Forced ventilation system of engine crankcase

A technology of forced ventilation and crankcase, which is applied in crankcase ventilation, engine components, machines/engines, etc. It can solve the problems of no oil-gas separation ability and increase engine oil consumption rate, etc., and achieve improved scavenging effect and oil-gas separation efficiency , Prevent the oil from deteriorating and corroding the machine parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

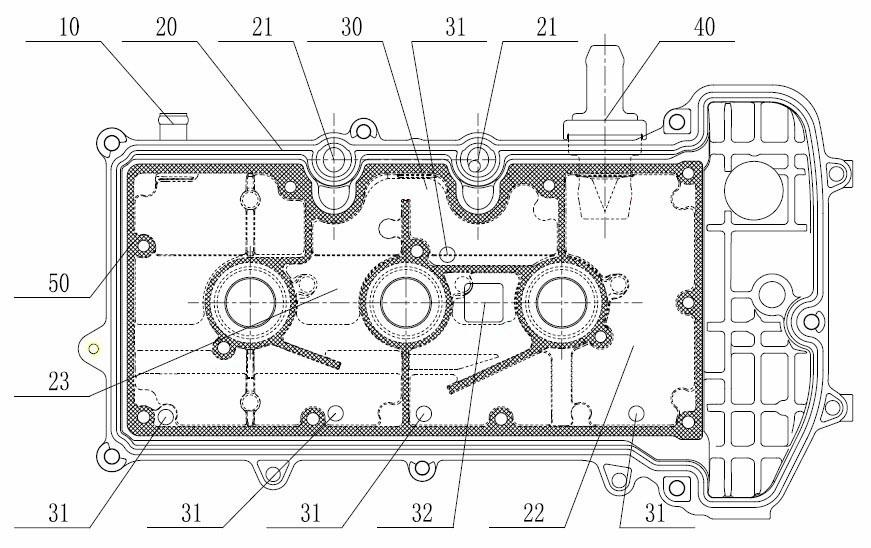

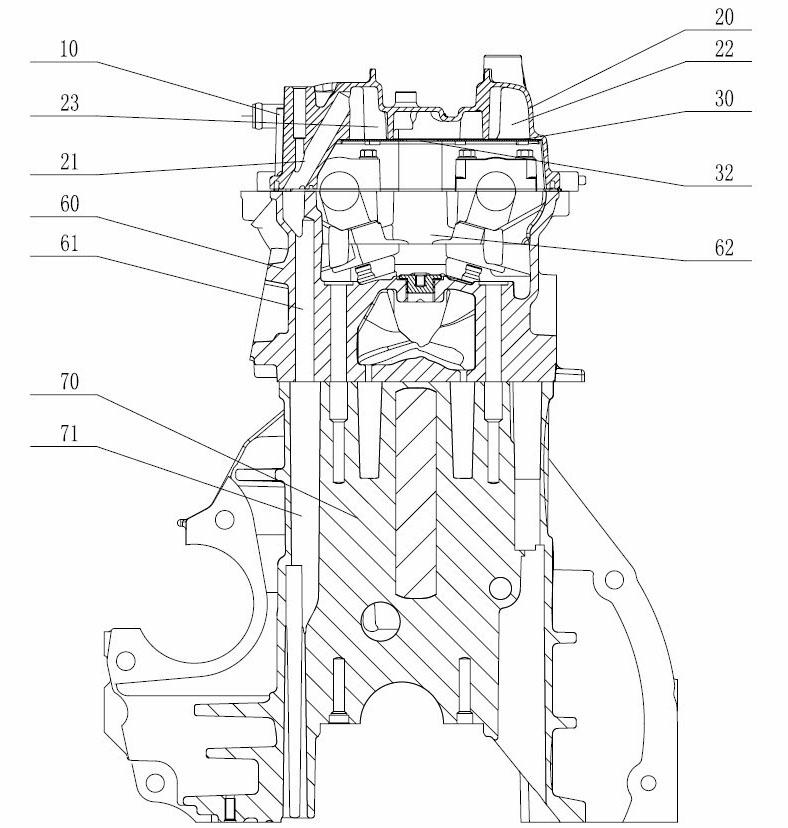

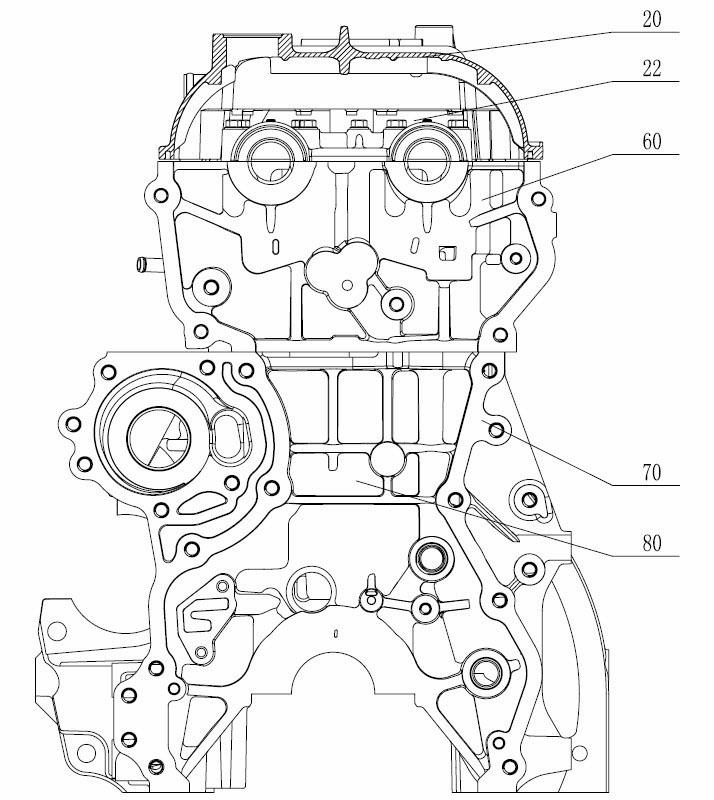

[0021] see figure 1 and figure 2 The shown forced ventilation system for a crankcase of an engine includes a PCV valve oil-gas separation chamber 22 and a breather pipe oil-air separation chamber 23 formed by a vent cover plate 30 and a cylinder head cover 20 connected thereon, and is arranged on the cylinder head cover. And the needle type PCV valve 40 communicated with the oil-gas separation chamber 22 of the PCV valve, the breather pipe 10 which is arranged on the cylinder head cover and communicates with the oil-gas separation chamber 23 of the breather pipe, the oil-gas separation chamber 22 of the PCV valve communicates with the intake manifold through the pipeline Connected, the vent pipe oil-gas separation chamber 23 is connected with the air filter through a pipeline; in order to improve the oil-gas separation efficiency of the vent pipe passage, the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com