Distribution valve and mud or concrete pump with same

A technology for distributing valves and mud, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as large crushing force, inability to use one pump for multiple purposes or one valve for multiple purposes, and affect progress. Good sealing performance, improving the effect of not easy to segregate and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Single cylinder mud or concrete pump with one valve cylinder

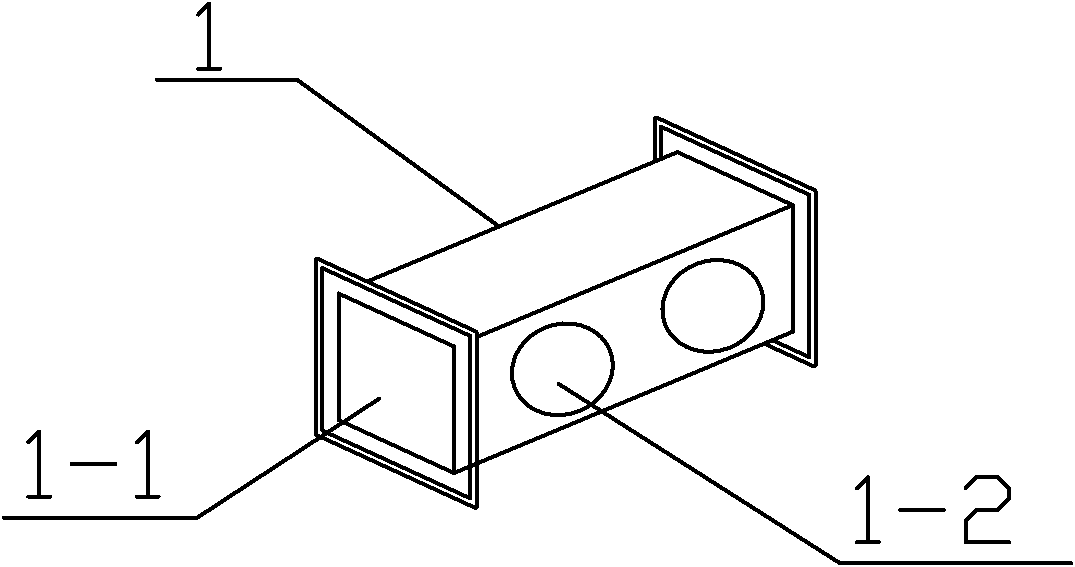

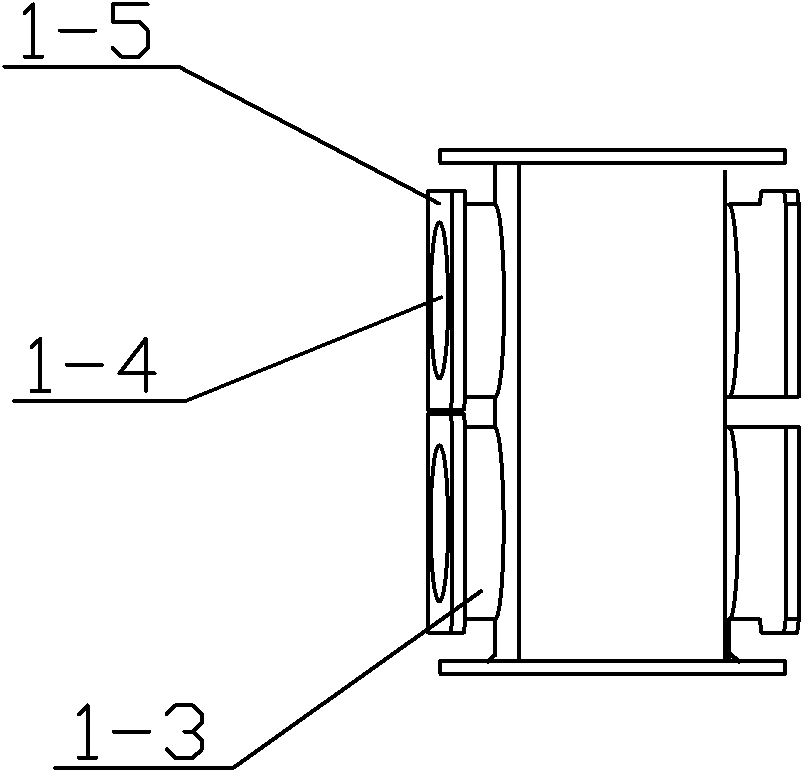

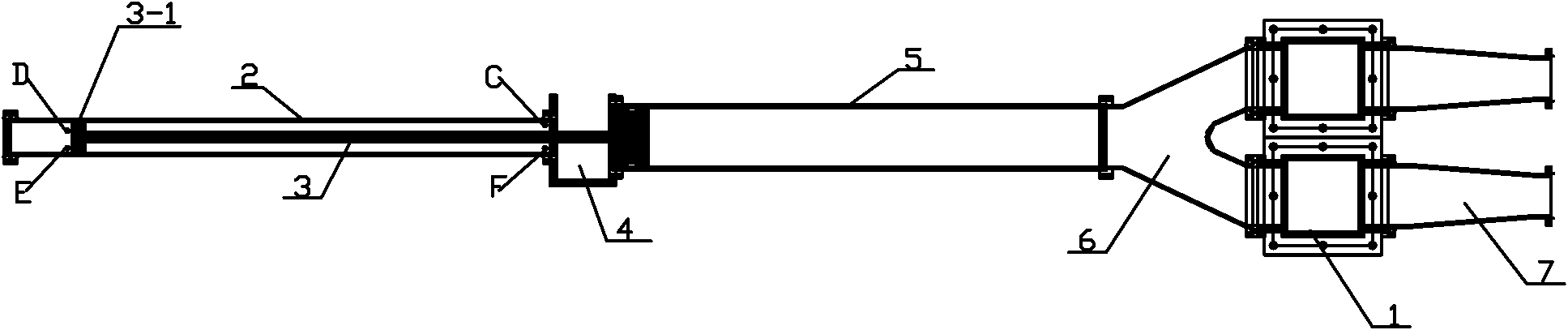

[0049] Such as image 3 , Figure 4-a and Figure 9 As shown, the mud cylinder 5 communicates with the two round pipes 1-3 of the distribution valve 1 through the V-shaped pipe 6, and the two round pipes 1-3 on the other side communicate with the straight pipe 7 respectively. The valve oil cylinder 9 is arranged above the valve block 1, the piston connecting rod 10 runs through the valve oil cylinder 9, and its two ends are connected with the plunger rod 8-2, and the middle part of the piston connecting rod 10 is fixed to make it move left and right in the valve oil cylinder 9. The piston 10 - 1 ; the piston connecting rod 10 is fixed to the valve block 1 through the bearing bracket 11 , and the bearing bracket 11 is fixed on the valve block 1 .

[0050] Working process of the present invention:

[0051] The pump production process uses a 32-horsepower diesel engine as the power source to driv...

Embodiment 2

[0053] Example 2: Single cylinder mud or concrete pump with two valve cylinders

[0054] Such as image 3 , Figure 4-b and Figure 9 As shown, the mud cylinder 5 communicates with the two round pipes 1-3 of the distribution valve 1 through the V-shaped pipe 6, and the two round pipes 1-3 on the other side communicate with the straight pipe 7 respectively. There is one valve oil cylinder on the left side and one right side of the valve block, and the plunger rod 8-2 extends into the valve oil cylinder 9; a shock absorber is arranged between the valve oil cylinder 9 and the column chamber 8, and the piston end of the plunger rod 8-2 is equipped with There is a buffer device.

[0055] Working process of the present invention:

[0056] First, the solenoid valve in the hydraulic station closes the output hole of the hydraulic station I# and opens the output hole of the hydraulic station II#, and sends the pressure oil of the hydraulic station to the accumulator, and then the a...

Embodiment 3

[0057] Example 3: Twin Cylinder Slurry or Concrete Pump with Two Valve Cylinders

[0058] Such as Figure 5 , Figure 6-a and Figure 9 As shown, the main oil cylinder 2, the piston rod 3, and the mud cylinder 5 each have two and are arranged in parallel. The two main oil cylinders 2 are connected to the mud cylinder 5 through the washing pool 4. Into, the tail ends of the two main oil cylinders 2 are connected in series. The mud cylinder 5-1 communicates with the two right circular pipes 1-3-1 in the vertical direction of the distribution valve through the V-shaped pipe 6, and the mud cylinder 5-2 communicates with the two left circular pipes in the vertical direction of the distribution valve through the V-shaped pipe 6. The tubes 1-3-2 are connected, and the two circular tubes 1-3-1 and 1-3-2 in the horizontal direction of the corresponding surface are respectively connected with the Y-shaped tube. The valve cylinder 9 is arranged above and below the valve block 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com