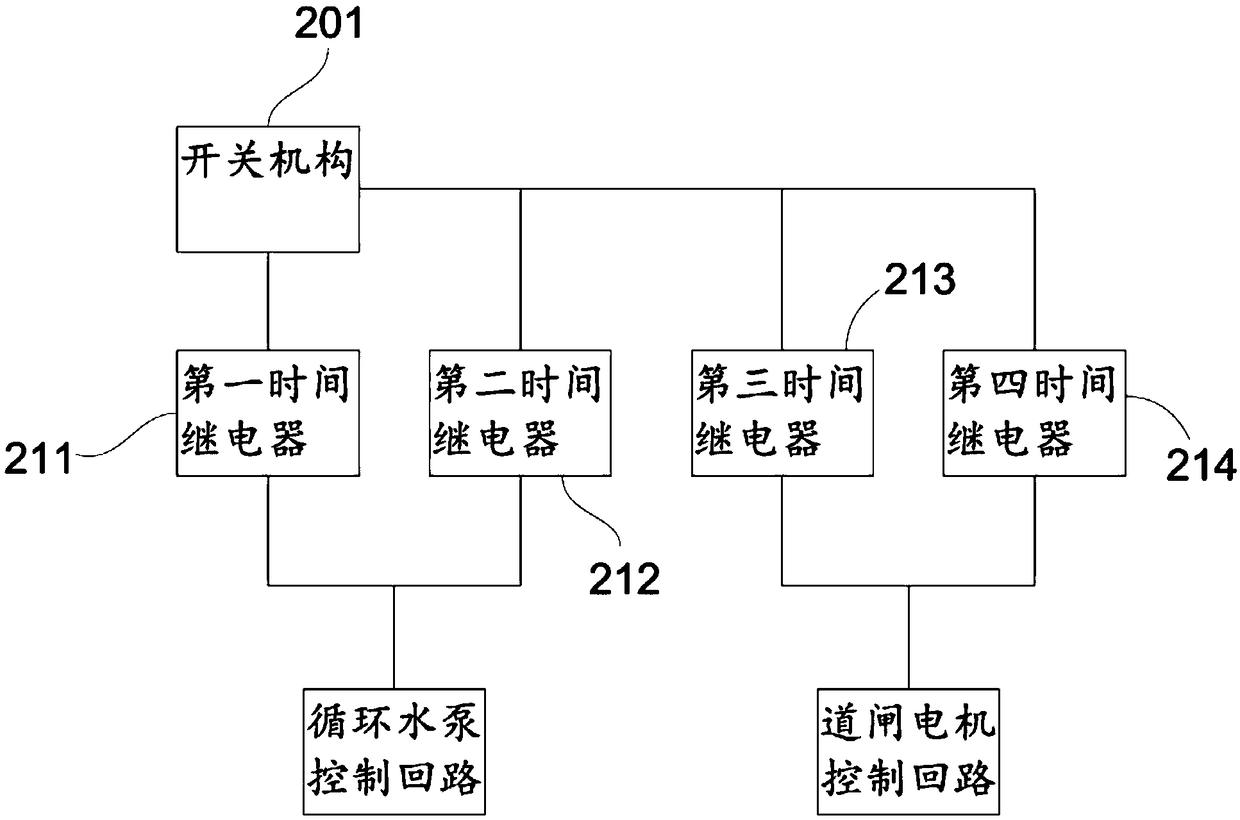

Cleaning device for engineering vehicle

InactiveCN109131244ARealize all-round cleaningTimely dischargeCleaning apparatus for vehicle exteriorsSedimentation settling tanksOmni directionalSedimentation

The invention discloses a cleaning device for an engineering vehicle. The cleaning device comprises a car washing sink, a sedimentation tank, a bearing bracket and a jet pipe mechanism. The car washing sink is arranged below the bearing bracket. Both sides of the bearing bracket are provided with an enclosure structure, and an inlet and an outlet for driving the engineering vehicle into and out ofthe bearing bracket are reserved at both ends. The spray conduit mechanism includes a first conduit disposed below the load bearing bracket, a first conduit provided with a first spray head for spraying water toward the bottom of the engineering vehicle through the load bearing bracket, and a second conduit disposed along the enclosure structure, and an end of the second conduit provided with a second spray head for spraying water toward the side of the engineering vehicle; the bottom of the car washing tank is provided with a drainage outlet for draining water into the settling tank, and a circulating water pump is arranged in the settling tank, and the circulating water pump is connected with a spray pipe mechanism. The cleaning device of the invention realizes the omni-directional washing of the engineering vehicle, the cleaning is cleaner and the efficiency is higher.

Owner:中铁二局第二工程有限公司

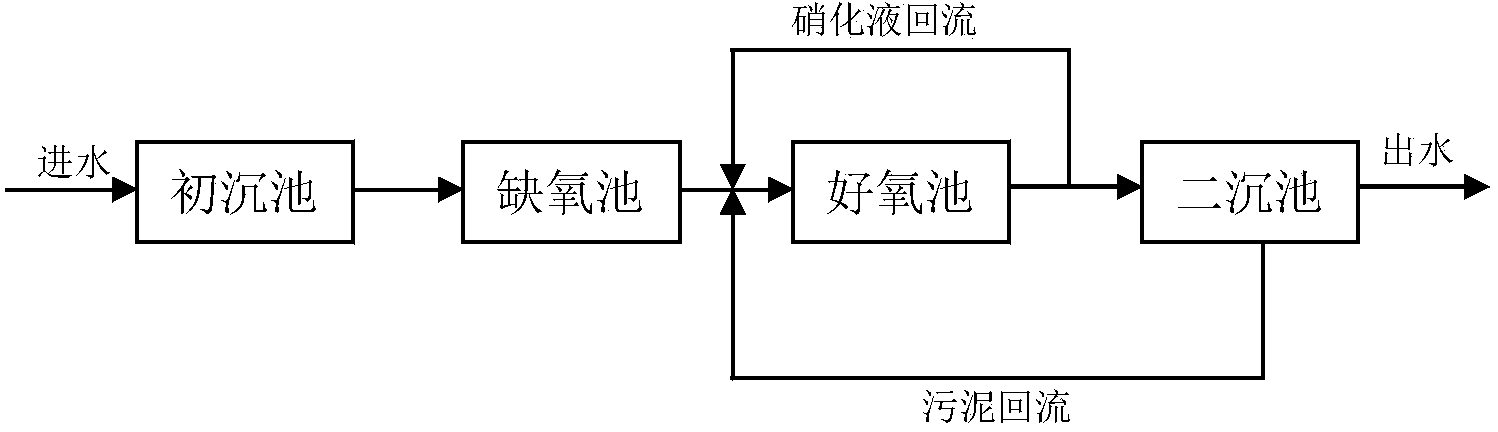

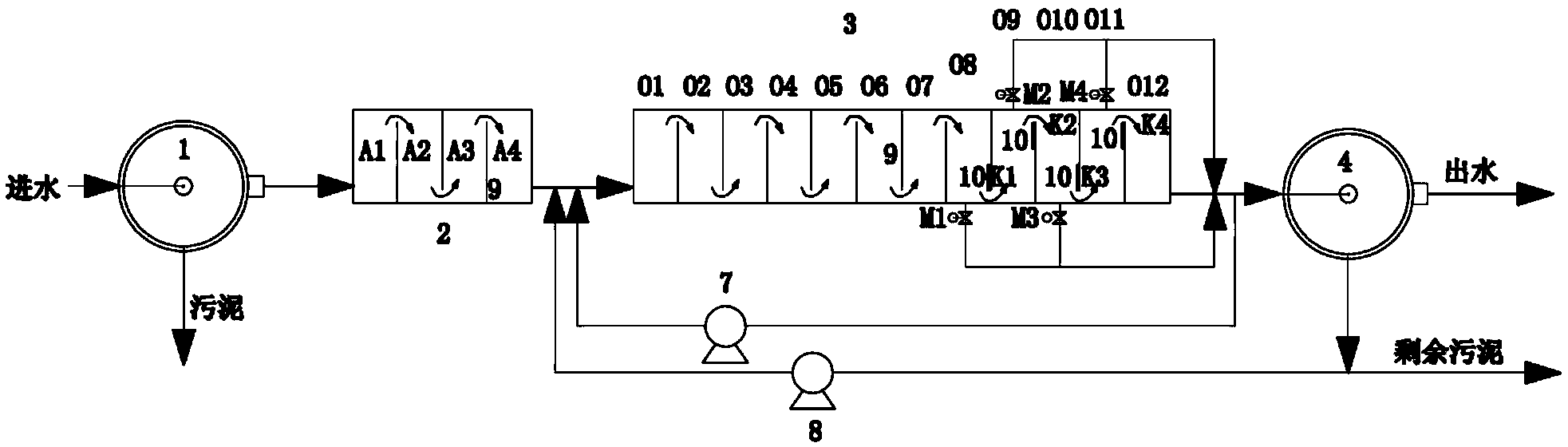

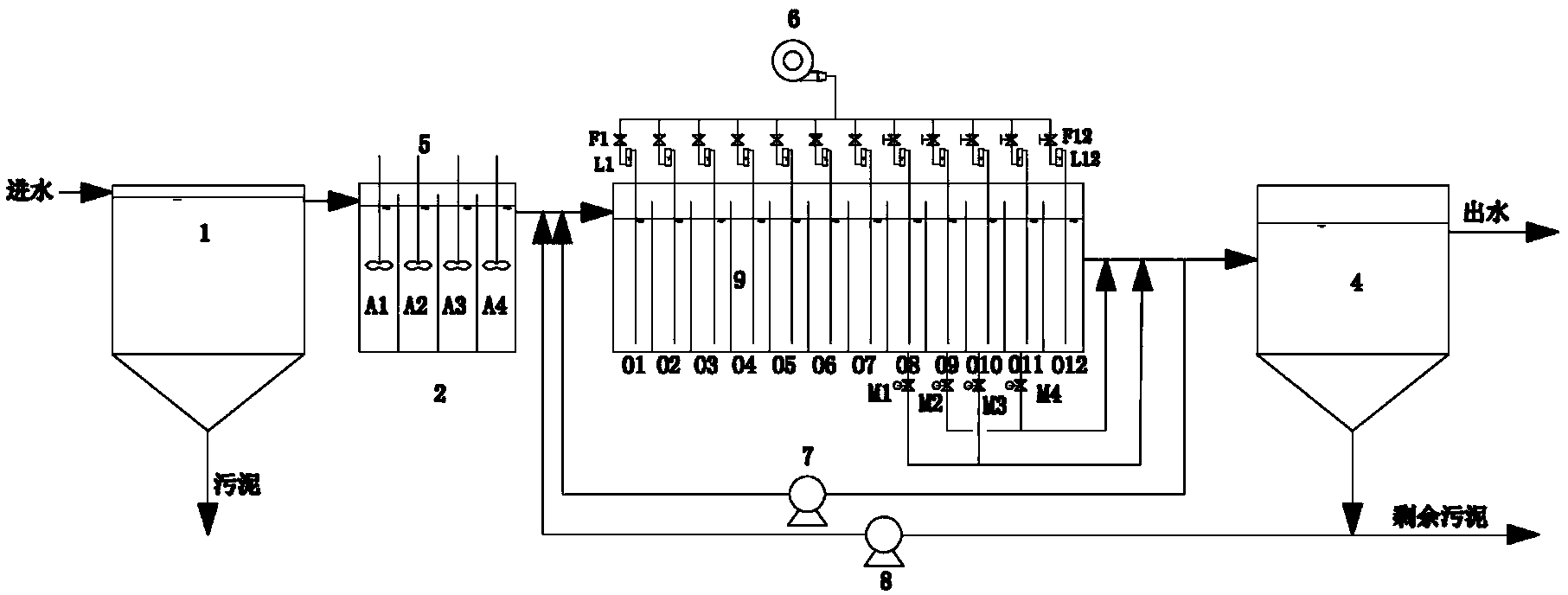

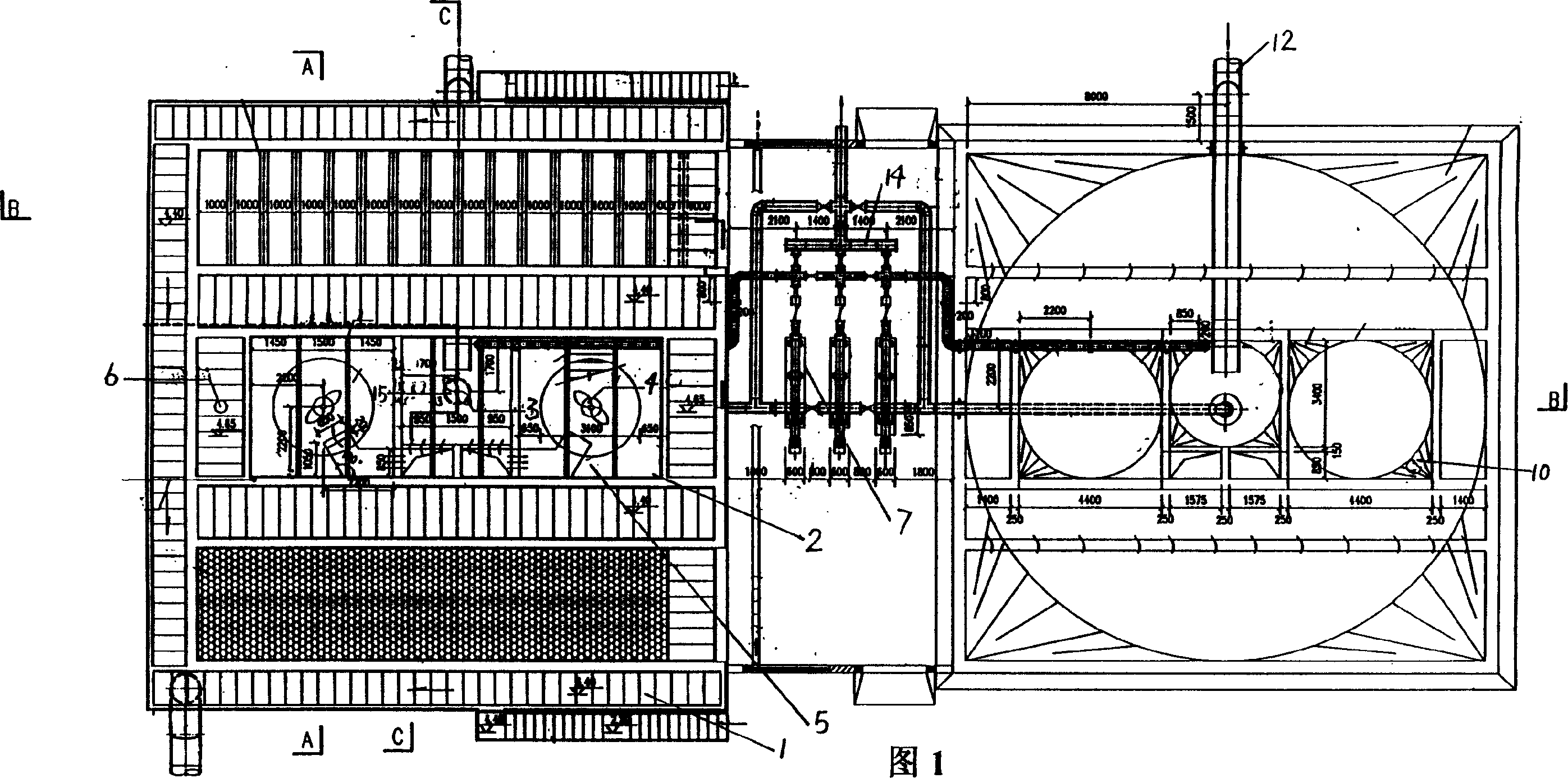

Sewage treatment system

ActiveCN103833183AFlexible adjustment of effective volumeIncrease flexibilityMultistage water/sewage treatmentSustainable biological treatmentAir compressorSewage treatment

The invention discloses a sewage treatment system. The sewage treatment system comprises a primary settling tank, an anaerobic tank, an aerobic tank and a secondary settling tank, which are sequentially communicated, and also comprises an air compressor connected with the aerobic tank, wherein the aerobic tank comprises a plurality of fixed lattices sequentially arranged at the front end, a plurality of movable lattices sequentially arranged at the tail end, bioassay parts arranged in the lattices and a central main control module connected with the bioassay parts, adjacent lattices are separated by a guide wall, an opening is reserved between each guide wall and the side wall of the lattice, a movable check plate is arranged near the opening of the guide wall of the movable lattice, the movable check plate is used for closing the opening of the guide wall, and the movable lattices are respectively provided with a mixed liquor outlet. The sewage treatment system can flexibly regulate the effective capacity of the aerobic tank, guarantees the effluent to meet the standard and avoids excessive aeration in subsequent steps, and can lower the aeration energy consumption sharply.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

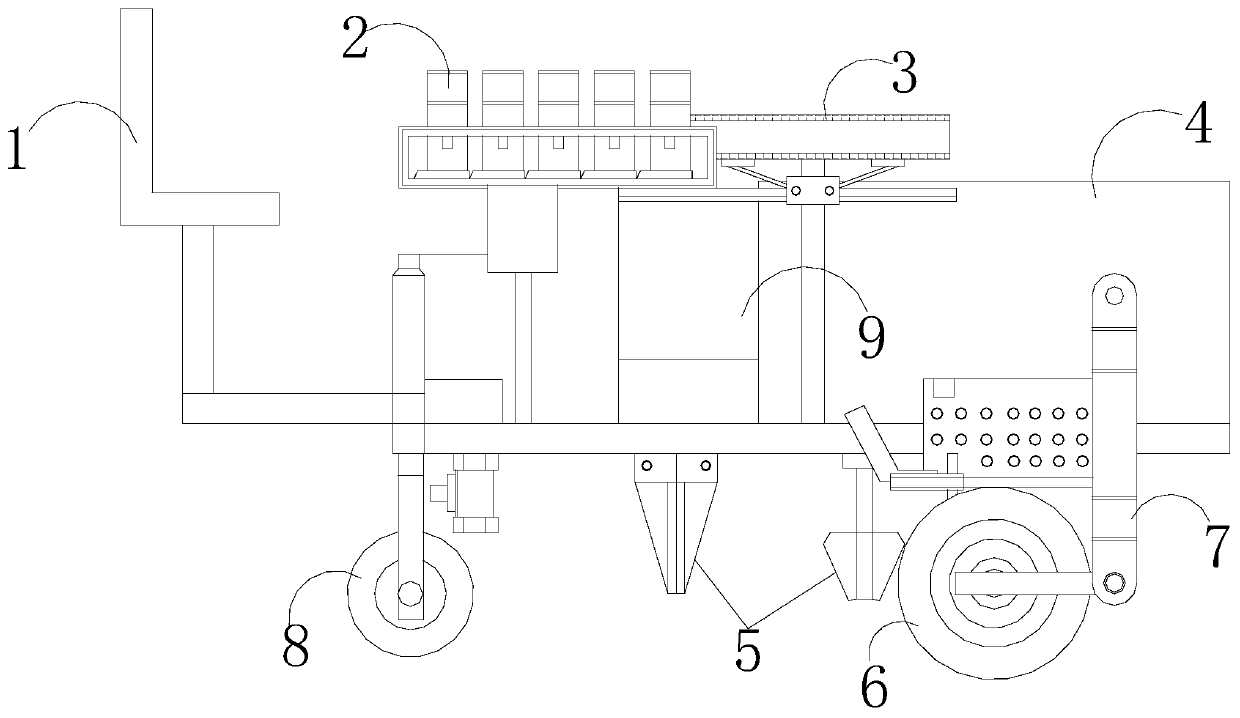

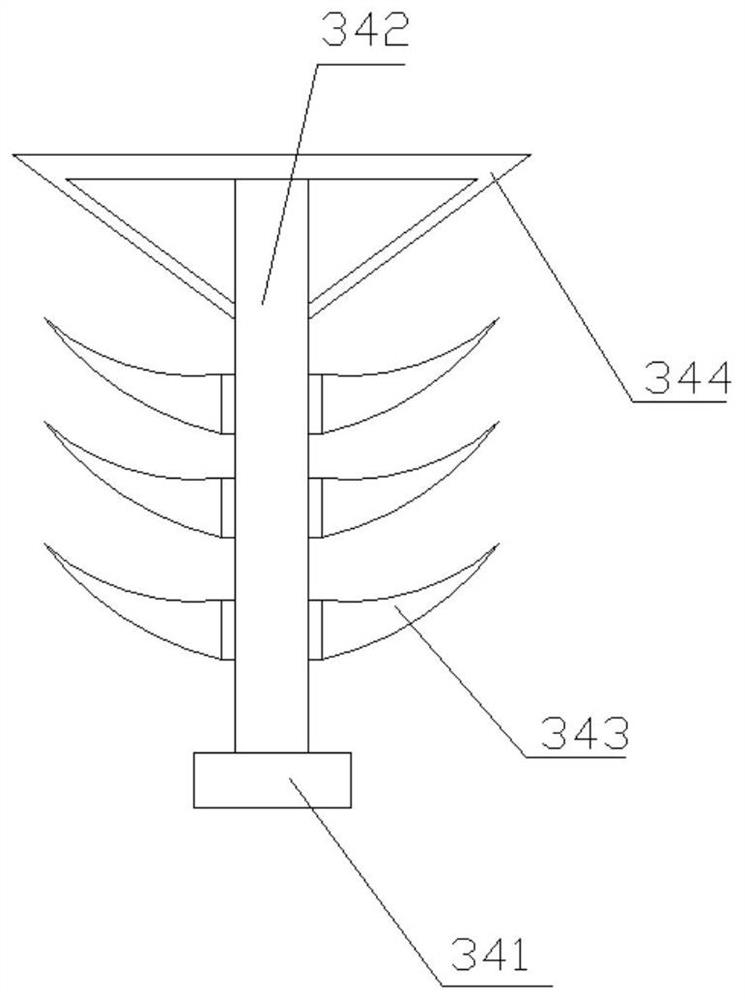

Vegetable seedling-cultivating and transplanting machine

InactiveCN111373910AImprove feeding efficiencyAvoid entry errorsTransplantingCircular discAgricultural engineering

The invention discloses a vegetable seedling-cultivating and transplanting machine. The vegetable seedling-cultivating and transplanting machine structurally comprises a seat, a revolving cup seedling-launching mechanism, a seedling feeding device, a machine frame, a hole opener, a rear wheel, a bracket, a front wheel and a seedling guide pipe; the seat is installed at the left side of the machineframe; the revolving cup seedling-launching mechanism and the seedling feeding device are mechanically connected onto the machine frame; the revolving cup seedling-launching mechanism is connected with the seedling guide pipe; the front wheel and the rear wheel are mechanically connected at the bottom of the machine frame; the hole opener is arranged at the bottom of the machine frame and positioned between the front wheel and the rear wheel; the bracket is connected to the rear wheel and the machine frame; the revolving cup seedling-launching mechanism is provided with a revolving cup connection plate, a revolving cup, a revolving cup base, a nick disc, a revolving cup belt wheel, a turntable centre shaft and a valve; the semi-circular structural revolving cup is matched with the seedling feeding device; the existing top feeding is changed into side feeding; a conveying belt can transmit several seedlings at the same time; under the match of a sorting baffle and a channel baffle, theseedlings are fed into the revolving cup regularly and completely; alignment is unnecessary in the process; and furthermore, the seedling feeding efficiency can be effectively increased in a condition that the seedlings are not damaged.

Owner:陶汉成

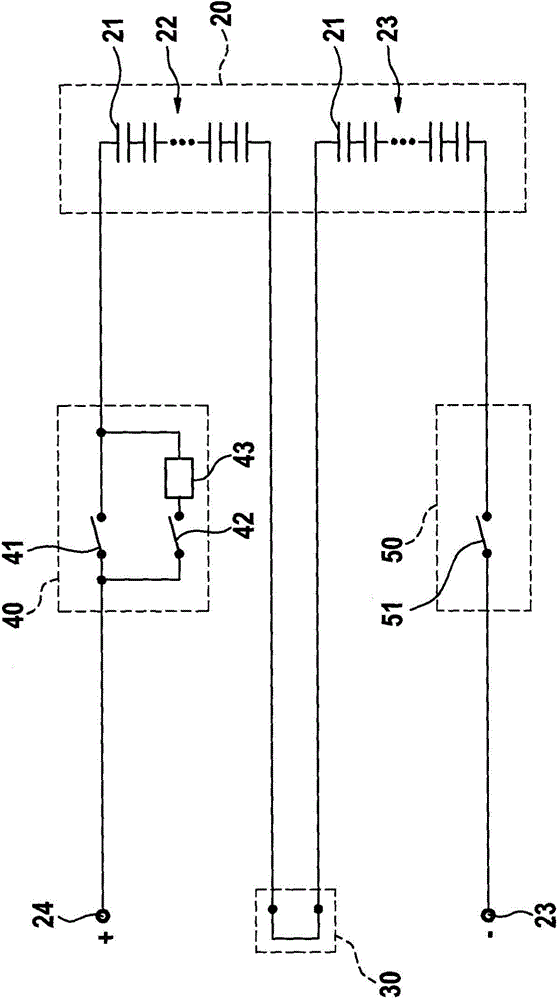

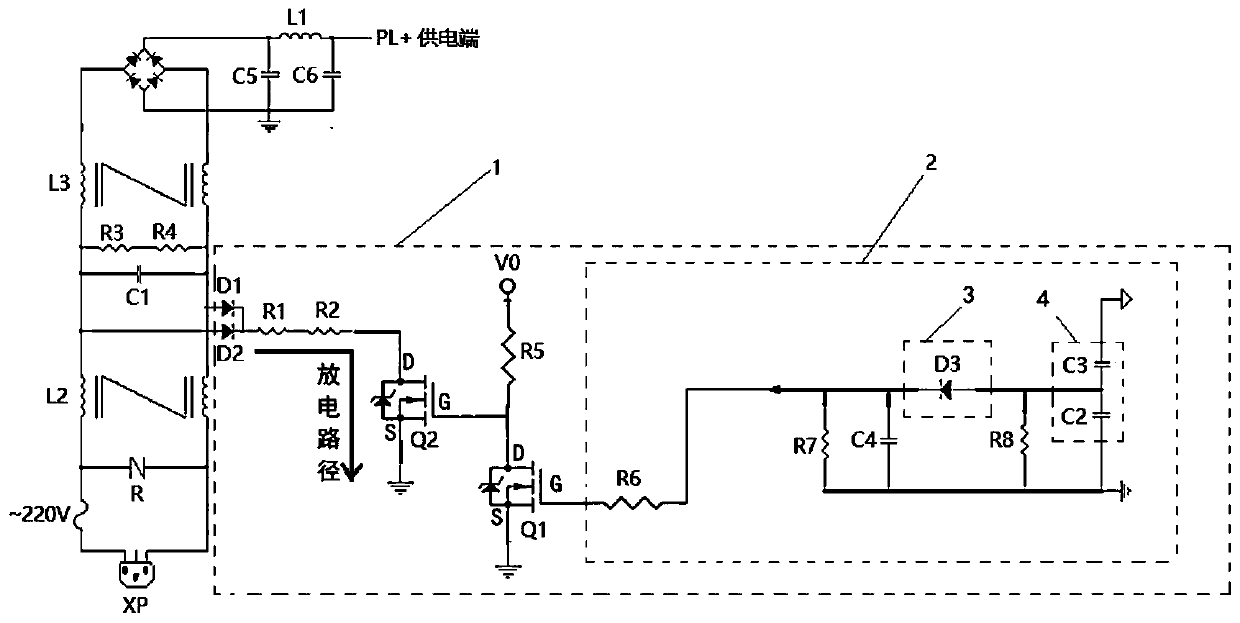

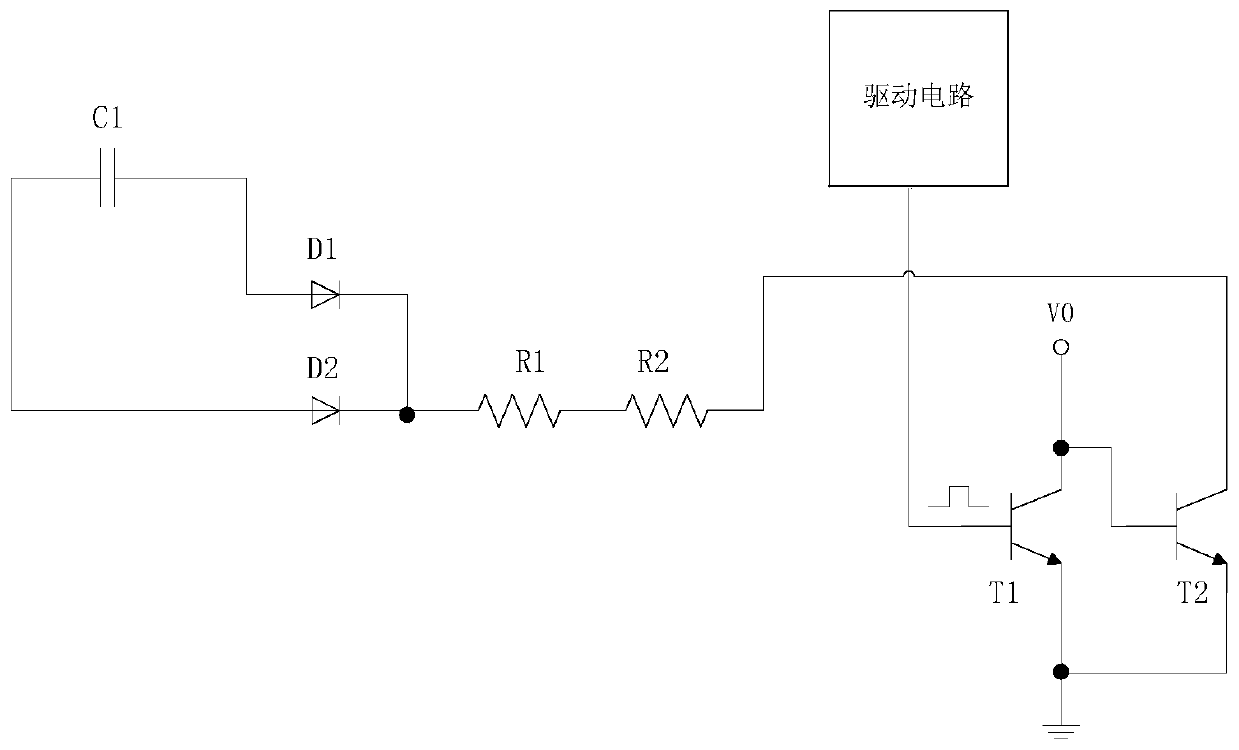

Switching power supply and X capacitor discharge circuit thereof

The invention relates to a switching power supply and an X capacitor discharge circuit thereof. The discharge circuit comprises a power supply, a first switching tube, a second switching tube and a driving circuit, wherein both the first switching tube and the second switching tube are provided with a control port and two switching ports, the input end of the driving circuit is connected with thepower supply output end of the switching power supply, and the output end of the driving circuit is connected with the control port of the first switching tube; the control port of the second switching tube is connected with the positive electrode of the power supply, the first switching port serving as input of the second switching tube is connected with an X capacitor, and the second switch porting serving as output of the second switching tube is grounded; the first switching port serving as input of the first switching tube is connected with the positive electrode of the power supply, andthe second switching port serving as output of the first switching tube is grounded. The circuit structure is greatly simplified, so that the cost is further reduced, and the problem that the existingdischarge circuit is complex in structure is solved.

Owner:QISDA SUZHOU +1

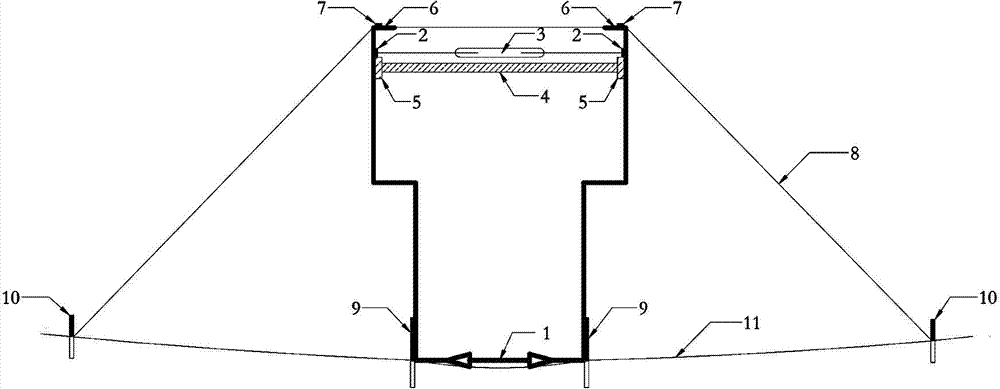

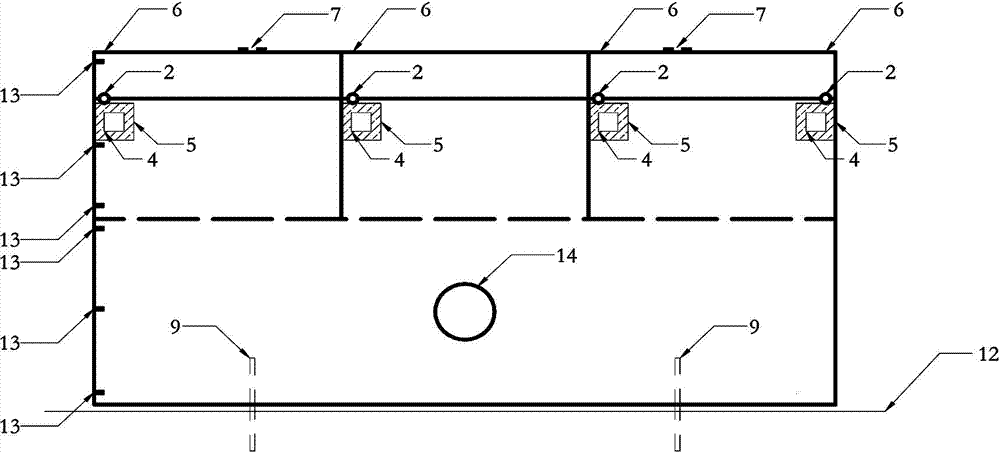

Inserted convex integral central drainage ditch device in road tunnel

The invention discloses an inserted convex integral central drainage ditch device in a road tunnel. The inserted convex integral central drainage ditch device comprises steel templates, a movable hinge, a turnbuckle, square timber cross arms and skids, wherein the two steel templates are arranged symmetrically; the bottom ends of the two steel templates are connected through the movable hinge; the upper ends of the two steel templates are fixedly connected through the turnbuckle, the square timber cross arms and the skids. The concept of water prevention and drainage is implemented in a template, so that structural drainage is realized, the effects of 'combination of prevention and blockage and rapid drainage' are achieved, problems of a central ditch system are prevented fundamentally, the stability and durability of a tunnel structure are ensured, and the operation and all-life effect of the tunnel are enhanced.

Owner:GANSU ROAD&BRIDGE NO 4 HIGHWAY ENG

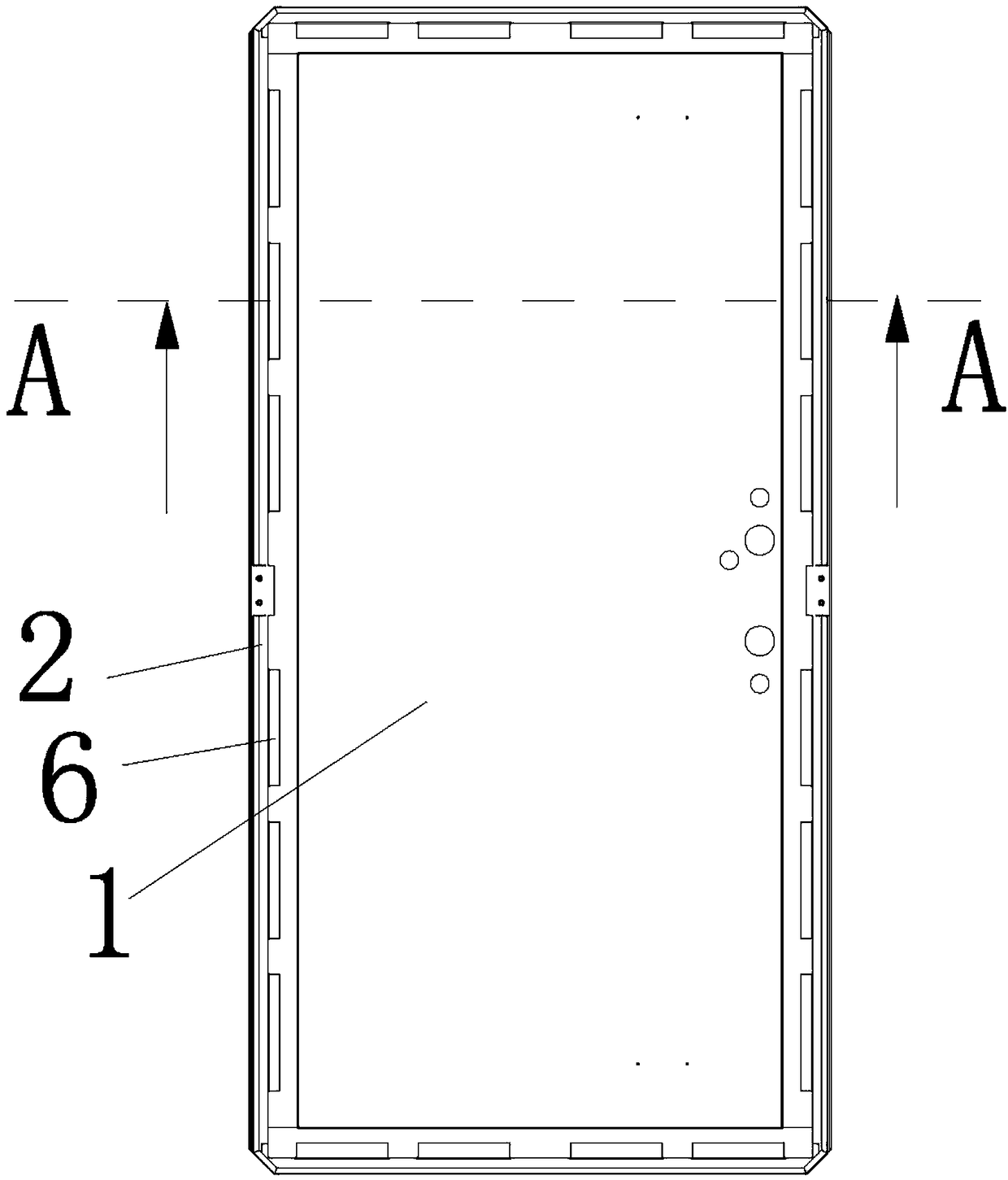

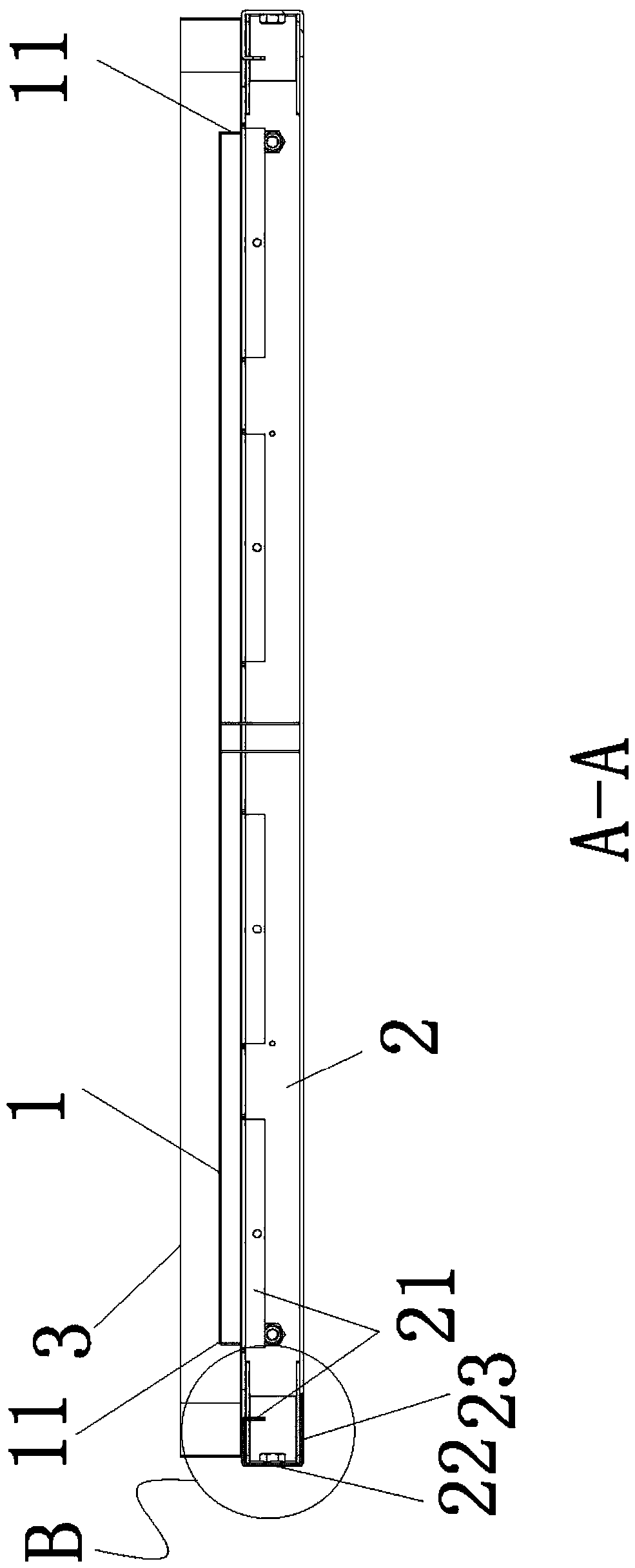

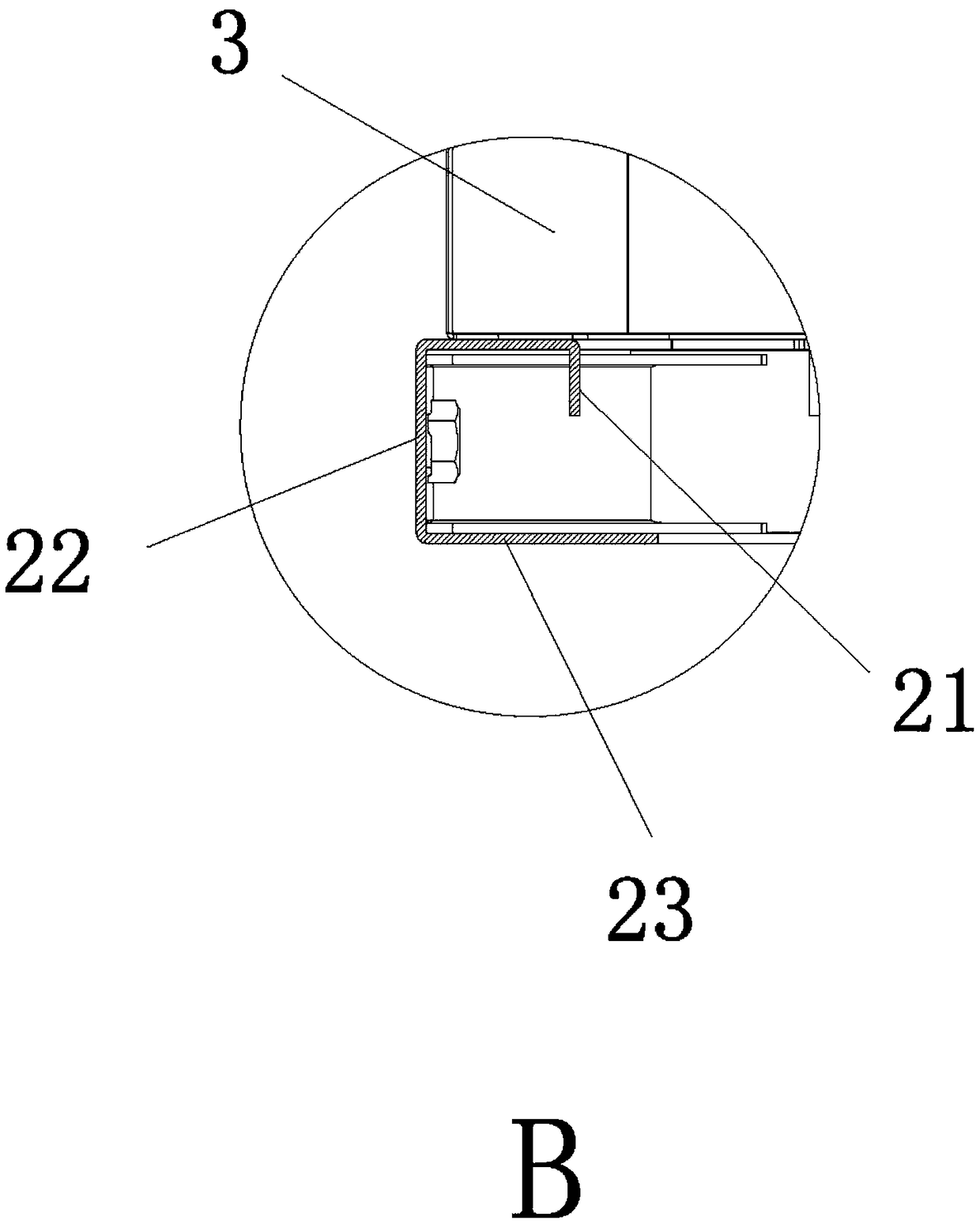

Water containing plate for heat exchanger

PendingCN108775697AGuaranteed to workEliminate surface tensionCondensate preventionLighting and heating apparatusManufacturing cost reductionElectricity

The invention relates to the technical field of heat exchangers, in particular to a water containing plate for a heat exchanger. The water containing plate for the heat exchanger comprises a bottom plate and a water guiding plate, wherein the water guiding plate is arranged on the periphery of the bottom plate in a surrounding way and can be detachably connected with the bottom plate; multiple first notches are arranged on the peripheral side of the bottom plate; the water guiding plate is provided with multiple second notches corresponding to the first notches; the first notches and the corresponding second notches enclose to form multiple drain holes for draining; and a hole wall of each drain hole downwards extends out of a flow guiding part. Compared with the prior art, the multiple drain holes are formed between the water guiding plate and the bottom plate and are formed in the periphery of the bottom plate in a surrounding way, the drain holes extend out of the flow guiding part,and during a draining process, the partial adhesion capacity and the surface tension of water are eliminated through the flow guiding part, so that defrosting water and condensation water can be drained out of the water containing plate along the flow guiding part, the water can be drained smoothly, and the occurrence of the phenomenon that the drain holes are secondarily frozen is avoided; and in addition, an electric auxiliary heating part can be omitted, so that the manufacturing cost is reduced, and the potential safety hazard is eliminated.

Owner:GUANGDONG HIWAVE TECH

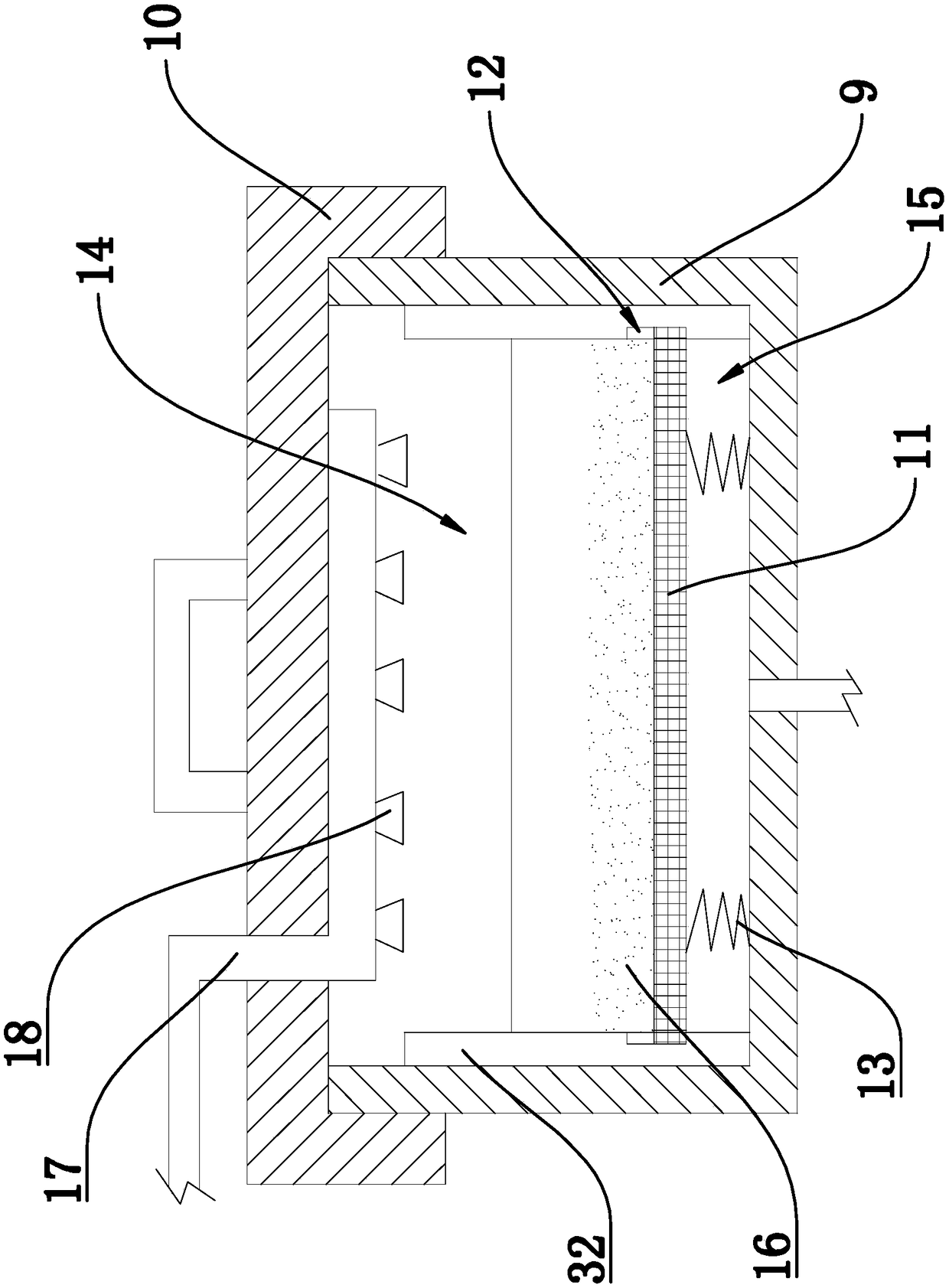

Magnetic abrasive finishing process machine

InactiveCN108747600ATimely dischargeInto fastEdge grinding machinesGrinding carriagesDraining tubeEngineering

The invention discloses a magnetic abrasive finishing process machine. The magnetic abrasive finishing process machine comprises a machine base, a processing box and a rotating magnetic disc, whereinthe machine base comprises a first supporting table and a second supporting table; the processing box is placed on the first supporting table, and the rotating magnetic disc comprises a rotating discand a magnet body; the magnet body is embedded and fixed to the rotating disc, a first motor is installed on the second supporting table, and the rotating disc is fixed to an output shaft of the firstmotor; the processing box comprises a box body and a cover body, a filter plate is arranged in the box body, and the filter plate and the box body are connected through a spring; the filter plate partitions the box body into a processing cavity and a chip removal cavity, a plurality of magnetic abrasives are placed in the processing cavity, and the pore size of filter holes is smaller than the size of the magnetic abrasives; a liquid inlet tube is fixed to the top of the inner wall of the cover body, and a plurality of spray heads are installed on the the liquid inlet tube; a first liquid storage barrel and a second liquid storage barrel are arranged on the sides of the machine base, the first liquid storage barrel is connected with the liquid inlet tube, and the first liquid storage barrel is used for supplying cooling liquid to the liquid inlet tube; and the second liquid storage barrel is connected with the chip removal cavity through a drain tube, and the second liquid storage barrel is used for collecting the cooling liquid and sweeps discharged from the processing box.

Owner:HAINING SHENGXIANG WIRE

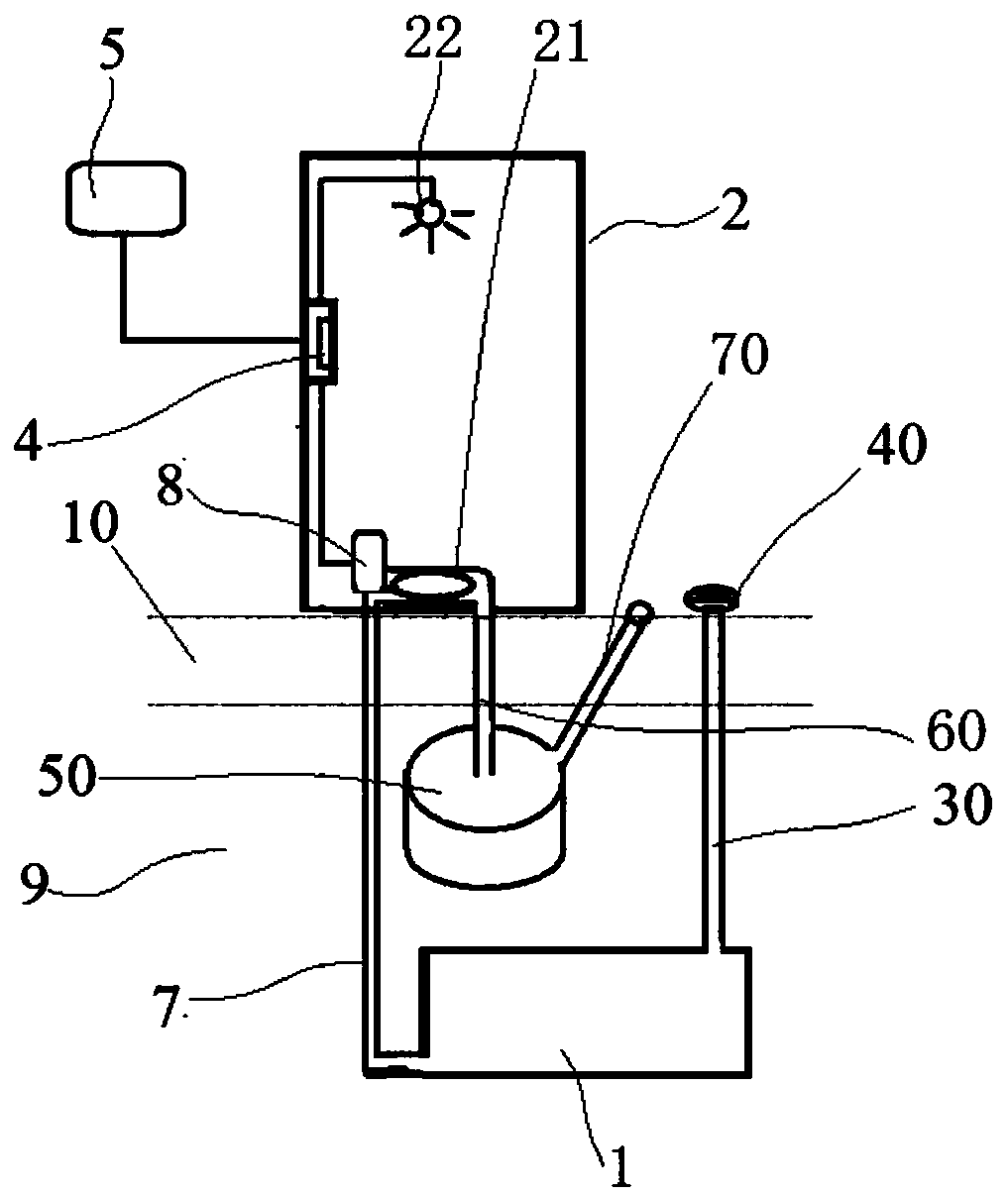

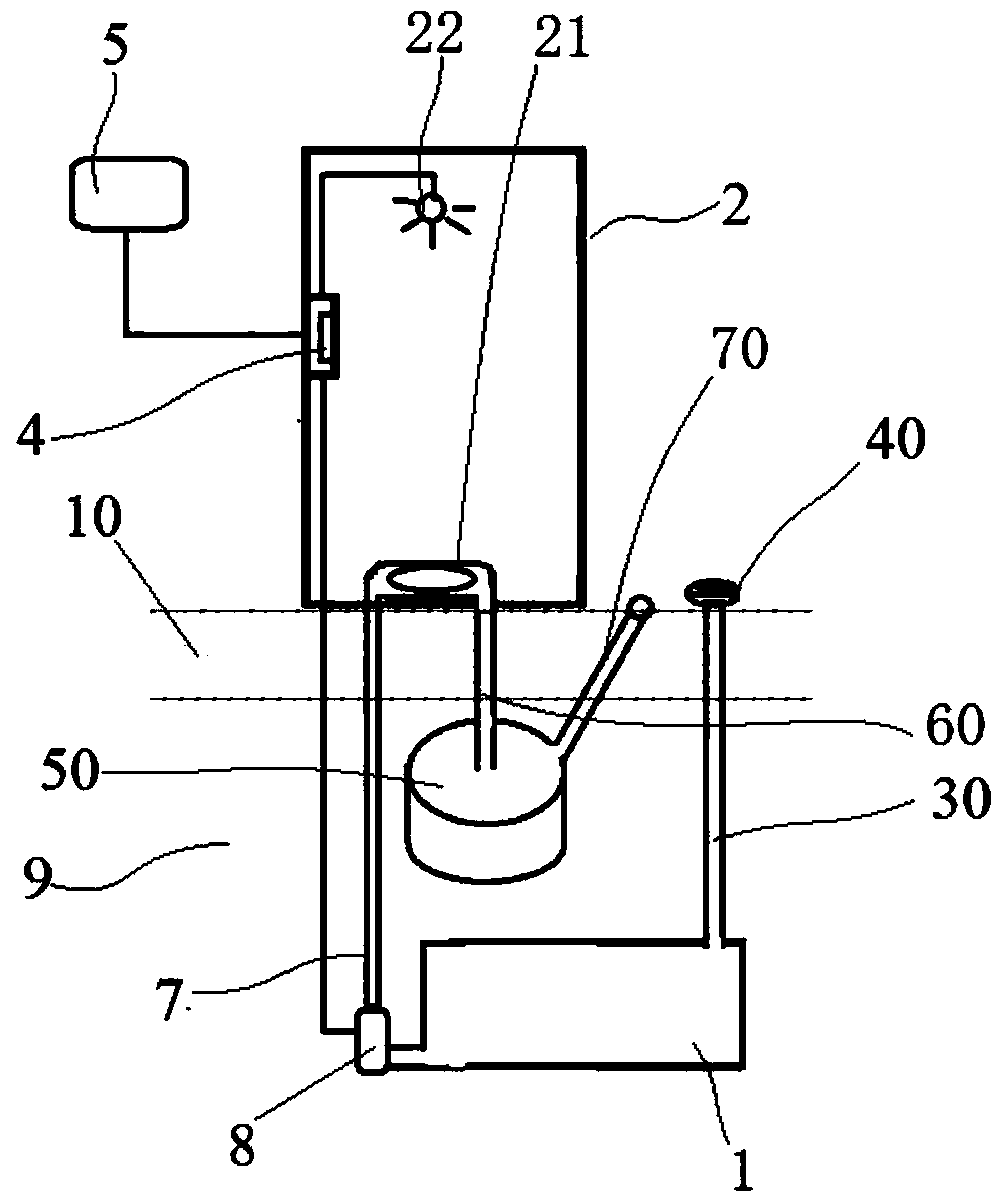

Anti-freezing flushing device and energy-saving, sanitary and environment-friendly toilet thereof

PendingCN110905038AAvoid breakingExtended service lifeSewerage structuresLavatory sanitoryWater dischargeWater source

The invention discloses an anti-freezing flushing device and an energy-saving, sanitary and environment-friendly toilet thereof. The anti-freezing flushing device is connected with a water supply system. The flushing device comprises a control switch, a water outlet pipeline and a water drainage pump; the water drainage pump is electrically connected with the control switch; the water supply system is arranged in an underground anti-freezing soil layer; the water drainage pump is connected with the water supply system and the water outlet pipeline; the water outlet pipeline penetrates througha ground frozen soil layer, and a water outlet of the water outlet pipeline extends out of the ground surface; when the water drainage pump is started through the control switch, water in the water supply system is pumped into the water outlet pipeline to form flushing water to be discharged; and when the water drainage pump is stopped, retained water in the portions, located on the frozen soil layer and the areas above, in the water outlet pipeline flows back into the water supply system. According to the anti-freezing flushing device and the energy-saving, sanitary and environment-friendly toilet, by controlling the flowback type water drainage pump, the retained water in the water outlet pipeline and the areas above can be rapidly and completely discharged, the retained water is made toflow back into the water supply system, water sources are saved, the problem that the water discharge pipeline freezes and the pipeline is fractured is avoided, and the problem that due to freezing,country dry latrine pits are dirty, disorderly and bad is solved.

Owner:管凤强

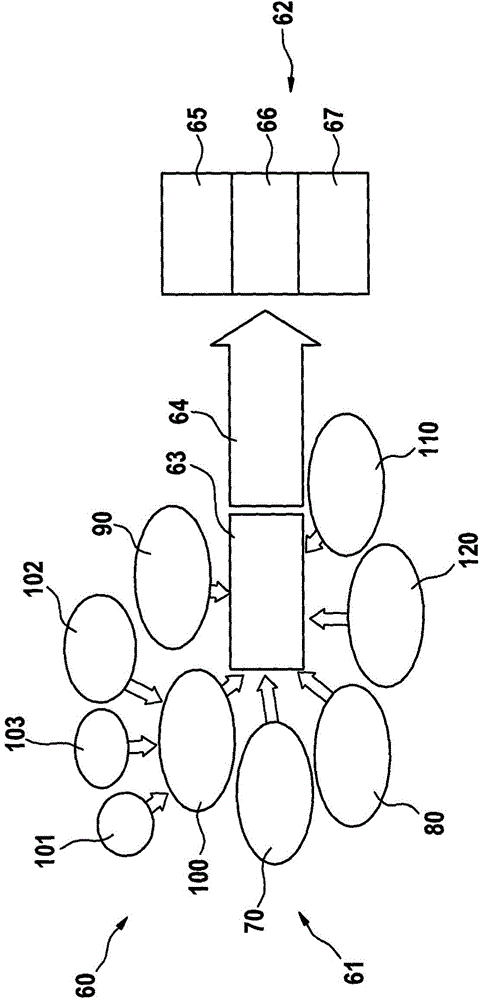

Scheme and method for promoting water utilization

ActiveCN107396810AReduce water lossStrengthen the water cycle of agricultural resourcesFatty/oily/floating substances removal devicesSewerage structuresSoil horizonWater reservoir

The invention relates to a scheme and method for promoting water utilization. The invention provides a farmland water utilization system with water storage and water supply functions. The farmland water utilization system comprises a water reservoir, a water supply mechanism and a farmland which is arranged obliquely, wherein the farmland and a horizontal plane form an included angle of 1 to 2 degrees, and the farmland comprises a planting soil layer, a quick infiltration layer, a water-permeable layer, a gravel layer and an impervious layer which are arranged sequentially from top to bottom. The invention provides a farmland construction method. According to the method, the utilization and cycling of agricultural water resources are promoted, the irrigation is timely, and irrigation volume can meet the growth needs of crops.

Owner:金中天水利建设有限公司

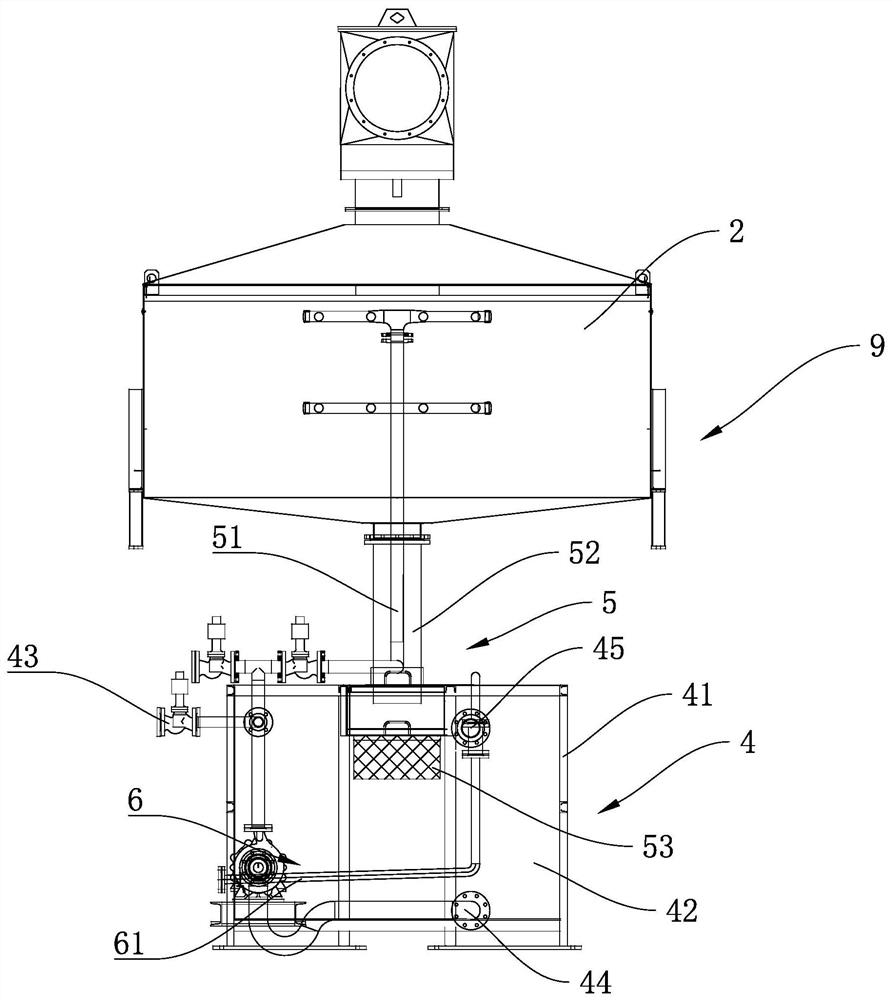

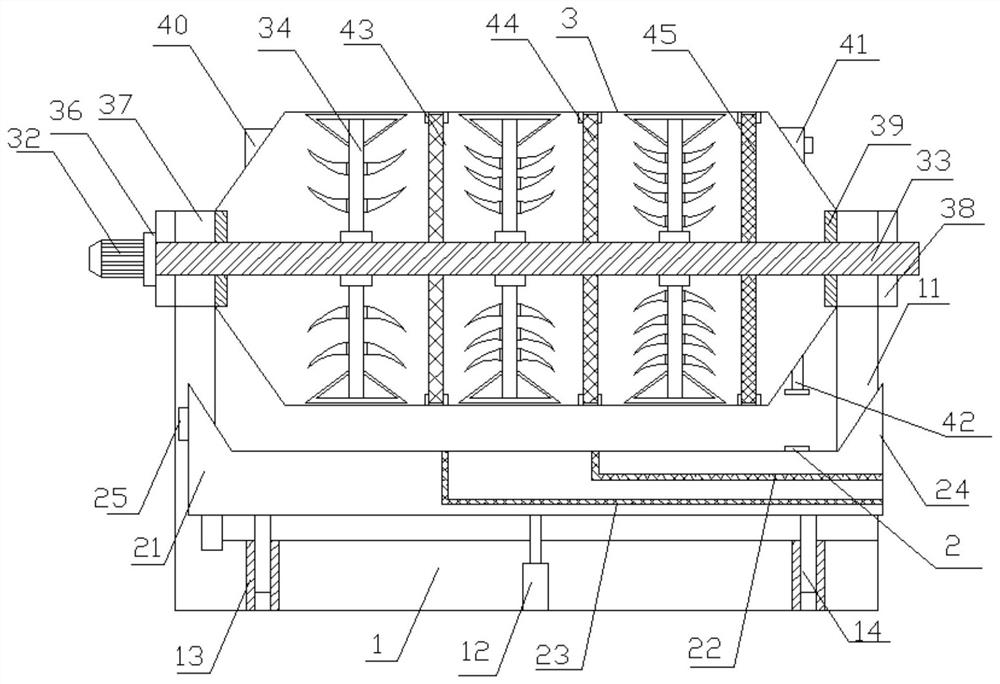

Centrifugal separation and extraction equipment for tea stoste

PendingCN112237752ARaise smashImprove efficiencySolid solvent extractionControl engineeringElectric machinery

The invention provides centrifugal separation and extraction equipment for a tea stock solution, and relates to the technical field of tea extraction. The centrifugal separation and extraction equipment comprises a base, a lifting extraction box and a centrifugal separation tank; the lifting extraction box is arranged above the base and can move in the vertical direction relative to the base, andthe centrifugal separation tank is arranged above the lifting extraction box; the centrifugal separation tank comprises a tank body, a driving motor, a stirring shaft and a plurality of stirring and crushing mechanisms for stirring a tea stock solution and carrying out multi-stage crushing on tea, the driving motor is connected with the end part of the stirring shaft through a coupler, and the plurality of stirring and crushing mechanisms are distributed in the radial direction from one end to the other end of the stirring shaft. According to the invention, continuous and synchronous centrifugal separation of the tea stock solution is facilitated, and the crushing and centrifugal separation efficiency of the tea stock solution is improved; centrifugal separation liquid is discharged into the extraction cavity in time through ascending of the lifting extraction box; meanwhile, the tank body is stably supported by the lifting extraction box, and the discharging stability of the centrifugal separation liquid is guaranteed.

Owner:贵州布依福娘茶业文化发展有限公司

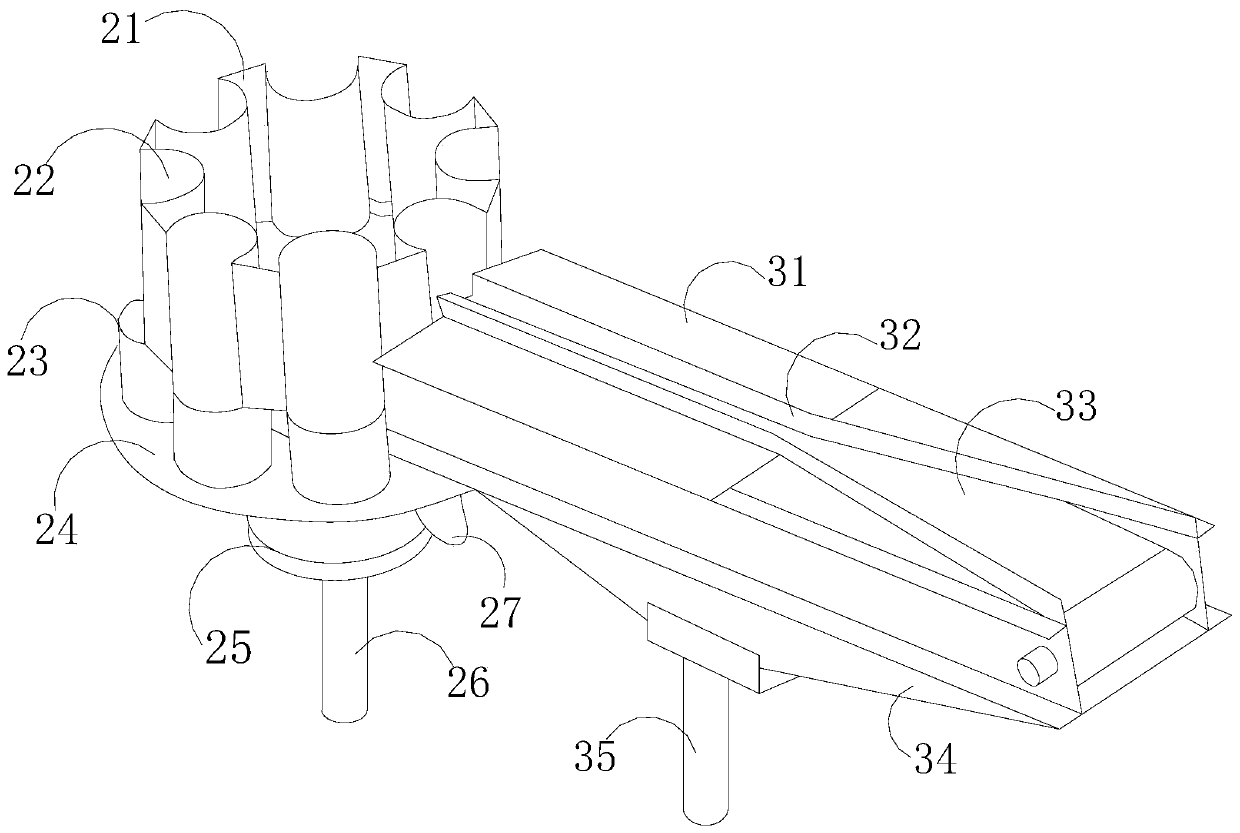

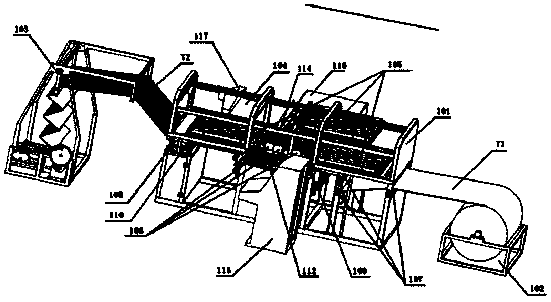

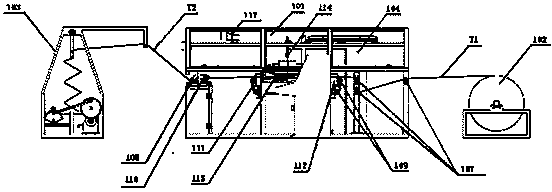

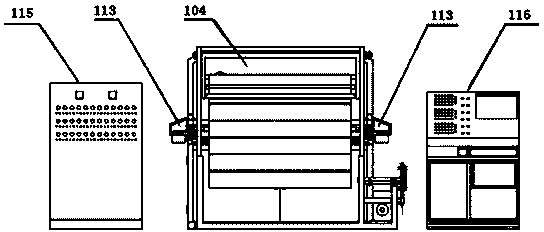

Laser processing pattern making machine

InactiveCN103831535AFast processingIncrease productivityWelding/soldering/cutting articlesLaser beam welding apparatusEngineeringMetallic materials

The invention discloses a laser processing pattern making machine. The laser processing pattern making machine comprises a processing body. A laser tube area is formed above the processing body, a plurality of laser tube sets are arranged in the laser tube area, and a plurality of scanner heads are arranged at the tail end of each laser tube set. A guide assembly and a transmission assembly are arranged in the processing body, the guide assembly comprises a plurality of front guide rollers located in the front of the processing body and a plurality of rear guide rollers located at the back of the processing body, and the transmission assembly comprises a supporting transmission device located in the middle of the processing body and a pulling device located at the back of the processing body. A negative-pressure adsorption device is arranged in the supporting transmission device, air extraction devices are arranged on the two sides of the supporting transmission device, and an air blowing device is also arranged in the laser processing area and located above the scanner heads. In this way, the laser processing pattern making machine is high in processing speed and production efficiency, wide in application range and suitable for processing various non-metallic materials such as textile materials, synthetic natural leather, acryl, wooden ware, bamboo ware, plastics, double-color adhesives, PCBs and paper.

Owner:武汉畅新科技股份有限公司

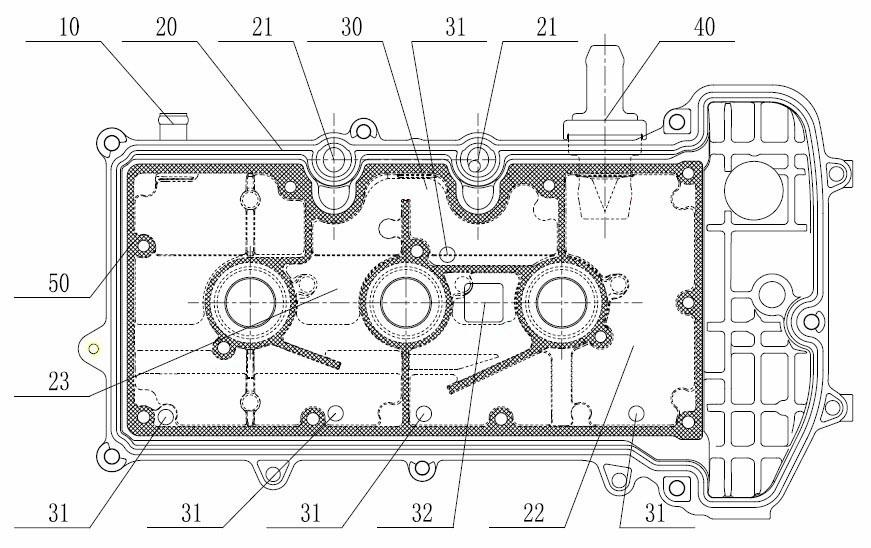

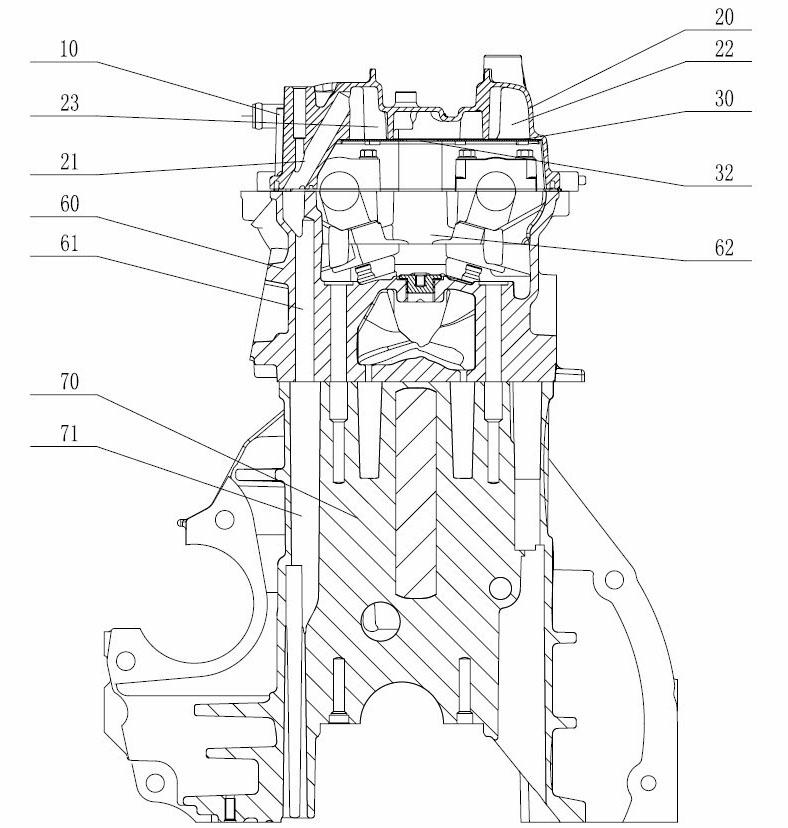

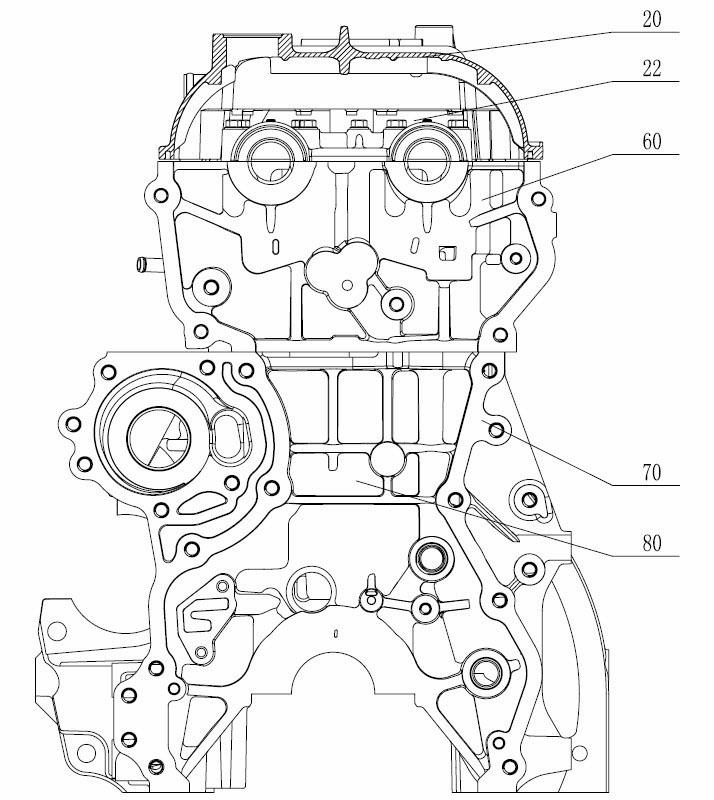

Forced ventilation system of engine crankcase

InactiveCN102425475AAvoid elevationImproved scavenging effectCasingsMachines/enginesCrankcaseControl valves

The invention discloses a forced ventilation system of an engine crankcase, wherein the forced ventilation system comprises a PCV (pollution control valve) oil gas separation chamber, a ventilation pipe oil gas separation chamber, a needle-type PCV and a ventilation pipe, wherein the PCV oil gas separation chamber is composed of a ventilation cover plate and an air cylinder cover; the needle-type PCV is communicated with the PCV oil gas separation chamber; and the ventilation pipe is communicated with the ventilation pipe oil gas separation chamber. The forced ventilation system is characterized in that the volume of the ventilation pipe oil gas separation chamber is greater than that of the PCV oil gas separation chamber; one end of each of two first blow-by channels arranged on the air cylinder cover is positioned in the ventilation pipe oil gas separation chamber, and the other end of each of the two first blow-by channel arranged on the air cylinder cover is corresponding to a second blow-by channel on the air cylinder cover; the second blow-by channel is corresponding to a third blow-by channel on the crankcase; and the bottom of the ventilation pipe oil gas separation chamber is provided with three oil return holes, and the bottom of the PCV oil gas separation chamber is provided with two oil return holes. Because the scavenging effect is improved obviously, the blow-by in the crankcase is timely exhausted into an air intake system so as to prevent accelerated engine oil deterioration and engine element corrosion caused by blowby; and the oil gas separation efficiency of the ventilation pipeline is improved greatly, thus the engine oil consumption of the engine is lowered.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

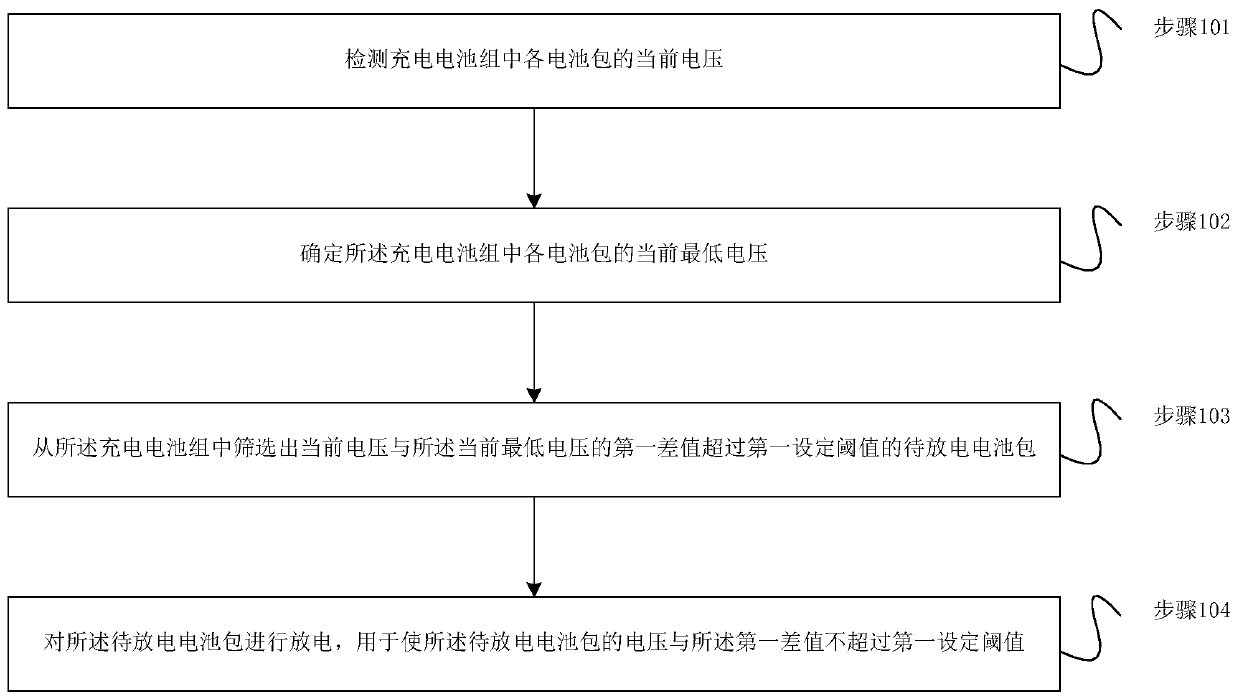

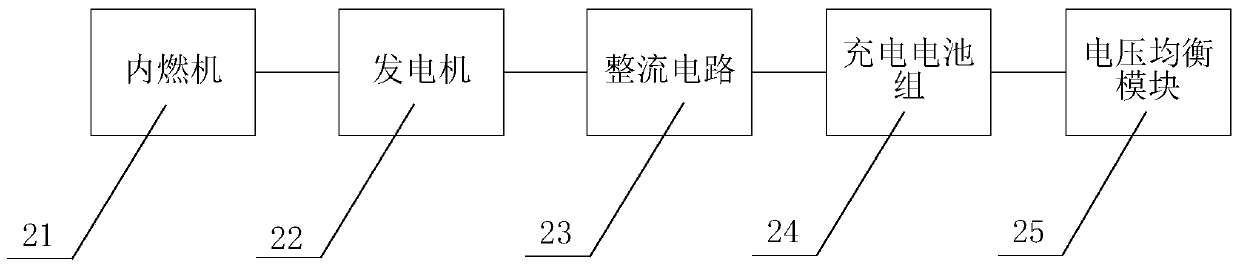

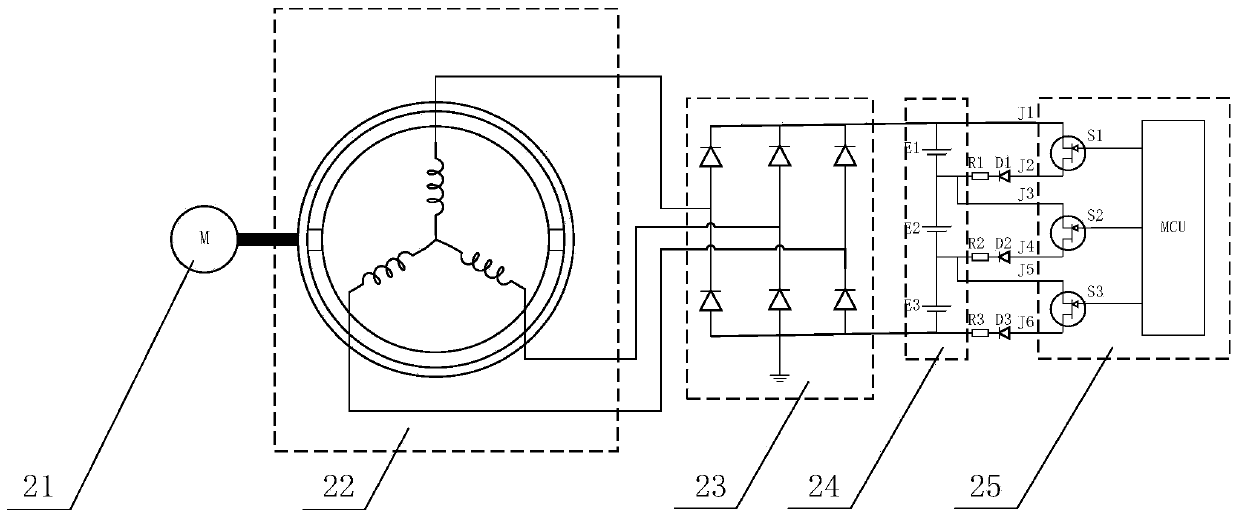

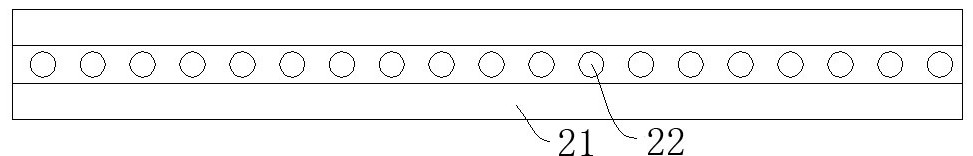

Battery management method for oil-electricity hybrid unmanned aerial vehicle, and oil-electricity hybrid unmanned aerial vehicle

PendingCN111071456AImprove power supply securityNormal dischargeElectric devicesVehicular energy storageElectrical batteryUncrewed vehicle

The invention relates to the technical field of battery management of oil-electricity hybrid unmanned aerial vehicles, and concretely relates to a battery management method for an oil-electricity hybrid unmanned aerial vehicle, and the oil-electricity hybrid unmanned aerial vehicle. The battery management method is carried out after the fuel-electric hybrid unmanned aerial vehicle executes a flight task, and comprises the following steps: detecting the current voltage of each battery pack in a rechargeable battery pack; determining the current minimum voltage of each battery pack in the rechargeable battery pack; screening out a to-be-discharged battery pack of which the first difference value between the current voltage and the current minimum voltage exceeds a first preset threshold value from the rechargeable battery pack; and discharging the to-be-discharged battery pack to enable the voltage of the to-be-discharged battery pack and the first difference value not to exceed the first preset threshold value. After the flight task is executed each time, the unbalanced battery packs are discharged to guarantee that all the battery packs are balanced when the oil-electricity hybridunmanned aerial vehicle executes the flight task next time, so the power supply safety performance of the oil-electricity hybrid unmanned aerial vehicle is improved.

Owner:BEIJING RICHENPOWER TECH CO LTD

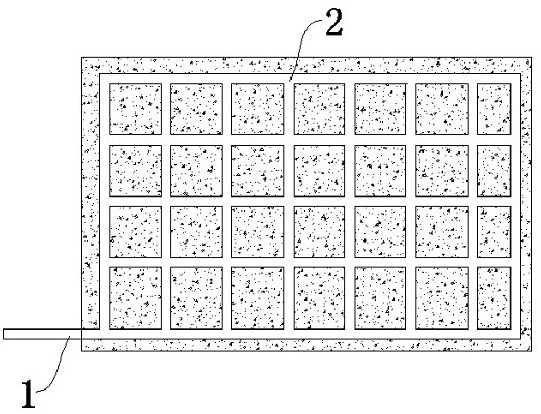

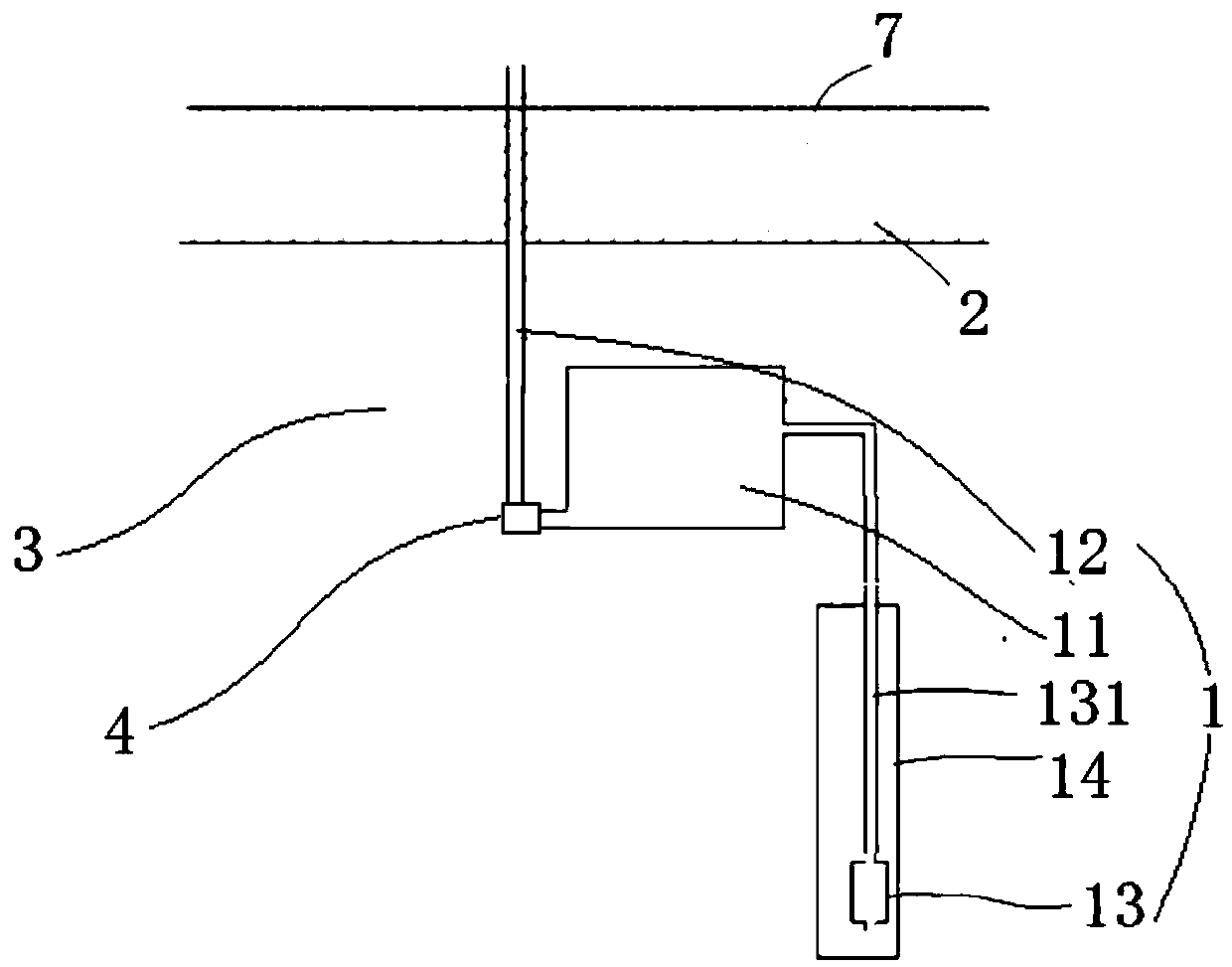

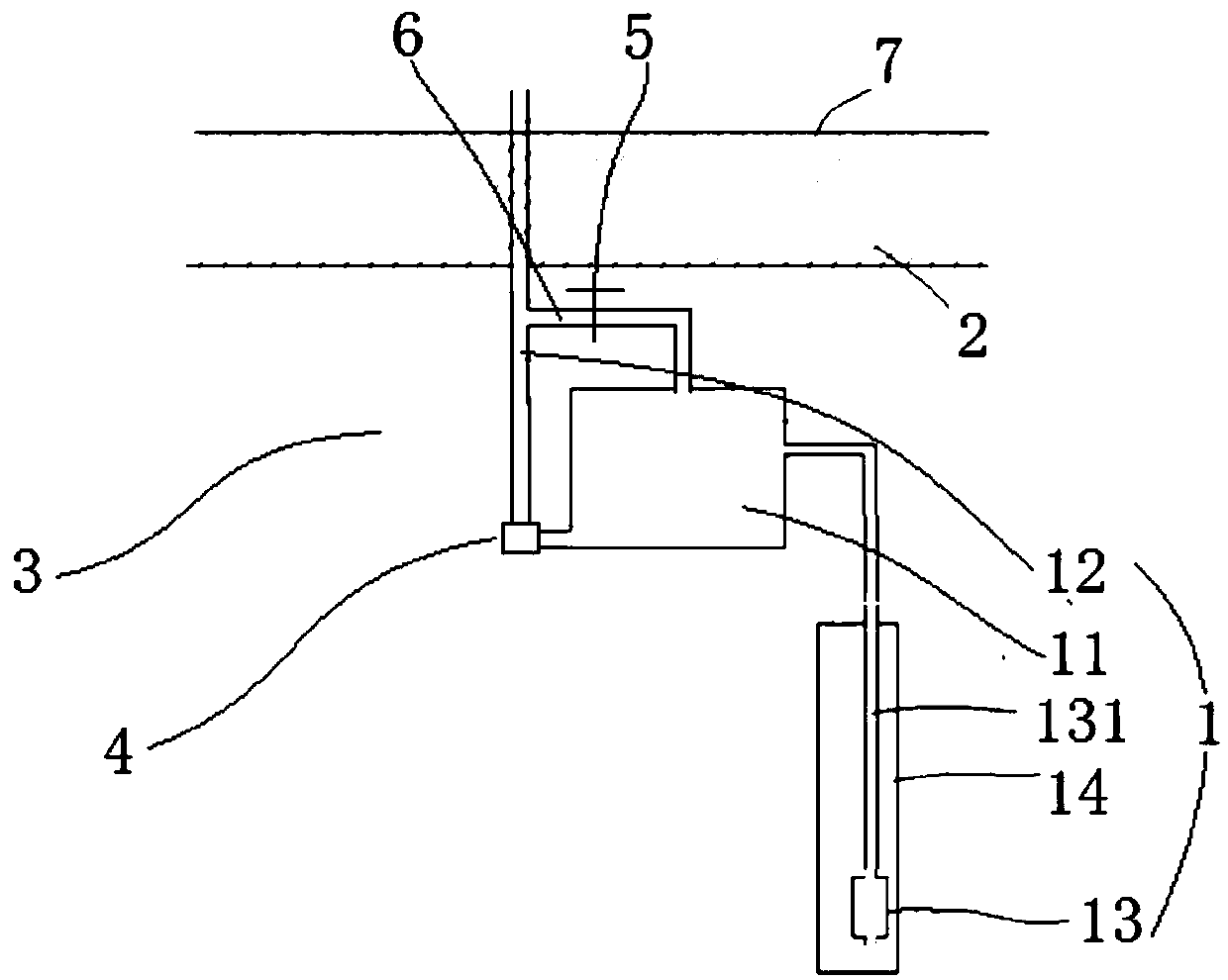

Water seepage system for sponge city

PendingCN112553998ADoes not affect aestheticsTimely dischargePaving gutters/kerbsSewage drainingSoil scienceEnvironmental engineering

The invention discloses a water seepage system for a sponge city. The system comprises water seepage blind ditches, a water seepage cover plate and a surface layer, the water seepage blind ditches intersect to form a net structure, a plurality of water seepage blind ditches are formed in a base layer and covered with the water seepage cover plate, water seepage seams allowing water to flow into the water seepage blind ditches are reserved in the water seepage cover plate, the surface layer is laid on the water seepage cover plate, splicing seams corresponding to the water seepage seams are reserved in the surface layer, and water on the surface layer sequentially passes through the splicing seams and the water seepage seams to flow into the water seepage blind ditches. The water seepage system has the beneficial effects that the water seepage cover plate is designed in a hidden mode, the attractiveness of a driving area and a pedestrian area cannot be affected under the effect of a water seepage function, rainwater can be drained into the water seepage blind ditch in time through the water seepage structure, then the rainwater infiltrates into an underground water system under natural soil through the water seepage blind ditch, ecological damage to underground water in a local area during restoration construction is avoided, and meanwhile water accumulation in pedestrian and driving areas of a high-end community is avoided.

Owner:基准方中建筑设计股份有限公司

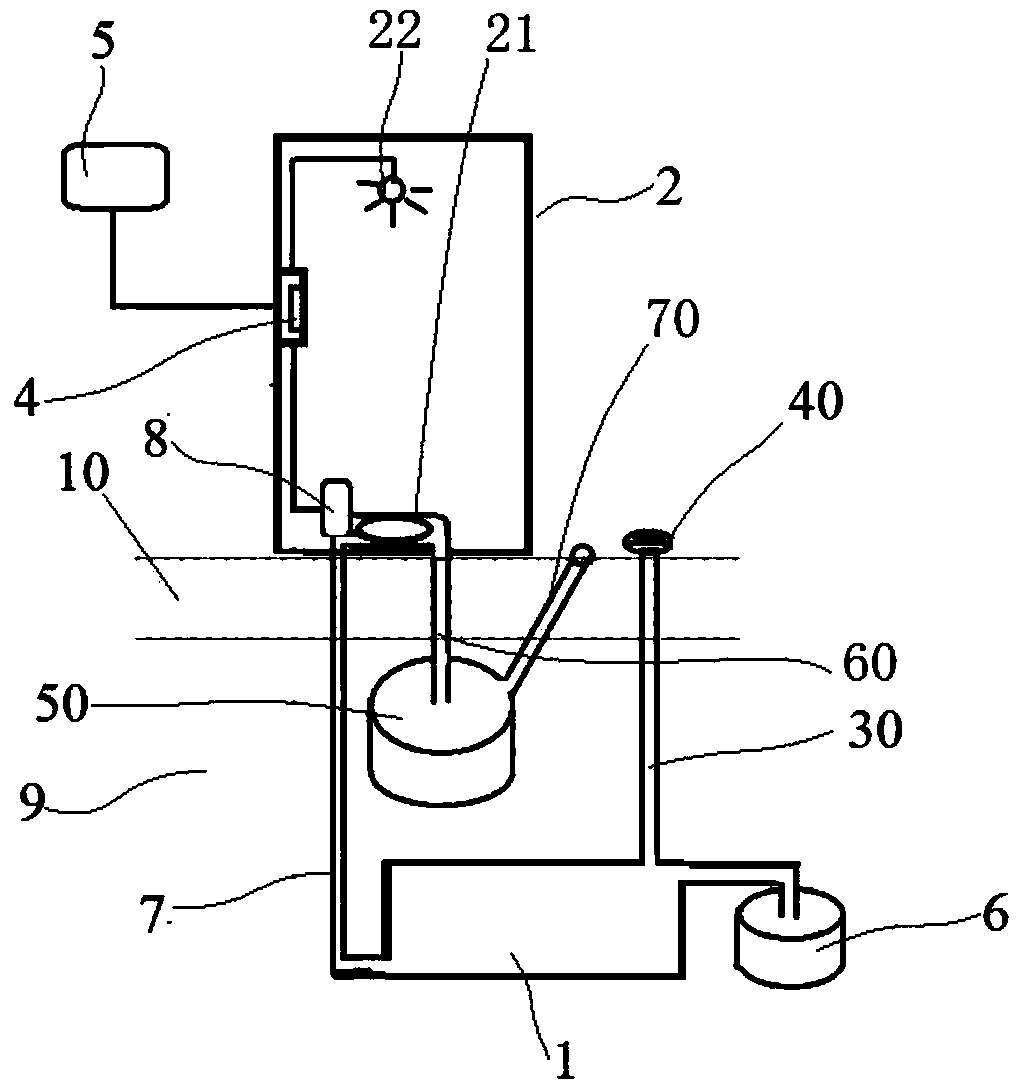

Normal-pressure water supply anti-freezing device

PendingCN110905049AAvoid breakingExtended service lifeService pipe systemsWater mainsWater sourceOutfall

The invention discloses a normal-pressure water supply anti-freezing device. The normal-pressure water supply anti-freezing device is connected with a water tank of a water supply system, a water outlet pipeline of the water supply system penetrates through a ground frozen soil layer, the water tank is a normal-pressure water tank placed in an underground anti-freezing soil layer, a water outlet of the water tank is connected with a drainage pump, the drainage pump is a backflow-type drainage pump, and a drainage port of the drainage pump is connected with the water outlet pipeline. When the drainage pump is started, water in the water tank is pumped into the water outlet pipeline to be discharged; and when the drainage pump is stopped, remaining water in the frozen soil layer and areas above the frozen soil layer in the water outlet pipeline flows back into the water tank from the drainage pump. According to the normal-pressure water supply anti-freezing device, by controlling the start and stop of the backflow-type drainage pump, the remaining water in the water outlet pipeline is quickly discharged and then flows back into the water tank, the water source is saved, the problemsof icing and breaking of the water outlet pipeline penetrating through the frozen soil layer and located on the ground part are avoided, and the service life of the water outlet pipeline and the drainage pump is greatly prolonged.

Owner:管凤强

Full Chinese type settling pond

ActiveCN100342943CEven distribution of waterWell mixedSedimentation settling tanksSludgeWater quality

The settling pond features that all the mixing stirrer, the raising stirrer and its stainless steel barrel, the mud scraper, the inclined plastic pipe area and the rectangular water outlet stainless steel tank are located inside the main pond; the sludge pipe communicates the sludge screw pump, the water inlet pipe and the concentrating sludge draining area in the lower part of the main pond; and the chemical adding pipe is set below the mixing stirrer. The present invention has reasonable structure and homogeneous water distribution. The raising stirrer and the sludge screw pump are connected with the frequency varying motor for flexible regulation based on the practical condition to ensure the water effluent quality. The mud scraper can centralize and concentrate sludge. The present invention is suitable for use in water works and sewage yard.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

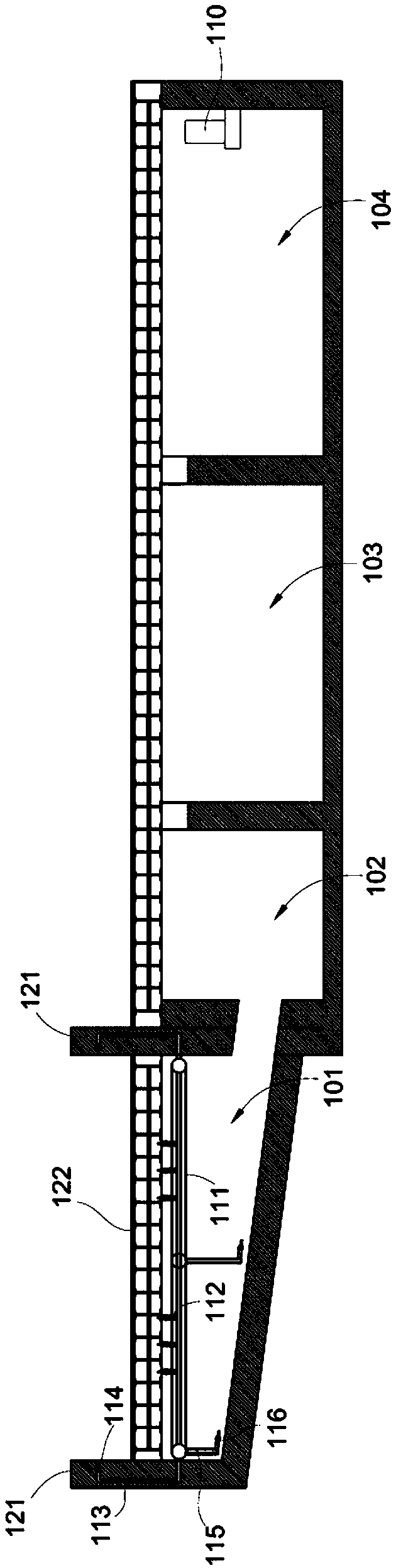

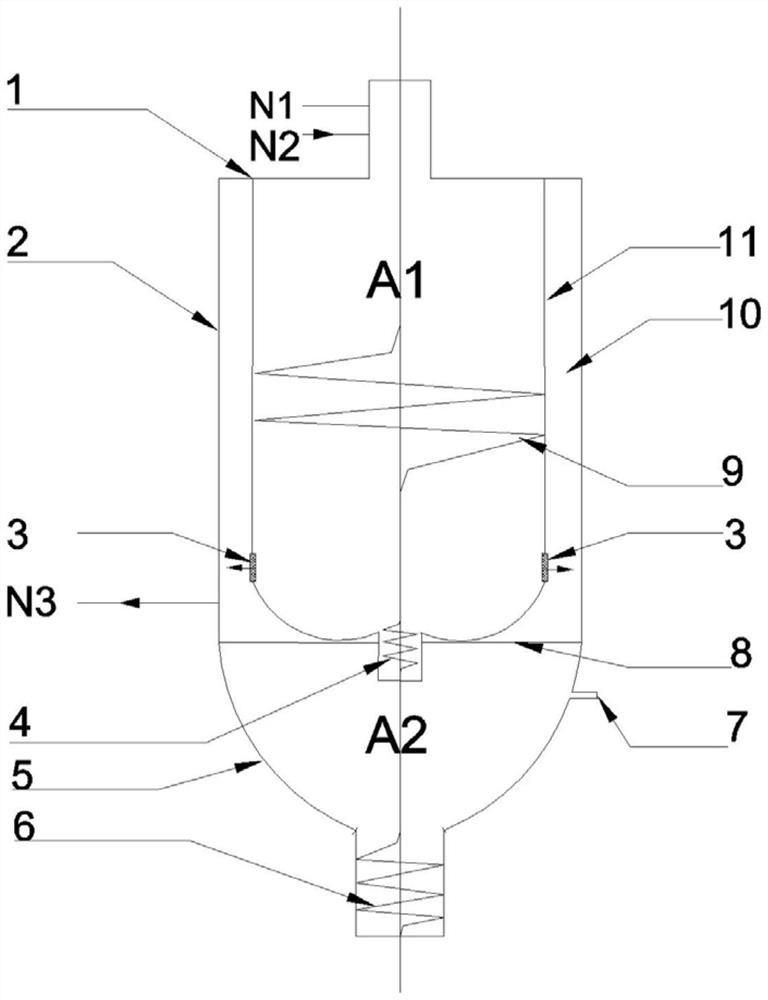

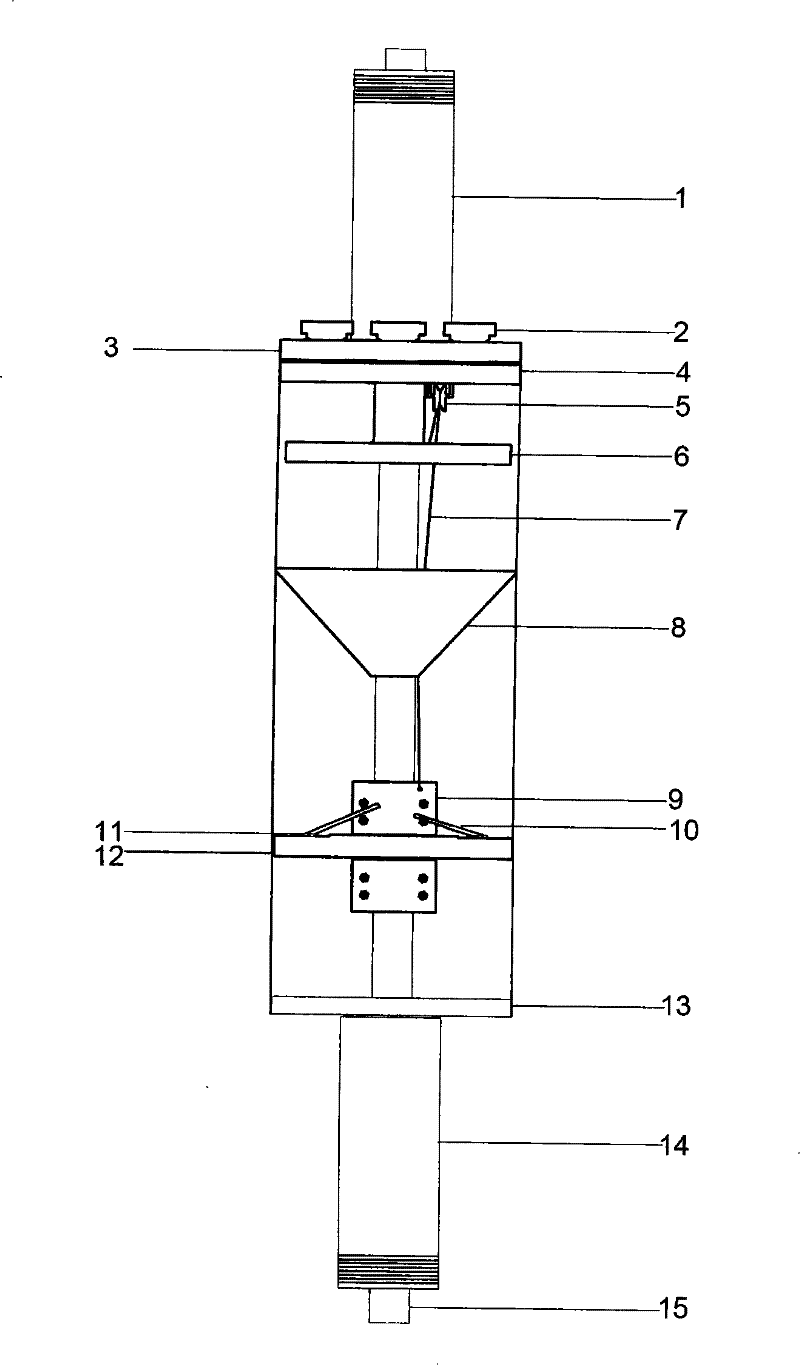

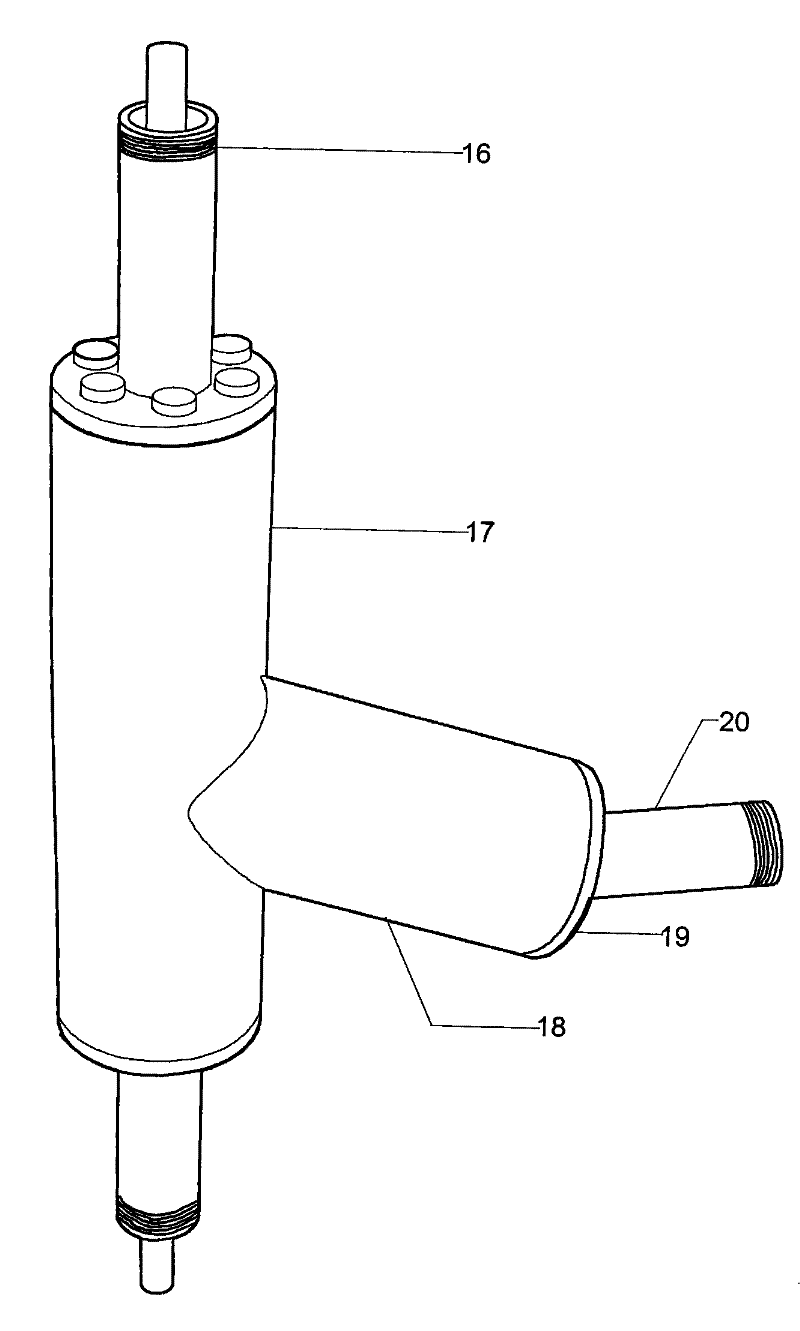

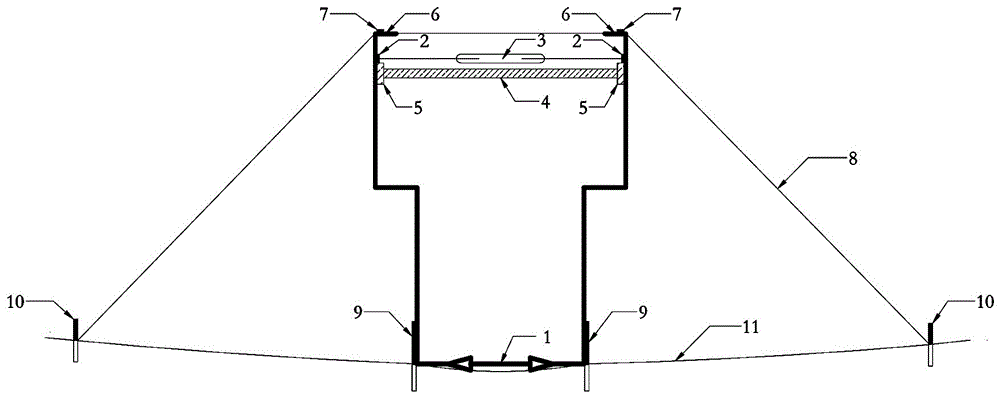

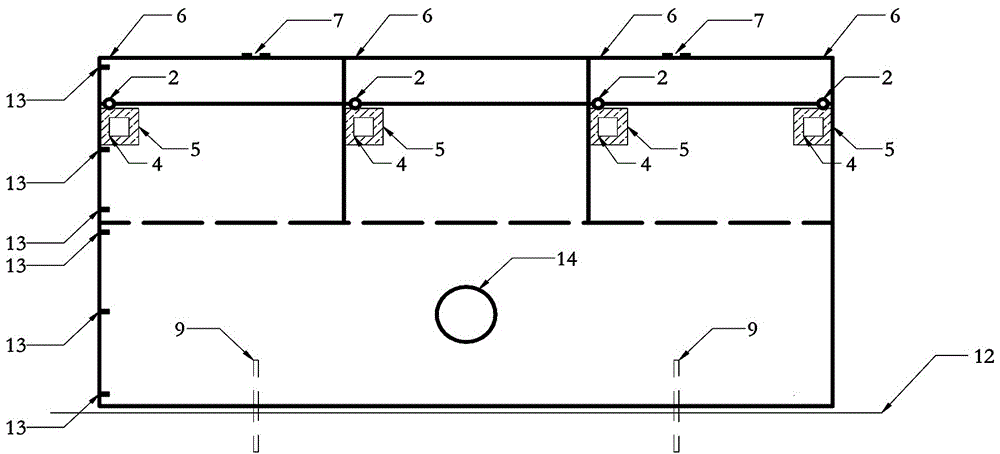

Supercritical water oxidation reactor for on-line desalination and salt elimination

PendingCN114804423ARealize the effect of online salt removalTimely dischargeWater contaminantsTreatment involving filtrationInorganic saltsDesalination

The invention discloses a supercritical water oxidation reactor for on-line desalination and salt elimination, which is characterized in that an oxidation space is arranged in a main body shell, and is used for carrying out supercritical water oxidation treatment on organic wastes; a mechanical desalting device is arranged in the oxidation space, a salt conveying device is arranged at the bottom of the oxidation space, a filtering device is arranged in the radial direction of the oxidation space, and the mechanical desalting device conducts online removal on inorganic salt in the oxidation space to prevent deposition of the inorganic salt and induction of under-scale corrosion; the filtering device is used for filtering fluid flowing out of the oxidation space, so that all inorganic salt is left in the reactor and is prevented from diffusing to important areas; inorganic salt is conveyed to the salt storage area through the salt conveying device, further reacts with the secondary oxidizing agent and is finally discharged out of the reactor through the sealed salt discharging device of the bottom conical section, and online salt discharging is achieved without shutdown.

Owner:XI AN JIAOTONG UNIV

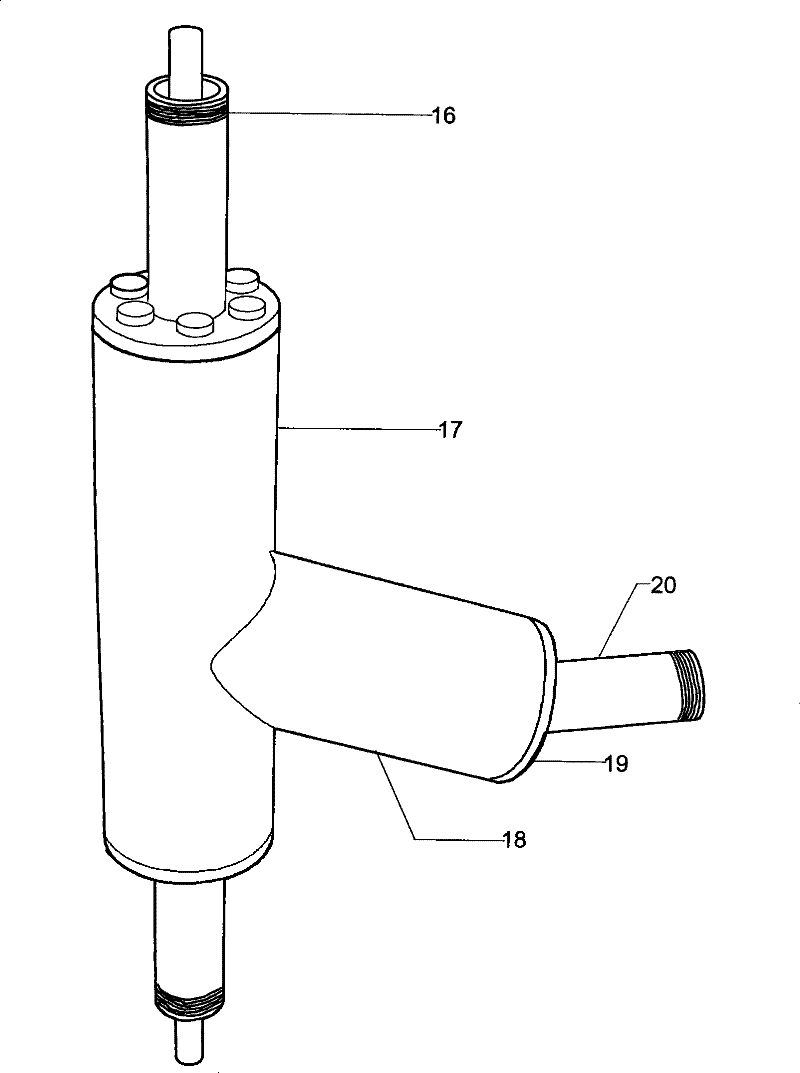

Oil well production increasing environment-friendly device

InactiveCN101289931BEliminate leaksPush smoothFluid removalSealing/packingReciprocating motionOil drilling

The invention relates to an oil well yield-increasing environmental protection device for wellhead equipment, belonging to the oil drilling and excavation technical field. The device is provided with a lower casing connected with an oil pipe of an oil well and an upper casing connected with an oil extractor. An outer casing is connected with between the upper casing and the low casing; the inner diameter of the outer casing is twice to three times that of the upper casing or that of the lower casing; the upper casing is in sealed connection with the lower casing through a flange; an oil-reservoir pipe is communicated with the middle part of the outer casing; and an outlet of the oil-reservoir pipe is connected with an entrance of the an oil outlet pipe. The outer casing is thickened to leave an enough oil-reservoir space inside the outer casing, so that crude oil can not reach and exceed the oil-reservoir space, thereby putting an end to the phenomena of the crude oil leakage and the replacement of used tight head. The outer casing is provided with a one-way valve mechanism which makes reciprocating movement up and down with a sucker rod of the oil extractor, that is, residual energy of the sucker rod is utilized to drive the sealed one-way valve to move up and down, thereby playing a role in extracting assistedly and achieving the effect of increasing yield.

Owner:康雄雄

Inverted-convex overall central drainage ditch device in highway tunnel

The invention discloses an inserted convex integral central drainage ditch device in a road tunnel. The inserted convex integral central drainage ditch device comprises steel templates, a movable hinge, a turnbuckle, square timber cross arms and skids, wherein the two steel templates are arranged symmetrically; the bottom ends of the two steel templates are connected through the movable hinge; the upper ends of the two steel templates are fixedly connected through the turnbuckle, the square timber cross arms and the skids. The concept of water prevention and drainage is implemented in a template, so that structural drainage is realized, the effects of 'combination of prevention and blockage and rapid drainage' are achieved, problems of a central ditch system are prevented fundamentally, the stability and durability of a tunnel structure are ensured, and the operation and all-life effect of the tunnel are enhanced.

Owner:GANSU ROAD&BRIDGE NO 4 HIGHWAY ENG

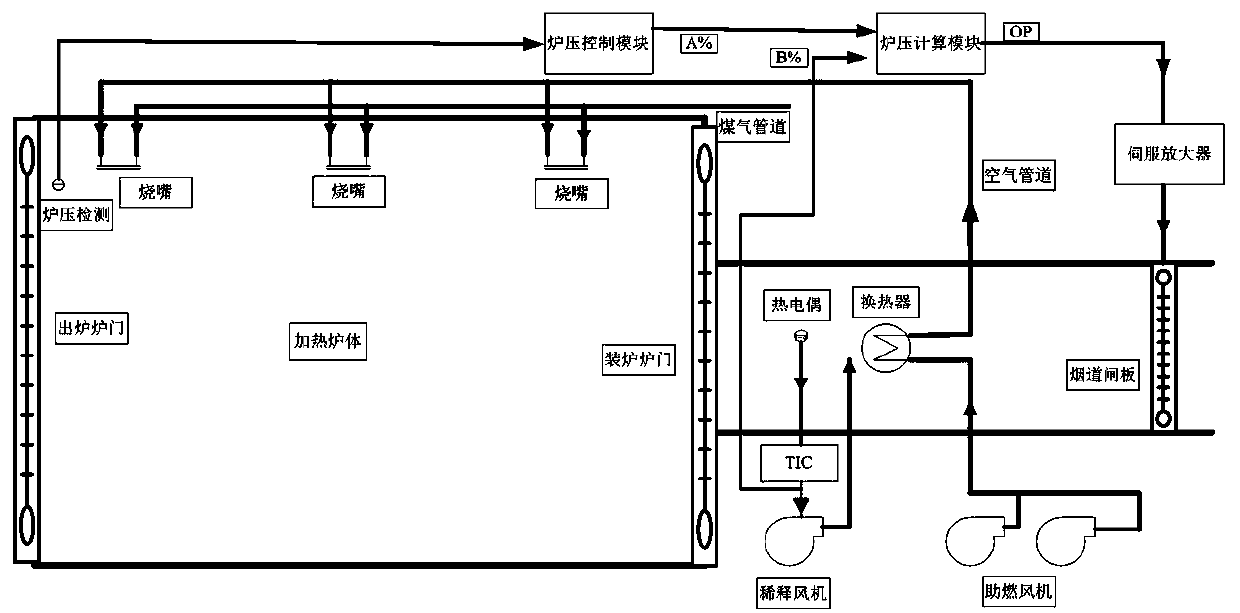

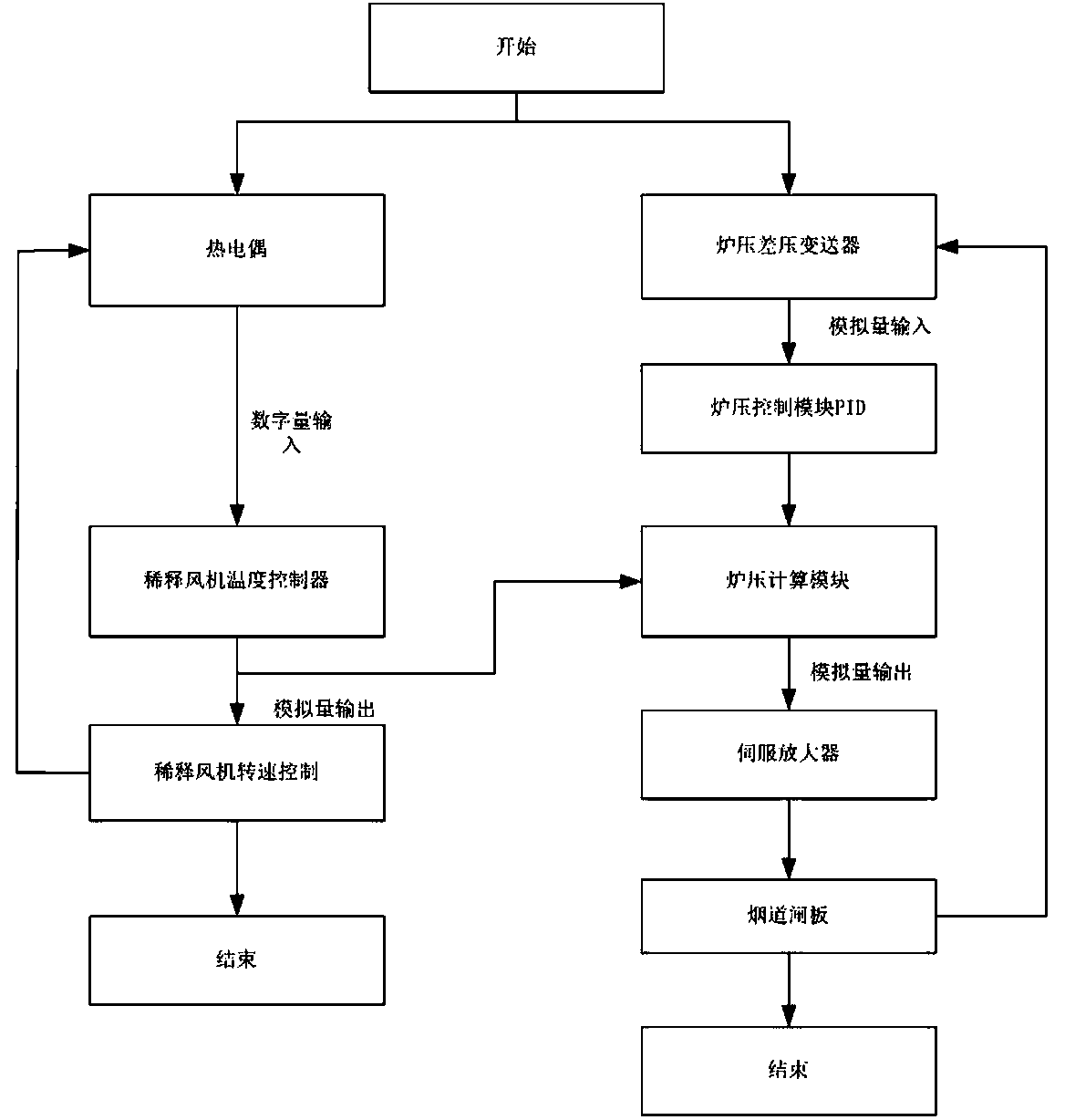

An Optimal Design Method for Furnace Pressure Control of Regenerative Industrial Heating Furnace

ActiveCN109141051BReduce the risk of fireReduce lossesControl devices for furnacesControl signalEngineering

The invention relates to an optimal design method for furnace pressure control of a regenerative industrial heating furnace. The regenerative industrial heating furnace comprises a furnace pressure detection device, a heating furnace body, a burner, a furnace pressure control module, a furnace pressure calculating module, a gas pipeline, an air pipeline, a servo amplifier, a heat exchanger, a thermocouple, a flue damper, a dilution fan temperature controller, a dilution fan and a combustion fan. The optimal design method comprises the steps: firstly, detecting a furnace pressure signal by a furnace pressure and differential pressure transmitter, and sending the furnace pressure signal into the furnace pressure control module; outputting a control signal according to a PID regulation rule,then sending the control signal and an output signal of the dilution fan temperature controller into the furnace pressure calculating module; adjusting a furnace pressure signal and the weighting coefficient of the rotating speed of the dilution fan, and thus obtaining different OP values; converting the OP values into a 4-20mA electrical signal by an output module of the controller to be sent tothe servo amplifier; and finally controlling the opening degree of the flue damper through the servo amplifier, and therefore completing the purpose that the flue damper is dynamically adjusted according to the furnace pressure signal and the rotating speed signal of the dilution fan.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

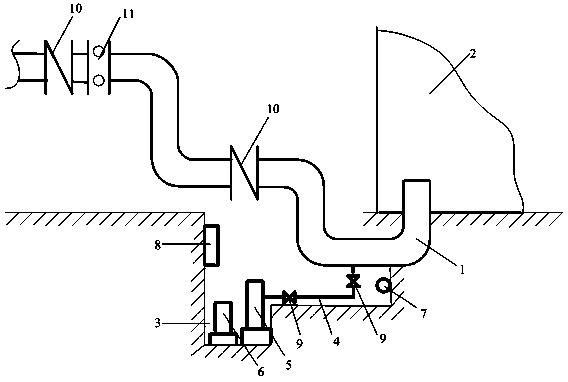

Open type water-sealed valve chamber of dry type blast furnace gas holder

InactiveCN103436647AHighlight substantiveSignificant progressBlast furnace componentsBlast furnace detailsProcess engineeringWater collection

The invention provides a technical scheme for an open type water-sealed valve chamber of a dry type blast furnace gas holder. The water-sealed valve chamber comprises a U-shaped gas channel communicated with the blast furnace gas holder, wherein a water collection tank is arranged below the U-shaped gas channel; one end of a delivery pipe is communicated with the bottom of the U-shaped gas channel; the other end of the delivery pipe is communicated with a water drainer which is arranged inside the water collection tank; the water collection tank is also internally provided with a sewage discharging pump; the delivery pipe is provided with a valve. The water-sealed valve chamber is open type, thereby being easy to operate and view; since the water drainer with an automatic stirring function is arranged, water can be drained in time; a CO audible and visual alarm is arranged and can be used for monitoring the open type water-sealed valve chamber area, so that whether gas is leaked can be known at any time; if gas is leaked, an explosion-proof axial flow fan is started to disperse blast gas and lower the gas concentration.

Owner:JIGANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com