Laser processing pattern making machine

A laser processing and parquet machine technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, low yield of finished products, poor continuity, etc., to achieve fast processing, high production efficiency, application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

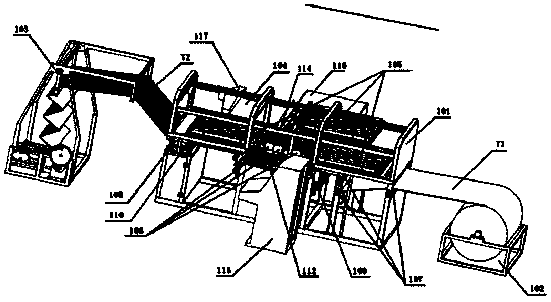

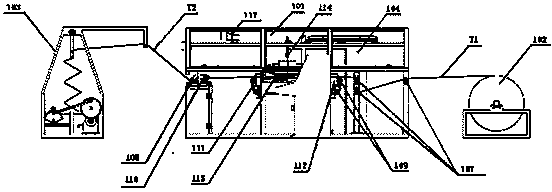

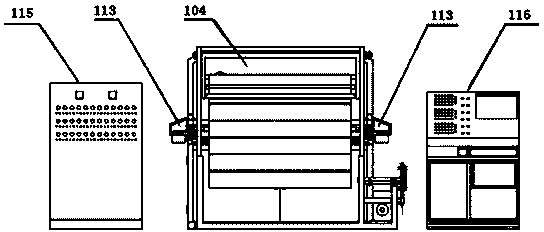

[0037] see Figure 1-3 , shows the laser processing mosaic machine of the present invention.

[0038] The laser processing mosaic machine includes a processing body 101, and the front and rear ends of the processing body 101 can be respectively provided with an unwinding machine 102 and a stacking machine 103. The unwinding machine 102 can be used to store raw materials T1, such as rolled leather, Cloth, etc., the stacking machine 103 can be used to process the finished product T2, the unwinding machine 102 and the stacking machine 103 are existing mature products in the field, and their structures will not be described here.

[0039] A laser tube area 104 is provided above the processing body 101, and multiple sets of laser tube groups 105 are arranged in the laser tube area 104. In the processing head, there are two angle-adjustable polarizers controlled by servo motors in each vibrating head 106 to be precisely controlled by the control system.

[0040] The processing bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com