Distraction and retraction assemblies

a technology of dislocation and assembly, applied in the field of dislocation and retraction assemblies, can solve the problems of increasing the number of steps needed, reducing the likelihood of post-operative complications, and limitations inherent in the conventional self-retaining retraction used widely in surgery, so as to facilitate tissue access, minimize soft tissue injury, and minimize the effect of soft tissue injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

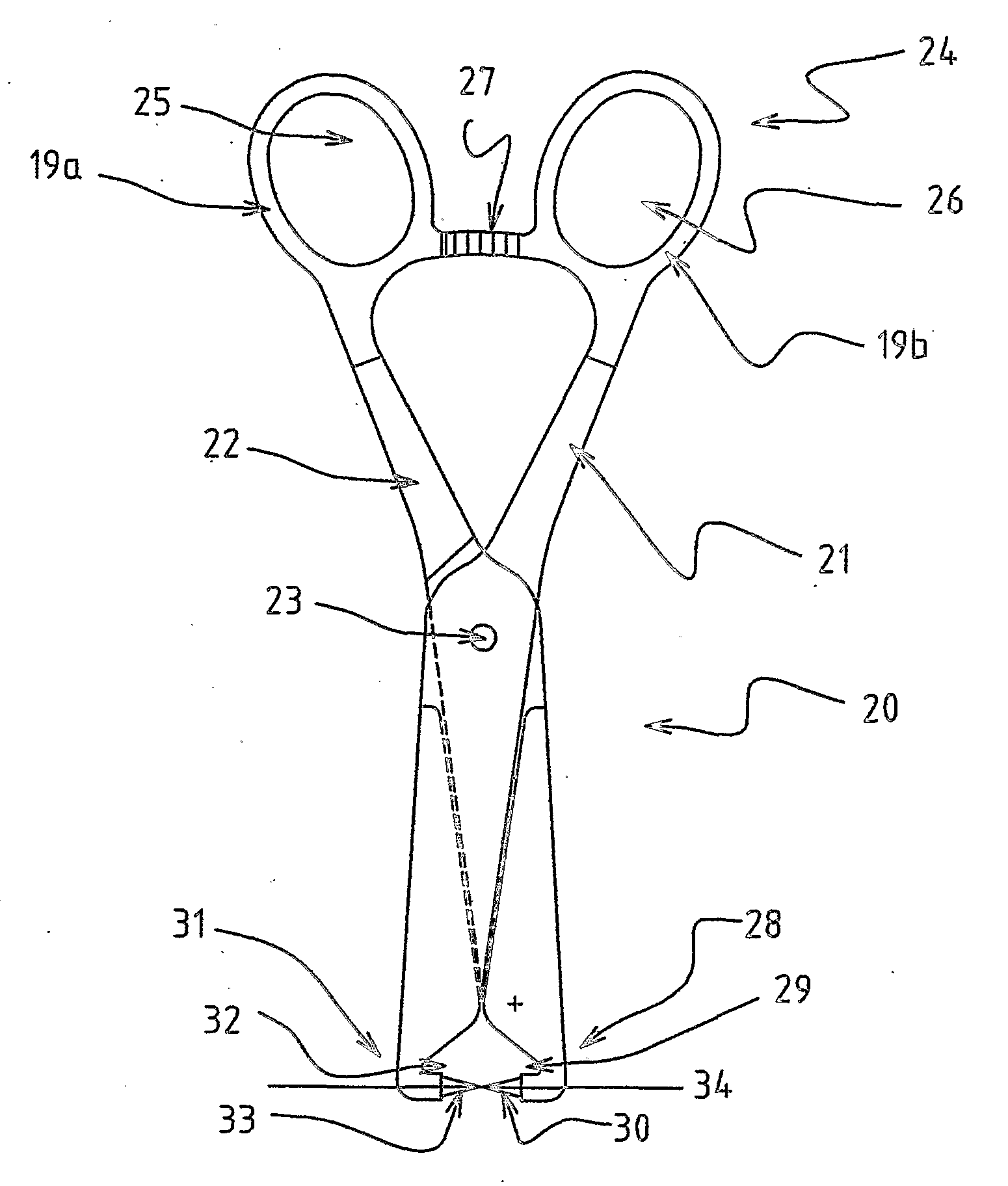

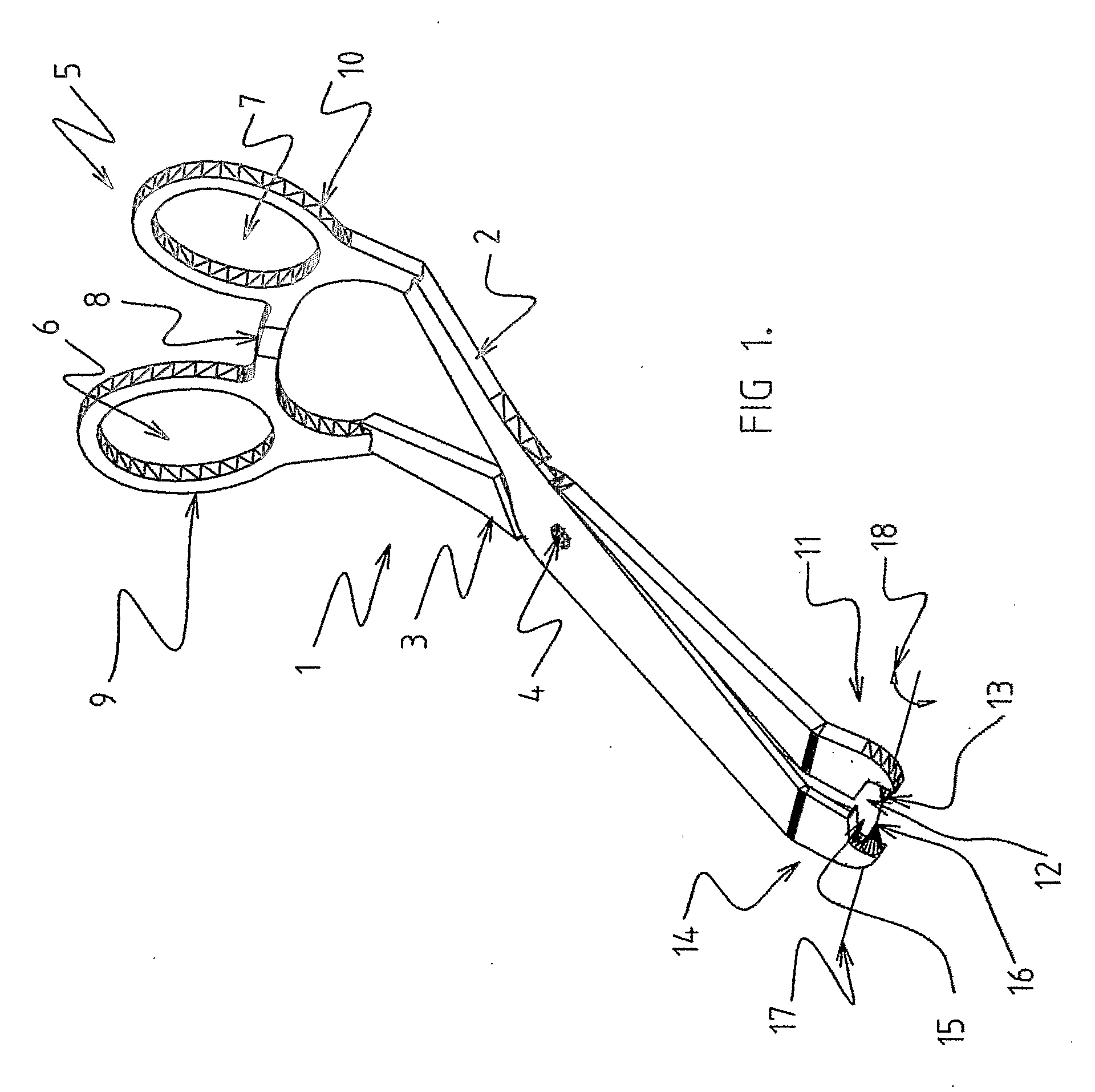

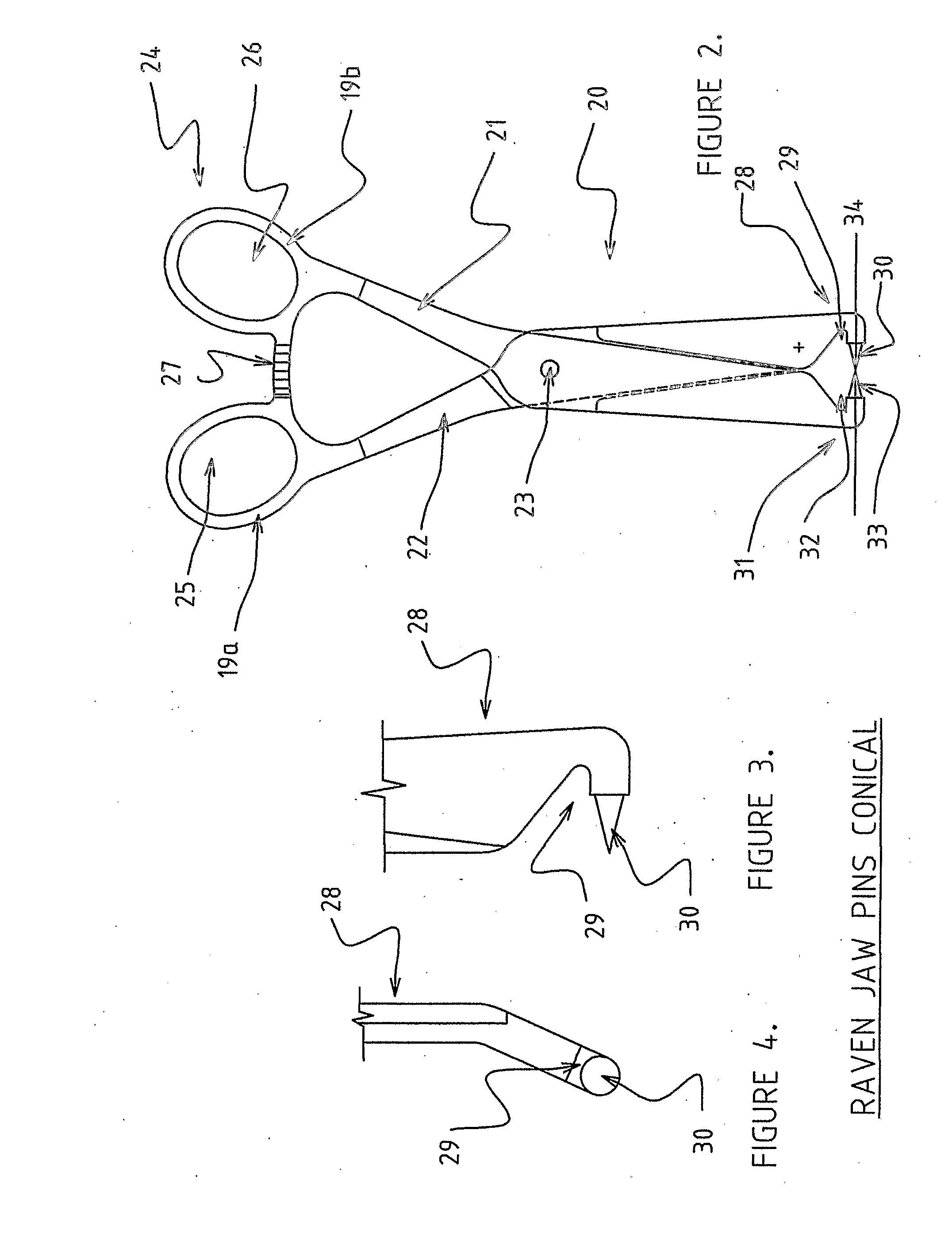

[0093]The present invention will now be described in more detail according to a preferred embodiment but non limiting embodiment and with reference to the accompanying illustrations.

[0094]Typically according to one method, cervical distraction of vertebrae involves the use of pins temporarily fixed to the vertebrae to be distracted. Generally two pins are used one above and one below a disc or vertebral body of interest. Traditionally in a Caspar system these pins have only been used for distraction purposes via sliding tubes that fit axially over the pins and connect to an associated distraction mechanism. According to one aspect the role of the pin has been expanded to perform one or more of the following roles. The pin acts as x-ray marker to estimate a midline of a spine for cage or prosthetic disc replacement. The known and commonly used Caspar type distracter is then secured to the spine. There is however known use of distracter tubes that each slide over respective pins and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com