Method of filtering oil fume by metal oil screen and easily cleaning oil screen thereof

A technology of mesh filtration and metal oil, which is applied in the direction of filtration and separation, oil fume removal, separation methods, etc., can solve the problems of poor air intake, difficulty in cleaning, and inability to reduce volume, so as to improve the separation degree of oil and increase the chance of contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

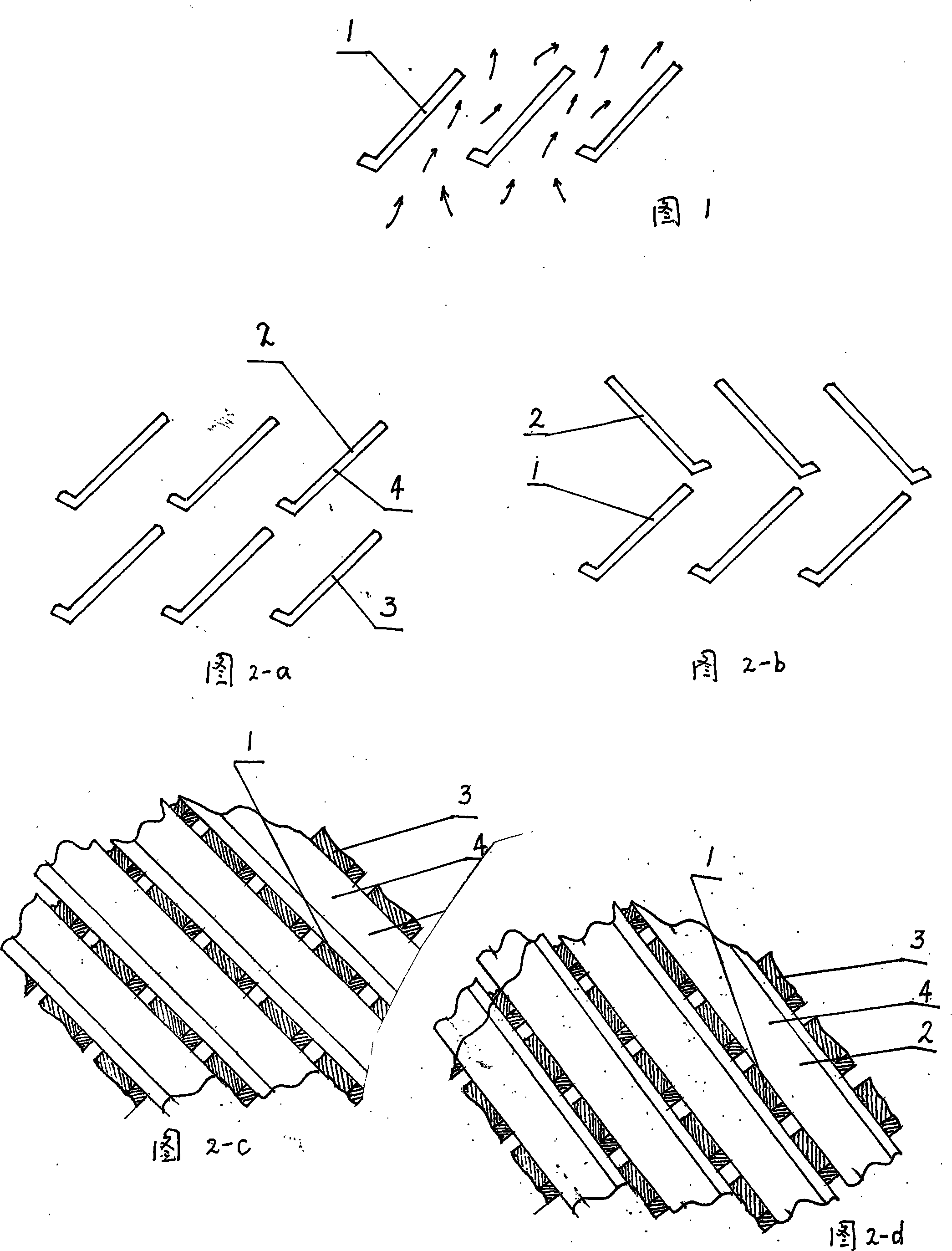

[0024] Embodiment 1, as shown in FIG. 1 : the left side of the mesh bar 1 is turned up, and the right side is turned up, so that two adjacent mesh bars form a side air inlet 5 . The oil fume passes through the mesh bar 1 upwards and sticks to the mesh bar to the upper right. According to the principle of fluid mechanics, the oil fume guides the mesh bar to roll upward, the oil fume contacts, collides, adheres to the mesh bar 1, and is finally exported. The filtered oil fume enters the fan upward and is discharged by the fan. Because it is side air intake, the air inlet 5 seen in the front is very small or just does not have, and there will be no oil dripping and oil leakage phenomenon to take place.

Embodiment 2

[0025] Embodiment two, as shown in Figure 2-a: divide the single-layer oil screen described in the implementation side one into front and back two layers, there is a gap between the front layer 3 and the back layer 4, the mesh strips of the back layer 4 and the front layer 3 The upturning direction of the mesh bar 1 is the same, so that the two layers of mesh bars are in the same direction. When the oil fume rises, it first enters the mesh bar 1 of the front layer 3, and the oil fume is filtered after adhesion and collision, and then enters the rear layer After the mesh bar 2 of 4 is also filtered, it enters the blower fan and discharges. Compared with the single-layer oil screen, the contact area between the double-layer oil screen and the oil smoke increases, the chance of contact and adhesion increases, and the oil separation degree is significantly improved.

[0026] If the front layer 3 and the back layer 4 are misplaced, the effect is the same as above.

Embodiment 3

[0027] Embodiment 3, as shown in Figure 2-b: the single-layer oil net described in Embodiment 1 is used as the front layer 3, and the right side of the mesh bar 2 of the rear layer 4 is turned up, and the left side is turned upward, so that the oil fume passes through the front layer The mesh bar 1 of 3 changes the direction of oil fume through the mesh bar 2 of rear layer 4, increases the contact chance of oil fume and mesh bar, and improves the oil filtration rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com