Single-acting plunger cylinder hydraulic system

A technology of hydraulic system and plunger cylinder, which is applied in the field of electromechanical-hydraulic integrated control equipment, can solve the problems of increasing the external dimension and self-weight of the hydraulic system, the volume and self-weight of the solenoid valve, and increasing the working pressure of the system, so as to reduce the self-weight and simplify the Structure, the effect of improving the oil return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

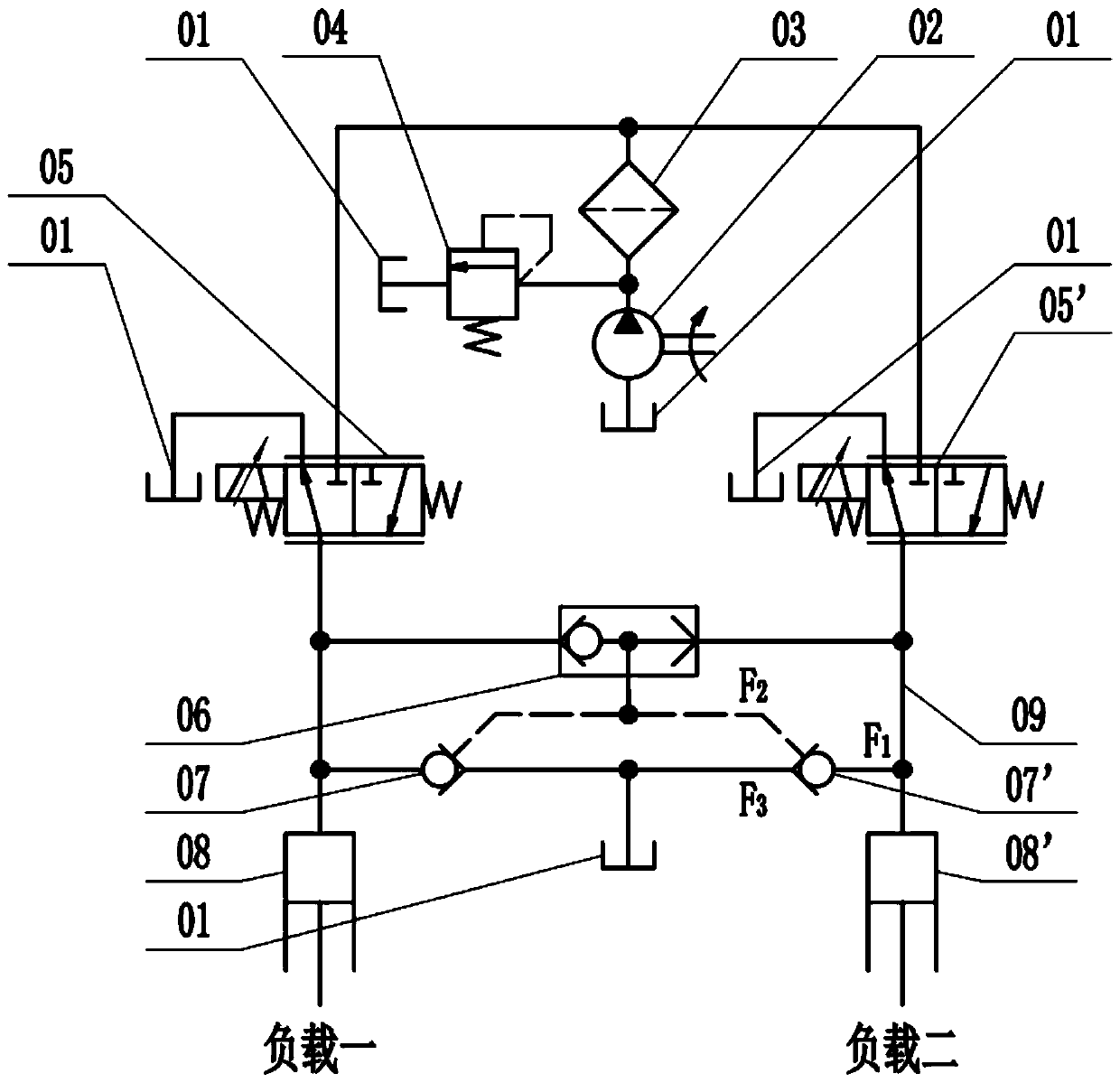

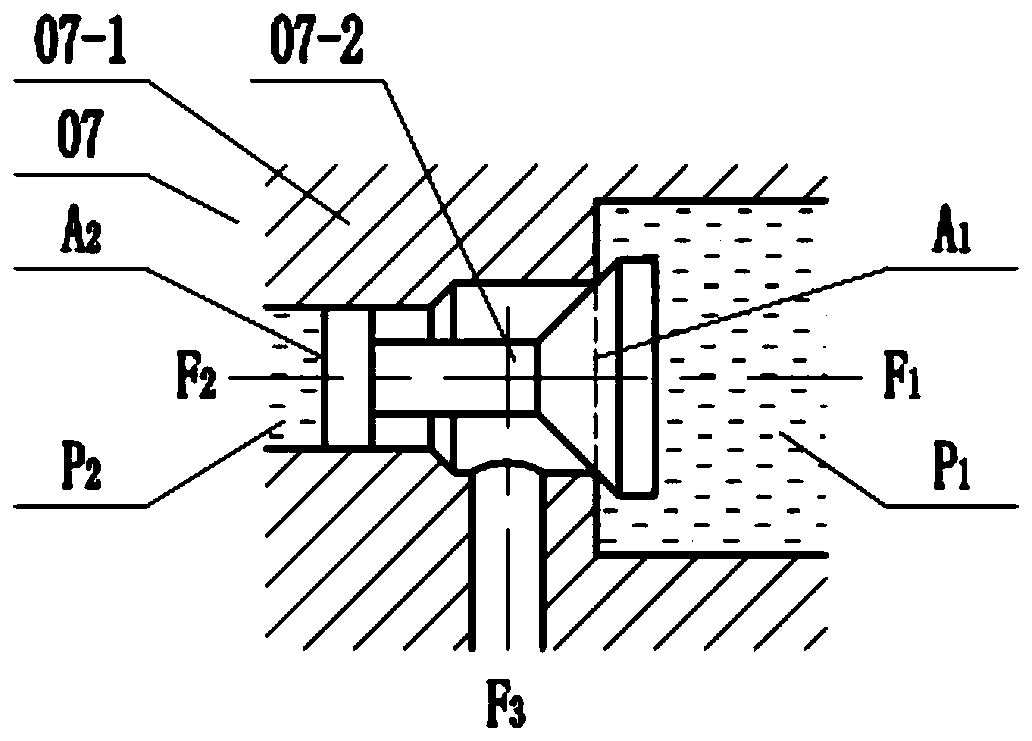

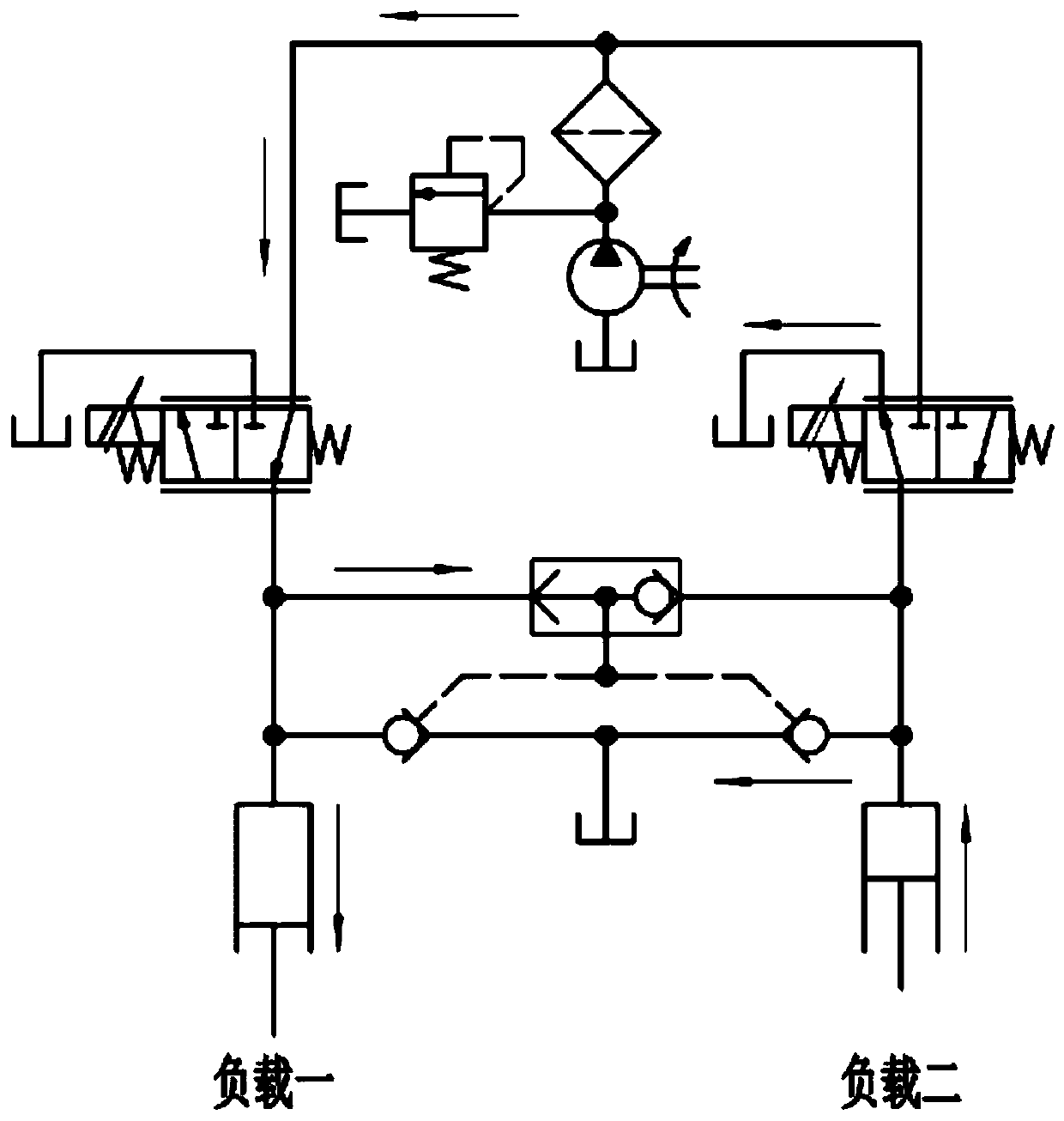

[0020] Such as figure 1 As shown, the hydraulic system is mainly composed of hydraulic oil tank 01, hydraulic pump 02, filter 03, overflow valve 04, left two-position three-way reversing valve 05, right two-position three-way reversing valve 05', shuttle valve 06 , the left hydraulic control check valve 07, the right hydraulic control check valve 07', the left single-acting plunger rod 08, the right single-acting plunger rod 08' and the hydraulic oil pipe 09.

[0021] The hydraulic oil tank 01 is connected with the hydraulic pump 02, and the whole system supplies hydraulic oil to various places through the hydraulic pump 02 driven by the motor. The outlet of the hydraulic pump 02 is equipped with a relief valve 04 connected to the hydraulic oil tank 01 to ensure that the system pressure does not exceed the design value . The hydraulic pump 02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com