Patents

Literature

238results about "Crocheting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

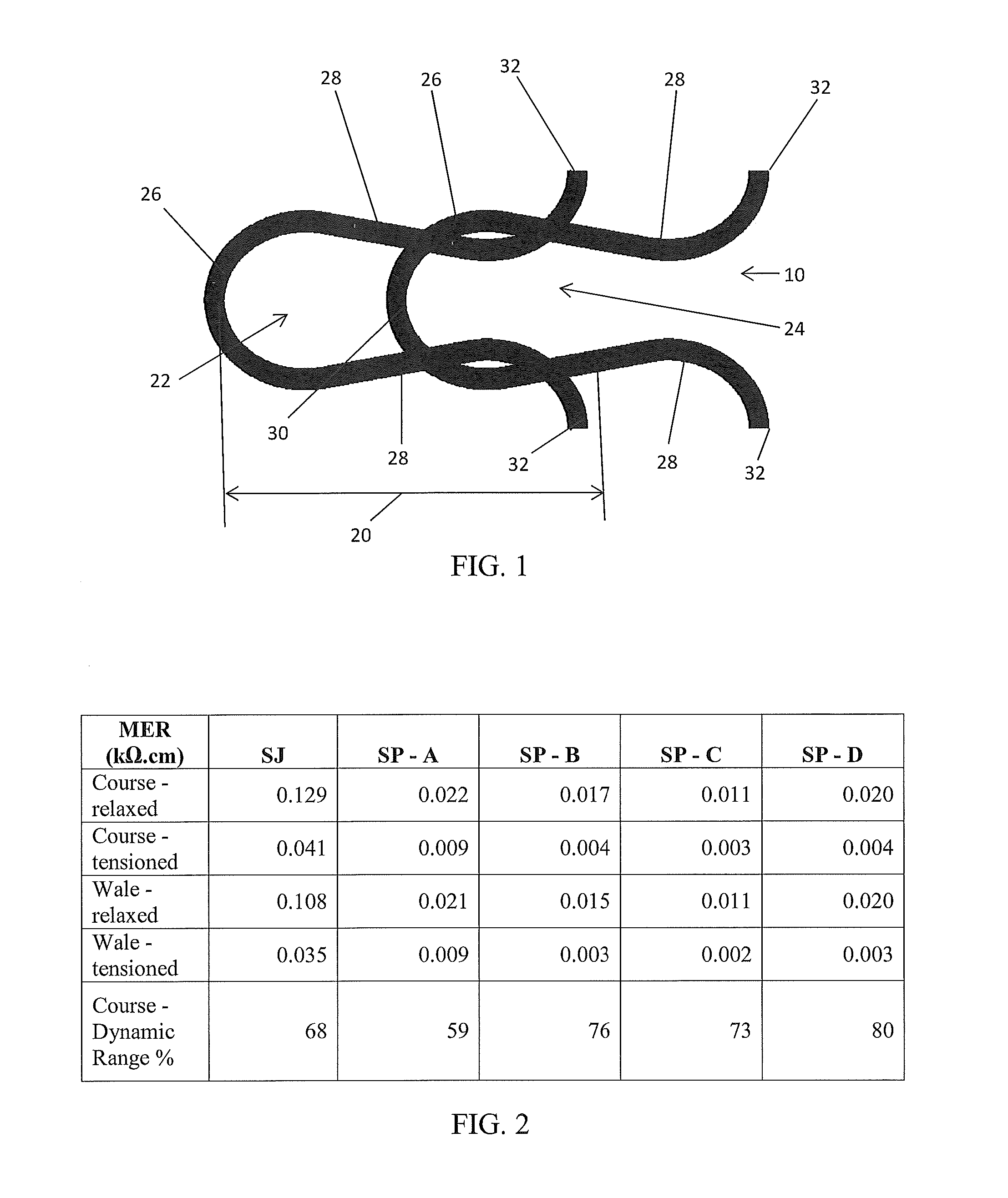

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

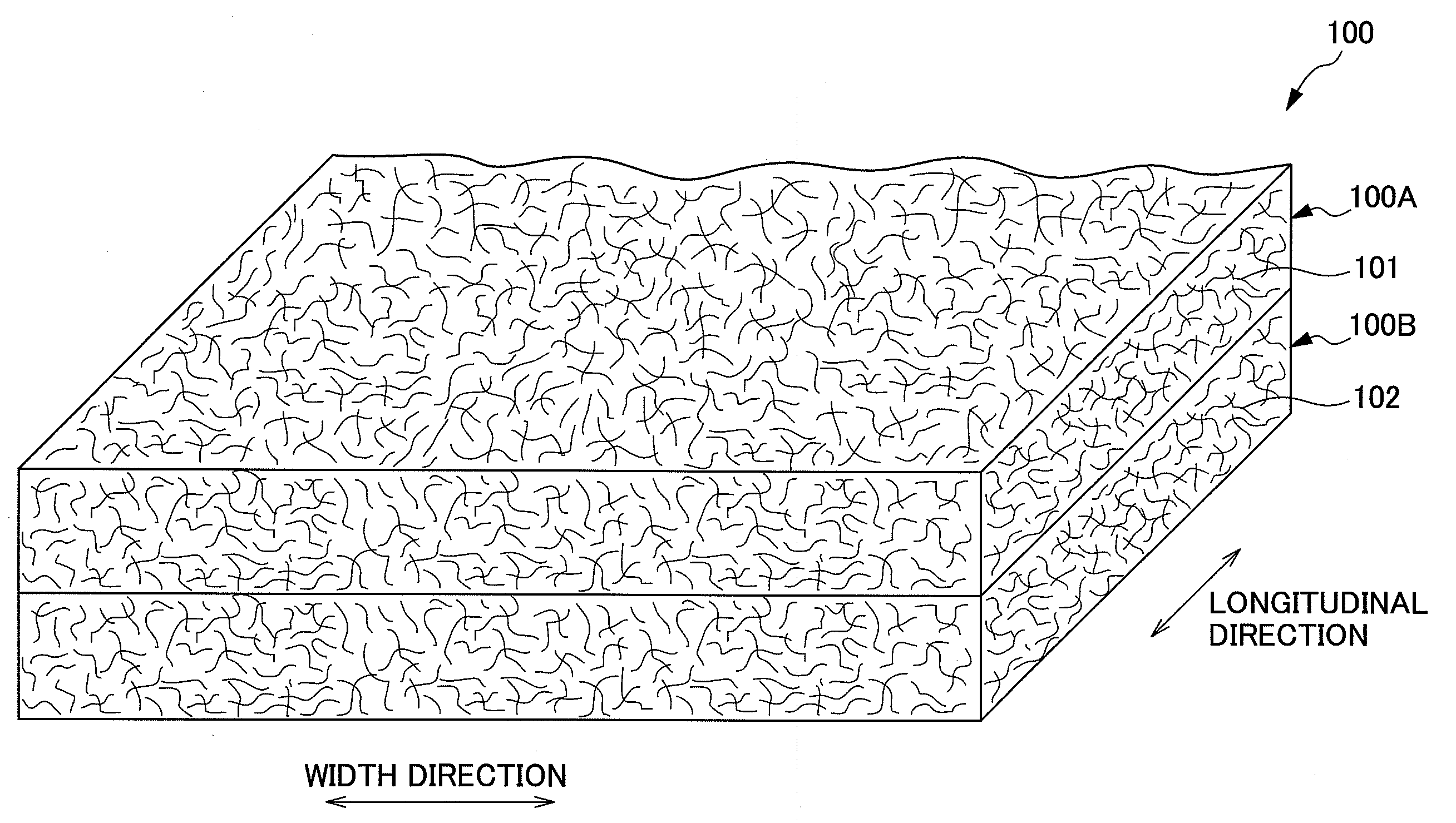

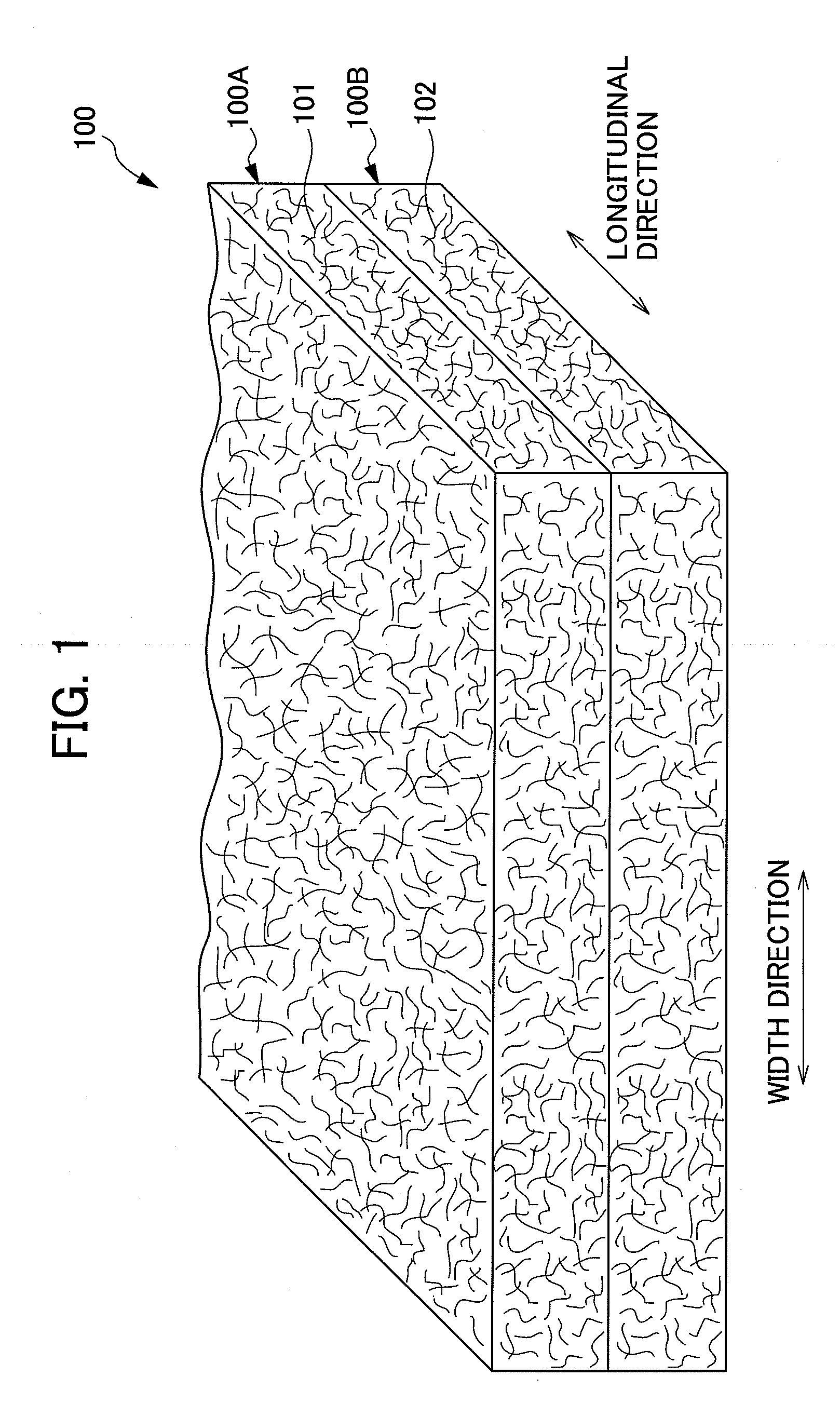

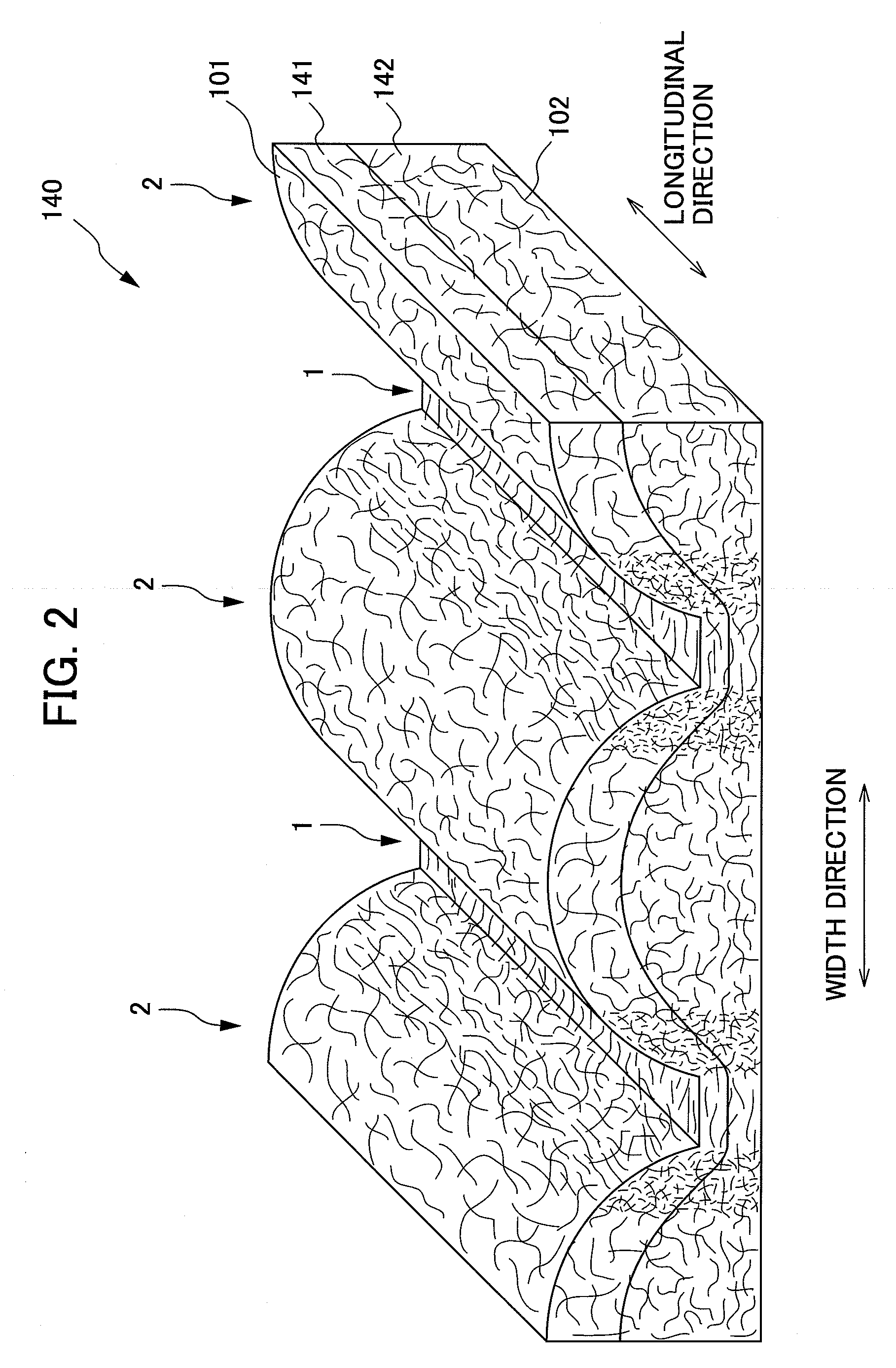

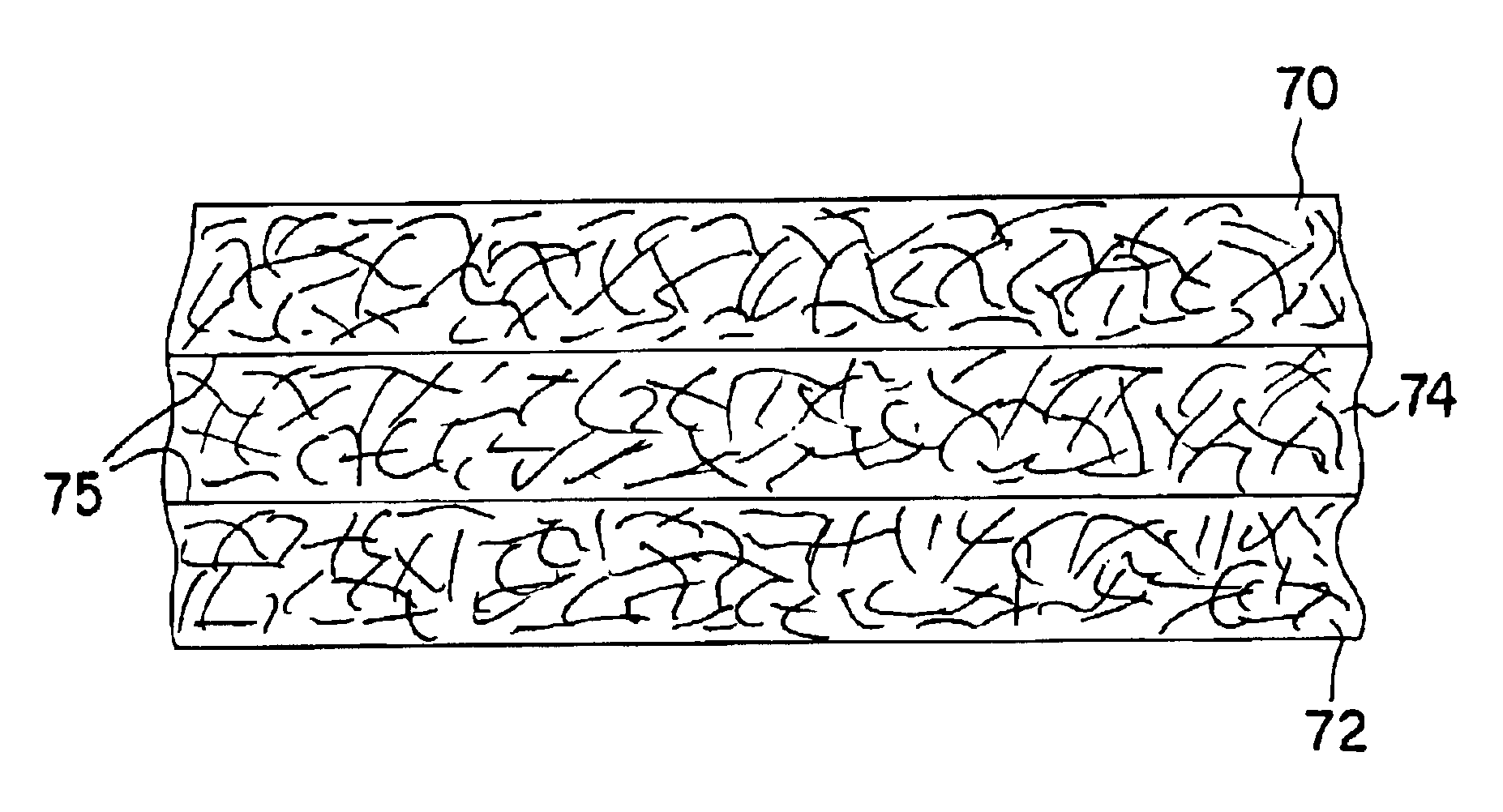

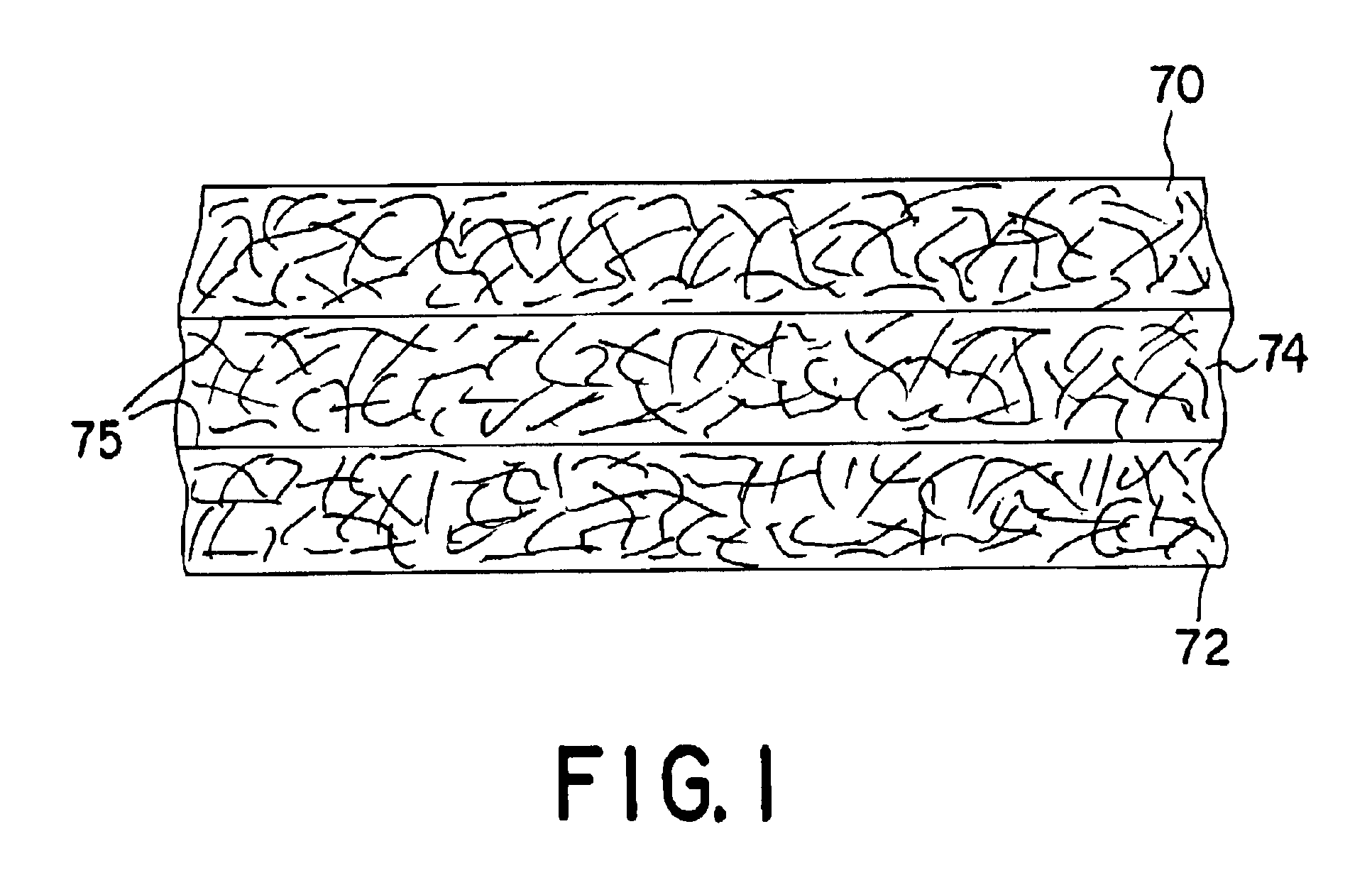

Multilayer nonwoven fabric and method of manufacturing the same

A multilayer nonwoven fabric comprises a first fiber layer and a second fiber layer laminated and arranged on a first surface of the first fiber layer, wherein a plurality of groove portions is formed along a prescribed direction in a shape depressed in a thickness direction of the multilayer nonwoven fabric and a plurality of raised ridge portions are formed adjacent to the plurality of groove portions in a shape projected in the thickness direction and in which the basis weight is greater than the basis weight in regions A constituting the bottoms of the groove portions 1 are formed, and the second fiber layer constituting each of the plurality of raised ridge portions is in such a shape that a surface, on the side of the first fiber layer, of the second fiber layer is projected in the same direction as the direction in which the second surface of the first fiber layer is projected.

Owner:UNI CHARM CORP

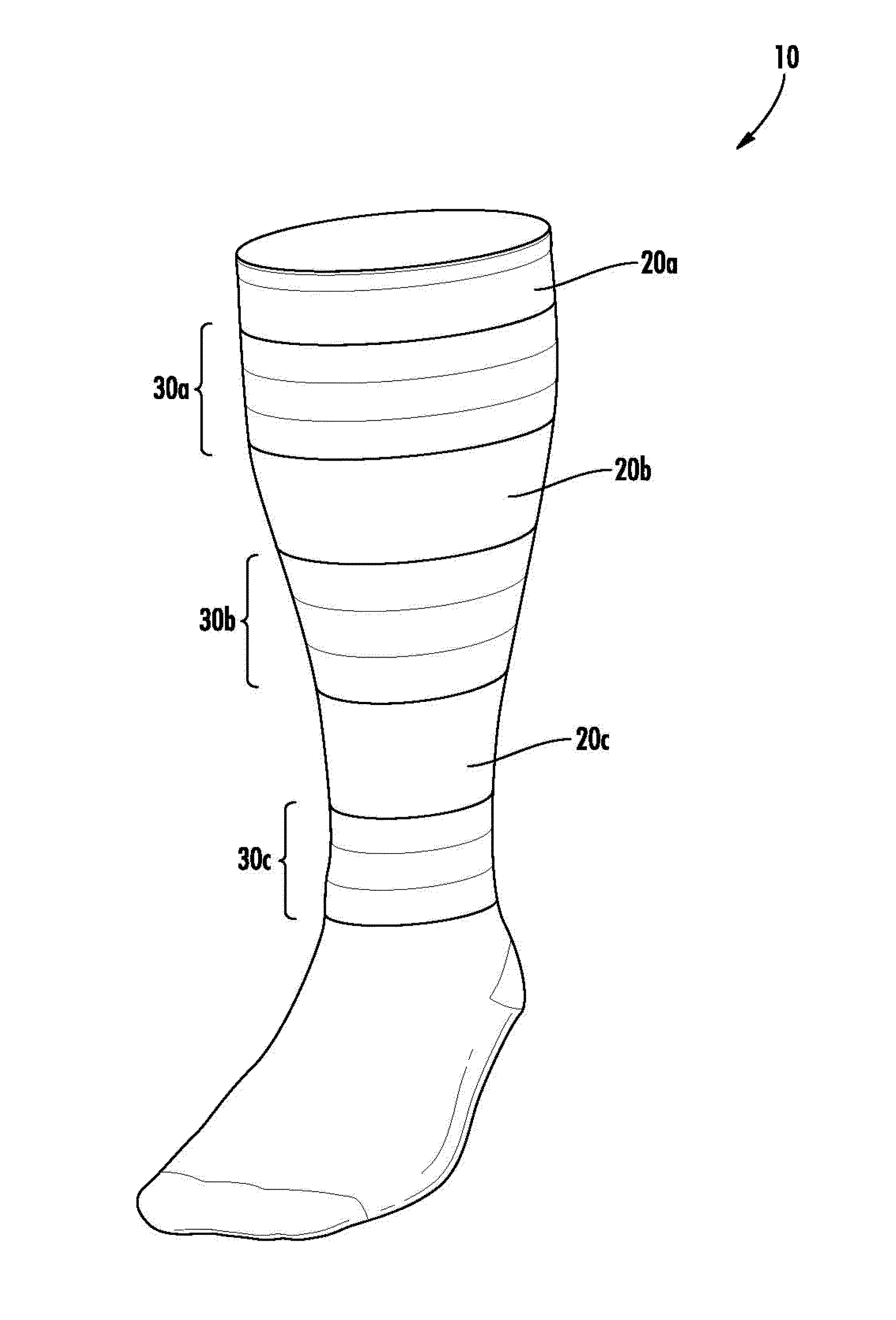

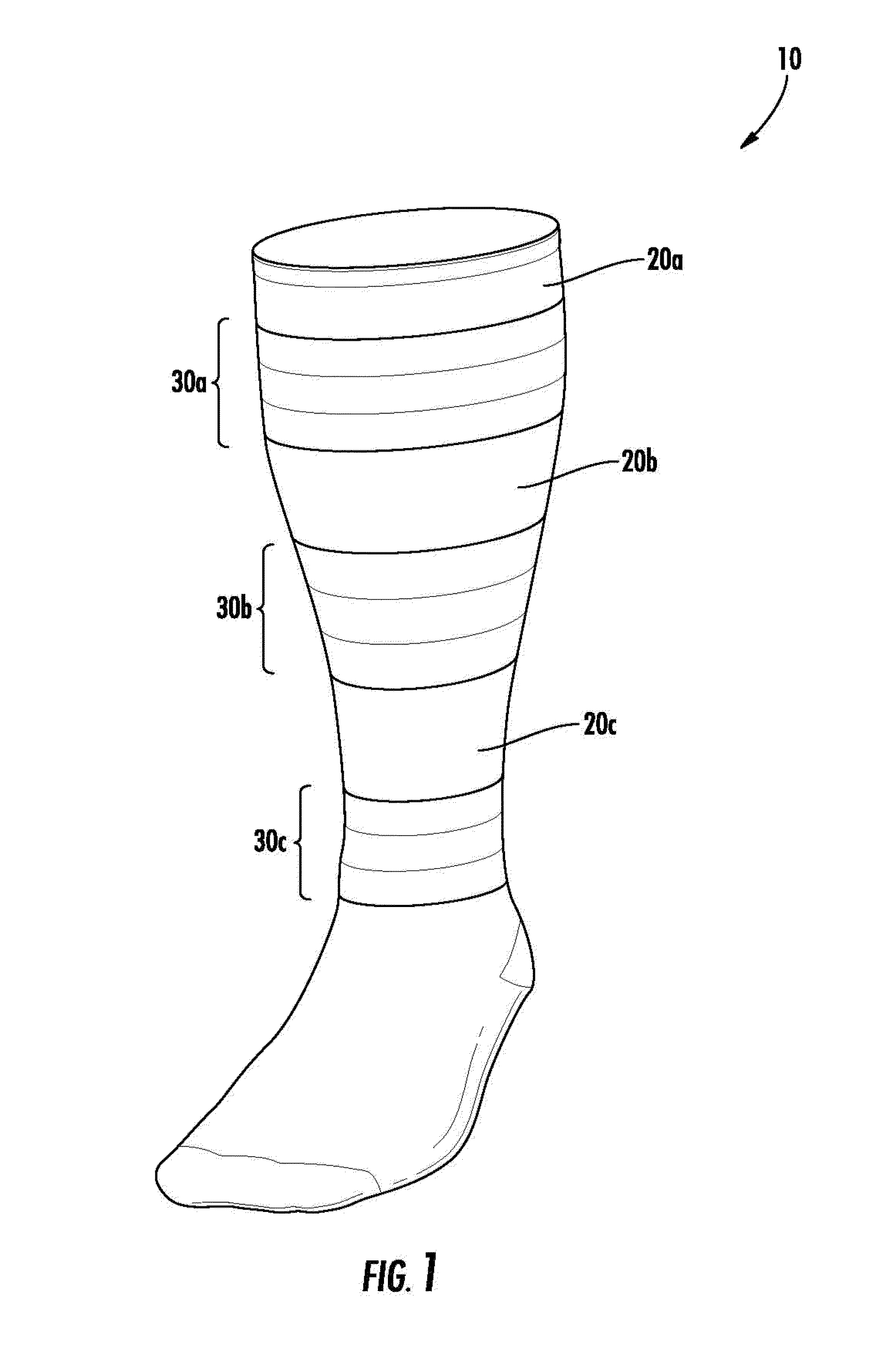

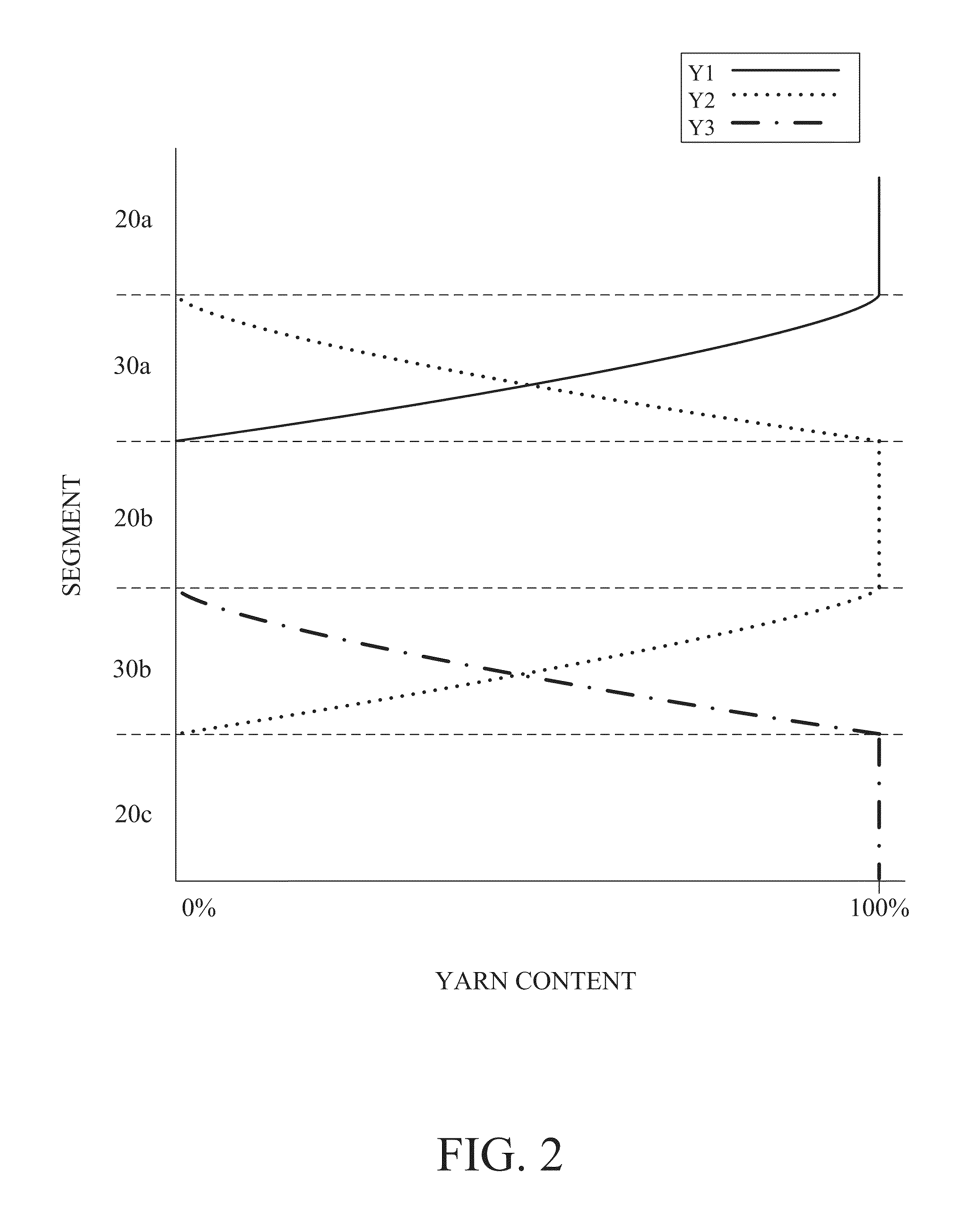

Compression fabrics with tailored comfort

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

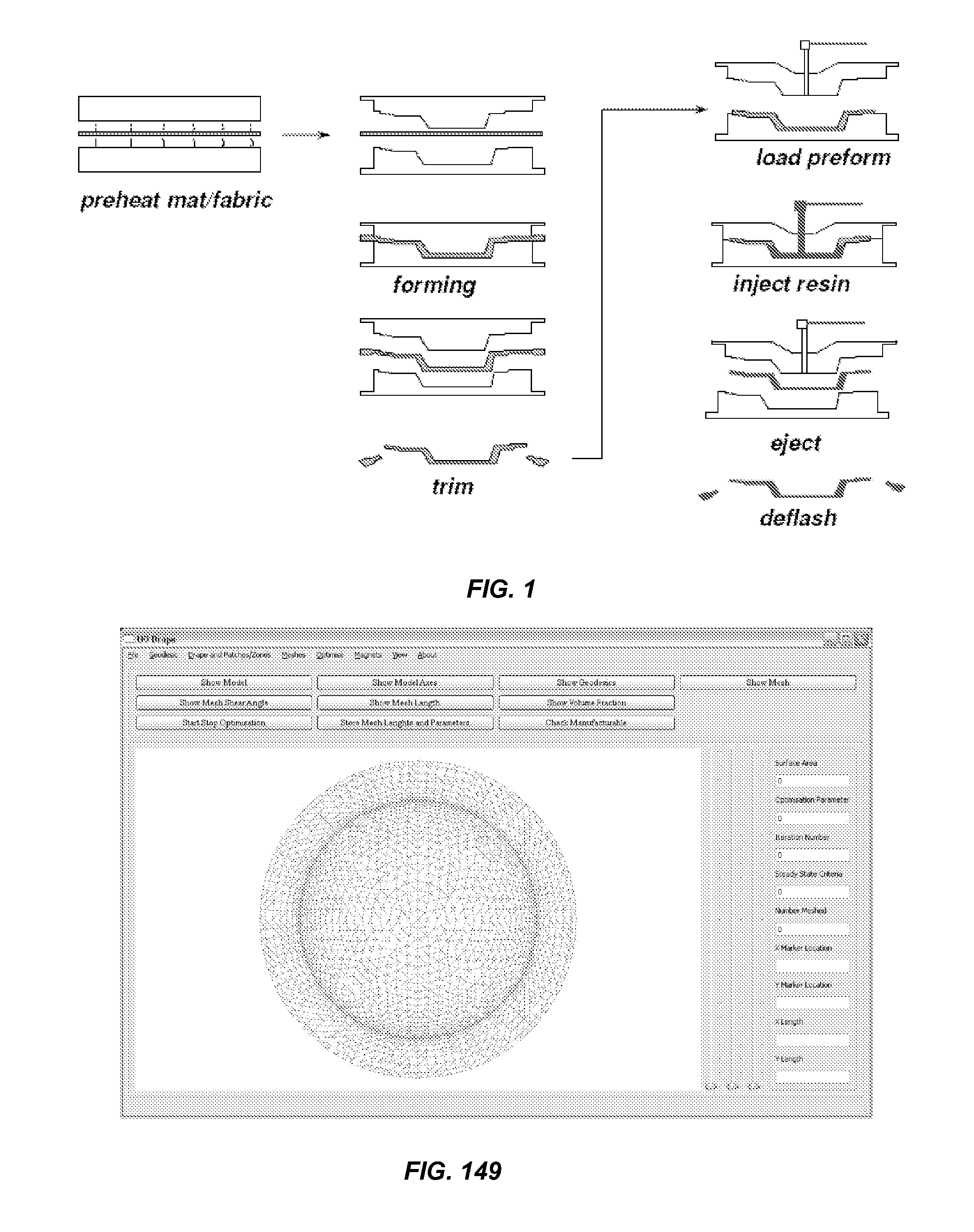

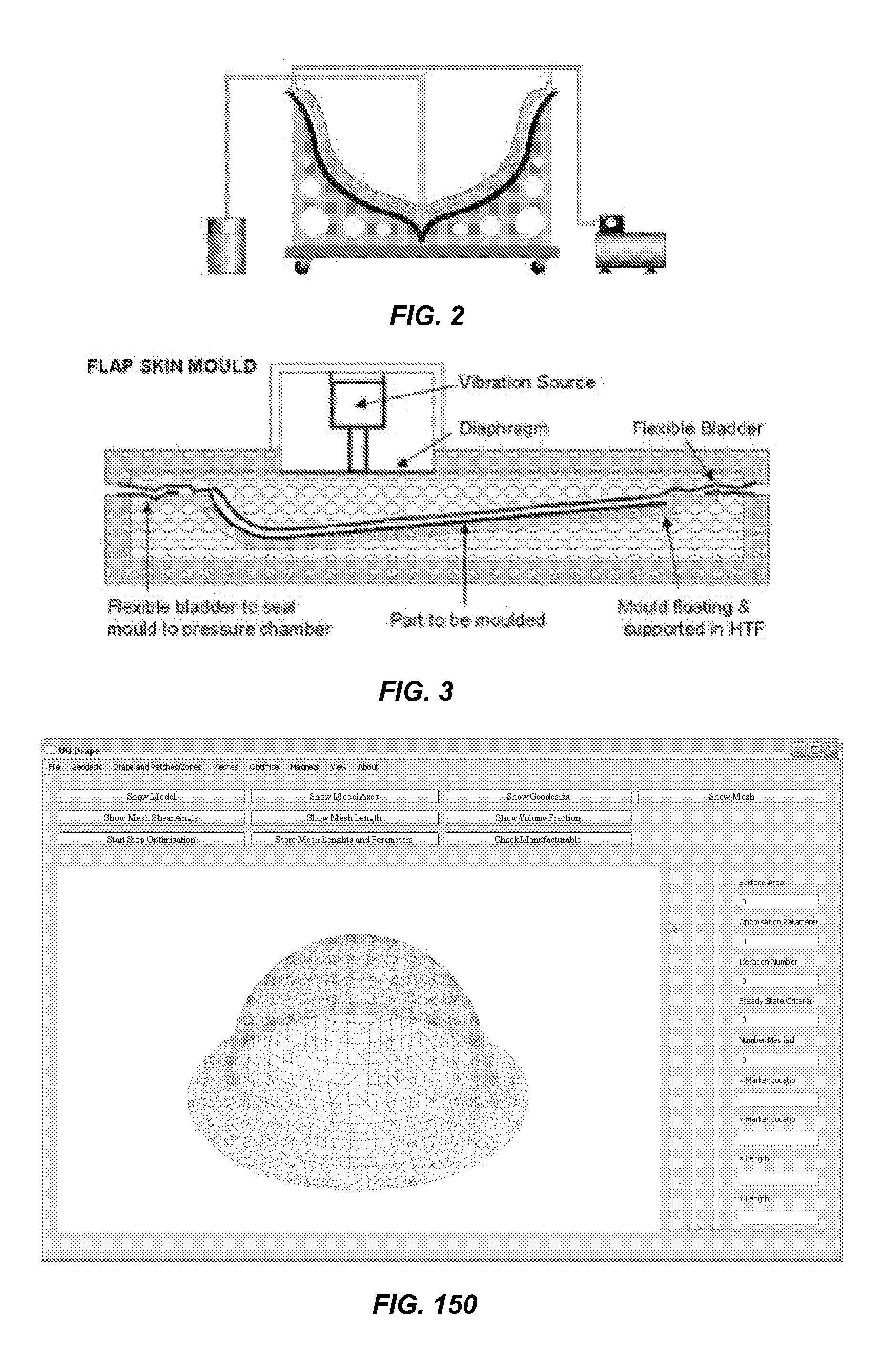

Novel composite parts, methods and apparatus for manufacturing the same

Owner:UNIVERSITY OF OTTAWA

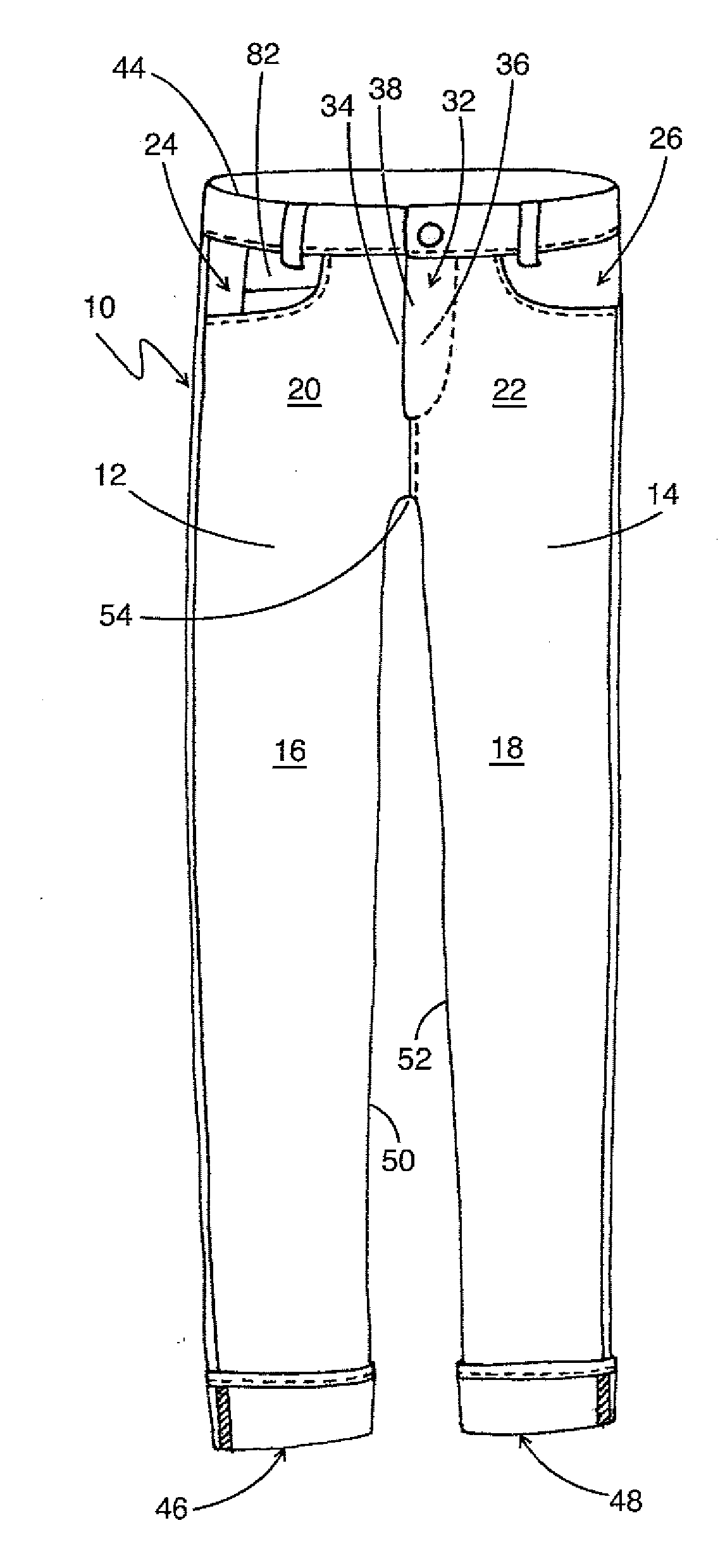

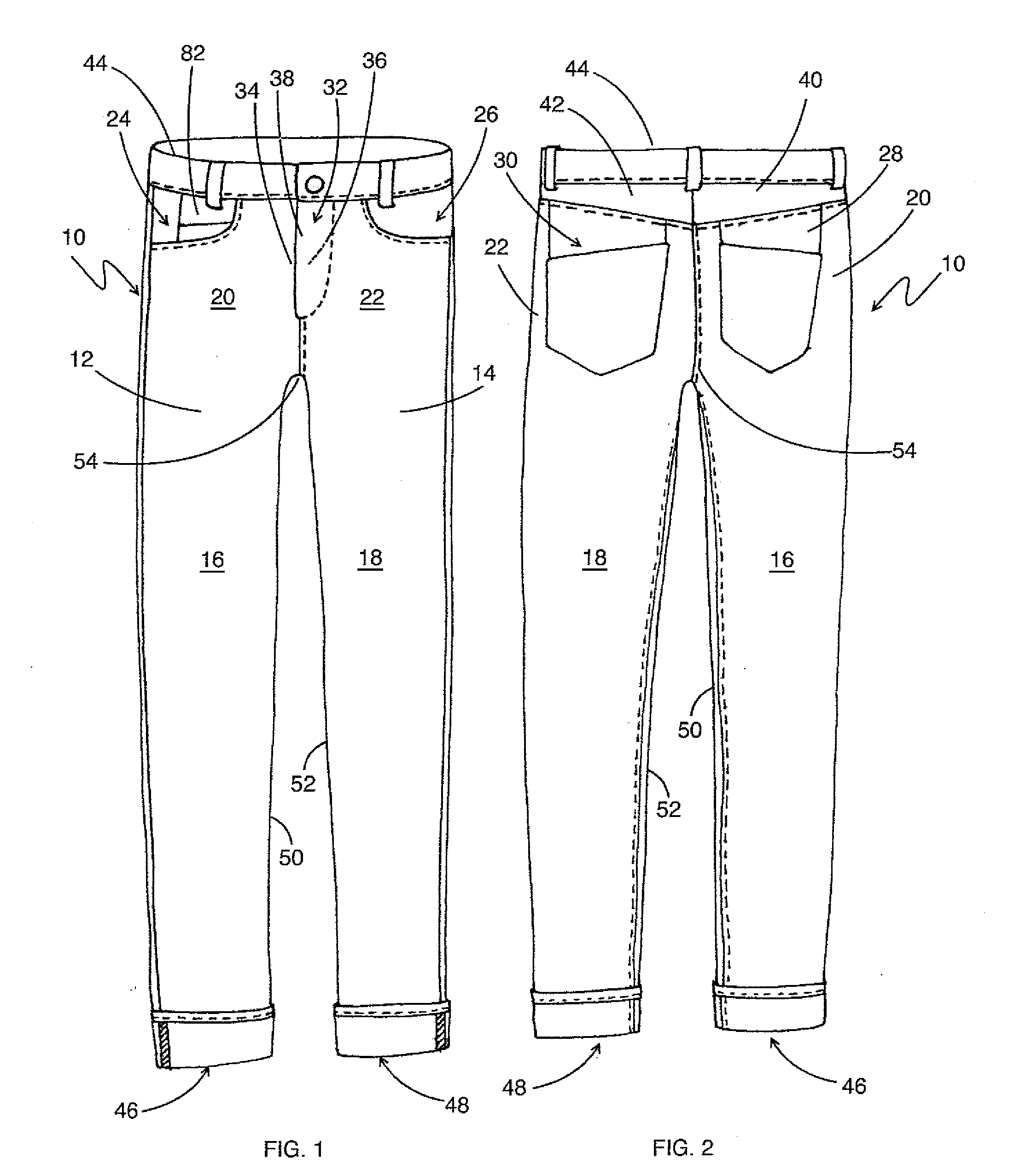

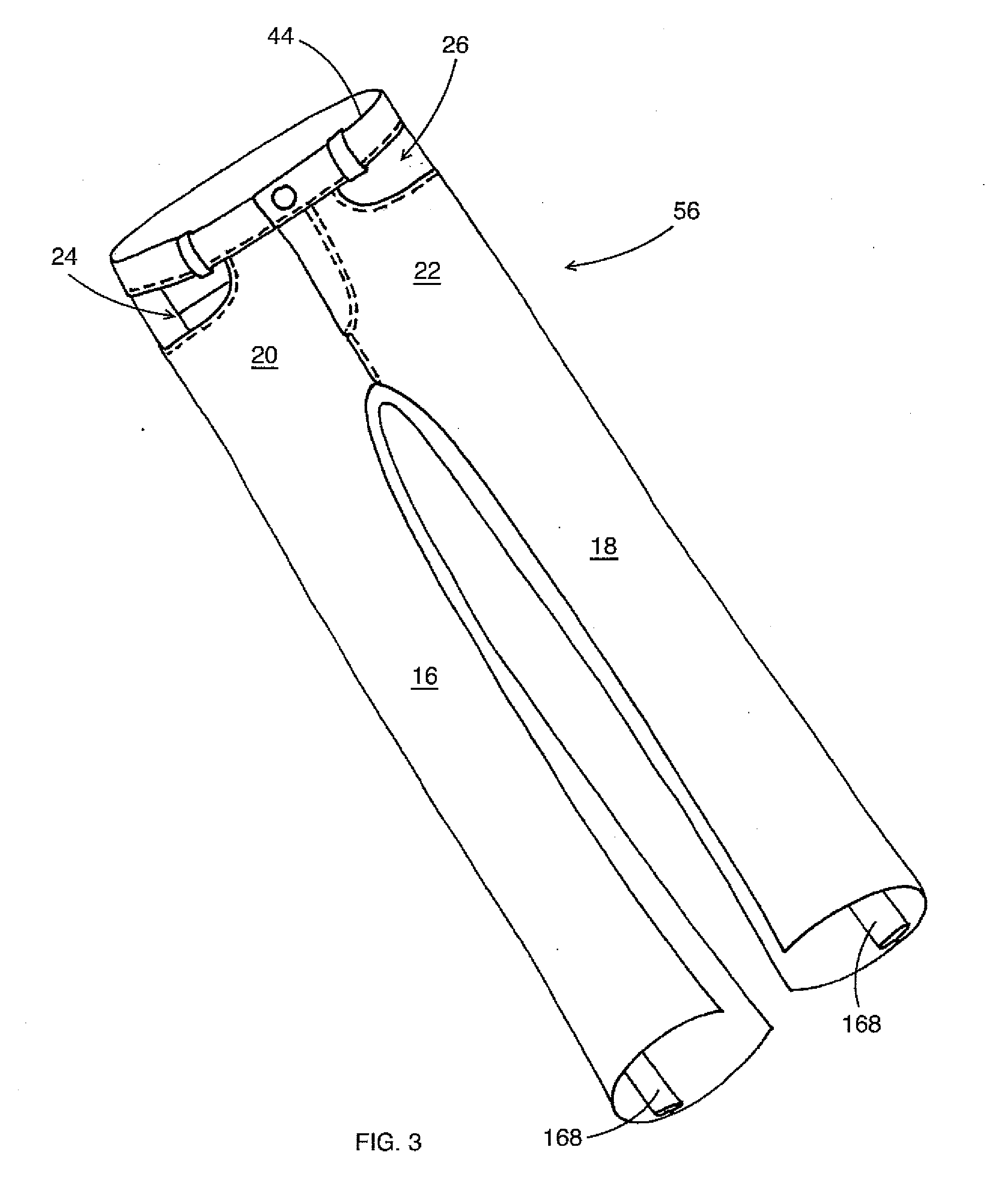

Methods for producing and merchandising a custom fit pant and custom fit pants

Methods for producing a pant, pants and methods for merchandising a pant. A pant is produced at a production facility by weaving right and left portions thereof using a multi-layer weaving process so as to produce an outer woven fly-cover layer and an inner woven left fly extension layer, or to form at least one pocket in at least one such portion, or both, and attaching the left portion of the pant to the right portion of the pant by stitching at least a portion of the crotch seam. The pant is then finished at a point of sale by stitching any remaining portion of the crotch seam and the inseams based on body dimensions and preferences of a purchaser to provide a custom fit. A pant produced at least in part by these steps is also presented.

Owner:CANDRIAN NATALIE A

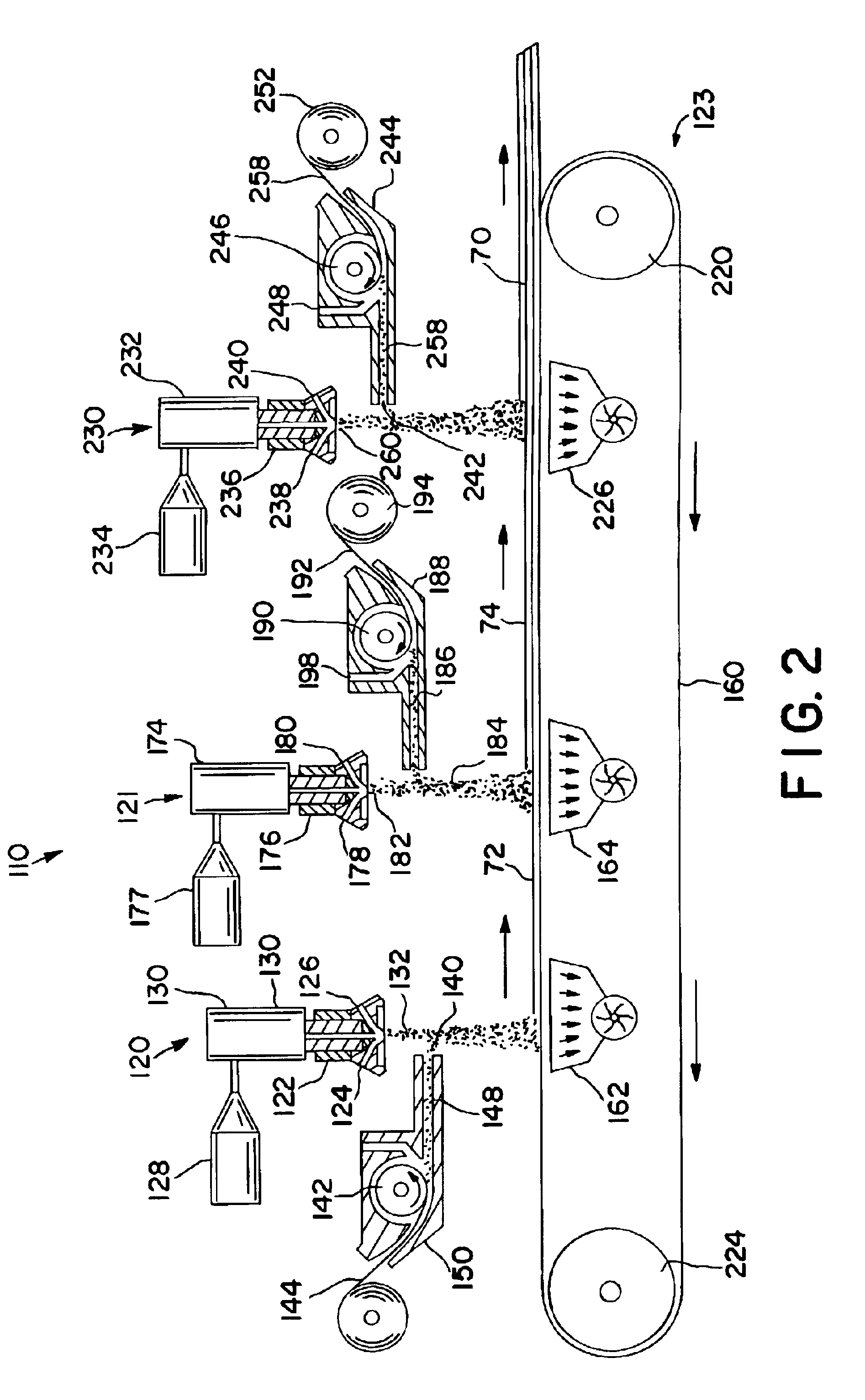

Method of forming composite absorbent members

InactiveUS6932929B2High weight percentageSmall diameterCrochetingInspecting textilesFiberEngineering

A method for forming a composite absorbent member is provided that includes:a) extruding a first fibrous component through a first meltblowing die and intermingling pulp fibers with the first fibrous component to form a first admixture;b) extruding a second fibrous component through a second meltblowing die and intermingling pulp fibers with the second fibrous component to form a second admixture; andc) codepositing the first and second admixtures on a collecting surface so as to form a composite structure having at least a first layer and a second layer. The second layer has a higher weight percentage of pulp fibers than the first layer, and the average diameter of the pores within the second layer is smaller than the average diameter of the pores within the first layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

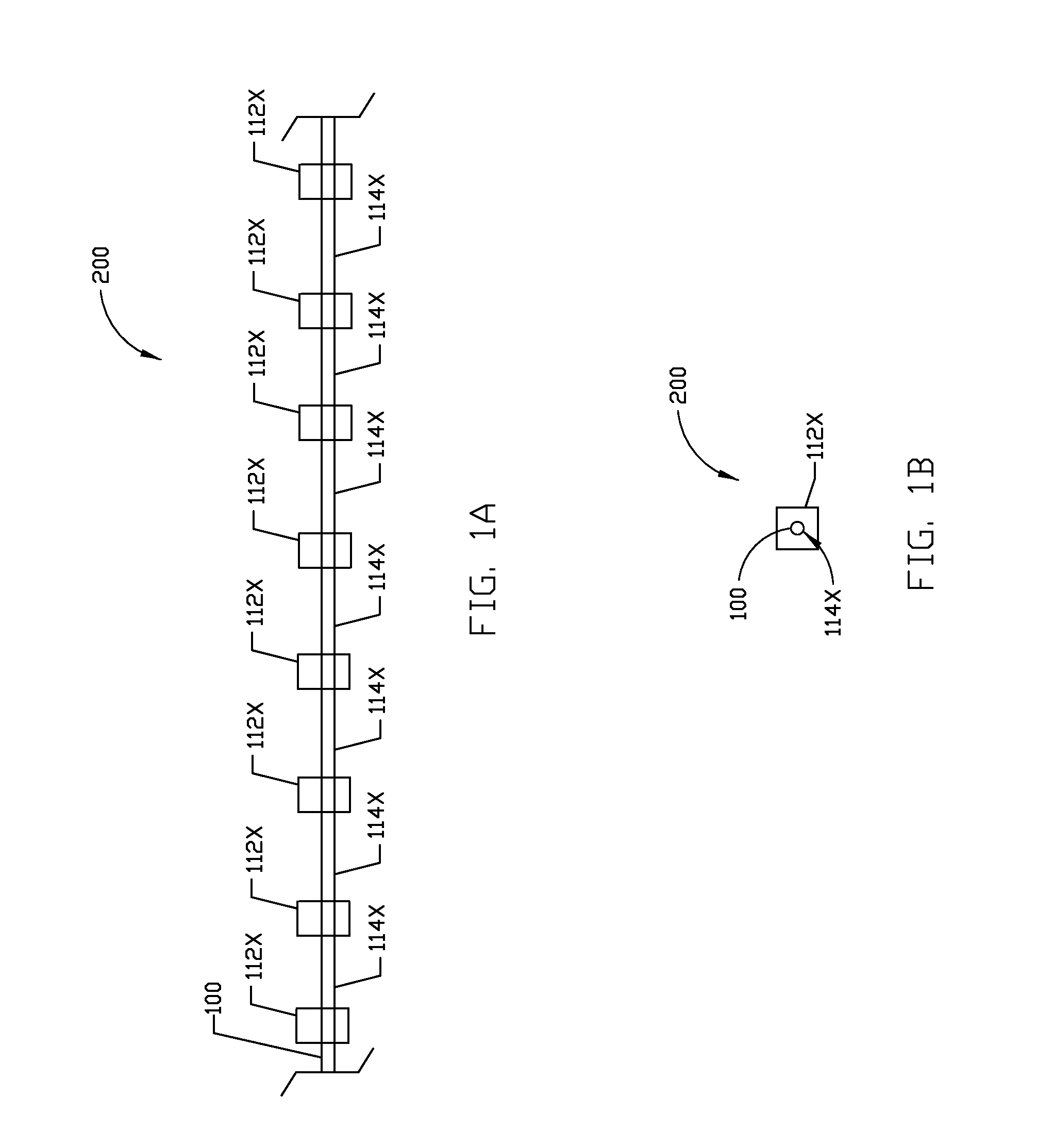

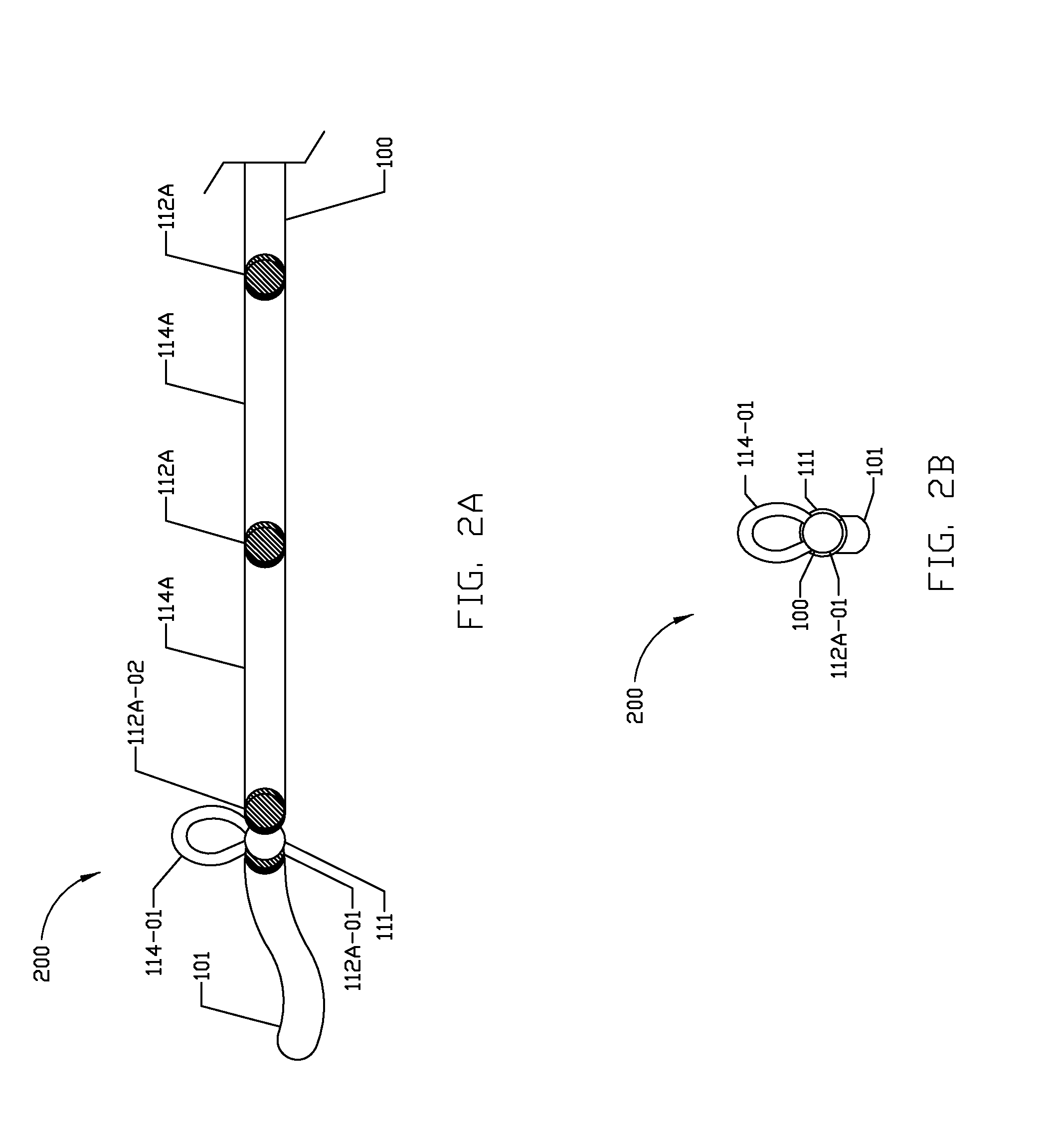

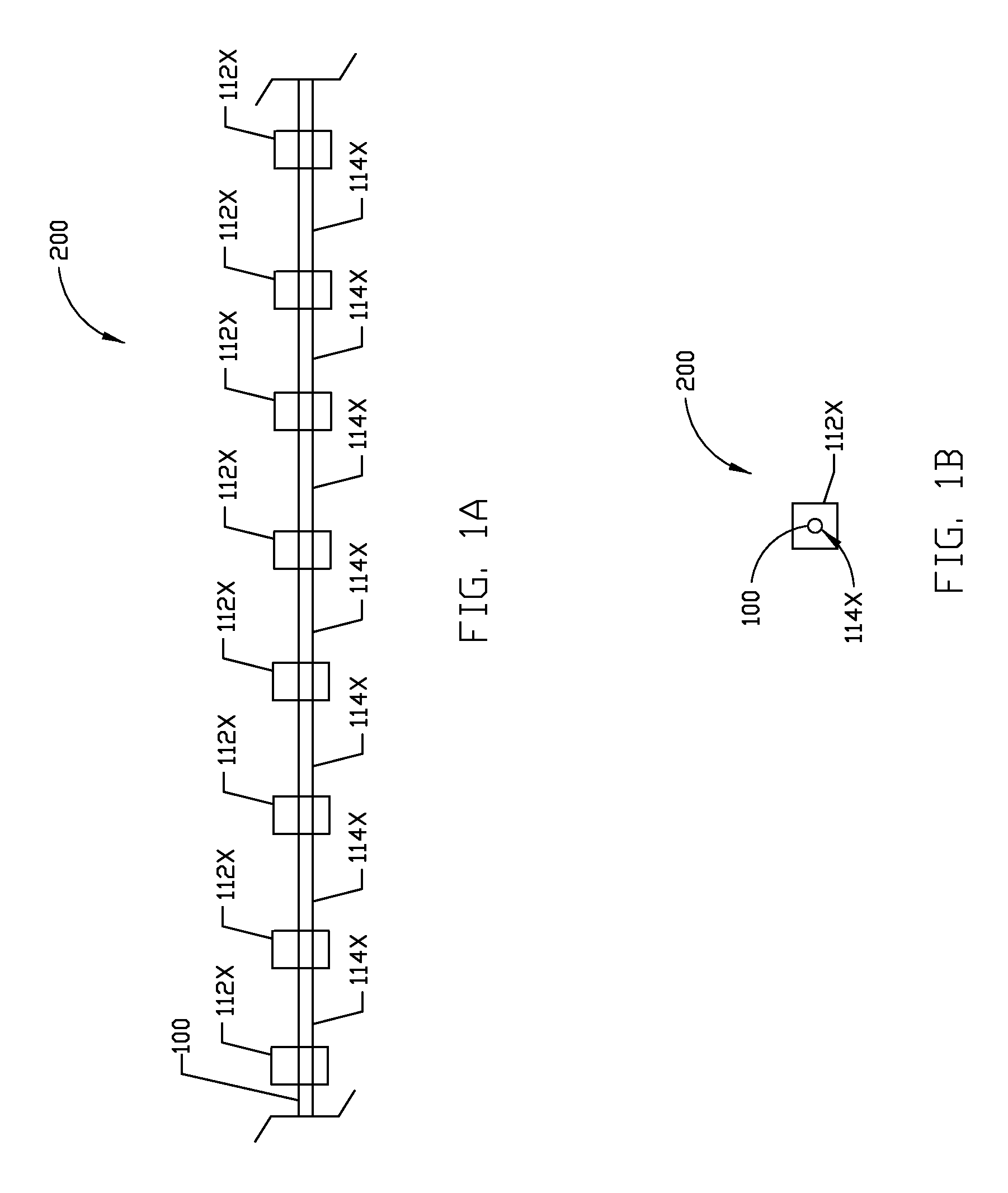

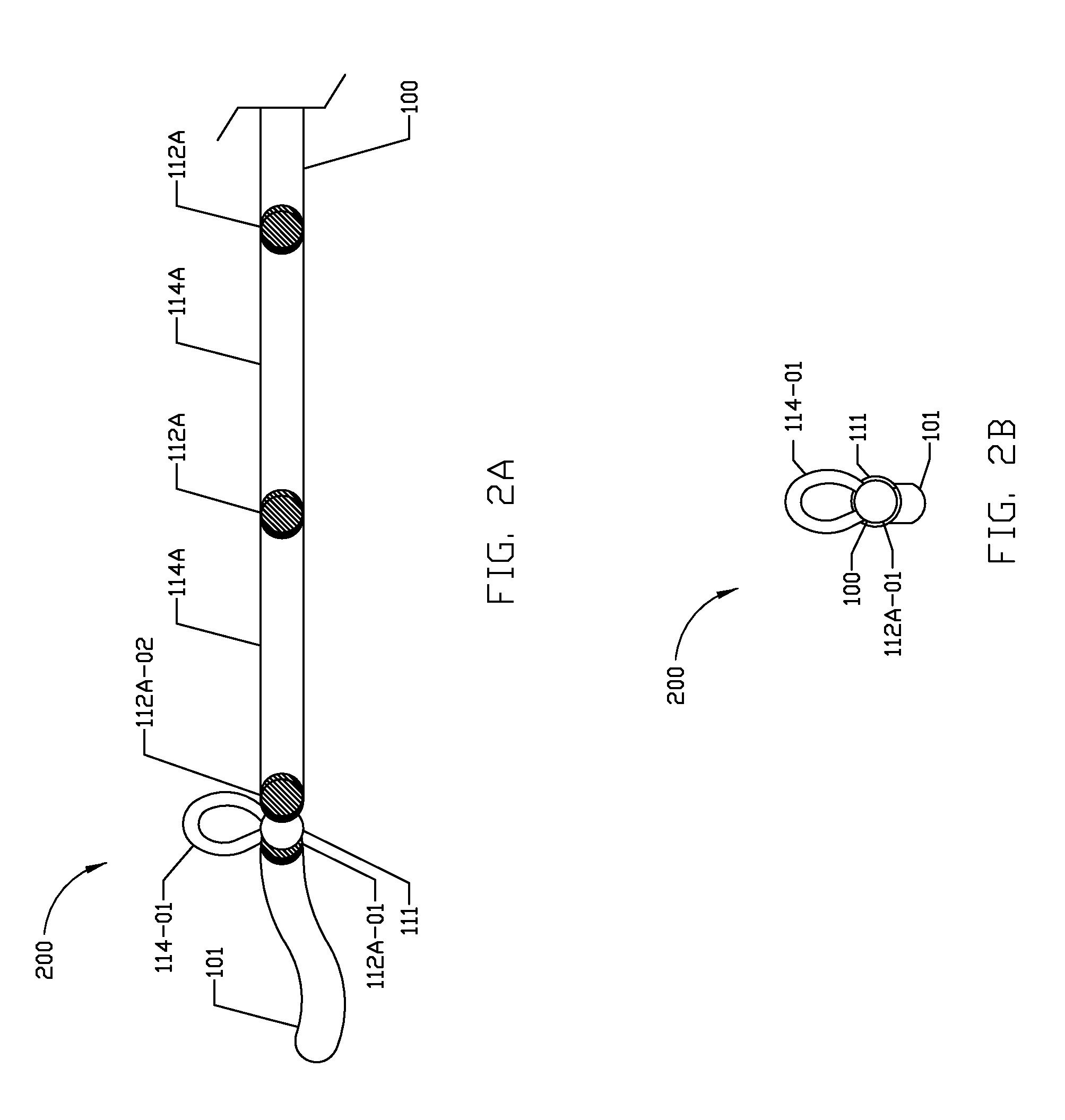

System and method for forming a design from a flexible filament having indicators

The present disclosure is directed to a flexible filament that includes a length of material configured to be used in forming at least a portion of a textile product to have at least a portion of a visual pattern that is visible on at least one of a first side or a second side of the textile product. The material includes a plurality of stitch indicators formed on the material to separate the material into a plurality of segmented regions, at least one of the stitch indicators or the segmented regions forming at least the portion of the visual pattern visible on the at least one of the first side or the second side of the textile product.

Owner:RAYNOR ALIDA CATHLEEN

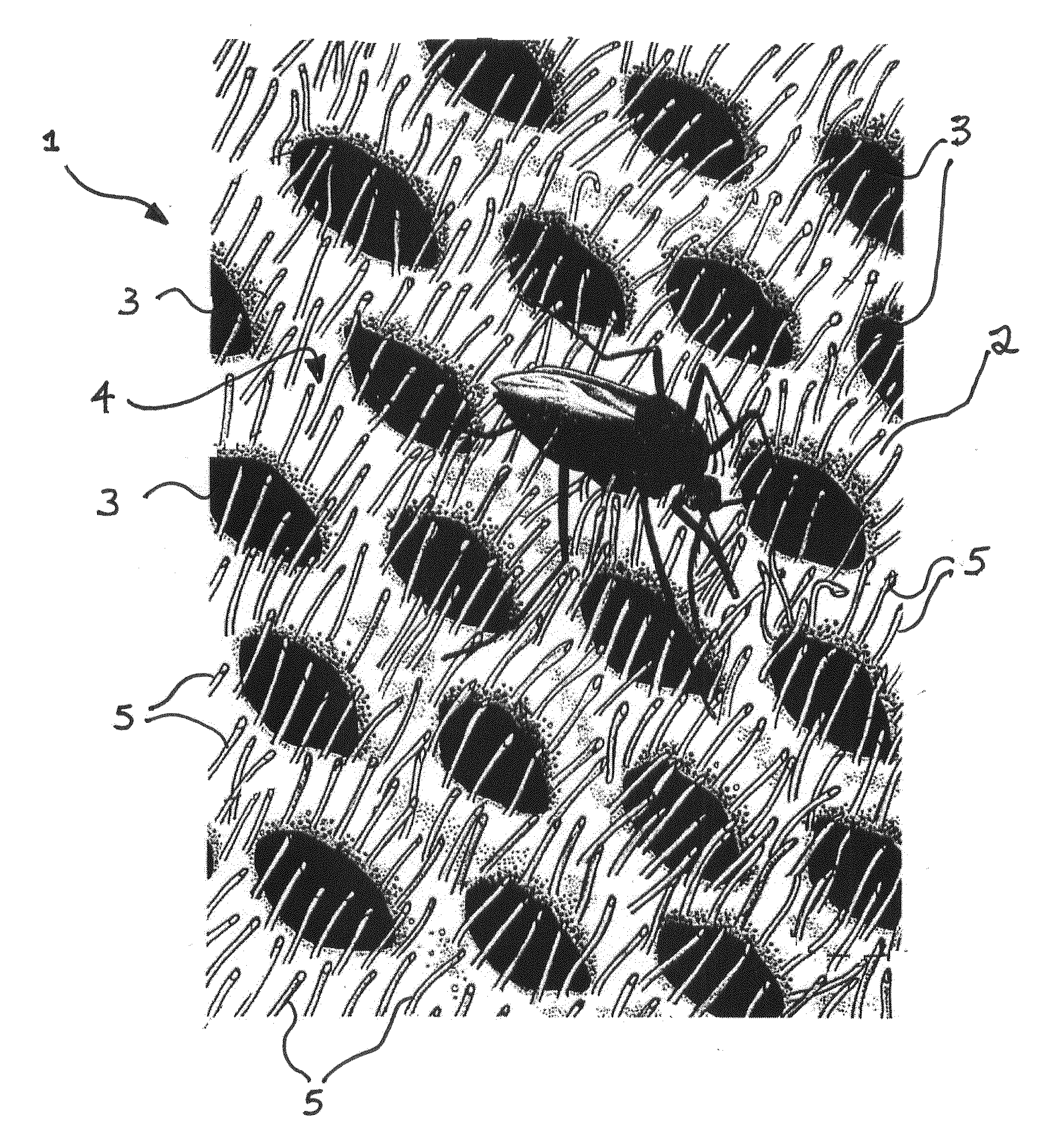

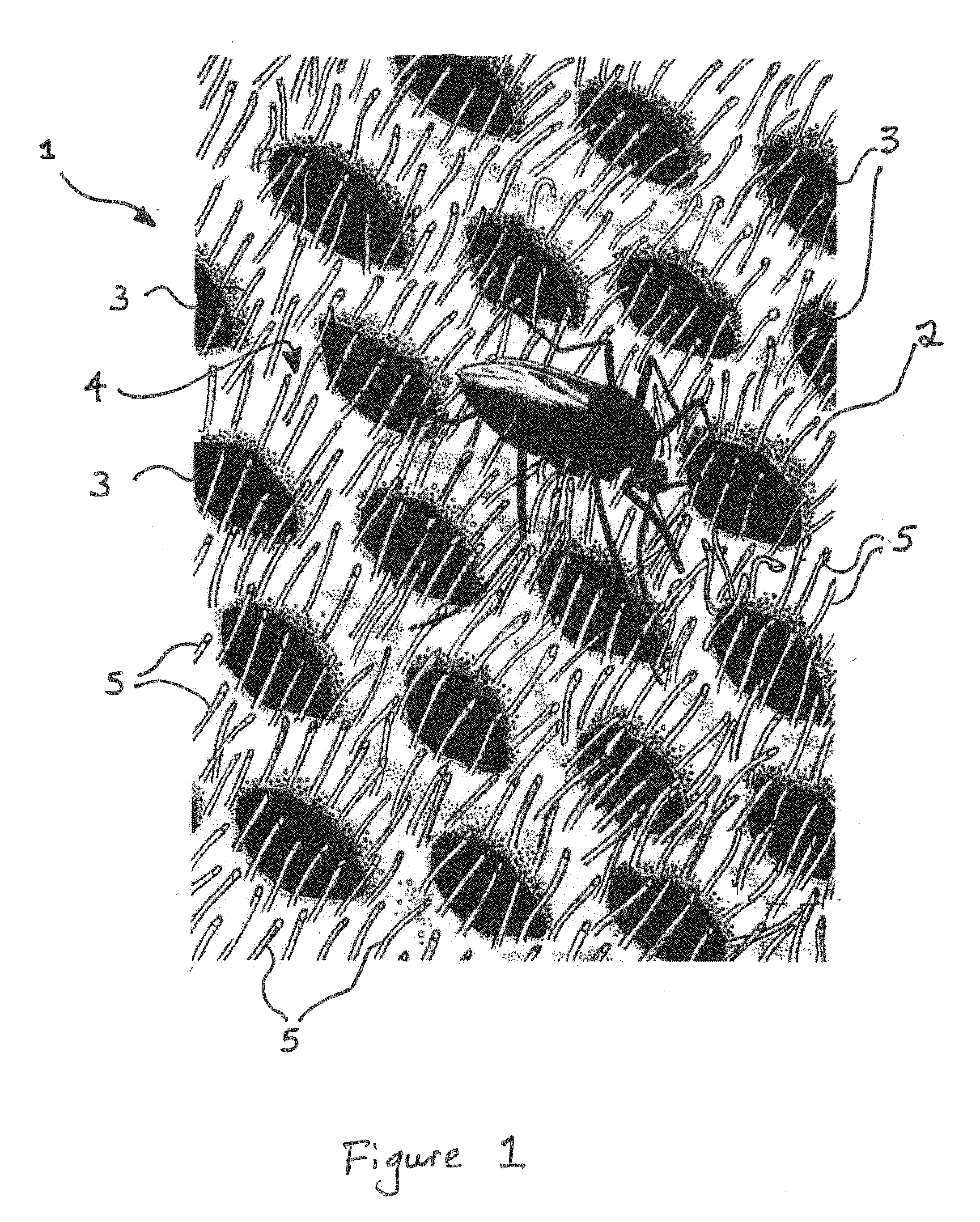

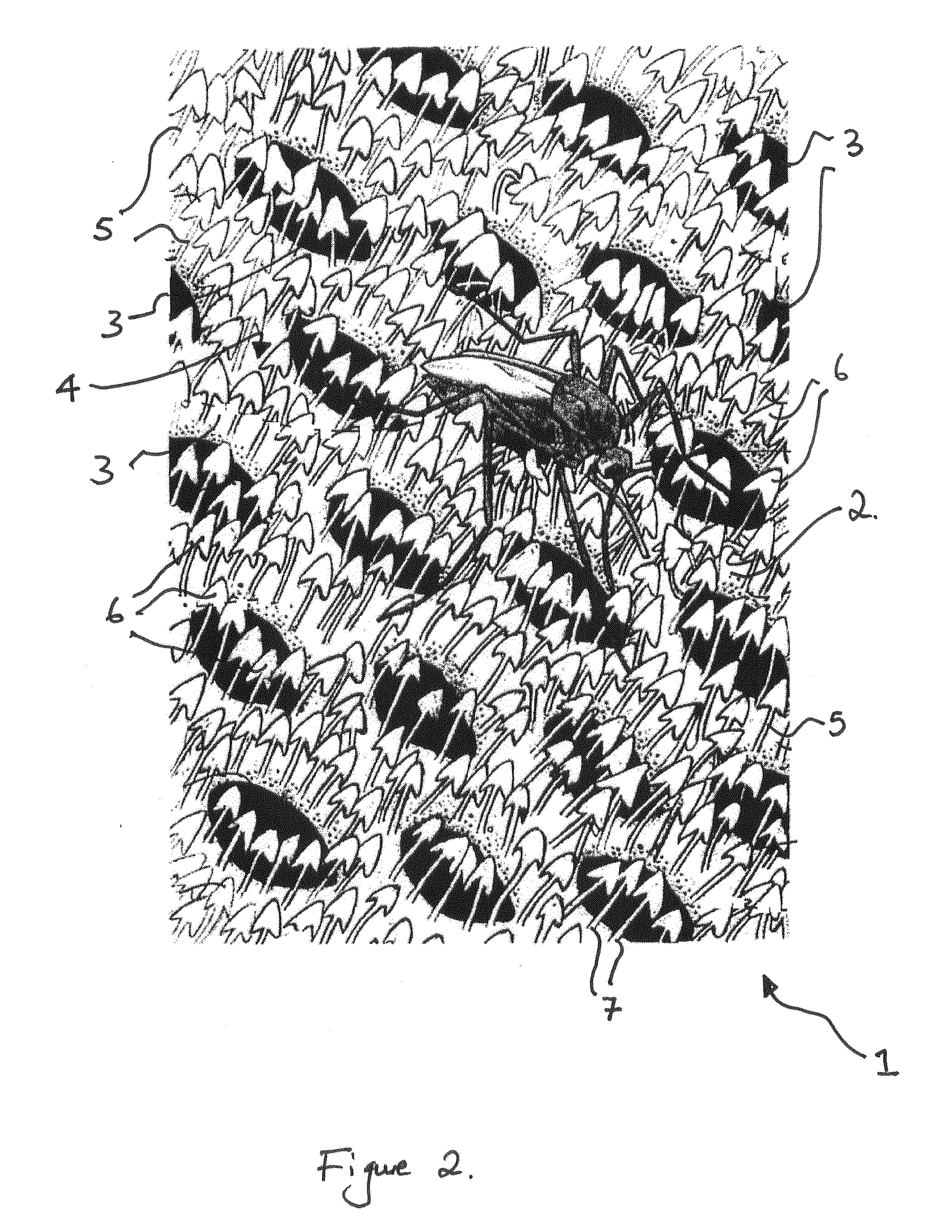

Pest control materials

InactiveUS20140041285A1Facilitate abrasionFacilitate mechanical interactionCrochetingTravelling sacksPaleontologyPest control

An open mesh insect control material is described which includes an insect contact surface, an internal surface, apertures communicating both surfaces and a plurality of filamentous projections protruding from the insect contact surface the projections at least partly occlude the apertures. The structure is suitable for use in pest control especially as a mosquito net.

Owner:INSECTSHIELD

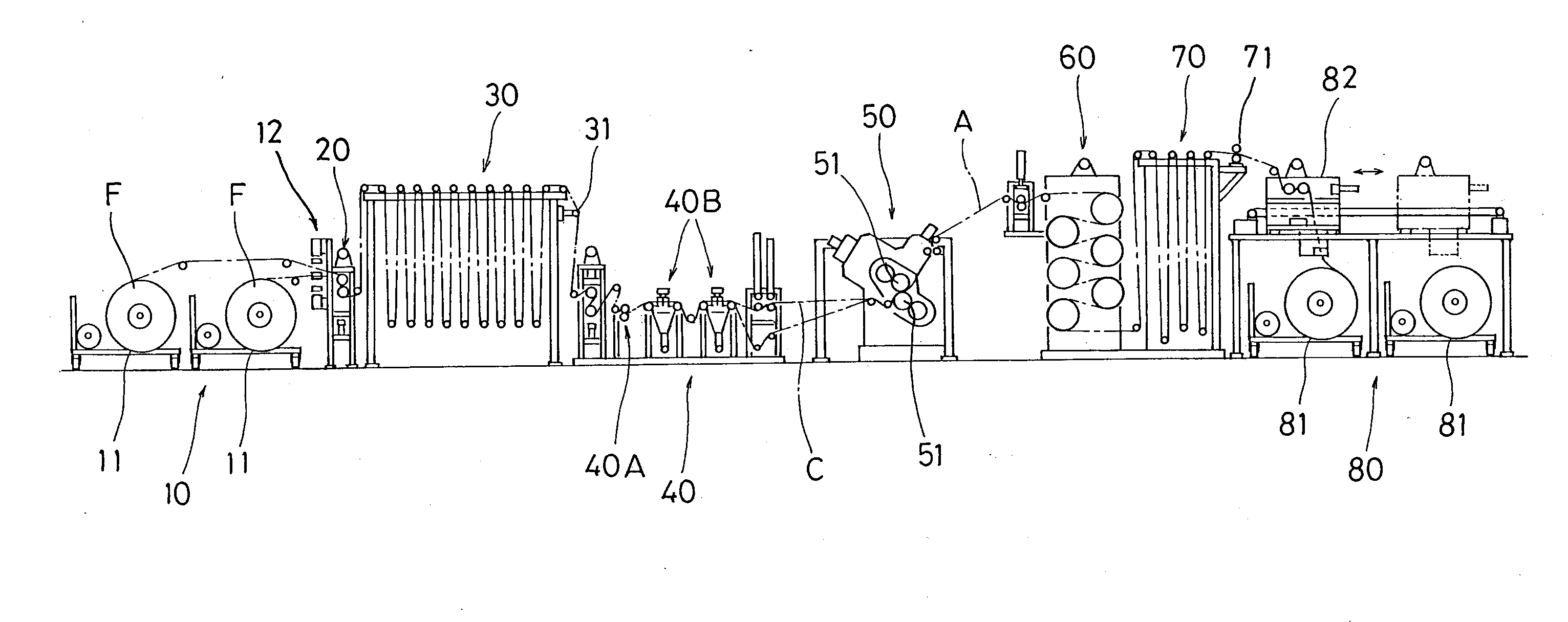

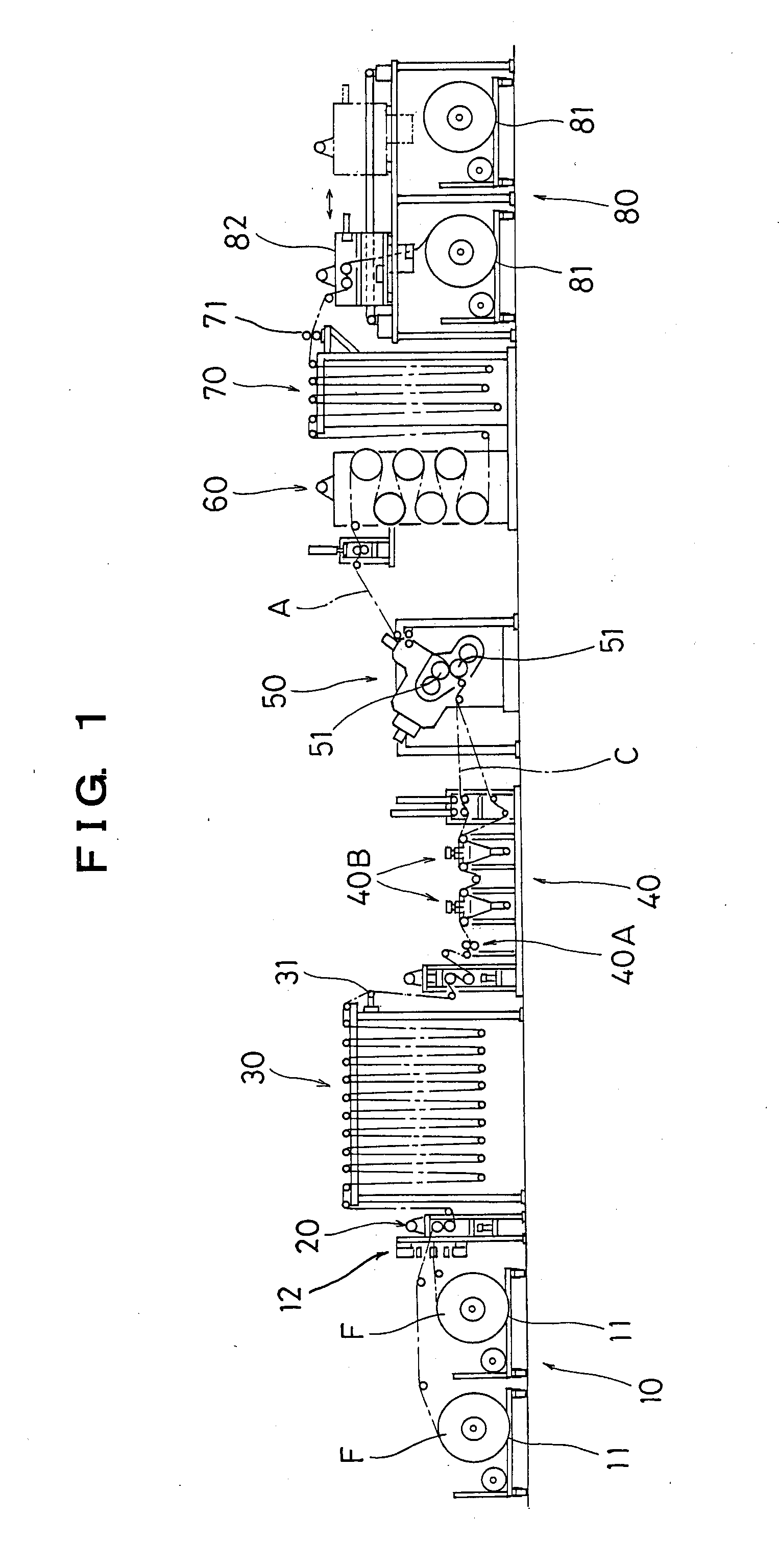

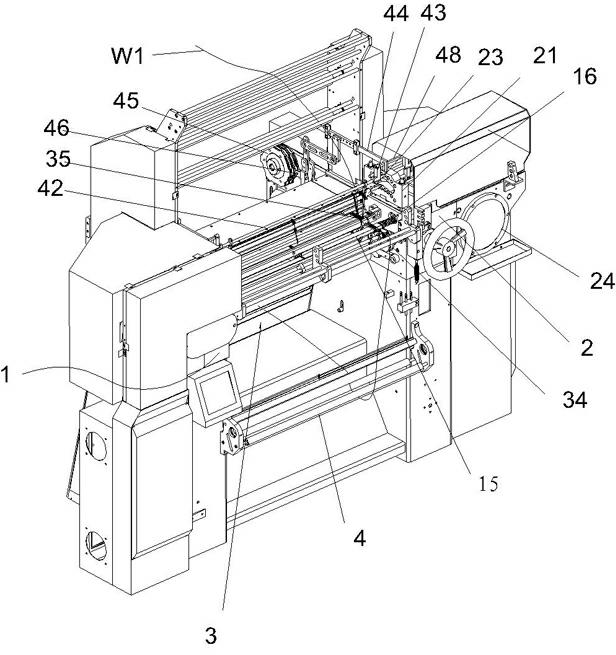

Method and apparatus of removing weft of cord fabric for topping sheet

ActiveUS20090249597A1Reduce failureQuality improvementCrochetingPaper/cardboard articlesEngineeringTextile

The invention can firmly and easily remove a finely divided weft piece without leaving the weft piece by constituting a method and an apparatus of removing weft from a cord fabric for a topping sheet in a calender line for topping rubber on a number of pieces of aligned cords by a calender roll. In the midst of transferring a cord fabric (F) transferred to a calender apparatus, weft is finely divided by passing the cord fabric (F) through weft dividing means, thereafter, a plurality of blades (45) arranged movably in a width direction on an upper face side of the cord fabric (F) are reciprocally moved in the width direction over an entire width thereof to be brought into contact with the cord fabric (F), and the divided weft piece (W1) is wiped off to remove by respectively striking respective cords (C) of the cord fabric (F) by the respective blades (45).

Owner:TOYO TIRE & RUBBER CO LTD

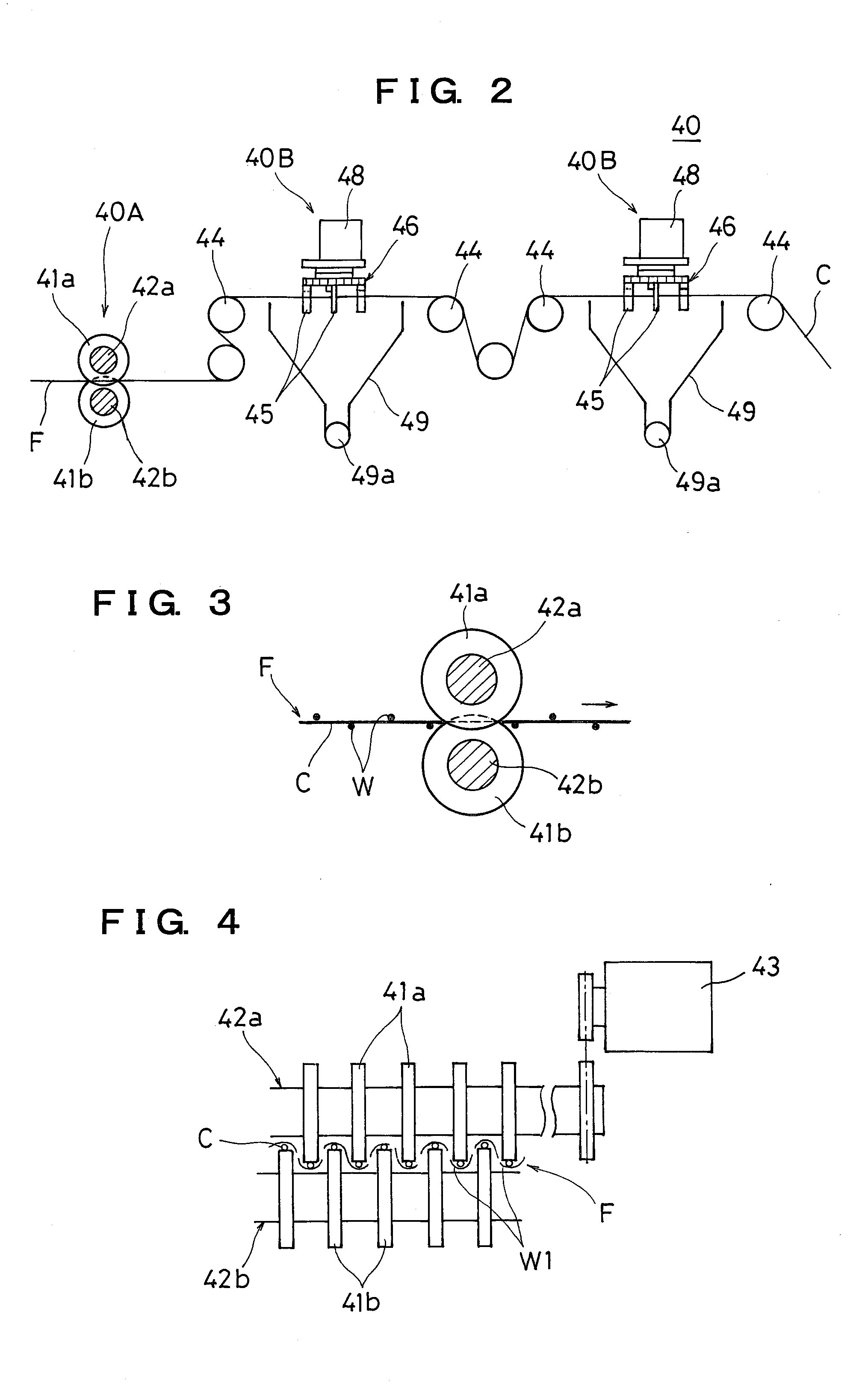

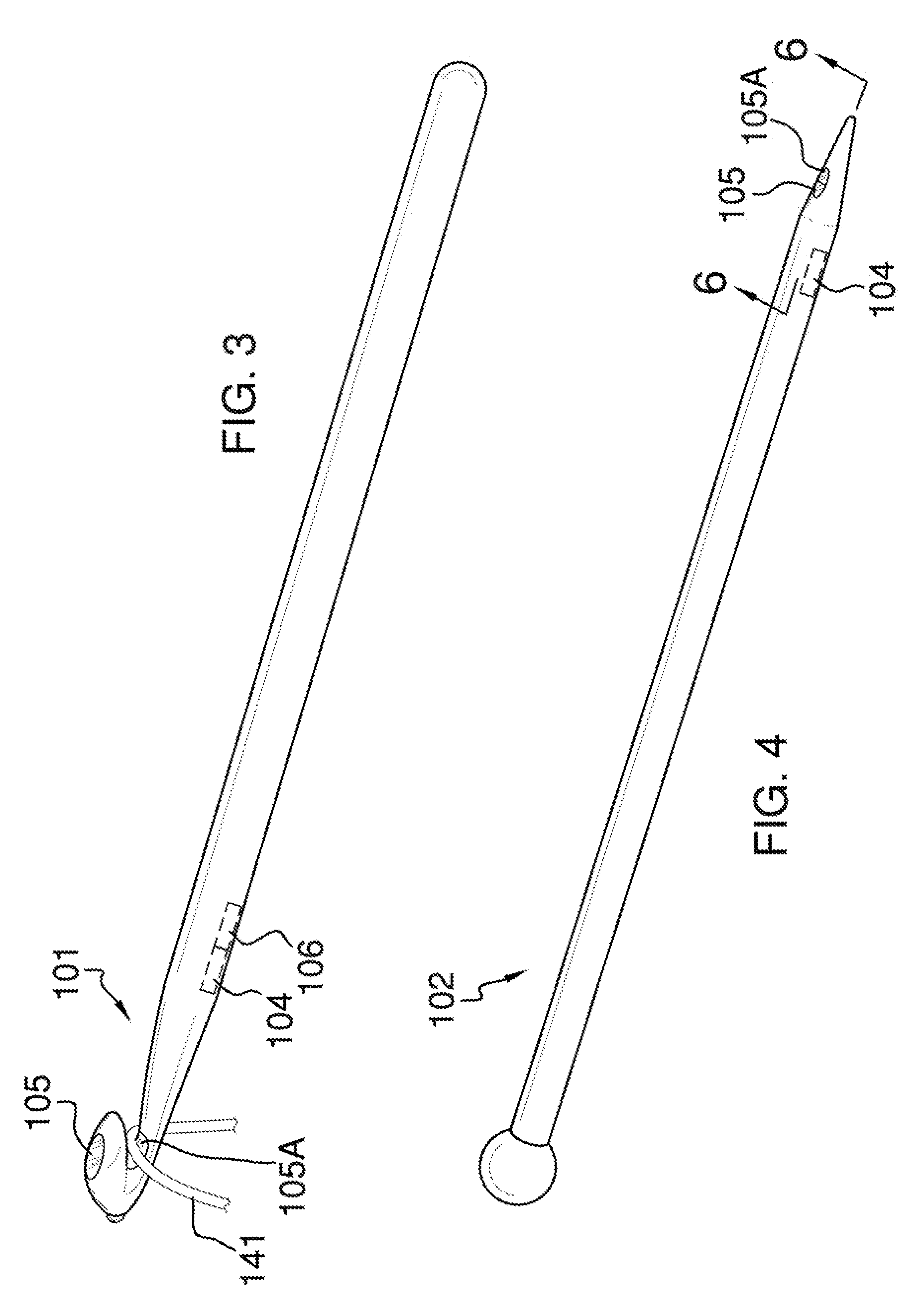

Interactive knitting and crocheting system

The interactive knitting and crocheting system includes at least one crocheting or knitting needle with a motion-based sensing capability integrated therein and a computing means. The computing means monitors movement of the respective needle to monitor proper crocheting or knitting technique, and upon detection of improper technique will provide an alert that an error has occurred, which shall prevent waste in work. The computing means provides notice of improper technique in the form of an audiovisual means, which can double as an instructional aid in teaching how to crochet or knit. The computing means also provides progress as to the stitch and pattern formed.

Owner:FELICE KAREN

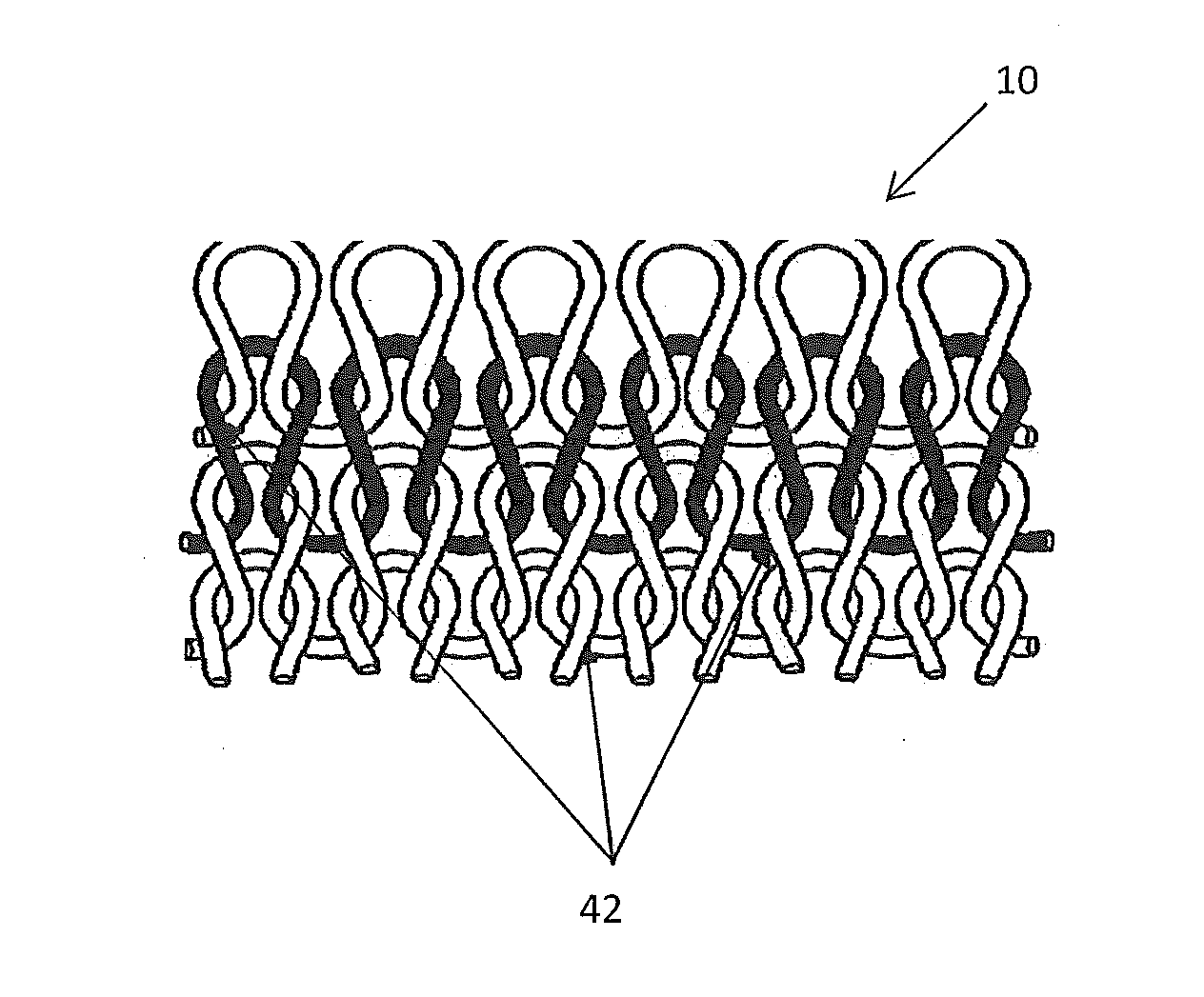

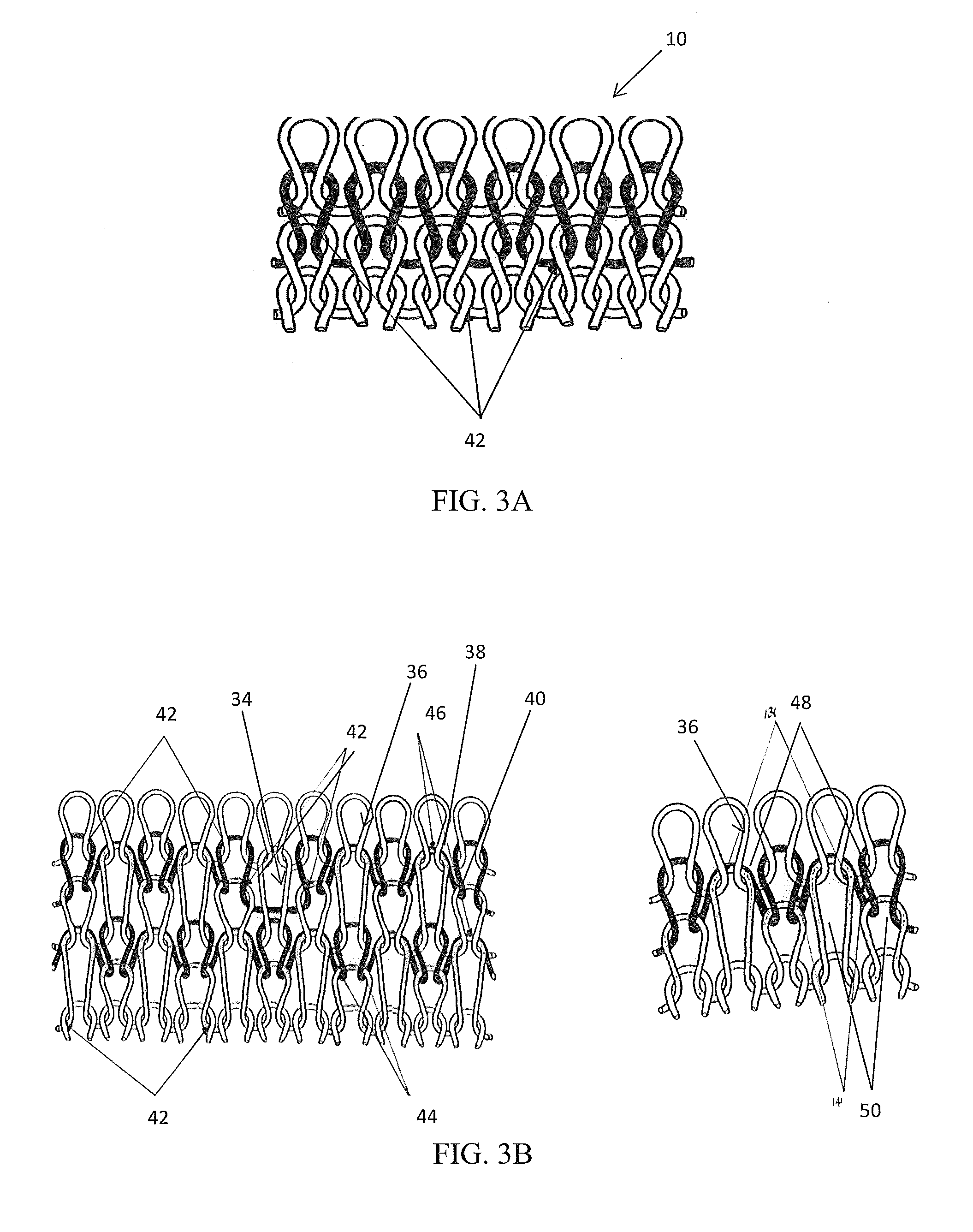

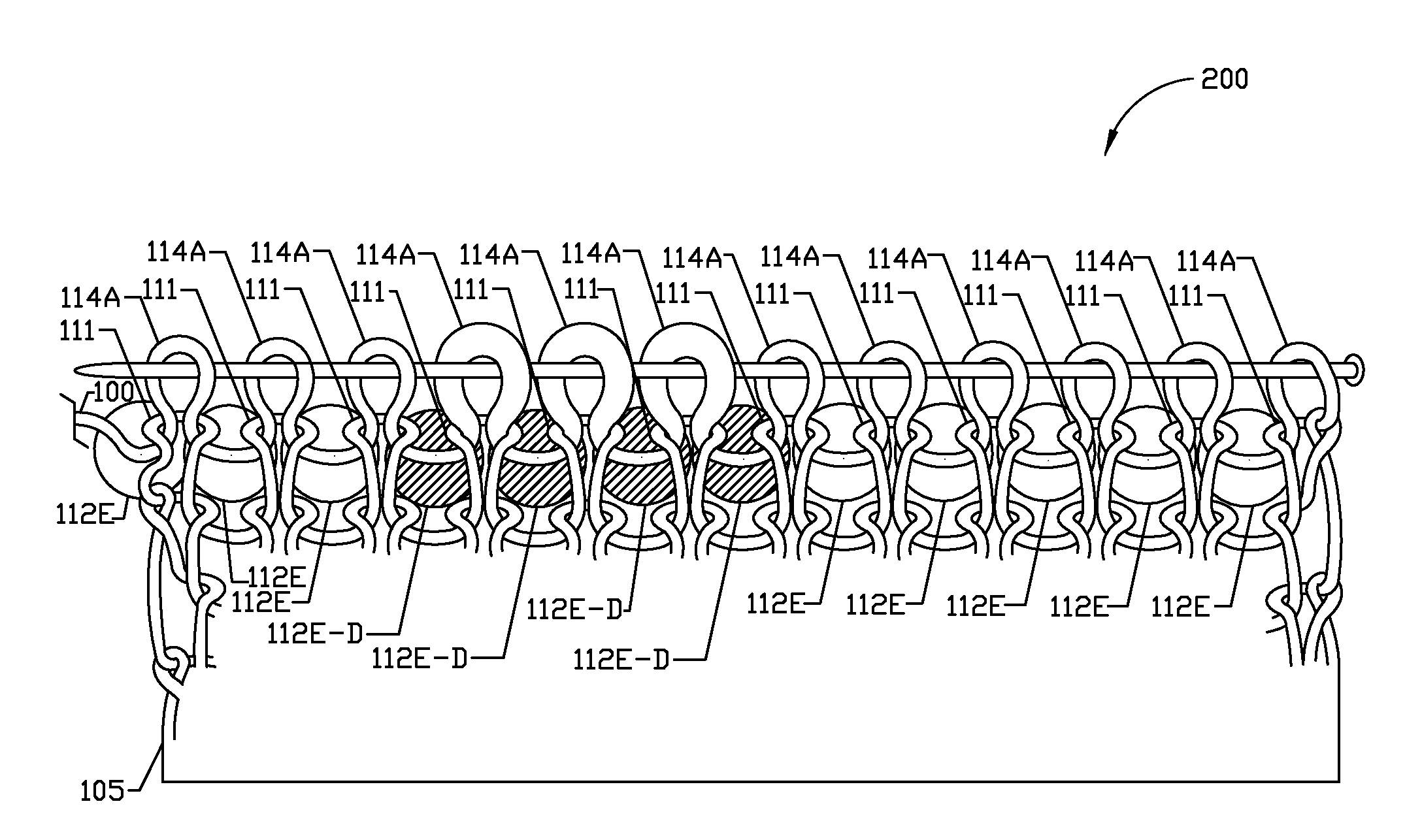

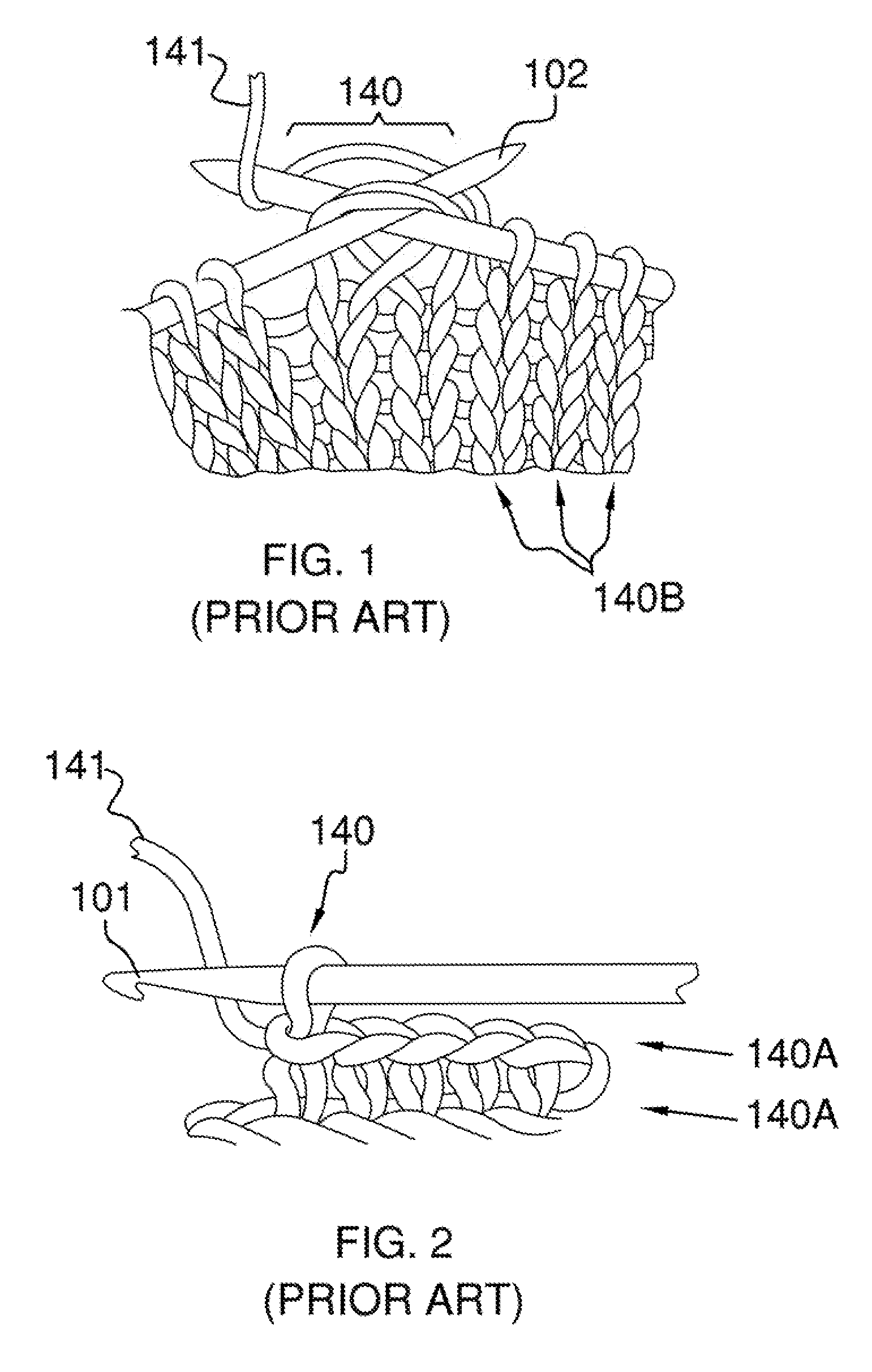

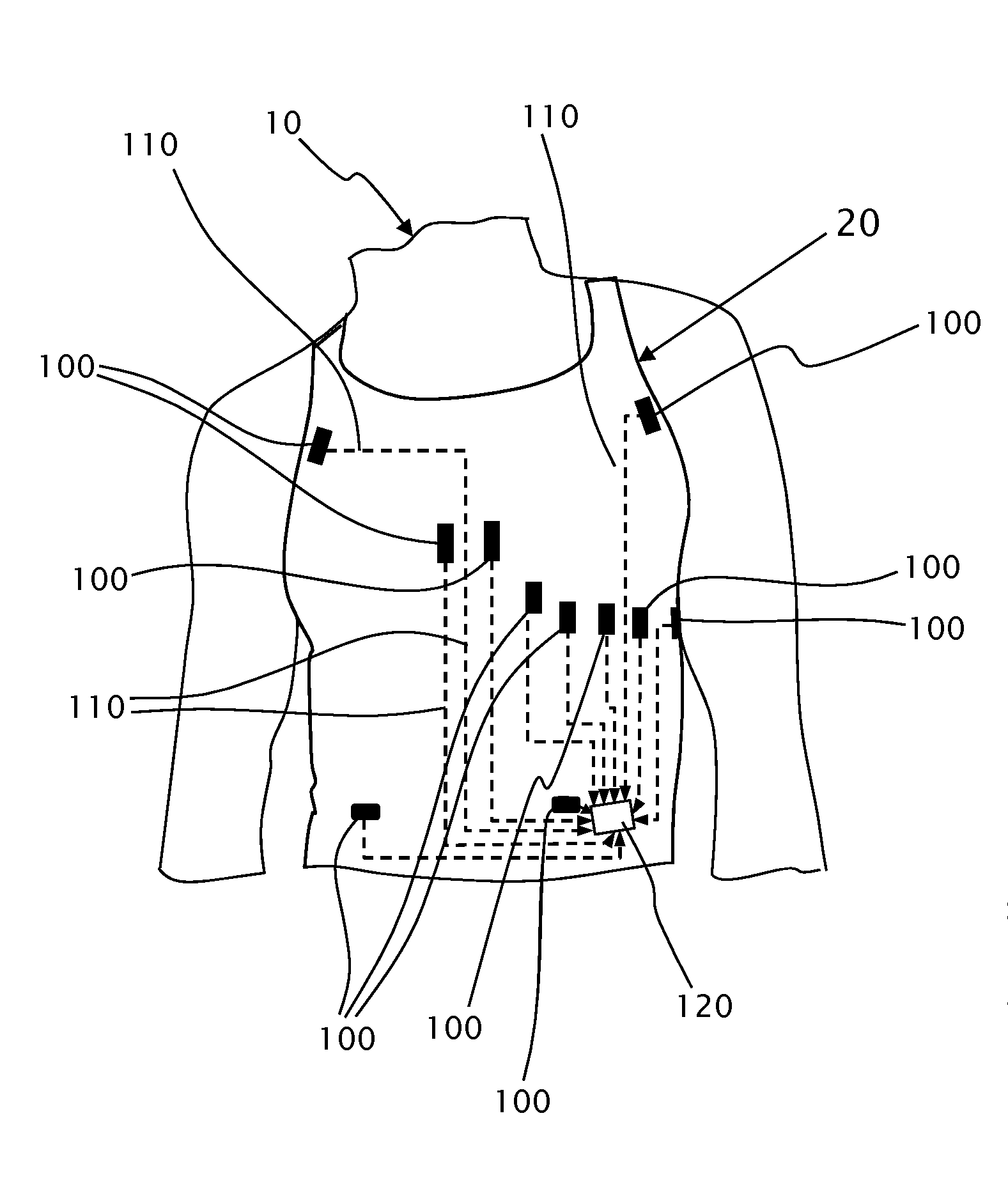

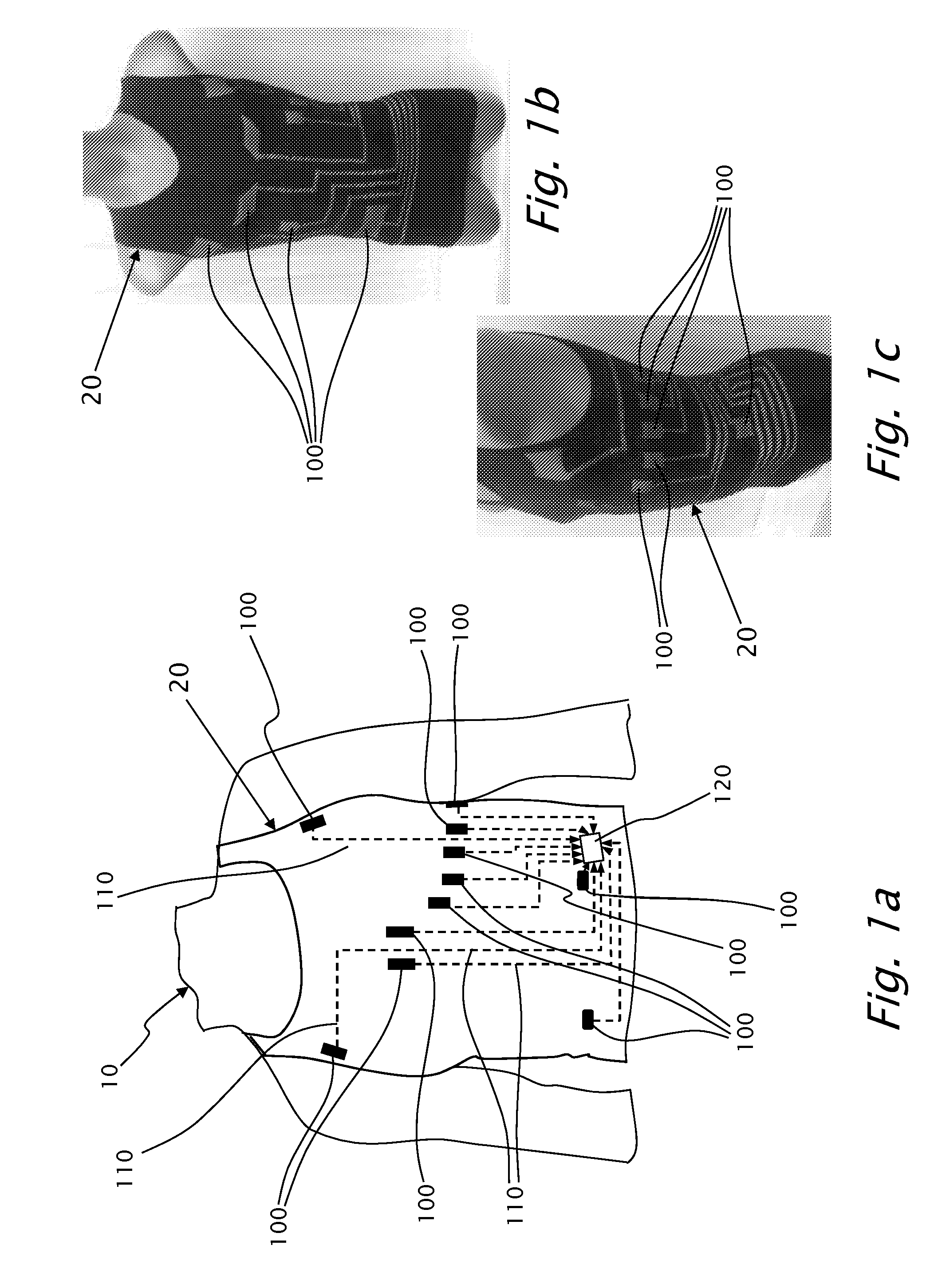

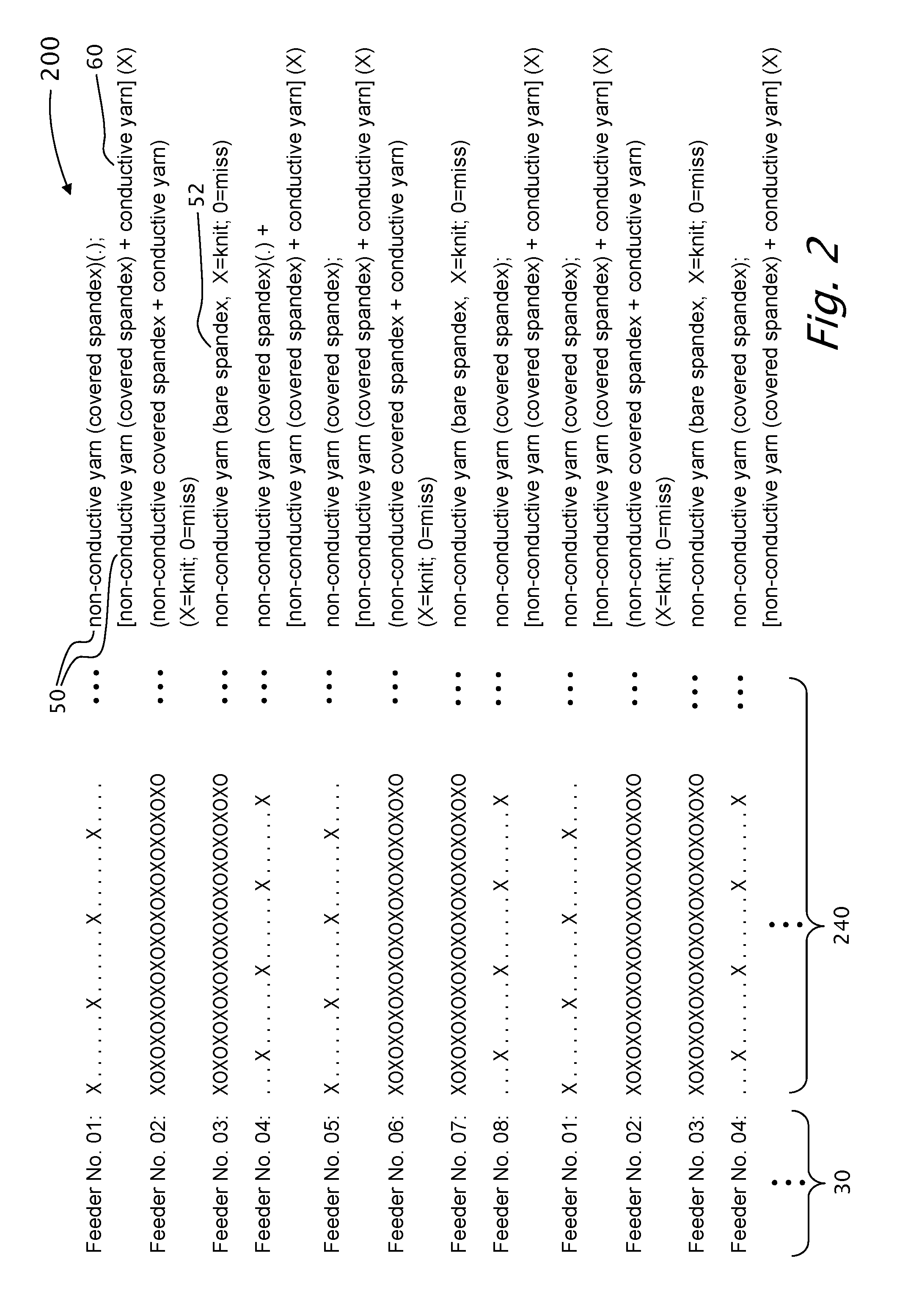

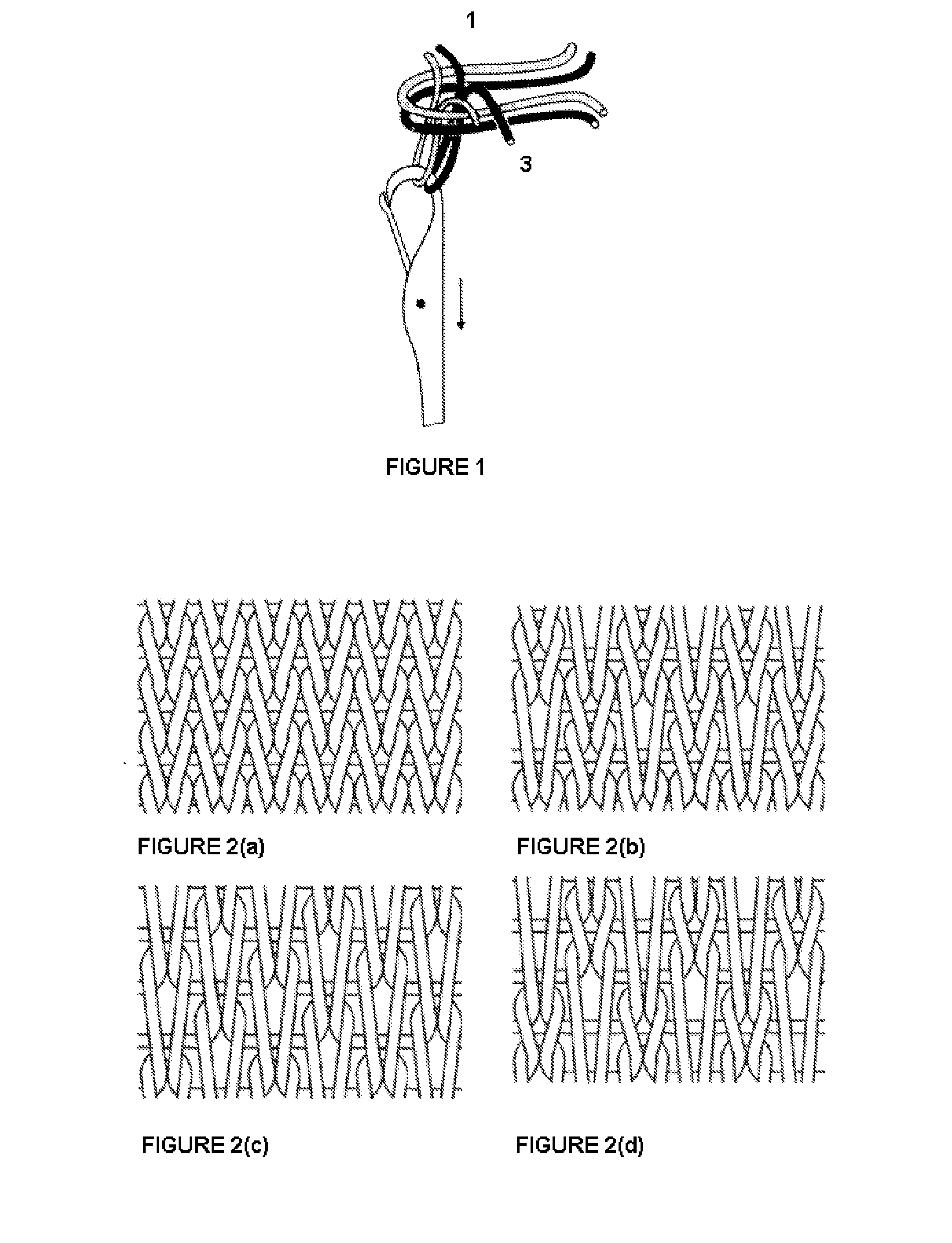

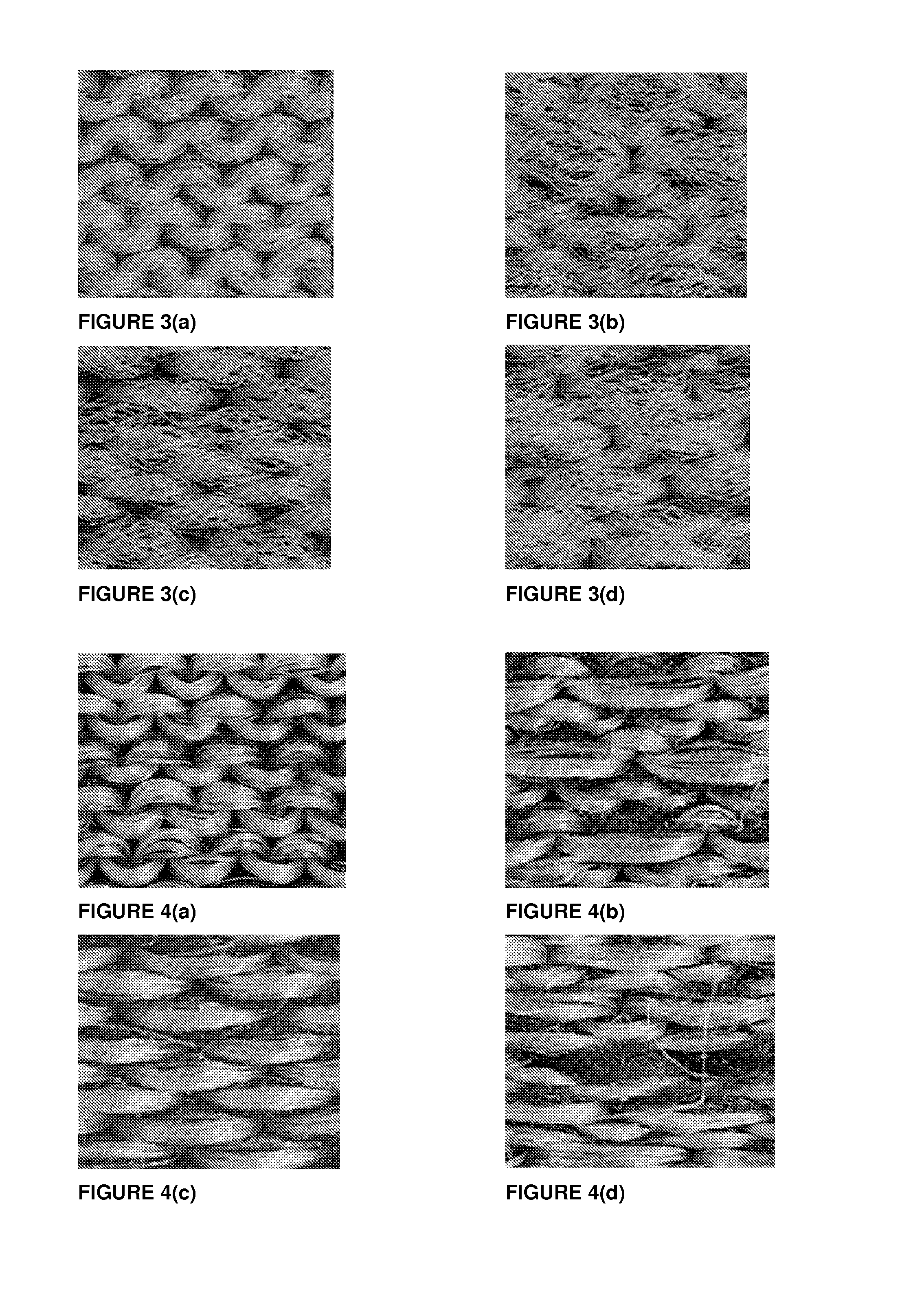

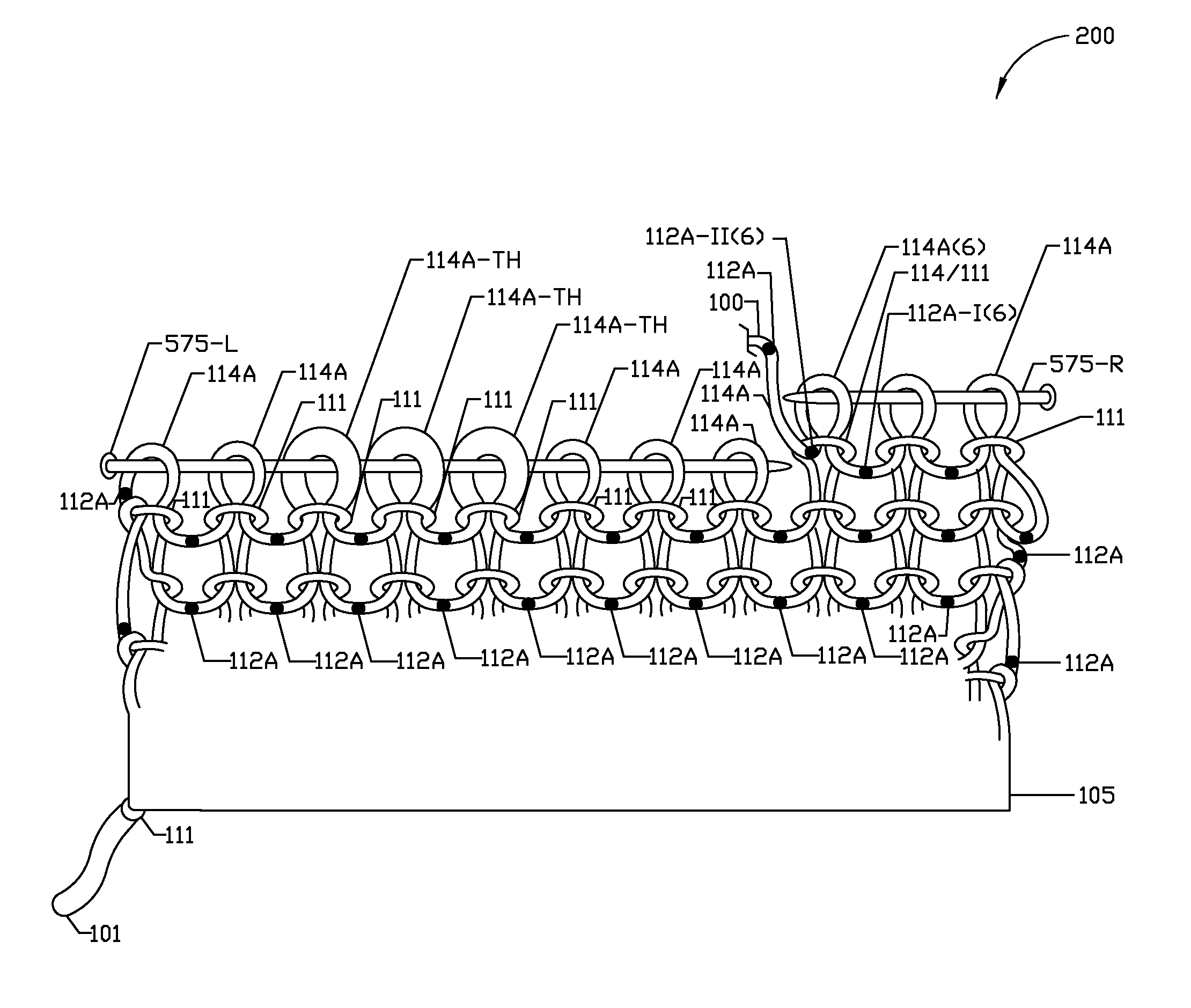

Float loop textile electrodes and methods of knitting thereof

ActiveUS20150297135A1Facilitate acquisitionSmooth connectionCrochetingOrnamental textile articlesConductive yarnLine segment

A method for knitting a garment having a tubular form, including knitting at least one conductive textile electrode on a machine having N participating feeders and M needles. The method includes the steps of continuously knitting the tubular form with one or more flexible non-conductive yarns, and knitting the electrode integrally within the tubular form, using a conductive yarn, in addition to the non-conductive yarns. The conductive yarn is knitted in a float-loop form by knitting a stitch and skipping over y needles, as follows: repeatably knitting a line segment Lk, using feeder Fi and starting at needle D1; and knitting line segment Lk+1, using the next feeder and start stitching the first float-loop at needle D1+s where 0<s<y. The tubular form has a preconfigured 10 knitting density, wherein the electrode has a knitting density that is higher than the preconfigured knitting density of the tubular form.

Owner:AUTONETWORKS TECH LTD

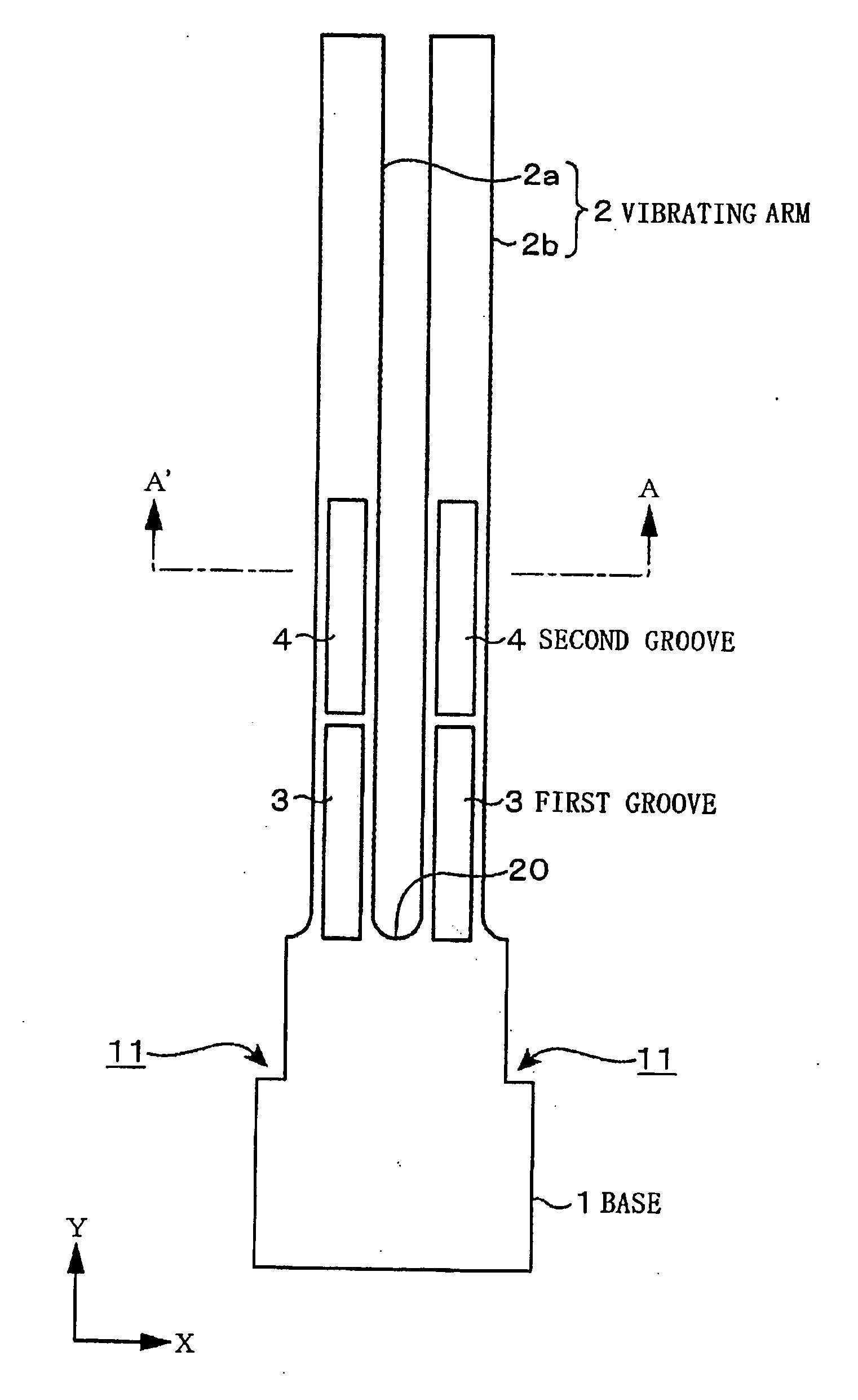

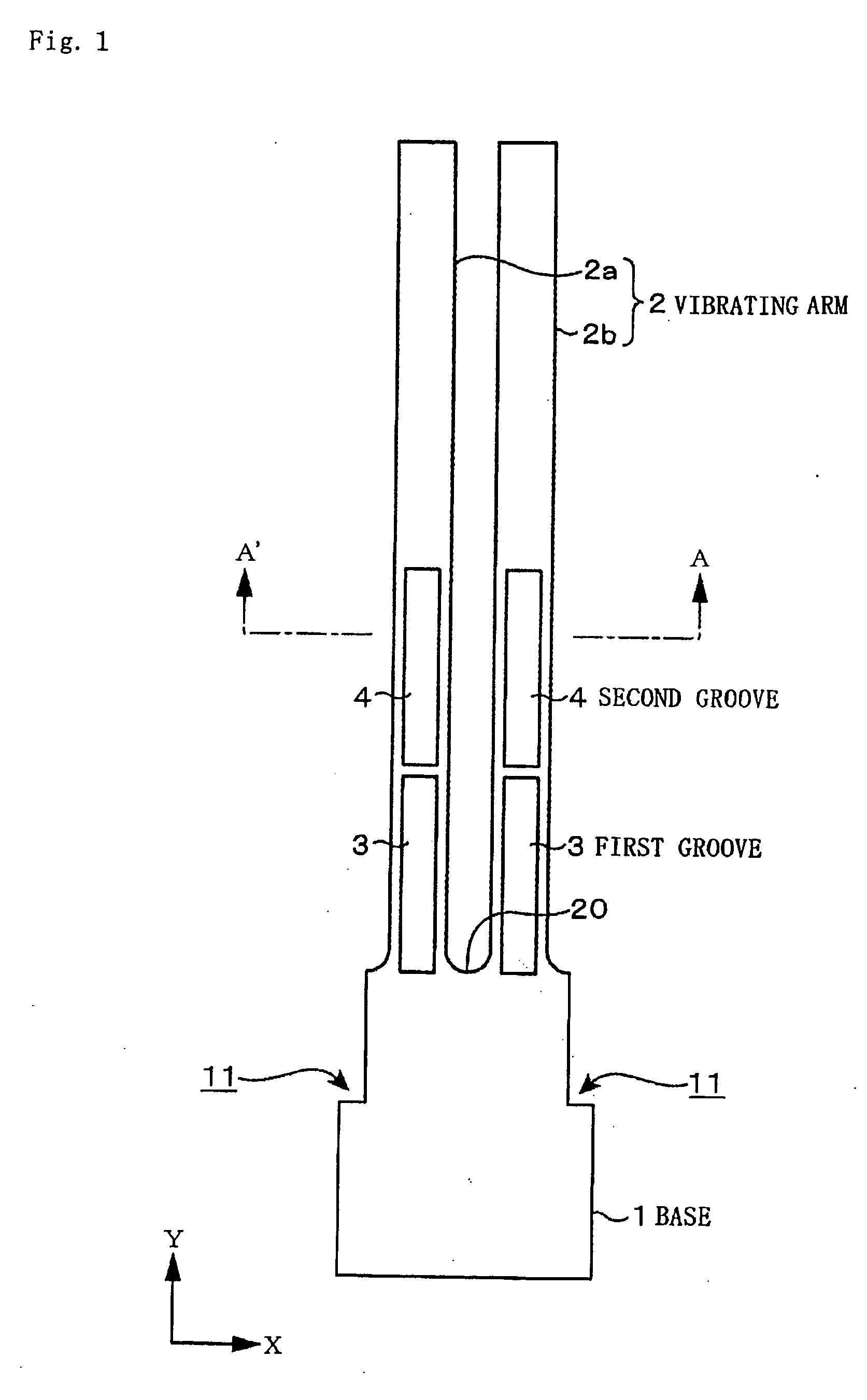

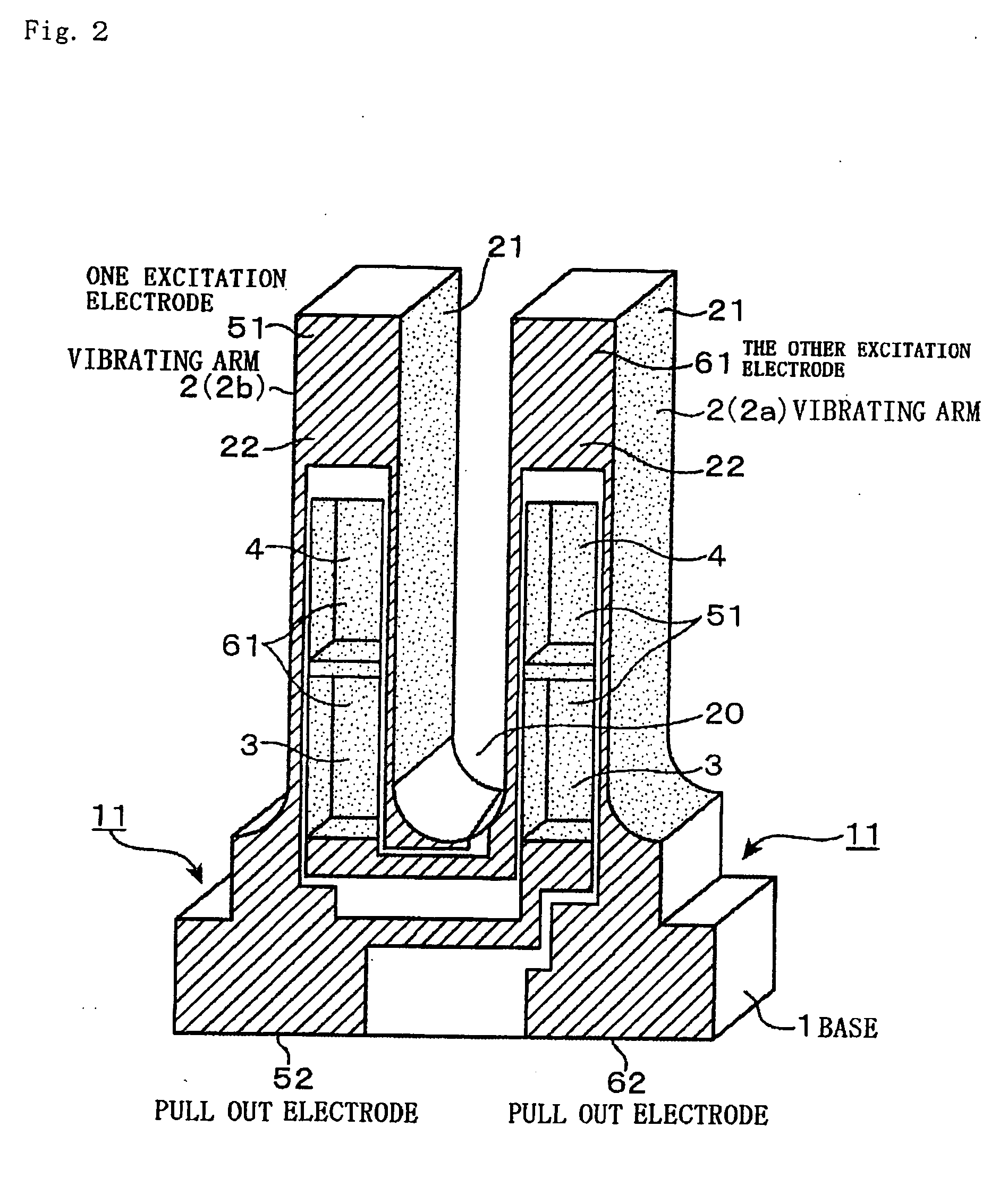

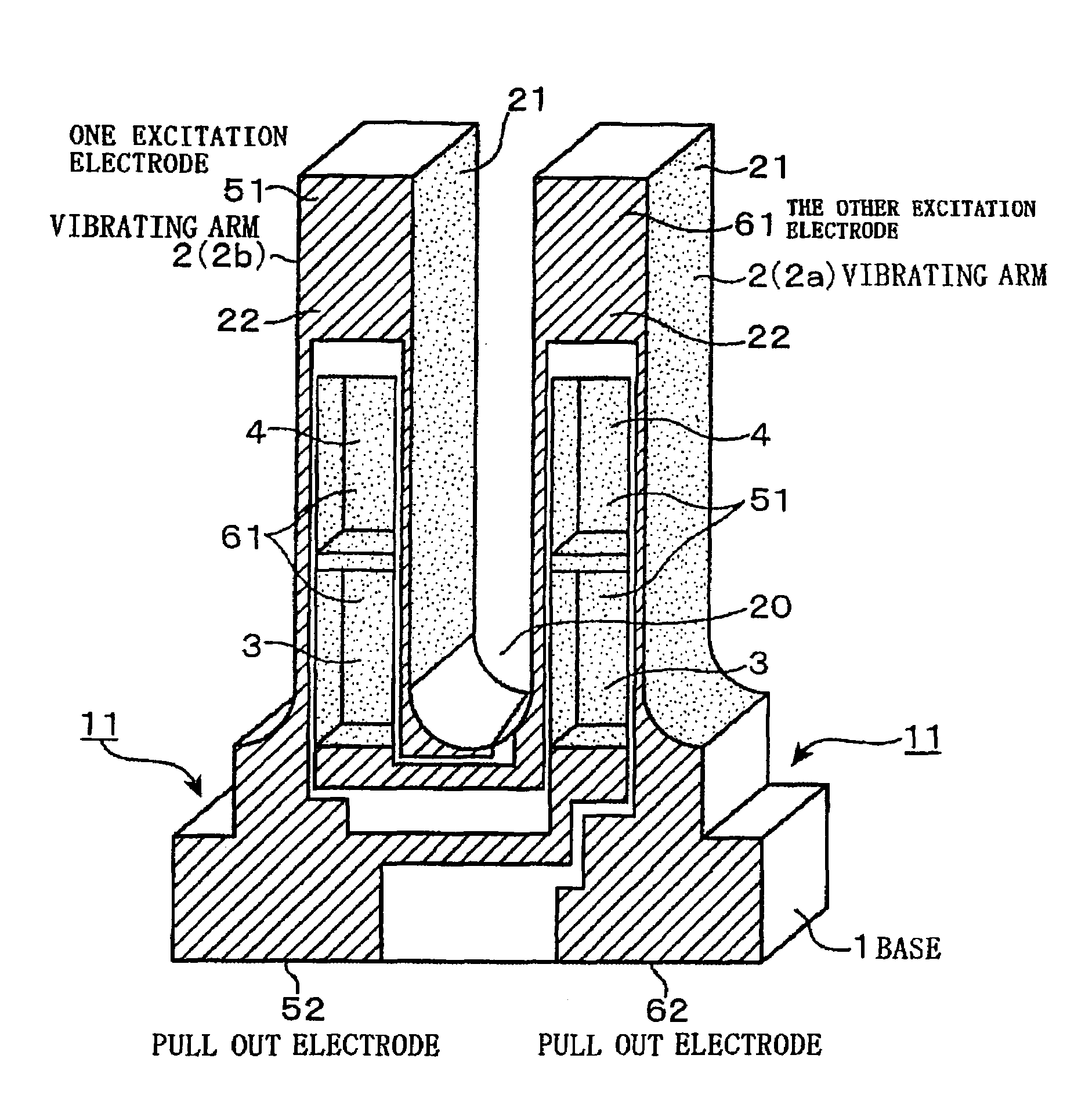

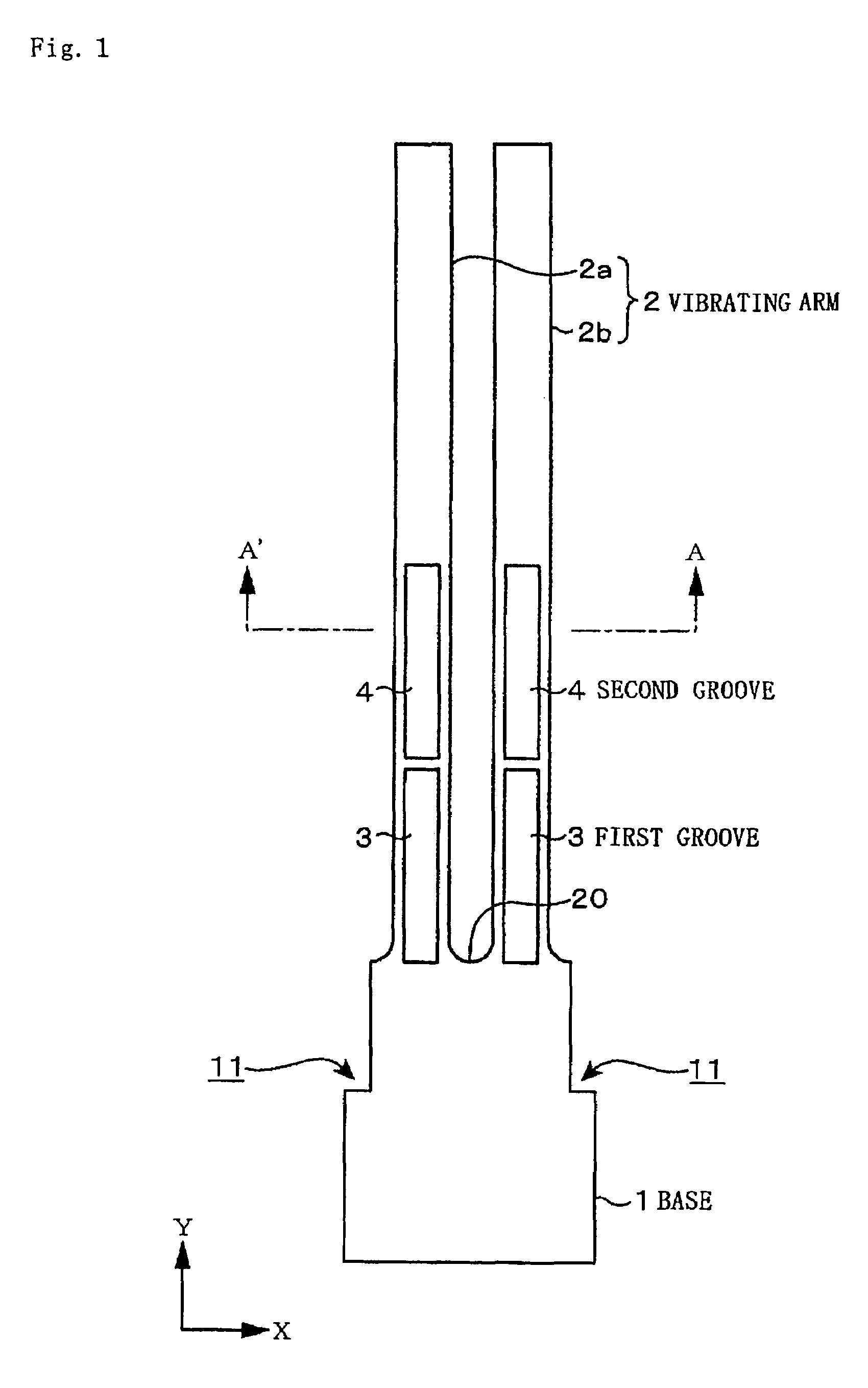

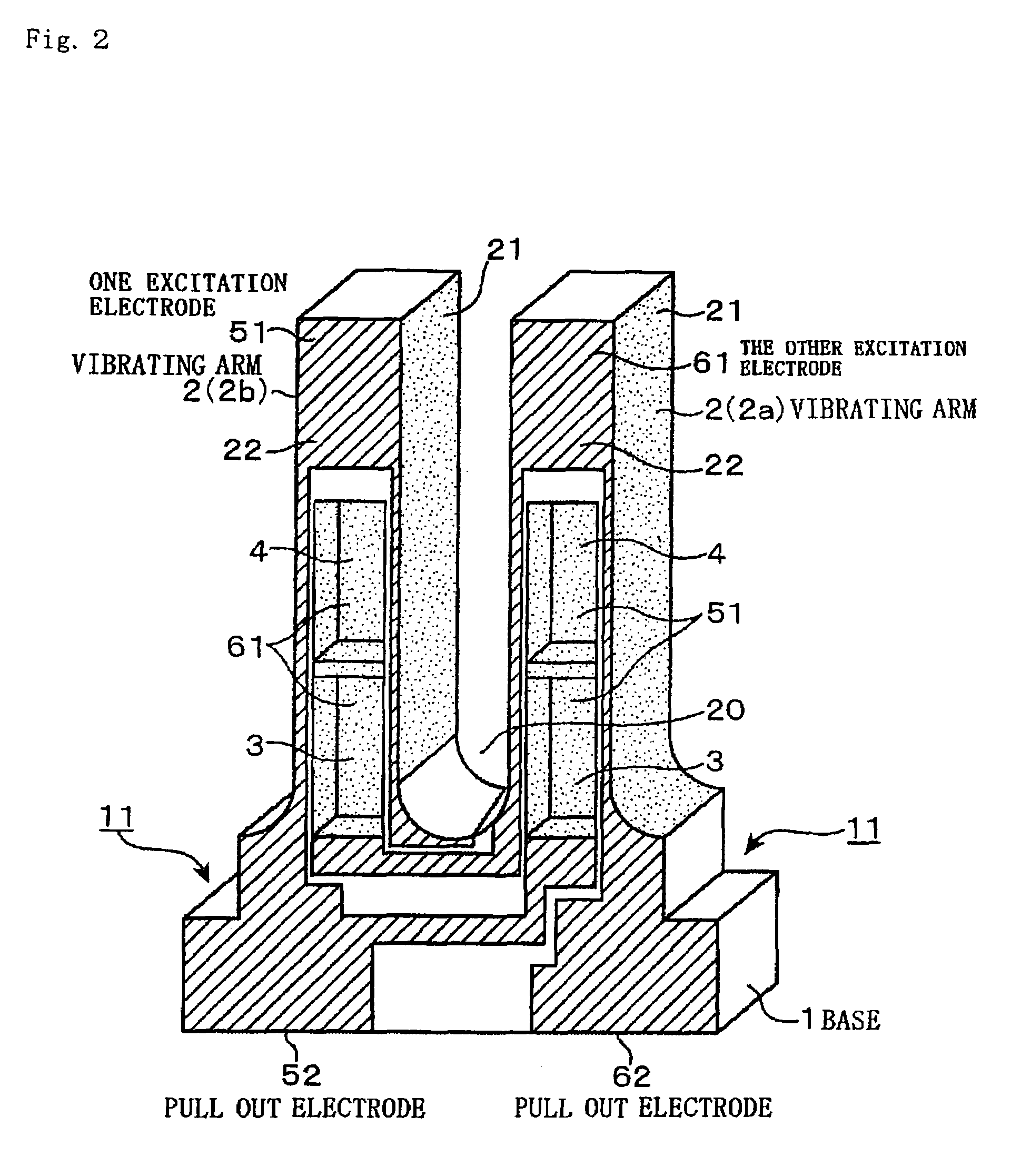

Piezoelectric vibrator

InactiveUS20060186768A1Improve seismic performanceCrochetingPiezoelectric/electrostriction/magnetostriction machinesTuning forkPiezoelectric actuators

In order to provide a tuning fork type piezoelectric vibrator provided with vibrating arms which can improve shock resistance while suppressing a CI value to a small value, a first groove (base end side) and a second groove (tip side) extending along the longitudinal direction from the base end of the vibrating arm and divided into two in the longitudinal direction are formed on at least one of a front surface or a back surface of the vibrating arms. Then, a ratio L2 / L1 which is the ratio of the length L2 of the first groove to the length L1 from the base end of the vibrating arm to the tip of the second groove, is set between 0.35 and 0.65, and a ratio d / L1 which is the ratio of a space d between the first groove and the second groove to the length L1 from the base end of the vibrating arm to the tip of the second groove, is set between 0.010 and 0.016.

Owner:NIHON DEMPA KOGYO CO LTD

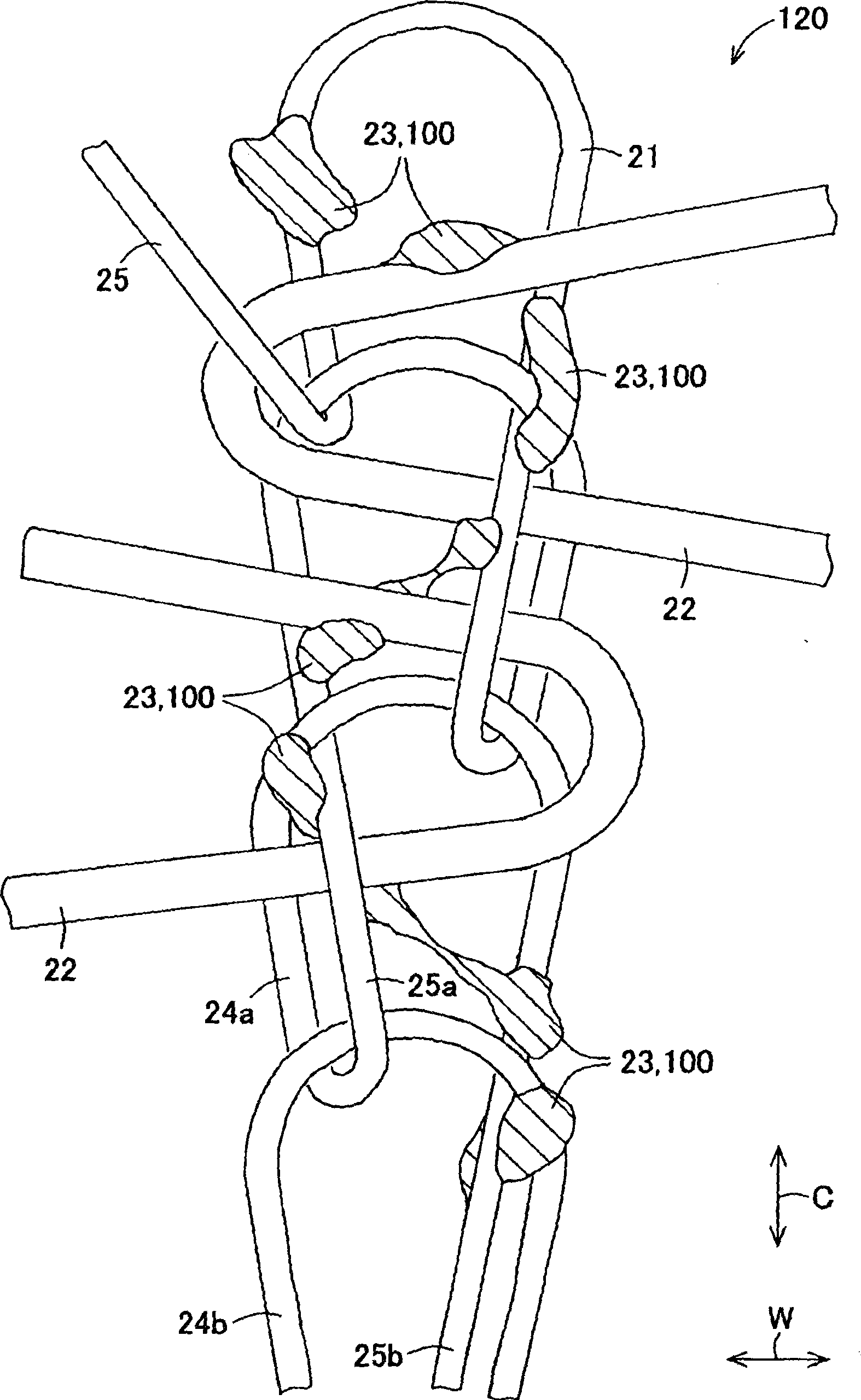

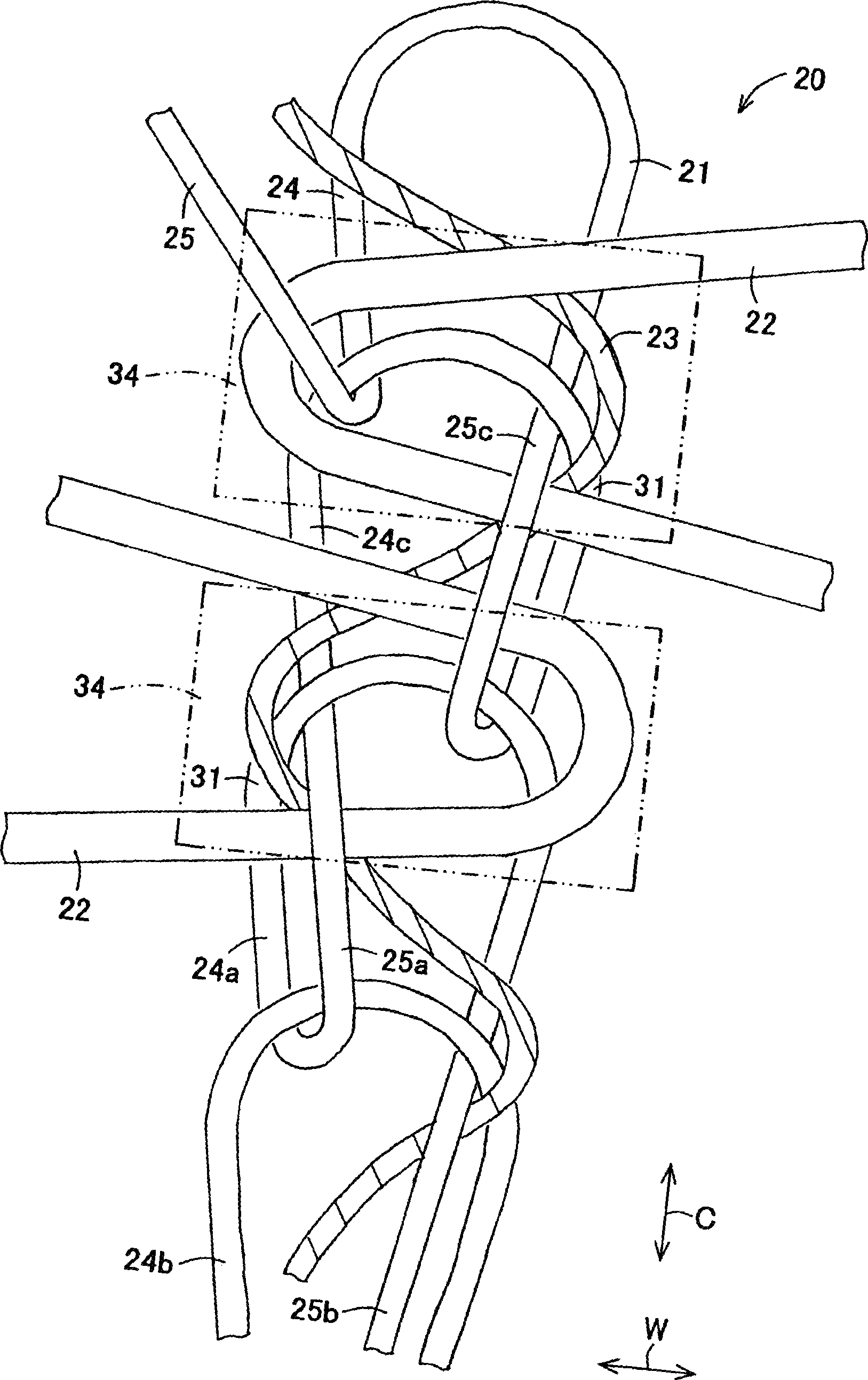

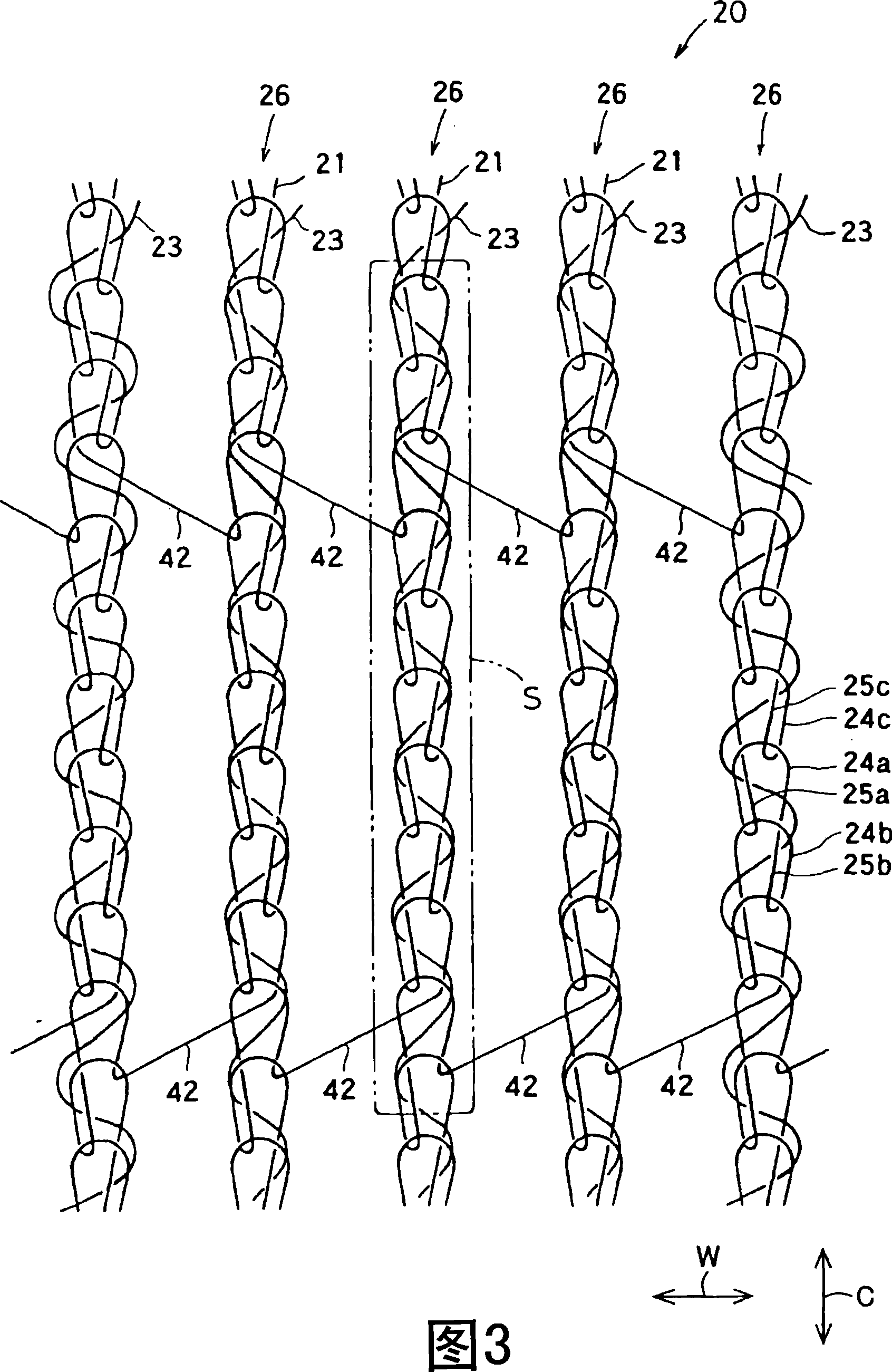

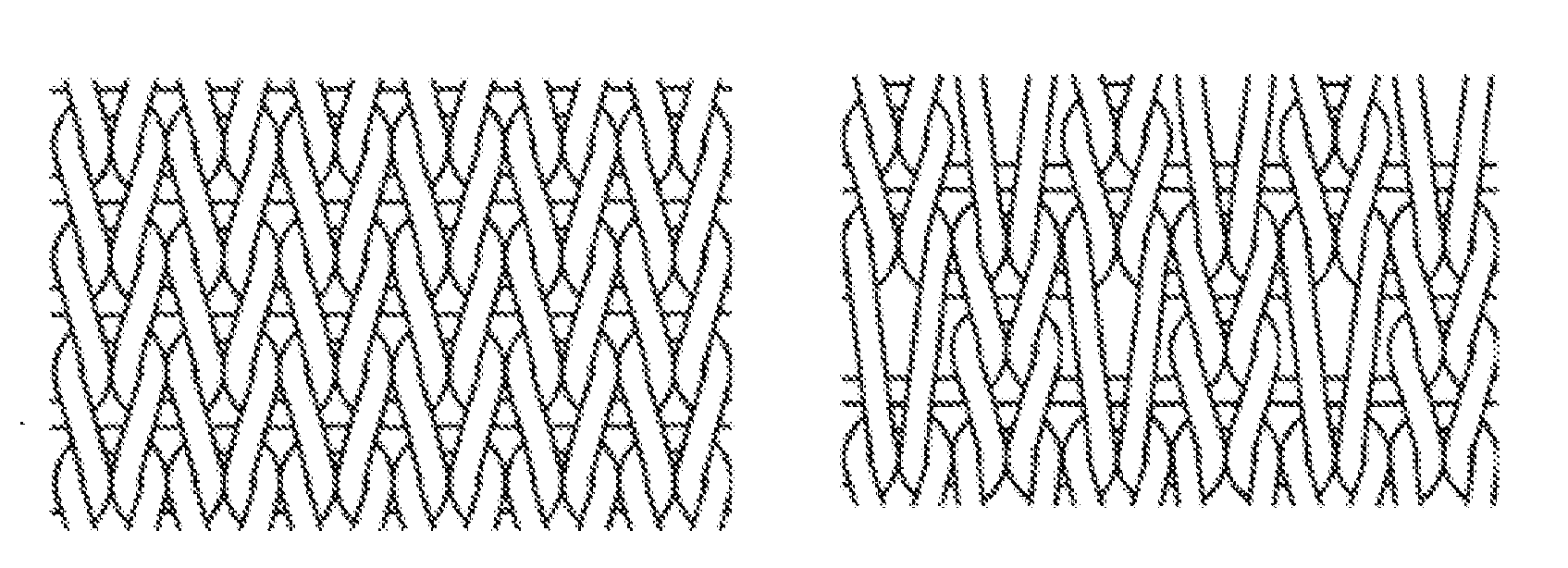

Method for producing knitted lace and knitted lace

A lace knitted fabric, and process for producing the same, capable of not only suppressing disfiguration but also preventing yarn fraying. Lace knitted fabric (120) after knitting operation is heated at a temperature which is below the melting temperature of chain stitch yarn (21) but not lower than the melting temperature of hot melt yarn (23) so that the hot melt yarn (23) is partially melted. Portion of the molten part sticks to the chain stitch yarn (21) and inserting yarn (22). As a result, the linking state of individual yarns (21-23) can be maintained to thereby prevent fraying of the yarns. Further, fusion bonded portion (100) can be formed by fracturing the hot melt yarn (23). Consequently, even when portion of the chain stitch yarn (21) constituting the chain stitch texture is segmentalized, fraying of the chain stitch texture can be prevented by the stuck portion of the hot melt yarn (23) so that fraying of the chain stitch texture beyond the stuck portion can be inhibited.

Owner:YOSHITA TEX

Fabric system

ActiveUS20160017521A1Suitable for useReduce harmCrochetingOrnamental textile articlesMedicinePolyurethane

A composite yarn comprising one or more ultra-high molecular weight polyethylene fibres wrapped around one or more polyurethane-polyurea copolymer fibres.

Owner:GRT DEV PTY +1

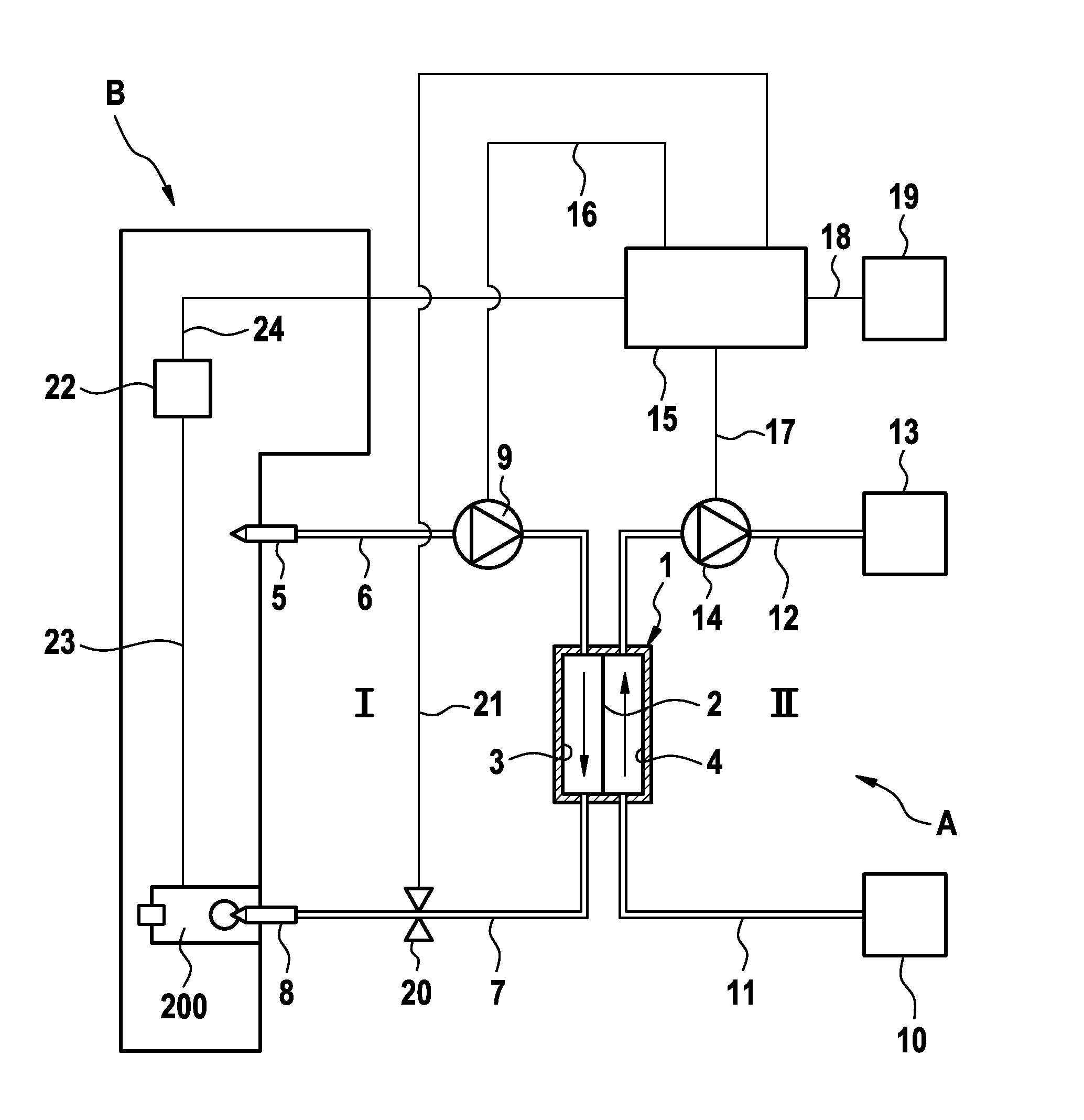

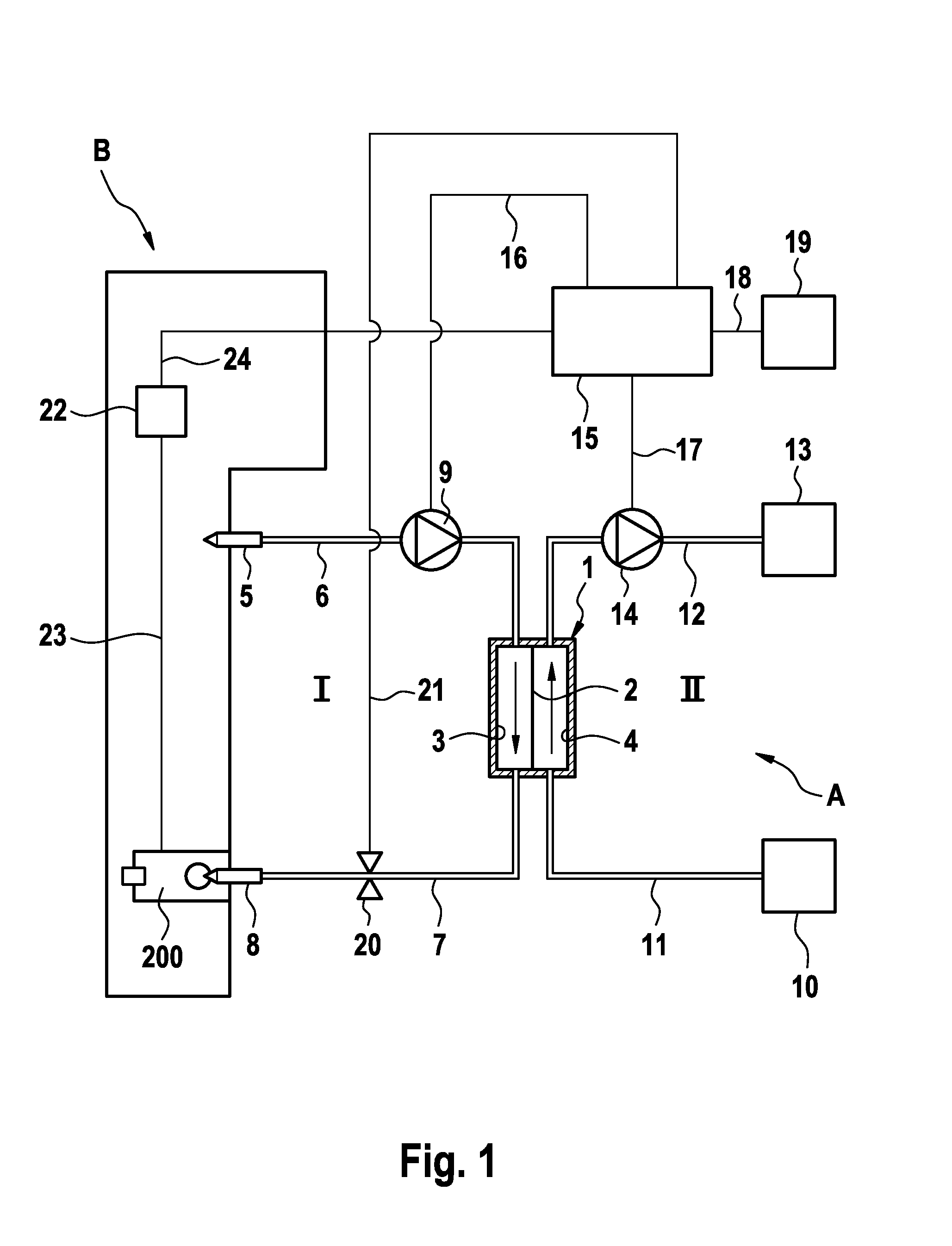

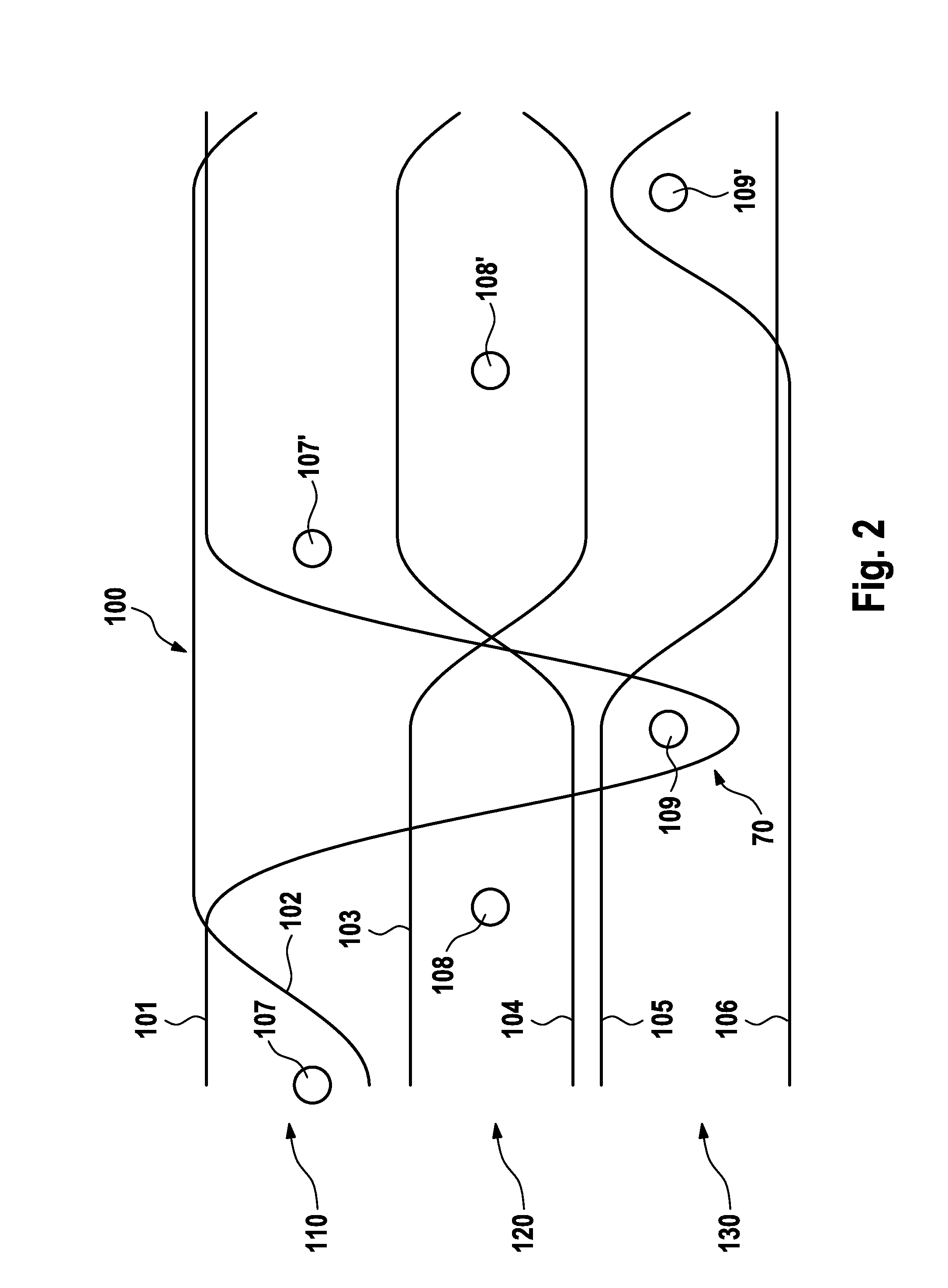

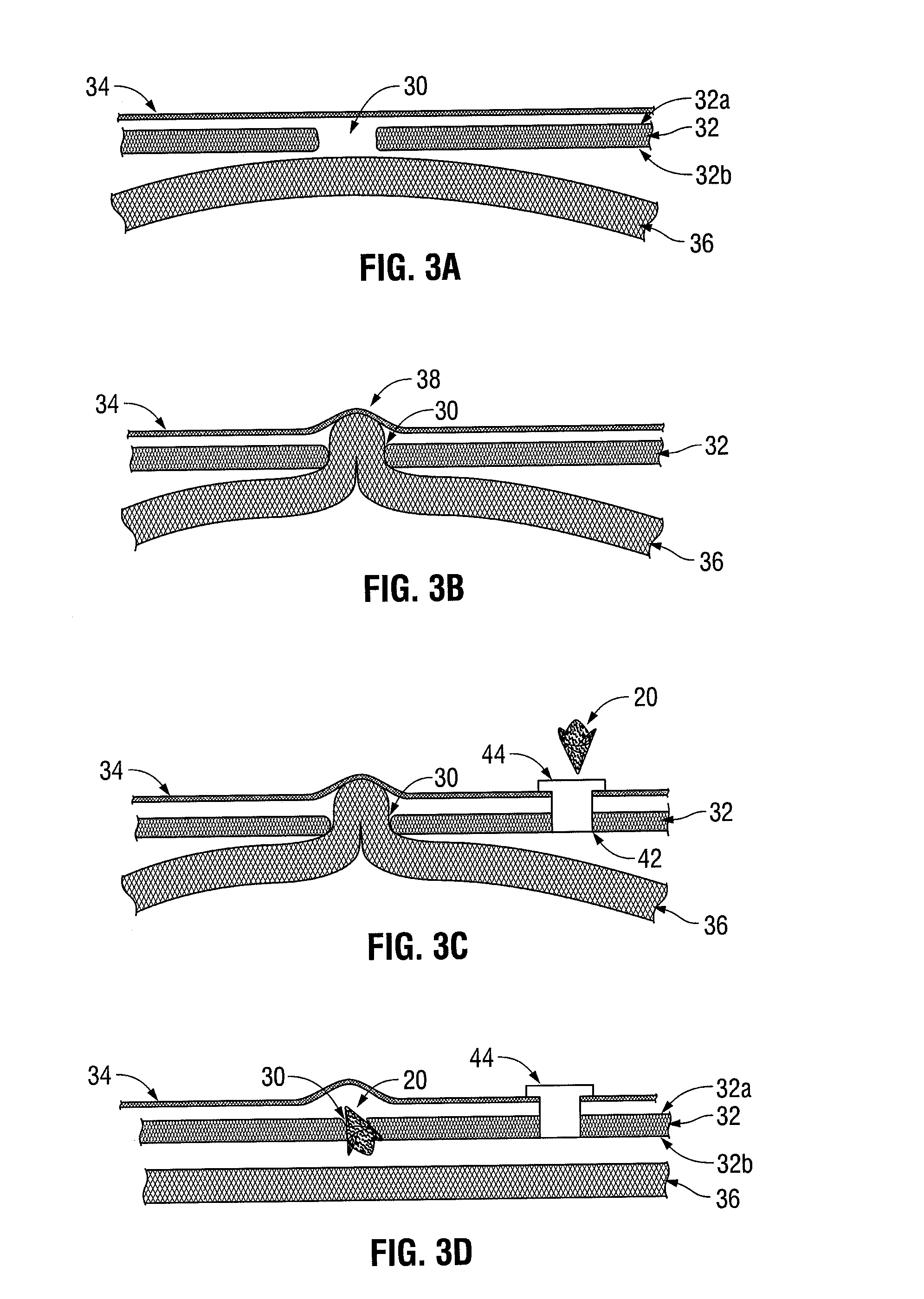

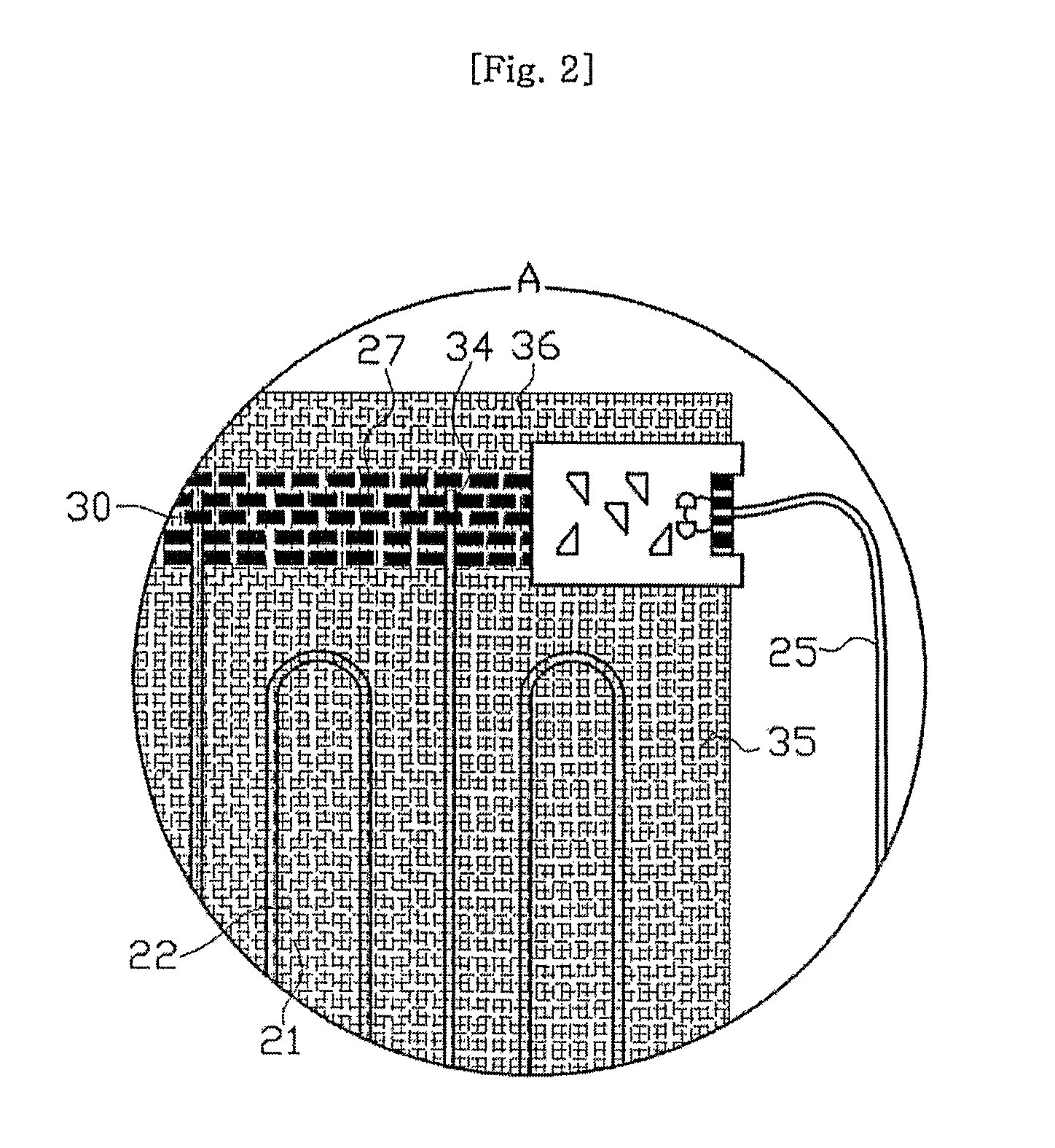

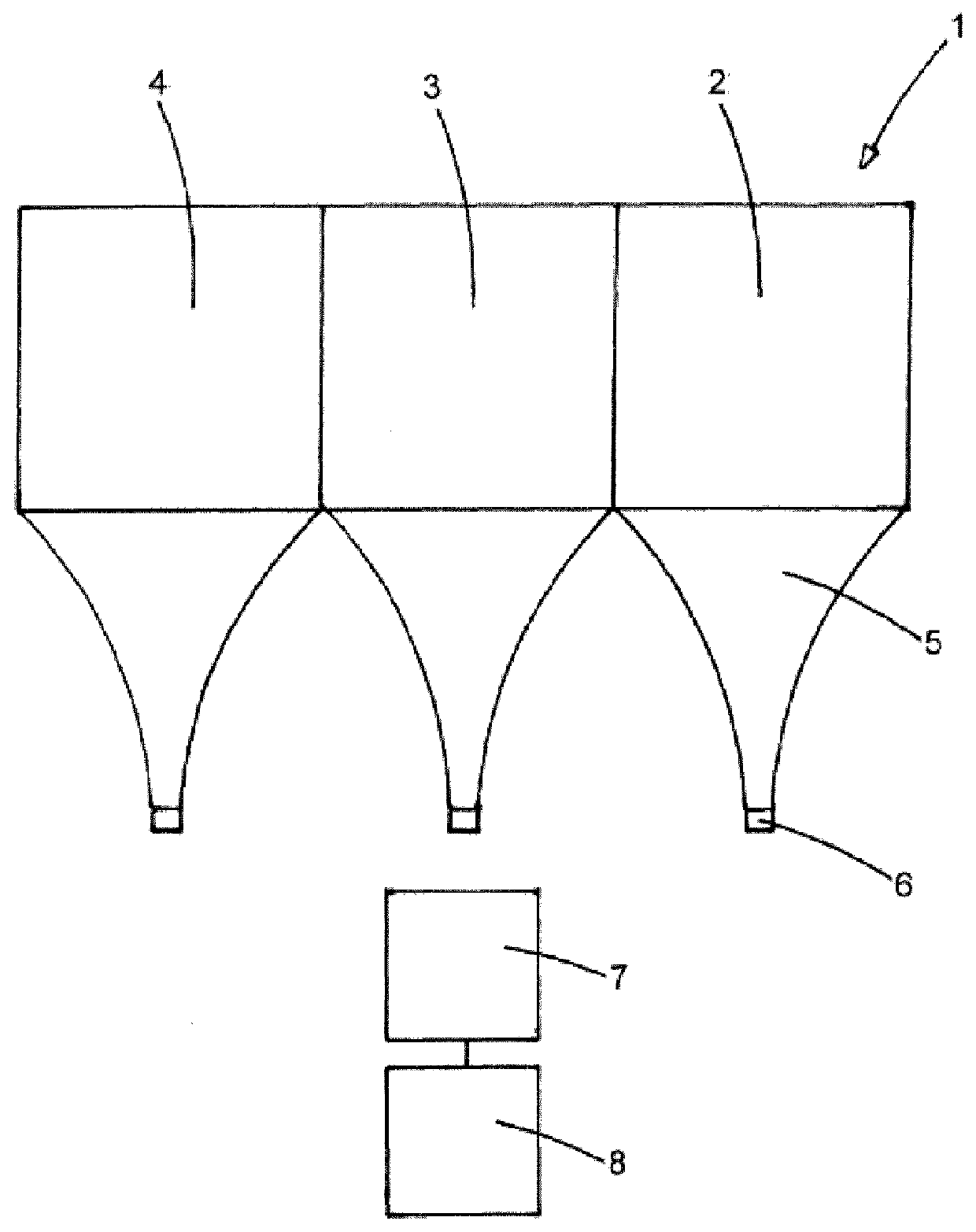

Weaving method for producing a plurality of moisture sensors for a device for monitoring a patient access

ActiveUS20130075018A1Produced cost-effectivelyLow production costCrochetingLiquid/gas/vapor article treatmentBlood treatmentsElectrical conductor

A weaving method for producing a plurality of moisture sensors for a device for monitoring an access to a patient, in particular for monitoring the vascular access in an extracorporeal blood treatment, wherein the moisture sensors are woven. During the weaving of the moisture sensors, non-conductive warp threads, non-conductive weft threads, conductive warp threads and conductive weft threads are disposed in the textile two-dimensionally extending structure, such that spatially demarcatable structures of electrical strip conductors are created. The strip conductor structures can be produced by spatial separation or contacting of the conductive warp or weft threads. In order to be able to produce the moisture sensors cost effectively in large numbers, a plurality of individual moisture sensors are repeatedly woven each time beside one another normal to the production direction on a common woven fabric web as the web progressively advances, so that the width of the woven fabric web is occupied in the best possible way by as many moisture sensors as possible. The individual moisture sensors are separated from one another after weaving.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

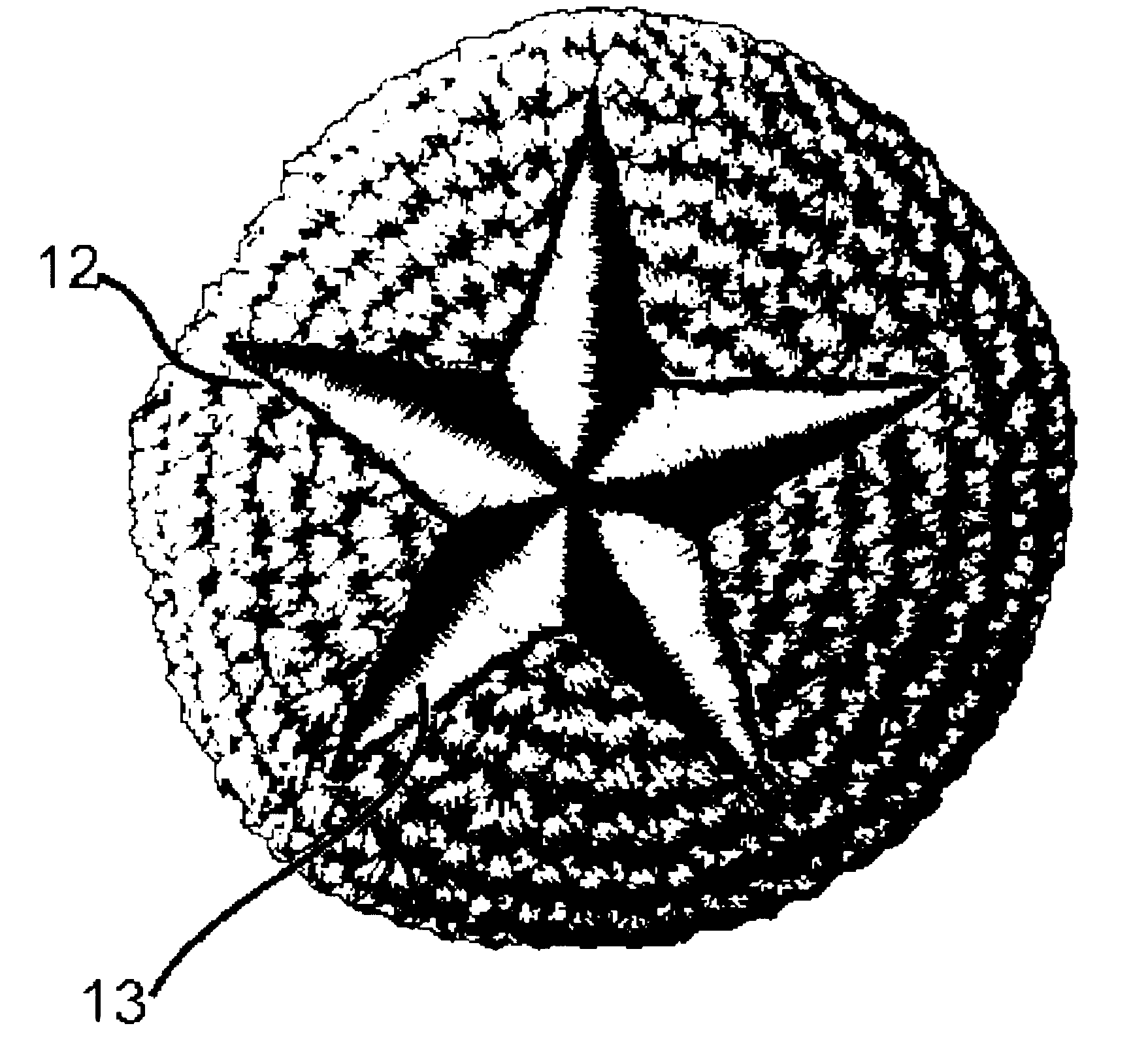

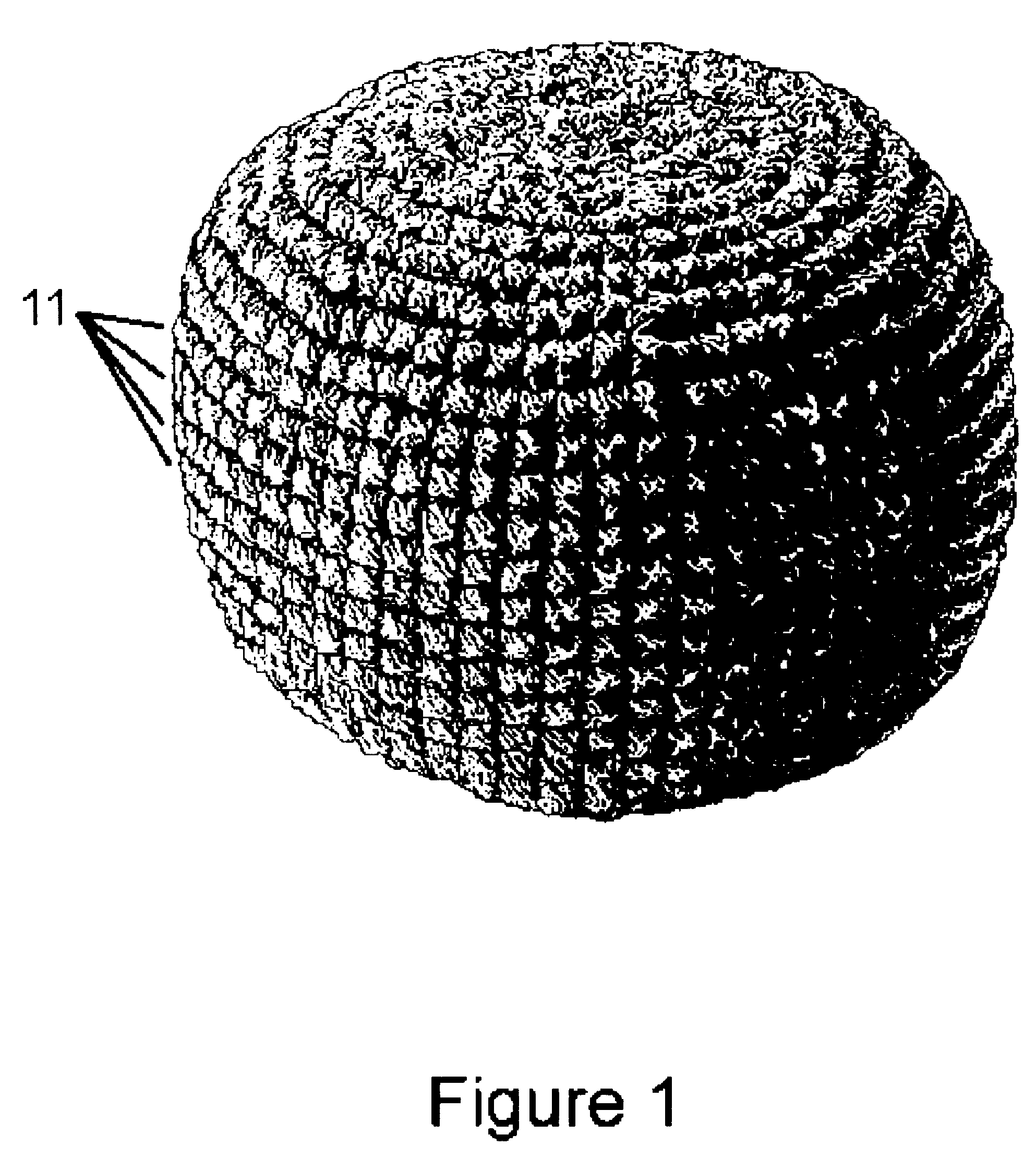

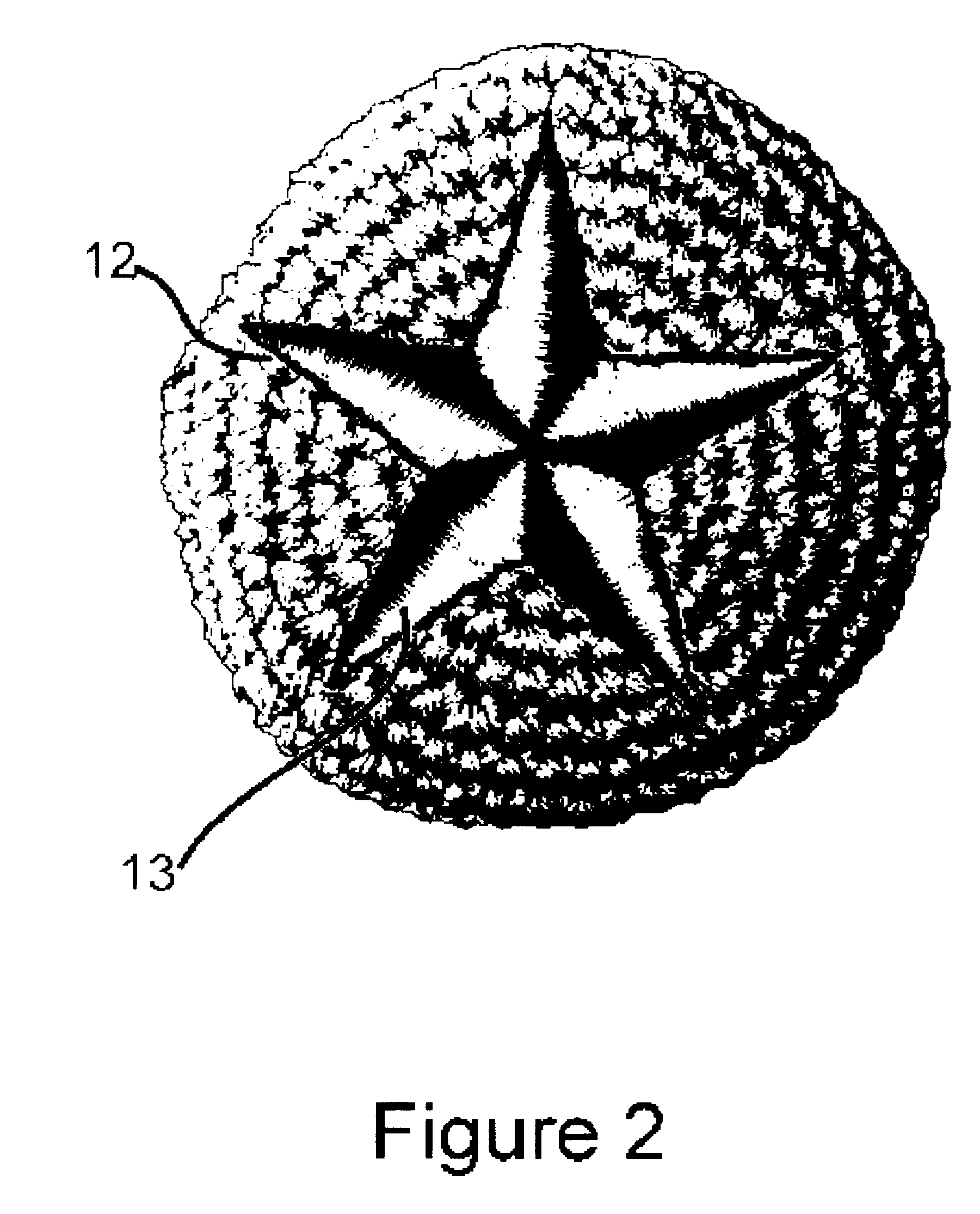

Spherical crocheted object having embroidery and the method of manufacture thereof

ActiveUS6994642B2Improve practicalityReduce quality problemsCrochetingOrnamental textile articlesEngineeringSpherical form

Owner:ADVENTURE TRADING

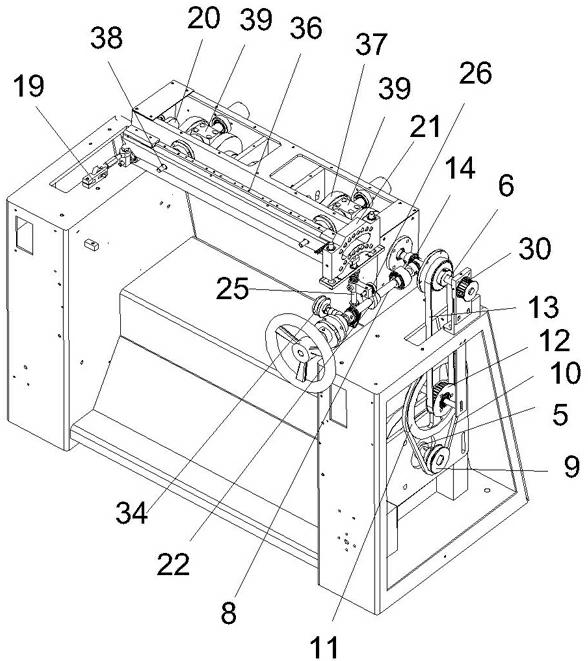

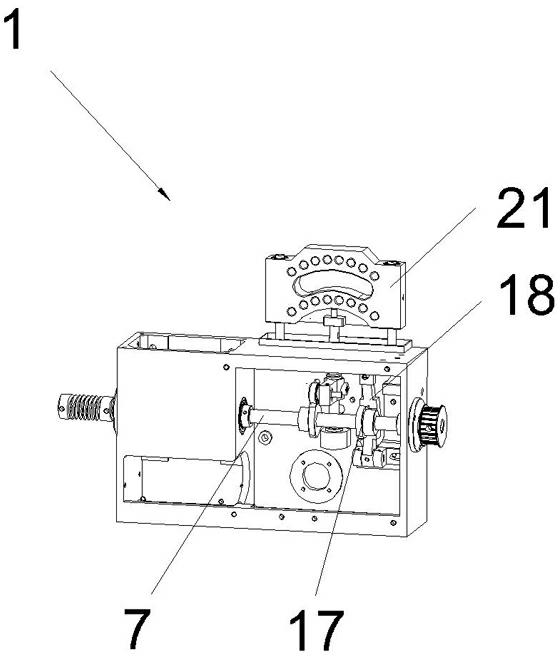

Multifunctional lace crochet machine

ActiveCN102154780ACollaborate closely with each otherSmooth power transmissionCrochetingSprocketEngineering

The invention mainly discloses a multifunctional lace crochet machine which comprises a power transmission device, a warp yarn mechanism, a weft yarn mechanism, a needle withdrawing mechanism, a needle blocking mechanism and a crossing mechanism. The needle blocking mechanism comprises a swing shaft, a blocking needle, a blocking needle drive arm and a needle blocking cam; one end of the needle blocking drive arm leans against the needle blocking cam driven by the power transmission device, and the other end of the needle blocking drive arm is fixedly connected with the swing shaft which rotates with the swing shaft of the needle blocking drive arm; and the swing shaft is fixedly connected with the blocking need which turns over inwards and outwards at the outer side of a needle bed with the swing shaft. The crossing mechanism comprises a weft yarn shaft, a swing arm, a shift fork and a floret chain transmission device, wherein the weft yarn shaft is mounted on the weft yarn mechanismand fixed with a weft yarn tube; the swing arm is fixedly sleeved on the weft yarn shaft; the shift form shifts the swing arm to swing; the floret chain transmission device supplies power to the shift fork; and a floret chainwheel in the floret chain transmission device is driven by the power transmission device. The multifunctional lace crochet machine disclosed by the invention is suitable for crocheting various flower forms, remarkably shortens the knitting time and has high production efficiency.

Owner:SHAOXING SANFANG MACHINERY

Piezoelectric vibrator

InactiveUS7352117B2Improve seismic performanceCrochetingImpedence networksTuning forkPiezoelectric actuators

A tuning fork type piezoelectric vibrator is provided with vibrating arms which can improve shock resistance while suppressing a CI value to a small value. A first groove (base end side) and a second groove (tip side) extend along a longitudinal direction from a base end of the vibrating arm and are formed on at least one of a front surface or a back surface of the vibrating arms. Then, a ratio L2 / L1 which is the ratio of a length L2 of the first groove to a length L1 from the base end of the vibrating arm to the tip of the second groove, is set between 0.35 and 0.65, and a ratio d / L1 which is the ratio of a space d between the first groove and the second groove to the length L1 from the base end of the vibrating arm to the tip of the second groove, is set between 0.010 and 0.016.

Owner:NIHON DEMPA KOGYO CO LTD

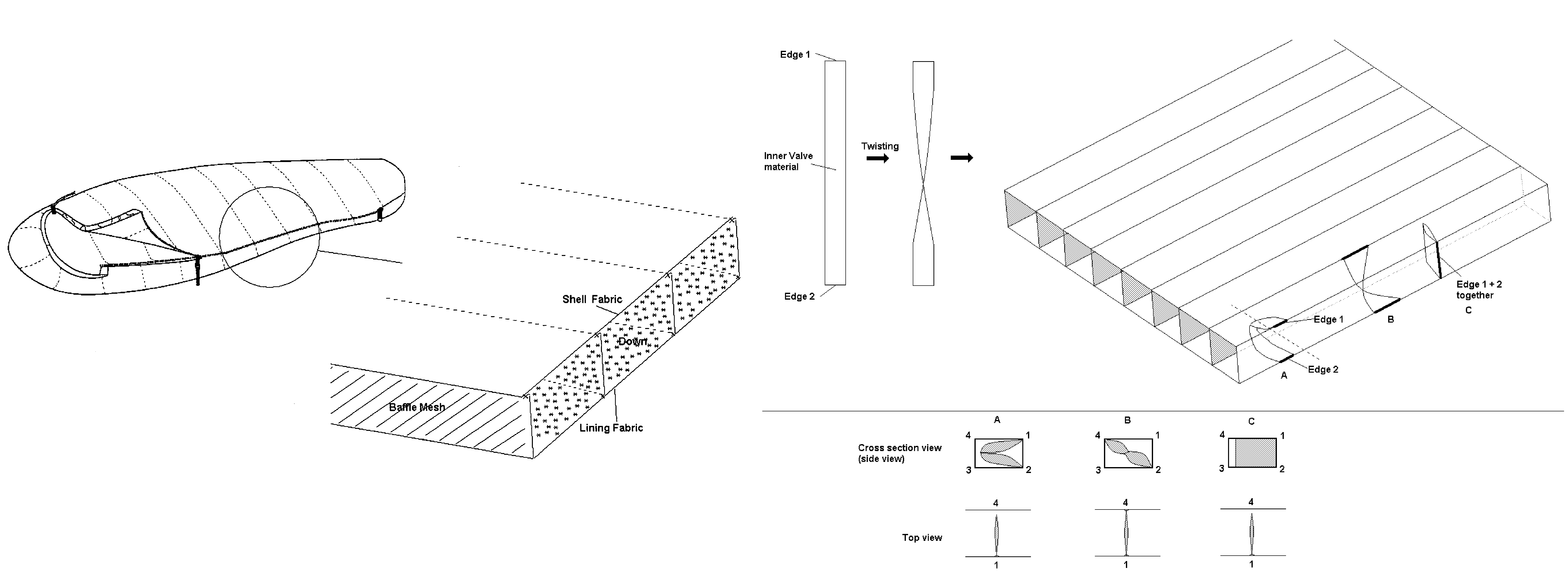

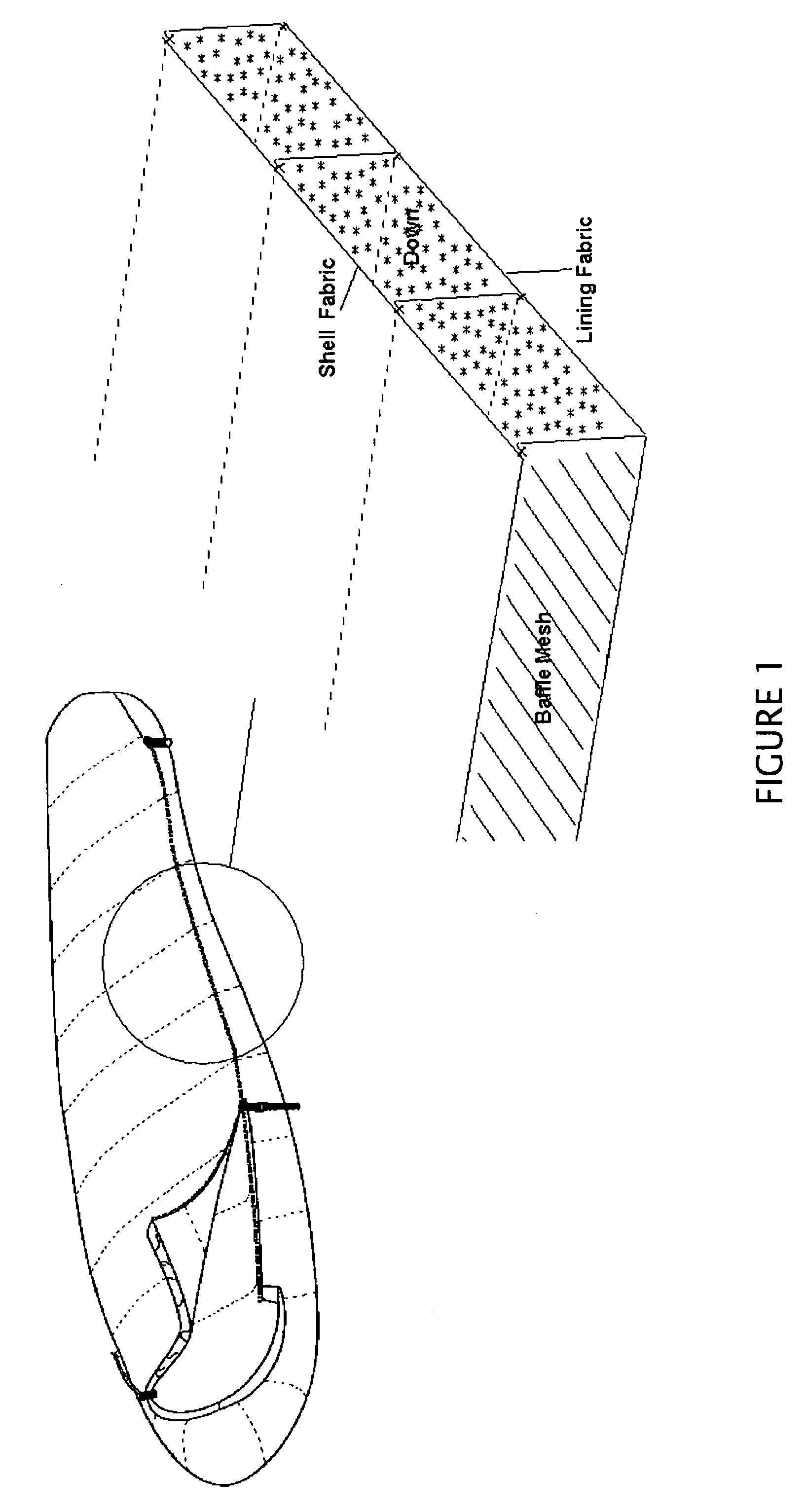

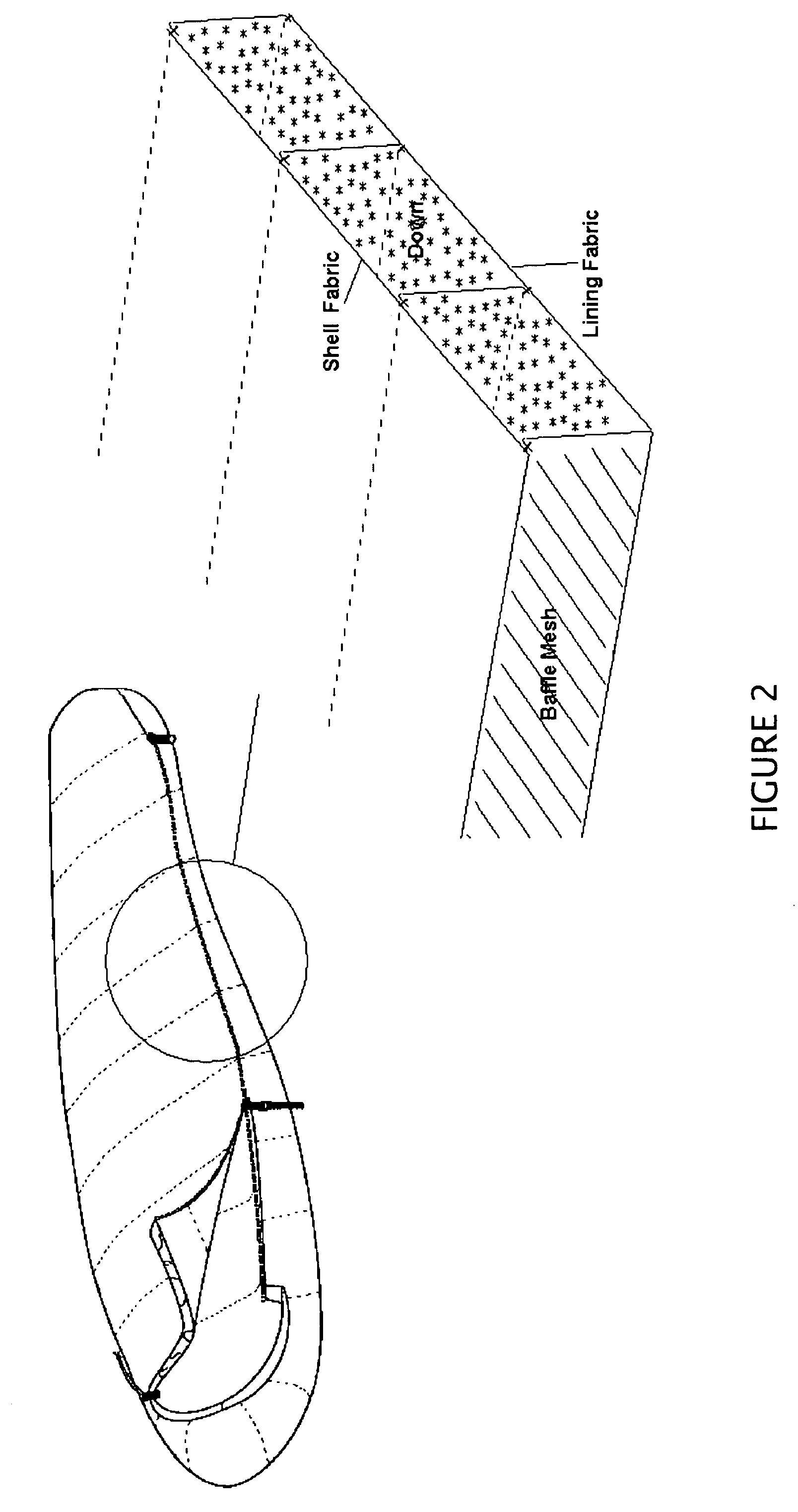

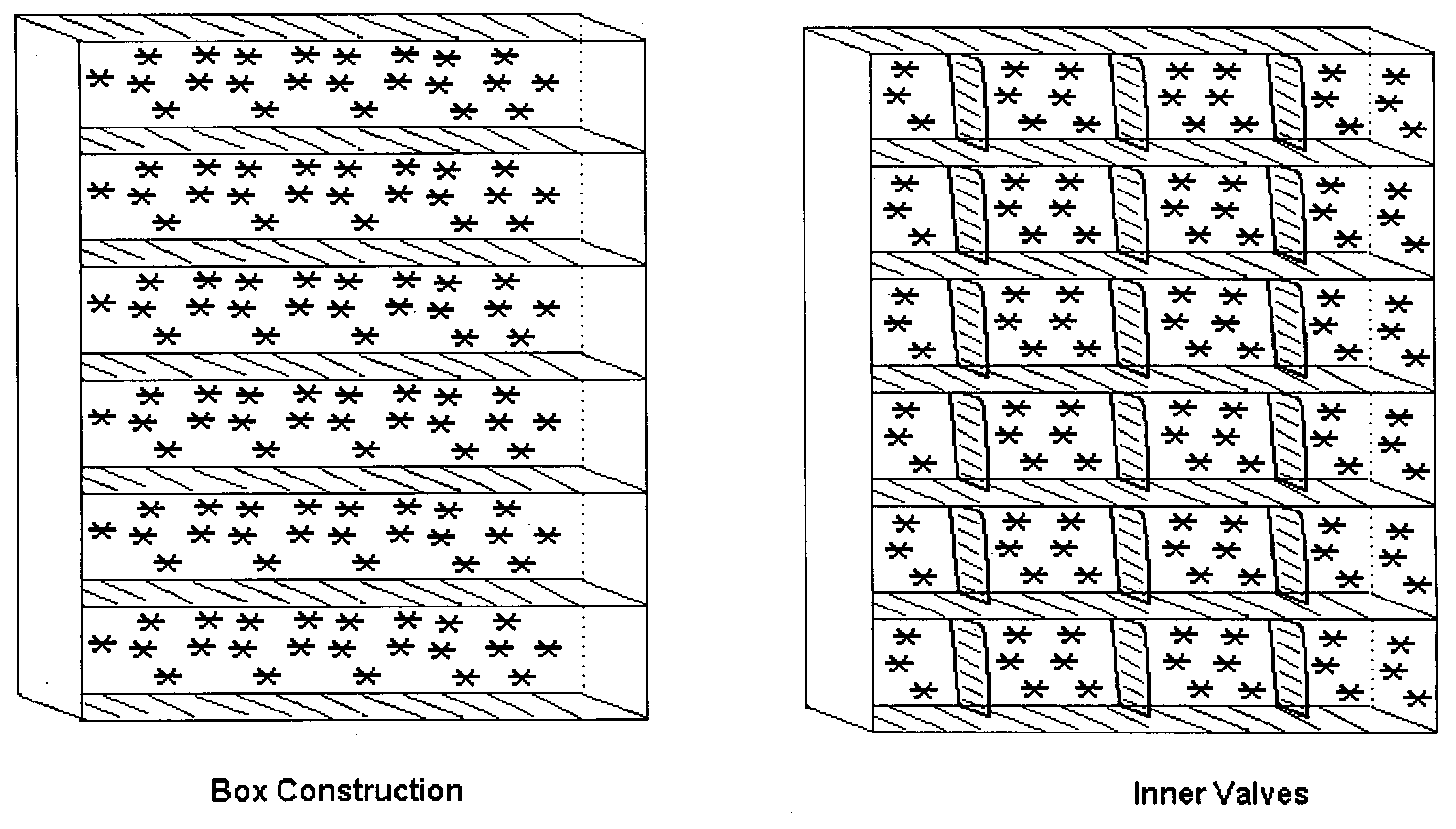

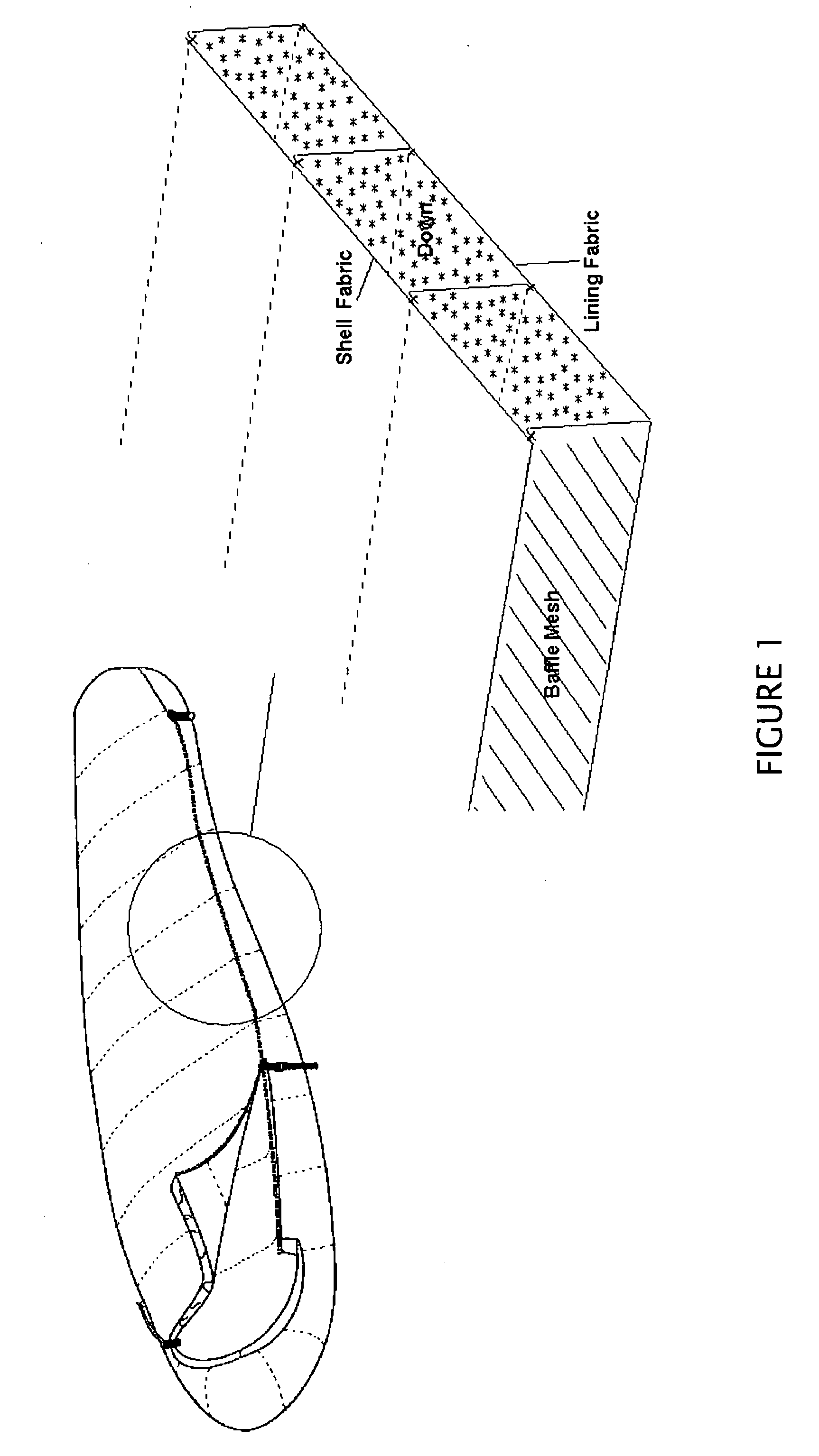

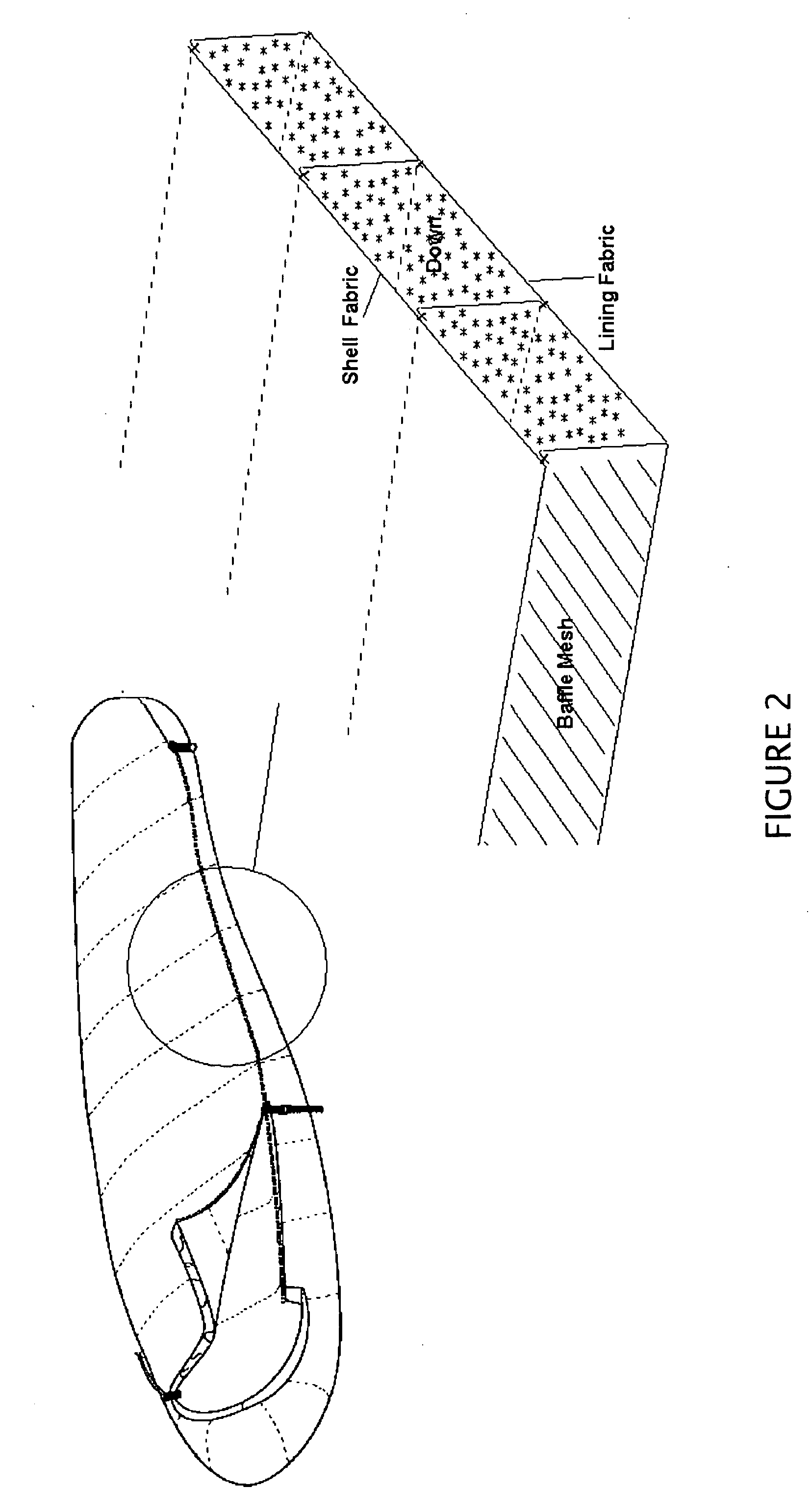

Insulated product

InactiveUS7818834B2More appearanceDesign moreCrochetingGarment special featuresEngineeringVALVE PORT

Owner:LI YICK LAP

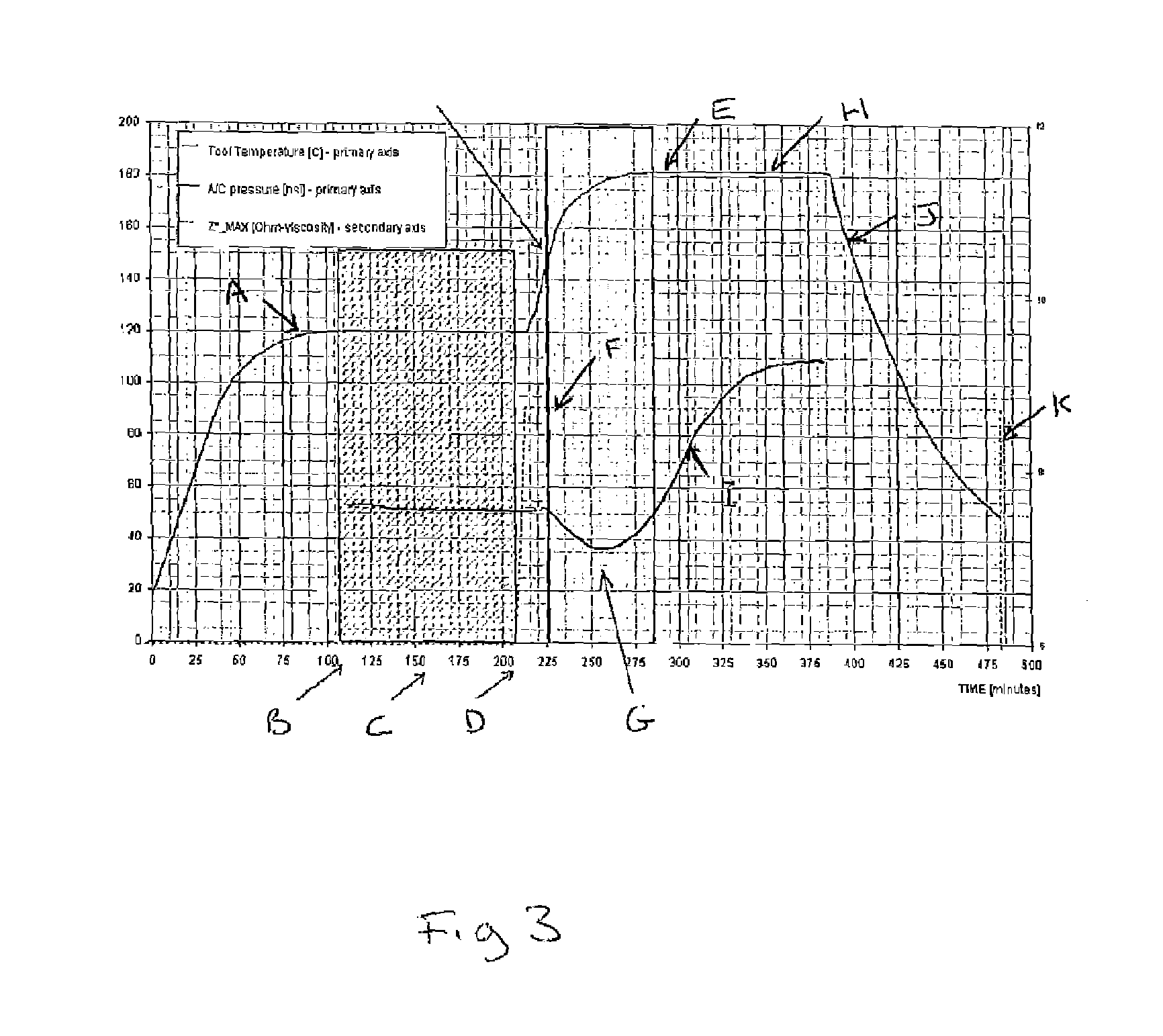

Method of forming a composite material with added nanoparticles and carrier material containing nanoparticles

A method of forming a nanocomposite material that includes nanoparticles includes disposing in a forming apparatus a fiber material, a carrier material with nanoparticles dispersed therein, the carrier material having a releasing trigger to release the nanoparticles, the releasing trigger being at least one of a releasing temperature and a releasing pressure, and a resin having an infusion temperature, increasing the temperature within the forming apparatus to a temperature at least equal to the infusion temperature of the resin to allow the resin to impregnate the fiber material without triggering the releasing trigger of the carrier material, and triggering the releasing trigger of the carrier material in the forming apparatus by increasing at least one of the temperature and the pressure within the forming apparatus to cause dispersion of the nanoparticles.

Owner:SHORT BROTHERS

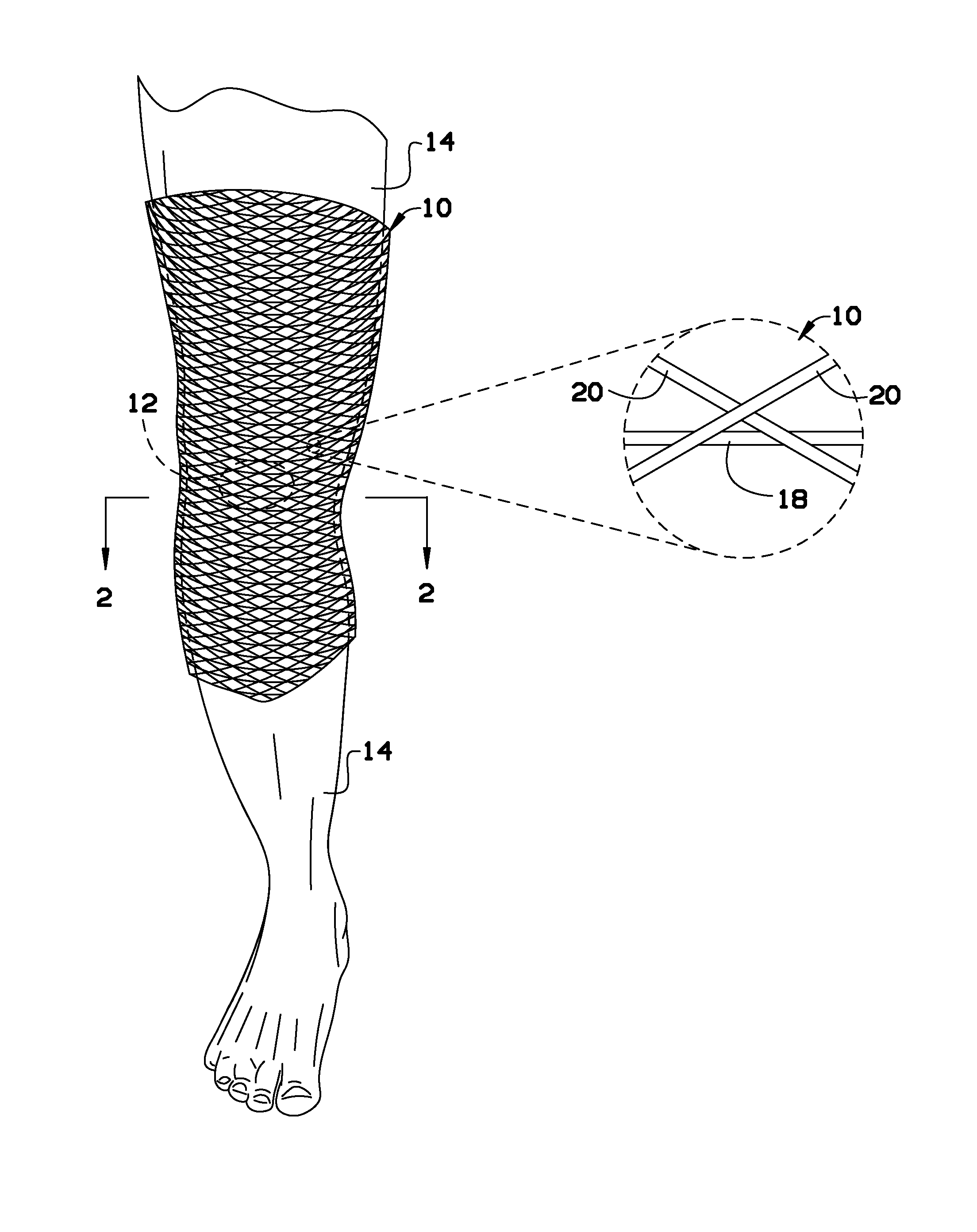

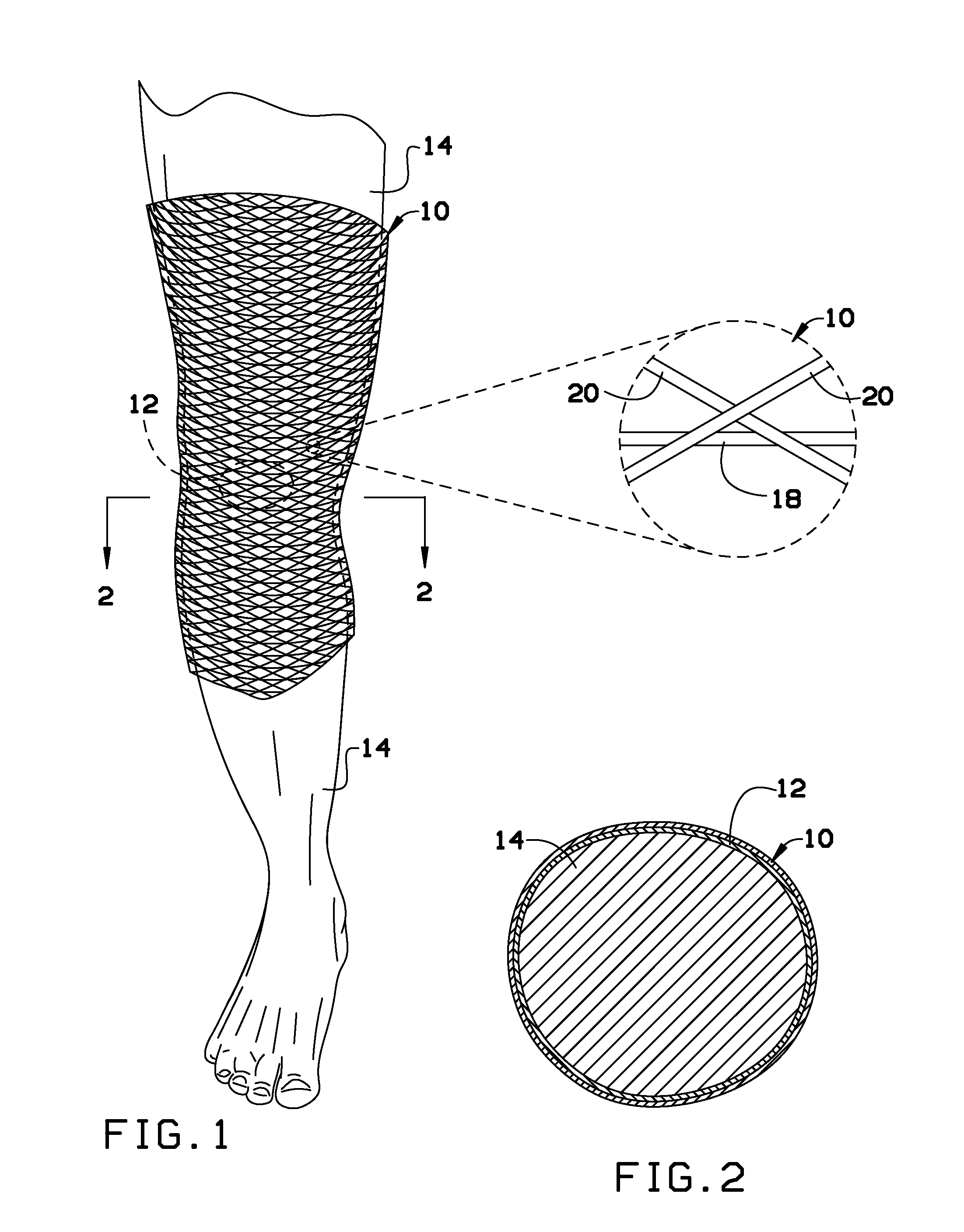

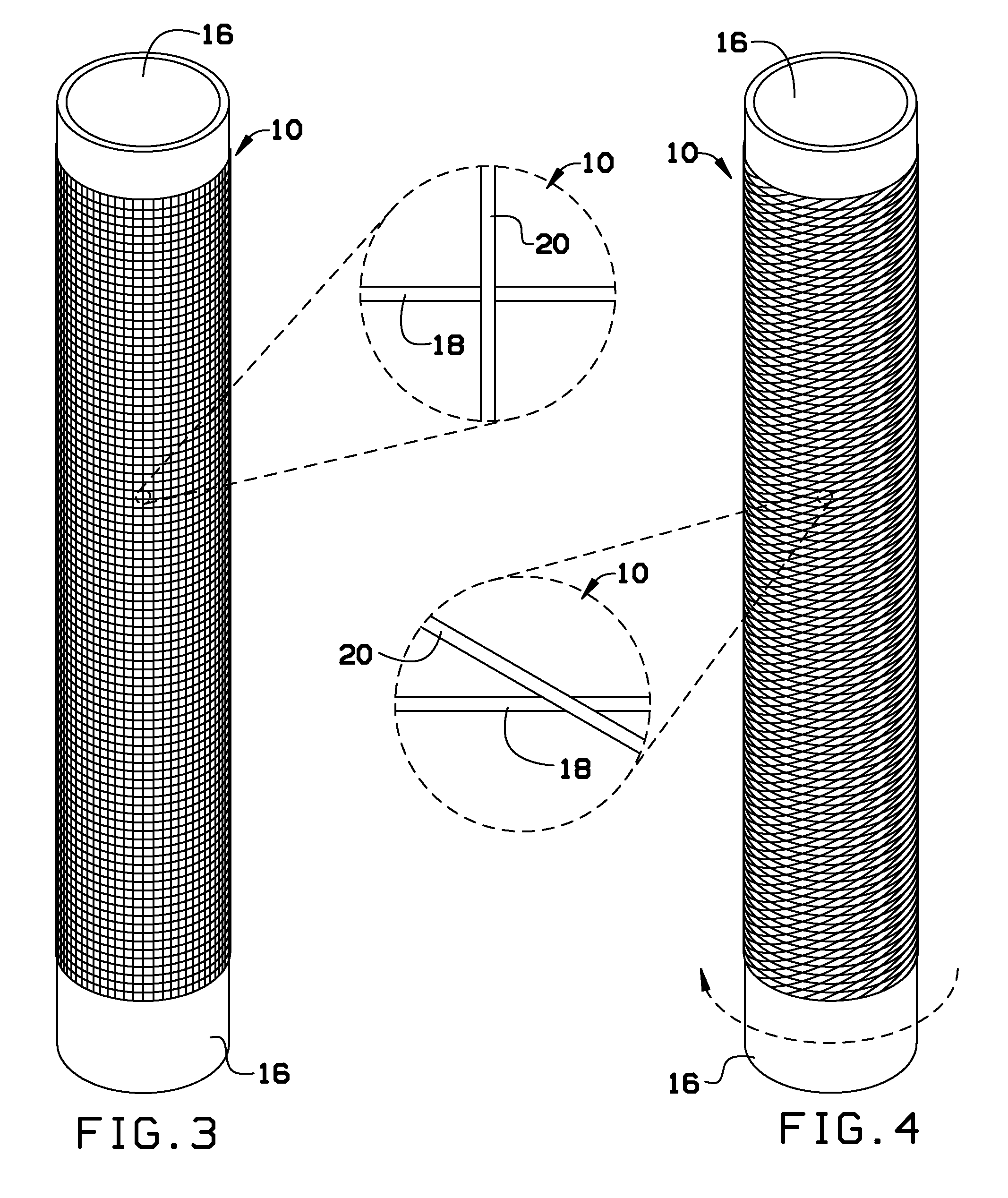

Joint support device

A joint support device is provided. The joint support device may include a first tubular layer and a second tubular layer both made of crisscrossing fibers. The crisscrossing fibers of the first tubular layer may be oriented in a spiral in a first direction and the crisscrossing fibers of the second tubular layer may be oriented in a spiral in an opposite direction of the first direction. The first and second tubular layers may be layered together and may be attached to an existing elastic knee brace.

Owner:CHANDLER JR FRANKLIN WOODROW

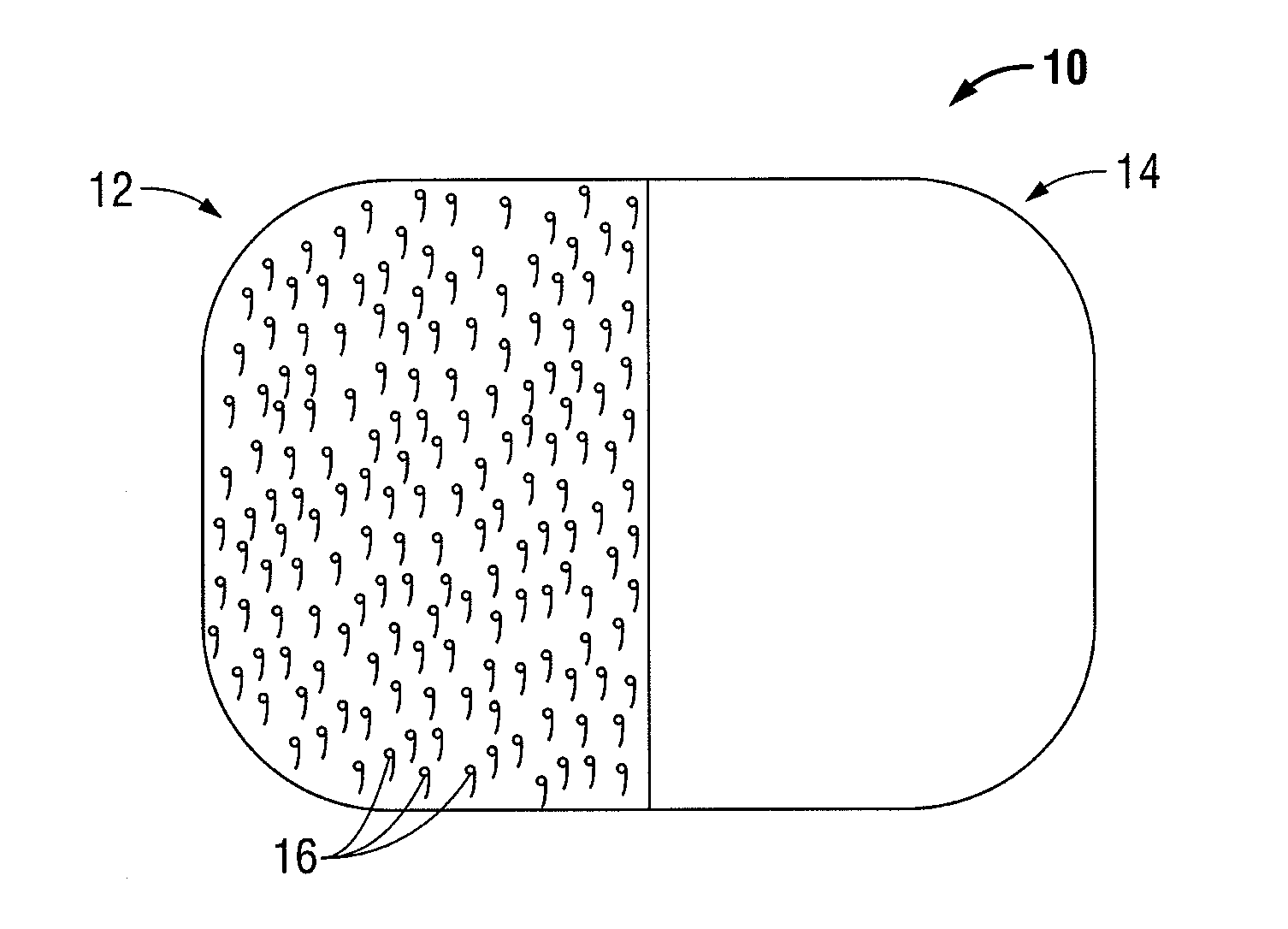

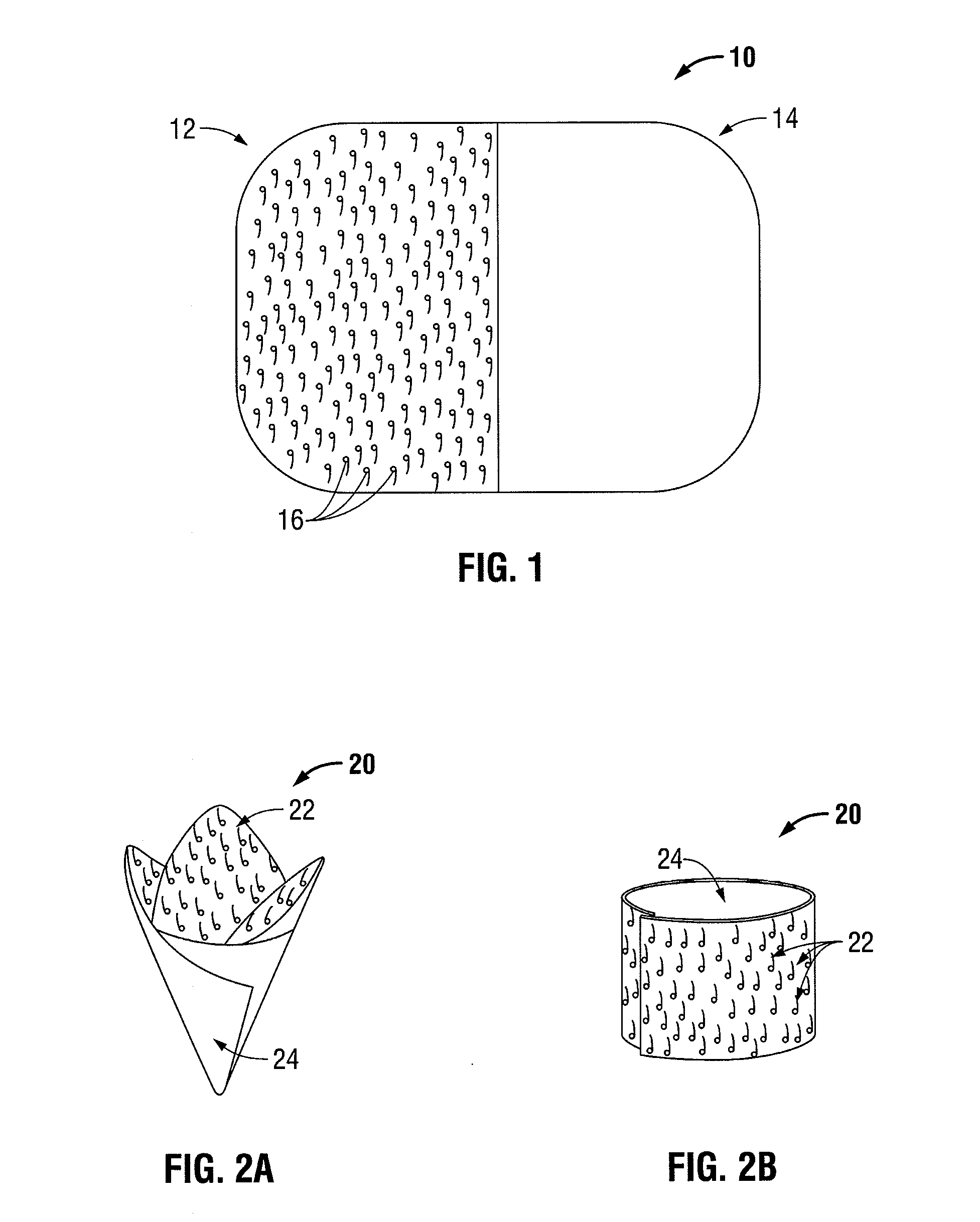

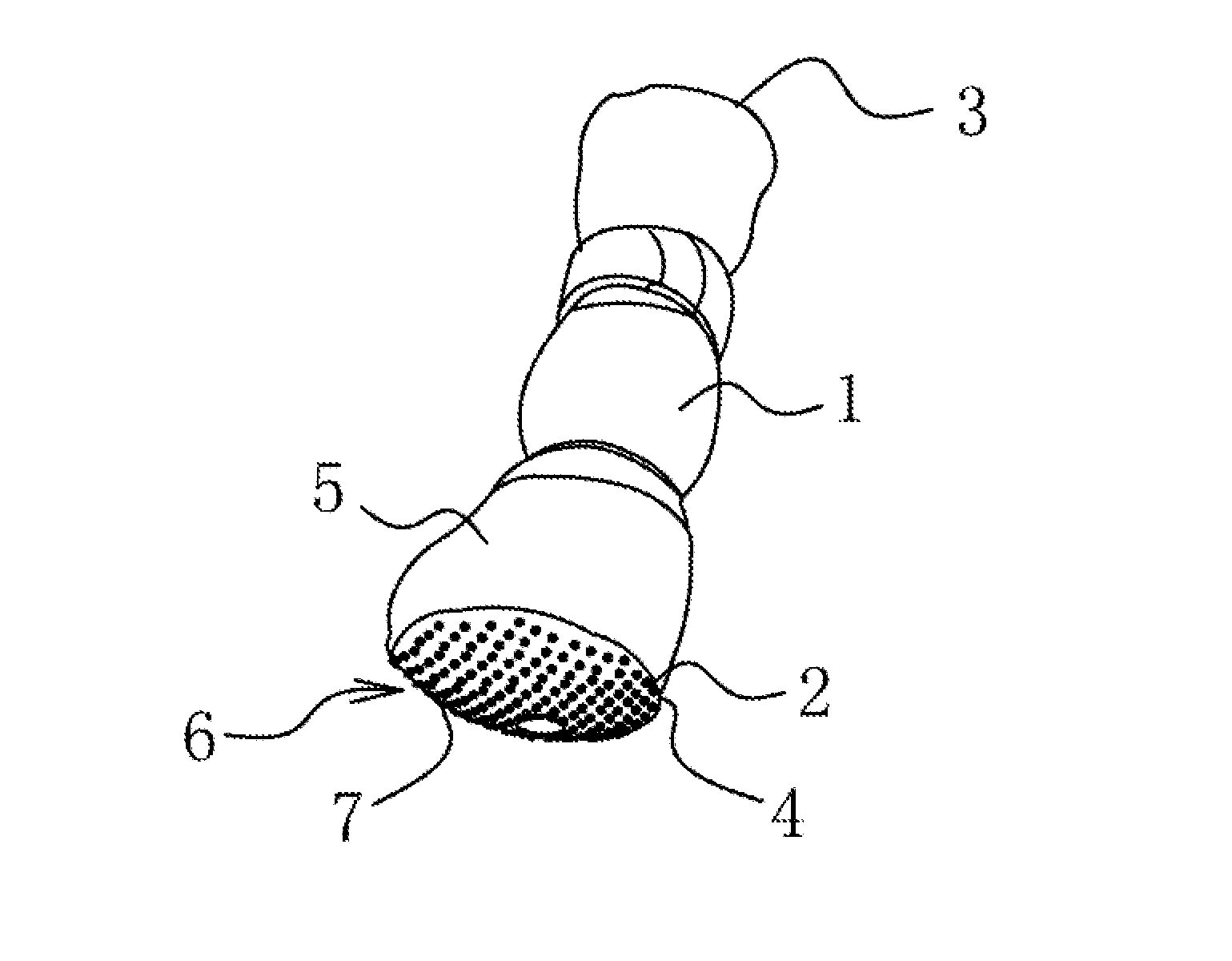

Three-dimensional surgical implant

Three-dimensional surgical implants include a grip-type knit mesh folded into a three-dimensional structure. Spiked naps provided on the mesh grip pores on the mesh to hold the implant in the three-dimensional structure.

Owner:TYCO HEALTHCARE GRP LP

System and method for forming a design from a flexible filament having indicators

The present disclosure is directed to a flexible filament that includes a length of material configured to be used in forming at least a portion of a textile product to have at least a portion of a visual pattern that is visible on at least one of a first side or a second side of the textile product. The material includes a plurality of stitch indicators formed on the material to separate the material into a plurality of segmented regions, at least one of the stitch indicators or the segmented regions forming at least the portion of the visual pattern visible on the at least one of the first side or the second side of the textile product.

Owner:RAYNOR ALIDA CATHLEEN

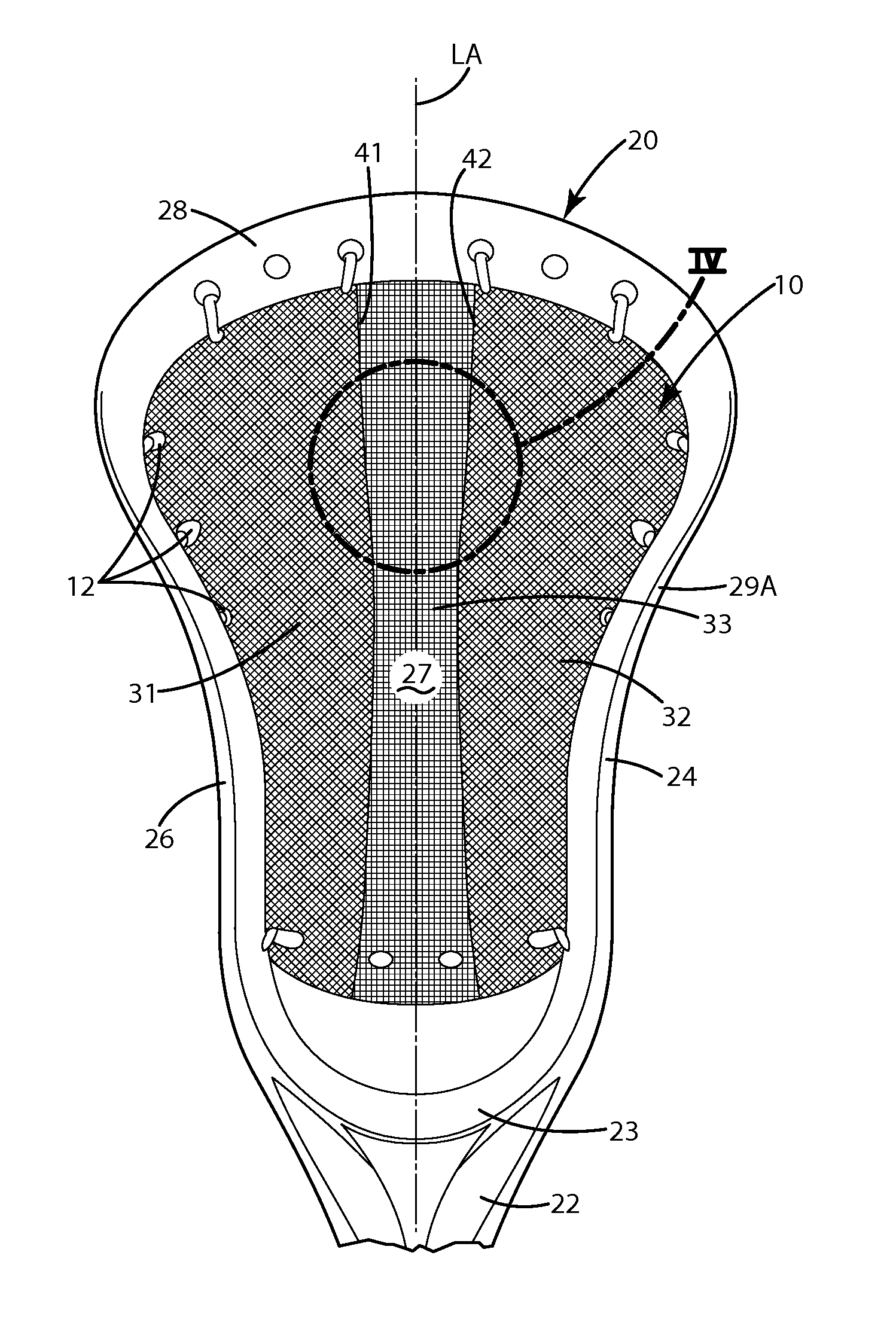

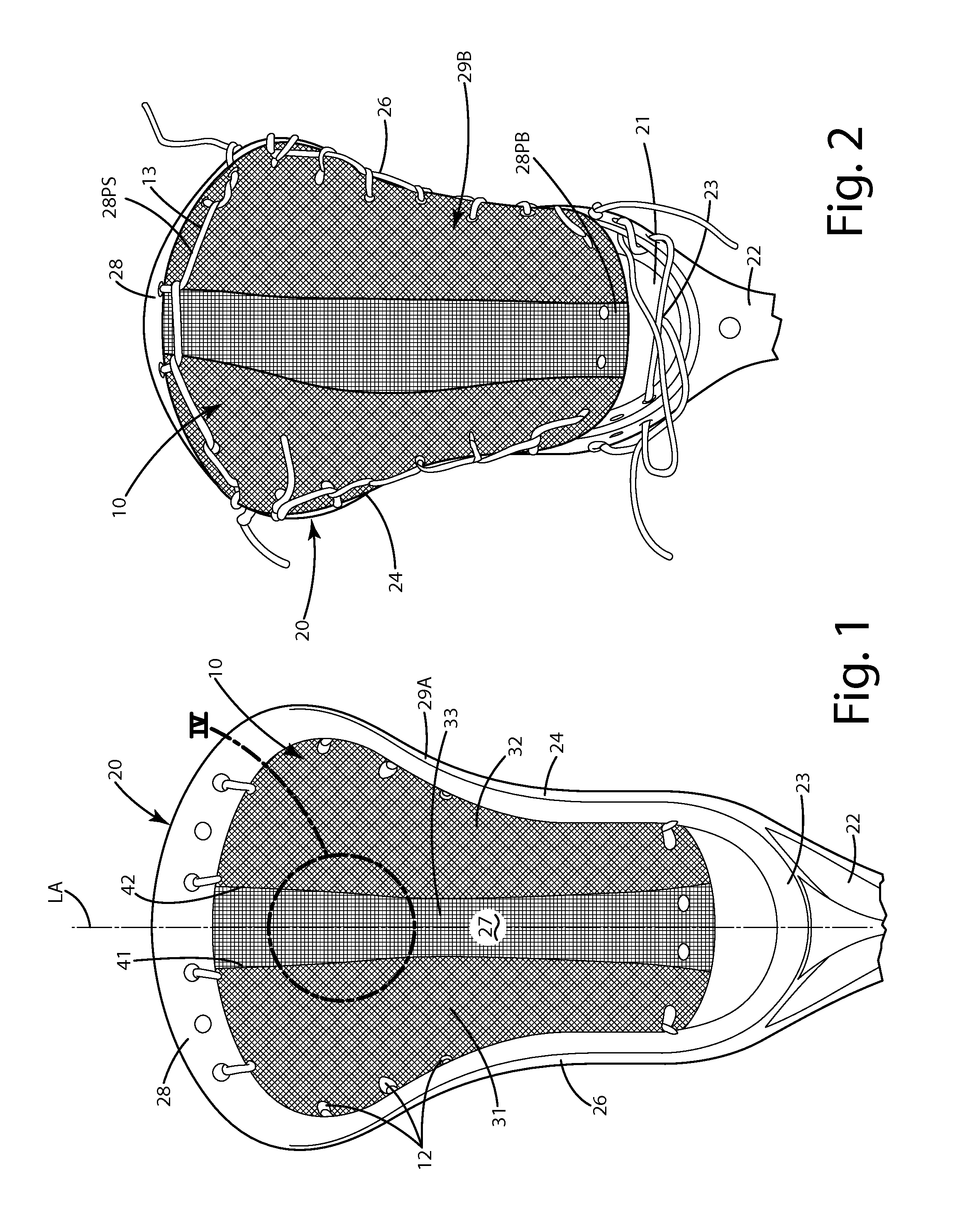

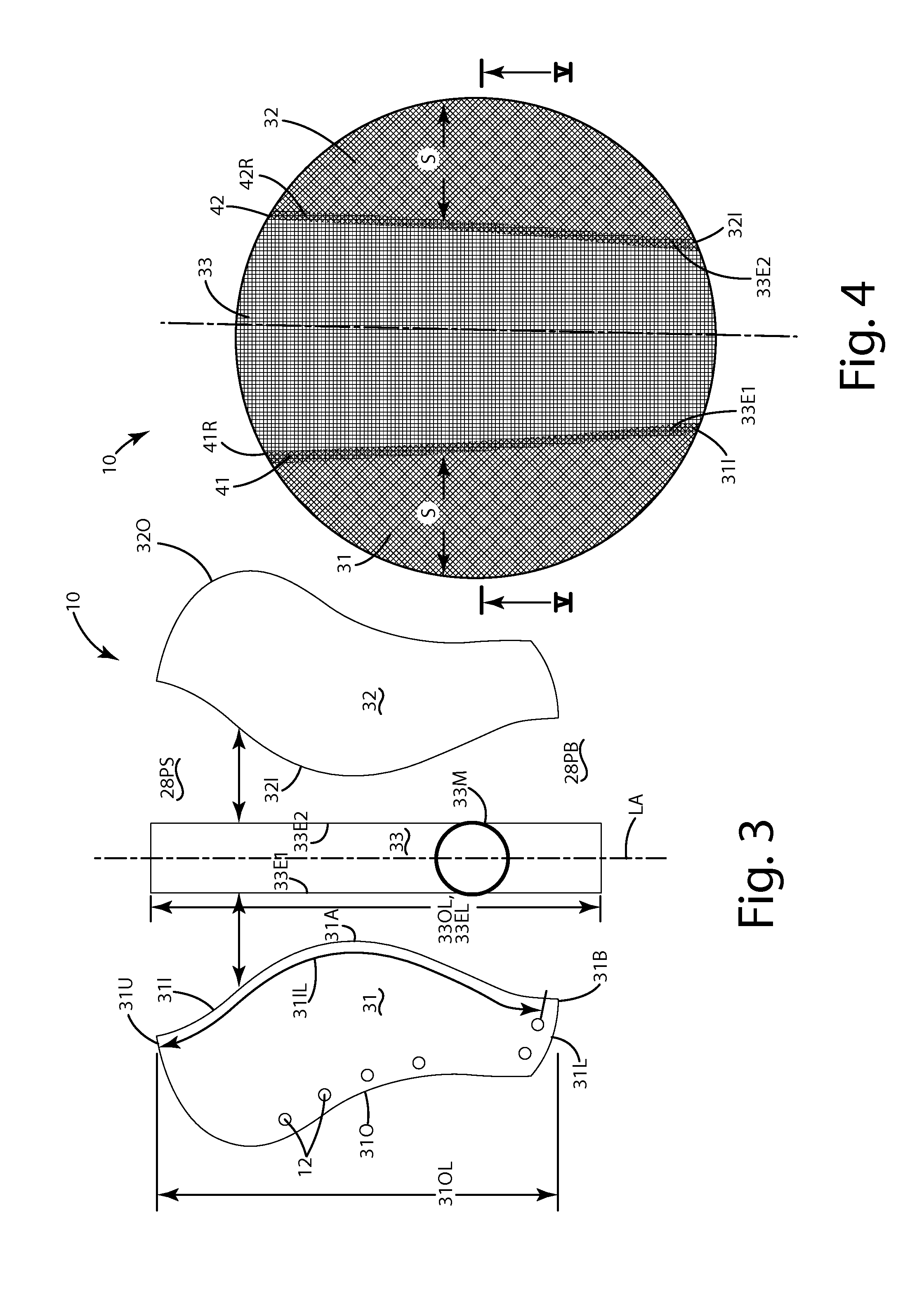

Lacrosse head pocket and related method of manufacture

ActiveUS20160038802A1Easy to manufactureEasy to replaceCrochetingOrnamental textile articlesEngineeringMechanical engineering

A lacrosse head pocket and a related method of manufacture are provided to facilitate consistent, repeatable and / or custom manufacture of lacrosse equipment. The pocket can be constructed from multiple different sections joined with one another, or can be knitted, weaved or otherwise assembled on an automated assembly machine from strands, and / or can be formed as a unitary textile material having regions / sections with different physical and / or mechanical properties. The pocket can be integrally molded within portions of a lacrosse head to eliminate manually constructed connections between the pocket and lacrosse head. The lacrosse head can be integrally molded with a lacrosse handle to provide a one-piece unitary lacrosse stick. Related methods of manufacturing also are provided.

Owner:WARRIOR SPORTS INC

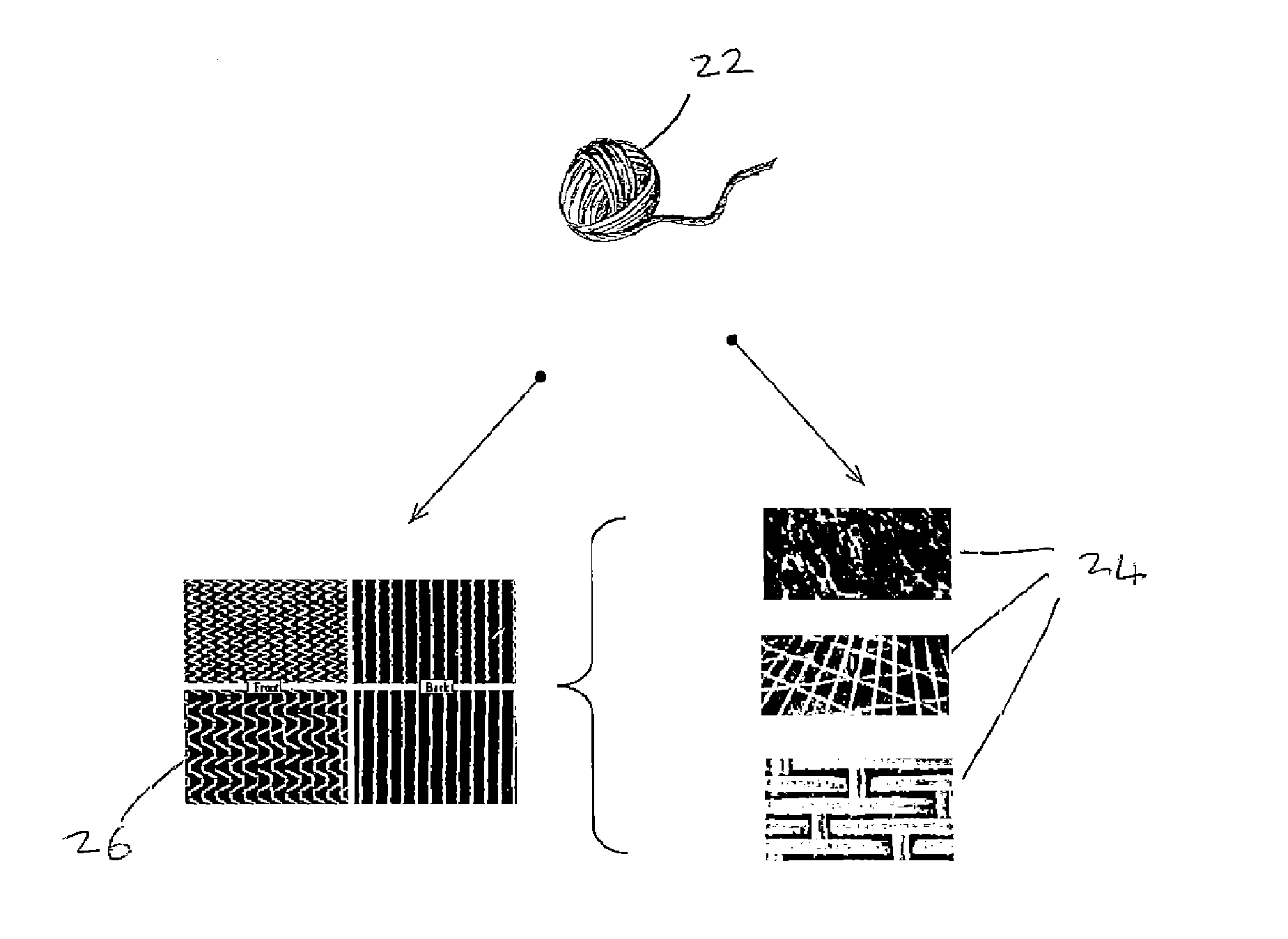

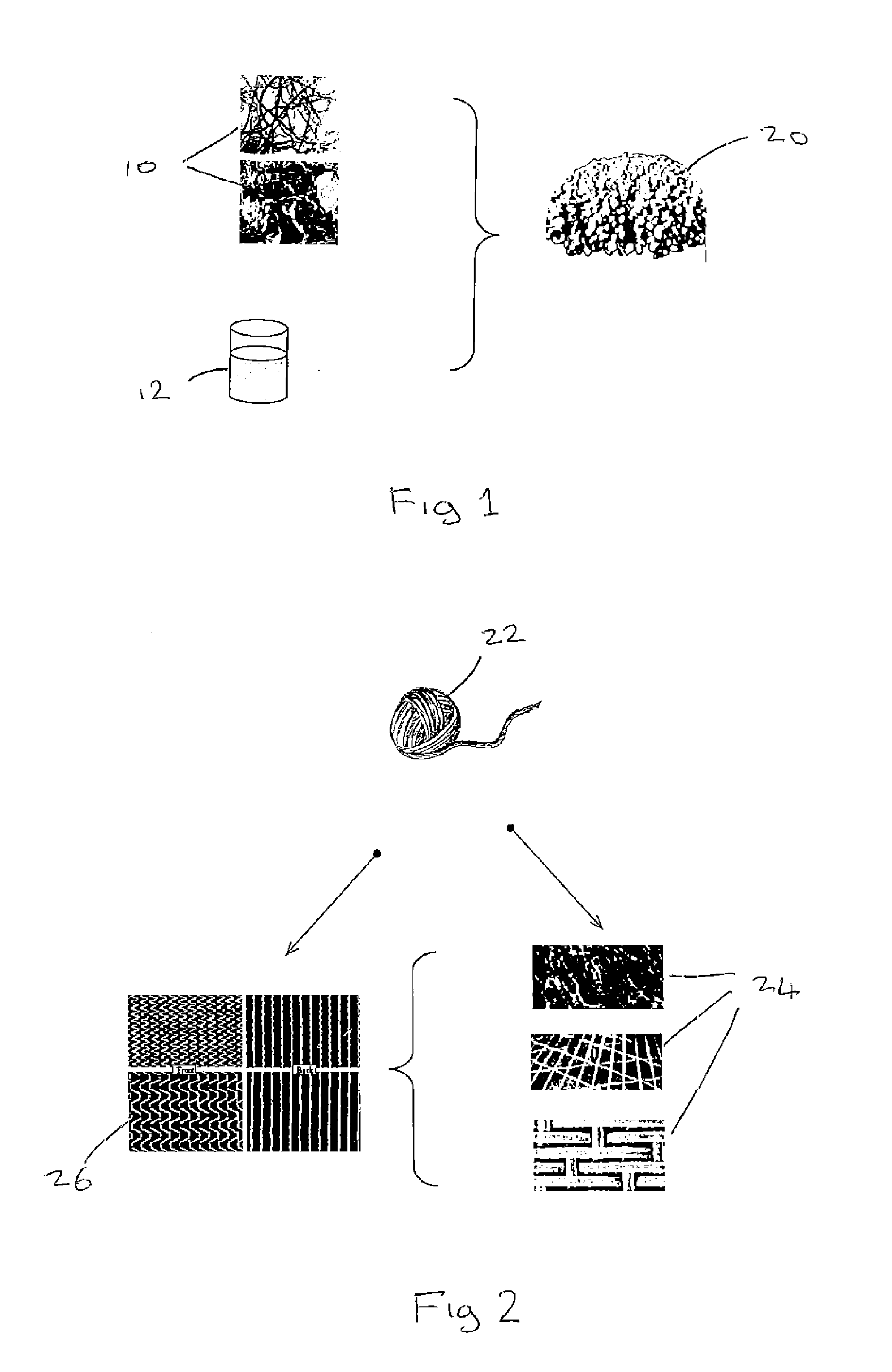

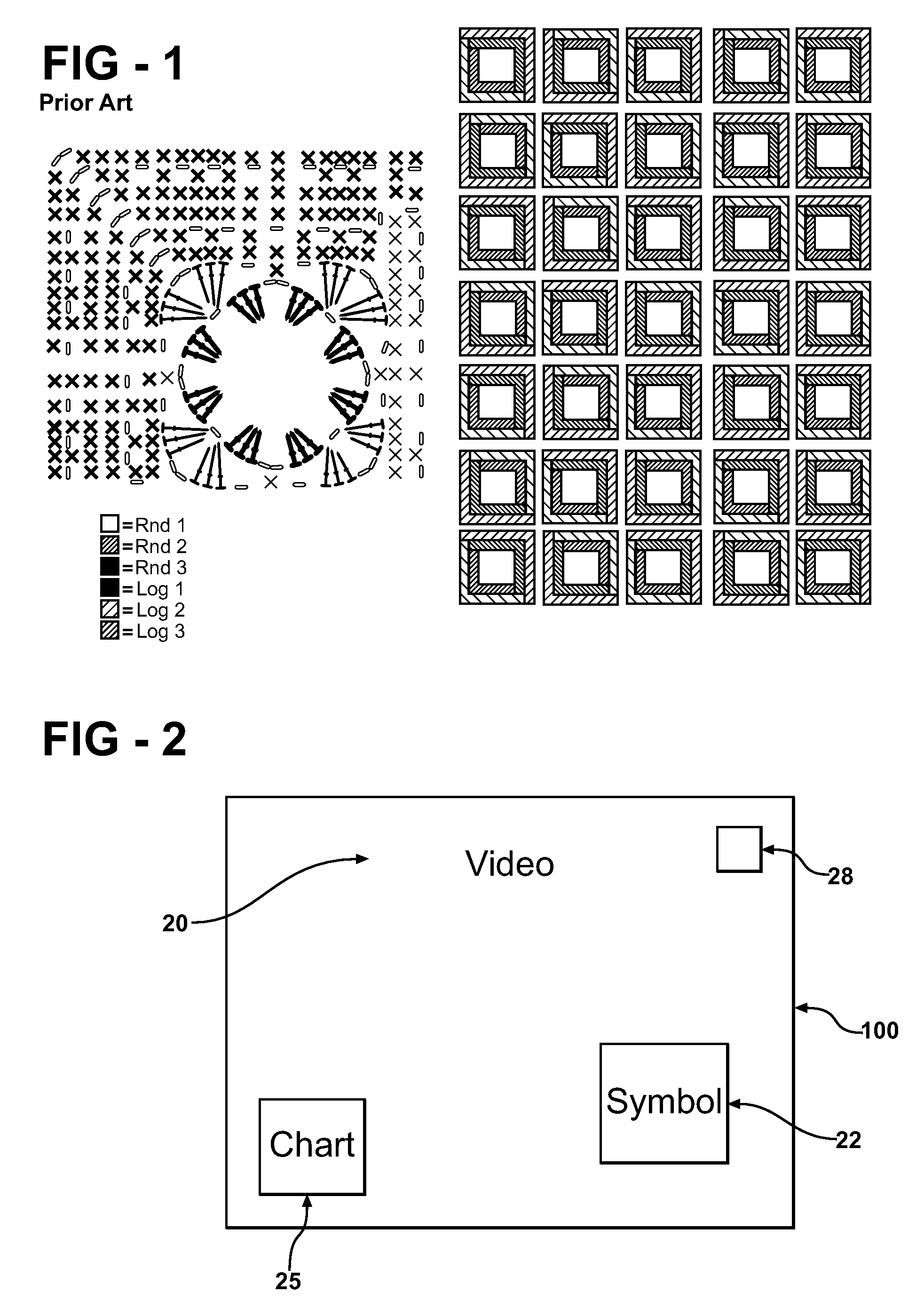

Animated digital charted yarncraft instruction

InactiveUS20080003546A1Minimizes problemCompletely successfulElectrical appliancesTeaching apparatusGraphicsAnimation

A method of animated yarncraft instruction includes providing a digital graphic file having a video object and an animated image object within the file. The animated image object is instructional of needlework and corresponds to the video object. Moreover, the animated image object represents individual steps taken for producing a yarncraft project, which is usable to advantage by a needlework hobbyist without resorting to or requiring an understanding of a needlework chart.

Owner:DUNBAR KIMBERLY L +1

Insulated product

InactiveUS20100024125A1More aesthetic appearanceMore appearance performanceCrochetingGarment special featuresEngineeringElectrical and Electronics engineering

Owner:LI YICK LAP

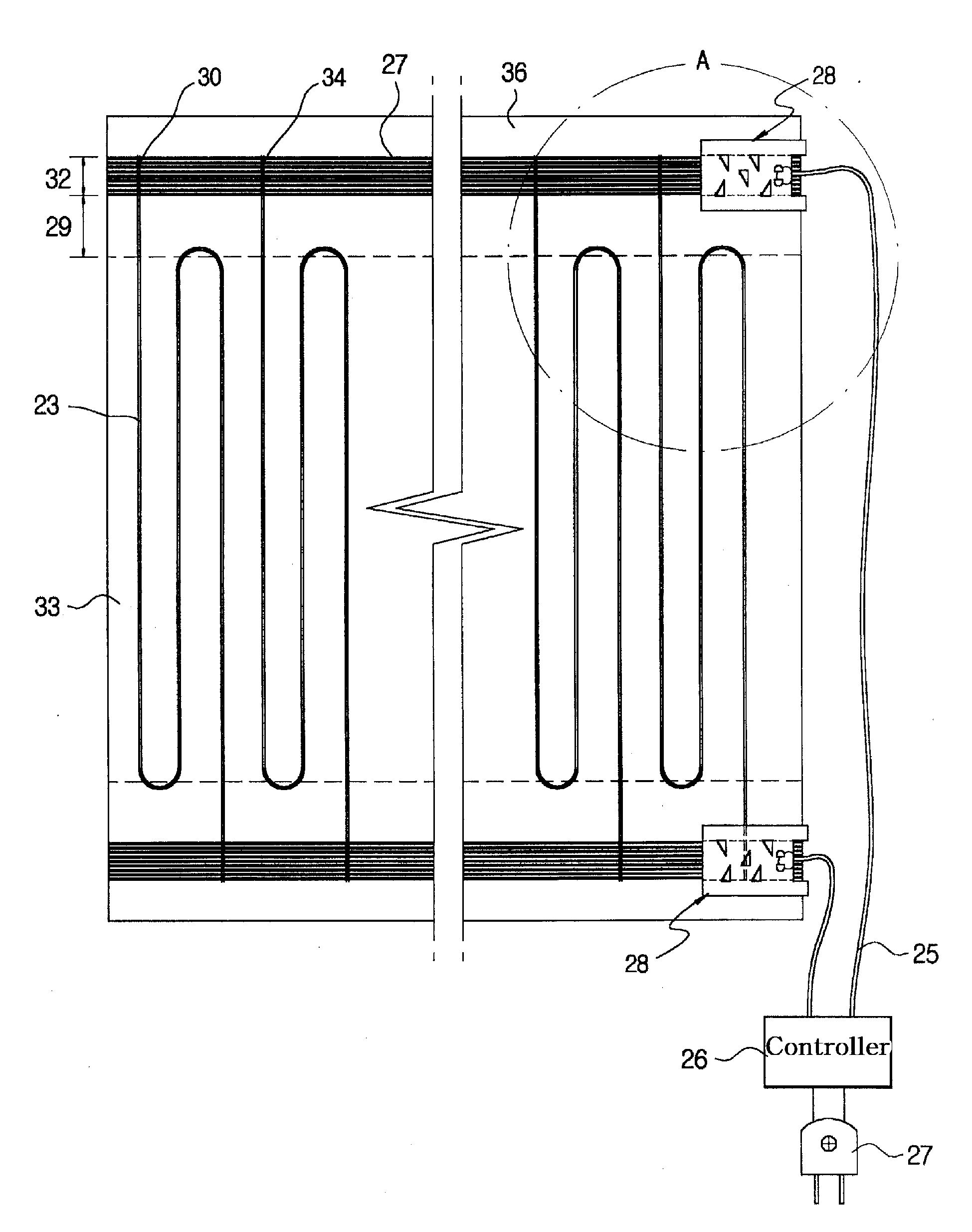

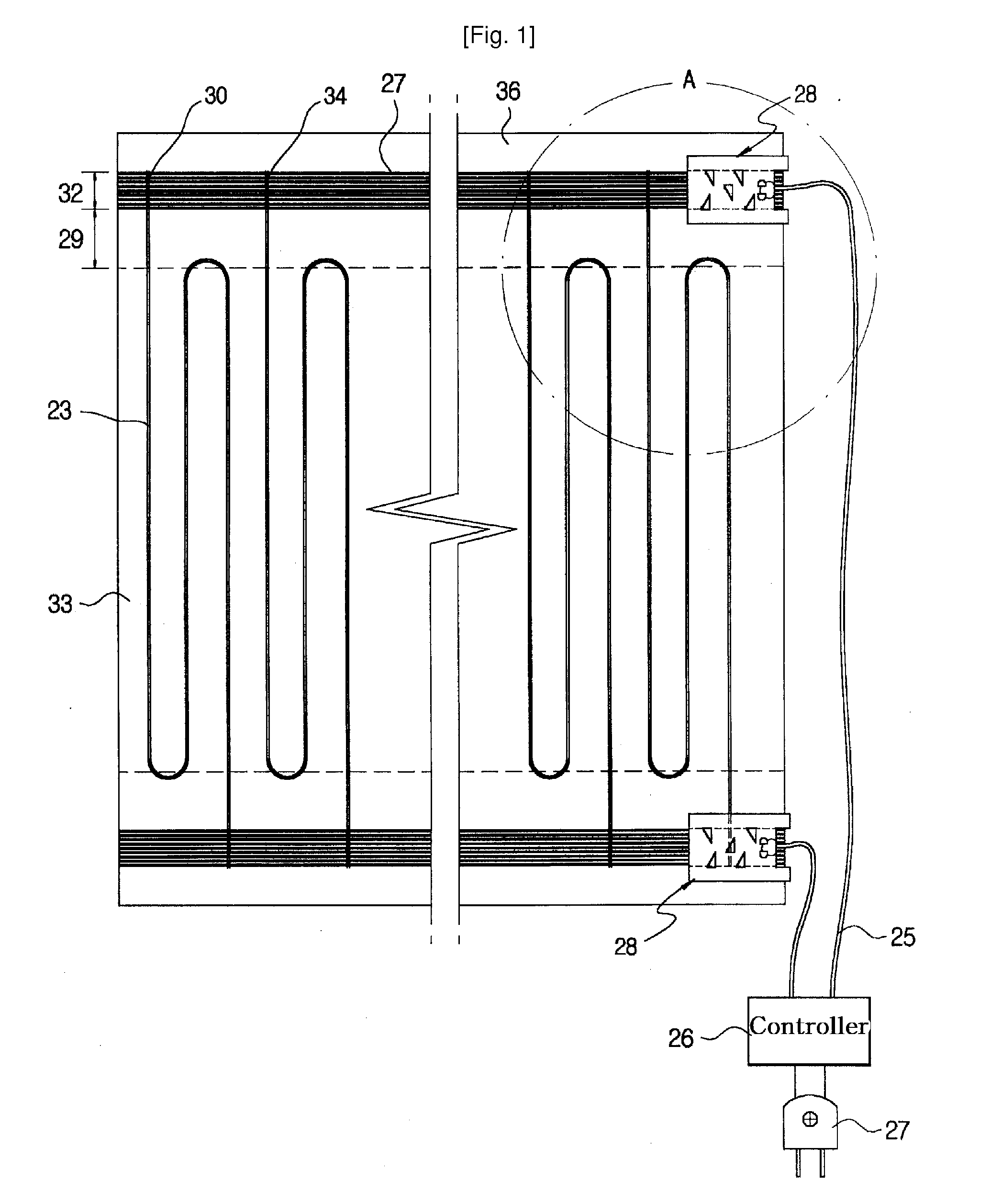

Heating Fabric and Manufacturing Method Thereof

InactiveUS20080135120A1Firmly connectedReduce product failureCrochetingOrnamental textile articlesFiberCarbon fibers

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

Pet socks and manufacturing method thereof

InactiveUS20150053148A1Rational designSimple structureCrochetingFabrics trimmingEngineeringCompanion animal

Owner:ZHUJI LONGBOW KNITTING

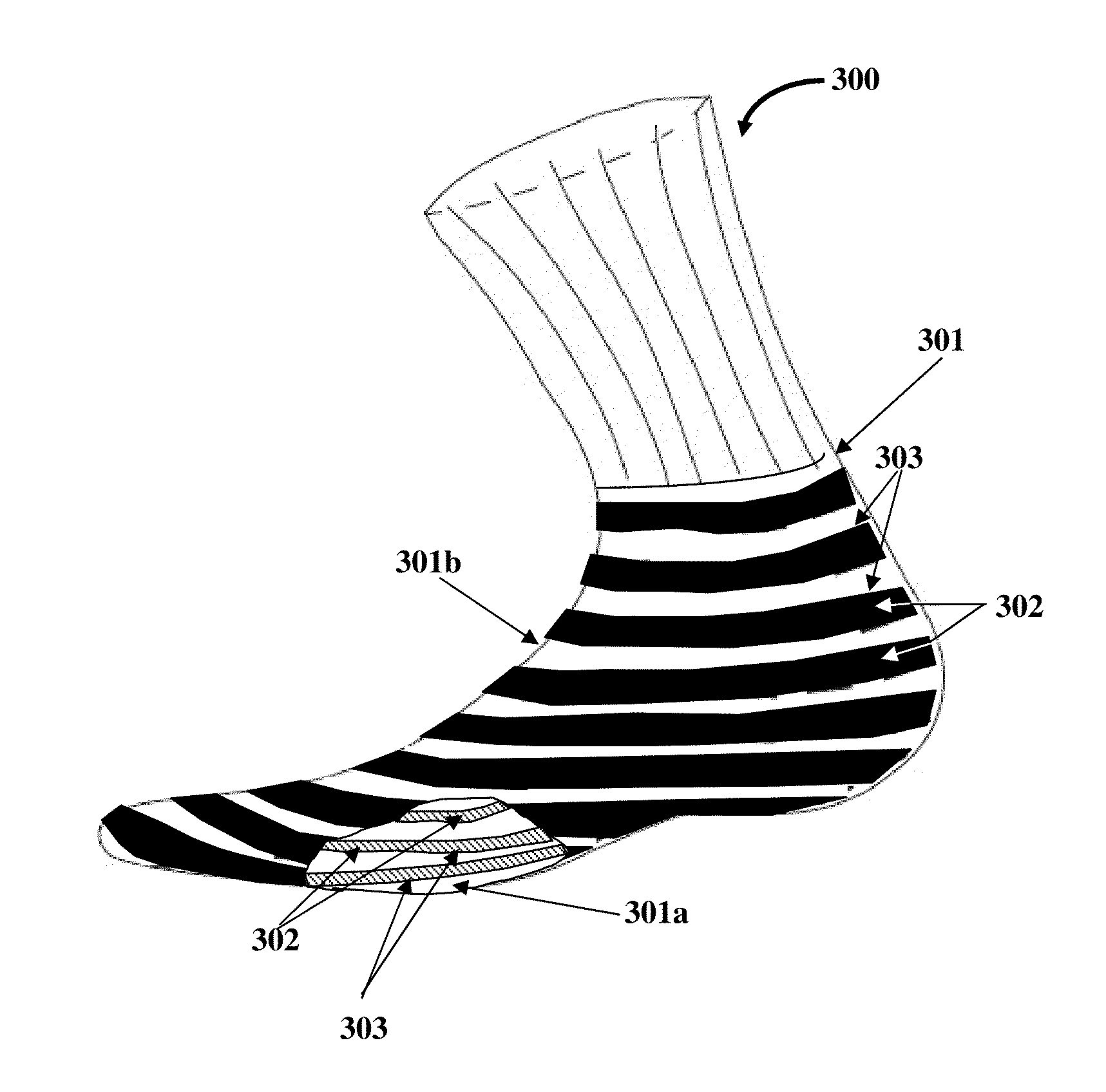

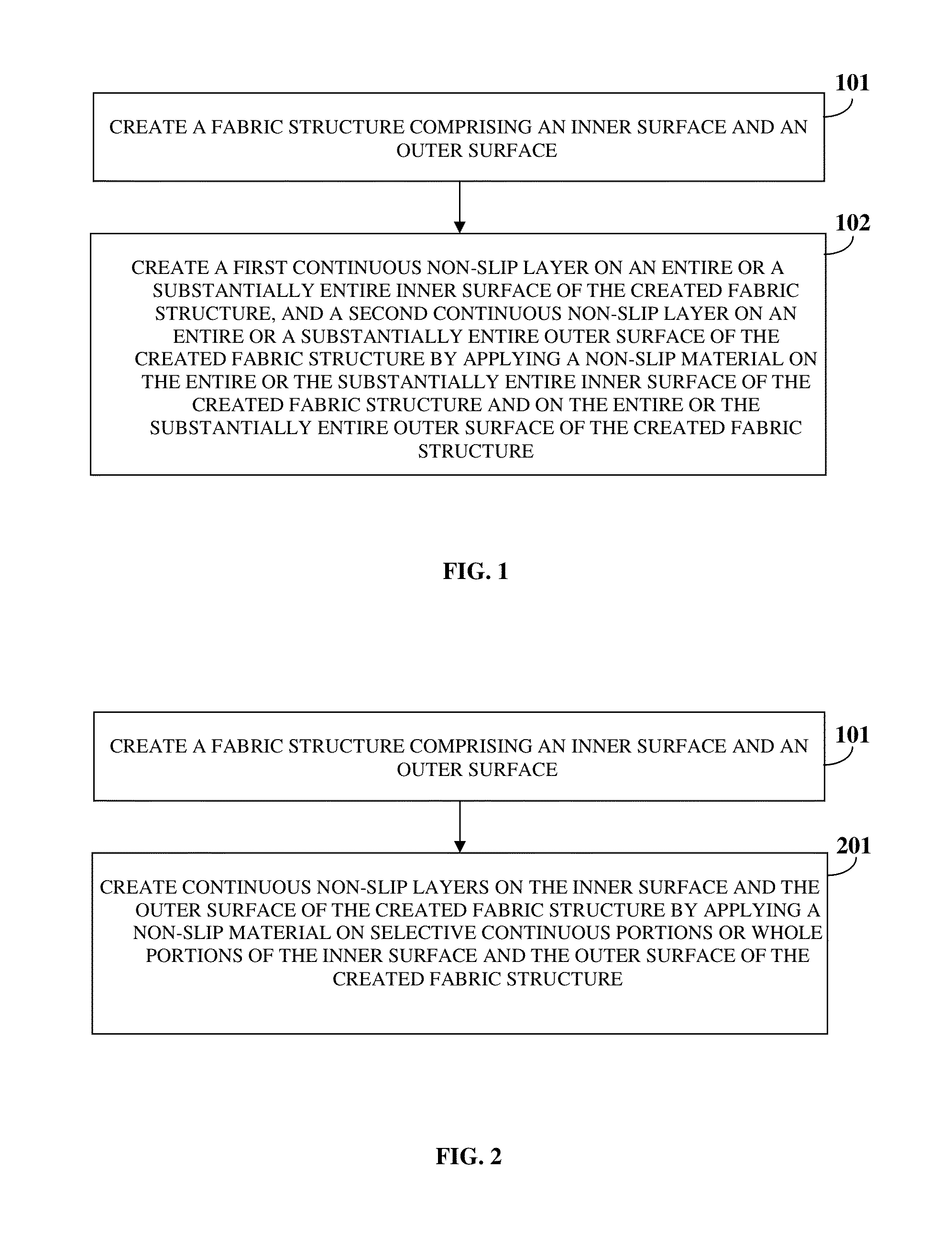

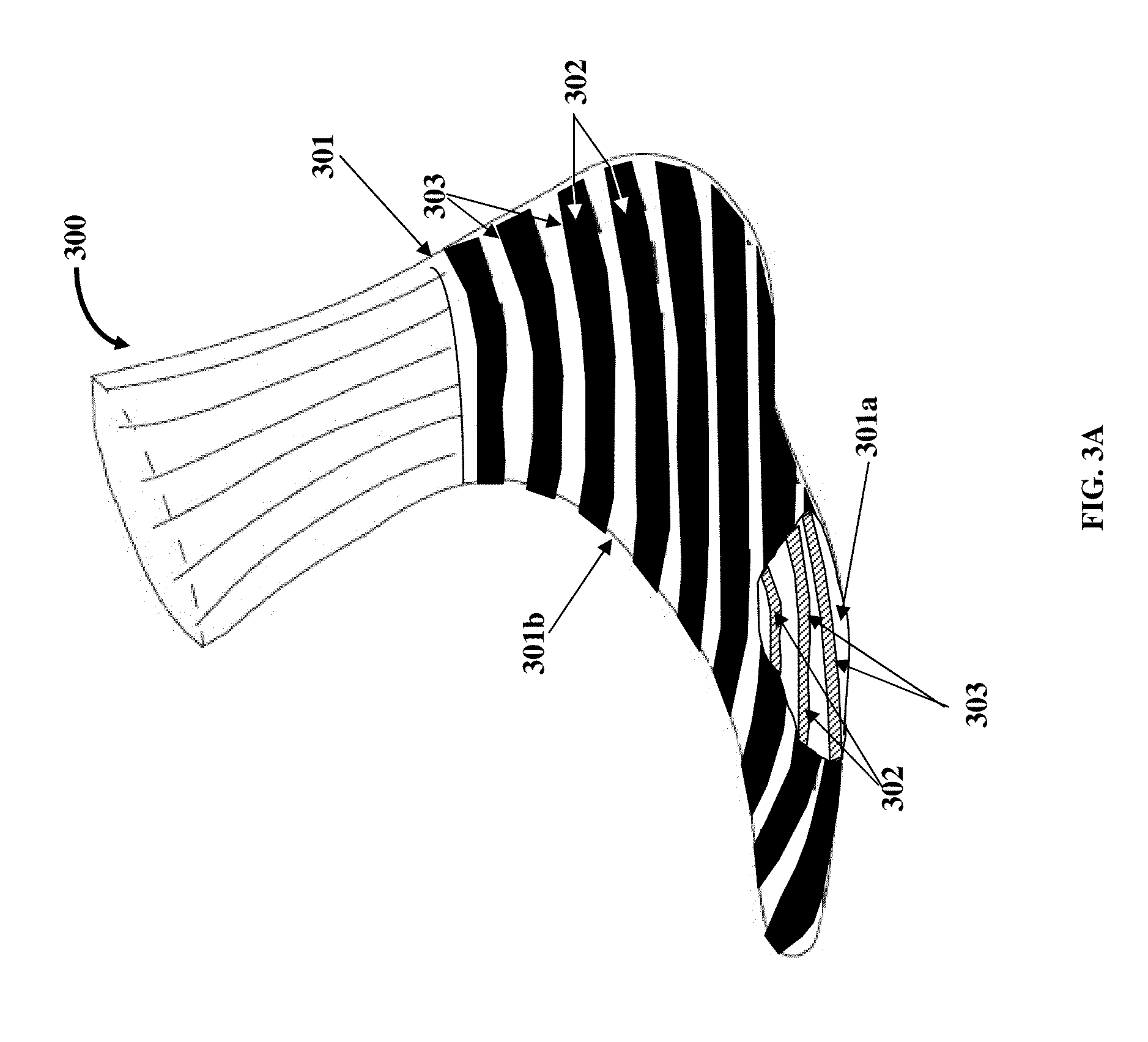

Continuous Non-slip Layered Garment

InactiveUS20150275422A1Prevent slippingCrochetingOrnamental textile articlesBiomedical engineeringFabric structure

A method for making a continuous non-slip layered garment includes creating a fabric structure having inner and outer surfaces, which conforms to a body part, and creating continuous non-slip layers on the inner and outer surfaces of the fabric structure. The inner surface is proximal to a user contact surface and distal to an external contact surface. The outer surface is proximal to the external contact surface and distal to the user contact surface. The continuous non-slip layers are created by applying a non-slip material on selective continuous portions, selective non-continuous portions, whole portions, or an entirety of the inner surface and the outer surface of the fabric structure. The continuous non-slip layers provide simultaneous gripping contact between the inner surface of the fabric structure and the user contact surface, and between the outer surface of the fabric structure and the external contact surface.

Owner:TRUSOX LLC

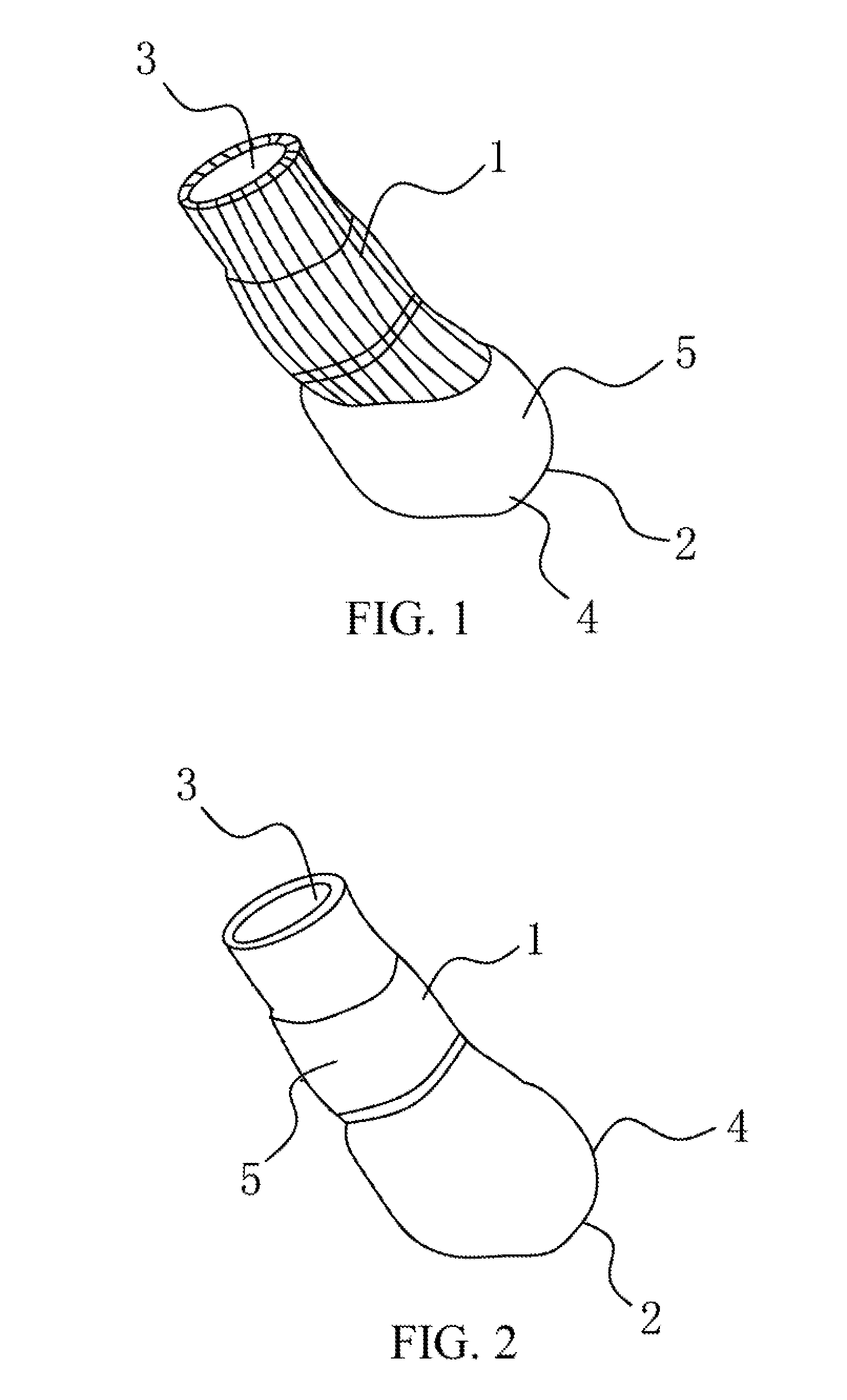

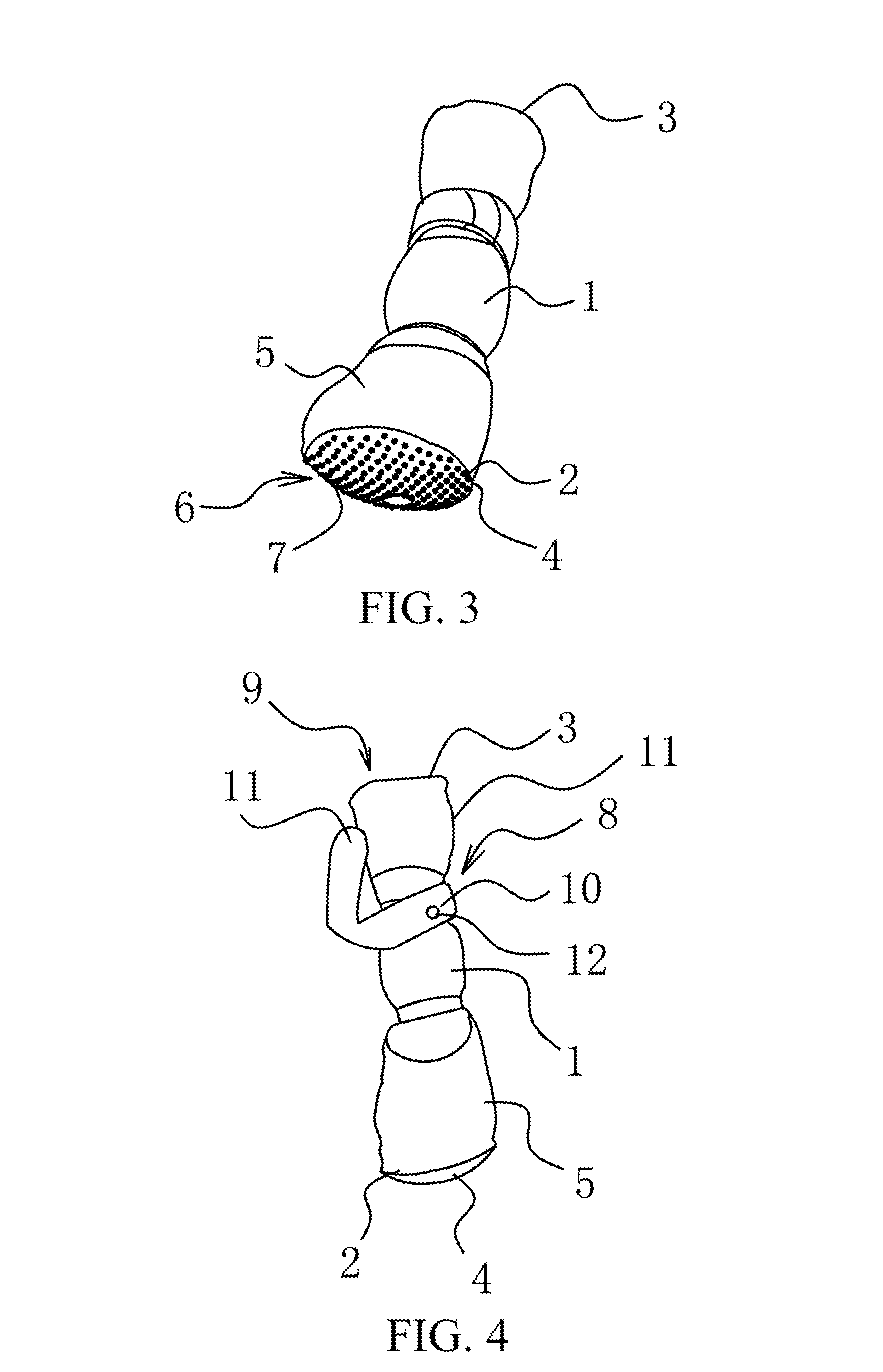

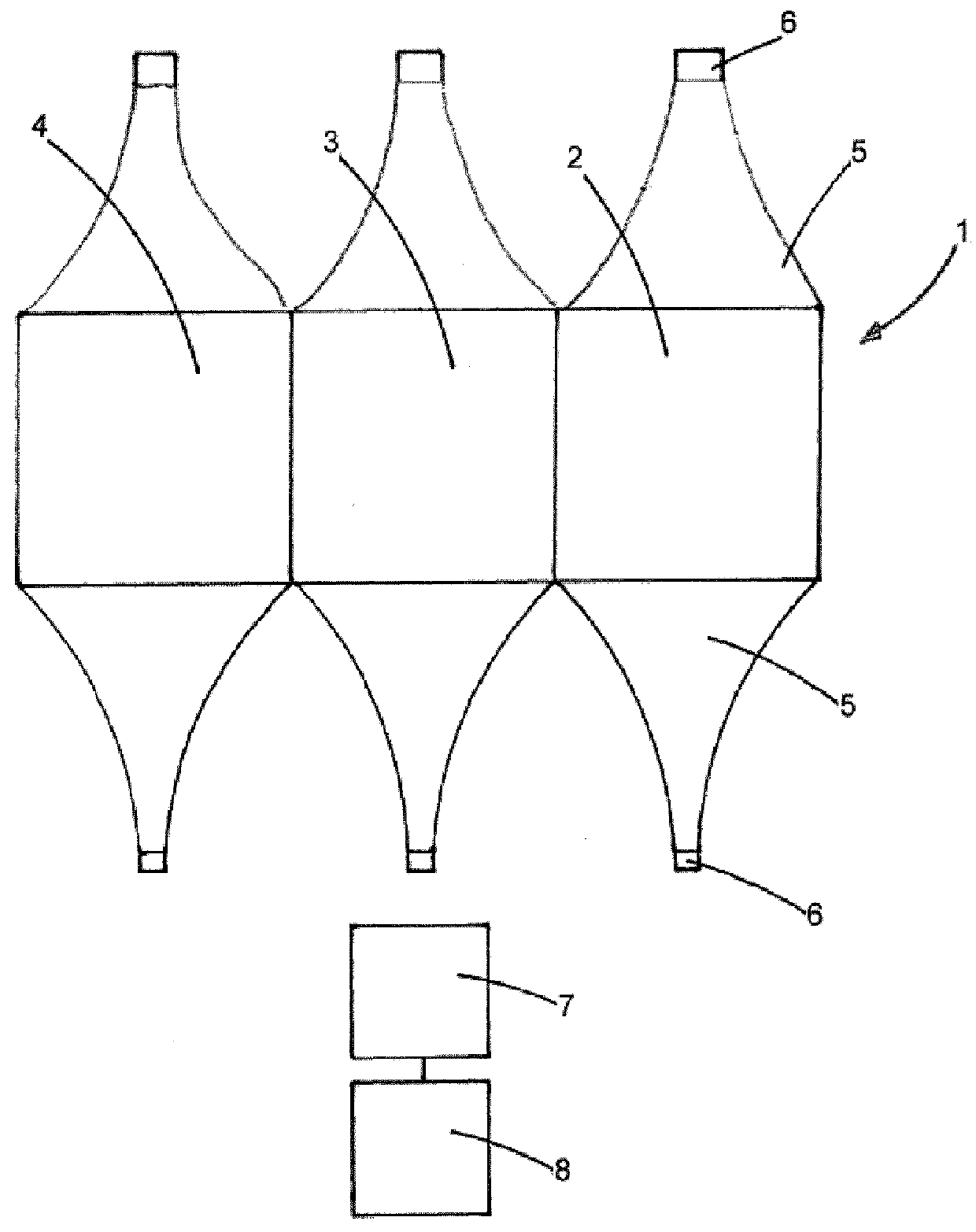

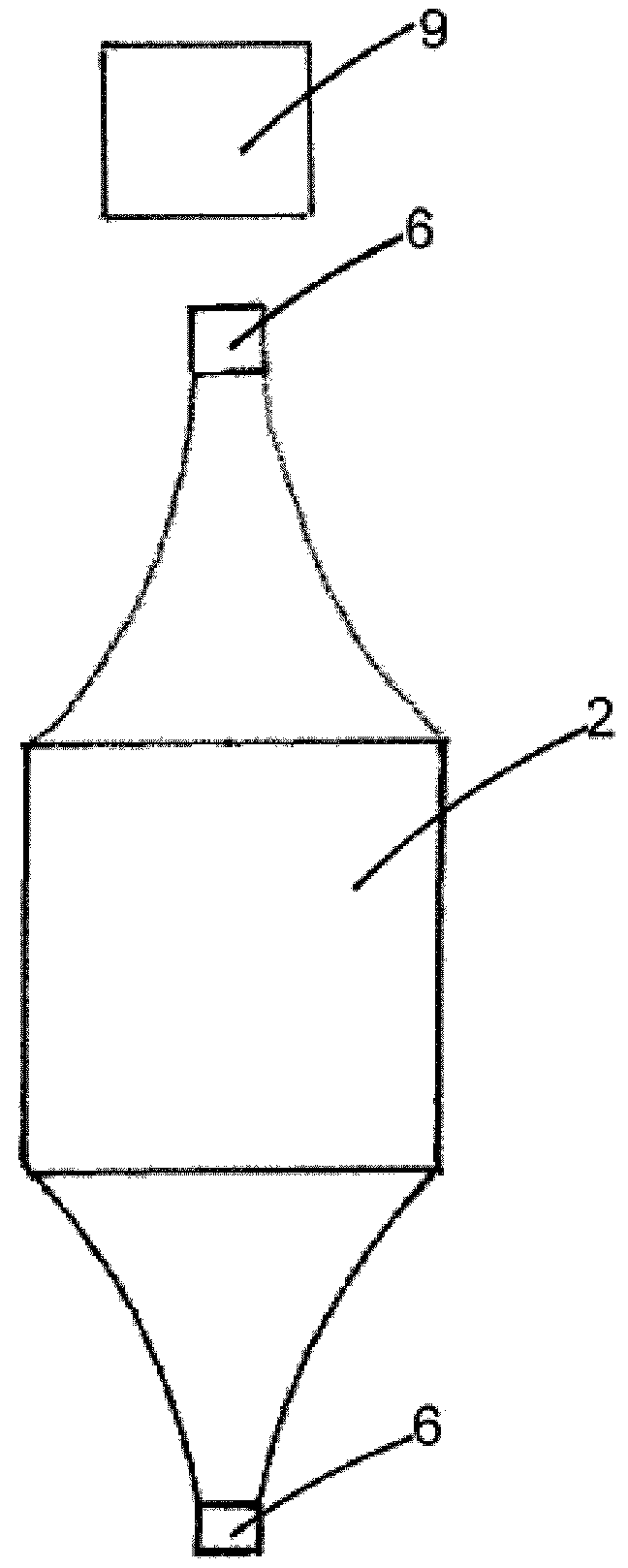

Medical Device, its Preparation Method and Applications Thereof

InactiveUS20160051832A1Facilitated DiffusionImprove homogeneityCrochetingElectrotherapyEngineeringLight emission

A medical device (1) comprising a flexible light source wherein said flexible light source comprises two or more individually manageable areas (2, 3, 4) of light emission and wherein each area (2, 3, 4) comprises a light diffuser textile comprising optical fibres (10) providing side diffusion of a light, method for its manufacture and medical uses.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com