Patents

Literature

61results about How to "Short drying cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

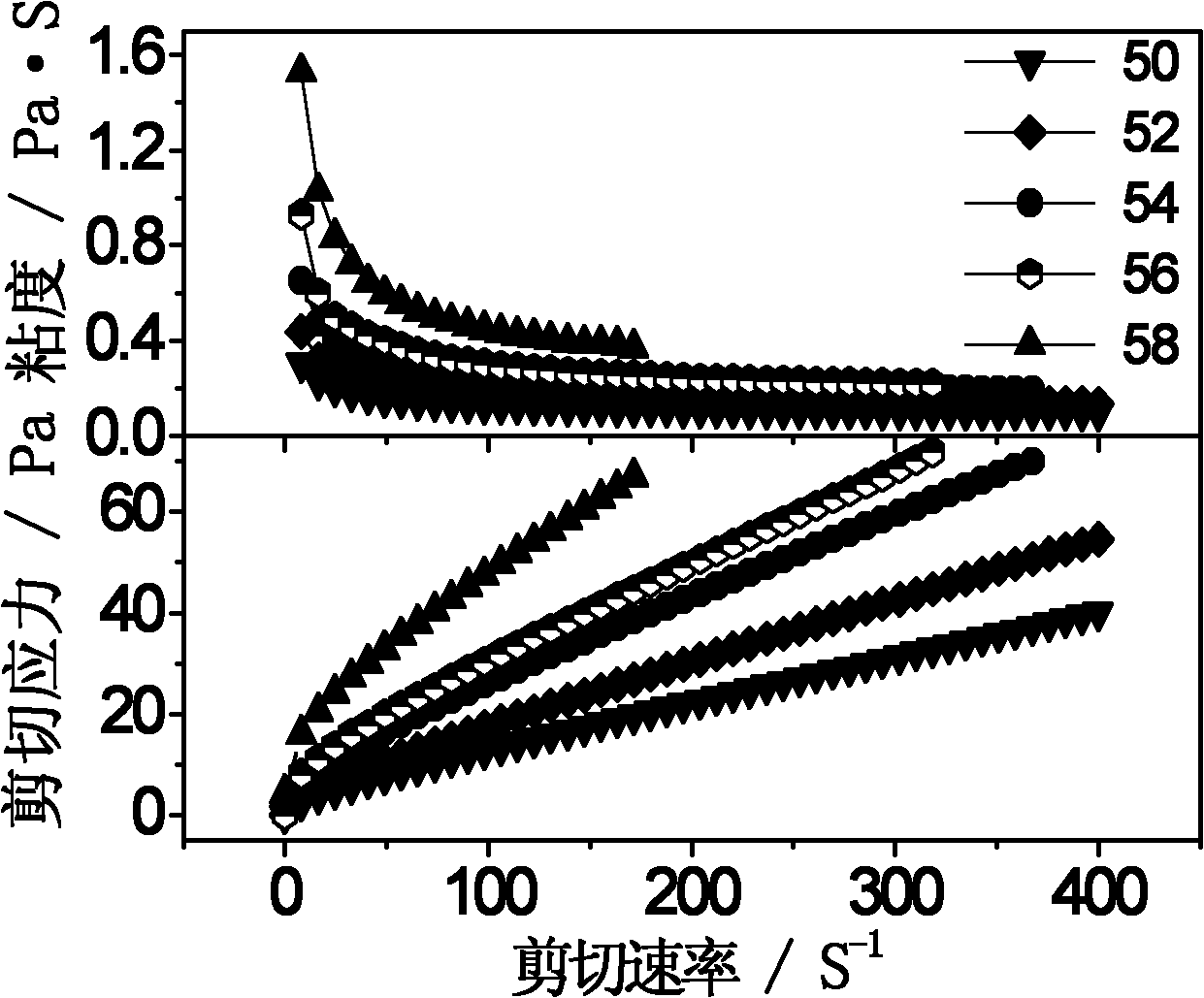

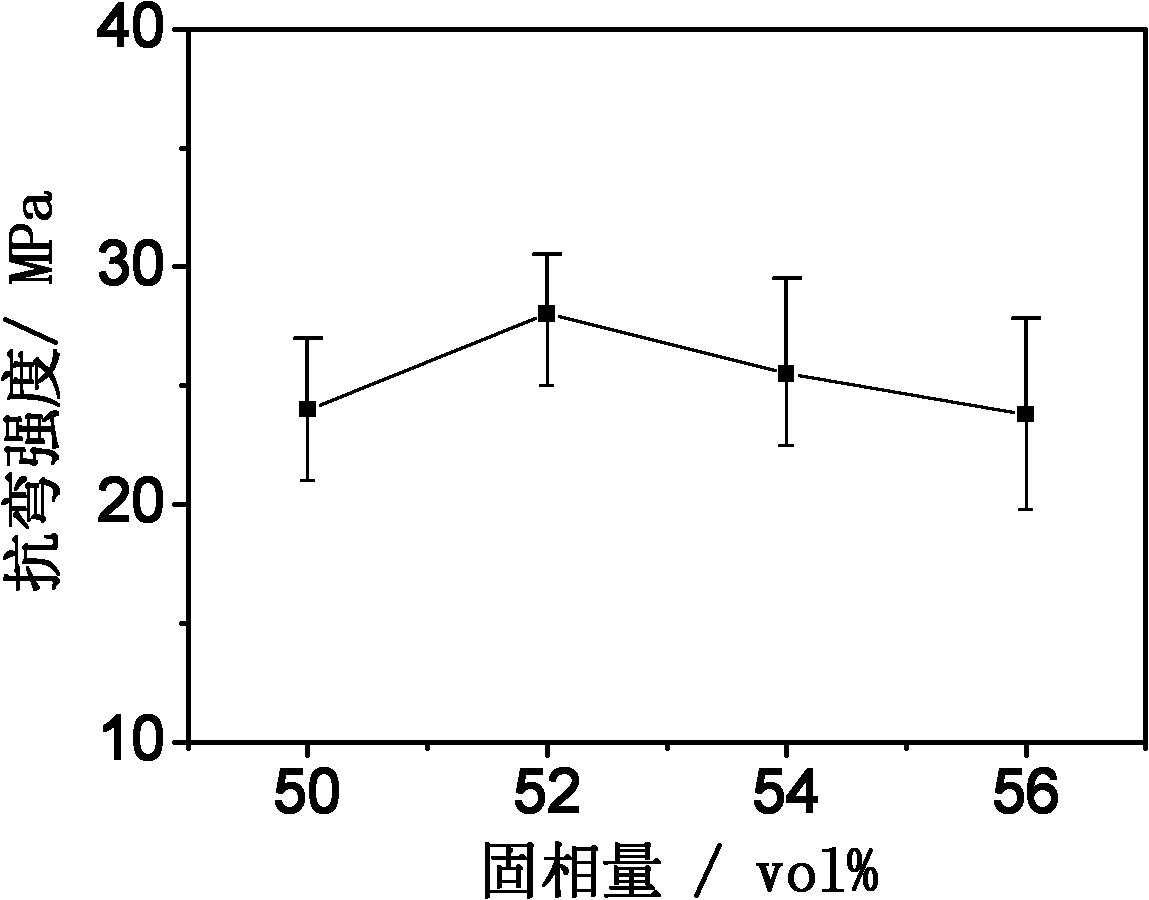

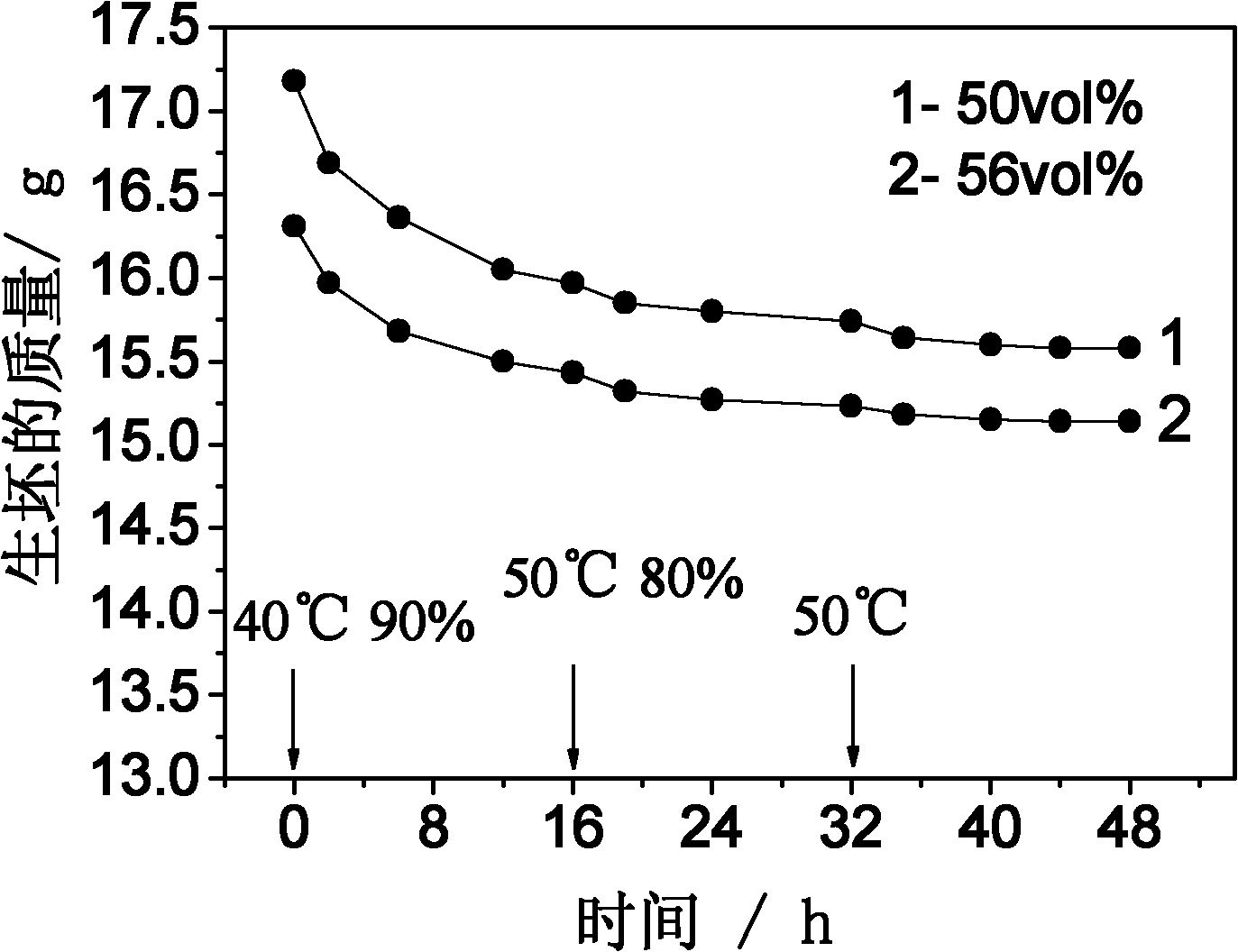

Method for preparing zirconium oxide ceramic

The invention relates to a method for preparing zirconium oxide ceramic, which comprises the following steps of: preparing high solid phase slurry by adopting low-toxicity gel and dispersant, then adding an initiator, performing vacuum deaeration, injecting the slurry into a mold, curing and stripping to obtain a green body, and drying and sintering the green body to obtain the ceramic. The method is used for preparing the green body which has good surface finishment, peeling resistance, cracking resistance, good uniformity and high strength, the strength of the green body is 20 to 40MPa, andthe green body can be directly machined so as to effectively reduce the subsequent processing cost; and the green body can be sintered into the ceramic at one time, the yield reaches 100 percent, theceramic has excellent performance and good stability, the strength is 800 to 1,200MPa, the fracture toughness is 10 to 20MPa.m1 / 2, the average strength is 550MPa compared with the strength of the drypressing molded ceramic, the average fracture toughness is 8MPa.m1 / 2, and the performance of the ceramic is greatly improved.

Owner:NANJING UNIV OF TECH

Coal ash-based mullite light heat-insulation brick and preparation method thereof

The invention relates to a coal ash-based mullite light heat-insulation brick and a preparation method thereof. According to the adopted technical scheme, the preparation method comprises the steps of: firstly, preparing 50-90wt% of coal ash and 10-50wt% of alumina serving as raw materials, adding 0.5-5.0wt% of swelling agent, 25-60wt% of water and 0.1-1.0wt% of water reducer relative to the raw materials, mixing 3-15min to obtain pug; then adding foam made by 0.5-2.0wt% of foaming agent relative to the raw materials, uniformly stirring, adding 1-5wt% of gel, 0.1-1.0wt% of thermosetting resin and 1-3wt% of curing agent relative to the raw materials, stirring 3-15min, moulding by casting, naturally drying for 3-10h, demoulding, baking for 12-24h at a temperature of 60-120 DEG C; and finally, preserving the heat for 3-12h at a temperature of 1150-1550 DEG C to obtain the coal ash-based mullite light heat-insulation brick. The preparation method has the characteristics of resource saving, environment friendliness, short demoulding time, short drying period and suitability for large-scale industrial production; and the coal ash-based mullite light heat-insulation brick has the advantages of high strength, low volume density and low heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

High-strength aluminum oxide light-weight heat insulation brick and preparation method thereof

ActiveCN103044045AReduce consumptionTo achieve the purpose of energy savingHeat conservationUltimate tensile strength

The invention relates to a high-strength aluminum oxide light-weight heat insulation brick and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: premixing 25-40 wt% of alpha-Al2O3 fine powder with the particle size of 0.074-0.147mm, 25-40 wt% of alpha-Al2O3 fine powder with the particle size of 0.043-0.074mm, 10-15 wt% of alpha-Al2O3 fine powder with the particle size of less than 0.043mm, 10-15 wt% of alpha-Al2O3 micropowder, 3-10 wt% of rho-Al2O3 micropowder and 2-10 wt% of three-stone used as raw materials with combustion improver (accounting for 0.1-1 wt% of the raw materials), water (accounting for 20-35wt% of the raw materials) and water reducing agent (accounting for 0.1-0.7 wt% of the raw materials) for 5-10 minutes to obtain a premix; and adding foam into the premix, evenly mixing, carrying out casting molding and microwave drying, and keeping the temperature of 1450-1750 DEG C for 3-6 hours to obtain the high-strength aluminum oxide light-weight heat insulation brick. The invention has the characteristics of simple technique and energy conservation. The product has the characteristics of high strength, small linear variation rate, low volume density, low heat conductivity coefficient and short drying cycle.

Owner:WUHAN UNIV OF SCI & TECH

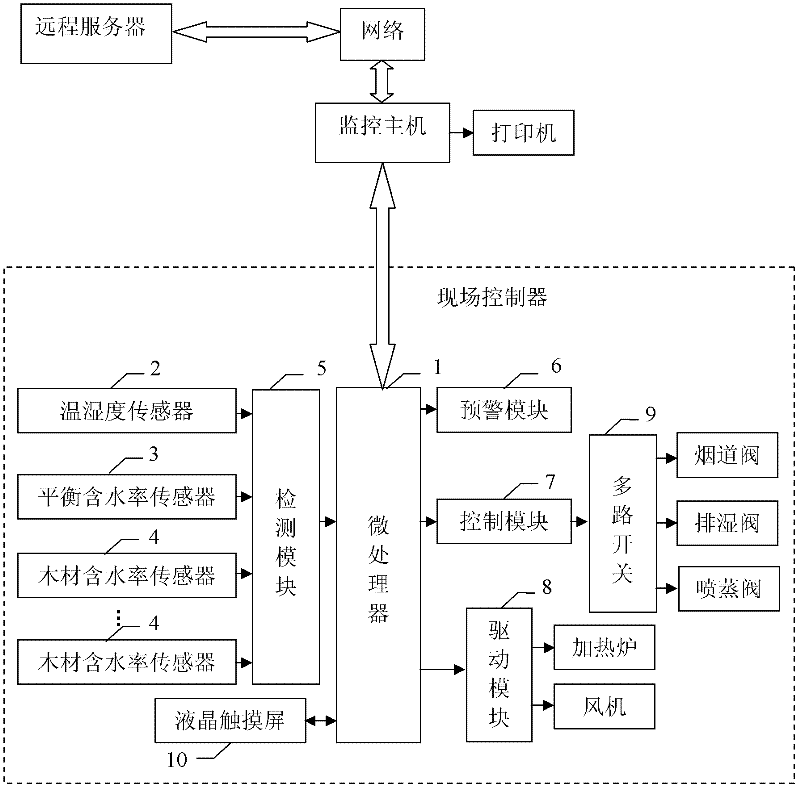

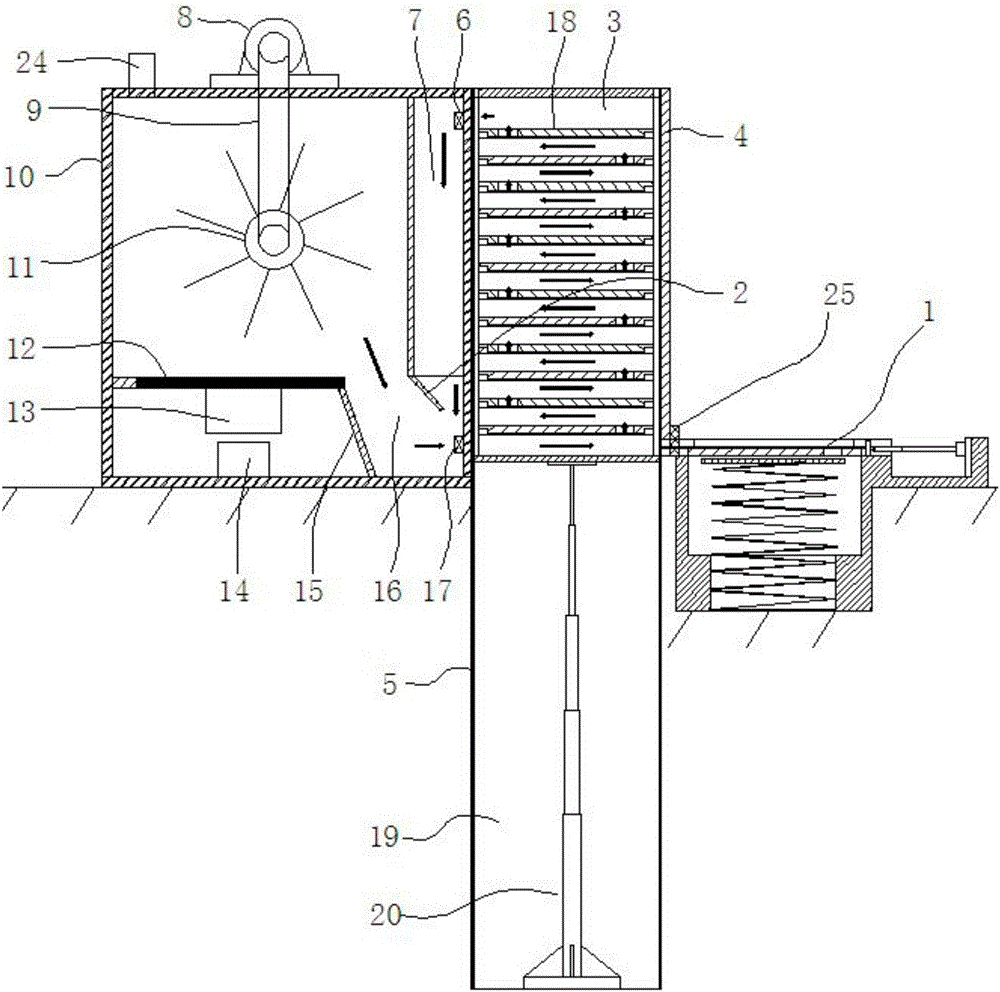

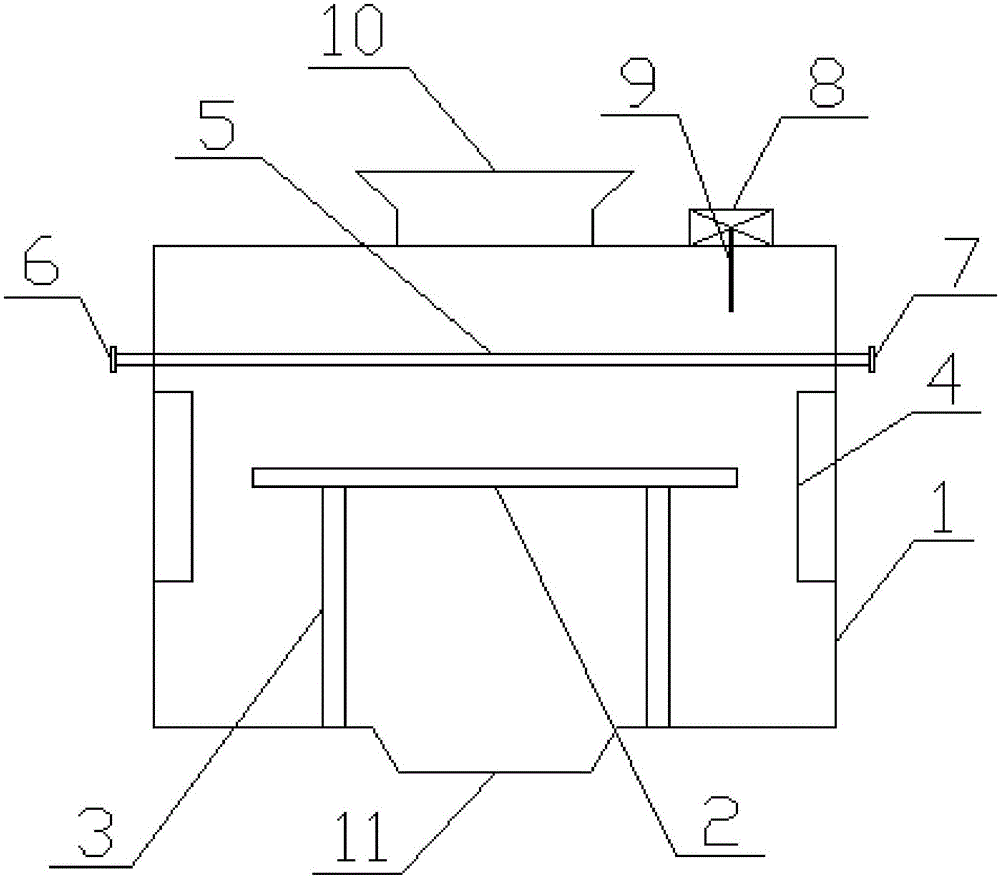

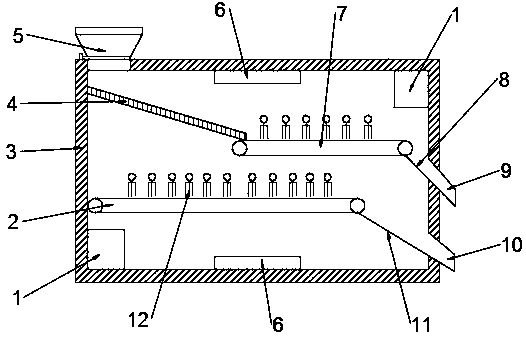

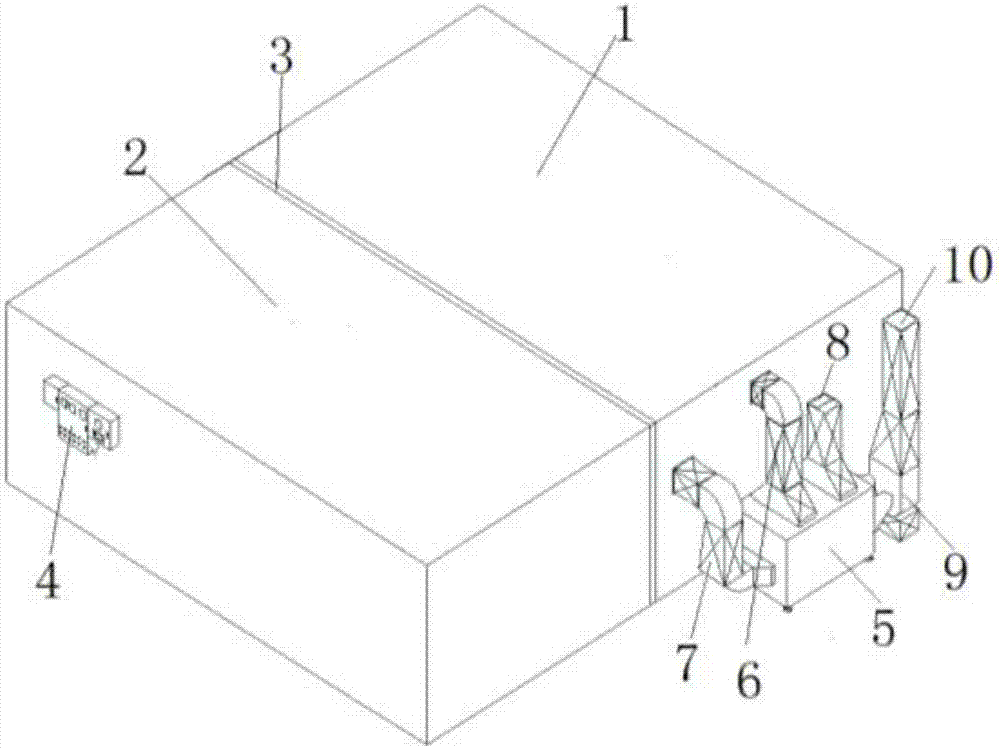

Wood drying remote monitoring system based on DSP (digital signal processor)

InactiveCN102564106AShort drying cycleImprove efficiencyDrying solid materialsDigital signal processingThe Internet

The invention discloses a wood drying remote monitoring system based on a DSP (digital signal processor), which relates to a wood drying remote monitoring system and solves problems of low drying efficiency and complication in operation of an existing wood drying remote monitoring system. The wood drying remote monitoring system comprises a remote server, a monitoring host and a field controller. The monitoring host and the field controller are in data transmission by a serial bus, the monitoring host and the remote server are in data transmission via an Internet according to the TCP (transmission control protocol), and the field controller can run independently, can also receive various commands from the remote server and the monitoring host via a network bus and the serial bus and feeds data back to the monitoring host after the commands are executed. The wood drying remote monitoring system is applicable to automatic wood drying places with middle and large-size drying kilns.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for processing thunberg fritillary bulb

InactiveCN101878807AShort drying cycleDry thoroughlyFruits/vegetable preservation by dehydrationNutrientChemistry

The invention discloses a method for processing thunberg fritillary bulb, which comprises the following steps of: cleaning the picked fresh thunberg fritillary bulb; airing the surface of the thunberg fritillary bulb; slicing the aired thunberg fritillary bulb; performing microwave drying on the sliced thunberg fritillary bulb by adopting microwave drying equipment; spreading the thunberg fritillary bulb subjected to microwave drying; drying the thunberg fritillary bulb which is spread for a certain period of time in a drying oven; cooling the dried thunberg fritillary bulb to normal temperature; and performing vacuum packaging. The method for processing the thunberg fritillary bulb has the advantages of no toxin or pollution, capacity of maintaining original flavor of the thunberg fritillary bulb without consuming plenty of water for soaking, capacity of maintaining nutrient components of the thunberg fritillary bulb to the greatest degree, complete dryness, long quality guarantee period, difficult deterioration, and short production cycle.

Owner:戴永峰

Solar drying technique for apricot

InactiveCN101171975AGolden colorSave energyFood processingFood preservationThermal energySolar drying

The invention provides a novel technology for drying apricot by combining the solar energy heating and the vapor heat energy heating, and combining the solar radiation drying and the hot blast convection drying. The drying processing of the apricot is divided into three steps, and the parameter such as dying temperature, humidness, etc. of each step is provided. The drying process cycle of the drying process is short, the energy is saved, and the dried apricot has the advantages that the color is golden, the taste is pure, and the quality product rate is high.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

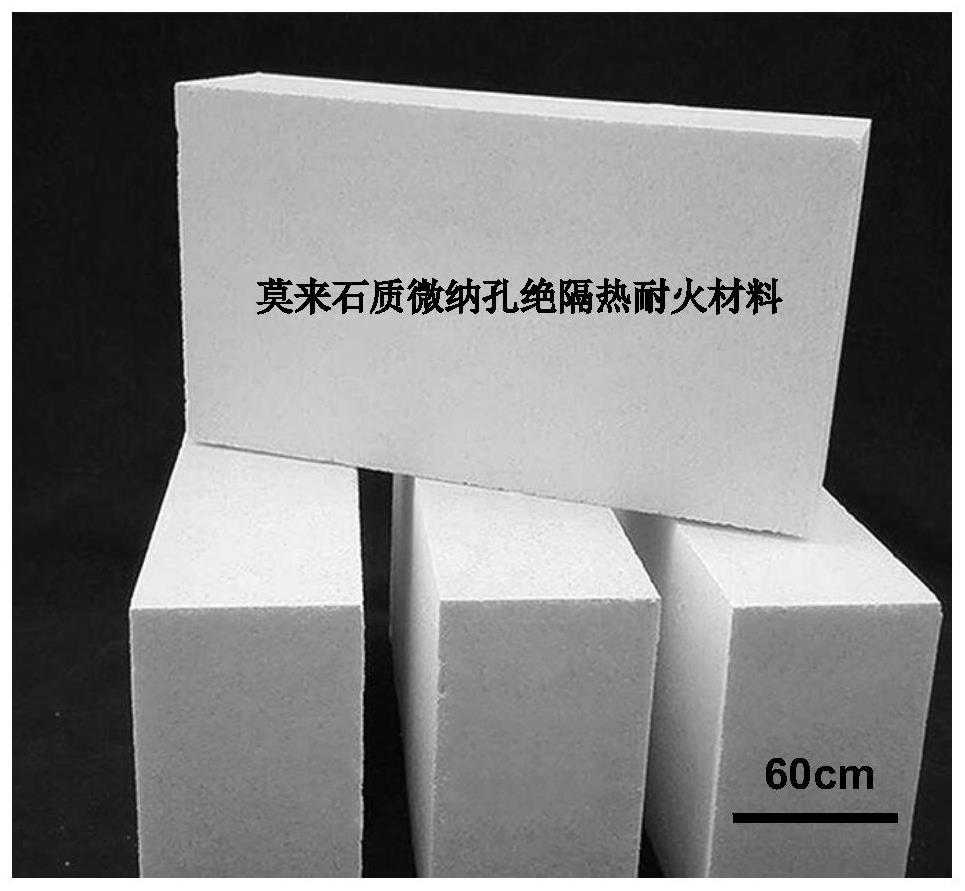

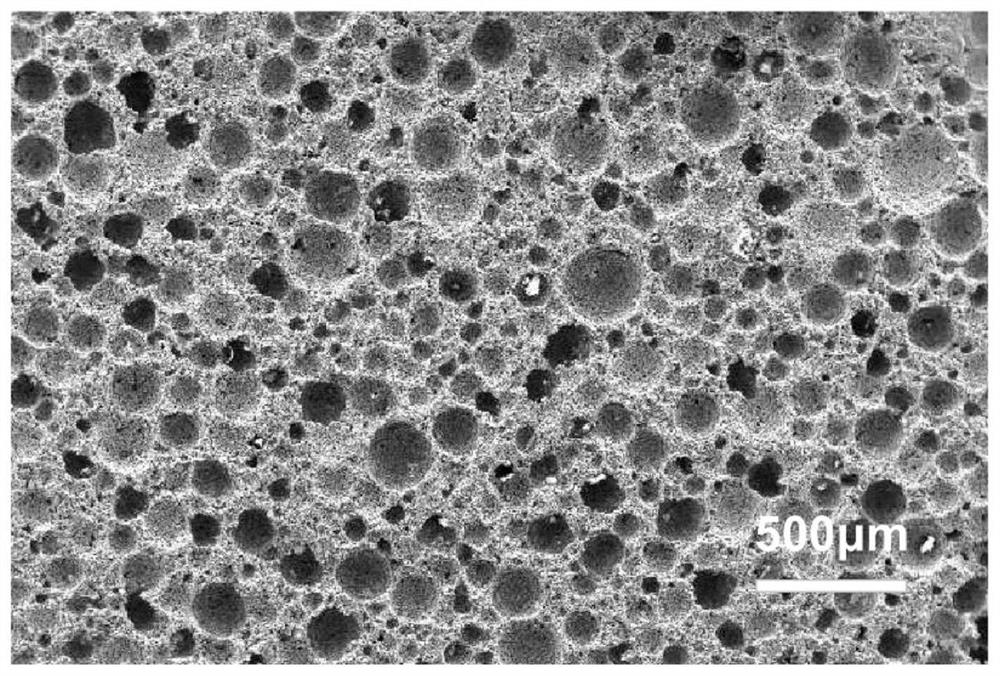

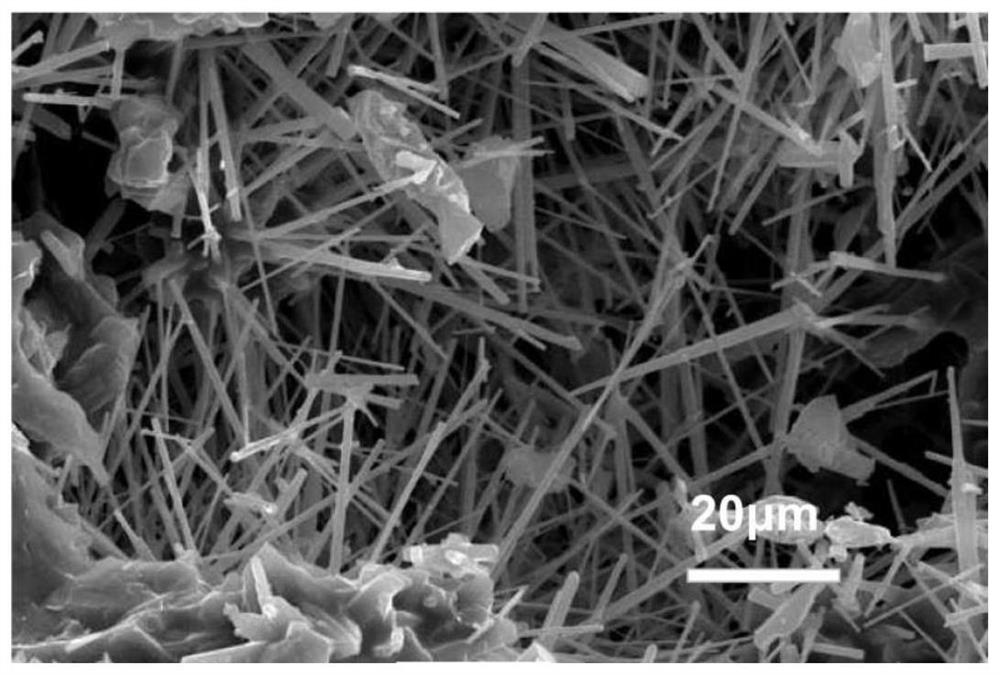

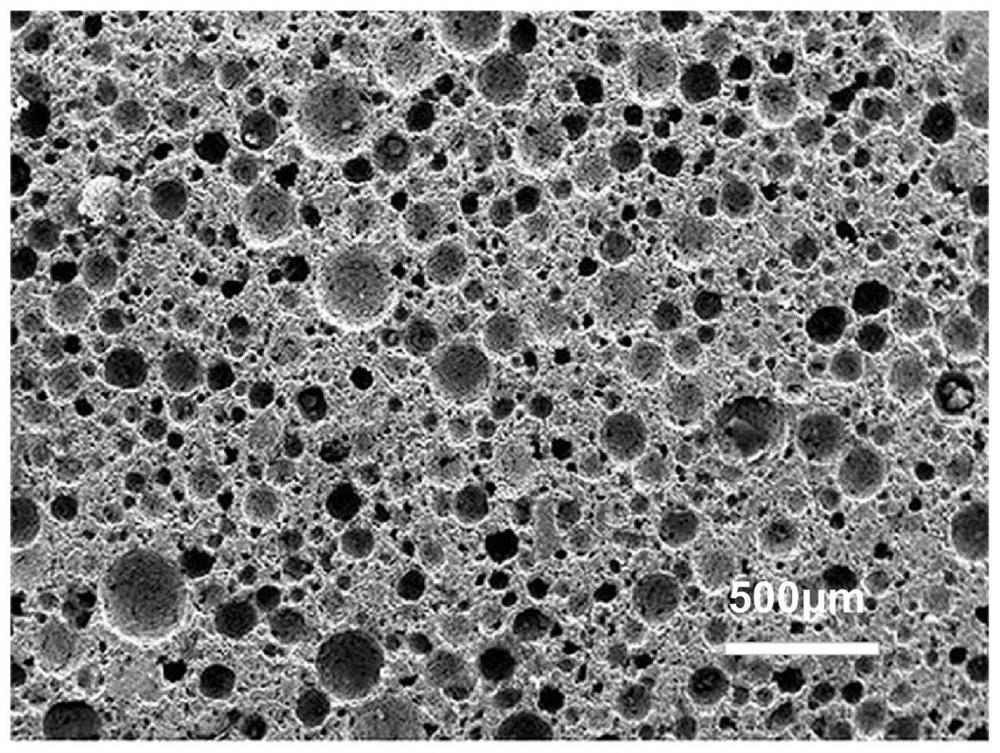

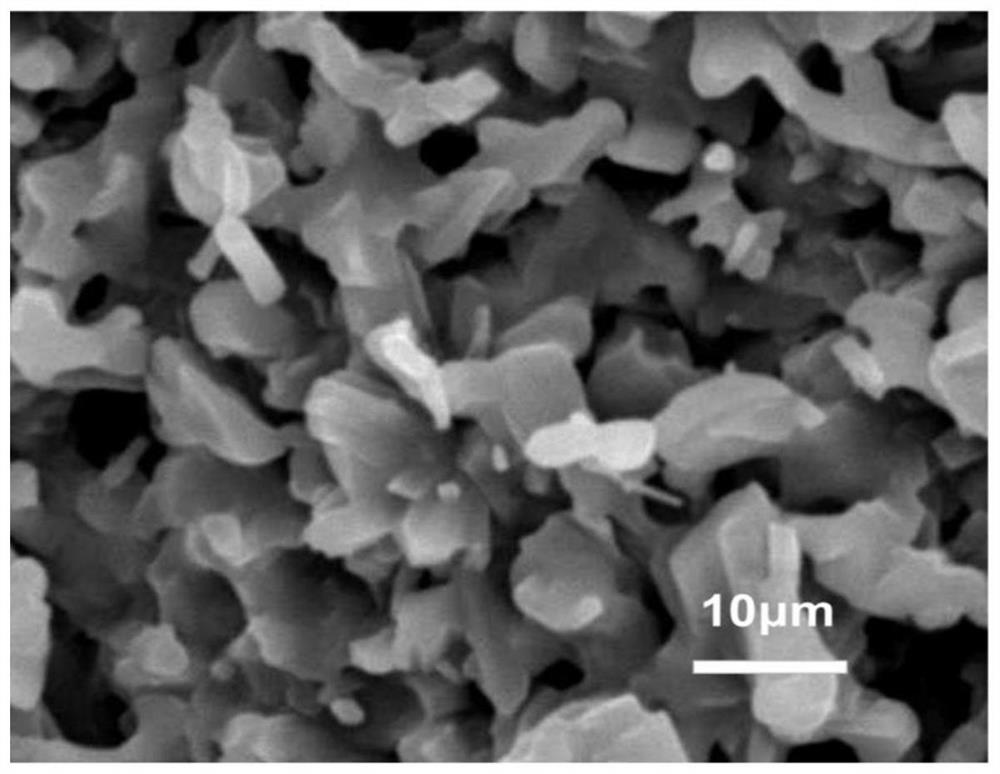

Mullite micro-nano pore heat insulation refractory material and preparation method thereof

The invention belongs to the technical field of refractory materials, and particularly relates to a mullite micro-nano pore heat insulation refractory material and a preparation method thereof. The heat-insulating refractory material is mainly prepared from a base material, an additive and water, and the preparation process is green, environment-friendly, pollution-free, simple and easy to control. The main crystalline phase of the heat insulation refractory material is large-size needle-shaped and columnar mullite. The appearance of the product is white or faint yellow, the pore size distribution of pores is 0.006-200 [mu] m, the average pore size is 0.1-19 [mu] m, and the closed spherical micro-nano pore structure ensures that the product has better heat insulation performance under the conditions of lower volume density and high strength. By regulating and controlling the use amount of each raw material and the process, the finally prepared heat-insulating refractory material can meet the requirements of low heat conductivity and light weight, and also has better mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

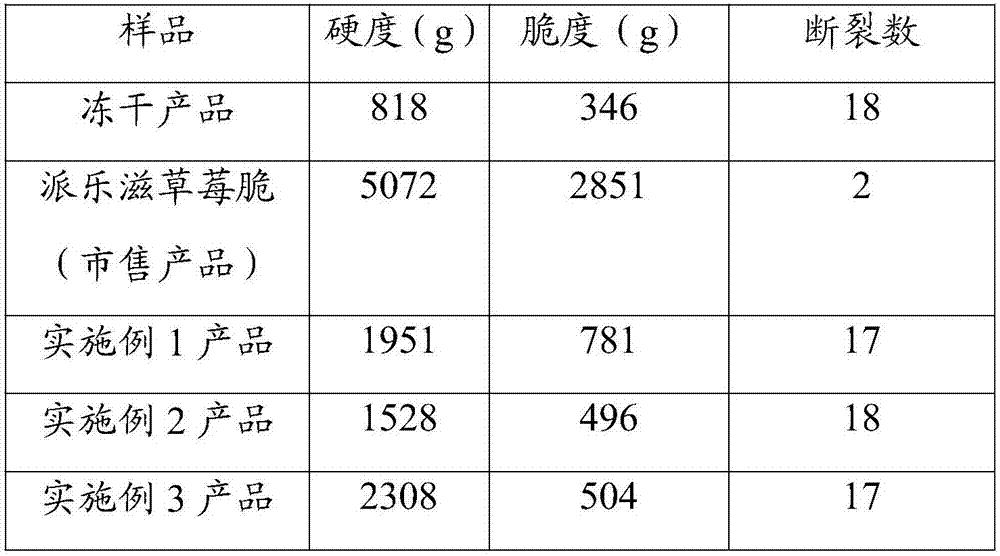

Method of preparing crisp strawberry snacks using soaking pretreatment and vacuum microwave combined freeze drying

PendingCN107251983ANo pollution in the processImprove drying rateFood freezingConfectioneryMicrowaveFreeze-drying

The present invention provides a method of preparing crisp strawberry snacks using a soaking pretreatment and a vacuum microwave combined freeze drying. Strawberries are washed and drained, the drained strawberries are subjected to an ultrasonic vacuum soaking in a mixed soaking liquid, then the soaked strawberries are subjected to a high-power instant vacuum microwave pre-puffing and pre-dehydrating treatment, and vacuum freeze-drying, etc. are conducted. The high-power instant vacuum microwave pre-puffing and pre-dehydrating treatment after the pretreatment is combined with the freeze-drying, and the method can significantly improve hardness and crispiness of the strawberry products after the drying, at the same time retains nutritional contents of the products, shortens the drying time and improves quality of the products.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

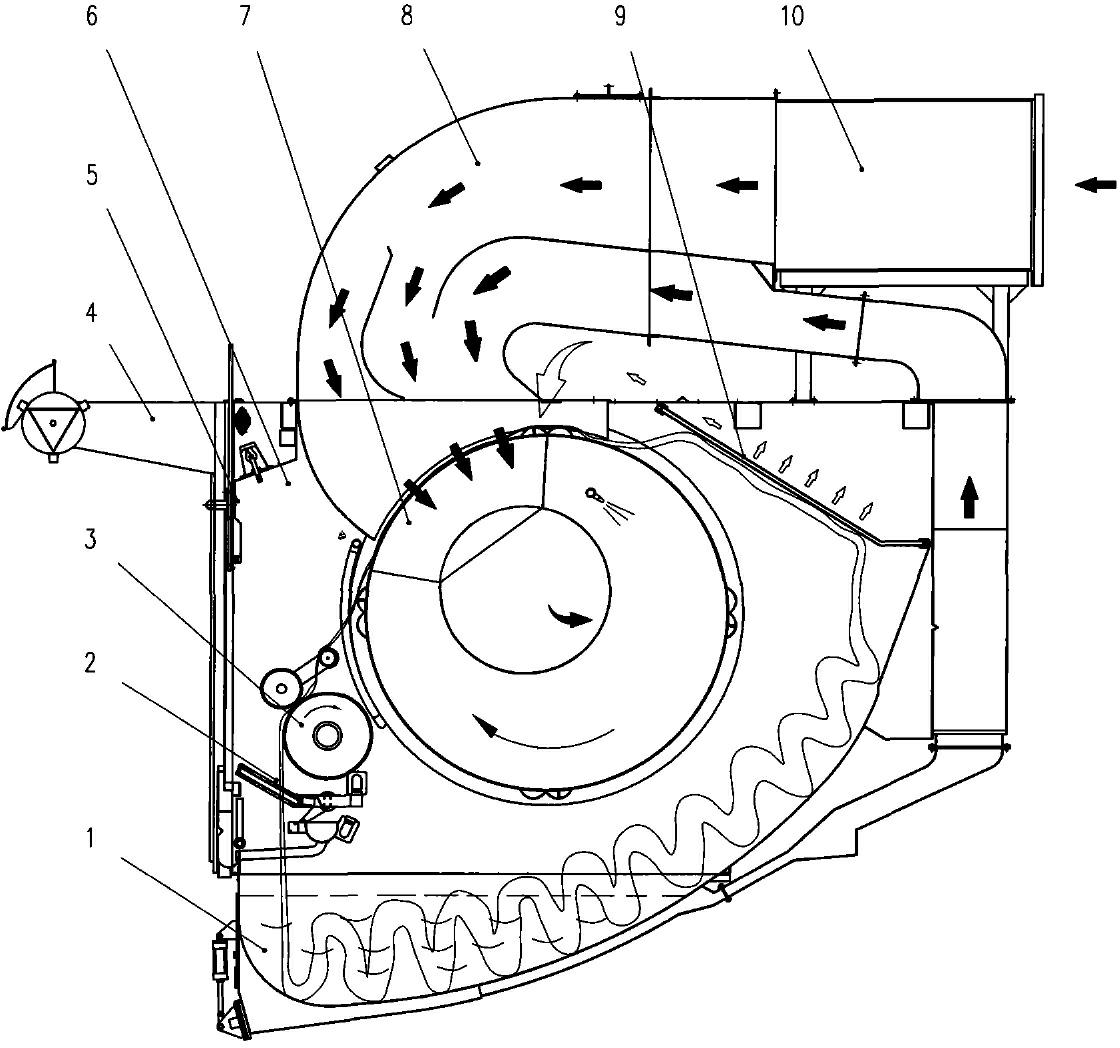

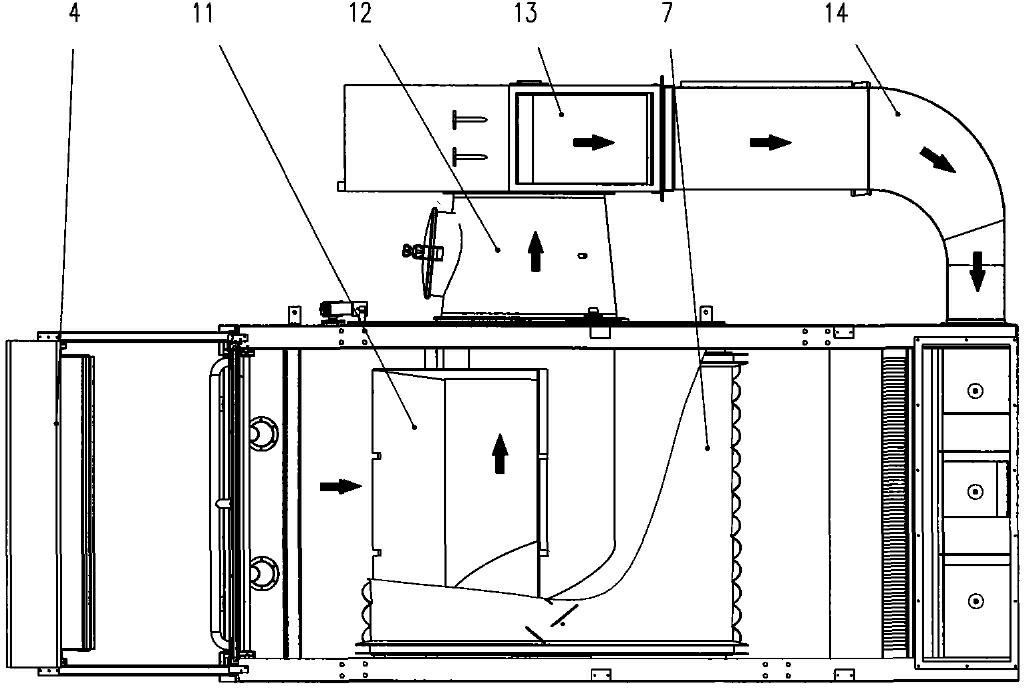

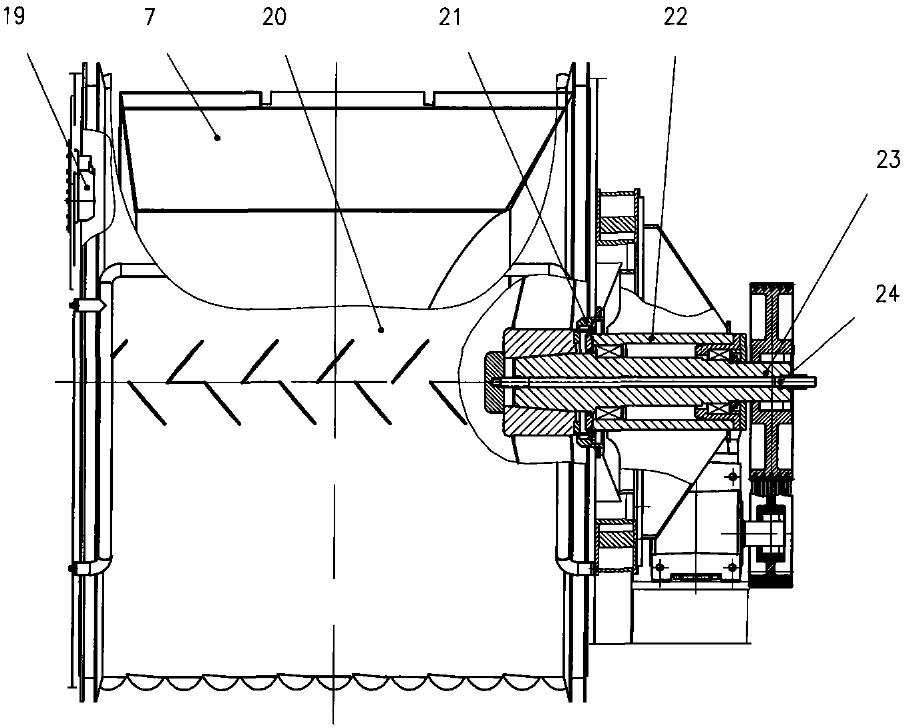

Multifunctional fulling and softening finishing machine

InactiveCN101798740AAvoid damageGuaranteed stabilityShrinkingFabric breaking/softeningFiberPulp and paper industry

The invention discloses a multifunctional fulling and softening finishing machine which comprises a box body, wherein a stainless steel roller is arranged in the box body and can be rotated with high speed under the driving of a driving device, air holes are evenly arranged on the wall of the roller, an impact plate is arranged at the rear of the roller, and a major trough for containing lotion is arranged below the roller; the roller is also provided with an airflow circulating device which can suck air from the inner side of the roller and then jet airflow onto the outer surface of the roller through a circulating pipeline from an air return port above the roller, wherein the width of the air return port is equivalent to that of the roller; and a fan is arranged on the circuiting pipeline. The invention solves the difficult problems of washing and softening treatments, and the like of light weight fabrics and knitted fabrics, such as cotton, hemp, wool, silk, chemical fiber and other materials, improves the treatment efficiency on the posttreatment process of fulling, softening, drying, and the like of fabrics and reduces the treatment cost and the environment pollution.

Owner:TAIAN COMPANION MACHINERY

Drying method for bamboo filaments of recombined bamboo

InactiveCN105666623AQuality improvementShort drying cycleReed/straw treatmentWood charring/burningCarbonizationKiln

The invention discloses a drying method for bamboo filaments of recombined bamboo and relates to the technical field of bamboo. The bundled bamboo filaments are transferred into a steeping pool of an alkaline solution with the pH value being 9-13 to be steeped; and then the bamboo filaments are taken out from the steeping pool, natural dehydration is conducted, then carbonization treatment is conducted, and finally drying is conducted. The strong alkaline solution is used for steeping the bamboo filaments under a high temperature, part of starch in the recombined bamboo is hydrolyzed, and protein in the recombined bamboo is denatured, then a high-temperature carbonizing method is used for making starch in the recombined bamboo hydrolyzed more thoroughly and protein in the recombined bamboo denatured more thoroughly, insects such as fungi lose nutrition sources, meanwhile, worm eggs and fungi in the bamboo are killed, and therefore the phenomenon that the recombined bamboo is prone to moth growth and mildew is avoided, and the quality of the recombined bamboo is better. A special bamboo filament drying kiln is used for drying, and the drying period is shorter.

Owner:GUANGXI ECO ENG VOCATIONAL & TECHN COLLEGE

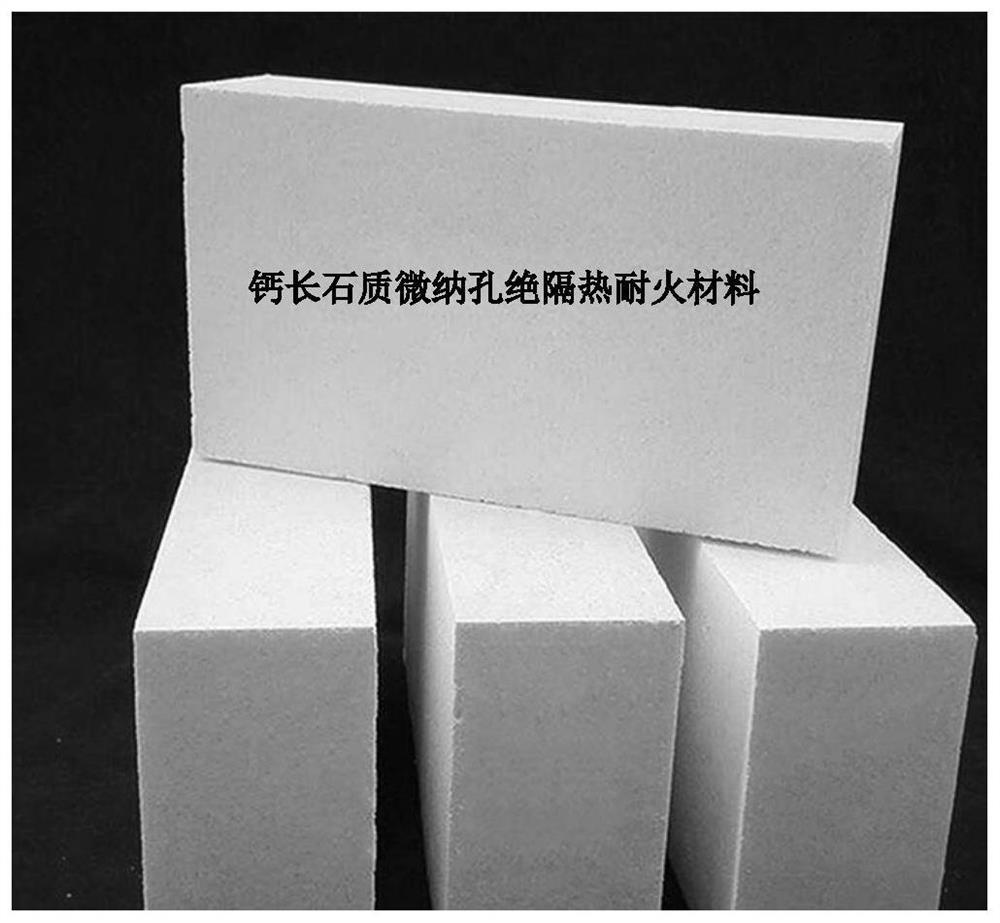

Aorthite micro-nano pore heat insulation refractory material and preparation method thereof

The invention belongs to the field of refractory materials, and particularly relates to an anorthite micro-nano pore heat insulation refractory material and a preparation method thereof. The anorthite micro-nano pore heat insulation refractory material is mainly prepared from a basic raw material, an additive and water. The anorthite micro-nano pore heat insulation refractory material is white, faint yellow or yellow in appearance, the principal crystalline phase of the product is anorthite, the mass content of CaO in the chemical composition is 4-22 wt%, the pore size distribution is 0.006-250 [mu] m, the average pore size is 0.1-19 [mu] m, and the pore structure of the micro-nano size ensures that the product has better heat insulation performance under the conditions of low volume density and high strength. The preparation method is green, environment-friendly and pollution-free, and the structure and performance of the product are easy to accurately regulate and control.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

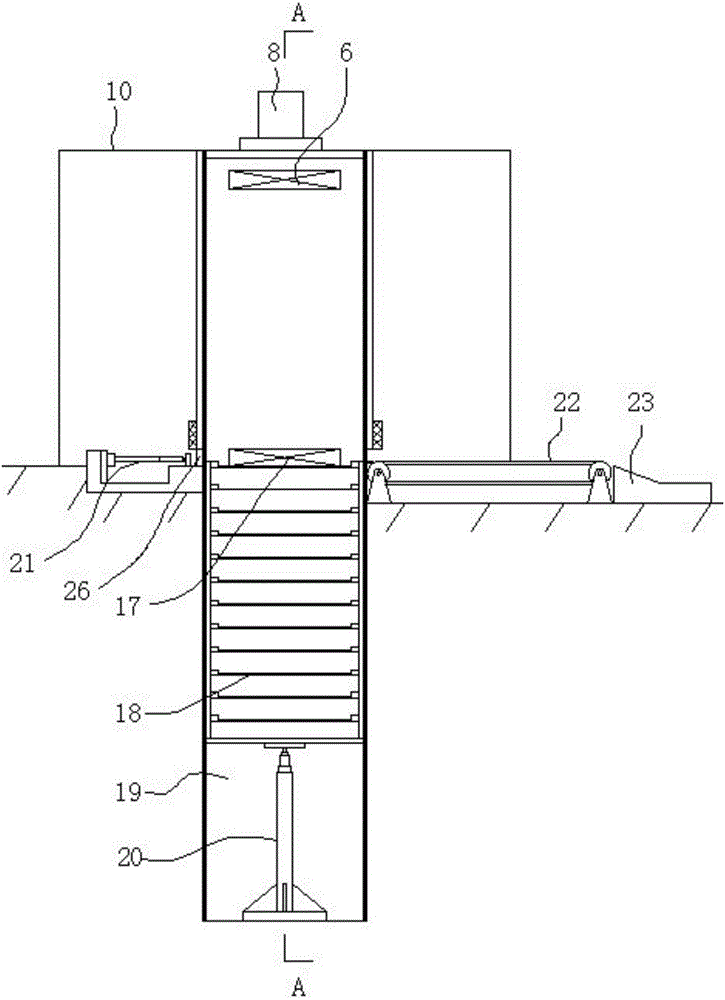

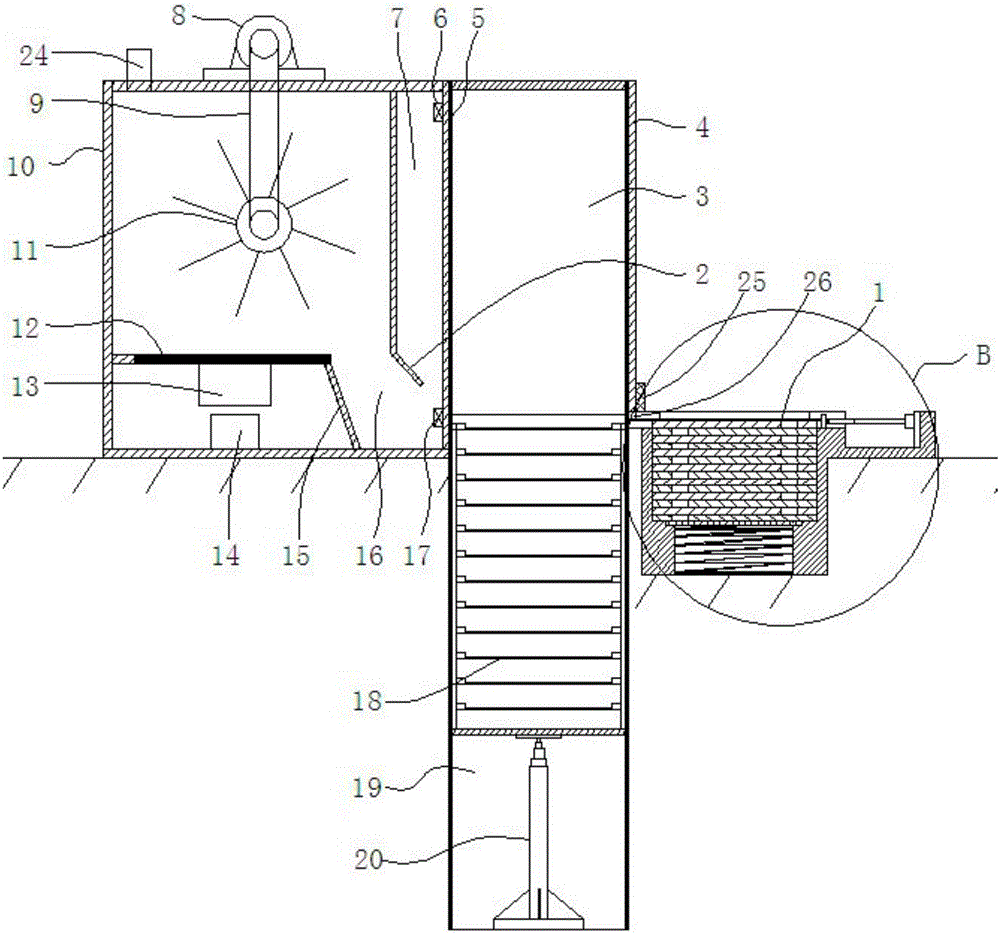

Efficient energy-saving bamboo shoot drying device with automatic feeding function

ActiveCN106017065AEasy to useImprove efficiencyDrying solid materialsTypes of drying goodsEngineeringAir blower

The invention discloses an efficient energy-saving bamboo shoot drying device with an automatic feeding function. The efficient energy-saving bamboo shoot drying device comprises a baking box and a drying box body. A drying chamber is arranged in the drying box body. A pit is arranged in the lower end of the drying box body. A guide rail is arranged on the inner side wall of the pit and the inner side wall of the drying chamber. The guide rail is provided with a lifting frame mechanism. An electrical lifting pull rod is arranged at the bottom of the lifting frame mechanism. Feeding ports are formed in the front side and back side of the bottom and the right side face of the drying box body. An automatic feeding mechanism is arranged in the position of the feeding port in the right side face of the drying box body. A pushing mechanism is arranged in the position of the feeding port in the front side of the drying box body. A suction fan is arranged at the upper left end of the drying box body. An air blower is arranged at the lower left end of the drying box body. The efficient energy-saving bamboo shoot drying device with the automatic feeding function is convenient to use, capable of achieving automatic feeding and discharging and saving the labor cost, short in drying cycle, high in drying efficiency, and good in drying effect, hot wind circulation is adopted, a preheating function can be sufficiently utilized for drying, and thus energy is saved.

Owner:桃江县竹缘林科开发有限公司

Drying method for teflon dispersed resin

ActiveCN101000208ASolve the problem of long drying cycleLow costDrying using combination processesDrying solid materials with heatPulp and paper industryDrying time

The invention relates to polytetrafluoroethylene dispersion resin drying method. Its features are that it adopts new type vacuum drier, introduce negative pressure induced draught fan to switch with the vacuum drier to change the negative pressure state in the drying system, takes out dried hot blast at the same time. This method can effectively control the drying time in 12-18 hours for the resin. Thus the production efficiency can be greatly improved. It has the advantages of short drying cycle, non expendable byproduct, saving cost, environmental protection.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

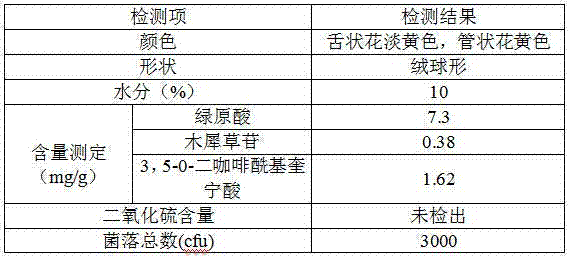

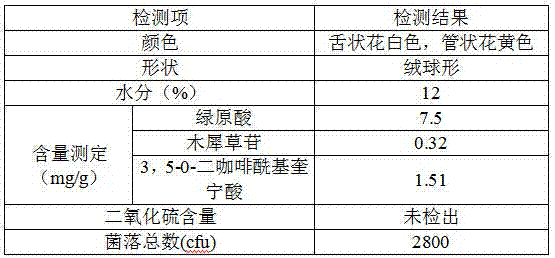

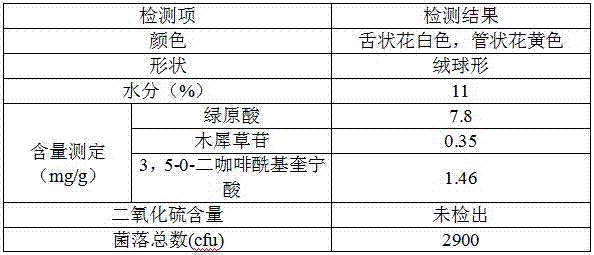

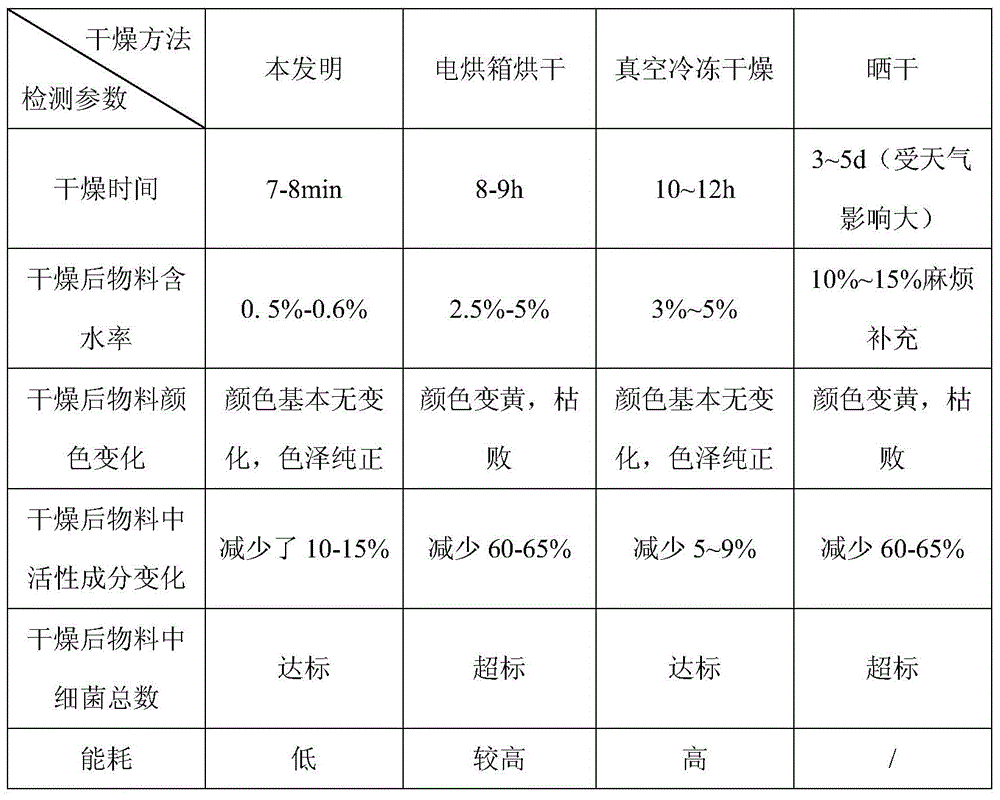

Method for jointly drying Chuzhou chrysanthemum flowers by steam fixation and heat pump microwaves

The invention discloses a method for jointly drying Chuzhou chrysanthemum flowers by steam fixation and heat pump microwaves. The method comprises the following steps: selecting damage-free and disease-free Chuzhou chrysanthemum flowers, grading according to sizes and colors, cleaning the Chuzhou chrysanthemum flowers, filtering to remove water for later use; placing the Chuzhou chrysanthemum flowers in a fixation tray, performing fixation by using saturated vapor, placing the Chuzhou chrysanthemum flowers in a drying tray, performing dehumidification drying in a heat pump drying oven; placing the Chuzhou chrysanthemum flowers in a softening device to ensure that petals and buds of the Chuzhou chrysanthemum flowers are consistent in water, placing the Chuzhou chrysanthemum flowers in a microwave dryer; and sorting and packaging the dried Chuzhou chrysanthemum flowers. The method is high in heat pump heat efficiency and little in energy consumption, short in Chuzhou chrysanthemum flower drying period which is within 10h, and high in working efficiency; the Chuzhou chrysanthemum flowers are dried under a low-temperature environment which does not exceed 50 DEG C, the obtained Chuzhou chrysanthemum flower product has a good flower type, yellowish color and little nutritional ingredient loss; the aerobic bacterial count of the finished Chuzhou chrysanthemum flowers is less than 3000cfu, so that the finished Chuzhou chrysanthemum flowers are safe and sanitary.

Owner:CHUZHOU UNIV

Roller for multifunctional fulling-softening finisher

The invention discloses a roller for a multifunctional fulling-softening finisher, which is arranged in a box body of the multifunctional fulling-softening finisher and can rotate at high speed under the drive of a driving device. The roller is characterized in that holes are uniformly distributed in the wall of the roller; and the roller is also provided with an airflow circulating device which is used for inspiring air from the inner side and spraying the airflow on the outer surface of the airflow circulating device from a return air port above the roller by a circulating pipeline. By using the softening finisher disclosed by the invention, the problems of washing, softening and the like of light and thin fabrics made of cotton, cambric, wool, silk, chemical fibers and the like, and knitwear are effectively solved. On the aspect of post-treatment procedures of fulling, softening, drying and the like of the fabrics, the treatment efficiency is increased, and the treatment cost and environmental pollution are reduced.

Owner:TAIAN COMPANION MACHINERY

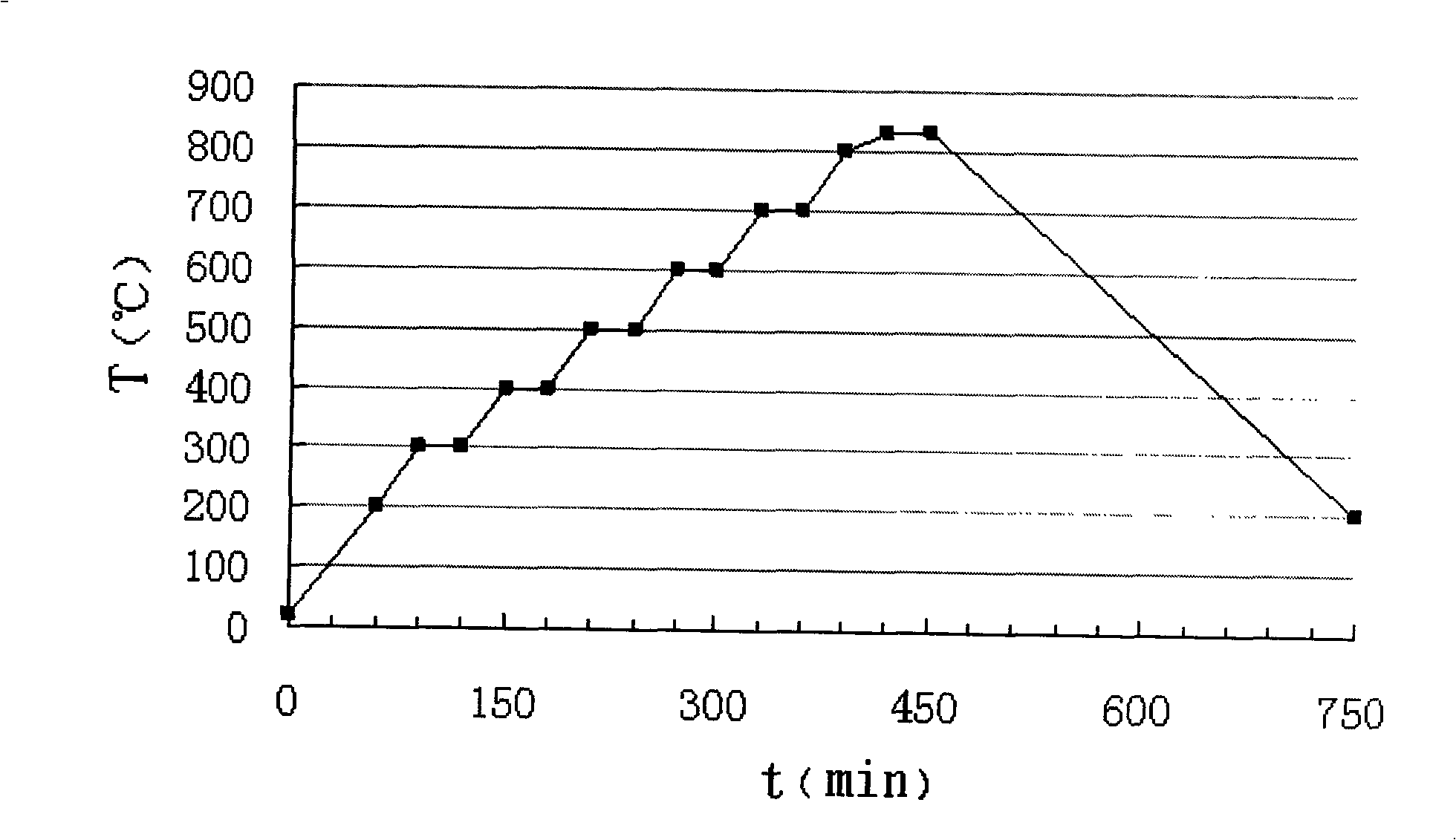

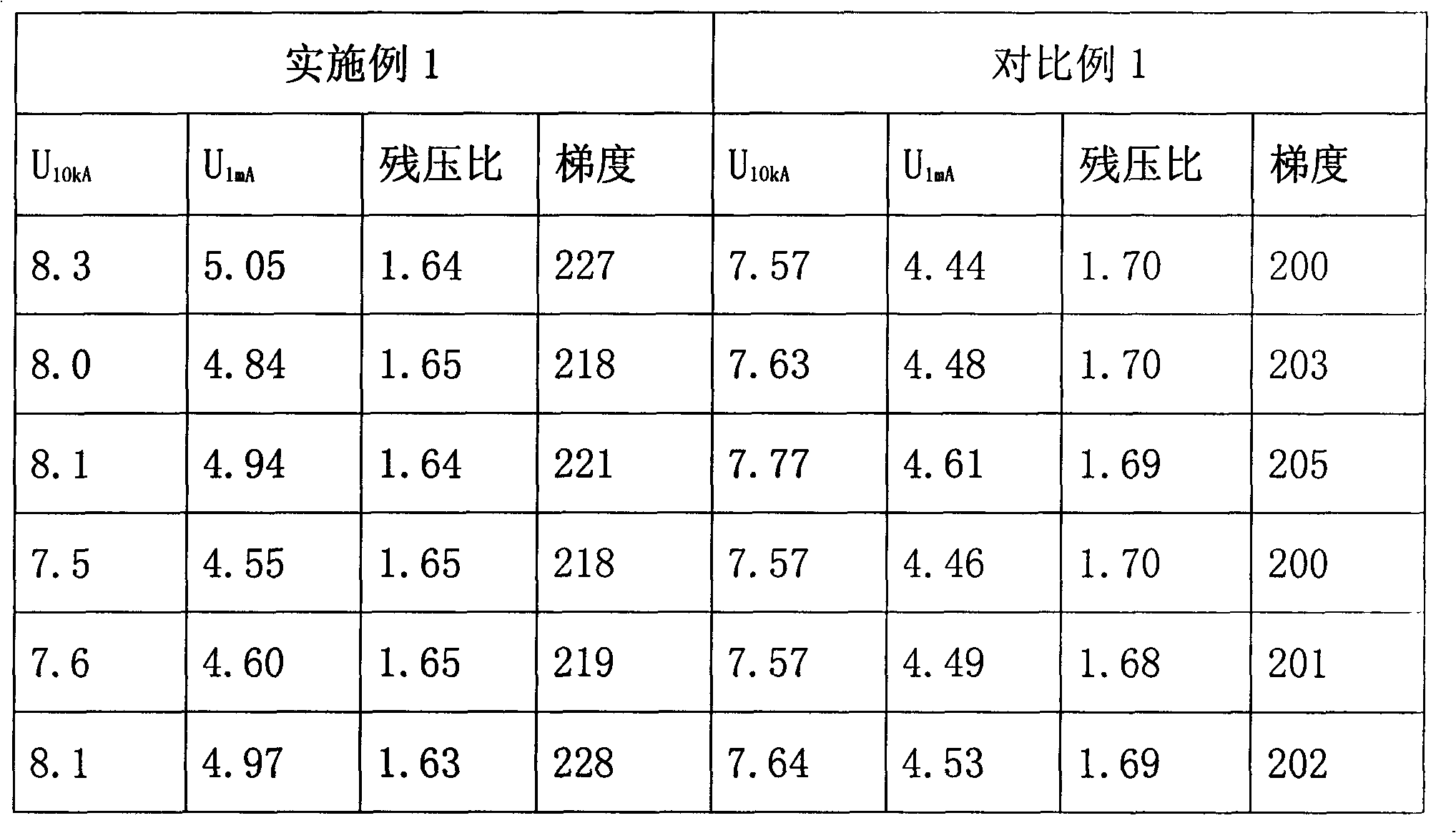

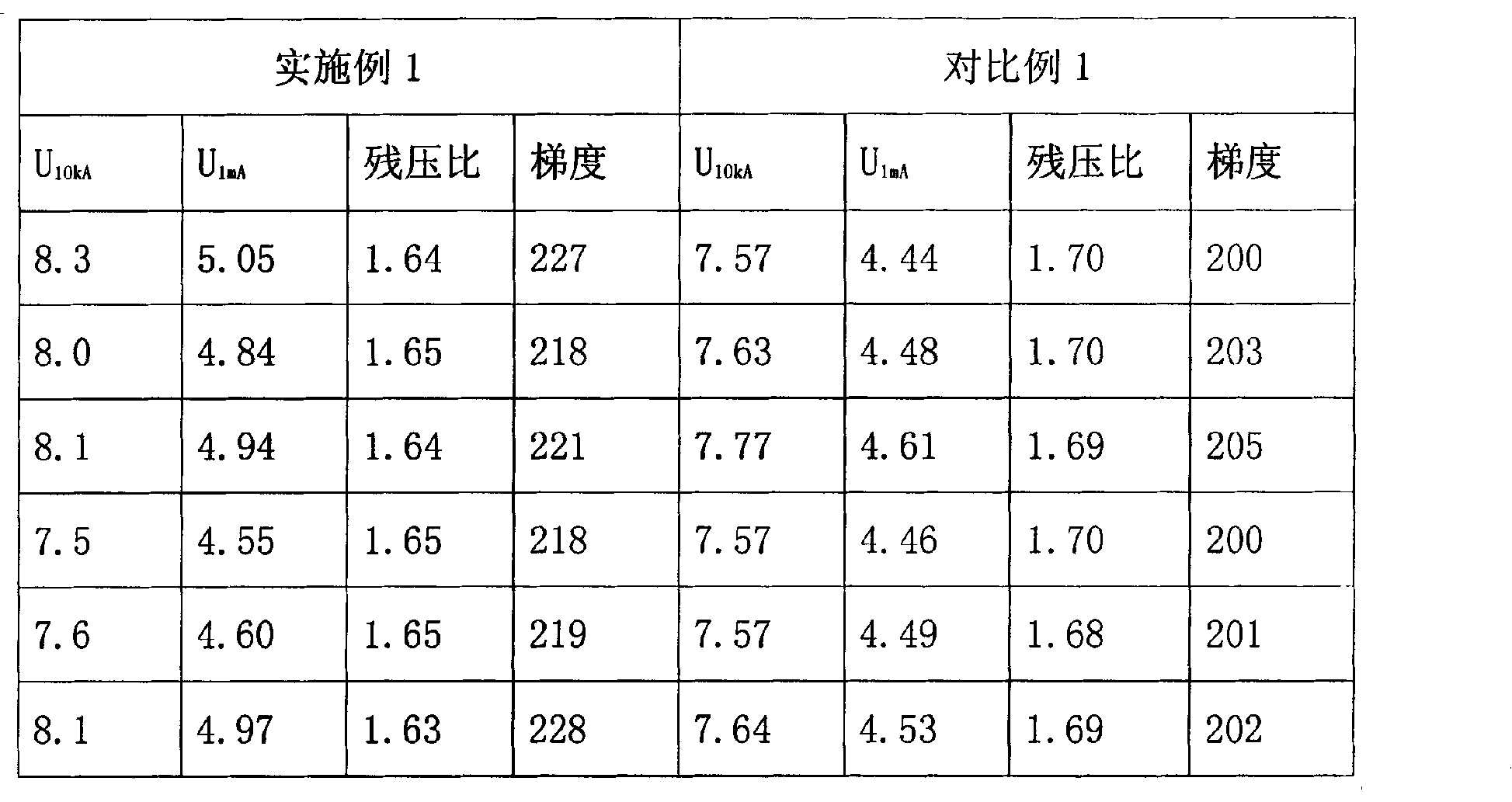

Method for preparing additive for zinc oxide resistance slice

ActiveCN101354936AShort drying cycleUse less equipmentResistor manufactureVaristor coresNonlinear resistorRoom temperature

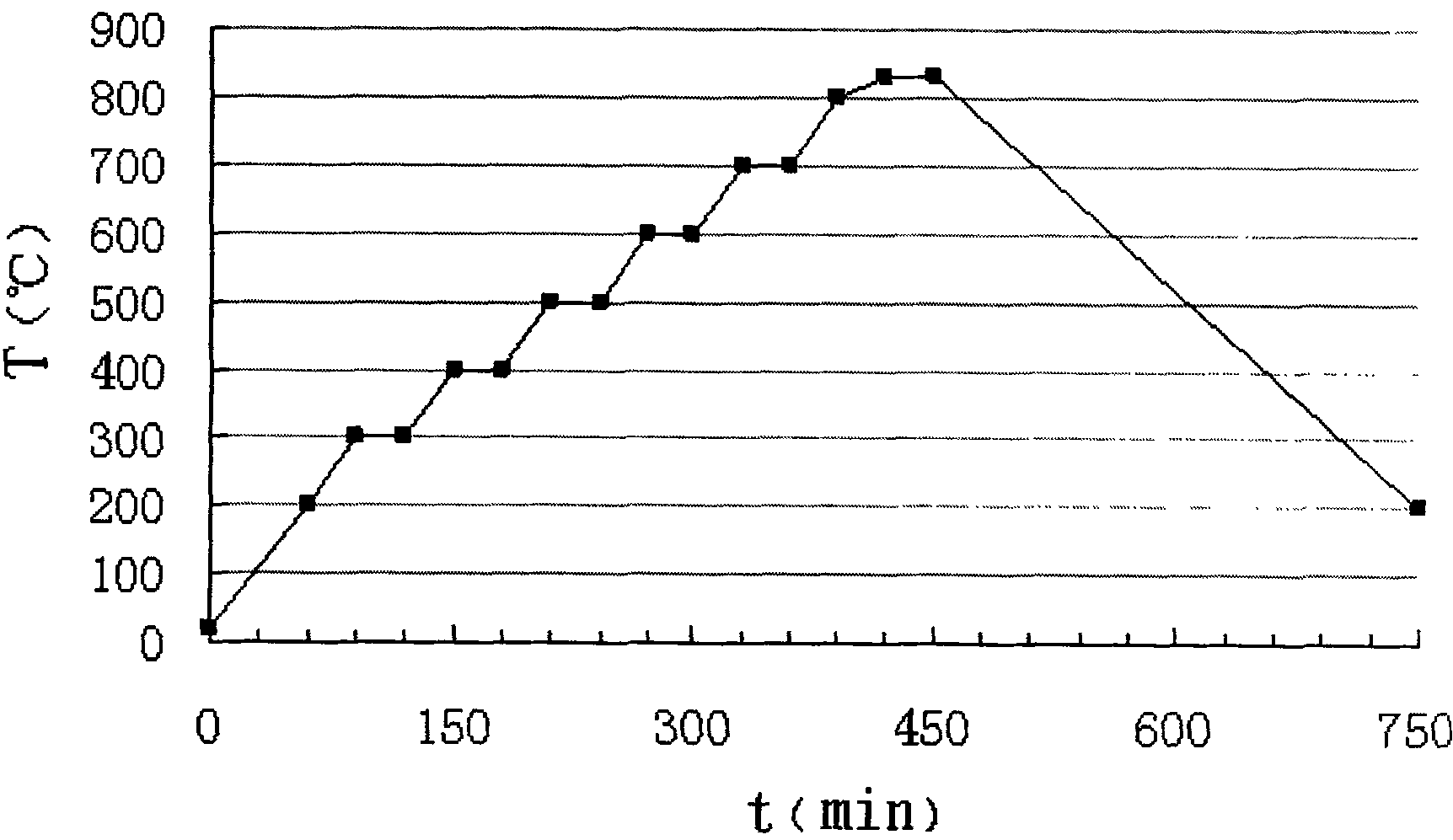

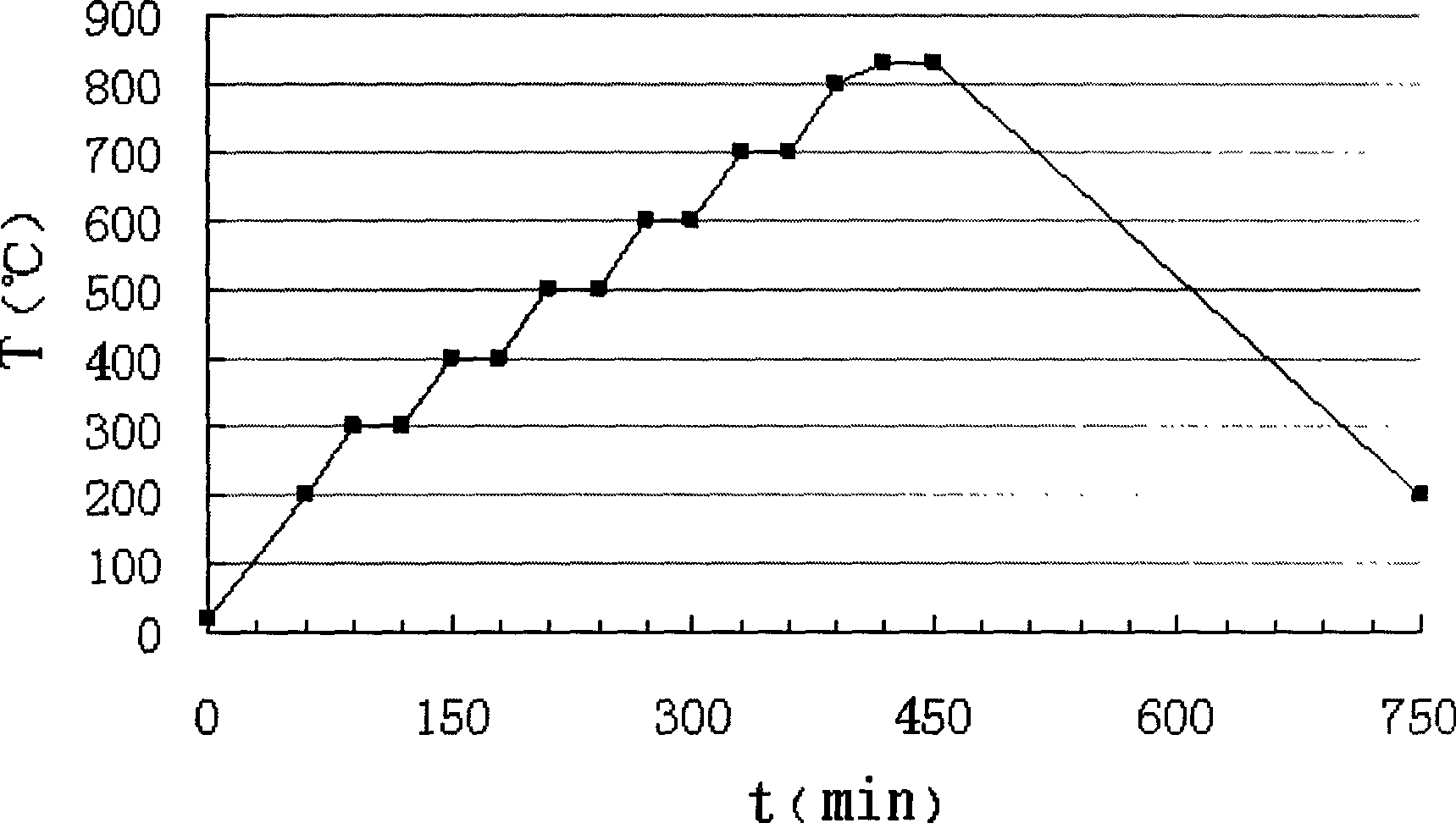

The invention relates to the manufacturing field of a nonlinear resistor plate and in particular discloses a method for preparing an additive for a zinc oxide resistor plate; the additive comprises the following compositions: 12 to 16 mol percent of Bi2O3, 21 to 26 mol percent of Sb2O3, 10 to 13 mol percent of Mn2CO3, 10 to 13 mol percent of Cr2O3, 10 to 13 mol percent of Co2O3 and 23 to 32 mol percent of SiO2; firstly, according to the mixture ratio, the compositions are weighed and used as raw materials; water, the weight of which is 1 to 1.5 times that of the raw materials is added and subjected to primary ball milling; the average particle diameter of the particles of a sizing agent is controlled to be 1 micron; secondly, the particles are dried in a pressure-type spray drying tower; the spray pressure is between 1.3 and 1.5 megapascal; the temperature of an inlet is between 250 and 380 DEG C; the temperature of an outlet is between 100 and 130 DEG C; thirdly, the particles are put into a calcining furnace; the room temperature rises to 200 DEG C within one hour and risen to 800 DEG C in a mode of rising 100 DEG C per 0.5 hour and keeping the temperature for 0.5 hour; the temperature rises form 800 DEG C to 830 DEG C for 0.5 hour and is kept for 40 minutes; the particles are cooled in the furnace; and finally the particles are crushed, sieved and subjected to secondary ball milling.

Owner:CHINA XD ELECTRIC CO LTD

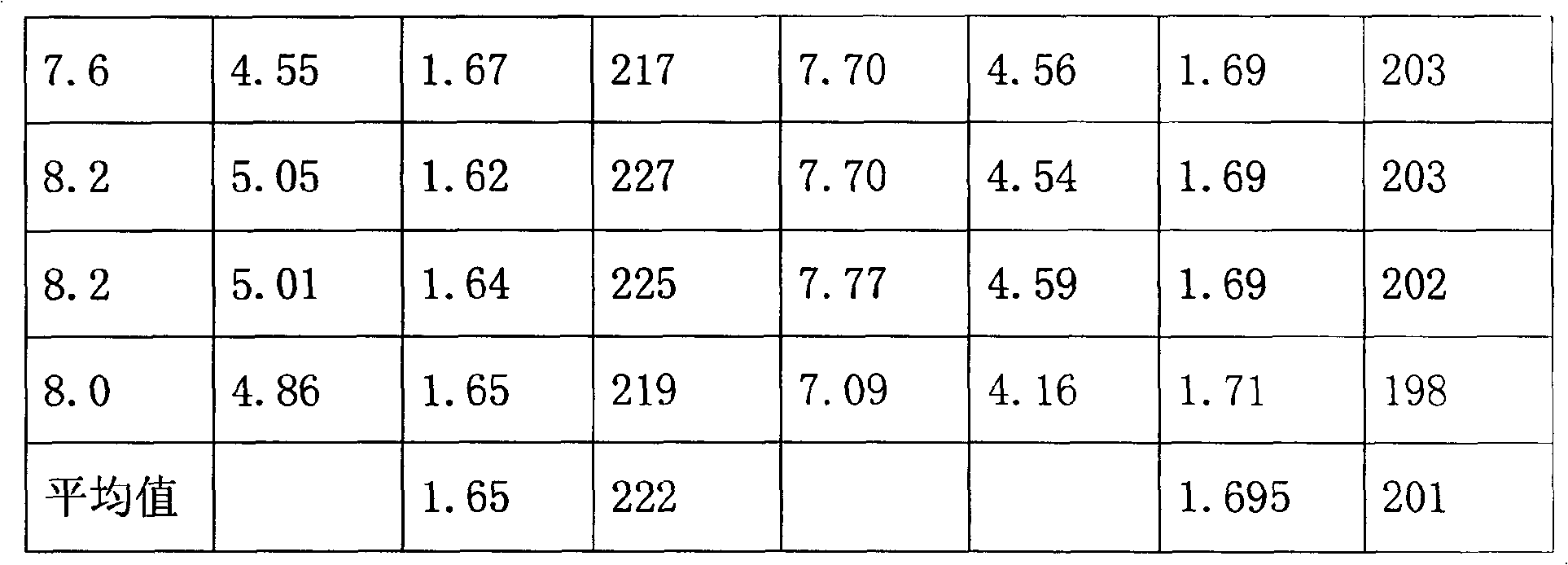

Traditional Chinese medicine extract drying method for preparing drug for curing osteoporosis

InactiveCN101700314AGood curative effectQuality improvementSkeletal disorderPlant ingredientsMedicinal herbsVacuum drying

The invention is a traditional Chinese extract drying method for preparing a drug for curing osteoporosis, which comprises the following steps of drying extract obtained by prescribing and extracting through a micro-wave vacuum drying sterilizer, spreading extract in a baking plate according to 3-5kg per baking plate, and drying under the conditions that the material temperature of the micro-wave vacuum drying sterilizer is set as 80-100 DEG C, the running time is 80-120min, and the vacuum degree is controlled at minus 0.08-minus 0.09MPa. The dried extract obtained by the method can effectively overcome the defects of decomposed thermal sensitivity component, reduced effective component content, high labor intensity, large thermal quantity consumption, lower thermal efficiency, hardened caked masses of materials, difficult crushing and the like caused by long-time high-temperature baking in vacuum tank drying method; the dried extract has the advantages of maintained fragrance of medicinal materials, moderate color, loose texture, easy crushing, low moisture, convenient preparation processing and product storage, good dissolubility in water and alcohol, less insoluble impurities, high content of effective components and good product quality.

Owner:SICHUAN MEDCO PHARML

Camellia drying device

InactiveCN105004156ASimple structureEasy to usePre-extraction tea treatmentDrying machines with non-progressive movementsTemperature control

The invention discloses a camellia drying device which comprises a box body. A filter steel wire screen is fixedly arranged in the box body through a pair of vibrators. A pair of heating bars is arranged on the inner wall of the box body. A temperature controller is further arranged on the top end face of the box body. A temperature control probe is arranged on the temperature controller and extends into the box body. The camellia drying device is good in drying effect, short in drying cycle and capable of having an effect sterilization effect, and the health degree of the drink containing camellia is high.

Owner:合肥维巧食品科技有限公司

Low-sugar candied radix asparagi and preparation method thereof

PendingCN112244133AReduce energy consumptionLow costFood ingredient as antioxidantSugar food ingredientsBiotechnologySucrose

The invention discloses low-sugar candied radix asparagi and a preparation method thereof. The preparation method comprises the following steps that fresh radix asparagi is taken as a raw material, and cleaning, enzymolysis, freezing, blanching, hardening, color protection, vacuum sugar permeability, vacuum drying and the like are carried out; enzymolysis is carried out on radix asparagi peel by using a small amount of compound enzyme preparation, through short-time freezing treatment, the radix asparagi is taken out for short-time boiling water blanching or steam treatment, then the radix asparagi is taken out, quickly cooled, peeled, hardened and subjected to protecting color, sugar liquid is prepared for vacuum sugar permeability, vacuumizing is carried out first, sucrose proportioningliquid with the concentration of less than or equal to 40% is injected, treating is carried out for 30 minutes at the vacuum degree of 0.07-0.095 MPa and the temperature of 80-90 DEG C, and soaking iscarried out for 4-6h at normal pressure and temperature; and in order to improve the permeation and filling effects of the sugar liquid, a composite filling agent is added, then drying is carried out, so that the low-sugar candied radix asparagi with the sugar content of 36%-40% is finally prepared, the high-sugar characteristic of the original traditional candied radix asparagi is improved, thecolor is smooth, the mouthfeel quality is good, and the character, unique flavor and nutritional ingredients of original radix asparagi are preserved to the maximum extent.

Owner:四川天益百草生物科技有限公司 +1

Moringa oleifera leaf drying method

InactiveCN105660824AShort drying cycleSimple processFruits/vegetable preservation by dehydrationMicrowave cavityMORINGA OLEIFERA LEAF

The present invention discloses a moringa oleifera leaf drying method. The method comprises the following steps: (1) fresh moringa oleifera leaves are sent into a material distributing bin of a microwave drying device to conduct mechanical material distribution, and the moringa oleifera leaves are spread horizontally on a conveyor belt of the microwave drying device; (2) the distributed moringa oleifera leaves are transferred into a microwave cavity of the microwave drying device, the microwave is used to conduct drying, and at the same time, a dehumidifier is used to discharge moisture in the cavity of the microwave drying device; and until the moringa oleifera leaves are dried into a water content of 0.5%-3%, and the materials can be discharged at a material discharge temperature of 45-55 DEG C; and (3) the treated moringa oleifera leaves by the step (2) are sent into an ultrafine crusher to conduct crushing, and then the crushed materials are inspected and the inspected materials are packaged to obtain dried moringa oleifera leaf finished products. The drying method is short in time, simple in processes and high in efficiency. The dried moringa oleifera leaf finished products have basically unchanged color, are pure in color and luster, and less in nutritional active ingredient damage, and the obtained moringa oleifera leaf powder is high in nutritional quality.

Owner:HENAN BODA MICROWAVE EQUIP

Ceramic sanitary ware production device with rapid water draining system

The invention discloses a ceramic sanitary ware production device with a rapid water draining system. The device comprises a die assembly capable of being opened and closed, a grouting system, a lifting mechanism and the rapid water draining system. The grouting system is communicated with grouting space, when the die assembly is in the die assembly state, the grouting space can be grouted, the lifting mechanism is connected with the die assembly, at least one die in the die assembly is driven to move, and die assembly and disassembly can be finished; the rapid water draining system comprisesan air supply system and an air supply pipe set connected with the air supply system; an outlet of the air supply pipe set is located in a body of at least one die of the die assembly. The ceramic sanitary ware production device with the rapid water draining system comprises the rapid water draining system, the air supply pipe set of the rapid water draining system can blow air to the body of thedie assembly, water draining of the die assembly can be accelerated, the drying time of the die assembly can be shortened, accordingly, the grouting period can be shortened, production efficiency canbe improved,, and production cost is reduced.

Owner:唐山森兰瓷科技有限公司

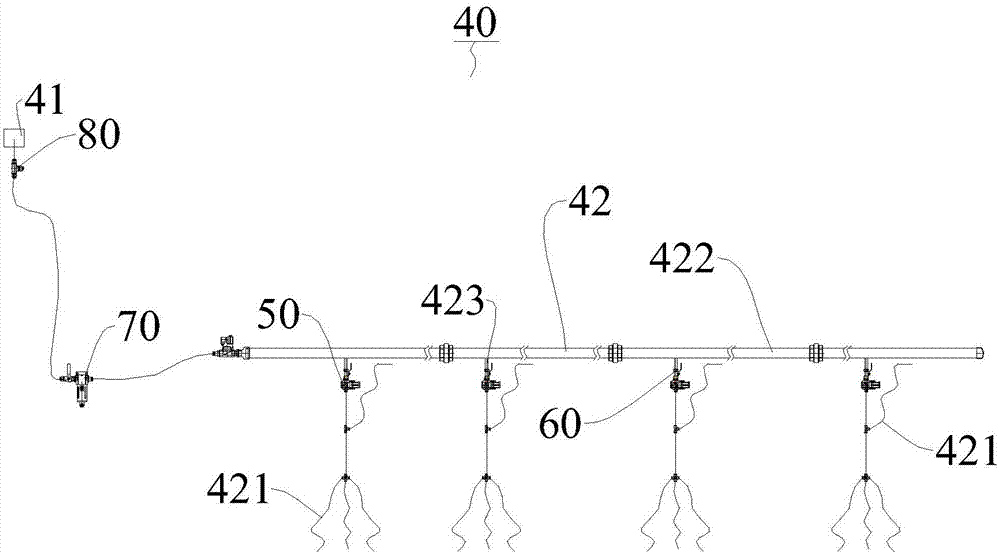

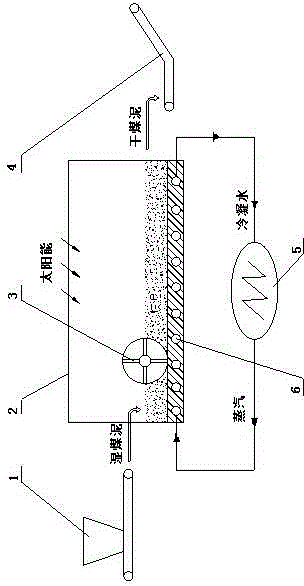

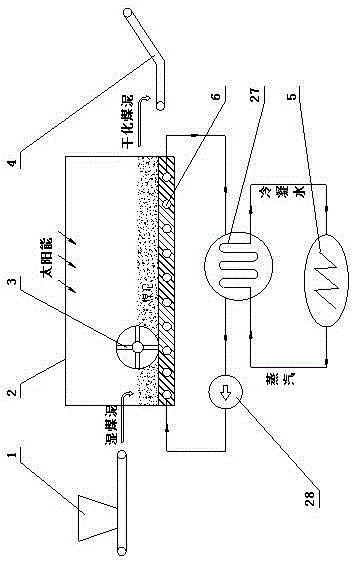

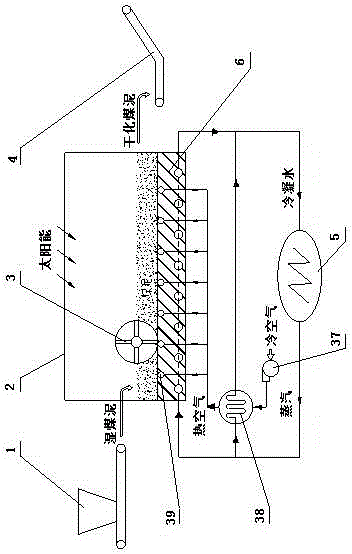

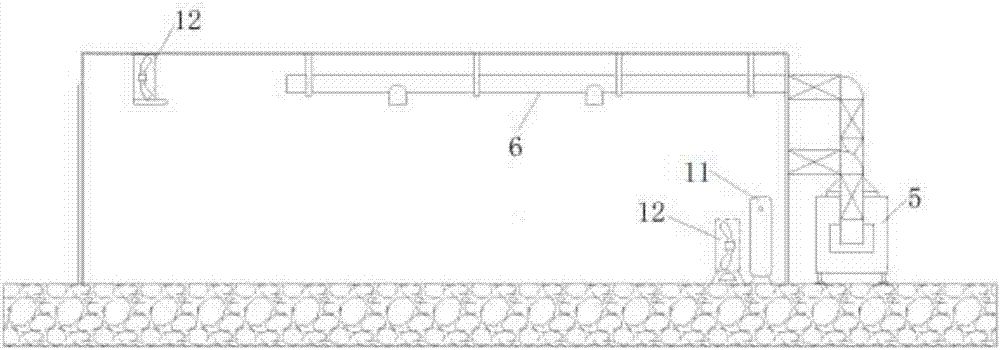

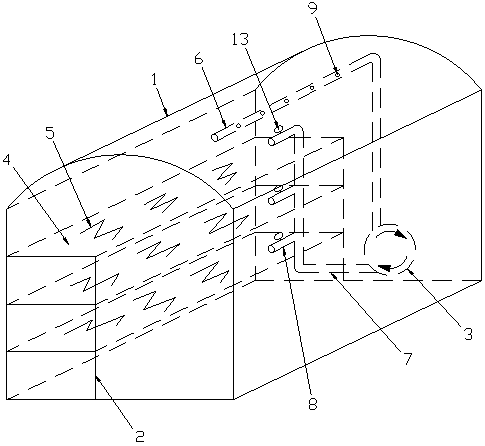

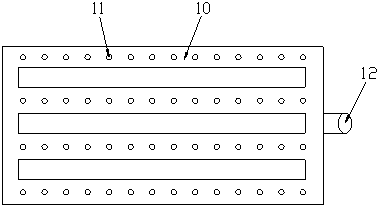

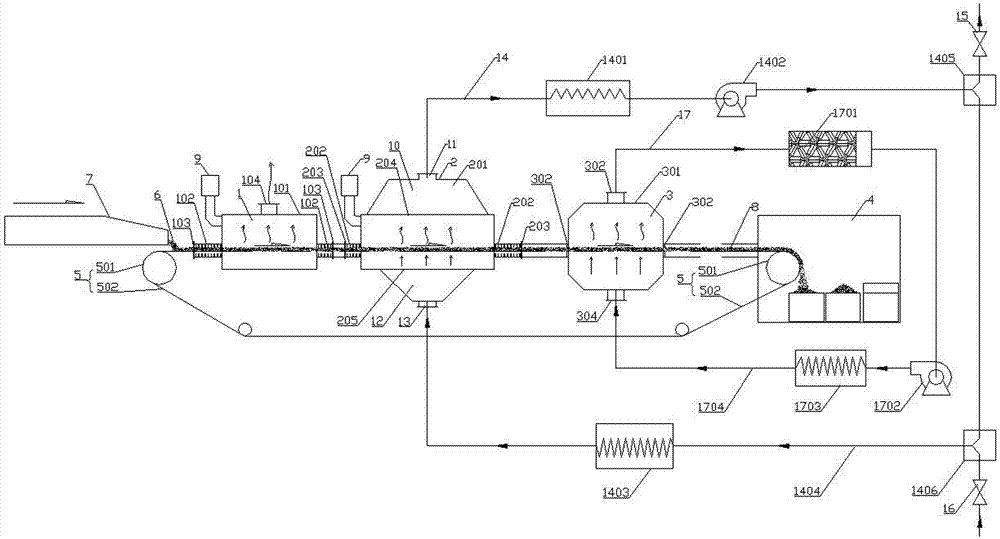

Coal slime drying system and method using electric power plant low-grade steam and solar energy

ActiveCN104654740AImprove efficiencyAchieve dryingDrying solid materials with heatHearth type furnacesHeat energyEquipment use

The invention discloses a coal slime drying system using electric power plant low-grade steam and solar energy. The system comprises coal slime conveying equipment used for conveying to-be-dried wet coal slime, a solar greenhouse used for providing coal slime drying and solar irradiation, a coal slime turning machine used for paving, turning throw, conveying and cutting the coal slime into fine coal slime particles, dried coal slime conveying equipment used for conveying dried coal slime, an electric power plant thermodynamic system used for proving low-grade steam, and a floor heating device used for absorbing the heat energy of the low-grade steam to supply heat energy required by coal slime drying. The invention also provides a coal slime drying method using electric power plant low-grade steam and solar energy. The method has the advantages of high system transparency, good environment coordination, stable and sate operation, low operation maintenance cost, energy source saving and the like.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

Mullite light insulating brick and preparation method thereof

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing additive for zinc oxide resistance slice

ActiveCN101354936BShort drying cycleUse less equipmentResistor manufactureVaristor coresNonlinear resistorRoom temperature

The invention relates to the manufacturing field of a nonlinear resistor plate and in particular discloses a method for preparing an additive for a zinc oxide resistor plate; the additive comprises the following compositions: 12 to 16 mol percent of Bi2O3, 21 to 26 mol percent of Sb2O3, 10 to 13 mol percent of Mn2CO3, 10 to 13 mol percent of Cr2O3, 10 to 13 mol percent of Co2O3 and 23 to 32 mol percent of SiO2; firstly, according to the mixture ratio, the compositions are weighed and used as raw materials; water, the weight of which is 1 to 1.5 times that of the raw materials is added and subjected to primary ball milling; the average particle diameter of the particles of a sizing agent is controlled to be 1 micron; secondly, the particles are dried in a pressure-type spray drying tower; the spray pressure is between 1.3 and 1.5 megapascal; the temperature of an inlet is between 250 and 380 DEG C; the temperature of an outlet is between 100 and 130 DEG C; thirdly, the particles are put into a calcining furnace; the room temperature rises to 200 DEG C within one hour and risen to 800 DEG C in a mode of rising 100 DEG C per 0.5 hour and keeping the temperature for 0.5 hour; the temperature rises form 800 DEG C to 830 DEG C for 0.5 hour and is kept for 40 minutes; the particles are cooled in the furnace; and finally the particles are crushed, sieved and subjected to secondary ball milling.

Owner:CHINA XD ELECTRIC CO LTD

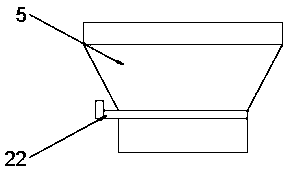

Novel positive pole material drying device of power lithium battery

InactiveCN109539697AImprove drying efficiencyFast dryingGranular material dryingPreliminary solid treatment for dryingMicrowave emissionEnergy consumption

The invention discloses a novel positive pole material drying device of a power lithium battery. The novel positive pole material drying device comprises a device body, microwave emitters and a dehumidifier, wherein a feeding hopper is arranged at the upper end of the device body and is used for adding a positive pole material to be dried into the device body; the right side wall of the device body is provided with a first discharge port and a second discharge port; the number of the microwave emitters is two, the two microwave emitters are arranged on the top wall and the bottom surface of the device body respectively, and the microwave emitters can emit microwaves to carry out microwave drying on the material in the device body; and the dehumidifier is further arranged in the device body, and the dehumidifier is used for dehumidifying the device body. According to the novel positive pole material drying device of the power lithium battery, the microwave emitters, a sieve plate and the dehumidifier are arranged, and the positive pole material is dried in a microwave drying mode, so that materials with different sizes can be separately dried by the sieve plate, the drying efficiency is greatly improved by arranging the dehumidifier, the drying speed is high, the drying period is short, and the energy consumption is reduced.

Owner:枣庄领创新能源科技有限公司

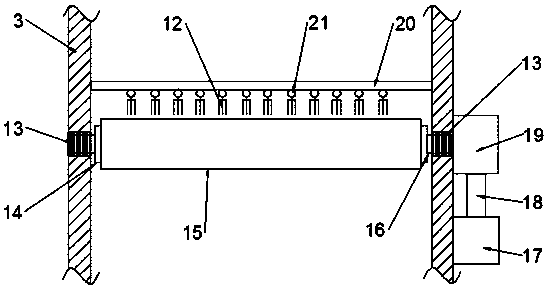

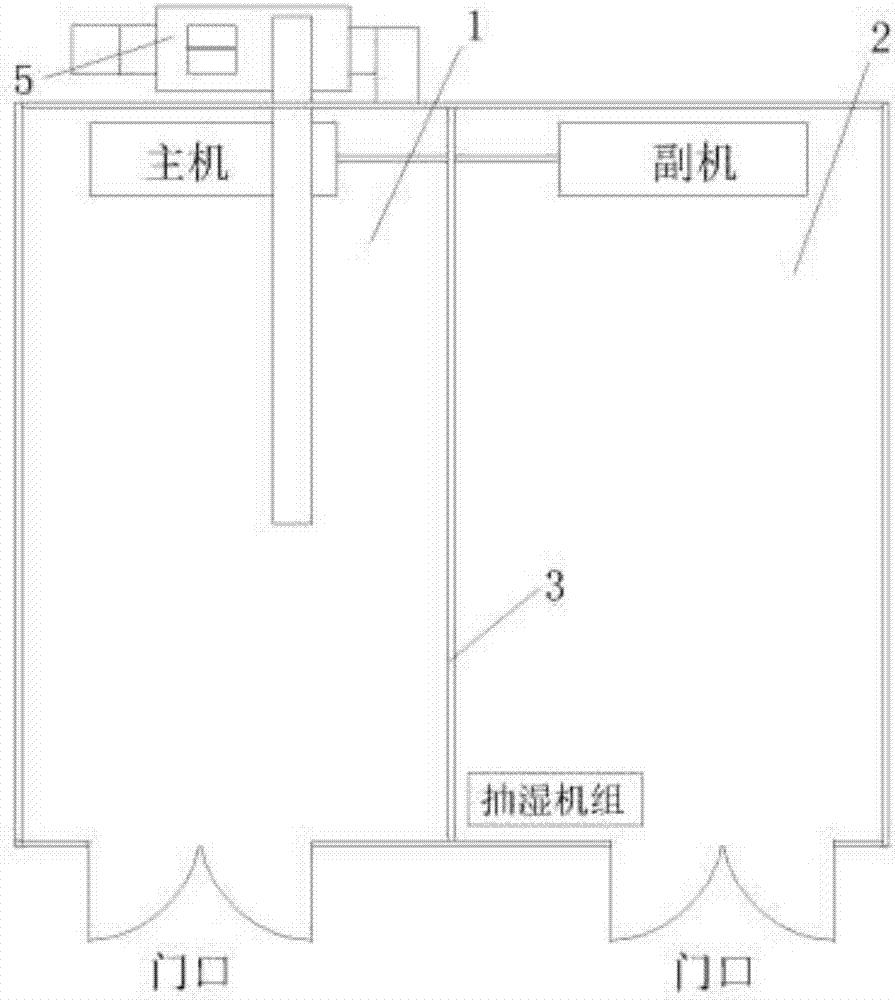

Novel drying room

PendingCN106979672AImprove drying efficiencyReduce energy consumptionDrying gas arrangementsDrying solid materialsProcess engineeringDamper

The invention discloses a novel drying room and relates to the technical field of drying mechanisms. A separation plate is arranged between a hot room and a cold room. A control electric box is installed on the side wall of the cold room. A dehumidification pipeline and a wind inlet pipeline are connected in the hot room in a penetrating mode and are both connected with a heat cycle converter. A control damper is installed on the heat cycle converter. A high-speed centrifugal fan is installed on an exhaust outlet of the heat cycle converter. A humidity removing pipeline is installed on the high-speed centrifugal fan. An auxiliary machine and a high-speed high-temperature fan are installed in the hot room. A high-speed high-temperature fan, a main machine and a dehumidification unit are installed in the cold room. The novel drying room provided by the invention integrates high-temperature drying and low-temperature drying, the temperature is uniform, the drying period is short, the drying efficiency is high, the quality of a dried product is high, energy consumption is low, and production cost is low.

Owner:JIANGMEN HUAYAN AUTOMATION EQUIP

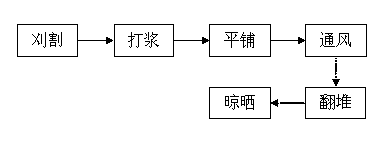

Chinese pennisetum drying method

InactiveCN103267404ASimple processImprove drying efficiencyDrying solid materials with heatDrying gas arrangementsGreenhousePulp and paper industry

The invention relates to a Chinese pennisetum drying method which is characterized in that a Chinese pennisetum drying device is provided. The Chinese pennisetum drying method includes steps of (1) mowing: Chinese pennisetum plants are mowed when Chinese pennisetum grows to be 1.5-2.5m high; (2) pulping: Chinese pennisetum is made to be grass pulp through a pulping machine without water; (3) flat laying: the grass pulp is flat laid on all layers of drying beds of drying bed frames, and the weight of the grass pulp on each drying bed frame is preferentially 5kg / m<2>-15kg / m<2>; (4) ventilating: upper layer hot air in a greenhouse is blown into grass pulp stacks for ventilating for 20-40 min by opening an air blower at the interval of 0.5-1.5 h; (5) turning: the grass pulp stacks are plowed and harrowed for one to three times every day; and (6) drying: the grass pulp stacks are dried for 3-7 days until the grass pulp is dried to be grass powder with 10-15% of water content, and then the grass powder can be stored or used. The Chinese pennisetum drying method has the advantages of being simple in process, high in drying efficiency, short in drying period and low in cost, being favorable for storing Chinese pennisetum nutrient substances and the like.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

Drier for industrial paint

The invention discloses a drier for industrial paint. The drier is characterized by being composed of the following components in parts by weight: 5 to 12 parts of polyoxyethylene, 1 to 7 parts of polyoxypropylene, 1 to 5 parts of manganese carbonate, 1 to 2 parts of glycerol, 10 to 20 parts of ethanol, 5 to 10 parts of lead oxide, and 1 to 2 parts of copper hydroxide. The drier has the advantages that the catalytic efficiency is high under a normal pressure at a room temperature, and the drying period is short.

Owner:武汉鸿信通科技有限公司

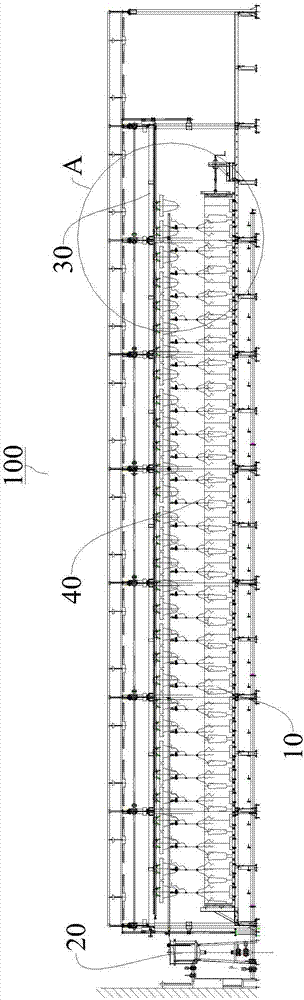

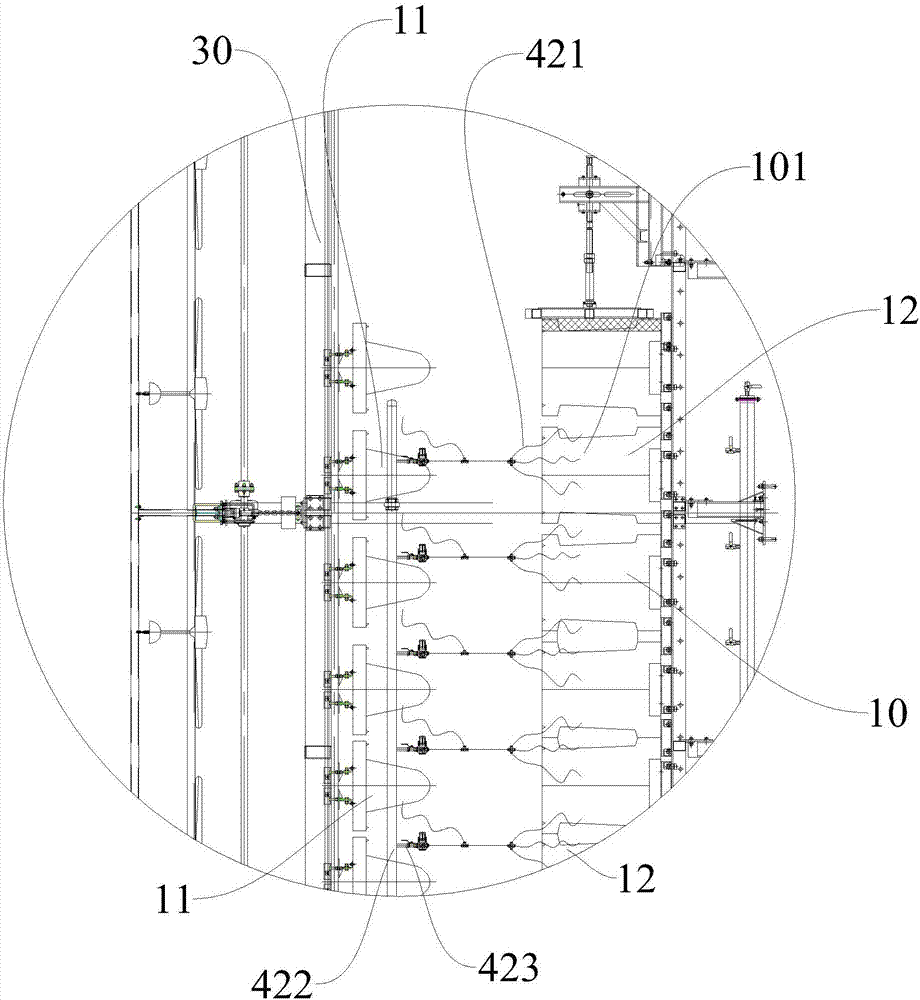

Method and system for drying wet polytetrafluoroethylene dispersion resin particles

ActiveCN107449264AResidue reductionImprove efficiencyDrying solid materials with heatGranular material dryingTetrafluoroethyleneCaking

The invention belongs to the technical field of organic chemical drying and discloses a method and a system for drying wet polytetrafluoroethylene dispersion resin particles. A drying device, a decontaminating device, a low-temperature air cooling device and hermetical packaging device are connected through a mesh belt conveying device to form a tunnel type continuous processing cyclic conveying loop to orderly and effectively complete procedures of wet feeding, microwave drying, microwave superheat steam drying and decontaminating, cooling and hermetical packaging of polytetrafluoroethylene dispersion resin particles, and consequently high-quality polytetrafluoroethylene dispersion resin particles low in moisture content and impurity residue and free of caking and fiberizing are produced while environmental influences are effectively avoided. In addition, the method and the system are short in material drying period, high in drying system efficiency, easy in automatic feedback control and suitable for large-scale industrial production.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

Drying method for fruits and vegetables

ActiveCN103875797BImprove qualityGood for post-dryingFood processingFruits/vegetable preservation by dehydrationDried fruitDried fruits

The invention relates to a drying method for fruits and vegetables. The drying method comprises the following steps: (1) a pre-drying phase, namely putting sliced fruit and vegetable raw materials into a heat pump drying equipment to be dried; when the drying of the fruit and vegetable raw materials enters a speed-reducing drying phase, stopping drying; (2) a negative-pressure spraying and blasting phase, namely putting the fruit and vegetable raw materials into a material tank; raising the temperature so as to enable the pressure in the material tank to raise to 0.15-0.4MPa, keeping the pressure and instantly reducing the pressure; and (3) a secondary heat pump drying phase, namely putting the fruit and vegetable raw materials in the negative-pressure spraying and blasting phase into a drying chamber; drying by using dry hot air; discharging the dried fruit and vegetable raw materials out of the drying chamber, and storing and uniformly humidifying in a heat-insulation box; putting the fruit and vegetable raw materials which are uniformly humidified into the drying chamber to be repeatedly dried; and repeating until the content of water of the fruit and vegetable raw materials is reduced to be lower than 10%. The drying method for the fruits and the vegetables is simple, convenient, practical, and good in drying effect and has the environment-friendly and energy-saving effects; the quality of fruits and vegetables is not influenced.

Owner:HENAN ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com