Patents

Literature

268results about "Shrinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

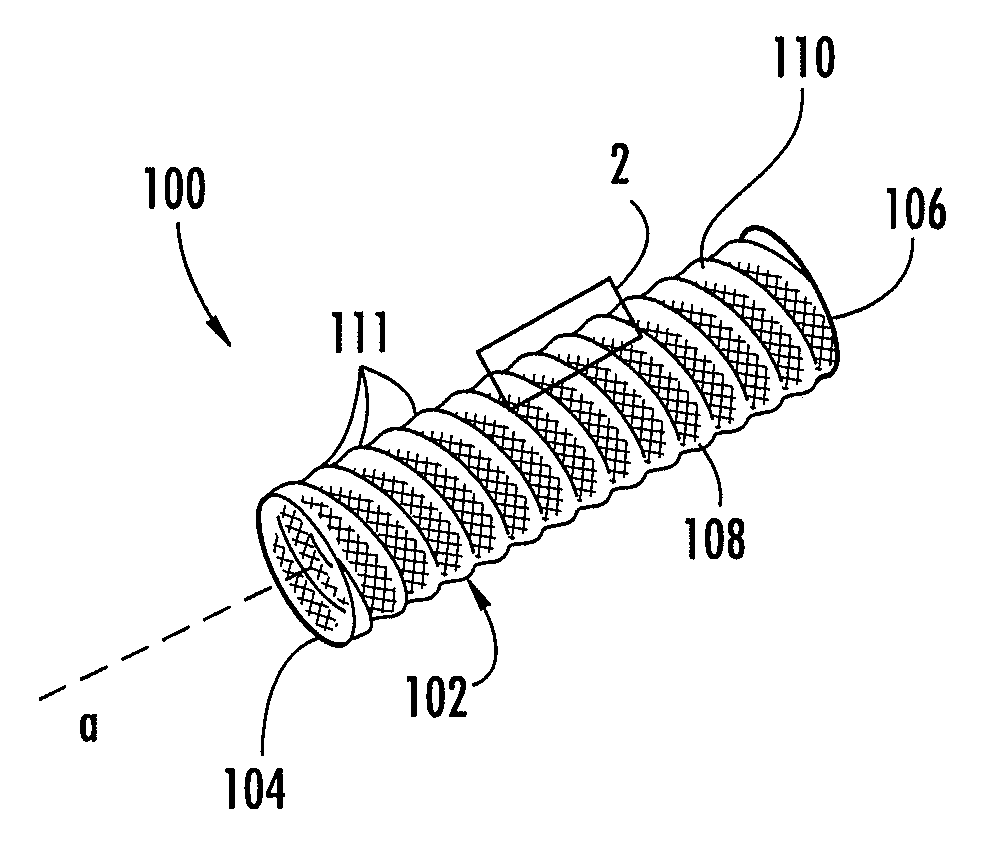

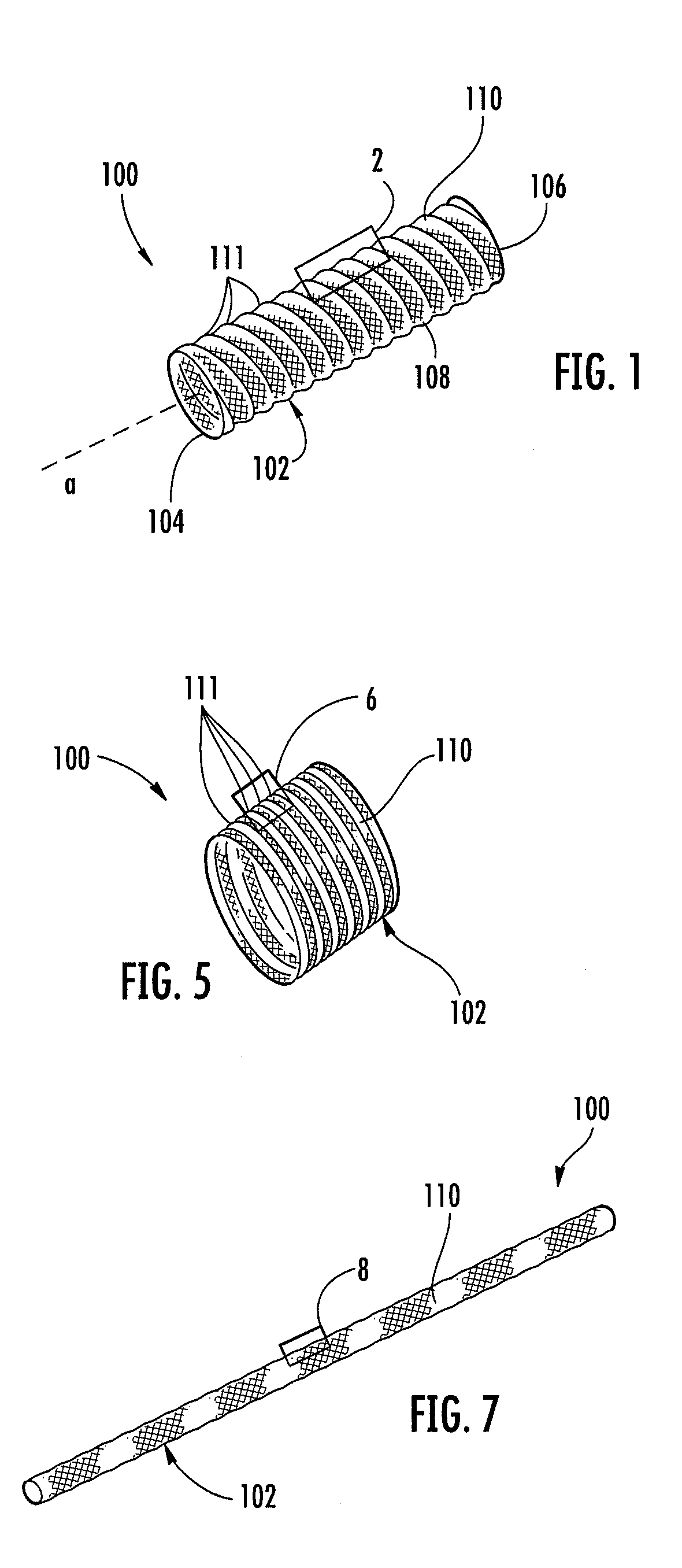

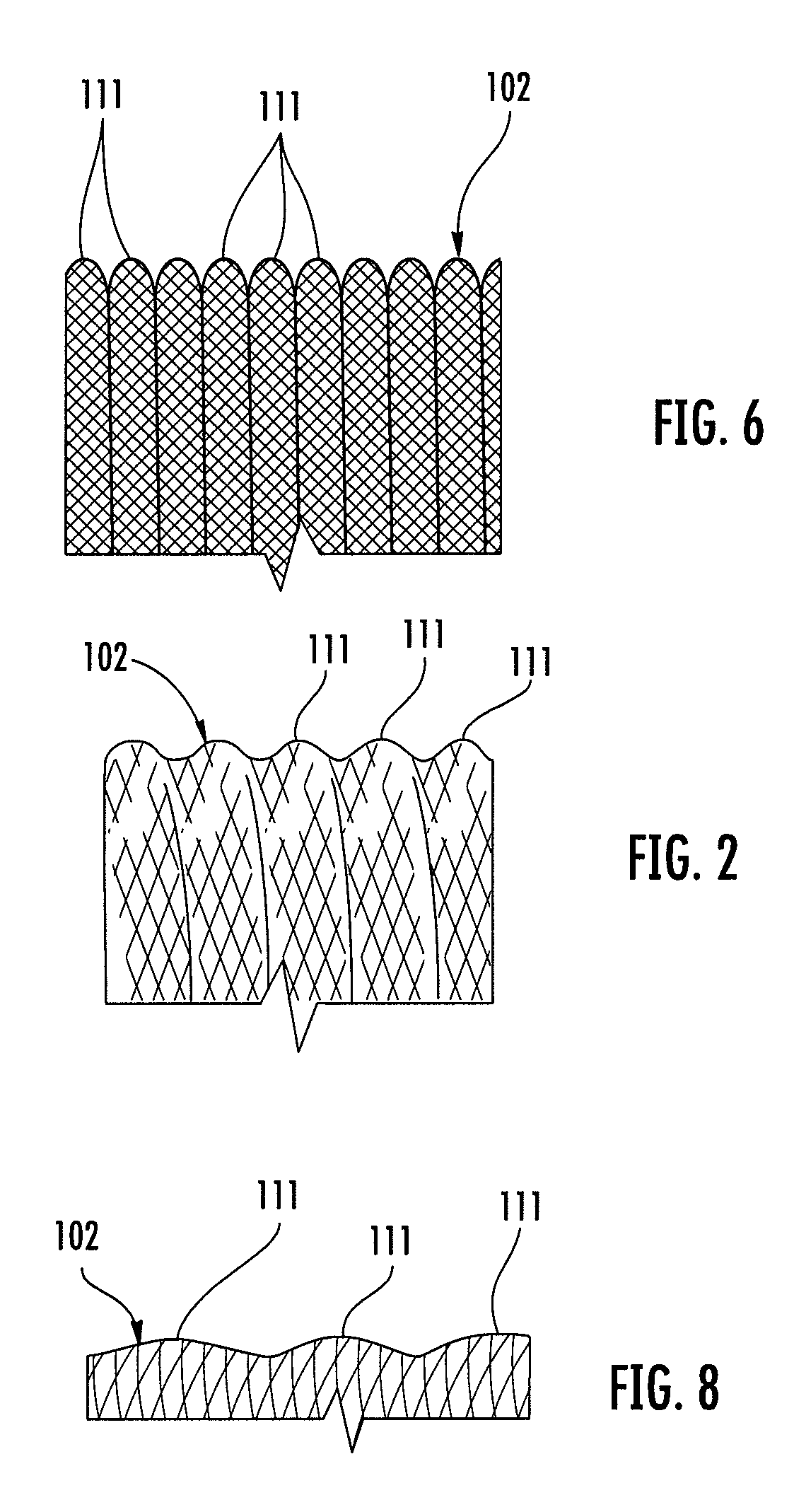

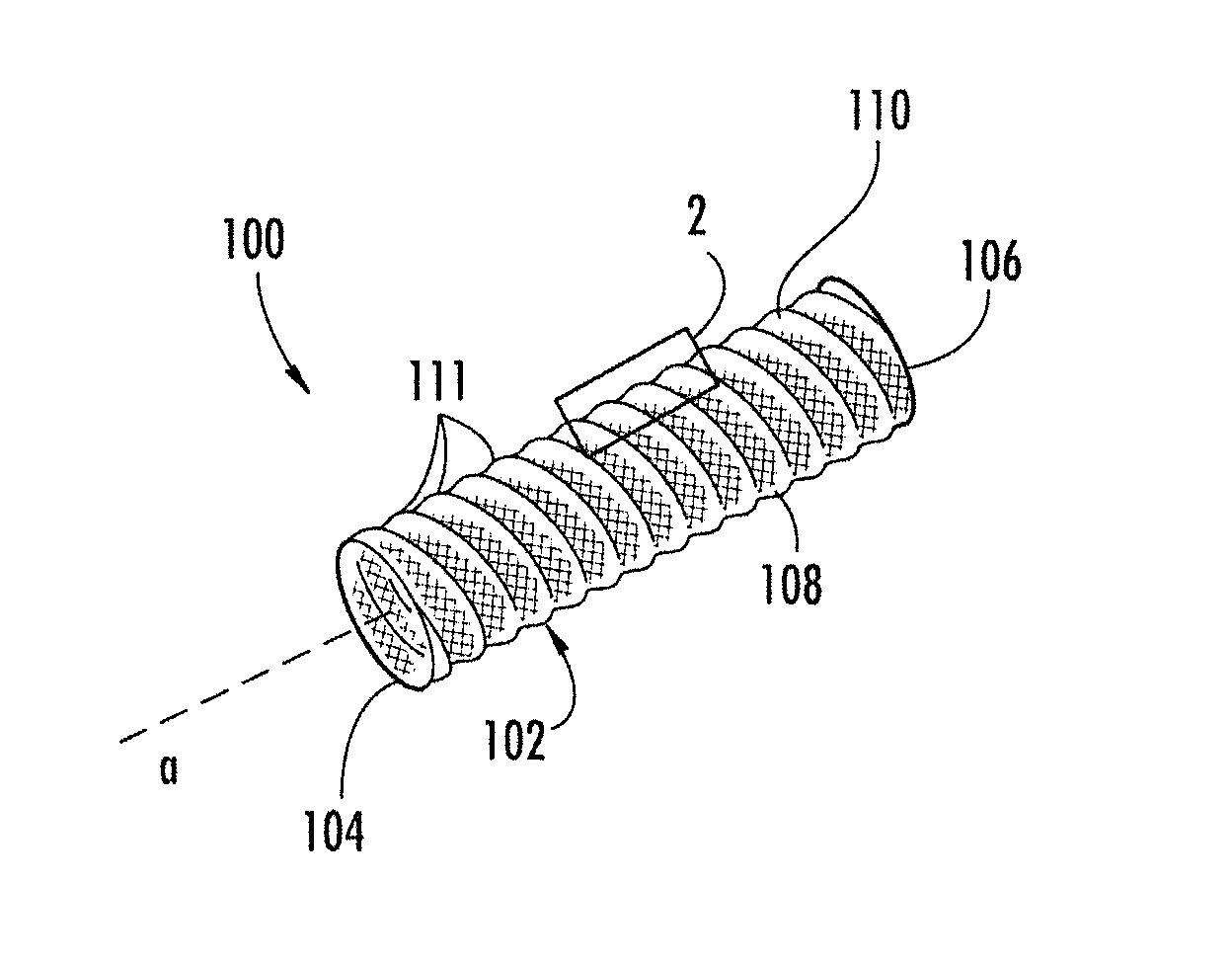

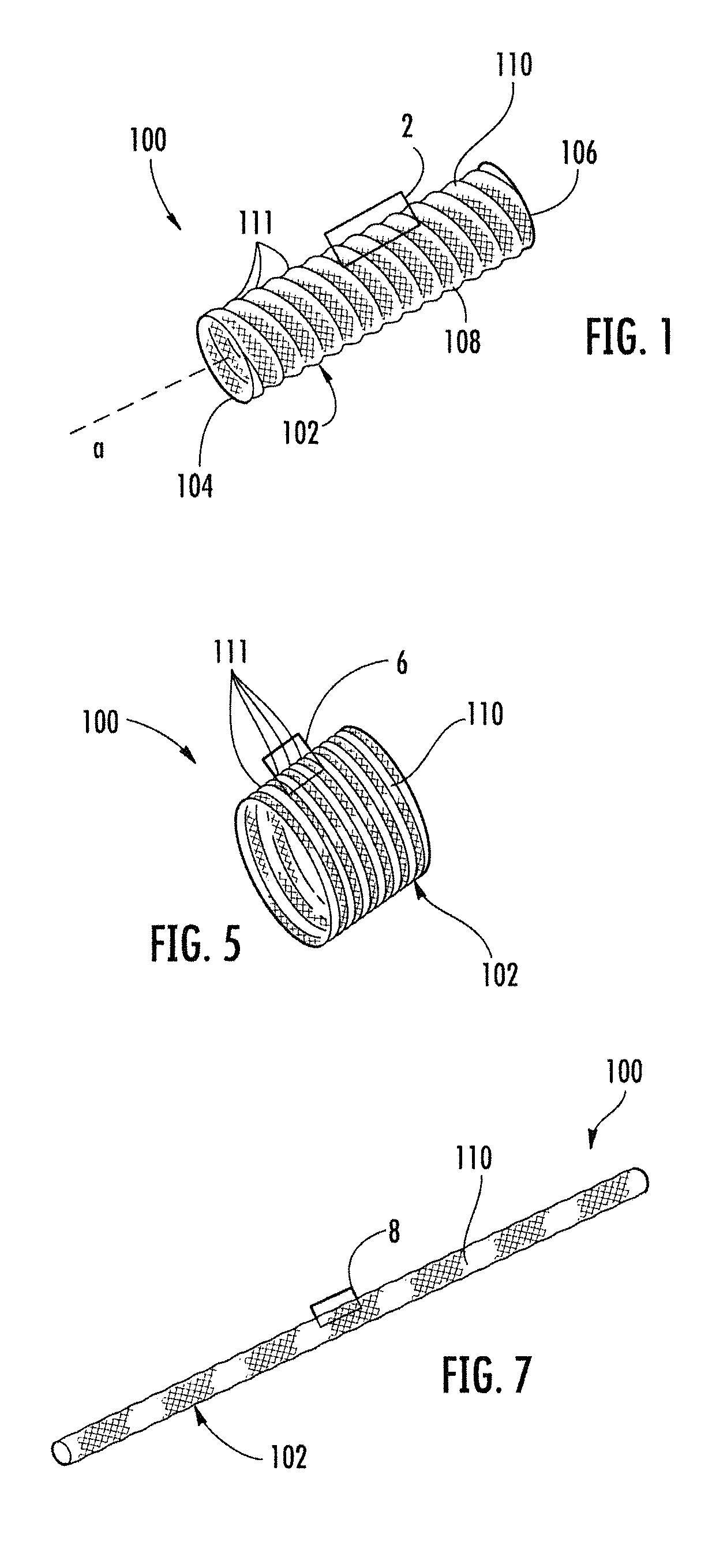

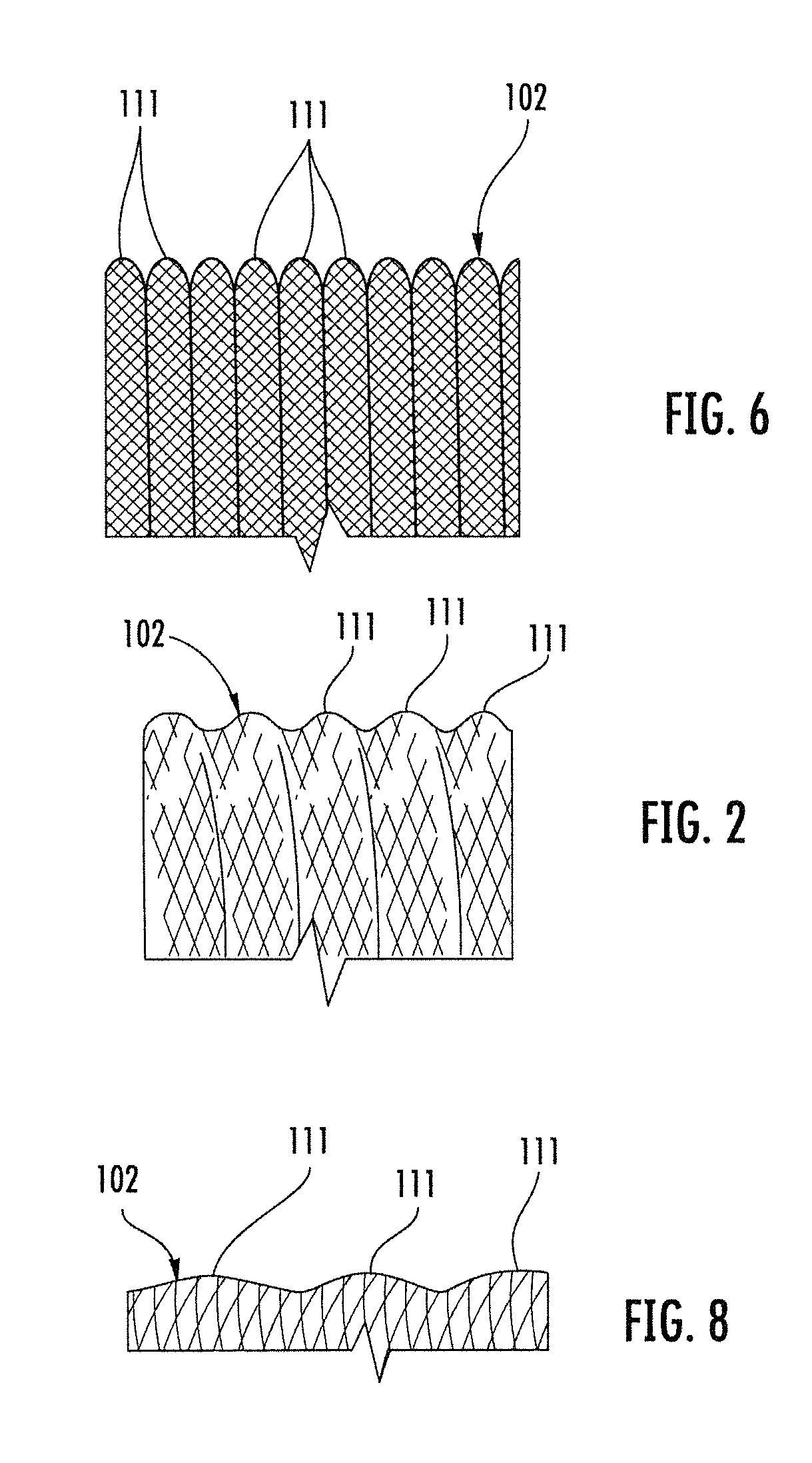

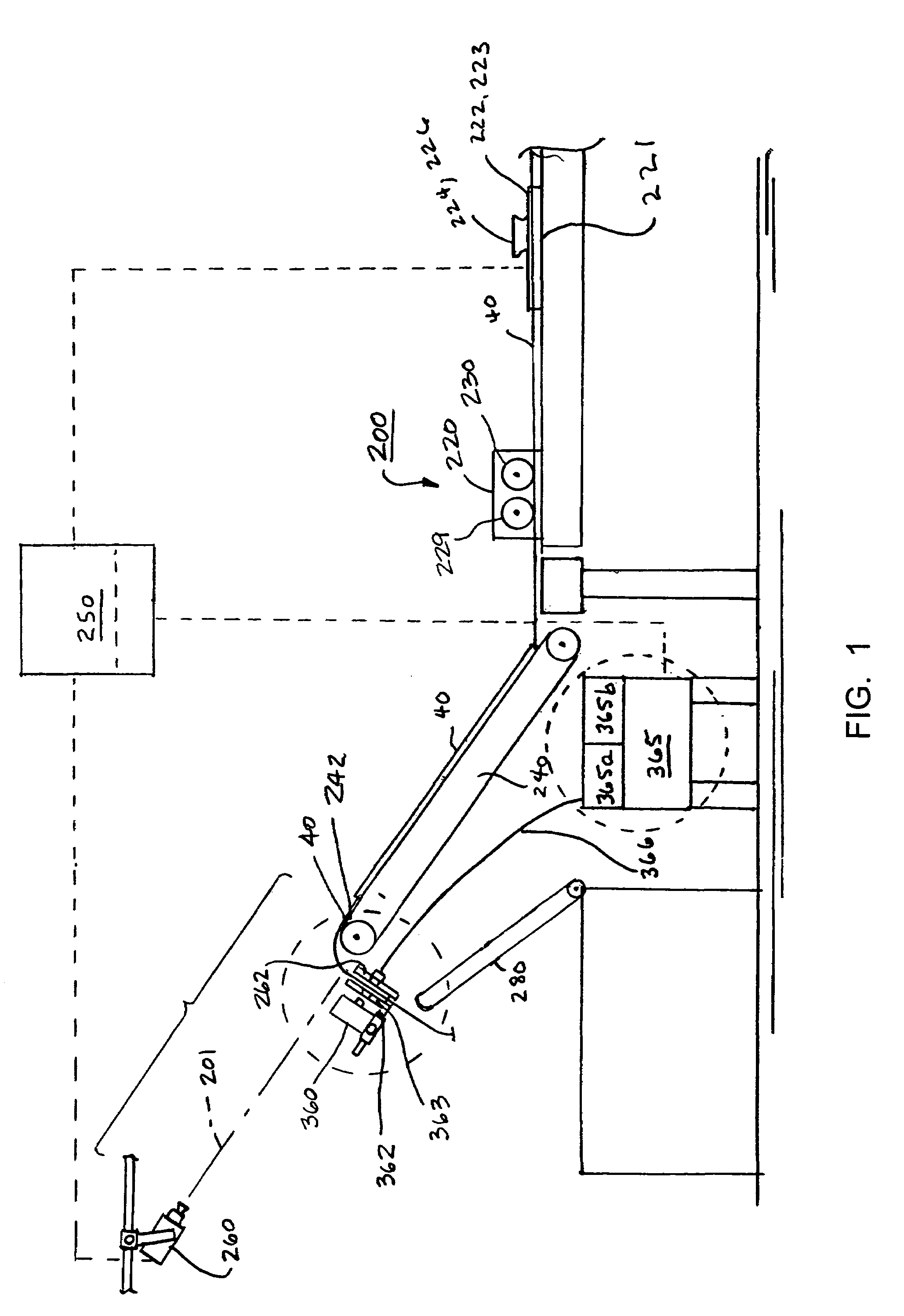

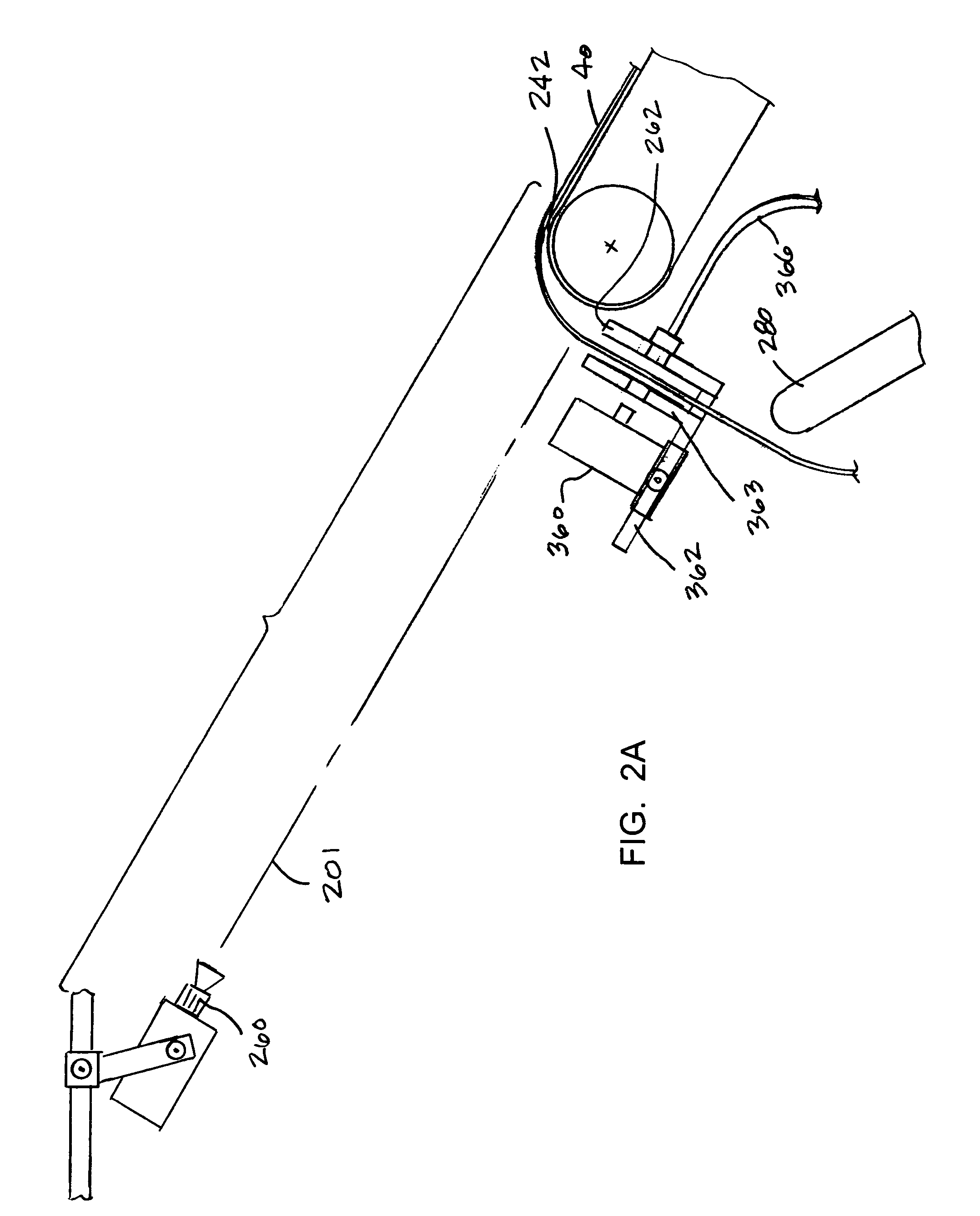

Medical device including corrugated braid and associated method

Embodiments of the present invention provide medical devices for treating a target site within the body and associated methods for fabricating and delivering medical devices. According to one embodiment, a medical device includes a tubular structure having proximal and distal ends and a side wall extending therebetween. At least a portion of the side wall can have a corrugated surface. The side wall further includes at least one layer of a metallic fabric configured to be compressed and heat set to define the corrugated surface. The tubular structure may comprise an expanded shape, and may be configured to be constrained to a smaller diameter than the expanded shape for delivery within a catheter to a target site and to assume the expanded shape upon release from the catheter.

Owner:AGA MEDICAL CORP MS US

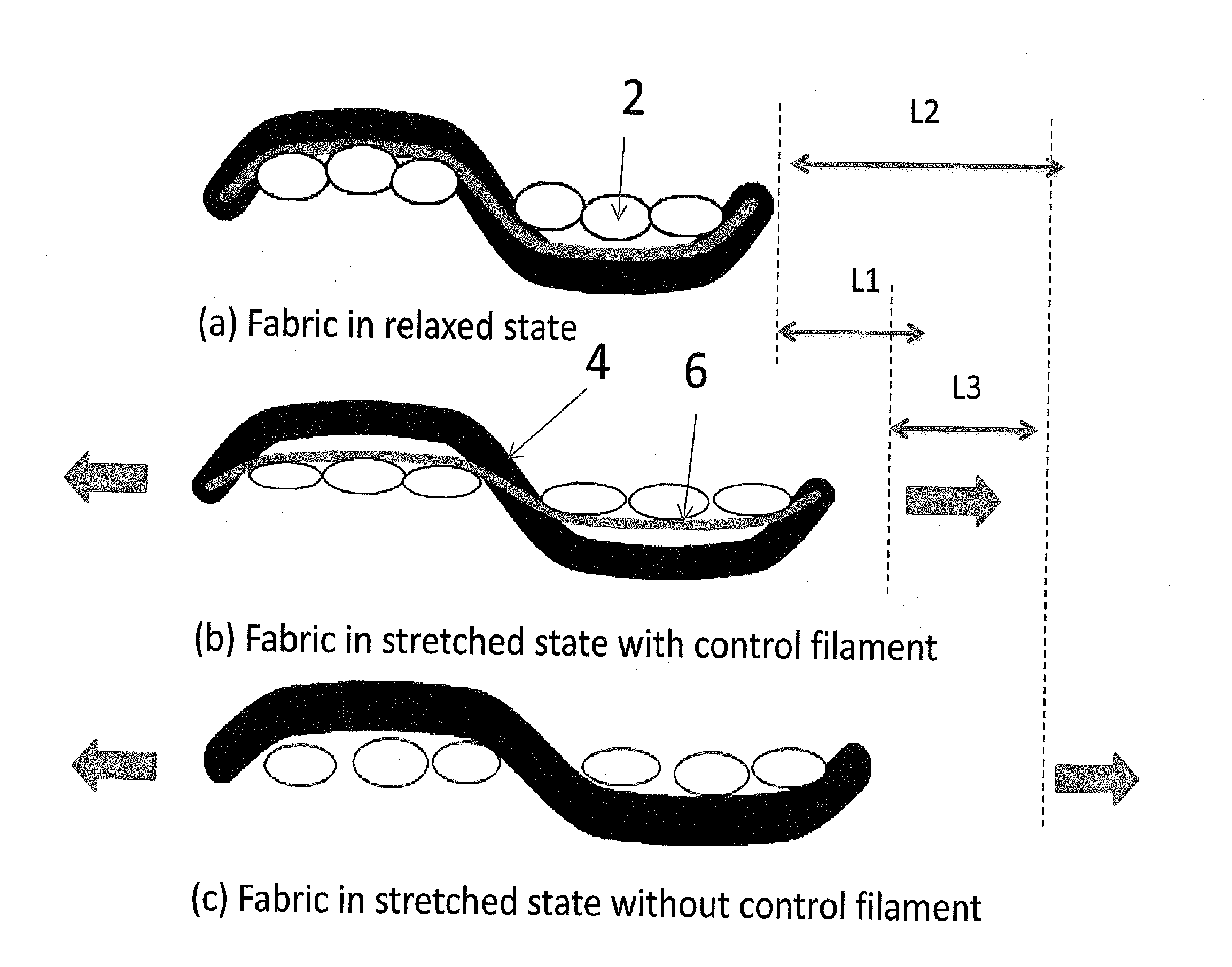

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

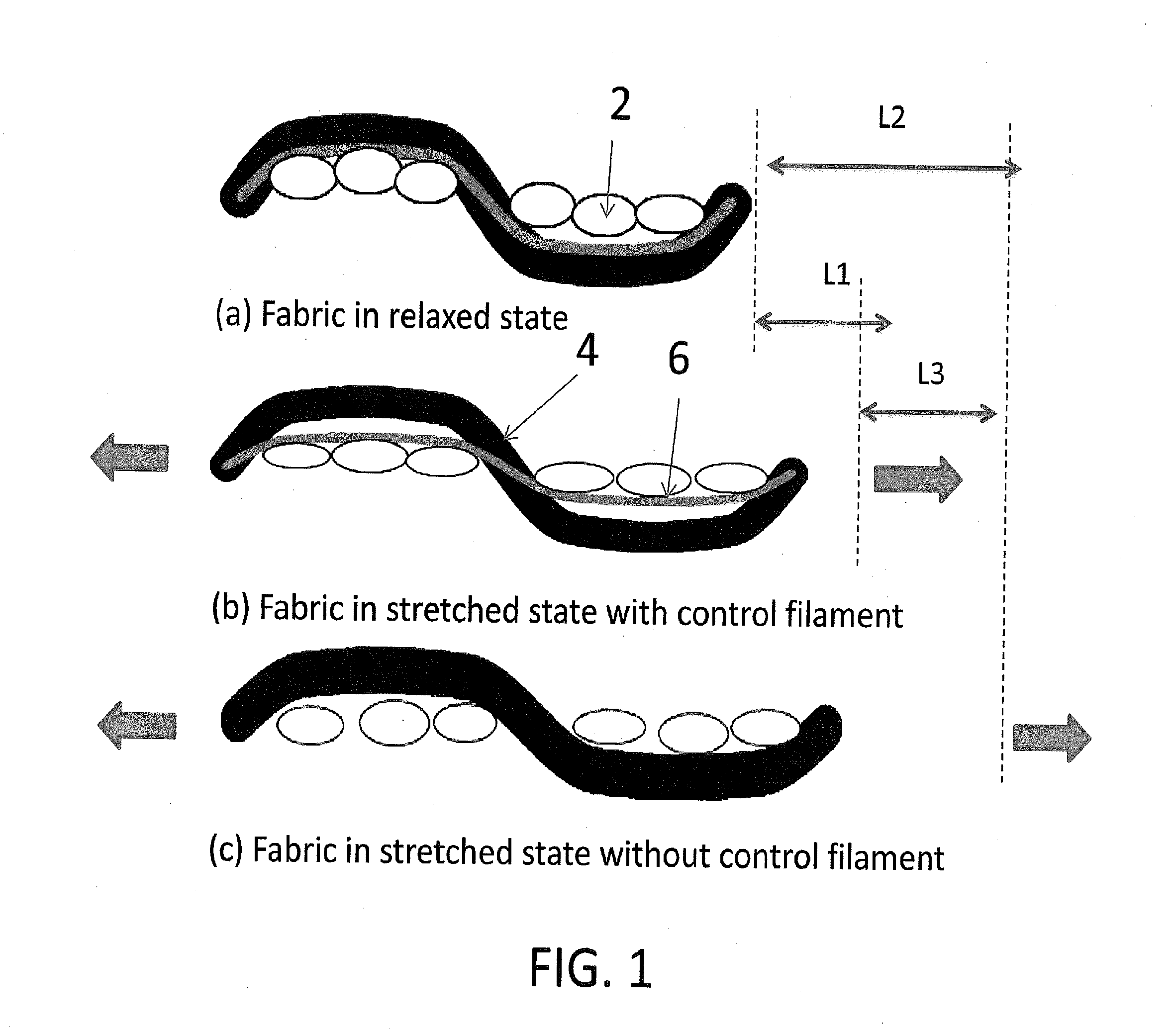

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

Compression fabrics with tailored comfort

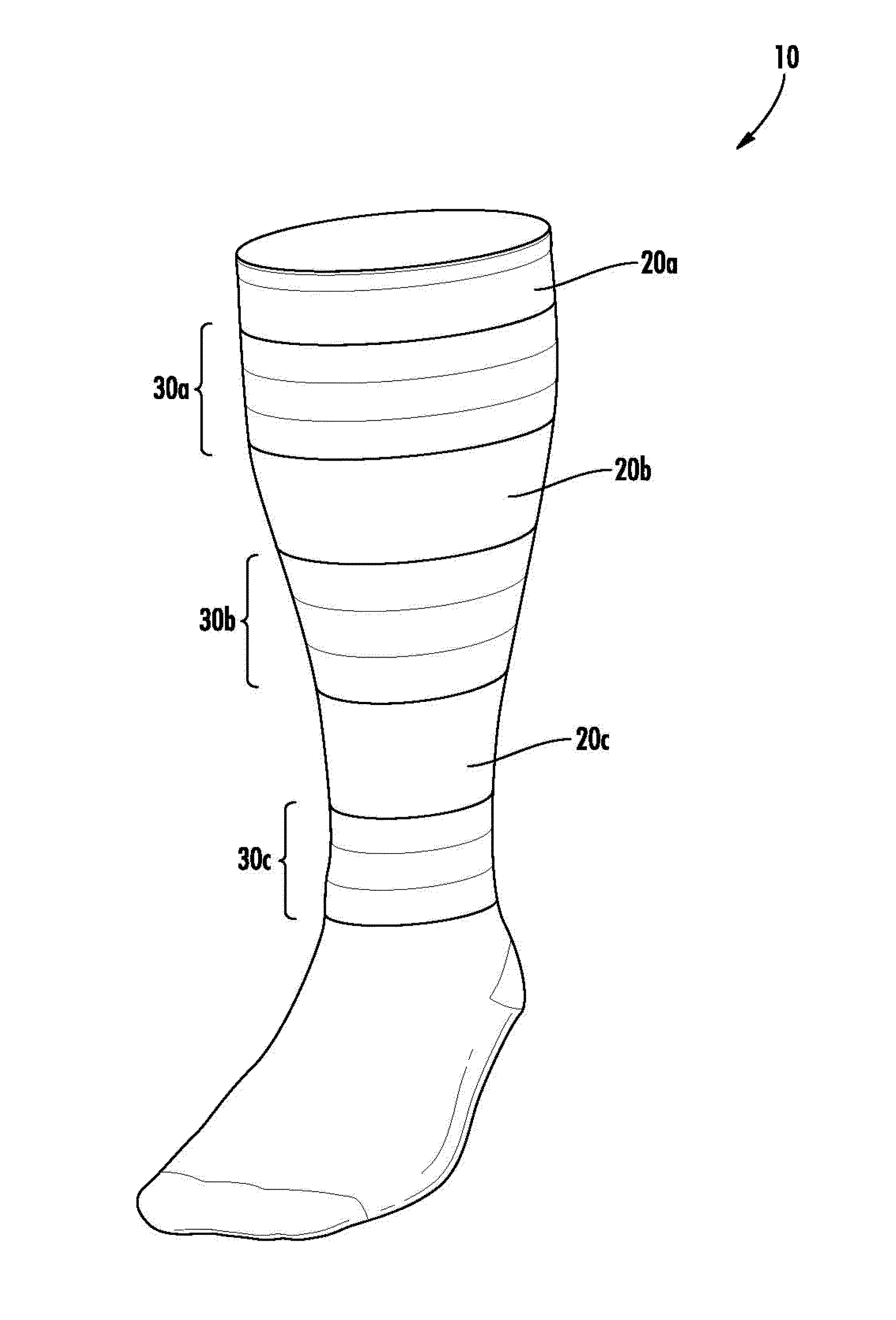

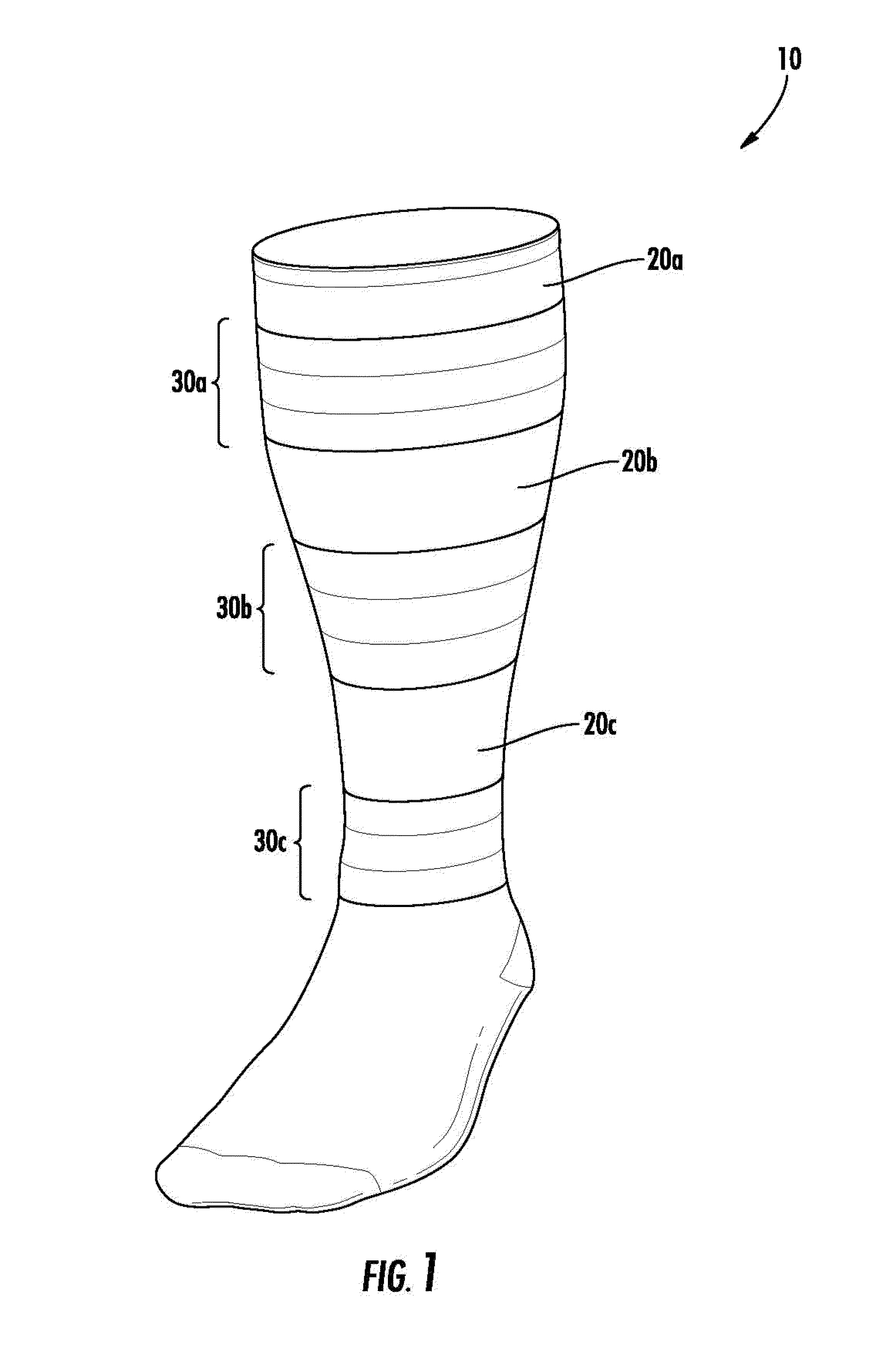

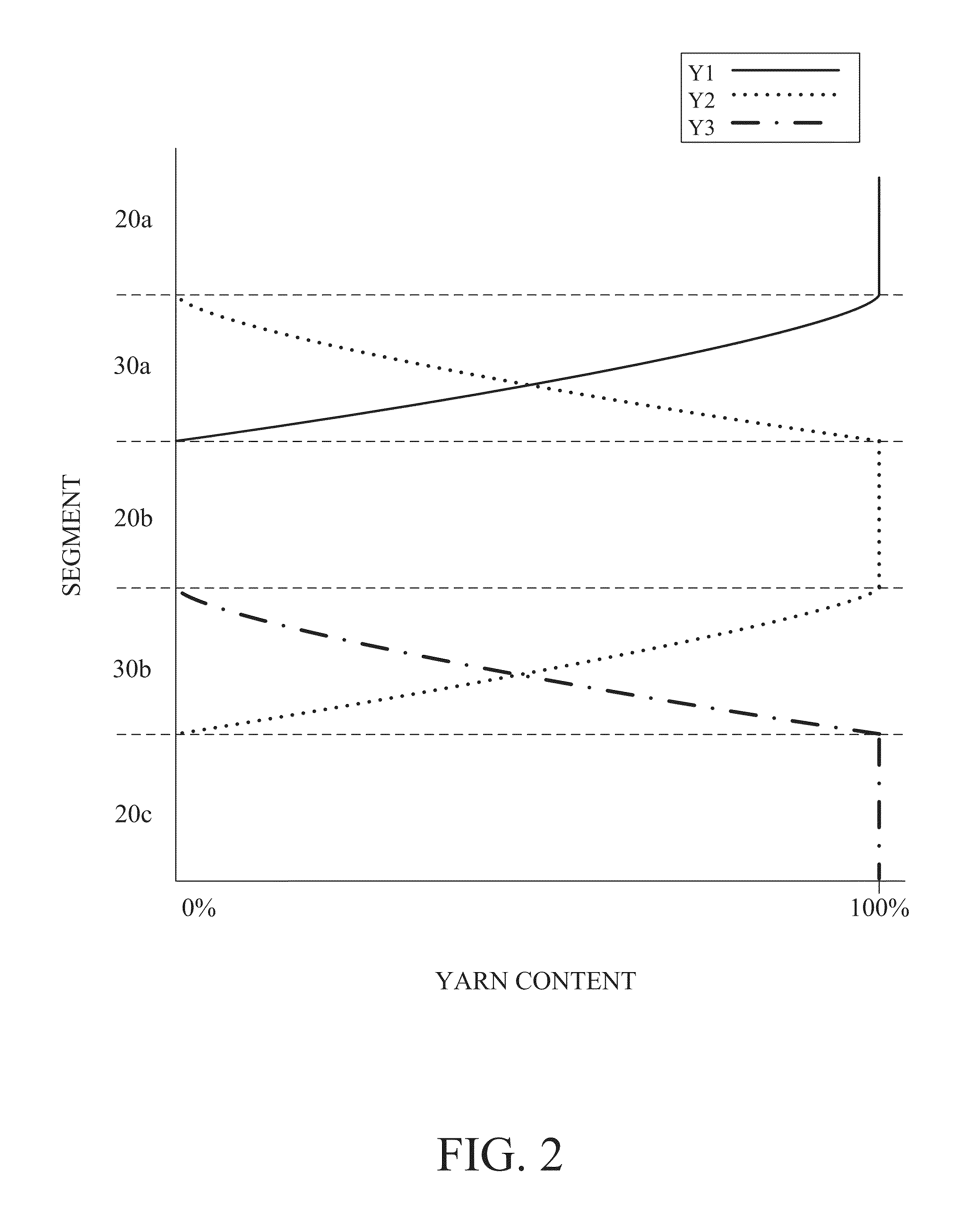

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

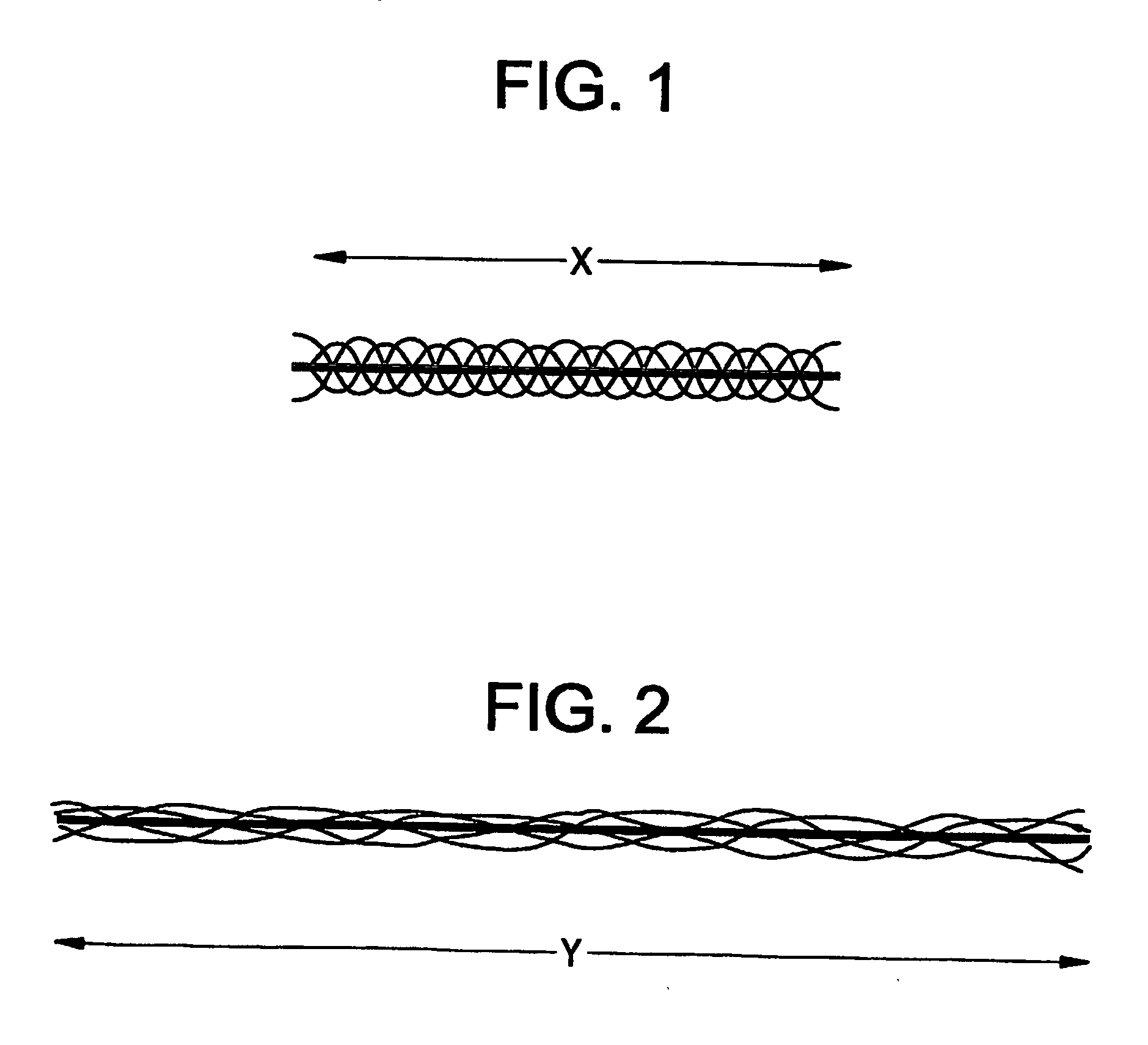

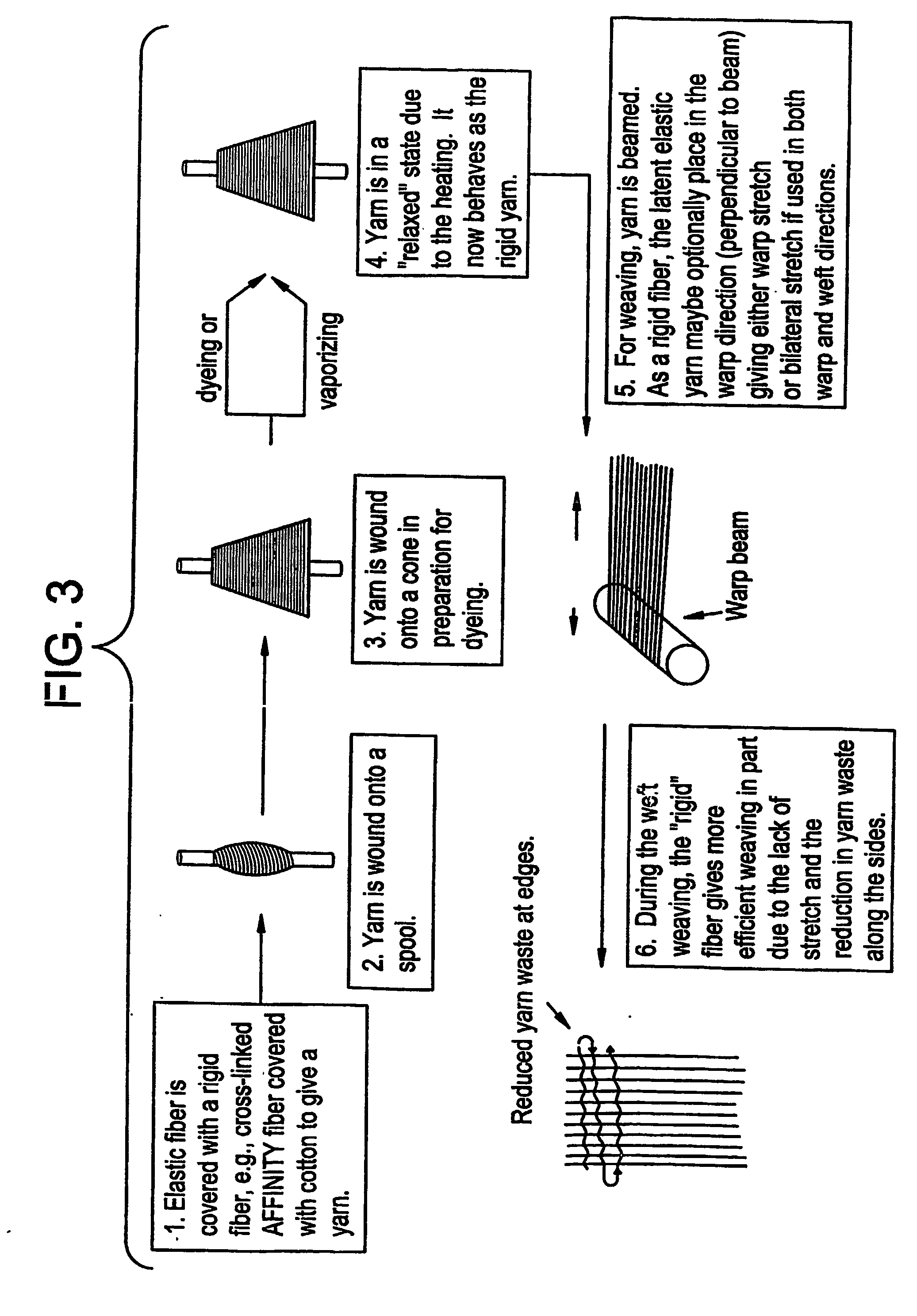

Reversible, heat-set, elastic fibers, and method of making and articles made from same

ActiveUS20050165193A1Reduce stepsReduce the amount requiredShrinkingMonocomponent polyurethanes artificial filamentFiberElastic fiber

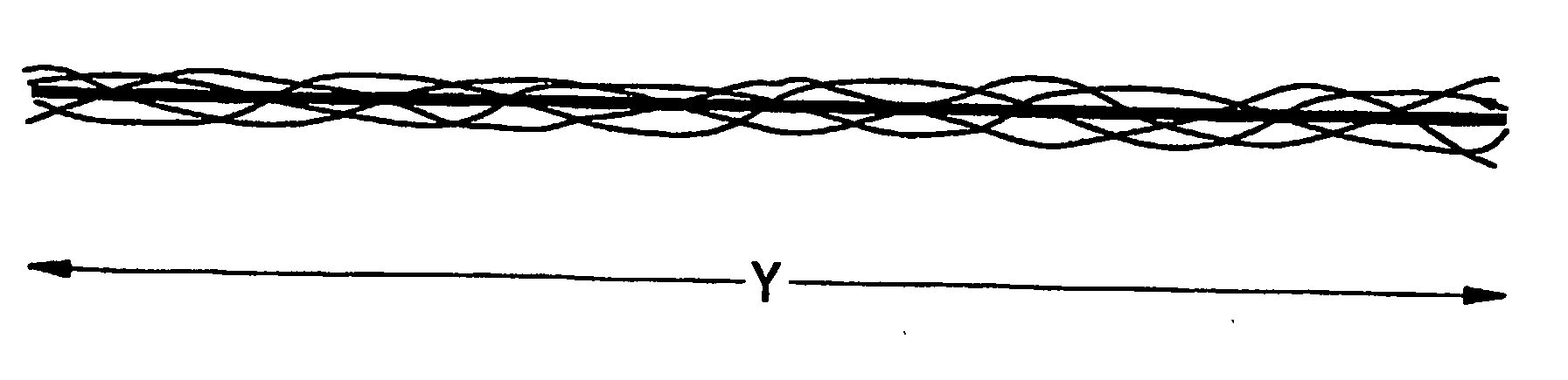

A reversible, heat-set covered fiber is described, the covered fiber comprising: A. A core comprising an elastic fiber comprising a substantially crosslinked, temperature-stable, olefin polymer, and B. A cover comprising an inelastic fiber. The fiber is head set by a method comprising: (a) Stretching the covered fiber by applying a stretching force to the covered fiber; (b) Heating the stretched covered fiber of (a) to a temperature in excess of the crystalline melting point of the olefin polymer for a period of time sufficient to at least partially melt the olefin polymer; (c) Cooling the stretched and heated covered fiber of (b) to a temperature below the crystalline melting point of the olefin polymer for a period of time sufficient to solidify the polymer; and (d) Removing the stretching force from the covered fiber.

Owner:DOW GLOBAL TECH LLC

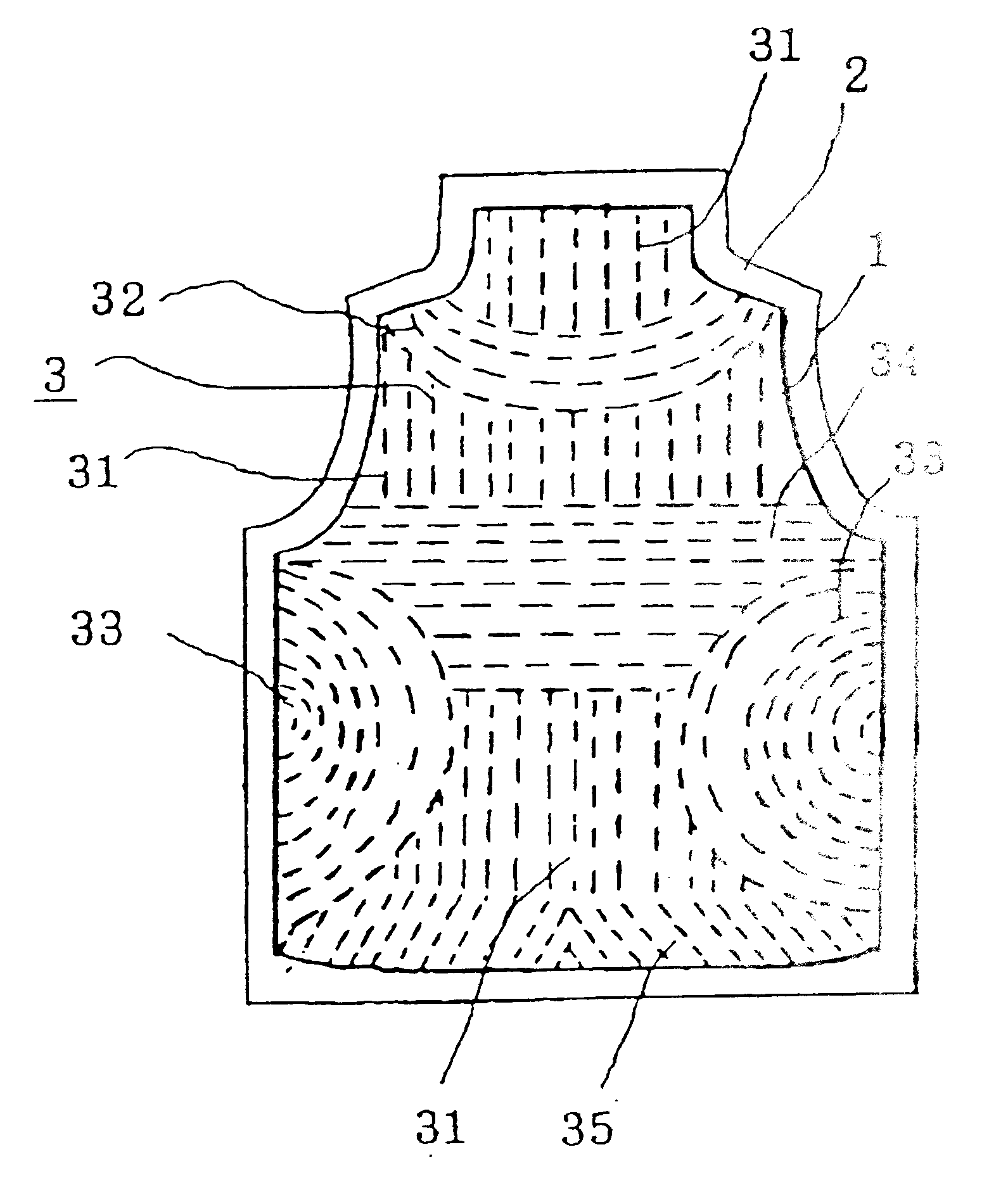

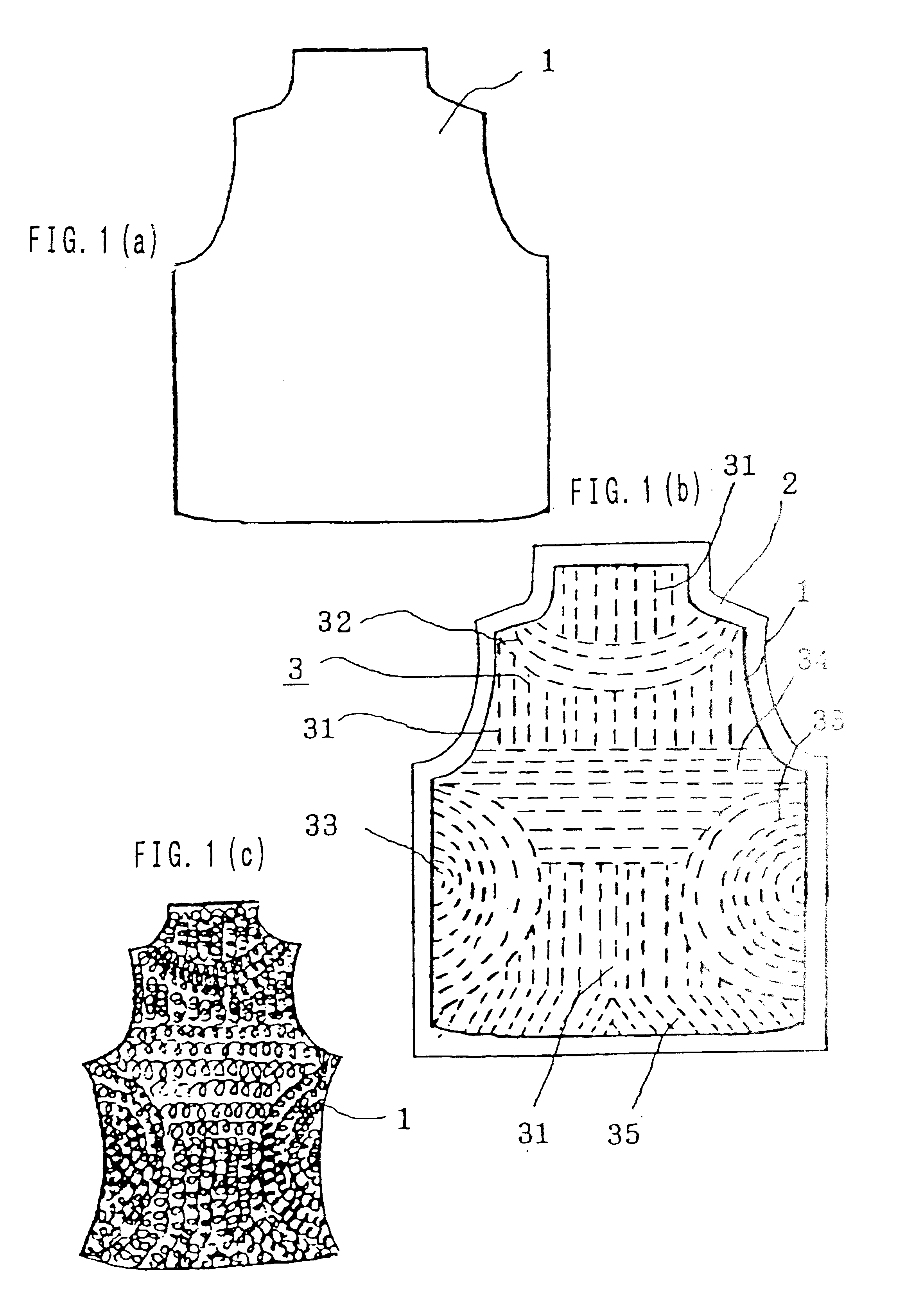

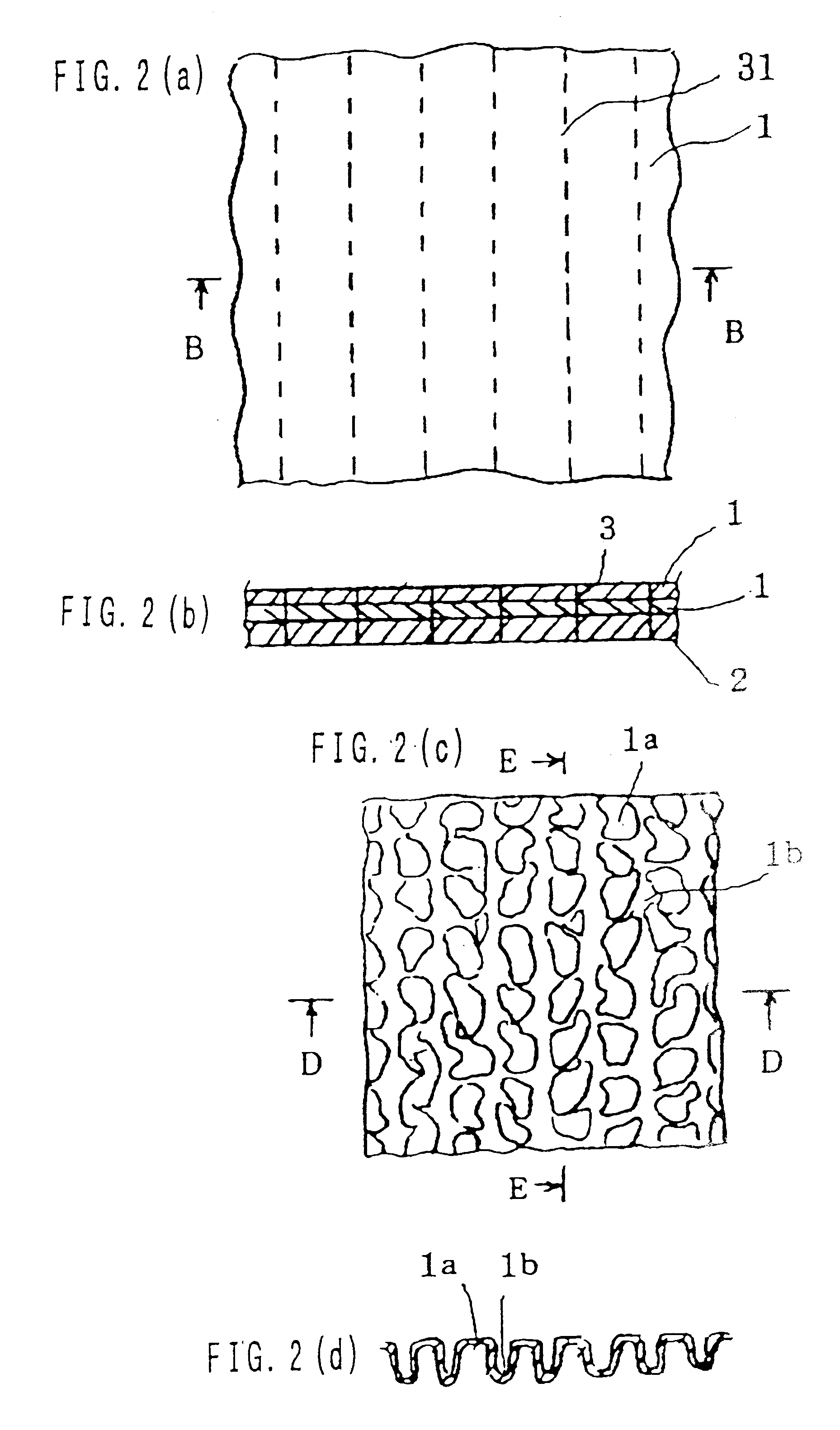

Method of making convexities and/or concavities on cloths of a garment

A method for forming convexities and / or concavities on cloths for a garment at almost entire portions of the garment or any desired portion of the garment without any substantial limitation from a design point of view. The method for forming a garment having convexities and / or concavities which can expand and contract in both the weft and wrap directions like a knitted fabric. Cloths including thermoplastic fiber are cut into parts of the garment, the parts are sewn in a shape of the garment. The garment is overlaid on a thermo-shrinkable cloth. They are sewn together with stitches of water-soluble threads. The sewn cloths are heated under dry heat and without applying any pressure to the cloths so as to permit the thermo-shrinkable cloth to shrink and form convexities and / or concavities on the cloths of the garment. The water-soluble threads are solved and removed, and the cloths of the garment are separated from the thermo-shrinkable cloth.

Owner:YOSHIKI HISHINUMA CO LTD

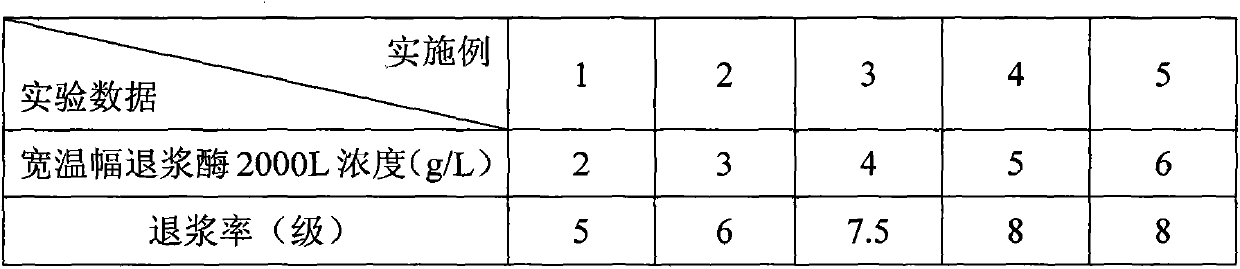

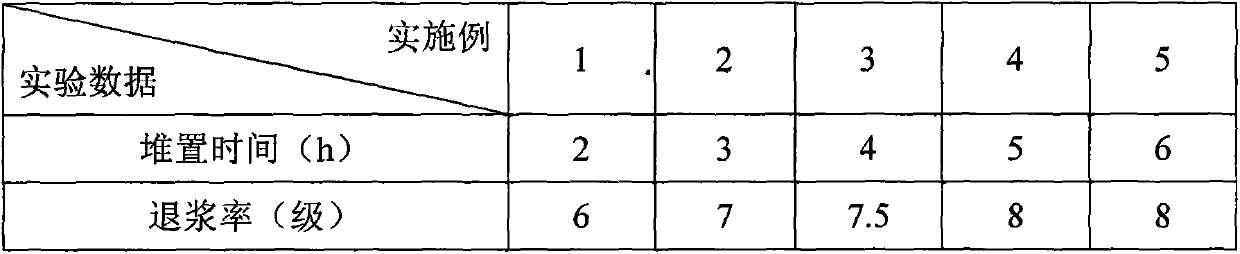

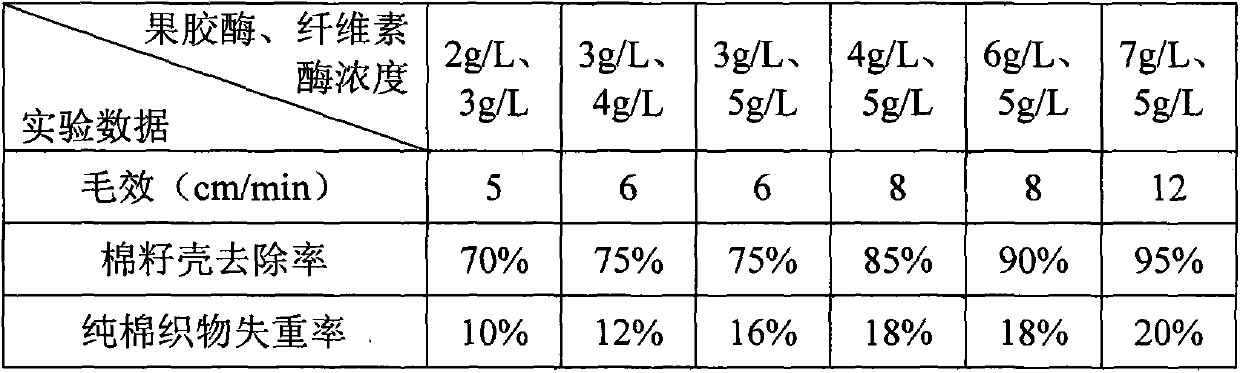

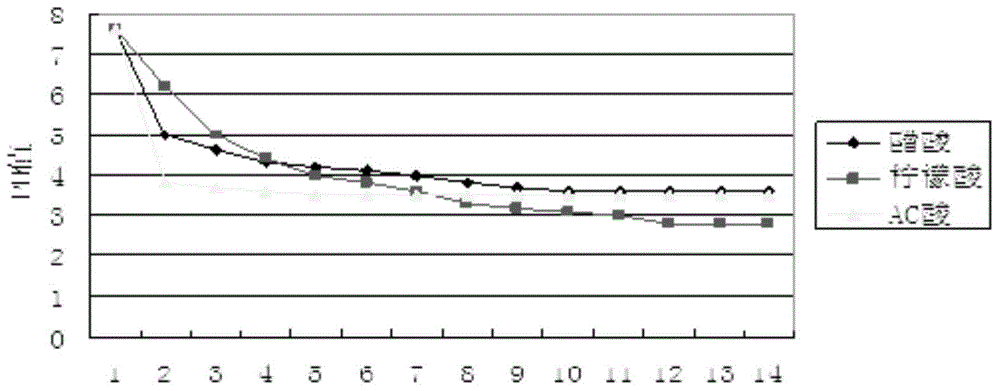

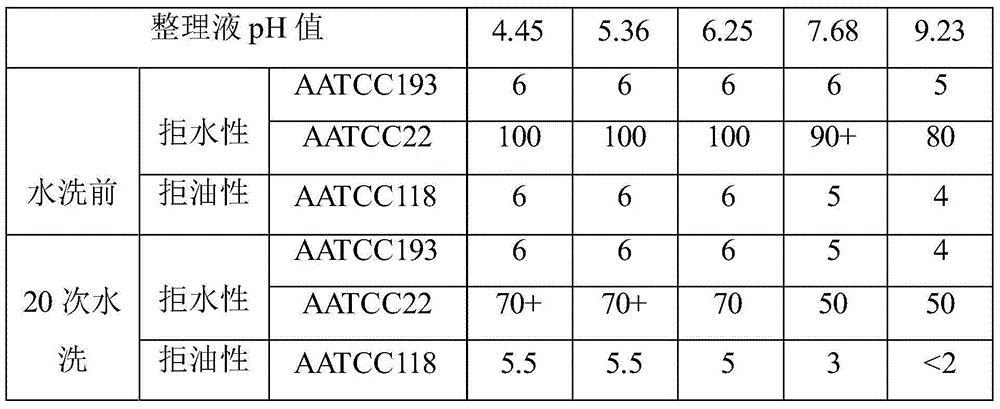

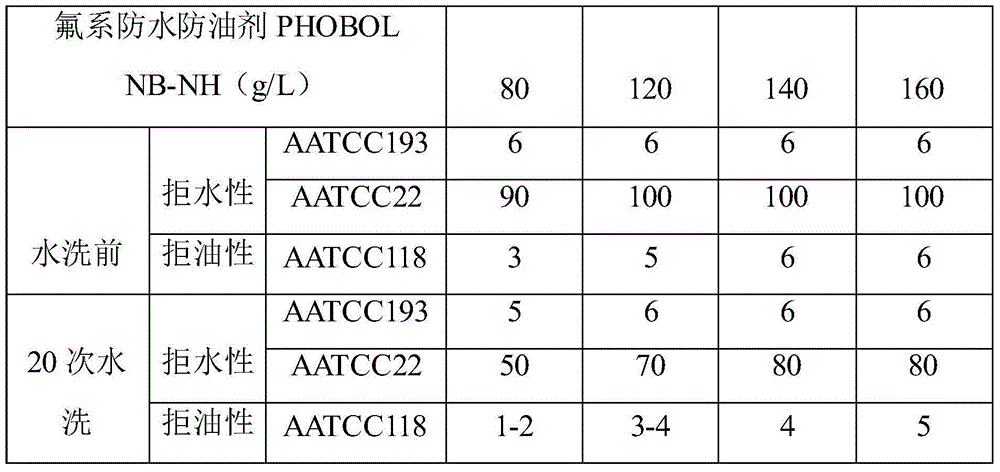

Dyeing treatment process for pure cotton fabrics based on pure natural biological preparations

ActiveCN103437141AHarm reductionEasy to operateShrinkingFabric breaking/softeningWastewaterEngineering

The invention discloses a dyeing treatment process for pure cotton fabrics based on pure natural biological preparations, which is designed for solving the technical problems that the environment is seriously harmed in an existing pure cotton fabric dyeing treatment process, and the human health is harmed in an application process. The adopted technical scheme is as follows: the dyeing treatment process comprises the steps of singeing, desizing, boiling-out, bleaching, dyeing, softening treatment and preshrinking treatment, and the key point is that biological preparations, which are respectively a desizing enzyme solution, a boiling-out enzyme solution, glucose oxidase solution and a plant dye, are respectively adopted in the steps of desizing, boiling-out, bleaching and dyeing. The dyeing treatment process has the technical effects that the operation is simple; the pure natural biological preparations almost do not contain any toxic substance, and wastewater produced in the treatment process is less and biodegradable, so that under the premise of keeping the characteristics such as softness, sweat absorption, comfortableness and naturalness and the like of pure cotton fabrics, the harm to the environment is alleviated, and the harm to human body is avoided, and therefore, the process has a zero-pollution environmental friendliness characteristic.

Owner:HEBEI NINGFANG GRP

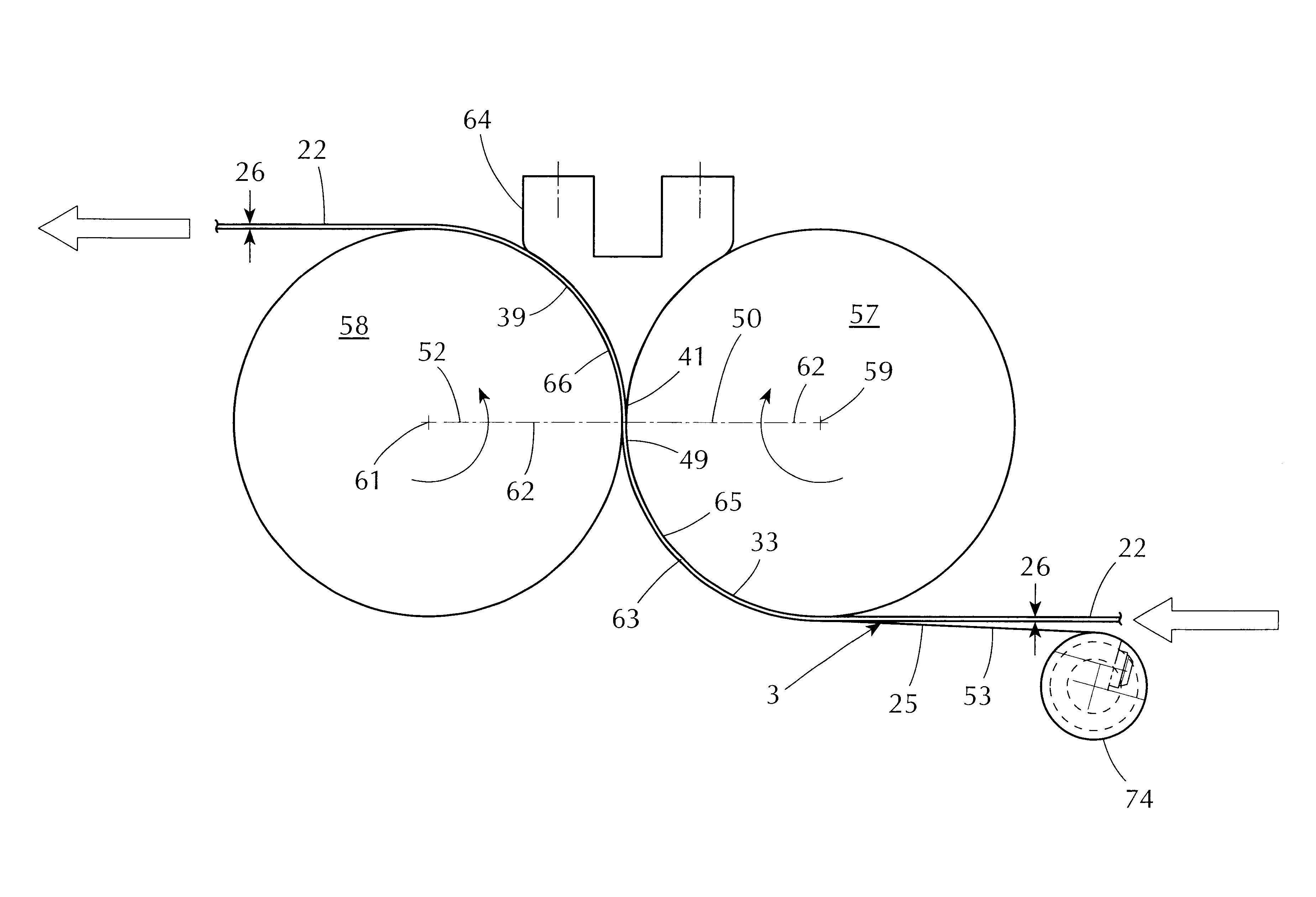

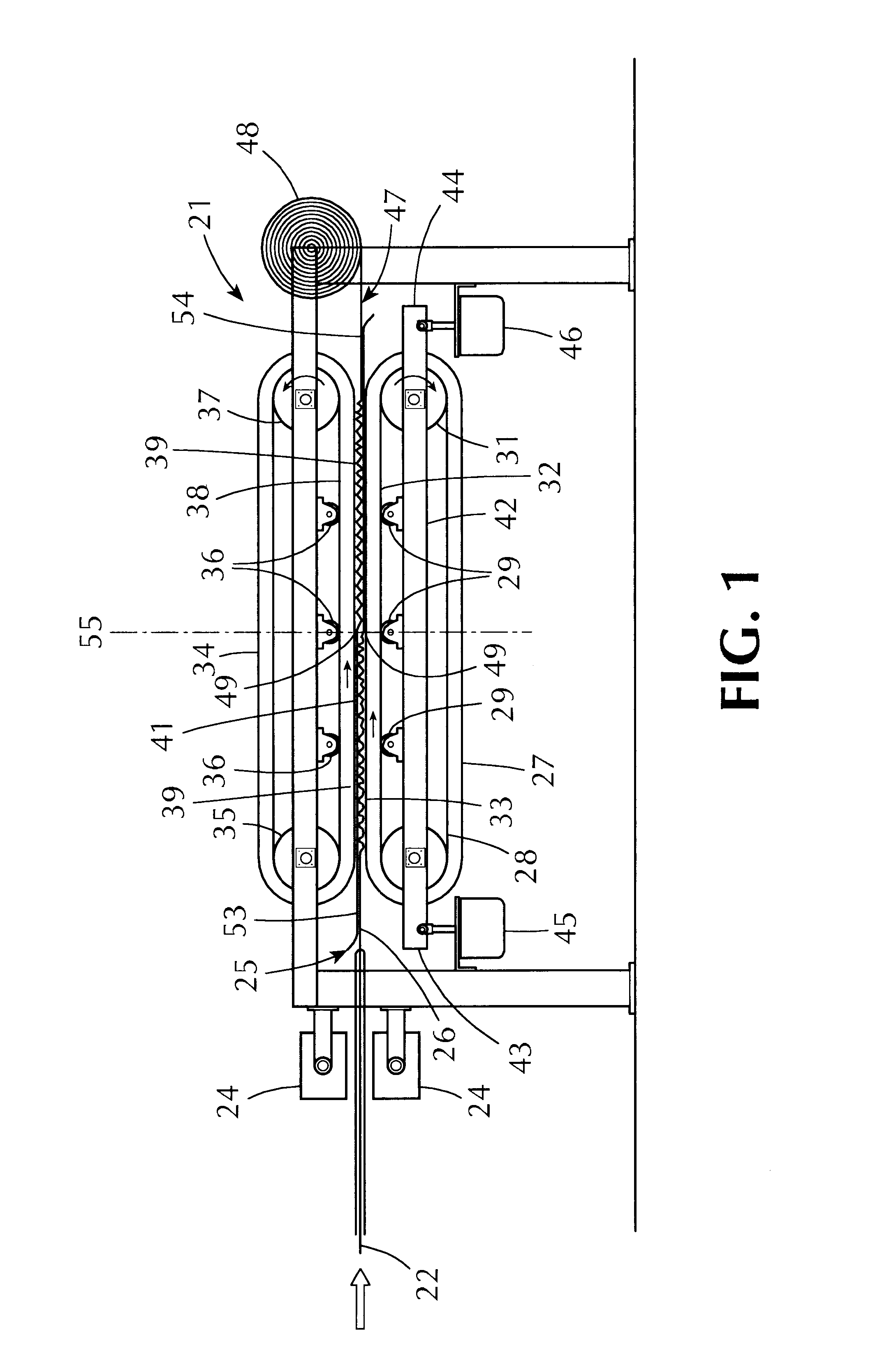

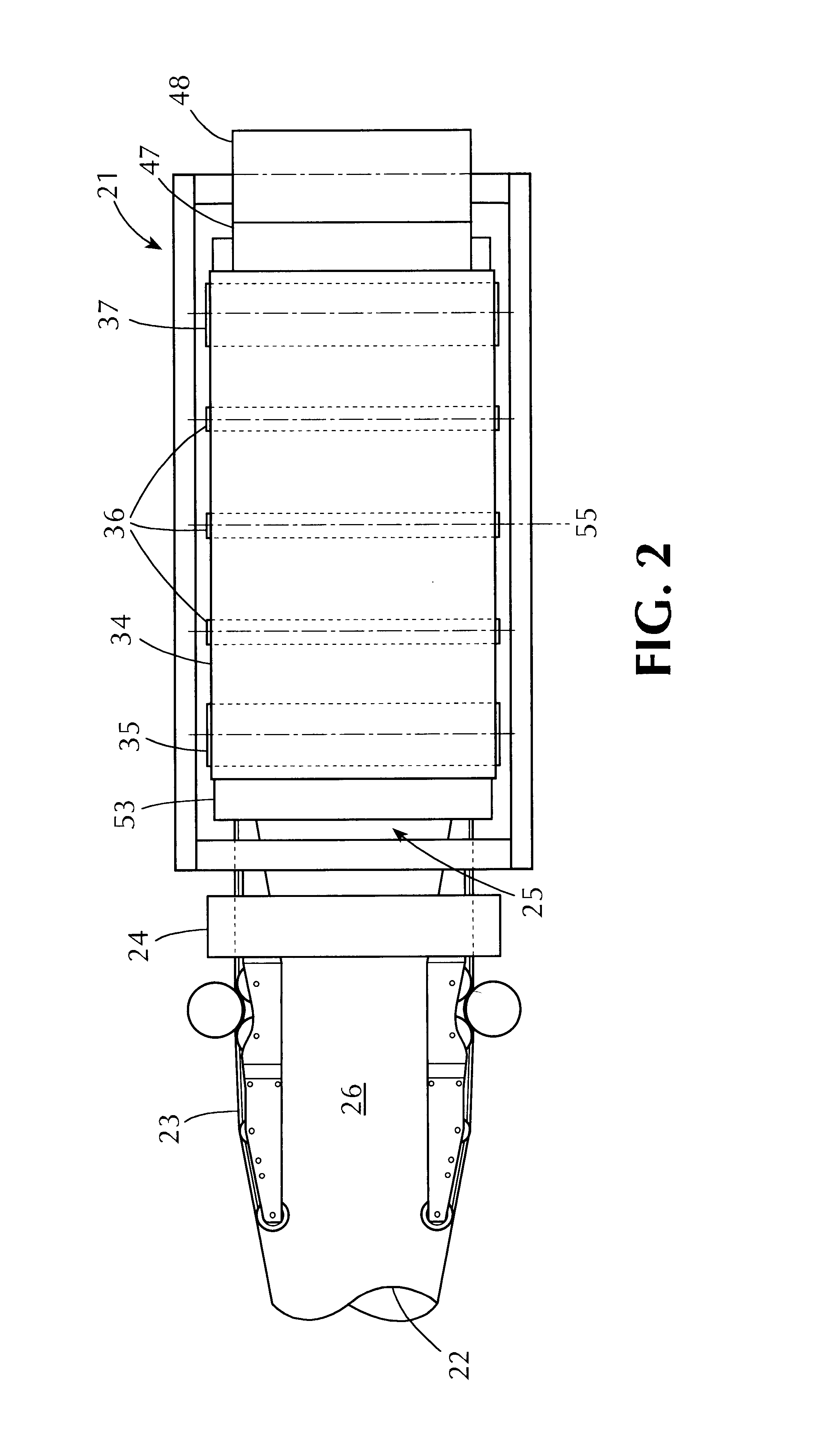

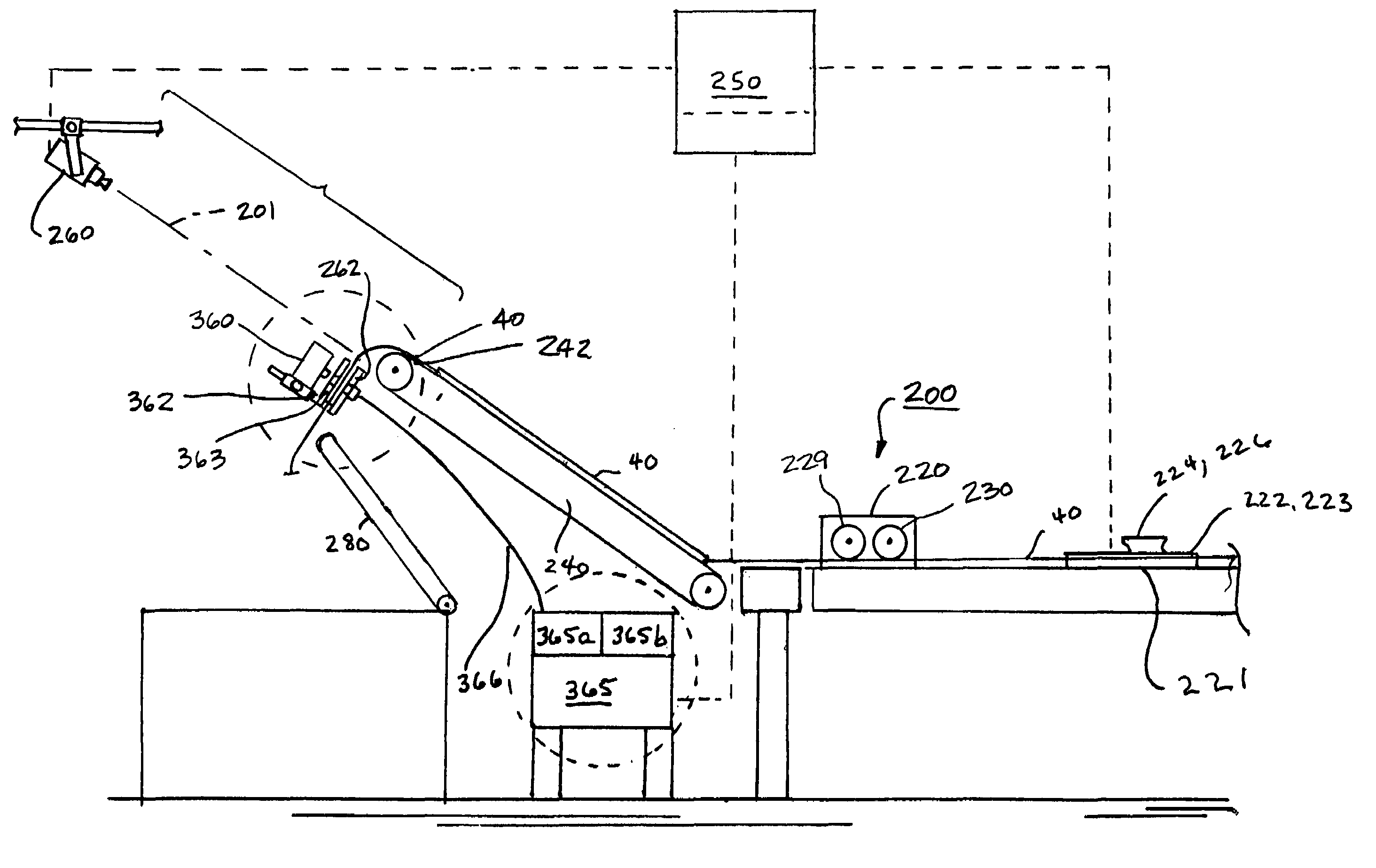

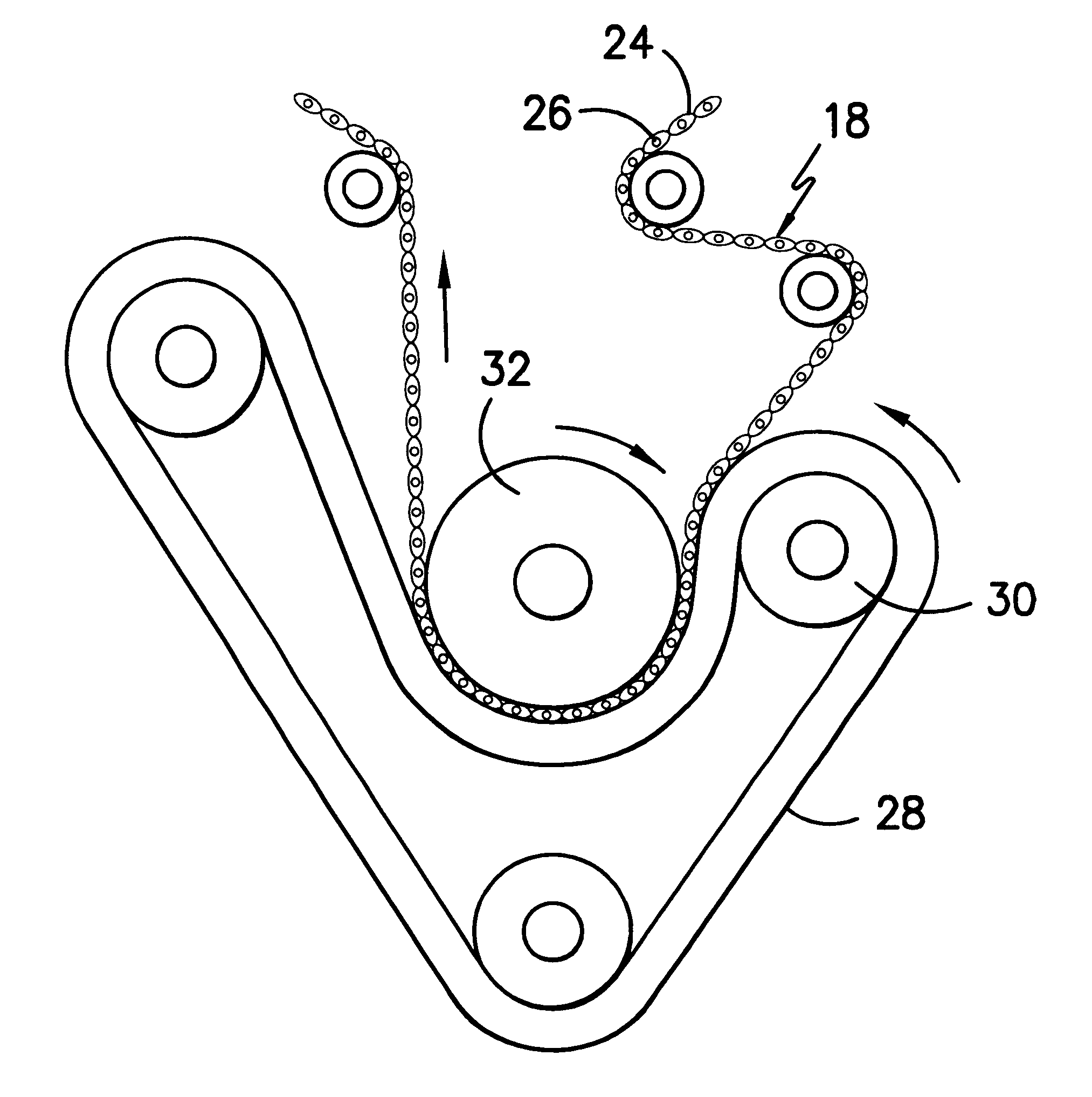

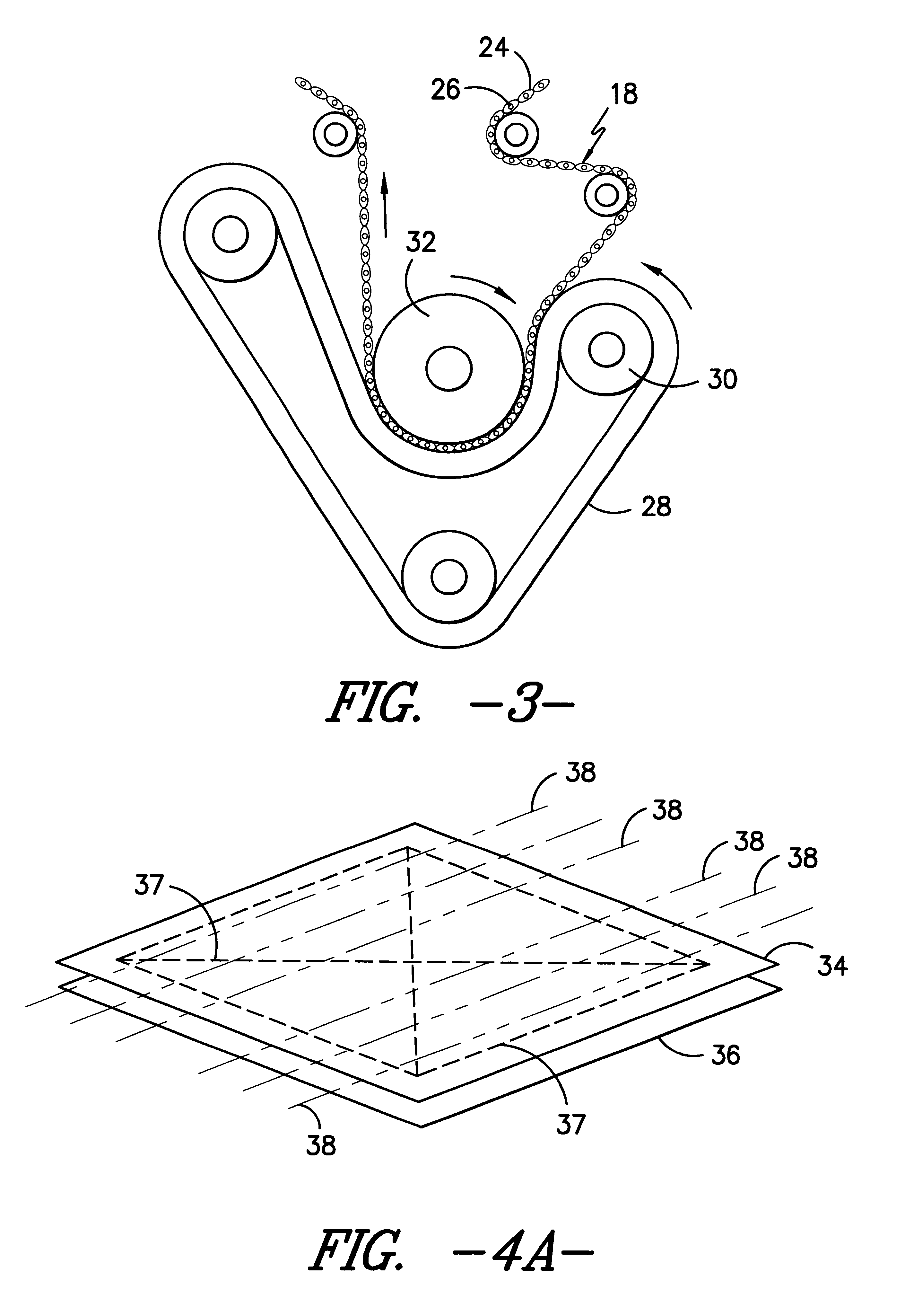

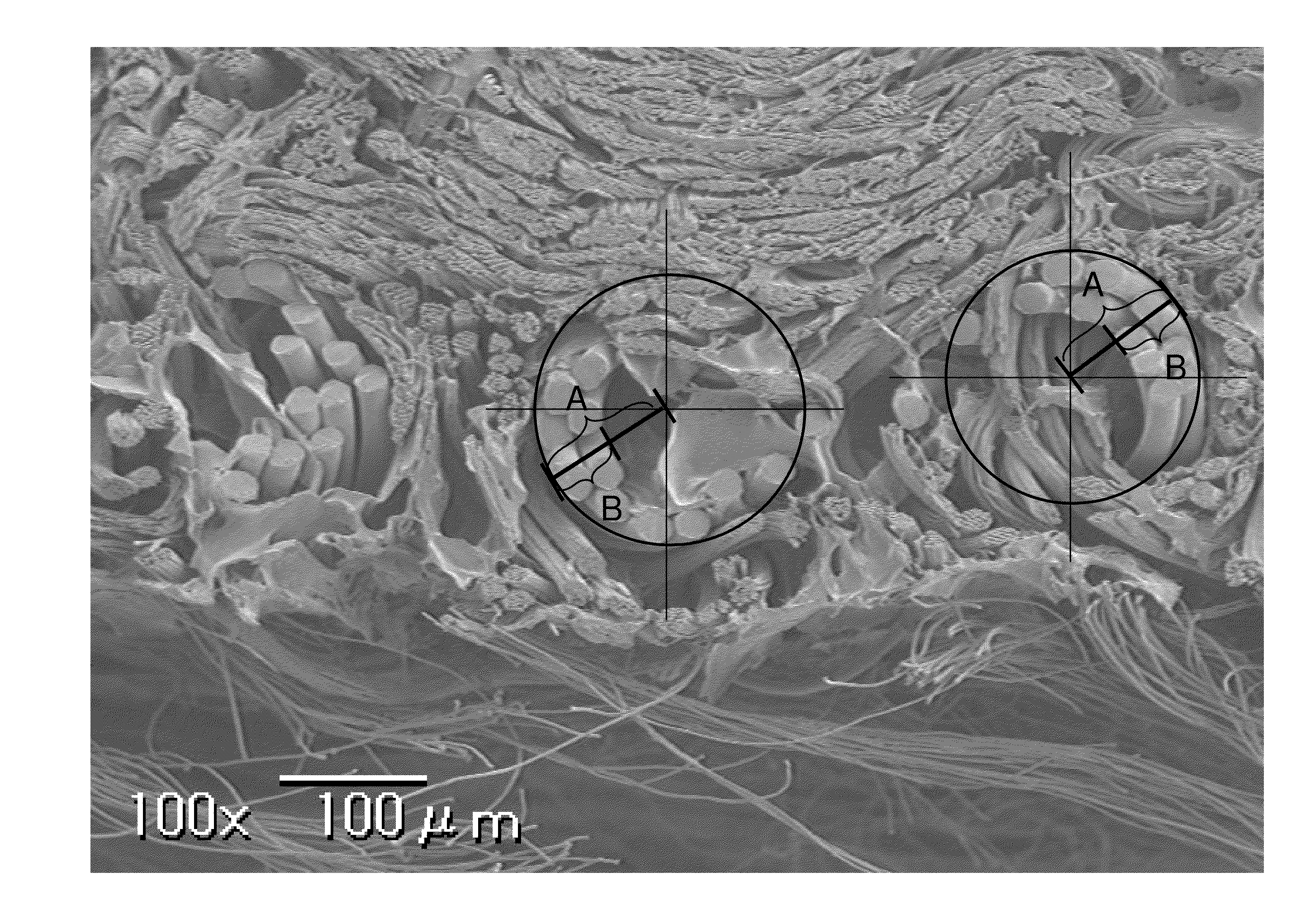

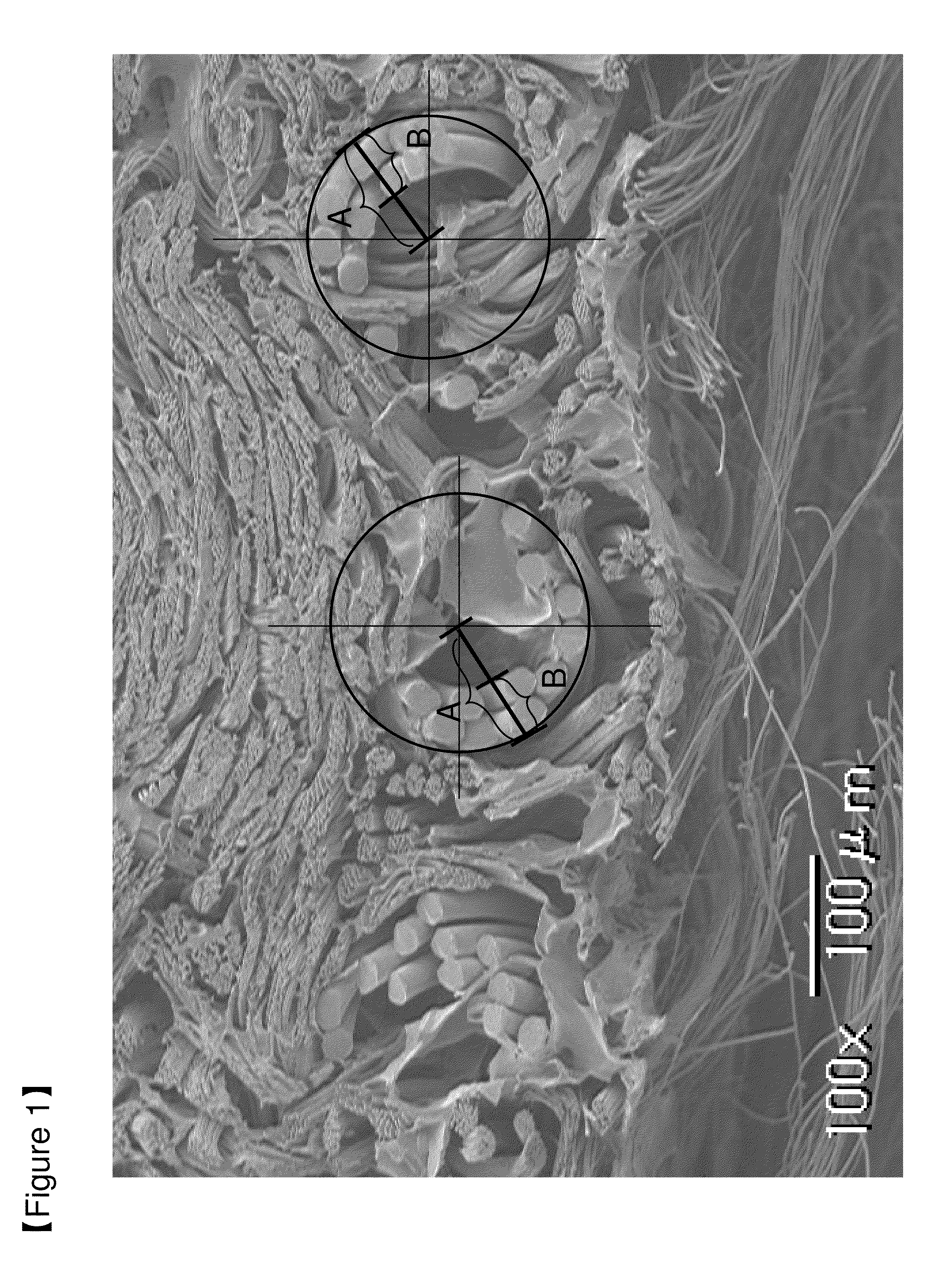

Dual-slip compressive shrink-proofing apparatus for fabric and related method

InactiveUS6681461B1Superior-quality controlled permanent compactionReduced Power RequirementsShrinkingMechanical cleaningFiberYarn

A method and related apparatus for shrink-proofing a fabric, typically a knitted textile composed of interlocked loops of yarn made of natural and / or man-made fibers. The loops interlock along stitch rows that may become skewed. According to the invention the fabric is confined from expanding as it is delivered to and discharged from an in-line compression zone free of obstructions such as crimps, bends or kinks. The fabric is confined, preferably resiliently, coming to, passing through and leaving the compression zone so as to accommodate variation of thickness and irregularities of the fabric being compacted in the compression zone. The interlocked loops are organized whereby they are allowed to move toward each other orthogonally along their related stitch row so as to reduce volume of the fabric. Non-woven textiles, papers, papers with additives and the like are shrink-proofed in the same manner.

Owner:CATALLO FRANK

Cotton/viscose glue and acetate fiber mixed fabric dyeing and finishing process

ActiveCN103243590ASolve the problem of matching dyeing and finishing processResolve interactionShrinkingBiochemical fibre treatmentViscosePulp and paper industry

The invention provides a cotton / viscose glue and acetate mixed fabric dyeing and finishing process. The dyeing and finishing process is carried out in a jig and comprises steps of: fabric pretreatment, dyeing processing and fabric aftertreatment. The fabric pretreatment comprises steps of: singeing, desizing and bleaching. The fabric aftertreatment comprises steps of: softening and sizing, calendaring and shrinkage. According to the invention, cotton / viscose glue and acetate fiber mixed fabric is dyed by a mesothermal one-bath one-step method. Colors are not mutually stained. The process provided by the invention has advantages of differential dyeing, simple equipment requirement, simple and feasible process and color control, energy saving and emission reduction and green and environmentally friendly dyeing and finishing processing. By the adoption of the process, fabric design style, color, pattern effects are fully presented, variable-pigment stereo effect of high-grade cotton / viscose glue / acetate fiber mixed figured cloth is highlighted, novelty is increased, and novel fabric dyeing and finishing matching technology requirements and market requirements are met.

Owner:江苏欧化纺织有限公司

Manufacturing method of novel terylene satin imitated silk fabric

The invention discloses a manufacturing method of novel terylene satin imitated silk fabric. The method comprises the following steps of A. weaving, B. sizing and oil applying, C. desizing and refining, D. alkali peeling, E. finalizing, F. sanding, G printing, H. post-finalizing drying and I. settling. Terylene semi-extinction filaments 75D / 72F are used, satin weave is used as foundation weave, meanwhile, by proper twisting, diffuse reflection phenomena of polyester fibers on light are achieved, metallic luster of triangle isomerism polyester fibers can be weakened and is close to real silk luster, and the draping performance of fabric is improved. By detecting of the heat resistance, the damp obstruction, the wrinkle recovering degree, the static draping degree, friction color fastness, perspiration fastness and saliva resistance color fastness, and novel terylene satin imitated silk fabric completely achieves the effect of real silk.

Owner:CHANGXING YUXIN TEXTILE PRINTING & DYEING

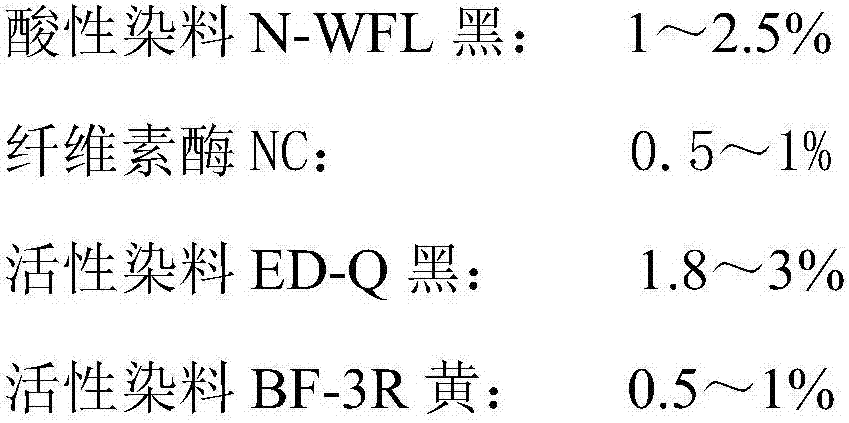

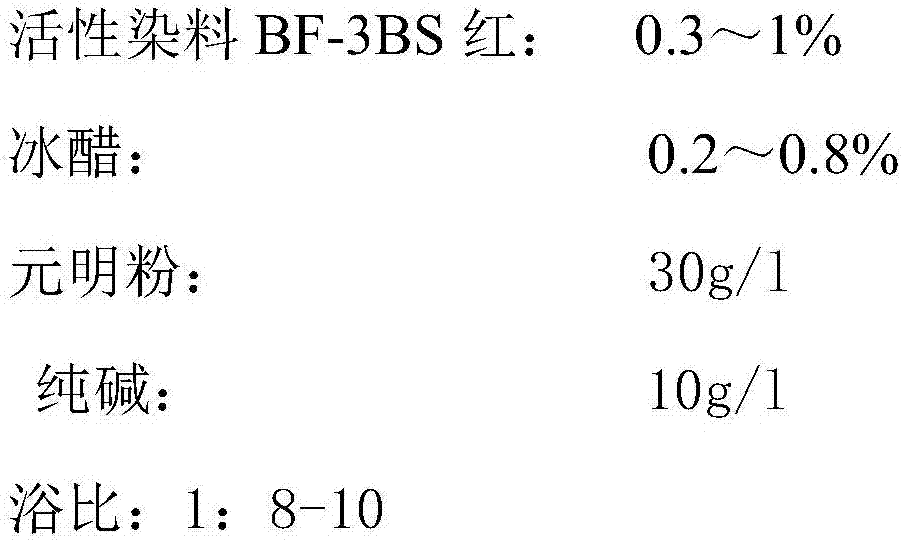

Nylon/cotton fabric hair removal and reactive dye dyeing one-bath process

InactiveCN106958152AReduce consumptionReduce production processShrinkingMercerising of indefinite length fabricsHair removalNylon material

The invention relates to a one-bath dyeing process, in particular to a one-bath process for hair removal and reactive dye dyeing of brocade / cotton fabrics. Follow the steps below: select sample cloth → gray cloth desizing → gray cloth pre-setting → gray cloth mercerizing → dyeing formula design → sample vat dyeing → drying and setting → oiling and setting → pre-shrinking finishing → finished product inspection. A one-bath process of hair removal and reactive dye dyeing of nylon / cotton fabrics, which has obvious energy-saving and emission-reduction effects, and the hand-feel elasticity, color fullness, and various quality internal indicators of the processed fabrics can meet the requirements of different customers.

Owner:HANGZHOU AOMEI PRINTING & DYEING

Production process for cotton-linen knitted belt

InactiveCN107385877ASoft touchEasy to processShrinkingMercerising of indefinite length fabricsConvex structureMoisture permeability

The invention relates to a production process for a cotton-linen knitted belt. According to the invention, multiple steps of the production process for the cotton-linen knitted belt are improved from multiple aspects, so the produced cotton-linen knitted belt is ensured to be good in elasticity and wear resistance, stable in dimension, small in washing shrinkage, straight, not prone to creasing, easy to wash and fast to dry under dry and wet conditions; the linen component of the knitted belt is capable of preventing ultraviolet rays and suppressing and resisting bacteria; the production process for the cotton-linen knitted belt overcomes the inherent disadvantage of stiff and itchy handle feel of natural fibrilia fabrics; and the prepared cotton-linen knitted belt has a special concave-convex structure, excellent low irritability, moisture permeability and crease resistance, and good indexes like moisture absorption performance and permeability, is knitted by fully natural fiber, is a low-carbon environment-friendly belt, and accords with the current fashionable trend of international textiles and garments.

Owner:HUZHOU UNIFULL LABEL FABRIC CO LTD

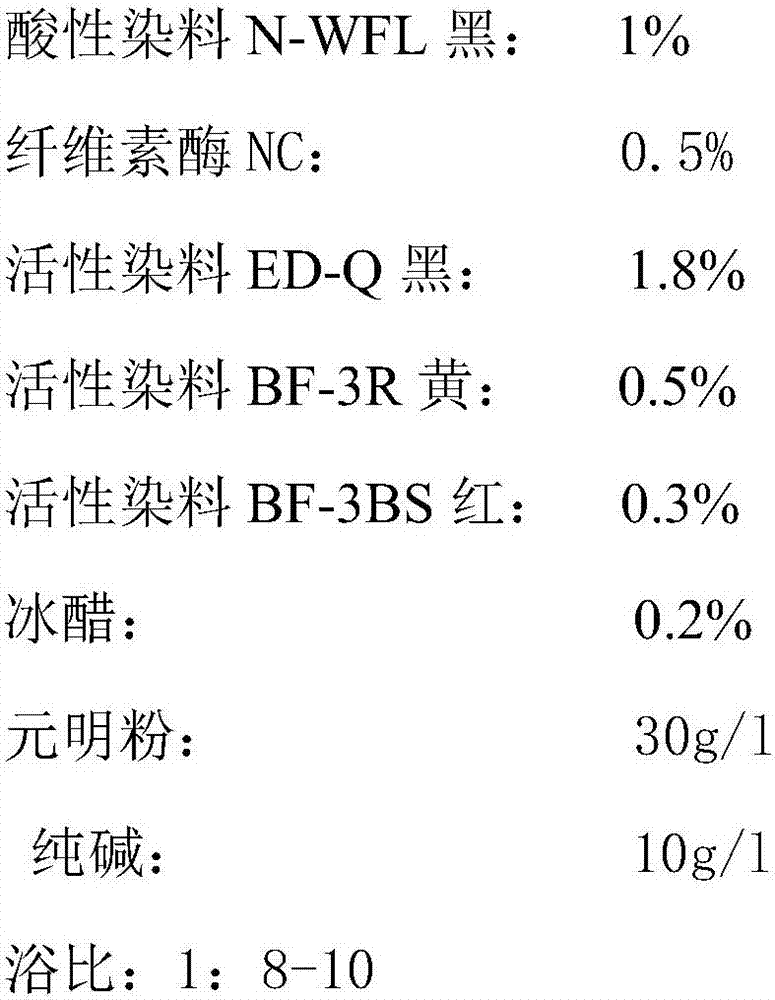

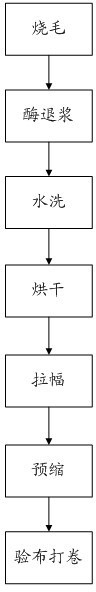

Finishing process for textile fabrics

InactiveCN102587067AReduce printing and dyeing processReduce pollutionShrinkingSingeingEngineeringPollution

The invention discloses a finishing process for textile fabrics. The warps of the textile fabrics are made of colored cotton and the wefts of the textile fabrics are made of natural colored hemp. The finishing process includes the following steps: (a) singeing, (b) enzyme desizing, (c) water washing, (d) oven drying, (e) tentering, (f) pre-shrinking, and (g) cloth inspection and rolling. The finishing process for textile fabrics provided by the invention adopts purely physical finishing process, and does not need to use chemicals, so as to reduce pollution. The finishing process is environment-friendly.

Owner:JIANGSU MENGLAN GROUP

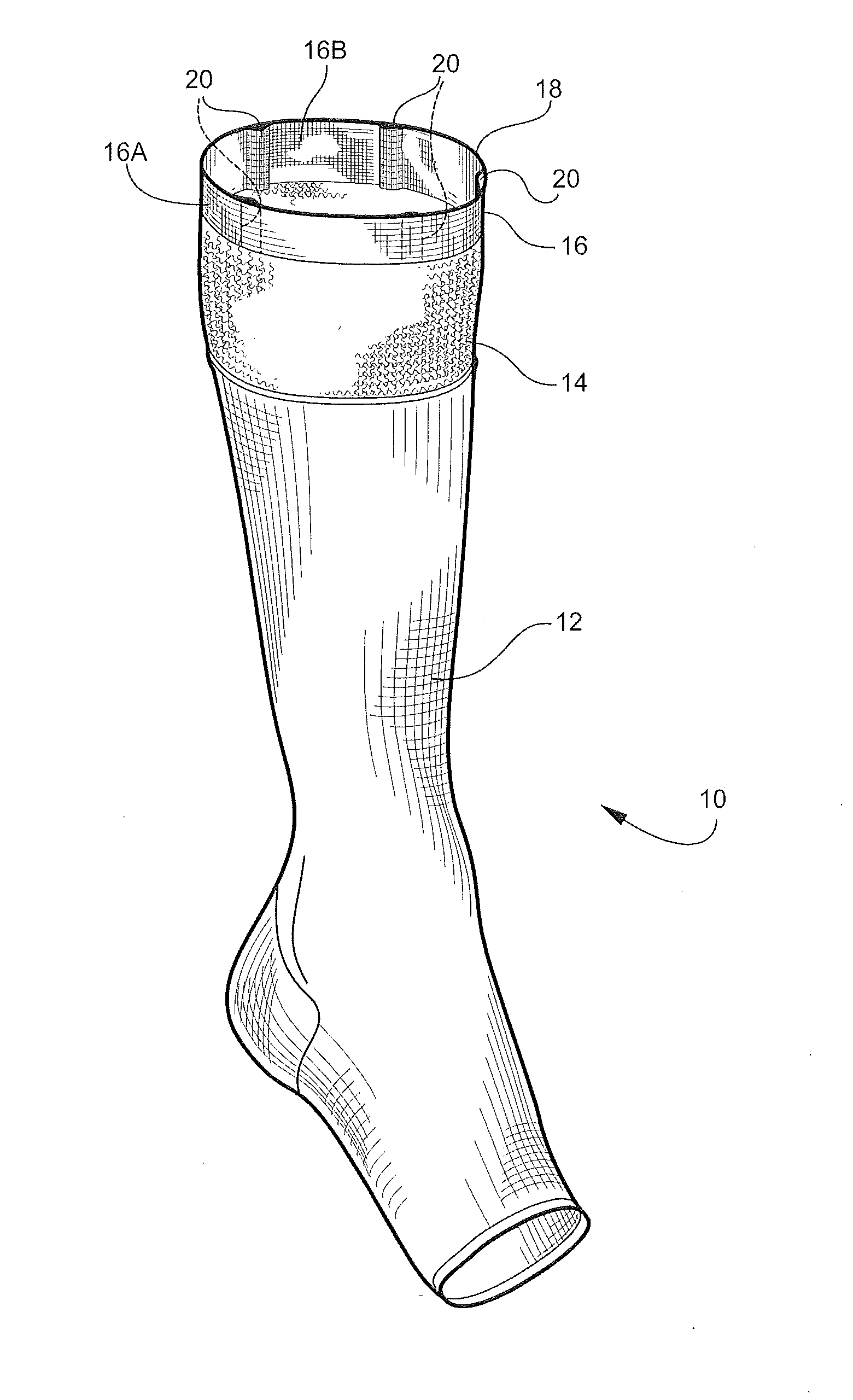

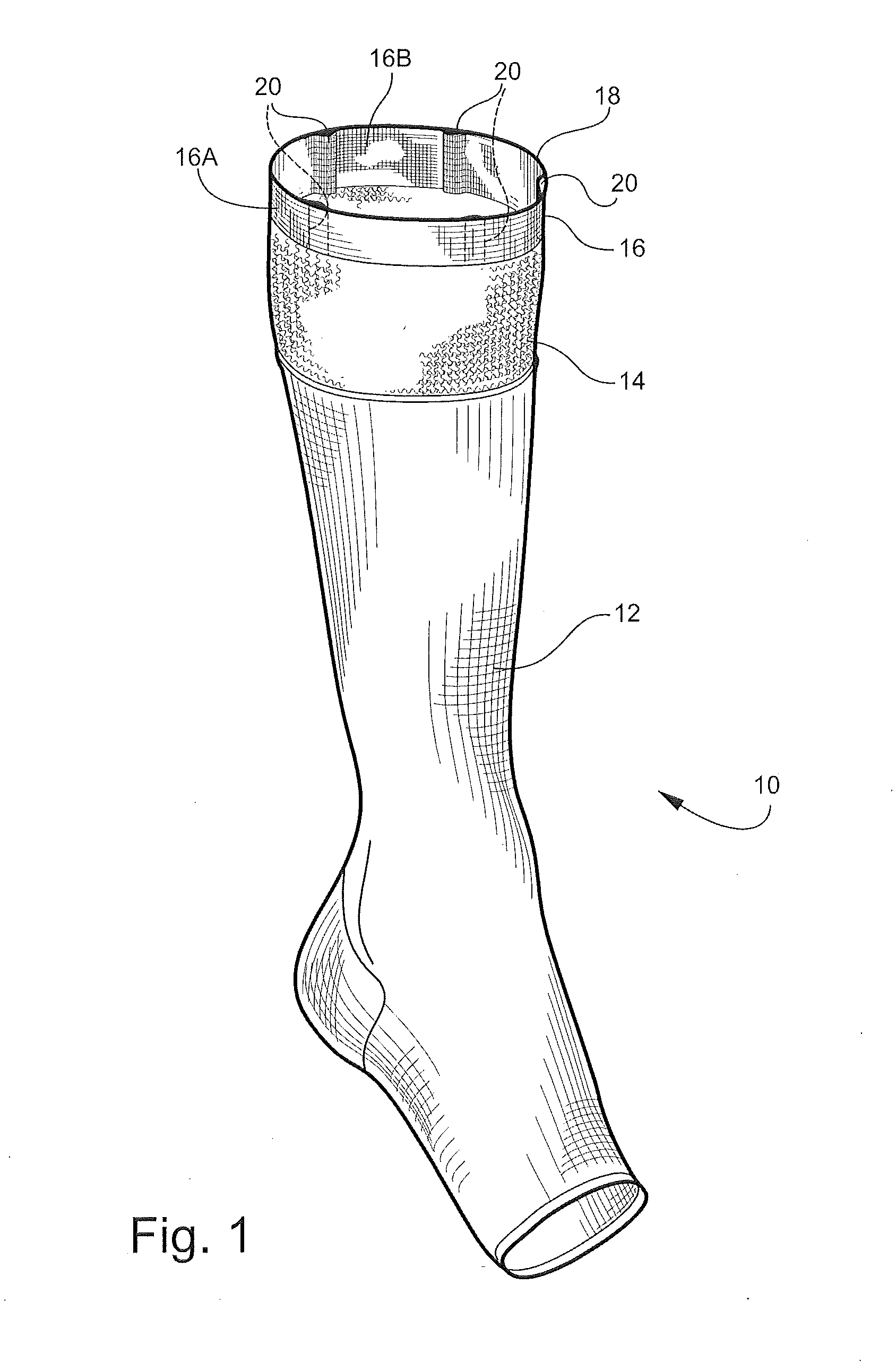

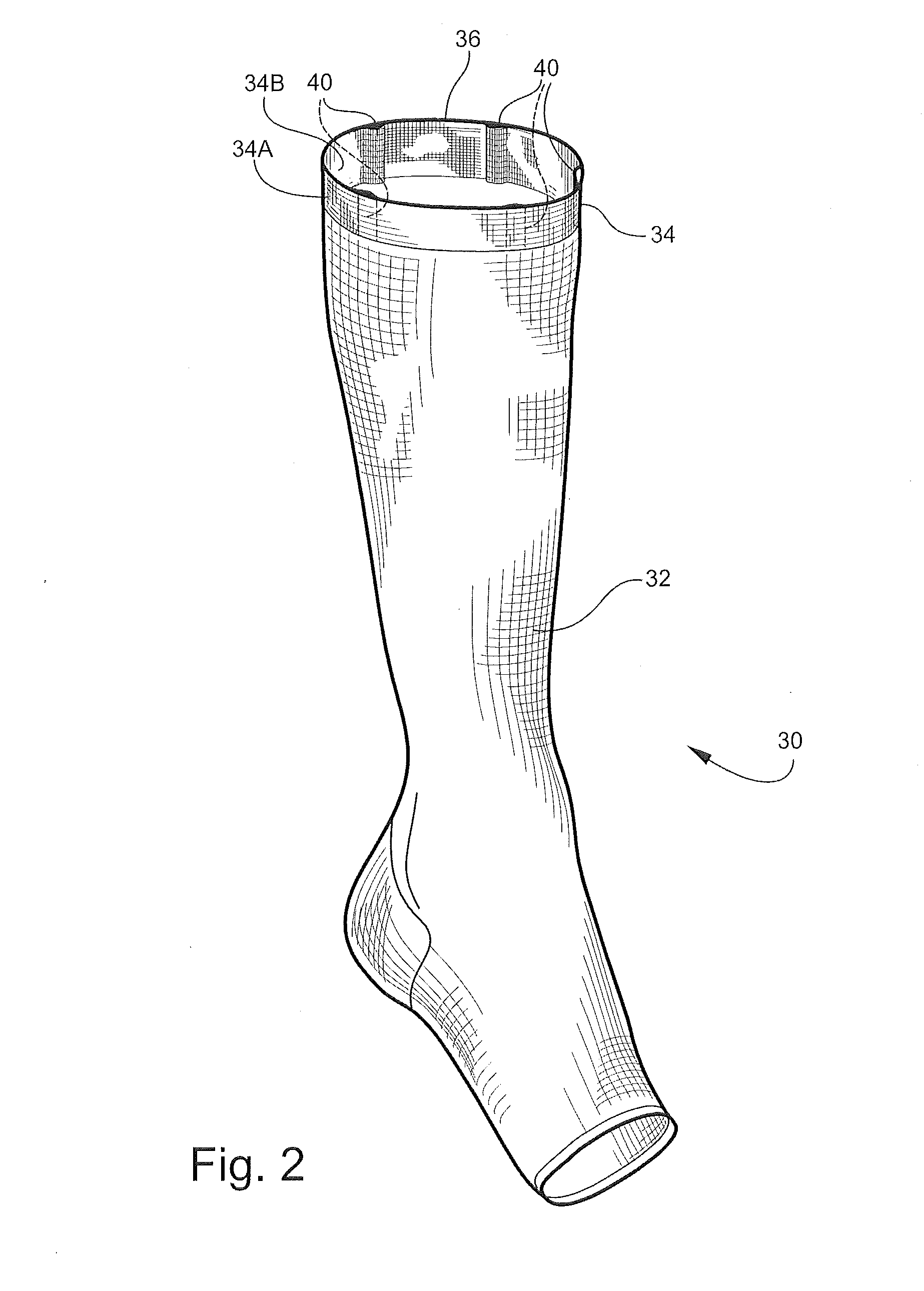

Therapeutic medical compression garment and method

ActiveUS20160038346A1Inhibit wearWelt becomes stableShrinkingNon-adhesive dressingsEngineeringBiomedical engineering

A therapeutic medical garment including a knitted welt proximate one end thereof with a surface adapted for residing against the wearer's skin. The garment includes a ground yarn and a plurality of raised, skin-engaging stabilizer elements, such as elongate bars extending in spaced-apart relation around an inner surface of the welt and along a longitudinal axis of the garment to reduce a tendency of the welt to roll over on itself.

Owner:BSN MEDICAL INC

Medical device including corrugated braid and associated method

InactiveUS20130112070A1Increase resistanceHigh strengthShrinkingStentsMedical deviceBiomedical engineering

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

Antibacterial, deodorant and moisture-absorbing child bed sheet shell fabric and production technology thereof

The invention discloses antibacterial, deodorant and moisture-absorbing child bed sheet shell fabric. The shell fabric is formed by weaving weft yarn and warp yarn by the ratio of 1:2 in a twilled mode, wherein the warp yarn is formed by blending super-absorbent hollow polyester fibers and bamboo pulp fibers by the ratio of 1:1, and lycra fibers are adopted as the weft yarn. The production technology includes the steps of weaving, singeing, desizing, oxygen bleaching, pretreating, dyeing, soaping, mercerizing, tentering and shaping, preshrinking and detecting. The antibacterial, deodorant and moisture-absorbing child bed sheet shell fabric absorbs water, dries quickly and is breathable, moisture permeable, uvioresistant, antibacterial, deodorant and resistant to acid, alkaline, sweat, dry cleaning and abrasion, and service life is prolonged.

Owner:南通梭子纺织科技有限公司

Production process for Tencel cotton spinning silk style fabric

InactiveCN106811857AColorfulIncrease elasticityShrinkingMercerising of indefinite length fabricsProduct inspectionEngineering

The invention relates to a silk-style fabric, in particular to a production process of Tencel cotton imitation silk-style fabric. Follow the steps below: select samples→cloth distribution→loose cloth→width cutting→grain cloth singeing treatment→mercerizing treatment→open width boiling and bleaching→setting and drying→cold dyeing→cold stacking→soaping→drying→finished product shaping→rubber Blanket shrinking → finished product inspection. The production process of a Tencel cotton imitation silk style fabric has the characteristics of flatness, bright colors, good elasticity, good moisture absorption, strong wrinkle resistance, stable size, good air permeability and melt hole resistance, and significantly reduces wool fabric fluffing and fluffing Balls and static electricity also reduce the price of woolen fabrics.

Owner:HANGZHOU HAORAN TEXTILE TECH CO LTD

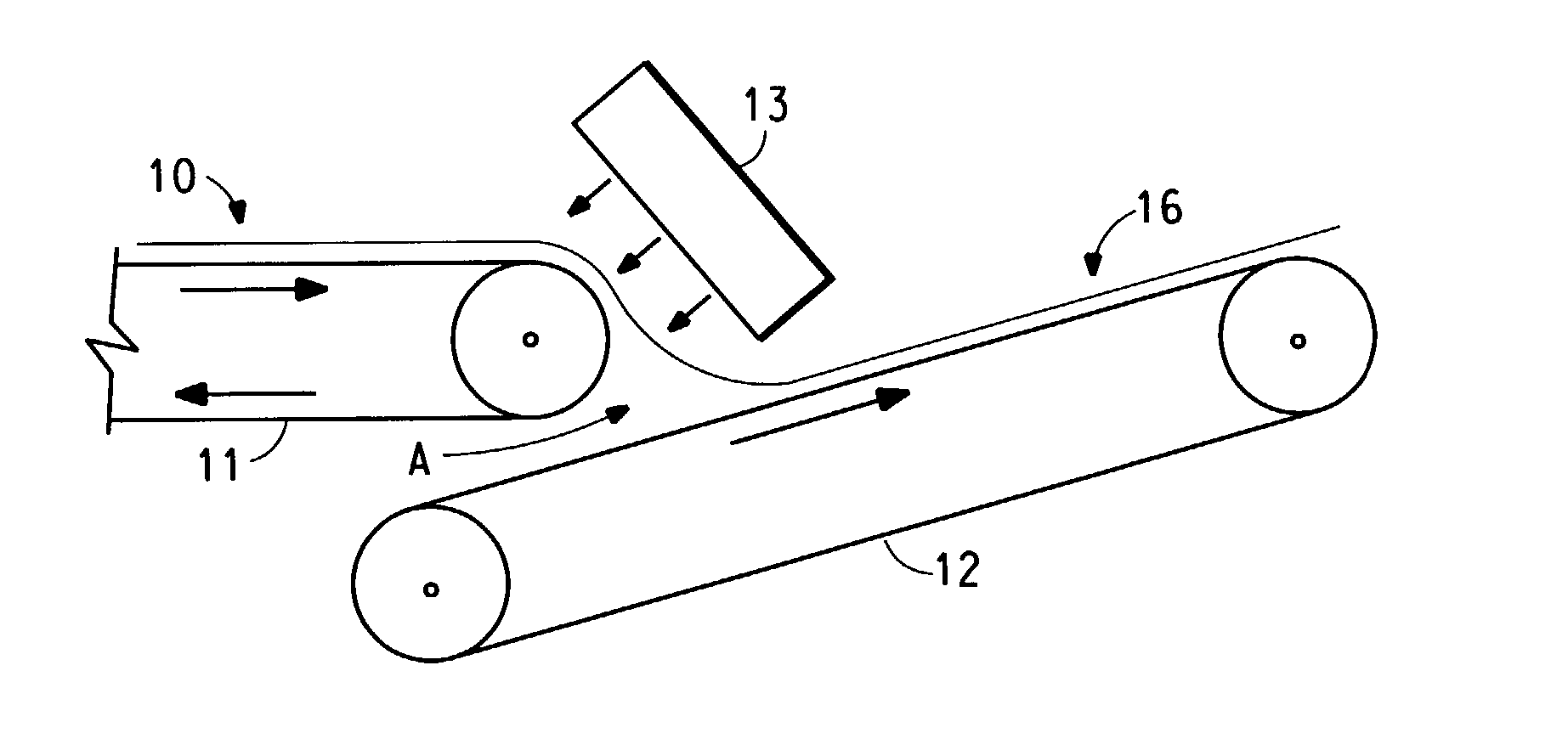

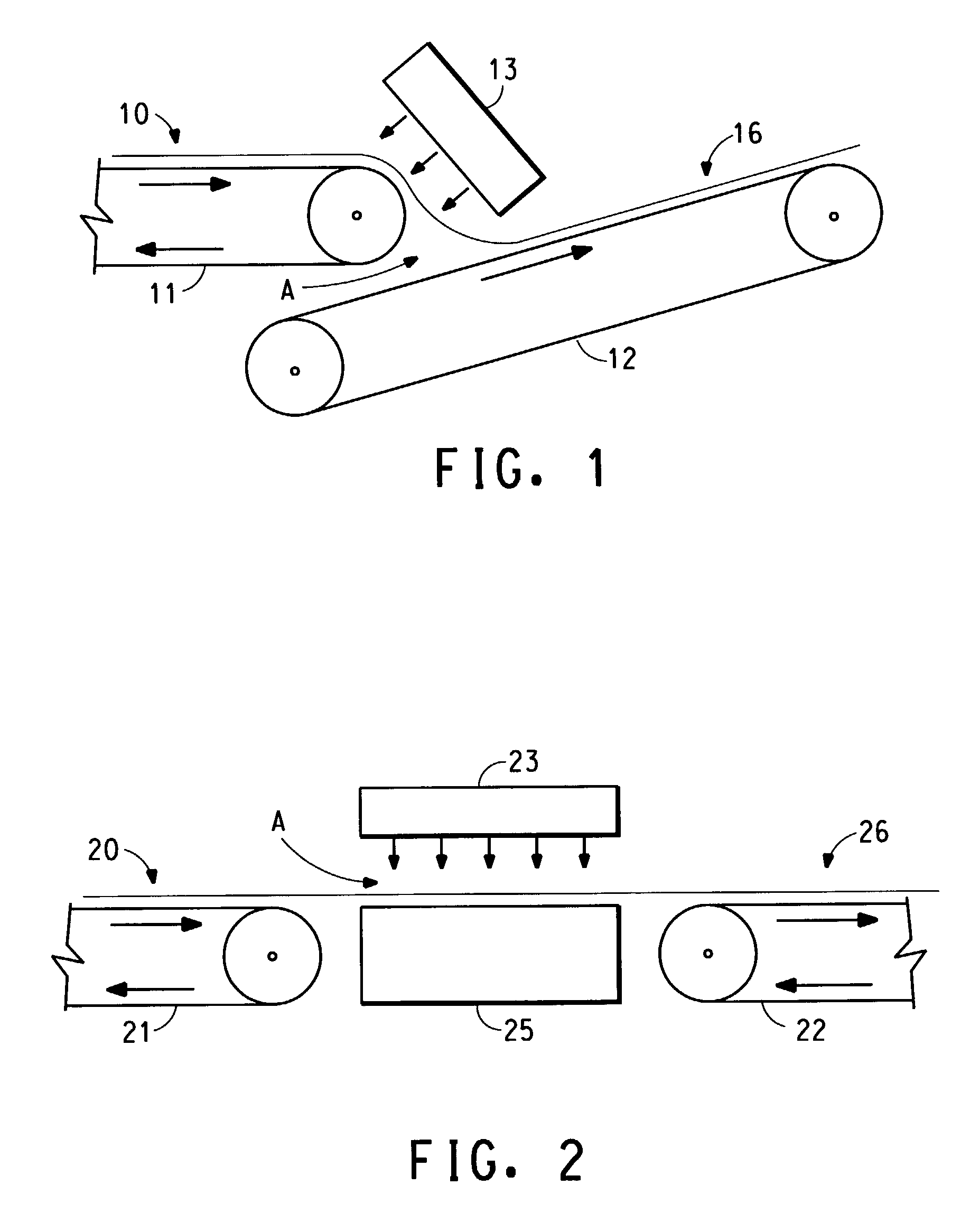

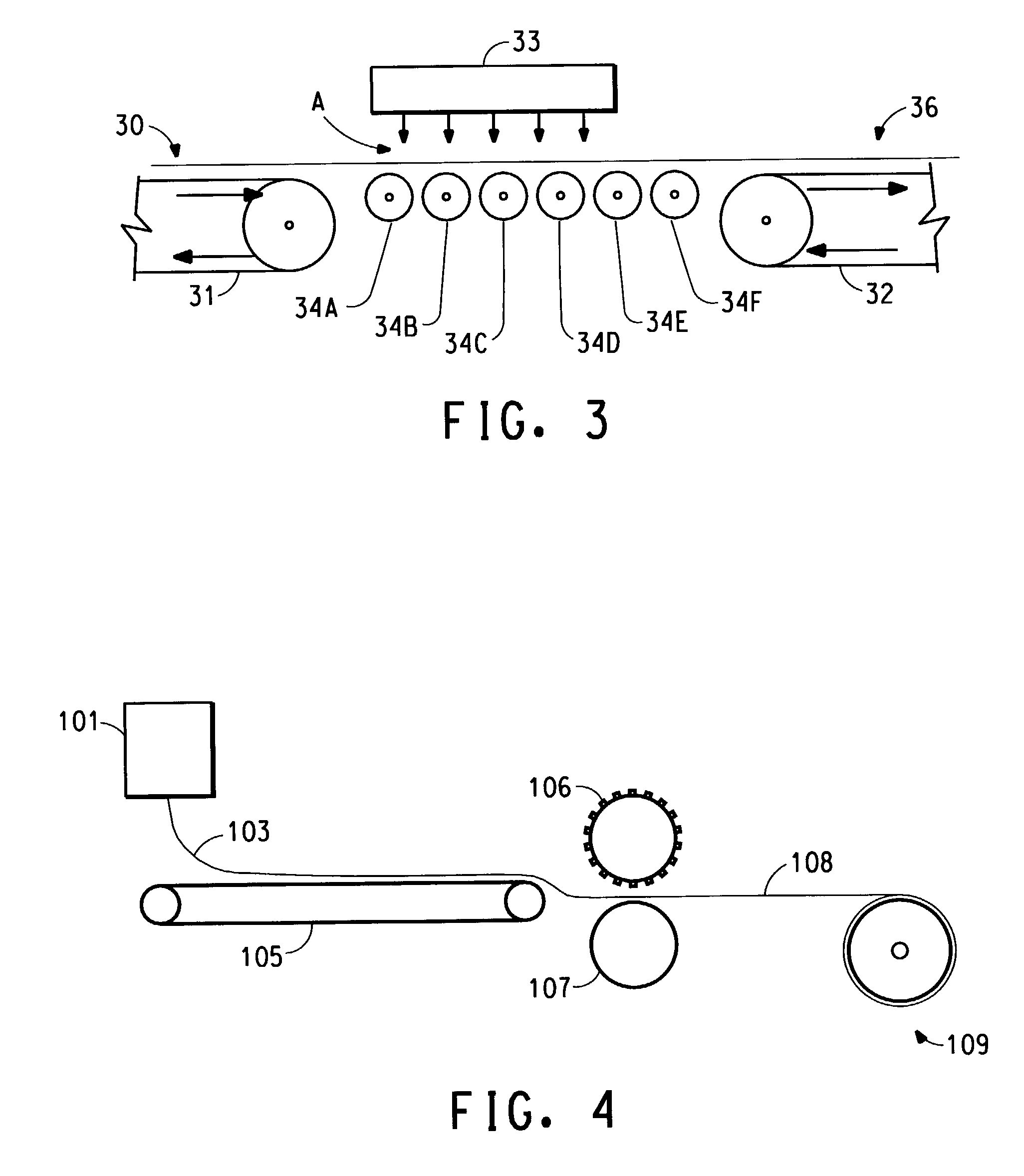

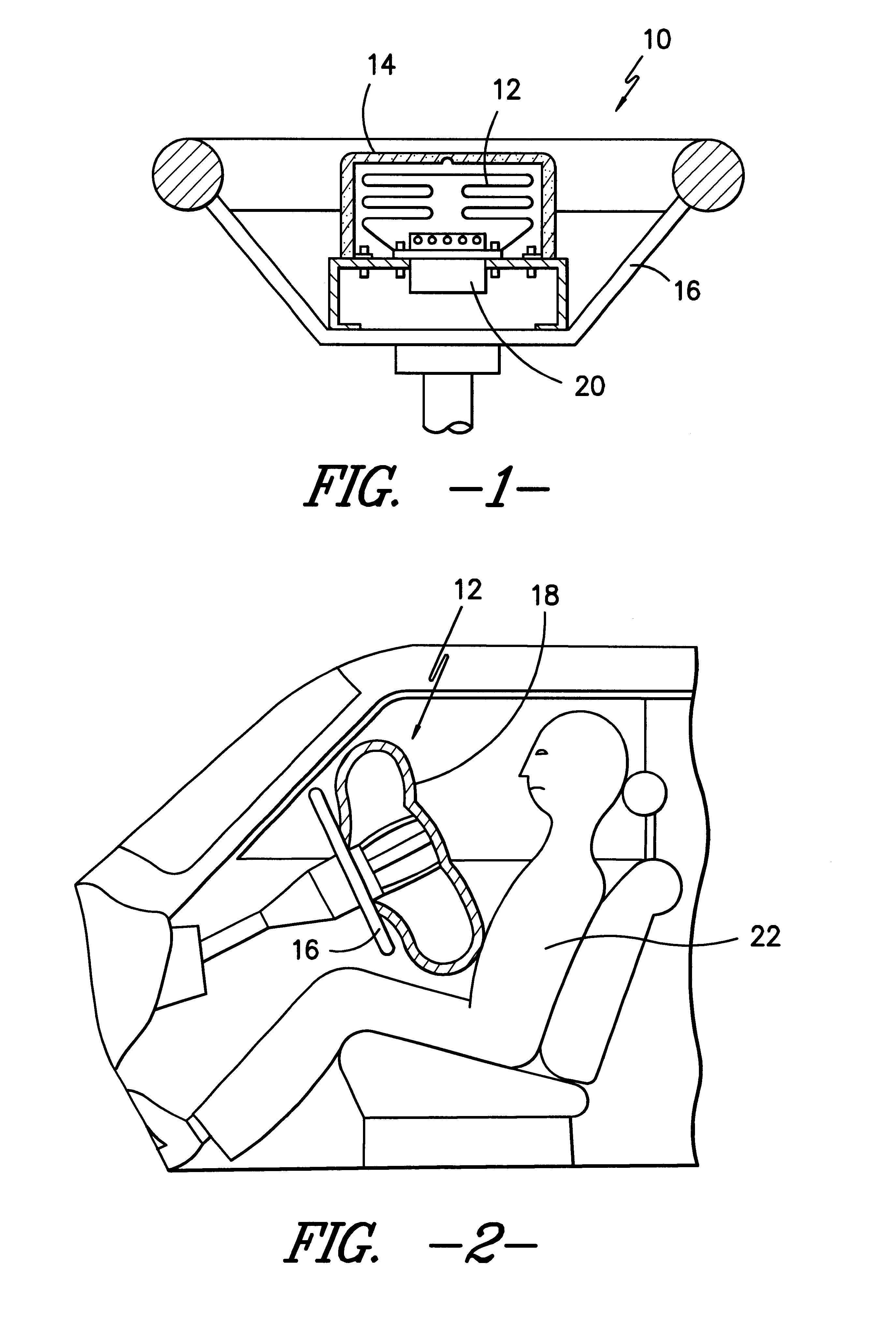

System and method for controlling width and stitch density of a fabric web

ActiveUS6950717B1Accurate fabric web width measurementAccurate locationShrinkingInspecting textilesVolumetric Mass DensityEngineering

A system for controlling the width and stitch density of a moving fabric web compacted by a fabric compaction system. The width control subsystem comprises a first camera which captures an image of a moving fabric web, and a first controller, wherein the first controller receives the captured image, calculates the width of the fabric web, and compares the calculated width to a first width set point. The stitch count control subsystem comprises a second camera that captures an image of a moving fabric web, and a second controller, wherein the second controller receives the captured image, calculates the stitch count of the fabric web, and compares the calculated stitch count to a first stitch count set point.

Owner:HBI BRANDED APPAREL ENTERPRISES

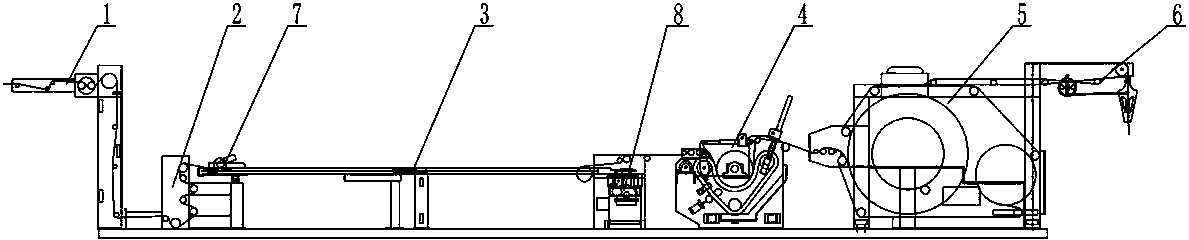

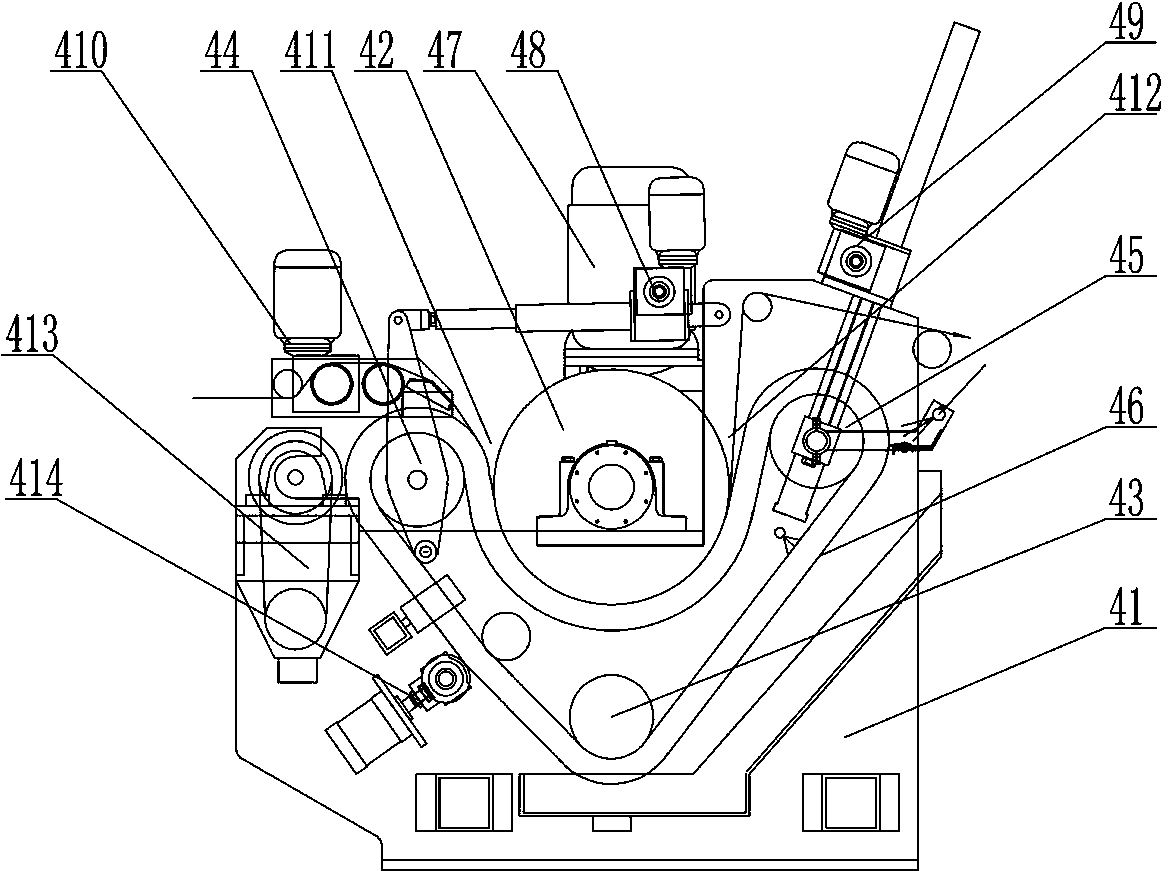

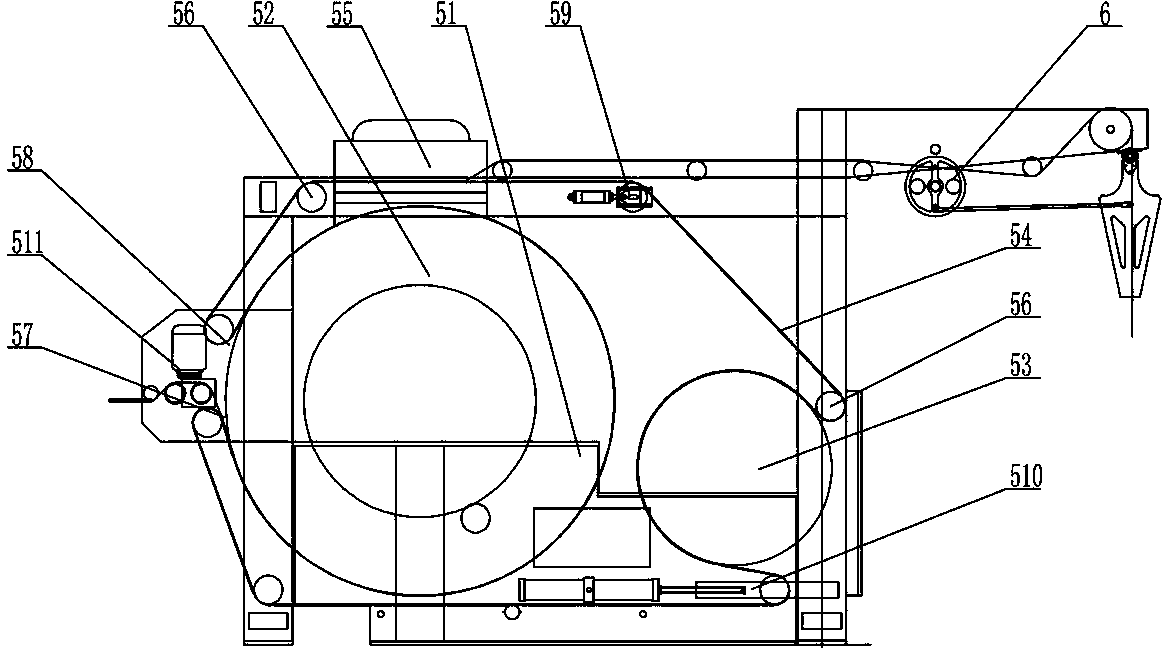

Open-width knitted fabric pre-shrinking machine and pre-shrinking process thereof

ActiveCN104018311AGuaranteed dryingMake sure to ironShrinkingTextile treatment cleaning apparatusShrinkage rateAgricultural engineering

The invention discloses an open-width knitted fabric pre-shrinking machine, comprising an open-width cloth-feeding device, a mechanical weft-straightening device, a steam conditioning and stentering device, a rubber blanket pre-shrinking device and an open-width plaiting device, wherein the front end of the steam conditioning and stentering device is provided with an overfeed pinning device; and a felt finishing device is arranged between the rubber blanket pre-shrinking device. The open-width knitted fabric pre-shrinking machine comprises the felt finishing device; and the fabric is finished by the felt finishing device after passing through the rubber blanket pre-shrinking device, thereby guaranteeing the fabric to be dried and flatten, further improving handfeel of the fabric and increasing glossiness of the fabric surface. Meanwhile, shrinkage rate of the fabric can be more stable, so that the open-width knitted fabric with flat cloth surface, good surface glossiness, good handfeel and stable shrinkage rate can be processed.

Owner:浙江瑞格机械科技有限公司

Method for producing woolen shiner herringbone

InactiveCN101225567AIncrease color glossImproved flash effectShrinkingLiquid/gas/vapor removalPulp and paper industryHerringbone pattern

The invention relates to a production method for a woolen shiner herringbone cloth, which is characterized in comprising the following steps: 80% 70 yarn count Australian wools and 20% polyamide fibers are adopted to be spun into 20 wool yarns, which are then combined into parallel yarns together with 150D bright terylene shiners and 30D polyamide fiber filaments; then, by means of weaving and post-finishing processes, the intended woolen shiner herringbone is produced. The production method combines woolen yarns and bright shiners to develop a fabric with herringbone-shaped patterns, which is a casual fashion fabric plain in appearance yet fashionable in style, with the excellent qualities, such as soft hand feeling, thinness as well as strong depth perception of the herringbone patterns. Therefore, the woolen shiner herringbone cloth has the advantages of softness and light weight, delicate fabric, strong depth perception, comfortableness for wearing, and easiness for maintenance.

Owner:江阴市天鹅制呢厂有限公司

Stretchable multiple-component nonwoven fabrics and methods for preparing

A method for preparing stretchable bonded nonwoven fabrics which involves forming a substantially nonbonded nonwoven web of multiple-component continuous filaments or staple fibers which are capable of developing three-dimensional spiral crimp, activating the spiral crimp by heating substantially nonbonded web under free shrinkage conditions during which the nonwoven remains substantially nonbonded, followed by bonding the crimped nonwoven web using an array of discrete mechanical, chemical, or thermal bonds. Nonwoven fabrics prepared according to the method of the current invention have an improved combination of stretch-recovery properties, textile hand and drape compared to multiple-component nonwoven fabrics known in the art.

Owner:THE LYCRA CO LLC

Air bag fabric possessing improved packed volume and stable air permeability

InactiveUSRE38769E1Improve foldabilityIncreasing air permeability characteristicShrinkingPedestrian/occupant safety arrangementYarnEngineering

A fabric for use in an air bag is provided. The fabric of the invention is produced by mechanically compressing a preliminary fabric constructed substantially of synthetic yarn such that the packed volume per unit area of the compressed fabric is less than the packed volume per unit area of the preliminary fabric. Air permeability is not adversely affected.

Owner:MILLIKEN & CO

Finishing technology of warp and weft cotton wrapped spandex four-way-stretch easy-care yarn-dyed fabric

InactiveCN107794671AGuaranteed four-way flexibilityGuaranteed smooth productionShrinkingSucessive textile treatmentsYarnCooking & baking

The invention discloses a finishing technology of a warp and weft cotton wrapped spandex four-way-stretch easy-care yarn-dyed fabric, and relates to a finishing technology of a cotton type elastic easy-care fabric. The technology comprises the steps of singeing, desizing, mercerizing, washing, preshrinking, high-temperature setting, easy-care finish and baking. An ordinary yarn-dyed fabric production route is changed in the technology process, wherein washing is conducted after mercerizing is conducted, and then sufficient alkali removing can be guaranteed; preshrinking is conducted directly,it is guaranteed that large enough elasticity is achieved in the radial direction. Accordingly, it can be guaranteed that the warp and weft cotton wrapped spandex four-way-stretch easy-care yarn-dyedshirt fabric is produced smoothly, a shirt is made by adopting the warp and weft cotton type elastic easy-care fabric, when people do body movement, limitation does not exist in the four directions, and people feel comfortable and free when wearing the shirt; due to the fact that elastic yarns exist in four directions, after deformation, the elastic yarns can return to the original position, and the aesthetic feeling of being neat in shape is guaranteed.

Owner:JIANGSU JAMES TEXTILE

Processing method for chemical-preventing fabric

ActiveCN104963188AImprove permeabilityImprove breathabilityShrinkingLiquid/gas/vapor removalCooking & bakingYarn

The invention discloses a processing method for chemical-preventing fabric, and belongs to the technical field of textile industry. The method is carried out on the basis of gray fabric woven from pure cotton yarns or polyester cotton yarns, and comprises the processes of blank inspection, seam overturning, singeing, cold batching, short steaming, washing and dyeing. The method is characterized by also comprising the steps of A, open-width washing, B, chemical-preventing arrangement, C, preshrinking treatment, and D, baking. The chemical-preventing fabric processed by the method has a function of preventing sulfuric acid, hydrochloric acid, nitric acid and caustic soda, has a good function of preventing chemical solvents such as o-xylene, methyl alcohol and acetone, and meets an EN14325 chemical-preventing standard.

Owner:HEBEI NINGFANG GRP

Multifunctional fulling and softening finishing machine

InactiveCN101798740AAvoid damageGuaranteed stabilityShrinkingFabric breaking/softeningFiberPulp and paper industry

The invention discloses a multifunctional fulling and softening finishing machine which comprises a box body, wherein a stainless steel roller is arranged in the box body and can be rotated with high speed under the driving of a driving device, air holes are evenly arranged on the wall of the roller, an impact plate is arranged at the rear of the roller, and a major trough for containing lotion is arranged below the roller; the roller is also provided with an airflow circulating device which can suck air from the inner side of the roller and then jet airflow onto the outer surface of the roller through a circulating pipeline from an air return port above the roller, wherein the width of the air return port is equivalent to that of the roller; and a fan is arranged on the circuiting pipeline. The invention solves the difficult problems of washing and softening treatments, and the like of light weight fabrics and knitted fabrics, such as cotton, hemp, wool, silk, chemical fiber and other materials, improves the treatment efficiency on the posttreatment process of fulling, softening, drying, and the like of fabrics and reduces the treatment cost and the environment pollution.

Owner:TAIAN COMPANION MACHINERY

Processing process of yakwool silk double-faced woolen goods

ActiveCN105839252AWindproofMoisture-proofShrinkingHeating/cooling textile fabricsSpinningEngineering

The invention discloses a processing process of yakwool silk double-faced woolen goods. The processing process includes the steps of spinning, weaving, body inspection, sewing, preliminary washing, dehydration, milling, inspection, intensive washing, dehydration, baking and brushing, decatizing, fuzzing, shearing and lustring, inspection and sizing, so that processing of the yakwool silk double-faced woolen goods is completed. The environment suitable for combined processing of yakwool fibers and silk fibers is constructed by adjusting the processing temperature, time, consumption of auxiliaries, mechanical pressure and the like; the formed double-faced woolen goods have tenacity, warm keeping performance, waterproof performance, windproof performance and dampproof performance of yakwool, also have the advantages of being light, smooth, capable of absorbing damp and breathable of silk and are free of shrink after being washe.

Owner:西藏圣信工贸有限公司 +1

Polymeric binders having specific peel and cure properties and useful in making creped webs

InactiveUS8012285B2High degree of softness and absorbencyReduce productionShrinkingNon-fibrous pulp additionFiberEmulsion polymerization

This invention is directed to alkylphenol ethoxylate (APE)-free polymer binders formed by aqueous free radical emulsion polymerization and having specific peel and cure properties. The APE-free polymeric binders have a peel value, when adhered to a heated metal surface, of 35% to 200% of the peel value shown by a standard APE-based polymer binder control and exhibit a cure profile such that at least 55% cure is achieved within 30 seconds at a temperature required for cure, and a wet tensile strength at 30-seconds of cure of at least 1000 g / 5 cm. Wet tensile strength is used as a measure of cure. Binders having the peel and cure properties described herein can be considered for use in crepe processes, especially DRC processes.

Owner:WACKER CHEM CORP

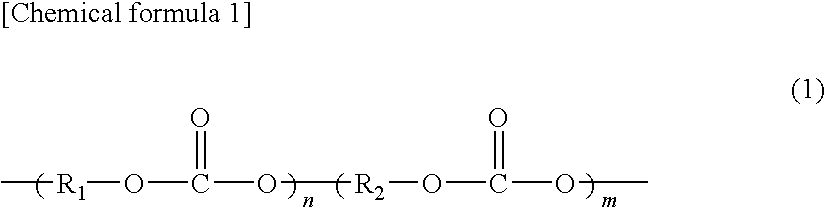

Fabric interweaving with polyolefin elastic fiber and polyester fiber, and its machining process

InactiveCN1800470AIncrease elasticityGood chemical resistanceShrinkingWarp knittingPolyesterPolyolefin

The invention discloses a face fabric of intercrossed polyolefin flexible fiber and polyester fiber, and relative processing technique. The face fabric is formed by DOW XLA polyolefin flexible fiber in 15-35% weight and the PTT polyester fiber in 65-85% weight; the woven structure can be warp velveteen, double velveteen or double fabric. The processing technique comprises: knitting, pre-treating before colorizing, pre-shaping before colorizing, colorizing and shaping. The surface fabric has better flexibility and anti-chemical property, which has small flexible change even it is dipped in water / seawater for long time. It has better extension recover property, which is higher 2-3 times than nylon, with soft feeling, eliminated rough feeling, and high anti-ultraviolet property.

Owner:上海彩艳实业有限公司

Stretchable sheet and method for producing the same

ActiveUS20100105265A1Excellent surface appearanceGood touchShrinkingFibre typesElastomerPolymer science

A sheet is produced by (i) producing a sheet by entangling woven or knitted material including a thread composed of a composite fiber such that two kinds or more of polyethylene terephthalate polymers different in intrinsic viscosity are stuck together in a side-by-side type along the fiber length direction and / or of a core-in-sheath type composite fiber such that two kinds or more of polyethylene terephthalate polymers different in intrinsic viscosity form an eccentric core-in-sheath structure, with a fiber capable of converting into ultra fine fibers composed of two kinds or more of polymeric substances different in solubility in solvent, (ii) developing an ultra fine fiber with an average single fiber fineness of 0.001 dtex or more and 0.5 dtex or less by treating the sheet with a solvent to thereafter provide elastomer having polyurethane as a main component by impregnating and solidifying solvent solution of elastomer having polyurethane as a main component into the sheet, or of providing elastomer having polyurethane as a main component by impregnating and solidifying solvent solution of elastomer having polyurethane as a main component into the sheet to thereafter develop an ultra fine fiber with an average single fiber fineness of 0.001 dtex or more and 0.5 dtex or less by treating the sheet with a solvent, and (iii) rubbing and shrinking the woven or knitted material under the condition of 110° C. or more.

Owner:TORAY IND INC

Comfortable worsted wool shirt fabrics and processing technology

The invention discloses a kind of comfortable worsted wool shirt fabrics and a processing technology. The comfortable worsted wool shirt fabrics is made by weaving 50-80% mercerising wool, 10-20% soft thread, 10-30% polyester fibers and 2-4% elastic fiber, as expressed in weight percent. The processing technology comprises the following steps: green compact fixing-shrinking-boiling-drying-middle inspection-mature repairing-brushing-softening-hot lightening-softening-moistening-full decatizing-preshrinking- hot lightening-finished product; add wool drawing and cropping between hot lightening and softening. The invention has the advantages that the design is reasonable; four kinds of raw materials, namely mercerising wool, soft thread, polyester fibers and elastic fiber are used; procedures of wool drawing and cropping are added; wool drawing is first conducted to draw certain fine wool and then cropping is conducted, in this way, the scratchiness when using mercerising wool as the shirt fabrics is overcome, and the material can be used for making shirts that are in contact with the skin.

Owner:JIANGSU AOYANG TEXTILE IND

Low-shrinkage treatment method and afterfinishing method of high-elastic fabric and high-elastic fabric

ActiveCN106988072ASmall shrinkageSolve curlingShrinkingSucessive textile treatmentsEnvironmental engineeringLow shrinkage

The invention discloses a low-shrinkage treatment method and afterfinishing method of high-elastic fabric and high-elastic fabric; the low-shrinkage treatment method of the high-elastic fabric comprises: washing the high-elastic fabric; dewatering the treated high-elastic fabric; scotching the high-elastic fabric; drying the high-elastic fabric. The low-shrinkage treatment method of the high-elastic fabric provided herein has an additional treatment step in the original fabric afterfinishing method; low-shrinkage treatment is arranged before pre-shrinkage treatment. The high-elastic fabric treated by the low-shrinkage treatment method gains high elasticity and low shrinkage, the difficulty in manufacturing high-elasticity ready-made apparel and washing the ready-made apparel is reduced greatly.

Owner:GUANGDONG FORWARD DENIM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com