Patents

Literature

151 results about "Valve oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Valve oil is a lubricant for valves of brass instruments. It is typically mostly mineral oil with a small amount of other ingredients, although synthetic oils are increasingly available.

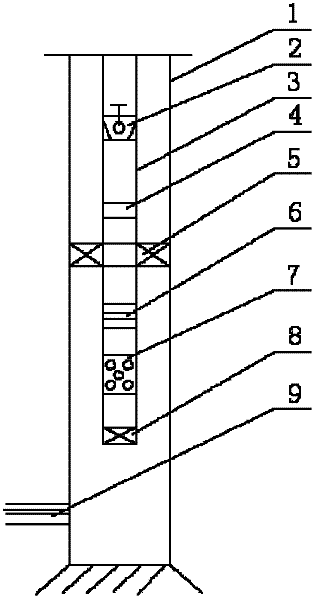

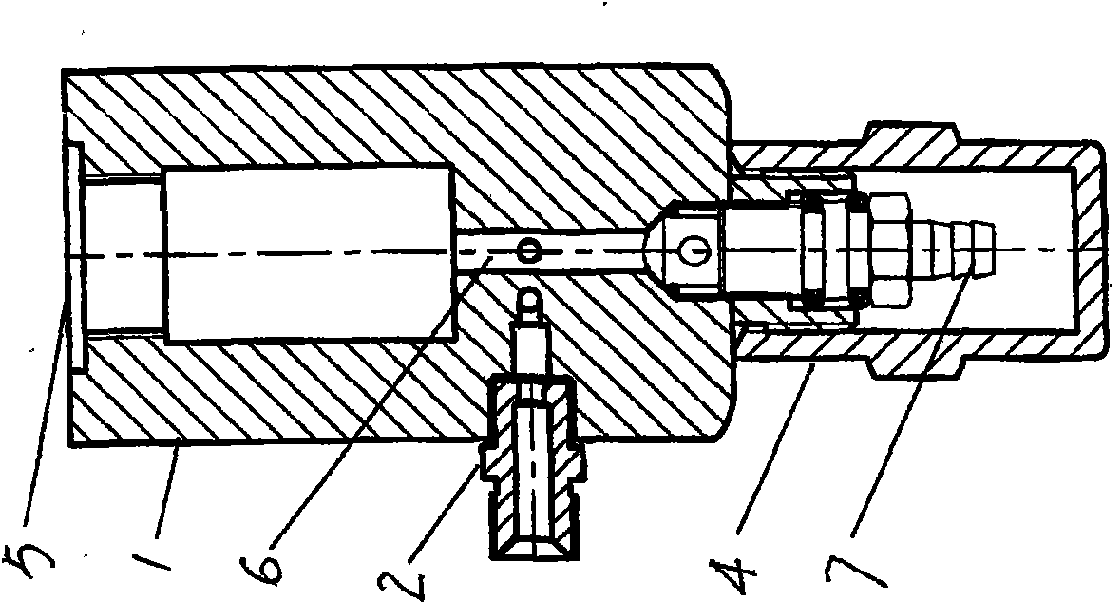

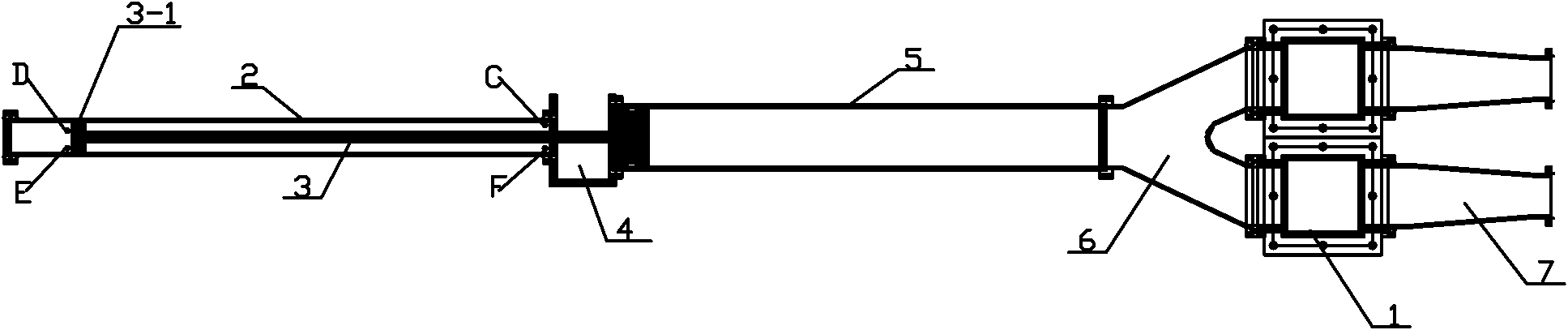

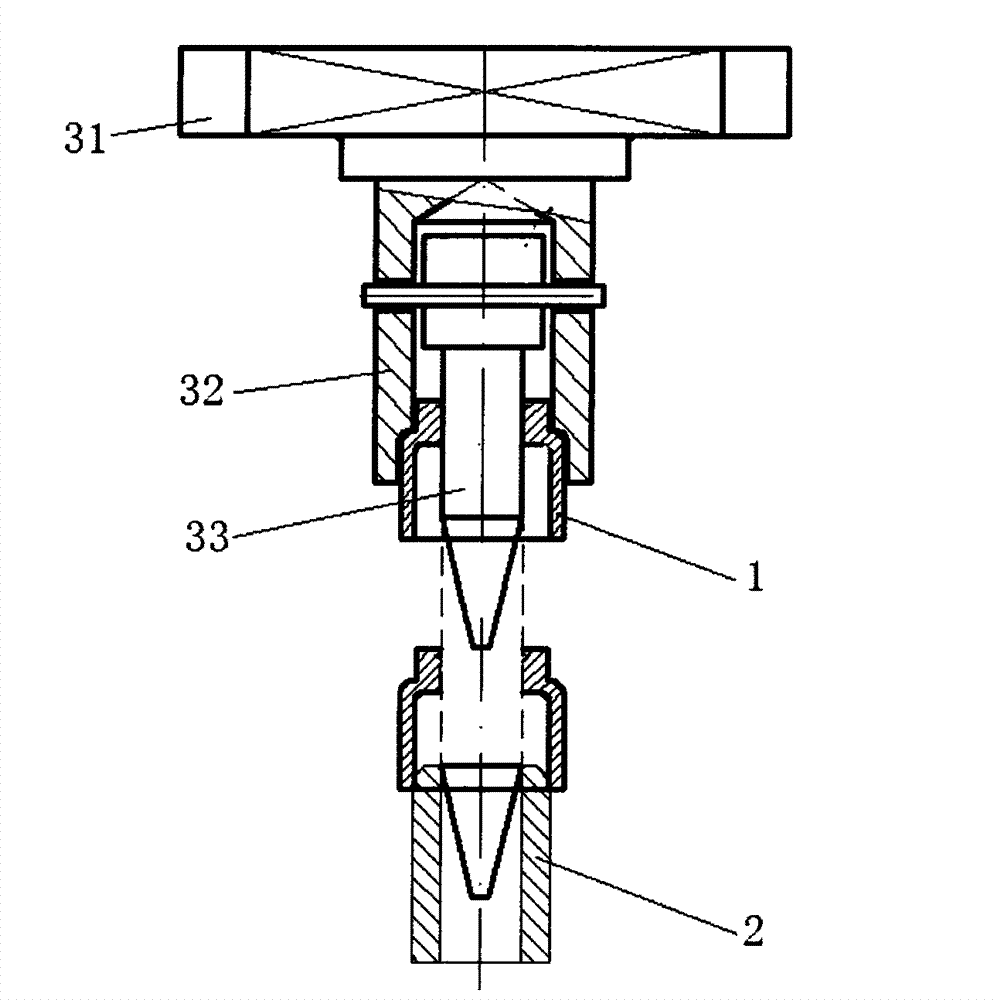

Negative pressure de-plugging and oil extraction process and device

The invention relates to a negative pressure de-plugging and oil extraction process which comprises the following steps: preprocessing an oil well sleeve; detecting the pressure of an oil layer and determining the negative pressure value for de-plugging; descending a negative pressure de-plugging device; installing a wellhead production tree; adjusting the height of the liquid column in an oil pipe above a negative pressure valve; opening the negative pressure valve; opening a well flushing valve; and descending a fishable oil well pump with the fixed valve to carry out the oil extraction operation. The invention also relates to the negative pressure de-plugging and oil extraction device which comprises the oil pipe, a plug, a sieve pipe, a packer, the negative pressure valve, the well flushing valve and the fishable fixed valve oil well pump, wherein the plug and the sieve pipe are sequentially installed at the bottom end of the oil pipe from bottom to top; and the packer seals and packs the annular space of an oil isolation sleeve. The invention has the obvious advantages of simple process, low operation cost, short period, good production increase effects on oil gas wells and strong generality, is safe and reliable, does not need large-scale auxiliary equipment and can obtain high economic effects.

Owner:TIANJIN LONGXIN PETROLEUM MACHINERY MFG CO LTD

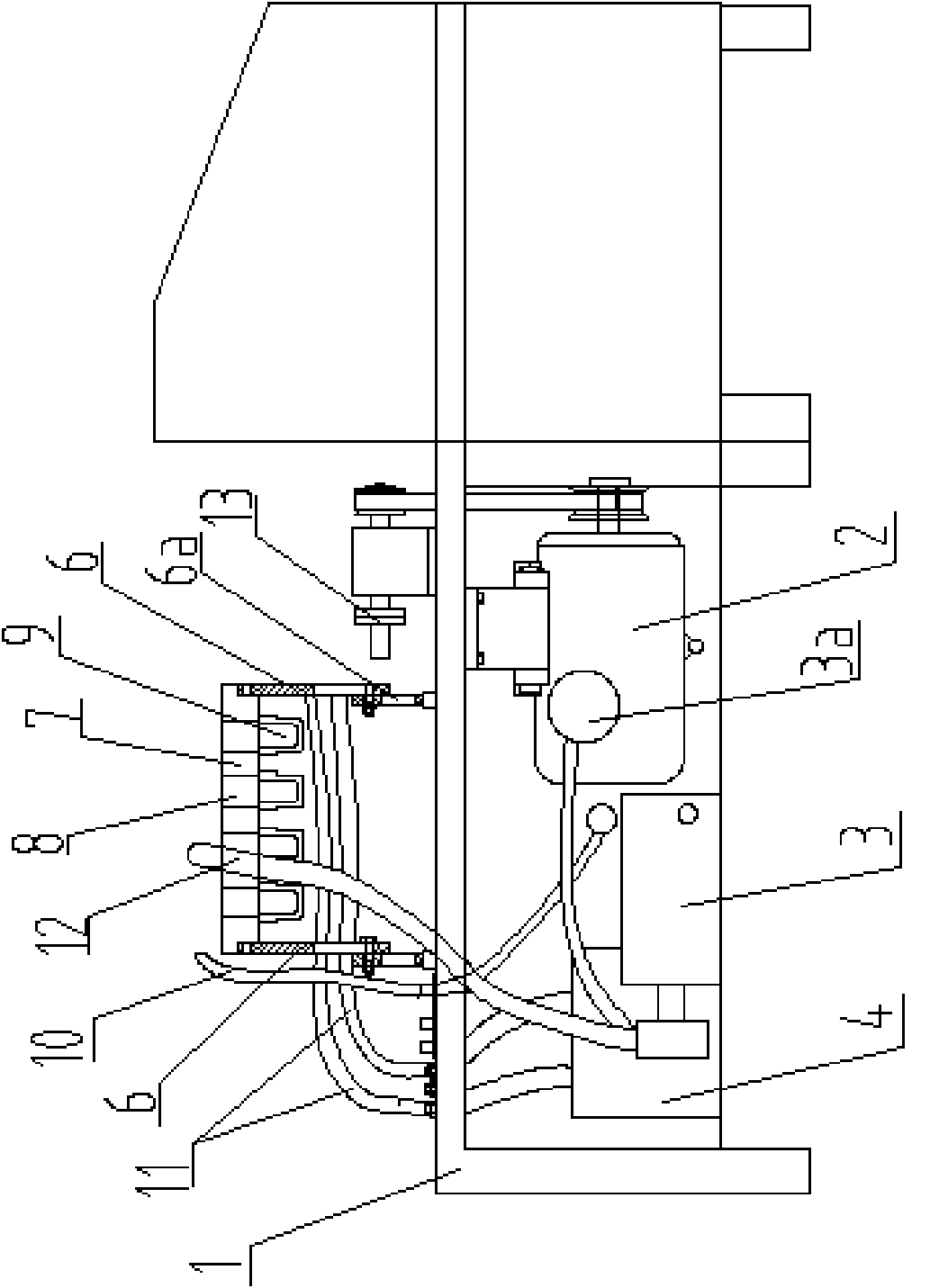

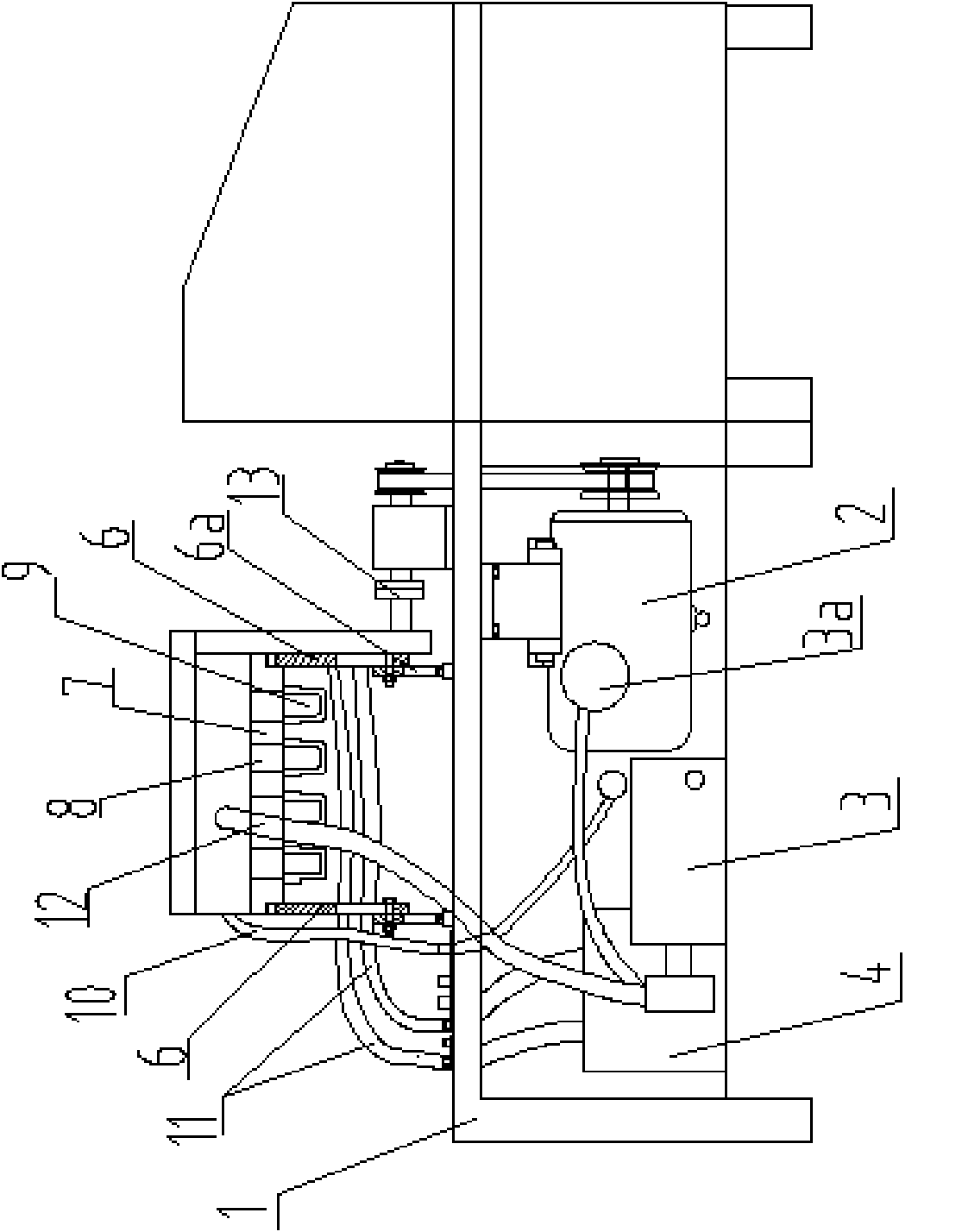

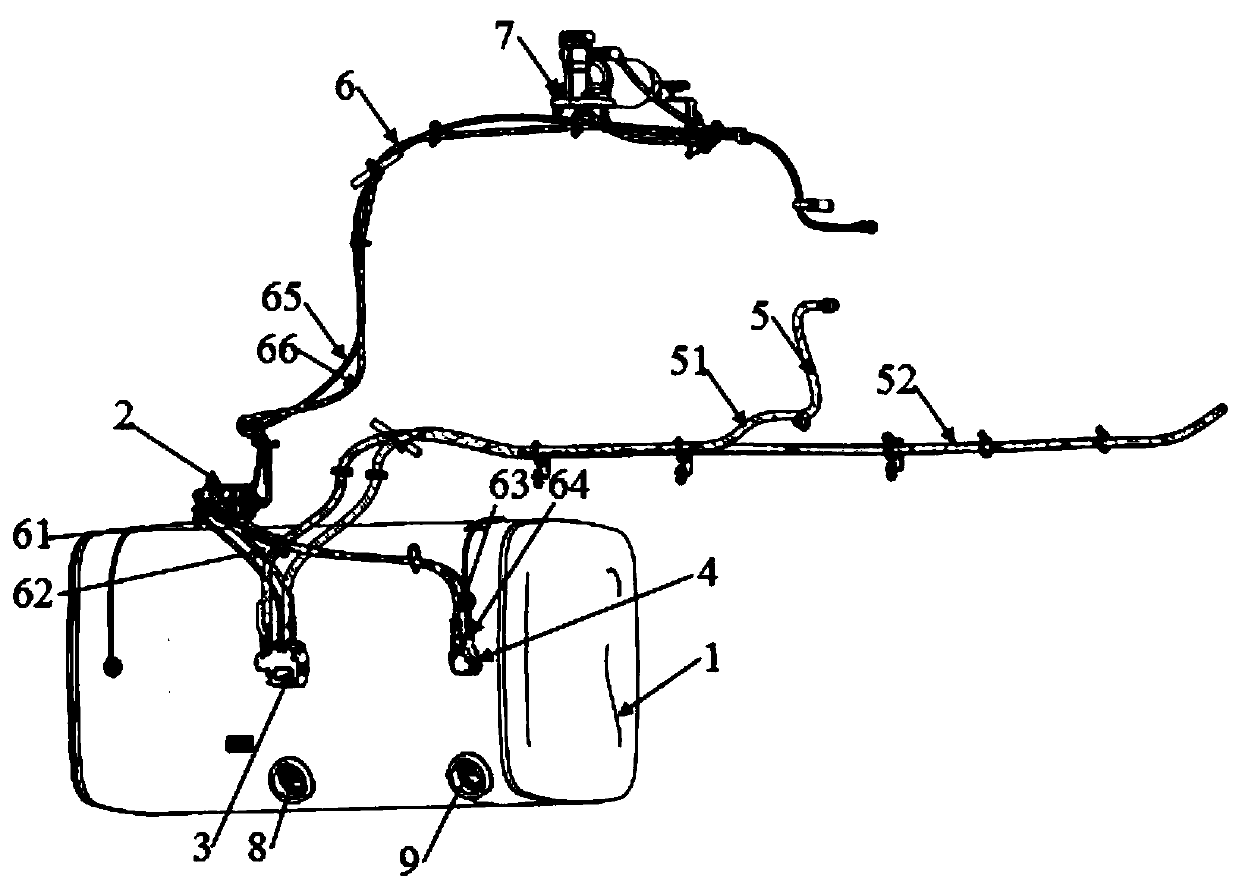

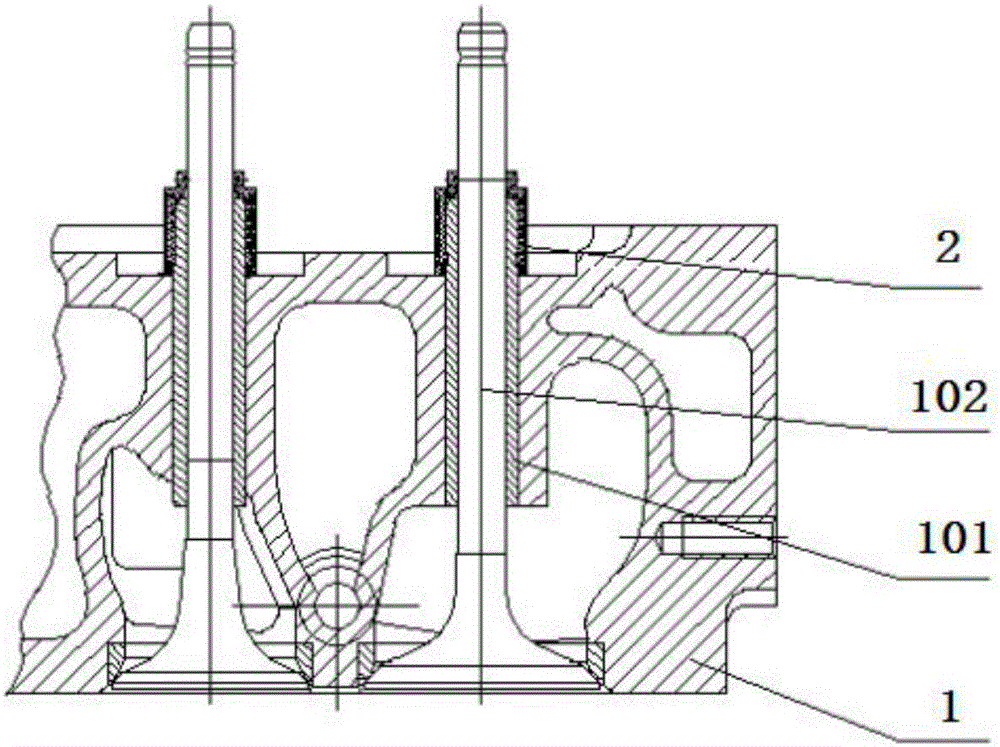

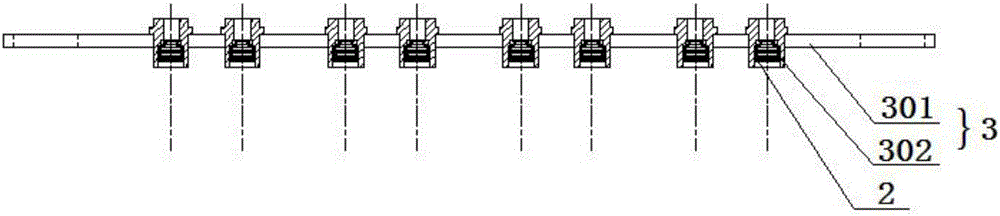

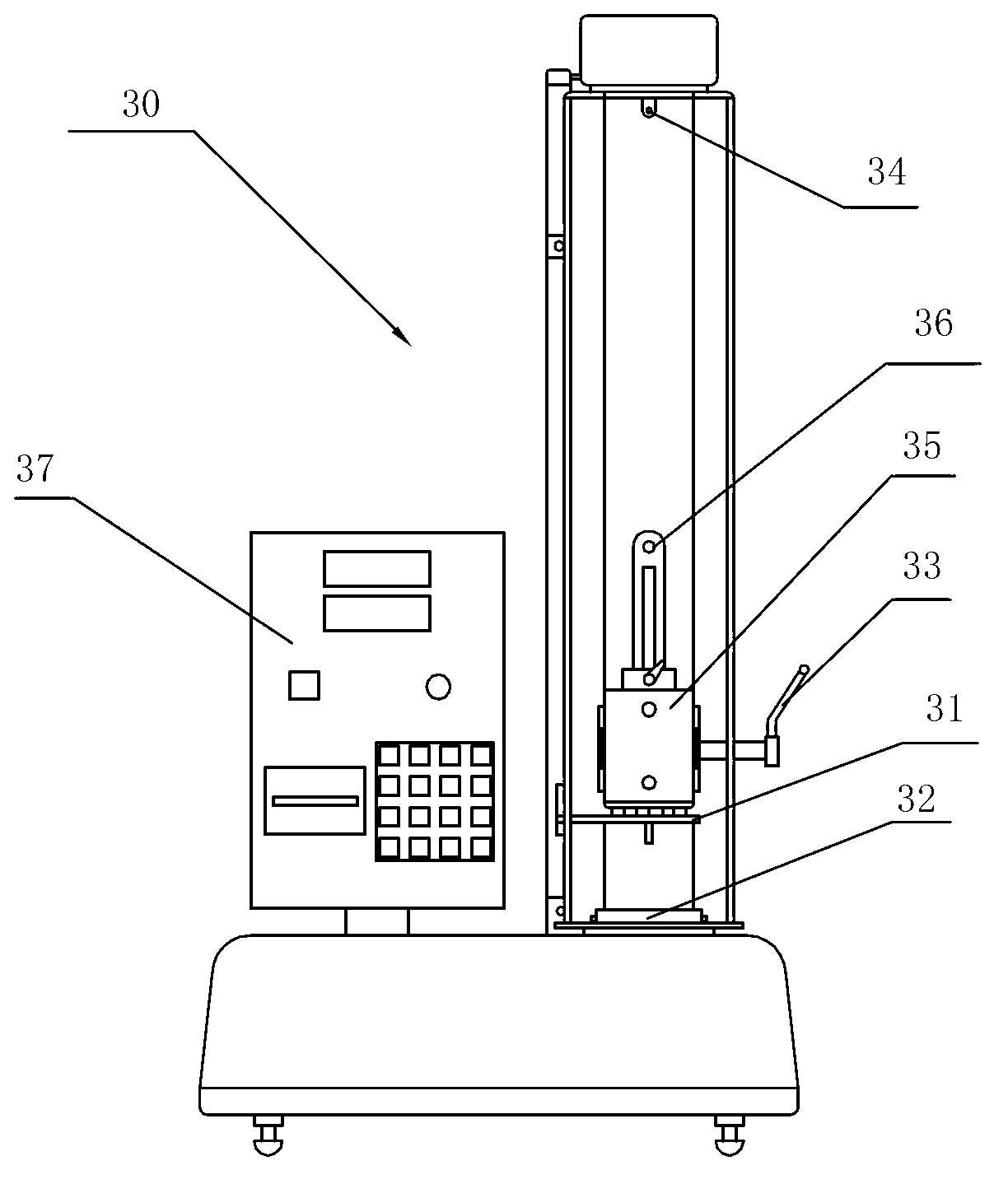

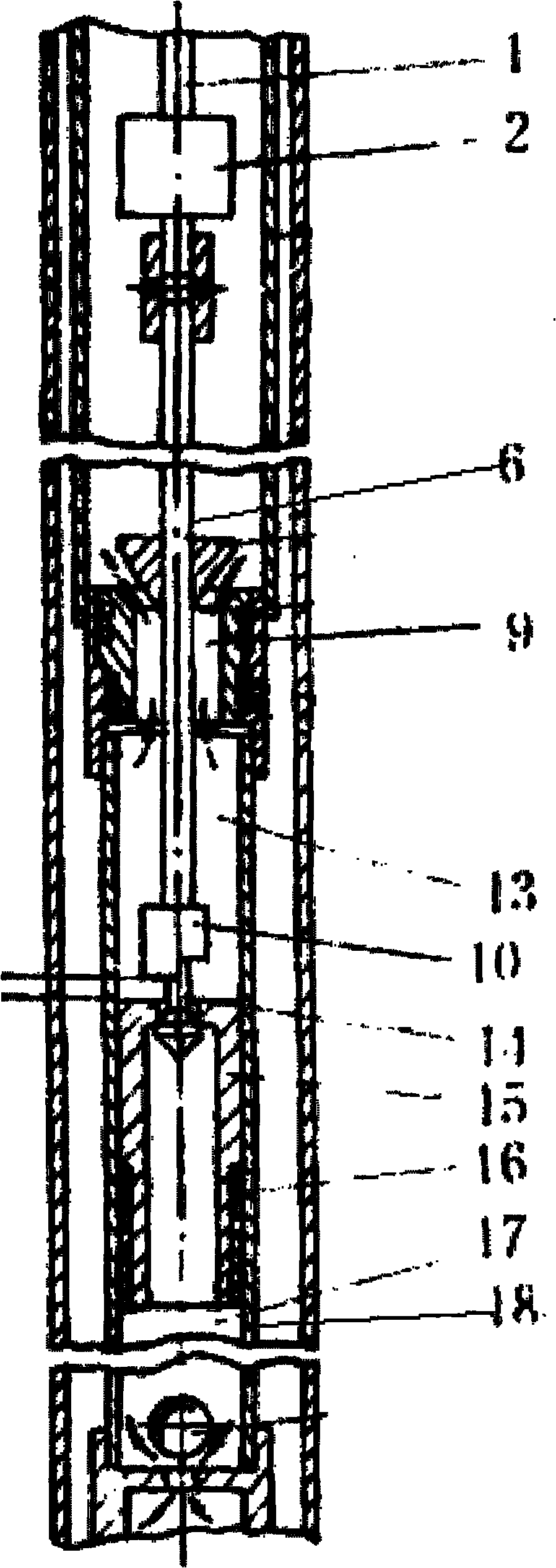

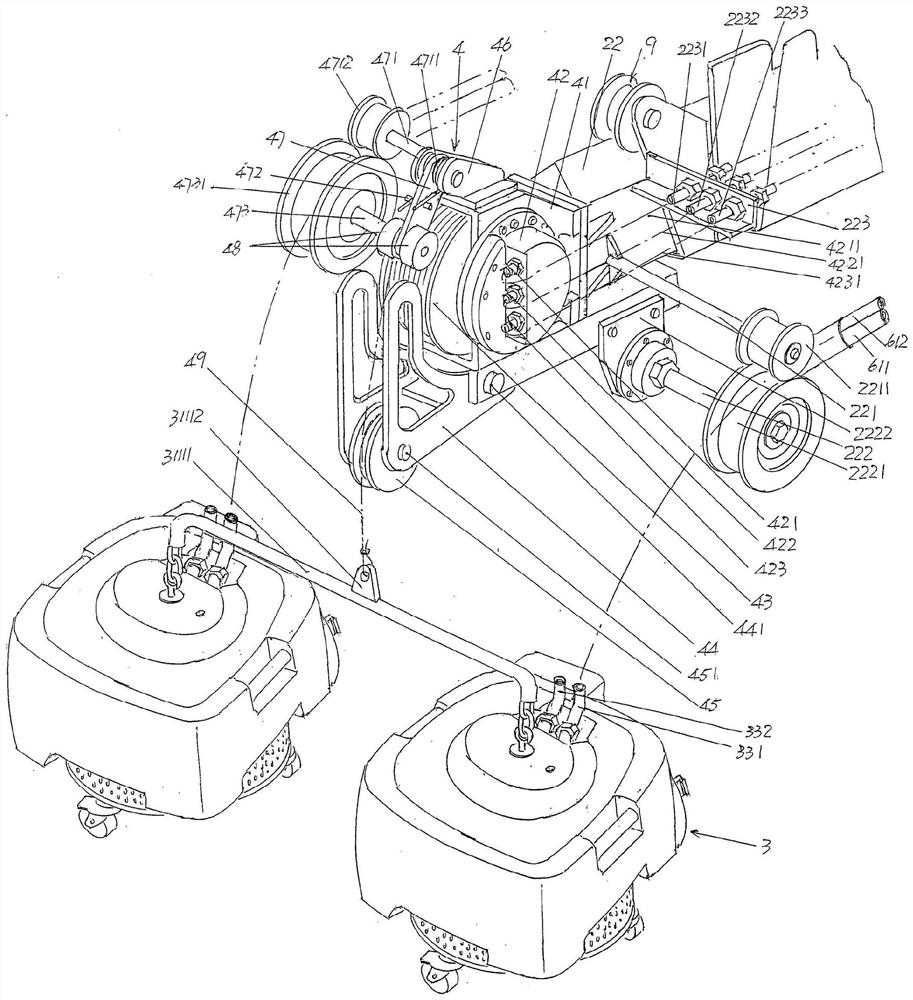

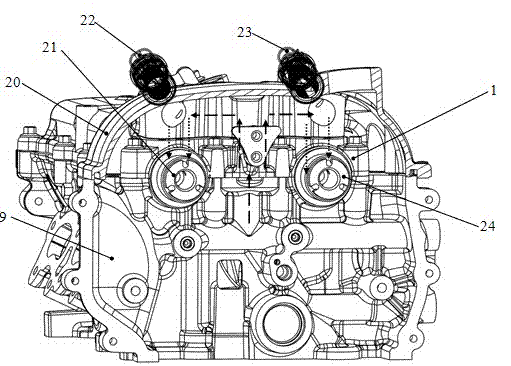

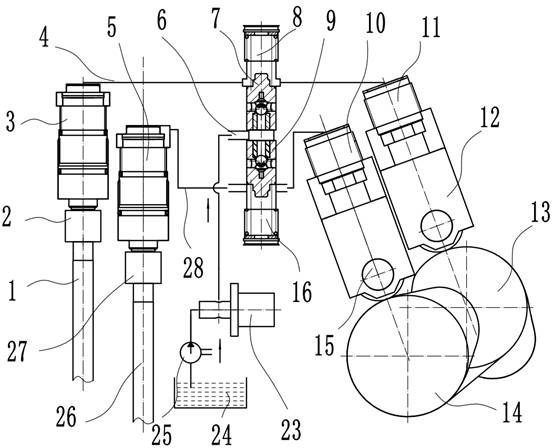

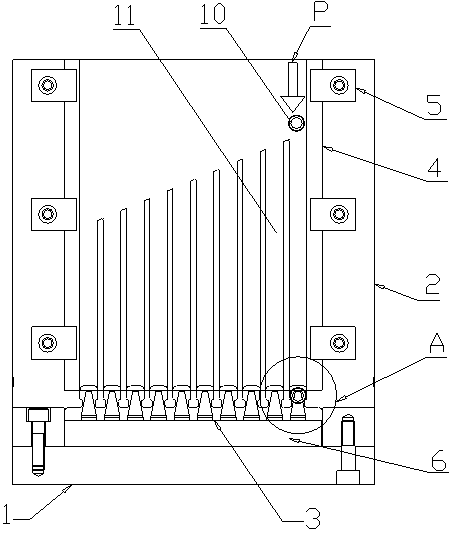

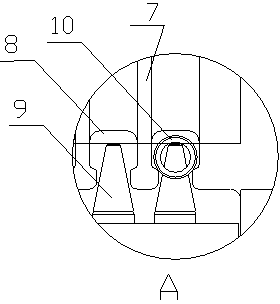

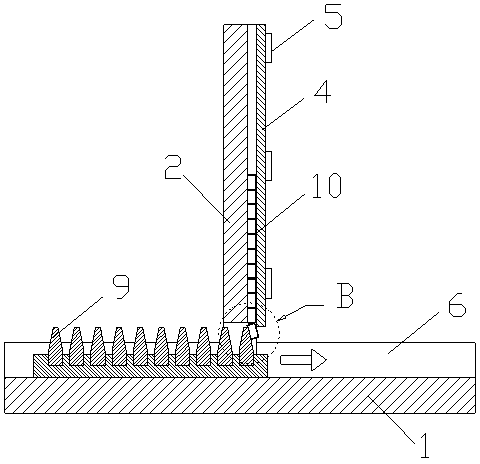

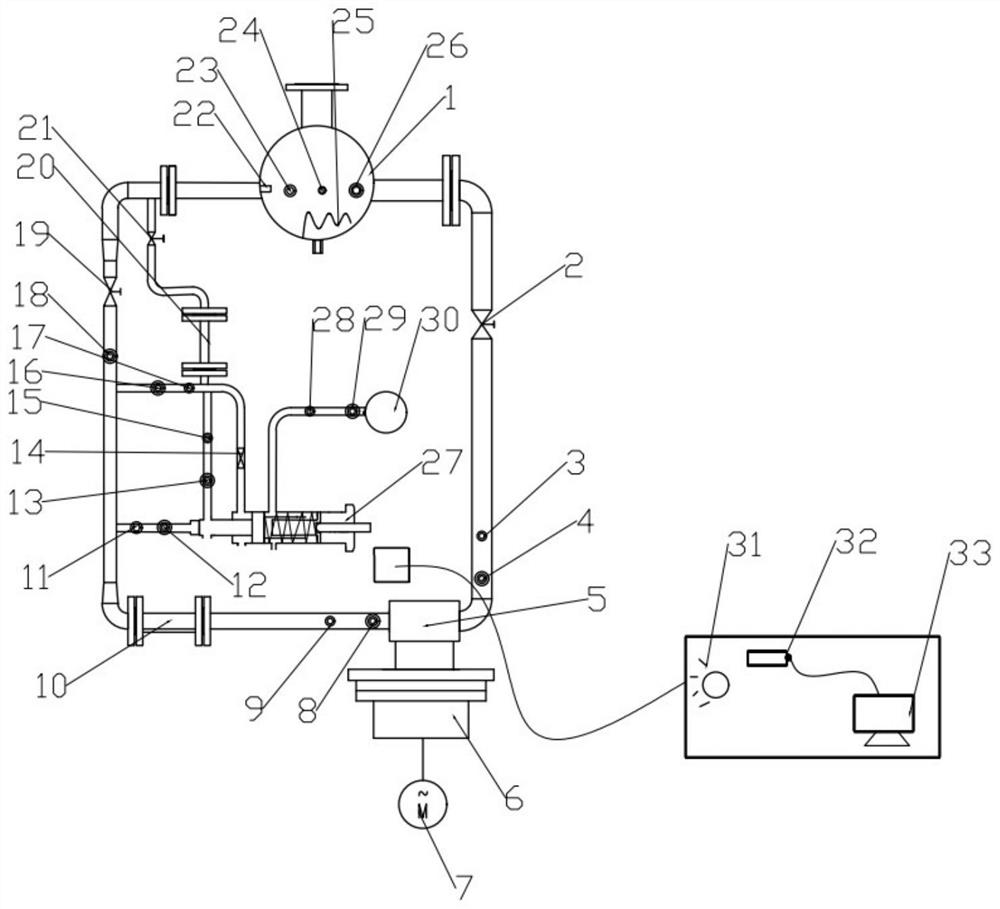

Engine valve oil seal test stand

ActiveCN101581628AAccurate measurementMeasurement of fluid loss/gain rateEngine testingStanding frameHydraulic pump

The invention discloses an engine valve oil seal test stand comprising a stand frame (1), a motor (2), a vacuum pump (3), an oil tank (4), a hydraulic pump (5), a cylinder cover supporting vertical plate (6) and a cylinder cover supporting bottom plate (7). The motor (2), the vacuum pump (3), the oil tank (4) and the hydraulic pump (5) are fixedly arranged on the stand frame (1). The table surface of the stand frame (1) is provided with a sliding groove. The engine valve oil seal test stand can correctly measure the leak tightness of valve oil seals of engines with different models and the amount of engine oil entering an engine cylinder body from valve oil seal lips and ensure the leak tightness of the valve oil seal of an engine cylinder cover which leaves a factory to conform to relative requirements.

Owner:CHENGDU SHENGBANG SEALS

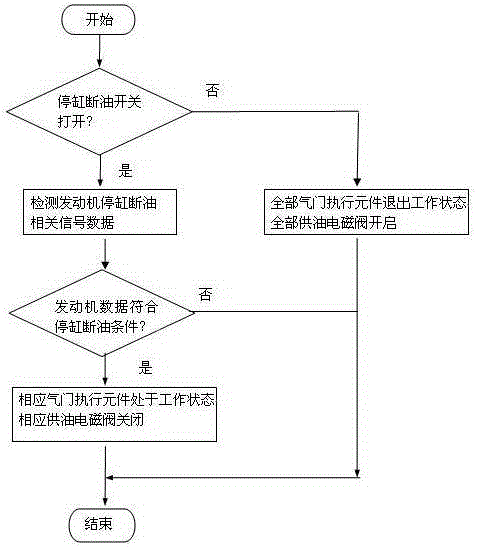

Engine exhaust system, air valve oil supply exhaust comprehensive control system and control method

ActiveCN105179057AReduce fuel consumptionExtended service lifeElectrical controlExhaust apparatusExhaust valveControl system

The invention discloses an engine exhaust system, an air valve oil supply exhaust comprehensive control system and a control method. A valve is arranged on a double-path exhaust pipe composed of an exhaust pipe and an exhaust branch pipe, and an air valve starting mechanism enables an air valve to be in the starting state all the time; a control module integrates engine relevant data to comprehensively control an exhaust valve, an air valve starting mechanism and an oil supply electromagnetic valve, so that an engine has three excellent properties of pressure reduction starting, cylinder stop oil stopping and exhaust valve brake; oil consumption can be reduced, emissions are reduced, the service life of an engine and the service life of a starting system are prolonged, and the safety guarantee of an automobile in mountain driving is improved; and according to the scheme, the structure is simple, and the system is suitable for matching mounting of most engine types.

Owner:牛刚学

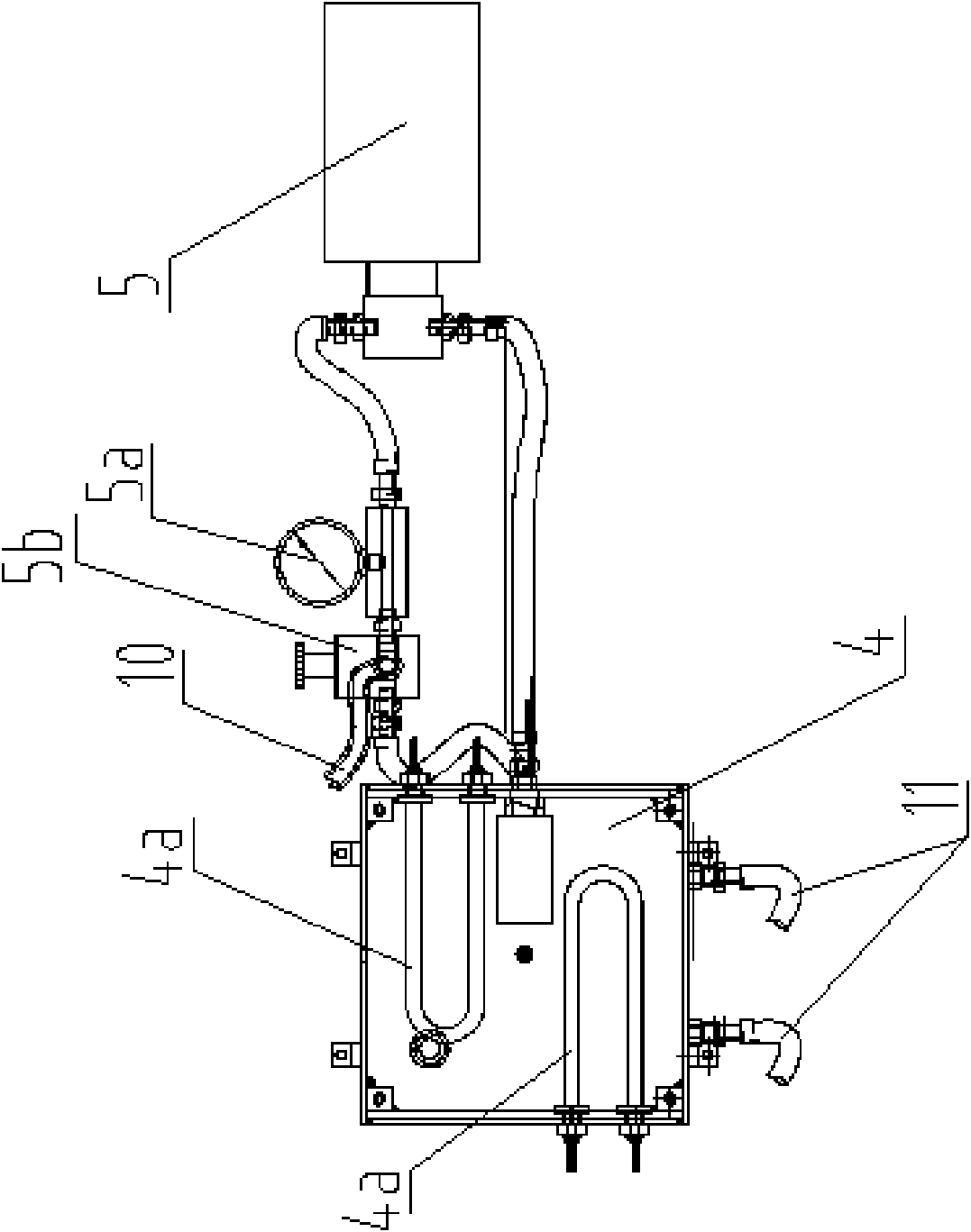

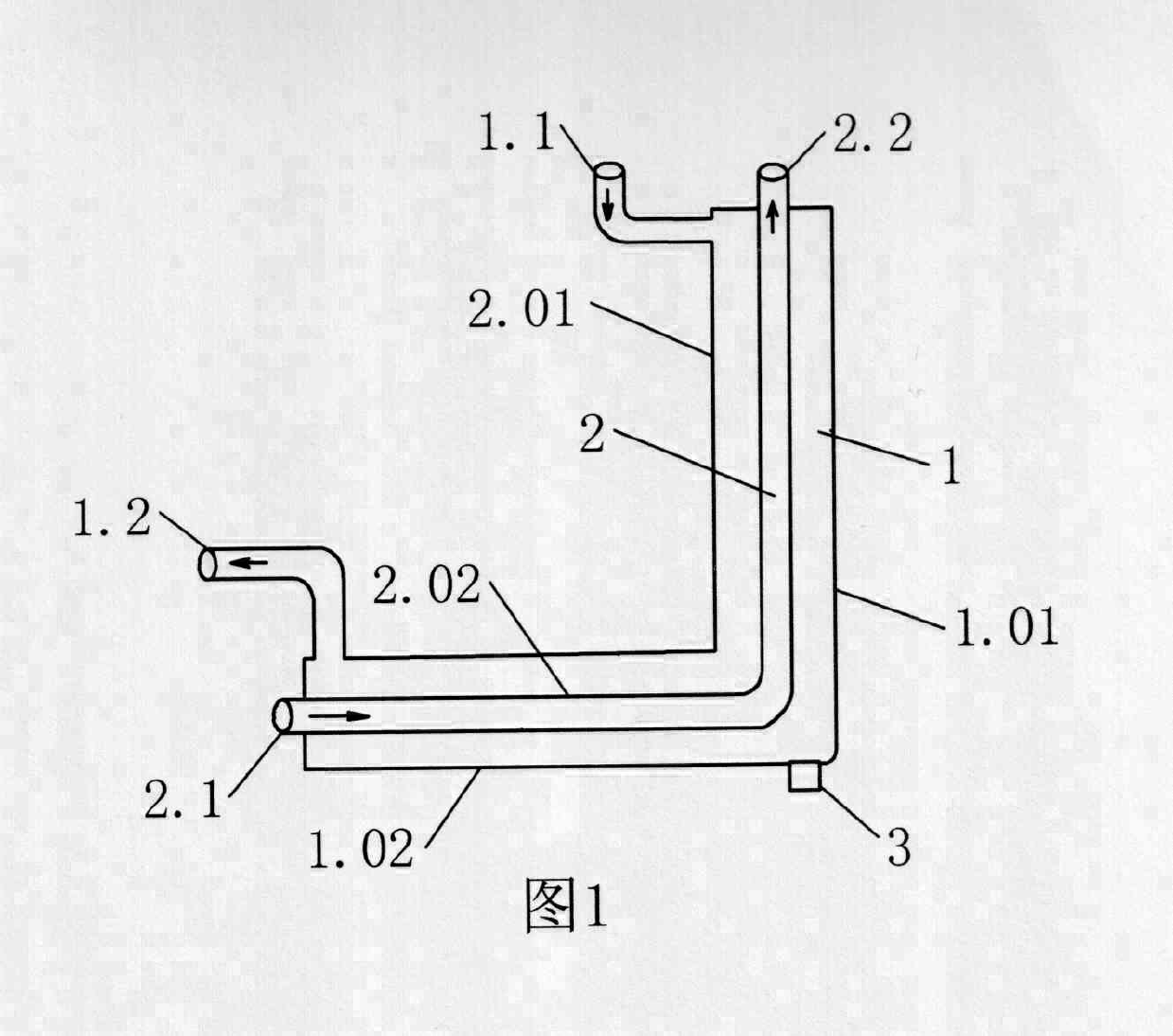

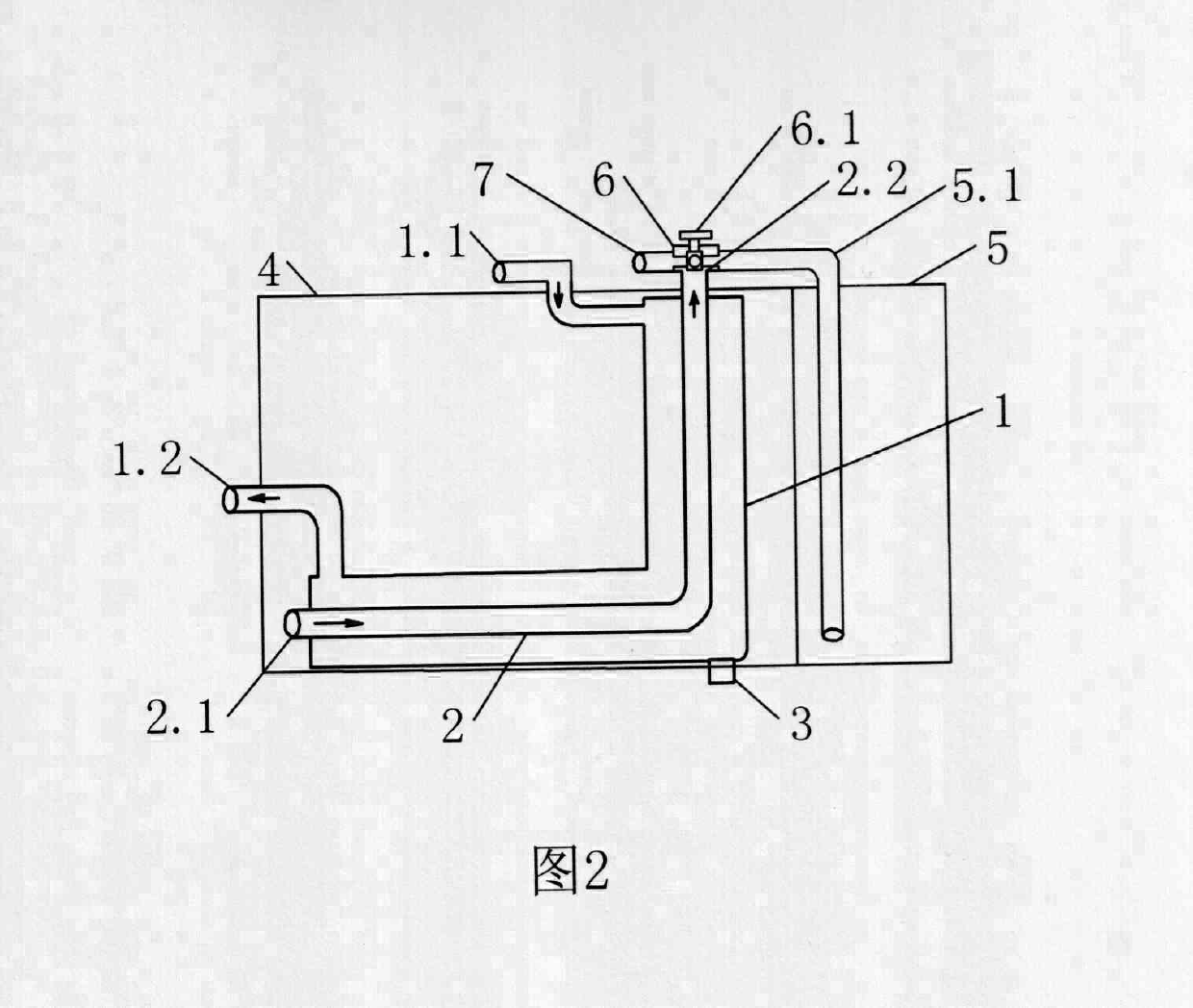

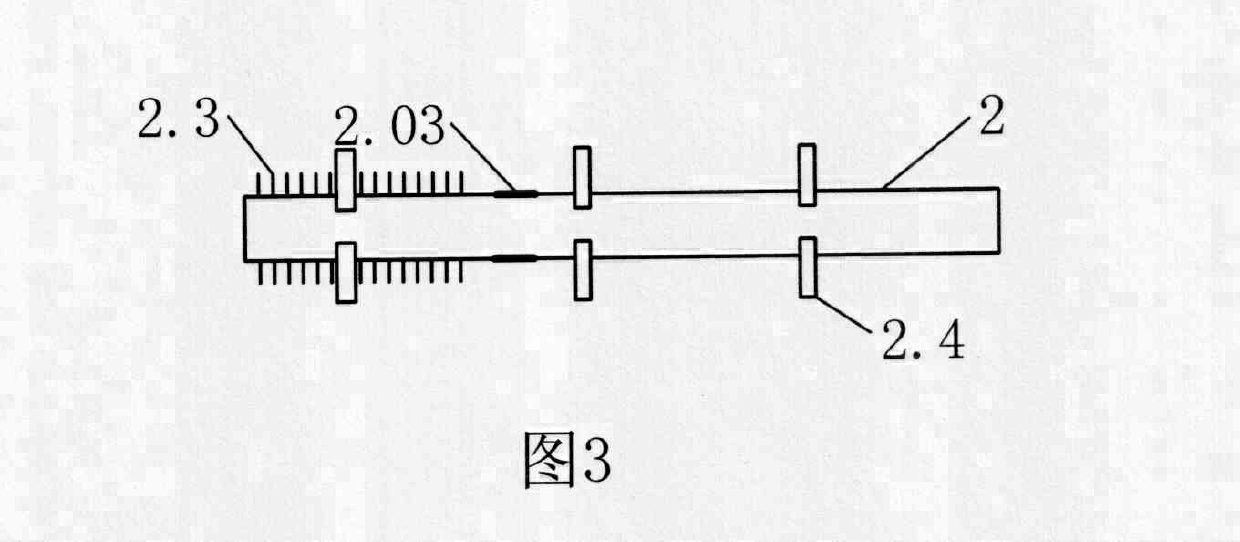

Oil-in-water type heater oil tank

ActiveCN102606356AIncrease oil temperatureIncrease the heating areaMachines/enginesThermal treatment of fuelFuel tankWater jacket

The invention provides an oil-in-water type heater oil tank. A heater formed by inserting an oil suction pipe into a water sleeve which is composed of a water sleeve transverse pipe and a water sleeve vertical pipe is arranged in a main oil tank, the oil suction pipe and a high number oil suction pipe are respectively communicated with a three-way oil valve; thereby forming the oil-in-water type heater oil tank. An auxiliary oil tank is arranged in the main oil tank of the heater oil tank; a water sleeve is arranged in the main oil tank; the oil suction pipe is arranged in the water sleeve, the high number oil suction pipe is arranged in the auxiliary oil tank, and then the oil suction pipe and the high number oil suction pipe are respectively communicated with an oil supply pipe after being communicated with the three-way oil valve. The oil-in-water type heater oil tank is characterized in that the water sleeve and the oil suction pipe are composed of vertical sections and transverse sections; the vertical sections are located at the bottom of the main oil tank, and the vertical sections are located at the middle part of the oil tank. The heater oil tank has the characteristics that the heater oil tank is large in heating area, high in oil temperature, great in energy-saving effect, and environment friendly. Therefore, the heater oil tank is appropriate for the oil tank at the low-temperature state of diesel engines and diesel vehicles.

Owner:刘晶

Split electronic delay control fuel oil heating system

PendingCN110848051AReduce consumptionAvoid wasting high-grade dieselInternal combustion piston enginesEngine controllersVehicle frameFuel tank

The invention discloses a split electronic delay control fuel oil heating system. The system comprises a double-cavity oil tank which is internally provided with a main oil tank and an auxiliary oil tank, and is characterized by further comprising a delay fuel oil switching valve, a main oil tank oil quantity sensor, an auxiliary oil tank oil quantity sensor, a heating water pipe and a fuel oil pipeline. The main oil tank oil quantity sensor and the auxiliary oil tank oil quantity sensor are fixed to the main oil tank and the auxiliary oil tank respectively, the delay fuel oil switching valveis fixed to a frame, and the main oil tank oil quantity sensor and the heating water pipe communicate with an engine to form cooling water circulation. The delay fuel oil switching valve makes the main oil tank oil quantity sensor and the auxiliary oil tank oil quantity sensor communicate with the engine to form fuel oil circulation through the fuel oil pipeline. By means of the delay fuel oil switching valve, after a vehicle is started, high-grade oil in a whole vehicle oil path can flow back into an auxiliary chamber, and the consumption of the expensive high-grade oil is reduced. Before parking, No.0 oil in the whole vehicle oil path flows back into the main oil tank first, so that the starting problem caused by oil mixing is avoided.

Owner:DONGFENG COMML VEHICLE CO LTD

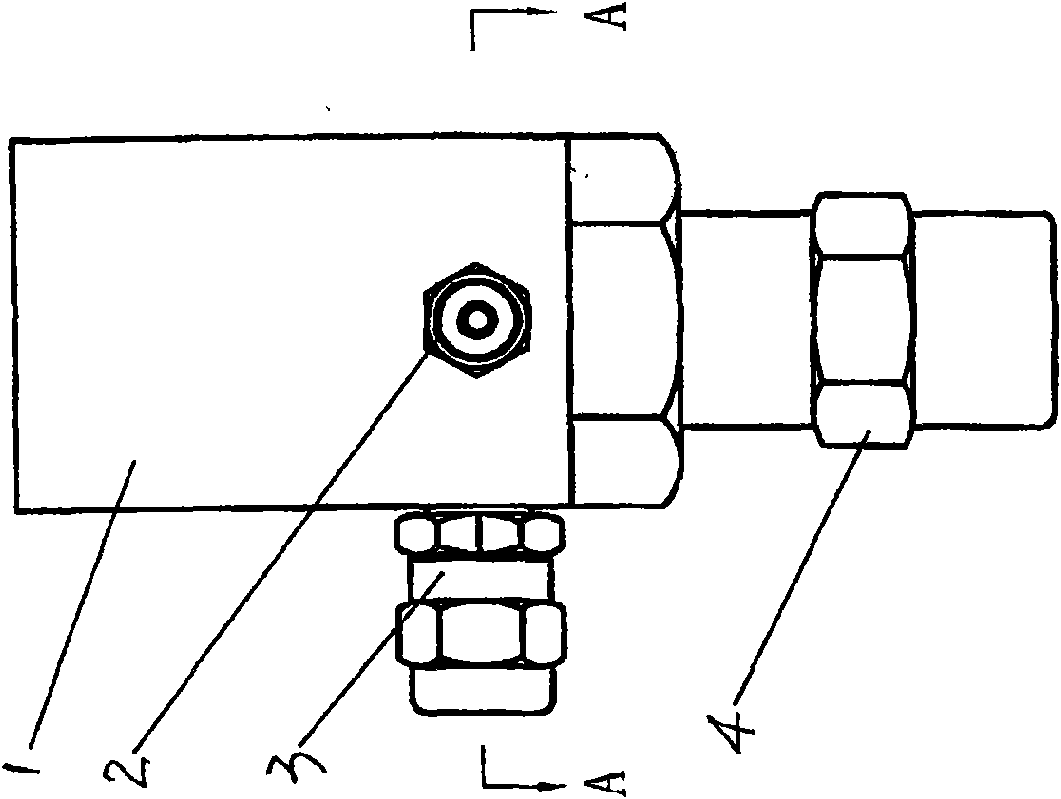

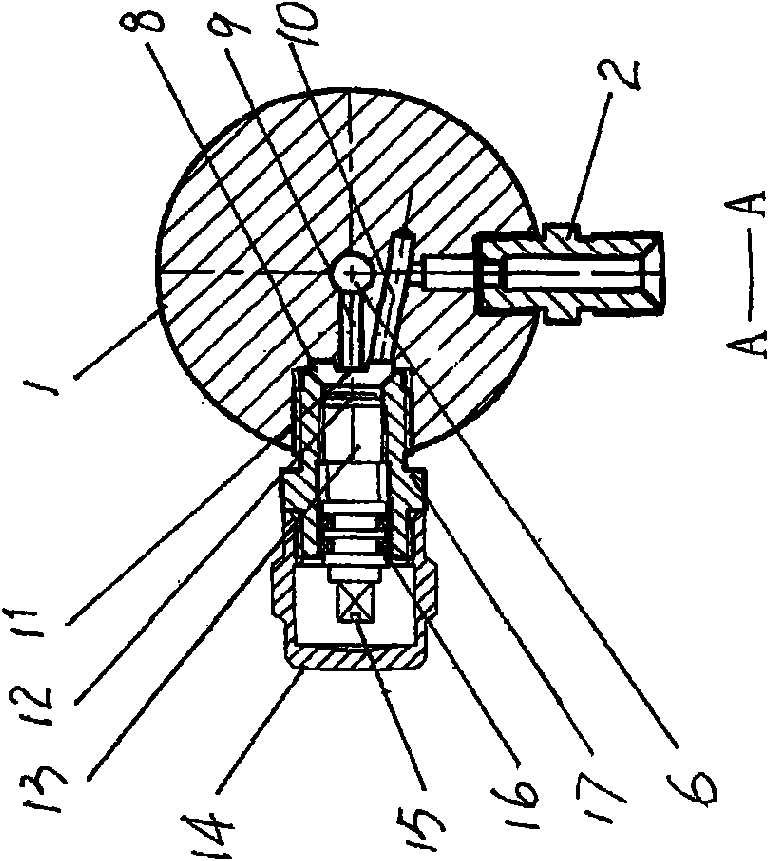

Multi-sampling-port insulating oil sampling valve

ActiveCN101592566ASampling to meetEasy to installComponent separationWithdrawing sample devicesMonitoring systemSampling valve

The invention relates to a multi-sampling-port insulating oil sampling valve, wherein one sampling port is used for oil chemical analysis sampling in a laboratory, the other sampling port is used for insulating oil online monitoring system sampling, a chromatogram online sampling connecting port is arranged on a lateral wall of the valve body, the chromatogram online sampling connecting port and a stop valve thereof are arranged at two different positions respectively, the chromatogram online sampling stop valve is also arranged on the lateral wall of the sampling valve body, and the horizontal directions of the chromatogram online sampling connecting port and the chromatogram online sampling stop valve are on a same plane and are separated from each other by 90 degrees; and a sampling oil way passage of the chromatogram online sampling connecting port comprises that a sampling valve oil passage gets out of the chromatogram online sampling connecting port stop valve body and then enters the chromatogram online sampling connecting port. One valve member of the sampling valve can finish two types of samplings, has the function of respective individual control without an external switch valve, simplifies the mounting and effectively avoids oil leakage, and oil ways are safe and do not affect each other during working; besides, the multi-sampling-port insulating oil sampling valve not only can satisfy the oil chemical analysis sampling in the laboratory, but also can satisfy the insulating oil online monitoring system sampling.

Owner:HENAN ZHONGFEN INSTR +1

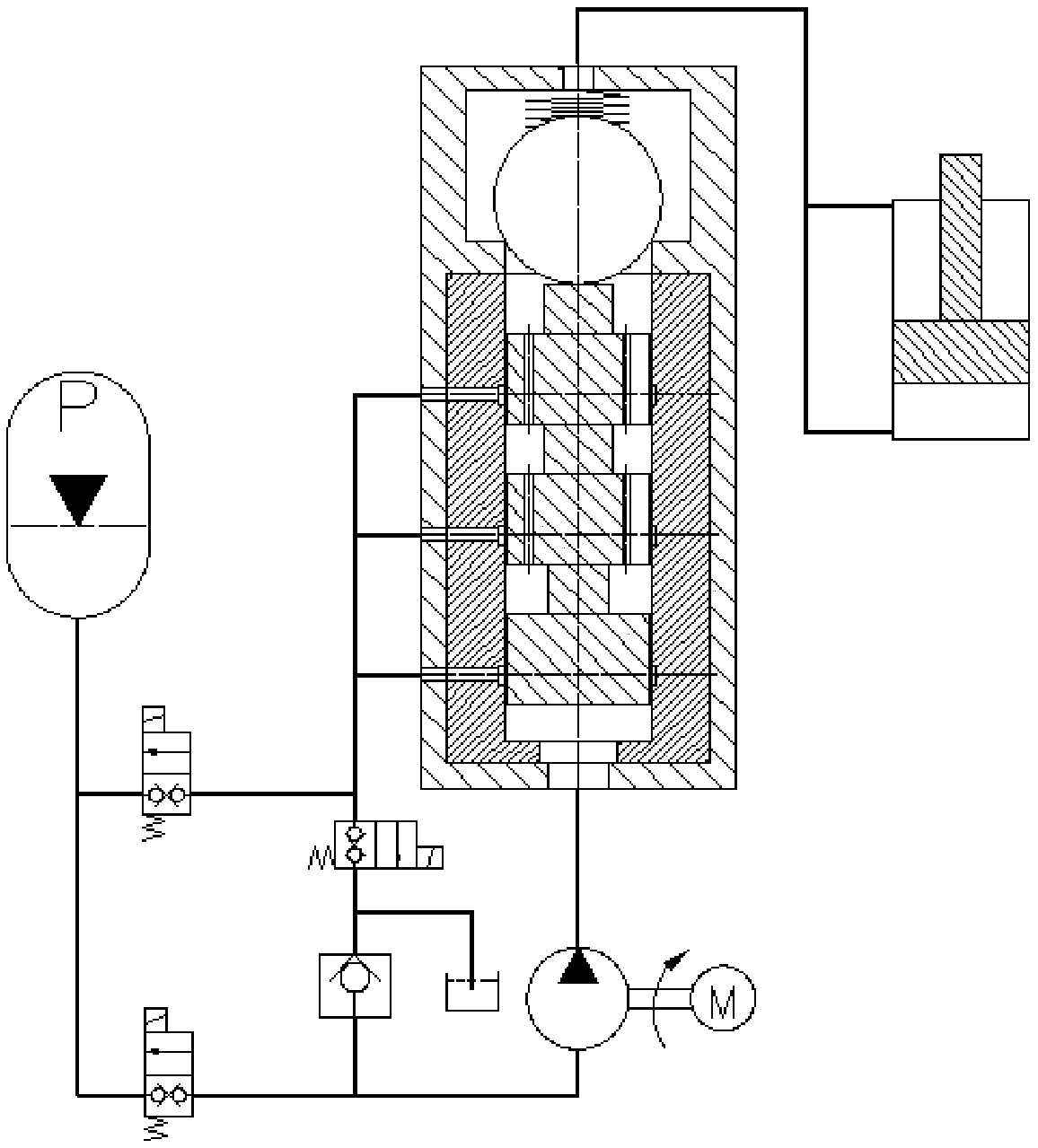

Oil pump performance test loop

The invention discloses an oil pump performance test loop which comprises an oil pump, a pressure control valve, a slide valve and a first oil return tank. The pressure control valve is provided witha control valve oil inlet, a control valve oil outlet and a control valve oil return port, and the pressure control valve is an electromagnetic valve; the slide valve is provided with a slide valve oil inlet, a slide valve first oil outlet, a slide valve second oil outlet, a communication hole and a feedback hole; the control valve oil inlet, the slide valve oil inlet and a feedback hole are connected with the oil pump through pipelines; the control valve oil inlet and the slide valve oil inlet are formed in parallel, and the control valve oil outlet is communicated with the communication holethrough a pipeline; the control valve oil return port, the slide valve first oil outlet and the slide valve second oil outlet are connected with the first oil return tank through pipelines. The oil pump performance test loop can be used for adjusting the oil pressure of the slide valve oil inlet of the slide valve by adjusting the pressure of the control valve oil outlet of the pressure control valve, and the outlet pressure of the oil pump is adjusted.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

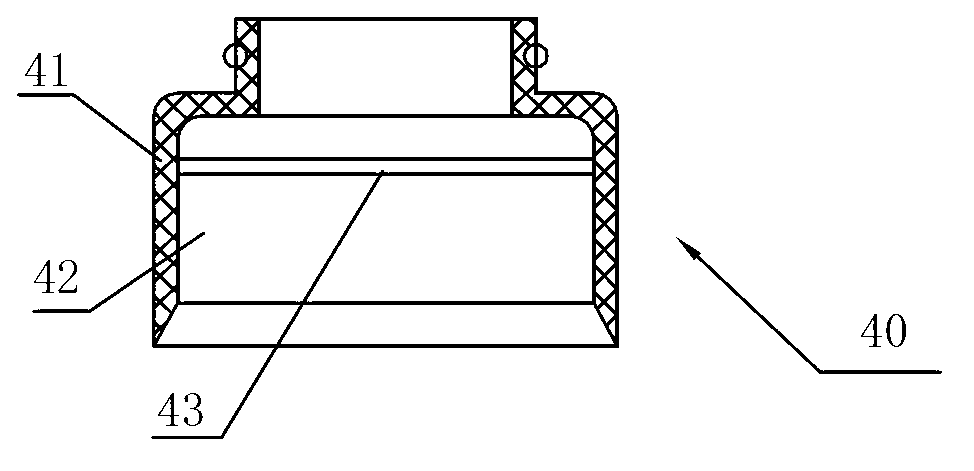

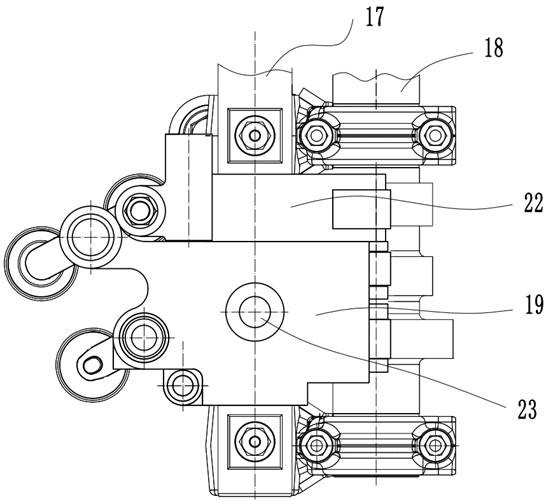

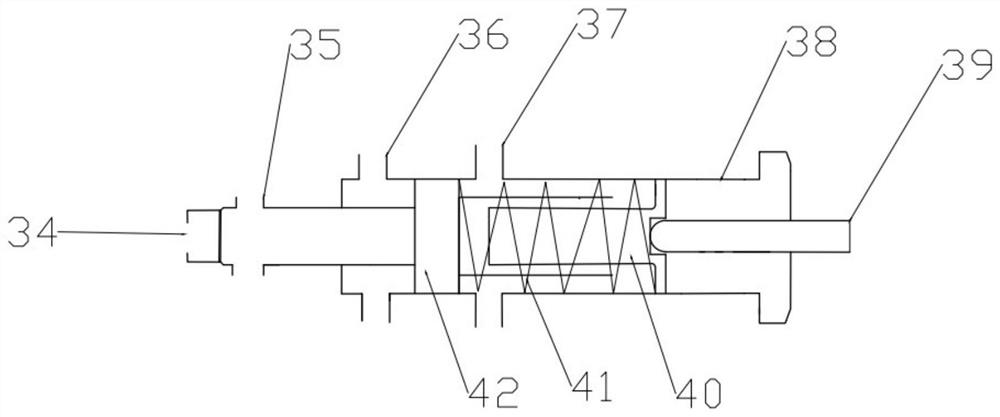

Quick assembling device for cylinder cover valve oil seal

ActiveCN106271541AReduce shockQuality improvementOptical detectionMetal working apparatusCylinder ValveGuide tube

The invention discloses a quick assembling device for a cylinder cover valve oil seal. The quick assembling device comprises a cylinder cover, the oil seal, a connection pressing base and press fitting equipment. The cylinder cover is provided with a valve through a guide pipe in advance, the connection pressing base is composed of a pressing plate and a plurality of pressing heads, three-step positioning holes are formed in the pressing heads, the guide pipe in the cylinder cover is arranged on the valve in a sleeving mode and ensures that the head of the valve is exposed, and the connection pressing base and the oil seal are located on the upper portion of the cylinder cover provided with the valve in advance and are assembled to the guide pipe of the cylinder cover at a time in a press fitting mode through the press fitting equipment. According to the quick assembling device, different connection pressing bases are selected according to different machine types, and various air cylinder valve oil seals are quickly assembled through the special press fitting equipment; effective mechanical guide positioning is adopted for the three-step holes in the pressing heads in the connection pressing base, slow press fitting is ensured with a gas-liquid pressure cylinder, impact to the oil seal in the press fitting process is reduced, and high quality press fitting is ensured.

Owner:合肥云内动力有限公司

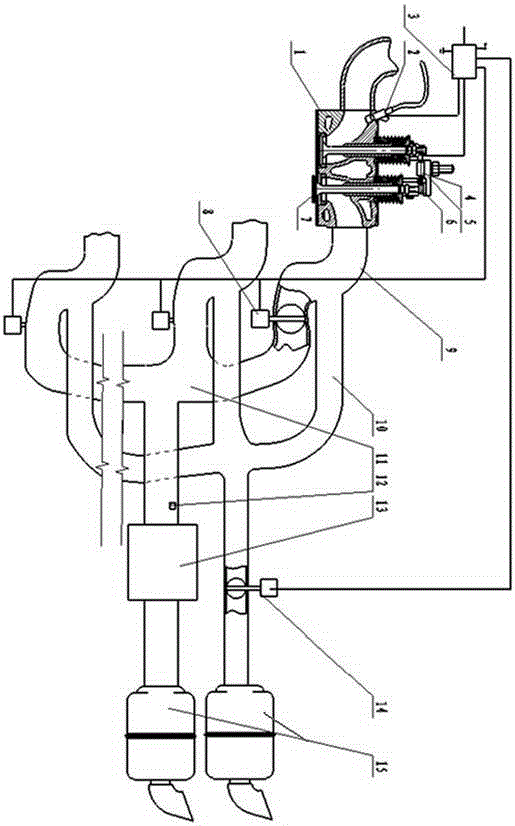

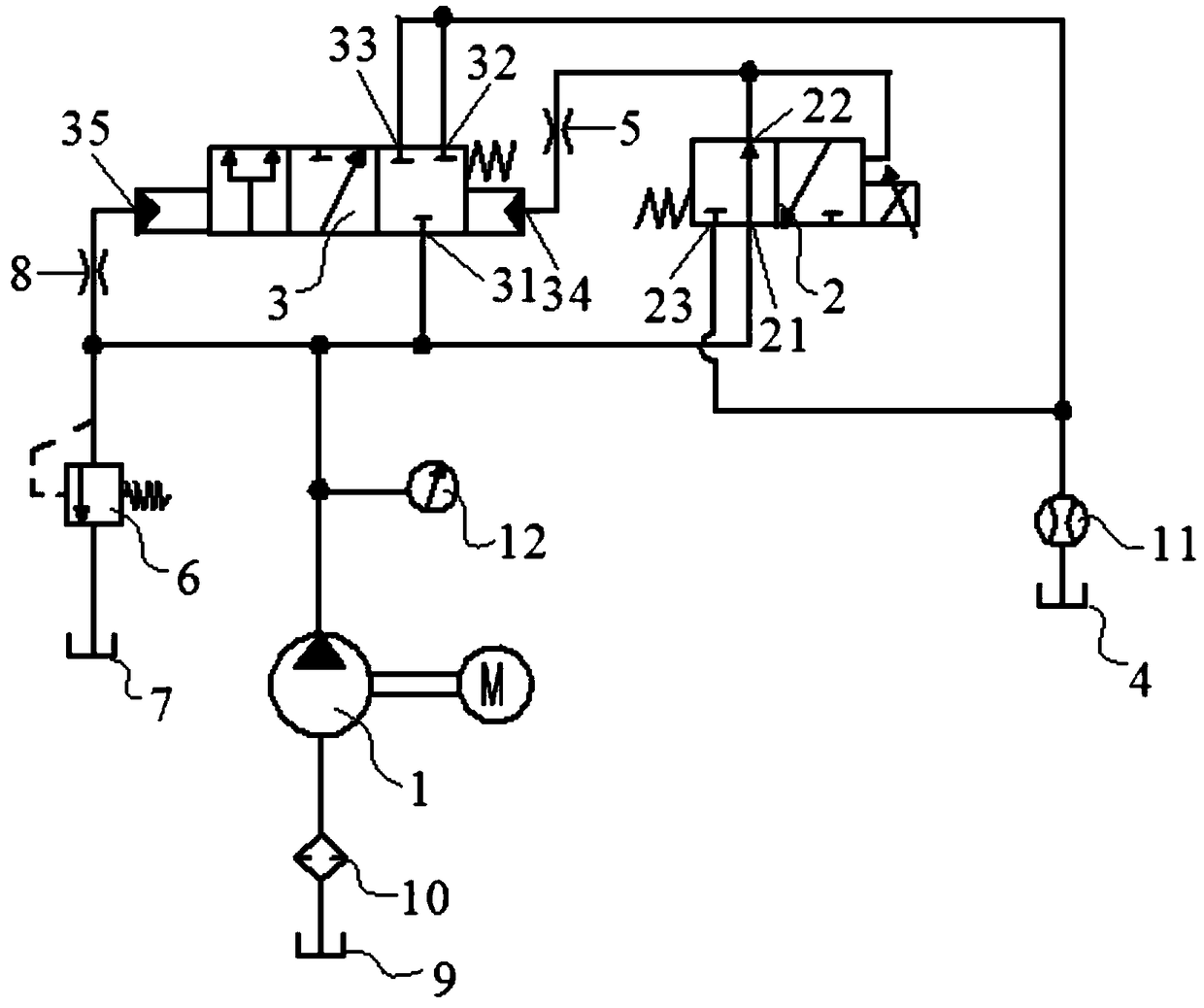

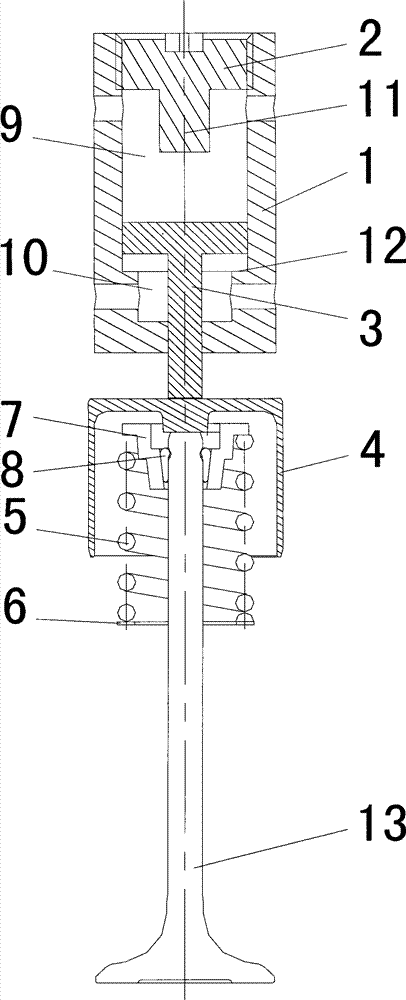

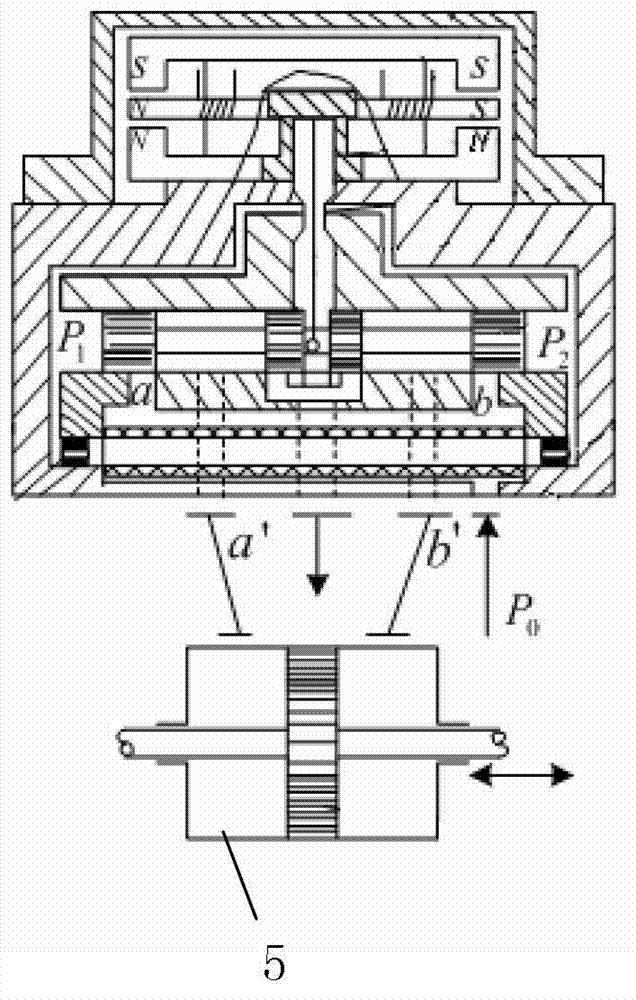

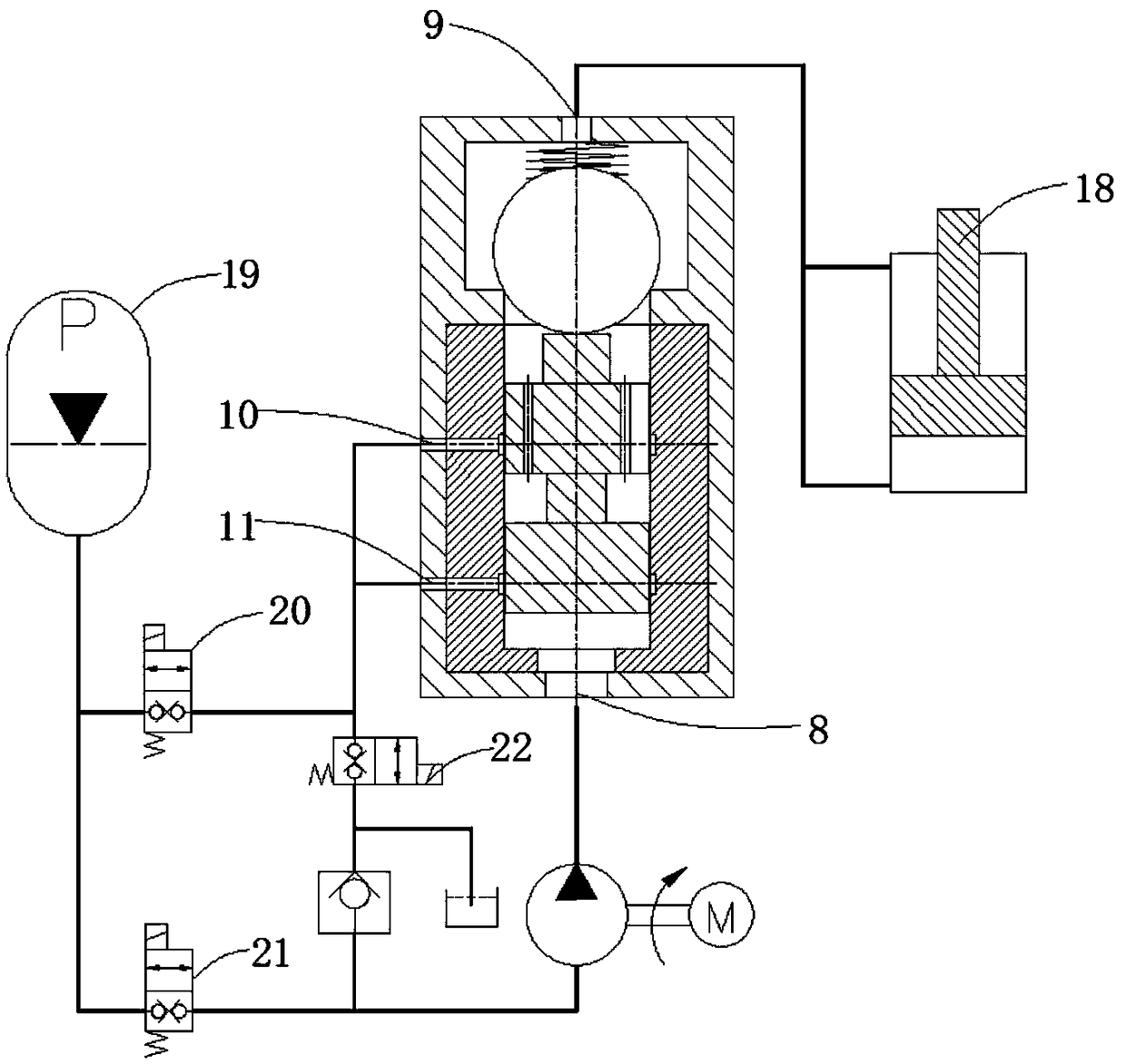

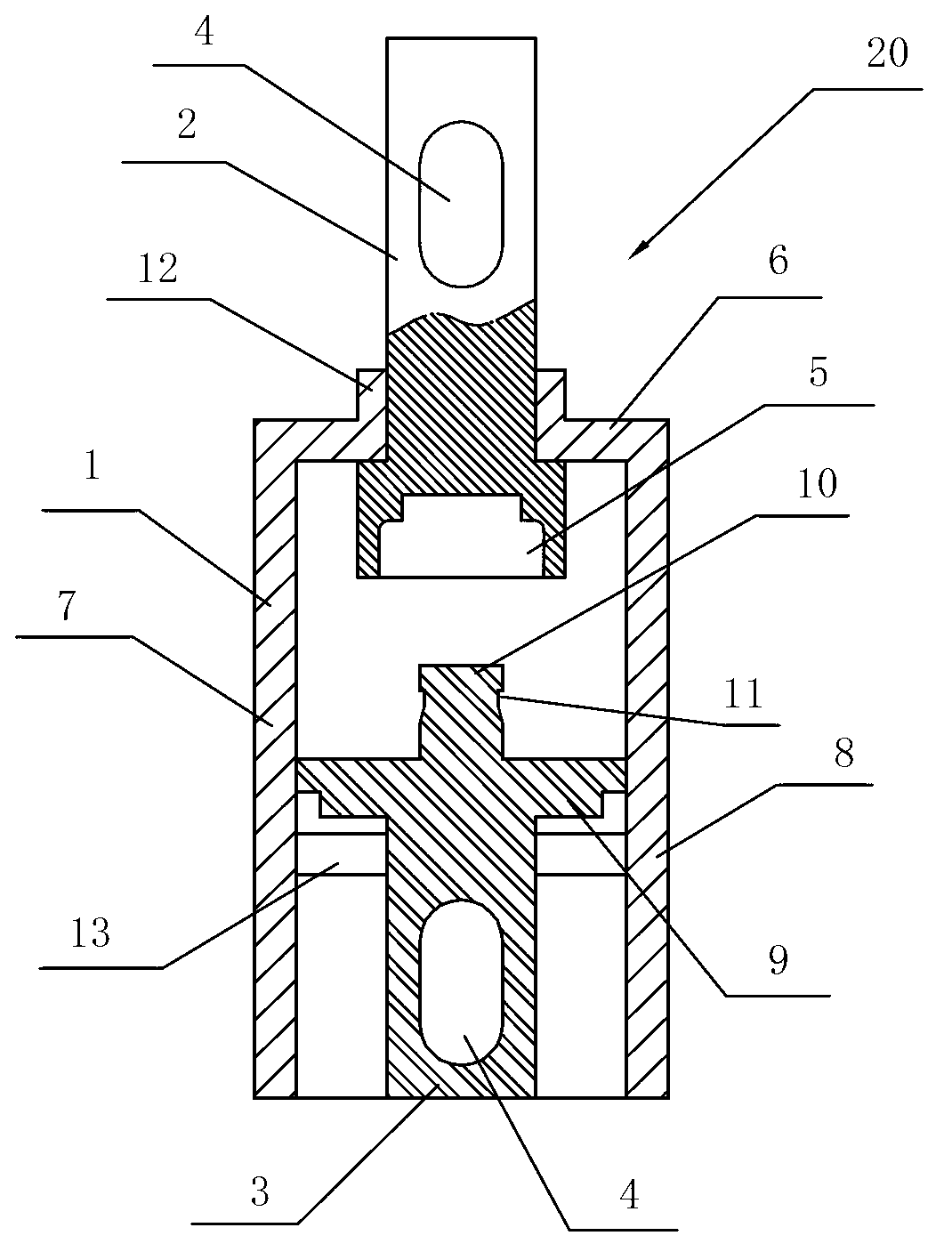

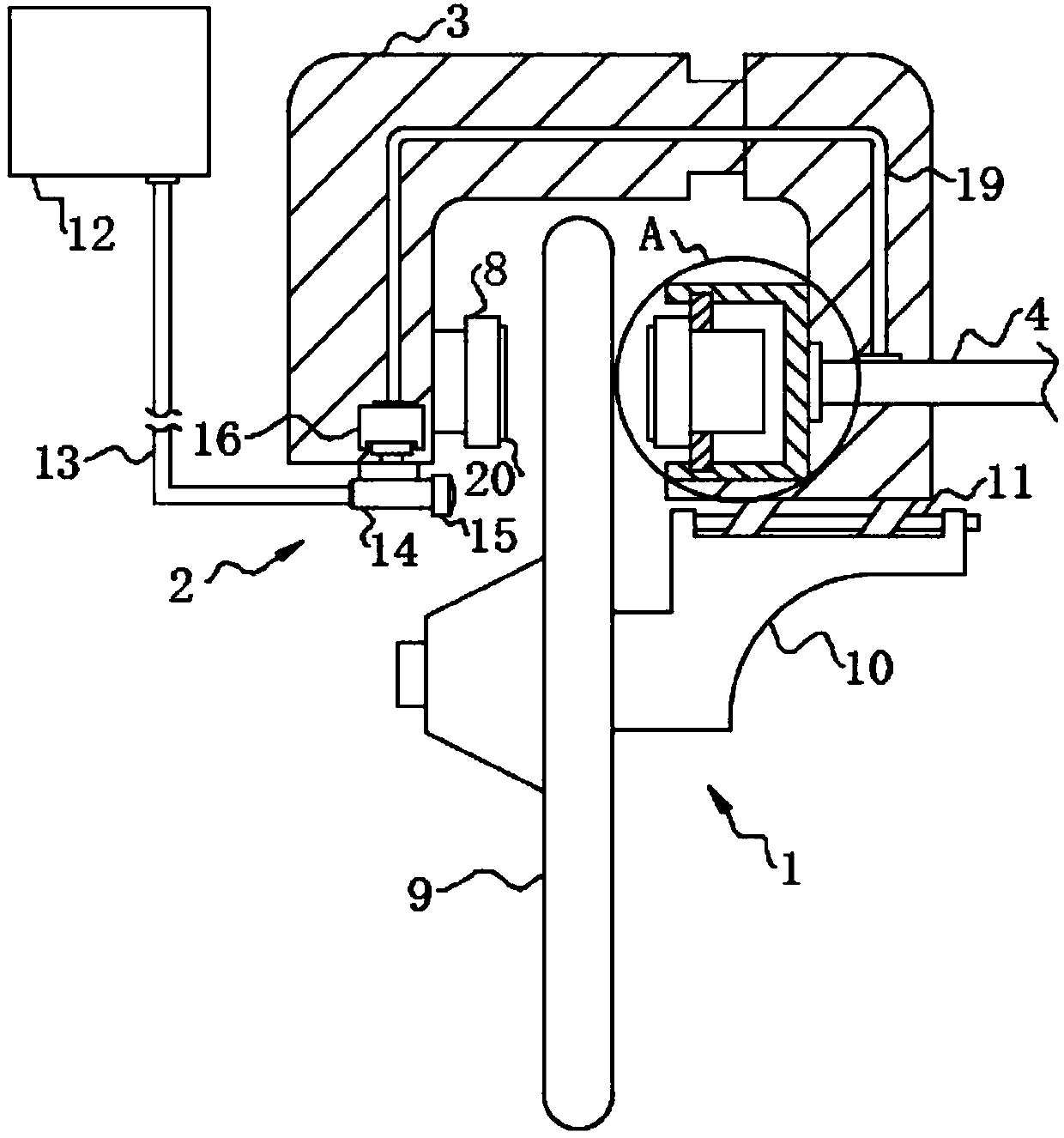

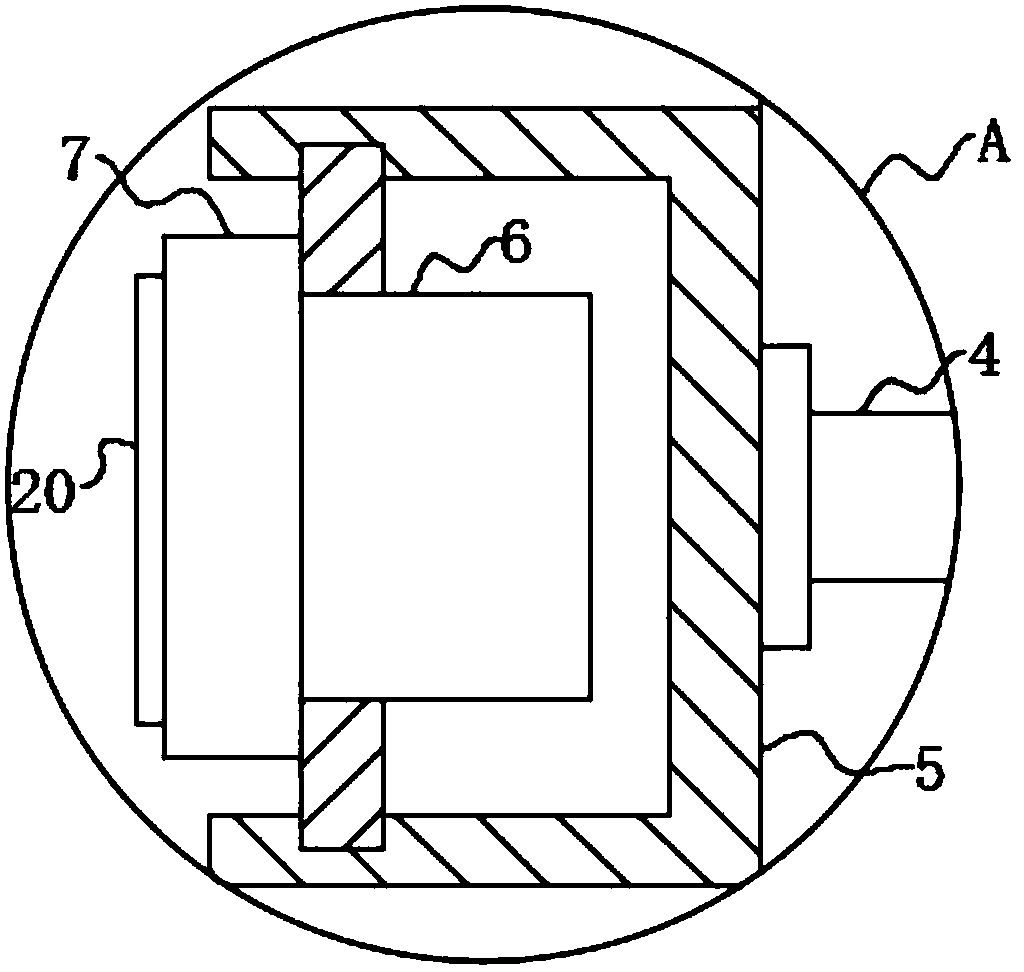

Electro-hydraulic valve for engine and working system thereof

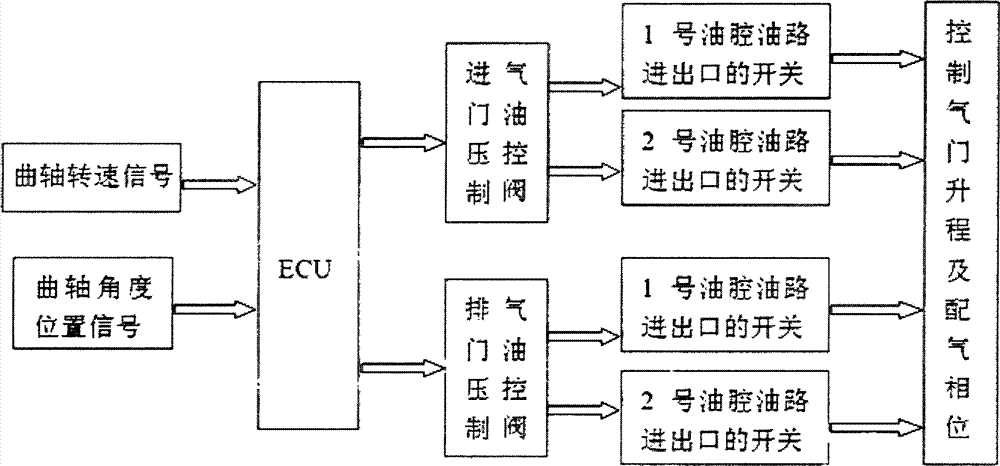

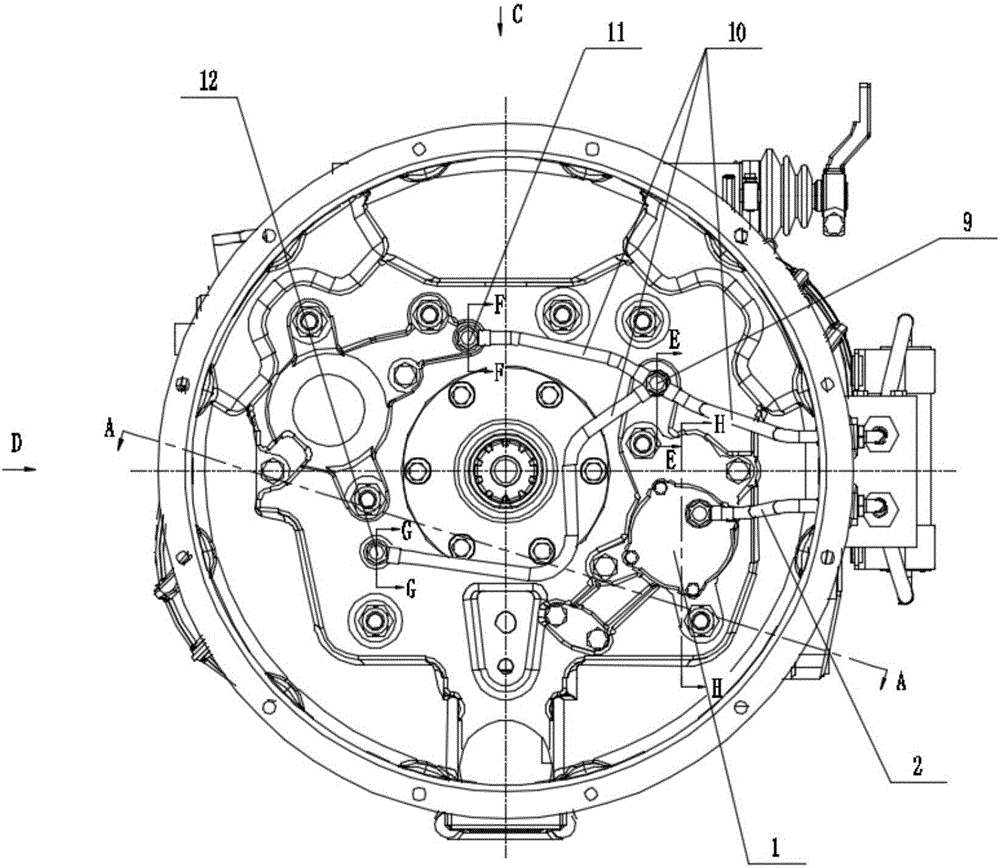

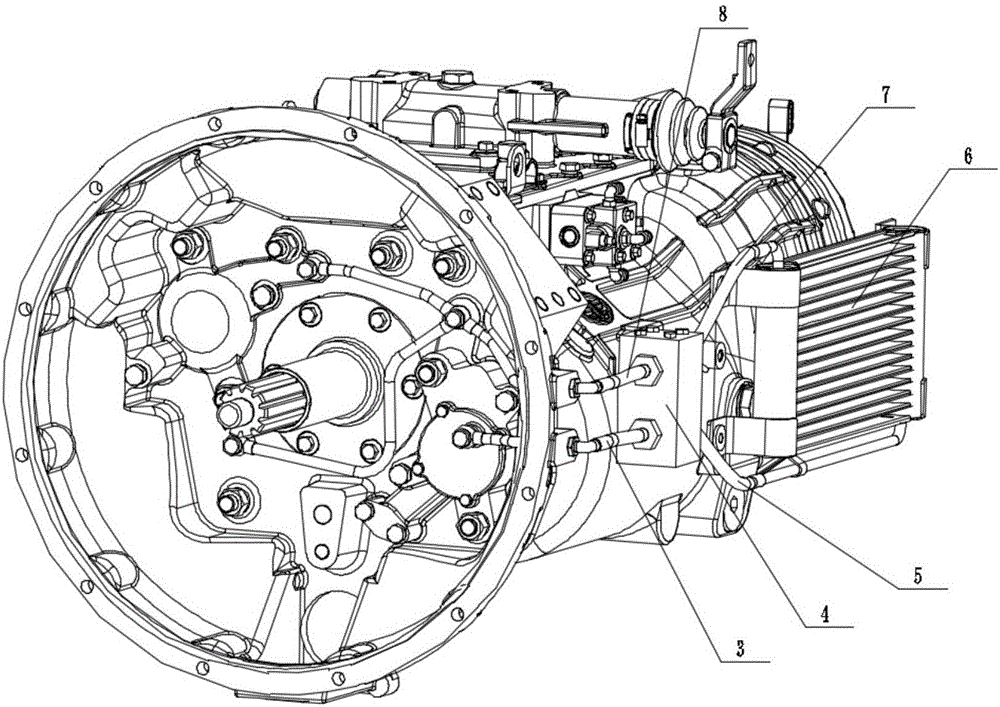

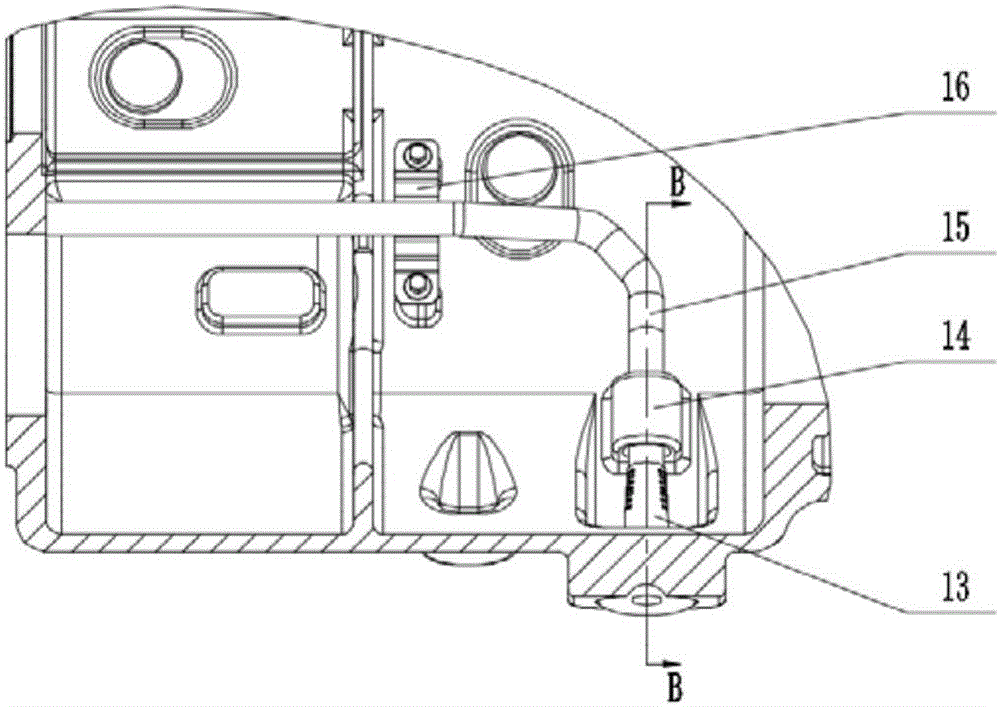

InactiveCN103939169AImprove intake and exhaust effectsGood intake and exhaust effectOutput powerMachines/enginesExhaust valveInlet valve

The invention discloses an electro-hydraulic valve for an engine and a working system thereof. The electro-hydraulic valve for the engine comprises an oil cylinder, a plunger and a valve body. An oil cylinder cover is arranged on the top of the oil cylinder, and a first oil cavity and a second oil cavity which are communicated with each other are formed in the oil cylinder. The plunger comprises a piston and a piston rod, wherein one end of the piston rod is perpendicularly arranged in the middle of the lower surface of the piston, the piston is arranged in the first oil cavity, and the other end of the piston rod penetrates through the second oil cavity, stretches out of the oil cylinder and can push the valve body to move vertically. According to the working system of the electro-hydraulic valve for the engine, an automobile computer controls opening or closing of an intake valve oil pressure control valve or an exhaust valve oil pressure control valve according to signals acquired by a crankshaft rotation speed signal sensor and a crankshaft angle and position signal sensor, and therefore the valve body in the electro-hydraulic valve for the engine can move to achieve intake or exhaust of the engine. By means of the electro-hydraulic valve for the engine and the working system thereof, the optimal intake or exhaust effect of the engine can be achieved.

Owner:王欣亮 +1

Heavy type speed changer cooling and lubricating system and cooling and lubricating method

ActiveCN106594253AGuaranteed Cooling RequirementsGuaranteed service lifeGear lubrication/coolingWind energy generationTemperature controlGear oil

The invention discloses a heavy type speed changer cooling and lubricating system and a cooling and lubricating method. The heavy type speed changer cooling and lubricating system comprises an oil pump, a filter, a temperature control valve, a radiator, an oil discharging bolt, two oil spraying pipes and an oil spraying head. When the temperature control valve is closed, a temperature control valve oil inlet pipe is communicated with a temperature control valve oil outlet pipe; when the temperature control valve is opened, the temperature control valve oil inlet pipe is communicated with a cooling oil inlet pipe, and the cooling oil outlet pipe is communicated with the temperature control valve oil outlet pipe. An input end of the oil discharging bolt is connected with the temperature control valve oil outlet pipe; three output ends of the oil discharging bolt are respectively connected with the two oil spraying pipes and the oil spraying head. Both the two oil spraying pipes extend from a primary box to a secondary box; a plurality of spraying holes are formed in each oil spraying pipe. The temperature control valve is used for determining whether gear oil enters the radiator or not. According to the heavy type speed changer cooling and lubricating system and the cooling and lubricating method, the external radiator and oil pump forced lubricating are combined, so that the lubricating and cooling requirements of shaft teeth, bearings, sealing pieces, lubricating oil and the like under special complex working conditions are ensured; meanwhile, the heavy type speed changer cooling and lubricating system and the cooling and lubricating method have the advantages of simple structure, reliable performance, and remarkable cooling and lubricating effects.

Owner:CHINA FIRST AUTOMOBILE

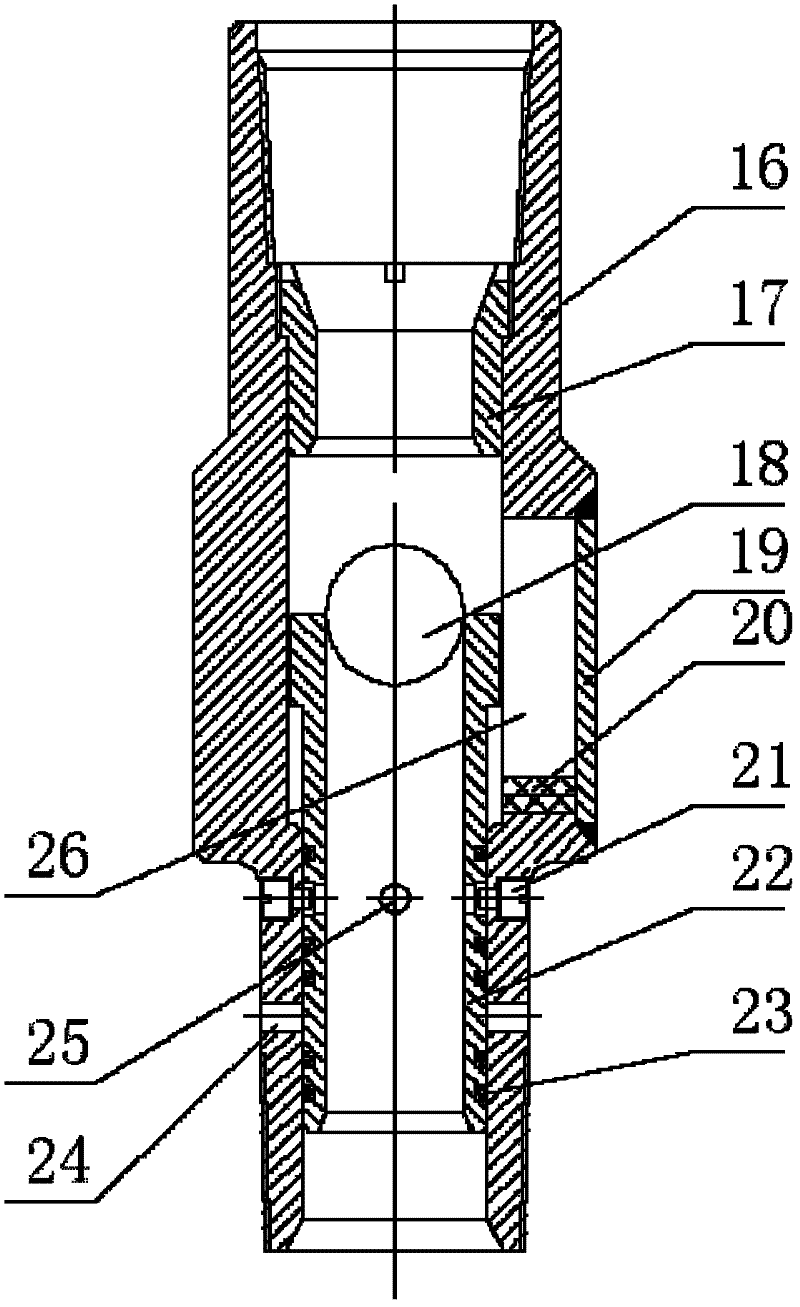

Oil pumping technique based on mechanical open-and-close valve oil well pump

InactiveCN103133309AAvoid "air lock"Positive displacement pump componentsFlexible member pumpsInlet valvePlunger

The invention discloses an oil pumping technique based on a mechanical open-and-close valve oil well pump. The technique includes an upstroke and a downstroke. The upstroke includes: an oil pumping rod is elevated to enable a plunger oil outlet valve to be closed, a plunger is driven to move upward, and an oil inlet valve is opened to for oil in-taking; and the pressure of an upper cavity is increased, oil and gas in the upper cavity are exhausted into an oil pipe in advance, and the airlock phenomenon is effectively prevented from occurring. The downstroke includes: the oil pumping rod moves downward to open the plunger oil outlet valve and the upper cavity and a lower cavity to be communicated; when the oil pumping rod moves downward, the plunger is driven to move downward, oil and gas in the lower cavity enter the upper cavity; and during the period of time when the plunger approaches a bottom death center and then leaves the bottom death center, the upper cavity and the lower cavity of the plunger oil outlet valve are communicated by a gas outlet hole to complete gas exhausting and ensure that the plunger oil outlet valve is opened timely in the upstroke. A push block and the gas outlet hole are designed on a valve rod, and when the plunger whether approaches the bottom death center or moves upward for a small distance in a reversing direction, the upper cavity and the lower cavity of the plunger oil outlet valve can be communicated to discharge oil and gas in the upper cavity into the oil pipe in advance, so that the airlock phenomenon is effectively prevented from occurring.

Owner:严欢

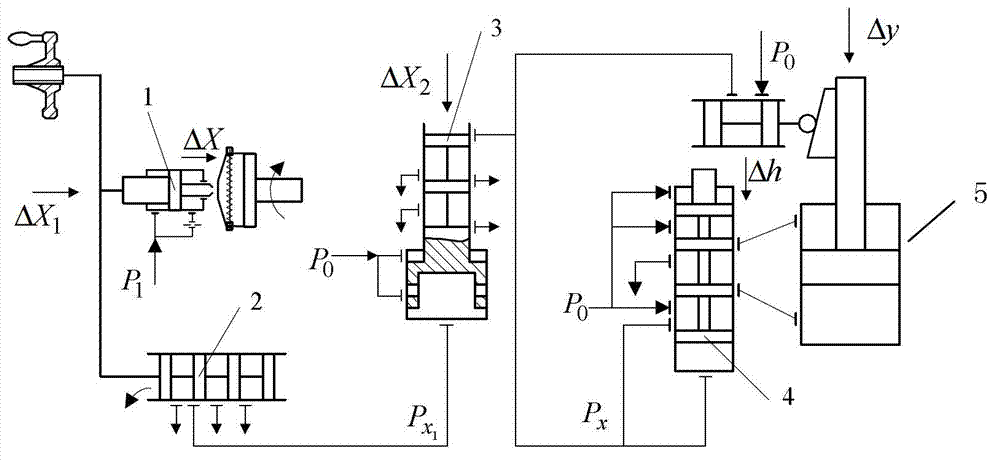

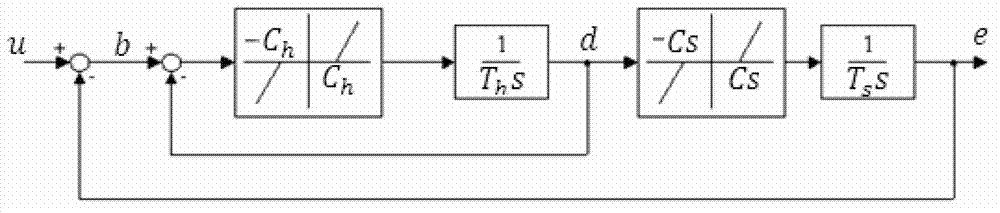

Steam turbine regulating system jam fault diagnosis method based on strong tracking Kalman filtering

The invention provides a steam turbine regulating system jam fault diagnosis method based on strong tracking Kalman filtering, and relates to a steam turbine regulating system jam fault diagnosis method which can give jam fault information in the early stage through on-line diagnosis and detection, so that necessary processing measures an be taken in time to avoid major accidents. The steam turbine regulating system jam fault diagnosis method comprises the following main steps: describing a slide valve-oil servomotor jam fault model, discretizing the model, calculating the partial derivative of the model, and performing state estimation with a strong tracking Kalman filter. The steam turbine regulating system jam fault diagnosis method is mainly characterized in that the strong tracking Kalman filter is used to simultaneously estimate the jam magnitudes of the slide valve and the oil servomotor in the slide valve-oil servomotor jam model, thereby providing a theoretical basis to the actual on-line jam fault diagnosis. According to the invention, by inputting an oil servomotor control command u and an oil servomotor output e, the slide valve jam magnitude and the oil servomotor jam magnitude of the system can be simultaneously and accurately diagnosed without increasing additional measuring points of the system, thereby realizing the on-line diagnosis.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

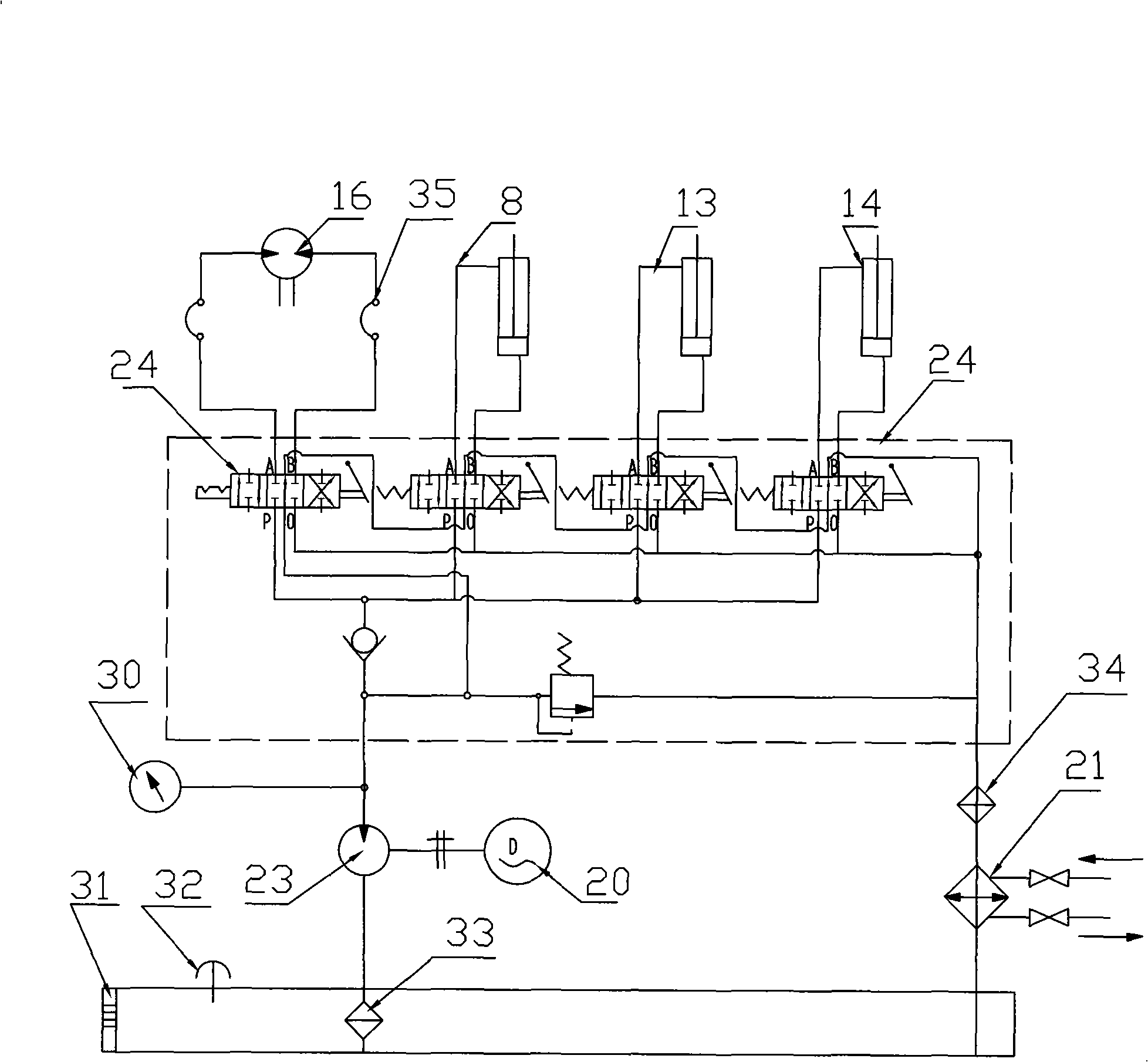

Crane and its load sensitive hydraulic control system

ActiveCN102336363ASmall pressure fluctuationsProblems affecting the pulsation of working pressureServomotor componentsLoad-engaging elementsControl systemEngineering

The invention discloses a load sensitive hydraulic control system, comprising a multipath directional control valve and a load sensitive pump having a load sensitive valve, wherein, a liquid inlet and an oil drain port of the multipath directional control valve are respectively communicated with a liquid outlet and an oil tank of the load sensitive pump, a load feedback port of the multipath directional control valve is communicated with a sensitive cavity of the load sensitive valve, and each uniting valve oil port of the multipath directional control valve is respectively connected with the corresponding executive component; the passage between the load feedback port of the multipath directional control valve and the sensitive cavity of the load sensitive valve is provided with a damper valve; the oil duct between an oil inlet and an oil outlet of the damper valve is provided with at least two dampings, and the oil duct between the adjacent two dampings is provided with a chamber having an enlarged cross section; and the oil outlet is communicated with the load feedback port of the multipath directional control valve, and the oil inlet is communicated with the sensitive cavity of the load sensitive valve. In addition, the invention provides a crane having the load sensitive hydraulic control system.

Owner:XUZHOU HEAVY MASCH CO LTD

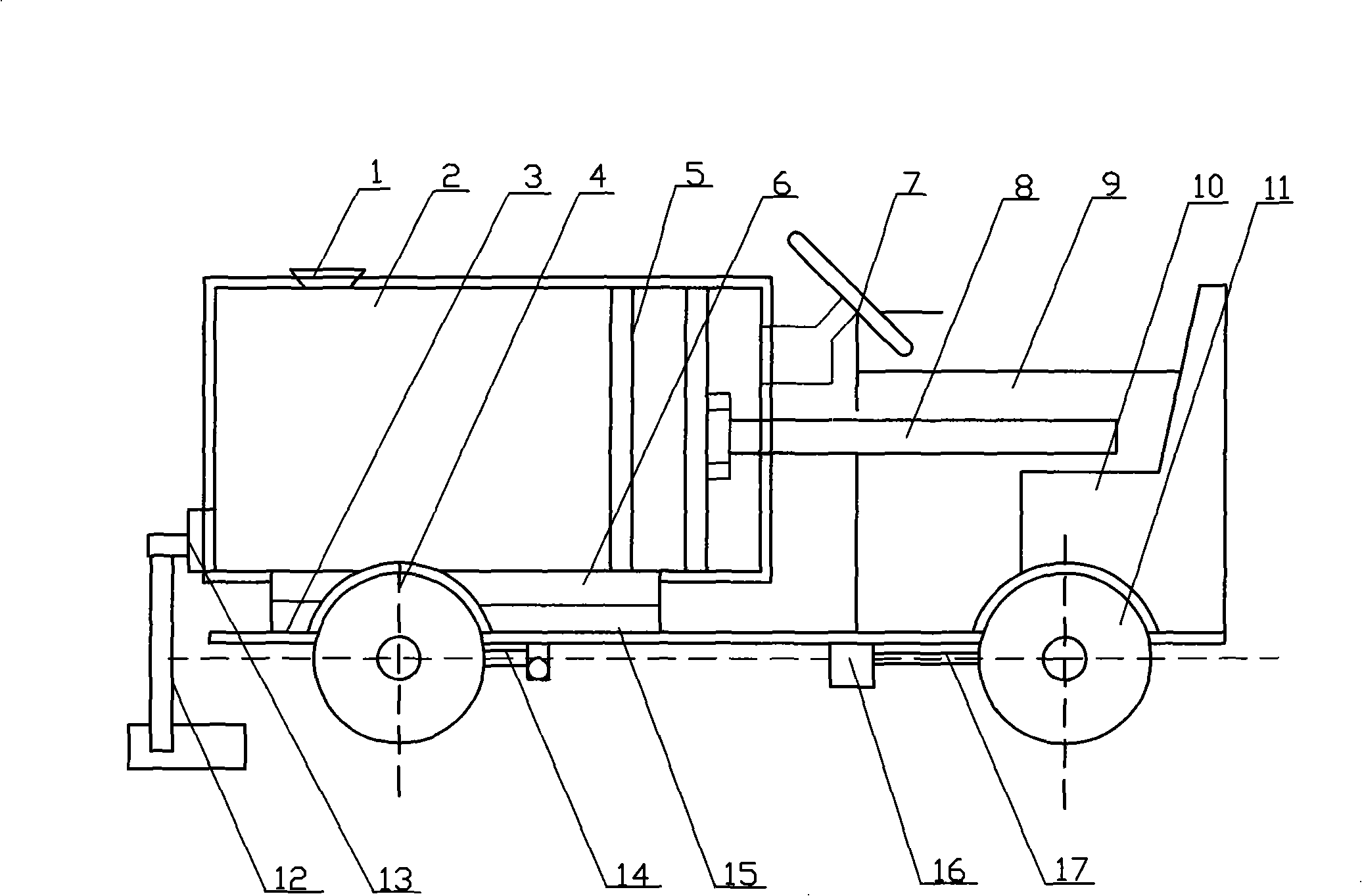

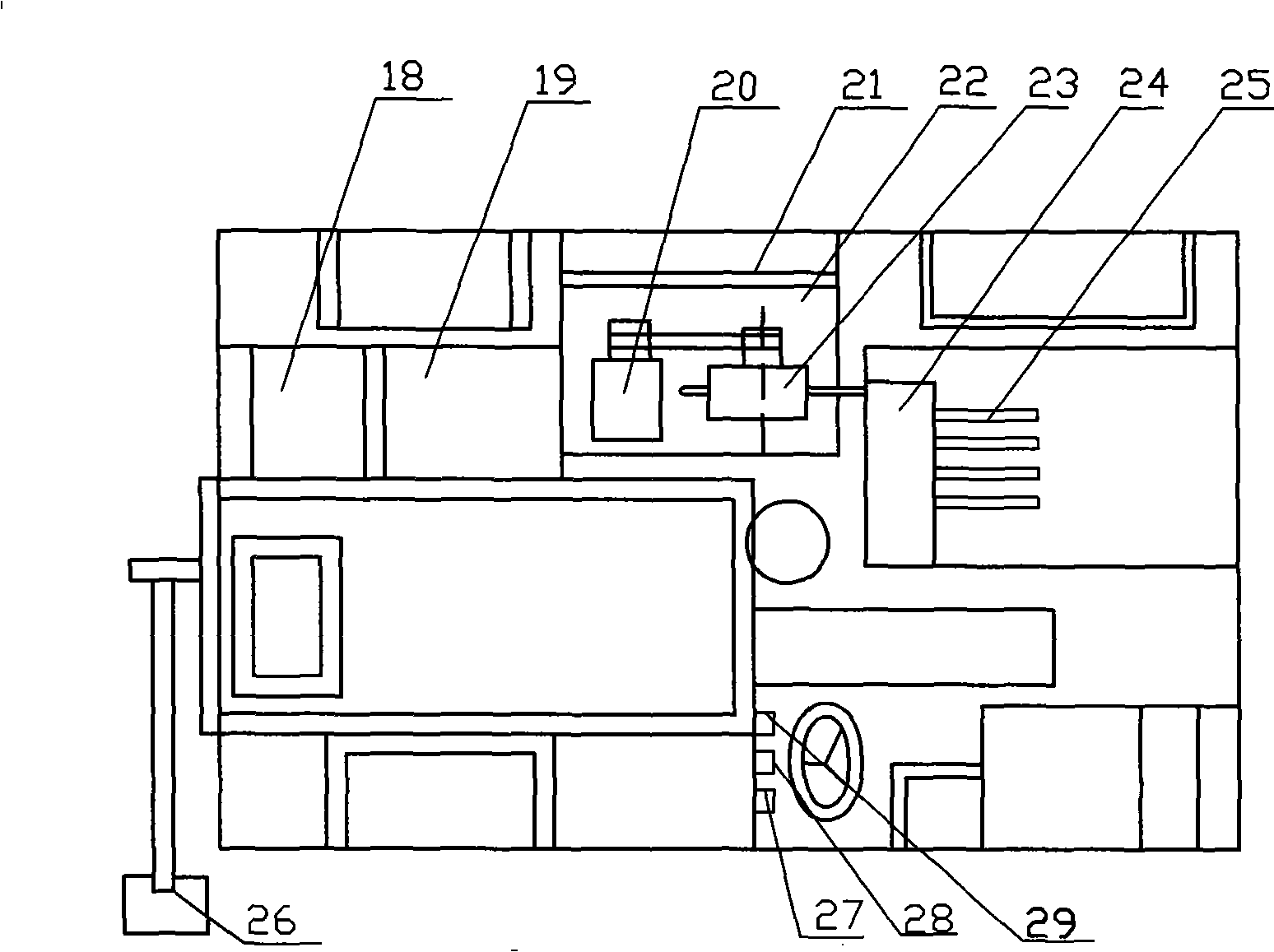

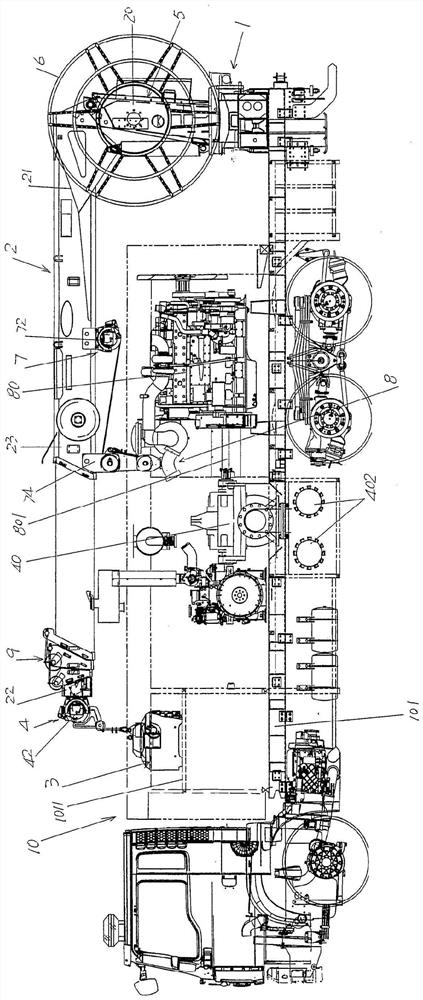

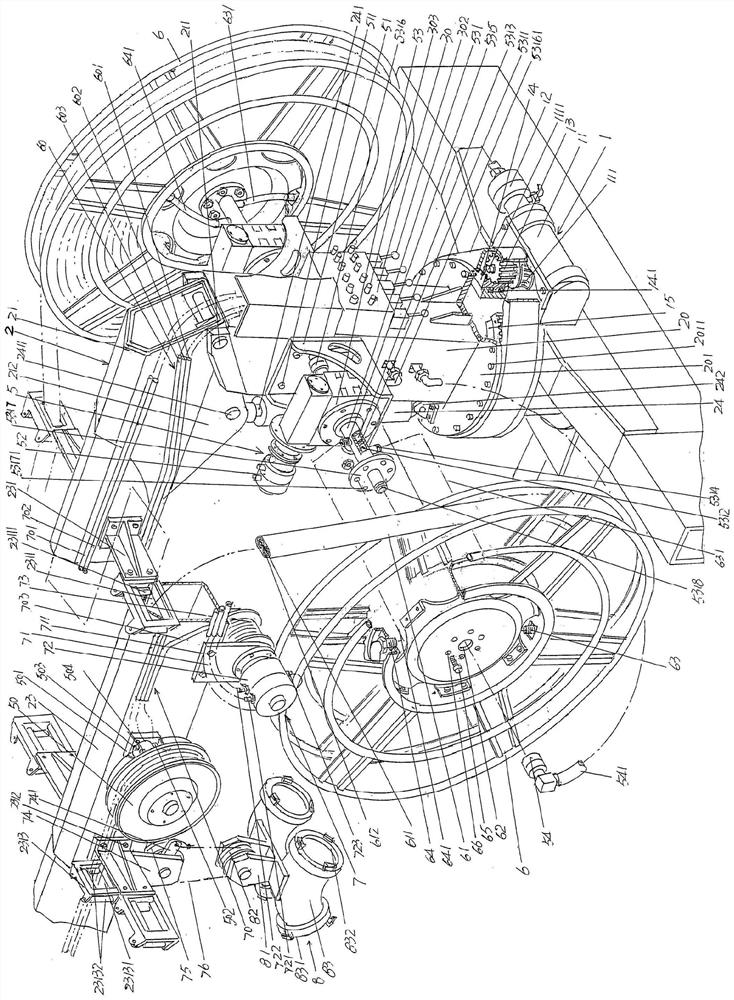

Multifunctional hydraulic scribing and fissure cementing machine

The invention provides a multi-functional hydraulic lineation and joint sealing machine, which mainly solves the technical problems that a manpower hand-pushing machine has high labour intensity, low efficiency, etc. The key point of the technical proposal is that the lower part of a special chassis is provided with a steering wheel and a driving wheel which is connected with a steering operation system; the special chassis is provided with a hot-melting tank, a hydraulic motor, a diesel engine and a hydraulic system; the hydraulic motor is matched with and connected with a transmission shaft which is matched with and connected with a driving wheel; a hydraulic oil pump which is connected with the diesel engine is connected with the hydraulic motor; a hydraulic medium transmission pipeline is provided with a plurality of reversing valves and operation handles; a plurality of reversing valves are respectively connected with a top-pushing oil cylinder, a valve oil cylinder, a steering oil cylinder and the hydraulic motor; the hot-melting tank is fixedly provided with a material inlet; the external end of the valve oil cylinder which is arranged on the hot-melting tank is connected with a material outlet guiding pipe and an operation head; the hot-melting tank is internally provided with a piston-typed pushing plate; the external side of the piston-typed pushing plate is connected with the top-pushing oil cylinder; a burner is matched below the hot-melting tank. The multi-functional hydraulic lineation and slit-pouring machine can be widely applied to the construction operations of roads and various level grounds.

Owner:湖南力威液压设备股份有限公司

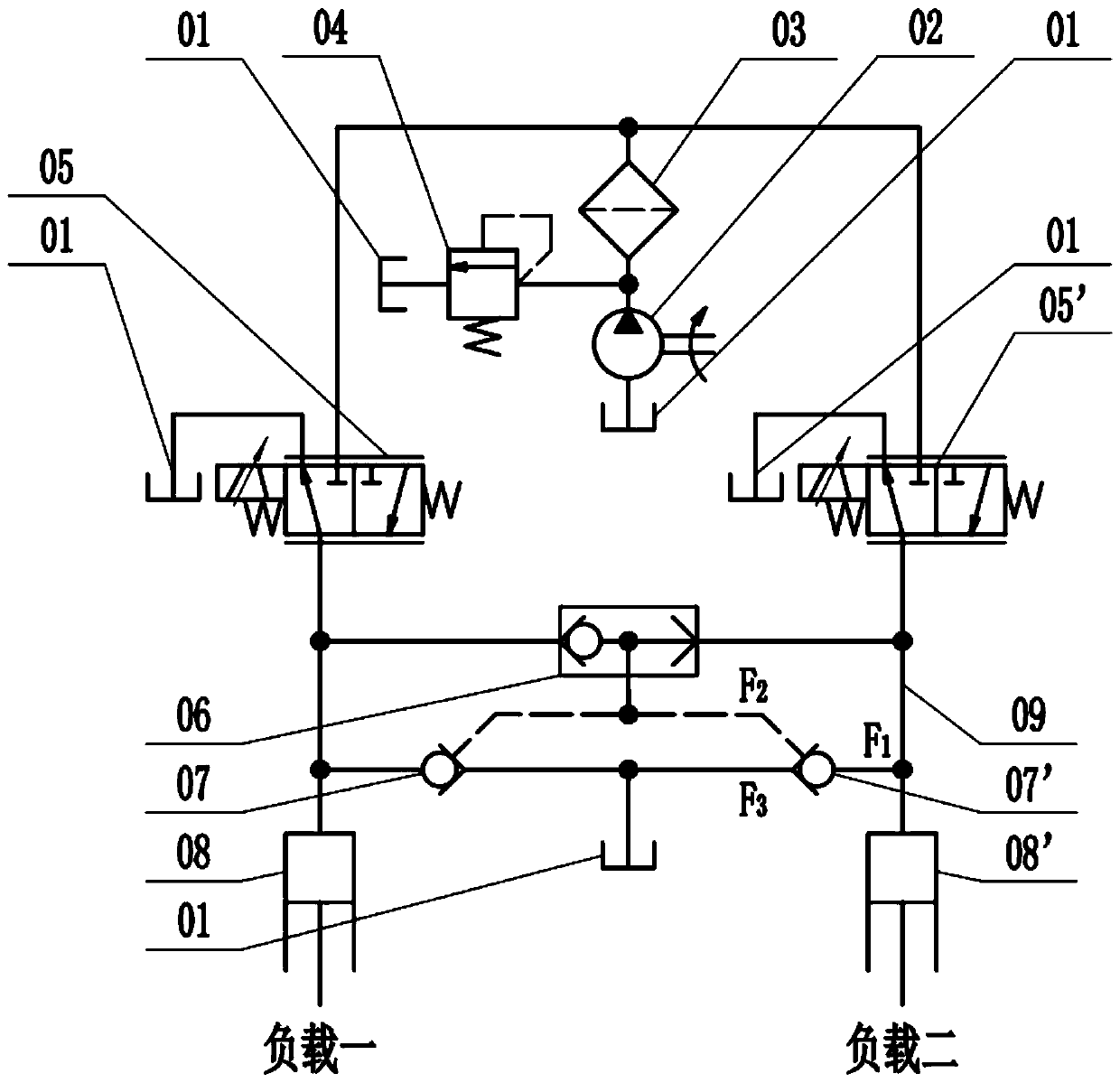

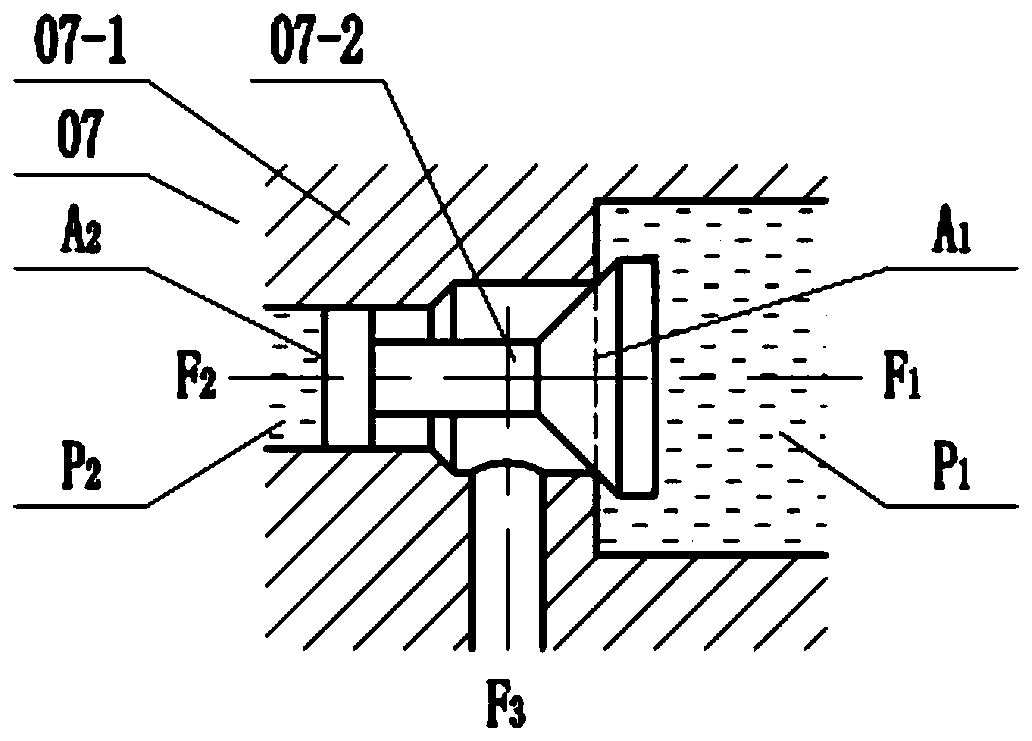

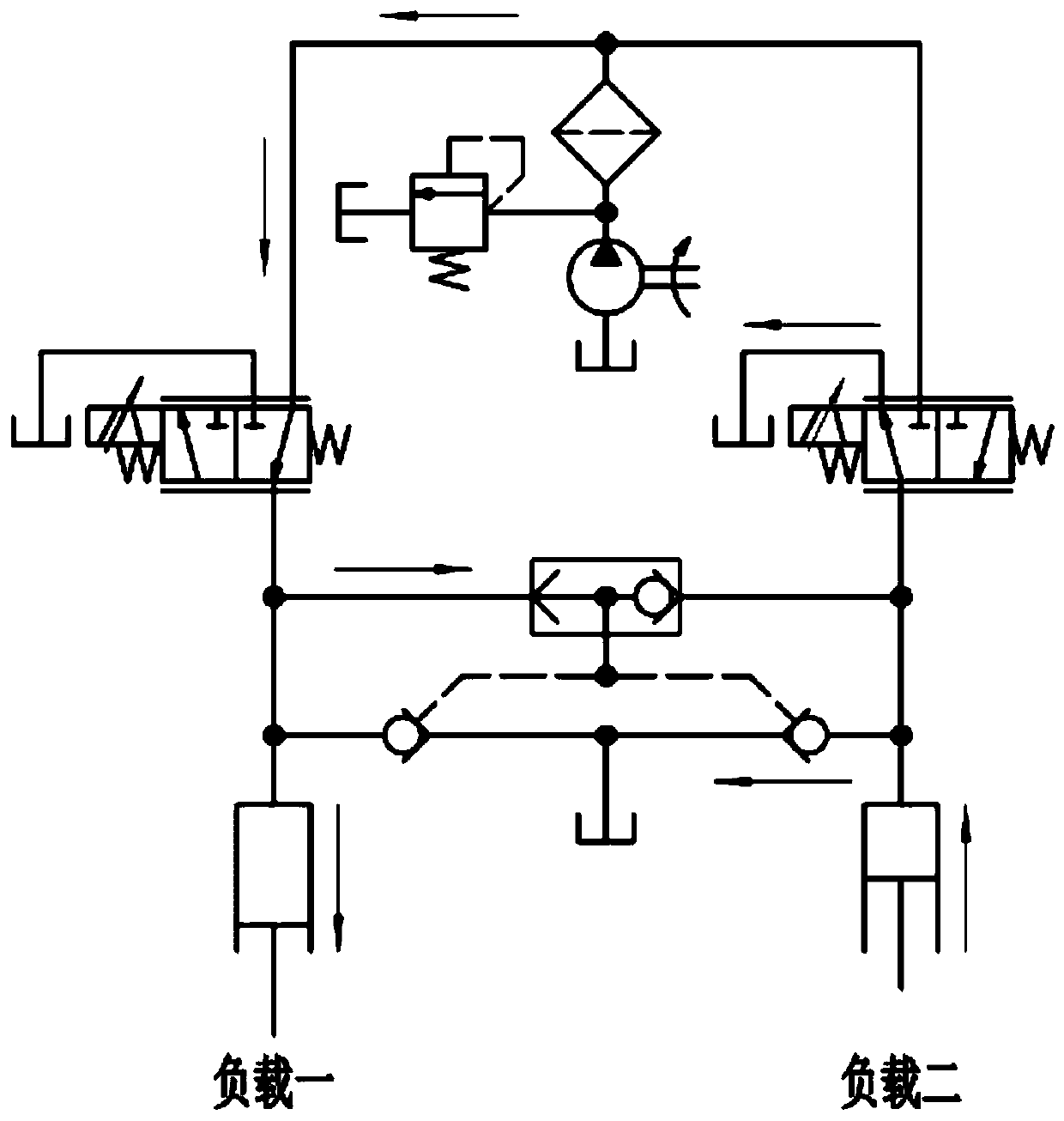

Flow-matched balance and energy recovery system

PendingCN109356897ASimple structureReduce processing difficultyServomotor componentsHydraulic pumpSystem pressure

The invention discloses a flow-matched balance and energy recovery system. The flow-matched balance and energy recovery system comprises a flow-matched balance valve, electromagnetic valves, a hydraulic pump, an oil tank, an energy accumulator and an oil cylinder; the flow-matched balance valve consists of a valve body, a valve sleeve, a valve element, a ball valve element, a pressing spring and acommunicating oil way; a bottom oil port is formed in the bottom of the valve body; a top oil port is formed in the top of the valve body; the valve body is radially provided with an upper oil way and a lower oil way corresponding to the valve sleeve; the bottom oil port is connected with system pressure oil; the top oil port is connected with an oil cylinder; the upper oil way and the lower oilway communicate with one end of a first electromagnetic valve; the other end of the first electromagnetic valve is connected with the energy accumulator; the energy accumulator is connected with an oil inlet of the hydraulic pump through a second electromagnetic valve; one end of a third electromagnetic valve is connected with a balance valve oil way; and the other end is connected with the oil tank. The flow-matched balance and energy recovery system is simple in structure, excellent in reliability, low in throttling loss and non-sensitive to oil temperature and cleanness, can effectively guarantee the balance and the safety of a hydraulic system, and can recover hydraulic energy.

Owner:杭州诺祥科技有限公司

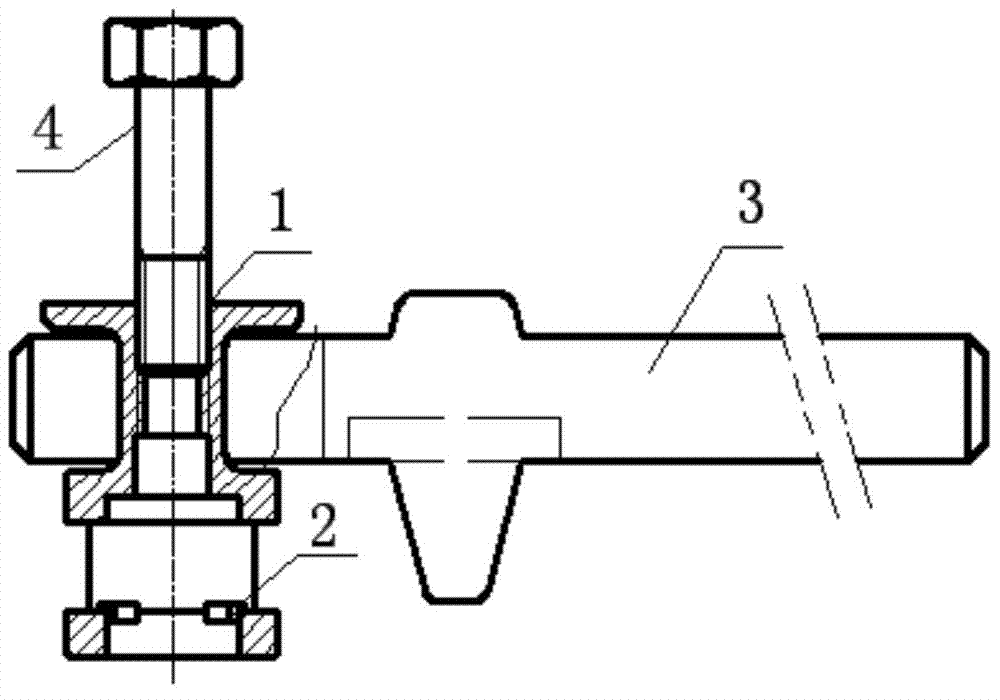

Air charging and exhausting valve oil seal inner flange gauge and detecting method thereof

The invention relates to an air charging and exhausting valve oil seal inner flange gauge and a detecting method thereof. The air charging and exhausting valve oil seal inner flange gauge comprises a valve oil seal measuring tool and a spring testing instrument. The valve oil seal measuring tool comprises a base, an upper pull rod and a lower pull rod, wherein the upper pull rod and the lower pull rod are arranged on the base and can slide on the base vertically. The bottom end of the upper pull rod and the top end of the lower pull rod are opposite, and a hook hole is respectively arranged on the upper pull rod and the lower pull rod. The detecting method includes that by matching the spring testing instrument and the valve oil seal measuring tool, pressing force is controlled, and pulling force is measured so as to judge whether the diameter of the valve oil seal inner flange is qualified. The air charging and exhausting valve oil seal inner flange gauge and the detecting method greatly reduce effects of human factors, are good in measuring result repeatability and stability, correct in measuring, favorable for controlling the valve oil seal quality strictly and convenient to operate, save time and improve detecting efficiency.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +2

Control logic coordination valve of undercarriage cabin door uplock

PendingCN112520020AReduce volumeReduce weightNon-mechanical controlsUndercarriagesActuatorControl logic

The invention discloses a control logic coordination valve of an undercarriage cabin door uplock, which is wide in coordination range and higher in reliability. According to the technical scheme, an oil inlet pipe nozzle supplies pressure, an upper lock is in linkage with a pressing rod through a pressing mechanism, a valve element reset spring is compressed through a stepped shaft, a valve seat is driven to seal a valve element, and the oil pipe nozzle is closed; when the cabin door uplock is completely opened, the uplock applies pressing force to the pressing rod through the motion trail ofthe pressing mechanism, the pressing rod pushes the valve element, compresses the valve element reset spring, separates the valve seat of the valve and triggers the valve oil holes distributed in theconical shell of the valve element, and hydraulic oil liquid enters a valve cavity of the rear end cover through a cabin door actuator cylinder pressure supply oil way. The oil flows from the oil outlet pipe nozzle to the cabin door actuator cylinder, the actuator cylinder is pushed to open the cabin door, the compression valve element reset spring and the valve element reset spring press the pressing rod at the initial position under the action of elastic force, simultaneous pressure supply of the uplock and the cabin door actuator cylinder is achieved, and the control logic of the sequentialmovement sequence is completed through the trigger type coordination valve.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

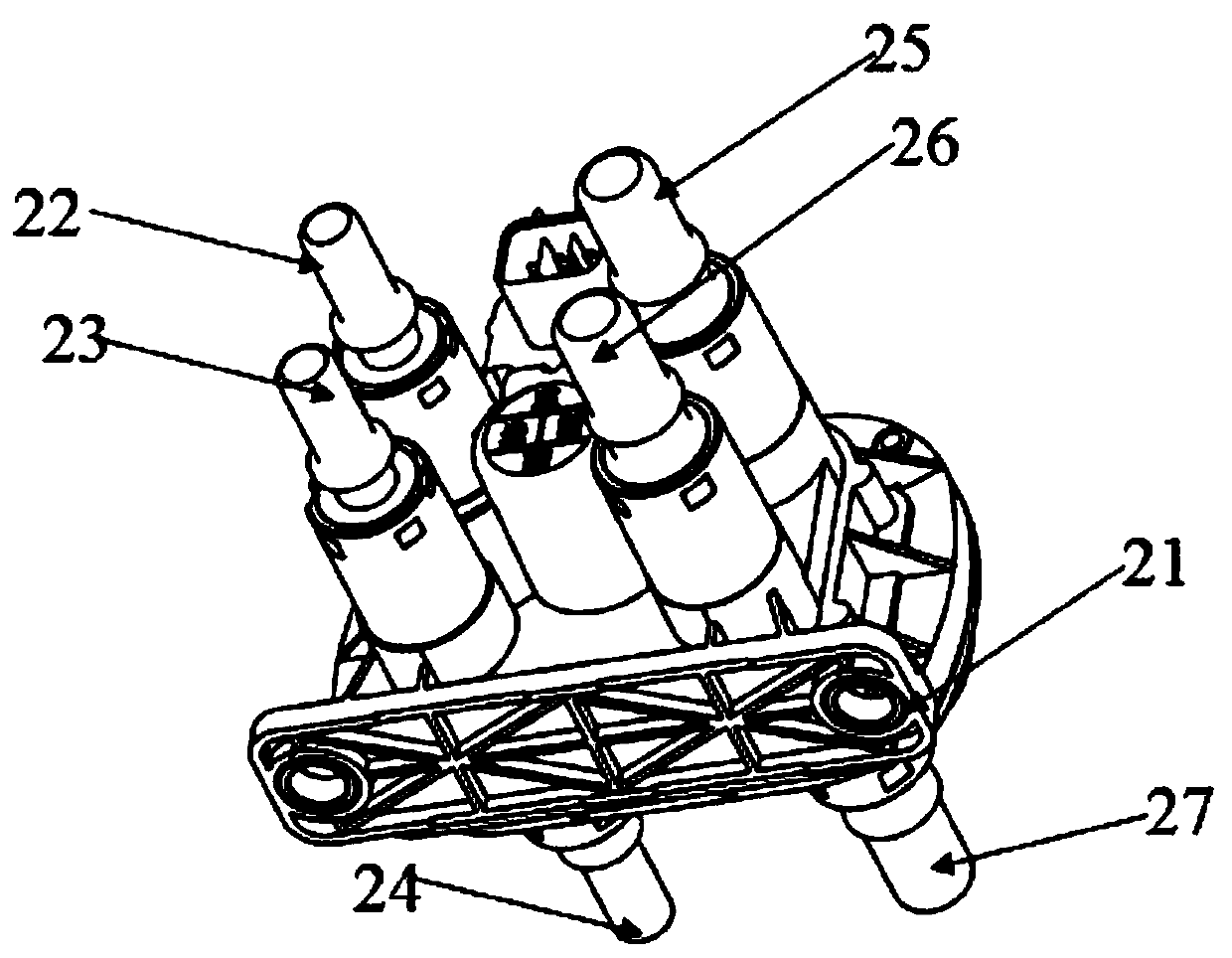

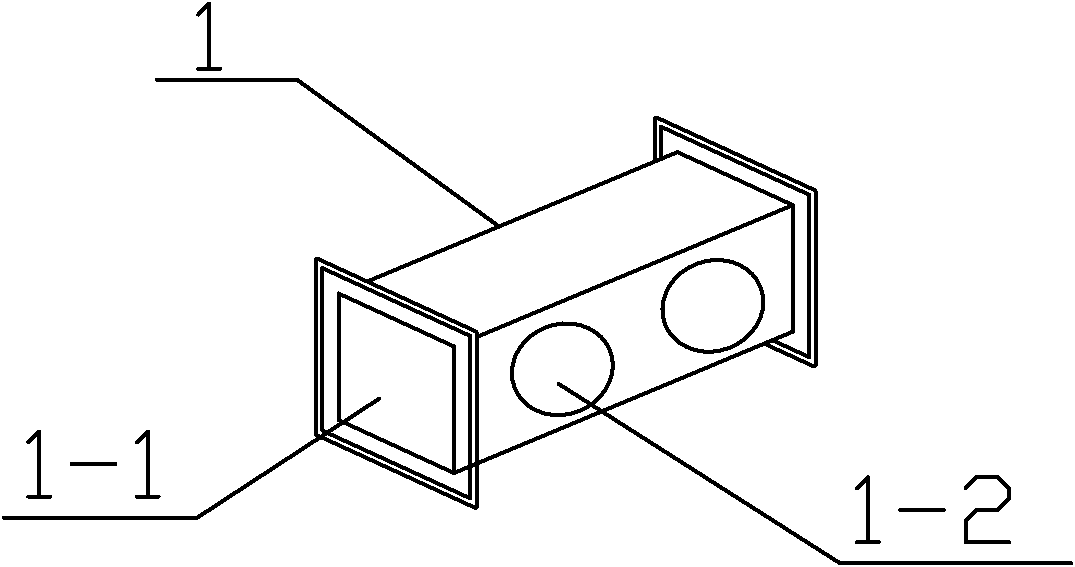

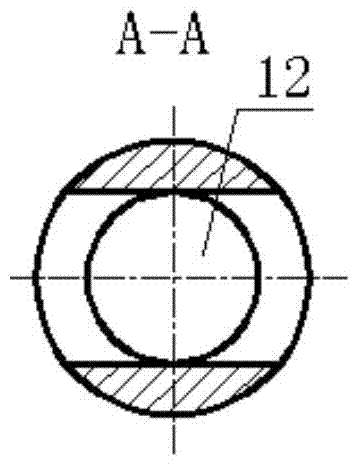

Distribution valve and mud or concrete pump with same

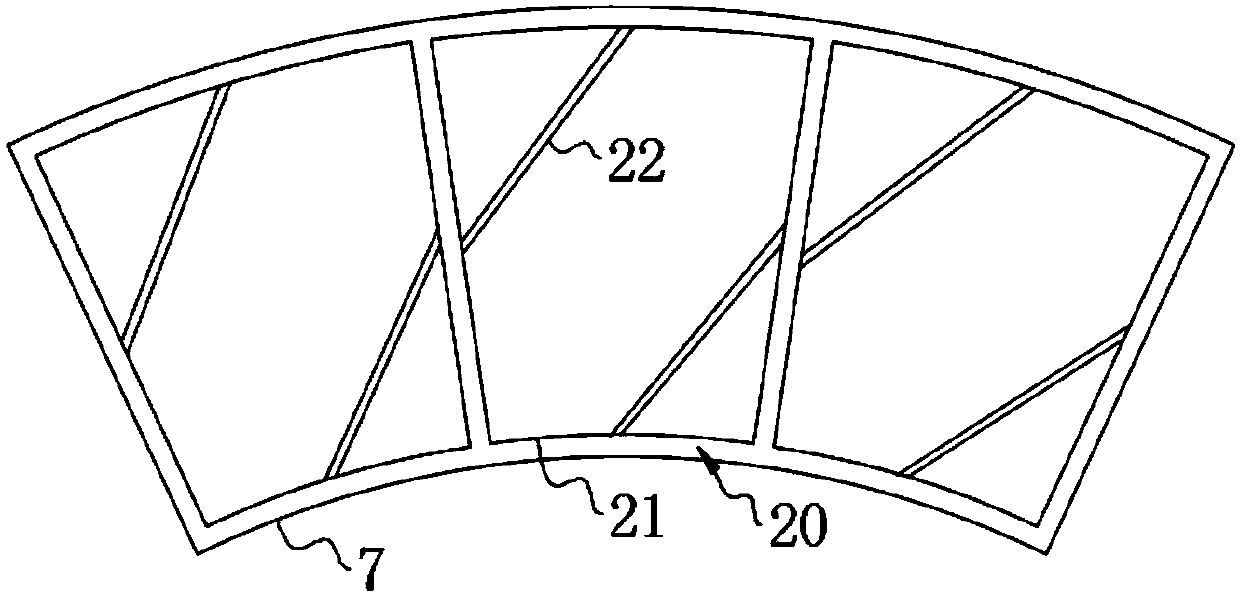

ActiveCN101929458ANo resistanceNo crushing forcePositive displacement pump componentsPumpsConcrete pumpPiston

The invention discloses a distribution valve and a mud or concrete pump with the same. The distribution valve comprises a valve block, a valve oil cylinder and a column compartment, the valve block is internally and transversely provided with a square section channel; two surfaces perpendicular to the square-shaped section channel are both provided with two circular holes communicated with the square-shaped section channel; circular tubes with flanges extends outwards from the circular holes; the circular tubes are internally provided with sleeves; the square-shaped section channel of the valve block is communicated with the column compartment of a uniform section; the column compartment is internally provided with a rectangular-column plunger; the outer end of the rectangular-column plunger is provided with a plunger rod; and the valve oil cylinder is arranged outside the valve block. A main oil cylinder of the mud or concrete pump is connected with a mud cylinder through a wash trough; a sensor is arranged above the wash trough; and the mud cylinder is communicated with the two circular tubes of the distribution valve through a V-shape tube. The invention adequately reflects theadvantages of multi-functions of the distribution valve and the mud or concrete pump. The mud or concrete pump is not only a self-suction type mud pump, but also a medium-pressure concrete pump; and in addition, the distribution valve can be used for a transmission part and can be used as a compensating cylinder.

Owner:海宁经开产业园区开发建设有限公司

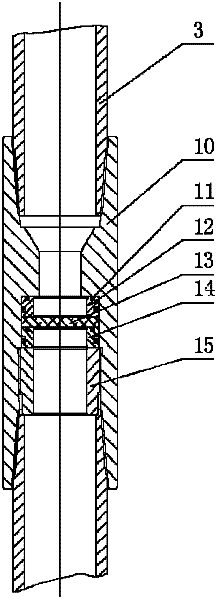

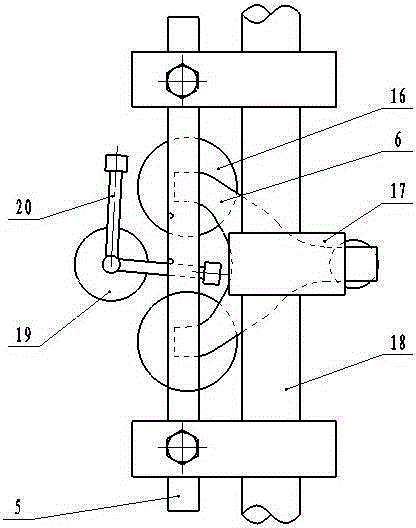

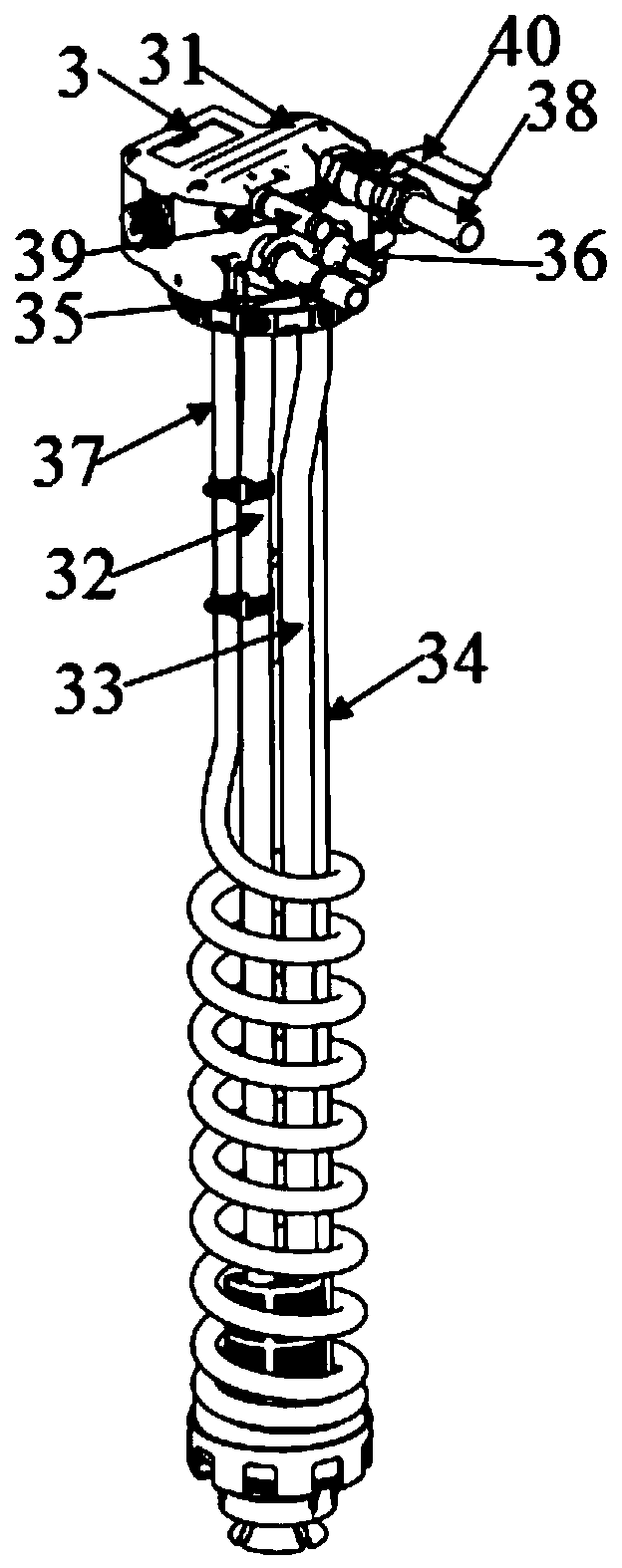

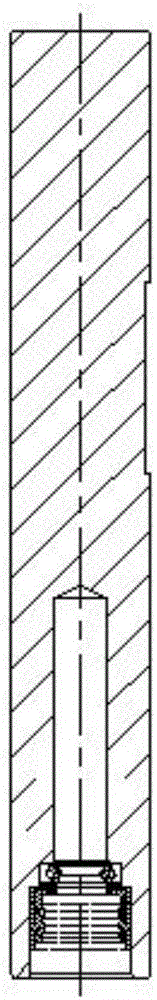

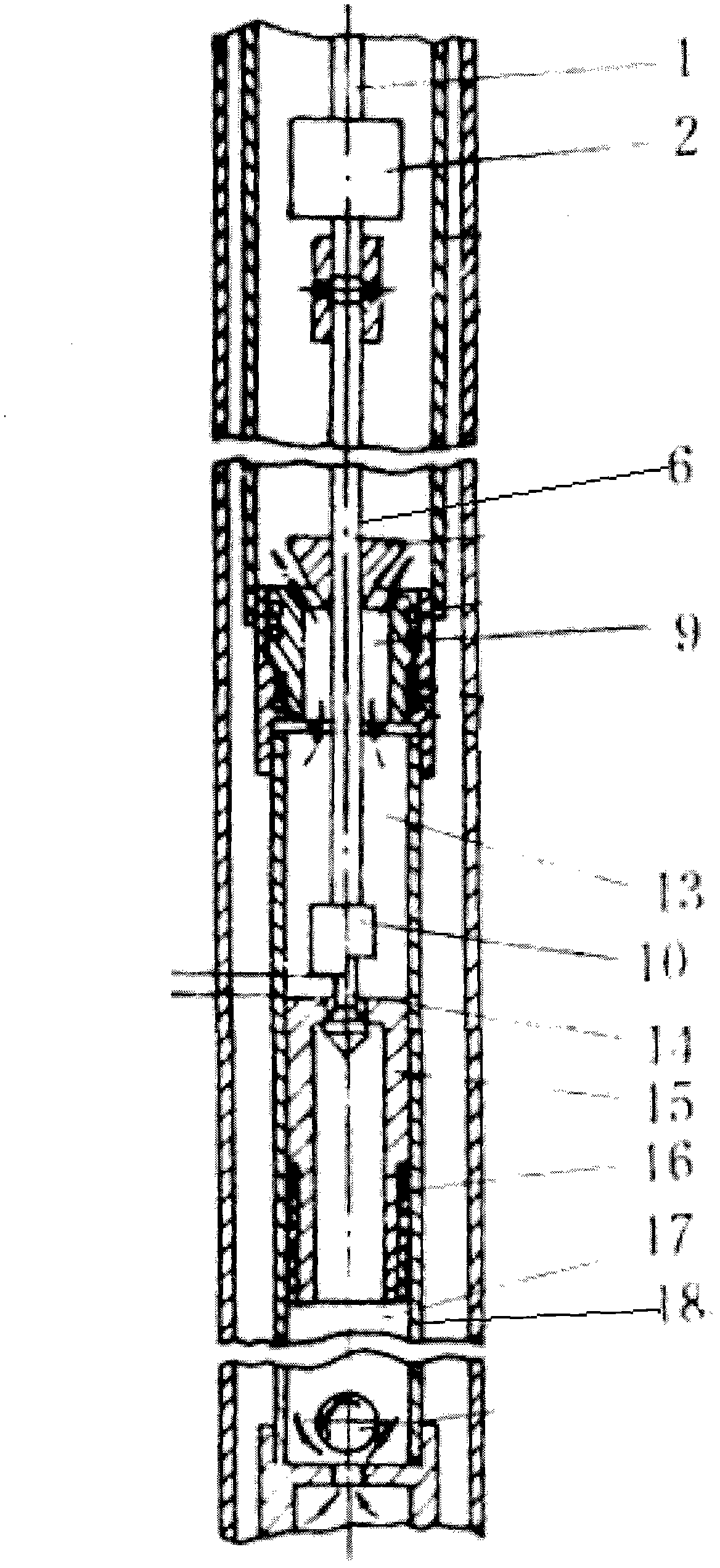

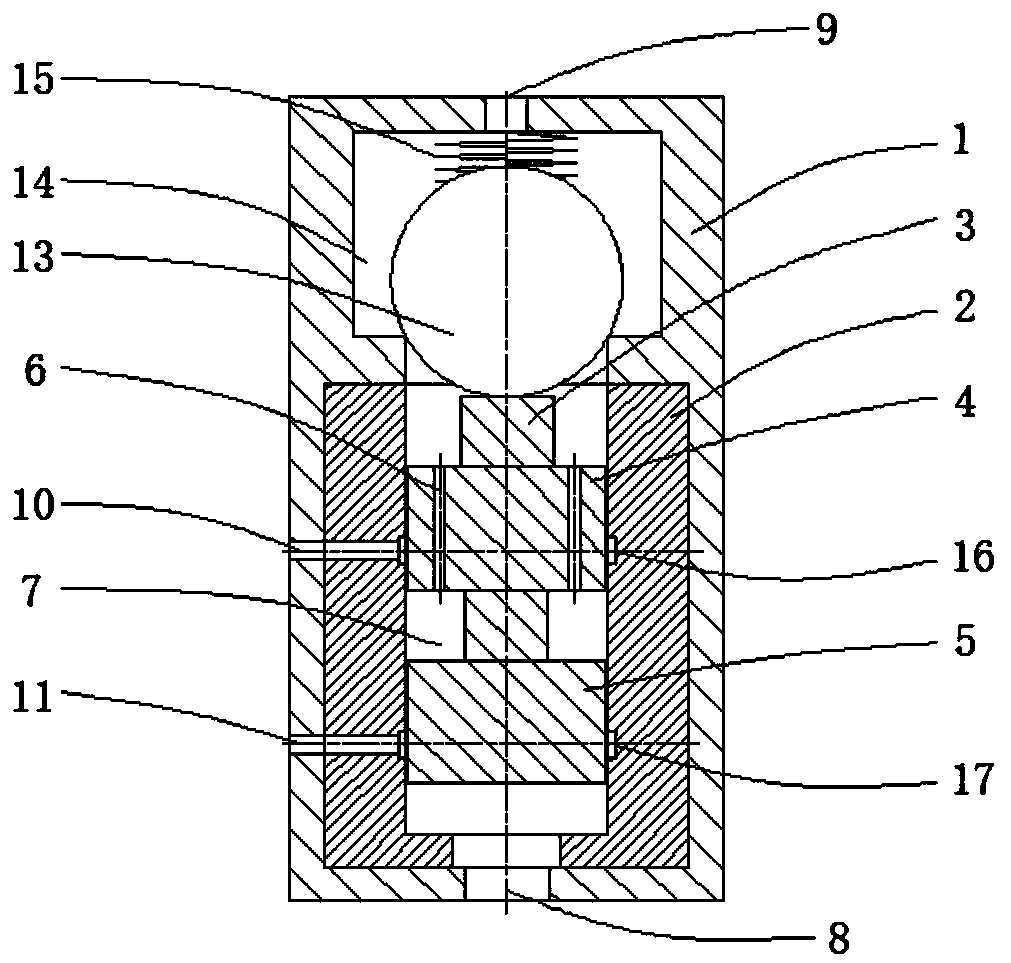

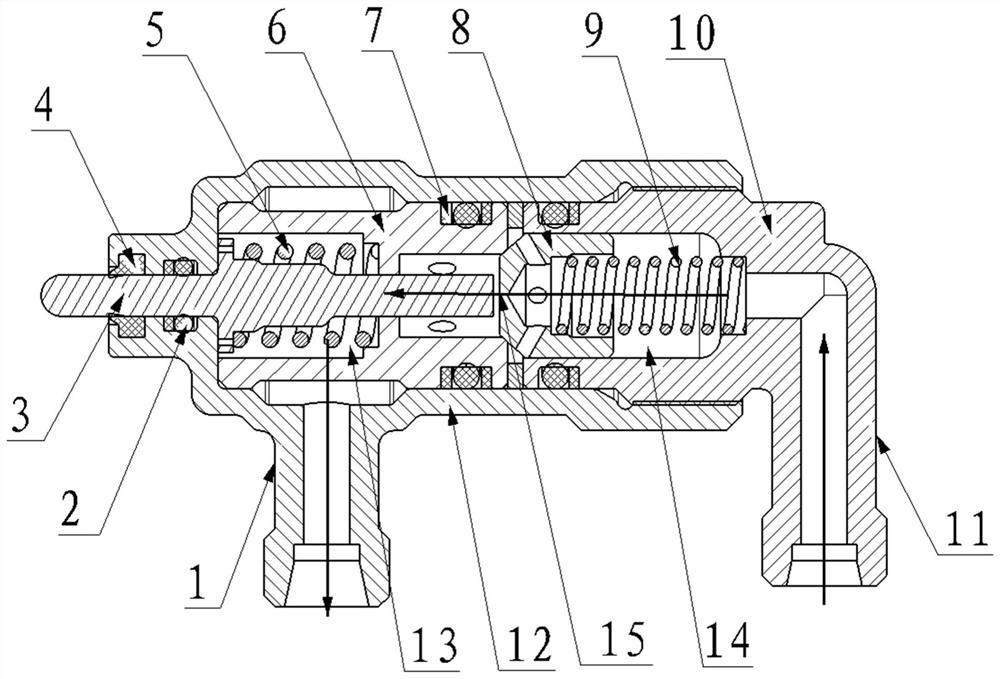

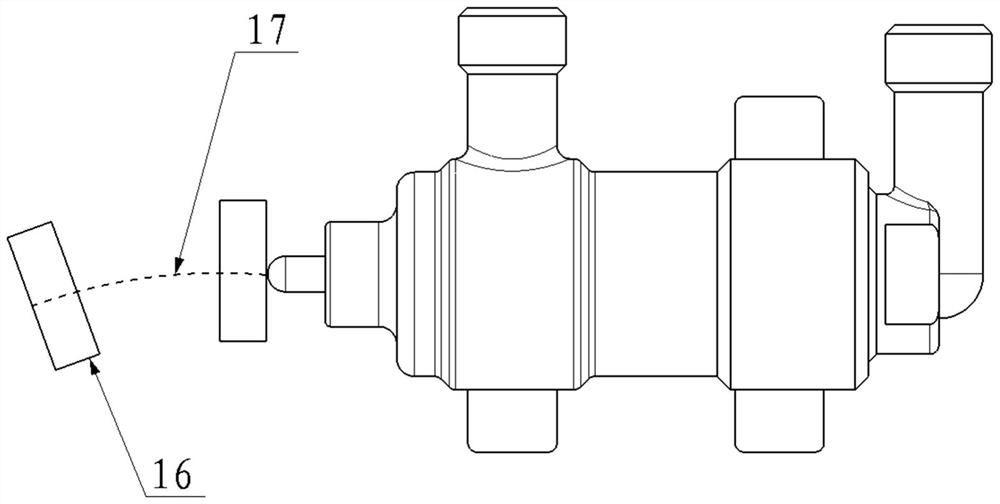

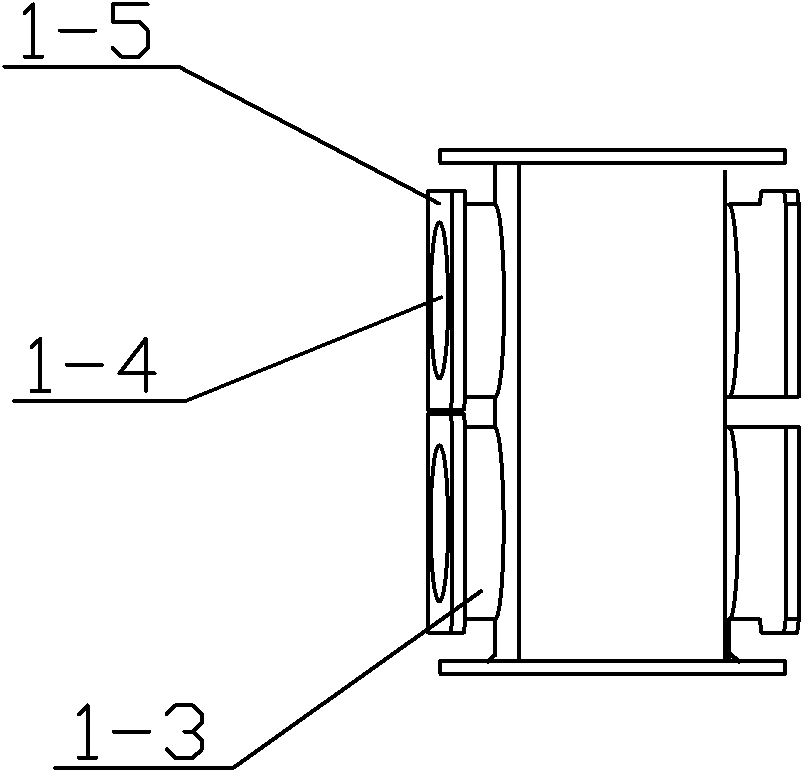

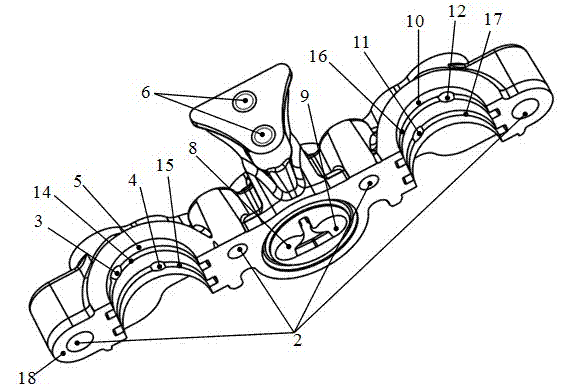

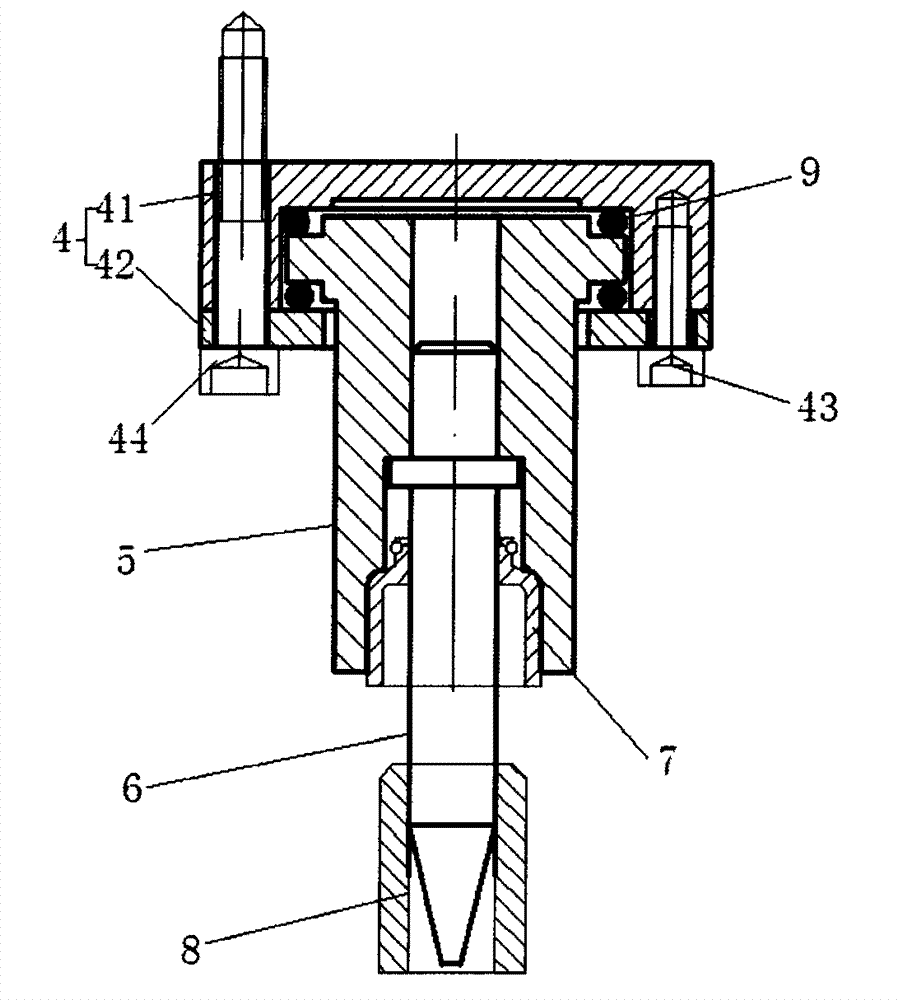

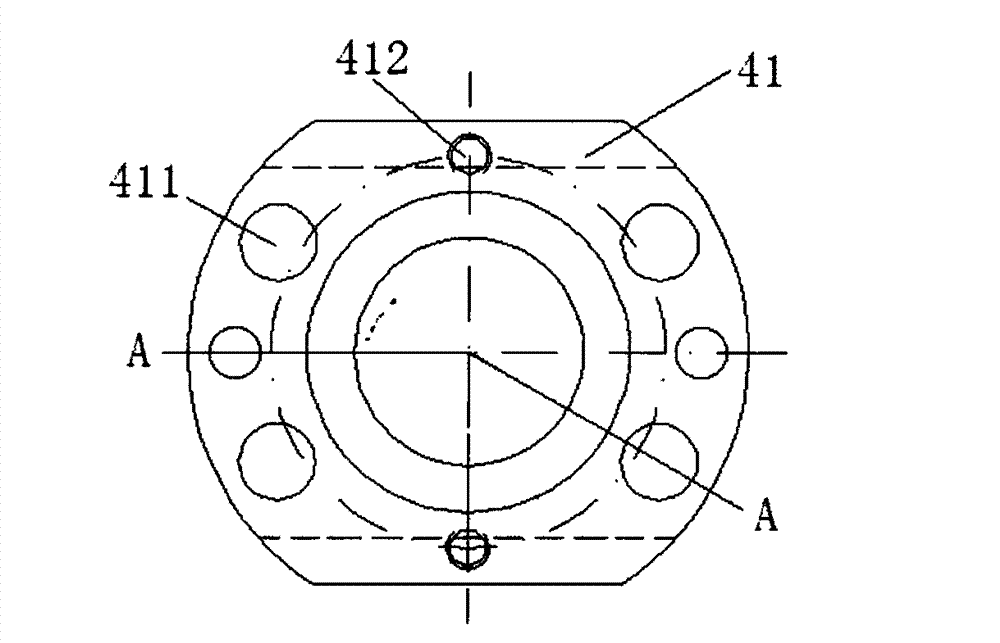

Mechanical switch valve oil-well pump

InactiveCN103133315AAvoid "air lock"Flexible member pumpsPositive-displacement liquid enginesEngineeringPlunger

The invention discloses a mechanical switch valve oil-well pump which is mainly composed of a pump cylinder (18), a valve rod (9) arranged in the pump cylinder (18), and a plunger arranged at the lower end of the valve rod (9). The plunger partitions the interior of the pump cylinder (18) into an upper cavity chamber (13) and a lower cavity chamber (17). A pushing block and an air-bleed hole are arranged on the valve rod, a plunger delivery valve upper cavity and a plunger delivery valve lower cavity can be communicated when the plunger is close to a bottom dead center and reverses to ascend for a small section of distance, oil gas in the upper cavity chamber is exhausted into an oil tube in advance, and therefore 'airlock' is effectively prevented from happening.

Owner:严欢

Automatic water diversion fire truck

An automatic water diversion firefighting vehicle, comprising a vehicle body; a column is arranged on a rotary driving mechanism of the column, on which a hydraulic oil distribution valve is fixed, the hydraulic oil distribution valve is connected with a hydraulic oil pipe of a hydraulic station, and the hydraulic station is arranged on the chassis of the vehicle body Above, the column rotation drive mechanism is set on the chassis and is located at the right end of the chassis; the lifting mechanism is connected with the column; the water diversion mechanism is connected with the traction mechanism, and the traction mechanism is set on the lifting mechanism; On the front and rear sides of the column, each is connected with a hoisting coil of oil pipe, on which the hoisting coil oil pipe is arranged, and the water diversion mechanism is connected with the oil pipe of the hoisting coil; the lifting mechanism of the pulley seat is arranged on the lifting mechanism and distributed with the hydraulic oil The valve oil circuit is connected; the fire water lead-out mechanism is pulled by the pulley seat lifting mechanism and connected with the water diversion mechanism. The automation effect is ideal, and the work intensity is reduced; it can avoid sinking and be affected by the silt in the water; it can keep the water diversion mechanism away from the shore to ensure the water diversion effect.

Owner:JIEDA FIRE PROTECTION VEHICLE EQUIP CO LTD SUZHOU CITY

Disassembly assembly for valve parts

ActiveCN103878739AImprove integrityRealize pressing and pulling operationsMetal-working hand toolsEngineeringScrew thread

The invention discloses a disassembly assembly for valve parts. The disassembly assembly comprises a sleeve, a lock piece set, a pressing rod and a stud. A necking-down section is arranged at the upper end of the sleeve, a cavity is formed in the side wall of the lower end of the sleeve, a center hole penetrating through the cavity is formed inside the lower end of the sleeve, the inner diameter of the center hole is matched with the outer diameter of a valve oil seal, and the inner bottom face of the cavity forms the flange face of the center hole. The lock piece set comprises two same arc-shaped rings, the outer walls of the arc-shaped rings are in a ladder shape, the arc-shaped rings can be buckled in the center hole, and the step portions of the outer walls of the arc-shaped rings abut against the flange face. The pressing rod is a cylinder, a U-shaped groove is formed in the front end of the cylinder, a hollow protrusion is arranged on the upper surface of the middle portion of the cylinder, and a solid protrusion is arranged on the lower surface of the middle portion of the cylinder. The stud can be screwed into a bolt hole in an air cylinder cover, a threaded hole matched with the stud is formed inside the upper end of the sleeve, and the threaded hole is communicated with the center hole downwards. The disassembly assembly can selectively disassemble valve parts.

Owner:GUANGXI YUCHAI MASCH CO LTD

Single-acting plunger cylinder hydraulic system

ActiveCN110886729AReduce complexitySmall form factorServomotor componentsServomotorsMarine engineeringHydraulic pump

The invention discloses a single-acting plunger cylinder hydraulic system. A hydraulic oil tank is connected with an inlet of a hydraulic pump, an outlet of the hydraulic pump is simultaneously connected with oil inlets of left-side and right-side two-position three-way reversing valves, and oil return openings of the left-side and right-side two-position three-way reversing valves are respectively connected with the hydraulic oil tank; an oil outlet of the left-side two-position three-way reversing valve is simultaneously connected with an inlet of a left-side hydraulic control one-way valveand an oil port of a left-side single-acting plunger cylinder and is further connected with one inlet of a shuttle valve; a valve oil outlet of the right-side two-position three-way reversing valve issimultaneously connected with an inlet of a right-side hydraulic control one-way valve and an oil port of a right-side single-acting plunger cylinder and is further connected with the other inlet ofthe shuttle valve; an outlet of the shuttle valve is simultaneously connected with hydraulic control ports of the left-side hydraulic control one-way valve and the right-side hydraulic control one-wayvalve; outlets of the left-side hydraulic control one-way valve and the right-side hydraulic control one-way valve are connected with the hydraulic oil tank; and the effective hydraulic area of the inlets of the hydraulic control one-way valves is larger than the effective hydraulic area of the hydraulic control ports. The complexity of a traditional hydraulic system is reduced, the external dimensions of elements and the system are reduced, and the structure is more compact.

Owner:SOUTHWEST JIAOTONG UNIV

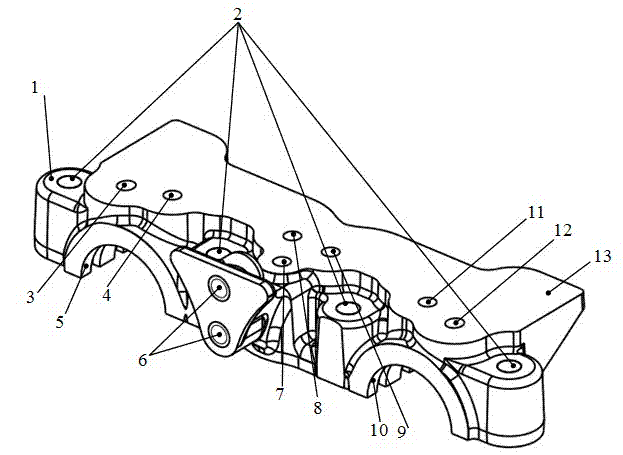

Engine cam shaft bearing cap integrated with VVT oilway

InactiveCN103711540ARealize the VVT functionValve arrangementsLubrication of auxillariesCylinder headCam

An engine cam shaft bearing cap integrated with a VVT oilway is characterized in that a first oil groove and a second oil groove are peripherally parallelly formed in the wall of a half-shaft hole on the air inlet side, a first oil hole and a second oil hole which are communicated to an upper seal face are respectively formed in the first oil groove and the second oil groove, the first oil hole and the second oil hole are respectively communicated with an OCV valve oil return hole A and B on the air inlet side, a third oil groove and a fourth oil groove are peripherally parallelly formed in the wall of a half-shaft hole on the exhaust side, a third oil hole and a fourth oil hole which are communicated to the upper seal face are respectively formed in the third oil groove and the fourth oil groove, the third oil hole and the fourth oil hole are respectively communicated with an OCV valve oil return hole A and B on the exhaust side, an air inlet side OCV valve oil supply hole and an exhaust side OCV oil supply hole which penetrate from a lower seal face to the upper seal face are formed between the air inlet side half-shaft hole and the exhaust side half-shaft hole of a cover. The engine cam shaft bearing cap has the advantages that engine oil is guided to the OCV valve mounted on a cylinder head cover by modifying the oilway, the oil returned by the OCV valve is supplied to a cam shaft, the oil supply requirement of normal operation of the OCV valve is satisfied, and an engine VVT function is achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

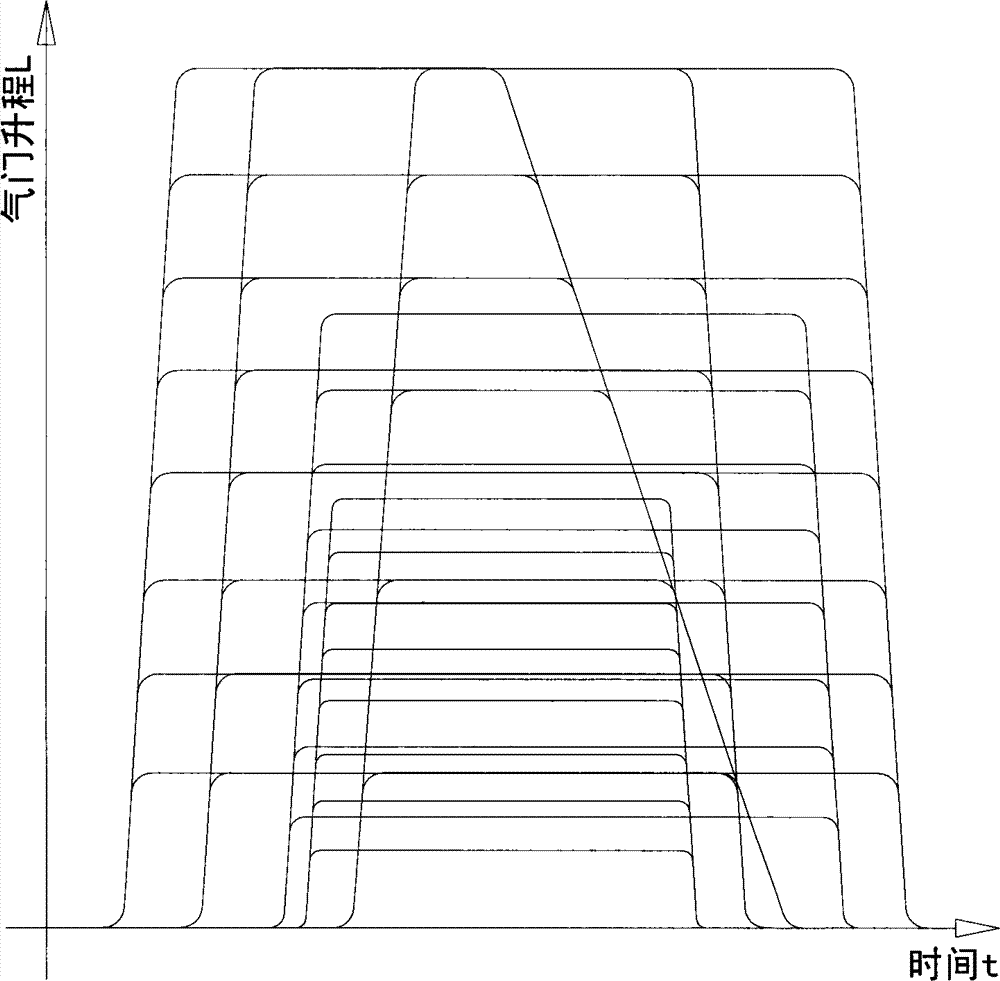

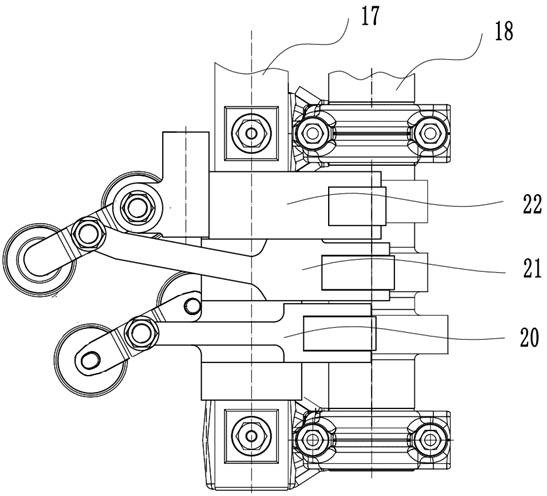

Engine cylinder closing valve control device and method

ActiveCN114087076AMeet the needs of different working conditionsGuaranteed normal drivingOutput powerMachines/enginesSpool valveHydraulic pump

The invention provides an engine cylinder closing valve control device and method, and relates to the technical field of engines. The engine cylinder closing valve control device comprises a valve oil way and a control oil way; the control oil way comprises a sliding valve, a control valve and a hydraulic pump; the hydraulic pump is connected into a control port of the sliding valve through the control valve; the sliding valve is provided with a middle channel and a valve element; the valve oil way is connected with the middle channel in series; the control valve adjusts the position of the valve element through the control port so that the valve element can block or open the middle channel. For solving the problem that the reliability is low when a mechanical blocking structure is adopted during cylinder closing of an existing engine, the sliding valve is arranged on a driving valve oil way, the driving valve oil way is blocked or opened through the sliding valve, and the valve can be closed to achieve cylinder closing during blocking; and during opening, the driving valve oil way can operate normally, normal driving of a valve is kept, and the working requirements of an engine in different states are met.

Owner:LONGKOU ZHONGYU THERMAL MANAGEMENT SYST SCIAND TECH

Novel motorcycle brake mechanism

PendingCN107559354AIncrease temperatureGuaranteed braking effectBraking membersFriction liningControl theoryPiston rod

The invention provides a novel motorcycle brake mechanism. The novel motorcycle brake mechanism comprises a brake mechanism body and a cooling mechanism. The brake mechanism body comprises a hydraulicoil header pipe. The hydraulic oil header pipe is fixedly connected with a brake oil pump. A brake piston is arranged in the brake oil pump and fixedly connected with a movable brake pad frame. A brake caliper body is fixedly connected with a fixed brake pad frame. A brake disc is arranged between the fixed brake pad frame and the movable brake pad frame. The cooling mechanism comprises a water tank. The water tank is fixedly connected with a water outlet pipe. The water outlet pipe is fixedly connected with a stop valve. The stop valve is fixedly connected with a spray pipe. A valve rod of the stop valve is fixedly connected with a piston rod of a valve oil pump. The valve oil pump is fixedly connected with a hydraulic oil branch pipe. The hydraulic oil branch pipe is fixedly connected with the hydraulic oil header pipe. The novel motorcycle brake mechanism is simple in structure and convenient to use, hydraulic oil is used as driving force for controlling a spray pipe valve to openand spray water to cool the motorcycle brake disc, the temperature of the disc plate is effectively prevented from being too high, and the brake performance of a brake pad is ensured.

Owner:重庆光盈科技有限公司

Automatic arranging and falling device for metal framework of valve oil seal

The invention discloses an automatic arranging and falling device for a metal framework of a valve oil seal, comprising a back plate, a tool supporting plate, a transparent panel and a guide block, wherein the tool supporting plate is provided with a raised guide post corresponding to a mold core of a mould; the transparent panel is arranged in front of the obverse side of the back plate; a clearance capable of holding the metal framework is formed between the transparent panel and the back plate; the back plate is provided with vertical guide bars at intervals; a guide slot of the metal framework is formed between the two guide bars; the bottoms of the guide bars are provided with a buckle capable of buckling the metal framework; the buckle corresponds to the guide post; the top of the guide post is lower than the bottom of the transparent panel; and the metal framework located on the buckle is turned up and falls on the guide post when the guide post horizontally passes through the buckle. The automatic arranging and falling device for the metal framework of the valve oil seal, disclosed by the invention, is simple and reasonable in structure and has the effects of increasing the production efficiency and reducing the production cost; and an operator is prevented from being in contact with the surface of the metal framework of the oil seal, and the surface of the metal framework is prevented from being polluted.

Owner:CHENGDU SHENGBANG SEALS

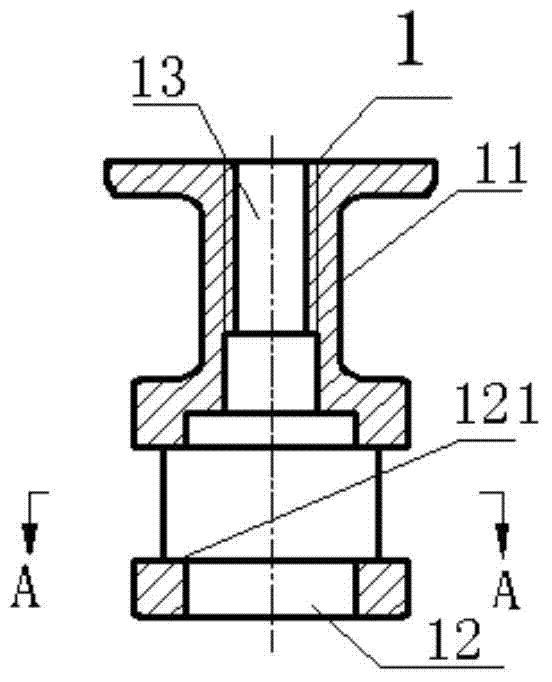

Pressure head of valve oil seal

InactiveCN103707035AImprove press fit accuracyIncrease success rateMetal working apparatusEngineeringPerpendicular direction

The invention discloses a pressure head of a valve oil seal. The pressure head of the valve oil seal comprises a base, an oil seal pressing sleeve and a guide shaft. An upper shell and a lower cover of the base are fastened with each other to form a connecting cavity, the oil seal pressing sleeve is tubular, the upper end of the oil seal pressing sleeve is arranged in the connecting cavity and is connected with the connecting cavity in a ball suspension manner, and a lower port of the oil seal pressing sleeve is matched with the valve oil seal to be subjected to press-fitting; the guide shaft is cylindrical and is inserted into the oil seal pressing sleeve, and a tapered guide head is arranged at the lower end of the guide shaft. The pressure head of the valve oil seal has the advantages that the oil seal pressing sleeve of the pressure head of the valve oil seal is connected with the base in the ball suspension manner, so that the oil seal pressing sleeve and the guide shaft can keep in perpendicular directions while the oil seal pressing sleeve and the guide shaft can be finely repositioned in the left-right directions on ball planes, press-fitting guiding and positioning can be conveniently carried out by the guide shaft when a valve guide pipe is not aligned with the pressure head of the valve oil seal, the press-fitting precision can be improved, and a press-fitting success rate can be increased.

Owner:GUANGXI YUCHAI MASCH CO LTD

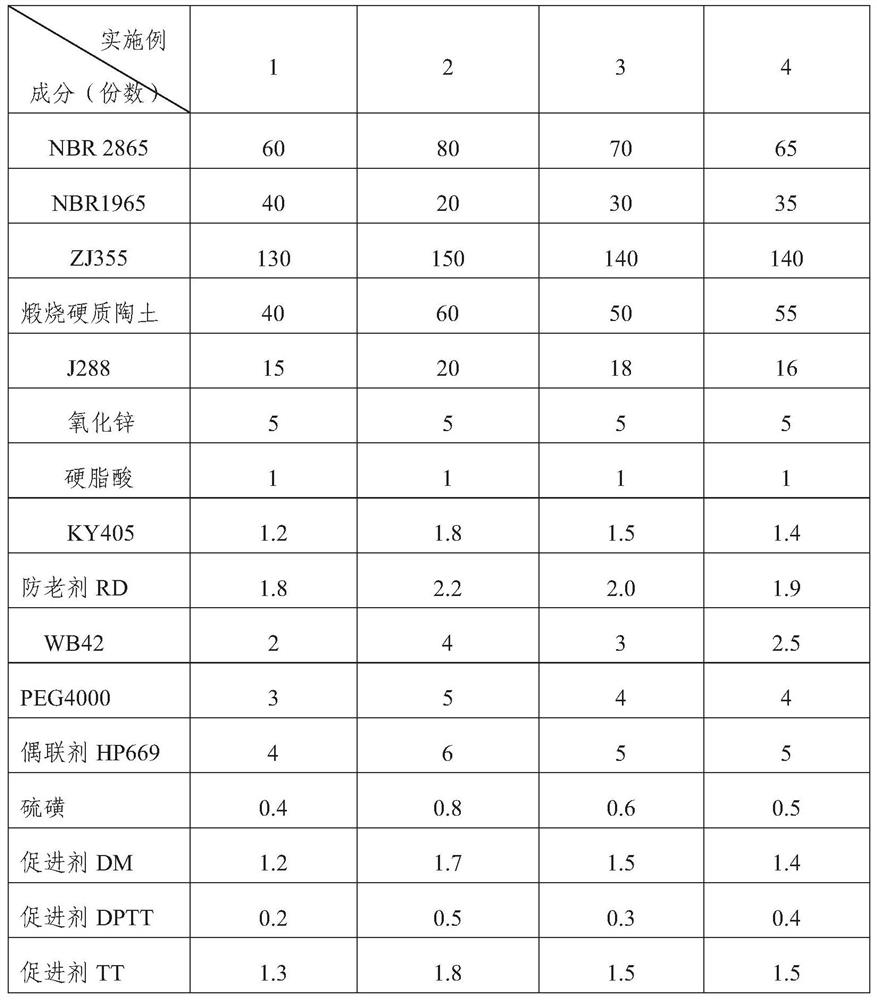

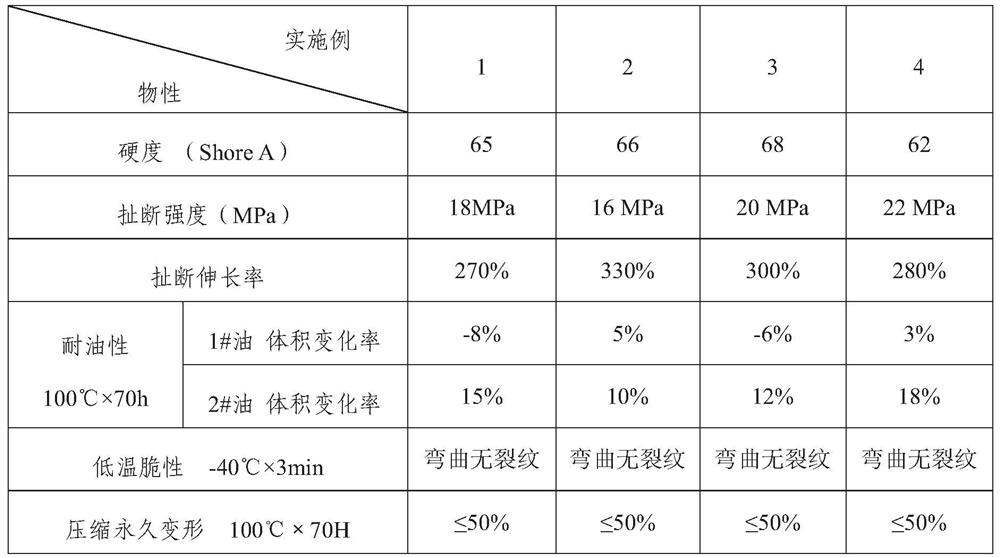

Colored throttle valve oil-resistant rubber material

PendingCN112521669AGuaranteed oil resistanceGuaranteed Low Temperature PerformanceRubber materialPolymer science

The invention discloses a colored throttle valve oil-resistant rubber material, which comprises the following components: nitrile rubber NBR 2865, nitrile rubber NBR 1965, a reinforcing agent ZJ355, calcined hard pottery clay, an environment-friendly plasticizer J288, zinc oxide, stearic acid, an antioxidant KY405, an antioxidant RD, a processing aid WB42, polyethylene glycol PEG4000, a coupling agent HP669, sulfur S, an accelerator DM, accelerator DPTT and an accelerator TT. The rubber material has the advantages of excellent oil resistance, favorable low-temperature properties, low permanentcompression set and favorable basic physical and mechanical properties, and is suitable to be used as a colored oil-resistant rubber material.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Differential pressure regulating valve dynamic performance test bench and measurement method thereof

The invention provides a differential pressure regulating valve dynamic performance test bench and a measurement method thereof, the differential pressure regulating valve dynamic performance test bench comprises a valve pipeline main body, an oil tank, an air compressor and a high-speed photography acquisition system; the valve pipeline main body comprises a closed loop, a valve inlet pipeline, avalve oil supply pipeline, a valve overflow pipeline and a valve middle cavity inlet pipeline; a third temperature sensor and a third pressure sensor are mounted on the valve inlet pipeline; a fourthpressure sensor and a fourth temperature sensor are mounted on the valve oil supply pipeline; the valve overflow pipeline is used for connecting an overflow outlet and an oil tank inlet, the valve middle cavity inlet pipeline is used for connecting an air compressor and a middle cavity pressure inlet, and the high-speed photography acquisition system is used for acquiring valve core movement conditions in different states. According to the invention, the dynamic characteristic test of the differential pressure regulating valve under a specific working condition can be achieved.

Owner:JIANGSU UNIV +2

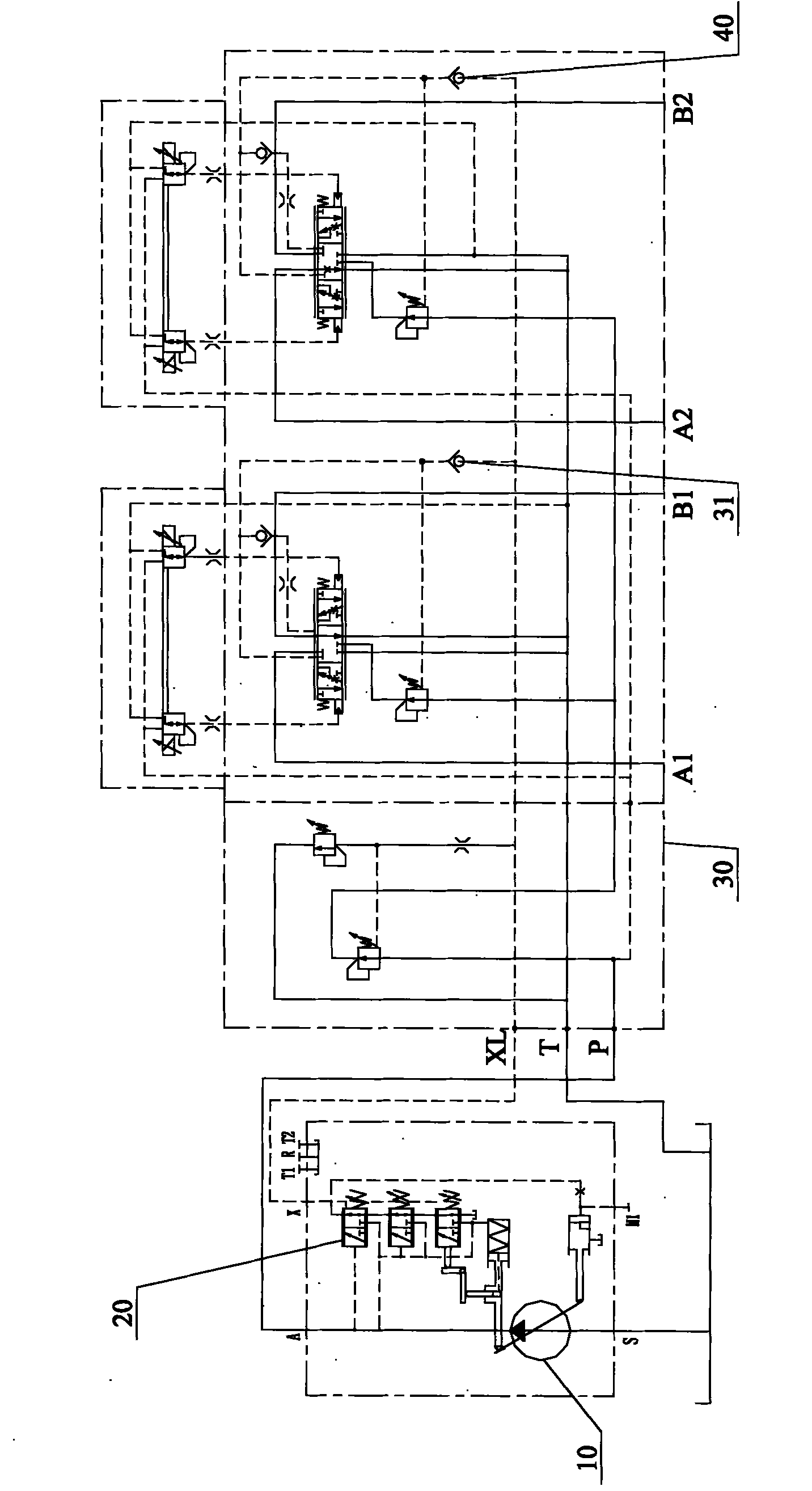

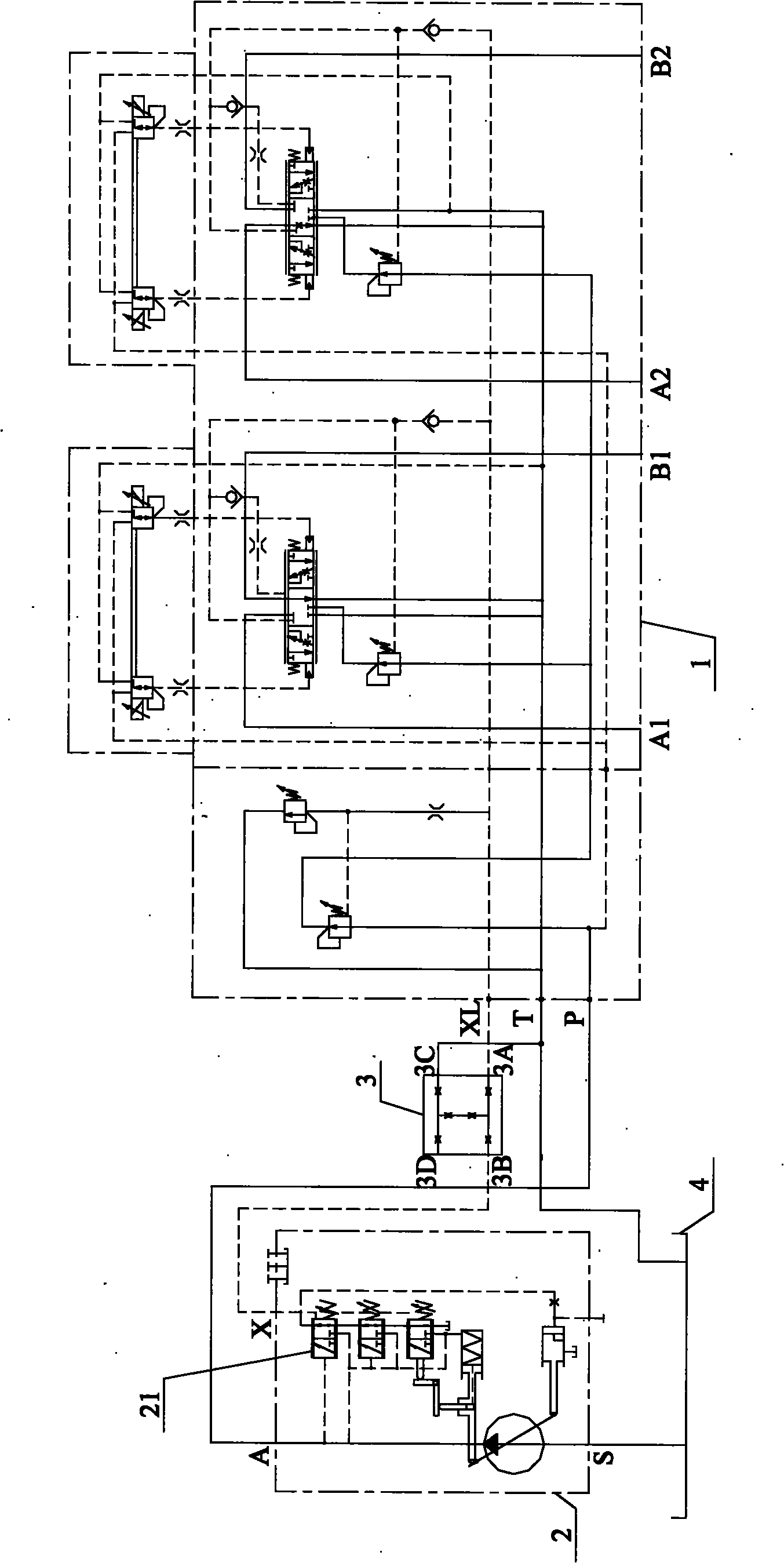

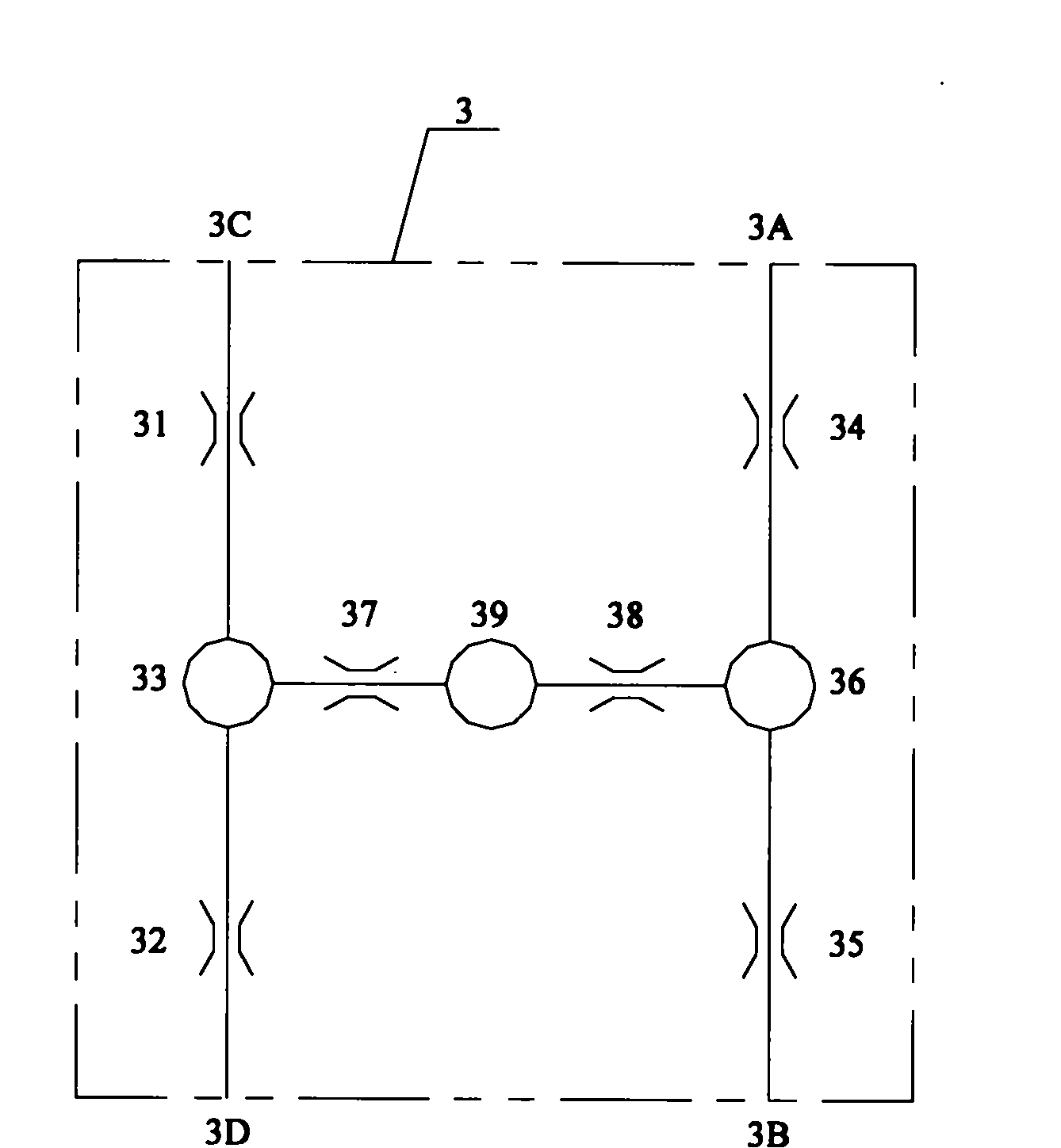

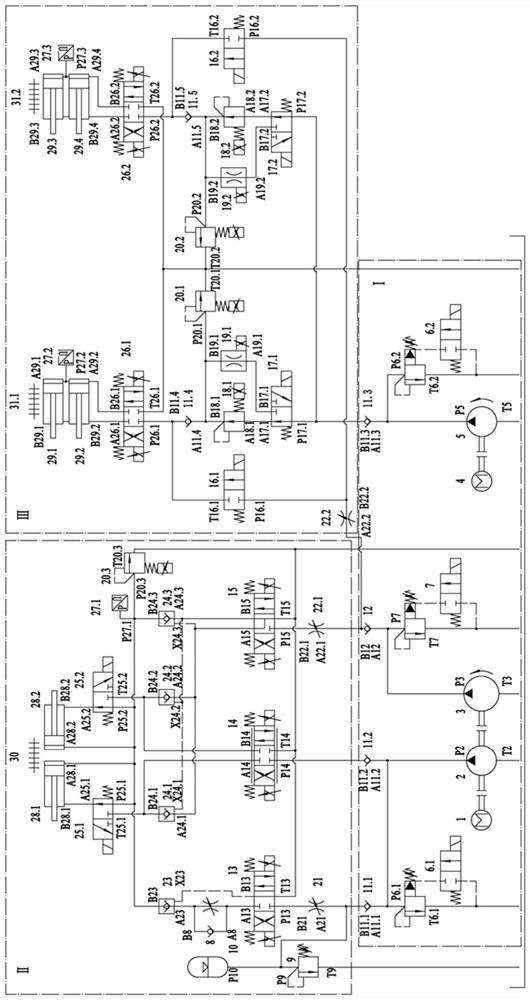

High-efficiency and energy-saving TBM (tunnel boring machine) horizontal posture adjustment hydraulic system

ActiveCN111828406AGuarantee molding qualityQuality assuranceServomotorsHydraulic cylinderClassical mechanics

The invention discloses a high-efficiency and energy-saving TBM (tunnel boring machine) horizontal posture adjustment hydraulic system. The system comprises an oil source system I, a tight propping system II, a propelling system III and an oil tank, wherein the oil source system I is connected with the oil tank through a hydraulic pump oil suction pipeline and an overflow valve oil drain pipeline;the tight propping system II and the propelling system III are connected with the oil source system I through a high-pressure pipeline and connected with the oil tank through an oil return pipeline;and the tight propping system II and the propelling system III are not connected. According to the system, while high-accuracy propelling and horizontal posture adjustment of a TBM are guaranteed, rapid return of a propelling hydraulic cylinder and rapid output and rapid return of a tight propping hydraulic cylinder are realized; and an energy accumulator is adopted to maintain pressure of high-pressure tight propping condition of the propping hydraulic cylinder, and by means of a check valve, the tight propping hydraulic cylinder keeps pressure needed by tight propping all the time in the high-accuracy posture adjustment condition process and energy is saved as well. While forming quality of a tunnel is guaranteed, construction progress is accelerated, and energy is saved,

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com