Patents

Literature

74results about How to "Fast oil return" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

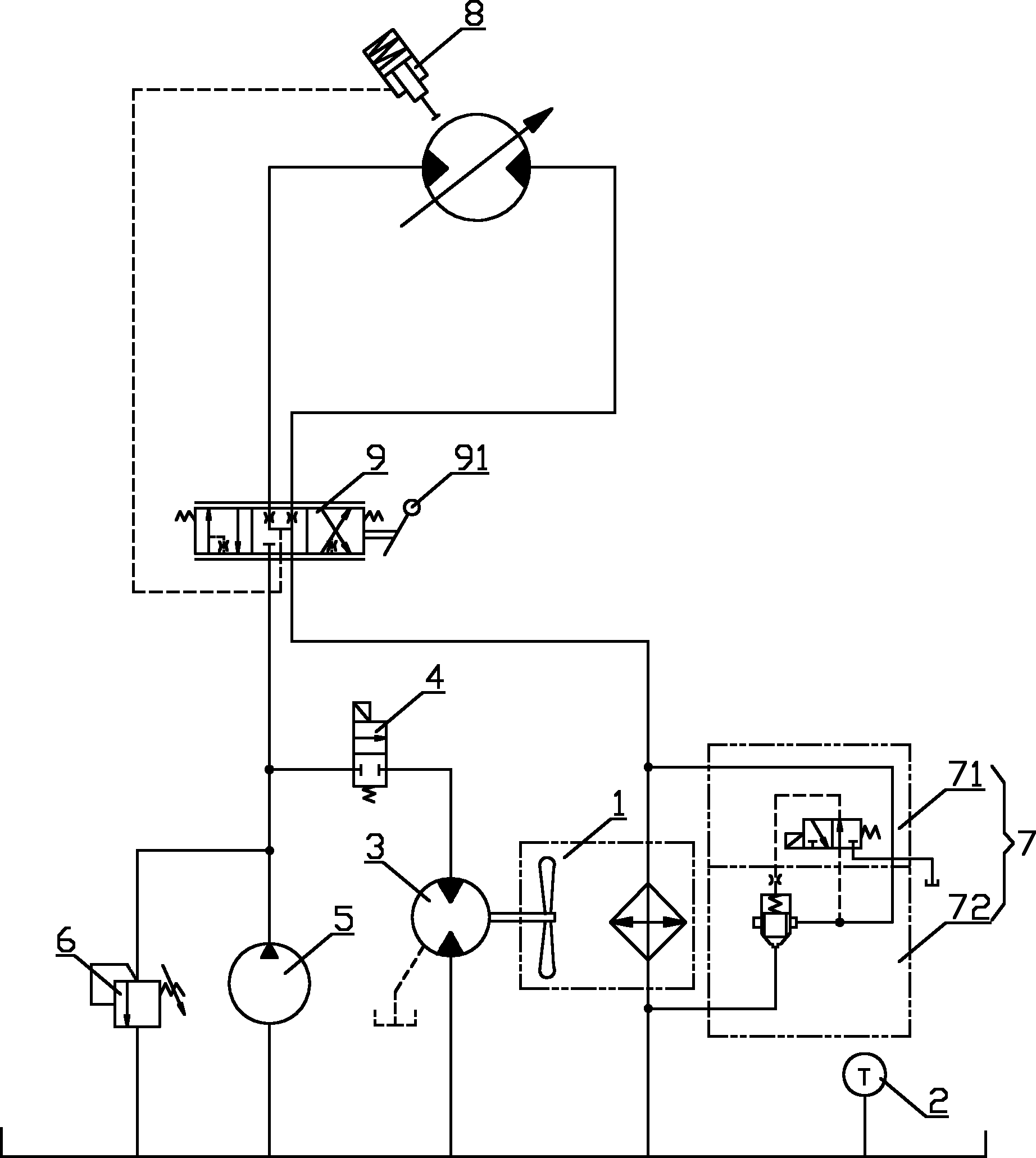

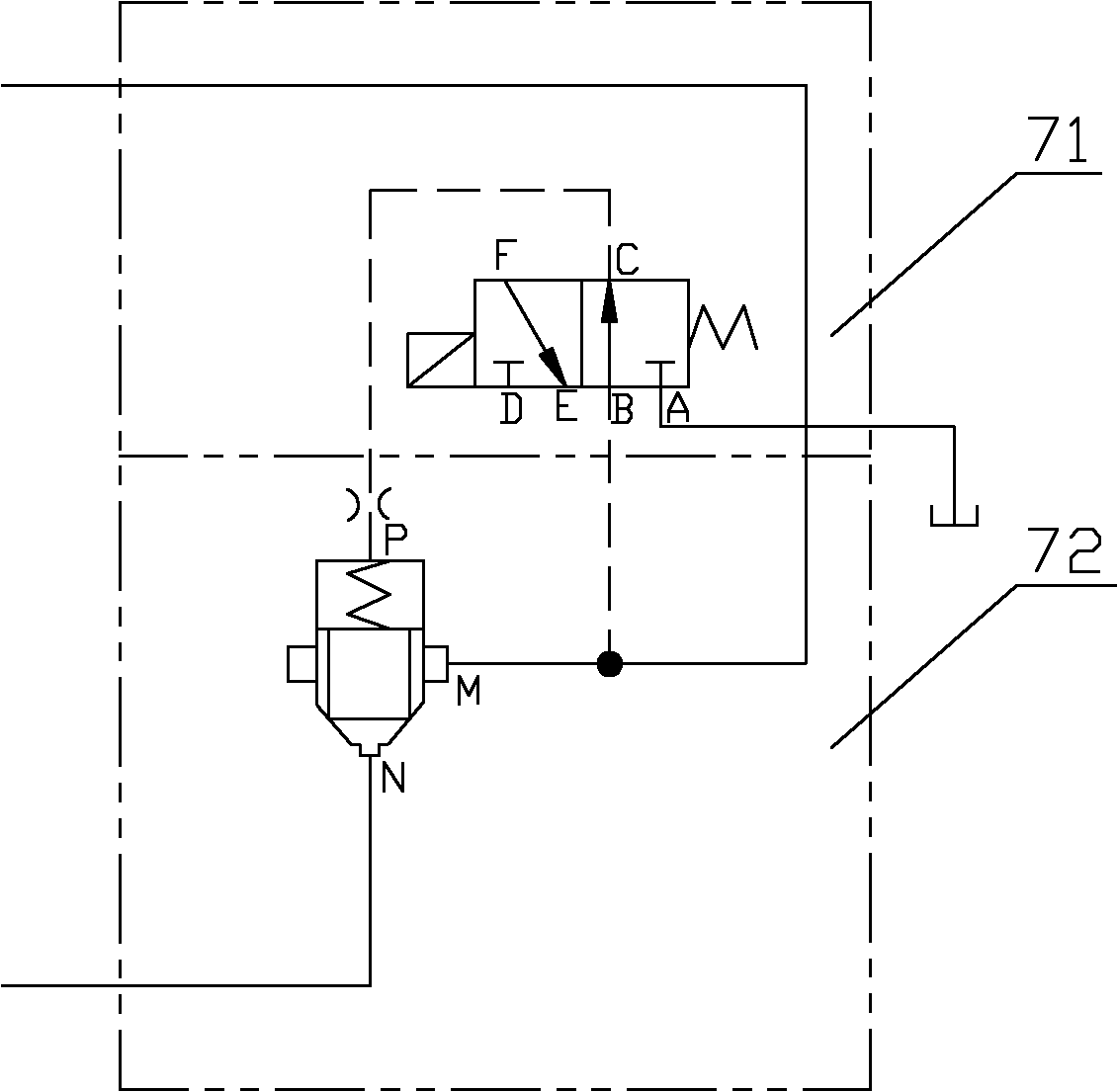

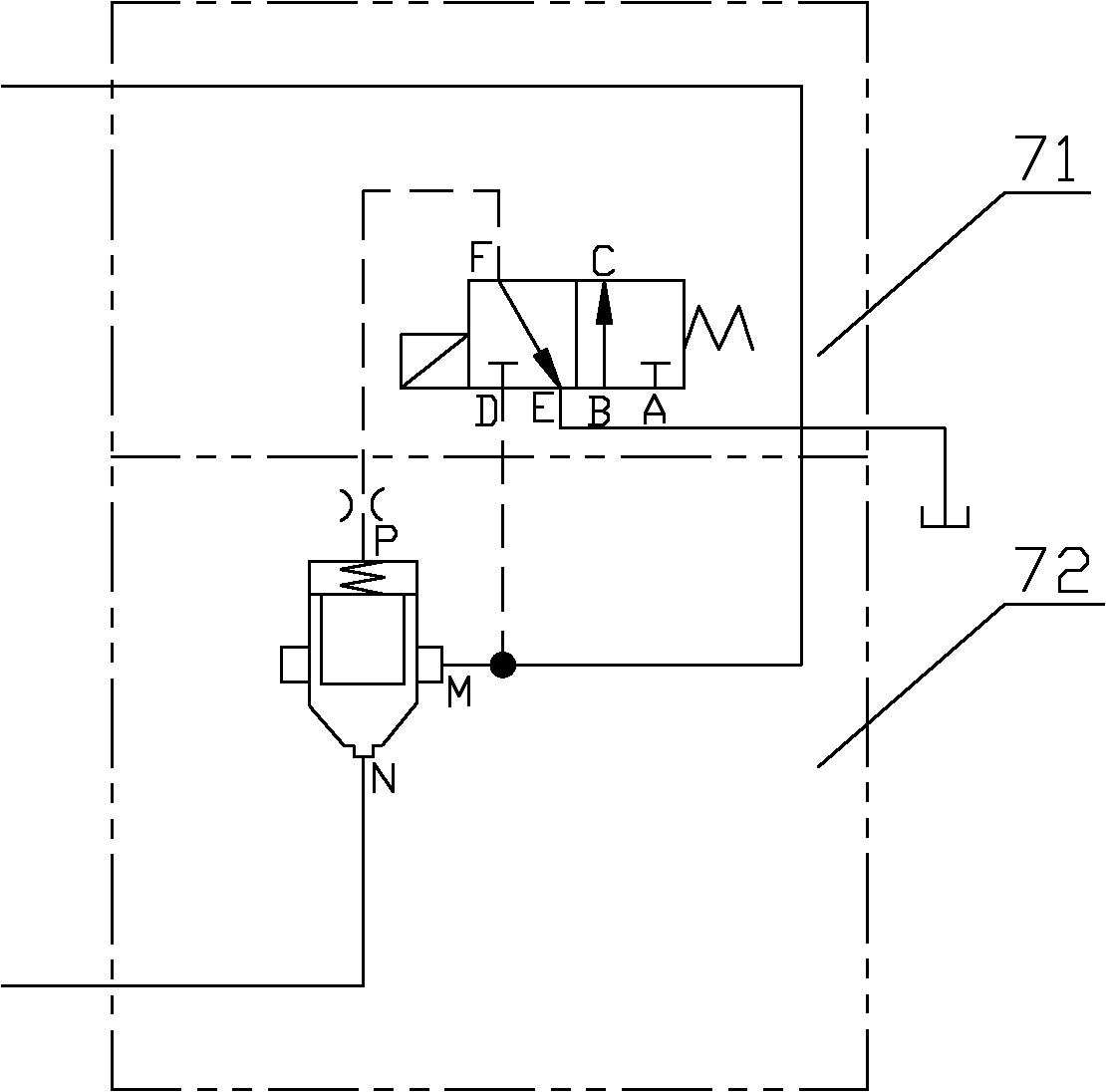

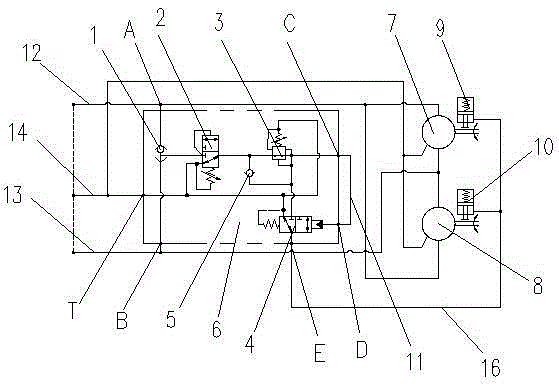

Wheeled crane and hydraulic oil cooling system and control method thereof

ActiveCN102011769AWork lessReduce dependenceFluid-pressure actuator componentsCranesAutomatic controlControl signal

The invention discloses a wheeled crane and a hydraulic oil cooling system and control method thereof. The disclosed cooling system comprises a radiator, a power part driving the radiator, a detection part, a control part and an execution part, wherein the detection part is used for detecting the temperature of hydraulic oil; the control part receives a temperature signal of the hydraulic oil, compares the temperature with the preset temperature, and generates a control signal according to the comparison information; and the execution part controls the power part to work or stop according to the control signal. By the coordinated operation of the detection part, the control part and the execution part, the radiator can be automatically started or stopped, so as to enable the temperature of the hydraulic oil to be always maintained in the preset temperature range, reduce the possibility of super high temperature, simultaneously prolong the service life of the hydraulic elements of the system and give play to the optimum heat dissipation function of the cooling system. At the same time, the start or stop of the radiator can be automatically controlled, thus the work of operators can be reduced, the dependence of the system safety on the manual operation can be reduced and the safe reliability of the system can be improved.

Owner:XUZHOU HEAVY MASCH CO LTD

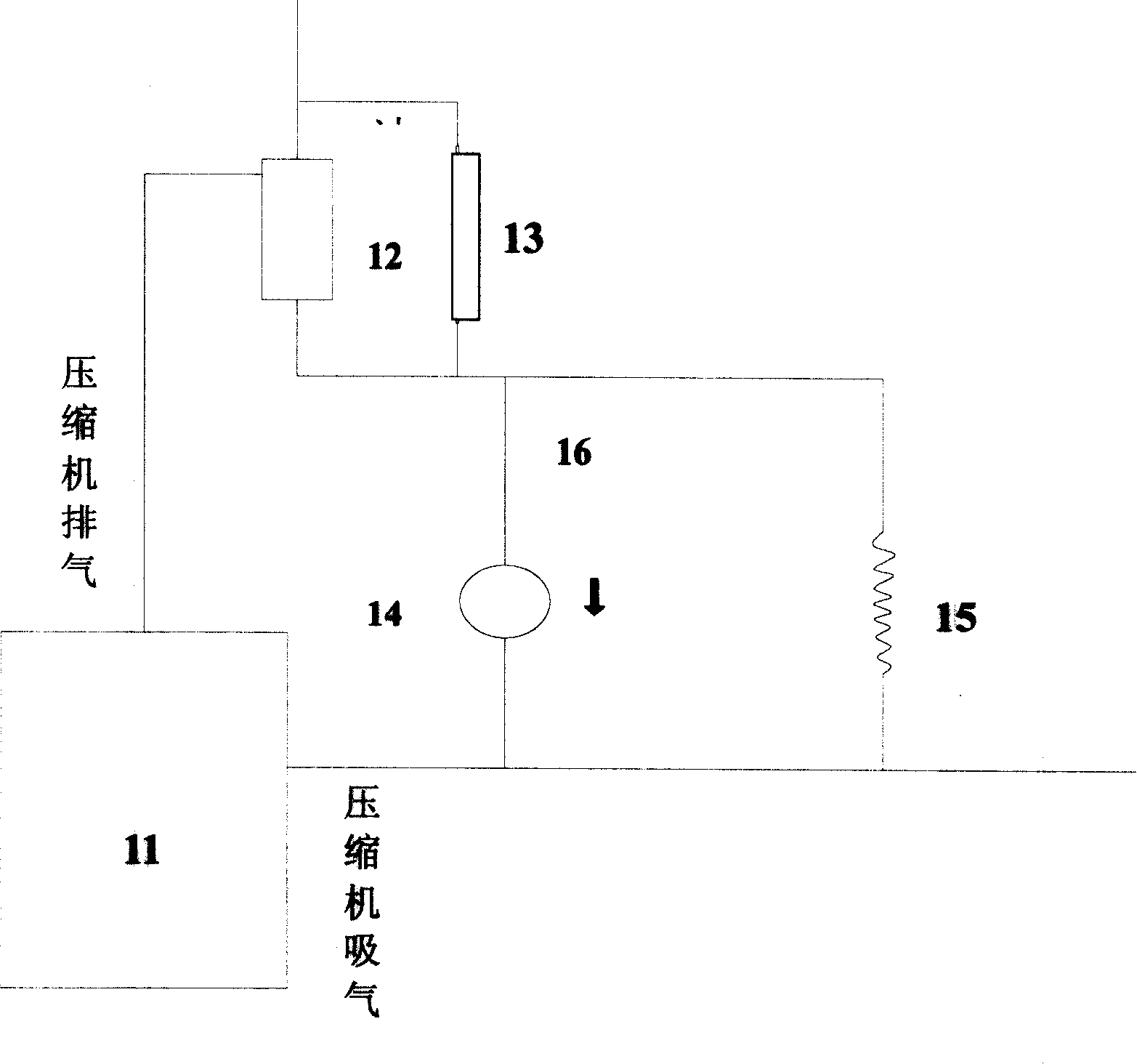

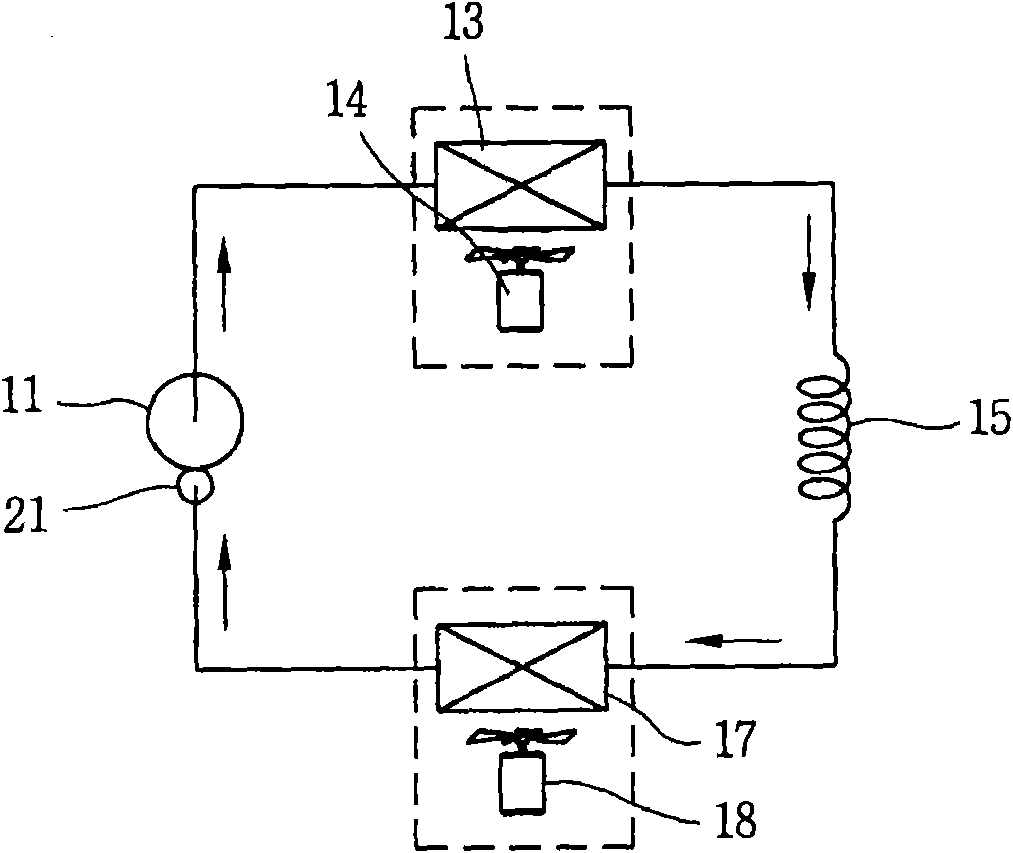

Oil eliminator auxiliary device of air conditioning system and control method thereof

InactiveCN101173656ASufficient oil returnEER/COP improvementPositive displacement pump componentsPositive-displacement liquid enginesFrequency conversionSolenoid valve

The invention relates to an auxiliary device of an oil separator in an air-conditioning system and a control method for the auxiliary device, which comprises a compressor, an oil separator and a return capillary. A pipe branch is in parallel provided with the return capillary between an oil outlet of the oil separator on exhausting side of the compressor and an air suction pipe of the compressor. A solenoid valve is connected in series on the pipe branch. The solenoid valve and an unloading valve of the air-conditioning system are merged into a whole, and oil unloading or return is carried out through controlling the solenoid valve respectively by the program. The control method for the auxiliary device of the oil separator is composed of selecting the return capillary and controlling opening period and duration of the solenoid valve. The invention has the advantages of effectively solving contradiction between normal oil return of the compressor assured by frequency conversion or variable capacity air-conditioning system and realizing high EER / COP and good cooling or heating, the unloading valve and the solenoid valve being merged into a whole, oil return of the compressor being optimized and cost of the system being not increased.

Owner:HAIER GRP CORP +1

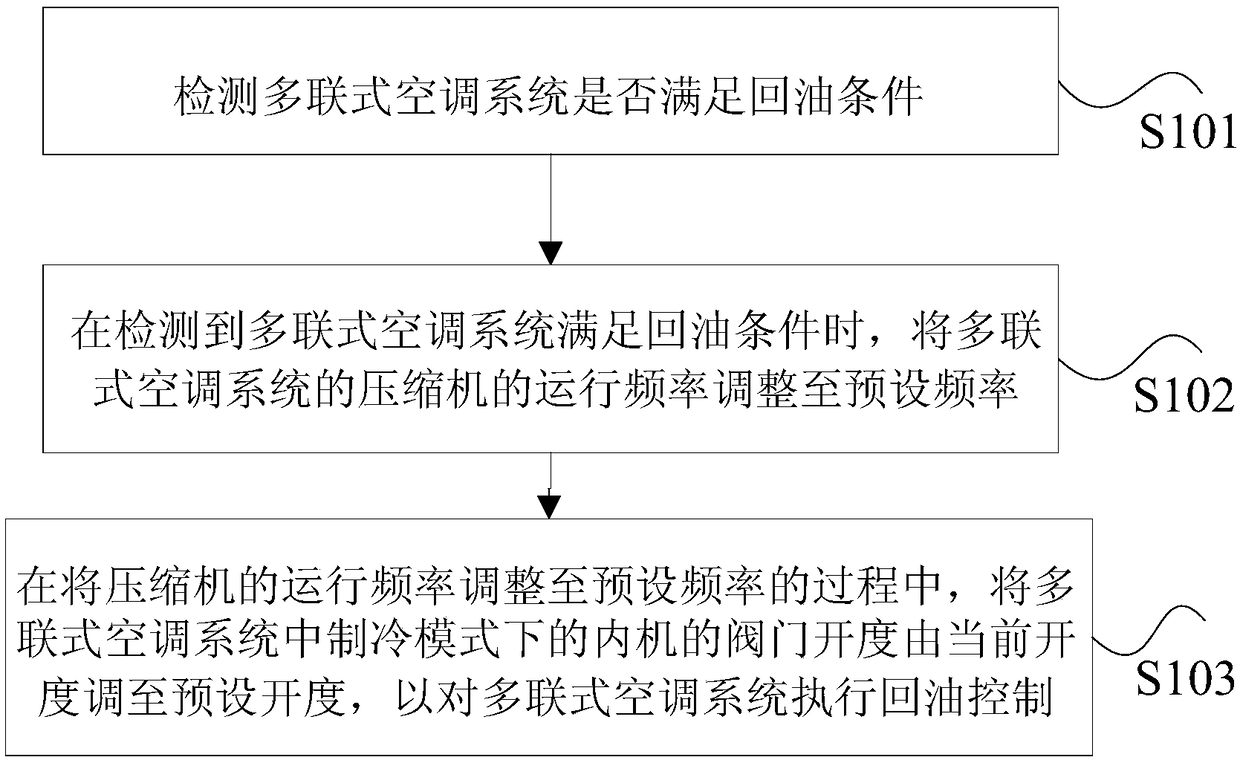

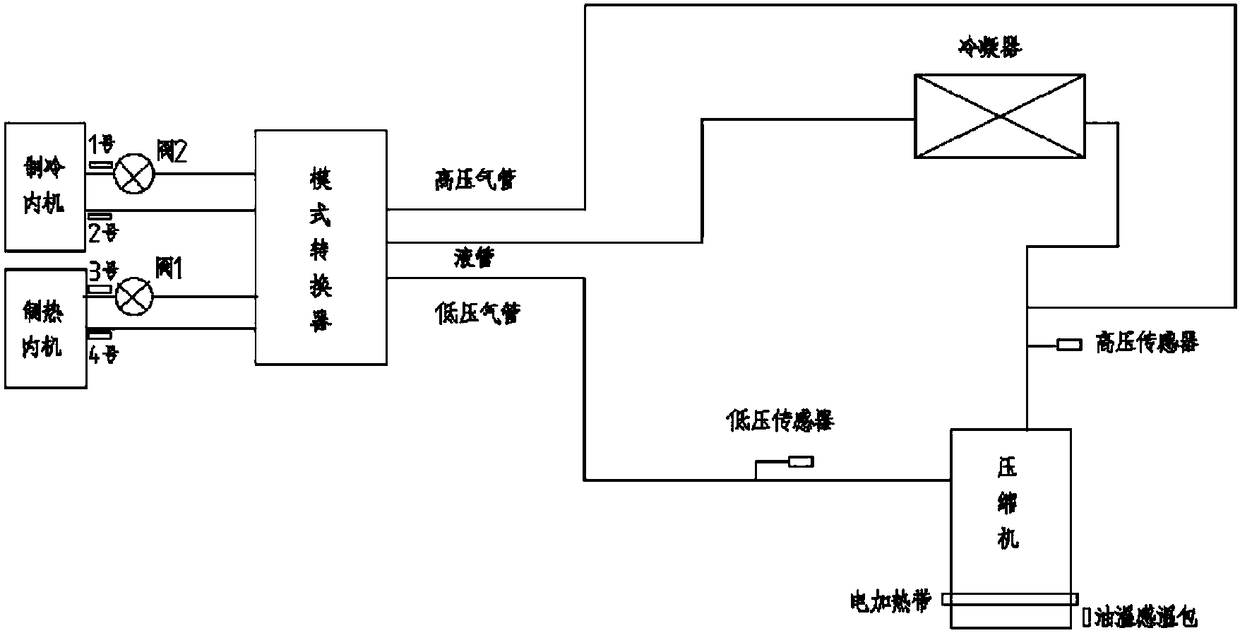

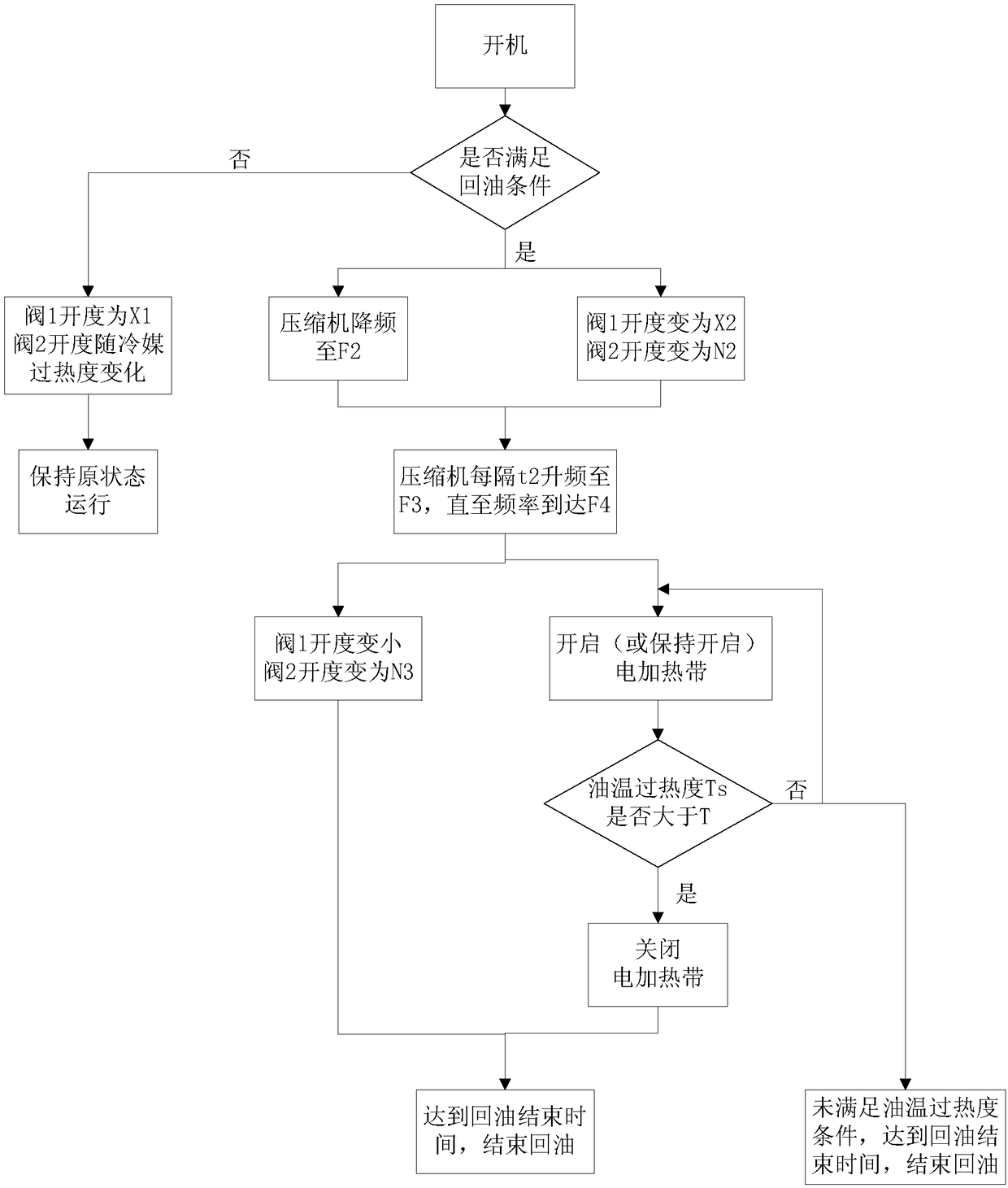

Air conditioner oil return control method and device

PendingCN108613434APrevent overcurrentPrevent rapid oil returnCompressorRefrigeration safety arrangementEngineeringElectronic expansion valve

The invention discloses an air conditioner oil return control method and device. The method comprises the steps that whether a multi-connected air-conditioning system meets the oil return condition ornot is detected; when it is detected that the multi-connected air-conditioning system meets the oil return condition, the operation frequency of a compressor of the multi-connected air-conditioning system is adjusted to the preset frequency; and in the process that the operation frequency of the compressor is adjusted to the preset frequency, the opening degree of a valve of an inner unit, in therefrigeration mode, of the multi-connected air-conditioning system is adjusted to the preset opening degree from the current opening degree so that oil return control can be conducted on the multi-connected air-conditioning system, and the preset opening degree is larger than the current opening degree. Through the air conditioner oil return control method and device, the problem that in relatedtechnologies, when a heat recovery multi-connected unit conducts oil return, the opening degree of an electronic expansion valve of a refrigeration inner unit is decreased, thus, compressor overflowing is caused, and oil return is influenced is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Baking composite non-dairy cream and preparation method thereof

InactiveCN105211322AEasy to operateImprove efficiencySugar food ingredientsFood freezingSucroseSodium Caseinate

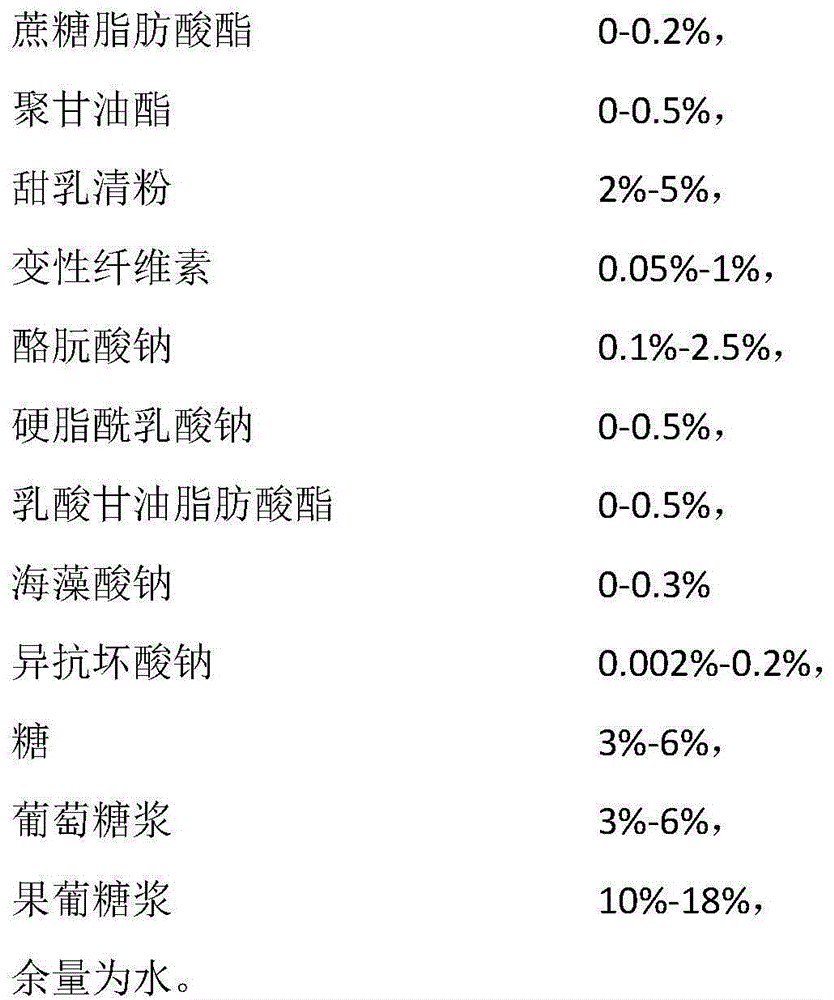

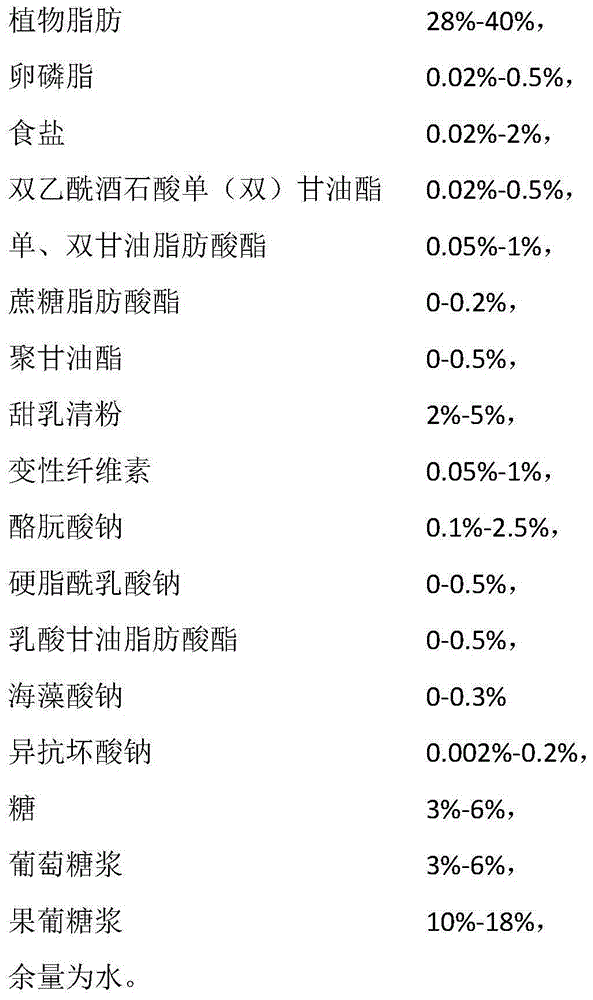

The invention discloses a baking composite non-dairy cream and a preparation method thereof. The baking composite non-dairy cream is prepared from the following raw materials in percentage by weight: 28 to 40 percent of vegetable fat, 0.02 to 0.5 percent of lecithin, 0.02 to 2 percent of edible salts, 0.02 to 0.5 percent of diacetyl tartaric acid ester of mono-and diglycerides, 0.05 to 1 percent of mono-and diglycerides of fatty acids, 0 to 0.2 percent of sucrose fatty acid ester, 0 to 0.5 percent of polyglycerol ester, 2 to 5 percent of crino whey powder, 0.05 to 1 percent of modified cellulose, 0.1 to 2.5 percent of sodium caseinate, 0 to 0.5 percent of sodium stearoyl lactylate, 0 to 0.5 percent of lactic acid glycerin fatty acid ester, 0 to 0.3 percent of sodium alginate, 0.002 to 0.2 percent of sodium scorbate, 3 to 6 percent of sugar, 3 to 6 percent of glucose syrup, 10 to 18 percent of high fructose corn syrup and the balance of water. The baking composite non-dairy cream and the preparation method thereof disclosed by the invention have the beneficial effects that operation steps are simplified, and the efficiency is improved; the influence of human experience is avoided, and the finished product rate is improved; by using the synergistic effect of the modified cellulose, the sodium caseinate and stearoyl lactylate, a cake is automatically cracked when a pound cake is baked and the condition that the cake is pulled out of a baking chamber for artificially cutting is avoided, so that the baking time and energy consumption are saved; better water holding and wetting properties are obtained, and the shelf life is prolonged.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

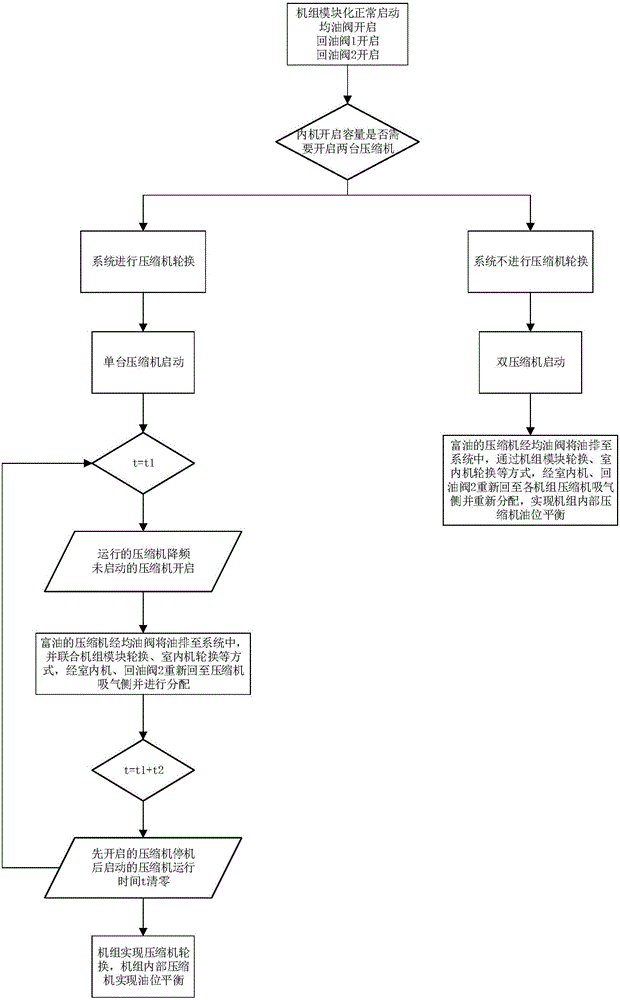

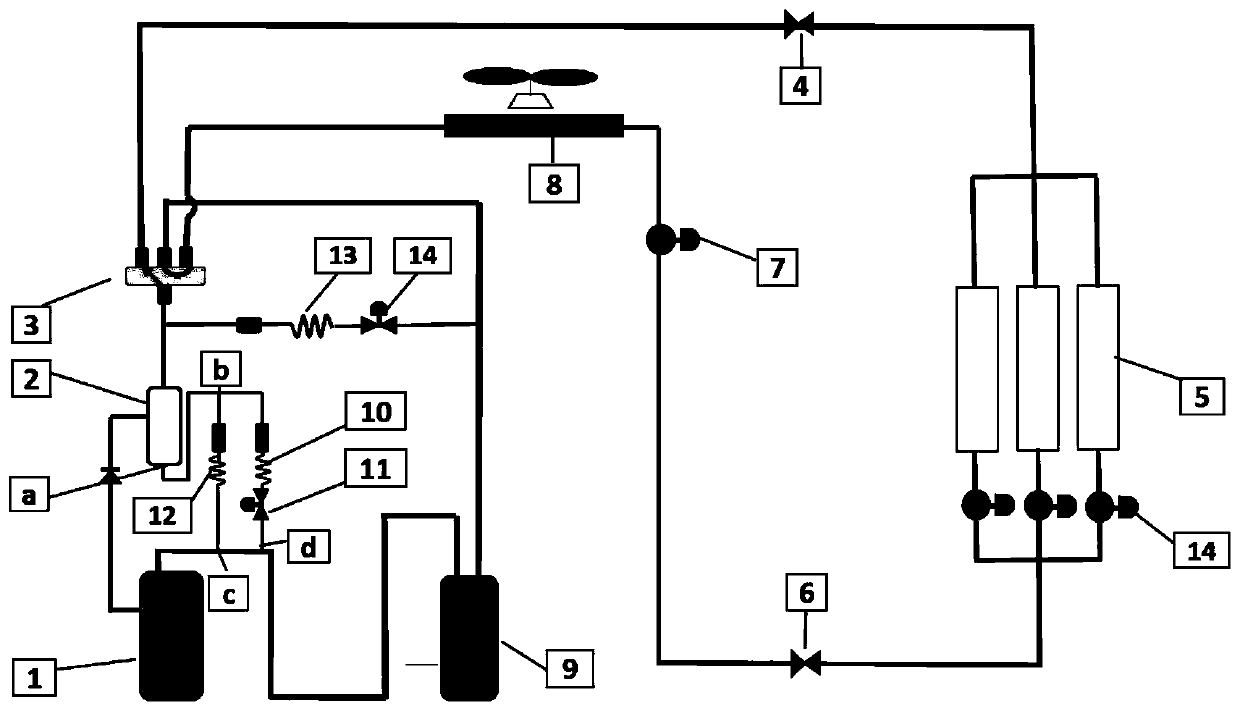

Oil balancing and returning air conditioning unit and control method thereof

ActiveCN106440572AEvenly distributedAddressing uneven distributionRefrigeration componentsVapor–liquid separatorAir conditioning

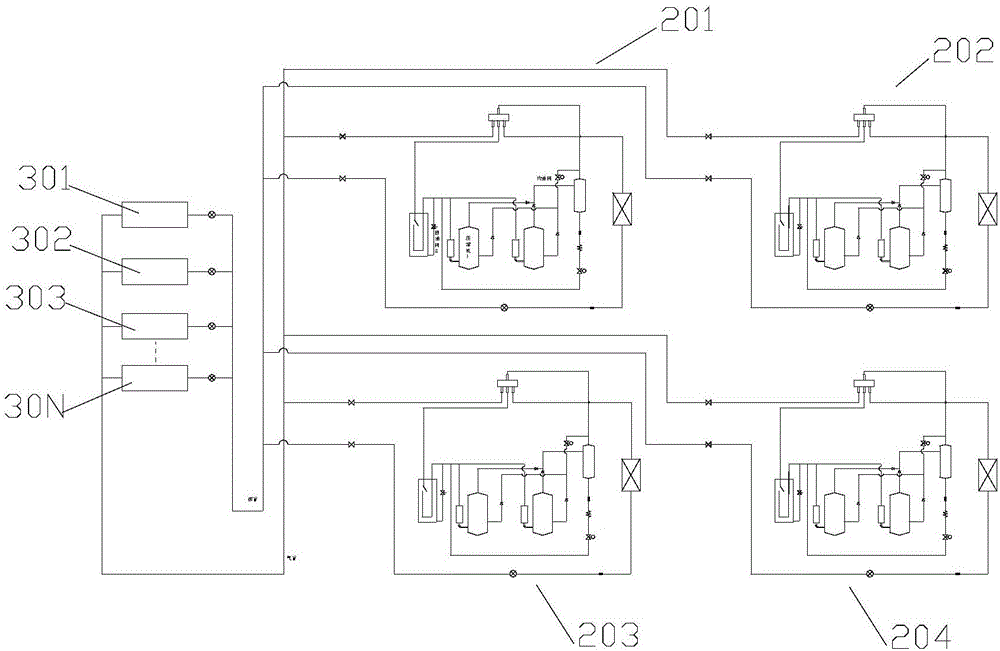

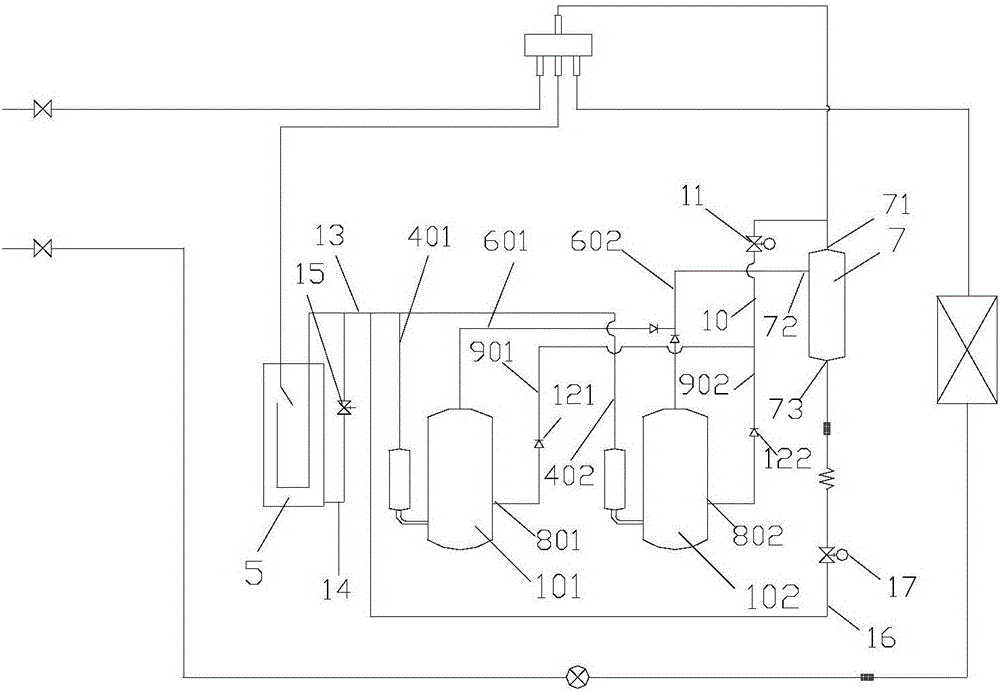

The invention provides an oil balancing and returning air conditioning unit and a control method thereof. The oil balancing and returning air conditioning unit comprises outdoor units (201, 202, 203, 204) and indoor units (301, 302, 303, 304), each outdoor unit comprises more than two compressors (101, 102) which are arranged in parallel, air suction pipes (401,402) of each of the compressors are converged and connected to a gas-liquid separator (5), and exhaust pipes (601, 602) of each of the compressors are converged and connected to an oil separator (7), wherein each compressor is also provided with oil balancing holes (801, 802) used for discharging oil inside the compressor and oil balancing pipes (901, 902) connected with the oil balancing holes, and the oil balancing pipes of each of the compressors are converged and connected to a refrigerant outlet end of the oil separator (7). By using the oil balancing and returning air conditioning unit, oil in the compressors which are rich in oil can be effectively and uniformly distributed into each compressor and each outdoor unit through the oil balancing pipes, so that the problems of oil quantity distribution nonuniformity and oil level unbalance are solved.

Owner:GREE ELECTRIC APPLIANCES INC

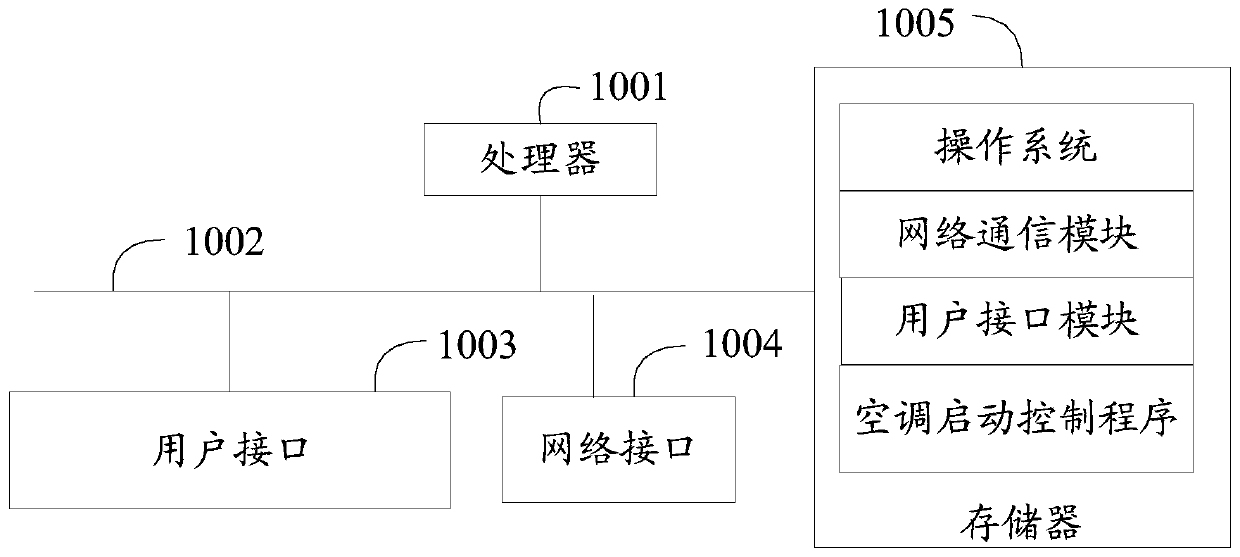

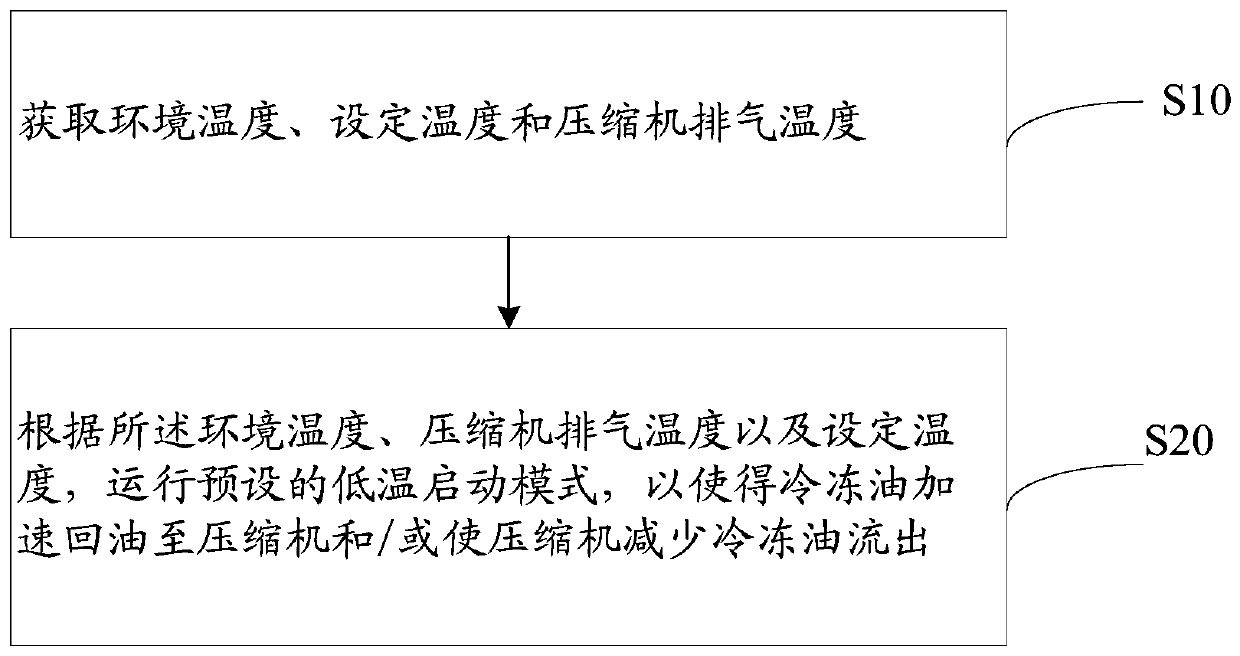

Air conditioner starting control method, air conditioner and storage medium

ActiveCN110375411AAvoid oil shortageFast oil returnMechanical apparatusSpace heating and ventilation safety systemsThree stageEngineering

The invention discloses an air conditioner starting control method, an air conditioner and a storage medium. The method comprises the following steps that a first environment temperature, a second environment temperature, a compressor exhaust temperature and a set temperature input by a user are obtained, and a preset three-stage low-temperature starting mode is operated according to the first environment temperature, the second environment temperature, the compressor exhaust temperature and the set temperature, so that the refrigeration oil is accelerated to return to a compressor and / or theamount of refrigeration oil flowing out of the compressor is reduced. Under the condition that the air conditioner is started at the low temperature, the refrigeration oil in a unit is effectively returned to the compressor through the mode, so that the operation reliability of the air conditioner is improved.

Owner:GUANGDONG TCL INTELLIGENT HEATING & VENTILATING EQUIP CO LTD

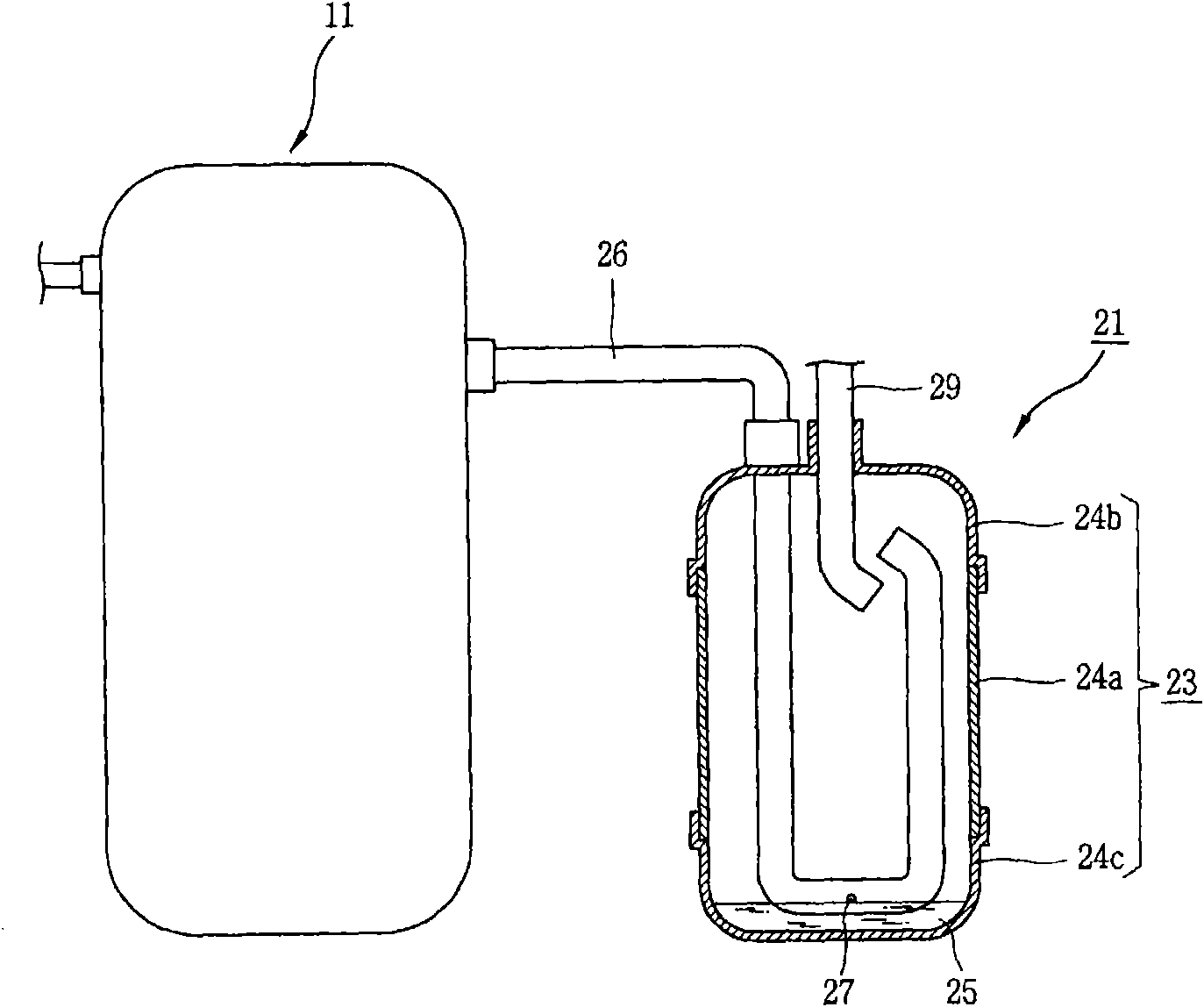

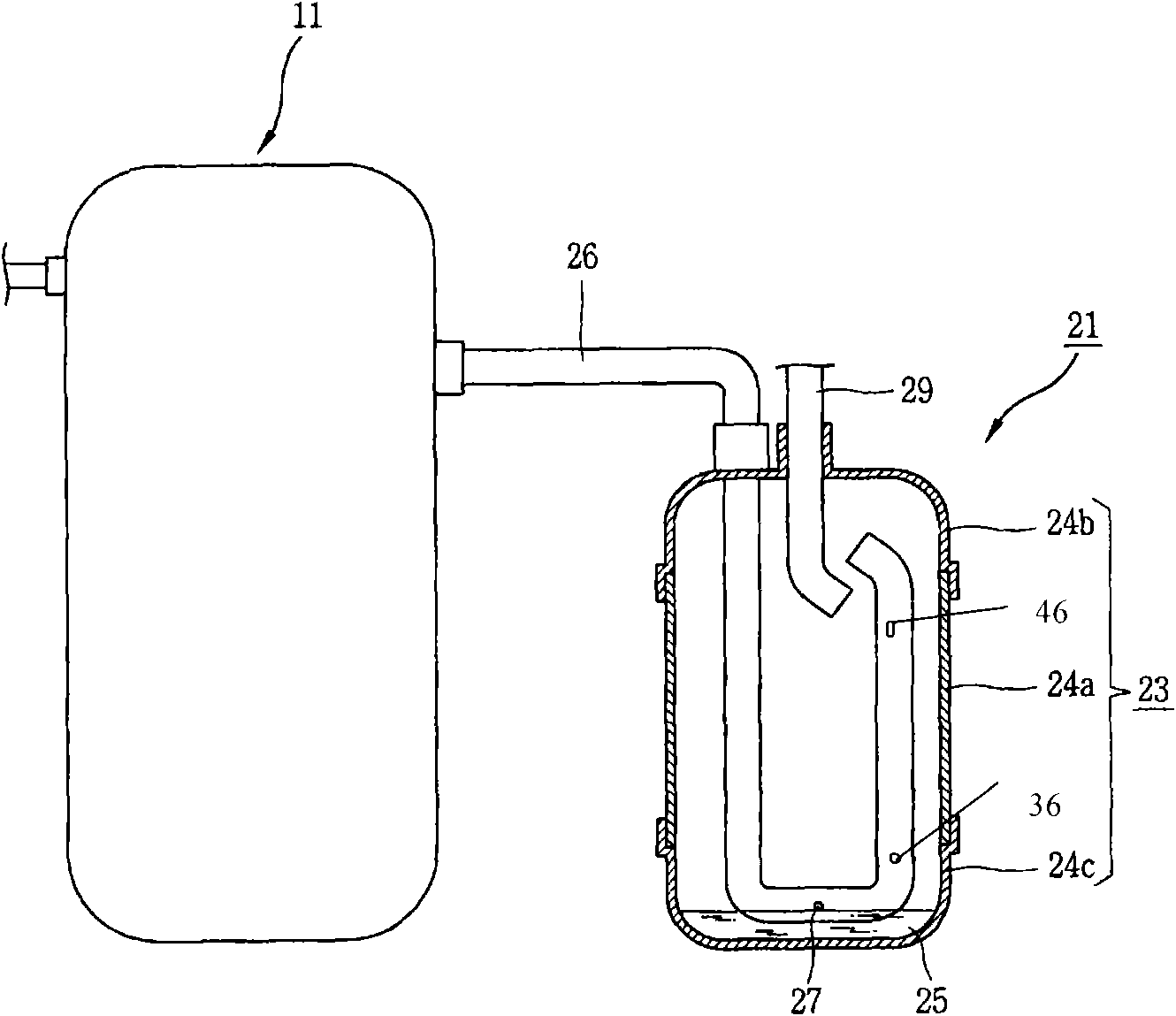

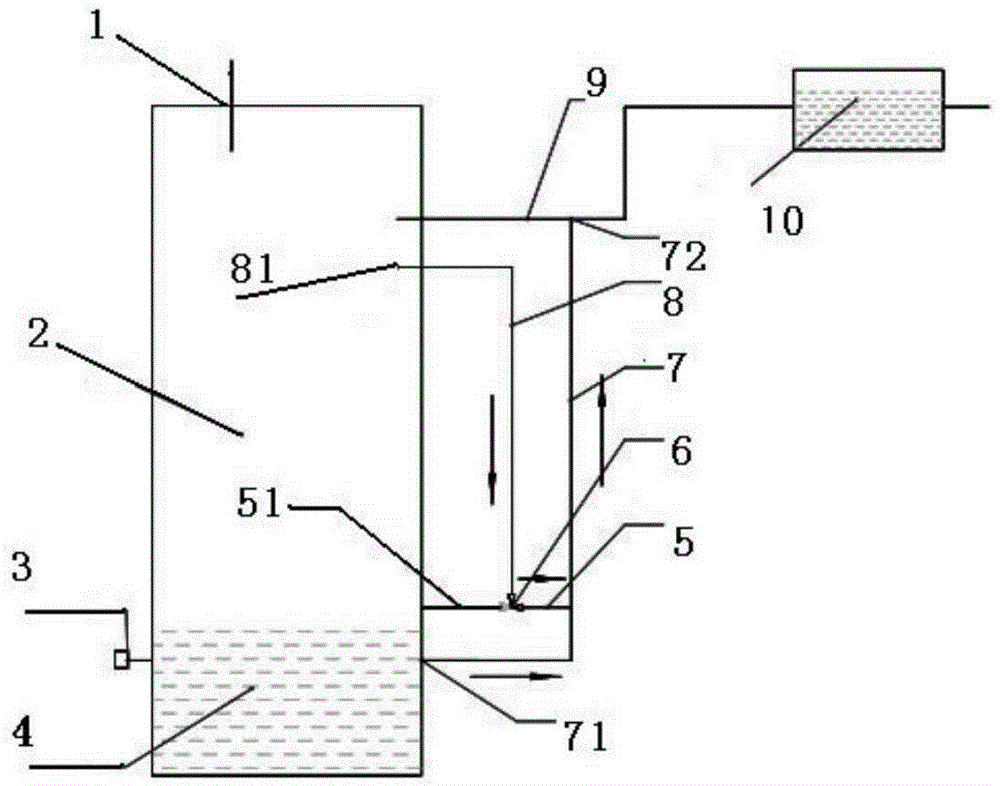

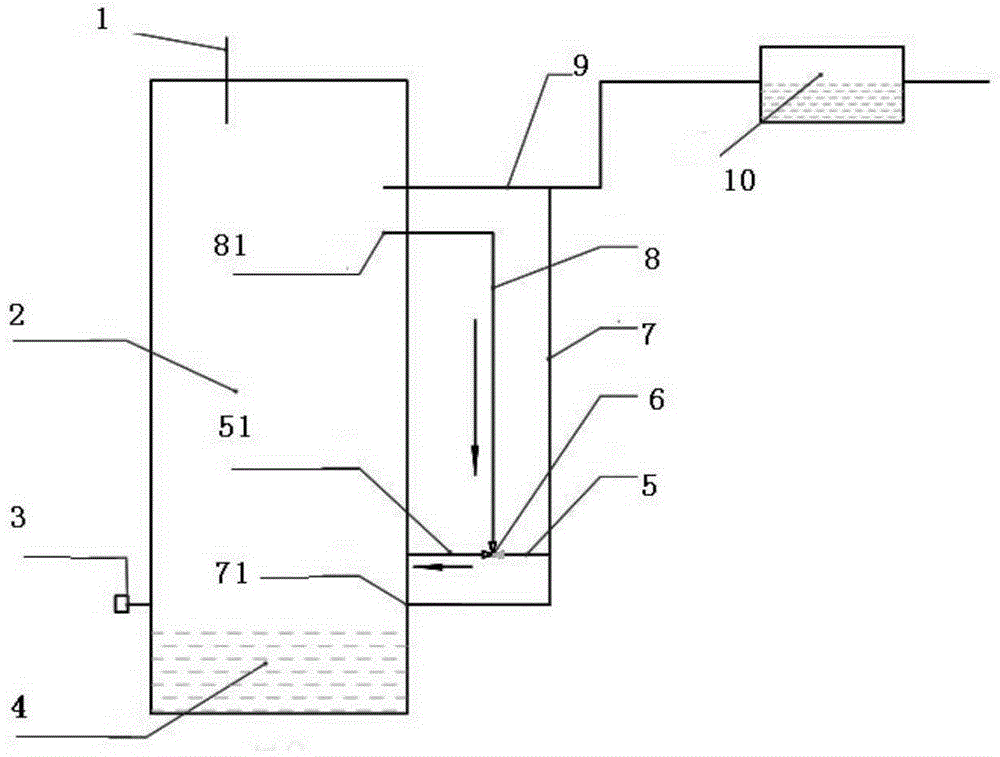

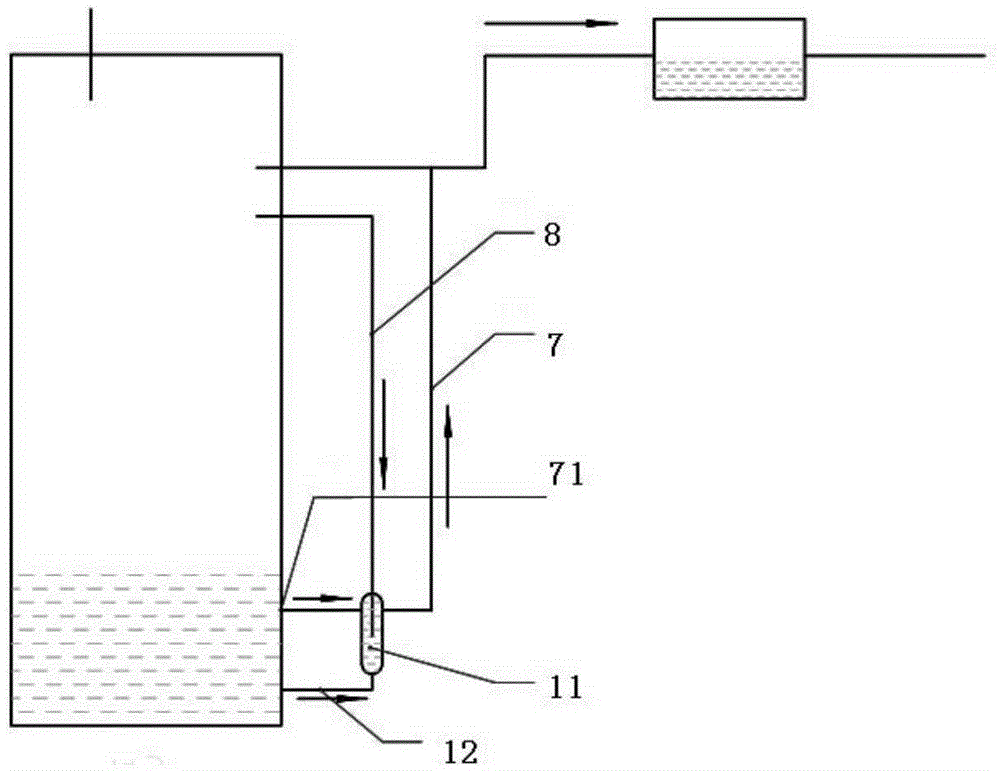

Liquid storage tank with multiple oil return holes

InactiveCN102141328AAvoid failure to return oilInhibit oil shortageCompressorLiquid storage tankResidual oil

The invention discloses a liquid storage tank with multiple oil return holes, comprising a shell the interior of which forms a coolant holding space. In order to make sure that coolant flowing out from the interior of the casing is sucked into a compressor, one side of an efflux pipe is mutually communicated with the compressor, the other side of the efflux pipe is inserted to the interior of the casing, and the inserted part is bent to extend upwards after reaching the bottom of the casing; the bent area of the efflux pipe is provided with an oil return hole in a communicating mode, and the oil return hole can suck oil at the bottom of the casing so as to recover oil to the compressor; and the pipeline part of the efflux pipe, which is bent to extend upwards after reaching the bottom of the casing, is also provided with a plurality of auxiliary oil return holes. According to the invention, in-time oil return can be ensured under various heights of oil level, thereby avoiding the occurrence of incapability of oil return due to over-high oil level under harsh conditions and preventing the phenomenon of insufficient oil of the compressor; and as the interior of the casing does not have residual oil, oil complementary amount can be reduced.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

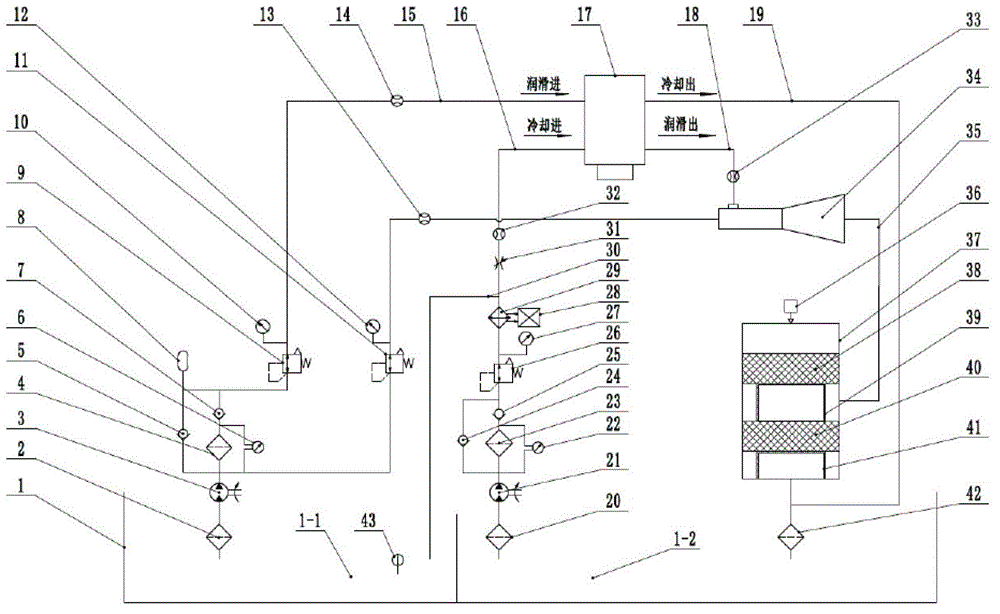

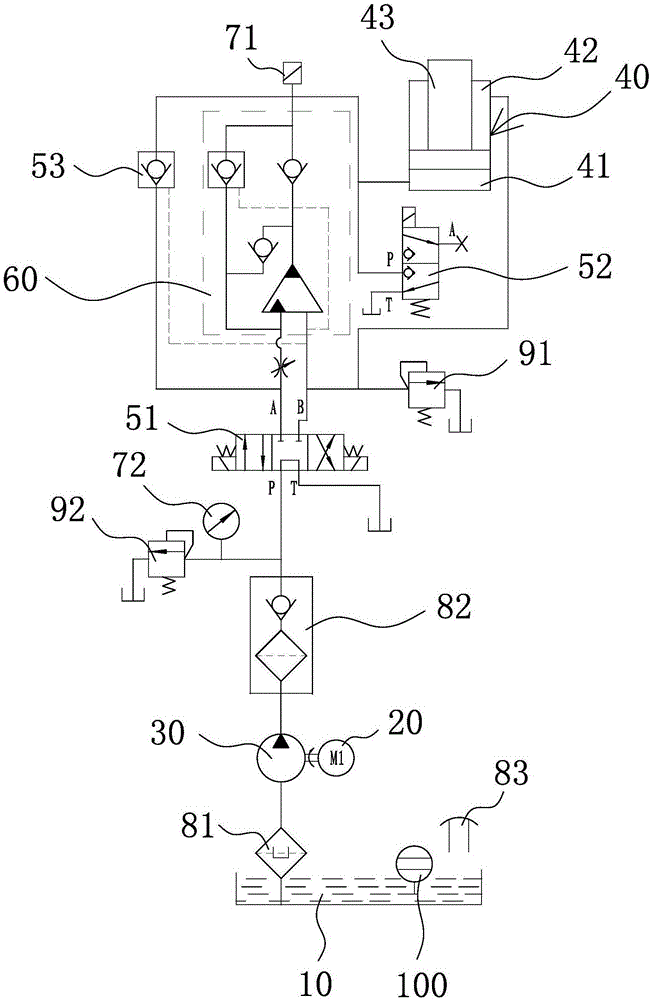

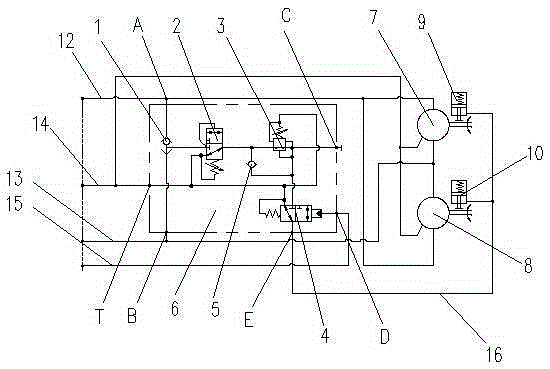

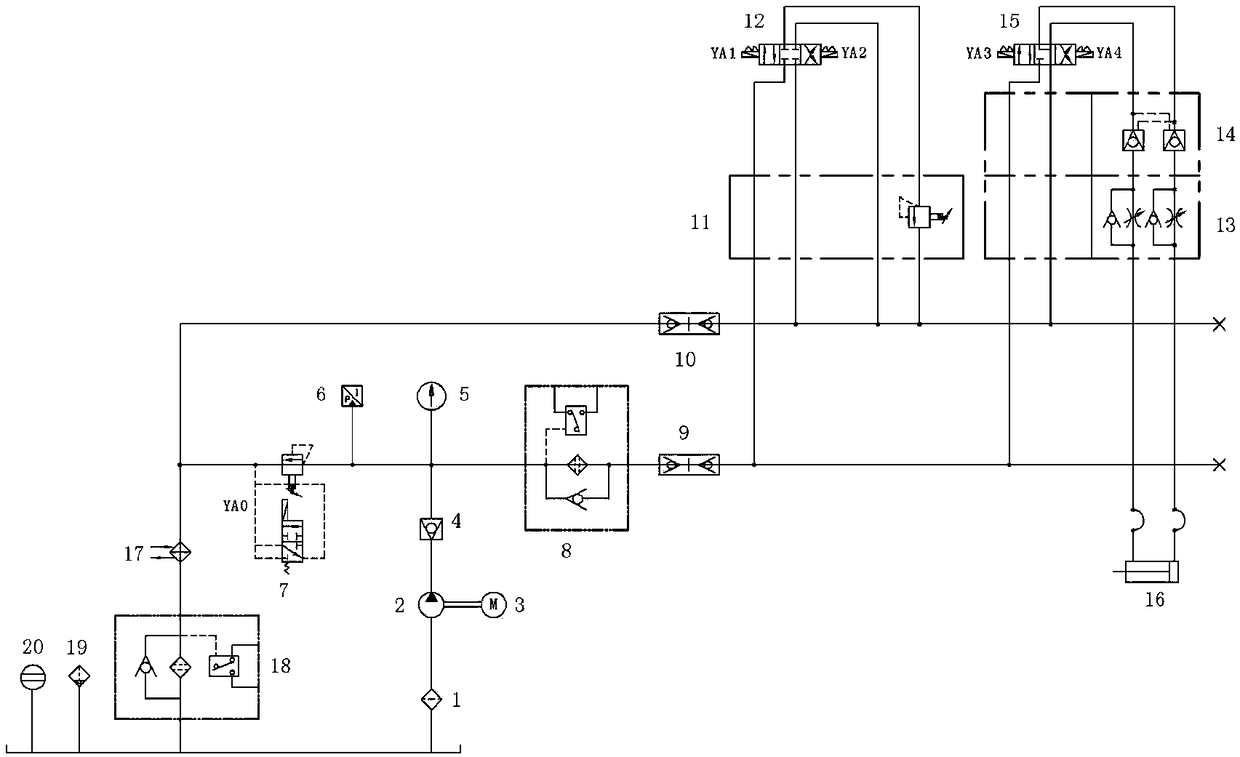

Intelligent hydraulic station

The invention discloses an intelligent hydraulic station, which comprises a lubricating oil feeding subsystem, a cooling oil feeding subsystem, a lubricating oil return subsystem and a cooling oil return subsystem. The intelligent hydraulic station is characterized in that the lubricating oil feeding subsystem and the cooling oil feeding subsystem respectively comprise a precision filter assembly, the precision filter assemblies comprise a precise filter, two one-way valves and a differential pressure sensor, the lubricating oil return subsystem comprises a jet device, a lubricating oil return channel of an electric spindle is connected with a negative pressure chamber interface of the jet device, and oil is sprayed out through the ejection port of the jet device. Defects of failure in oil supply and non-prompt lubricating oil return in case of filter blockage in the prior art can be overcome, smoothness of pressure lubricating oil supply and return can be ensured, bubbles generated in oil return process can be removed, the real-time monitoring of the oil feeding quantity and oil return quantity of the electric spindle lubricating system can be realized, and the intelligent hydraulic station can be widely applied in lubricating oil circulation systems for electric spindles and other hydrodynamic and hydrostatic functional components.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

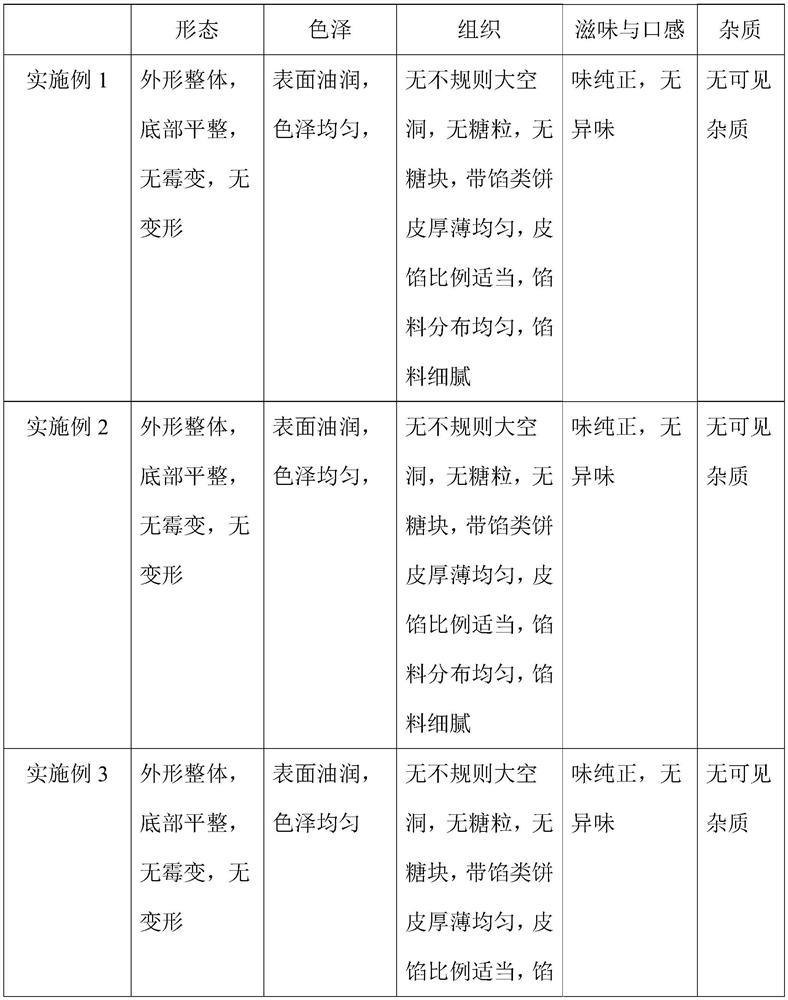

Chicory spiced salt moon cake and making process thereof

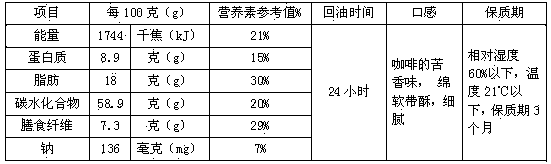

ActiveCN103621598AIncrease the content of dietary fiberFast oil returnDough treatmentBakery productsBiotechnologyAlkaline water

The invention discloses a chicory spiced salt moon cake and a making process of the chicory spiced salt moon cake. The chicory spiced salt moon cake comprises, by weight, 20-25 parts of cooked flour, 9-14 parts of weak strength flour, 8-12 parts of white sweetened bean paste, 4-6 parts of chicory syrup, 7-10 parts of peanut kernels, 4-7 parts of white gourd strips, 4-7 parts of sesame, 2-5 parts of inulin, 3-5 parts of Cantonese syrup, 3-5 parts of medium strength flour, 2-5 parts of soft sugar, 2-5 parts of peanut oil, 2-5 parts of salad oil, 2-5 parts of white lotus paste, 2-5 parts of sunflower seeds, 2-5 parts of lard, 0.5-1.5 parts of chicory powder, 0.3-0.8 part of onion, 0.1-0.4 part of paprika powder, 0.1-0.3 part of salt and 0.1-0.3 part of alkaline water. Finished products are made through the procedures of dosage, preprocessing, preparation of wrapper, preparation of filling, formation and baking, and the moon cake has the advantages of being high in dietary fiber content, fast in oil return, good in taste, long in quality guarantee period, free of any preservative, and the like.

Owner:ZUOYUAN GRP

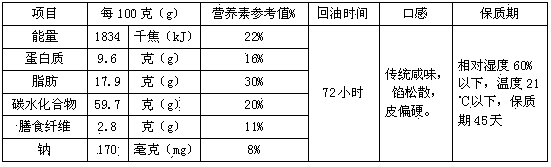

Endive assorted mooncake and making technology thereof

ActiveCN103609642AIncrease the content of dietary fiberFast oil returnDough treatmentBakery productsBiotechnologyInulin

The invention discloses an endive assorted mooncake and a making technology thereof. The endive assorted mooncake comprises, by weight, 15-25 parts of white bean paste, 8-15 parts of weak strength flour, 3-6 parts of medium strength flour, 6-12 parts of salad oil, 5-10 parts of soft plantation white sugar, 2-5 parts of endive syrup, 2-5 parts of syrup in Canton style, 5-8 parts of cooked flour, 4-6 parts of white gourd strips, 2-5 parts of peanut kernels, 2-5 parts of peanut oil, 2-5 parts of kumquat, 2-5 parts of candied apples, 2-5 parts of green candied fruit shreds, 2-5 parts of red candied fruit shreds, 2-5 parts of white lotus seed paste, 2-5 parts of sesame, 1-4 parts of endive powder, 0.2-0.5 part of almonds, 2-6 parts of inulin and 0.1-0.3 part of water containing soda. The making technology of the endive assorted mooncake comprises the steps of preparation of product raw materials, preprocessing of the product raw materials, preparation of skin materials, preparation of stuffing, forming and baking. The endive assorted mooncake has the advantages that the content of dietary fibers is high, the oil returning property is good, the taste is good, the shelf life is long, and no preservative is added to the mooncake.

Owner:ZUOYUAN GRP

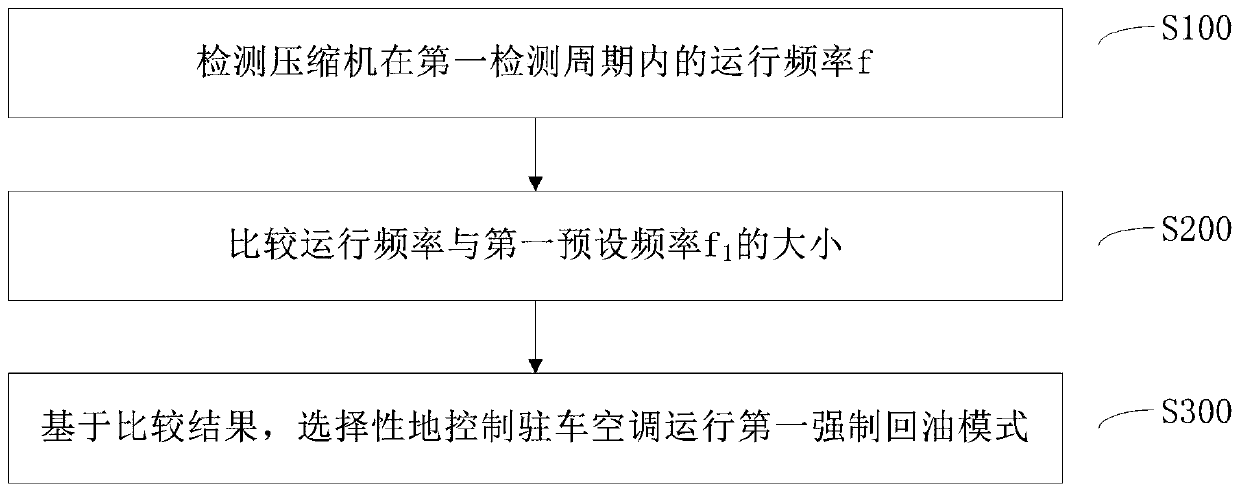

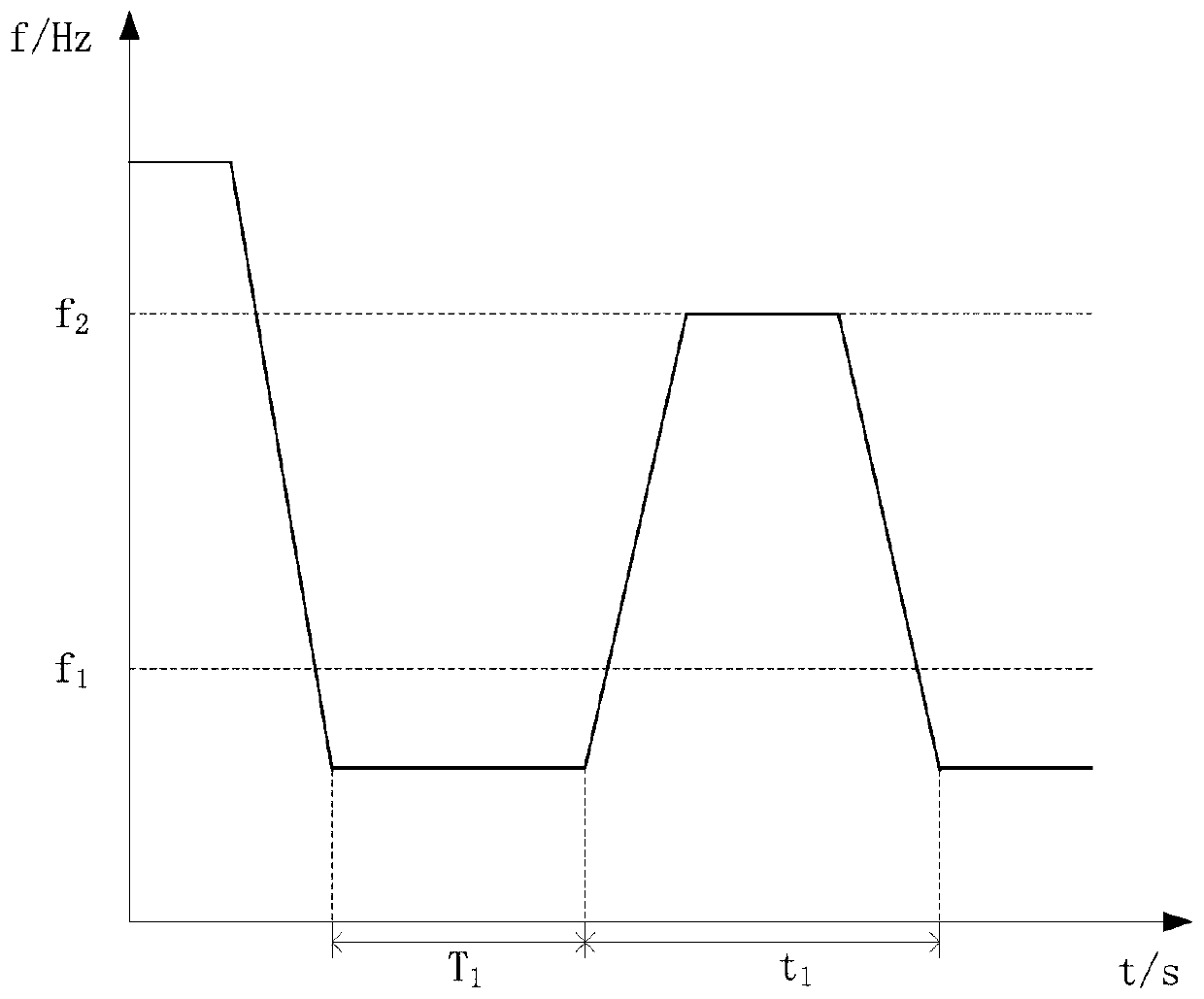

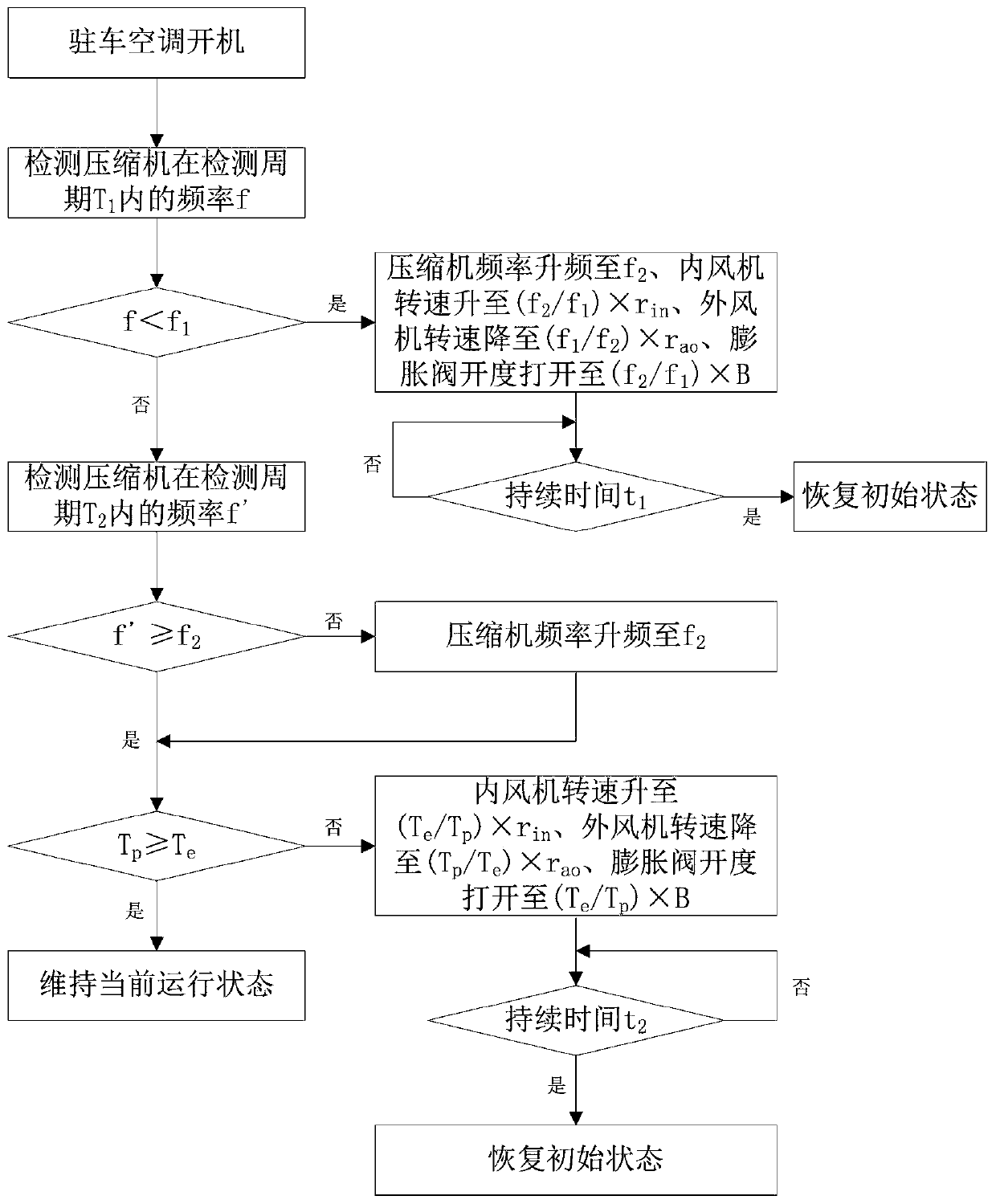

An oil return control method for a parking air-conditioner

ActiveCN110341429AImprove stabilityFully lubricatedAir-treating devicesVehicle heating/cooling devicesControl mannerOperating frequency

The invention relates to the technical field of parking air conditioners, and in particular relates to a method for controlling oil return of a parking air conditioner. The invention aims to solve theproblem that existing parking air conditioners can not guarantee the normal oil return of a compressor. To solve the above problem, the parking air conditioner of the present invention includes a compressor, an indoor radiator, an internal fan, a throttle valve, an outdoor radiator and an external fan. The parking air conditioner is installed in a vehicle. The vehicle is equipped with a storage battery which is connected to the parking air conditioner to supply power to the parking air conditioner. The oil return control method includes steps of detecting the operating frequency f of the compressor in a first detecting period T1; comparing the operating frequency with the magnitude of the first preset frequency f1; and selectively controlling the parking air conditioner to operate a firstforced oil return mode based on the comparison result. Through the above control method, the oil return control method for the parking air conditioner of the present application can realize effectiveoil return during the parking air conditioner operation, and fully lubricate the compressor to ensure the user's use experience.

Owner:QINGDAO HIGHLY ELECTRIC

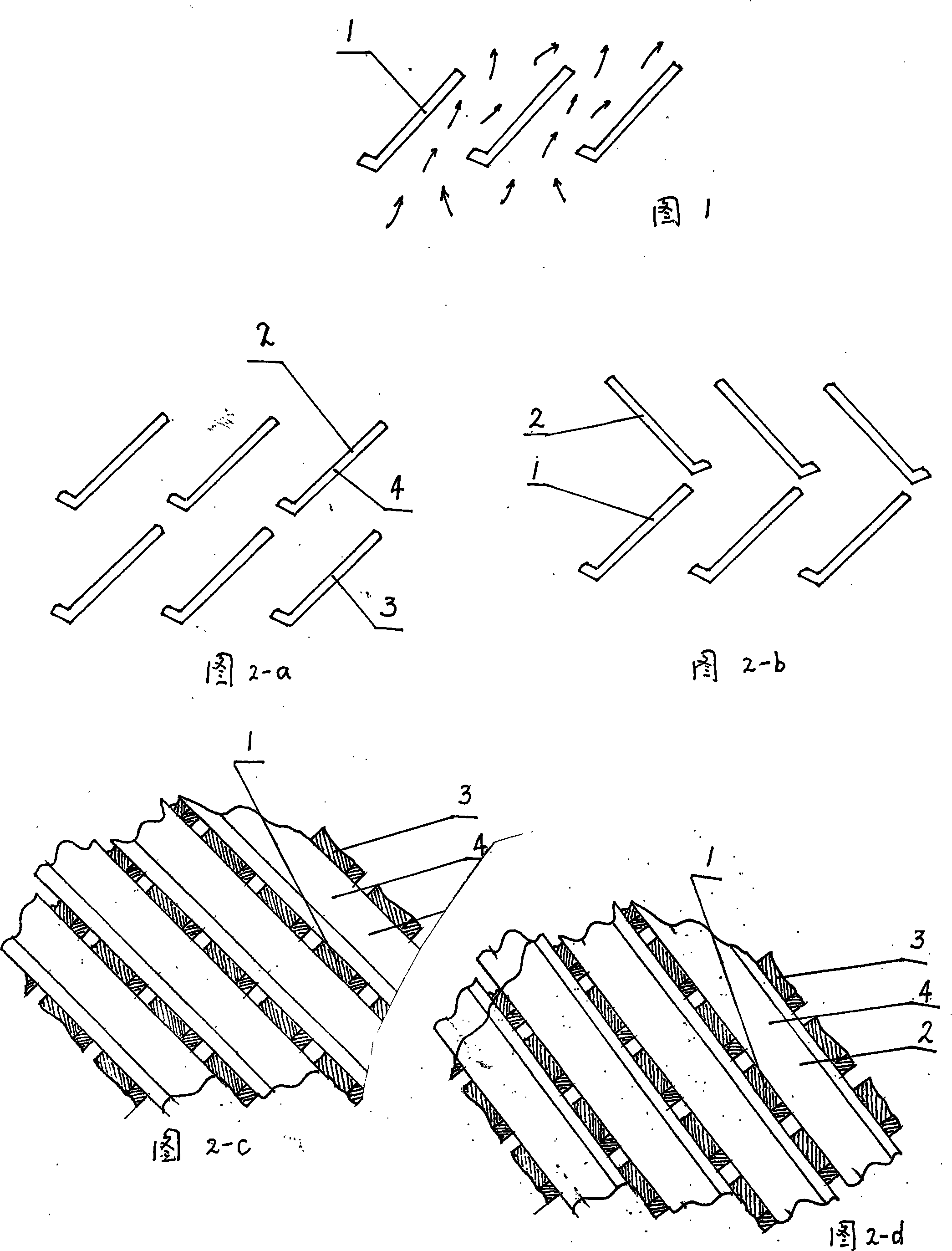

Method of filtering oil fume by metal oil screen and easily cleaning oil screen thereof

InactiveCN101224360AIncrease exposureEasy to separateDomestic stoves or rangesDispersed particle filtrationOil and greasePunching

The invention provides an oil fume filtering method by a metal oil strainer and an easy-cleaning oil strainer adopting the method. The invention is characterized in that the oil strainer can be an one-layer or multi-layer structure; one side of a strainer strip is turned and the other side is raised, and a mould punching shaping is adopted to shape the strainer, and air enters from a side face. If the strainer has a multi-layer structure, the oil strainer has various oil fume filtering methods so as to enhance oil filtering efficiency. The invention not only has elegant appearance, but also can enhance the separation degree of grease, and the air intake and guiding are easy, and both oil-dipping and leaking can be avoided, and the oil strainer cannot be jammed and oil guiding and returning are also quick. And the strainer strips can be easily cleaned. The invention is convenient and practical.

Owner:顾逸民

Method for making mellow-taste Chaoshan-style mooncakes

ActiveCN102870851AHigh speedImprove conversion rateDough treatmentBakery productsVegetable oilProcess engineering

The invention discloses a method for making mellow-taste Chaoshan-style mooncakes. The method comprises the following production steps of: (1) baking salted egg yolk at the temperature of between 150 and 170DEG C for 12 to 15 minutes; (2) boiling clear water, adding granulated sugar, boiling for 16 to 18 minutes, adding lemon juice, uniformly stirring, continuously boiling for 2 to 4 minutes, andremoving a pot from a fire; (3) mixing flour with lard oil, vegetable oil, syrup and other auxiliary materials, uniformly stirring to obtain a crust raw material, fumigating the crust raw material byusing white spirit, and pressing into crusts; (4) filling stuffing in the crusts; (5) brushing egg slurry on mooncake blanks filled with the stuffing, and baking in a normal temperature baking rotaryfurnace; and (6) cooling the baked mooncakes to the temperature of between 40 and 50DEG C, and packaging to obtain the products. The process is unique, the made mooncakes have mellow taste, are smooth, fresh and sweet, and are soft, tasty and refreshing when being eaten, the crusts are nutritious and delicious, and the method is applied to mooncakes with different stuffing.

Owner:广东真美食品股份有限公司

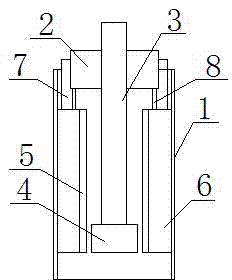

Novel hydrostatic pressure thrust bearing device

ActiveCN110230642AEliminate misalignment errorsGuaranteed rotation accuracyLiquid cushion bearingsCouplingThrust bearing

The invention belongs to the field of bearings, and particularly discloses a novel hydrostatic pressure thrust bearing device. The novel hydrostatic pressure thrust bearing device comprises a rotary workbench, a thrust bearing and a main shaft mechanism, wherein the rotary workbench is horizontally arranged on the upper surface of the thrust bearing and fixedly connected with a main shaft; the thrust bearing is provided with an annular oil cavity, an oil return groove, an oil supply hole which is in communication with the annular oil cavity, and an oil return hole which is in communication with the oil return groove; the main shaft mechanism comprises the main shaft and a cross rolling coupling; the main shaft penetrates the thrust bearing and is matched with the thrust bearing through twoparallel cylindrical roller bearings; the upper end of the main shaft is connected with the rotary workbench, and the lower end of the main shaft is connected with the cross rolling coupling; the cross rolling coupling comprises an upper transmission seat, a lower transmission seat and a transmission disc positioned between the upper transmission seat and the lower transmission seat; and the transmission disc is in sliding fit with the upper transmission seat and the lower transmission seat through four roller cam guide apparatuses which are distributed on the upper surface and the lower surface of the transmission disc in a cross manner. The novel hydrostatic pressure thrust bearing device has the advantages of being high in rotation precision, small in friction coefficient and good in stability.

Owner:HUAZHONG UNIV OF SCI & TECH

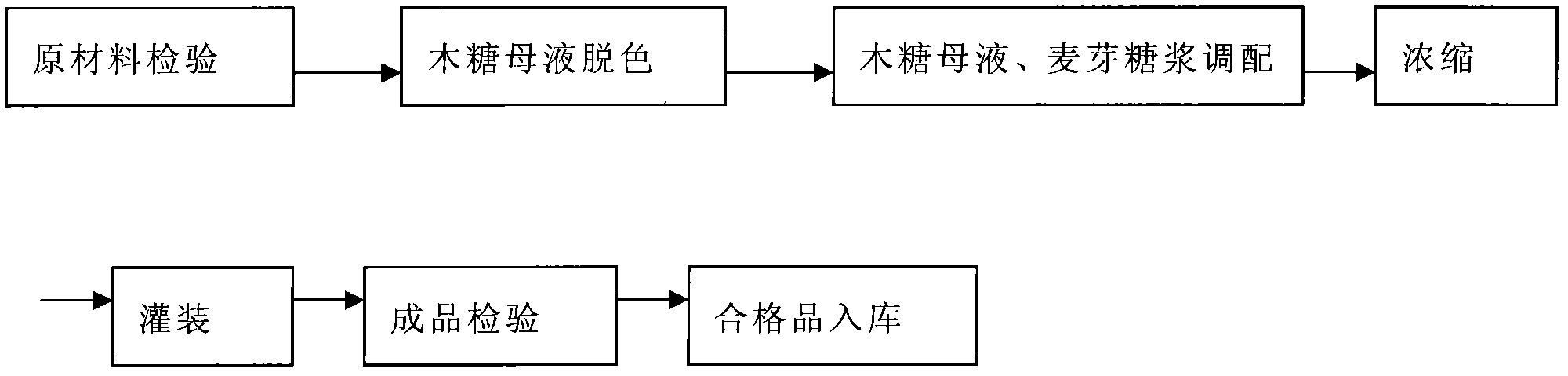

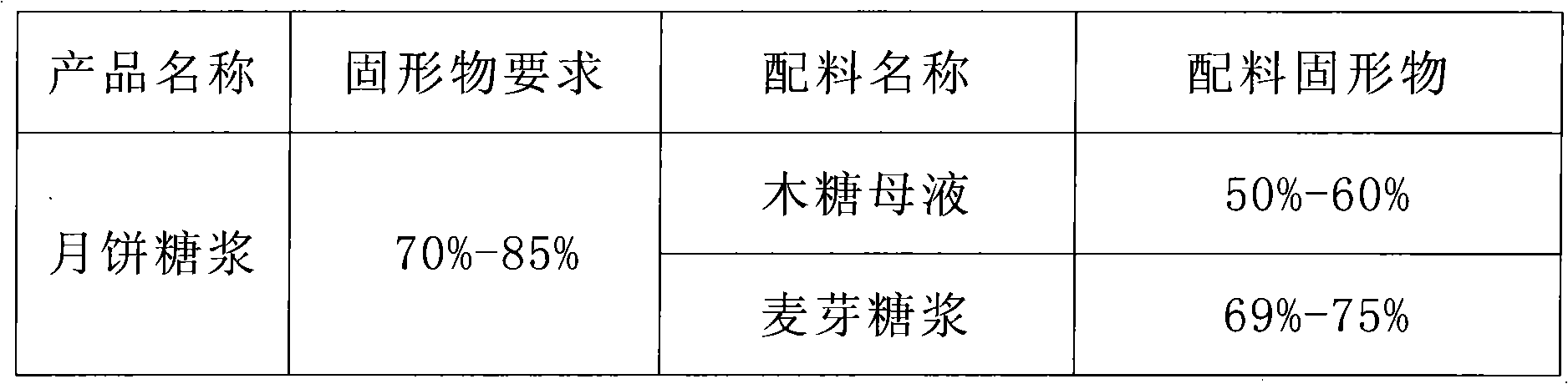

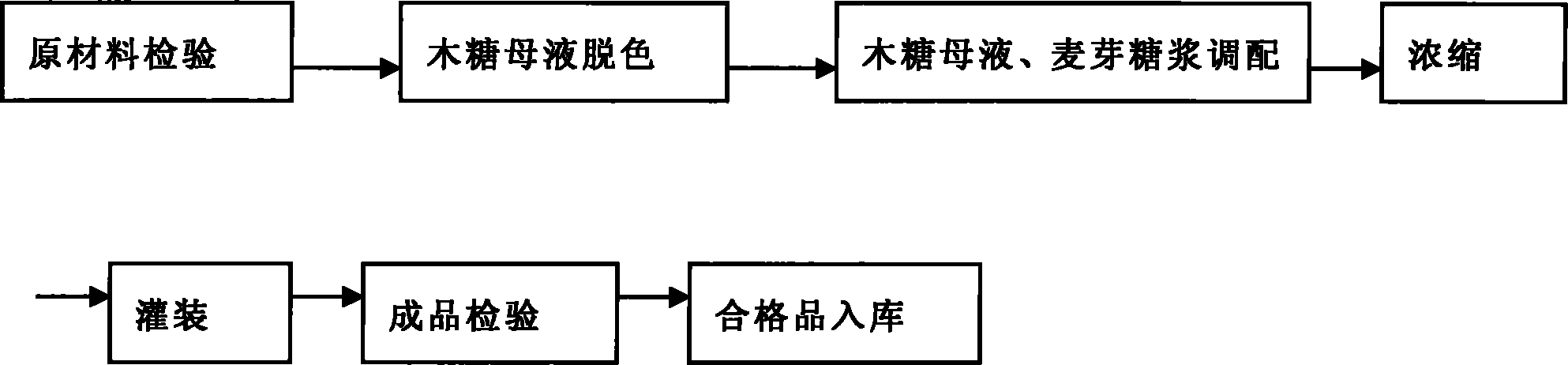

Syrup for roasting and preparation method thereof and mooncakes prepared from syrup

The invention relates to a mooncake formula and a preparation method for mooncakes, in particular to syrup for roasting and a preparation method thereof and mooncakes prepared from the syrup. The syrup for roasting is characterized by comprising components of xylose mother liquor and malt syrup in a weight ratio of 1-6:1. The products difficult to treat in xylose production, namely the xylose mother liquor and malt syrup are taken as raw materials, and are treated by processes such as decoloration, mixing, concentration and the like to be prepared into the syrup for roasting applied to mooncake production; and the mooncakes prepared from the syrup for roasting are quick to return oil, are easy to color during roasting, have good quality and low cost, and are convenient to apply in the mooncake producing process.

Owner:山东文远生物技术有限公司

Damper

InactiveCN102954141ASimple structureFast oil returnSpringsLiquid based dampersPiston rodSteering system

The invention relates to the technical field of automobile steering systems, in particular to a damper. The damper comprises a shell, a rubber oil seal, a piston rod, a piston and cylinders, wherein the rubber oil seal is disposed at the upper end of the shell, the piston rod is disposed in the shell, the piston is disposed at the lower end of the piston rod, and the cylinders are disposed on two sides inside the shell. An oil storage chamber is arranged on one side of each cylinder. a guide bearing is disposed between the shell and the rubber oil seal. A oil through hole is arranged above each oil storage chamber. The damper has the advantages that the damper is simple in structure, practical, convenient, and fast in oil return, oil leakage is avoided, quality and safety of the damper is improved, the service life is prolonged, replacement frequency and application cost are reduced while maintenance cost is also reduced, and popularization is facilitated.

Owner:常州轩柯新材料科技有限公司

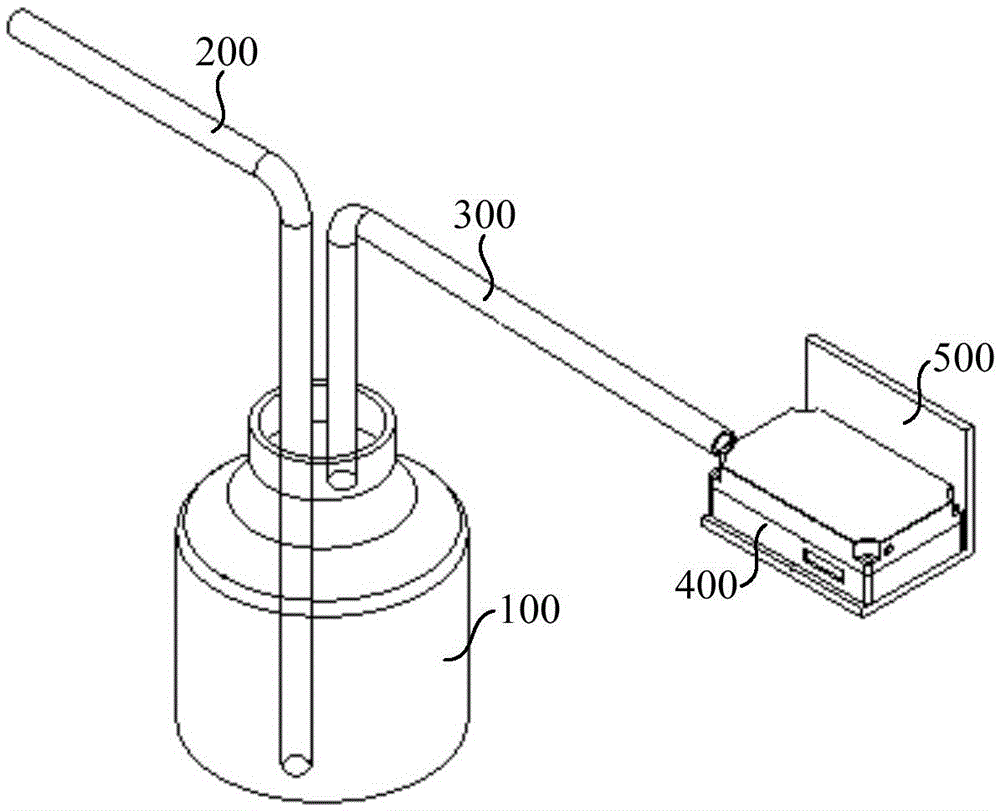

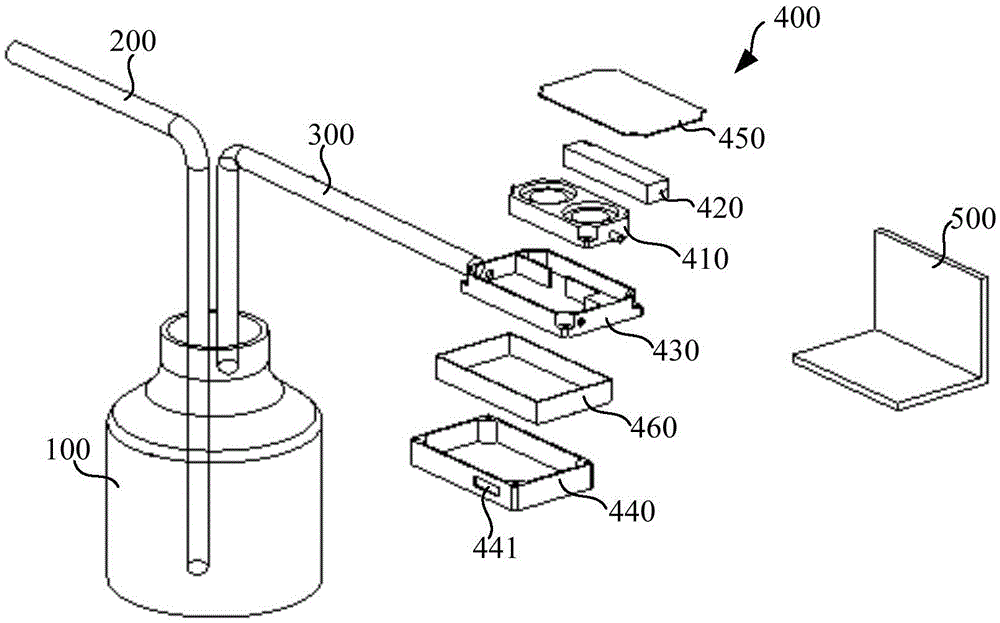

Lubricating system and equipment with same

InactiveCN105465590AStrong oil return abilityFast oil returnGear lubrication/coolingMachines/enginesPetroleum engineering

The invention provides a lubricating system. The provided lubricating system comprises a lubricating oil recovery vessel (100), an oil return pipeline (200), a lubricating pump, an auxiliary negative pressure pipeline (300) and an auxiliary negative pressure source, wherein the oil return pipeline (200) is communicated with the lubricating oil recovery vessel (100); the lubricating pump is used for driving lubricating oil to carry out oil return flowing; the auxiliary negative pressure source is communicated with the lubricating oil recovery vessel (100) through the auxiliary negative pressure pipeline (300) so as to ensure that an inner cavity of the lubricating oil recovery vessel (100) is in a negative pressure environment; and both the negative pressure environment and the lubricating pump are used for applying an acting force for enabling lubricating oil flowing through the oil return pipeline (200) to flow towards the inner cavity of the lubricating oil recovery vessel (100). According to the scheme, the problem that the lubricating system in the background art cannot return oil in time or is relatively low in oil return speed can be solved. The invention also provides equipment with the lubricating system.

Owner:TAIYUAN HEAVY IND

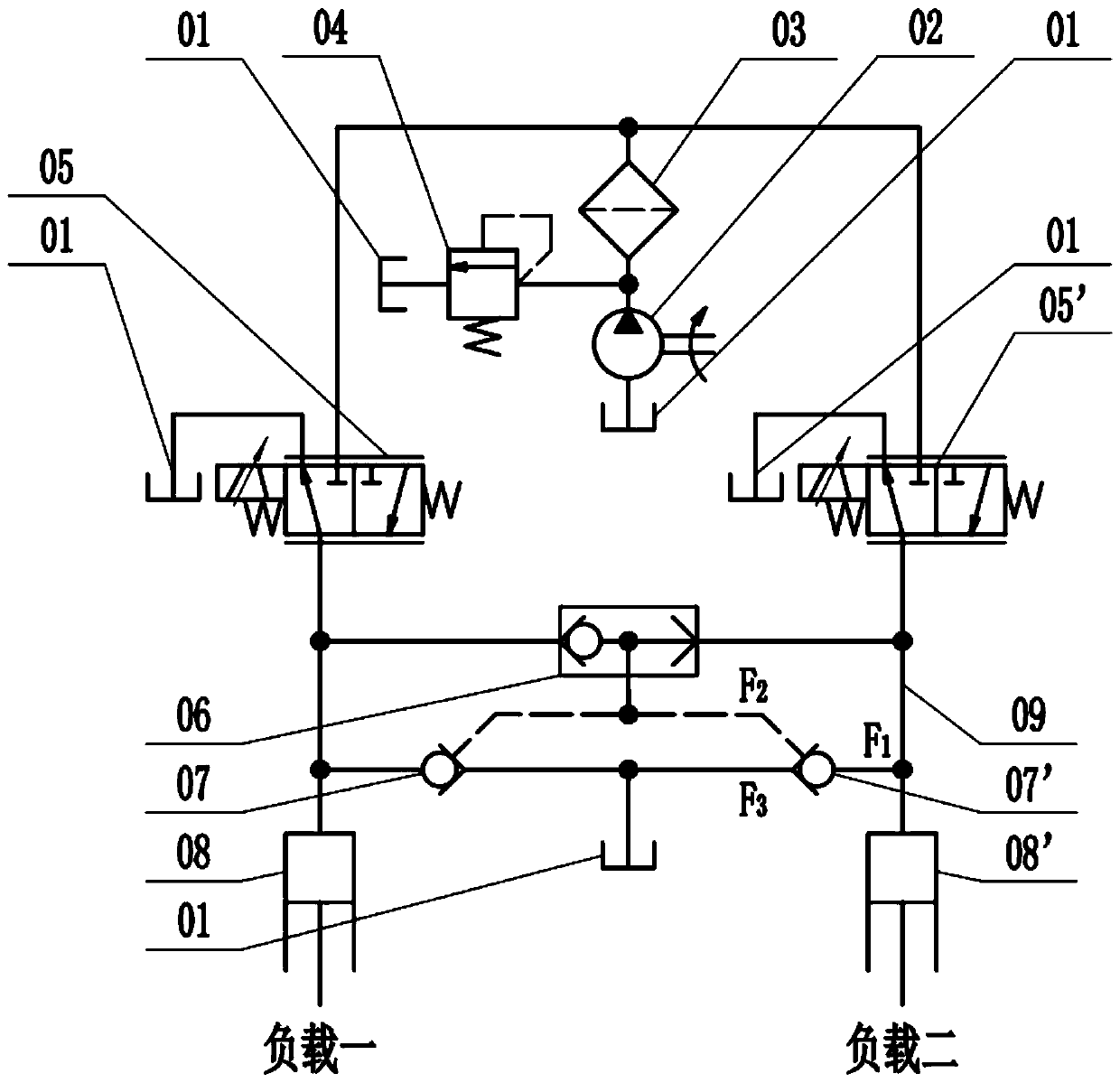

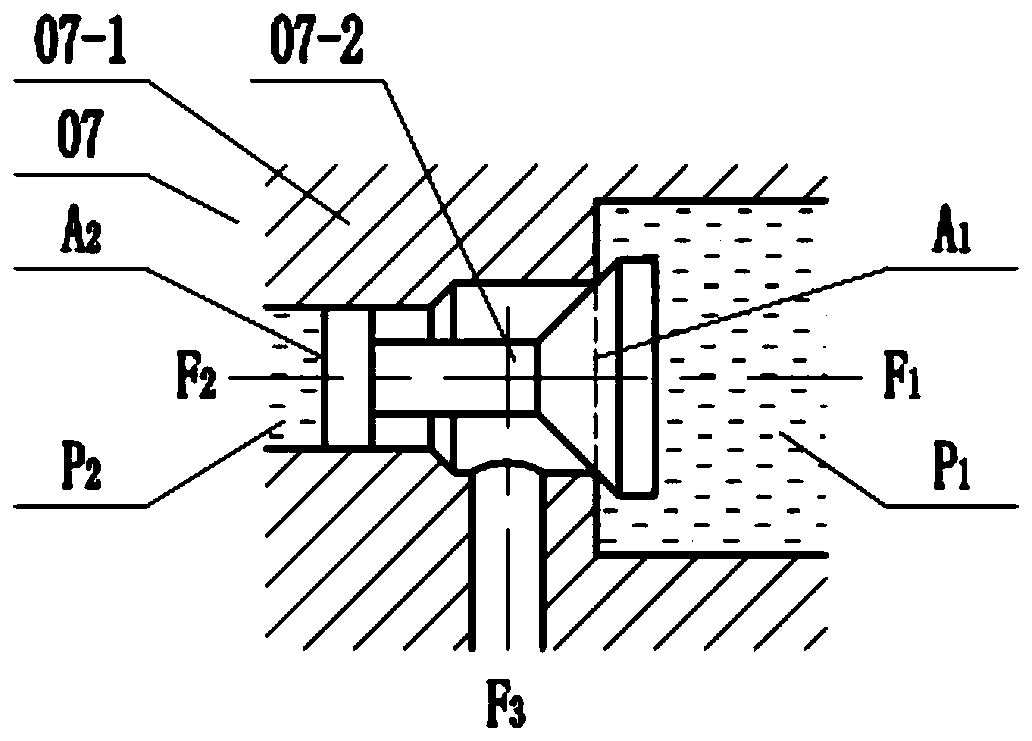

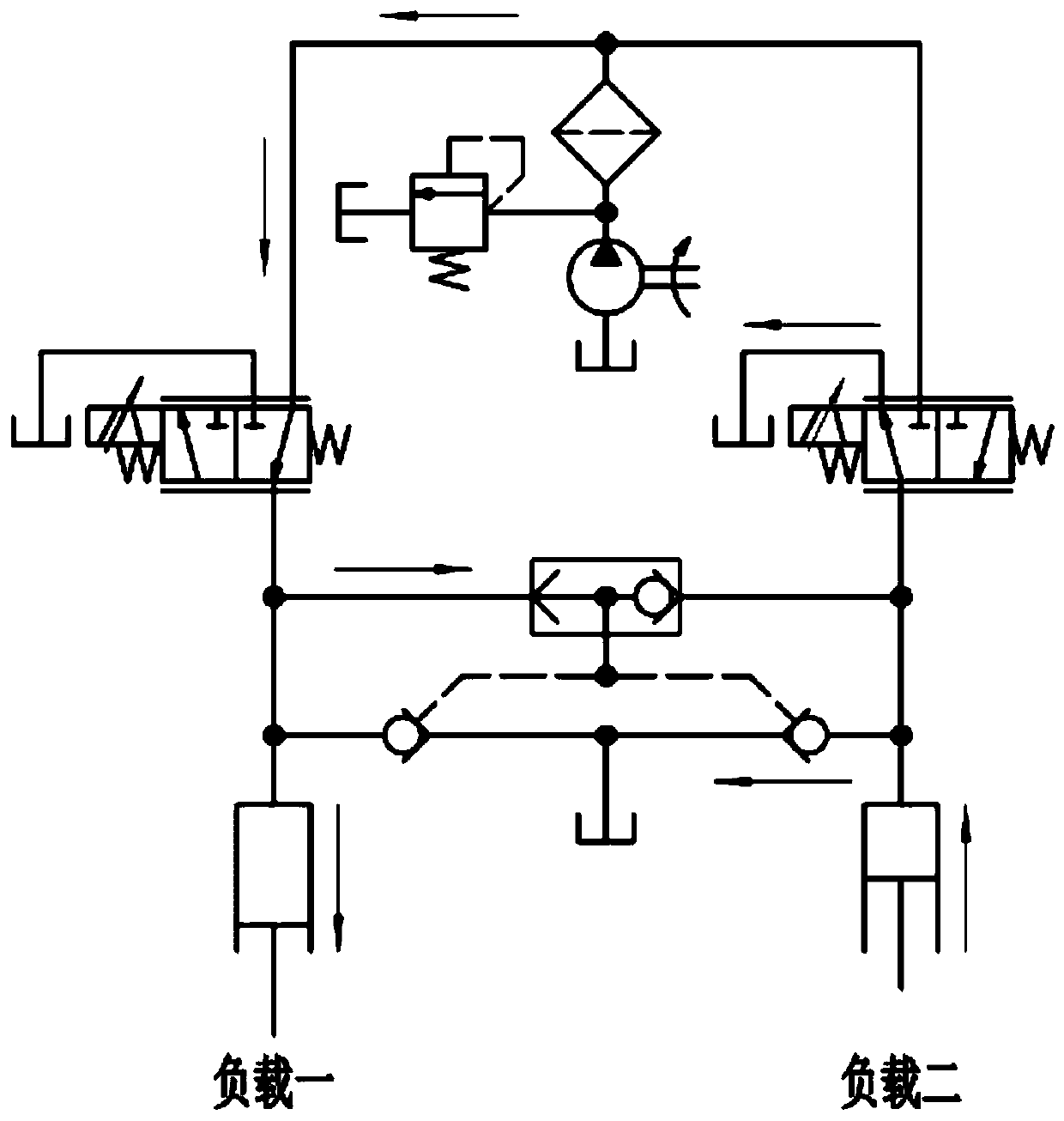

Single-acting plunger cylinder hydraulic system

ActiveCN110886729AReduce complexitySmall form factorServomotor componentsServomotorsMarine engineeringHydraulic pump

The invention discloses a single-acting plunger cylinder hydraulic system. A hydraulic oil tank is connected with an inlet of a hydraulic pump, an outlet of the hydraulic pump is simultaneously connected with oil inlets of left-side and right-side two-position three-way reversing valves, and oil return openings of the left-side and right-side two-position three-way reversing valves are respectively connected with the hydraulic oil tank; an oil outlet of the left-side two-position three-way reversing valve is simultaneously connected with an inlet of a left-side hydraulic control one-way valveand an oil port of a left-side single-acting plunger cylinder and is further connected with one inlet of a shuttle valve; a valve oil outlet of the right-side two-position three-way reversing valve issimultaneously connected with an inlet of a right-side hydraulic control one-way valve and an oil port of a right-side single-acting plunger cylinder and is further connected with the other inlet ofthe shuttle valve; an outlet of the shuttle valve is simultaneously connected with hydraulic control ports of the left-side hydraulic control one-way valve and the right-side hydraulic control one-wayvalve; outlets of the left-side hydraulic control one-way valve and the right-side hydraulic control one-way valve are connected with the hydraulic oil tank; and the effective hydraulic area of the inlets of the hydraulic control one-way valves is larger than the effective hydraulic area of the hydraulic control ports. The complexity of a traditional hydraulic system is reduced, the external dimensions of elements and the system are reduced, and the structure is more compact.

Owner:SOUTHWEST JIAOTONG UNIV

Cantonese-style water chestnut paste stuffing mooncake

InactiveCN105594810AImprove ductilityNot easy to crackDough treatmentBakery productsFlavorWater Chestnuts

The invention relates to the field of bakery product processing, in particular to cantonese-style water chestnut paste stuffing mooncake which comprises skin and stuffing. The stuffing comprises 100 parts of water chestnut paste, 10-30 parts of sucrose powder and 10-20 parts of edible oil. A method for manufacturing the stuffing comprises the steps of water chestnut powder manufacture, water chestnut paste manufacture and cold storage and the like. Fresh water water chestnuts which are extensive in source are utilized to manufacture the water chestnut paste stuffing mooncake having peculiar flavor of the water chestnuts, the stuffing is unique in taste and rich in nutrition, and the style of conventional Cantonese-style mooncake is retained.

Owner:项小飞

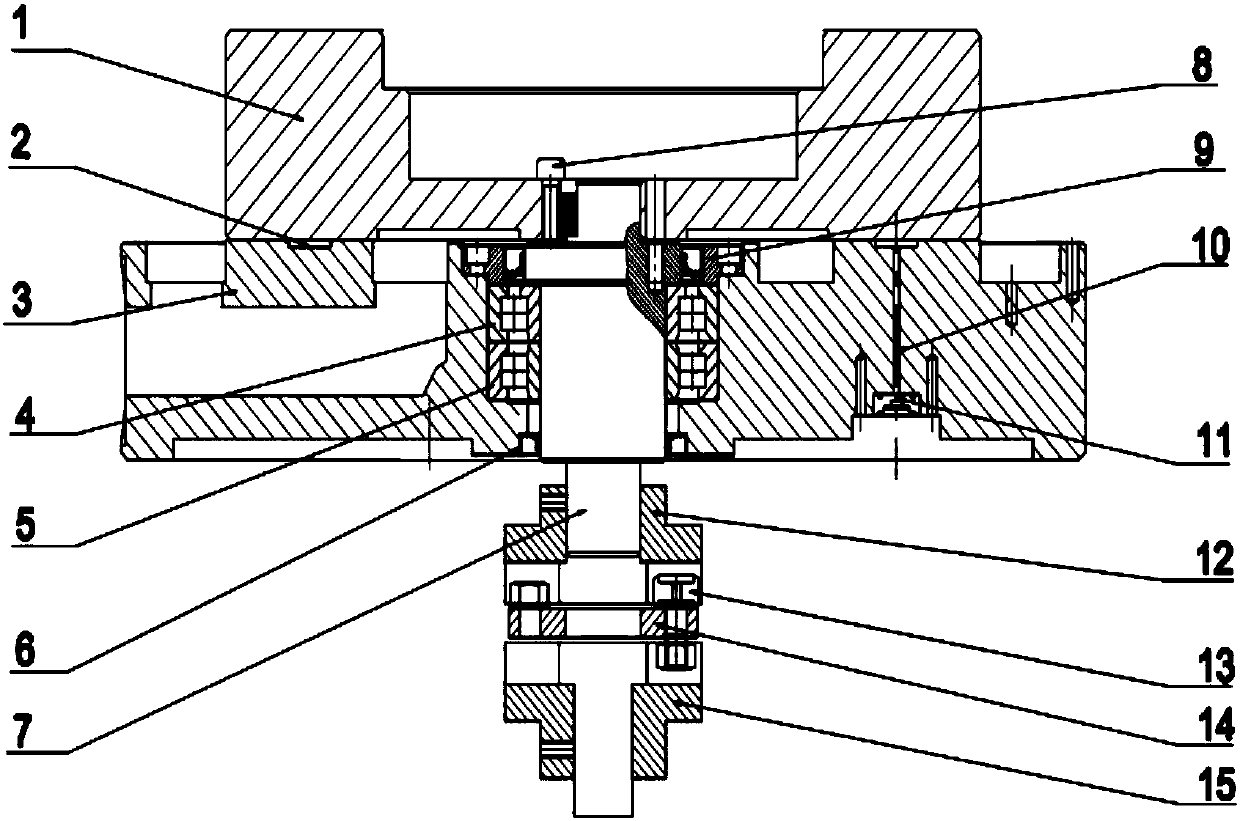

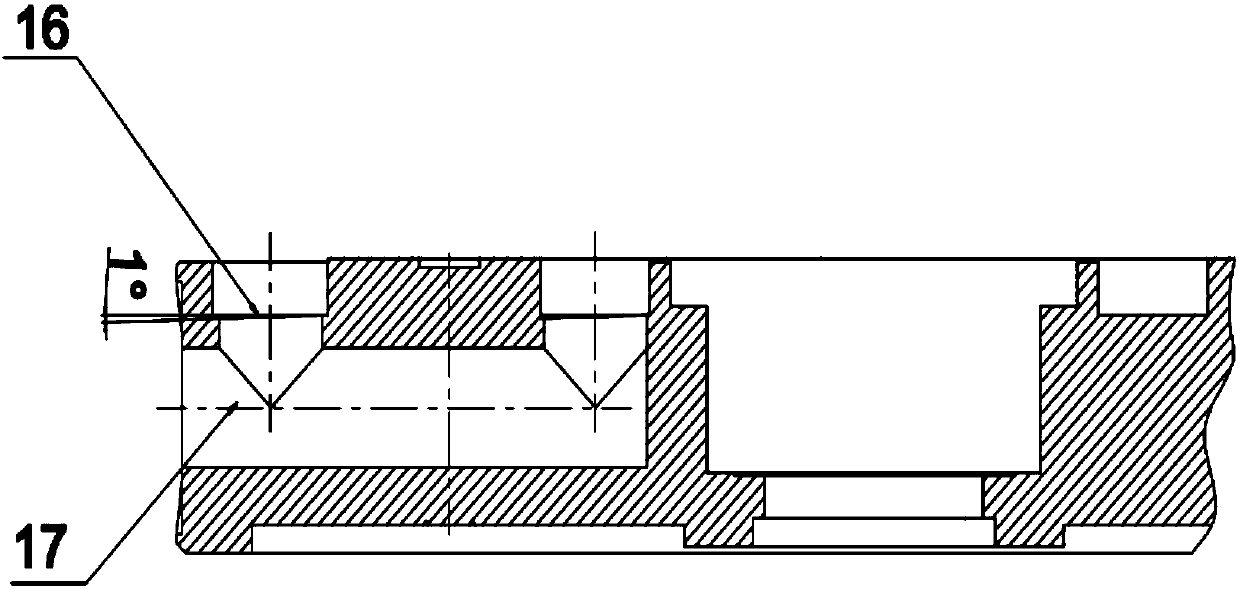

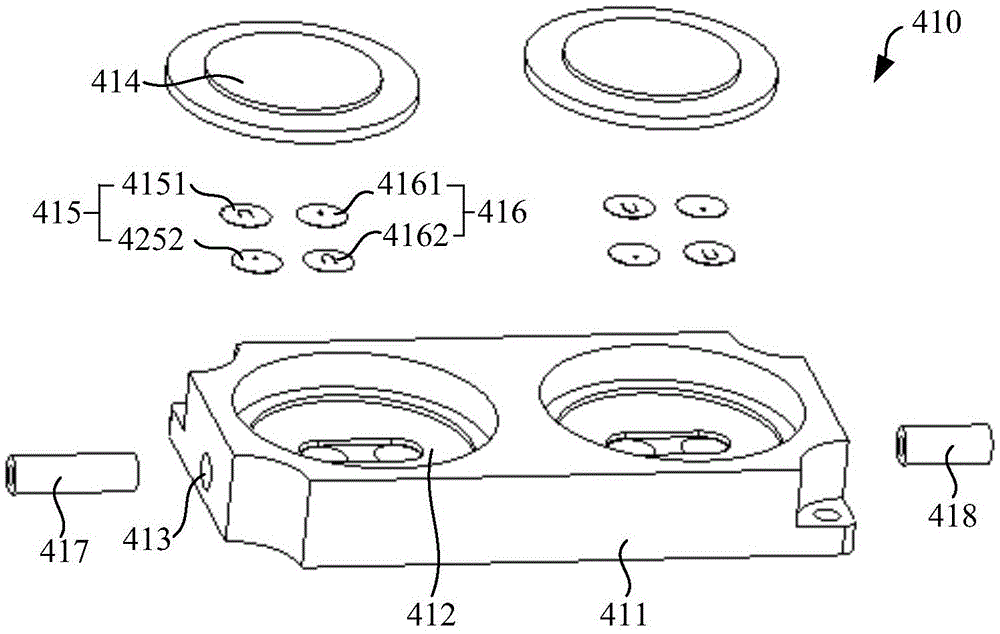

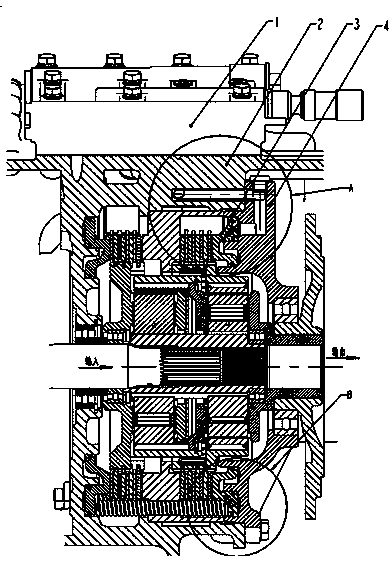

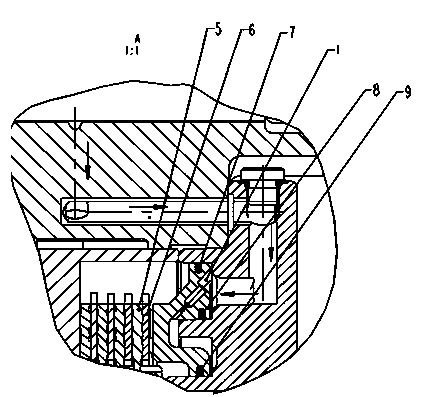

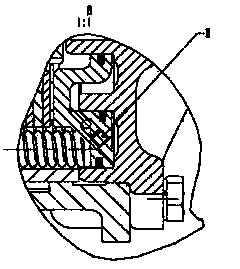

Oil charge buffering device of hydraulic gear-shifting gearbox clutch

The invention provides an oil charge buffering device of a hydraulic gear-shifting gearbox clutch. A circular groove is formed in an outer oil cylinder, a circular boss is arranged on an outer piston, and the circular groove formed in the outer oil cylinder is matched with the circular boss arranged on the outer piston to form an inner oil cylinder. A buffering control loop is formed between an outer oil cylinder oil cavity of the outer oil cylinder and an oil cavity of the inner oil cylinder and formed by connecting a one-way valve and an orifice valve in parallel. The one-way valve is arranged in the mode that in the oil charging process, the one-way valve is locked and oil can not pass, and oil passes through the one-way valve in out-of-gear situation; the one-way valve and the orifice valve are arranged in the outer piston with the outer piston as a valve body, one end of the one-way valve and one end of the orifice valve are communicated with the oil cavity of the outer oil cylinder, and the other end of the one-way valve and the other end of the orifice valve are communicated with the oil cavity of the inner oil cylinder. The oil charge buffering device can achieve stable combination in gear shifting of the clutch, lower gear shifting impact, and achieve quick oil return in out-of-gear.

Owner:GUANGXI LIUGONG MASCH CO LTD

Oil way system of crimping machine and oil way control method thereof

The invention provides an oil way system of a crimping machine and belongs to the technical field of hydraulic transmission. By means of the oil way system, the problem that an existing oil way system of a crimping machine is low in work efficiency is solved. The oil way system of the crimping machine comprises an oil pump, an oil cylinder and an oil tank used for storing oil. The oil pump is arranged in the oil tank and connected with a motor, and the motor can drive the oil pump to pump out the oil in the oil tank. The oil pump and the oil cylinder are communicated through an electromagnetic reversing valve, a booster for increasing the pressure of the oil way system is arranged between the electromagnetic reversing valve and the oil cylinder, and the booster is communicated with the electromagnetic reversing valve and the oil cylinder. The invention further provides an oil way control method of the oil way system of the crimping machine. The oil way system has the advantages that the structure is simple, and oil input and return are rapid.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

Moon cake syrup and preparation method thereof

The invention relates to a moon cake syrup and a preparation method thereof. The method is characterized in that the maltose syrup with a mass percent concentration of 75% (or 80%) is boiled (concentrated) to a refractive index of 85%; and F42 fructose syrup (or F30 or F55) is concentrated to the refractive index of 75% or more, the materials can be pumped to a material tank, and uniformly stirredand mixed. The method comprises the following steps: (1) raw material acceptance; (2) condensation; (3) mixing of ingredients; (4) loading; and (5) packaging and warehousing. The method has the beneficial effects that the preparation process is heated under the condition of negative pressure and full closure, and the phenomena of sand prevention, heavy metal and microbial exceeding the standard can be eliminated, the shelf life is up to 18 months, the sweetness is similar to that of sucrose, the sweetness is soft, the taste is pure, the concentration is high, the mooncake is well colored, andthe oil and softness can be returned rapidly. The mooncake made with the syrup is both nutritious and healthy.

Owner:山东金田生物科技有限公司

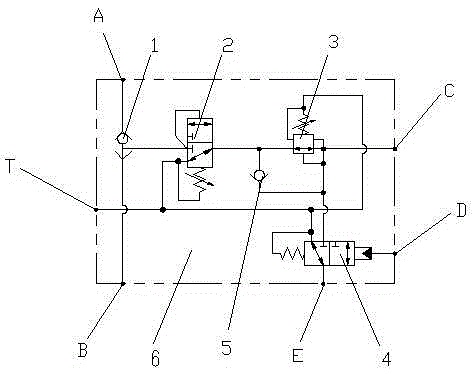

Combined brake control device

ActiveCN105351407ARelease sensitiveFast brake releaseServomotor componentsServomotorsShuttle valvePetroleum engineering

The invention provides a combined brake control device. A shuttle valve, a hydraulic change-over valve, a pressure reducing overflow valve, a pilot hydraulic change-over valve and a one-way valve are arranged in a valve body of the device, the oil outlet of the shuttle valve is communicated with the oil inlet of the hydraulic change-over valve, the oil outlet of the hydraulic change-over valve is communicated with the oil inlet of the pressure reducing overflow valve, the oil outlet of the pressure reducing overflow valve is communicated with the oil inlet of the pilot hydraulic change-over valve, the oil inlet of the pilot hydraulic change-over valve is connected with the oil inlet of the one-way valve, the oil inlet of the shuttle valve is respectively communicated with an oil inlet A and an oil inlet B on the valve body, and the oil outlet of the pilot hydraulic change-over valve is communicated with a brake oil port E. The device adopts the combination of various valve bodies for control, after entering into the valve bodies, hydraulic oil can directly reach a brake opening through the pilot hydraulic change-over valve, the brake releasing speed is fast, and the brake releasing is sensitive.

Owner:中石化四机石油机械有限公司 +1

Isolation transformer based on power network security system

ActiveCN114050032AImprove cooling effectFast oil returnTransformers/inductances coolingThermodynamicsHeat conducting

The invention discloses an isolation transformer based on a power network safety system, and the isolation transformer comprises an oil tank, an isolation plate and an oil conservator; a movable cavity is formed in the isolation plate, a heat conduction piece is fixedly connected to the lower portion of the movable cavity, and a piston block is movably connected to the interior of the movable cavity; and a mercury layer is arranged on the lower side of the piston block in the movable cavity. By designing the movable cavity, the piston block, the mercury layer, the large air bag, the heat conducting piece, the air outlet groove and the air outlet pipe, heat generated in the oil tank is transmitted to the mercury layer in the movable cavity through the heat conducting piece, so that the mercury layer is heated to rise to drive the piston block to move upwards and extrude the large air bag; the large air bag releases air in the large air bag through the air outlet groove and the air outlet pipe to take away heat on the heat-conducting fins, and heat dissipation of the heat-conducting fins is accelerated; meanwhile, the flowing of air flow in the air outlet pipe can take away heat of cooling oil outside the air outlet pipe, and heat dissipation of the cooling oil in the oil tank is further accelerated.

Owner:SHANGQIU POWER SUPPLY CO OF STATE GRID HANAN ELECTRIC POWER CO

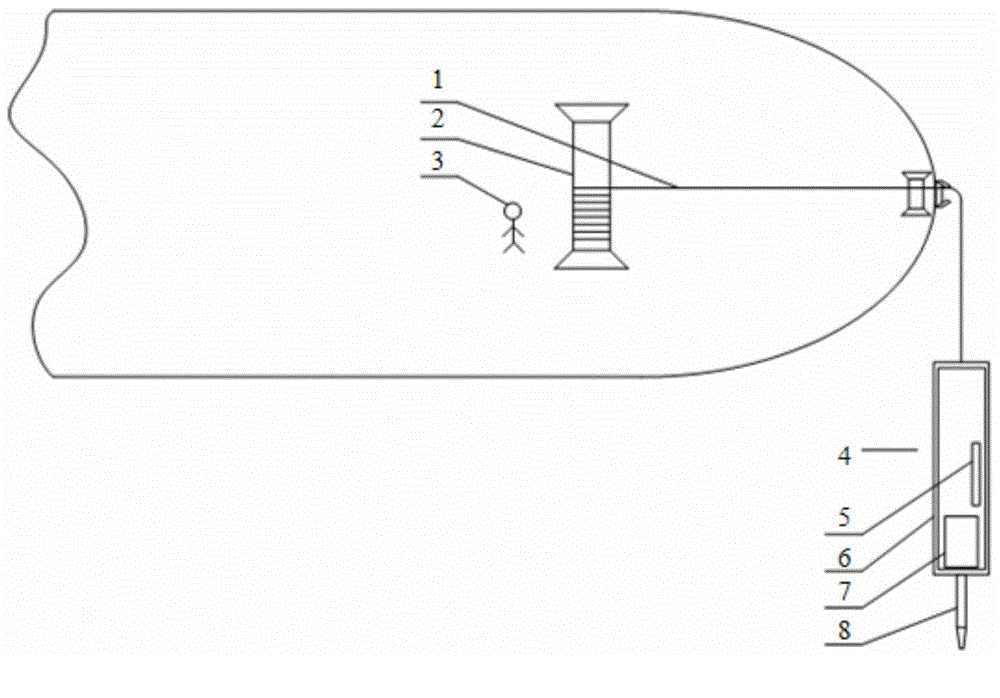

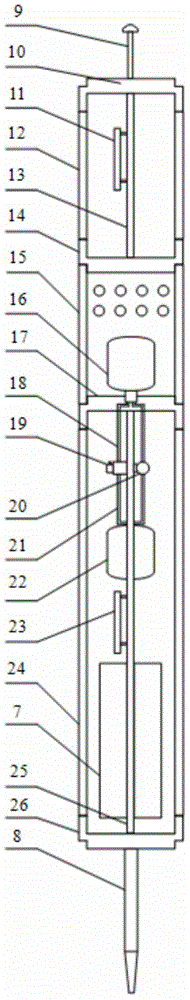

Three-drum unattended turbulence profile measurement device

InactiveCN104897139AIncrease buoyancyReduce volumeMeasuring open water movementWater resource assessmentMeasurement deviceButt joint

The invention discloses a three-drum unattended turbulence profile measurement device composed of a communication drum, a connecting drum and a driving drum in butt joint. A high-pressure plunger pump and a hydraulic electromagnetic valve control hydraulic oil mass change to change buoyancy of the profile measurement device in seawater, and the measurement device is enabled to automatically submerge and float in seawater. A turbulence measurement probe arranged outside a driving drum bottom endcap measures turbulence parameters, and collected turbulence data are sent out via a collection control module, a communication module and a satellite antenna. The three-drum unattended turbulence profile measurement device is of the three-drum structure, so that stability of the device is improved; the measurement device can submerge and float automatically and quickly, unattended turbulence observation is realized, and the requirement on turbulence observation under severe sea conditions is met.

Owner:STATE OCEAN TECH CENT

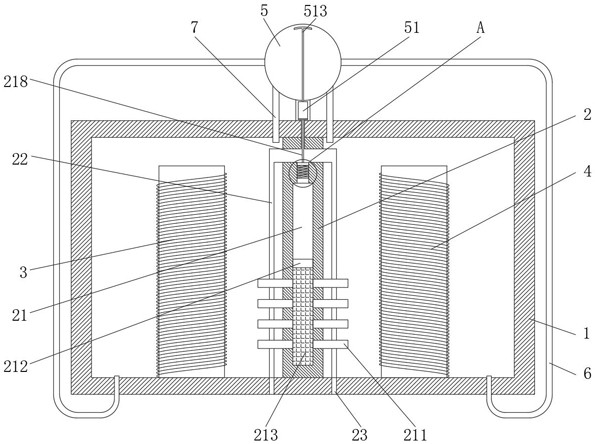

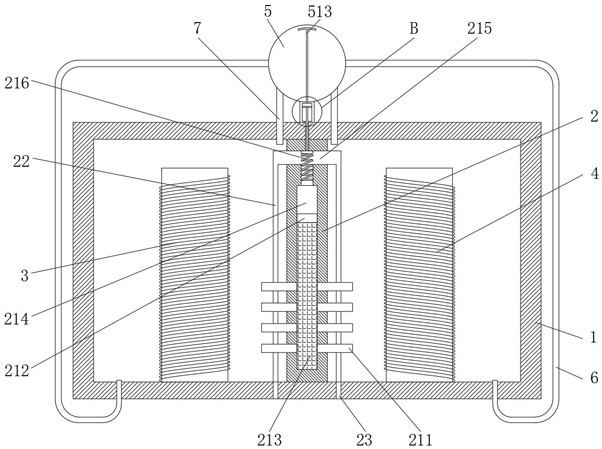

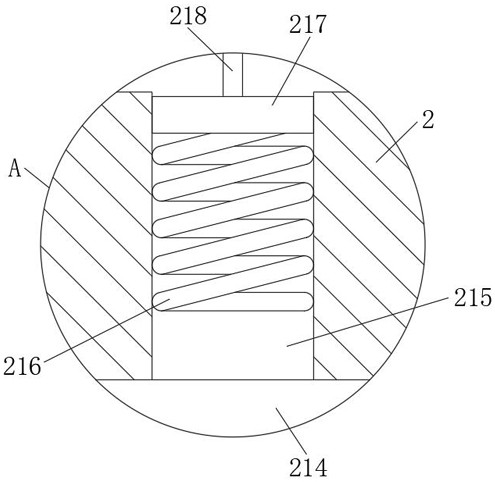

Oil return control mechanism and compressor

PendingCN112377415AImprove operational reliabilitySolve the technical problem that the oil storage in the compressor cannot be well controlledRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsThermodynamicsWell control

The invention discloses an oil return control mechanism and a compressor, relates to the technical field of compressors, and solves the problem that an oil return structure in the prior art cannot well control the oil storage amount in the compressor when the compressor operates at a high speed. An adjusting valve and an elastic piece of the oil return control mechanism are located in a containingpart and can move in the axial direction of the containing part based on the rotating speed of the compressor, and the adjusting valve and the elastic piece have the first state of closing an oil return channel and the second state of opening the oil return channel. When the adjusting valve and the elastic piece are in the first state, lubricating oil is recycled to an oil pool through a channelassembly; when the adjusting valve and the elastic piece are in the second state, the lubricating oil is recycled to the oil pool through the oil return channel or the oil return channel and the channel assembly. When the compressor operates at a low rotating speed, the lubricating oil is recycled to the oil pool through the channel assembly, and when the compressor operates at a high rotating speed, the lubricating oil is recycled to the oil pool through the oil return channel or the oil return channel and the channel assembly, and therefore the operation reliability of the compressor at thesame rotating speed is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

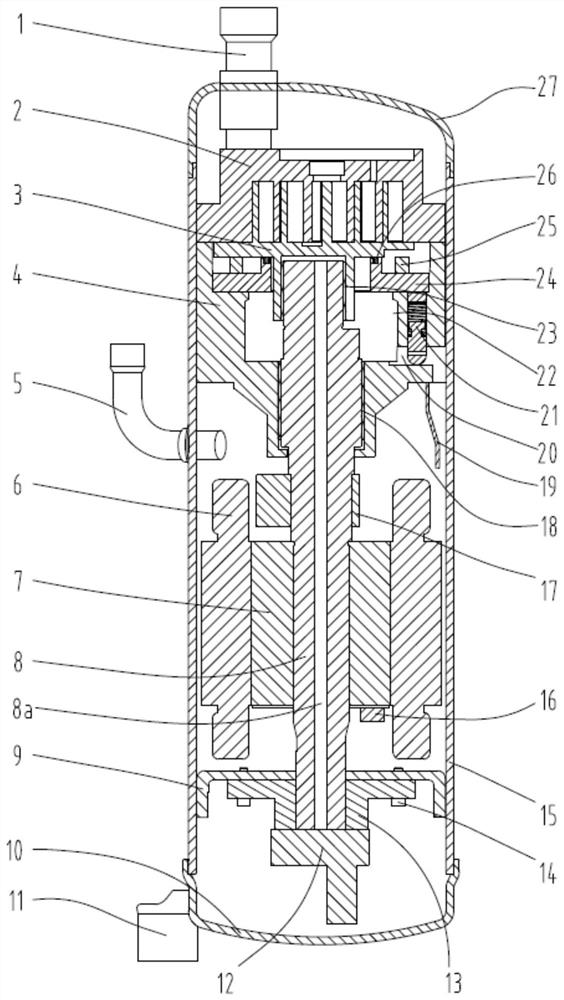

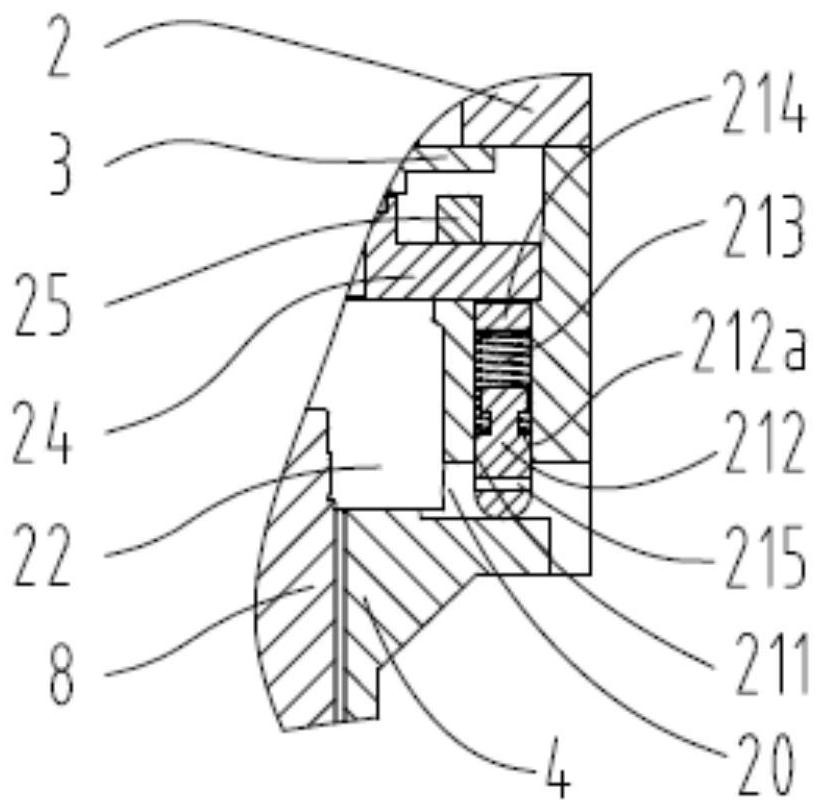

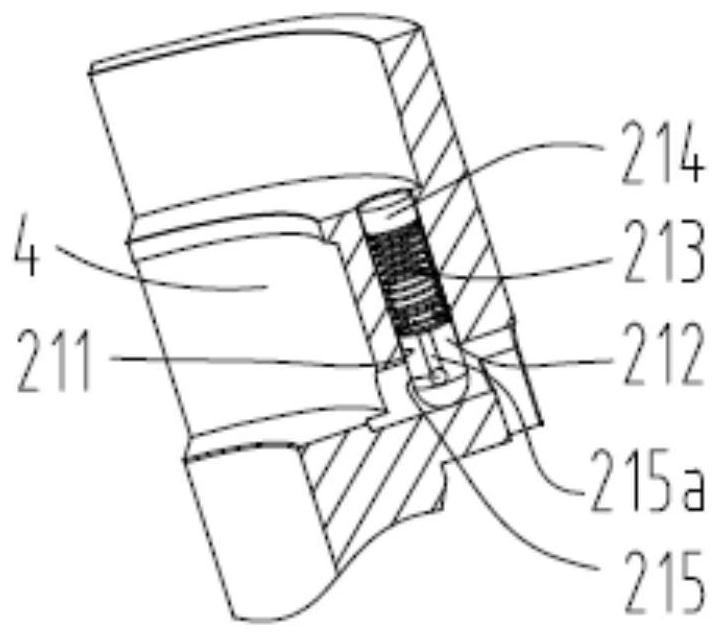

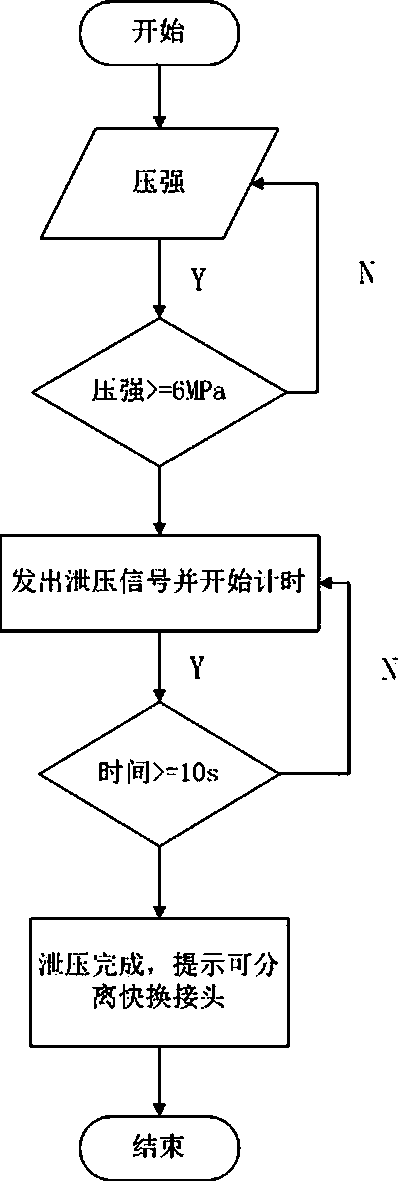

High-pressure oil pipe pressure relief circuit and method with quick-change connectors

PendingCN108953264AFast oil returnServomotor componentsFluid-pressure actuator componentsControl systemComputer module

The invention belongs to the technical field of urban environmental sanitary equipment and particularly relates to a high-pressure oil pipe pressure relief circuit with quick-change connectors. The high-pressure oil pipe pressure relief circuit with the quick-change connectors comprises an oil feeding module, a first quick-change connector, a first reversing valve, a second quick-change connectorand an oil return module, wherein the oil feeding module, the first quick-change connector, the first reversing valve, the second quick-change connector and the oil return module are sequentially connected. An electromagnetic overflow valve and a pressure transmitter are arranged between the oil feeding module and the oil return module. Through additional arrangement of the reversing valve, an oilreturn path is changed and avoids the electromagnetic overflow valve, and therefore the oil return speed can be greatly improved; besides, a prompting function is provided, an operator can separate amain machine and a hydraulic control system according to prompt, and the situation that due to misoperation, the high-pressure oil pipe is not completely decompressed, and environmental pollution andresource waste are caused is avoided.

Owner:湖南湘一环境科技有限公司

Compressor and oil-return switching method

ActiveCN105422419AFast oil returnOil equilibration time reducedPositive displacement pump componentsPositive-displacement liquid enginesPetroleum engineering

The invention discloses a compressor and an oil-return switching method. The compressor comprises an oil return pipeline and an oil uniformizing pipeline. The inlet end of the oil uniformizing pipeline and the outlet end of the oil return pipeline are connected to a bottom oil pool of the compressor, the inlet end of the oil return pipeline is connected to an oil return port of an upper oil pool of the compressor, and a preset oil level is set in the bottom oil pool of the compressor. The compressor further comprises an oil way switching device connected with the oil uniformizing pipeline and the oil return pipeline, and the oil way switching device has an oil uniformizing state and an oil return state. The compressor is capable of quickly returning oil and quickly uniformizing oil, oil balancing time is greatly shortened, existing oil is fully utilized for being distributed between all compressors, the oiling amount is effectively reduced, and oil utilization cost is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

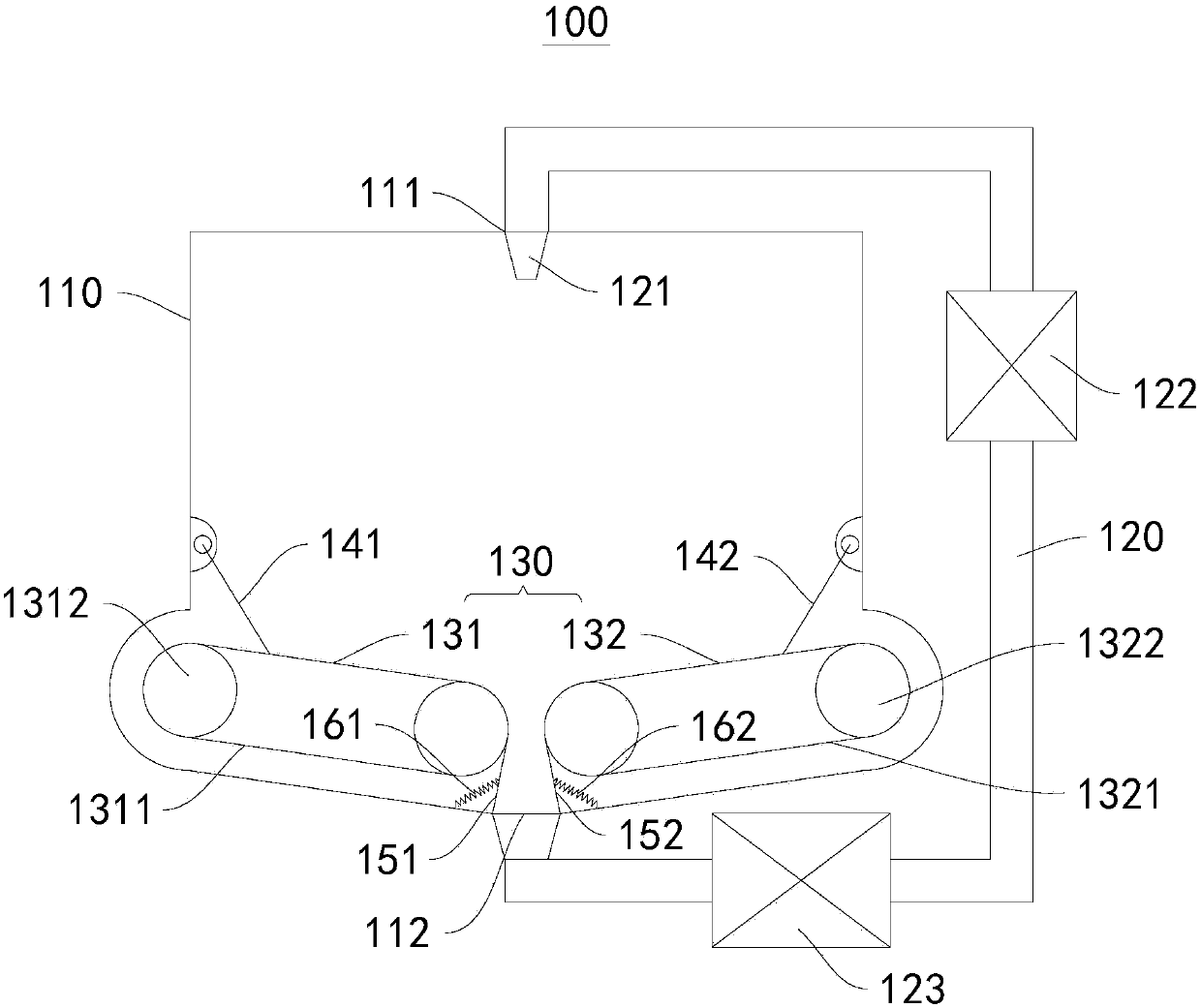

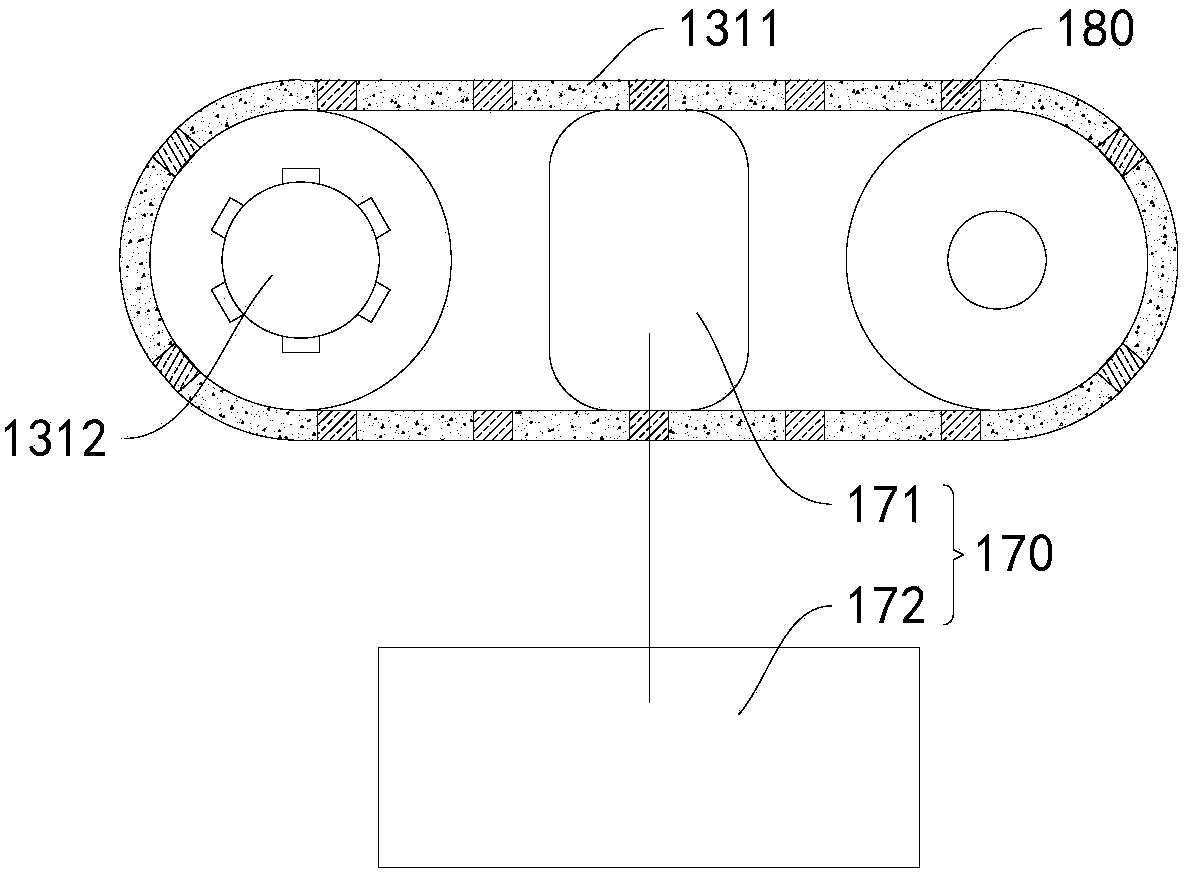

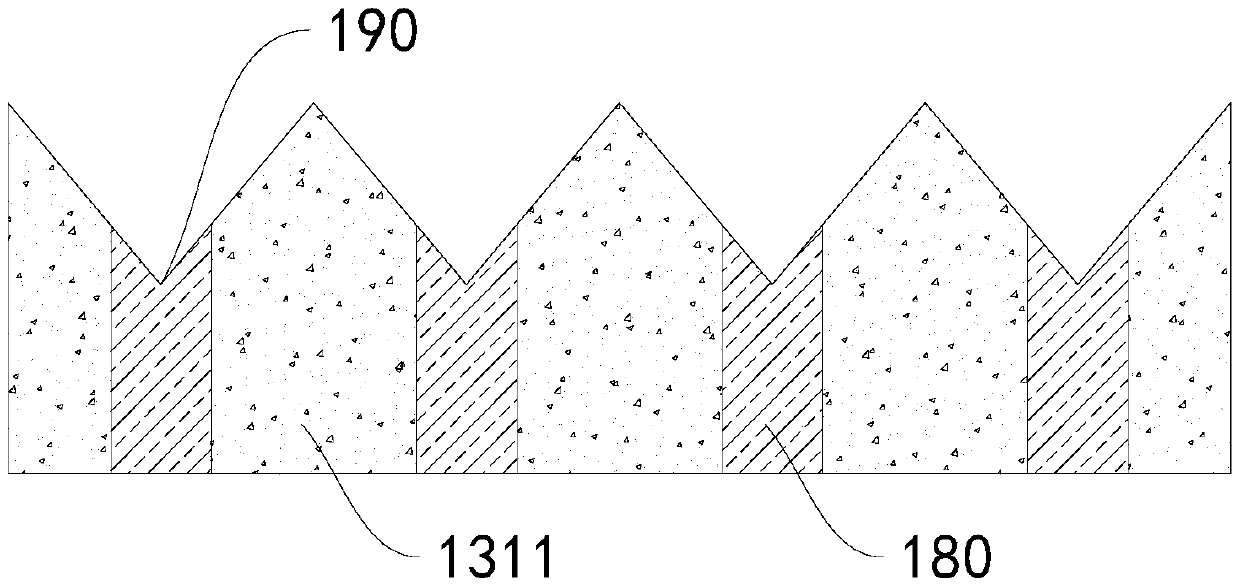

Oil return device and double-oil-return system for gearbox

PendingCN107606120AFast oil returnGood oil return effectGear lubrication/coolingConveyor beltIndustrial engineering

The invention provides an oil return device and a double-oil-return system for a gearbox, and belongs to the field of gearboxes. The oil return device for the gearbox comprises a box body and guide devices; first through holes are formed in the box body; the guide devices are arranged inside the box body, and the guide devices each comprise a first guide piece and a second guide piece; the first guide pieces comprise first rolling wheels and first conveyor belts, and the first rolling wheels drive the first conveyor belts to move; and the second guide pieces comprise second rolling wheels andsecond conveyor belts, and the second rolling wheels drive the second conveyor belts to move. The double-oil-return system for the gearbox comprises the oil return device for the gearbox, and the number of the guide devices in the oil return device for the gearbox is two. According to the oil return device for the gearbox, the purpose of fast oil return can be achieved; and according to the double-oil-return system for the gearbox, the oil return at a higher speed can be realized, and the oil return effect is improved.

Owner:南京创力传动机械有限公司

Cantonese mooncake crust and preparation method thereof

PendingCN113396954ASoft tasteLoose tissueDough treatmentModified nutritive productsBiotechnologyVegetable oil

The invention discloses Cantonese mooncake crust and a preparation method thereof, and relates to the technical field of food processing. The Cantonese mooncake crust comprises the following components in parts by weight: 100-150 parts of syrup, 3-7 parts of alkaline water, 50-60 parts of vegetable oils, 150-220 parts of Triticum aestivum L. flour, 60-80 parts of Avena sativa L. flour, 20-40 parts of Manihot esculenta Crantz flour and 3-5 parts of cyclodextrin. In the Cantonese mooncake crust, the Triticum aestivum L. flour has a soft taste and loose tissues, the Avena sativa L. flour can increase the particle size and adjust the content of wet gluten, contains rich [beta]-glucan and rich dietary fibers and has various physiological functions of reducing blood sugar, reducing blood fat and the like, and the Manihot esculenta Crantz flour can improve the viscosity of flour dough, can improve elasticity and plasticity and is not likely to crack. Due to compounding of the Triticum aestivum L. flour, the Avena sativa L. flour and the Manihot esculenta Crantz flour, the mooncake crust has good rheological properties, and can be endowed with the characteristics of soft tissues and a high oil return speed under the condition that the use amount of syrup is relatively low.

Owner:广州市锦华食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com