Multifunctional fulling and softening finishing machine

A multi-functional, finishing machine technology, applied in the direction of fabric kneading/softening, adding compressed water, textile material processing, etc., can solve the problems of deformation efficiency, complex operation, fabric pleating, etc., to reduce processing costs, operation The effect of simple, soft fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical contents not mentioned below can adopt or learn from the prior art.

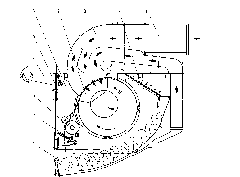

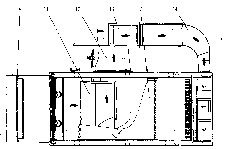

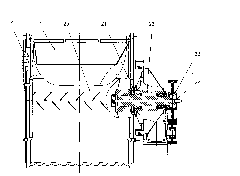

[0021] Such as figure 1 , 2 , 3, 4, 5, and 6 show that the fabric is connected end to end through sewing, bypassing the shrinking equipment 2, the water rolling machine 3 and the main roller 7 successively, and the rest sinks into the washing liquid of the main tank 1, and the fan 13 High-speed suction from the main roller 7, the airflow passes through the air duct 8, and the air holes 25 on the roller are blown back to the surface of the main roller 7. On the surface of the main roller 7, the roller rotates at a high speed, which drives the fabric to move to the rear side. After passing through the highest point, the pressure and suction of the airflow are lost. Due to inertia, the fabric hits the impact plate 9 on the rear side, thereby achieving washing and cleaning. For the purpose of softness, the surface of the main roller 7 is welded with a fleece, which can fully displace the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com