Enclosed pickup automobile tank and tank cover assembly

A cover assembly and closed technology, which is applied in the field of pickup truck boxes and their cover components, can solve the problems of inconvenient removal of the box cover, application restrictions, and inability to load, and achieves simple structure, improved safety, and prevention of accidental falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (Example 1. Pickup car trunk cover assembly)

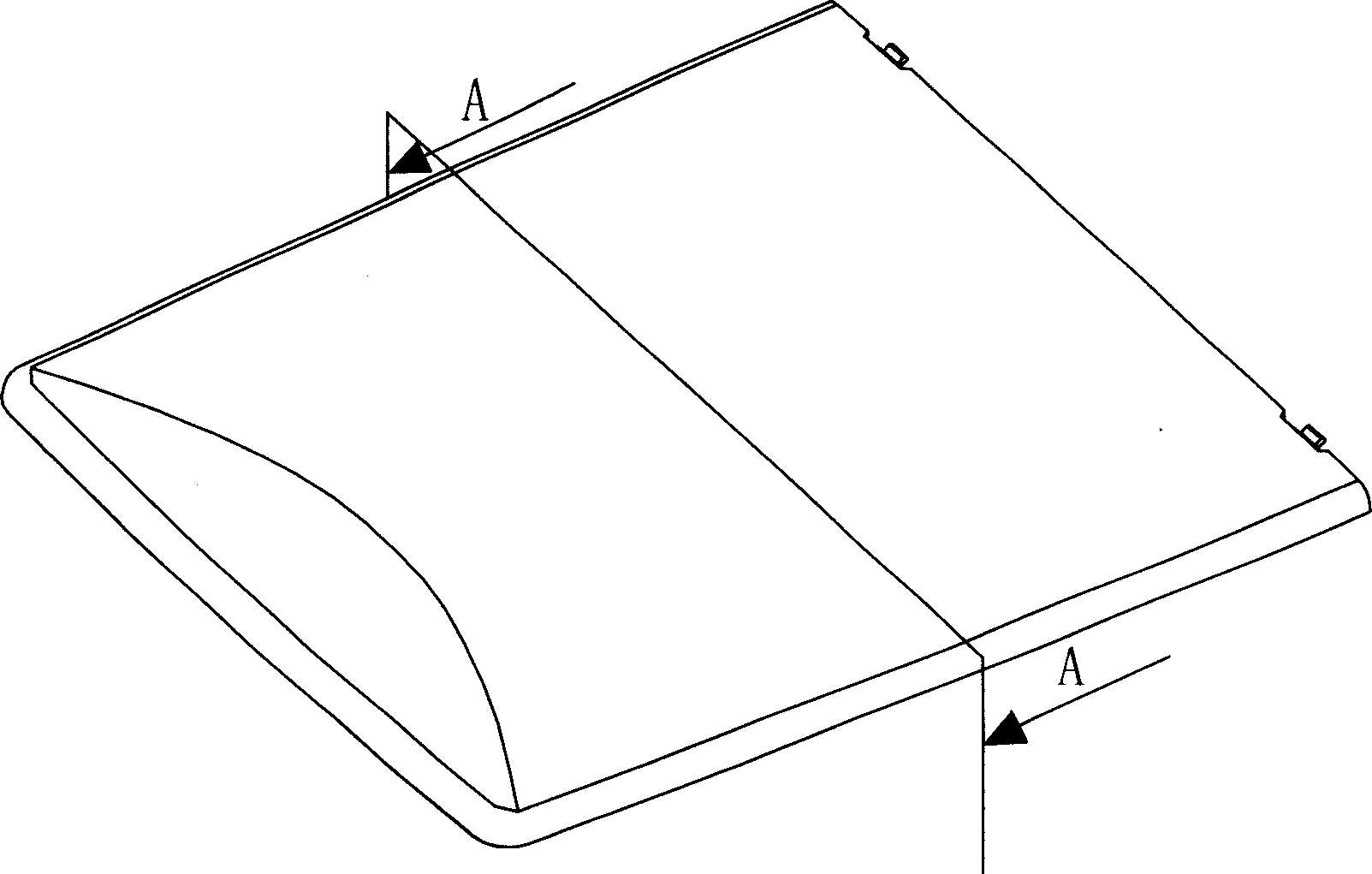

[0023] see Figure 1 to Figure 3 , The pickup truck box cover assembly of this embodiment has a box cover 2, a plug-in board 33 and a box cover mounting seat 41. The box cover 2, the box cover mounting seat 41 and the plug-in plate 33 form an integral piece.

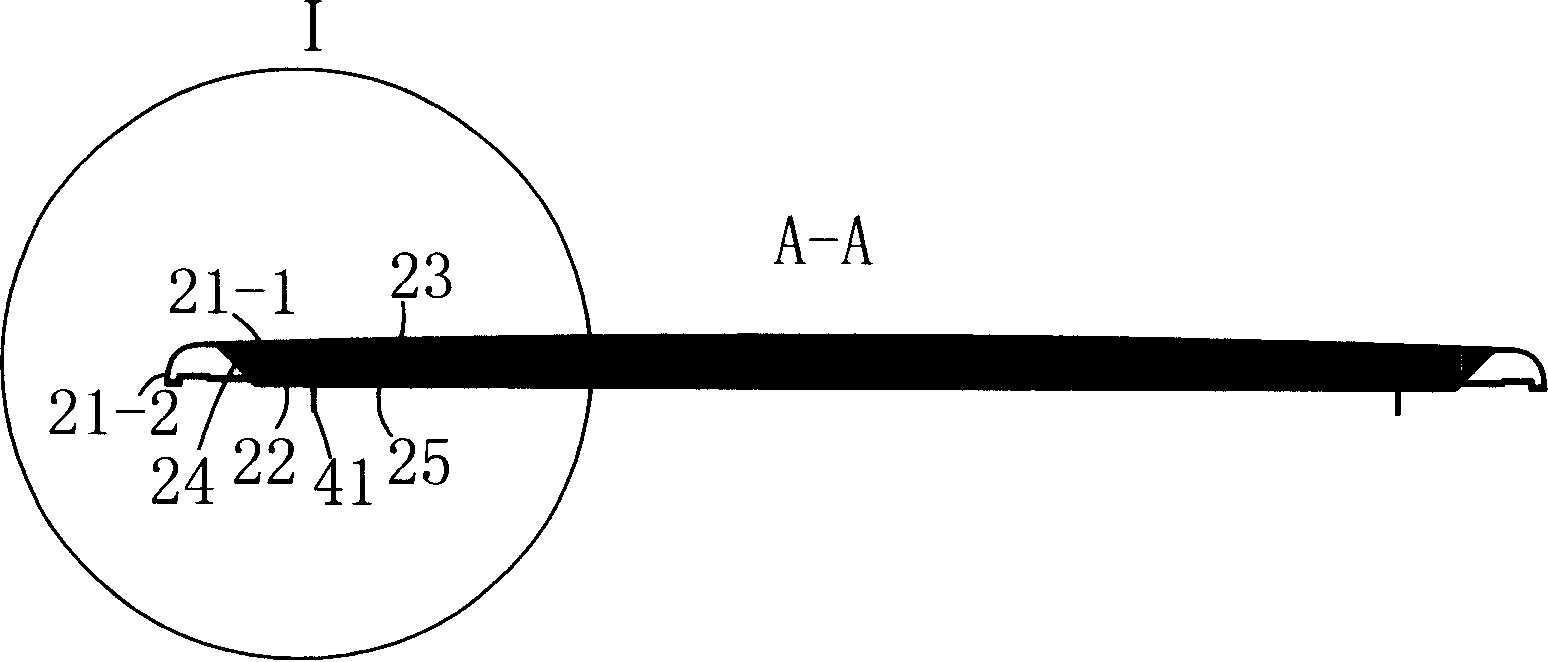

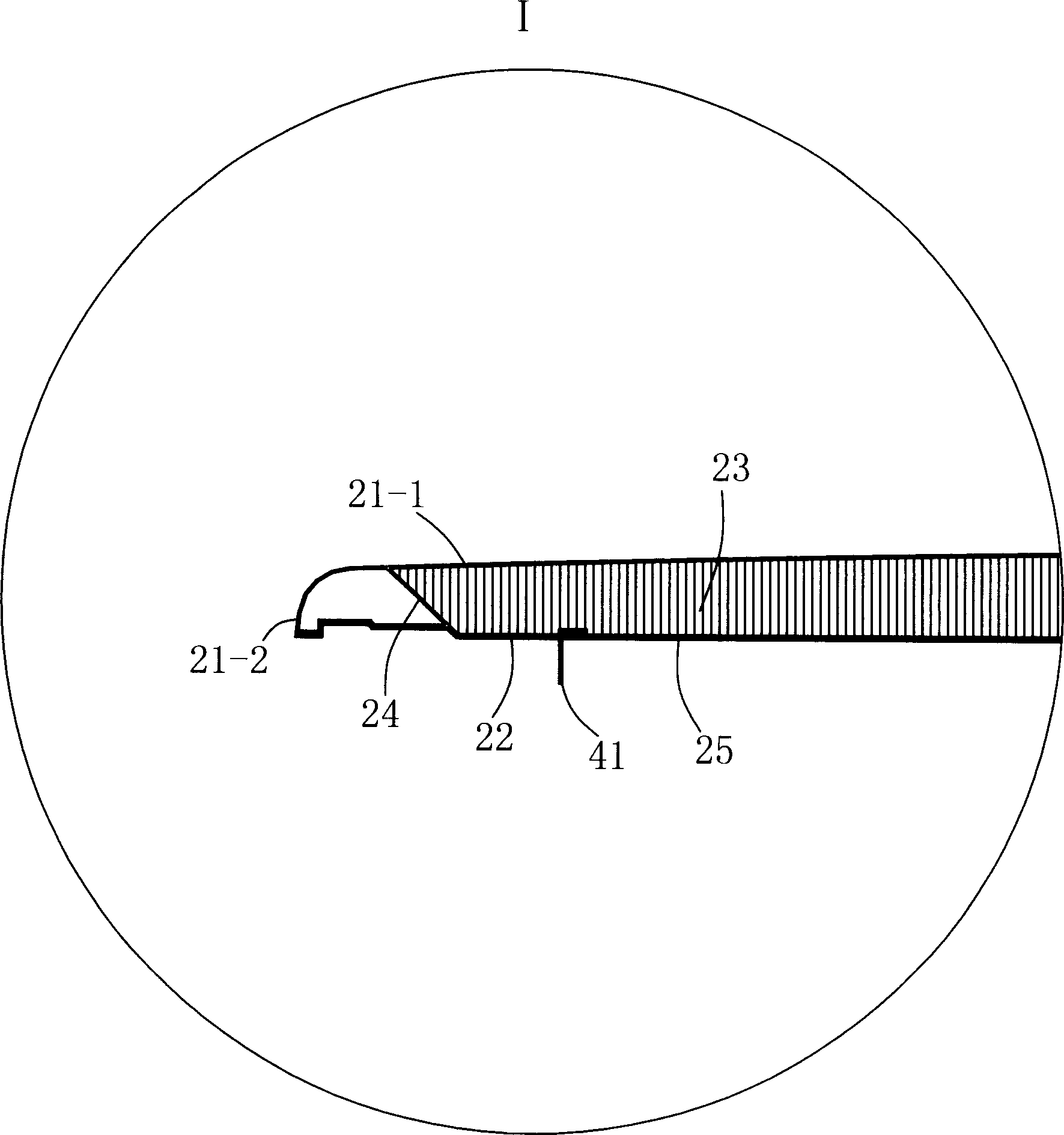

[0024] see figure 2 with image 3 The box cover 2 has an upper surface layer 21, a lower layer 22, a reinforcement layer 23 and a peripheral layer 24; the upper surface layer 21, the lower layer 22 and the peripheral layer 24 are all FRP material layers, and the reinforcement layer 23 is a FRP material with a honeycomb structure. The honeycomb structure of the reinforcement layer 23 is made of honeycomb paper; the upper surface layer 21 of the box cover 2 has a middle part 21-1 and a peripheral part 21-2, and the middle part 21-1 of the upper surface layer 21 is in contact with the reinforcement layer 23 , The peripheral part 21-2 of the upper surface layer 21 is provide...

Embodiment 2

[0028] (Embodiment 2, closed pickup truck compartment)

[0029] see Figure 4 to Figure 7 The enclosed pickup truck box of this embodiment has a box body 1, a box cover 2, a connecting assembly 3, a support assembly 4, a rubber sealing strip 5, an anti-dropping member 6 and a box lock. The box 1 has a front baffle, a left side panel, a right side panel, a rear baffle, and a bottom plate. The box cover 2 is connected to the box body 1 through the connecting assembly 3 and the supporting assembly 4. The connecting assembly 3 is a plug-in assembly; the plug-in assembly 3 has a mounting seat 31, a steel plug-in buckle 32 and a steel plug-in plate 33. The mounting base 31 is made of aluminum angle iron. The mounting base 31 is "U"-shaped and is riveted and fixed on the front baffle of the box 1 and the front of the left and right side plates; the plug buckle 32 is welded and fixed on the mounting base 31 . The box cover 2 and the steel plug-in board 33 are obtained from Example 1. As ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com